Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Realize automatic clamping and fixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

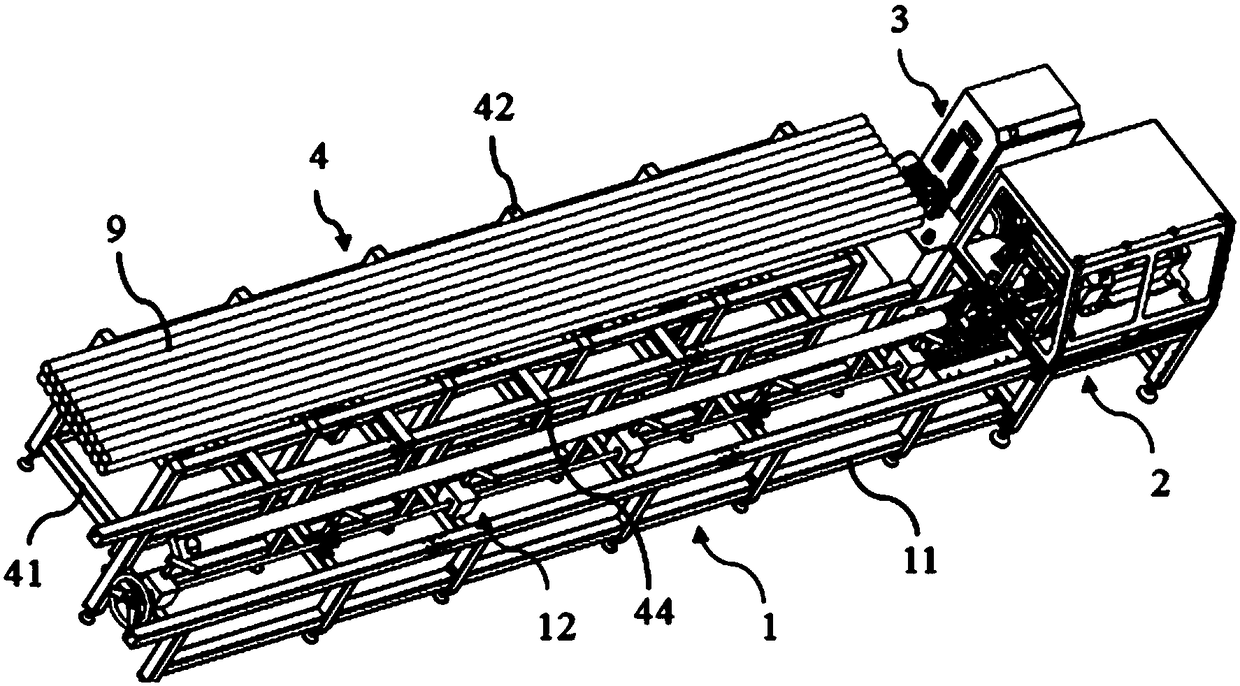

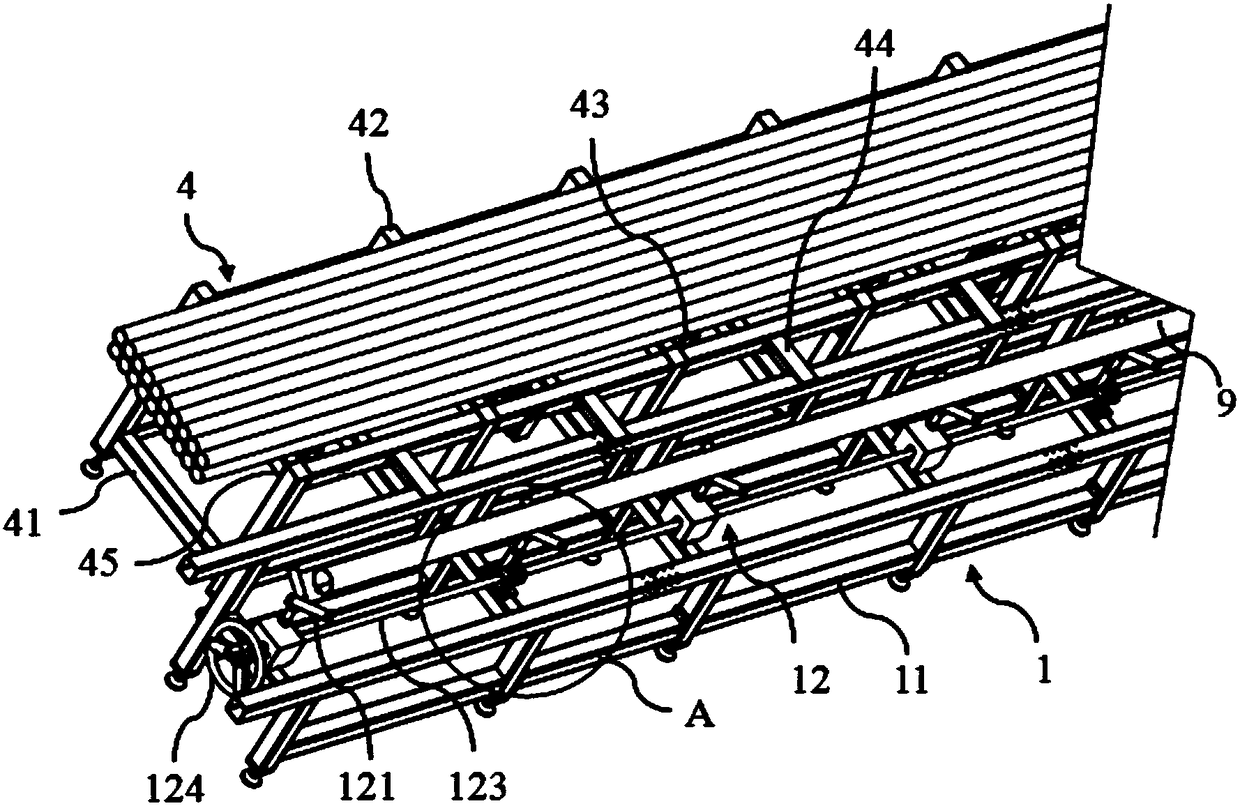

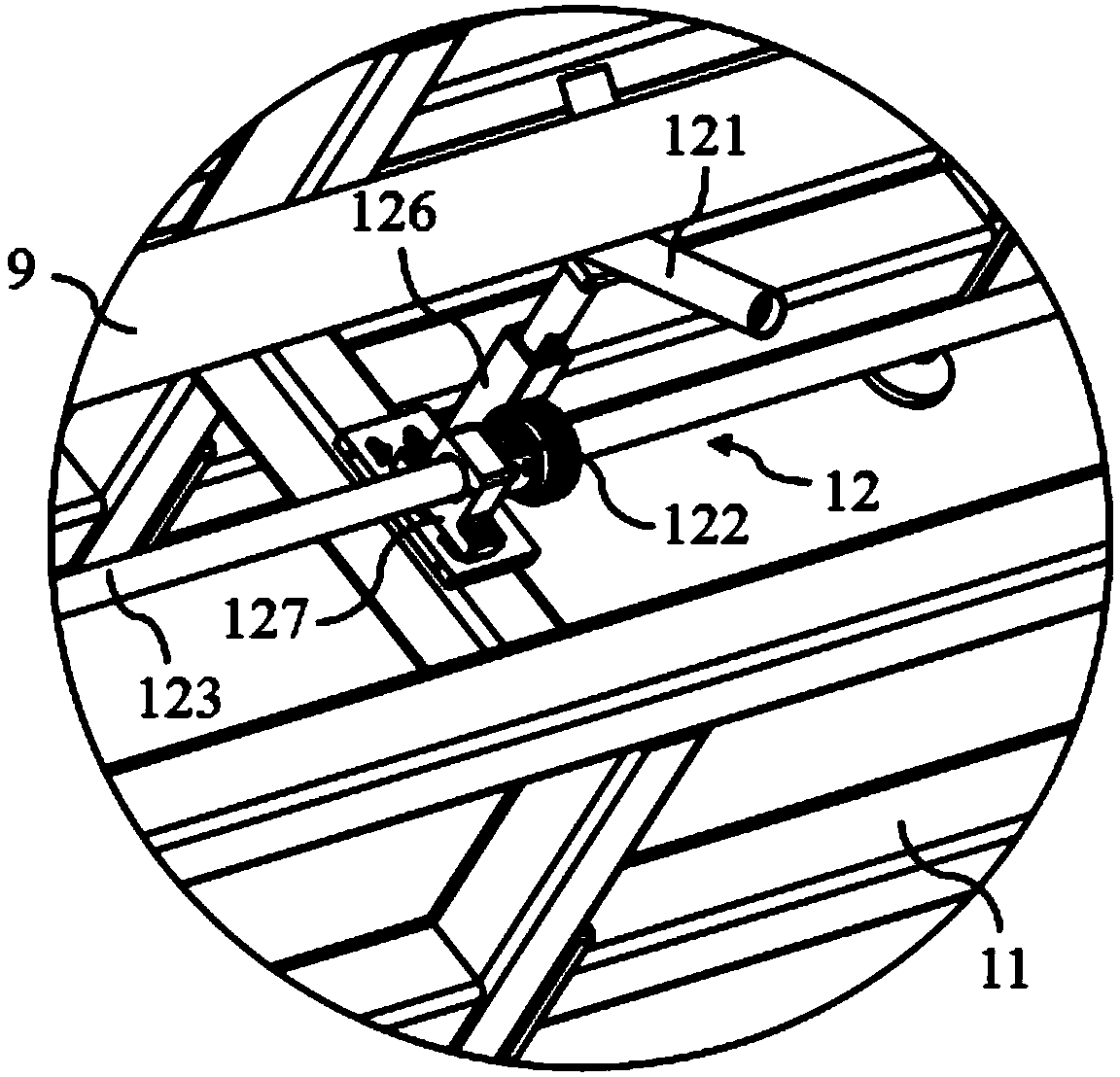

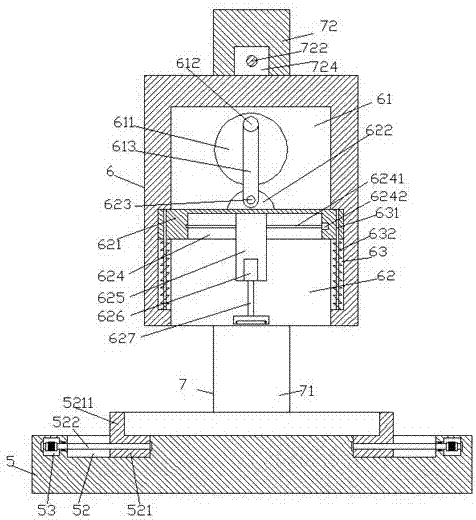

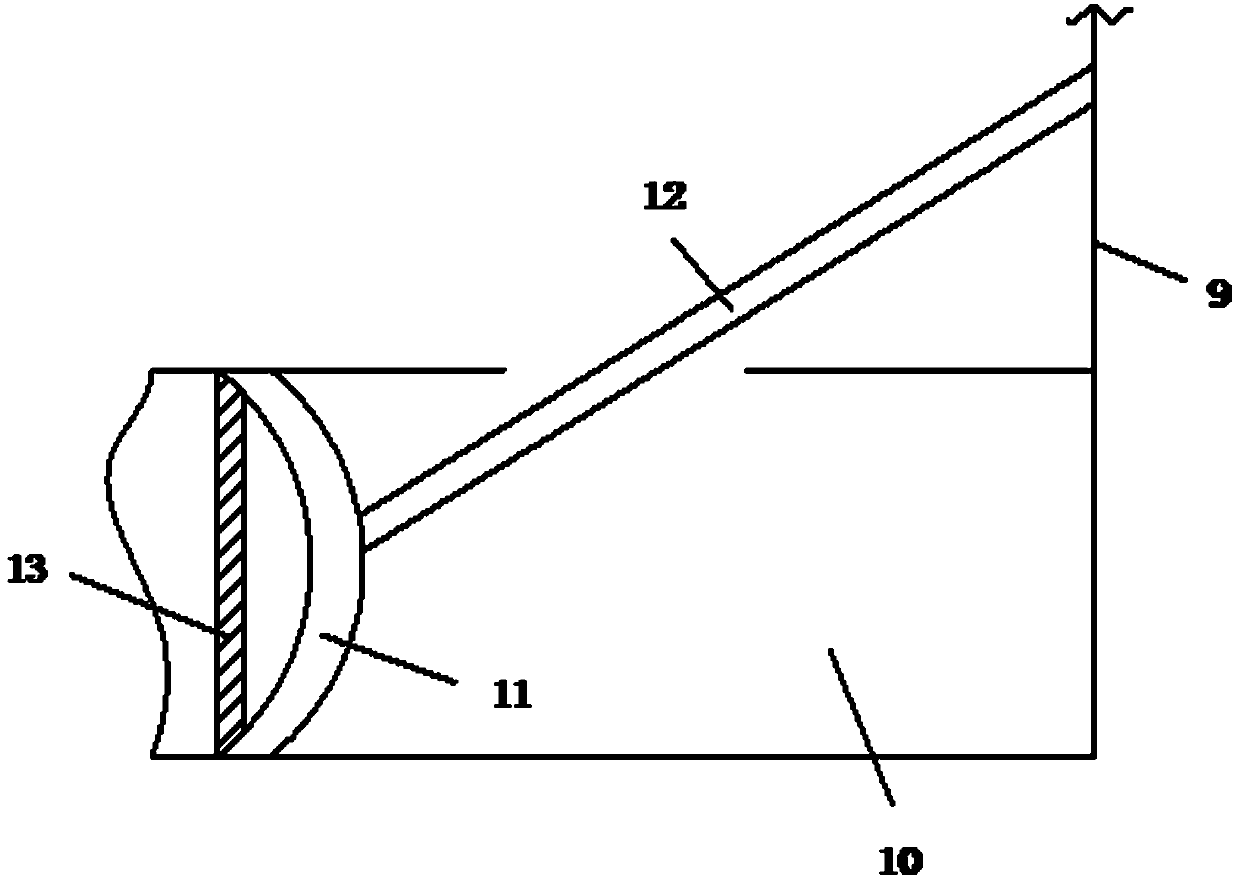

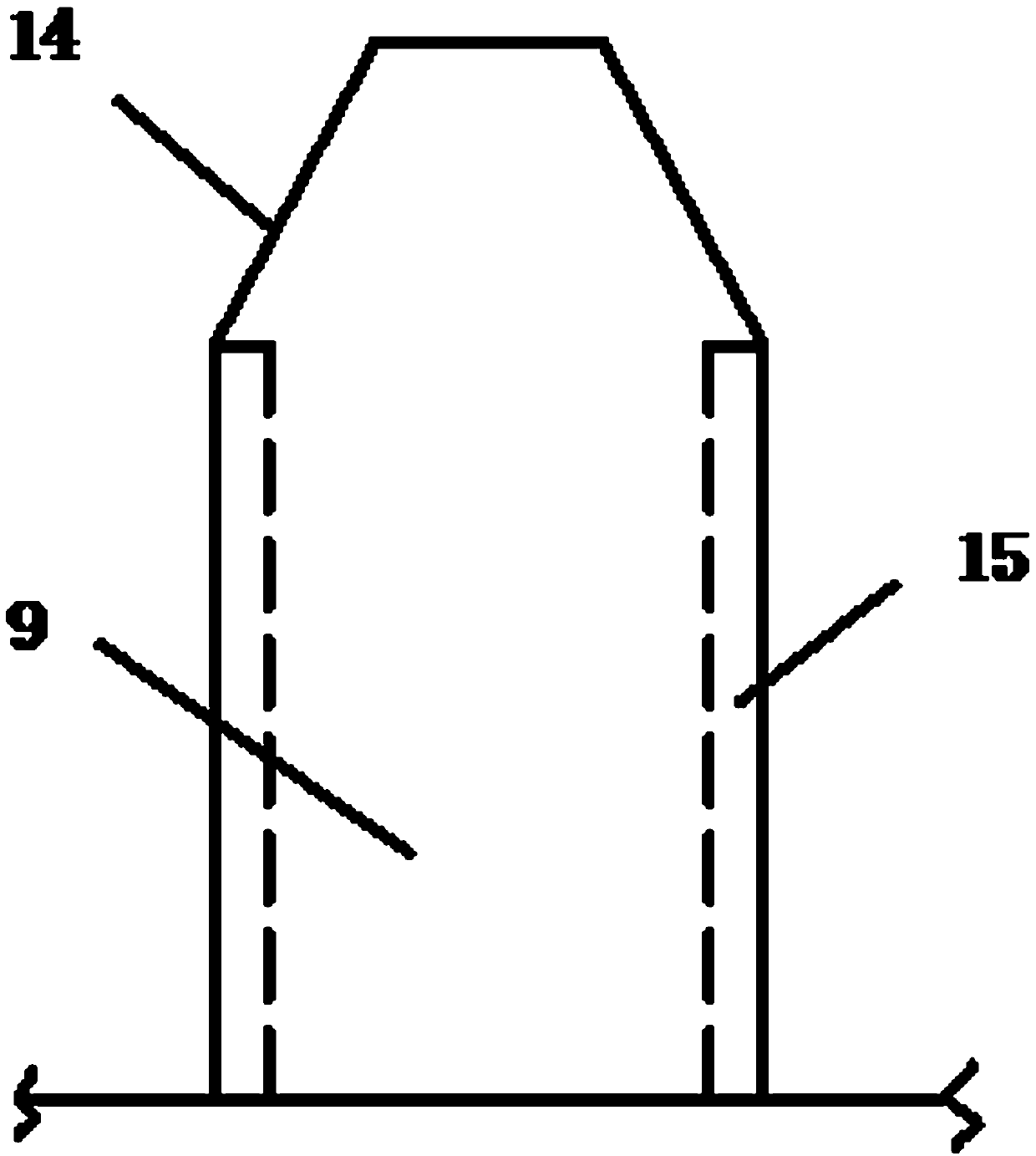

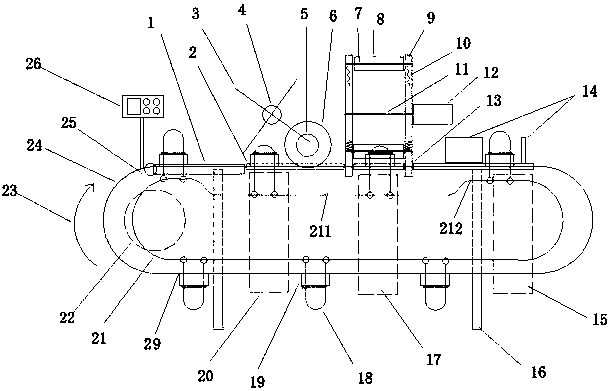

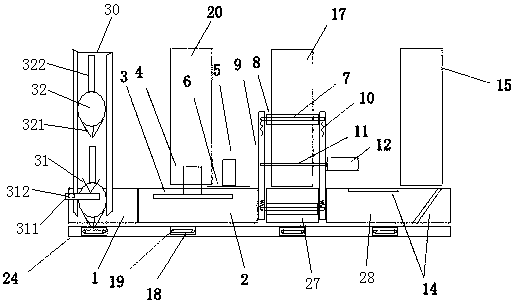

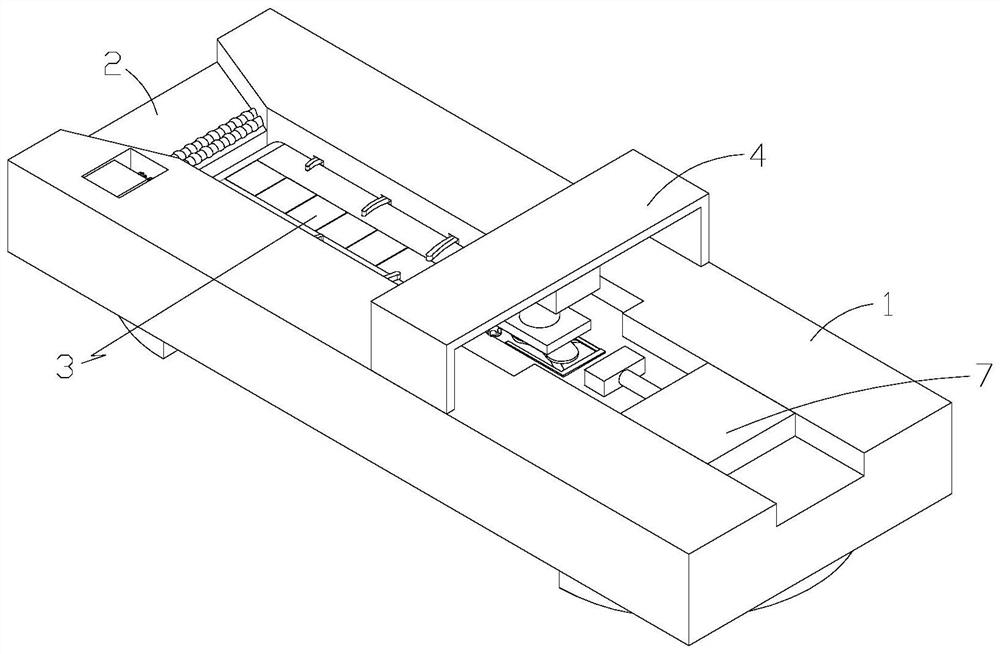

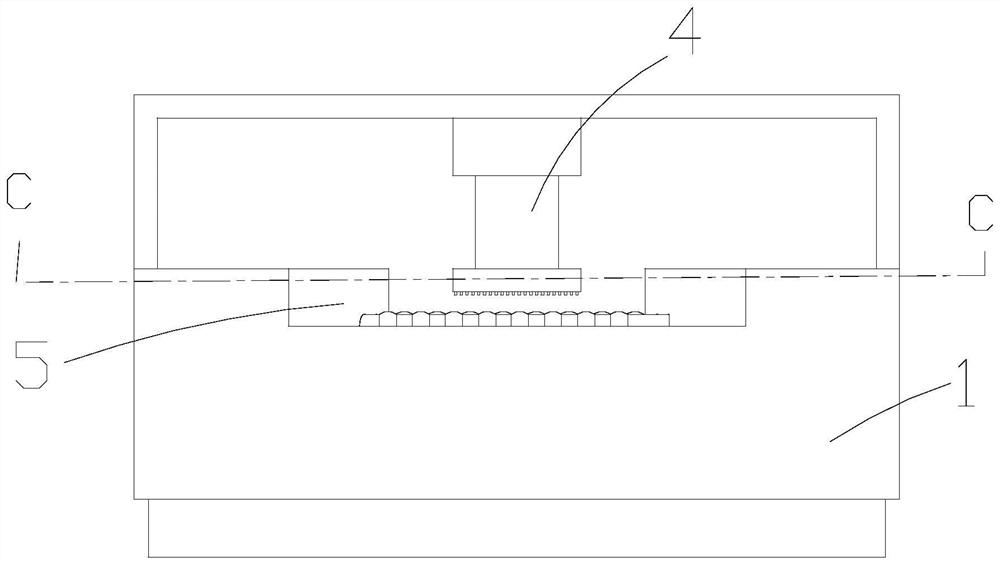

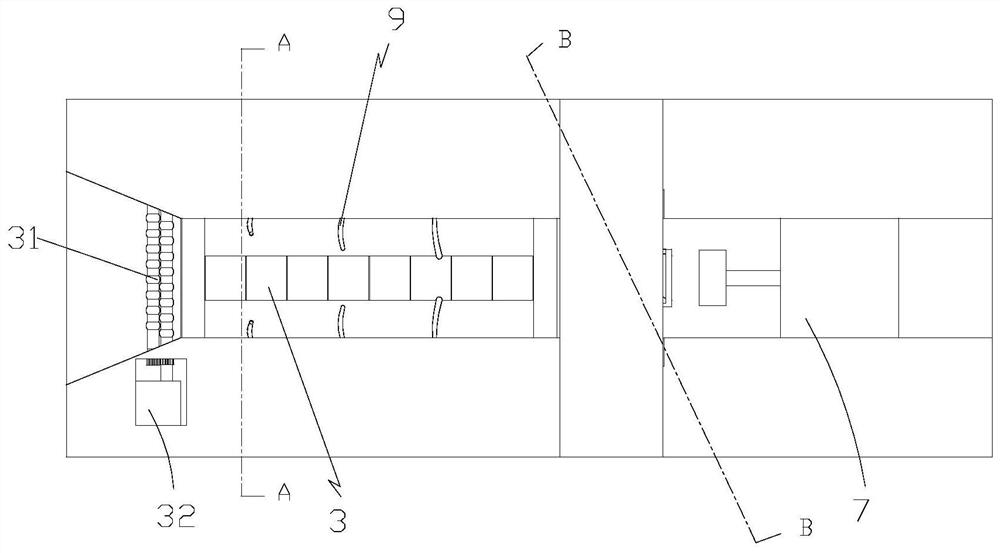

