Method of vibration and extrusion for cast-in-place concrete in pile hole and its vibration rod device

A concrete and vibrating rod technology, applied in sheet pile wall, building material processing, building structure, etc., can solve the problems of strong vibration, unsuitability, high noise, etc., and achieve low power, low energy loss, and environmental impact. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

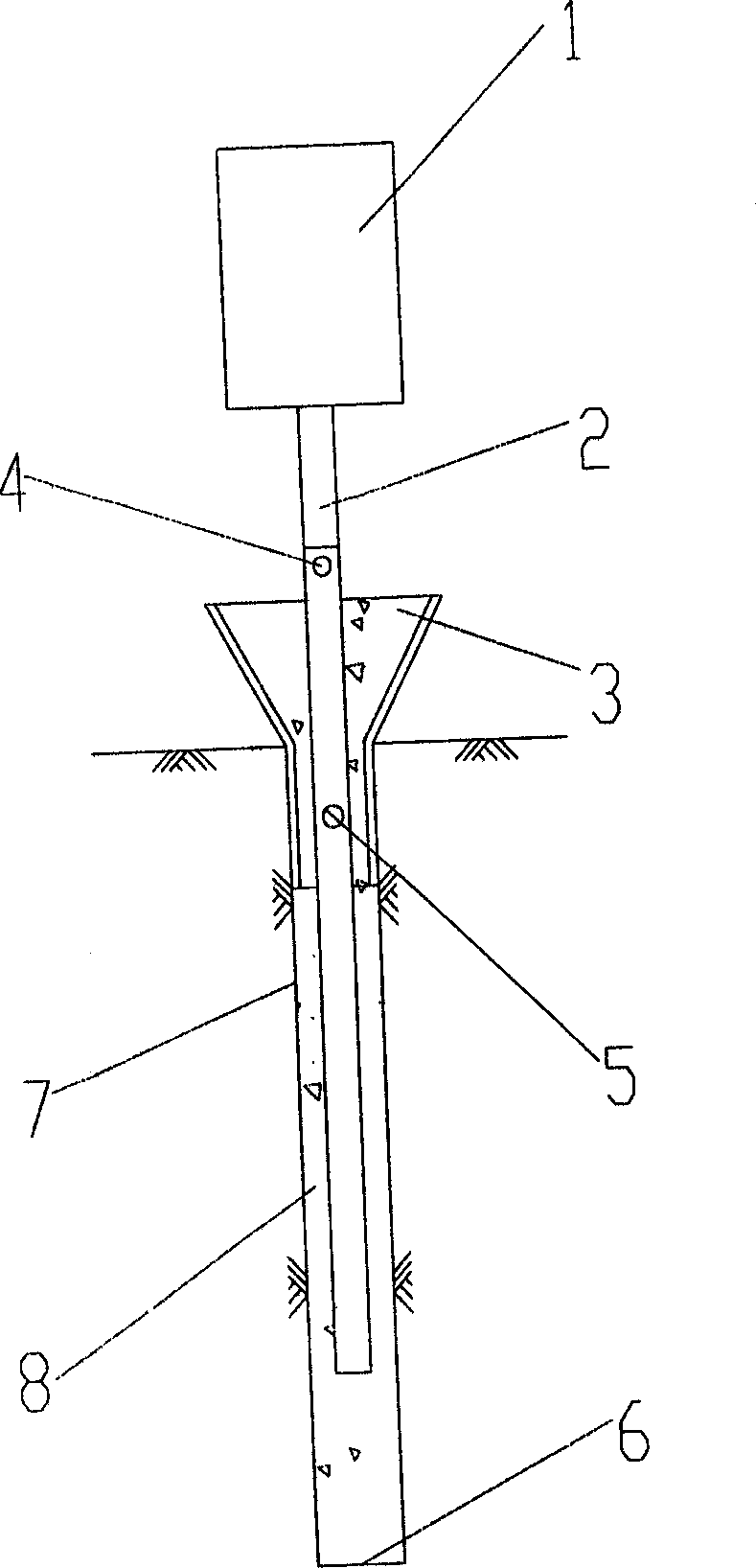

[0019] Embodiment 1: refer to figure 1 Schematic diagram of the construction of a single steel pipe force transmission member vibrator rod. It describes the method of vibrating and compacting the concrete in the pile hole of plain concrete piles when the pile diameter is small. The vibration source 1 is connected with the steel pipe 2 to form a vibration rod.

