Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Improve truncation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

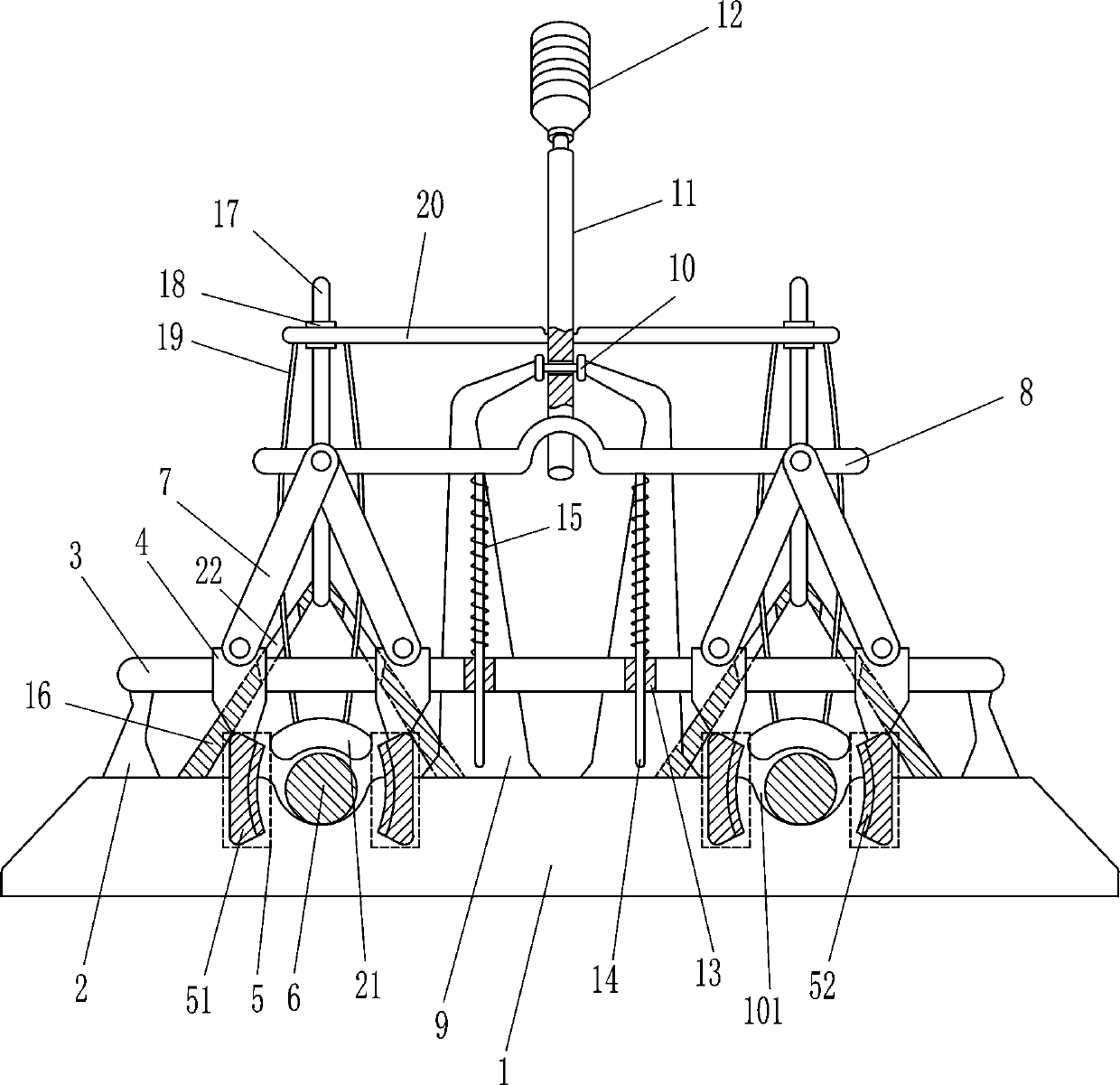

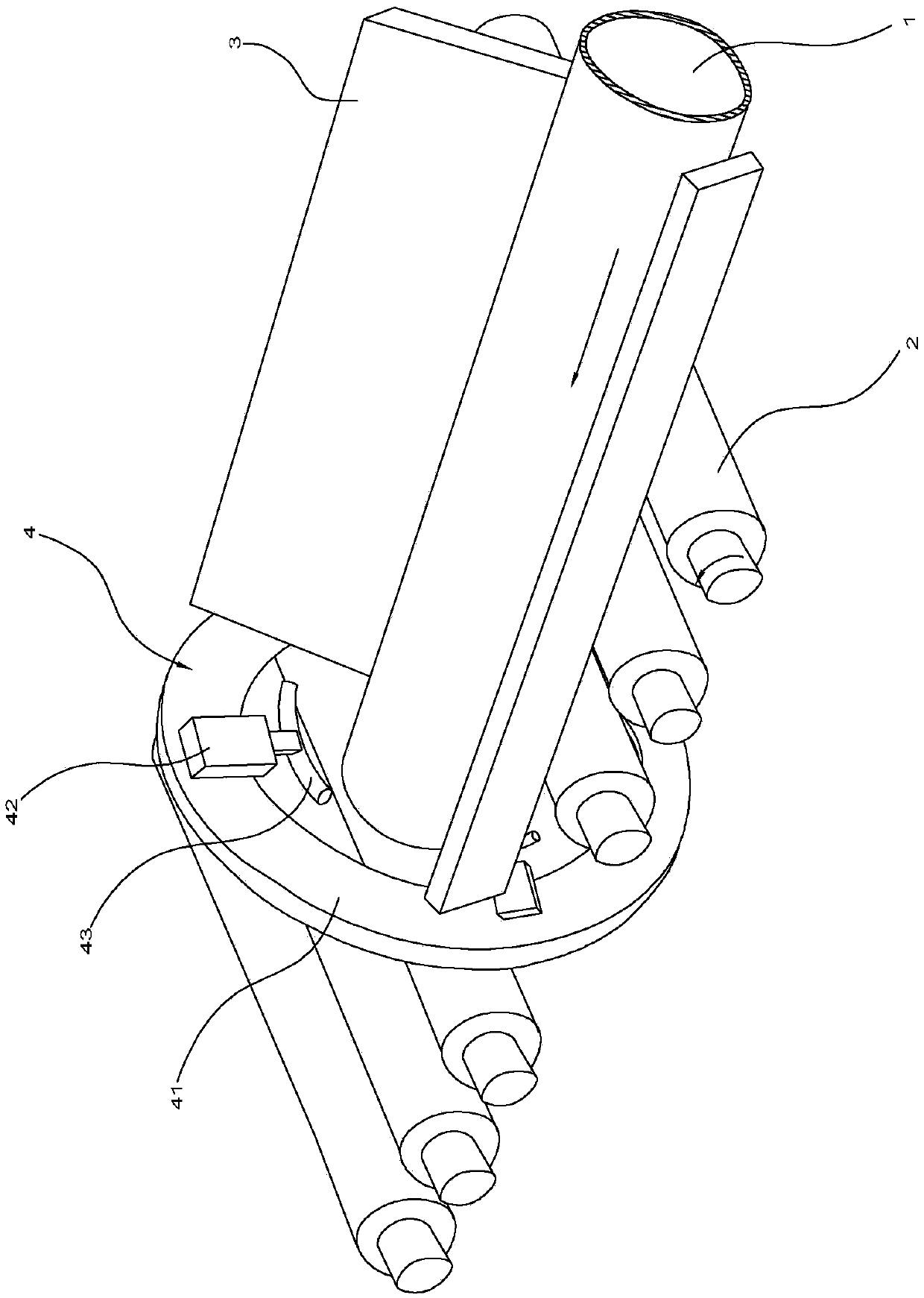

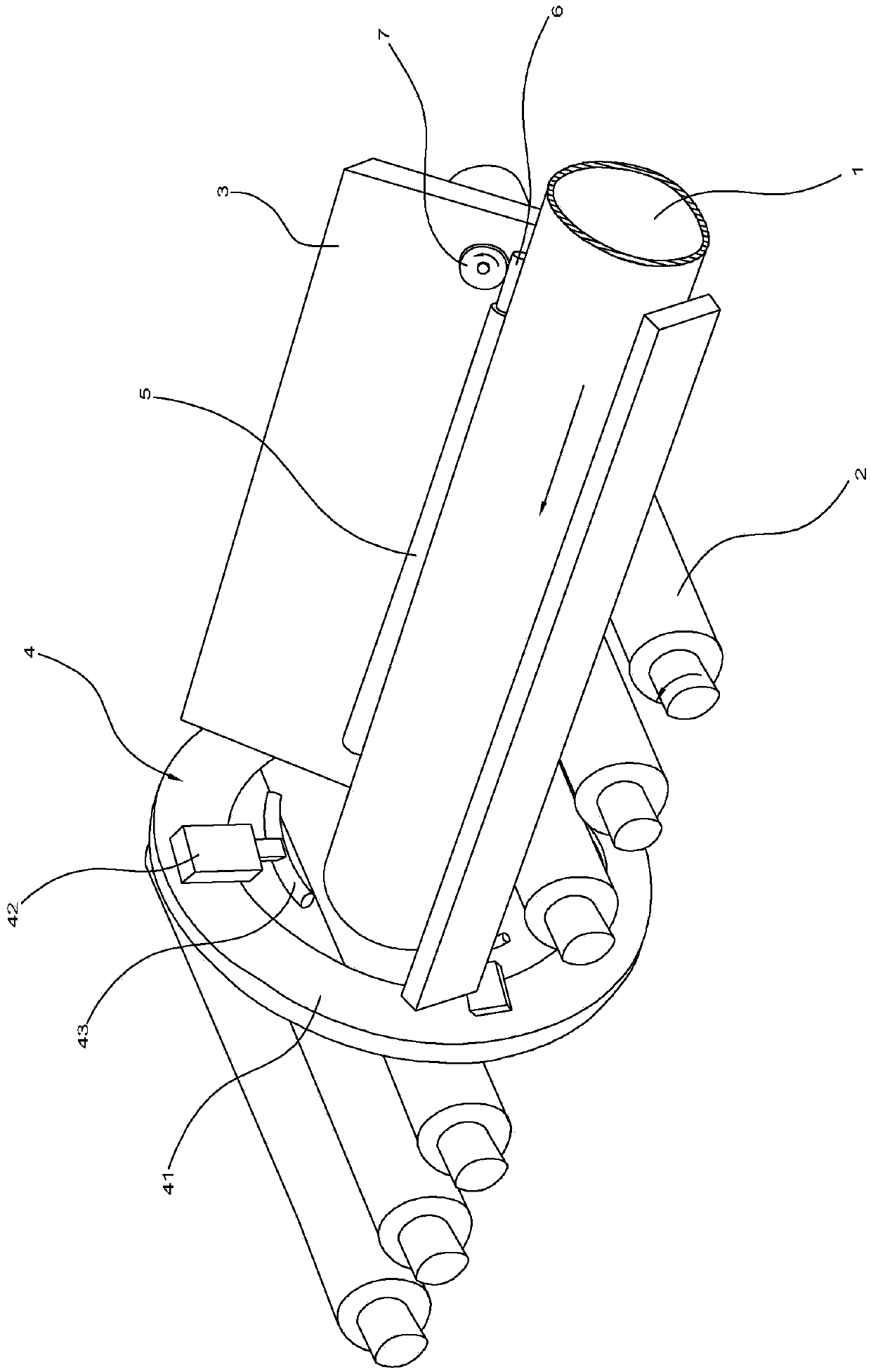

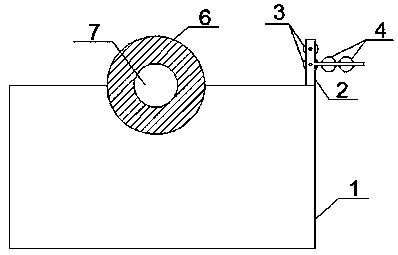

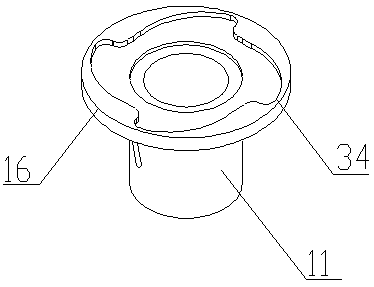

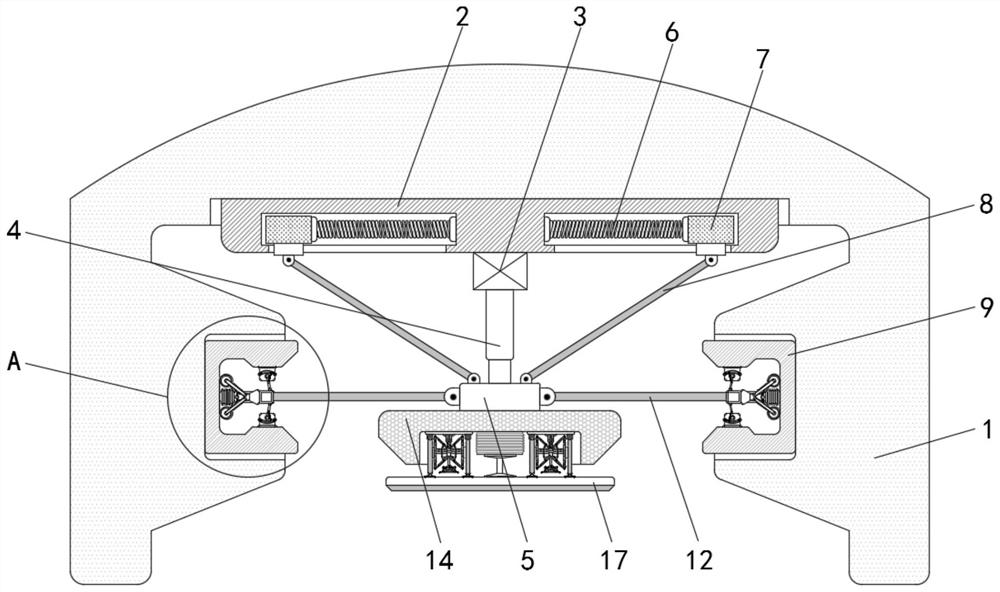

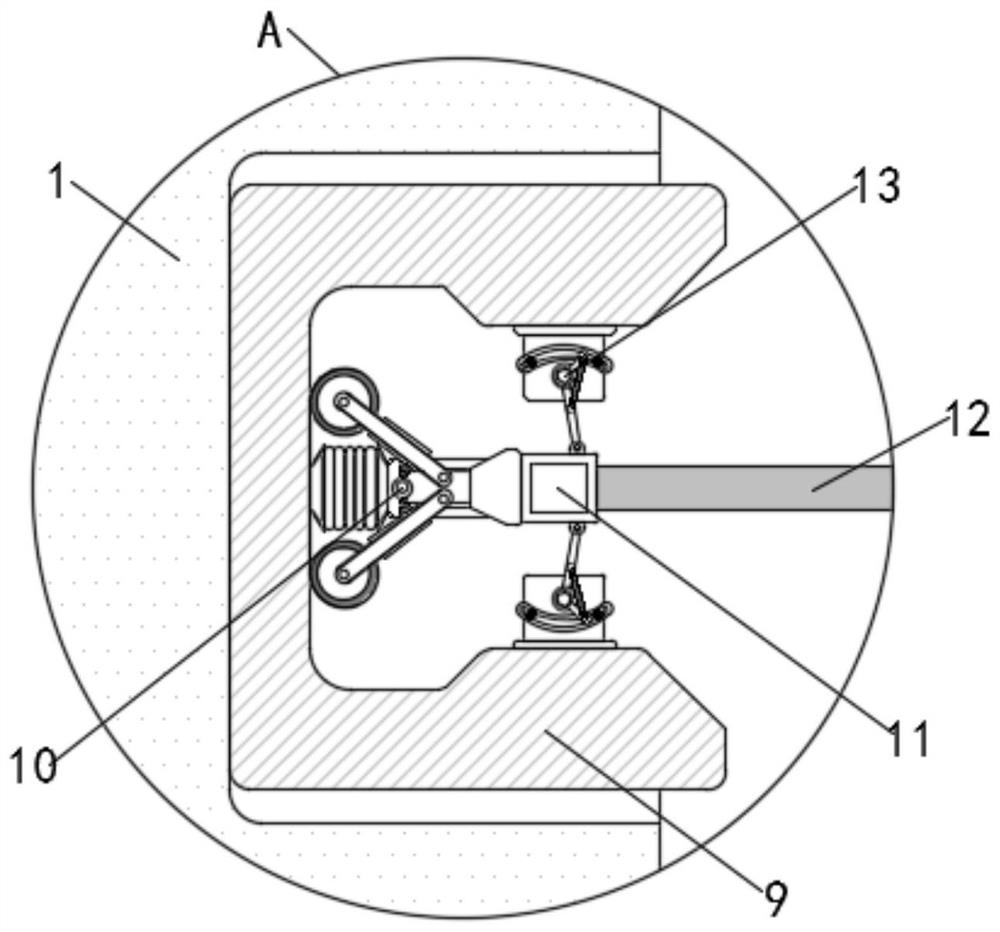

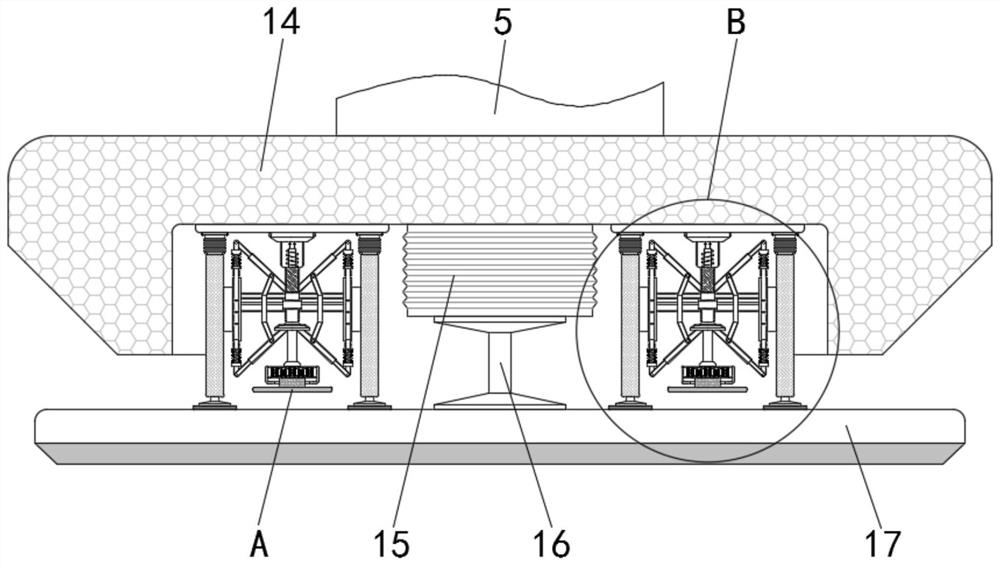

Steel bar cutter for well lid installing

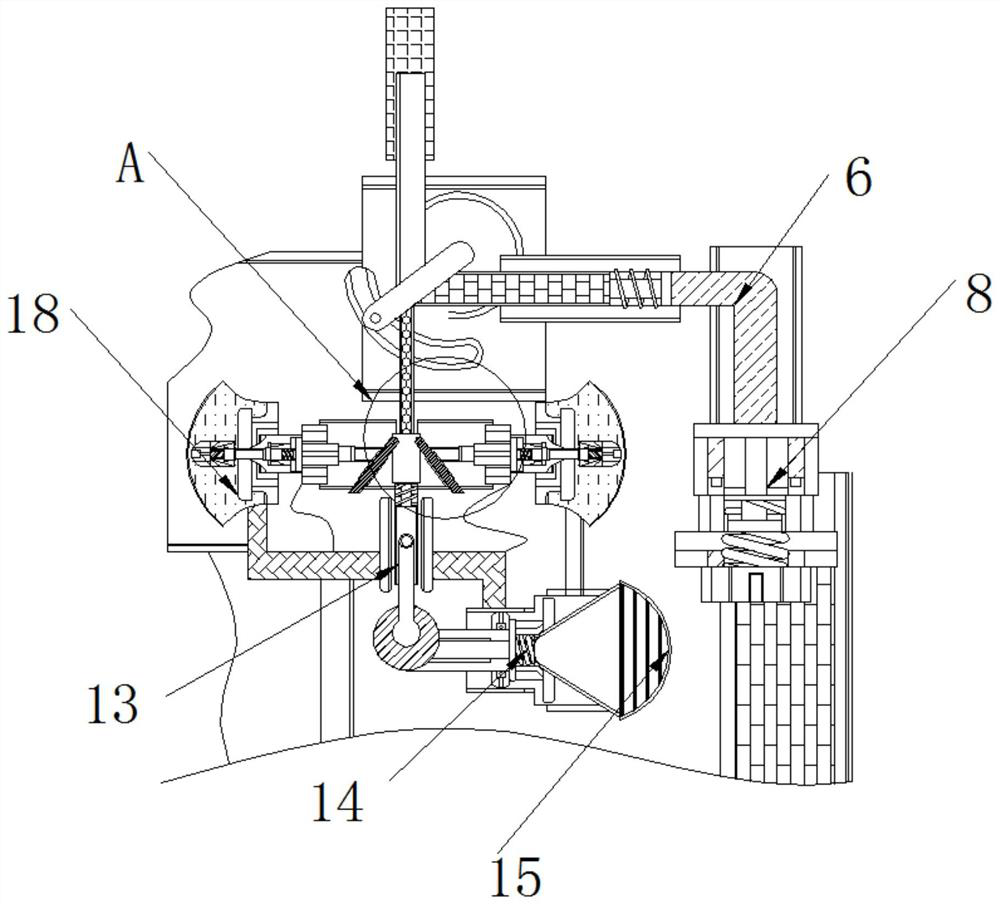

