Compression resistance detection device for mechanical part machining

A technology of mechanical parts and detection devices, which is applied in the field of mechanical parts processing, can solve problems that affect the accuracy of detection data, fixation is not firm enough, troublesome operation, etc., and achieve the effects of saving manpower, improving the scope of application, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

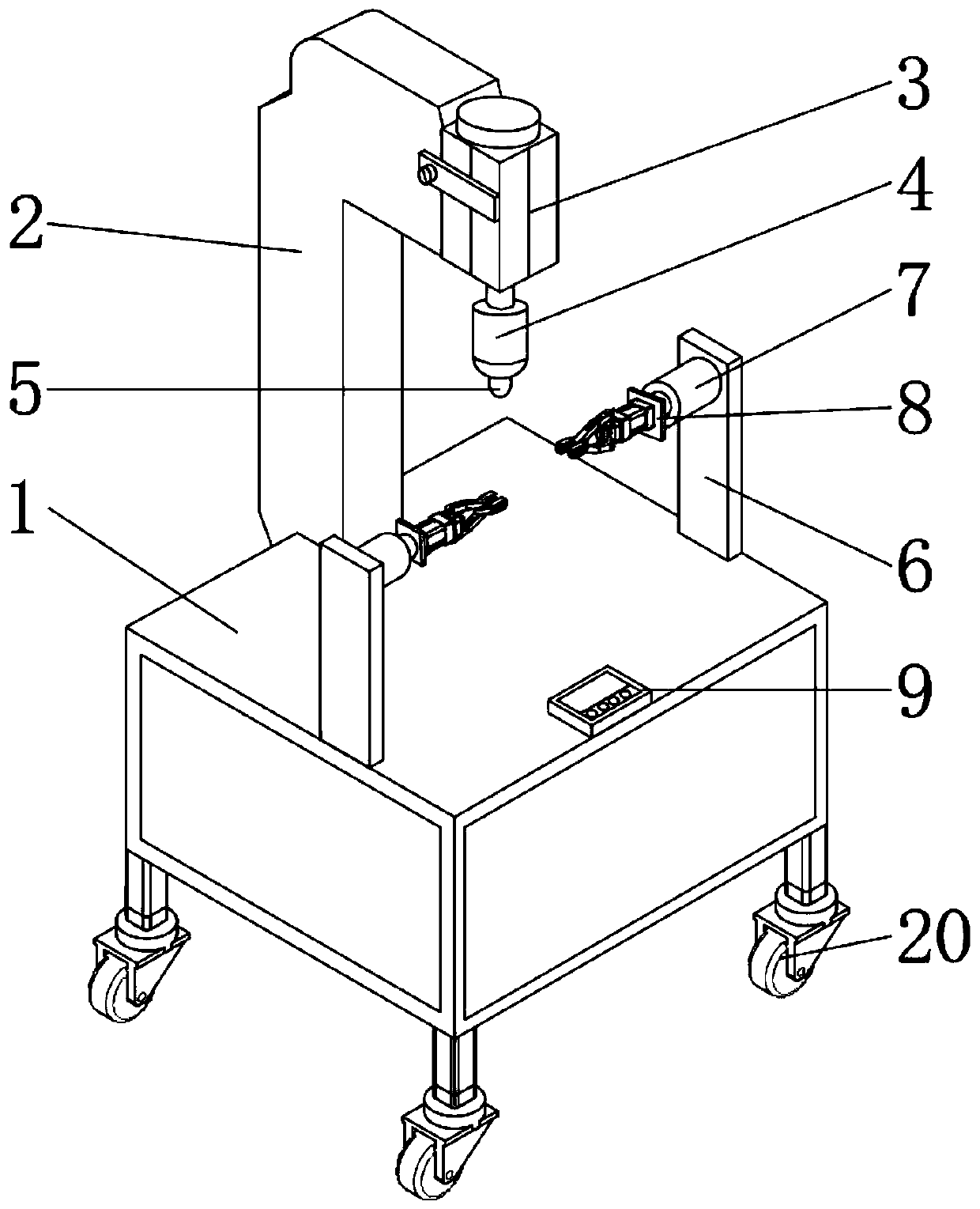

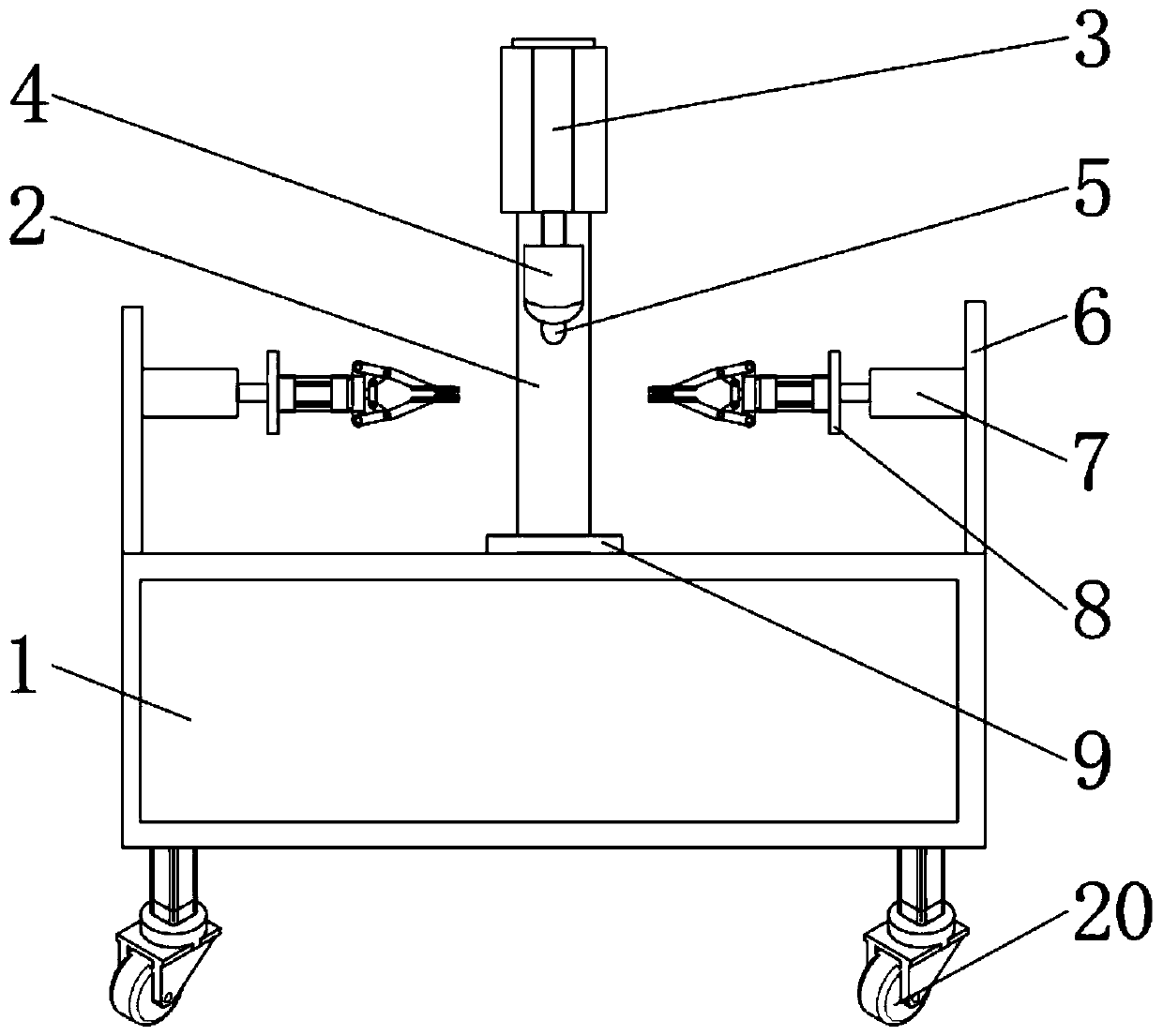

