Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Low processing and assembly requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

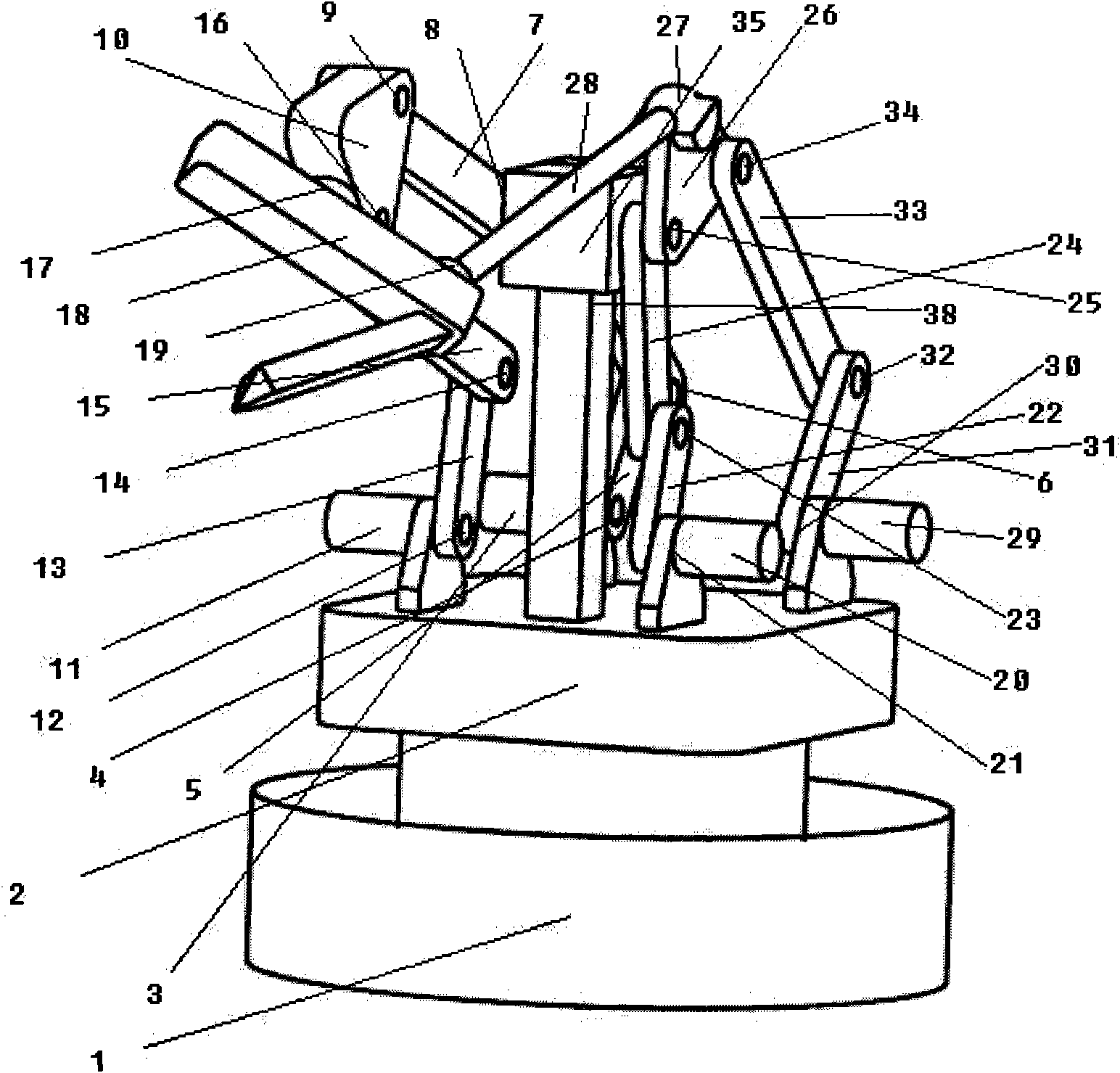

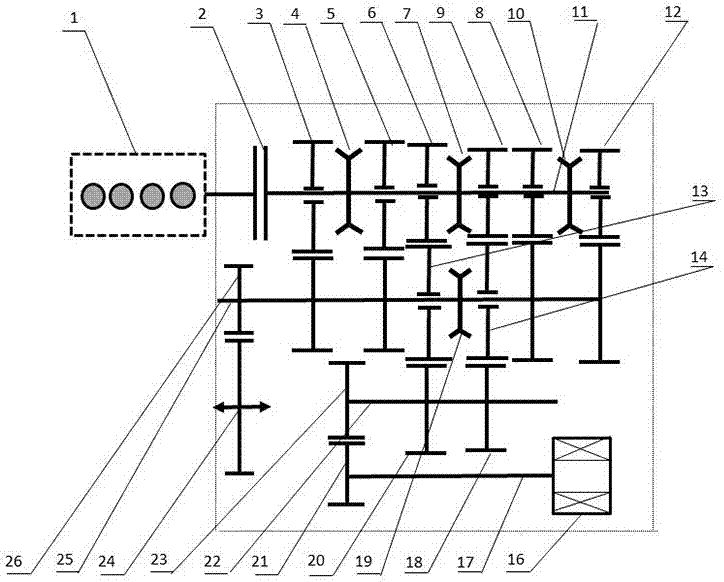

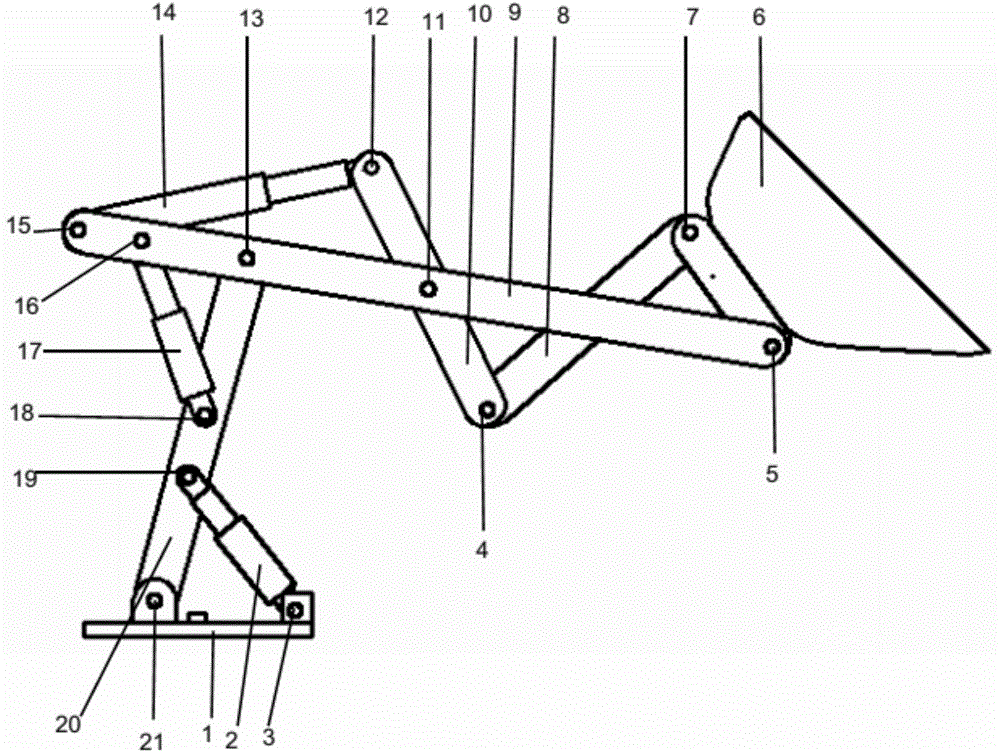

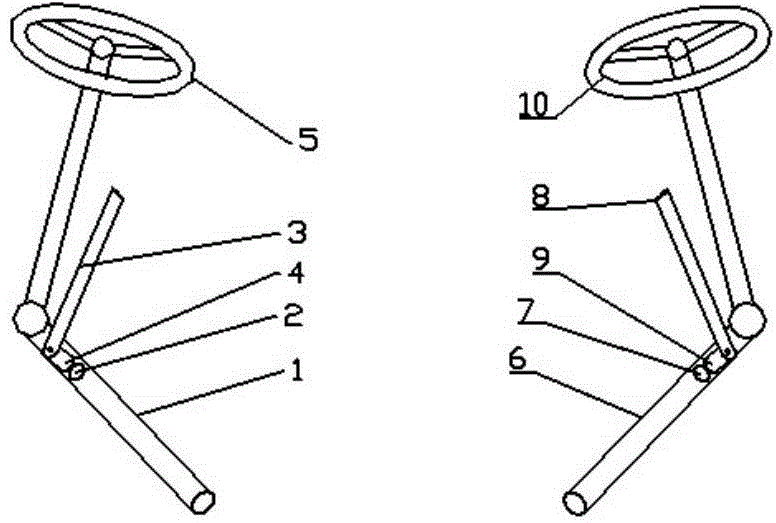

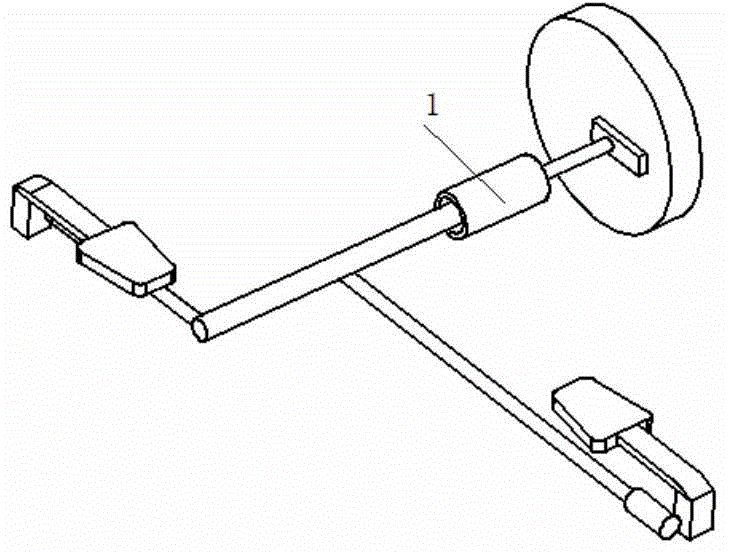

Simple spot-welding robot mechanism

InactiveCN102091899AReduce weightSmall moment of inertiaWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention relates to a simple spot-welding robot mechanism which comprises a first welding torch rack position adjusting mechanism, a first welding torch rack attitude adjusting mechanism, a second welding torch rack position adjusting mechanism, a second welding torch rack attitude adjusting mechanism, a welding torch rack and a stand, wherein the welding torch rack is composed of a swinging rack and a rotating rack, the swinging rack is connected with the rotating rack by a fourteenth rotating pair, the swinging rack is connected with the first welding torch rack position adjusting mechanism by a fifteenth rotating pair, the swinging rack is connected with the first welding torch rack attitude adjusting mechanism by a tenth rotating pair, the rotating rack is connected with the second welding torch rack attitude adjusting mechanism by a second spherical pair, and a welding torch is arranged on the rotating rack. The simple spot-welding robot mechanism provided by the invention is driven by external rotating pairs, and all servo motors are installed on the stand, therefore, the weight of working bar parts can be reduced effectively, the accurate positioning of the working bar parts can be realized, and the working efficiency of the working bar parts can be improved.

Owner:GUANGXI UNIV

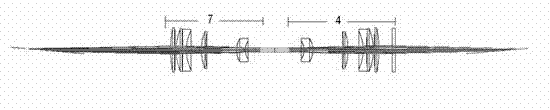

Focusing and leveling device and method

ActiveCN103365103AIncrease profitLow processing and assembly requirementsPhotomechanical exposure apparatusMicrolithography exposure apparatusLight beamTest object

The invention provides a focusing and leveling device which is used for the adjustment of a focal plane of a plane to be tested and the correction of a self zero plane. The focusing and leveling device comprises a light source module, an optical lens module, a tested object and a detector module, and is characterized in that the optical lens module comprises projection diaphragms, a focusing double-optical-wedge assembly, a projection optical assembly, a zero plane adjusting assembly and a detecting optical assembly, a light beam emitted from the light source module passes through the projection diaphragms, the projection optical assembly and first focusing double optical wedges, and then is reflected by the tested object so as to form a reflection light beam, and the reflection light beam sequentially passes through the projection optical assembly, the zero plane adjusting assembly and second focusing double optical wedges and then is received by the detector module. Meanwhile, the invention provides a focusing and leveling method.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

