Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Reduce reflective area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

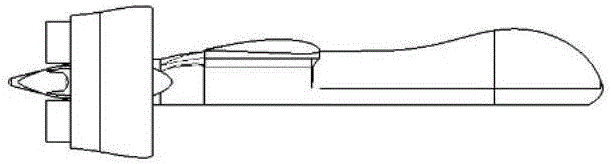

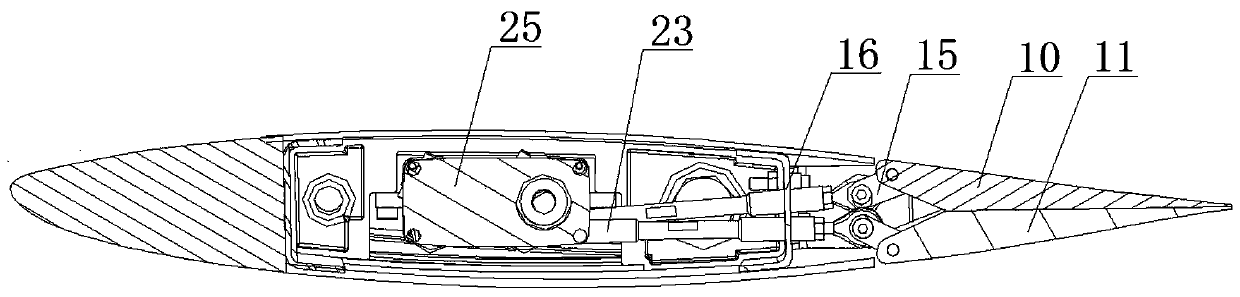

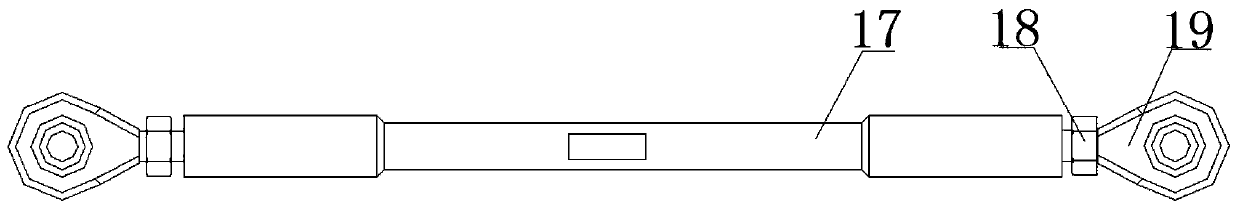

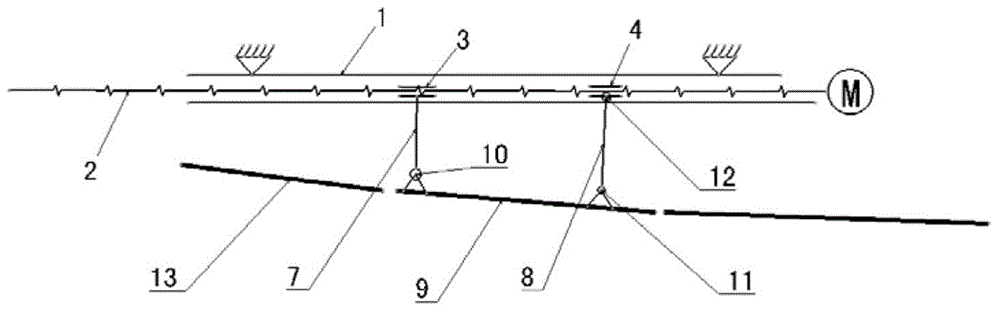

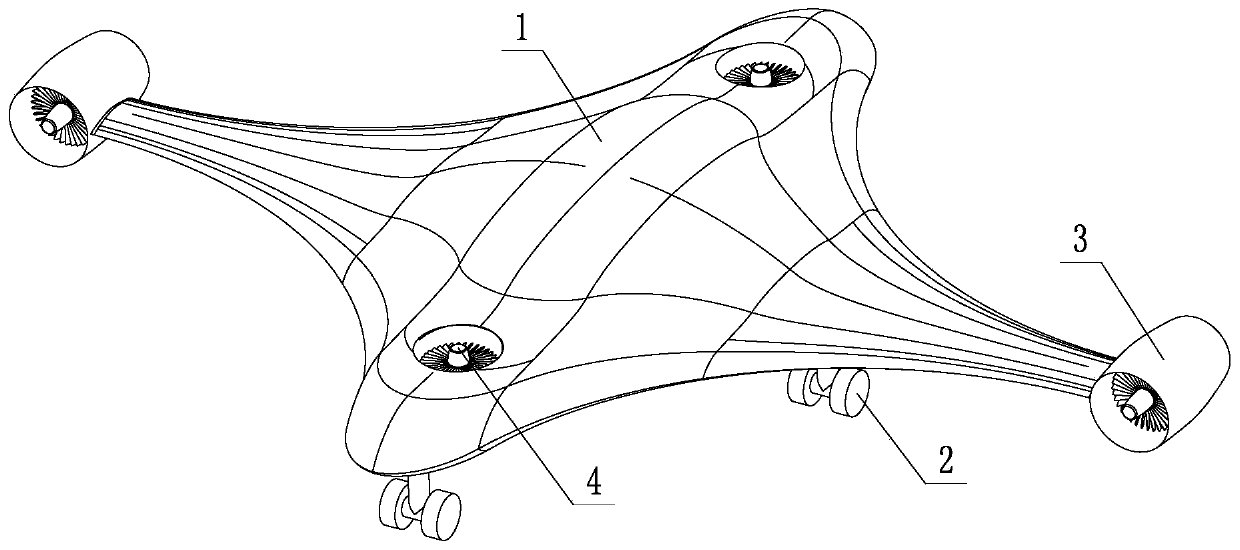

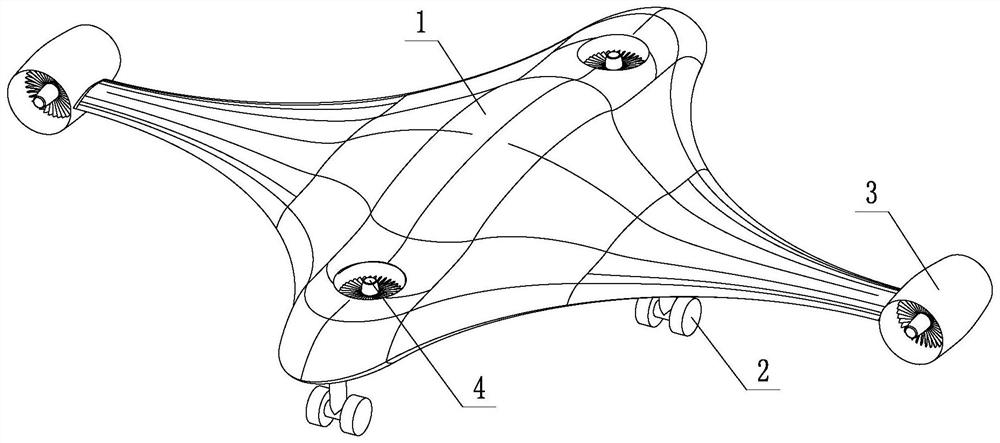

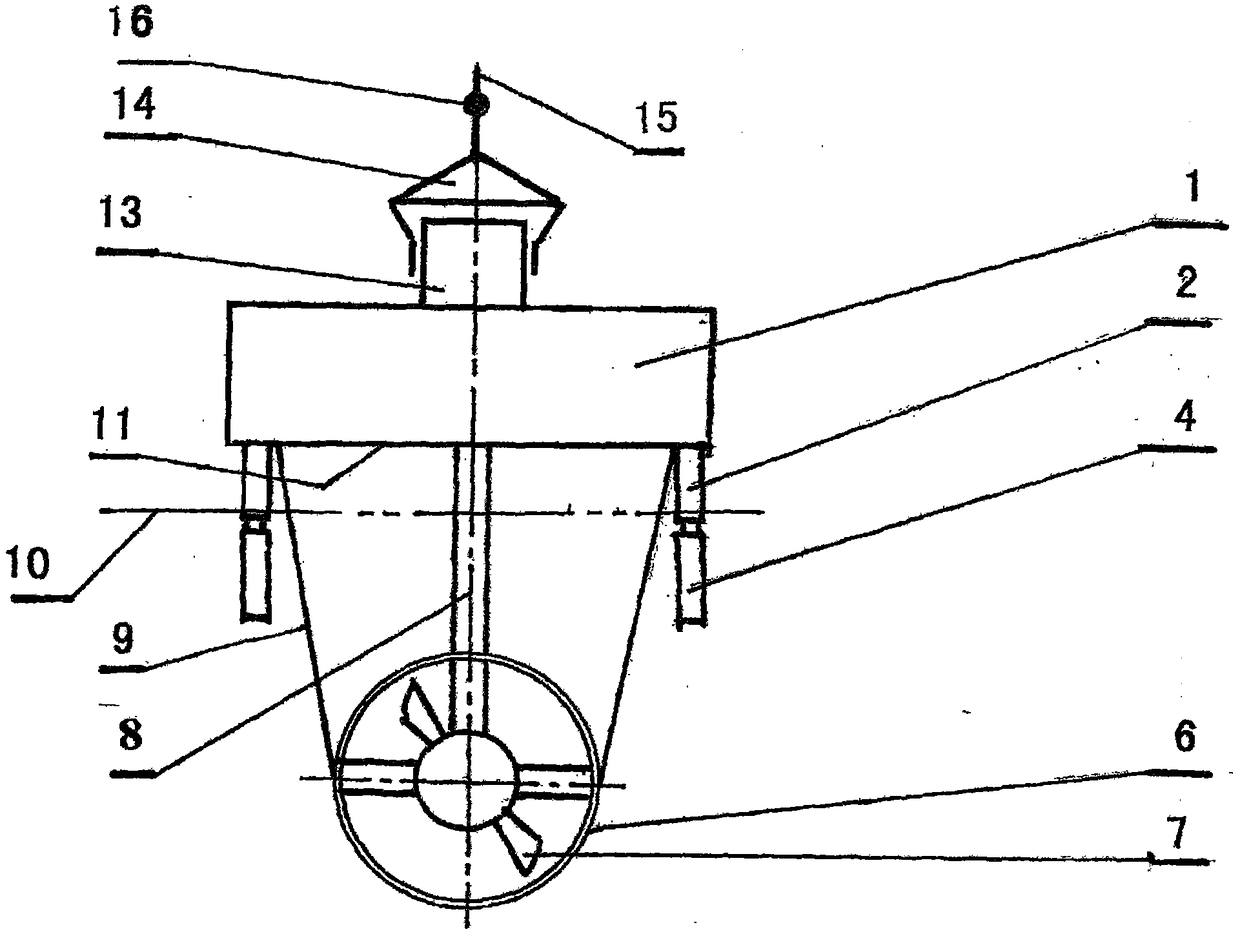

Vertical takeoff and landing unmanned aerial vehicle with foldable fixed wings based on dual-duct fan power system

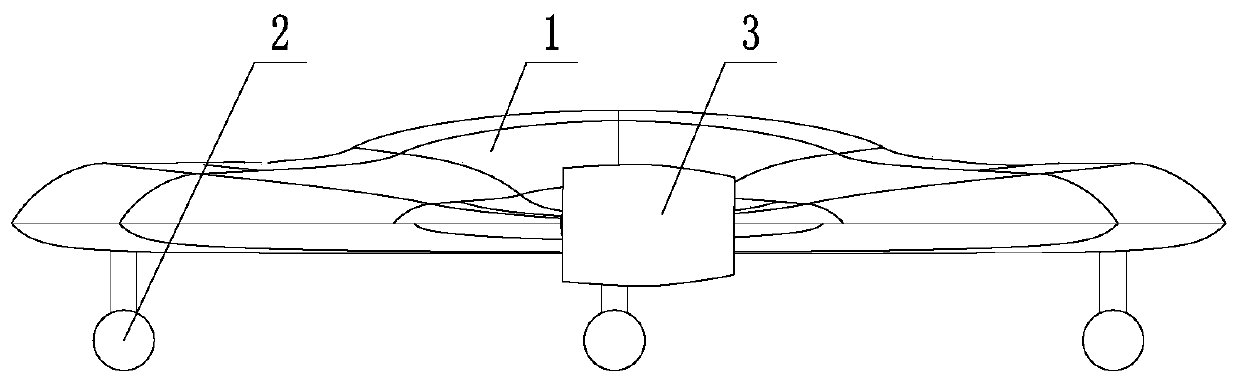

ActiveCN107176286AImprove aerodynamic performanceBarrier formationPropellersRemote controlled aircraftLow speedTrailing edge

The invention discloses a vertical takeoff and landing unmanned aerial vehicle with foldable fixed wings based on a dual-duct fan power system. A dual-duct fan power system which is horizontally arranged at the tail of the body of the unmanned aerial vehicle in a tail-driving arrangement is adopted, so that lifting force for vertical takeoff and landing and thrust for horizontal flying are provided for an aircraft; a control surface which is arranged at the exit of each duct in a deflected manner is used for providing vector thrust, so that quick attitude change is realized; wings adopt a folding wing configuration, when the aircraft vertically takes off and lands / flies at a low speed, the wings are folded to decrease the frontal area of cross wind, and when the aircraft flies horizontally, the wings are unfolded to obtain large lifting force; and combined optimization of ducts and the wings is adopted, the wings are arranged in a specific duct air flow region, the duct suction generates a Coanda effect at a wing edge, so that the properties of the wings are improved. Multi-mold flight tasks such as vertical takeoff and landing, high-speed cruise, and the like of the aircraft are realized; the vertical takeoff and landing aircraft is high in aerodynamic efficiency during hanging in the air / flying at a low speed; and the vertical takeoff and landing unmanned aerial vehicle is high in anti-disturbance capacity during takeoff and landing / hanging in the air. The vertical takeoff and landing unmanned aerial vehicle is low in energy consumption, small in noise and high in safe reliability.

