Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Minimize assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

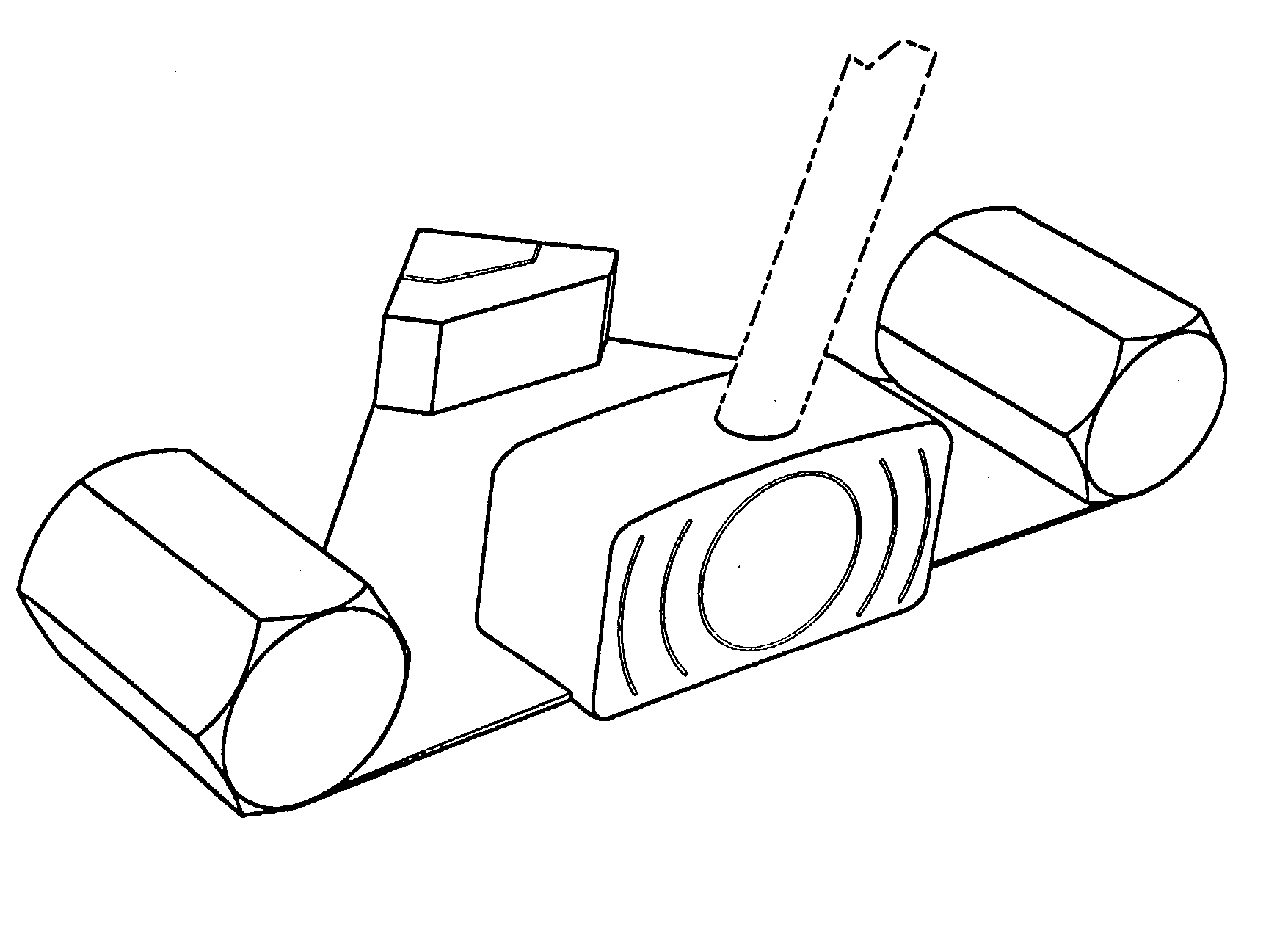

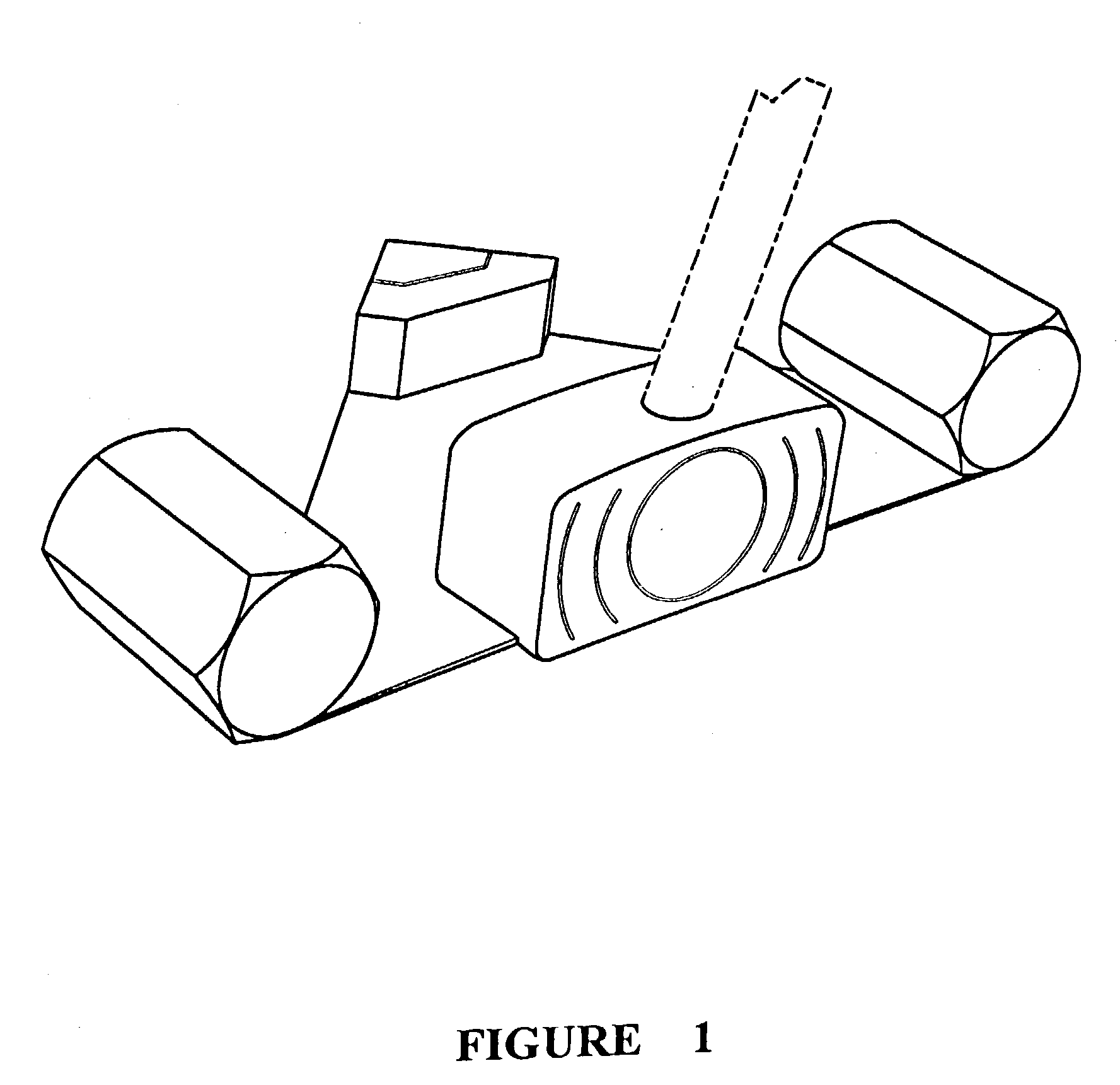

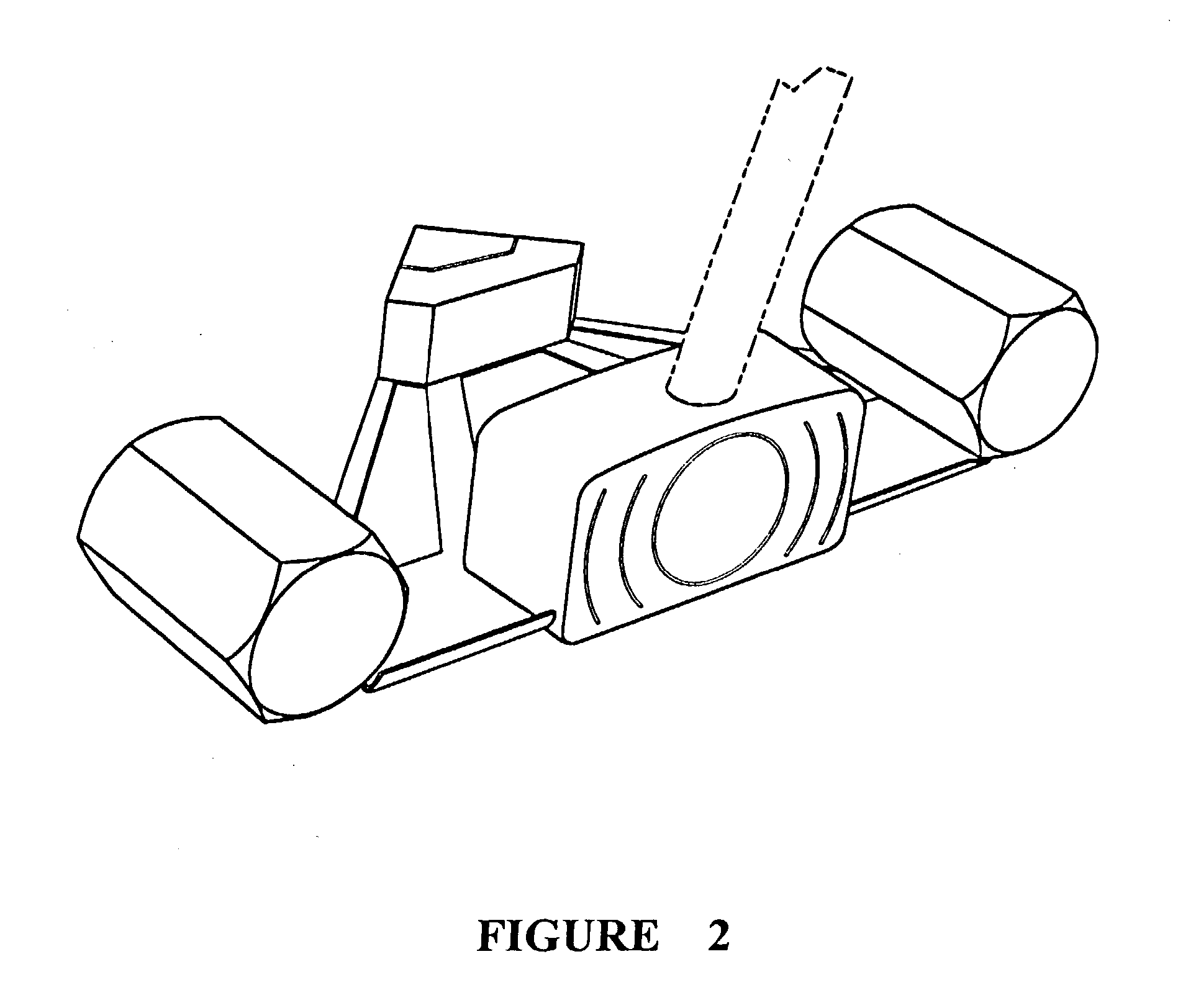

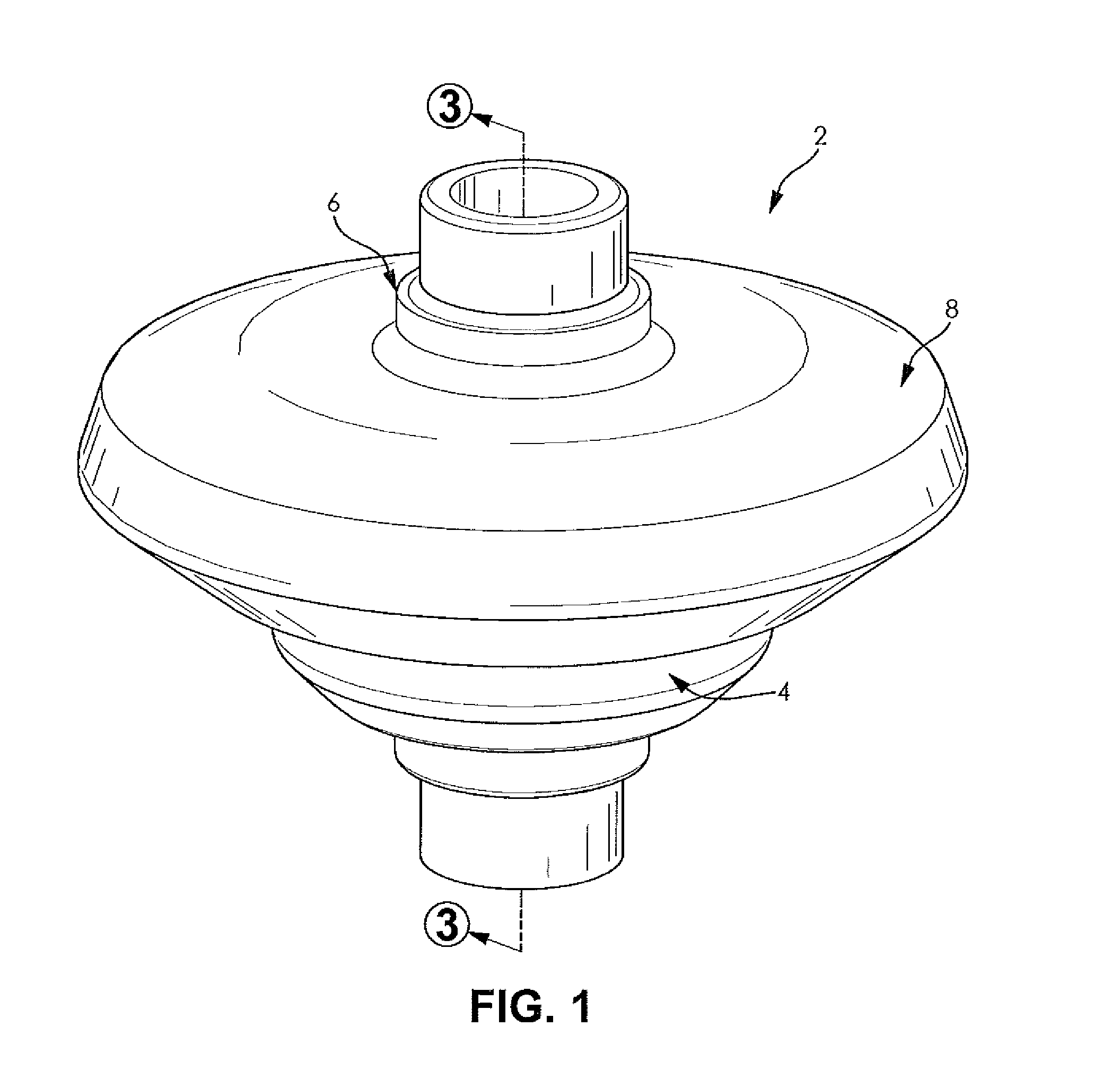

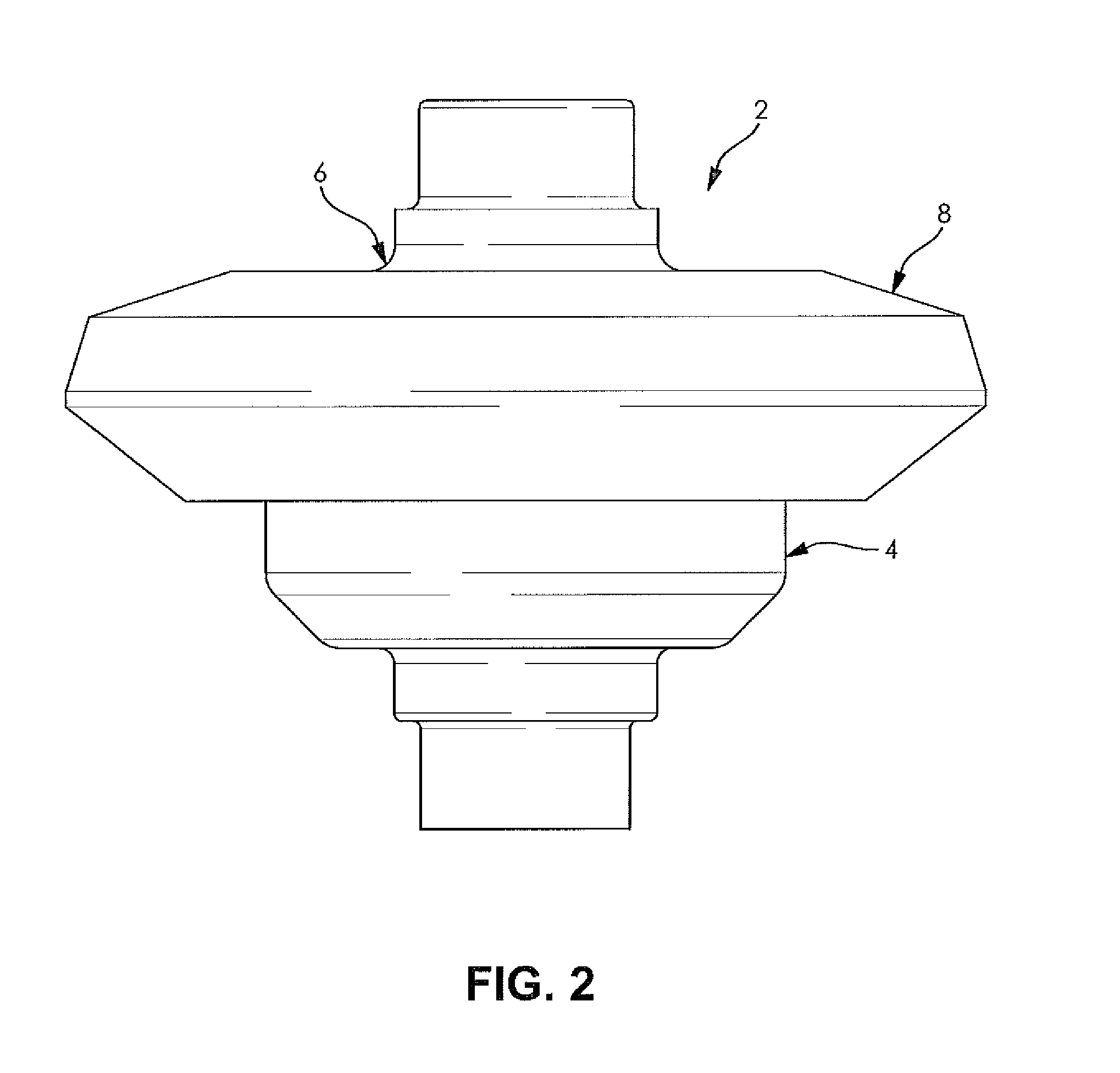

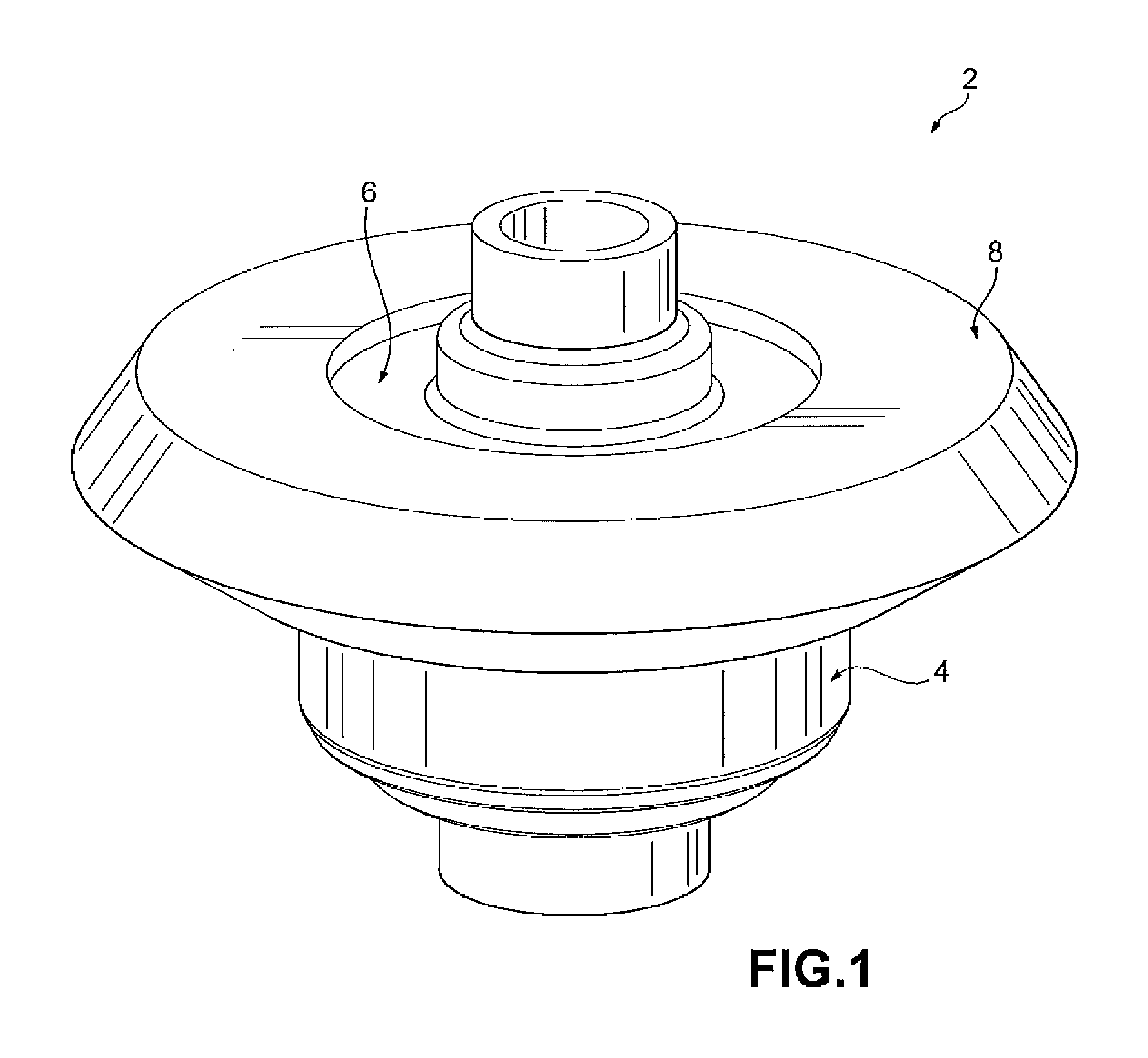

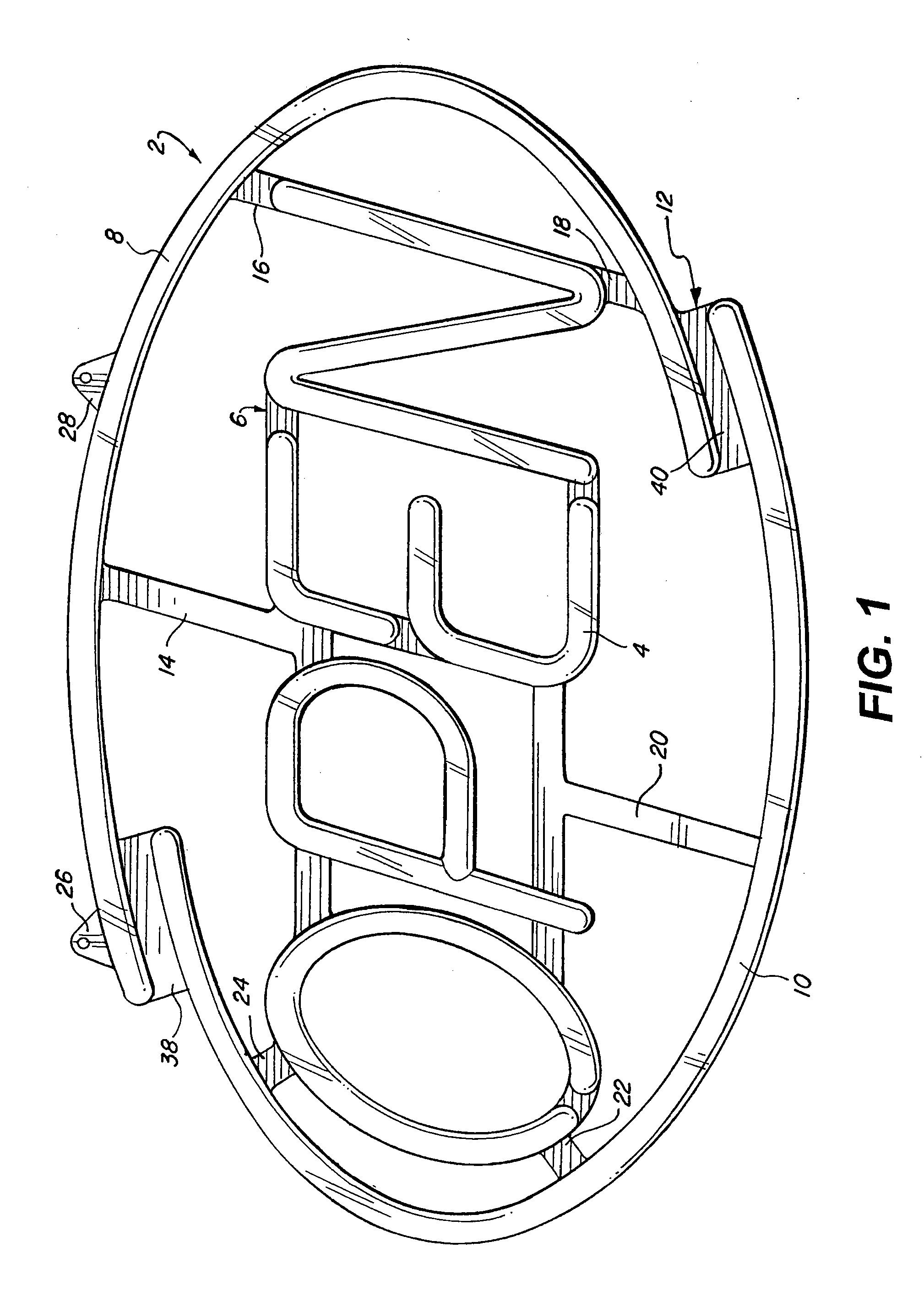

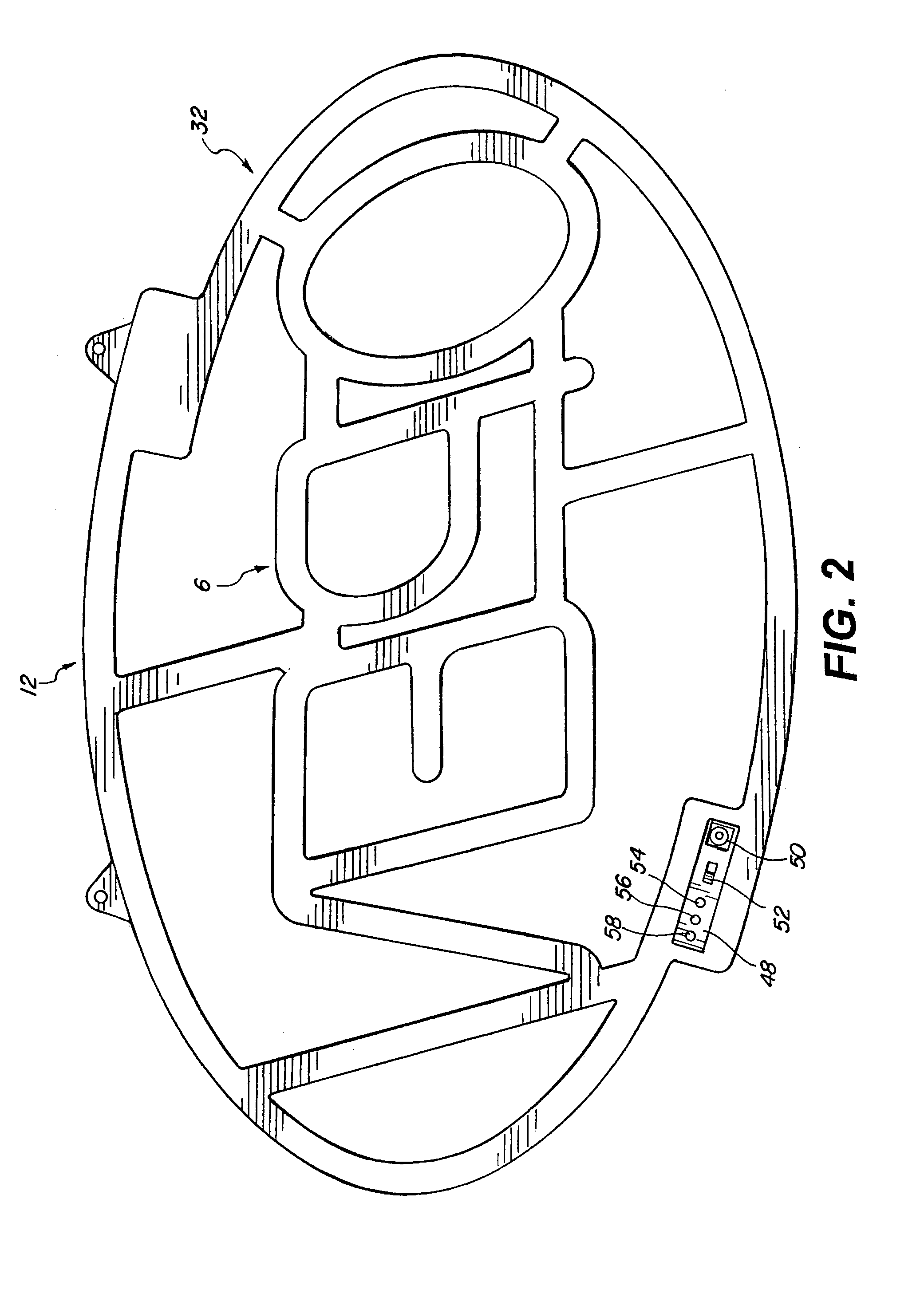

Aim-enhancing, swing-stabilizing, resonant golf putter head

InactiveUS20030144077A1Good effectMaximize ease of assemblingGolf clubsRacket sportsSingle elementResonance

An aim-enhancing, swing-stabilizing, resonant golf putter head with central striking element, torque-resisting stabilizer, focusing element, and resonance-enhancing structure. A preferred embodiment includes the torque-resisting side stabilizer comprised as a single element, curved behind the central striking element and connecting to both the left and right side thereof, differentially massed with the majority of the mass being divided equally between the right and left sides beyond the center of balance of the central striking element. A preferred embodiment includes the torque-resisting side stabilizer which does not stay within the horizontal plane of the central striking element.

