Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Play the effect of reducing vibration and noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

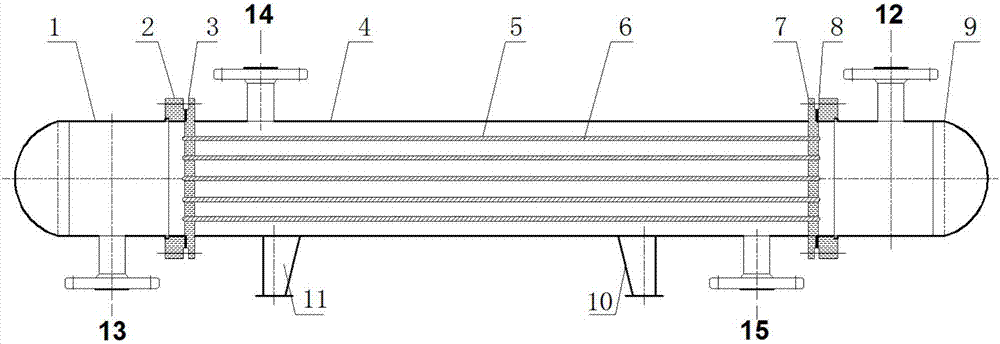

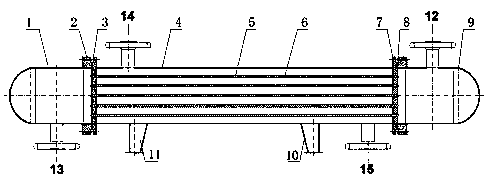

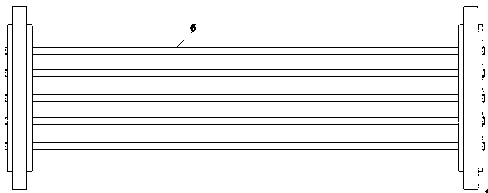

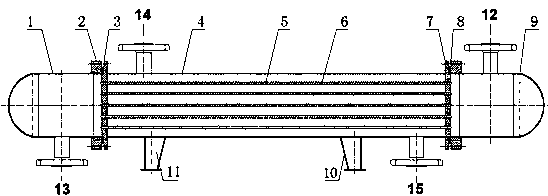

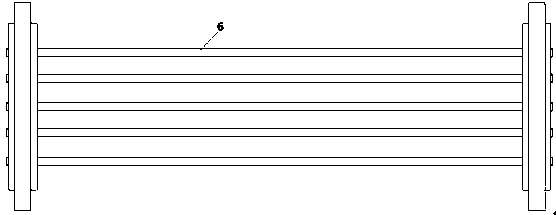

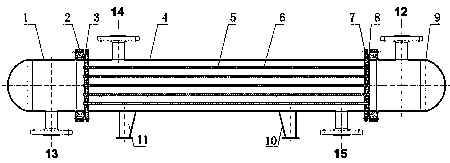

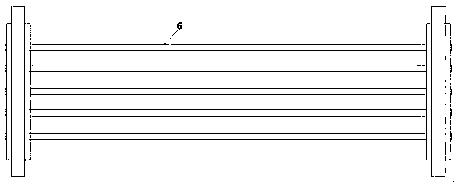

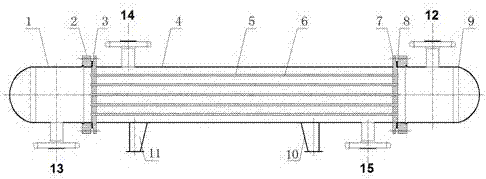

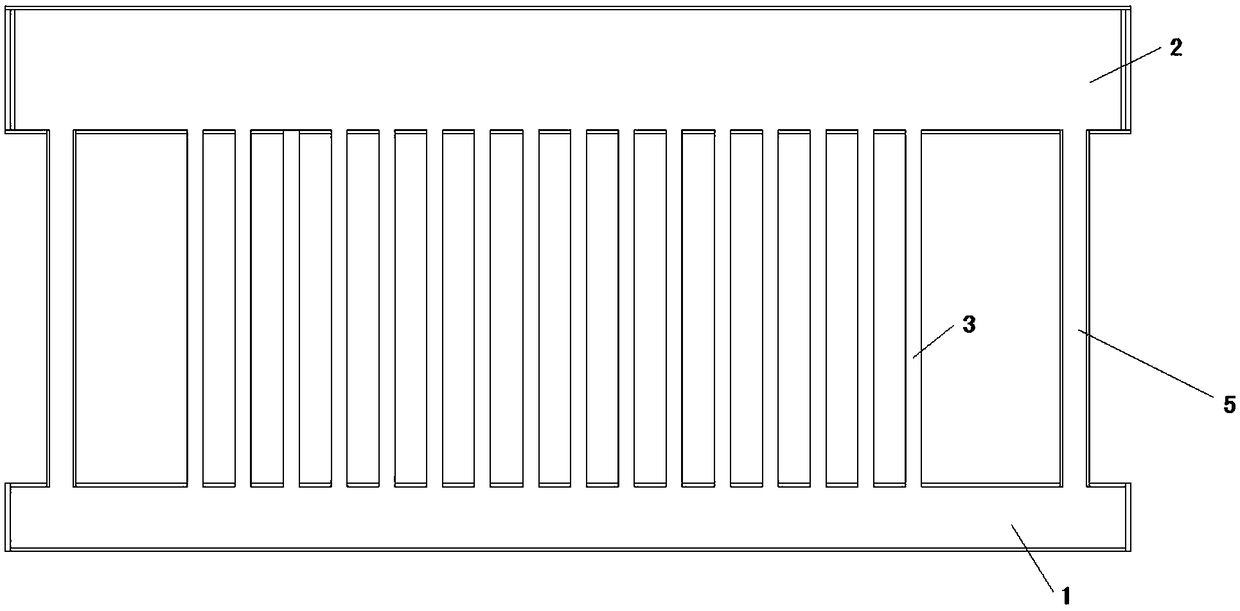

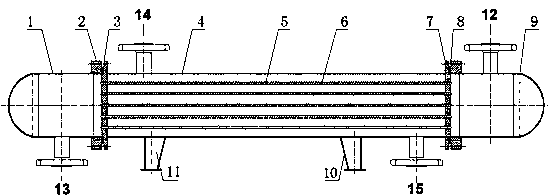

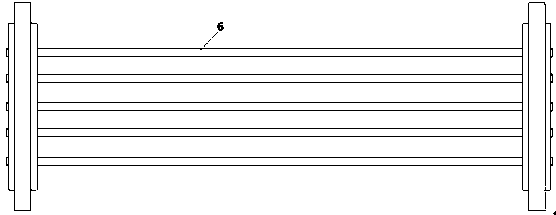

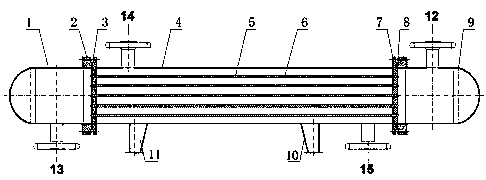

Length-variable condensable annular separation device heat exchanger

ActiveCN106969652AShorten the lengthReduce vibrationStationary tubular conduit assembliesHeat transfer modificationVapor liquidNoise level

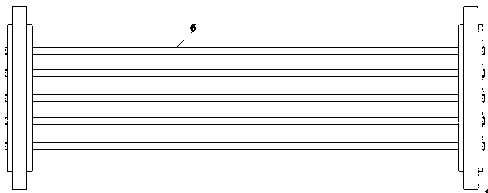

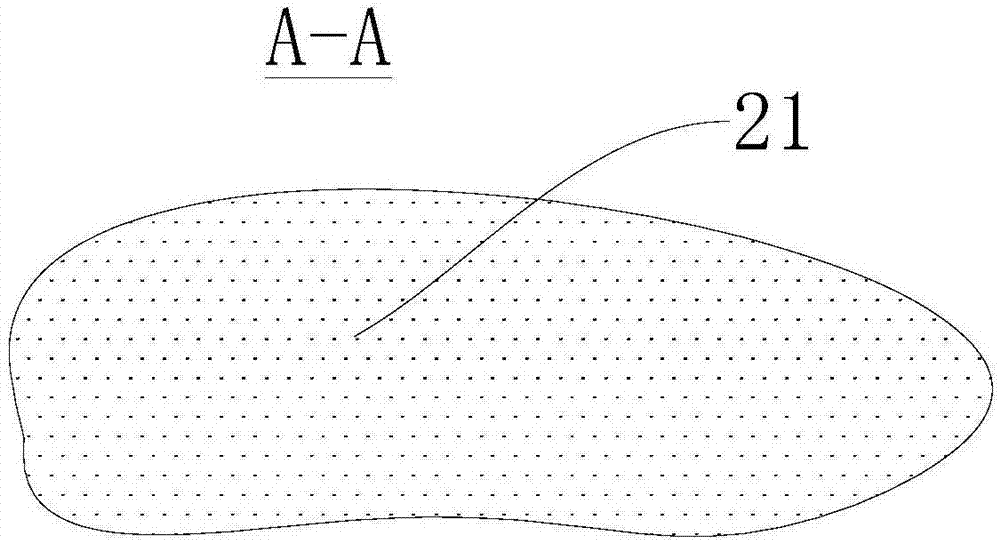

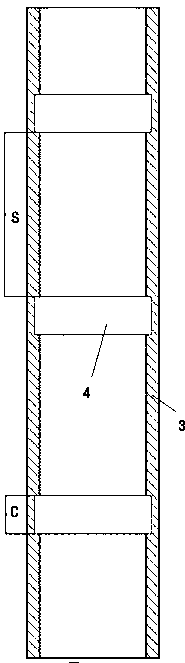

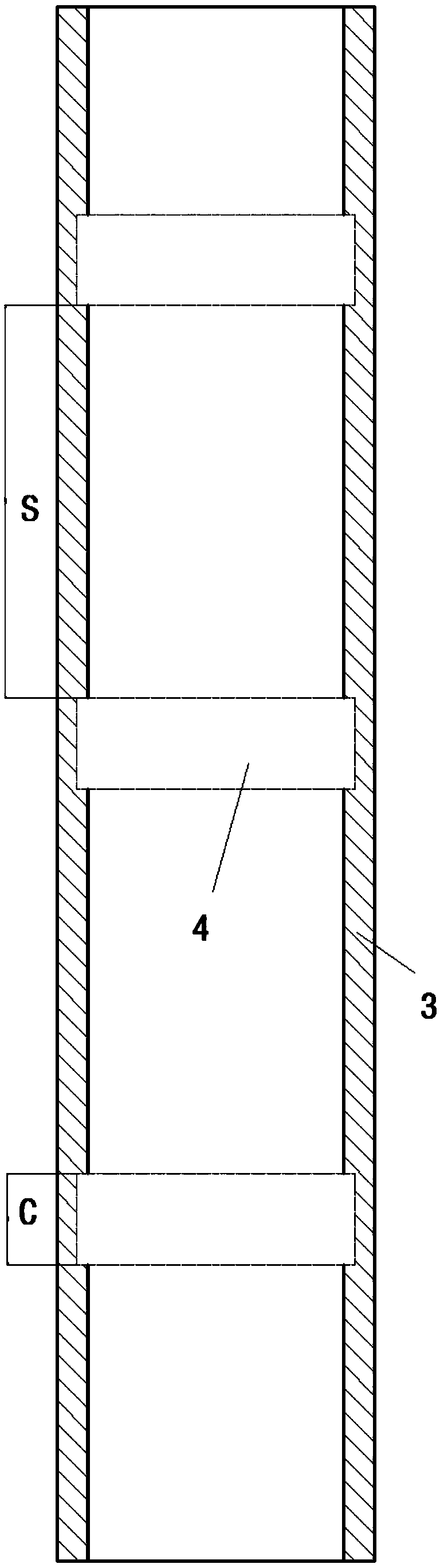

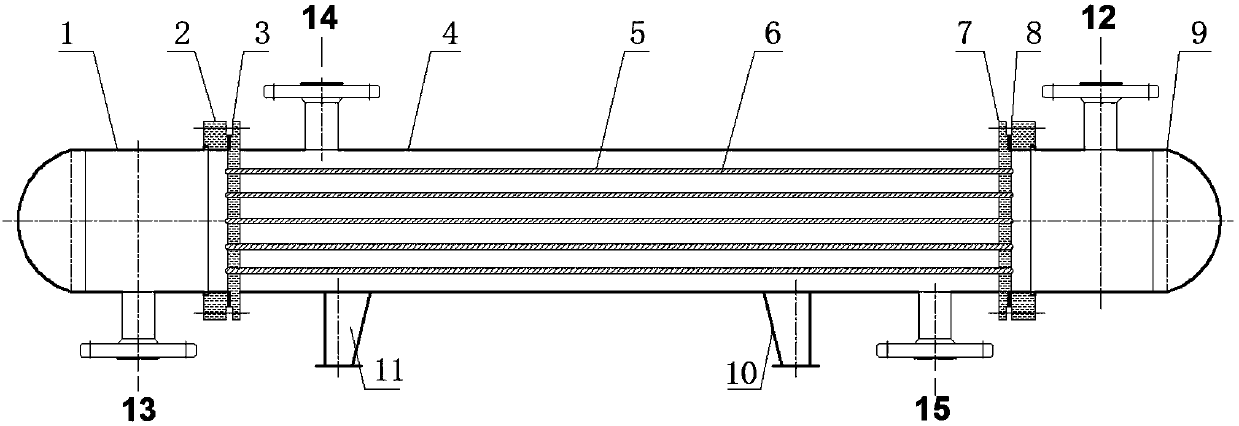

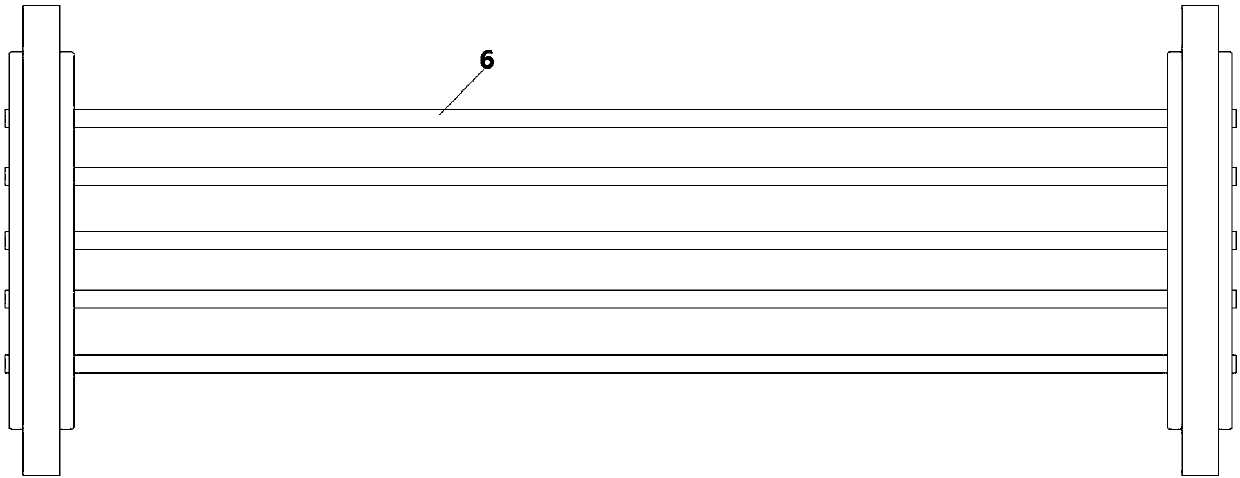

The invention provides a vapor-liquid two-phase flow tube shell type heat exchanger. The heat exchanger comprises a shell, wherein sealing heads are arranged at two ends of the shell respectively; tube plates are arranged in connection positions between the sealing heads and the shell; heat exchange tubes are connected with the tube plates at two ends; vapor phase in vapor-liquid two-phase flow can be condensed into liquid phase in the heat exchange process; the vapor-liquid two-phase flow flows in a tube process; separation devices used for decreasing vibration and reducing noise are arranged in the heat exchange tubes; a plurality of separation devices are arranged in the same heat exchange tube; the length of the separation devices is gradually reduced along the flowing direction of flow in the heat exchange tubes. According to the vapor-liquid two-phase flow tube shell type heat exchanger, the vibration of the tubes can be decreased to a maximum extent due to the length change of the separation devices when the vapor-liquid two-phase flow flows in the tubes; the noise level is reduced; meanwhile, the flowing resistance is reduced; the heat exchange uniformity is improved.