Owner:SOUTH CHINA UNIV OF TECH

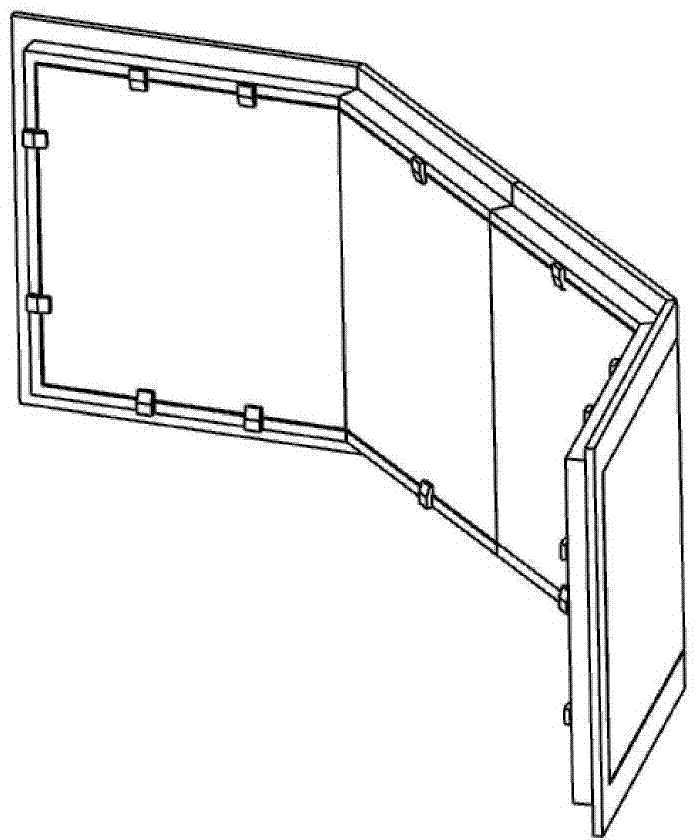

Splicing type conformal optical window

ActiveCN104749735ASatisfy invisibilityFulfil requirementsMountingsVisual field lossEnvironment effect

The invention provides a splicing type conformal optical window, and relates to the field of aeronautical facilities. The problems that by the existing optical window, only an optical load visual field angle in one direction can be expanded, and expansion of a large range of the visual field is limited are solved. The splicing type conformal optical window comprises seven pieces of flat-plate optical glass, wherein the seven pieces of flat-plate optical glass are glued together and mainly comprise a piece of main window glass, a first group of side glass, a second group of side glass and a third group of side glass; each group of side glass consists of two pieces of side glass with the same size and the same shape; sides of each two adjacent pieces of side glass are fixedly glued; and one sides of each group of side glass are fixedly glued with a corresponding side of the main window glass. On the premise that requirements of a main visual field of an inner effective load are met, the splicing type conformal optical window has enough strength and enough rigidity to resist influences of an external environment, and requirements of dynamics performance and invisibility of an aircraft can be met.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

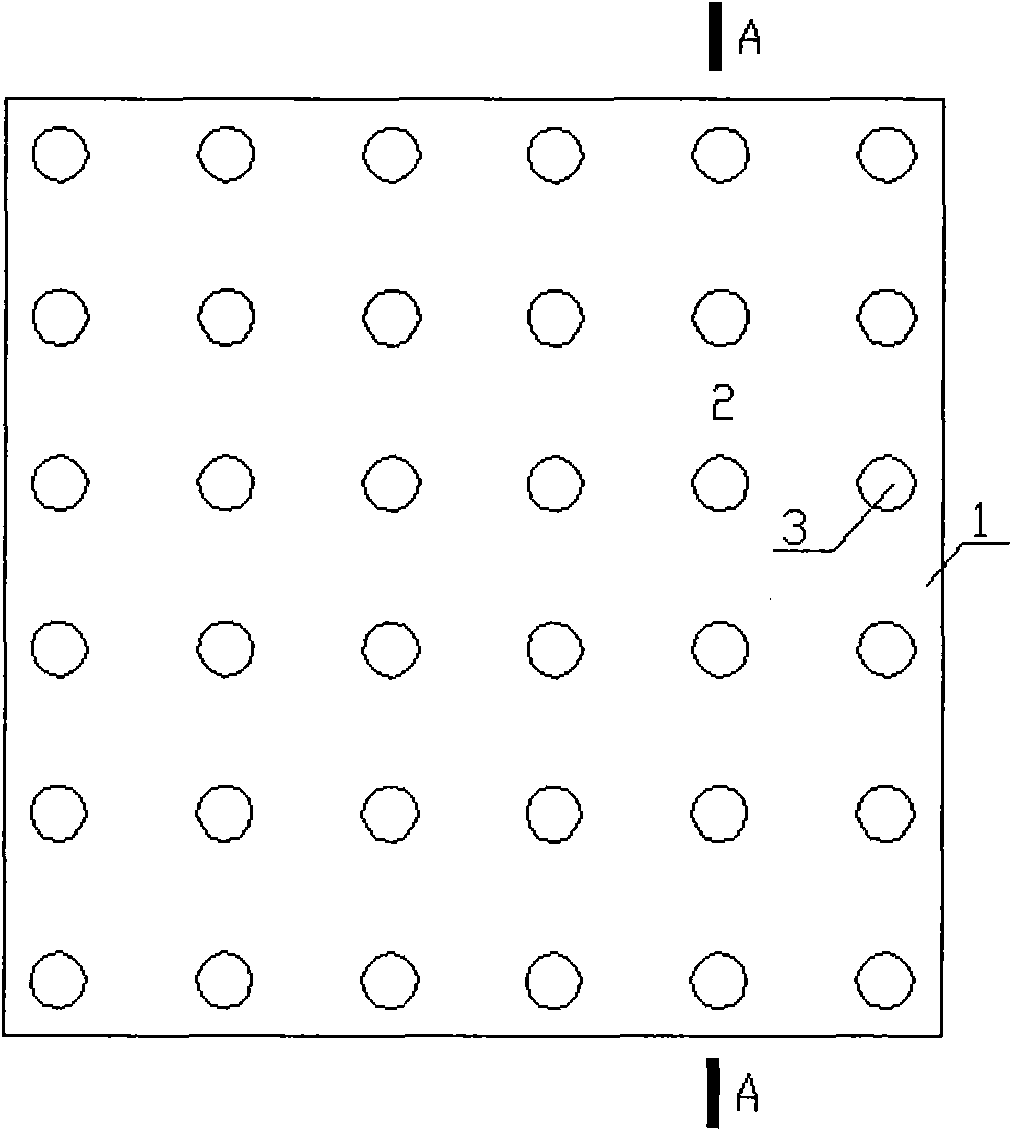

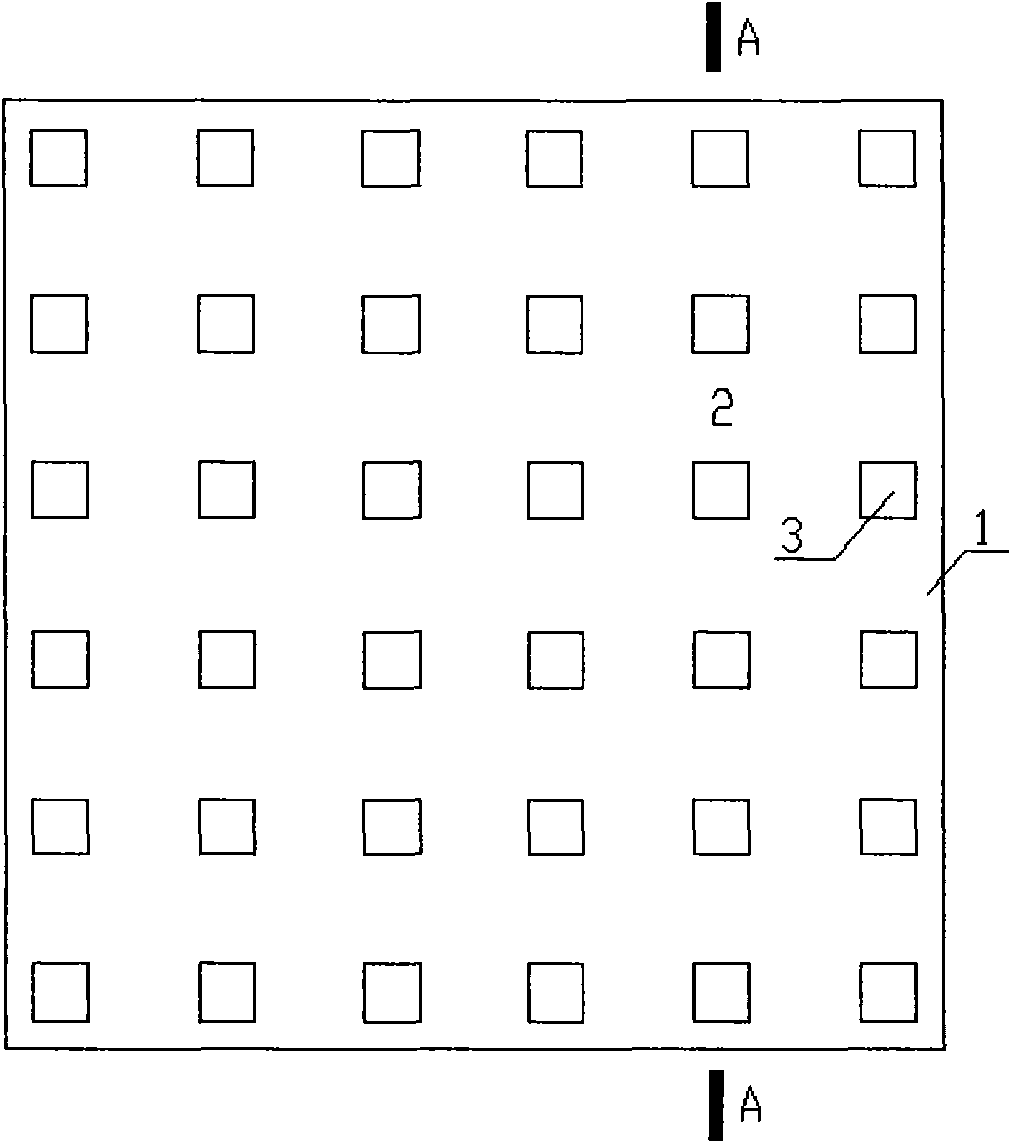

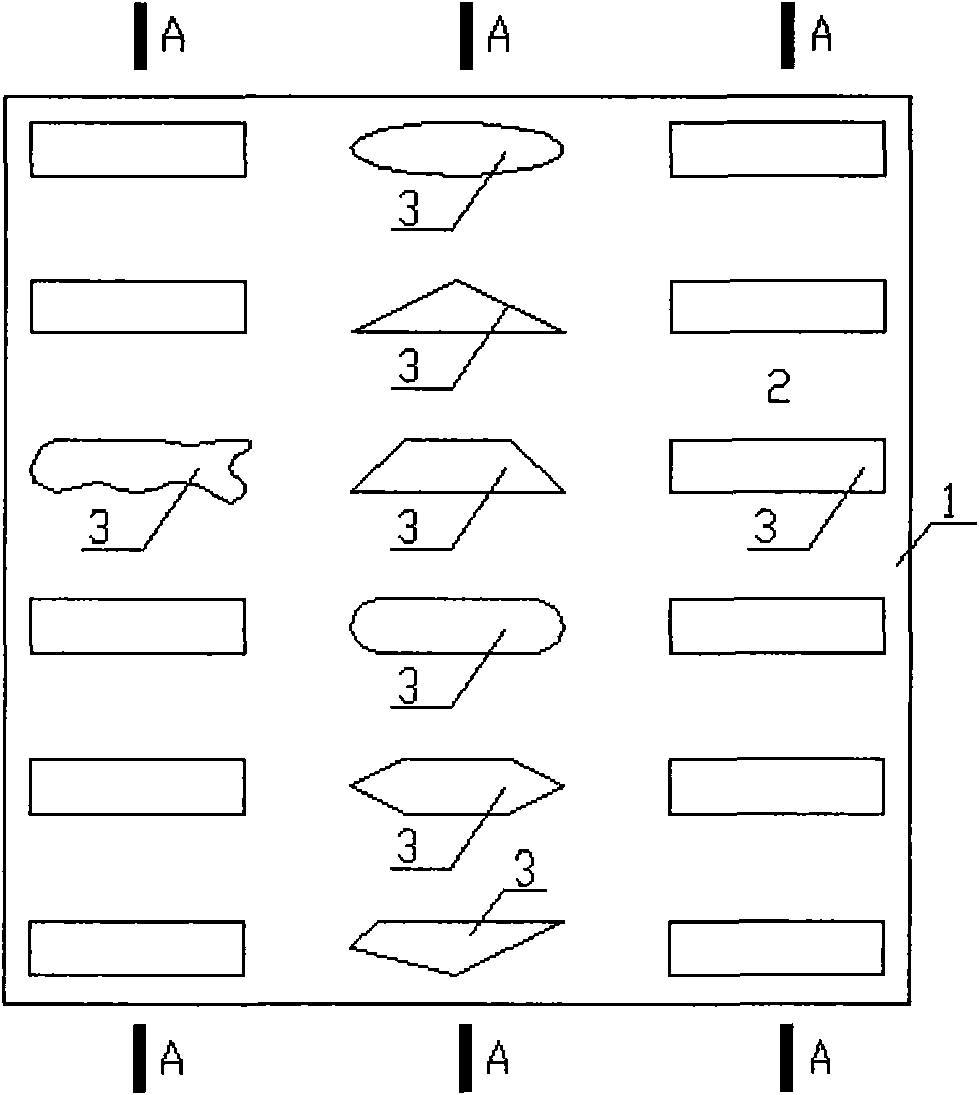

Porous glass plate and structures adopting porous glass plate

InactiveCN101654995AWith transparencyBreathableWallsNoise reduction constructionSound barrierGlass sheet

The invention discloses a porous glass plate and structures adopting the porous glass plate, which adopt the technical scheme that: the porous glass plate is provided with pores, the pores are perforated in a thickness direction and are in regular or irregular distribution in a plane direction, the opening ratio is more than or equal to 0.5 percent and is less than or equal to 60 percent, and thepores are circular or in any shape; and the structures adopting the porous glass plate comprise building and structure windows adopting the porous glass plate, vehicle windows adopting the porous glass plate, enclosures adopting the porous glass plate, sound barriers adopting the porous glass plate, totally enclosed structures of traffic passages adopting the porous glass plate, and paravents adopting the porous glass plate. The porous glass plate has the advantages of having air permeability and being favorable for the ventilation, having the sound-absorbing effect of a perforated plate and amicroperforated plate and certain sound insulation effect, having the effects of keeping out the wind and reducing the wind pressure, and having the rainproof and antitheft effects. The porous glassplate is applicable to windows or glass curtain walls of buildings and structures, vehicle windows, enclosures, sound barriers, enclosed structures of traffic passages and paravents.