Owner:CULLEN H LEO

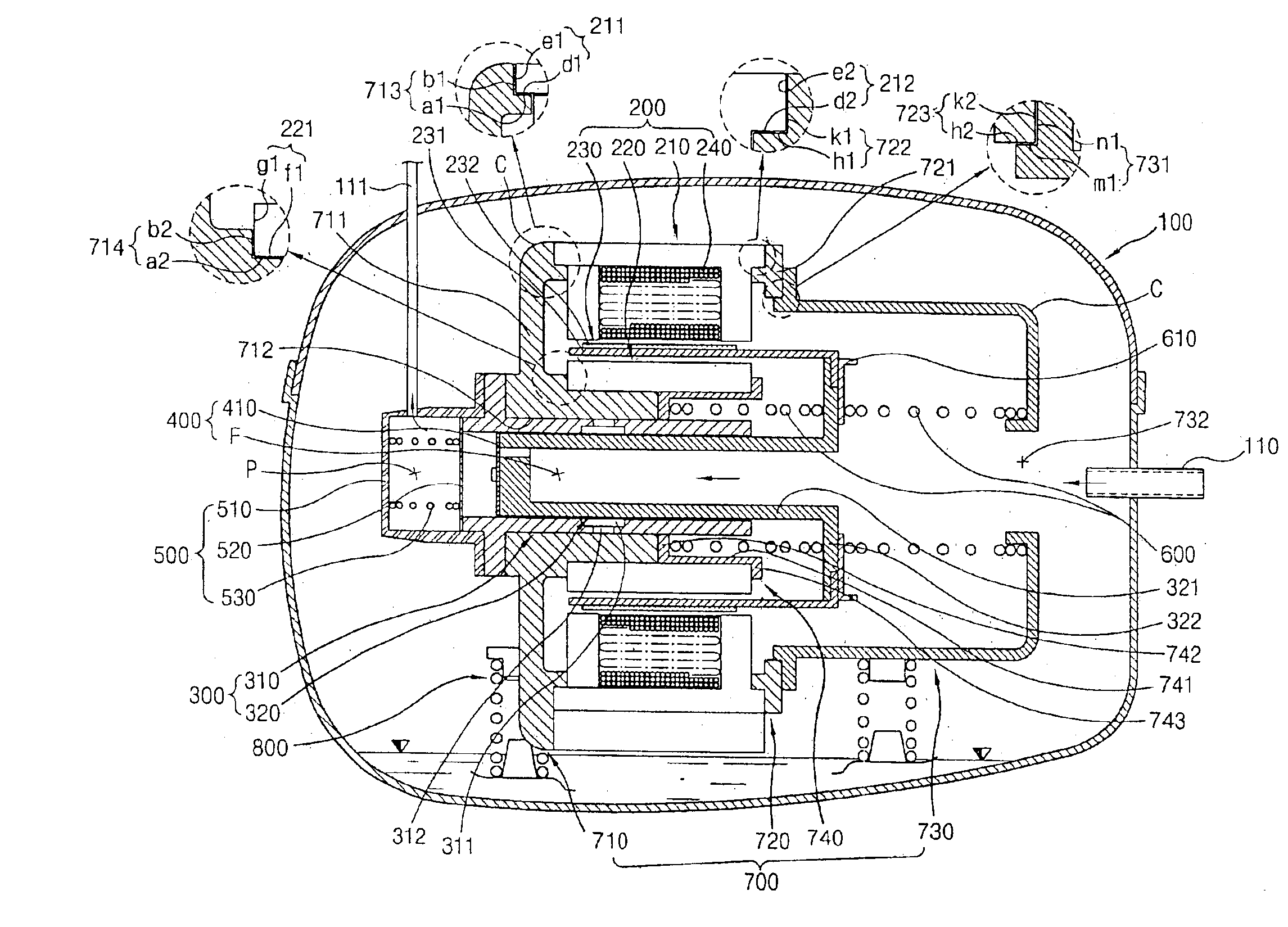

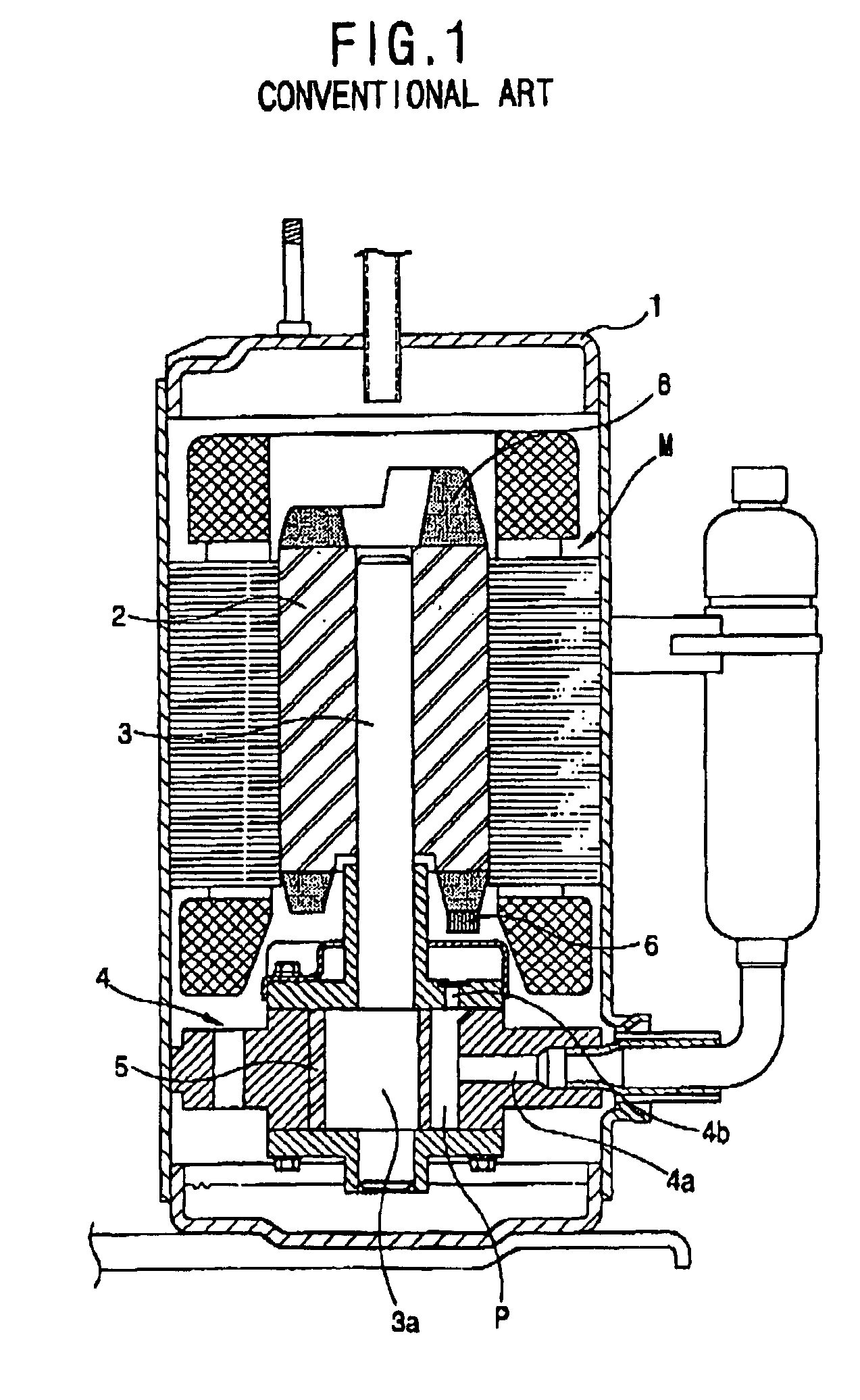

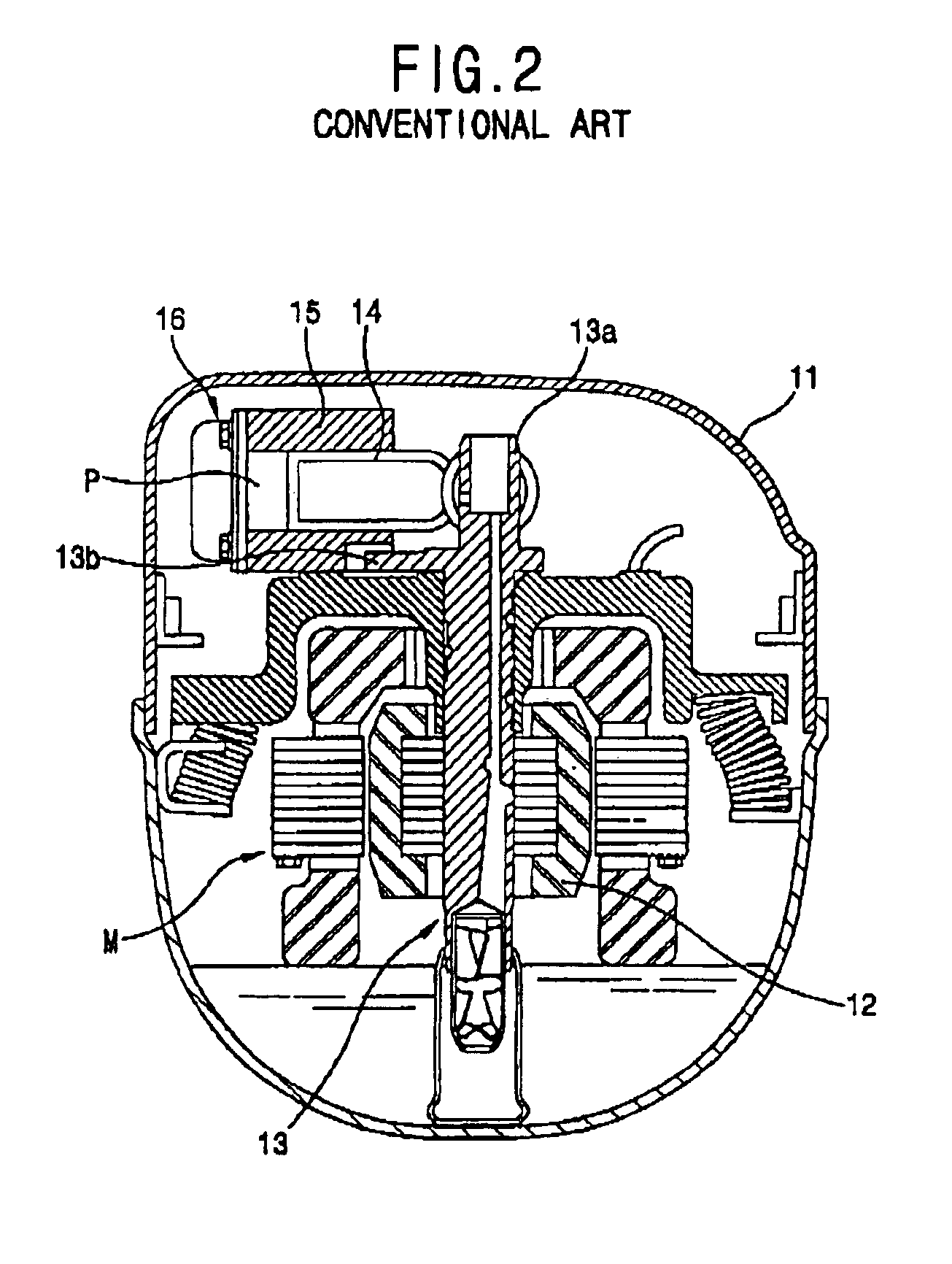

Reciprocating compressor having reduced vibration

InactiveUS6881042B2Easy to controlVibration minimizationPositive displacement pump componentsPiston pumpsResonanceElectric machine

A reciprocating compressor includes: a reciprocating motor, an outer stator and an inner stator provided with at least one step portion at both sides thereof, and an armature linearly moving therebetween; a compression unit having a cylinder and a piston inserted in the cylinder to receive a linear and reciprocal driving force of the reciprocating motor and compress a gas; a suction unit sucking a gas into the compression unit; a discharge unit discharging the gas compressed in the compression unit to outside the container; a resonance spring unit elastically supporting the piston and the armature; and a frame unit supporting the compression unit and the reciprocating motor. Because stable driving is achieved in its operation, generation of vibration and noise can be minimized, heightening reliability. In addition, the amount of gas discharge can be accurately controlled.

