Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102results about How to "Prevent material leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

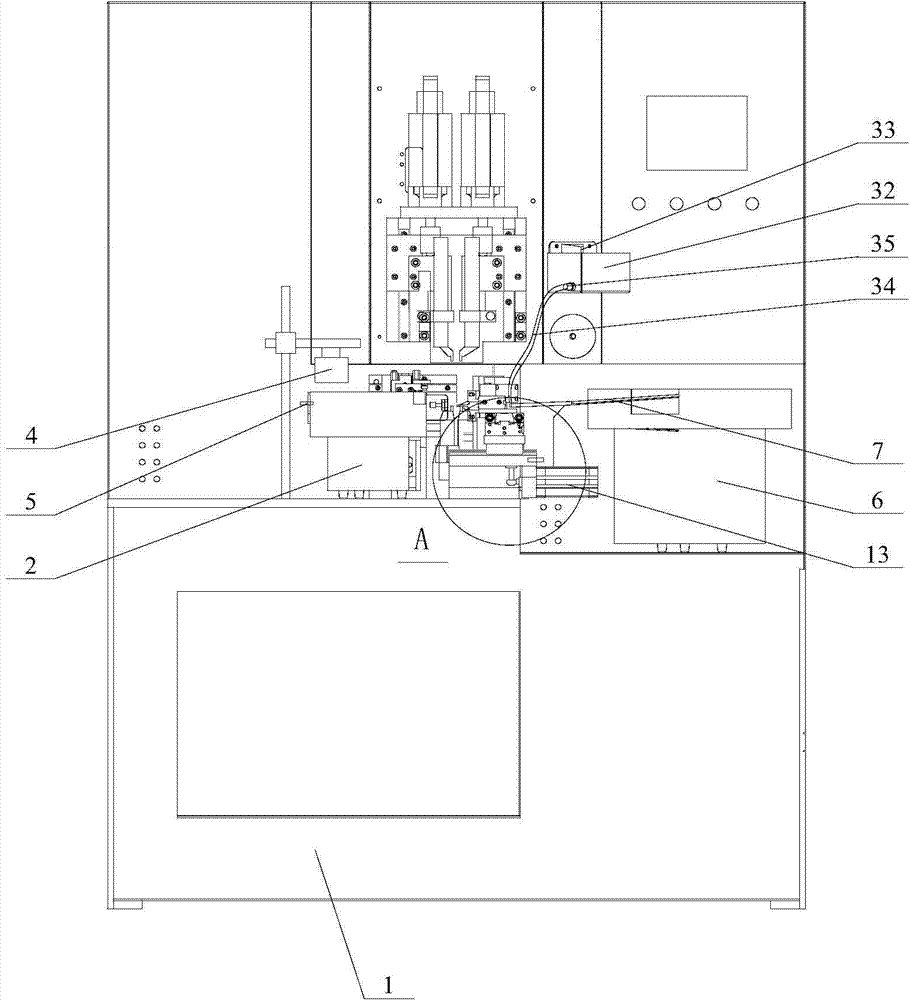

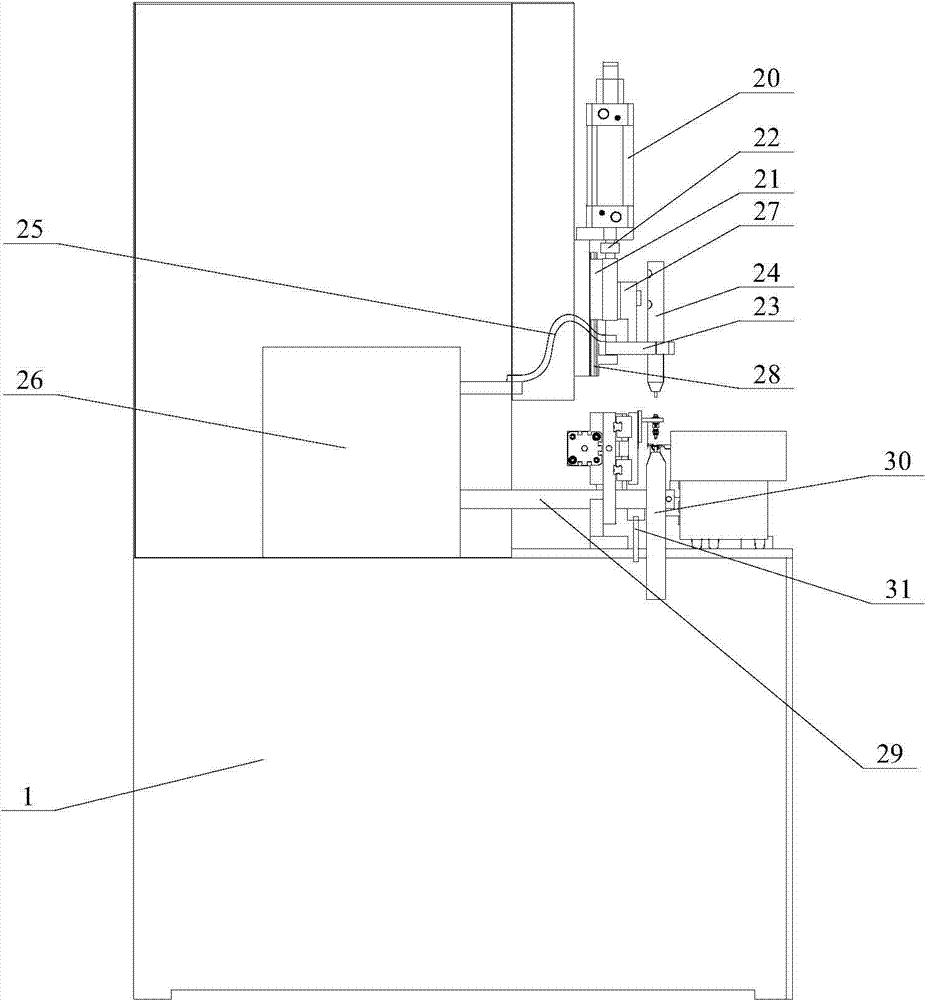

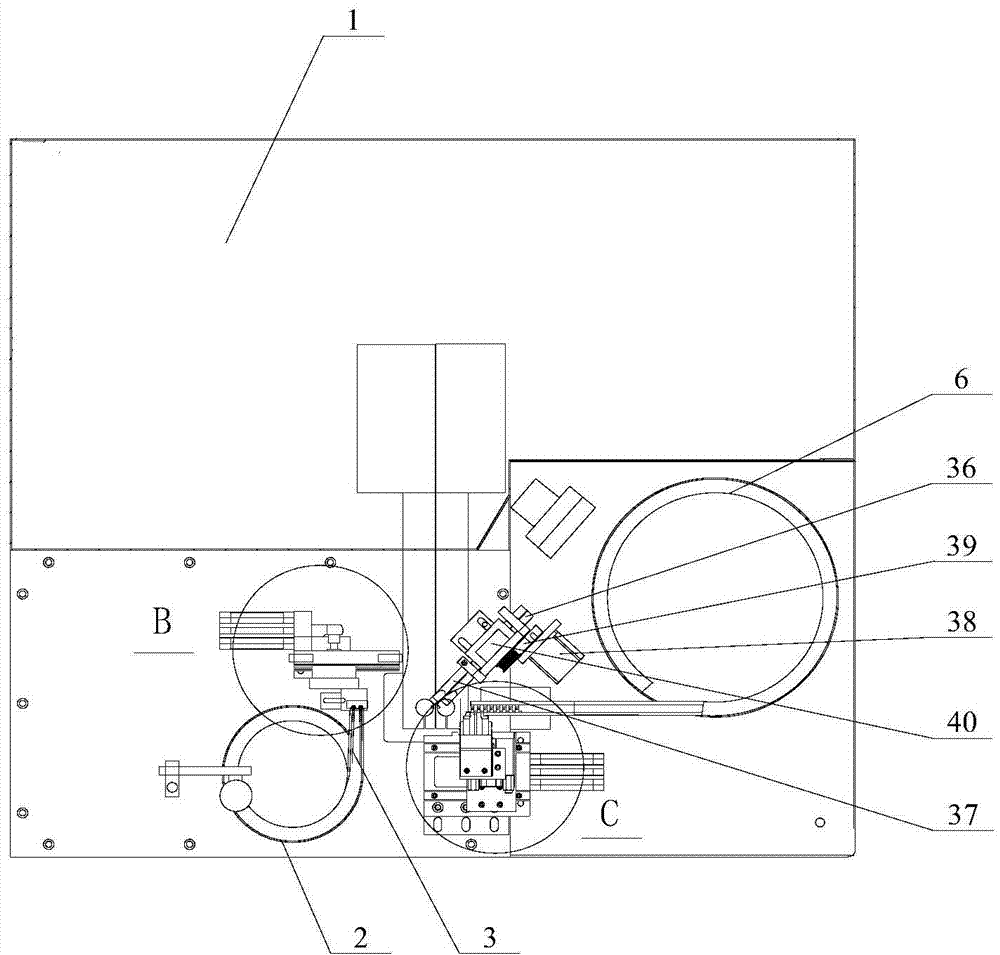

Full-automatic spot welding machine

InactiveCN104493350AGuaranteed uptimeReasonable structural designResistance welding apparatusAutomatic controlControl system

The utility model discloses a full-automatic spot welding machine which comprises a spot welding machine body, a first material distributing device, a second material distributing device, a first feeding device, a second feeding device, a welding device, a flux adding device, a tin belt adding device and a control system, wherein the control system comprises a control panel arranged on the spot welding machine body, and the control system controls the running or stopping of the full-automatic spot welding machine by controlling the control panel. The full-automatic spot welding machine is reasonable in structural design and adopts full-automatic control, effectively avoids material blocking and material leakage through a sensor, and can meet normal and stable running, so that high production efficiency, good stability and high welding quality are ensured, and full-automatic welding for small accessories such as contactors, contact pieces, small electrical accessories and artware can be realized.

Owner:张校阳

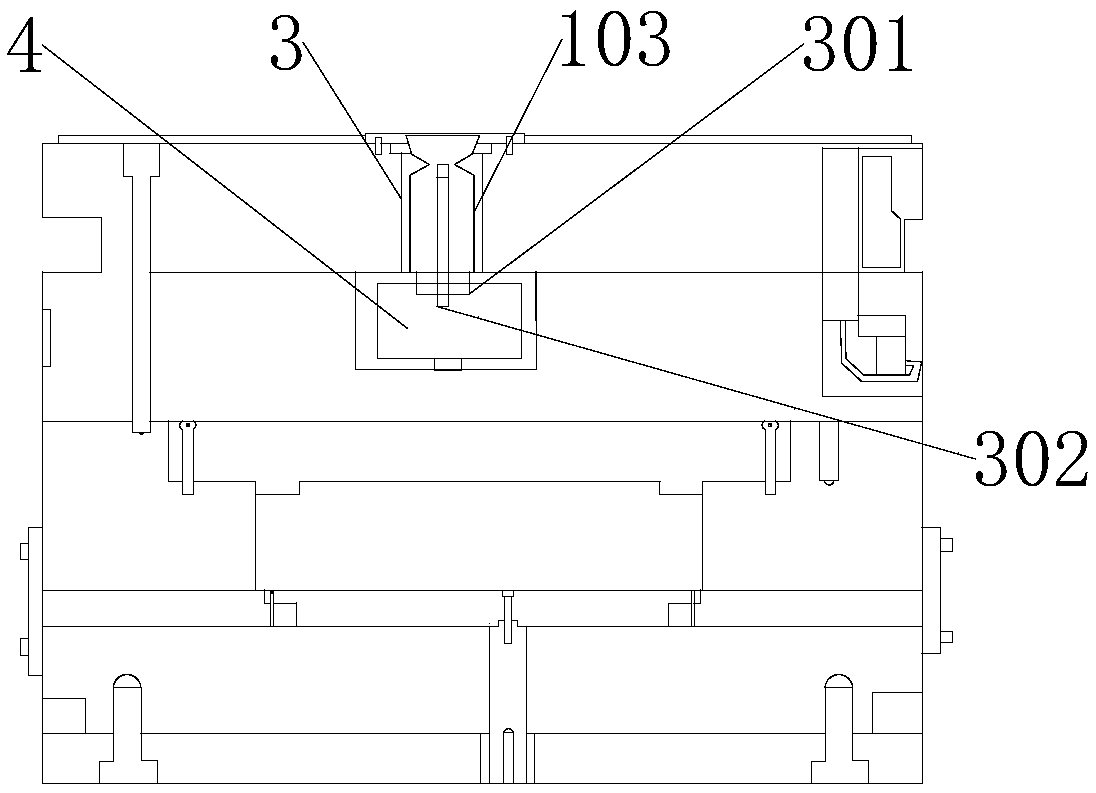

Battery jar and battery cover hot runner plastic mold for storage battery

PendingCN108638446AWon't happenAvoid it happening againDomestic articlesHot runnerTemperature control

The invention discloses a battery jar and battery cover hot runner plastic mold for a storage battery. The mold comprises a mold main body; a heating system is arranged inside the mold main body; anda movable interface is arranged in the mold main body and is fixedly connected to the mold main body through screws. The battery jar and battery cover hot runner plastic mold for the storage battery adopts a hot runner plastic mold, a temperature control cabinet is arranged and has the over-high temperature warning function and the automatic adjusting function, the temperature in an integral hot runner system can be effectively adjusted through the temperature control cabinet, so that the temperature change of a solution body can be controlled within the required precision range, raw materialsremaining inside the mold cannot be cooled and can be prevented from being crushed by crushing equipment again, no dust can be generated on a production site, occupational injuries to staff can be avoided, environmental pollution can be avoided, and therefore the environmental protection effect can be achieved.

Owner:苏州优耐富自动化设备有限公司

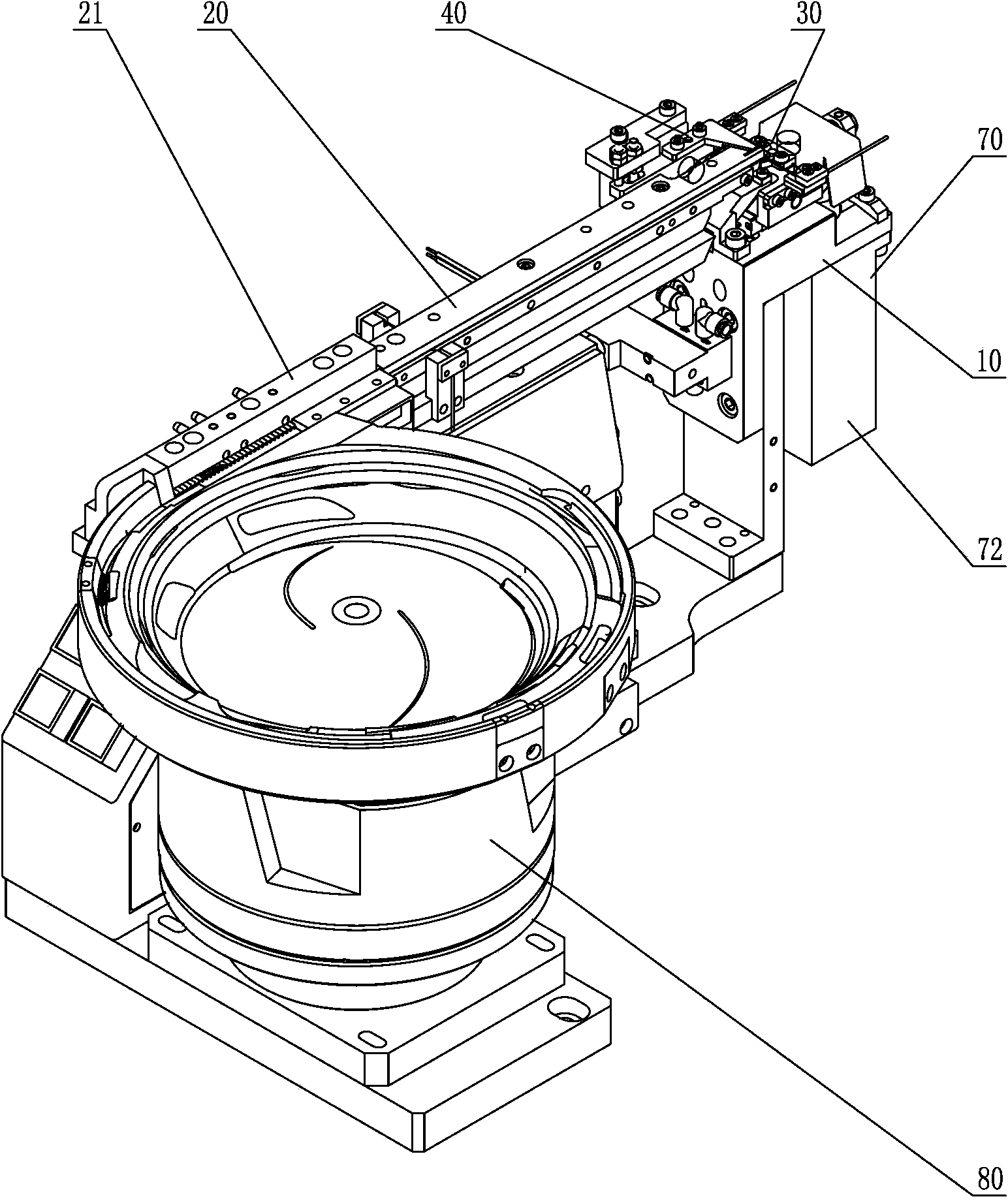

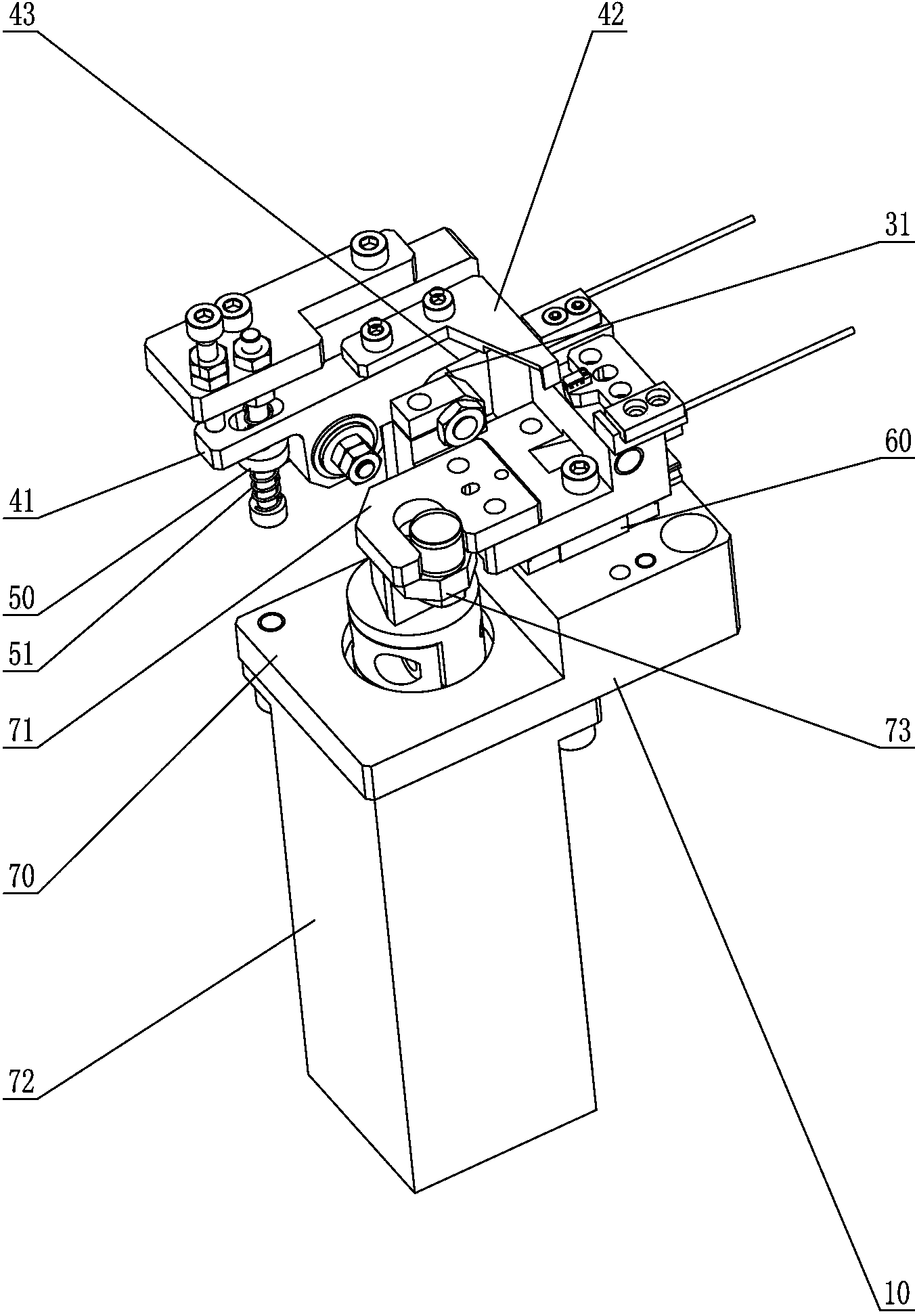

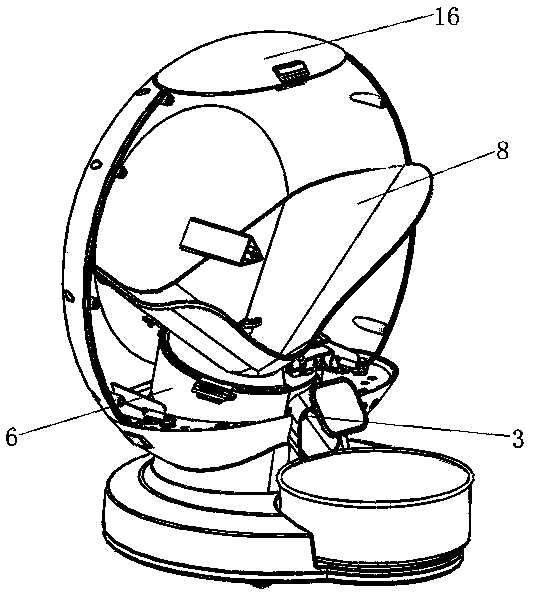

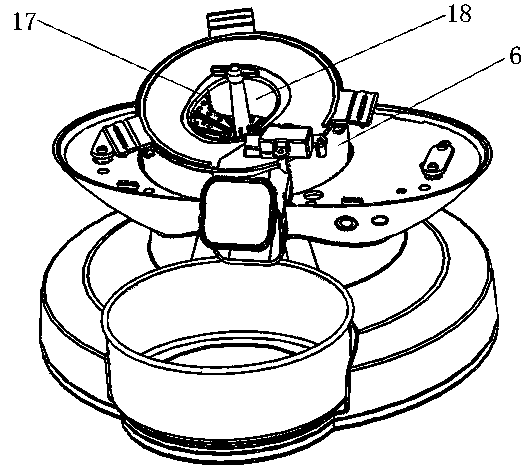

Feeding apparatus

ActiveCN104114015ASolve the bottleneck problem of production and processing efficiencyImprove feeding efficiencyElectrical componentsEngineeringMagnet

The invention discloses a feeding apparatus. The feeding apparatus comprises a pedestal, a channel connected with the pedestal, a material fixing mechanism which is arranged at one end of the channel and can horizontally move relative to the channel, and a material blocking mechanism which is used for blocking materials in the channel. The material blocking mechanism comprises a swing block and a blocking sheet connected with the swing block. The swing block comprises a guide surface. The material fixing mechanism further comprises a roller which is contacted with and cooperates with the guide surface. The feeding apparatus further comprises a vibration disc arranged at the other side of the channel. One side, which is close to the vibration disc, of the channel is provided with a magnet. The feeding apparatus with such a structure can rapidly separate the multiple materials which are tidily arranged in the channel and are closely attached and send the materials to a next processing station.

