Steel rail cladding vibration reduction structure of embedded type railway and preparation method thereof

A vibration damping structure and embedded technology, which is applied in the direction of track, rail, track maintenance, etc., can solve the problems of aggravated rail corrugation and limited vibration damping effect, solve the problem of corrosion, facilitate and simple construction, and reduce corrugation phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

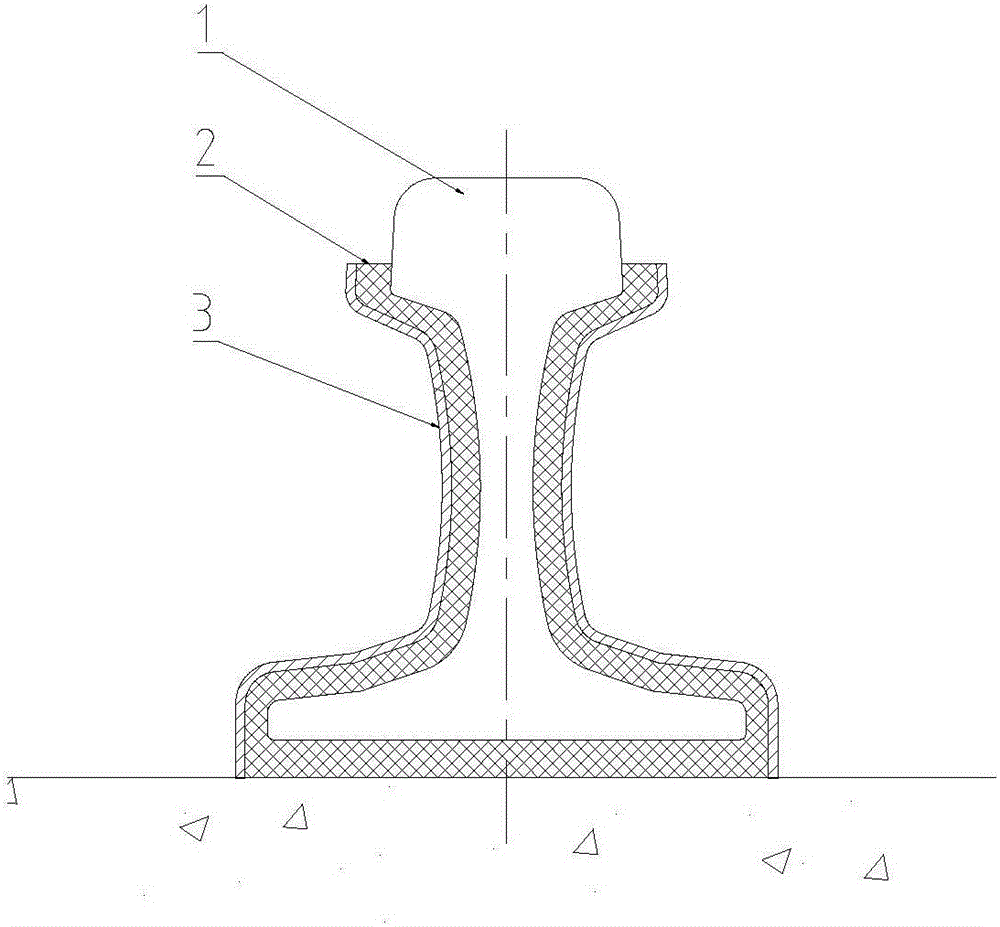

[0028] The embedded track rail cladding damping structure of this embodiment includes a rail 1 and a polymer elastic damping layer 2, the outer layer of the rail 1 is filled with a polymer elastic damping layer 2; the polymer elastic damping The body layer 2 wraps the two sides and the bottom surface of the rail 1 .

