Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Flexible output trajectory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

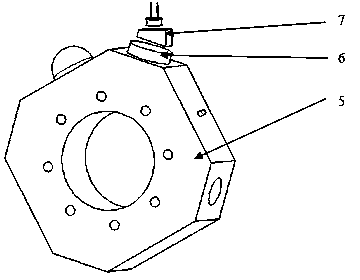

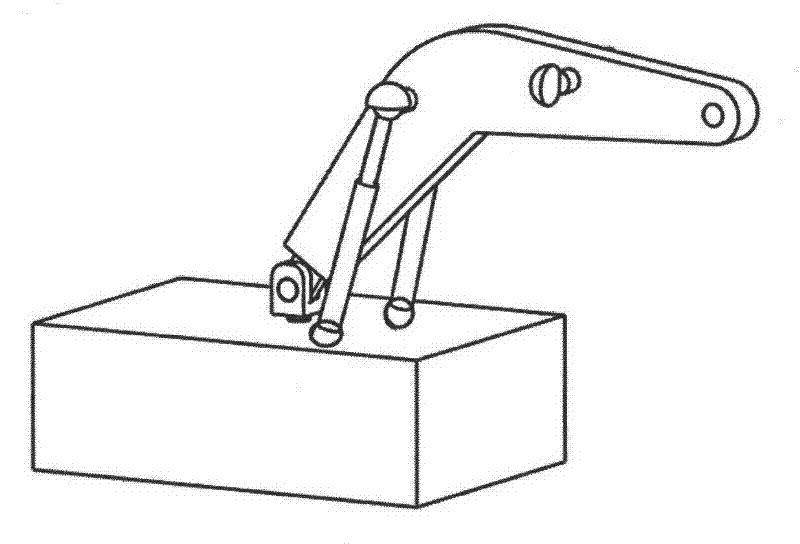

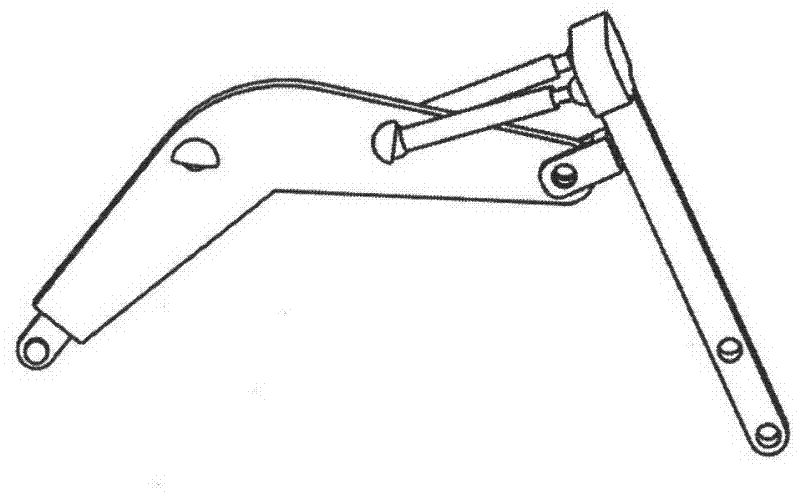

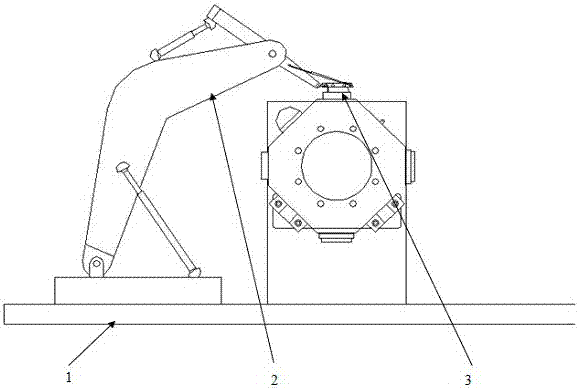

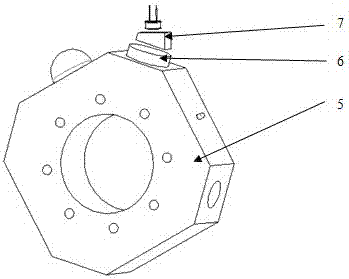

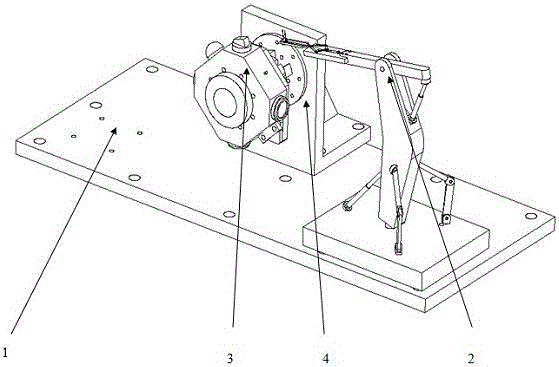

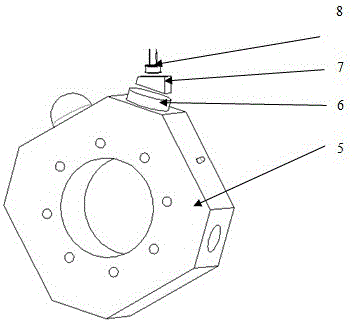

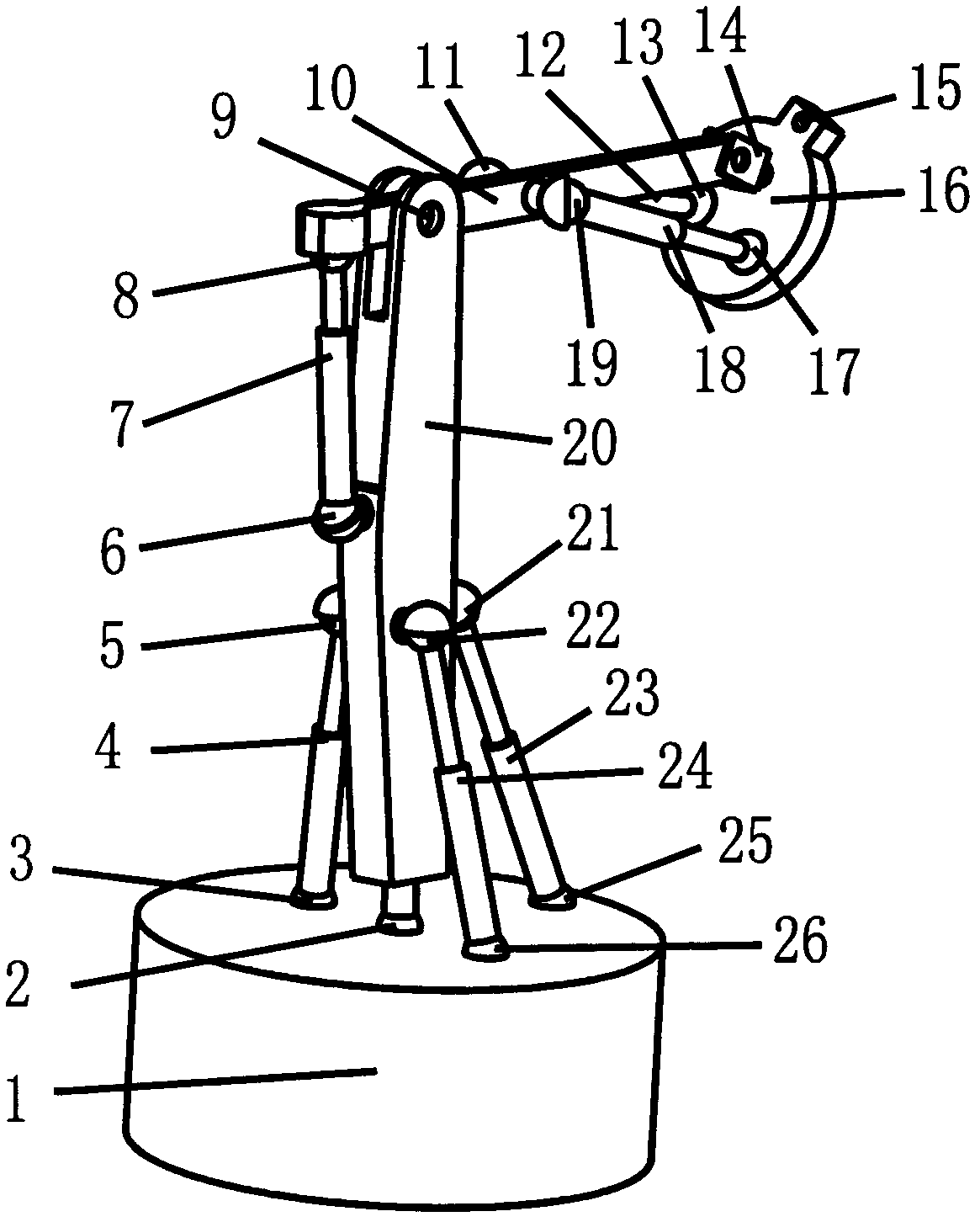

Novel light combination prism adjusting device

InactiveCN104006826AImprove regulation efficiencyQuality improvementSagnac effect gyrometersMountingsGyroscopeElectric machinery

The invention relates to a novel light combination prism adjusting device which comprises an optical platform, a light combination prism adjusting mechanism and a to-be-assembled optical element, wherein the light combination prism adjusting mechanism is arranged on the left side of the optical platform; the to-be-assembled optical element is arranged on the right side of the optical platform; a linear drive rod is arranged in the light combination prism adjusting mechanism to drive the light combination prism adjusting mechanism to move, and four micro motors drive the light combination prism adjusting mechanism to clamp the to-be-assembled optical element, so that a light combination prism is adjusted. The light combination prism adjusting mechanism constructed by adopting a motor and linear drive rod combined control method is flexible in motion output track, large in operating space, high in operability and high in positioning accuracy, the angle and position adjusting functions of the light combination prism are improved, and the quality and efficiency of a laser gyroscope light combination process are further improved.

Owner:SHANGHAI UNIV

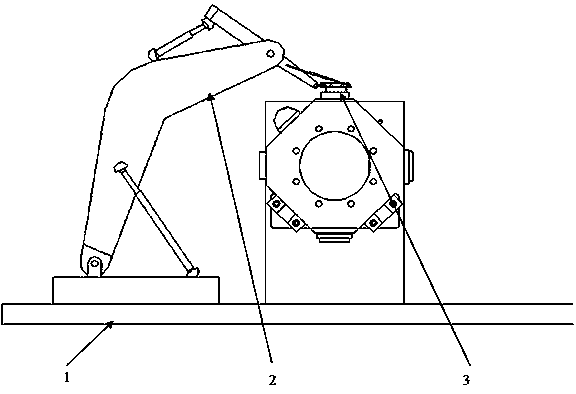

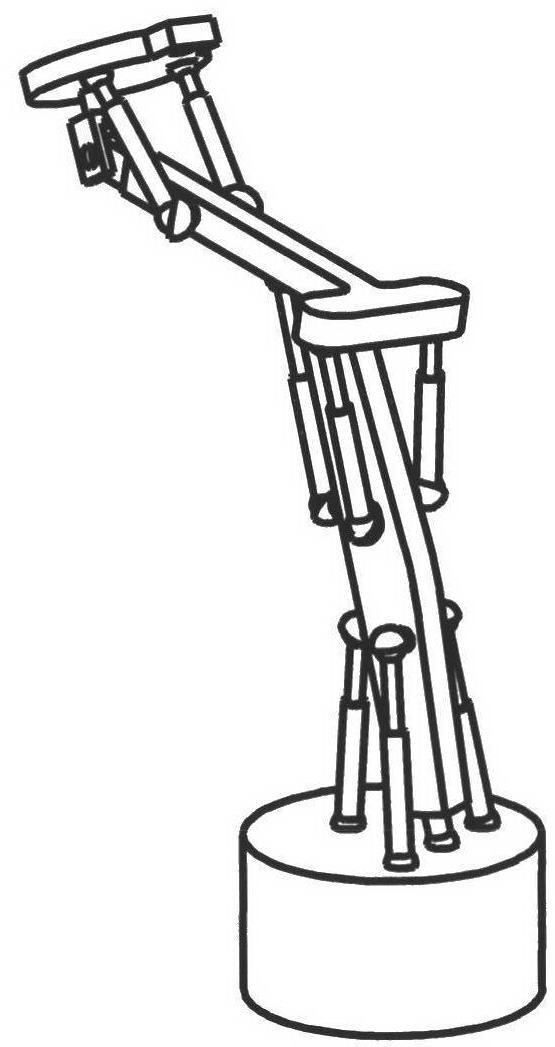

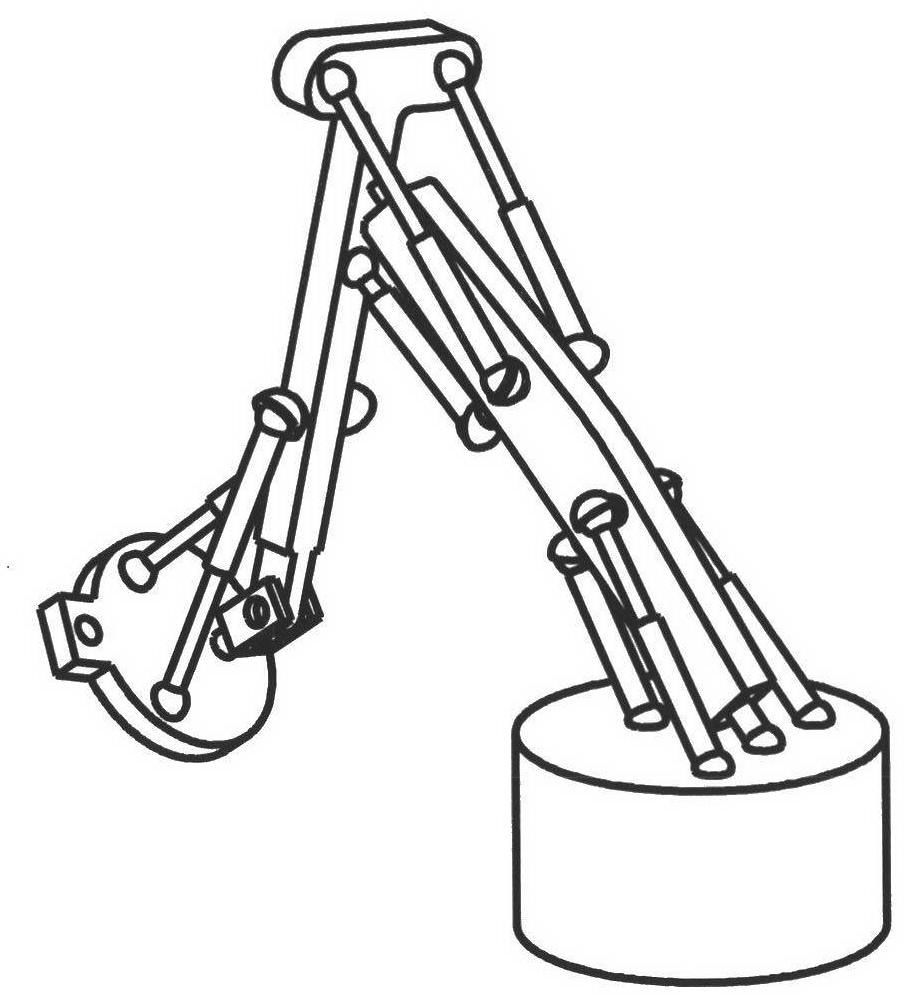

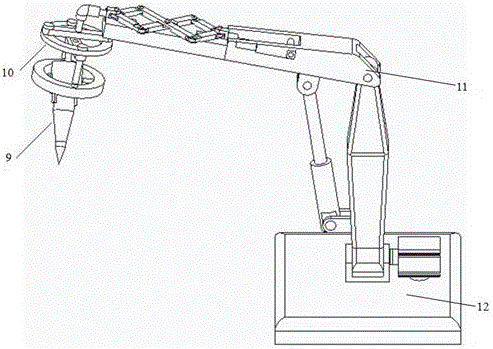

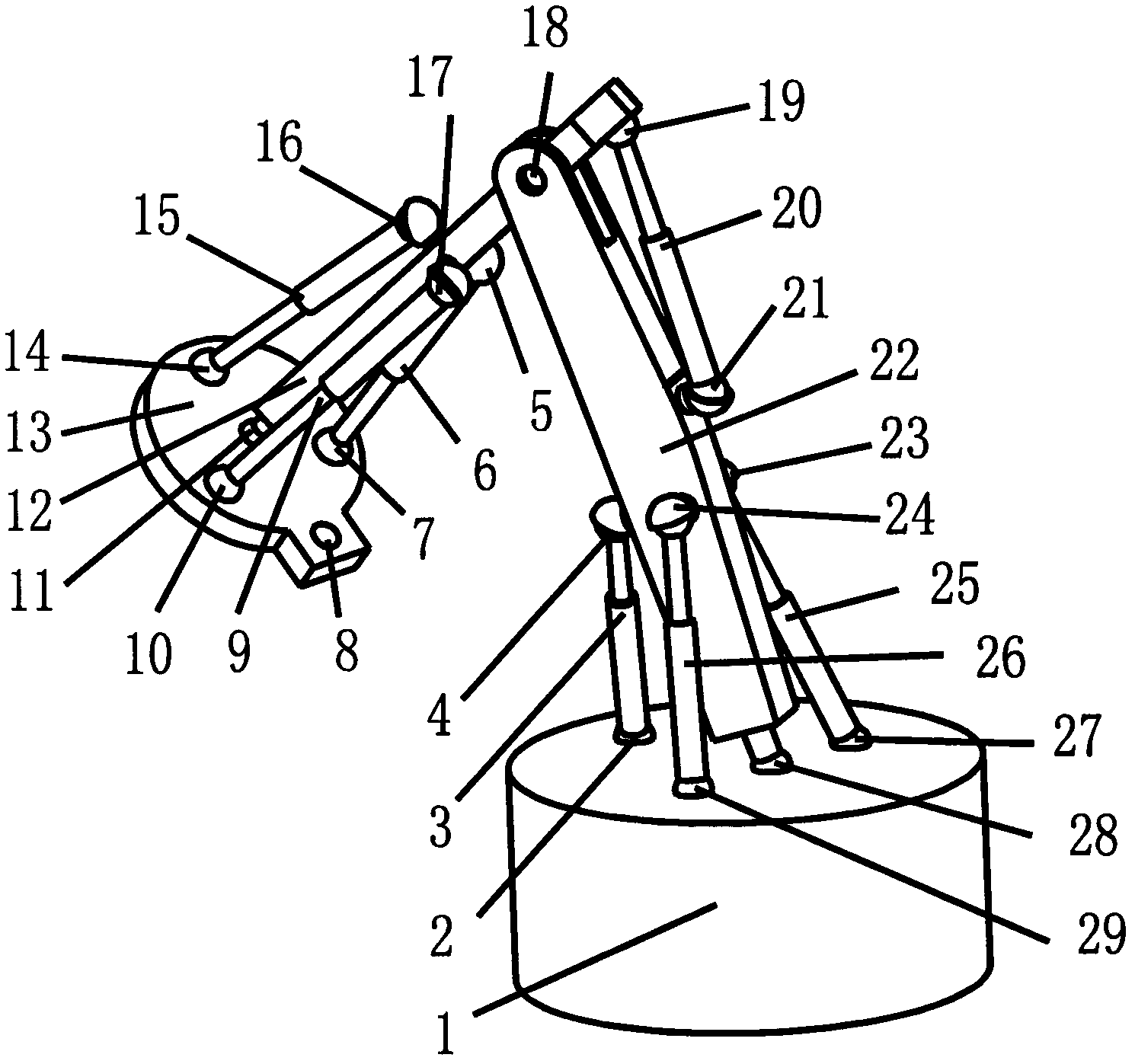

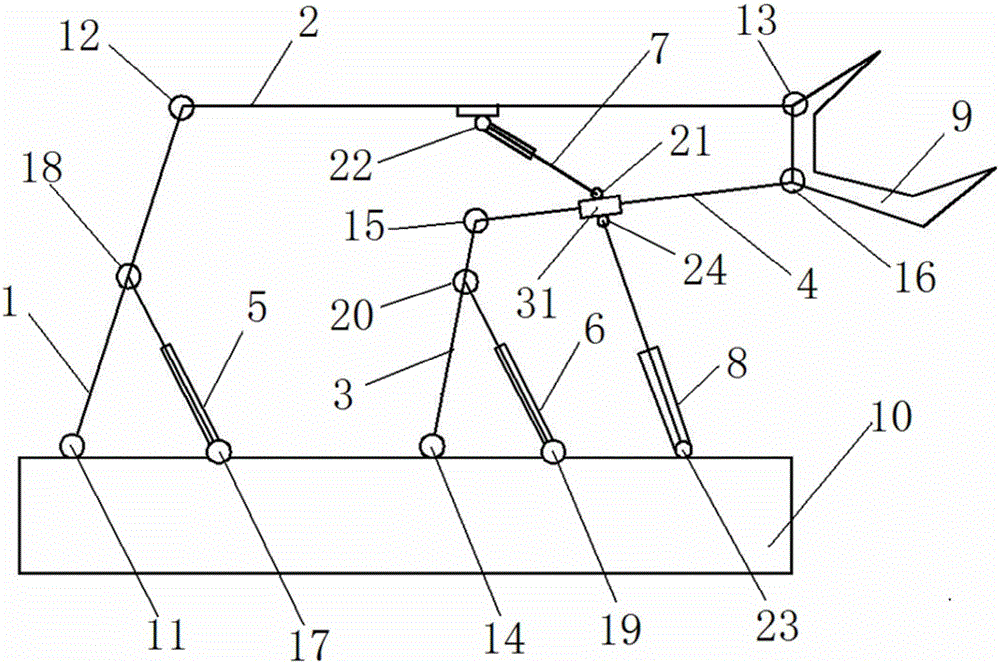

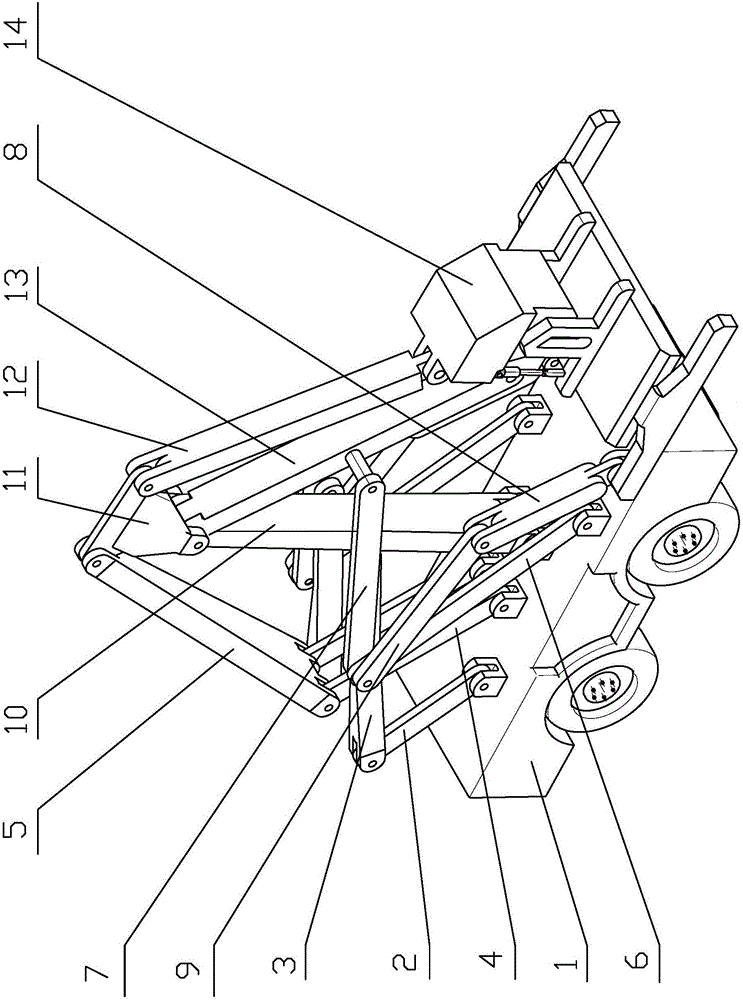

Eight-spatial-degree-of-motion spraying robot

InactiveCN102513254AFlexible output trajectoryThe output track is accurateSpraying apparatusEngineeringWorking space

The invention relates to an eight-spatial-degree-of-motion spraying robot, which comprises a first connecting rod, a second connecting rod, a moving platform, eight linear drivers and a machine frame. One end of the first connecting rod is connected to the machine frame through a first spherical pair, and the other end of the connecting rod is connected to the second connecting rod through a second spherical pair; the other end of the second connecting rod is hinged to the moving platform by a first Hooke; and the whole robot is driven by the eight linear drivers to output eight spatial degrees of motion. The spraying robot has the characteristics of flexible and accurate output track, high flexibility, large working space, easy operation and maintenance and is particularly suitable for two-dimensional rotation output spraying which needs the first connecting rod and the second connecting rod to do three-dimensional rotation and the moving platform to output three-dimensional rotation.