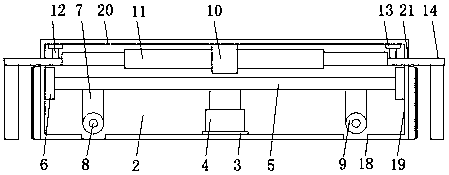

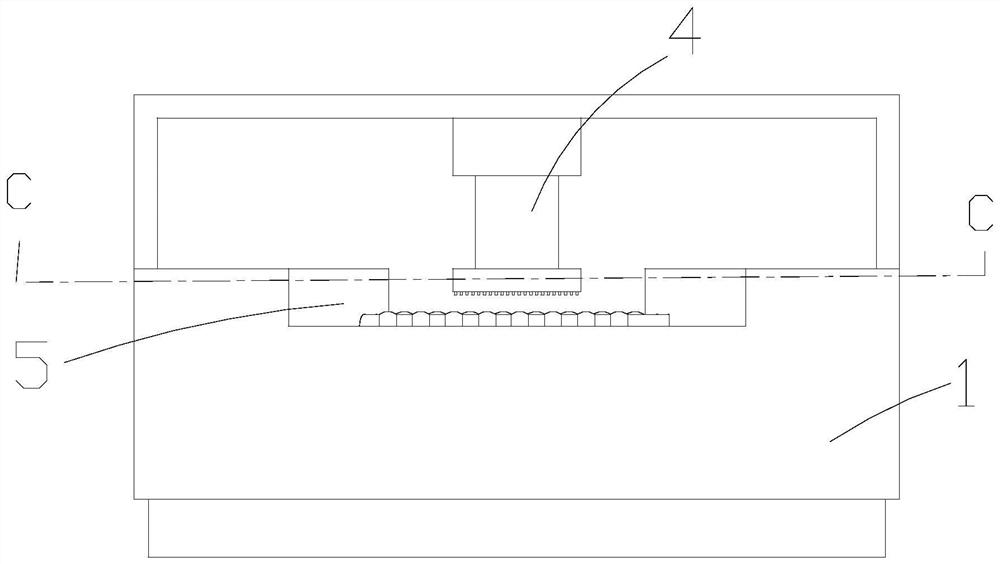

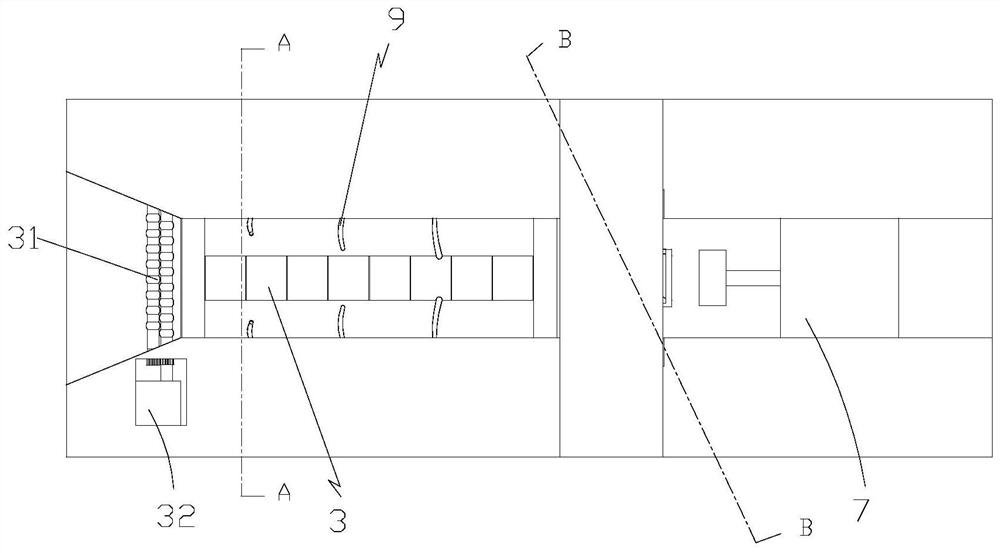

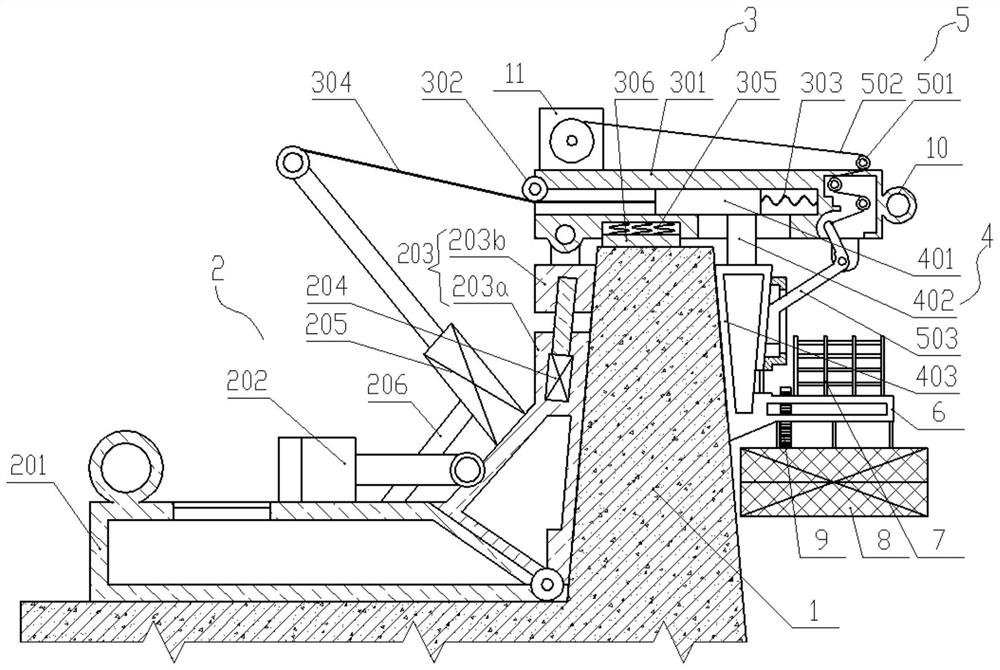

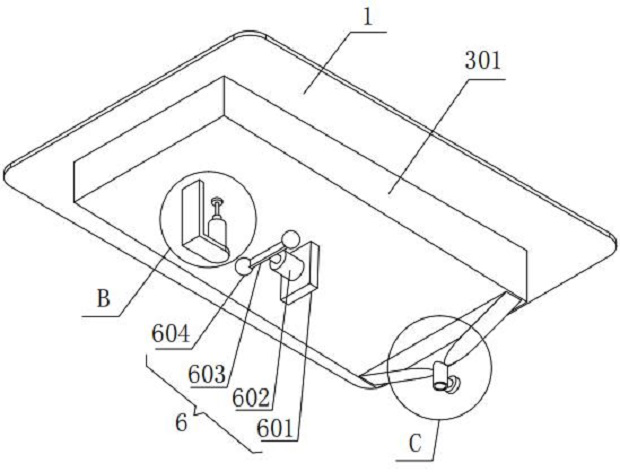

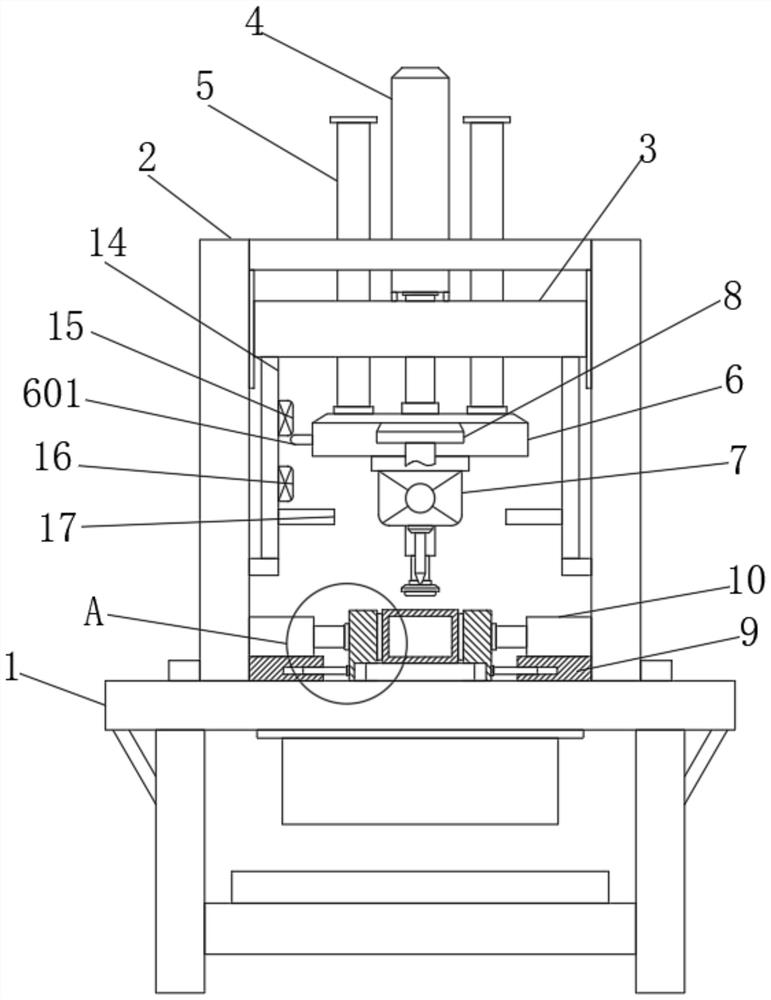

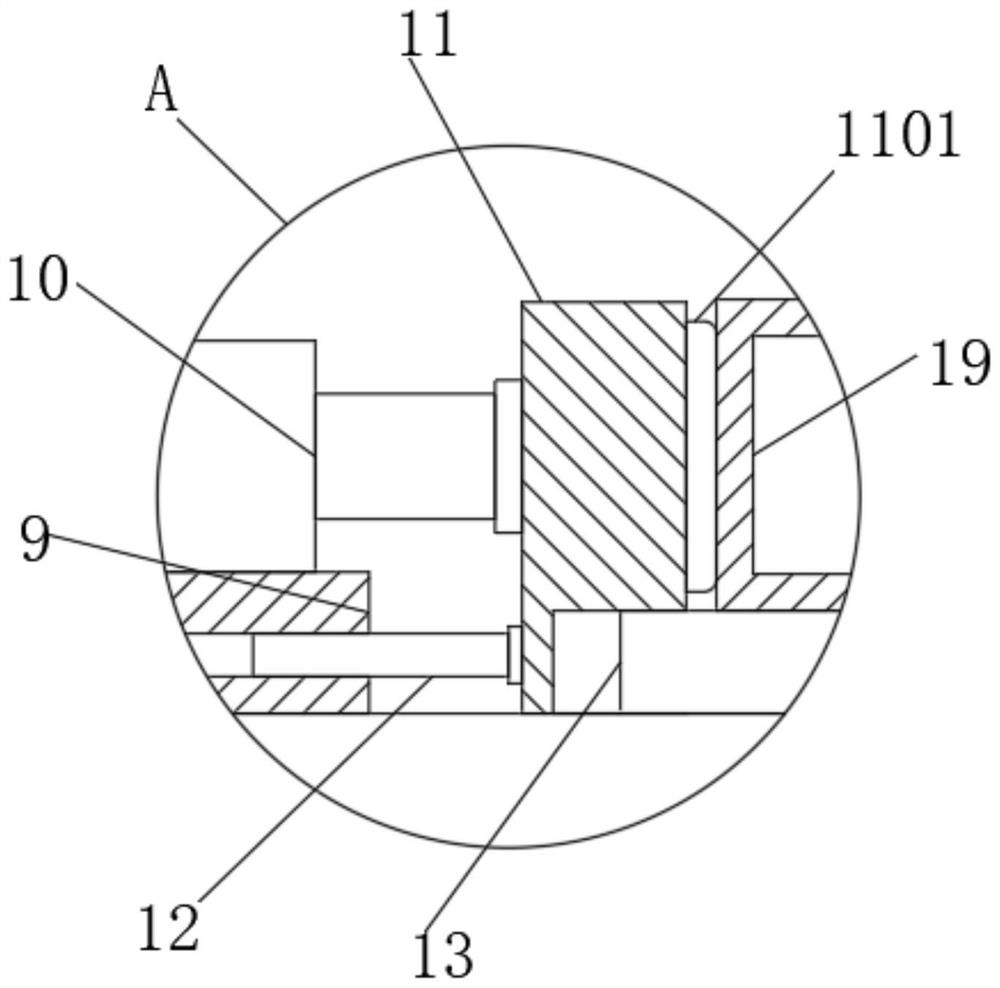

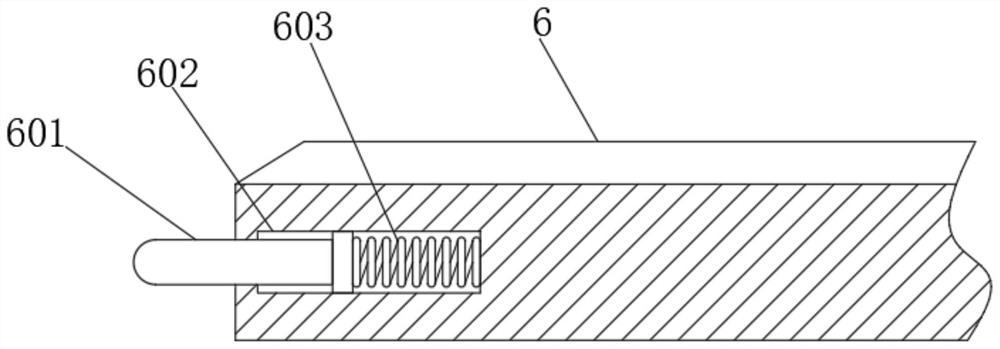

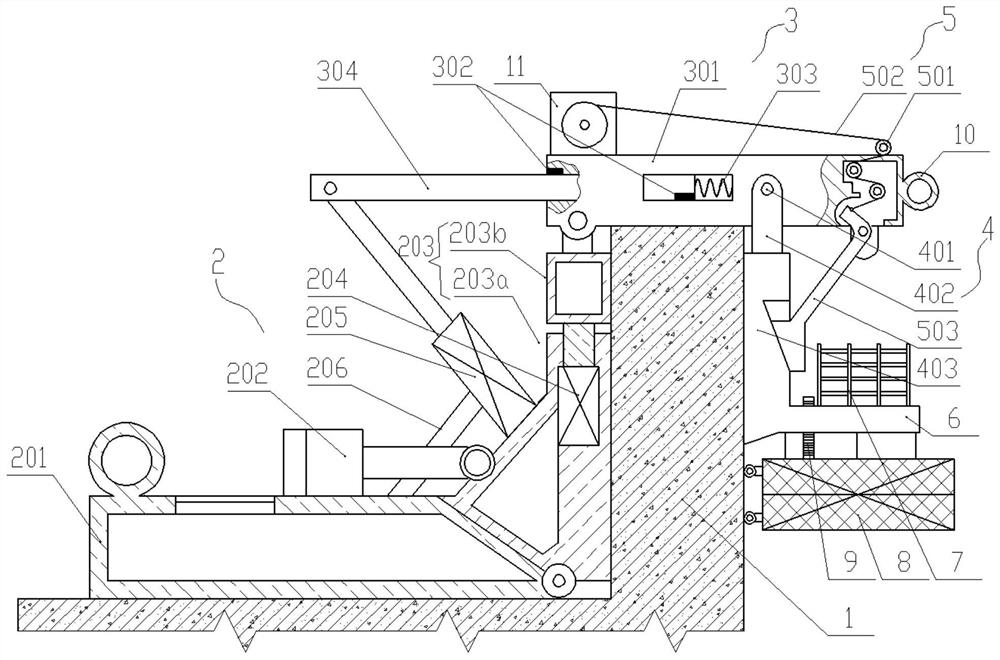

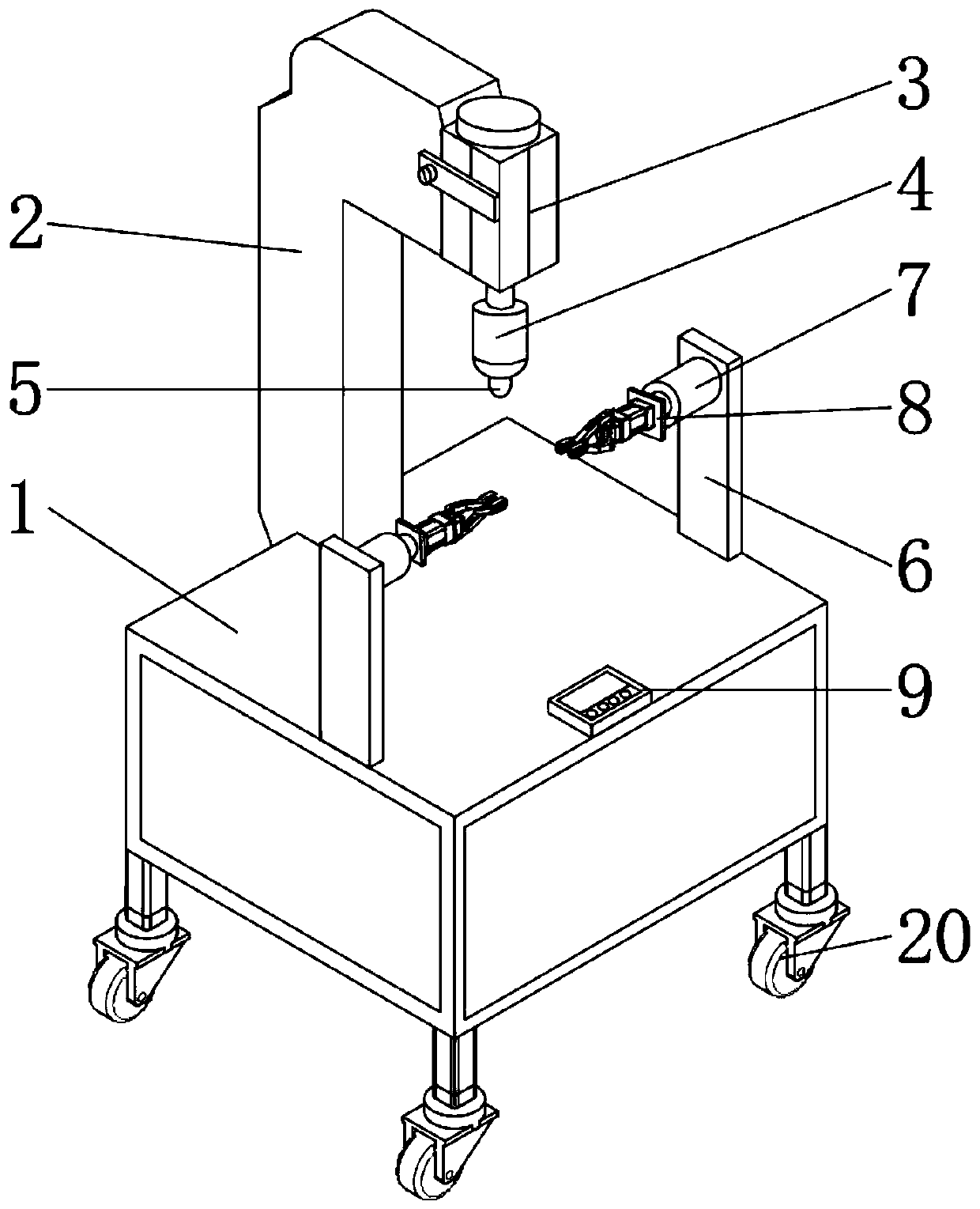

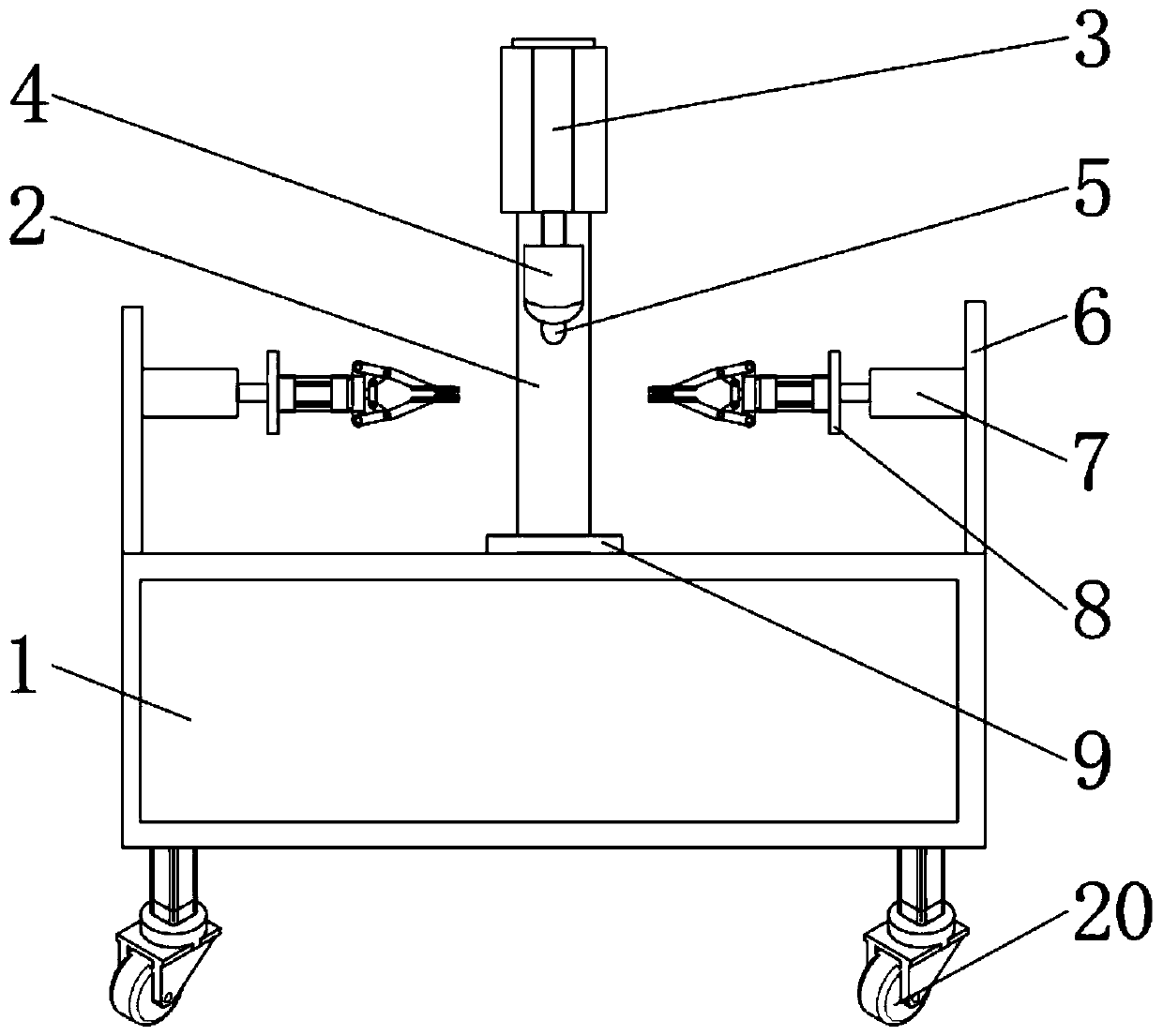

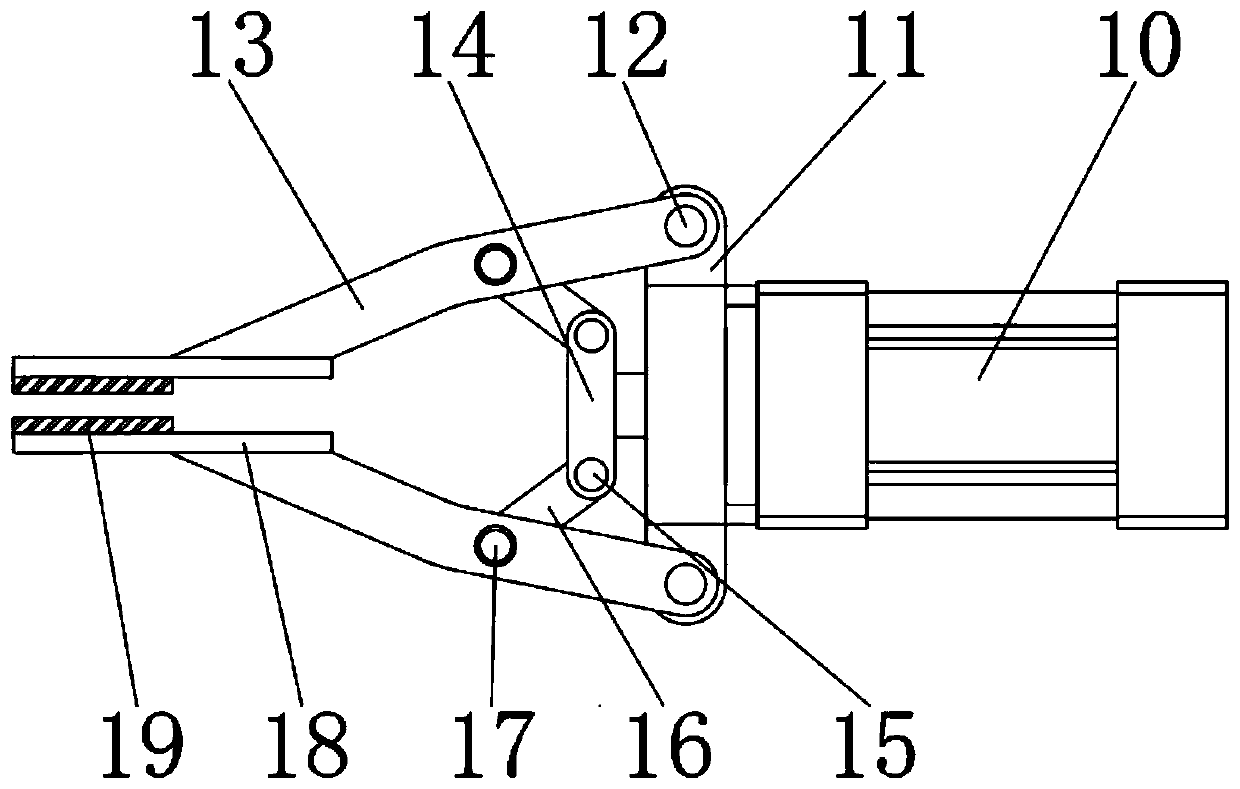

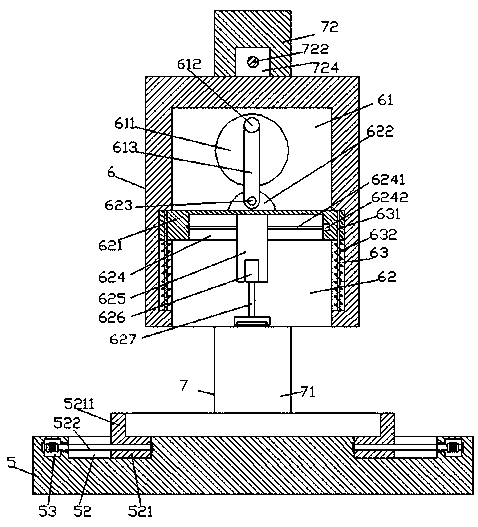

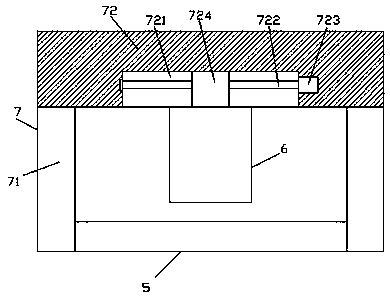

