Four-way material distributer free of material blocking

A distributor and material jamming technology, applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of electro-hydraulic push rod overload, equipment failure, unreliability, etc., to expand the receiving caliber, prevent material leakage, and operate reliably Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the drawings and embodiments.

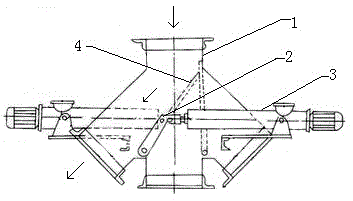

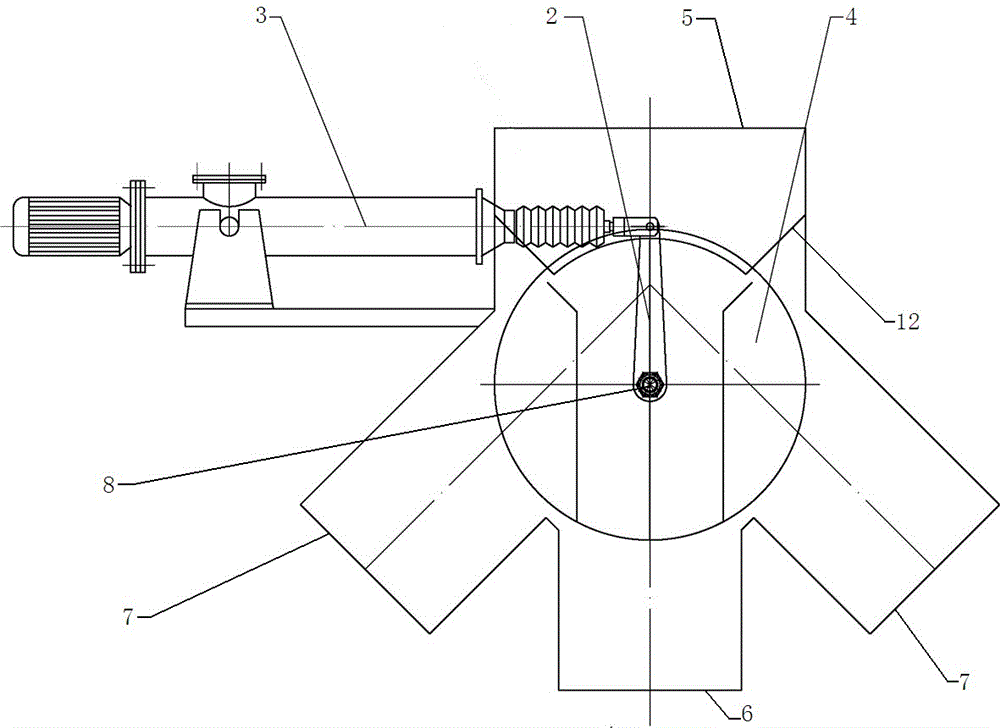

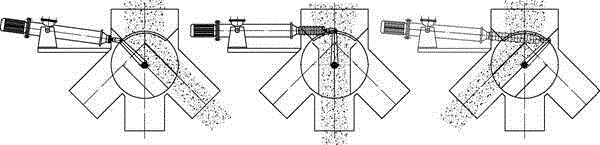

[0025] Such as figure 2 As shown, a non-jamming four-way distributor includes a housing 1, a vertical feed interface 5 is provided on the top of the housing 1, and a vertical discharge interface 5 is provided directly below the vertical feed interface 5 Interface 6, on both sides of the vertical discharging interface 6 are provided with two symmetrical oblique discharging interfaces 7 (when in use, the vertical feeding interface 5 is connected to an upstream conveying equipment through a flange, and the vertical discharging interface 6 And the two oblique discharging interfaces 7 are respectively connected to three downstream conveying equipment through flanges), the part where the vertical feeding interface 5, the vertical discharging interface 6 and the two inclined discharging interfaces 7 are combined is a cavity. The feature of the invention is that the four-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com