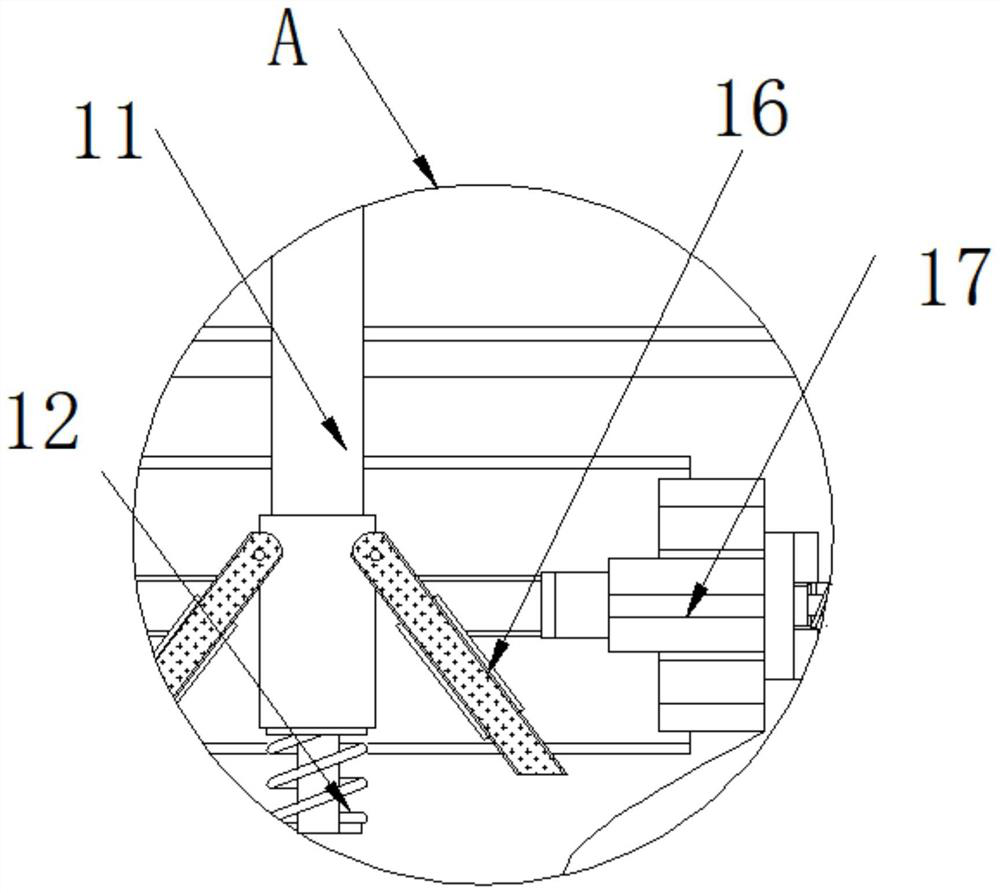

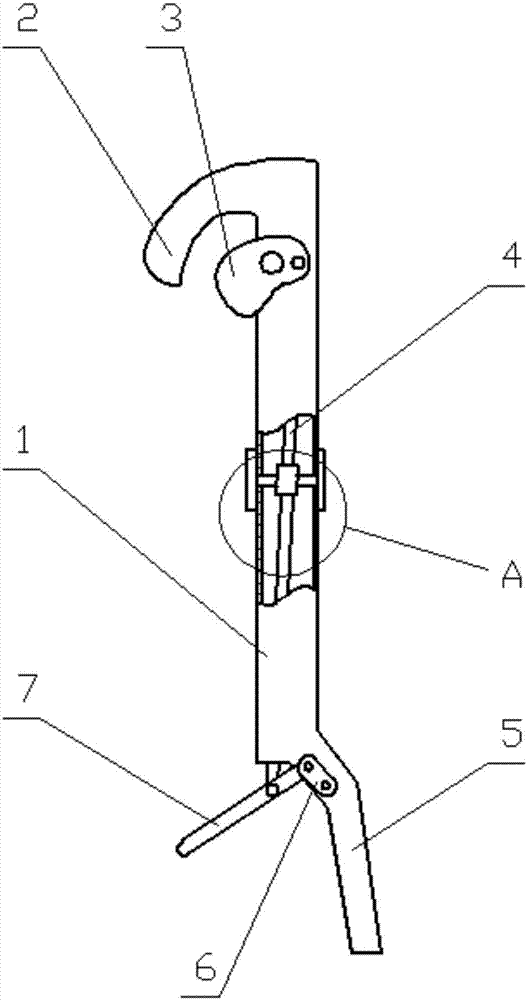

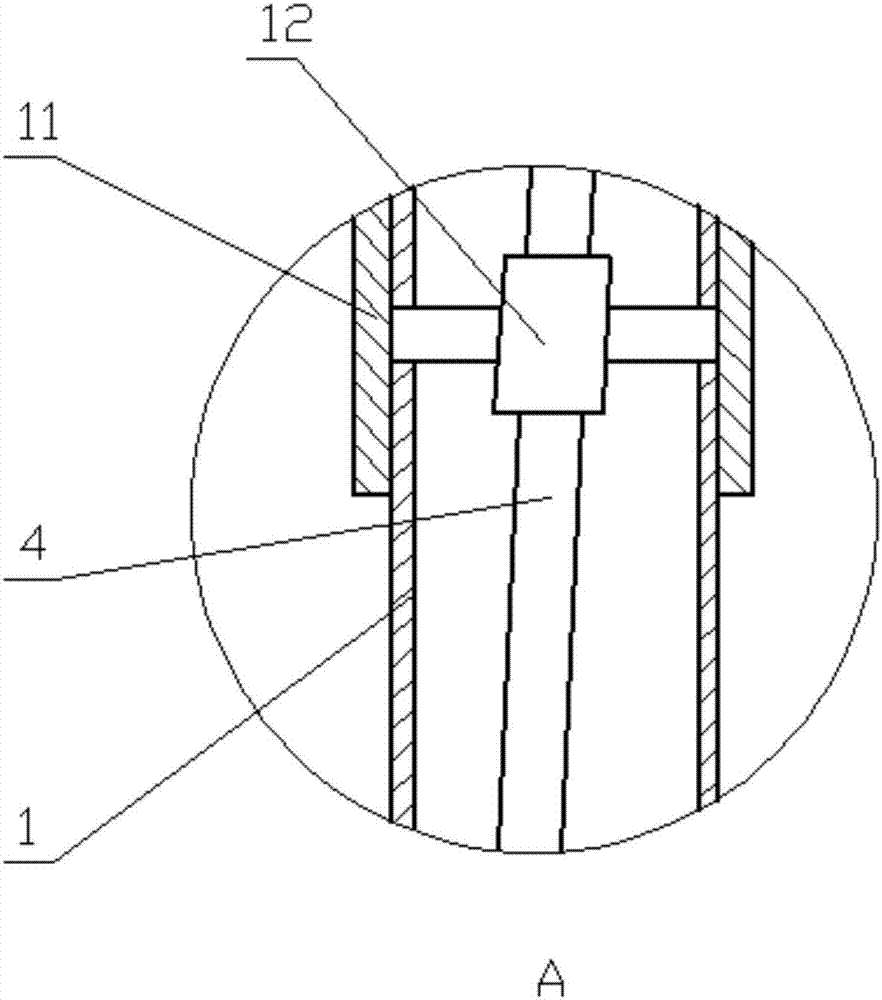

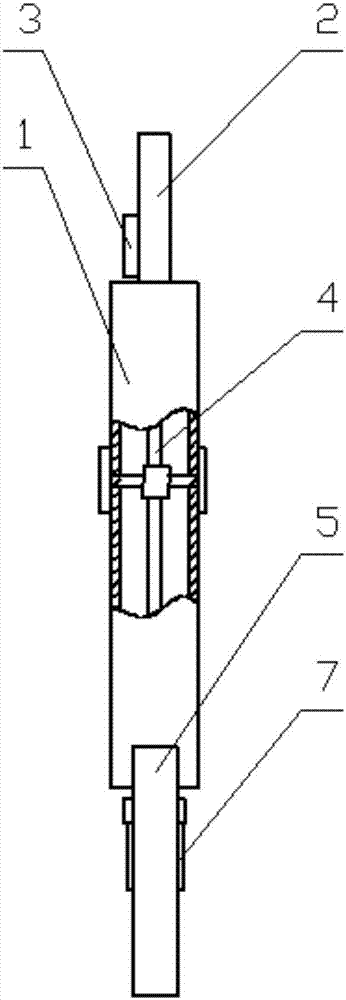

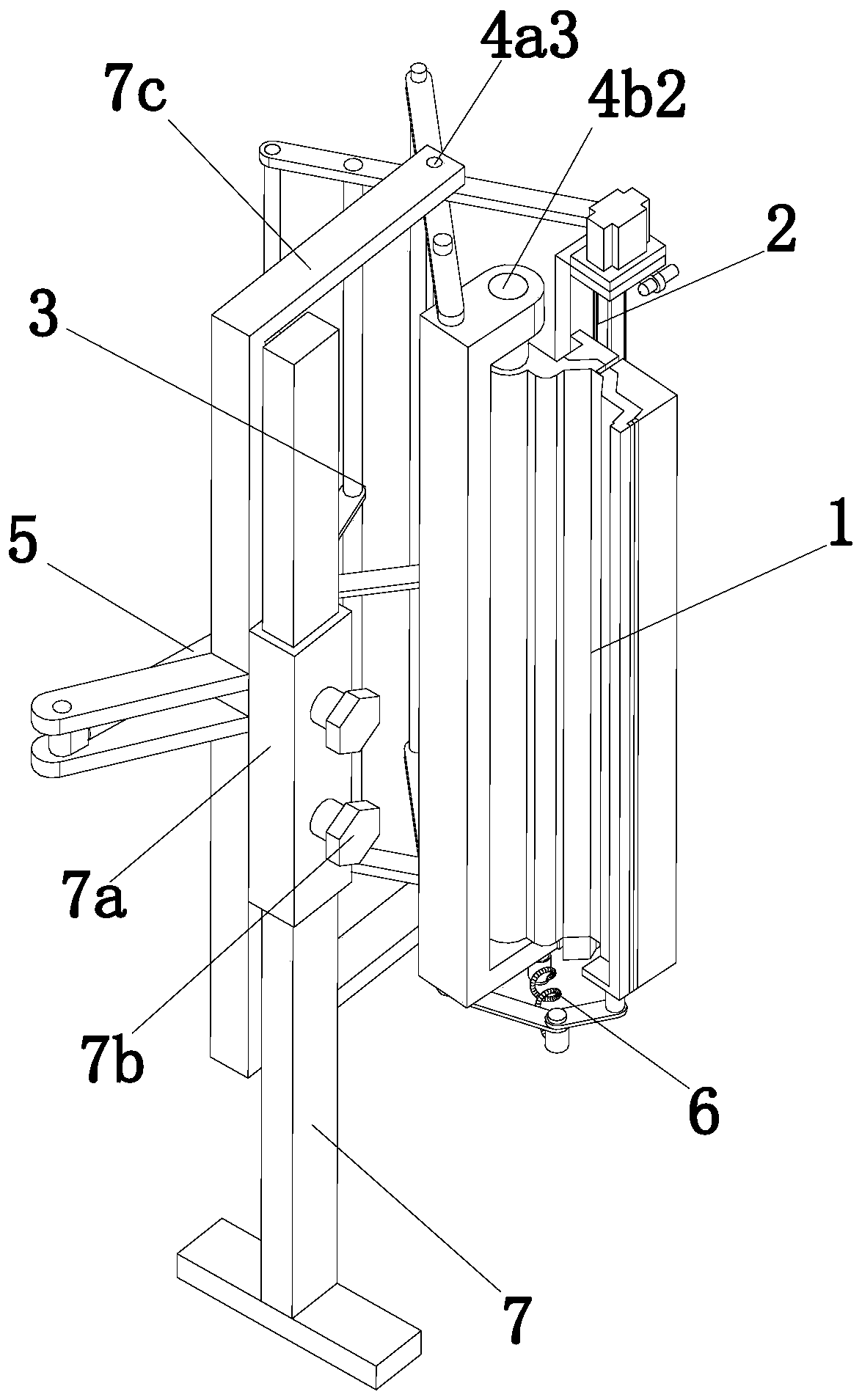

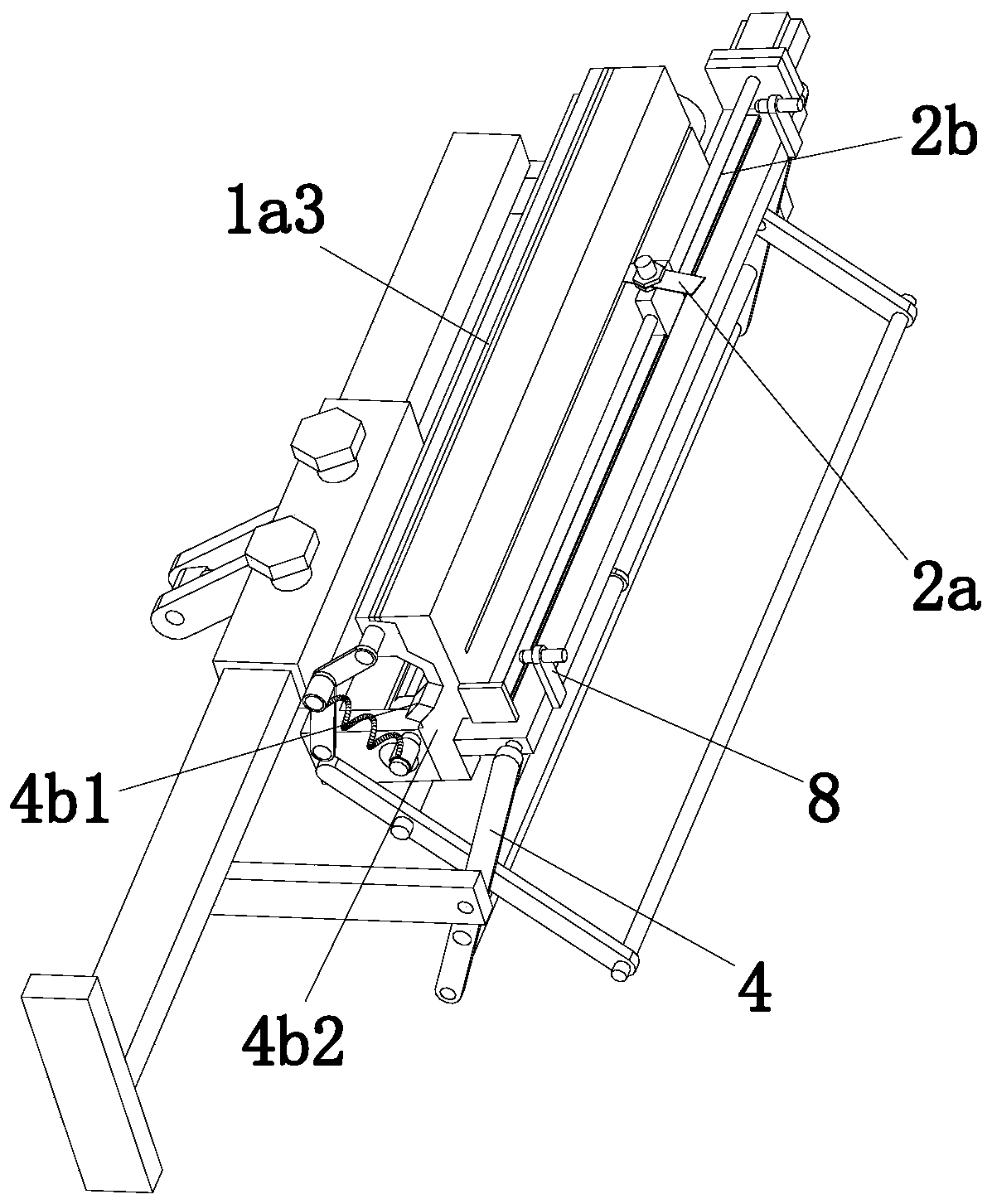

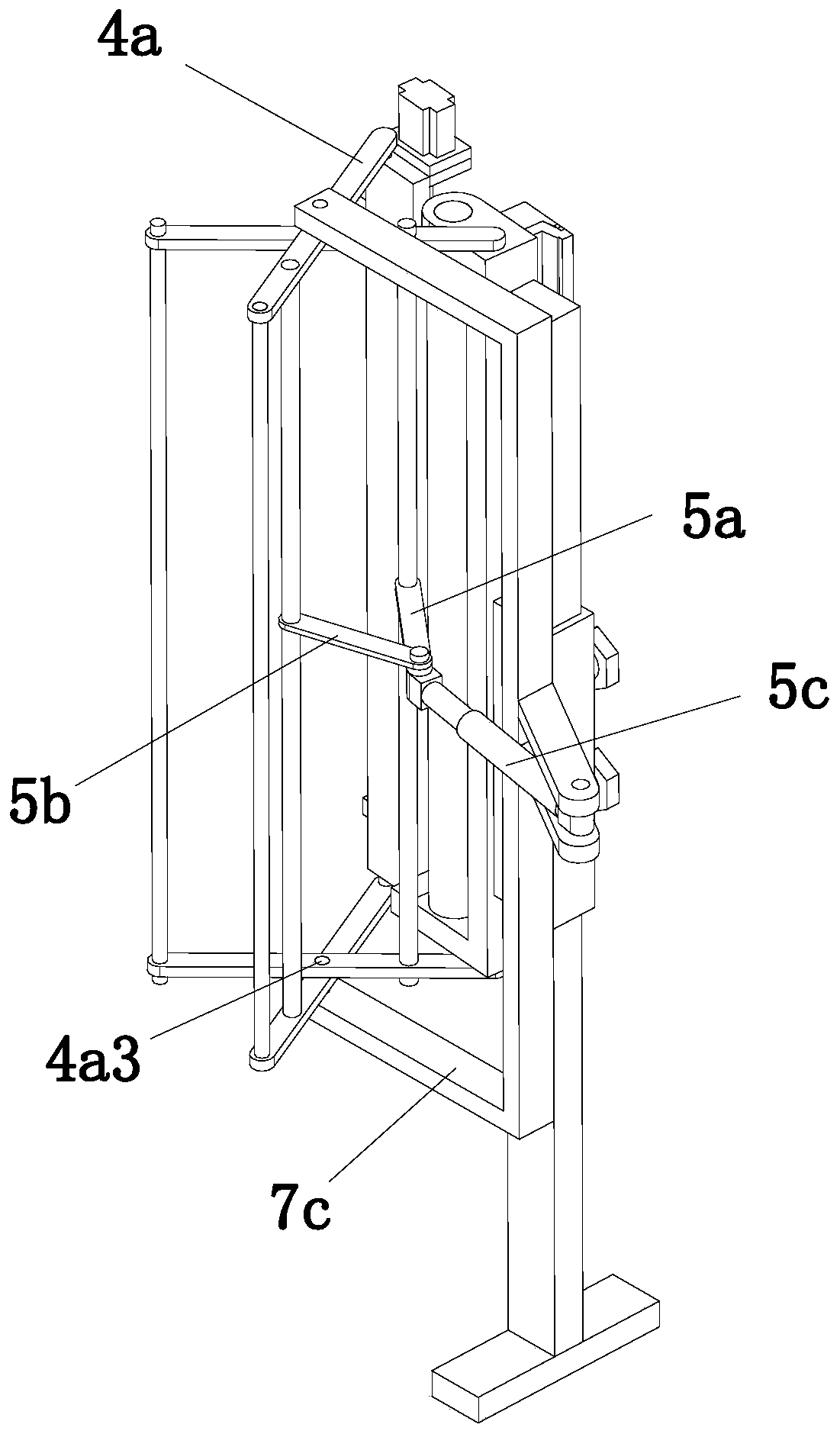

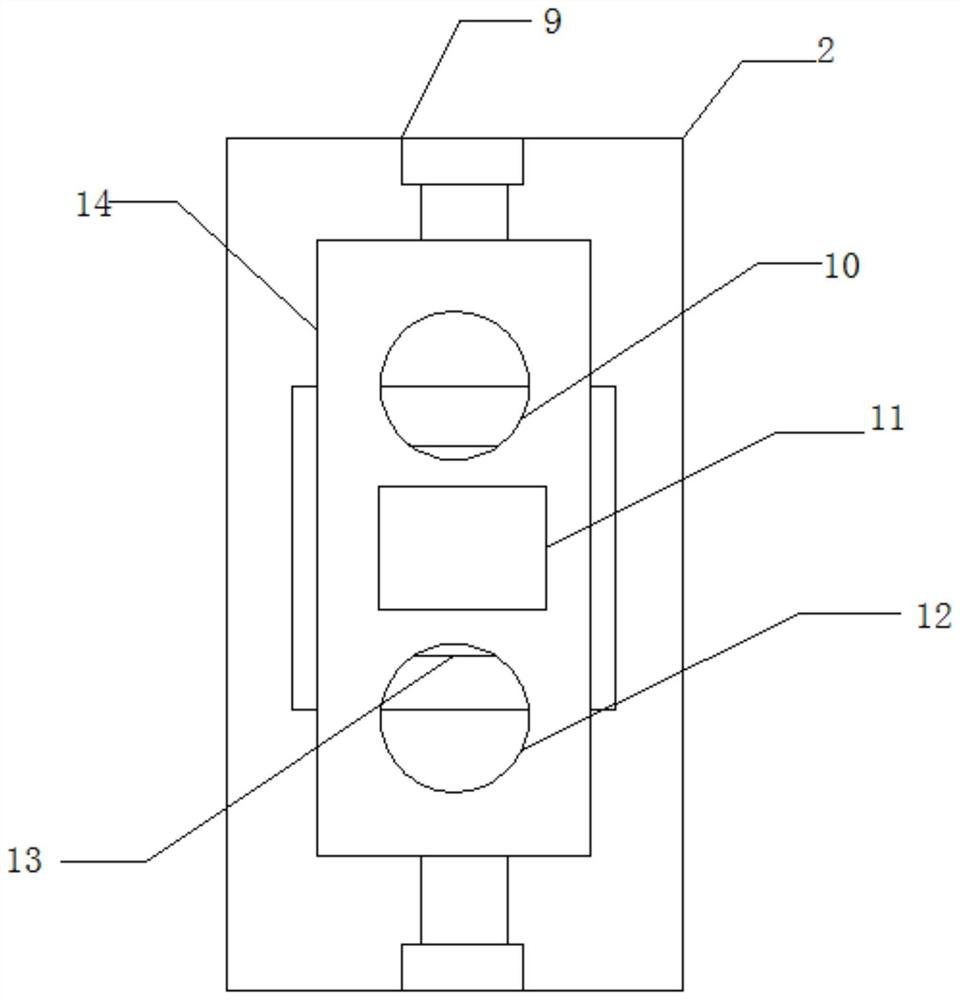

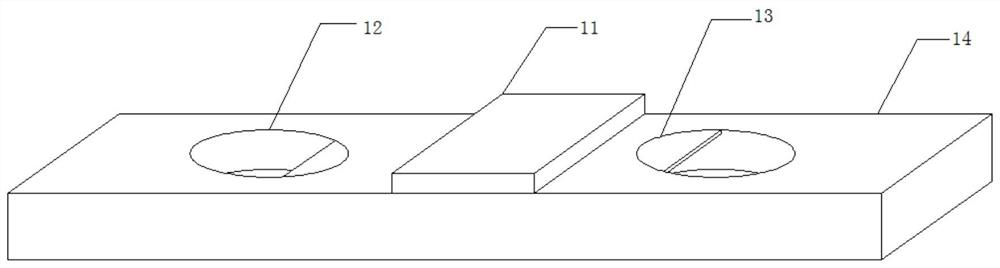

The invention relates to a steel bar cutter, in particular to a steel bar cutter for well lid installing. The technical propose that the steel bar cutter for well lid installing can prevent arm achingand improve the cutting efficiency is achieved. According to the technical scheme, the steel bar cutter for well lid installing comprises a bottom plate, supporting rods, a guiding rail, guiding blocks, cutting devices, steel bar bodies, connecting rods, a concave rod, a connecting plate, a rotating joint, a telescopic rod, a holding handle, guiding sleeves and the like; and the left side and theright side of the top of the bottom plate are each provided with a containing groove used for containing the corresponding steel bar body, the supporting rods are fixed to the left side and the rightside of the top of the bottom plate, the guiding rail is arranged between the top ends of the left supporting rod and the right supporting rod, and the four guiding blocks are arranged. According tothe steel bar cutter for well lid installing, the steel bar bodies can be cut in the mode that the cutting devices on the left side and the right side are close to each other, therefore, a user does not need to hold steel bar pliers to cut the steel bar bodies, arm aching can be prevented, and the cutting efficiency can be improved.

