Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Large gear ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

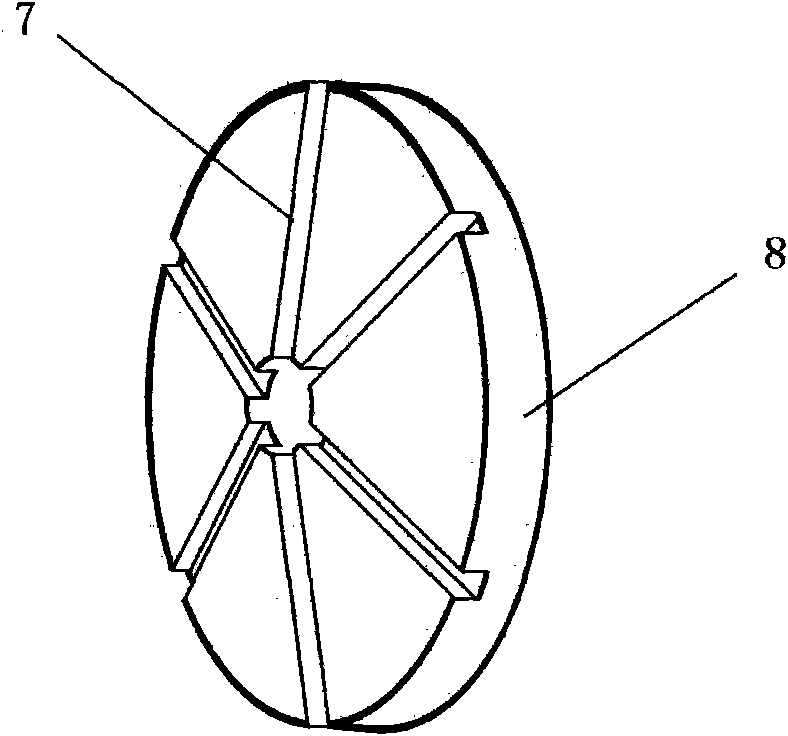

Stepless speed change device and application thereof

InactiveCN105035251AImprove comfortOvercome the disadvantage of unstable speed changeWheel based transmissionGear wheelEngineering

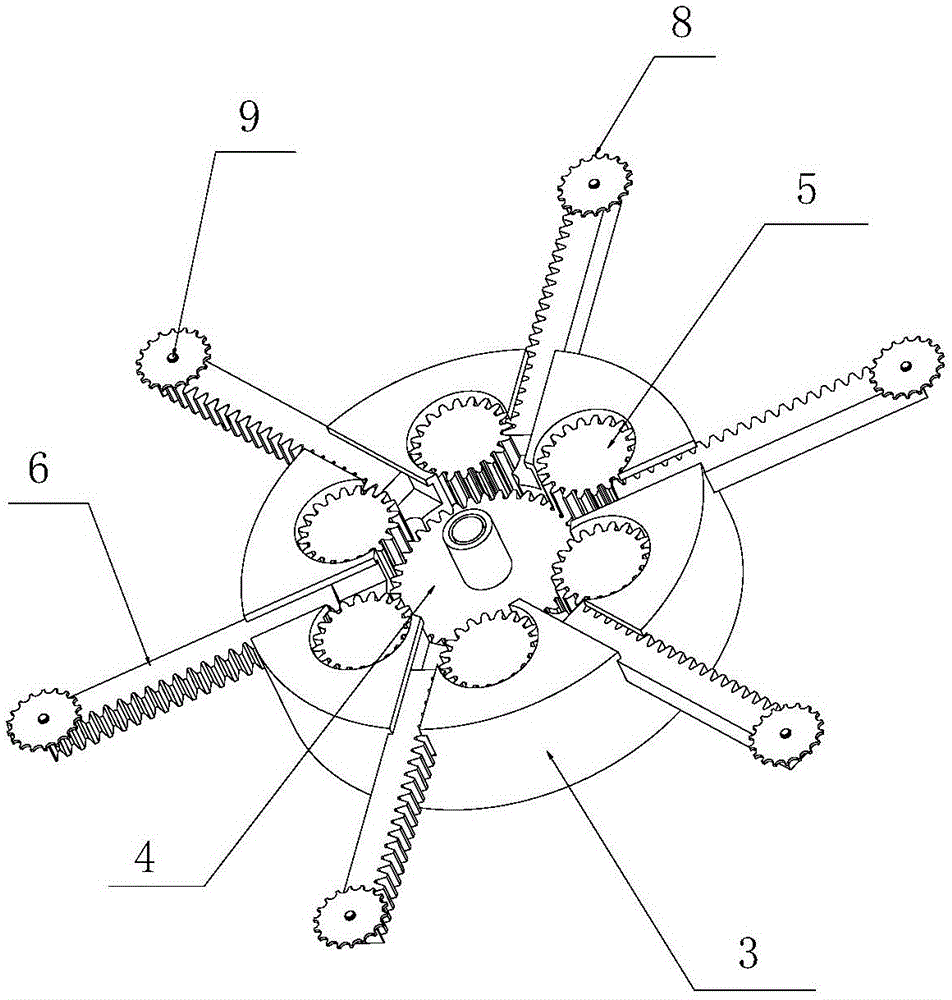

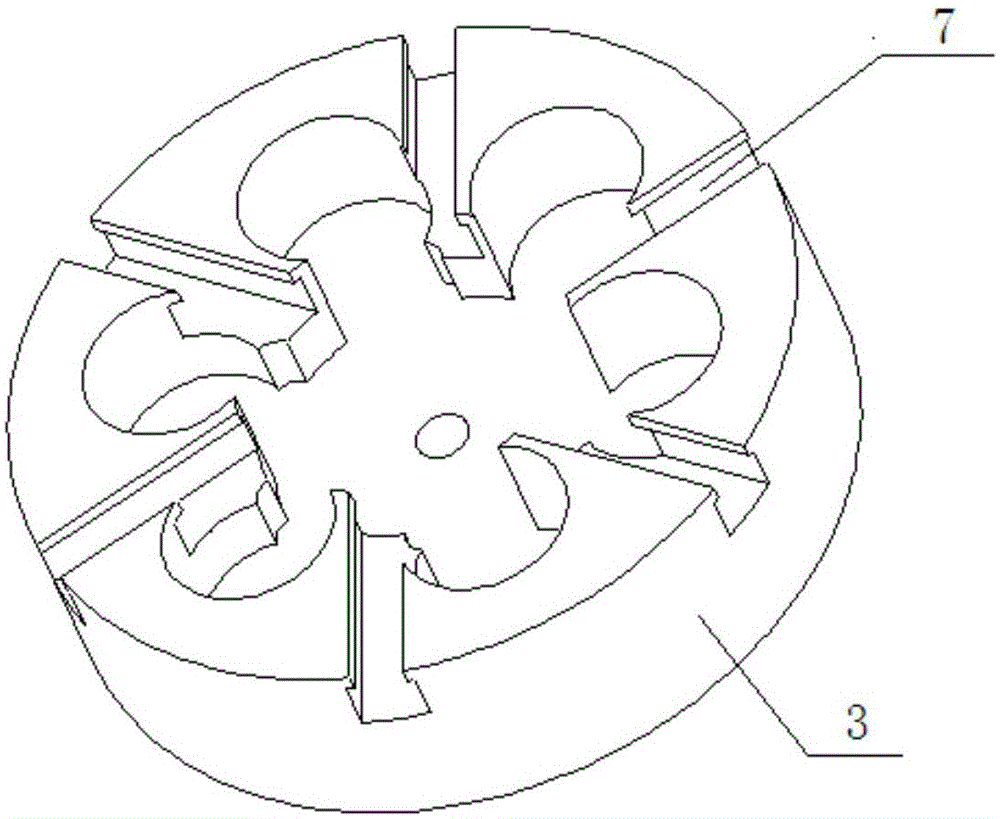

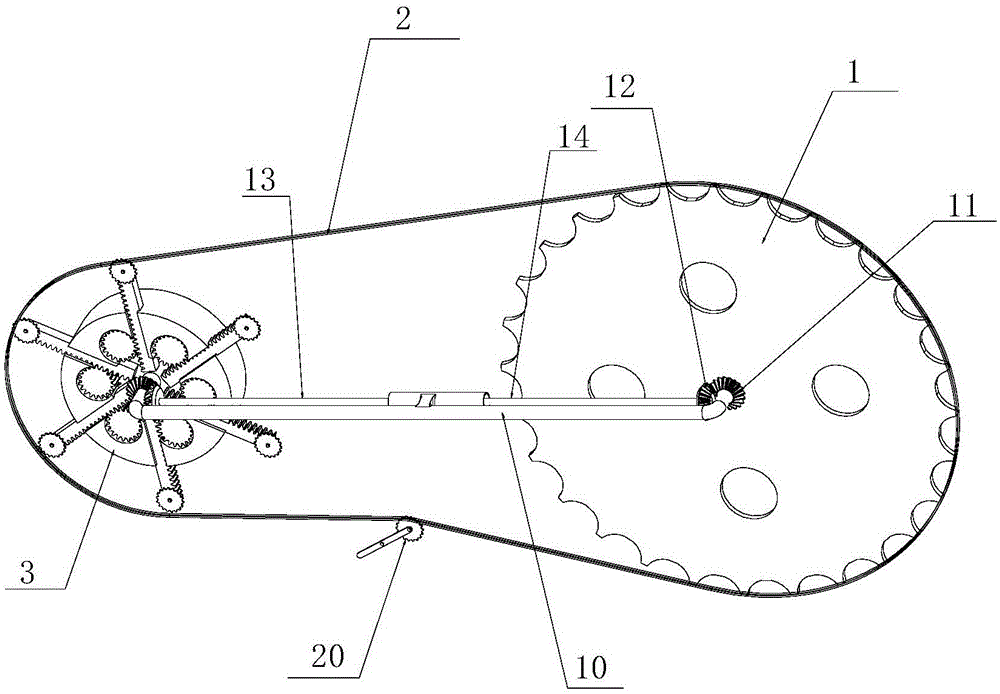

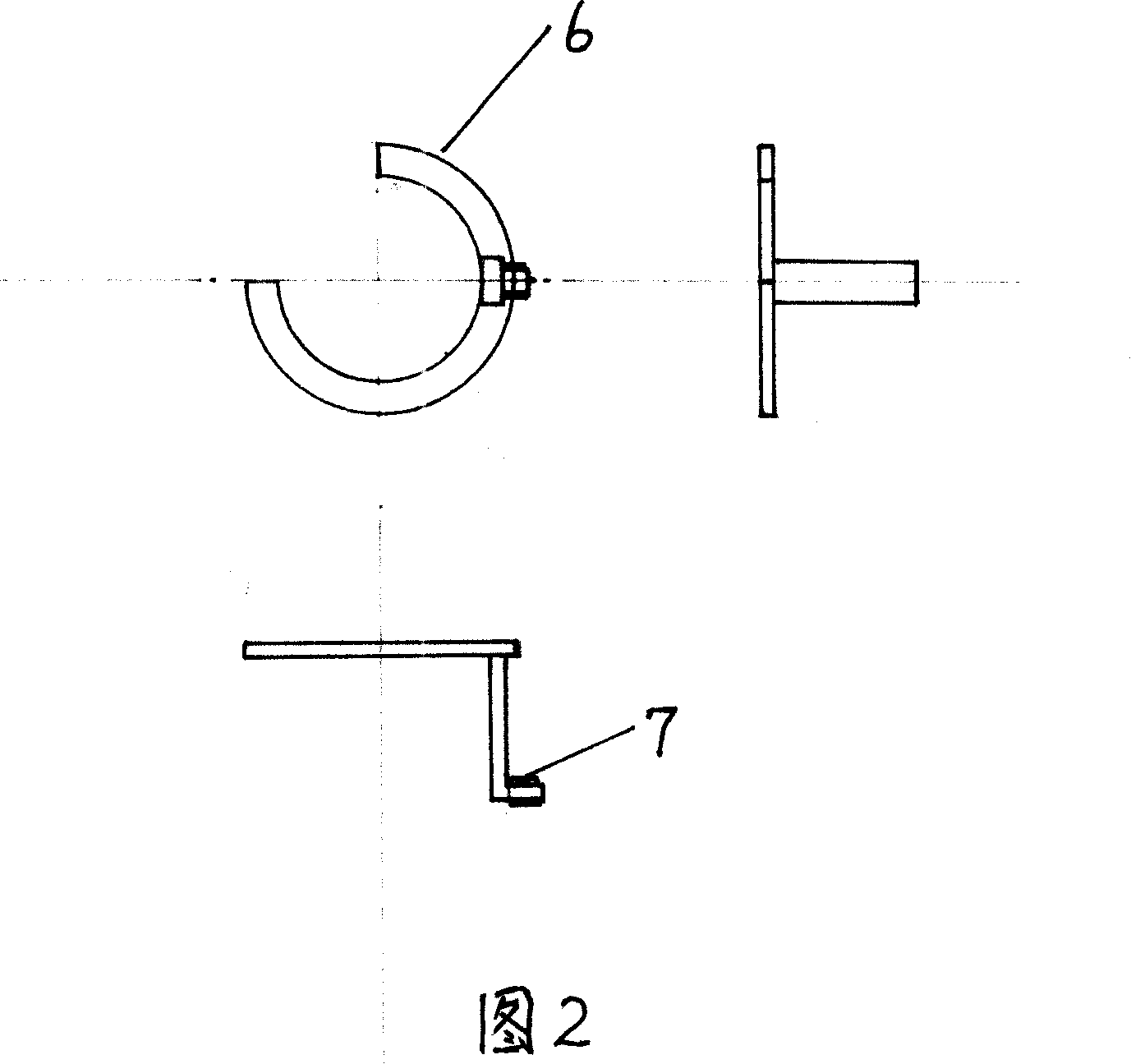

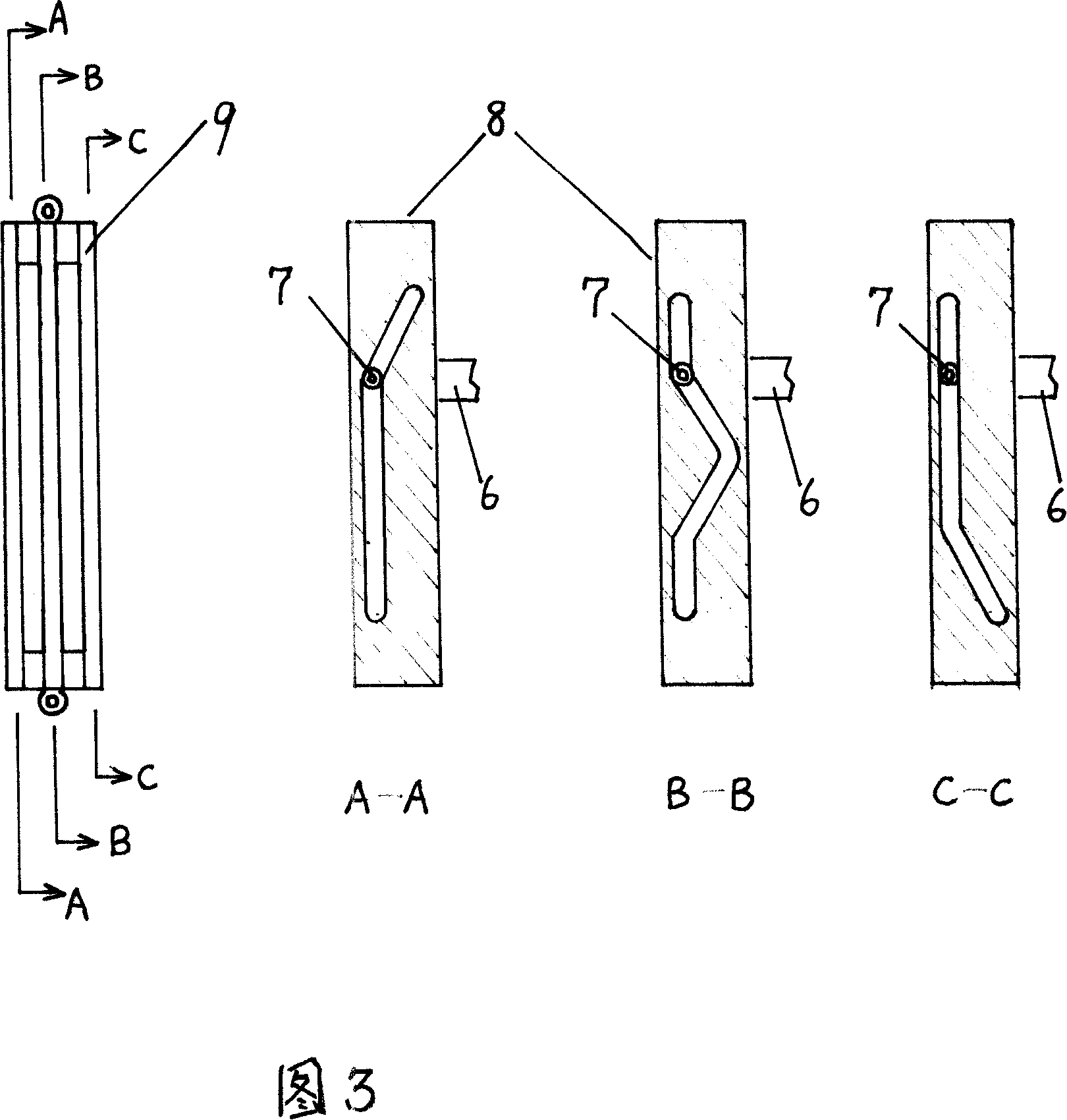

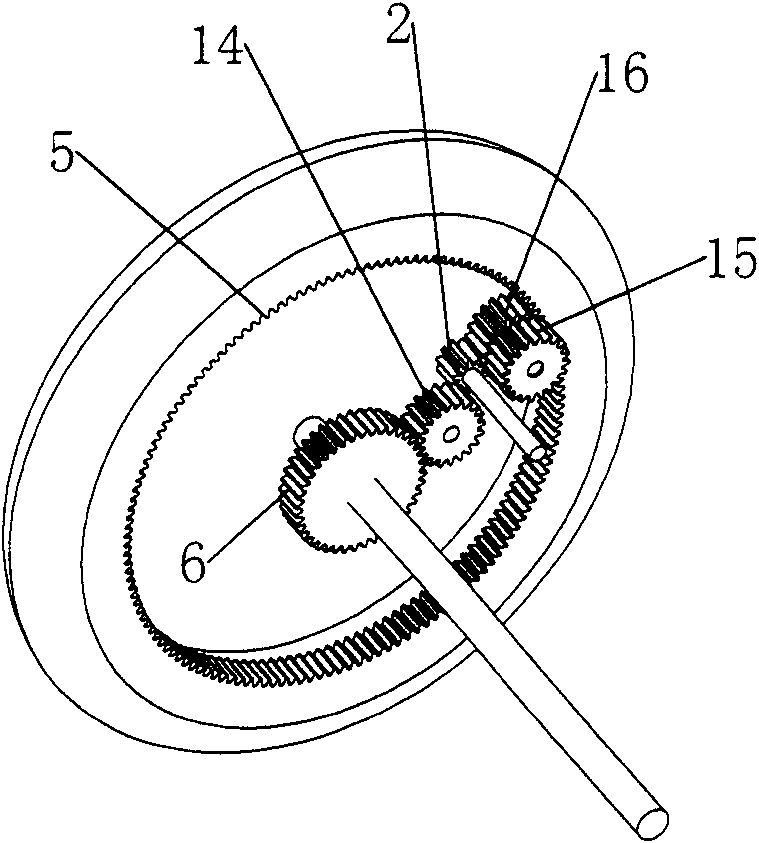

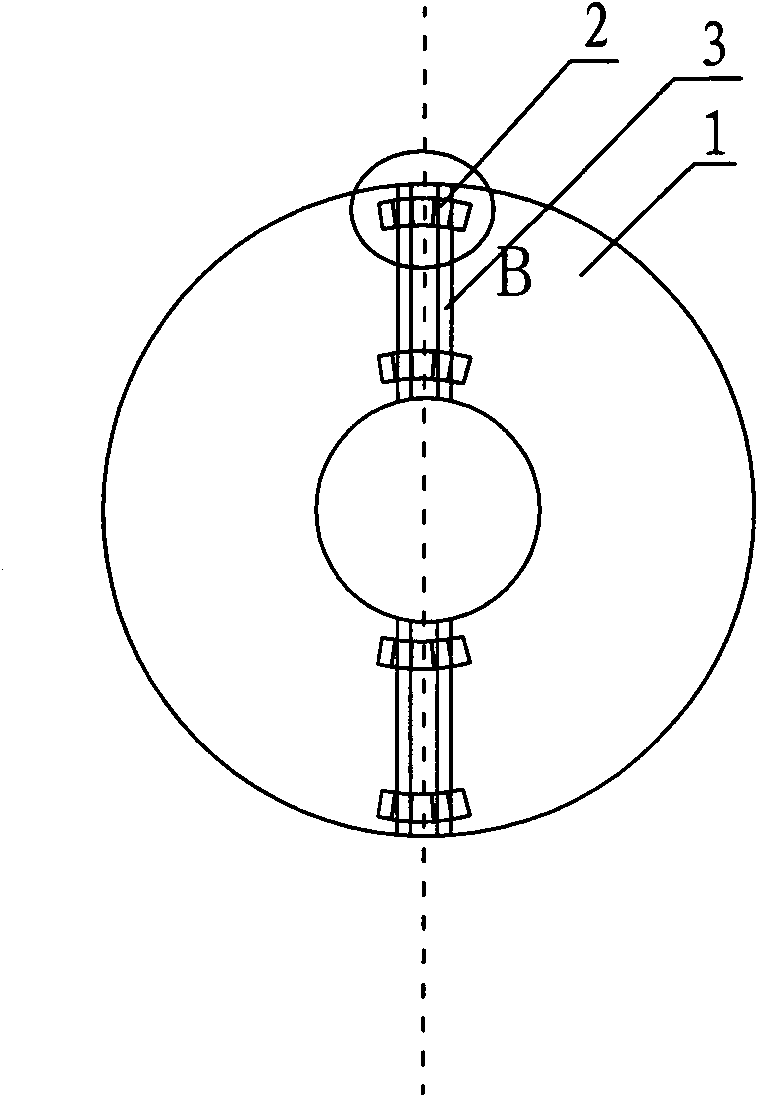

The invention discloses a stepless speed change device and application thereof. The stepless speed change device comprises a gearbox body. The gearbox body is internally provided with a large gear and a plurality of small gears. The small gears are distributed at the periphery of the large gear in a meshed mode. One side of each small gear is meshed with a speed change rack. T-shaped grooves are formed in the gearbox body in the radial direction. The speed change racks are movably embedded in the T-shaped grooves and stretch out of the gearbox body. The tail ends of the speed change racks are provided with chain tooth discs or small belt wheels. The stepless speed change device can be applied to bicycles or the industry and is stable in speed change, easy to control, convenient to use and high in transmission efficiency.