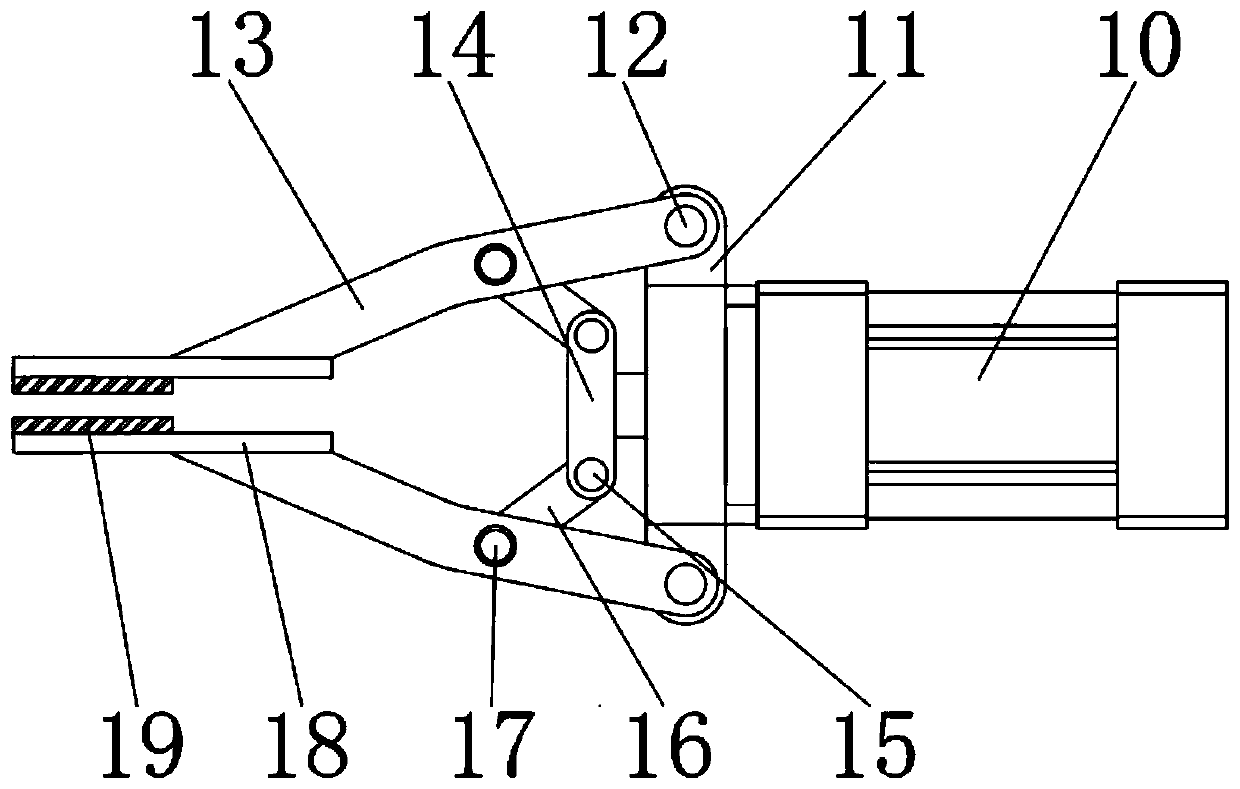

[0018] see Figure 1~3 , in the embodiment of the present invention, a kind of anti-pressure detection device that is used for the machining of mechanical parts, comprises detection table 1, and the upper side of detection table 1 is fixedly connected with the L-shaped frame 2 that vertically arranges, and L-shaped frame 2 is away from One end of the detection platform 1 is fixedly connected with a vertically arranged first electric telescopic rod 3, and the lower end of the first electric telescopic rod 3 is fixedly connected with a pressure block 4, and a pressure sensor 5 is arranged on the pressure block 4, and the first electric telescopic rod 3 is started. The electric telescopic rod 3 pushes the pressing block 4 to move down, and is pressed against the mechanical parts until it is squeezed, deformed or broken. The upper side of the detection table 1 is fixedly connected with two vertically arranged fixed plates 6, and the two fixed plates 6 are opposite to each other. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com