Owner:LG ELECTRONICS INC

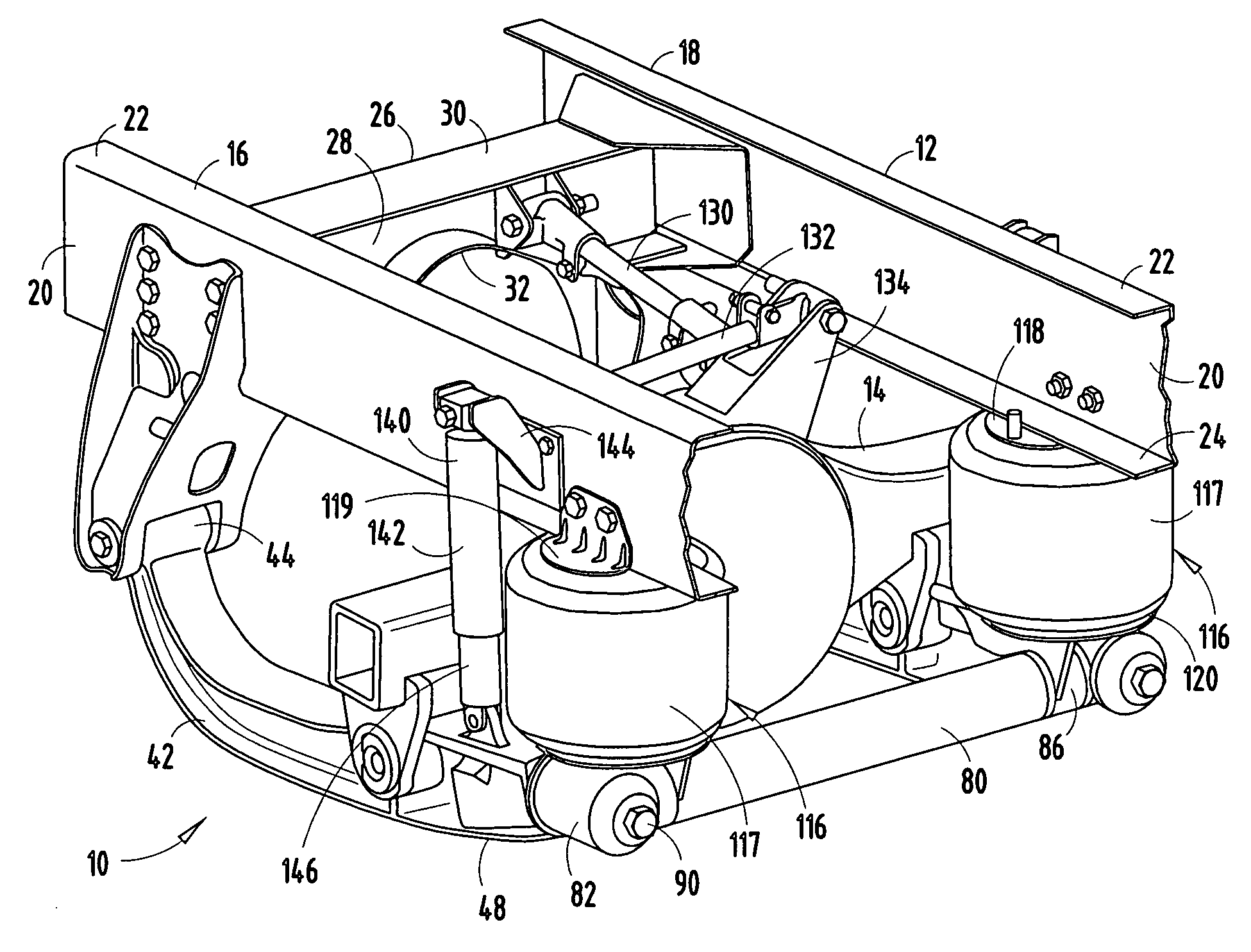

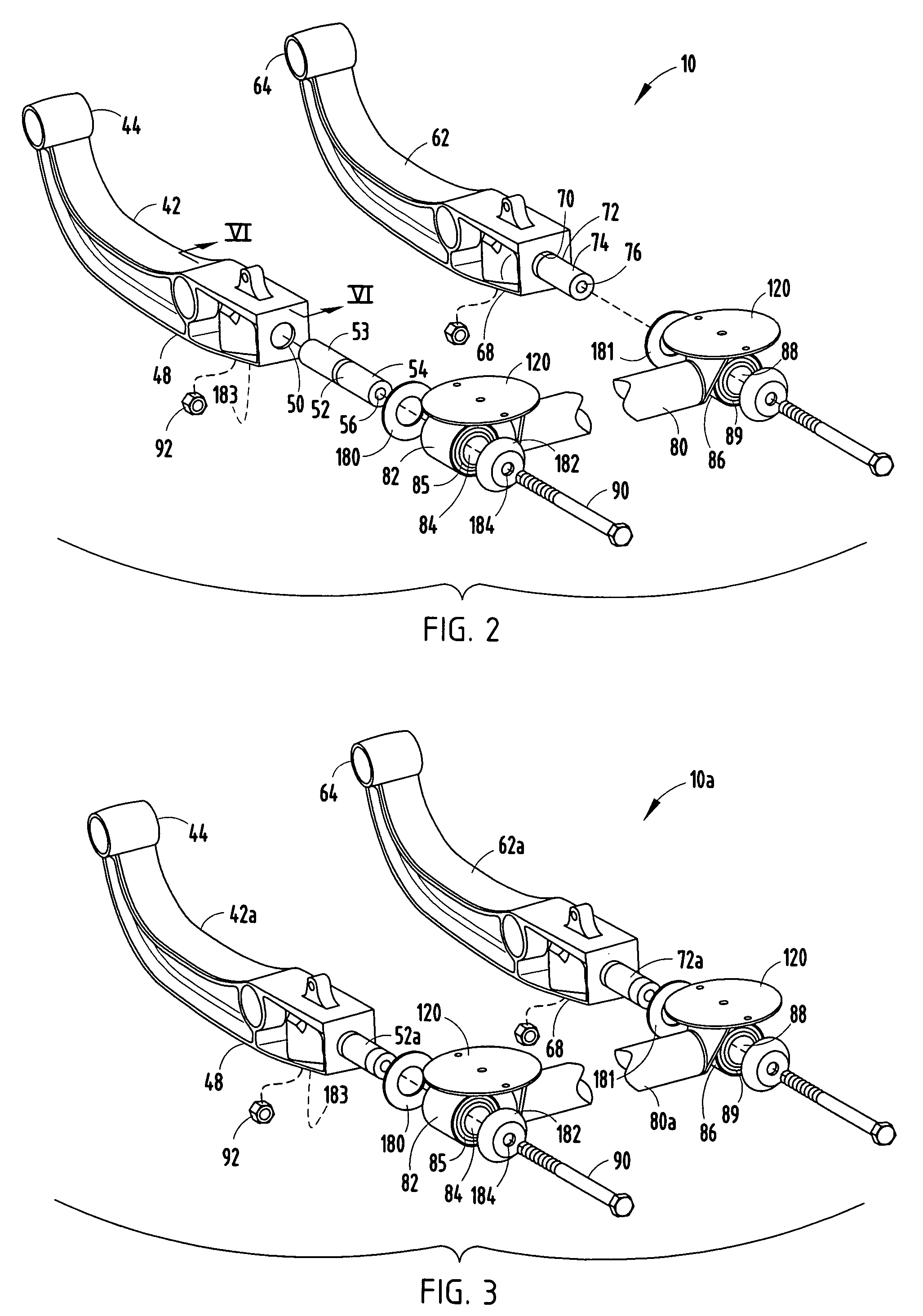

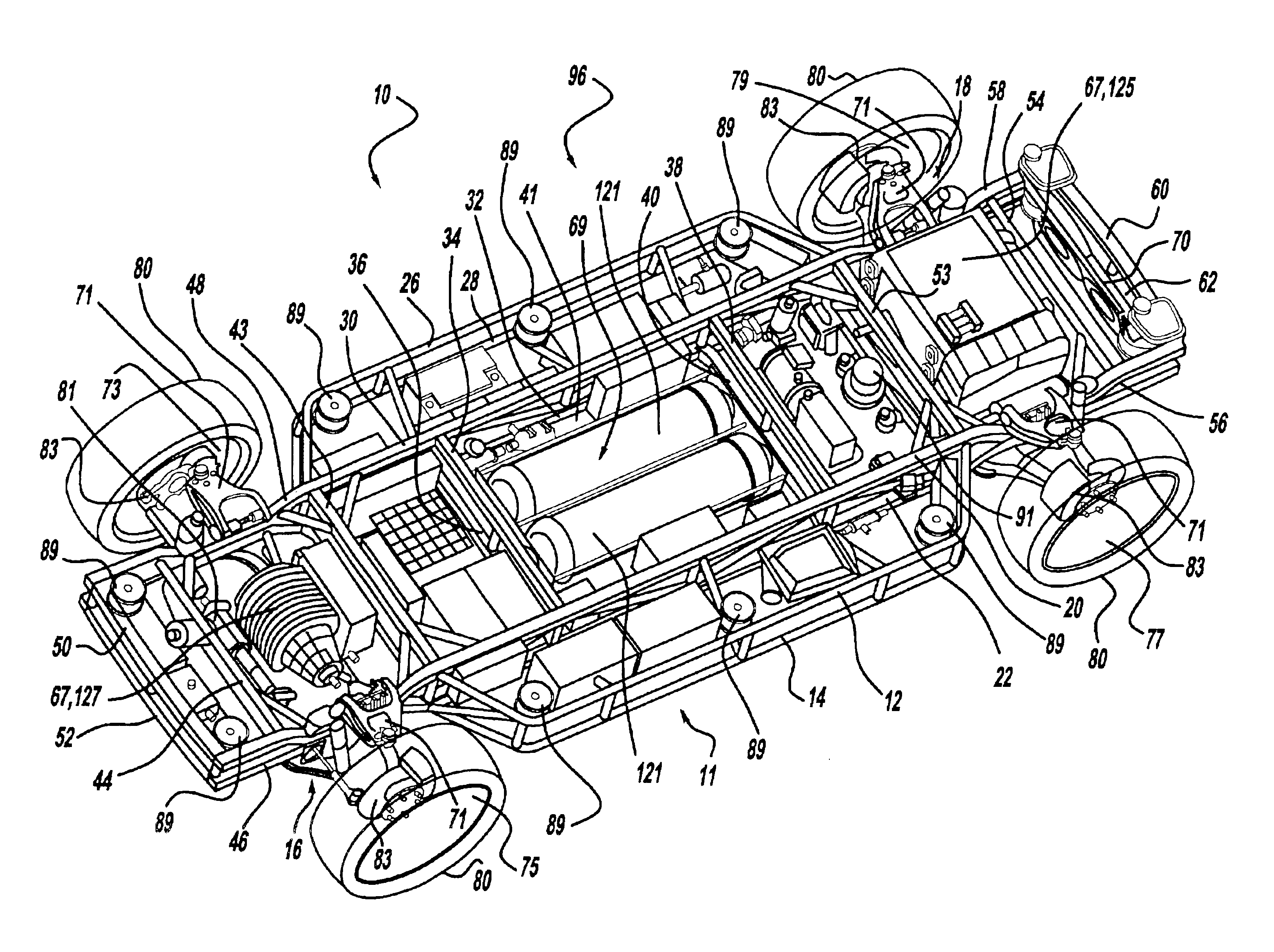

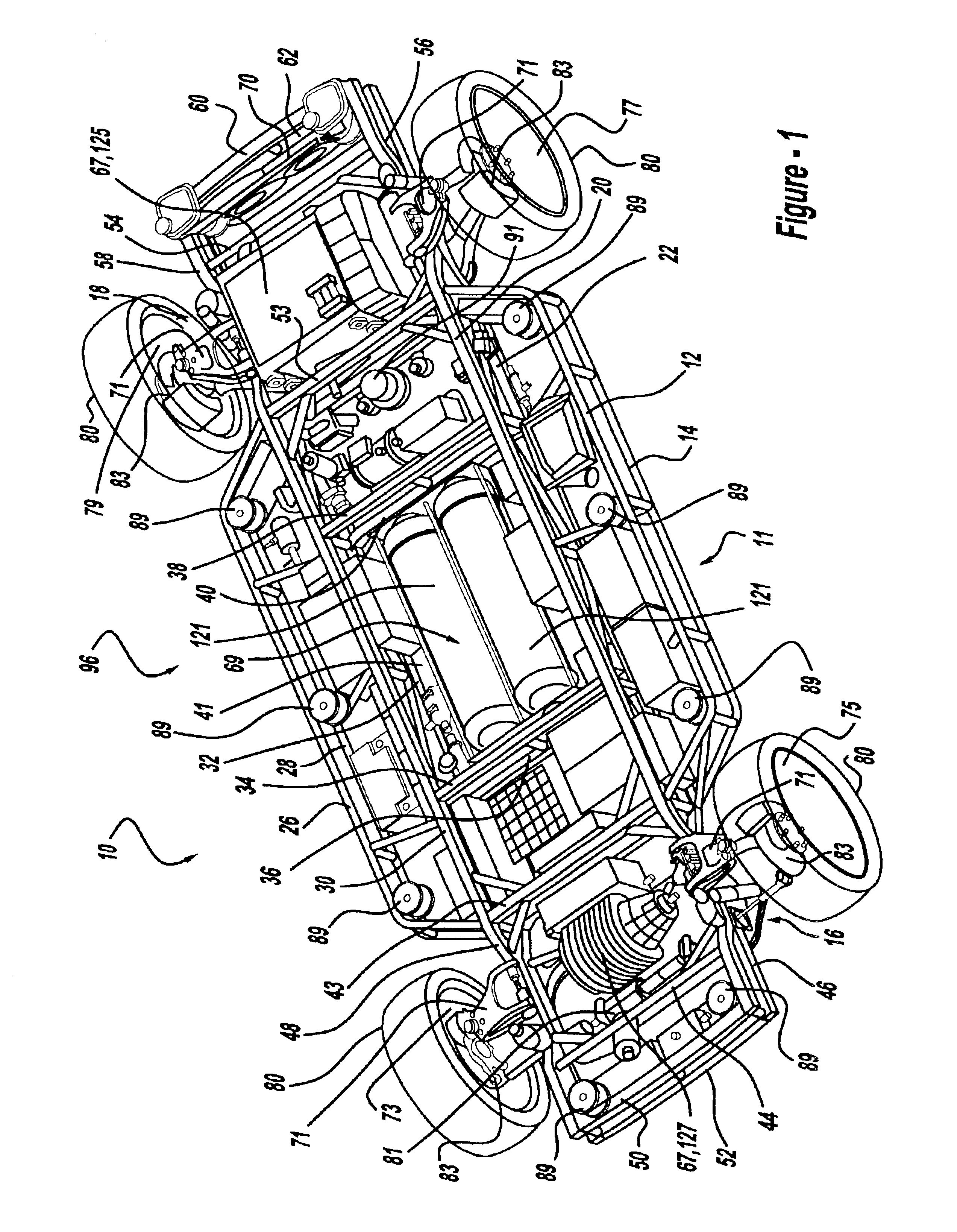

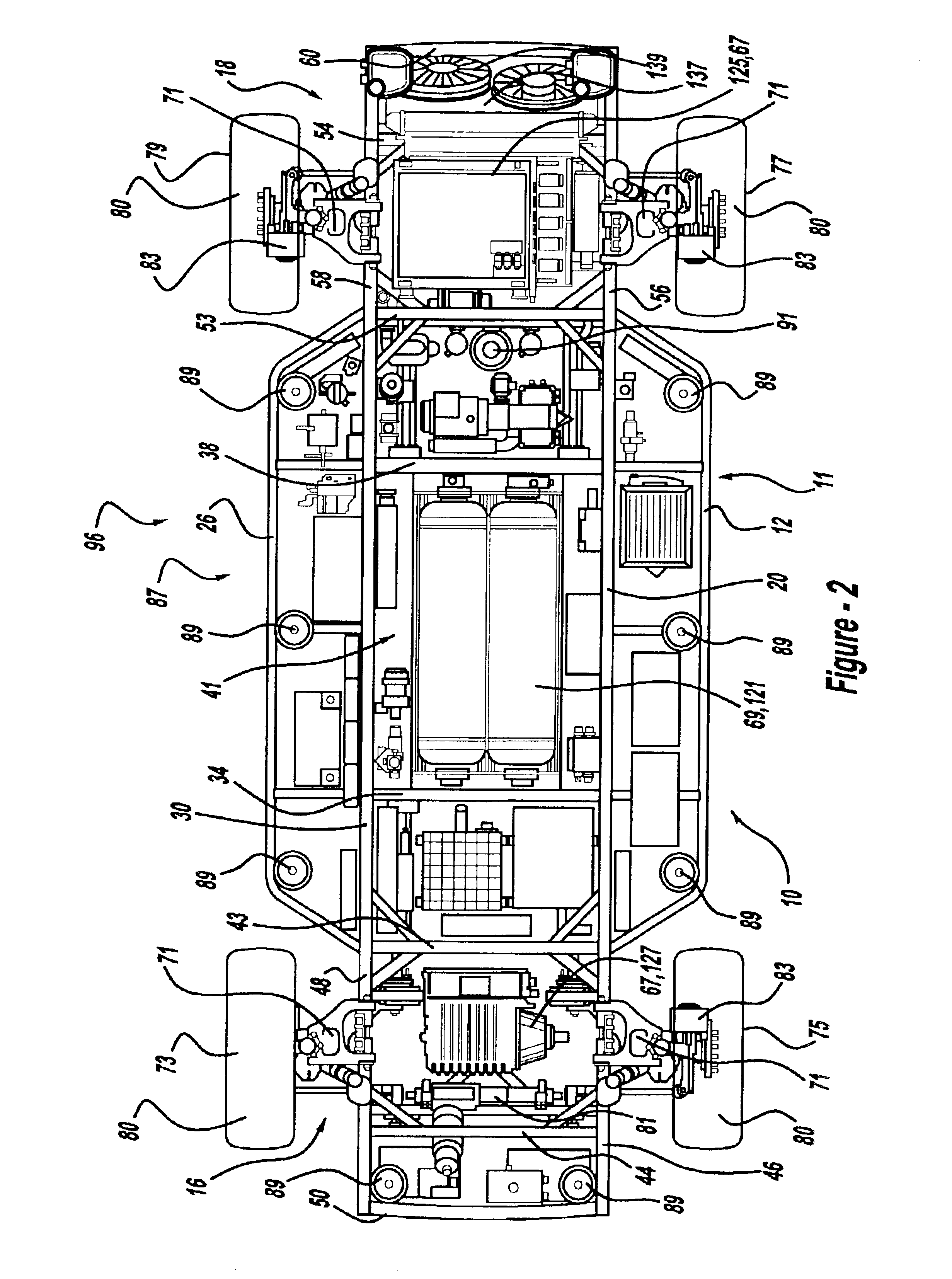

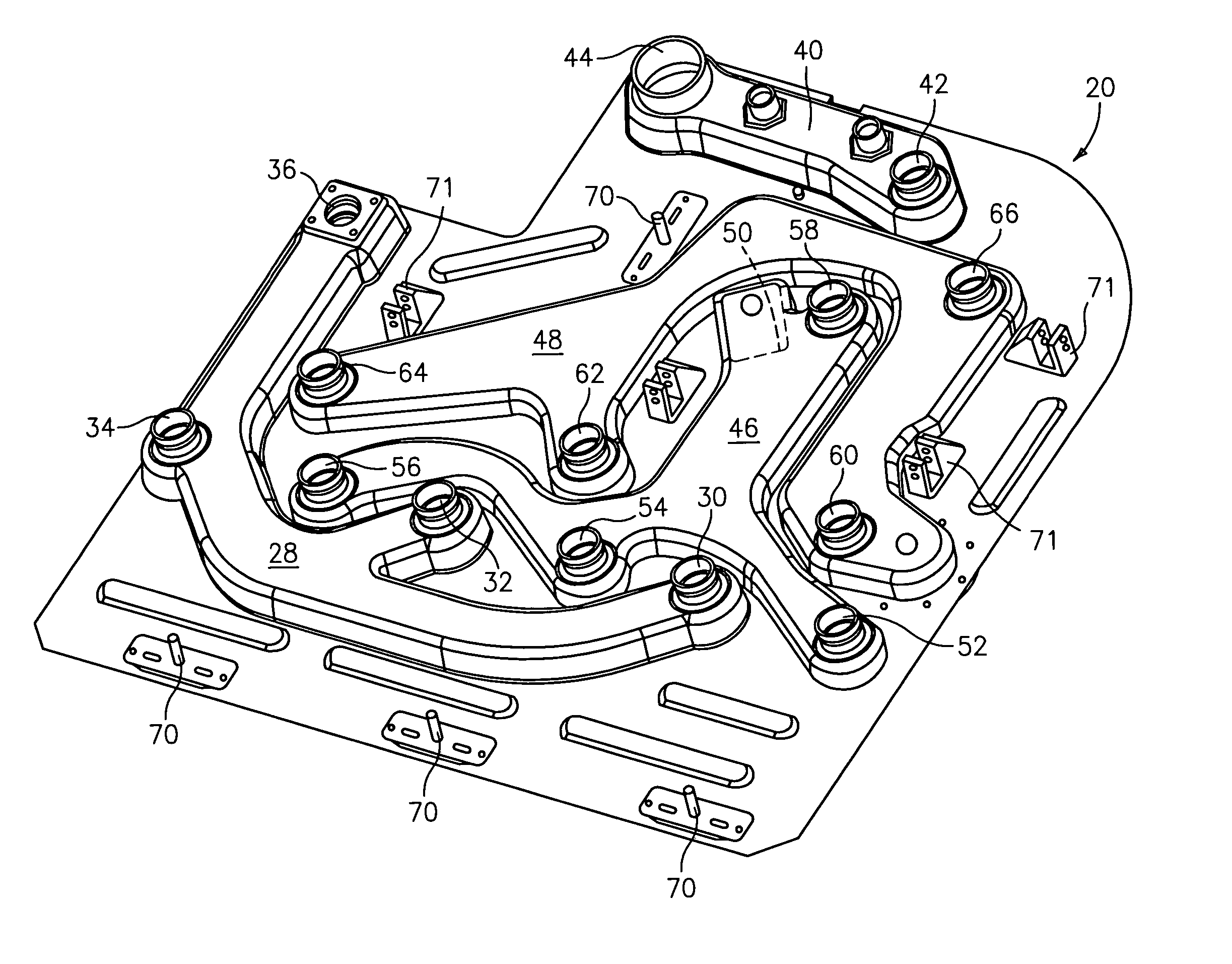

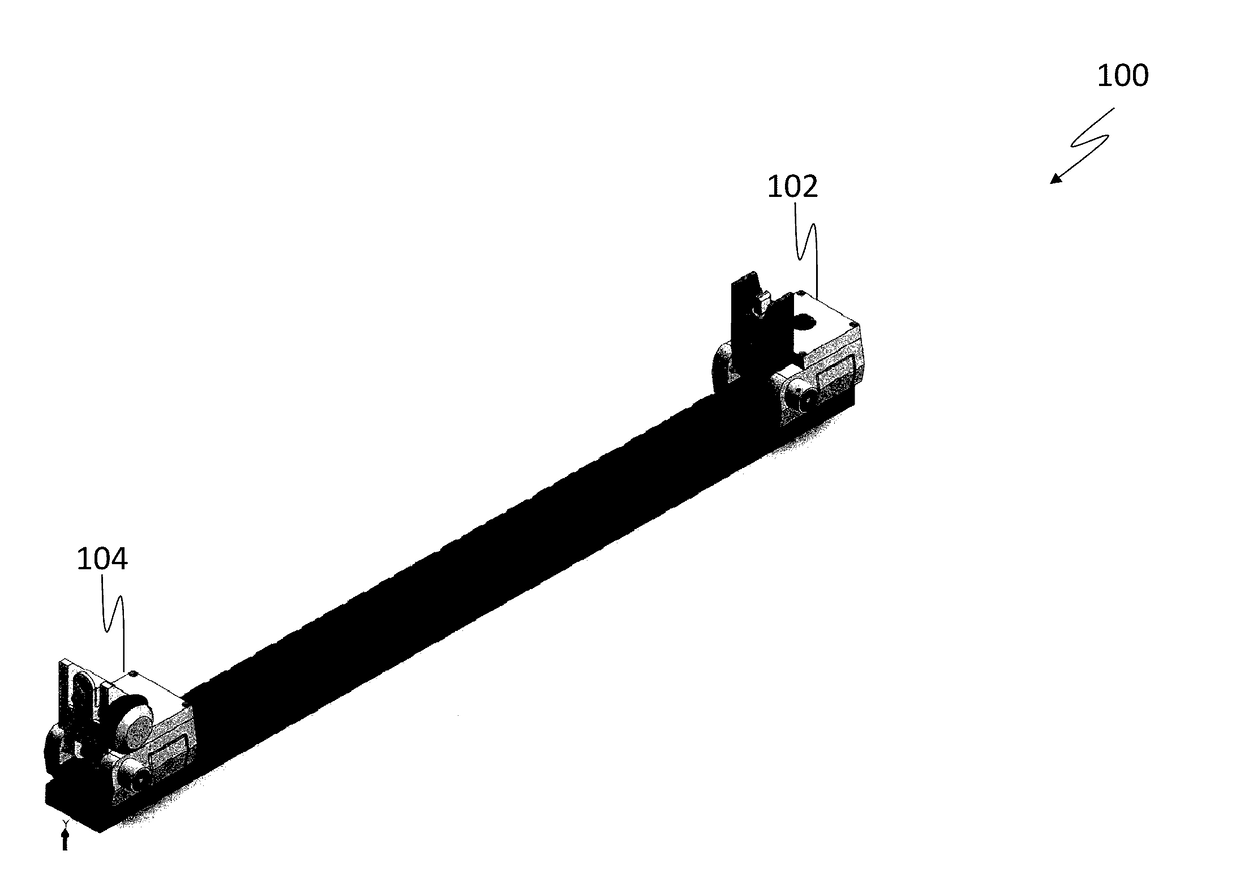

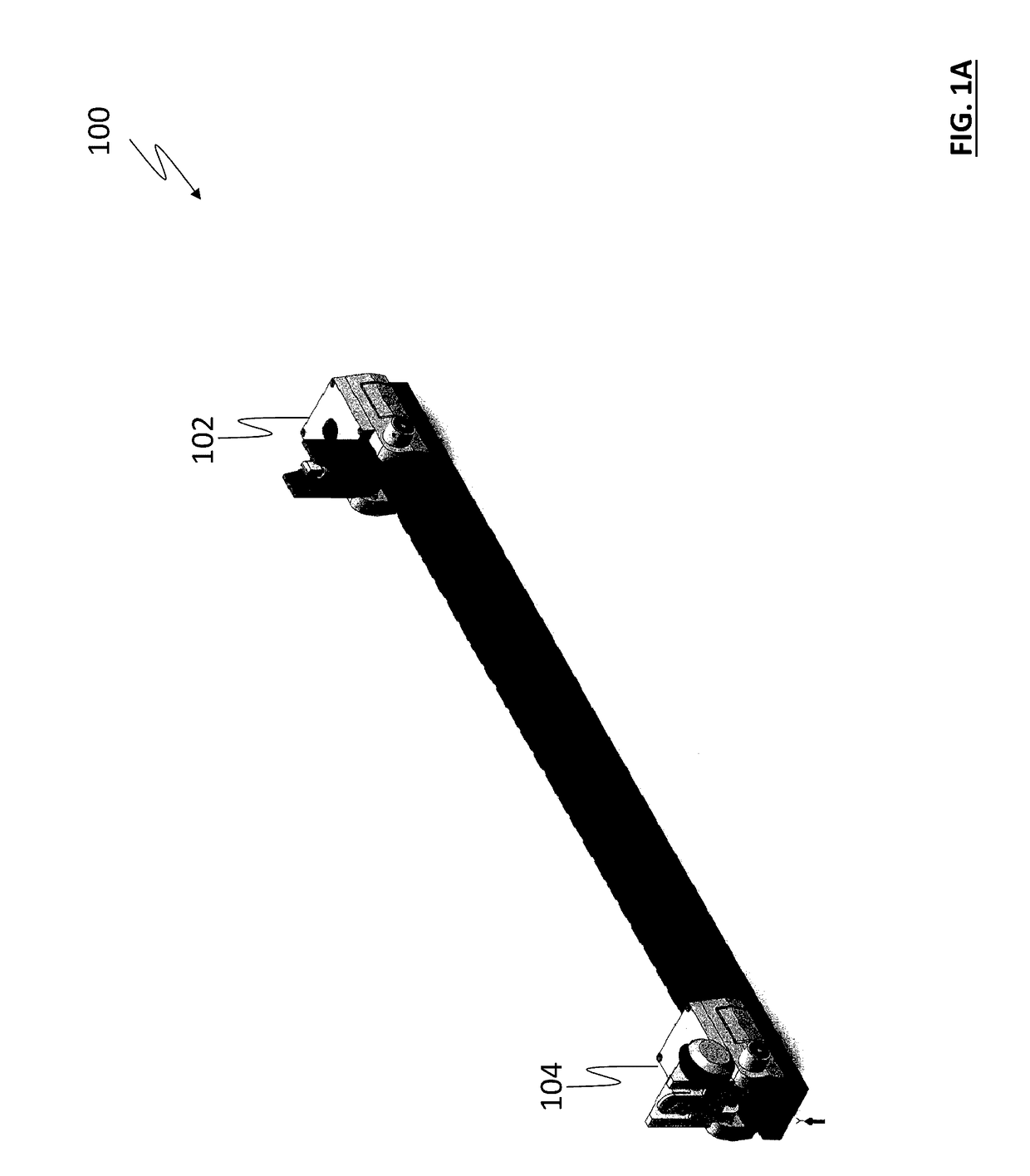

Vehicle suspension assembly

ActiveUS20060255557A1Increase resistanceMinimize assemblyRigid suspensionsInterconnection systemsInterference fitVehicle frame

A vehicle suspension assembly that includes first and second main beams each having a first end operably coupled to a vehicle frame, and a second end having a cavity formed therein, and first and second extension members each having an aperture extending therethrough, wherein the first and second extensions are interference-fit within and extend outwardly from the cavity of the first and second main beams, respectively. The assembly further including a torsion member having apertured first and second ends that receive the first and second extension members therein, and threaded mechanical fasteners extending through the apertures of the first and second extension members and engage nuts that are frictionally engaged by the first and second main beams.

Owner:THE HOLLAND GROUP

Vehicle suspension assembly

ActiveUS7416200B2Increase resistanceMinimize assemblyRigid suspensionsInterconnection systemsInterference fitVehicle frame

A vehicle suspension assembly that includes first and second main beams each having a first end operably coupled to a vehicle frame, and a second end having a cavity formed therein, and first and second extension members each having an aperture extending therethrough, wherein the first and second extensions are interference-fit within and extend outwardly from the cavity of the first and second main beams, respectively. The assembly further including a torsion member having apertured first and second ends that receive the first and second extension members therein, and threaded mechanical fasteners extending through the apertures of the first and second extension members and engage nuts that are frictionally engaged by the first and second main beams.

Owner:THE HOLLAND GROUP

Vehicle body manufacturing process

InactiveUS6836943B2Simple interfaceEliminate mechanical controlAuxillary drivesVehicle seatsEngineeringStandardization

A method of designing and manufacturing vehicle bodies includes establishing a common, standardized interface system for attaching vehicle bodies to vehicle chassis wherein connection components are arranged in a predetermined spatial relationship on the bodies and chassis to facilitate selective attachment of any of a plurality of different body types to the chassis. A plurality of different bodies are designed and manufactured having different body types and configured to conform to the standardized interface system for attachment to chassis which also conform to the standardized interface system. The vehicle bodies can be produced independently of the chassis. Eliminating the chassis and its hardware from the body manufacturing process can reduce current vehicle manufacturing plant sizes and system complexity. The result is an enabler to produce many vehicle bodies that can be distributed directly to dealers, customers, etc. either with or without a specified rolling platform. Smaller and customized production runs are enabled, as well as localized manufacturing plants, reduced investment costs and faster response time for order to delivery.