Owner:QINGDAO UNIV OF SCI & TECH

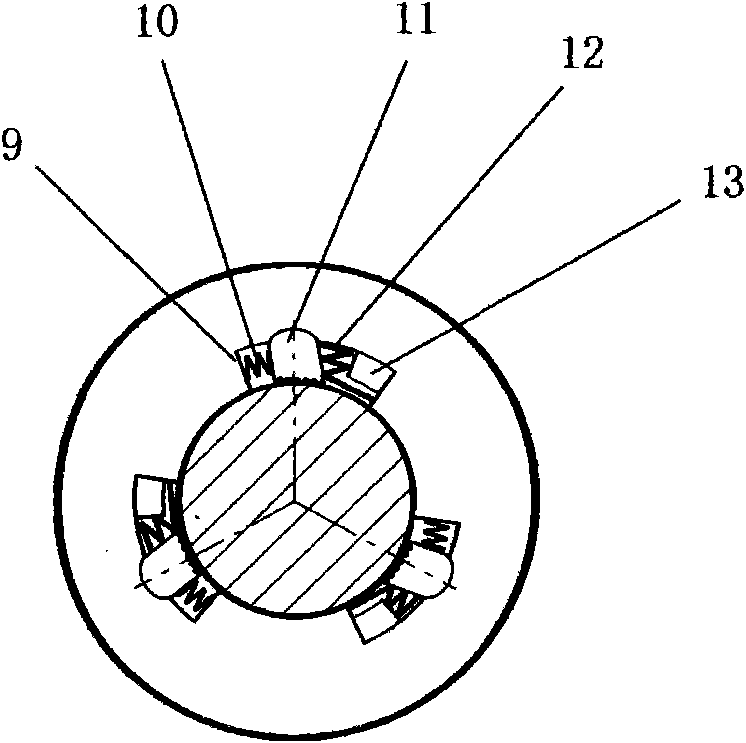

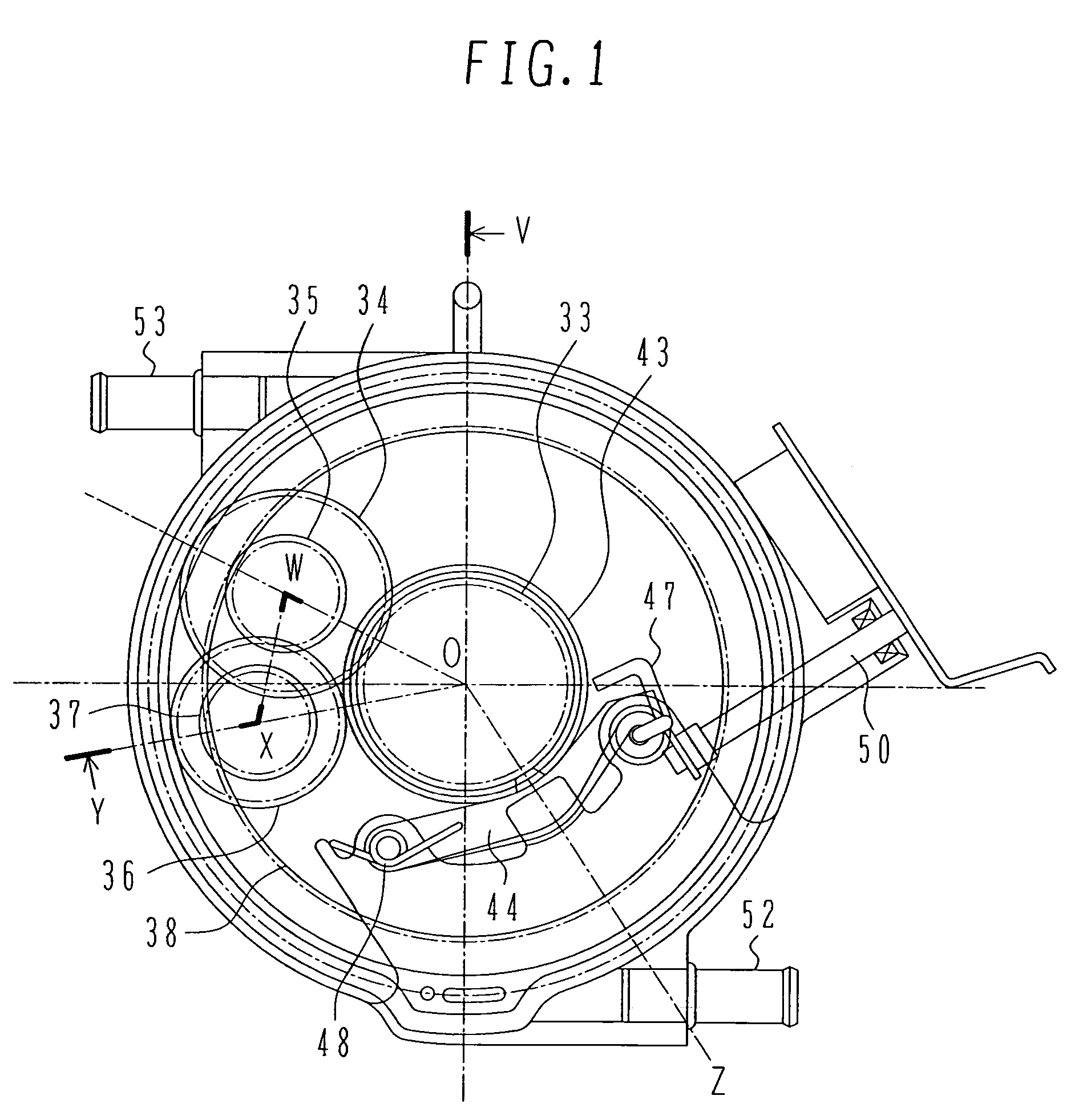

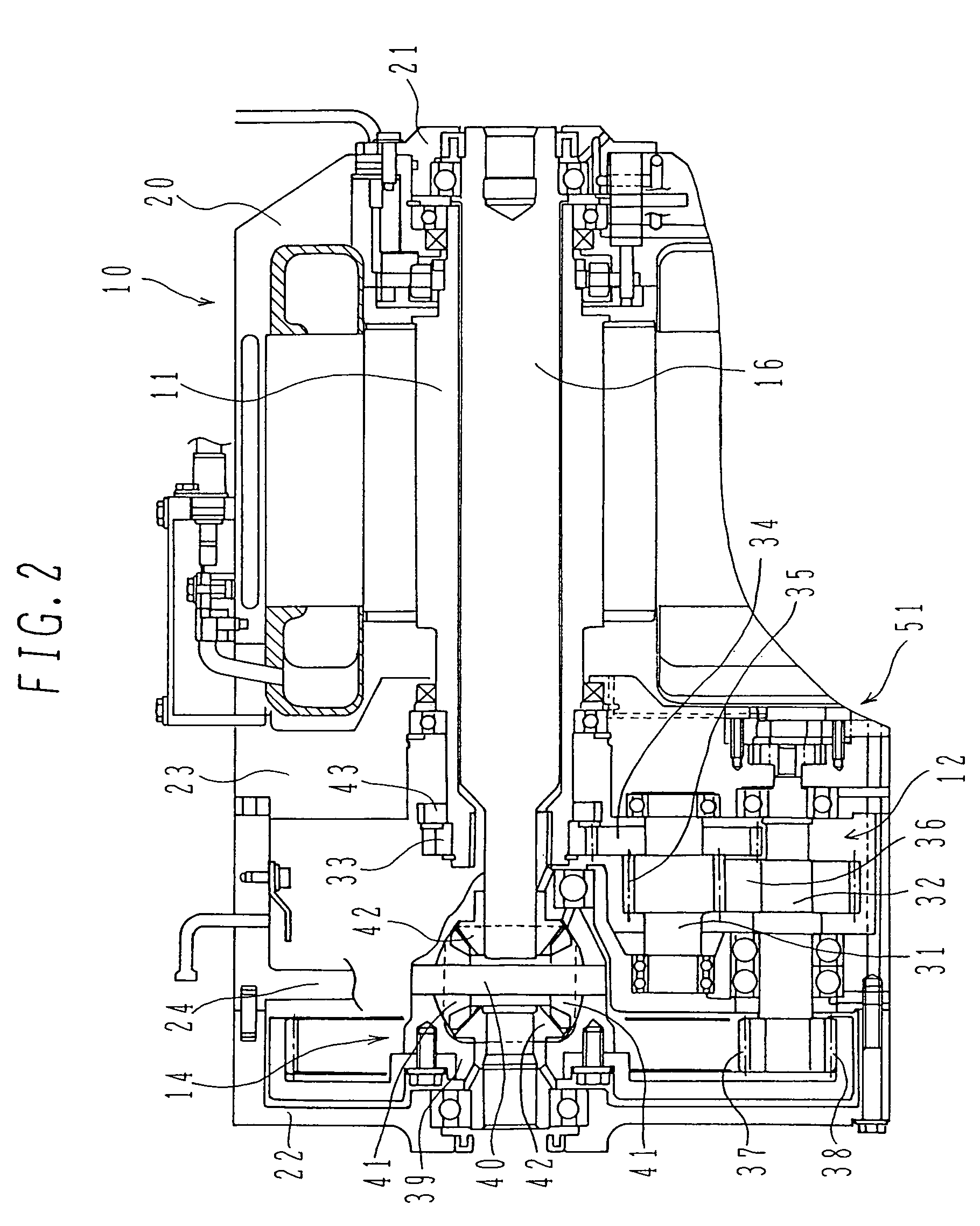

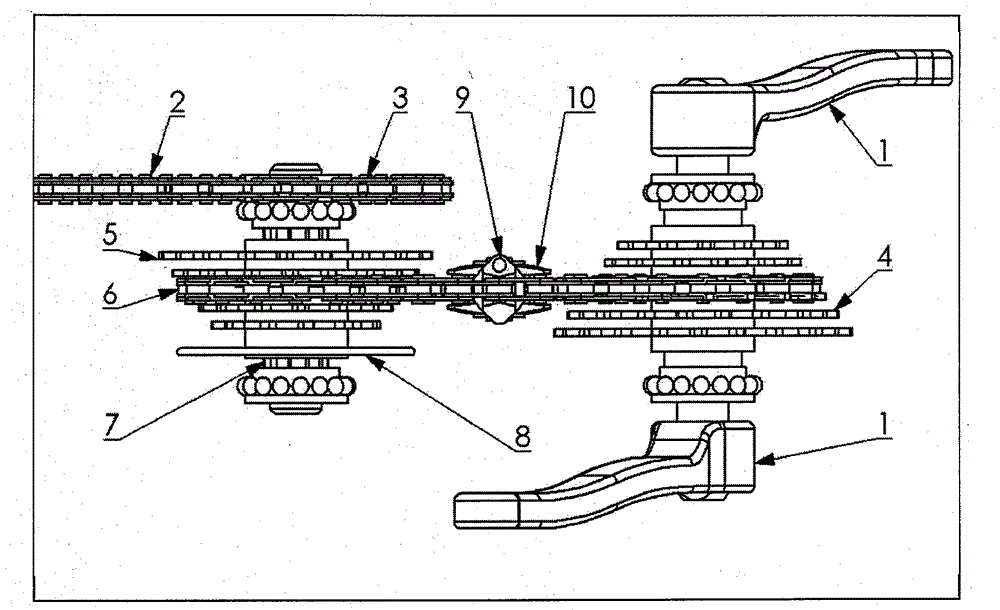

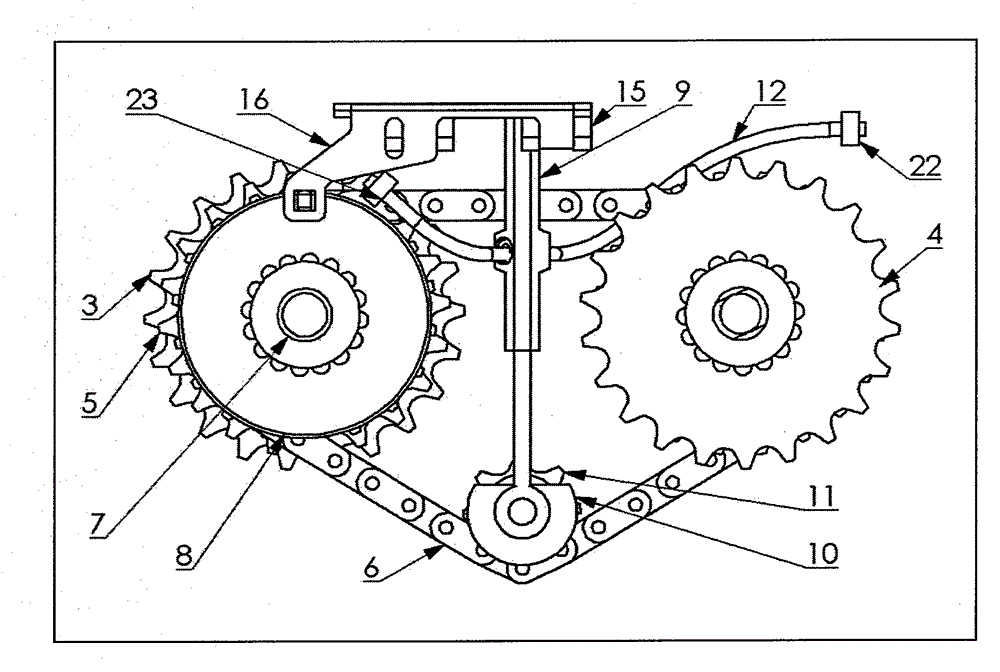

High-power stepless transmission

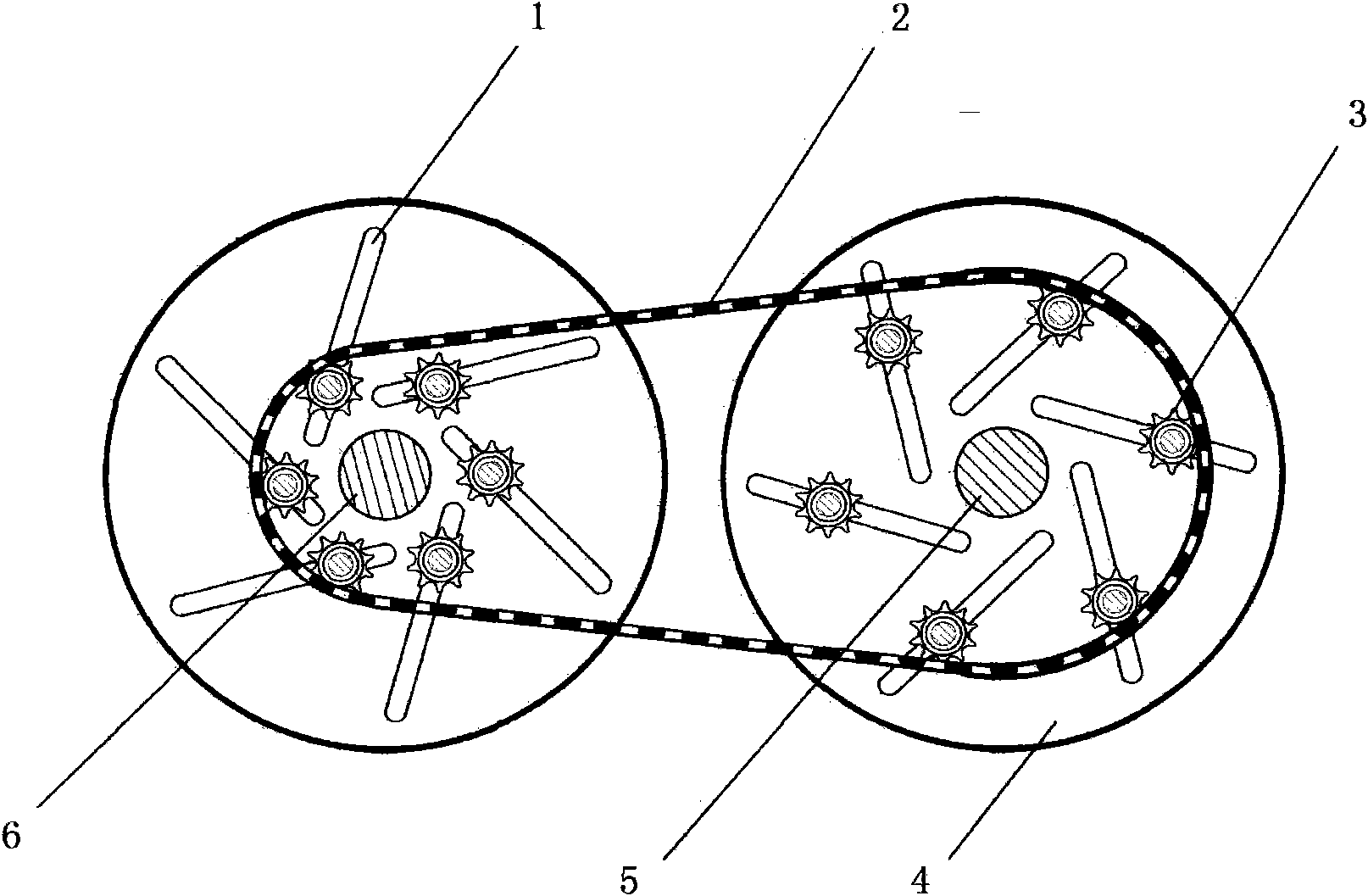

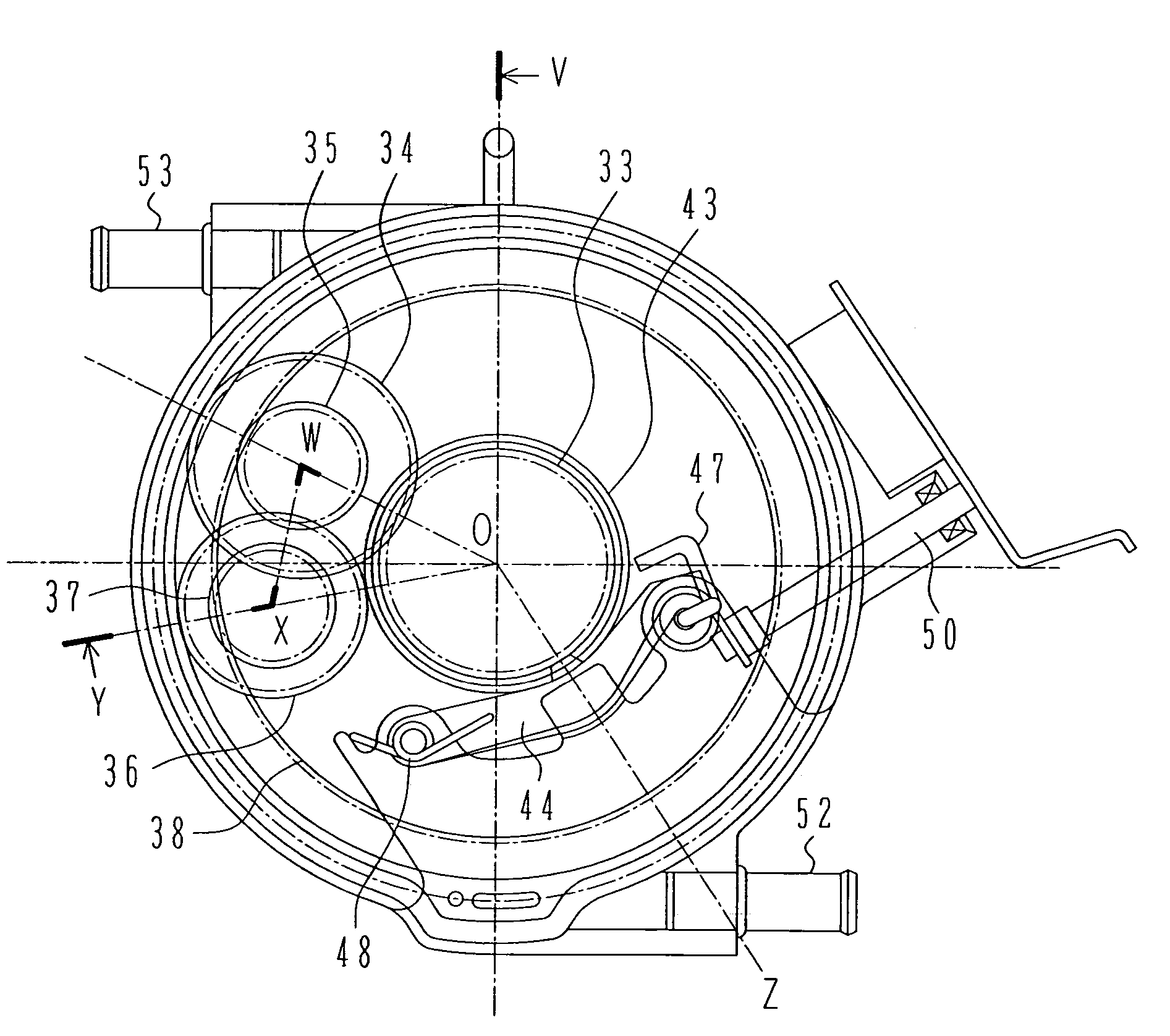

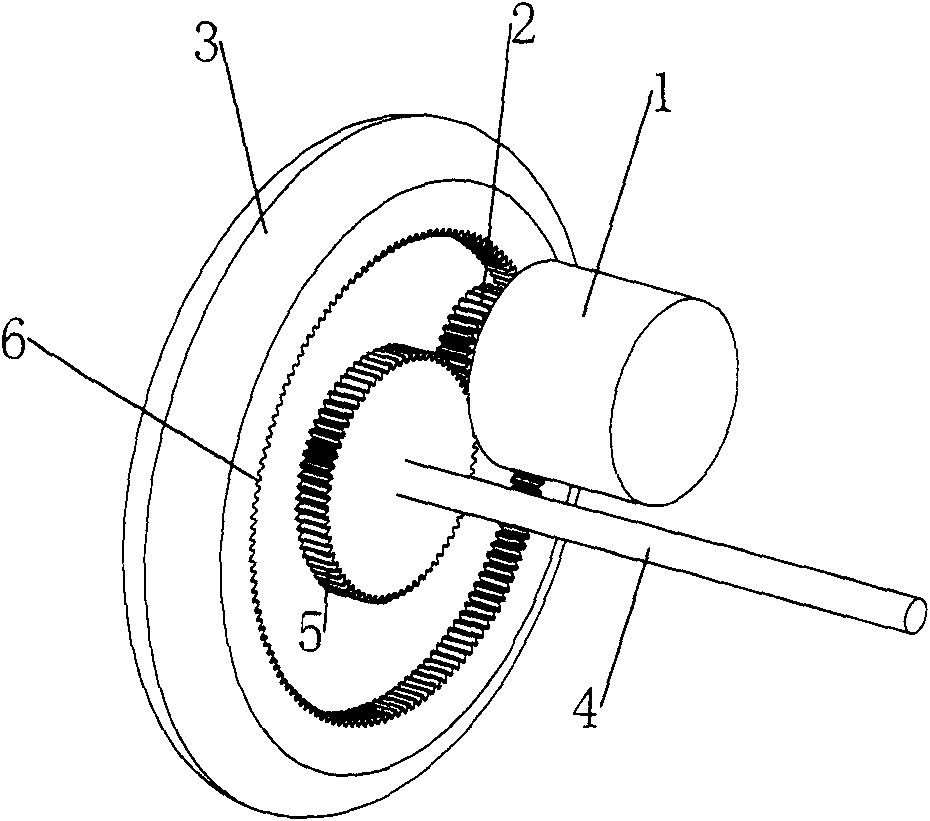

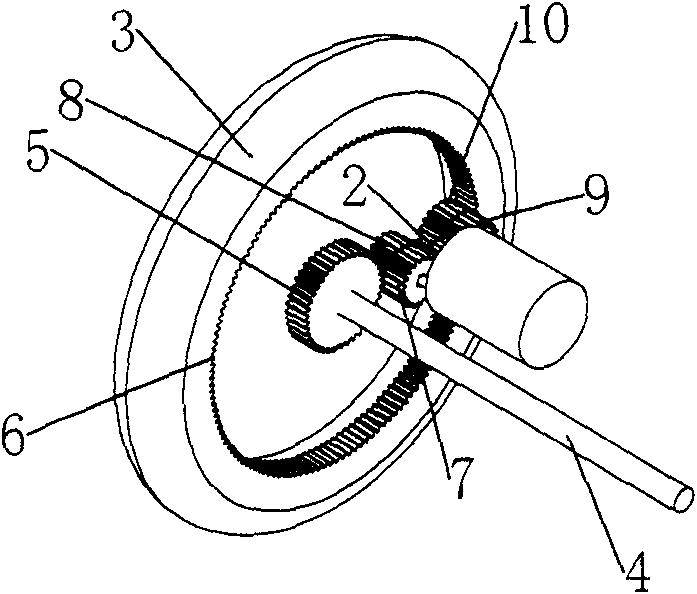

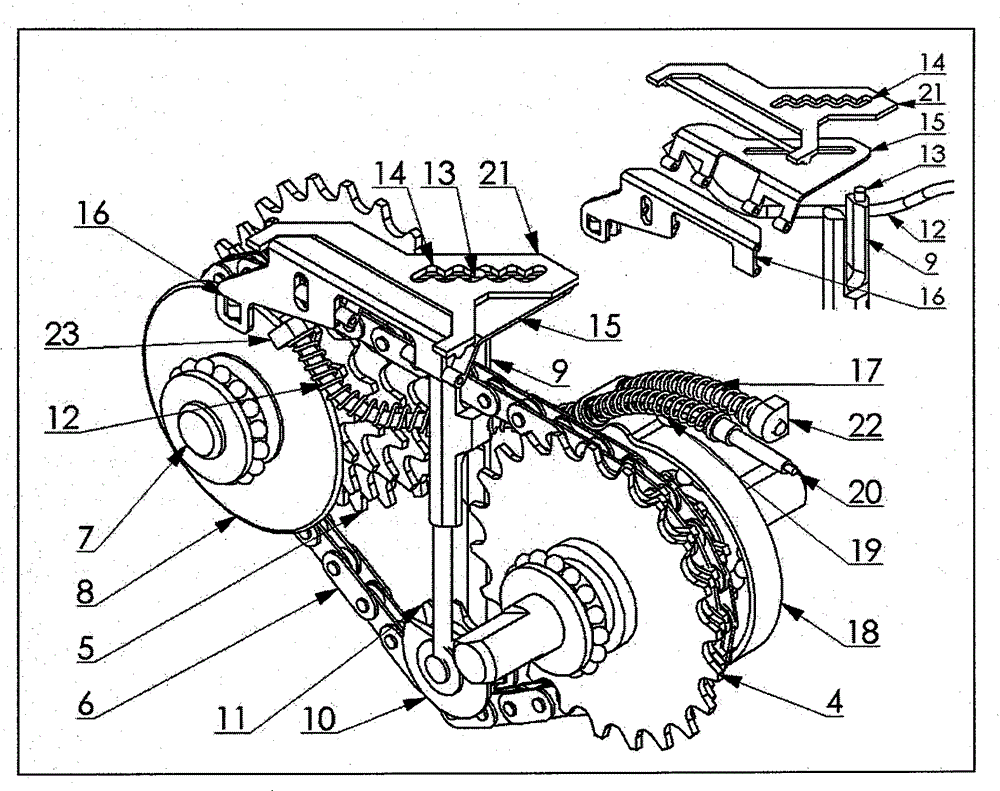

The invention relates to a tooth chain type stepless transmission for an automobile. A tooth chain is arranged around a plurality of planetary gears which can unidirectionally rotate; all the planetary gears can move in a corresponding radial chute on a drive wheel; and stepless transmission is realized by changing the revolution diameter of the planetary gears. An unlocking key is arranged in a one-way clutch of each planetary gear; and when the tooth chain and the planetary gears are meshed and separated, the unlocking key can be driven so that the clutch is maintained in a one-way locking state or unlocking state. The invention breaks through the traditional theory that the stepless transmission is only friction power transmission, solves the problem of carrying out stepless transmission by utilizing a gear, can effectively improve the transfer power of the stepless transmission and has the advantages of large force transmission, high rotating speed, stable running, reliable work, and the like.

Owner:刘爱诗

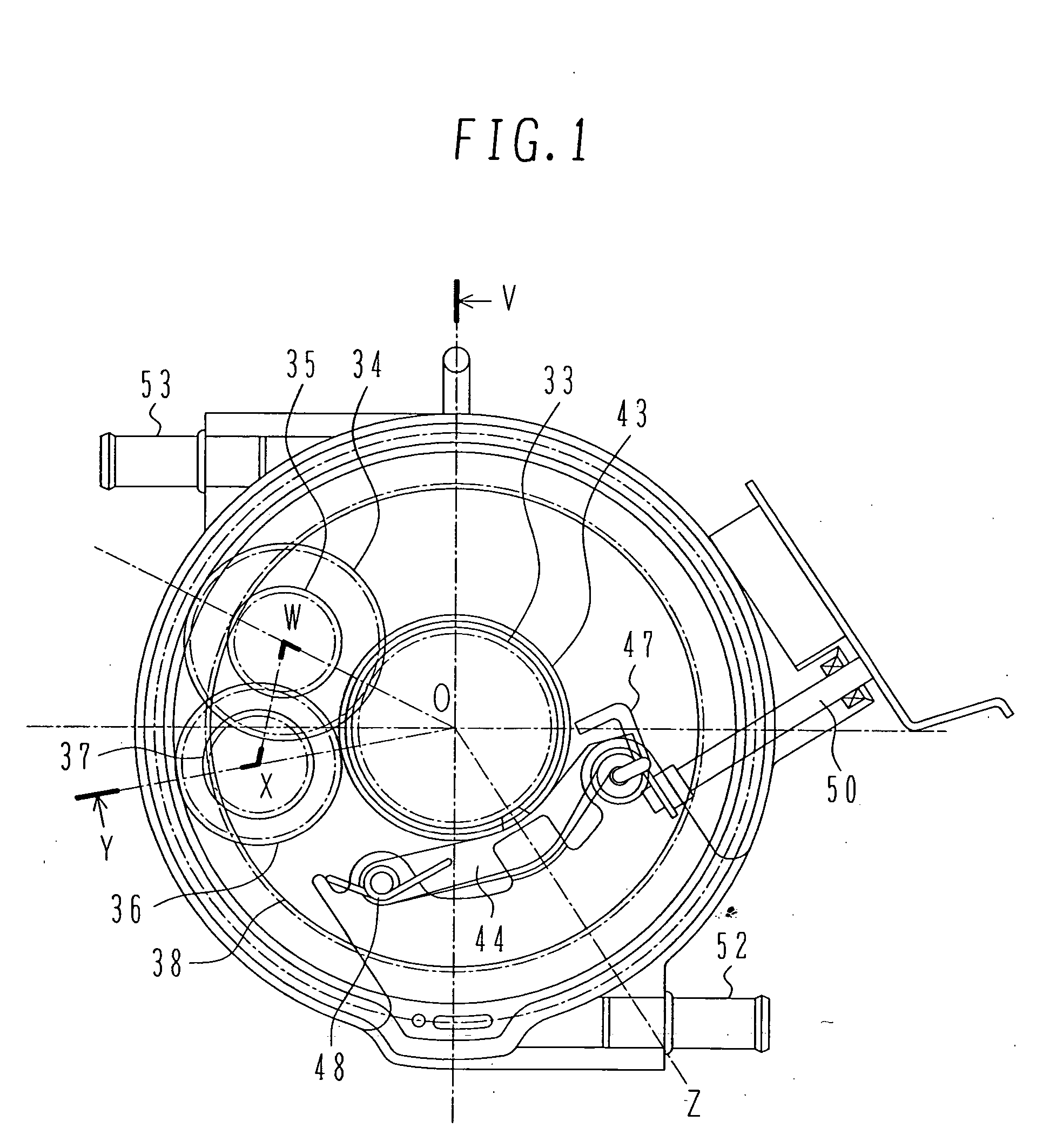

Power transmission apparatus for vehicle and vehicle-driving electric machinery system using the same

InactiveUS20050143210A1Power transmission efficiency is reducedReduce transmission efficiencyElectric propulsion mountingToothed gearingsGear ratioFixed position

The invention provides a power transmission apparatus for vehicle which can realize a high torque transmission efficiency and a high reduction gear ratio of a reduction gear unit with a more compact structure, and a vehicle-driving electric machinery system using the power transmission apparatus for vehicle. The power transmission apparatus for vehicle comprises a motor, a reduction gear unit for decelerating power outputted from the motor, and a differential gear unit for distributing the power decelerated by the reduction gear unit to left and right wheels. The reduction gear unit is a reduction gear mechanism including a plurality of gears mounted over a shaft which is rotatably held by a housing in a fixed position. The reduction gear unit and the differential gear unit are arranged within an area in oppositely facing relation to an axial end surface of the motor.