Owner:马兴华

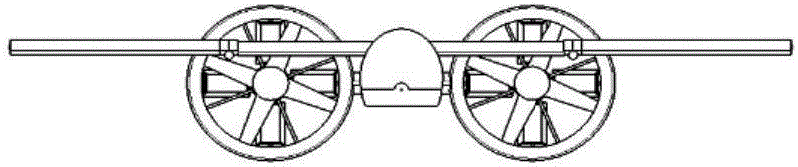

Flapping-wing flying water automobile

InactiveCN1377790AControl thrustControl liftConvertible vehiclesOrnithoptersFlapping wingControl system

The flapping-wing fling water automobile includes engine, double-blade air screw propeller, right and left hydraulic screw propellers, right and left wings, control system, safety lifesaving equipment, and four-wheel undercarriage, hanging damper and fuselage, with the wings being connected to the fuselage via mechanical and hydraulic mechanism. The present automobile is one traffic facility for land, water and air use simultaneously, and has high efficiency and maneuverability. Its wings may be folded for land running.

Owner:程纪

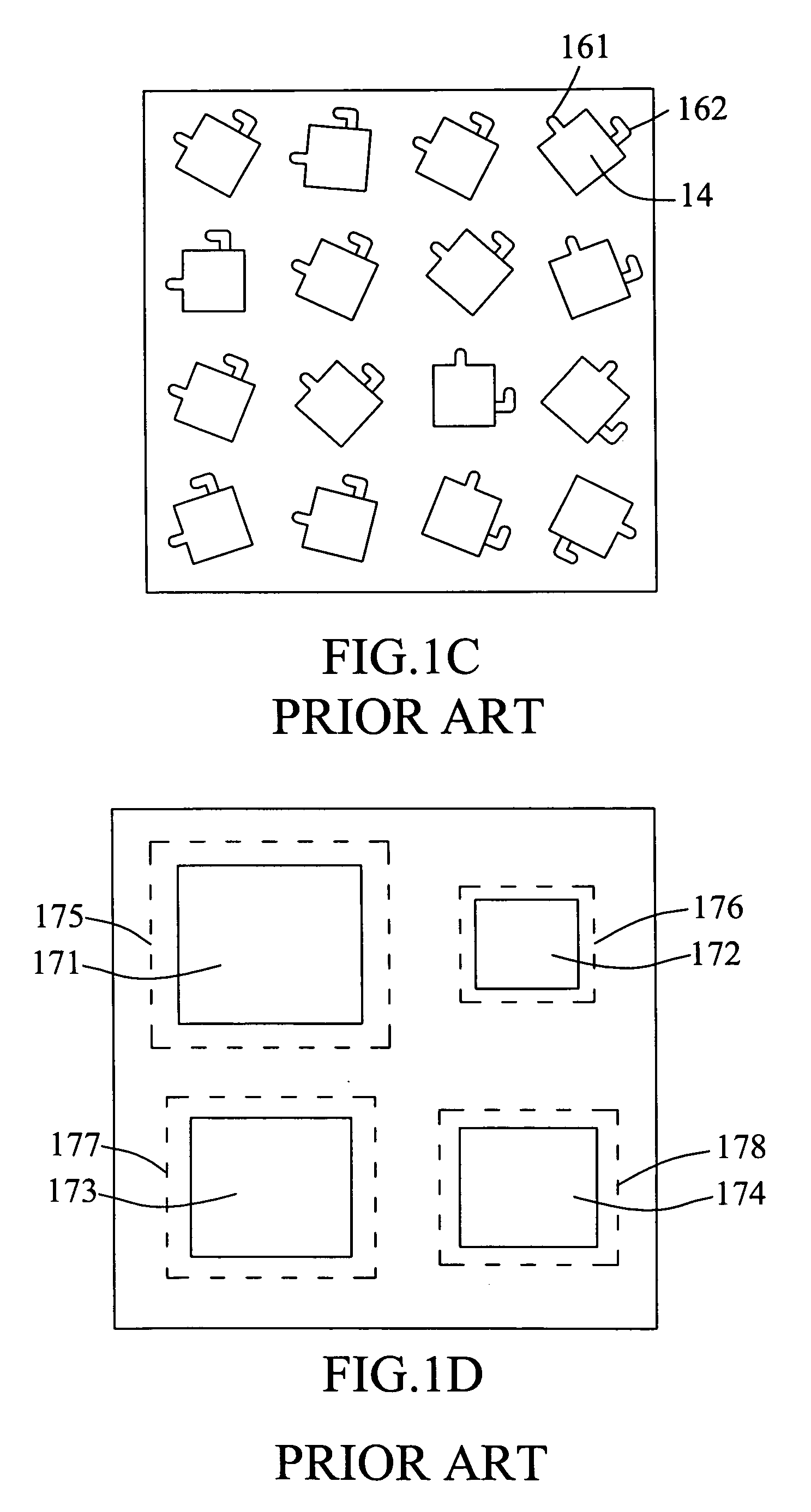

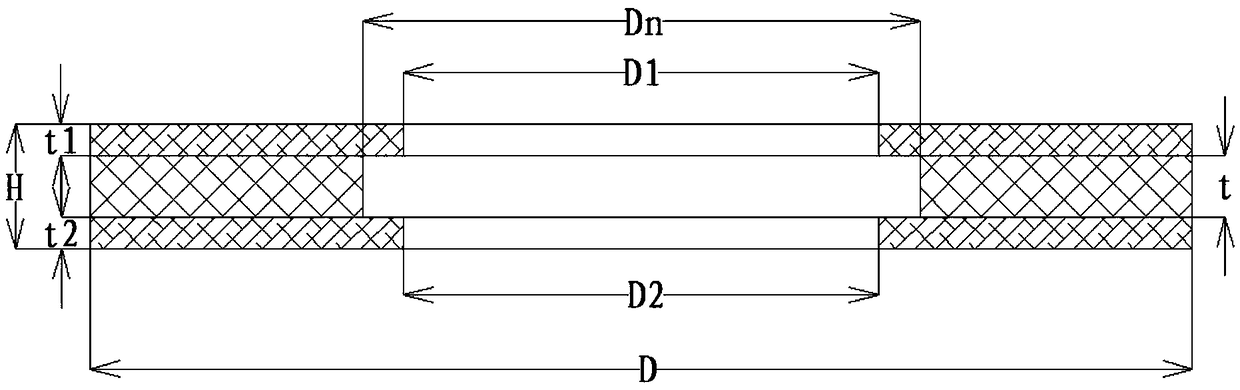

Reflecting board with variable slot size for a microstrip reflectarray antenna

InactiveUS7259721B2Improve design flexibilitySensitivity of the performance of the microstrip reflectarray antenna toSimultaneous aerial operationsRadiating elements structural formsMicrostripMicrostrip antenna

The present invention relates to a reflecting board for a microstrip reflectarray antenna and, more particularly, to a reflecting board with variable slot size that can improve the design flexibilities of the reflecting board and reduce the sensitivity to the manufacturing tolerances of the microstrip reflectarray antenna. The reflecting board comprises a bottom substrate having a first lower surface, and a top substrate. Plural first microstrip antenna patches, and plural second microstrip antenna patches with rectangular slots are disposed on the upper surface and the second lower surface of the top substrate, respectively. The area of the second microstrip antenna patches is larger than that of the first microstrip antenna patches. Besides, the ratio of the maximum border-length of the rectangular slot to the maximum border-length of the corresponding second microstrip antenna patch is identical for each second microstrip antenna on the second lower surface of the top substrate.

Owner:TATUNG UNIVERSITY +1

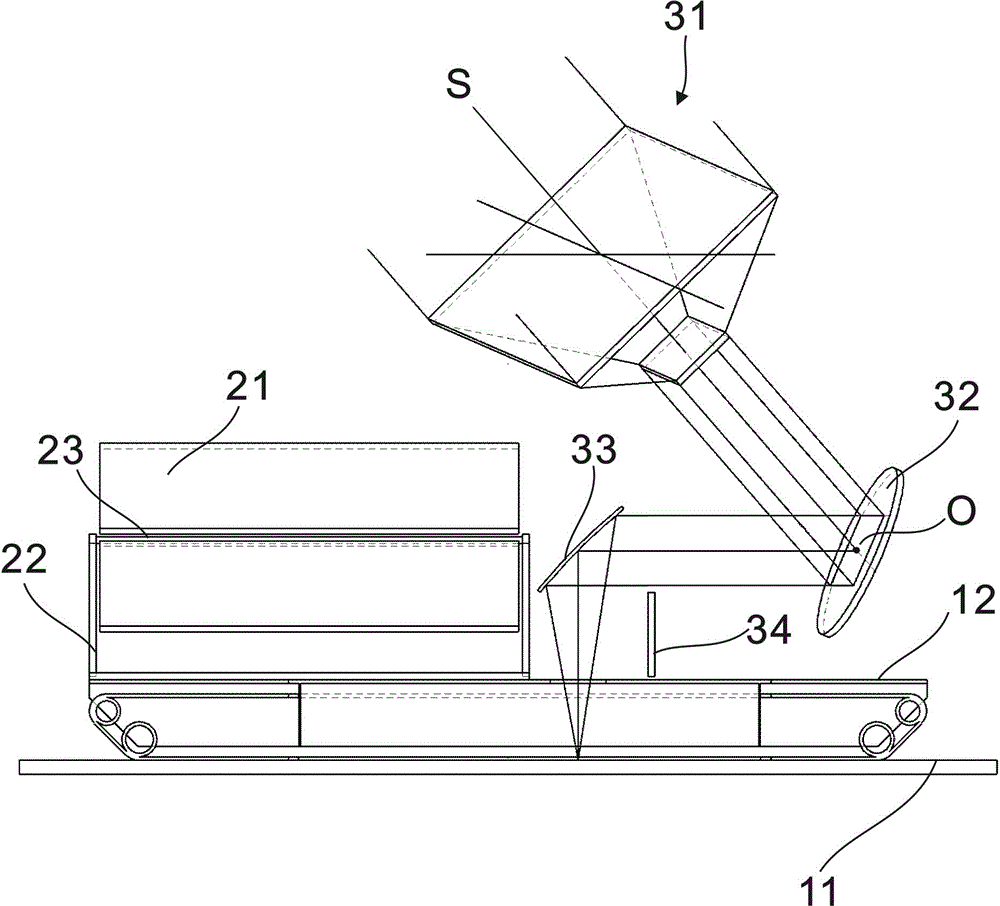

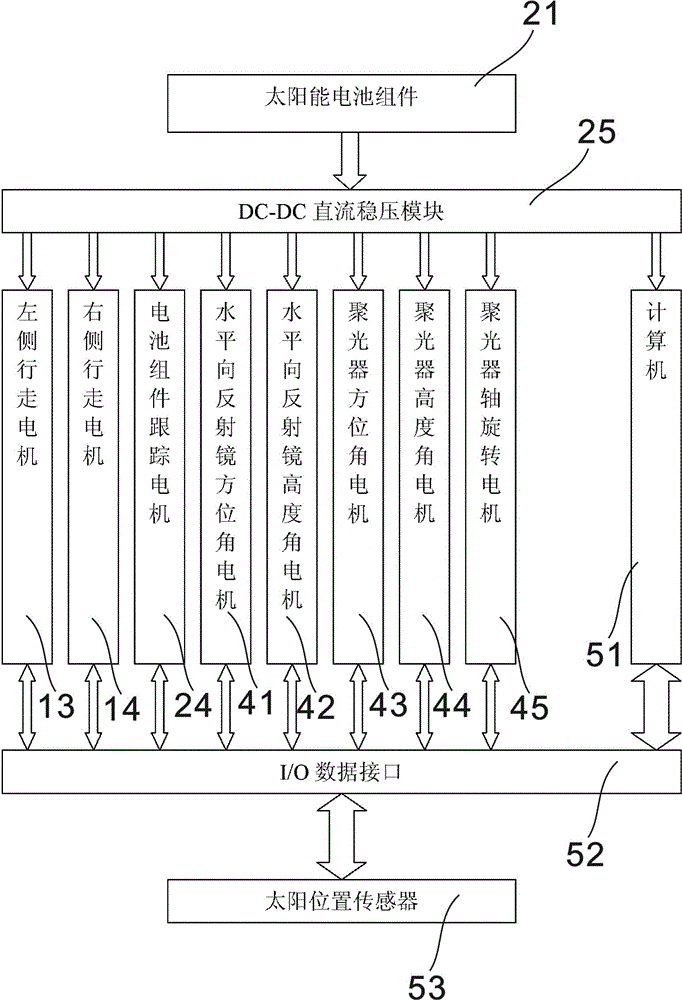

Solar orienting line condensation desert surface hardening system

InactiveCN102877457AReduce reflective areaConducive to manufacturingPhotovoltaic supportsMountingsAtmospheric sciencesRadiation

The invention provides a solar orienting line condensation desert surface hardening system which comprises a condenser, a horizontal reflector, a parabolic reflector, a shading reflector, a computer, a sun position sensor, a horizontal sand surface and the like. The condenser is a parallel light condenser and is used for carrying out accurate azimuth angle and altitude angle tracking on the sun; output parallel condensed light rays are all irradiated to the horizontal reflector; and by the reflection of the horizontal reflector and the focusing of the parabolic reflector, condensed light rays which are positioned on the horizontal sand surface and have the same radiation intensities are formed. According to the system, in the process of carrying out melting and hardening on the surface of a desert, both the motion energy and the energy for melting and hardening the sand surface are from the solar energy and the fossil energy is not consumed; the utilization time of the solar energy can be longer and the condensing utilization mode can be more reasonable; the line focusing is adopted, the efficiency of carrying out melting and hardening under the control of the computer is higher and the quality of carrying out melting and hardening under the control of the computer is better; and the unmanned automatic operation can be implemented, so that the manual cost is further reduced.