Owner:GUANGXI UNIV

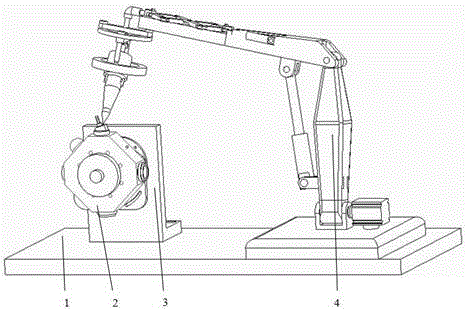

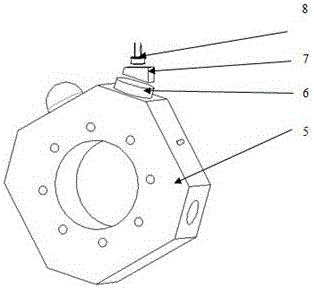

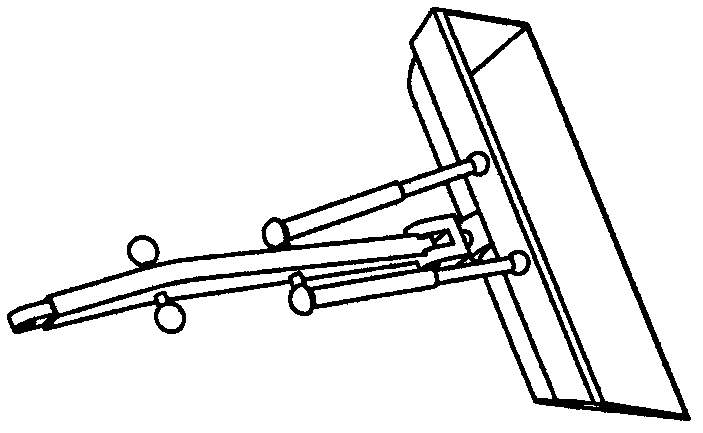

Accurate dispensing locating device for light combination assembly of laser gyroscope

ActiveCN106269402AOutstanding FeaturesHighlight significant technological advancesLiquid surface applicatorsMeasurement devicesGyroscopeOptical table

The invention relates to an accurate dispensing locating device for light combination assembly of a laser gyroscope. The accurate dispensing locating device comprises an optical platform, a laser gyroscope shaking device, to-be-assembled elements in light combination assembly of the laser gyroscope, and an accurate dispensing locating system, wherein the accurate dispensing locating system is mounted on the right side of the optical platform; the laser gyroscope shaking device is mounted on the left side of the optical platform; and the to-be-assembled elements in light combination assembly of the laser gyroscope are mounted on the laser gyroscope shaking device. According to the accurate dispensing locating device, rough adjustment and fine adjustment locating systems are combined, the track of dispensing motion of a dispensing arm is output through a cooperative control method of a linear driving mechanism and a motor, the device has the characteristics that the working space is large, the operation is sensitive, the locating is accurate, accurate dispensing can be achieved at any angle, and the university is high, and the efficiency and quality of an light combination technology of the laser gyroscope are greatly improved.