Owner:HITACHI LTD

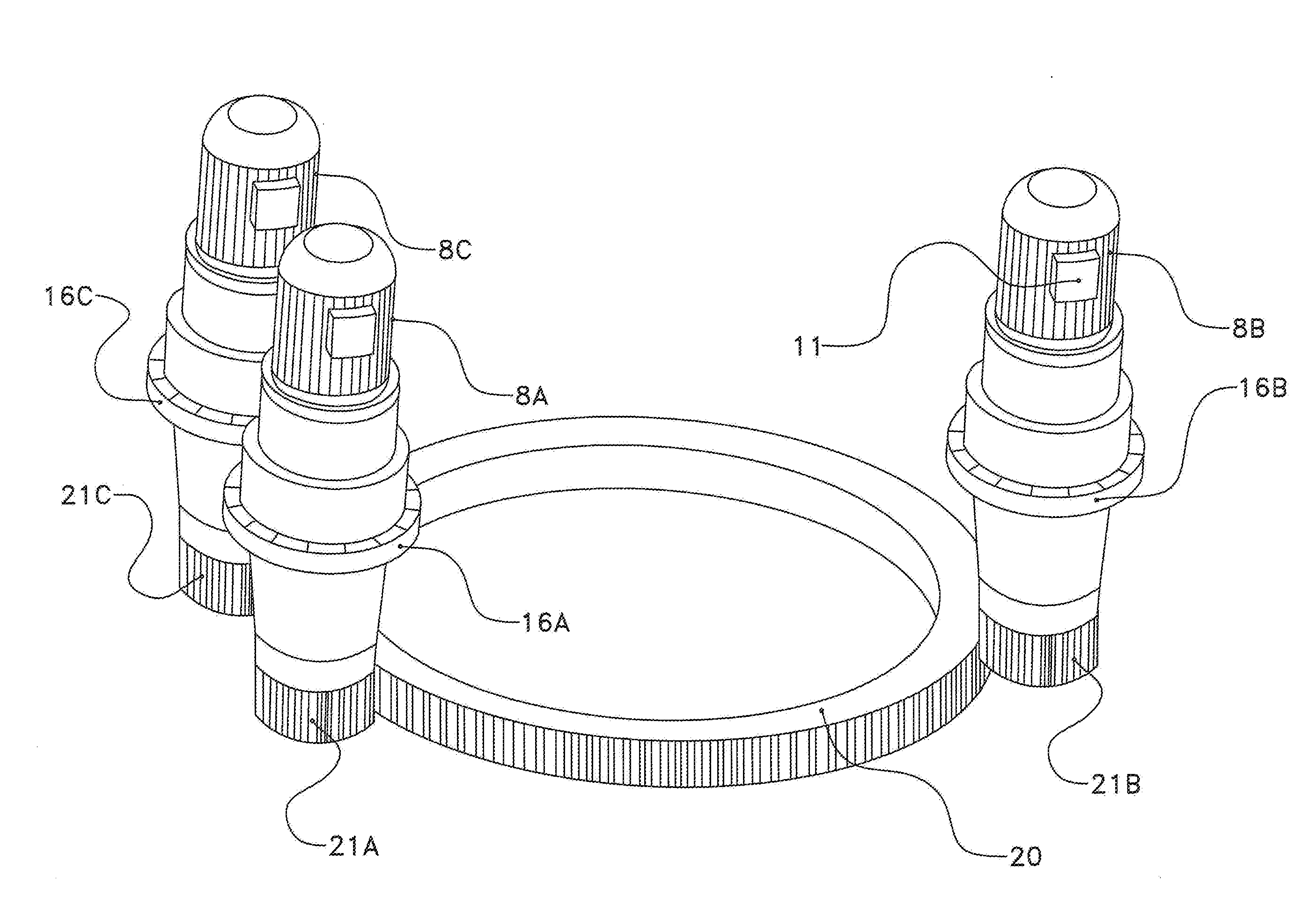

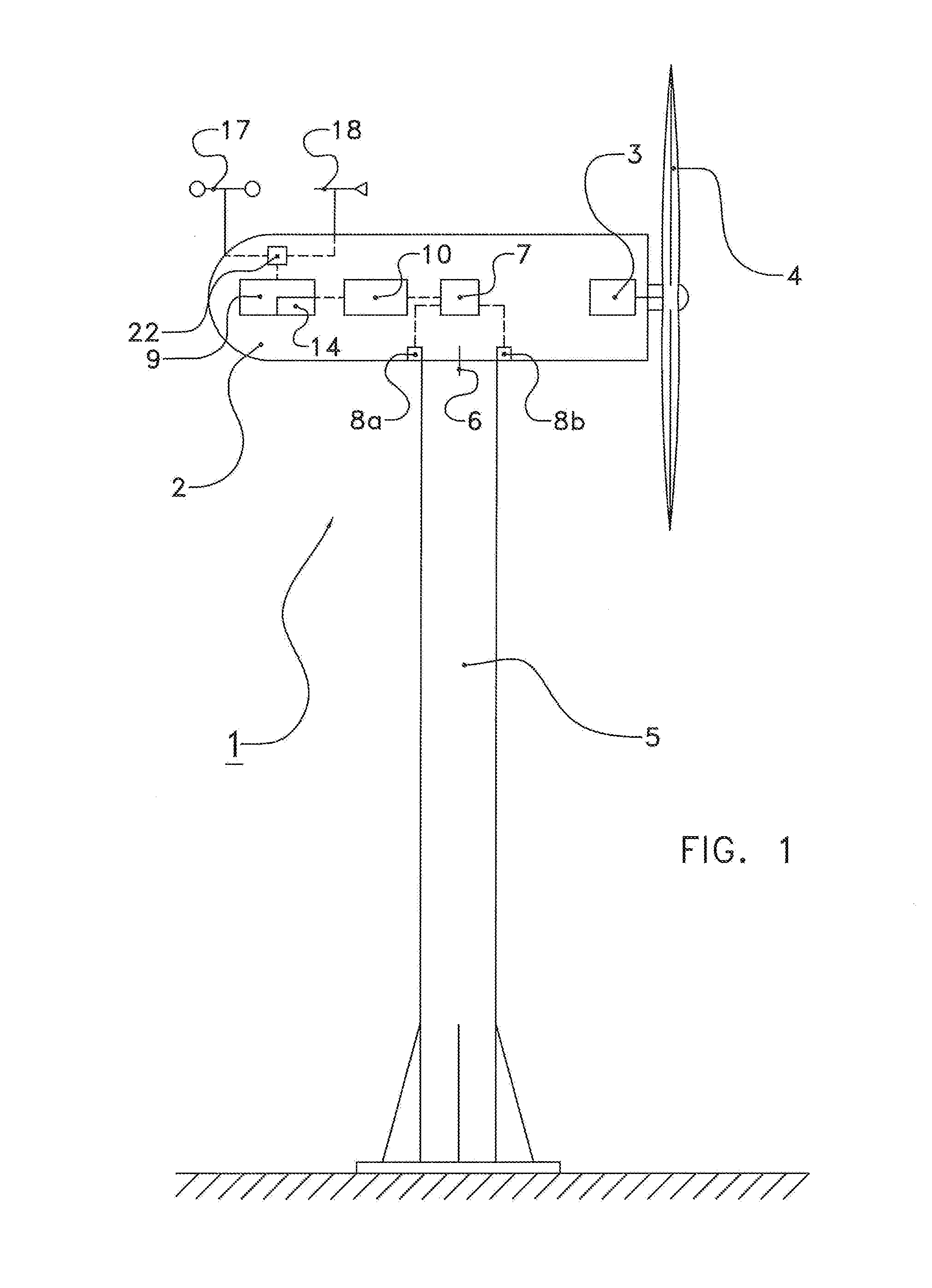

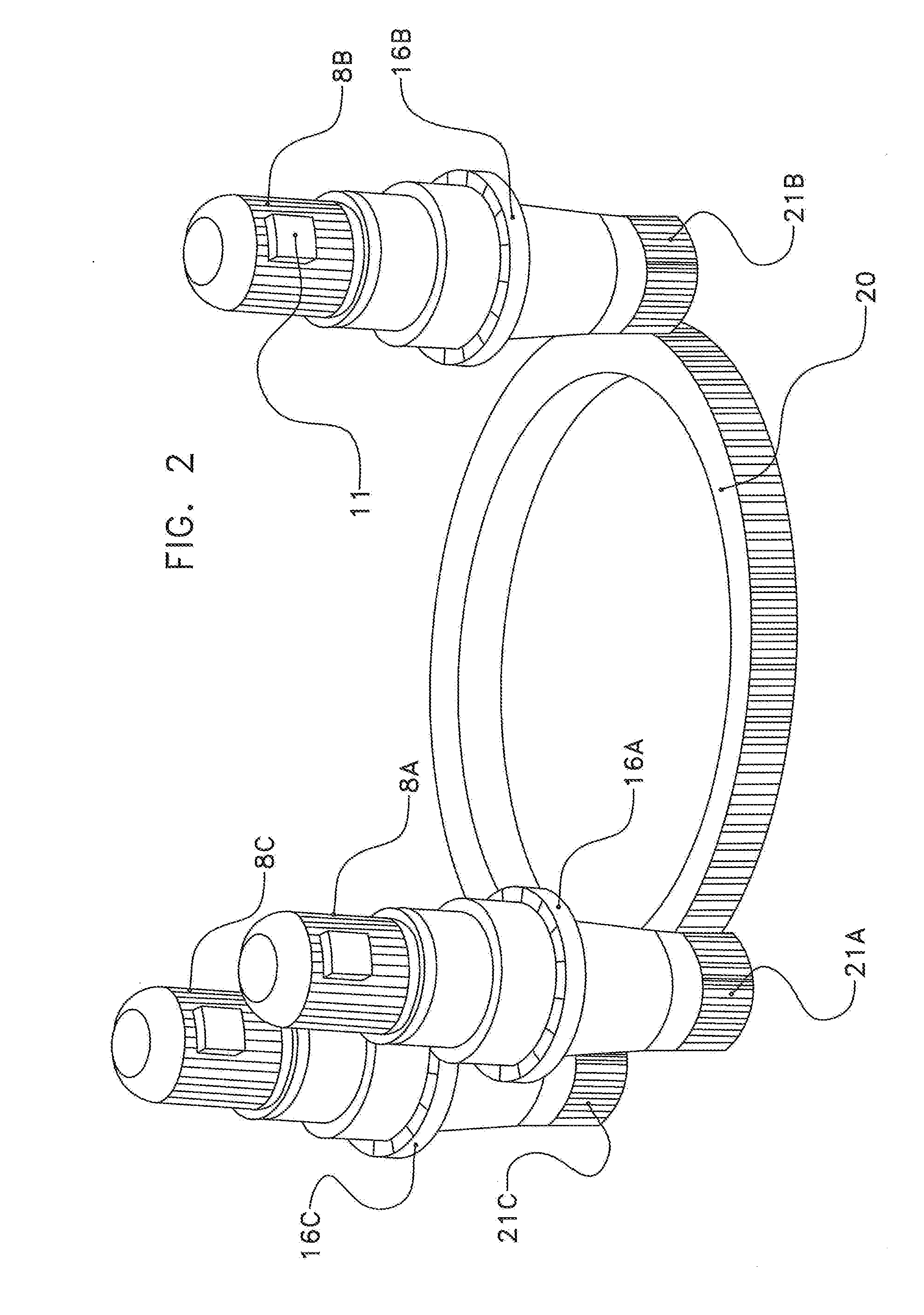

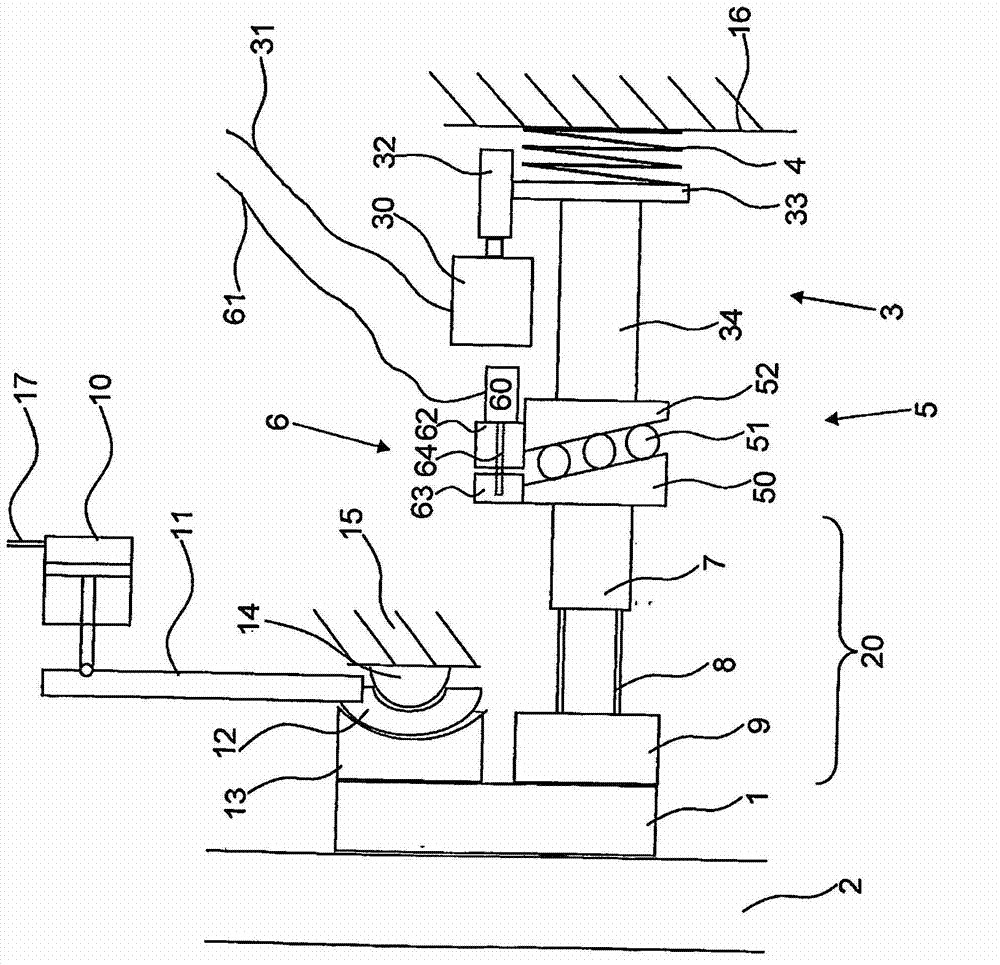

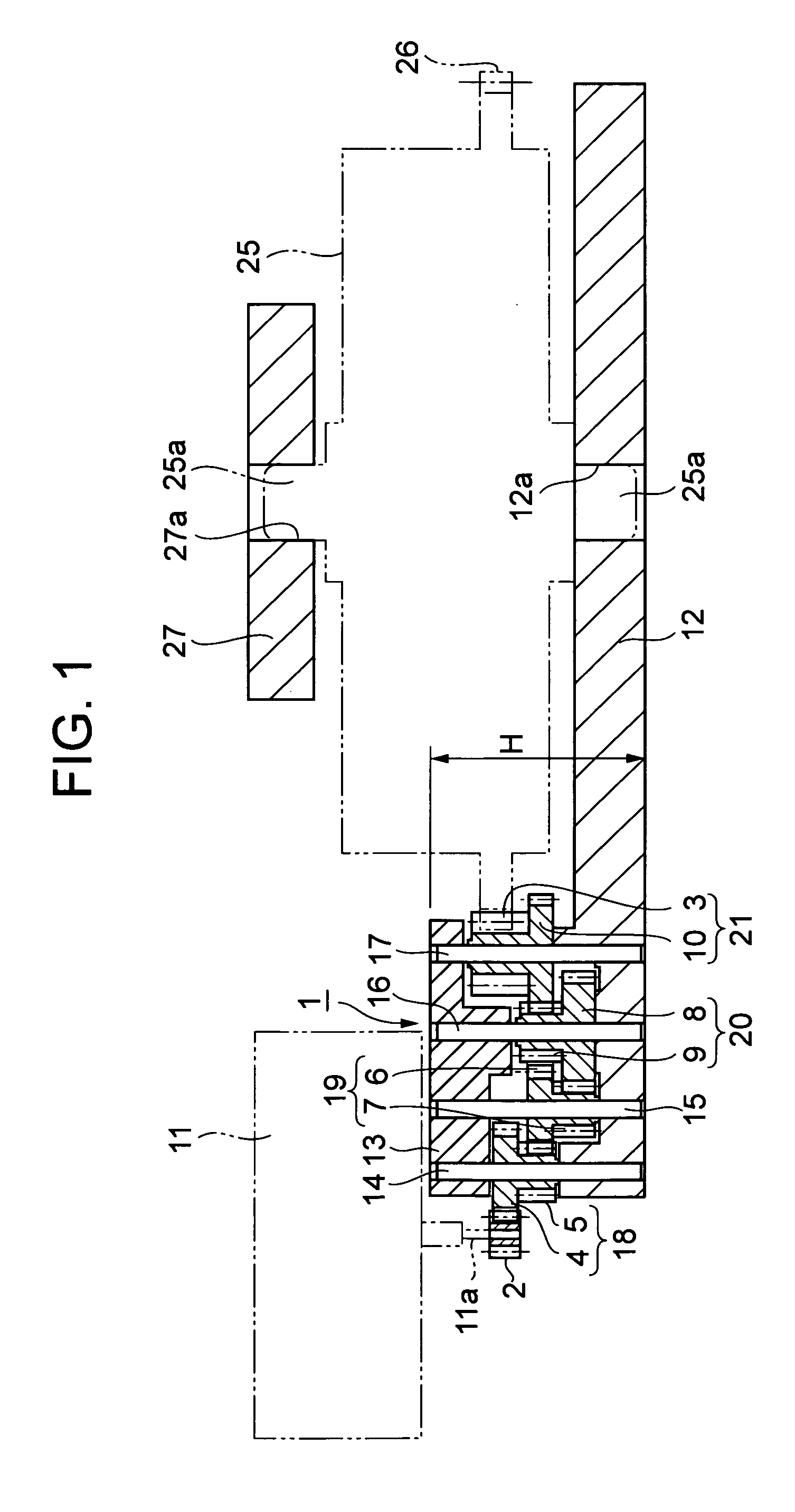

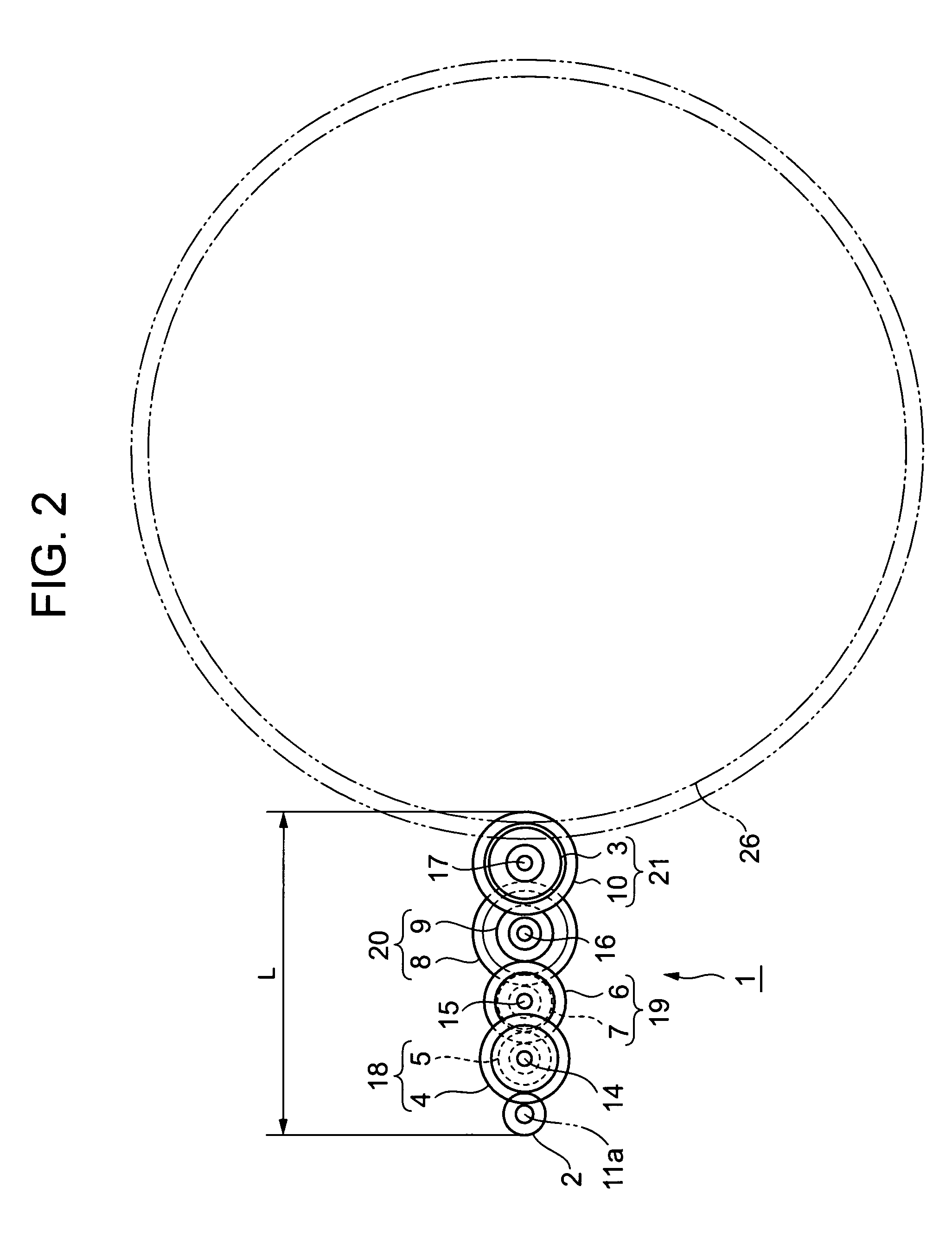

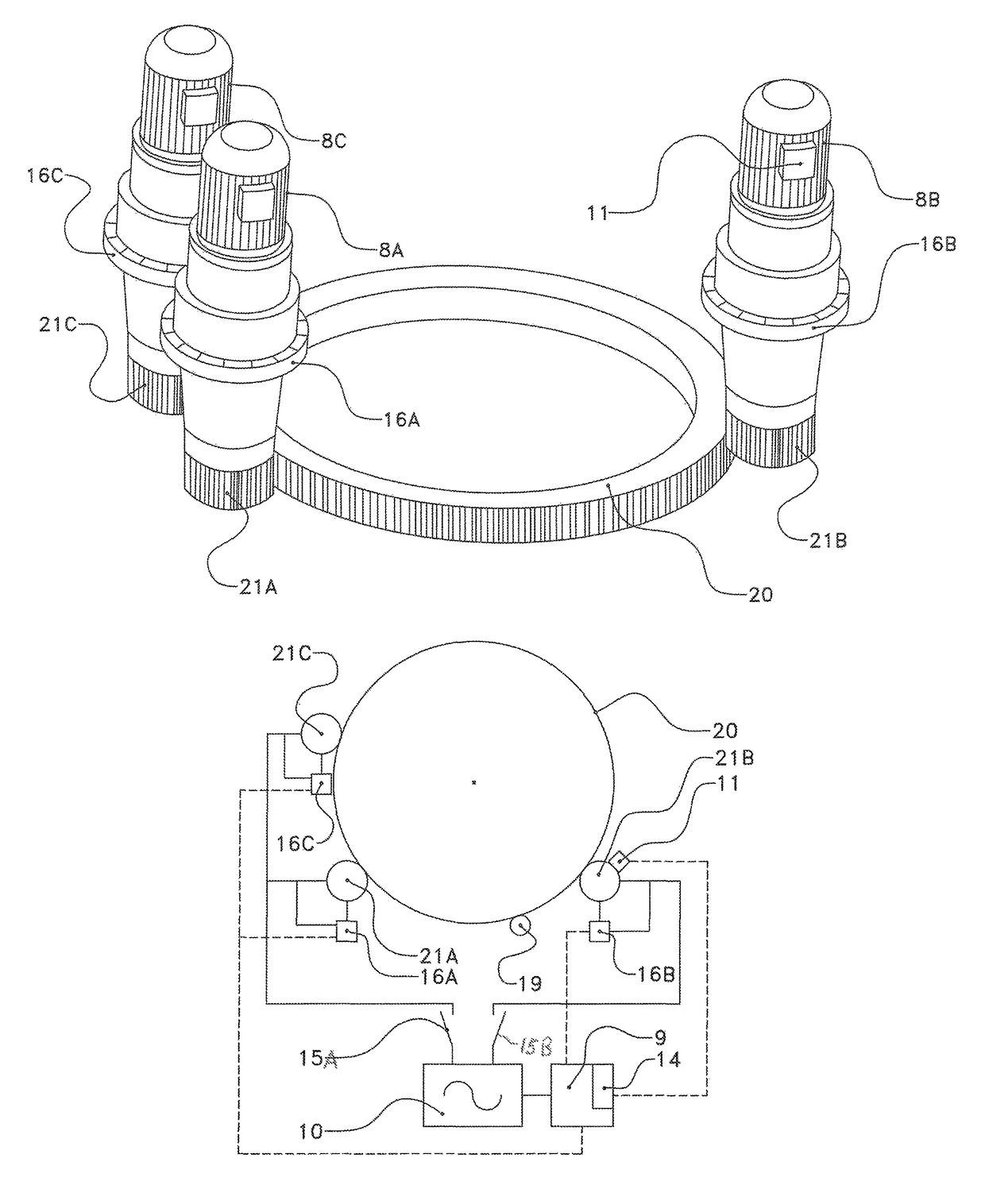

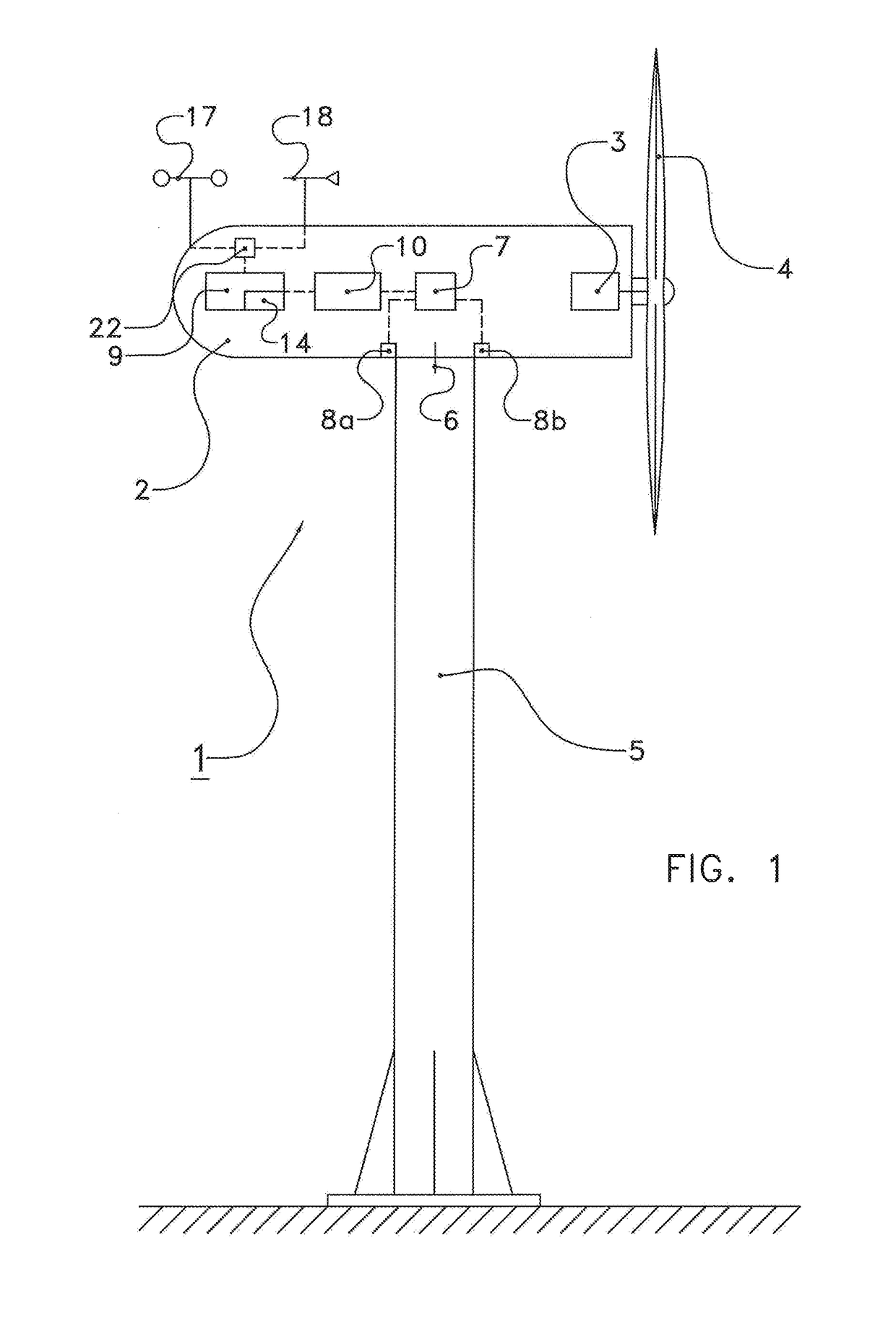

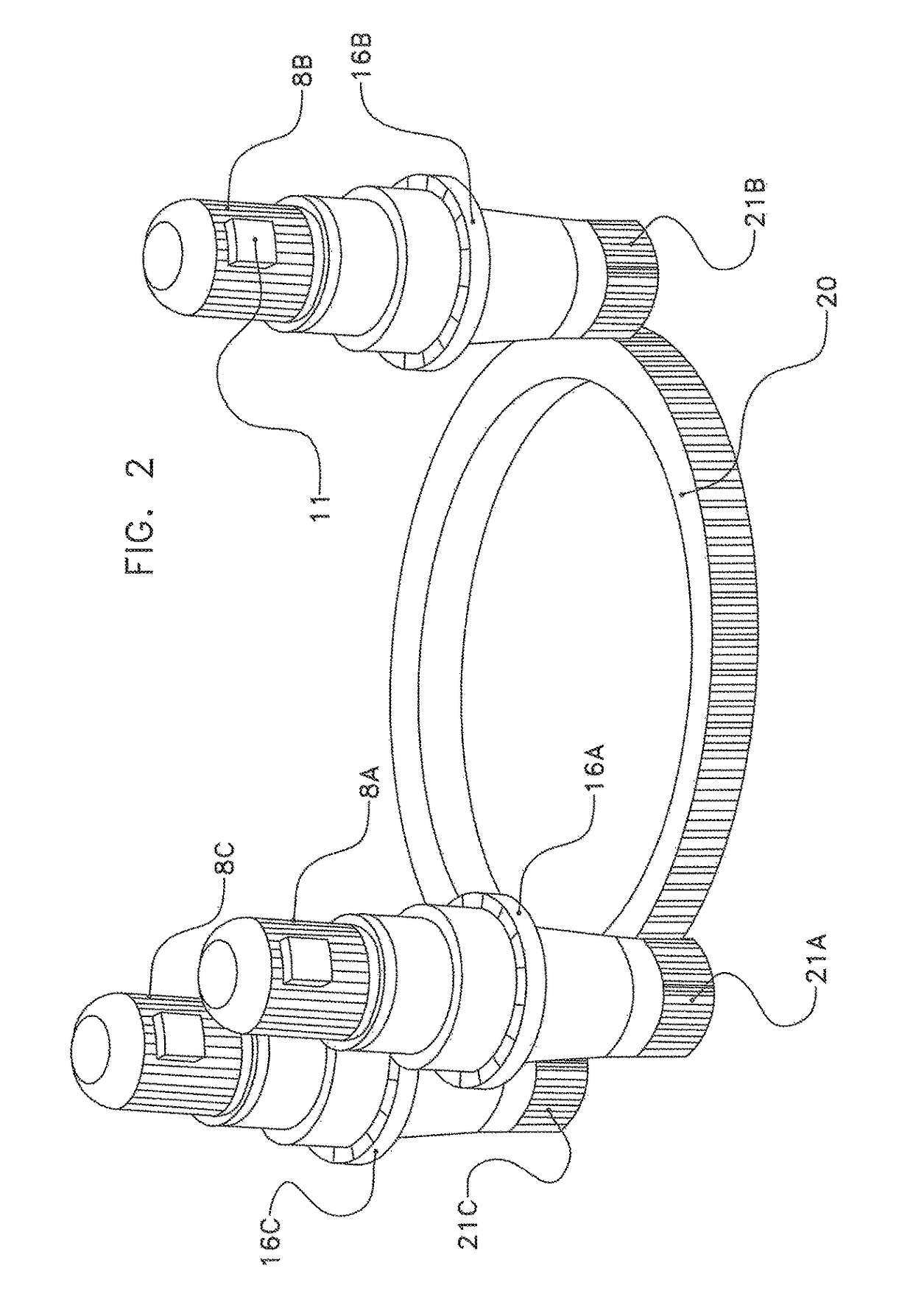

Wind turbine and method of operating a wind turbine

InactiveUS20160131106A1Simple and robust azimuth driveEasy to disengagePropellersWind motor controlFrequency UnitNacelle

Wind turbine comprising a nacelle with a generator and wind turbine blades for driving the generator, a tower supporting the nacelle wherein the nacelle is rotatable about a vertical axis an azimuth drive for rotating the nacelle around the axis, said azimuth drive comprising a plurality of asynchronous yaw motors and an azimuth controller with a frequency unit for controlling the plurality of asynchronous yaw motors, wherein the azimuth controller is arranged to connect all of the plurality of asynchronous yaw motors to the one frequency unit in a rotating mode and to connect only a subset of the plurality of asynchronous yaw motors from the one frequency unit in a locking mode.

Owner:BESTWATT BV

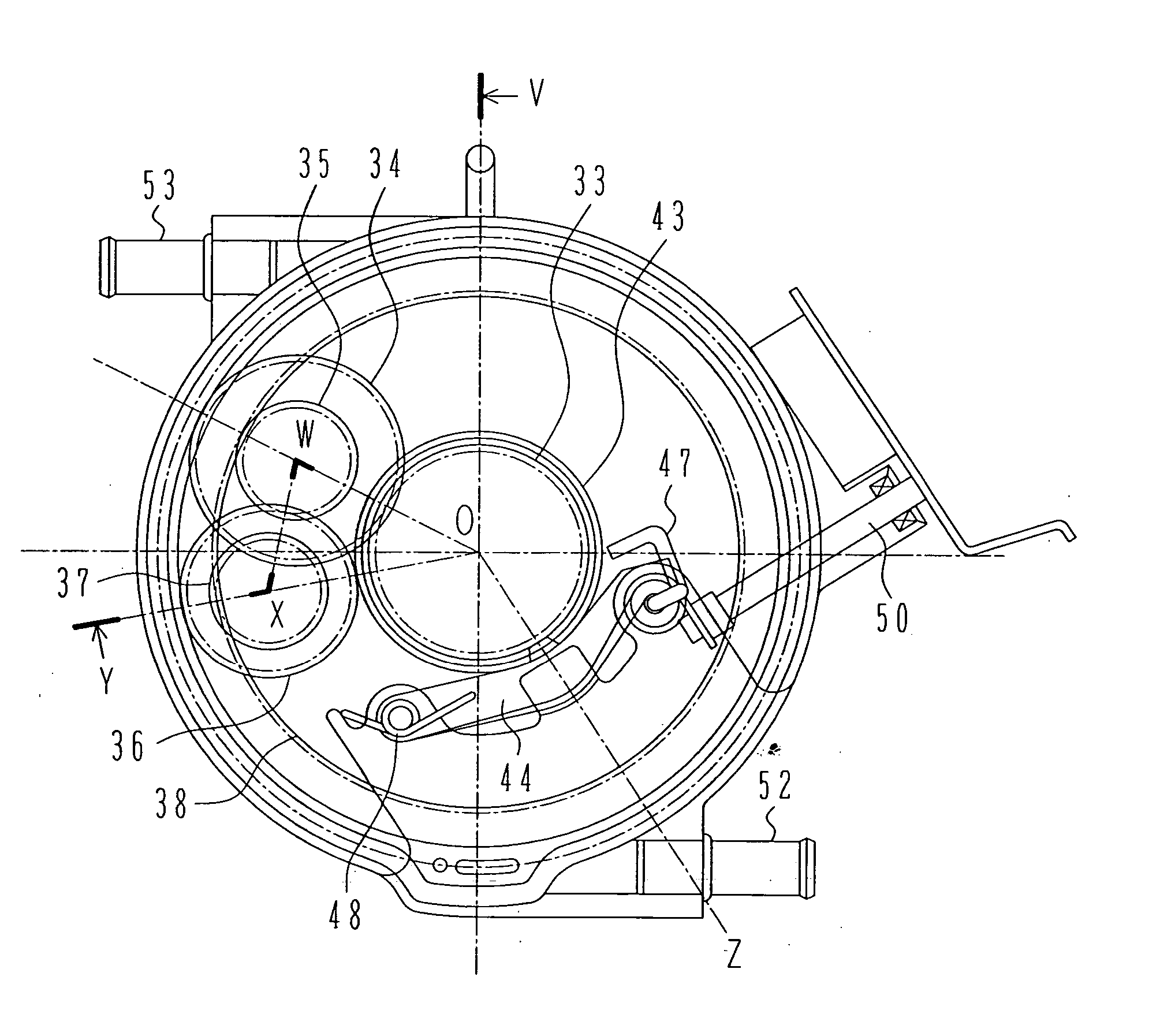

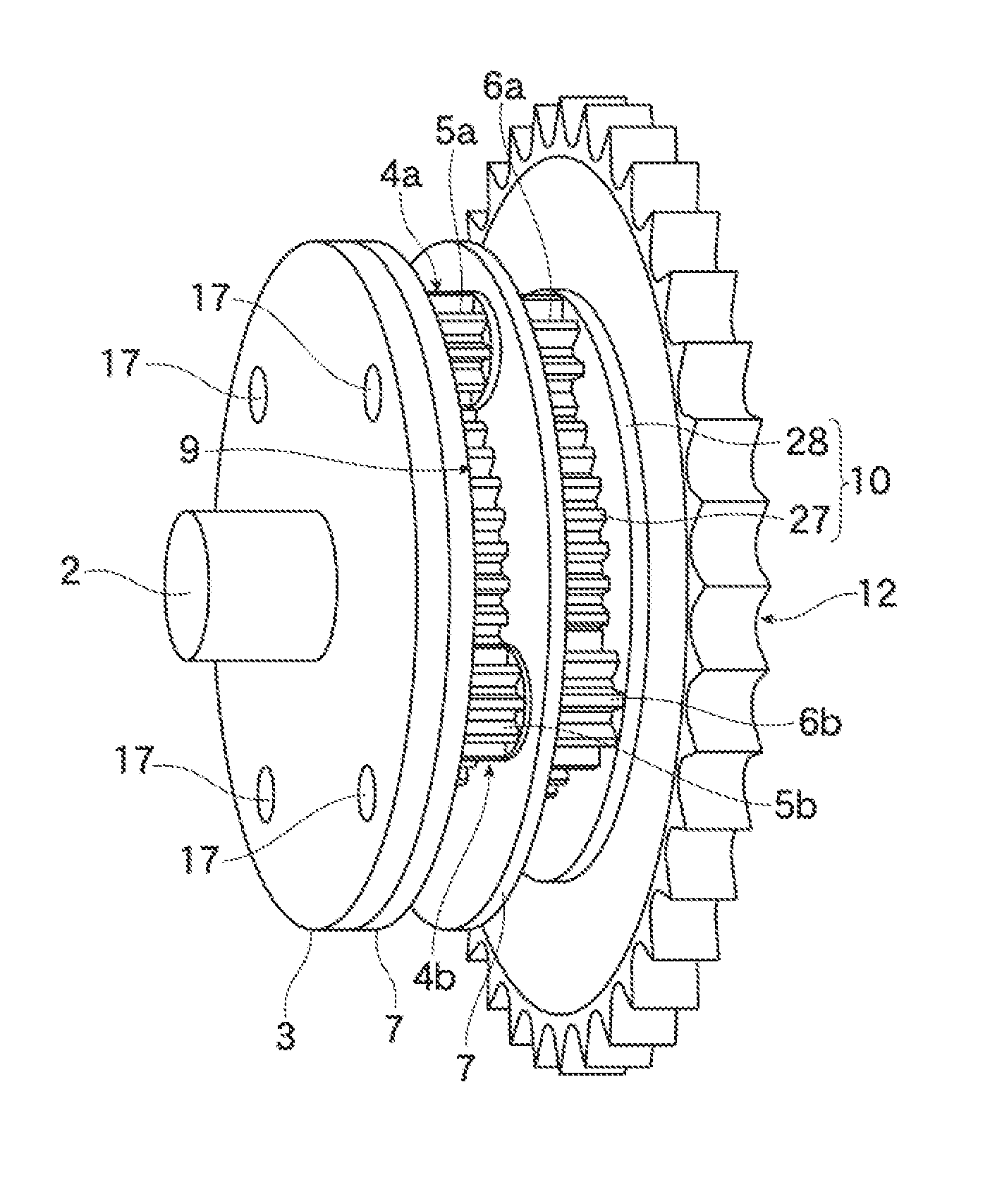

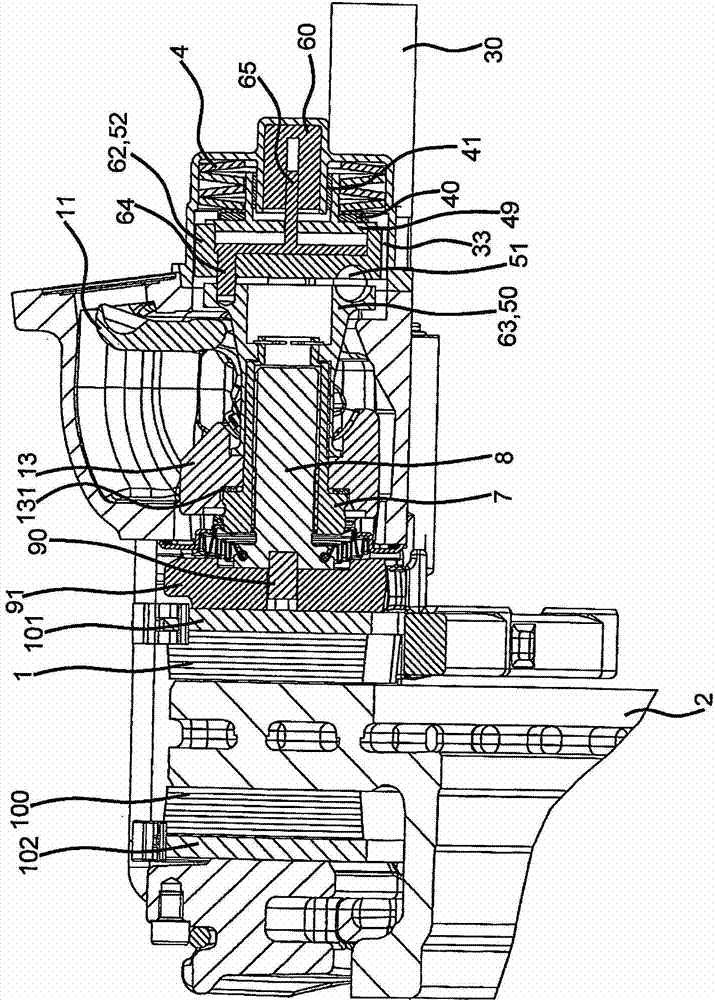

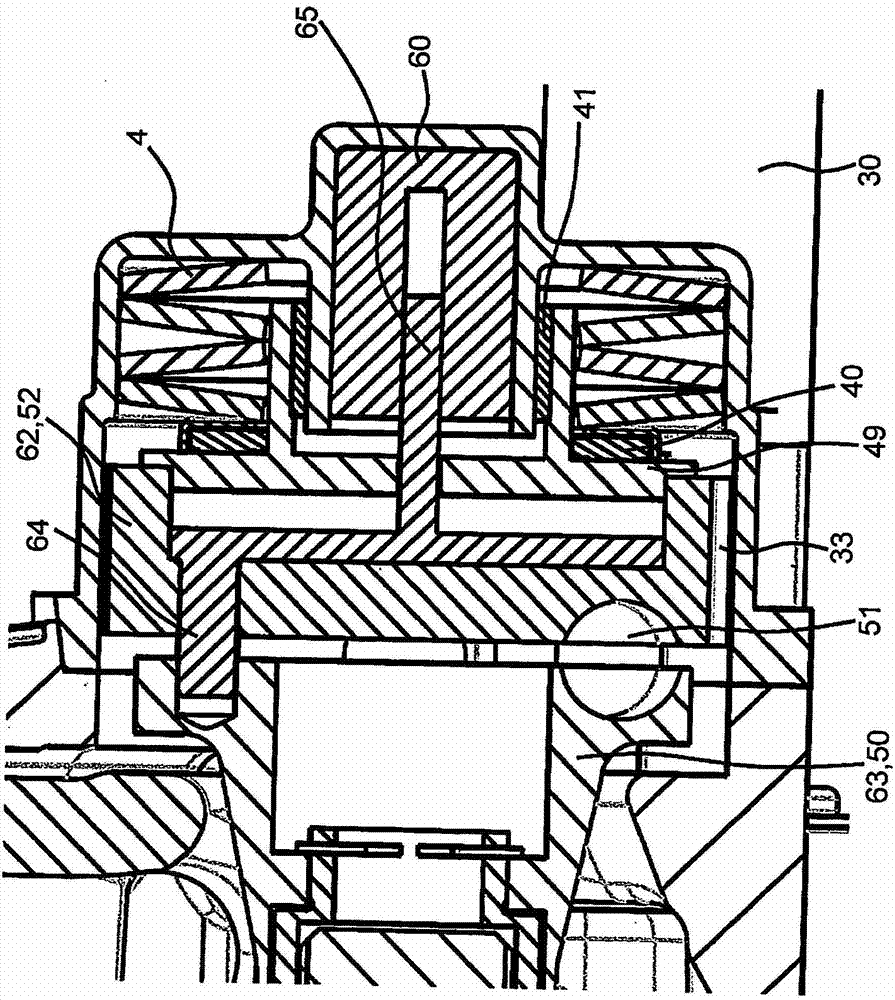

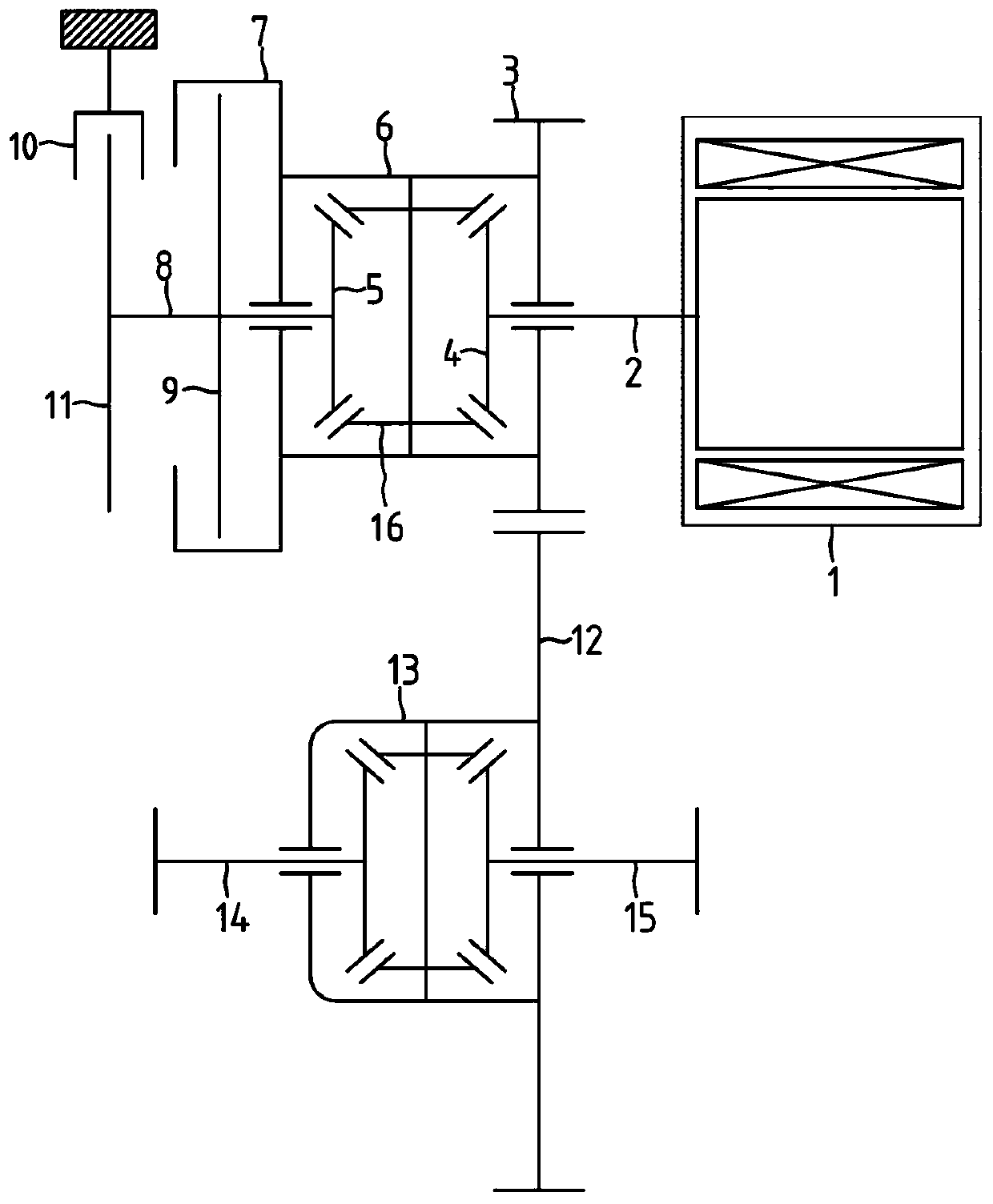

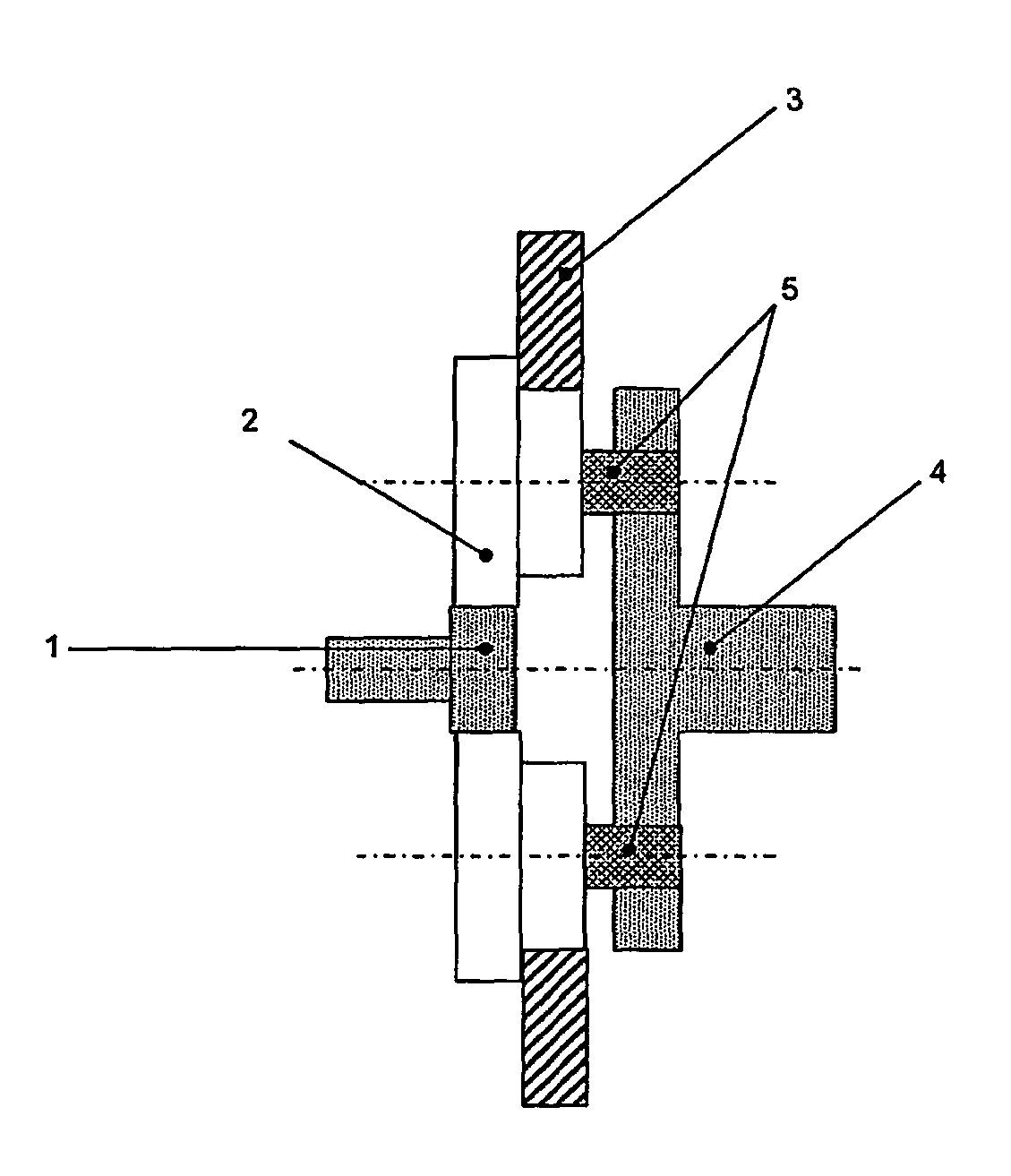

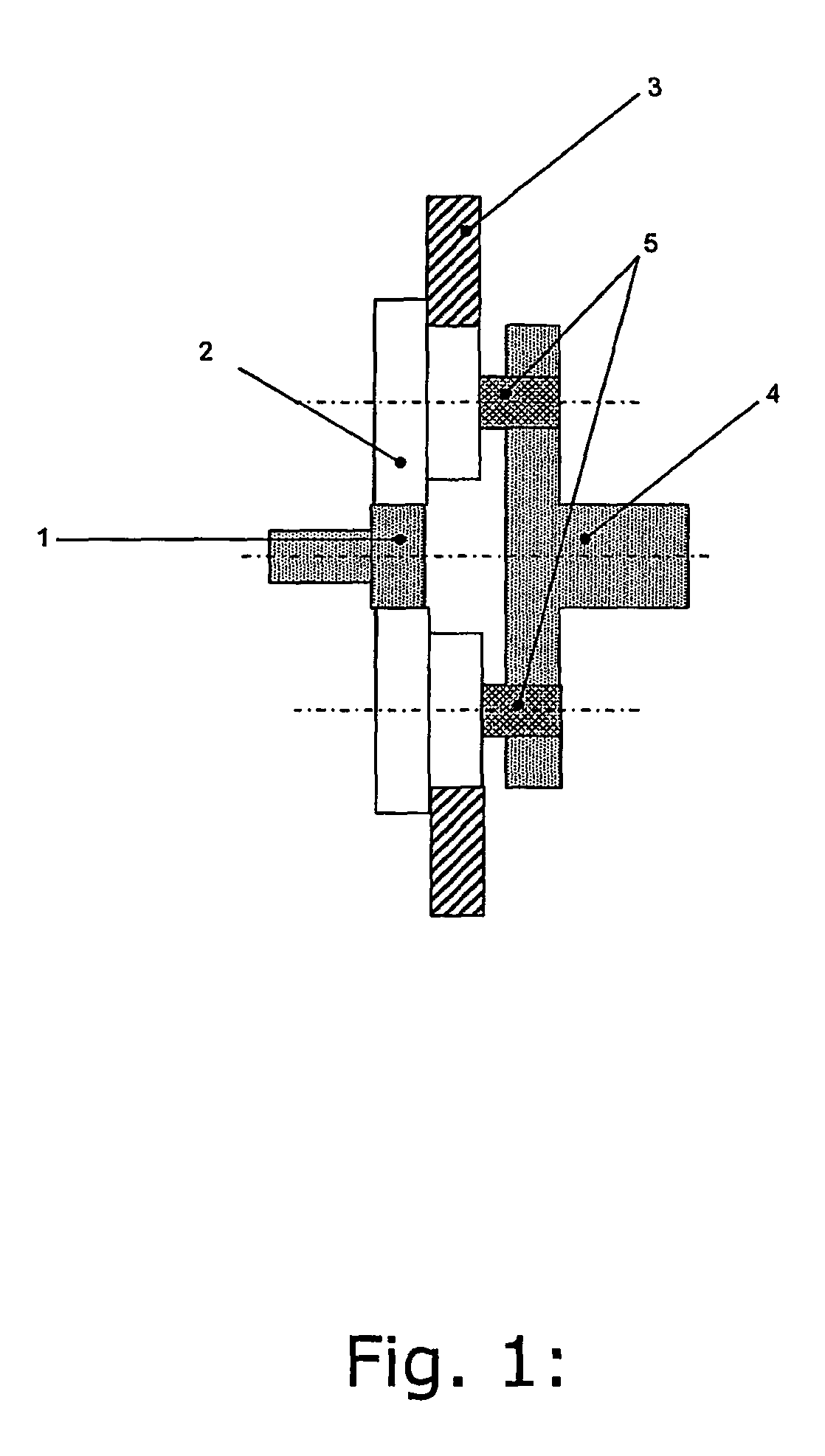

Transmission

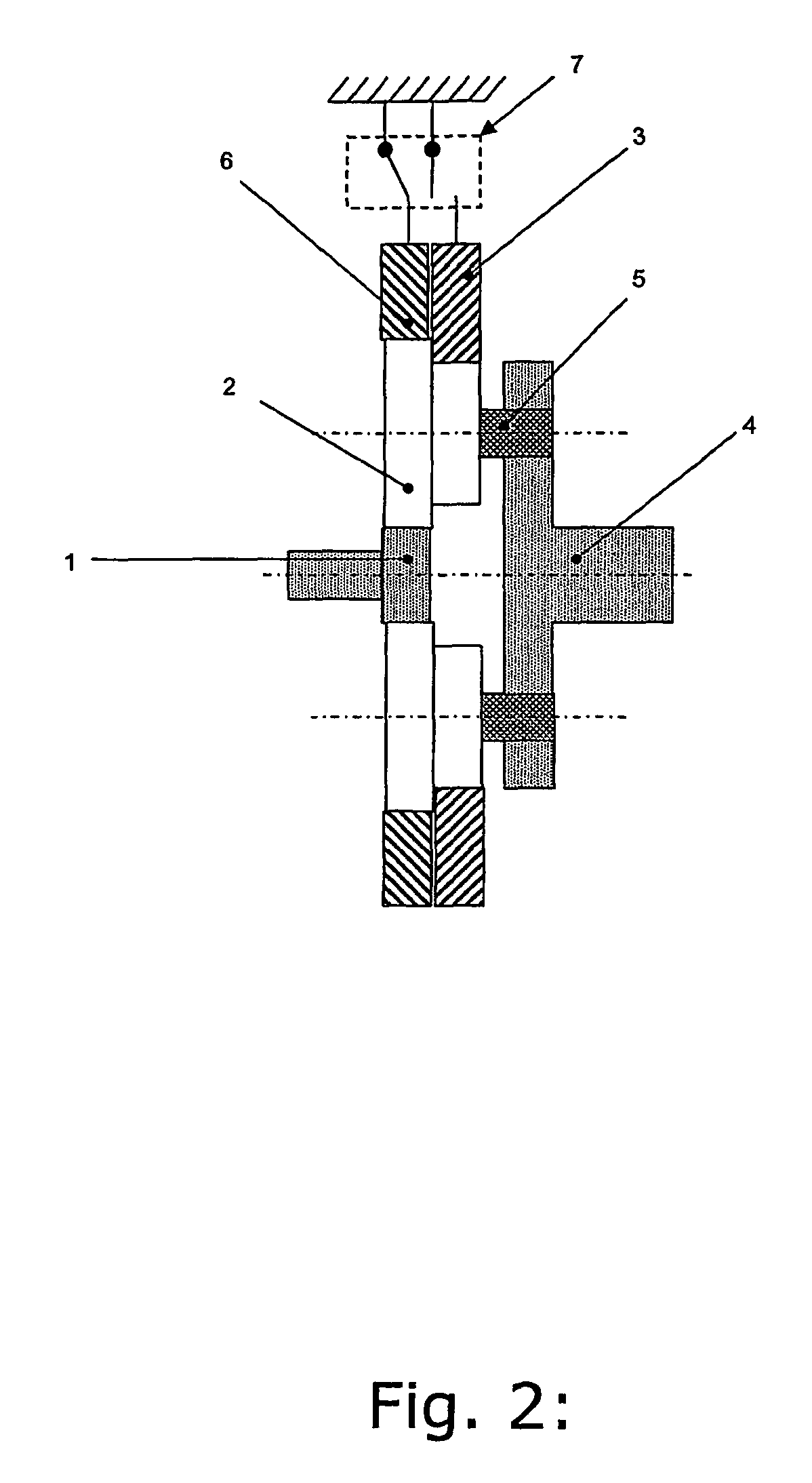

InactiveUS20100227732A1Large gear ratioCompact gearToothed gearingsTransmission elementsGear wheelEngineering

The invention provides a transmission providing a gear ratio between an input shaft and an output shaft. The transmission comprises an annulus ring, a sun wheel being rotatable around a central axis of the transmission, a planet carrier being rotatable around the central axis of the transmission, and a set of planet wheels, each wheel comprising a plurality of wheel segments with different diameters, the planet wheels being fixed in rotational bearings of the planet carrier and being arranged to rotate epicyclically around the central axis. The annulus ring and the sun wheel each interacts with one of the wheel segments e.g. via meshing toothed gear wheels. The gear facilitates various interaction means at different locations in the gear, and thus facilitates a potentially less noisy, lighter, smaller or stronger gear by use of a low amount of components.