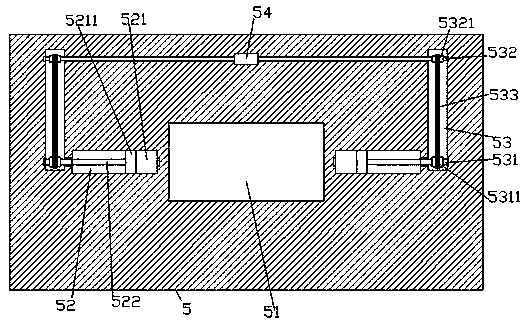

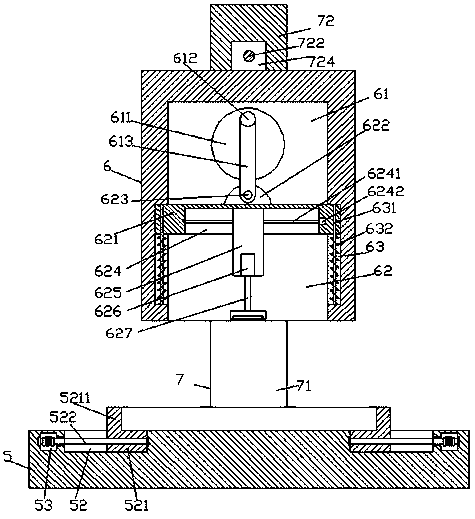

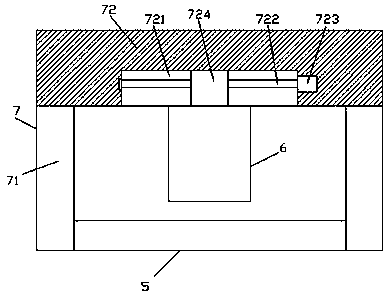

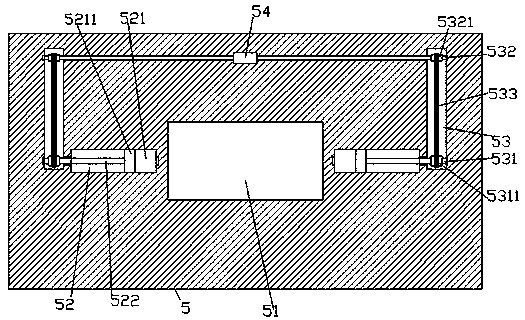

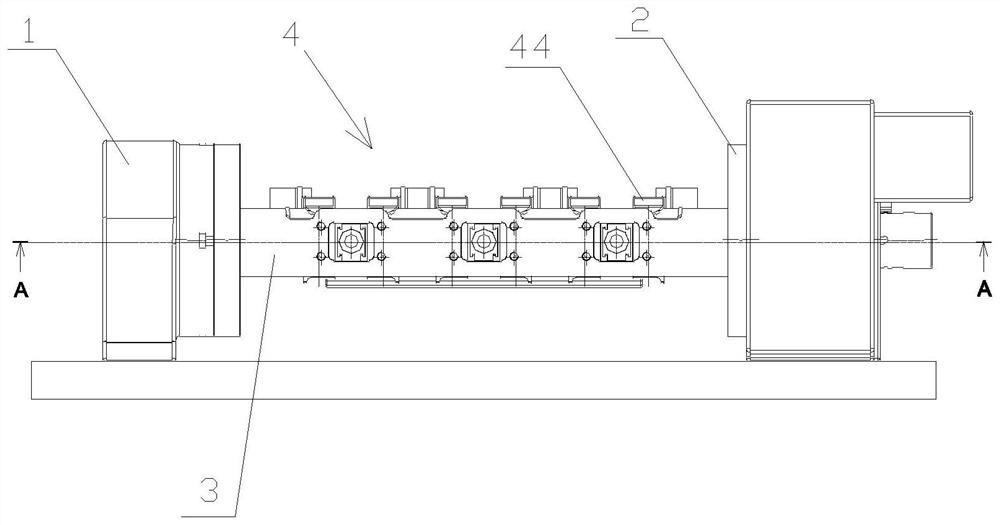

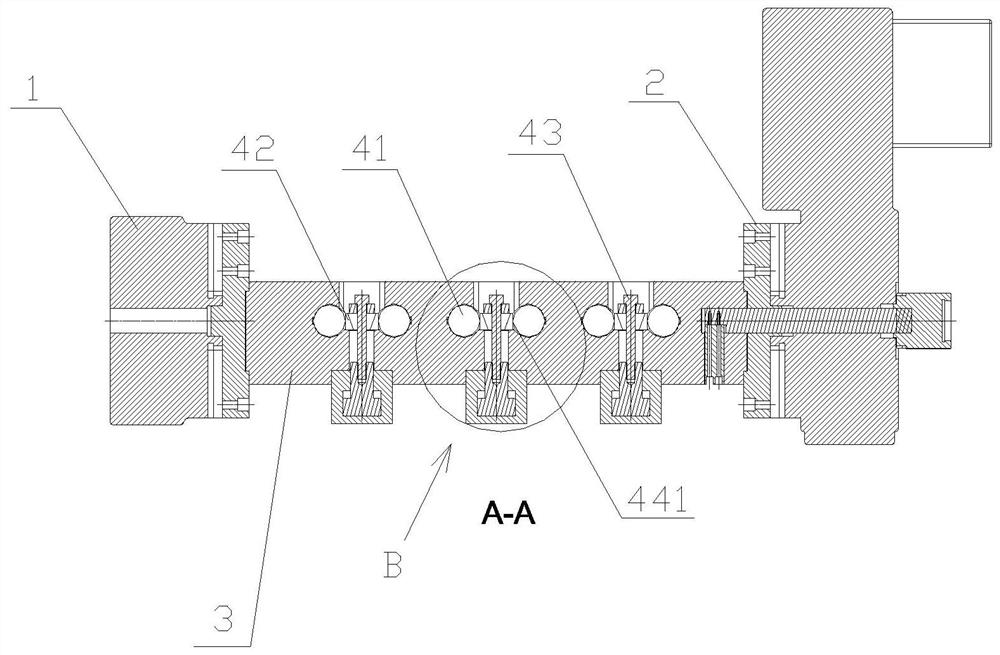

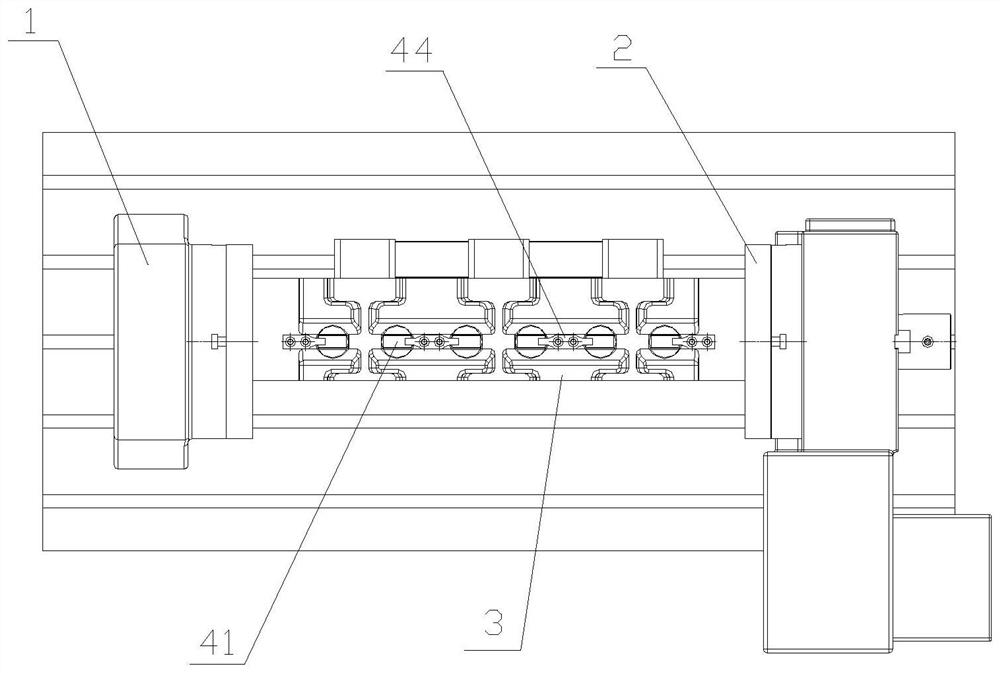

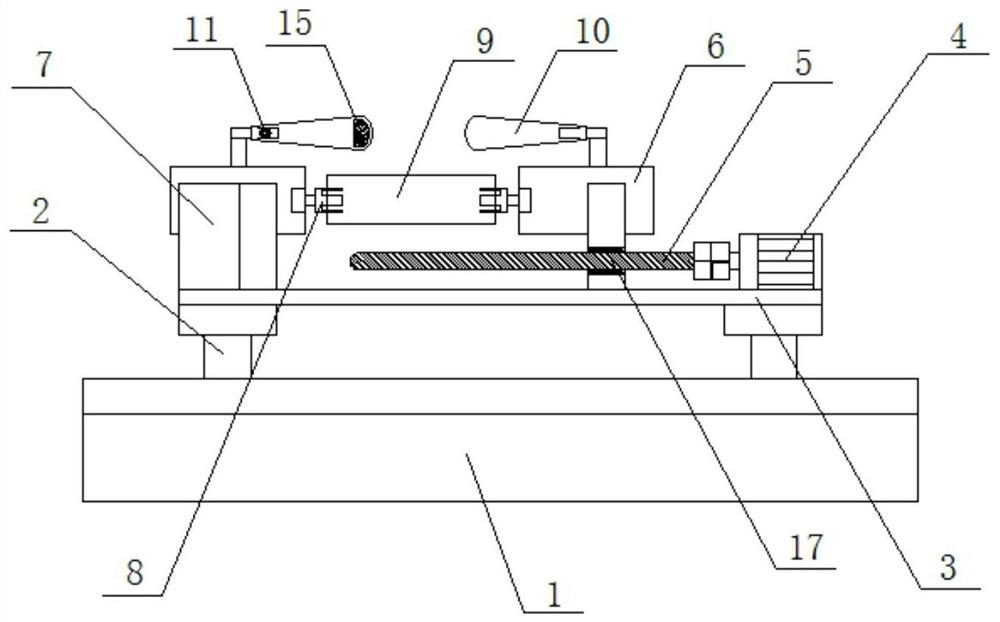

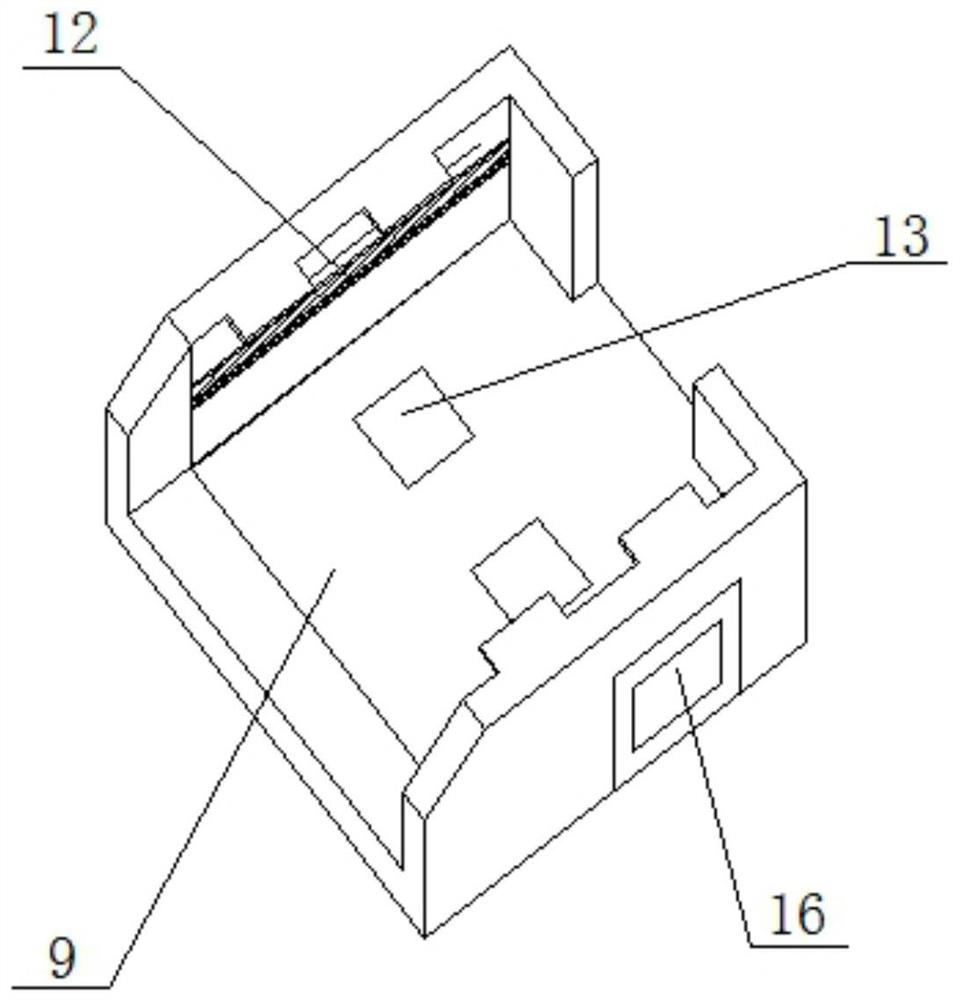

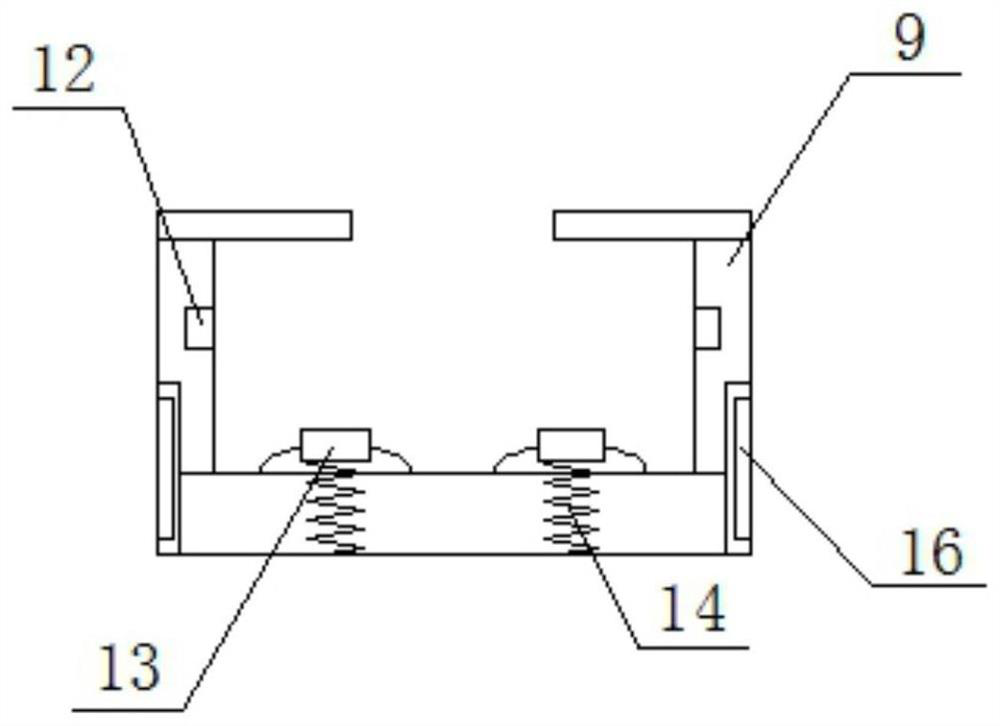

Automatic pipe fitting cutting equipment

InactiveCN108818103ARealize automatic clamping and fixingAvoid safety hazardsMetal working apparatusPositioning apparatusPipe fittingEngineering