Owner:SHANGHAI UNIV

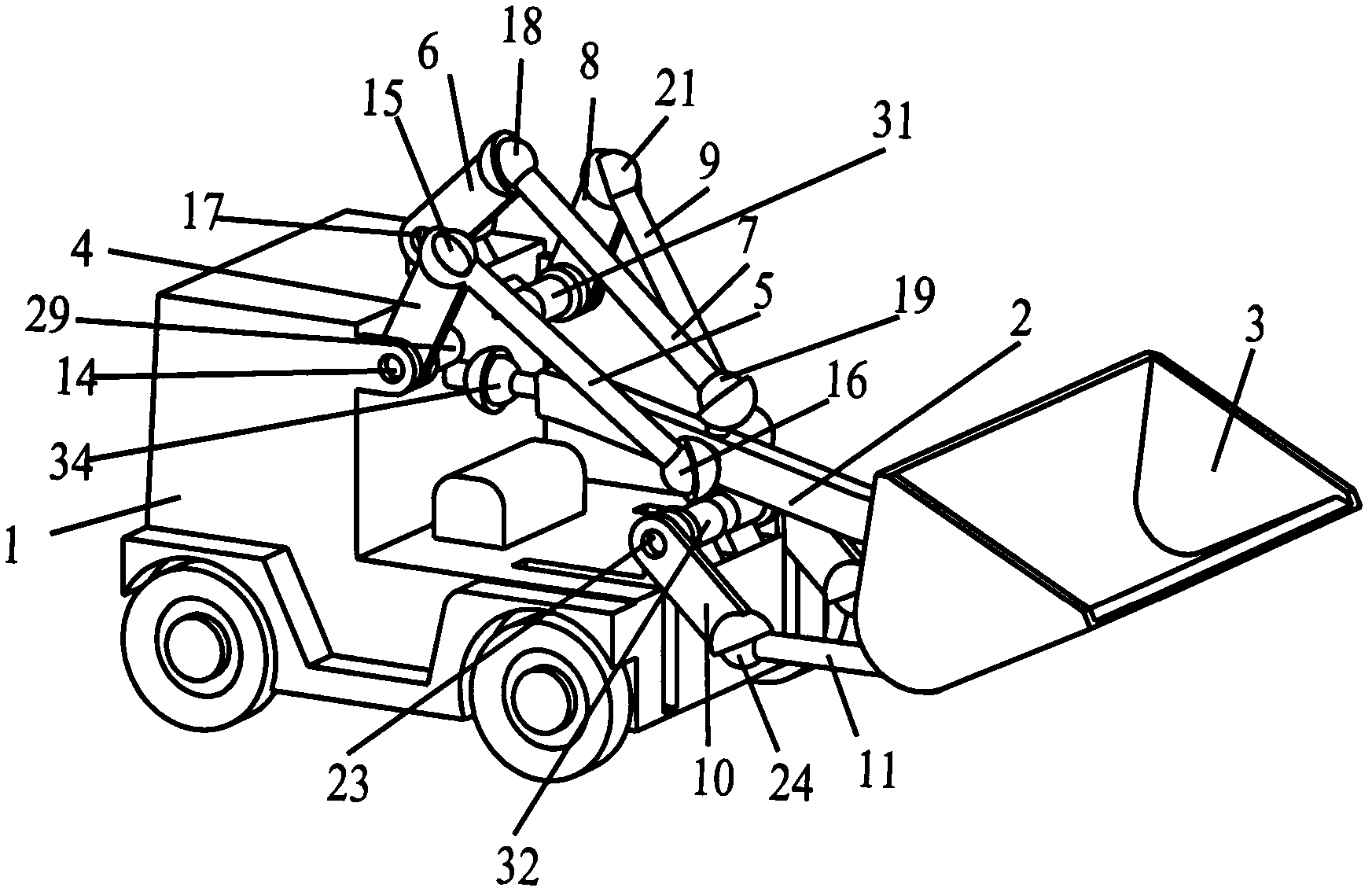

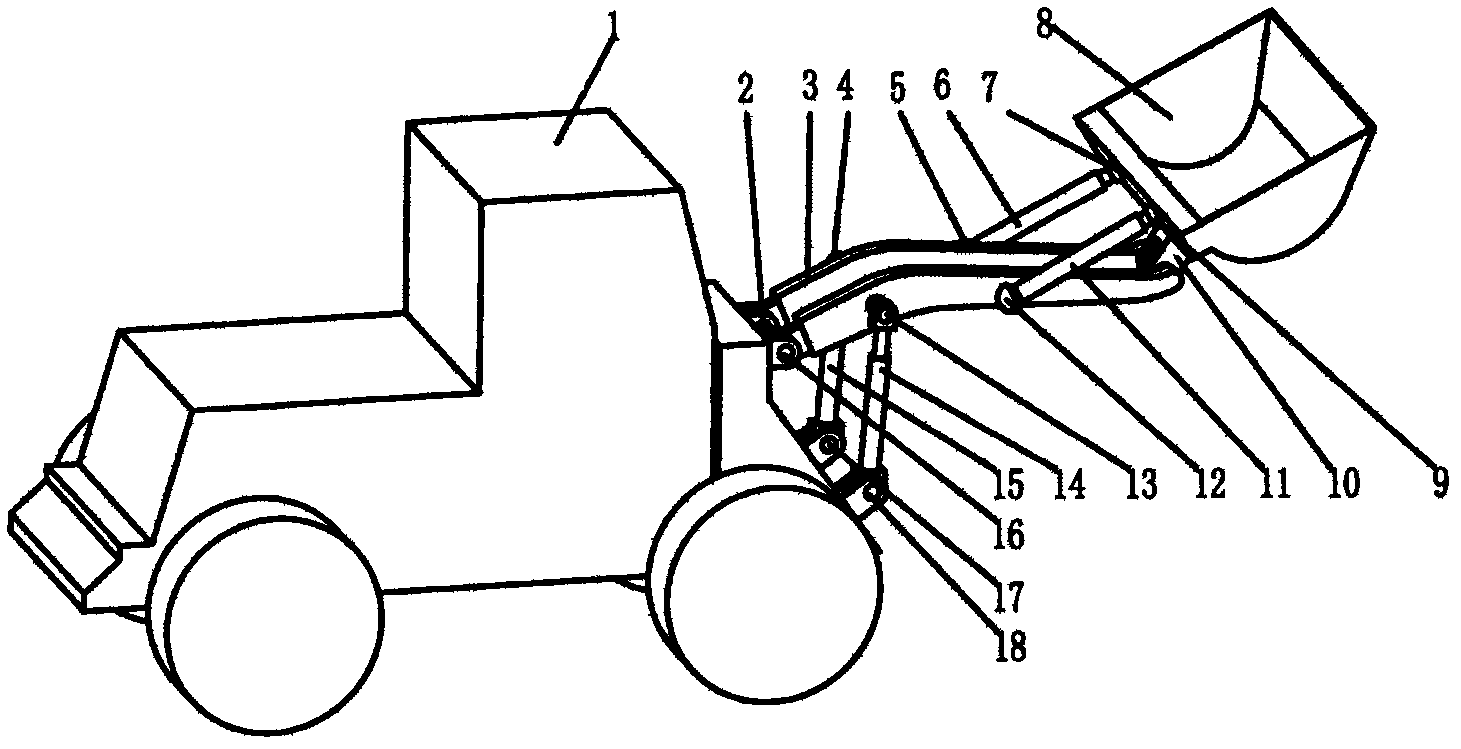

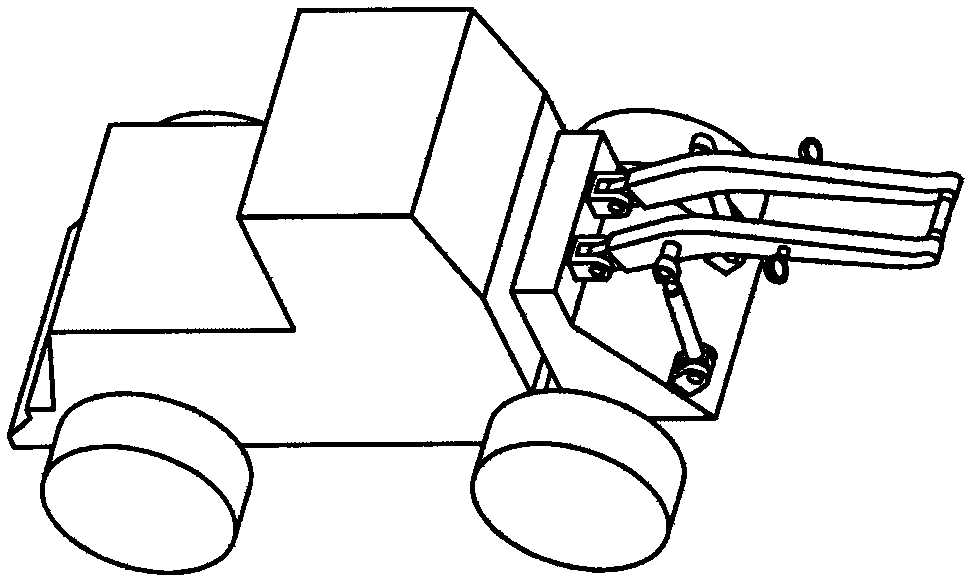

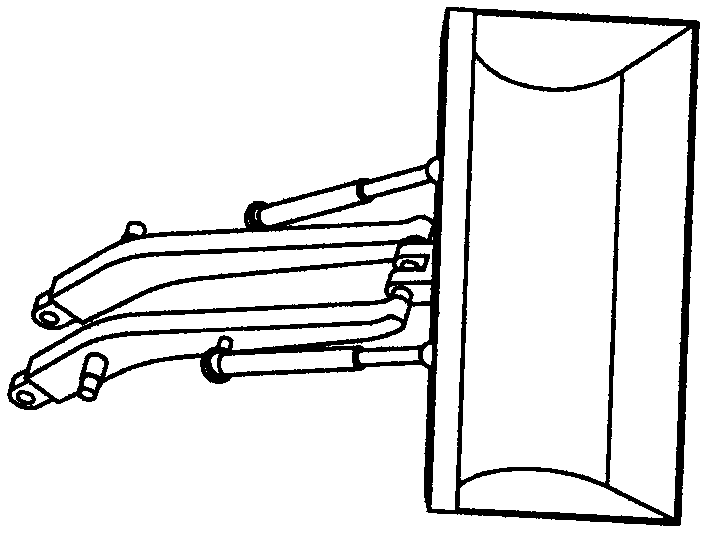

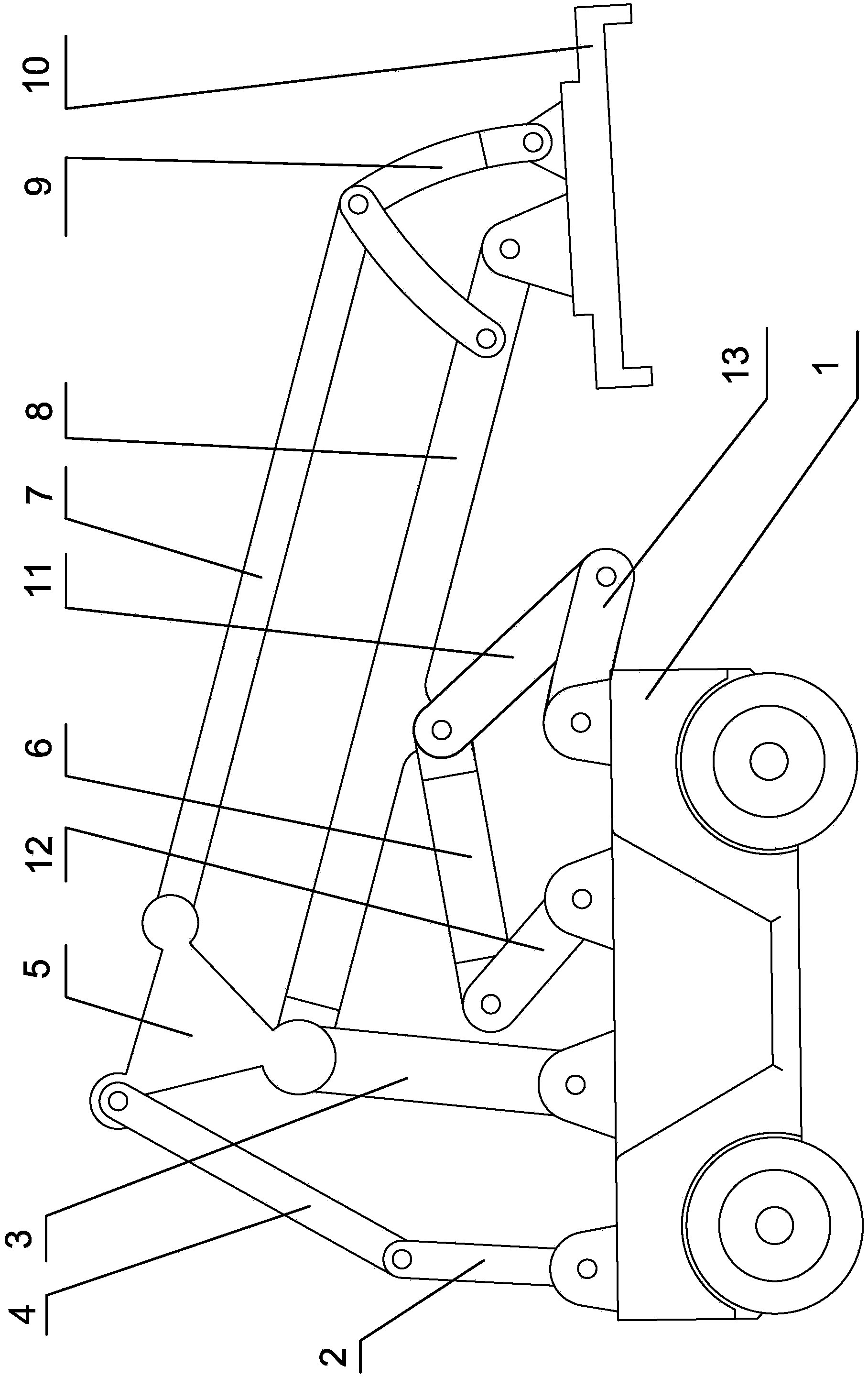

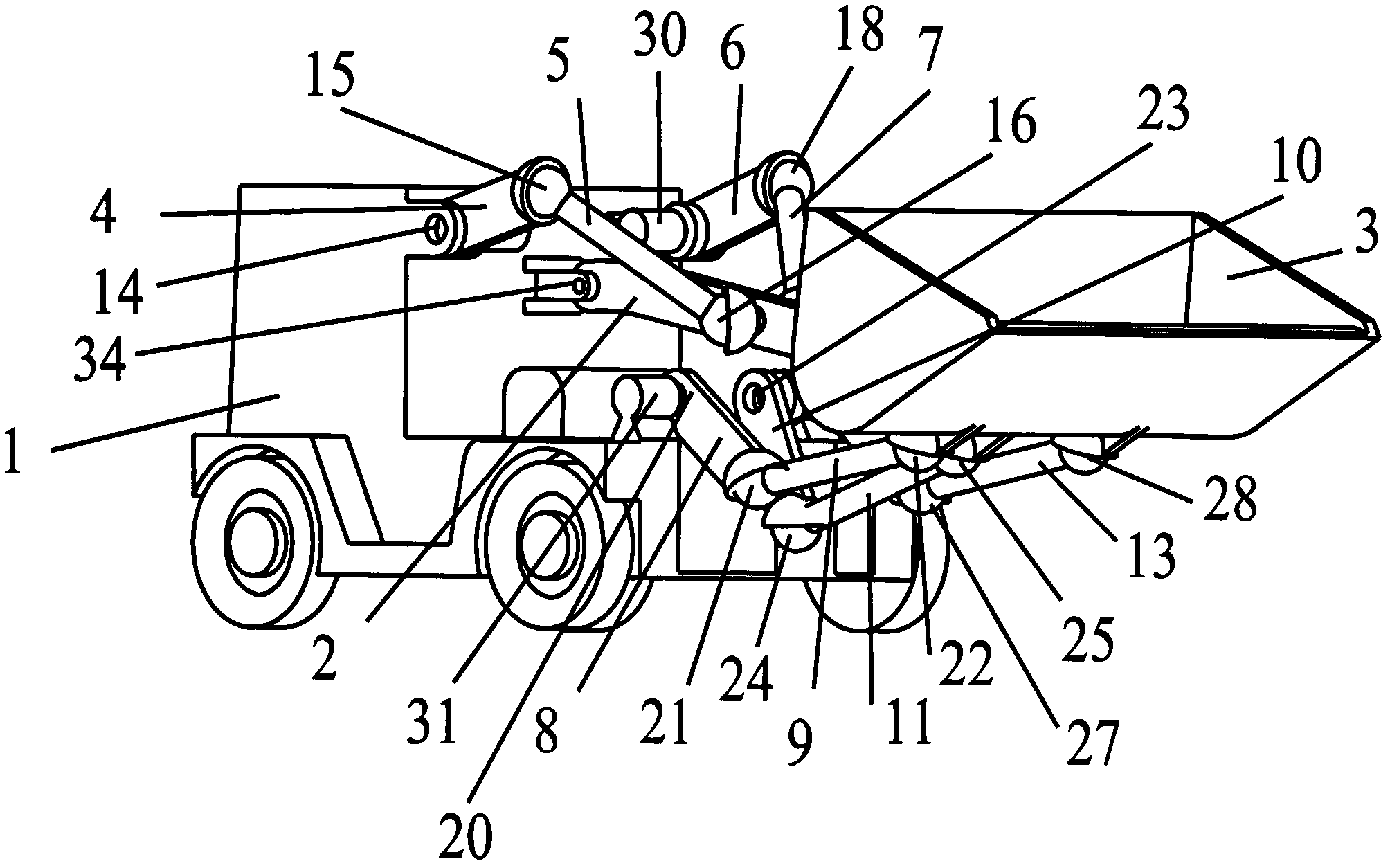

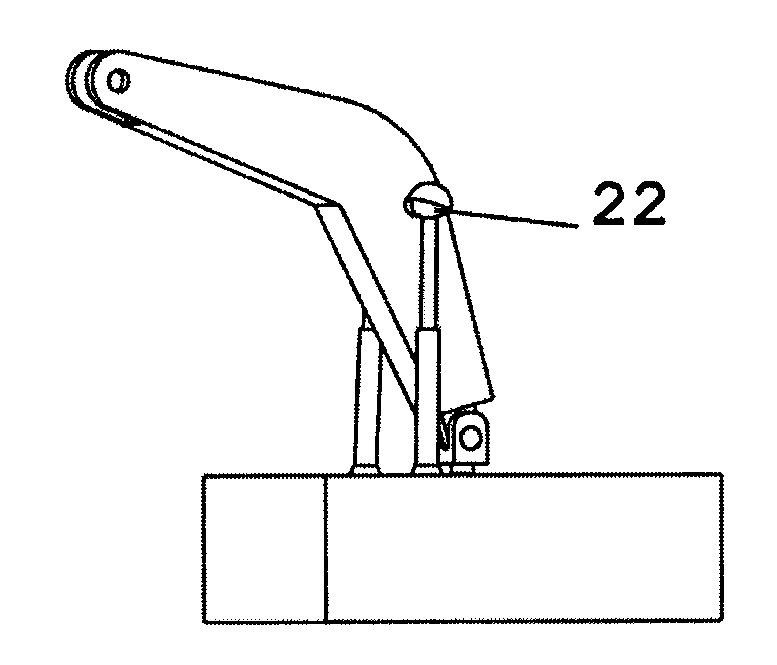

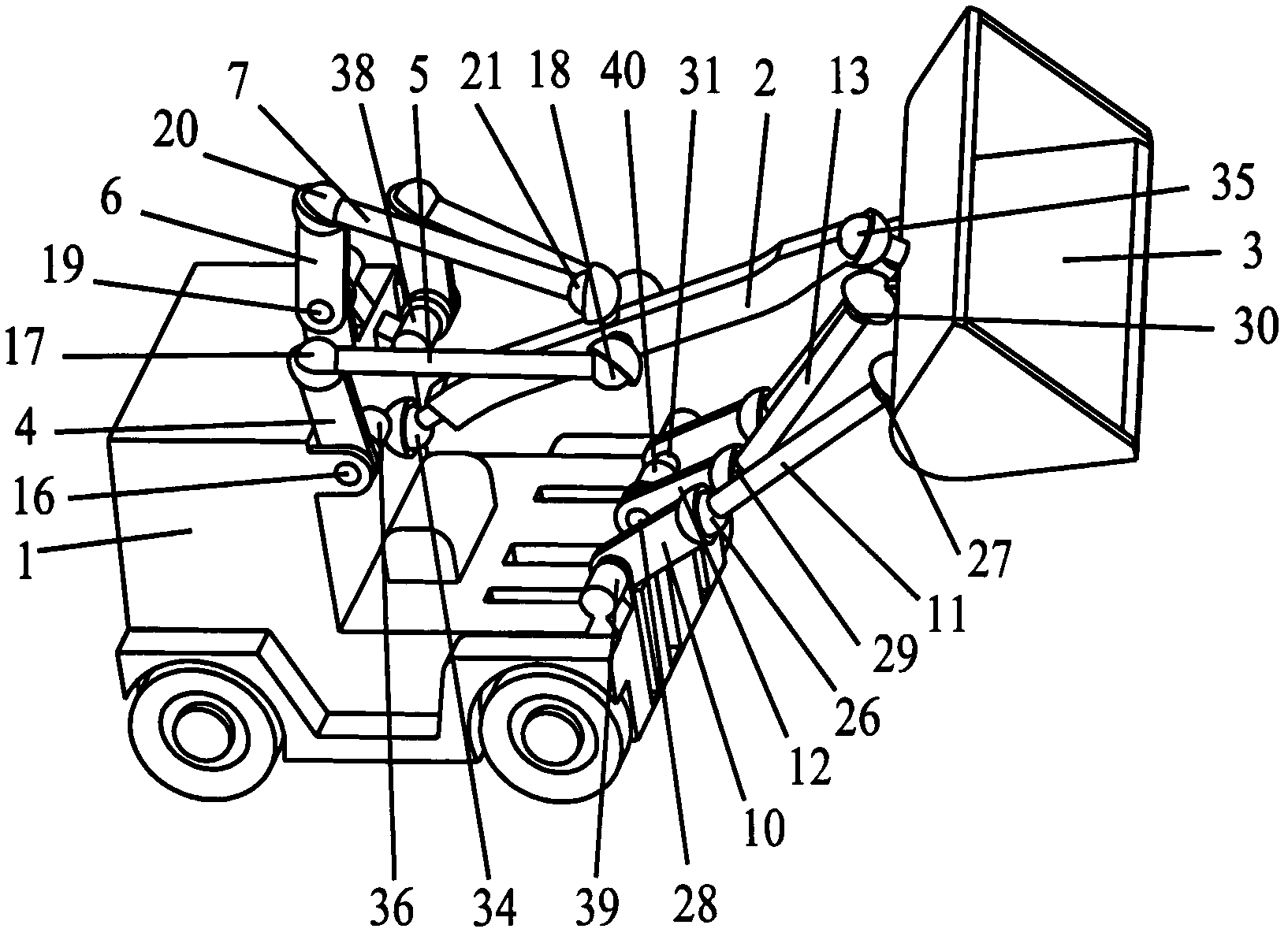

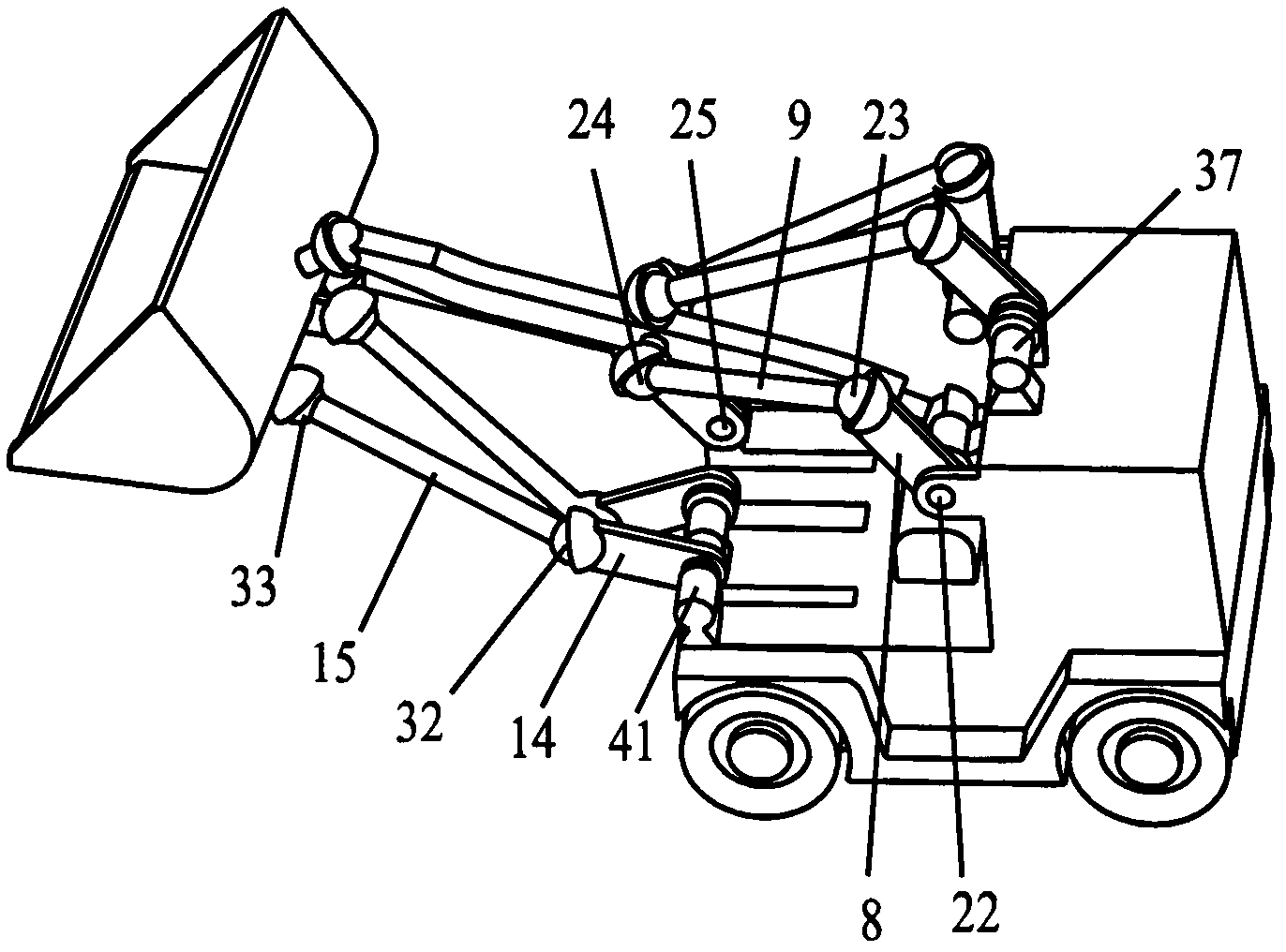

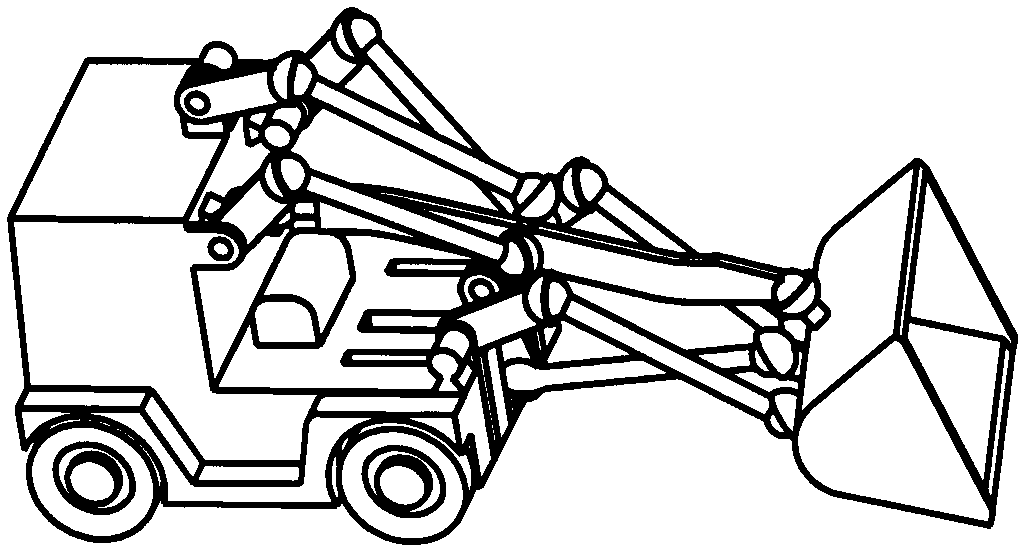

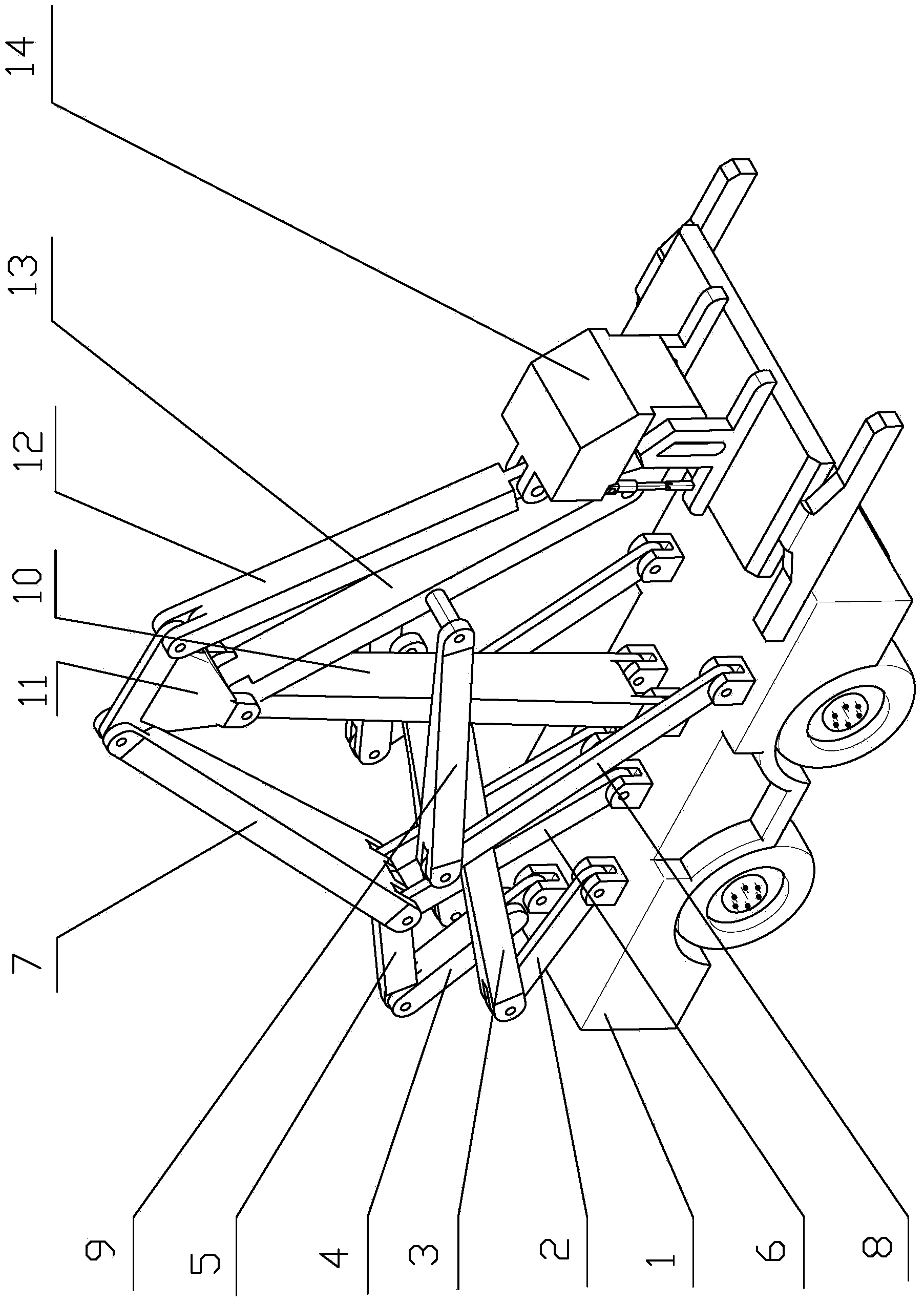

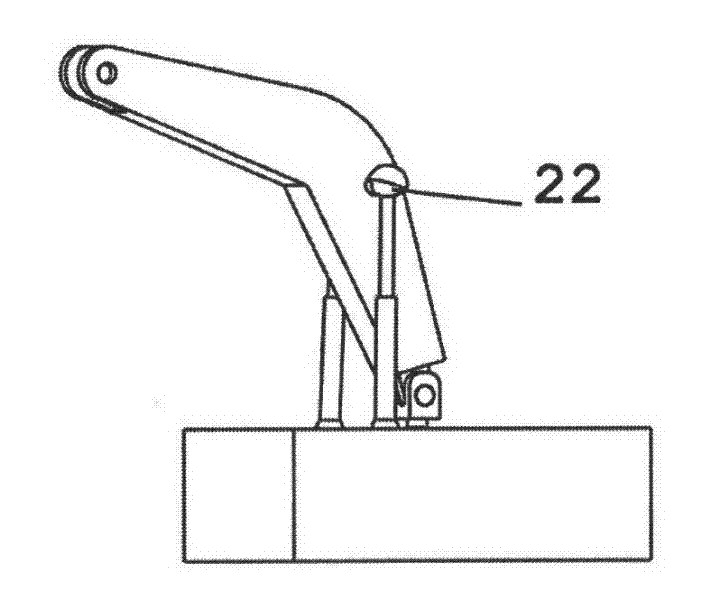

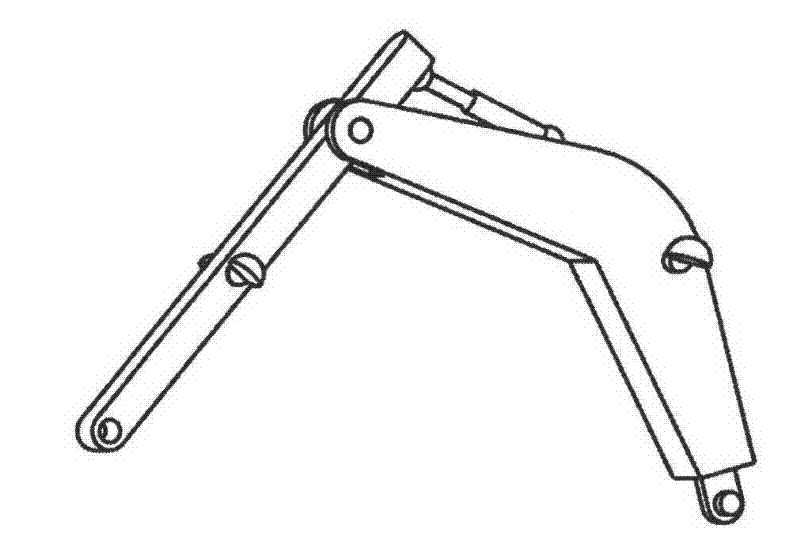

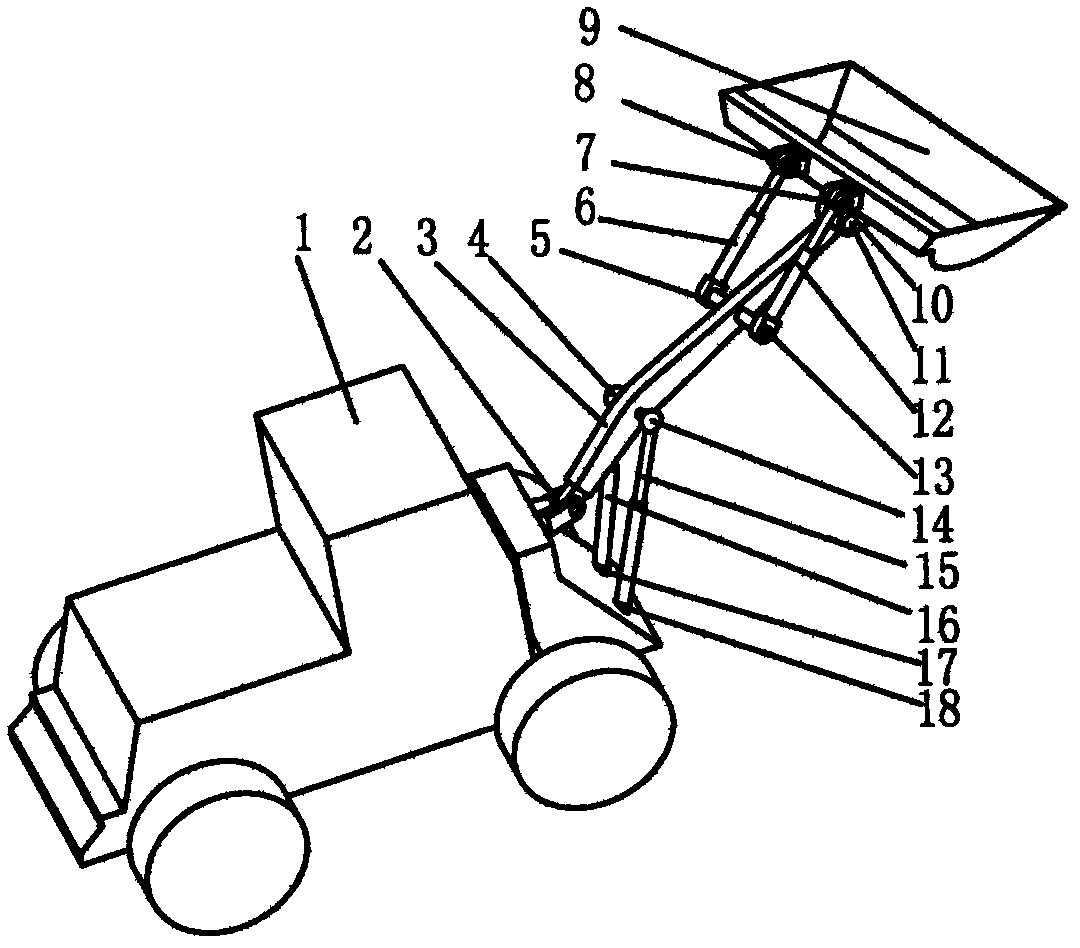

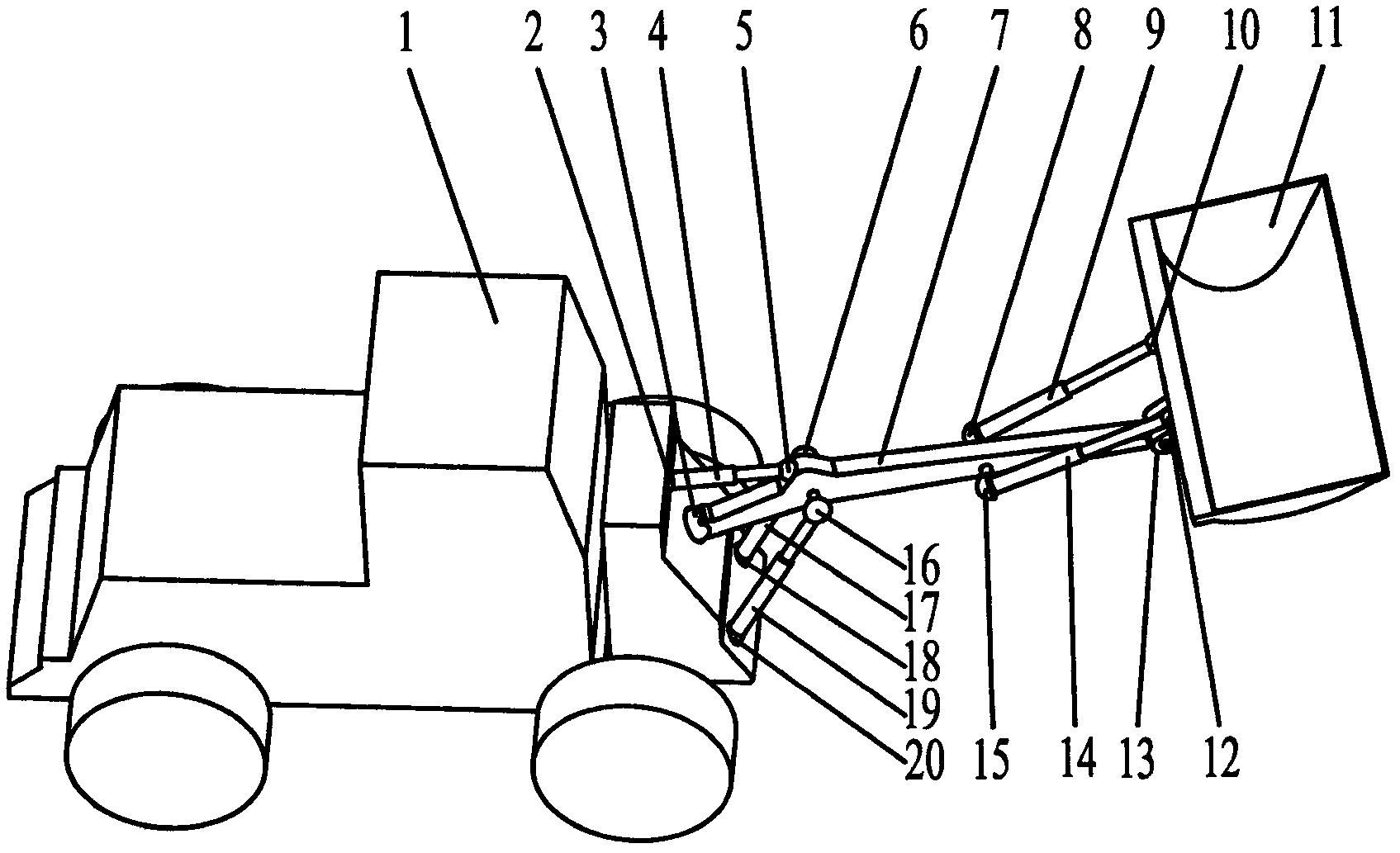

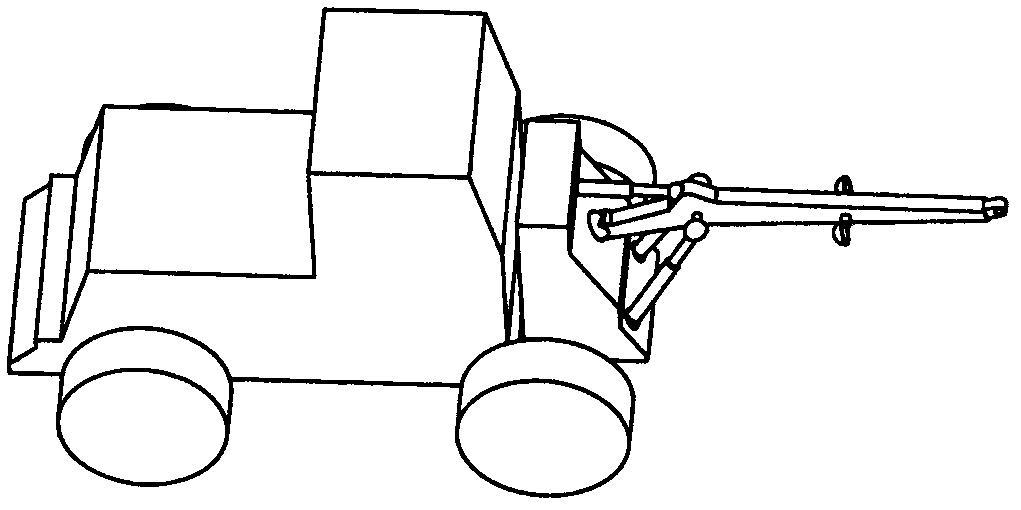

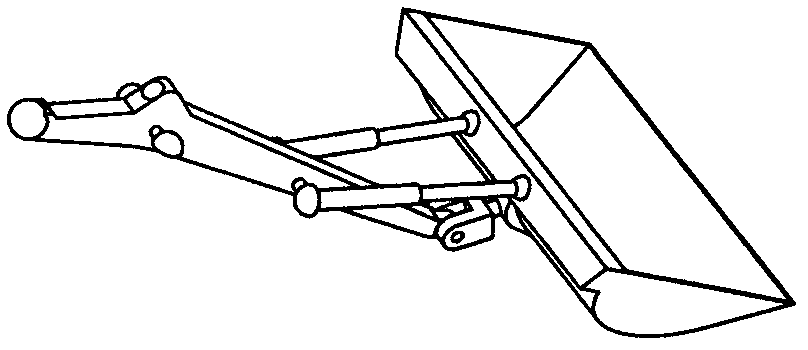

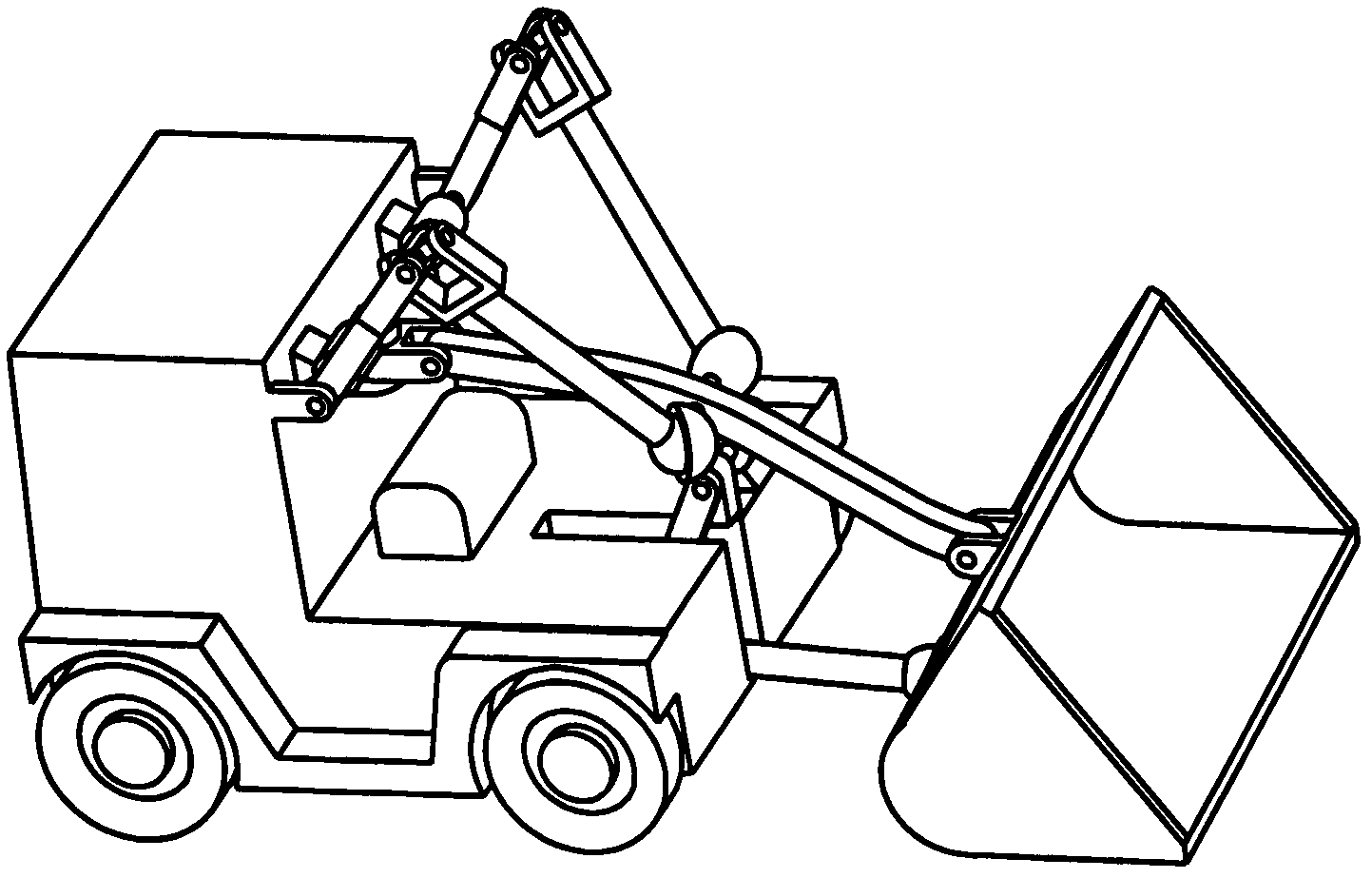

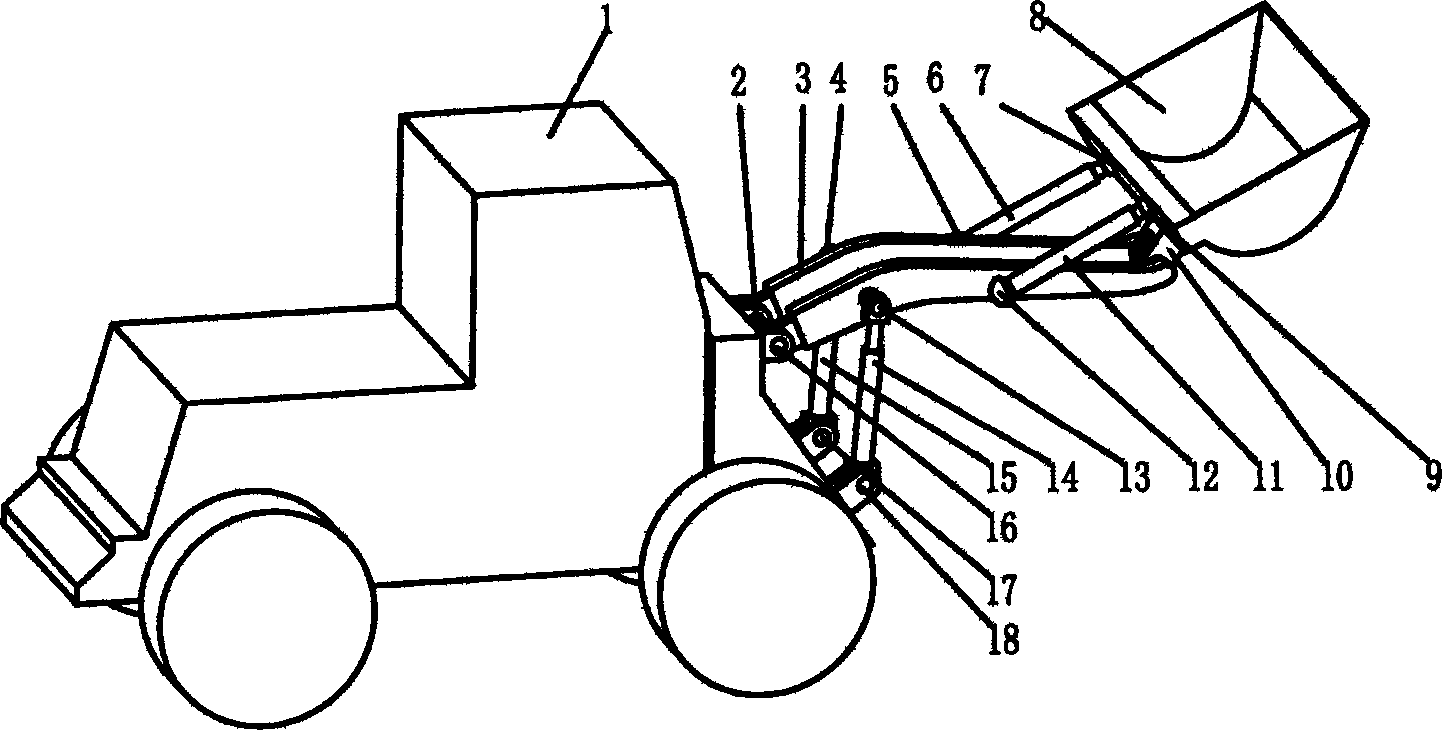

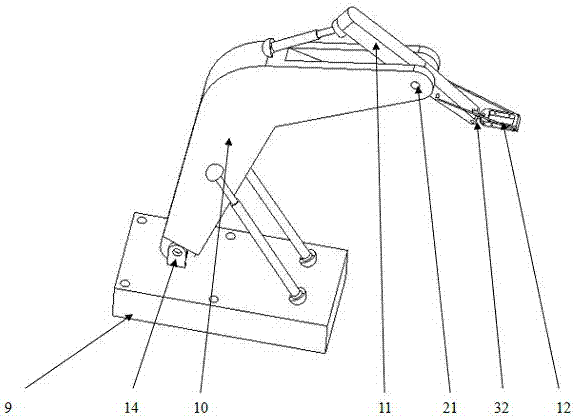

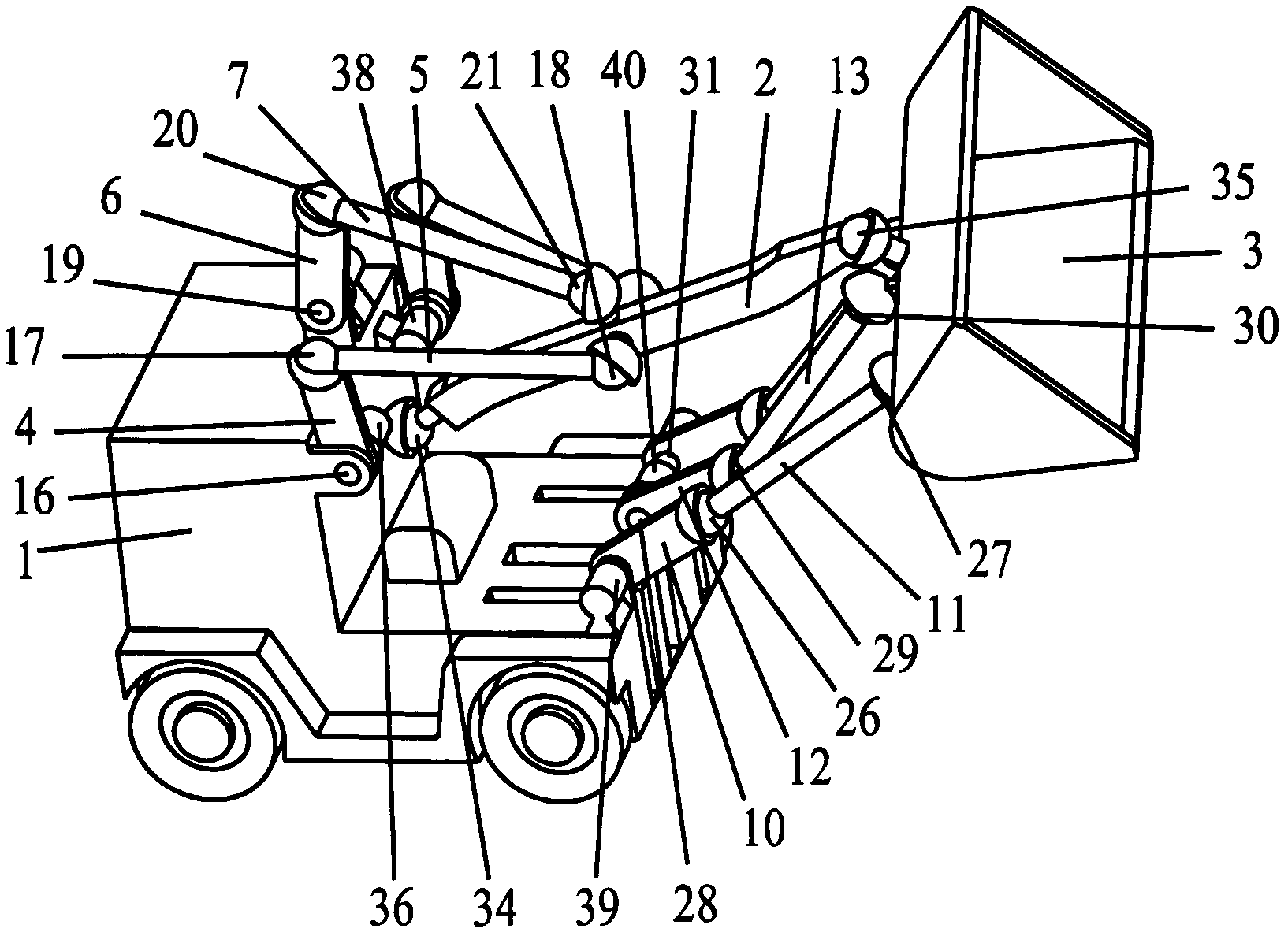

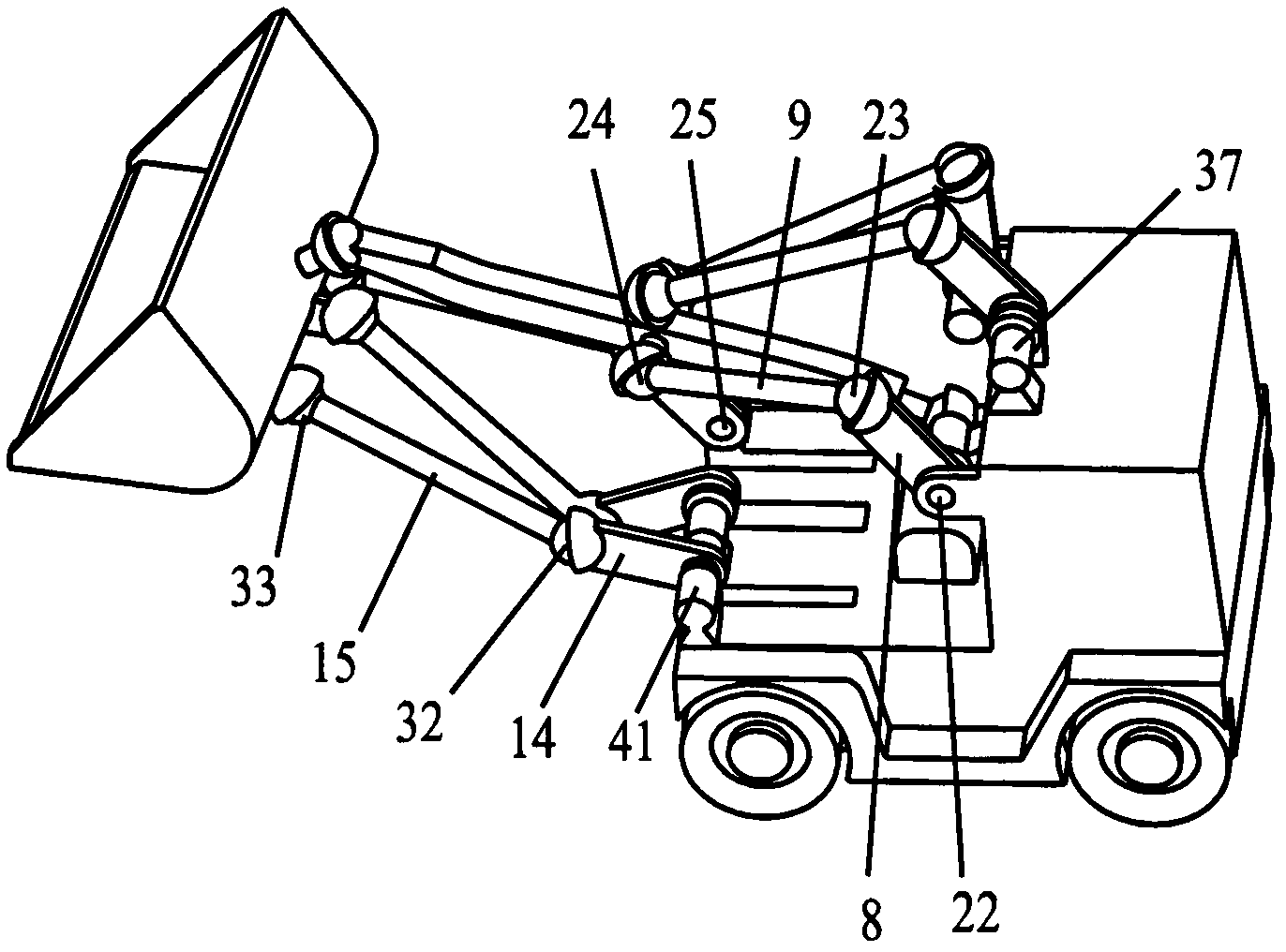

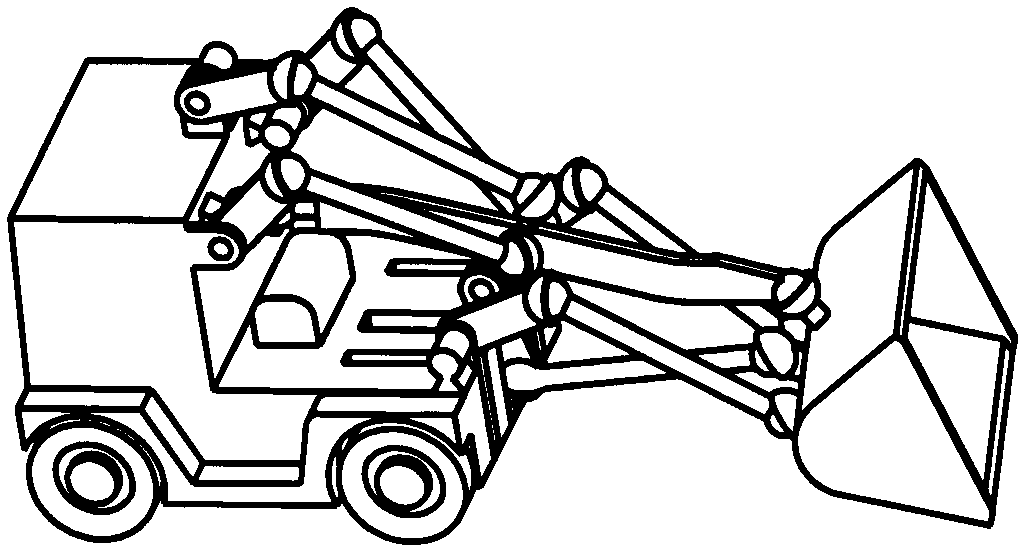

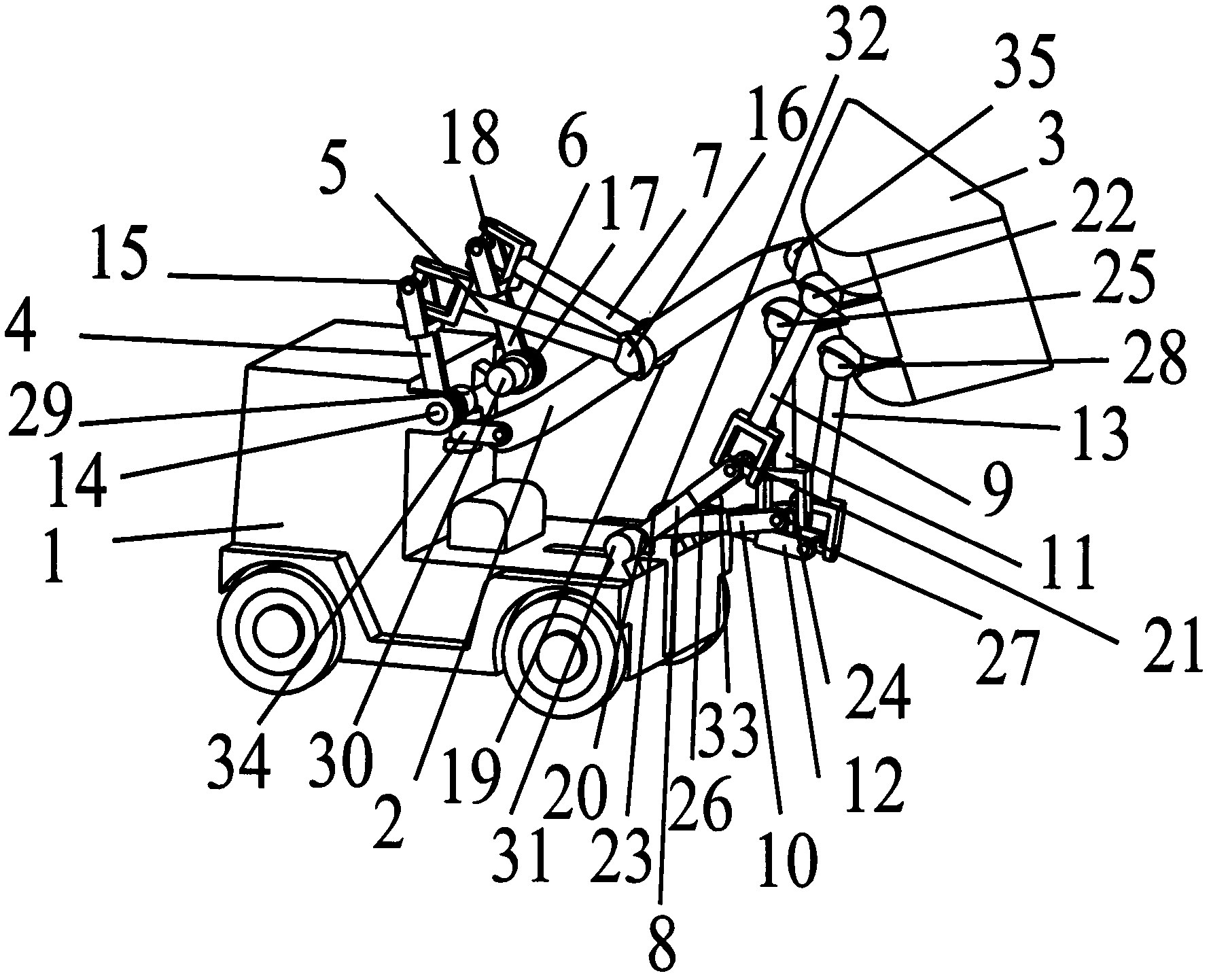

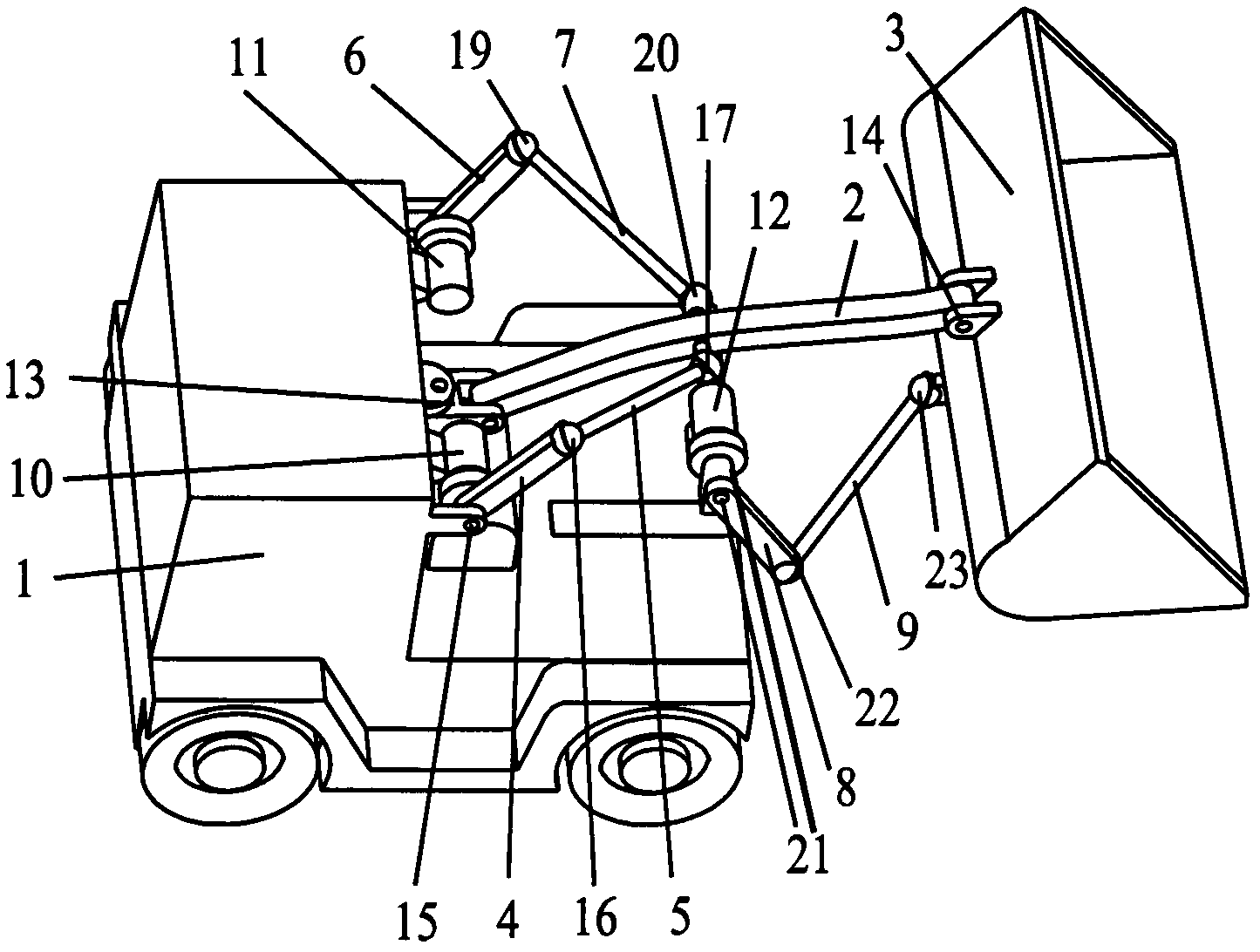

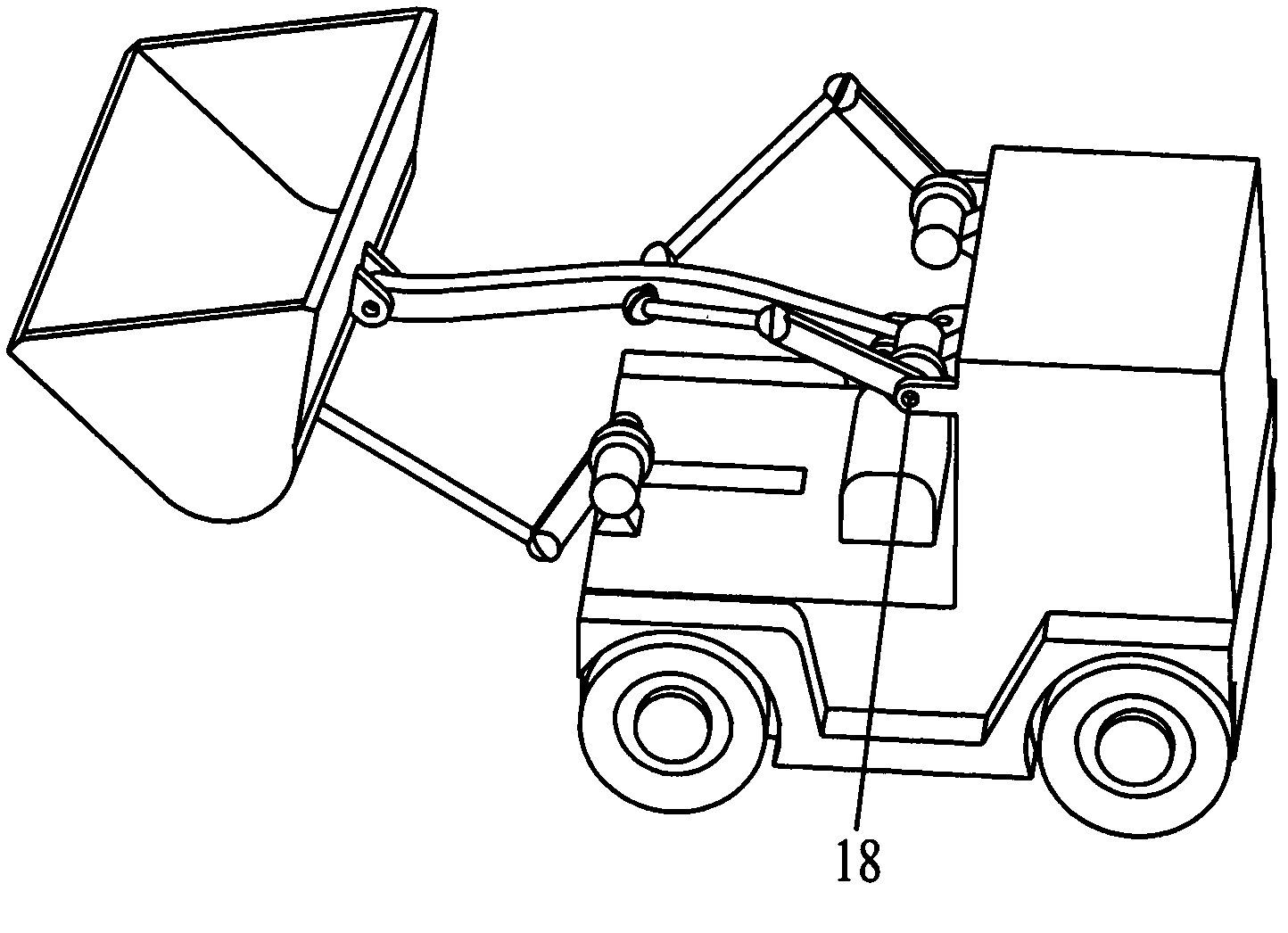

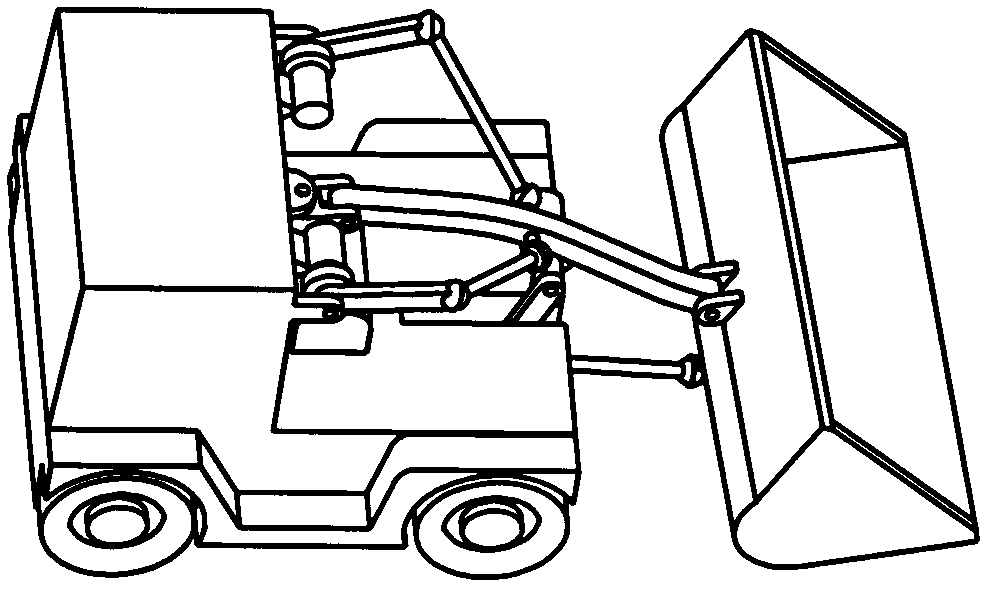

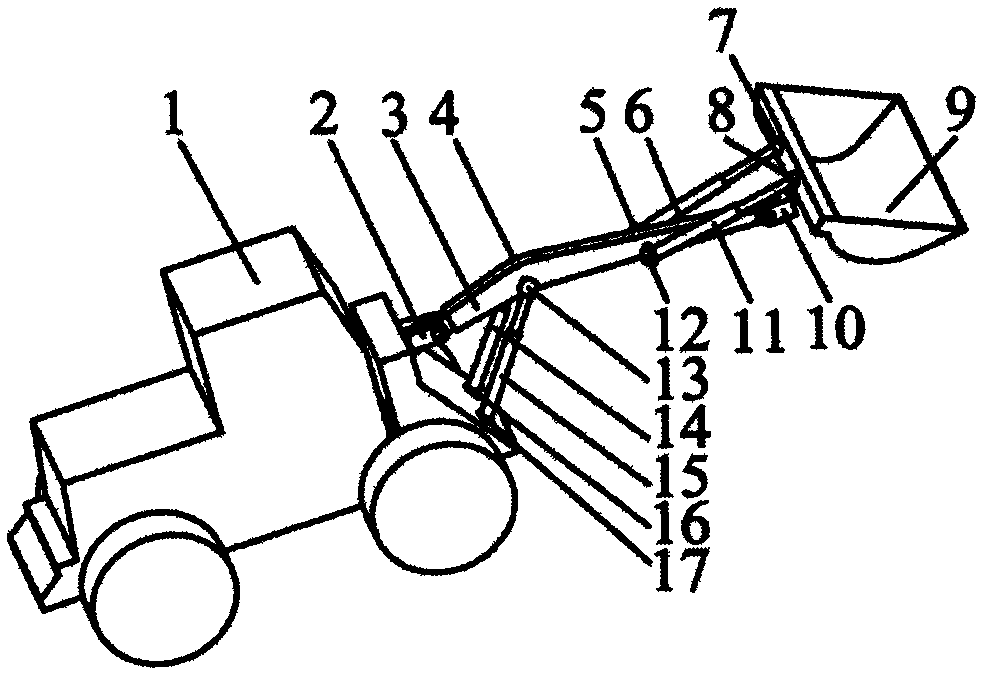

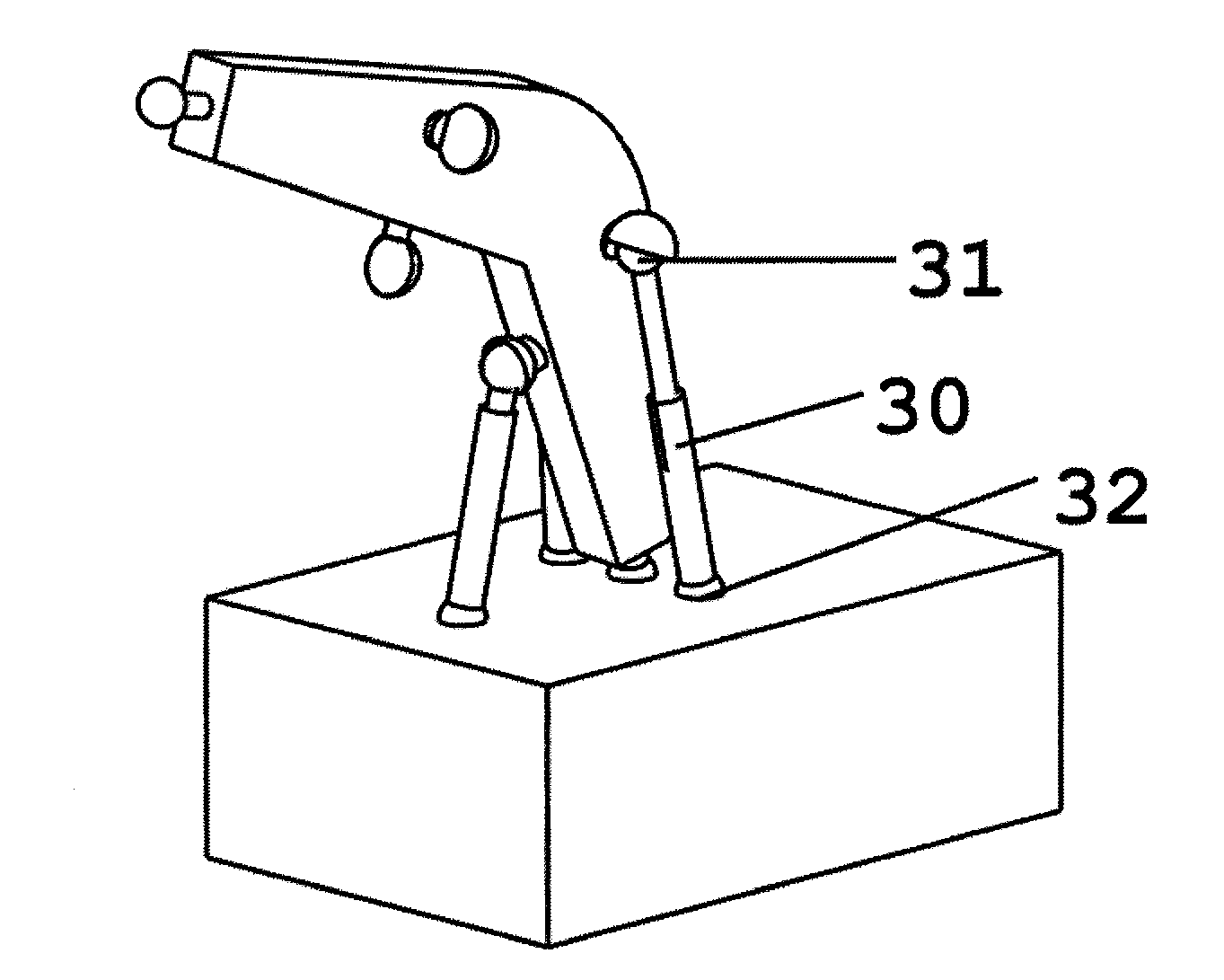

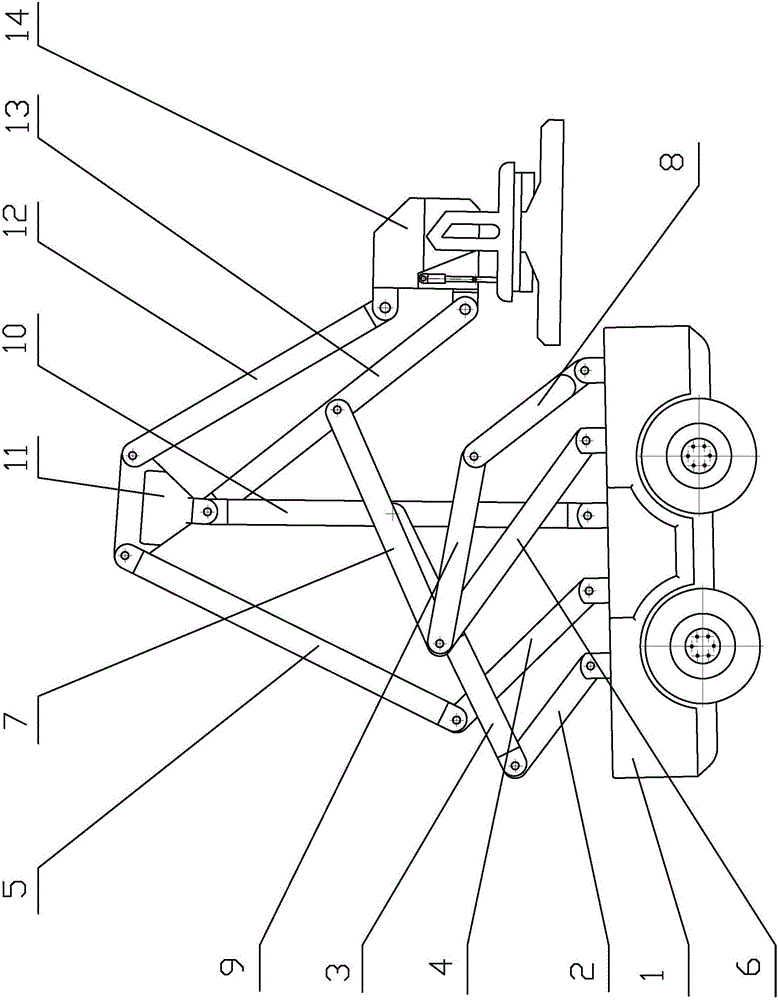