Owner:TOMACTECH

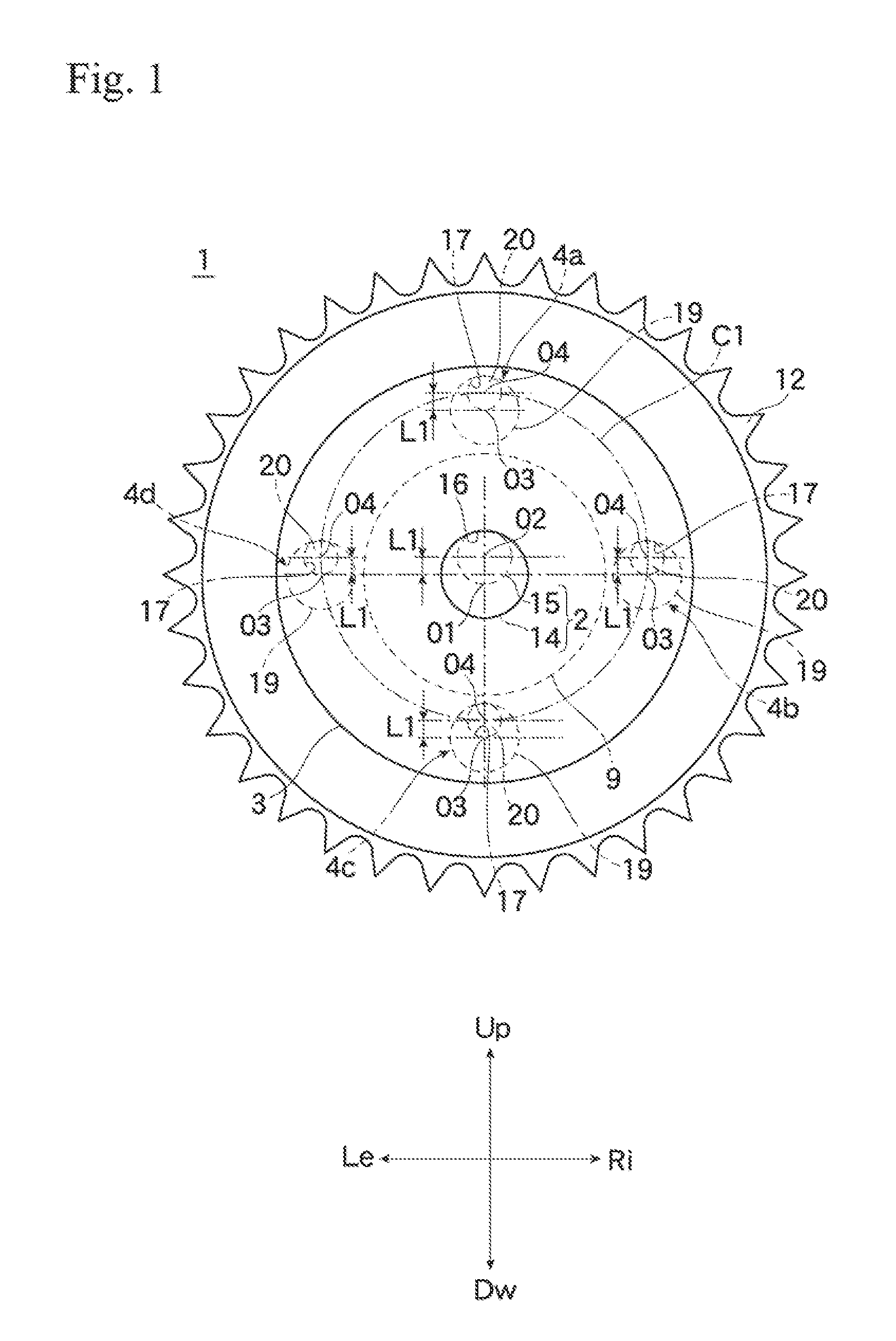

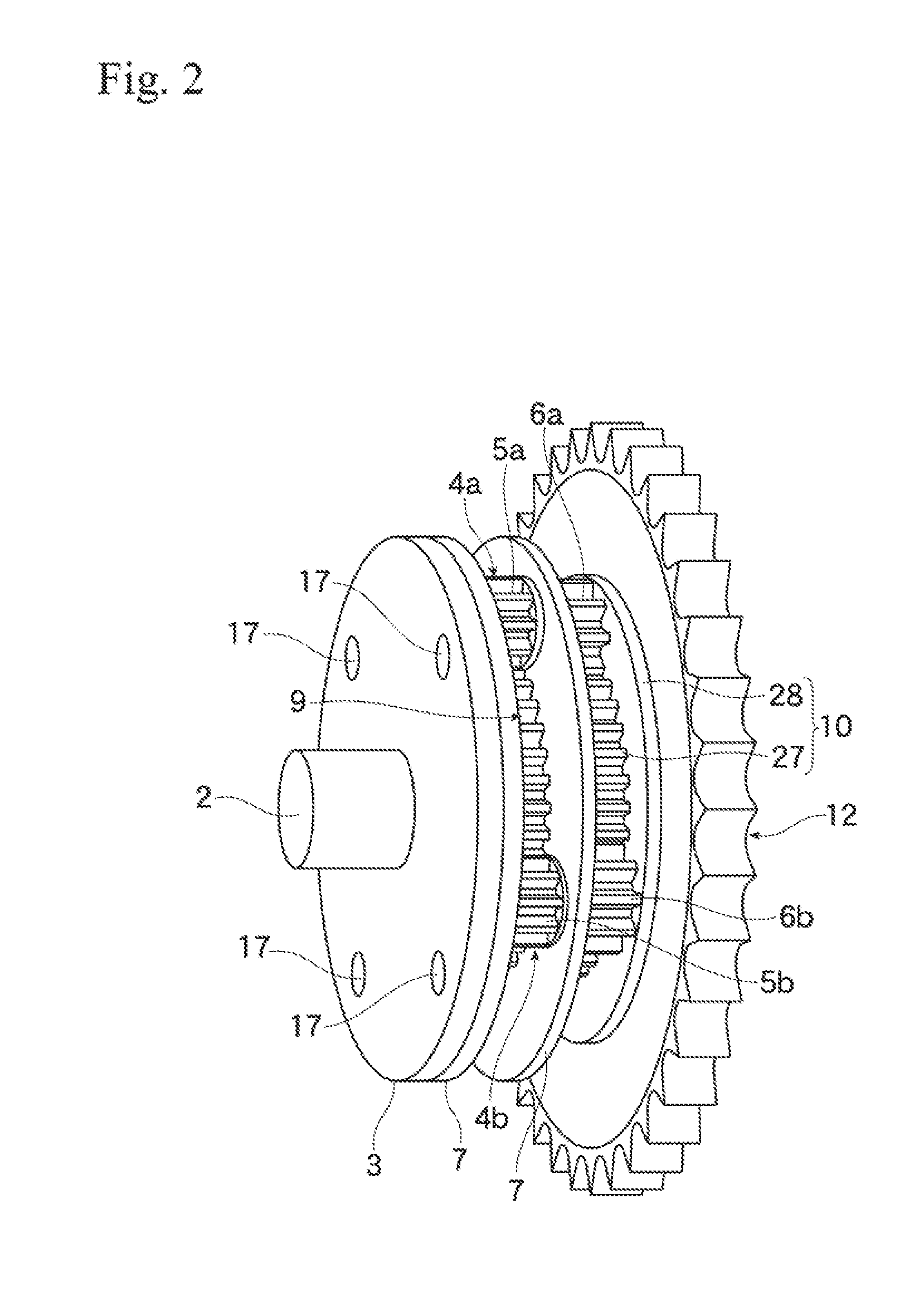

Planetary gear reduction mechanism

InactiveUS20140031165A1Reduce outer diameterReduce gear ratioToothed gearingsGearing detailsOut of phaseRotational axis

A compact planetary gear reduction mechanism having a universal gear reduction ratio is provided, which comprises: an input shaft rotatable about a first rotational axis; at least one planetary gear having a first and a second gear of the same shape integrated together rotatably about a third rotational axis (O3) but in out of phase with each other; an eccentric rotary plate for transmitting the rotational motion of the input shaft to a shaft mechanism which in turn transmits the eccentric rotation of the eccentric rotary plate to the planetary gear; an external fixed sun gear meshed with the first gear of the planetary gear; and an external driven sun gear to be connected to the output shaft of the gear reducer, having a different number of gear teeth than the fixed situ gear and meshed with the second gear of the planetary gear.

Owner:NITTAN VALVE CO LTD

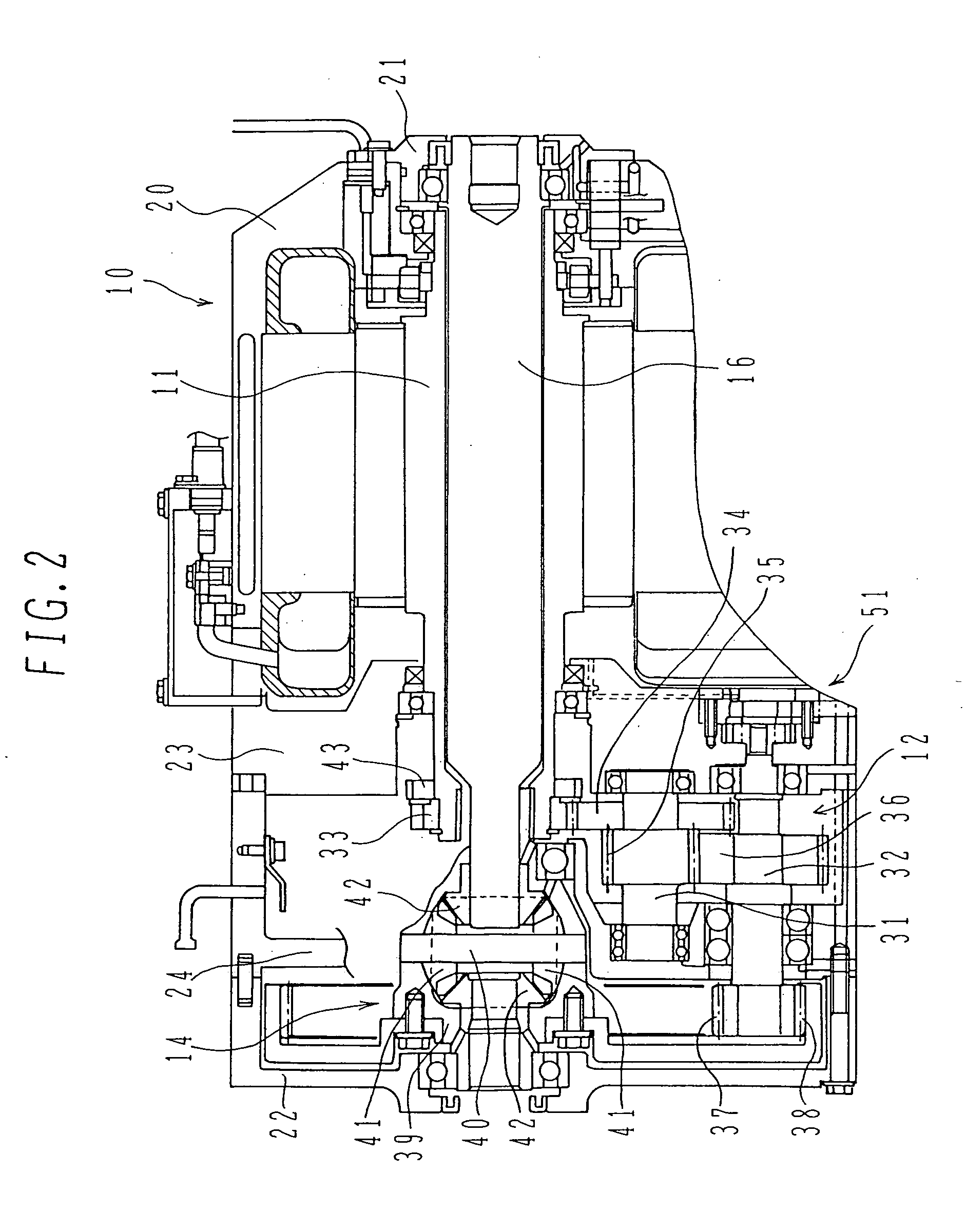

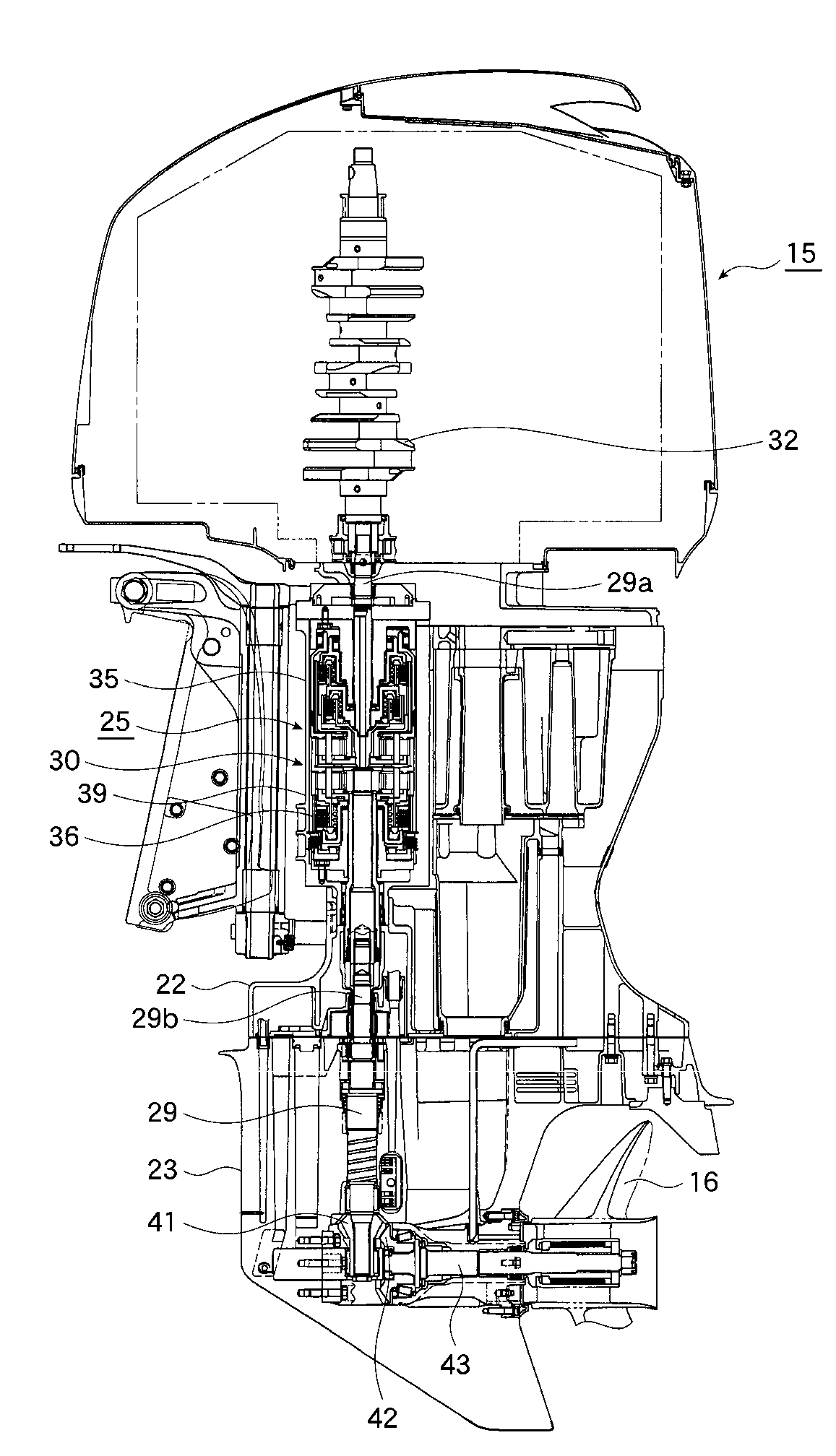

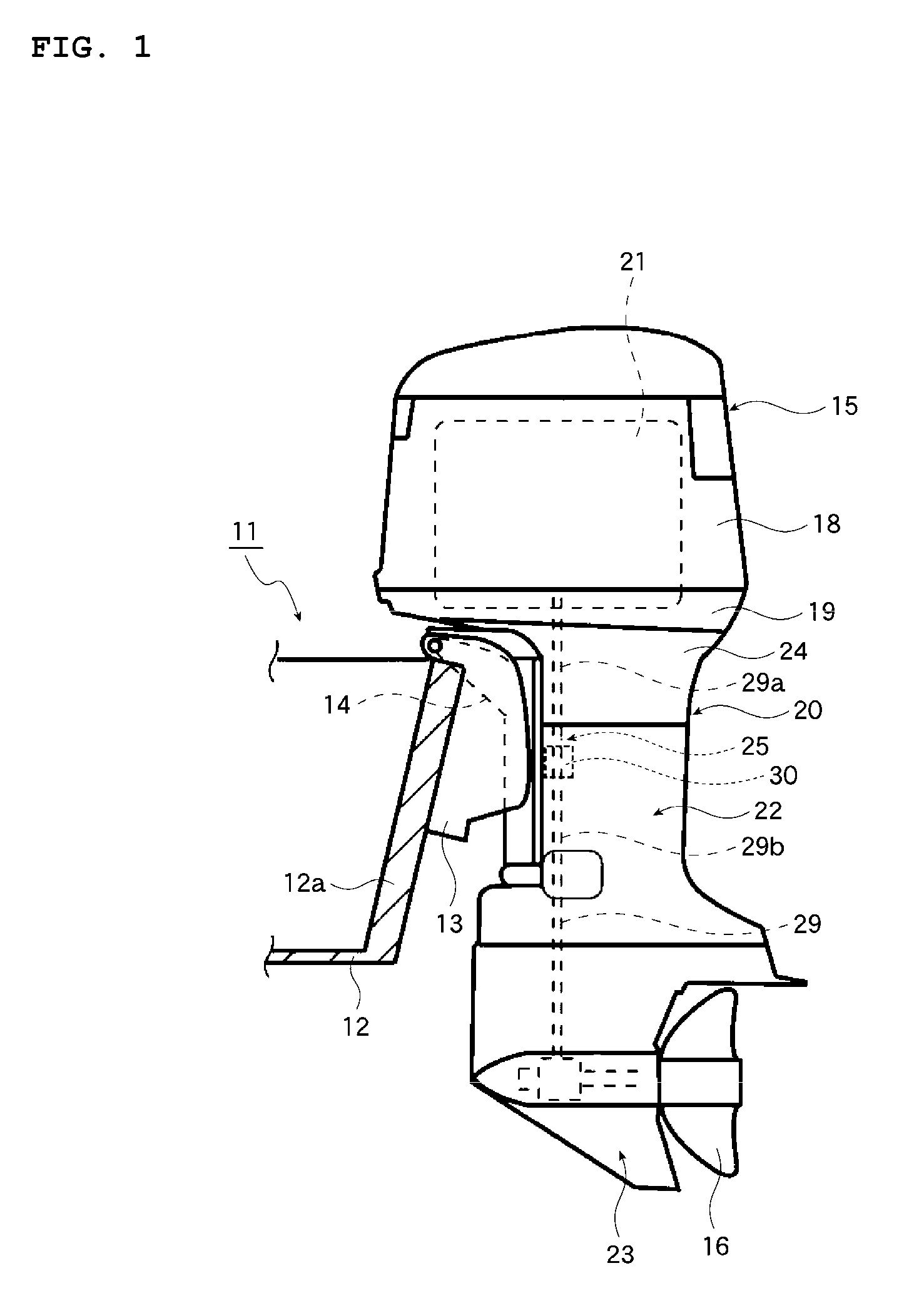

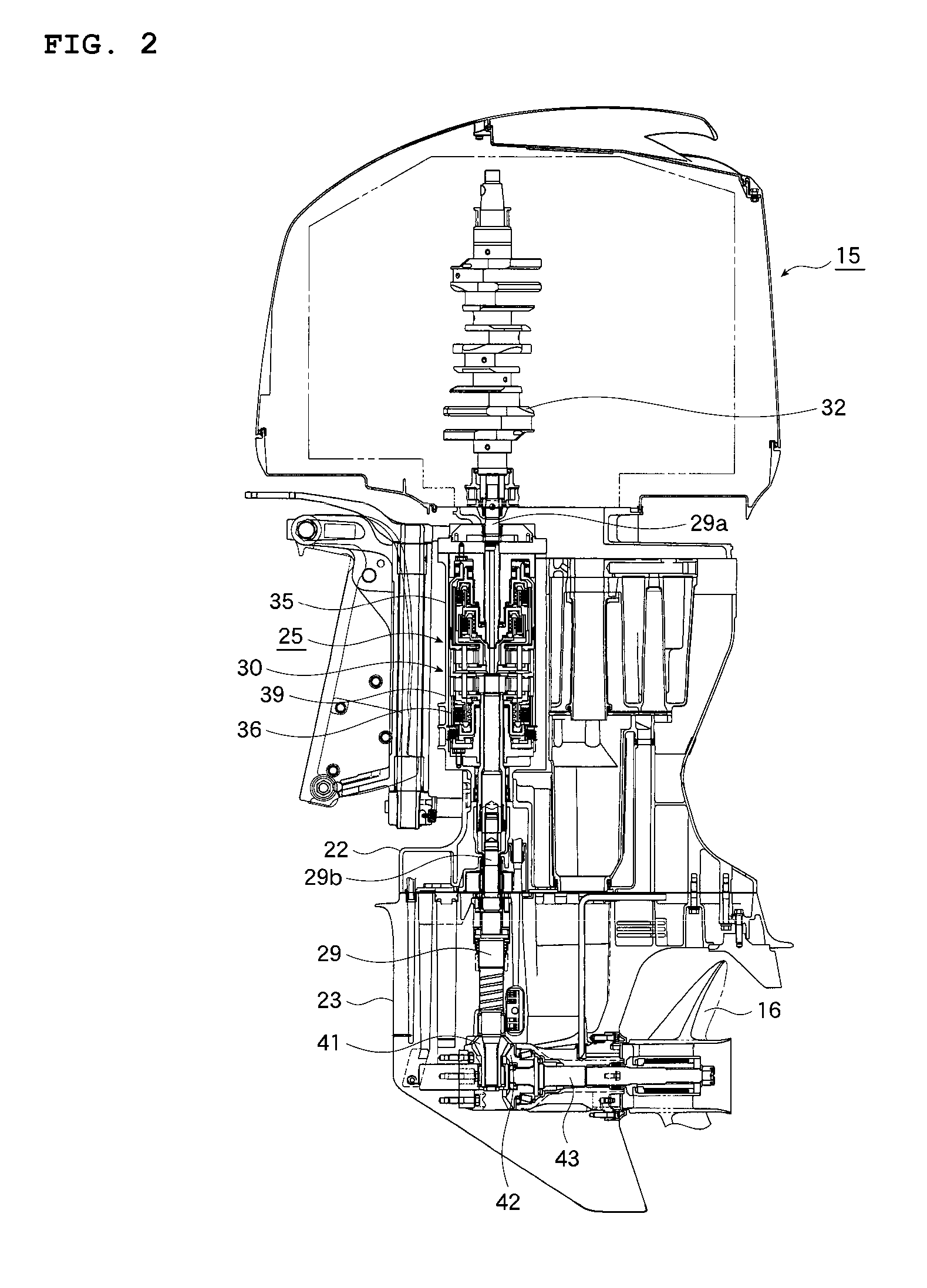

Outboard motor

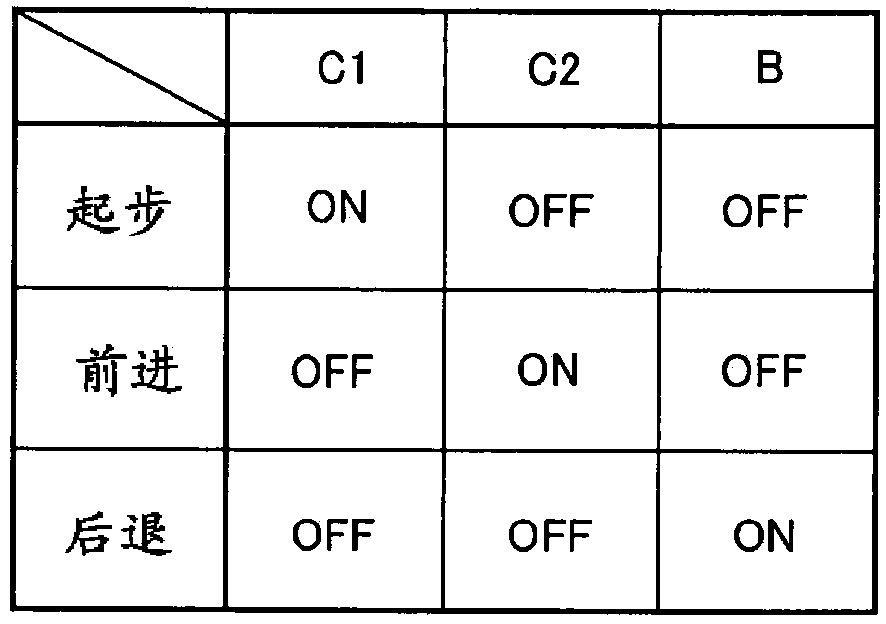

ActiveUS20080227585A1Large reduction ratioSimple structurePropulsion power plantsMuscle operated startersPropellerGear train

A power transmission mechanism transferring a power output from an engine to a propeller includes a transmission planetary gear train that transforms the output power of the engine before it is transferred to the propeller. The transmission planetary gear train includes a transmission sun gear, a transmission double planetary gear set, and a transmission internal gear, in which the transmission sun gear is connected via the first clutch to the input end shaft extending into the engine, and the transmission sun gear is also connected via the second one-way clutch to the housing. In addition, the transmission double planetary gear set is connected via the second clutch to the input end shaft extending into the engine, and the transmission double planetary gear set is also connected via the first one-way clutch to the housing. Further, the transmission internal gear is connected to the output end shaft extending toward the propeller.

Owner:YAMAHA MOTOR CO LTD

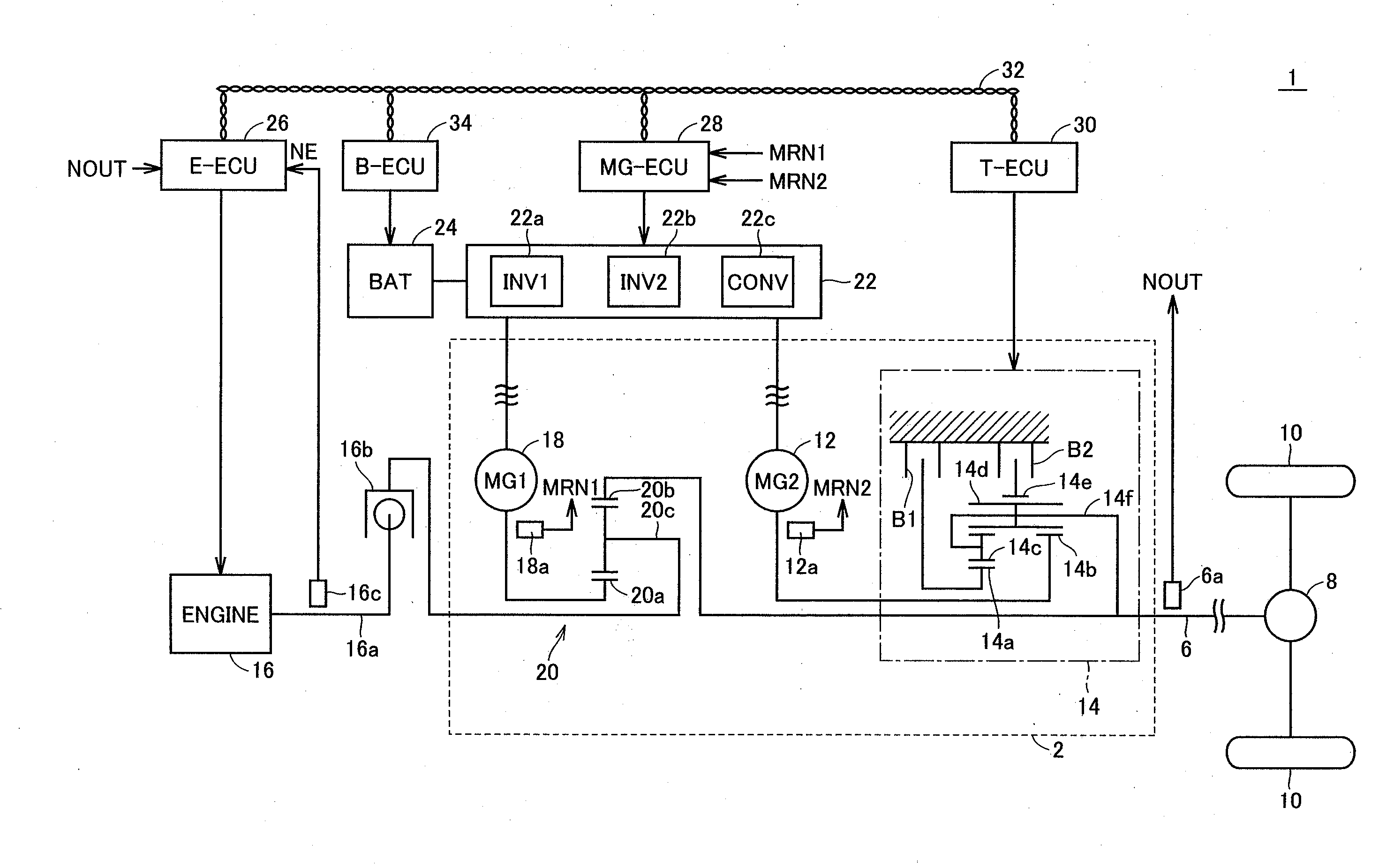

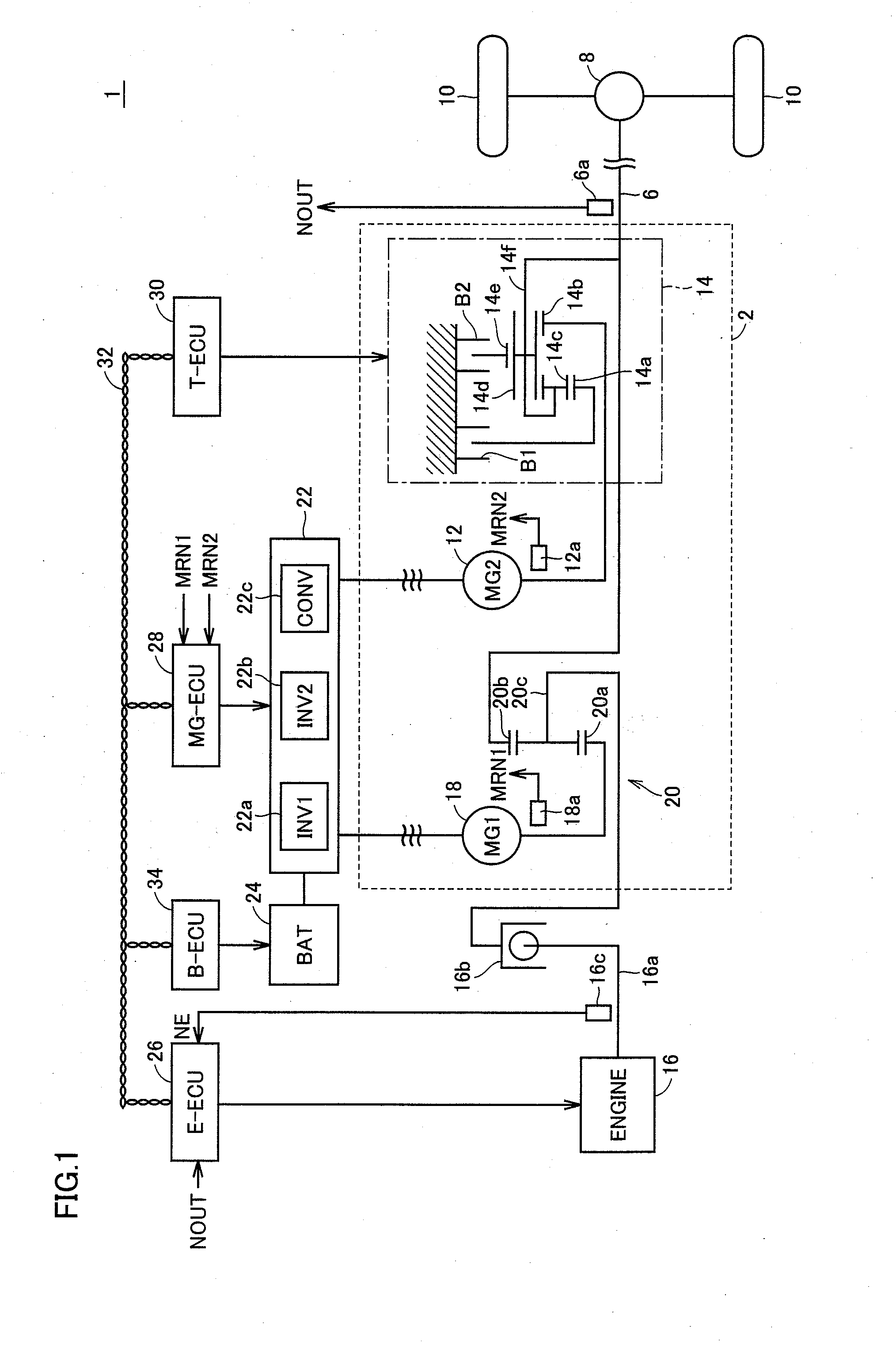

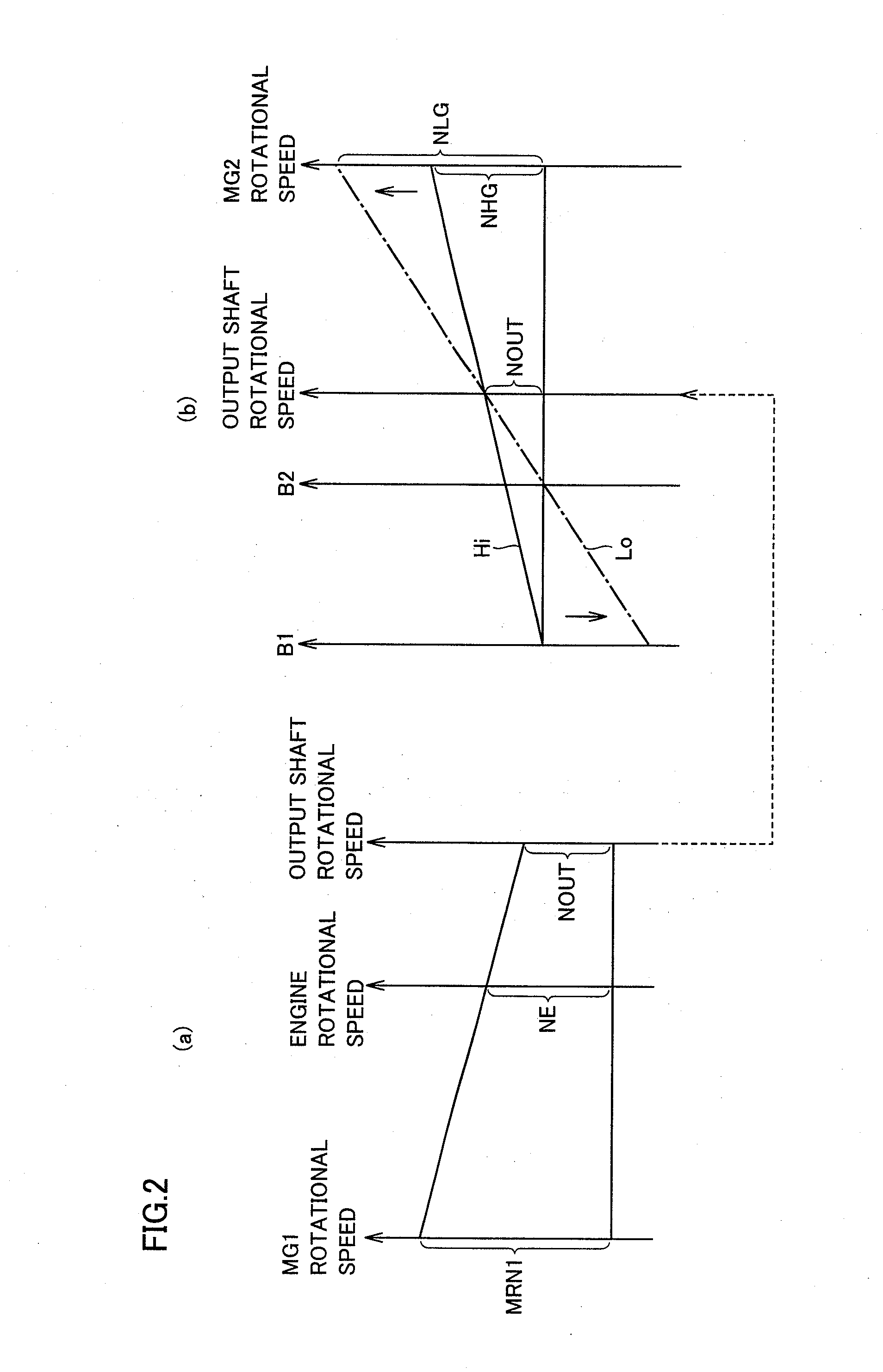

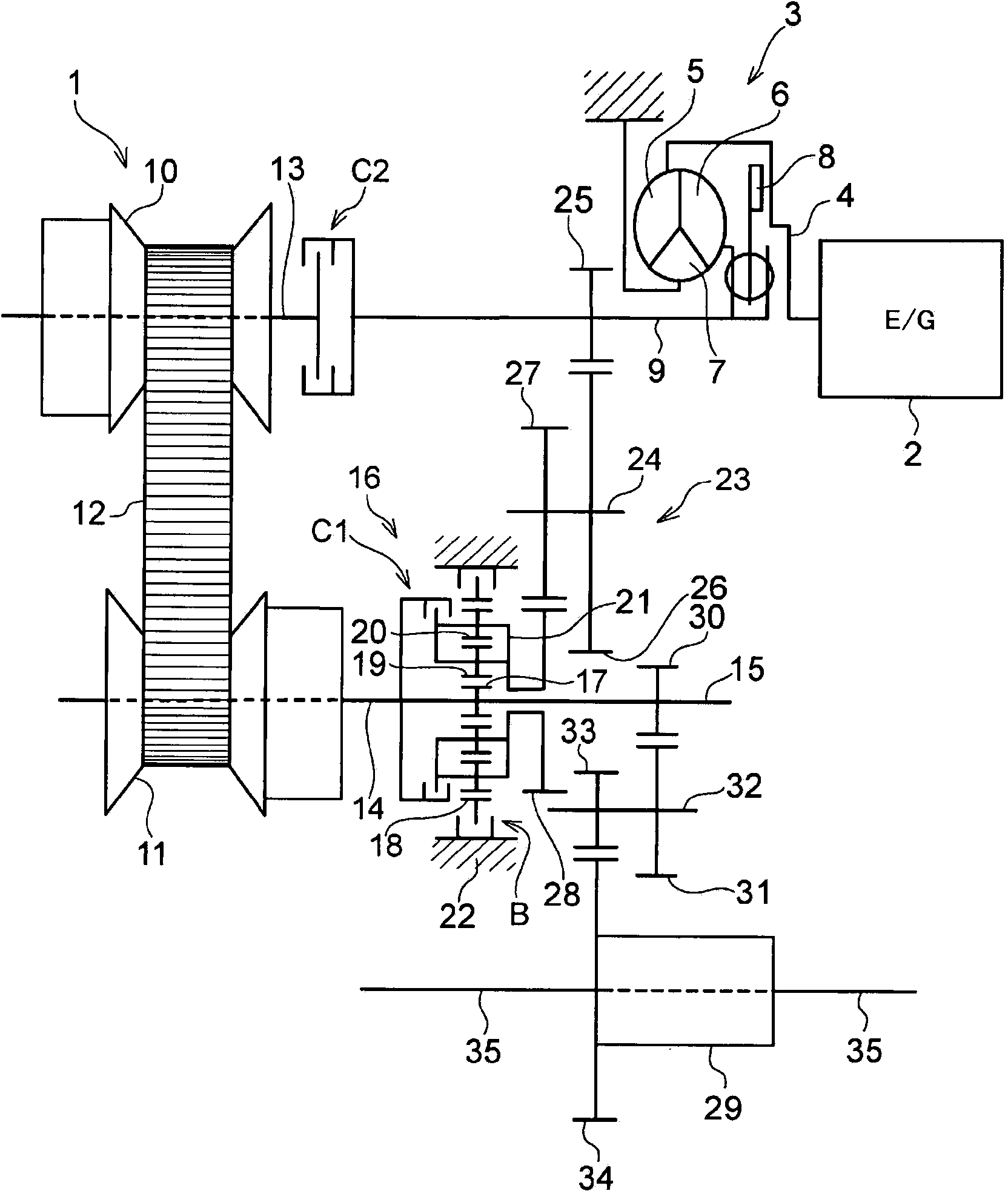

Hybrid driving apparatus, vehicle with the same and control method of the same

For raising an MG2 rotational speed MRN2 to a target rotational speed (low-gear rotational speed NLG), an output torque of an MG2 starts to increase at a time t4. During an inertia phase (period α), the output torque of the MG2 is limited not to exceed a first limit value TLIM1 determined according to a shift progress degree PRG and a second limit value TLIM2 determined according to a rotational speed margin NEmgn. Since the output torque of the MG2 is sufficiently small in a final stage of the inertia phase (period α), output variations occurring at a time t6 when torque down is performed on the MG2 can be small. The torque down of the MG1 and MG2 does not raise engine rotational speed NE.

