Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Lower the center of gravity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

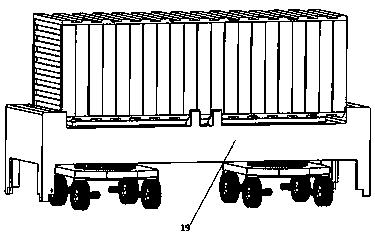

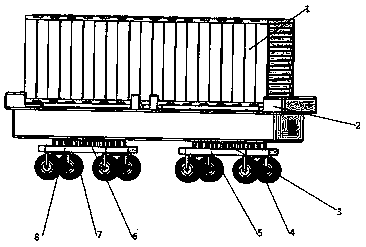

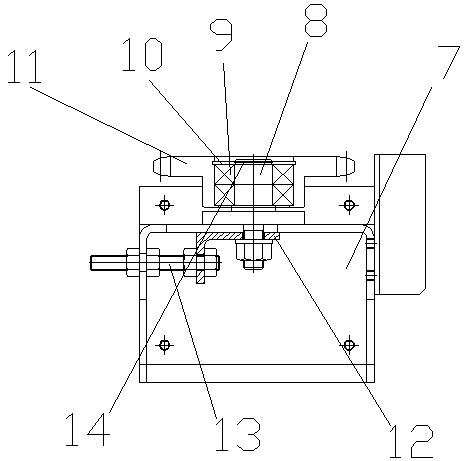

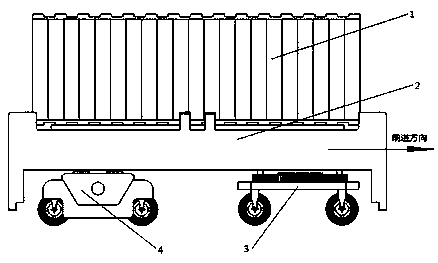

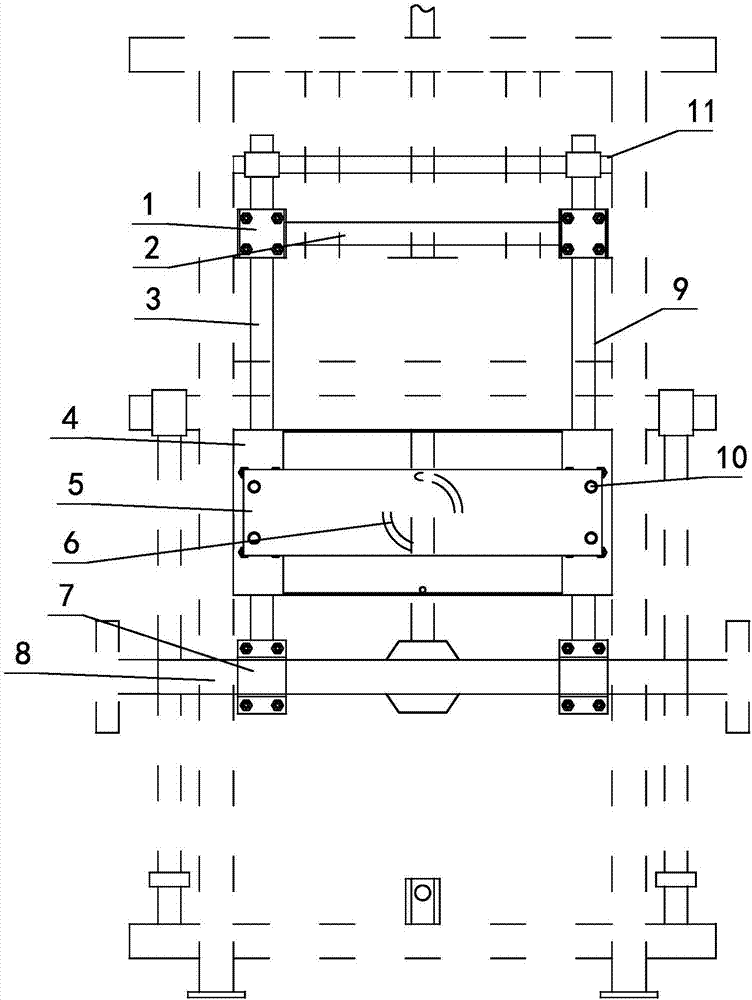

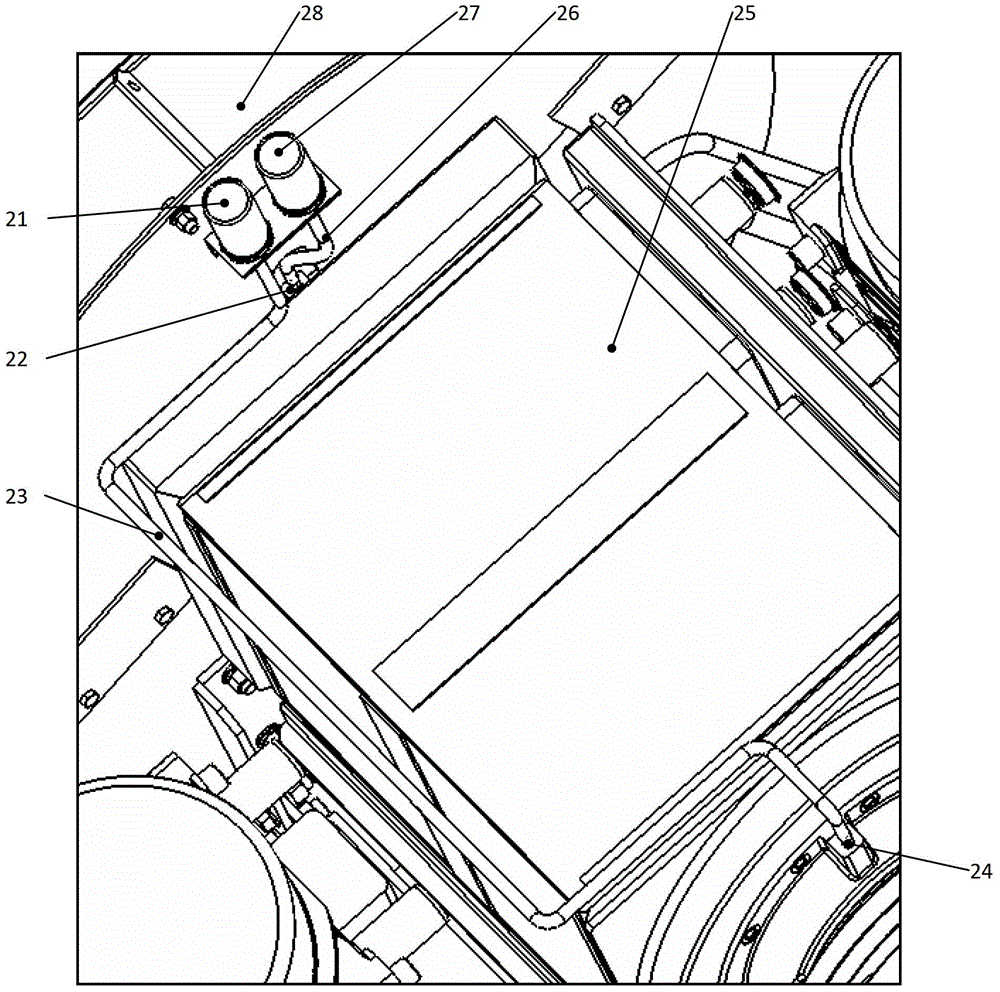

Slewing bearing fast reversing container AGV transferring trolley

InactiveCN108860367ASolve safety hazards such as tiltingSmall turning radiusVehiclesGravity centerEngineering

The invention provides a slewing bearing fast reversing container AGV transferring trolley, and relates to the field of intelligent equipment for warehousing logistics. The trolley comprises steeringsupports and driving devices thereof and running supports and driving devices thereof. The steering device uses two slewing mechanisms to realize the steering of the transferring trolley, so that themovement of the transferring trolley can be more convenient. The running device is driven by each wheel respectively. The device is provided with two slewing mechanisms and eight tires, and can achieve the movement of various directions of the transferring trolley, including advancing, retreating, left and right lateral movements and motions of various angles, the size of the tire is reduced, theturning radius of the transferring trolley is reduced, and the transferring trolley can achieve carrying in a narrow space, therefore, the working efficiency of the transferring trolley is improved; furthermore, the working gravity center of the whole transferring trolley is lowered, and the running safety of the transferring vehicle is enhanced.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

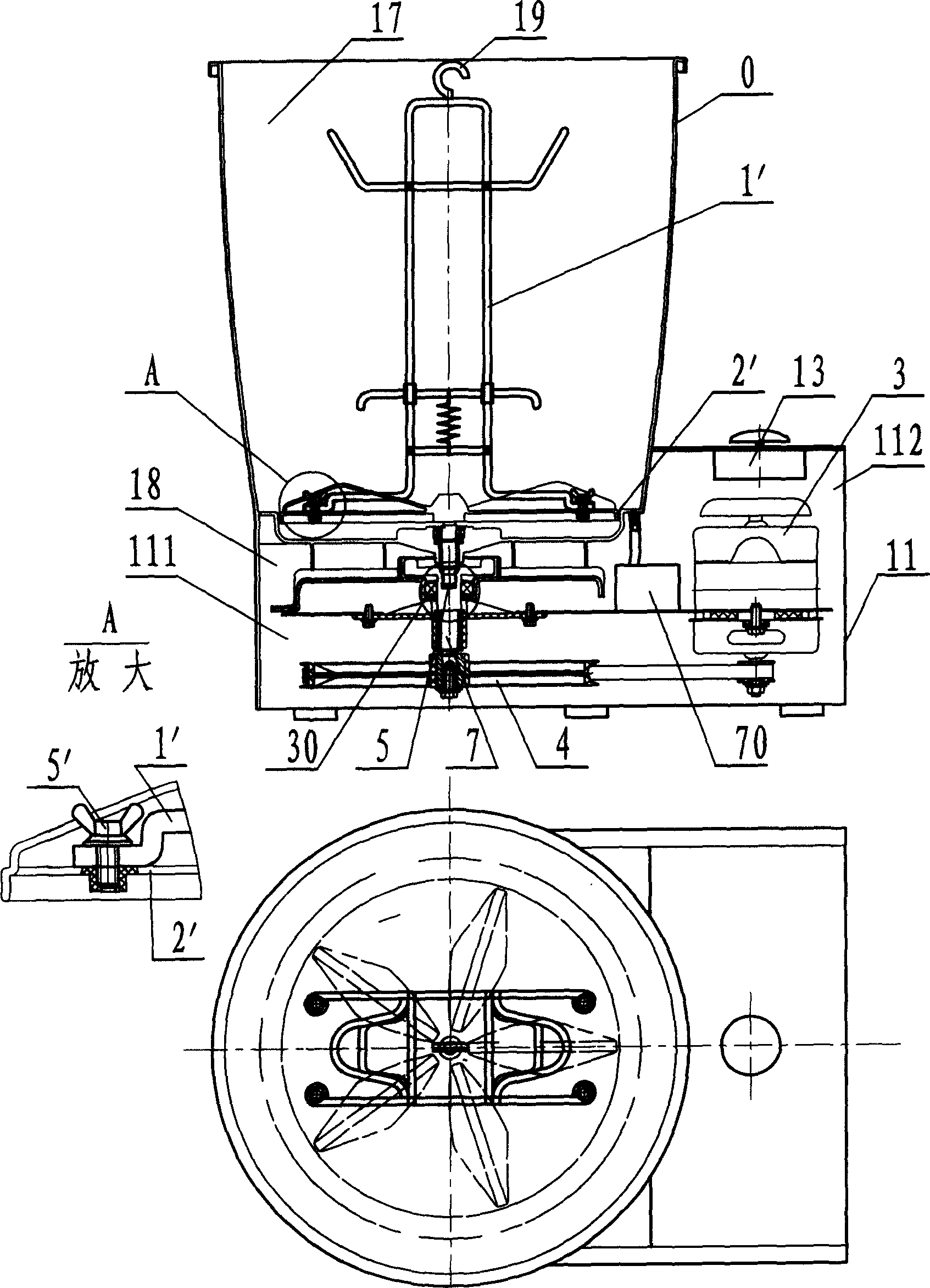

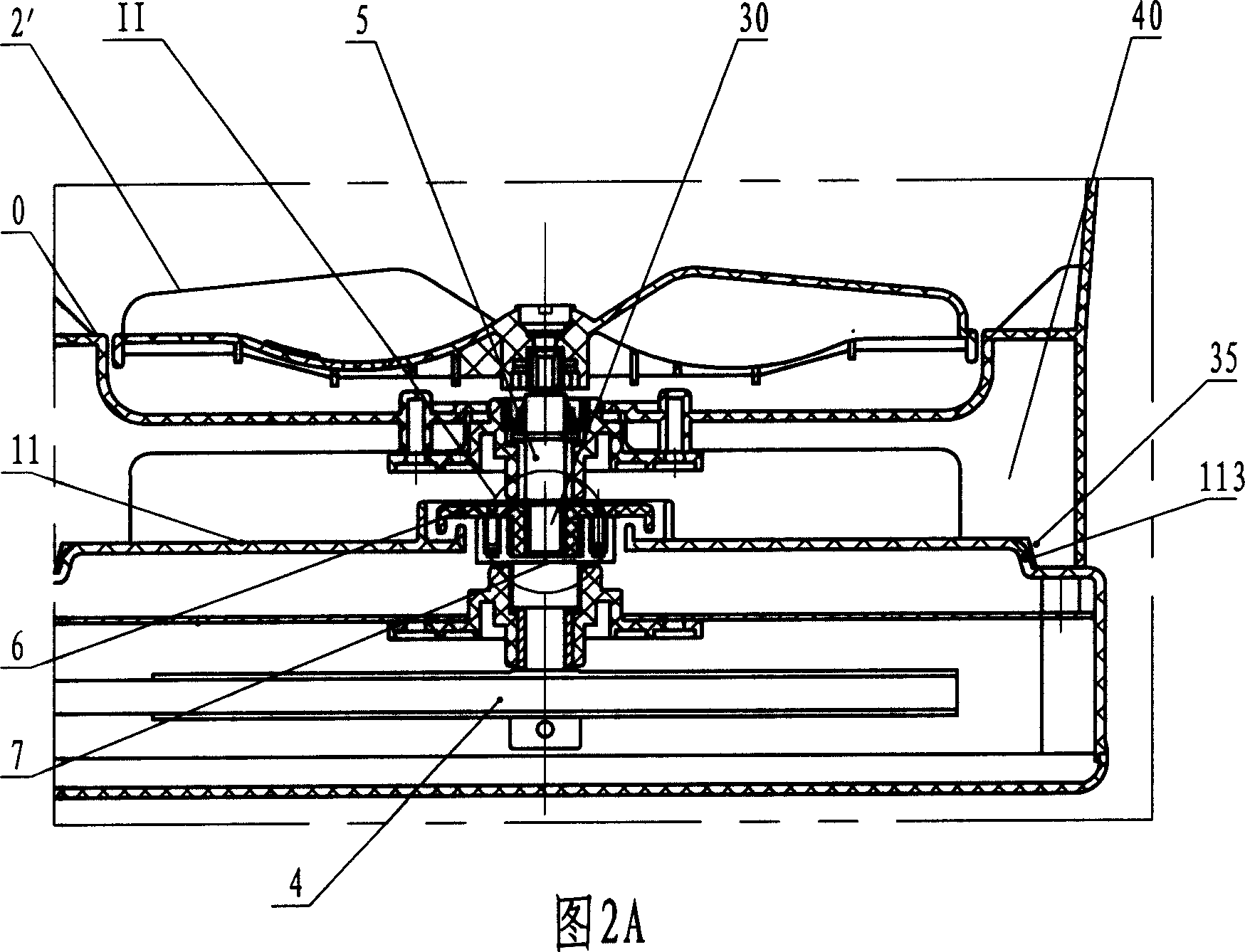

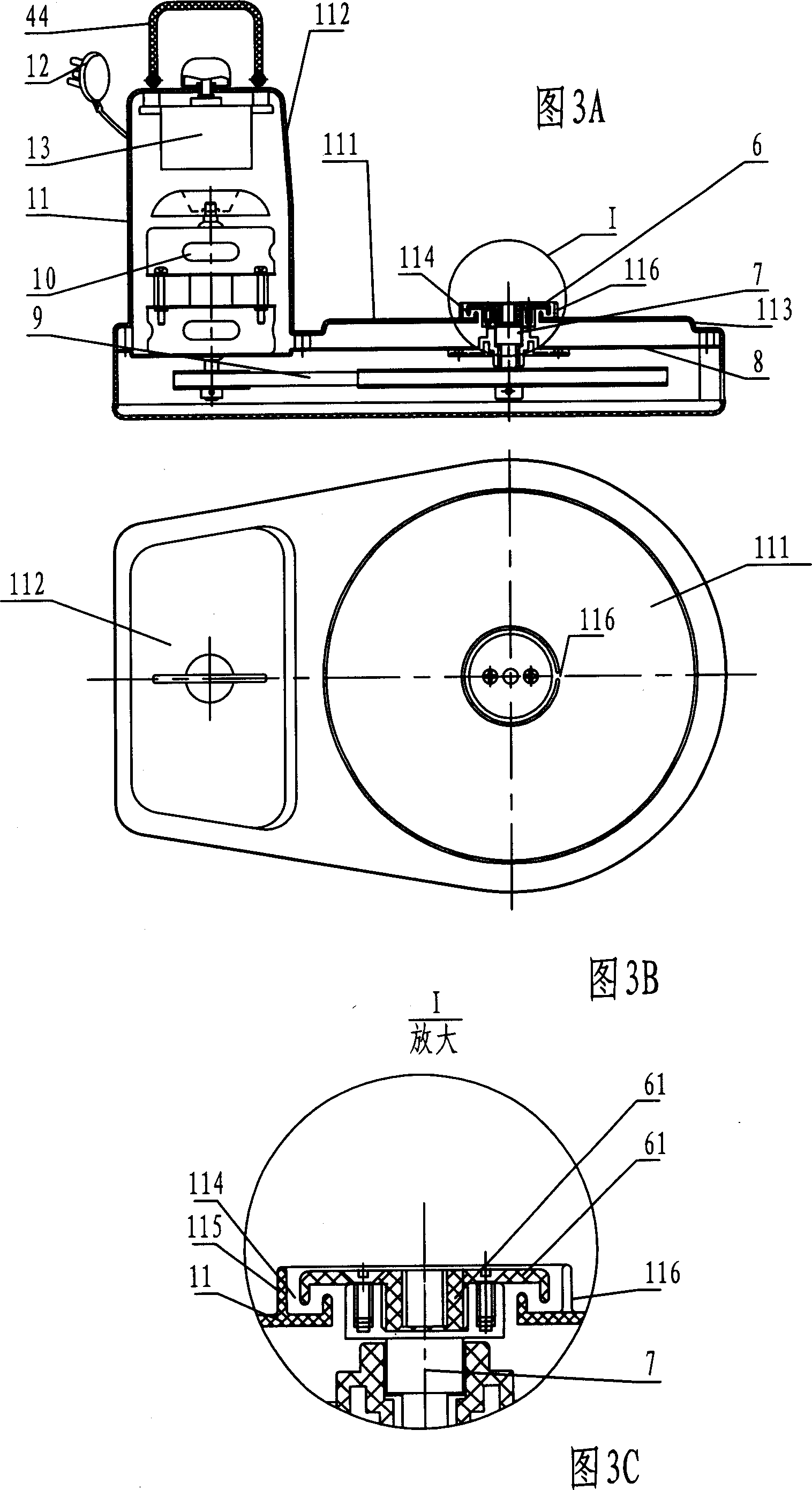

Shoe-washing machine

InactiveCN1528234ALow costAvoid electrical installation failuresWashing machine with receptaclesTextiles and paperEngineeringBody positions

The present invention relates to a shoe-washing machine, including driving device portion and shoe-washing cylinder portion. The driving device portion comprises a shell body, motor, driving device and cotnrol device, said shell body is formed from a horizontally-arranged plate shell body and an electric shell body perpendicularly-arranged on its one end, the electric shell body is basically perpendicularly-arranged on the side face of shoe-washing cylinder, the control device is placed in the electric shell body. The shoe-washing cylinder portion includes a water-holding cylinder positioned on the plate shell body, a drive rotating body positioned in the bottom portion of water-holding cylinder interior and coupled with outer shaft and a shoe-fixing device fixed on the rotating body. Said invention is compact in structure, also can be used as washing machine.

Owner:JINLING ELECTRICAL CO LTD

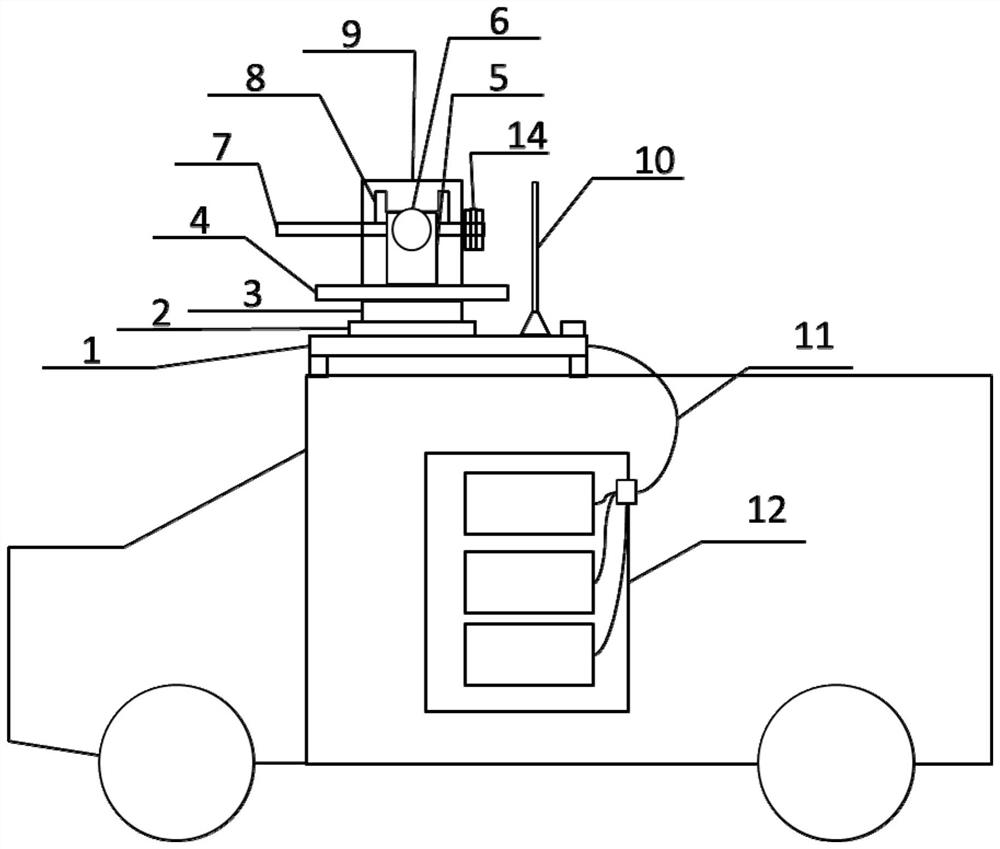

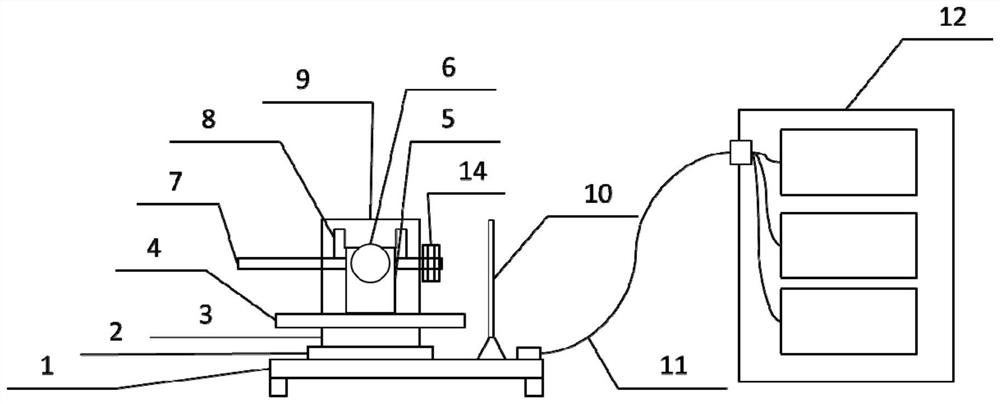

Multifunctional self-positioning broken pavement milling machine

InactiveCN104389260AReduce maintenance costsCompact structureRoads maintainenceRoad surfaceVision sensor

The invention discloses a multifunctional self-positioning broken pavement milling machine. The multifunctional self-positioning broken pavement milling machine comprises a machine frame, a cutting device, a hammering device, a milling device and a positioning control system, wherein the cutting device, the hammering device and the milling device are arranged on the machine frame in an integration manner; the positioning control system is used for positioning a broken pavement and comprises vision sensors, displacement sensors and a central controller. When the multifunctional self-positioning broken pavement milling machine is used, the vision sensors which are mounted on all the devices are used for scanning back and forth by virtue of a computer control technology, the positions of irregular pits needing to be processed in the pavement are recorded, the irregular pits are self-positioned and are processed into regular pits which can be filled with asphalt according to the feedback information of each sensor, and the machine has the advantages of high intelligence, quickness, high maneuverability, high efficiency and reliability.

