Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Load and secure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porous graphene loaded titanium dioxide composite material and preparation method thereof

InactiveCN106215920AAvoid reunionImprove stabilityPhysical/chemical process catalystsCvd graphenePhotocatalytic degradation

The invention discloses a porous graphene loaded titanium dioxide composite material and a preparation method thereof. The preparation method includes the steps: (1) preparing graphene quantum dot suspension liquid; (2) preparing loaded titanium dioxide graphene quantum dots; (3) performing surface treatment; (4) preparing the composite material. The graphene quantum dots are used as titanium dioxide carriers, nano titanium dioxide is finally attached onto porous graphene after surface treatment, can be more effectively loaded and fixed and can be prevented from agglomeration, stability of the nano titanium dioxide is remarkably improved, and agglomeration of the composite material is avoided, so that obtained porous graphene / titanium dioxide photocatalysts have excellent photocatalytic degradation performance and can be widely applied to the environmental protection field of sewage treatment and the like.

Owner:佛山市高明区尚润盈科技有限公司

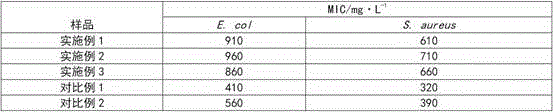

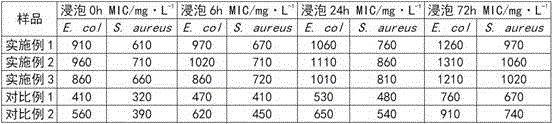

Preparing method of antibacterial polylactic acid material

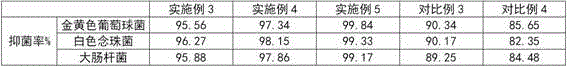

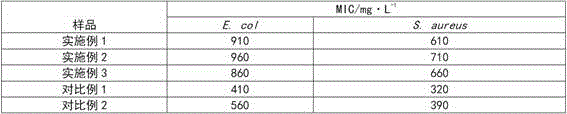

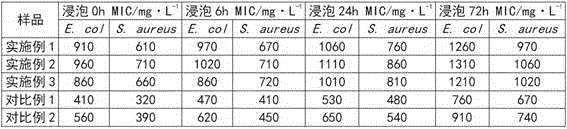

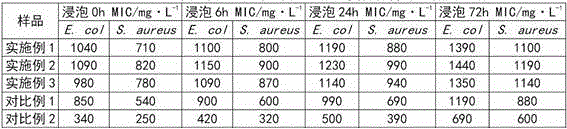

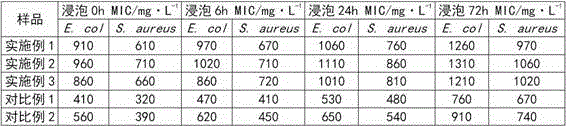

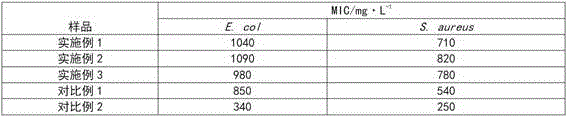

The invention discloses a preparing method of an antibacterial polylactic acid material. The method comprises the steps of 1, dispersing antibacterial compound into lactic acid, preparing solution with a concentration of 0.1-2g / L, conducting ultrasonic agitation (500-800W ultrasonic power at a rate of agitation of 500-800rpm) for 60-90min to obtain antibacterial lactic acid solution; 2, placing the antibacterial lactic solution into a vacuum oven at a temperature of 50-80 DEG C to vacuum dry for 24-36h until no redundant water is in the mixed liquor; obtaining the antibacterial polylactic acid material through direct condensing method. According to the antibacterial compound method, grapheme quantum dots after laser irradiation are adopted as the carrier of silver, then covered with silicon dioxide lamella for surface treatment, and finally adhered on porous grapheme, which can better load and fix silver nano particles, prevent the silver nano particles from agglomeration and remarkably improve the stability of the silver nano particles and enable longer antibacterial activity of the silver nano particles; application of the antibacterial compound on polylactic acid fiber film enables lasting and effective antibacterial activity and properties of high stability, broad-spectrum antibacterial and biodegradation.

Owner:佛山市高明区尚润盈科技有限公司

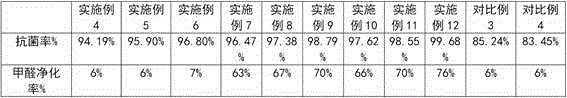

Functional synthetic fiber capable of removing formaldehyde and preparation and application of fiber

ActiveCN103861624ASolving Recycling ProblemsSolve the reuse problemPhysical/chemical process catalystsDispersed particle separationLight drivenPollution