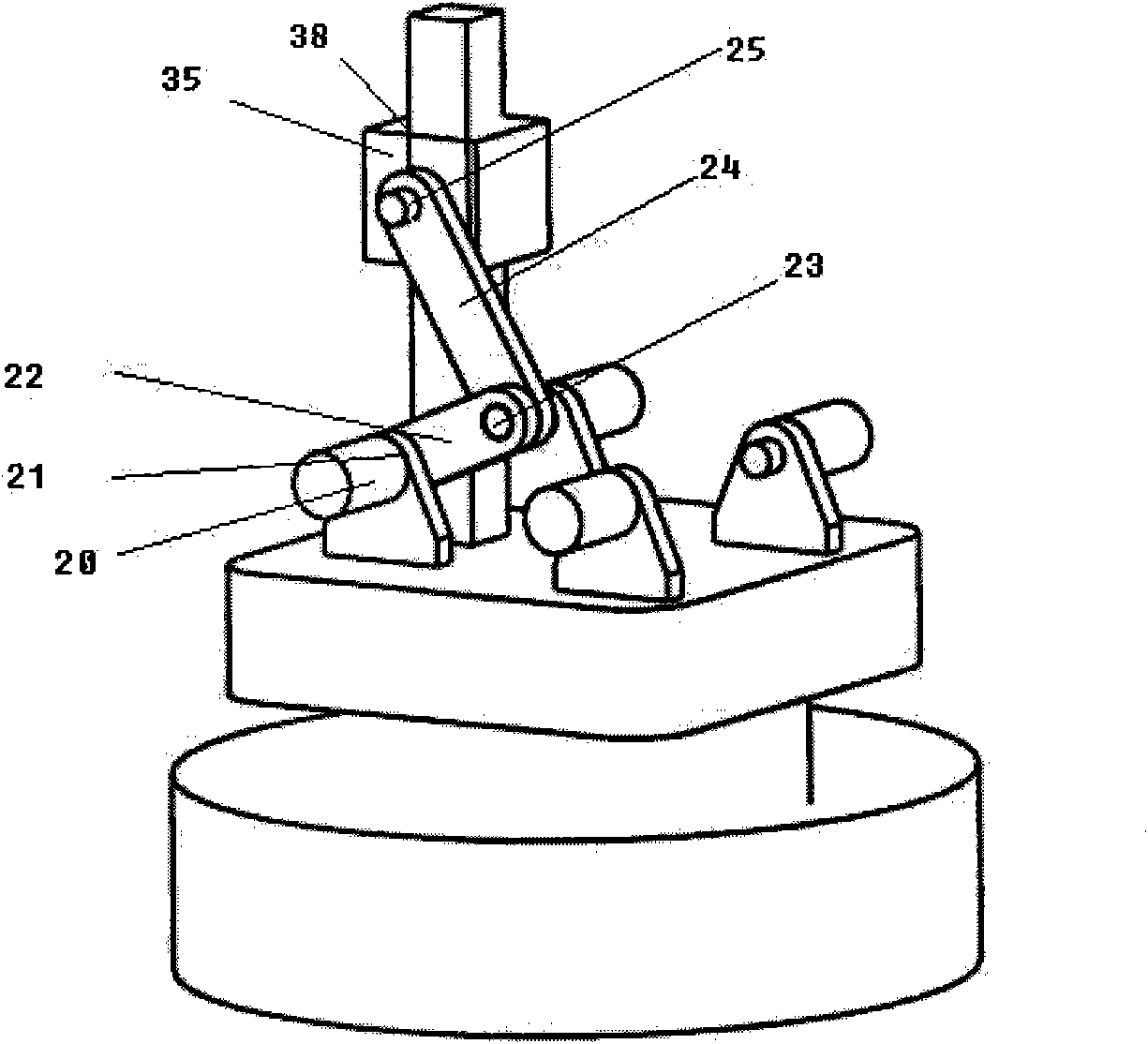

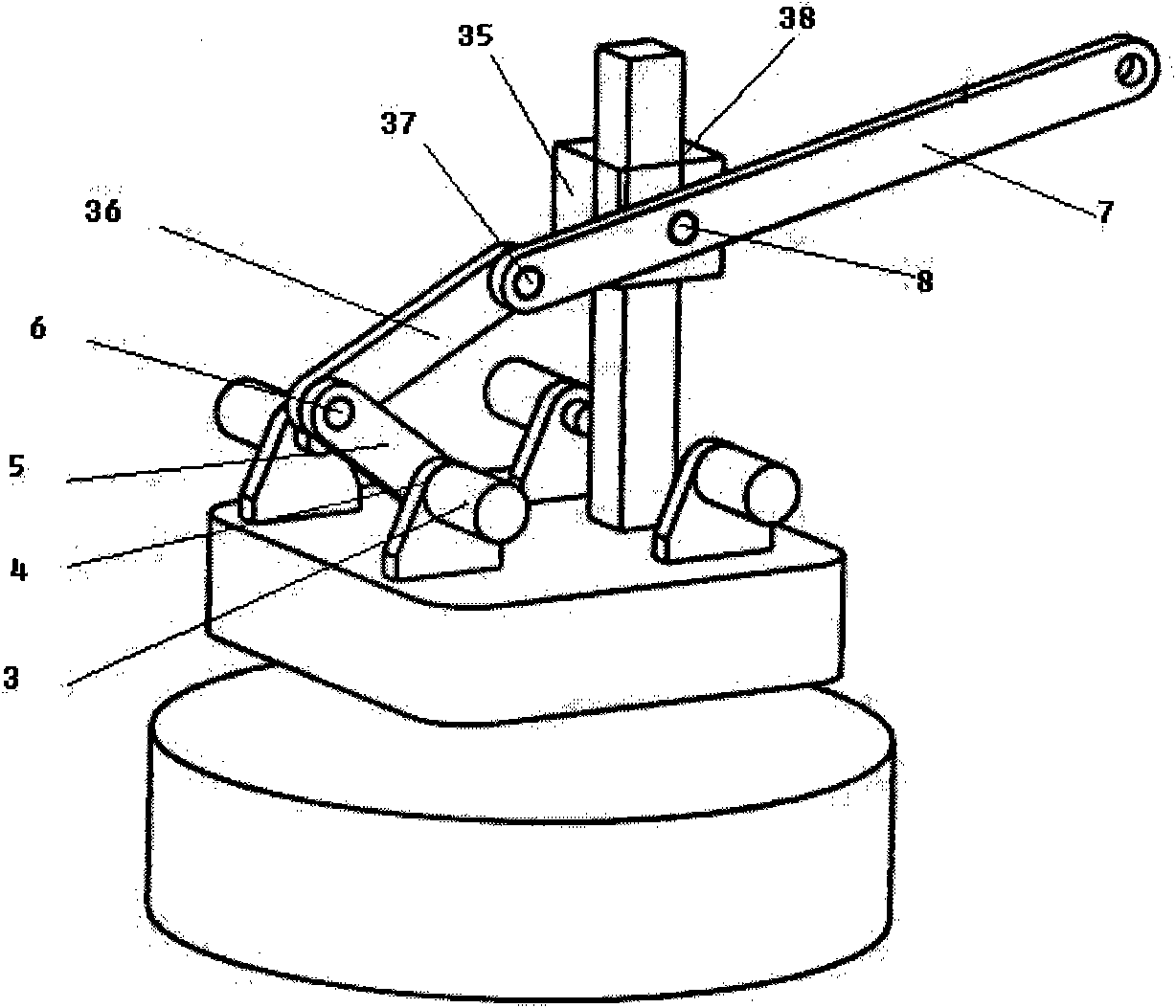

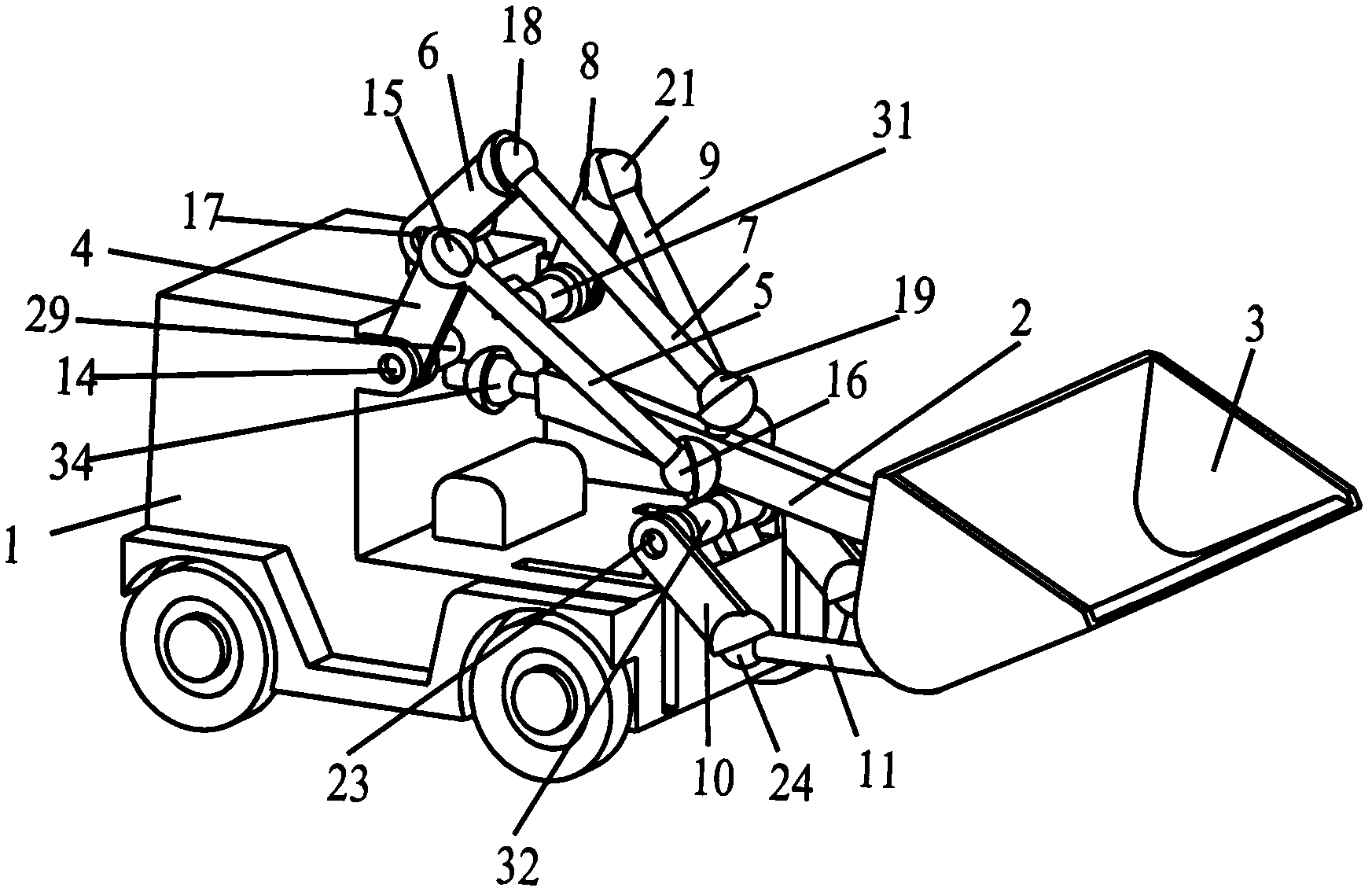

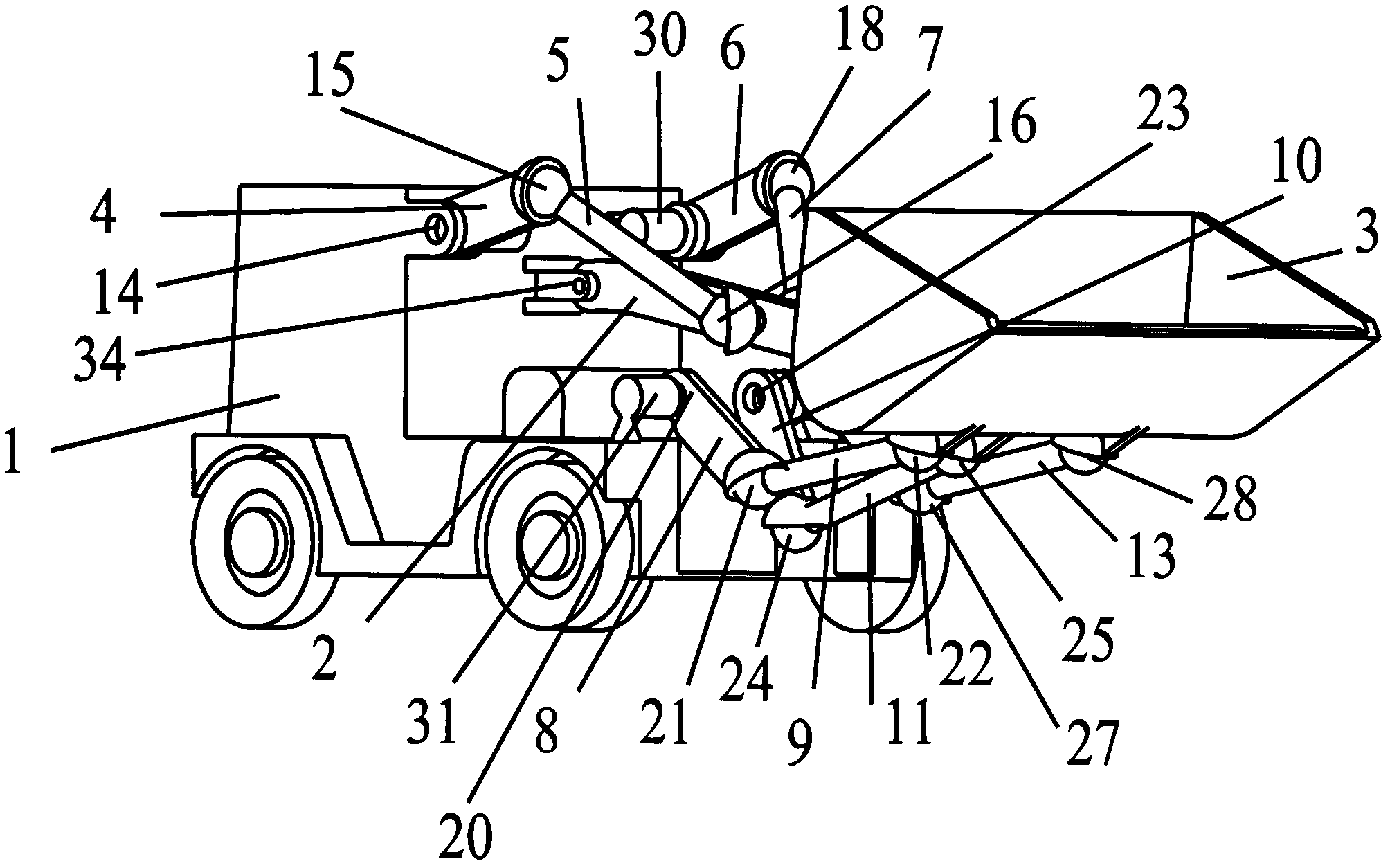

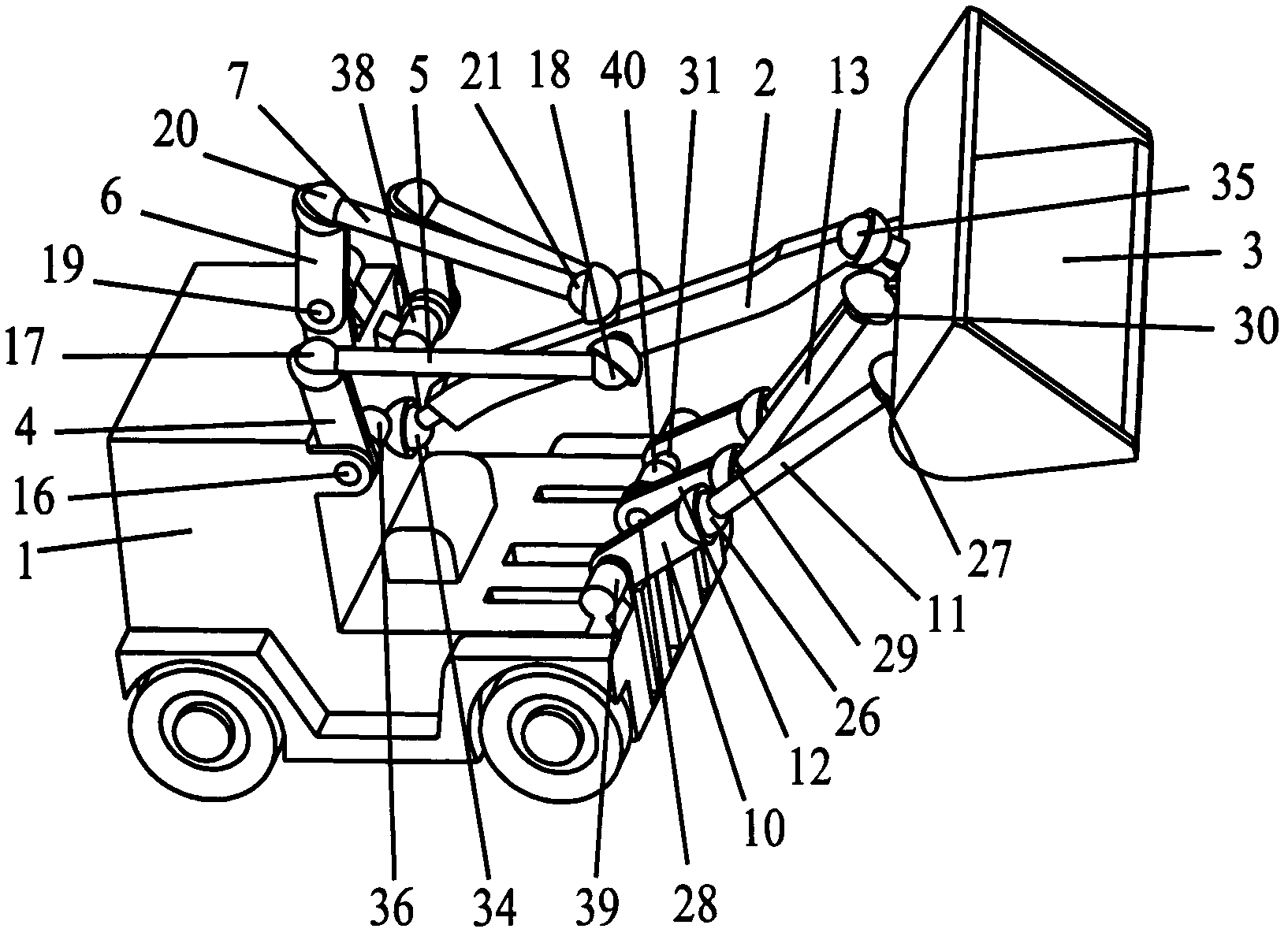

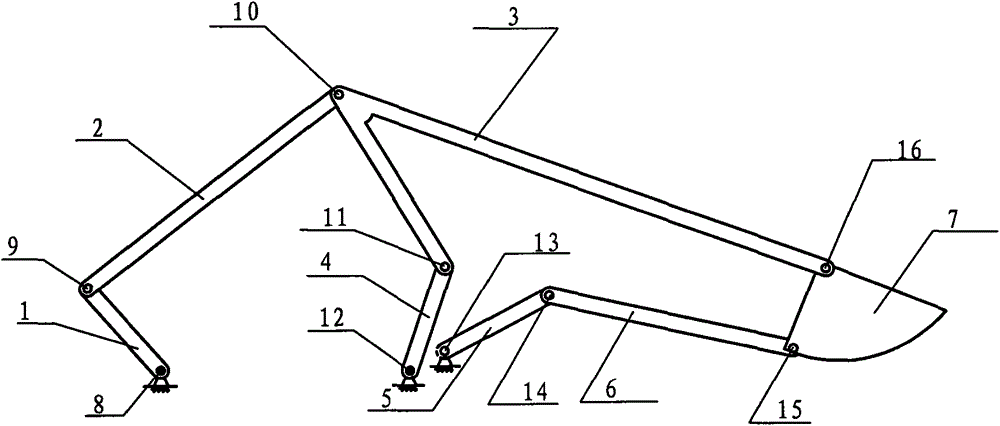

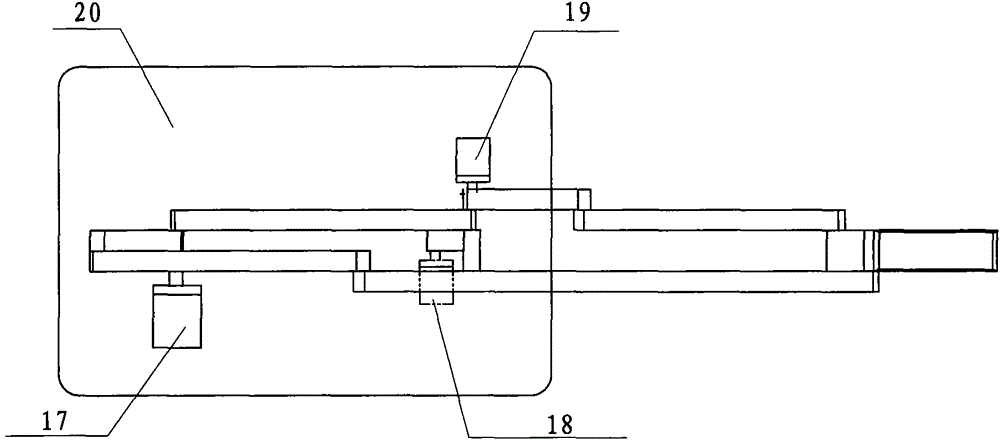

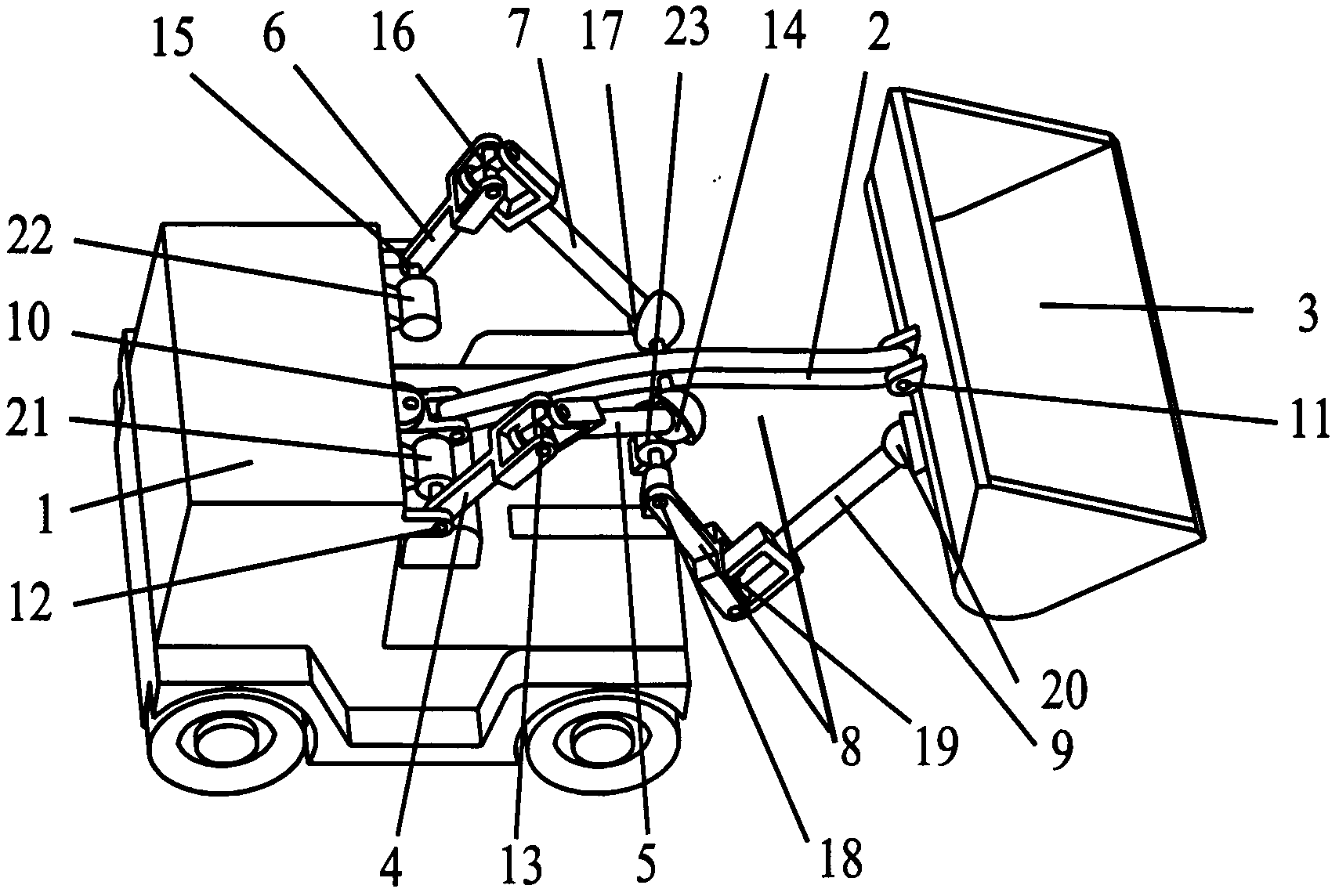

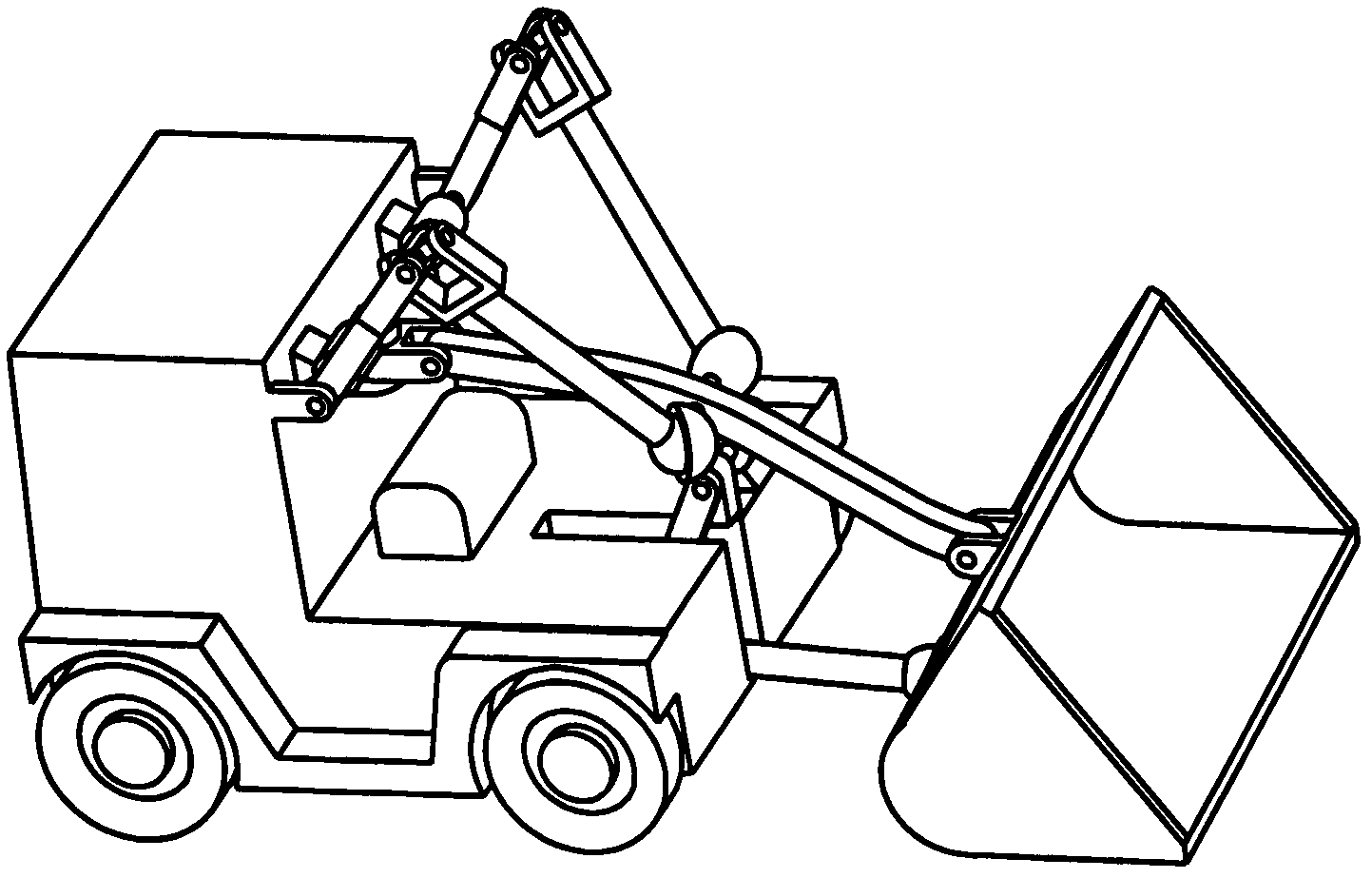

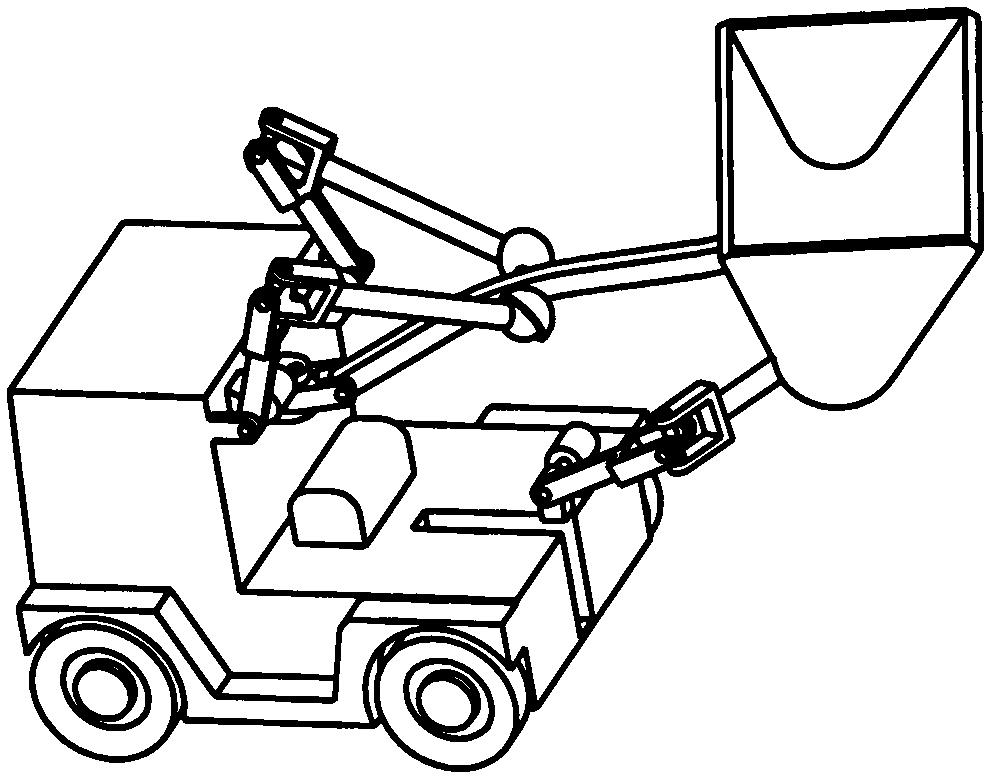

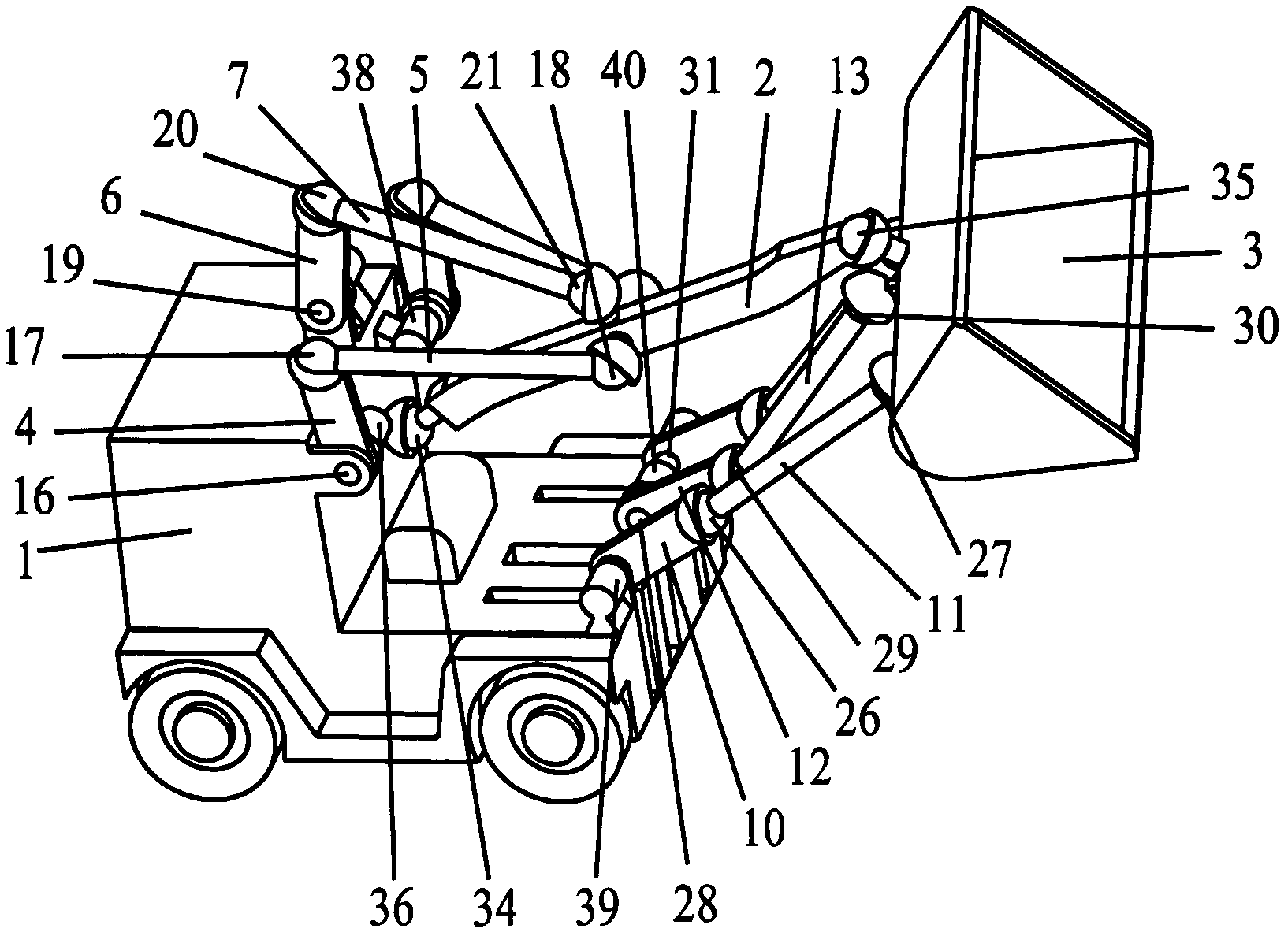

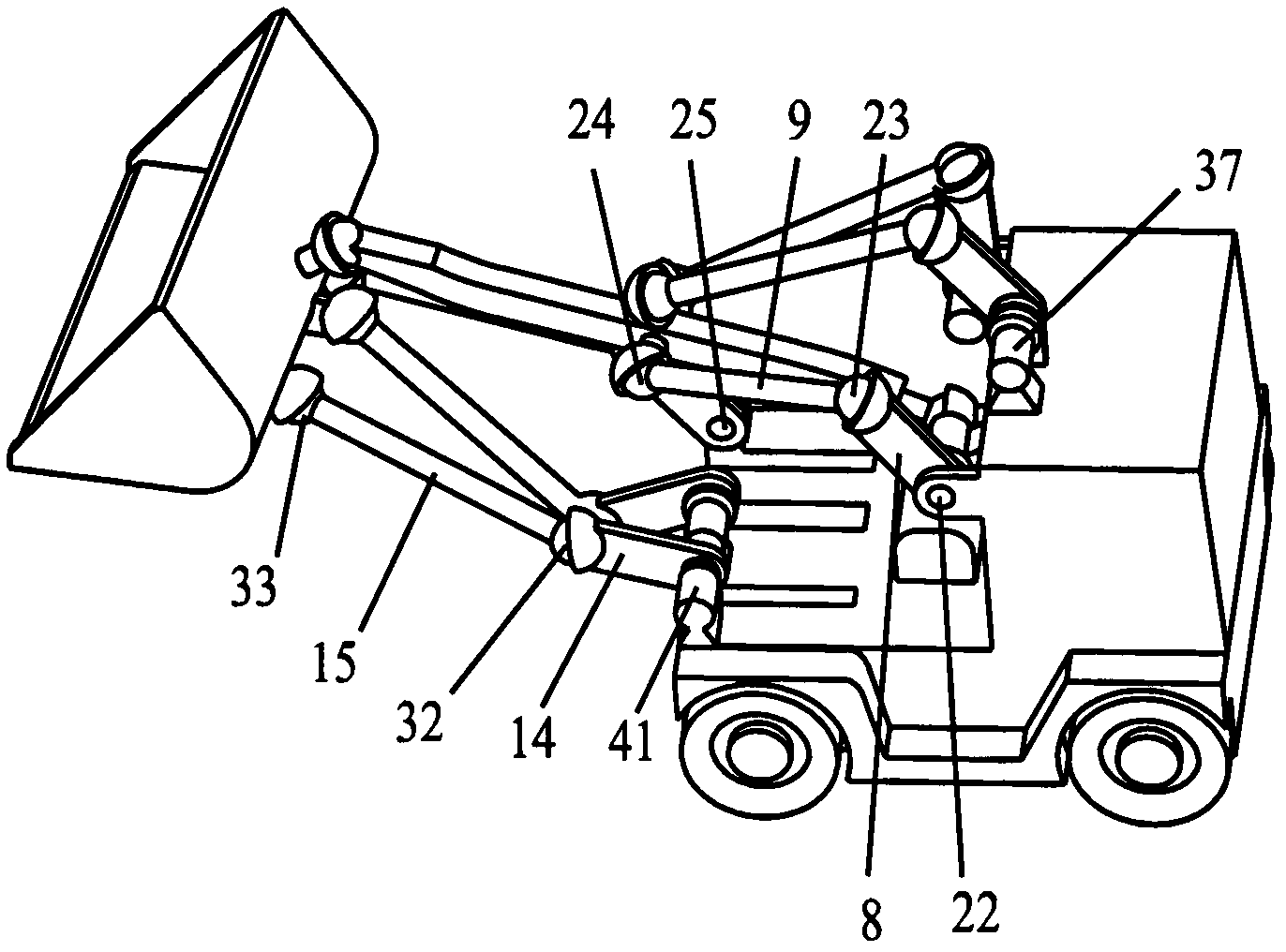

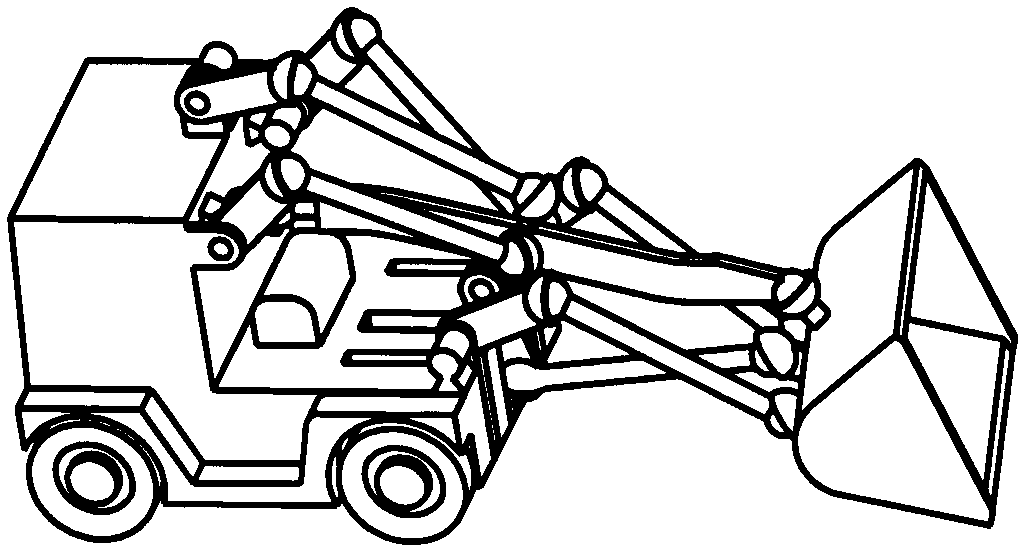

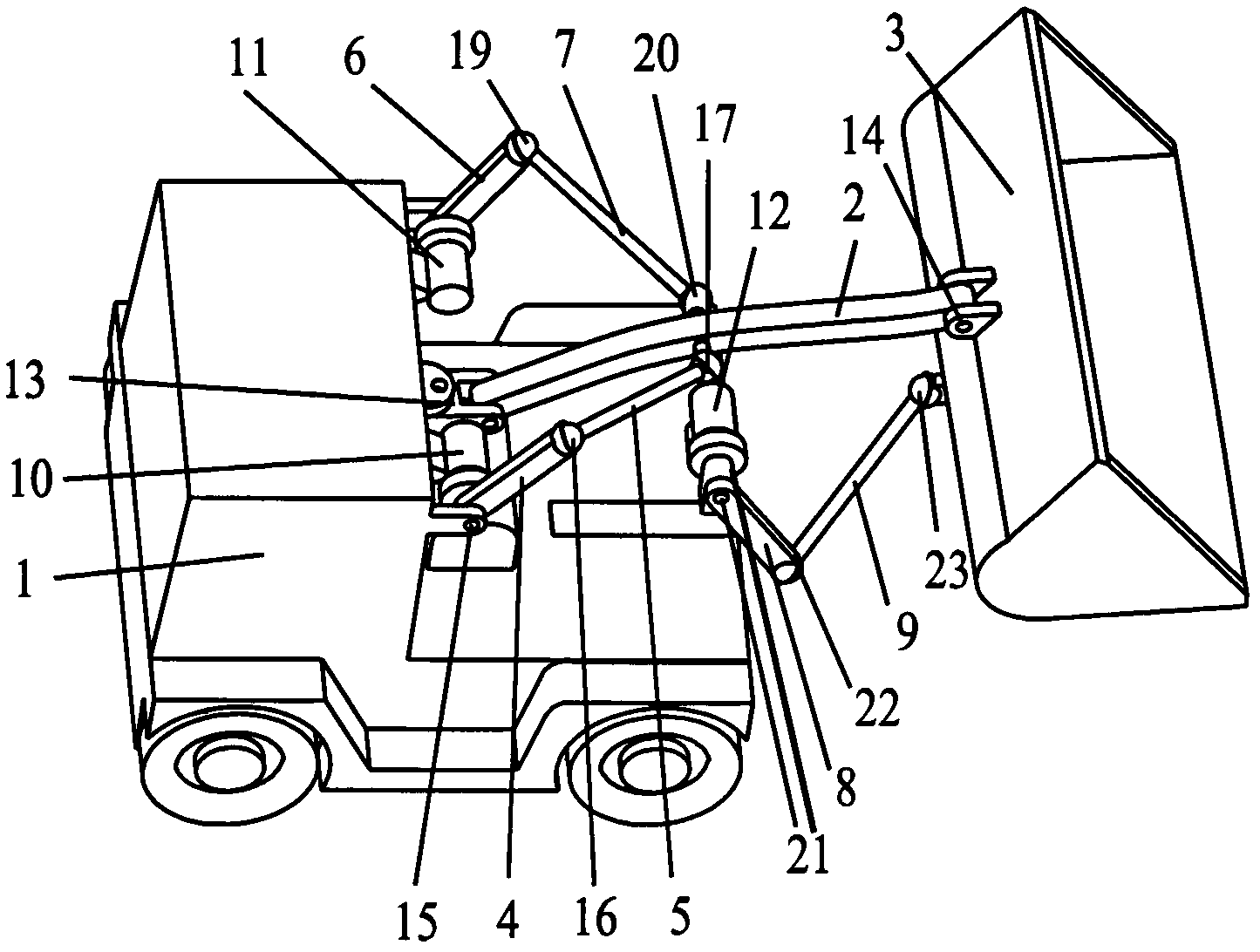

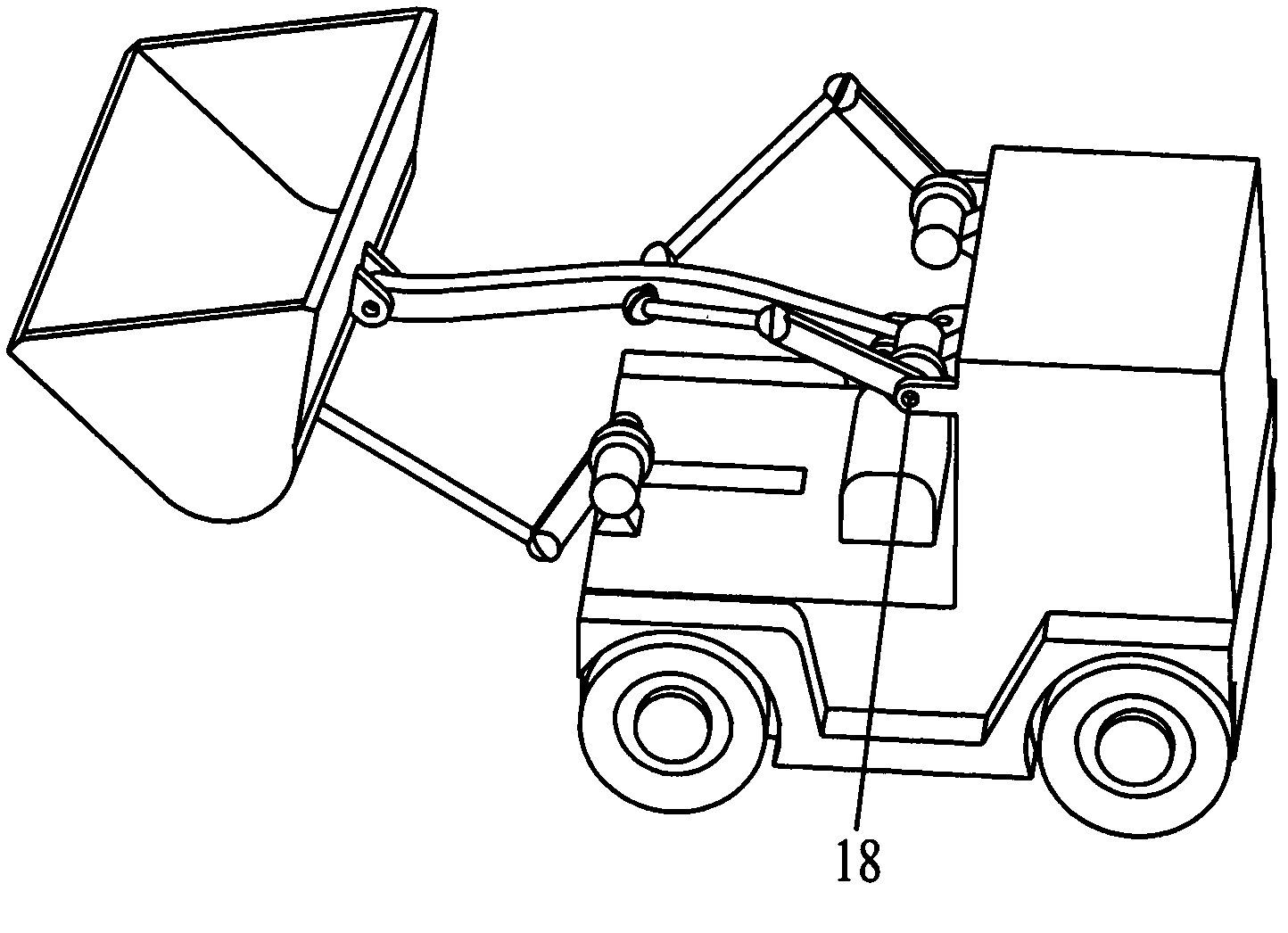

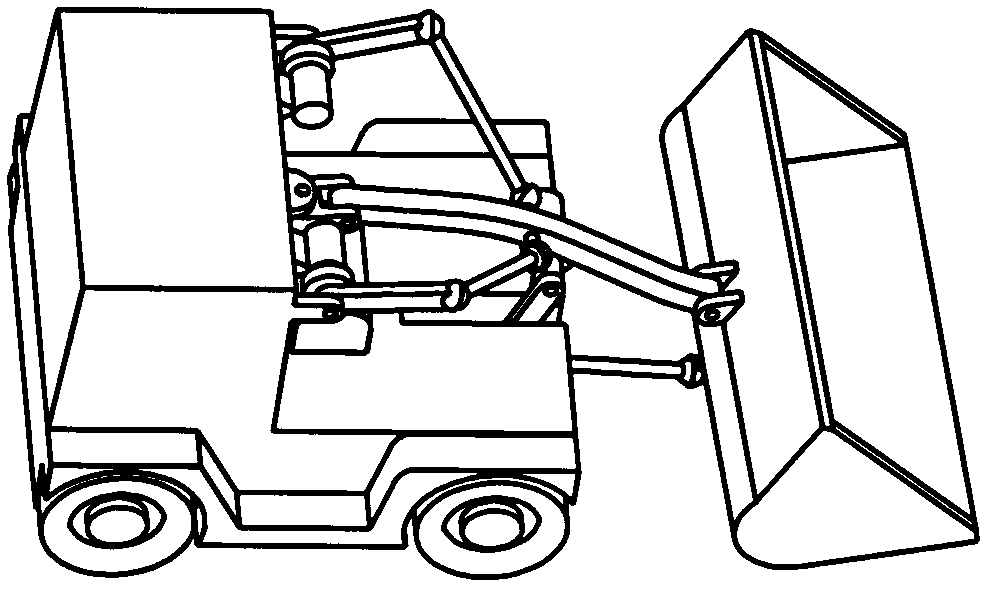

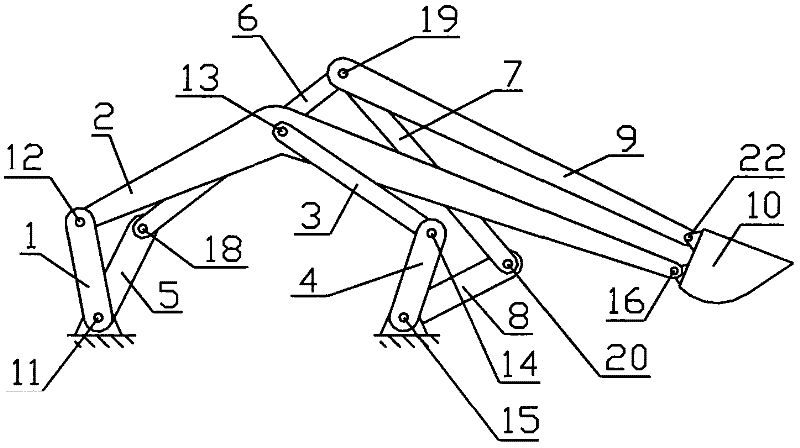

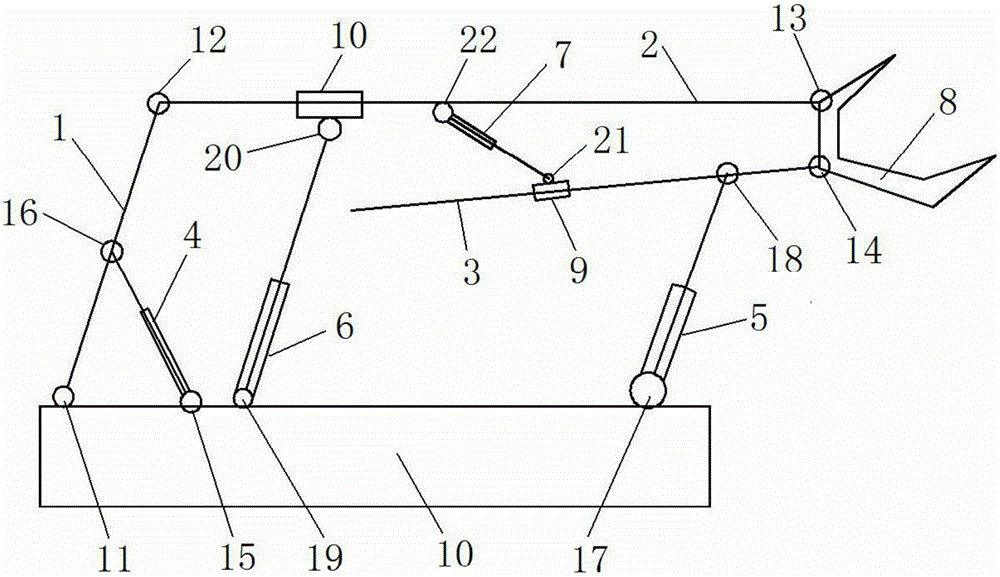

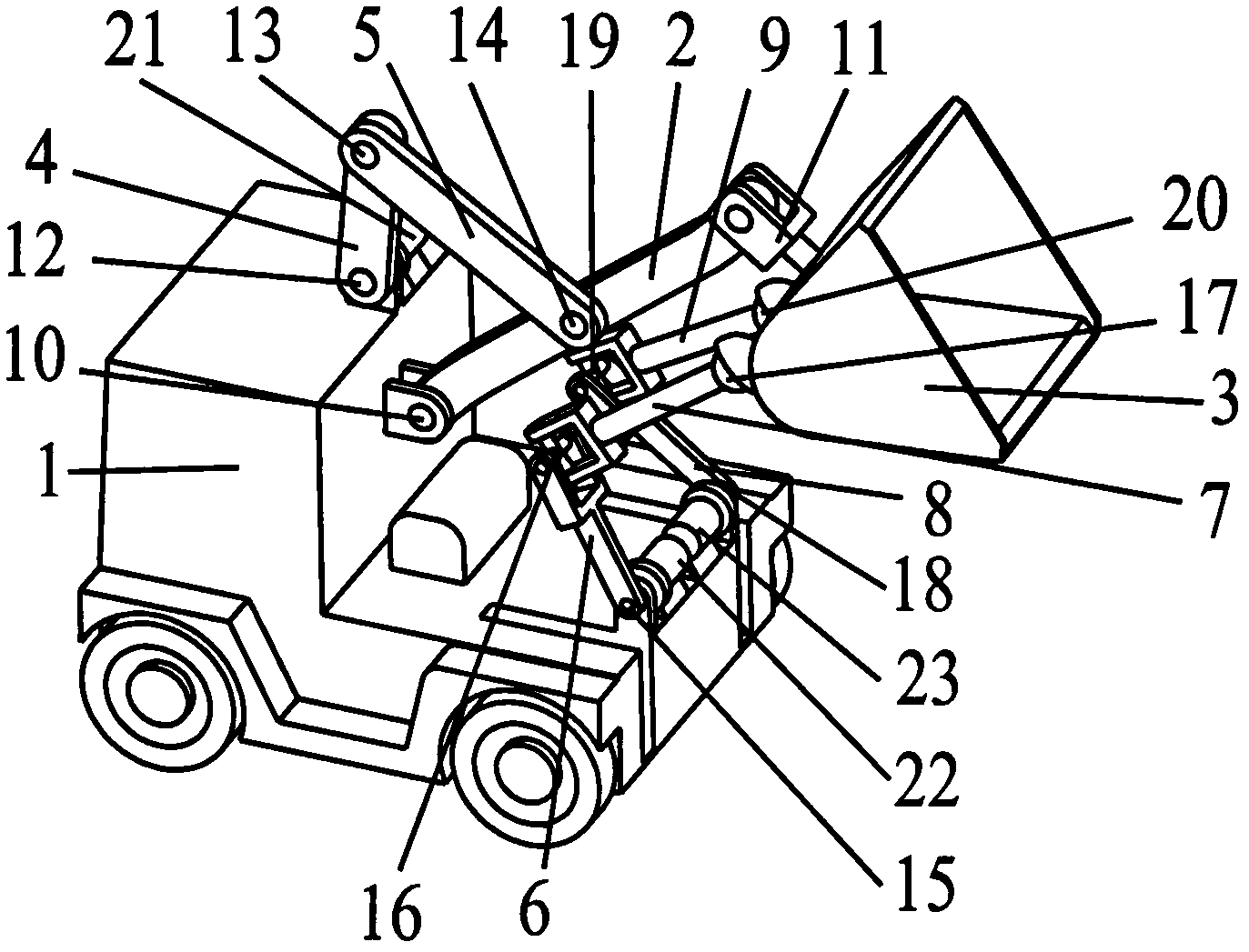

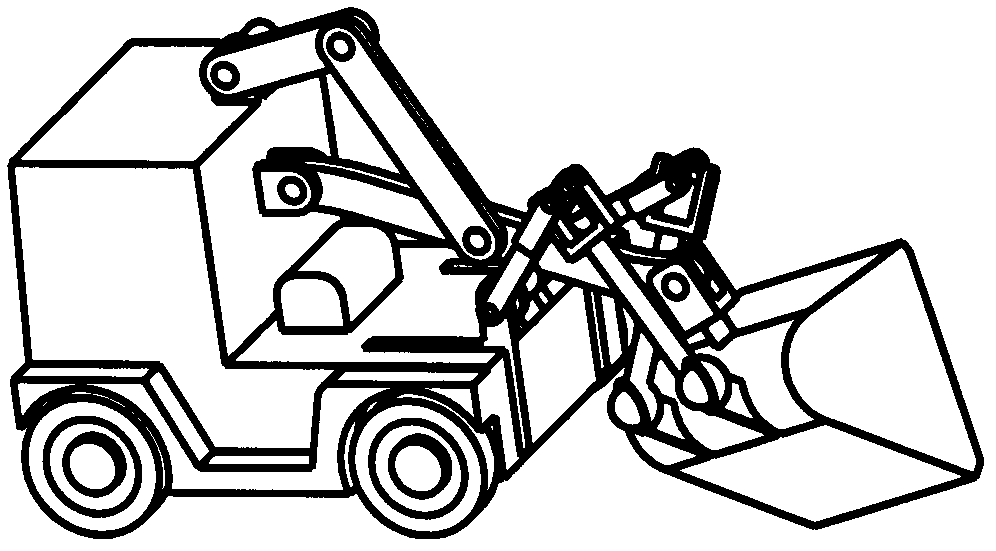

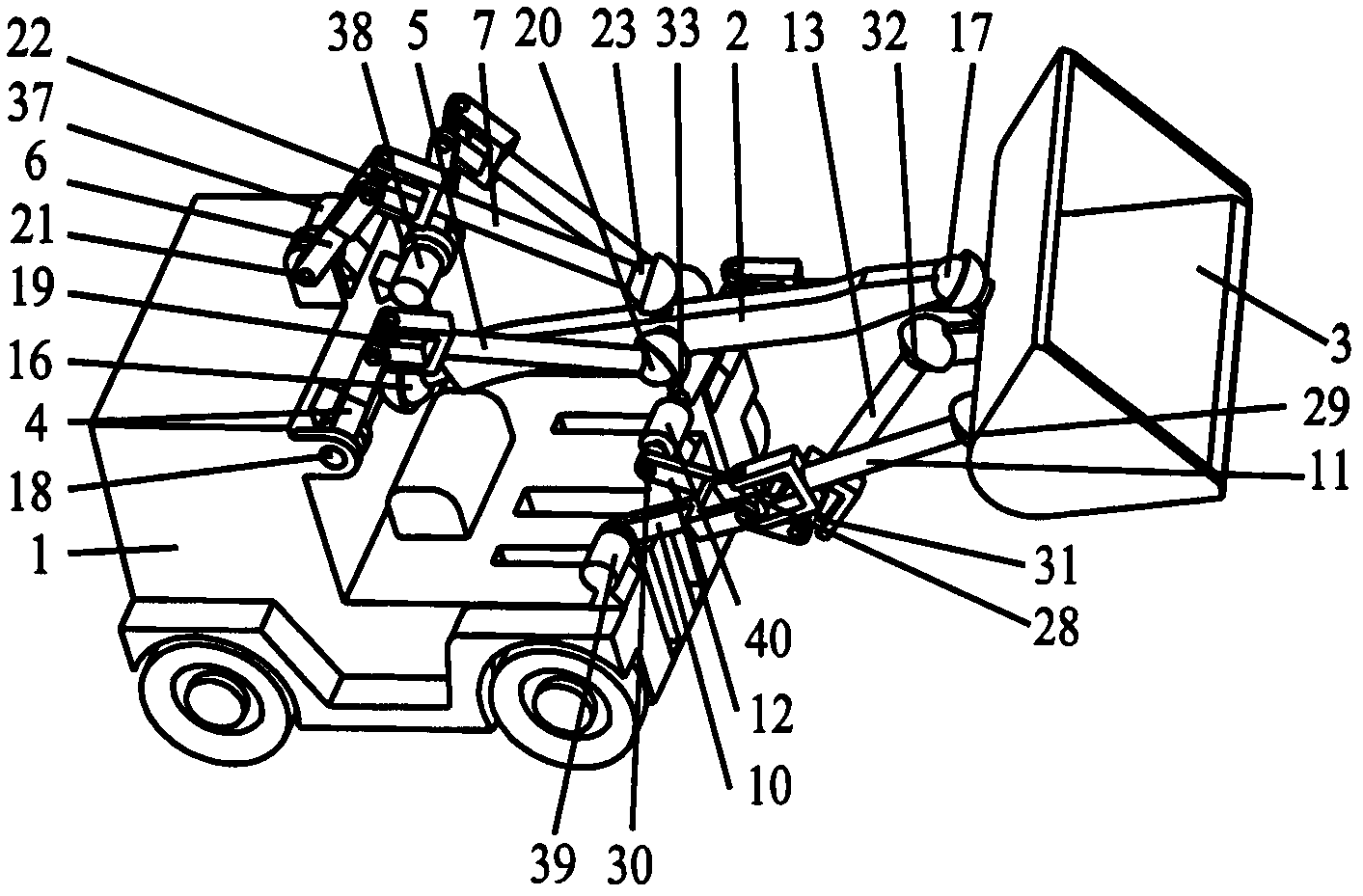