Owner:SHANDONG UNIV

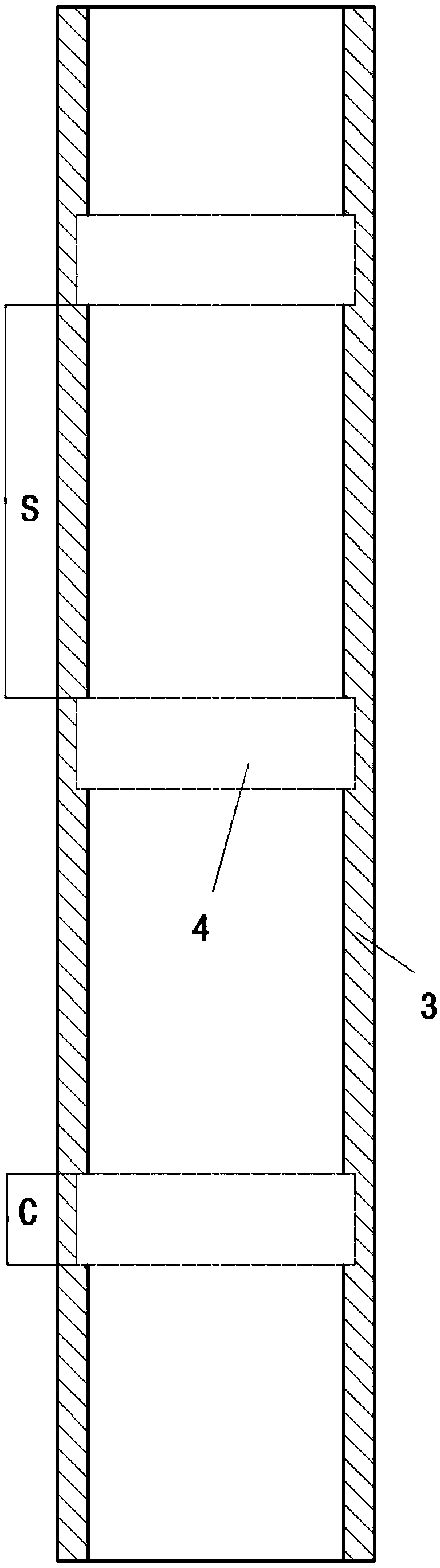

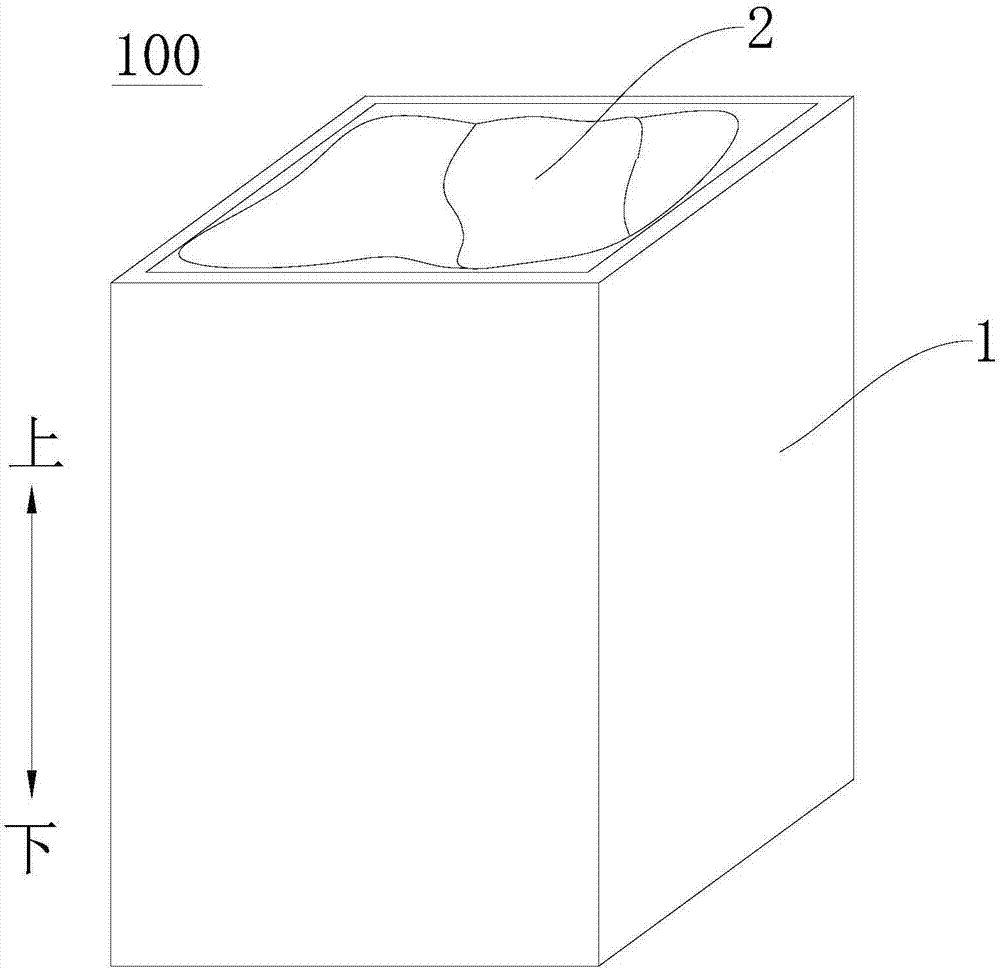

Heat pipe with multi-hole flow stabilizing devices

ActiveCN107044789AReduce vibrationImprove heat transfer performanceIndirect heat exchangersVapor liquidNoise level

The invention provides a heat pipe which comprises an evaporation collecting pipe, a condensation collecting pipe, ascending pipes and return pipes, wherein the ascending pipes are communicated with each of the evaporation collecting pipe and the condensation collecting pipe; the evaporation collecting pipe is positioned at the lower part; the condensation collecting pipe is positioned at the upper part; a fluid absorbs heat and evaporates in the evaporation collecting pipe, the vapor passes through the ascending pipes to enter the condensation collecting pipe and is condensed in the condensation collecting pipe after being subjected to heat exchange, and the condensed fluid returns back into the evaporation collecting pipe through the return pipes; the flow stabilizing devices are arranged in each of the same ascending pipe; the lengths of the flow stabilizing devices are constantly increased in the height directions of the ascending pipes;. According to the heat pipe with multi-hole flow stabilizing devices, the lengths of the flow stabilizing devices are changed, so that when vapor-liquid two-phase flows exist in the ascending pipes, heat transfer is enhanced, the vibration of the ascending pipes is weakened, and the noise level is reduced.