Owner:新疆熠金能源科技有限公司

Broadband Tunable External-Cavity Laser Using Small Mems Mirror

ActiveUS20170025819A1Compact structureOptimize volumeLaser optical resonator constructionOptical resonator shape and constructionWavelength-division multiplexingA d converter

A Raman pump laser control apparatus comprises a wavelength division multiplexer, a tap coupler, a photoelectric detector, an analogue amplification processing circuit, an analogue-to-digital converter, a fast Raman pump control unit, an digital-analog converter, and a Raman pump laser. The fast Raman pump control unit, after having known anticipated output light power of the Raman pump laser, based on a direct relationship between a current anticipated output light power of the Raman pump laser and input digital quantity that is needed by the digital-analog converter, uses a feedforward control mechanism so that actual output light power of the Raman pump laser fastly approximates the anticipated output light power thereof, and then synchronously combines with a feedback control mechanism so that the actual output light power of the Raman pump laser is precisely locked on the anticipated output light power, thereby achieving fast and precise control of the Raman pump laser.

Owner:ACCELINK TECHNOLOGIES CO LTD

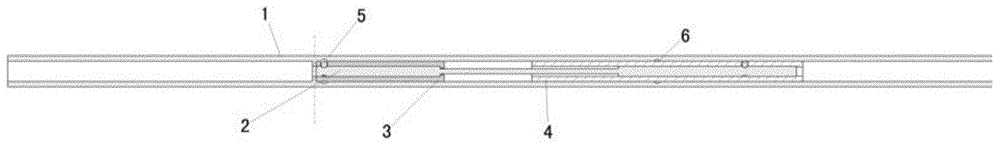

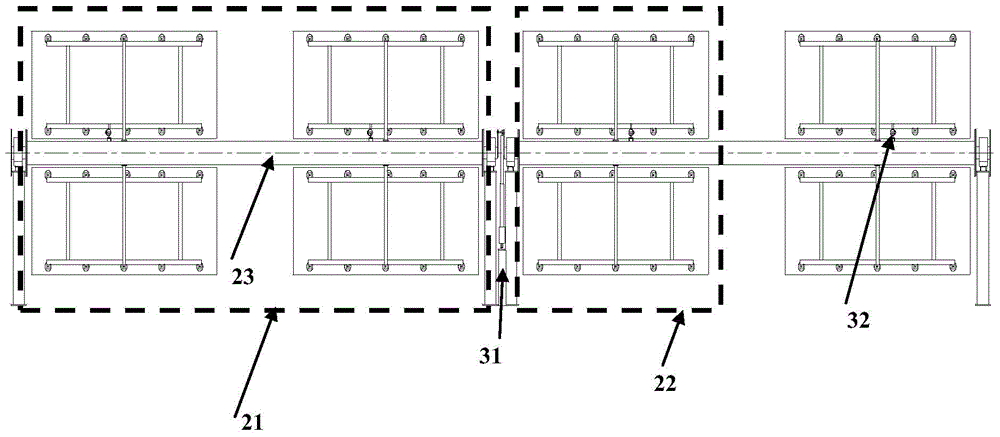

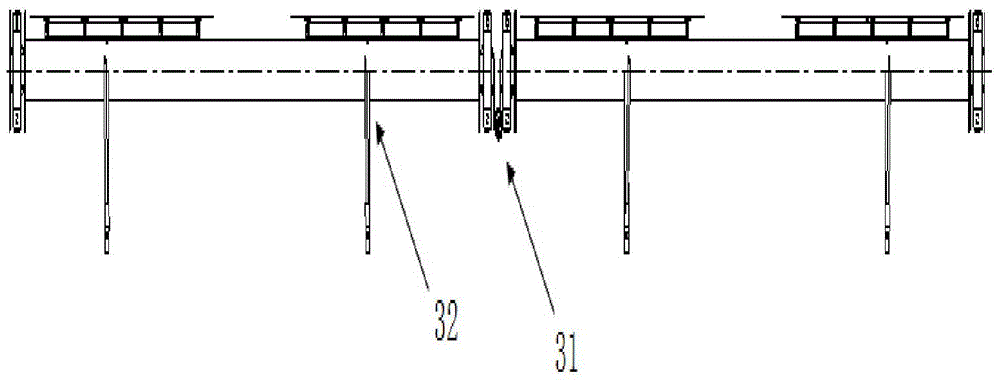

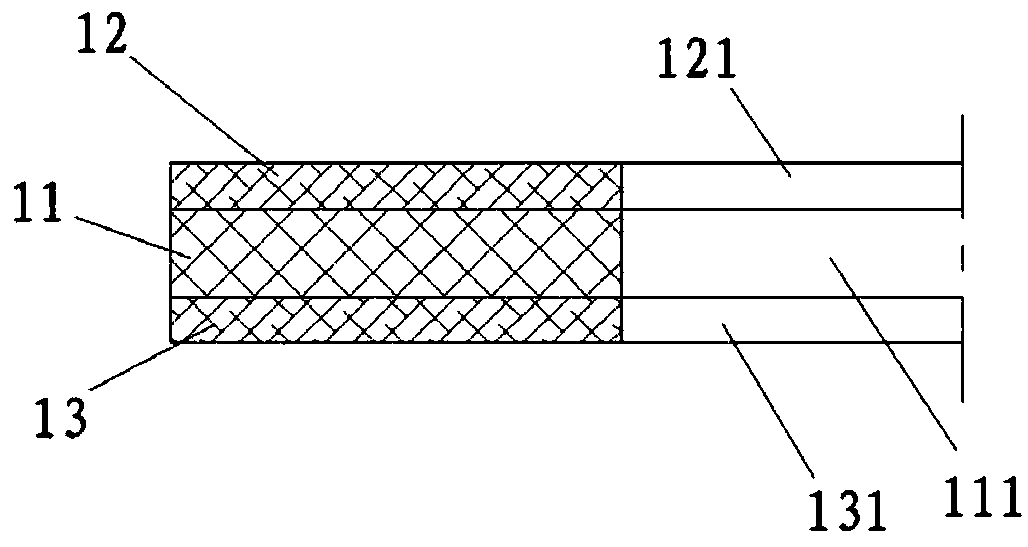

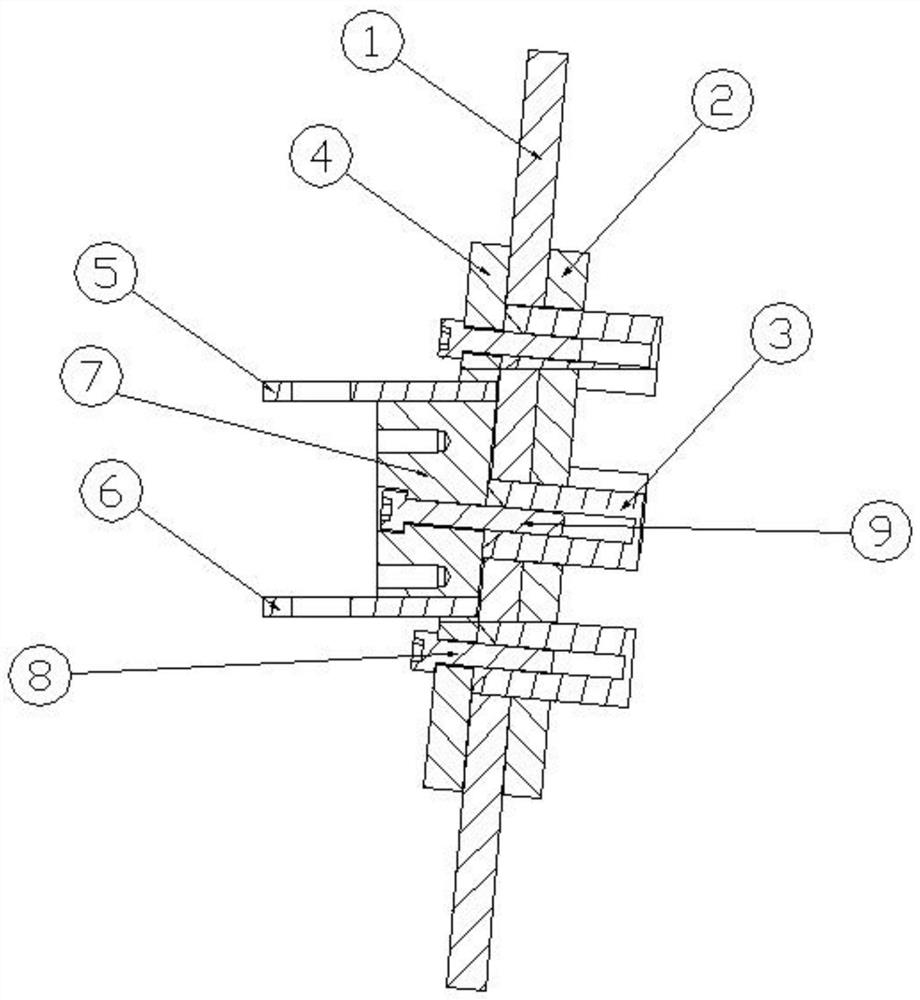

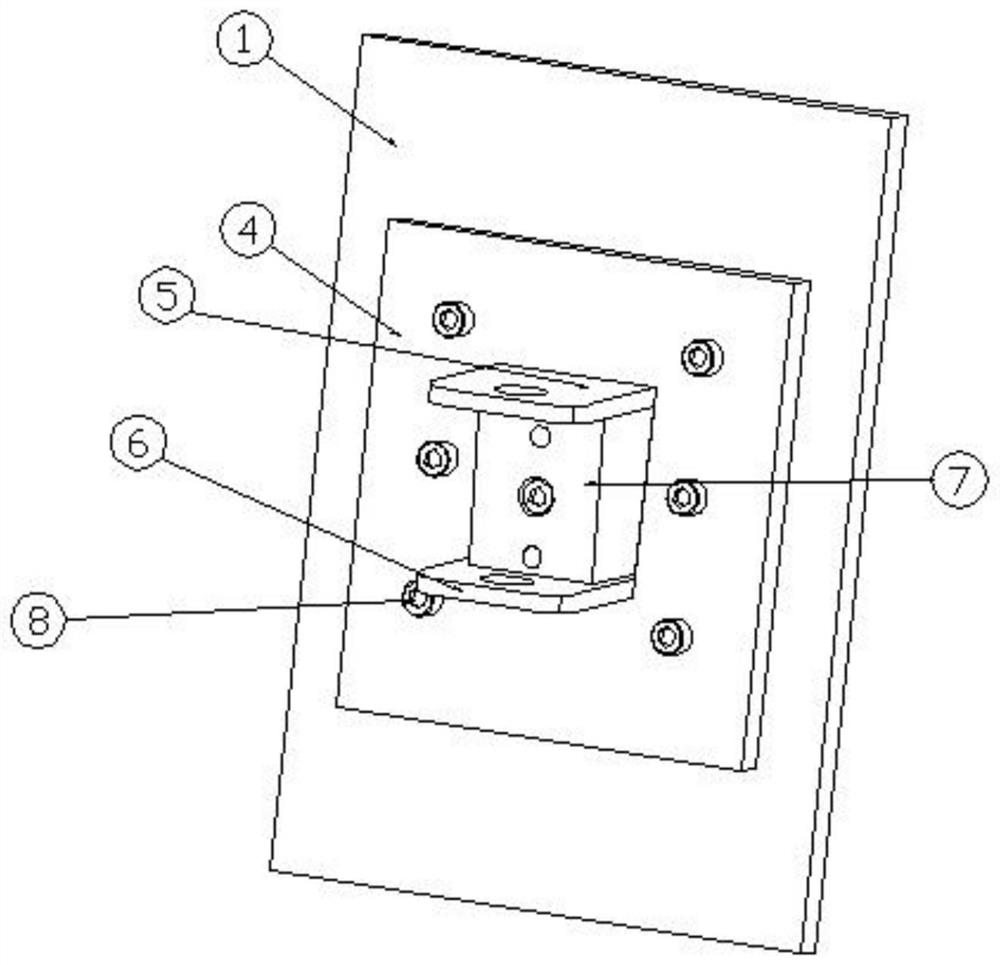

Flying wing configuration drone aircraft invisibility control surface mounting structure

PendingCN111380409AReduce reflective areaTo achieve the effect of stealthAircraft controlMovable targetsSurface mountingWing configuration

The invention provides a flying wing configuration drone aircraft invisibility control surface mounting structure. The flying wing configuration drone aircraft invisibility control surface mounting structure comprises an auxiliary wing unit and a resistance direction rudder unit, the auxiliary wing unit comprises an auxiliary wing steering engine, a first steering engine rocker arm, a first steering engine connecting rod, an inclined rib, a right side supporting base, a control surface and a left side connecting base, the resistance direction rudder unit comprises two resistance direction rudder steering engines, a second steering engine rocker arm, a second steering engine connecting rod, a resistance direction rudder upper control surface, a resistance direction rudder lower control surface, a right side mounting base, a left side mounting base, a transverse shaft, a resistance direction rudder pull base and a stabilizing plane rear beam, and the flying wing configuration drone aircraft invisibility control surface mounting structure is reasonable in design, capable of enabling the lower surface of an aircraft to be free of convex objects, small in reflection area during radar irradiation, capable of achieving the invisibility function and in addition capable of enabling the control surface to be detachable and convenient to maintain.