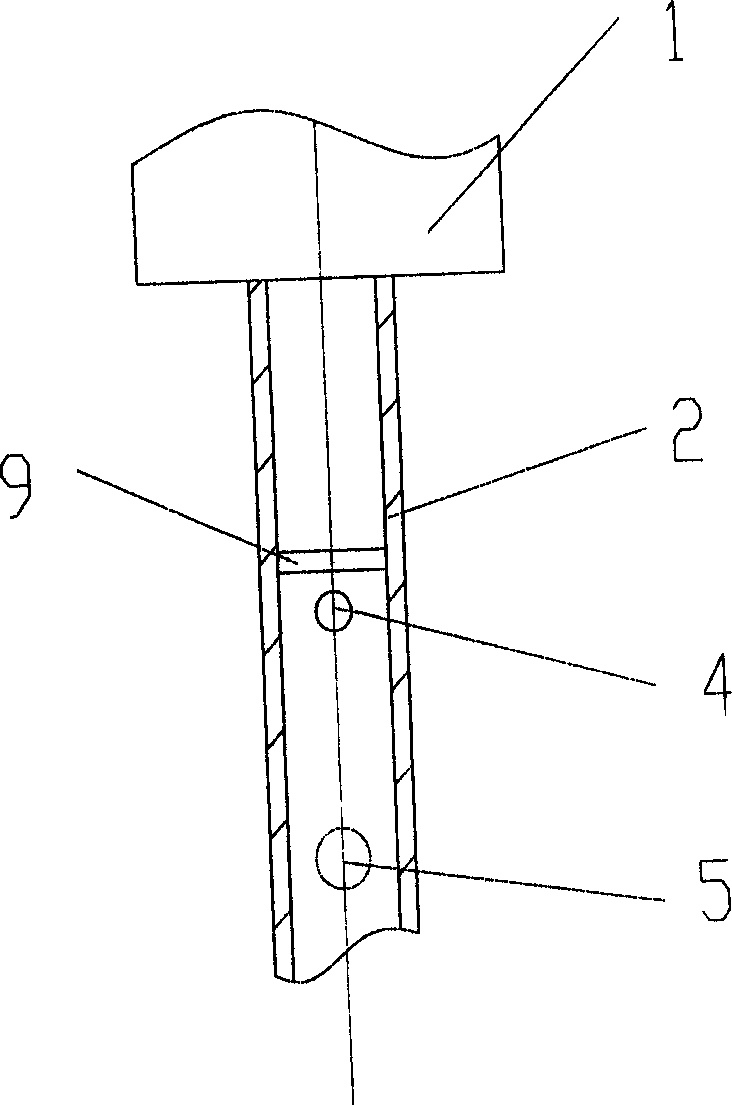

[0020] refer to figure 2 , the upper part of the steel pipe 2 has a vent hole 4, and the upper edge of the vent hole 4 in the inner cavity of the steel pipe is welded with a sealing partition 9. The middle and upper part of the steel pipe 2 opens a material hole 5 . The diameter of the feed hole 5 is larger than that of the air hole 4 . The lower end of the steel pipe 2 is open.

[0021] Its technological process is:

[0022] 1. Drilling

[0023] 2. Pour concrete into the pile hole.

[0024] 3. Clean up the dregs at the orifice, and insert the orifice protection barrel 3 into the pile hole. Into the concrete s...