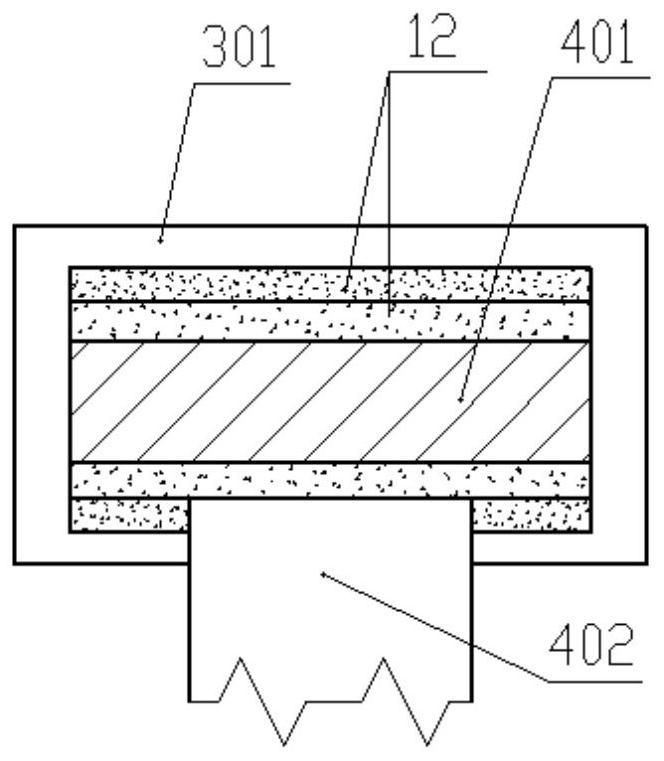

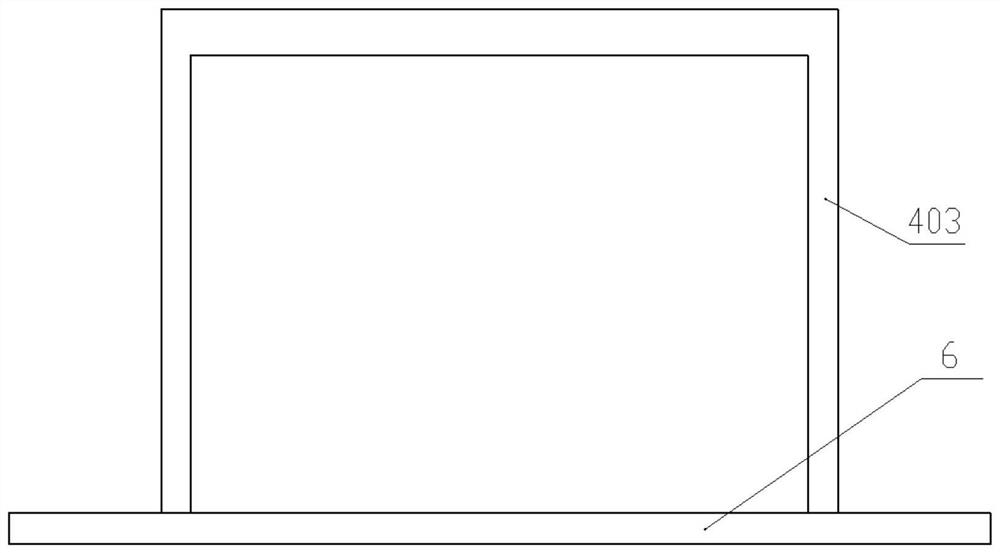

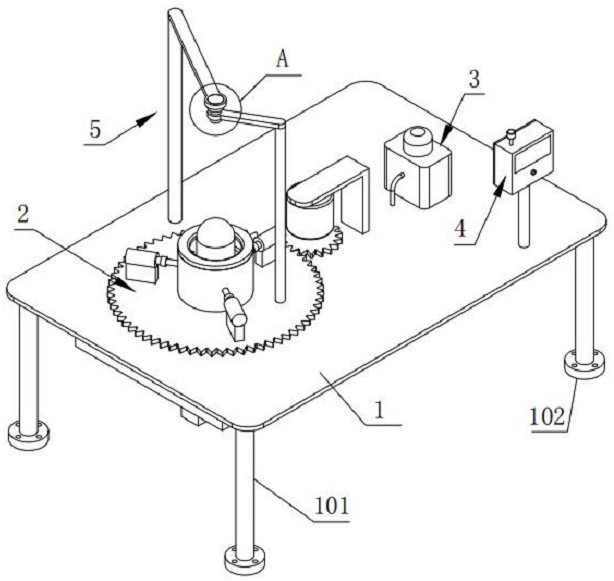

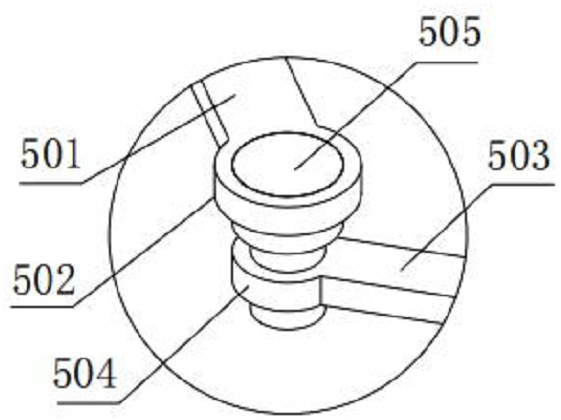

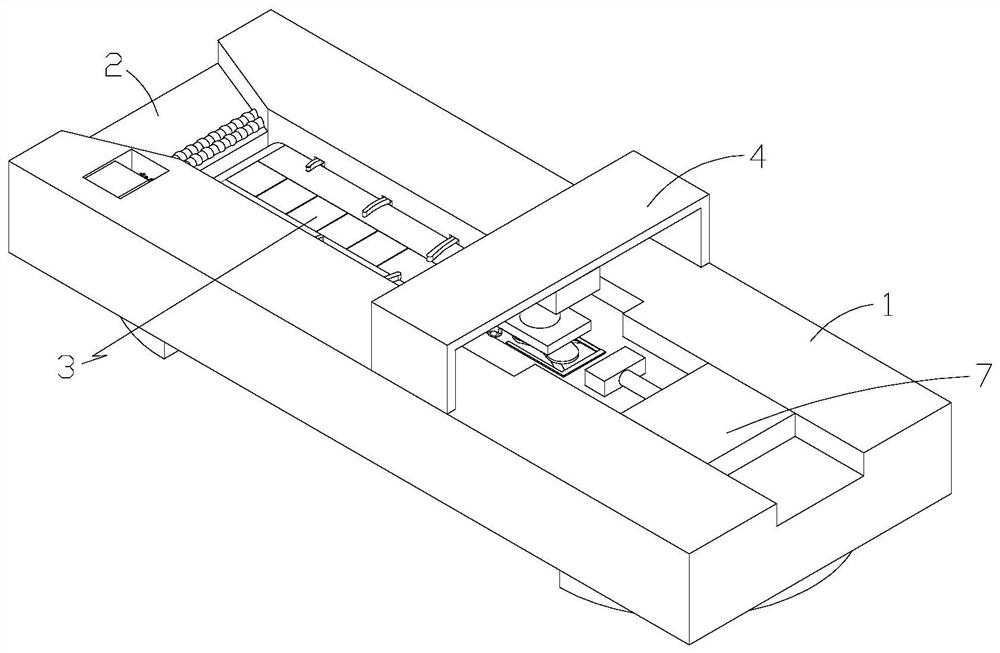

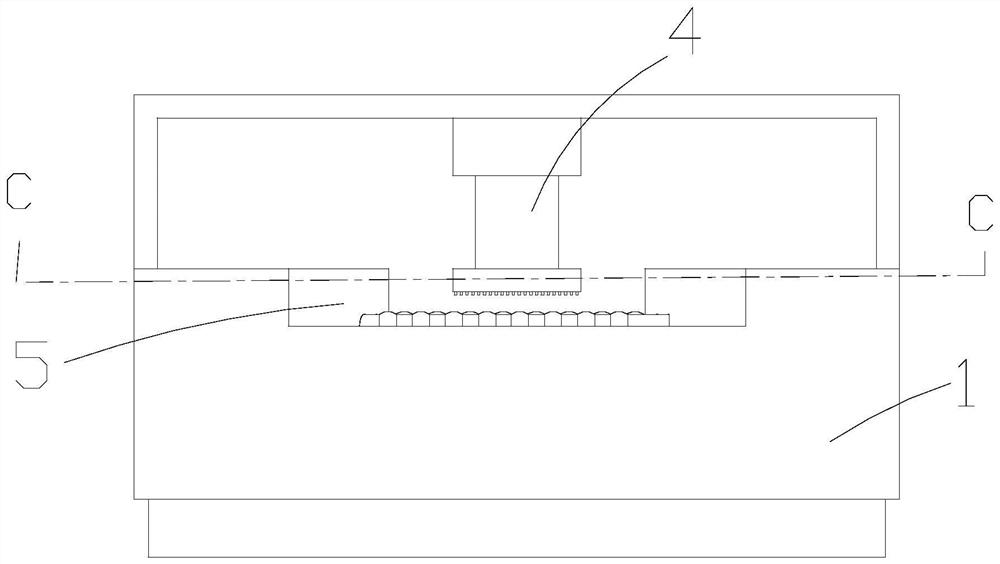

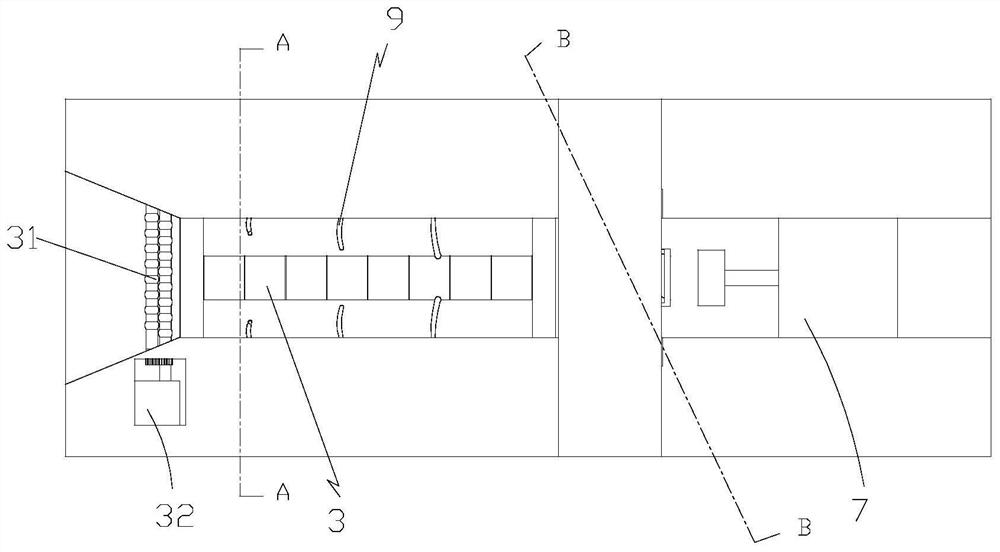

The invention discloses automatic pipe fitting cutting equipment. The equipment comprises a delivery mechanism, a machining mechanism and a control mechanism; the delivery mechanism comprises a support, a liftable support mechanism is installed on the upper portion of the support, the machining mechanism comprises a clamping mechanism, a pressing mechanism, a cutting mechanism and a limiting mechanism, the clamping mechanism is arranged at one end of the support, the pressing mechanism, the cutting mechanism and the limiting mechanism are sequentially arranged on a rack, the clamping mechanismand the pressing mechanism are used for fixing and clamping a pipe fitting, the limiting mechanism is used for determining the position of the pipe fitting, and the control mechanism is electricallyconnected with the machining mechanism. According to the automatic pipe fitting cutting equipment, by means of mutual cooperation of the loading mechanism, the delivery mechanism, the machining mechanism and the control mechanism, full-automatic operation of loading, clamping fixing, cutting and discharging of the pipe fitting is achieved, the phenomena that high-temperature scraps are generated in the pipe fitting cutting process, pipe fitting fixing is not firm and breaks away from the pipe fitting cutting equipment, and potential safety hazards are caused to workers are avoided, the labor cost is greatly reduced, and the work efficiency is improved.

Owner:ZHANGJIAGANG INST OF IND TECH SOOCHOW UNIV +1

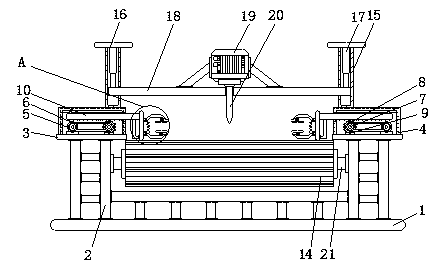

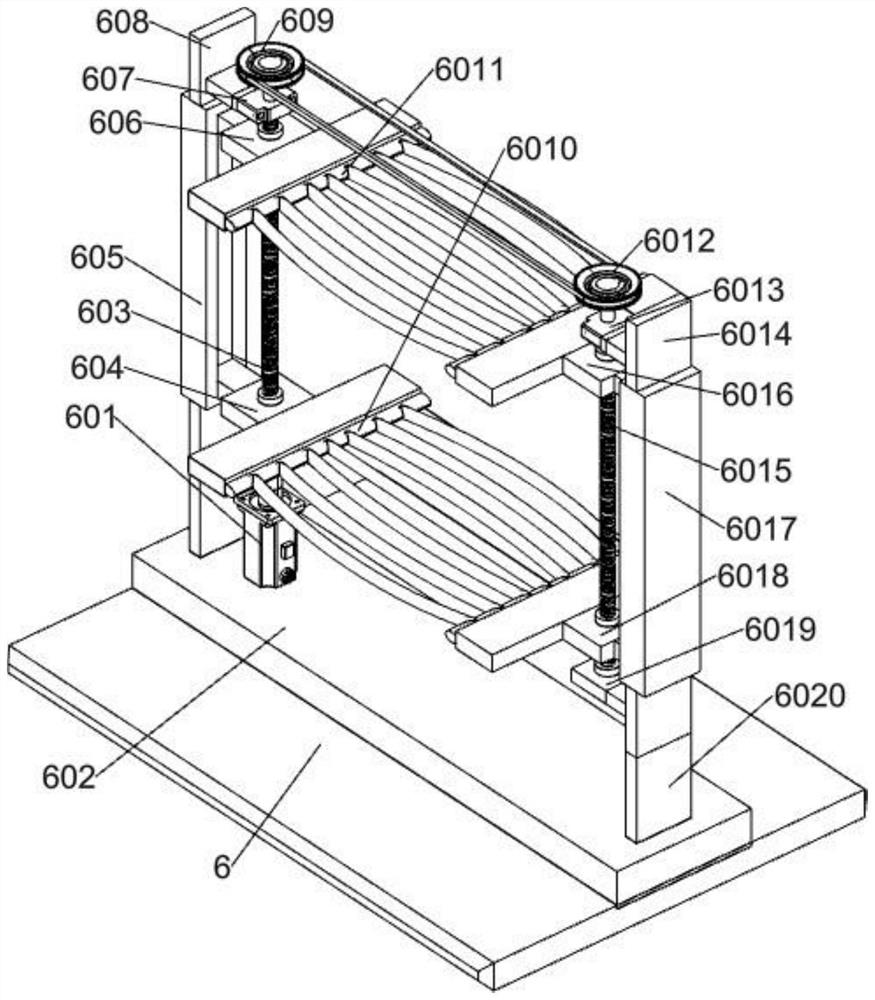

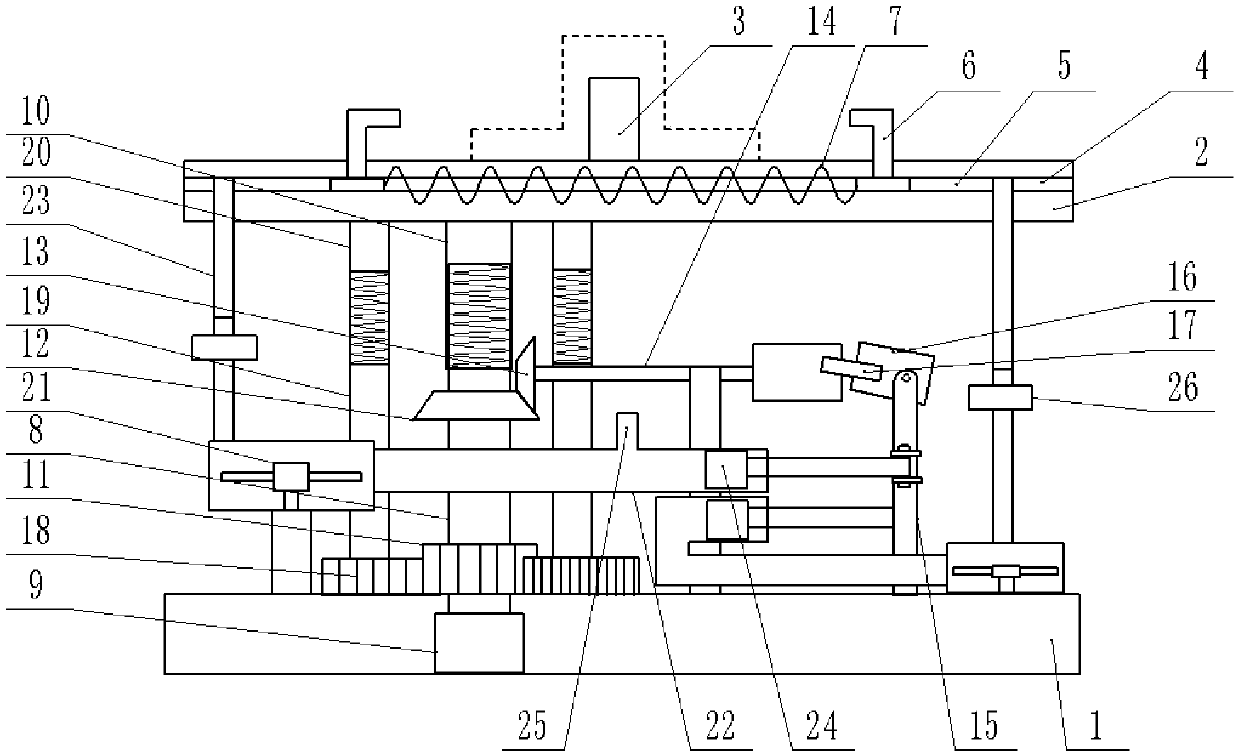

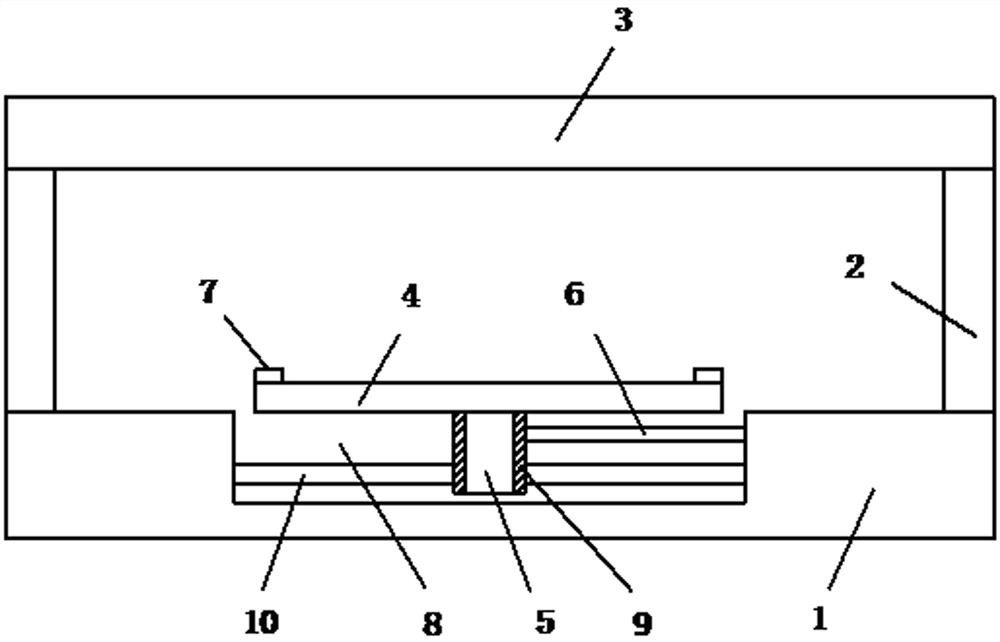

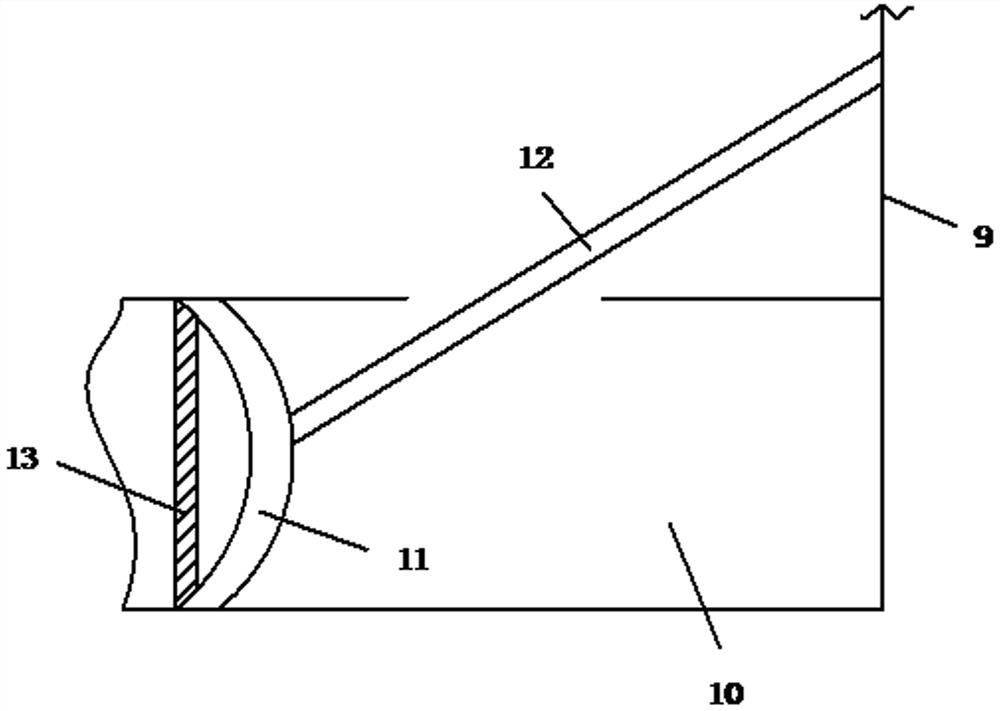

Biomedical metal plate polishing device

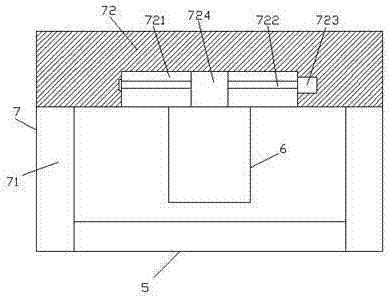

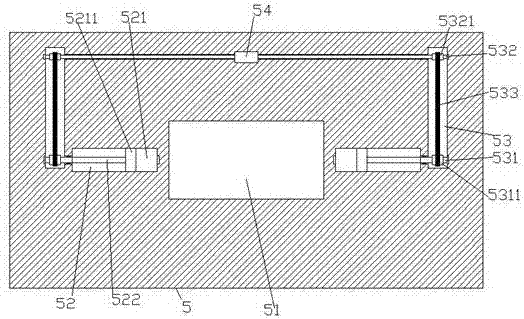

ActiveCN107052923AImprove grinding efficiencyRealize automatic clamping and fixingGrinding work supportsPlane surface grinding machinesEngineeringMechanical engineering

The invention discloses a biomedical metal plate polishing device comprises a seat, a polishing structure and a frame. The frame comprises frame columns and top beam. The frame columns are arranged in a front-back opposite mode. The top beam is fixed between the tops of the frame columns. The seat is arranged between the bottoms, below the top beam, of the frame columns. A first sliding conveying groove extending front and back is formed in the bottom face of the top beam. A first spiral rod is extending front and back is arranged in the first sliding conveying groove. A first sliding conveying block is connected to the first spiral rod in a matched mode. The bottom of the first sliding conveying block is fixedly connected with the top end of the polishing structure. A conveying cavity is formed in the polishing structure. A connecting cavity communicates with the bottom of the conveying cavity. A disc is arranged on the rear side wall of the polishing structure. The biomedical metal plate polishing device is simple in structure, reasonable in design, low in manufacturing cost and maintenance cost, capable of adjusting a polishing position in a multidirectional mode, convenient to operate, capable of achieving automatic telescopic left and right polishing, high in safety, and capable of automatically clamping and fixing a metal plate and improving polishing stability.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