Owner:AEROSPACE SHENZHOU AIRCRAFT

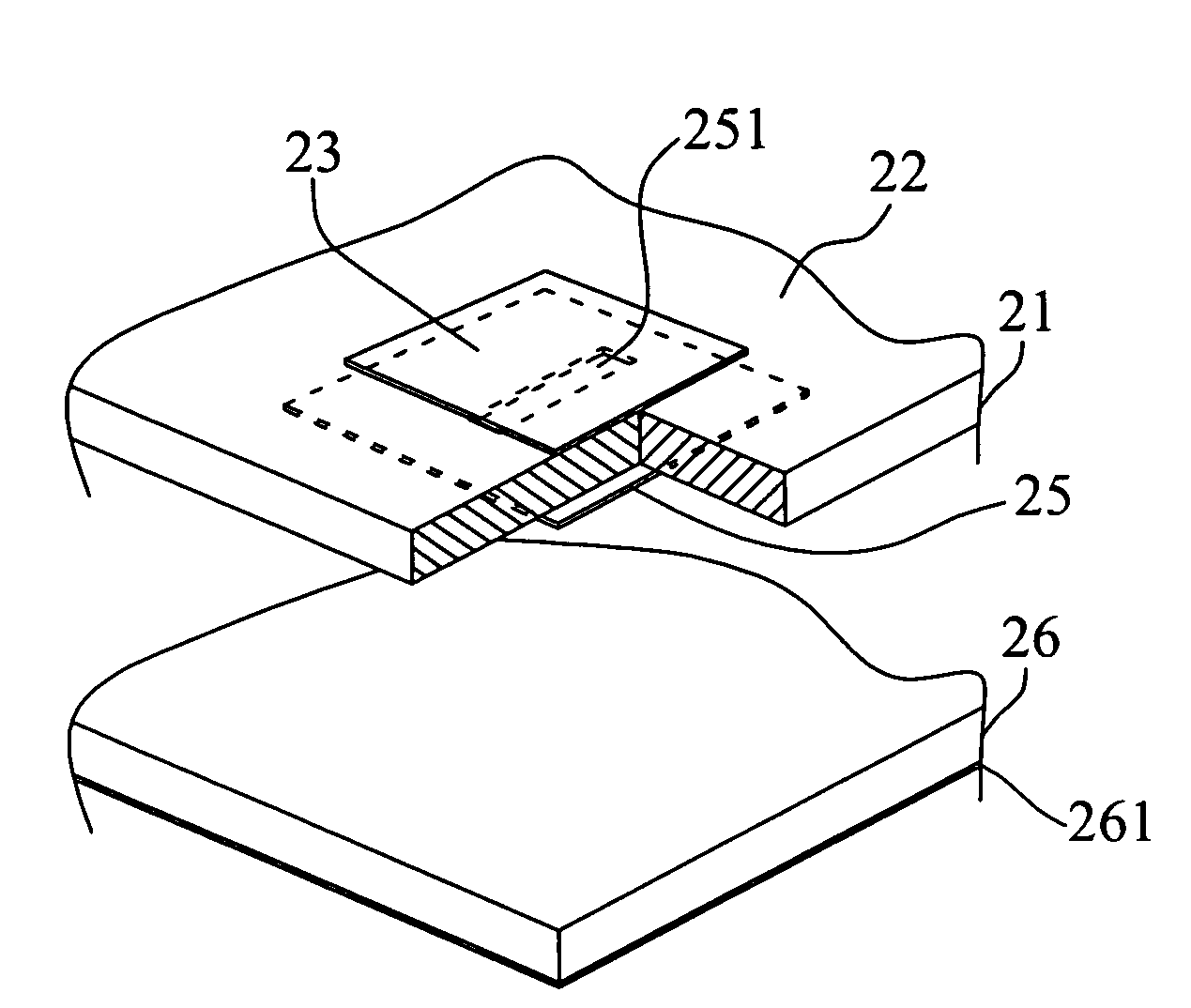

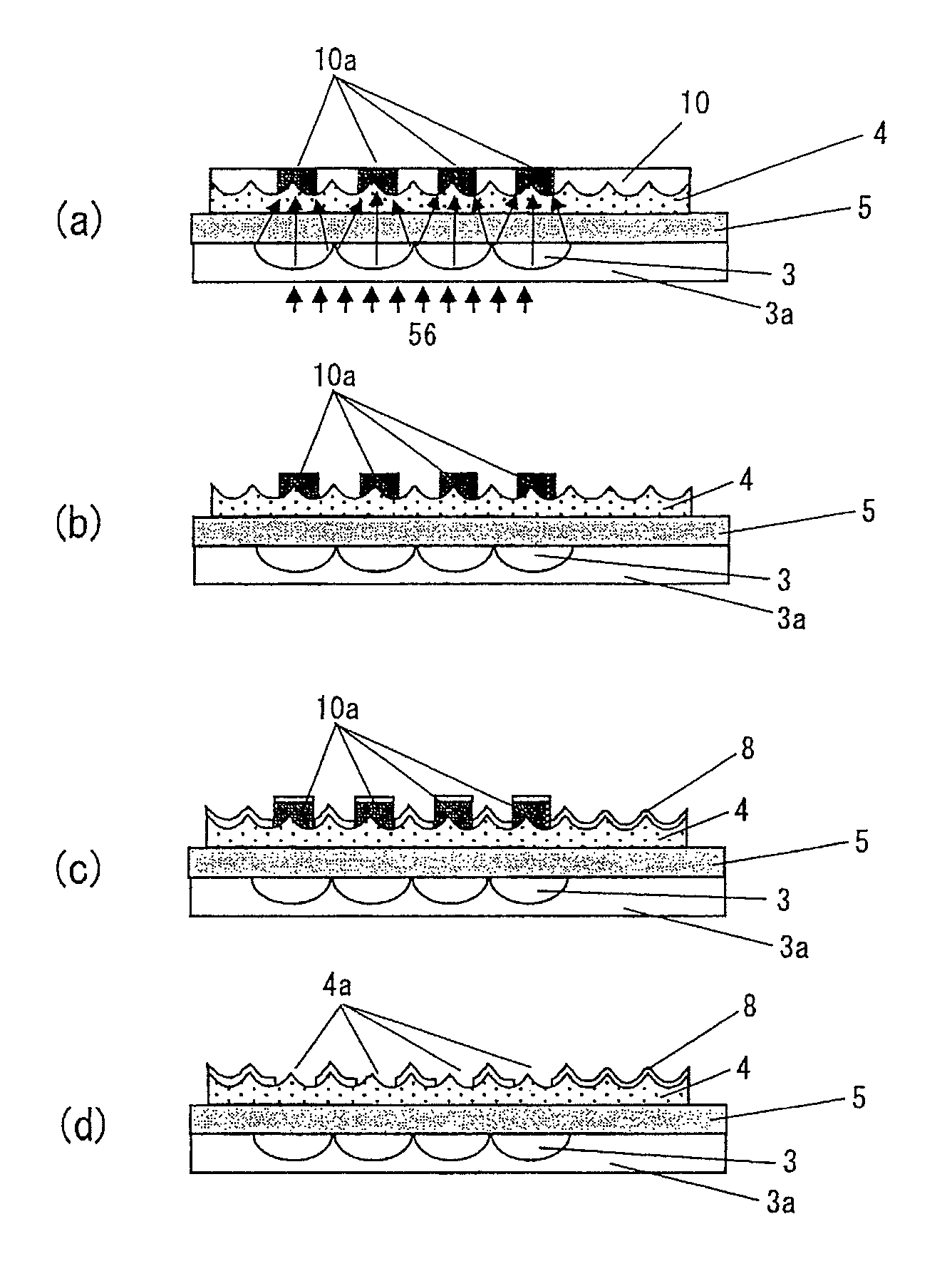

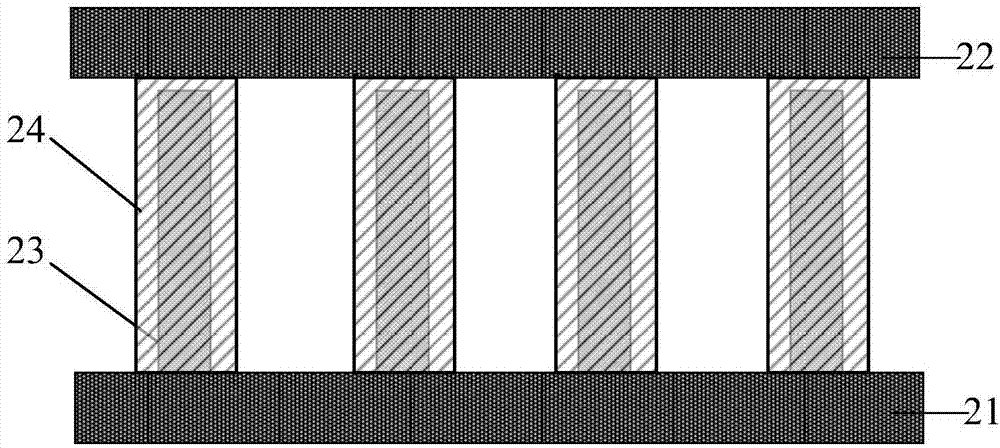

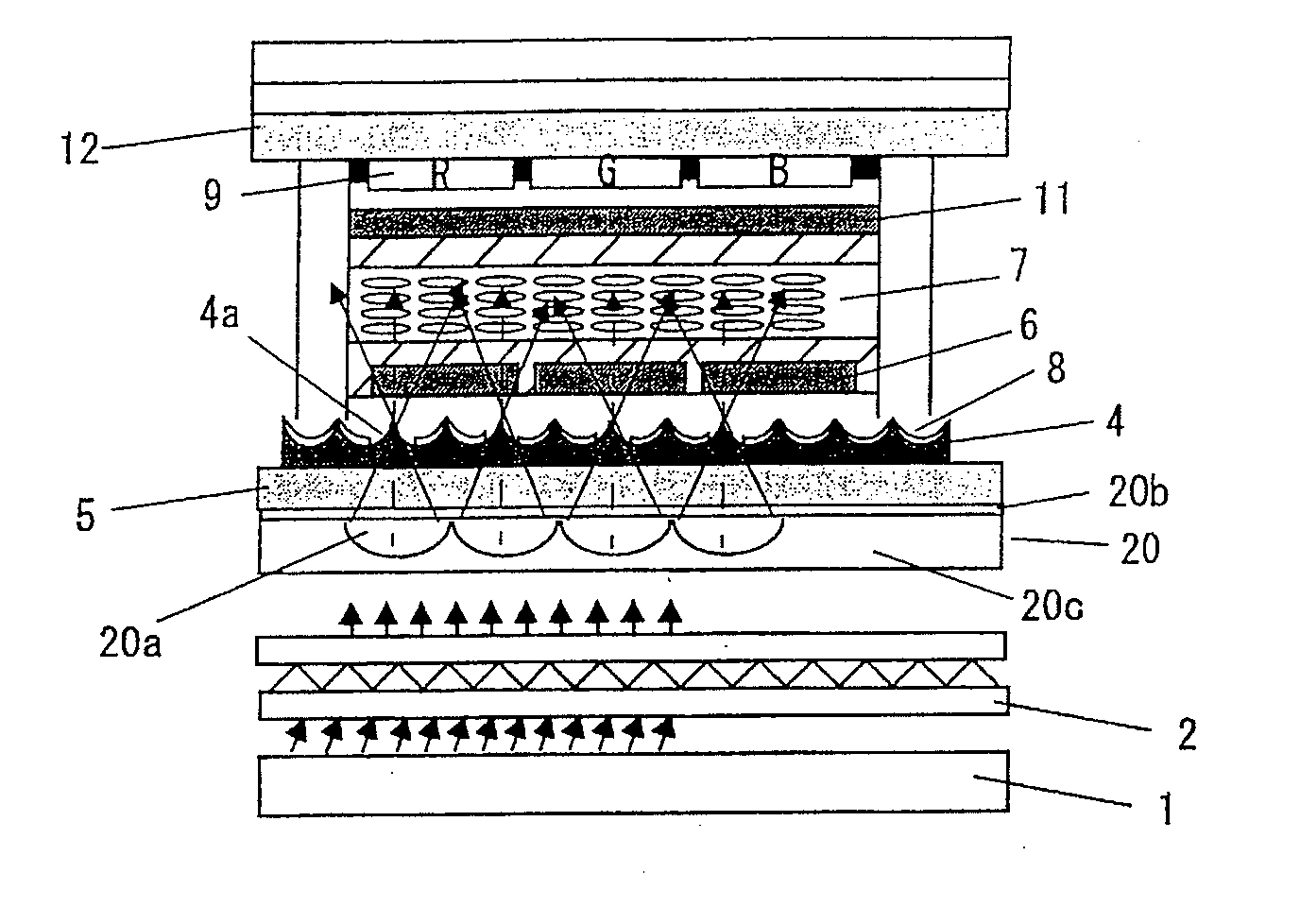

Method for producing apertures in a diffuse reflector layer having a metal reflection film

