Granite ore treatment device

A technology for ore processing and granite, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve problems such as high iron content, lung disease pneumoconiosis, and uneven shape of granite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

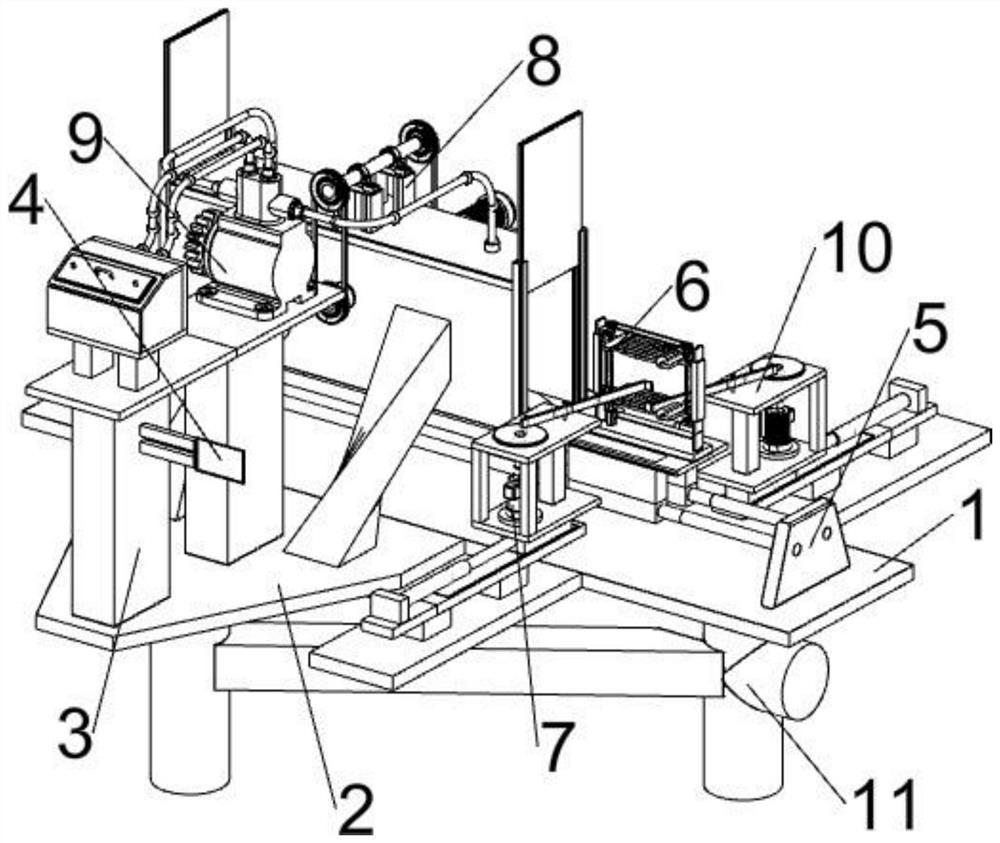

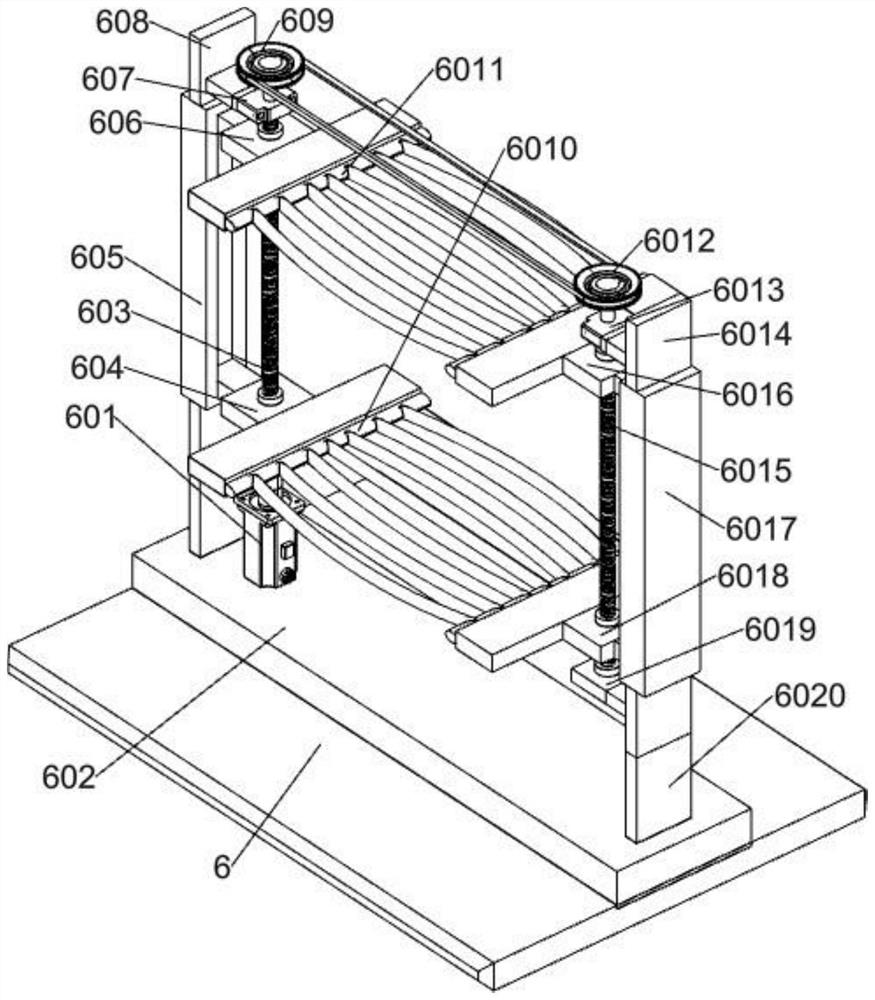

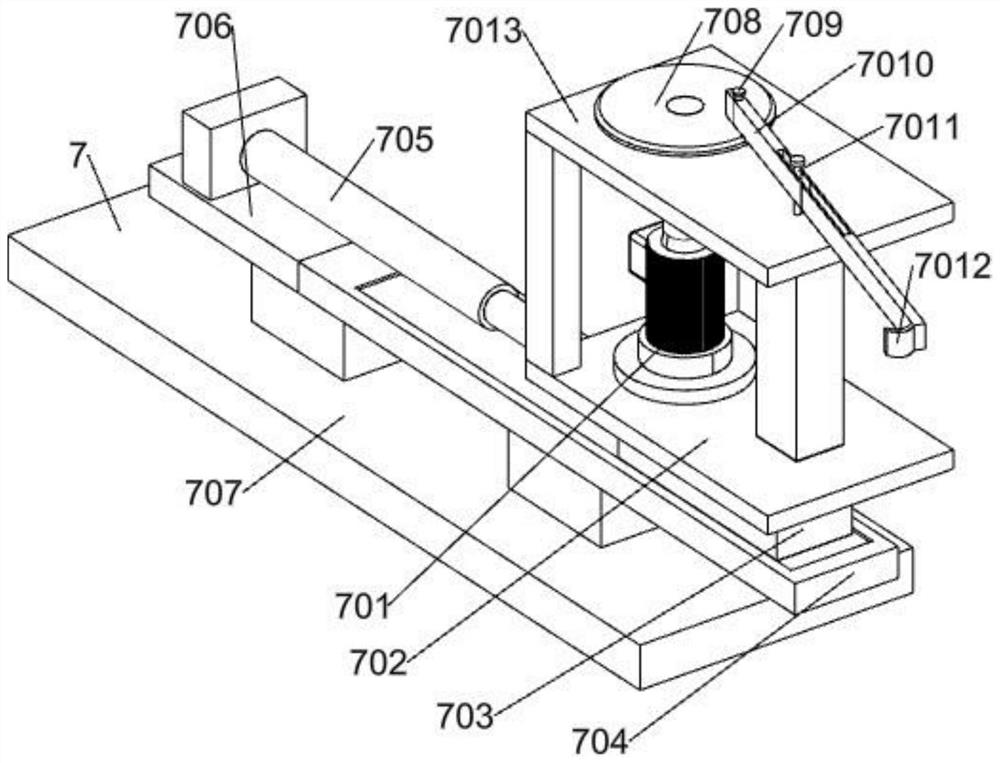

[0030] A granite ore processing device, such as Figure 1-8 As shown, it includes a machine assembly board 1, a first side machine board 2, an elevated platform column 3, a real-time control panel 4, a long-distance transmission electric slide rail 5, a clamping movement control mechanism 6, and a first toggle reversing mechanism 7 , a closed cutting mechanism 8, a stone powder processing mechanism 9, a second toggle reversing mechanism 10 and a tripod chassis 11; the lower part of the machine tool assembly plate 1 is welded to the tripod chassis 11; the machine tool assembly plate 1 is welded to the first side machine tool plate 2 One side of the machine tool assembly board 1 is connected with the first toggle reversing mechanism 7, and the other side of the machine tool assembly board 1 is connected with the second toggle reversing mechanism 10; the top of the machine tool assembly board 1 is connected with the long distance transmission electric slide The rail 5 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com