Space controllable mechanism-type loader with three-dimensional rotational moving arm and two-dimensional rotational bucket

InactiveCN102535540ALow processing and assembly requirementsOvercoming demandsMechanical machines/dredgersEngineeringWorking space

The invention relates to a space controllable mechanism-type loader with a three-dimensional rotational moving arm and a two-dimensional rotational bucket, which comprises a loader body, the moving arm, the bucket, five drive bars, five connecting bars and five servo motors. The moving arm is capable of rotating three-dimensionally and independently, the bucket is capable of rotating two-dimensionally and independently, and the whole loader is capable of generating movement in a space with five degrees of movement. The space controllable mechanism-type loader effectively overcomes the shortages that hydraulic elements of a hydraulic loader are high in processing precision requirement, high in maintenance cost, difficult in reliable guarantee, easy to leak oil and the like, and also solves the problems of insufficient movement flexibility, limited work space, low work efficiency and the like due to the fact that a plane loader only generates paths in a plane.

Owner:GUANGXI UNIV

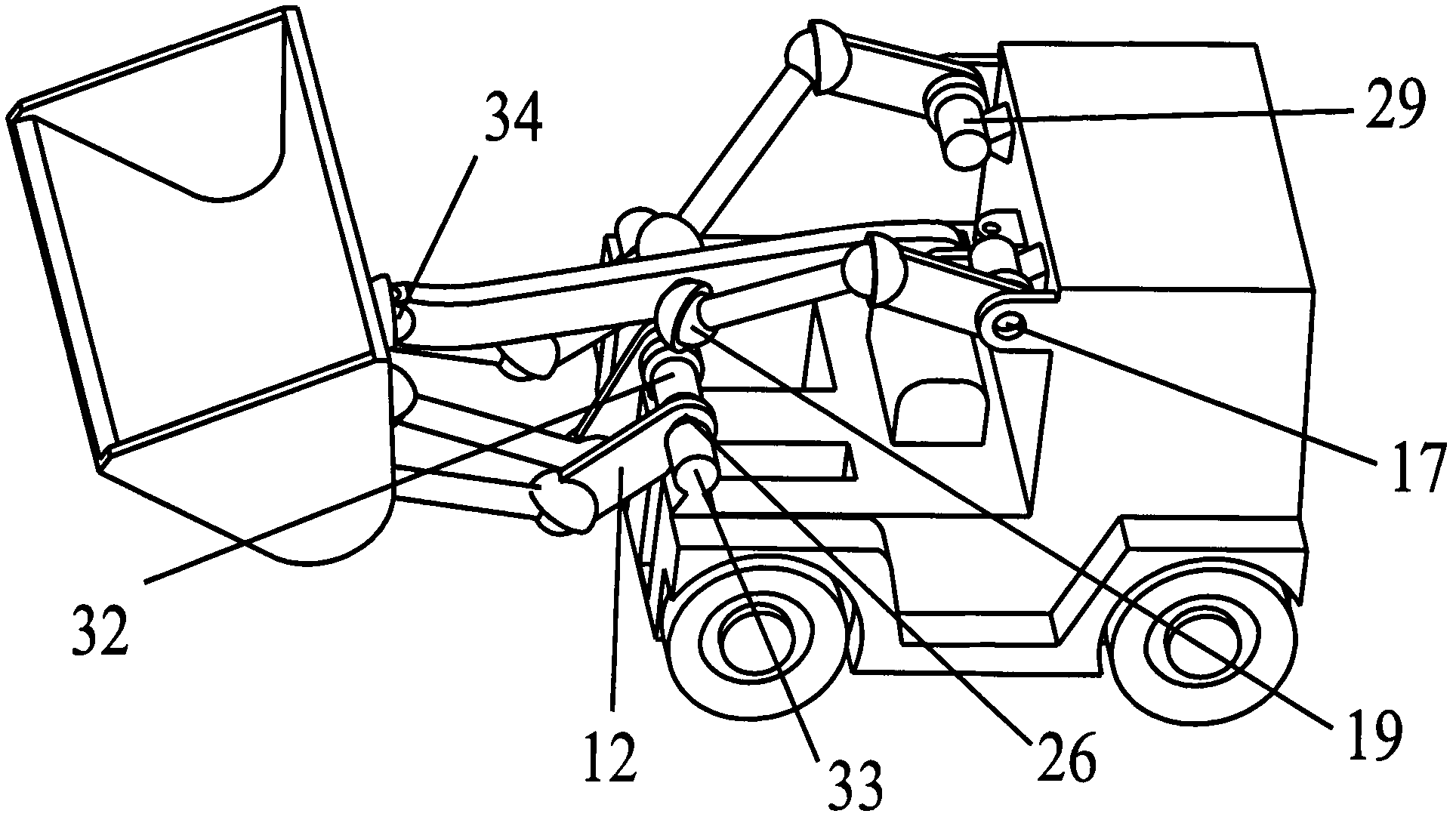

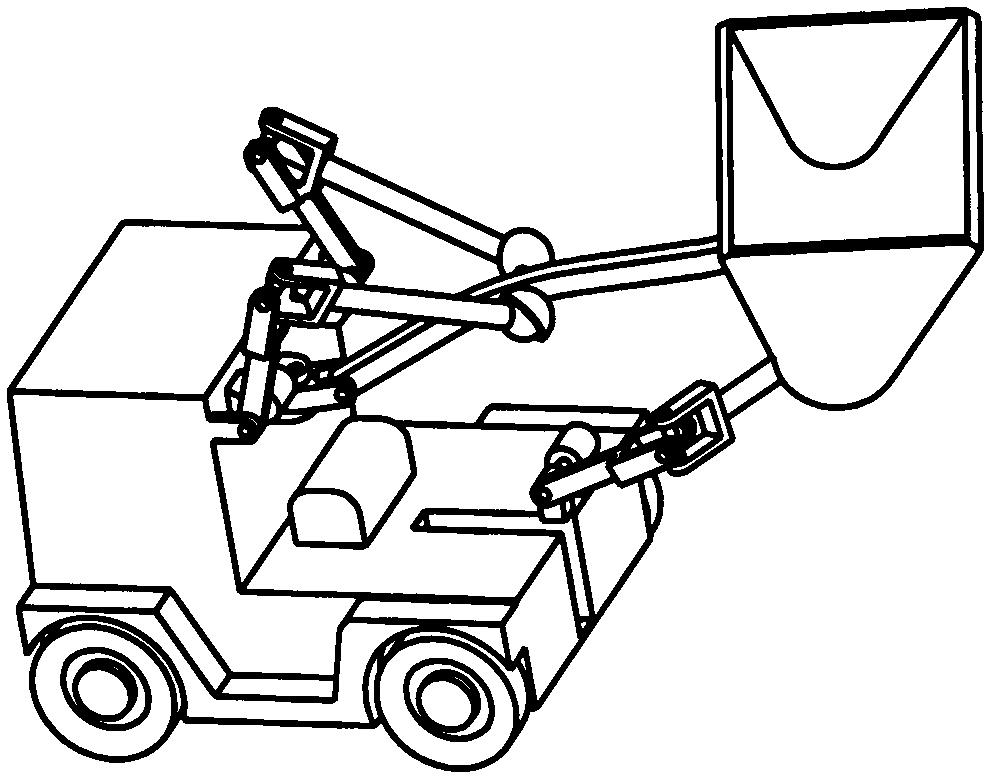

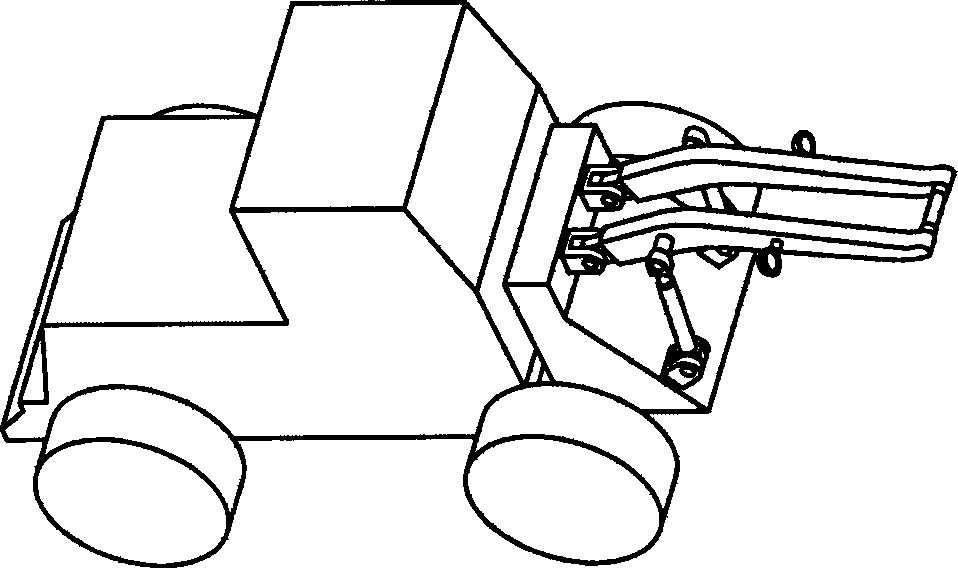

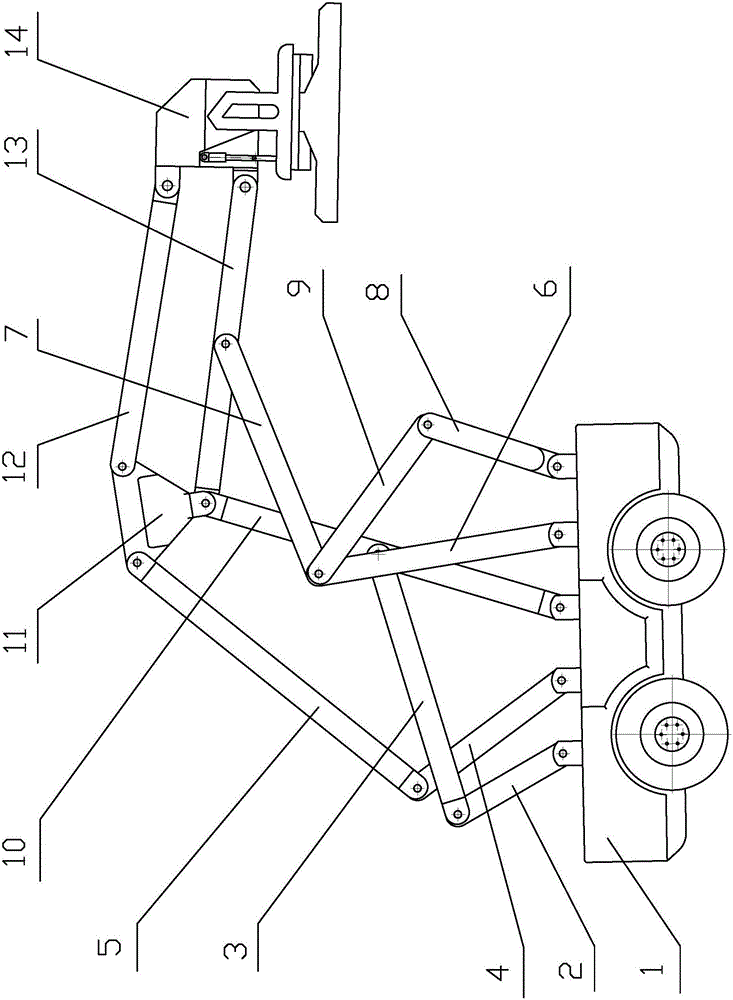

Space hydraulic loading machine with bucket capable of realizing two-dimensional rotation

InactiveCN102400475AFlexible output trajectoryLarge working spaceMechanical machines/dredgersHydraulic cylinderHydraulic load

The invention discloses a space hydraulic loading machine with a bucket capable of realizing two-dimensional rotation. The space hydraulic loading machine comprises a one-dimensional rotary arm mechanism and a two-dimensional rotary bucket mechanism, wherein the one-dimensional rotary arm mechanism comprises a one-dimensional rotary arm, a first hydraulic cylinder and a second hydraulic cylinder; and the two-dimensional rotary bucket mechanism comprises a two-dimensional rotary bucket, a third hydraulic cylinder and a fourth hydraulic cylinder. Independent space twp-dimensional rotation of the bucket of the novel loading machine can be realized; the mechanism output trace is flexible, the working space is large and the working efficiency is high; and the space hydraulic loading machine plays a better role in construction sites with severe environments and small spaces as well as in sites in which quick loading is required.

Owner:GUANGXI UNIV

Heavy-load-type container reach stacker crane

InactiveCN103848352AStrong carrying capacityIncrease power outputCranesElectric machineryVehicle frame