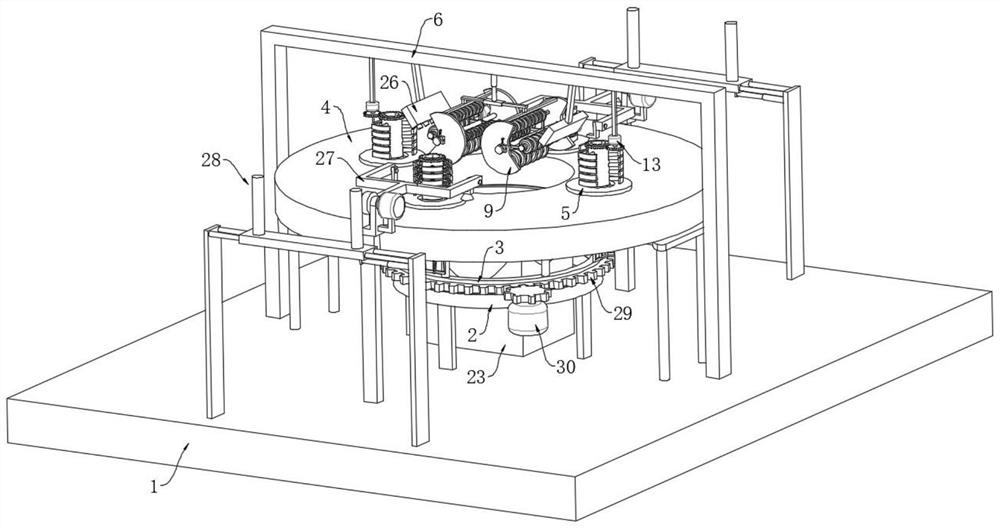

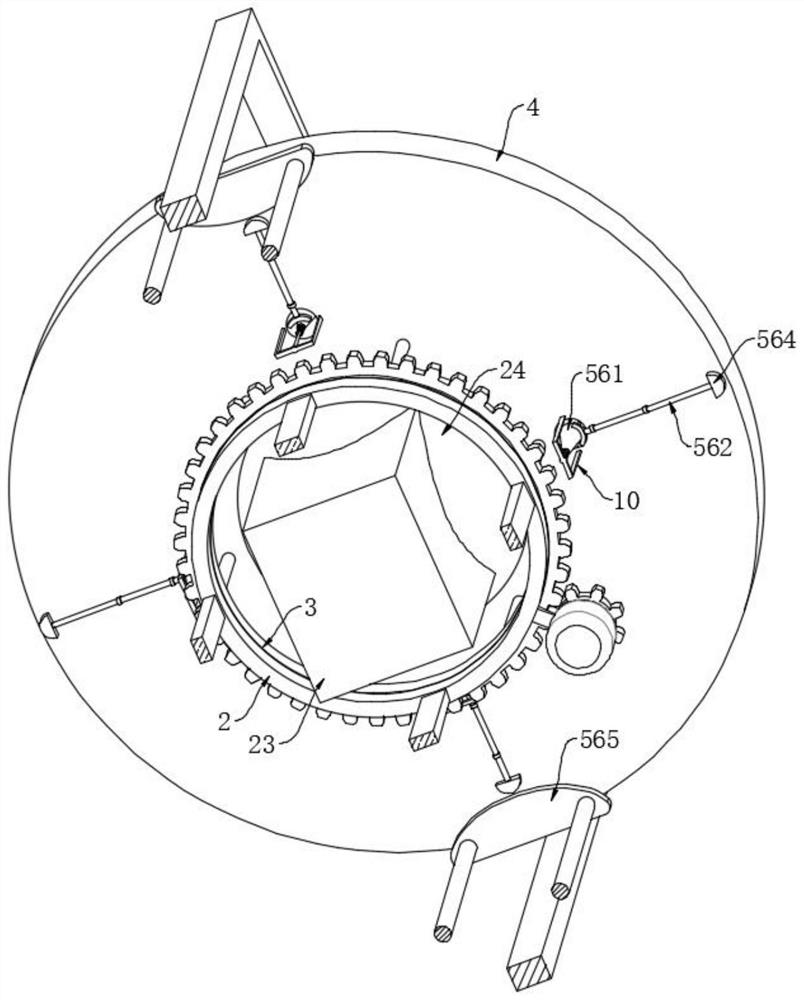

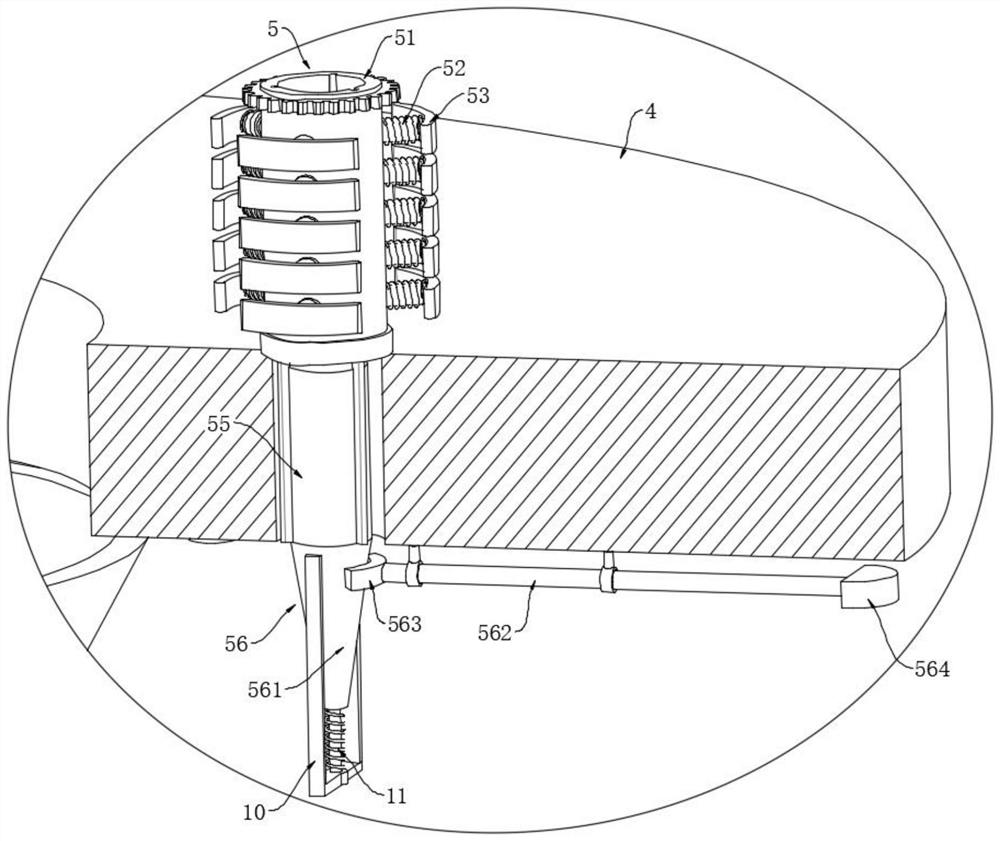

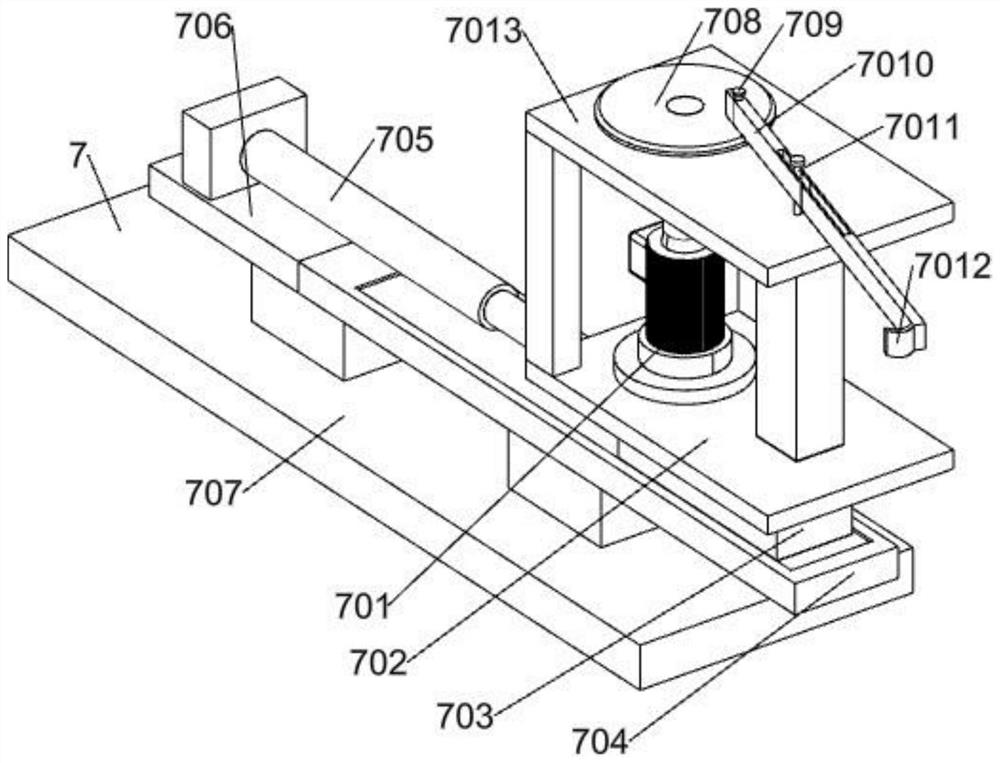

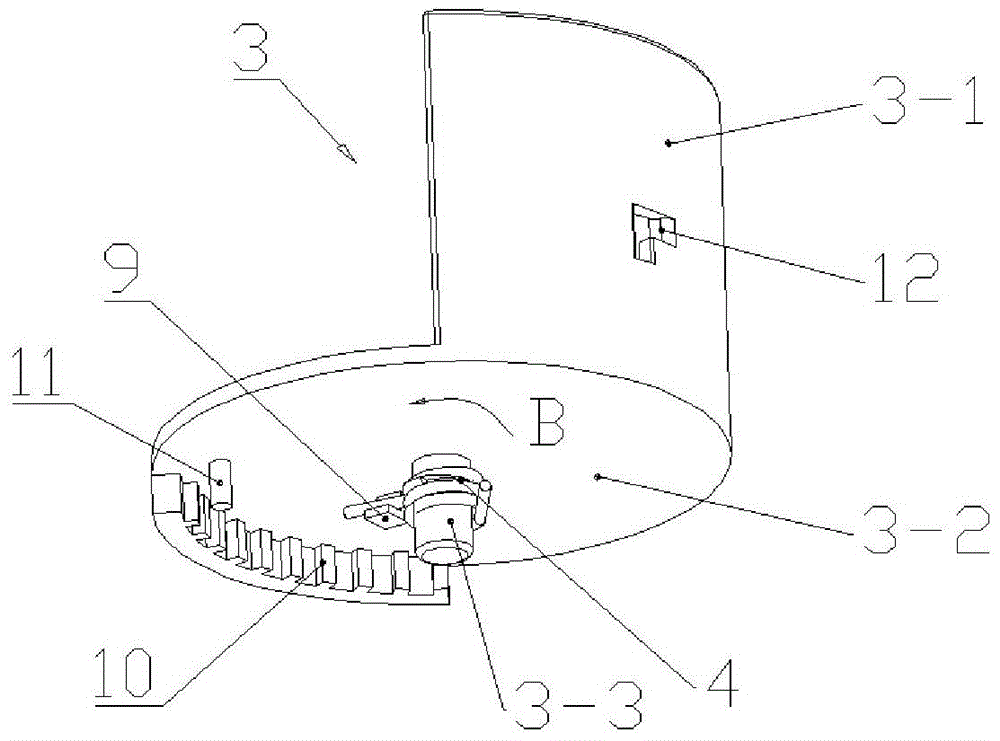

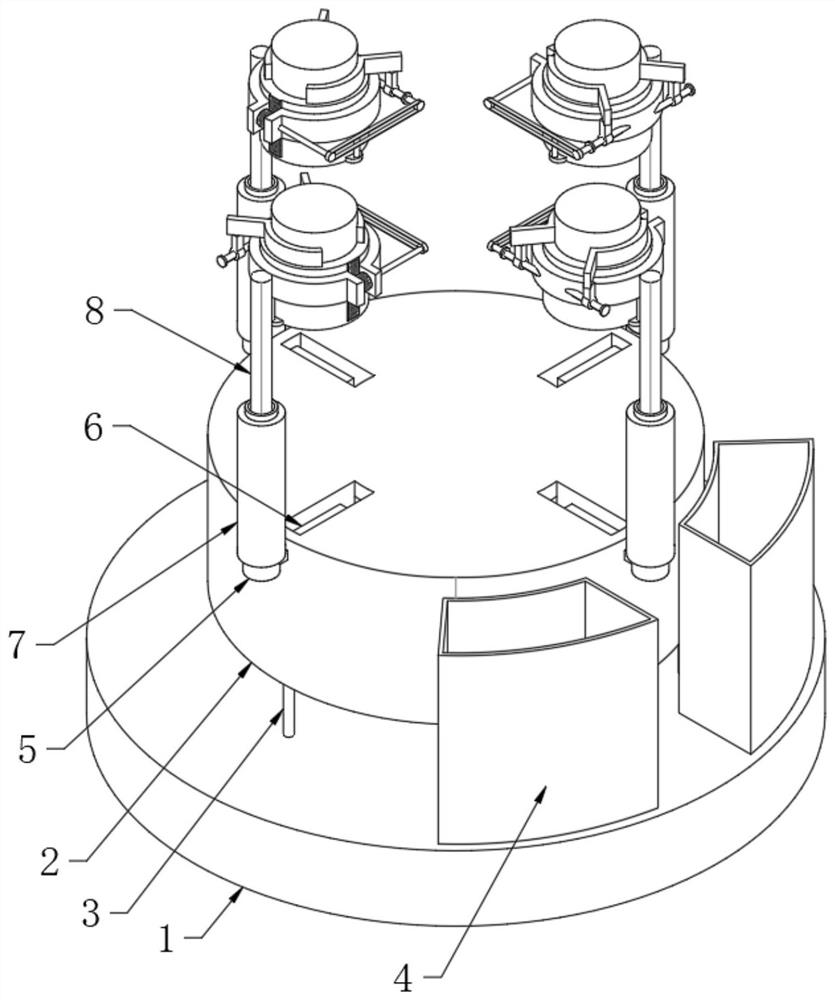

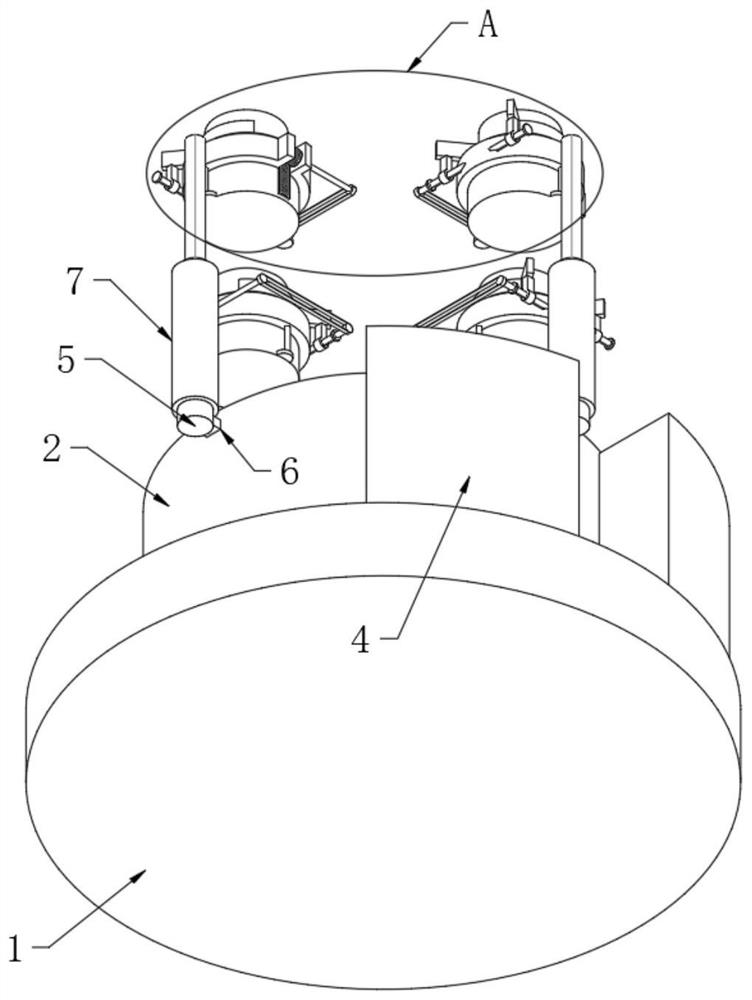

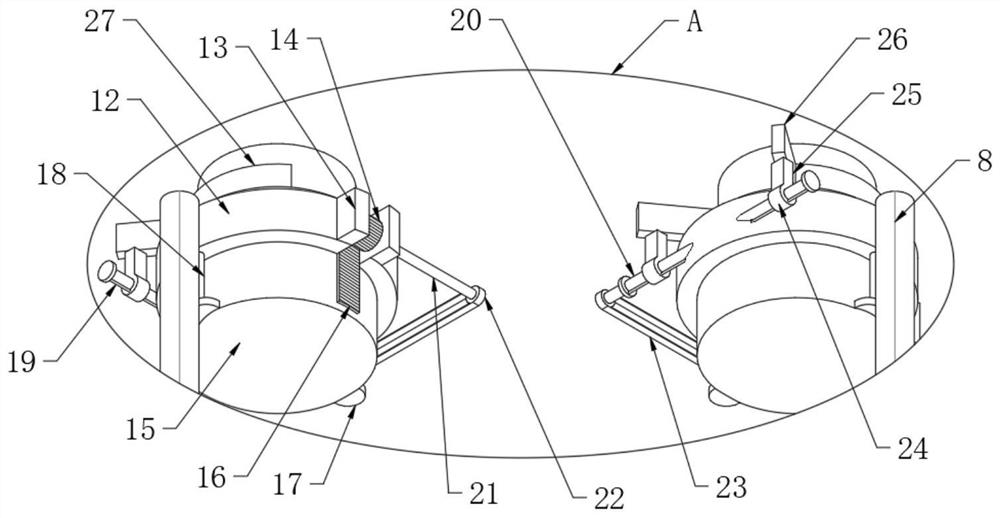

Molding device for driving assembly of wind power generation equipment

ActiveCN114535719AEasy to change and adjustImprove Turning Forming EfficiencyWind energy generationGear-cutting machinesGear wheelEngineering

The invention discloses a forming device for a driving assembly of wind power generation equipment, and relates to the technical field of machining of parts of the wind power generation equipment. The wind power generation equipment driving assembly forming device comprises a supporting plate base, the upper end face of the supporting plate base is fixedly connected with a first mounting ring through a vertical rod, a plurality of clamping mechanisms used for clamping and limiting a gear blank are installed on the circumference of the upper end face of an annular mounting disc at equal intervals, and the upper end face of the supporting plate base is fixedly connected with an n-shaped frame; according to the gear machining device, cutting tools of different specifications can be rapidly switched according to gears of different specifications, operation is easy and convenient, two gear blanks can be machined at the same time, the machining efficiency is improved, the machining cost is reduced, and the machining efficiency is improved. And the processing efficiency is improved.

Owner:睢宁核源风力发电有限公司

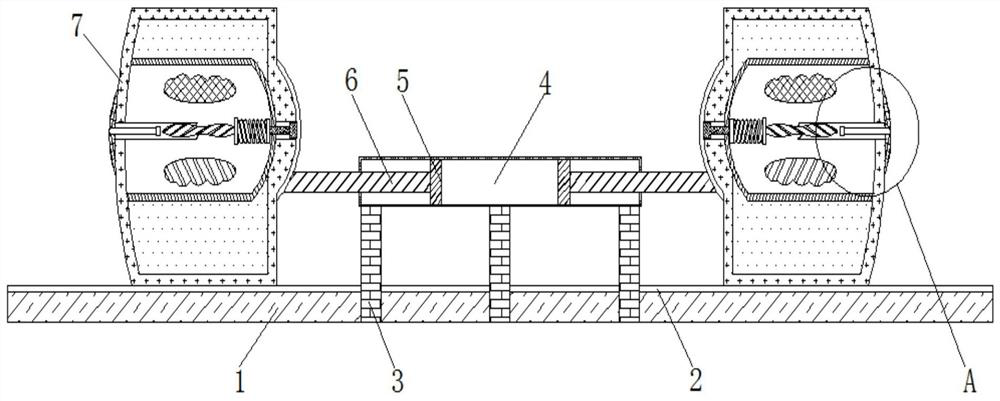

Use-convenient drilling device for automatic production line fitting machining

PendingCN108818051AEasy to usePlay a protective effectPositioning apparatusMetal-working holdersProduction lineEngineering

The invention discloses an use-convenient drilling device for automatic production line fitting machining. The device comprises a base plate; support legs are fixedly connected to the two sides of thetop of the base plate; a mounting plate is fixedly connected to the tops of the support legs; a protective cover is fixedly connected to the top of the mounting plate; a first motor is fixedly connected to one side of the top of the mounting plate through a connecting block and positioned in the protective cover; one end of an output shaft of the first motor is fixedly connected with a first beltwheel; a movable shaft is movably connected to the other side of the top of the mounting plate through a support plate and positioned in the protective cover; a second belt wheel is fixedly connectedto the surface of the movable shaft; and the invention relates to the technical field of fitting production. The use-convenient drilling device for automatic production line fitting machining can realize automatic clamping and fixation of fittings on a conveying belt, needs no manual operation, reduces a certain manpower, is convenient to use, and meanwhile, reduces a certain potential safety hazards.

Owner:苏州谊佳润机电制造有限公司

Forging process for difficult-to-deform high-temperature alloy plate slab

ActiveCN110802189ARealize automatic clamping and fixingHeating evenlyForging press detailsAlloyHigh heat

The invention discloses a forging process for difficult-to-deform high-temperature alloy plate slab. The forming process comprises the following steps: A, heating plate slab to a temperature of 975-1005 DEG C, and preserving the heat for 1-2 hours; B, putting the plate slab into a forging press to forge, wherein forging pressing speed is 5-10 mm / min; C, taking out the plate slab to re-heat to a temperature of 850-910 DEG C and preserving heat for 3-5 hours while forging deformation amount achieves 70% of the standard value; and D, putting the plate slab into the forging press to forge again until forging is accomplished, wherein forging pressing speed is 1-3 mm / min. The forging process can improve the defects of the prior art, and realizes low-temperature forging of the difficult-to-deformhigh-temperature alloy.