Owner:深圳市复德科技有限公司

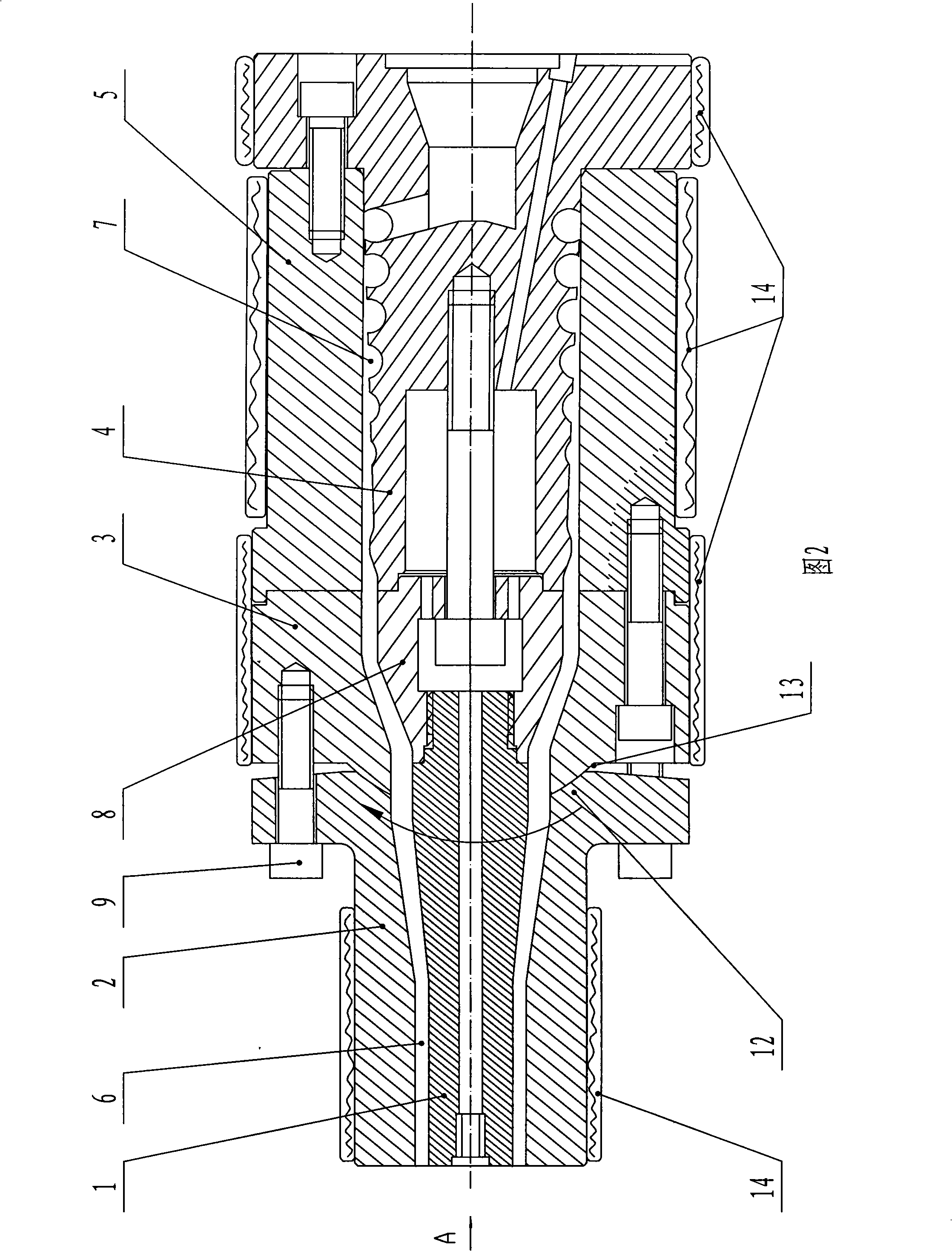

Cooler

ActiveCN101109603AEasy to installEasy maintenanceDirect contact heat exchangersHandling discharged materialBogieReciprocating motion

The invention relates to a cooler for cooling materials, which comprises a feeding end, a discharging end, side walls, a grate bed comprising grates for receiving and supporting the materials to be cooled, a drive, and an air chamber. The invention is characterized in that, at least one grate is a beaded grate, which comprises a conventional grate and at least one bead for pushing the materials that is arranged cross to the advancing direction of the materials to be cooled; the beaded grate is placed on a movable bogie, which is connected with the drive; the drive makes the beaded grate to move back and fro along the moving direction of the materials to be cooled. As the invention changes the fixed grate bed for fixing and supporting in prior technology into a movable grate bed comprising beaded grates that can move back and fro, the back and fro movement of the bead driven by the beaded grate pushes the materials to be cooled to move forward, so separate driving board and its accessories are eliminated, this has not only greatly simplified the whole cooler, but also is easy to install and maintain.

Owner:北京四方联新技术开发有限公司

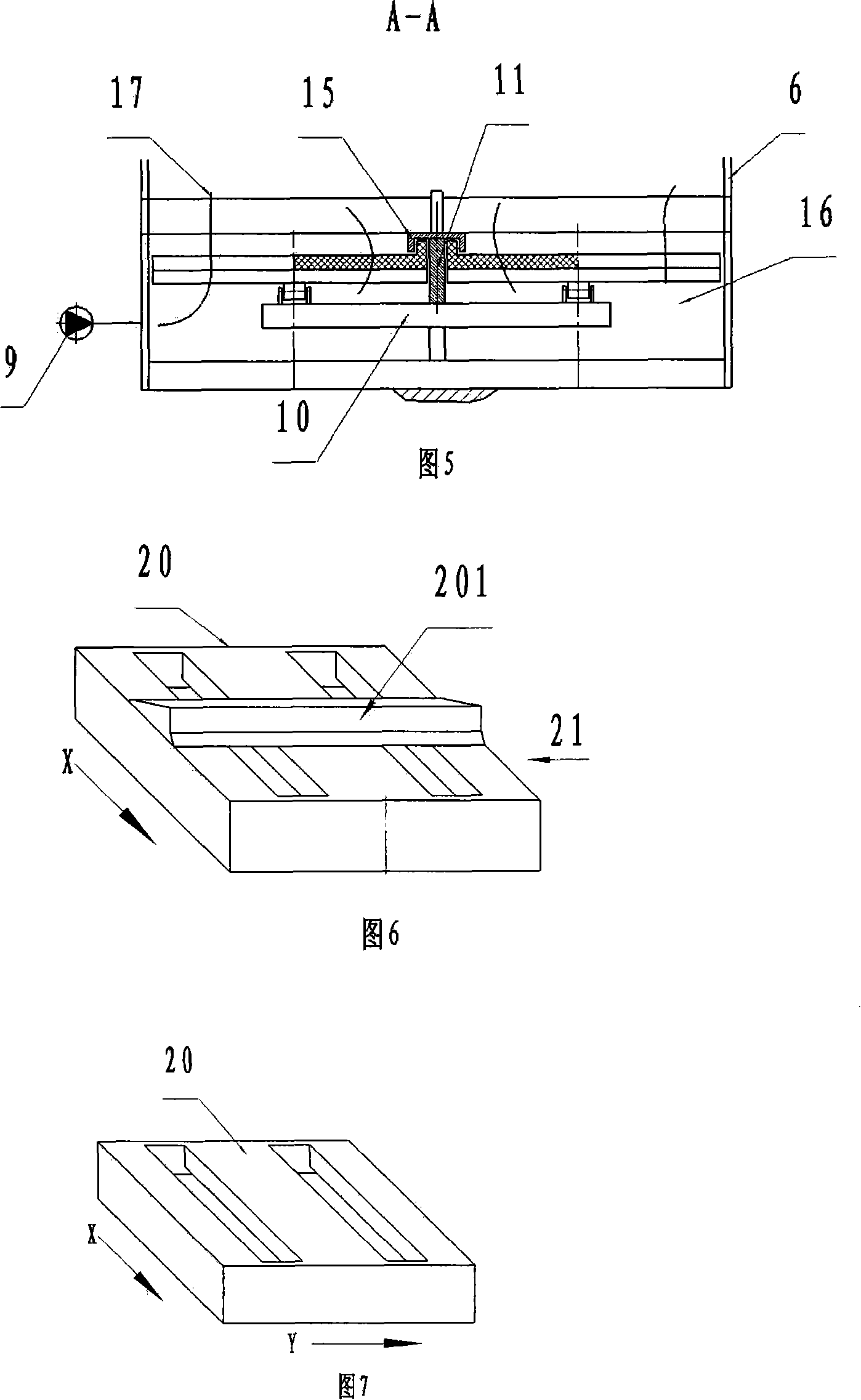

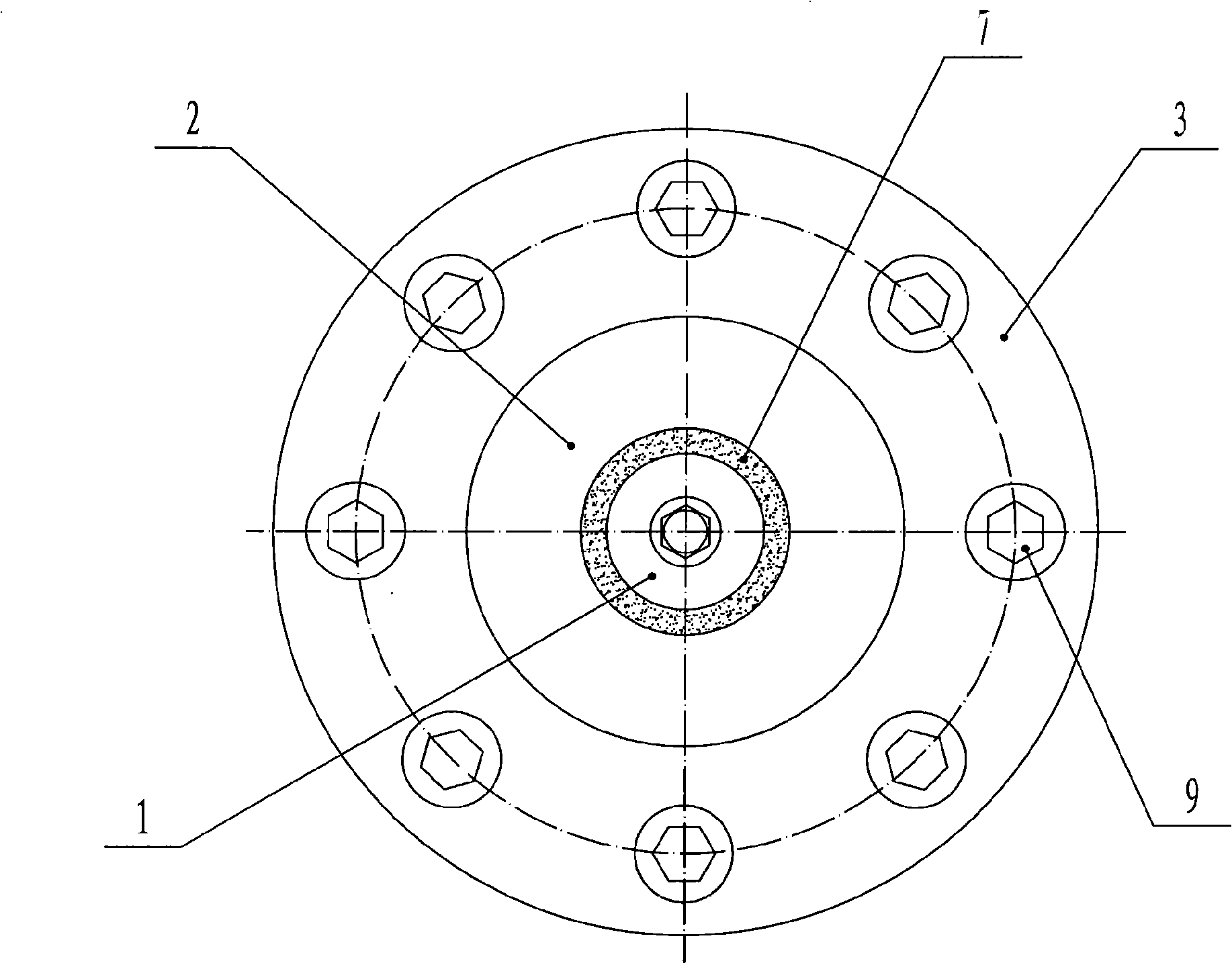

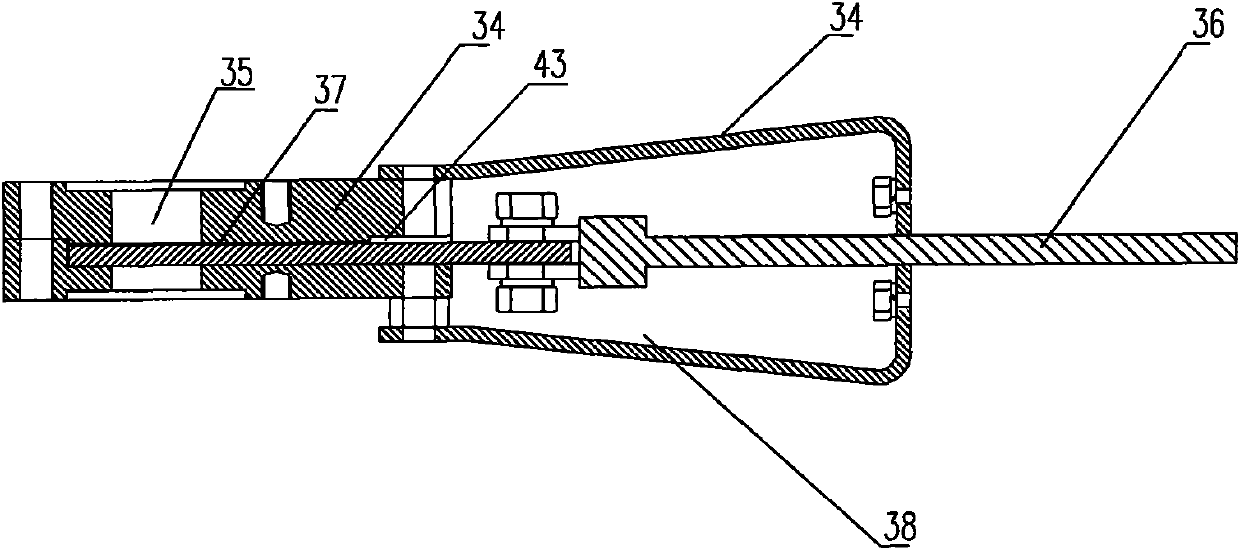

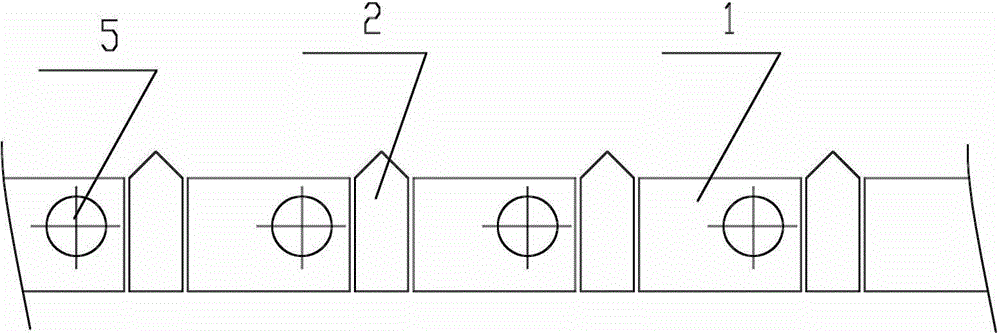

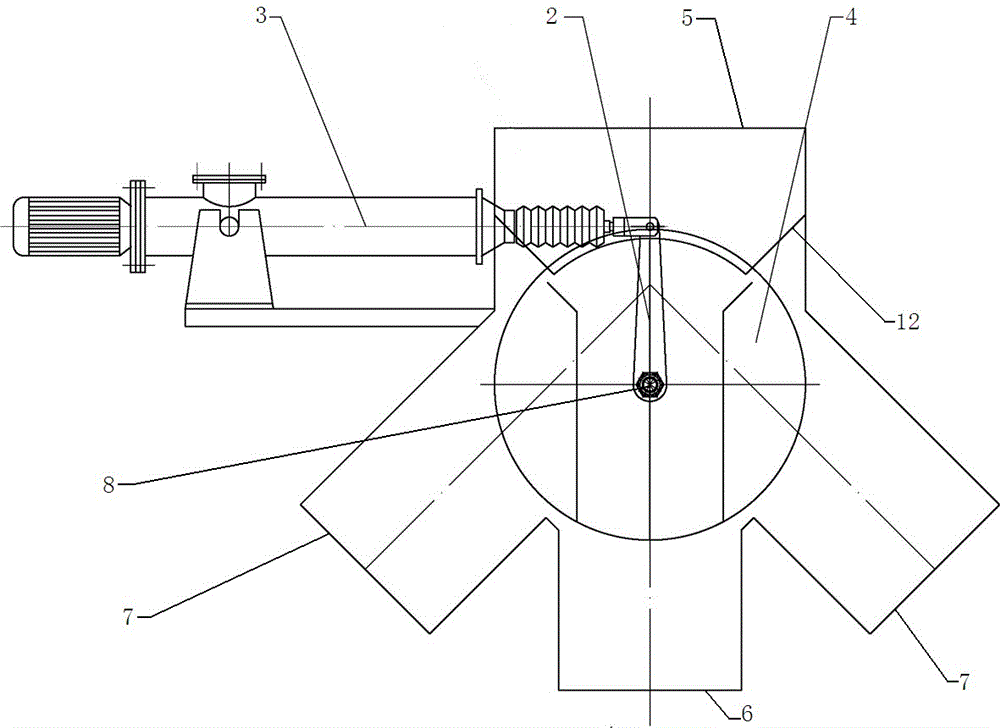

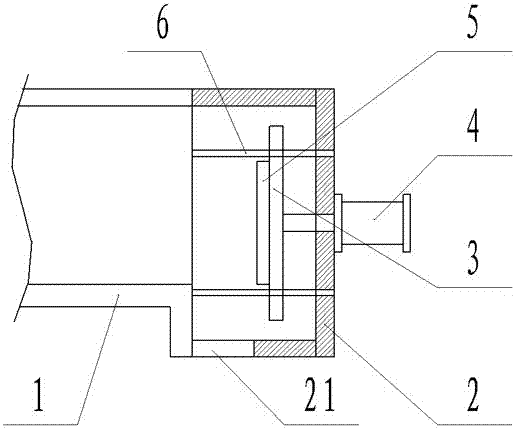

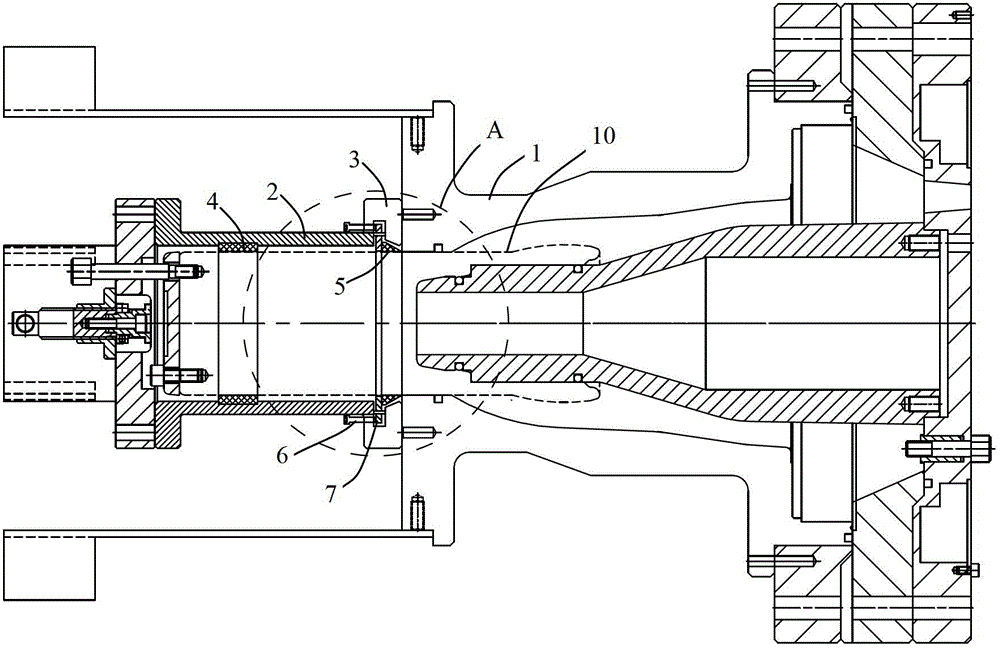

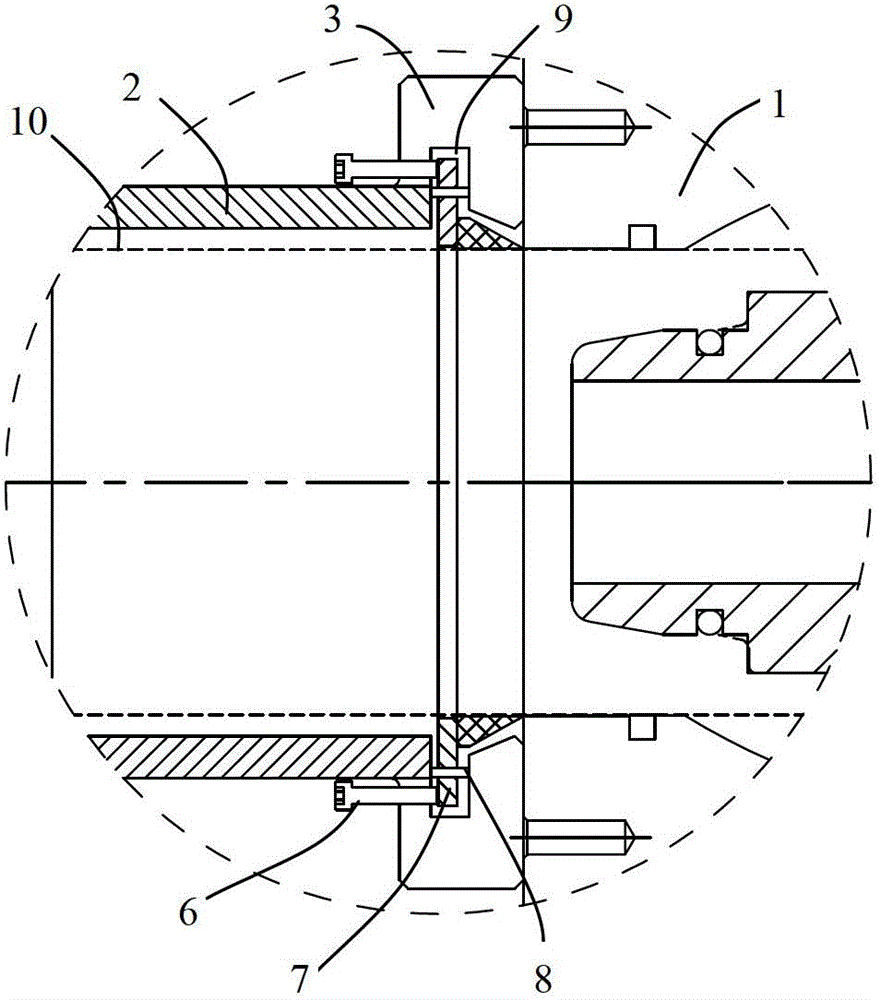

Extrusion mould head for plastic tube

ActiveCN101314254AAchieve regulationClearance adjustment is simpleTubular articlesMechanical engineeringExtrusion

The invention discloses a plastic pipe extrusion die head, comprising a core die (1) fixed on a die core rear body (4), a die (2) the left end face of which is parallel to the left end face of the core die (1), an adjusting seat (3), an outer die rear body (5) the right end of which is fixed with the right end of the die core rear body (4) and adjusting screws (9) the number of which is multiple of four, wherein, the die (2) is connected with the adjusting seat (3) through the adjusting screws (9) which are uniformly distributed on the die and axes of which are parallel to the axis of the die head; the center of the right end of the die (2) is a concave spherical surface I(12); the center of the right end of the adjusting seat (3) is a convex spherical surface II(13); and the concave spherical surface I(12) and the convex spherical surface II(13)are mutually attached. The plastic pipe extrusion die head has the advantages that: the plastic pipe extrusion die head not only can simply adjust a gap of a straight section between a core die outer wall and a die inner wall, but also can make plastics flow smoothly in the die head in the adjusting process, without accumulation, coke charge and leakage.