Owner:TOYOTA JIDOSHA KK

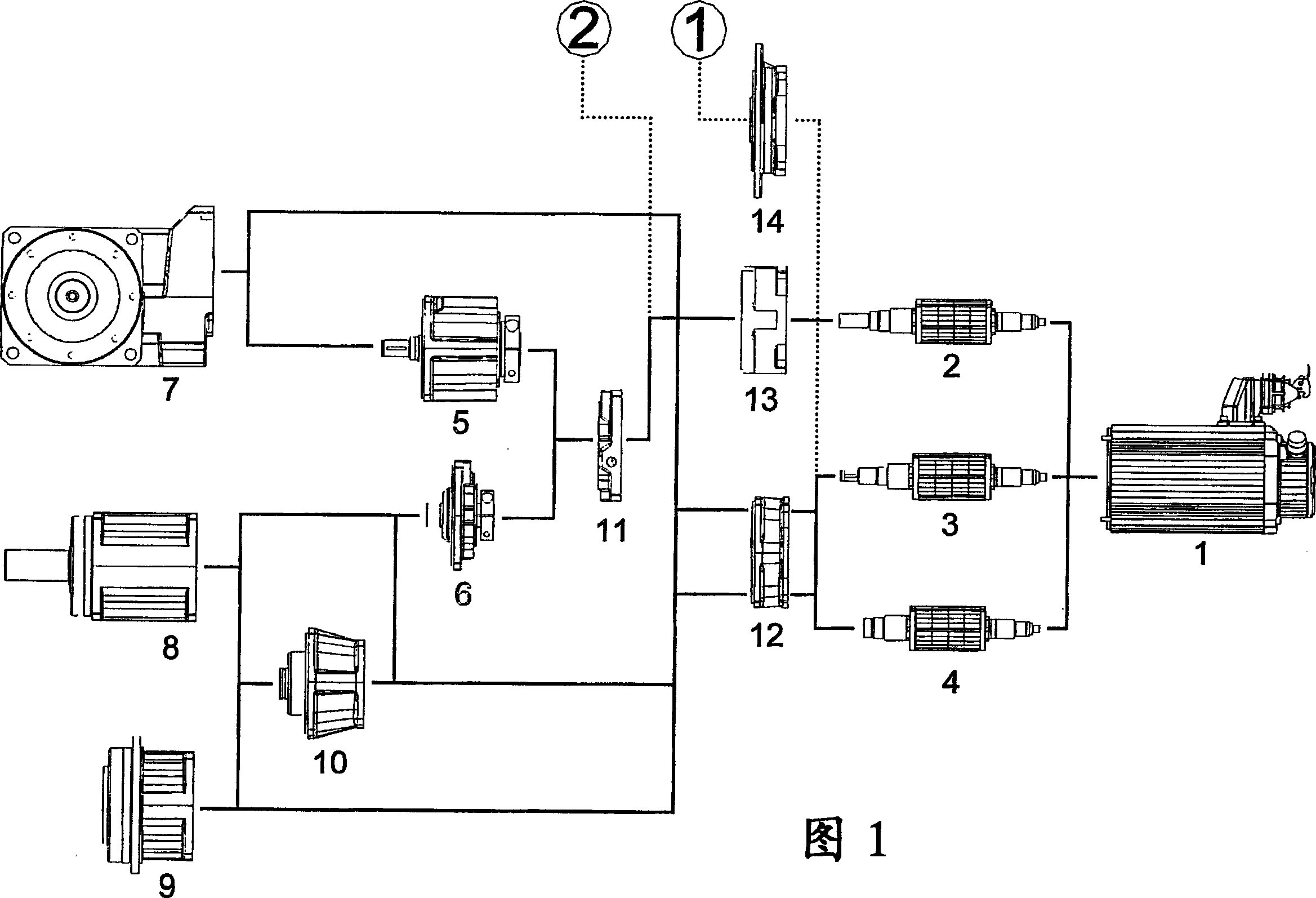

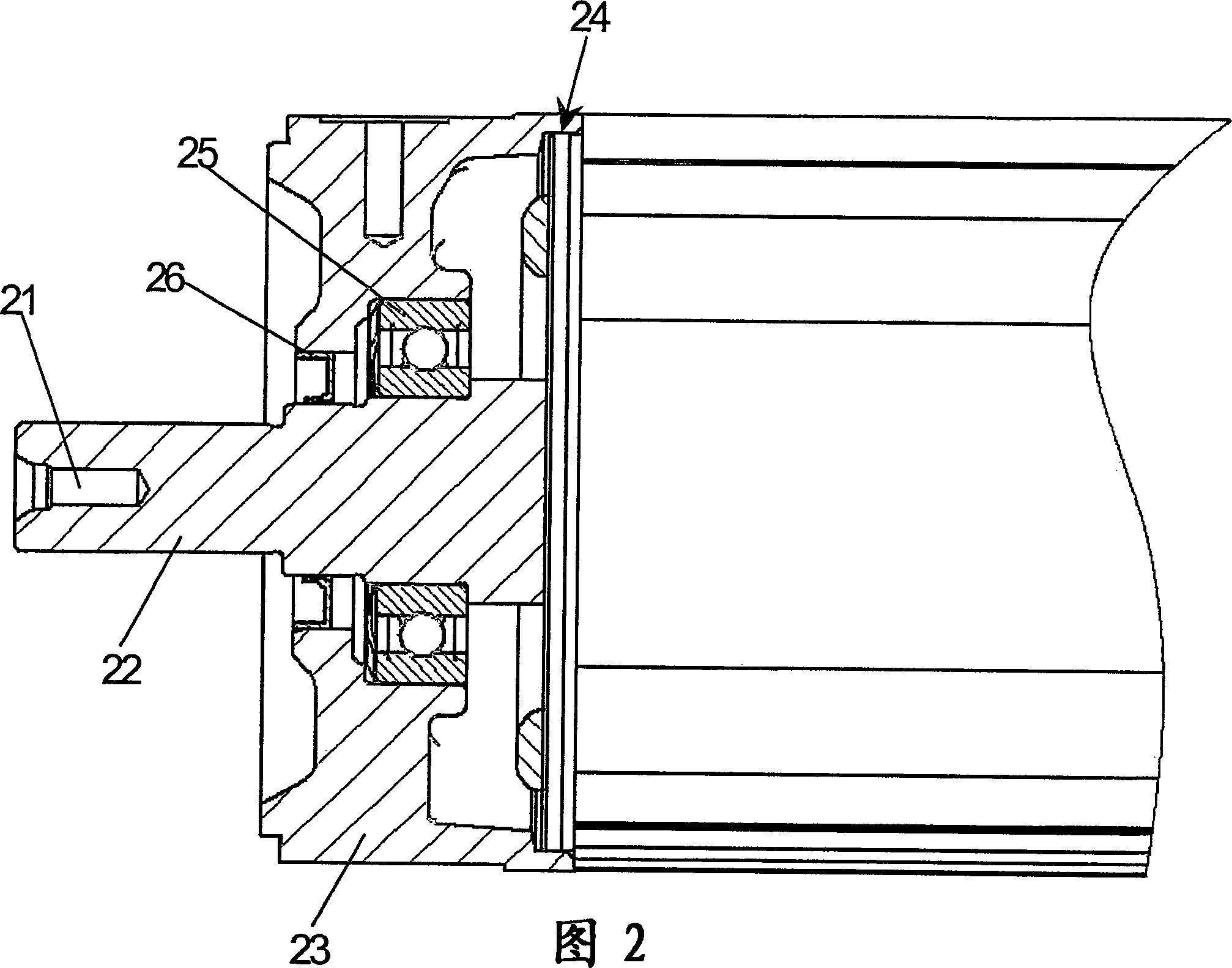

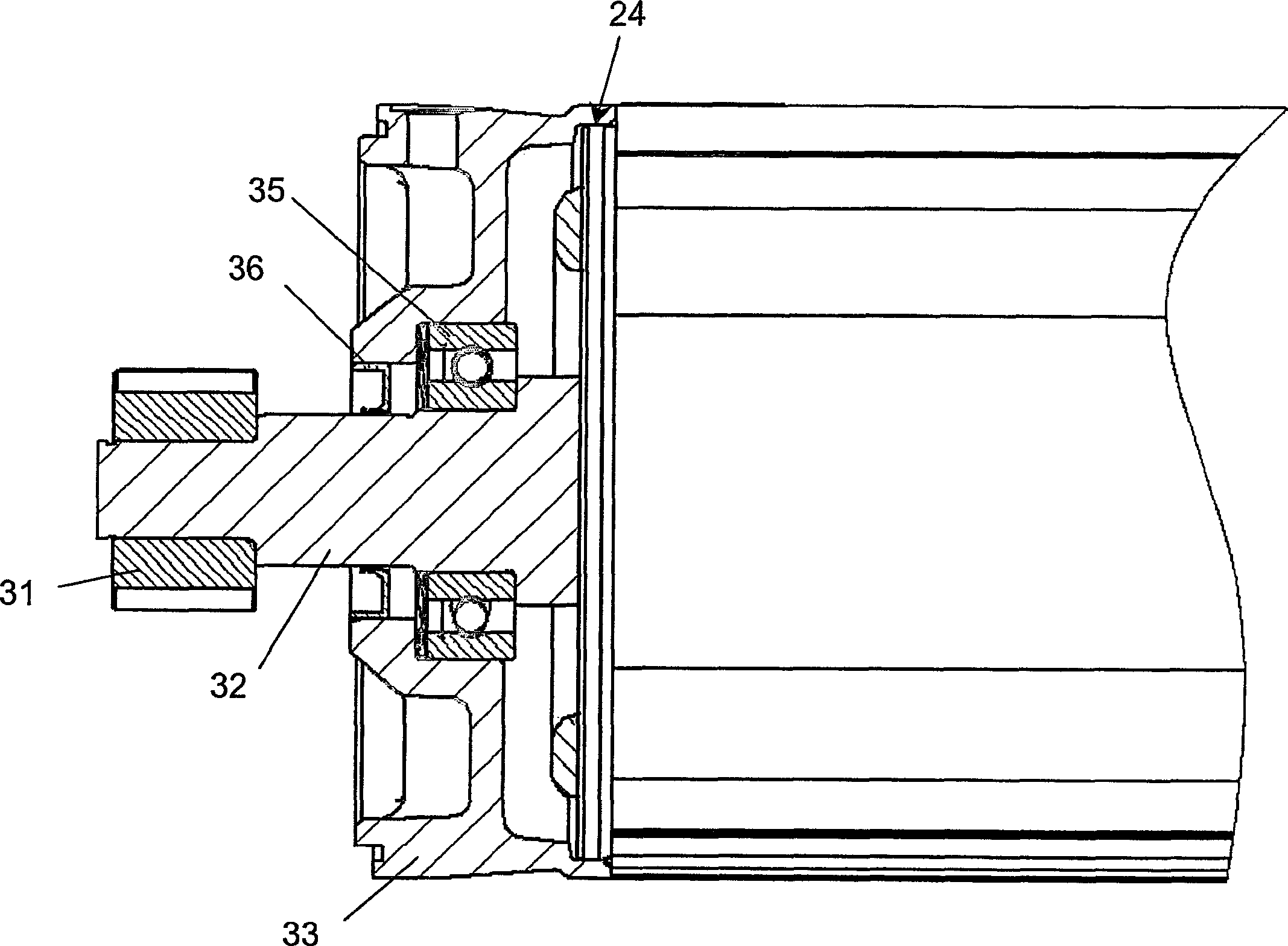

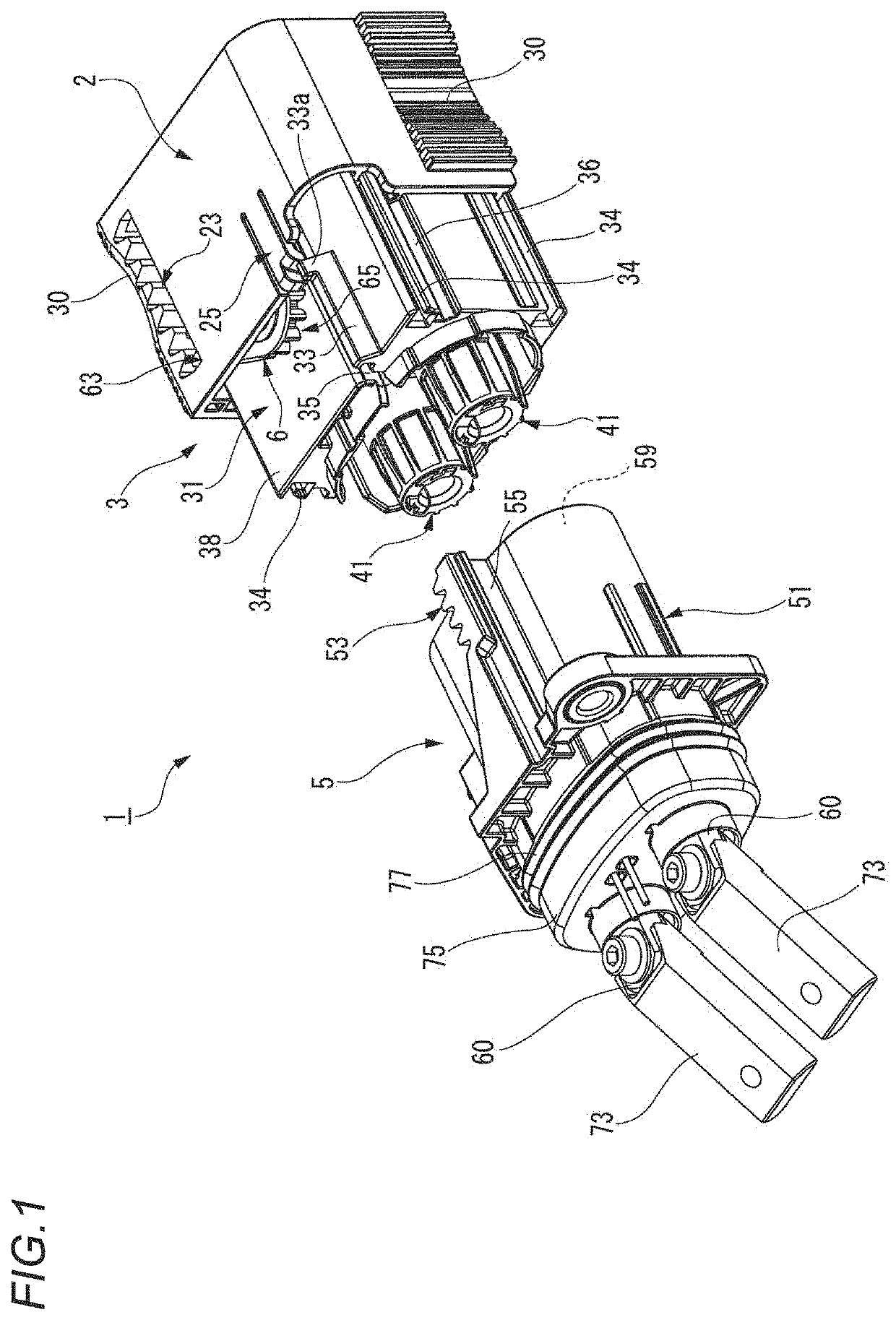

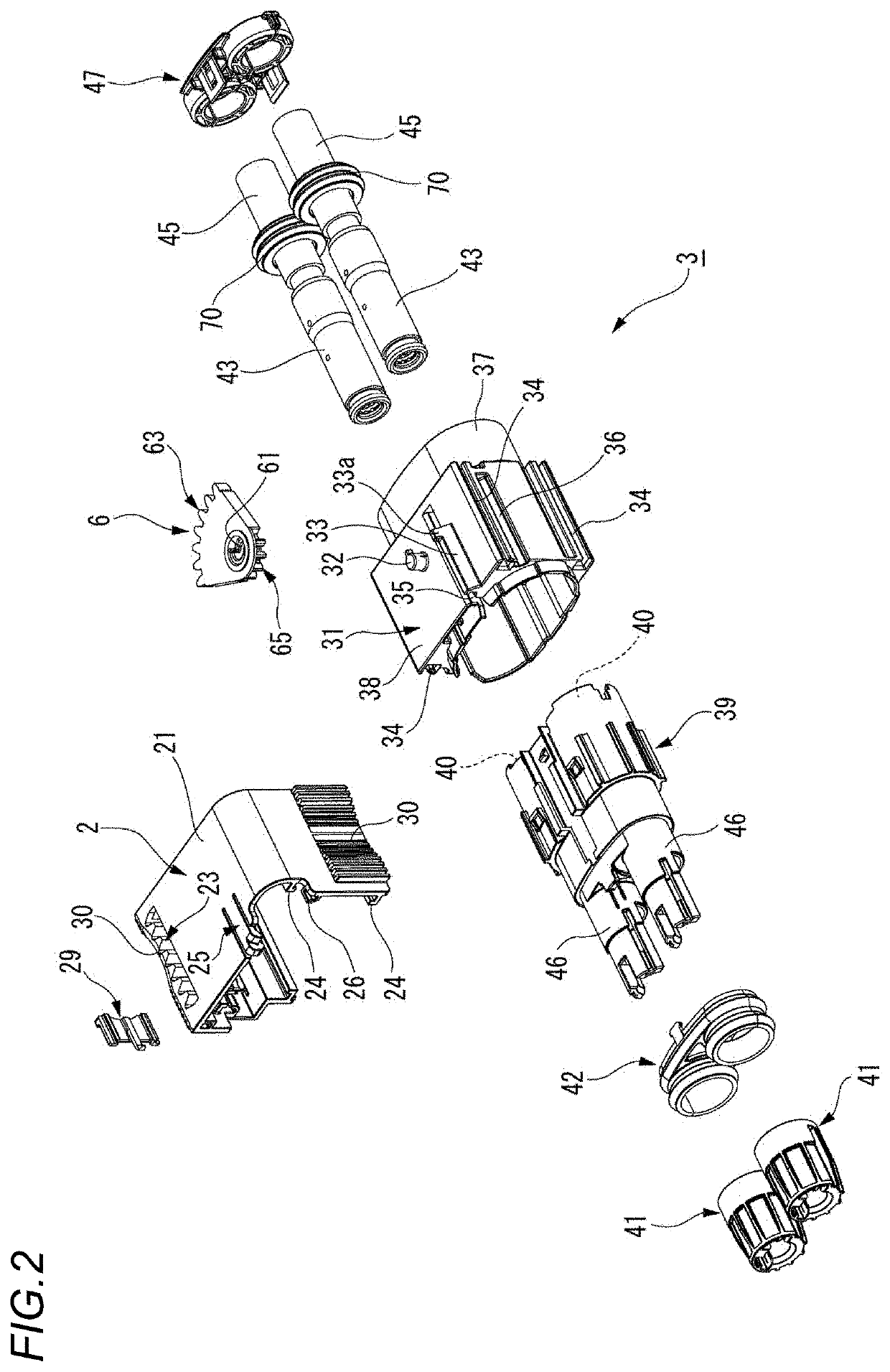

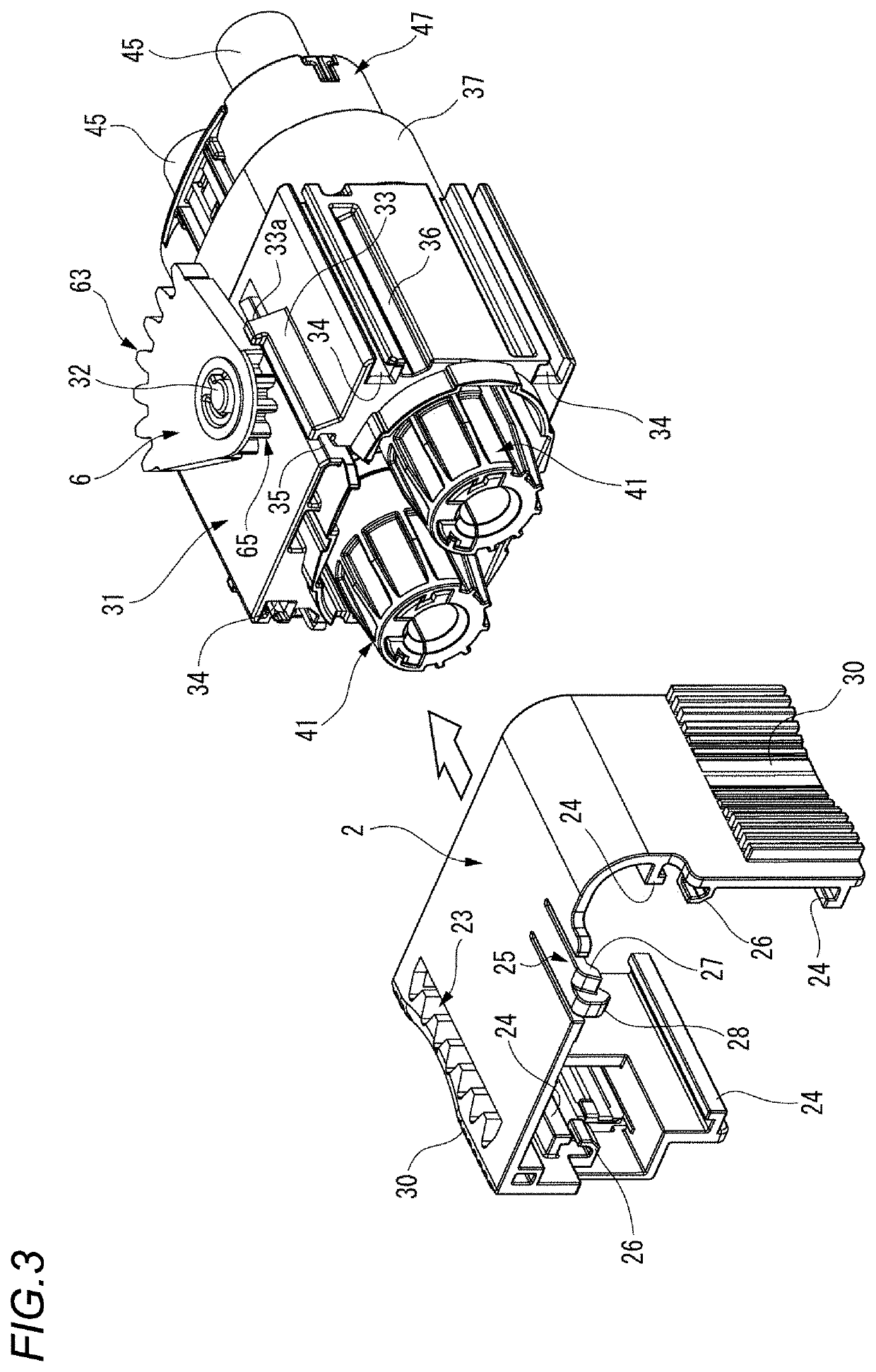

Spare part set for a gearmotor series

ActiveCN1754298ASmall manufacturing tolerancesLow costYielding couplingGearboxesGear transmissionGeometric quantity

The present invention relates to a structure constituent for a gearmotor series. The mentioned gearmotor includes gear transmission equipment drived by electromotor, this structural series includes at least structural quantity which characteristics can be described by at least one physical quantity, mechanical quantity and / or geometric quantity, especially the structural quantity is rating power, axis height or torque. The electromotor always includes at least a electromotor shell, a rotor containing rotor axis and a electromotor bearing cover on driving side, thus, the electromotor shell of the electromotor has a junction region with the electromotor bearing cover on the output side so as to have at least two various deformation of the output side electromotor bearing cover to connect with the electromotor shell.

Owner:SEW-EURODRIVE GMBH & CO KG

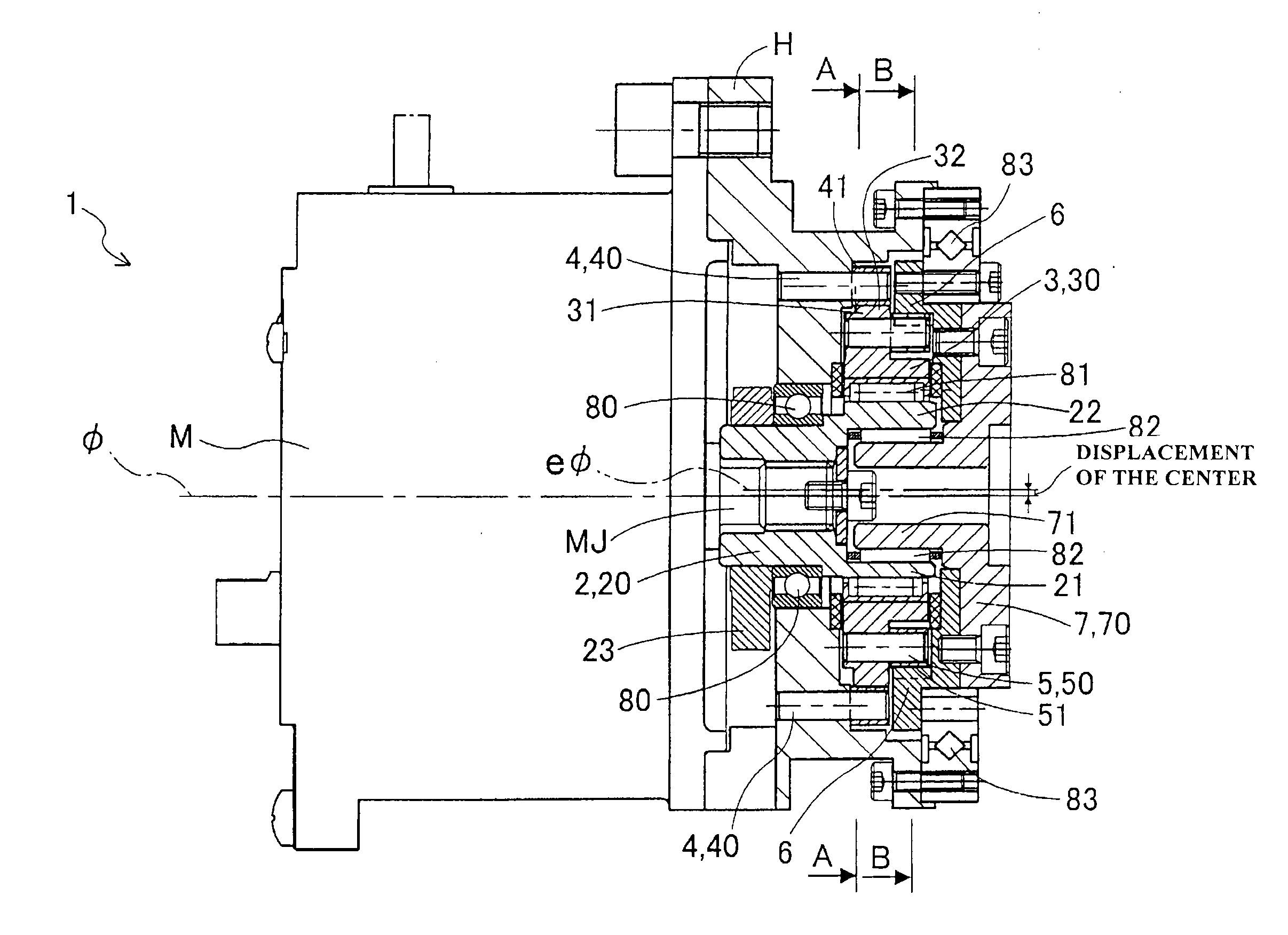

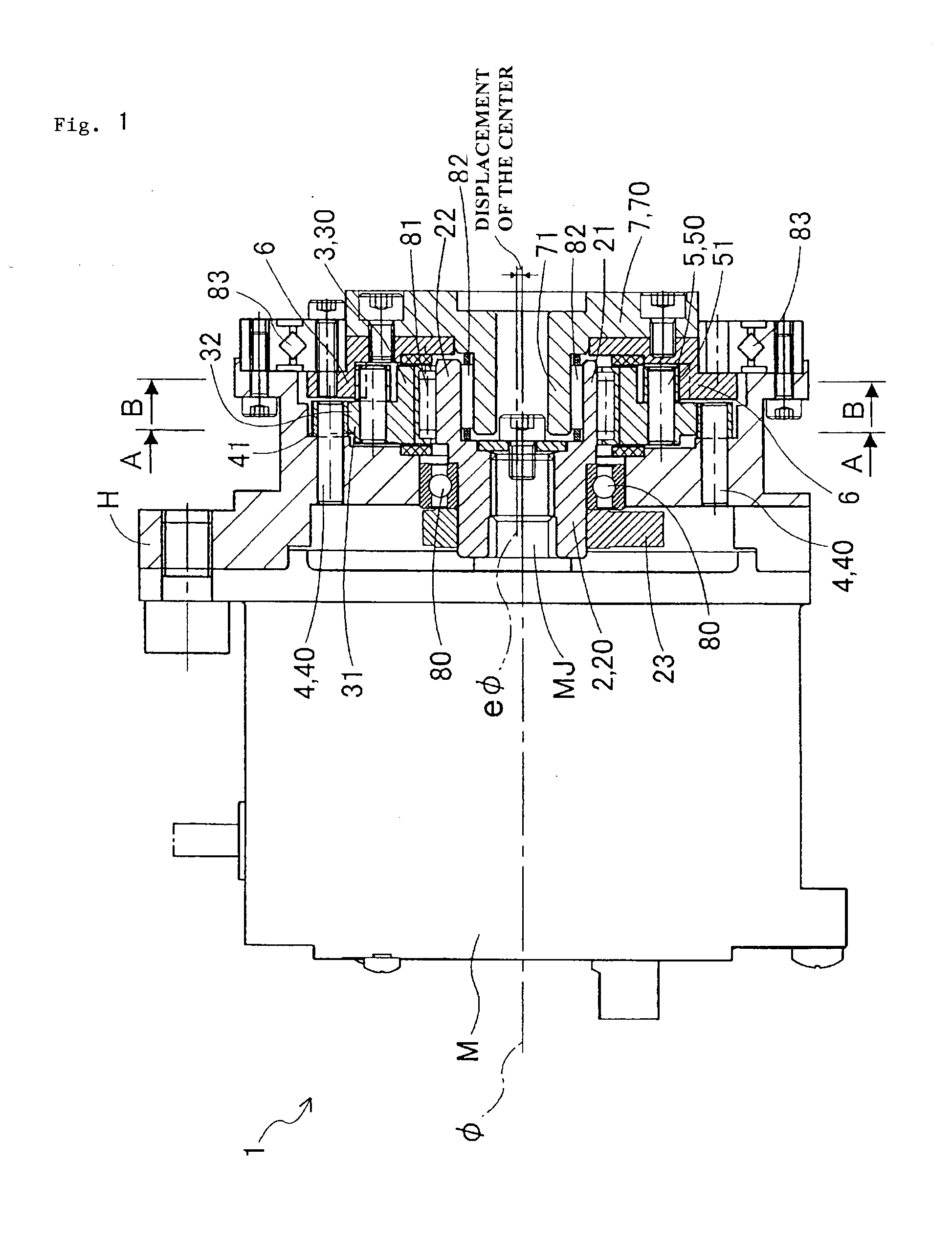

Power transmission apparatus for vehicle and vehicle-driving electric machinery system using the same

InactiveUS7244210B2Reduce total powerLow efficiencyElectric propulsion mountingToothed gearingsElectric machineEngineering

The invention provides a power transmission apparatus for vehicle which can realize a high torque transmission efficiency and a high reduction gear ratio of a reduction gear unit with a more compact structure, and a vehicle-driving electric machinery system using the power transmission apparatus for vehicle. The power transmission apparatus for vehicle comprises a motor, a reduction gear unit for decelerating power outputted from the motor, and a differential gear unit for distributing the power decelerated by the reduction gear unit to left and right wheels. The reduction gear unit is a reduction gear mechanism including a plurality of gears mounted over a shaft which is rotatably held by a housing in a fixed position. The reduction gear unit and the differential gear unit are arranged within an area in oppositely facing relation to an axial end surface of the motor.

Owner:HITACHI LTD

Planetary gear mechanism

InactiveUS20120100949A1Large gear ratioSmall sizeToothed gearingsDifferential gearingsGear wheelEpicyclic gearing

Owner:JTEKT CORP

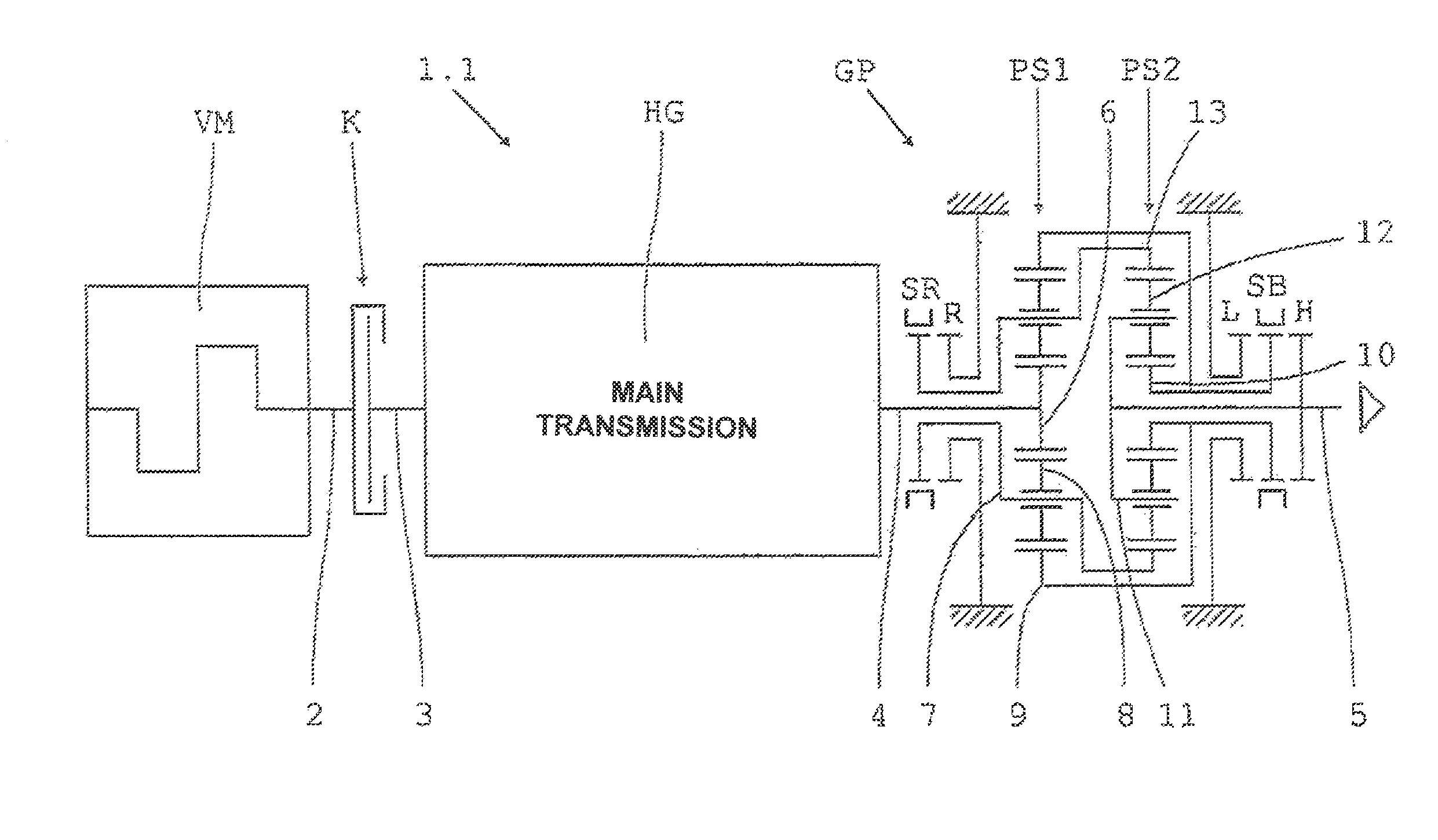

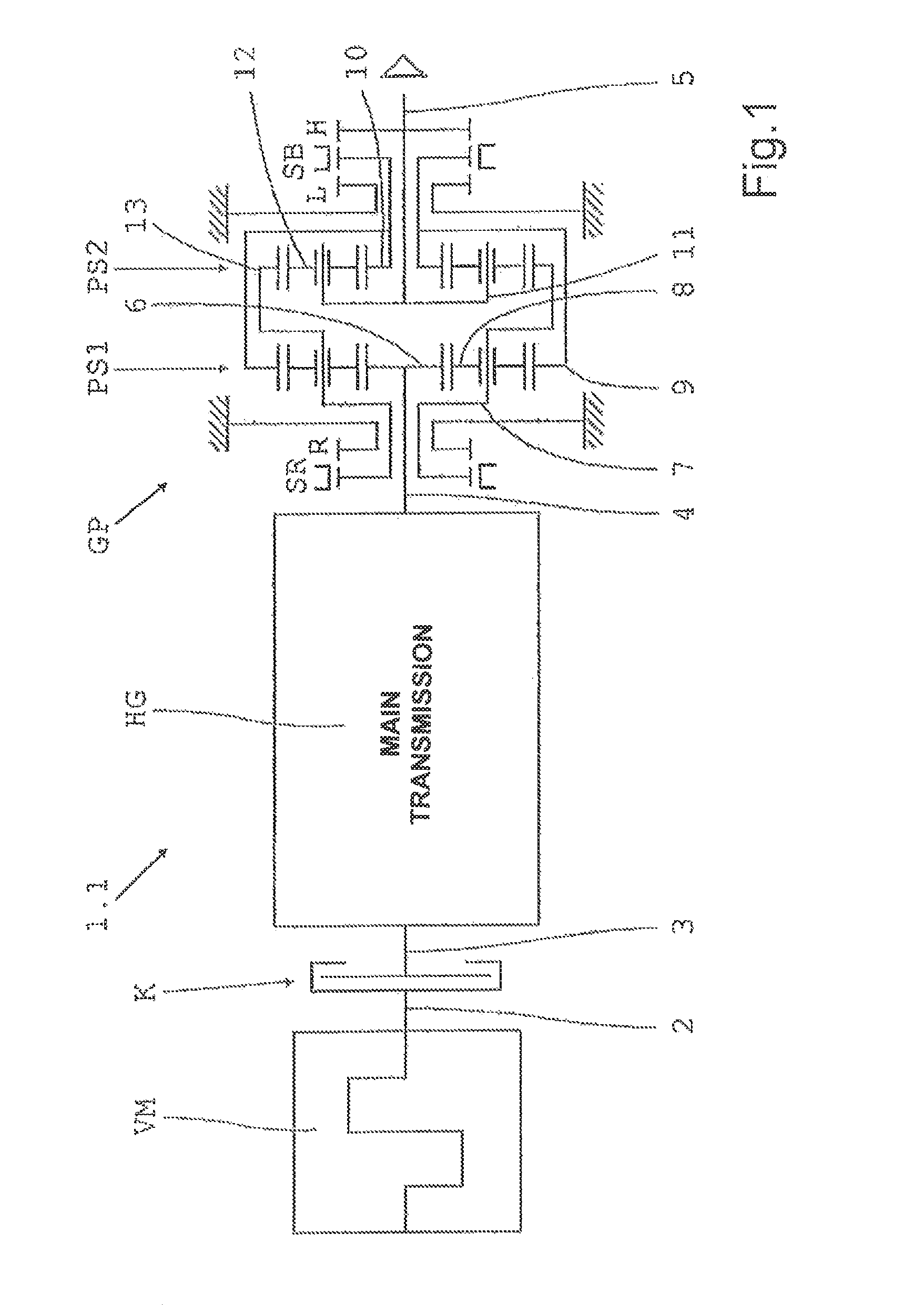

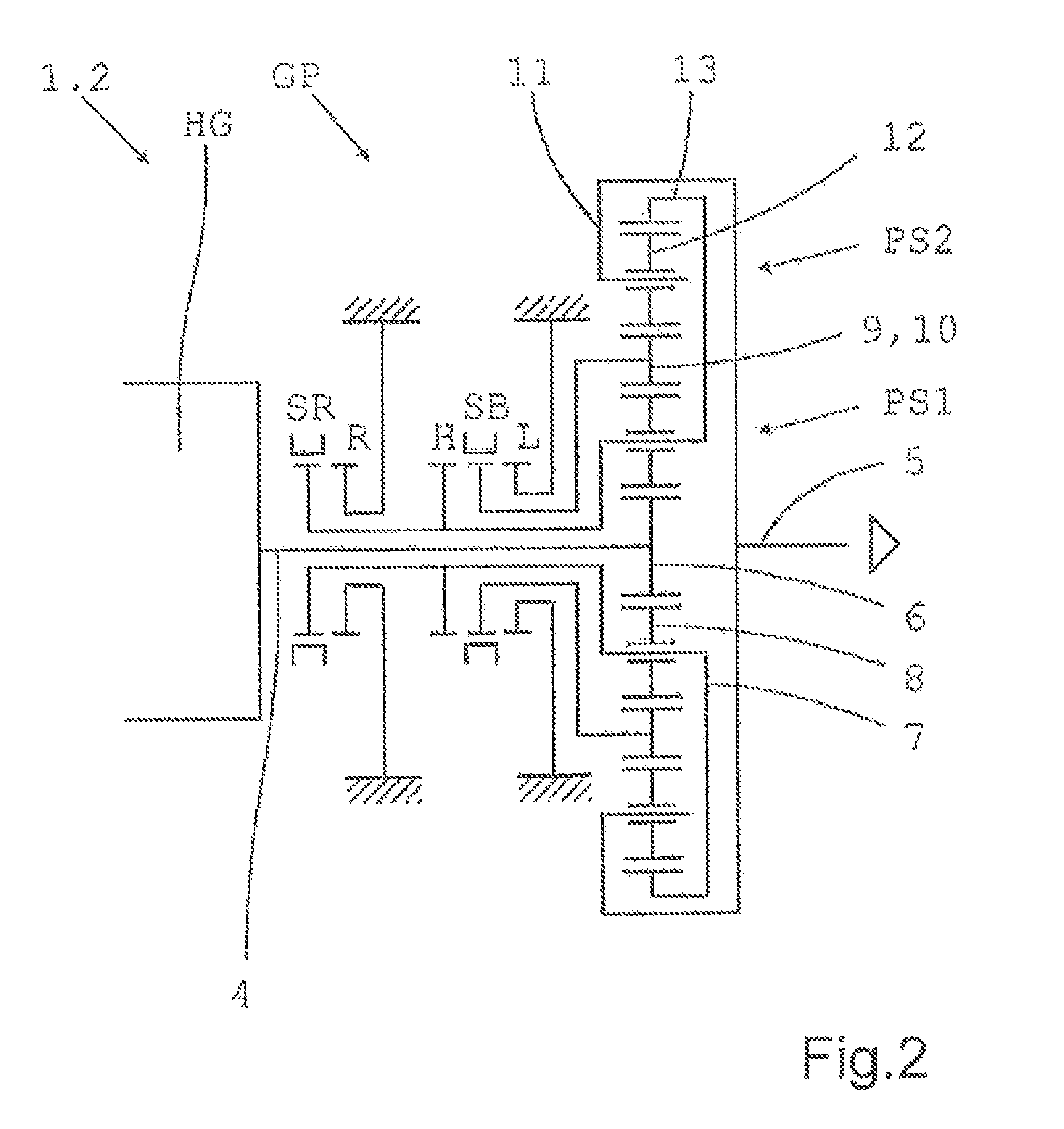

Planetary gear and group transmission with planetary gear

InactiveUS20150219193A1Simple designSimple processGearingTransmission elementsEngineeringMechanical engineering