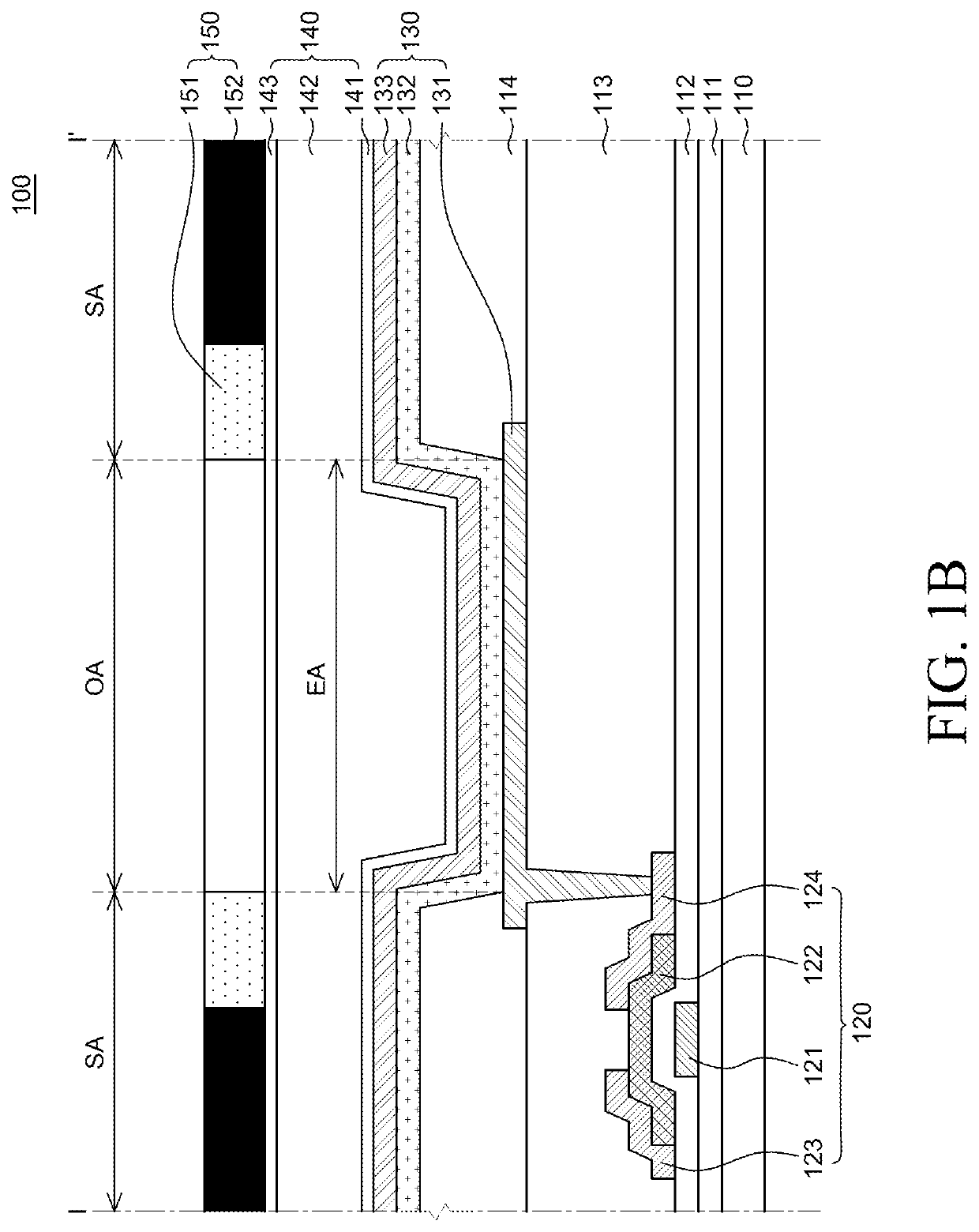

InactiveUS7889310B2Minimize light blockedReduce collection efficiencyDiffusing elementsNon-linear opticsVisibilityLiquid-crystal display

A transflective type liquid crystal display has display side members; rear side members which include a diffuse reflector layer with apertures, and a glass substrate; and a liquid crystal layer interposed between the display side members and the rear side members, wherein on the opposite side from the diffuse reflector layer, the glass substrate has aperture-forming lenses used for exposure and removal during formation of the apertures of the diffuse reflector layer, and a flattening layer used to flatten a concave and convex surface produced by the aperture-forming lenses. This makes it possible to implement a transflective type liquid crystal display with excellent visibility regardless of whether an external light or internal lighting source is used.

Owner:RESONAC CORPORATION

Solar cell, solar cell manufacturing method and electrical equipment

InactiveCN106898663AIncrease profitImprove practicalityMaterial nanotechnologyFinal product manufactureEngineeringSolar cell

The invention provides a solar cell, a solar cell manufacturing method, and electric equipment. The solar cell includes a first substrate and a second substrate disposed opposite to each other; and a plurality of PN junctions disposed between the first substrate and the second substrate, each PN junction being connected with the first substrate and the second substrate and including an inner core as a P electrode and a cladding layer as an N electrode and covering the inner core. According to the invention, the PN junctions of the solar cell are formed by encircling the P electrodes with the N electrodes and such structural design can increase the contact area between the N electrodes and the P electrodes, so that electrons can be quickly separated from empty holes and transmitted and the utilization of solar cells is effectively improved; and in addition, the PN junctions of the embodiment can reduce the reflection area of the light compared to the PN junctions of a laminated structure in the prior art, thus, no anti-reflection layer is required, and manufacturing procedures and the production cost are reduced.

Owner:BOE TECH GRP CO LTD

Method for manufacturing reflective film with opening and liquid crystal display having a part of transmitive region with the same

InactiveUS20070177079A1Minimize light blockedReduce collection efficiencyDiffusing elementsNon-linear opticsVisibilityLiquid-crystal display

A transflective type liquid crystal display has display side members; rear side members which include a diffuse reflector layer with apertures, and a glass substrate; and a liquid crystal layer interposed between the display side members and the rear side members, wherein on the opposite side from the diffuse reflector layer, the glass substrate has aperture-forming lenses used for exposure and removal during formation of the apertures of the diffuse reflector layer, and a flattening layer used to flatten a concave and convex surface produced by the aperture-forming lenses. This makes it possible to implement a transflective type liquid crystal display with excellent visibility regardless of whether an external light or internal lighting source is used.

Owner:HITACHI CHEM CO LTD

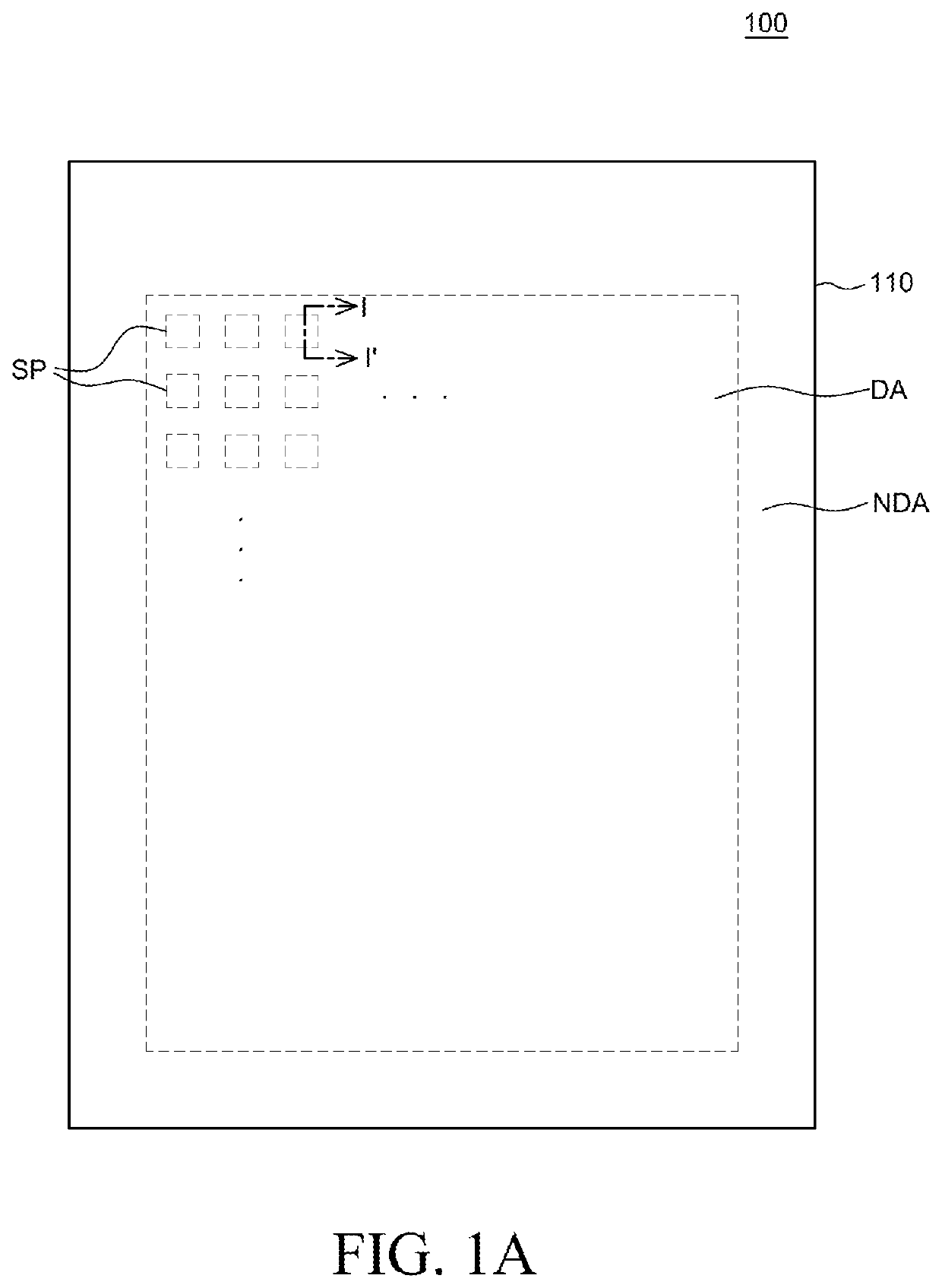

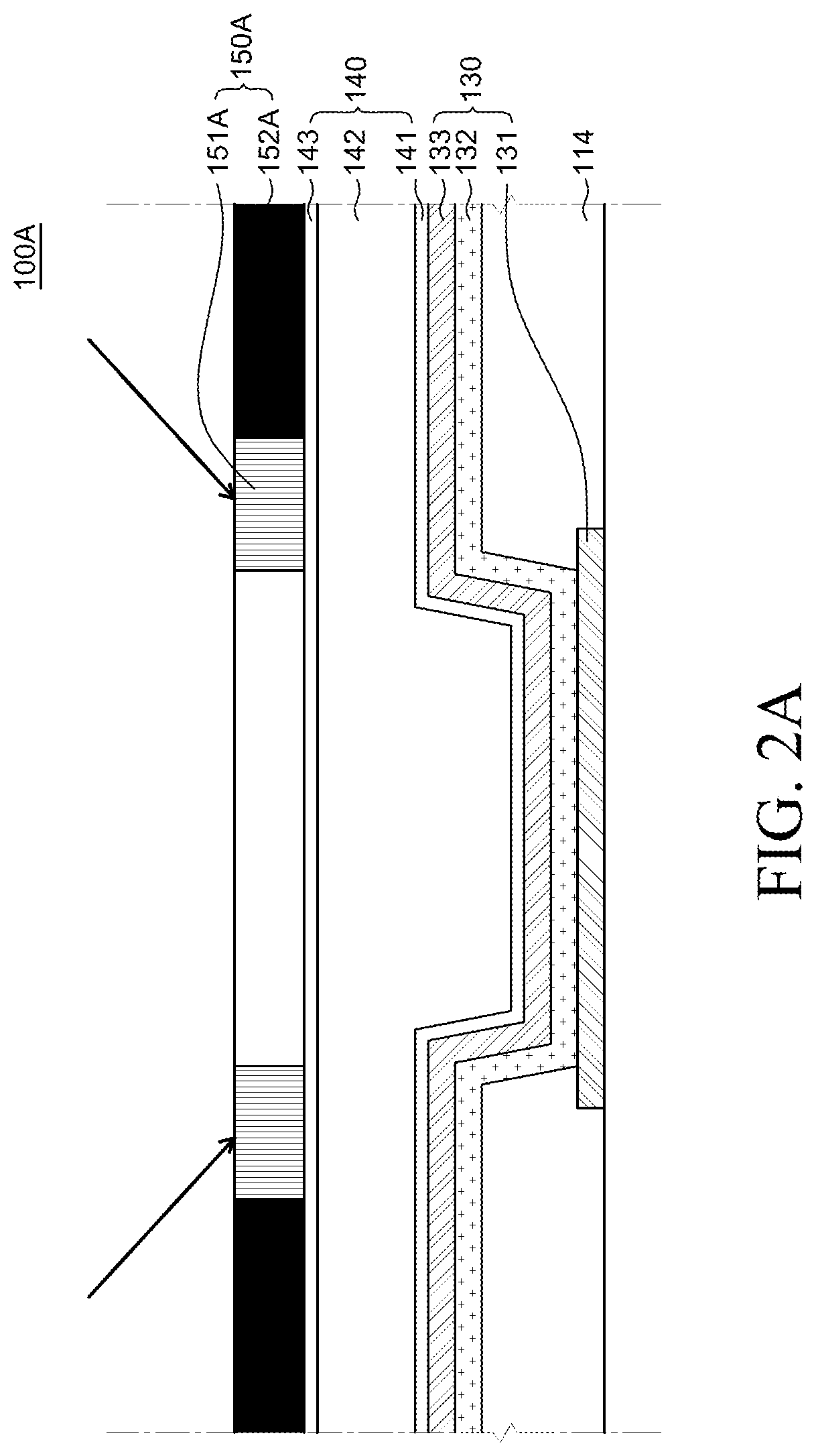

Display device having variable light shielding black matrix layer

PendingUS20210118962A1Reduce power consumptionExtend your lifeSolid-state devicesDiodeDisplay deviceMaterials science

A display device includes a substrate, a thin film transistor, a first electrode, an organic light emitting layer, a second electrode and a black matrix layer which is includes a shielding area and an opening area. The opening area is formed in a position corresponding to an emission area where light is emitted from the organic light emitting layer and the shielding area includes a variable light shielding unit which is adjacent to the opening area and has a light transmittance varying in accordance with a wavelength of incident light and a light shielding unit with a constant light transmittance.

