A Forging Process of Difficult-to-Deform Superalloy Slabs

A high-temperature alloy, hard-to-deform technology, applied in the field of metallurgy, can solve problems such as poor plasticity and difficult processing, achieve the effects of simple structure, improve distribution uniformity, and avoid small-angle shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

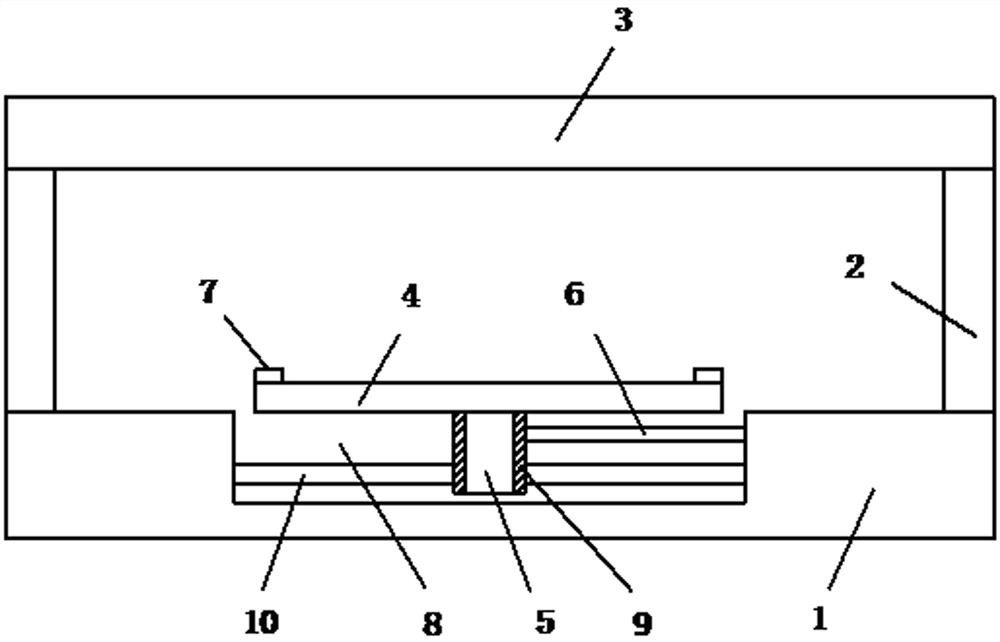

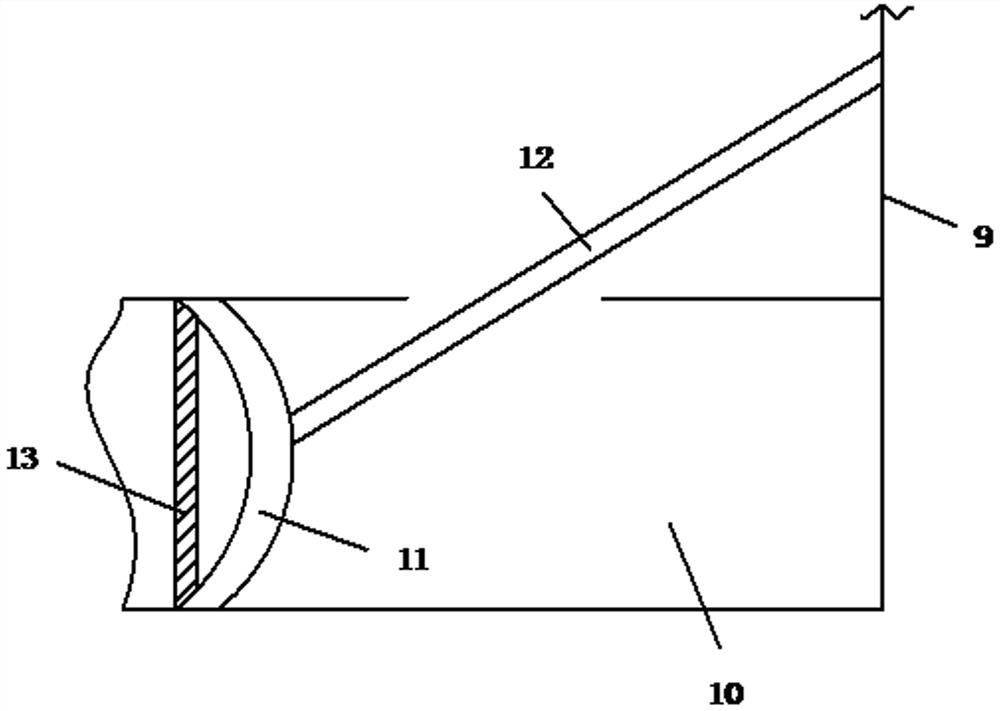

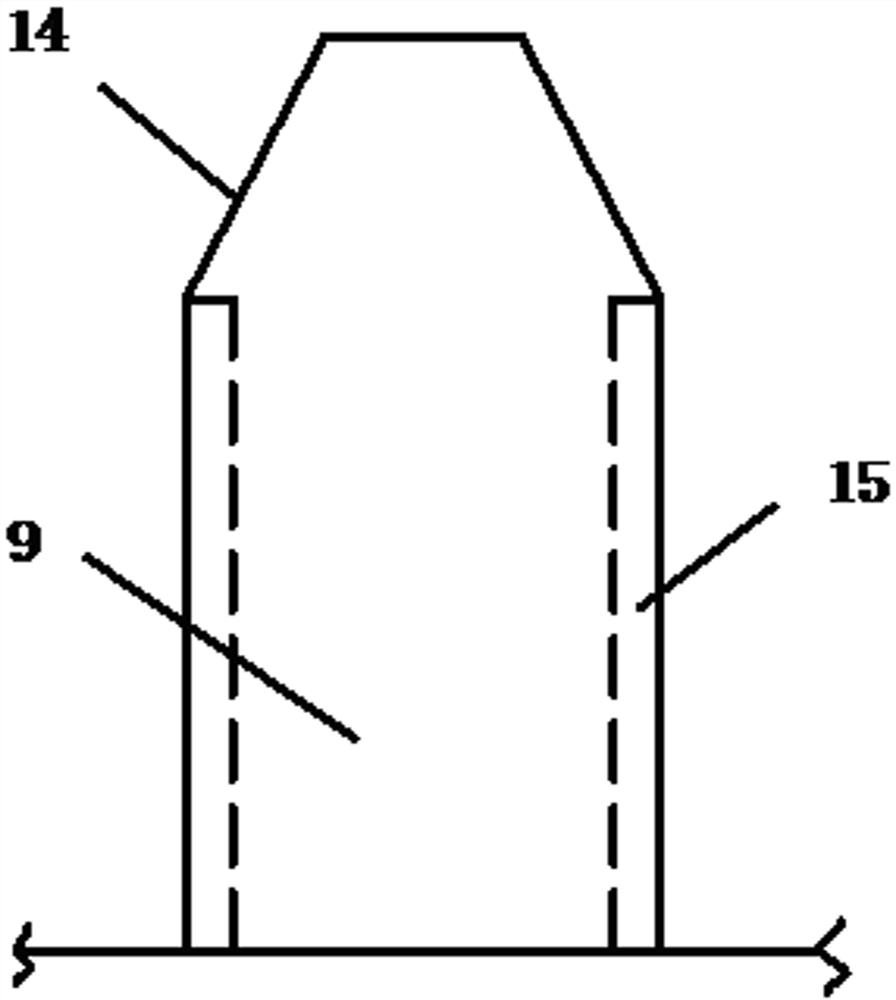

Method used

Image

Examples

specific Embodiment approach

[0021] A specific embodiment of the present invention comprises the following steps:

[0022] A. Heat the slab to 995°C and keep it warm for 2 hours;

[0023] B. Put the slab into the forging press for forging, and the forging pressing speed is 6mm / min;

[0024] C. When the forging deformation reaches 70% of the standard value, take out the slab and reheat it to 880°C for 4 hours;

[0025] D. Put the slab back into the forging press for forging, the forging pressing speed is 3mm / min, until the forging is completed.

[0026] The thickness of the slab is 65mm, and the slab comprises the following components,

[0027] 0.02wt% C, 4.5wt% Fe, 5wt% Al, 7wt% Ti, 12wt% W, 13wt% Co, 7wt% Cr, 0.5wt% Mn, 2.5wt% Mo, and The amount is Ni.

[0028] In step A, the temperature is first raised to 750°C at a rate of 75°C / min, then kept at a temperature of 15 minutes, and then raised to the set temperature.

[0029] In step C, the initial temperature rise rate is 50°C / min, and the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com