Owner:CHONGQING JIAOTONG UNIVERSITY

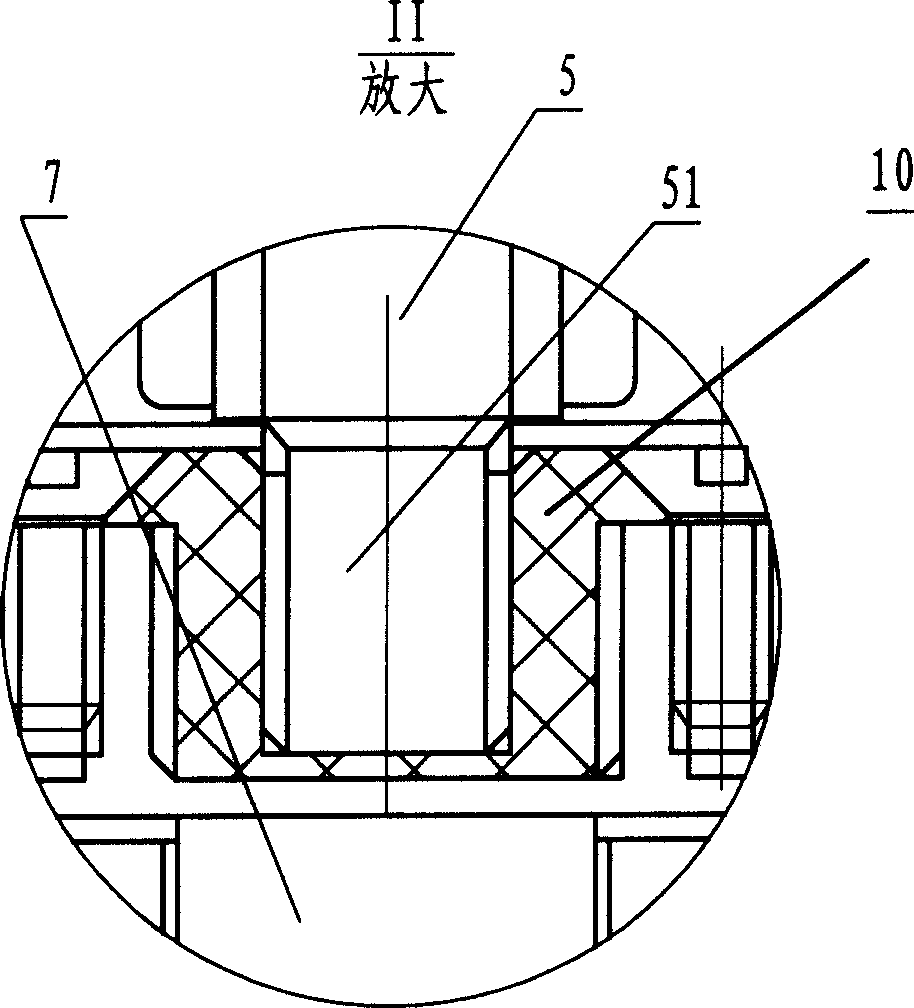

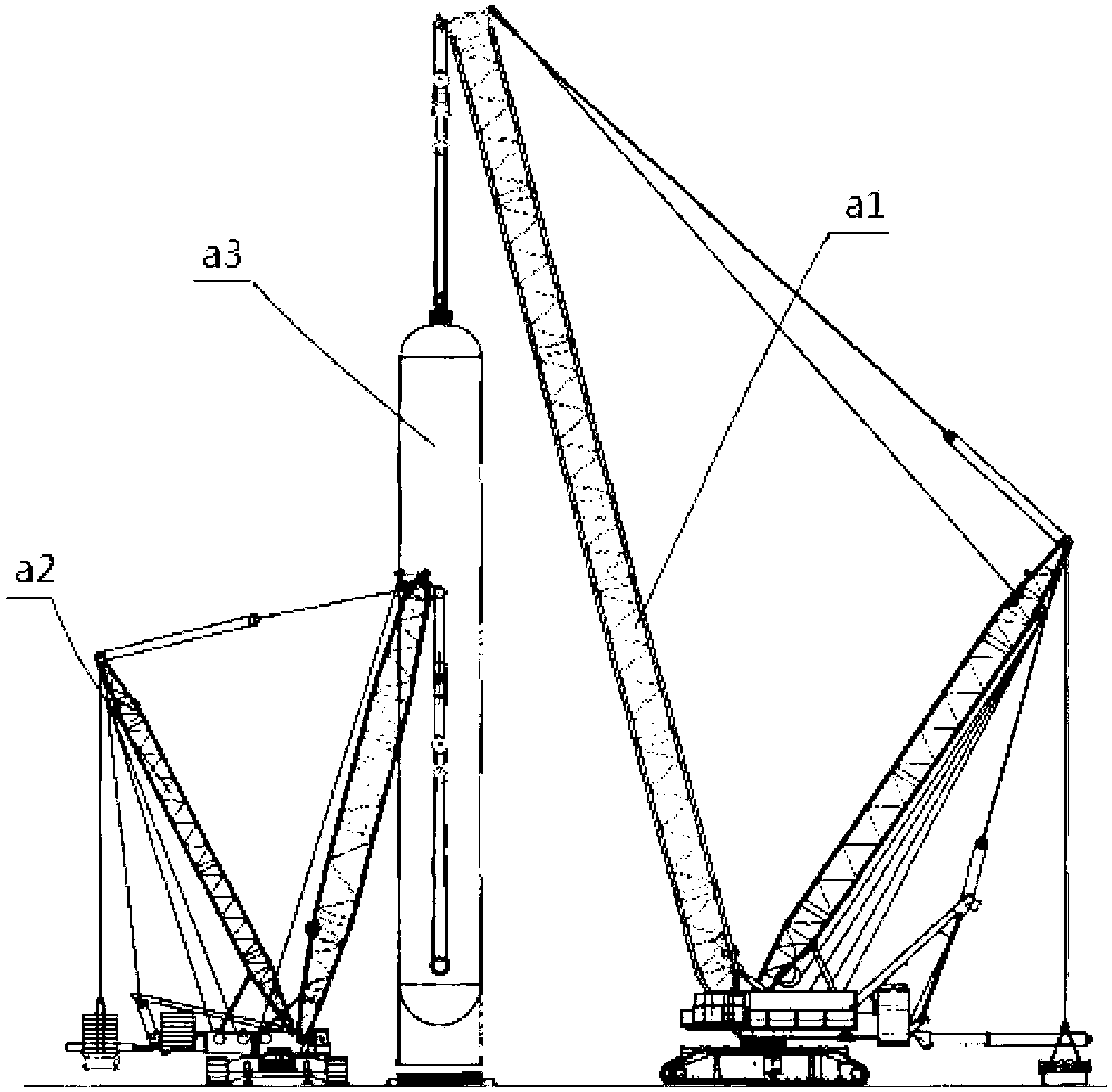

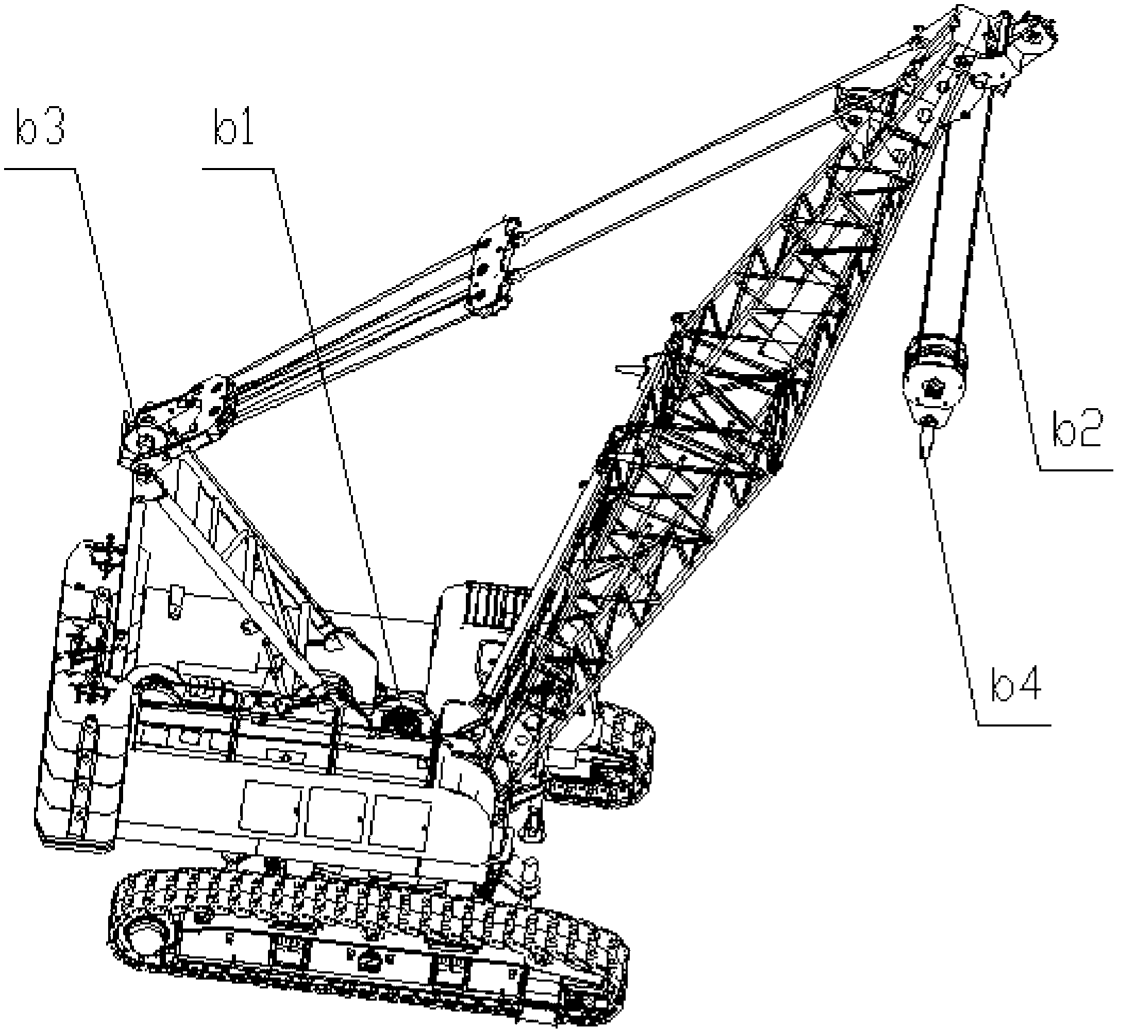

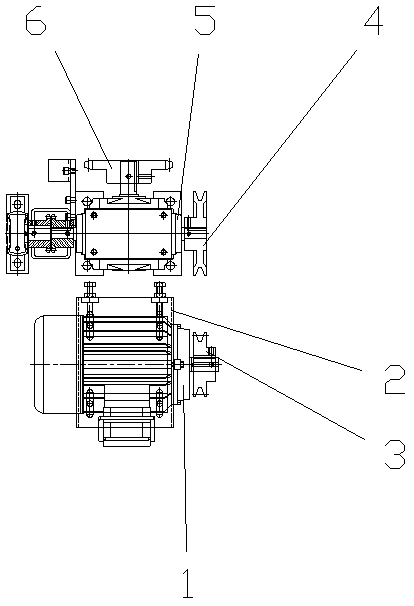

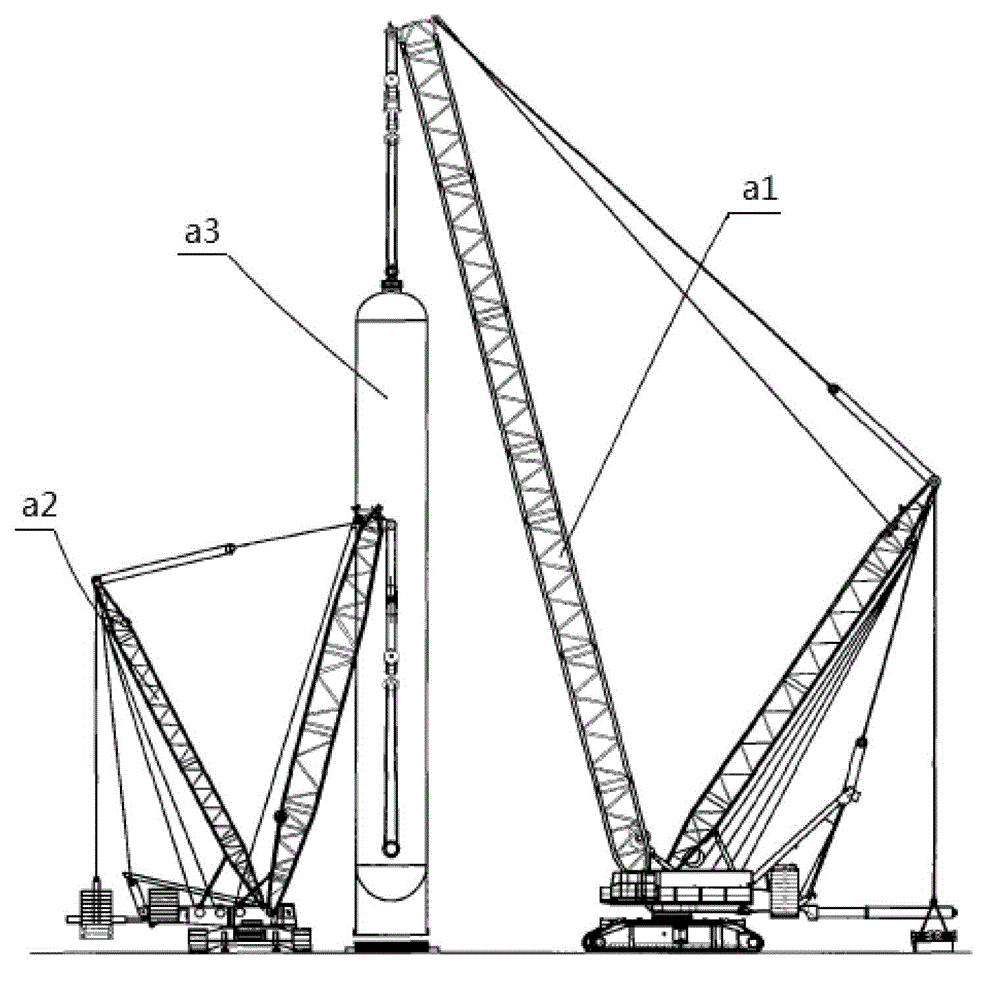

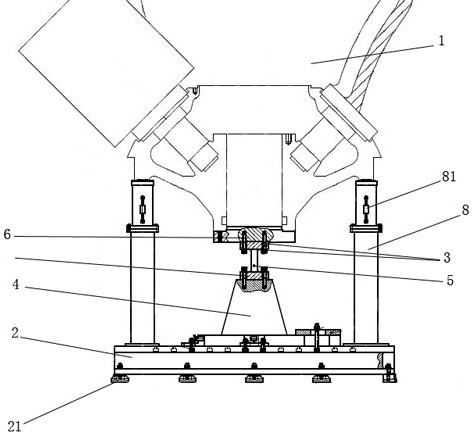

Lifting mechanism suitable for tail end lifting operation of vertical equipment

ActiveCN103303793ALower the center of gravityReduced risk of rolloverLoad-engaging elementsBlock and tackleGravity center

The invention relates to a lifting mechanism suitable for tail end lifting operation of vertical equipment. The lifting mechanism is arranged on a platform structure of a tail sliding machine and a crawler chassis. The lifting mechanism comprises a horizontal pushing oil cylinder, a fixed pulley group, a movable pulley frame and a cable, wherein a front hinged point of the horizontal pushing oil cylinder and the fixed pulley group are both fixed on the crawler chassis, and a barrel of the horizontal pushing oil cylinder is installed on the platform structure; the movable pulley frame is arranged on the upper surface of the platform structure, is fixed with a rear hinged point of the horizontal pushing oil cylinder, and is internally provided with the movable pulley group; the cable goes out of the movable pulley group and rolls the upper side of the fixed pulley group to the side, close to the crawler chassis, of the fixed pulley group so as to be connected with a lifting point on the bottom or the lower part of the vertical equipment. Compared with an existing tail sliding crane, the lifting mechanism provided by the invention is simpler in structure, is free of the working procedures, such as stringing and arm connecting, that consume long time, and has higher assembly efficiency. In addition, the operation barycenter of the complete mechanism is low, and thus the tipping risk of the complete mechanism is low.

Owner:SINOPEC TENTH CONSTR +1

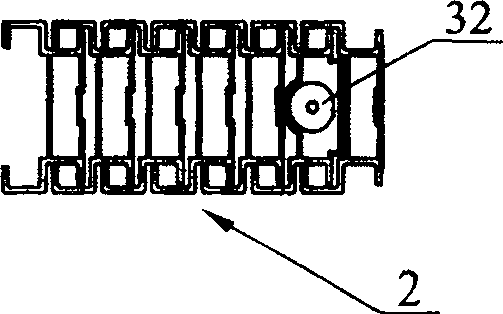

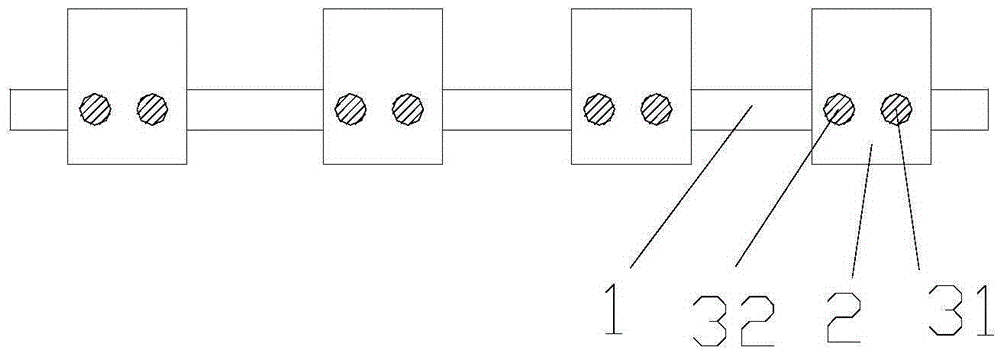

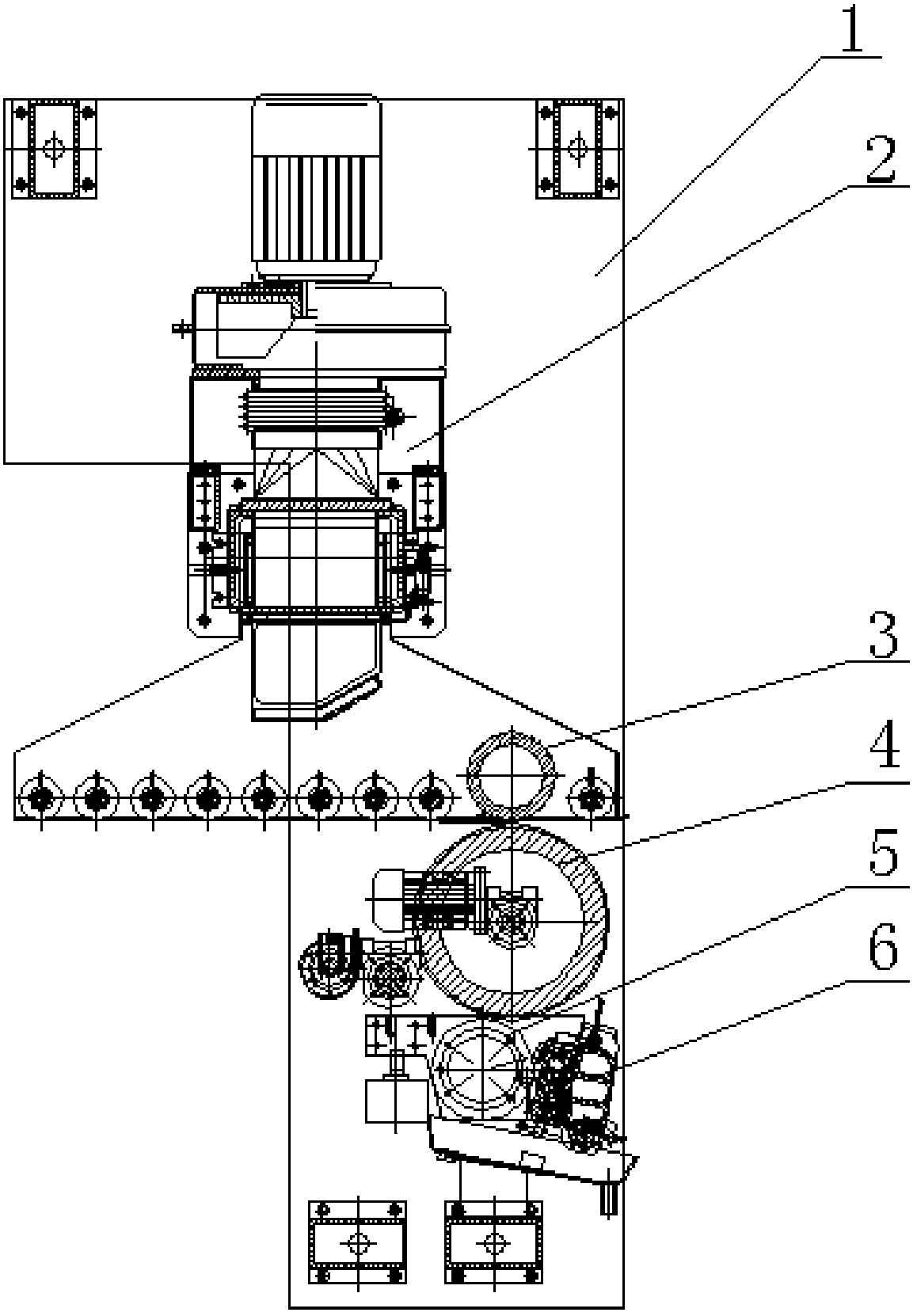

A sock shaping device

ActiveCN106436119BReasonable structural designEasy maintenanceShaping/stretching tubular fabricsWorking pressureWorking space

A sock shaping and shaping equipment includes a track, a fan structure, a driving device, a transmission chain mechanism and a standby mechanism. Compared with the existing sock shaping and shaping equipment, the present invention has more reasonable structural design, realizes more effective use of space, and has the characteristics of convenient maintenance. The vertical height of the sock shaping and shaping equipment is reduced by cutting the shaping room, the working center of gravity is lowered, the working stability is increased, and at the same time, it is convenient for transportation and maintenance; by changing the force mode of the driving device, the original closed structure is avoided, and the number of workers is increased. At the same time, it is convenient for the internal monitoring and maintenance of the sock shaping and shaping equipment; through the standby mechanism, the working time of workers is increased, the requirements for work proficiency and the working pressure of workers are reduced, and the cost of the enterprise is reduced; the transmission chain mechanism increases Improve the operation stability of the transmission chain and increase the service life.

