Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Reduce multiplicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

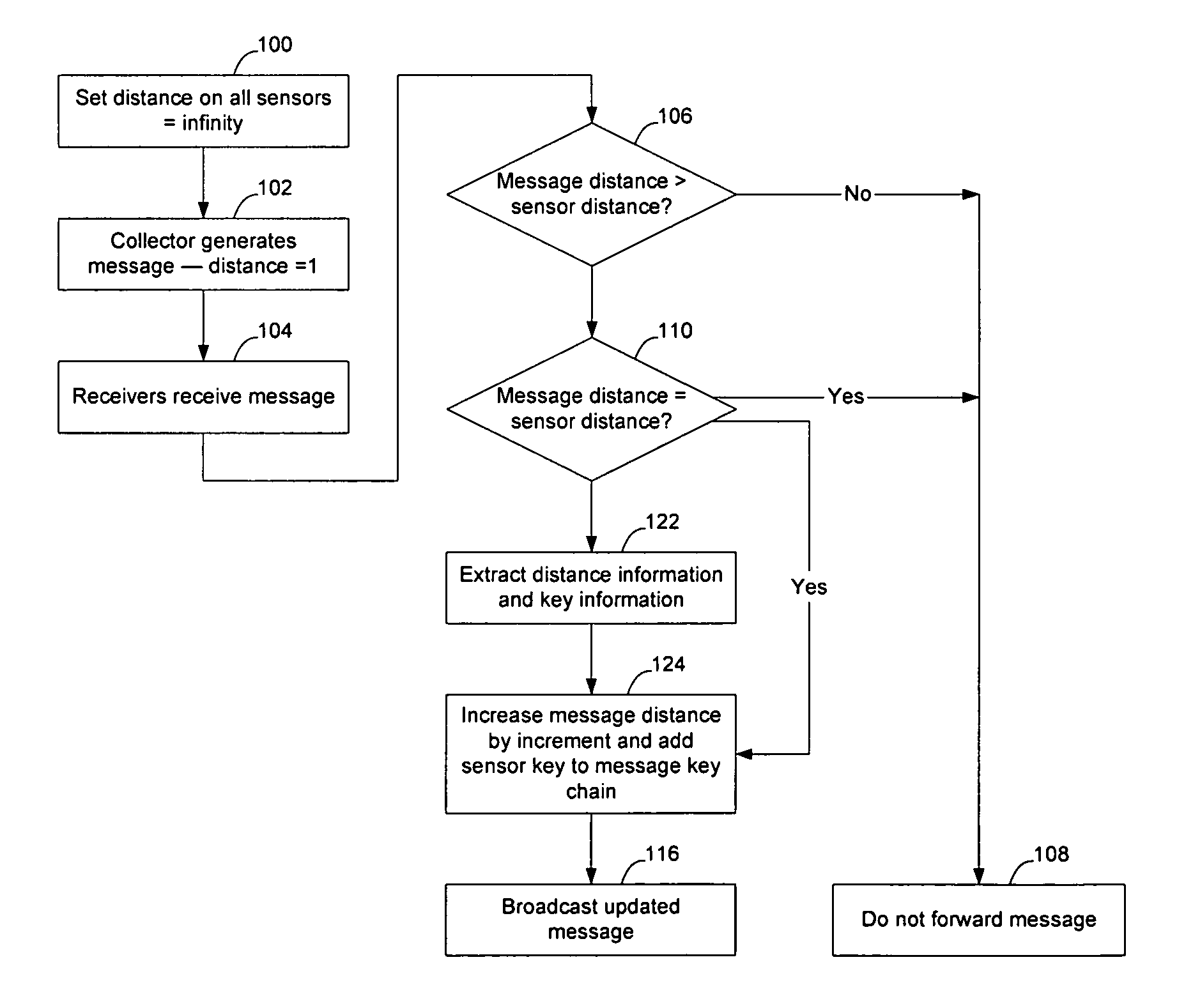

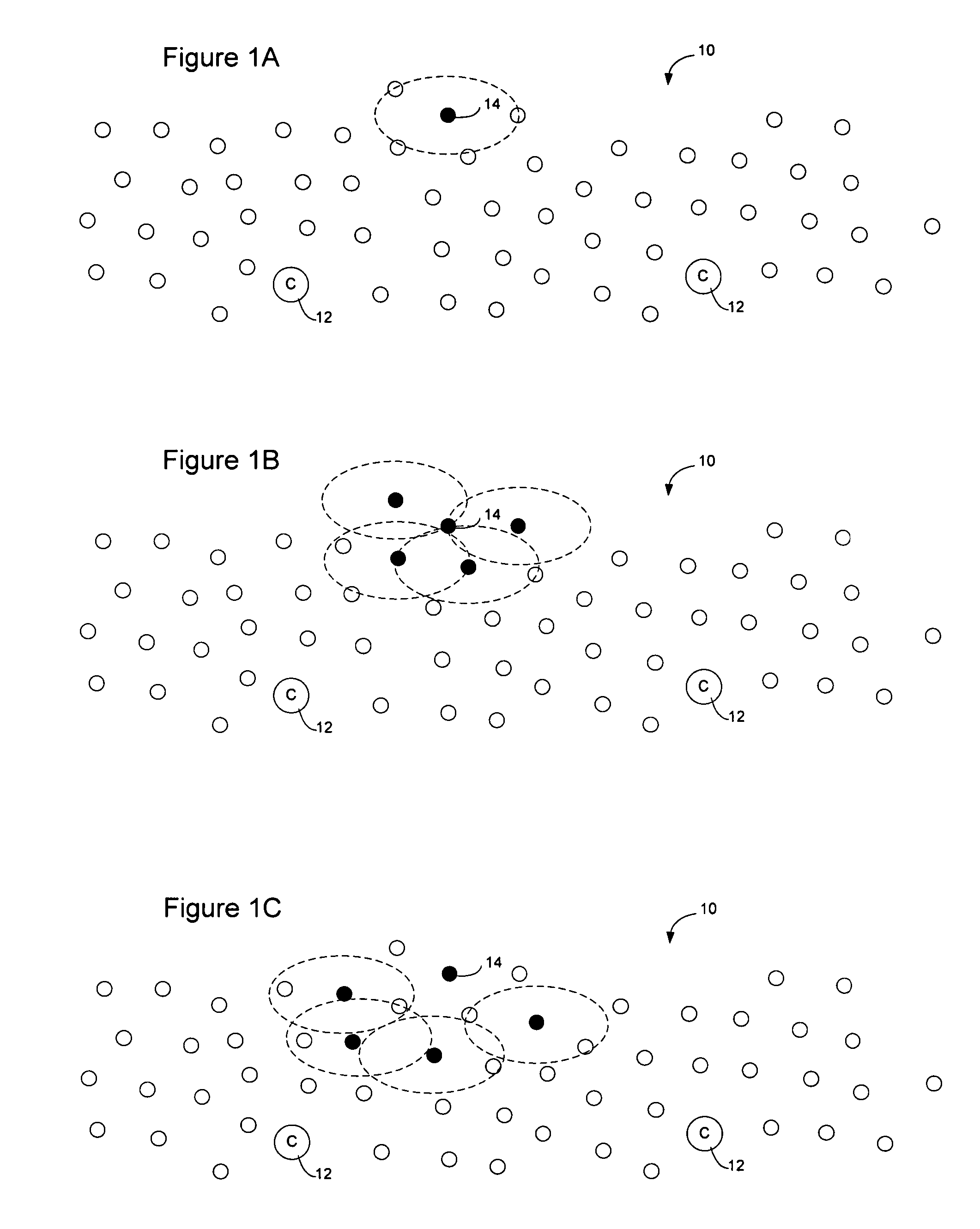

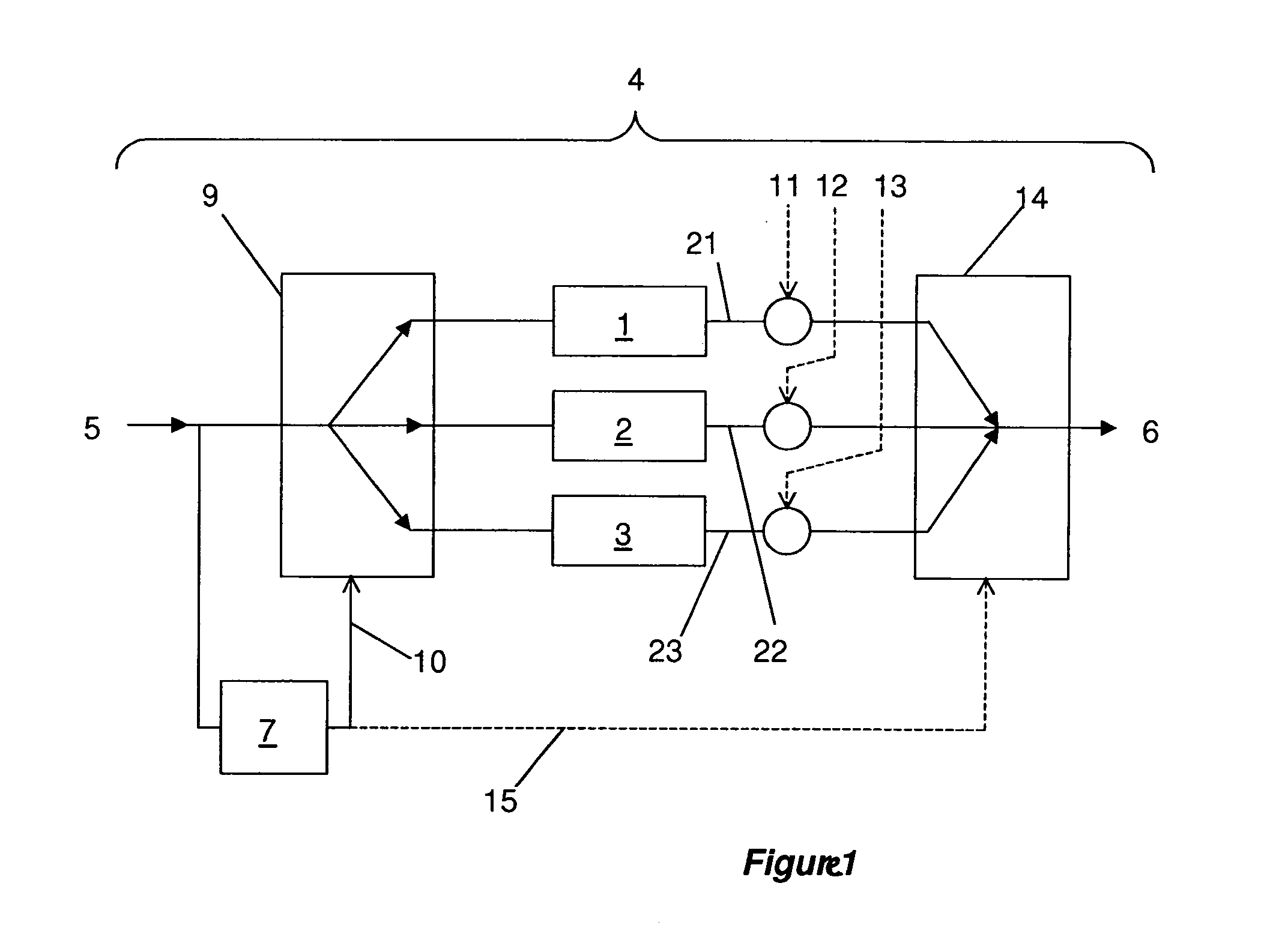

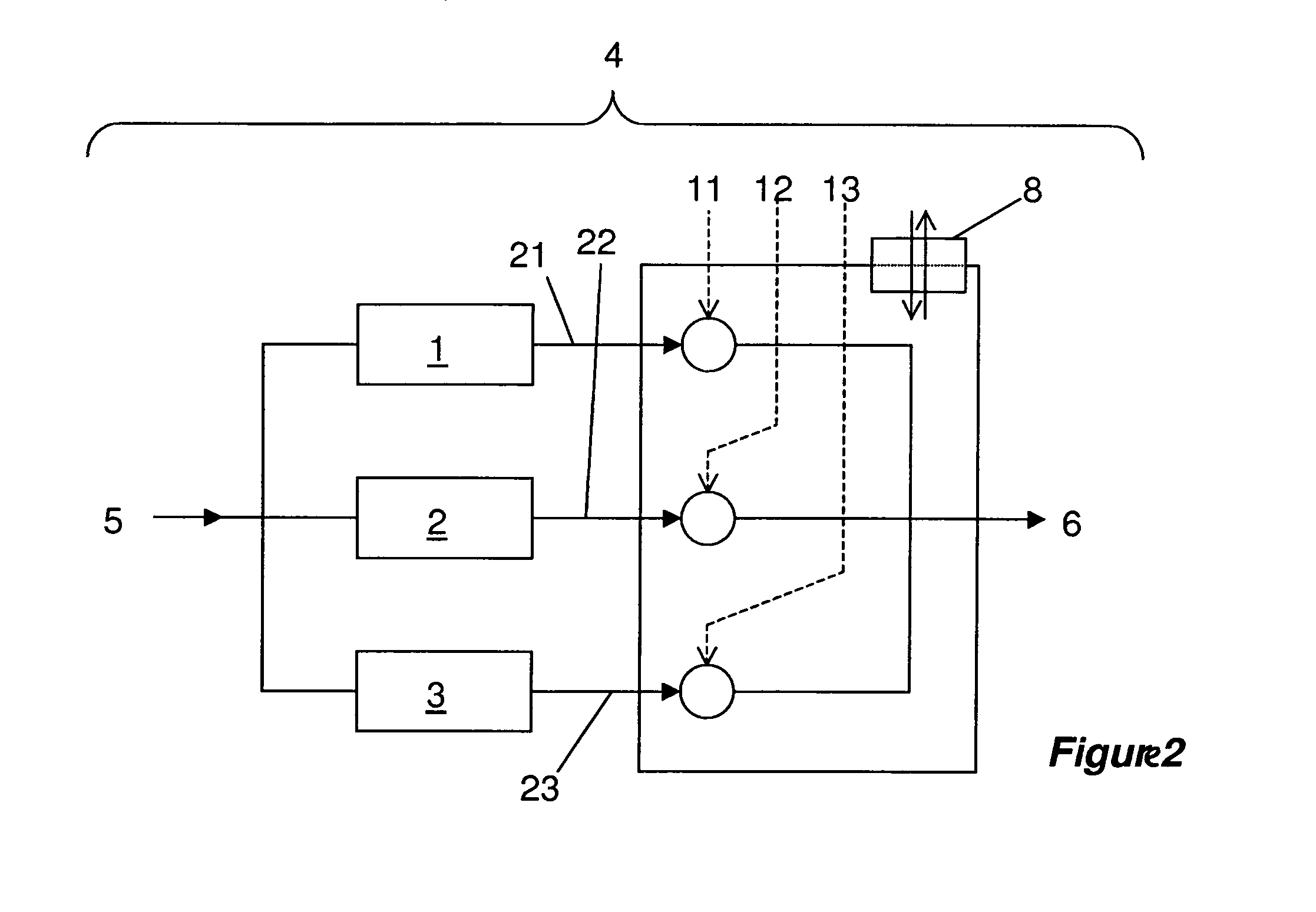

Method and apparatus for sensor network routing

InactiveUS7466681B2Reduce multiplicityNetwork topologiesData switching by path configurationTraffic conditionsComputer science

Owner:RPX CLEARINGHOUSE

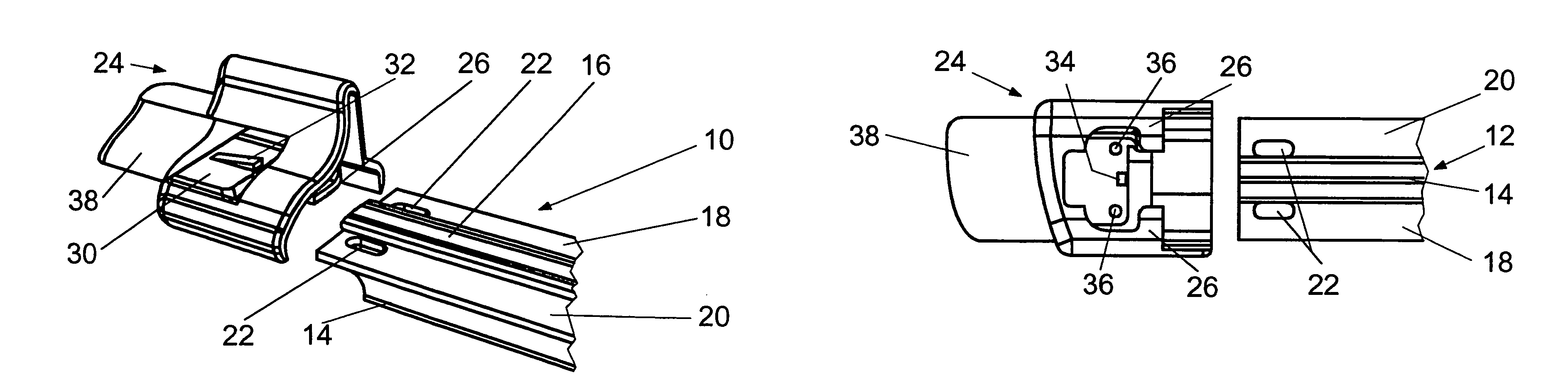

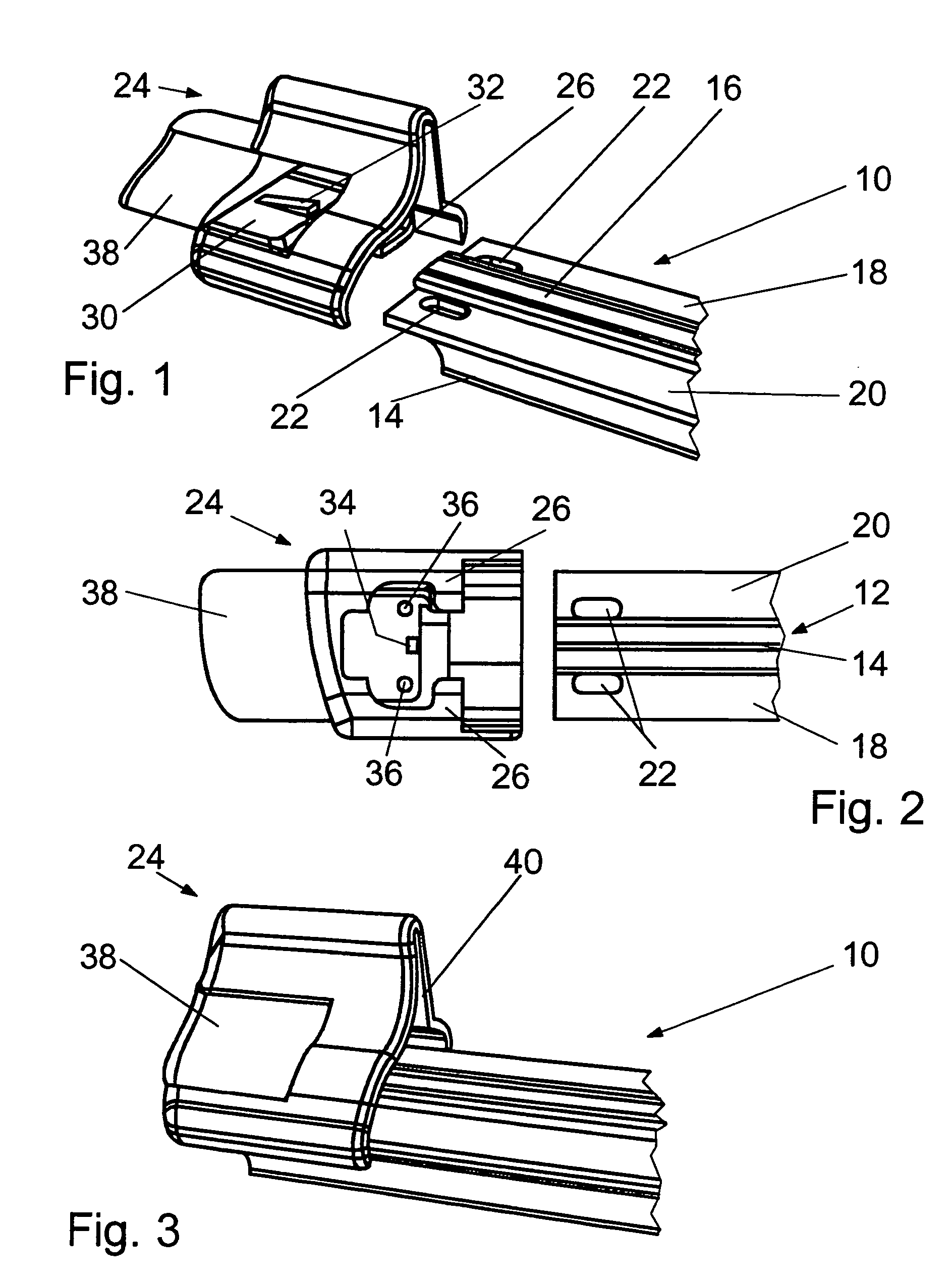

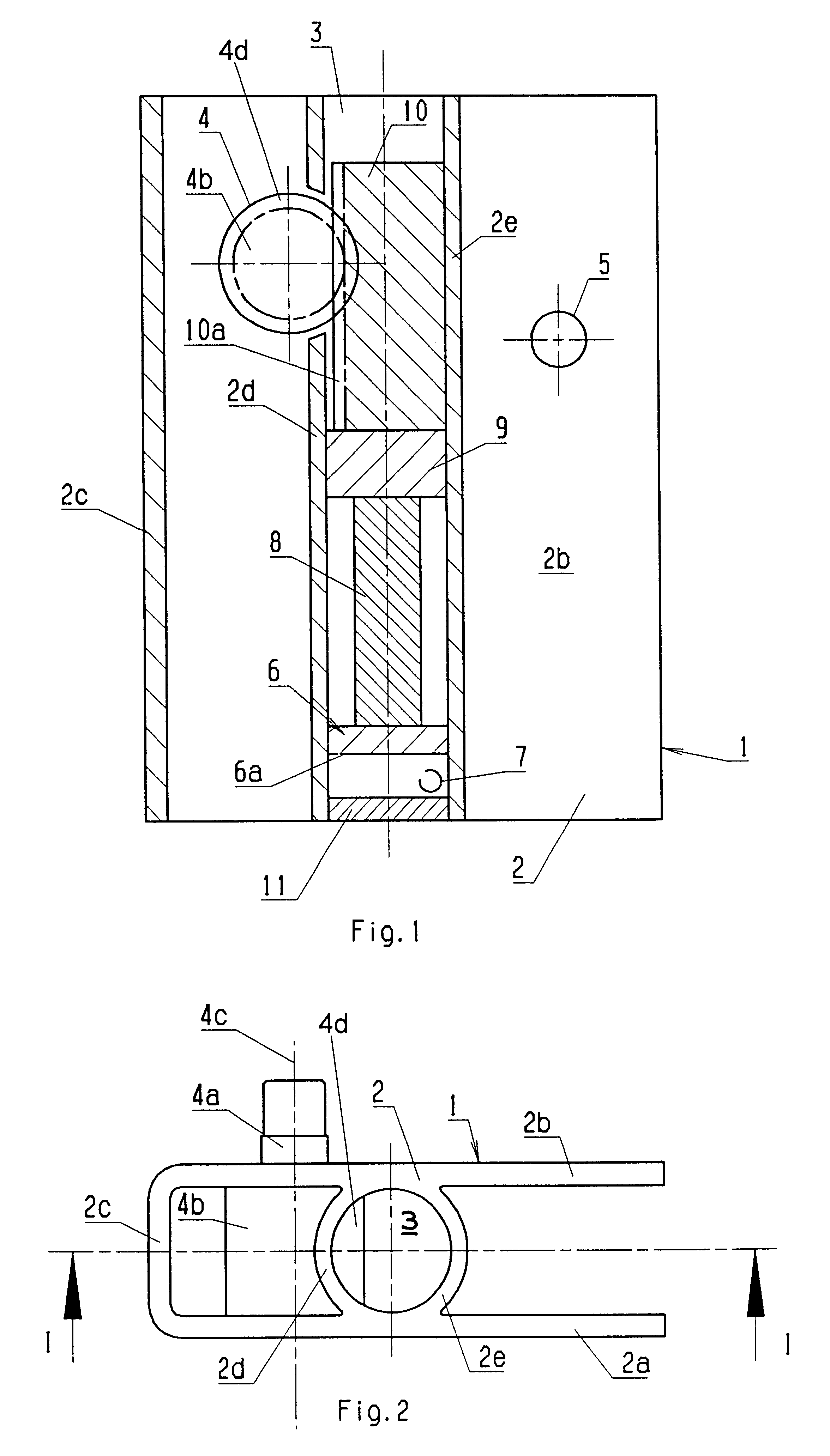

Wiper blade

InactiveUS7805800B2Reduce multiplicityProtection worksBrush bodiesWindow cleanersWindscreen wiperEngineering

Owner:ROBERT BOSCH GMBH

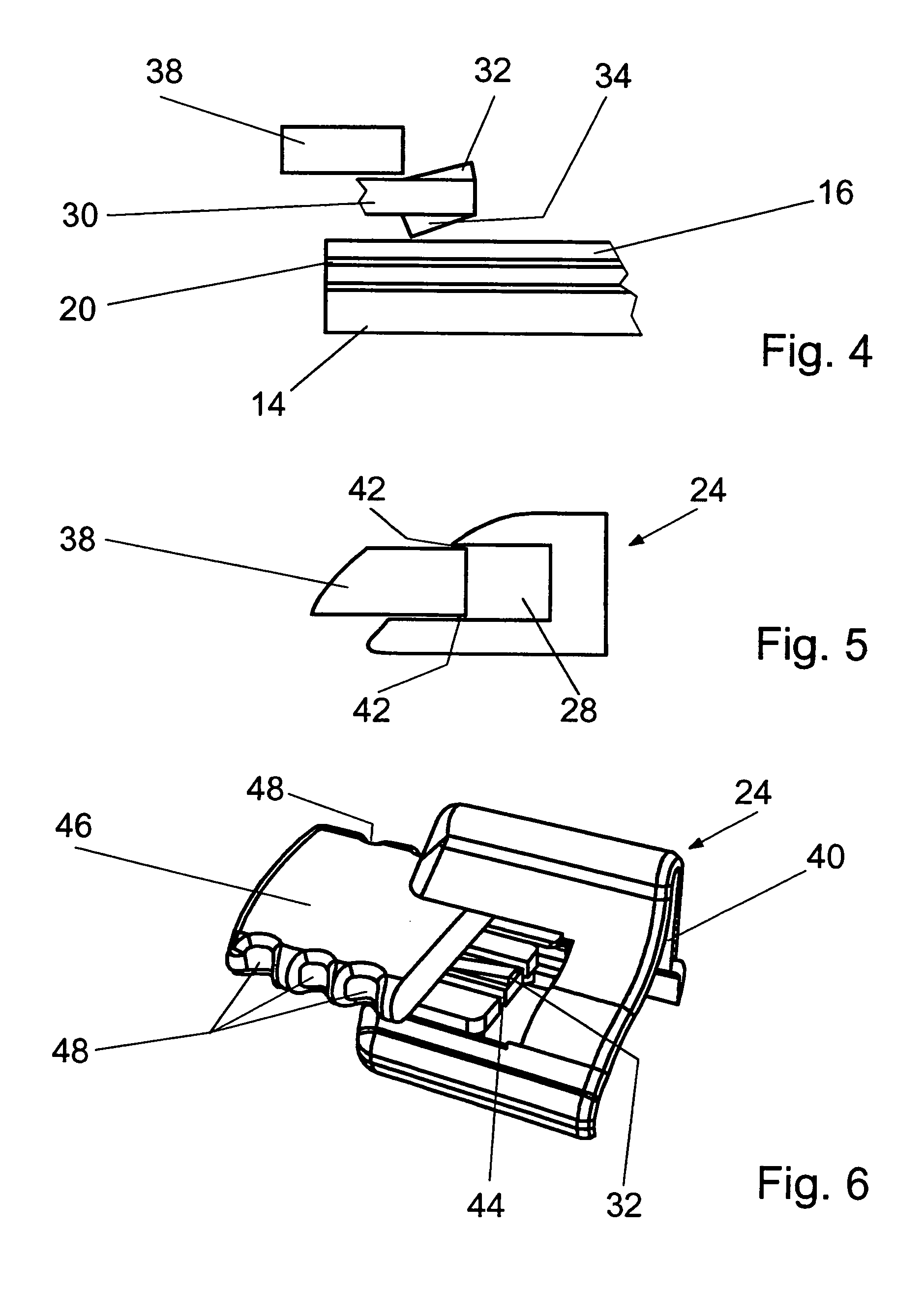

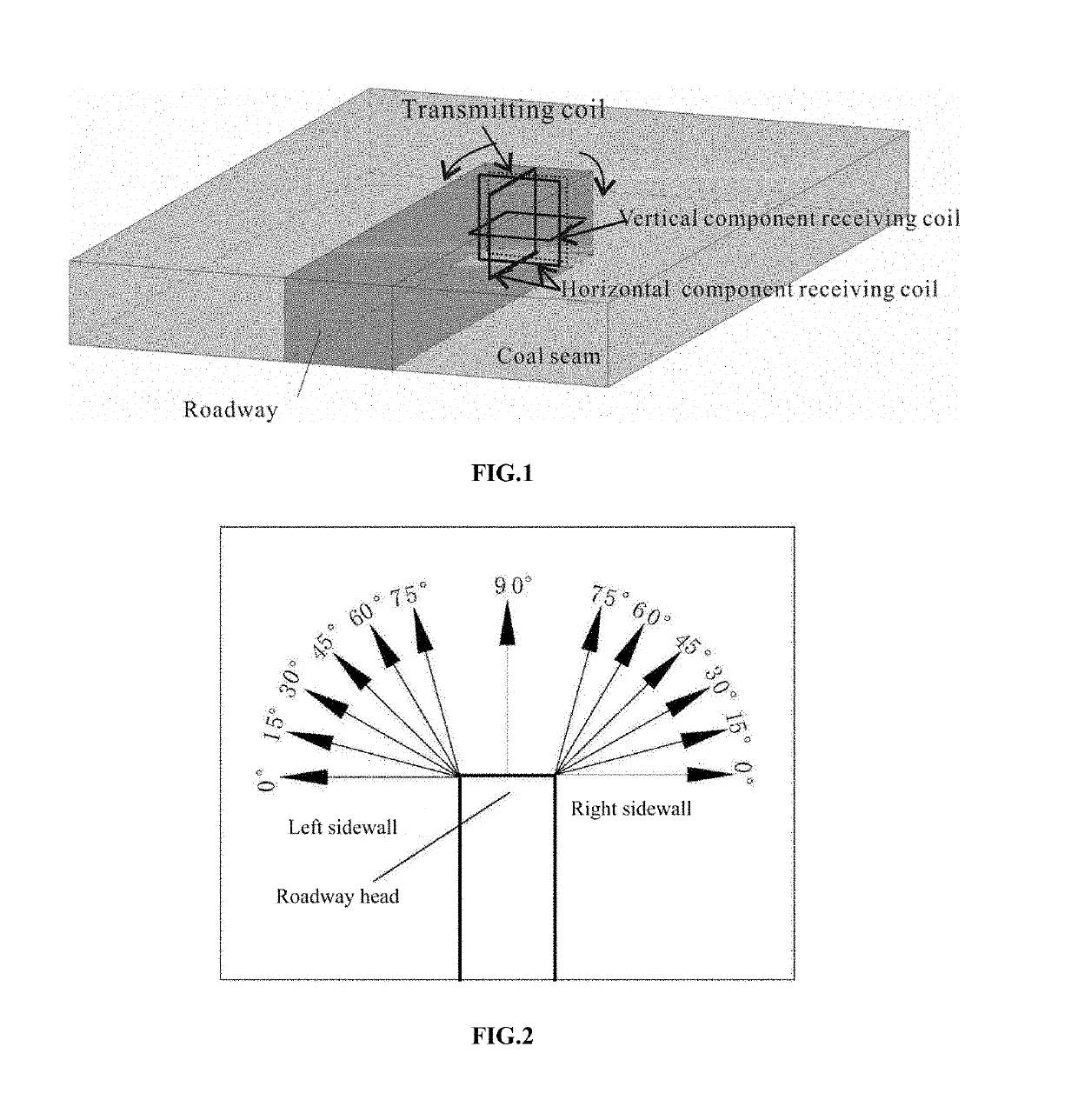

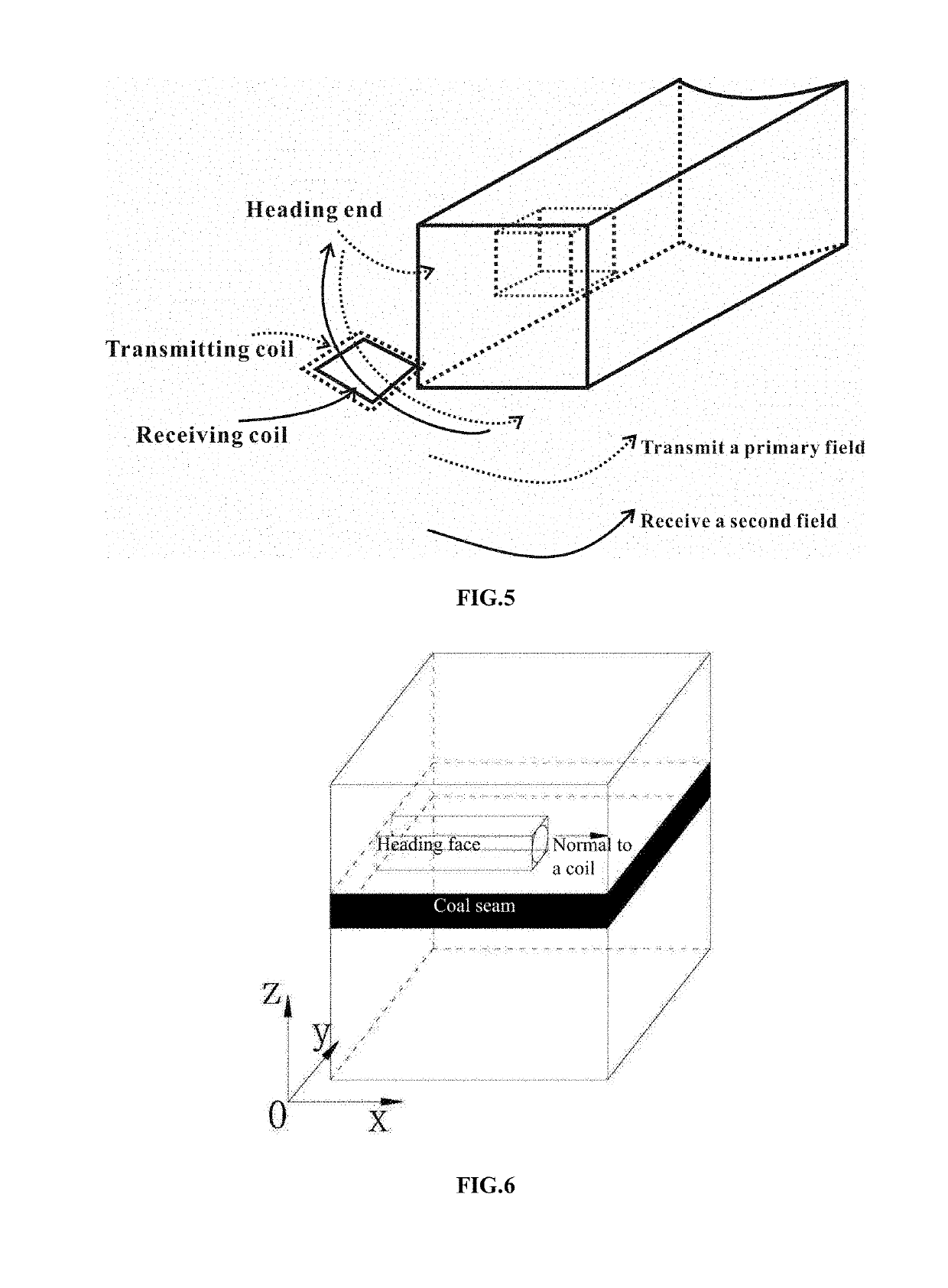

Mine tem three-component detection method

ActiveUS20190339413A1Detect spatial positionAccurately determineElectric/magnetic detection for well-loggingGeomodellingElectromagnetic responseUltimate tensile strength

The present disclosure discloses a mine transient electromagnetic (TEM) three-component detection method. TEM transmitting coils and receiving coils are adjusted according to geological features in a coal mine. Depending on different measurement manners, the number of magnetic-field lines cut by a low-resistance body greatly varies, and thus the strength of the resulting secondary fields also greatly varies. The present disclosure uses three sets of receiving coils that are arranged perpendicular to each other. One of the three sets of receiving coils and a transmitting coil are arranged according to a coincident loop device, such that response data in all directions can be received from a single transmission. At an underground roadway head, fan shape scan is achieved by changing angles of the transmitting coil and the receiving coils, to obtain more electromagnetic responses, such that a water-rich region in the formation can be more accurately determined.