Owner:GM GLOBAL TECH OPERATIONS LLC

Flow-formed differential case assembly

ActiveUS20120325047A1Required packaging spaceEasy to weldCooking-vessel materialsGearboxesEngineeringMechanical engineering

A differential case assembly includes a differential case and an integral end cap and ring gear assembly. The differential case has an open end and a side wall with an exterior surface. The integral end cap and ring gear assembly is disposed over the open end of the differential case and adjacent the exterior surface. A first interior portion of the integral end cap and ring gear assembly abuts the exterior surface of the differential case to define a weld joint interface. The integral end cap and ring gear assembly is configured to permit a welding operation at the weld joint interface.

Owner:METAL FORMING & COINING

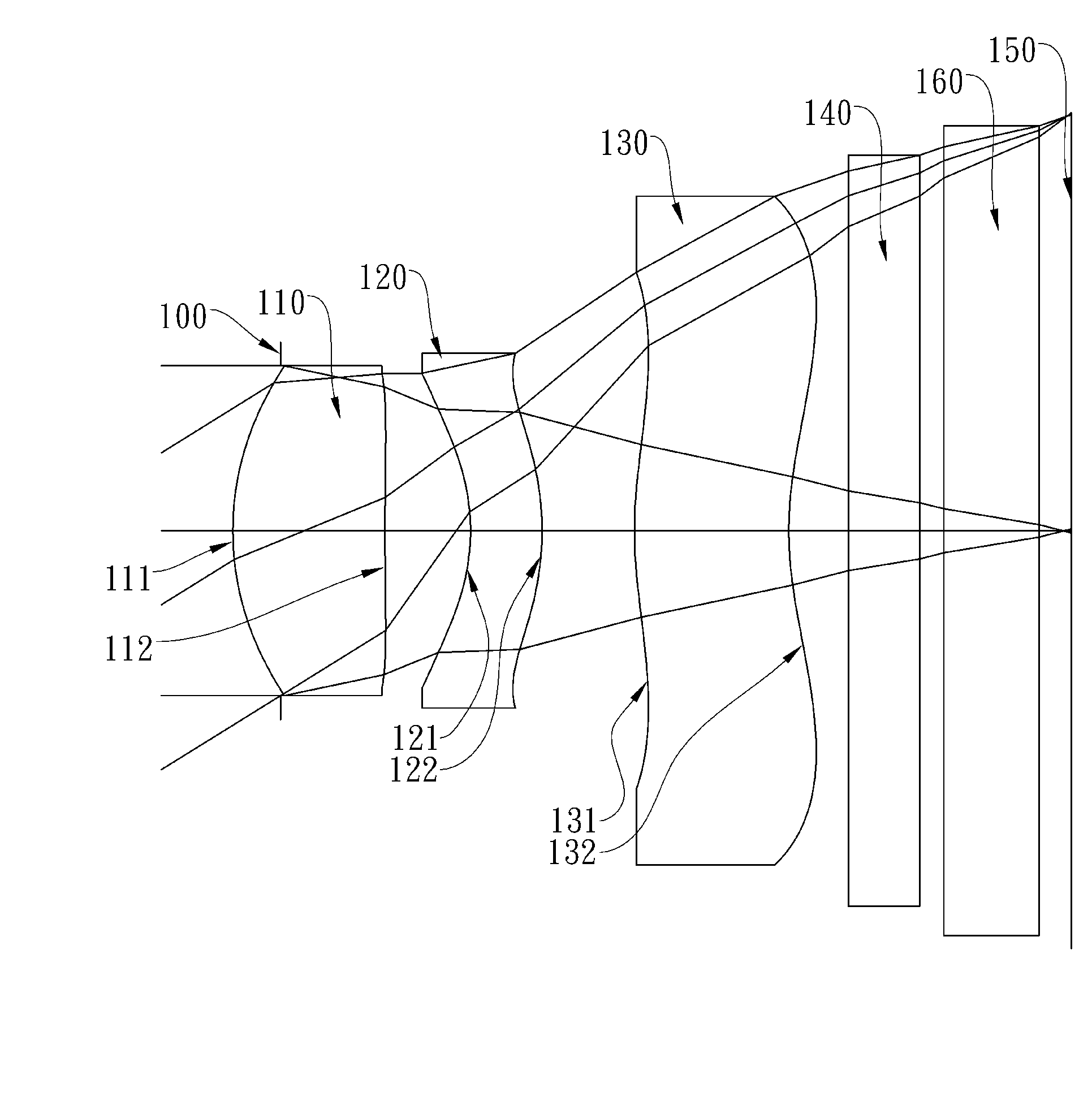

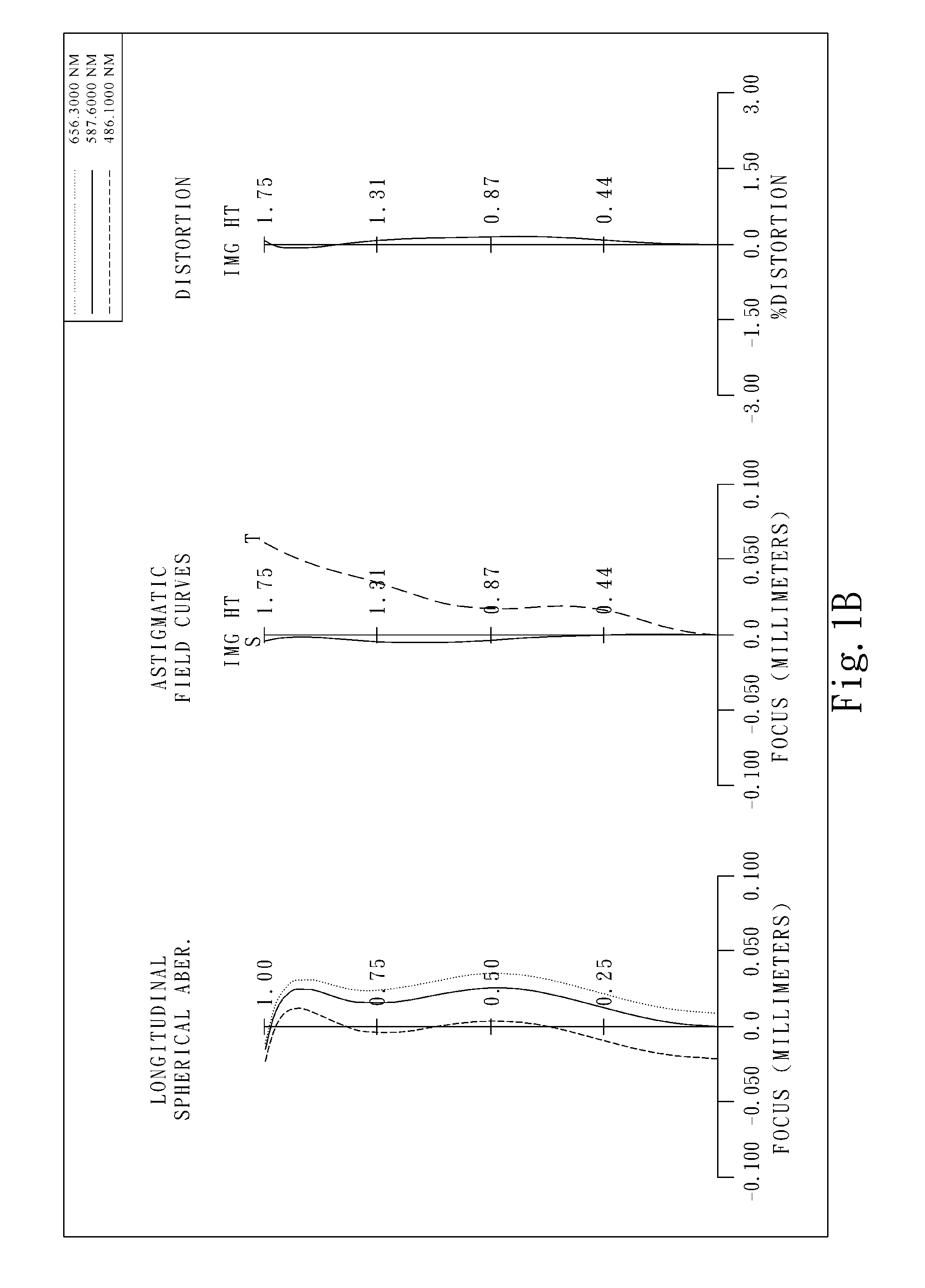

Photographing optical lens assembly

The present invention provides a photographing optical lens assembly comprising, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface and a concave image-side surface; a second lens element with negative refractive power having a concave object-side surface and a convex image-side surface, the object-side and image-side surfaces thereof being aspheric; and a third lens element with negative refractive power having a convex object-side surface and a concave image-side surface, the object-side and image-side surfaces thereof being aspheric and at least one inflection point being formed on the image-side surface, wherein the lens assembly is further provided with a stop disposed between an object and the first lens element.

Owner:LARGAN PRECISION

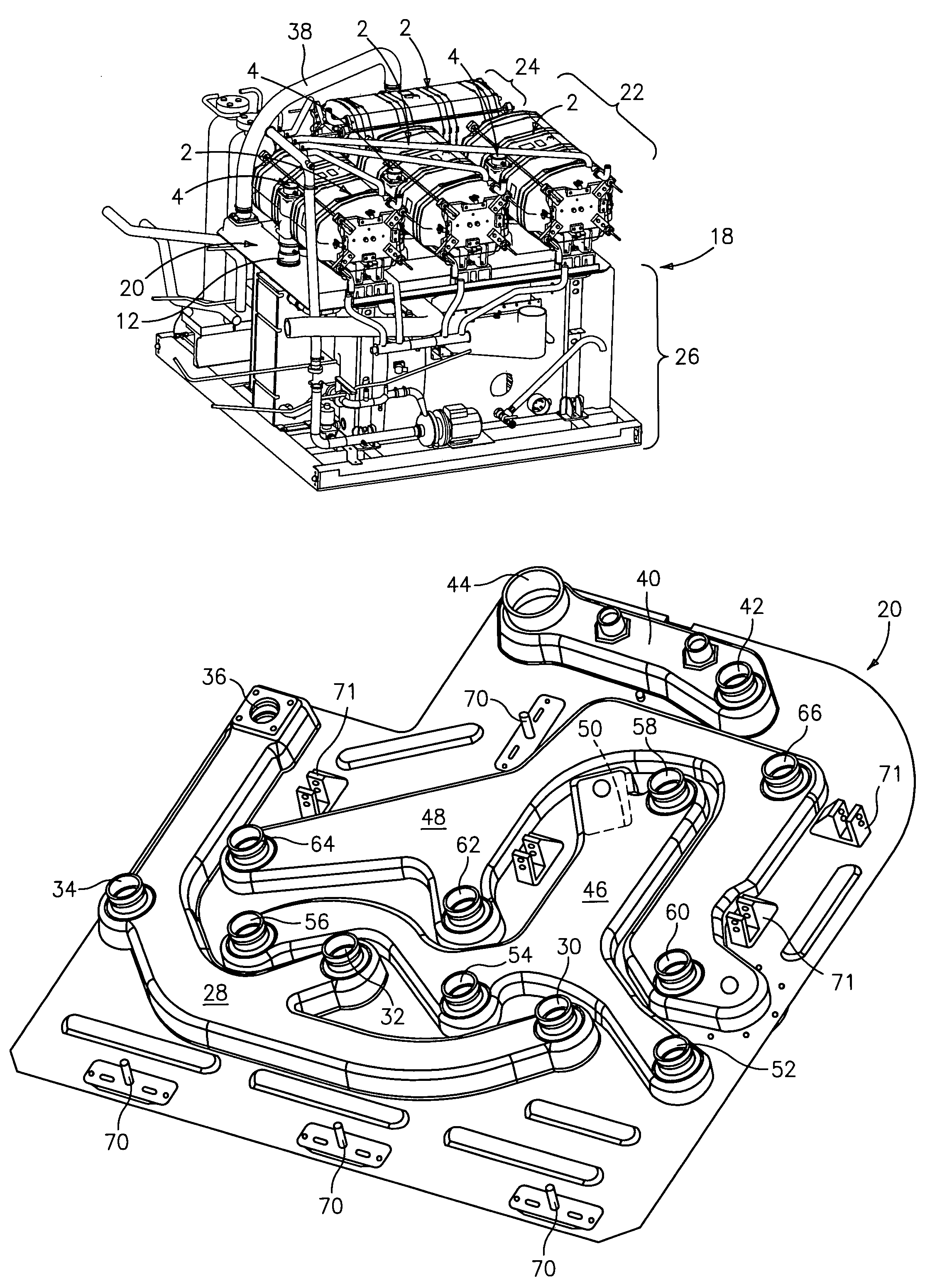

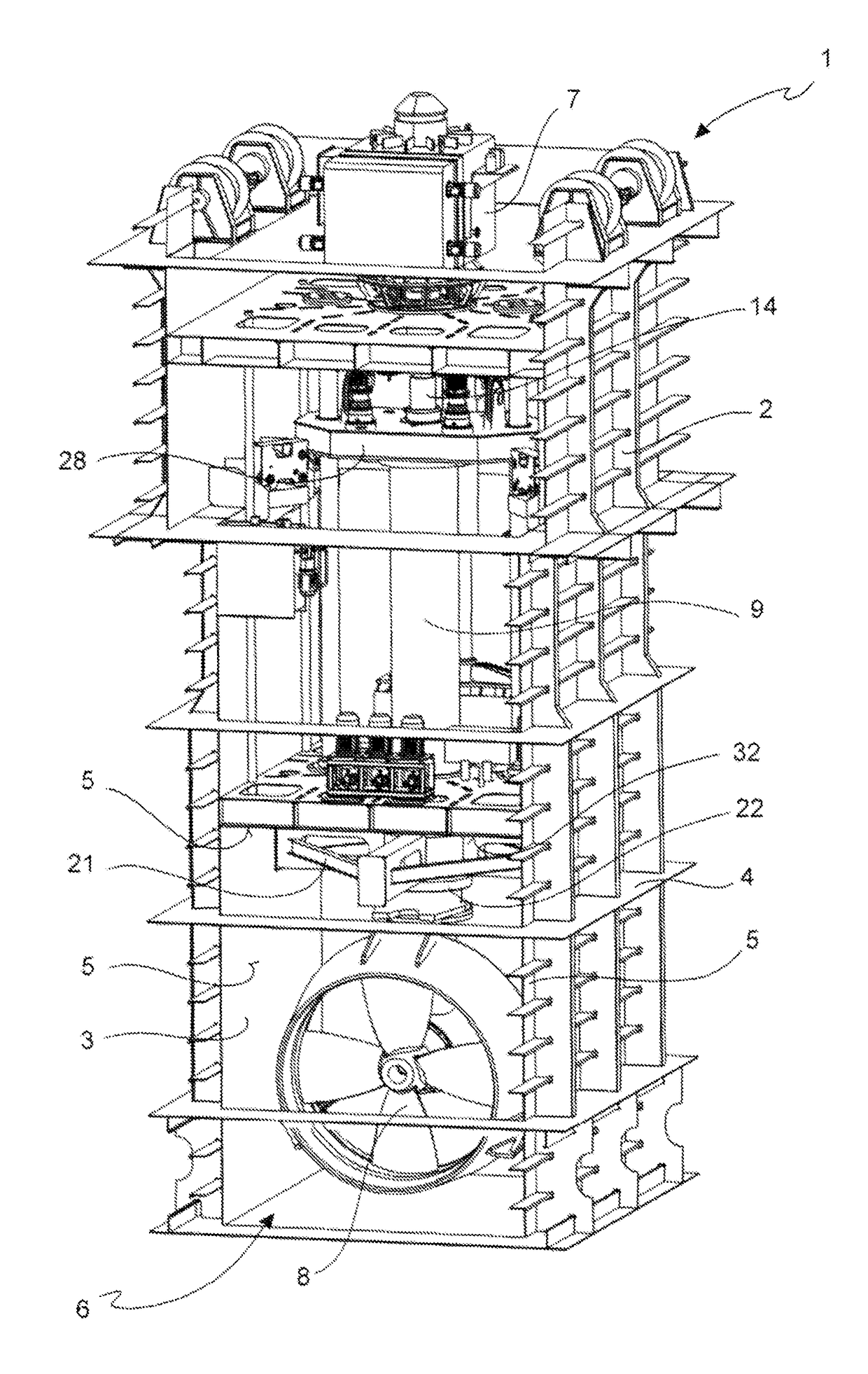

Fuel and air flow control in a multi-stack fuel cell power plant

ActiveUS20050064269A1Simplified fuelSimplified air distribution mechanismFuel cells groupingFuel cell auxillariesFuel cellsPower station

A fuel cell power plant includes a plurality of fuel cell stacks which are operatively associated with each other so that both the air stream and fuel stream for the stacks are shared by each of the stacks in the power plant. The air and fuel streams are fed into an initial stack stage in the power plant, and after the air and fuel streams pass through the initial stack stage, the fuel exhaust streams are then fed into one or more subsequent stack stages in the power plant. The fuel streams are passed from the initial fuel cell stack stage to the subsequent fuel cell stack stage by means of a common manifold on which each of the fuel cell stacks in the power plant is mounted. The air streams are routed to all of the fuel cell stacks via a channel in the common manifold. Air exhaust from the fuel cell stacks is collected in an air exhaust channel in the manifold. The use of a single manifold greatly simplifies the fuel and air transfer plumbing which is necessary when one or more fuel cell stacks in a power plant are operated with air and fuel from other fuel cell stacks in the power plant. The manifold can be made by thermoforming the flow channels in a plastic sheet.

