Counting and feeding device of injection molding machine for recycling waste

A technology for recycling waste and injection molding machines, which is applied in the field of counting and blanking devices for injection molding machines, which can solve the problems of time-consuming, labor-intensive, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

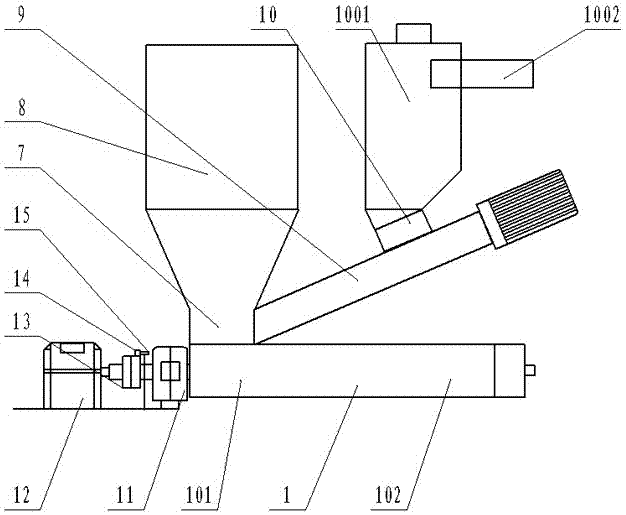

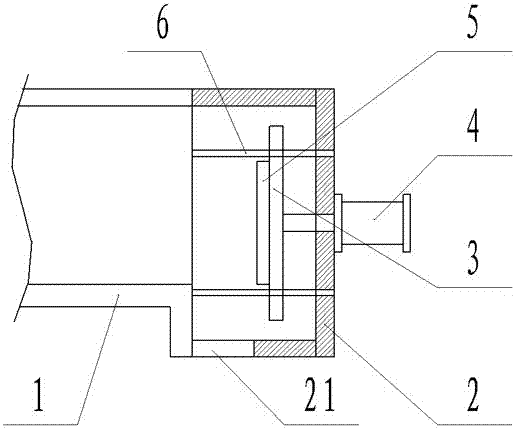

[0016] see Figure 1-2 , a counting blanking device for an injection molding machine that recycles waste, including a blanking auger 1, a valve holder 2 and a hopper 8; the left side of the blanking auger 1 is provided with a blanking motor 11, and the blanking motor 11 passes through a reduction box The reducer coupling 13 of 12 is mechanically connected with the blanking auger 1, and a photoelectric induction baffle 14 is arranged on the reducer coupling 13, and a photoelectric counter 15 is fixed by a bracket next to the reducer coupling 13, and the photoelectric counter There is an interval between 15 and the reducer coupling 13, the photoelectric induction baffle 14 rotates together with the reducer coupling 13, the photoelectric induction baffle 14 approaches the photoelectric counter 15, the photoelectric counter 15 starts counting, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com