Owner:AVIC SHANGDA METAL REGENERATION TECH

Gordon enryale fruit shell peeler

Owner:CHUZHOU UNIV

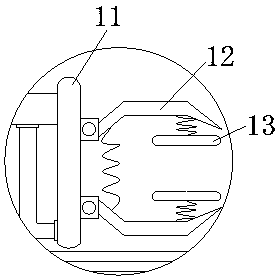

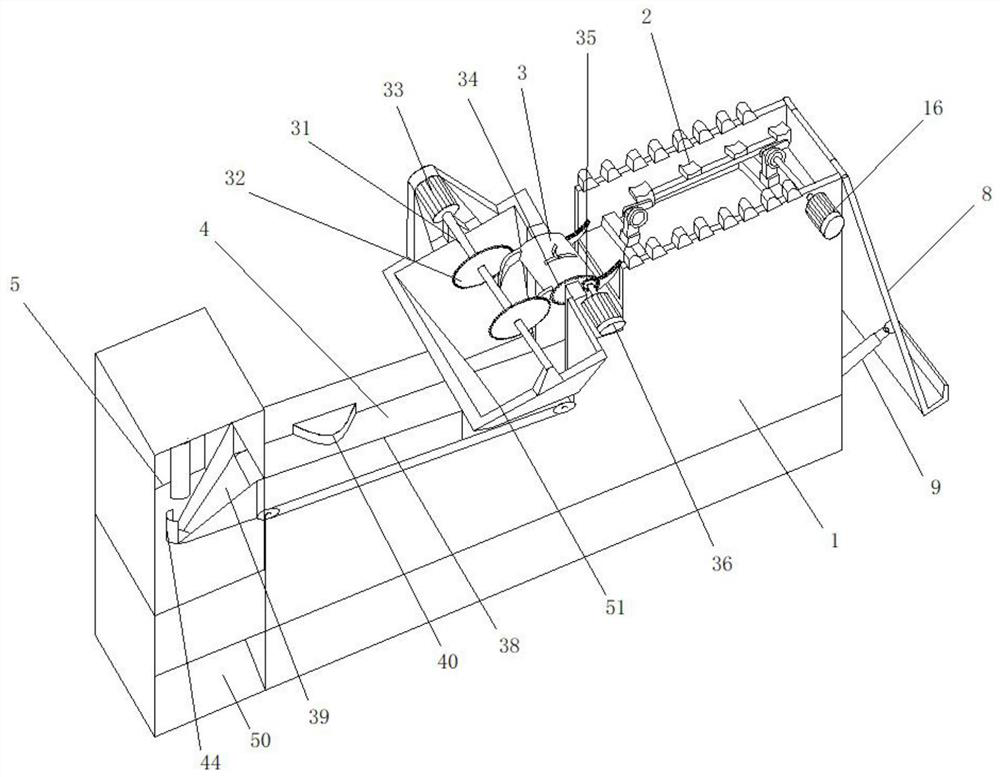

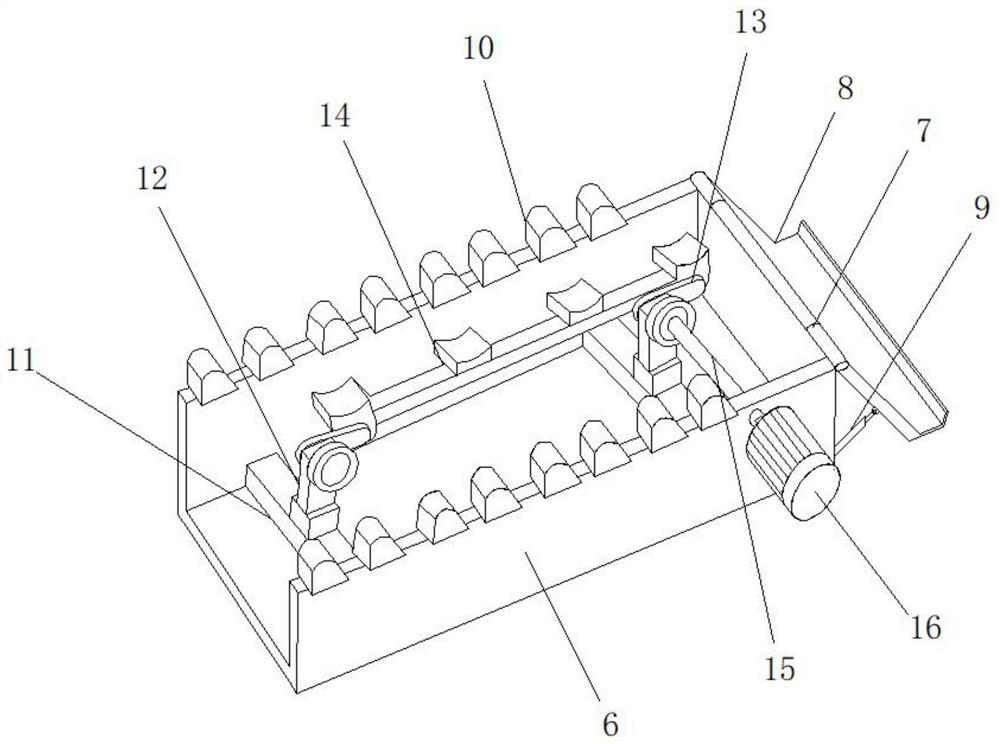

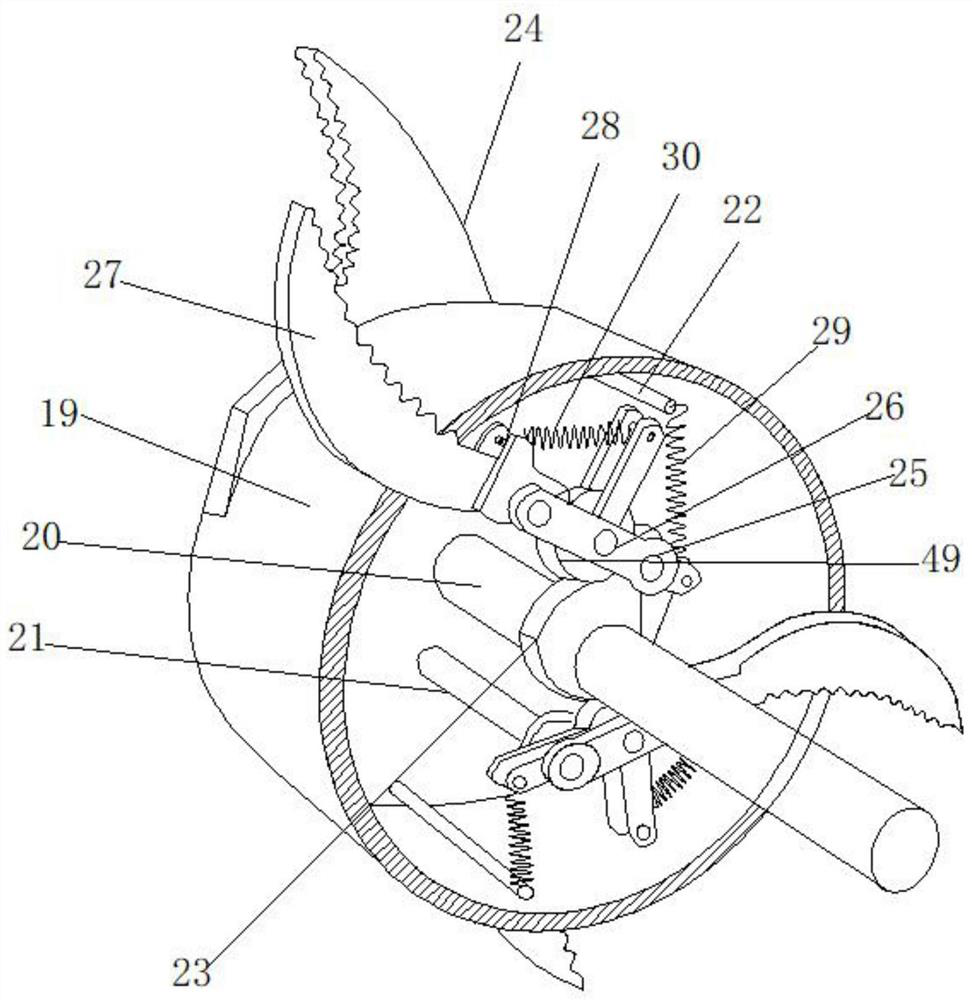

Picking equipment for high-strength motorcycle steel backing based on contact surface barb mechanism

ActiveCN111889959AImprove efficiencyImprove stabilityPositioning apparatusMetal working apparatusStructural engineeringManufacturing engineering

The invention discloses picking equipment for a high-strength motorcycle steel backing based on a contact surface barb mechanism. The picking equipment comprises a shell body, a feeding hole, a conveying device, a barb machine, a workbench, a clamping device and a discharging claw, the clamping device comprises a guide mechanism, a limiting block, a first spring, an adsorption disc and a clampingmechanism; the limiting block is embedded in the workbench in a manner of moving up and down, the surface, opposite to the guide mechanism, of the limiting block is an inclined surface; and the adsorption disc is located at the middle point of the workbench. According to the picking equipment for the high-strength motorcycle steel backing based on the contact surface barb mechanism, a steel backing blank is placed on the conveying device through the feeding port, then the position of the steel backing blank is automatically aligned on the conveying device; further, the steel backing blank is pushed to a workbench through the guide mechanism; then the steel backing blank is fixed to a workbench under the simultaneous action of the clamping mechanism and the adsorption disc, the steel backing is picked at a time through the barbing machine, the working efficiency is improved; and meanwhile, the clamping effect is improved through the simultaneous action of the adsorption disc and the clamping mechanism, the stability of the steel backing is further improved, and the picking quality is improved.

Owner:浦江搏纳汽车零部件有限公司

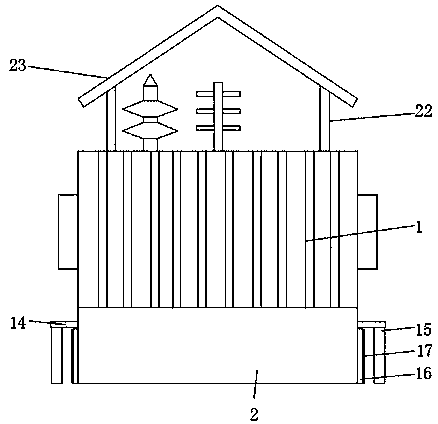

Transformer convenient to move and install for electric power

InactiveCN107731454AEasy to moveEasy to installTransformers/reacts mounting/support/suspensionTransformers/inductances casingsTransformerElectric power system

The invention provides a transformer convenient to move and install for electric power, and relates to the field of transformers. The transformer convenient to move and install for the electric powercomprises a transformer body, a fixing base is fixedly connected to the bottom of the transformer body, a connecting plate is fixedly connected to the bottom of the inner wall of the fixing base, anda first electric telescopic rod is fixedly connected to the top of the connecting plate. According to the transformer convenient to move and install for the electric power, the structure is simple, and operation is convenient; through the first electric telescopic rod arranged in the fixing base, under extension and retraction of the first electric telescopic rod, through cooperation of a moving column, first sliding blocks and first sliding grooves, the effect that rolling wheels on supporting rods are driven to conveniently move is achieved, so that the rolling wheels move out of the fixingbase, it is more convenient for the transformer body to move, a large amount of labor and physical strength are saved when the transformer body moves, and the problem that an existing transformer forthe electric power is very inconvenient to move and install during use is solved.

Owner:无锡匡威变压器有限公司

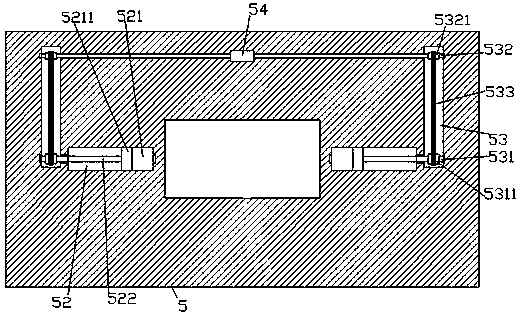

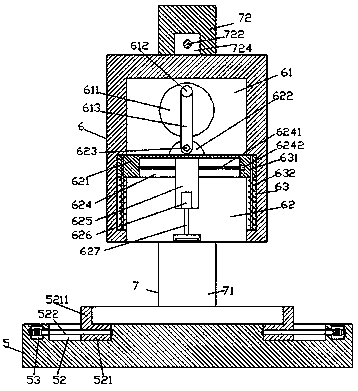

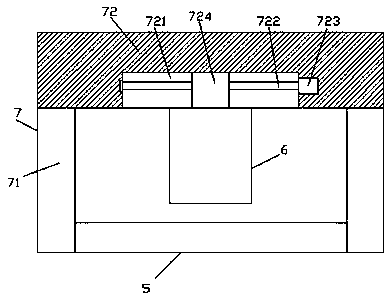

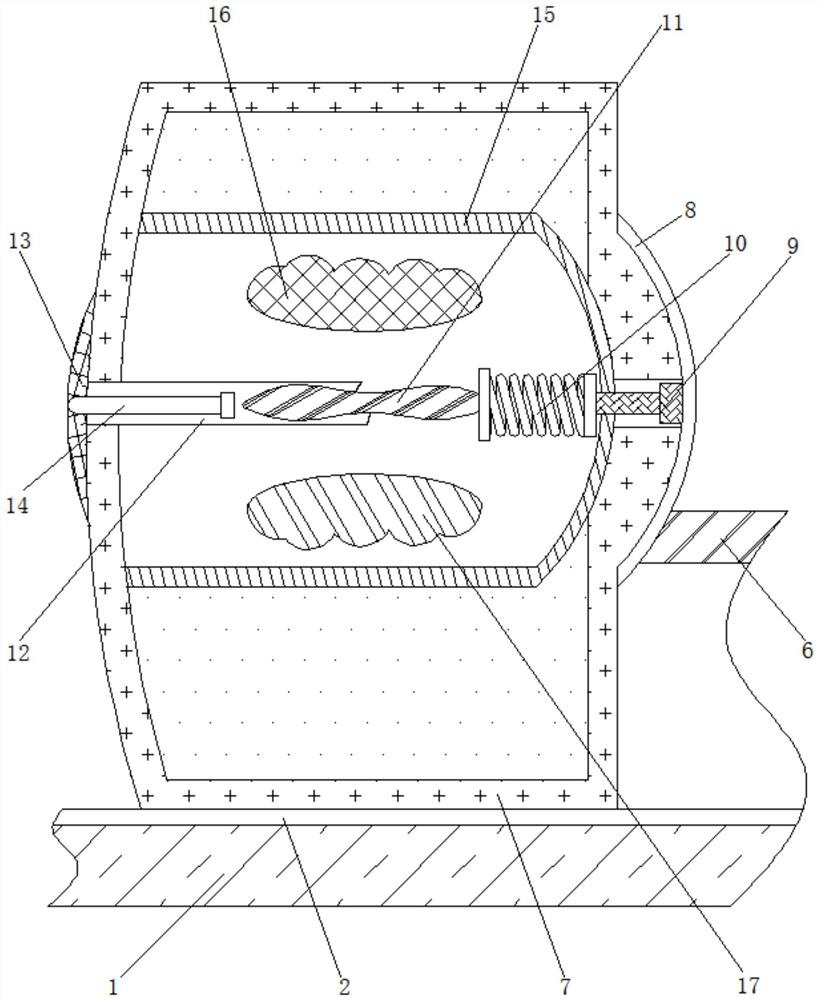

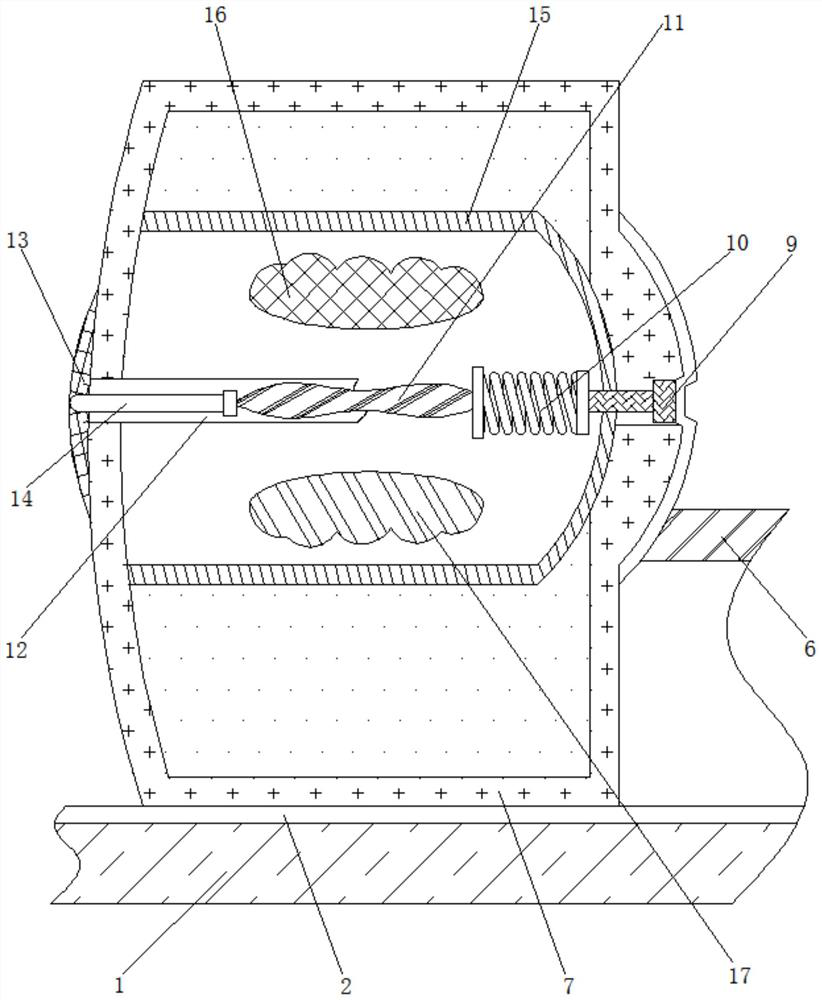

Granite ore treatment device

InactiveCN111844462ARealize automatic clamping and fixingPrevent health problemsWorking accessoriesStone-like material working toolsMining engineeringIron removal

The invention relates to the field of ores, in particular to a granite ore treatment device. The invention aims to provide the granite ore treatment device. The granite ore treatment device comprisesa machine tool collection plate, a clamping movement control mechanism, a first stirring reversing mechanism, a closed cutting mechanism, a stone powder treatment mechanism, a second stirring reversing mechanism, a three-legged chassis and the like, wherein the lower part of the machine tool collection plate is welded with the three-legged chassis. According to the granite ore treatment device, granite ore is automatically clamped and fixed, meanwhile, the problem that stone powder dissociates into air and is inhaled by a human body to affect the health of the human body is completely eradicated in a closed cutting mode, meanwhile, aiming at multi-face cutting of the granite ore, an automatic ore overturning mode is adopted, and iron removal operation is conducted on the granite powder with the high iron content, and the effect of pure granite powder capable of being used for subsequent processing is achieved.

Owner:卢昌敏

Fast-assembly type construction platform based on bridge anti-collision wall

InactiveCN111877154ARealize compression and fixationAvoid Rollover SituationsBridge structural detailsClassical mechanicsEngineering

The invention provides a fast-assembled construction platform based on a bridge anti-collision wall, and the platform comprises an inner side positioning part and a cantilever part; the inner side positioning part comprises a first inner side sub-positioning part, a second inner side sub-positioning part and a second hydraulic rod which are hinged with one another, and the first inner side sub-positioning part is of a right-angled trapezoidal plate body structure which can be flatly placed on a bridge, and the inclined surface is arranged towards one side of the anti-collision wall; the surface of the side, facing the anti-collision wall, of the second inner side sub-positioning piece can be attached to the inner surface of the anti-collision wall; the surface of the side, facing the anti-collision wall, of the cantilever part can be attached to the top face of the anti-collision wall, a sliding shaft is installed in the cantilever part in a sliding fit mode, and one end of the slidingshaft is inserted into a sliding hole of the cantilever part from the end, facing the inner side of the bridge, of the cantilever part and connected with the bottom of the sliding hole through an elastic element, and the other end of the spring extends out of the sliding hole and is hinged with the free end of the first hydraulic rod. The platform is simple in structure, easy to manufacture and use, safe and reliable, and does not influence traffic.

Owner:孙喜军

A barb removal device for high-strength motorcycle steel back based on contact surface barb mechanism

ActiveCN111889959BRealize automatic clamping and fixingImprove stabilityPositioning apparatusMetal working apparatusEngineeringWorkbench

The invention discloses a high-strength motorcycle steel back barb-picking device based on a contact surface barb mechanism, which includes a housing, a feeding port, a transmission device, a barb machine, a workbench, a clamping device, and a discharge claw; The clamping device includes a guide mechanism, a limit block, a first spring, an adsorption disc, and a clamping mechanism; the limit block can move up and down and is embedded on the workbench, and the surface of the limit block opposite to the guide mechanism is an inclined plane; The suction disc is located at the midpoint of the workbench; the invention places the steel back blank on the conveying device through the feed port, and then automatically adjusts the position on the conveyer; further pushes the steel back blank to the workbench through the guide mechanism Then, under the simultaneous action of the clamping mechanism and the suction plate, the steel back blank is fixed on the workbench, and the steel back is stabbed at one time by the barb machine; the work efficiency is improved, and at the same time, the suction plate and the clamping mechanism Simultaneous action improves the clamping effect, further increases the stability of the steel back, and improves the quality of the burr.