Owner:CHINA UNIV OF MINING & TECH

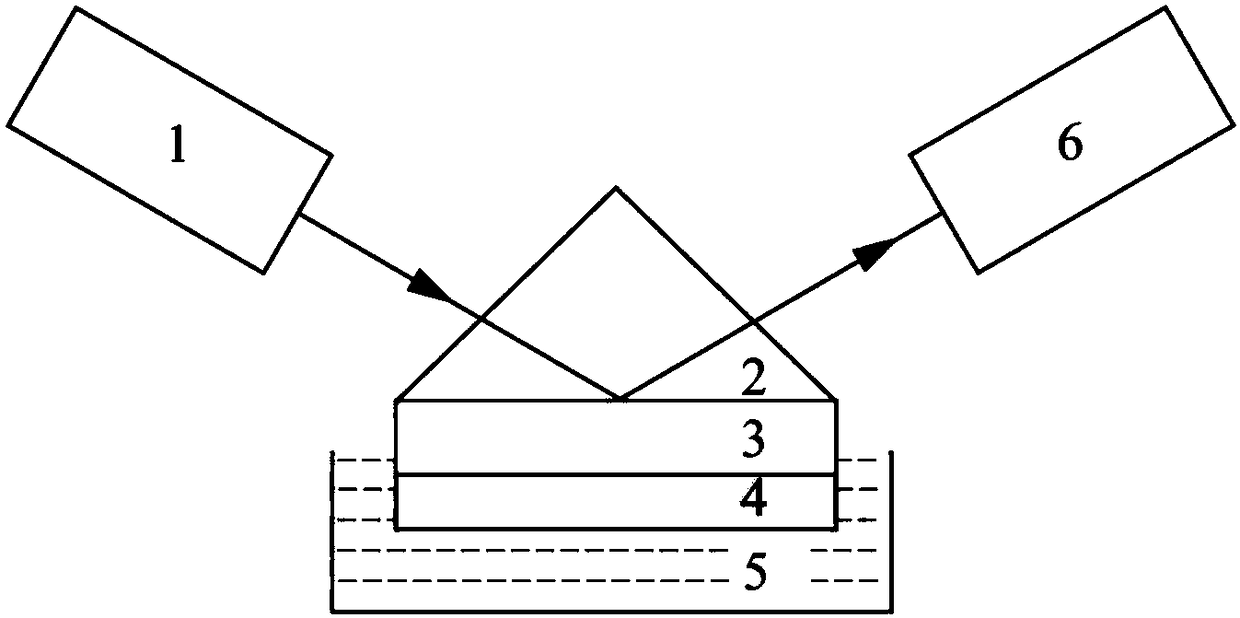

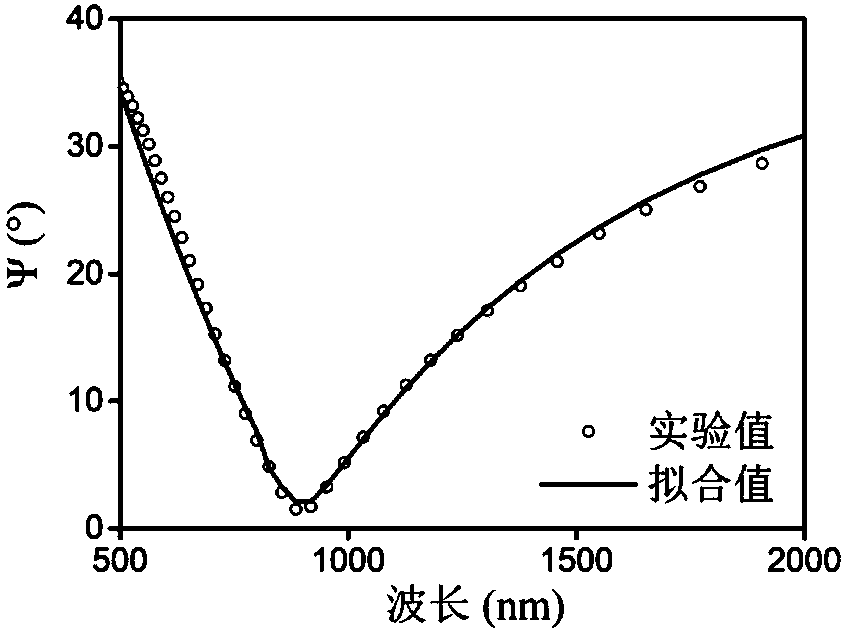

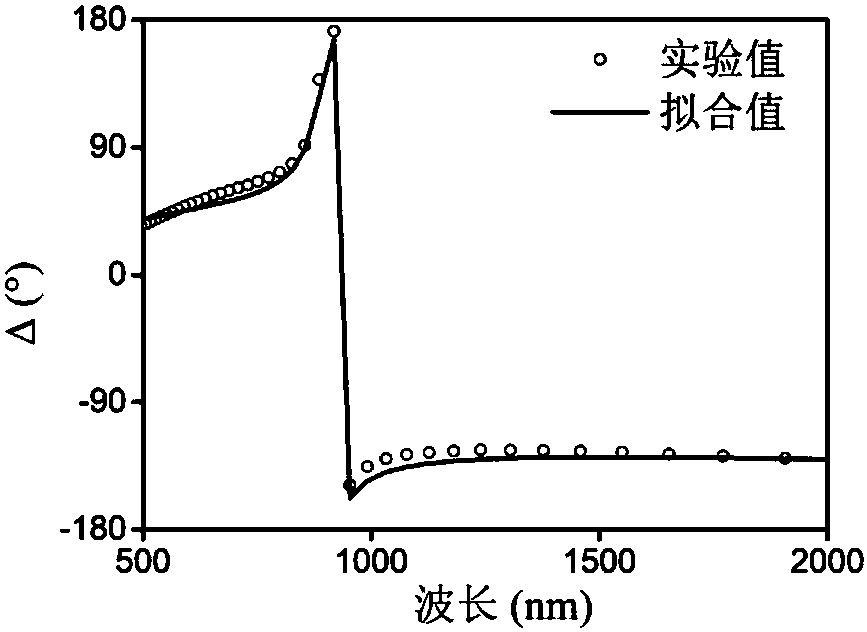

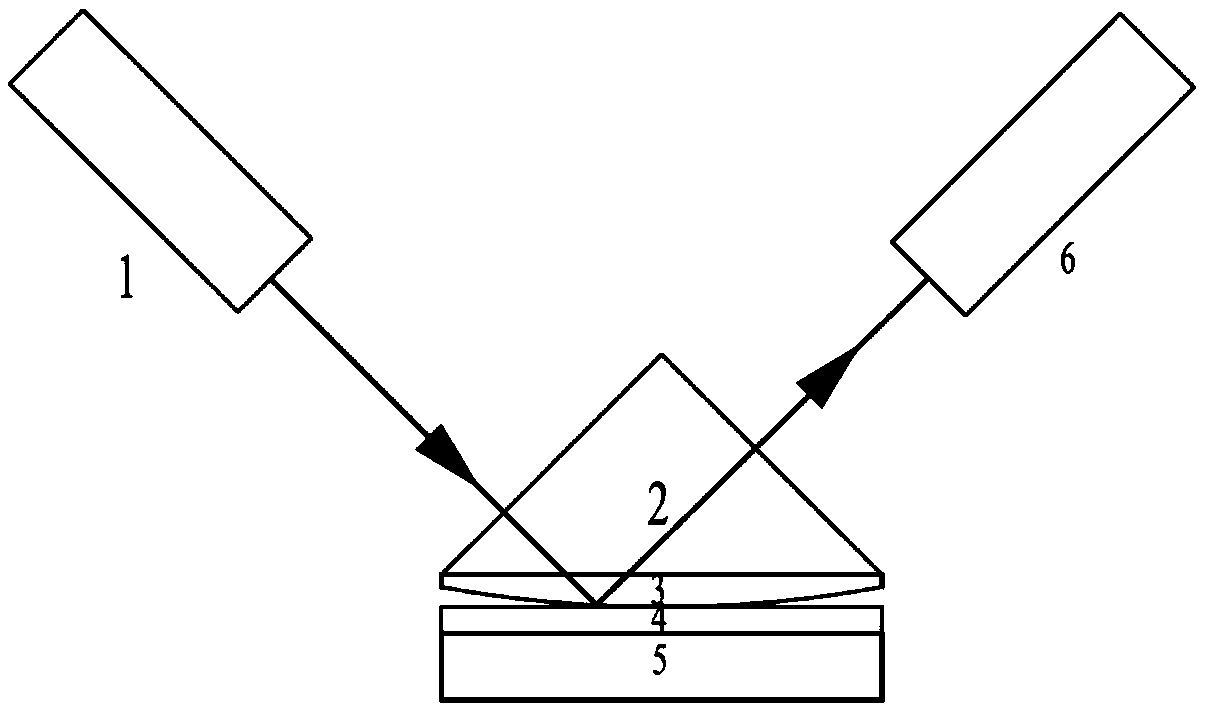

Method and device for improving precision of measuring ultra-thin film layer by ellipsometer

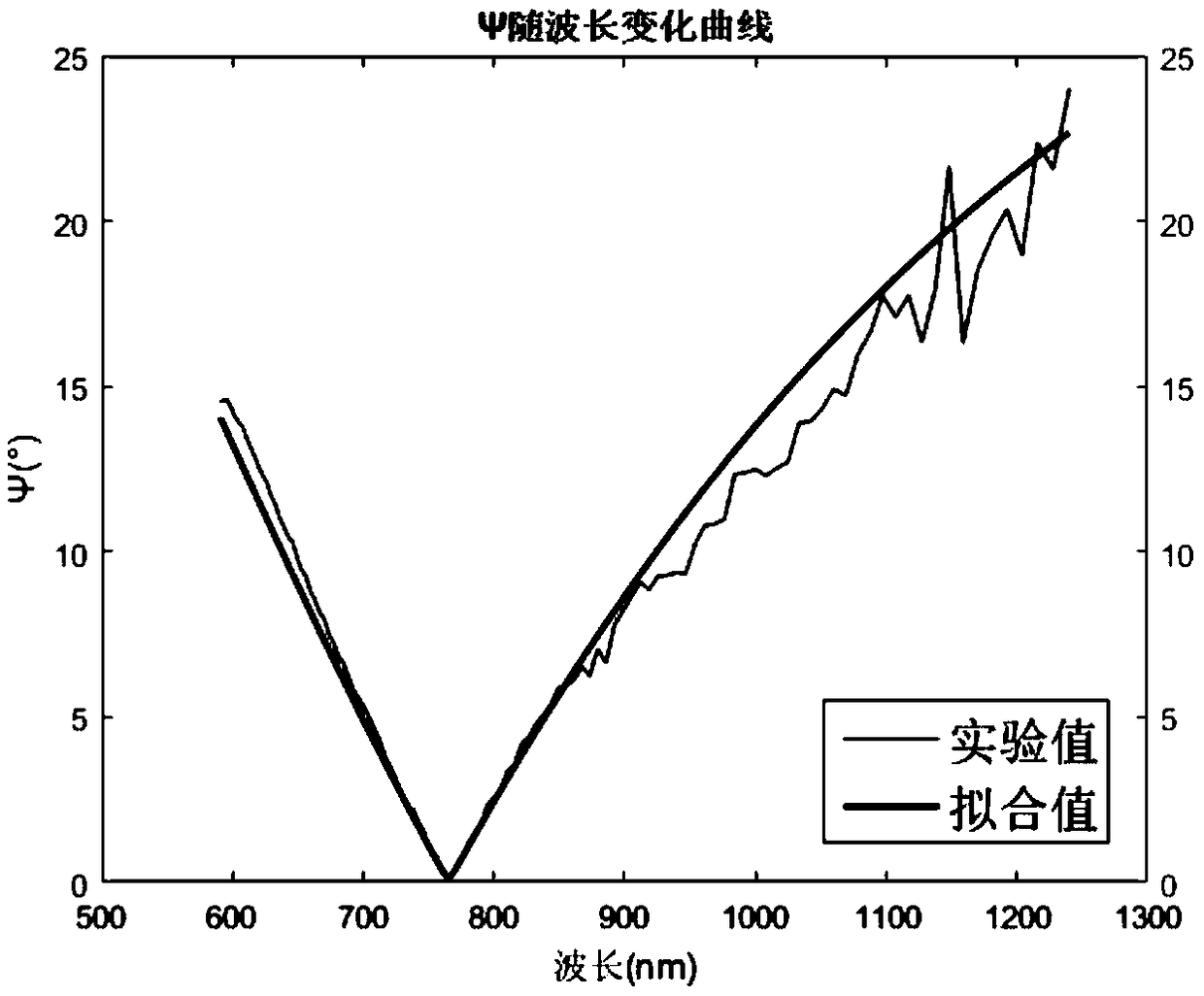

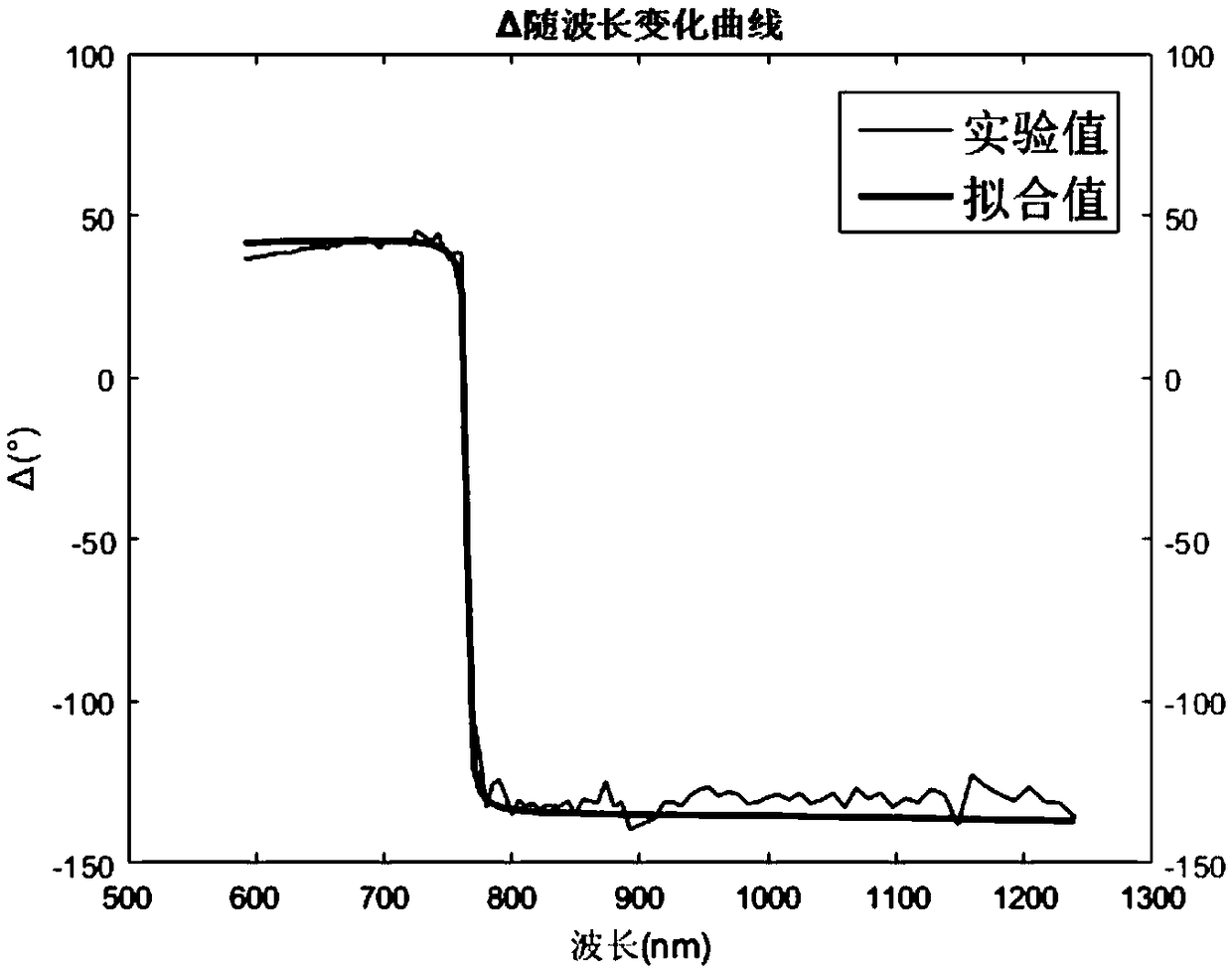

ActiveCN106403830AImprove test accuracySimplify the solution processUsing optical meansTesting optical propertiesMicrometer scaleLight beam

The invention provides a device for improving precision of measuring an ultra-thin film layer by an ellipsometer. The device comprises a right-angle prism, a plano-convex spherical lens, the ultra-thin film layer and a glass substrate. According to the method and the device, an Otto structure is introduced into the ellipsometer for exciting surface plasma resonance, a curve of elliptical polarization parameters changing along with incident wavelength, incident angle and air gap thickness is tested and analyzed by utilizing micrometer-scale light beams, a thickness of an optical constant of the ultra-thin film layer are obtained through fitting the elliptical polarization parameter curve; and the surface plasma resonance is very sensitive to the optical constant of the film layer, Psi and Delta can be obtained simultaneously by adopting the ellipsometry, and the elliptical polarization test precision can be improved by combining the Psi with the Delta.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

E2 subunit vaccine comprising recombinant pestivirus E2 protein

InactiveUS6919085B2Increased and improved yieldProduce improveSsRNA viruses positive-senseViral antigen ingredientsCell culture mediaProtein C

The invention relates to a method of increasing protein expression in baculo vector virus expression systems. The invention provides a method to produce a recombinant protein in insect cell culture which comprises selecting a recombinant baculovirus expressing said protein, growing insect cells in growth medium in a culture vessel and infecting the cells with an inoculum of at least one baculovirus at a cell density of 1×105 to 5×106 cells / ml with an m.o.i of <0.01. The invention also provides a method to produce recombinant pestivirus E2 or Em9 protein or fragments thereof in insect cell culture characterized by a final concentration of the protein fragments in the growth medium at harvest of at least 100 μg / ml. The invention also provides a method of producing recombinant FSH, α-units and / or β-units, and complexes and fragments thereof, at a concentration in the growth medium at harvest of at least 15 μ / ml.

Owner:STICHTING INST VOOR DIERHOUDERIJ & DIERGEZONDHEID +1

A measuring device and a measuring method for the thickness and the optical constants of ultrathin film

InactiveCN107504907AWon't breakWith online real-time non-contact measurementMaterial analysis by optical meansUsing optical meansPlasma resonanceMeasurement precision

The invention provides a measuring device and a measuring method for the thickness and the optical constants of ultrathin film. The method comprises the steps of collecting plasma resonance images under different polarizing angles and analyzing angles, performing analysis to obtain an ellipsometry parameter curve of plasma resonance guide and performing fitting of the ellipsometry parameter curve, and using an optical solution as a measurement result to obtain the thickness and optical constants of ultrathin film. The measuring device and the measuring method have the advantages of online real-time non-contact measurement and high measurement accuracy and cause no damage to the surfaces of to-be-measured samples.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