Owner:LG DISPLAY CO LTD

Organic electroluminescent device and preparation method thereof

ActiveCN104485346AReduce reflective areaReduce reflectivitySolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceOLED

The invention belongs to the field of organic electroluminescence and relates to an organic electroluminescent device. Organic light emitting diodes are internally provided with black matrix layers; each matrix layer occupies a certain area proportion in each organic light emitting diode, so that light reflection area can be effectively reduced; a reflection rate of the organic electroluminescent device is reduced on the premise of not sacrificing brightness and power consumption of the organic electroluminescent device; and furthermore, the organic electroluminescent device is simple in structure and suitable for large-scale industrial production application. At the same time, the invention relates to a preparation method of the organic electroluminescent device. The purpose of reducing the reflection rate of the organic electroluminescent device on the premise of not sacrificing the brightness and the power consumption of the organic electroluminescent device can be achieved by arranging the matrix layers in the organic light emitting diodes only by a photoetching technology, the technology is simple, and the preparation cost is low.

Owner:北京维信诺光电技术有限公司

Time sequence logic control mechanism

The invention belongs to a structural design technology and relates to a time sequence logic control mechanism. The time sequence logic control mechanism comprises a fixed slide rail, a driving shaft, a front driving slider, a rear driving slider, a front ball, a rear ball, a front cantilever, a rear connecting rod and a cabin door. The mechanism achieves logic switch among the closed state, the inward inclination state and the opening state of the cabin door in a narrow and small space and achieves state locking. Compared with the prior art, the number of the parts needed for the mechanism is small, and the mechanism is light, small in occupied space and simple. Compared with the prior art, the mechanism is simple, high in bearing capacity and high in reliability.

Owner:CHENGDU AIRCRAFT DESIGN INST OF AVIATION IND CORP OF CHINA

Light source components and lamps

InactiveCN103363324BChange angleThe light range can be adjustedElectric lightingLight fasteningsEngineeringLight source

The invention discloses a light source assembly which comprises a fixing assembly, at least two light sources and at least one pair of reflectors. The light source assembly further comprises a reflector rotating assembly. The fixing assembly comprises two opposite installing faces, and at least two light sources are arranged on the two installing faces in a one-to-one corresponding mode. Two reflectors in each pair of reflectors are connected with two sides of the fixing assembly oppositely in a rotation mode, reflecting sides of the reflectors face the light sources, the reflecting sides and the installing faces define accommodating cavities with emergent light openings, each light source is accommodated in a corresponding accommodating cavity, emergent light directions of the emergent light openings are parallel to the installing faces, and the reflector rotating assembly drives the two reflectors in each pair of reflectors to rotate to be away from each other or close to each other. By using the reflector rotating assembly to drive the two reflectors in each pair of reflectors to rotate to be away from each other or close to each other, light emitting included angles are changed, and the light sources with adjustable lighting ranges are obtained. In addition, a lamp comprising the light source assembly is further provided.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

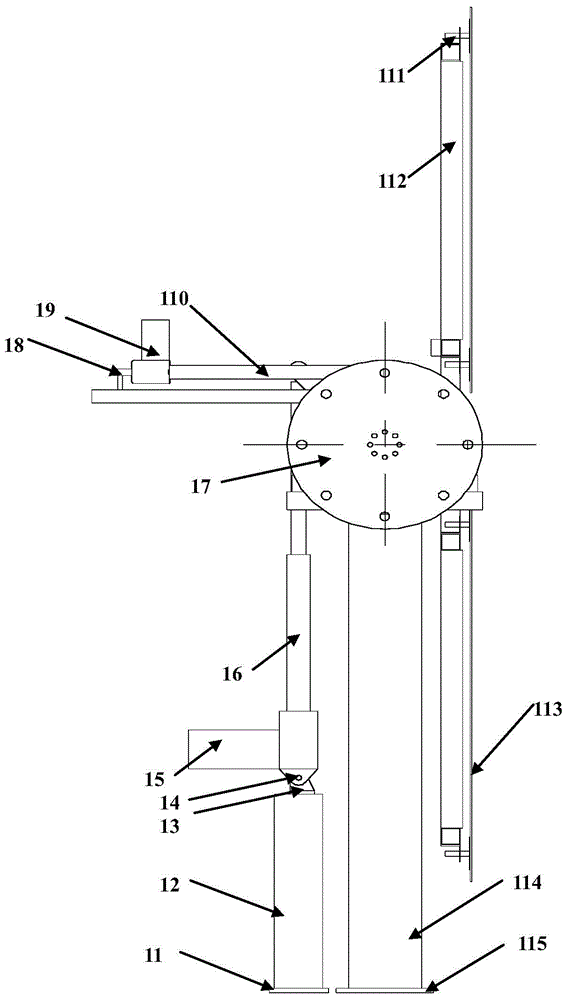

Novel linkage heliostat

ActiveCN104483979ALower the altitudeReduce weightControl using feedbackEngineeringMechanical engineering

The invention discloses a novel linkage heliostat. The novel linkage heliostat is characterized by comprising an elevation angle driving mechanism, wherein the elevation angle driving mechanism drives at least two reflector modules to commonly do elevation angle rotation movement. The novel linkage heliostat employs combined motion setting of the multiple reflector modules, unit reflectors are connected in series through a torque axis to form a reflector module, the multiple reflector modules are connected through flange discs, the multiple reflector modules are driven to simultaneously move by employing the elevation angle driving mechanism, through reducing height of the reflector modules and the reflection area of the reflector modules to reduce wind load, weight of the reflector modules per a reflection area unit is reduced, mounting and debugging difficulty is reduced, relevant cost is reduced, moreover, the novel linkage heliostat can guarantee tracking precision of multiple unit reflectors in the elevation angle direction, so cost of the elevation angle driving mechanism is further reduced.

Owner:STATE GRID CORP OF CHINA +3

Vertical Take-Off and Landing Unmanned Aerial Vehicle Having Foldable Fixed Wing and Based on Twin-Ducted Fan Power System

ActiveUS20220081111A1Reduce power lossHigh lift-to-weight ratioFuselage framesPropellersSuction forceLevel flight

A vertical take-off and landing (VTOL) unmanned aerial vehicle having a foldable fixed wing and a twin-ducted fan power system (7) arranged at a tail portion of a fuselage in a transverse and tail propulsion arrangement provides lift for vertical take-off and landing and propulsion for horizontal flight. By means of deflection of a control servo plane arranged at a duct exit, a vectored thrust is provided to enable a fast attitude change. When the aerial vehicle takes off and lands vertically / flies at a low speed, the wing is folded to reduce the frontal area exposure to crosswind. When the aerial vehicle is flying horizontally, the wing is expanded to obtain larger lift. A Coanda effect is created at a trailing edge of the wing by suction of the duct to improve performance.

Owner:SOUTH CHINA UNIV OF TECH

Vertical take-off and landing unmanned aerial vehicle and control method thereof

InactiveCN111422348AStable vertical takeoffSmooth landingAircraft navigation controlPower plant typeTransverse axisLevel flight

The invention discloses a vertical take-off and landing unmanned aerial vehicle and a control method thereof. The unmanned aerial vehicle comprises a wing body fusion fuselage, a power system and an undercarriage, and the power system comprises turbofan engines and lift fan engines; the wing body fusion fuselage adopts a structure which is symmetrical along the longitudinal axis and the transverseaxis of the overlooking plane; the two turbofan engines are symmetrically and externally connected to the left side and the right side of the wing body fusion fuselage, and the turbofan engines are connected with the wing body fusion fuselage through tilting transmission mechanisms; the two lift fan engines are symmetrically buried at the front end and the rear end of the wing body fusion fuselage. The control method comprises the following five stages of stage 1, vertical take-off and hovering, stage 2, hovering in the air and performing level flight, stage 3, level flight, stage 4, level flight-hovering in the air, and stage 5, hovering in the air and vertically landing. When the unmanned aerial vehicle takes off and lands vertically, lift force and auxiliary balance are provided by thefour engines, the aircraft is low in control difficulty and large in internal space of the fuselage, and the problems that an existing vertical take-off and landing unmanned aerial vehicle is difficult to control and small in load capacity are solved.

Owner:SHENYANG AEROSPACE UNIVERSITY

Vertical take-off and landing unmanned conveyor and control method thereof

The invention discloses a vertical take-off and landing unmanned aerial vehicle and a control method thereof, and belongs to the field of aviation. According to the unmanned transport plane, the liftfan is used for providing lift and assisting balance during vertical take-off and landing; meanwhile, through the design of the aircraft structure and the aerodynamic layout, the control difficulty ofthe aircraft is reduced, the goods carrying space of the aircraft is increased, the problems that an existing vertical take-off and landing unmanned aerial vehicle is difficult to control and small in load capacity are effectively solved, vertical and short-distance take-off and landing are achieved, and the aircraft has the advantages of flexible and stable flight, wide application range, largeload capacity and the like.

Owner:SHENYANG AEROSPACE UNIVERSITY

Flapping-wing flying water automobile

InactiveCN1118385CControl thrustControl liftConvertible vehiclesOrnithoptersFlapping wingControl system

The flapping-wing fling water automobile includes engine, double-blade air screw propeller, right and left hydraulic screw propellers, right and left wings, control system, safety lifesaving equipment, and four-wheel undercarriage, hanging damper and fuselage, with the wings being connected to the fuselage via mechanical and hydraulic mechanism. The present automobile is one traffic facility for land, water and air use simultaneously, and has high efficiency and maneuverability. Its wings may be folded for land running.

Owner:程纪

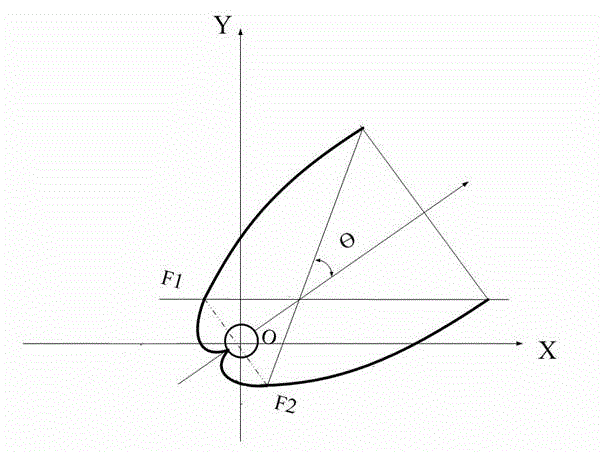

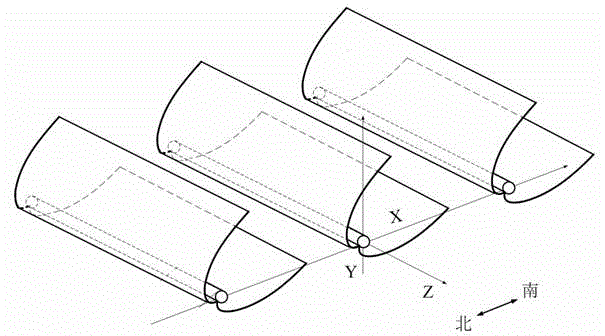

Horizontal axis type asymmetric single-parabola composite track-free solar concentrator

InactiveCN102914061AReduce reflective areaLow failure rateSolar heating energyMirrorsEngineeringReflective layer

The invention relates to a horizontal axis type asymmetric single-parabola composite track-free solar concentrator, which comprises involute light gathering plates with unequal spread angles, a single-side parabola light gathering plate, a cylindrical vacuum tube, a reflecting layer, a bracket, a coaxial hollow seat and a dust washing hole, wherein the reflecting layer is rigidly connected with the light gathering plate; the light gathering plate is rigidly connected with the bracket; the coaxial hollow seat is rigidly connected with the bracket; the cylindrical vacuum tube is fixed in the inner hole of the coaxial hollow seat; and the dust washing hole is arranged on the bottom of the light gathering plate. According to the horizontal axis type asymmetric single-parabola composite track-free solar concentrator, the reflecting area is reduced, and the north-south lighting angle is increased, the sunlight in the elevation angle range of 90 degrees can be collected all day without light tracking; the lighting efficiency of unit area is greatly increased, the production cost is reduced, the failure rate is reduced, and the convenience in installation and maintenance is achieved. The horizontal axis type asymmetric single-parabola composite track-free solar concentrator is suitable for solar medium-low temperature heat collection of the vacuum tube with a cylindrical heat absorbing body, and can form a large-scale solar medium-low temperature heat collecting array.