Owner:NINGBO FANGLI GRP

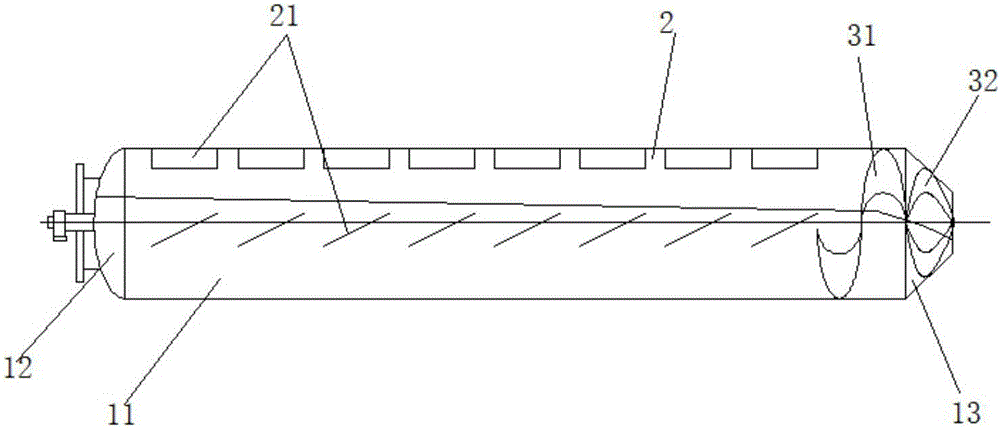

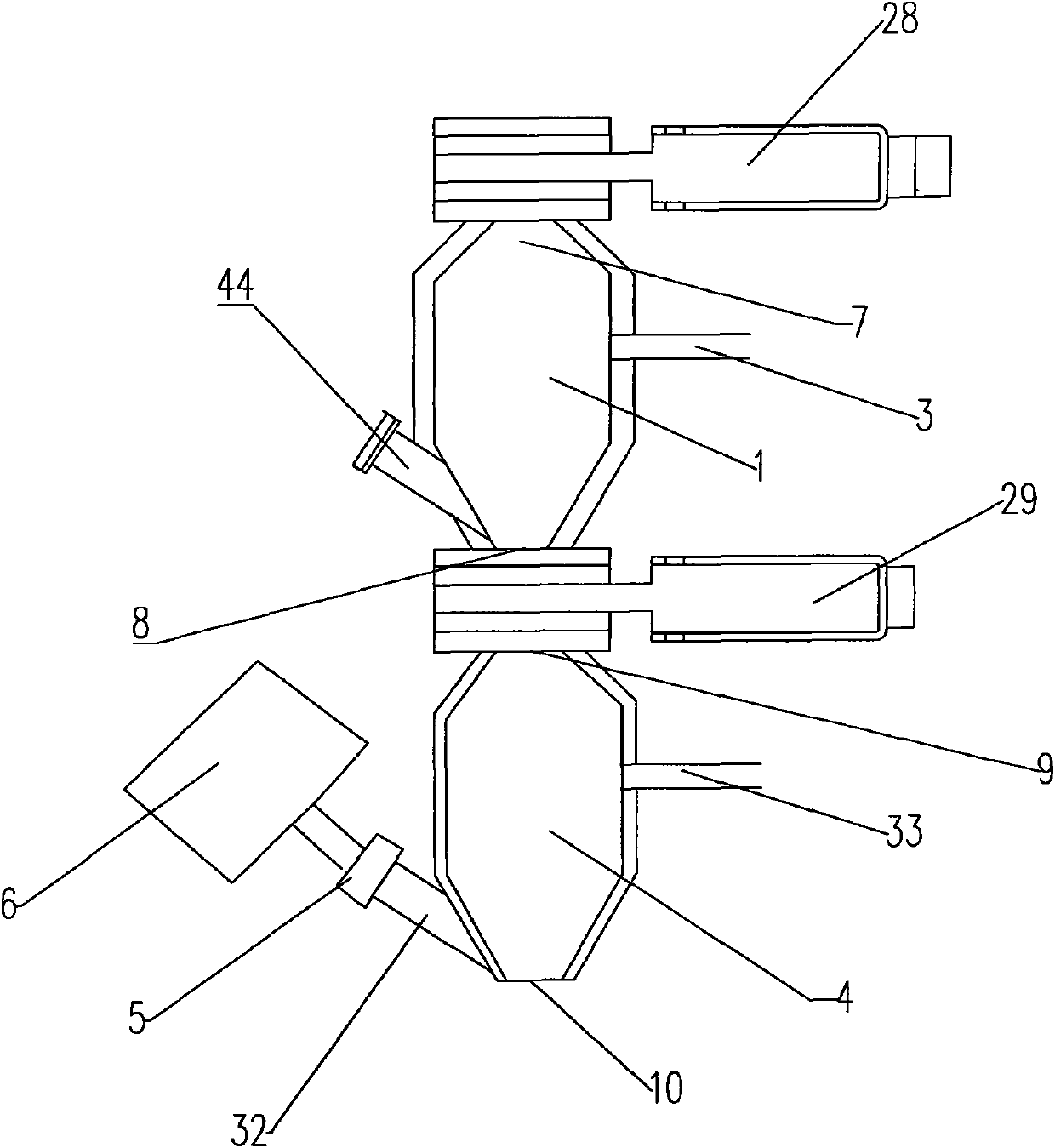

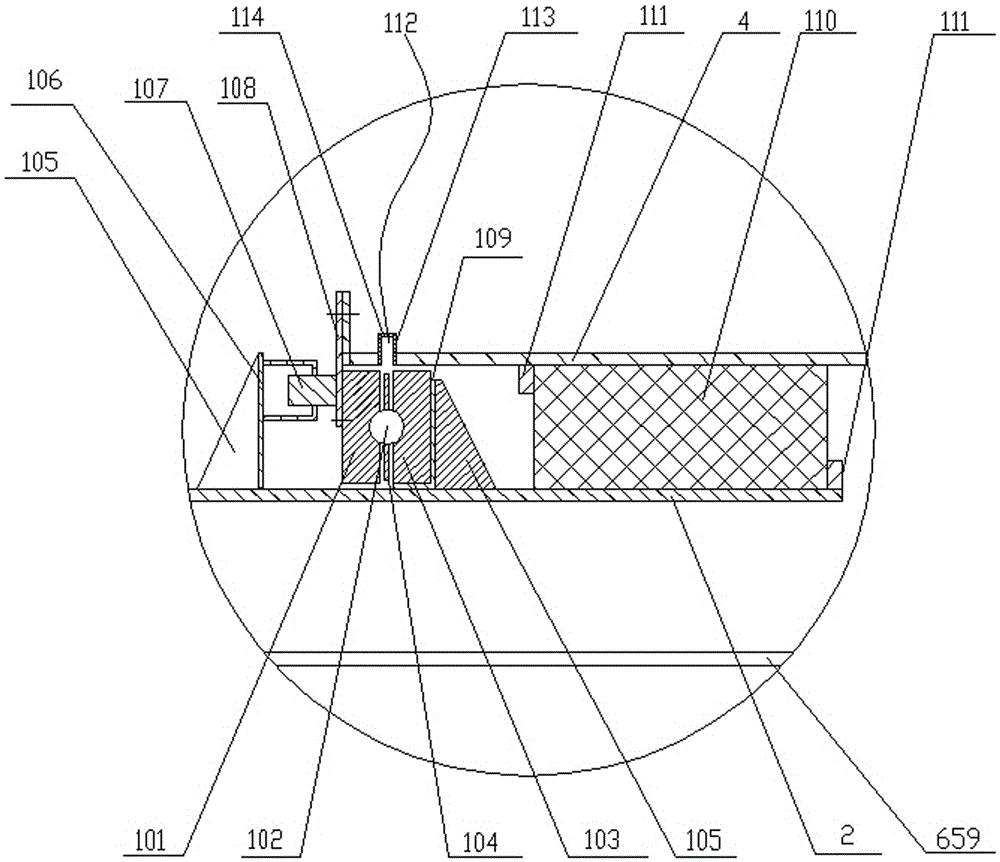

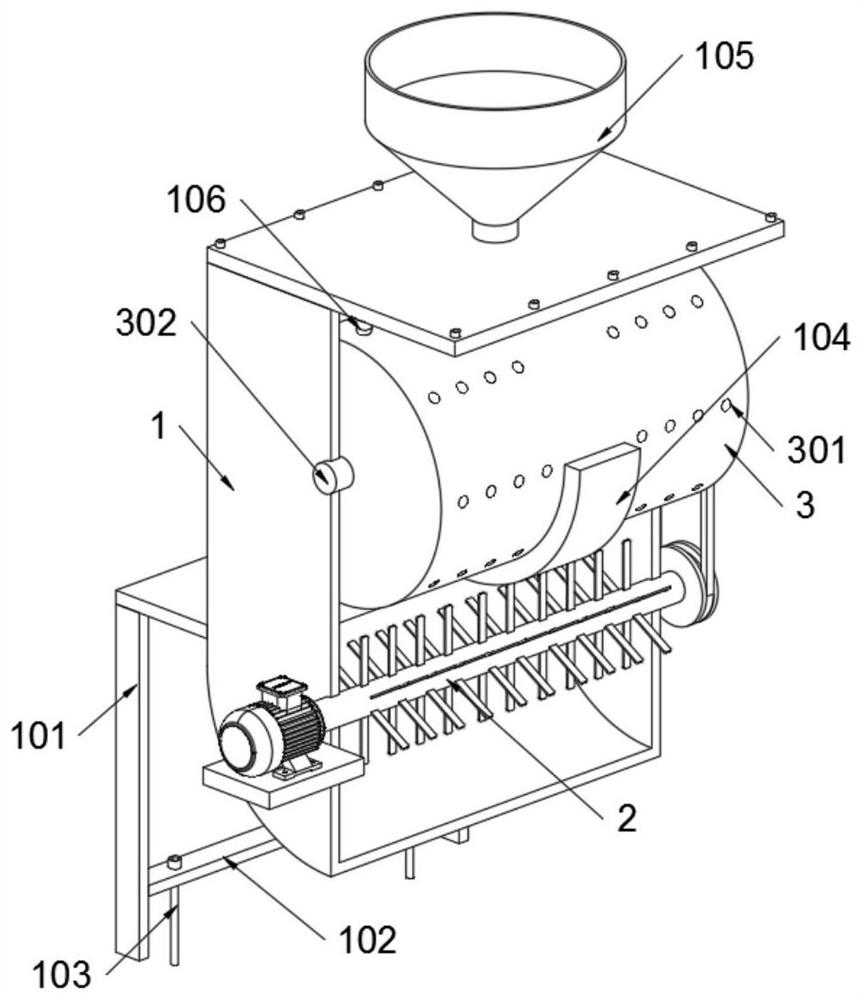

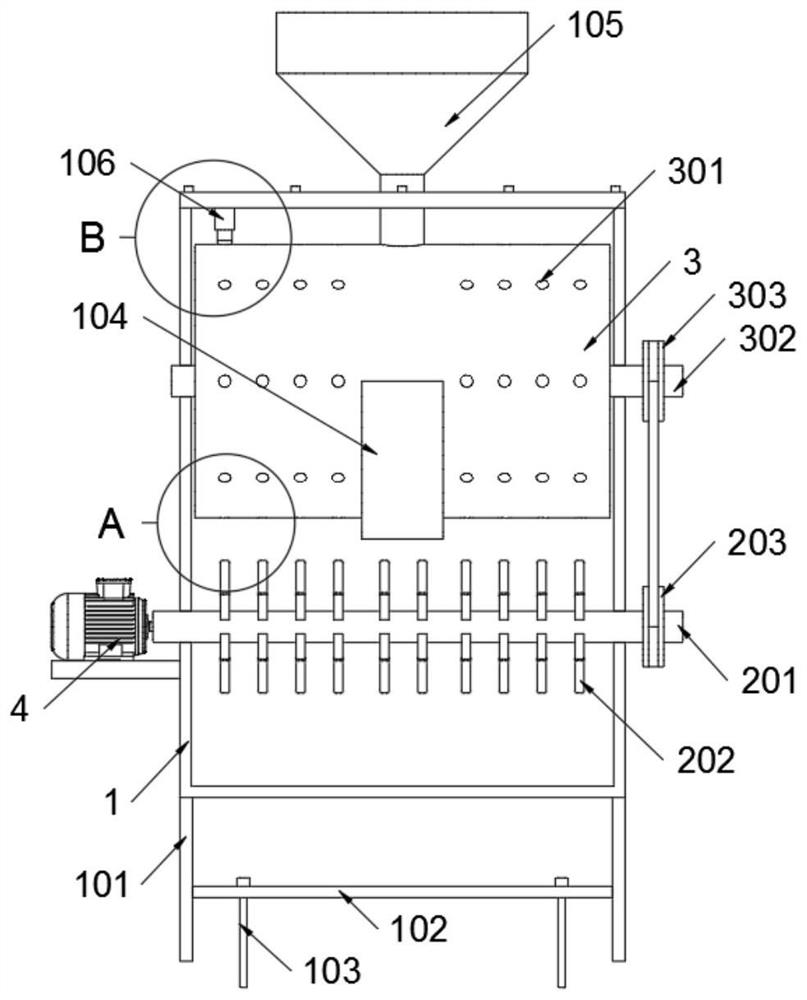

Horizontal type rotary drum stirring, feeding and discharging device

PendingCN106701530AWell mixedUniform output speedBioreactor/fermenter combinationsBiological substance pretreatmentsSpiral bladeFermentation

The invention relates to a horizontal type rotary drum stirring, feeding and discharging device which comprises a rotary drum body and a stirring device. A fermentation tank comprises a columnar cylinder body, a left sealing head and a right sealing head, the stirring device is arranged in the columnar cylinder body and is disconnected blades, the disconnected blades include sub-blades, and the sub-blades are fixed to the inner wall of the rotary drum body in an axial equally-spaced arrangement mode. The device further comprises a feeding and discharging device, wherein the feeding and discharging device is feeding and discharging screw blades, and the feeding and discharging screw blades are spiral blades fixed to one end of the inner wall of the rotary drum body. The horizontal type rotary drum stirring, feeding and discharging device has the advantages that the disconnected blades can spread a material and can also push materials towards two sides, a stirring effect can be achieved only through one-way rotation, a stirring effect is stronger compared with traditional common spiral blades, the fermentation efficiency is improved, the designed feeding and discharging screw blades achieve forward feeding and reverse discharging, the feeding and discharging speed is uniform and rapid, and the material level is flat.

Owner:山西金龙鱼梁汾醋业有限公司

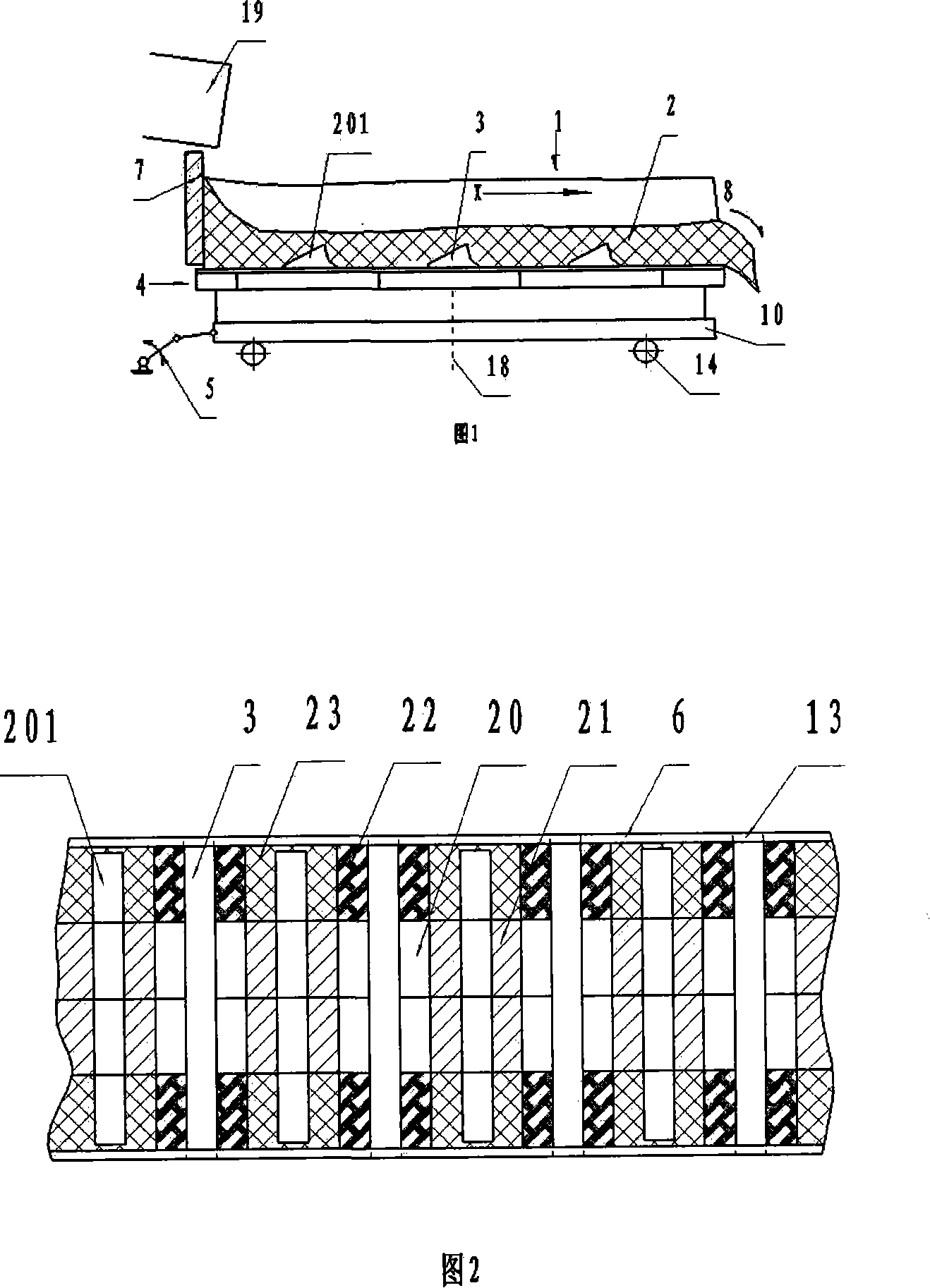

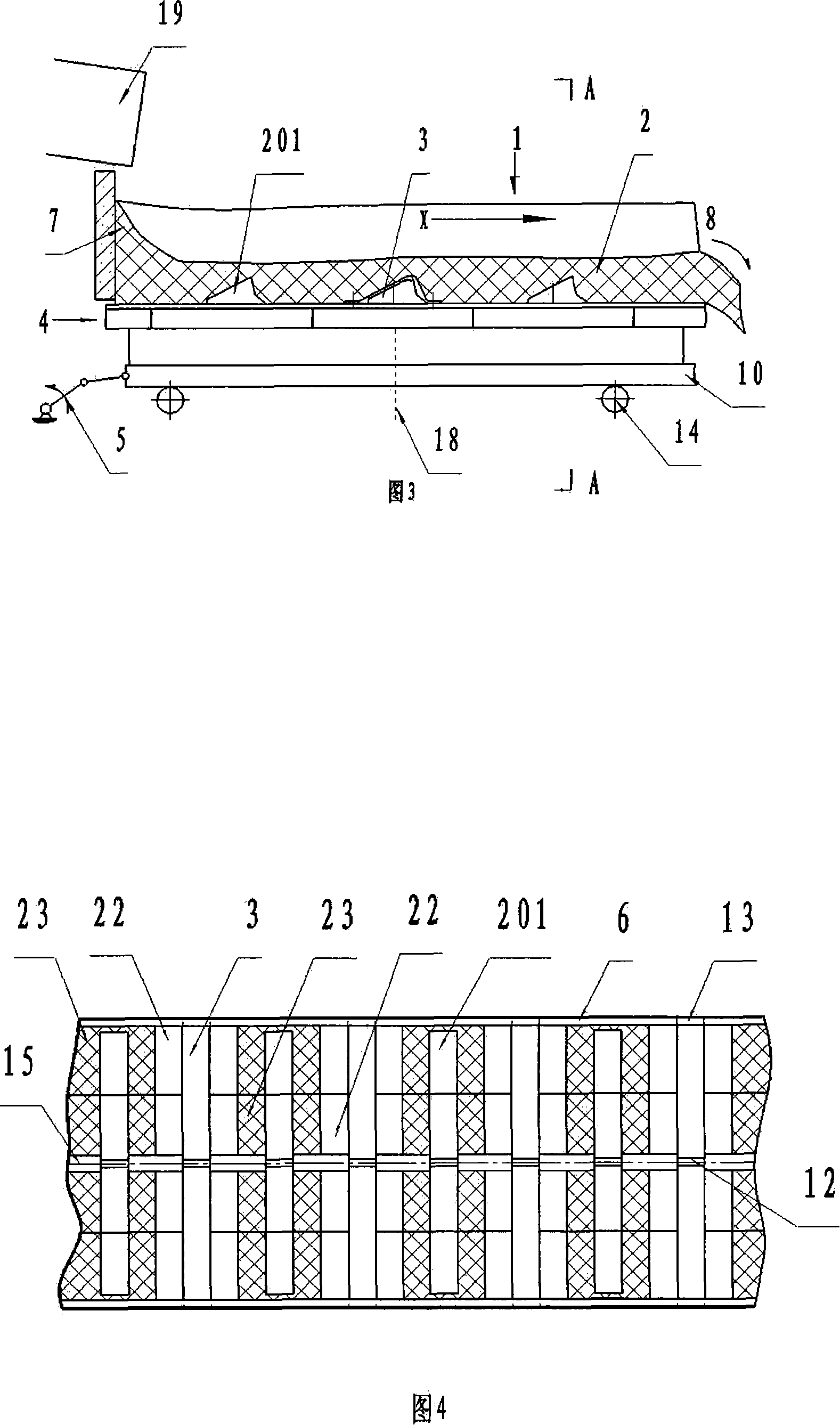

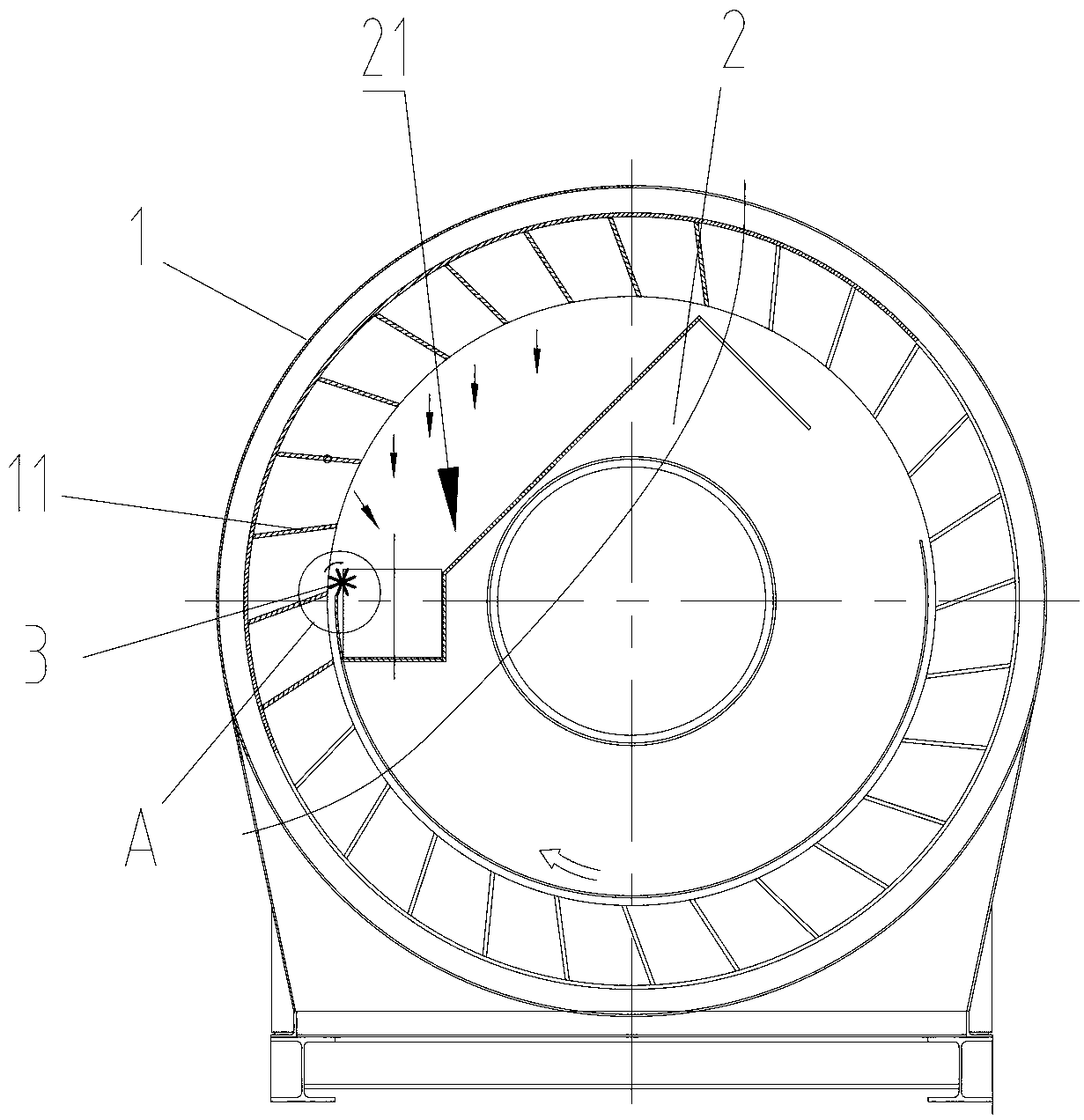

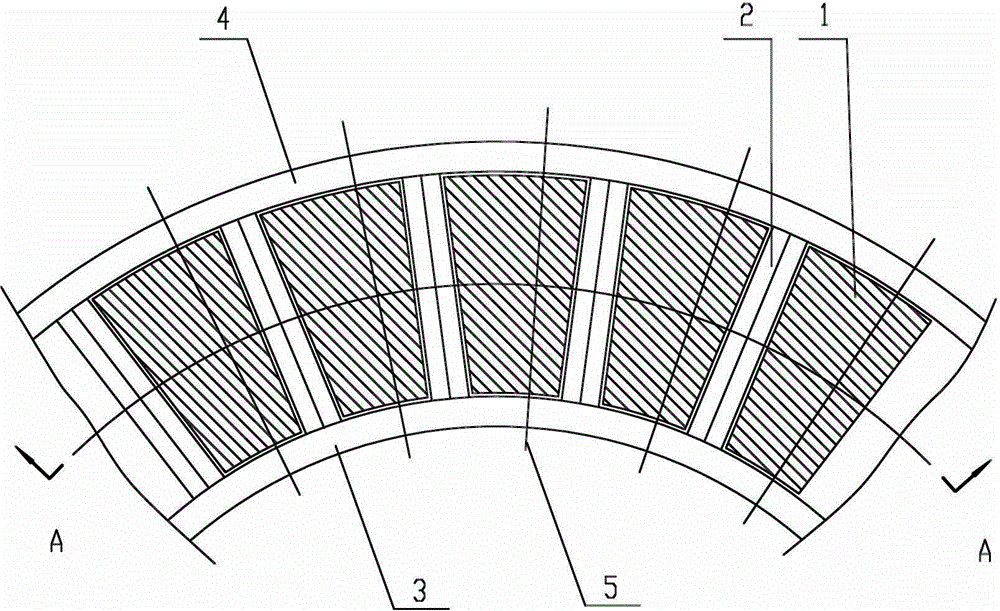

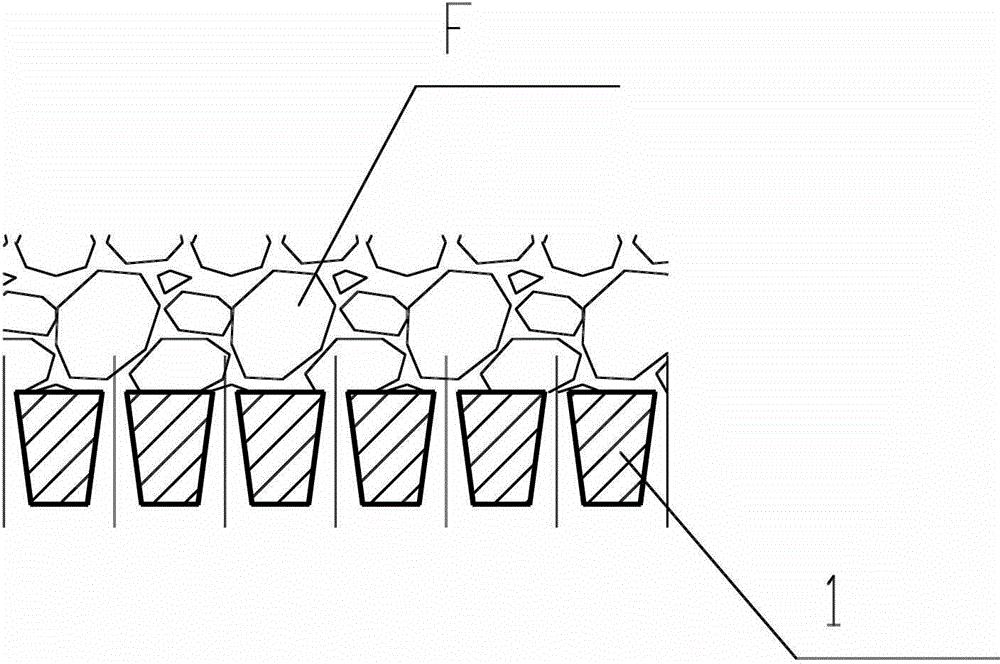

Drying roller and asphalt agitating device

ActiveCN103015294AImprove feeding efficiencyPrevent material leakageRoads maintainenceEngineeringMechanical engineering