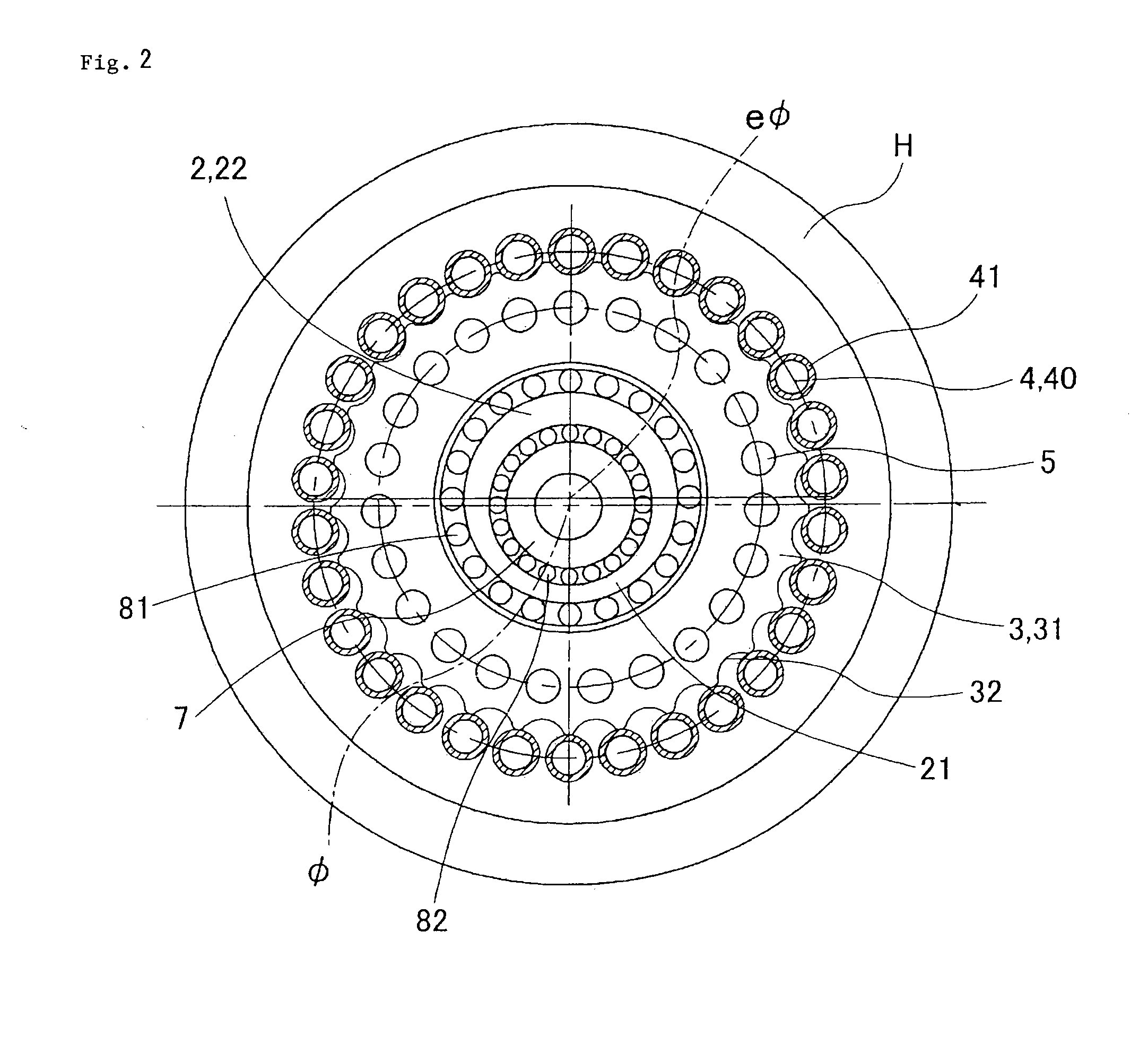

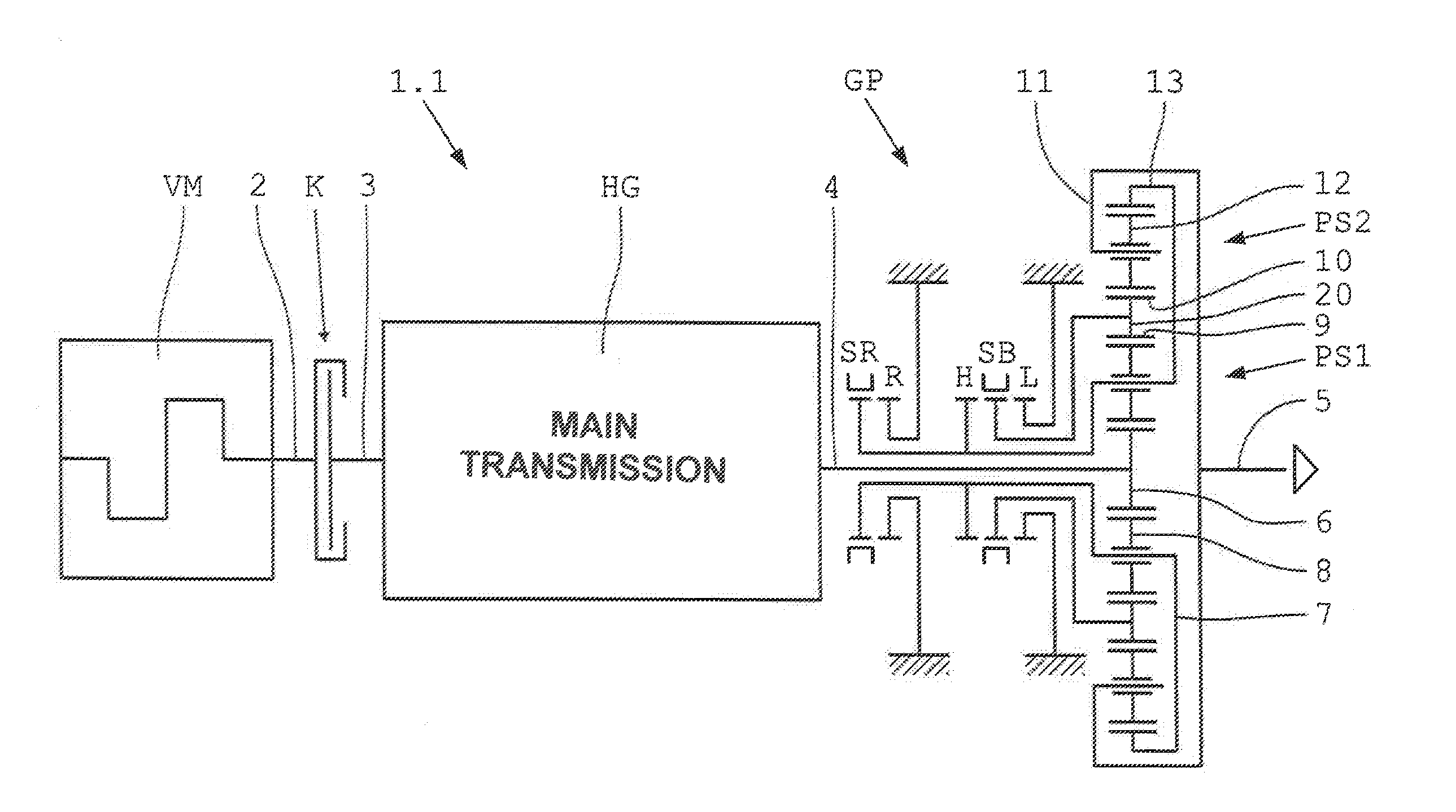

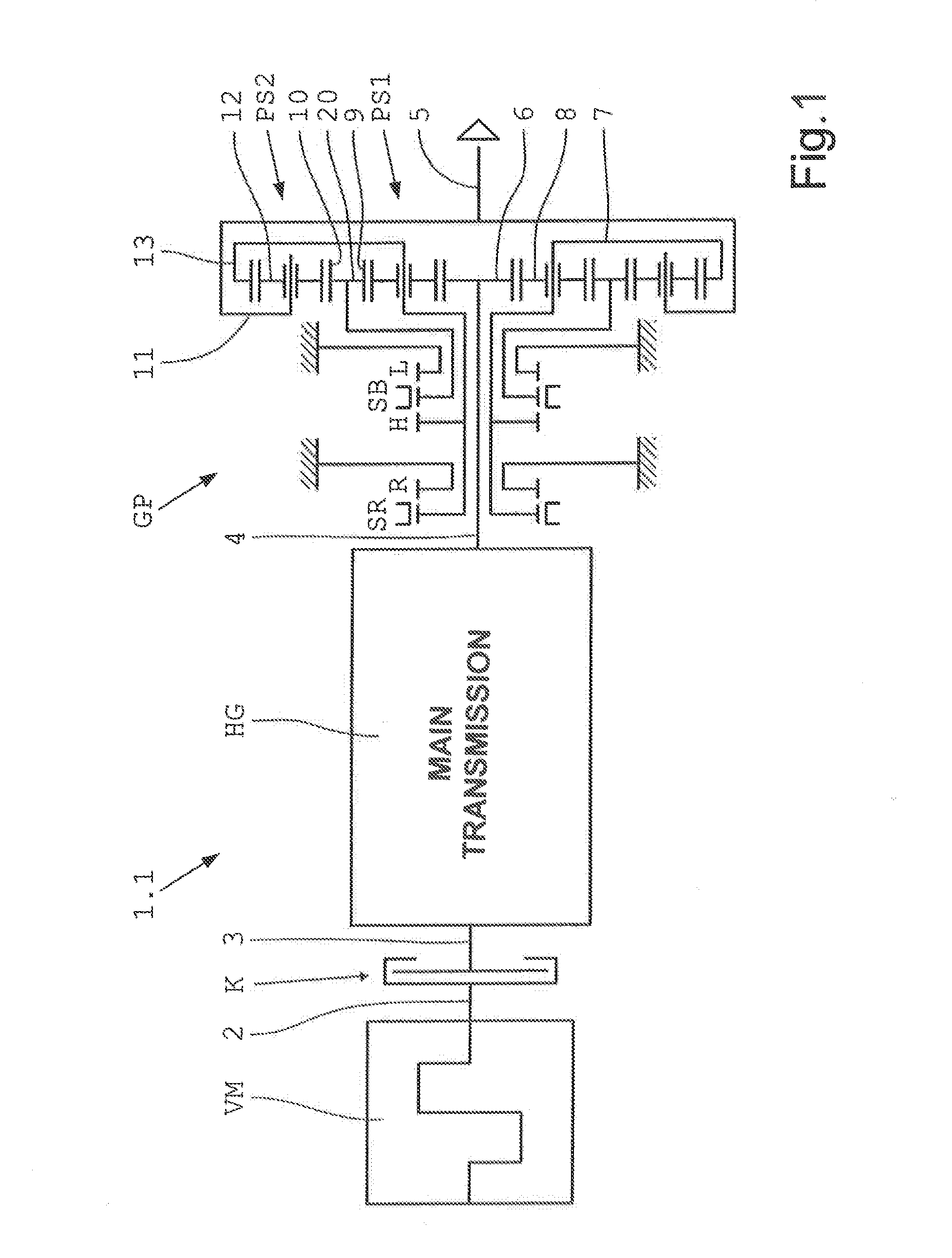

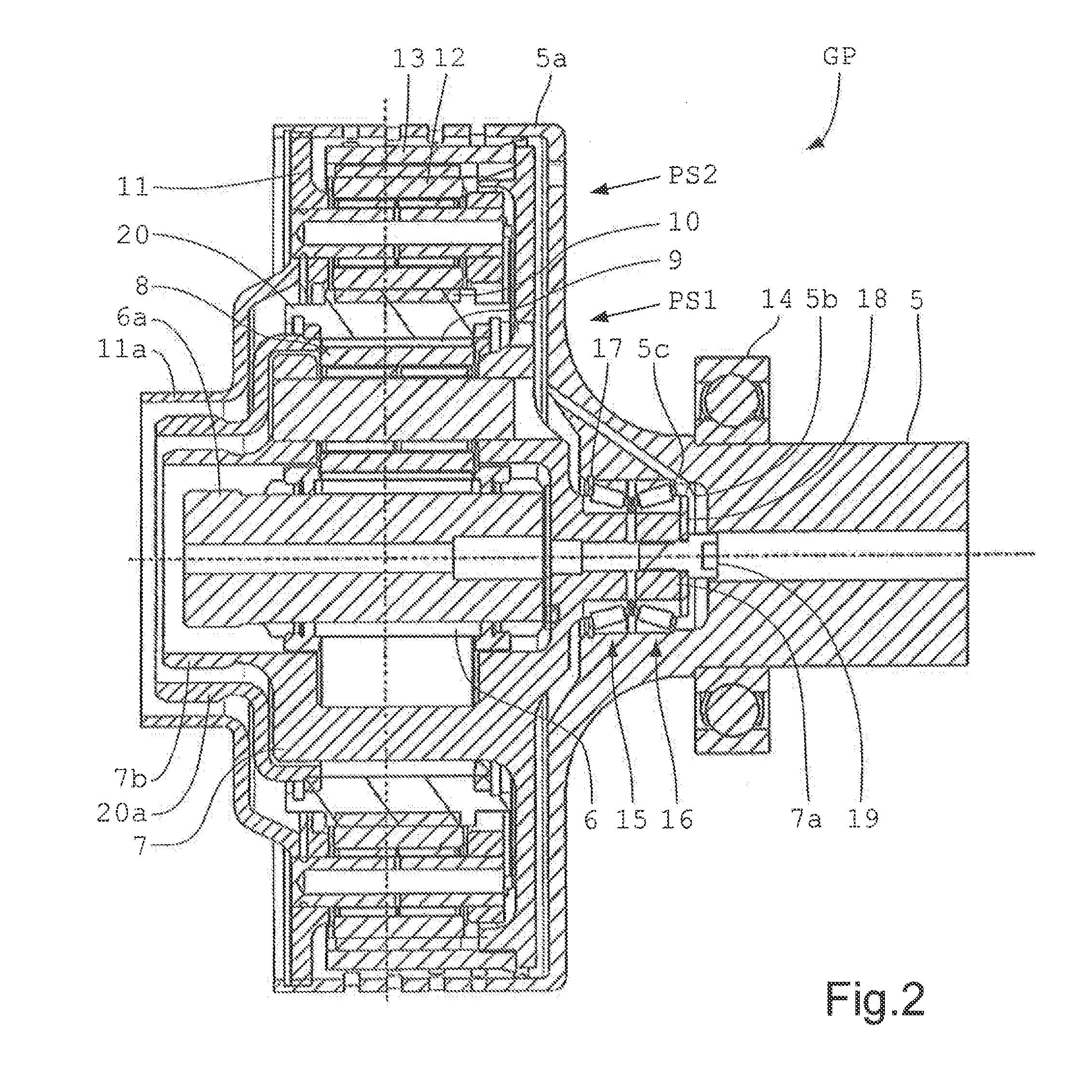

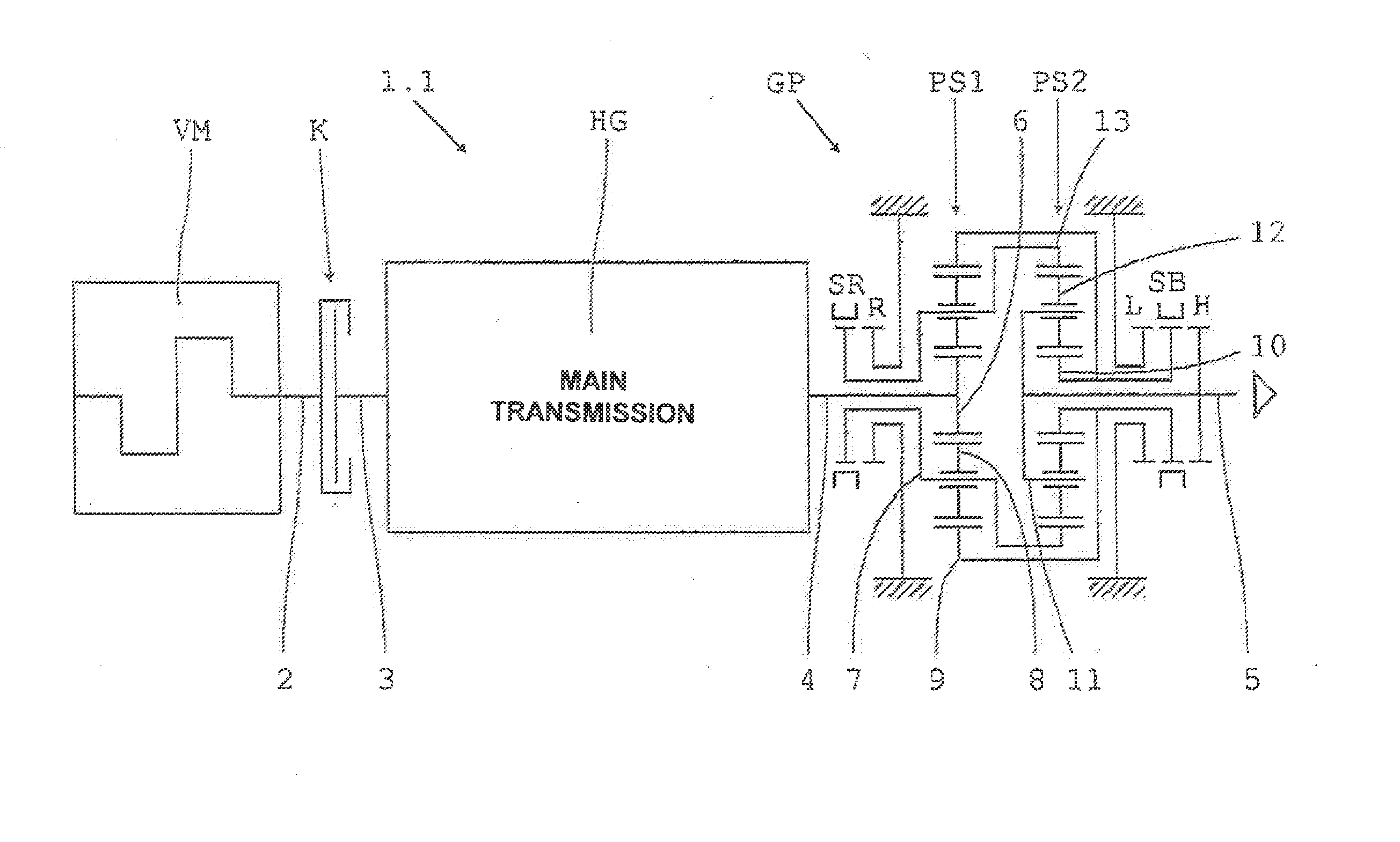

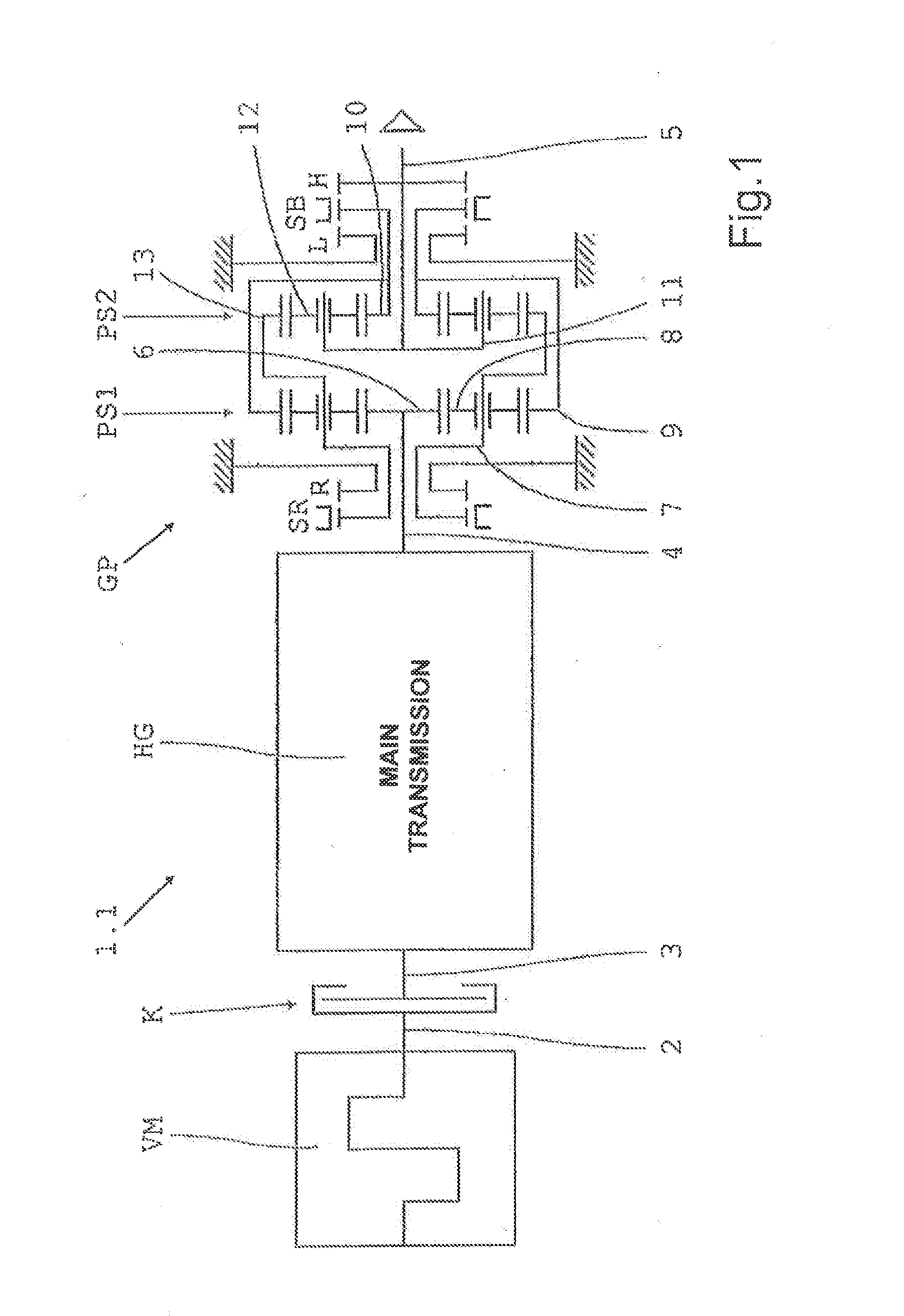

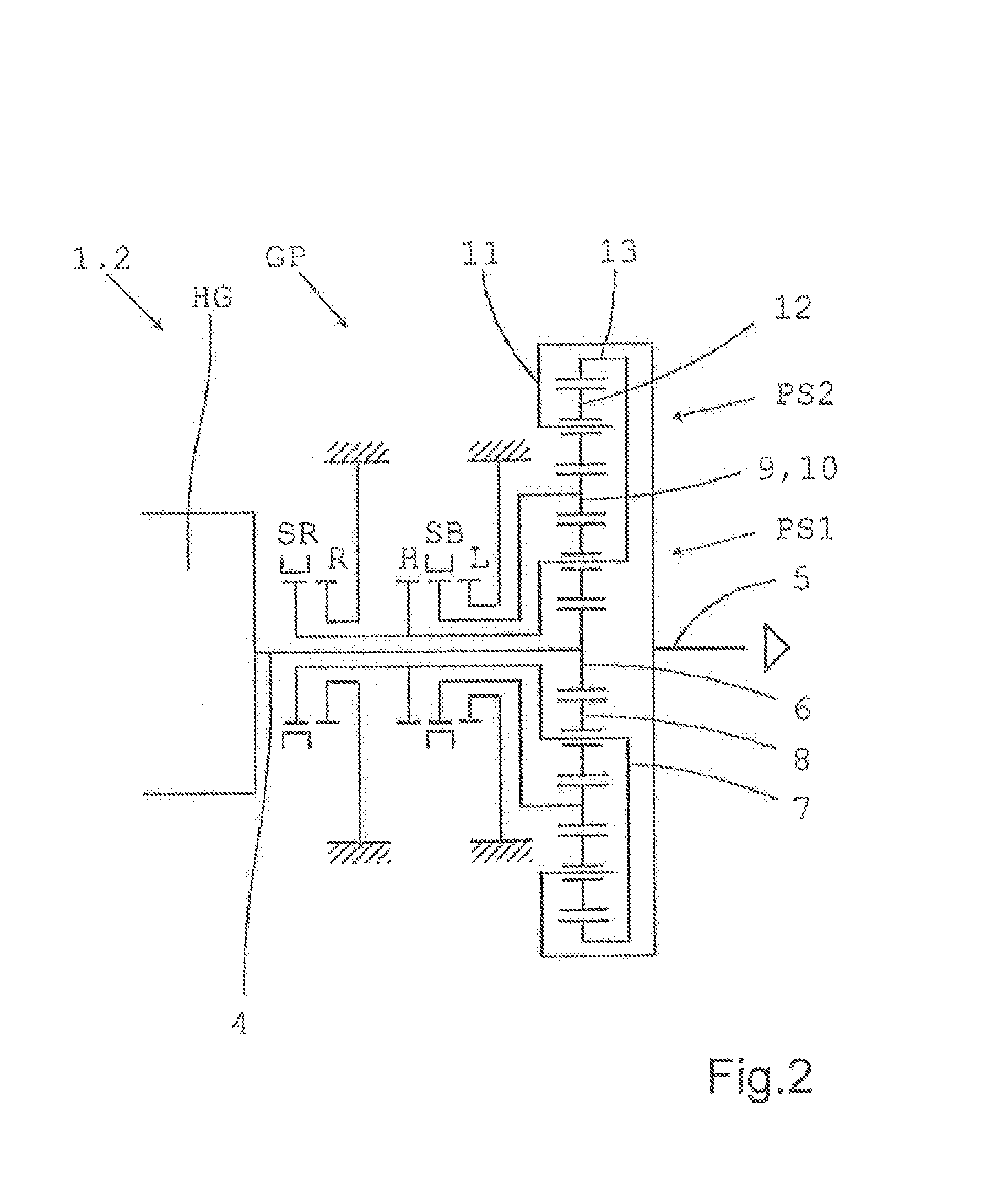

Planetary gearsets (PS1, PS2) are coupled and arranged coaxially and radially offset relative to one another. Gearset (PS1) is arranged radially inside gearset (PS2) and each have a carrier on which planet gears (8, 12) respectively rotate. A support ring, having inner and outer teeth, is radially arranged between the planet gears (8, 12). A sun gear, which meshes with planet gears (8) which mesh with the inner teeth of the support ring, is radially within gearset (PS1). A ring gear, which meshes with planet gears (12) which mesh with inner teeth of the support ring, is radially outside gearset (PS2). The sun gear of gearset (PS1) is fixed to an input shaft. The carrier of gearset (PS1) is fixed to the ring gear of gearset (PS2) and mounted, via a radial-axial bearing, on the output shaft. The carrier of gearset (PS2) is fixed to an output shaft.