Owner:林向亮

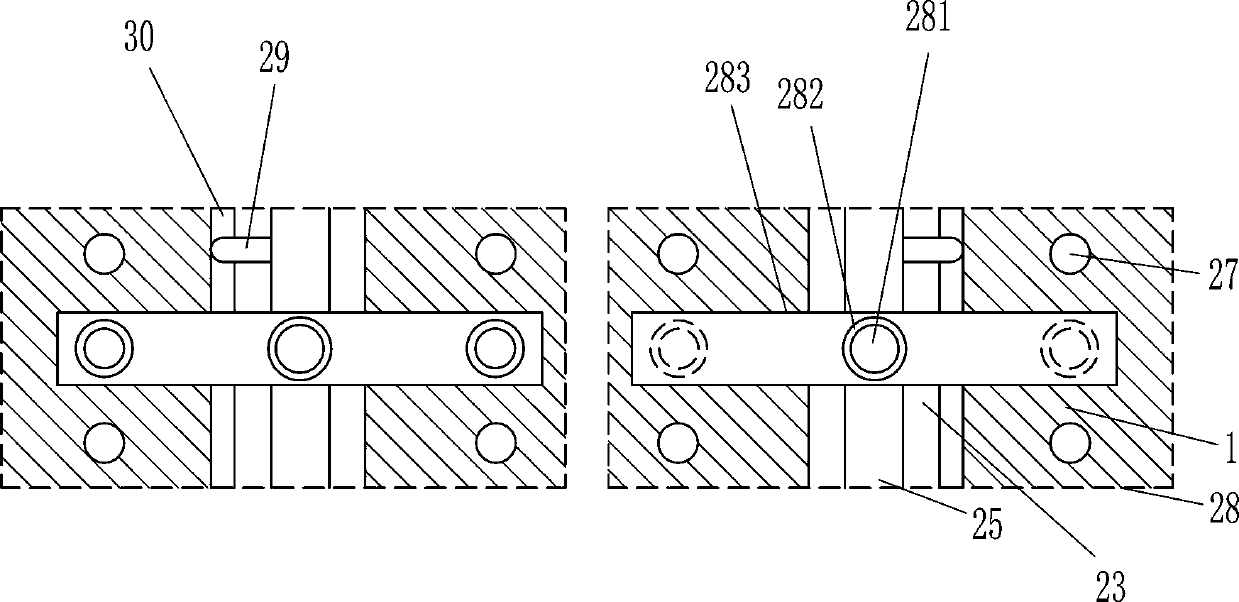

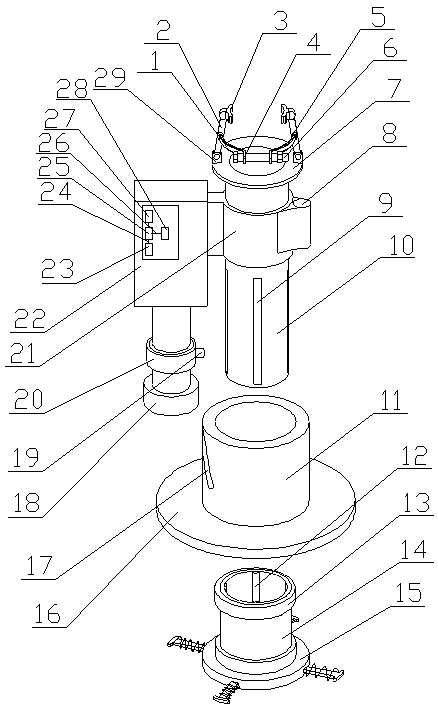

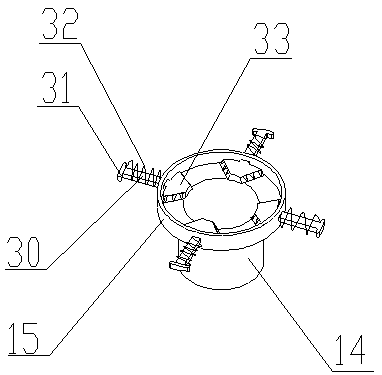

Cut-off equipment for superconductor lead screw

ActiveCN111570929ASolve the problem of low truncation efficiencyReduce the temperatureWork clamping meansPositioning apparatusEngineeringMachining