Owner:浙江容易富机械科技有限公司

Air guide component and cabinet type air conditioner indoor unit with same

ActiveCN108709236ALower the center of gravityPrevent dust from fallingLighting and heating apparatusHeating and ventilation casings/coversDrive motorEngineering

The invention provides an air guide component. The air guide component comprises a shell, an air outlet frame and a driving device, wherein the bottom wall and the top wall of the shell are provided with an air inlet opening and an air outlet opening, the air outlet frame can rotate around a pivoting shaft fixed at the rear part of the shell, and a driving device drives the air outlet frame to rotate between an opening position where the air outlet of the air outlet frame is exposed above the air outlet opening and a closed position which is completely located in the shell. The driving devicecomprises a base, a driving motor, a gear and a guiding part, the base is fixedly connected with the air outlet frame, the driving motor is fixedly connected with the base, the gear is in driving connection with an output shaft of the driving motor, and the guide part is fixedly connected with the shell and is provided with an arc-shaped rack which is meshed with the gear. According to the air guide component, the rack is fixedly connected with the shell, so that the driving motor for driving the gear to rotate is fixedly connected with the air outlet frame; and the characteristics that the size of the gear is small, the movement stroke is short, and the machining precision is easier to control are utilized, so that the movement of the air outlet frame is more stable.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

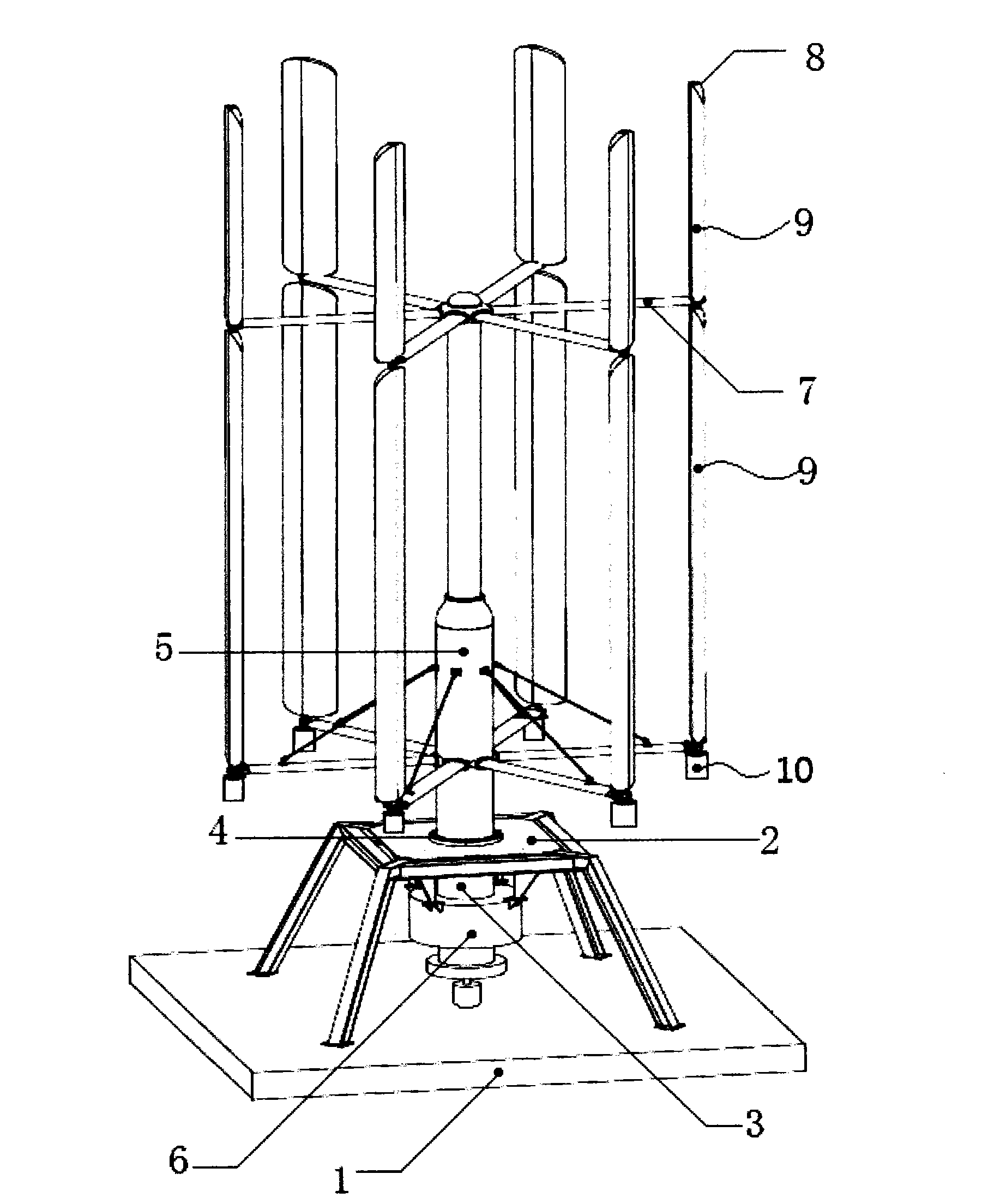

Sail type generator

InactiveCN102072081AHigh wind-to-electricity conversion efficiencyLower the center of gravityWind motor controlEngine fuctionsLeading edgeElectricity

The invention discloses a sail type generator, which comprises a tower body base, wherein a tower body pedestal is arranged on the tower body base, a group of swing bearing is arranged on the tower body pedestal and is internally provided with a tower body spindle, the lower end of the tower body spindle is fixedly connected with the upper end of a coupler, the lower end of the coupler is connected with a generator, the outer side of the tower body spindle is provided with a plurality of sails through sail supporting arms, and the sails drive the tower body spindle to revolve by obtaining wind power and are connected with external driving devices which control the sails to rotate. The rotation direction of the sails and the revolution direction of the tower body spindle are opposite, the sails rotate once while the tower body spindle revolves once towards the reverse direction, the leading edges of the sails always point at a wind direction, and mathematical analysis is carried out on an included angle between an equivalent plane of the sails and wind direction on the circumference on which the tower body spindle revolves according to function rules. The sail type generator disclosed by the invention has high wind-electricity conversion efficiency, and large unit output power.

Owner:张晓鹤

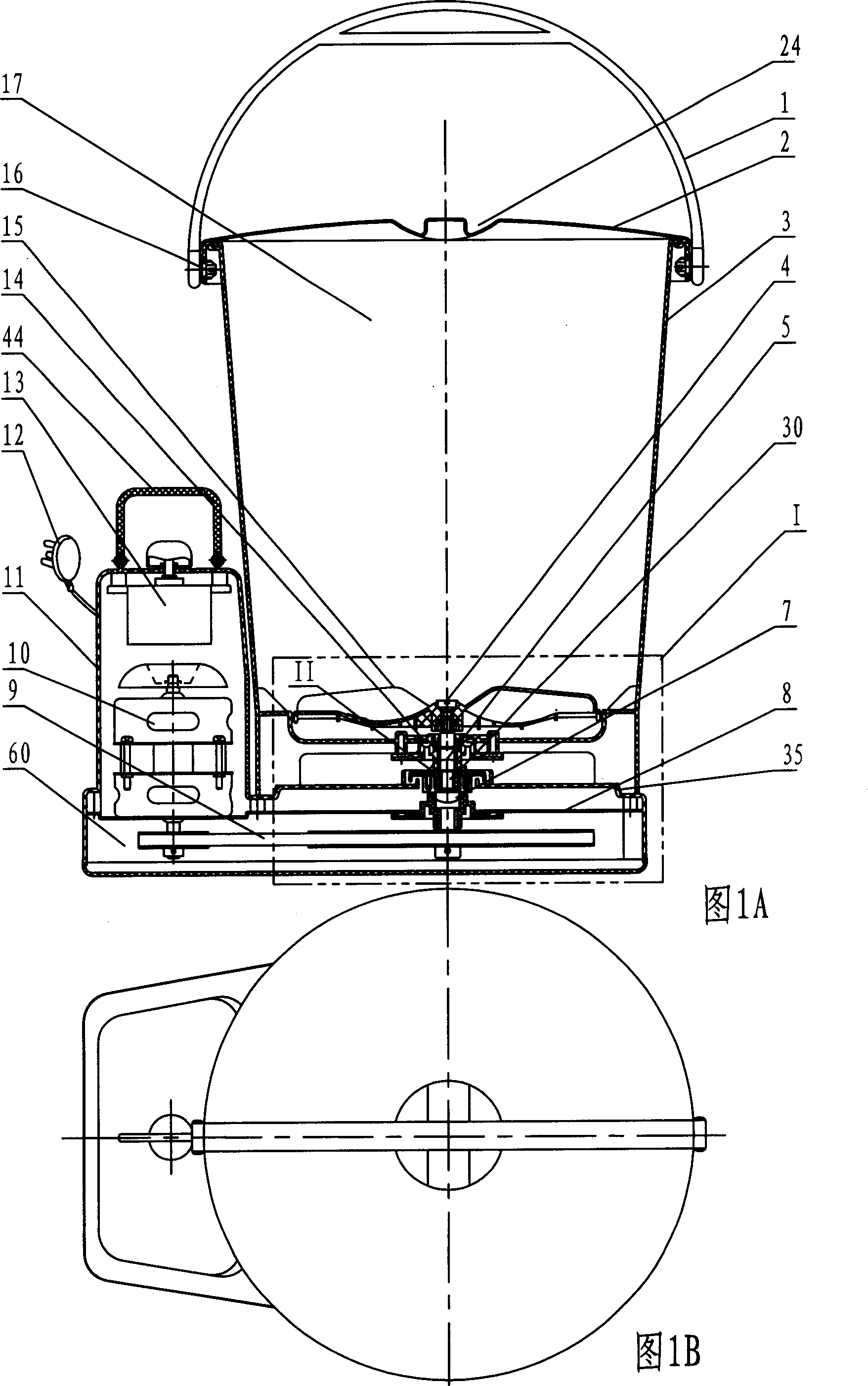

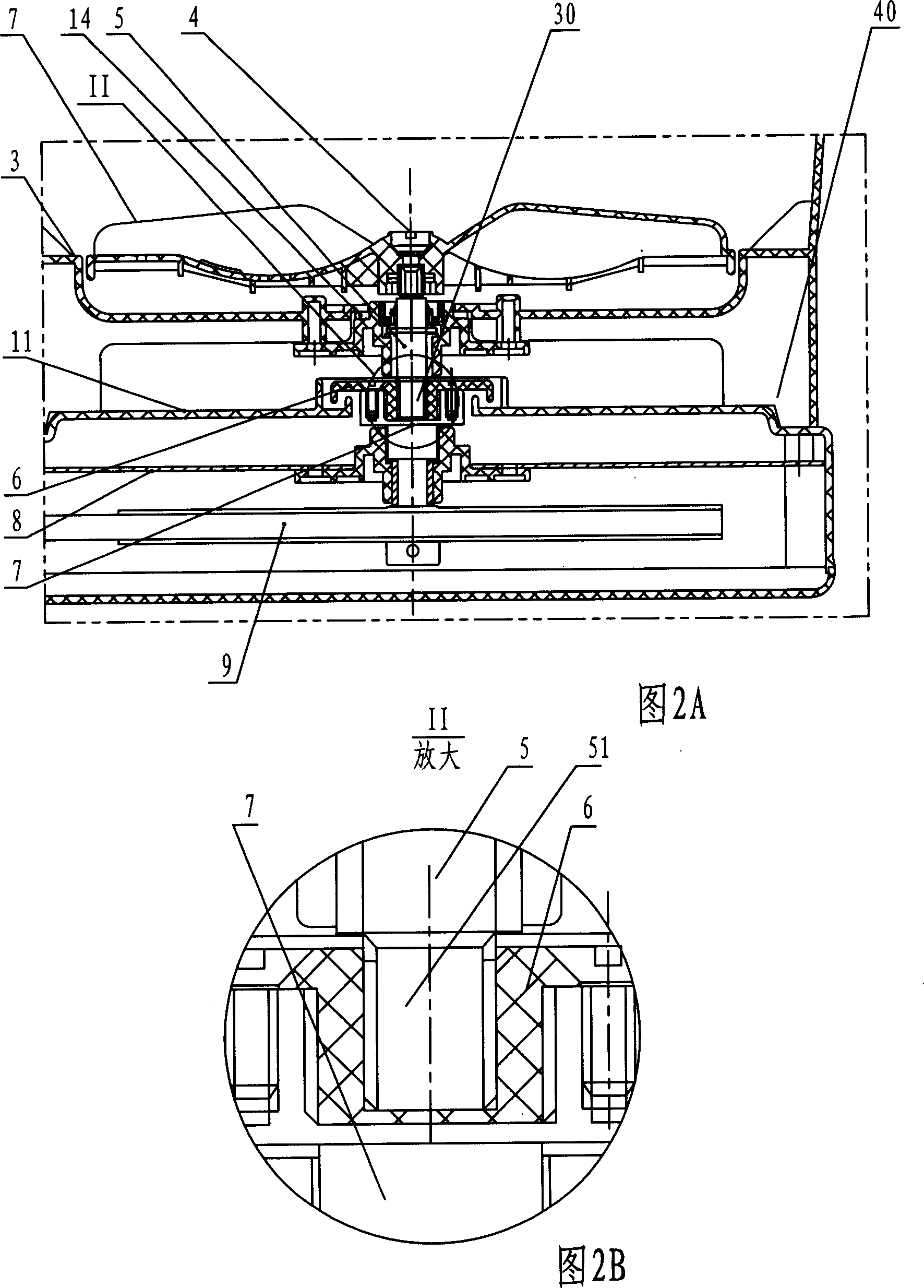

Portable split washing machine

InactiveCN1448573ALower the center of gravityStable jobOther washing machinesWashing machine with receptaclesCouplingMotor controller

The portable separated washing machine consists of two parts including separable washing barrel assembly and driver assembly. The washing barrel assembly includes washing barrel and stirring wheel installed on the rotating shaft in the bottom; and the driver assembly includes motor, transmission mechanism connected to the motor, motor controller and casing for holding the said parts. The casingis one L-shaped one comprising one horizontal casing and one vertical electric element casing with communicated inner cavities. The output shaft of the motor is set downwards inside the electric element casing, and the output shaft of the transmission mechanism is connected to the shaft of the stirring wheel via a detachable transmission coupling mechanism. The present invention has lower working gravity center, high stability and safety and low cost, and is favorable to setting belt transmission unit with great transmission ratio and preventing leakage.

Owner:JINLING ELECTRICAL CO LTD

Ground testing device and testing method for optical atmosphere data system

PendingCN114167391ALow costImprove test accuracyWave based measurement systemsAerodynamic testingEngineeringAtmospheric sciences

The invention belongs to the field of ground testing of an optical atmosphere data system, and particularly relates to a ground testing method and device for evaluating a laser atmosphere data system. The problems encountered in the process of evaluating the optical atmosphere data system are improved and solved, the device is reliable, the precision is excellent, the cost is controllable, the test can be repeatedly and conveniently carried out in the ground environment, and the evaluation on the performance of the optical atmosphere data system is comprehensively completed.