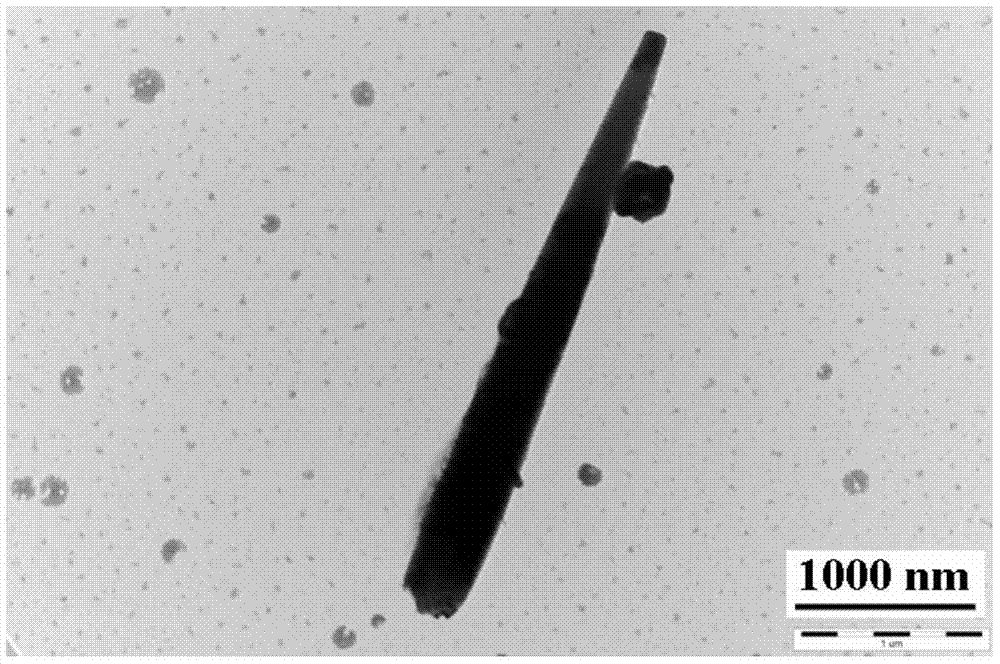

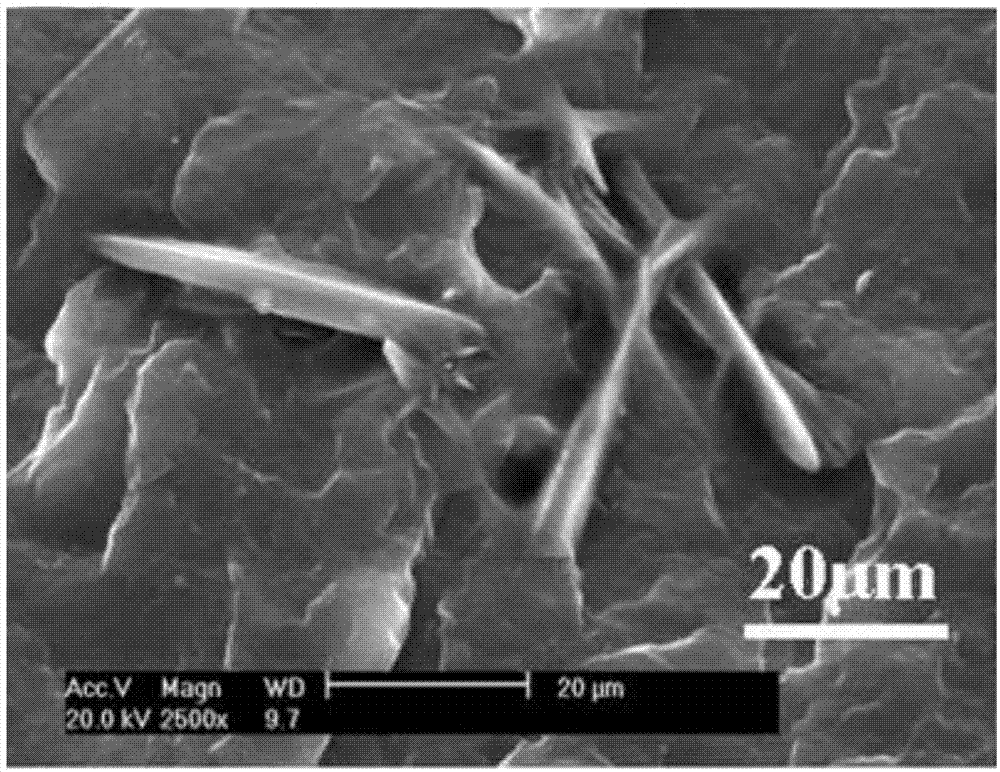

The invention discloses a functional synthetic fiber capable of removing formaldehyde and preparation and application of the fiber. Rod-like zinc oxide is adopted as a vector, loaded with a halogen bismuth oxide, and then added to a synthetic fiber by adopting a fusing method, so as to obtain the functional synthetic fiber capable of removing the formaldehyde. The functional synthetic fiber has the advantages and effects that (1) the rod-like zinc oxide is adopted as the vector, so that the agglomeration of the halogen bismuth oxide can be prevented, and the catalyst activity is obviously improved; (2) the rod-like zinc oxide is taken as the vector, loaded with a halogen bismuth oxide visible-light-driven photocatalyst, and then fused and added to the synthetic fiber, so that the problems of recovery and reutilization of the visible-light-driven photocatalyst can be solved, the functional synthetic fiber has the reusability, the secondary pollution can be avoided, and the cost is reduced; (3) the obtained functional synthetic fiber has the visible-light catalytic activity, and can play a role of removing the formaldehyde under irradiation of visible light, so as to prepare curtains, clothes, textiles and the like with the effect of removing the formaldehyde. Thus, the application range of the synthetic fiber is further expanded.