Owner:QINZHOU UNIV

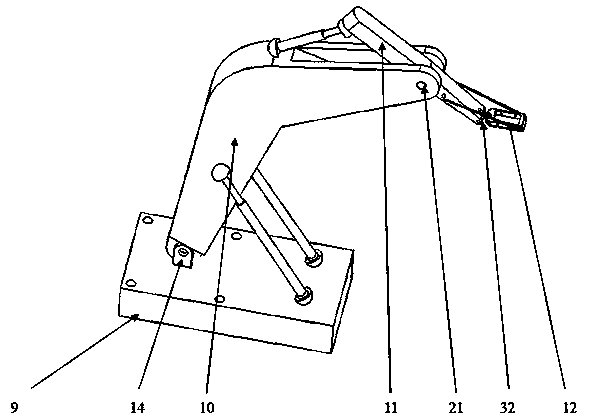

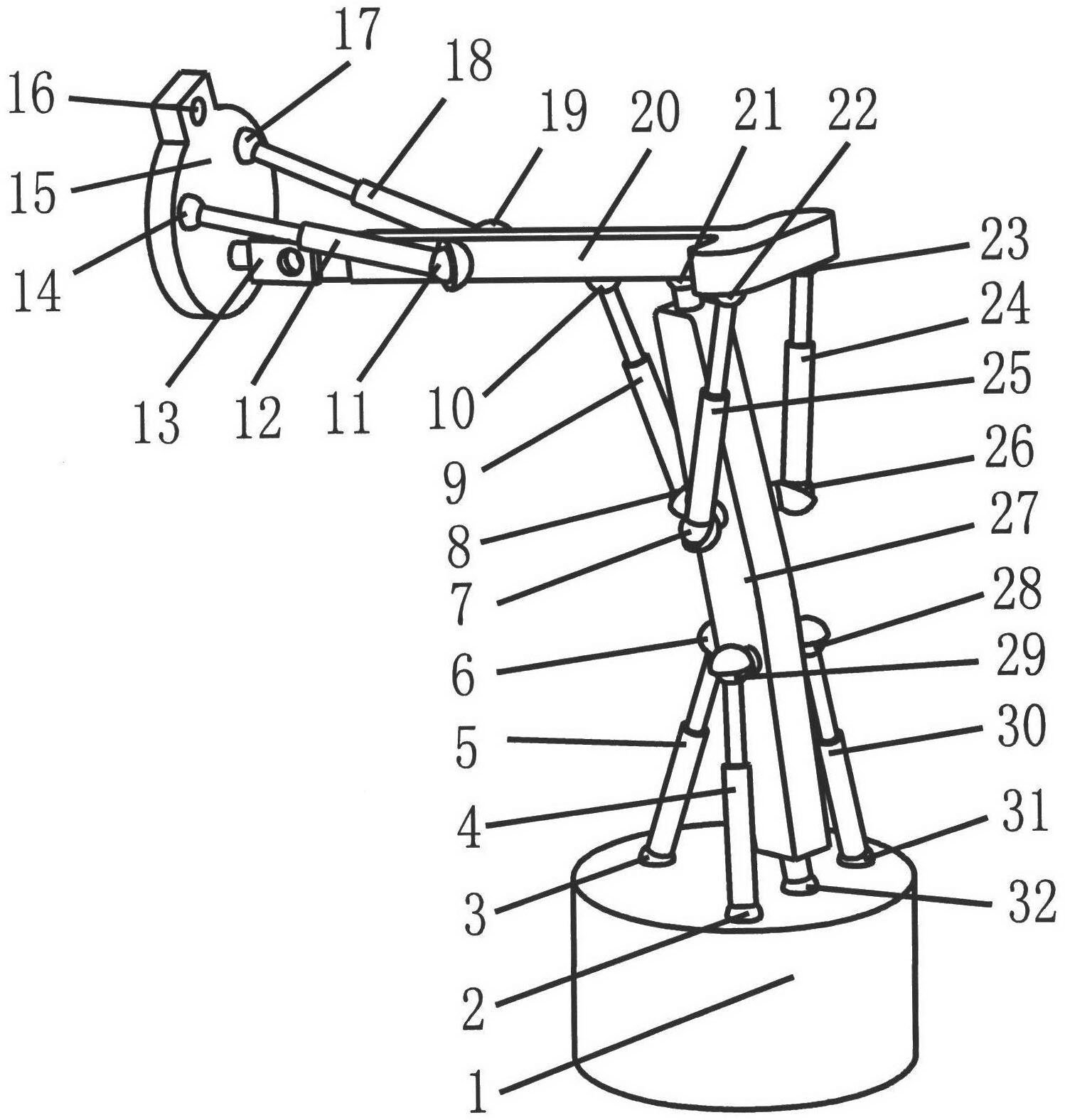

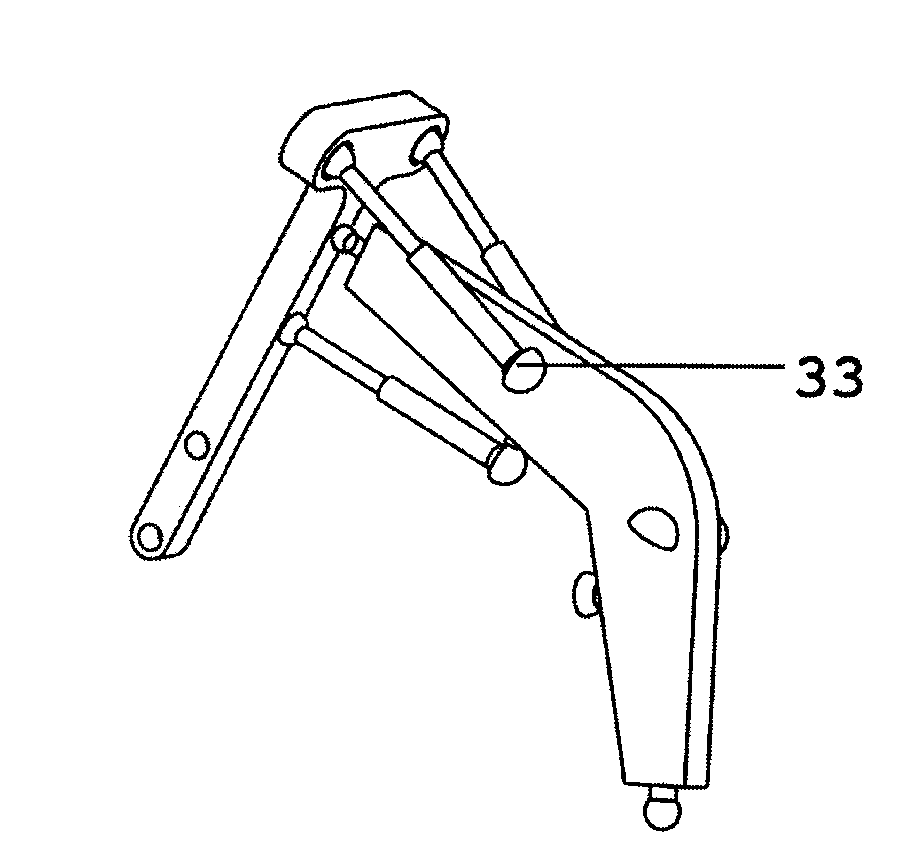

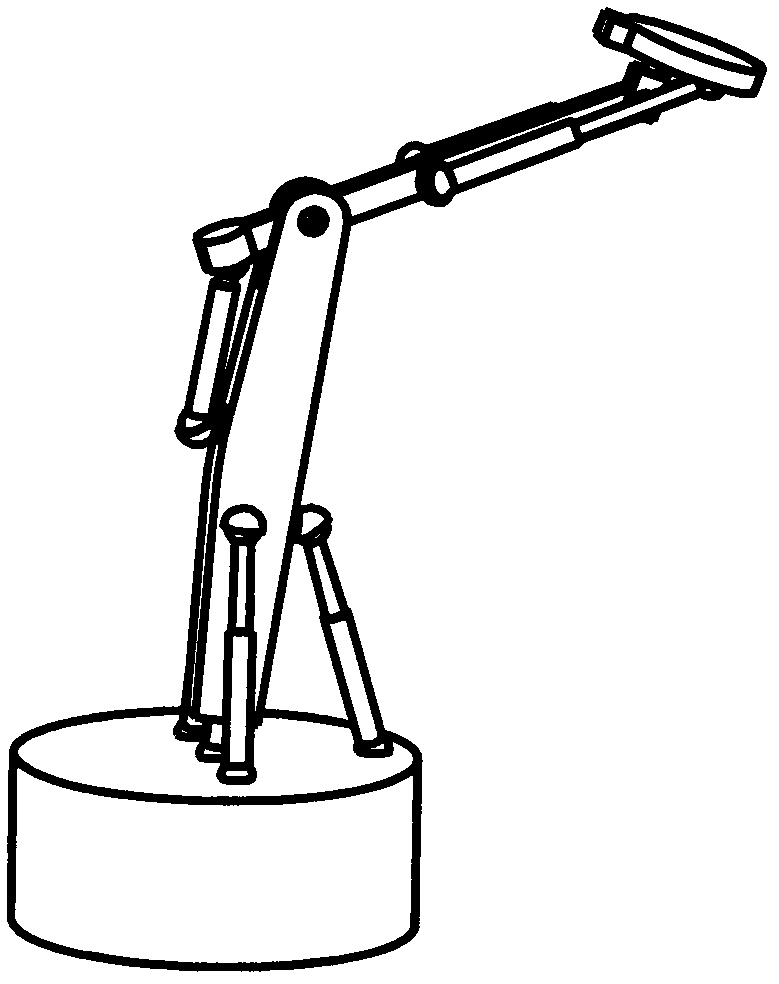

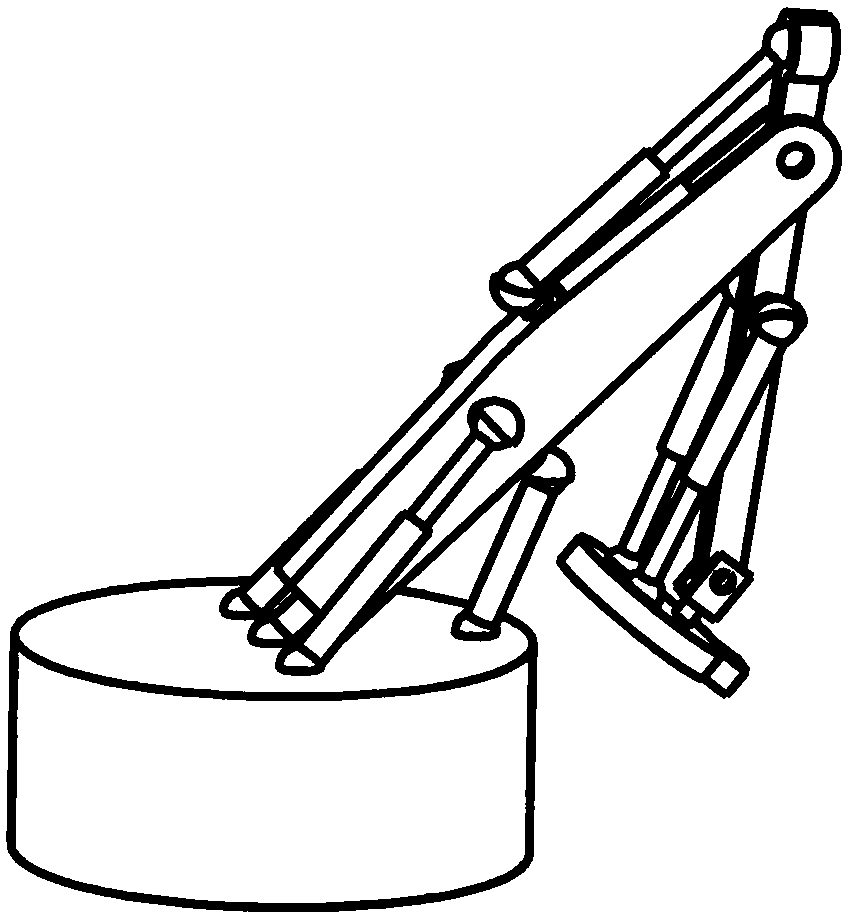

Seven-mobility spraying robot mechanism

InactiveCN102513255AFlexible output trajectoryThe output track is accurateSpraying apparatusControl theoryWorking space

The invention relates to a seven-mobility spraying robot mechanism, which comprises a first connection rod, a second connection rod, a movable platform, seven linear drivers and a frame. One end of the first connection rod is connected to the frame through a first spherical pair, the other end of the first connection rod is connected to the second connection rod through a first rotary pair, the other end of the second connection rod is connected to the movable platform through a second spherical pair, and the whole robot driven by the seven linear drivers in a joint mode can output movement with seven-mobility space. The seven-mobility spraying robot mechanism is flexible and accurate in output track, large in flexibility and working space, easy to operate and maintain and especially suitable for spraying operation occasions requiring both the first connection rod and the movable platform to achieve three-dimensional rotation output.

Owner:GUANGXI UNIV

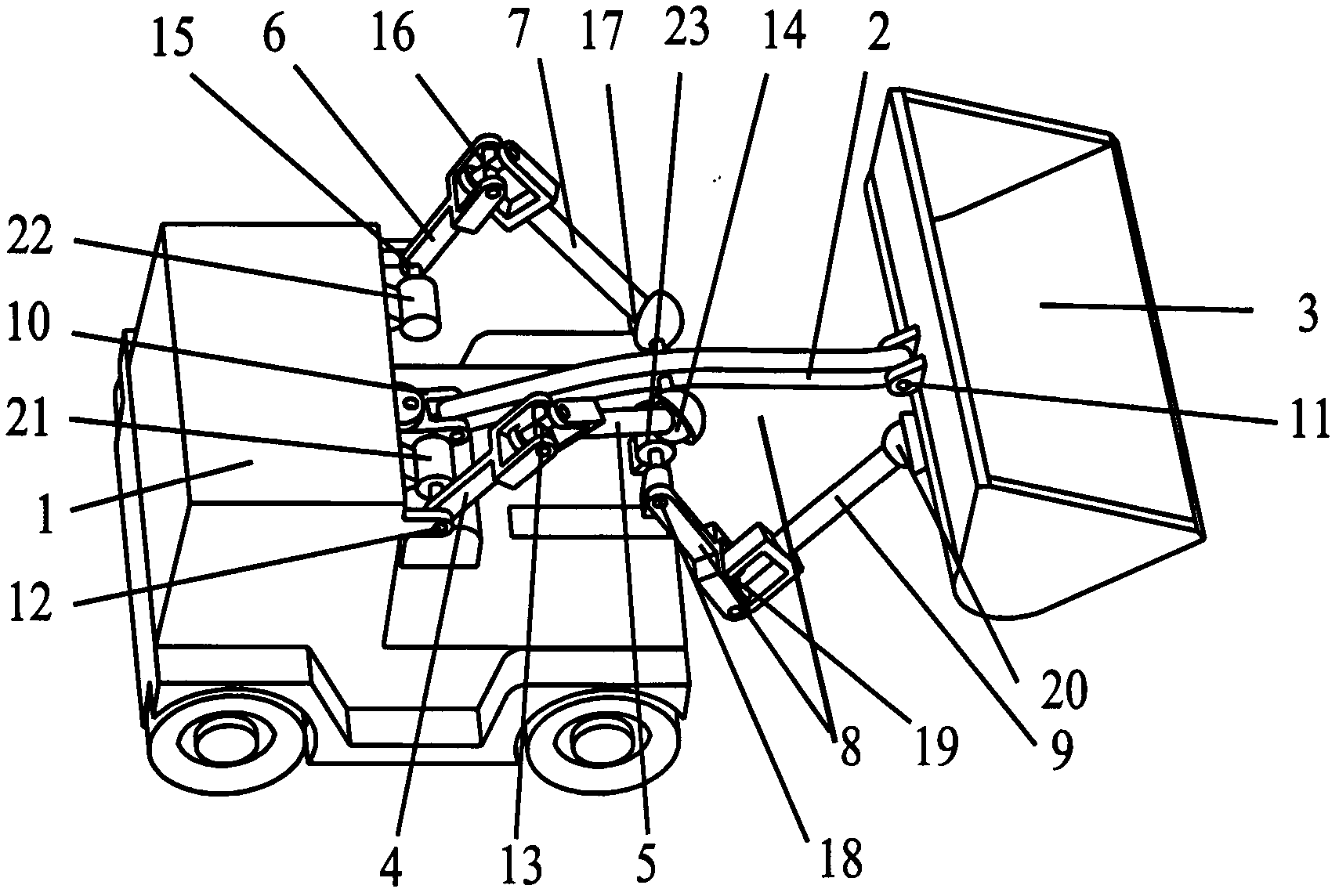

Spatially controllable mechanism type loader with two-dimensional rotary moving arm and three-dimensional rotary bucket

InactiveCN102561417ALow processing and assembly requirementsOvercoming demandsMechanical machines/dredgersRange of motionEngineering

The invention relates to a spatially controllable mechanism type loader with a two-dimensional rotary moving arm and a three-dimensional rotary bucket, which comprises a loader body, a moving arm, a bucket, five drive bars, five connecting bars and five servo motors. The moving arm is capable of independently rotating in two dimensions, the bucket is capable of independently rotating in three dimensions, and the whole loader is capable of moving with five spatial ranges-of-motion. By means of the spatially controllable mechanism type loader with the two-dimensional rotary moving arm and the three-dimensional rotary bucket, the shortages that hydraulic elements of a hydraulic loader are high in precision requirements, high in maintenance cost, difficult in reliability guarantee, prone to oil leakage and the like are solved, and the problems, action inflexibility, limitedness of operation space, low operating efficiency and the like due to the fact that a plane loader only can output plane tracks, are solved.