Owner:山东路德交通科技有限公司

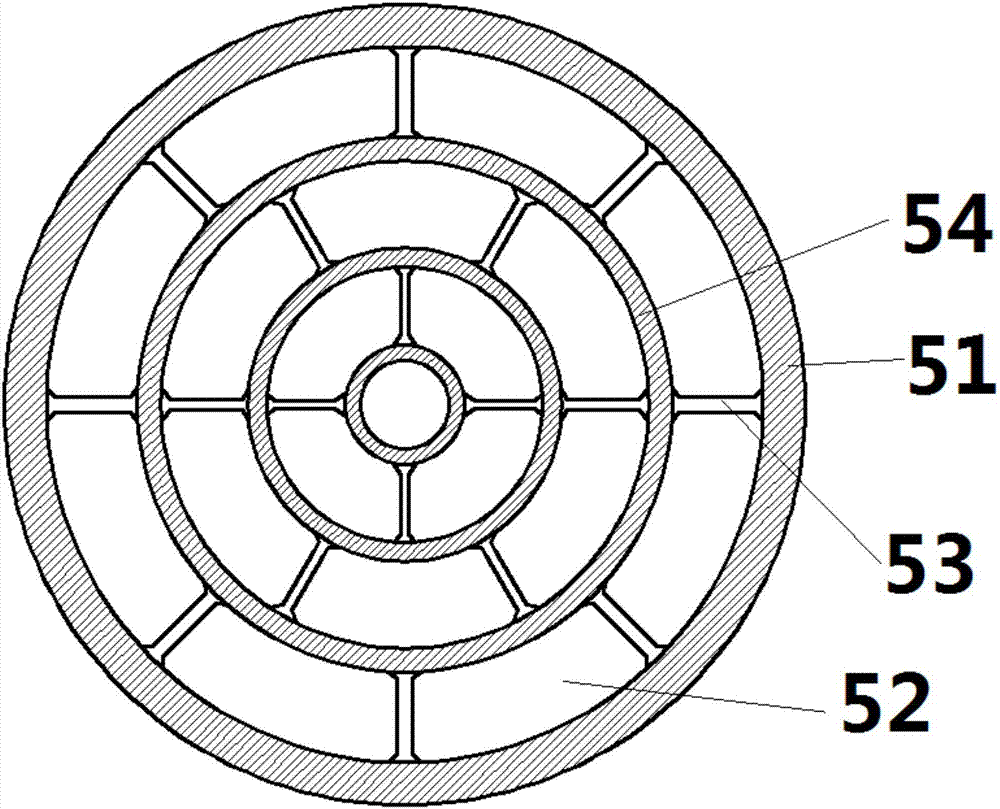

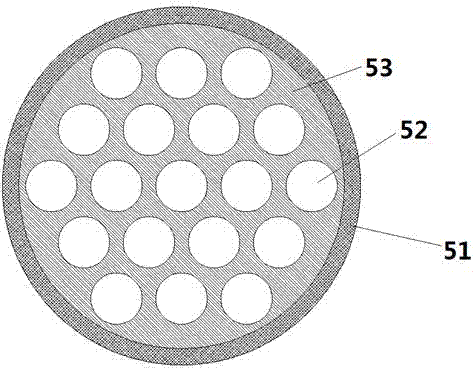

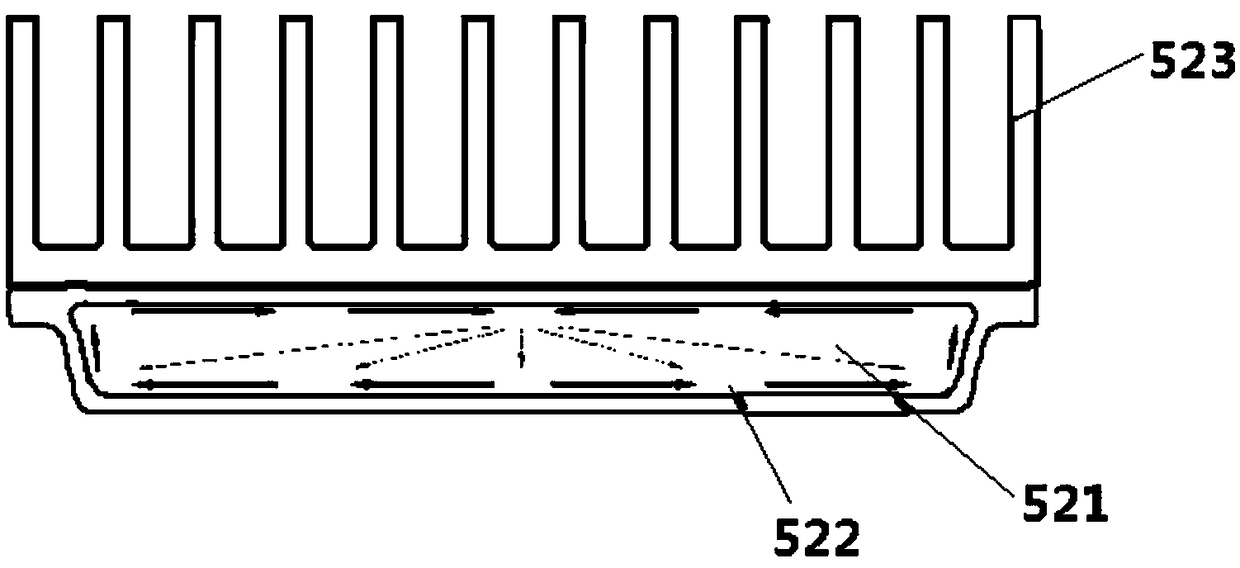

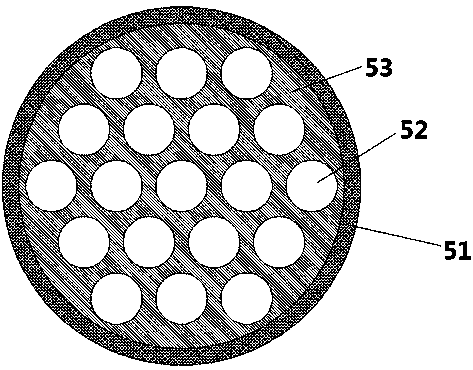

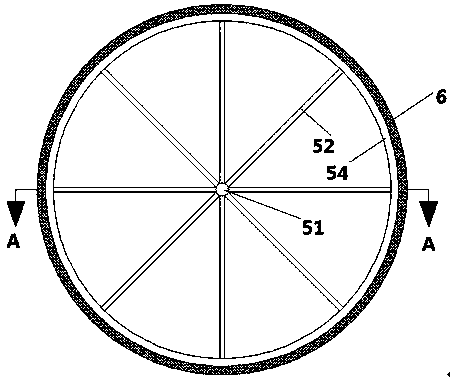

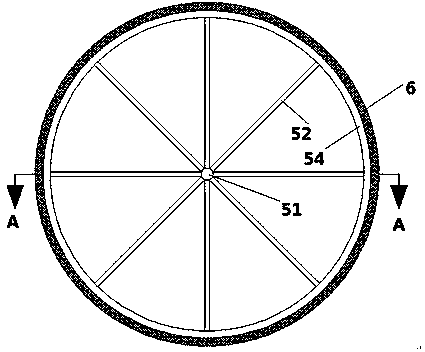

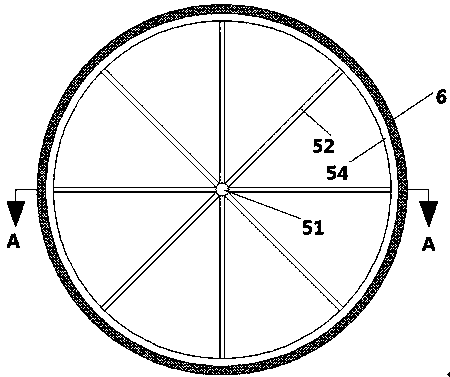

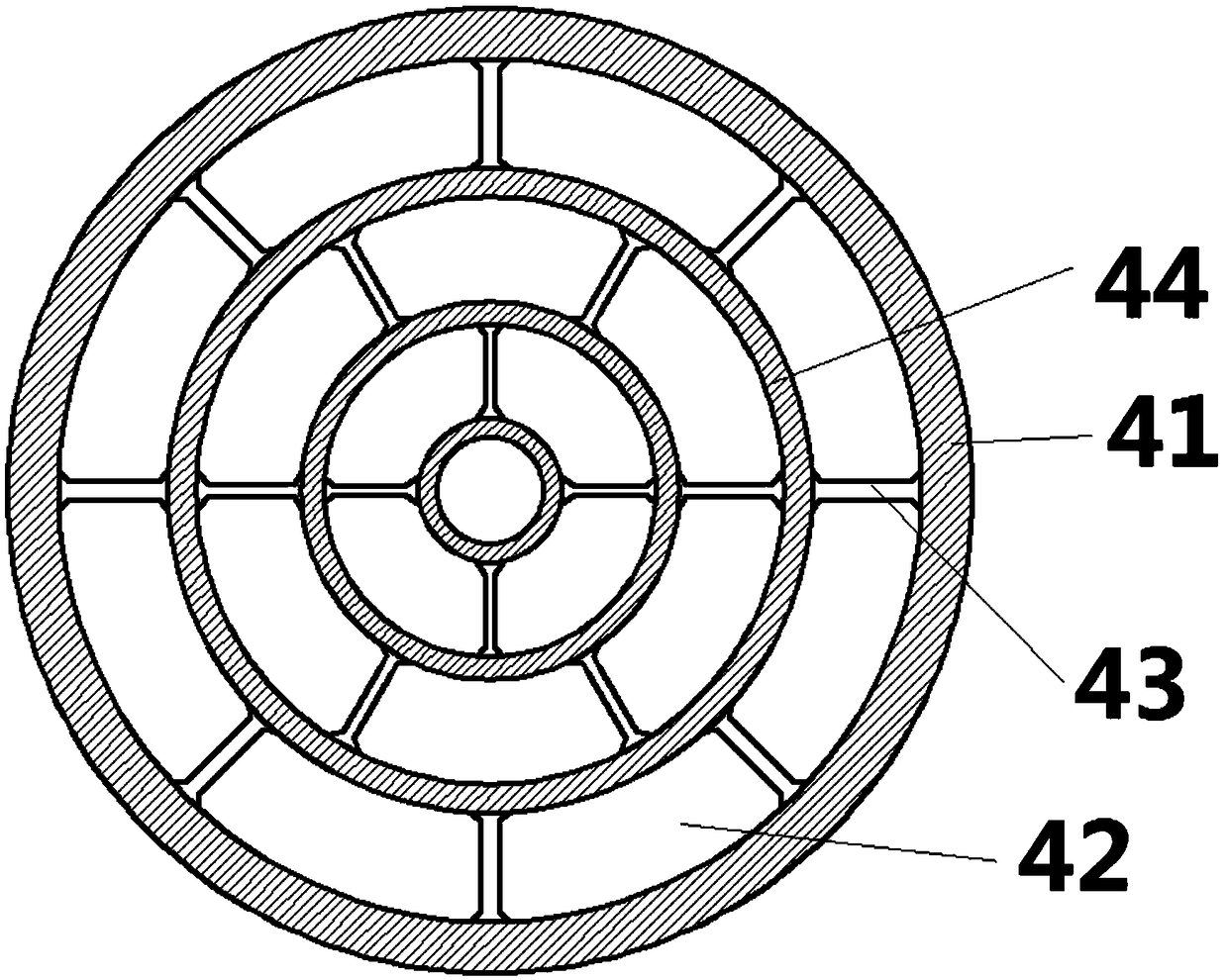

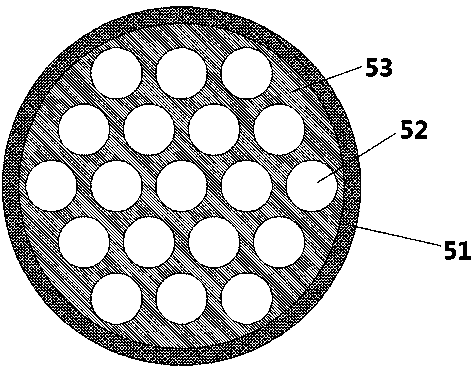

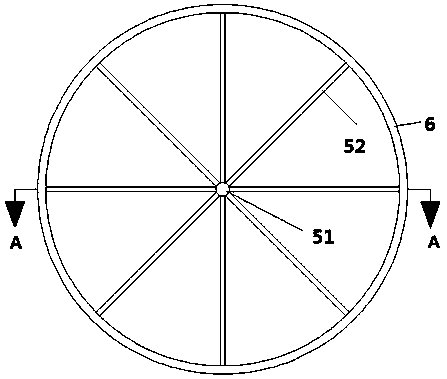

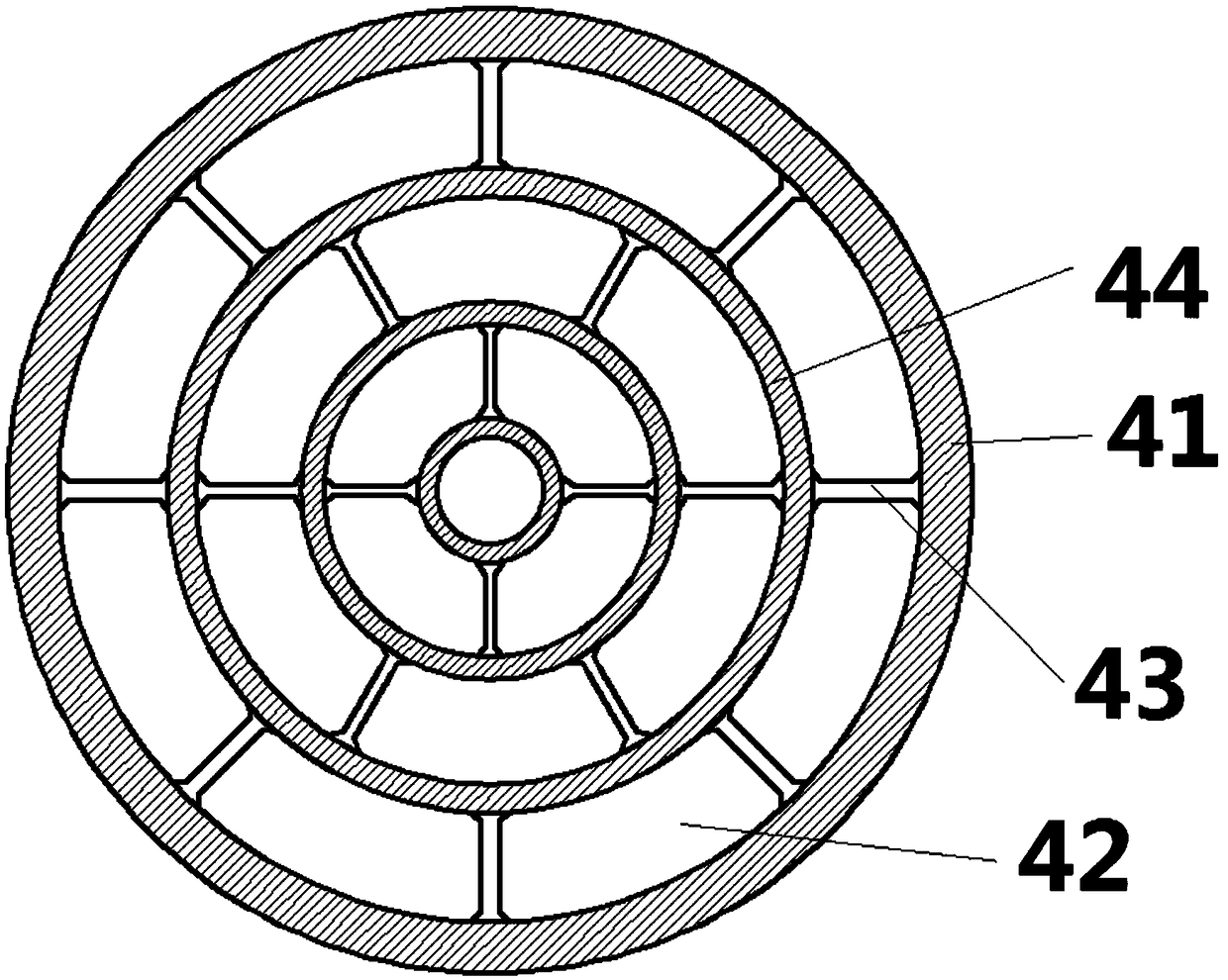

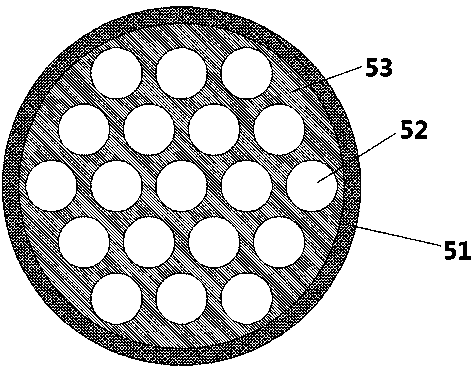

Condensable heat exchanger with annular separation devices

ActiveCN107044788AInhibit refluxStable flowStationary tubular conduit assembliesHeat transfer modificationEngineeringLiquid phase

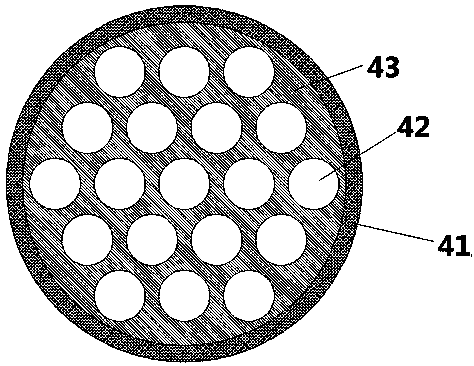

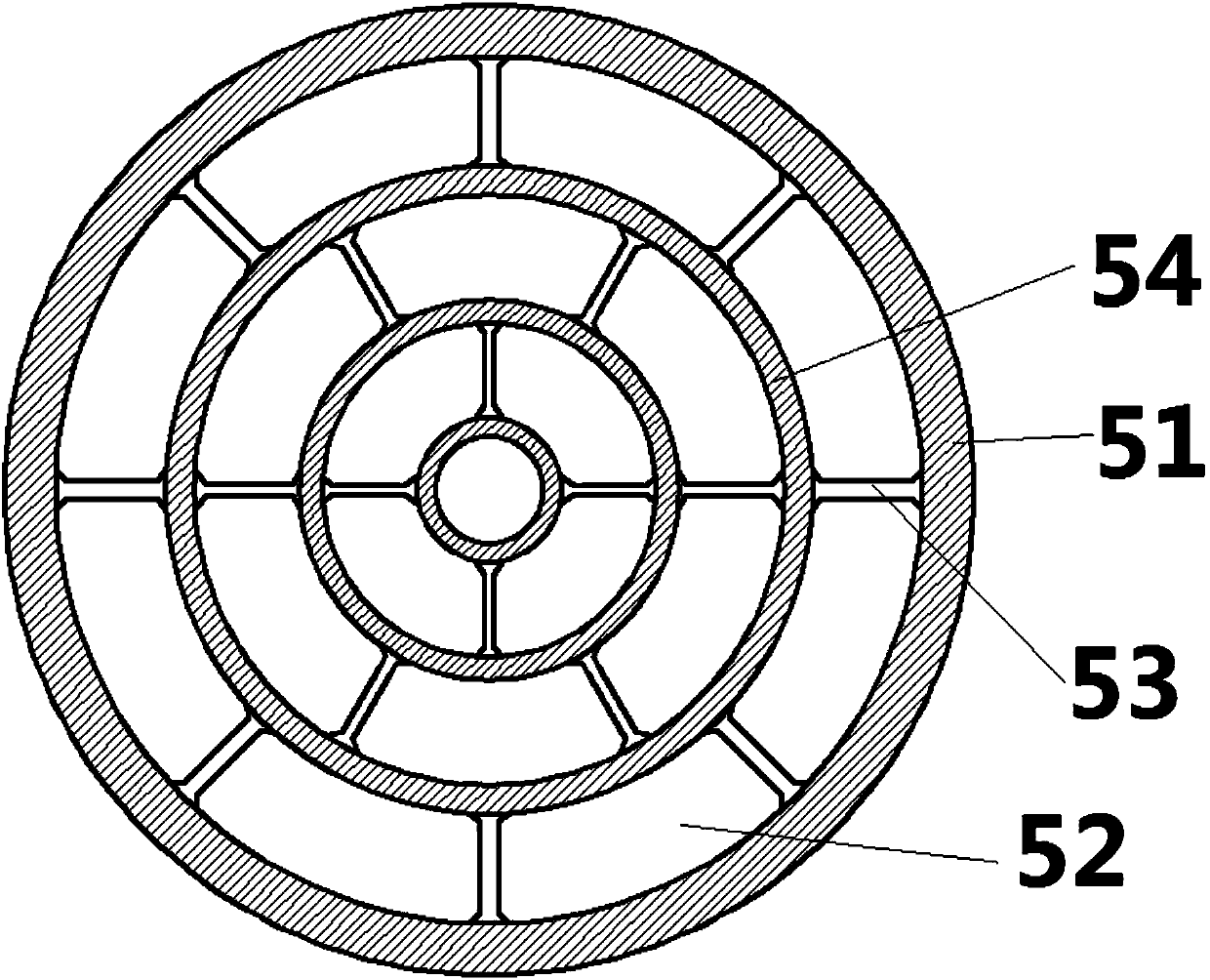

The invention provides a condensable heat exchanger with annular separation devices. The condensable heat exchanger comprises a shell. End sockets are arranged at the two ends of the shell correspondingly. A pipe plate is arranged at the connecting position of each end socket and the shell. A heat exchange pipe is connected with the pipe plates at the two ends. A steam phase in steam-phase and liquid-phase flow can be condensed to form a liquid phase in the heat exchange process, and the steam-phase and liquid-phase flow flows in a pipe pass. The separation devices are arranged in the heat exchange pipe. Each separation device comprises a core and a housing, wherein the core is arranged in the housing, the housing is connected with and fixed to the inner wall of the heat exchange pipe, the core comprises a plurality of concentric pipes and fins, and the fins are connected with the adjacent concentric pipes. According to the heat exchanger of a novel structure and with the separation devices, heat transfer is intensified when the steam-phase and liquid-phase flow flows in the pipe, meanwhile, pipe vibration is weakened, and the level of noise is lowered.