[0029] The polymer elastic damping body layer is made of two-component polyurethane grouting material;

[0030] The two-component polyurethane grouting material includes A component and B component, and the A component includes by weight: polyether polyol: 70 parts, chain extender: 7 parts, antioxidant: 1 part , catalyst: 0.02 parts, leveling agent: 0.5 parts, color paste: 0.1 parts; the B component is polyurethane prepolymer; the weight ratio of A component to B component is 100:12.5-13.5.

[0031] The production process of the A component is as follows: Weigh the raw materials in parts by weight, add polyether polyol, chain extender, antioxidant, leveling agen...

Embodiment 2

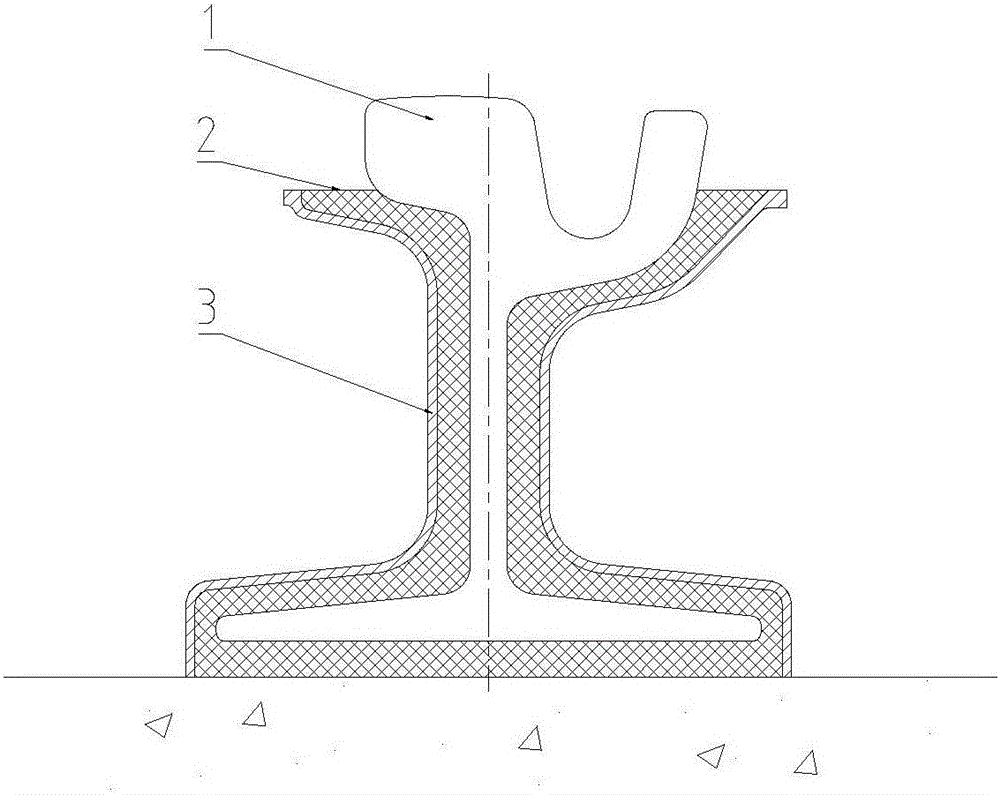

[0037] The embedded track rail cladding damping structure of this embodiment includes a rail 1, a polymer elastic damping layer 2 and a skeleton material 3, and the outer layer of the rail 1 is filled with a polymer elastic damping layer 2; The polymer elastic damping layer 2 wraps the two sides and the bottom of the rail 1; the skeleton material 3 is located outside the polymer elastic damping layer 2.

[0038] The polymer elastic damping body layer is made of two-component polyurethane grouting material;

[0039] The two-component polyurethane grouting material includes A component and B component, and the A component includes by weight: polyether polyol: 90 parts, chain extender: 15 parts, antioxidant: 0.5 part , catalyst: 0.1 part, leveling agent: 1 part, color paste: 0.5 part; the B component is a polyurethane prepolymer; the weight ratio of A component to B component is 100:12.5-13.5.

[0040] The production process of the A component is as follows: Weigh the raw materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com