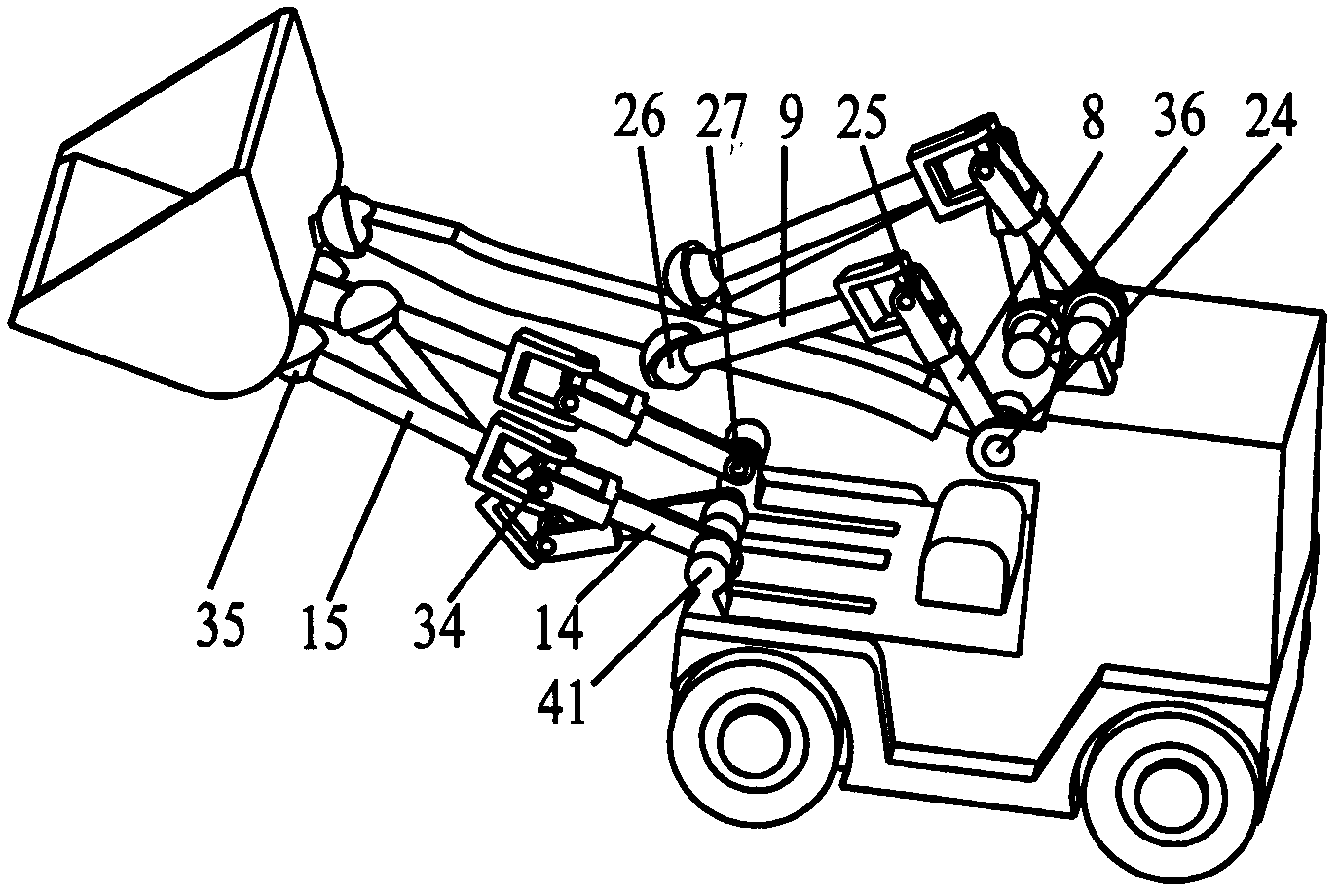

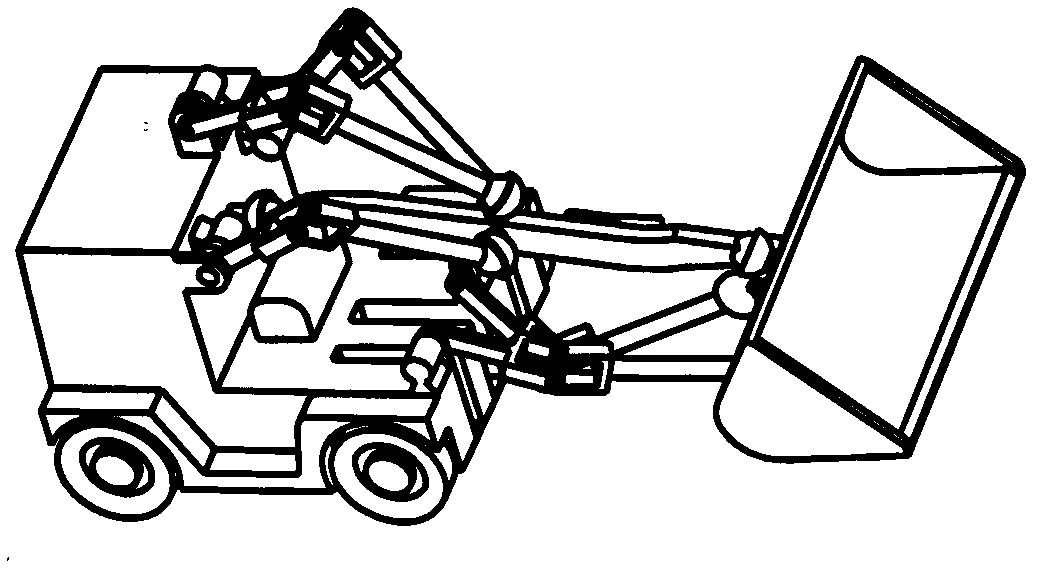

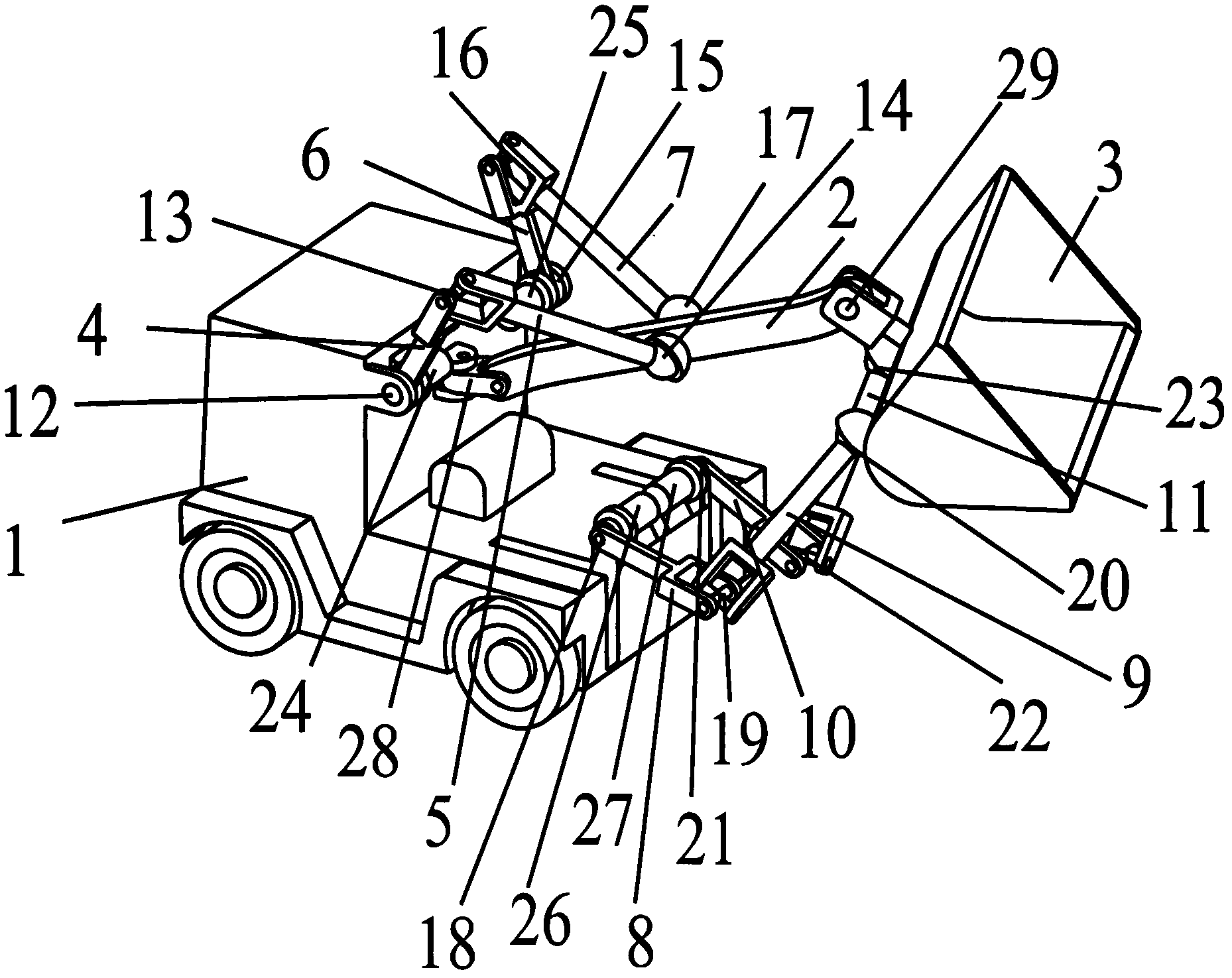

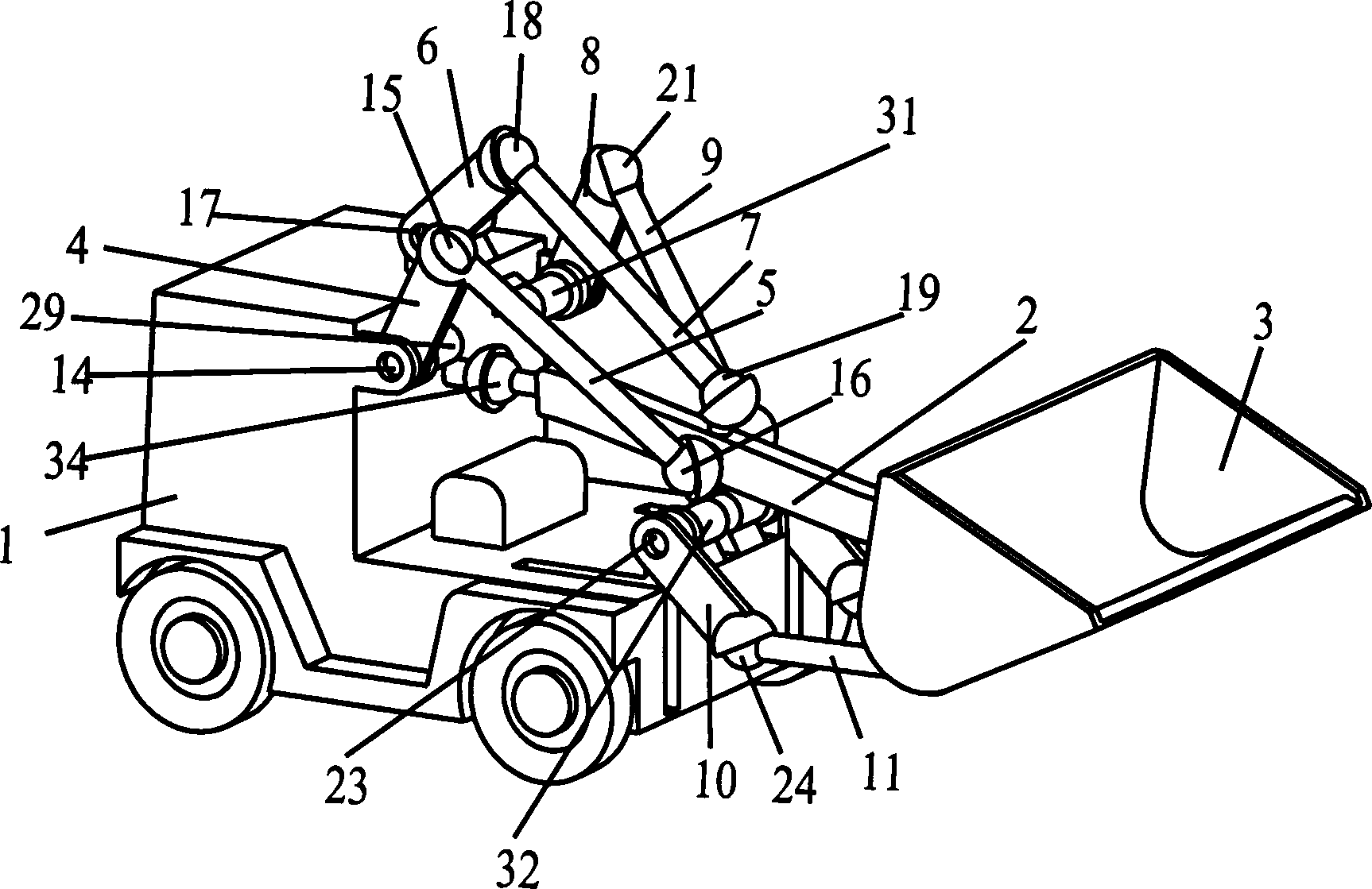

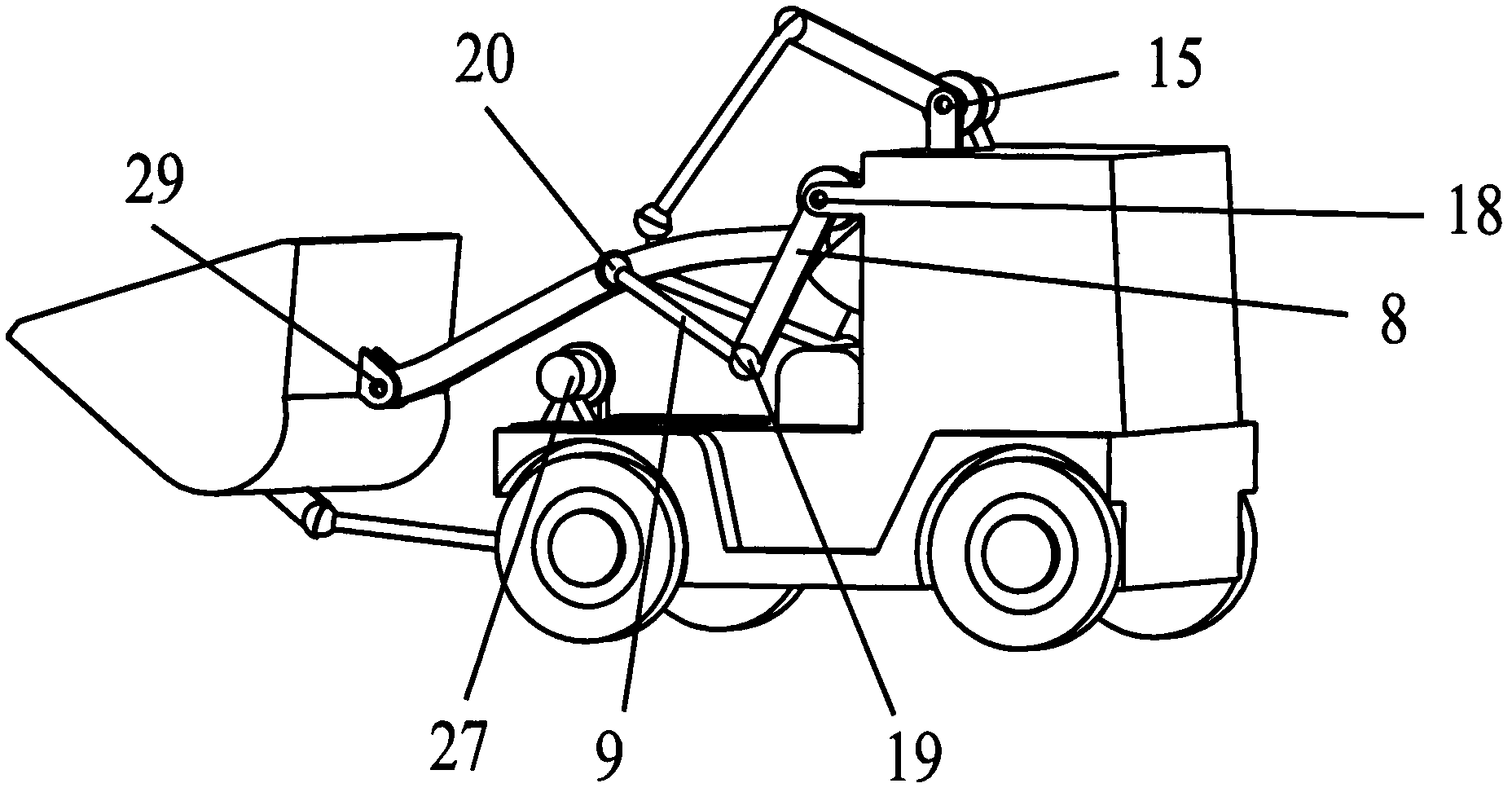

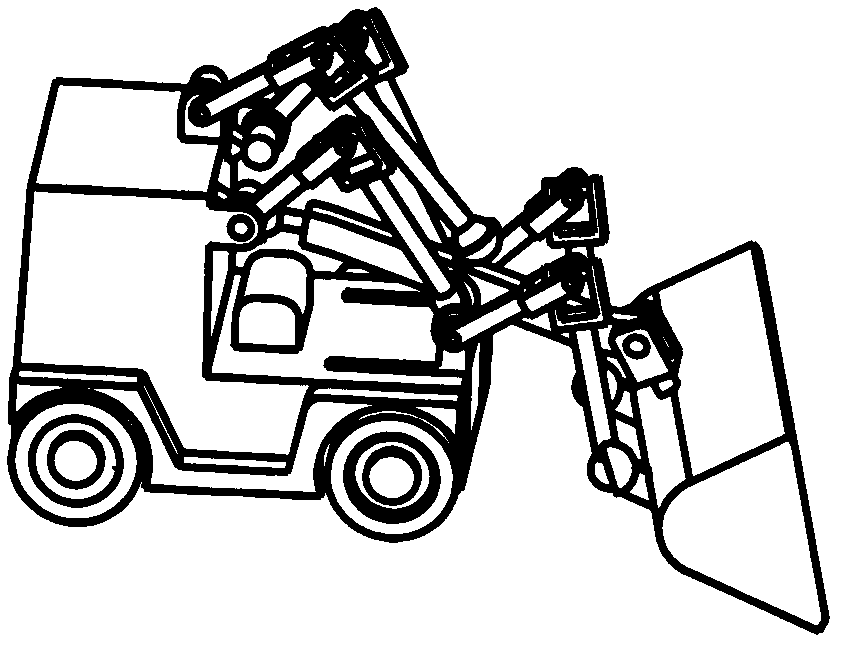

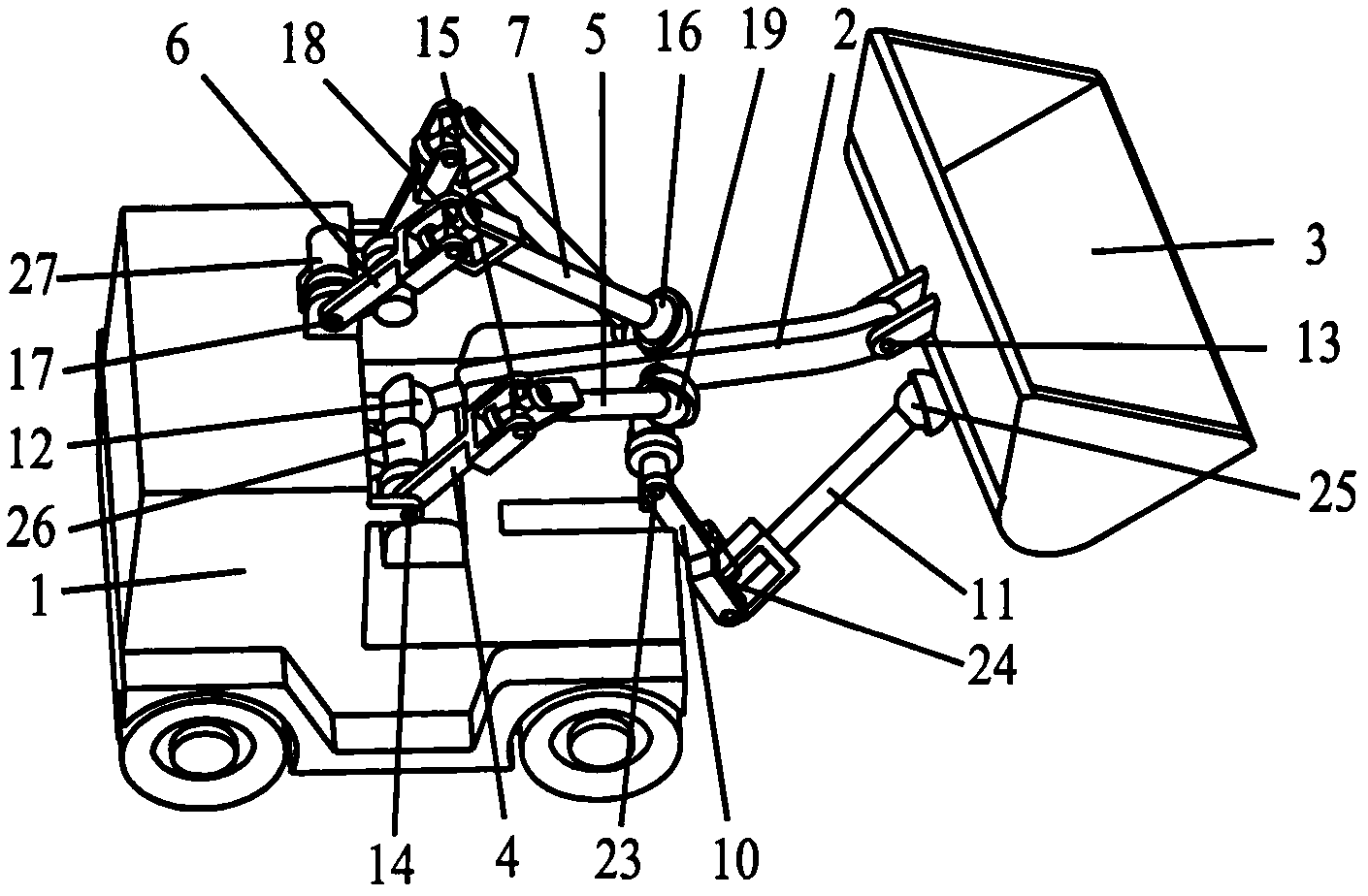

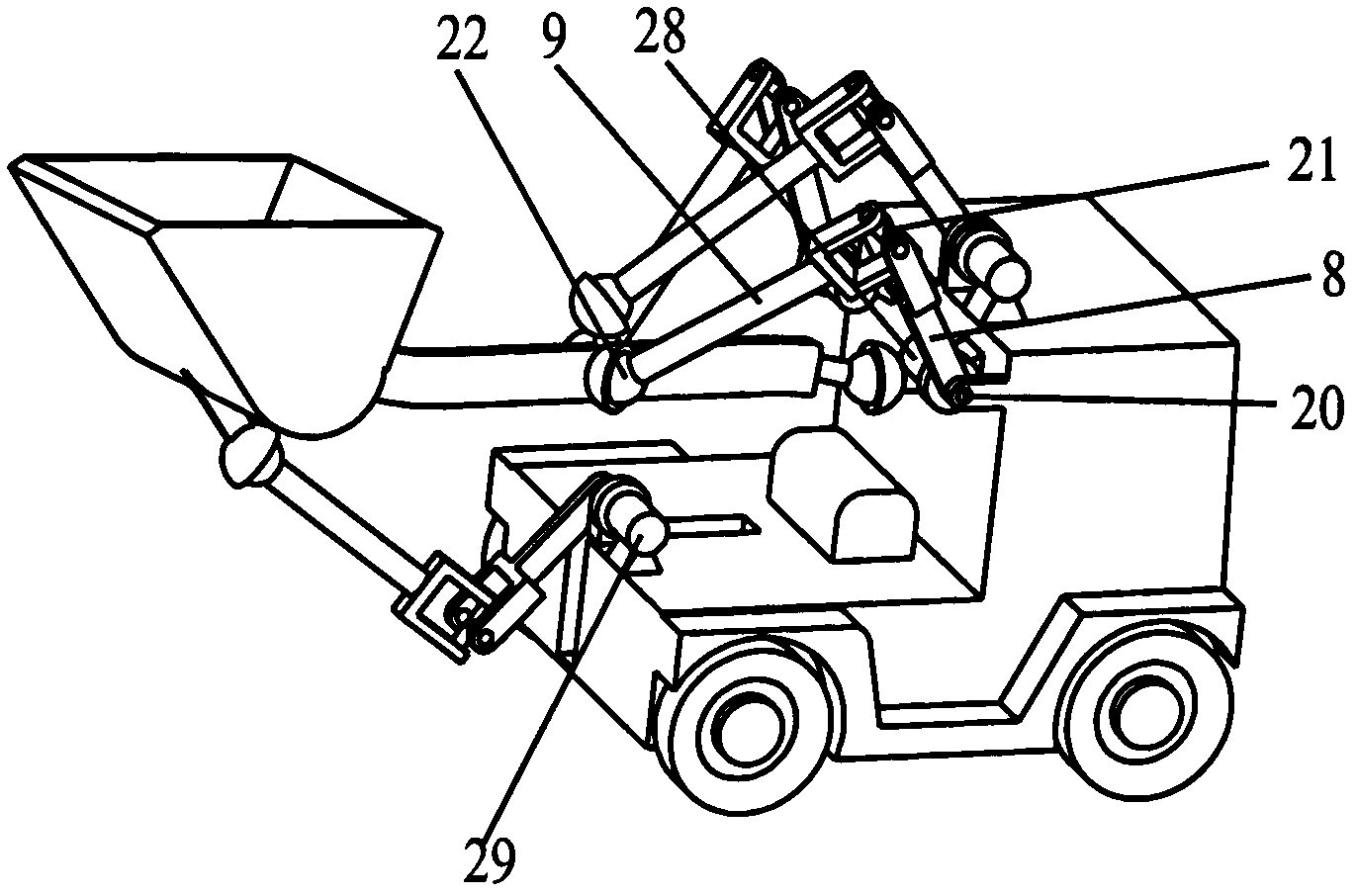

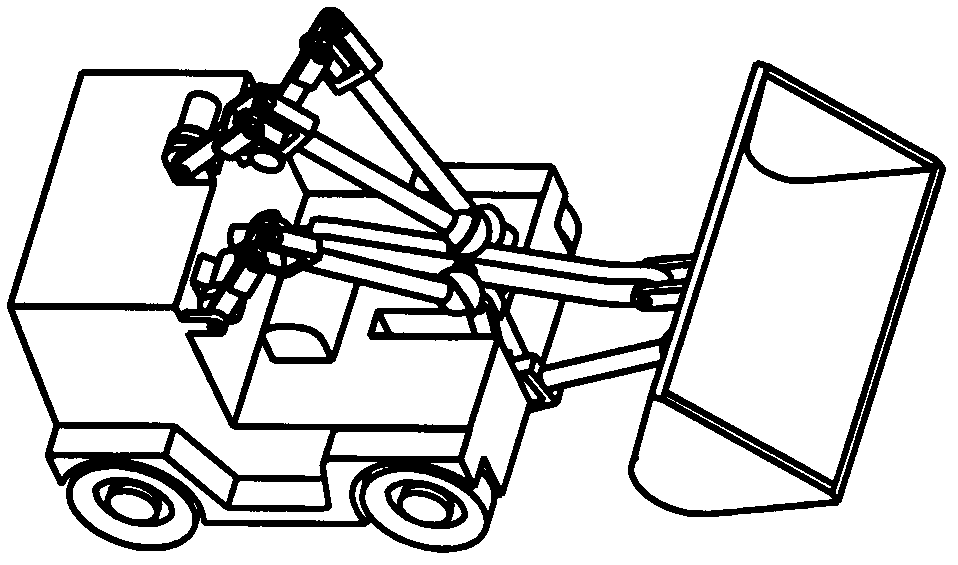

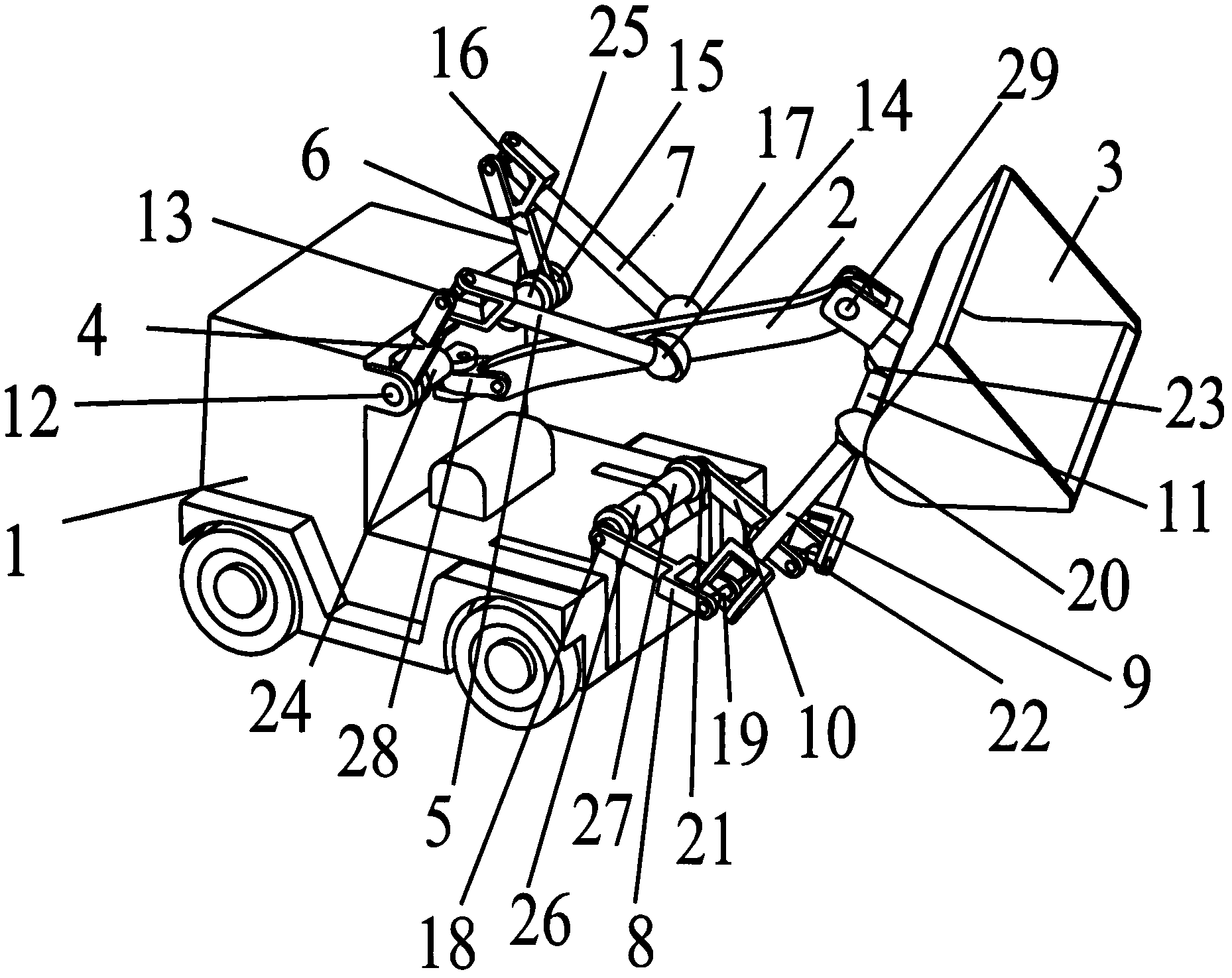

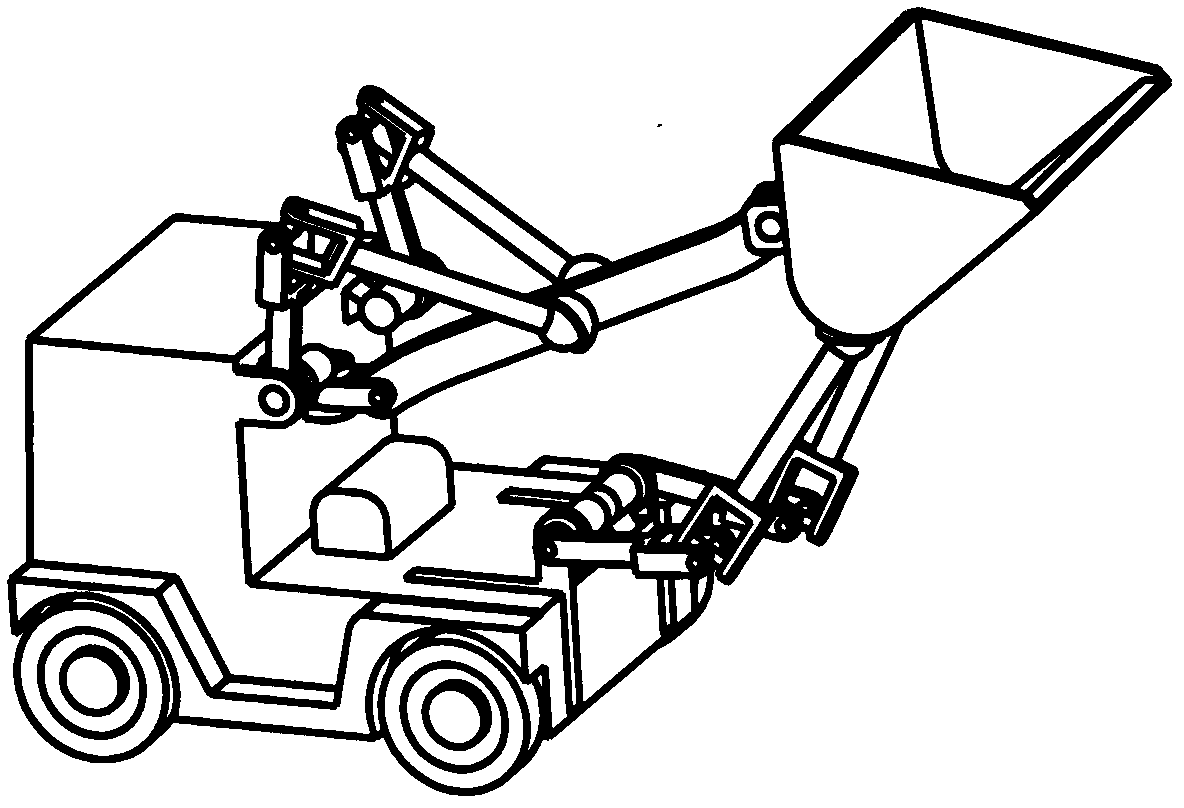

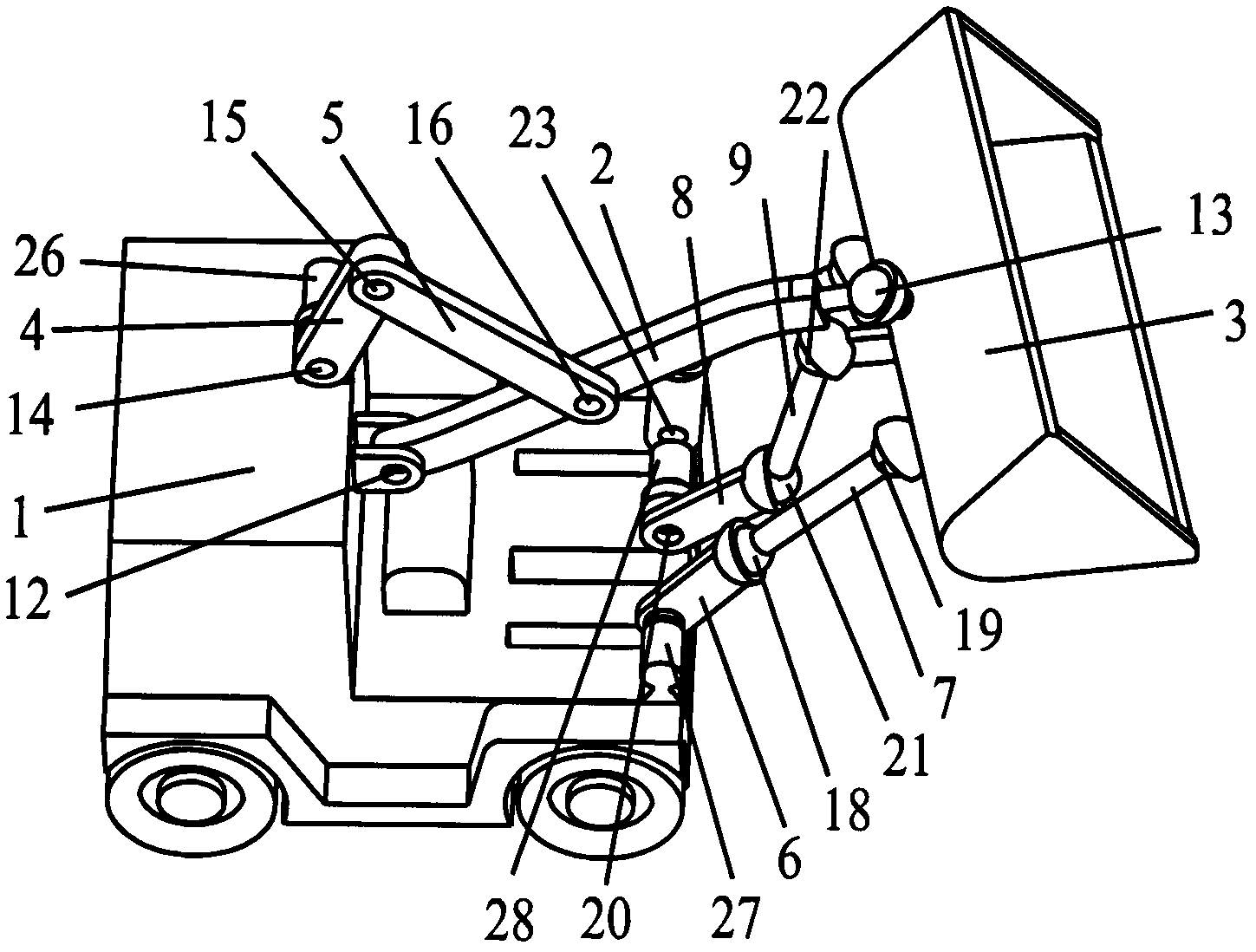

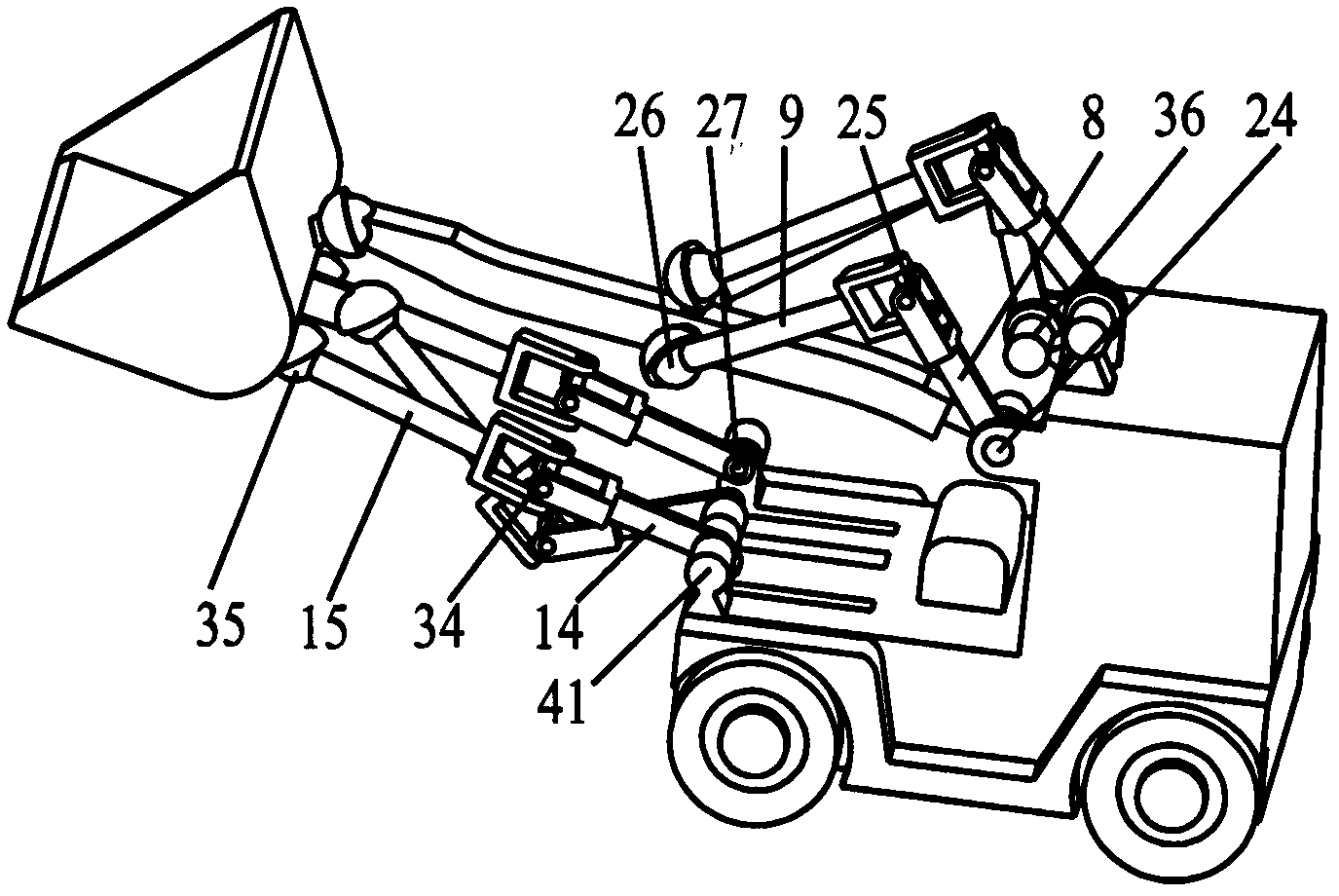

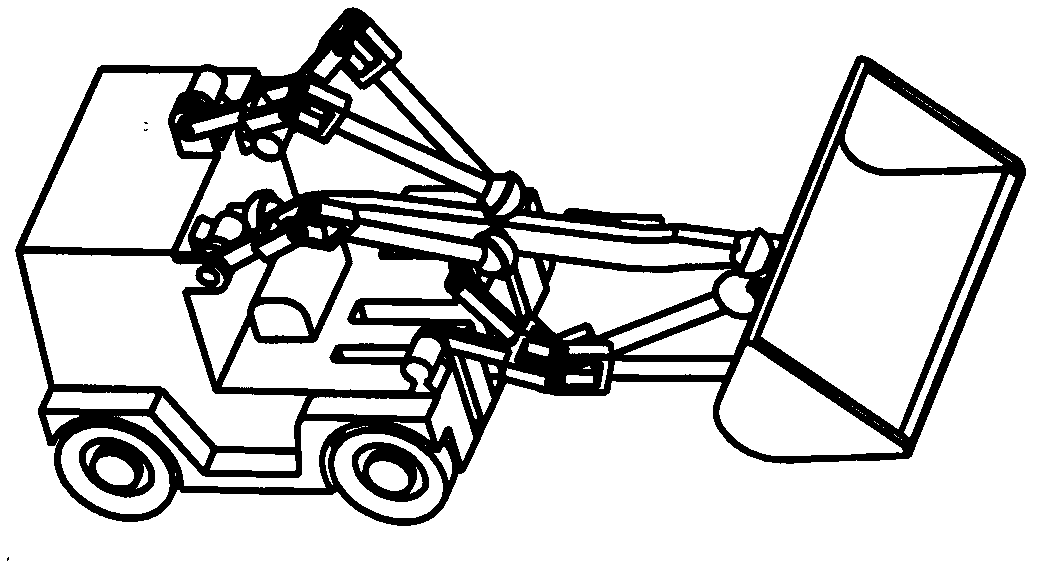

Space controllable mechanism-type loader with three-dimensional rotational moving arm and two-dimensional rotational bucket

InactiveCN102535540ALow processing and assembly requirementsOvercoming demandsMechanical machines/dredgersEngineeringWorking space

The invention relates to a space controllable mechanism-type loader with a three-dimensional rotational moving arm and a two-dimensional rotational bucket, which comprises a loader body, the moving arm, the bucket, five drive bars, five connecting bars and five servo motors. The moving arm is capable of rotating three-dimensionally and independently, the bucket is capable of rotating two-dimensionally and independently, and the whole loader is capable of generating movement in a space with five degrees of movement. The space controllable mechanism-type loader effectively overcomes the shortages that hydraulic elements of a hydraulic loader are high in processing precision requirement, high in maintenance cost, difficult in reliable guarantee, easy to leak oil and the like, and also solves the problems of insufficient movement flexibility, limited work space, low work efficiency and the like due to the fact that a plane loader only generates paths in a plane.