Owner:GUANGDONG VOCATIONAL & TECHNICAL COLLEGE

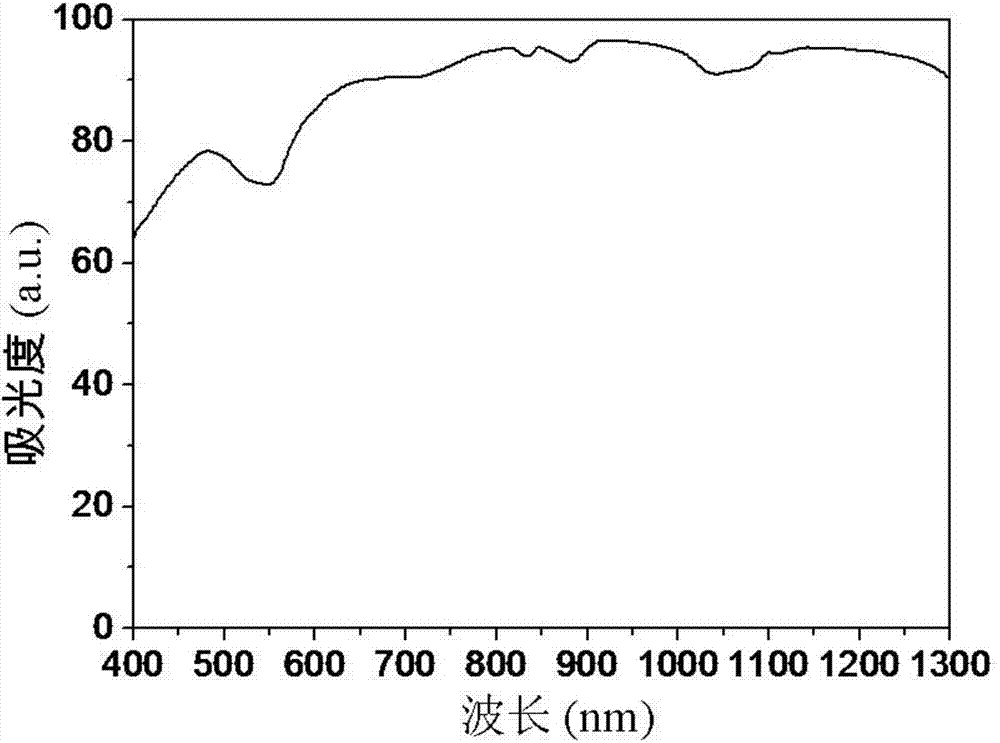

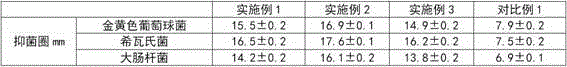

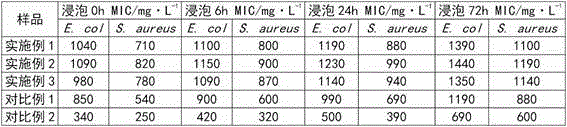

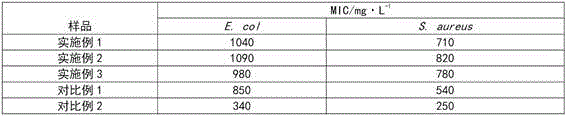

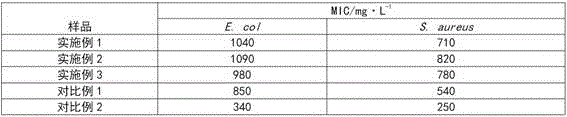

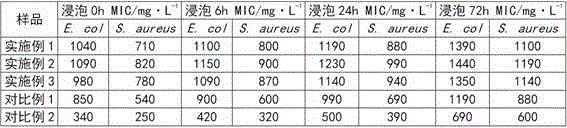

Porous graphene zinc-oxide-loaded antibacterial composite material and preparation method thereof

InactiveCN106359373ALoad and secureAvoid reunionBiocideDead animal preservationPorous grapheneZno nanoparticles

The invention discloses a porous graphene zinc-oxide-loaded antibacterial composite material and a preparation method thereof. The preparation method comprises the following steps: (1) preparing graphene quantum dot suspension liquid; (2) preparing zinc-oxide-loaded graphene quantum dots; (3) carrying out surface treatment; (4) preparing a composite material. According to the method, the graphene quantum dots irradiated by laser are taken as carriers of nano-zinc oxide, are then subjected to the surface treatment, and are finally attached to porous graphene, so that the nano-zinc oxide is better loaded and fixed so as to be prevented from agglomerating. After the method is adopted, the stability of the nano-zinc oxide is obviously improved, and the nano-zinc oxide is enabled to have a more long-acting antibacterial activity, so that the porous graphene zinc-oxide-loaded antibacterial composite material has wide prospect in industrial application.

Owner:佛山市高明区尚润盈科技有限公司

Preparation method of antibacterial composite fiber membrane

ActiveCN106192214ALoad and secureImprove stabilityElectro-spinningNon-woven fabricsFiberPolymer science

The invention discloses a preparation method of an antibacterial composite fiber membrane. The preparation method comprises the following steps: (1) preparing an antibacterial spinning solution, namely, weighing a proper amount of polyethylene glycol 400 and putting the polyethylene glycol 400 into a conical flask with a plug; raising the temperature to 50 DEG C and adding dichloromethane, wherein the volume ratio of the dichloromethane to the polyethylene glycol is 7 to 2; adding PLLA (Poly L Lactic Acid) with the molecular weight of 100000 and stirring by a magnetic force for 2 h at a room temperature; stirring at the speed of 100 rpm-300 rpm and dropwise adding an antibacterial compound dispersion solution with the concentration of 0.01mol / l-0.1mol / l; further stirring for 30 min-40 min to prepare the antibacterial spinning solution; and (2) carrying out electrostatic spinning to prepare the antibacterial composite fiber membrane. A specially prepared antibacterial compound is applied to a polylactic acid fiber membrane, so that the fiber membrane has lasting and effective antibacterial activity, good air permeability, high stability, broad-spectrum antibacterial property and biodegradable property.

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

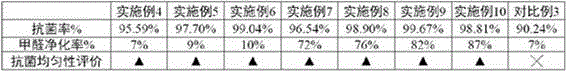

Preparation method of anti-corrosion, antibacterial and formaldehyde-scavenging paint

InactiveCN106366848ALoad and secureAvoid reunionAntifouling/underwater paintsPaints with biocidesDeodorantAqueous solution

The invention discloses a preparation method of anti-corrosion, antibacterial and formaldehyde-scavenging paint. The preparation method comprises the following steps that 1, a resin solution is prepared; 2, one half of the resin solution is stirred through ultrasonic, an antibacterial composite aqueous solution is dropwise added, and ultrasonic stirring continues to be conducted; 3, one half of the resin solution is stirred through ultrasonic, kieselguhr / inorganic oxide is added, and ultrasonic stirring continues to be conducted; 4, amino resin, pigments, a defoaming agent, poly hydroxy acid sodium salt, dibutyl phthalate, a flatting agent and mosquito repellent particles are added into a grinder to be ground; 5, the materials prepared in the second step, the third step and the fourth step are mixed and then stirred, bentonite is added, all the materials are stirred, ground, filtered and then sealed and packaged. According to the preparation method of anti-corrosion, antibacterial and formaldehyde-scavenging paint, by reasonably matching synergistic effects among kieselguhr / inorganic oxide, antibacterial composite materials and functional additives, the paint has the excellent antibacterial and deodorant properties and anti-formaldehyde characteristic and a mosquito repellent effect, requirements of multifunctional photo-curing paint are met, and application of the pohto-curing paint is further widened.