Owner:AUDI AG

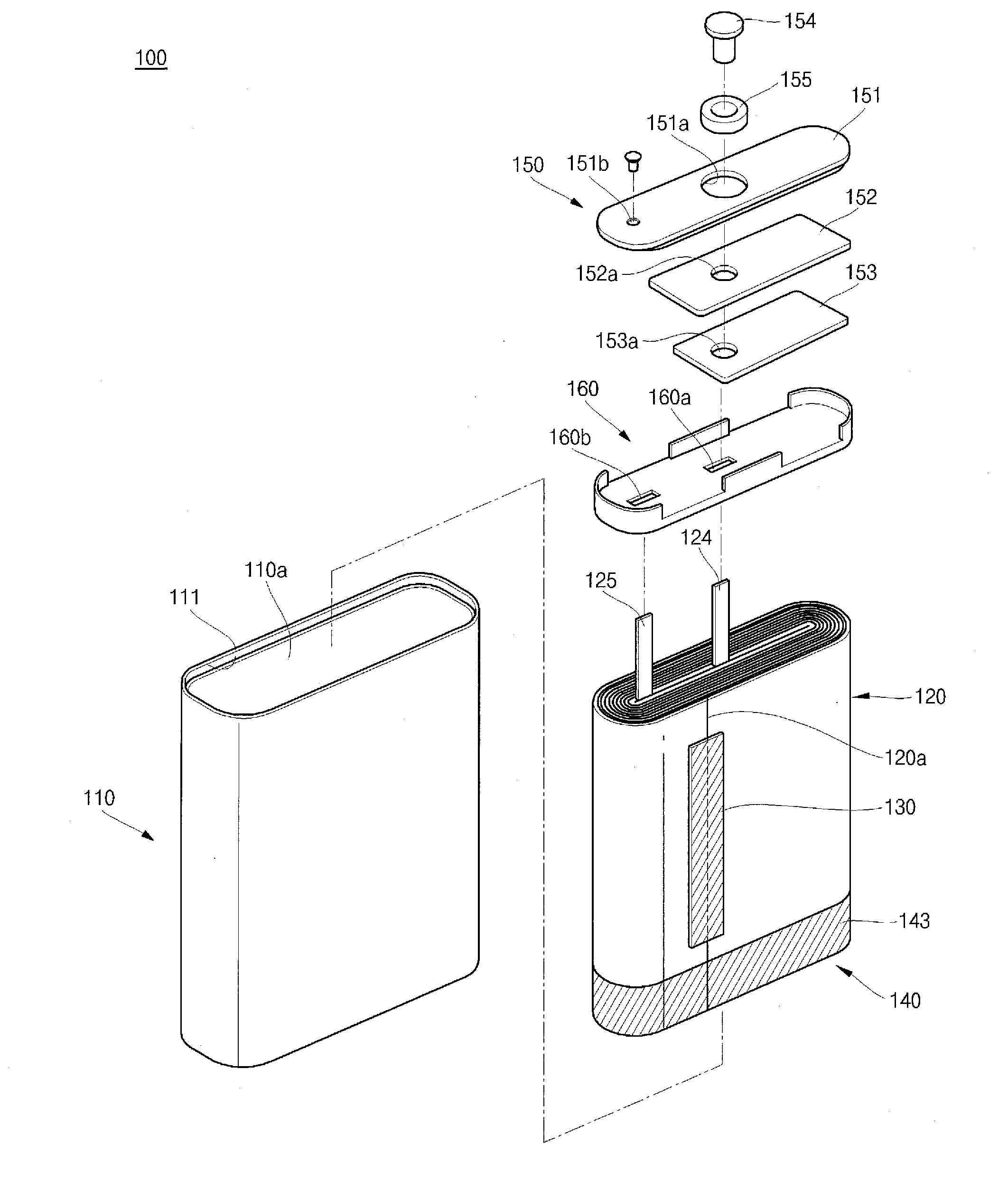

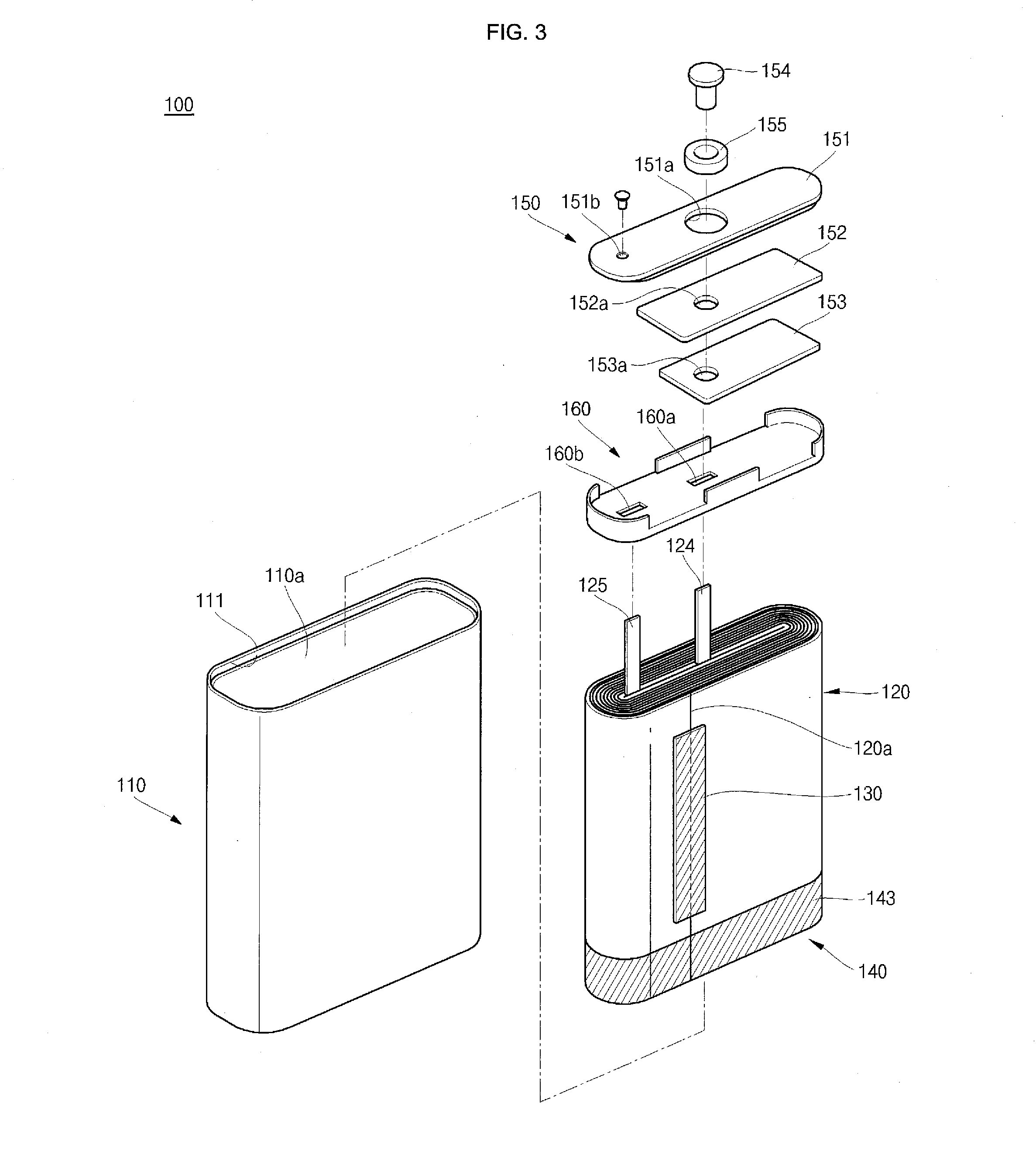

Secondary battery

ActiveUS20150104684A1Minimize assemblyMinimize impactFinal product manufactureCell electrodesElectrodeShort circuit

Provided are a finishing tape, which can prevent a short circuit while preventing impacts applied to an electrode assembly, and a secondary battery including the same. The secondary battery includes a case having an opening defining an internal space, an electrode assembly in the internal space of the case, and a cap assembly coupled to the opening of the case sealing the case. The electrode assembly may include a finishing tape on an outer surface of the electrode assembly between the case and the electrode assembly. The finishing tape may include a first substrate and a second substrate. The cap assembly may include a cap plate coupled to the opening of the case. The secondary battery may further include an insulation case between the electrode assembly and the cap assembly.

Owner:SAMSUNG SDI CO LTD

Flow-formed differential case assembly

A differential case assembly includes a differential case having an open end and a side wall with an interior surface. A plurality of major internal splines is formed on the interior surface of the side wall. The differential case assembly further includes a gear assembly with a retainer insert and a cross pin. The retainer insert is disposed adjacent the interior surface of the side wall between a pair of the major internal splines. The retainer insert has a hole formed therein. The cross pin has an end received in the hole of the retainer insert. The gear assembly is thereby aligned within the differential case.

Owner:METAL FORMING & COINING LLC

Guillotine cutter

ActiveUS20100192746A1Reduce cost of produceMinimize assemblyGang saw millsMetal working apparatusBearing surfaceEngineering

An improved guillotine cutter for a printer is disclosed. The guillotine cutter includes a guillotine blade having a cutting motion that helps to urge the cut media from the exit chute of the frame. This reduces the likelihood of the cut media becoming pulled into the frame of the cutter, requiring that the user fish the cut media out. The guillotine cutter further provides a frame having integrated bearing surfaces for supporting many of the movable components of the cutter. This minimizes the complexity of the assembly of the cutter, reducing the number of parts (by elimination of separate bearings and other such additional components) and time required to assemble the cutter.

Owner:BRADY WORLDWIDE INC

Touch control panel securing device and electronic apparatus having the touch control panel securing device

ActiveUS8477482B2Easy to assembleEasy to controlDetails for portable computersElectrical apparatus contructional detailsLocking mechanismEngineering

Owner:WISTRON CORP

Fuel and air flow control in a multi-stack fuel cell power plant

ActiveUS7108929B2Simplified fuel and air distribution mechanismMinimal pressure dropFuel cells groupingFuel cell auxillariesPower stationFuel cells

A fuel cell power plant includes a plurality of fuel cell stacks which are operatively associated with each other so that both the air stream and fuel stream for the stacks are shared by each of the stacks in the power plant. The air and fuel streams are fed into an initial stack stage in the power plant, and after the air and fuel streams pass through the initial stack stage, the fuel exhaust streams are then fed into one or more subsequent stack stages in the power plant. The fuel streams are passed from the initial fuel cell stack stage to the subsequent fuel cell stack stage by means of a common manifold on which each of the fuel cell stacks in the power plant is mounted. The air streams are routed to all of the fuel cell stacks via a channel in the common manifold.

Owner:AUDI AG

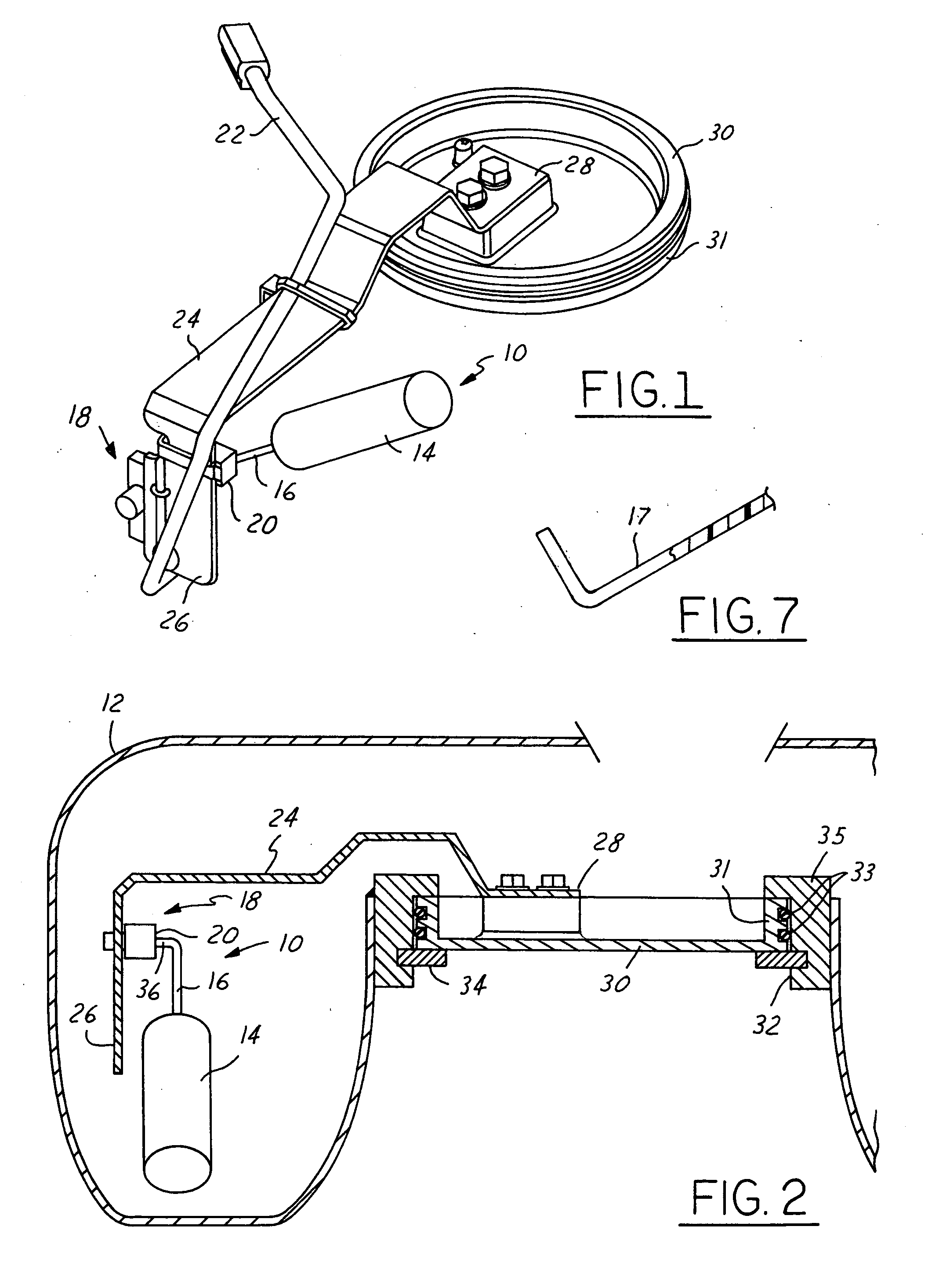

Float arm assembly and method of manufacture

InactiveUS20050284220A1Lower potentialImprove accuracyCeramic shaping apparatusMachines/enginesEngineeringPosition sensor

A float arm assembly and method of construction therefore has a float arm with a free end and another end arranged for operable communication with a float arm position sensor. A float is molded to the float arm to provide a unitary and rigid float arm assembly.

Owner:WALBRO ENGINE MANAGEMENT

Illuminated Sight System

An illuminated sighting system is provided and includes a front sight and a rear sight, wherein the front sight includes a front aperture and a front base, wherein, the front aperture further includes a front LED and a front sight post wherein the front sight post is adjustable in height and is optically communicated with the front LED such that when the front LED is illuminated, at least a portion of the front sight post is illuminated and wherein, the rear aperture further includes a sighting halo and a rear LED wherein the sighting halo is laterally adjustable and associated with the rear LED such that when the rear LED is illuminated, at least a portion of the sighting halo is illuminated.

Owner:BRIGHTSIGHT LLC

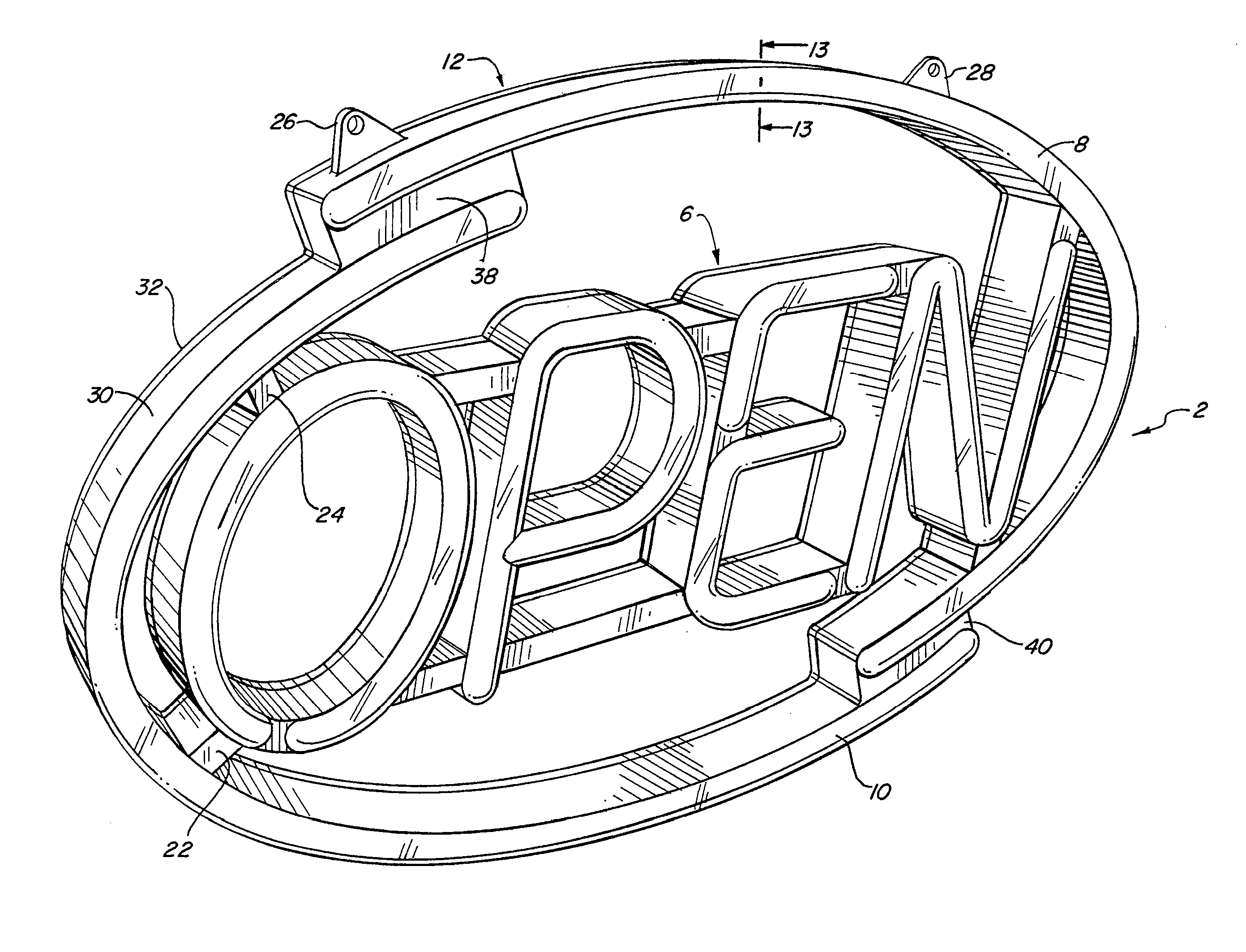

Method and apparatus for providing a simulated neon sign

InactiveUS20120159818A1Good light scattering propertiesEliminate hot spotShaping conveyorsIlluminated signsLight equipmentEngineering

A lighting apparatus for simulating a neon sign and method of making is provided. An outer housing having a central opening and defining a perimeter of the lighting apparatus can be connected with an inner housing configured as a plurality of symbols for conveying a message. Mounted within the interior of the outer and inner housing can be a series of lighting units such as SMD light emitting diodes. Respective outer housing and inner housing can have a cross-sectional inverted U-shape capped by a base member with the upper member having a curved diffuser for transmitting light through a transmissive plastic resin while integrally mounted black or opaque straight legs of a U-shape can enhance the simulated neon glow.