The invention discloses a drying roller, which comprises a rotatable barrel (1) and a discharge box (2) at the discharge end of the rotatable barrel (1). A plurality of lifting blades (11) for lifting materials are arranged on the inner wall of the barrel when the barrel rotates. A receiving port (21) of the discharge box corresponds to the lifting blades to receive materials falling from the lifting blades. A receiving mechanism (3) is arranged between the receiving port and the lifting blades. The receiving mechanism conveys materials received to the receiving port. The invention further discloses an asphalt agitating device for the drying roller. As the receiving mechanism which conveys materials to the receiving port is arranged between the receiving port and the lifting blades, material leakage between the feed inlet at the discharge end of the drying roller and the barrel is avoided, so that the lifting efficiency of the lifting blades is improved, and the environmental pollution is avoided.

Owner:ZOOMLION HEAVY IND CO LTD

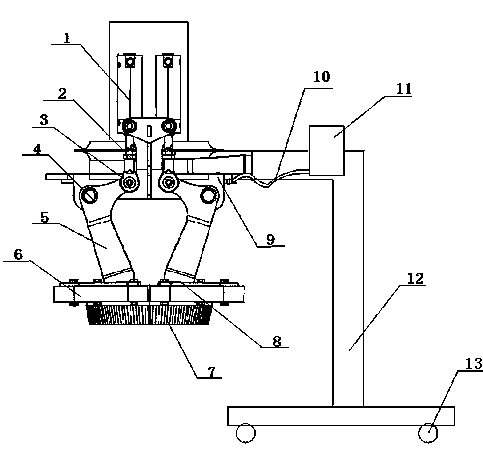

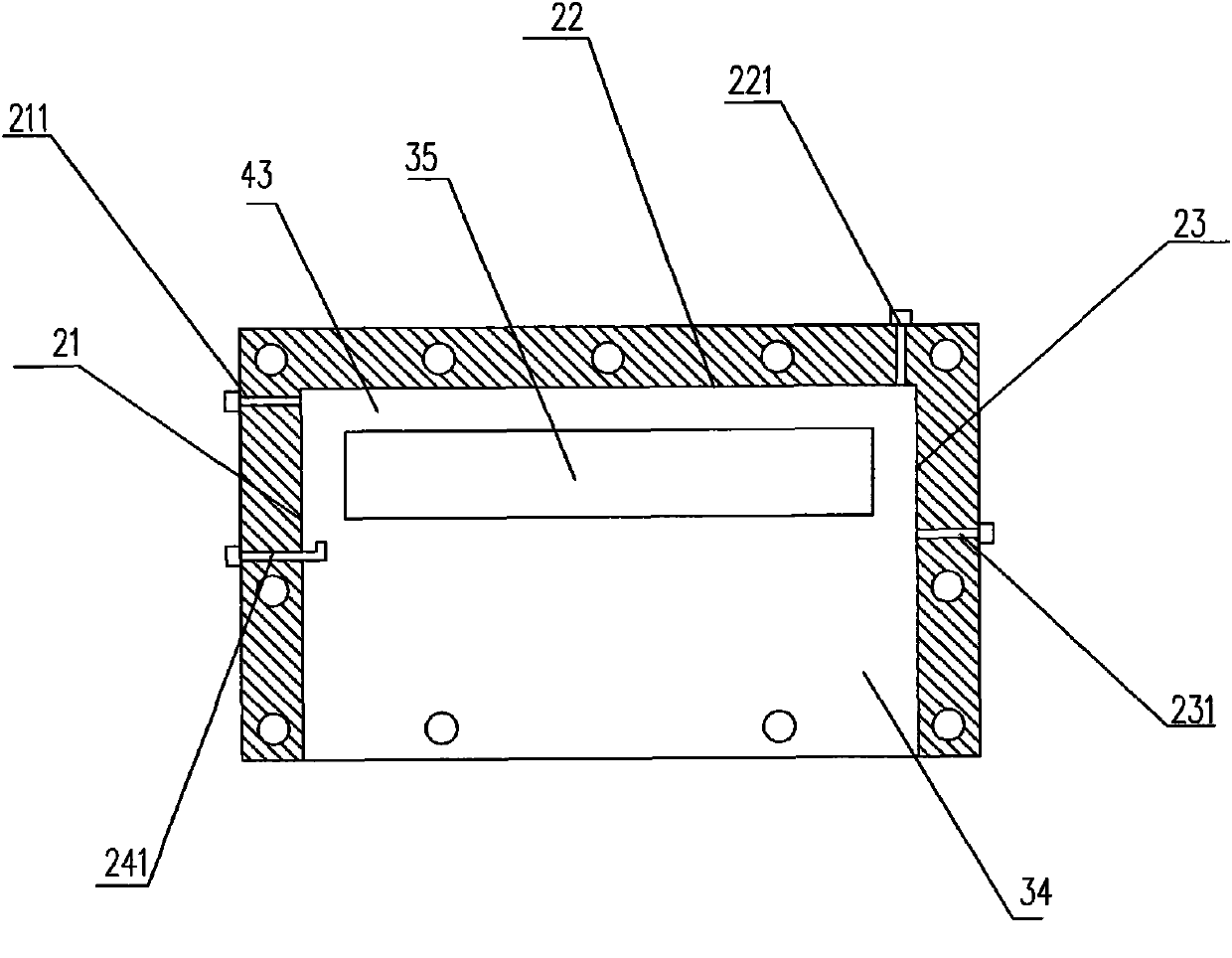

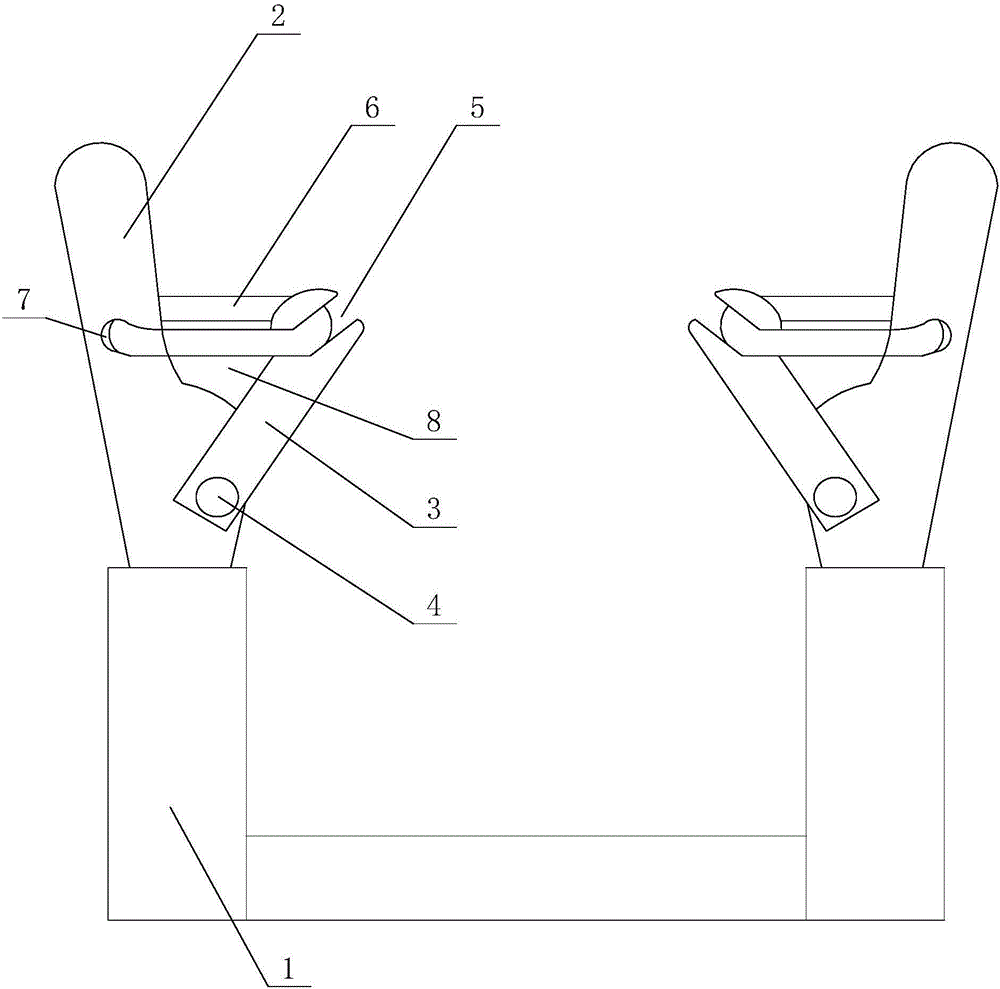

Bag-clamping device for opening bag packing machine

The invention relates to a bag-clamping device for an opening bag packing machine. The bag-clamping device comprises a support provided with two bag-clamping arms; the middles of the bag-clamping arms are hinged to the support; first free ends of the bag-clamping arms are connected with a lifting device respectively; when the lifting devices drive the first free ends of the bag-clamping arms to ascend, second free ends of the bag-clamping arms rotate around the middle hinging points to realize the clamping. The bag-clamping arms are clamped or opened by using a cylinder to drive the lifting devices to lift up and down, when the bag-clamping arms are opened, an opening of the packing bag can be properly opened to avoid the material leaking phenomenon of the packing bag. The bag-clamping device for the opening packing machine is strong in clamping strength without causing the stripping of the packing bag, and due to the scheme, bag packing can be performed without assisting manpower, and the full automation of the packing machine can be realized.

Owner:CHINA WEIGHING EQUIP SUZHOU FACTORY

Steam sterilization device with control valves

The invention provides a steam sterilization device with control valves. The invention is characterized in that a first control valve is connected at the feed inlet of a sterilization cabin of the sterilization device, a second control valve is arranged at the connection portion between the feed inlet of a cooling cabin of the sterilization device and the discharge port of the sterilization cabin, the three side walls of the first control valve and the second control valve are respectively provided with a first purging air inlet, a second purging air inlet, a third purging air inlet, and a fourth purging air inlet, the purging air inlets are communicated with a flashboard cavity, the first, second, and third purging air inlets are arranged opposite to the side walls, the fourth purging air inlet is arranged on the first side wall and opposite to the third purging air inlet and in a valve cavity, and the fourth purging air inlet is arranged towards the second side wall. According to the invention, the arrangement of purging air inlets can thoroughly remove material particles attached to the flashboard cavity, thus material accumulation in the flashboard cavity is effectively prevented, and the stability of the operation of the control valve is guaranteed.

Owner:LANZHOU NONGZHIPIN ECOLOGICAL TECH CO LTD

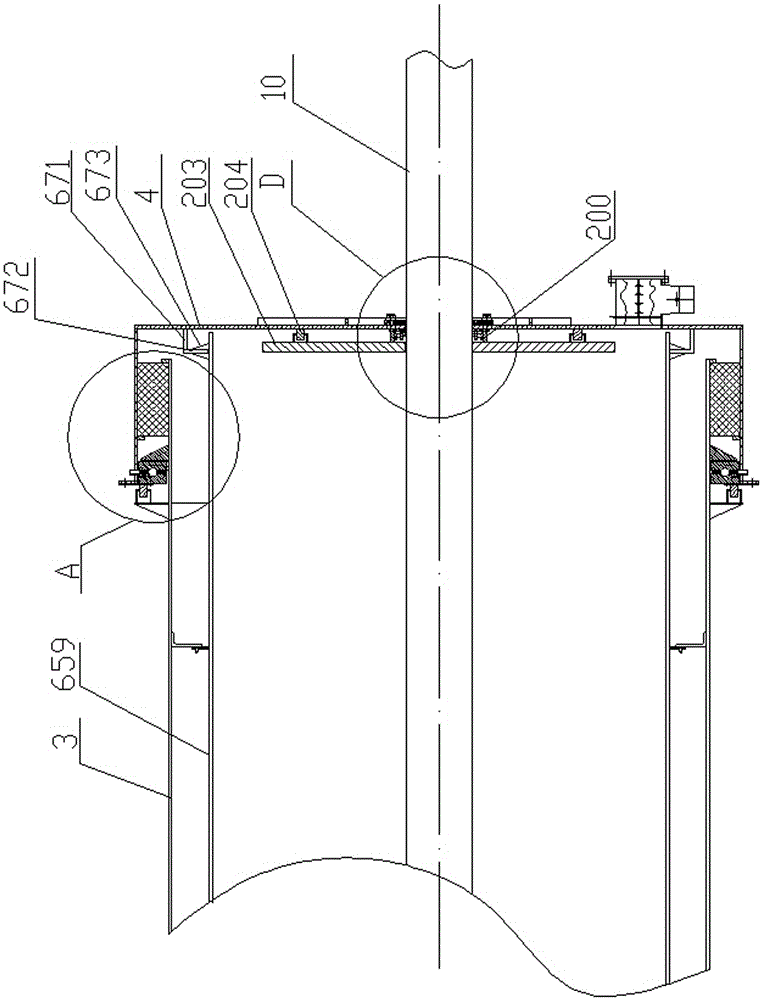

Multifunctional sintering blowing ring circular cooler

ActiveCN103604301AGuaranteed StrengthGuaranteed stiffnessHandling discharged materialEngineeringGranular media

The invention relates to a multifunctional sintering blowing ring circular cooler comprising a cooler frame, inner and outer support rolls, inner and outer rotating frames, a connecting beam, a trolley, a trolley shaft, inner and outer trolley panels, a U-shaped sealing hood, a transmission device, first inner and outer seals, and second inner and outer seals. The multifunctional sintering blowing ring circular cooler is characterized in that the section of the connecting beam is in the shape of a round tubular part, two ends of the connecting beam are connected with sides, in contact with material, of the lower portions of vertical plates, close to the sintering trolley, of the inner and outer rotating frames respectively, the first and outer seals are composed of U-sectioned inner and outer sealing channels disposed on a bellows frame, particles disposed in the inner and outer sealing channels, and inner and outer circular sealing plates, one ends of the inner and outer circular sealing plates are fixedly connected with the inner and outer rotating frames of the sintering trolley respectively, the other ends of the inner and outer circular sealing plates are inserted into the particles in the inner and outer sealing channels respectively, and the second inner and outer seals are lap seals. The multifunctional sintering blowing ring circular cooler has the advantages of good airtightness, energy saving, and environmental friendliness.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

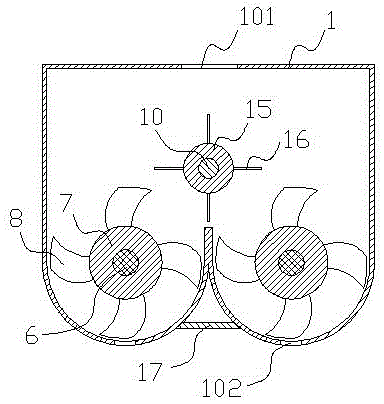

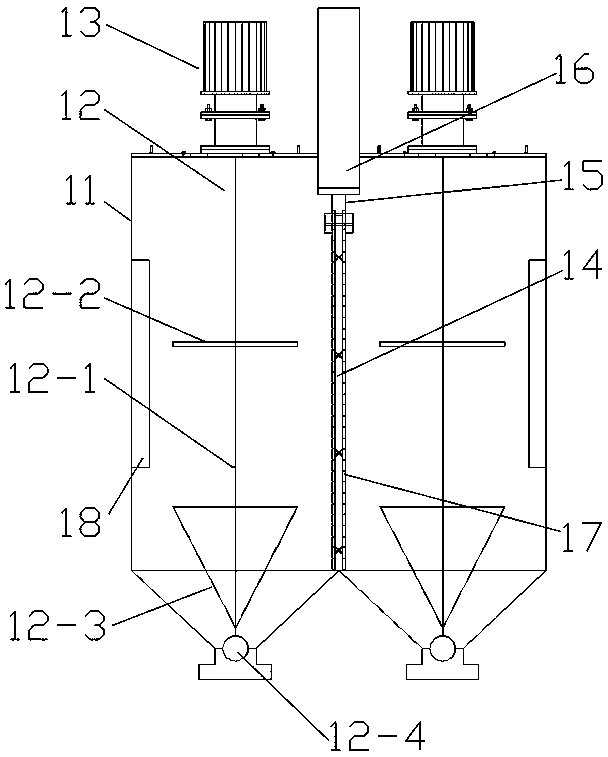

Mixing all-in-one machine used for processing synthetic mica

ActiveCN105126663AImprove the mixing effectQuality improvementRotary stirring mixersMixer accessoriesButt jointEngineering

The invention relates to a mixing all-in-one machine used for processing synthetic mica. A material lifting inlet and a material lifting outlet are formed in a material lifting device; the material lifting outlet is connected to a feeding hole of a material mixing device through a butt joint pipe; a discharging hole of the material mixing device is connected with a discharging device; a second rotary shaft is arranged at the upper part of a material mixing box body of the material mixing device, and two first rotary shafts are arranged at the lower part of the material mixing box body; the central line of the second rotary shaft is located on front and back symmetrical planes of the material mixing box body; the first rotary shafts are symmetrical about the front and back symmetrical planes of the material mixing box body; the first rotary shafts and the second rotary shaft are located in the material mixing box body and are in sleeving joint with first rotary barrels and a second rotary barrel respectively; stirring blades are arrayed on the first rotary barrel in a staggered manner and stirring rods are arrayed on the second rotary barrel in the staggered manner. According to the mixing all-in-one machine, the three rotary shafts are distributed in a triangular shape for mixing materials, so that the material mixing efficiency is extremely improved and the material mixing time is shortened; meanwhile, the material mixing quality can also be improved; the material lifting device is arranged, so that the materials can be fed to a high-efficiency material mixing device very well.

Owner:PINGJIANG XINGKE MICA PRODS

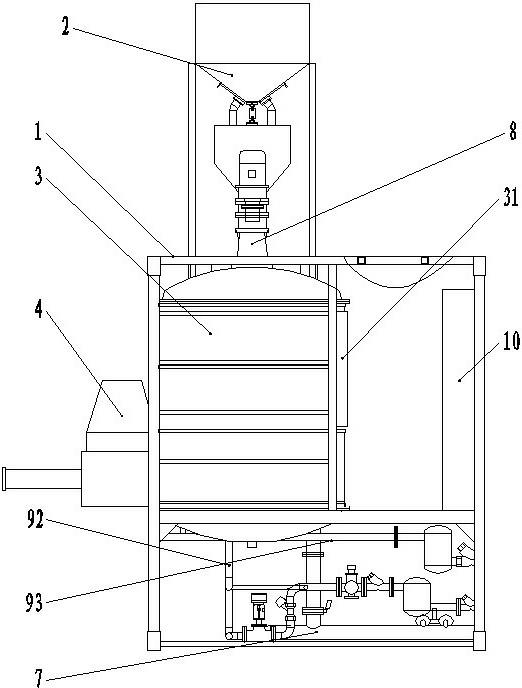

Pre-expansion machine of foam

The invention relates to a pre-expansion machine of foam, which is mainly used for producing plastic foam. The pre-expansion machine of the foam with a reasonable structural design and reliable performances is not existed at present. The pre-expansion machine of the foam comprises a machine frame, a material loading device, a barrel body, a material door device, a material level control device, a scraper device, a sewage discharge device, a stirring device, an electrical box, a steam pipeline and a compressed air pipeline; the barrel body and the electrical box are both arranged on the machine frame; the material loading device, the material door device and the material level control device are all arranged on the barrel body; the scraper device is arranged at the bottom of the stirring device; the stirring device is arranged in the barrel body; and the sewage discharge device, the steam pipeline and the compressed air pipeline are all connected with the barrel body. The invention is characterized in that the scraper device comprises a scraper base, a left long scraper, a right long scraper, a front short scraper and a back short scraper; and the left long scraper and the right long scraper are both fixedly arranged on the scraper base, and the front short scraper and the back short scraper are both fixedly arranged on the scraper base. As the pre-expansion machine of the foam has the reasonable structural design, the materials cannot be collected at the bottom of a barrel, and a material leakage phenomenon cannot be generated on a material door.

