Hybrid-driven controllable excavation mechanism

A hybrid drive and frame technology, which is used in mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problem of inability to complete flexible and changeable excavation actions and high requirements for hydraulic system components , Bucket teeth can not generate cutting force and other problems, to overcome the high requirements of hydraulic components, low processing and assembly requirements, and large digging force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

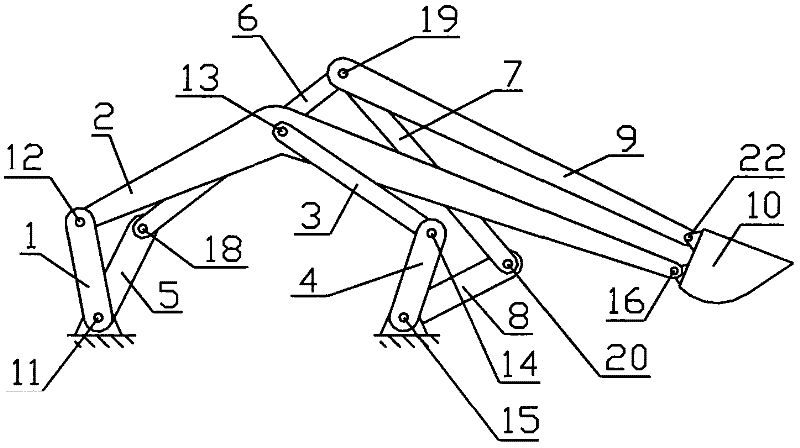

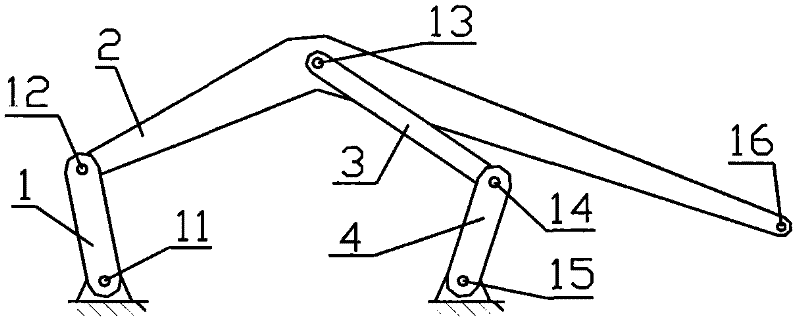

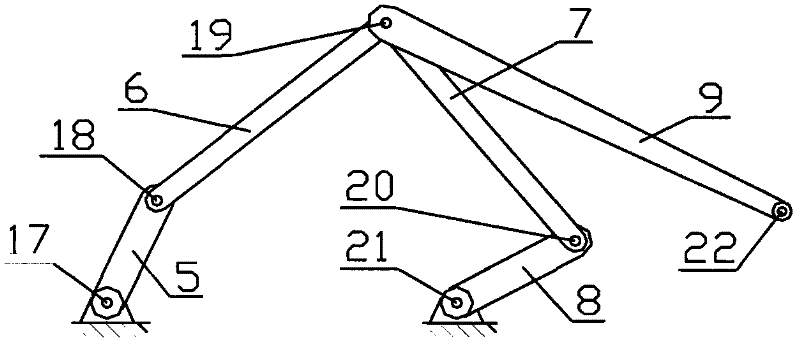

[0020] control figure 1 , 4 , a hybrid drive controllable excavating mechanism, including two sets of excavating arms, a positive shovel bucket and a frame.

[0021] control figure 1 , 2 and 4, the first excavating arm of the hybrid drive controllable excavating mechanism is a group of planar two-degree-of-freedom hybrid drive controllable mechanisms, consisting of the first active rod 1, the second active rod 4, the first connecting rod 2, the second The connecting rod 3 and the frame 27 are connected to form. One end of the first active rod 1 is hinged on the frame 27 through the first hinge hole 11, the other end is hinged with the first connecting rod 2 through the second hinge hole 12, and one end of the second active rod 4 is hinged on the third hinge of the frame 27. On the hole 15, the other end is hinged with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com