Owner:佛山市高明区尚润盈科技有限公司

Preparation method of waterborne antibacterial odor removal inorganic coating

InactiveCN106221316ACompound AntibacterialLoad and secureAntifouling/underwater paintsPaints with biocidesPolymer solutionAqueous solution

The invention discloses a preparation method of a waterborne antibacterial odor removal inorganic coating. The preparation method includes the steps: (1) dispersing diatomaceous earth into water solution, dripping and adding antibacterial compound water dispersions, standing, drawing, filtering, washing, and drying to obtain a diatomaceous earth / antibacterial compound; (2) mixing and stirring water and antifoaming agents, then adding pigment, fillers and diatomaceous earth / inorganic oxide to obtain solution A; (3) mixing silica solution and polymer solution, sufficiently stirring, then adding the diatomaceous earth / antibacterial compound, and stirring to obtain solution B; (4) adding coalescing agents and thickening agents into the solution B, and sufficiently stirring to obtain solution C; (5) dripping and adding the solution C into the solution A, sufficiently stirring and filtering. According to the preparation method, the diatomaceous earth / inorganic oxide and the diatomaceous earth / antibacterial compound are reasonably matched, synergistic effects between functional additives are achieved, so that the inorganic coating has the advantages of excellent bacterium resistance and formaldehyde resistance, multifunctional requirements are met, and application of the inorganic coating is further broadened.

Owner:佛山市高明区尚润盈科技有限公司

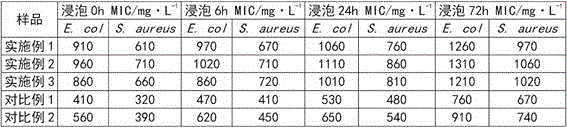

Antimicrobial composite material and preparation method thereof

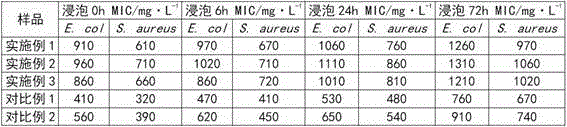

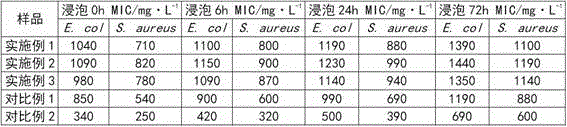

InactiveCN106376557ACompound AntibacterialLoad and secureBiocideFungicidesPorous grapheneAntibacterial activity

The invention discloses an antimicrobial composite material and a preparation method thereof. The preparation method comprises the following steps: (1) preparing a graphene quantum dot suspension; (2) preparing zinc oxide-loaded graphene quantum dots; (3) preparing silver-loaded graphene quantum dots coated by SiO2; (4) preparing silver / titanium dioxide-loaded graphene quantum dots; (5) surface treatment; (6) preparing an antibacterial composite material. According to the method, firstly, the zinc oxide-loaded graphene quantum dots and the silver / titanium dioxide-loaded graphene quantum dots are prepared respectively and then the surface treatment is conducted. Finally, the above two types of graphene quantum dots are adhered onto the porous graphene. Therefore, silver and zinc oxide can be better loaded and fixed. The agglomeration of silver and zinc oxide is avoided, and the stability of silver and zinc oxide is improved remarkably. As a result, the antibacterial activity of silver nanoparticles and zinc oxide lasts for a longer period of time.

Owner:佛山市高明区尚润盈科技有限公司

Preparation method of PET/PTT alloy capable of purifying air

The invention discloses a preparation method of PET / PTT alloy capable of purifying air. A used antibacterial compound uses graphene quantum dots obtained after laser irradiation as carriers of antibacterial agents, surface treatment is carried out, and attachment to porous graphene is finally carried out, so that silver nanoparticles and other antimicrobial agents can better loaded and fixed, agglomeration thereof is prevented, the stability of the antimicrobial agents is significantly improved, and thus the PET / PTT alloy has more long-lasting antibacterial activity; meanwhile, diatomaceous earth can adsorb harmful gases in air, especially formaldehyde, so that the PET / PTT alloy also has an air purifying effect besides an antibacterial effect. Through reasonable collocation of a diatomite / antimicrobial composite material and diatomite / porous carbon and under a synergistic action of functional additives, the alloy has excellent antibacterial and formaldehyde-resistant characteristics, multifunctional needs are met, and thus the application of the PET / PTT alloy capable of purifying air is further widened.

Owner:佛山市高明区尚润盈科技有限公司

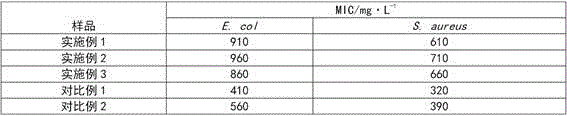

Preparation method for silver-containing titanium dioxide antibacterial agent

InactiveCN108902177AImprove stabilityLong-lasting antimicrobial activityBiocideFungicidesAmmonium hydroxideTitanate

The invention discloses a preparation method for silver-containing titanium dioxide antibacterial agent. The preparation method comprises the following steps: (1) adding butyl titanate into absolute ethyl alcohol, continuously stirring until the absolute ethyl alcohol finishes being dripped, dripping dilute nitric acid, stirring by magnetic force for 20-30min under a water bath condition of 30-60DEG C to obtain titanium dioxide sol, wherein the volume ratio of butyl titanate, absolute ethyl alcohol to dilute nitric acid is 5:(10-20):(0.5-1.5); (2) adding silver nitrate solution into the titanium dioxide sol, stirring for 10-20min, dripping 3% ammonium hydroxide until sediments just disappear, then, adding formaldehyde solution, carrying out magnetic stirring for 2-3h under a water bath condition of 50-60DEG C to obtain silver-titanium dioxide sol mixture; (3) carrying out centrifugation on the above silver-titanium dioxide sol mixture, cleaning the sediments with ethanol aqueous solution for 3-5 times, and drying in a drying oven at the temperature of 50-60DEG C for 10-20h to obtain the silver-containing titanium dioxide antibacterial agent. In the silver-containing titanium dioxide antibacterial agent, titanium dioxide can favorably load and fix silver nanoparticles, and the silver nanoparticle has long-acting antibacterial activity.