Owner:HANGZHOU FUYANG DONGSHAN PLASTIC MACHINERY

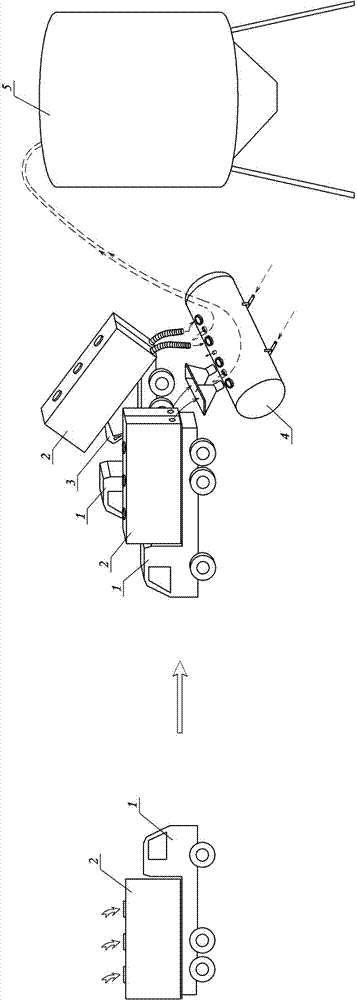

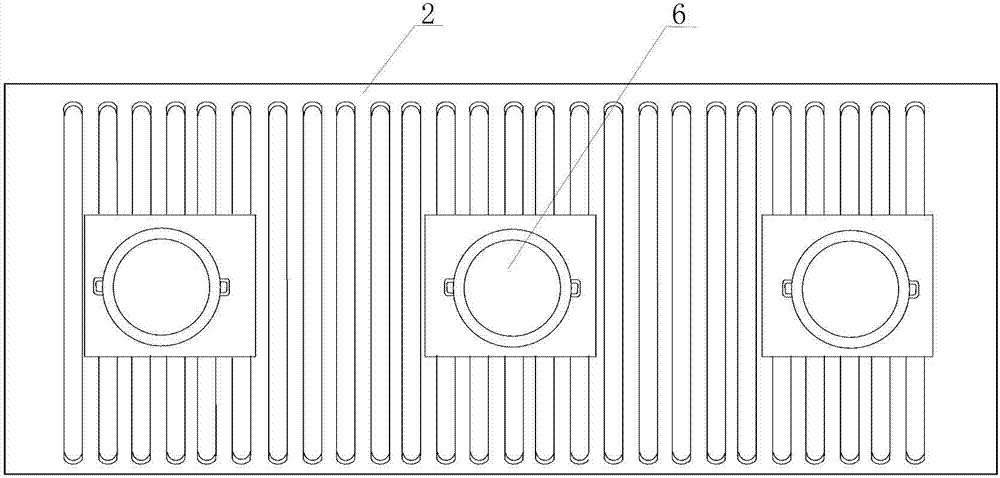

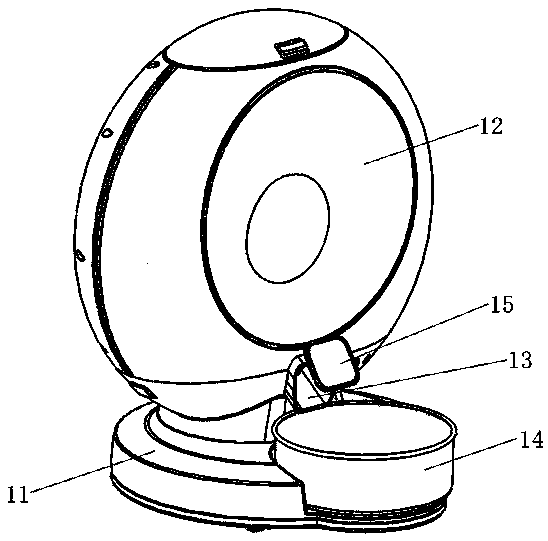

System and method for powder transportation

ActiveCN103086095AImprove loading efficiencyEasy to manufactureLarge containersInternational standardFluidized bed

The invention discloses a system and a method for powder transportation. An international standard container is used, the top of the transformed container is provided with a feeding port, and the bottom of a back door of the transformed container is provided with a discharging port. At the departure place, after the powder is loaded with zero pressure through the feeding port, the feeding port is sealed, the container serves as a multimodal transport device to transport the powder to the destination, a fluidized bed feeding tank is arranged at the destination, the discharging port of the container and an inlet of the fluidized bed feeding tank are aligned, and thereby the powder discharges automatically under own gravity. By means of the system and the method for powder transportation, an international standard container can be utilized directly and transformed, and thereby the advantages of simple production and strong generality are provided, and the purpose of international multimodal transportation is achieved. The method adopted is simple, the transportation efficiency of the powder can be improved greatly, the working environment is improved, the workers and workload are reduced, the transportation cost is reduced, and the market competitiveness is improved.

Owner:姚平

Feeding structure and feeder applying same

The invention belongs to the technical field of material conveying, and particularly relates to a feeding structure. The structure comprises a rotating body, one side of the rotating body is arranged to be a feeding surface which is oblique, the feeding surface forms a downward curved surface from the center to the periphery, a feeding passage extending in the rotating direction of the rotating body is formed in the feeding surface, a feeding hole of the feeding passage is located on the first low side of the feeding surface, a discharging hole of the feeding passage is located on the second low side of the feeding surface, the first low side is isolated from the second low side, and the feeding surface is provided with multiple raised lines and / or strip-shaped grooves which extend to the periphery along the center. Accordingly, by means of oblique arrangement of the feeding surface, it can be guaranteed that when the rotating body drives the feeding surface to rotate, material particles on the feeding surface can rotate along with the feeding surface under the action of the raised lines and / or the strip-shaped grooves, and can slide along the obliquely arranged feeding surface to the discharge hole to drop down in the rotating process, and the material jamming phenomenon is not likely to occur.

Owner:MANGO IOT CHANGZHOU CO LTD

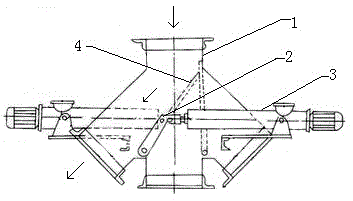

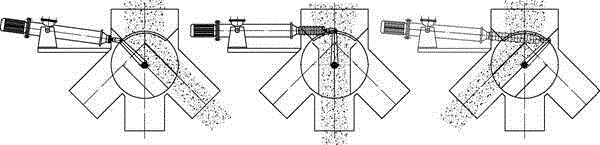

Four-way material distributer free of material blocking

ActiveCN105540284AThere will be no material jam phenomenonLow costLoading/unloadingEngineeringMechanical engineering

The invention relates to a four-way material distributer free of material blocking. A set of electric liquid pushing rods, a swing arm and an overturning plate are adopted for the four-way material distributer. The electric liquid pushing rods are arranged on a shell. The overturning plate is rotationally fixed in a cavity through a rotating shaft. One end of the swing arm is fixed to the rotating shaft, and the other end of the swing arm is hinged to the electric liquid pushing rods. The overturning plate comprises two parallel baffles and a plurality of partition plates vertically fixed between the baffles and parallel to each other. The two baffles are right opposite to the inner walls on the two sides of the cavity. A material collecting opening is formed in the bottom end of a vertical material inlet and always located between the two baffles. The overturning plate is made to rotate, materials are limited by the baffles and guided by the partition plates to enter a material discharge connector to which the partition plates point. The four-way material distributer effectively prevents the material clamping phenomenon, switching of three flow directions can be achieved through the set of electric liquid pushing rods, the swing arm and the overturning plate, cost is low, and operation is reliable.