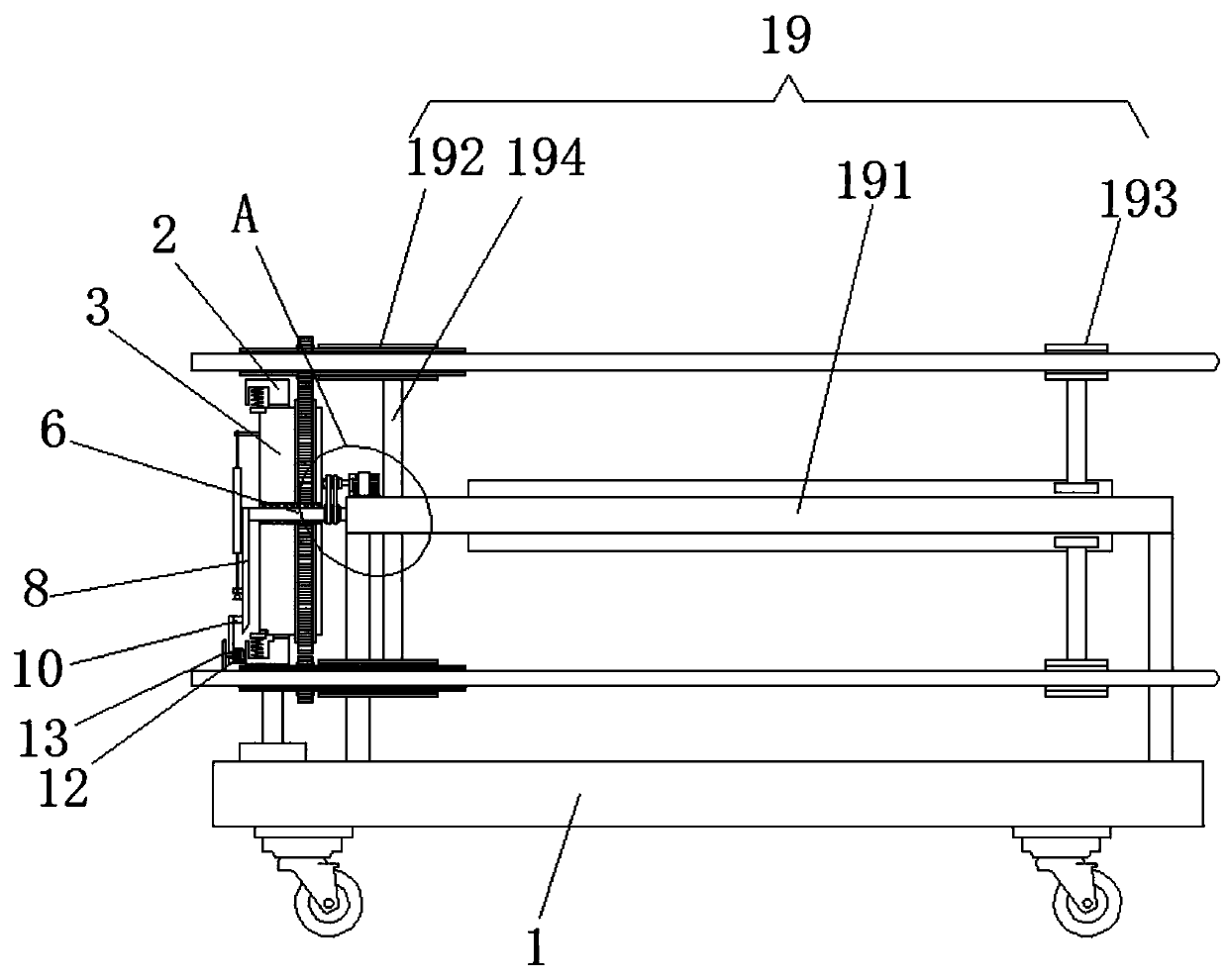

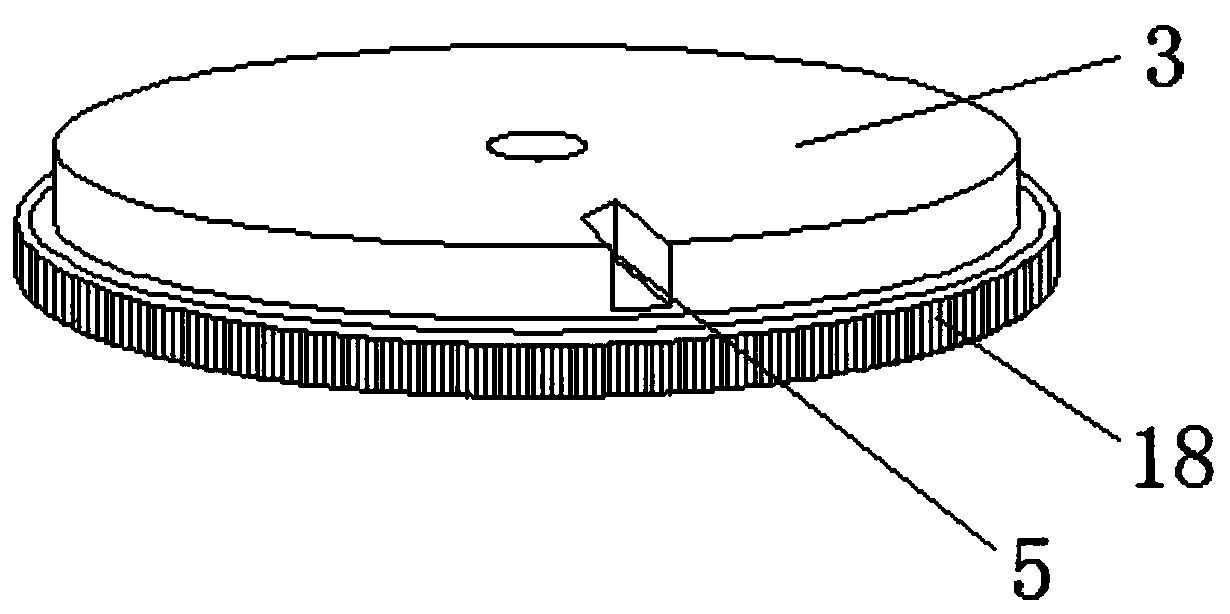

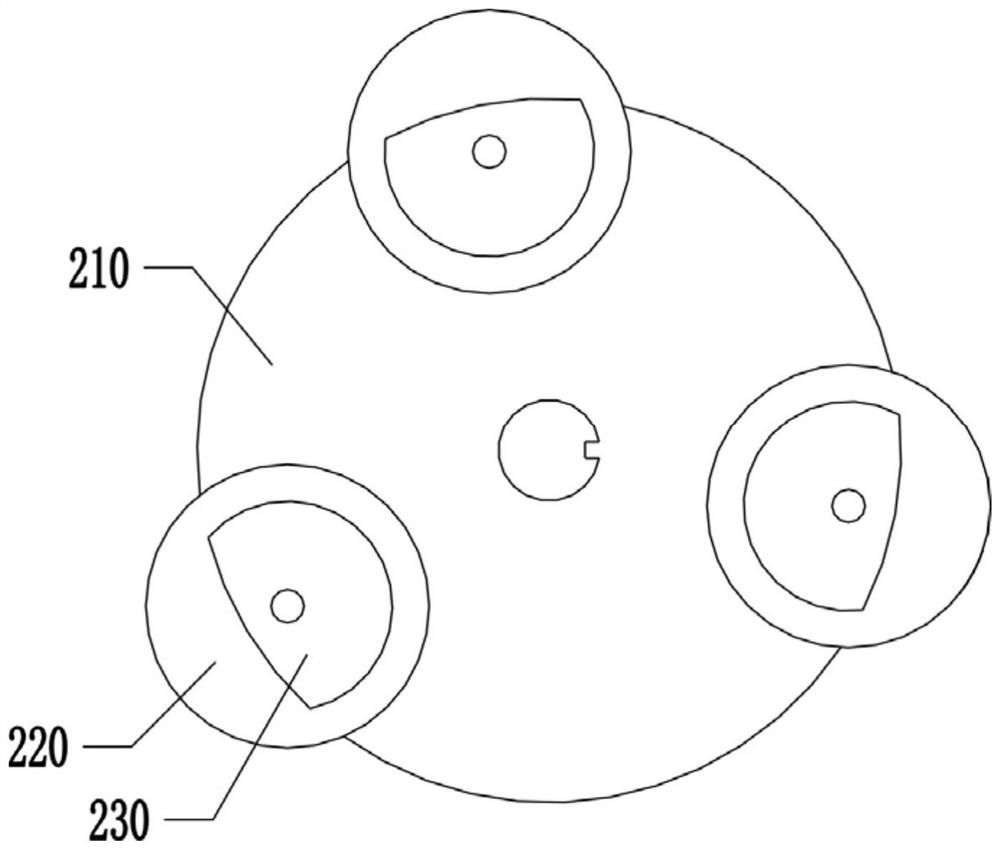

The invention discloses cut-off equipment for a superconductor lead screw, and particularly relates to the field of cut-off equipment. The cut-off equipment comprises a base, a rotary disc base and aninner rotary disc. The rotary disc base and the inner rotary disc are both located above the base, and the inner rotary disc is located on the inner side of the rotary disc base. The inner rotary disc and the rotary disc base are rotationally connected, and the periphery of the inner side of the rotary disc base is fixedly connected with limiting assemblies. Each limiting assembly comprises a strip-shaped groove, a first trapezoidal wedge block, a second trapezoidal wedge block, a third trapezoidal wedge block and a fourth trapezoidal wedge block. According to the cut-off equipment, by arranging the rotary disc base, the inner rotary disc, the limiting assemblies and a linkage mechanism, the problem that a traditional cut-off device of the superconductor lead screw is low in cut-off efficiency is solved; gas is sprayed to a cut-off machining position, and the temperature generated by cut-off machining can be effectively reduced; and meanwhile cutting dust in air around a cut-off tablecan be blown off to one side, and the situation that chipping dust layers generated in the cut-off process of the lead screw are attached to a tool rest, and the cut-off effect of the superconductorlead screw is influenced is avoided.

Owner:苏州科知律信息科技有限公司

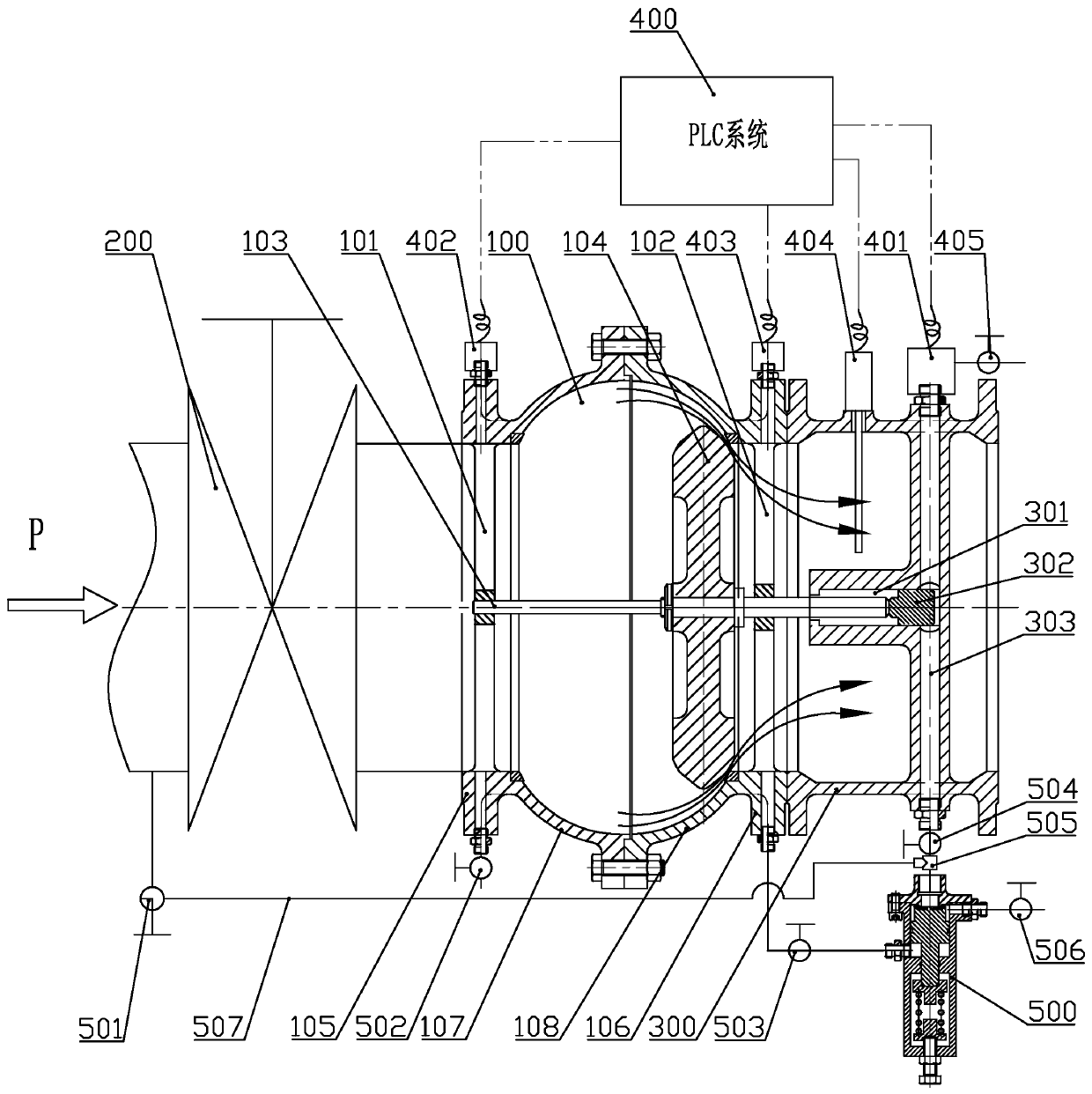

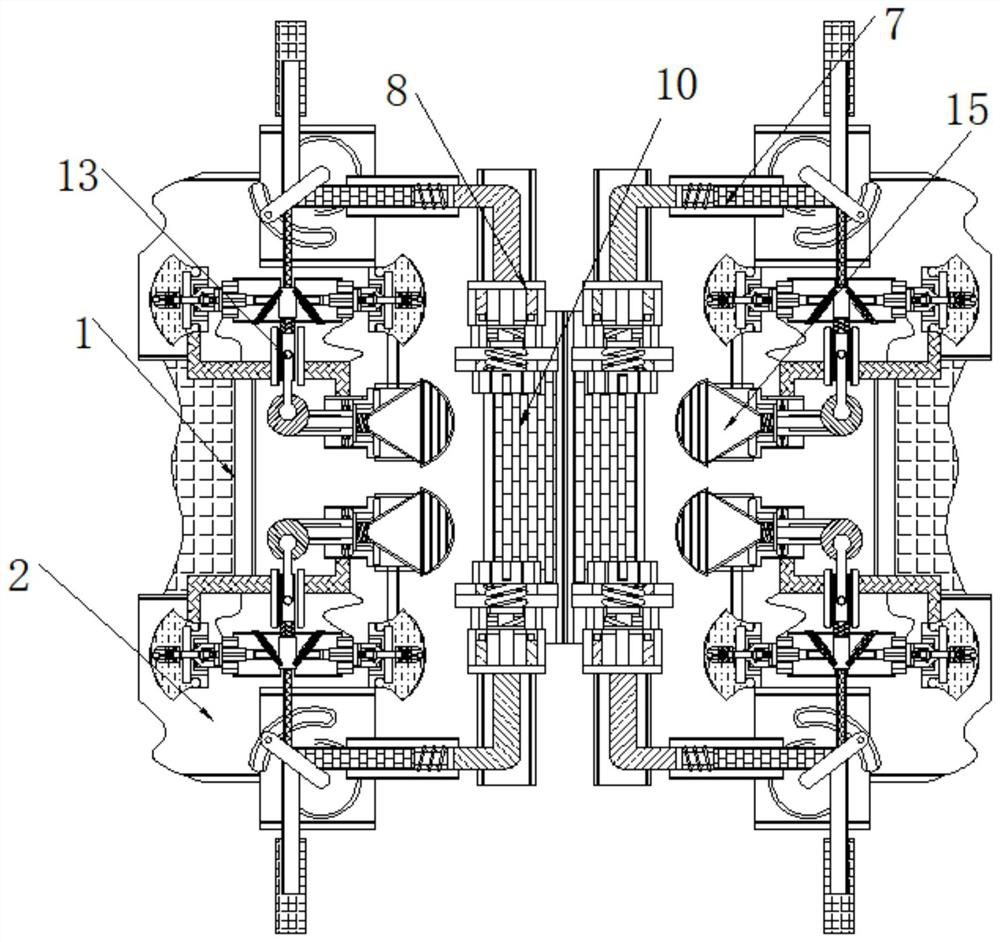

Tube explosion cut-off valve

PendingCN109973694AImprove truncation efficiencyWork reliablyEqualizing valvesSafety valvesWater flowPiston