Owner:KAOH ANDY K F

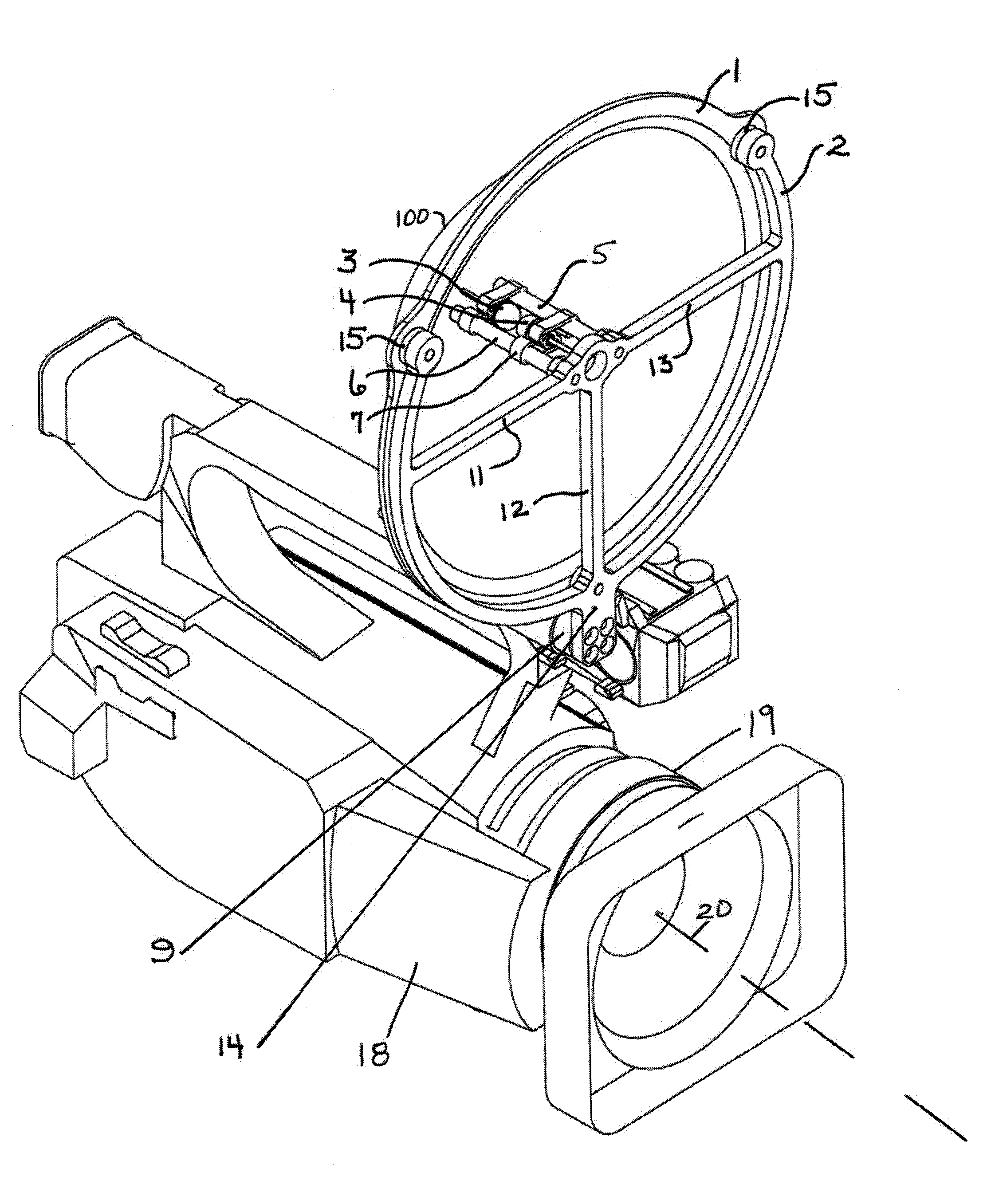

Camera-Mountable Acoustic Collection Assembly

ActiveUS20150350768A1Highly focusedHigh quality soundMouthpiece/microphone attachmentsFrequency/directions obtaining arrangementsEngineeringMicrophone

An acoustic collection and collection assembly comprises an acoustic collection dish, a support frame, and a microphone mount extending from the support frame that allows one or more microphones to be positioned at the acoustic focal point of the dish for optimal capture of distant sounds.

Owner:KLOVER PROD

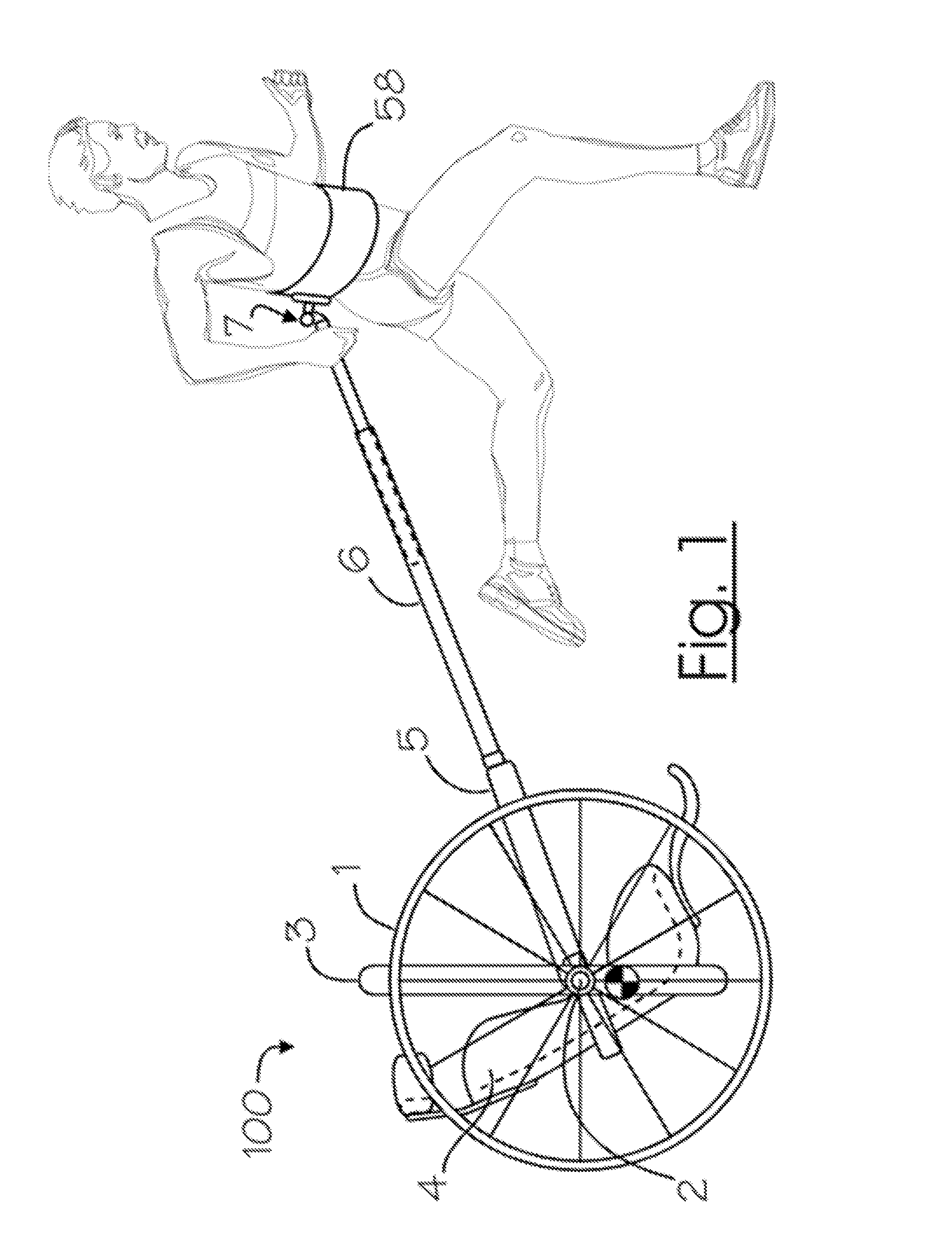

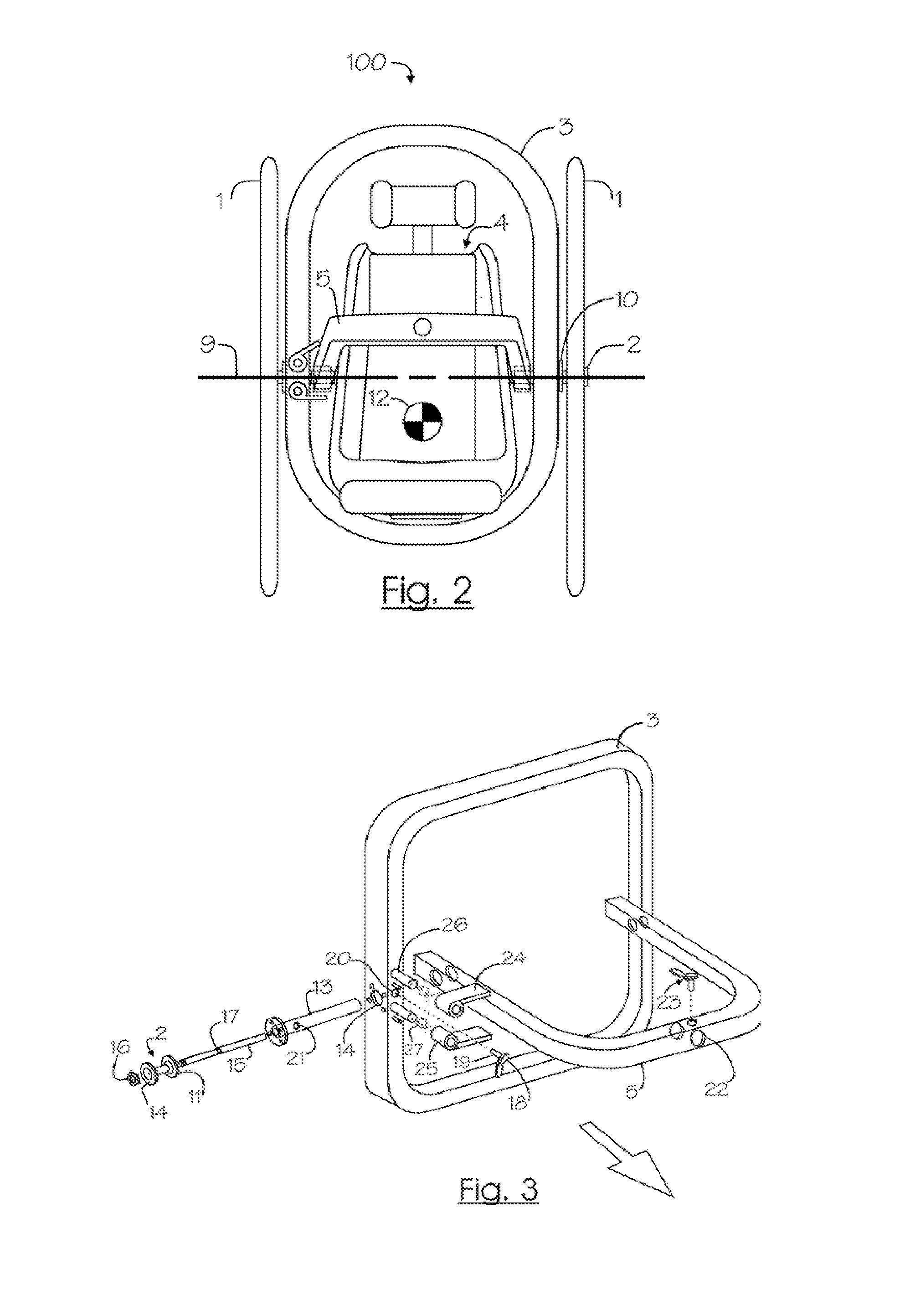

Tow type running stroller

ActiveUS20140203529A1Minimized vertical loadReduce vertical movementCarriage/perambulator accessoriesCarriage/perambulator with single axisEngineeringGravity center

A two-wheeled stroller is disclosed and claimed. The stroller is a tow-type stroller to enable a child to accompany an attendant who is engaged in walking or running activity over a variety of ground surfaces and grades at various walking and running velocities. The stroller includes a carnage assembly, a tow bar assembly, and a harness assembly. The carnage assembly includes a seat upon which the child being transported is seated and two wheels, with the center of gravity of the carriage assembly and child (if present) positioned below the wheel axis of rotation. The harness assembly is adjustably affixed to the attendant, and is connected to the carriage assembly by the tow bar assembly.

Owner:ORTEGA GIOVANI M

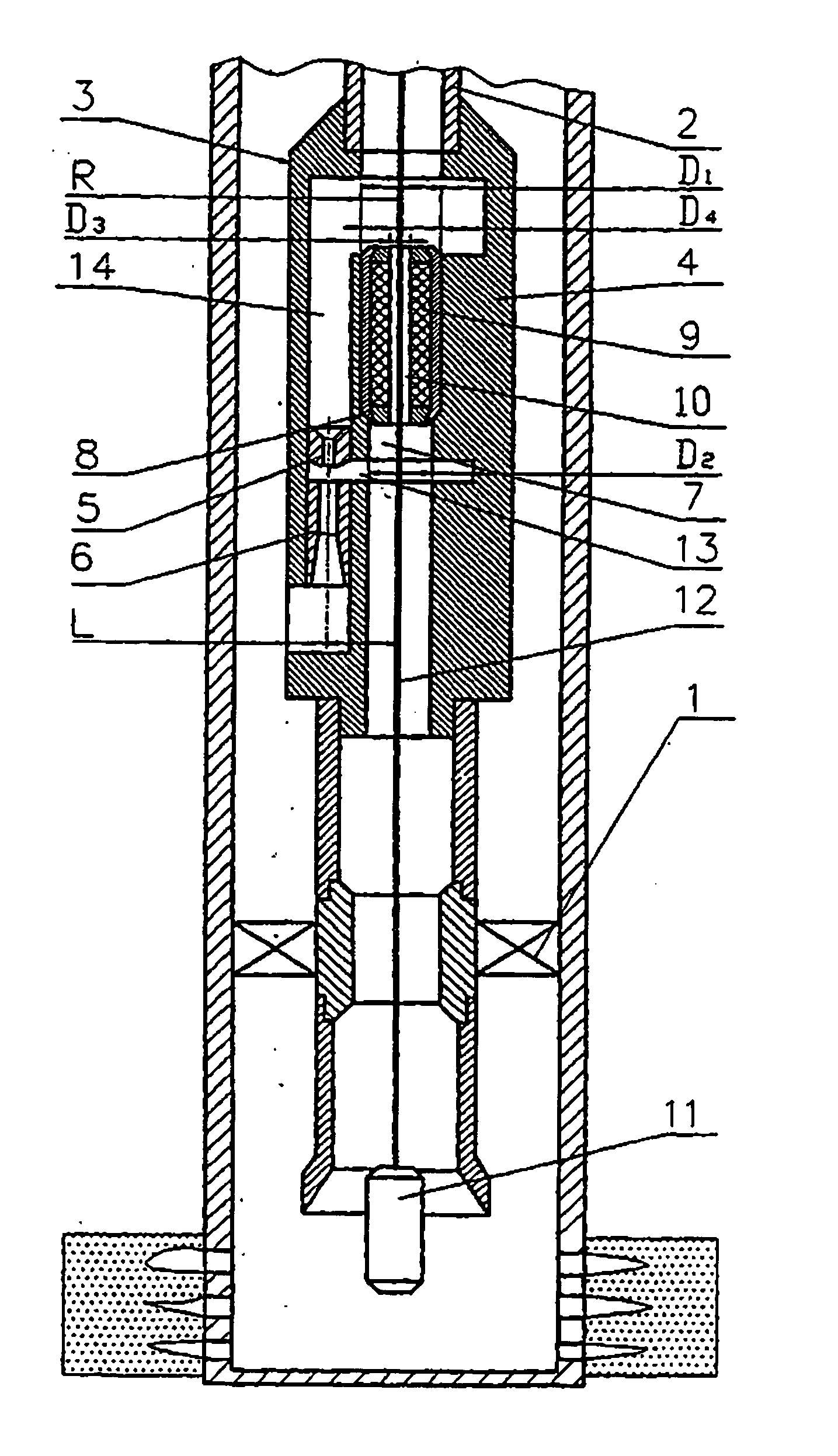

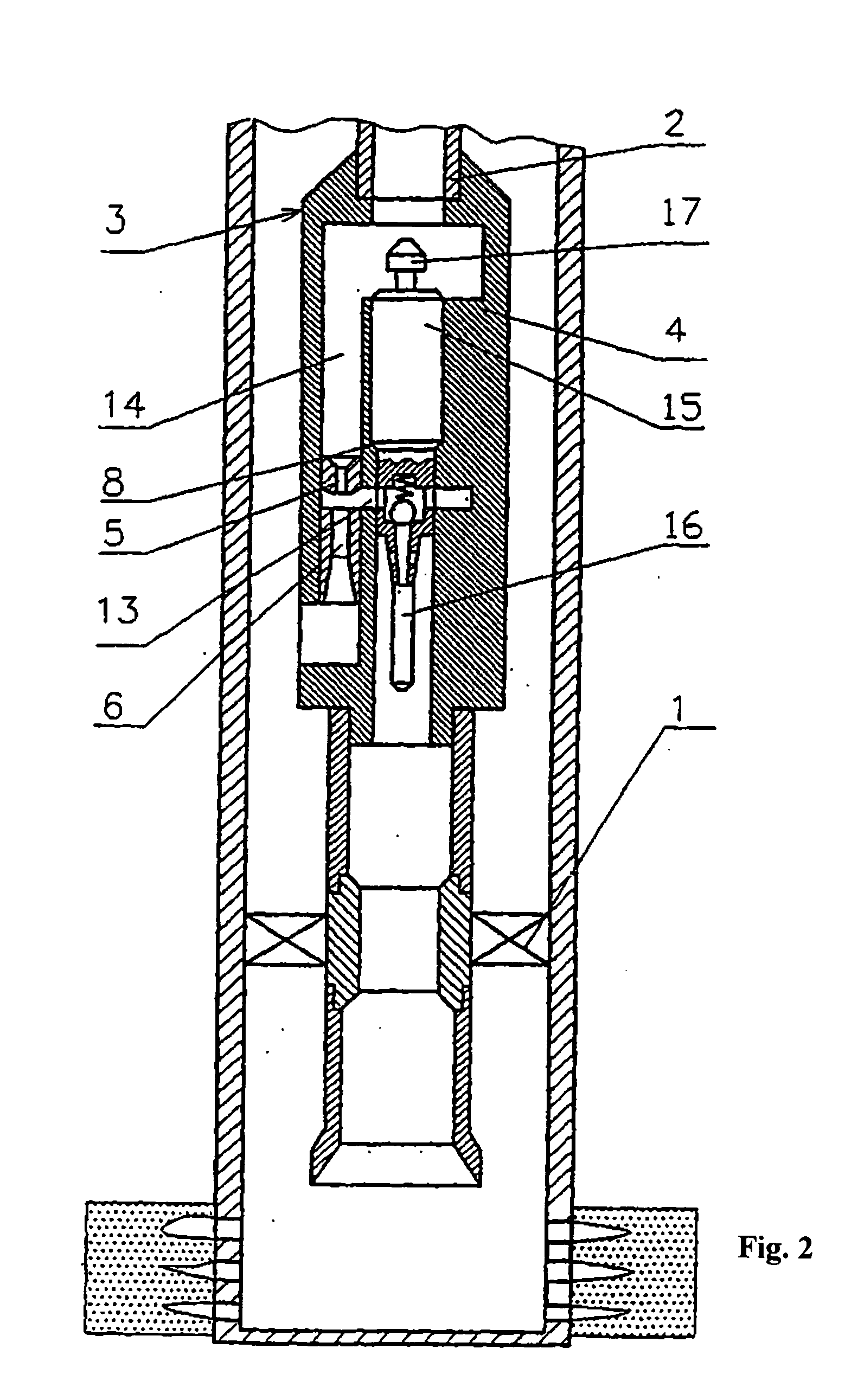

Well jet device for well testing and developing and the operating method for said well jet device

InactiveUS20040129416A1Improve efficiencyImprove reliabilityJet pumpsFluid removalPhysical fieldEngineering

The invention relates to jet device used for extracting oil from wells. The inventive device comprises a packer, a pipe column, a jet pump, a transmitter and a receiver of physical fields. The body of the pump comprises a through stepped channel embodied in a parallel position with respect to the axes of the pipe column and having a seat disposed between steps for arranging a sealing unit, which is provided with an axial channel. Said pump body is also provided with an active nozzle. The axis of the active nozzle is disposed in a parallel position with respect to the axis of the through channel at a distance equal to or higher than 1.1 of the radius thereof. The diameter of the through channel above the seat is 0.5 mm greater than the diameter thereof below said seat. The diameter of the axial channel of the sealing unit is equal to or less than 0.6 of the external diameter thereof. The sealing unit is arranged in such a way that it is movable along a cable above a bit and successfully replaceable by the following functional inserts: a blocking insert, depression insert etc. Said inserts are provided with attachments for transporting them to the pump and extracting therefrom and for arranging instruments and samplers thereon. Said invention makes it possible to optimise the dimensions of the elements of the device and increases the reliability thereof.

Owner:KHOMYNETS ZINOVIY DMITRIEVICH

Touch control panel securing device and electronic apparatus having the touch control panel securing device

ActiveUS20110304961A1Easily and conveniently mounted fixedlyEasily and conveniently to and dismountedDetails for portable computersElectrical apparatus contructional detailsLocking mechanismElectrical and Electronics engineering

A touch control panel securing device is used for fixing a touch control panel. The touch control panel includes a housing formed with an opening, the touch control panel being mounted within the housing and being registered with the opening; at least one pressing member for pressing the touch control panel, and including a first engaging portion engaging the housing, and a second engaging portion disposed opposite to the first engaging portion; and a locking mechanism including at least one engaging part for engaging the second engaging portion and a pressing part operable to be pressed for disengaging the engaging part from the second engaging portion.