Owner:SHANDONG UNIV

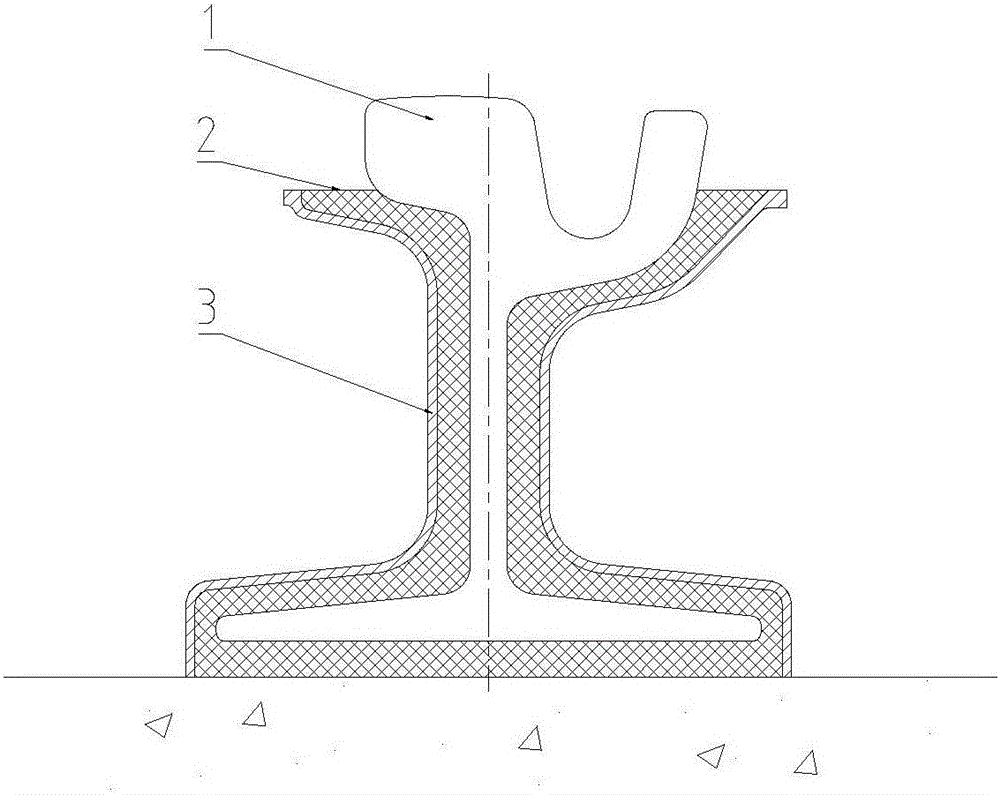

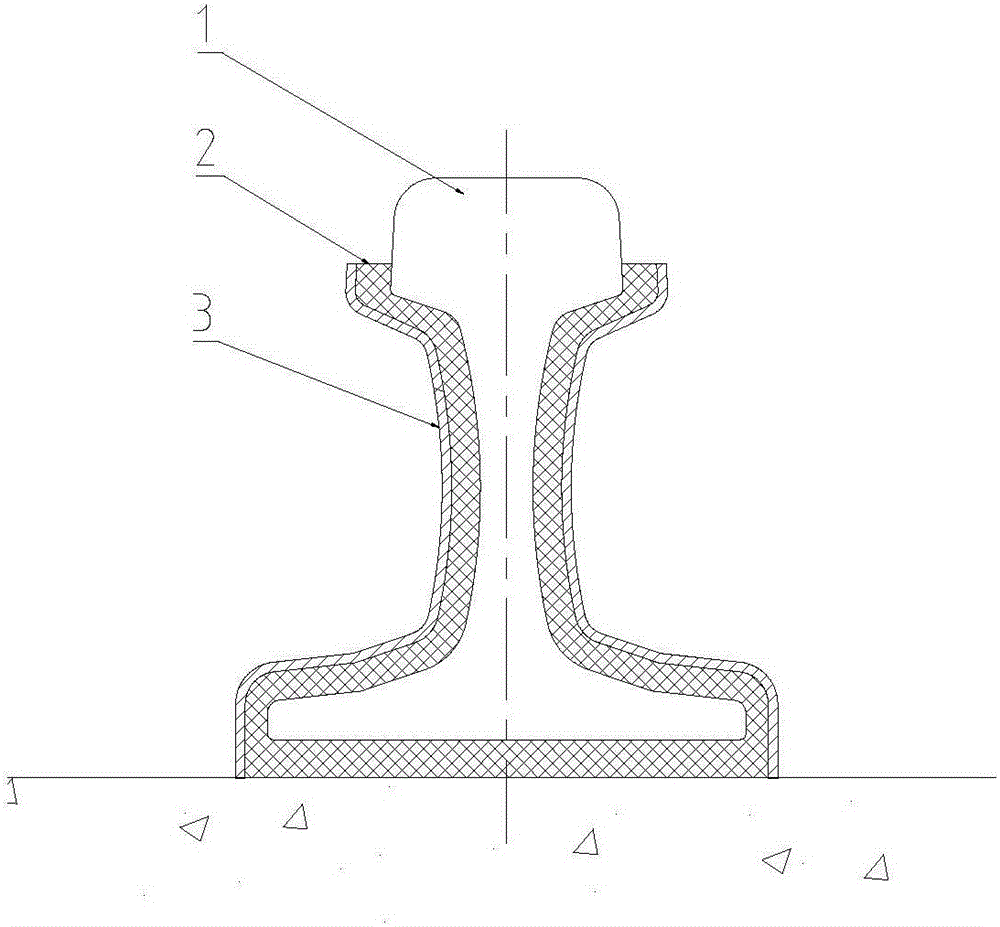

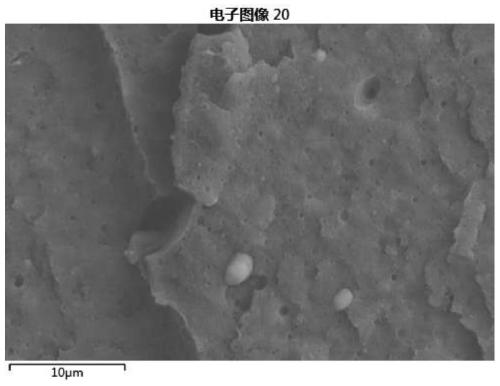

Steel rail cladding vibration reduction structure of embedded type railway and preparation method thereof

InactiveCN105735057ASolve the rustEasy constructionRailsRailway track constructionNoise reductionCorrosion

The invention belongs to the technical field of railway traffic equipment and relates to a steel rail cladding vibration reduction structure of an embedded type railway capable of being resistant to corrosion for a long time in the operation process and a preparation method of the steel rail cladding vibration reduction structure. The steel rail cladding vibration reduction structure comprises a steel rail, a macromolecule elastic damping body layer and a framework material. The outer layer of the steel rail is filled with the macromolecule elastic damping body layer. The two side surfaces and the bottom surface of the steel rail are wrapped with the macromolecule elastic damping body layer which is made of a two-component polyurethane grouting material. Construction is convenient and easy, and the vibration and noise reduction effects of the steel rail can be effectively improved.