Owner:徐涌涛

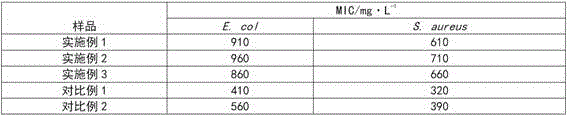

Porous graphene silver-loaded antibacterial composite material and preparation method thereof

InactiveCN106172494ALoad and secureAvoid reunionBiocideDead animal preservationPorous grapheneThin layer

The invention discloses a porous graphene silver-loaded antibacterial composite material and a preparation method thereof. The preparation method comprises the following steps: (1) preparing graphene quantum dot suspension liquid; (2) preparing silver-loaded graphene quantum dots; (3) preparing SiO2 coated silver-loaded graphene quantum dots; (4) carrying out surface treatment on the SiO2 coated silver-loaded graphene quantum dots; and (5) preparing the antibacterial composite material. The method disclosed by the invention takes laser irradiated graphene quantum dots as carriers of silver, and the silver is coated with silicon dioxide thin layers; finally, the silver is attached to porous graphene, so that silver nanoparticles can be loaded and fixed very well and are prevented from being agglomerated; the stability of the silver nanoparticles is remarkably improved so that the silver nanoparticles have relatively long-acting antibacterial activity; and meanwhile, the safety is improved, the utilization cost is reduced and the porous graphene silver-loaded antibacterial composite material has a wide application prospect in industrial application.

Owner:佛山市高明区尚润盈科技有限公司

Antimicrobial deodorizing gravure water-based ink and preparation method thereof

The invention discloses a formaldehyde-removing gravure water-based ink and a preparation method thereof. The formaldehyde-removing gravure water-based ink is prepared from the following components in percentage by weight: 70-75% of water-soluble resin, 10-15% of deionized water, 5-10% of water-based organic pigment, 3-6% of ethanol, 0.5-1% of diatomite / antimicrobial composite, 1-2% of dispersing agent, 0-1% of retarder, 0.5-1% of water-based leveling agent, 0.5-1% of water-based wax emulsion, 0.5-1% of diatomite / inorganic oxide, 0.5-1% of organic amine and 0.5-1% of defoaming agent. By reasonably matching the diatomite / antimicrobial composite material and diatomite / inorganic oxide under the synergistic actions among the functional additives, the ink has the excellent antimicrobial, anti-formaldehyde and deodorizing characteristics, and satisfies the demands for multiple functions, thereby further widening the applicability of the ink.

Owner:佛山市高明区尚润盈科技有限公司

Preparation method for anti-bacterial anti-radiation PLA (Poly Lactic Acid) material

InactiveCN106366591ACompound AntibacterialLoad and secureTenebresent compositionsRadiation propertiesAnti bacterial

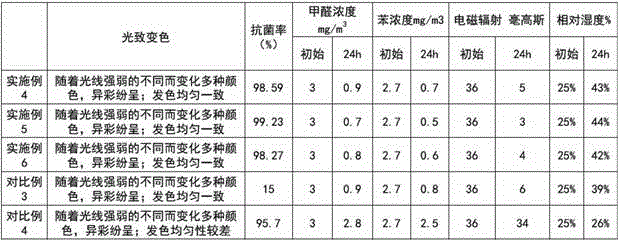

The invention discloses a preparation method for an anti-bacterial anti-radiation PLA (Poly Lactic Acid) material. The preparation method comprises the following steps: (1) mixing and dispersing an anti-bacterial compound and nano-bamboo charcoal according to the weight ratio of (1-3):(2-5) in lactic acid, preparing a solution with the concentration of 1 to 2 g / L, and performing ultrasonic stirring for 60 to 90 minutes to obtain an anti-bacterial / anti-radiation lactic acid solution; (2) dispersing a photochromic compound in the lactic acid, preparing the solution with the concentration of 0.5 to 2 g / L, and performing ultrasonic compound for 60 to 90 minutes to obtain a photochromic lactic acid solution; (3) mixing the anti-bacterial / anti-radiation lactic acid solution and the photochromic lactic acid solution, and performing vacuum drying on the mixed solution in a vacuum drying box at 50 to 80 DEG C until the mixed solution does not contain irreducible water, wherein the PLA material is obtained by a direct condensing method. According to the preparation method for the anti-bacterial anti-radiation PLA material, the PLA material has anti-bacterial property and also has a photochromic function and anti-radiation property through scientific compatibility; the application range of the poly lactic acid material is further enlarged.

Owner:佛山市高明区尚润盈科技有限公司

Formaldehyde-removing resin composite material and preparation method thereof

InactiveCN106349622AGood dispersionImprove stabilityOther chemical processesTenebresent compositionsPorous carbonPolyresin

The invention discloses a formaldehyde-removing resin composite material and a preparation method thereof. The method includes the steps of firstly, performing amination preprocessing on polyacrylonitrile macroporous resin; secondly, adding the polyacrylonitrile macroporous resin of the first step into a diatomite / porous carbon dispersing solution, performing ultrasonic stirring, standing for 60 minutes, and drying under 60-80 DEG C to obtain the formaldehyde-removing resin composite material, wherein antibacterial composite materials account for 0.5-1% of the total weight of the polyacrylonitrile macroporous resin, and diatomite / porous carbon accounts for 0.5-1% of the total weight of the polyacrylonitrile macroporous resin. The formaldehyde-removing resin composite material and the preparation method thereof have the advantages that diatomite and the antibacterial composite materials are reasonably coordinated to allow the resin material to have excellent antibacterial and formaldehyde-removing performance, the requirements of the multifunctional resin material are satisfied, and the application of the resin material is further expanded.