Owner:WISTRON CORP

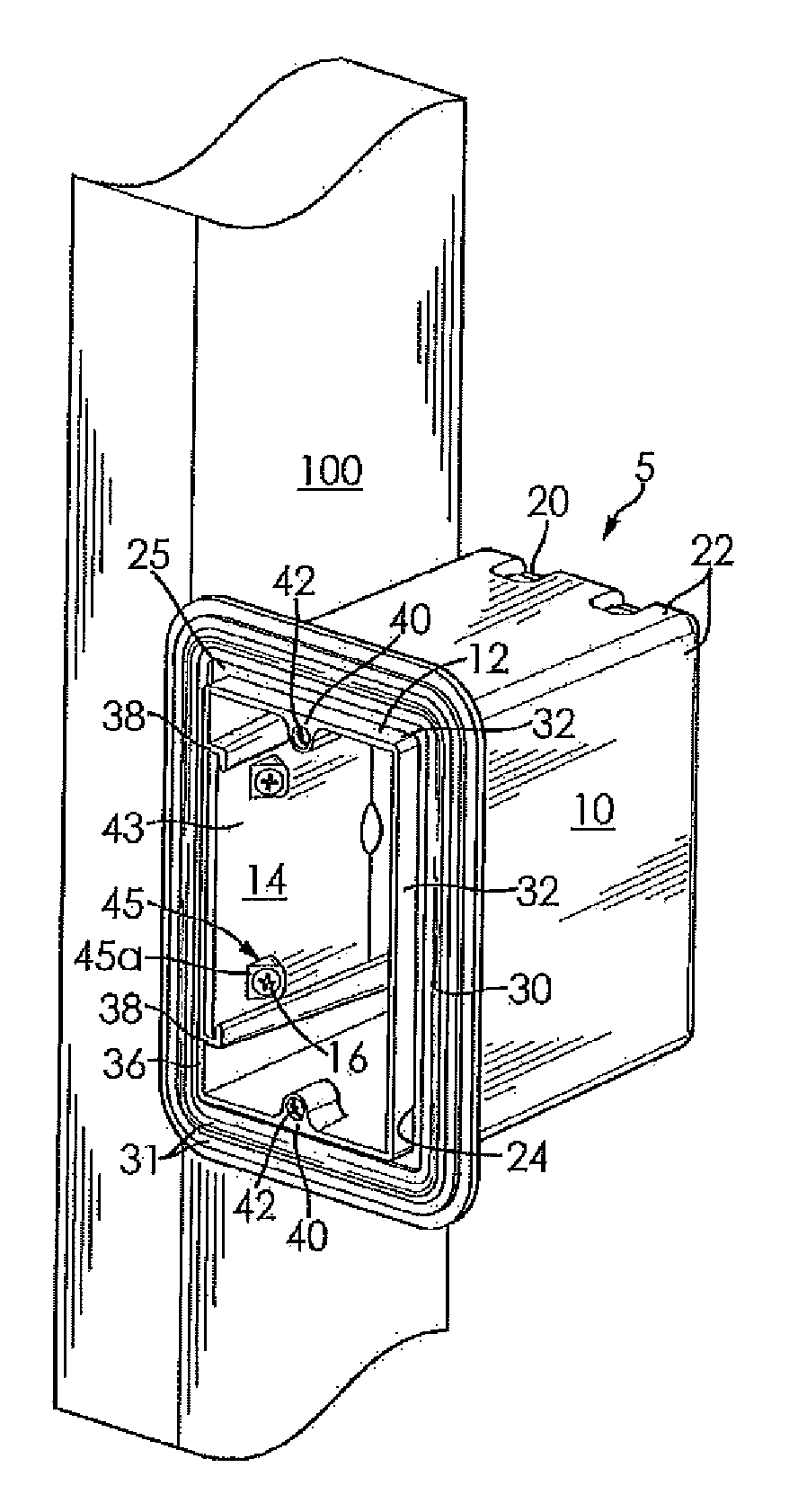

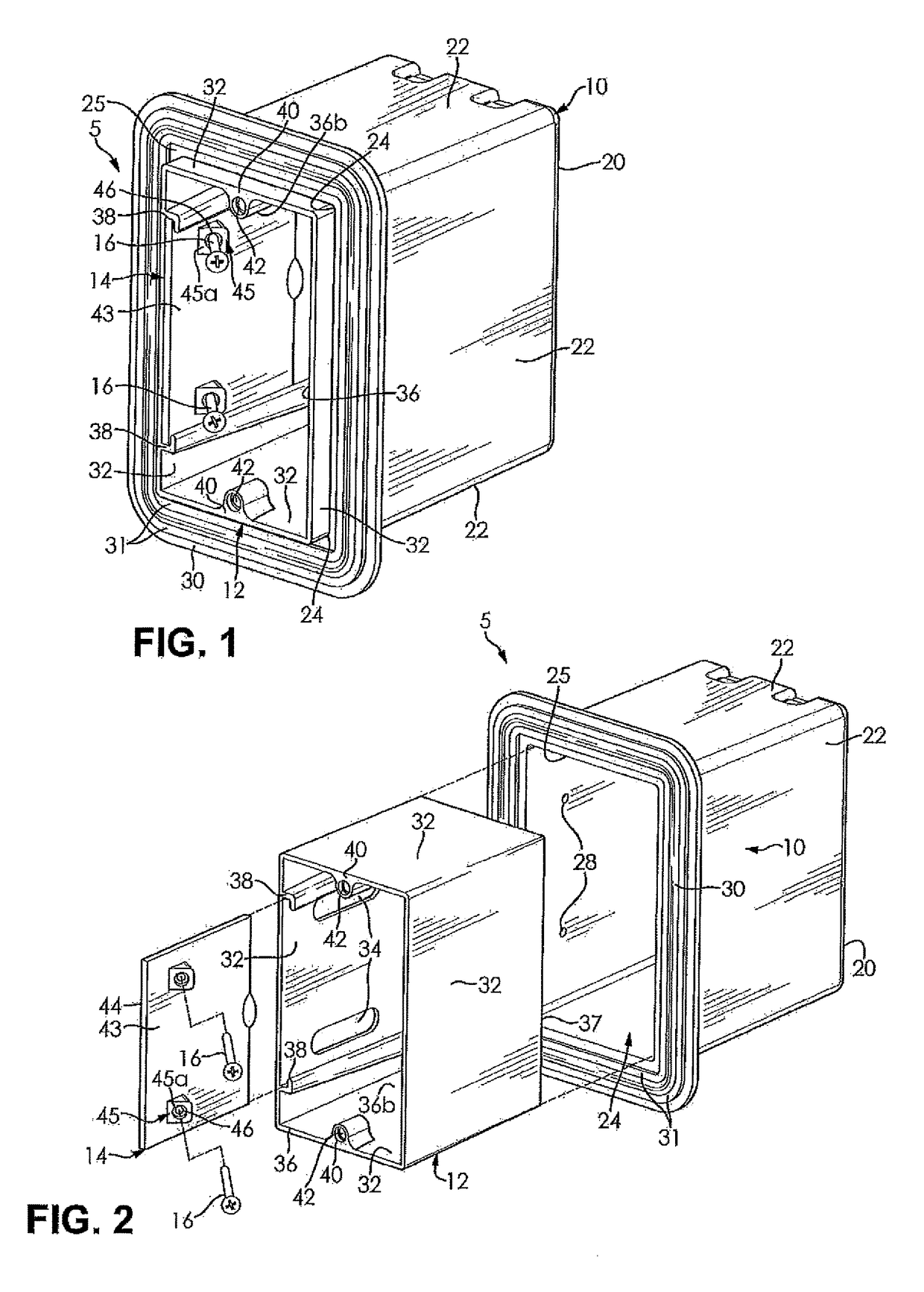

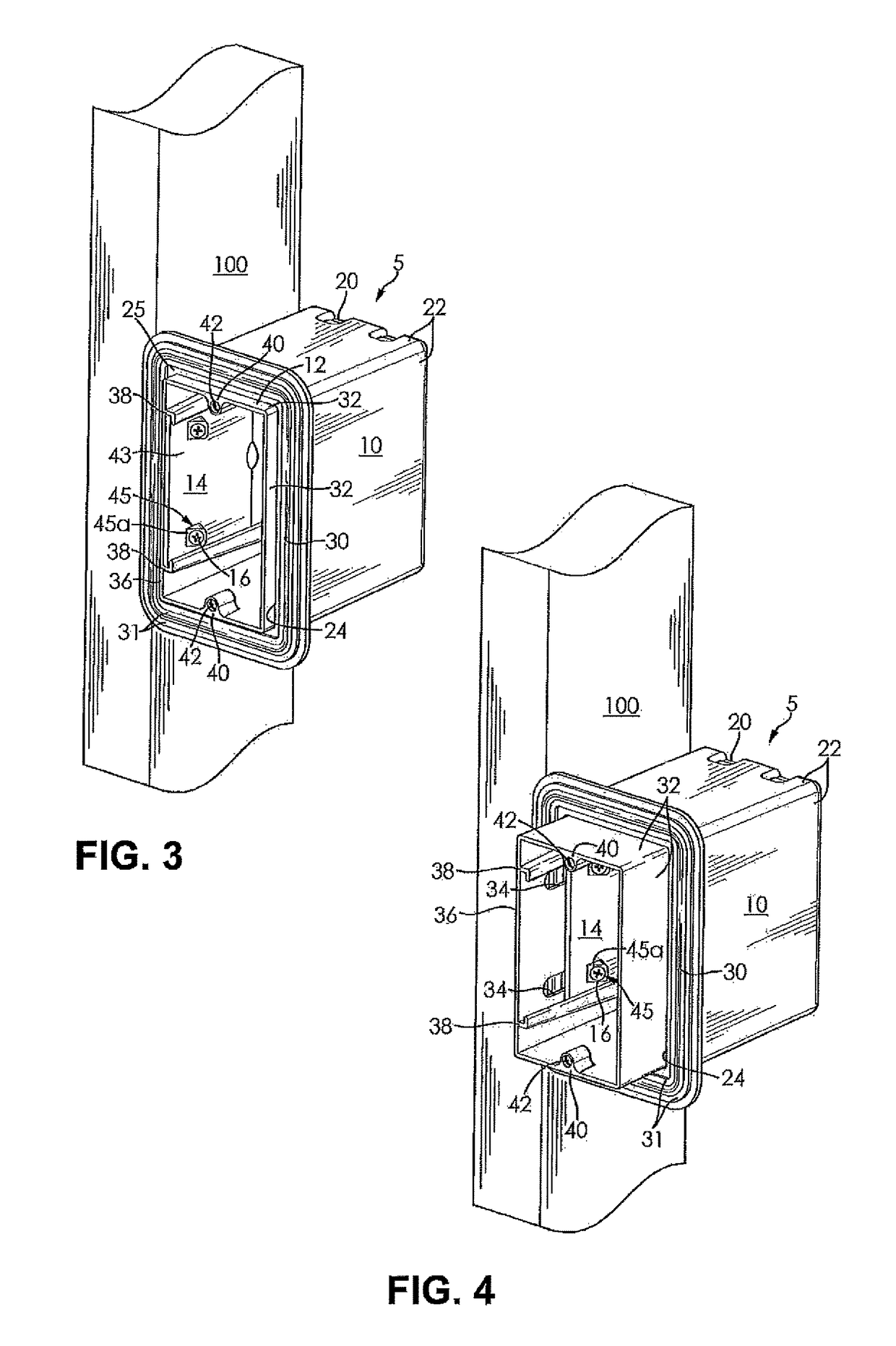

Electrical box with adjustable sleeve

ActiveUS9893503B2Easy to adjustMinimize assemblyElectrical apparatusEngineeringMechanical engineering

An electrical box assembly includes an outer box having a sidewall and a front opening. A sleeve having an inner surface is received in the front opening of the outer box and selectively extendable in respect of the outer box. A mounting plate is disposed on the inner surface of the sleeve. The mounting plate cooperates with the sleeve to selectively position the sleeve in respect of the outer box.

Owner:ALLIED MOLDED PRODS

Retractable thruster

ActiveUS9623942B2Minimize assemblyEasy constructionPropulsion power plantsSteering by propulsive elementsDrive shaftClosed chamber

A propulsion assembly of a ship or floating platform includes a housing within a hull or platform. The housing is watertight except for an opening external to the hull. A stationary motor is arranged in the hull external to the housing. A thruster is external to the hull to generate thrust on the ship or floating platform. A telescopic driving shaft passes sealingly through a housing wall to connect the motor and the thruster and to transmit movement from the motor to the thruster. The thruster retracts within the housing through the opening. A separate submersible movable hatch is disconnectable from the thruster and the housing and passes externally to the hull, and seals the opening to form a watertight closed chamber. A fluid evacuation device evacuates fluid within the closed chamber so the thruster, when retracted in the housing and closed by the hatch, forms the closed chamber.

Owner:FINCANTIERI

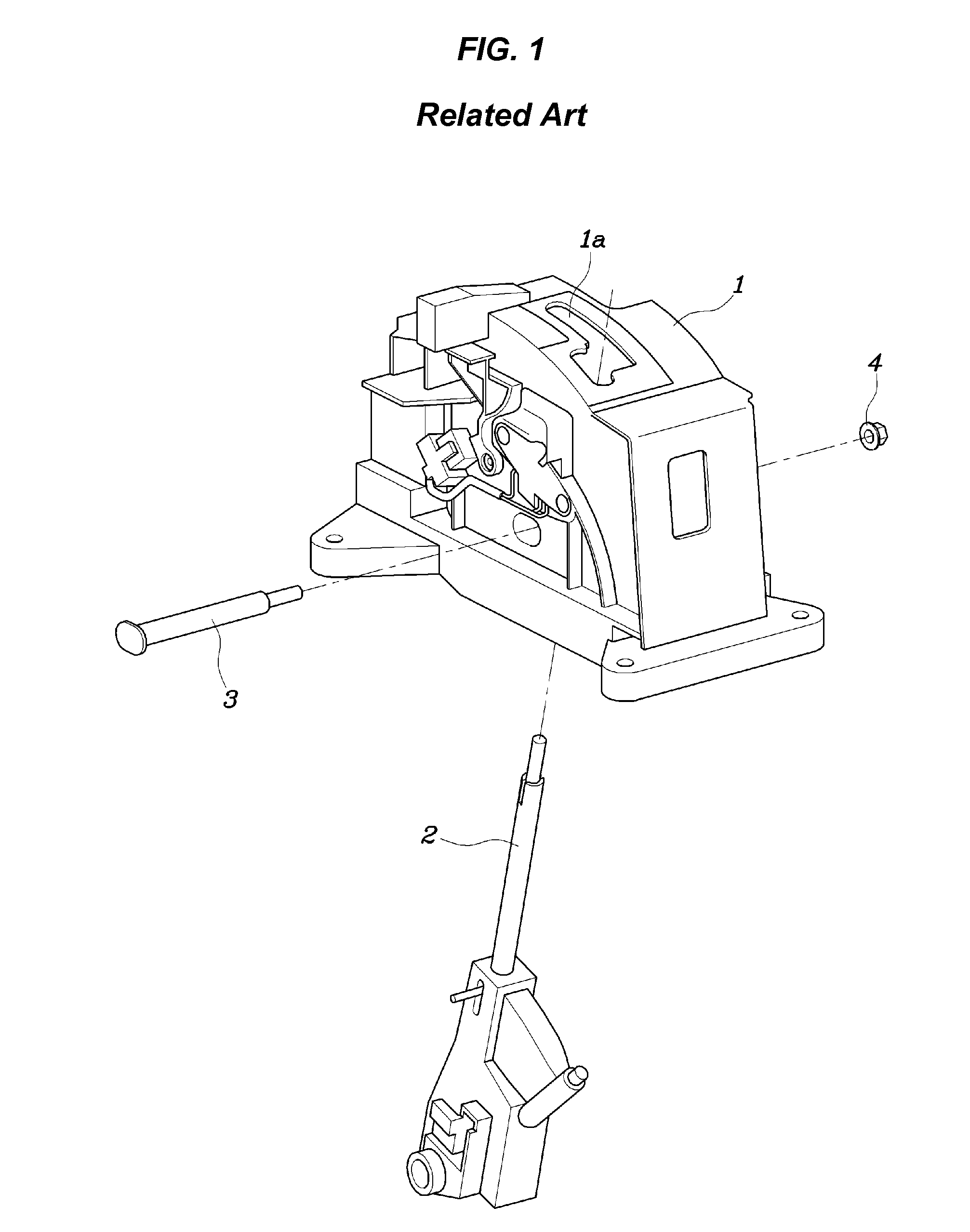

Shift lever assembly for automatic transmission vehicle and assembling method thereof

ActiveUS20150107390A1Reduce frictionImprove productivityGearing controlMetal working apparatusAutomatic transmissionElectrical and Electronics engineering

A shift lever assembly and assembling method for an automatic transmission vehicle may include a shift lever housing including divided components to be assembled, a shift lever, when assembled, one end of which is disposed in the divided components and connected pivotably to one or more of the divided components and the other end of which is arranged to protrude outside through a range hole formed in one of the divided components, and a plurality of elastic pins that are fitted cooperatively into the divided components when assembled to connect integrally the divided components.

Owner:HYUNDAI MOTOR CO LTD +1

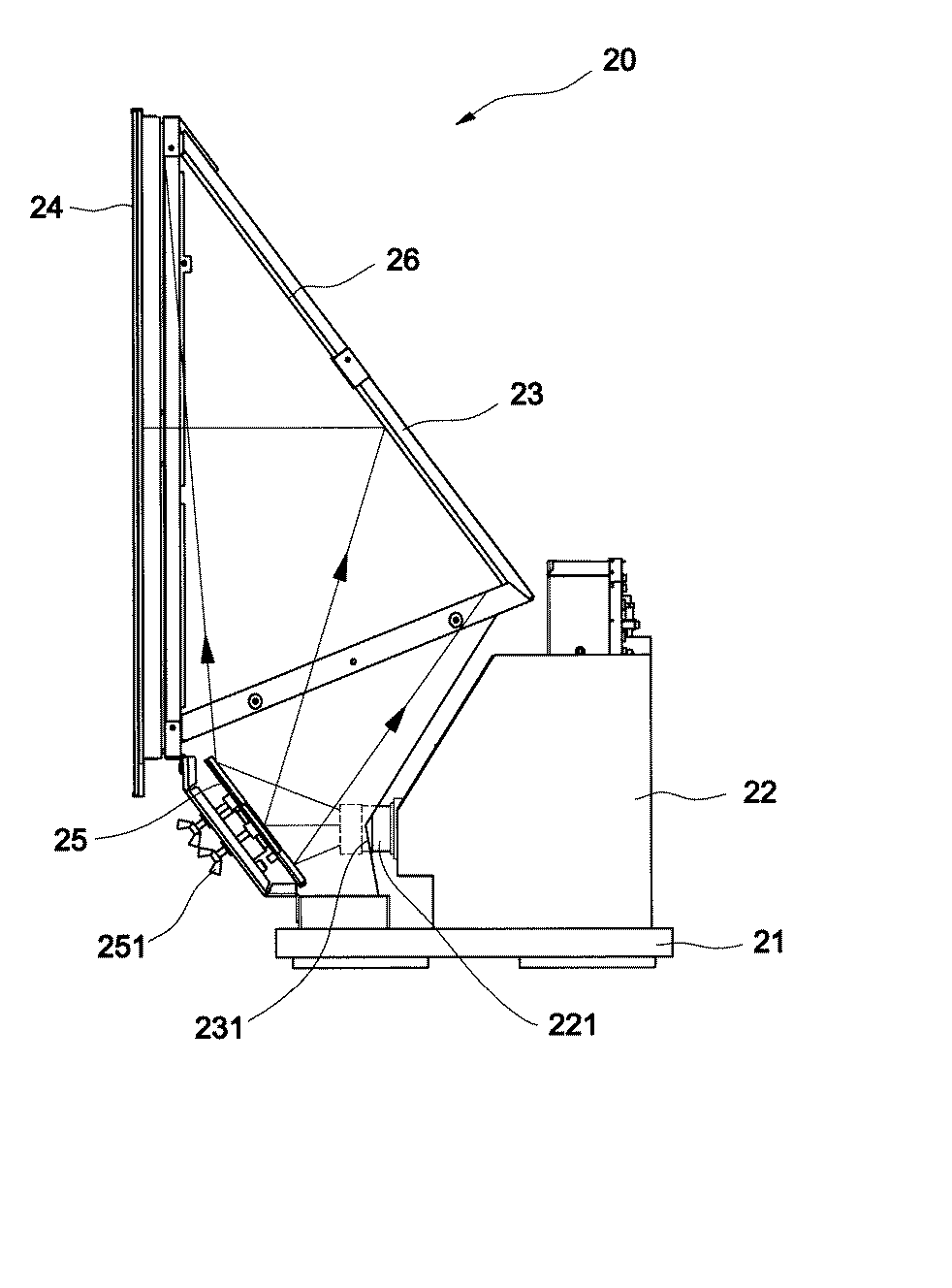

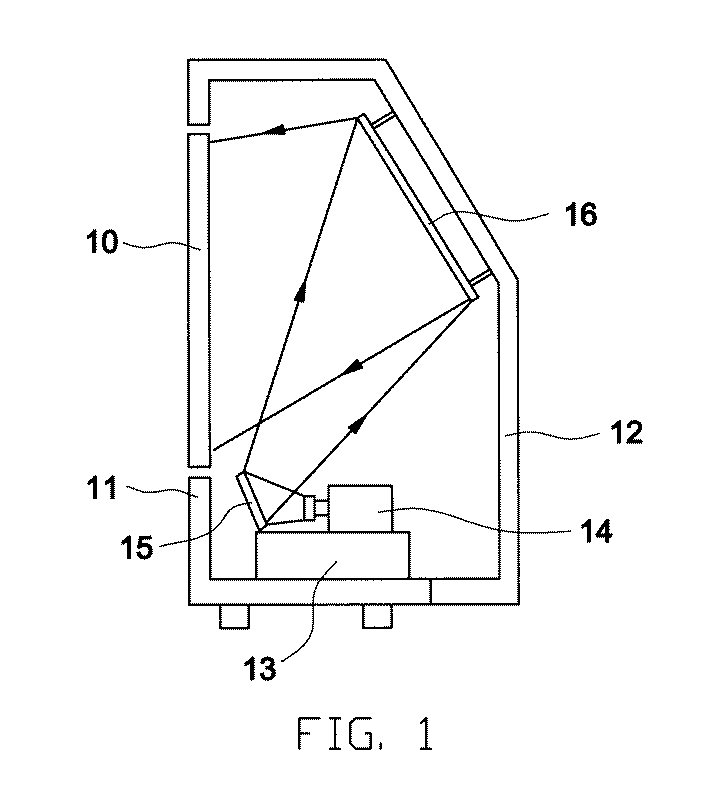

Optical assembly for rear projection television

InactiveUS20030133083A1Minimizes assembling errorImprove video qualityTelevision system detailsTelevision system scanning detailsOptical reflectionCamera lens

Abstract of Disclosure The rear projection television of the present invention comprises an optical assembly; an optical engine disposed on the lower supporting base of the optical assembly; a hood member coupled to an end of the supporting base at the front end of the optical engine; an inlet disposed on the hood member, the inlet having an elastic sealed cover which allows the projection lens of the optical engine to be extended inside the hood member and closely wraps the external diameter of the projection lens; a first mirror disposed in front of the projection lens; a second mirroris disposed on the upper end of the inner side of the hood member along the optical path of the small reflective projection lens. A screen is coupled to the outlet of the hood member along the optical reflection path of the second mirror. Covering the components one by one by means of a hood member and a screen according to the size of the optical path and excluding the optical engine of the heat-generating element outside constitute a sealed space with an isolation of air from the exterior for preventing the external dust, moisture, and temperature. Thus, such arrangement constitutes an optical assembly of the present invention.

Owner:CORETRONIC

Self-engaging rod retaining clip

A self-engaging rod retaining clip assembly for retaining a rod and a method of retaining the rod to a vehicle closure support component is disclosed. The self-engaging rod retaining clip assembly holds a rod retaining clip in a desired position on a vehicle closure support component until the rod is installed. Installing the rod includes pressing the rod against a rod pivoting flange, which causes clip retention flanges to flex outward around a clip support arm until the rod is sufficiently retained inside a rod channel in the support component. The clip retention flanges then snap towards each other to retain the clip, and hence the rod, in the support component.

Owner:GM GLOBAL TECH OPERATIONS LLC

Device for actuating the closure of a movable part

InactiveUS20100171327A1Minimize assemblyMinimize complexityWing handlesWing knobsEngineeringMotorized vehicle

The invention relates to a device (10) for actuating the closure of a movable part (12) of a motor vehicle, in particular a door, or hatchback, or similar, comprising a support (11) that can be fixed to the inner face of the movable part (12), a bearing unit (20) that can be pivoted about a first axis (13) provided on the support (11) and a handle element (40) with a first (41) and a second end (42), said first and second end (41, 42) being located on the bearing unit (20). According to the invention, the bearing unit (20) is equipped with a retaining element (24) which lies at a distance from the first axis (13) and on which the first end (41) is situated. Said first end (41) at least partially surrounds the retaining element (24).