Owner:WISDRI ENG & RES INC LTD

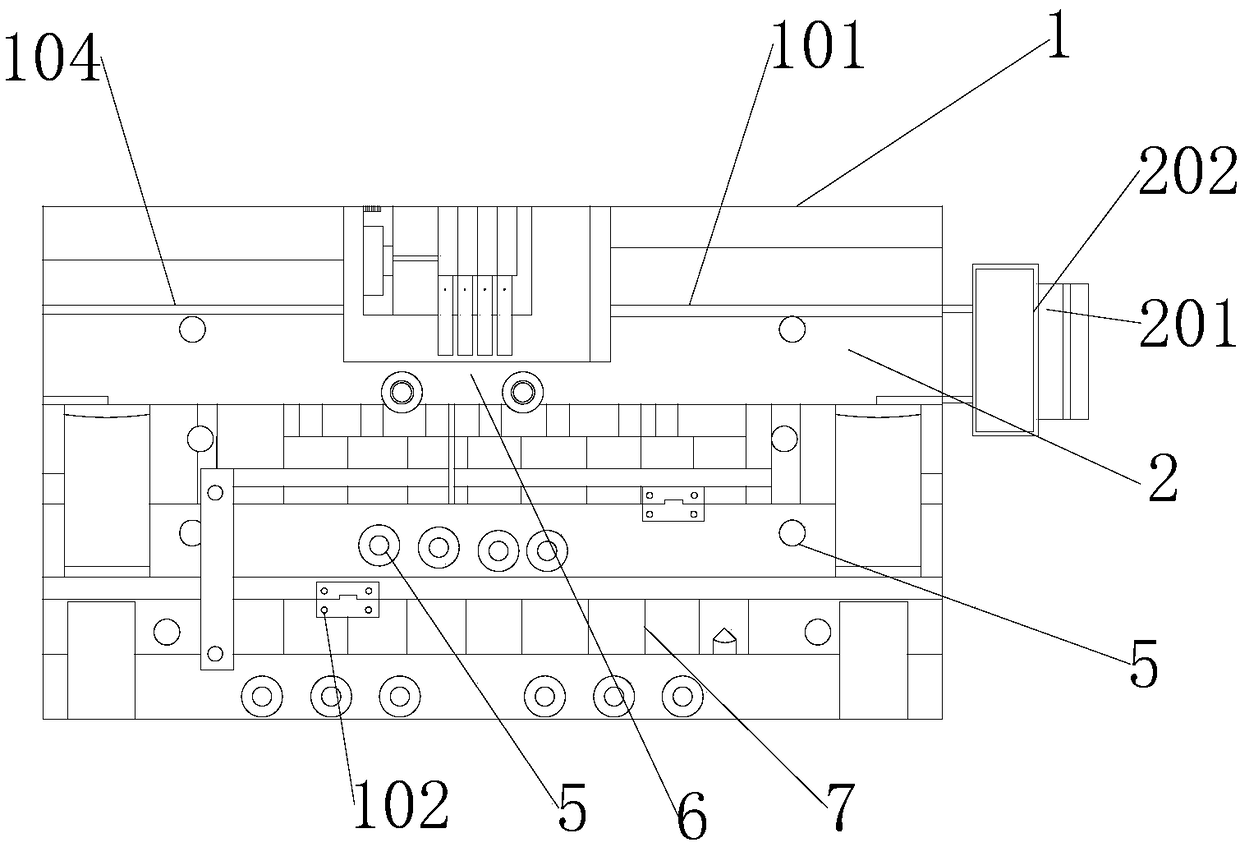

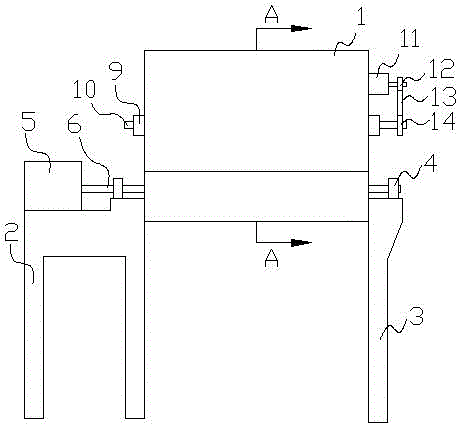

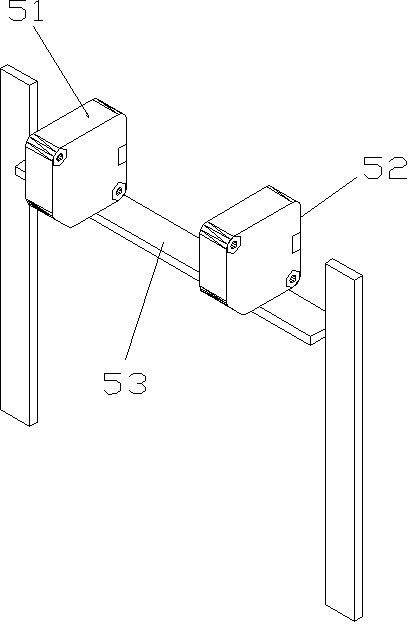

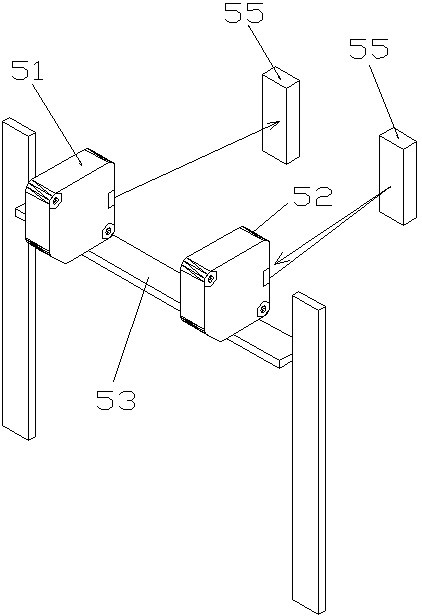

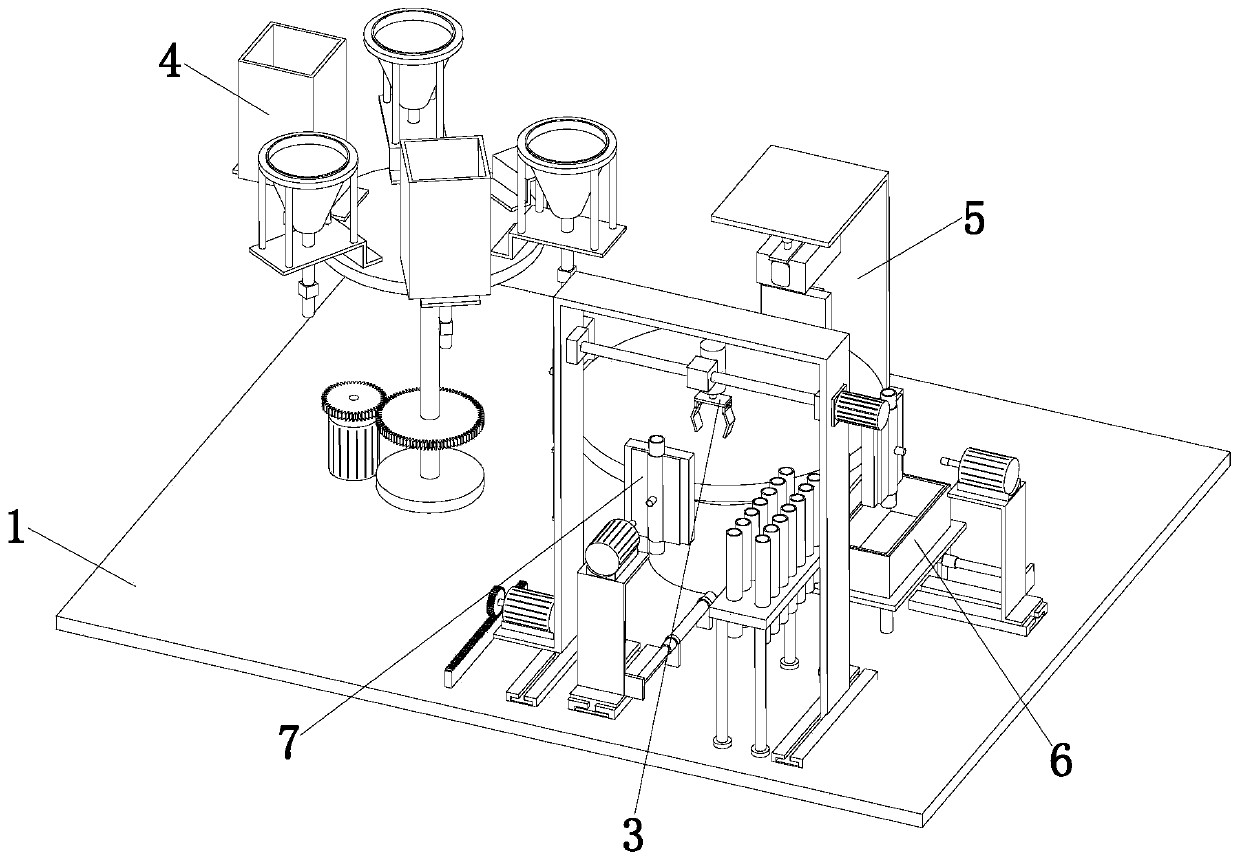

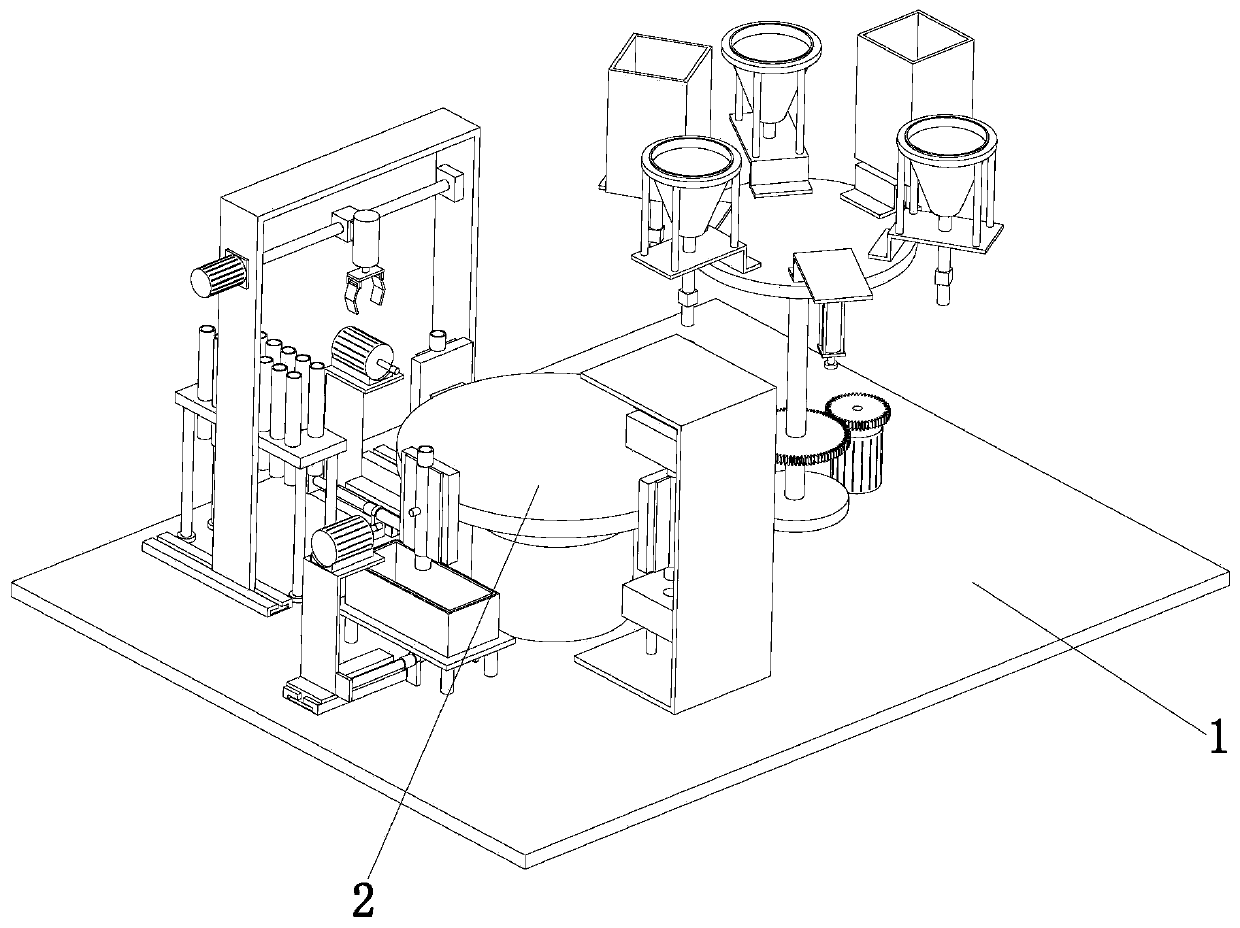

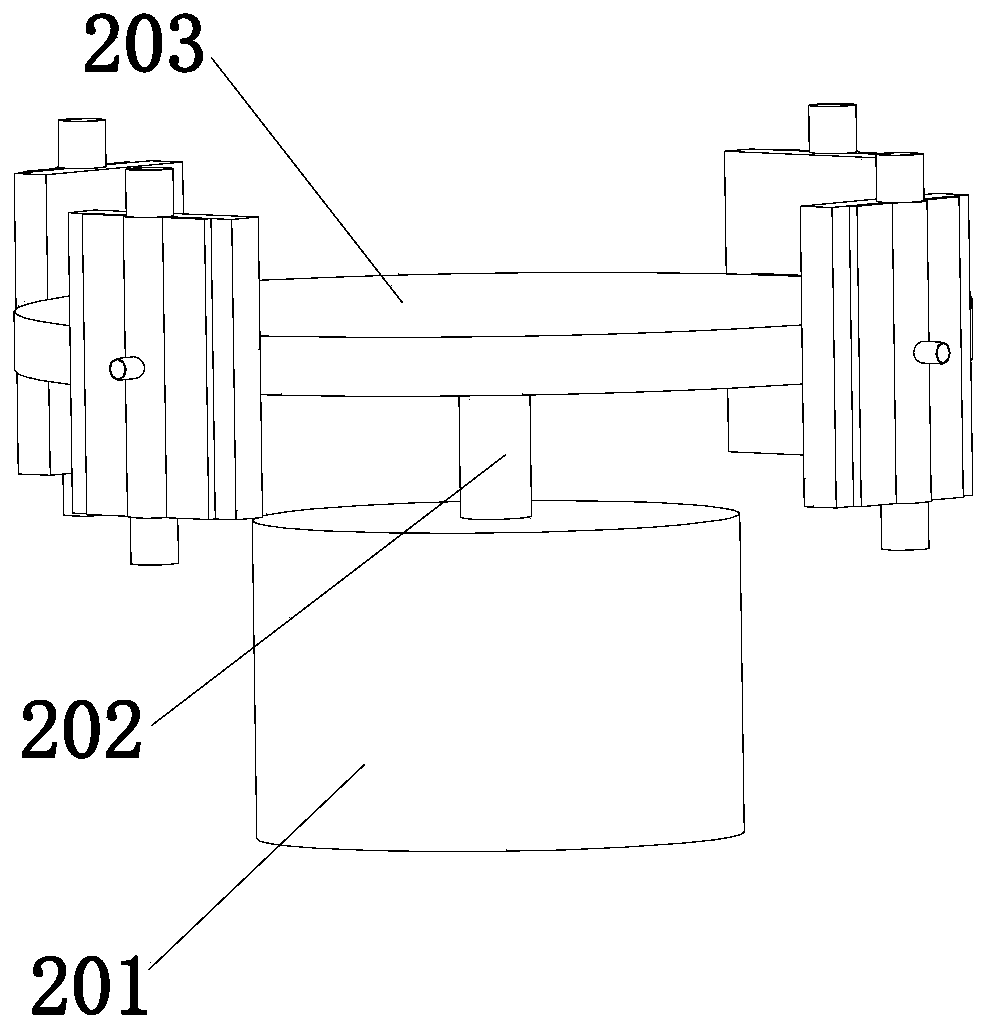

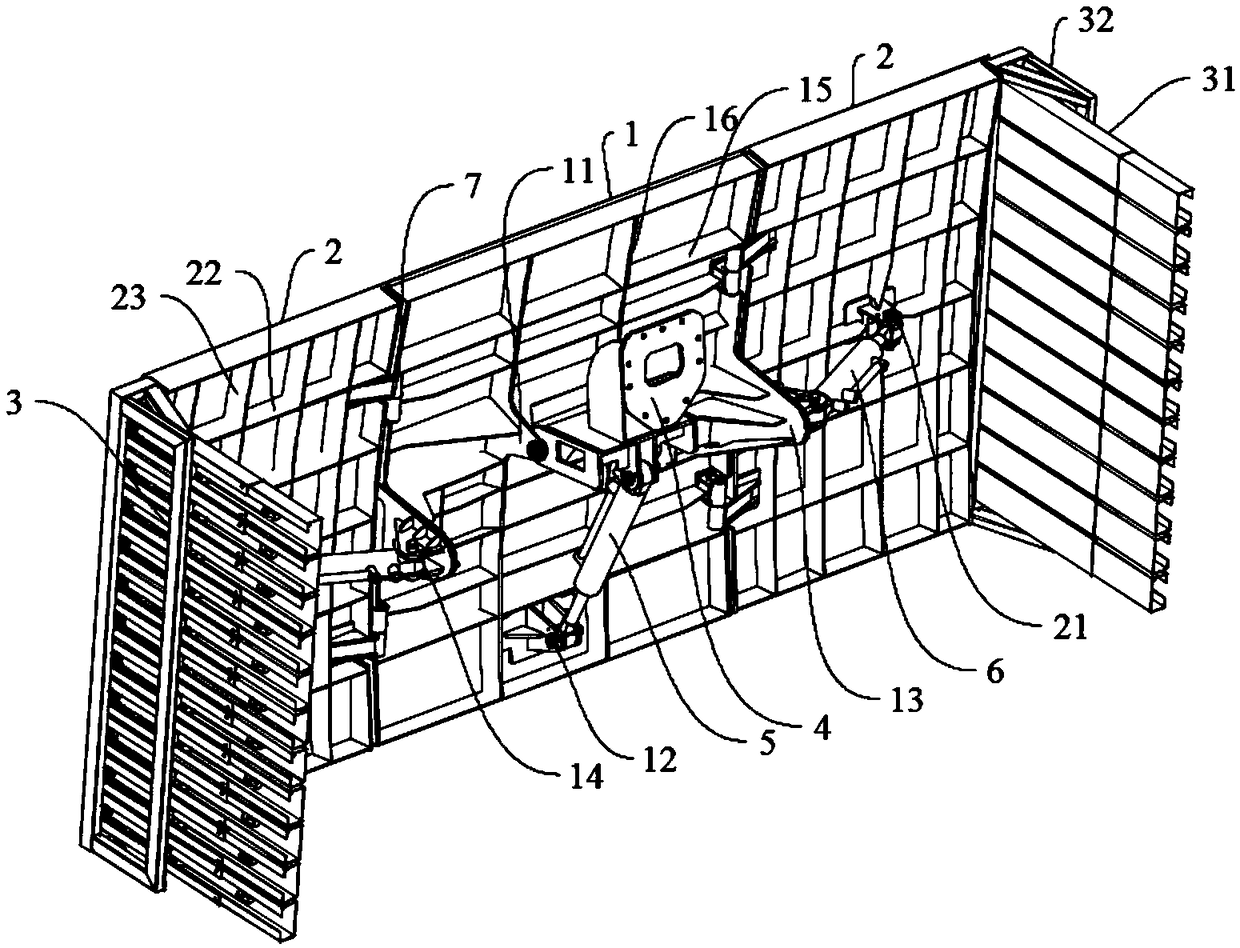

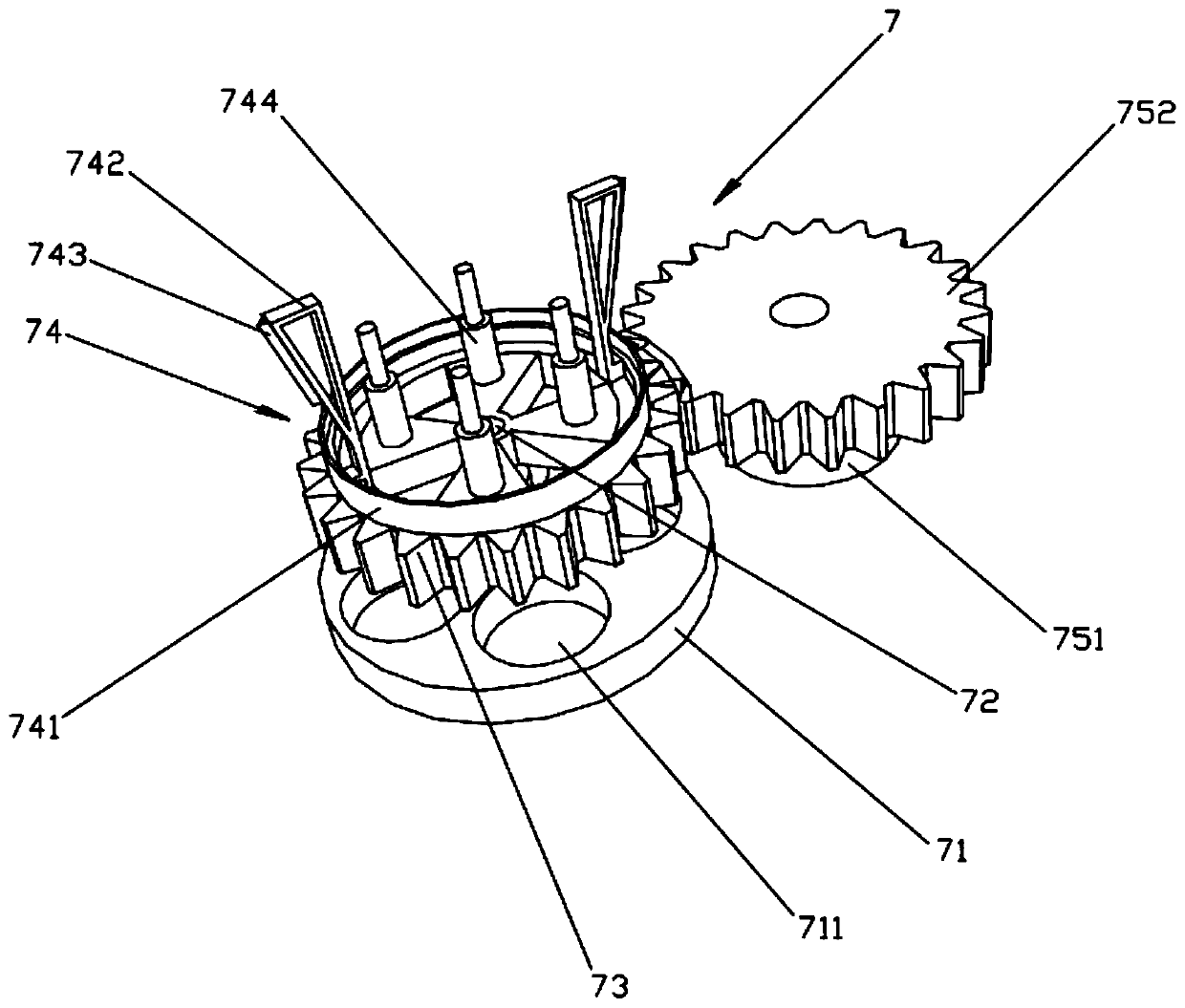

Automatic production line for mixed type active carbon sampling tube

The invention provides an automatic production line for a mixed type active carbon sampling tube, and belongs to the technical field of active carbon sampling tube processing. The automatic productionline comprises a base plate, a rotary conveying assembly, a loading assembly, a filling assembly, a sealing assembly, an unloading assembly and four workpiece positioning assemblies, wherein the rotary conveying assembly is arranged on the base plate; the four workpiece positioning assemblies are arranged on the rotary conveying assembly at equal spacing; the loading assembly, the filling assembly, the sealing assembly and the unloading assembly are sequentially arranged beside the rotary conveying assembly; and the loading assembly, the filling assembly, the sealing assembly and the unloading assembly separately correspond to the four workpiece positioning assemblies. The automatic production line solves the problem that production quality is affected as production efficiency of an existing mixed type active carbon sampling tube is low, and number of filled active carbon particles is not precise.

Owner:王璐炳

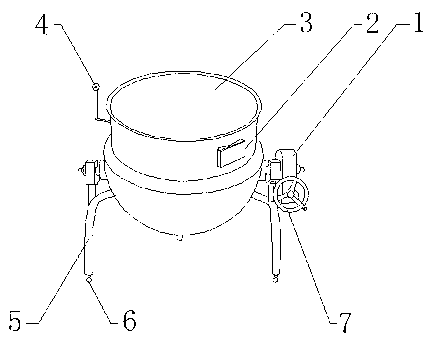

Tilting-type jacketed kettle

InactiveCN102987906AImprove work efficiencyEasy to moveEnlarged heating surface vesselsEngineeringSafety valve

The invention discloses a tilting-type jacketed kettle and relates to the field of food machine. The tilting-type jacketed kettle comprises a tilting rack and a kettle body, wherein the kettle body is arranged on the tilting rack; a supporting lug is connected to the bottom of the tilting rack; a safety valve is connected to one end of the supporting lug; a box is connected to the sidewall of the kettle body; an opening is formed on the upper part of the box; and as the box with the opening is arranged on the sidewall of the kettle body, the kettle cover can be closed on the kettle body for discharging, so that food flows out of the opening of the box by tilting the kettle; therefore, leakage during discharging can be avoided.

Owner:SUZHOU MAIKE FOOD MACHINERY PLASTIC CEMENT

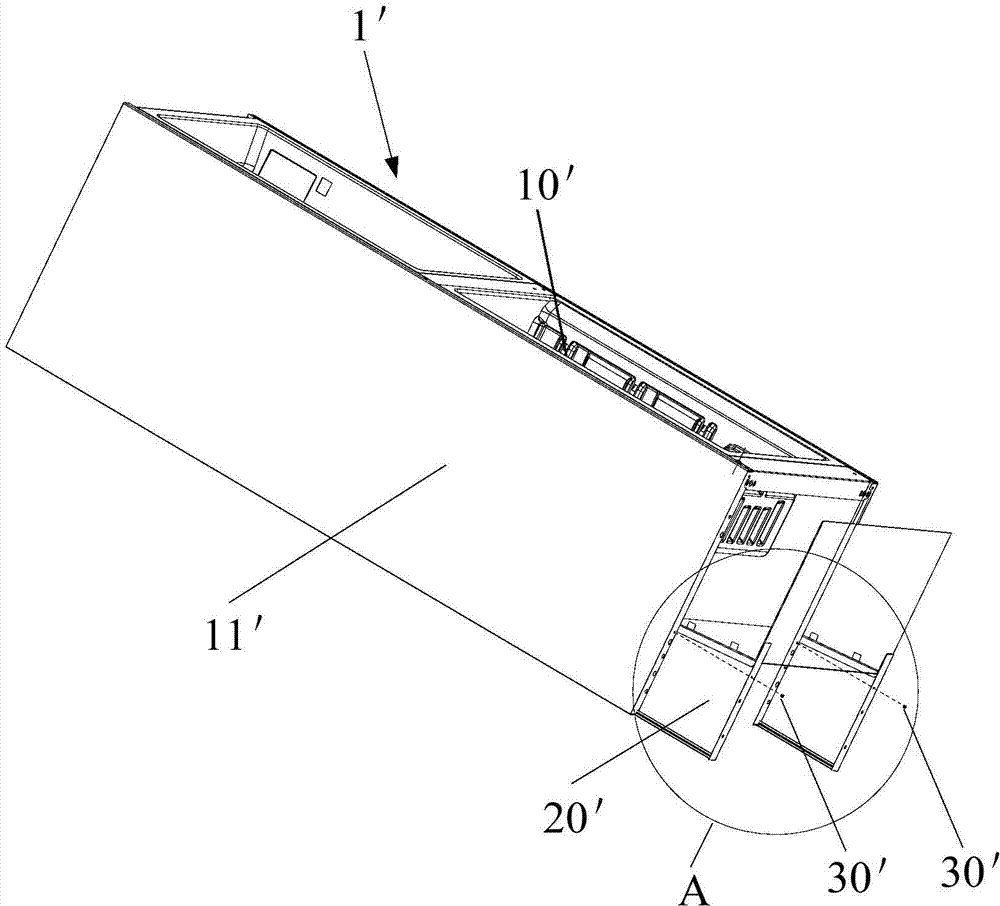

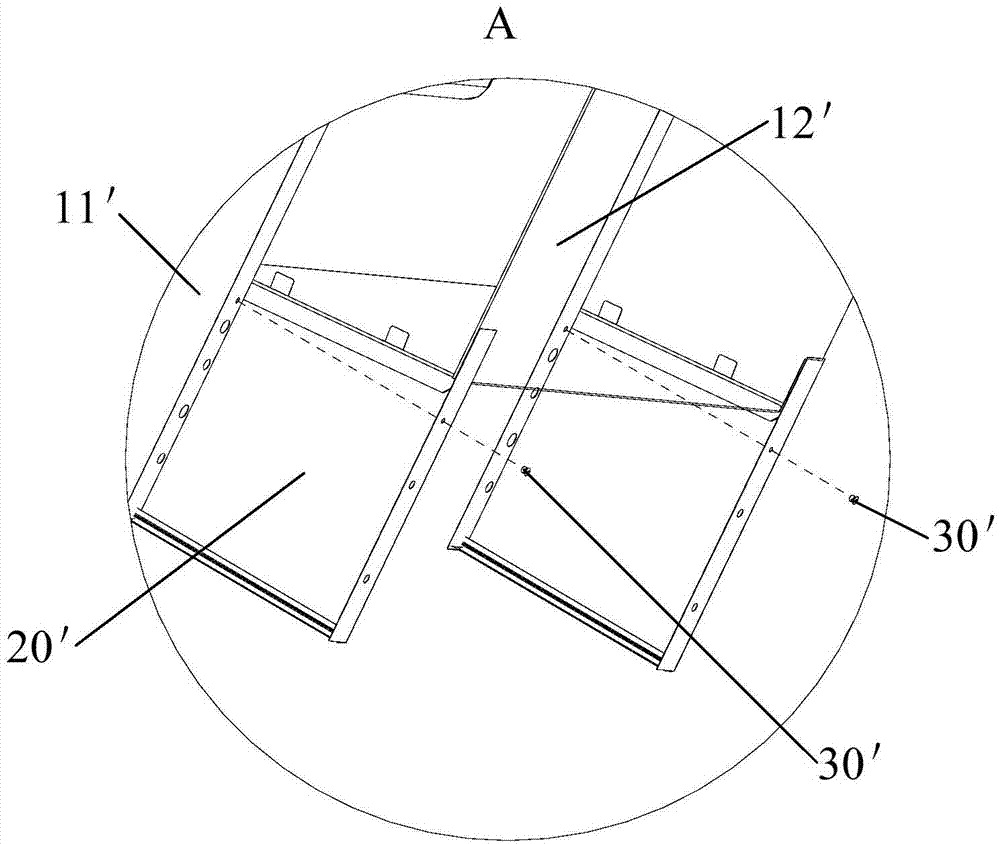

Refrigerator

ActiveCN104729185APrevent material leakageSimple structureLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Stirring and forming device assembly and method for producing building block blank body by stirring and forming device assembly

PendingCN109435057AFlexible and free movementReduce manufacturing costDischarging arrangementFeeding arrangmentsFoaming agentEngineering

The invention discloses a stirring and forming device assembly. The stirring and forming device assembly comprises a stirring device for stirring slurry, a forming device for enabling the slurry to befoamed and formed and a grabbing device for separating the forming device from foamed formed building blocks. A mold track is arranged at a discharging outlet of the stirring device, the forming device is slidably mounted on the mold track, and the grabbing device is erected above the mold track. According to the stirring and forming device assembly, the structures of the stirring device, the forming device and a pulling device are separately improved, so that the stock of the foamed building blocks on the same track is greatly increased, and the production efficiency can be nearly doubled. The invention relates to a method for producing a building block blank body. The method for producing the building block blank body comprises the following steps of (1) stirring and preparing the slurry, (2) adding a foaming agent for secondary stirring, (3) foaming and forming, and (4) separating a mold. Two stirring mechanisms can separately stir two independent chambers, so that the stirring effect of the slurry is remarkably improved.

Owner:中创环能建材科技有限公司

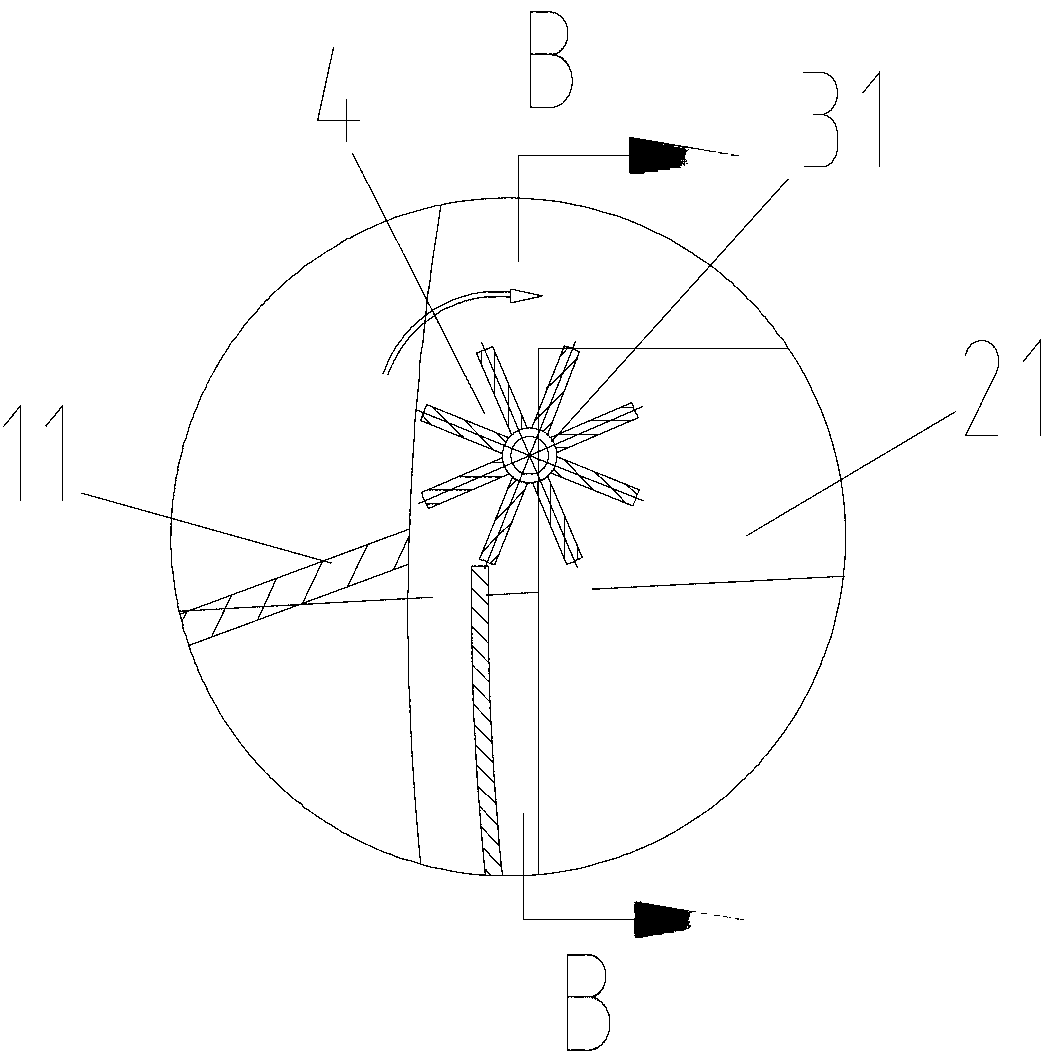

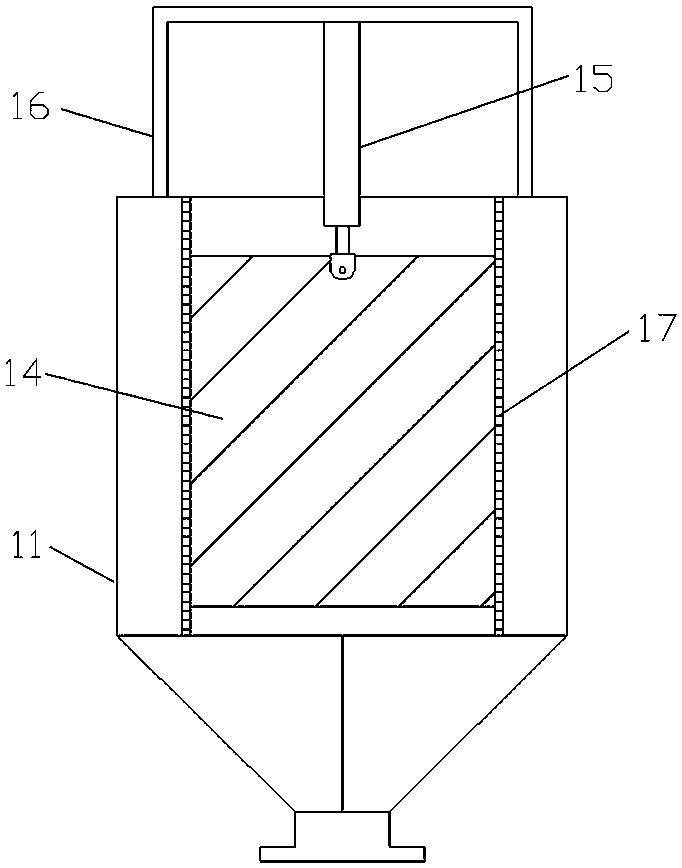

Closed double-layer barrel aerobic fermentation cylinder

InactiveCN105646013AReduce frictional resistancePrevent material leakageClimate change adaptationOrganic fertilisersTreatment effectEngineering

The invention discloses a closed double-layer barrel aerobic fermentation cylinder, comprising a support device, a barrel, a powder driving device, a ventilation device and a feeding and discharging system, wherein the barrel and the power driving device are respectively arranged on the support device; the barrel comprises a feeding fixed end cover, a middle rotating barrel and a discharging fixed end cover; the middle rotating barrel comprises an inner barrel and an outer barrel which are arranged along the same axial direction and are fixedly connected with each other by a connecting support plate; a material retaining seal structure is arranged between one end of the inner barrel of the middle rotating barrel and the feeding fixed end cover, and another material retaining seal structure is positioned between the other end of the inner barrel of the middle rotating barrel and the discharging fixed end cover; the feeding fixed end cover and the discharging fixed end cover are respectively connected with the middle rotating barrel by an end cover fixing device; each end cover fixing device comprises a rotation fixing structure and a rotation support structure. The closed double-layer barrel aerobic fermentation cylinder is simple in structure, high in working efficiency and degree of automation, reliable in operation and good in treatment effect, is free from odor spillover in the treatment process, and is capable of realizing harmless and resource utilization of kitchen wastes.

Owner:张共敏 +2

Non-layering cosmetic powder uniform mixing equipment

InactiveCN112934097ASpread evenlyPrevent material leakageRotating receptacle mixersRotary stirring mixersElectric machineryDrive motor

The invention provides non-layering cosmetic powder uniform mixing equipment, relates to the technical field of cosmetic processing, and solves the problems that premixing cannot be realized through structural improvement, and a premixing structure cannot be organically combined with a mixing structure, the follow path between the powder and a barrel is short and the mixing quality is influenced, and the vibration type cleaning of the residues adhered to the inner wall of the barrel cannot be realized while the rotary mixing is performed through the improvement on the structure. The non-layering cosmetic powder uniform mixing equipment comprises a box body; a mixing structure is mounted in the box body, the barrel is rotatably connected in the box body, and the box body is fixedly connected with a driving motor through bolts. The elastic telescopic rod is fixedly connected to the inner wall of the box body through the bolts, and the head end of the elastic telescopic rod is of a hemispherical structure. The elastic telescopic rods are aligned with the sieve holes, the elastic telescopic rods are elastically clamped with the sieve holes, and the elastic telescopic rods and the sieve holes jointly form the vibration structure of the barrel, so that powder can be prevented from remaining on the inner wall of the barrel.

Owner:杨晓菲

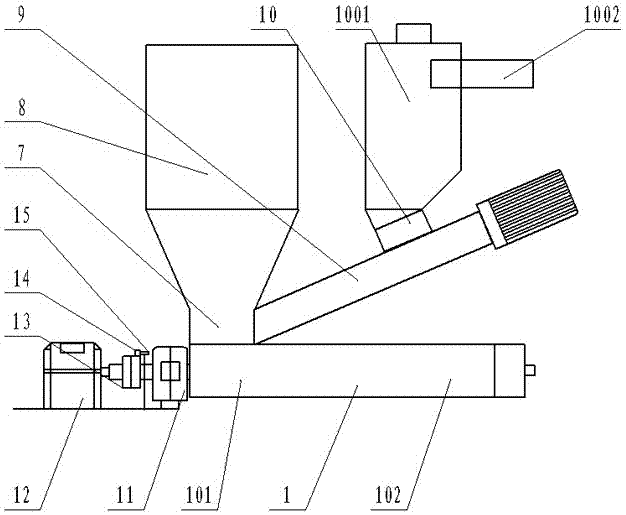

Counting and feeding device of injection molding machine for recycling waste

The invention discloses a counting and feeding device of an injection molding machine for recycling waste. The counting and feeding device comprises a feeding packing auger, a valve support and a hopper. A feeding motor is arranged on the left side of the feeding packing auger and mechanically connected with the feeding packing auger through a speed reducer coupler of a gearbox. A photoelectric induction baffle is arranged on the speed reducer coupler, a photoelectric counter is fixedly arranged beside the speed reducer coupler through a support, and an interval exists between the photoelectric counter and the speed reducer coupler. The photoelectric induction baffle and the speed reducer coupler rotate together. By means of the baffle, materials are prevented from being stored in a transition material opening, a certain interval exists between the baffle and a machine body, powder can be prevented from being stacked on the transition material opening, and it can be avoided that residual materials obtained after discharging hinder closing of a valve gland, and consequently the valve gland is closed untightly; and sealing performance is good, the phenomenon of materail leakage is avoided, time, labor force and resources are saved, and production efficiency is improved.