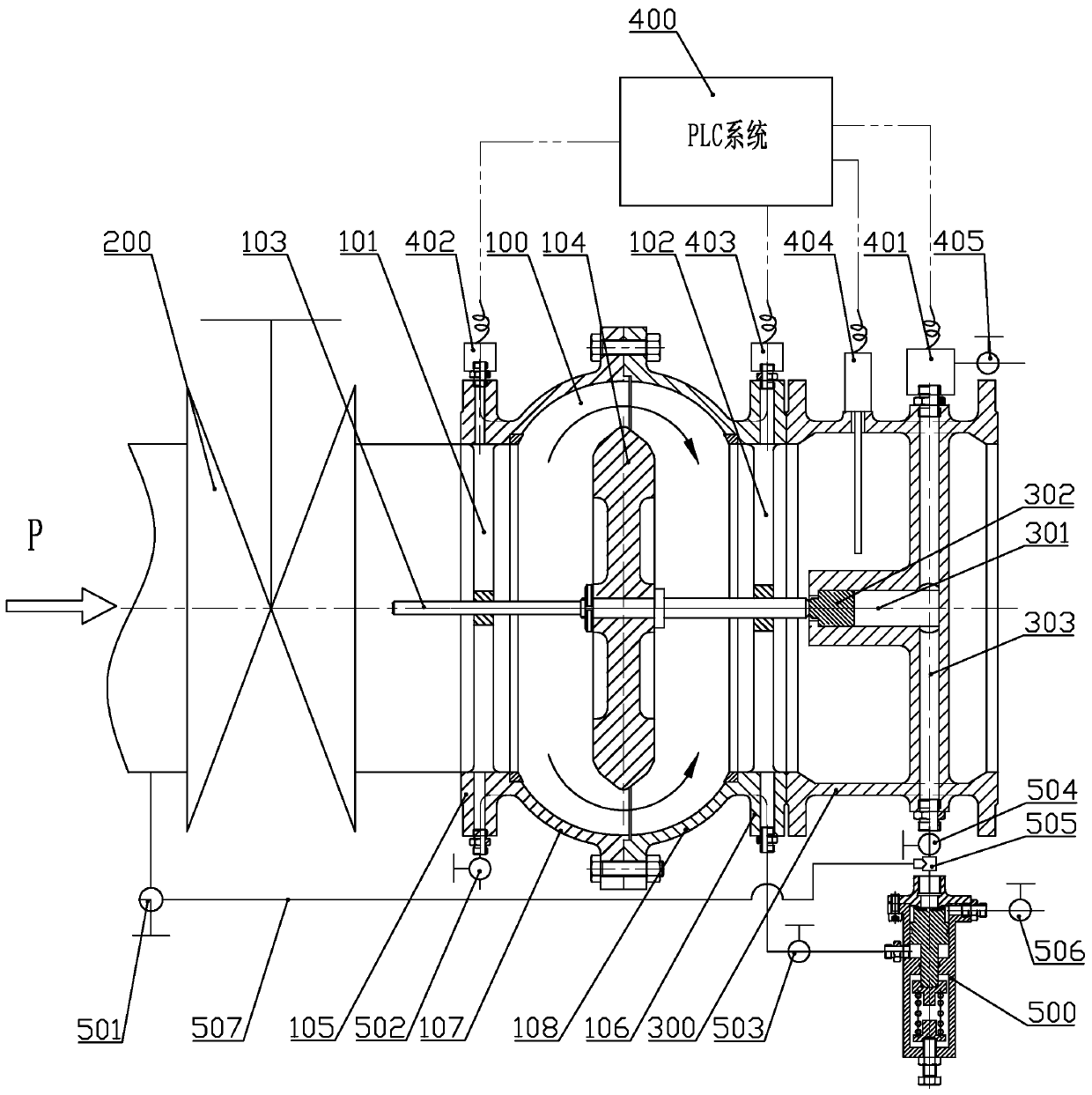

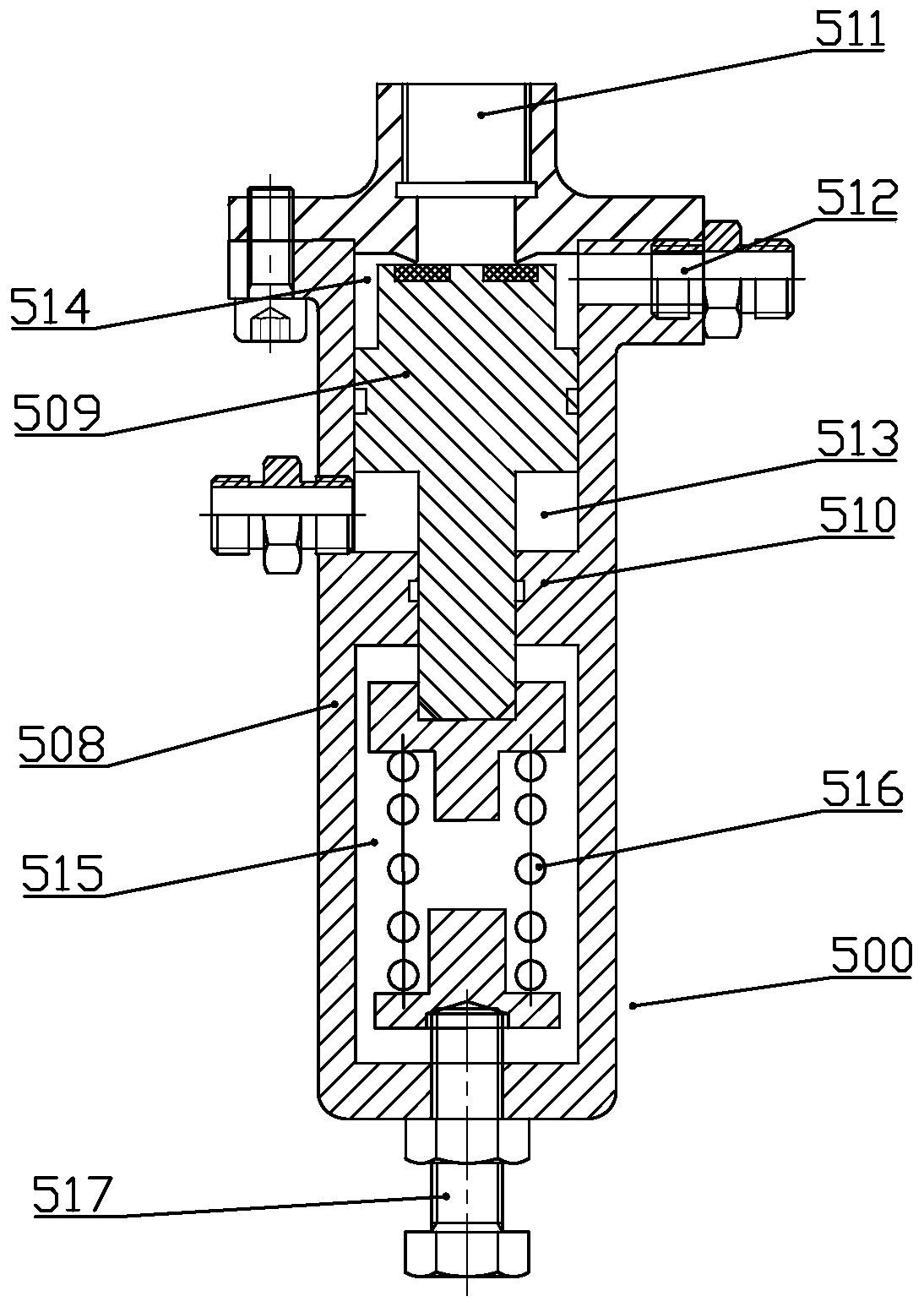

The invention discloses a tube explosion cut-off valve which comprises a main valve body, a back valve body and an electromagnetic pilot valve system and / or a mechanical pilot valve system, wherein the main valve body is provided with a valve cavity, a first water inlet and a first water outlet; a valve rod is arranged in the main valve in a penetrating manner, the valve rod penetrates a valve cavity and is fixedly provided with a valve plate in the valve cavity, and the valve plate can close the first water inlet or the first water outlet; the back valve body is mounted on the main valve bodyand communicates to the first water outlet, the back valve body is provided with a first piston cavity, a sensing piston is mounted in the first piston cavity, a penetrating hole is formed in the end, close to the valve rod, of the first piston cavity, a sensing channel is also formed on the back valve body, and the sensing channel communicates to the first piston cavity; and the electromagneticpilot valve system and / or the mechanical pilot valve system communicates to the sensing channel and is started automatically when a pressure value in the sensing channel reaches a set value or is greater than the set value. The tube explosion cut-off valve not only can cut-off a water flow upstream during tube explosion, but also can cut-off the water flow downstream during tube explosion, and ishigh in cut-off efficiency, reliable to work, relatively low in production cost and high in environmental adaptability.

