Low CLTE (coefficient of linear thermal expansion) electroplating PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene) alloy material and preparation method thereof

A technology of low linear expansion and alloy materials, which is applied in the fields of polymer blending and polymer molding processing, can solve the problems of failure to pass the cold and heat shock test, large difference in linear expansion coefficient, large shrinkage deformation, etc., to achieve easy implementation, surface Smooth, shrink cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

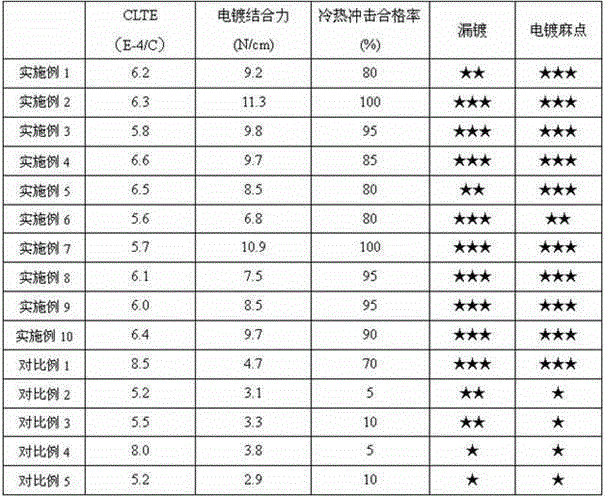

Examples

Embodiment 1

[0042] Example 1 Preparation of electroplated PC / ABS alloy material of the present invention (1)

[0043] a) In parts by weight, add 80 parts of PC resin, 15 parts of ABS resin, 1 part of talcum powder I, 0.1 part of antioxidant and 0.1 part of lubricant into a mixing mixer;

[0044] b) The mixture obtained in step a) is blended and granulated through a twin-screw extruder, wherein the barrel temperature of the twin-screw extruder is 200-260°C, and the screw speed is 200-600rpm to obtain an electroplated PC with a low linear expansion coefficient / ABS alloy particles.

Embodiment 2

[0045] Example 2 Preparation of electroplated PC / ABS alloy material of the present invention (2)

[0046] a) By weight, add 30 parts of PC resin, 65 parts of ABS resin, 5 parts of talcum powder I, 0.4 part of antioxidant and 0.3 part of lubricant into a mixing mixer;

[0047] b) The mixture obtained in step a) is blended and granulated through a twin-screw extruder, wherein the barrel temperature of the twin-screw extruder is 200-260°C, and the screw speed is 200-600rpm to obtain an electroplated PC with a low linear expansion coefficient / ABS alloy particles.

Embodiment 3

[0048] Example 3 Preparation of electroplated PC / ABS alloy material of the present invention (3)

[0049] a) By weight, add 50 parts of PC resin, 45 parts of ABS resin, 5 parts of talcum powder I, 0.4 part of antioxidant and 0.3 part of lubricant into a mixing mixer;

[0050] b) The mixture obtained in step a) is blended and granulated through a twin-screw extruder, wherein the barrel temperature of the twin-screw extruder is 200-260°C, and the screw speed is 200-600rpm to obtain an electroplated PC with a low linear expansion coefficient / ABS alloy particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com