Owner:XIAN FLIGHT SELF CONTROL INST OF AVIC

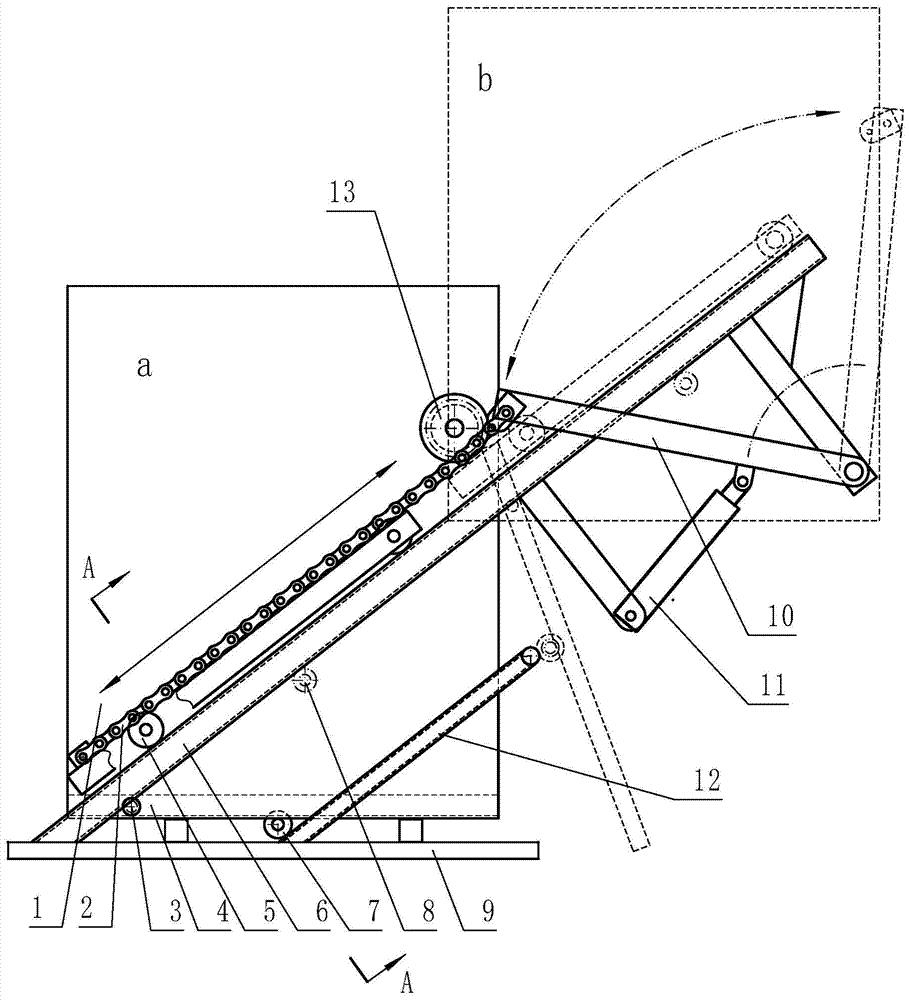

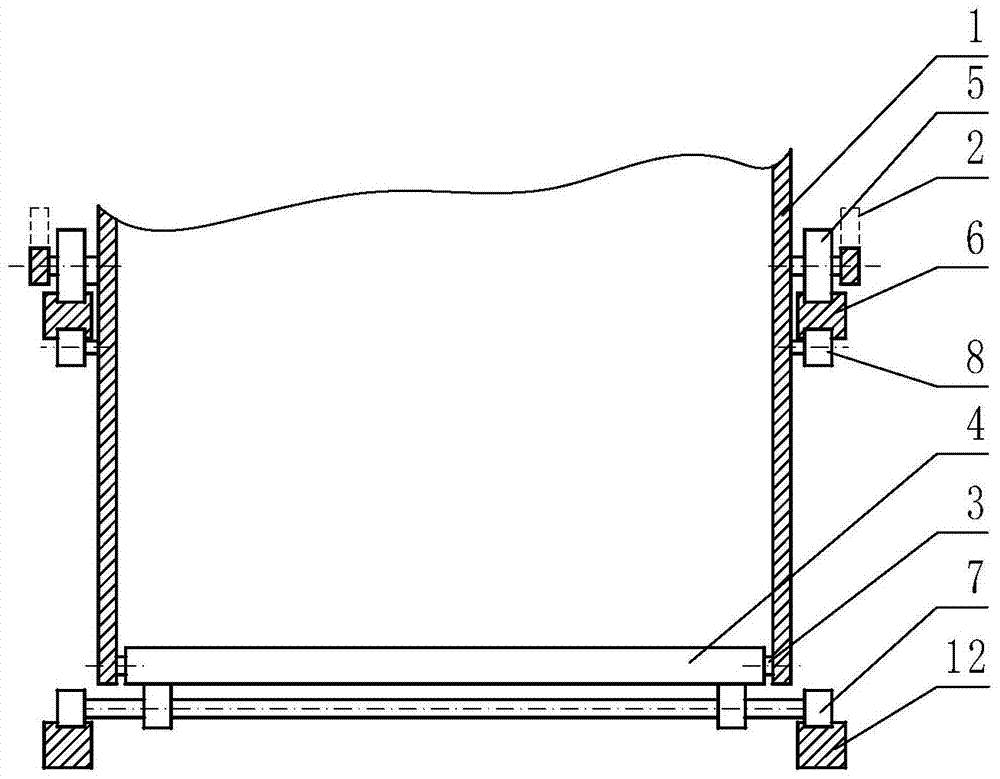

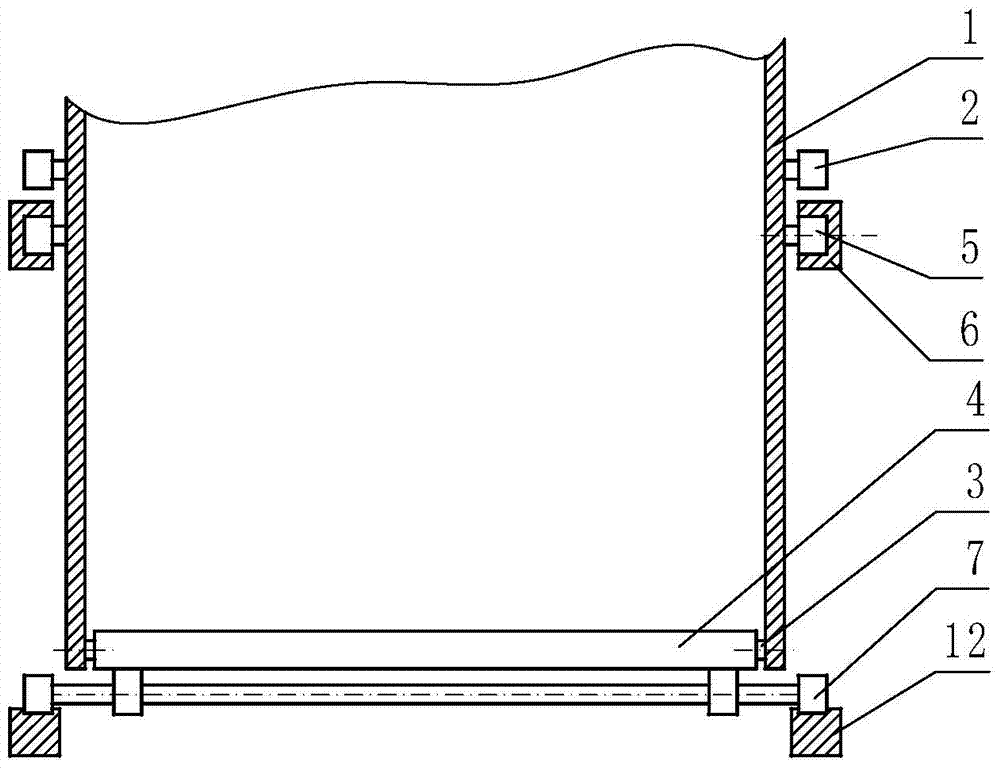

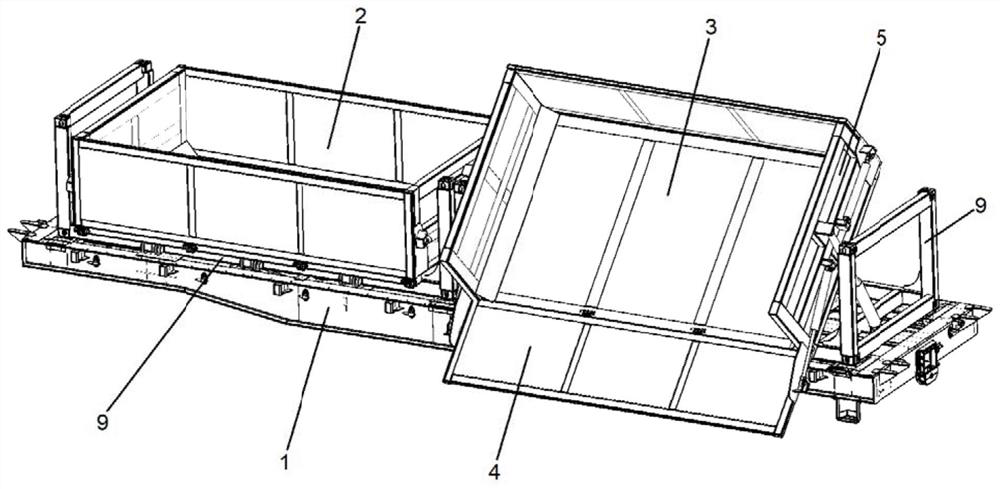

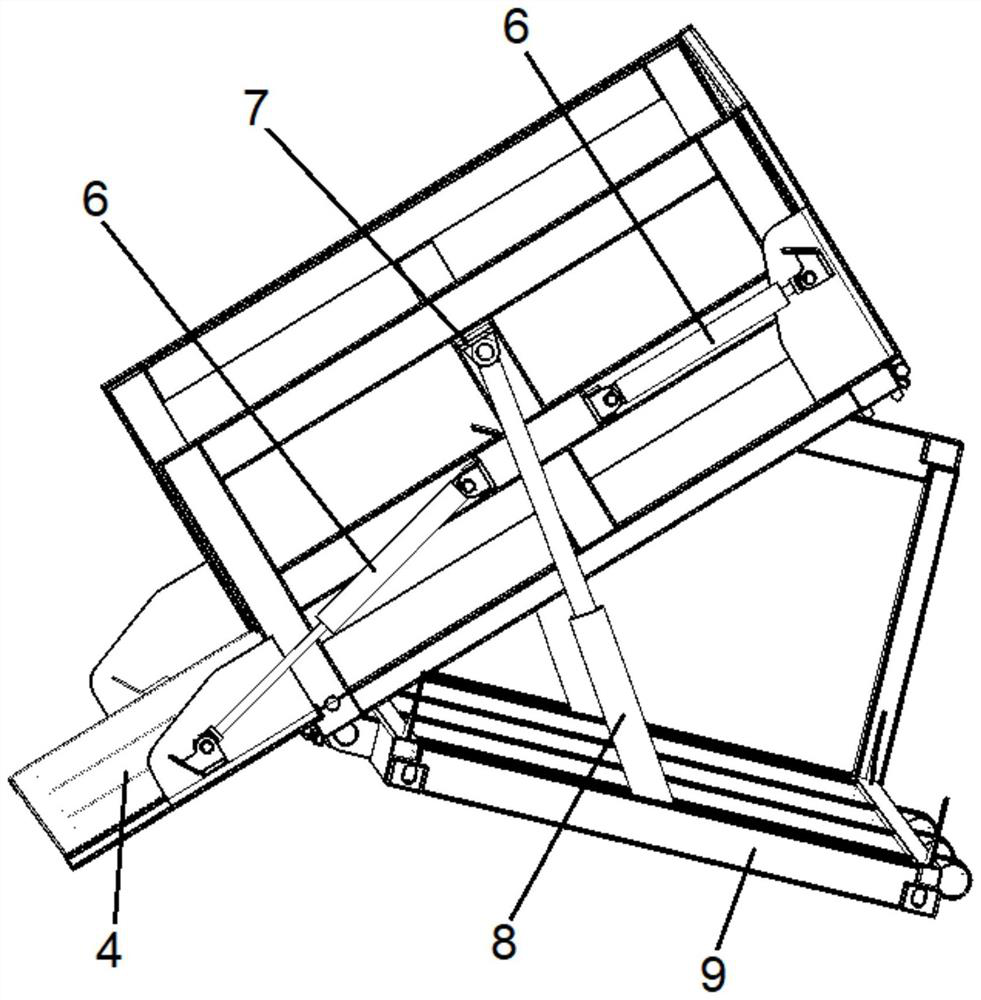

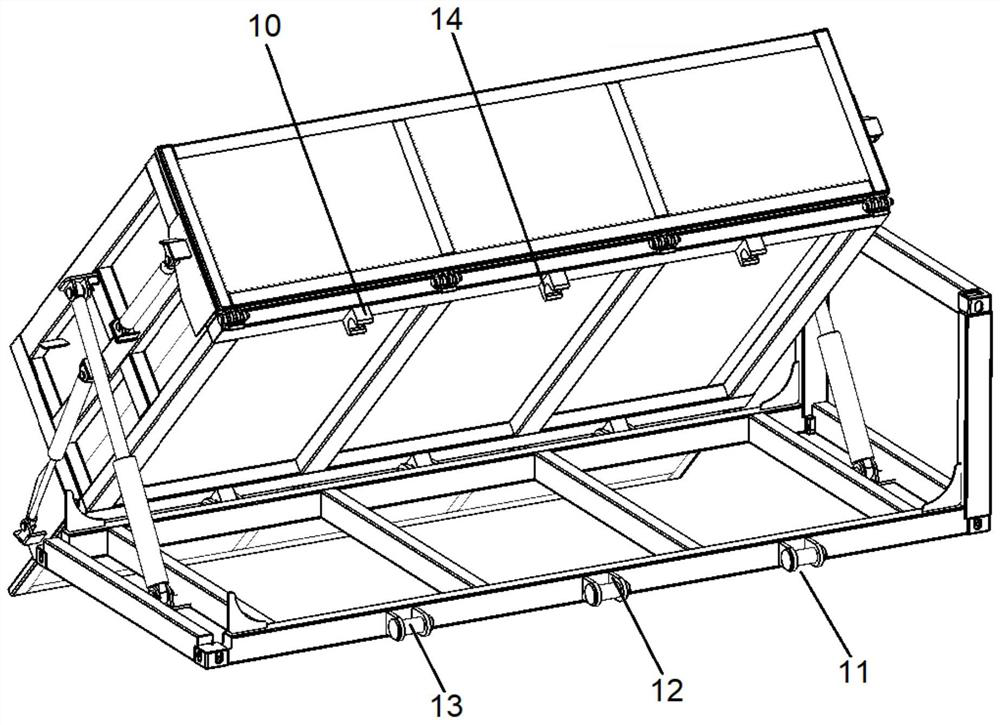

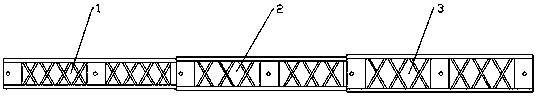

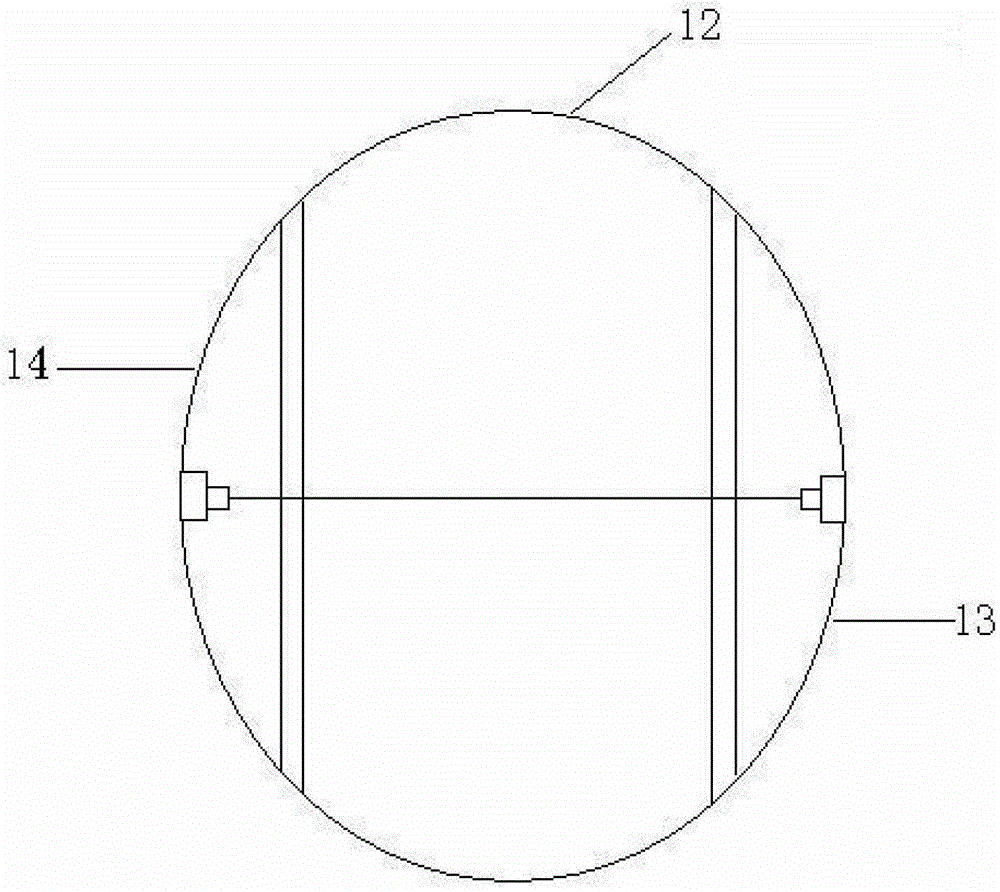

Aggregating devices for agricultural harvesting machinery

InactiveCN105084032BLower the center of gravityGuaranteed stabilityLarge containersLoading/unloadingEngineeringGravity center

The invention discloses a collecting device of an agricultural harvesting machine. The collecting device comprises a rack (9) moving along with a main machine body. Two sets of rails which incline upwards are arranged on the rack (9). A material box at least comprises side plates (1) and a bottom plate (4), and at least the bottom plate (4) is a movable plate and is hinged to the side plates (1) of the material box through pin shafts (3). At least two sets of rollers A (5) are arranged between the side plates (1) of the material box and the rail A (6), rollers B (7) are arranged between the bottom plate (4) and the rail B (12). A traction mechanism is arranged between the rack (9) and the material box (1) to enable the material box (1) to move along the tracks of the rail A (6). Compared with the prior art, a low working gravity center can be maintained in picking or collecting operation, so that stability under the condition of large bearing capacity is guaranteed; when being unloaded, materials can be unloaded to a high platform, for example, the materials are directly unloaded to a transportation carriage, the process of material pouring can be omitted, and the operation process is greatly simplified, so that the operation efficiency is improved, and the production cost is lowered.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

Air guide component and cabinet indoor air conditioner equipped with air guide component

ActiveCN108800510ALower the center of gravityPrevent dust from fallingLighting and heating apparatusAir conditioning systemsDrive motorIndoor air

The invention provides an air guide component which comprises a shell, an air outlet frame and a driving device, wherein an air inlet opening is formed in the bottom wall of the shell; an air outlet opening is formed in the top wall of the shell; the air outlet frame is capable of rotating around a pivot shaft fixed at the rear part of the shell; the driving device is used for driving an air outlet of the air outlet frame to rotate between an open position set above the air outlet opening and a closed position completely set in the shell, and comprises a base, a driving motor, a gear and a guide part; the base is fixedly connected with the air outlet frame; the driving motor is fixedly connected with the base; the gear is in driving connection with an output shaft of the driving motor; andthe guide part is fixedly connected with the shell and comprises an arc-shaped gear rack meshed with the gear. The base further comprises rolling wheels capable of limiting the arc-shaped gear rack between the base and the gear, so that the circumstance that the position, relative to the shell, of the gear changes due to thermal expansion and cold shrinkage of the air outlet frame, and then the gear gets rid of the meshing relation with the arc-shaped gear rack can be avoided.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