Owner:QINGDAO SRI TECH CO LTD

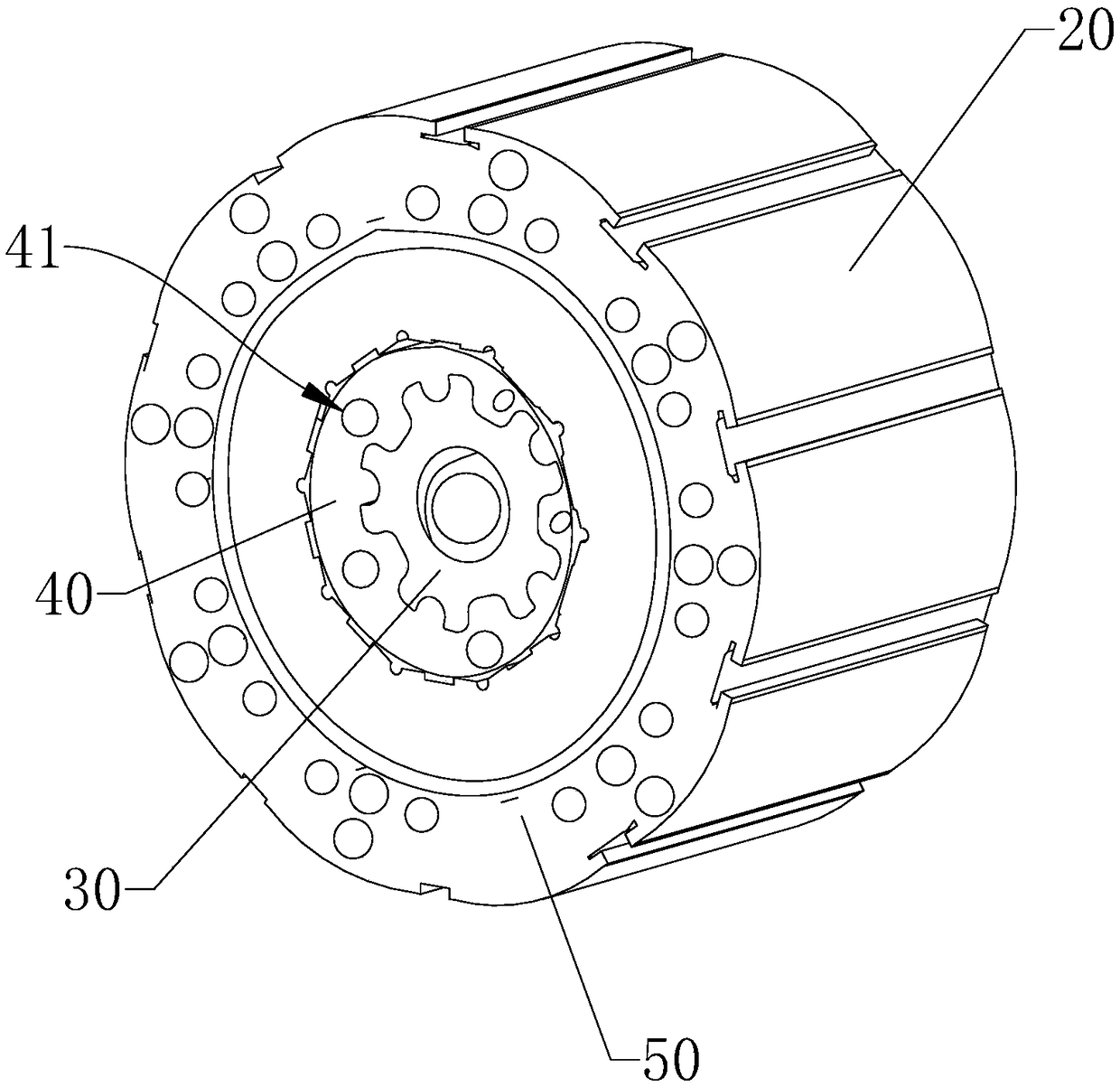

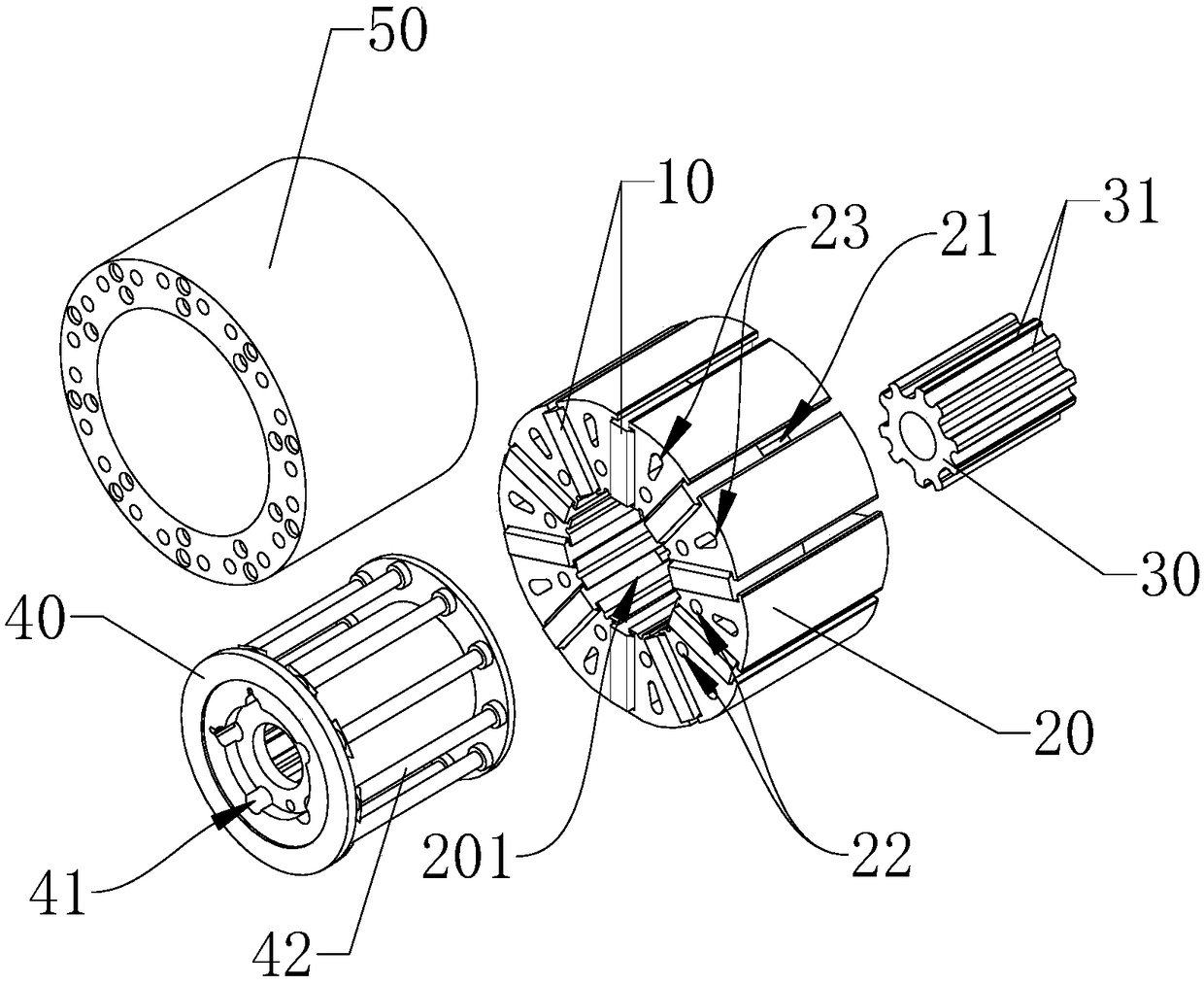

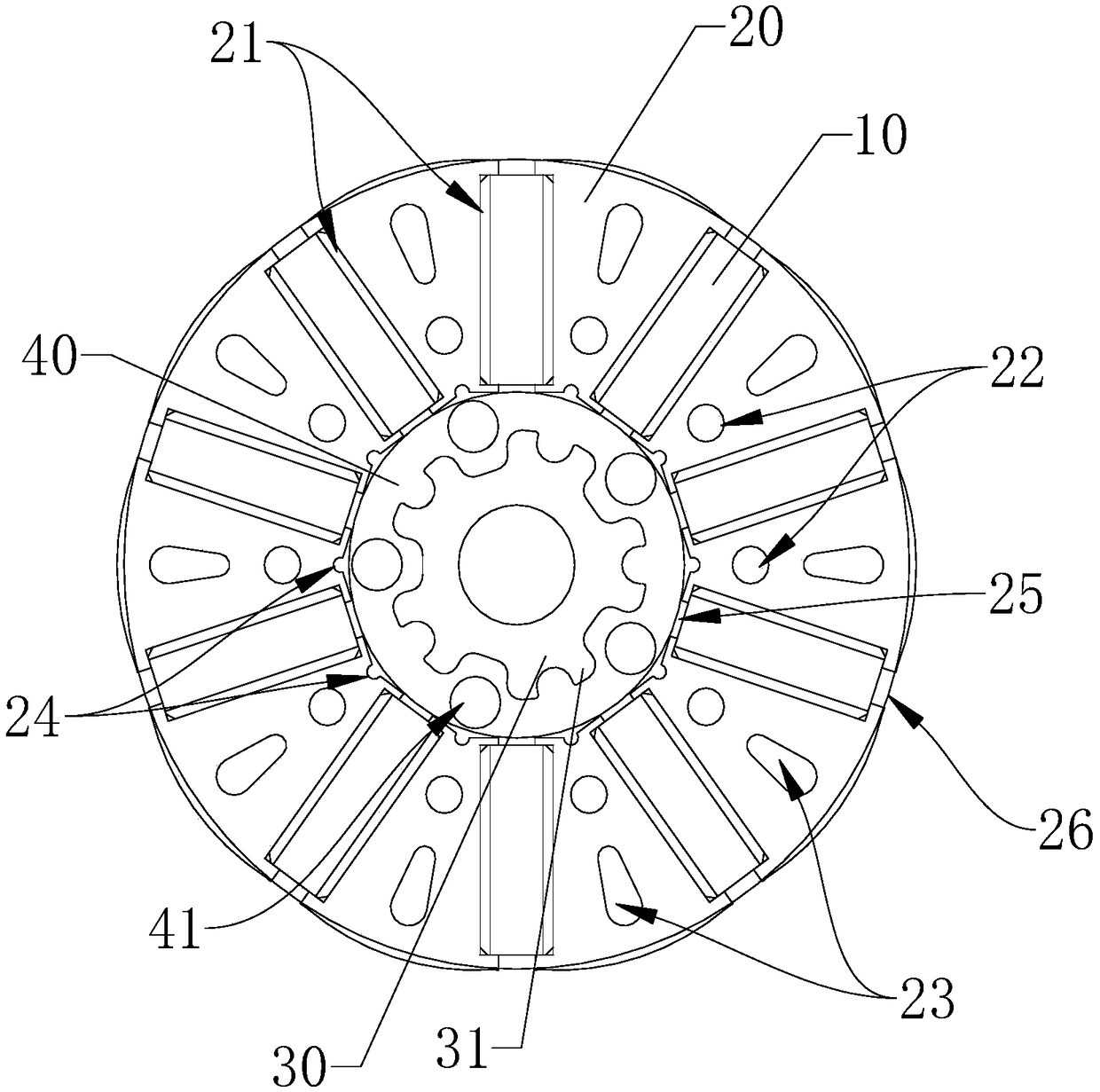

A sub-block vibration-damping rotor

A sub-block vibration-damping rotor includes a magnet, an outer core, an inn core, an engagement portion, and an elastic bonding portion. The outer iron core is provided with a through channel, a magnetic groove, a plurality of positioning gluing holes and a reinforcing hole which penetrate the outer iron core in the axial direction. The magnet is inserted in the magnetic slot, and the inner coreis embedded in the channel inside the outer core. A PBT material is injected into that reinforcing hole, and the PBT material is distributed at both ends of the outer iron core along the reinforcing hole to form a joint part, so that the out iron core and the magnet are molded into a one-time molded product by one-time injection molding of the PBT material. An elastic glue is injected into the positioning glue hole and an elastic glue part is integrally formed at both ends of the outer iron core and the inner iron core and between the outer iron core and the inner iron core respectively, so that the primary molded product and the inner iron core are secondary molded into a secondary molded product by the elastic glue. The elastic glue can cushion the force between the outer core and the inner core, so as to play the effect of vibration and noise reduction.

Owner:WOLONG ELECTRIC GRP CO LTD

Annular separating device heat exchanger with non-condensable gas

ActiveCN107036478AInhibit refluxSpeed up the flowHeat exchanger casingsStationary tubular conduit assembliesShell and tube heat exchangerGas phase

The invention provides an annular structure separating device shell-and-tube heat exchanger with non-condensable gas. The heat exchanger comprises a shell body, heads are arranged at the two ends of the shell body correspondingly, a tube plate is arranged on the connection position of each head and the shell body, heat exchange tubes are connected with the tube plates at the two ends, and the gaseous phase in two-phase gas-liquid flow is an insoluble or slightly soluble gas, namely the gas does not dissolve in liquid in the heat exchange process; and separating devices are arranged in each heat exchange tube, each separating device comprises a core body and a shell, the cores are arranged in the shells, each shell is fixedly connected with the inner wall of the corresponding heat exchange tube, each core body comprises a plurality of concentric tubes and fins, and the fins connect adjacent concentric tubes. According to the annular structure separating device shell-and-tube heat exchanger with non-condensable gas, a heat exchanger with separating devices with a novel structure is provided, when two-phase gas-liquid flow exists in a pipeline, compared with the background technology, the heat exchanger further enhances heat transfer, weakens vibration of the pipeline and reduces the noise level.

Owner:SHANDONG UNIV

Heat pipe

ActiveCN107062959AInhibit refluxSpeed up the flowSafety devices for heat exchange apparatusIndirect heat exchangersNoise levelEvaporation

The invention provides a heat pipe which comprises an evaporation header, a condensation header, a rising pipe and a backflow pipe. The rising pipe is communicated with the evaporation header and the condensation header, the evaporation header is located at the lower portion, the condensation header is located at the upper portion, fluid absorbs heat and evaporates in the evaporation header, passes through the rising pipe to enter the condensation header and conducts heat exchange and condensation in the condensation header, and condensation fluid returns to the evaporation header through the backflow pipe; and a current stabilizer is arranged in the rising pipe and comprises a core body and a shell, the core is arranged in the shell, the shell is fixedly connected with the inner wall of the rising pipe, the core is an integrated structure piece extending in the length direction of the shell, and a plurality of through holes are formed in the structure piece. According to the heat pipe with the current stabilizer of the new structure, when vapor-liquid two-phase flow exists in the rising pipe, heat transfer strengthening is achieved; and meanwhile, vibration of the rising pipe is weakened, and the noise level is reduced.