Owner:佛山市高明区尚润盈科技有限公司

Preparation method of photochromic polylactic acid material

The invention discloses a preparation method of a photochromic polylactic acid material. The method includes the following steps of firstly, dispersing an antibacterial compound in lactic acid to prepare a solution with concentration of 0.1-2 g / L, and conducting ultrasonic stirring for 60-90 min to obtain an antibacterial lactic acid solution; secondly, dispersing a photochromic compound in lactic acid to prepare a solution with concentration of 0.5-2 g / L, and conducting ultrasonic stirring for 60-90 min to obtain a photochromic lactic acid solution; thirdly, mixing the antibacterial lactic acid solution and the photochromic lactic acid solution to be standing still in a vacuum oven at 50-80 DEG C, conducting vacuum drying for 24-36 h till the mixed liquid is free of residual water, and obtaining a polylactic acid material through a direct condensation method. By scientifically matching the antibacterial compound and the photochromic compound, the polylactic acid material has the antibacterial characteristic and also has a photochromic function, and the application range of the polylactic acid material is further widened.

Owner:佛山市高明区尚润盈科技有限公司

Preparation method for antibacterial formaldehyde-removal glass fiber reinforced plastic packing box

The invention discloses a preparation method for a deodorant glass fiber reinforced plastic packing box. According to an antibacterial composite used by the packing box, graphene quantum dots obtained after laser irradiation serve as carriers of antibacterial agents, surface treatment is conducted, the graphene quantum dots are attached to porous grapheme finally and can load and fix silver nanoparticles and other antibacterial agents better, agglomeration of the antibacterial agents is prevented, the stability of the antibacterial agents is improved significantly, and thus the antibacterial agents have more long-acting antibacterial activity. According to the preparation method, through reasonable matching of kieselguhr / the antibacterial composite and kieselguhr / inorganic oxide and the synergistic effect of function additives, and then epoxy resin used in the glue injection step is added and modified into antibacterial glue. In this way, after glue injection, a body has antibacterial performance from inside to outside, thus the antibacterial performance and antibacterial stability and durability of the packing box are promoted, meanwhile, the formaldehyde-removal performance and deodorant performance are further achieved, the multifunctional requirements are met, and application of the packing box is further broadened.

Owner:佛山市高明区尚润盈科技有限公司

Preparation method of water-soluble photochromic ink

The invention discloses a preparation method of a water-soluble photochromic ink. The method comprises the following steps: (1) preparing a diatomite / antimicrobial composite; (2) adding a styrene-acrylic emulsion into a container, and dropwisely adding the diatomite / antimicrobial composite water solution while stirring; stirring to obtain an antimicrobial dispersion solution; (3) adding an EVA (ethylene-vinyl acetate) emulsion into the container, dropwisely adding a diatomite / inorganic oxide water solution and a photochromic composite while stirring, and continuing stirring for 30-60 minutes to obtain a photochromic dispersion solution; (4) mixing the antimicrobial dispersion solution and photochromic dispersion solution, adding deionized water, alcohol ester-12, PE (polyethylene) water-based wax, an ink compound, a water-based leveling agent, a water-based defoaming agent and a nonionic surfactant into a dispersion kettle, and stirring to obtain the water-soluble photochromic ink. The ink has the characteristics of excellent antimicrobial property, excellent formaldehyde resistance and excellent deodorizing property, is photochromic, and satisfies the multifunctional demands, thereby widening the application range of the ink.

Owner:佛山市高明区尚润盈科技有限公司

Method for preparing photochromic PET/PTT alloy

The invention discloses a method for preparing a photochromic PET / PTT alloy. The photochromic PET / PTT alloy comprises, by weight parts, 50-60 parts of PET, 10-30 parts of PTT, 2-5 parts of SMA, 5-6 parts of MBS, 1-5 parts of diatomaceous earth / anti-bacterial compound undergoing surface treatment by a coupling, 1-3 parts of diatomaceous earth / inorganic oxide undergoing surface treatment by a coupling, 1-3 parts of photochromic compound, 0.5-2 parts of nano silica, 0.1-0.5 part of antioxidant and 0.1-1 part of lubricant. By reasonable matching of the photochromic compound, the diatomaceous earth / anti-bacterial compound and the diatomaceous earth / inorganic oxide and through synergistic effects between function additives, the photochromic PET / PTT alloy has excellent anti-bacterial, anti-formaldehyde and deodorization characteristics and photochromic characteristics and meets multifunctional requirements, and the application of the photochromic PET / PTT alloy is further broadened.

Owner:佛山市高明区尚润盈科技有限公司

Preparation method of antimicrobial and radiation-proof glass fiber reinforced plastic packaging box

The invention discloses a preparation method of an antimicrobial and radiation-proof glass fiber reinforced plastic packaging box. The preparation method comprises the following steps: (1) according to the size of the packaging box, manufacturing a mould; (2) performing composite fixing by using resin to form a fiber reinforced layer; (3) laying reinforcing ribs; (4) laying fiber cloth to form a first composite layer; (5) forming a second composite layer; (6) injecting antibacterial / radiation-proof plastic through vacuum injection; (7) curing; (8) demoulding to obtain the radiation-proof glass fiber reinforced plastic packaging box. Through reasonable collocation of a photochromic compound, a diatomite / antimicrobial composite material and diatomite / nano bamboo charcoal and under a synergistic action of functional additives, epoxy resin used in a plastic injecting step is added and the epoxy resin is modified into the antibacterial / radiation-proof plastic, so that the box body has antibacterial performance from the inside to the outside, and thus the antibacterial performance, the antibacterial stability and the antibacterial persistence of the packaging box are improved; meanwhile, the packaging box further has radiation-proof and photochromic characteristics, multifunctional needs are met, and thus the application of the packaging box is further widened.

