Automatic filling and compacting equipment and construction method for compaction pile foundation treatment

A technology of automatic filling and compaction piles, which is applied in the direction of foundation structure engineering, soil protection, construction, etc., can solve the problems of unstable quality of compaction piles and the inability to give full play to the best compaction effect of packing compaction, so as to reduce the Number of piles, stable quality, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

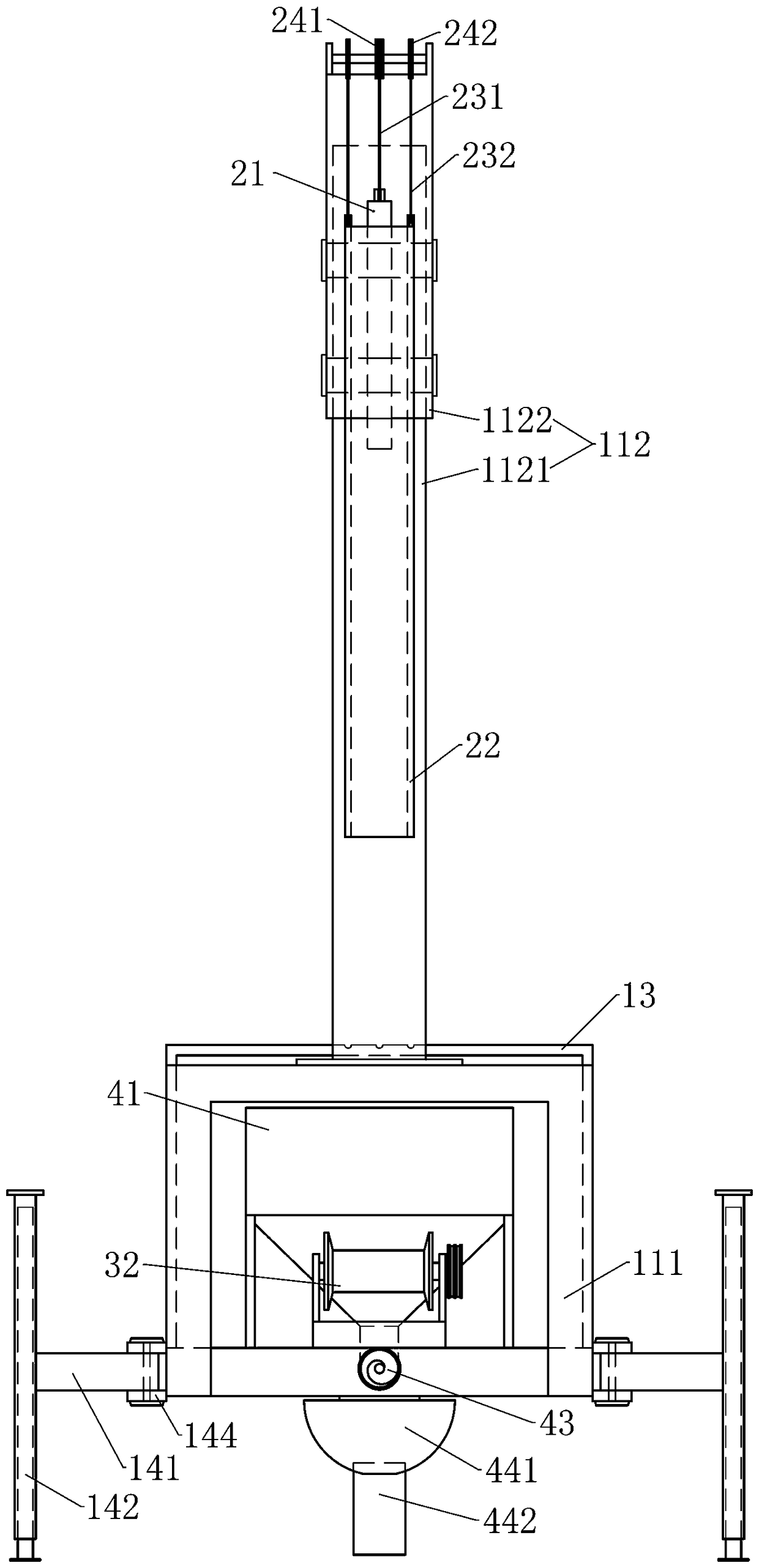

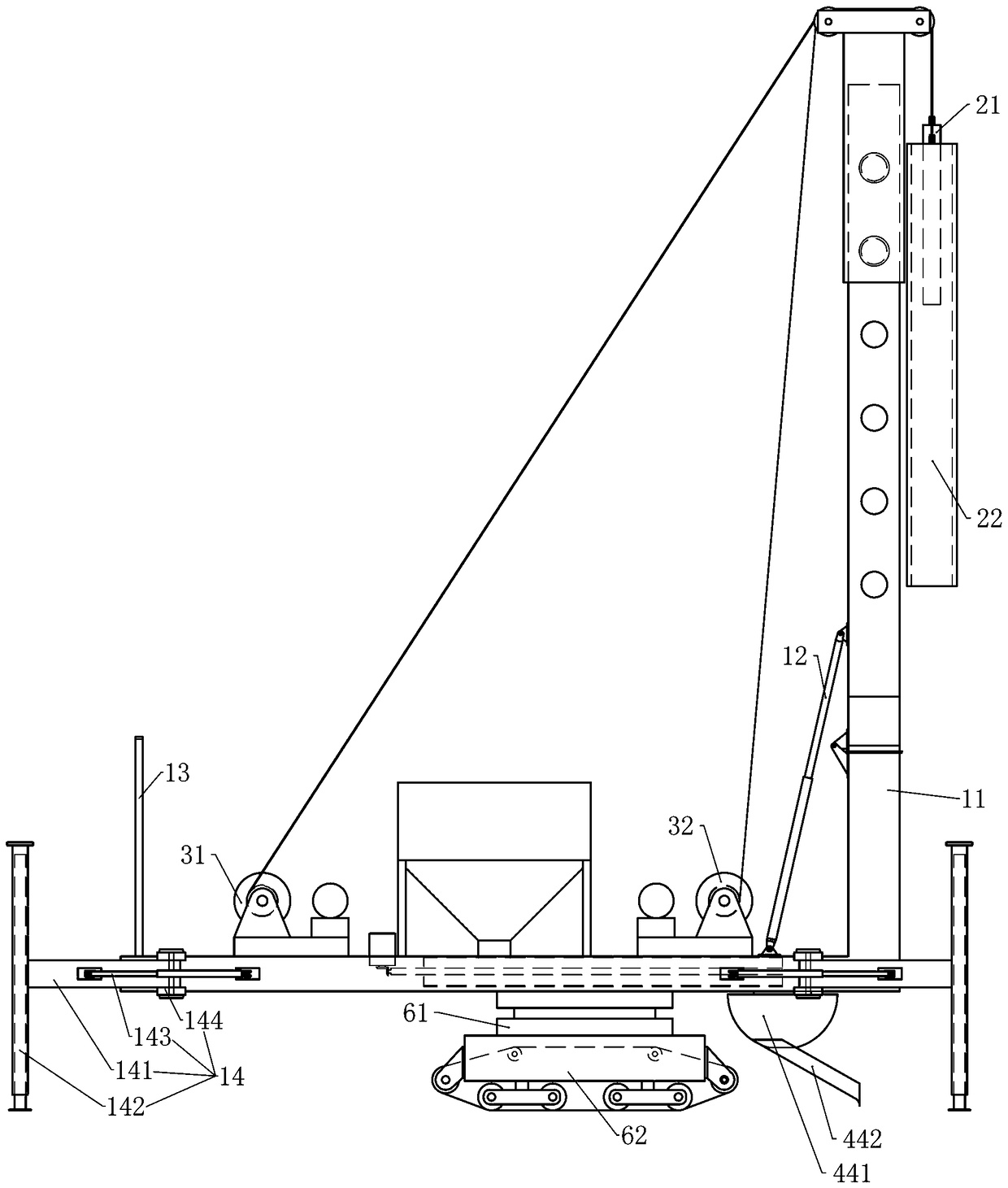

[0024] Embodiment 1: a kind of automatic packing compaction equipment, see Figure 1-3 , including a structural platform 1, a compacting component 2, a feeding mechanism 4, and an electric control device.

[0025] see Figure 1-3 , A stand 11 is provided on the structural platform 1 . In this embodiment, the vertical frame 11 adopts a folding structure, and a support seat 111 is provided on the upper surface of the structural platform 1, and an independent frame 112 is hinged on the support seat 111. In this embodiment, the support seat 111 is a gantry frame, Independent frame 112 can be bar-shaped, well-tac-toe frame, inverted L-shaped frame, T-shaped frame, and the telescopic rod 12 that is used to receive independent frame 112 and is used to support the independent frame 112 after folding is also installed on structure platform 1. Support 13, the height of support seat 111 and support 13 is set to: when stand 11 is folded and when supported by support seat 111 and support...

Embodiment 2

[0039] Embodiment 2: A construction method for foundation treatment of compacted piles, comprising the following steps: setting the automatic packing and compacting equipment in Embodiment 1 next to the compacted pile foundation hole, and coordinating the winch 31 and the power unit 42 through the controller, so as to Make the quantity of filling in the hole of the compacted pile foundation by the feeding mechanism 4 linked with the hammering frequency of the compacting hammer 21 . The optimal value of the linkage is determined by those skilled in the art on the basis of common knowledge in the art and combined with limited experiments. In this way, the problem of low tamping efficiency caused by the tamping hammer being unable to effectively tamp the filler or too little filler can be avoided.

[0040] After using the controller to link the feeding mechanism and the hoist 31, the hammering frequency and the amount of filler are linked together. The automatic filler compaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com