Owner:GUANGXI UNIV

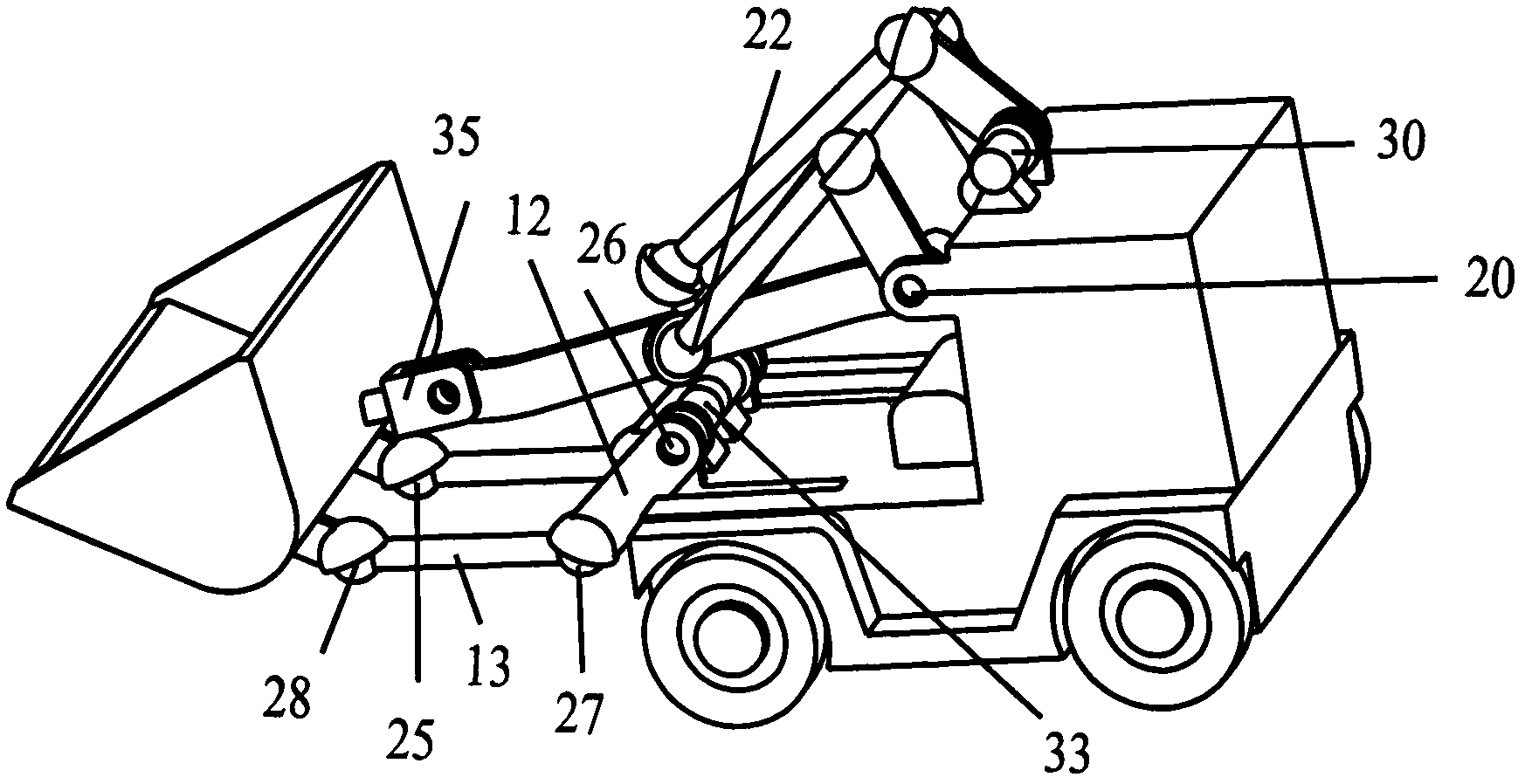

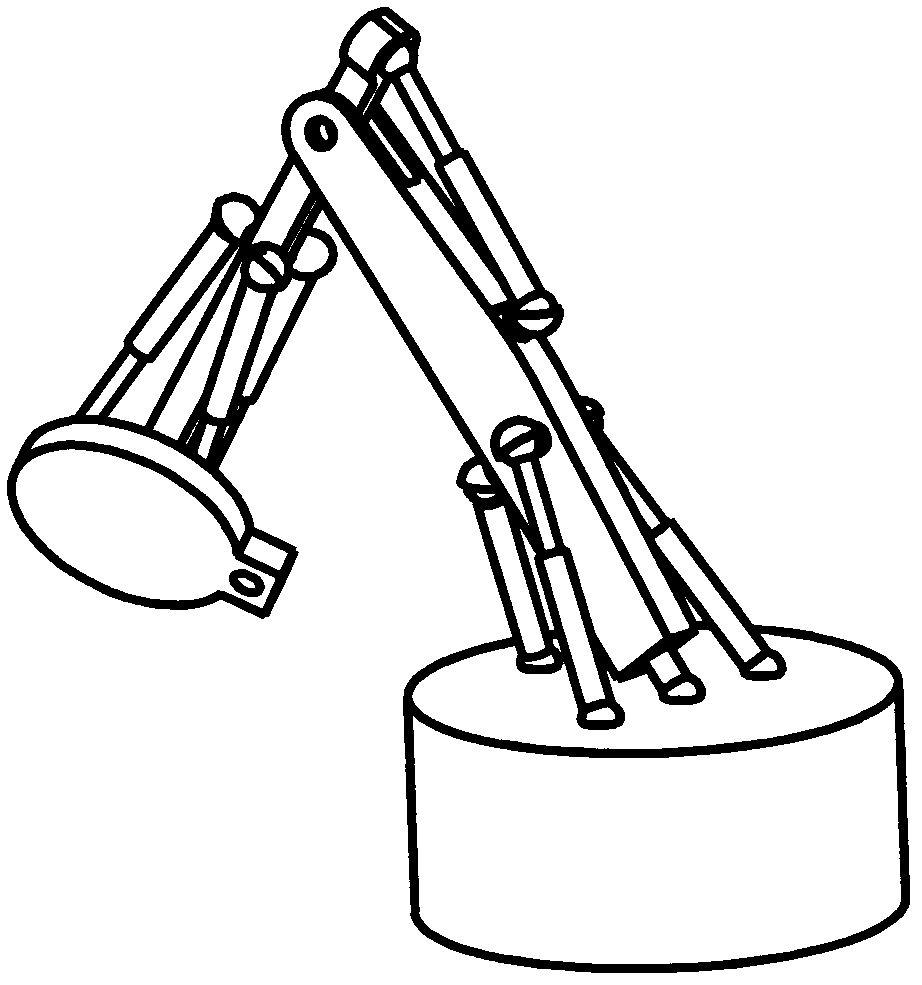

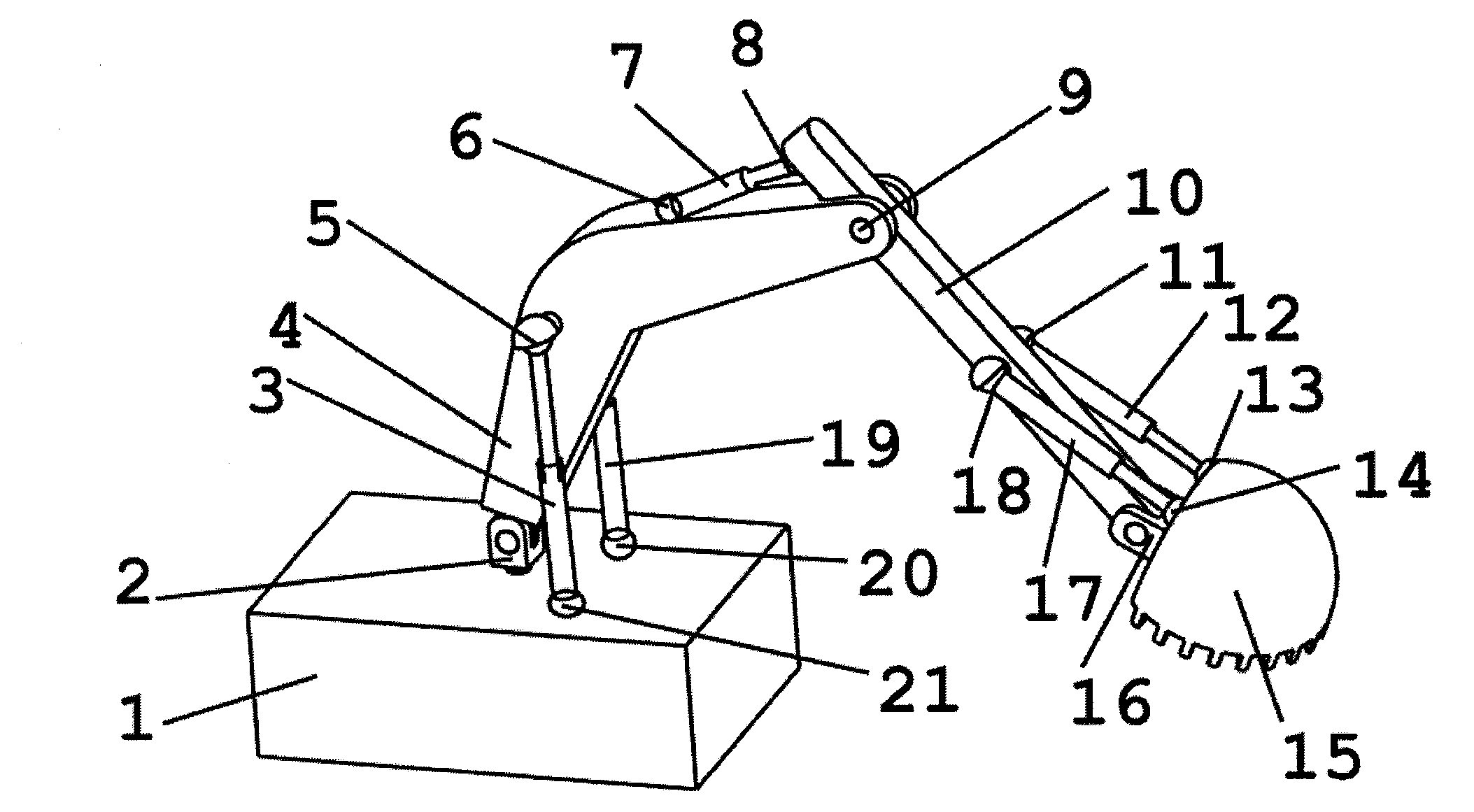

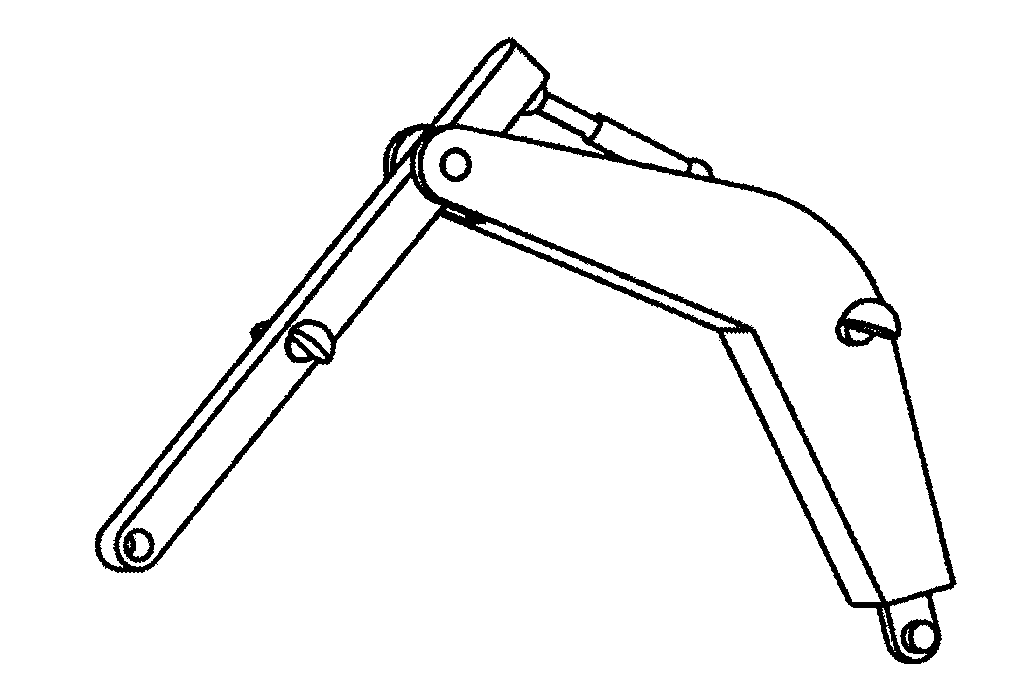

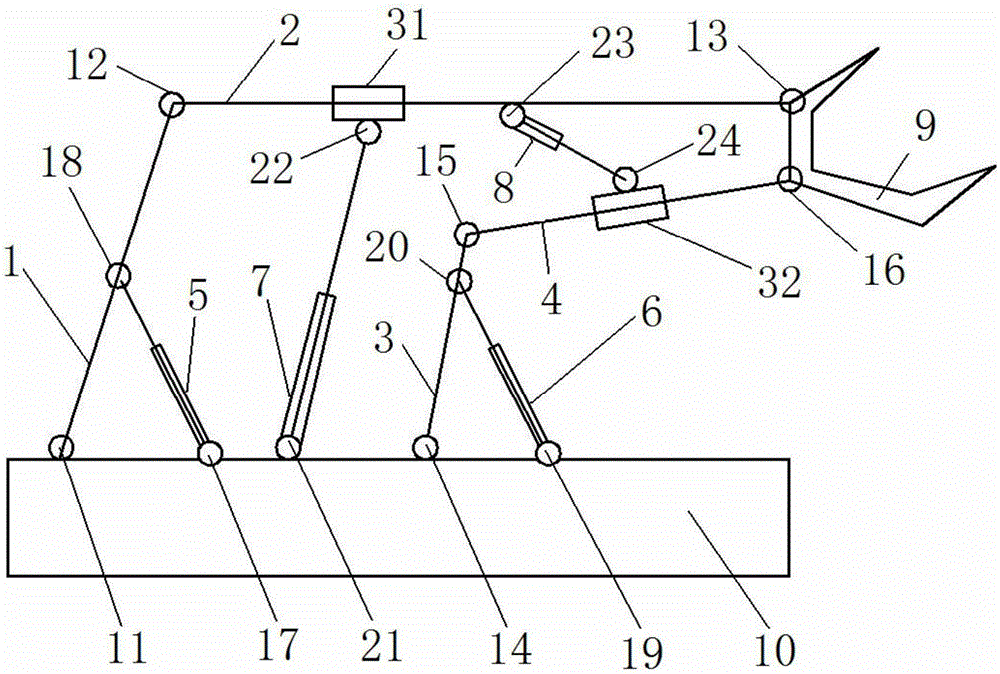

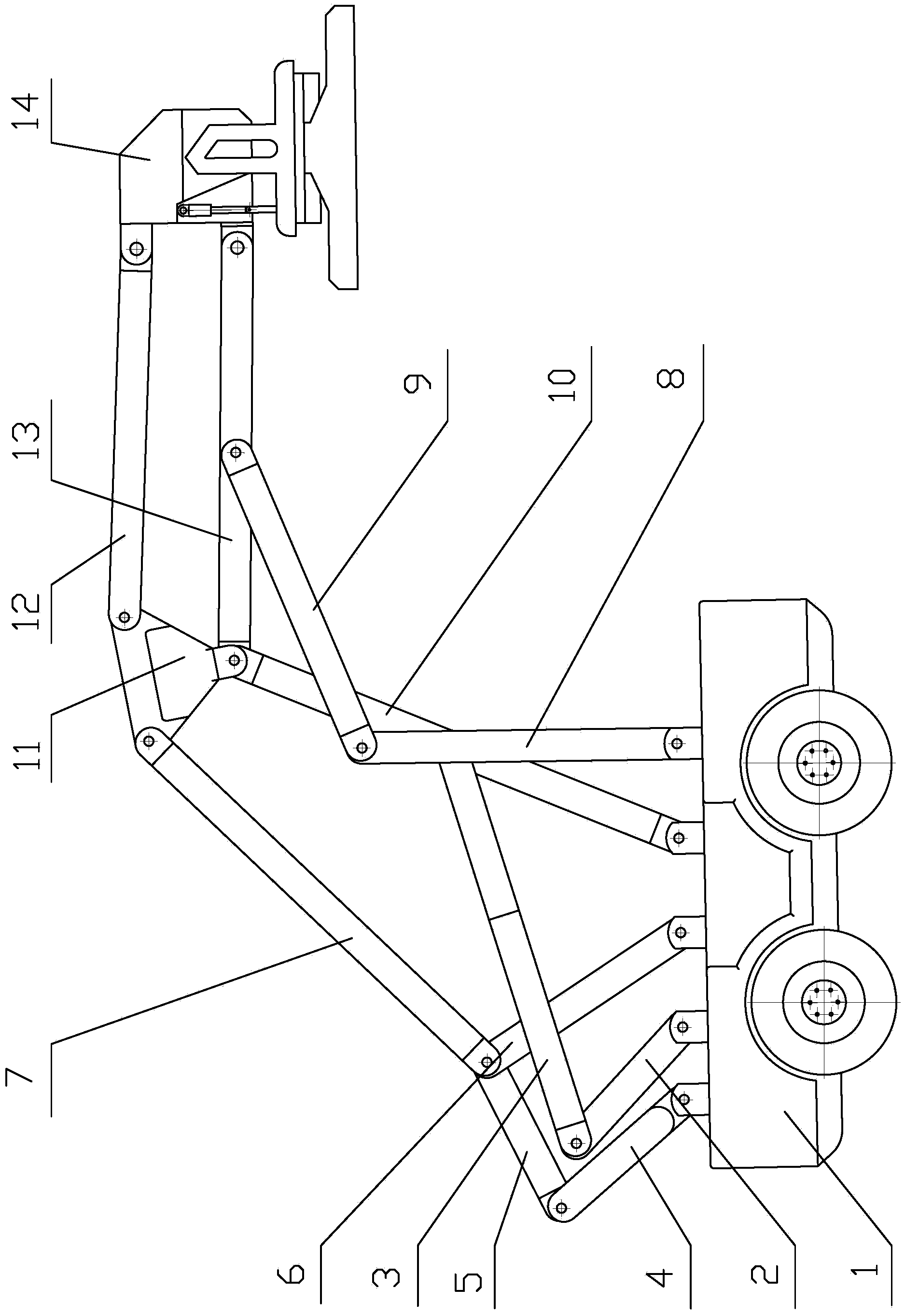

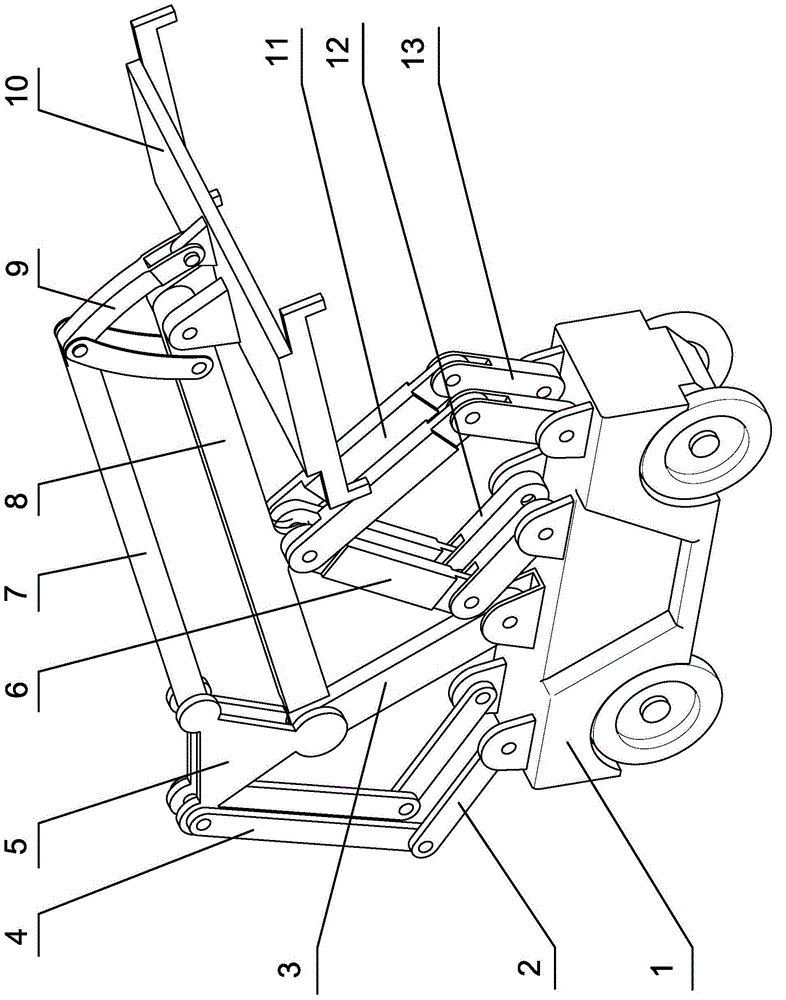

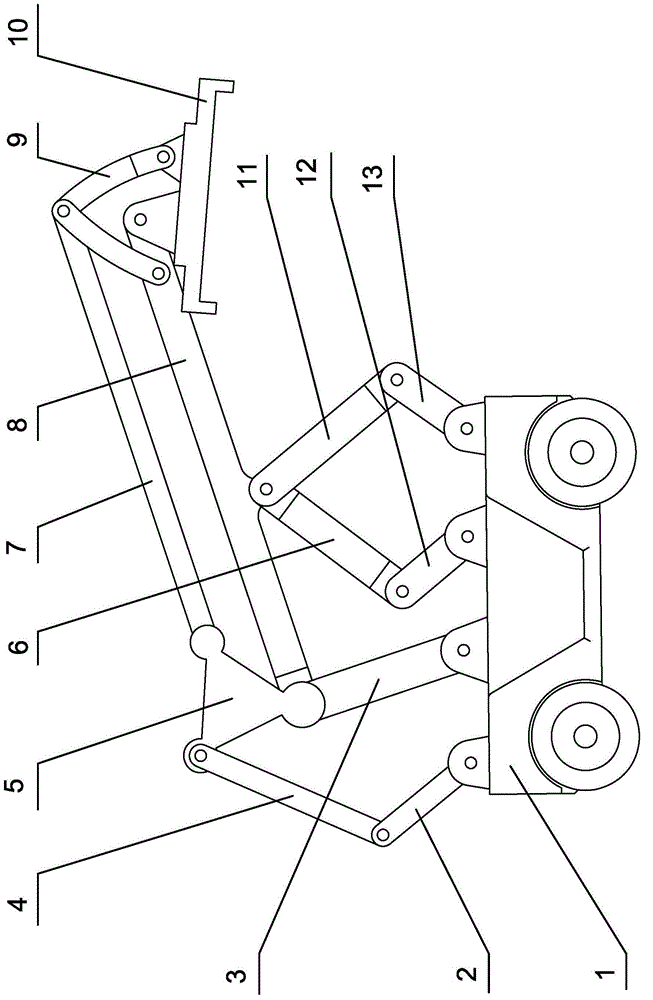

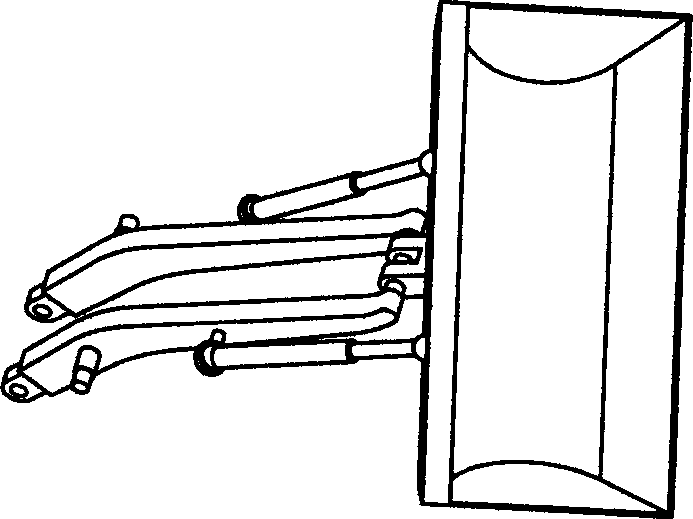

Spatial excavator with two-range-of-motion (two-ROM) movable arm, one-ROM bucket rod and two-ROM bucket

InactiveCN102363968BFlexible output trajectoryLarge working spaceMechanical machines/dredgersHydraulic cylinderRange of motion

The invention discloses a spatial excavator with a two-range-of-motion (two-ROM) movable arm, a one-ROM bucket rod and a two-ROM bucket. The excavator comprises a two-dimensional rotating arm mechanism, a one-dimensional rotating bucket rod mechanism and a two-dimensional rotating bucket mechanism. The two-dimensional rotating arm mechanism comprises a two-dimensional rotating arm, a first hydraulic cylinder and a second hydraulic cylinder; the one-dimensional rotating bucket rod comprises a one-dimensional rotating bucket rod and a third hydraulic cylinder; and the two-dimensional rotating bucket mechanism comprises a two-dimensional rotating bucket, a fourth hydraulic cylinder and a fifth hydraulic cylinder. Both the movably arm and the bucket of the novel excavator can realize independent spatial two-dimensional rotation, so that the whole excavator can realize spatial five-ROM motion; and the excavator is flexible in mechanism output loci, large in working space and high in work efficiency, and can play a good role in construction sites of severe environment and narrow space and emergency rescue sites in need of quick digging, obstacle clearing and flattening.

Owner:GUANGXI UNIV

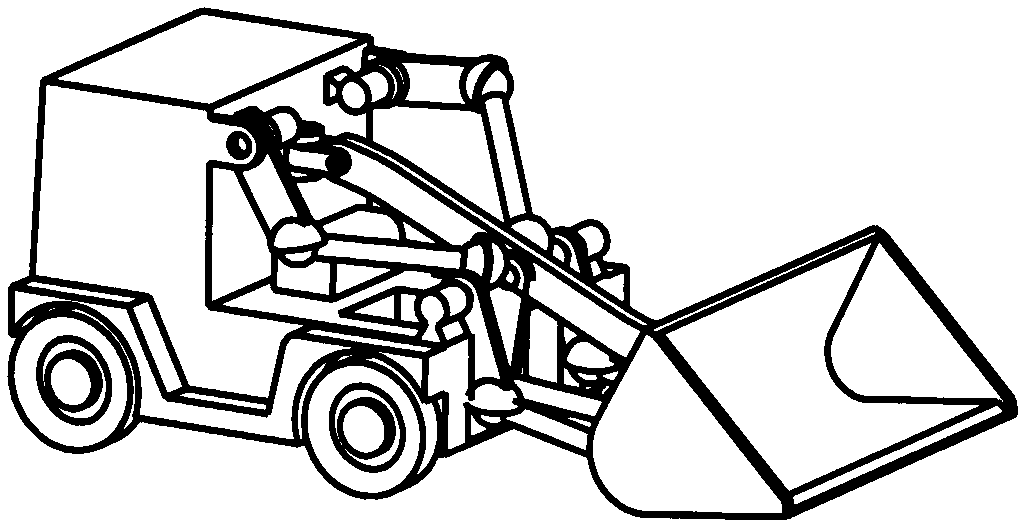

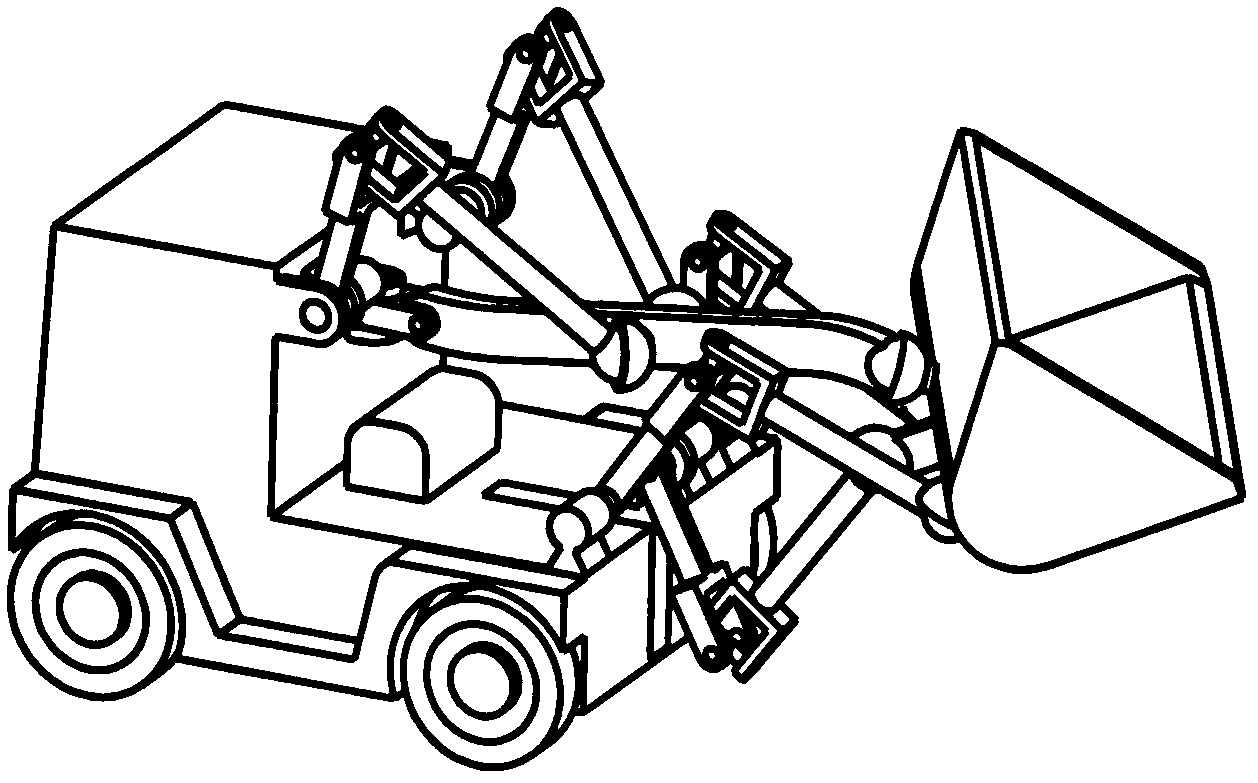

Space-controllable mechanism type loader with three-dimensional rotating movable arm and one-dimensional rotating bucket

InactiveCN102561419ALow processing and assembly requirementsFlexible output trajectoryMechanical machines/dredgersEngineeringWorking space

The invention relates to a space-controllable mechanism type loader with a three-dimensional rotating movable arm and a one-dimensional rotating bucket, comprising a vehicle, the movable arm, the bucket, six driving rods, six connecting rods and six servo motors; both the movable arm and bucket can rotate three-dimensionally independently; and the whole loader can realize the output of six degrees of space motion. The space-controllable mechanism type loader can effectively overcome the defects of high requirement for the processing precision of the hydraulic elements, high maintenance cost, difficult guarantee of reliability and easy oil leakage of the hydraulic loader and solve the problems of inflexible motion, limited work space and low work efficiency due to the output of the trajectory only in the plane of the plane loader.

Owner:GUANGXI UNIV

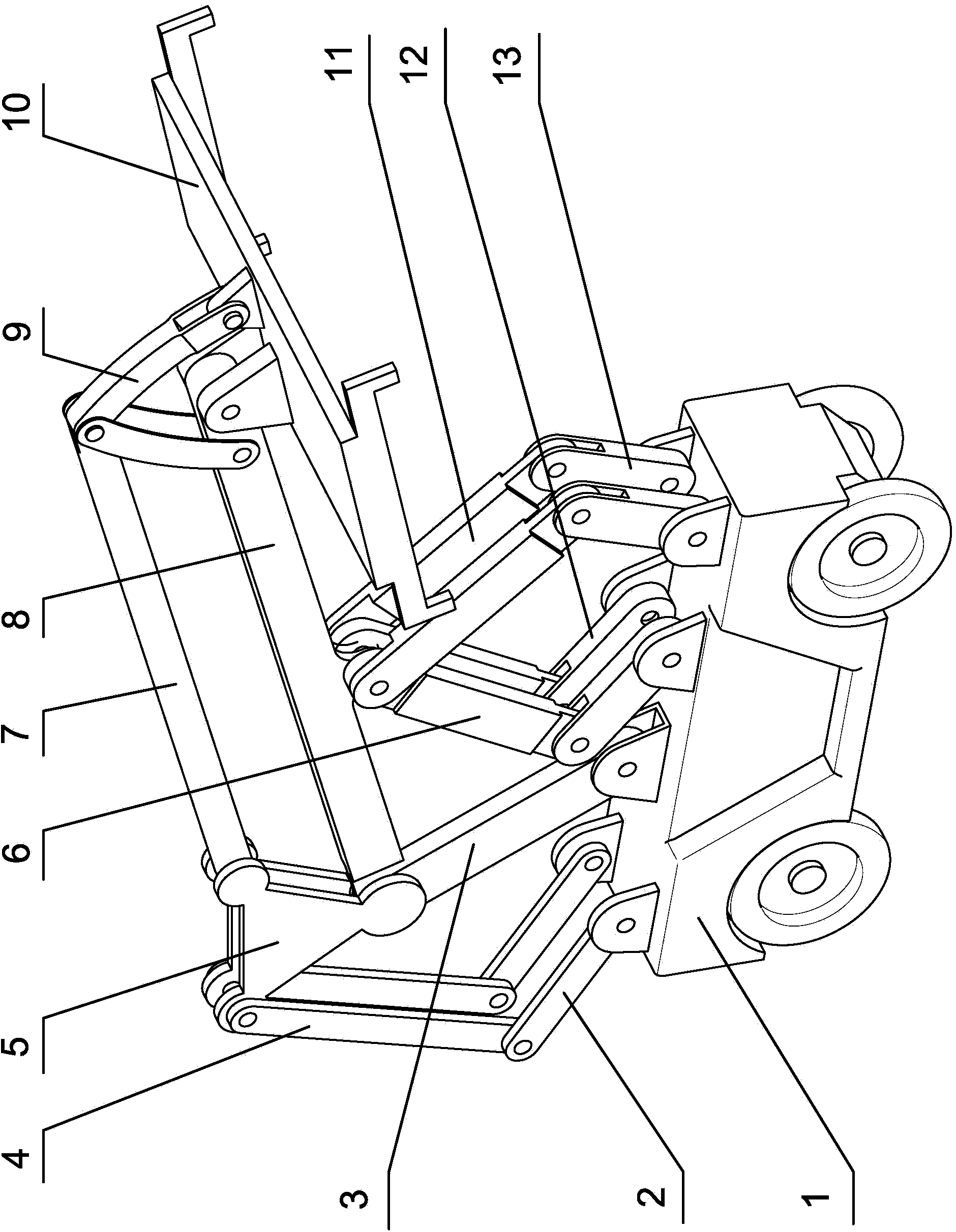

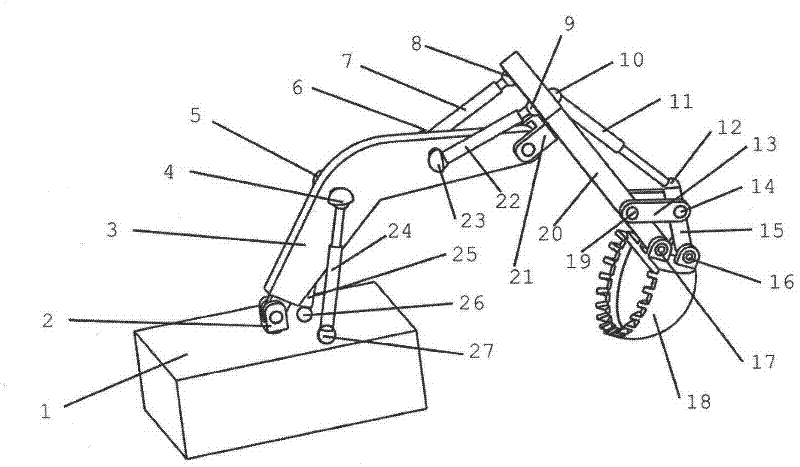

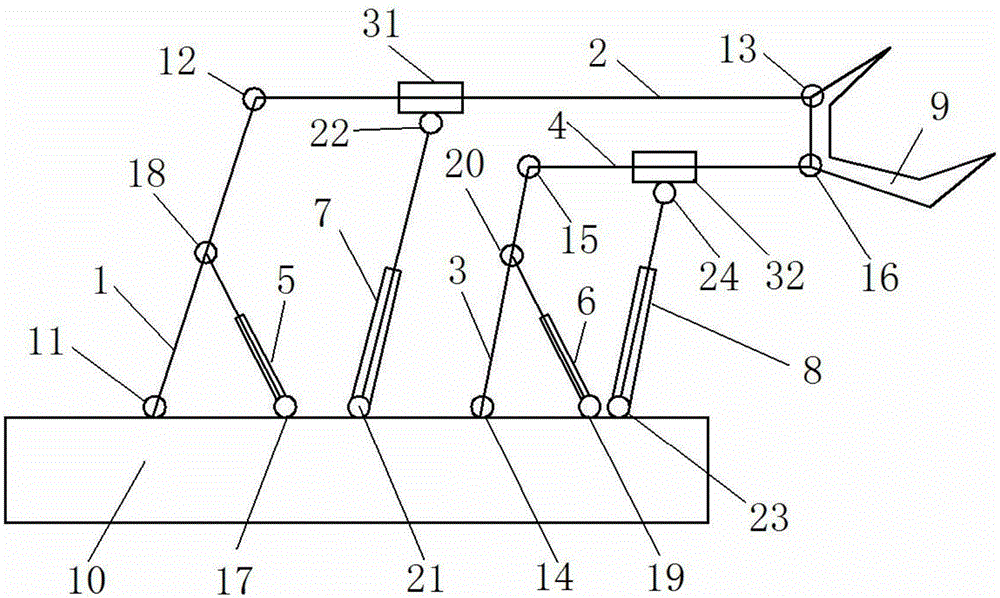

Connecting rod controllable type excavation mechanism capable of working by multiple angles

The invention relates to a connecting rod controllable type excavation mechanism capable of working by multiple angles. One end of a first connecting rod is connected to a rack. The other end of the first connecting rod is connected with one end of a second connecting rod. The other end of the second connecting rod is connected to a bucket. One end of a third connecting rod is connected to the rack. The other end of the third connecting rod is connected with one end of a fourth connecting rod. The other end of the fourth connecting rod is connected to the bucket. One end of a first telescopic rod is connected to the rack. The other end of the first telescopic rod is connected to the first connecting rod. One end of a second telescopic rod is connected to the rack. The other end of the second telescopic rod is connected to the third connecting rod. One end of a third telescopic rod is connected to the rack. The other end of the third telescopic rod is connected to a first sliding block. The second connecting rod is sleeved with the first sliding block. One end of a fourth telescopic rod is connected to the second connecting rod. The other end of the fourth telescopic rod is connected to a second sliding block. The fourth connecting rod is sleeved with the second sliding block. The connecting rod controllable type excavation mechanism is light in motion part, high in speed, good in dynamic response, flexible in mechanism output track, large in work space and high in work efficiency, and the problem that a traditional single-freedom-degree mechanical excavator cannot achieve complex action can be solved.

Owner:GUANGXI UNIV

Spatial excavator with dual-mobility movable arm, dual-mobility bucket rod and single-mobility bucket

InactiveCN102444150AFlexible output trajectoryLarge working spaceMechanical machines/dredgersHydraulic cylinderEngineering

A spatial excavator with a dual-mobility movable arm, a dual-mobility bucket rod and a single-mobility bucket comprises a two-dimensional rotating arm mechanism, a two-dimensional rotating bucket rod mechanism and a one-dimensional rotating bucket mechanism, wherein the two-dimensional rotating arm mechanism comprises a two-dimensional rotating arm, a first hydraulic cylinder and a second hydraulic cylinder; the two-dimensional rotating bucket rod mechanism comprises a two-dimensional rotating bucket rod, a third hydraulic cylinder and a fourth hydraulic cylinder; and the one-dimensional rotating bucket mechanism comprises a one-dimensional rotating bucket, a fifth hydraulic cylinder, a first link and a second link. The movable arm and the bucket rod of the novel excavator both are capable of performing independent spatial two-dimensional rotation; the whole excavator is capable of performing spatial quintuple-mobility motion, and is flexible in mechanism output track, large in working space and high in working efficiency; and the spatial excavator is capable of playing a good role in construction sites with severe environment and narrow space and emergency accident rescue sites needing quick excavation, barrier clearance and flattening.