Owner:安徽大松树脂有限公司

Resin composite material and preparation method thereof

InactiveCN106366532AImprove antibacterial propertiesImprove stabilityBiocideDead animal preservationPorous grapheneAntibacterial activity

The invention discloses a resin composite material and a preparation method thereof. The method comprises the following steps that amination pretreatment and nanocarbon modification are conducted on polyacrylonitrile macroporous adsorption resin; the polyacrylonitrile macroporous adsorption resin is added into an antibacterial composite material dispersing solution, ultrasonic stirring and standing are conducted in sequence, drying is conducted at the temperature of 60 DEG C to 80 DEG C, and then the resin composite material can be obtained, wherein the weight of an antibacterial composite material accounts for 0.5%-1% of the total weight of the polyacrylonitrile macroporous adsorption resin. According to the resin material, the excellent antibacterial property is achieved, graphene quantum dots irradiated by a laser are adopted as carriers of silver, then the carriers are coated with silicon dioxide thin layers and titanium dioxide, surface treatment is conducted, silver is attached to porous graphene finally, therefore, silver nanoparticles and nano-titanium dioxide can be better loaded and fixed to the carbon-modified resin, agglomeration of the silver nanoparticles and nano-titanium dioxide is prevented, the stability of the silver nanoparticles and the like is significantly improved, and the more long-acting antibacterial activity is achieved; meanwhile, the antibacterial properties of the silver particles and titanium dioxide are combined, and compared with a single nano-silver antibacterial agent, the better and lasting antibacterial effects are achieved.

Owner:佛山市高明区尚润盈科技有限公司

Preparation method of polylactic acid antimicrobial master batch

InactiveCN106189146ACompound AntibacterialLoad and secureBiocideDisinfectantsOrganic solventInorganic oxide

The invention discloses a preparation method of a polylactic acid antimicrobial formaldehyde-removing master batch. The method comprises the following steps: (1) pretreating a polylactic acid raw material; (2) dissolving half of the pretreated polylactic acid in an organic solvent, dropwisely adding an antimicrobial composite water dispersion under the action of ultrasonic agitation, carrying out ultrasonic agitation, and carrying out spray drying to obtain an antimicrobial master batch; (3) dissolving the other half of the pretheated polylactic acid in an organic solvent, dropwisely adding a diatomite / inorganic oxide water dispersion under the action of ultrasonic agitation, carrying out ultrasonic agitation, and carrying out spray drying to obtain a formaldehyde-removing master batch; and (4) uniformly mixing the two master batches to obtain a mixture, and granulating to obtain the polylactic acid antimicrobial formaldehyde-removing master batch. By reasonably matching the diatomite / inorganic oxide and antimicrobial composite material under the synergistic actions among the functional additives, the polylactic acid master batch has the excellent antimicrobial and deodorizing properties and anti-formaldehyde characteristics, and satisfies the demands of the multifunctional polylactic acid master batch, thereby further widening the applicability of the polylactic acid master batch.

Owner:佛山市高明区尚润盈科技有限公司

Photo chromic resin composite material and preparation method thereof

The invention discloses a photo chromic resin composite material and preparation thereof. The method comprises the steps of 1, pretreating the pan macro porous adsorption resin by amination; 2, adding the pan macro porous adsorption resin processed in step 1 into diatomaceous earth or porous carbon dispersed solution, conducting ultrasonic agitation and static drying for using; 3, adding antibacterial composite material dispersion solution, conducting ultrasonic agitation and static drying for using; 4, adding photo chromic composite dispersion, conducting ultrasonic agitation and static drying, so that the photo chromic resin composite material is obtained. As the result of the reasonable collocation of diatomite, photo chromic compounds and antibacterial composite material, the resin material has excellent antibacterial properties, formaldehyde removal properties, and photo chromic properties with the synergistic effect of the three. The resin material meet the demand of multifunctional resin materials, thereby further broadening the application of resin materials.

Owner:佛山市高明区尚润盈科技有限公司

Preparation method of water-based photochromic inorganic coating

InactiveCN106189400ACompound AntibacterialLoad and secureBiocideAntifouling/underwater paintsWater basedFiltration

The invention discloses a preparation method of a water-based photochromic inorganic coating. The preparation method comprises the following steps: (1) dispersing kieselguhr into an aqueous solution, dropping antibacterial compound aqueous dispersion, performing stewing, suction filtration and cleaning, and drying to obtain a kieselguhr / antibacterial compound; (2) mixing and stirring water and a defoaming agent, then adding pigments, filler and kieselguhr / inorganic oxide, and stirring to obtain a solution A; (3) mixing and fully stirring silica sol and a polymer solution, adding the kieselguhr / antibacterial compound, and performing stirring to obtain a solution B; (4) adding a coalescing agent, a thickening agent and a photochromic compound into the obtained solution B, and fully stirring to obtain a solution C; (5) dropping the solution C into the solution A, and performing full stirring and filtration. The inorganic coating has excellent antibacterial and anti-formaldehyde characteristics as well as the photochromic property, and can meet the requirement for multiple functions; the application of the inorganic coating can be further expanded.

Owner:佛山市高明区尚润盈科技有限公司

Manufacturing method for glass fiber reinforced plastic packaging box

The invention discloses a manufacturing method for a glass fiber reinforced plastic packaging box. The manufacturing method comprises the following steps of: (1) manufacturing a mould according to the dimension of the packaging box; (2) forming a fiber reinforcing layer by resin compounding and fixing; (3) paving reinforcing ribs; (4) paving fiber cloth to obtain a first compound layer; (5) forming a second compound layer; (6) vacuum-injecting antibacterial glue; (7) curing; and (8) de-molding to obtain the glass fiber reinforced plastic packaging box. According to the manufacturing method disclosed by the invention, antibacterial composite is added into epoxy resin used in a glue injecting step, so that epoxy resin is modified into antibacterial glue; and after glue injection, a box body has antibacterial performance from inside to outside, so that antibacterial performance and antibacterial stable durability of the packaging box are improved.