Owner:ZF FRIEDRICHSHAFEN AG

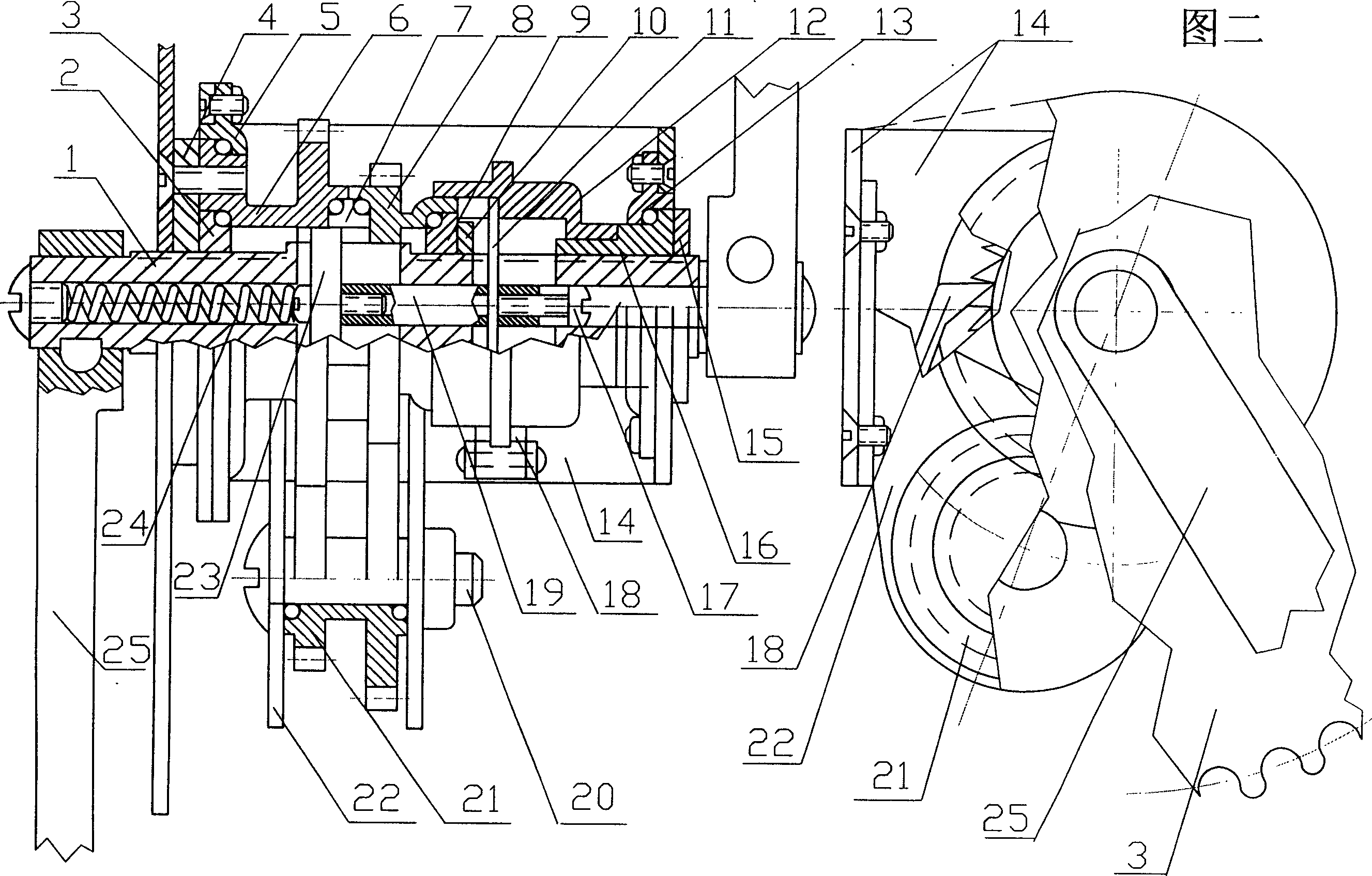

Pneumatic wheel brake for a vehicle

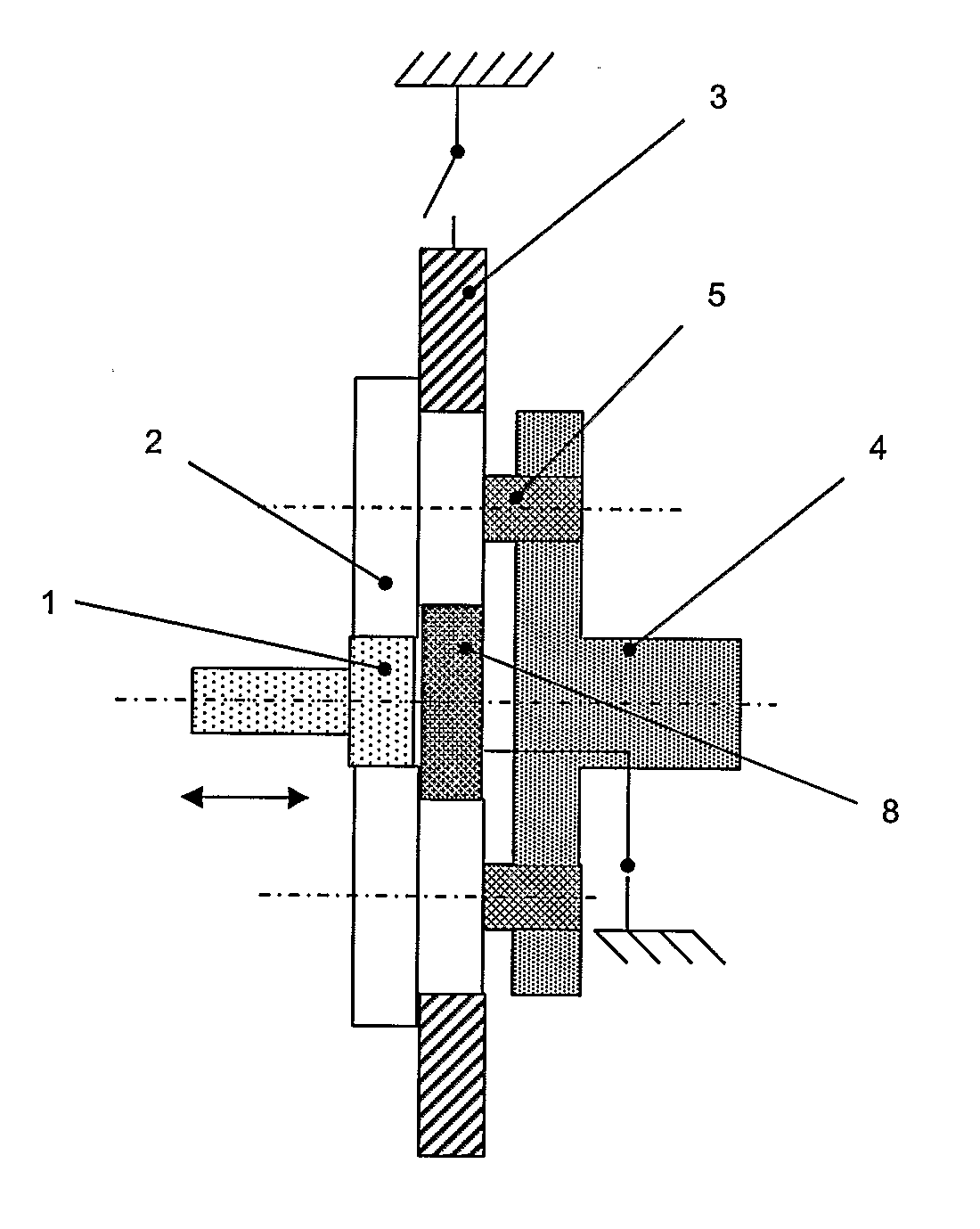

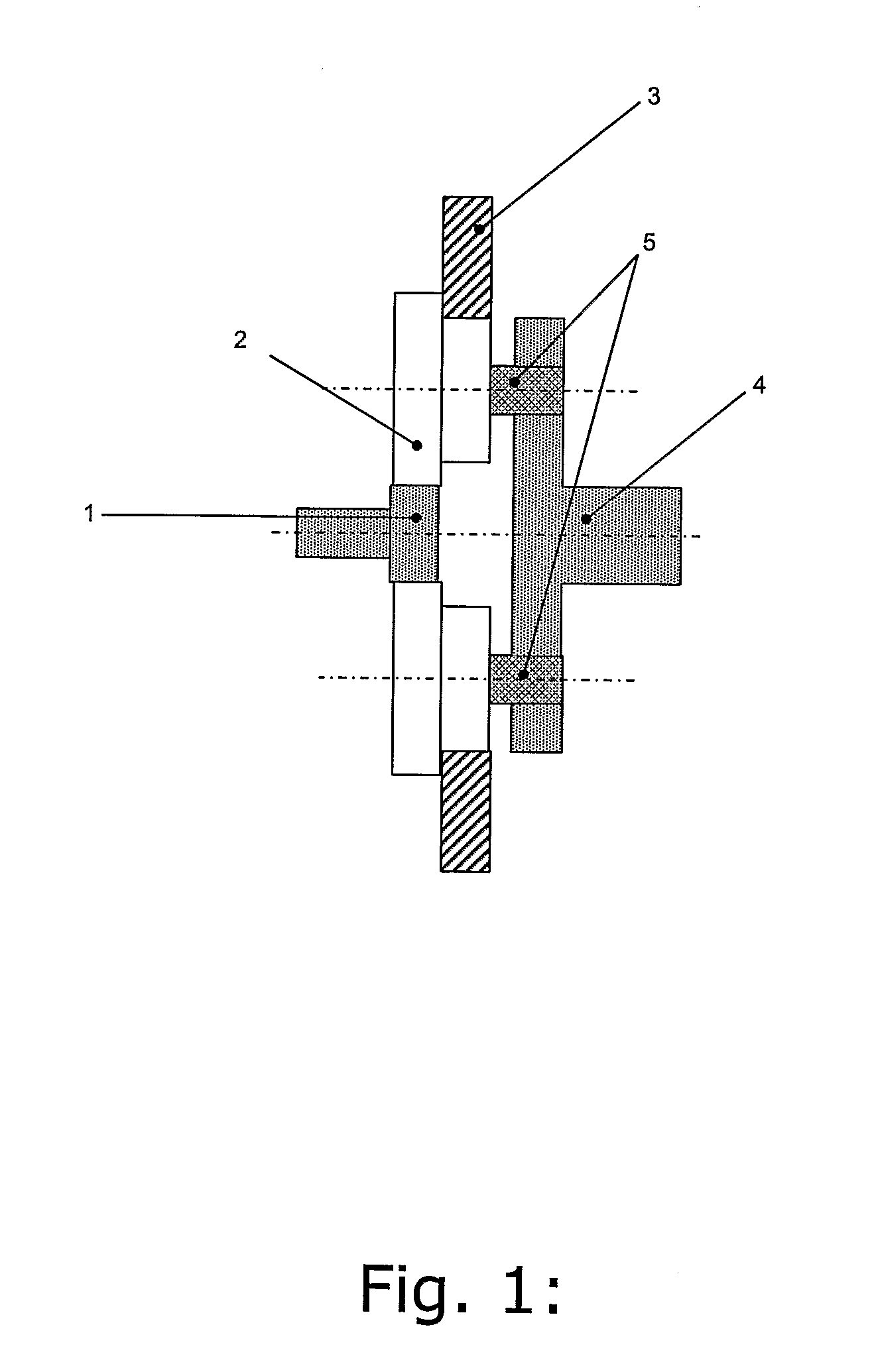

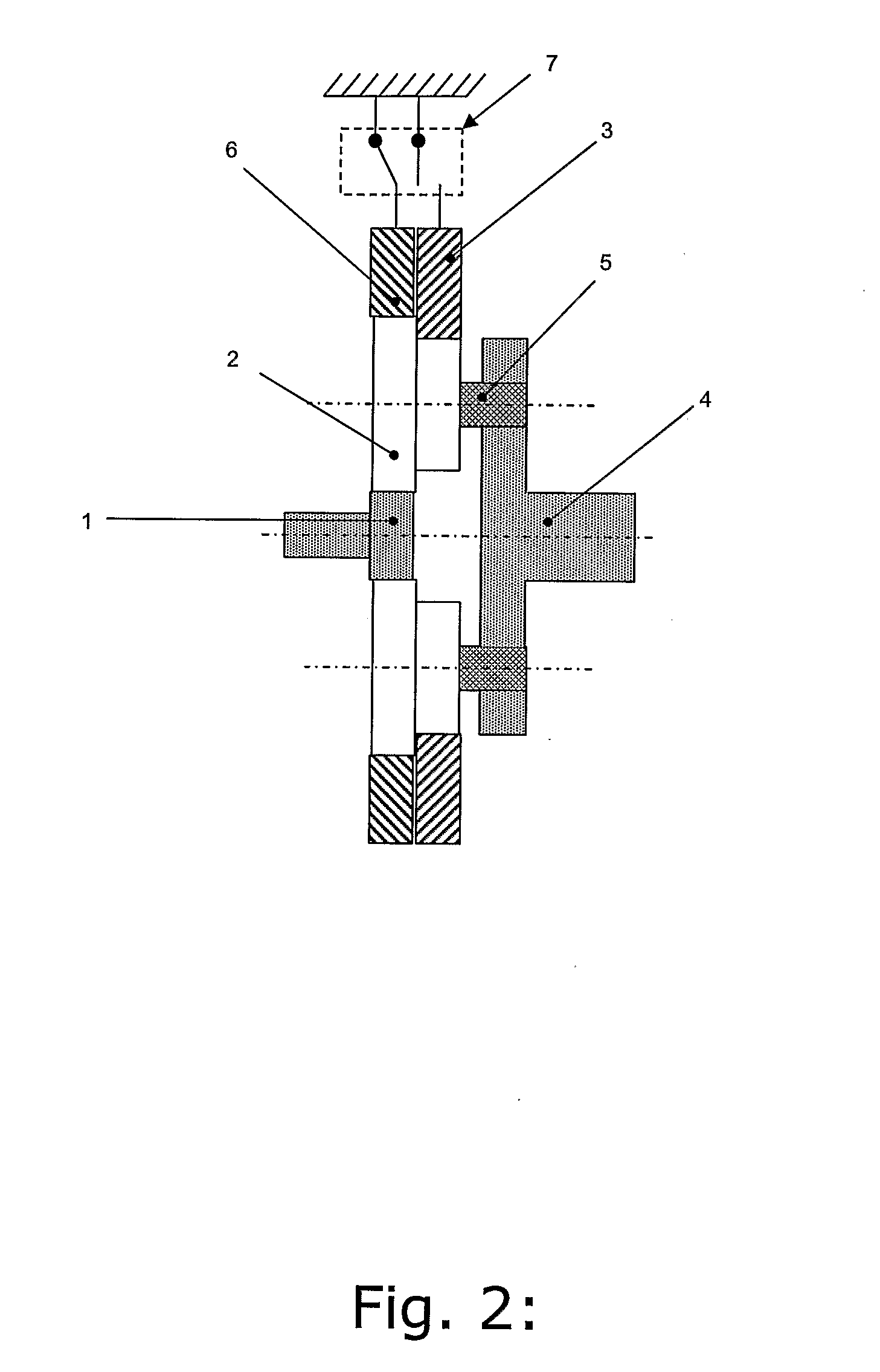

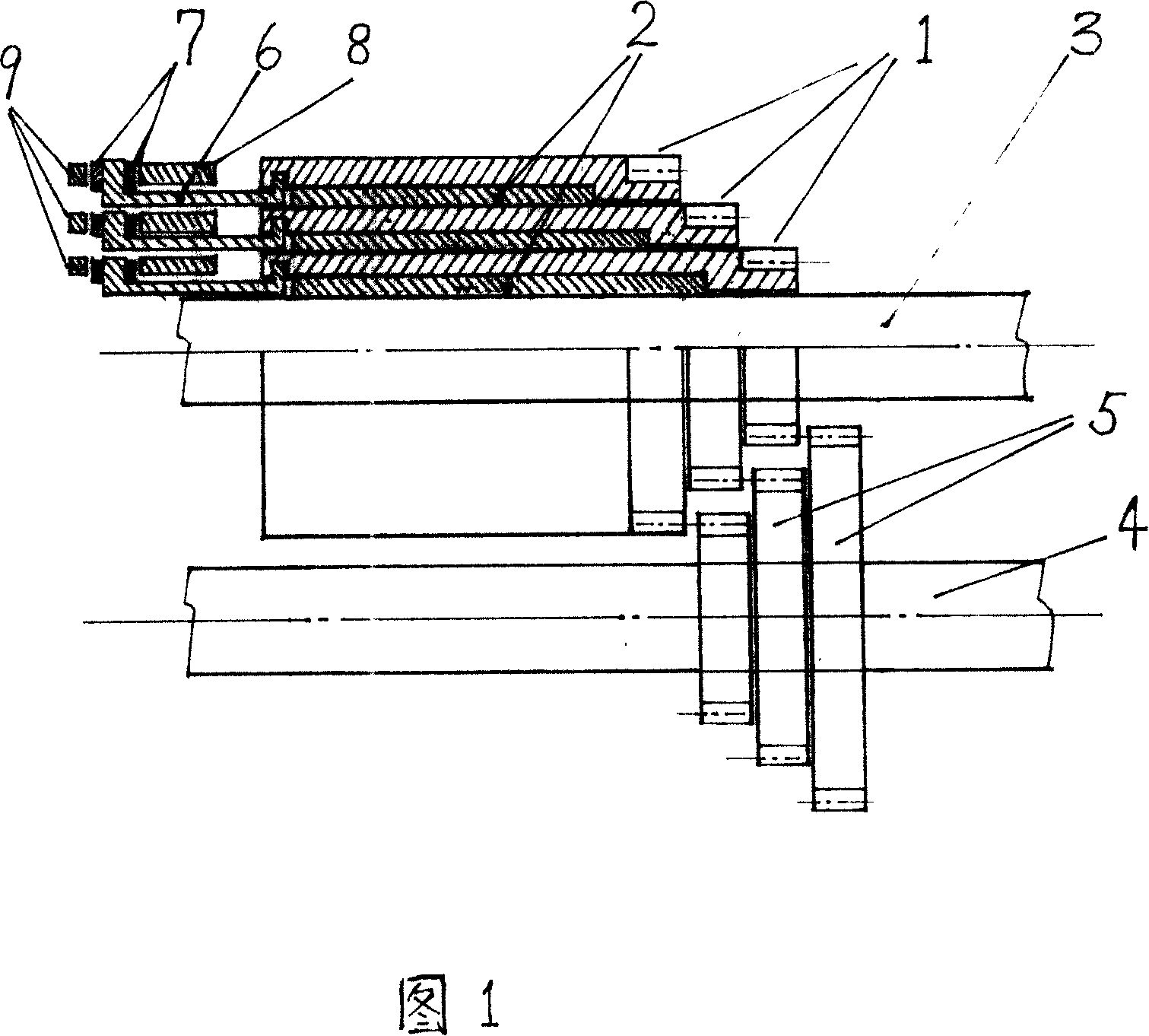

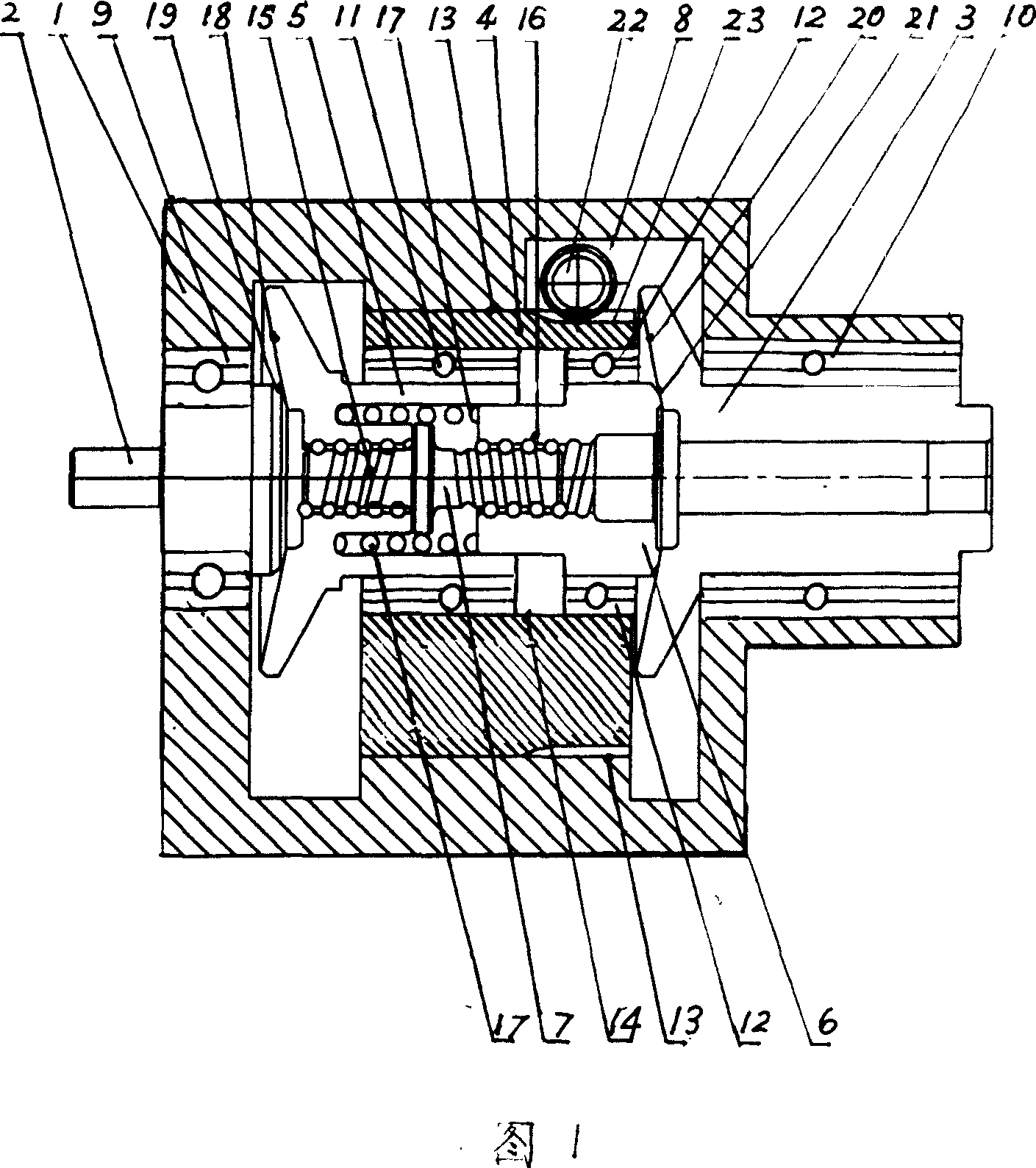

ActiveCN102959269ASimple structureCompact structureBraking element arrangementsAxially engaging brakesEngineeringCompressed air

The invention relates to a pneumatic wheel brake for a vehicle, wherein the wheel brake has at least one brake lever (11) that can be operated by a compressed air cylinder (10) and a brake application device (20) that can be operated by the brake lever (11), wherein by means of said brake application device a first brake element (1) can be pressed against a second brake element (2) when the brake lever (11) is operated, and the wheel brake has an actuating device (3) that can be driven by an electric motor, wherein by means of said actuating device force can be applied to at least parts (7, 8, 9) of the brake application device (20), at least when the brake lever (11) is not operated, and thereby the first brake element (1) can be pressed against the second brake element (2). Furthermore, the wheel brake has a spring accumulator element (4), which is arranged outside the compressed air cylinder (10), wherein force can be applied to the spring accumulator element (4) by the actuating device (3) that can be driven by an electric motor and force can be applied to at least parts (7, 8, 9) of the brake application device (20) by the spring accumulator element, at least when the brake lever (11) is not operated, and thereby the first brake element (1) can be pressed against the second brake element (2).

Owner:ZF CV SYST EURO BV

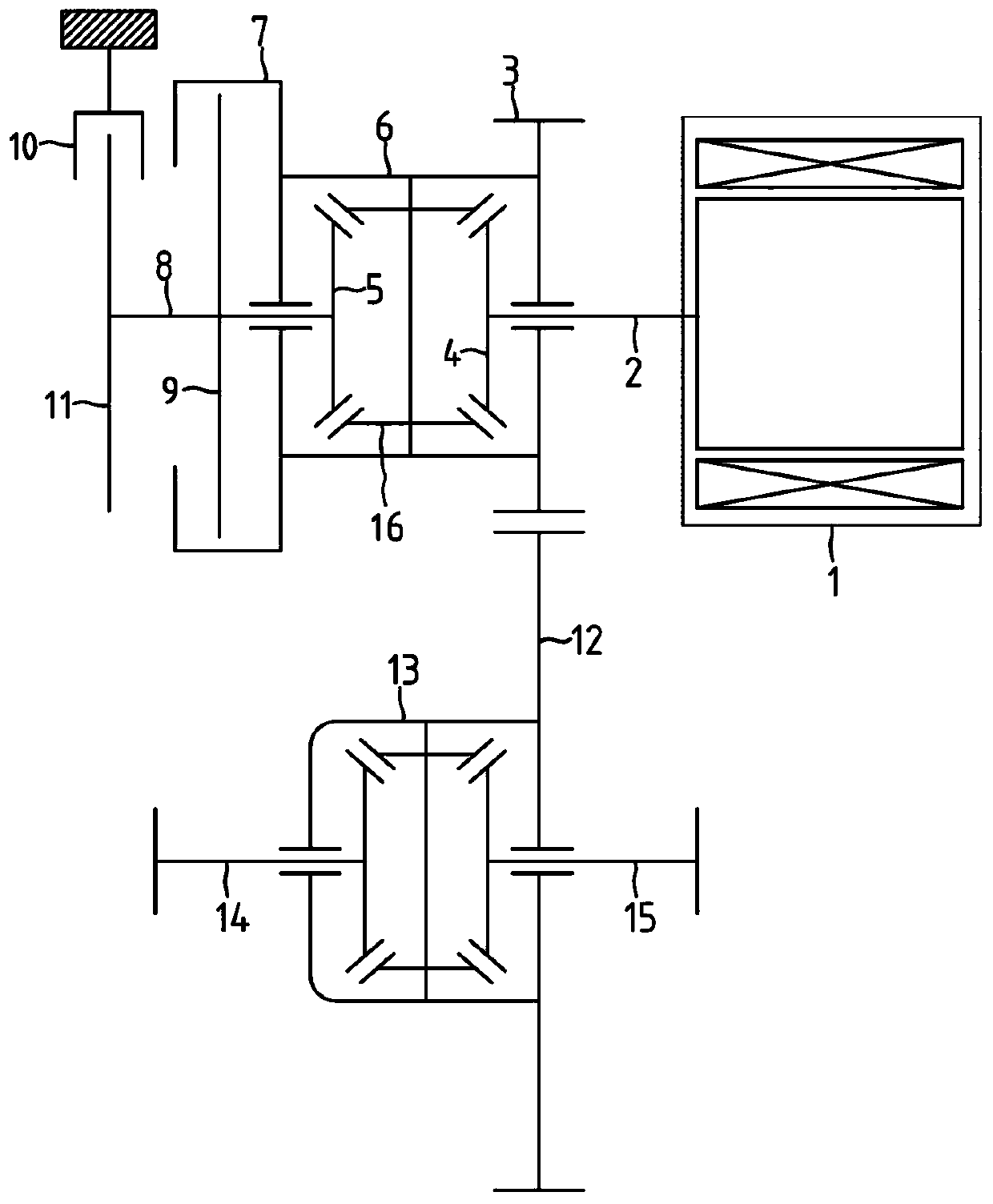

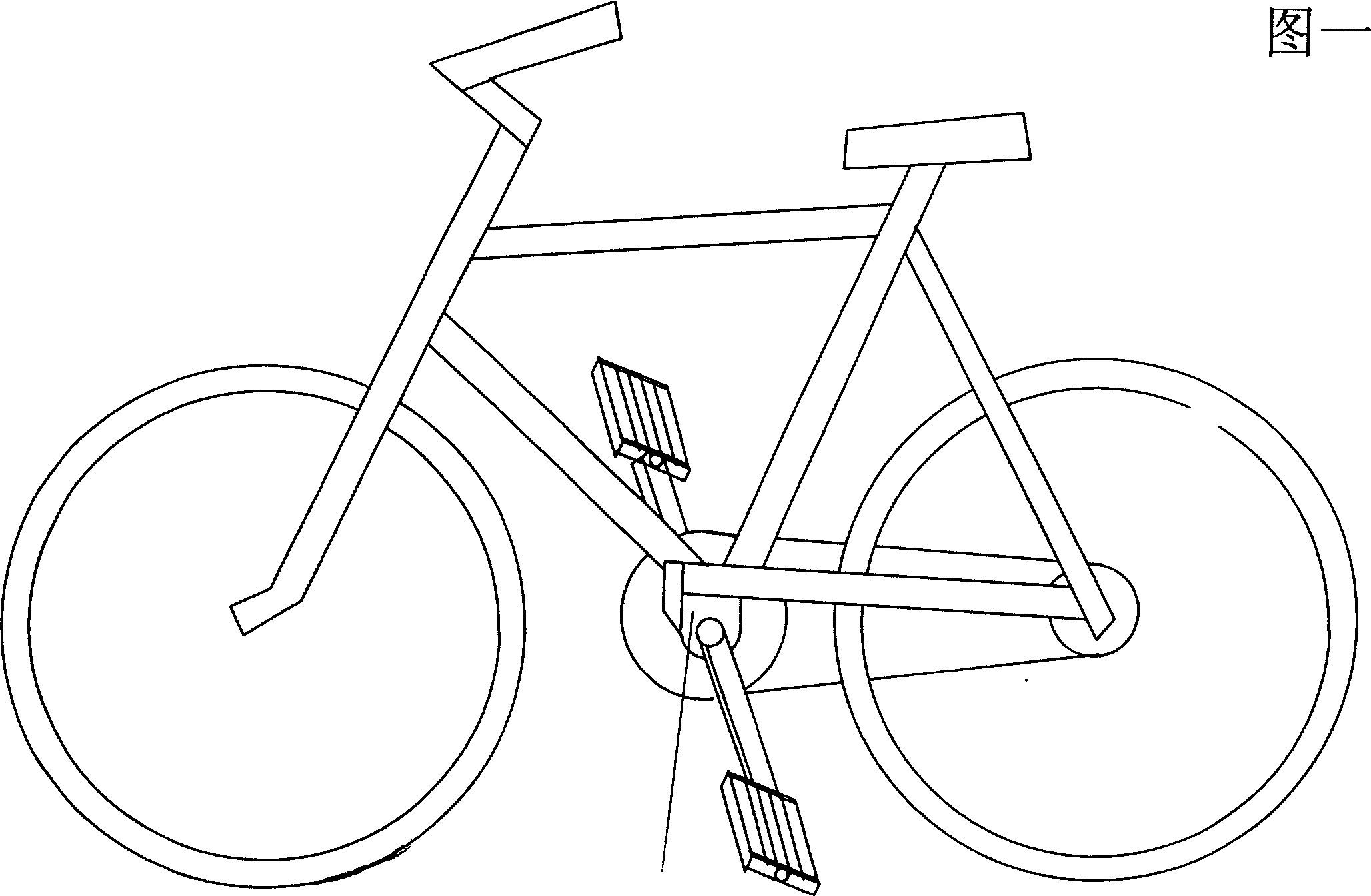

Housing gear speed variator and foldable bicycle

InactiveCN101130381AAccurate transmissionSmooth transmissionWheel based transmissionFoldable cyclesGear transmissionVariator

The invention relates to a sleeve-gear transmission and folding bicycle. There is a group of sleeve gears matched with a group of fixed gears. A part is driven to move or rotate by rope or bar to extrude a sleeve gear matched with a fixed gear. When the part moves again matched sleeve gear retracts. Another sleeve gear extrudes and is matched with another fixed gear to change speed. Moving is carried out continuously reciprocating speed increasing and speed decreasing can be realized. Speed-variable process is lightness and smooth. The transmission is set on the oblique bar of bicycle and is connected with gear, ratchet wheel and two straight driving wheels. The diameter of wheel is small than 10cm and the speed exceeds in prior bicycle. A pin is drawn out the main cubage of folded bicycle is only 8X15X99 cm. The transmission also can be used in electrical bicycle, motorcycle and other mechanism.

Owner:张明亮

Transmission gear system of motor vehicle

The invention discloses a transmission gear system of a motor vehicle. The system comprises a drive motor; a drive gear is arranged on a drive shaft of the drive motor; an external gear is arranged on a wheel and around an axle; an internal gear is arranged on the wheel and at the periphery of the external gear; the drive gear drives the internal gear or the external gear; and the internal gear or the external gear drives the wheel to rotate. Since the transmission gear system of the motor vehicle is provided with the smaller-diameter external gear and the larger-diameter internal gear, the internal gear and the external gear are arranged on the wheel, and the wheel has larger diameter, so that the internal gear conditionally has the diameter greater than that of the external gear, a larger gear ratio can be generated when the drive gear drives the wheel by the internal gear or the external gear respectively, and the purpose of substantially regulating variable speed is achieved. Moreover, the system, which is provided with the internal gear and the external gear, is simple in structure and low in cost, so that the cost performance of a product is greatly improved.

Owner:朱政

Vehicle power transmission device

InactiveCN104334925AWide range of gear ratioLarge gear ratioGearingTransmission elementsGear wheelTorque transmission

Owner:TOYOTA JIDOSHA KK

Pure electric two-speed differential device power assembly

InactiveCN109955718ASimple structureThe transmission mechanism is simpleControl devicesMotor driveLow speed

The invention discloses a pure electric two-speed differential device power assembly for an electric vehicle. A motor drives a first differential device; a first differential device casing is providedwith an input gear; the input gear transmits an output gear in an engaged way; the output gear is arranged in a second differential device casing; the non-gear side of one differential device is coaxially provided with a braking shaft; a clutch is also installed and connected through a self casing; a clutch disc is arranged at the braking shaft in a sheathing way; the clutch disc can generate axial reciprocating motion along the braking shaft; the clutch disc and the clutch are in mutual and clutch transmission. On the basis of the clutch function of the clutch, a brake is matched and selected for closing and / or releasing the differential device; various driving modes such as high-speed gear, low-speed gear, parking or neutral gear are realized; the requirements of precise and compact transmission mechanism, great gear ratio, high efficiency, small vibration noise, no power intermittent gear shifting, small loss, ultralow cost and ultrahigh reliability are realized; the cost performance of a vehicle is shown; the pure electric two-speed differential device power assembly is applicable to various electric vehicles.

Owner:GUANGZHOU XINYU POWER TECH CO LTD

Foot controlled speed changing device for bicycle

InactiveCN1597437ADoes not change the structure of the central axisEasy to installWheel based transmissionCycle actuatorsGear wheelSprocket

A foot-controlled gear of bicycle is coaxially installed on the chain wheel axle. It consists of a quick gear, a slow gear, and a switching sleeve. The quick gear and slow gear is equipped with inner spline. The chain wheel is engaged with the quick gear at end surfaces. A servo-gear is installed below the chain wheel to engaged with the quick gear and the slow gear. An energy-storing spring and a gear-linking bar are used for the mechanism to change speed by pedaling in an opposite direction of rotation. The gear omits a gear cable, works reliably, changes speed easily, and is installed simply.

Owner:罗明端

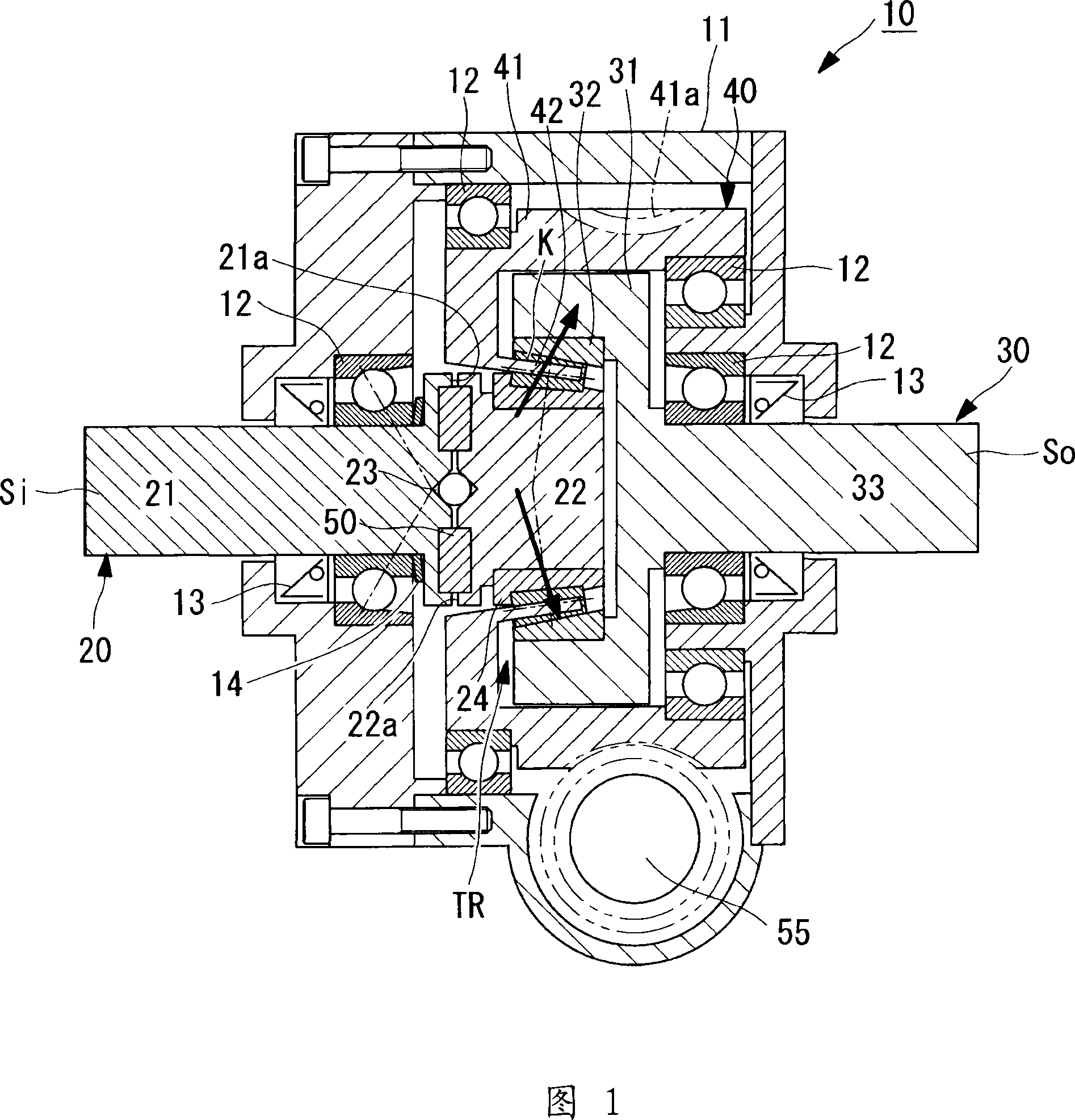

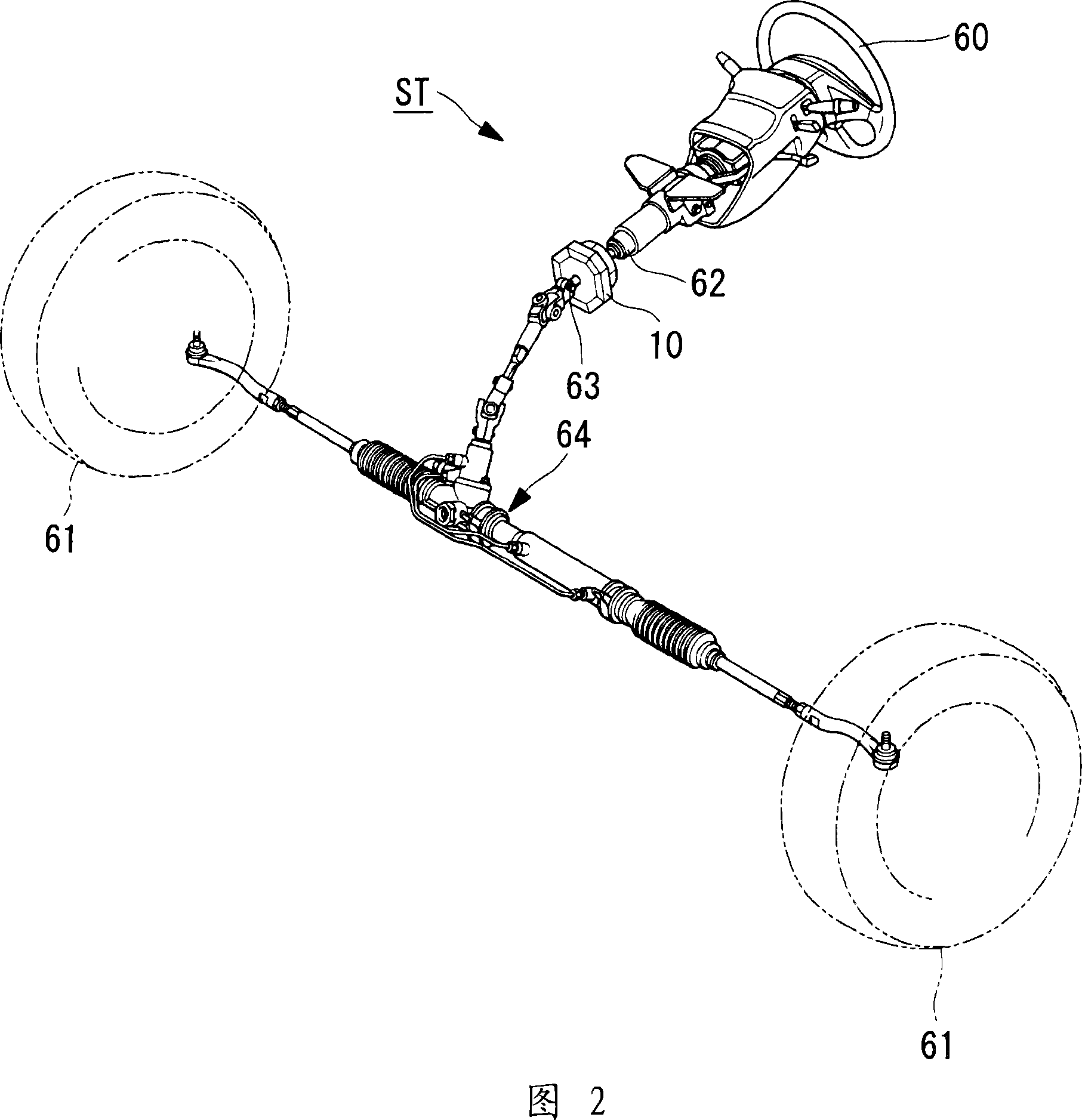

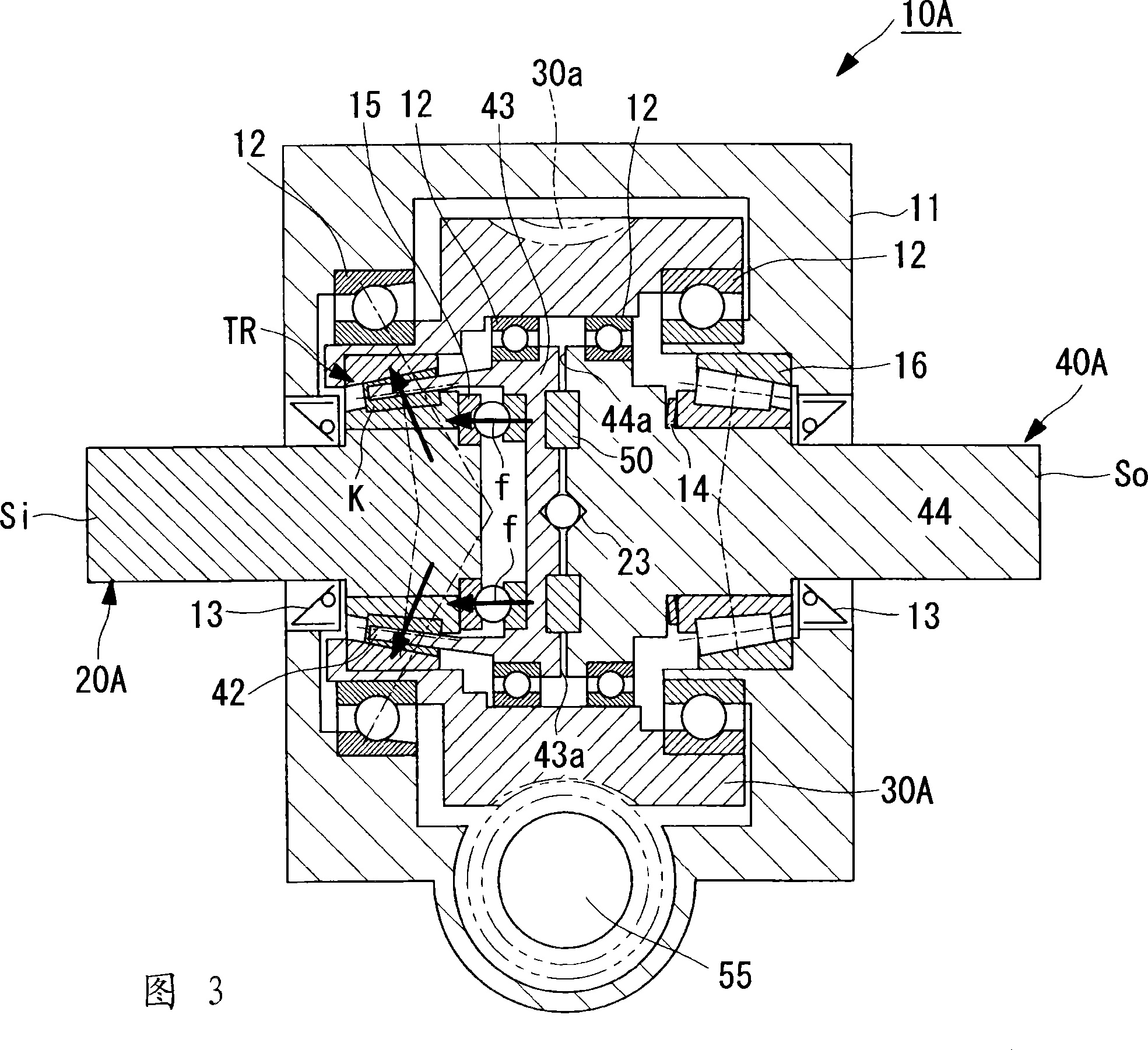

Torque transmission structure, traction drive transmission device, and steering device for vehicle

InactiveCN101006293AAdjust gear ratioIncrease high torque outputFriction gearingsTorque transmissionCam

The invention provides a variable-speed traction drive transmission device compact and having high durability. The traction drive transmission device (10) varies, by the use of traction of rolling bodies (K) arranged between an input shaft (Si) and an output shaft (So), the speed of rotation of the input shaft (Si) into a desired transmission ratio to output the result by the output shaft (So). The traction drive transmission device (10) is placed inclined so that the rotation axes of the rolling bodies (K) are not orthogonal to the axes of the input shaft (Si) and the output shaft (So), and has a load regulation cam (50) and a transmission ratio variation mechanism of a differential type using a worm gear (55). The load regulation cam (50) automatically varies a preload applied to the rolling bodies (K) according to torque of the input shaft (Si). The transmission ratio variation mechanism is connected to a retainer (40) as the traction input-output member of the rolling bodies (K) and varies a transmission ratio by controlling the speed of rotation of the retainer (40).

