Six-mobility spraying mechanical arm

A six-degree-of-movement, manipulator technology, applied in manipulators, program-controlled manipulators, injection devices, etc., can solve the problems of small working space, inflexible movements, and accumulation of joint errors in parallel robot mechanisms, and achieve flexible output trajectory of the mechanism and mechanism structure Simple, large workspace effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

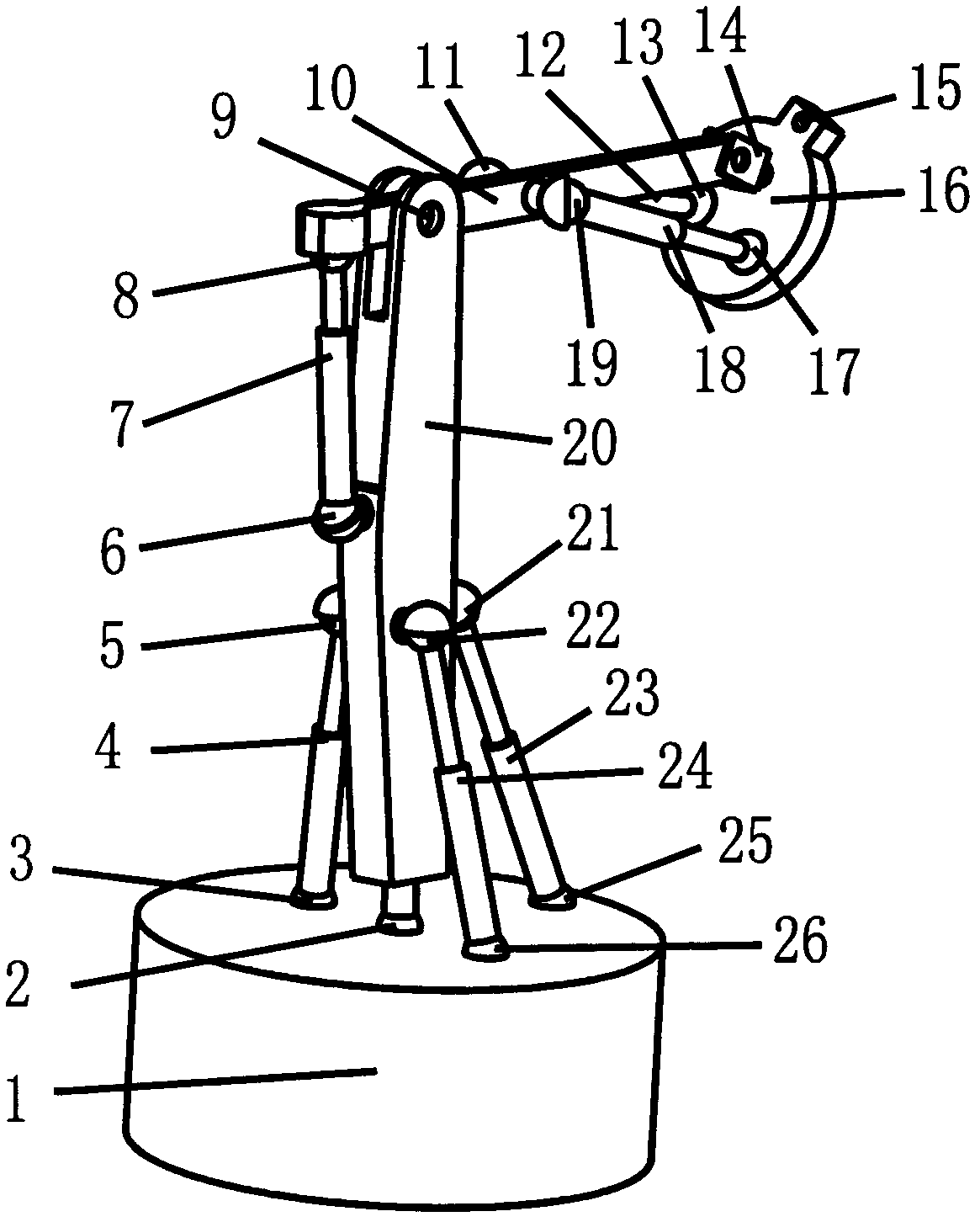

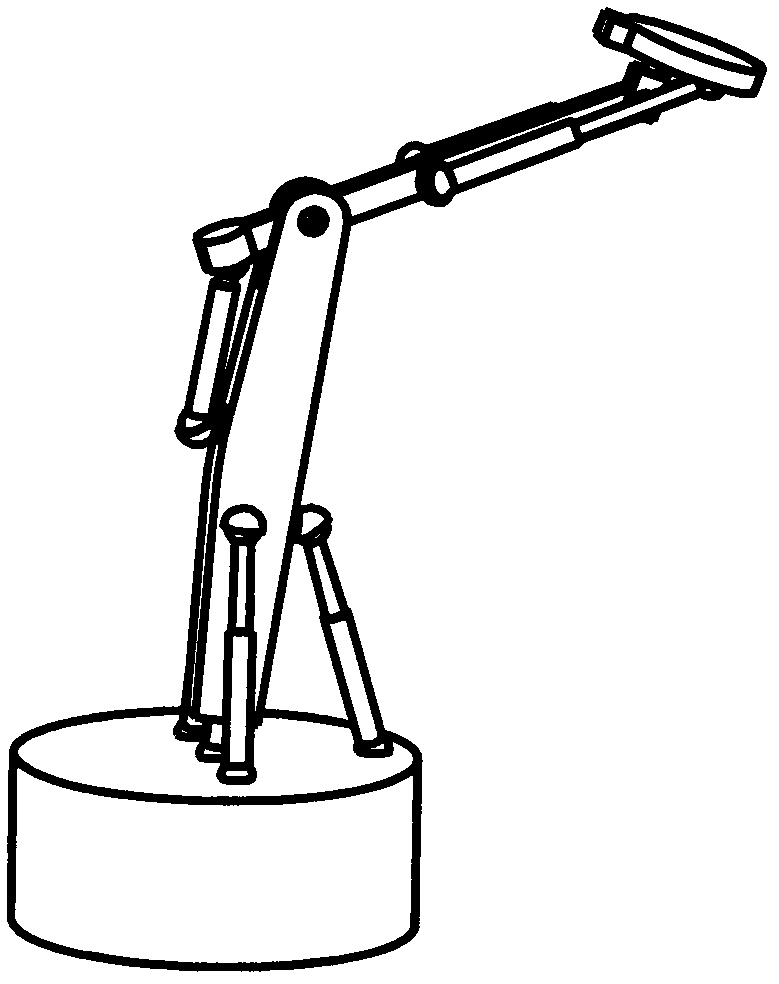

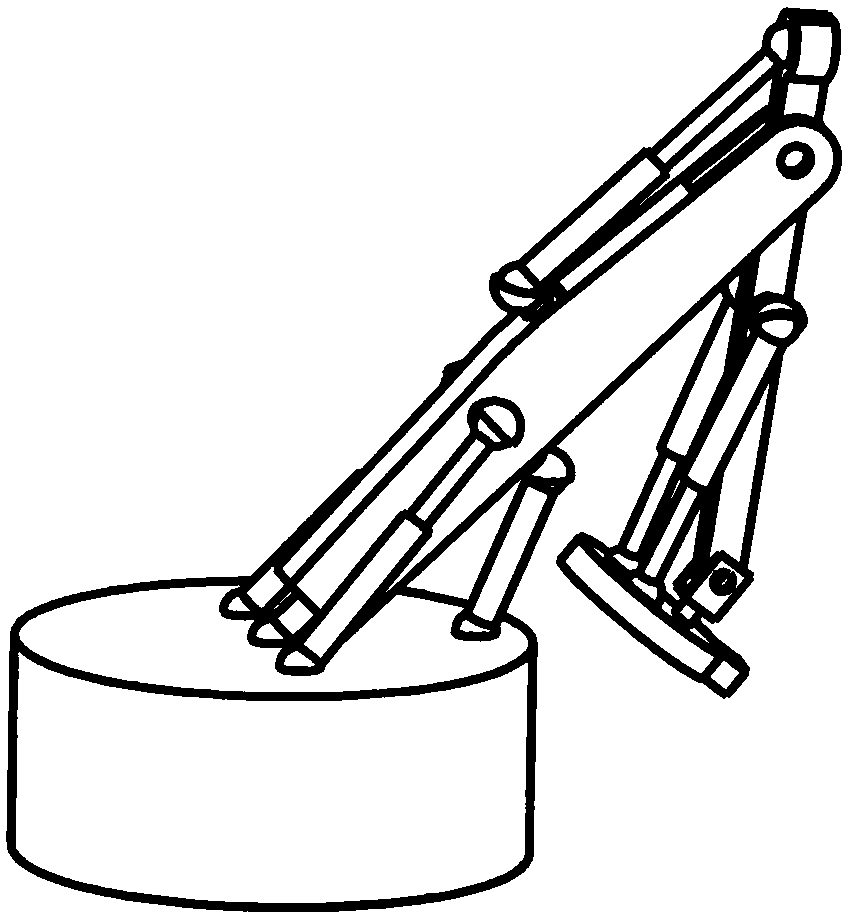

[0016] control figure 1 , 2 , 3, 4 and 5, the six-degree-of-motion spraying manipulator consists of the first connecting rod 20, the second connecting rod 10, the moving platform 16, the first linear driver 4, the second linear driver 23, the third linear driver 24, The fourth linear driver 7 , the fifth linear driver 12 , the sixth linear driver 18 and the frame 1 are composed.

[0017] control figure 1 , one end of the first connecting rod 20 is connected to the frame 1 through the first spherical pair 2, the other end of the first connecting rod 20 is connected to the second connecting rod 10 through the first rotating pair 9, and the second connecting rod 10 is another One end is connected to the moving platform 16 through the first Hooke hinge 14, one end of the first linear drive 4 is connected to the frame 1 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com