Owner:GUANGXI UNIV

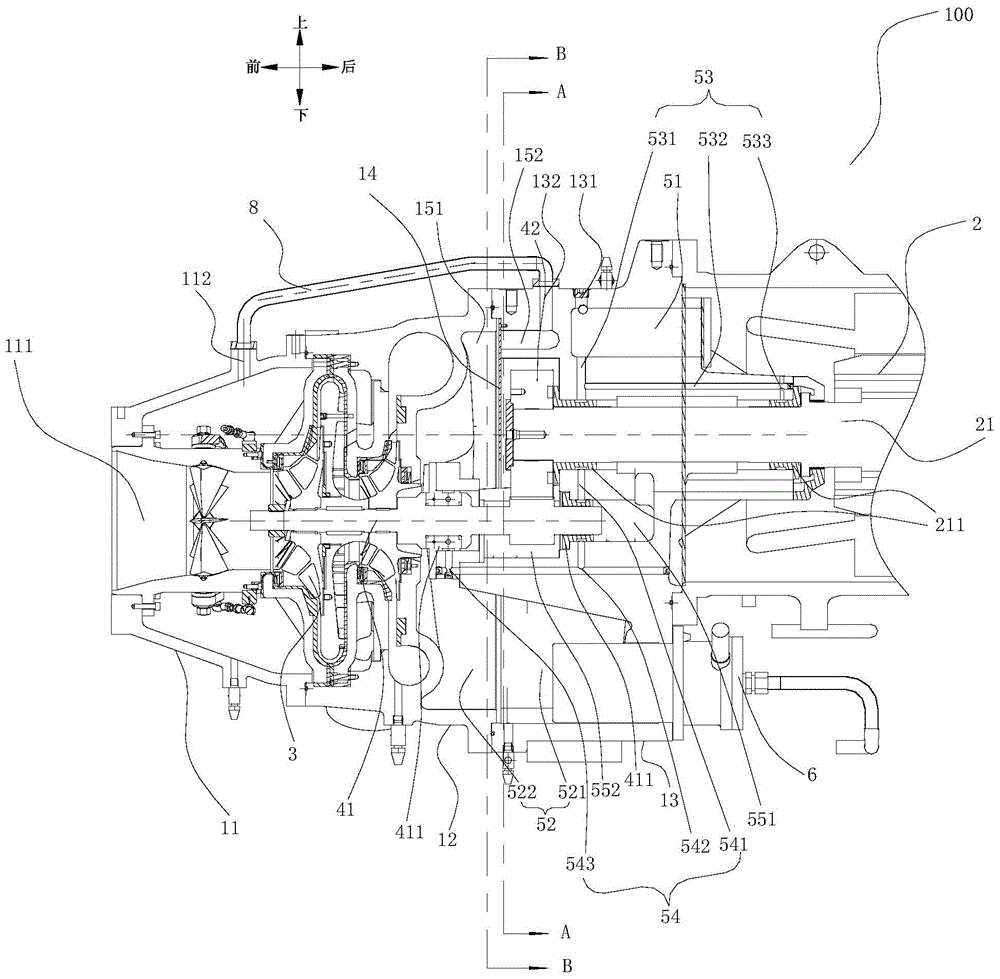

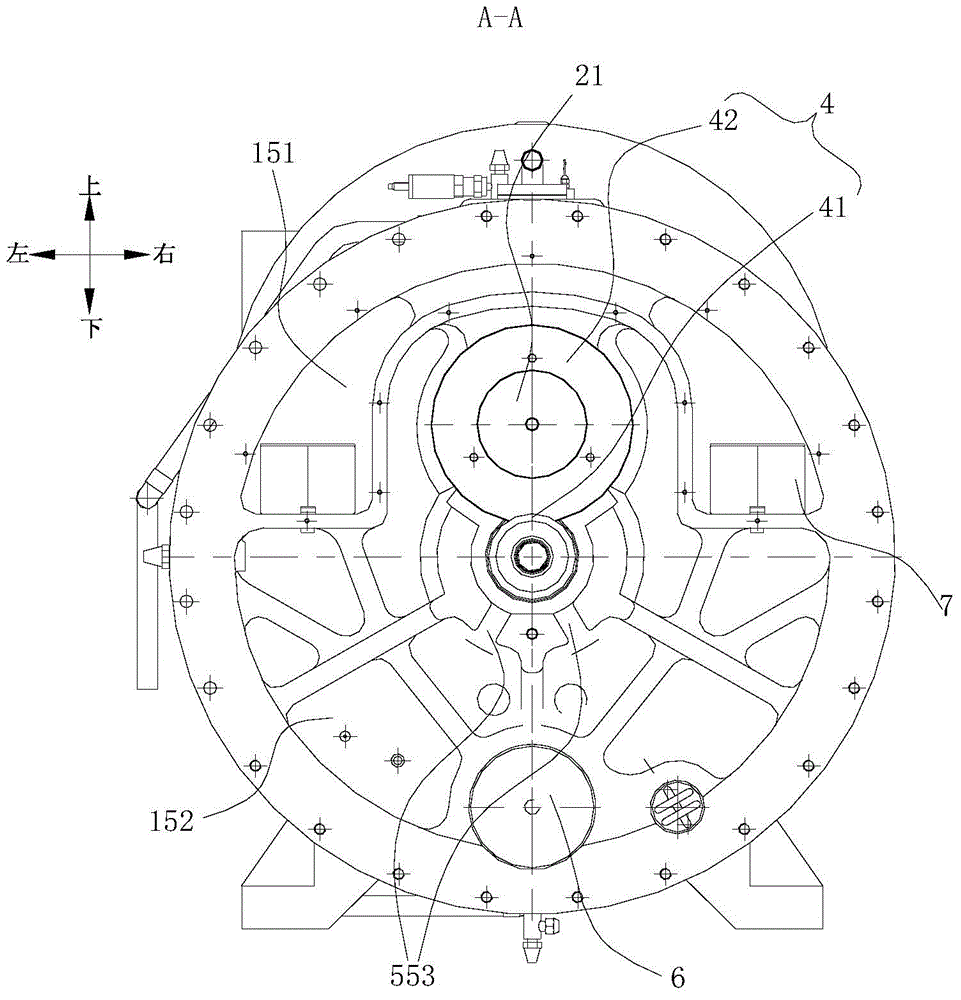

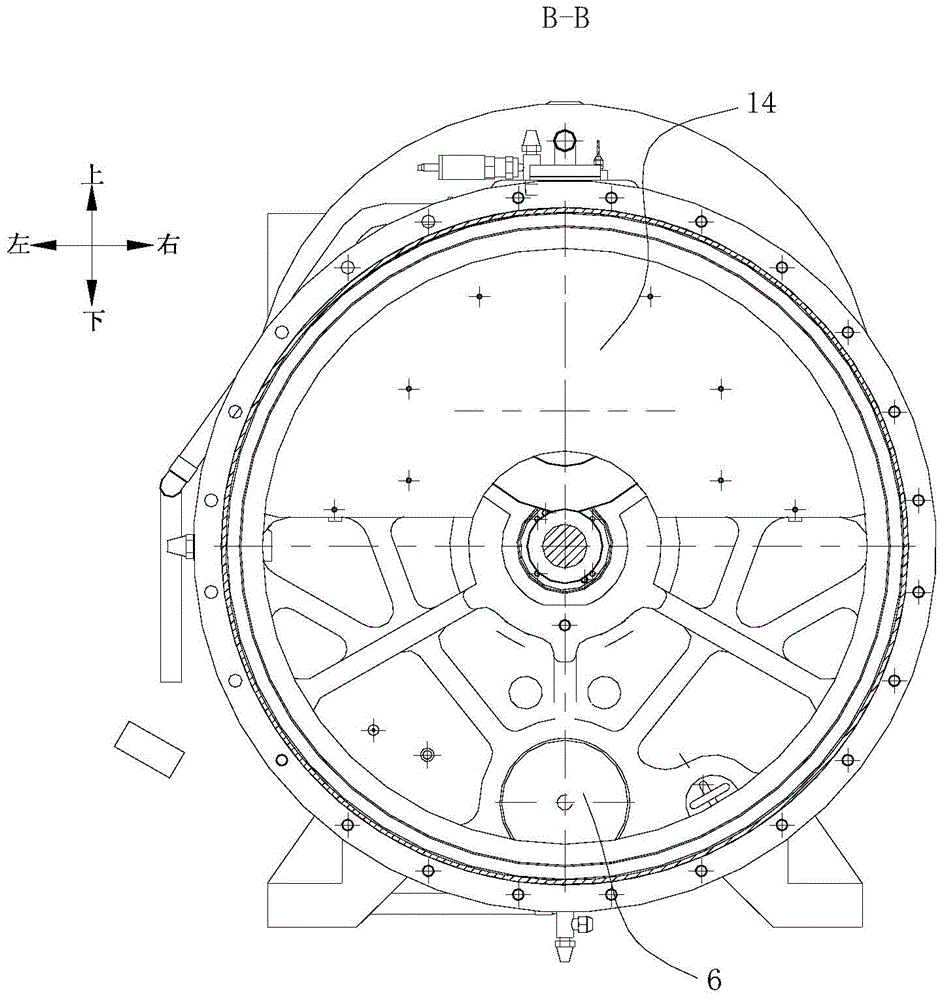

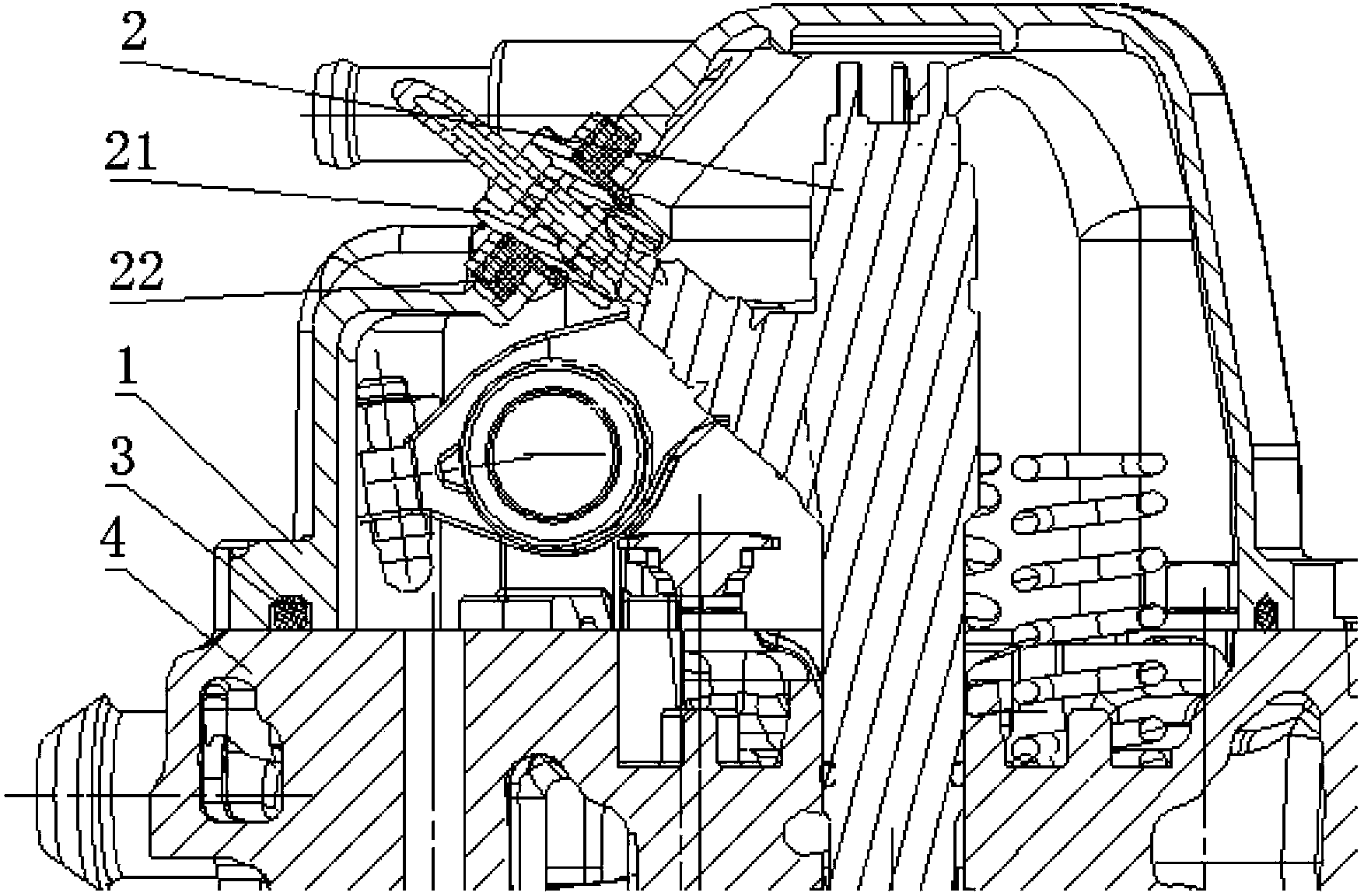

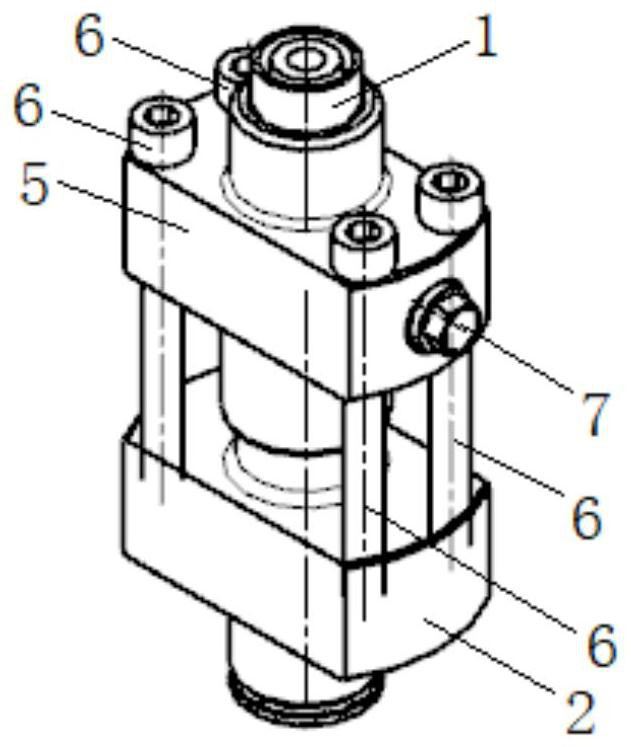

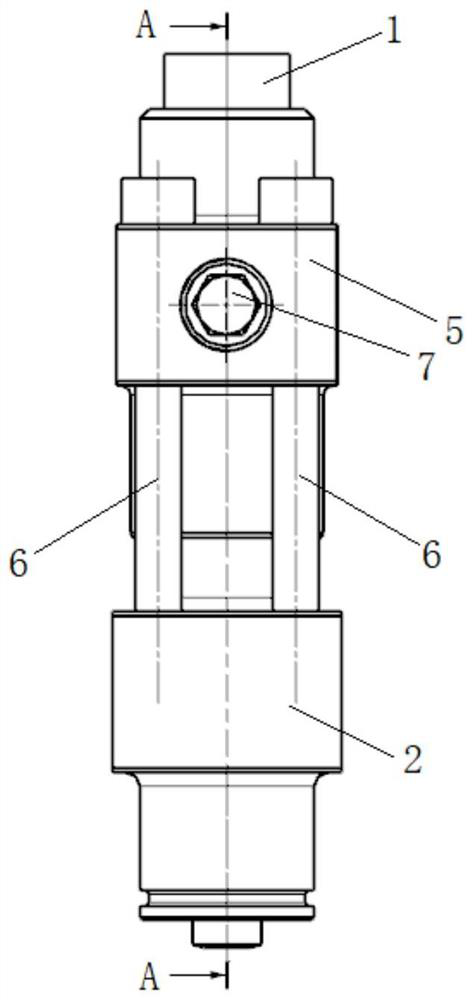

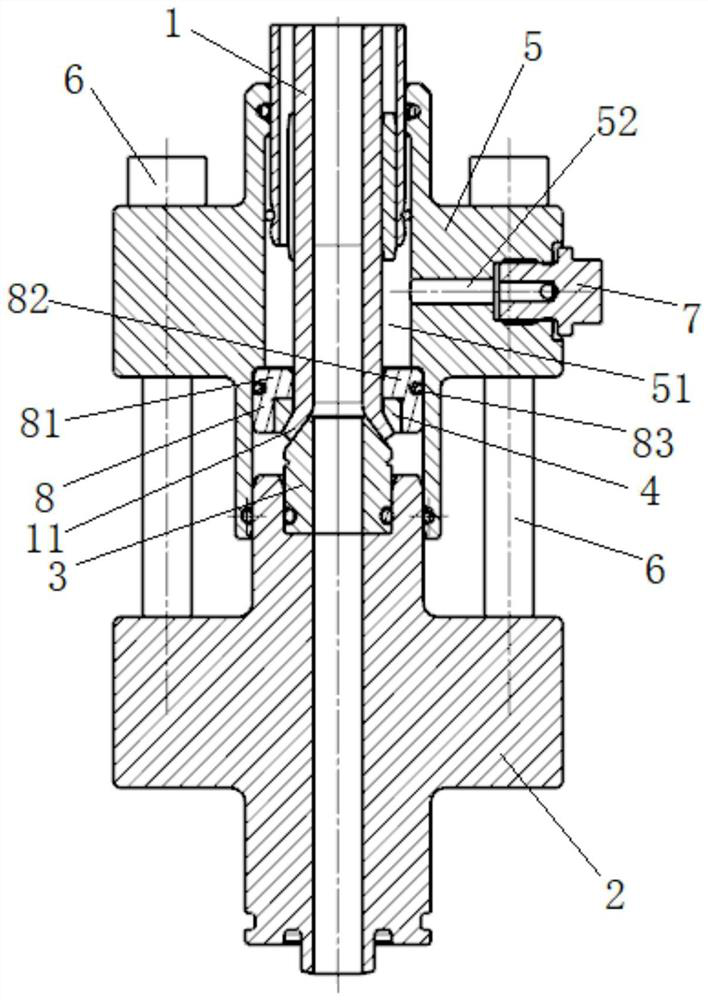

Cantilever centrifugal compressor

ActiveCN105298871AImprove stabilityCompact structurePump componentsPump installationsVertical planeDrive shaft

The invention discloses a cantilever centrifugal compressor which comprises a shell, a motor, an impeller driven by the motor to rotate, a transmission assembly and a lubricating oil way system symmetric about the vertical plane left and right. An output shaft of the motor is supported in the shell through two first bearings which are axially spaced. The transmission assembly is connected with the output shaft. A transmission shaft of the transmission assembly is supported in the shell through two second bearings which are axially spaced. The transmission shaft is sleeved with the impeller. The transmission shaft and the output shaft are located in the same vertical plane. The lubricating oil way system is arranged in the shell and used for lubricating the two first bearings and the two second bearings. According to the cantilever centrifugal compressor, the gravity center is located on the center plane, stability is high, the structure is compact, occupied space is small, the structure for supporting the shell is simple, the lubricating oil way system is simple, lubricating efficiency and reliability are high, the machining and assembling requirements of the transmission assembly are low, and cost is low.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP

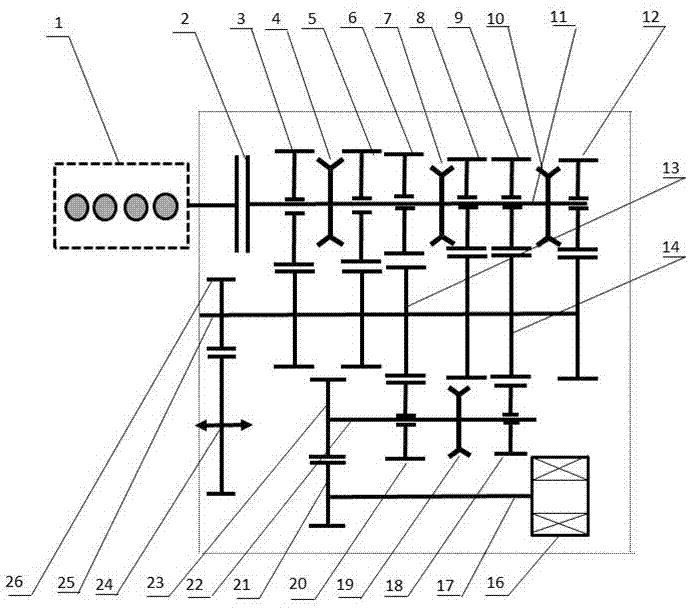

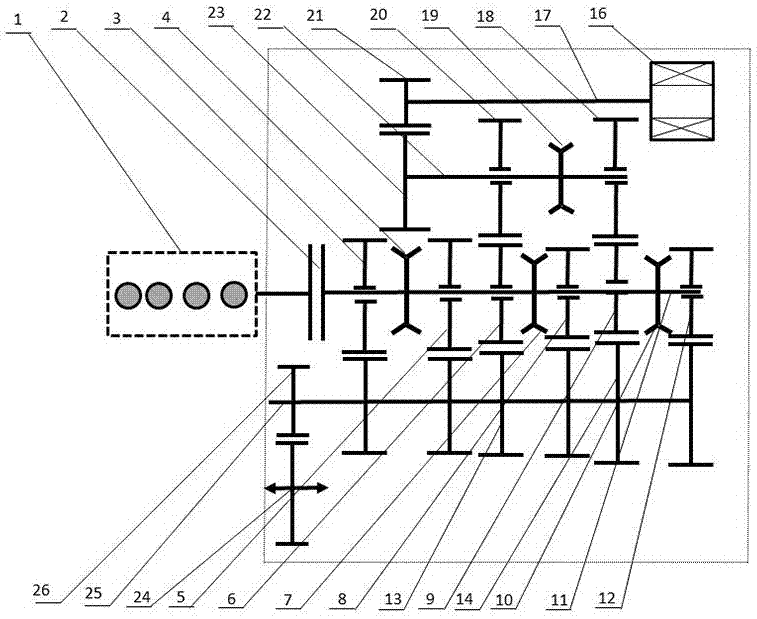

Hybrid coupling device based on mechanical automatic transmission

InactiveCN107187310AEliminates torque interruptionReduced risk of torsional vibrationGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingAutomatic transmissionCoupling

The invention discloses a hybrid coupling device based on a mechanical automatic transmission. The hybrid coupling device comprises an engine, a drive motor, a differential, synchronizers, an engine input shaft assembly, an output shaft assembly and a drive motor input shaft assembly, and further comprises a drive motor shift shaft assembly. The hybrid coupling device disclosed by the invention is compact in structure and convenient to use; the engine and the drive motor can provide sufficient power separately or in a matching manner; when outputting power, the engine input shaft assembly and the drive motor input shaft assembly simply need to respectively output power to the same output shaft assembly; the engine and the drive motor can respectively achieve different speed ratios; on the basis of guaranteeing good power output performance, the structural complexity is reduced; technical complexity and performance are well balanced; machining and assembling requirements are relatively low; output without power interruption can be achieved; the impact on parts is small during shifting; and the hybrid coupling device is low in cost input, safe and reliable, energy-saving and cost-reducing and worthy of widespread use in the technical field.