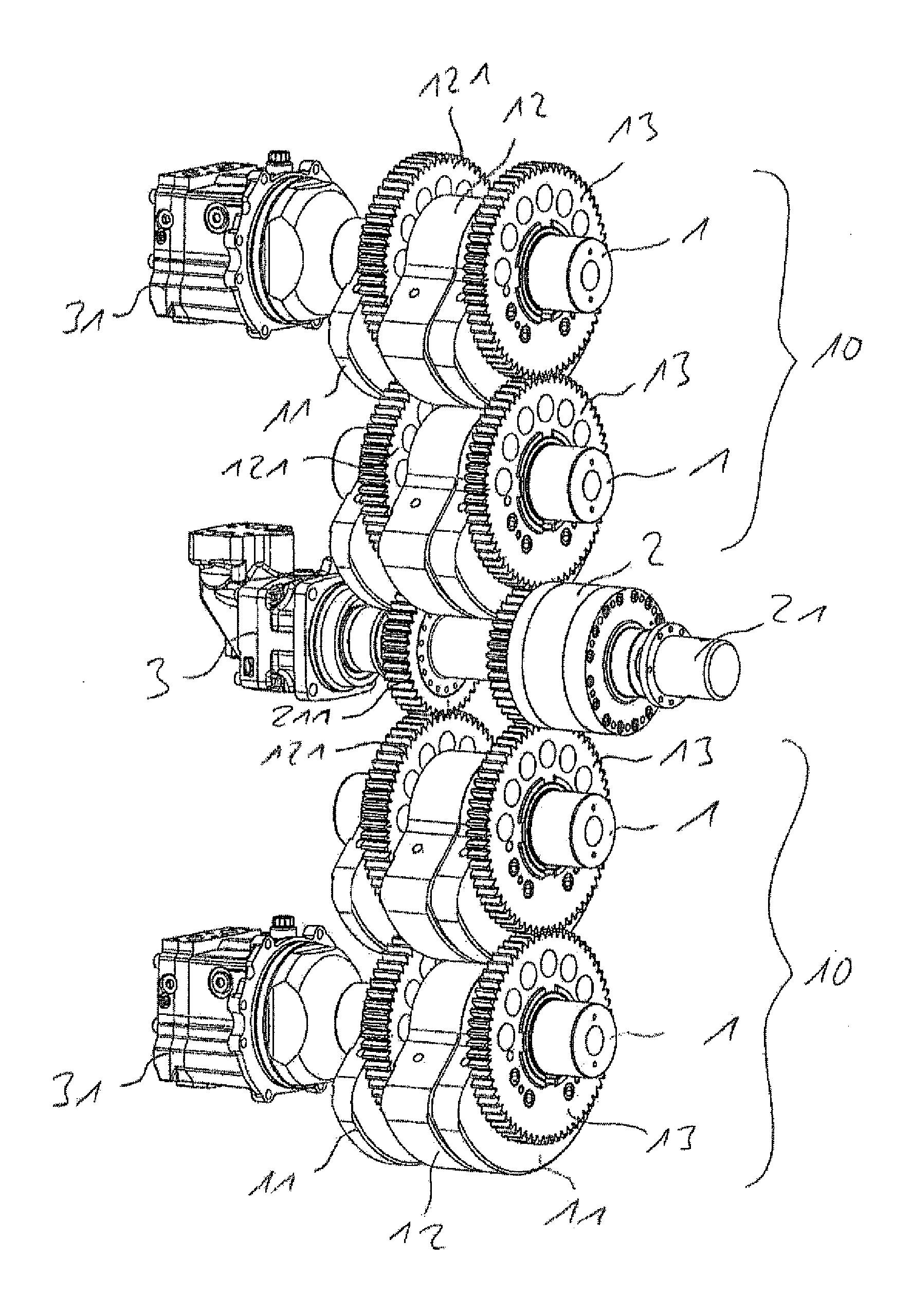

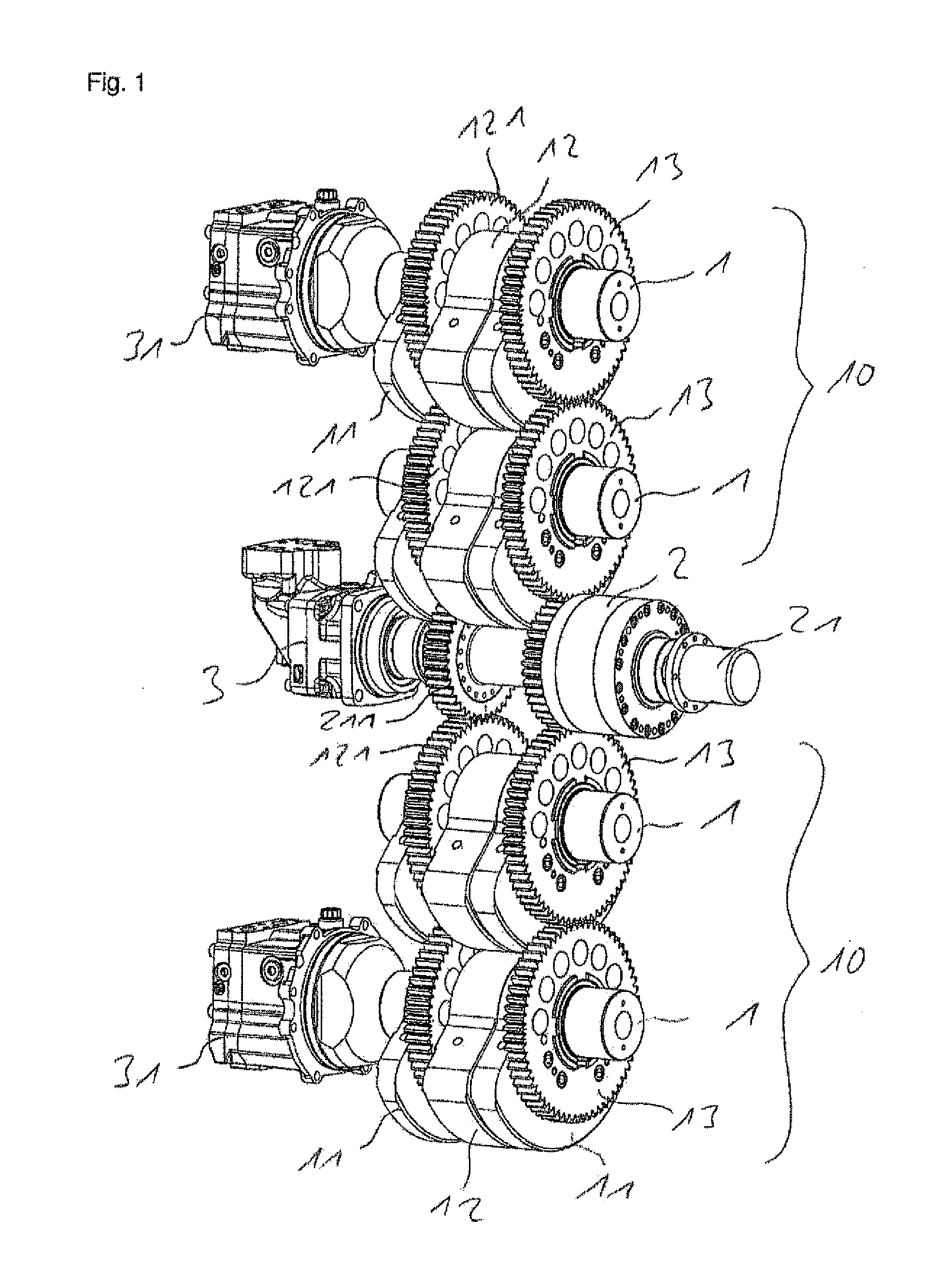

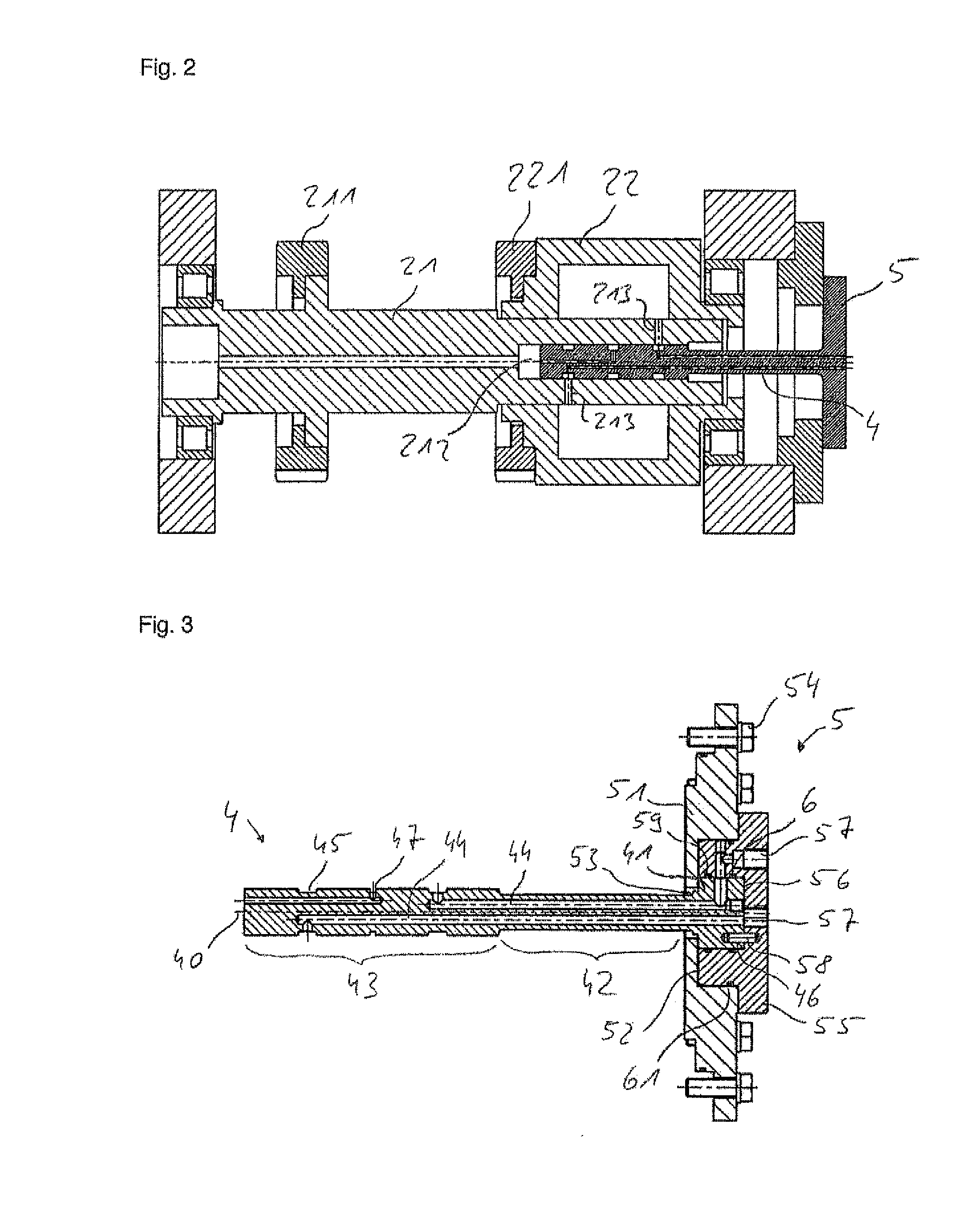

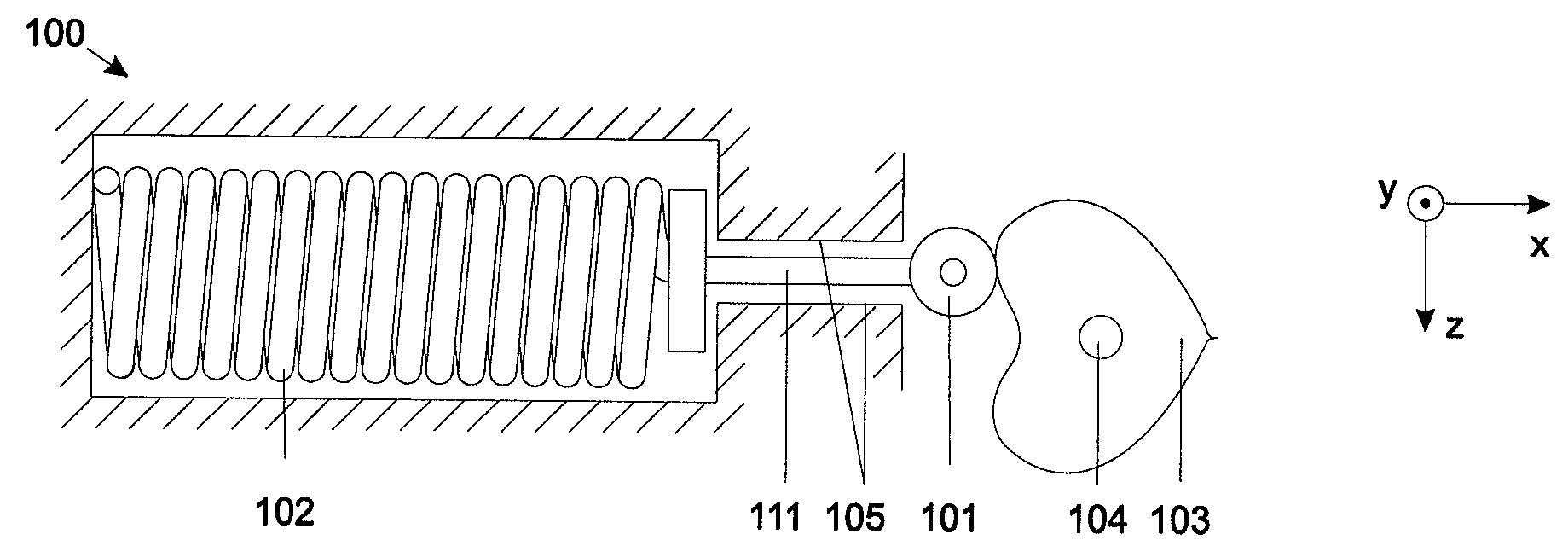

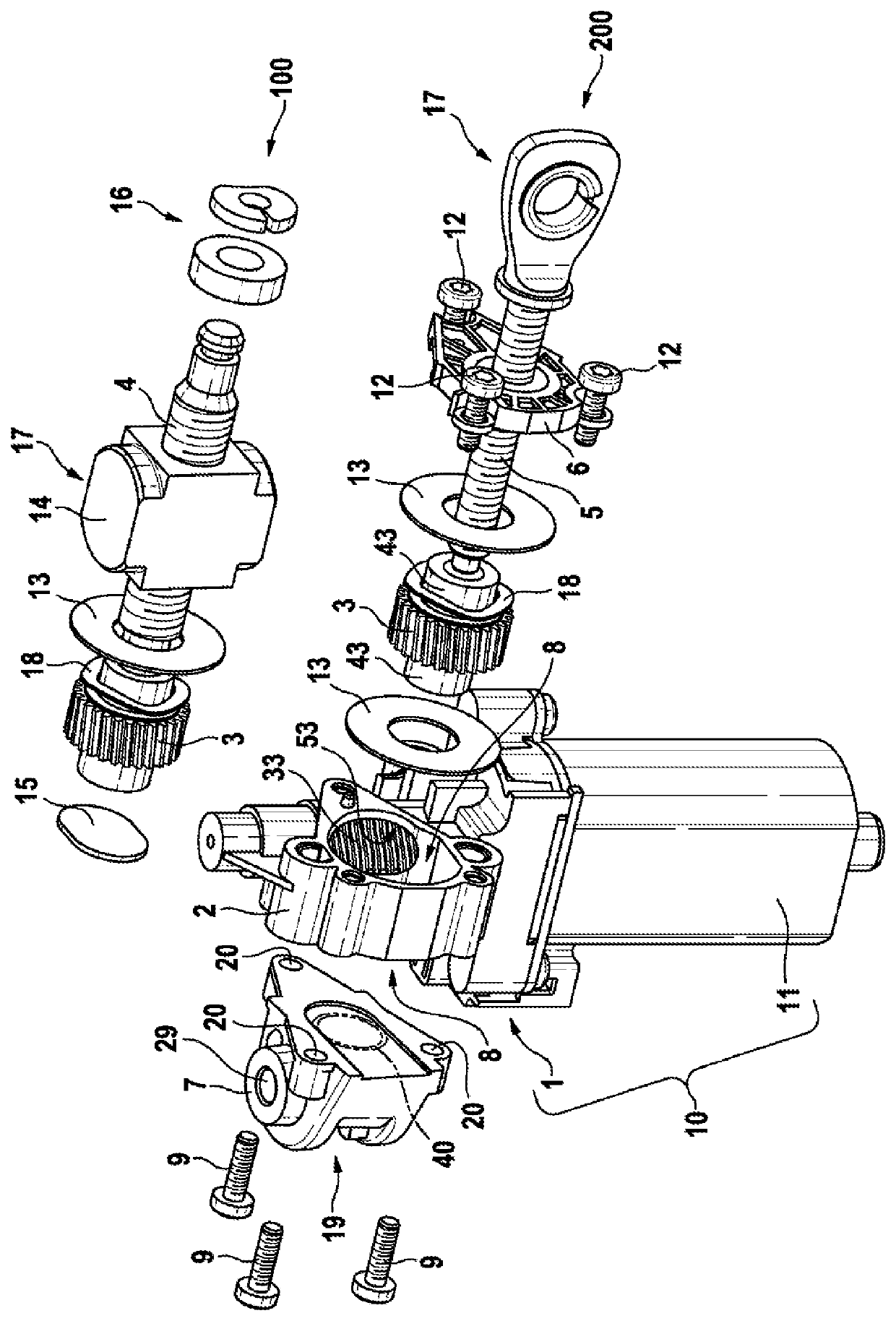

Vibration exciter

InactiveUS20140305234A1Increase the diameterAttachment is possibleGearingMechanical vibrations separationVibration exciterControl theory

A vibration exciter, particularly for a vibration pile driver, includes at least two shafts disposed parallel to one another, as well as at least two imbalance masses, which are attached on one or more of the shafts. A pivot motor provided for adjustment of the relative rotational position of the imbalance masses with regard to one another, includes a pivot motor shaft and a pivot motor housing. The pivot motor shaft is an integral part of one of the shafts, and the rotational position of the pivot motor housing relative to the pivot motor shaft can be changed. The pivot motor is disposed axially offset, in such a manner that it is disposed outside of the regions through which the imbalance masses move.

Owner:ABI ANLAGENTECHN BAUMASCHEN INDBEBEDARF

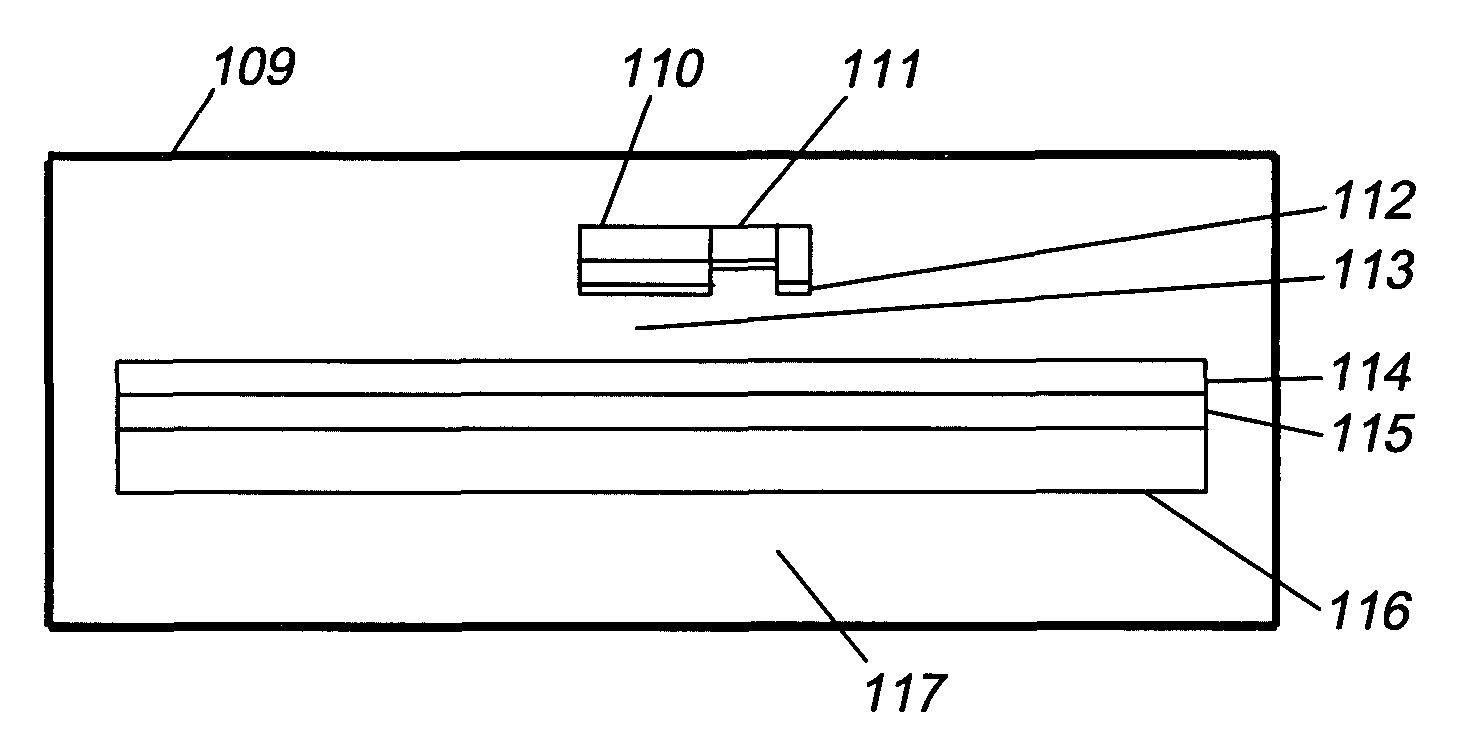

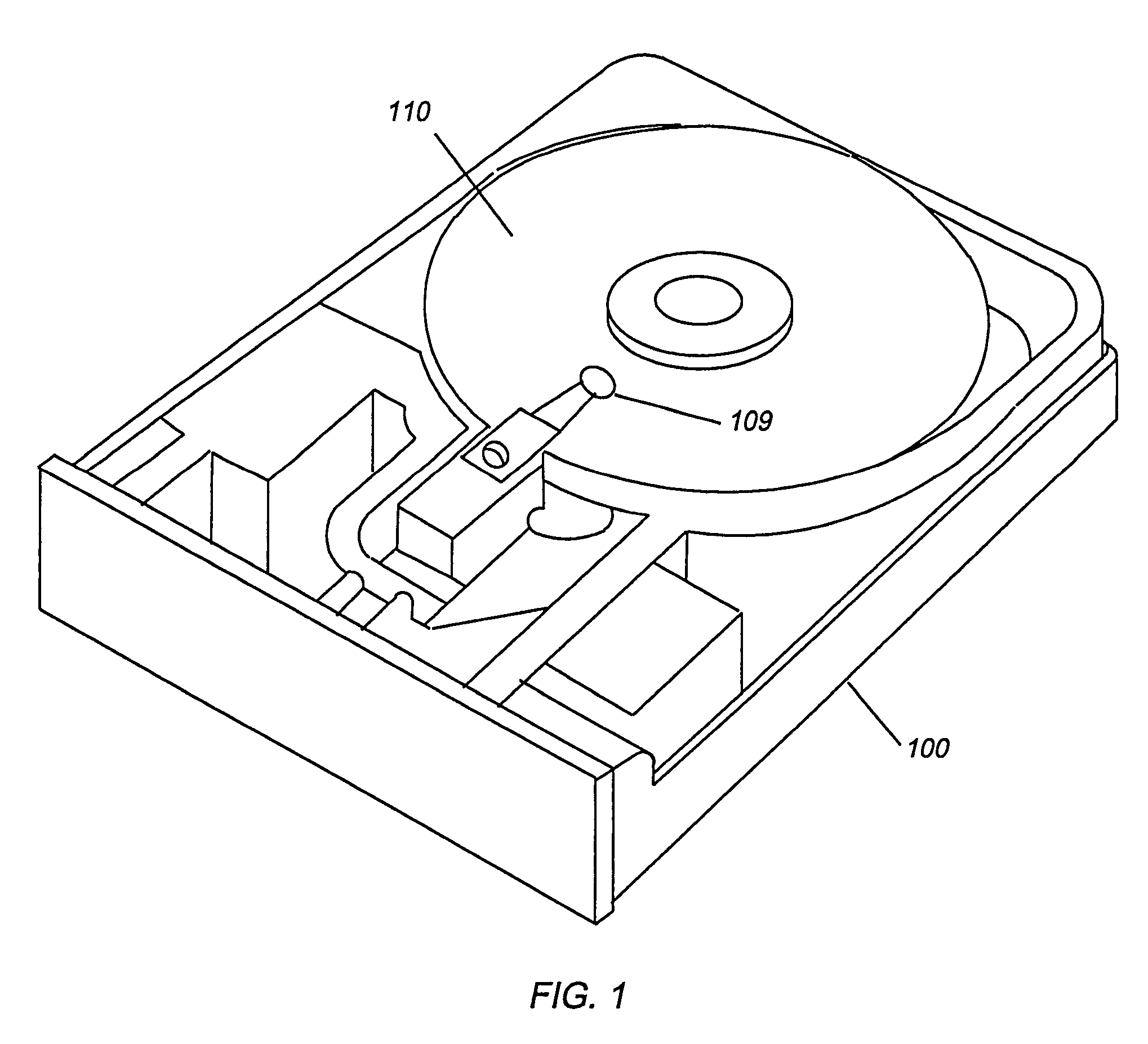

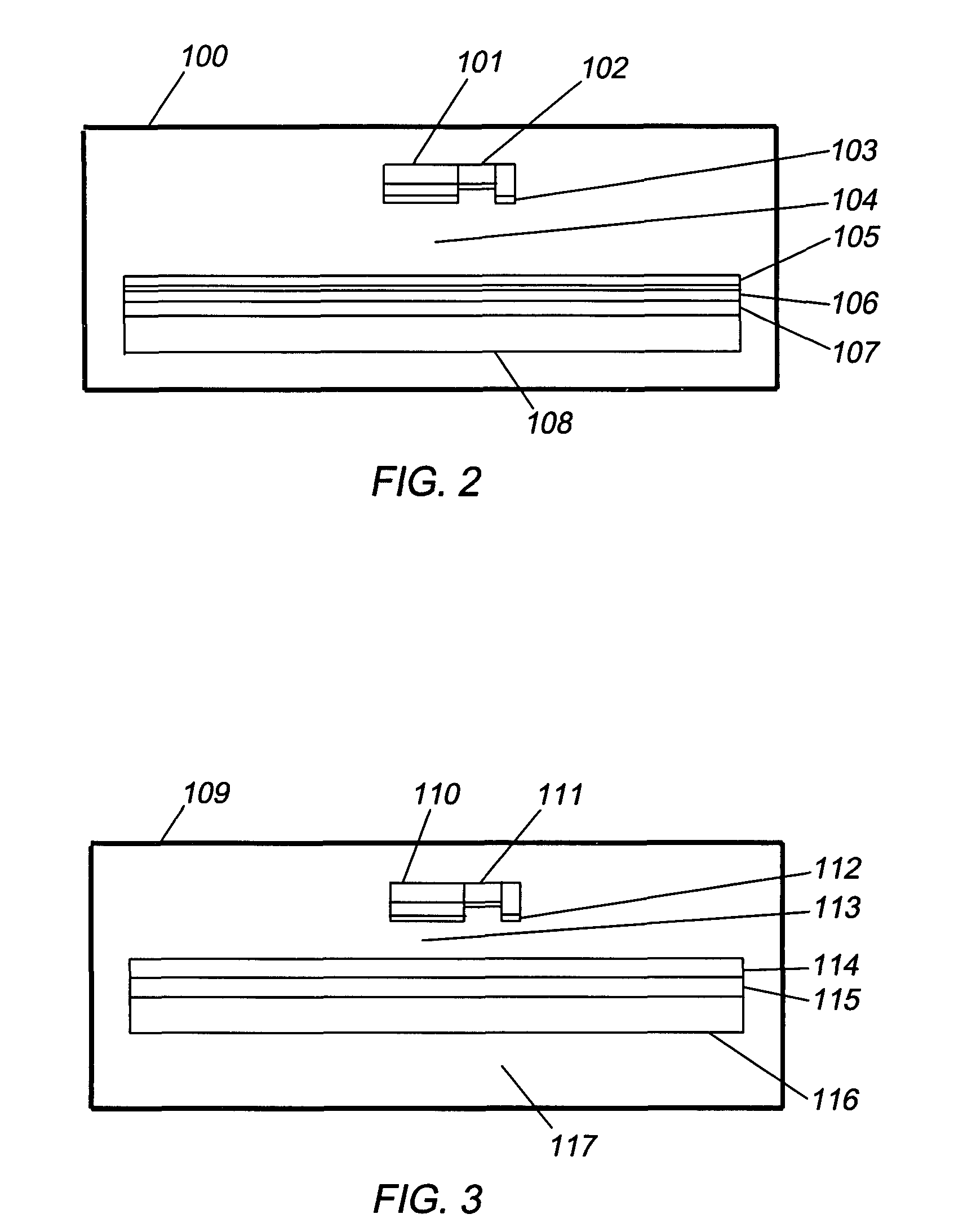

High performance computer hard disk drive with a carbon overcoat and method of improving hard disk performance

InactiveUS7961427B2Reduce seek timeIncrease areal densityManufacture head surfaceProtective coatings for layersHard disc driveHydrogen

Owner:GALLEON INT CORP +1

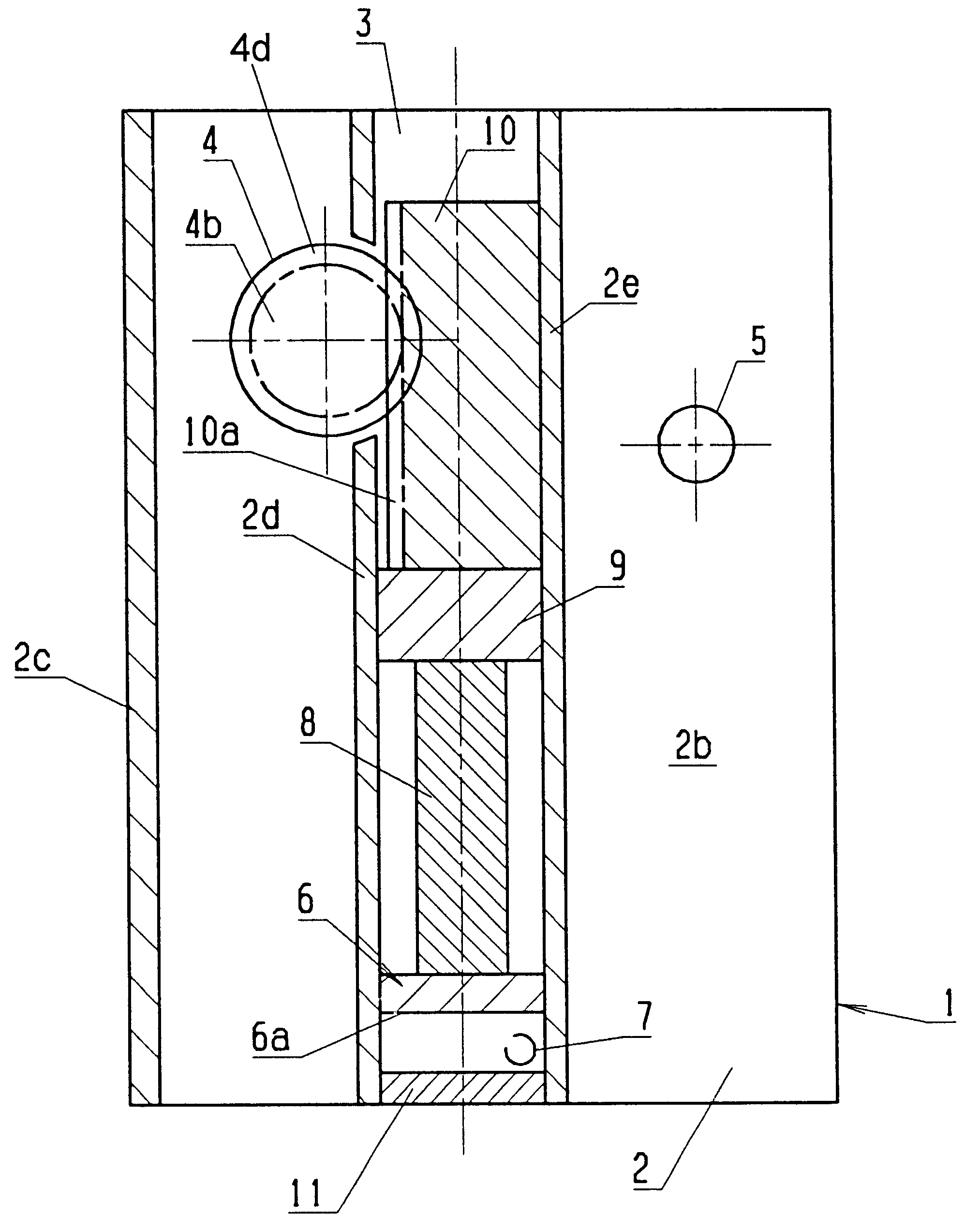

Door closer

ActiveUS8732904B2Reduce manufacturing costProportion of the torque can be modifiedBuilding braking devicesHingesEngineeringCam

A door closer is described, which has an output shaft, on which a cam disc is torsion-resistantly disposed, and has a pressure roller. By means of an operational connection, a closer spring presses the pressure roller against a running surface of the cam disc. In relation to an axial center of the output shaft, the pressure roller is disposed such that, during opening or closing of a swing leaf coupled to the output shaft, the pressure roller is movable along a path. Due to the fact that the path bypasses the axial center of the output shaft and on account of the configuration of the running surface of the cam disc, at a respective opening angle of the swing leaf, in different modes of operation of the door closer, a very similar or identical torque is respectively applied to the output shaft.

Owner:DORMAKABA DEUT GMBH

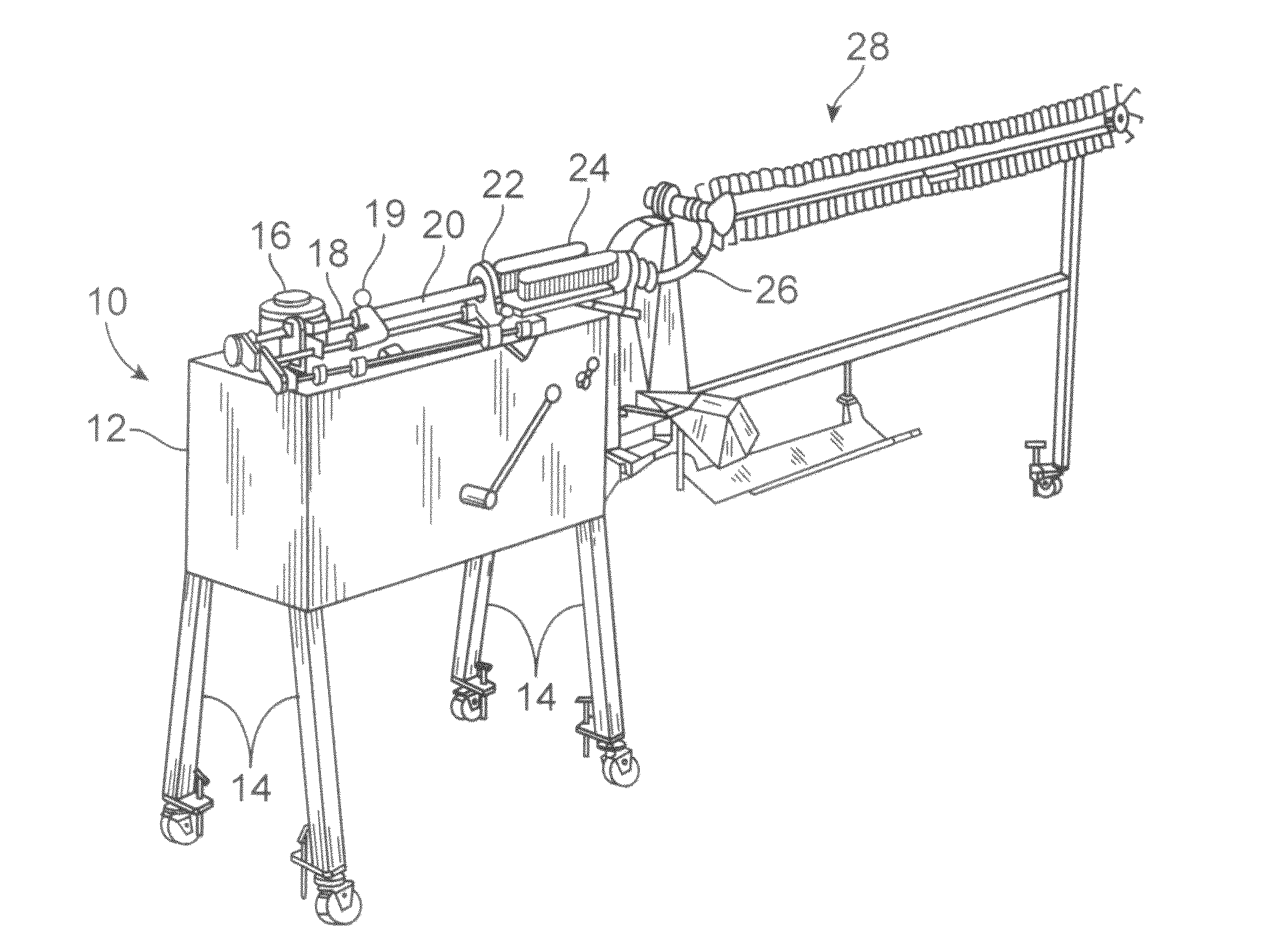

Spindle gearbox and drive unit of an electric seat drive

ActiveUS20190009693A1Additional componentLower requirementGearingMovable seatsStructural engineeringPower seat

