a lift

A lift and lift plate technology, applied in the field of lifts, can solve problems such as wheel and axle slippage, safety accidents, slippage, etc., and achieve the effects of avoiding slippage, avoiding slippage, and simplifying operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

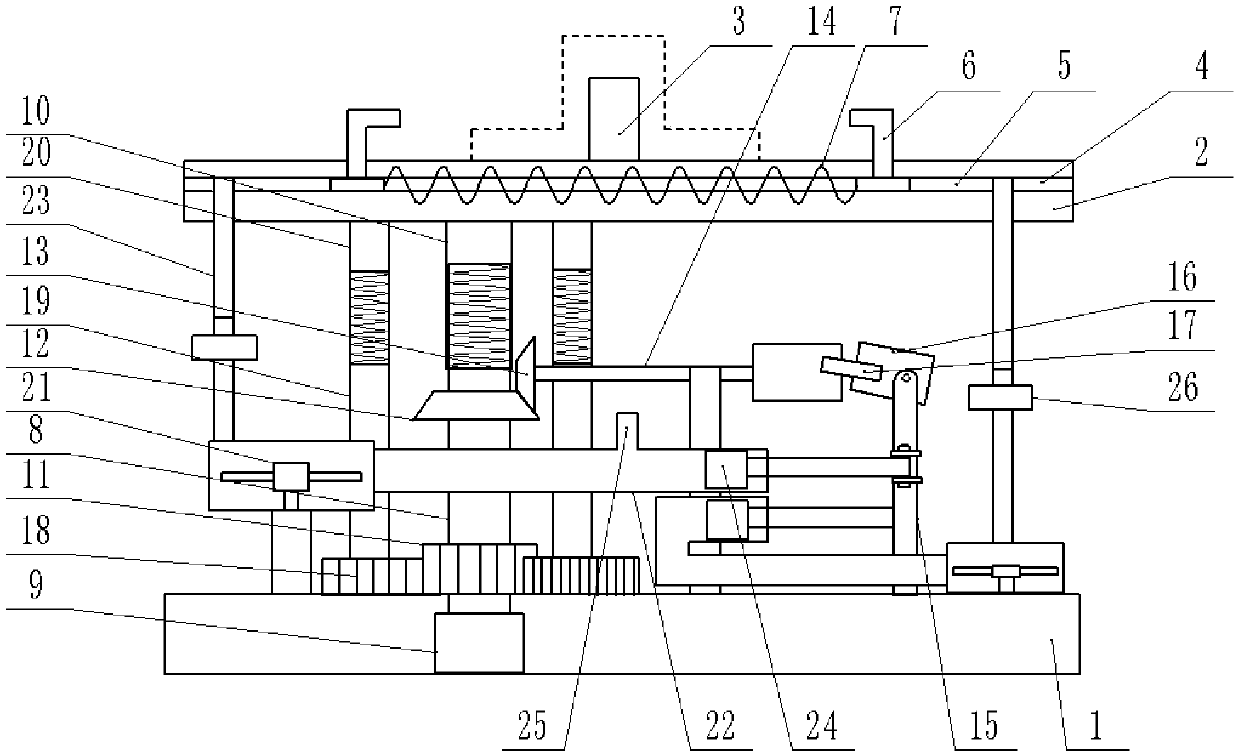

[0016] The reference signs in the accompanying drawings of the specification include: machine table 1, lifting plate 2, positioning shaft 3, chute 4, inflation tube 5, chuck 6, spring 7, column 8, motor 9, main sliding sleeve 10, driving gear 11. First bevel gear 12, second bevel gear 13, rotating shaft 14, vertical shaft 15, swing head 16, support arm 17, driven gear 18, support rod 19, auxiliary sliding sleeve 20, fan 21, air inlet pipe 22 , air outlet pipe 23, piston 24, air inlet 25, pipe clip 26.

[0017] The embodiment is basically as figure 1 Shown: a lift, including a machine platform 1, a lifting plate 2 is slidably connected to the machine platform 1, and an integrated positioning shaft 3 is provided on the upper end of the lifting plate 2, and a column 8 and a vertical shaft 15 are connected to the machine platform 1 through bearing rotation , the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com