Owner:湖州伊立机械有限公司

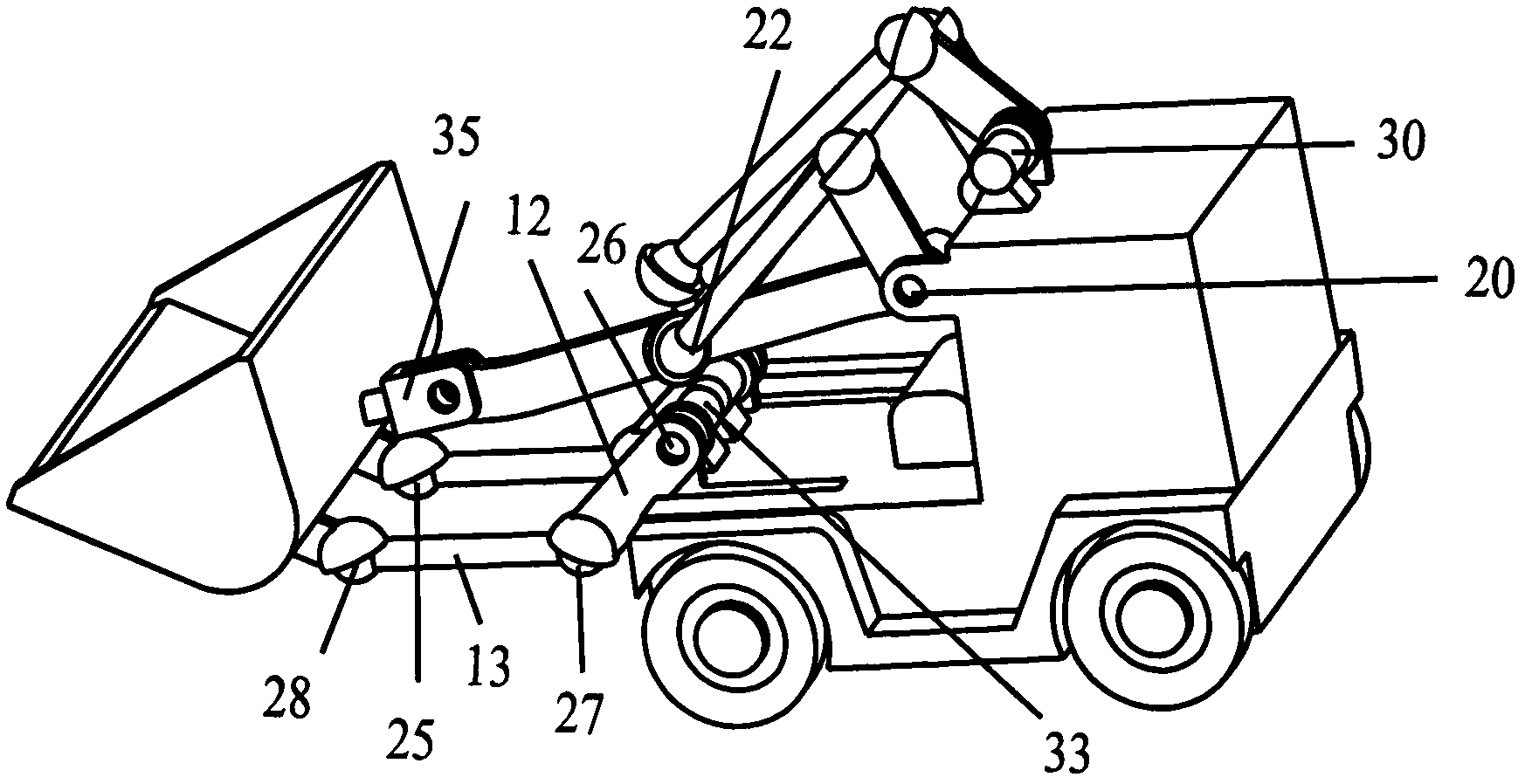

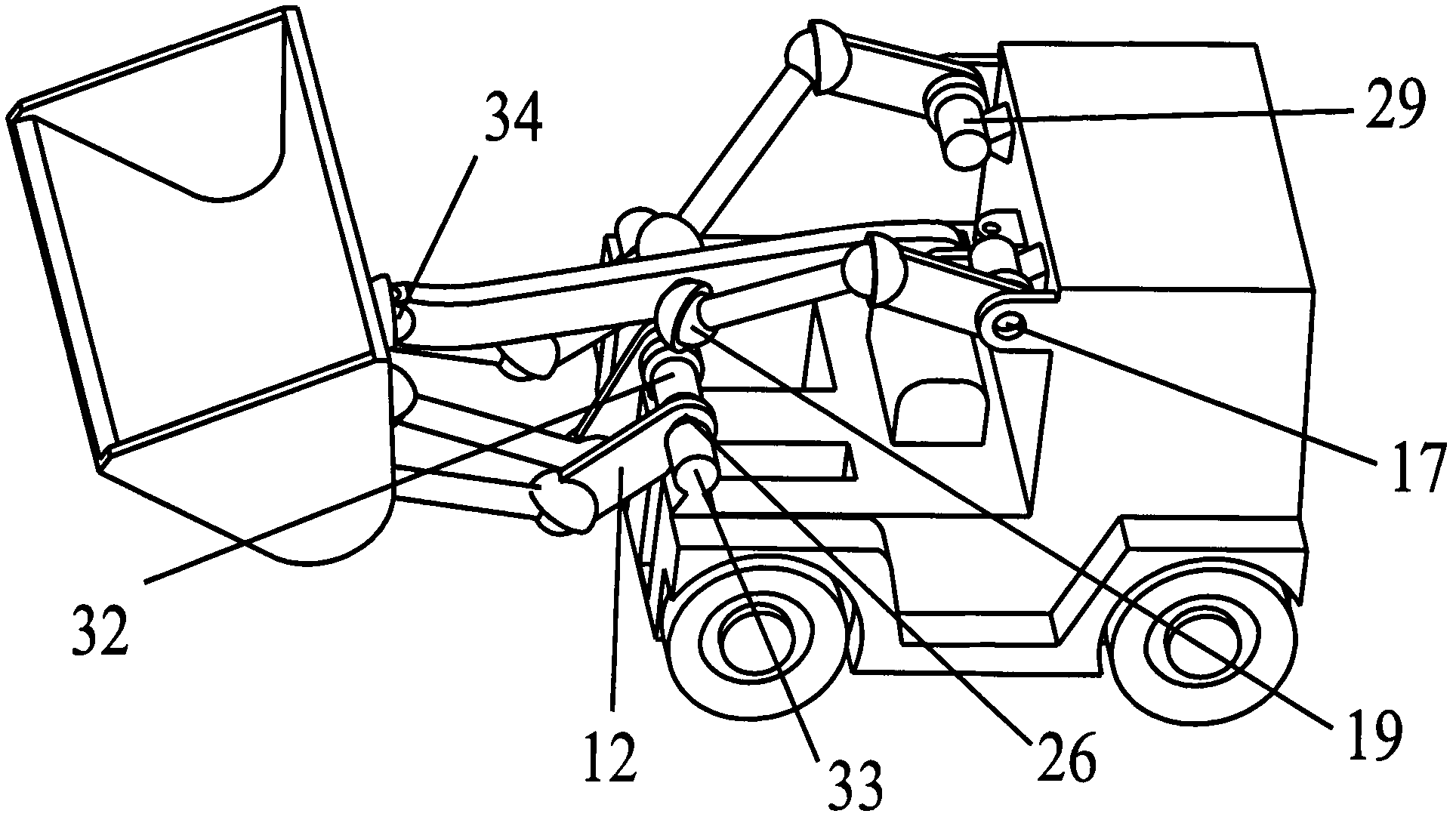

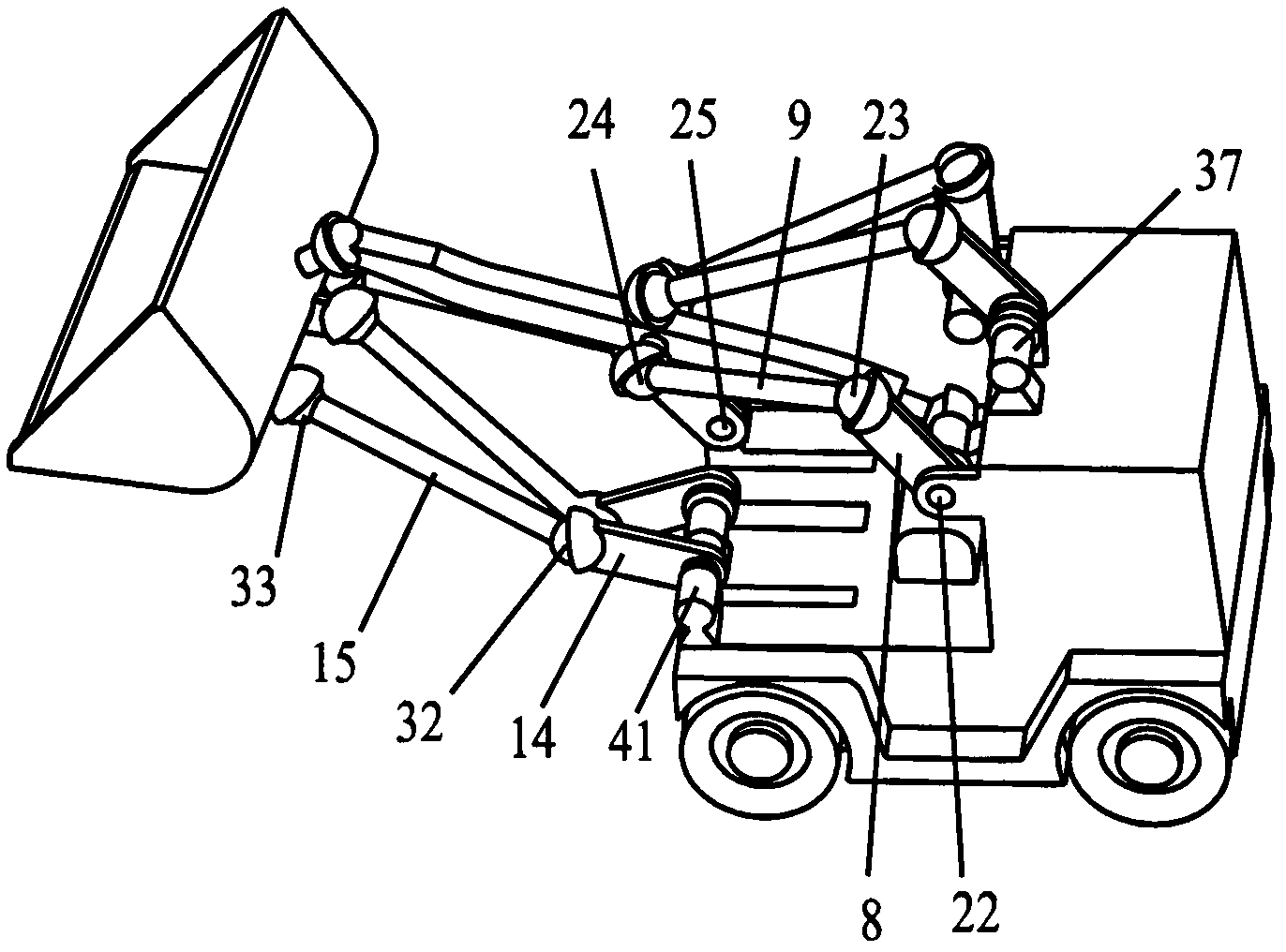

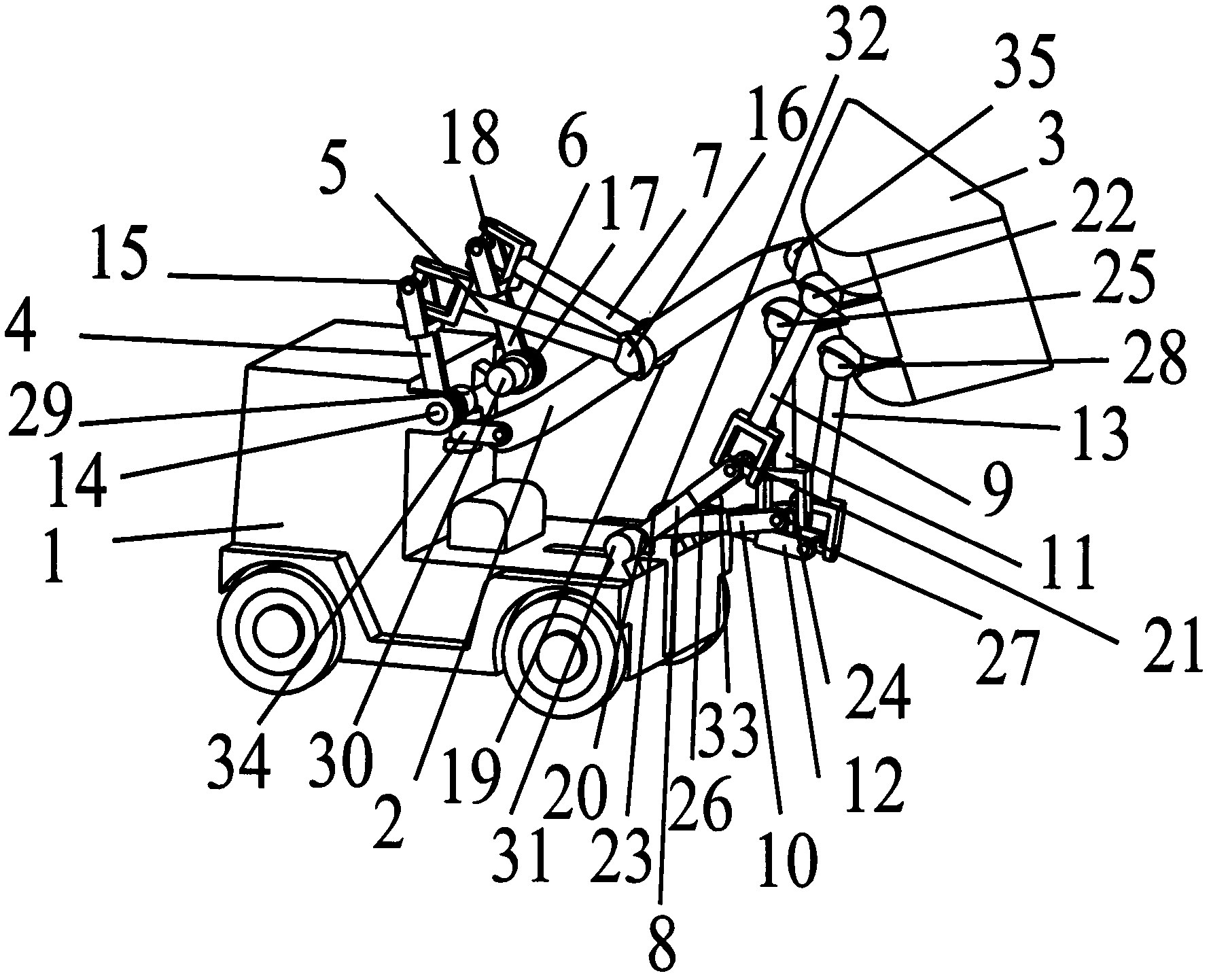

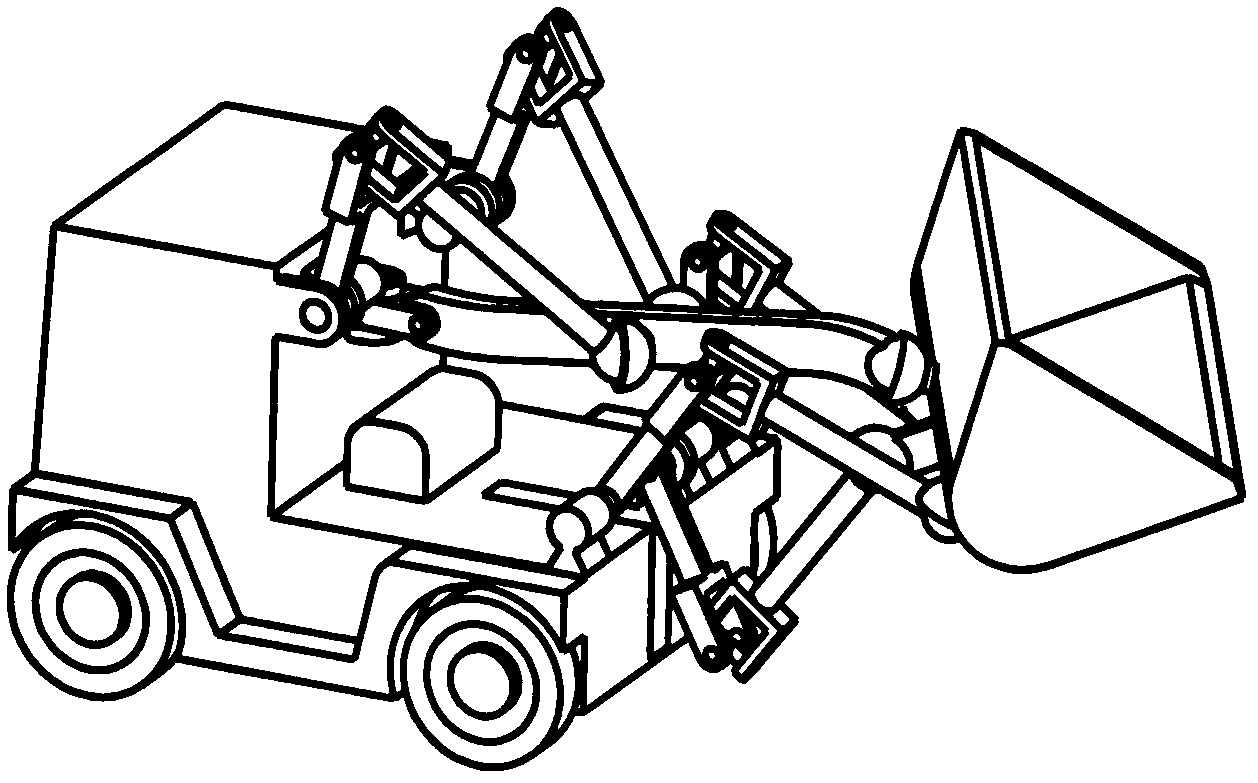

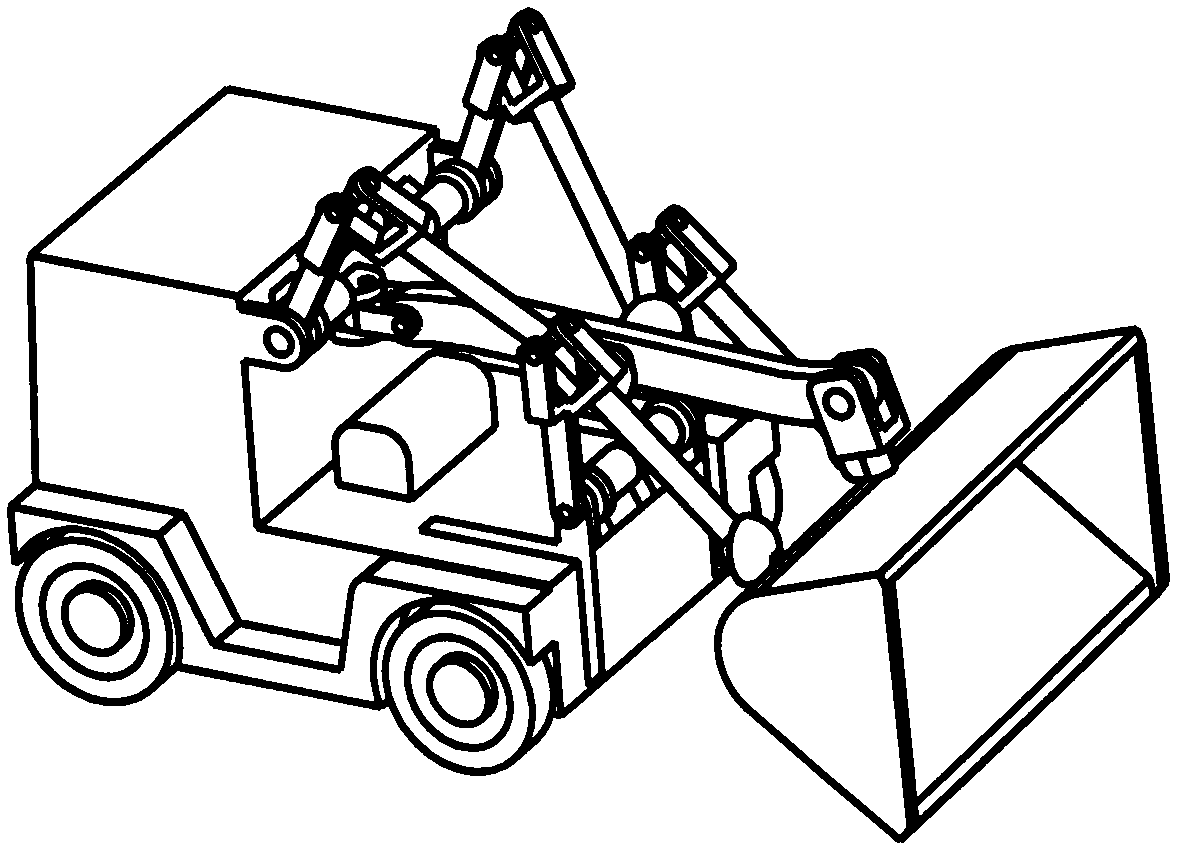

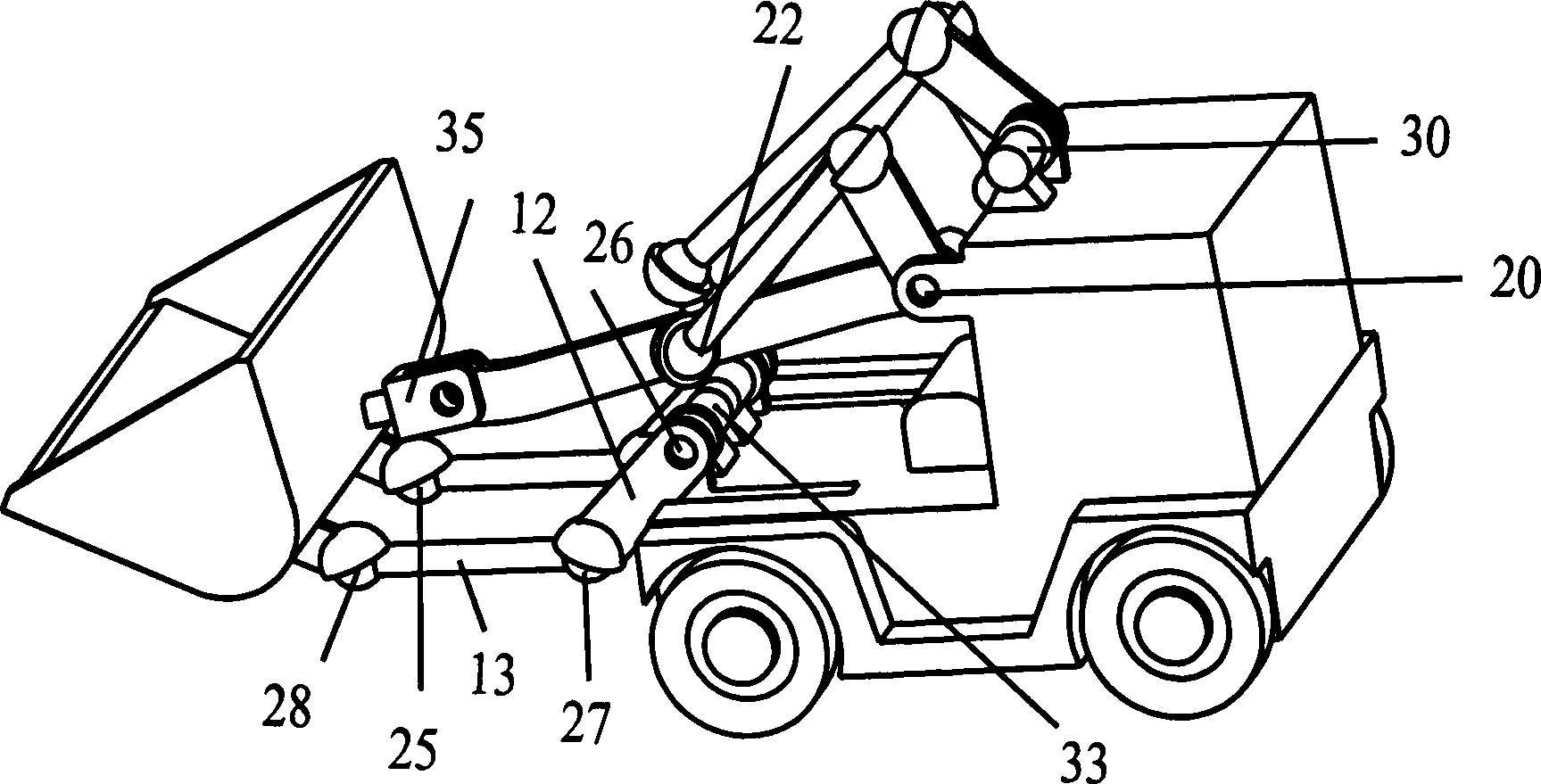

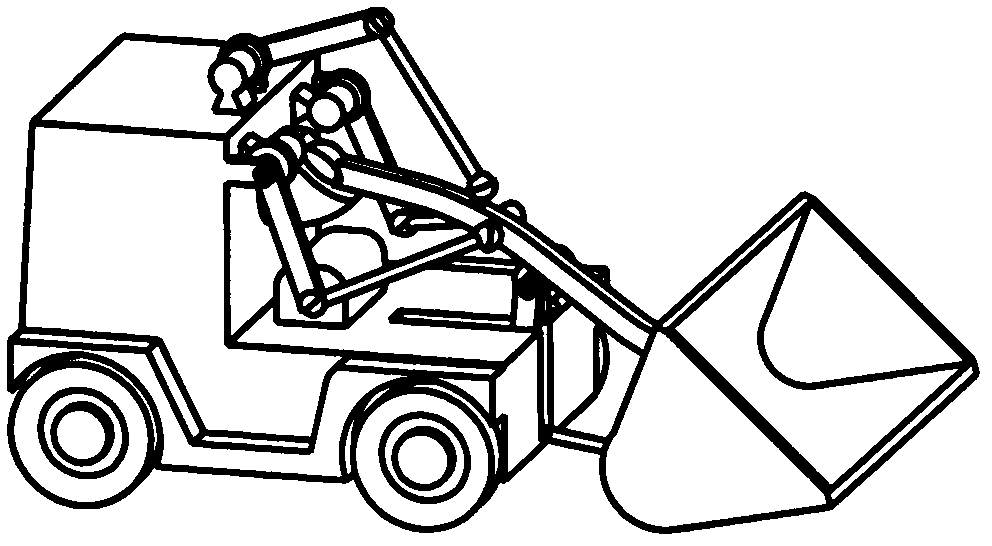

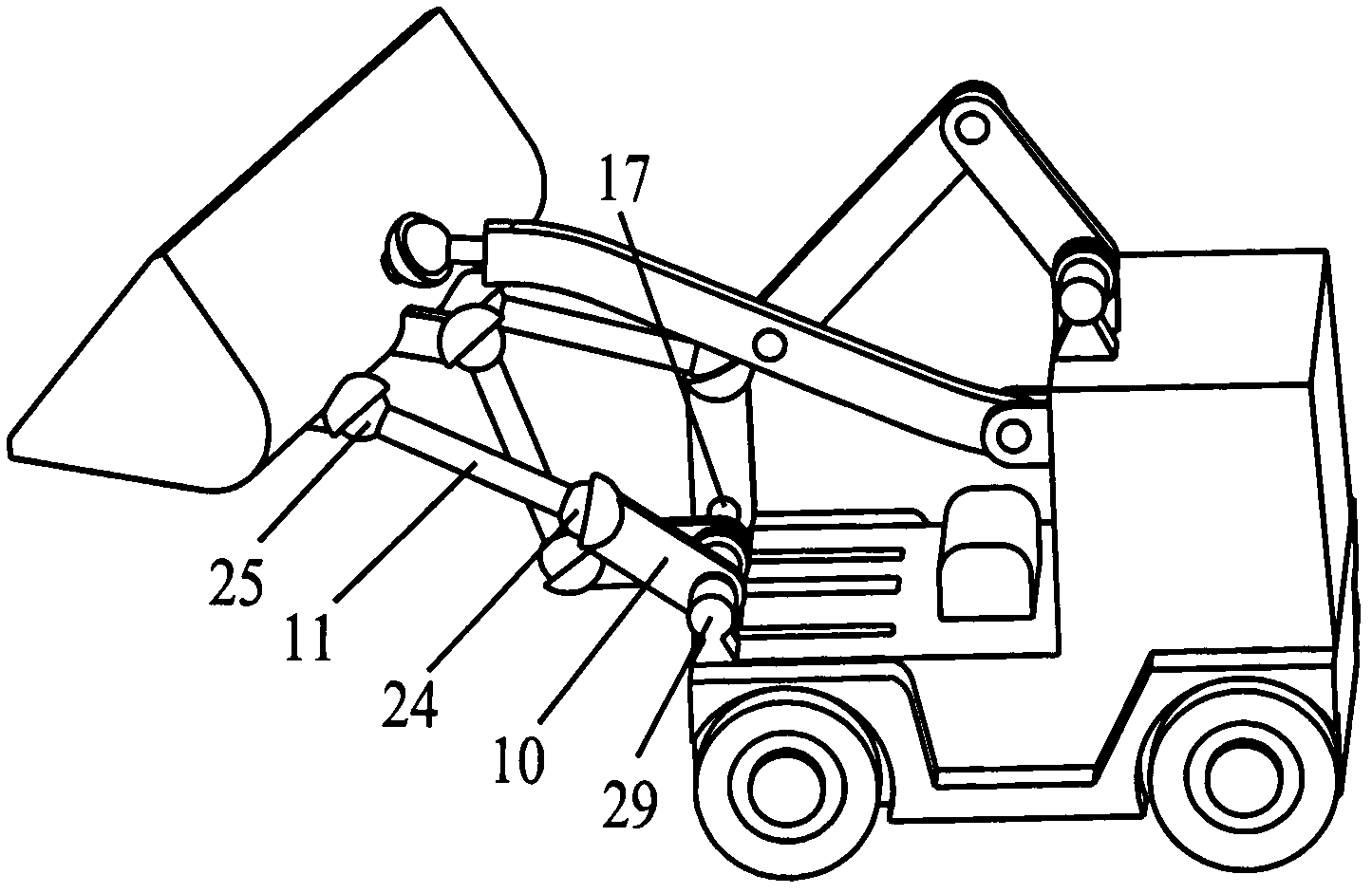

Spatially controllable mechanism type loader with two-dimensional rotary moving arm and three-dimensional rotary bucket

InactiveCN102561417ALow processing and assembly requirementsOvercoming demandsMechanical machines/dredgersRange of motionEngineering

The invention relates to a spatially controllable mechanism type loader with a two-dimensional rotary moving arm and a three-dimensional rotary bucket, which comprises a loader body, a moving arm, a bucket, five drive bars, five connecting bars and five servo motors. The moving arm is capable of independently rotating in two dimensions, the bucket is capable of independently rotating in three dimensions, and the whole loader is capable of moving with five spatial ranges-of-motion. By means of the spatially controllable mechanism type loader with the two-dimensional rotary moving arm and the three-dimensional rotary bucket, the shortages that hydraulic elements of a hydraulic loader are high in precision requirements, high in maintenance cost, difficult in reliability guarantee, prone to oil leakage and the like are solved, and the problems, action inflexibility, limitedness of operation space, low operating efficiency and the like due to the fact that a plane loader only can output plane tracks, are solved.