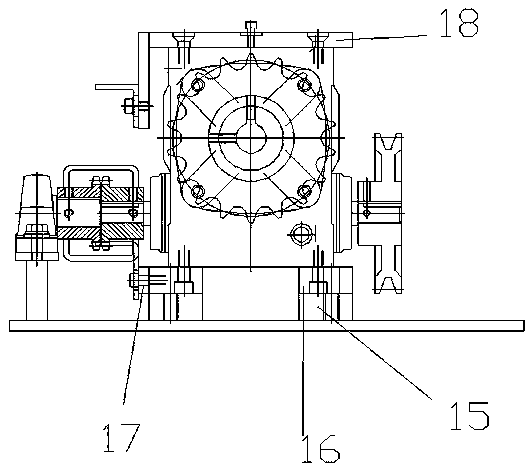

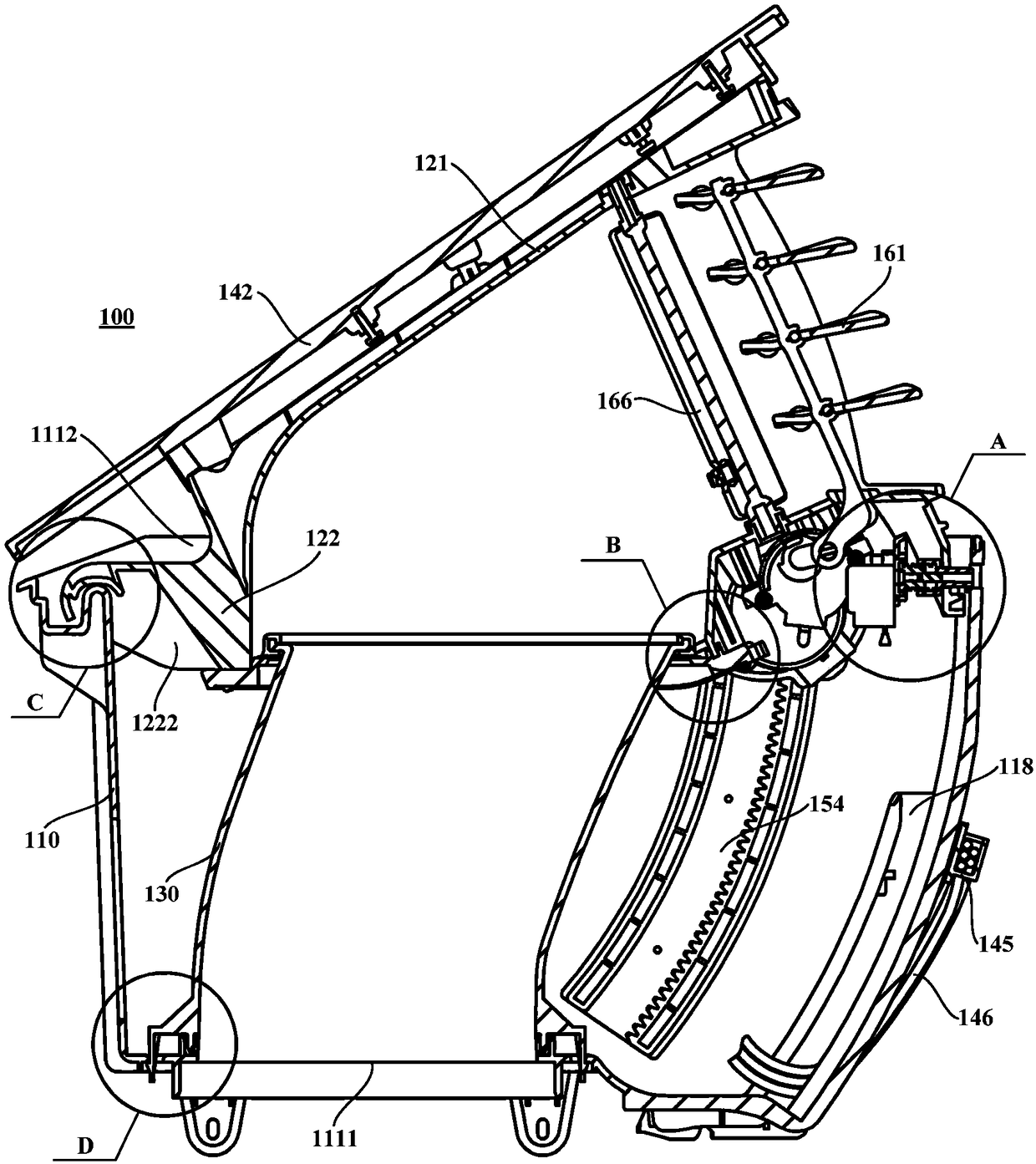

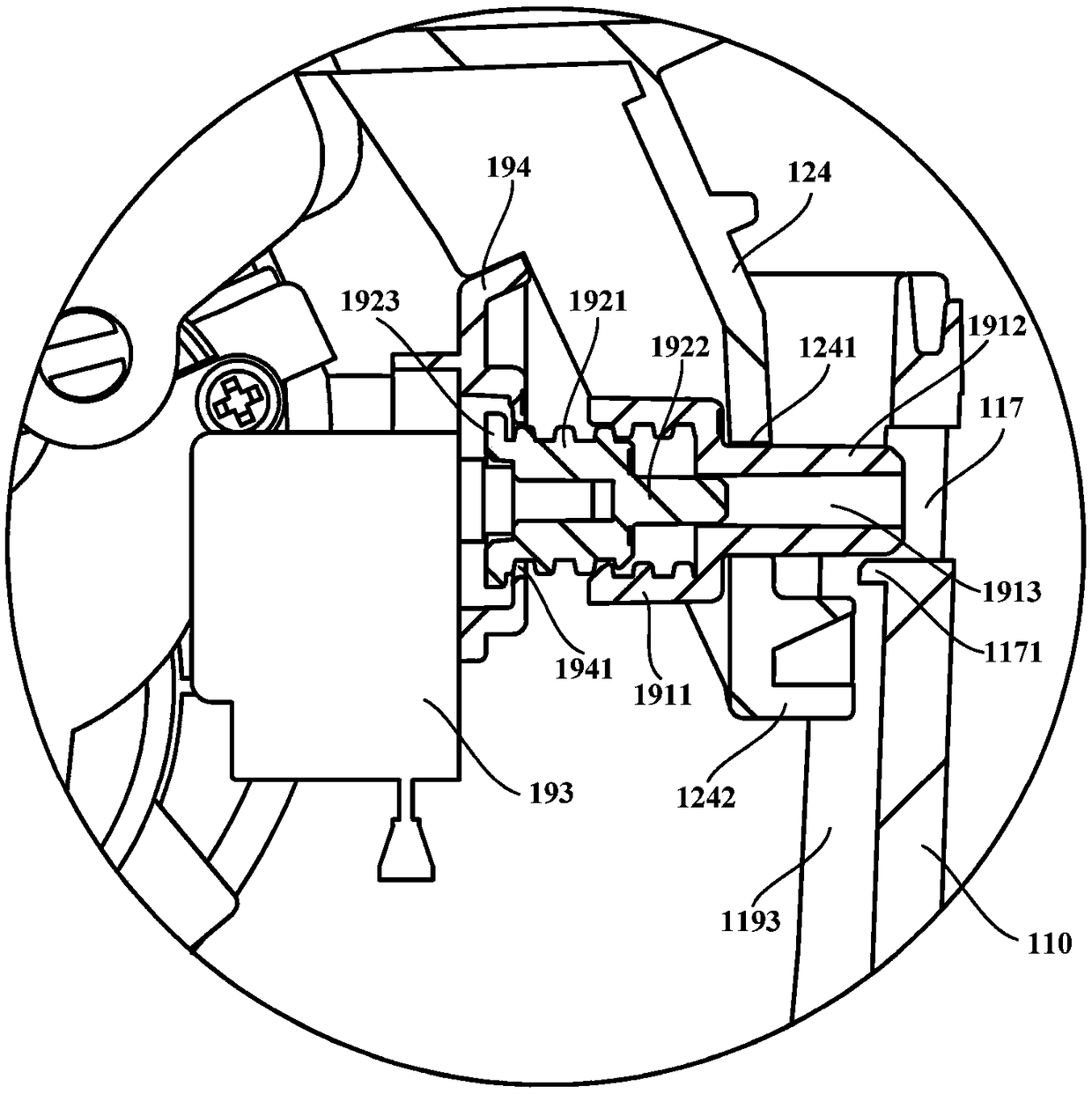

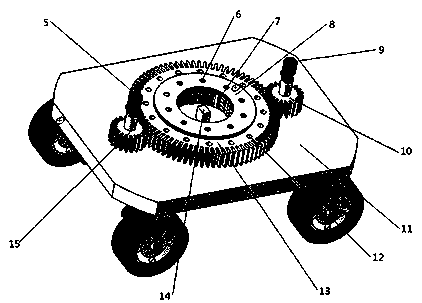

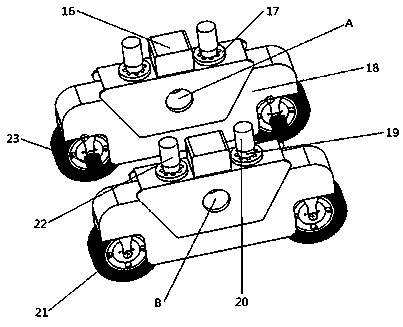

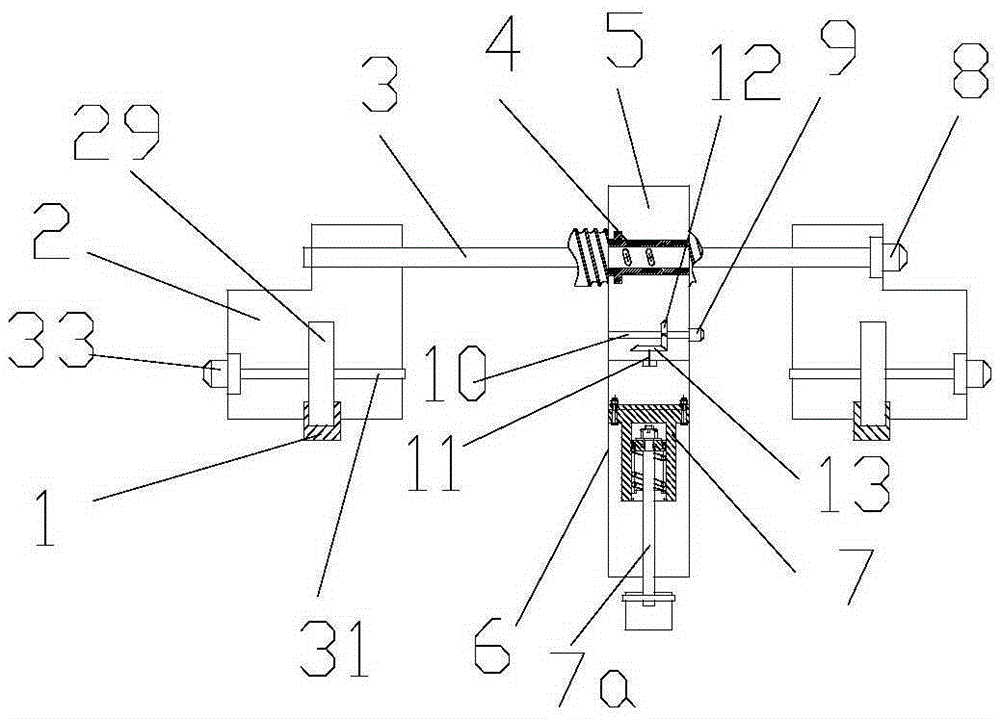

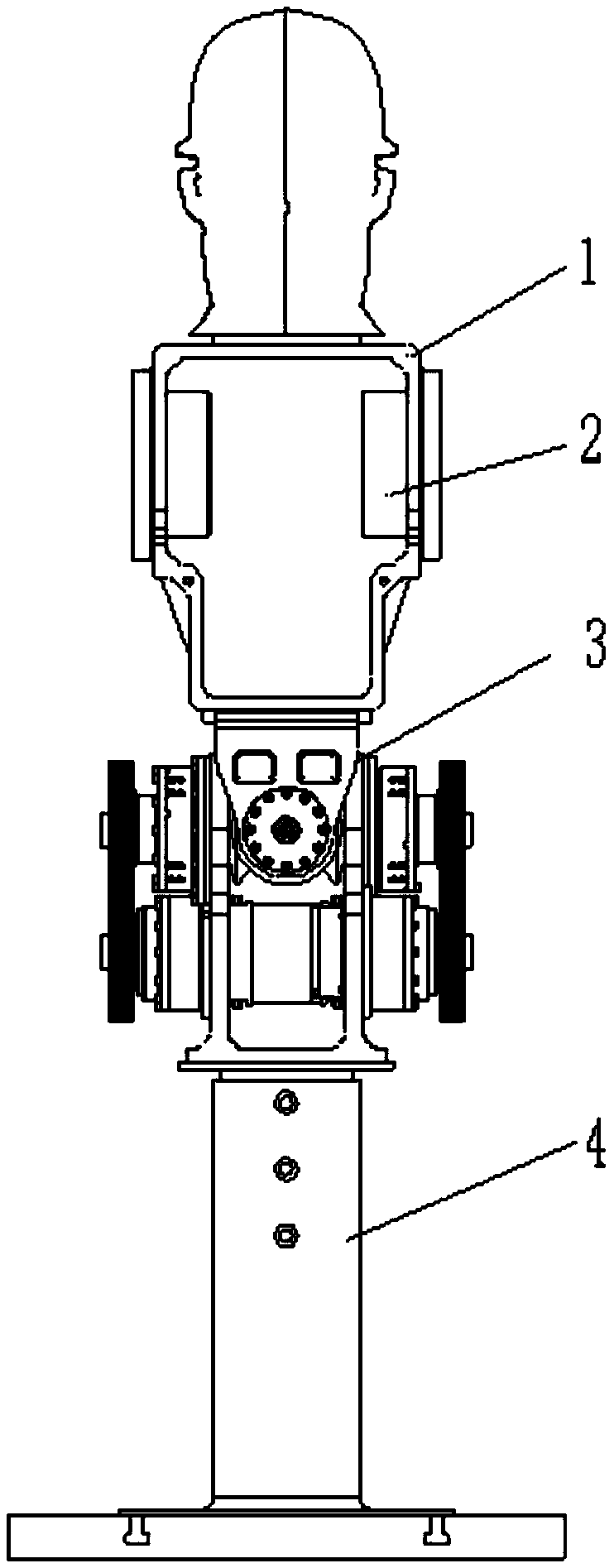

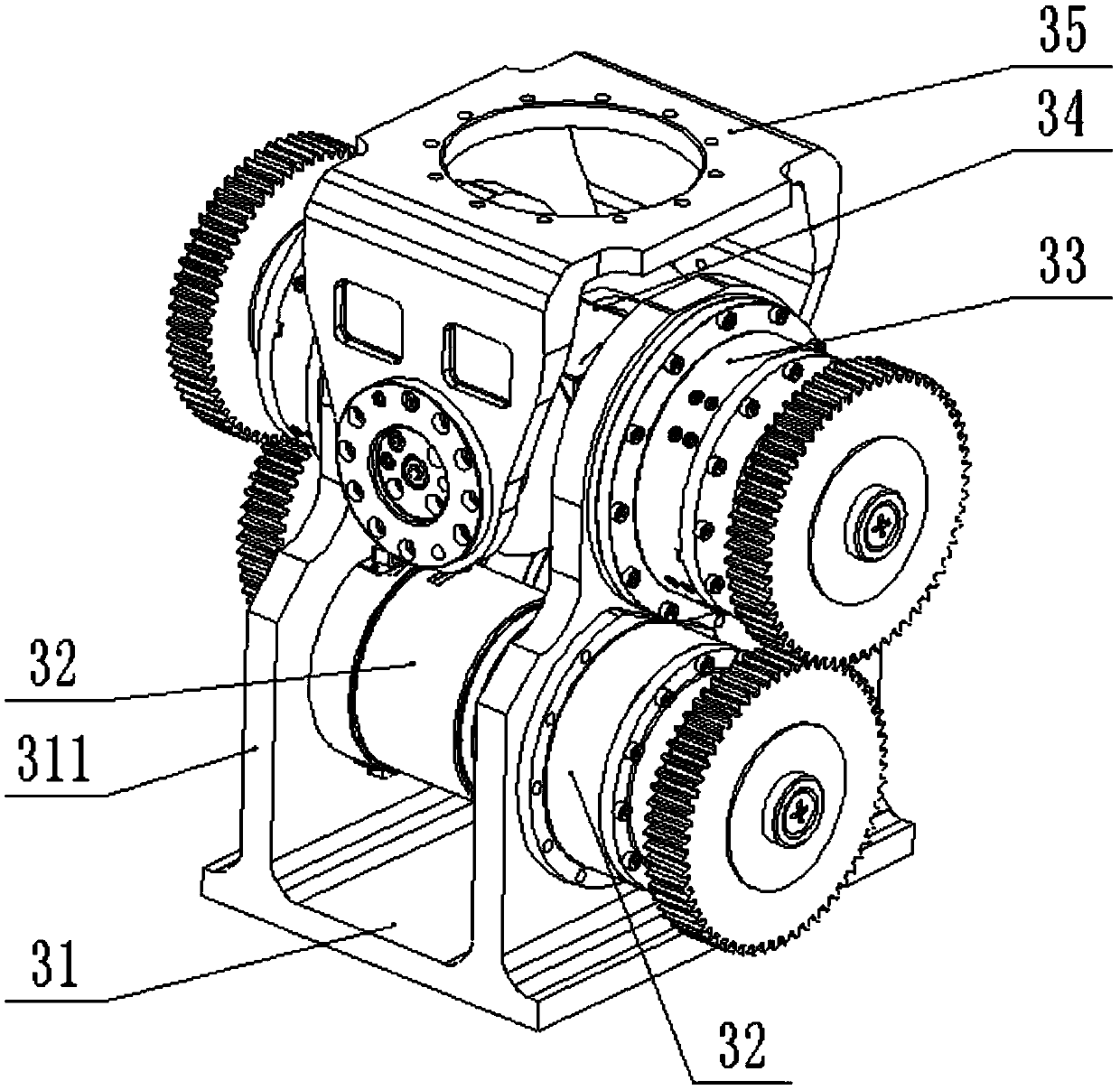

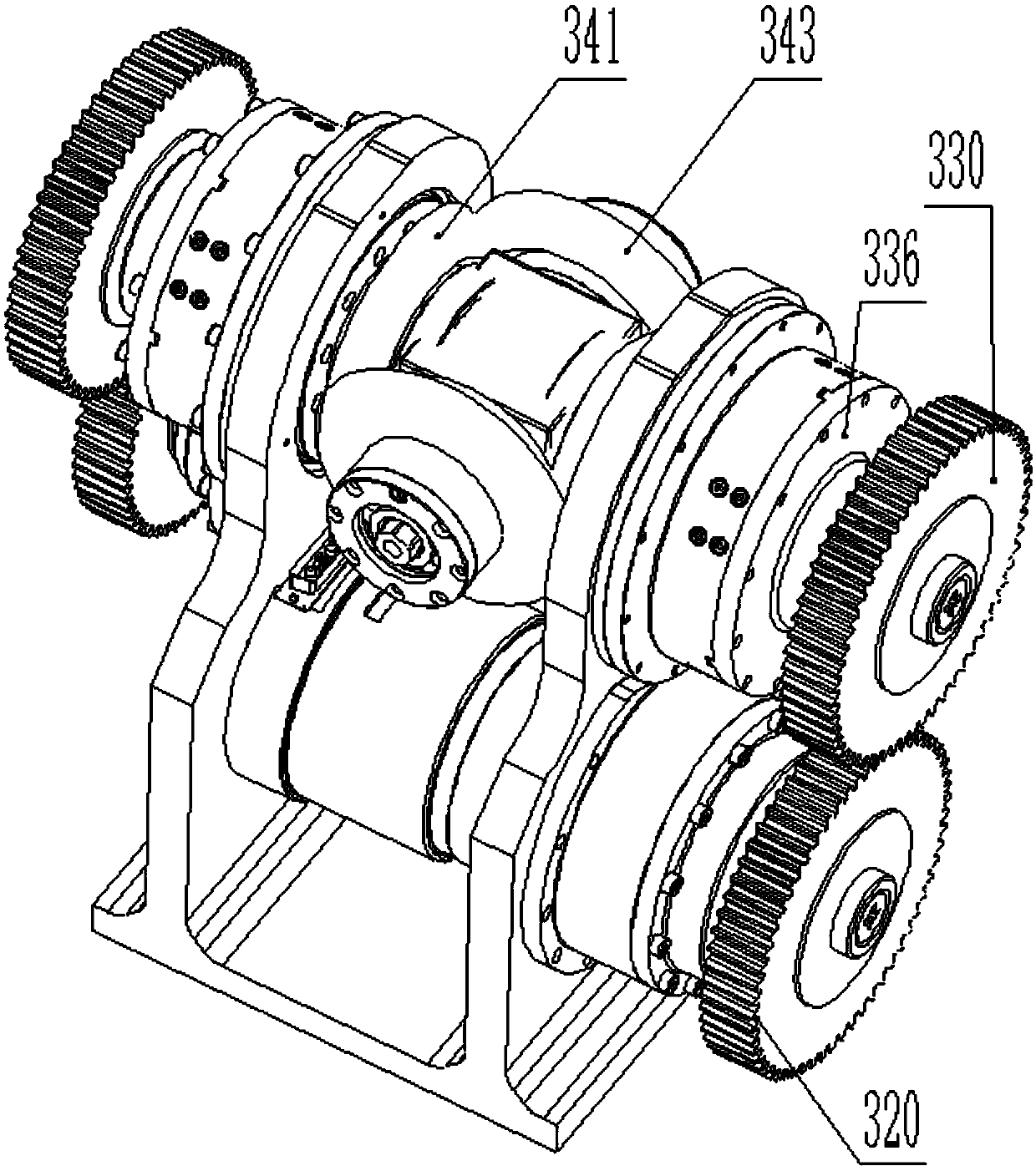

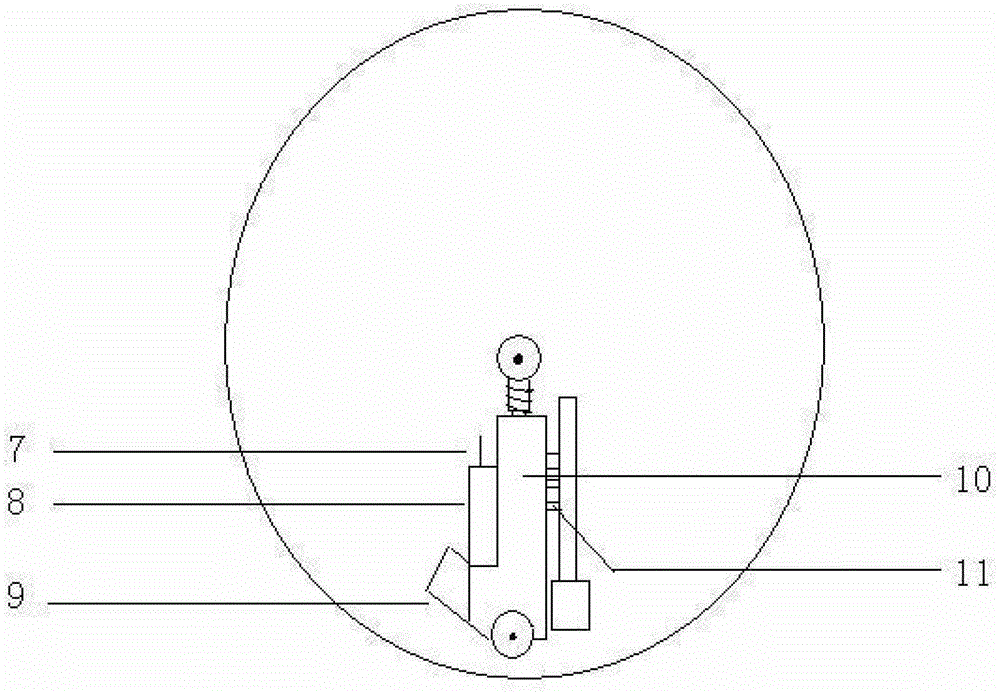

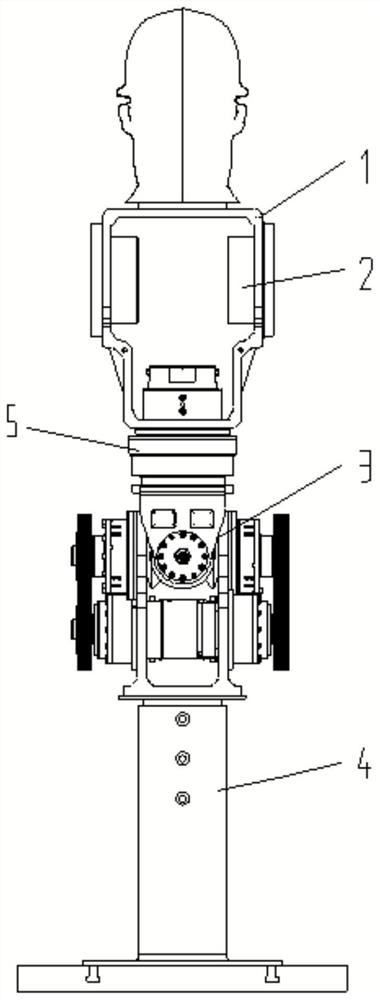

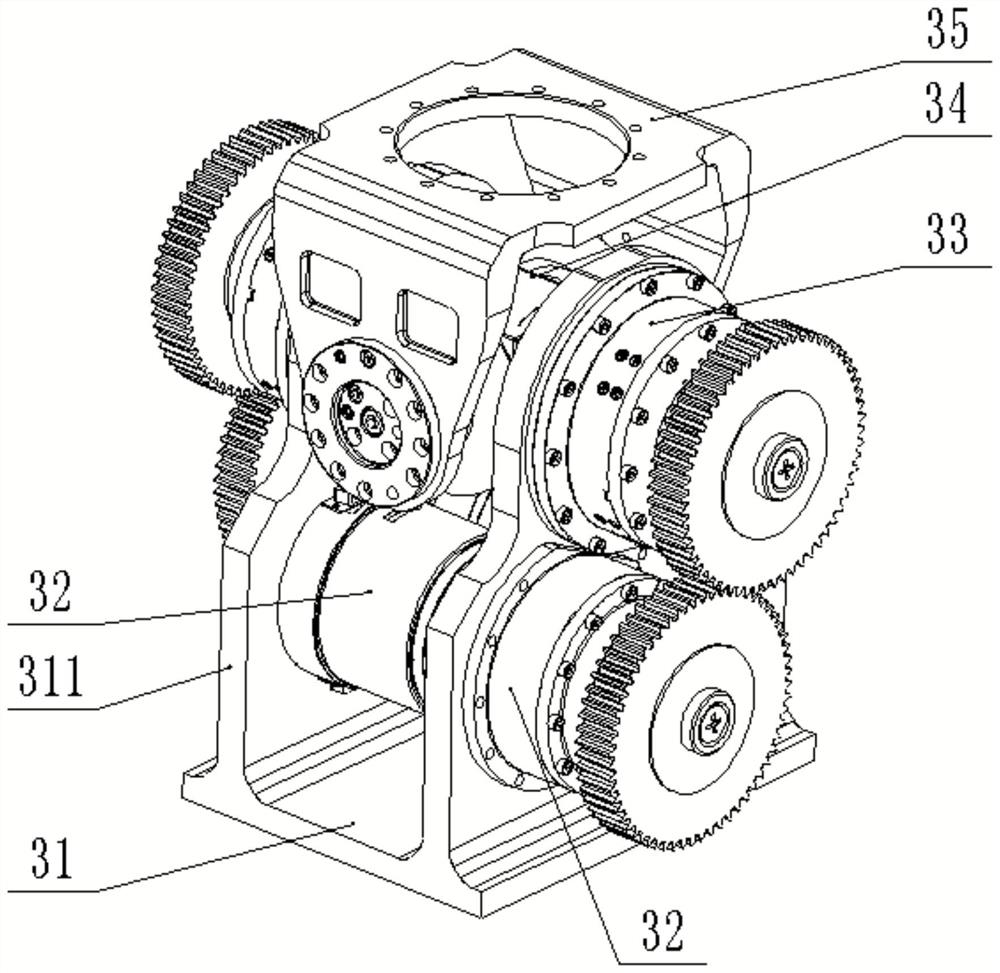

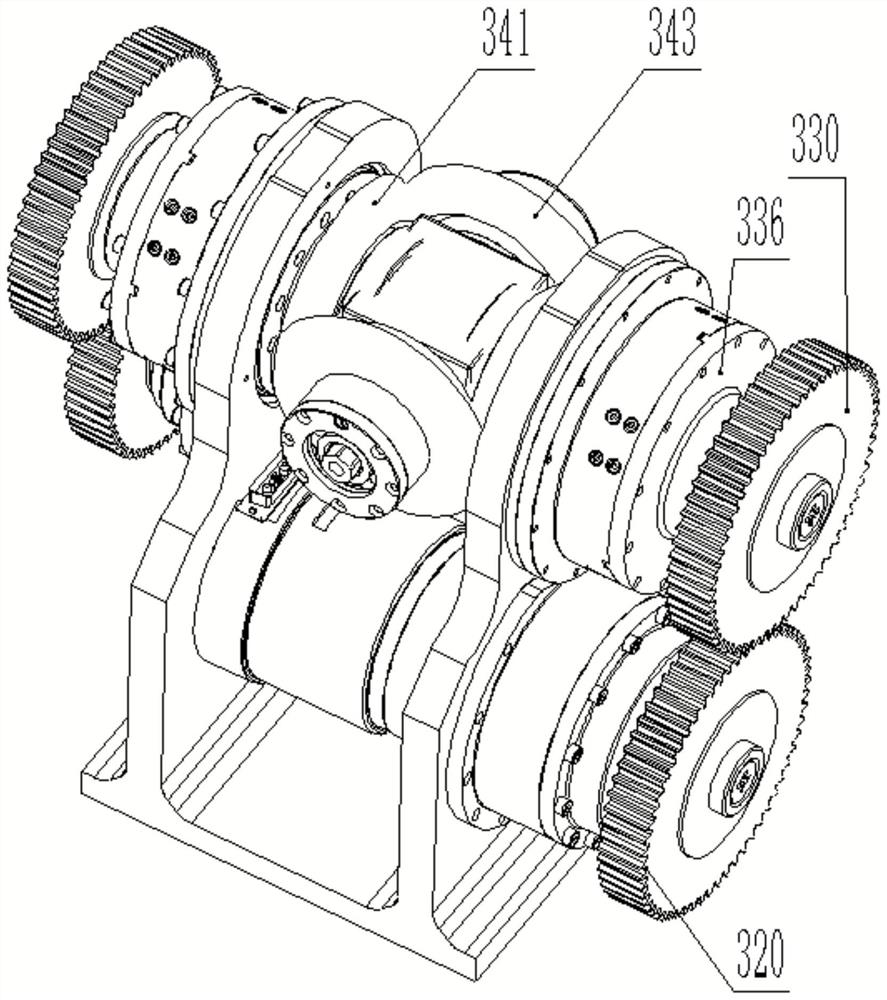

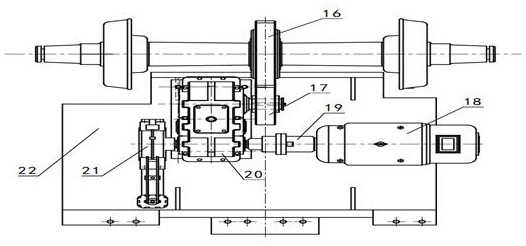

An AGV transfer vehicle resembling a three-point statically determinate support

InactiveCN109017989ALower the center of gravityImprove securitySteering partsVehiclesElastomerVehicle frame

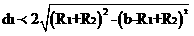

The invention provides an AGV transferring vehicle with three-point static definite support, which relates to the field of intelligent equipment for warehousing logistics. Includes a slewing bearing support with large gears and two running equalizer trolley supports. The steering of the vehicle can be realized by driving the slewing car with four wheels to rotate around the slewing axis (point) bypinion gears, which can make the change of direction of the transferring vehicle more convenient and controllable. Two equalizing trolleys for running support pass through a horizontal column hinge respectively, The two vertical guide columns and the elastomer in the middle are connected with the upper frame, and the upper flange of the steering support bearings forms an approximate three-point static support on the upper frame, which is favorable to the wheel pressure equalization and the reasonable stress on the vehicle body. Theoretically, the static structure can guarantee and prolong thelife of the wheel, the vehicle body and the driving device in the design, manufacture and use. This car body adopts eight wheels, which can reduce the diameter of tyre, reduce the center of gravity of the whole transfer vehicle, and enhance the safety of AGV transfer vehicle automatic operation.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