Embodiment 2

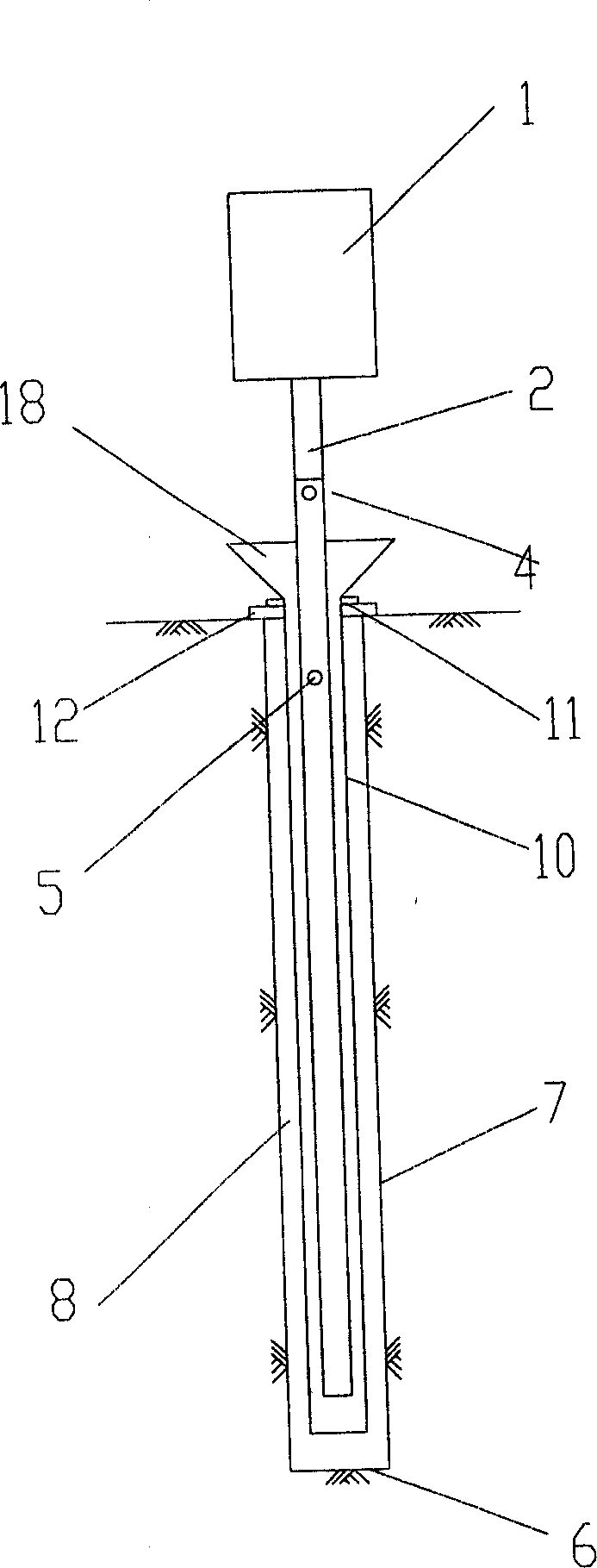

[0030] Example 2: image 3 It is a schematic diagram of the construction of the vibrating rod of the set of double steel pipe force transmission components. This method is adopted when the pile diameter is large, the pile length is long, and there is mud stagnant in the upper part of the cast-in-place concrete in the pile hole. Upper mud. Internal steel pipe 2 with figure 1 The structure shown is the same, with the lower end open. The outer steel pipe 10 is open at the lower end and the upper end, the pipe wall is not perforated, and the lower end is provided with a temporary seal. Its construction process is:

[0031] 1. Drill holes in place.

[0032] 2. Put the reinforcement cage and detect the sediment at the bottom of the hole.

[0033] 3. Lower the conduit and pour concrete underwater. Pull out the concrete pipe.

[0034] 4. Temporarily seal the lower part of the double-tube ultra-long vibrating rod in the set, and after inserting it into the concrete, remove the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com