Owner:JIANGSU TONGSHENG HEAT EXCHANGER

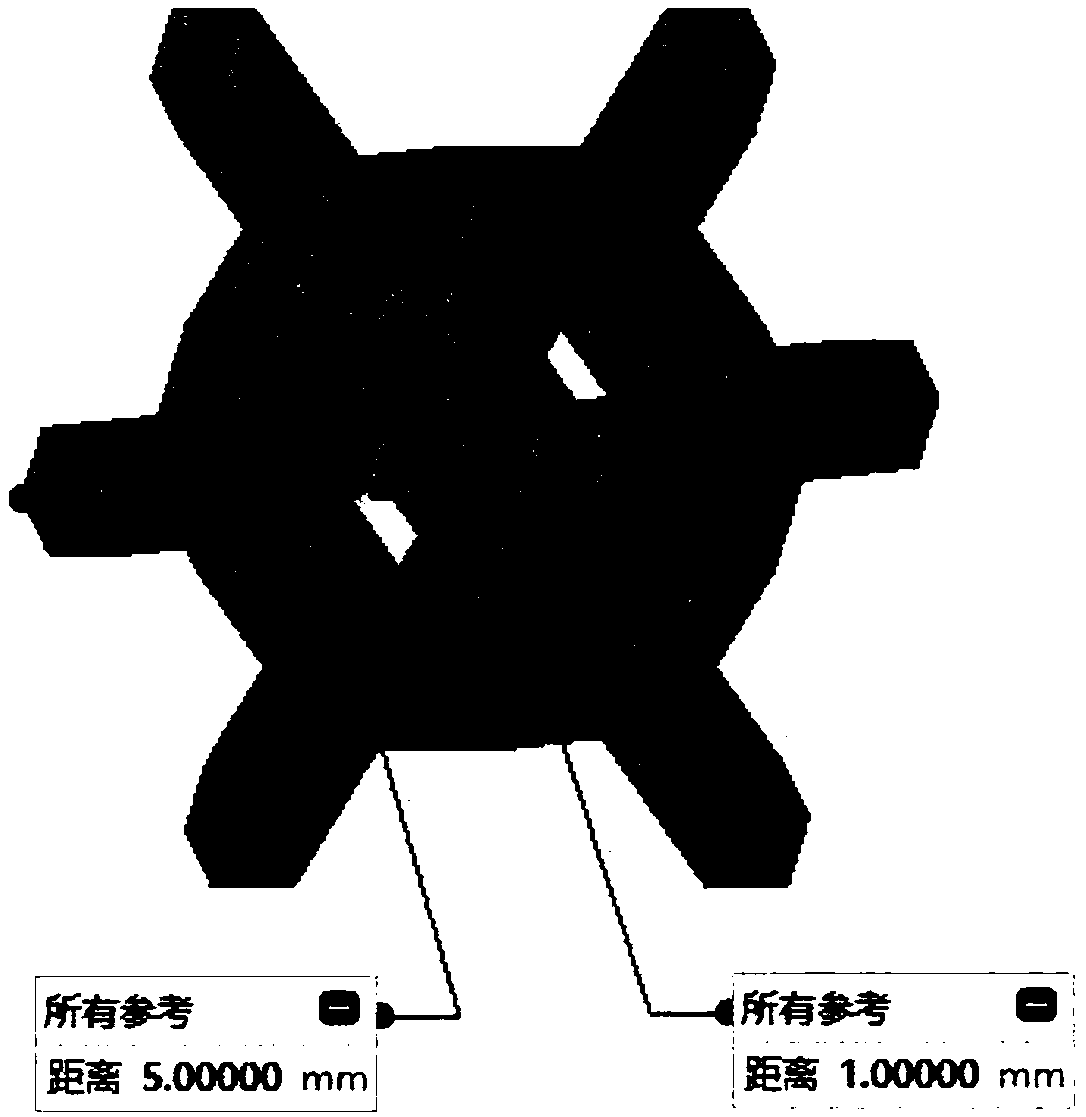

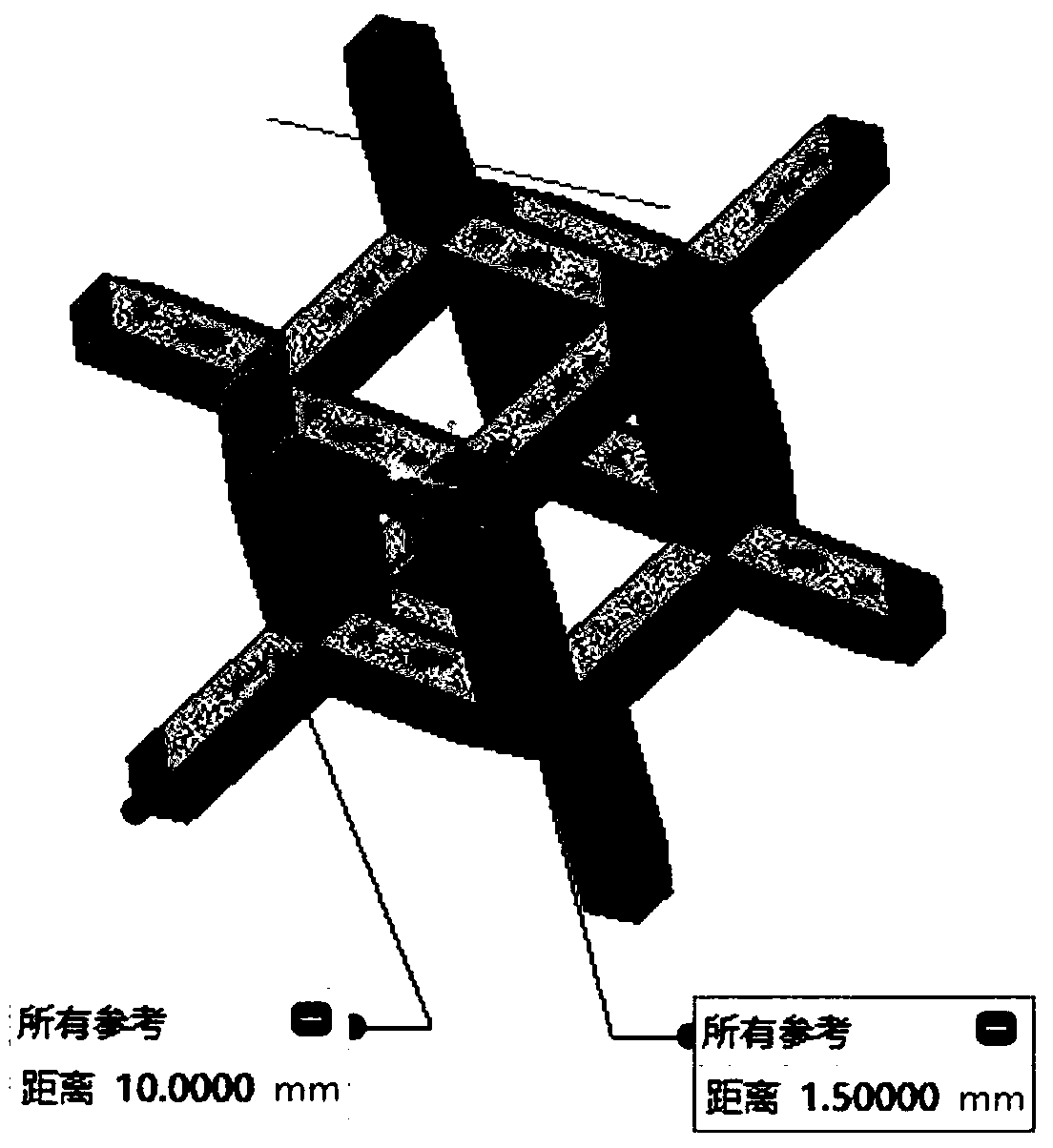

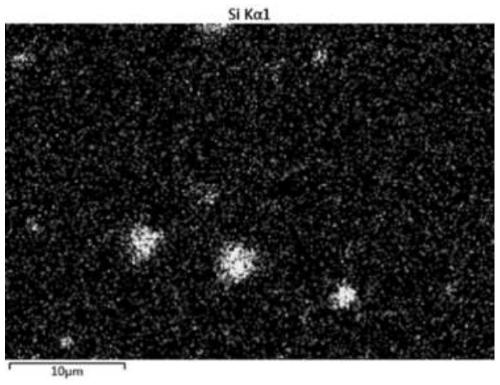

Lattice structure with high energy dissipation capacity based on laser additive manufacturing

InactiveCN109635320AIncrease energy dissipationPlay the effect of reducing vibration and noiseAdditive manufacturing apparatusDesign optimisation/simulationDot matrixHigh energy

The invention relates to a lattice structure with high energy dissipation capacity based on laser additive manufacturing, and belongs to the technical field of vibration and noise reduction engineering. According to the dot matrix structure, the length L, the width W and the height H of the dot matrix structure are determined according to needs, and then a plurality of cell element structures arearrayed in three directions to obtain the needed dot matrix structure. According to the lattice structure with the high-energy dissipation capacity based on laser additive manufacturing, due to the specific periodicity, when elastic waves are propagated in the lattice structure, the elastic waves in some frequency ranges cannot be propagated, the elastic wave band gap characteristic enables the lattice structure to have the high-energy dissipation capacity, and the effects of vibration reduction and noise reduction are achieved. The dot matrix structure is prepared through the laser additive manufacturing technology, and rapid and accurate preparation can be achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

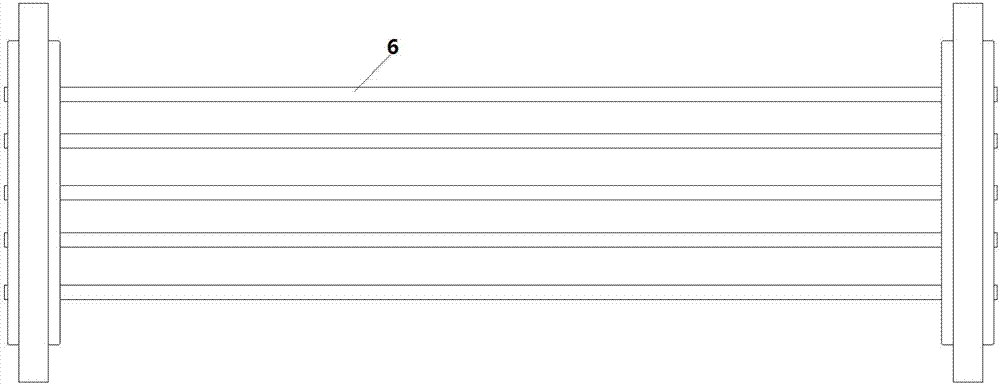

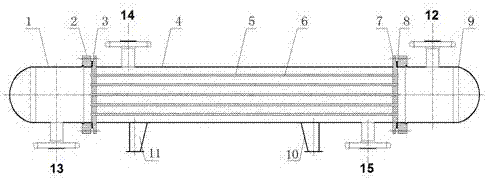

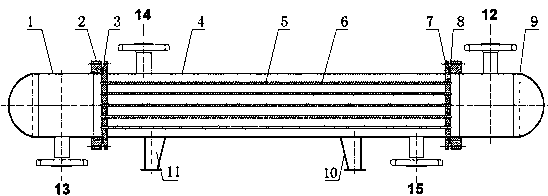

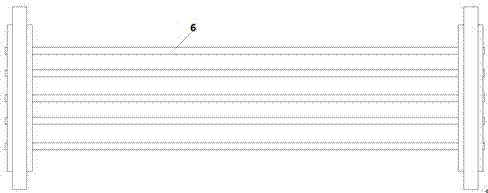

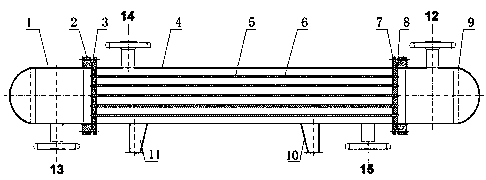

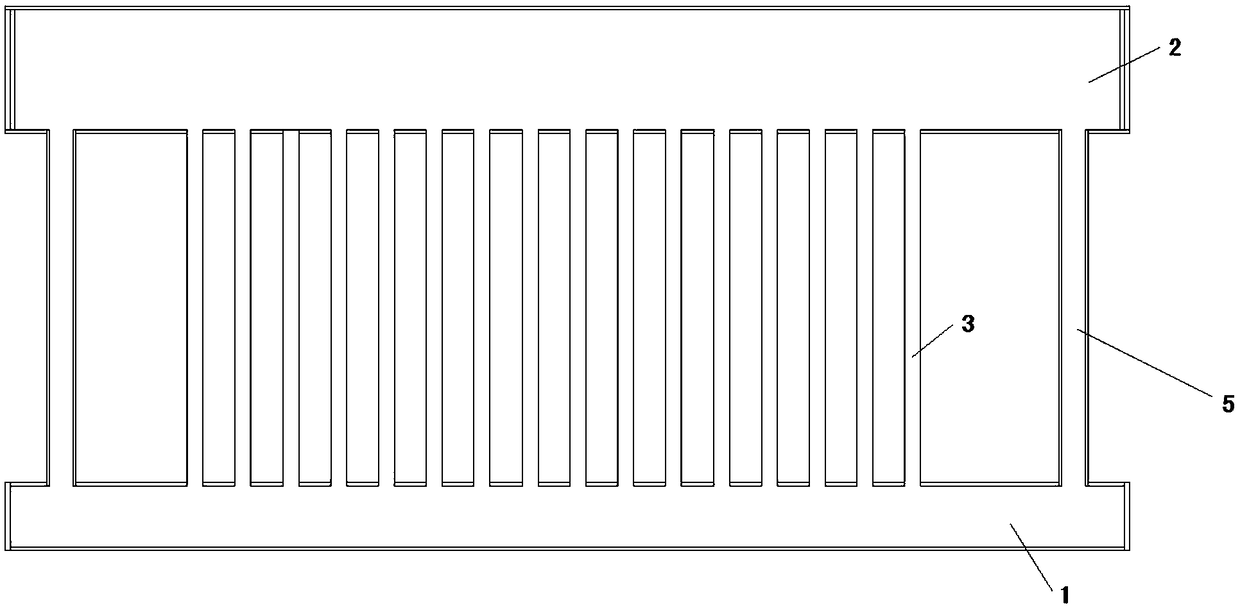

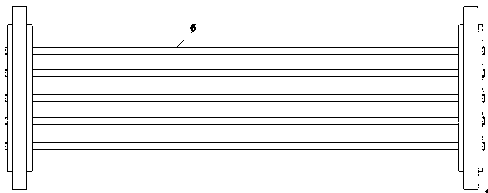

Tubular heat exchanger

ActiveCN108827036AReduce vibrationReduce noise levelHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerGas phase

The invention provides a tubular heat exchanger. The tubular heat exchanger comprises a shell, heat exchange tubes, a tube pass inlet tube, a tube pass outlet tube, a tube pass inlet connecting tube and a tube pass outlet connecting tube. A heat exchange tube bundle formed by the multiple heat exchange tubes which are arranged in parallel is connected to a front tube plate and a rear tube plate. The front end of the front tube plate is connected with a front sealing head. The rear end of the rear tube plate is connected with a rear sealing head. The tube pass inlet tube is arranged on the rearsealing head. The tube pass outlet tube is arranged on the front sealing head. The tube pass inlet connecting tube and the tube pass outlet connecting tube are both arranged on the shell. Fluid of two-phase flow enters through the tube pass inlet tube, carries out heat exchange through the heat exchange tubes, and goes out of the tube pass outlet tube. The fluid in the heat exchange tubes is thegas and liquid two-phase flow in which the gas phase is insoluble or slightly soluble gas, and in other words, the gas will not dissolve in the liquid in the process of heat exchange. The ratio of thelength L of each heat exchange tube to the diameter of the shell of the heat exchanger ranges from 6 to 10. The tubular heat exchanger is a gas and liquid two-phase flow heat exchanger of a novel structure.

Owner:SHANDONG UNIV

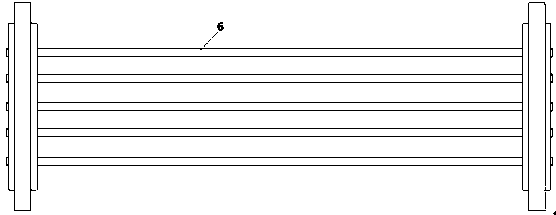

Length-changing non-condensable gas porous flow stabilizer heat exchanger

ActiveCN107976094AReduce vibrationReduce noise levelSafety devices for heat exchange apparatusStationary tubular conduit assembliesLength changeProduct gas

The invention provides a length-changing non-condensable gas porous flow stabilizer heat exchanger which comprises a shell. Sealing heads are arranged at the two ends of the shell correspondingly. A pipe plate is arranged at the connecting position of each sealing head and the shell. Heat exchange pipes are connected with the pipe plates at the two ends. A gas phase in gas-liquid two-phase flow isinsoluble or indissolvable gas, that is, gas cannot be dissolved in liquid in the heat exchange process. Flow stabilizers used for vibration reduction and noise reduction are arranged in each heat exchange pipe. The corresponding multiple flow stabilizers are arranged in the same heat exchange pipe. In the flowing direction of fluid in the heat exchange pipes, the lengths of the flow stabilizersare gradually decreased to a certain position, and then the lengths of the flow stabilizers are gradually increased from a certain position. According to the length-changing non-condensable gas porousflow stabilizer heat exchanger, through length changing of the flow stabilizers, when gas-liquid two-phase flowing exists in a pipeline, pipeline vibration is weakened to the largest degree, the noise level is reduced, and meanwhile flowing resistance is reduced.

Owner:广西自贸区见炬科技有限公司 +1

Variable-length and condensable porous heat exchanger with flow stabilizing devices

ActiveCN107966052AReduce vibrationReduce noise levelSafety devices for heat exchange apparatusStationary tubular conduit assembliesVapor phaseVariable length

The invention provides a liquid-vapor two-phase flow tubular shell type heat exchanger. The heat exchanger comprises a shell, wherein the two ends of the shell are separately provided with end sockets, tube plates are arranged at the connecting positions of the end sockets and the shell, and heat exchange pipes are connected with the tube plates at the two ends; a vapor phase in liquid-vapor two-phase flow can be condensed into a liquid phase in the heat exchange process, and the liquid-vapor two-phase flow flows in a tube pass; and flow stabilizing devices used for reducing vibration and noise are arranged in the heat exchange pipes, a plurality of flow stabilizing devices are arranged in the same heat exchange pipe, and the length of the flow stabilizing devices is gradually reduced in the flowing direction of fluid in the heat exchange pipes. According to the heat exchanger provided by the invention, through the length variation of the flow stabilizing devices, when the liquid-vaportwo-phase flow occurs in the pipeline, the vibration of the pipeline is reduced to an utmost degree, and the noise level is reduced; and at the same time, flow resistance is reduced, and the heat exchange uniformity is improved.

Owner:开封市九泓化工有限公司

Low-shrinkage HIPS composite material for solving abnormal sound, and preparation method thereof

The invention discloses a low-shrinkage HIPS composite material for solving abnormal sound, and a preparation method thereof. The material comprises, by weight, 60-80 parts of HIPS resin, 3-10 parts of a rubber composite material, 8-20 parts of a reinforcing agent, 3-10 parts of a blocking agent, 0.3-1.5 parts of a weather-proof agent, 0.1-0.6 part of an antioxidant and 0.1-0.6 part of a lubricant. The material not only has excellent strength, toughness and dimensional stability, but also can play a role in vibration and noise reduction, can solve the common abnormal sound problem of current household appliances and improve the living environment of people, and is low in comprehensive cost and wide in application range.