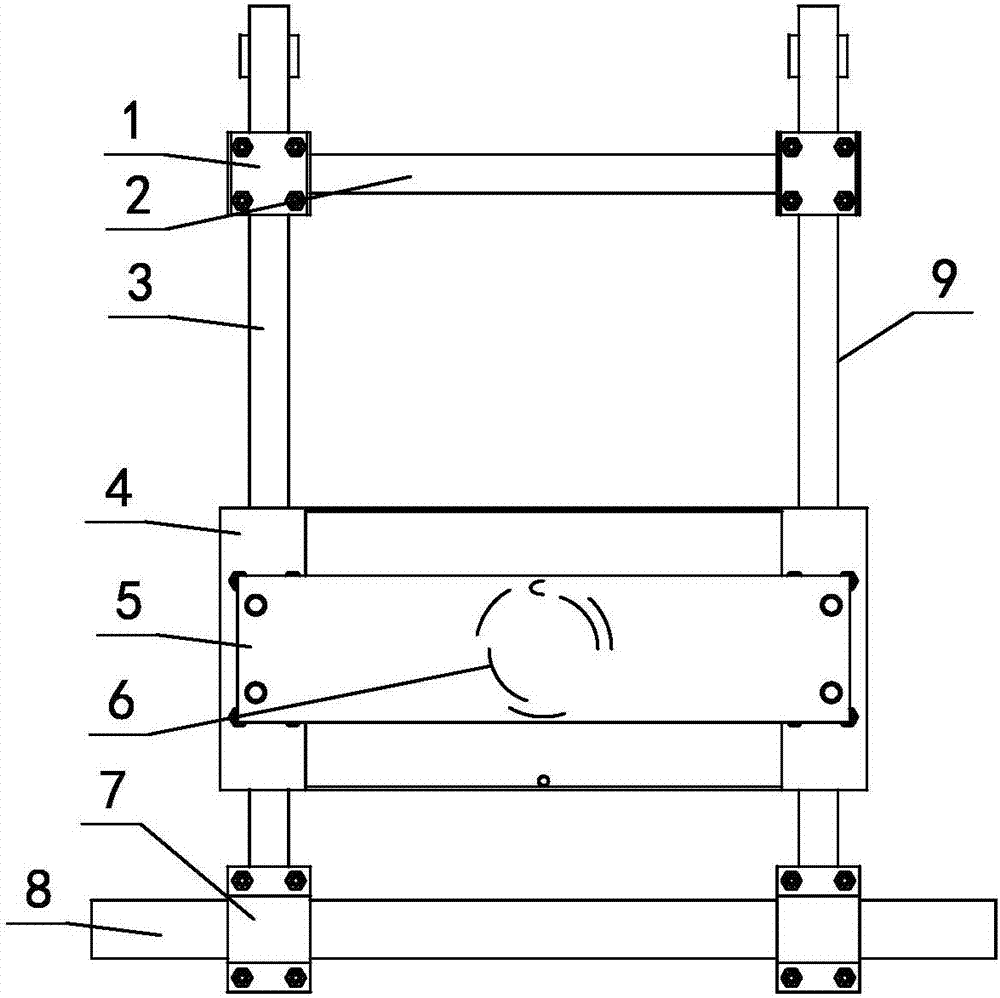

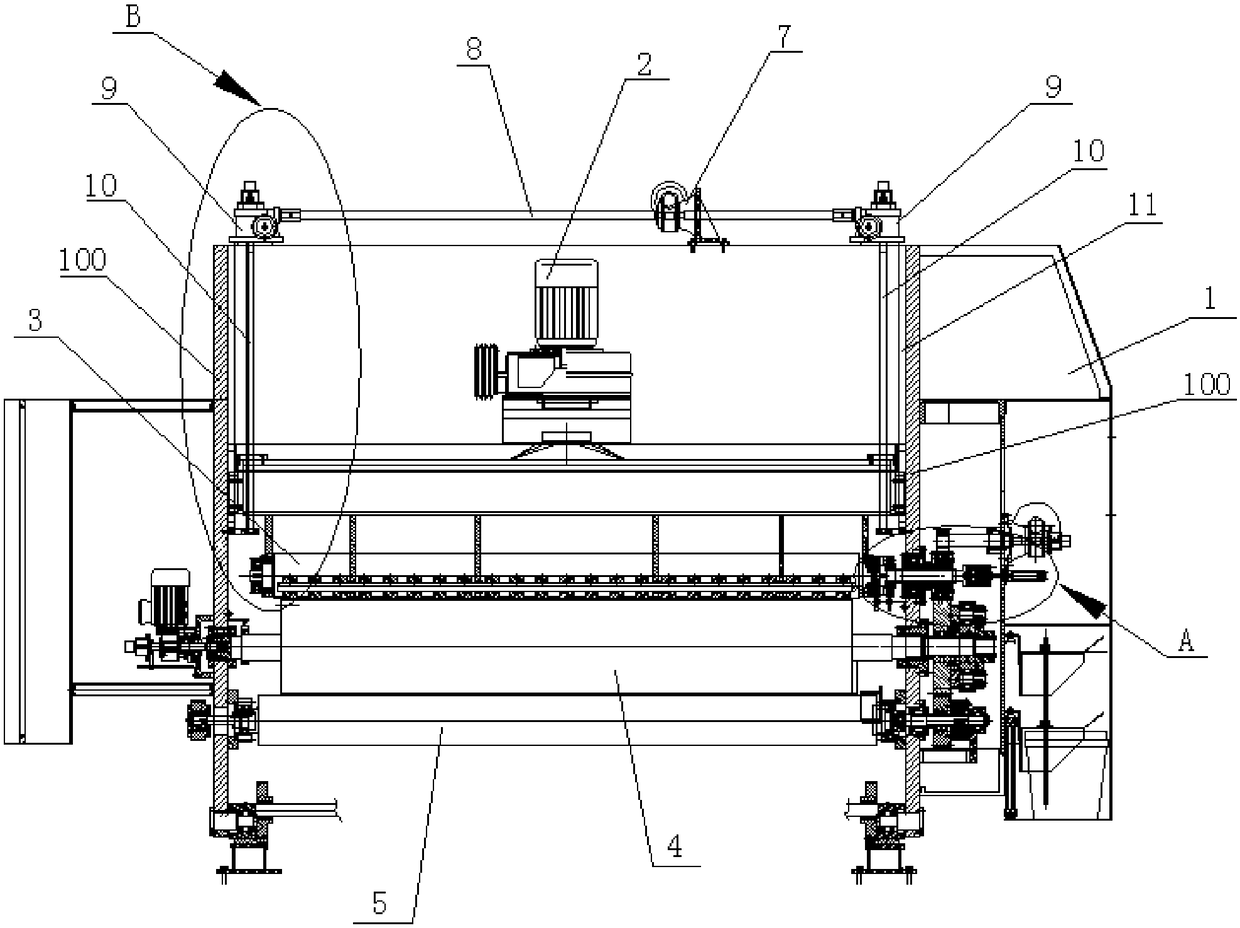

Automatic control system of horizontal type coated pipeline

ActiveCN103111399AImprove securityLower the center of gravityLiquid surface applicatorsCoatingsProduction lineAutomatic control

The invention relates to a coating production technology and particularly relates to an automatic control system of a horizontal type coated pipeline. The automatic control system is characterized by comprising a material supplying system for providing a coating raw material and a coating trolley for horizontally placing a pipeline or a steel bar cage, wherein the upper end of the material supplying system is provided with a casting wheel for coating work; the coating trolley carries the pipeline or the steel bar cage to be coated to do horizontal straight-line movement along the lower end of the casting wheel; and a process of uniformly coating is finished by taking the pipeline or the steel bar cage to be coated as a self axis as a center to be rotatably matched with the coating raw materials sprayed out by the casting wheel. According to the automatic control system disclosed by the invention, a horizontal coating manner is adopted so that the safety is greatly improved, the size limitation on the coated pipeline does not exist and the energy consumption of a coating production line is greatly reduced; the automatic control system is good for recycling the coating raw materials and reducing air pollution; and a workshop space of the coating production line is greatly reduced and the production efficiency is greatly improved.

Owner:四川伟力得能源股份有限公司

Railway side dumper

InactiveCN111775981ASimple structural designLower the center of gravityTipping wagonsTruckTransport engineering

The invention relates to the technical field of rail wagons, and particularly relates to a railway side dumper. The railway side dumper comprises a vehicle underframe and a carriage; the carriage is mainly defined by a bottom plate, side plates and an end wall; the bottom edges of the side plates are rotationally connected with the corresponding side edges of the bottom plate; a side plate drivingpart is arranged on the end wall, the side plate driving part drives the side plates on the two sides to rotate, a connecting seat is arranged in the middle of the end wall, the connecting seat is connected with a tipping driving part for driving the carriage to tip over, supports are arranged on the two sides of the bottom plate, and the supports are movably connected with a supporting seat forsupporting the carriage. The structural design of the carriage is simplified, the gravity center of the carriage is lowered, and the advantages of stable running, flexible use and high loading, unloading and transporting efficiency are achieved; the carriage is also suitable for miniaturization application, can be directly hoisted and transported to be used as a container for transferring goods, and is flexible and convenient to use.

Owner:CRRC ZHUZHOU ROLLING CO LTD

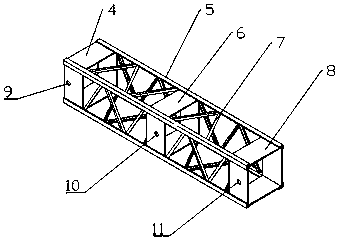

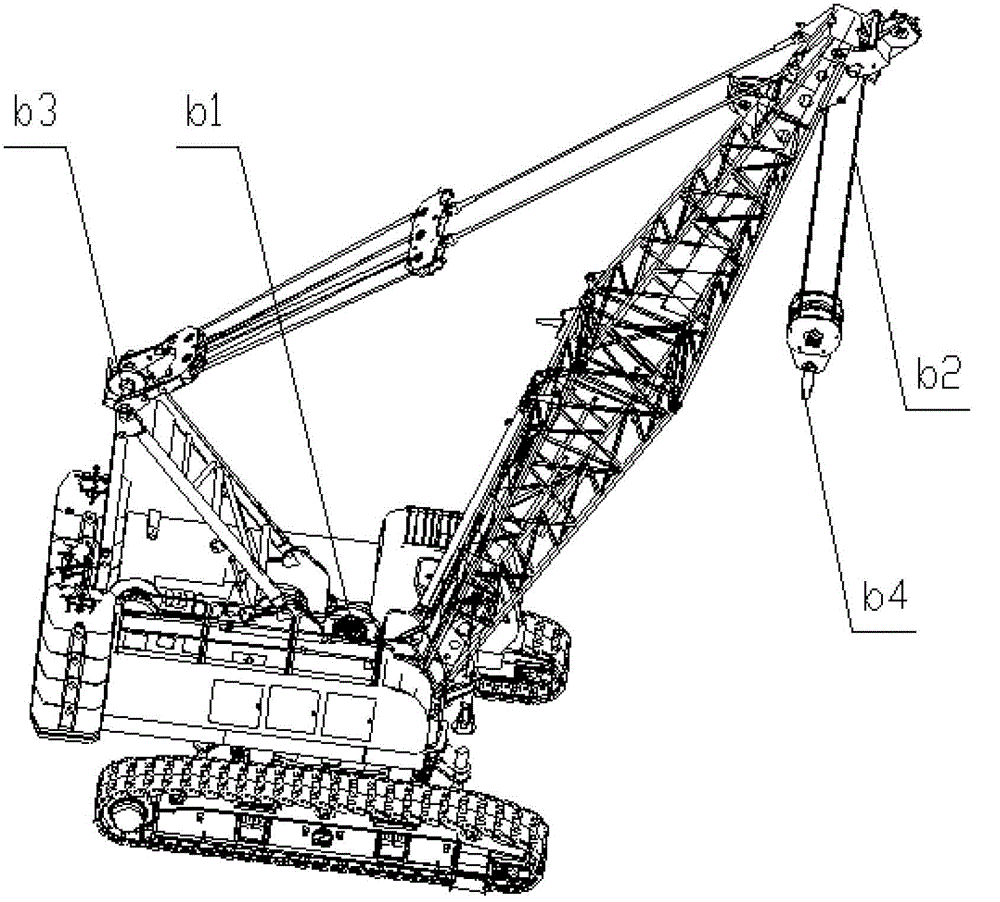

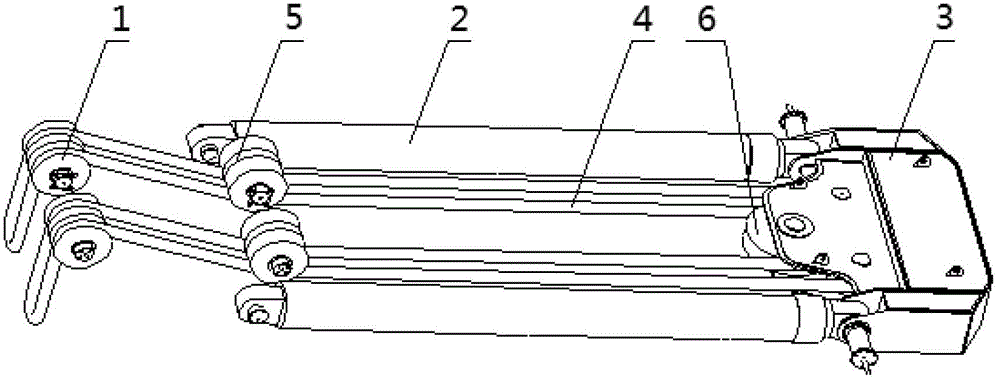

Plate enhanced telescopic truss arm structure

InactiveCN108190764AImprove stabilityImprove reliabilityCranesStructural engineeringUltimate tensile strength

The invention provides a plate enhanced telescopic truss arm structure, and relates to the field of engineering machinery. The plate enhanced telescopic truss arm structure is characterized in that plates are welded in a truss structure, so that a crane telescopic arm structure for enhancing the truss structure is formed. The plate enhanced telescopic truss arm structure can be utilized in severalsections of telescopic arms of the topmost end of an all-terrain crane and conventional combined sub arms of the all-terrain crane and a crawler crane, the plates are welded in the truss structure, the advantage that the effect of wind load on the truss structure is small is reserved, strength of the root part of the sub arm of the crane can be strengthened, the arm rising condition of the craneis improved, and the problem that the truss telescopic arm needs to be disassembled and assembled at any time and cannot quickly extend and retract is solved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

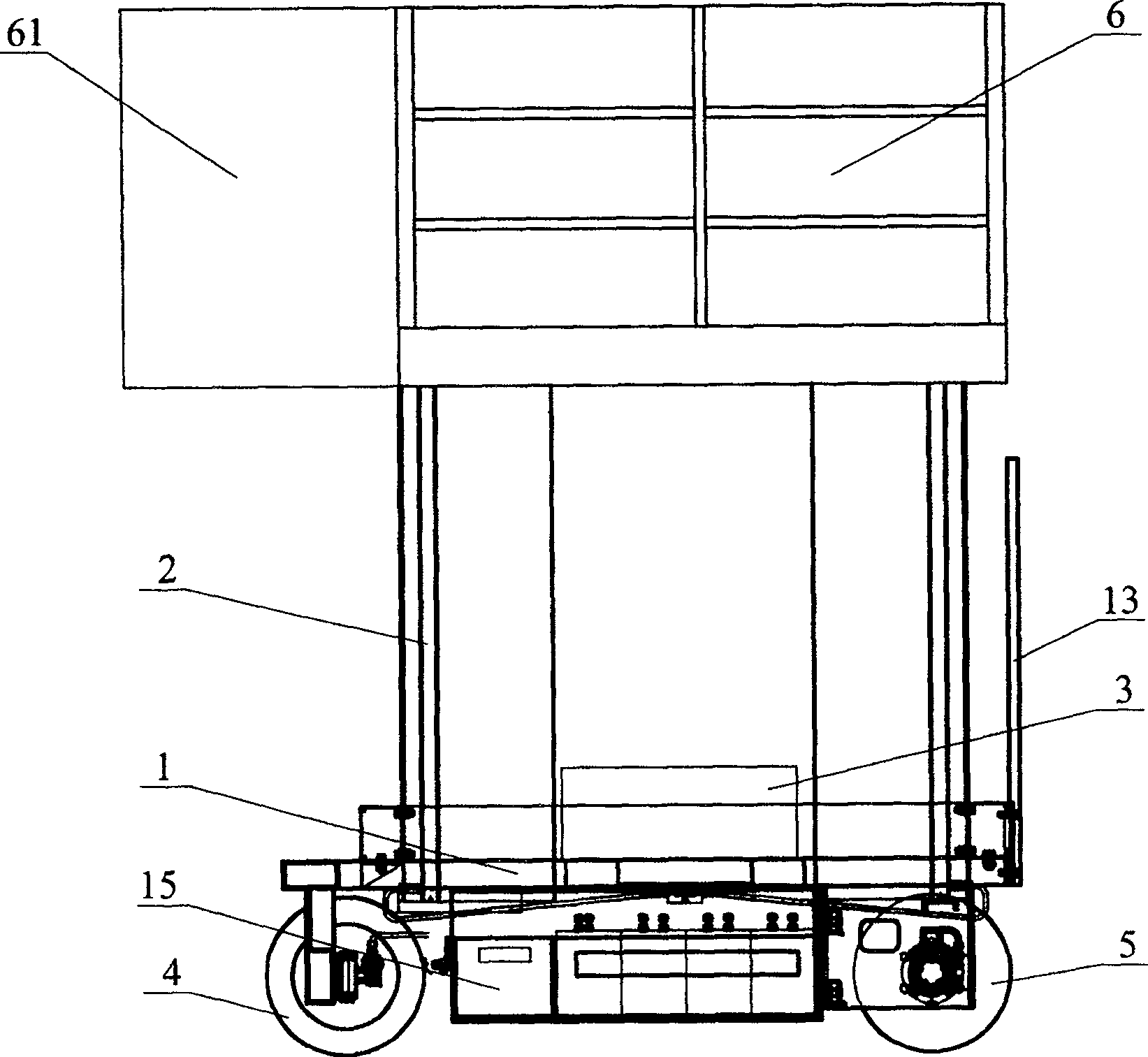

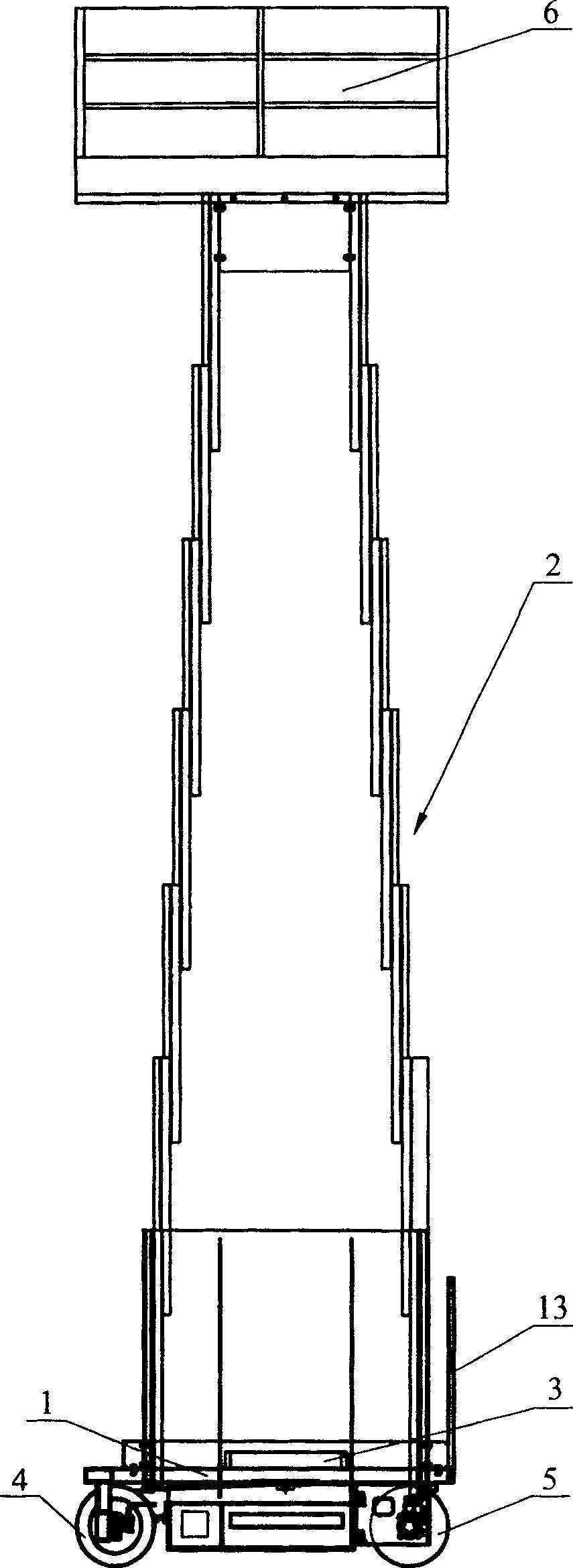

Self-walking column type overhead operation platform

The present invention relates to aloft work machinery, and is especially mast type aloft work platform comprising chassis, mast with aloft work stage in the top, controller, hydraulic station and mast elevating hydraulic cylinder. The mast type aloft work platform features the dispersed walking wheels driven with hydraulic motor obtaining pressure medium from the hydraulic station and the steering wheel driven with the steering oil cylinder obtaining pressure medium from the hydraulic station. The mast type aloft work platform can move easily during aloft work and has small covered area, less aloft work ready time and auxiliary work time, and high work efficiency.

Owner:HANGZHOU SAIQI MACHINERY CO LTD

Sock shaping and fixing apparatus

ActiveCN106436119AAvoid position shiftReduce the impactShaping/stretching tubular fabricsWorking pressureEngineering

A sock shaping and fixing apparatus comprises a track, a blower structure, a driving device, a driving chain mechanism and an awaiting mechanism. Compared with present sock shaping and fixing apparatuses, the apparatus has the advantages of reasonable structure design, realization of effective utilization of the space, and convenience in maintenance. A cutting and fixing chamber reduces the vertical height of the sock shaping and fixing apparatus, reduces the work focus, increases the work stability, and is convenient to transport and maintain; the force bearing mode of the driving device is changed, so an original sealing structure is prevented, the workers' working space is increased, and the internal of the sock shaping and fixing apparatus is convenient to monitor and maintain; the awaiting mechanisms prolongs the workers' working time, reduces the working proficiency requirement and the workers' working pressure and reduces the enterprises' cost; and the driving chain mechanism increases the running stability of a driving chain and prolongs the service life.

Owner:浙江容易富机械科技有限公司

Multifunctional self-positioning damaged road surface milling machine

InactiveCN104389260BReduce maintenance costsCompact structureRoads maintainenceRoad surfaceEngineering

The invention discloses a multifunctional self-positioning broken pavement milling machine. The multifunctional self-positioning broken pavement milling machine comprises a machine frame, a cutting device, a hammering device, a milling device and a positioning control system, wherein the cutting device, the hammering device and the milling device are arranged on the machine frame in an integration manner; the positioning control system is used for positioning a broken pavement and comprises vision sensors, displacement sensors and a central controller. When the multifunctional self-positioning broken pavement milling machine is used, the vision sensors which are mounted on all the devices are used for scanning back and forth by virtue of a computer control technology, the positions of irregular pits needing to be processed in the pavement are recorded, the irregular pits are self-positioned and are processed into regular pits which can be filled with asphalt according to the feedback information of each sensor, and the machine has the advantages of high intelligence, quickness, high maneuverability, high efficiency and reliability.