Owner:ROBERT BOSCH GMBH

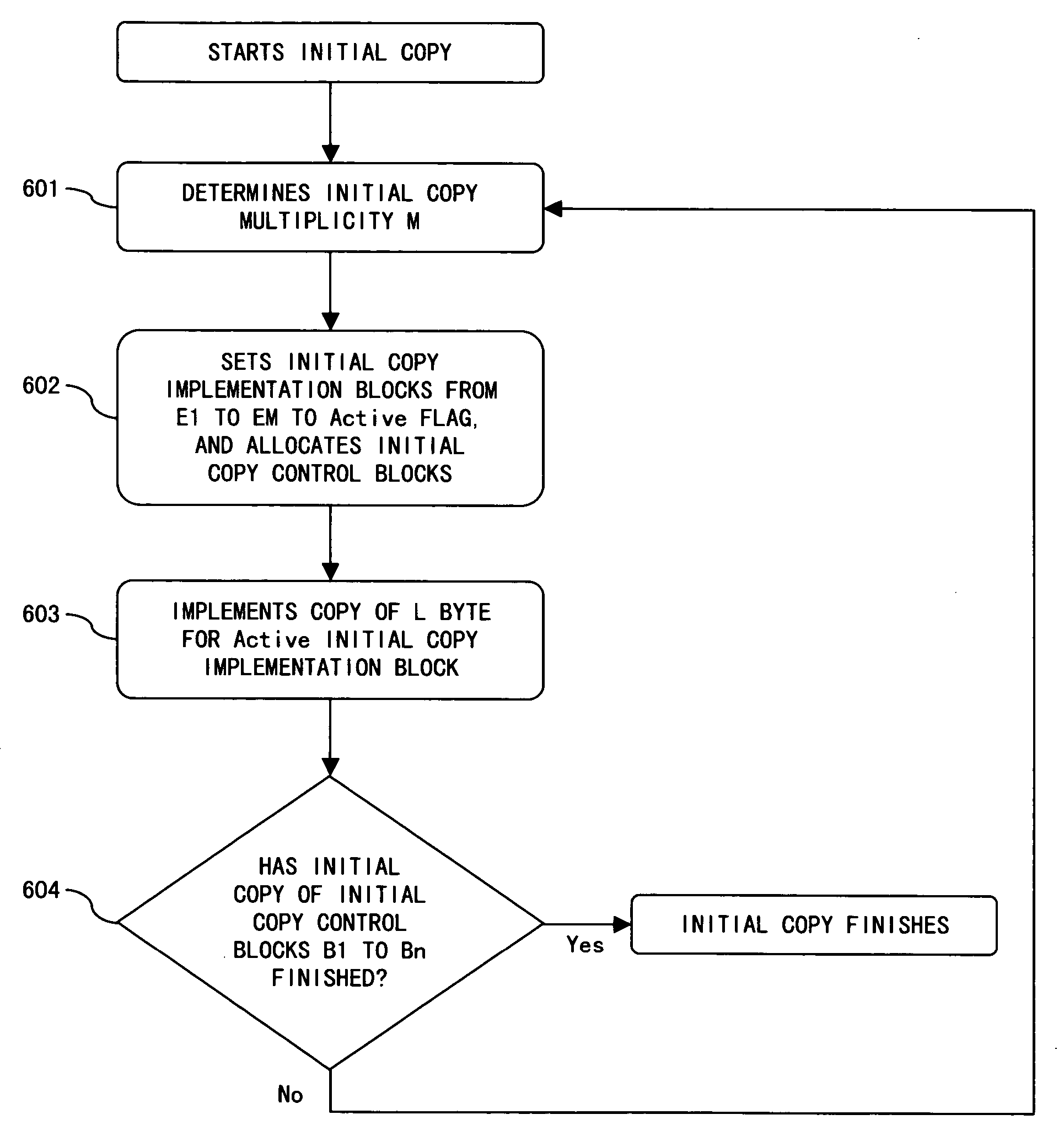

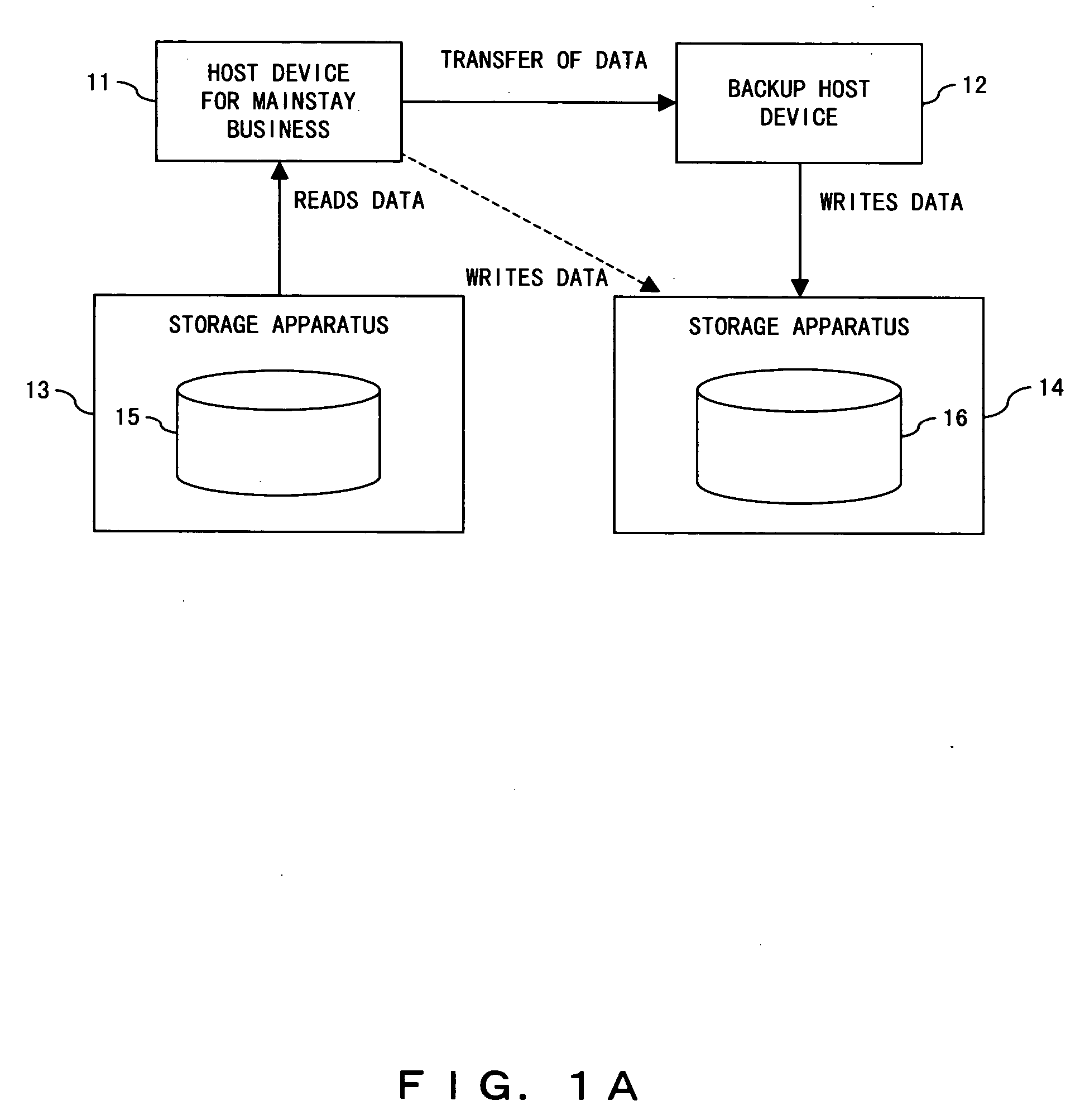

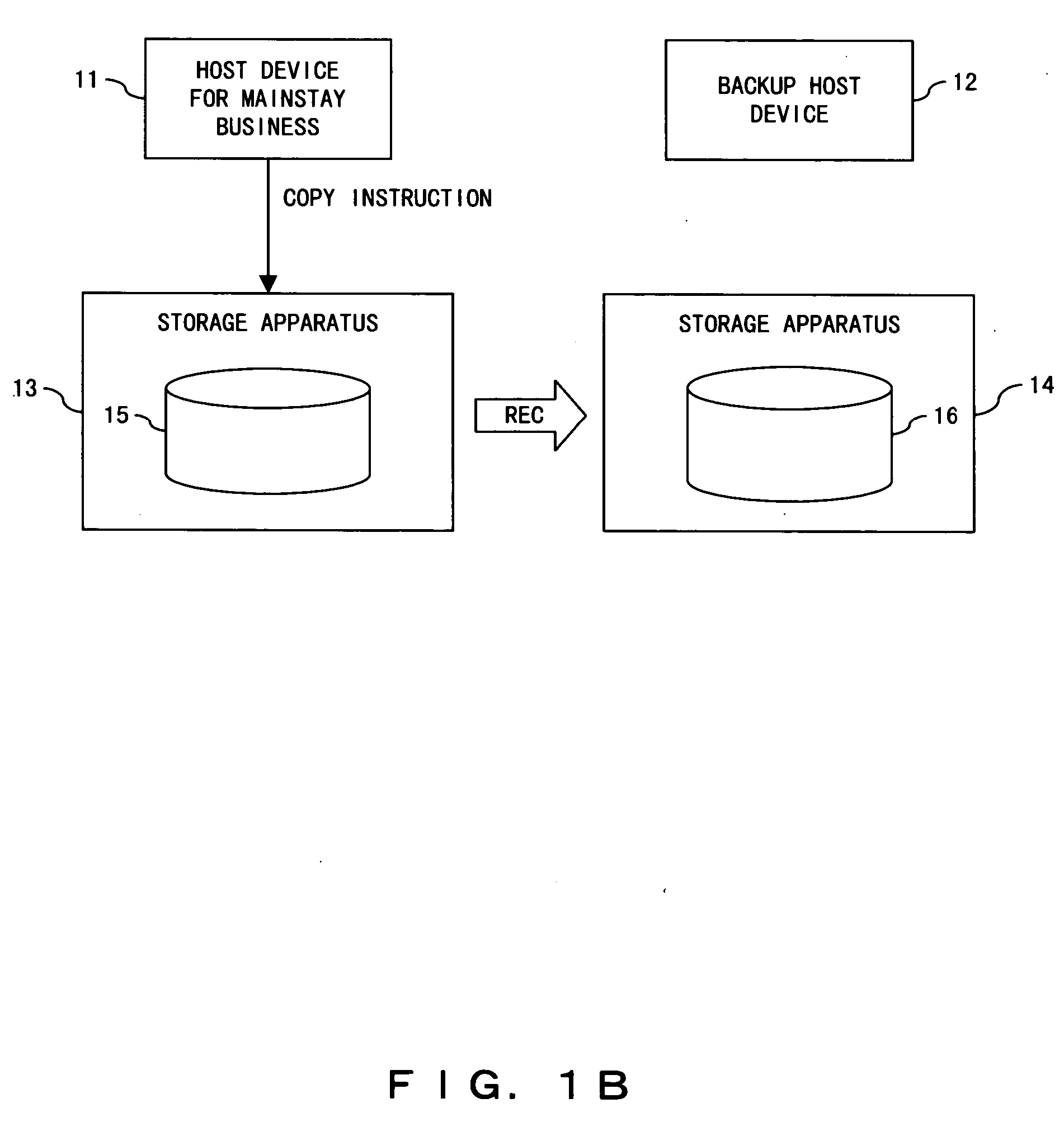

Copy control apparatus and method

InactiveUS20050216688A1Secure performanceReduce multiplicityInput/output to record carriersMemory loss protectionDatabaseCopy control

A copy control apparatus implements initial copies which copy data of the storage apparatus of a copy source to the storage apparatus of a copy destination, and, in the control of keeping the data of the copy source and that of copy destination equivalent, decreases the multiplicity in accordance with the increase of the number of write requests in which the updating of the data of the copy source is not yet reflected to the data of the copy destination, and implements a plurality of initial copies within the decreased range of multiplicity.

Owner:FUJITSU LTD

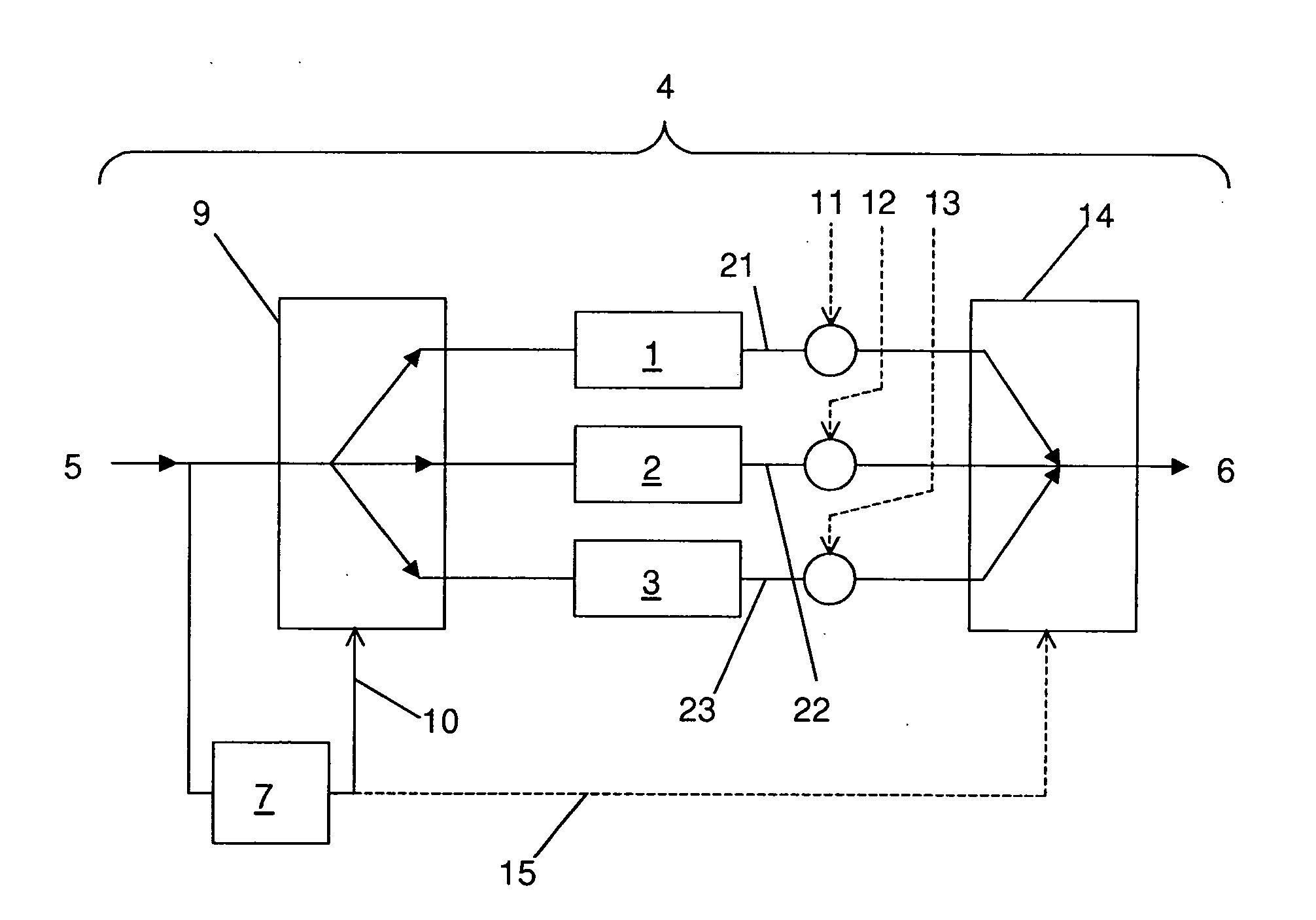

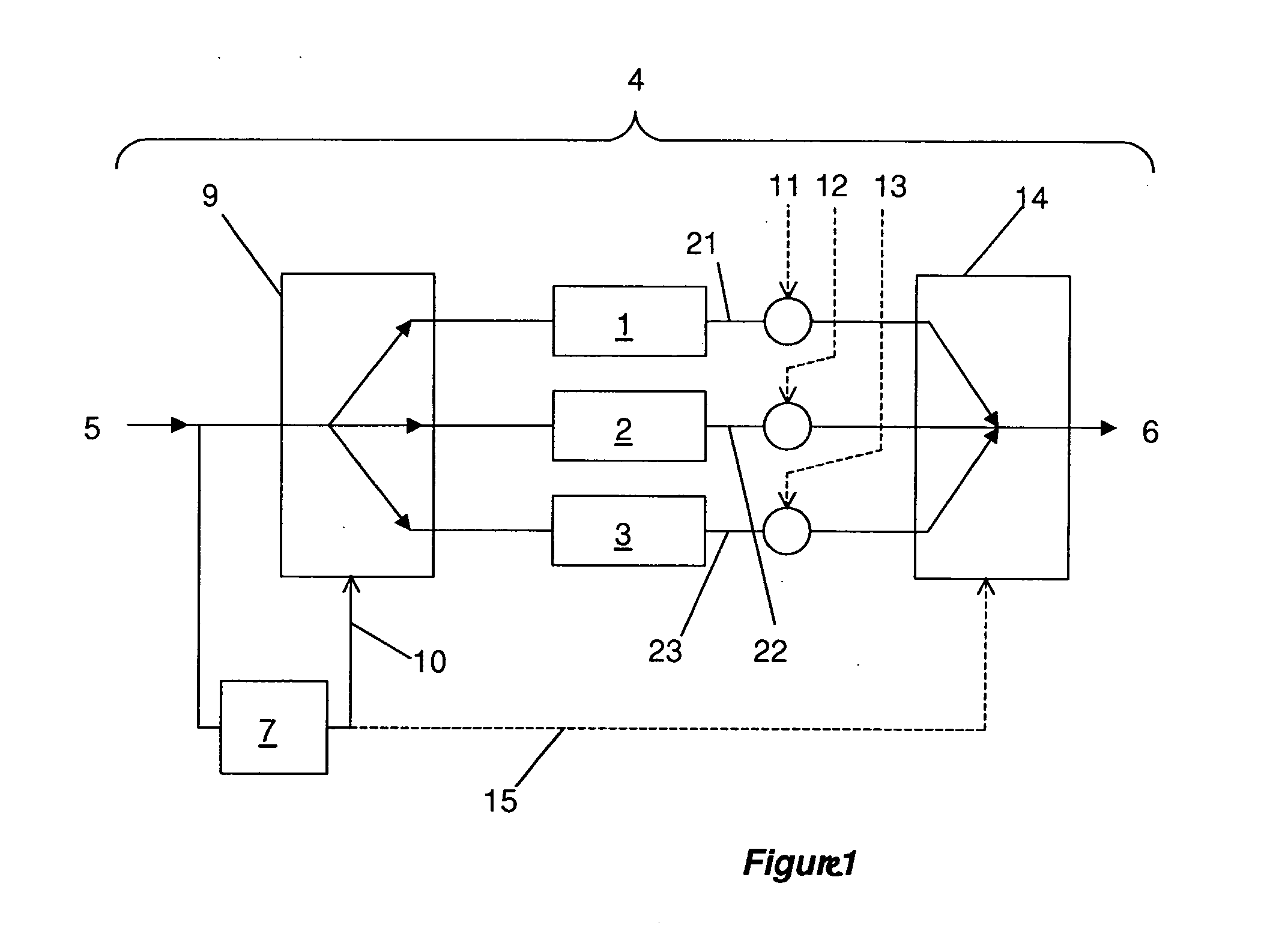

Evaluation Circuit for Processing Digital Signals, Method, and Sensor Assembly

ActiveUS20090306938A1No lossLarge dynamic rangeAmplifier modifications to reduce noise influenceDigital computer detailsComputer scienceDigital signal

An evaluation circuit for processing digital signals, the evaluation circuit processing an input data word and outputting an output data word, and a method for processing digital signals in an evaluation circuit, and to a sensor assembly.

Owner:ROBERT BOSCH GMBH

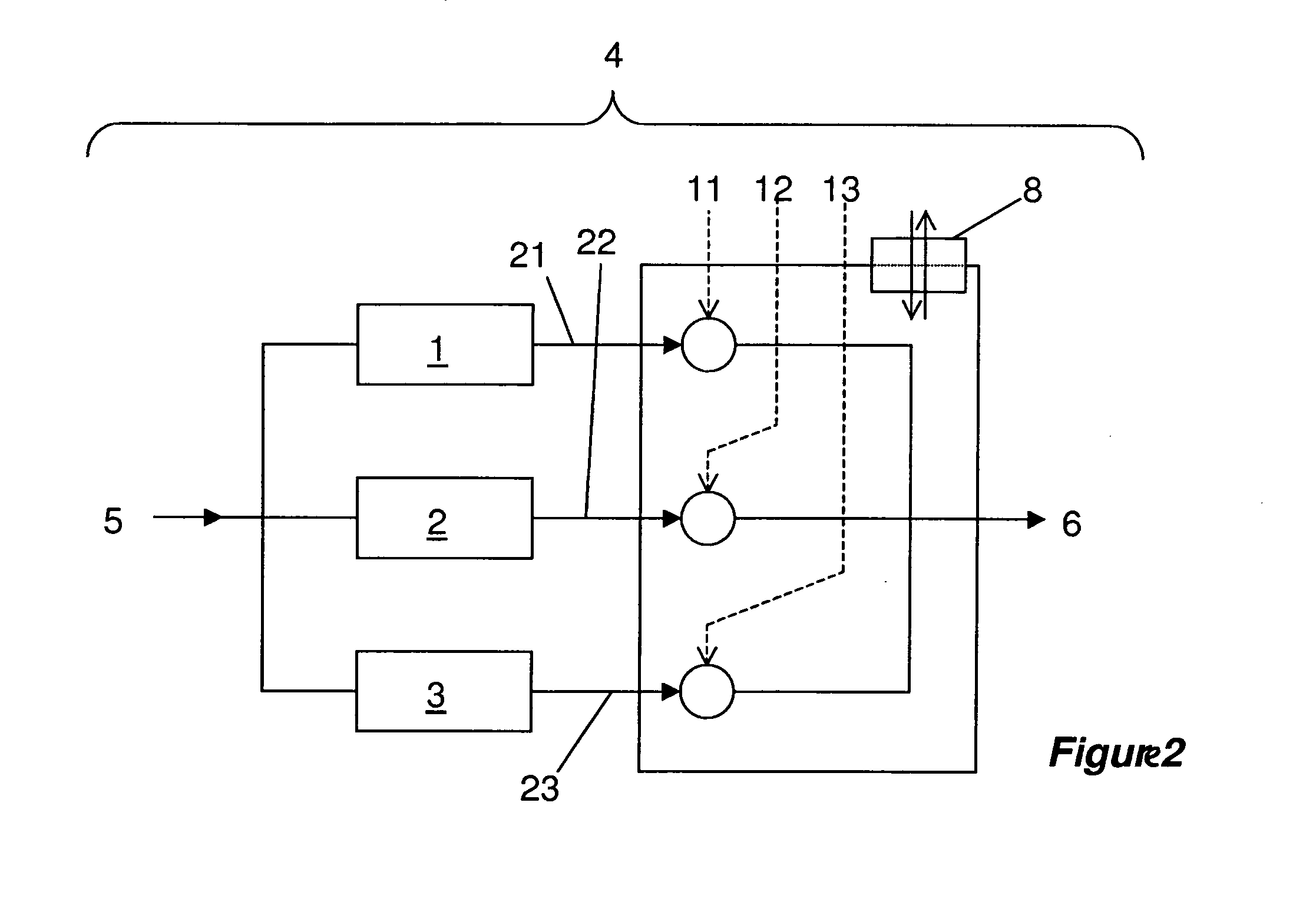

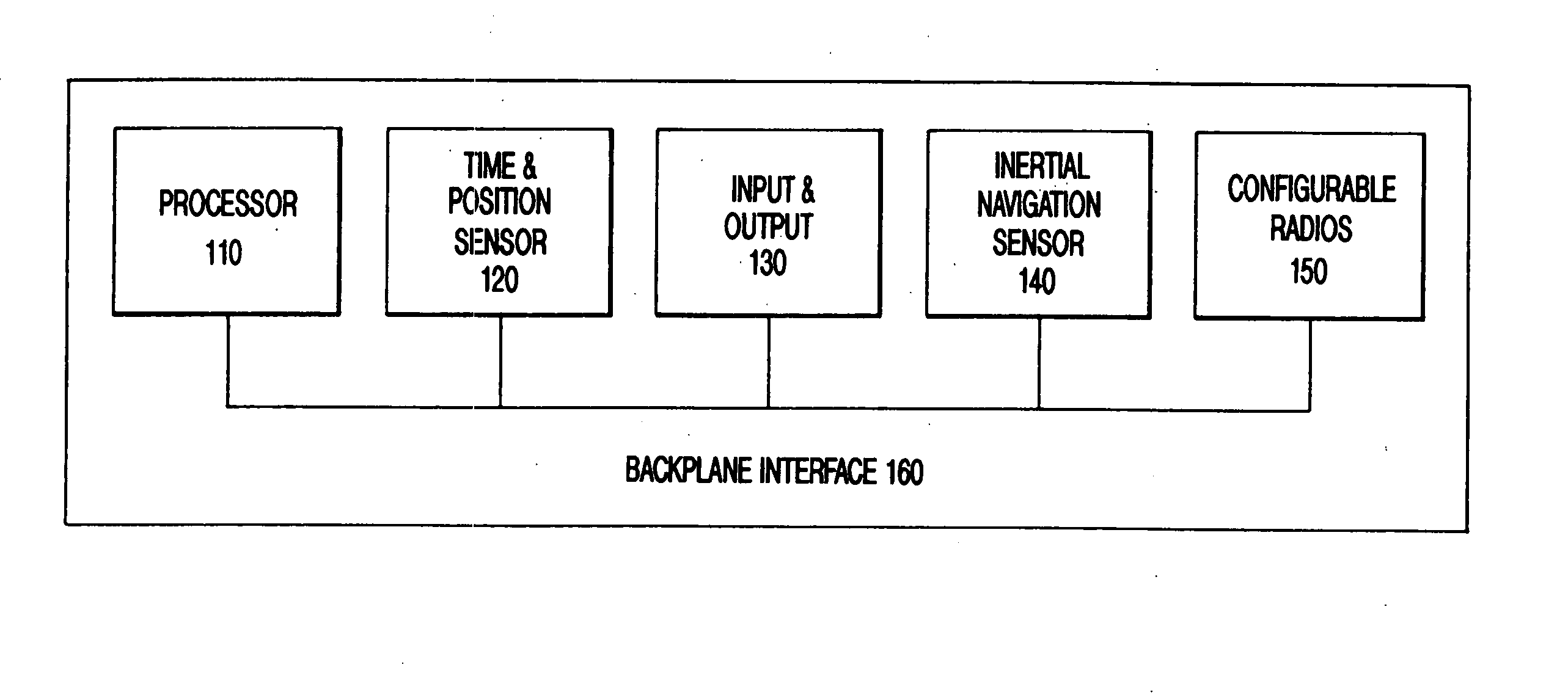

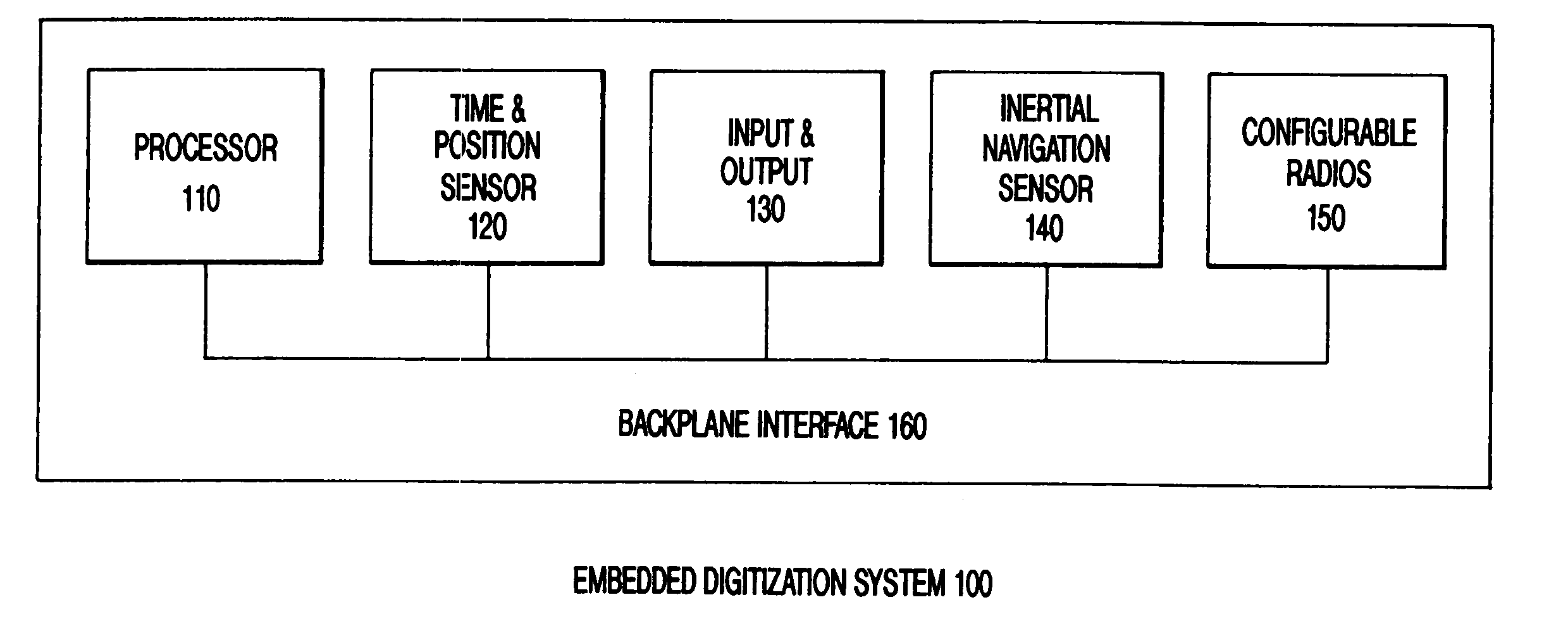

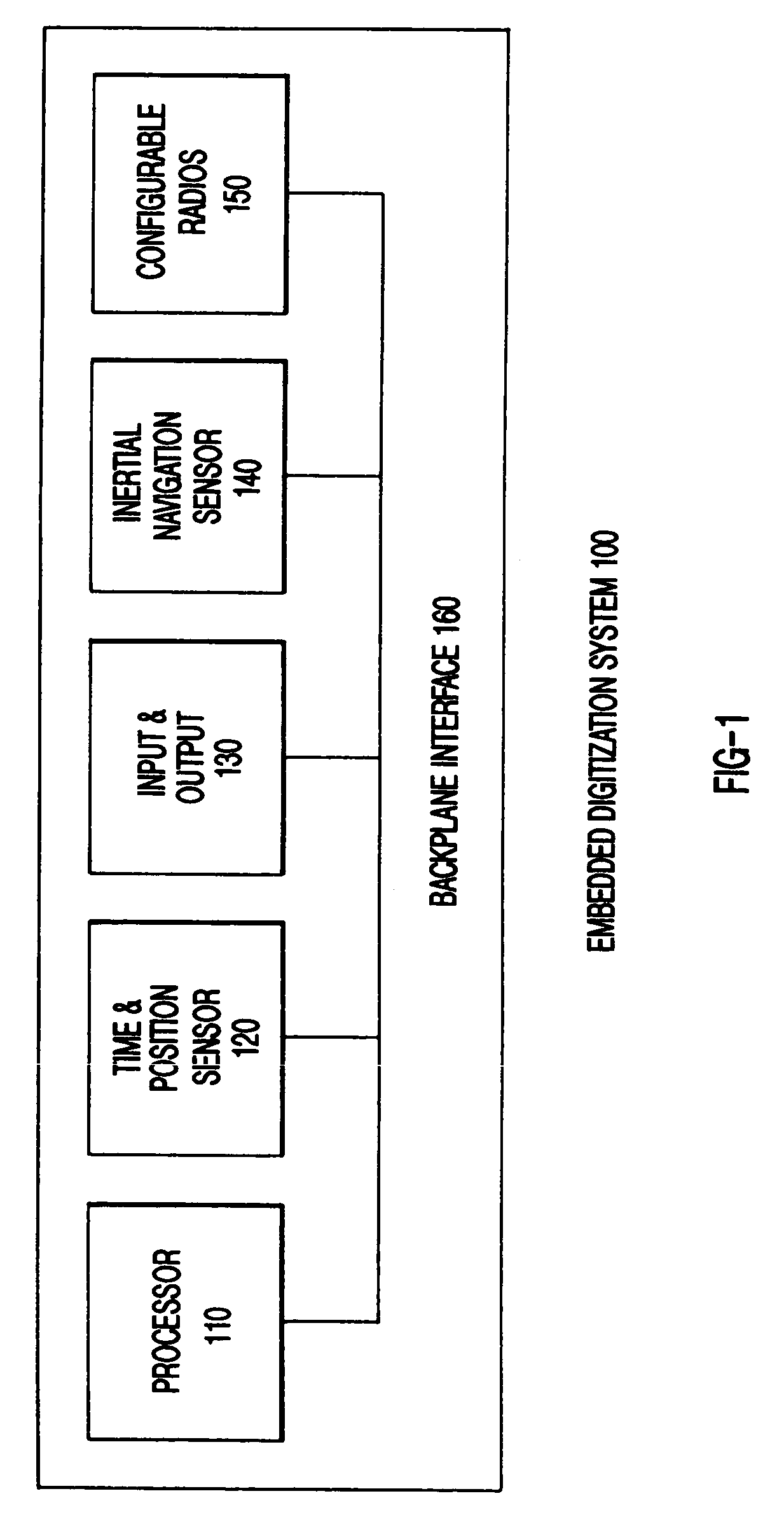

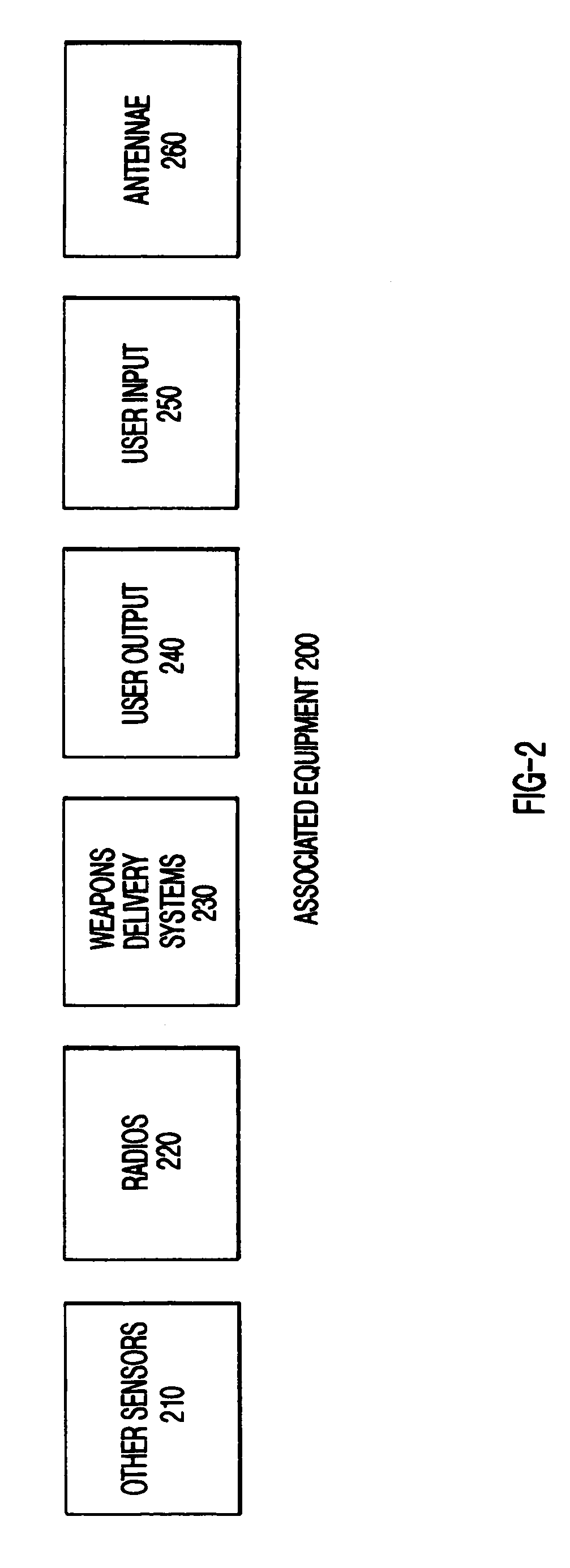

Embedded digitization system

InactiveUS20050017877A1Reduce multiplicityLow costRoad vehicles traffic controlNavigation by speed/acceleration measurementsInformation interoperabilityApplication software

An embedded digitization system enables a military platform to receive, transmit and process a variety of types of information for a variety of purposes. An apparatus and method provides a means to ensure information interoperability between the invention and external sources. The invention provides a development environment that enables a developer to automatically and interactively develop the middleware services and functions that contain the aspects for interoperability with external sources. The invention ensures interoperability through reuse of functions and services known to satisfy requirements for interoperability. When functions and services that satisfy requirements for interoperability are not available, the invention provides a means to develop new functions and services that satisfy requirements for interoperability. The new functions and services are then added to those functions and services known to satisfy requirements for interoperability, and are also made available for use in future applications.