Owner:浦江搏纳汽车零部件有限公司

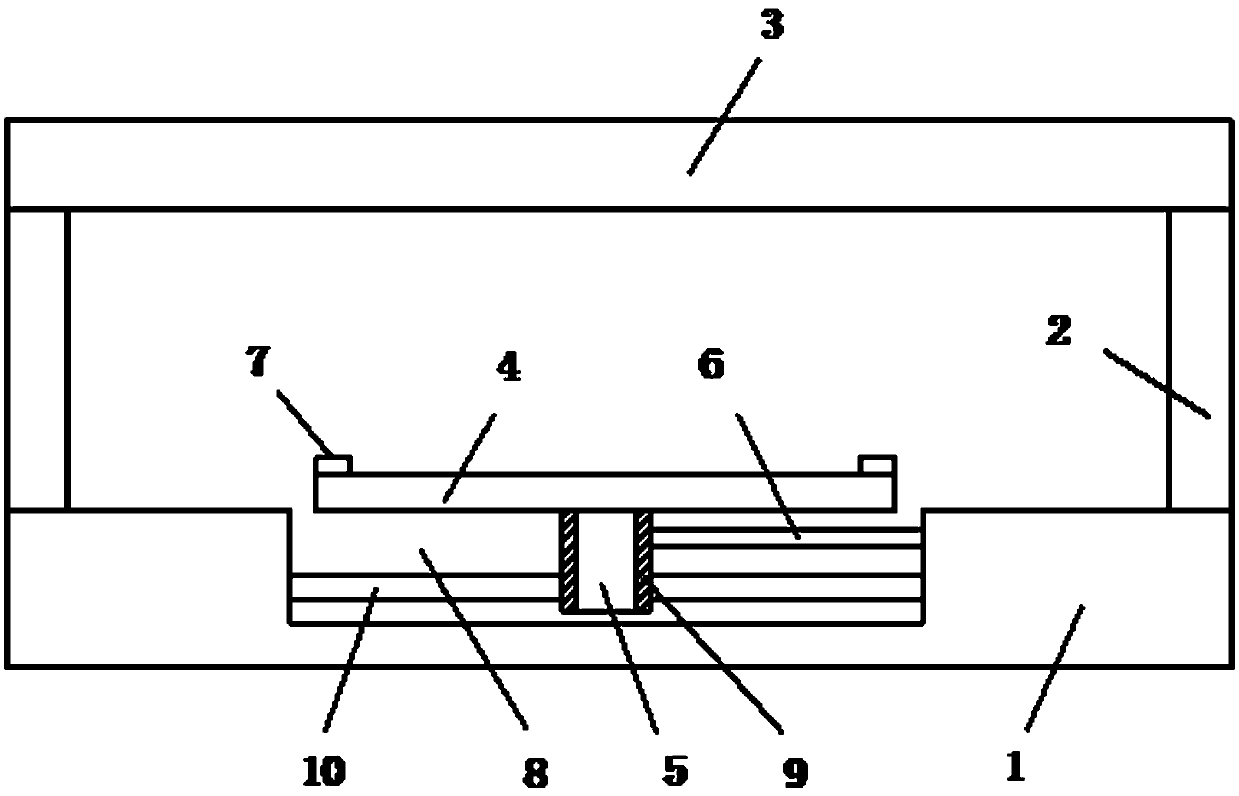

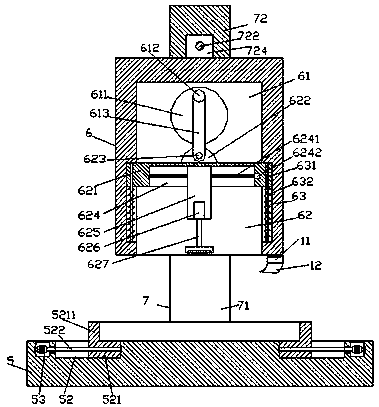

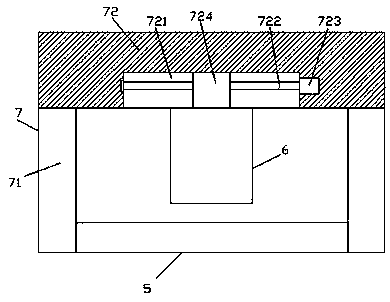

A precise biomedical metal plate grinding device

ActiveCN107685262BImprove grinding efficiencyRealize automatic clamping and fixingGrinding carriagesGrinding work supportsPunchingEngineering

The invention discloses an accurate biomedical metal plate grinding device. The accurate biomedical metal plate grinding device comprises a base, a grinding structure and a frame. The frame comprisesframe columns oppositely arranged front and back, and a top beam fixed between the tops of the frame columns. The base is arranged between the bottoms of the parts, below the top beam, of the frame columns. A sliding and moving groove extending front and back is formed in the bottom face of the top beam and internally provided with a first screwed rod extending front and back. The first screwed rod is connected with a first sliding and moving block in a matched manner. The bottom of the first sliding and moving block and the top end of the grinding structure are fixedly connected, a transferring cavity is formed in the grinding structure, a communication cavity is formed in the bottom of the transferring cavity in a communication manner, and a disc is arranged on the rear side wall of thegrinding structure. The accurate biomedical metal plate grinding device is simple in structure, reasonable in design, low in manufacturing cost and maintaining cost, capable of achieving multi-direction grinding position adjustment, convenient to operate, capable of achieving automatic left and right telescopic grinding, high in safety, and capable of achieving automatic panel clamping and fixingand improving the punching stability.

Owner:成都微知猫知识产权运营有限公司

A high-efficiency biomedical metal plate grinding device

ActiveCN107685263BImprove grinding efficiencyAchieve clampingGrinding carriagesGrinding work supportsEngineeringMechanical engineering

The invention discloses a high-efficiency biomedical metal plate polishing device. The high-efficiency biomedical metal plate polishing device comprises a base body, a polishing structure and a frame.The frame comprises frame columns which are oppositely arranged front and back and a top beam fixed between the tops of the frame columns. The base body is arranged between the bottoms of the frame columns under the top beam. The bottom face of the top beam is internally provided with a first sliding and conveying groove which extends front and back. The first sliding and conveying groove is internally provided with a first spiral rod which extends front and back. The first spiral rod is connected with a first sliding and conveying block in a cooperated manner. The bottom of the first slidingand conveying block is fixedly connected with the top end of the polishing structure. The polishing structure is internally provided with a conveying cavity, the bottom of the conveying cavity is provided with a connection cavity in a communicating manner, and the rear side wall of the polishing structure is provided with a disk. The high-efficiency biomedical metal plate polishing device is simple in structure, reasonable in design, low in manufacturing cost and maintaining cost, capable of achieving multidirectional adjustment of polishing positions, convenient to operate, capable of achieving automatic extensible and retractable polishing on left and right, high in safety and capable of achieving automatic clamping and fixing of metal plates, and the polishing stability is improved.

Owner:MA SHIRUI BIOTECHNOLOGY JIANGSU CO LTD

Construction anti-falling device for municipal bridge engineering

InactiveCN111778872AGuaranteed stabilityAvoid overall rolloverSafety devices for lifting equipmentsBridge erection/assemblyRoad traffic safetyCantilever

The invention provides a construction anti-falling device for municipal bridge engineering. The device comprises an inner side positioning part, a cantilever part, an outer side positioning part and an auxiliary pressing part; the outer side positioning part can cling to the outer side surface of an anti-collision wall; a sliding connecting part is arranged at the top end of the outer side positioning part; the sliding connecting part is in sliding connection with the cantilever part; one end of the sliding connecting part is connected with the cantilever part through a second elastic part, the other end of the sliding connecting part is connected with the free end of the first hydraulic rod through a steel cable, and the outer side positioning part is tightly attached to the outer side surface of the anti-collision wall; a workbench extending towards the outer side of the bridge is further fixed to the outer side positioning part, a fence is installed on the upper surface of the workbench; and the auxiliary pressing part comprises a pressing plate, a rolling wheel, a traction rope and a winch. The device is simple in structure, easy to manufacture and use, safe and reliable, and does not influence traffic.

Owner:孙喜军

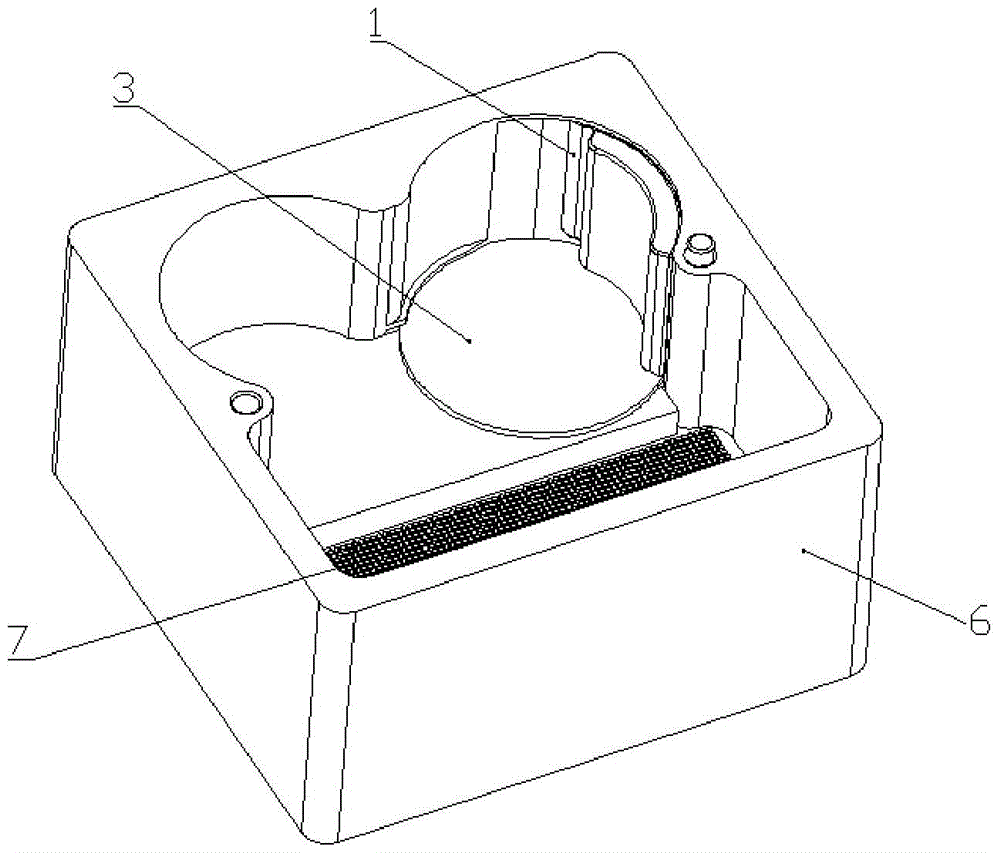

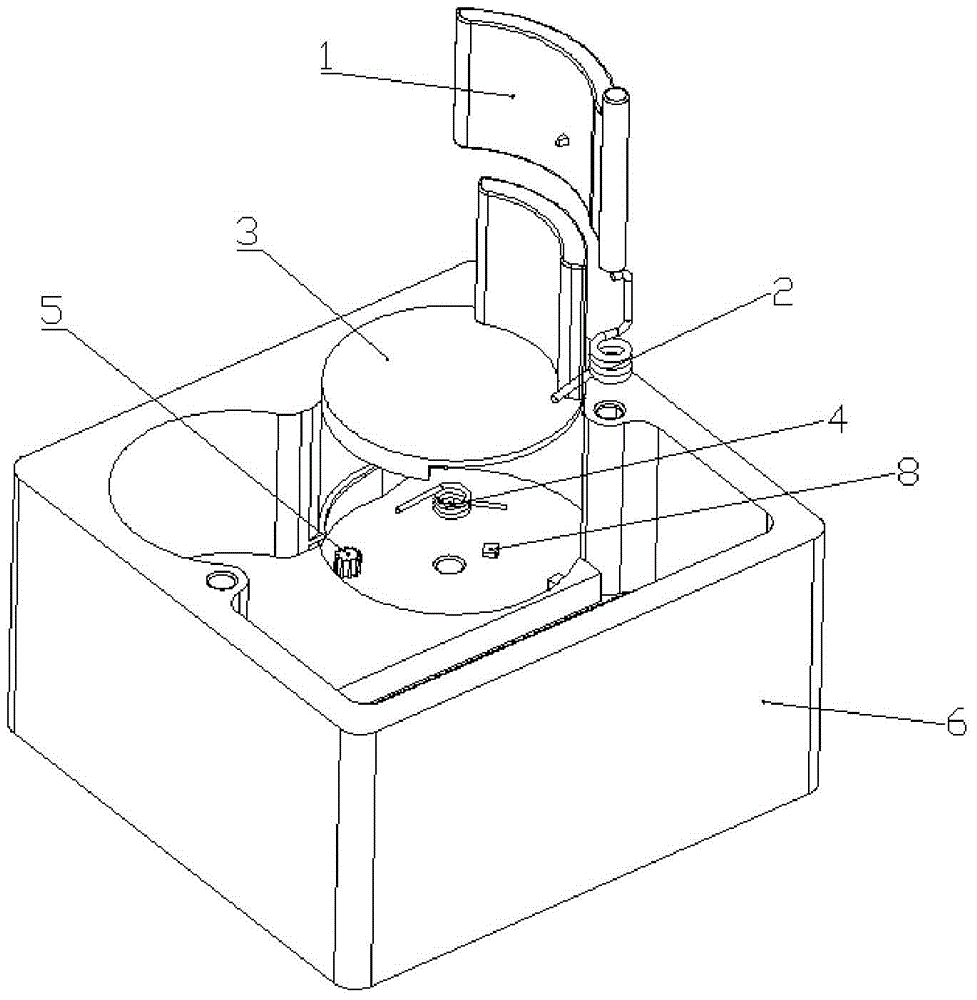

Laser cutting machine part production equipment

ActiveCN113927468APlay a polishing effectSolve the difficulty of polishingEdge grinding machinesSievingMachine partsProcess engineering

The invention provides laser cutting machine part production equipment, and belongs to the technical field of laser cutting machine production, and the laser cutting machine part production equipment comprises a bottom plate, a driving rotation device, a polishing sand supply device, a power supply assembly, a vibration mechanism and a control unit. According to the laser cutting machine part production equipment, the problem that the inner wall of an existing laser cutting machine part gas storage tank is difficult to polish can be solved; the arranged polishing sand supply device further has a screening function, polishing sand with the particle diameter decreased in the polishing process can be separated out in the working process, therefore the polishing effect is guaranteed, and the polishing quality of the inner wall of the laser cutting machine part gas storage tank is improved; and the intelligent degree is high, the purposes of automatically clamping and fixing the laser cutting machine part gas storage tank, automatically sealing the laser cutting machine part gas storage tank and automatically polishing the inner wall of the laser cutting machine part gas storage tank can be achieved, and the working efficiency is effectively improved.

Owner:广东睿丰机械科技有限公司

a lift

Owner:菏泽智慧新材料科技有限公司

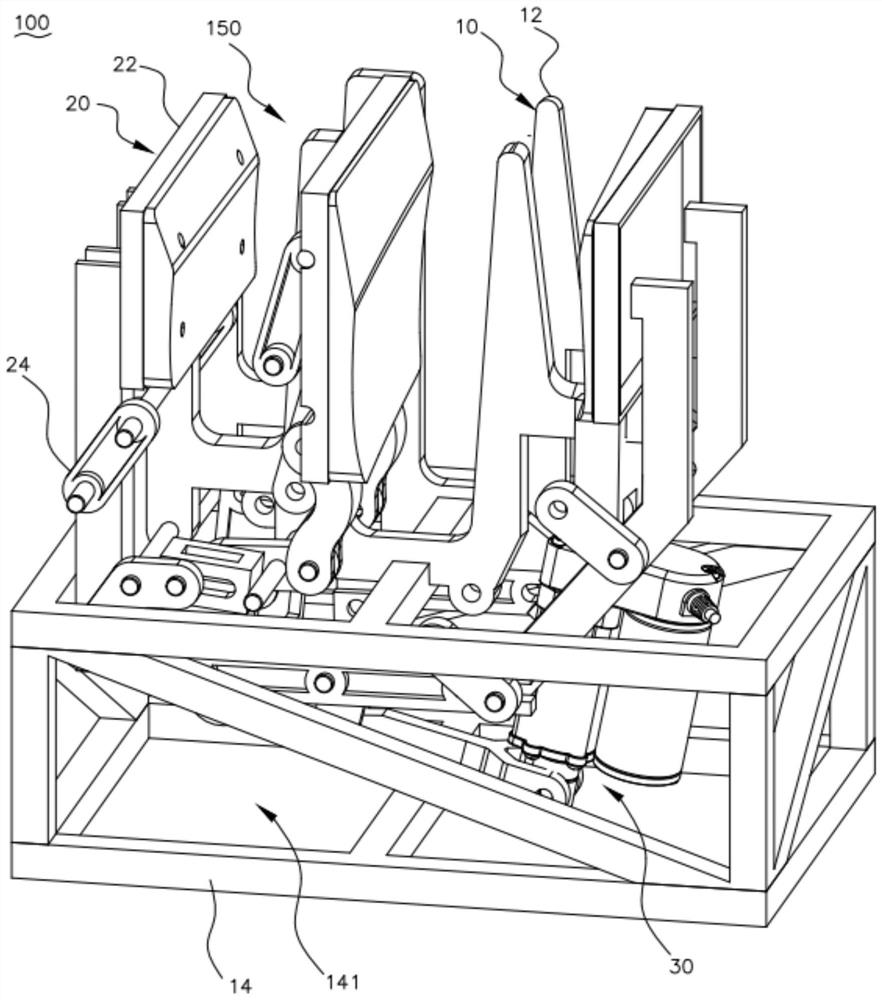

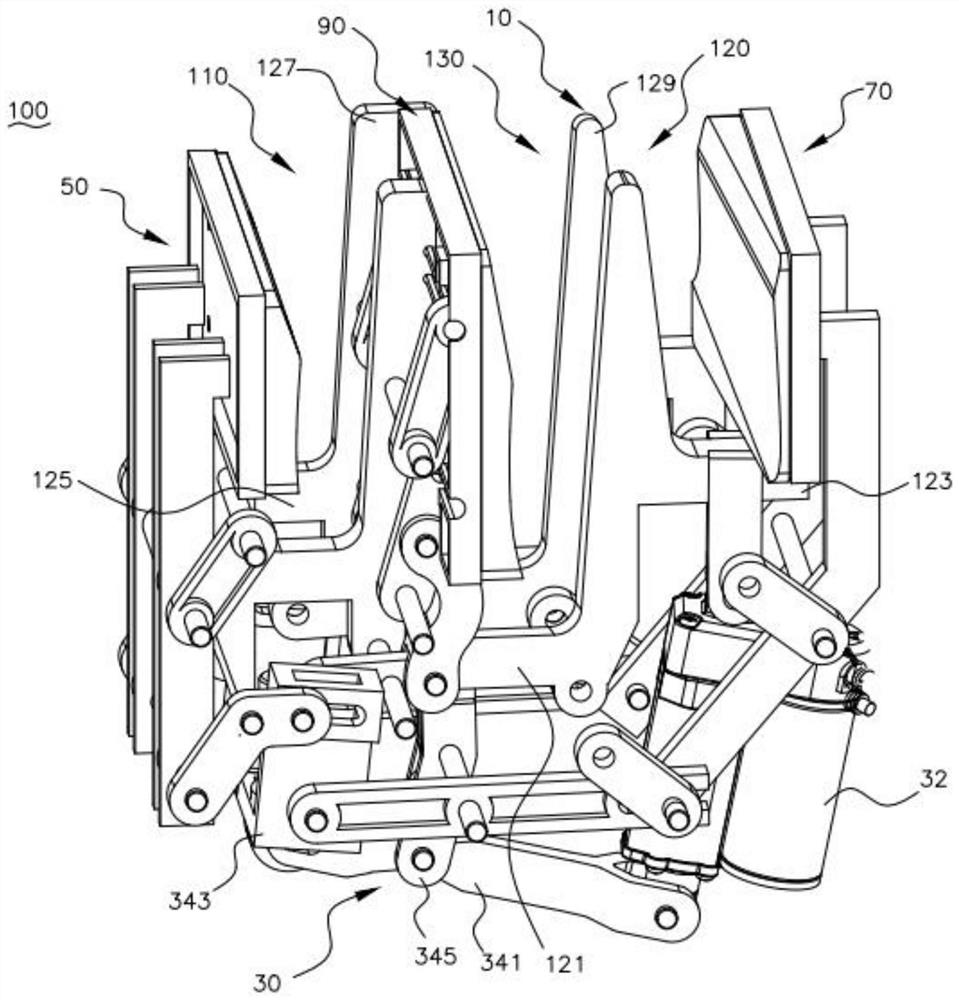

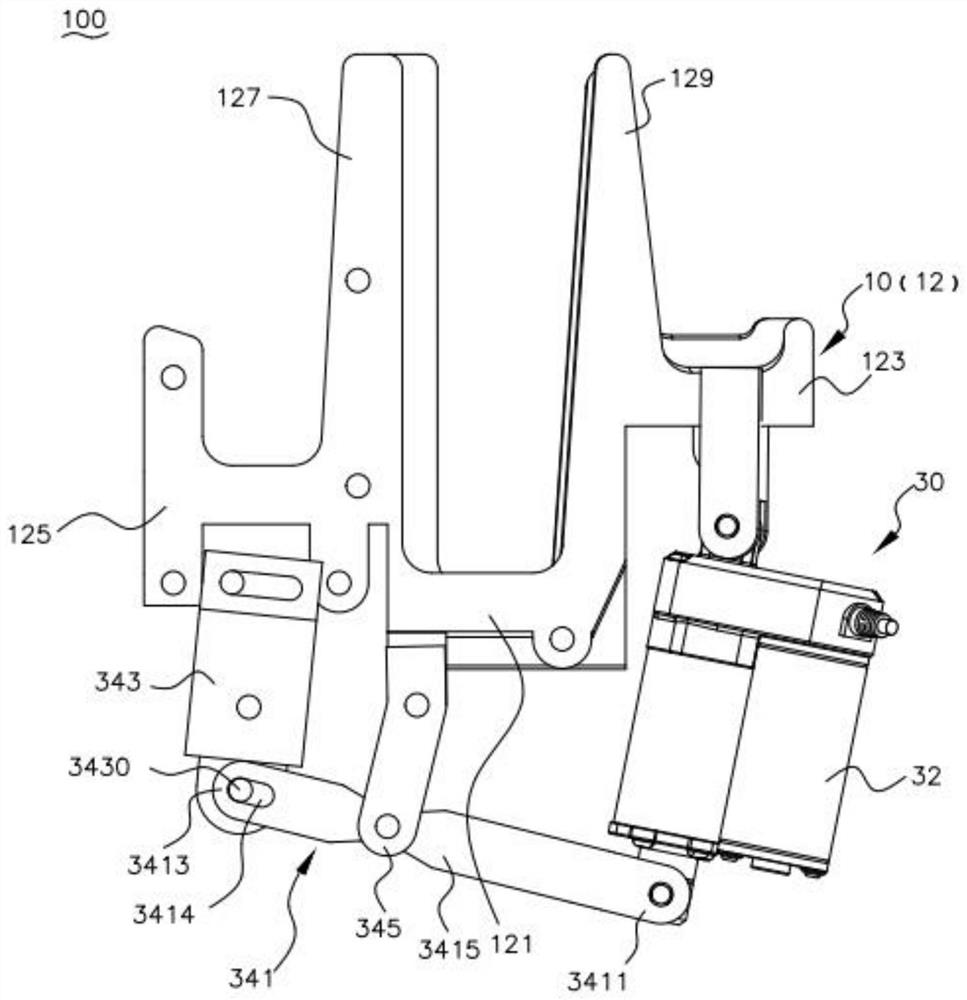

Propeller fixing device and flight equipment

ActiveCN114013231AChange sizeAchieve fixationPropellersAircraft convertible vehiclesPropellerStructural engineering

The invention relates to a propeller fixing device and flight equipment. The propeller fixing device comprises a fixing base, a driving mechanism and a clamping mechanism. The driving mechanism is arranged on the fixing seat, the clamping mechanism is movably connected to the fixing seat and comprises a transmission connecting rod set and a clamping piece, the transmission connecting rod set is connected between the fixing seat and the driving mechanism, the clamping piece is connected to the transmission connecting rod set, the clamping piece and the fixing seat are arranged in a spaced mode, a clamping space suitable for clamping paddles is formed between the clamping piece and the fixing seat, and the transmission connecting rod set is driven by the driving mechanism to drive the clamping piece to move so as to change the size of the clamping space. The flight equipment comprises a flight main body, a propeller and the propeller fixing device, the propeller is rotatably connected to the flight main body, the propeller comprises blades, the blades can be arranged in the clamping space in a penetrating mode when in a static state, and the clamping piece and the fixing base clamp the blades. According to the fixing device, the driving piece drives the transmission connecting rod set and the clamping piece to move, and automatic clamping and fixing of the paddle can be achieved.

