Low-shrinkage HIPS composite material for solving abnormal sound, and preparation method thereof

A composite material, low shrinkage technology, applied in the field of polymer materials, can solve the problems of poor dimensional stability, large shrinkage rate changes, easy deformation of parts, etc., and achieve the effect of low linear expansion coefficient, improved mechanical properties, and reduced noise sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

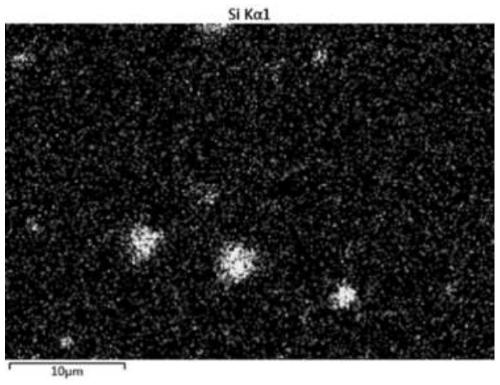

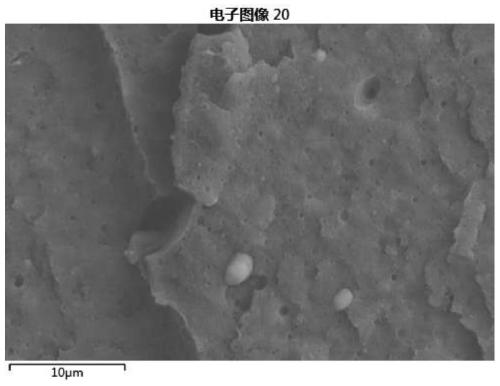

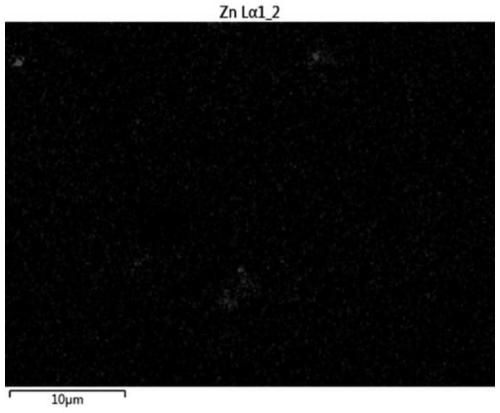

Image

Examples

Embodiment 1

[0029] A low-shrinkage HIPS composite material for solving abnormal noise, including the following raw materials in parts by weight: 60 parts of HIPS resin, 3 parts of rubber composite material, 8 parts of reinforcing agent, 3 parts of barrier agent, 0.3 part of weather resistance agent, and 0.1 part of antioxidant , 0.1 part of lubricant.

[0030] The preparation method of the low-shrinkage HIPS composite material for solving abnormal sound comprises the following steps:

[0031] S1. Premix HIPS resin, rubber composite material, barrier agent, weather resistance agent, antioxidant and lubricant for 8 minutes to obtain a mixture;

[0032] S2. Add the compound described in step S1 into the twin-screw extruder from the main feeding port, and add the reinforcing agent into the twin-screw extruder from the side feeding port to melt, knead and extrude to obtain the solution to the abnormal sound. Low Shrinkage HIPS Composite.

[0033] Wherein, the rubber composite material compri...

Embodiment 2

[0036] A low-shrinkage HIPS composite material for solving abnormal noise, including the following raw materials in parts by weight: 80 parts of HIPS resin, 10 parts of rubber composite material, 10 parts of reinforcing agent, 10 parts of barrier agent, 1.5 parts of weather resistance agent, and 0.6 parts of antioxidant , 0.6 part of lubricant.

[0037] The preparation method of the low-shrinkage HIPS composite material for solving abnormal sound comprises the following steps:

[0038]S1. Premixing HIPS resin, rubber composite material, barrier agent, weather resistance agent, antioxidant and lubricant for 15 minutes to obtain a mixture;

[0039] S2. Add the compound described in step S1 into the twin-screw extruder from the main feeding port, and add the reinforcing agent into the twin-screw extruder from the side feeding port to melt, knead and extrude to obtain the solution to the abnormal sound. Low Shrinkage HIPS Composite.

[0040] Among them, the rubber composite mate...

Embodiment 3

[0043] A low-shrinkage HIPS composite material for solving abnormal noise, including the following raw materials in parts by weight: 78 parts of HIPS resin, 7 parts of rubber composite material, 10 parts of reinforcing agent, 5 parts of barrier agent, 0.5 part of weather resistance agent, and 0.3 part of antioxidant , 0.5 part of lubricant.

[0044] The preparation method of the low-shrinkage HIPS composite material for solving abnormal sound comprises the following steps:

[0045] S1. Premix HIPS resin, rubber composite material, barrier agent, weather resistance agent, antioxidant, and lubricant for 10 minutes to obtain a mixture;

[0046] S2. Add the compound described in step S1 into the twin-screw extruder from the main feeding port, and add the reinforcing agent into the twin-screw extruder from the side feeding port to melt, knead and extrude to obtain the solution to the abnormal sound. Low Shrinkage HIPS Composite.

[0047] Among them, the rubber composite material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com