Owner:HONEYWELL INT INC

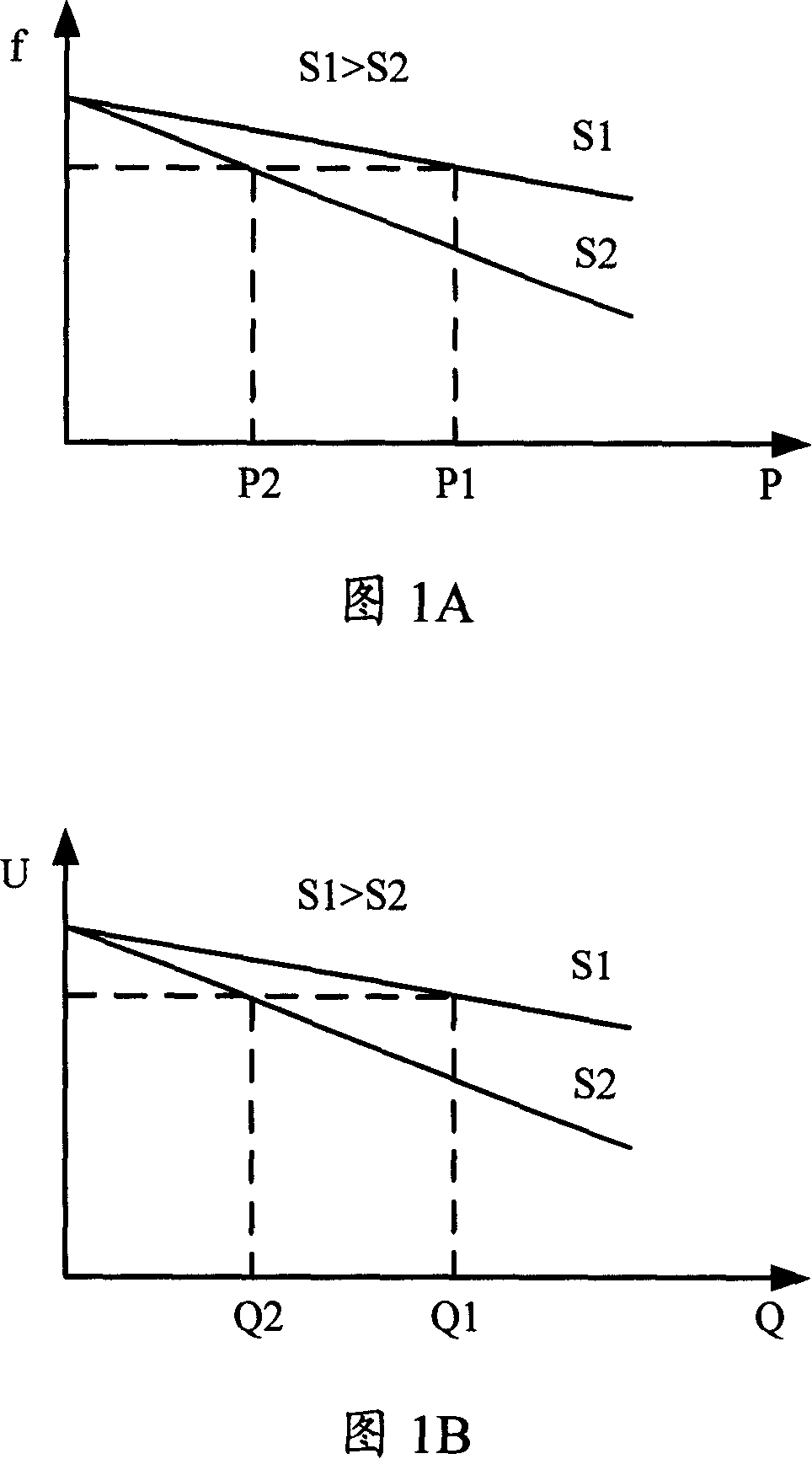

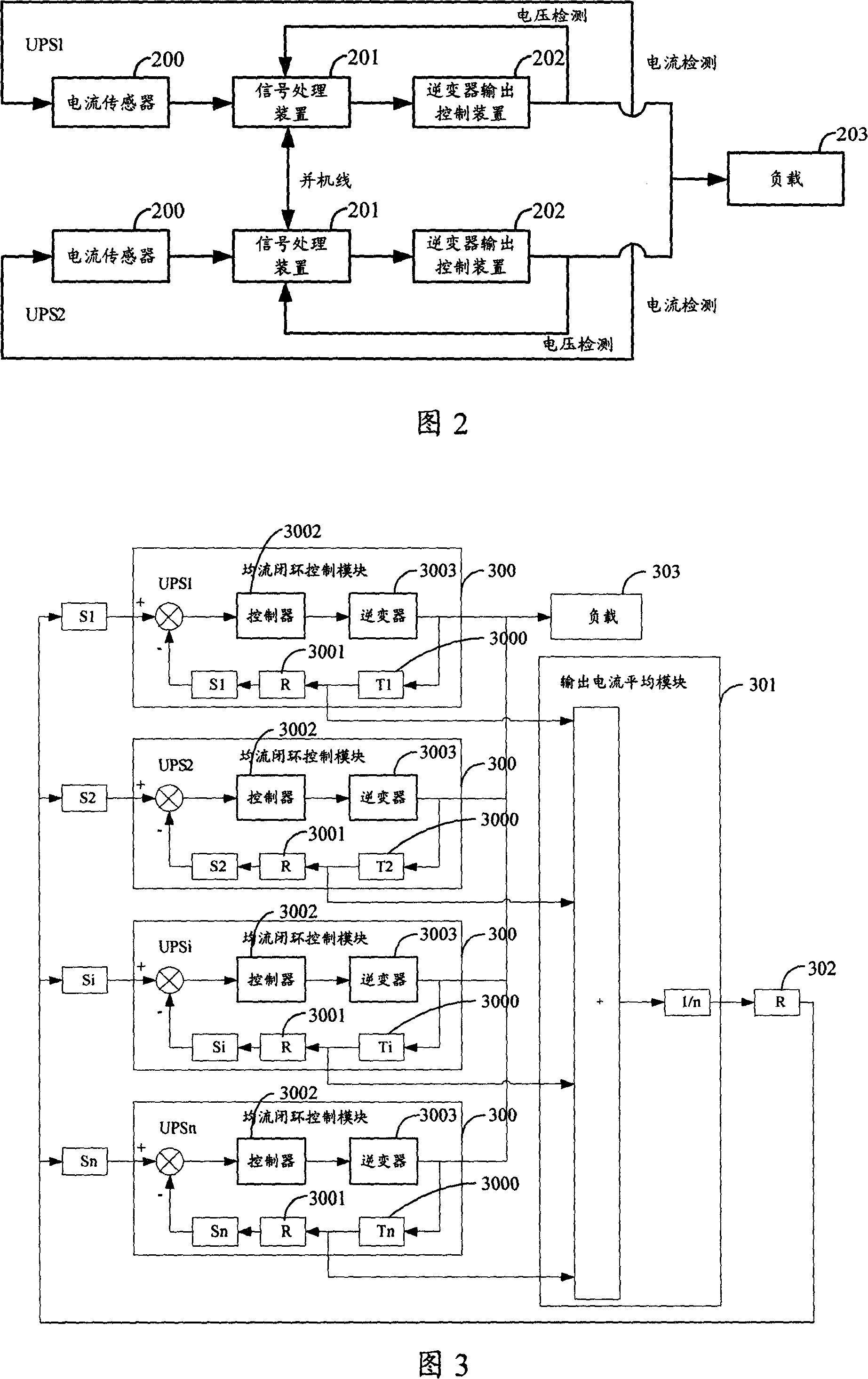

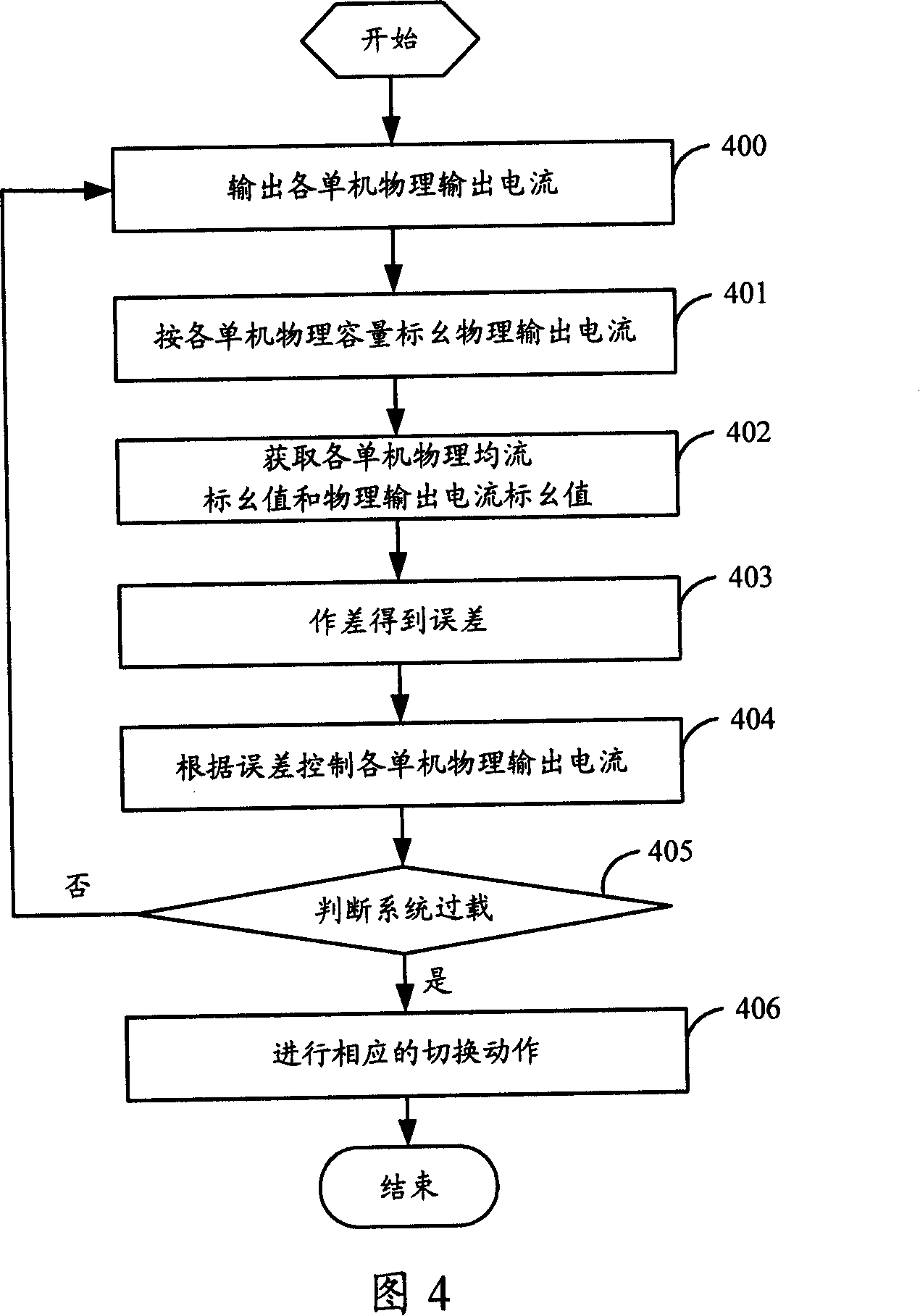

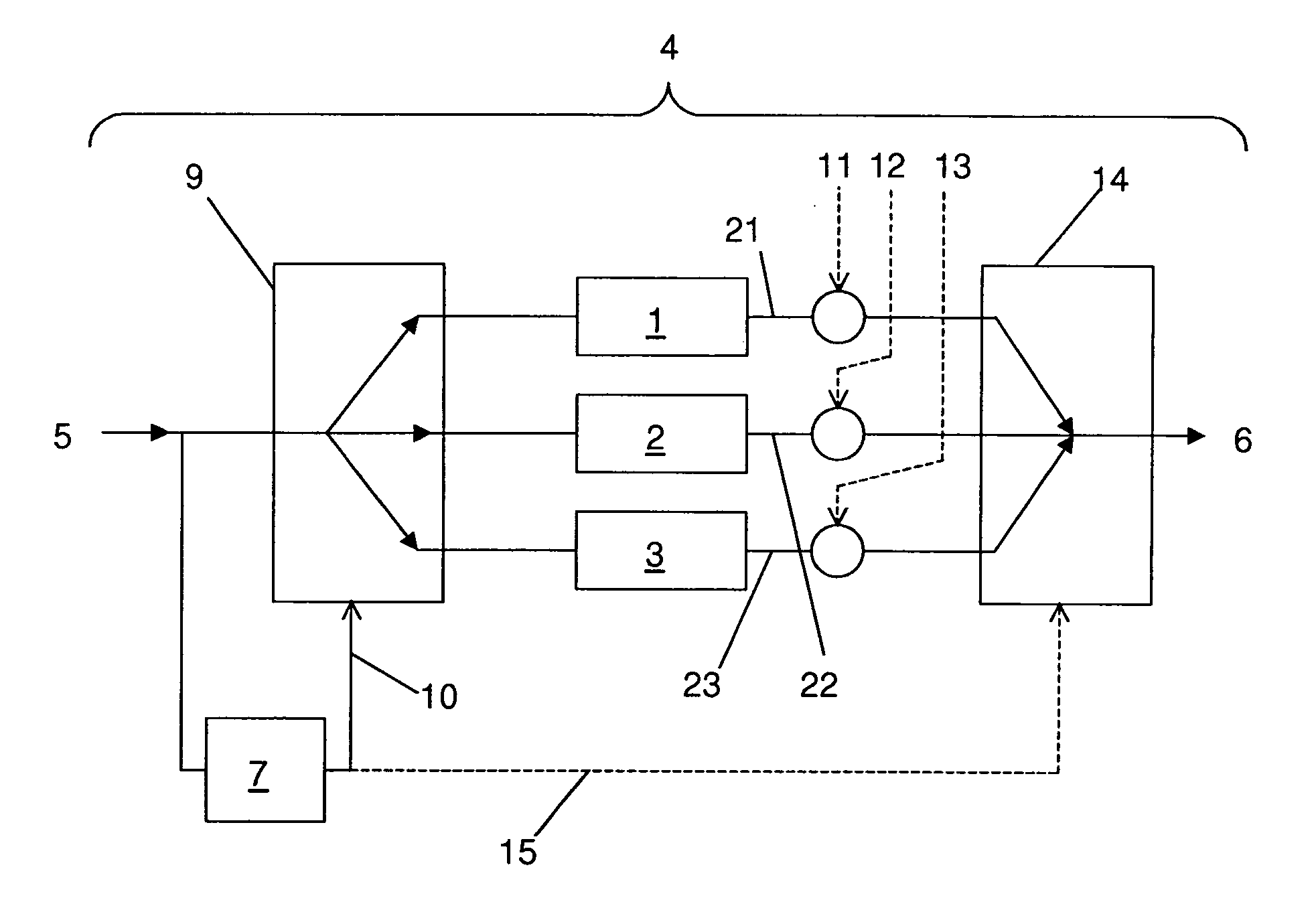

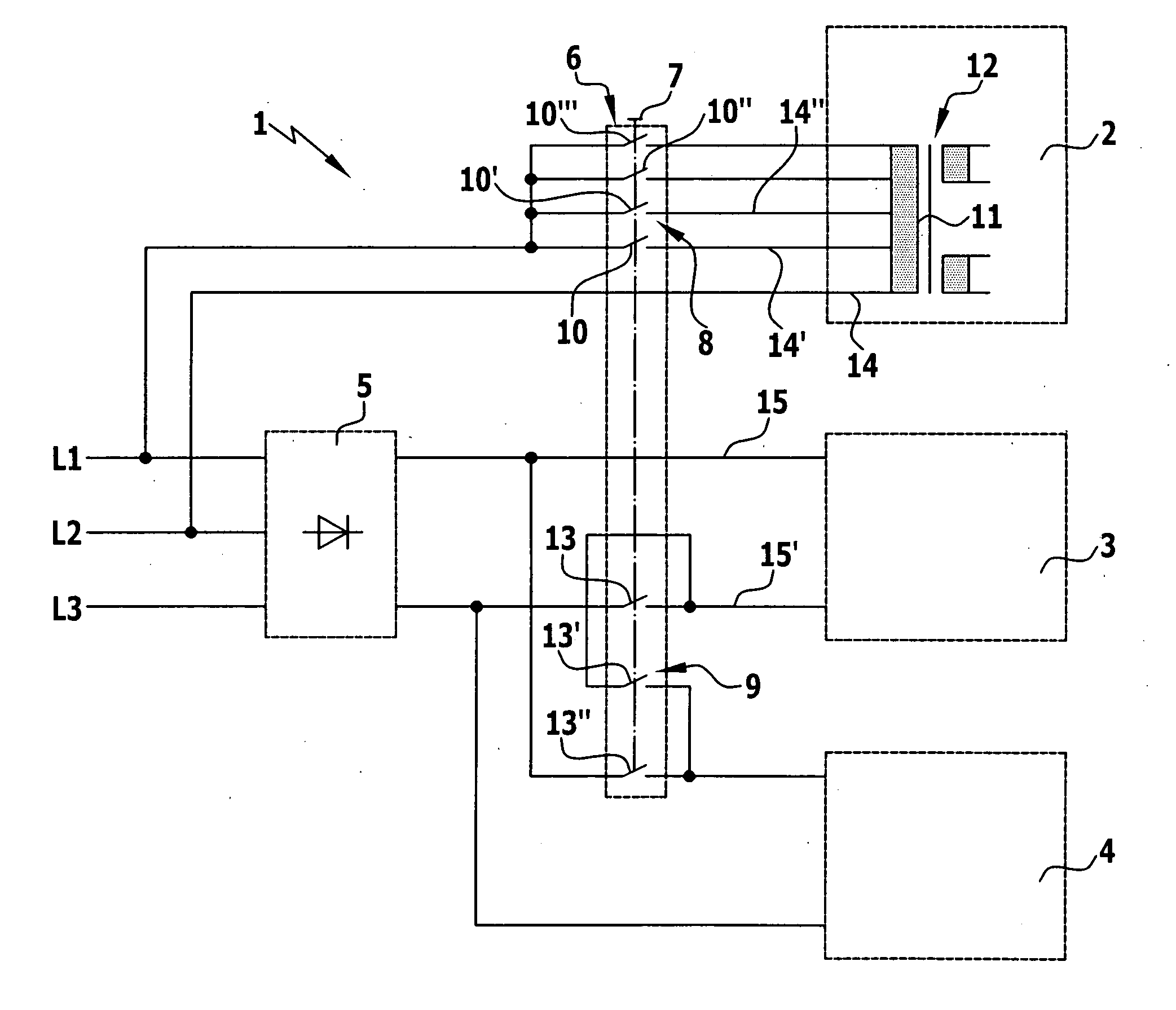

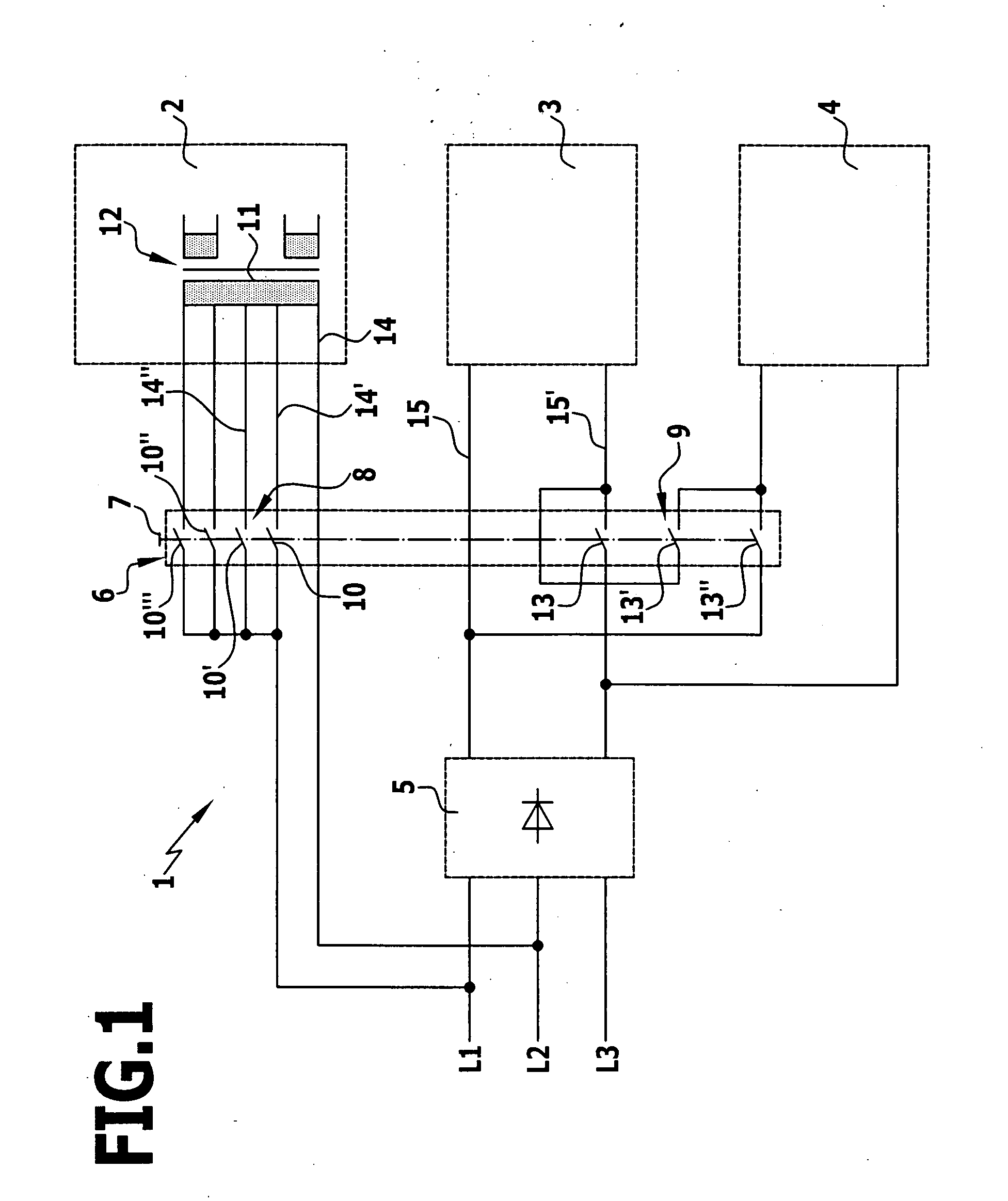

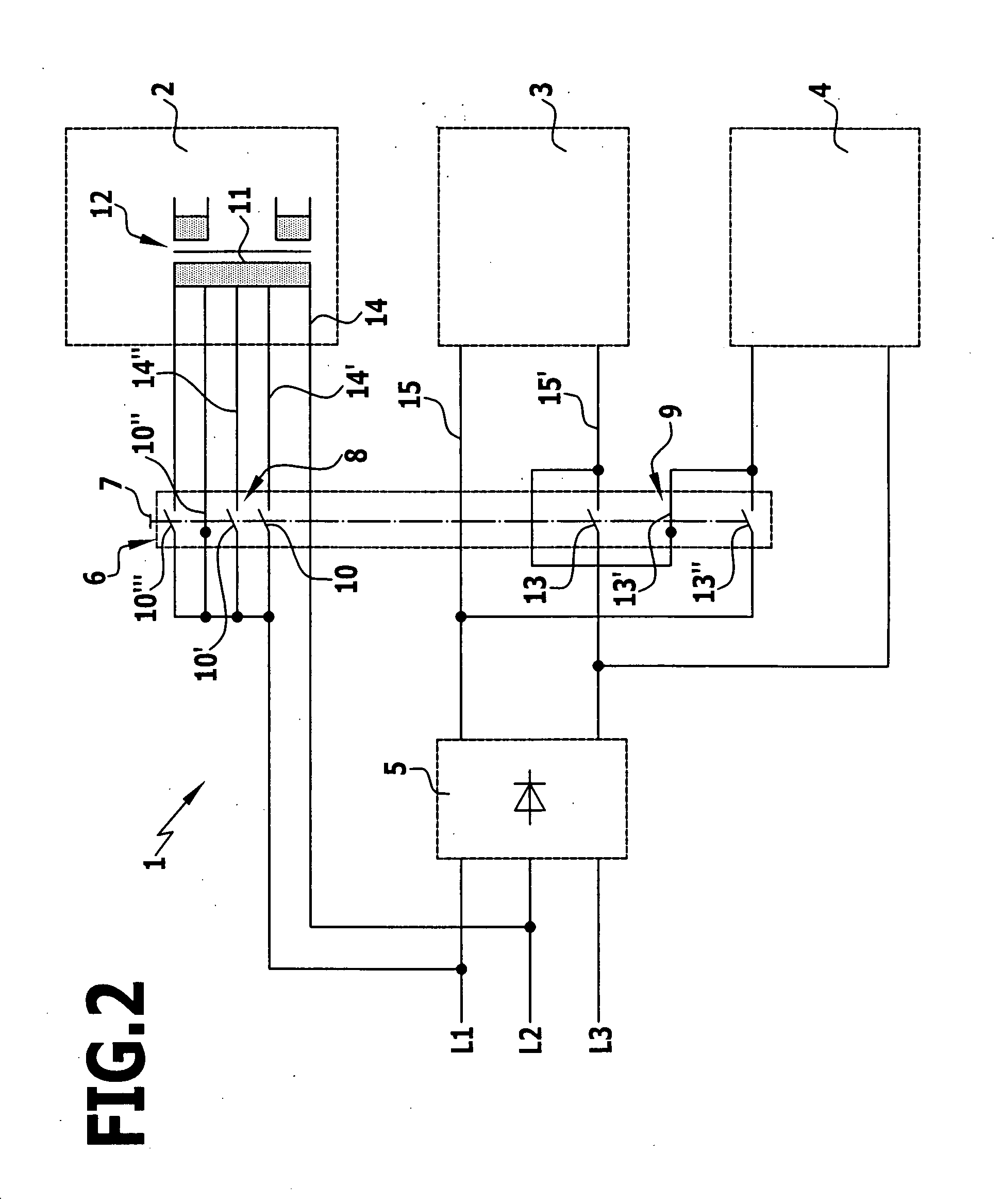

Method and system for parallel connection of UPS with different capacitance grade

ActiveCN101154826ALoad sharingReduce multiplicityBatteries circuit arrangementsElectric powerCapacitanceEngineering

The invention discloses a parallel connection method of different capacity level UPS, which is to solve the problems of the poor system precision and the poor stability precision ofoutput voltage caused by structuring the droop characteristics of UPS to realize the parallel connection between different capacity level UPS in the prior art. The method includes the following steps that: the physical output current is per-united according to the physical capacity of each stand-alone; each per-united physical output current is averaged to get the per-united equalized value of the physical output current of each stand-alone; the per-united physical output current value and the physical equalized current value are respectively converted to get the physical output current per-united value and physical equalized current per-united value of each stand-alone; the physical output circuit of each stand-alone is controlled by taking advantage of the error between the physical output current per-united value and physical equalized current per-united value of each stand-alone. The invention discloses a different capacity level UPS parallel system at the same time.

Owner:VERTIV CORP

Evaluation circuit for processing digital signals, method, and sensor assembly

ActiveUS8370112B2Large dynamic rangeEfficient use ofAmplifier modifications to reduce noise influenceDigital computer detailsComputer scienceDigital signal

An evaluation circuit for processing digital signals, the evaluation circuit processing an input data word and outputting an output data word, and a method for processing digital signals in an evaluation circuit, and to a sensor assembly.

Owner:ROBERT BOSCH GMBH

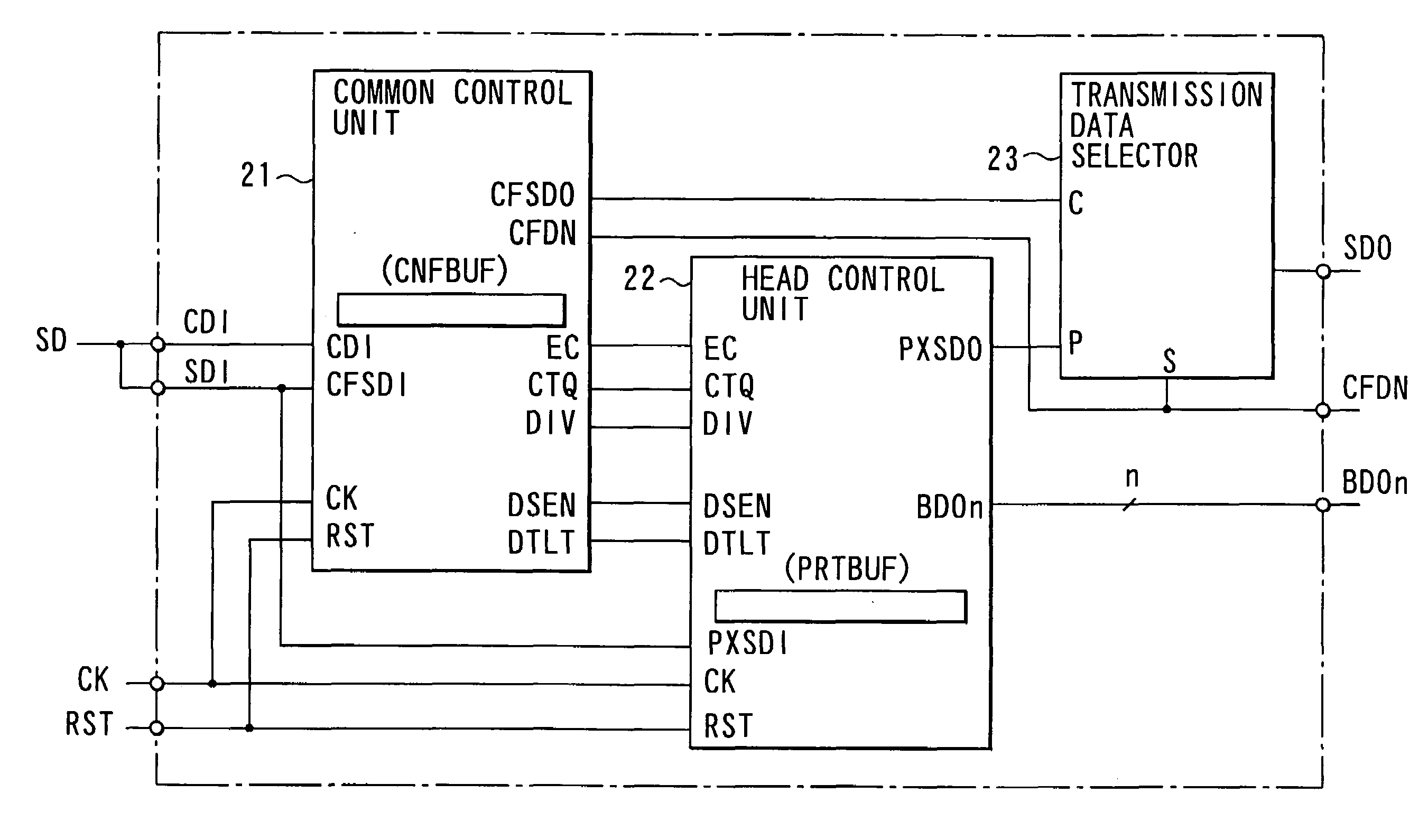

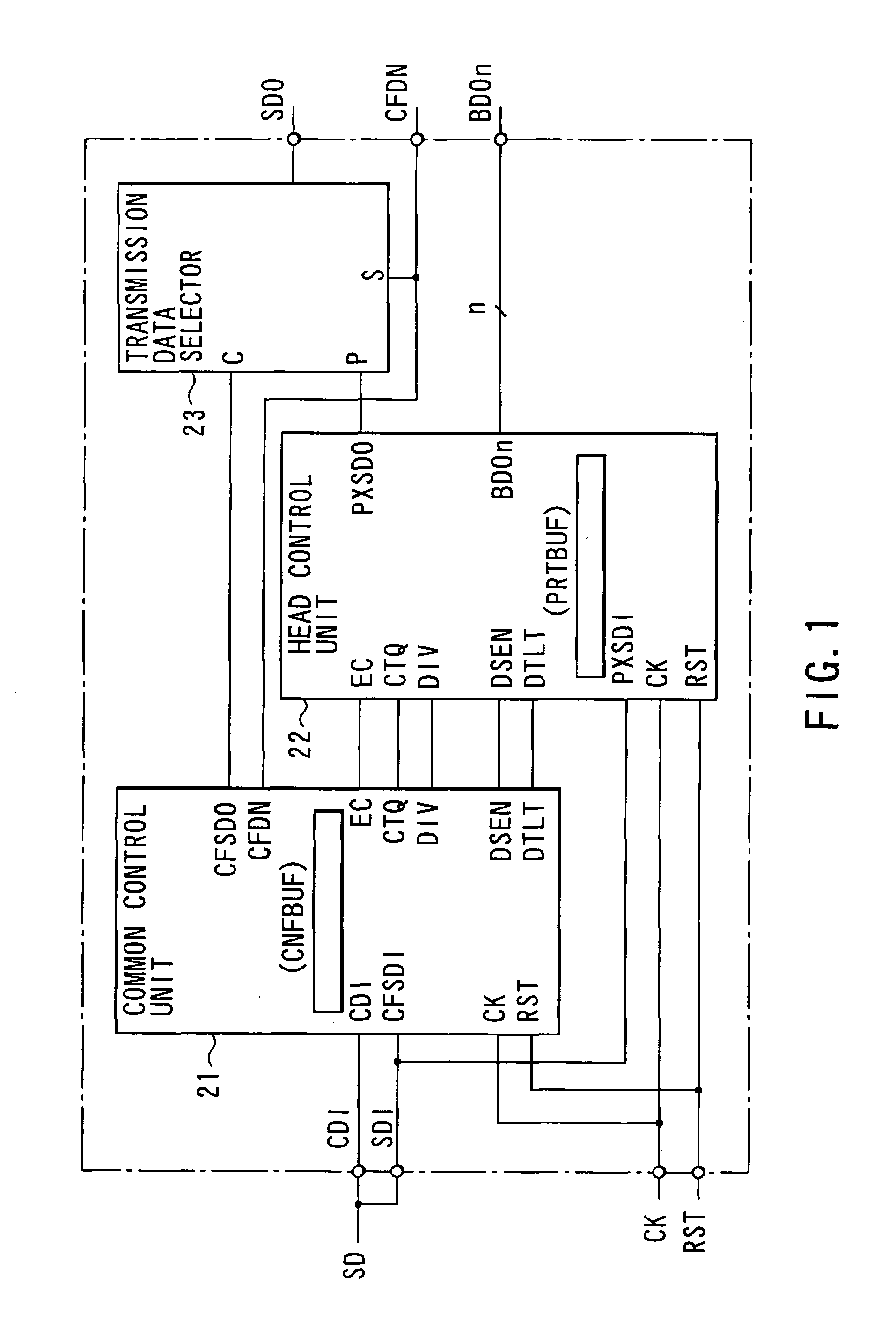

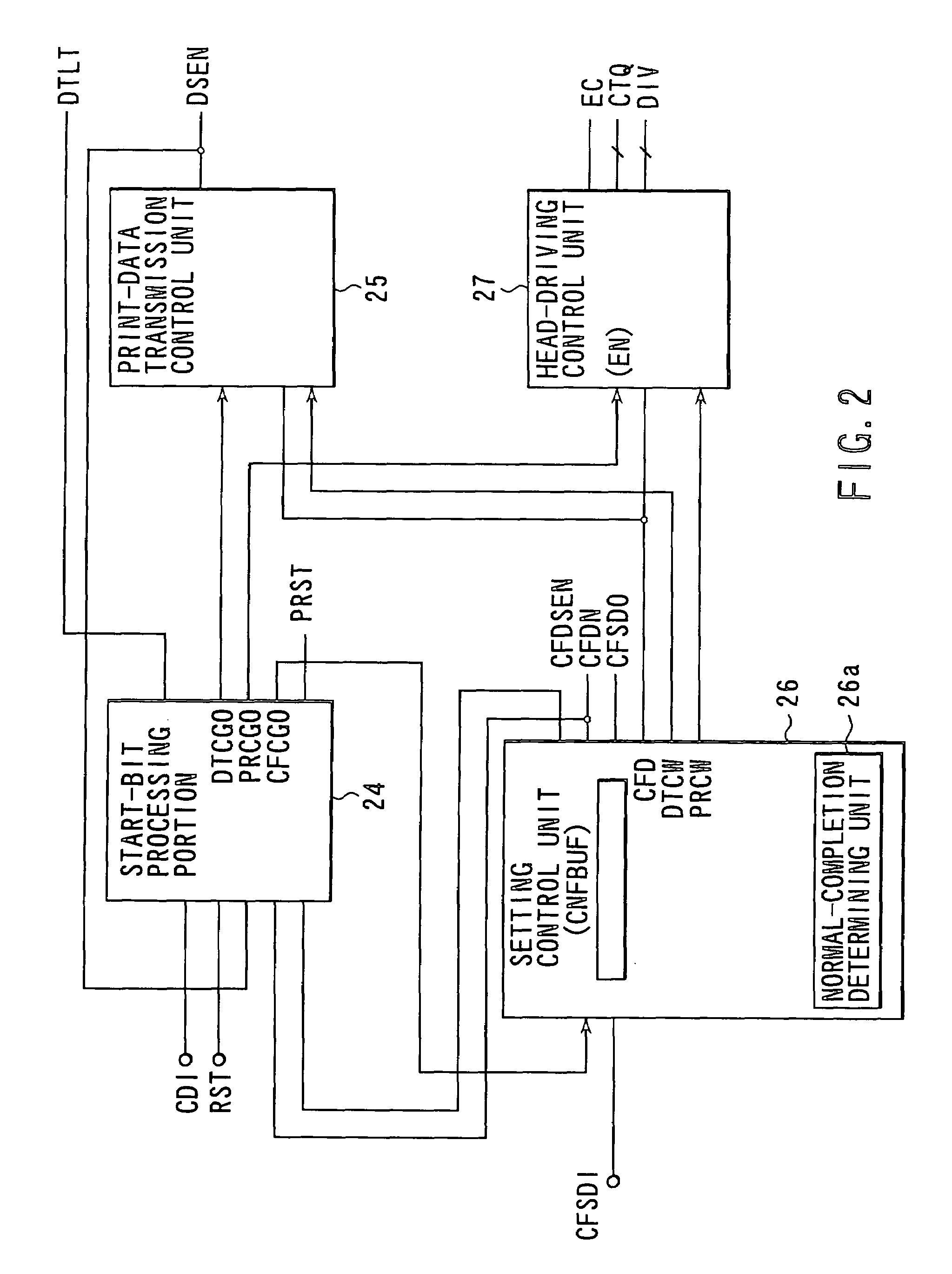

Driving control apparatus and driving control method

InactiveUS6943911B1Reduce multiplicityLow costDigitally marking record carriersDigital computer detailsStart timeControl signal

A driving control apparatus incorporating a forming circuit for receiving serial data including start bit data and driving control data, detecting the start bit data from the serial data and forming a control signal in accordance with the detected start bit data, a storing portion for storing the driving control data in a storing region in accordance with the control signal formed by the forming circuit, and a generating circuit for generating a driving signal for driving a subject which must be driven in accordance with the driving control data stored in the storing portion and the control signal formed by the forming circuit. Since the start bit data provides start timing, a multiplicity of control signals are not required.

