Space controllable mechanism-type loader with one-dimensional rotational moving arm and two-dimensional rotational bucket

A mechanism type, bucket technology, applied to the field of space-controllable mechanism type loaders with one-dimensional rotating boom and two-dimensional rotating bucket, can solve the problems of difficulty in ensuring reliability, low processing and assembly requirements, and inflexible movements, etc. Overcome the effects of high machining accuracy requirements, low machining and assembly requirements, and flexible output trajectories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

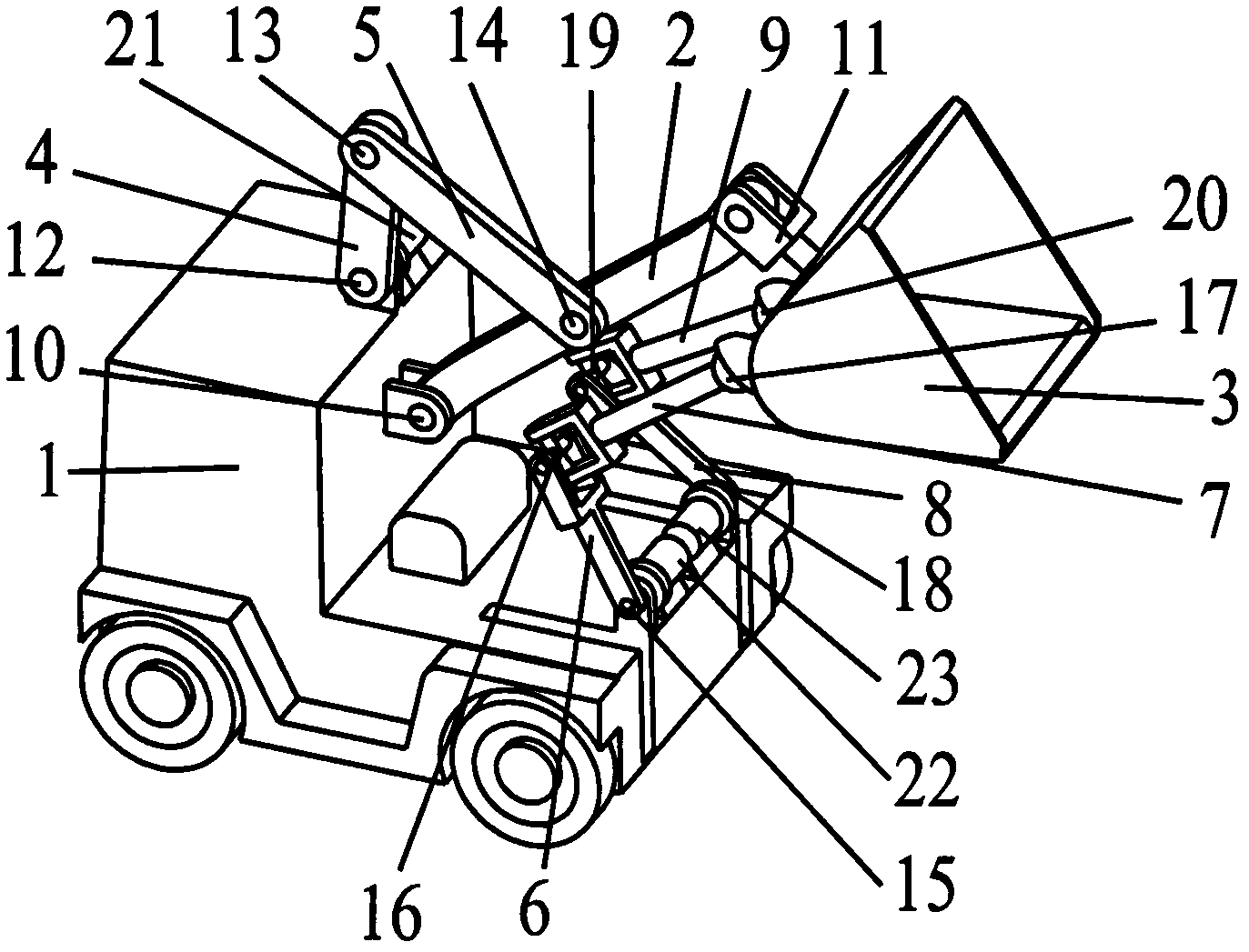

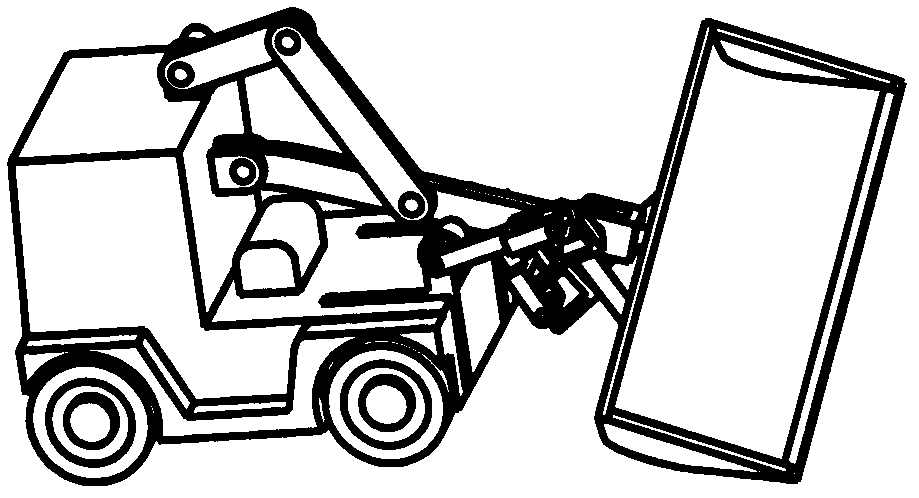

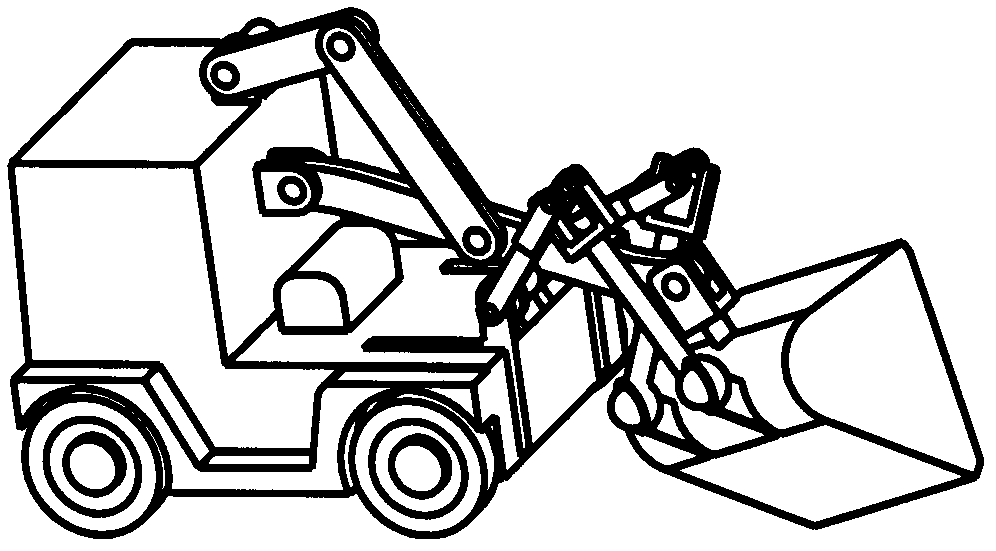

[0016] control figure 1 , a space-controllable mechanism loader with one-dimensional rotating boom and two-dimensional rotating bucket, comprising a car body 1, a boom 2, a bucket 3, a first active rod 4, a second active rod 6, and a third active rod 8. The first connecting rod 5, the second connecting rod 7, the third connecting rod 9, the first servo motor 21, the second servo motor 22 and the third servo motor 23, the structure and connection method are as follows:

[0017] One end of the boom 2 is connected to the car body 1 through the first swivel joint 10, the other end is connected to the bucket 3 through the first Hooke hinge 11, and one end of the first active lever 4 is connected to the car body 1 through the second swivel joint 12. The first servo motor 21 is connected, and the other end is connected with one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com