Owner:JIANGSU KUNTAI MACHINERY

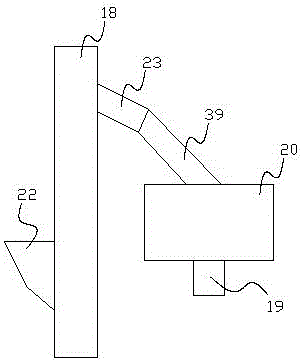

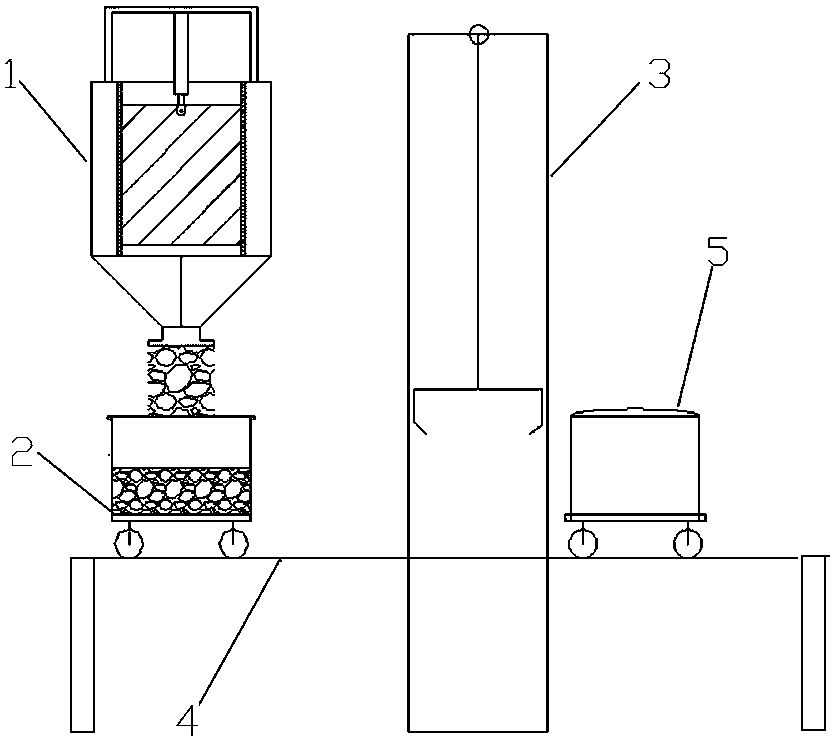

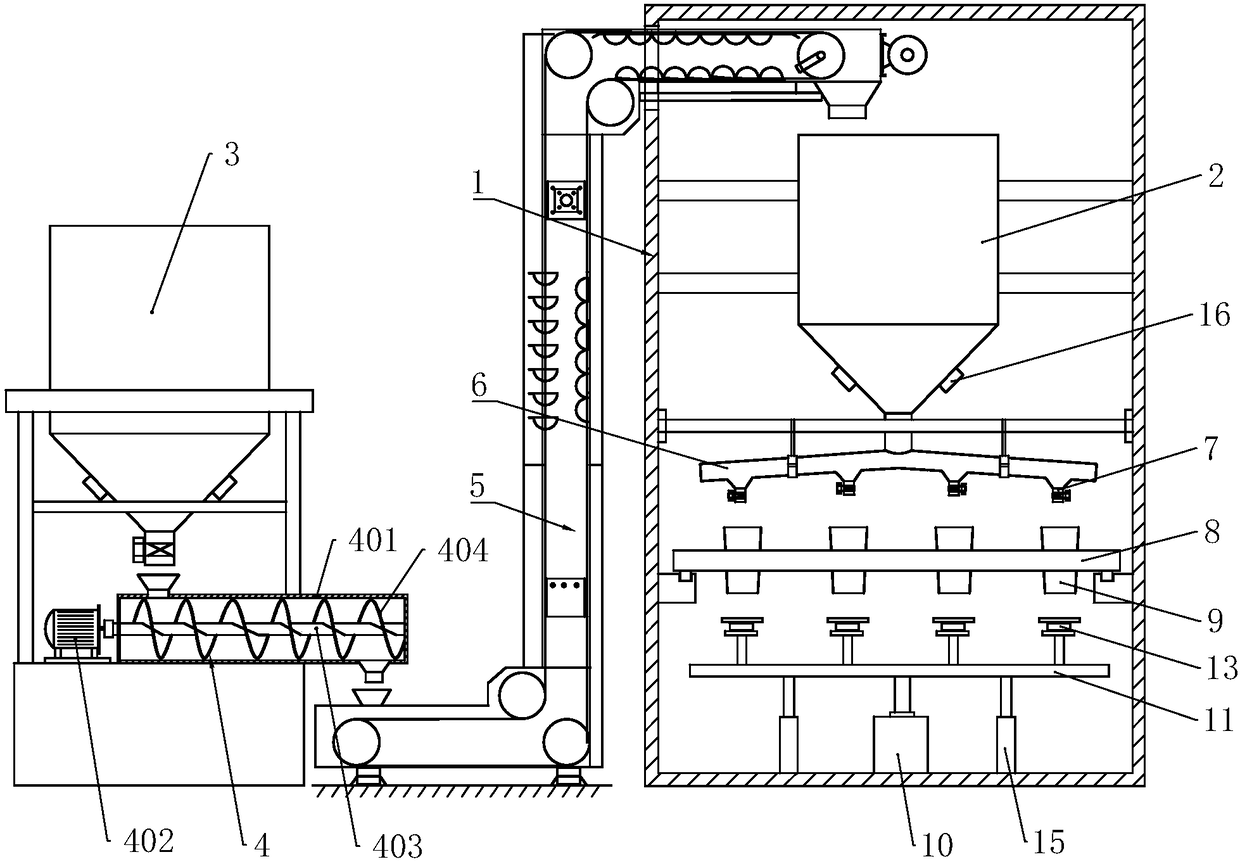

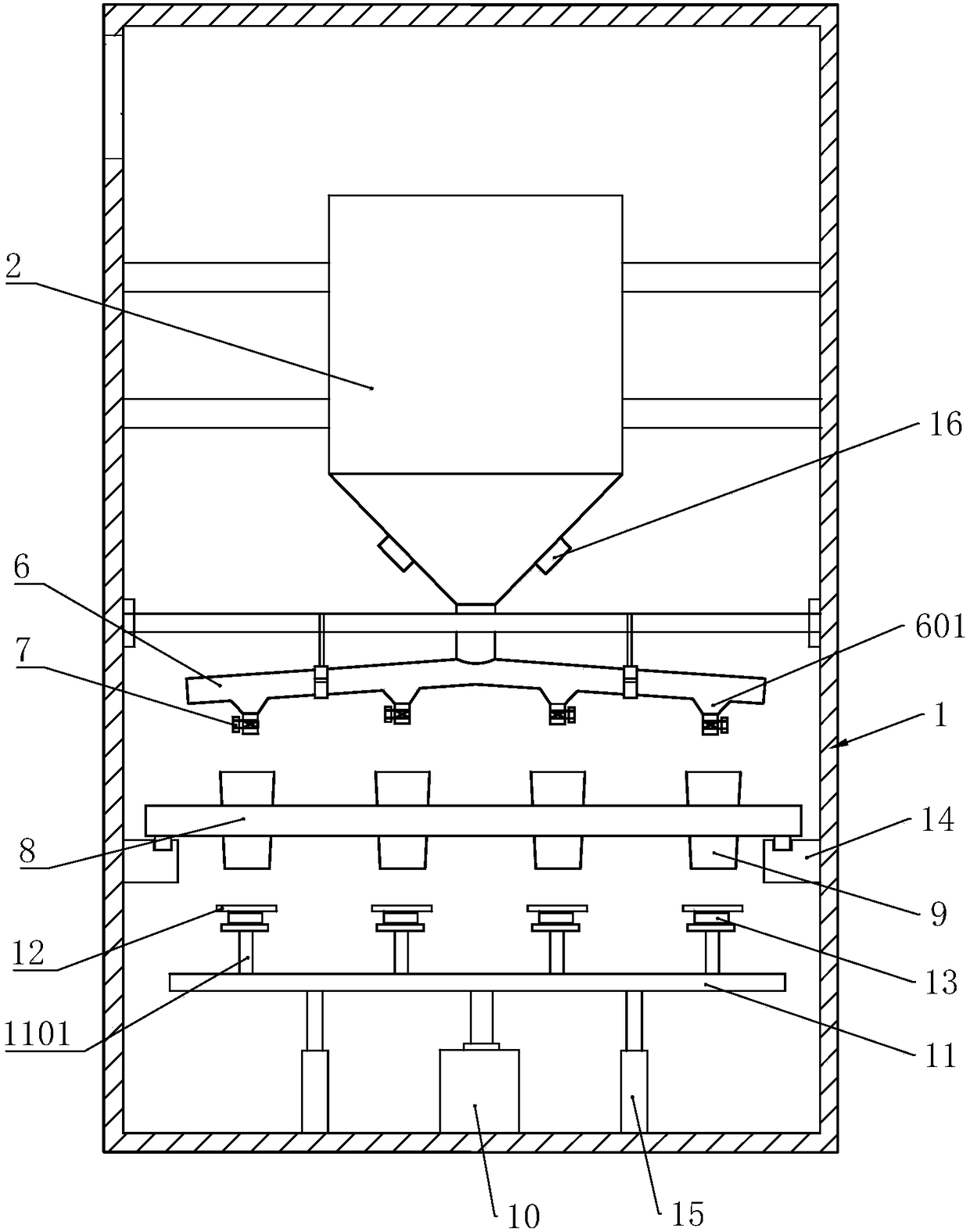

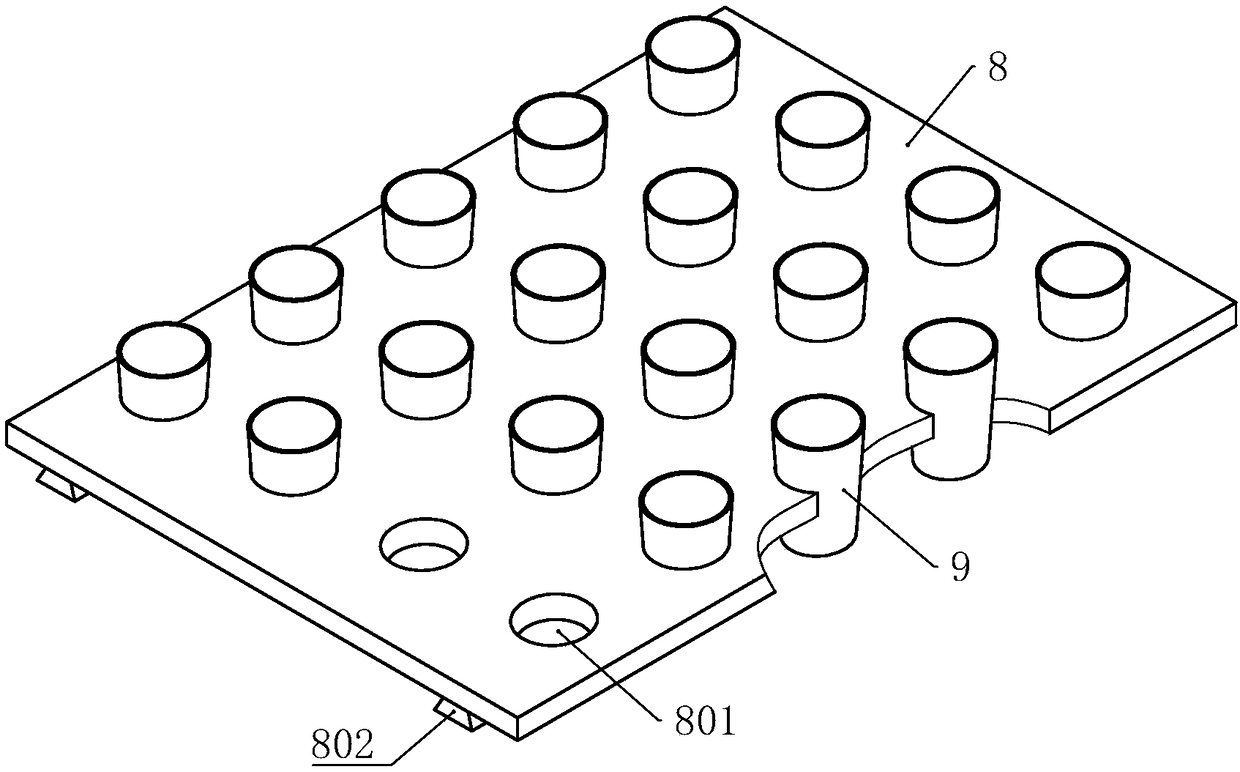

Automatic weighting and distributing device and application thereof in aspect of processing raw materials of brake pads and medicine

PendingCN108298333AImprove distribution efficiencyExtended service lifeLoading/unloadingMechanical conveyorsElectricityEngineering

The invention relates to an automatic weighting and distributing device and an application thereof in the aspect of processing raw materials of brake pads and medicine. The invention belongs to the technical field of weighing and distribution, and provides an automatic weighting and distributing device. The automatic weighting and distributing device comprises a distributing box body, a feeding mechanism, a distributing mechanism, a bearing mechanism and a weighing mechanism, wherein a storage hopper is fixedly installed in the distributing box body; the feeding mechanism comprises a batch hopper, a mixing conveyor and a rotary bucket lifting machine; the distributing mechanism comprises a distributing pipe which communicates with the storage hopper, and a plurality of distributing openings on which electromagnetic valves are respectively installed are formed in the distributing pipe; the bearing mechanism comprises a sliding plate, a plurality of through holes are formed in the sliding plate, and material cups are put in the through holes; and the weighing mechanism comprises an air cylinder, cup ejection rods, trays and weighing sensors, a piston rod of the air cylinder is fixedly connected with the cup ejection rods, the trays are installed on the cup ejection rods by virtue of the weighing sensors and correspond to the through holes, and the weighing sensors are electrically connected with the electromagnetic valves which are vertically and correspondingly arranged respectively. The automatic weighting and distributing device has the advantages of simple structure and low cost, simultaneous precise distribution of multiple material cups is realized, and the distributing efficiency of raw materials of products is improved.

Owner:青岛创高世纪信息科技有限公司

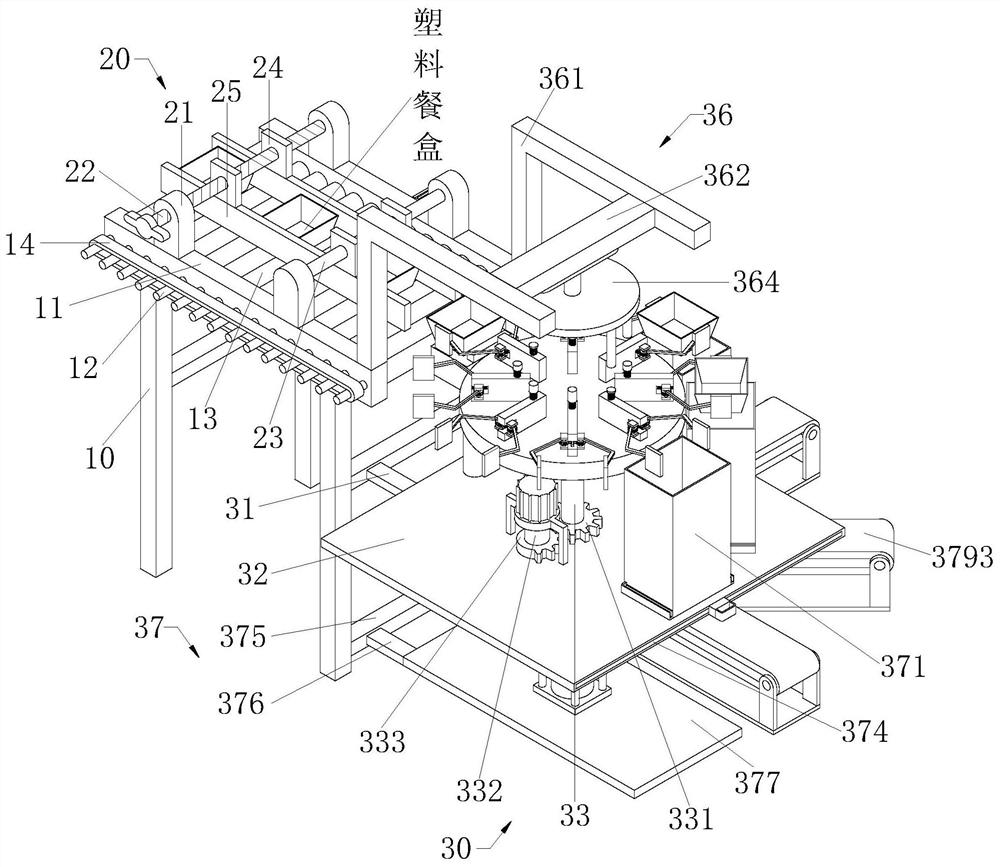

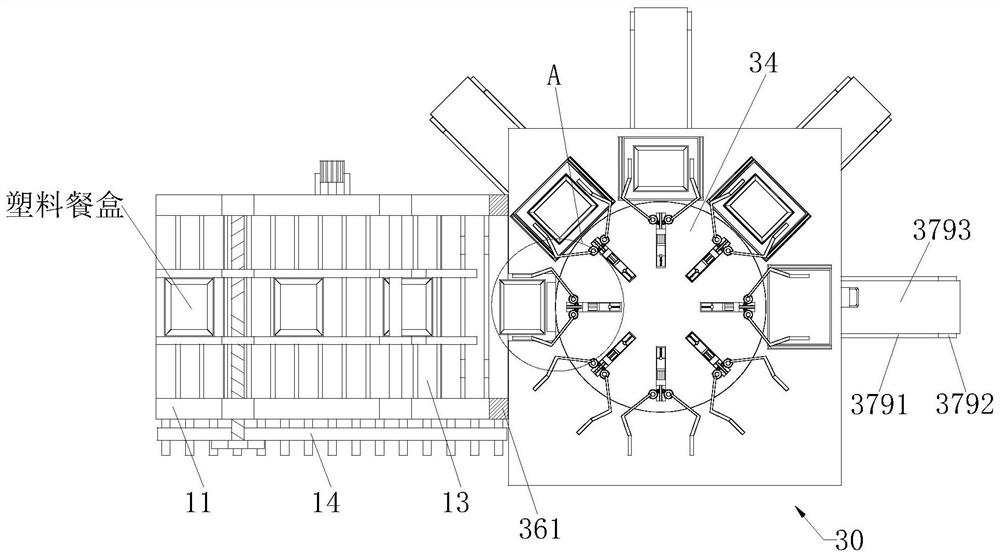

Automatic processing system for injection molding production of food-grade antibacterial plastic meal boxes

The invention discloses an automatic processing system for injection molding production of food-grade antibacterial plastic meal boxes. The automatic processing system comprises H-shaped frames arranged in a bilateral symmetry mode and limiting devices arranged above the H-shaped frames, and a stacking device is arranged on the right sides of the H-shaped frames; through the cooperation of clamping plates, connecting springs, inclined plates and protrusions, the two sets of inclined plates can rotate around round pins under the elastic force effect of the connecting springs, so that the two sets of inclined plates can clamp the outer walls of plastic meal boxes of different sizes, the connecting springs have the buffering effect, the situation that the two sets of inclined plates are clamped too tightly, the to-be-processed plastic meal boxes are easy to deform or crack, the resources are wasted is prevented, friction force between the inclined plates and the outer walls of the to-be-processed plastic meal boxes can be increased through the protrusions, and the phenomenon that the to-be-processed plastic meal boxes shift or leak in the moving process is prevented.

Owner:合肥索然包装材料有限公司

Material-receiving device for filter press

ActiveCN106110721ASimple structureEasy to implementPackagingFiltration separationEngineeringFilter press

The invention discloses a material-receiving device for a filter press. The material-receiving device comprises a material-receiving bag and a material-receiving frame, wherein a plurality of material-receiving suspenders are arranged on the material-receiving bag; a plurality of material-receiving pothooks are arranged on the material-receiving frame; the material-receiving pothooks of the material-receiving bag are hung on the material-receiving pothooks; the material-receiving pothooks comprise vertical rods fixed on the material-receiving frame; hanging rods are in rotatable connection with the lower parts of the vertical rods; opening slots are arranged at the ends of the hanging rods; hanging rings are in rotatable connection with the upper parts of the vertical rods; in a use process, the hanging rings are clamped in the opening slots of the hanging rods; the hanging rings and the hanging rods are matched with the vertical rods so as to form the hanging receiving slots for hanging the material-receiving suspenders. The material-receiving device for the filter press has a simple structure and is easy to realize; a tray can be mounted on the lower part of the material-receiving bag; after the materials are fully loaded, the materials are directly pulled through an electric hydraulic vehicle, and then the next material-receiving bag can be replaced; the operation is convenient and simple; after the material-receiving suspenders are hung in the hanging receiving slots, the opening of the material-receiving bag is opened and the leakage phenomenon is prevented from happening.