Owner:TOSHIBA TEC KK

Embedded digitization system

InactiveUS7196638B2Reduce multiplicityLow costSpatial transmit diversityRoad vehicles traffic controlInformation interoperabilityApplication software

An embedded digitization system enables a military platform to receive, transmit and process a variety of types of information for a variety of purposes. An apparatus and method provides a means to ensure information interoperability between the invention and external sources. The invention provides a development environment that enables a developer to automatically and interactively develop the middleware services and functions that contain the aspects for interoperability with external sources. The invention ensures interoperability through reuse of functions and services known to satisfy requirements for interoperability. When functions and services that satisfy requirements for interoperability are not available, the invention provides a means to develop new functions and services that satisfy requirements for interoperability. The new functions and services are then added to those functions and services known to satisfy requirements for interoperability, and are also made available for use in future applications.

Owner:HONEYWELL INT INC

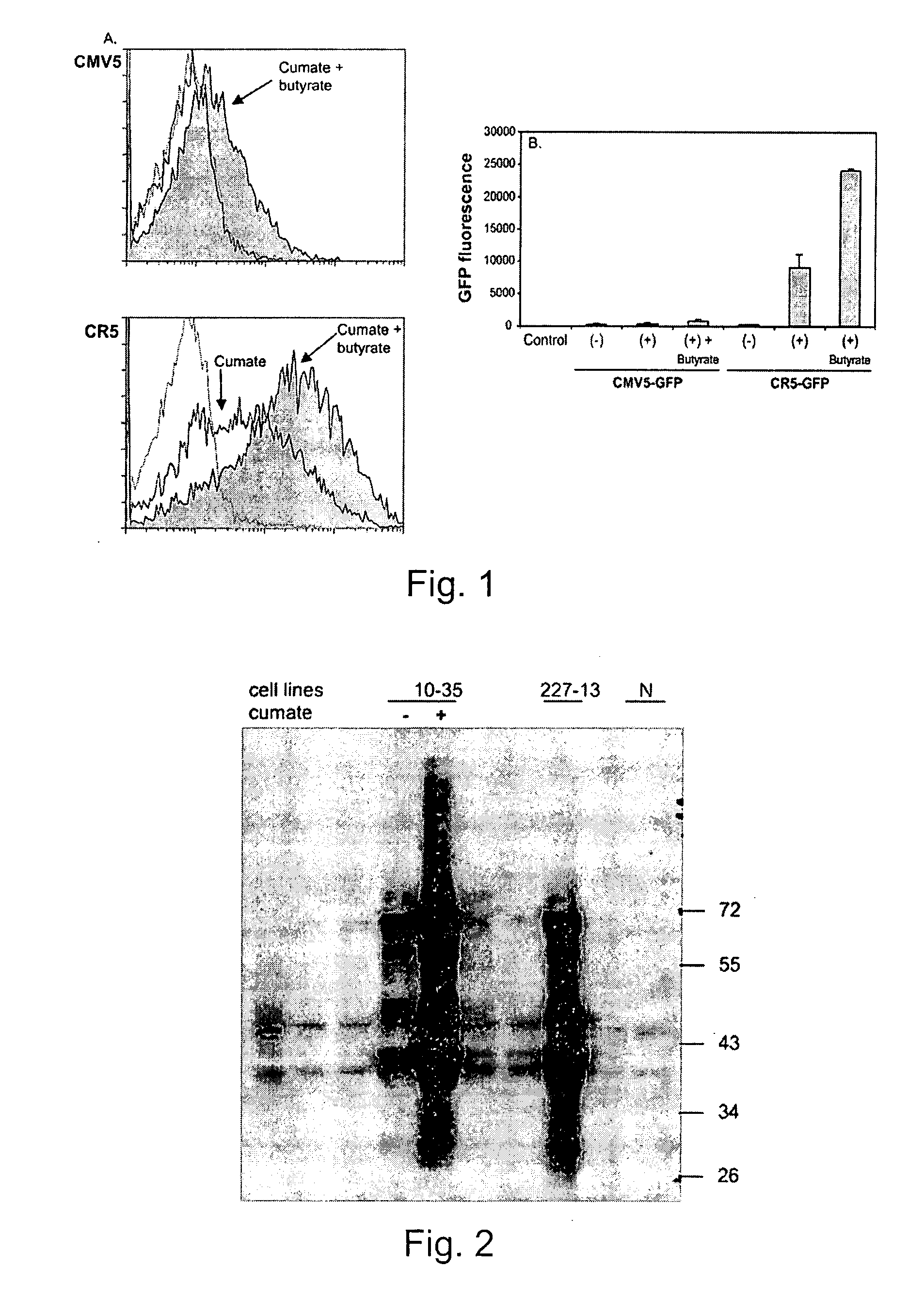

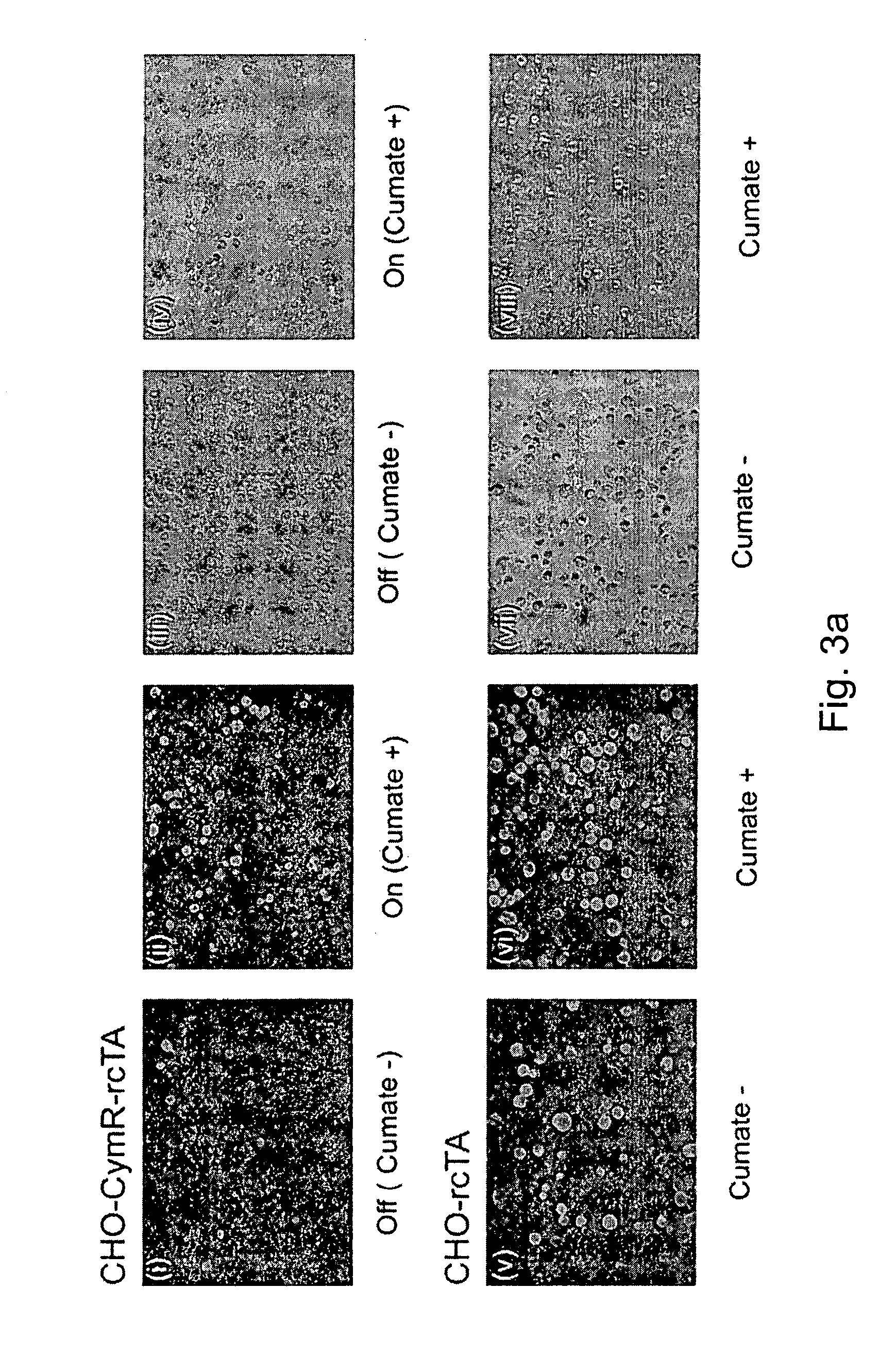

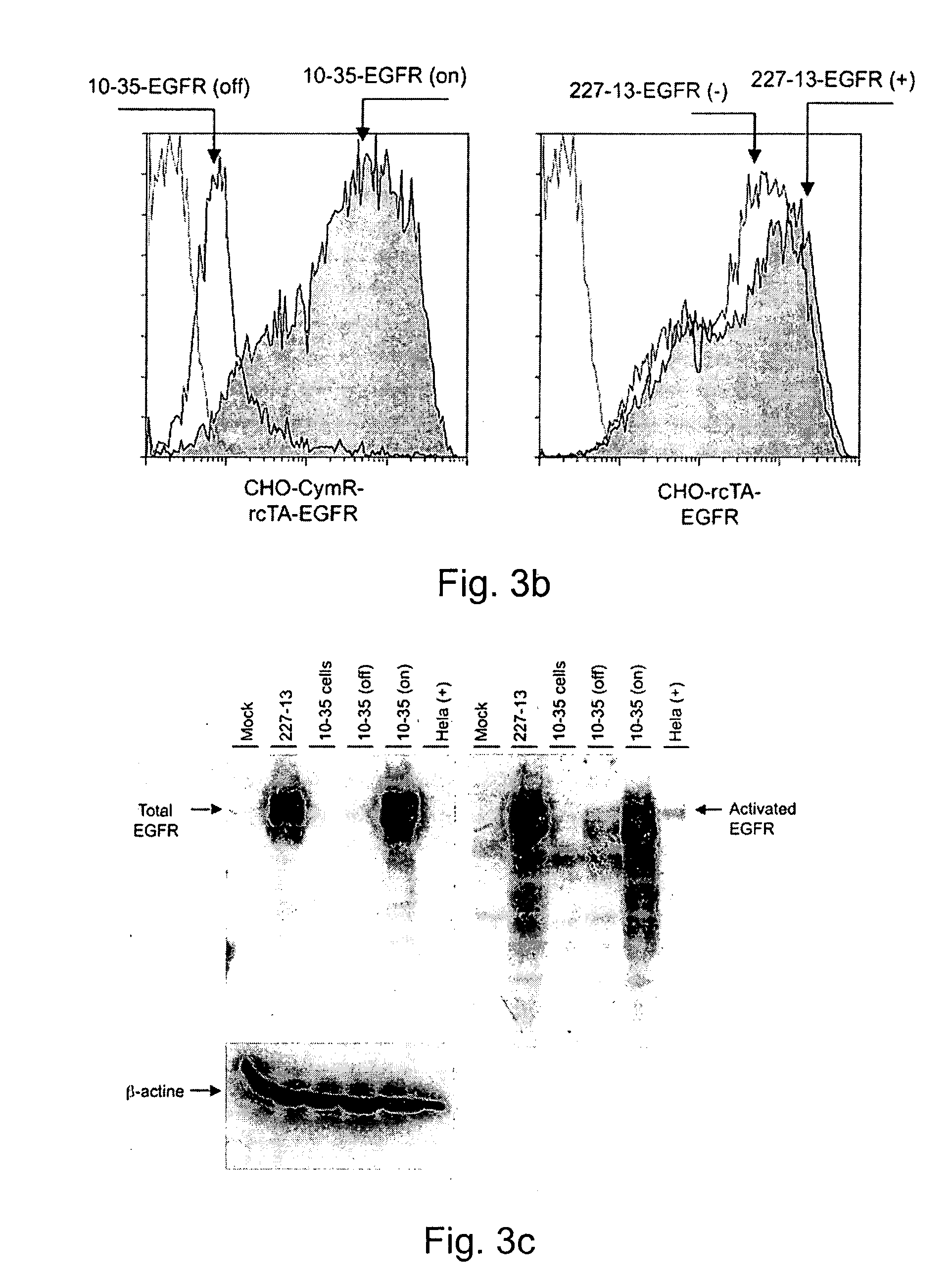

System for regulated and enhanced baculovirus mediated transient transgene expression in mammalian cells

A baculovirus-based expression system under control of CR5 promoter improves expression of transgenic nucleic acid molecules in mammalian cells. It also provides a platform for regulated expression of transgenic nucleic acid molecules in mammalian cells.