Owner:GUANGXI UNIV

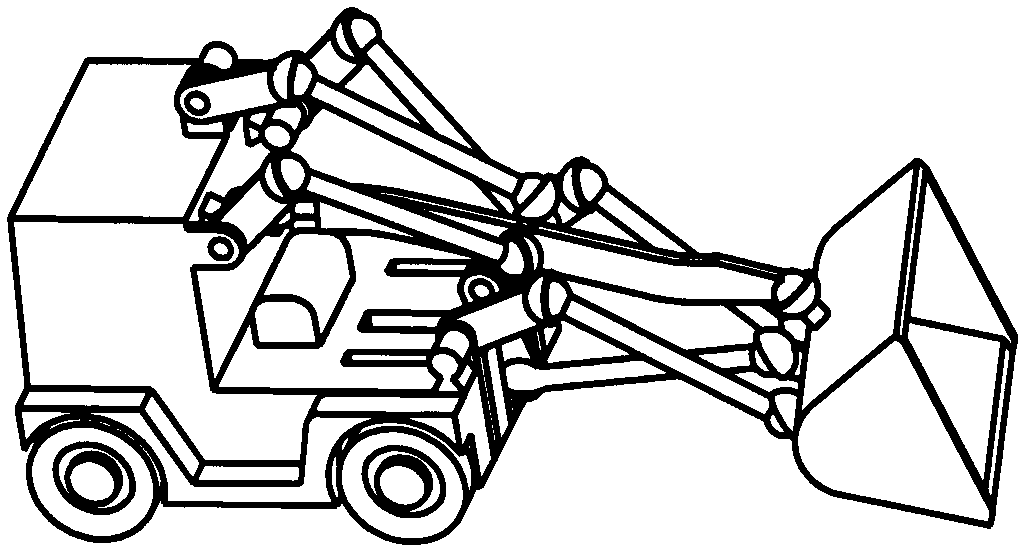

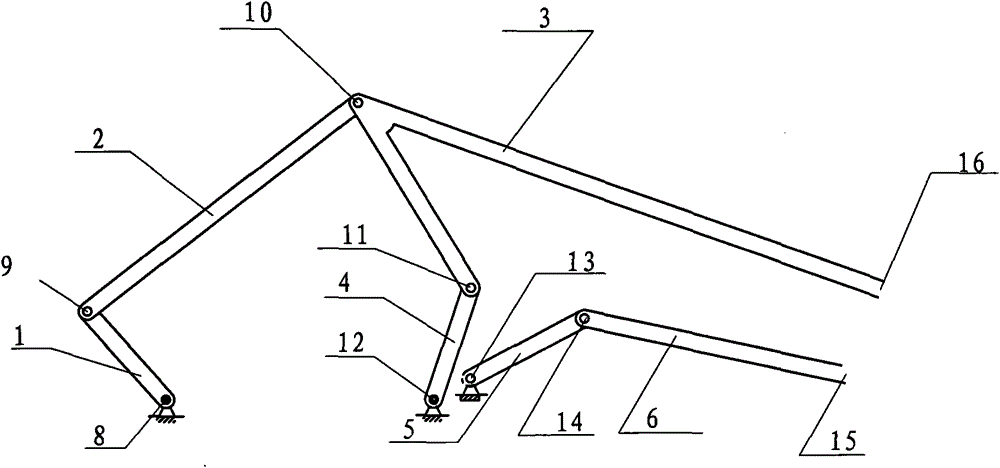

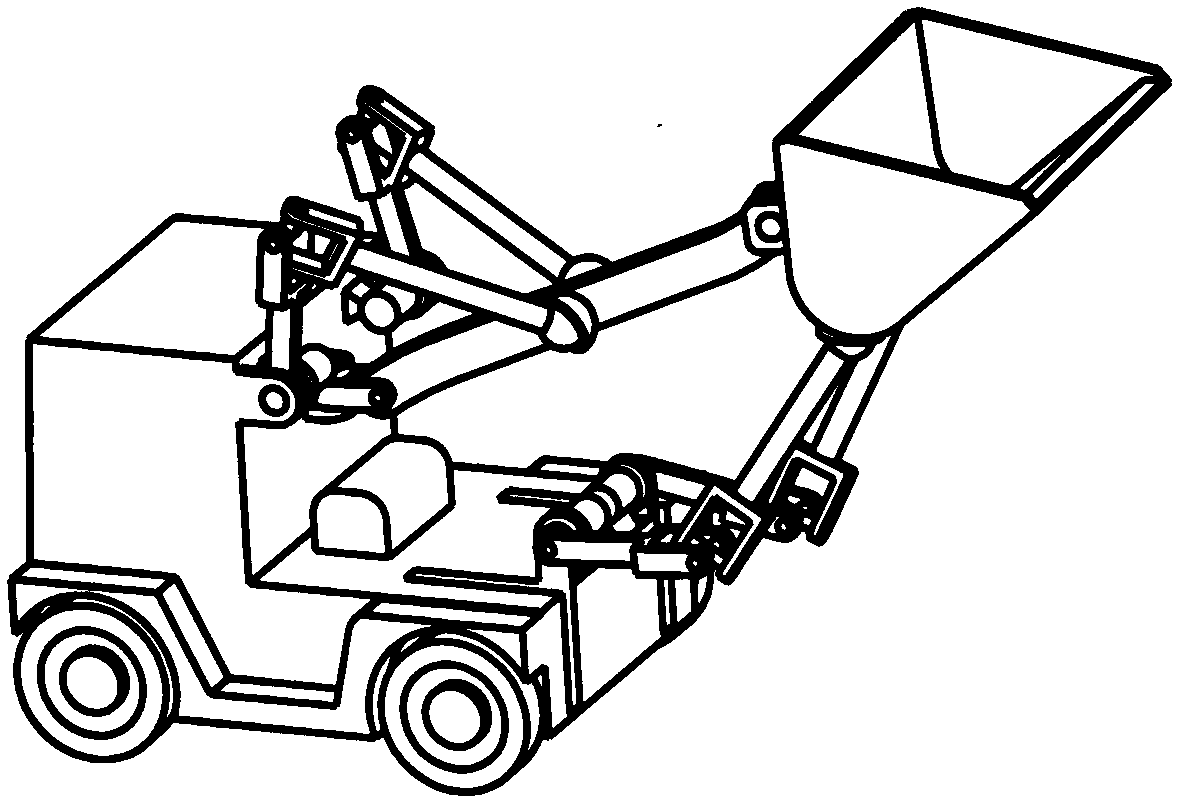

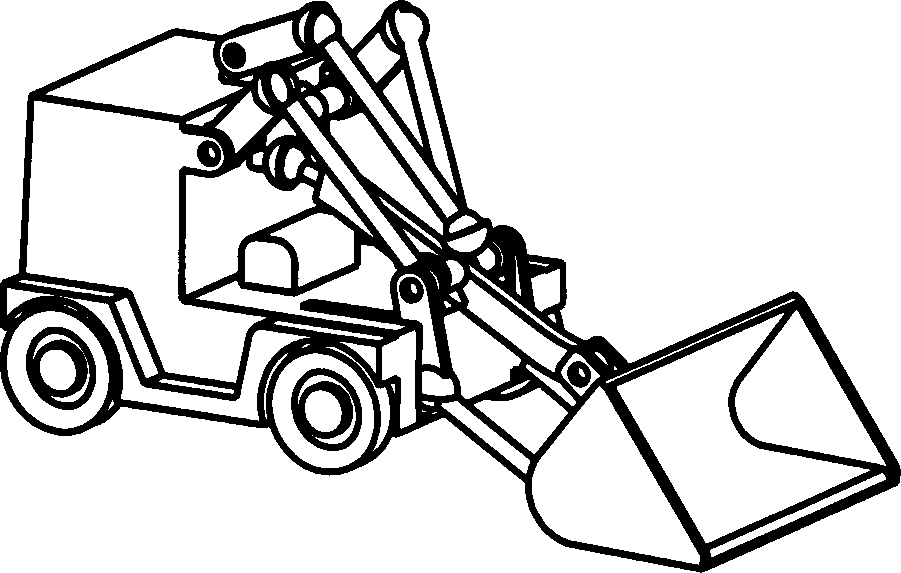

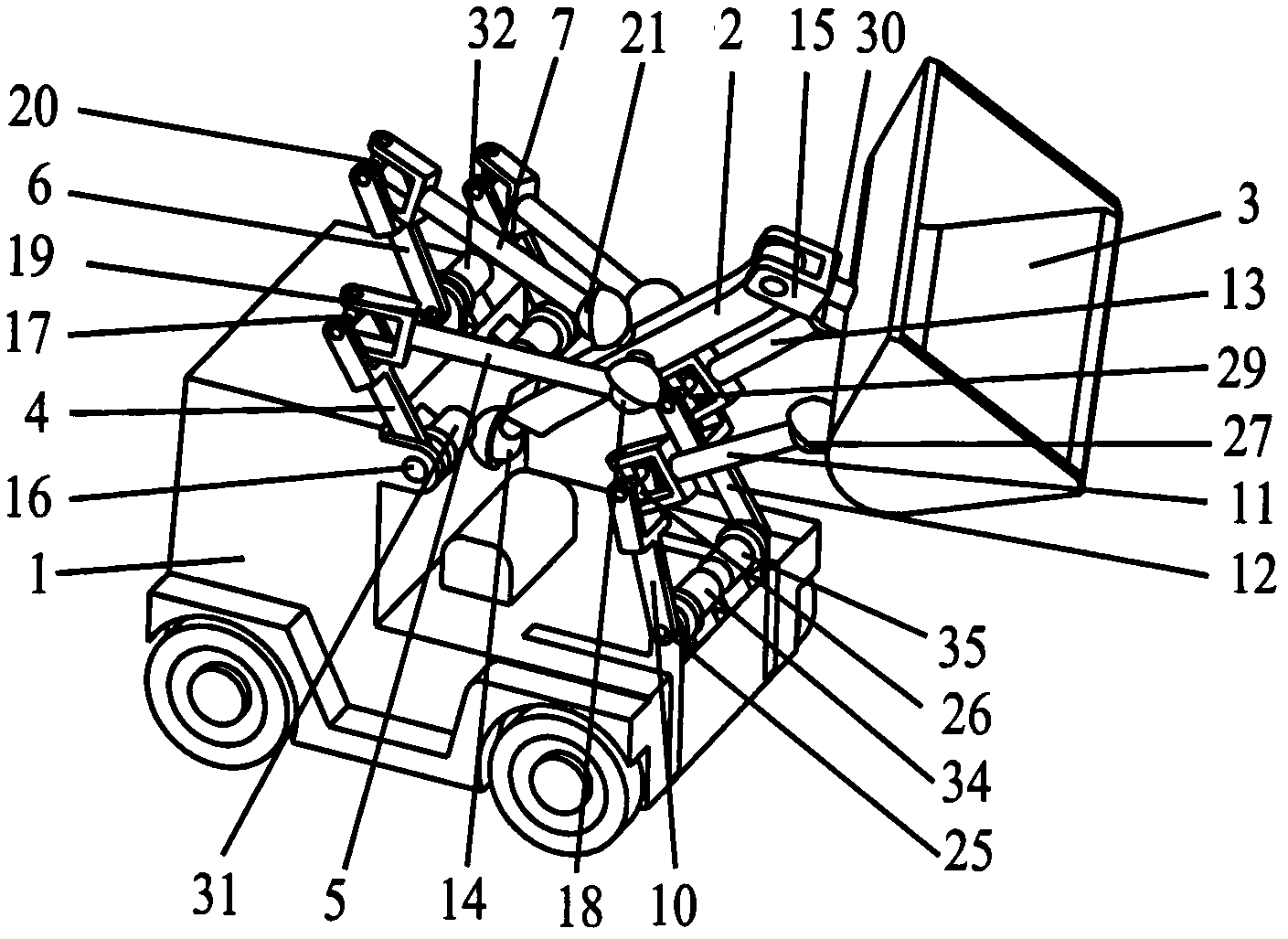

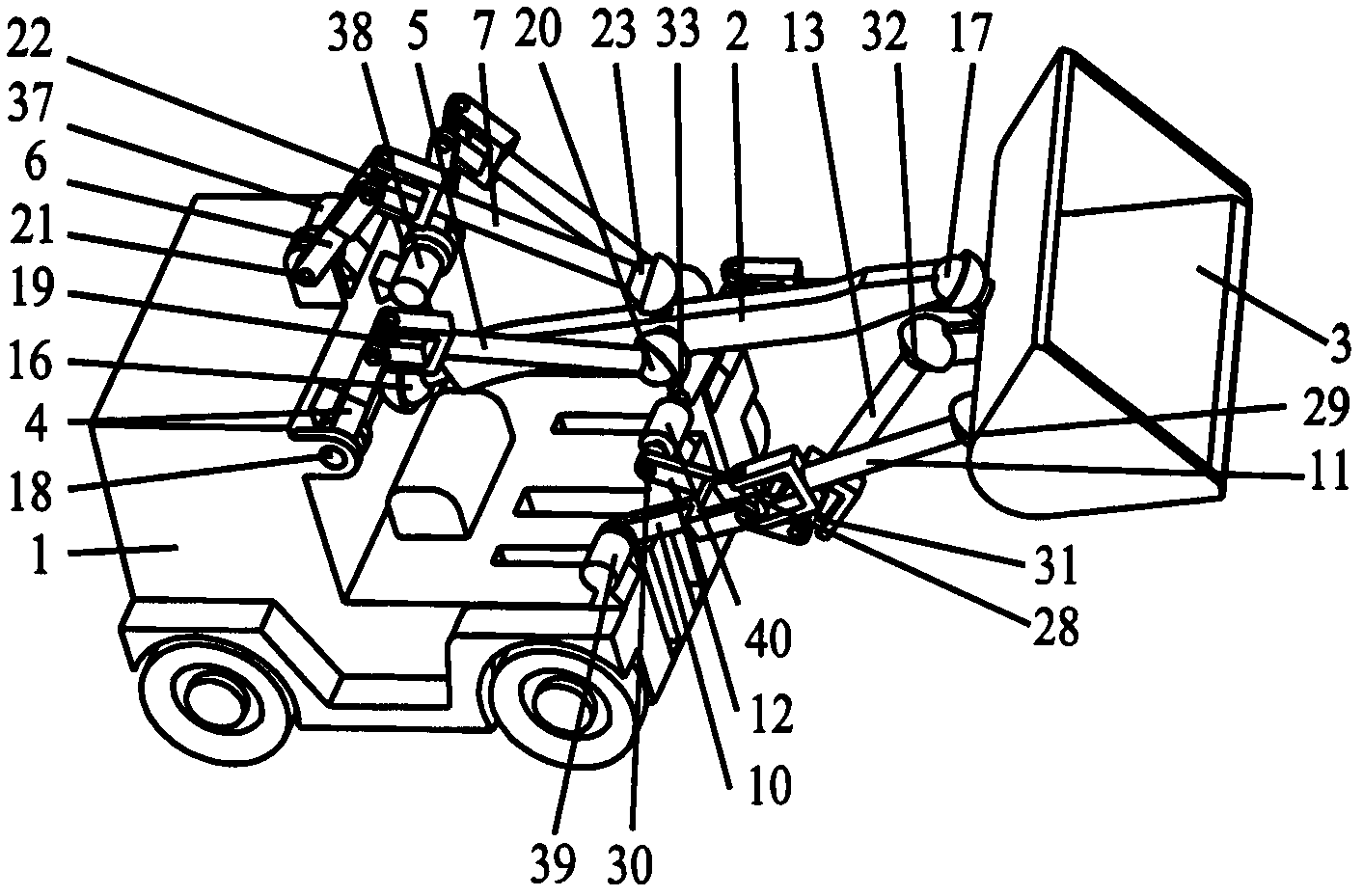

Space-controllable mechanism type loader with three-dimensional rotating movable arm and one-dimensional rotating bucket

InactiveCN102561419ALow processing and assembly requirementsFlexible output trajectoryMechanical machines/dredgersEngineeringWorking space

The invention relates to a space-controllable mechanism type loader with a three-dimensional rotating movable arm and a one-dimensional rotating bucket, comprising a vehicle, the movable arm, the bucket, six driving rods, six connecting rods and six servo motors; both the movable arm and bucket can rotate three-dimensionally independently; and the whole loader can realize the output of six degrees of space motion. The space-controllable mechanism type loader can effectively overcome the defects of high requirement for the processing precision of the hydraulic elements, high maintenance cost, difficult guarantee of reliability and easy oil leakage of the hydraulic loader and solve the problems of inflexible motion, limited work space and low work efficiency due to the output of the trajectory only in the plane of the plane loader.

Owner:GUANGXI UNIV

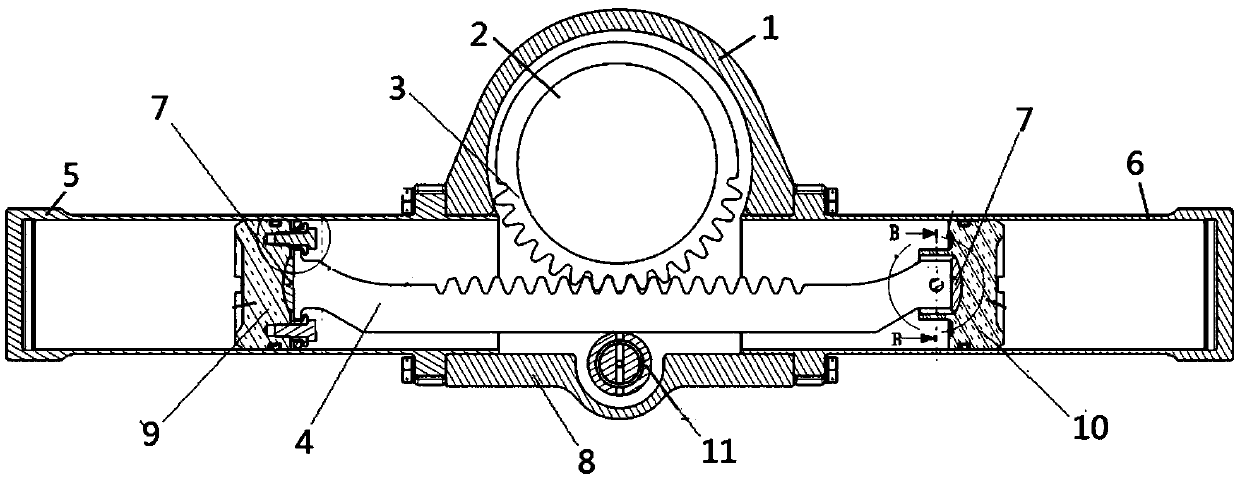

Aircraft turning mechanism

The invention discloses an aircraft turning mechanism. The aircraft turning mechanism is connected between an undercarriage outer cylinder and a rotating piston rod, and comprises a first actuating cylinder, a second actuating cylinder, a rack, a gear and a supporting frame, the gear is connected to the rotating piston rod of an undercarriage, one end of the rack is connected with a pushing pistonof the first actuating cylinder, the other end of the rack is connected with a pushing piston of the second actuating cylinder, the supporting frame is located on the lower part of the rack, the rackand the pushing piston are in clearance connection, and the rack and the supporting frame are in rolling connection.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

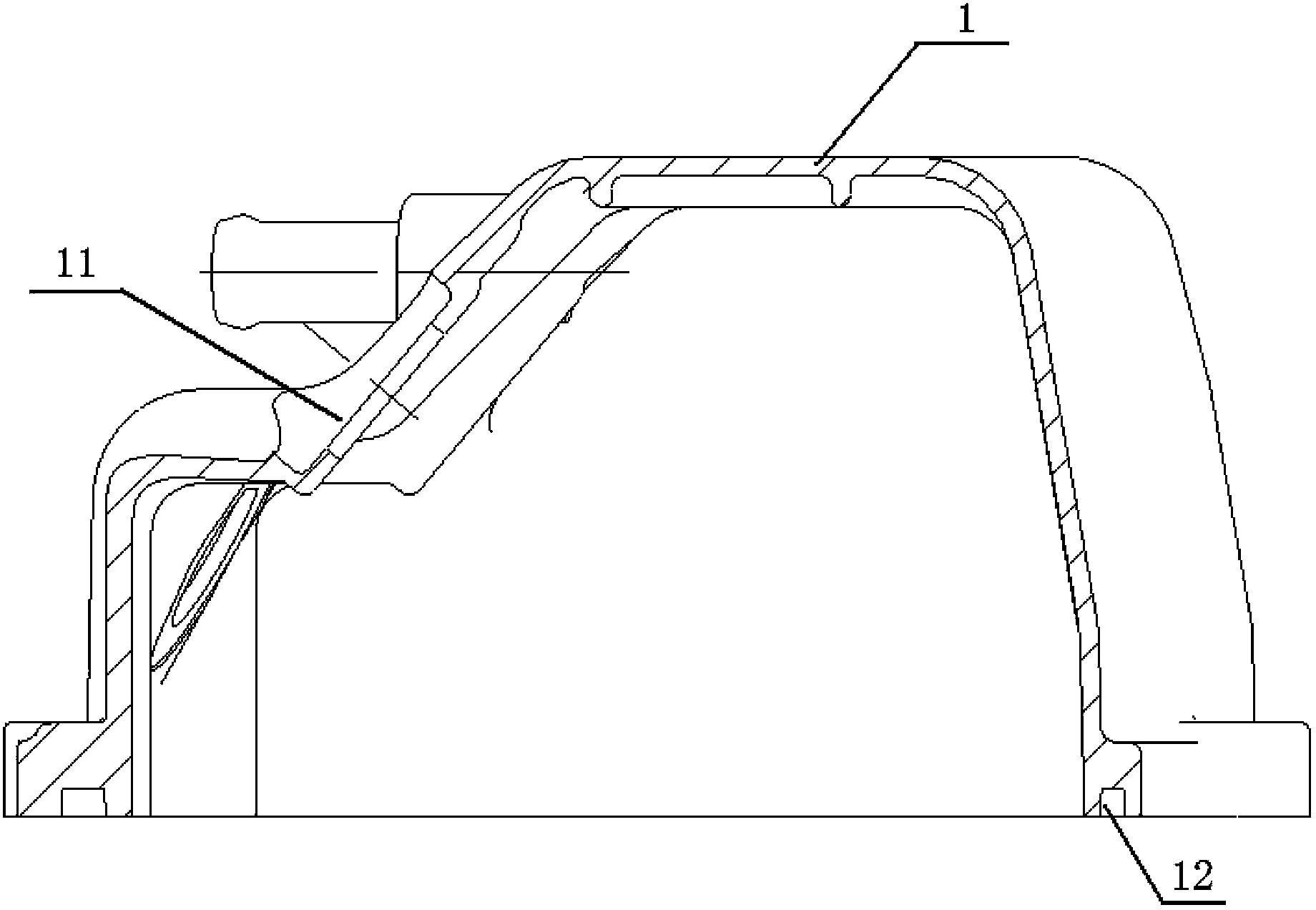

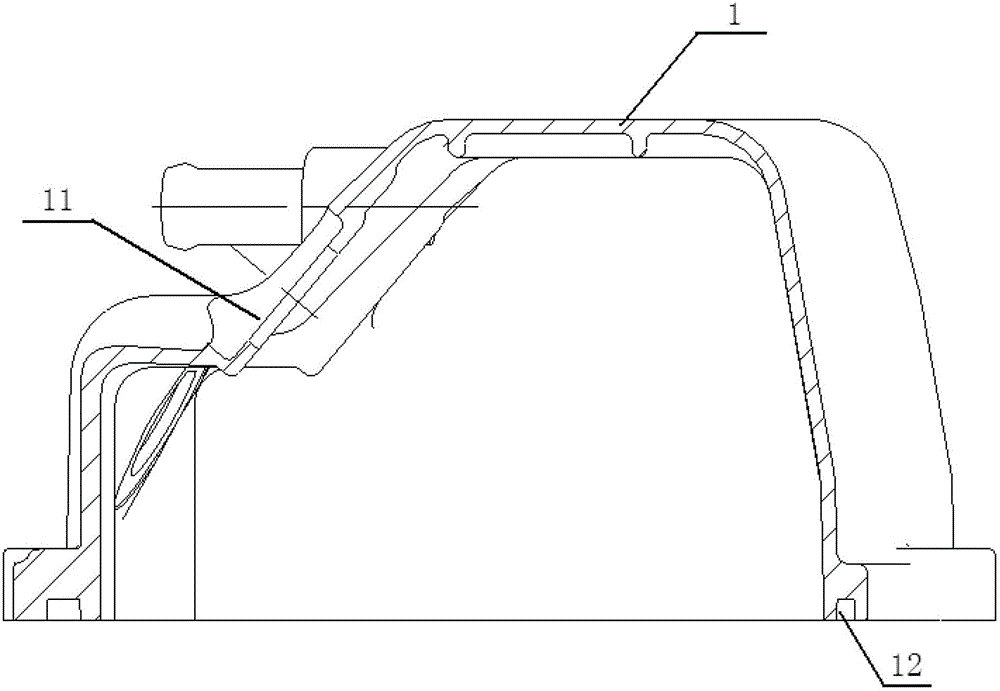

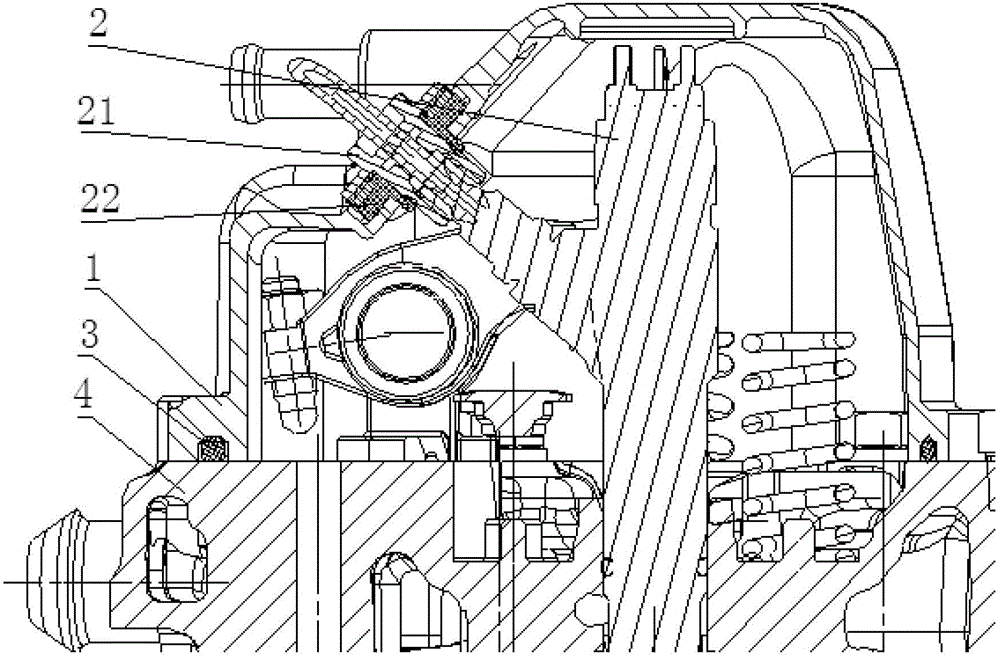

Diesel engine cylinder head cover

ActiveCN103410630ASimple structureImproves sealing reliabilityCasingsSealing arrangements for enginesCylinder headEngineering

The invention discloses a diesel engine cylinder head cover. The diesel engine cylinder head cover comprises a cylinder head cover body, an oil sprayer installation through hole and a cylinder head cover gasket seal positioning groove, wherein the cylinder head cover body is arranged on a cylinder head in a covering mode through an installation flange at the bottom of the cylinder head cover body; the oil sprayer installation through hole is of a big-end-up stepped hole structure and comprises an upper installation countersunk groove and a lower sleeve nut penetrating hole, and a high-pressure oil pipe seal ring is in clearance fit with the sleeve nut penetrating hole and forms end face seal with the connection stepped face of the installation countersunk groove and the sleeve nut penetrating hole; the cylinder head cover gasket seal positioning groove is formed in the face of the installation flange of the cylinder head cover body. The diesel engine cylinder head cover is simple and reasonable in structure; due to the fact that radial close fit seal between a high-pressure oil pipe sleeve nut and the oil sprayer installation through hole is improved to end face seal, processing and assembling requirements are lowered, and seal reliability is improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

Hybrid drive controllable parallel-connection excavation mechanism

InactiveCN104153405AAvoid disadvantagesTo overcome the shortage of large quantitiesMechanical machines/dredgersThree degrees of freedomSingle degree of freedom

The invention relates to a hybrid drive controllable parallel-connection excavation mechanism. The hybrid drive controllable parallel-connection excavation mechanism comprises an excavation arm, a forward shoveling type bucket and a machine frame, wherein the excavation arm is a three-degree-of-freedom hybrid drive controllable mechanism and is formed by connecting a composite hinge, a connecting rod and the forward shoveling type bucket. The excavation arm is installed on the machine frame and driven by a large-power normal-speed motor and two small-power servo motors in a hybrid mode, and large excavation force and certain output flexibility can be realized. The hybrid drive controllable parallel-connection excavation mechanism not only resolves the problems that a traditional single-degree-of-freedom mechanical excavation mechanism is simple in realization movement, and a hydraulic excavation mechanism is prone to oil leakage, but also resolves the problem that an existing two-degree-of-freedom hybrid drive excavation mechanism needs two normal-speed motors, eliminates one normal-speed motor, has a certain energy-saving effect and is low in manufacturing cost and high in excavation efficiency.

Owner:ZHONGBEI UNIV

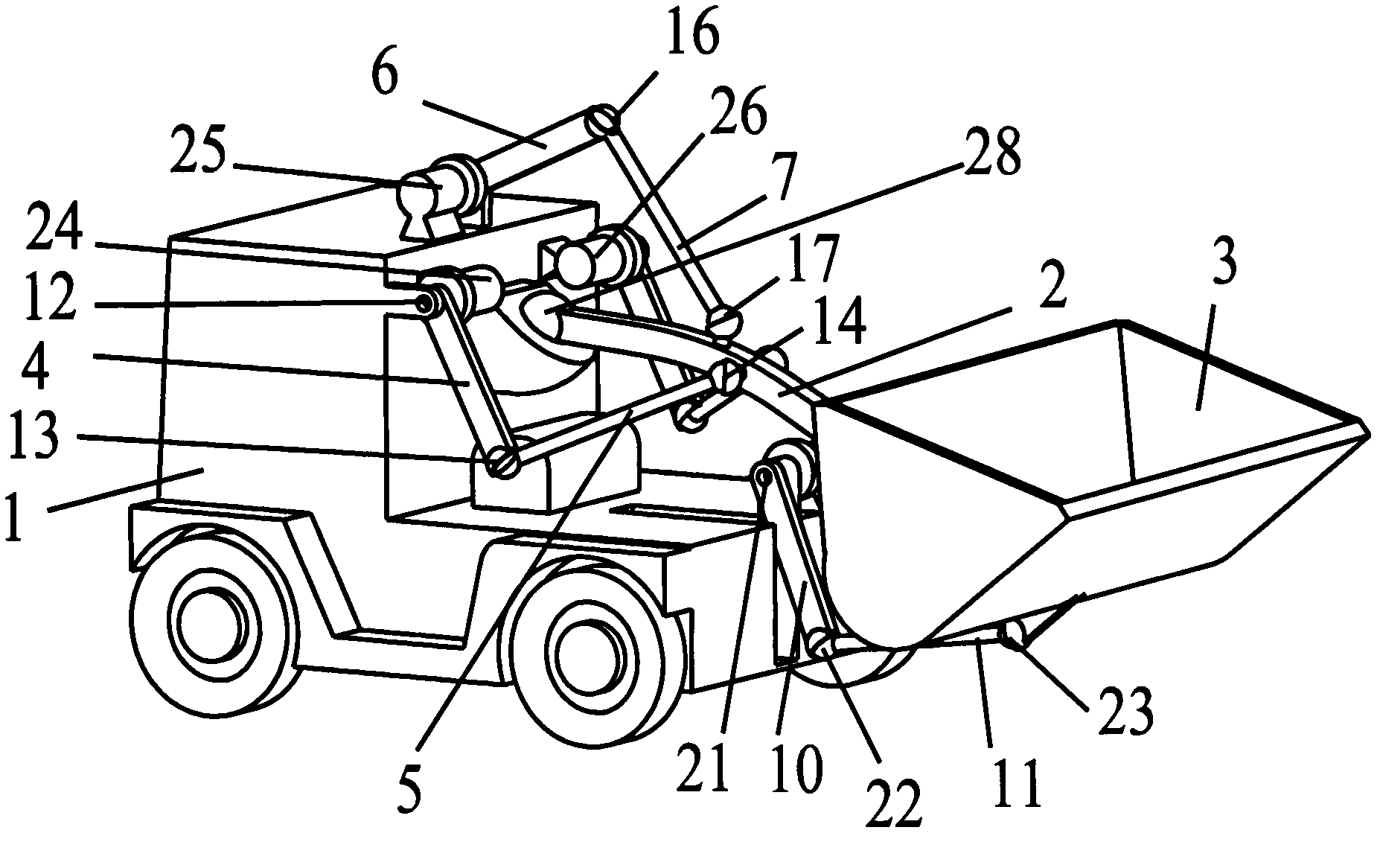

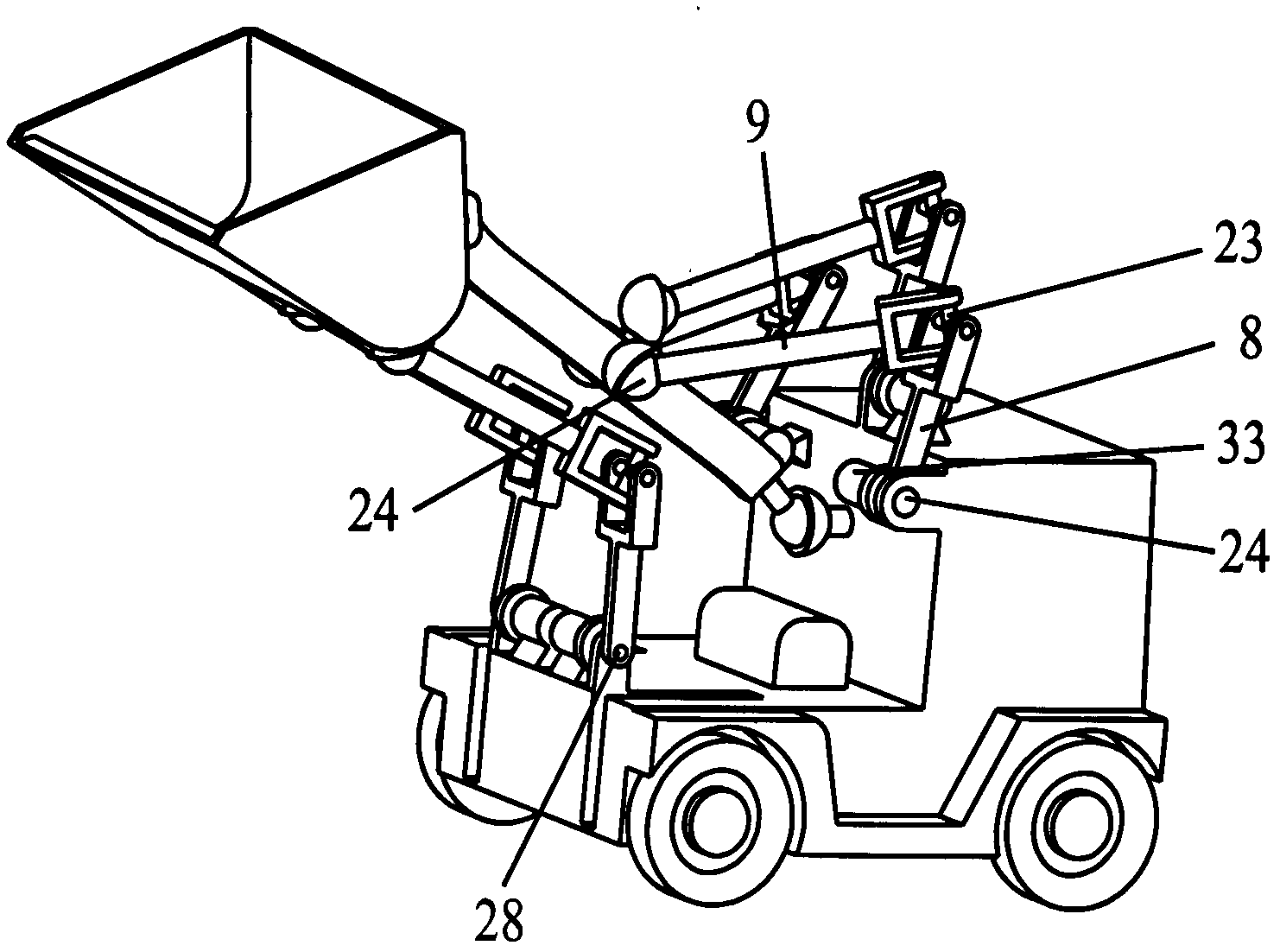

Space controllable mechanism type loader with movable arm capable of two-dimensionally rotating and bucket capable of one-dimensionally rotating

InactiveCN102561421ALow processing and assembly requirementsOvercoming demandsMechanical machines/dredgersEngineeringWorking space

The invention relates to a space controllable mechanism type loader with a movable arm capable of two-dimensionally rotating and a bucket capable of one-dimensionally rotating. The space controllable mechanism type loader comprises a loader body, the movable arm, the bucket, three driving rods, three connecting rods and three servo motors, the movable arm can two-dimensionally rotate independently, the bucket can one-dimensionally rotate independently, and the total loader can realize spatial movable output with three degrees of movement. The space controllable mechanism type loader can effectively overcome shortcomings that requirements on processing precision of hydraulic elements of a hydraulic loader are high, repair and maintenance costs are high, reliability is difficult to be guaranteed, oil leaks easily and the like. In addition, the space controllable mechanism type loader can resolve problems that a planar loader only can realize output along a trace in a plane, actions are not flexible, a working space is limited, work efficiency is low, and the like.

