Fan bearing platform assembly improving pile uplift bearing capacity

A technology of anti-pull bearing capacity and wind turbines, which is applied in the field of wind turbine foundation piles, can solve the problems that the anti-pull effect is not fully utilized, the pile foundation structure is unreasonable, and the foundation is self-heavy, so as to reduce the excavation and support of foundation pits Difficulty, reducing excavation volume of cap foundation soil, and reducing the effect of covering soil thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

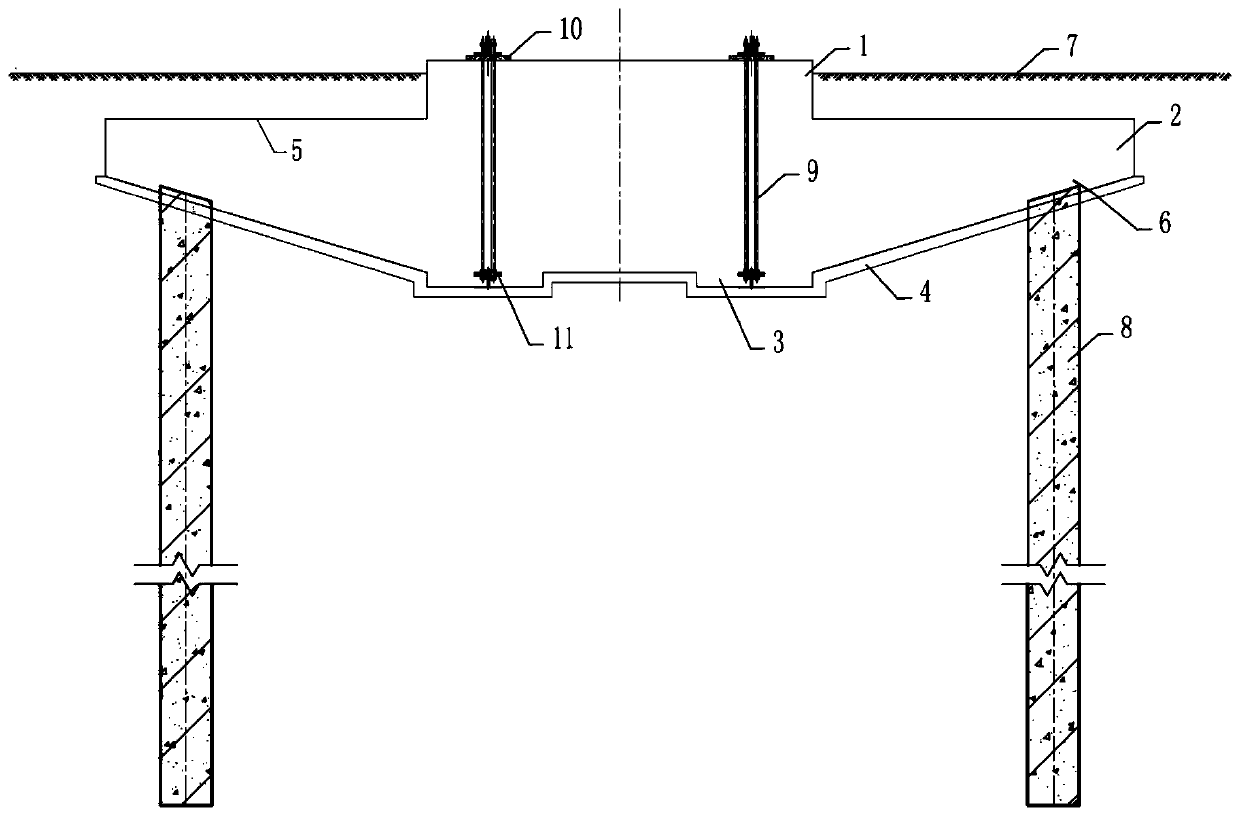

[0018] Such as figure 1 , 2 As shown, the fan cap assembly for improving the pile uplift bearing capacity of the present invention includes a cap 5 and a foundation pile 8 supporting the cap, and the cap 5 includes a cylindrical upper column 1 connected concentrically and axially, a central cylindrical Platform 2, bottom rounded platform 6 and the annular bottom boss 3 at the bottom; the diameter of upper platform 1 is less than the diameter of cylindrical middle platform 2, and the upper large diameter of bottom rounded platform 6 is the same as the diameter of cylindrical middle platform 2 , the outer diameter of the bottom boss 3 is the same as the small diameter of the lower part of the lower rounded platform 6, and the anchor cage 9 connected with the fan tower extends into the bottom of the cap; the lower anchor plate 11 of the anchor cag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com