Owner:CHONGQING JIAOTONG UNIVERSITY

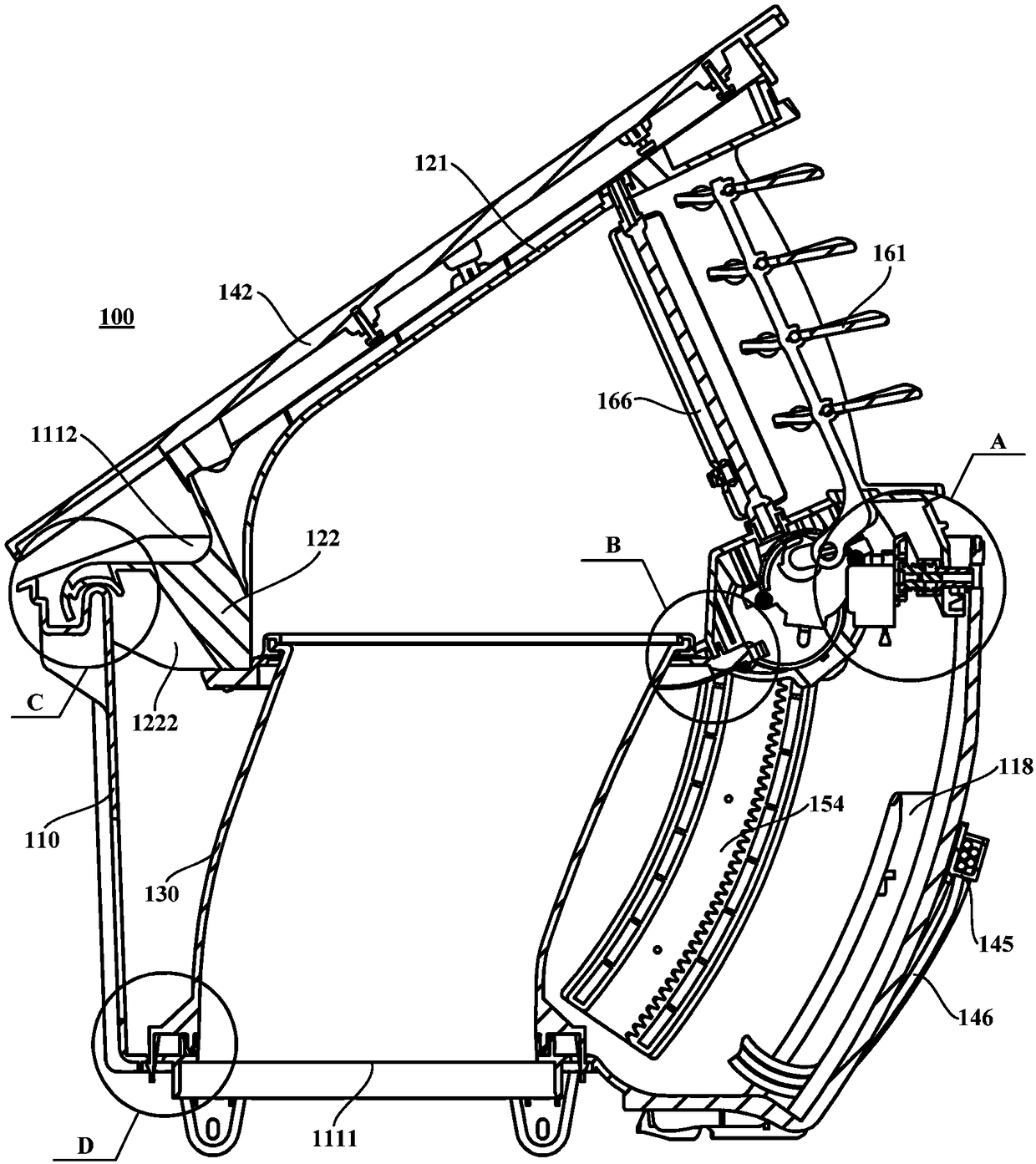

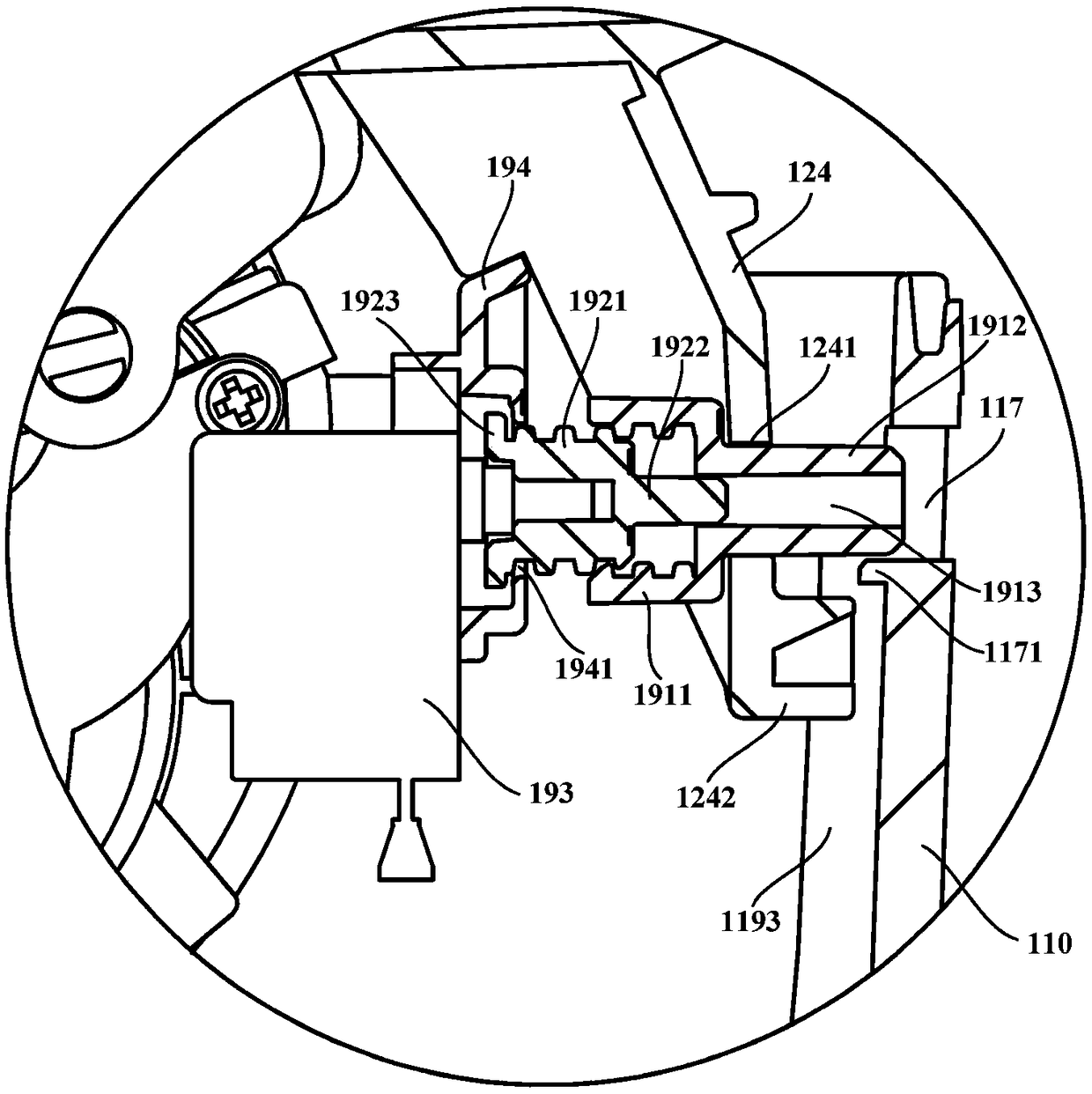

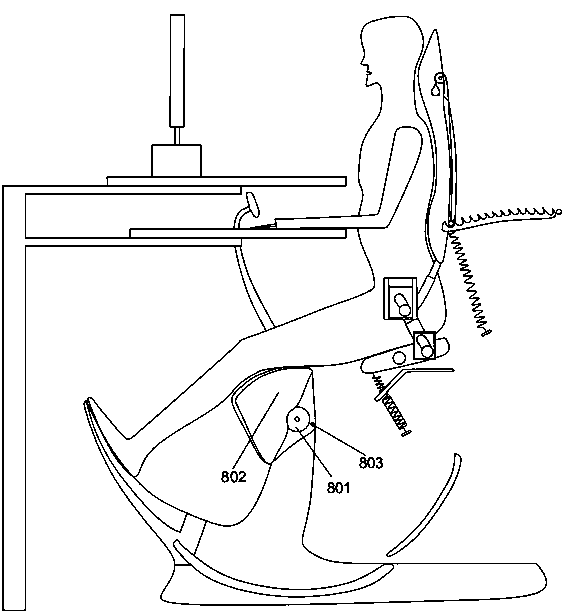

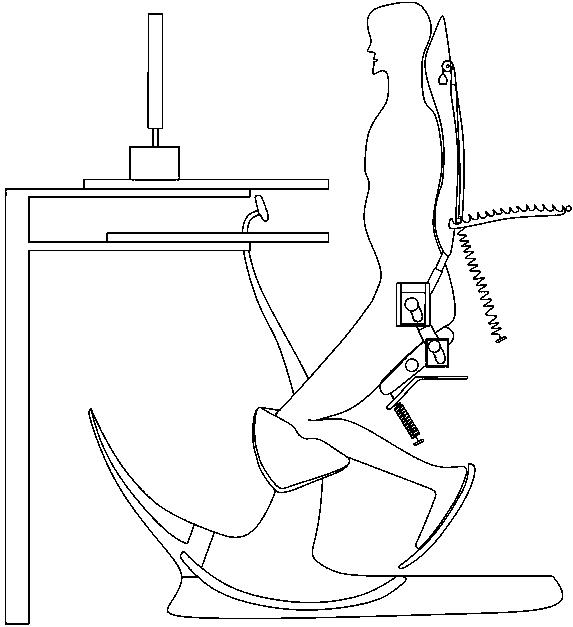

Chair suitable for various body postures and table matched with chair

InactiveCN111345611AImprove local stressAdapting to involuntary sitting behaviorOffice stoolsOffice tablesPhysical medicine and rehabilitationEngineering

The invention discloses a chair suitable for various body postures and a table (workbench) matched with the chair. A seat frame, a bracket, a front pedal, a middle pedal and the like are arranged on abase, a knee joint (or feet) bearing device is arranged in the middle of the bracket, an abdomen supporting and blocking device is arranged on the upper portion of the bracket, and a rear pedal, a seat plate-backrest linkage device, a backrest inclination angle adjusting device and the like are arranged on the seat frame. The use requirements of basic postures such as standing, sitting, kneelingand lying and some combined postures of people can be met. A liftable table (workbench) matched with the chair is provided with a tabletop, a left tray rack and a right tray rack, the tabletop, the left tray rack and the right tray rack can move forwards and backwards together, inclination angles of a left tray and a right tray on the left tray rack and the right tray rack can be independently adjusted, and brackets of the chair can pass through gaps.

Owner:成业兴

Lifting mechanism suitable for tail end lifting operation of vertical equipment

ActiveCN103303793BLower the center of gravityReduced risk of rolloverLoad-engaging elementsBlock and tackleIndustrial engineering

The invention relates to a lifting mechanism suitable for tail end lifting operation of vertical equipment. The lifting mechanism is arranged on a platform structure of a tail sliding machine and a crawler chassis. The lifting mechanism comprises a horizontal pushing oil cylinder, a fixed pulley group, a movable pulley frame and a cable, wherein a front hinged point of the horizontal pushing oil cylinder and the fixed pulley group are both fixed on the crawler chassis, and a barrel of the horizontal pushing oil cylinder is installed on the platform structure; the movable pulley frame is arranged on the upper surface of the platform structure, is fixed with a rear hinged point of the horizontal pushing oil cylinder, and is internally provided with the movable pulley group; the cable goes out of the movable pulley group and rolls the upper side of the fixed pulley group to the side, close to the crawler chassis, of the fixed pulley group so as to be connected with a lifting point on the bottom or the lower part of the vertical equipment. Compared with an existing tail sliding crane, the lifting mechanism provided by the invention is simpler in structure, is free of the working procedures, such as stringing and arm connecting, that consume long time, and has higher assembly efficiency. In addition, the operation barycenter of the complete mechanism is low, and thus the tipping risk of the complete mechanism is low.

Owner:SINOPEC TENTH CONSTR +1

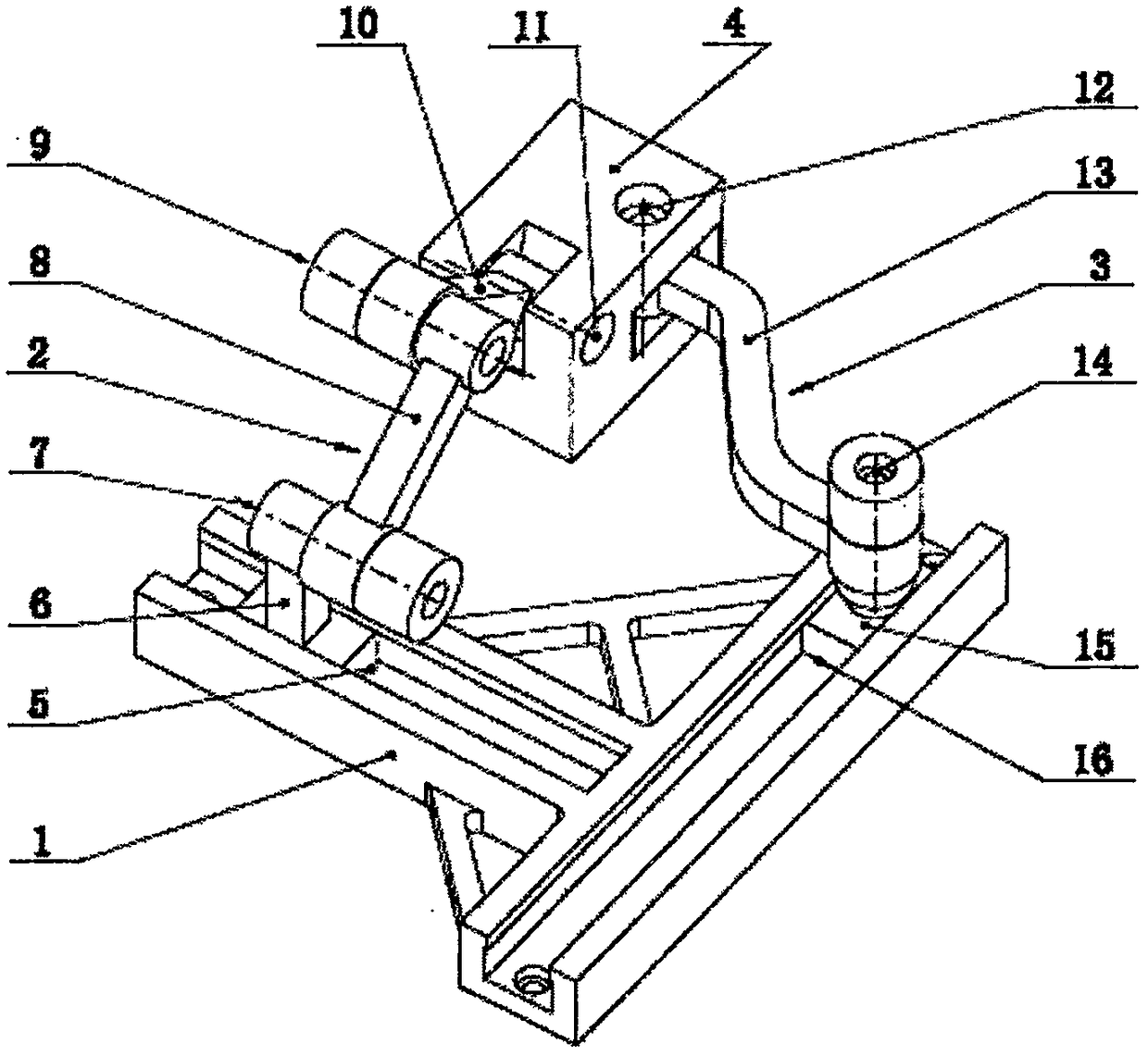

Mechanical simulation device for sitting lumbar vertebra manipulation training based on flexible differential driving

InactiveCN111415562ALower the altitudeSafe and flexibleEducational modelsPhysical medicine and rehabilitationEngineering

The invention discloses a mechanical simulation device for sitting lumbar vertebra manipulation training based on flexible differential driving. The mechanical simulation device comprises a base, driving joints, an elastic unit, a differential driving bevel gear train and an output connecting rod, the two driving joints are respectively arranged on the two supporting plates of the base, and the differential driving bevel gear train is arranged between the two supporting plates; two driving bevel gears of the differential driving bevel gear train are connected with the cross spoke output pieceof the elastic unit through bevel gear input shafts respectively, the motion input piece of the elastic unit is in transmission connection with the joint output shafts of the driving joints, and the output connecting rod is in transmission connection with the driven bevel gear of the differential driving bevel gear train. The device can simulate the multi-directional movement of the waist, has twodegrees of freedom, and has certain safety and flexibility. The mechanical property similar to the waist of a human body when the human body accepts the sitting lumbar vertebra rotation technique canbe simulated, so that a vivid training, practicing and examining platform is provided for unskilled operating technique personnel.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

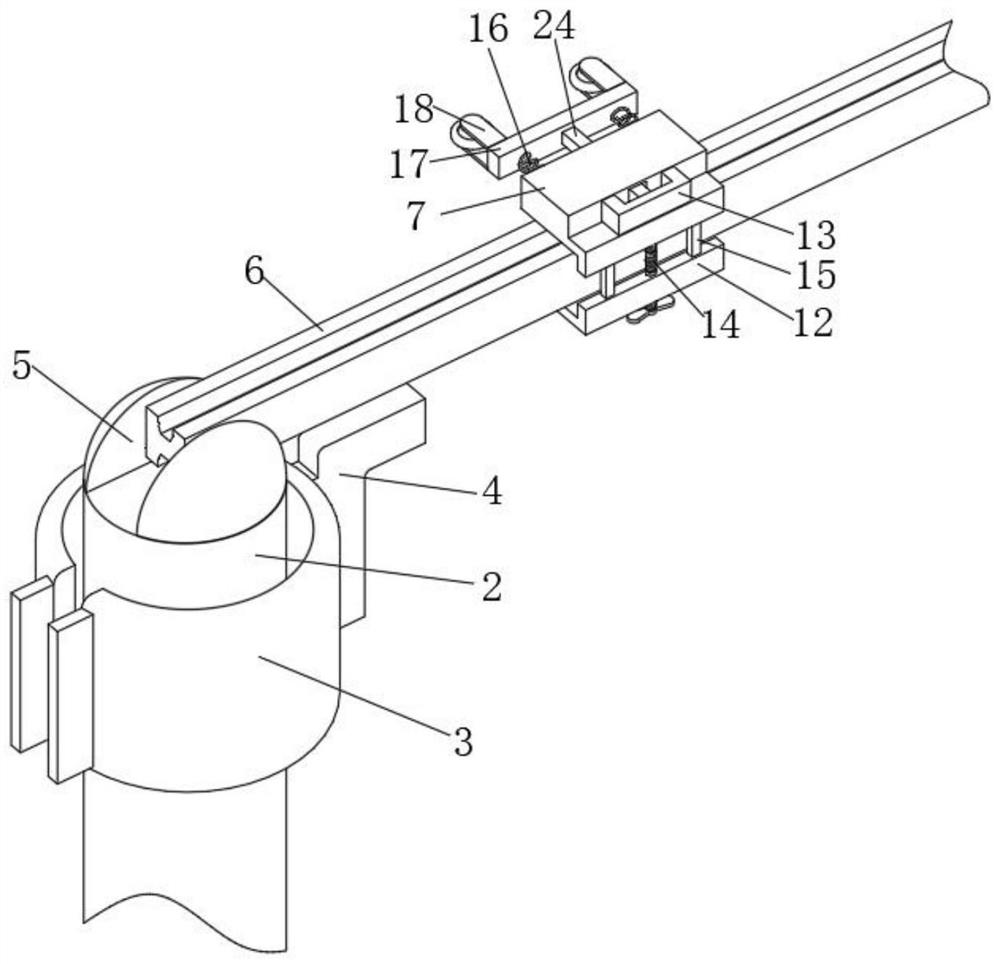

Partially-decoupled two-degree-of-freedom movement parallel mechanism

PendingCN108858159AIncrease stiffnessLower the center of gravityProgramme-controlled manipulatorPhotovoltaic energy generationKinematicsTwo degrees of freedom

The invention provides a partially-decoupled two-degree-of-freedom movement parallel mechanism. The partially-decoupled two-degree-of-freedom movement parallel mechanism is mainly composed of a movement platform, a fixed platform, and two movement branches which are fixedly connected between the two platforms respectively, wherein the first movement branch comprises three rotary pairs R1R2R3 withrotary axes which are parallel to one another, a movable pair P1, a first connection rod and a second connection rod which are used for connecting the three rotary pairs R1R2R3 and the movable pair P1, and a first sliding block; the second connection rod is connected with the movement platform through the rotary pair R3; the rotary pair R2 is connected with the second connection rod and the firstconnection rod; the rotary pair R1 is connected with the first connection rod and a first sliding block; the first sliding block is connected with the fixed platform through the movable pair P1; the second branch comprises two rotary pairs R4R5 with rotary axes which are parallel to each other, a movable pair P2, a third connection rod for connecting the rotary pairs R4R5 and the movable pair P2,and a second sliding block; the third connection rod is connected with the movement platform through the rotary pair R4; the rotary pair R5 is connected with the third connection rod and the second sliding block; the second sliding block is connected with the fixed platform through the movable pair P2. The partially-decoupled two-degree-of-freedom movement parallel mechanism has the advantages ofsimple structure, high rigidity, low working gravity center, small volume ratio, high precision and small errors; a movement part of the movement platform is partially decoupled so that the partially-decoupled two-degree-of-freedom movement parallel mechanism has good kinematics performance and flexibility.

Owner:HUNAN TECHN COLLEGE OF WATER RESOURCES & HYDROPOWER

A spherical remote control toy

InactiveCN103961879BLower the center of gravityImprove stabilityRemote-control toysToy vehiclesElectricityRemote control

The invention relates to an electric toy, in particular to a spherical remotely-controlled toy. The spherical remotely-controlled toy comprises a spherical shell, as well as a center rod, a slot, an inserted rod, a spring, an oscillating bar, a hammer, a driving gear motor, a steering gear motor, wheels and a circuit board, which are arranged in the spherical shell, wherein the center rod penetrates through the center of the spherical shell; the two ends of the center rod are connected with the spherical shell; the slot is rotatably formed in the center position of the center rod; the output shafts on two sides of the driving gear motor are respectively connected with the wheels; the wheels are propped against the inner wall of the spherical shell; the steering gear motor is arranged above the driving gear motor, and perpendicular to the axial direction of the driving gear motor; the output end of the steering gear motor is connected with the oscillating bar; the lower end of the oscillating bar is connected with a pendulum bob; the inserted rod is arranged above the steering gear motor and inserted in the slot; a spring sleeves the slot; the circuit board is arranged on one side of the steering gear motor, and respectively electrically connected with the driving gear motor and the steering gear motor. The spherical remotely-controlled toy is simple in structure and high in stability.