Owner:合肥圆融新材料有限公司

A vapor-liquid two-phase flow shell-and-tube heat exchanger

ActiveCN108332580BInhibit refluxSpeed up the flowStationary tubular conduit assembliesLaminated elementsVapor liquidPlate heat exchanger

The invention provides a gas-liquid two-phase flow shell-and-tube heat exchanger, which includes a shell, and the two ends of the shell are respectively provided with heads, and the connection position between the head and the shell is set with a tube plate, and the heat exchange tube Connect the tube sheets at both ends, the vapor phase in the vapor-liquid two-phase flow can condense into a liquid phase during the heat exchange process, and the vapor-liquid two-phase flow flows in the tube side, and a flow stabilization device is installed in the heat exchange tube, and the stabilization The flow device includes a central rod arranged along the central axis of the heat exchange tube and a plurality of radial rods extending radially along the central rod, and a plurality of radial rods are arranged on the radial rods in the direction opposite to the fluid flow Extended fins having tips extending in opposite directions of fluid flow. The invention provides a heat exchanger of a flow stabilizing device with a new structure, which can enhance heat transfer, weaken the vibration of the pipeline and reduce the noise level when there is a vapor-liquid two-phase flow in the pipeline.

Owner:安徽盛博冶金环保科技有限公司

Hot pipe of which pipe through holes are communicated with one another

ActiveCN108871019AInhibit refluxSpeed up the flowSafety devices for heat exchange apparatusIndirect heat exchangersGas phaseEvaporation

Owner:盐城韩资工业园产业发展有限公司

Steady flow evaporator and seawater desalination system

ActiveCN109231320AReduce water hammerImprove utilizationGeneral water supply conservationSeawater treatmentEvaporationEngineering

The invention provides a steady flow evaporator. The steady flow evaporator comprises an inlet header, an outlet header, and a heat exchange component connected between the inlet header and the outletheader, wherein the inlet header and the outlet header are respectively connected with a steam inlet pipe and a condensate outlet pipe; the steam inlet pipe of the inlet header is internally providedwith a flow stabilizer, and the flow stabilizer has a sheet structure; the sheet structure is arranged on the cross section of the steam inlet pipe; the flow stabilizer is formed by a square structure and a regular octagonal structure, so that a square through hole and a regular octagonal through hole are formed. The flow stabilizer with the novel structure is adopted, namely, a flow stabilizer in a loop heat pipe is subjected to field transfer and is applied to an inlet pipe at an evaporation end of the loop heat pipe, so that a water hammer phenomenon caused by the space expansion when a steam-water mixture enters the inlet header can be reduced.

Owner:SHANDONG UNIV

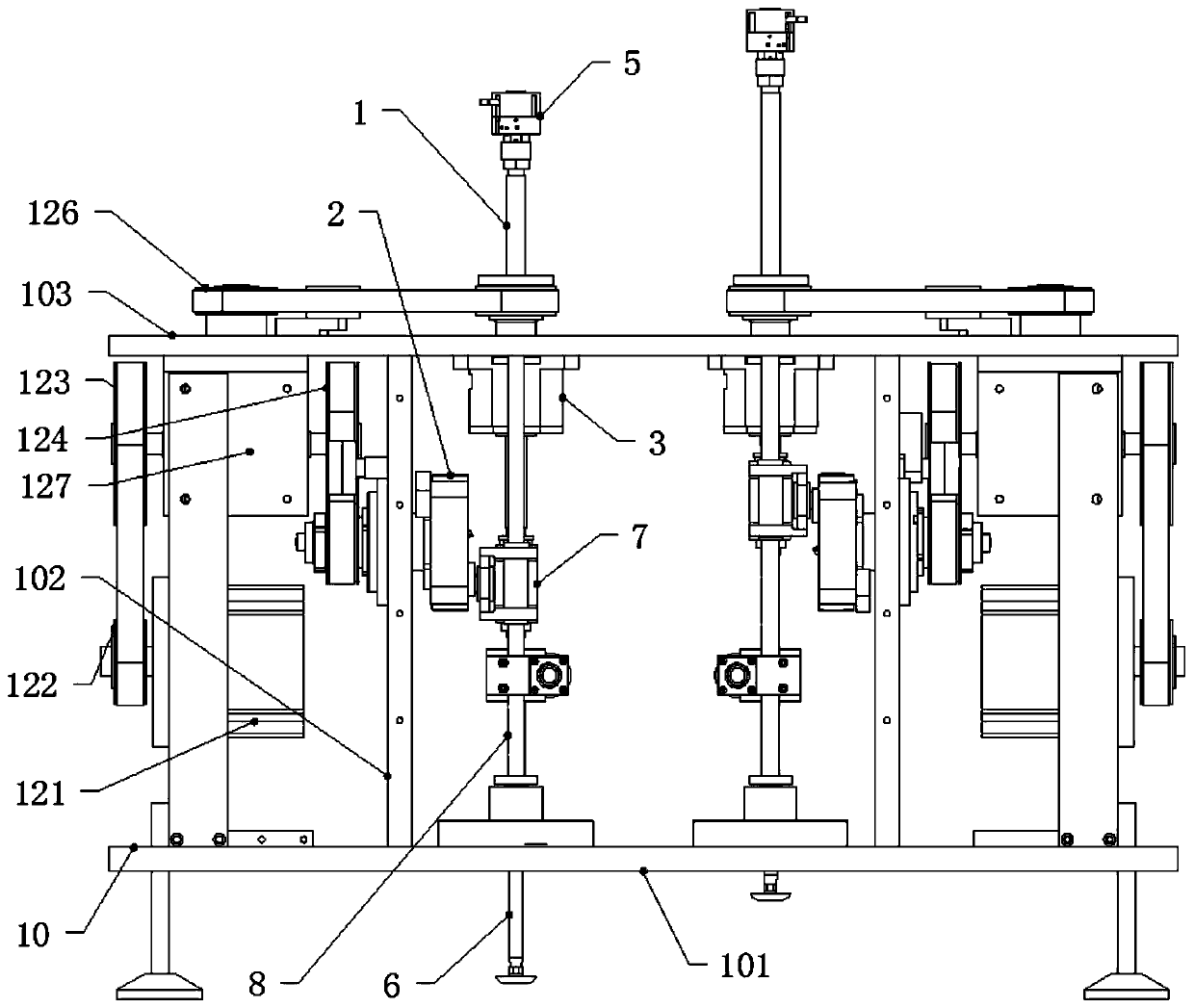

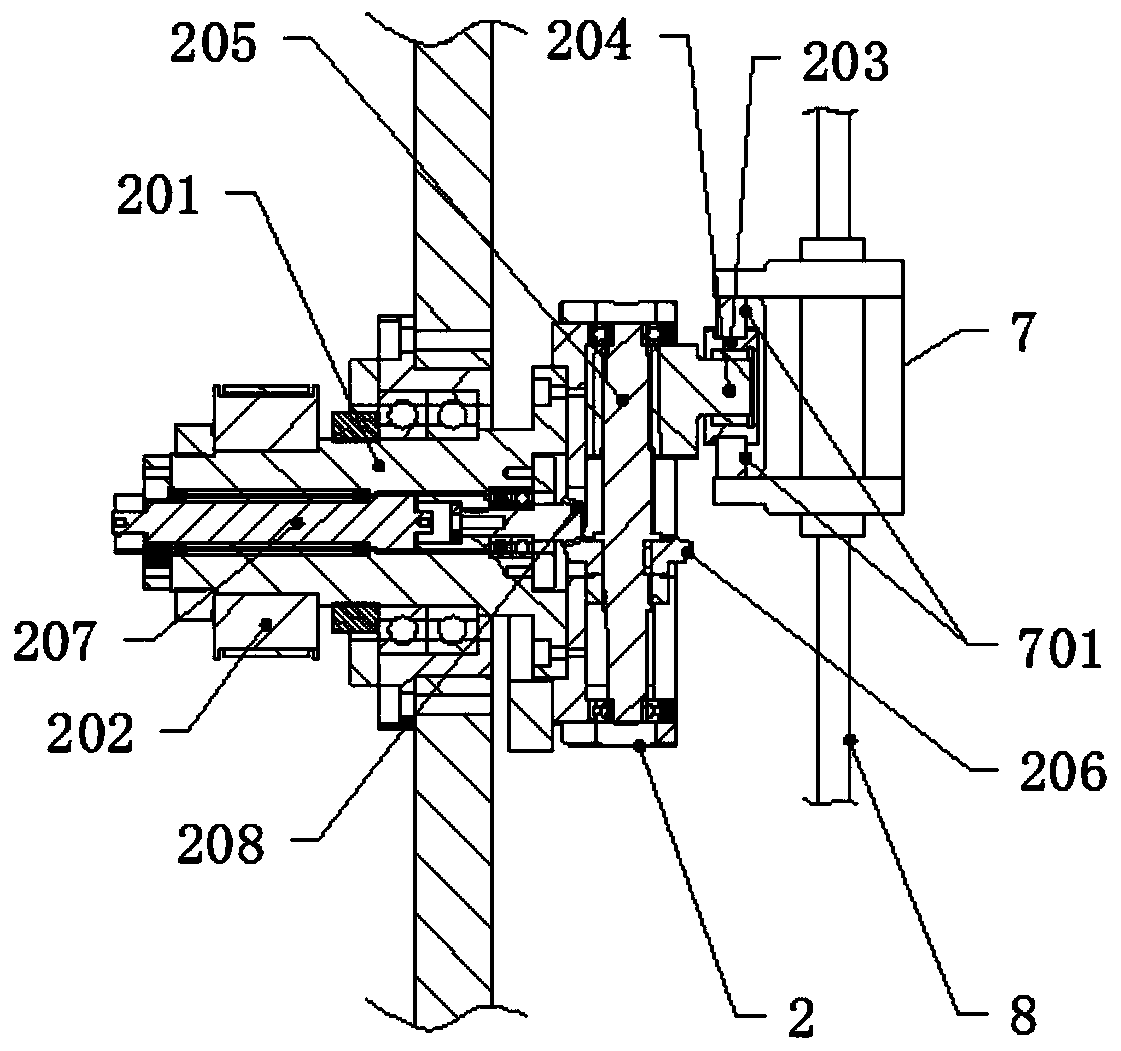

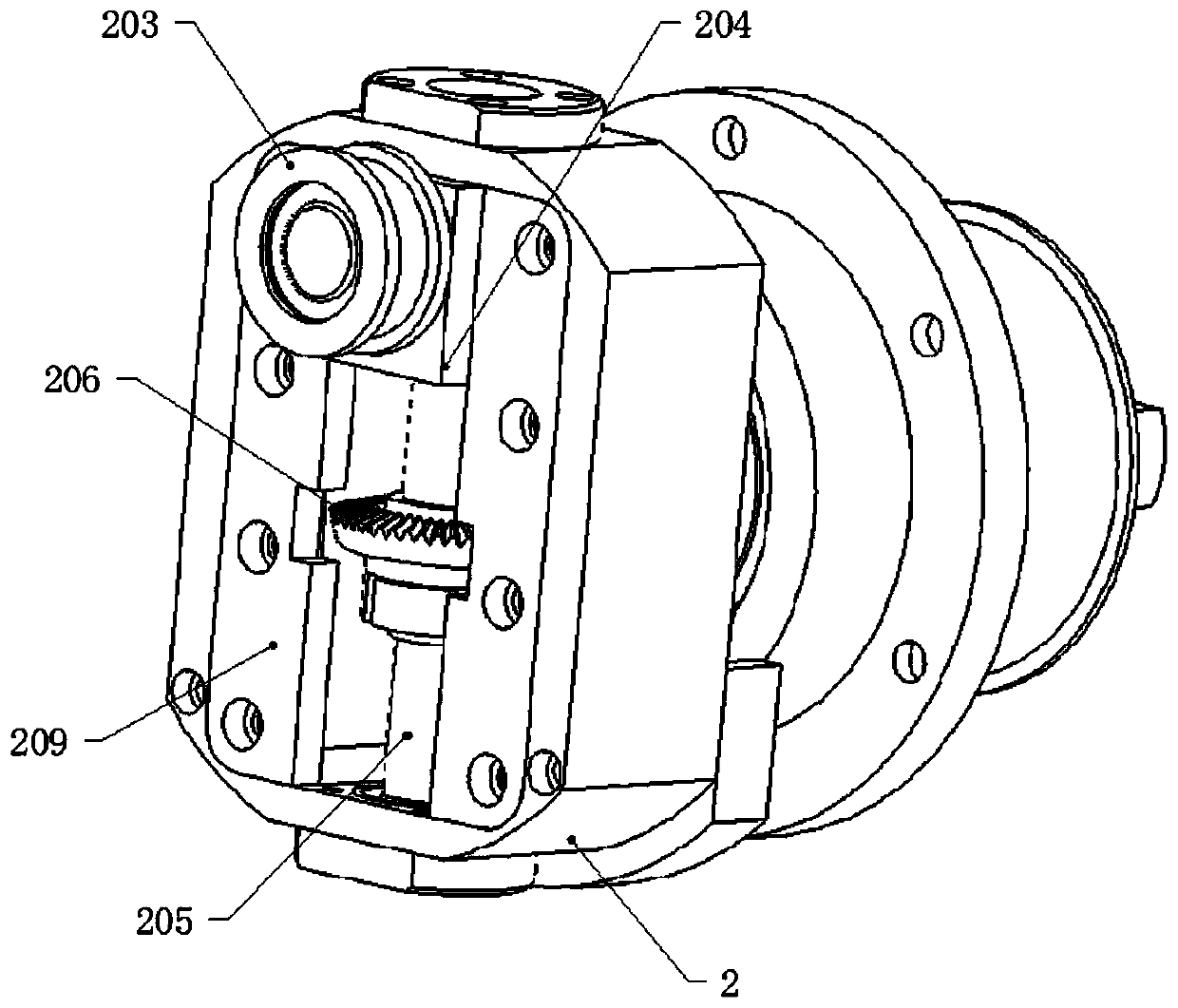

Vibration reduction mechanism of stator winding machine

PendingCN109768679AReduce vibrationPlay the effect of reducing vibration and noiseInertia force compensationManufacturing dynamo-electric machinesWinding machineEngineering

The invention discloses a vibration reduction mechanism of a stator winding machine. The vibration reduction mechanism comprises a rack and two winding driving mechanisms. Each winding driving mechanism comprises a power source, an upper flying fork rod, a cam, a sliding block, a winding head and a guide rod, wherein the guide rod is vertically arranged on the rack, the sliding block is installedon the guide rod in a sleeving mode, the cam is rotationally connected to the rack and is driven by the power source to rotate, the winding head is arranged on the upper flying fork rod, the lower endof the upper flying fork rod is connected with the sliding block, and the middle of the upper flying fork rod is connected with the rack in a sliding mode. According to the two winding driving mechanisms, the cams of the two winding driving mechanisms rotate periodically with a degree difference on phase in the working process. The vibration reduction mechanism has the advantages that since the two winding driving mechanisms are arranged at the left and the right of the rack respectively, the cams of the two winding driving mechanisms rotate periodically with the degree difference of 180 degrees on phase in the winding working process, in this way, inertia forces of up-and-down motion of the two groups are mutually offset, consequently, vibration of the winding machine is reduced, and theeffects of reducing vibration and lowering noise are achieved.