Owner:上海镁双莲太阳能科技有限公司

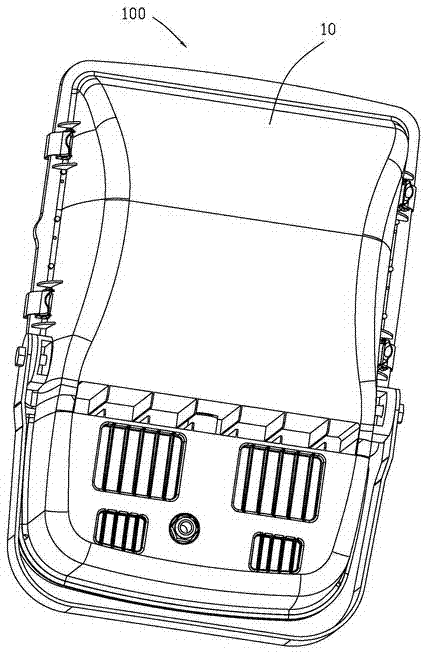

Disc-shaped manned four-rotor aircraft

InactiveCN104743117AAvoid bumping intoImprove securityAircraft power transmissionAircraftsDrive shaftOperability

The invention relates to an aircraft and in particular relates to a disc-shaped manned four-rotor aircraft which is strong in cruising ability, good in operability and stability, safe, reliable, and attractive in appearance. According to the technical scheme adopted by the invention, an engine compartment is arranged on the bottom of a body, a flight compartment is arranged on the top of the body, an undercarriage is arranged at the bottom of the engine compartment, a split-flow transmission gearbox is arranged in the center of the body, the split-flow transmission gearbox is connected with a power transmission gearbox; the power transmission gearbox is connected with an engine through a clutch; the engine is mounted at the bottom of the body; steel tube beams are arranged at four output ends of the transmission gearbox; rotor gearboxes are arranged on the end parts of the steel tube beams; the split-flow transmission gearbox is connected with the rotor gearboxes through transmission shafts; the transmission shafts are positioned inside the steel tube beams; rotors are mounted on output shafts of the rotor gearboxes. The disc-shaped manned four-rotor aircraft is widely applied to various four-rotor aircrafts.

Owner:河南金原碟科技有限公司

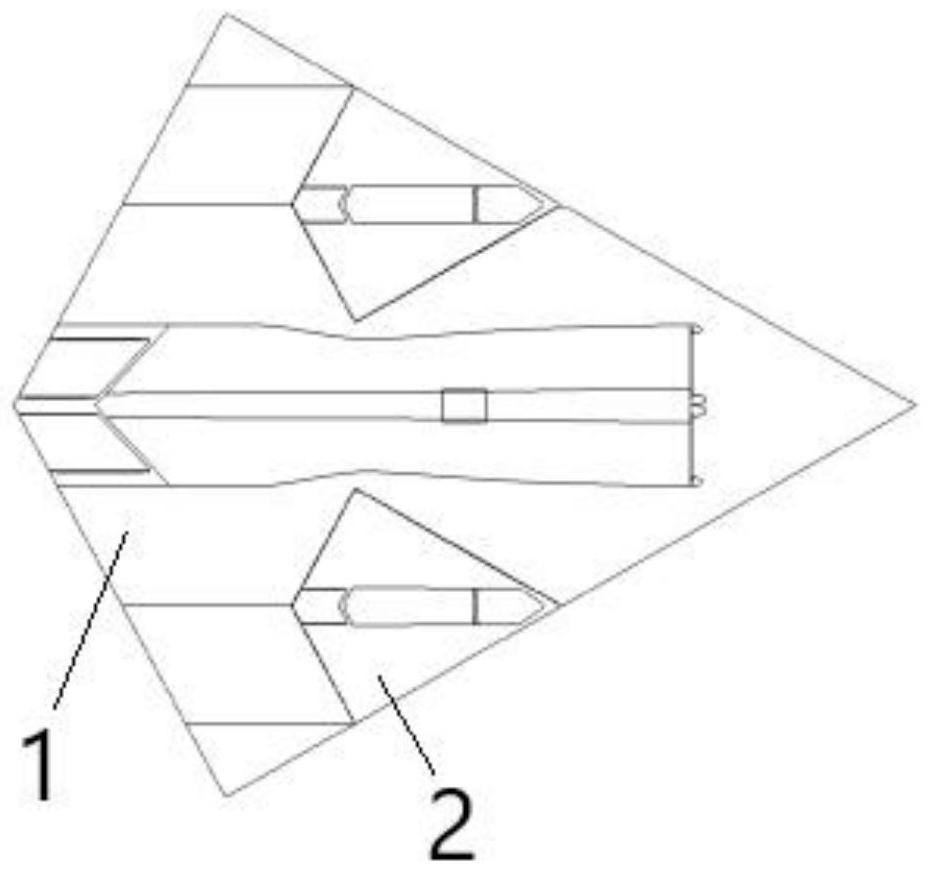

Combined aircraft aerodynamic layout structure for cooperative tasks

PendingCN113928537AStable controlLittle changeConvertible aircraftsWing shapesFlight vehicleControl engineering

The invention discloses a combined aircraft aerodynamic layout structure for cooperative tasks, and particularly relates to the field of overall design of aircrafts. The combined aircraft aerodynamic layout structure for the cooperative tasks comprises a main machine and two sub-machines, the main machine adopts the layout of a front rhombic wing and a rear sweep-forward wing, the two sub-machines are symmetrically distributed on the two sides of the main machine, each sub-machine is embedded between the rhombic wing and the sweep-forward wing of the main machine, and the main machine and the two sub-machines have a complete flying wing layout in a combined state. By the adoption of the technical scheme, the problem that gravity center change and pneumatic center change are caused by neutron machine separation of an existing combined aircraft is solved, and different flight task requirements can be met.

Owner:中国空气动力研究与发展中心空天技术研究所

Light shielding sheet and lens

The invention relates to a light shielding sheet and a lens, wherein the light shielding sheet comprises: a base layer; a base layer through hole disposed on the base layer; a first surface layer; a first through hole disposed on the first surface layer; a second surface layer; and a second through hole disposed on the second surface layer. The first surface layer and the second surface layer aredisposed on the two opposite sides of the base layer respectively. The base layer through hole, the first through hole and the second through holes are disposed coaxially. The first surface layer andthe second surface layer are film layers containing wax material. In the process of punching the first surface layer and the second surface layer, the first surface layer and the second surface layerare easy to be subjected to machining and matting treatment because of the wax material. The wax material has the advantage of reducing the friction during the processing so as to improve shearing efficiency, reduce machined burrs at a cross-section position, and smooth the cross section during the punching, thereby contributing to improvement in the image quality of the lens.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Light source assembly and lamp

InactiveCN103363322ASimplify the installation processReduce reflective areaElectric lightingLight fasteningsLocking mechanismEngineering

A light source assembly comprises a fixing assembly, light sources, reflectors, a fixing plate and a locking mechanism. The fixing assembly comprises a first fixing end, a second fixing end and two opposite installing faces, the first fixing end and the second fixing end are arranged oppositely, the installing faces are arranged between the first fixing end and the second fixing end, and the light sources are arranged on the two installing faces in a one-to-one corresponding mode. Two reflectors are arranged on two sides of the fixing assembly oppositely, reflecting sides of the reflectors face the light sources, the reflecting sides and the installing faces define accommodating cavities with emergent light openings, each light source is accommodated in a corresponding accommodating cavity, and emergent light directions of the emergent light openings are parallel to the installing faces. The fixing plate comprises a load bearing face and a clamping portion. The clamping portion is fixed on the load bearing face and clamped with the first fixing end, and the locking mechanism is fixed on the load bearing face and comprises a telescopic piece. When the telescopic piece is stretched, the telescopic piece is clamped on the second fixing end, and when the telescopic piece is retracted, the second fixing end is released. The fixing assembly can be clamped or released through stretching and retracting of the locking mechanism, and light source installing and detaching are simplified. In addition, a lamp comprising the light source assembly is further provided.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

A vertical take-off and landing unmanned aerial vehicle and its control method

InactiveCN111422348BSmooth landingIncreased maximum take-off weightAircraft navigation controlPower plant typeTransverse axisLevel flight

A vertical take-off and landing unmanned aerial vehicle and its control method. The unmanned aerial vehicle includes a wing-body fusion fuselage, a power system, and a landing gear. The power system includes a turbofan engine and a lift fan engine; The plane’s longitudinal axis and horizontal axis are both symmetrical structures; two turbofan engines are symmetrically connected to the left and right sides of the wing-body fusion fuselage, and the turbofan engines are connected to the wing-body fusion fuselage through a tilting transmission mechanism; the two lift The fan engines are buried symmetrically at the front and rear ends of the wing-body fusion body. The control method includes five stages, stage 1: vertical take-off → hovering in the air; stage 2: hovering in the air → level flight; stage 3: level flight; stage 4: level flight → hovering in the air; stage 5: hovering in the air → vertical landing. When the UAV takes off and lands vertically, four engines provide lift and auxiliary balance. The control difficulty of the aircraft is low and the internal space of the fuselage is large, which solves the problems of difficult control and small load of the existing vertical take-off and landing unmanned aircraft.

Owner:SHENYANG AEROSPACE UNIVERSITY

Bulkhead type hidden connecting joint

The invention discloses a bulkhead type hidden connecting joint. The connecting joint comprises a back flitch plate, a second through hole is formed in the back flitch plate, an internal thread roundsteel cylinder is welded in the second through hole, a first threaded hole and a conical groove are formed in the internal thread round steel cylinder, and a first through hole is formed at the position, at the connecting joint, of a bulkhead. The back flitch plate is fixedly connected to the inner side of the bulkhead through welding, and the head of the internal thread round steel cylinder is installed in the first through hole; when equipment is not connected, a cross countersunk bolt is fixedly mounted in a first threaded hole; when a structure is erected or other equipment is hung, the first threaded hole is fixedly provided with a second connecting pair through a first outer hexagon bolt and a second outer hexagon bolt; after the structure is adopted, the bulkhead can be flat and free of protrusions, and the appearance is attractive; the radar reflection area is effectively reduced, so that a ship has better stealth performance; and the fixed connecting joint is provided when anexternal structure is erected on the ship, operation is easy, and safety and reliability are achieved.

Owner:马鞍山市华奇维亚科技发展有限公司

Manufacturing process of periscopic camera module shell

ActiveCN114669963AThickness is small and controllableInhibitionVacuum evaporation coatingSputtering coatingImaging qualityEngineering

The invention belongs to the technical field of camera modules, and particularly relates to a manufacturing process of a periscopic camera module shell, which at least comprises the following steps: etching: placing a base material subjected to coating, exposure and development treatment in an etching solution for etching treatment to obtain a substrate with a light through hole, and forming a chamfer structure on the inner side edge of the light through hole; film plating: plating an absorbing film layer on the substrate by adopting a plasma sputtering film plating process, and in the film plating process, shielding a non-film-plating region by using a jig, so that the absorbing film layers are attached to the film plating region and the chamfering structure; bending is conducted, specifically, stamping and bending operation is conducted on the coated substrate, and a shell frame is obtained; and the shell frame obtained in the third step is subjected to laser welding, and the needed shell is obtained. Compared with the prior art, light reflection of the light through hole can be reduced to the maximum extent under the dual effects of reducing the reflection area and reducing the reflectivity, so that stray light is inhibited, the thickness of the film layer is small and controllable, and the image quality and definition of the camera are improved.

Owner:GUANG DONG YUPIN IND CO LTD

hovercraft

An air cushion attach boat belongs to the technical field of air cushions and is formed by a boat body, air cushion apron boards on two sides and an air sac formed by a front and back air cushion apron plates and propellers. The air cushion attack boat can interfere, strike, attack or suicidally attack an enemy warship via unmanned and remote-control operation; the air cushion attack boat can also navigate at irregular high speed and can suspense and backwardly navigate; and the air cushion attack boat can navigate with an air cushion, semi-diving navigate or shallow-diving navigate. The air cushion attack boat can flexibly turn over and sensitively change speed; with small size, the air cushion attack boat requires low cost; a plurality of air cushion attack boats can go with ocean waves up and down, in twists and turns and disappearing and appearing; the air cushion attack boats can attack in groups from all around directions in an irregular advancing way; and the air cushion attack boats are like poisonous bees difficult to be dispelled and the air cushion attack boats can conduct attacks on enemy warships in turns for many times.

Owner:戴旭苗

A bionic folding wing based on 4D printing and its preparation method and application

ActiveCN110304246BHigh folding rateAchieve foldingAdditive manufacturing apparatusOrnithoptersFlapping wingFlight vehicle

The invention belongs to the field of aircraft, and specifically discloses a bionic folding wing based on 4D printing and its preparation method and application. The folding wing sheath of the bionic folding wing is connected with the bionic flapping wing skeleton, which is used to protect and store the bionic folding wing in a folded state. The flapping wing skeleton can be stretched and folded according to the temperature of the water in the water circulation flow channel. The water circulation control system is connected with the water circulation flow channel to control the temperature of the water in the water circulation flow channel. The flapping wing film covers the surface of the bionic flapping wing skeleton. The bionic folding wing based on 4D printing provided by the present invention can ensure that the bionic folding wing has a great folding rate, and at the same time only need the water circulation control system to adjust the temperature of the water in the water circulation channel to realize the unfolding and folding of the bionic folding wing, which can avoid Using a cumbersome mechanical structure, it has the advantages of simplicity, high efficiency, high mobility, and intelligence.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com