Owner:徐学谦

Tricycle balance mechanism

The invention relates to a tricycle balance mechanism, belonging to the technical field of tricycle balance, comprising a balance bracket vertically and horizontally arranged, and an elastic component for pressure balance is arranged horizontally and horizontally on the balance bracket, and the front end of the balance bracket is a hinged end hinged with the tricycle frame , the rear end of the balance bracket is used to compress the pressing end of the upper pressing plate of the leaf spring of the tricycle. The tricycle balance mechanism of the present invention has a simple structure. When in use, due to the design of elastic components, and the front end of the balance bracket is hinged with the tricycle frame, its rear end is pressed tightly on the upper plate of the leaf spring of the tricycle. When bumping or turning, when the wheel on one side tends to leave the ground, under the action of the elastic component, the wheel on the other side is used as the fulcrum to force the wheel to contact the ground, effectively avoiding the bumping of the tricycle on the road. Or rollover occurs when turning.

Owner:郑艇

A mechanical simulation device for sitting lumbar manipulation training based on flexible differential drive

ActiveCN111415563BSafe and flexibleLower the altitudeJointsEducational modelsThree degrees of freedomEngineering

The invention discloses a mechanical simulation device for seated lumbar manipulation training based on flexible differential drive, which includes a trunk, a single-degree-of-freedom flexible rotating joint and a flexible differential-driven lumbar motion simulation mechanism, the trunk and the single-degree-of-freedom flexible rotating joint The joint cover is connected, and the output link of the single-degree-of-freedom flexible rotary joint is connected with the output link of the flexible differential drive lumbar motion simulation mechanism; the output link can rotate relative to the joint cover, and the output The link is able to rotate relative to two horizontal axes perpendicular to each other. The invention has three degrees of freedom, can simulate the omni-directional movement of the waist, and has a certain degree of safety and flexibility, and can simulate the similar mechanical characteristics of the human waist when the human being accepts the lumbar rotation technique in a sitting position, thus providing a Realistic training, practice and assessment platform.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

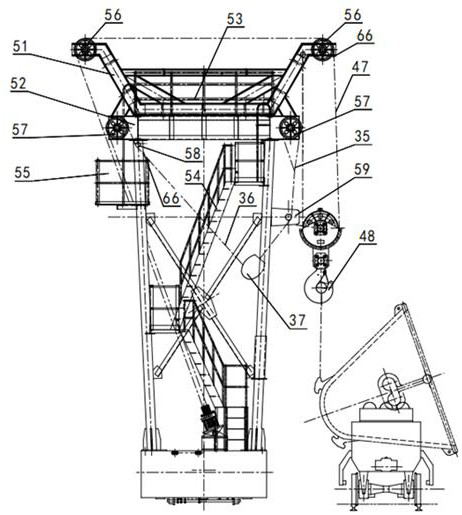

Track self-walking, tank overturning and tank colliding deslagging method

PendingCN114014166AHigh degree of automationImprove work efficiencyTrolley cranesProcess efficiency improvementSteelmakingMechanical engineering

The invention belongs to the technical field of steelmaking waste slag treatment, and relates to a track self-walking, tank overturning and tank colliding deslagging method, in particular to a track self-walking, tank overturning and tank colliding integrated deslagging method for tank overturning in a slag yard. The method comprises the following steps that a slag pot car runs into an unloading area; a lifting hook is hooked with a lifting lug of the slag pot car; the lifting hook is lifted to turn over the tank; the lifting hook lifts to turn over the slag tank, and the slag tank turns over by an angle of 101 degrees for slag pouring and discharging; and when the steel slag in the slag tank is completely dumped, the lifting hook falls down, the slag tank is reversely overturned to return to the original position, and the next slag tank is dumped. The method integrates track self-walking, tank turning and tank colliding, and can be operated by one person to complete tank aligning, tank turning and tank colliding operations. The method is simple in structure, convenient to operate, safe, reliable and high in operation efficiency, and a solution is provided for solving the problems of steel slag dumping and incomplete steel slag dumping in the industry.

Owner:甘肃酒钢集团西部重工股份有限公司

Fixed bottom printing unit and its printing machine

The invention provides a fixed printing unit, which includes a frame, a vacuum transmission mechanism, an embossing roller, a typesetting roller, an anilox roller, a lifting mechanism and a separation mechanism arranged on the frame; the typesetting roller and The anilox roller is fixed on the frame, the embossing roller is suspended on the frame and located above the typesetting roller, the embossing roller is arranged on the vacuum transmission mechanism, and the lifting mechanism is connected to The vacuum transfer mechanism and the separation mechanism are located at one end of the embossing roller. The fixed bottom printing unit of the present invention can effectively reduce the working center of gravity of the fixed bottom printing unit by setting the separation mechanism and the lifting mechanism, and avoid the occurrence of Larger vibrations will cause the printed characters to be skewed or misplaced, and the running speed of the fixed bottom printing unit will be increased, thereby improving production efficiency and reducing production costs.

Owner:广东台一精工机械有限公司

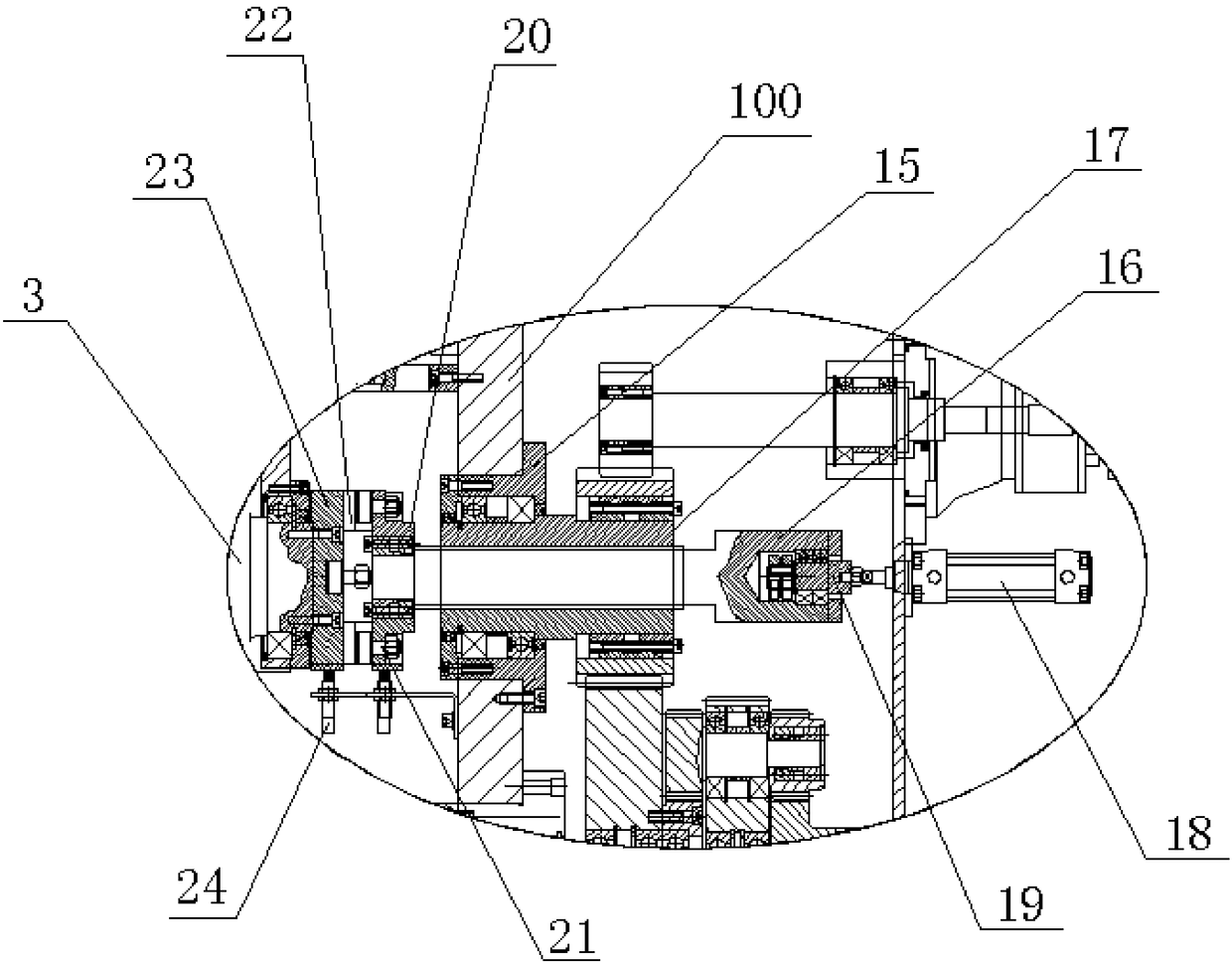

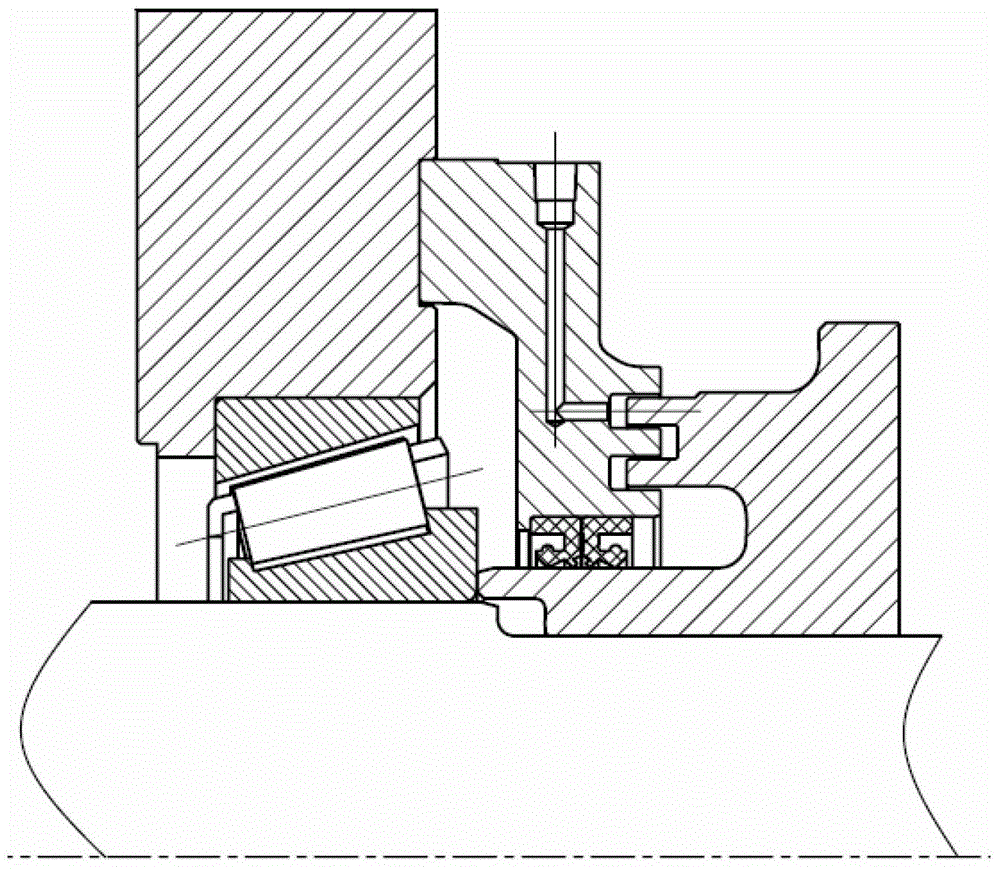

Horizontal vibrating centrifuge

ActiveCN103567079BExtended service lifeSimple structureEngine sealsRotary centrifugesFrequency changerAutomatic control

The invention relates to a horizontal type vibration centrifugal machine, comprising a spindle, a sleeve, a vibration box, a vibration motor, belt wheels and a screen basket, wherein the sleeve is sleeved outside the spindle; the vibration box is sleeved outside the sleeve and is fixedly connected with the sleeve; the vibration motor is arranged outside the vibration box; the belt wheels are respectively arranged at the two ends of the spindle; fixed labyrinths are respectively arranged at the two ends of the vibration box; the end, close to the screen basket, of the spindle is sleeved with a rotatable labyrinth adaptive to the fixed labyrinths; the horizontal type vibration centrifugal machine also comprises an automatic control system used for controlling the vibration motor, wherein the automatic control system comprises a vibration centrifugal machine working parameter obtaining device, a controller and a frequency converter; the vibration centrifugal machine working parameter obtaining device is connected with the frequency converter by the controller; the frequency converter is connected with the vibration motor; the vibration centrifugal machine working parameter obtaining device obtains the processing amount of the vibration centrifugal machine, the water content of materials, the working amplitude of the vibration centrifugal machine and the working frequency of the vibration centrifugal machine.

Owner:西安海泰科技有限公司

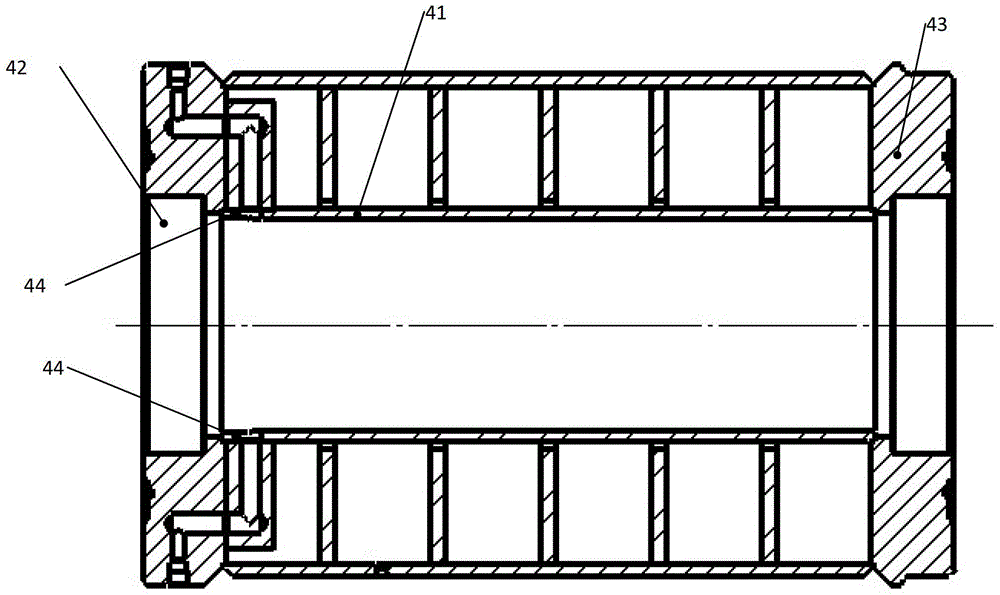

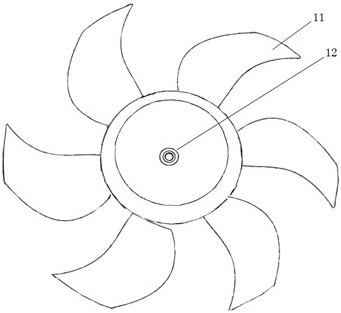

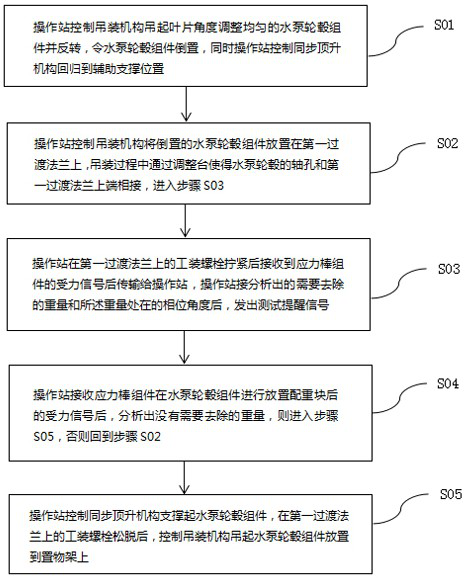

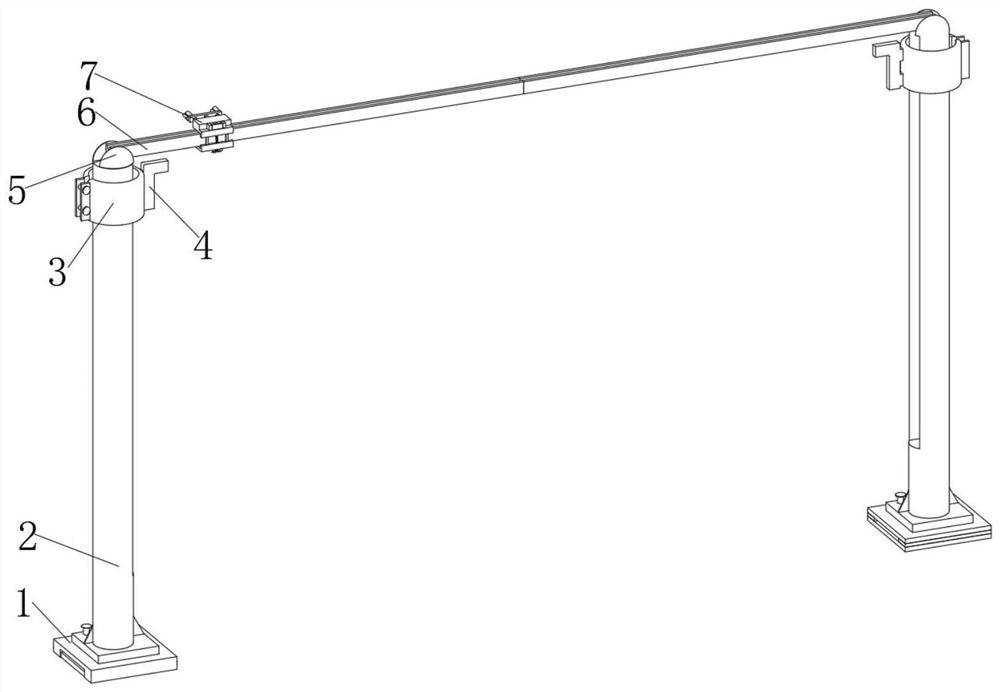

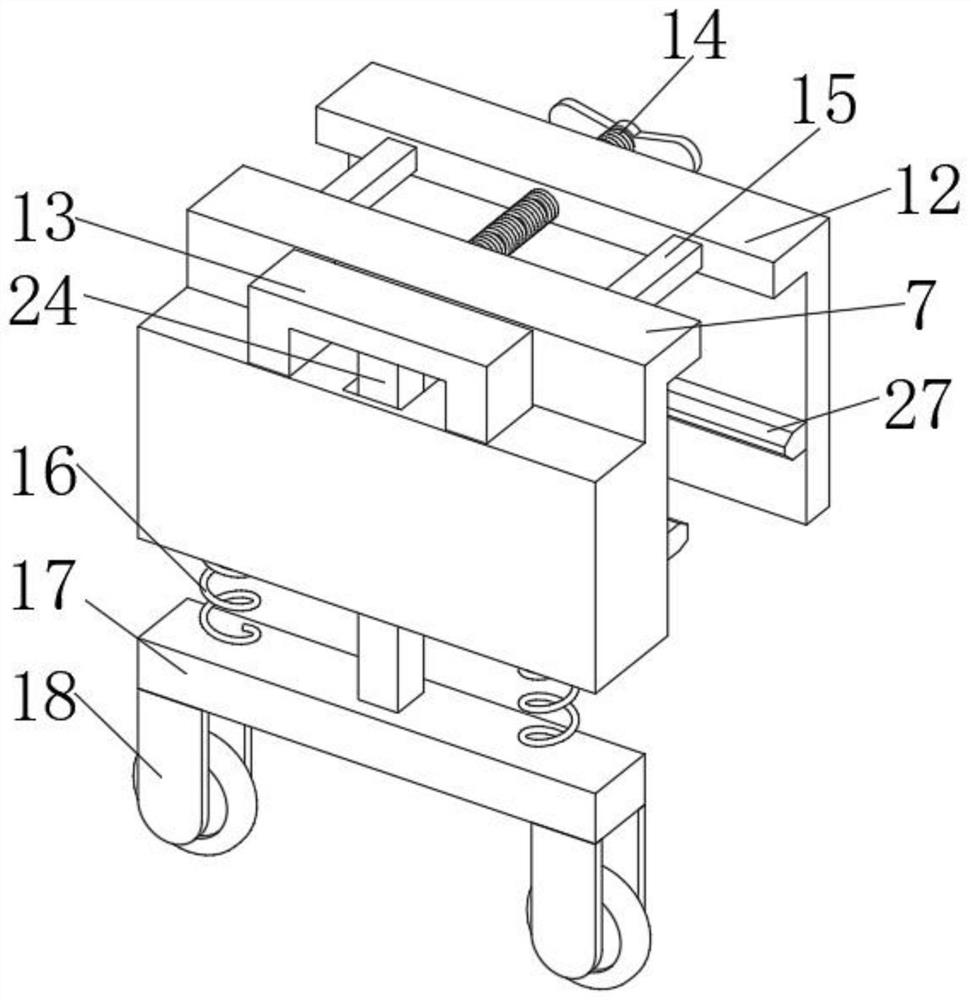

Static balance detection device and method for large blade adjustable water pump hub assembly of nuclear power plant

InactiveCN111852932AApplicable measurementEasy to adjust the positionPump componentsPump controlNuclear plantStructural engineering

The invention relates to a static balance detection device and a method for a large blade adjustable water pump hub assembly of a nuclear power plant, and belongs to the technical field of detection.The static balance detection device for the large blade adjustable water pump hub assembly of the nuclear power plant comprises a lifting mechanism, a support base and an operating station; the support base comprises an adjusting table, a support table, a stress bar assembly, a first transition flange, a second transition flange and a synchronous jacking mechanism; the support table and the synchronous jacking mechanism are arranged on the adjusting table; a lower end of the stress bar assembly is connected with the second transition flange, and the upper end of the stress bar assembly is connected with the first transition flange; the second transition flange is arranged on the support table; and the first transition flange supports an inverted water pump hub assembly, and an upper end ofthe first transition flange is connected with a shaft hole of a water pump hub. The static balance detection method for the large blade adjustable water pump hub assembly of the nuclear power plant is realized by the above device. The invention can verify whether the detected position adding weight and quality are accurate and marked timely, and the detection is stable with minor errors.

Owner:SANMEN NUCLEAR POWER CO LTD

Building measuring equipment capable of detecting flatness of different wall surfaces

ActiveCN111911782AHigh precisionLower the center of gravityMeasurement devicesStands/trestlesMeasuring equipmentStructural engineering

The invention relates to the technical field of wall surface measuring equipment, in particular to building measuring equipment capable of detecting flatness of different wall surfaces. The building measuring equipment comprises a measuring equipment main body, the measuring equipment main body comprises a fixing base, the bottom end of the fixing base is connected with a fixing mechanism, and thesurface of one end of the fixing base is connected with a supporting rod; the outer surface of the top end of the supporting rod is sleeved with a first connecting sleeve, the outer surface of one side of the first connecting sleeve is fixedly connected with the supporting rod, the surface of the top end of the supporting rod is fixedly connected with the fixing base, the inner wall of the fixingbase is hinged to a first connecting rod, and the surface of the first connecting rod is sleeved with a measuring mechanism; and the fixing mechanism comprises an inner connecting block, a supportingleg, an upper connecting base, a plug pin, a first fixing rod, an inner rotary disc and a first bearing rod. According to the building measuring equipment, by the arrangement of the fixing mechanism,the supporting rod can be conveniently fixed and supported; and by the arrangement of the measuring mechanism, the wall surfaces can be conveniently detected, and the flatness detection precision isimproved.

Owner:宇旺建工集团有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com