Owner:佛山市高明区尚润盈科技有限公司

Preparation method of deodorizing fiberglass packaging box

The invention discloses a preparation method of a deodorizing fiberglass packaging box. The preparation method comprises the following steps: (1) according to the size of the packaging box, manufacturing a mould; (2) compounding and fixing to form a fiber reinforced layer by using resin; (3) laying reinforcing ribs; (4) laying fiber cloth to form a first compound layer; (5) forming a second compound layer; (6) injecting antibacterial glue under vacuum; (7) curing; (8) demoulding to obtain the deodorizing fiberglass packaging box. Through reasonable matching of a diatomite / antibacterial composite material and diatomite / inorganic oxide, a synergistic effect between functional additives is achieved; then, epoxy resin used in the glue injecting step is injected and is modified into the antibacterial glue, so that after glue injection, the box body has the antibacterial performance from the inside to the outside, and thus the antibacterial performance and the antibacterial stability and persistence of the packaging box are improved; meanwhile, the packaging box has anti-formaldehyde and deodorant characteristics, meets multifunctional needs, and further widens application of the packaging box.

Owner:佛山市高明区尚润盈科技有限公司

Preparation method of water-soluble deodorizing ink

The invention discloses a preparation method of water-soluble deodorizing ink. The preparation method includes following steps: (1), preparing a diatomite / antibacterial compound; (2), adding a styrene-acrylic emulsion into a container, stirring while dropwise adding a water solution of the diatomite / antibacterial compound, and stirring to obtain an antibacterial dispersion solution; (3), adding an EVA emulsion into the container, stirring while dropwise adding a diatomite / inorganic oxide water solution, and continuing stirring for 30-60 min to obtain a formaldehyde removing dispersion solution; (4), mixing the antibacterial dispersion solution with the formaldehyde removing dispersion solution, adding deionized water, alcohol ester-12, PE waterborne wax, varnish, a waterborne leveling agent, a waterborne defoamer and a nonionic surfactant into a dispersion kettle, and stirring to obtain the water-soluble deodorizing ink. By reasonably matching a diatomite / antibacterial composite material and diatomite / inorganic oxide and through synergism among functional additives, the ink has excellent antibacterial, anti-formaldehyde and deodorizing characteristics and meets multifunctional needs, and application range of the ink is further expanded.

Owner:佛山市高明区尚润盈科技有限公司

Photochromic gravure water-based ink and preparation method thereof

The invention discloses photochromic gravure water-based ink and a preparation method thereof. The photochromic gravure water-based ink is prepared from, by weight, 70%-75% of water soluble resin, 10%-15% of deionized water, 5%-10% of water-based organic pigment, 3%-6% of ethyl alcohol, 0.5%-1% of kieselguhr / antibacterial compound, 1%-2% of dispersing agent, 0%-1% of slow drying agent, 0.5%-1% of water-based flatting agent, 0.5%-1% of water-based wax emulsion, 0.5%-1% of kieselguhr / inorganic oxide, 0.5%-1% of organic amine, 0.5%-1% of antifoaming agent and 0.1%-2% of photochromic compound. The ink has excellent antibacterial, anti-formaldehyde and deodorization properties and photochromic properties and meets the need for multiple functions, and the application range of the ink is further widened.

Owner:佛山市高明区尚润盈科技有限公司

Preparation method of glass fiber reinforced plastic packaging box capable of purifying formaldehyde

The invention discloses a preparation method of a glass fiber reinforced plastic packaging box capable of purifying formaldehyde. The preparation method comprises the following steps: (1) manufacturing a mold according to the size of the packaging box; (2) compounding and fixing by resin to form a fiber reinforced layer; (3) paving reinforcing ribs; (4) paving fiber cloth to form a first composite layer; (5) forming a second composite layer; (6) injecting antibacterial glue under the vacuum condition; (7) curing; and (8) demolding to obtain the glass fiber reinforced plastic packaging box capable of purifying the formaldehyde. A diatomite / antibacterial composite material and diatomite / porous carbon which are matched reasonably, and functional additives with synergistic effect are added in epoxy resin used in the glue injecting process, and the epoxy resin is modified into the antibacterial glue, so the box body has antibacterial property from inside to outside, and the antibacterial property and the antibacterial stability and durability of the packaging box are improved; meanwhile, the packaging box has formaldehyde resistance and meets multifunctional requirements.

Owner:佛山市高明区尚润盈科技有限公司

Preparation method of anti-radiation PET/PTT alloy

The invention discloses a preparation method of an anti-radiation PET / PTT alloy. The anti-radiation PET / PTT alloy is prepared from the following raw materials by weight: 50 to 60 parts of PET, 10 to 30 parts of PTT, 2 to 5 parts of SMA, 5 to 6 parts of MBS, 1 to 5 parts of a diatomite / antimicrobial composite subjected to coupling reagent surface treatment, 1 to 5 parts of nano-bamboo charcoal subjected to coupling reagent surface treatment, 1 to 3 parts of a photochromic composite, 0.5 to 2 parts of nano-silica, 0.1 to 0.5 part of an antioxidant and 0.1 to 1 part of a lubricant. Due to reasonable combination of the photochromic composite, the diatomite / antimicrobial composite and nanometer bamboo charcoal, and synergy of functional additives, the anti-radiation PET / PTT alloy has excellent antibacterial, anti-formaldehyde and anti-radiation characteristics, and also has a photochromic characteristic, so as to meet multi-functional requirements and further broaden the application of the anti-radiation PET / PTT alloy.

Owner:佛山市高明区尚润盈科技有限公司

Anti-radiation gravure water-based ink and preparing method thereof

The invention discloses anti-radiation gravure water-based ink and a preparing method thereof. The anti-radiation gravure water-based ink is prepared from, by weight, 70-75% of water-soluble resin, 10-15% of deionized water, 5-10% of water-based organic pigment, 3-6% of ethyl alcohol, 0.5-1% of kieselguhr / antibacterial composition, 1-2% of dispersant, 0-1% of slow drying agent, 0.5-1% of water-based flatting agent, 0.5-1% of water-based wax emulsion, 1-2% of nano bamboo charcoal, 0.5-1% of organic amine, 0.5-1% of defoaming agent and 0.1-2% of photochromic composition. The ink has excellent antibacterial and radiation resistance, has photochromic characteristic and meets the multifunctional requirement, and application of the ink is further broadened.

Owner:佛山市高明区尚润盈科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com