Owner:MITSUBISHI HEAVY IND LTD

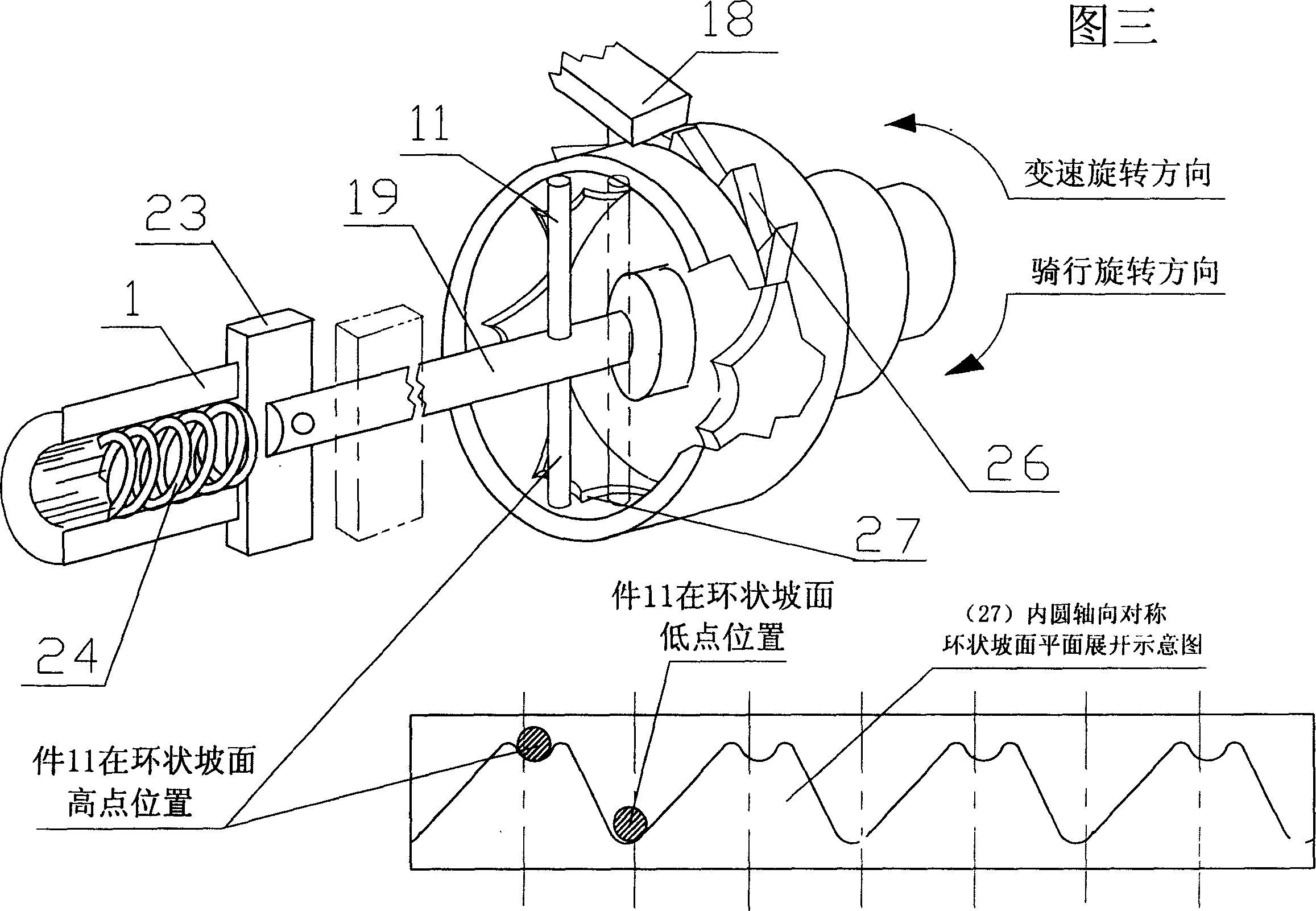

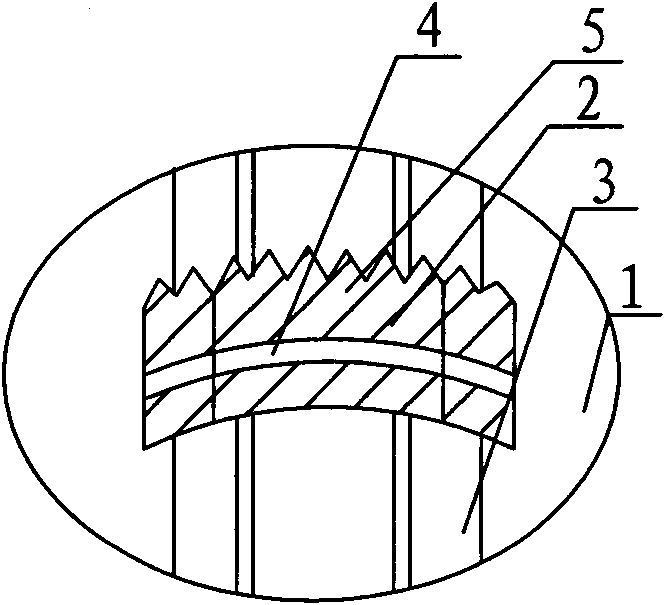

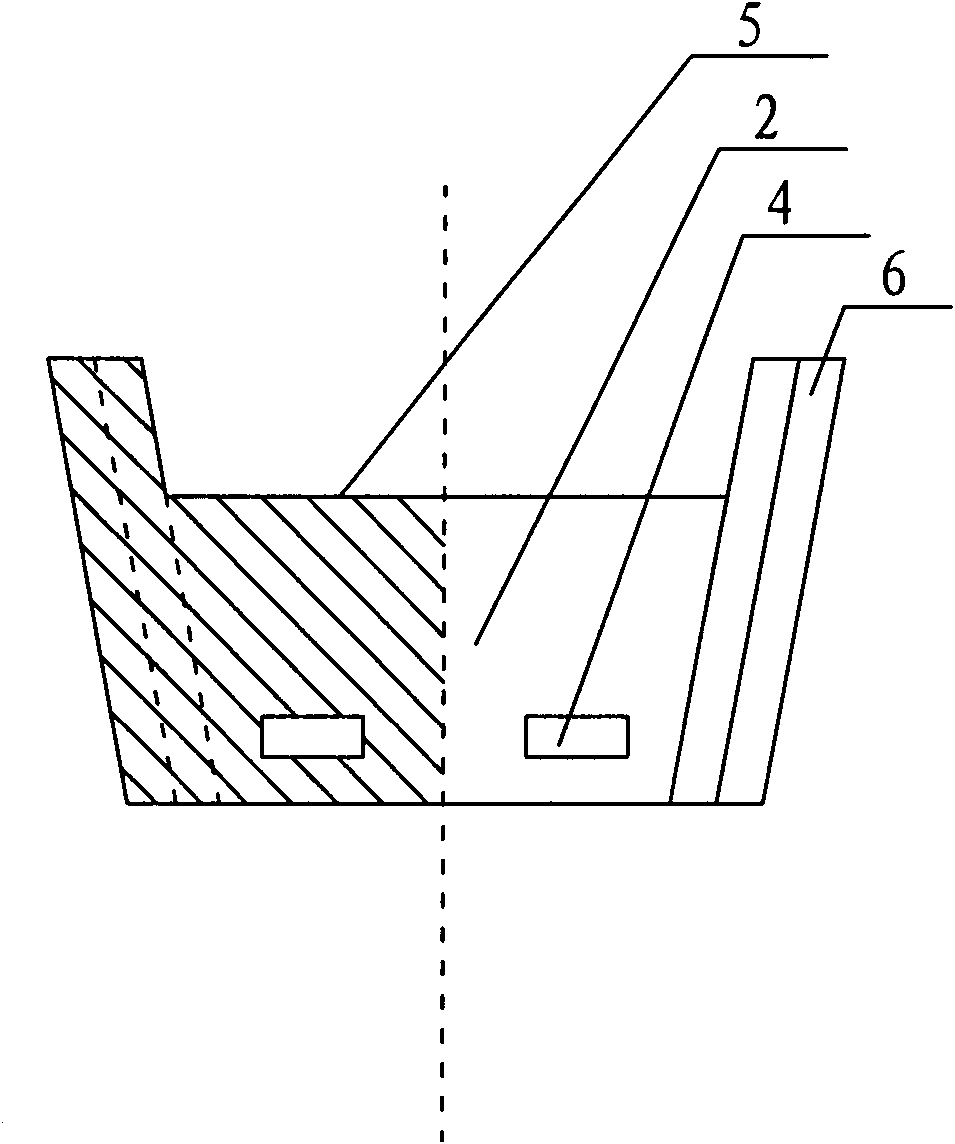

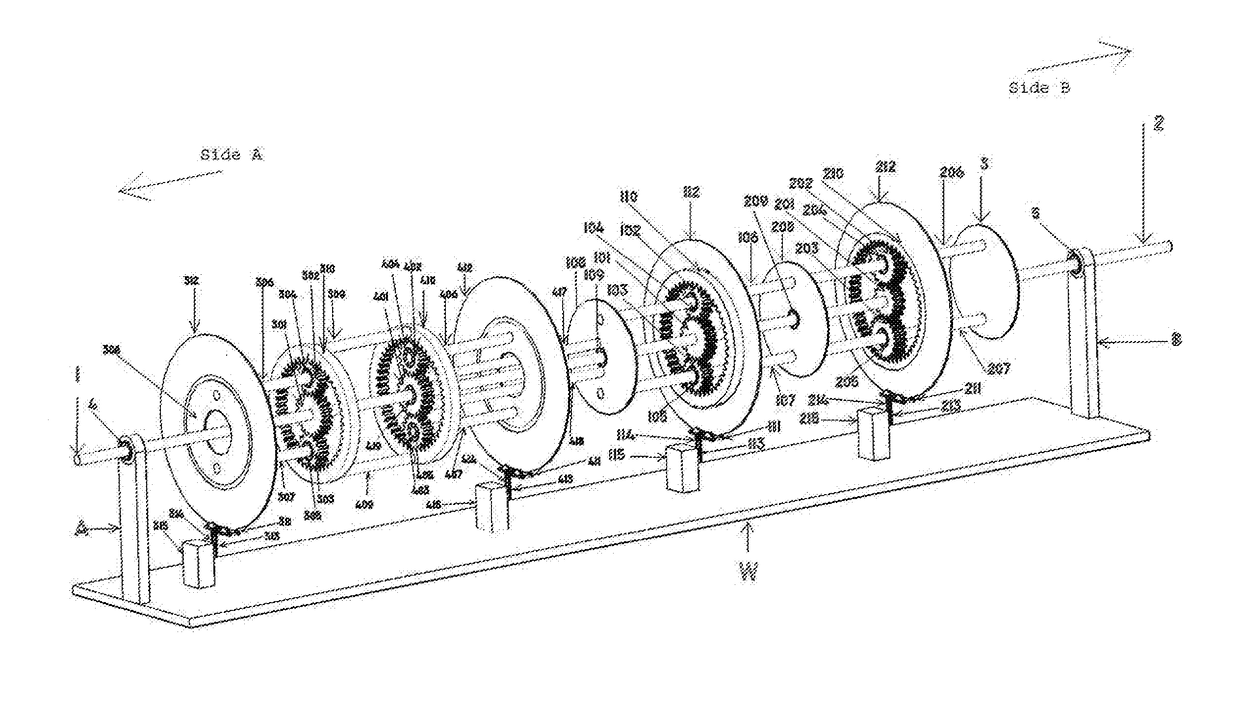

Movable teeth quasi-stepless speed change device

The invention provides a movable teeth quasi-stepless speed change device, comprising a metal band, a driving shaft and a driven shaft, wherein, the driving shaft and the driven shaft are respectivelyinstalled with a fixed cone disc and a corresponding removable cone disc; the cone disc is provided with two to three groups of equant dovetail grooves which are vertical to the rotating direction; the fixed cone disc and the dovetail grooves on the removable cone disc correspond mutually; more than two movable teeth bodies constitute a movable teeth base; the movable teeth body is provided withdovetail blocks and teeth; the dovetail blocks on the movable teeth body are embedded into dovetail grooves; and when the fixed cone disc and the removable cone disc approach or separate, the two to three groups of equant movable teeth bases glide radially in an equal radius, thus changing the working radius of the movable teeth base, achieving the purpose of speed change, changing the friction transmission to gear transmission, and greatly improving the transmission power, the torsion and the mechanical efficiency. The invention also provides a novel structure of mechanical automatic pressurizing and speed adjusting to substitute the common hydraulic pressurizing system.

Owner:郭质刚

Connector

ActiveUS20200014146A1Improve machinabilityReliable engagementVehicle connectorsCoupling device detailsGear wheelEngineering

Owner:YAZAKI CORP

Double-cone-wheel transmission for bicycle

The invention discloses a double-cone-wheel transmission based on a bicycle chain rotating mechanical device. The double-cone-wheel transmission mainly comprises an active chain wheel driven by foot rest levers, a passive chain wheel, a sliding chain axle, a driving chain wheel, an internal chain, a speed-changing chain jumping mechanism and the like. According to the double-cone-wheel transmission, the number of chain discs of the active chain wheel is one larger than that of chain discs of the passive chain wheel, the passive chain wheel can transversely move back and forth on the passive axle by a chain disc interval under the action of a passive wheel transverse shifting fork, each passive chain wheel tooth disc is only meshed with two corresponding active chain wheel tooth discs, the internal chain can be connected with one of any two active chain wheel tooth discs on a rotating plane of a tooth disc of the passive chain wheel under the action of chain jumping mechanism, and therefore the number of steps of speeds can be twice that of the number of the passive chain wheel discs. According to the double-cone-wheel transmission, the thickness of the bicycle transmission and the diameters of the chain wheels are effectively decreased, and multi-step uniform speed changing can be achieved within a small space and under the action of a small number of parts.

Owner:李凌军

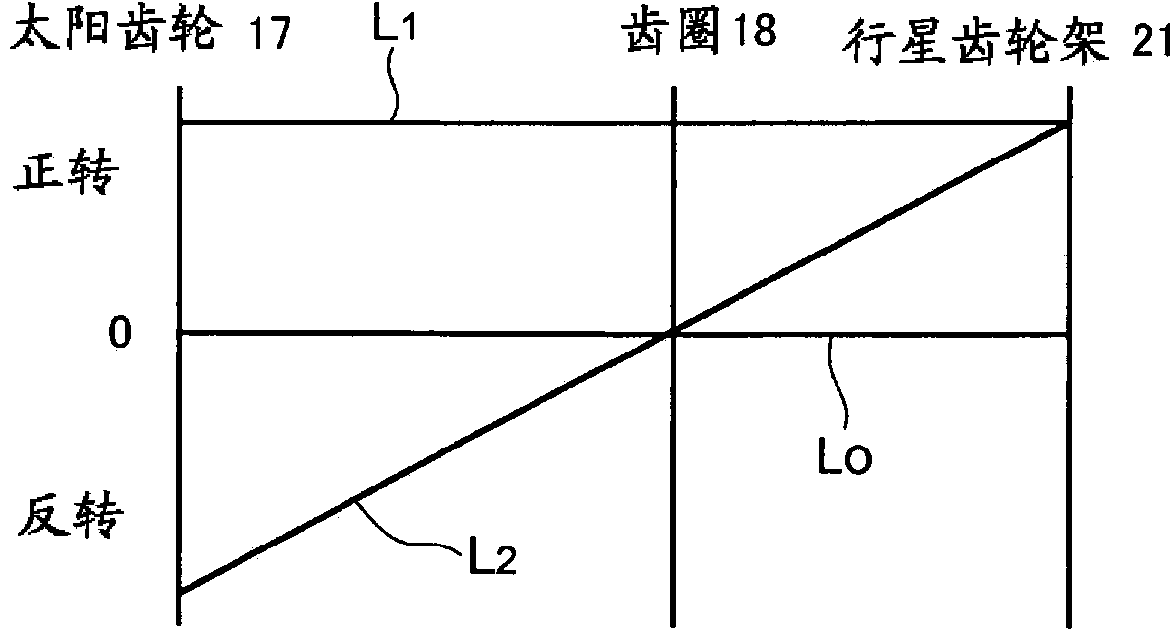

Range-change transmission of a motor vehicle

ActiveUS20150354681A1Optimization mechanismIncrease spaceGearingTransmission elementsLow speedEngineering

A group transmission of a motor vehicle having a main transmission and a downstream range group. The range group has two gear steps for different speed ranges and a reversing step for reverse driving. The range group has two planetary gearsets, each with a planet carrier, a sun and ring gears. To engage a driving range for lower speeds, the sun gear of the second gearset and the ring gear of the first gearset are locked to the housing by a first clutch. To engage a driving range for higher speeds, two respective elements of the two gearsets can be connected to one another, in a rotationally fixed manner, by a second clutch. To engage a reversing driving range, the planet carrier of the first gearset and the ring gear of the second gearset are locked relative to the housing by a third clutch.

Owner:ZF FRIEDRICHSHAFEN AG

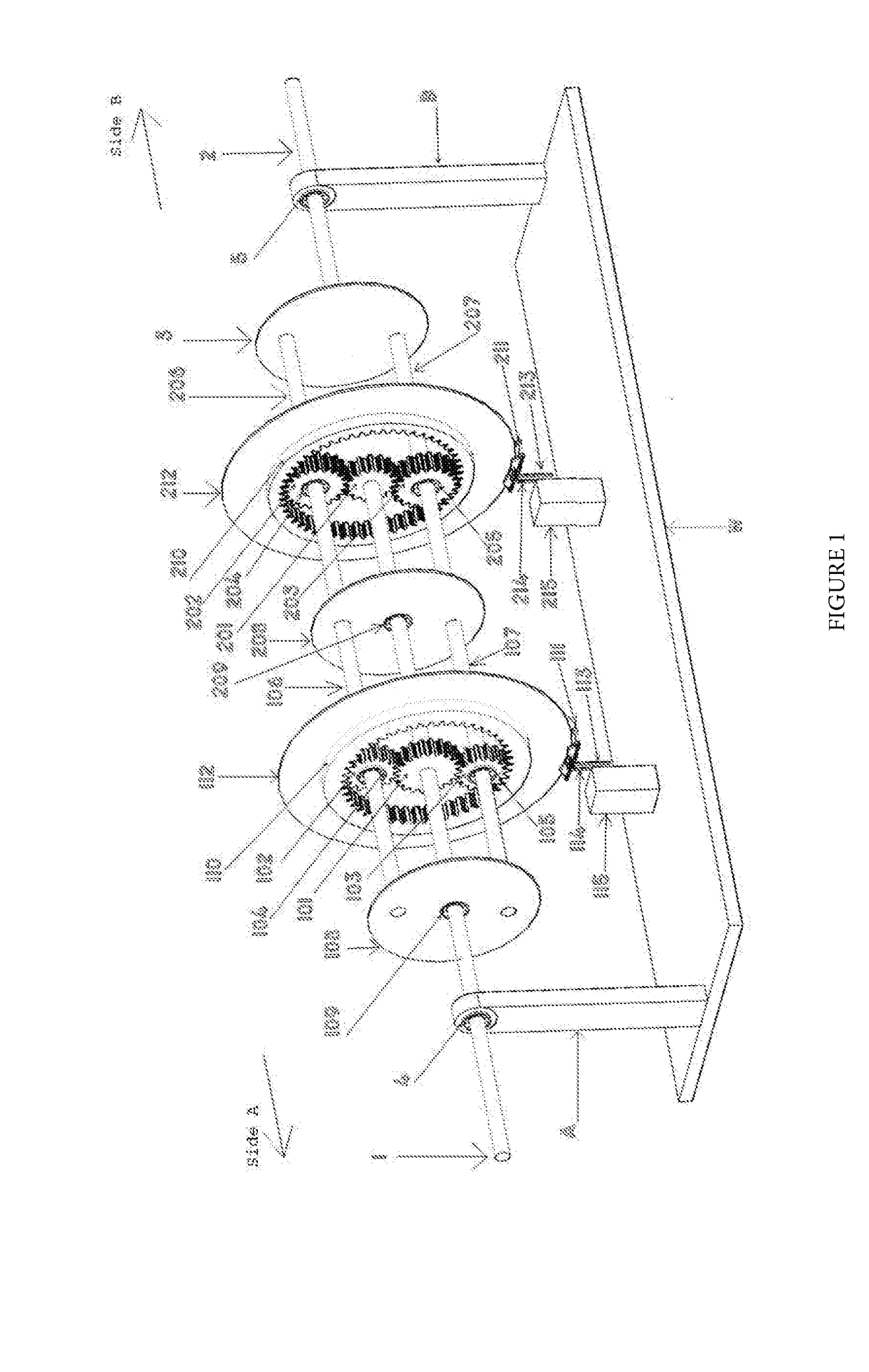

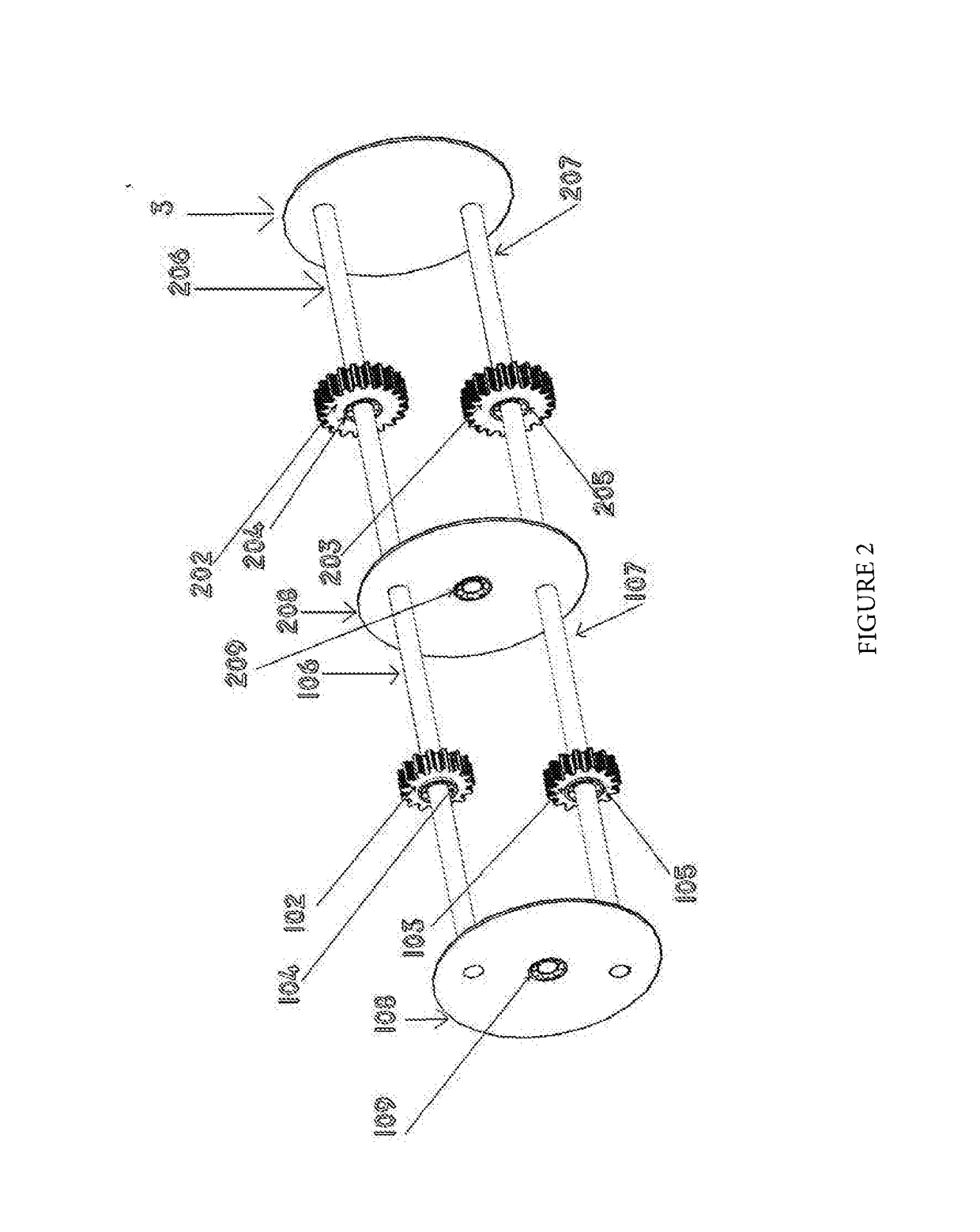

A planetary gearbox

ActiveUS20180320761A1Reduce and nullify wearReduce and nullify and tearToothed gearingsTransmission elementsDrive shaftGear train

Parallel shafting gearbox have problems like the frictional losses, gear shifting is very hard under load, wear and tear of gears while shifting and operating of the gears, load distribution on single driven gear and it is hard to derive large reductions gear ratio easily. Present invention introduces a gearbox as a solution for above problems using PGTU (planetary gear trains unit)s such that all the PGTUs in gear box are connected serially with axles on which planetary gears are mounted, of the PGTUs which are arranged between them, forming a series of CPCAs, for transmission from rotating driving shaft on which sun gears are mounted to the driven shaft by braking the motion of the ring gear of PGTU through which the transmission is to be carried out while setting free the ring gears of rest of the PGTUs in the gear box, It is useful in automobile vehicle etc.

Owner:PALASPAGAR SANDEEP RAMESH

Gear transmitting device and electronic apparatus

InactiveUS20050178226A1Low costAccurate shapeVisual indicationToothed gearingsInvolute gearMiniaturization

A gear transmitting device has such a structure as including an input gear, an output gear, and one or more intermediate gears for transmitting gear oscillation to the input and output gears. The gear transmitting device is also provided with a gear train including the input gear for transmitting oscillation to the output gear. The gear train includes, for gear engagement, one or more pairs of arc-circular tooth gears, and an involute tooth gear or a cycloidal tooth gear. With such a structure, the gear transmitting device can be reduced in size, and accordingly an electronic apparatus incorporating the gear transmitting device can be also reduced in size.

Owner:SEIKO INSTR INC

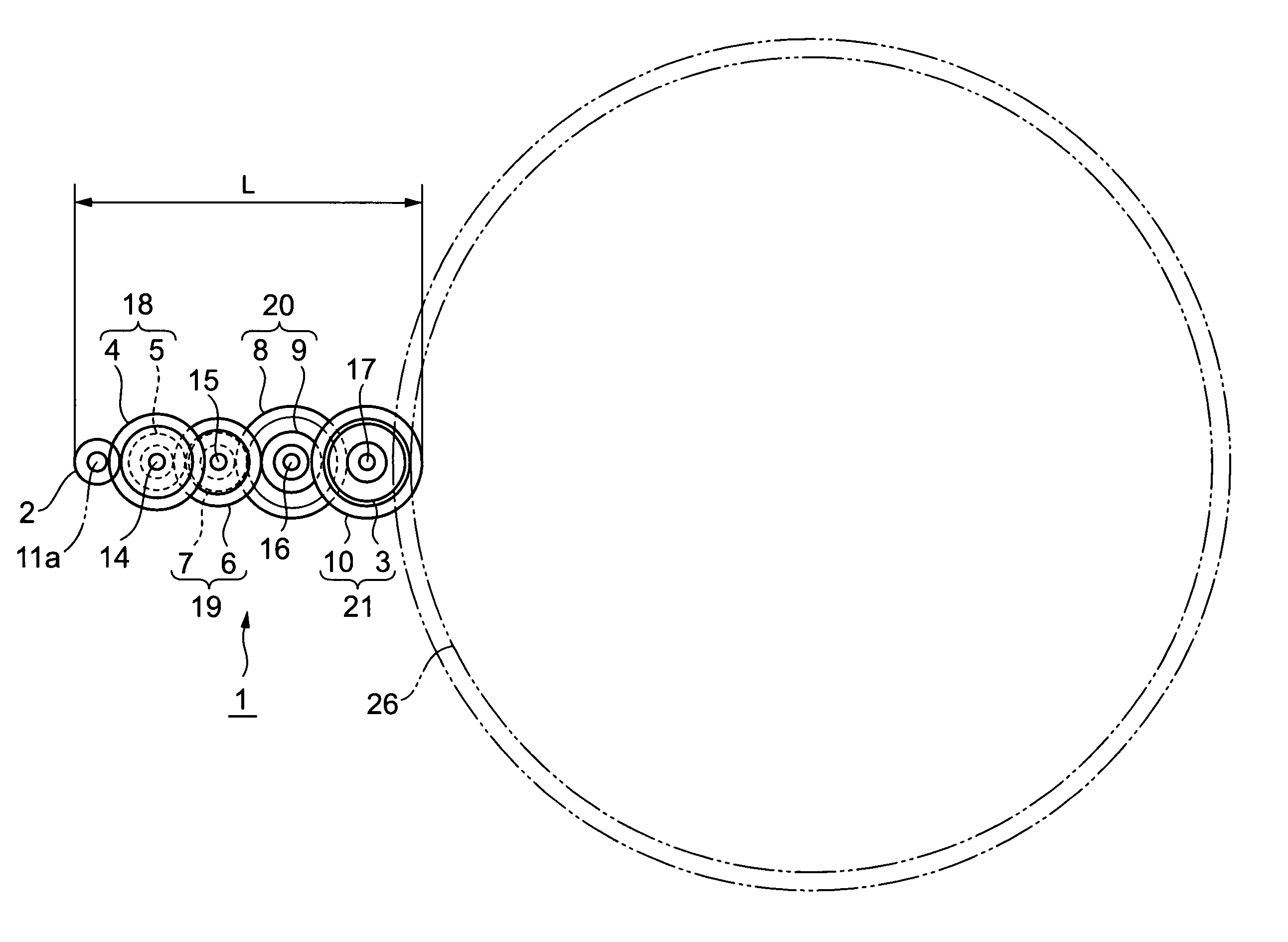

Transmission

InactiveUS8262533B2Large gear ratioCompact gearToothed gearingsTransmission elementsGear wheelEngineering

The invention provides a transmission providing a gear ratio between an input shaft and an output shaft. The transmission comprises an annulus ring, a sun wheel being rotatable around a central axis of the transmission, a planet carrier being rotatable around the central axis of the transmission, and a set of planet wheels, each wheel comprising a plurality of wheel segments with different diameters, the planet wheels being fixed in rotational bearings of the planet carrier and being arranged to rotate epicyclically around the central axis. The annulus ring and the sun wheel each interacts with one of the wheel segments e.g. via meshing toothed gear wheels. The gear facilitates various interaction means at different locations in the gear, and thus facilitates a potentially less noisy, lighter, smaller or stronger gear by use of a low amount of components.

Owner:TOMACTECH

Double-conic disc friction stepless speed changer

InactiveCN1932338AAutomatic contact pressureWon't slipGearing controlFriction gearingsContact pressureDrive shaft

The present invention relates to a double conical disk friction stepless speed changer. It is characterized by that its input shaft is mounted in the left end of external shell and its output shaft is mounted in the right end of said external shell; the eccentric sleeve is mounted in the inner hole of external shell, the medium friction drive disk and medium drive shaft are mounted in the inner hole of eccentric sleeve; the double-head bidirectional screw rod left end is mounted into the positive screw hole of medium friction drive disk by means of positive screw threads, and the double-head bidirectional screw rod right end is mounted into the negative screw hole of medium drive shaft by means of negative screw threads; the left end face of medium friction drive disk is conical recessed surface, the right end of input shaft is conical projected surface; the left end face of output shaft is conical recessed surface, the right end of medium drive shaft is conical projected surface; and the eccentric sleeve is driven by eccentric sleeve drive device and is rotated.

Owner:江从寿

Range-change transmission of a motor vehicle

A group transmission of a motor vehicle having a main transmission and a downstream range group. The range group has two gear steps for different speed ranges and a reversing step for reverse driving. The range group has two planetary gearsets, each with a planet carrier, a sun and ring gears. To engage a driving range for lower speeds, the sun gear of the second gearset and the ring gear of the first gearset are locked to the housing by a first clutch. To engage a driving range for higher speeds, two respective elements of the two gearsets can be connected to one another, in a rotationally fixed manner, by a second clutch. To engage a reversing driving range, the planet carrier of the first gearset and the ring gear of the second gearset are locked relative to the housing by a third clutch.

Owner:ZF FRIEDRICHSHAFEN AG

Wind turbine and method of operating a wind turbine

InactiveUS9932964B2Simple and robust azimuth driveEasy to disengageWind motor controlEngine fuctionsFrequency UnitNacelle

Wind turbine comprising a nacelle with a generator and wind turbine blades for driving the generator, a tower supporting the nacelle wherein the nacelle is rotatable about a vertical axis an azimuth drive for rotating the nacelle around the axis, said azimuth drive comprising a plurality of asynchronous yaw motors and an azimuth controller with a frequency unit for controlling the plurality of asynchronous yaw motors, wherein the azimuth controller is arranged to connect all of the plurality of asynchronous yaw motors to the one frequency unit in a rotating mode and to connect only a subset of the plurality of asynchronous yaw motors from the one frequency unit in a locking mode.

Owner:BESTWATT BV

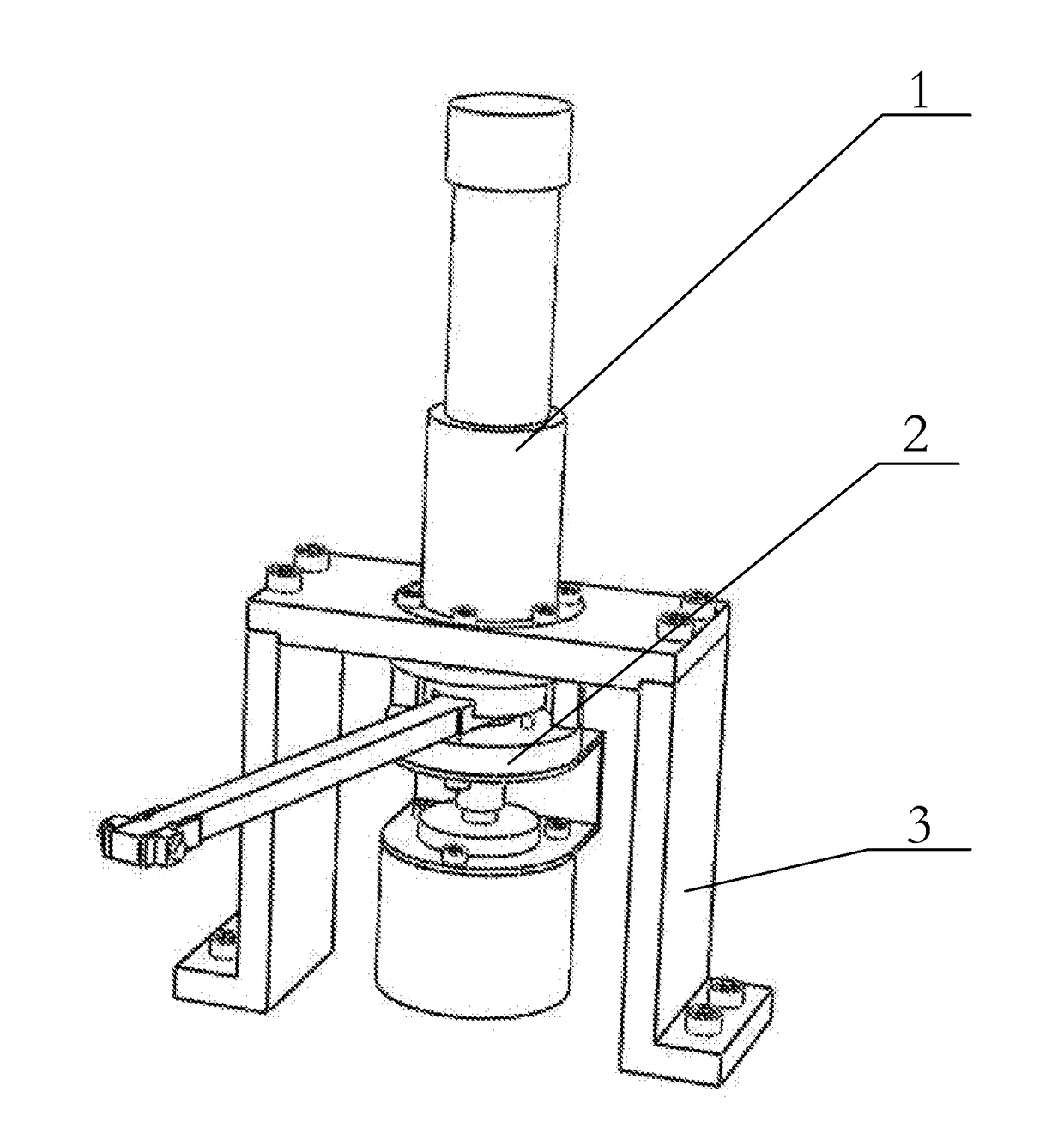

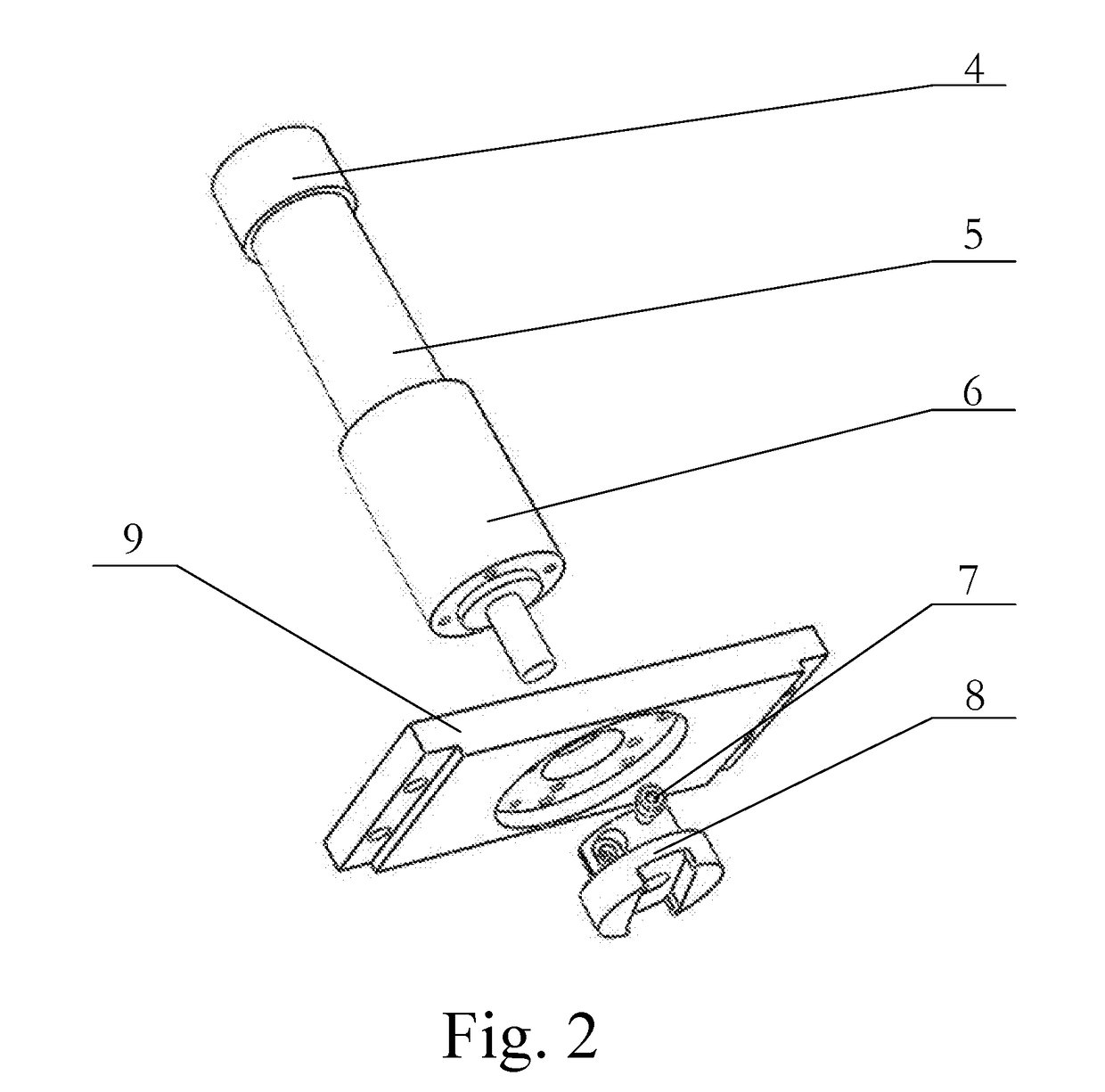

Force feedback handle device with a degree-of-freedom and working method thereof

ActiveUS20170235327A1Overcome the small stiffnessSlight frictionControlling membersLimiting/preventing/returning movement of partsHigh stiffnessDegrees of freedom

A force feedback handle device with a degree-of-freedom includes: a driving part (1), a link part (2) and a frame part (3); wherein the driving part (1) and the link part (2) are both installed on a top board (9), and a rotation axis of the link part (2) coincides with a rotation axis of the driving part (1); the driving part (1), the link part (2) and the frame part (3) are fixed and connected by bolts. A working method of the force feedback handle device includes four steps. The force feedback device of the invention has low inertia and high stiffness performance, which improves overall interaction performance of the force feedback device. The structure is simple and a manufacturing cost is low.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com