Owner:GUANGXI UNIV

Pipeline connecting structure

PendingCN113944815AFit closelyReduced stiffness requirementsSleeve/socket jointsFlanged jointsStructural engineeringMachining

The invention relates to the technical field of pipeline sealing, and discloses a pipeline connecting structure. The pipeline connecting structure comprises a pipeline piece, a matching piece, a conical surface piece, a pressing piece, a connecting flange and a locking piece, wherein a flaring portion is arranged at the end, facing the matching piece, of the pipeline piece, the conical surface piece is coaxially arranged on the matching piece and is matched with the flaring portion, the matching surface of the conical surface piece and the flaring portion is a conical surface, the pressing piece is arranged on the peripheral side of the flaring portion in a sleeving mode so as to press the flaring portion on the conical surface piece, and the connecting flange is arranged on the peripheral sides of the pipeline piece and the pressing piece in a sleeving mode and is connected with the matching piece through the locking piece. According to the pipeline connecting structure, the rigidity requirement of the flaring portion is reduced, then deviation generated in the machining and assembling process is made up, it is ensured that the matching surface of the conical surface piece and the flaring portion is in an ideal connection state, the sealing effect is good, and the machining and assembling requirements are low.

Owner:CSSC POWER INST CO LTD

Space-controllable mechanism type loader with three-dimensional rotating movable arm and one-dimensional rotating bucket

InactiveCN102561419BLow processing and assembly requirementsFlexible output trajectoryMechanical machines/dredgersEngineeringWork space

The invention relates to a space-controllable mechanism type loader with a three-dimensional rotating movable arm and a one-dimensional rotating bucket, comprising a vehicle, the movable arm, the bucket, six driving rods, six connecting rods and six servo motors; both the movable arm and bucket can rotate three-dimensionally independently; and the whole loader can realize the output of six degrees of space motion. The space-controllable mechanism type loader can effectively overcome the defects of high requirement for the processing precision of the hydraulic elements, high maintenance cost, difficult guarantee of reliability and easy oil leakage of the hydraulic loader and solve the problems of inflexible motion, limited work space and low work efficiency due to the output of the trajectory only in the plane of the plane loader.

Owner:GUANGXI UNIV

Spatially controllable mechanism type loader with two-dimensionally rotatable moving arm and three-dimensionally rotatable bucket

InactiveCN102605809BLow processing and assembly requirementsFlexible output trajectoryMechanical machines/dredgersRange of motionProcessing accuracy

The invention relates to a spatially controllable mechanism type loader with a two-dimensionally rotatable moving arm and a three-dimensionally rotatable bucket, which comprises a loader body, a moving arm, a bucket, five drive bars, five connecting bars and five servo motors. The moving arm is capable of rotating two-dimensionally and independently. The bucket is capable of rotating three-dimensionally and independently. The whole loader is capable of moving with five spatial ranges of motion. Using the spatially controllable mechanism type loader can effectively overcome the shortages that hydraulic loaders are high in hydraulic elements processing precision, high in maintenance cost, difficult in reliability guarantee, easy in oil leakage and the like, and can further solve the problems that plane loaders only capable of moving in a plane is inflexible in motion, has limited operating space, is low operating efficiency and the like.

Owner:GUANGXI UNIV

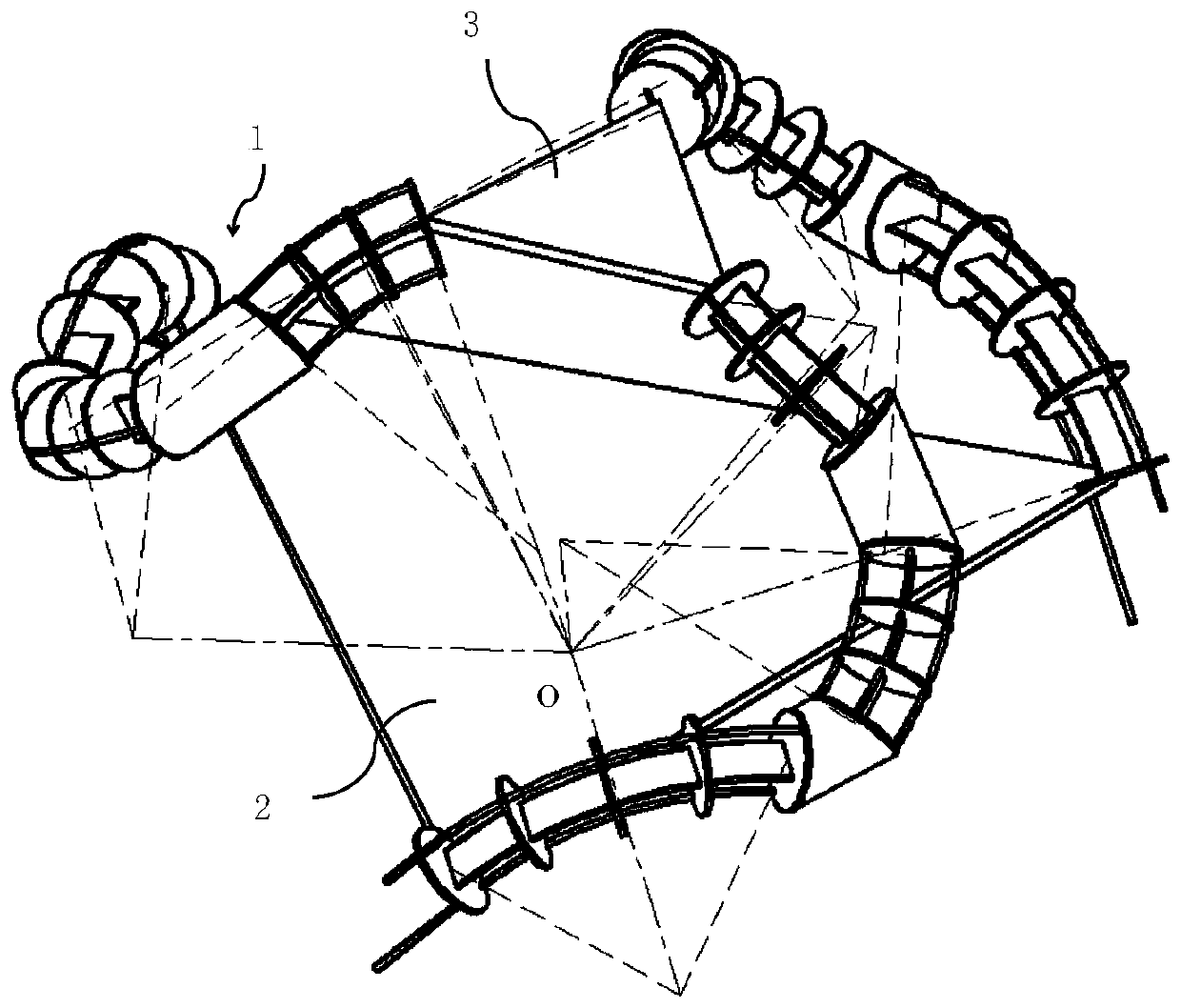

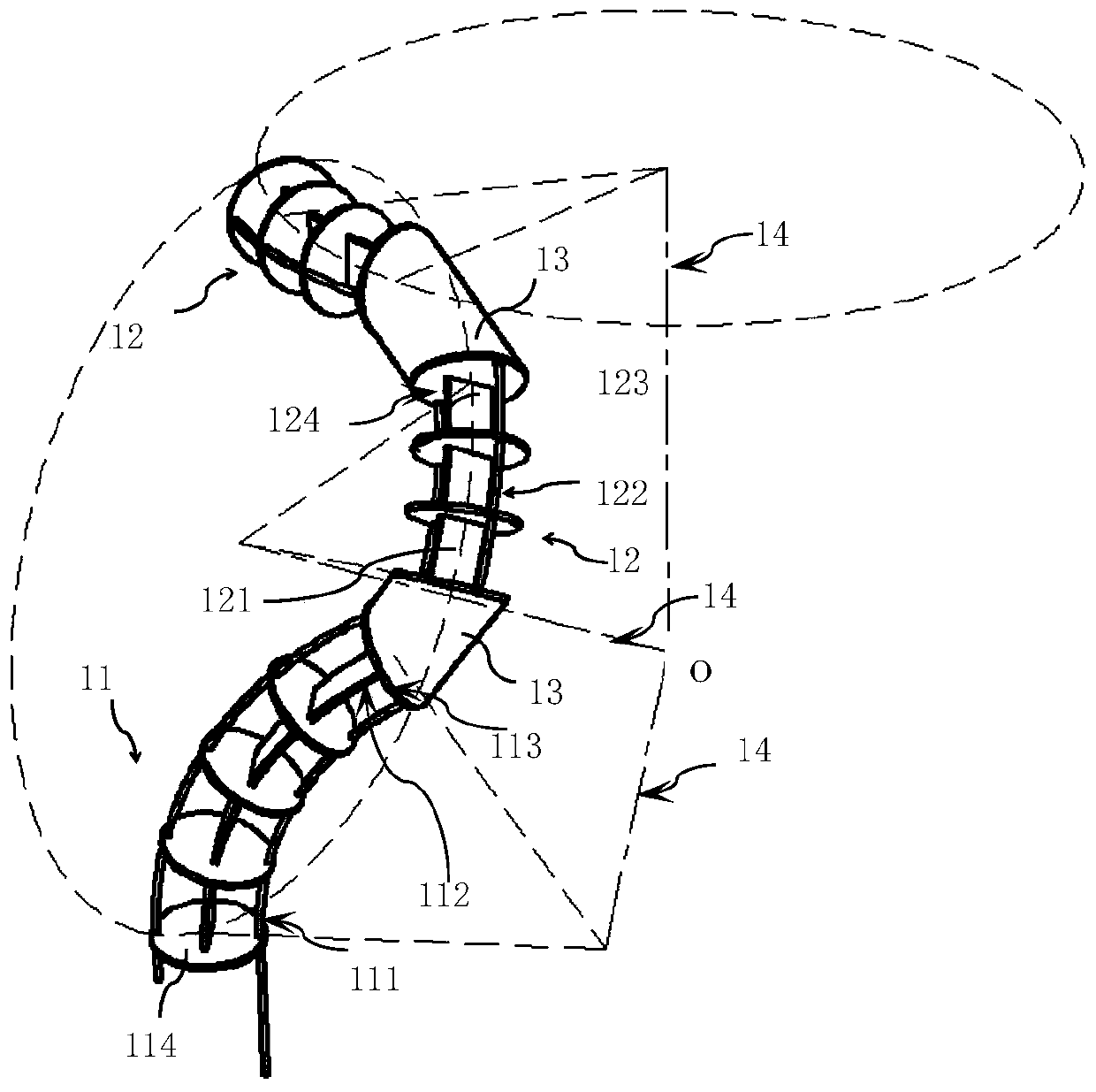

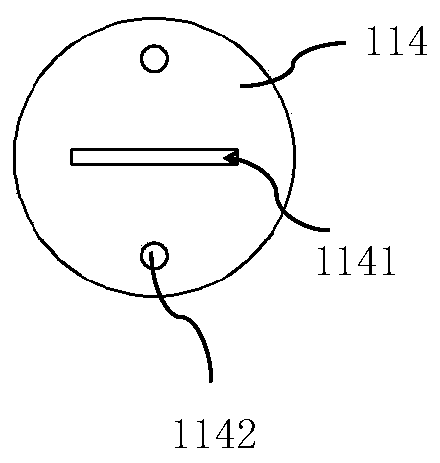

Spherical-motion flexible parallel mechanism

ActiveCN111203858ASimple structureAvoid interferenceProgramme-controlled manipulatorClassical mechanicsEngineering

The invention provides a spherical-motion flexible parallel mechanism. The flexible parallel mechanism comprises a plurality of flexible motion branch chains, wherein each flexible motion branch chainis sequentially provided with a first continuous body structure section and a branch chain unit which are connected with a rack, a second continuous body structure section at the tail end in each branch chain unit is connected with a motion platform, during motion, the motion axes of the first continuous body structure sections and the motion axes of the second continuous body structure sectionsintersect at one point, and the motion platform driven by the flexible parallel mechanism conducts spherical motion with the point as the sphere center. According to the flexible parallel mechanism, in the bending process, a linear actuator drives the first continuous body structure sections, the first continuous body structure sections drive the second continuous body structure sections to be passively bent, it is guaranteed that the whole mechanism achieves spherical motion, the flexible motion branch chains are simple in structure, interference among the branch chains is avoided, and the machining and assembling requirements are low.

Owner:BEIJING SURGERII TECH CO LTD

Spatially controllable mechanism type loader with two-dimensional rotatory moving arm and one-dimensional rotary bucket

InactiveCN102561416ALow processing and assembly requirementsFlexible output trajectoryMechanical machines/dredgersRange of motionEngineering

The invention relates to a spatially controllable mechanism type loader with a two-dimensional rotatory moving arm and a one-dimensional rotary bucket, which comprises a loader body, a moving arm, a bucket, three drive bars, three connecting bars and three servo motors. The moving arm is capable of independently rotating in two dimensions, the bucket is capable of independently rotating in one dimension, and the whole loader is capable of moving with three spatial ranges-of-motion. By means of the spatially controllable mechanism type loader with the two-dimensional rotatory moving arm and the one-dimensional rotary bucket, the shortages that hydraulic elements of a hydraulic loader are high in precision requirements, high in maintenance cost, difficult in reliability guarantee, prone to oil leakage and the like are solved, and the problems, action inflexibility, limitedness of operation space, low operating efficiency and the like due to the fact that a plane loader only can output plane tracks, are solved.

Owner:GUANGXI UNIV

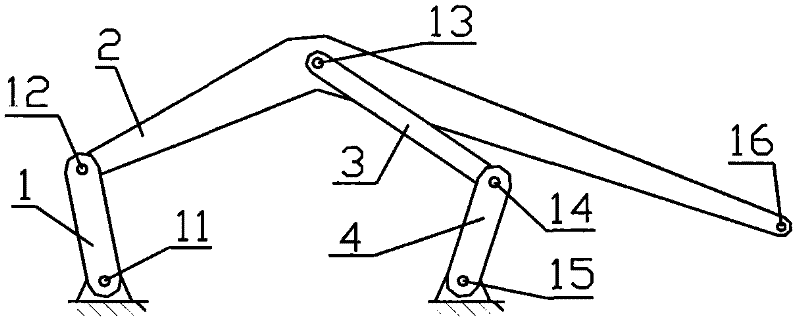

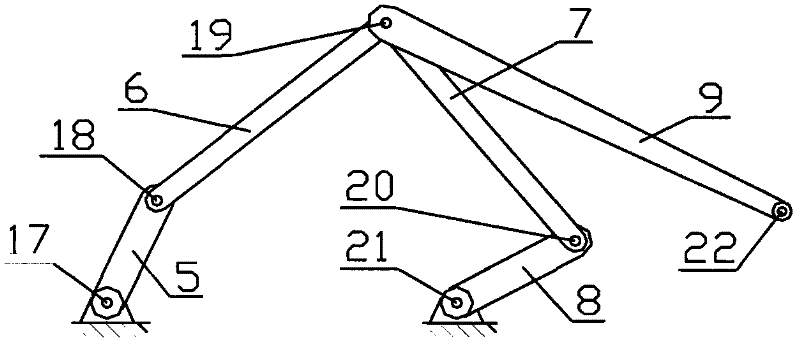

Hybrid-driven controllable excavation mechanism

InactiveCN102094433BBig digging forceImprove reliabilityMechanical machines/dredgersSingle degree of freedomTwo degrees of freedom

The invention discloses a hybrid-driven controllable excavation mechanism which comprises a first excavation arm, a second excavation arm, a forward shovel type bucket and a frame, wherein the first excavation arm and the second excavation arm are respectively formed by the connection of a two-degree-of-freedom hybrid-driven controllable mechanism with the forward shovel type bucket through a complex hinge and a connecting rod. The first excavation arm and the second excavation arm are both arranged on the frame and subjected to hybrid-driving of two high-power conventional motors and two low-power servo motors, and therefore, the requirements for large excavating force and concurrently flexible track output can be met simultaneously. The hybrid-driven controllable excavation mechanism disclosed by the invention can solve the problems that the traditional single-degree-of-freedom mechanical excavation mechanism is simple in implementation action, the hydraulic excavation mechanism is probably subjected to oil leakage, etc. Besides, the whole excavation mechanism has the advantages of high excavation efficiency, low manufacturing cost and low processing and assembling requirements.

Owner:GUANGXI UNIV

Multifunctional stacking robot

InactiveCN106272351ALow processing and assembly requirementsImprove automationProgramme-controlled manipulatorStacking articlesEngineeringActuator

The invention discloses a multifunctional stacking robot. One end of a first connecting rod is connected to a rack through a first rotation pair, and the other end of the first connecting rod is connected with one end of a second connecting rod through a second rotation pair. The other end of the second connecting rod is connected to an end effector through a third rotation pair. One end of a third connecting rod is connected to the end effector through a fourth rotation pair, and the other end of the third connecting rod is sleeved with a sliding block. One end of a first telescopic rod is connected to the rack through a fifth rotation pair, and the other end of the first telescopic rod is connected to the first connecting rod through a sixth rotation pair. One end of a second telescopic rod is connected to the rack through a seventh rotation pair, and the other end of the second telescopic rod is connected to the third connecting rod through an eighth rotation pair. One end of a third telescopic rod is connected to the rack through a ninth rotation pair, and the other end of the third telescopic rod is connected to the second connecting rod through a tenth rotation pair. One end of a fourth telescopic rod is connected to the sliding block through an eleventh rotation pair, and the other end of the fourth telescopic rod is connected to the second connecting rod. High reliability is achieved, control is easy, operation precision is high, the requirement for machining and assembling of components is low, and the maintaining cost is low.

Owner:GUANGXI UNIV

Space controllable mechanism-type loader with one-dimensional rotational moving arm and two-dimensional rotational bucket

InactiveCN102535541ALow processing and assembly requirementsOvercoming high machining accuracy requirementsMechanical machines/dredgersMoving partsEngineering

The invention relates to a space controllable mechanism-type loader with a one-dimensional rotational moving arm and a two-dimensional rotational bucket, which comprises a loader body, the moving arm, the bucket, three drive bars, three connecting bars and three servo motors. The moving arm is capable of rotating one-dimensionally and independently, the bucket is capable of rotating two-dimensionally and independently, and the whole loader is capable of generating paths in a space with three degrees of movement. The space controllable mechanism-type loader effectively overcomes the shortages that hydraulic elements of a hydraulic loader are high in processing precision requirement, high in maintenance cost, difficulty on reliability guarantee, easy to leak oil and the like, and also soles the problems of insufficient movement flexibility, limited work space, low work efficiency and the like due to the fact that a plane loader only generates paths in a plane.

Owner:GUANGXI UNIV

Space controllable mechanism-type loader with three-dimensional rotational moving arm and three-dimensional rotational bucket

InactiveCN102535544ALow processing and assembly requirementsOvercoming demandsMechanical machines/dredgersProcessing accuracyEngineering

The invention relates to a space controllable mechanism-type loader with a three-dimensional rotational moving arm and a three-dimensional rotational bucket, which comprises a loader body, the moving arm, the bucket, six drive bars, six connecting bars and six servo motors. The moving arm is capable of rotating three-dimensionally and independently, the bucket is capable of rotating three-dimensionally and independently, and the whole loader is capable of generating movement in a space with six degrees of movement. The space controllable mechanism-type loader effectively overcomes the shortages that hydraulic elements of a hydraulic loader are high in processing precision requirement, high in maintenance cost, difficulty on reliability guarantee, easy to leak oil and the like, and also solves the problems of insufficient movement flexibility, limited work space, low work efficiency and the like due to the fact that a plane loader only generates paths in a plane.

Owner:GUANGXI UNIV

Space controllable mechanism loader with two-dimensional rotating movable arm and two-dimensional rotating bucket

InactiveCN102535542BLow processing and assembly requirementsFlexible output trajectoryMechanical machines/dredgersMachiningProcessing accuracy

The invention relates to a space-controllable mechanism loader with a two-dimensional rotating boom and a two-dimensional rotating bucket, which includes a car body, a boom, a bucket, four active rods, four connecting rods and four servo motors. The arm can realize independent two-dimensional rotation, the bucket can realize independent two-dimensional rotation, and the whole loader can realize the motion output of four degrees of movement in space. This kind of space-controllable mechanism loader can effectively overcome the shortcomings of hydraulic loaders such as high machining accuracy requirements for hydraulic components, high maintenance costs, difficult reliability assurance, and easy oil leakage. It can also solve the problem that plane loaders can only achieve in-plane trajectory Output, resulting in problems such as inflexible movements, limited work space, and low work efficiency.

Owner:GUANGXI UNIV

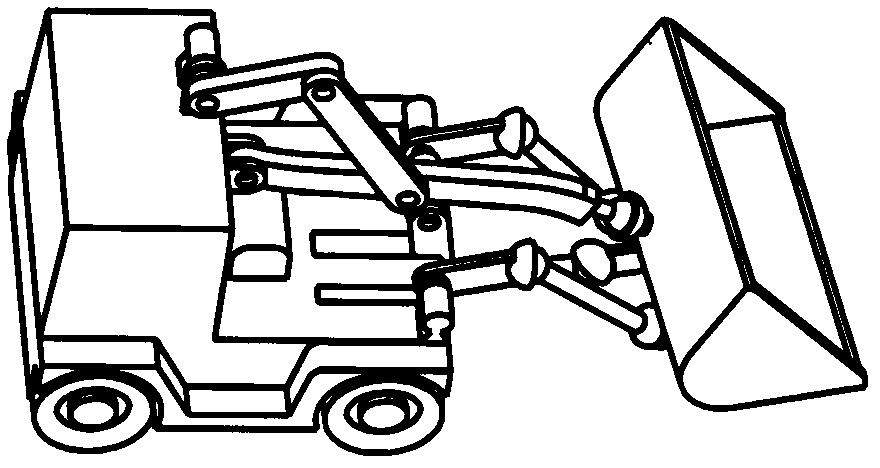

Space controllable mechanism-type loader with three-dimensional rotational moving arm and two-dimensional rotational bucket

InactiveCN102535540BLow processing and assembly requirementsFlexible output trajectoryMechanical machines/dredgersEngineeringWorking space

Owner:GUANGXI UNIV

Three-dimensional rotating boom One-dimensional rotating bucket space controllable mechanism loader

InactiveCN102561418BLow processing and assembly requirementsFlexible output trajectoryMechanical machines/dredgersEngineeringControl space

Owner:GUANGXI UNIV

Space controllable mechanism-type loader with three-dimensional rotational moving arm and two-dimensional rotational bucket

InactiveCN102535543BLow processing and assembly requirementsFlexible output trajectoryMechanical machines/dredgersEngineeringProcessing accuracy

The invention relates to a space controllable mechanism-type loader with a three-dimensional rotational moving arm and a two-dimensional rotational bucket, which comprises a loader body, the moving arm, the bucket, five drive bars, five connecting bars and five servo motors. The moving arm is capable of rotating three-dimensionally and independently, the bucket is capable of rotating two-dimensionally and independently, and the whole loader is capable of generating movement in a space with five degrees of movement. The space controllable mechanism-type loader effectively overcomes the shortages that hydraulic elements of a hydraulic loader are high in processing precision requirement, high in maintenance cost, difficulty on reliability guarantee, easy to leak oil and the like, and also solves the problems of insufficient movement flexibility, limited work space, low work efficiency and the like due to the fact that a plane loader only generates paths in a plane.

Owner:GUANGXI UNIV

Space controllable mechanism type loader with movable arm capable of three-dimensionally rotating and bucket capable of one-dimensionally rotating

InactiveCN102561422BLow processing and assembly requirementsFlexible output trajectoryMechanical machines/dredgersEngineeringProcessing accuracy

The invention relates to a space controllable mechanism type loader with a movable arm capable of three-dimensionally rotating and a bucket capable of one-dimensionally rotating. The space controllable mechanism type loader comprises a loader body, the movable arm, the bucket, four driving rods, four connecting rods and four servo motors, the movable arm can three-dimensionally rotate independently, the bucket can one-dimensionally rotate independently, and the total loader can realize spatial movable output with four degrees of movement. The space controllable mechanism type loader can effectively overcome shortcomings that requirements on processing precision of hydraulic elements of a hydraulic loader are high, repair and maintenance costs are high, reliability is difficult to be guaranteed, oil leaks easily and the like. In addition, the space controllable mechanism type loader can resolve problems that a planar loader only can realize output along a trace in a plane, actions are not flexible, a working space is limited, work efficiency is low, and the like.

Owner:GUANGXI UNIV

Diesel engine cylinder head cover

ActiveCN103410630BSimple structureImproves sealing reliabilityCasingsSealing arrangements for enginesCylinder headSprayer

The invention discloses a diesel engine cylinder head cover. The diesel engine cylinder head cover comprises a cylinder head cover body, an oil sprayer installation through hole and a cylinder head cover gasket seal positioning groove, wherein the cylinder head cover body is arranged on a cylinder head in a covering mode through an installation flange at the bottom of the cylinder head cover body; the oil sprayer installation through hole is of a big-end-up stepped hole structure and comprises an upper installation countersunk groove and a lower sleeve nut penetrating hole, and a high-pressure oil pipe seal ring is in clearance fit with the sleeve nut penetrating hole and forms end face seal with the connection stepped face of the installation countersunk groove and the sleeve nut penetrating hole; the cylinder head cover gasket seal positioning groove is formed in the face of the installation flange of the cylinder head cover body. The diesel engine cylinder head cover is simple and reasonable in structure; due to the fact that radial close fit seal between a high-pressure oil pipe sleeve nut and the oil sprayer installation through hole is improved to end face seal, processing and assembling requirements are lowered, and seal reliability is improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

Space controllable mechanism loader with two-dimensional rotating movable arm and two-dimensional rotating bucket

InactiveCN102535542ALow processing and assembly requirementsOvercoming high machining accuracy requirementsMechanical machines/dredgersRange of motionProcessing accuracy

The invention relates to a space controllable mechanism loader with a two-dimensional rotating movable arm and a two-dimensional rotating bucket. The loader comprises a vehicle body, the movable arm, the bucket, four driving rods, four connecting rods and four servo motors, wherein both the movable arm and the bucket can realize independent two-dimensional rotation; and the whole loader can realize space four-range-of-motion motion output. The space controllable mechanism loader can effectively overcome the defects of a high processing accuracy requirement, high maintenance cost, low reliability, high oil leakage probability and the like of a hydraulic element of a hydraulic loader, and can solve the problems of an inflexible action, a limited working space, low working efficiency and the like of a plane loader which only can output a trajectory in a plane.

Owner:GUANGXI UNIV

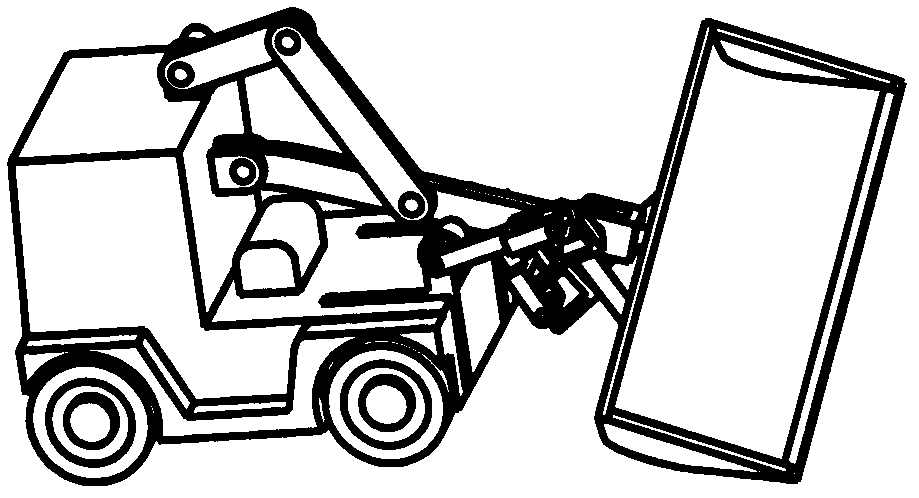

A multi-degree-of-freedom controllable mechanism garbage truck

Owner:GUANGXI UNIV

Space controllable mechanism-type loader with one-dimensional rotational moving arm and three-dimensional rotational bucket

InactiveCN102535538ALow processing and assembly requirementsFlexible output trajectoryMechanical machines/dredgersEngineeringProcessing accuracy

The invention relates to a space controllable mechanism-type loader with a one-dimensional rotational moving arm and a three-dimensional rotational bucket, which comprises a loader body, the moving arm, the bucket, four drive bars, four connecting bars and four servo motors. The moving arm is capable of rotating one-dimensionally and independently, the bucket is capable of rotating three-dimensionally and independently, and the whole loader is capable of generating movement in space with four degrees of movement. The space controllable mechanism-type loader effectively overcomes the shortages that hydraulic elements of a hydraulic loader are high in processing precision requirement, high in maintenance cost, difficult in reliability guarantee, easy to leak oil and the like, and also solves the problems of insufficient movement flexibility, limited work space, low work efficiency and the like due to the fact that a plane loader only generates paths in a plane.

Owner:GUANGXI UNIV

Space controllable mechanism-type loader with three-dimensional rotational moving arm and three-dimensional rotational bucket

InactiveCN102535544BLow processing and assembly requirementsFlexible output trajectoryMechanical machines/dredgersEngineeringWorking space

The invention relates to a space controllable mechanism-type loader with a three-dimensional rotational moving arm and a three-dimensional rotational bucket, which comprises a loader body, the moving arm, the bucket, six drive bars, six connecting bars and six servo motors. The moving arm is capable of rotating three-dimensionally and independently, the bucket is capable of rotating three-dimensionally and independently, and the whole loader is capable of generating movement in a space with six degrees of movement. The space controllable mechanism-type loader effectively overcomes the shortages that hydraulic elements of a hydraulic loader are high in processing precision requirement, high in maintenance cost, difficulty on reliability guarantee, easy to leak oil and the like, and also solves the problems of insufficient movement flexibility, limited work space, low work efficiency and the like due to the fact that a plane loader only generates paths in a plane.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com