Owner:GUANGXI UNIV

Linkage-mechanism excavator

A linkage-mechanism excavator is characterized in that one end of a first connecting rod is connected onto a rack; the other end of the first connecting rod is connected with one end of a second connecting rod; the other end of the second connecting rod is connected onto a bucket; one end of a third connecting rod is connected to the rack; the other end of the third connecting rod is connected with one end of a fourth connecting rod; the other end of the fourth connecting rod is connected to the bucket; one end of a first telescopic rod is connected to the rack; the other end of the first telescopic rod is connected onto the first connecting rod; one end of a second telescopic rod is connected onto the rack; the other end of the second telescopic rod is connected on the third connecting rod; one end of a fourth telescopic rod is connected onto the rack; the other end of the fourth telescopic rod is connected onto a first sliding block; the first sliding block sleeves the fourth connecting rod; one end of a third telescopic rod is connected onto the first sliding block; and the other end of the third telescopic rod is connected onto the second connecting rod. According to the linkage-mechanism excavator provided by the invention, the complete machine structure is simple and compact, and the part manufacturing and machining requirements are low; and the linkage-mechanism excavator can play a relatively good role in a severe-environment and narrow-space construction site as well as an accident rescue scene where rapid excavation, obstacle clearance and flattening are required.

Owner:GUANGXI UNIV

Spatial excavator with two-range-of-motion (two-ROM) movable arm, one-ROM bucket rod and two-ROM bucket

InactiveCN102363968AFlexible output trajectoryLarge working spaceMechanical machines/dredgersHydraulic cylinderEmergency rescue

The invention discloses a spatial excavator with a two-range-of-motion (two-ROM) movable arm, a one-ROM bucket rod and a two-ROM bucket. The excavator comprises a two-dimensional rotating arm mechanism, a one-dimensional rotating bucket rod mechanism and a two-dimensional rotating bucket mechanism. The two-dimensional rotating arm mechanism comprises a two-dimensional rotating arm, a first hydraulic cylinder and a second hydraulic cylinder; the one-dimensional rotating bucket rod comprises a one-dimensional rotating bucket rod and a third hydraulic cylinder; and the two-dimensional rotating bucket mechanism comprises a two-dimensional rotating bucket, a fourth hydraulic cylinder and a fifth hydraulic cylinder. Both the movably arm and the bucket of the novel excavator can realize independent spatial two-dimensional rotation, so that the whole excavator can realize spatial five-ROM motion; and the excavator is flexible in mechanism output loci, large in working space and high in work efficiency, and can play a good role in construction sites of severe environment and narrow space and emergency rescue sites in need of quick digging, obstacle clearing and flattening.

Owner:GUANGXI UNIV

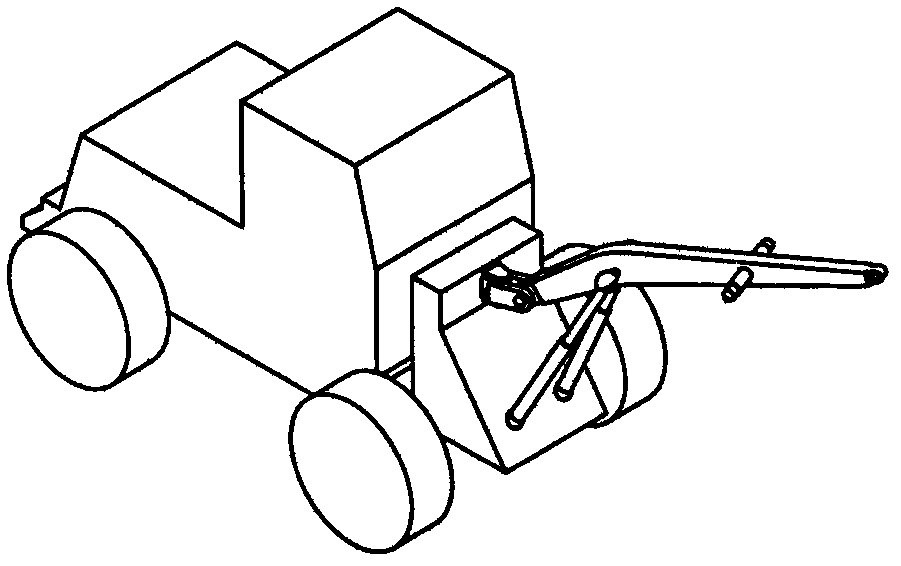

Spatial hydraulic loader with movable arm capable of horizontally swinging

InactiveCN102493502AMechanism output trajectory is flexibleLarge working spaceMechanical machines/dredgersEngineeringControl engineering

The invention discloses a spatial hydraulic loader with a movable arm capable of horizontally swinging. The spatial hydraulic loader comprises a two-dimensional swivel arm mechanism and a one-dimensional rotary bucket mechanism. The two-dimensional swivel arm mechanism comprises a two-dimensional swivel arm, a first hydraulic cylinder and a second hydraulic cylinder; and the one-dimensional rotary bucket mechanism comprises a one-dimensional rotary bucket, a third hydraulic cylinder and a fourth hydraulic cylinder. The movable arm of the novel loader can implement independent spatial two-dimensional rotation, the mechanism output track is flexible, the working space is large, the working efficiency is high, and the spatial hydraulic loader can achieve better effects on construction sites with severe environments and narrow spaces, and fields requiring quick loading.

Owner:GUANGXI UNIV

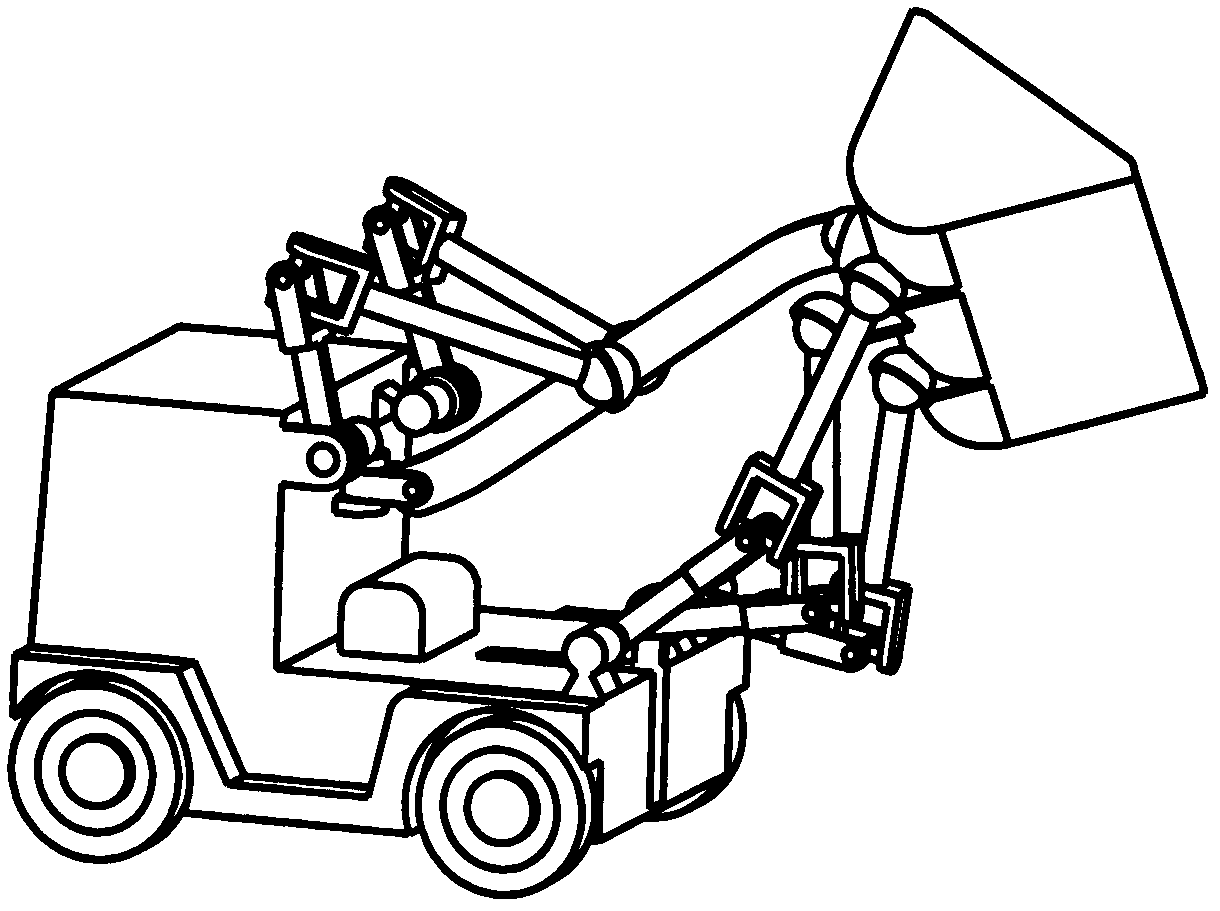

Space five-mobility hydraulic loader with three-dimensional rotation output movable arm

InactiveCN102493506AFlexible output trajectoryLarge working spaceMechanical machines/dredgersHydraulic cylinderEngineering

The invention discloses a space five-mobility hydraulic loader with a three-dimensional rotation output movable arm, and the loader comprises a three-dimensional rotation arm mechanism and a two-dimensional rotation bucket mechanism, wherein the three-dimensional rotation arm mechanism comprises a three-dimensional rotation arm, a first hydraulic cylinder, a second hydraulic cylinder and a third hydraulic cylinder; and the two-dimensional rotation bucket mechanism comprises a two-dimensional rotation bucket, a fourth hydraulic cylinder and a fifth hydraulic cylinder. Space three-dimensional rotation of the movable arm of the novel loader can be realized independently, two-dimensional rotation of the bucket can be realized independently, space five-mobility movement of the whole loader can be realized, the output tracks of mechanisms are flexible, the work space is large, the working efficiency is high, and the space five-mobility hydraulic loader can play a good role in construction sites with severe environment and small space and accident rescuing scenes needing rapid loading, obstacle removing and flatting.

Owner:GUANGXI UNIV

Space controllable mechanism type loader with movable arm capable of two-dimensionally rotating and bucket capable of one-dimensionally rotating

InactiveCN102561421ALow processing and assembly requirementsOvercoming demandsMechanical machines/dredgersEngineeringWorking space

The invention relates to a space controllable mechanism type loader with a movable arm capable of two-dimensionally rotating and a bucket capable of one-dimensionally rotating. The space controllable mechanism type loader comprises a loader body, the movable arm, the bucket, three driving rods, three connecting rods and three servo motors, the movable arm can two-dimensionally rotate independently, the bucket can one-dimensionally rotate independently, and the total loader can realize spatial movable output with three degrees of movement. The space controllable mechanism type loader can effectively overcome shortcomings that requirements on processing precision of hydraulic elements of a hydraulic loader are high, repair and maintenance costs are high, reliability is difficult to be guaranteed, oil leaks easily and the like. In addition, the space controllable mechanism type loader can resolve problems that a planar loader only can realize output along a trace in a plane, actions are not flexible, a working space is limited, work efficiency is low, and the like.

Owner:GUANGXI UNIV

Heavy-duty container reach stacker crane

InactiveCN103848352BImprove carrying capacityLow costProgramme-controlled manipulatorCranesVehicle frameEngineering

The invention discloses a heavy-load-type container reach stacker crane. A suspension arm comprises a rotating arm, an upper lift arm and a lower lift arm; the front ends of the upper lift arm and the lower lift arm are provided with clamping devices; a suspension arm lift mechanism comprises front and rear connecting rod assemblies which are symmetrically arranged at two sides of the suspension arm; the front connecting rod assembly is a five-connecting-rod mechanism arranged below the front part of the suspension arm and comprises front rocker rods, front connecting rods, middle connecting rods and middle rocker rods; the rear connecting rod assembly is arranged behind the suspension arm and comprises rear rocker rods and rear connecting rods; drives of the front rocker rods and the rear rocker rods are both conventional high-power motors correspondingly arranged on a carriage; drives of the middle rocker rods are low-power servo motors correspondingly arranged on the carriage. According to the invention, the strategy that the high-power conventional motor and the low-power servo motors are used for hybrid driving is adopted, compared with the mode of pure servo motors or hydraulic driving, the heavy-load-type container reach stacker crane has greater power output, higher reliability and larger working space; meanwhile, the whole crane is low in manufacturing cos, and is low in maintaining cost.

Owner:QINZHOU UNIV

Space hydraulic loading machine with bucket capable of realizing two-dimensional rotation

InactiveCN102400475BFlexible output trajectoryLarge working spaceMechanical machines/dredgersHydraulic cylinderEngineering

The invention discloses a space hydraulic loading machine with a bucket capable of realizing two-dimensional rotation. The space hydraulic loading machine comprises a one-dimensional rotary arm mechanism and a two-dimensional rotary bucket mechanism, wherein the one-dimensional rotary arm mechanism comprises a one-dimensional rotary arm, a first hydraulic cylinder and a second hydraulic cylinder; and the two-dimensional rotary bucket mechanism comprises a two-dimensional rotary bucket, a third hydraulic cylinder and a fourth hydraulic cylinder. Independent space twp-dimensional rotation of the bucket of the novel loading machine can be realized; the mechanism output trace is flexible, the working space is large and the working efficiency is high; and the space hydraulic loading machine plays a better role in construction sites with severe environments and small spaces as well as in sites in which quick loading is required.

Owner:GUANGXI UNIV

A light-combining prism adjustment device

InactiveCN104006826BImprove regulation efficiencyQuality improvementSagnac effect gyrometersMountingsGyroscopeMicro motor

The invention relates to a novel light combination prism adjusting device which comprises an optical platform, a light combination prism adjusting mechanism and a to-be-assembled optical element, wherein the light combination prism adjusting mechanism is arranged on the left side of the optical platform; the to-be-assembled optical element is arranged on the right side of the optical platform; a linear drive rod is arranged in the light combination prism adjusting mechanism to drive the light combination prism adjusting mechanism to move, and four micro motors drive the light combination prism adjusting mechanism to clamp the to-be-assembled optical element, so that a light combination prism is adjusted. The light combination prism adjusting mechanism constructed by adopting a motor and linear drive rod combined control method is flexible in motion output track, large in operating space, high in operability and high in positioning accuracy, the angle and position adjusting functions of the light combination prism are improved, and the quality and efficiency of a laser gyroscope light combination process are further improved.

Owner:SHANGHAI UNIV

Space-controllable mechanism type loader with three-dimensional rotating movable arm and one-dimensional rotating bucket

InactiveCN102561419BLow processing and assembly requirementsFlexible output trajectoryMechanical machines/dredgersEngineeringWork space

The invention relates to a space-controllable mechanism type loader with a three-dimensional rotating movable arm and a one-dimensional rotating bucket, comprising a vehicle, the movable arm, the bucket, six driving rods, six connecting rods and six servo motors; both the movable arm and bucket can rotate three-dimensionally independently; and the whole loader can realize the output of six degrees of space motion. The space-controllable mechanism type loader can effectively overcome the defects of high requirement for the processing precision of the hydraulic elements, high maintenance cost, difficult guarantee of reliability and easy oil leakage of the hydraulic loader and solve the problems of inflexible motion, limited work space and low work efficiency due to the output of the trajectory only in the plane of the plane loader.

Owner:GUANGXI UNIV

Spatially controllable mechanism type loader with two-dimensionally rotatable moving arm and three-dimensionally rotatable bucket

InactiveCN102605809BLow processing and assembly requirementsFlexible output trajectoryMechanical machines/dredgersRange of motionProcessing accuracy

The invention relates to a spatially controllable mechanism type loader with a two-dimensionally rotatable moving arm and a three-dimensionally rotatable bucket, which comprises a loader body, a moving arm, a bucket, five drive bars, five connecting bars and five servo motors. The moving arm is capable of rotating two-dimensionally and independently. The bucket is capable of rotating three-dimensionally and independently. The whole loader is capable of moving with five spatial ranges of motion. Using the spatially controllable mechanism type loader can effectively overcome the shortages that hydraulic loaders are high in hydraulic elements processing precision, high in maintenance cost, difficult in reliability guarantee, easy in oil leakage and the like, and can further solve the problems that plane loaders only capable of moving in a plane is inflexible in motion, has limited operating space, is low operating efficiency and the like.

Owner:GUANGXI UNIV

Spatially controllable mechanism type loader with two-dimensional rotatory moving arm and one-dimensional rotary bucket

InactiveCN102561416ALow processing and assembly requirementsFlexible output trajectoryMechanical machines/dredgersRange of motionEngineering

The invention relates to a spatially controllable mechanism type loader with a two-dimensional rotatory moving arm and a one-dimensional rotary bucket, which comprises a loader body, a moving arm, a bucket, three drive bars, three connecting bars and three servo motors. The moving arm is capable of independently rotating in two dimensions, the bucket is capable of independently rotating in one dimension, and the whole loader is capable of moving with three spatial ranges-of-motion. By means of the spatially controllable mechanism type loader with the two-dimensional rotatory moving arm and the one-dimensional rotary bucket, the shortages that hydraulic elements of a hydraulic loader are high in precision requirements, high in maintenance cost, difficult in reliability guarantee, prone to oil leakage and the like are solved, and the problems, action inflexibility, limitedness of operation space, low operating efficiency and the like due to the fact that a plane loader only can output plane tracks, are solved.

Owner:GUANGXI UNIV

Spatial hydraulic loader with two-motion-range movable arm and two-motion-range scraper pan

InactiveCN102373722BFlexible output trajectoryLarge working spaceMechanical machines/dredgersHydraulic cylinderFlexible Mechanisms

The invention discloses a spatial hydraulic loader with a two-motion-range movable arm and a two-motion-range scraper pan. The spatial hydraulic loader comprises a two-dimensional rotating movable arm mechanism and a two-dimensional rotating scraper span mechanism. The two-dimensional rotating movable arm mechanism comprises a two-dimensional rotating arm, a first hydraulic cylinder and a second hydraulic cylinder, and the two-dimensional rotating scraper span mechanism comprises a two-dimensional rotating scraper span, a third hydraulic cylinder and a fourth hydraulic cylinder. Both the movable arm and the scraper span of the novel loader can independently rotate in a spatial two-dimensional manner, the entire loader can move in a spatial four-motion-range manner, has the advantages of flexible mechanism output track, large working space and high working efficiency, and can play better roles in construction sites with severe environment and narrow space and emergency accident rescue sites in need of rapid loading, barrier removal and smoothing.

Owner:GUANGXI UNIV

3-3-1 type seven-mobility spatial hydraulic excavator

InactiveCN102359130BFlexible output trajectoryLarge working spaceMechanical machines/dredgersHydraulic cylinderControl engineering

The invention relates to a 3-3-1 type seven-mobility spatial hydraulic excavator which comprises a three-dimensional rotating arm mechanism, a three-dimensional rotating bucket rod mechanism and a one-dimensional rotating scraper bucket mechanism. The three-dimensional rotating arm mechanism comprises a three-dimensional rotating arm, a first hydraulic cylinder, a second hydraulic cylinder and a third hydraulic cylinder, the three-dimensional rotating bucket rod mechanism comprises a three-dimensional rotating bucket rod, a fourth hydraulic cylinder, a fifth hydraulic cylinder and a sixth hydraulic cylinder, and the one-dimensional rotating scraper bucket mechanism comprises a one-dimensional rotating scraper bucket, a seventh hydraulic cylinder, a first connecting rod and a second connecting rod. The moving arm and bucket rod of the novel excavator can realize independent spatial three-dimensional rotation respectively, the whole excavator can realize spatial seven-mobility motion, the mechanism output trajectory is flexible, the working space is large, the working efficiency is high, and the novel excavator can play a better role in construction sites with harsh environments andnarrow and small spaces, as well as sudden accident rescue scenes which need to be excavated, remove obstacles and be leveled fast.

Owner:GUANGXI UNIV

A photoelectric cell adjustment device for laser gyroscope light combination assembly

InactiveCN104567920BImprove regulation efficiencyQuality improvementMeasurement devicesGyroscopeOptical table

The invention relates to a photoelectric tube adjusting device for light combination assembly of a laser gyroscope. The photoelectric tube adjusting device comprises an optical platform, a photoelectric tube adjusting mechanism, a laser gyroscope shaking device and a to-be-assembled optical element in the light combination assembly of the laser gyroscope. The photoelectric tube adjusting device established by adopting the combined control method of a linear drive rod and a motor is flexible in motion output track, large in working space, good in operability and high in positioning precision, the angle and position adjusting precision of a photoelectric tube can be improved, and the quality and efficiency of the laser gyroscope light combination process can be further improved.

Owner:SHANGHAI UNIV

3DOF Servo Drive Container Reach Stacker Crane

InactiveCN103848354BFlexible output trajectoryAdaptableProgramme-controlled manipulatorCranesVehicle frameThree degrees of freedom

The invention discloses a three-freedom-degree servo-driven front lifting crane for containers. The three-freedom-degree servo-driven front lifting crane comprises a rotating arm, an upper hoisting arm and a lower hoisting arm which are arranged on the basis of a frame, wherein a lifting arm comprises the rotating arm, the upper hoisting arm and the lower hoisting arm; clamping devices are arranged at the front ends of the upper hoisting arm and the lower hoisting arm; the lifting-arm hoisting mechanism comprises a front connecting rod component, a middle connecting rod component and a rear connecting rod component which are symmetrically arranged at the two sides of the lifting arm; the front connecting rod component comprises a four-bar linkage mechanism and a transmission rod; the middle connecting rod component comprises a middle rocking rod and a middle connecting rod; the rear connecting rod component comprises a rear rocking rod and a rear connecting rod; the front rocking rod, the middle rocking rod and the rear rocking rod of the four-bar linkage mechanism are respectively driven by rocking-rod servo motors. The three-freedom-degree servo-driven front lifting crane disclosed by the invention has the advantage that the technical problems of high processing and assembling requirement, short service life, oil leakage, inflexible action and the like in a conventional two-freedom-degree hydraulic type front lifting crane for the containers are relatively well solved.

Owner:QINZHOU UNIV

Controllable mechanism type excavating robot

InactiveCN106337450AHigh speedLarge working spaceMechanical machines/dredgersActuatorBearing capacity

The invention discloses a controllable mechanism type excavating robot. One end of a first connecting rod is connected to a rack, and the other end of the first connecting rod is connected to one end of a second connecting rod. The other end of the second connecting rod is connected to a bucket. One end of a third connecting rod is connected to the rack. The other end of the third connecting rod is connected with one end of a fourth connecting rod. The other end of the fourth connecting rod is connected to the bucket. One end of a first telescopic rod is connected to the rack. The other end of the first telescopic rod is connected to the first connecting rod. One end of a second telescopic rod is connected to the rack, and the other end of the second telescopic rod is connected to the third connecting rod. One end of the third telescopic rod is connected to the rack, and the other end of the third telescopic rod is connected to a first sliding block. The second connecting rod is sleeved with the first sliding block. One end of a fourth telescopic rod is connected to the rack, and the other end of the fourth telescopic rod is connected to a second sliding block. The fourth connecting rod is sleeved with the second sliding block. The controllable mechanism type excavating robot has the characteristics that the robot is free of accumulative error, high in precision, compact in structure, large in bearing capacity and high in rigidity, and the inertia of a low tail end actuator is low.

Owner:GUANGXI UNIV

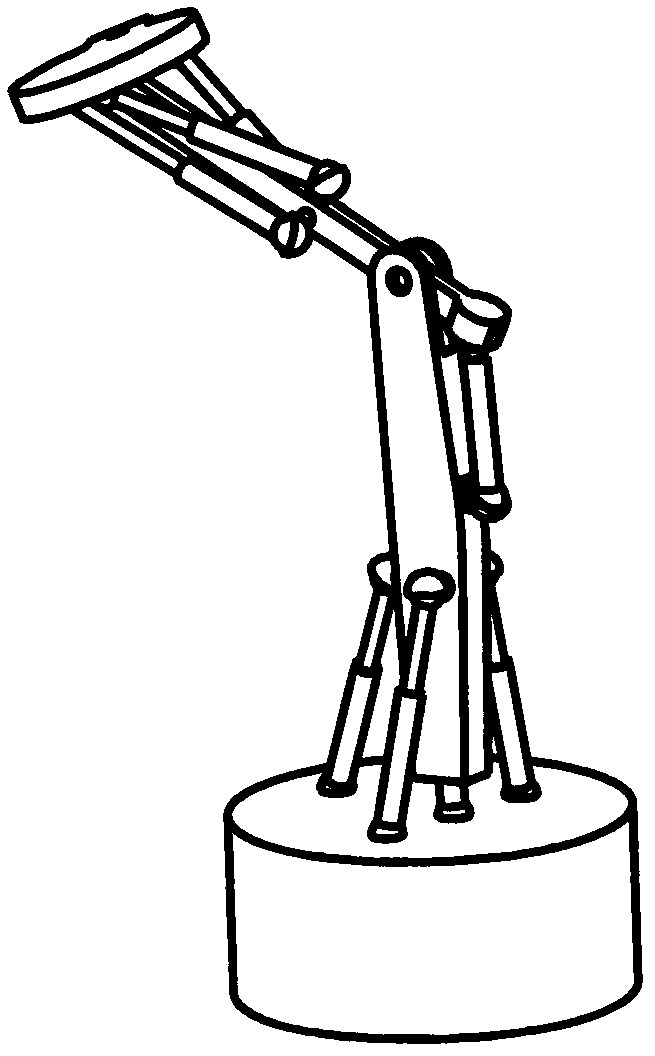

Six-mobility spraying mechanical arm

InactiveCN102513258BFlexible output trajectoryThe output track is accurateProgramme-controlled manipulatorSpraying apparatusEngineeringManipulator

The invention relates to a six-mobility spraying mechanical arm, which comprises a first connection rod, a second connection rod, a movable platform, six linear drivers and a frame. One end of the first connection rod is connected to the frame through a first spherical pair, the other end of the first connection rod is connected to the second connection rod through a first rotary pair, the other end of the second connection rod is connected to the movable platform through a first hook joint, and the whole mechanical arm driven by the six linear drivers in a joint mode can output movement with six-mobility space. The six-mobility spraying mechanical arm is flexible and accurate in output track, large in flexibility and working space, easy to operate and maintain and especially suitable for spraying operation occasions requiring the first connection rod to achieve three-dimensional rotation output and the movable platform to achieve two-dimensional rotation output.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com