Owner:KONCA SOLAR CELL

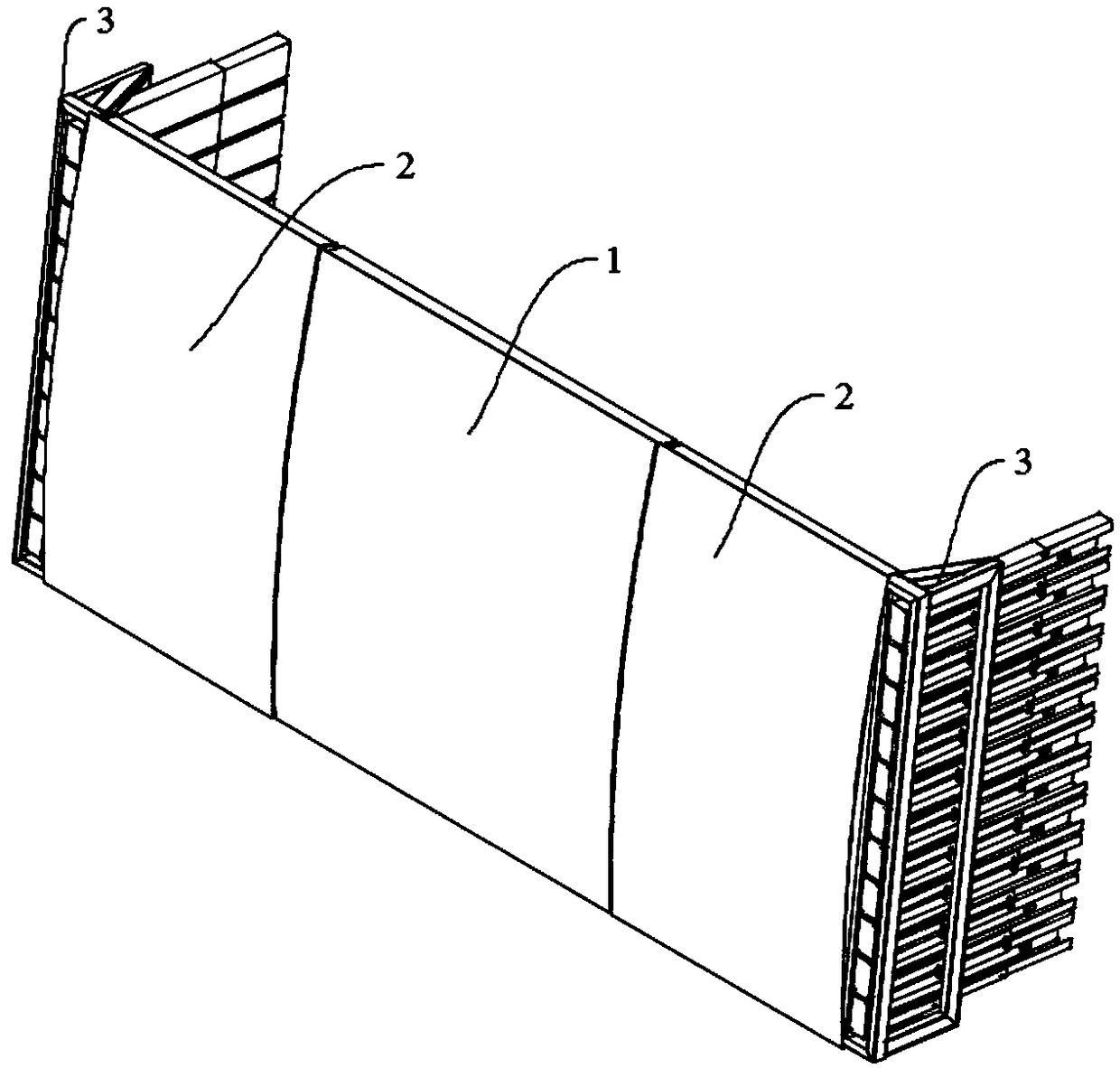

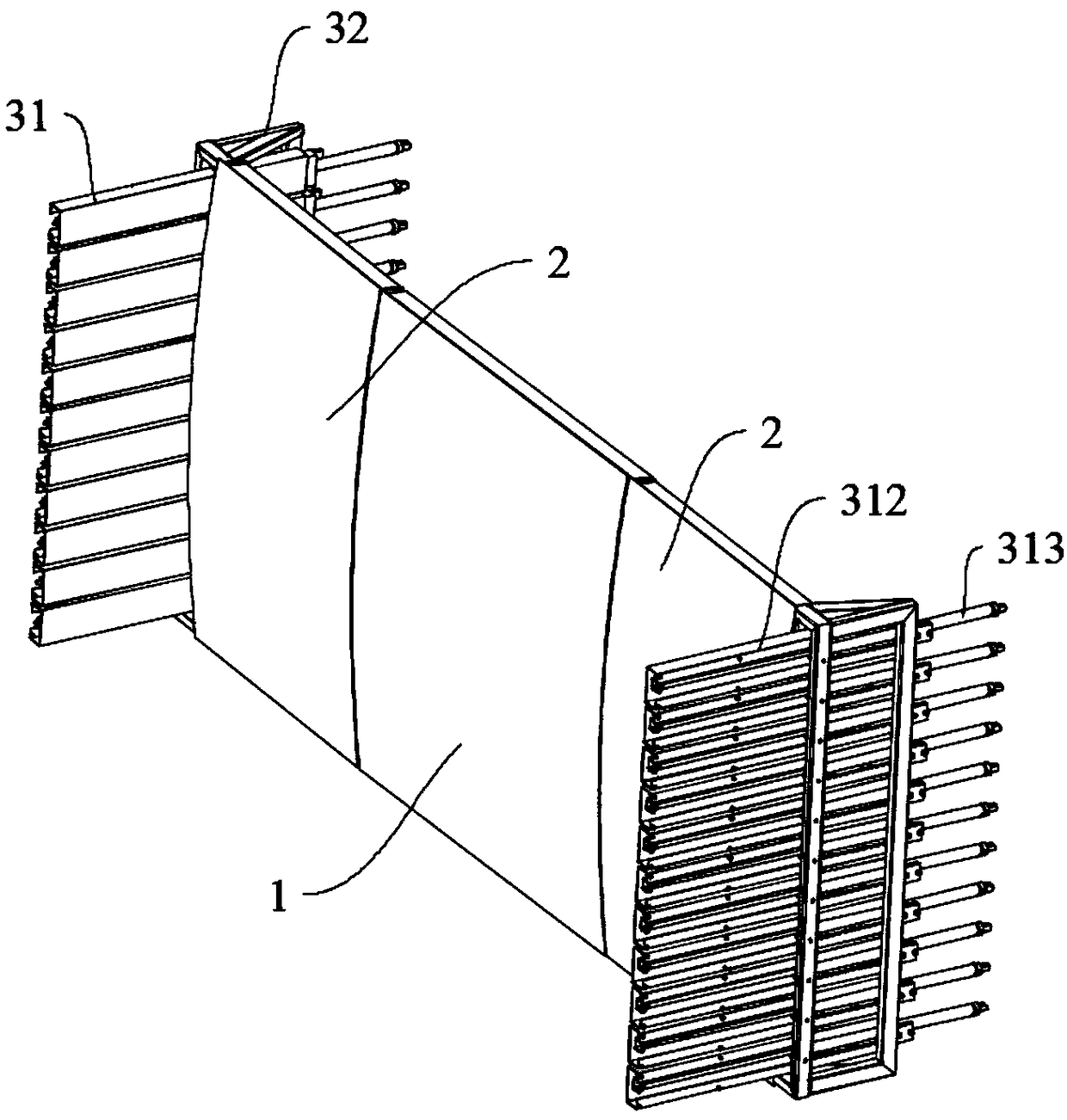

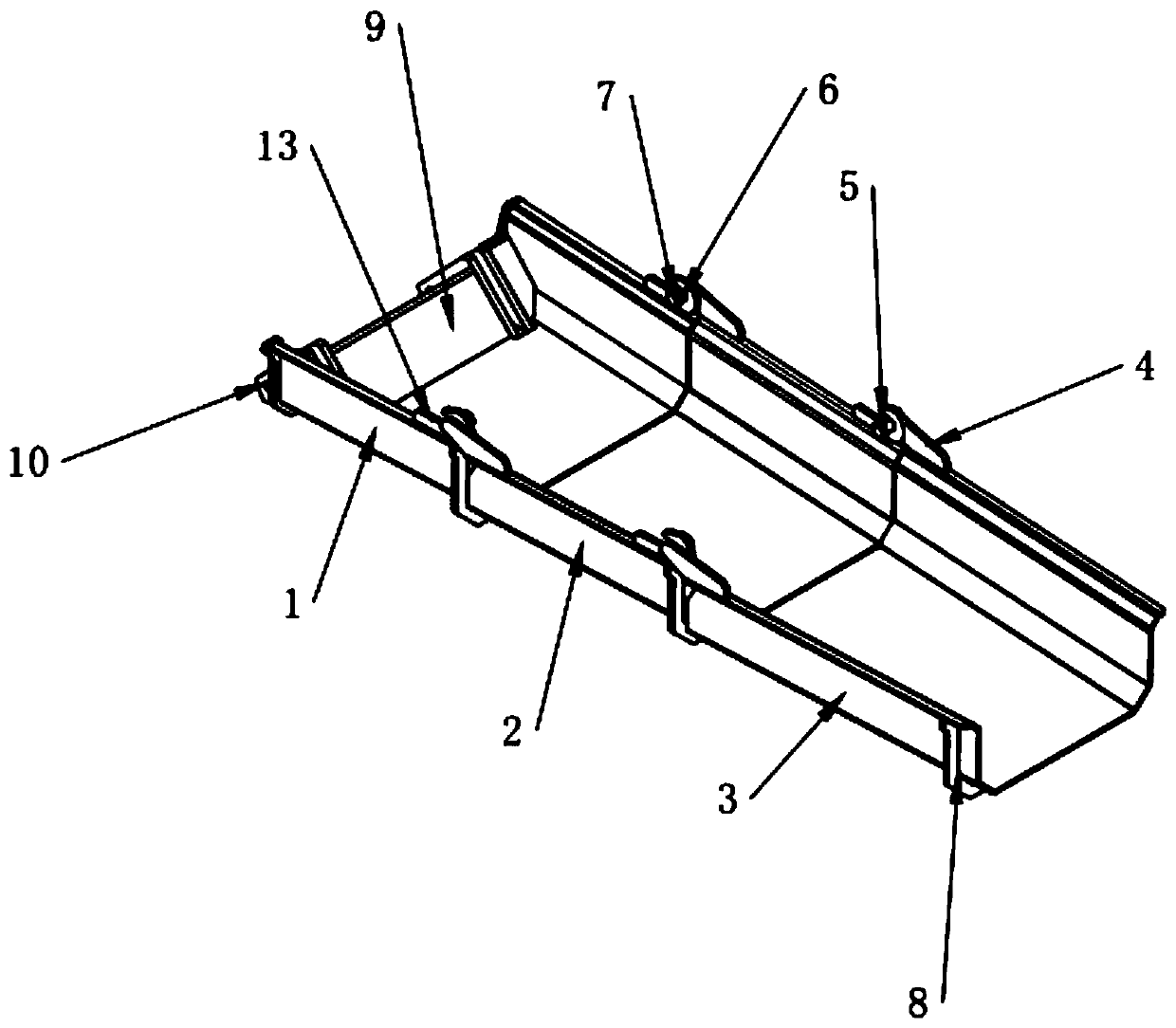

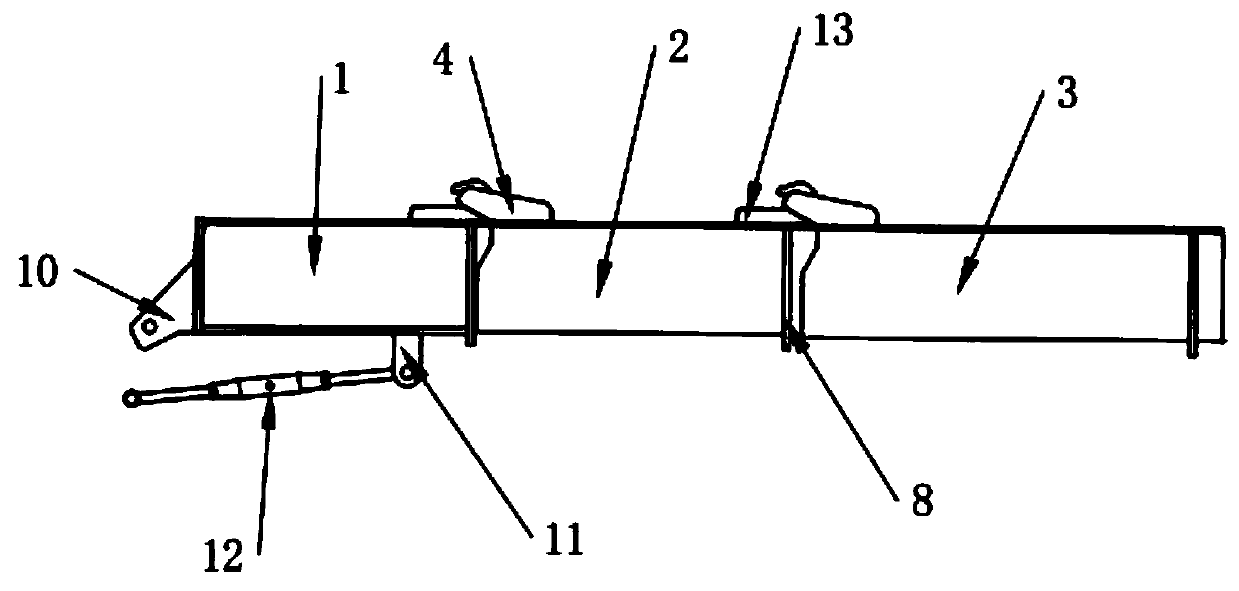

Side mold mechanism for concrete mold spraying

PendingCN109404013APrevent material leakageReduce dosageUnderground chambersTunnel liningMaterials scienceRaw material

The invention discloses a side mold mechanism for concrete mold spraying. The side mold mechanism for concrete mold spraying comprises a side mold supporting frame and a telescopic side mold plate assembly, wherein the side mold supporting frame is fixed to the edge part of a mold plate; the side mold plate assembly is mounted on the side mold supporting frame, and can extend and retract in the direction perpendicular to the mold plate, and the extended side mold plate assembly can abut against the rock surface of a tunnel, and thus the rock surface, the mold plate and the side mold plate assembly can match with each other to form a mold cavity. Through the side mold mechanism for concrete mold spraying matching with a tunnel primary supporting mold plate mechanism, the mold cavity is formed among a side mold plate mechanism, a mold plate mechanism and the rock surface, and thus a mold spraying operation can be carried out directly when a steel arch is not constructed; the phenomenon of material leaking caused by a gap between the mold plate mechanism and the steel arch or between the steel arch and the rock surface is avoided even if the pouring construction is performed on the mold cavity formed by being matched with the steel arch, and thus the dosage of pouring raw materials is further saved, and the construction quality of primary supporting spray pouring is improved.

Owner:SICHUAN LANHAI ENG EQUIP MFG CO LTD

Polyurethane foaming device

The invention relates to a polyurethane foaming device which comprises a foaming box and a metal mixing barrel with two open ends; an edge is arranged on the opening on the lower end of the metal mixing barrel, a rubber washer is installed at the lower side of the edge, and a lifting handle is arranged on the wall of the metal mixing barrel; the metal mixing barrel is arranged in the foaming box, and the rubber washer is in firm contact with the bottom of the foaming box. A mixed material is injected to the metal mixing barrel, and the mixed material is mixed in the metal mixing barrel again by the impact of the injection, the metal mixing barrel is lifted up after the injection operation, and the mixed material naturally flows to the foaming box to be foamed. The polyurethane foaming device is used for solving the problems of layering, cracking and non-uniform distribution caused by overlapping mixed materials with different reaction times and improving the quality of the product; and due to the weight of the metal mixing barrel, the rubber washer can be in tight contact with the bottom of the foaming box to avoid the material leakage phenomenon in the injection process.

Owner:LIYANG SHANHU IND CO LTD

Insert positioning structure in die

ActiveCN104029339AStrong anti-adhesivePrevent material leakageCoatingsPolytetrafluoroethyleneEngineering

The invention discloses an insert positioning structure in a die. The insert positioning structure comprises a bushing and a seal block, the bushing is fixedly connected with the seal block, and the seal block is fixedly connected with the body of the die; at least one positioning slot along the circumference direction of the bushing is arranged in the bushing, and a first polytetrafluoroethylene protection sleeve is arranged in the positioning slot; and a second polytetrafluoroethylene protection sleeve is arranged in the seal block. The insert positioning structure in the die realizes the convenience of the installation and positioning of the insert, and can prevent material leakage.

Owner:SHANGHAI ROX ELECTRIC

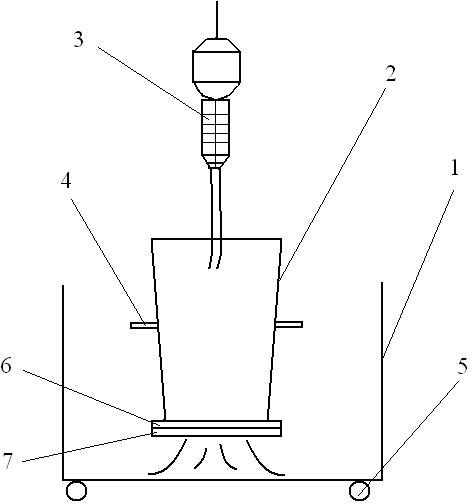

Concrete finished product hopper combined discharge valve

PendingCN111347553ARealize opening and closing controlPrevent material leakageHollow article cleaningCement mixing apparatusStructural engineeringSlurry

The invention provides a concrete finished product hopper combined discharge valve, and relates to the technical field of discharge valves. The concrete finished product hopper combined discharge valve comprises a raw material hopper and a vertical discharge valve which are sequentially arranged up and down, the raw material hopper is in the shape of an inverted circular truncated cone, both the top and the bottom of the vertical discharge valve are open, the lower end of the raw material hopper is connected with the top of the vertical discharge valve through a flange, an arc-shaped valve plate and a movable chute are sequentially arranged on the peripheral side of the vertical discharge valve from inside to outside, the arc-shaped valve plate comprises a left side plate, a right side plate and an arc-shaped bottom plate, the left side plate and the right side plate are both of fan-shaped hollowed-out structures, the circle centers of the left side plate and the right side plate are rotationally connected to the opposite outer walls of the vertical discharge valve through rotating shafts, the arc-shaped bottom plate is arranged between an arc-shaped edge of the left side plate andan arc-shaped edge of the right side plate and located at the bottom of the vertical discharge valve. The concrete finished product hopper combined discharge valve has the advantages that the phenomena of slurry leakage and material leakage when the discharge valve is closed can be avoided, concrete slurry splashing can be avoided when concrete mixers of different heights are fed, and the like.

Owner:NANJING XILONG MASCH EQUIP CO LTD

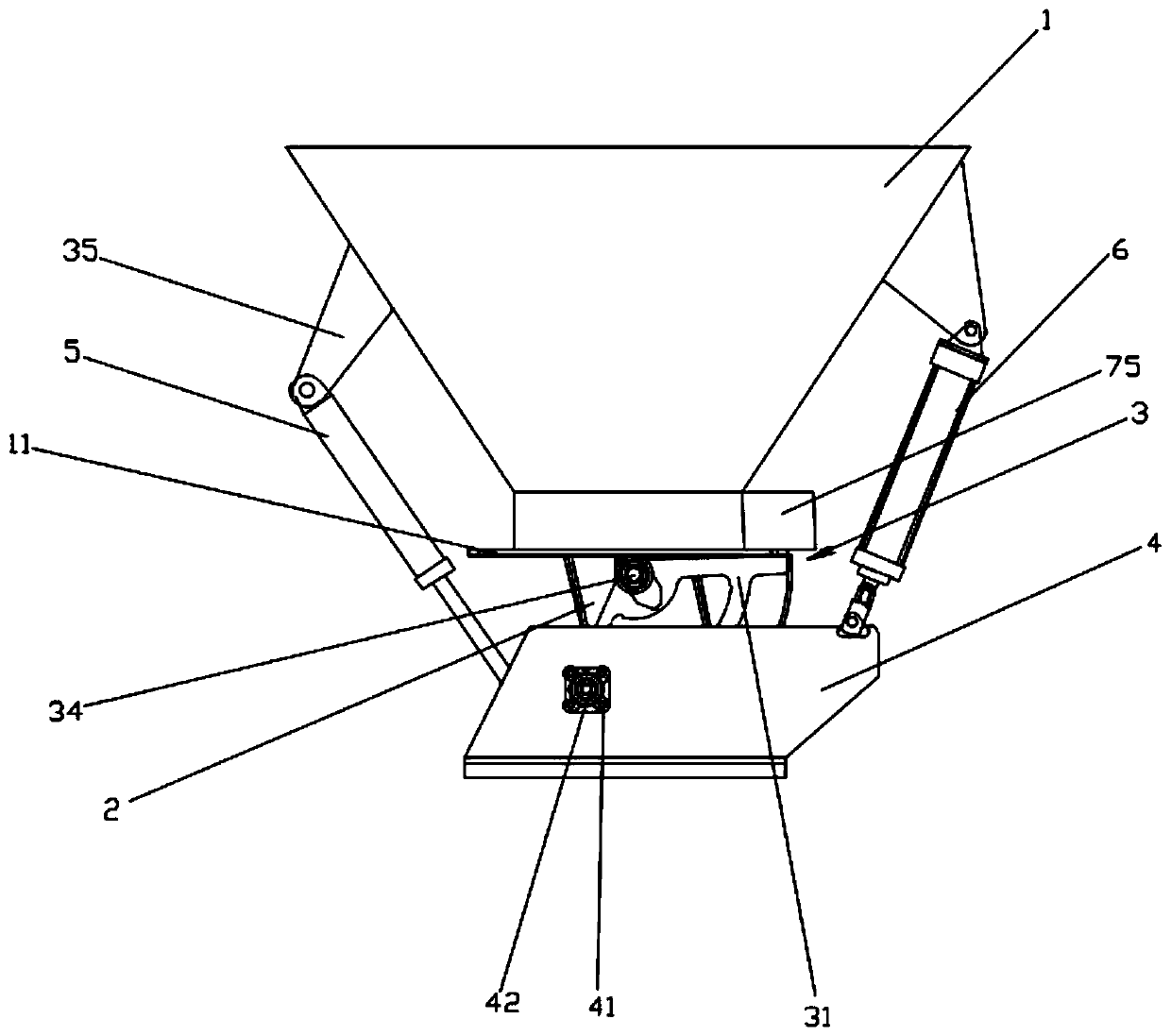

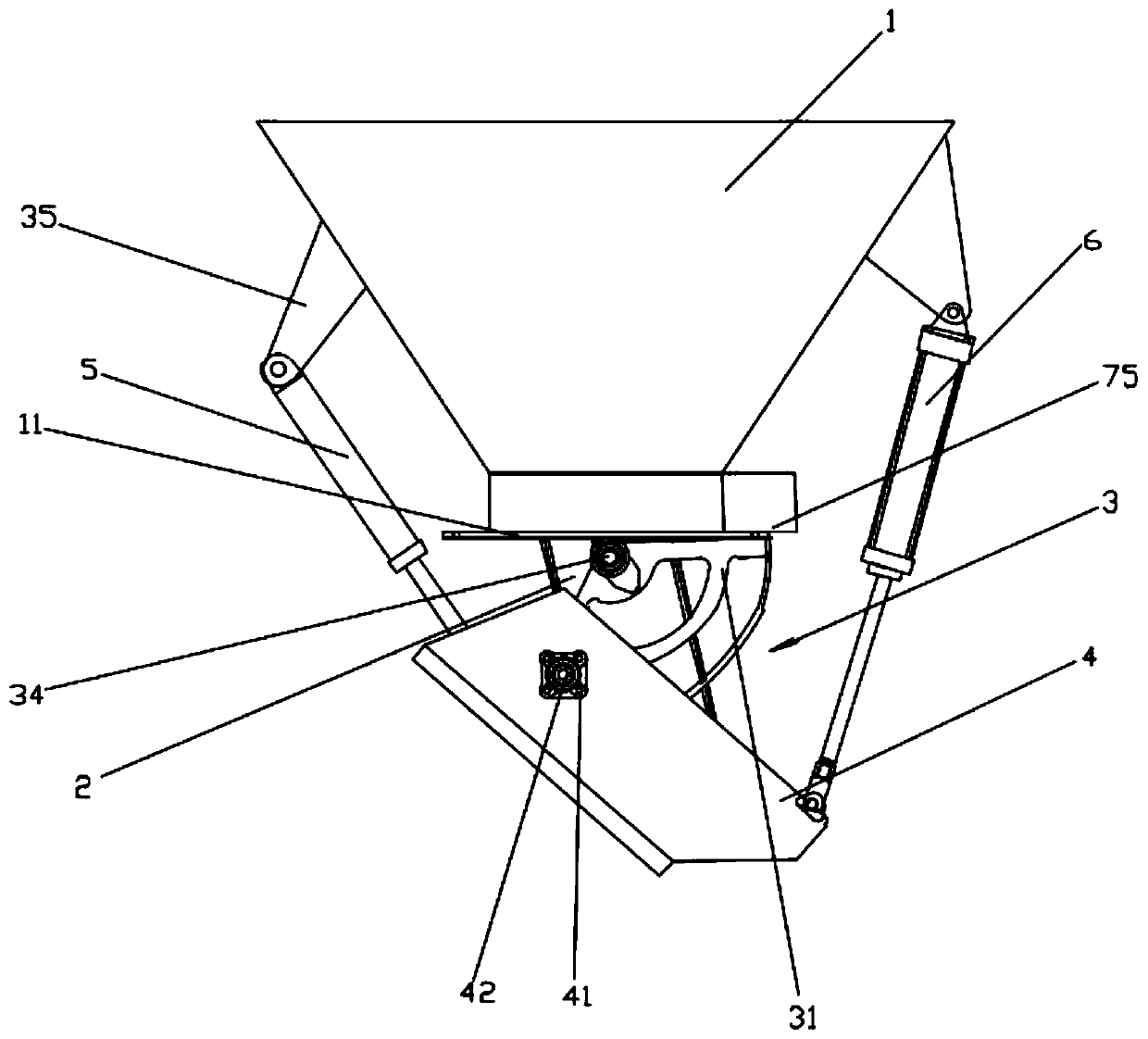

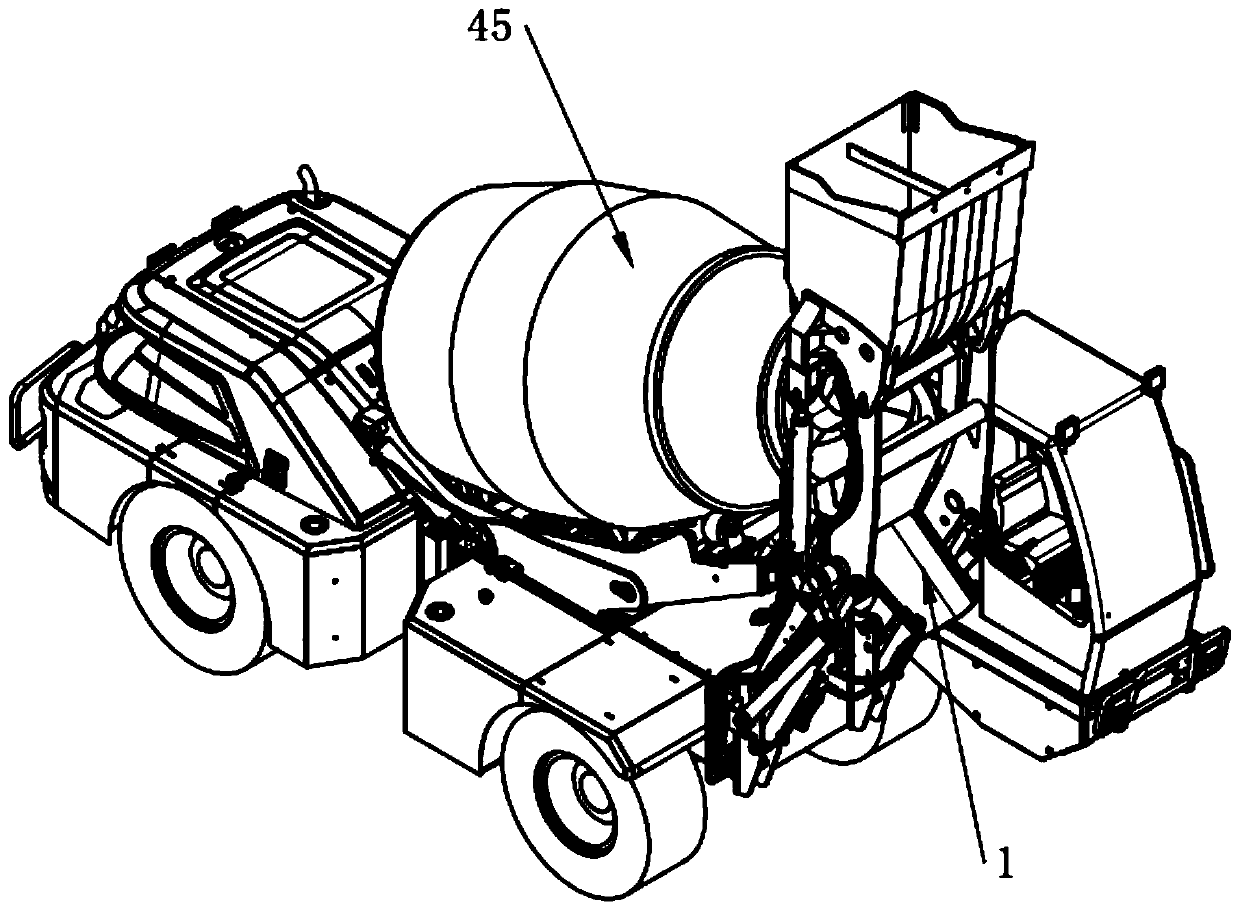

Automatic feeding and stirring tank truck

InactiveCN110000927AGuaranteed stabilityGuaranteed balance and stabilityDischarging apparatusCement mixing apparatusHydraulic cylinderBogie

The invention discloses an automatic feeding and stirring tank truck and relates to the technical field of stirring tank trucks. The tank truck comprises a supporting seat protection mechanism, a self-compensation supporting mechanism, a self-discharging mechanism and a discharge-guiding mechanism, wherein the supporting seat protecting mechanism comprises steering frames which are hinged to eachother, and buffer parts which are arranged on the steering frames and are used for preventing rigid collision during turning of the steering frames. According to the automatic feeding and stirring tank truck, in the case of a vehicle body in the prior art, the phenomenon that oil leakage from a supporting seat on a chassis because of vehicle body turning occurs frequently is avoided; the phenomenon that the axial line contact area between a tank body and a supporting wheel is gradually shortened is avoided; the problem that material is easy to leak during charging is solved; the problem that the reaction bending force acting on hydraulic cylinders can simply damage the hydraulic cylinders is solved; the problem that the discharging distance is limited, so that the discharging structure isnot easy to assemble and disassemble is solved; and the problem of material splashing during discharging is solved.

Owner:莱州市鲁樽机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com