Owner:NAT RES COUNCIL OF CANADA

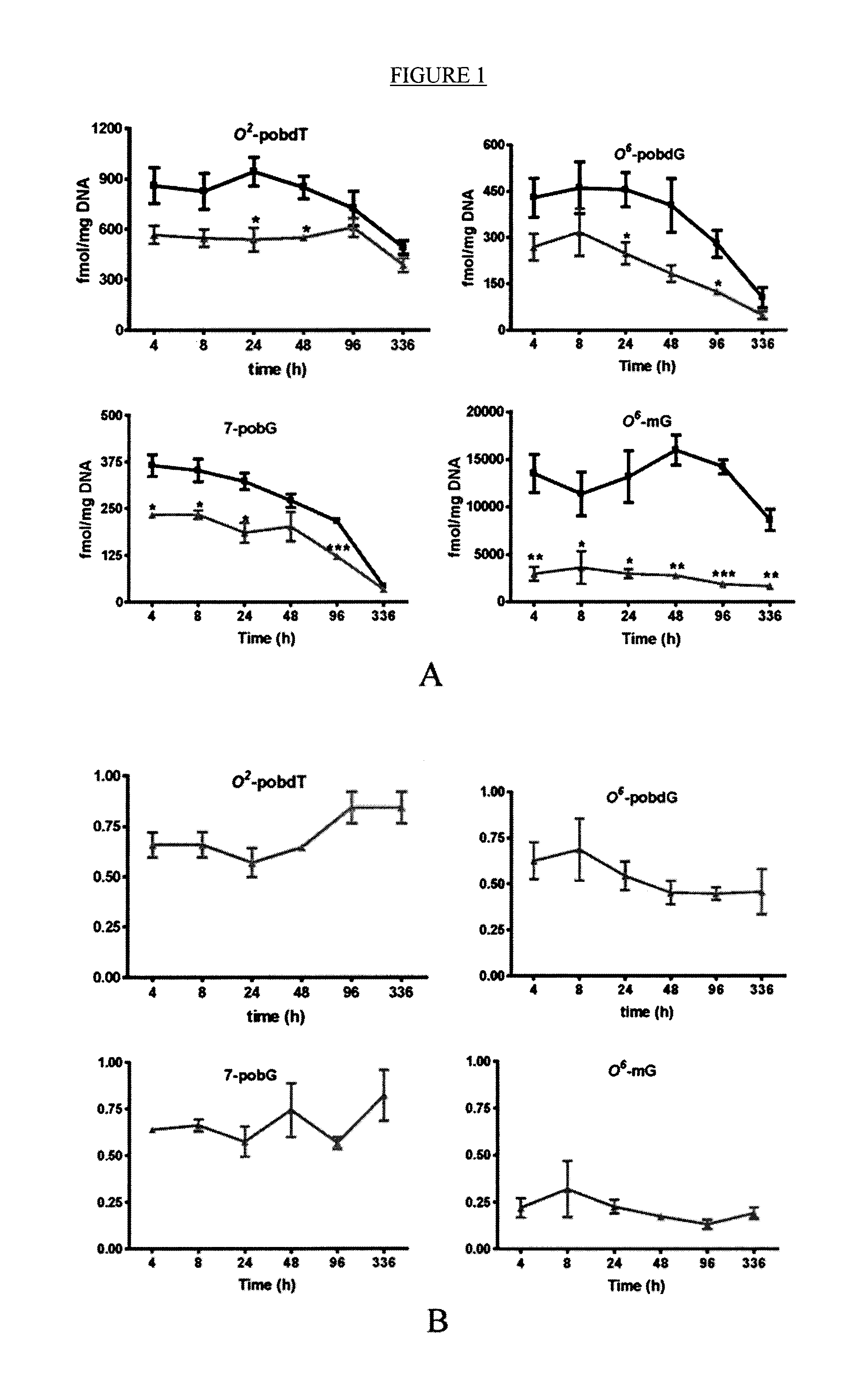

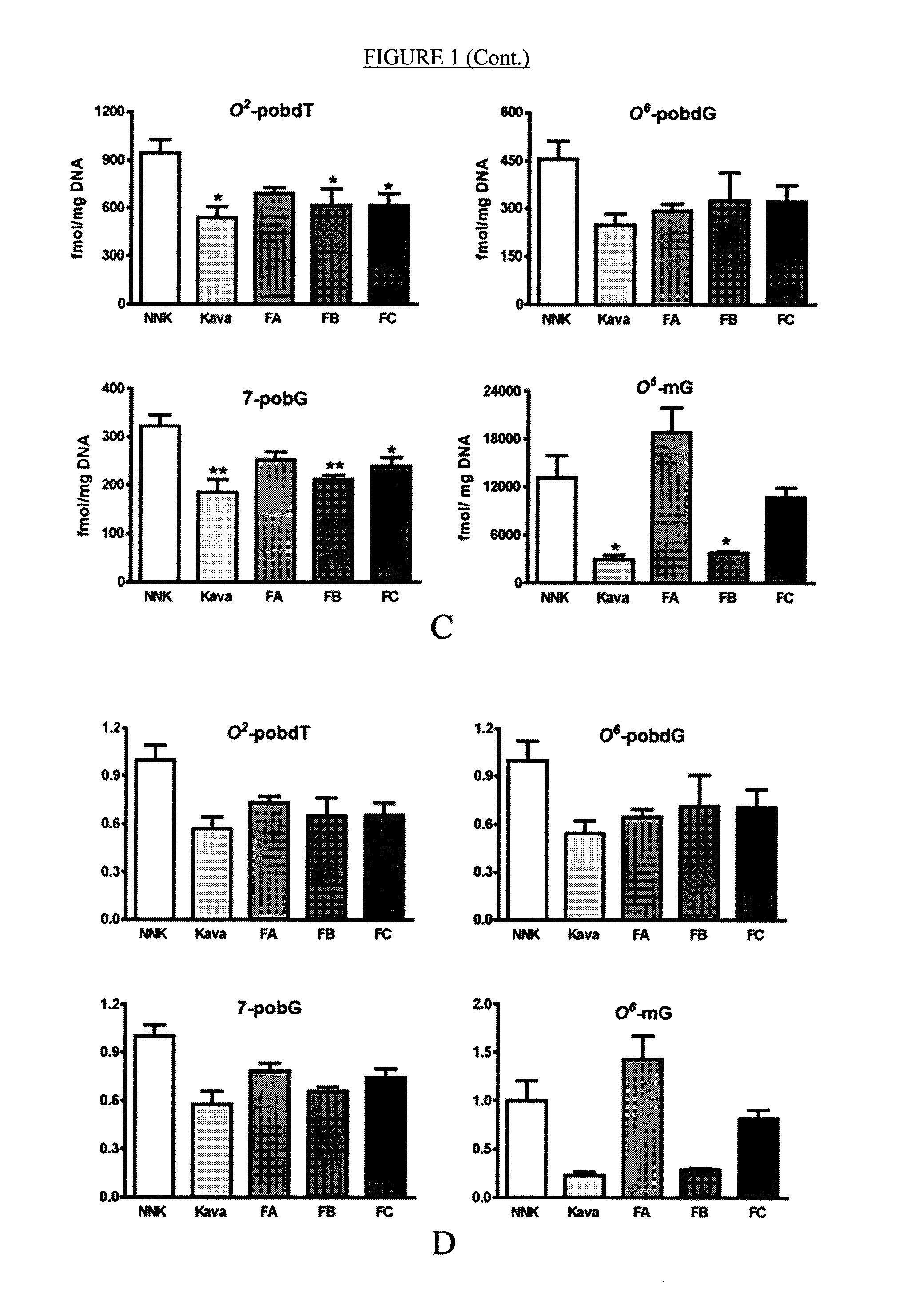

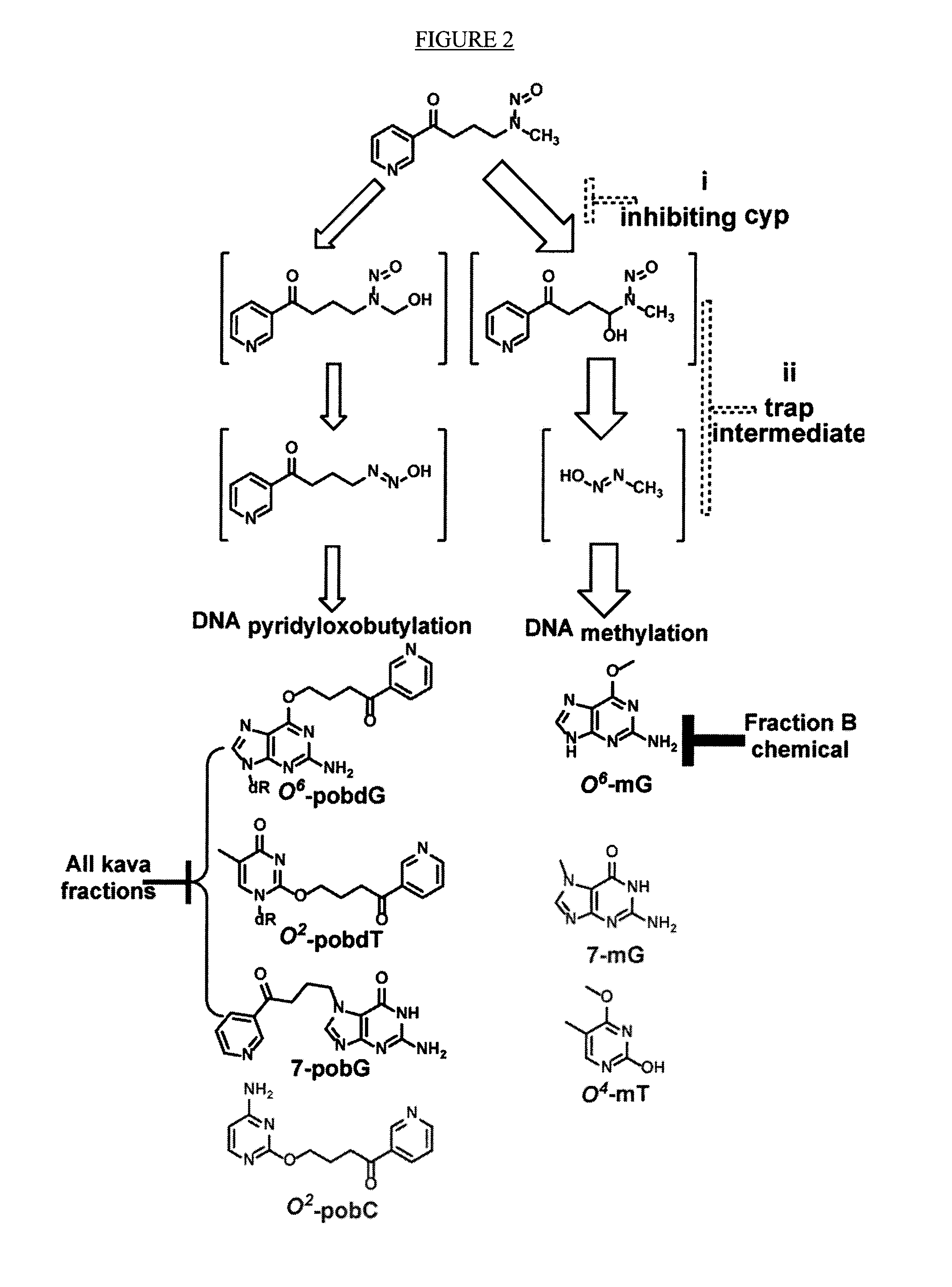

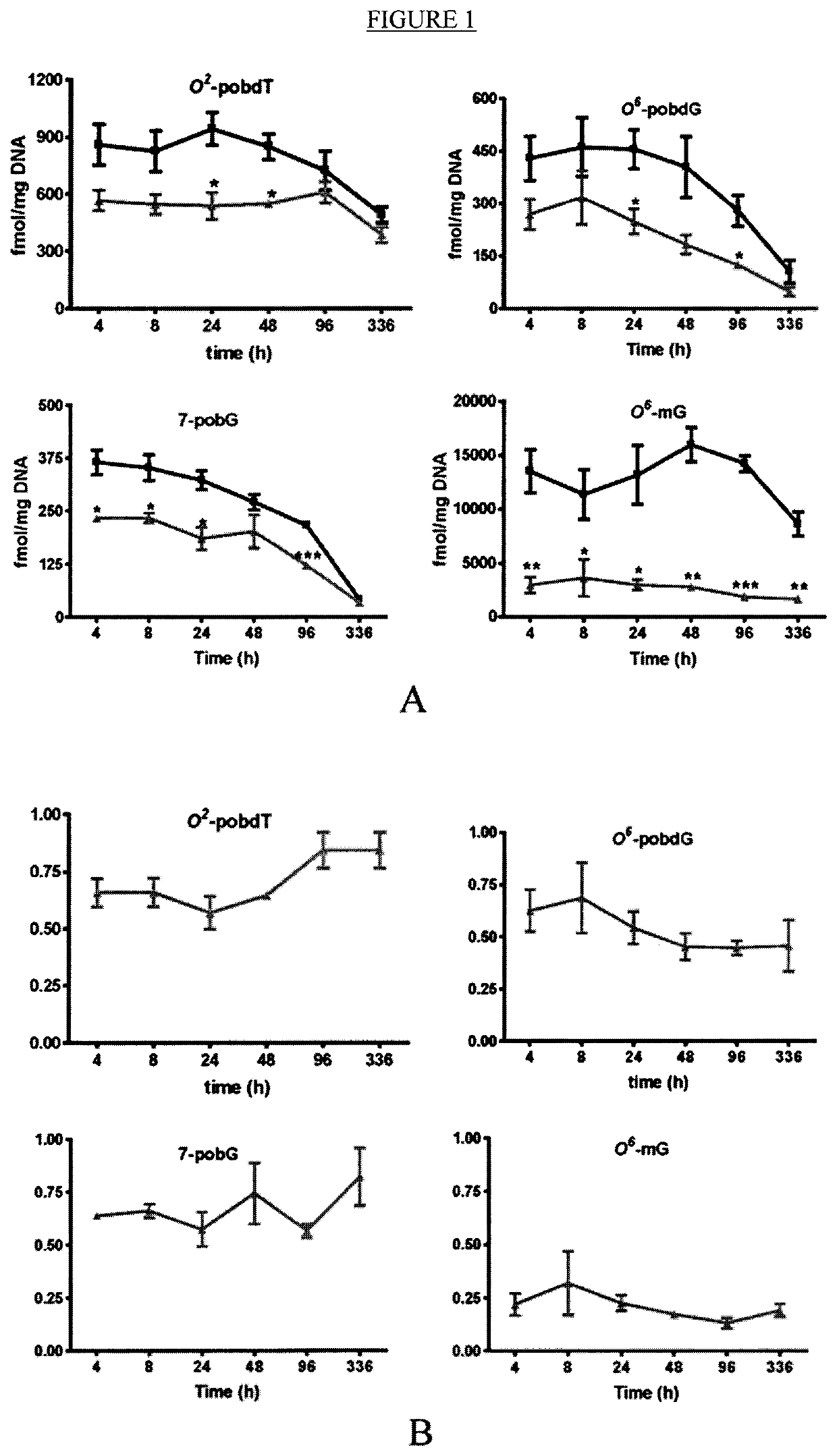

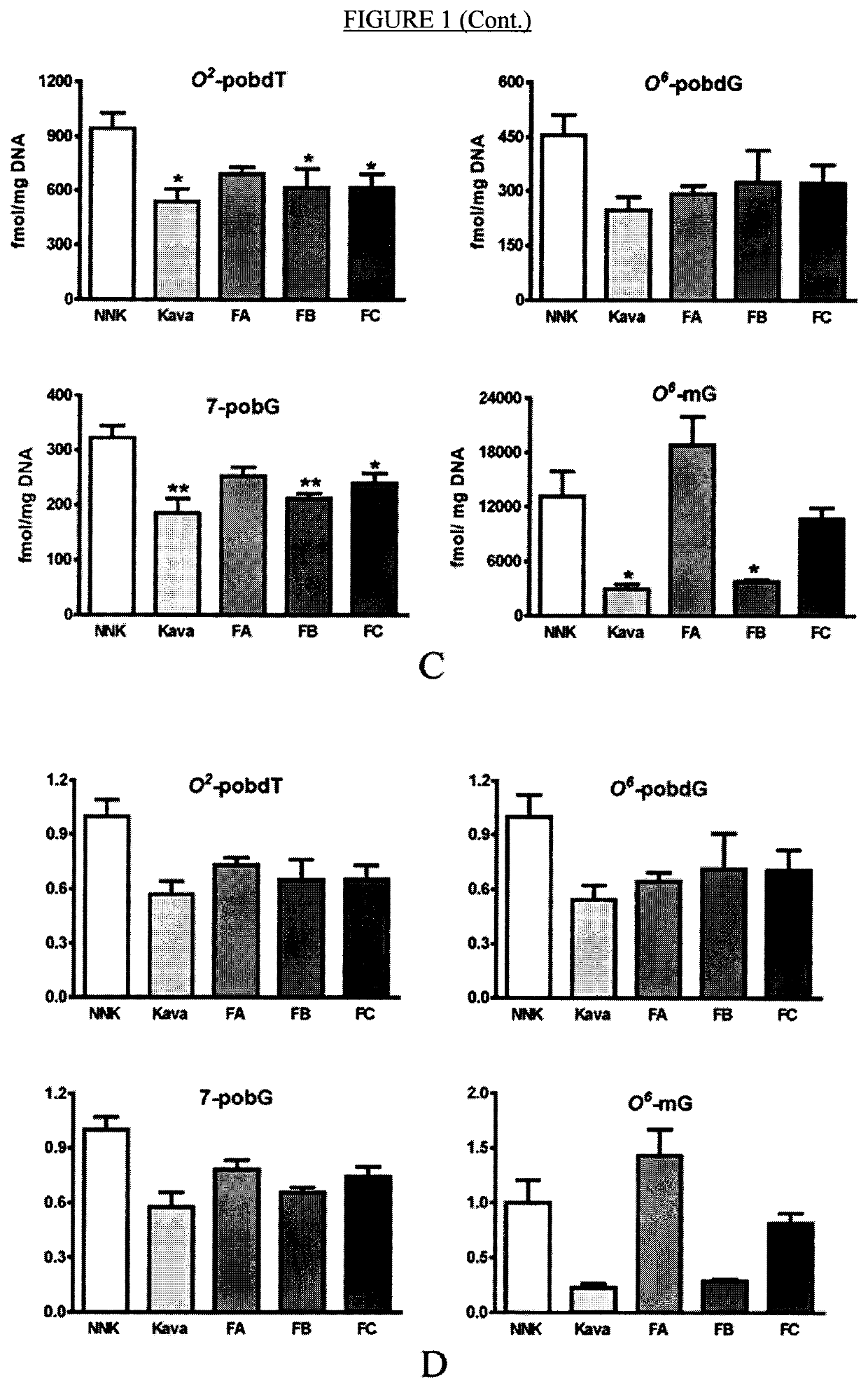

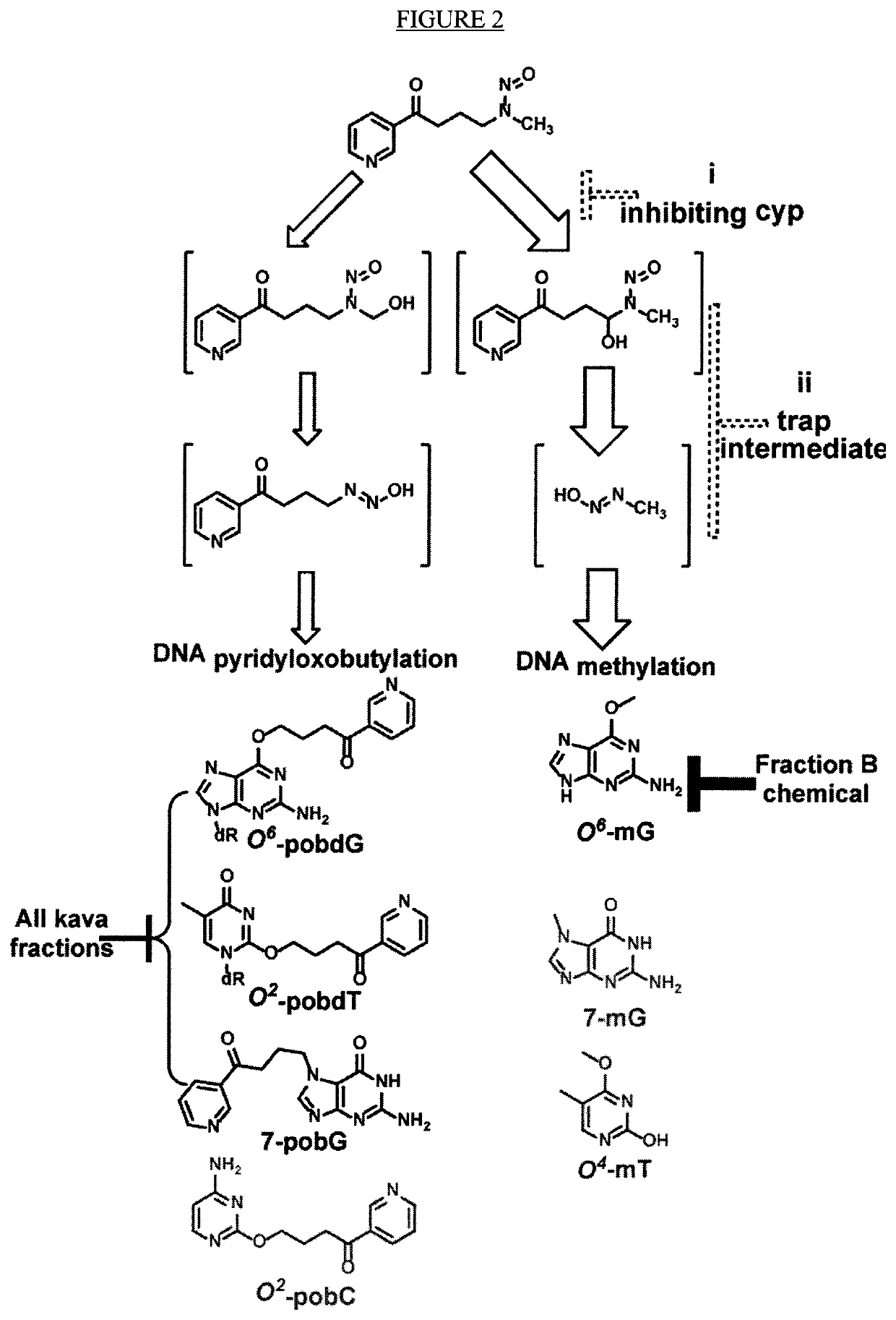

Kava derived therapeutic compounds and methods of use thereof

ActiveUS20160279184A1Inhibiting tumorigenesisReducing DNA damageKetone active ingredientsAntineoplastic agentsKavaDesmethoxyyangonin

Certain embodiments of the invention provide a composition comprising at least two compounds selected from the group consisting of dihydromethysticin, methysticin, dihydrokavain, kavain, desmethoxyyangonin and 11-methoxyyangonin, wherein the composition is substantially free of flavokawain B. Certain embodiments of the invention also provide a method for treating or preventing cancer in a mammal (e.g., a human) in need of such treatment comprising, administering to the mammal a carrier and a compound selected from the group consisting of dihydromethysticin, methysticin, dihydrokavain, kavain, desmethoxyyangonin and 11-methoxyyangonin, wherein the compound is substantially free of other kava extract components.

Owner:KUALITY HERBCEUTICS

Spindle gearbox and drive unit of an electric seat drive

Owner:ROBERT BOSCH GMBH

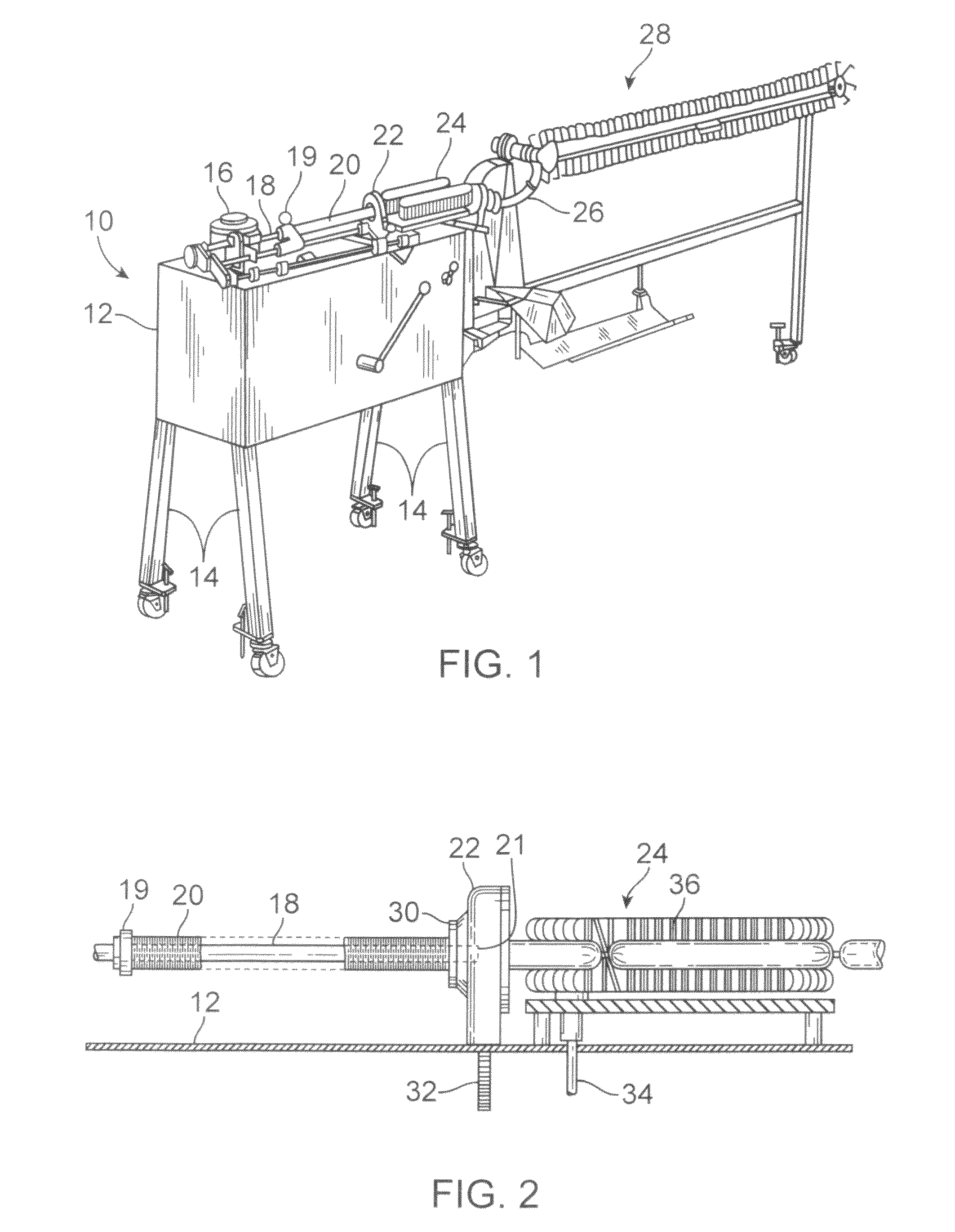

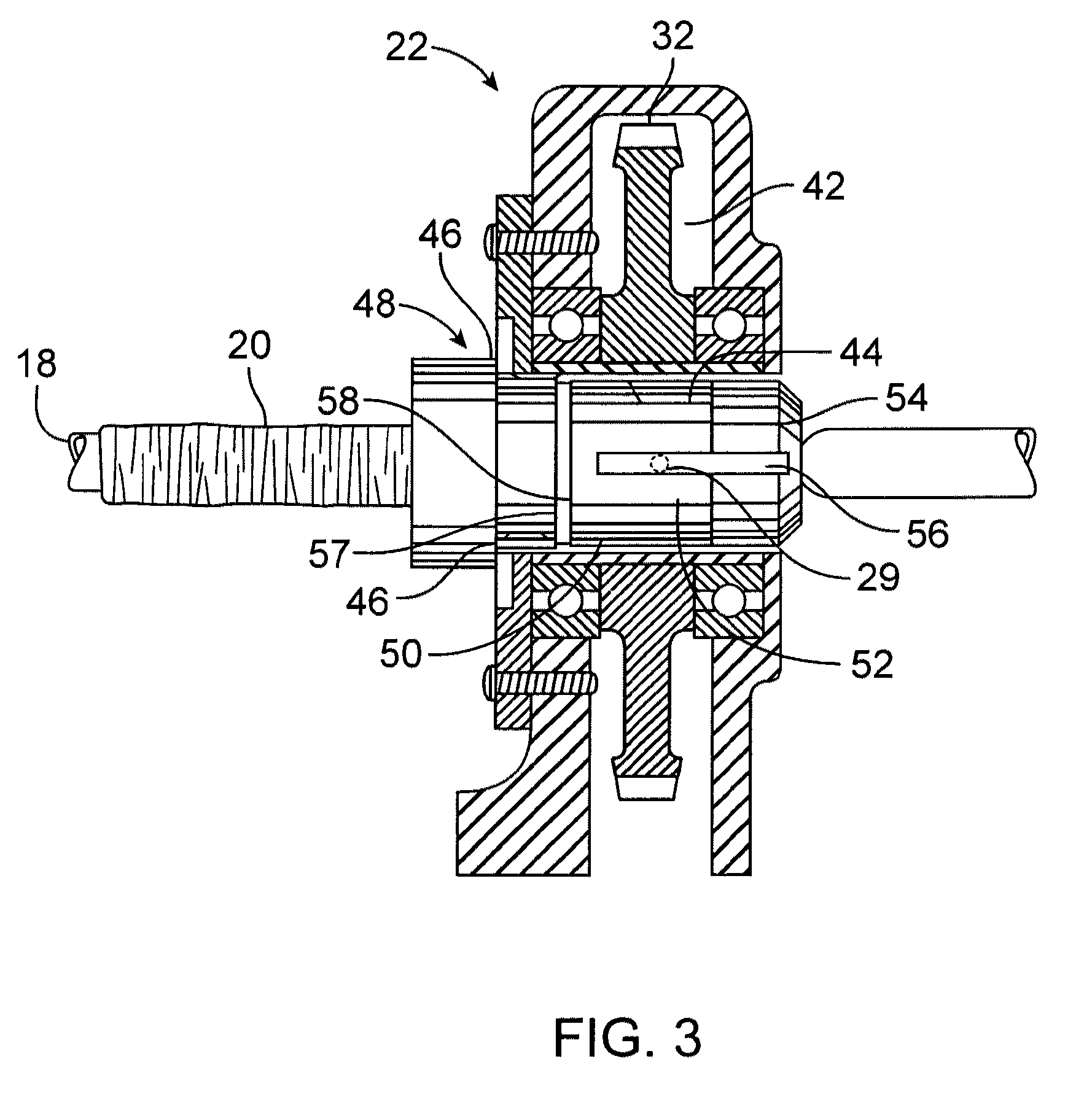

Casing chuck

InactiveUS8241096B1Increase holdback forceIncrease resistanceSausage twisting/linking machinesEngineeringMechanical engineering

Chucks for a meat encasing machine that increase the holdback force on plastic casing sticks resulting in fully formed initial links. The invention also includes a method for controlling the deshirr rate of shirred plastic casing sticks inserted in a meat encasing machine to generate fully formed initial sausage links.

Owner:VISCASE CORP

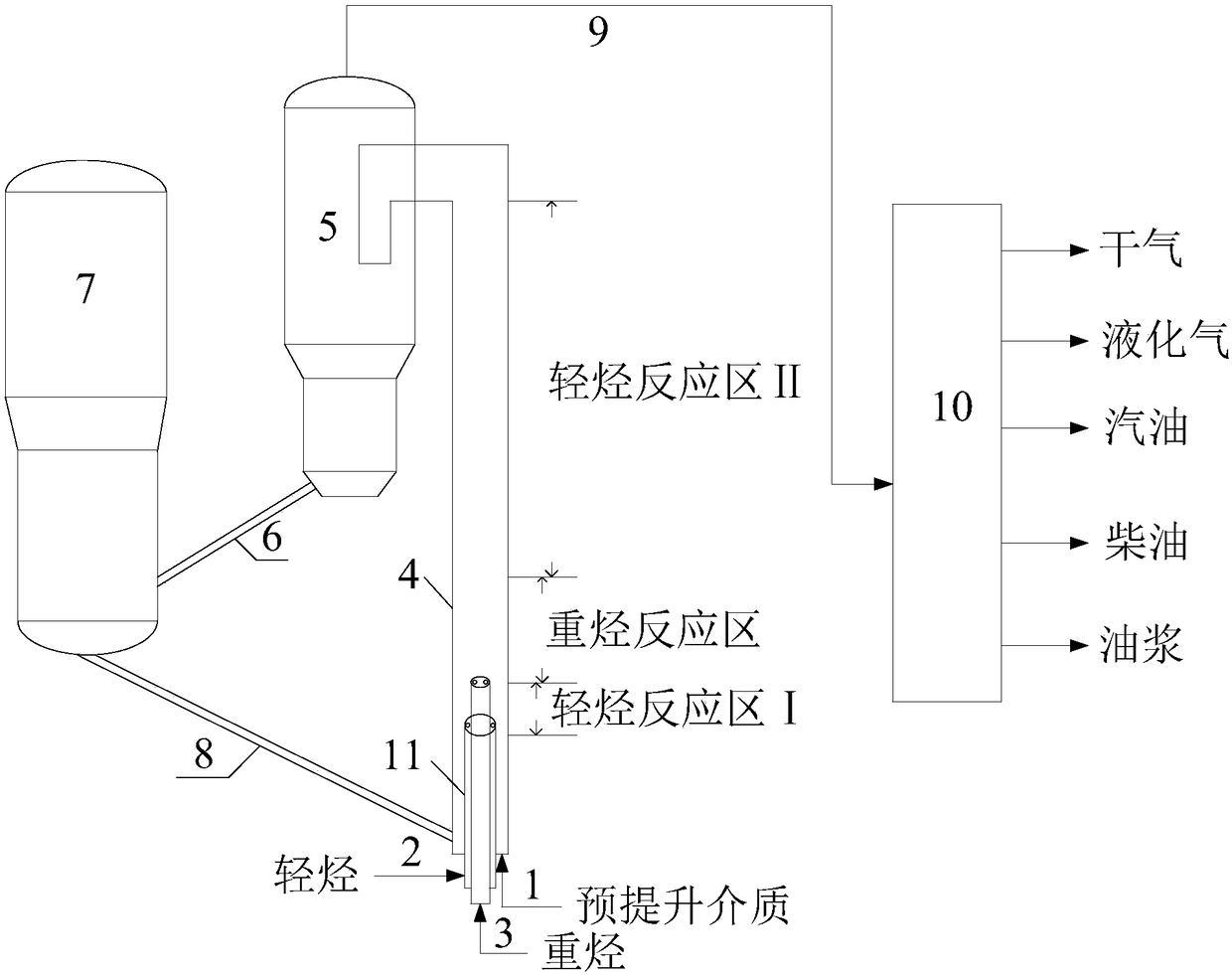

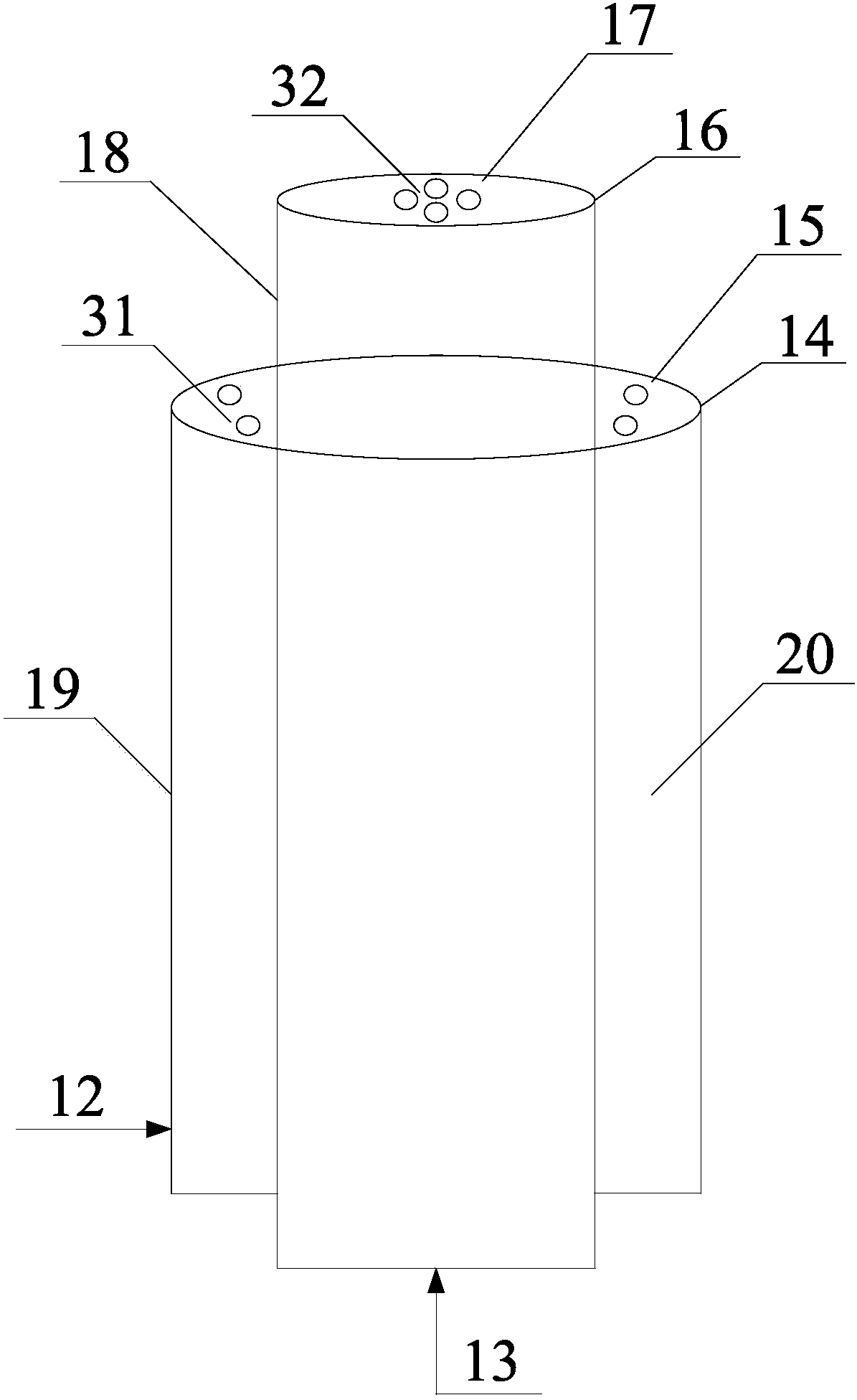

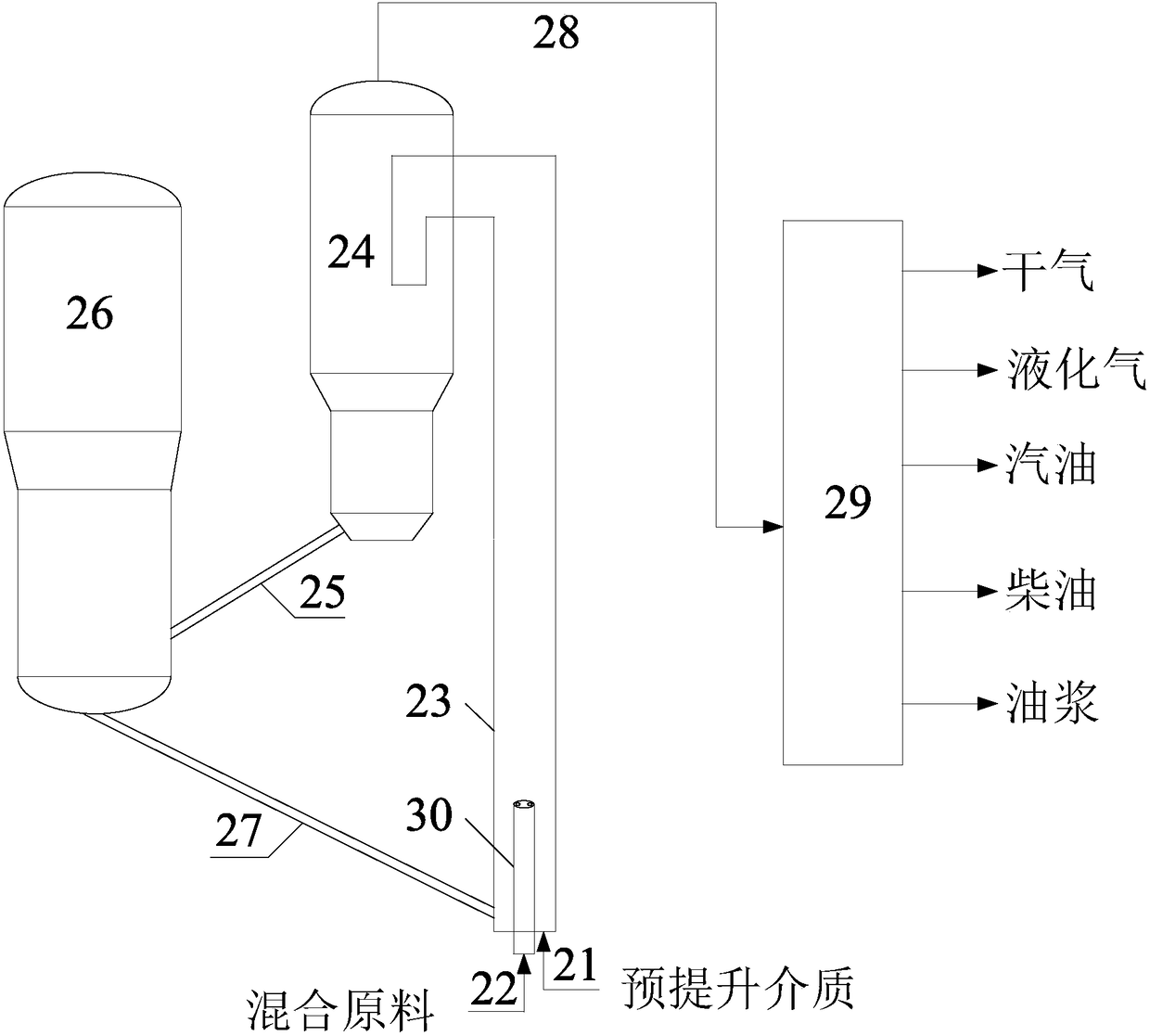

Catalytic conversion method for increasing yield of gasoline and improving octane number of gasoline

ActiveCN109385300AEven contactBoost octaneHydrocarbon oils treatmentCyclonic separationCarbon deposit

The invention relates to a catalytic conversion method for increasing the yield of gasoline and improving the octane number of the gasoline. The method of the invention mainly solves the problem of low gasoline yield in a conventional catalytic cracking process. The catalytic conversion method provided by the invention comprises the following steps: allowing preheated light hydrocarbons and heavyhydrocarbons to be simultaneously and respectively sprayed out from an integrated spray nozzle into different reaction zones of a lift pipe reactor to contact and react with a catalyst from a regenerator, allowing reaction products and a carbon deposit catalyst to flow out from the lift pipe reactor and to enter a cyclone separation system for separation, allowing a separated catalyst to undergo steam stripping, then enter the regenerator for charring and then return to the bottom of the lift pipe reactor for cyclic use, and allowing the reaction products to undergo fractional distillation viafractionating towers so as to obtain corresponding products, wherein the integrated spray nozzle is a spray nozzle capable of simultaneously and respectively spraying the light hydrocarbons and the heavy hydrocarbons out from different spray heads; and the reaction zones are composed of a light hydrocarbon reaction zone I, a heavy hydrocarbon reaction zone and a light hydrocarbon reaction zone IIsuccessively arranged along the vertical direction of the reactor from bottom to top. The catalytic conversion method provided by the invention has the characteristics of capacity of increasing the yield of the gasoline and improving the octane number of the gasoline.