Owner:HUF HULSBECK & FURST GMBH & CO KG

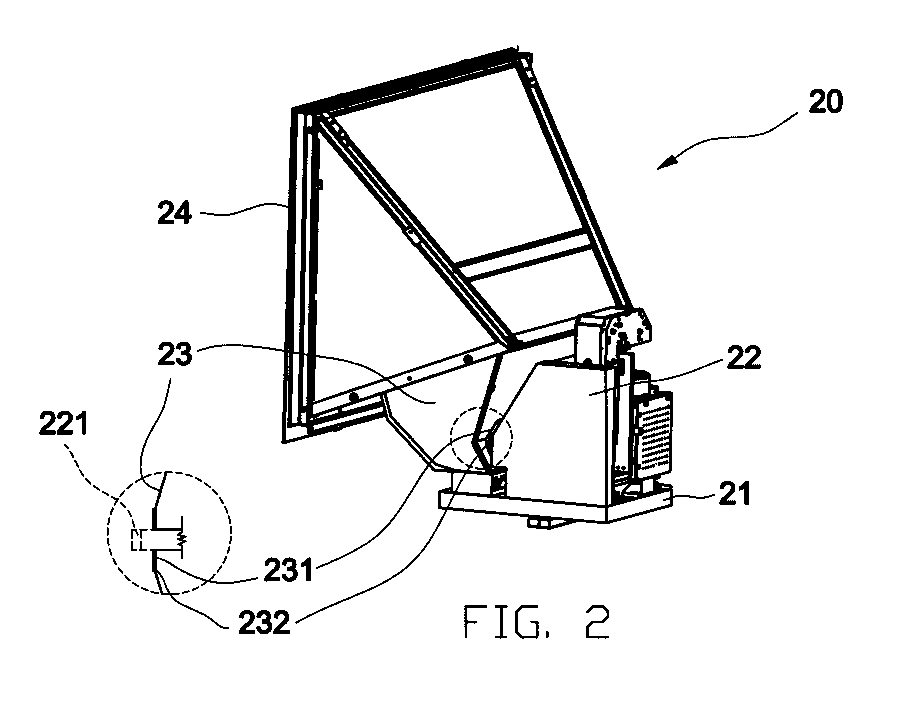

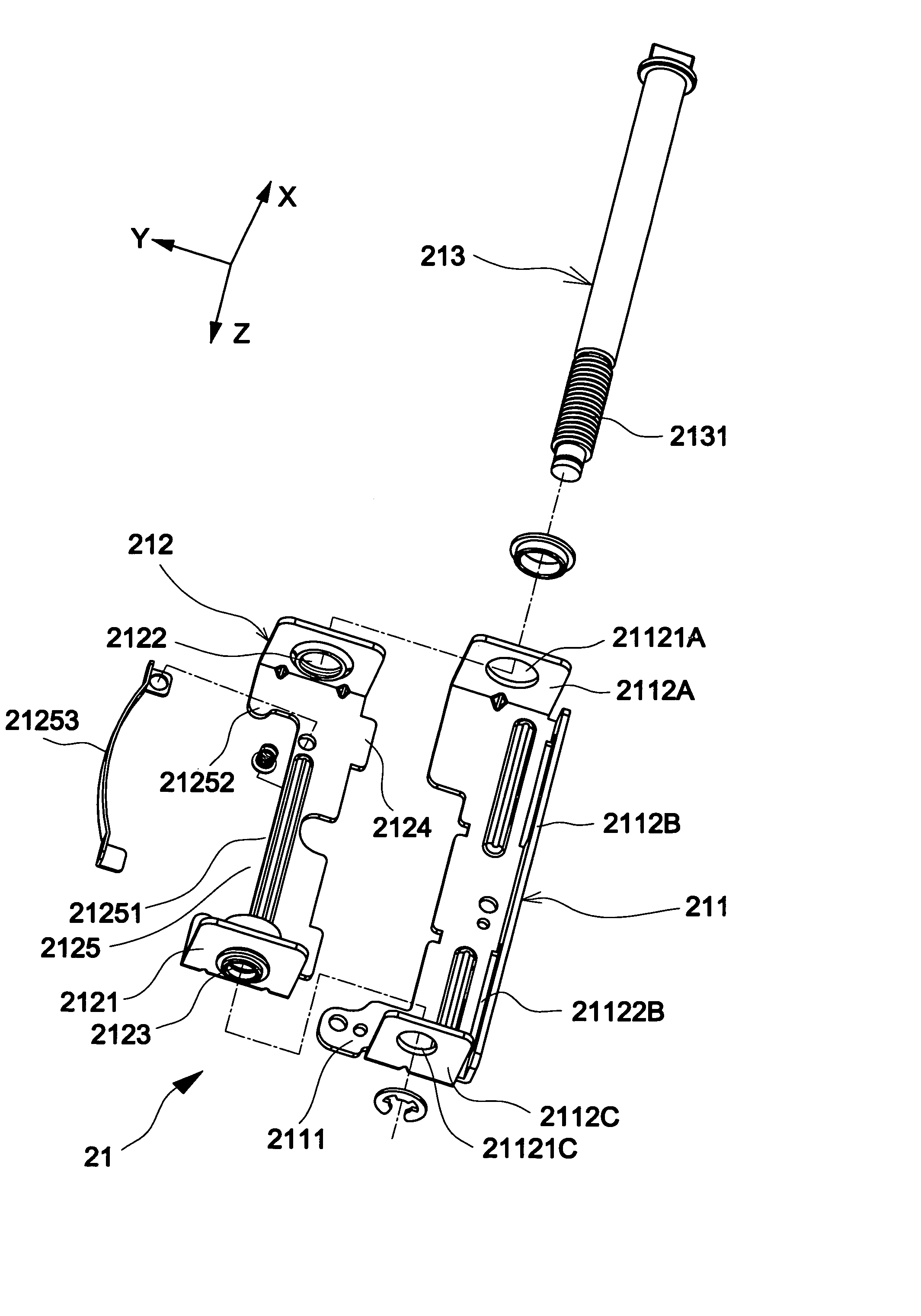

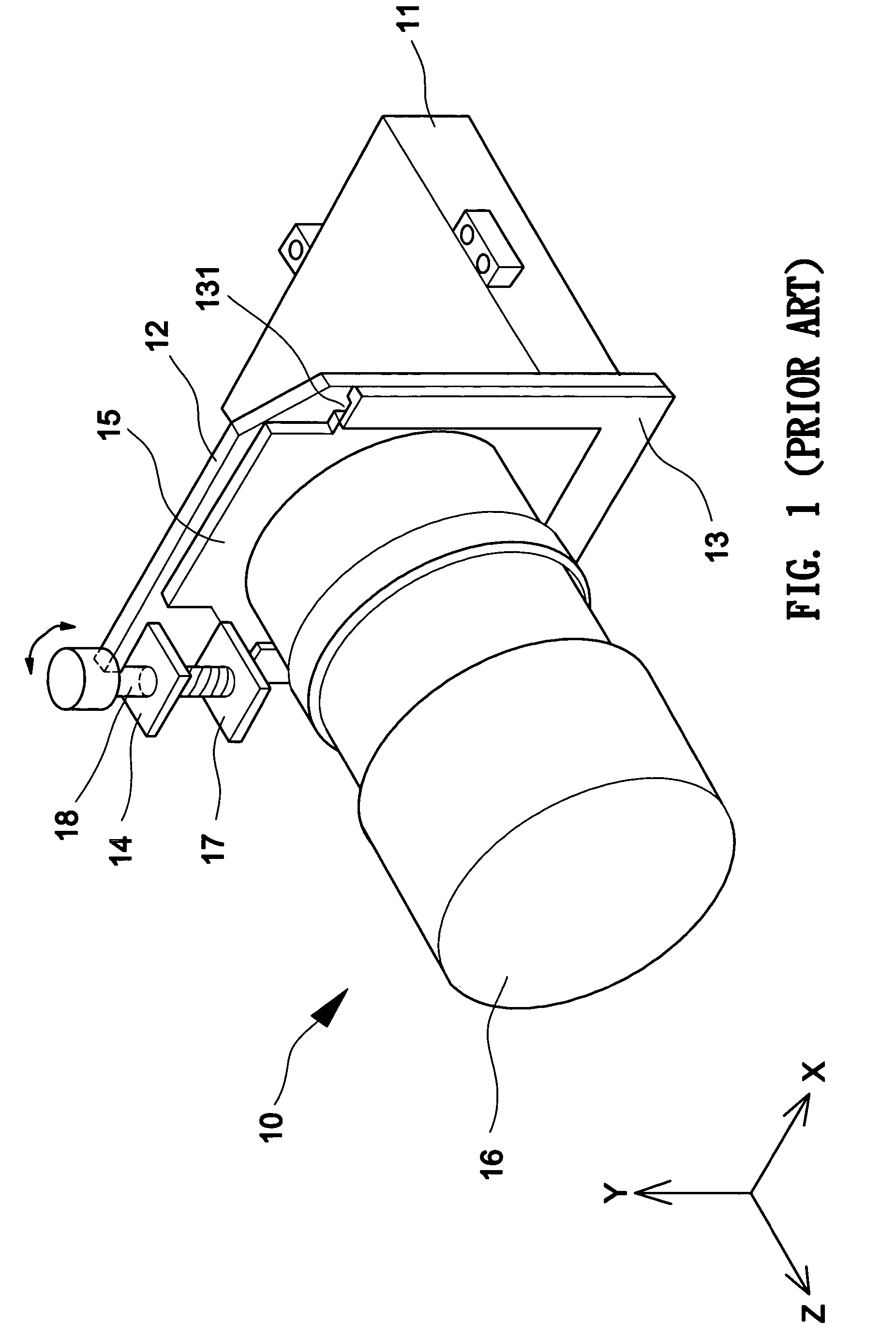

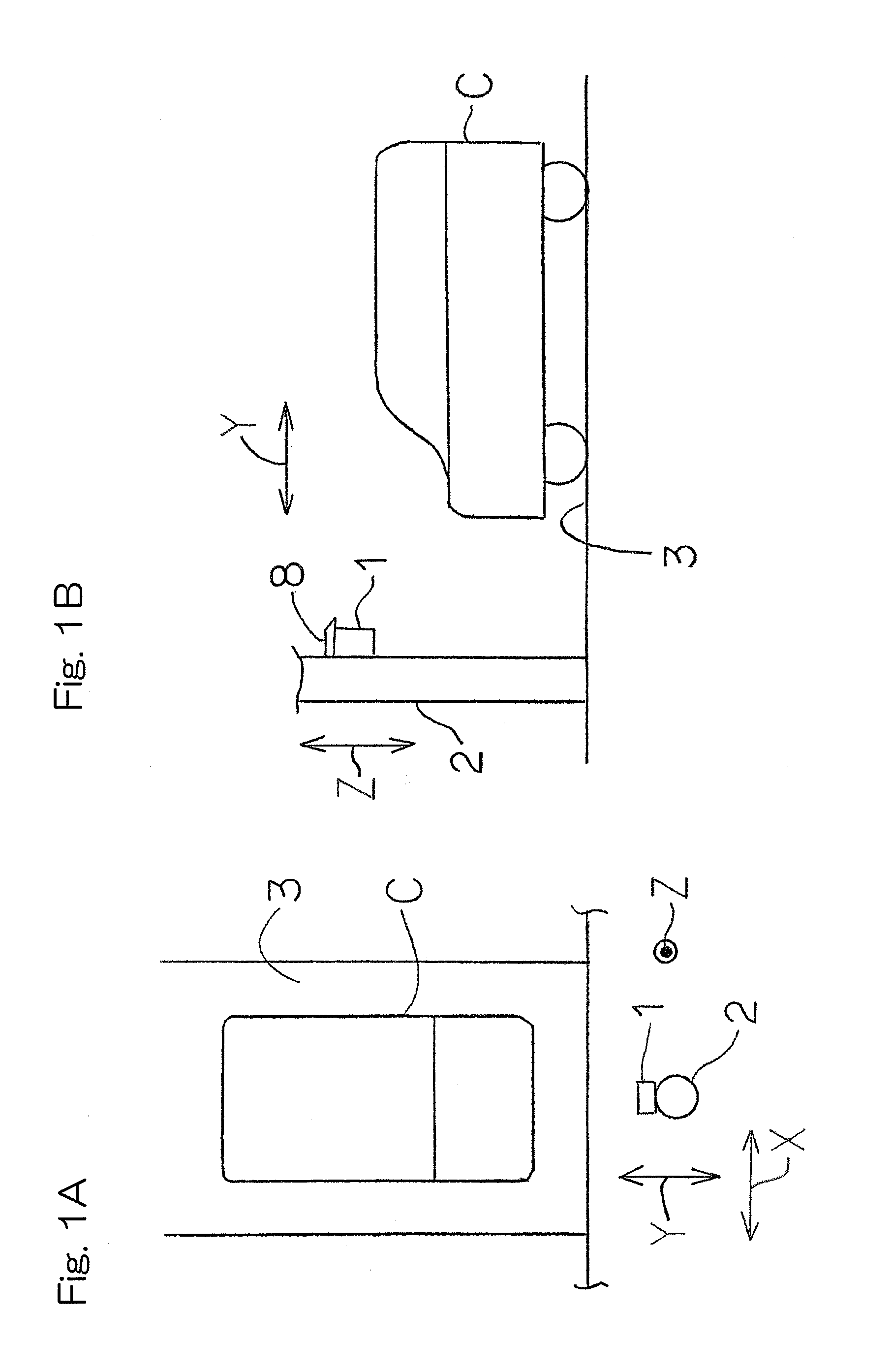

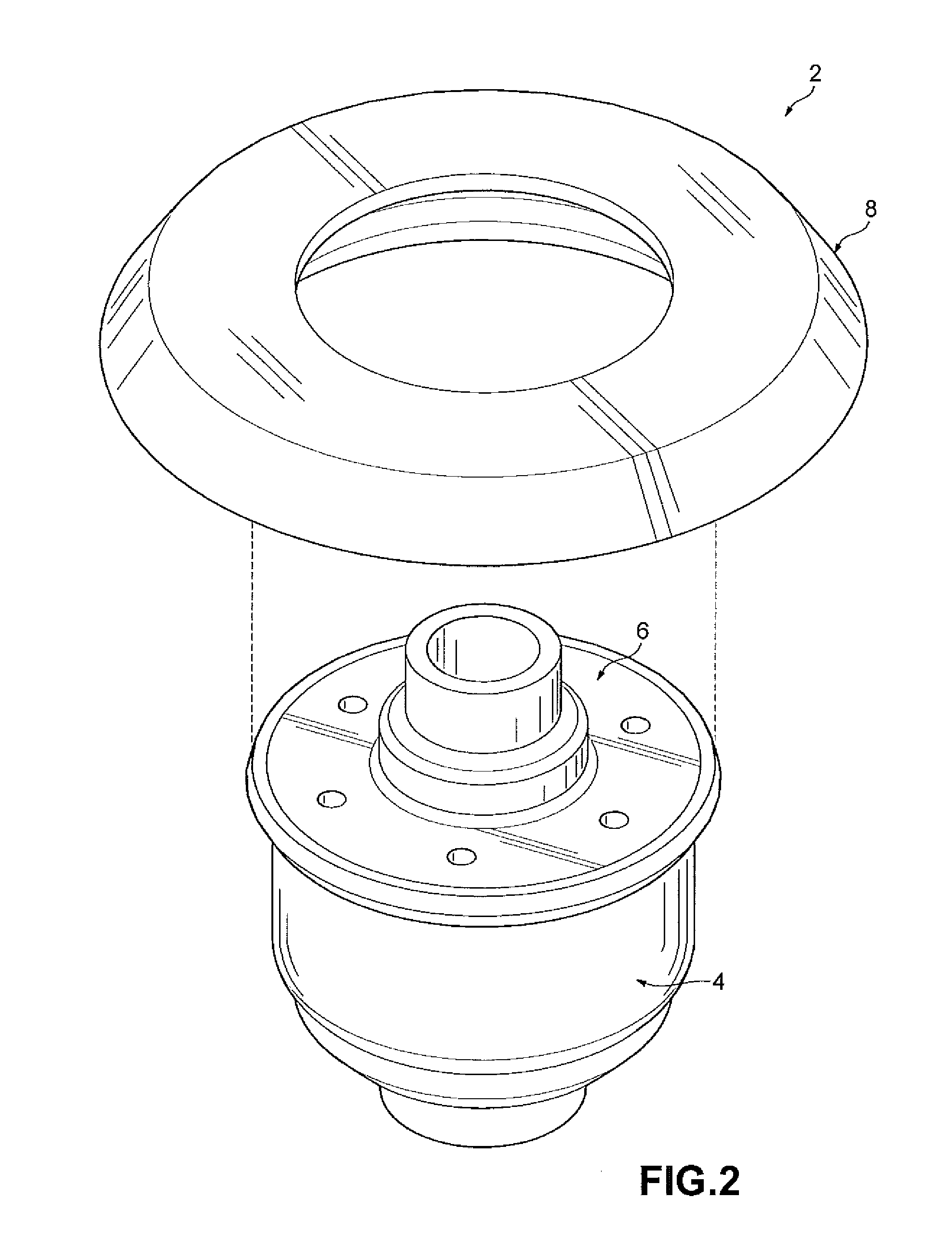

Projection lens movement-adjusting apparatus

ActiveUS7064910B2Improve machining accuracyGuaranteed accuracyProjector focusing arrangementCamera focusing arrangementCamera lensEngineering

A projection lens movement-adjusting apparatus comprises an adjusting module and a projection lens module. The adjusting module comprises a fixed support, an adjusting rod, a sliding seat and a fixing portion. The adjusting rod is pivoted to the fixed support. The sliding seat is mounted inside the fixed support and screwed to the adjusting rod. A fixing portion is disposed on one side of the sliding seat. The projection lens module is composed of projection lens and the linking unit fixed to one side of the projection lens, and a protruding board is on one side of the linking unit and is fixed firmly to the fixing unit and hence the projection lens module can be connected with the sliding seat.

Owner:YOUNG OPTICS

Vehicle detecting sensor assembly

InactiveUS20150130653A1Reduce the impactLimited detection rangeRadiating element housingsRadio wave reradiation/reflectionParking areaMicrowave

A vehicle detecting sensor assembly (1) includes a microwave module (4) and a radome (5) for detecting the presence or absence of a parked vehicle, parked in a predetermined parking area (3), according an FMCW scheme. A shielding member (10) is provided on each of left and right sides, each of upper and lower sides or each of upper and lower and left and right sides of the module so as to protrude in a direction, conforming to the direction of transmission of a microwave, so that a detection range angle by the microwave can be varied in dependence on the position of the sensor and the size of the parking area, and a so disposed that the distance of separation between the module and the radome, through which the microwave passes, may lie in the vicinity of n times the half-wave length of the microwave.

Owner:OPTEX CO LTD

Flow-formed differential case assembly

ActiveUS8628444B2Required packaging spaceMinimize assemblyGearboxesDifferential gearingsEngineeringMechanical engineering

A differential case assembly includes a differential case and a pinless gear assembly. The differential case has an open end and a side wall with an interior surface. The pinless gear assembly includes a retainer insert and a side gear with a shaft extending outwardly therefrom. The retainer insert is disposed adjacent the interior surface of the side wall, The retainer insert defines at least a portion of an aperture that receives an end of the shaft to align the gear assembly within the differential case.

Owner:METAL FORMING & COINING

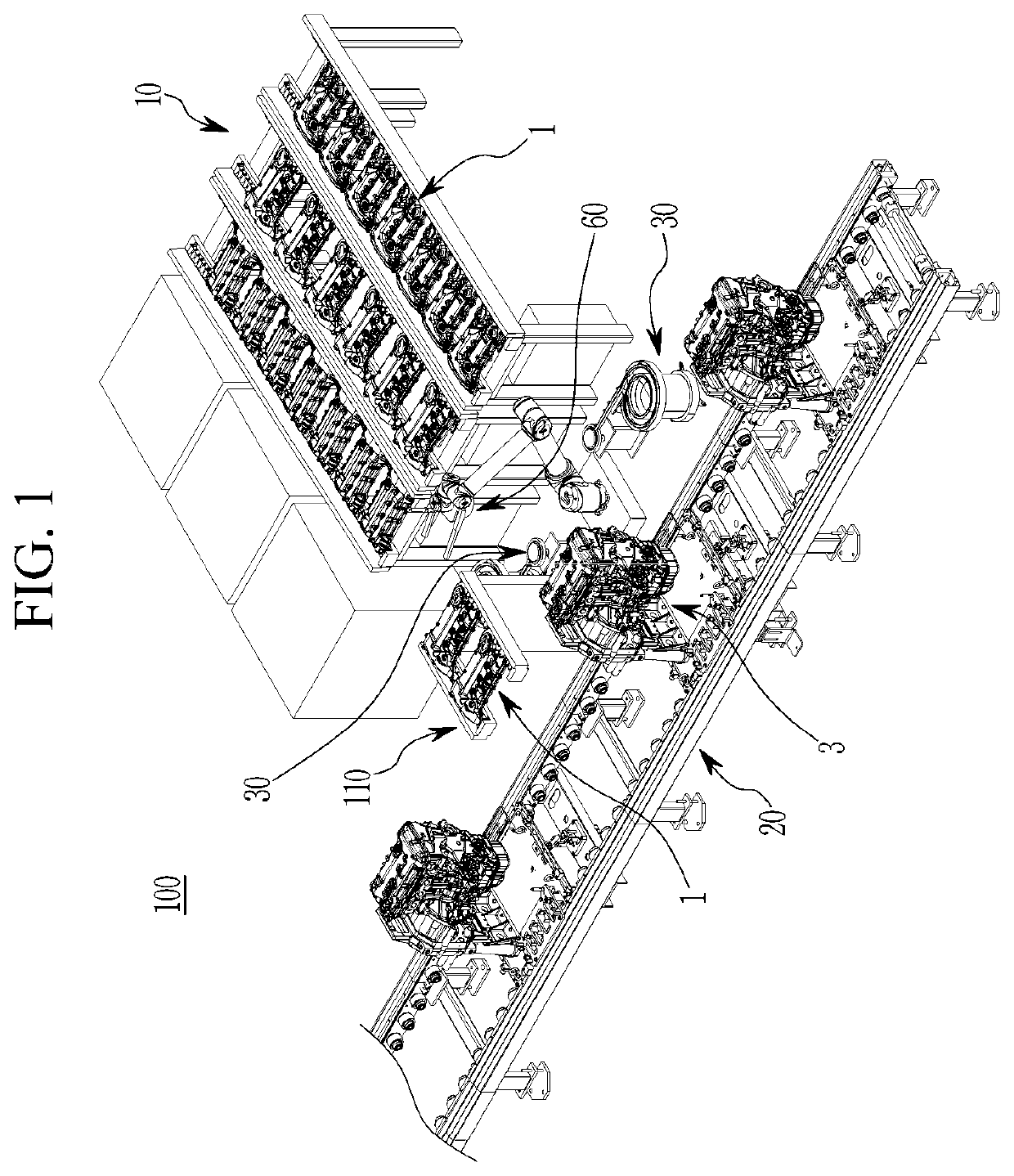

Parts assembling system and method

ActiveUS20210094170A1Shorten cycle timeMinimize assemblyProgramme-controlled manipulatorGripping headsMechanical engineeringIndustrial engineering

A part assembly system is disclosed that includes a first conveyor configured to convey fastening target parts and a second conveyor configured to convey correlated parts to which the fastening target part is to be fastened, including: i) a bolt supplying unit configured in a robot working section between the first and second conveyors and supplying bolts to a predetermined position; and ii) a robot gripper configured in the robot working section, picking up the bolts to distribute the bolts to a fastening position of the fastening target part, and moving the fastening target part to a manual working section of the second conveyor.

Owner:HYUNDAI MOTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com