Owner:ZTD TECH IND QINGDAO CO LTD

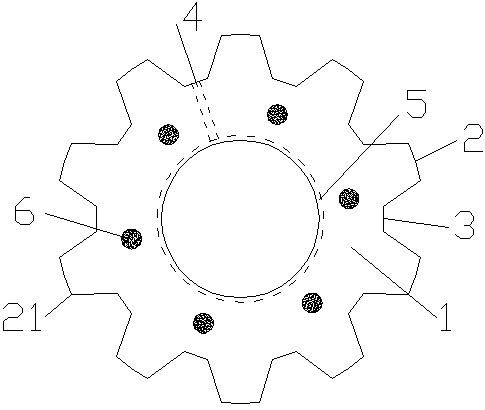

Rust-proof gear

InactiveCN107676458AReduce weightSimple structureGear lubrication/coolingPortable liftingEngineeringHardness

The invention discloses an anti-rust gear, which comprises a gear main body. The gear main body is provided with external teeth, and an external tooth groove is arranged between the external teeth and the external teeth. An oil injection hole is provided inside, and an oil groove is arranged inside the inner hole of the main body of the gear, and the oil injection hole communicates with the oil groove. There is nylon filler, and the outer surface of the gear body is provided with a protective layer, the protective layer is a sulfide layer, and the thickness of the sulfide layer is 3-6mm. The invention effectively softens the hardness of the gear surface by increasing the structure of vulcanized material on the working surface of the gear, increases the lubrication between the meshing gears, improves friction, reduces wear, and thus prolongs the service life of the gear.

Owner:QIDONG TIANSHAN TOOLS CO LTD

A Condensable Porous Steady Flow Device Heat Exchanger with Varying Spacing

ActiveCN107966051BReduce vibrationReduce noise levelSafety devices for heat exchange apparatusStationary tubular conduit assembliesVapor liquidEngineering

The invention provides a spacing variable condensable porous current stabilizer heat exchanger. The heat exchanger comprises a shell. The two ends of the shell are provided with end sockets correspondingly. Tube plates are arranged at the junctions between the end sockets and the shell. Heat exchange tubes are connected with the tube plates at the two ends. A vapor phase in vapor-liquid two-phaseflow can be condensed into a liquid phase in the heat exchange process. Current stabilizers used for vibration reduction and noise reduction are arranged in the heat exchange tubes. The multiple current stabilizers are arranged in the same heat exchange tube. The distance between the adjacent current stabilizers increases gradually in the flowing direction of fluid in the heat exchange tubes. According to the heat exchanger provided by the invention, vibration of a pipeline is weakened to the maximum extent according to change of the spacing between the current stabilizers when vapor-liquid two phases flow in the pipeline, and noise is lowered; meanwhile, flow resistance is reduced, and the heat exchange uniformity is improved.

Owner:河南盛宏丰化工有限公司

A gas-liquid two-phase flow shell-and-tube heat exchanger

ActiveCN108332578BInhibit refluxSpeed up the flowStationary tubular conduit assembliesHeat transfer modificationShell and tube heat exchangerPlate heat exchanger

The invention provides a gas-liquid two-phase flow heat exchange pipe. The gas phase of a gas-liquid two-phase flow is insoluble or slightly-soluble gas, that is, during heat exchange, the gas cannotbe dissolved in the liquid, and the gas-liquid two-phase flow flows in the heat exchange pipe. Flow stabilizers are arranged inside the heat exchange pipe; each flow stabilizer comprises a central rodaxially arranged along the center of the heat exchange pipe and multiple radial rods extending in the radial direction along the central rod; multiple fins extending from the radial rods to the direction opposite to the flowing direction of the flow are arranged on the radial rods; the fins comprise tips; and the tips extend in the direction opposite to the flowing direction of the flow. The heatexchange pipe is characterized in that the multiple flow stabilizers are arranged inside the heat exchange pipe; the distribution density of the fins inside the different flow stabilizers is reducedfrom the inlet of the heat exchange pipe to the middle of the heat exchange pipe; and the distribution density of the fins inside the different flow stabilizers is increased from the middle of the heat exchange pipe to the outlet of the heat exchange pipe. The heat exchange pipe which adopts the new structure and is provided with the flow stabilizers is provided, when the gas-liquid two-phase flowflows in the pipe, through the arrangement, the vibration and the noise can be reduced to the greatest extent, and meanwhile, the flowing resistance of the liquid can be reduced.

Owner:山东凯布尔化工有限公司

Vapor-liquid two-phase flow heat exchange pipe

ActiveCN109654917AReduce vibrationReduce noise levelStationary tubular conduit assembliesLaminated elementsVapor liquidNoise level

The invention provides a vapor-liquid two-phase flow heat exchange pipe. A vapor-liquid two-phase flow flows in the heat exchange pipe, and the vapor phase of the vapor-liquid two-phase flow can be condensed into the liquid phase during heat exchange. Multiple flow stabilizers are arranged inside the heat exchange pipe; each flow stabilizer comprises a core and a casing; each core is arranged inside the corresponding casing; each casing is connected and fixed to the inner wall of the heat exchange pipe; each core comprises a central rod axially arranged along the center of the heat exchange pipe and multiple radial rods extending in the radial direction along the central rod; multiple fins extending from the radial rods to the direction opposite to the flowing direction of the flow are arranged on the radial rods; the fins comprise tips; and the tips extend in the direction opposite to the flowing direction of the flow. The multiple flow stabilizers are arranged inside the heat exchange pipe, and the sizes of the fins of the flow stabilizers on the radial rods are increasing in the flowing direction of the flow inside the heat exchange pipe. The heat exchange pipe which adopts thenew structure and is provided with the flow stabilizers is provided, the vibration of the pipe is further reduced through change of the sizes of the fins of the radial rods, and thus the noise level is reduced.

Owner:PINGYI JINGFA INFORMATION SERVICE CO LTD

A shell-and-tube heat exchanger

ActiveCN108332579BInhibit refluxSpeed up the flowStationary tubular conduit assembliesLaminated elementsVapor liquidShell and tube heat exchanger

Owner:无锡市新五环节能科技有限公司

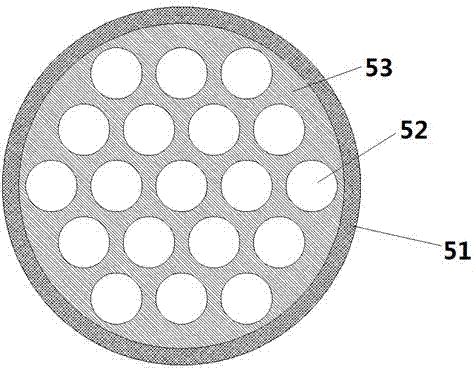

Condensable porous current stabilizer heat exchanger

ActiveCN107966053AInhibit refluxStable flowStationary tubular conduit assembliesHeat transfer modificationVapor phaseEngineering

The invention provides a vapor-liquid two-phase flow tube and shell heat exchanger. The tube and shell heat exchanger comprises a shell. The two ends of the shell are provided with end sockets. Tube plates are arranged at the junctions between the end sockets and the shell. Heat exchange tubes are connected with the tube plates at the two ends. A vapor phase in vapor-liquid two-phase flow can be condensed into a liquid phase in the heat exchange process. The vapor-liquid two-phase flow flows in a tube pass. Current stabilizers are arranged in the heat exchange tubes. Each current stabilizer comprises a core body and an outer shell, the core body is arranged in the outer shell, the outer shell is connected and fixed to the inner wall of the corresponding heat exchange tube, the core body isan integrated structural part extending in the length direction of the outer shell, and the structural part is provided with a plurality of through holes. The current stabilizer heat exchanger of a novel structure, provided by the invention, conducts enhanced heat transfer when the vapor-liquid two-phase flow flows in a pipeline. Meanwhile, vibration of the pipeline is weakened, and noise is lowered.

Owner:济宁市邦达煤化工有限公司

Loop Heat Pipe with Annular Divider with Varying Hydraulic Diameter

InactiveCN107167009BReduce vibrationReduce noise levelIndirect heat exchangersVapor liquidNoise level

The invention provides a heat pipe, comprising an evaporation header, a condensation header, a rising pipe and a return pipe, the rising pipe communicates with the evaporation header and the condensation header, the evaporation header is located at the lower part, and the condensation header The tube is located at the upper part, the fluid absorbs heat and evaporates in the evaporation header, enters the condensation header through the rising pipe, condenses after exchanging heat in the condensation header, and the condensed fluid returns to the evaporation header through the return pipe; the rising pipe is set As for the separating device, multiple separating devices are arranged in the same riser pipe, and the hydraulic diameters of the annular holes in different separating devices are getting smaller and smaller from the inlet of the riser pipe to the outlet of the riser pipe. In the present invention, through the change of the hydraulic diameter of the annular hole of the separation device, when there is a vapor-liquid two-phase flow in the riser pipe, the heat transfer is enhanced, the vibration of the riser pipe is weakened, and the noise level is reduced.

Owner:SHANDONG UNIV

A Condensable Porous Steady Flow Device Heat Exchanger

ActiveCN107966053BInhibit refluxSpeed up the flowStationary tubular conduit assembliesHeat transfer modificationVapor liquidPlate heat exchanger

The invention provides a vapor-liquid two-phase flow tube and shell heat exchanger. The tube and shell heat exchanger comprises a shell. The two ends of the shell are provided with end sockets. Tube plates are arranged at the junctions between the end sockets and the shell. Heat exchange tubes are connected with the tube plates at the two ends. A vapor phase in vapor-liquid two-phase flow can be condensed into a liquid phase in the heat exchange process. The vapor-liquid two-phase flow flows in a tube pass. Current stabilizers are arranged in the heat exchange tubes. Each current stabilizer comprises a core body and an outer shell, the core body is arranged in the outer shell, the outer shell is connected and fixed to the inner wall of the corresponding heat exchange tube, the core body isan integrated structural part extending in the length direction of the outer shell, and the structural part is provided with a plurality of through holes. The current stabilizer heat exchanger of a novel structure, provided by the invention, conducts enhanced heat transfer when the vapor-liquid two-phase flow flows in a pipeline. Meanwhile, vibration of the pipeline is weakened, and noise is lowered.

Owner:济宁市邦达煤化工有限公司

Compressor assembly, air conditioner outdoor unit and air conditioner

PendingCN107490084APlay the effect of reducing vibration and noiseReduce external communicationPositive displacement pump componentsLighting and heating apparatusEngineeringMechanical engineering

The invention discloses a compressor assembly, an air conditioner outdoor unit and an air conditioner. The compressor assembly comprises a box body, a compressor body and a flexible bag; the box body is in a shape with the closed bottom and the opened top, the compressor body is arranged in the box body, the box body is filled with a noise reduction filler, and the noise reduction filler wraps at least one portion of the compressor body, the flexible bag is internally filled with damping particles, and is placed in the box body, and the noise reduction filler is covered. According to the compressor assembly, through the large surface area and the extension of the flexible bag, the damping particles like rubber particles in the box body in a filling manner are packaged; through the flexible bag, an opening in the top of the box body can be sealed, outward spreading of the noise generated by the compressor body can be reduced, the noise reduction filler can be sealed, leakage of the noise reduction filler in the box body can be prevented, the flexible bag can achieve the vibration reduction and noise reduction effects, and the vibration reduction and noise reduction effects are improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

A loop heat pipe of a porous flow stabilization device

ActiveCN107131783BReduce vibrationImprove heat transfer performanceSafety devices for heat exchange apparatusHeat exhanger conduitsRefluxNoise level

The invention provides a heat pipe. The heat pipe comprises an evaporation header, a condensation header, an ascending pipe and a reflux pipe; the ascending pipe communicates with the evaporation header and the condensation header; the evaporation header is positioned at the lower part; the condensation header is positioned at the upper part; a fluid absorbs heat for evaporation in the evaporation header, is fed in the condensation header by the ascending pipe, and is condensed in the condensation header after heat exchange; the condensed fluid is returned to the evaporation header through the reflux pipe; current stabilizing devices are arranged in the ascending pipe; multiple current stabilizing devices are arranged in the same ascending pipe; and in the height direction of the ascending pipe, gaps between the adjacent current stabilizing devices are continuously reduced. Through the gap change of the current stabilizing devices, when steam-liquid two-phase flowing exists in the ascending pipe, the heat transfer is intensified, meanwhile, the vibration of the ascending pipe is weakened, and the noise level is lowered.

Owner:西安新港分布式能源有限公司

A shell-and-tube heat exchanger

ActiveCN108332581BInhibit refluxSpeed up the flowSafety devices for heat exchange apparatusStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

The invention provides a gas-liquid two-phase flow shell-and-tube heat exchanger, which includes a shell, the two ends of the shell are respectively provided with heads, the connection position between the head and the shell is set with a tube plate, and the heat exchange tube Connect the tube sheets at both ends, the gas phase in the gas-liquid two-phase flow is insoluble or insoluble gas, that is, during the heat exchange process, the gas will not dissolve in the liquid, and the gas-liquid two-phase flow flows in the tube side, and the inside of the heat exchange tube A flow stabilization device is provided, the flow stabilization device includes a central rod arranged along the central axis of the heat exchange tube and a plurality of radial rods extending radially along the central rod, and a plurality of radial rods are arranged on the radial rods A fin extending toward the stem opposite to fluid flow, the fin having a tip extending in a direction opposite to fluid flow. The invention provides a heat exchanger of a flow stabilizing device with a new structure, which can enhance heat transfer, weaken the vibration of the pipeline and reduce the noise level when there is a gas-liquid two-phase flow in the pipeline.

Owner:山东金谷信息技术有限公司

A loop heat pipe with the height direction of the annular partition device changing

InactiveCN107062960BReduce vibrationImprove heat transfer performanceSafety devices for heat exchange apparatusIndirect heat exchangersNoise levelEvaporation

Owner:SHANDONG UNIV

A non-condensable gas annular partition heat exchanger with variable length

ActiveCN107131781BReduce vibrationReduce noise levelSafety devices for heat exchange apparatusHeat exchanger casingsFlow resistivityNoise level

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com