Owner:GUANGDONG HUITIAN AEROSPACE TECH CO LTD

Drilling device for aluminum profile machining

PendingCN114192829ARealize automatic clamping and fixingGuaranteed stabilityFeeding apparatusPositioning apparatusMachiningDrilling machines

The invention relates to the technical field of aluminum profile machining, and particularly discloses a drilling device for aluminum profile machining, the drilling device comprises a drilling workbench, a drilling machine and an aluminum profile, a supporting frame is fixed to the top of the drilling workbench, a supporting plate is fixed to the top of the supporting frame, and an air cylinder is fixed to the top of the supporting plate; a power output shaft of the air cylinder movably penetrates through the supporting plate and is fixedly provided with a fixing block, and an ejector rod is arranged on one side of the fixing block. Two cushion blocks are fixed to the bottom of the inner side of the supporting frame. According to the aluminum profile drilling device, the drilling machine can effectively make contact with an aluminum profile and achieve drilling operation through pushing of an air cylinder, in the contact process, an electric telescopic rod can be started, so that a limiting sliding block is pushed to get close to and be tightly attached to the aluminum profile, finally, automatic clamping and fixing of the aluminum profile are achieved, the stability of the aluminum profile is guaranteed, and the production efficiency is improved. And the drilling accuracy of the aluminum profile is improved.

Owner:JIANGSU ZHAOLV METAL PROD CO LTD

Anti-falling equipment for bridge engineering construction

InactiveCN111877155ARealize compression and fixationAvoid Rollover SituationsBridge structural detailsBridge engineeringArchitectural engineering

The invention provides anti-falling equipment for bridge engineering construction, and the equipment comprises an inner side positioning part, a cantilever part, an outer side positioning part and a pressing part; the outer side positioning part can be tightly attached to the outer side surface of an anti-collision wall, and a sliding shaft is installed in the cantilever part in a sliding fit mode; one end of the sliding shaft is inserted into the sliding hole of the cantilever part from one end of the cantilever part towards the inner side of the bridge and is connected with the bottom of thesliding hole through an elastic element, and the other end extends out of the sliding hole and is hinged with the free end of the first hydraulic rod; the outer side positioning part can be tightly attached to the outer side surface of the anti-collision wall, the top end of the outer side positioning part is hinged to the bottom of the cantilever part, and a workbench extending towards the outerside of the bridge is fixed to the bottom end of the outer side positioning part; the workbench extending towards the outer side of the bridge is further fixed to the outer side positioning component, a fence is installed on the upper surface of the workbench, and the pressing component comprises a pressing plate, a rolling wheel, a traction rope and a winch. The equipment is simple in structure,easy to manufacture and use, safe and reliable, and does not influence traffic.

Owner:孙喜军

Cup holders and vehicles

ActiveCN104590078BRealize automatic clamping and fixingAvoid shakingVehicle arrangementsEngineeringMechanical engineering

Owner:GREAT WALL MOTOR CO LTD

Detection device for detecting quality of mechanical parts

PendingCN114871962ARealize automatic movementRealize automatic clamping and fixingWork holdersMechanical componentsGear wheel

The invention discloses a detection device for mechanical part quality detection, which comprises a base and a supporting block, a rotating motor is arranged in the base, the tail end of the output shaft of the rotating motor is fixedly connected with the bottom wall of the supporting block, and the base is also provided with a stabilizing mechanism matched with the supporting block. A power chamber and a transmission chamber communicating with the power chamber are arranged in the supporting block. By arranging the placing block, the placing groove, the clamping plate, the rack, the gear, the double-end threaded rod and other assemblies, after mechanical parts taken out of an assembly line are placed into the placing groove of the placing block, the placing block can be driven to descend relative to the fixing ring under the gravity effect, and the double-end threaded rod can be driven to rotate by means of the toothed plate, the rack and other assemblies; and therefore, automatic clamping and fixing of mechanical parts are achieved through automatic movement of the clamping plates, clamping and fixing can be automatically relieved after the placing block is manually supported, the convenience of the device is improved, and convenience is provided for use of operators.

Owner:江苏庆慈机械制造有限公司

Compression resistance detection device for mechanical part machining

InactiveCN111537341AEasy to operateSave human effortMaterial strength using tensile/compressive forcesPhysicsEngineering

The invention relates to the technical field of mechanical part machining, in particular to a compression resistance detection device for mechanical part machining. The upper side of a detection tableis fixedly connected with a vertically arranged L-shaped frame; and the end, away from the detection table, of the L-shaped frame is fixedly connected with a vertically-arranged first electric telescopic rod, the lower end of the first electric telescopic rod is fixedly connected with an abutting block, a pressure sensor is arranged on the abutting block, and the upper side of the detection tableis fixedly connected with two vertically-arranged fixing plates. In the present invention, by arranging a clamping mechanism, automatic clamping and fixing of mechanical parts can be achieved; the detection device is more convenient to operate, more labor-saving, firmer in fixation and more accurate in detection data; a second electric telescopic rod is arranged, and the distance between the twoclamping devices can be adjusted according to the specifications of the mechanical parts, so that the mechanical parts with different specifications can be clamped and fixed, and the application rangeof the detection device is widened.

Owner:周巧美

A biomedical metal plate grinding device

ActiveCN107052923BImprove grinding efficiencyAchieve clampingGrinding work supportsPlane surface grinding machinesEngineeringMechanical engineering

The invention discloses a biomedical metal plate polishing device comprises a seat, a polishing structure and a frame. The frame comprises frame columns and top beam. The frame columns are arranged in a front-back opposite mode. The top beam is fixed between the tops of the frame columns. The seat is arranged between the bottoms, below the top beam, of the frame columns. A first sliding conveying groove extending front and back is formed in the bottom face of the top beam. A first spiral rod is extending front and back is arranged in the first sliding conveying groove. A first sliding conveying block is connected to the first spiral rod in a matched mode. The bottom of the first sliding conveying block is fixedly connected with the top end of the polishing structure. A conveying cavity is formed in the polishing structure. A connecting cavity communicates with the bottom of the conveying cavity. A disc is arranged on the rear side wall of the polishing structure. The biomedical metal plate polishing device is simple in structure, reasonable in design, low in manufacturing cost and maintenance cost, capable of adjusting a polishing position in a multidirectional mode, convenient to operate, capable of achieving automatic telescopic left and right polishing, high in safety, and capable of automatically clamping and fixing a metal plate and improving polishing stability.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

A Forging Process of Difficult-to-Deform Superalloy Slabs

ActiveCN110802189BRealize automatic clamping and fixingHeating evenlyForging press detailsSuperalloyHigh heat

The invention discloses a hard-to-deform superalloy slab forging process, comprising the following steps: A, heating the slab to 975-1005°C, and keeping it warm for 1-2 hours; B, putting the slab into a forging press for forging, forging The pressing speed is 5-10mm / min; C. When the forging deformation reaches 70% of the standard value, take out the slab and reheat it to 850-910°C, and keep it warm for 3-5 hours; D. Put the slab back into the forging press Forging is carried out in the machine, and the forging pressing speed is 1-3mm / min until the forging is completed. The invention can improve the deficiencies of the prior art and realize the low-temperature forging of the difficult-to-deform superalloy.

Owner:AVIC SHANGDA METAL REGENERATION TECH

High-strength motorbike steel back processing device with barb structure

InactiveCN111890106ARealize automatic clamping and fixingImprove stabilityPositioning apparatusMetal working apparatusEngineeringWorkbench

The invention discloses a high-strength motorbike steel back processing device with a barb structure. The high-strength motorbike steel back processing device with the barb structure comprises a shell, a feeding port, a conveying apparatus, a barb machine, a workbench, a clamping apparatus and an unloading claw; the clamping apparatus comprises a guiding mechanism, a limiting block, a first spring, an adsorption disc and a clamping mechanism; the limiting block is embedded on the workbench in a mode of being capable of moving up and down, and a side, opposite to the guiding mechanism, of the limiting block is an inclined plane; and the adsorption disc is located at a middle point of the workbench. According to the high-strength motorbike steel back processing device with the barb structure, a steel back blank is placed on the conveying apparatus through the feeding port, and then, a position of the steel back blank is automatically corrected on the conveying apparatus; further, the steel back blank is pushed onto the workbench through the guiding mechanism; then, under simultaneous effect of the clamping mechanism and the adsorption disc, the steel back blank is fixed on the workbench, and a steel back is barbed one time through the barb machine; and working efficiency is improved, meanwhile, a clamping effect is improved through the simultaneous effect of the clamping mechanism and the adsorption disc, stability of the steel back is increased further, and quality of barbing is improved.

Owner:浦江搏纳汽车零部件有限公司

High-efficiency biomedical metal plate polishing device

ActiveCN107685263AImprove grinding efficiencyAchieve clampingGrinding carriagesGrinding work supportsCircular discEngineering

The invention discloses a high-efficiency biomedical metal plate polishing device. The high-efficiency biomedical metal plate polishing device comprises a base body, a polishing structure and a frame.The frame comprises frame columns which are oppositely arranged front and back and a top beam fixed between the tops of the frame columns. The base body is arranged between the bottoms of the frame columns under the top beam. The bottom face of the top beam is internally provided with a first sliding and conveying groove which extends front and back. The first sliding and conveying groove is internally provided with a first spiral rod which extends front and back. The first spiral rod is connected with a first sliding and conveying block in a cooperated manner. The bottom of the first slidingand conveying block is fixedly connected with the top end of the polishing structure. The polishing structure is internally provided with a conveying cavity, the bottom of the conveying cavity is provided with a connection cavity in a communicating manner, and the rear side wall of the polishing structure is provided with a disk. The high-efficiency biomedical metal plate polishing device is simple in structure, reasonable in design, low in manufacturing cost and maintaining cost, capable of achieving multidirectional adjustment of polishing positions, convenient to operate, capable of achieving automatic extensible and retractable polishing on left and right, high in safety and capable of achieving automatic clamping and fixing of metal plates, and the polishing stability is improved.

Owner:MA SHIRUI BIOTECHNOLOGY JIANGSU CO LTD

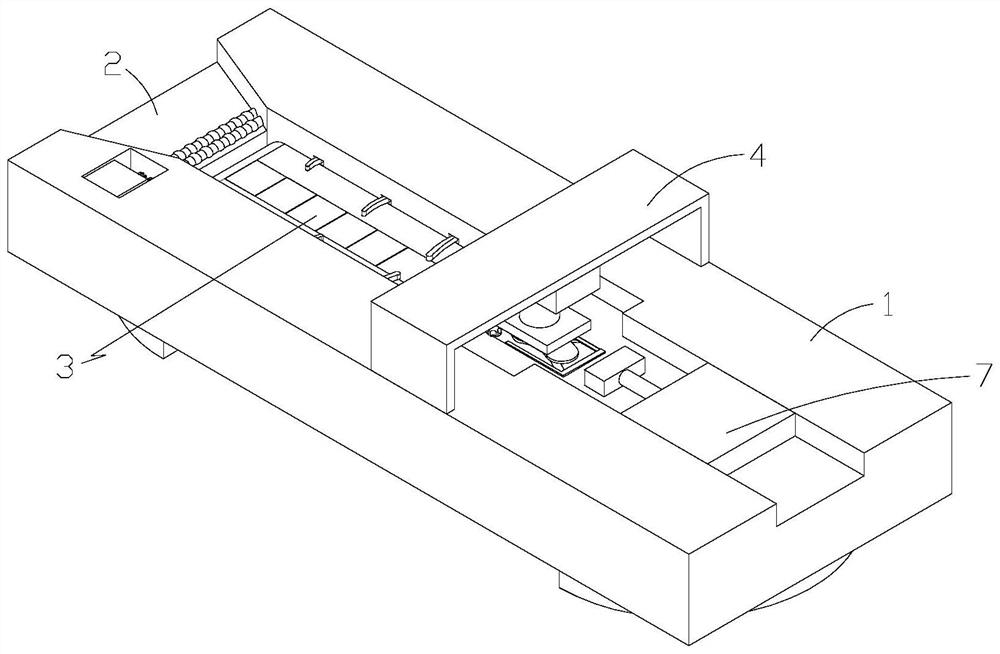

Automatic clamp tool assembly for steering knuckle master pin machining

PendingCN114654279ARealize automatic clamping and fixingRealize linkage clampingWork clamping meansPositioning apparatusEngineeringKingpin

The invention discloses an automatic clamp tool assembly for steering knuckle master pin machining, which comprises a machining table, mounting seats fixedly mounted on two sides of the upper part of the machining table, and a rotary automatic clamp mounted between the two mounting seats, and the rotary automatic clamp comprises a rotating body and more than two groups of master pin fixing pieces; the master pin fixing part comprises a master pin placing and fixing groove, an automatic locking block, a locking rod and a driving device, fixing openings are formed in the master pin placing and fixing groove, the automatic locking block is arranged between every two adjacent fixing openings in a matched mode, and the locking rod drives the automatic locking block to clamp a master pin body located in the master pin placing and fixing groove in the transverse direction. The cylinder is used for driving the lock rod and driving the automatic locking block to automatically clamp the master pins, automatic clamping and fixing can be achieved, linkage clamping can be achieved, all master pins placed in the fixing grooves are simultaneously clamped and fixed in a linkage mode at a time, the fixing efficiency is improved, follow-up machining is facilitated, and the machining precision is guaranteed.

Owner:福建冠维汽车零部件有限公司

Clamping device for television display screen detection

InactiveCN112518615AReduce frictionReduce collisionWork holdersDielectric plateMechanical engineering

The invention relates to the technical field of televisions, and discloses a clamping device for television display screen detection. The device comprises a base, wherein a movable groove is formed inthe top of the base, a supporting column is fixedly connected to the top of the base, a placement plate is movably connected to the top of the supporting column, a piston is movably connected to theinterior of the placement plate, the outer side of the piston is movably connected to a movable rod, the outer side of the movable rod is movably connected to a moving device, and the inner side of the moving device is movably connected to a contact block. According to the clamping device for television display screen detection, through the characteristics of an electrorheological fluid, when a dielectric plate moves towards the outer side, a current is generated between a positive plate and a negative plate, so that the electrorheological fluid is converted from liquid to solid, a display screen on the inner side is fixed, friction and collision between the screen and a fixing groove are reduced, loss is avoided, the production and maintenance cost is reduced, the operation is convenient,the time is saved, and the detection efficiency is improved.

Owner:南京樊冠商贸有限公司

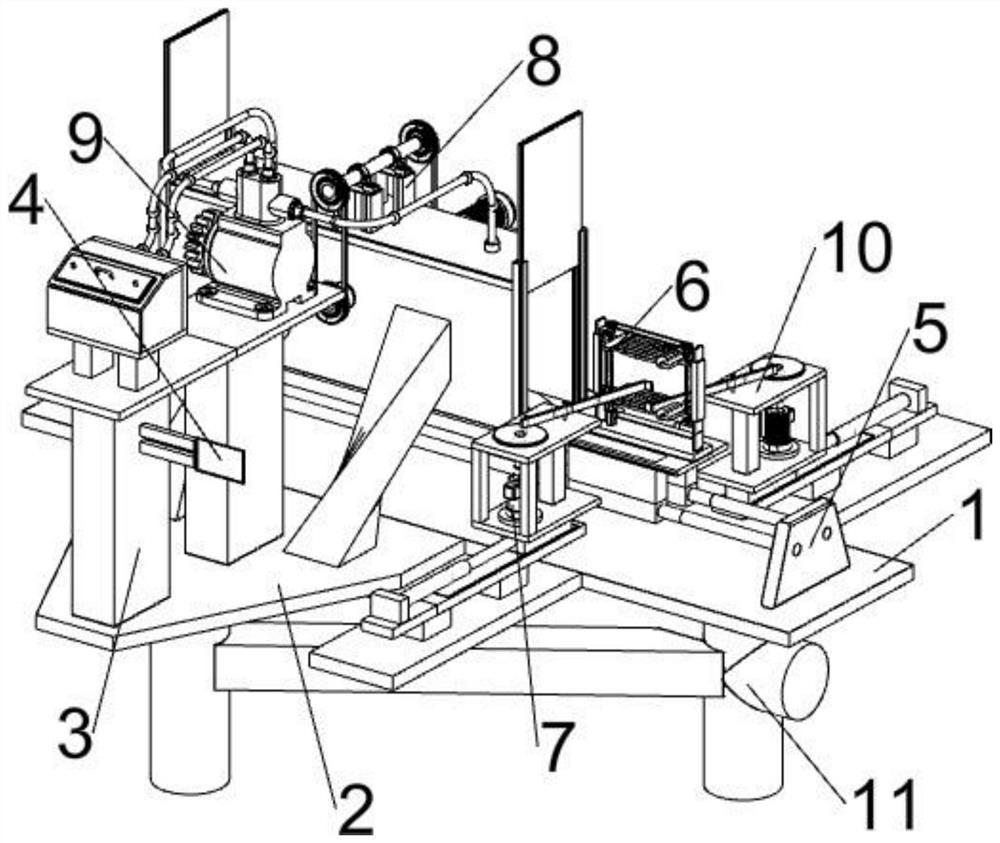

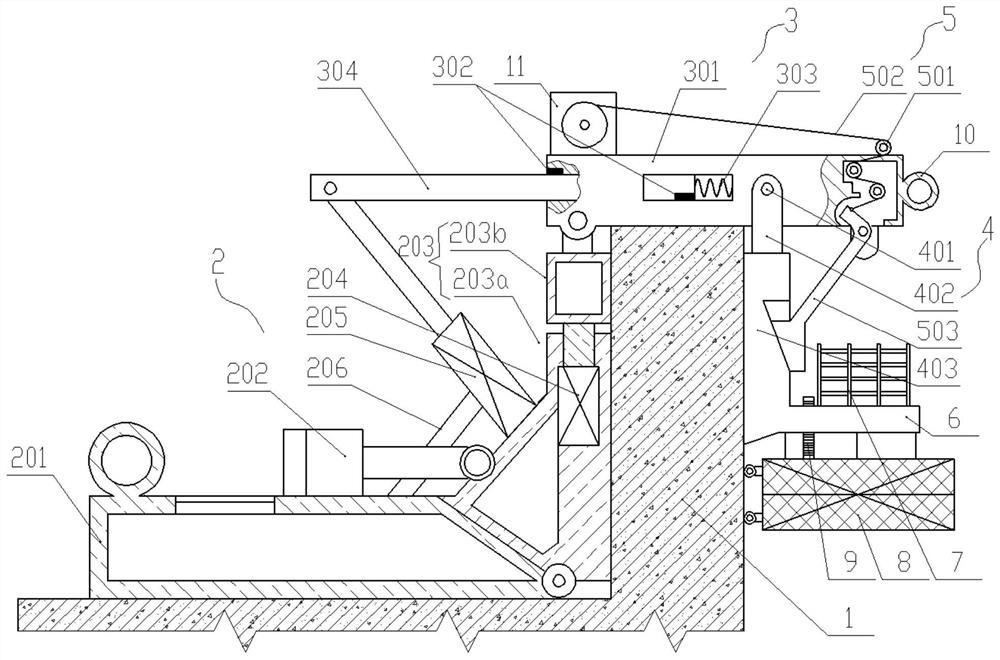

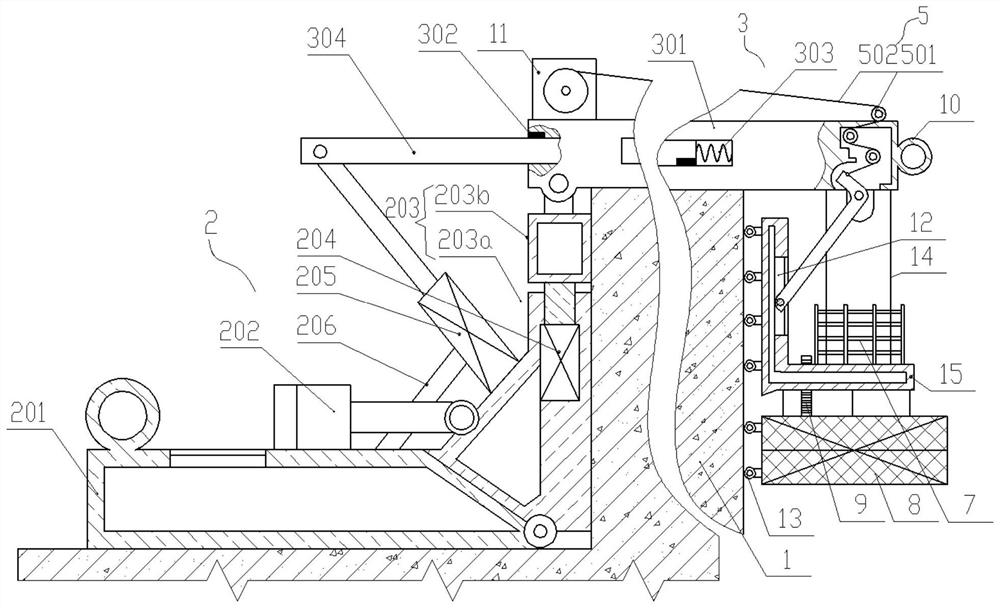

Progressive feeding and automatic clamping combined wood sawing and splitting device

InactiveCN113021534AEnsure personal safetyRun orderlyWood splittingFeeding devicesMan machineElectric machinery

The invention discloses a progressive feeding and automatic clamping combined wood sawing and splitting device. The device comprises a workbench and a motor, a progressive feeding mechanism, a wood sawing mechanism, a conveying turning mechanism and a splitting mechanism are arranged on the workbench, the progressive feeding mechanism comprises a U-shaped support, a hinge is arranged at the upper portion of the rear end of the U-shaped support, a hook-shaped feeding mechanism is arranged on the hinge, a first hydraulic rod is arranged between the rear portion of the hook-shaped feeding mechanism and the U-shaped support, a plurality of storage protruding blocks are arranged at the upper portions of the front end and the rear end of the U-shaped support in a matrix manner, supporting transverse rods are arranged at the left end and the right end of the inner bottom of the U-shaped support, and supporting columns are arranged on the supporting transverse rods. An L-shaped rotating rod is arranged in the top ends of the supporting columns, automatic clamping and fixing are achieved, wood is sawn, a semi-automatic manual wood sawing manner is replaced, manual operation is omitted, man-machine separation is achieved, the personal safety of workers is guaranteed, time and labor are saved, and automatic wood sawing operation does not need to consume manpower.

Owner:陈凯帝

Reagent card structure suitable for automatic and manual clamping

PendingCN113752172AGood practical effectThe overall structure is simpleWork holdersElectric machineryEngineering

The invention discloses a reagent card structure suitable for automatic and manual clamping. The reagent card structure comprises a base, supporting columns are welded and installed at the two sides of the upper portion of the base, a working plate is welded and installed on the upper portions of the supporting columns, a motor is installed at one side of the upper portion of the working plate through screws, and the output end of the motor is provided with a threaded rod through a coupler in a connected manner; a movable seat is mounted on the threaded rod in a sleeving manner, a fixed seat is mounted at the right side of the movable seat and on the working plate in a welding manner, a group of clamping claws are mounted on the end surfaces, close to each other, of the fixed seat and the movable seat, a reagent card fixing structure is mounted between the group of clamping claws, and a group of clamping arms are mounted on the upper part of the movable seat in a welding manner; and a first spring is welded and fixed between the clamping arms at the front side and the rear side, and the reagent card fixing structure is in a concave shape. The reagent card structure is reasonable in structural design, and the structure for automatically and manually clamping reagent cards is achieved.

Owner:无锡天纵易骏生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com