Owner:PETROCHINA CO LTD

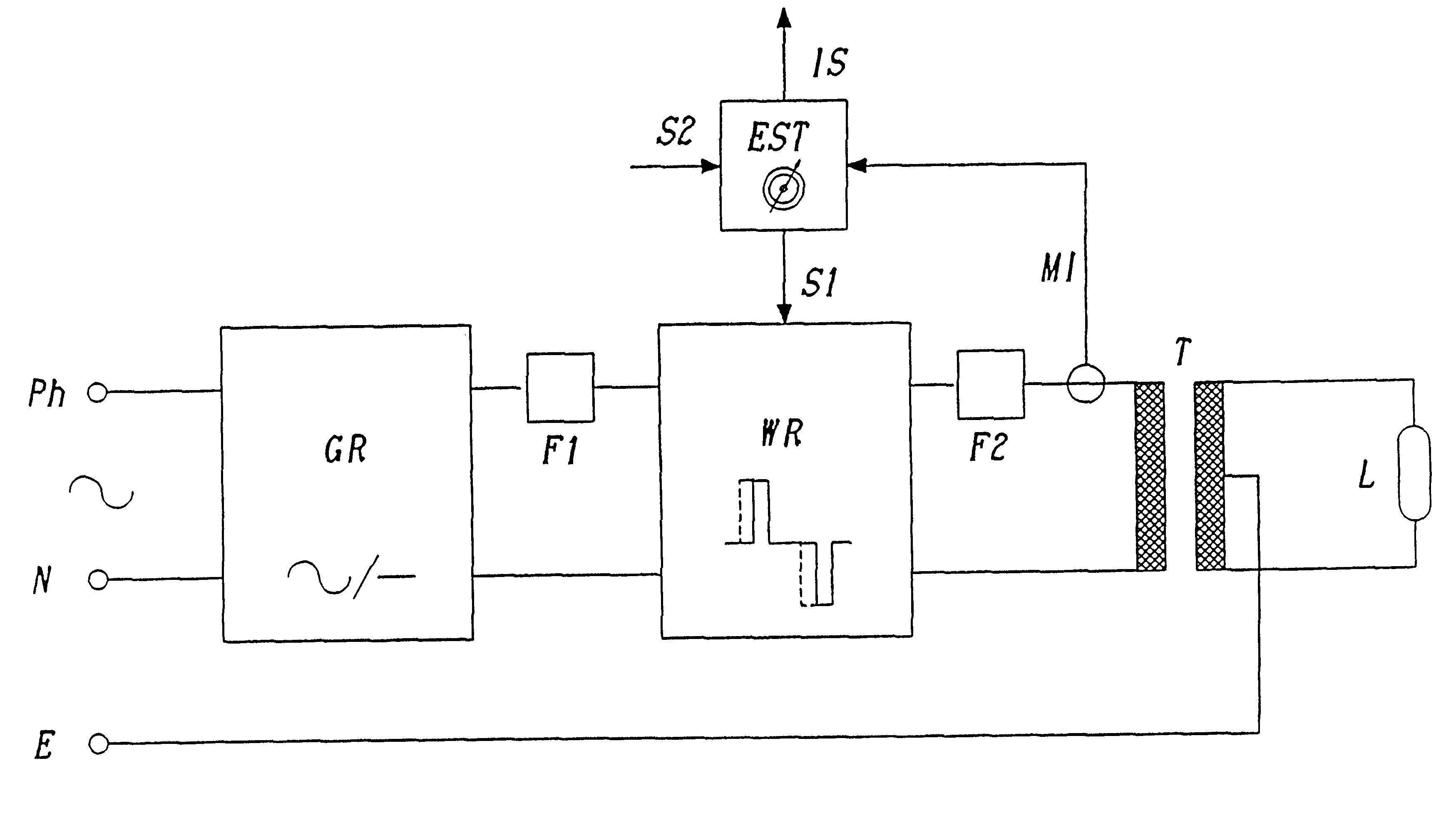

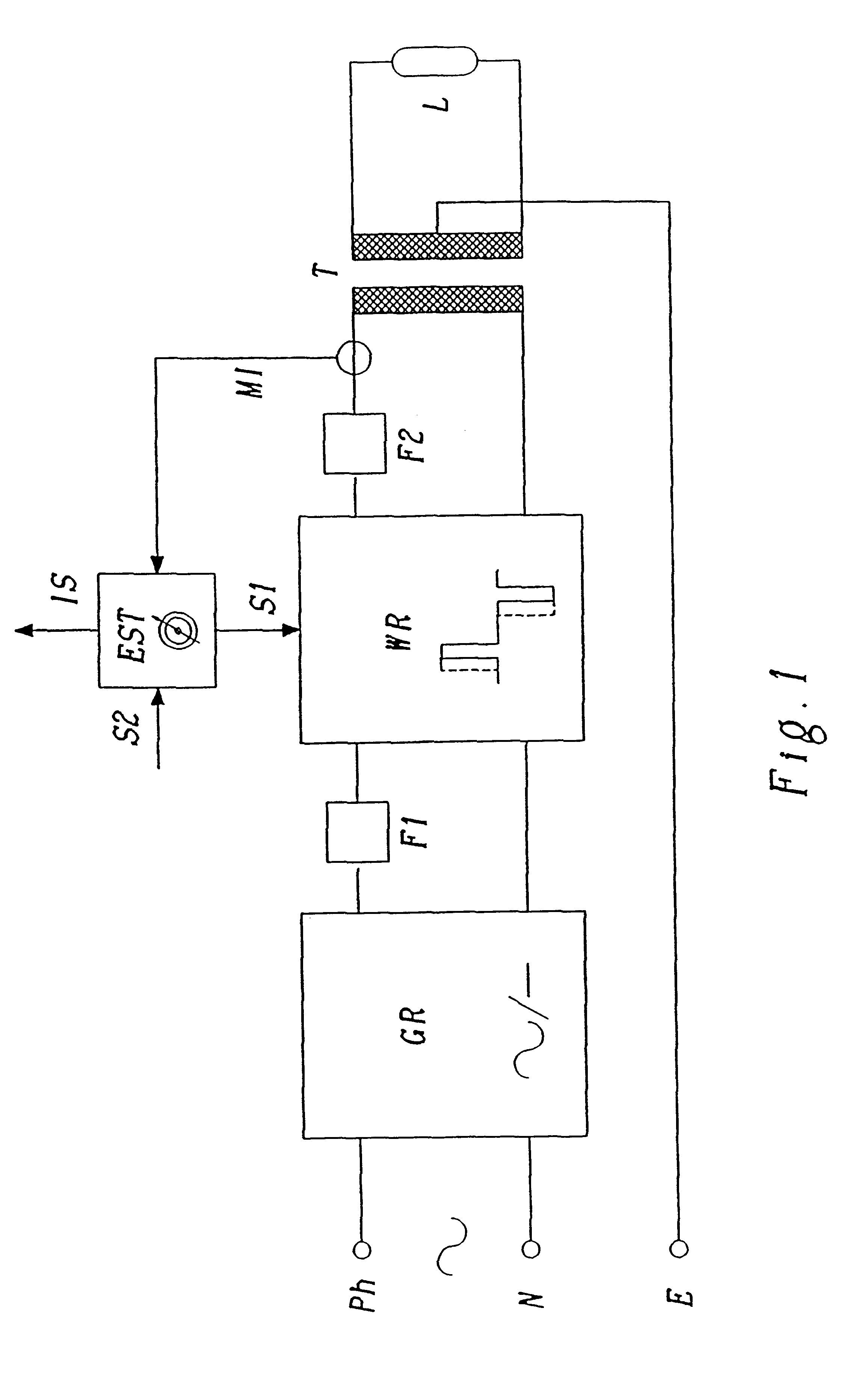

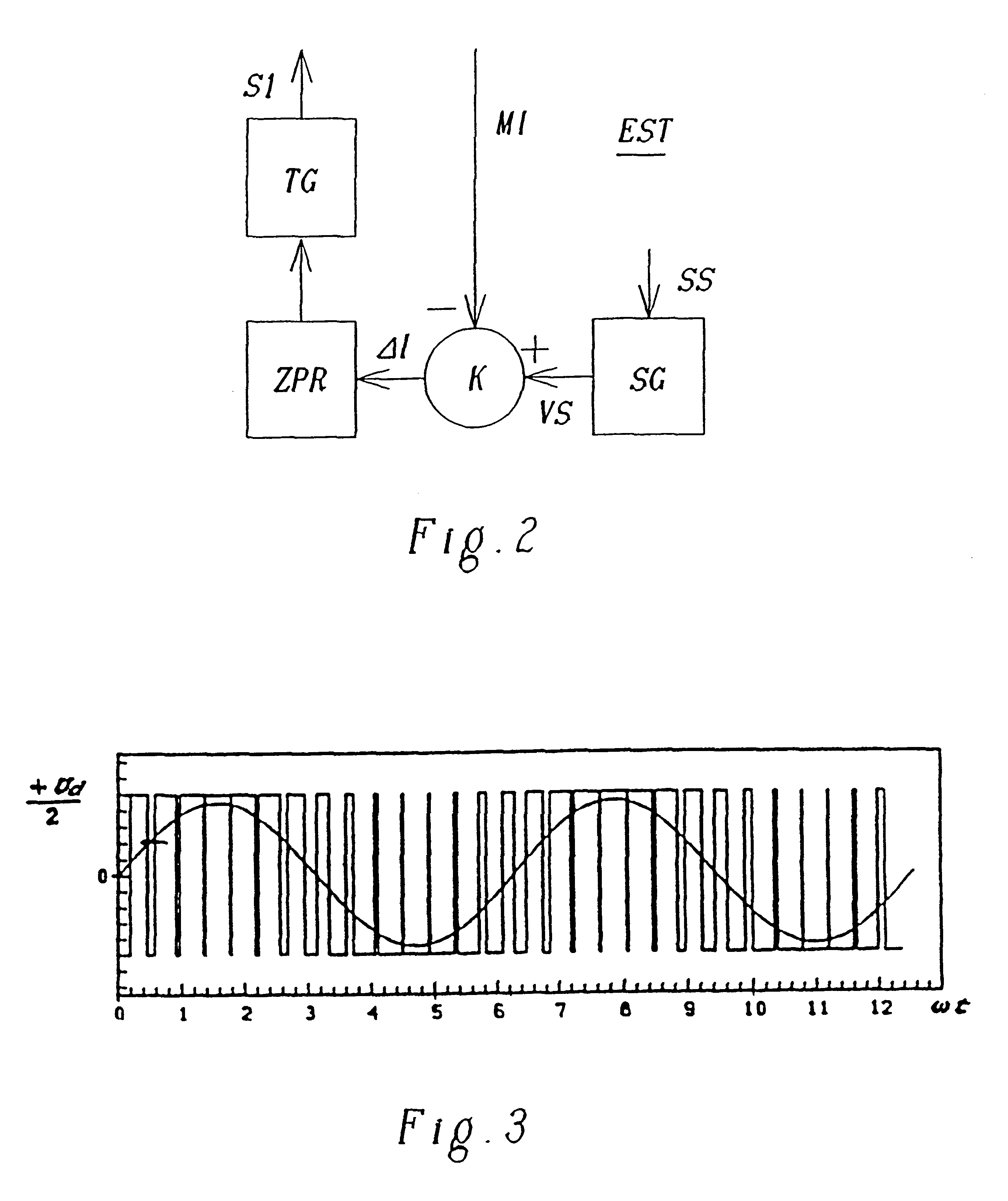

Supply circuit for a fluorescent tube installation

InactiveUS6236169B1Small sizeReduce weightElectric light circuit arrangementElectric discharge lampsCurrent limitingEngineering

A supply circuit for a fluorescent tube installation with a high-voltage transformer (T) which is connected, input-end, to a supply voltage with a frequency of several hundred Hz, and which is formed without an air gap. To replace the air gap in the transformer, an electronic regulator (EST) is nonetheless used in the supply circuit, which emulates the current-limiting function of an air gap. The frequency of the supply voltage is between 300 and 800 Hz, preferably 400 Hz. As these frequencies are higher than the usual network frequency of 50 / 60 Hz, the size and weight of the transformer can be considerably reduced.

Owner:AMTECA

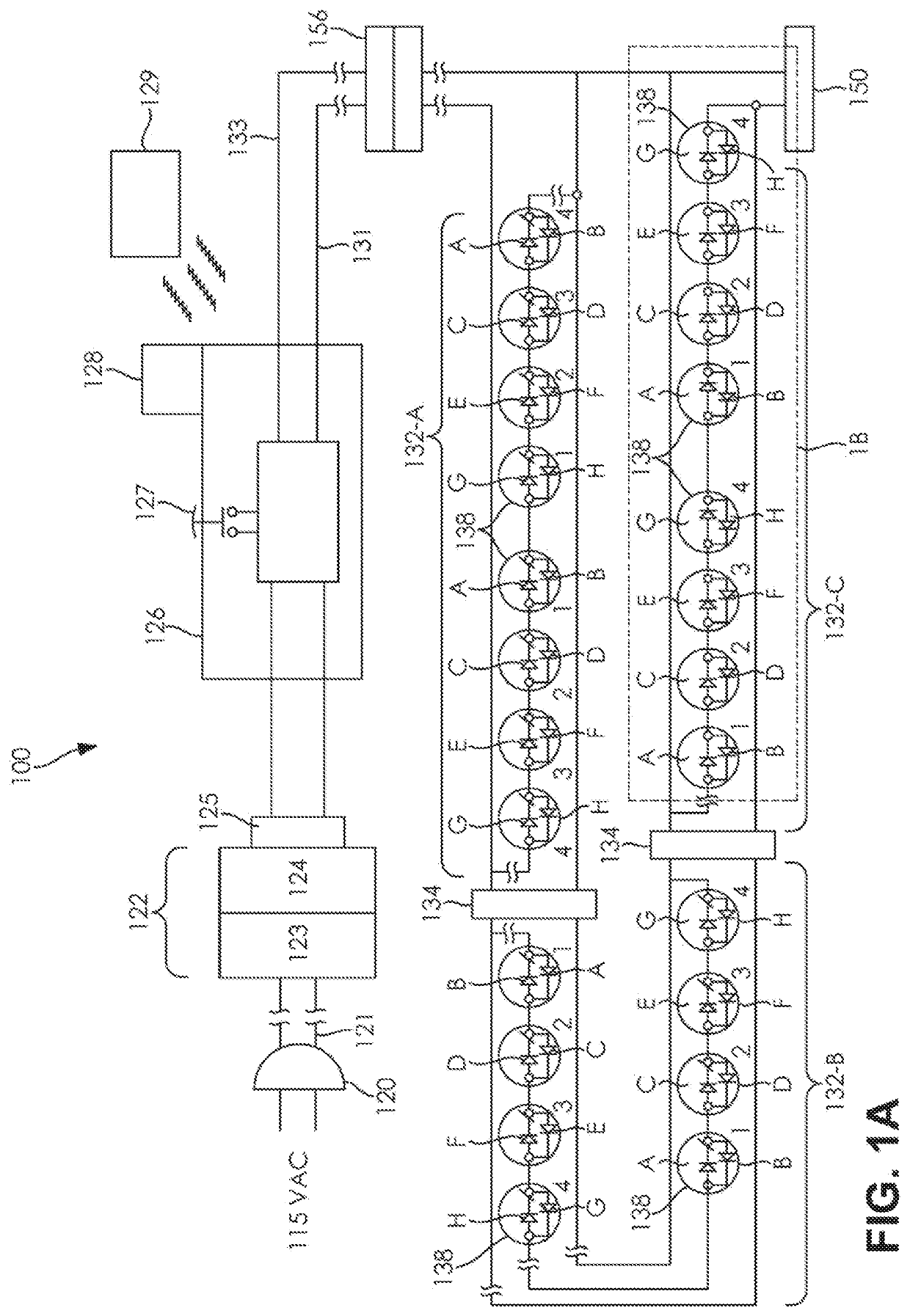

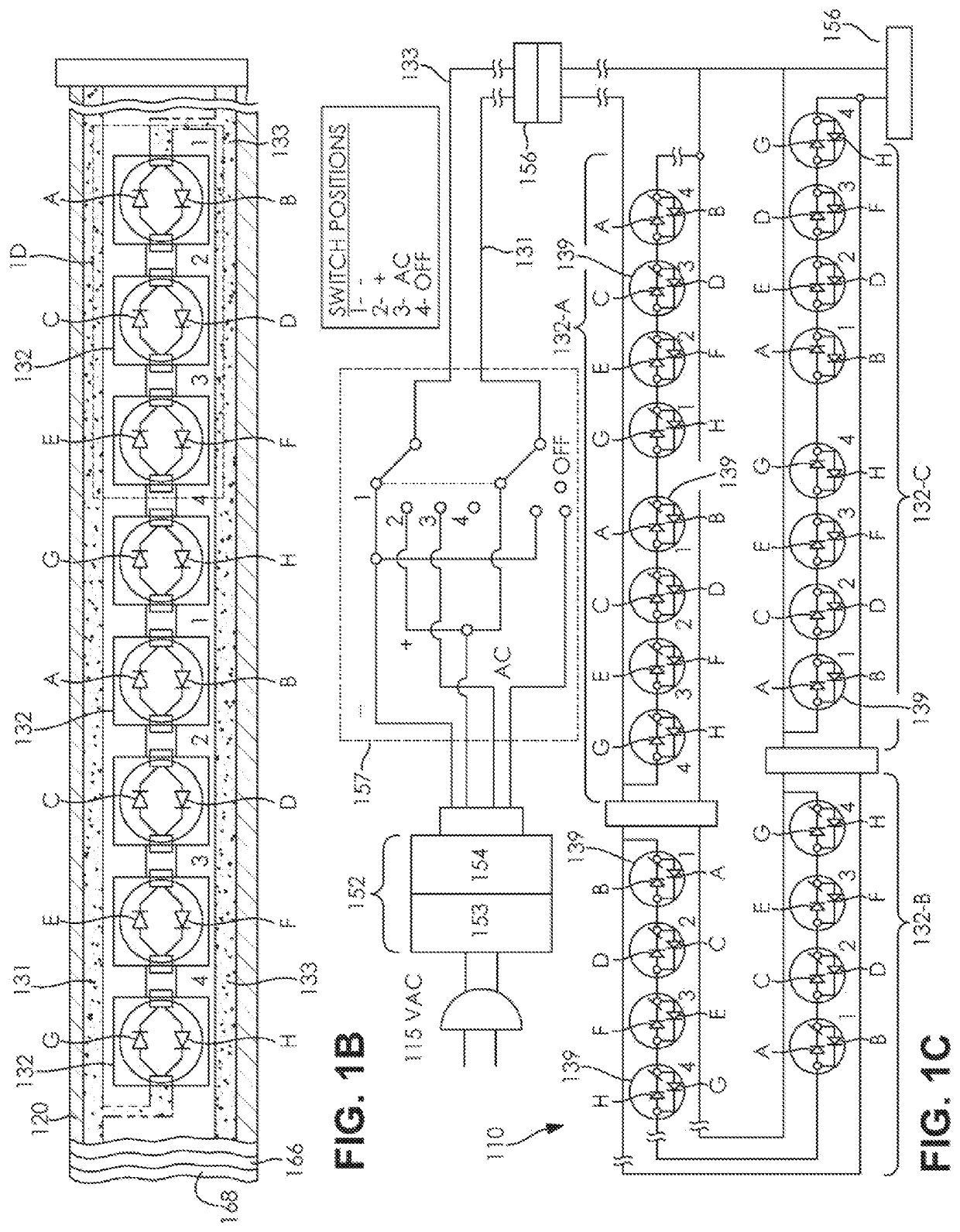

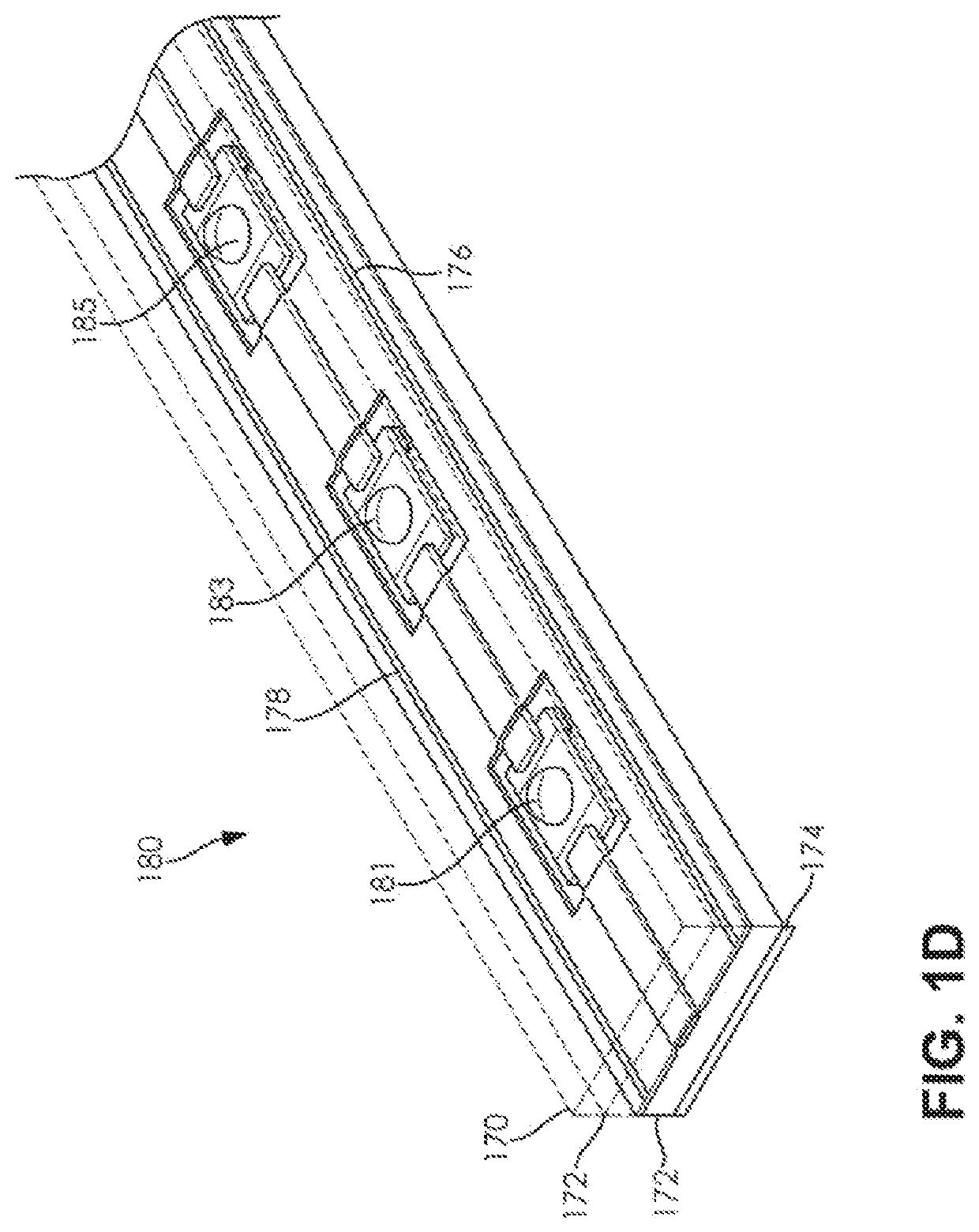

Multi-color flat rope light string system

ActiveUS20210100083A1Many solutionsEliminates of materialElectrical apparatusRope lightVoltage polarity

A system is disclosed. The system has a plurality of flat rope light strings, and a controller coupled to a power source at a first connection and at least one of the plurality of flat rope light strings at a second connection, said second connection including a plurality of connection leads, said second connection being polarized such that said plurality of flat rope light strings is capable of one connection orientation at said second connection, each of said plurality of flat rope light strings including a plurality of lighting elements, each of said plurality of lighting elements including a plurality of pairs of different colored lights, each of said plurality of pairs including a first light and a second light, said first light of said light pair activated via a first voltage polarity and said second light of said light pair activated via a second voltage polarity.

Owner:NAT CHRISTMAS PROD LLC

Main bearing unit for a convertible folding top

InactiveUS6533345B2Clear arrangementReduce weightEngine sealsVehicle sealing arrangementsEngineeringMechanical engineering

The invention relates to a main bearing unit for a convertible folding top, comprising a bearing plate, at least one kinematic pivot point of a folding-top linkage of the convertible folding top, which kinematic pivot point is mounted pivotably in the bearing plate, a linear force-introducing unit, a pin which is assigned to the folding-top linkage, wherein the linear force-introducing unit, in order to actuate the folding-top linkage, is in driving connection with the pin assigned to the folding-top linkage, and a hole in the bearing plate, wherein the force-introducing unit is held in the hole in the bearing plate and is integrated in the bearing plate.

Owner:WEBASTO EDSCHA CABRIO

Surface film plasmon resonance-based metal film measuring device and method

ActiveCN108169183AReduce in quantityReduce mistakesMaterial analysis by optical meansDielectricPhase difference

The invention discloses a surface film plasmon resonance-based metal film measuring device. The device comprises an isosceles right-angle prism. The bottom surface of the isosceles right-angle prism is orderly coated with a submicron-thickness dielectric film and a metal film to be tested and then the isosceles right-angle prism is immersed in a solution. Through rotation of a launch arm of an ellipsometer by a certain angle, the angle of incident lights to the interface between the isosceles right-angle prism and the dielectric film is greater than the total reflection critical angle of the interface, the excited surface plasmon resonance conditions are satisfied and the plasmon resonance on the excited surface of the metal film to be detected is realized. The light amplitude ratios Psi and phase difference Delta corresponding to different wavelengths are measured, the relation curve between the amplitude ratios Psi and phase difference Delta, and the incident wavelengths is fitted, and the thickness and the optical constant of the metal film to be detected is calculated through inversion. The device has the advantages of adjustability of resonance center wavelength, wide detection range of metal film thickness and few fitting parameters and has a large application potential in the field of accurate characterization of the optical constant of the ultrathin film and the detection of biochemical substance composition.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Kava derived therapeutic compounds and methods of use thereof

ActiveUS10624943B2Reduce incidenceIncrease diversityKetone active ingredientsAntineoplastic agentsDihydrokavainChemical compound

Certain embodiments of the invention provide a composition comprising at least two compounds selected from the group consisting of dihydromethysticin, methysticin, dihydrokavain, kavain, desmethoxyyangonin and 11-methoxyyangonin, wherein the composition is substantially free of flavokawain B. Certain embodiments of the invention also provide a method for treating or preventing cancer in a mammal (e.g., a human) in need of such treatment comprising, administering to the mammal a carrier and a compound selected from the group consisting of dihydromethysticin, methysticin, dihydrokavain, kavain, desmethoxyyangonin and 11-methoxyyangonin, wherein the compound is substantially free of other kava extract components.

Owner:KUALITY HERBCEUTICS

Method and device for improving accuracy of ultra-thin film layer measured by ellipsometer

ActiveCN106403830BImprove test accuracySimplify the solution processUsing optical meansTesting optical propertiesAngle of incidenceLight beam

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

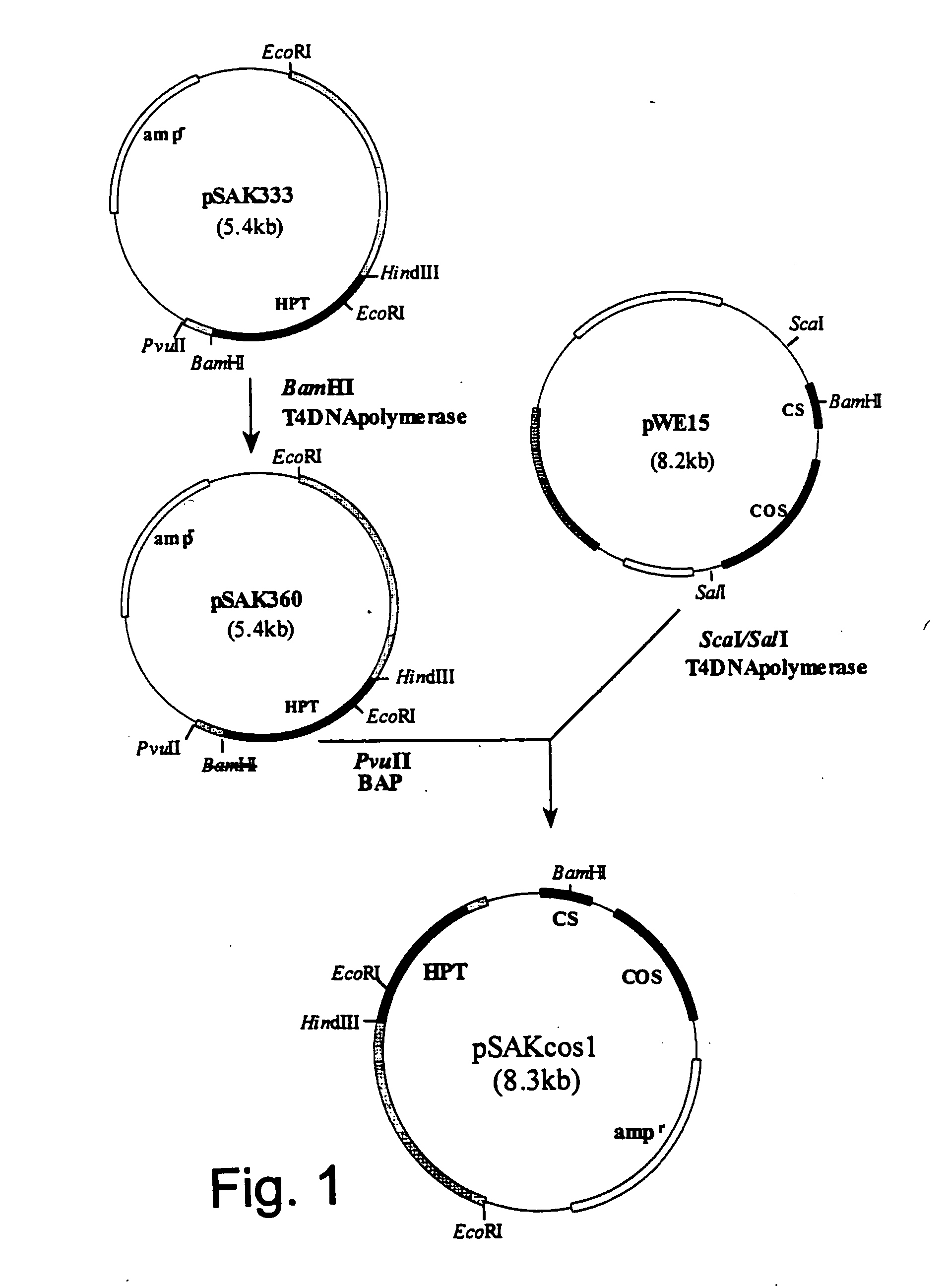

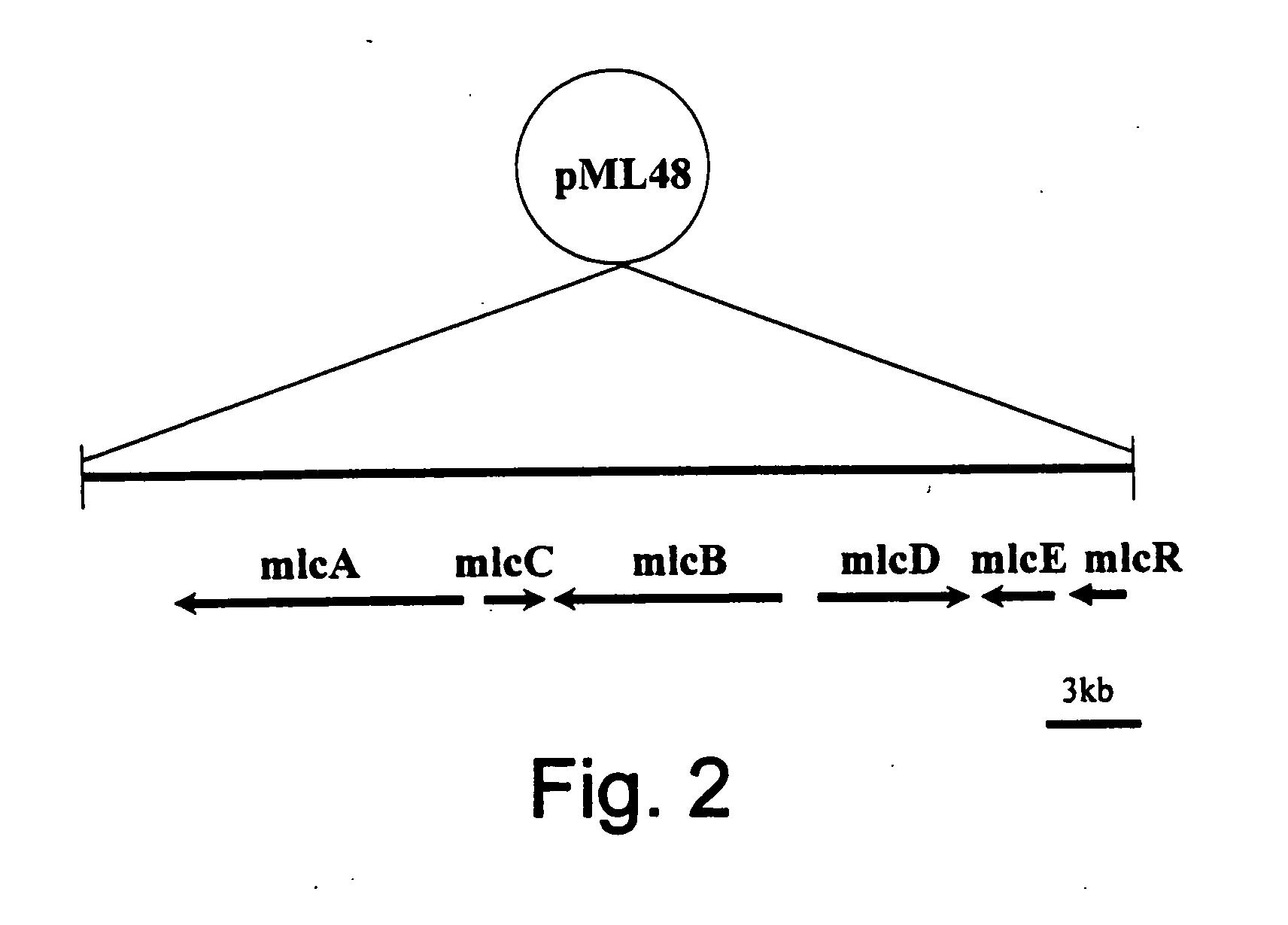

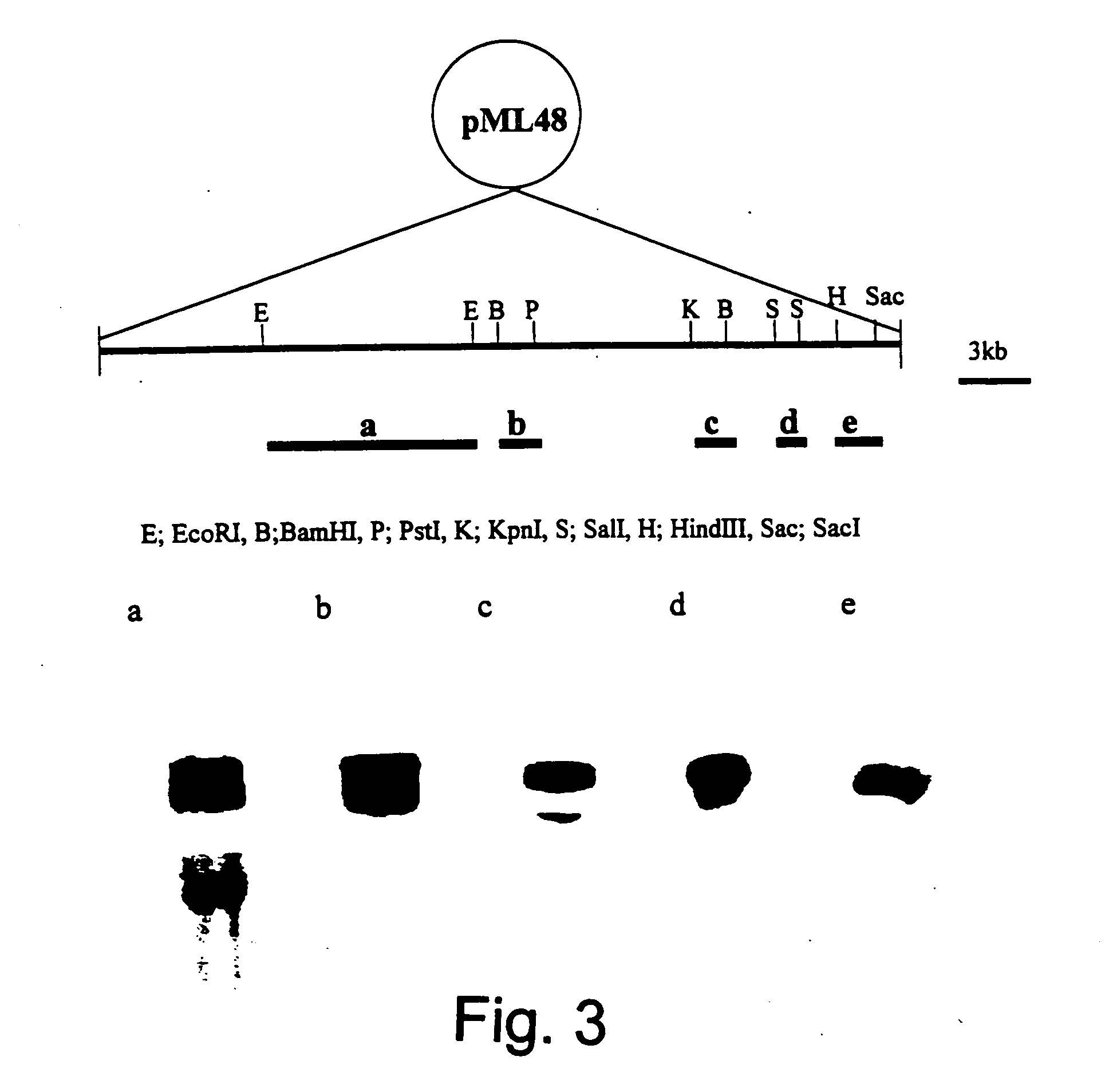

Genes from a gene cluster

InactiveUS20050214909A1Increase biosynthesisAccelerate the biosynthesis of ML-236BBacteriaSugar derivativesHMG-CoA reductaseMicroorganism

ML-236B is an inhibitor of HMG-CoA reductase and useful in preparing another such inhibitor, pravastatin. The preparation of ML-236B using an ML-236B-producing microorganism is enhanced using a polynucleotide encoding a gene related to the polyketide synthase cluster occurring in such a microorganism.

Owner:SANKYO CO LTD

Welding current source for a welding apparatus

InactiveUS20080035622A1Reduce intensityHigh strengthArc welding apparatusWelding electric suppliesLoad circuitEngineering

The present invention relates to a welding current source for a welding apparatus, having inputs for control and load circuits, which are connectable to different electric power networks and are reversibly switchable. The gist of the invention is that a switchover device with first and second switchover mechanisms which are simultaneously actuatable by a common handle is provided, the first switchover mechanism connecting the control circuit to the inputs in a reversibly switchable manner, and the second switchover mechanism connecting the load circuits to the inputs in a reversibly switchable manner.

Owner:LORCH SCHWEISSTECHNIK GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com