Owner:ZHEJIANG BANNINGER FLUID CONTROL CO LTD

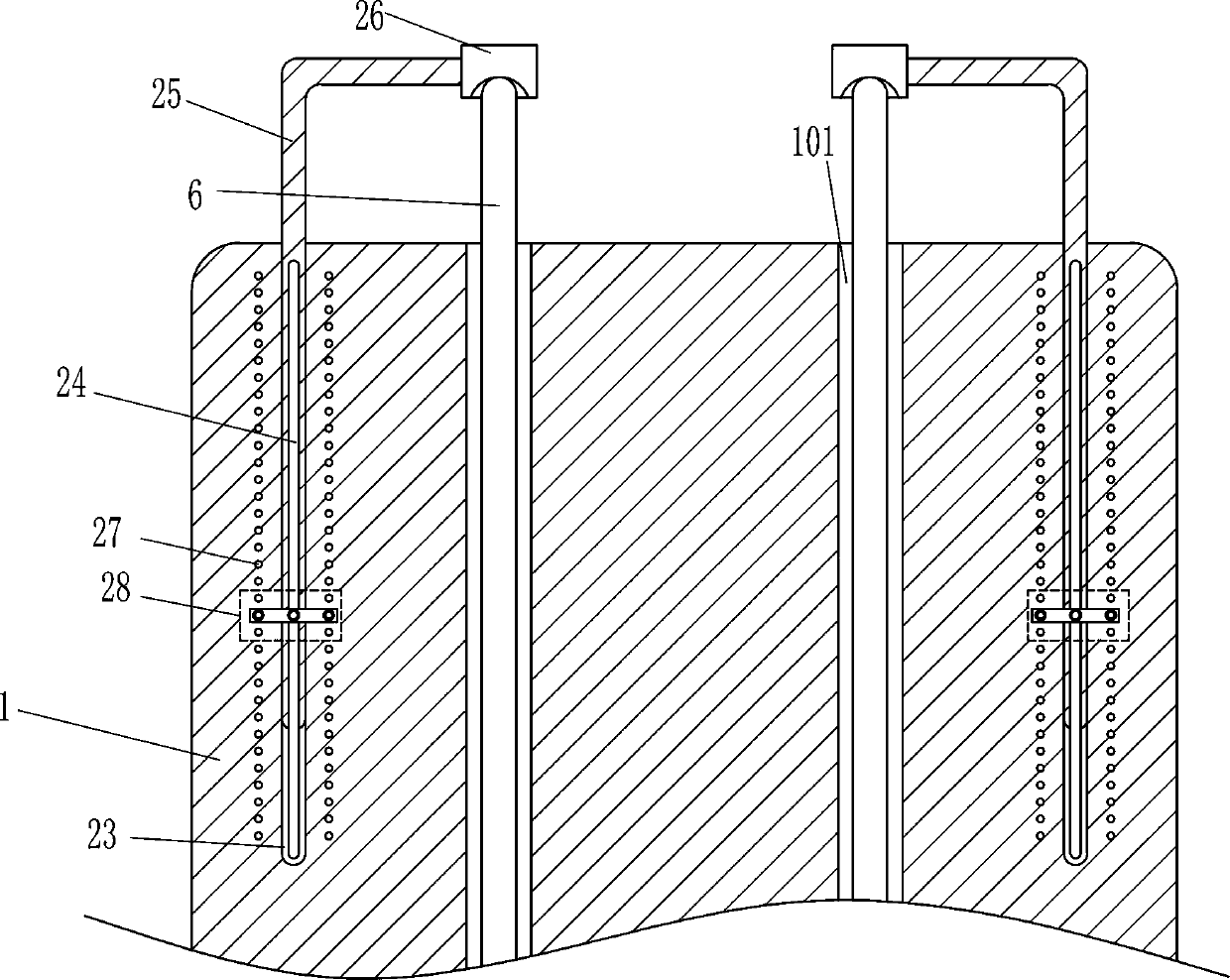

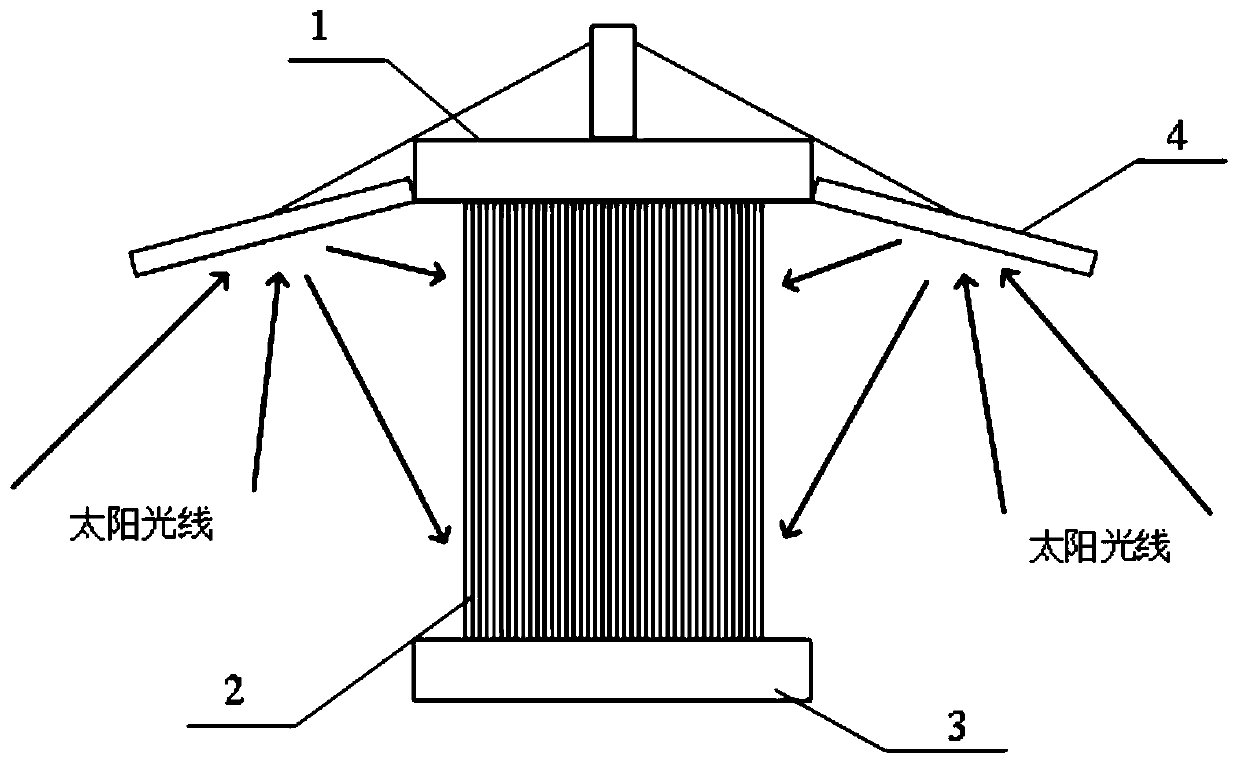

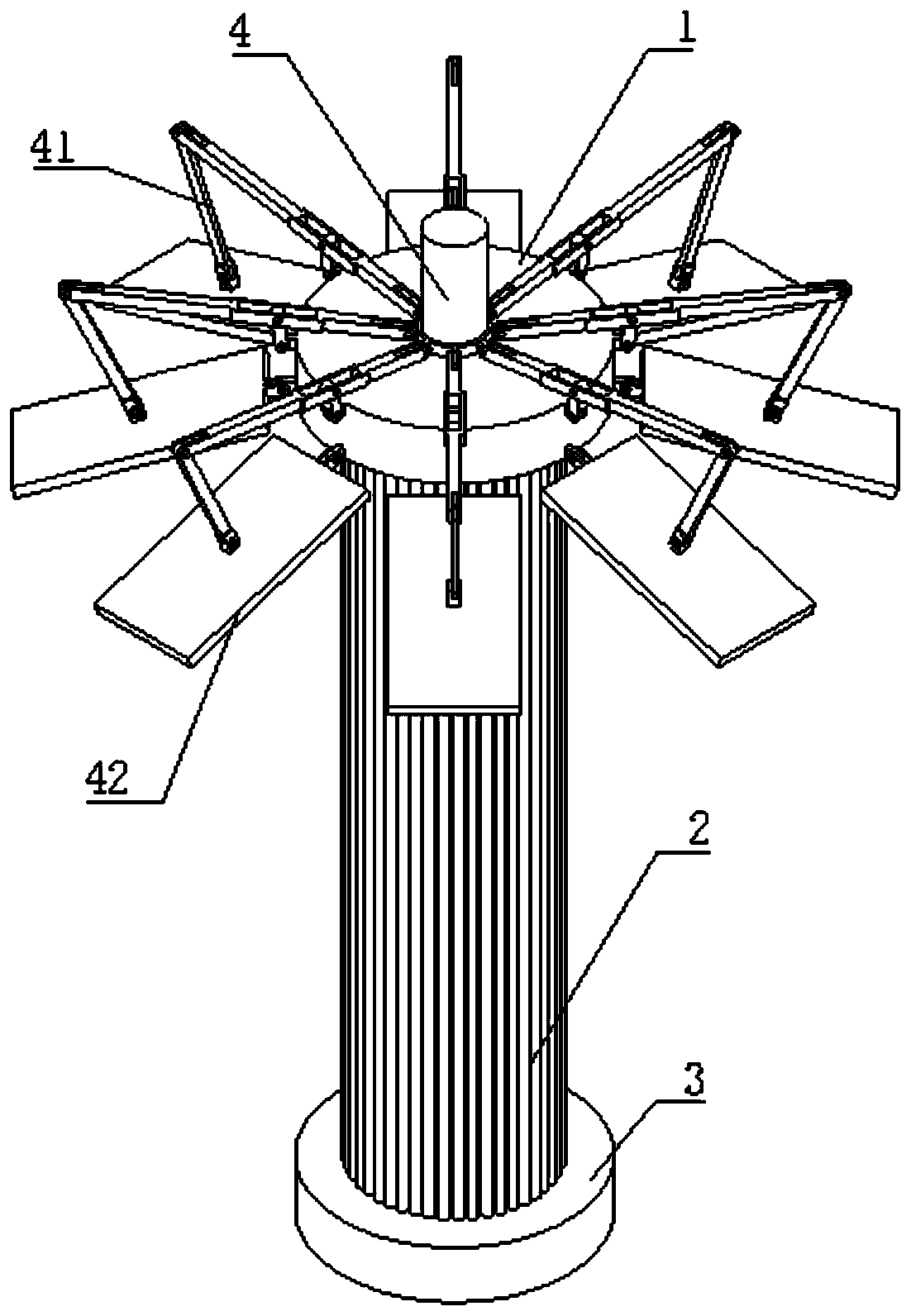

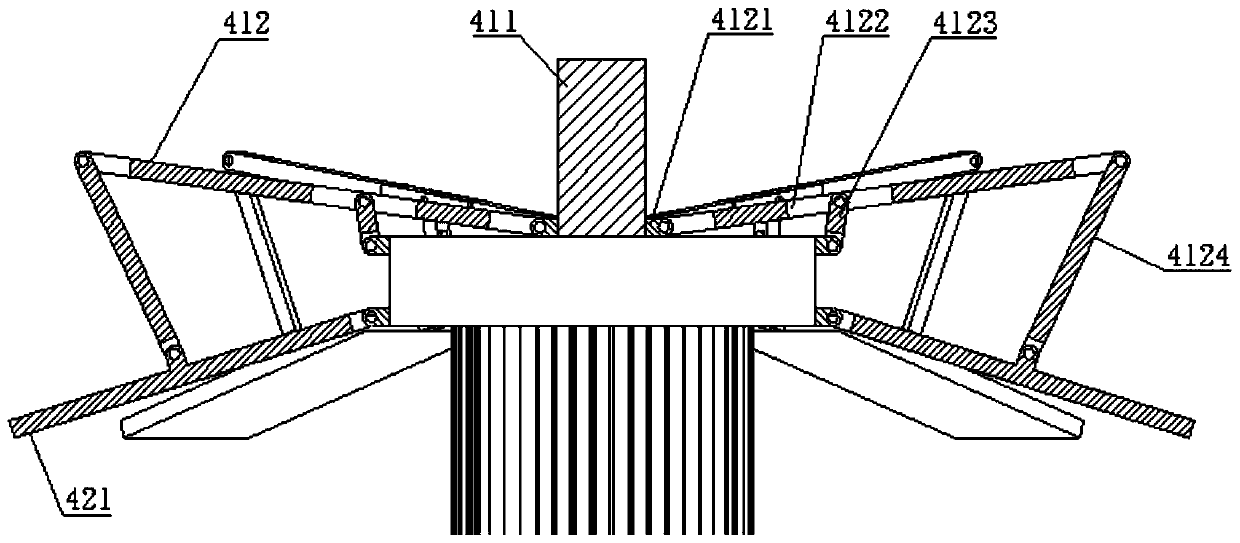

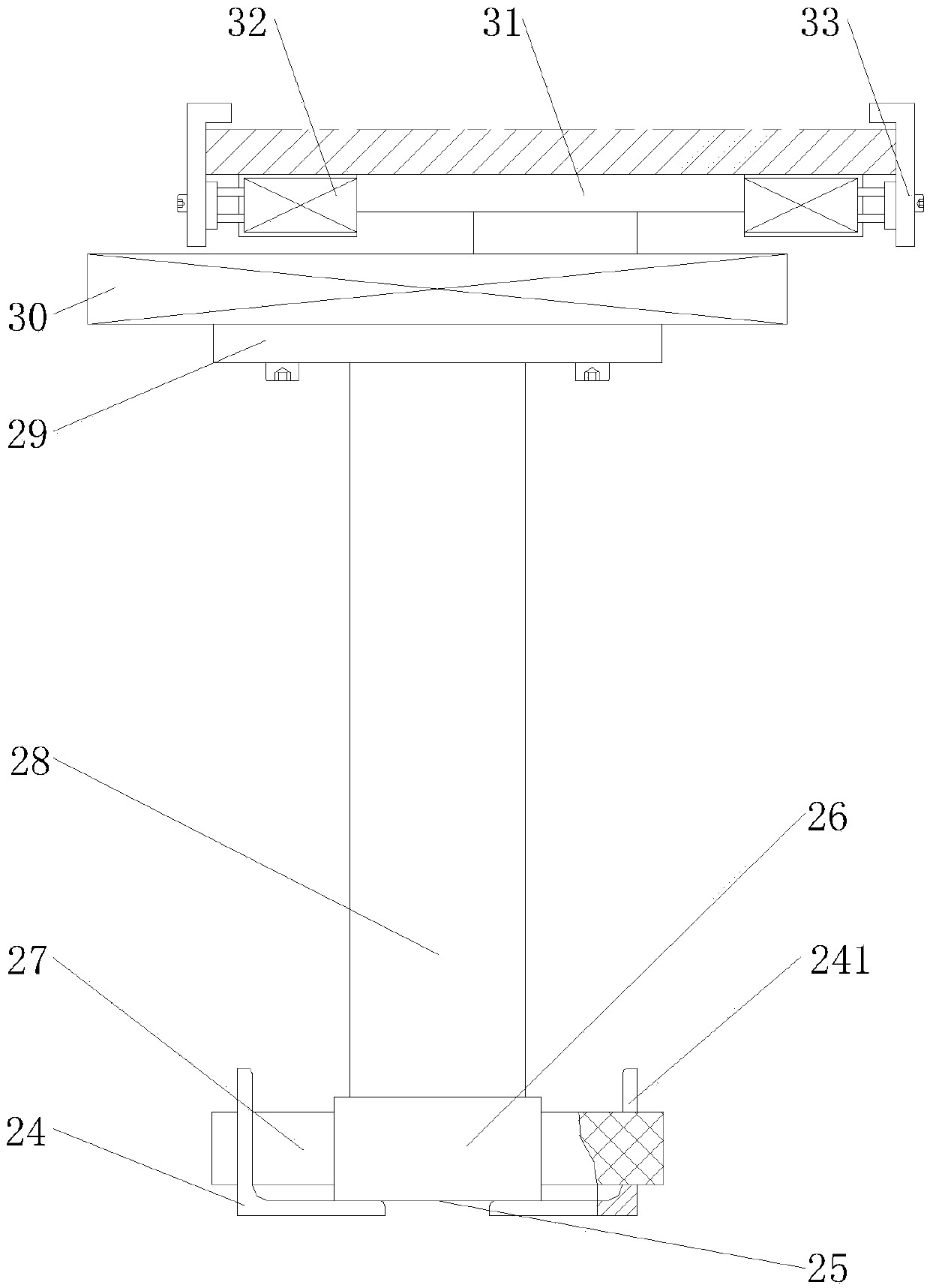

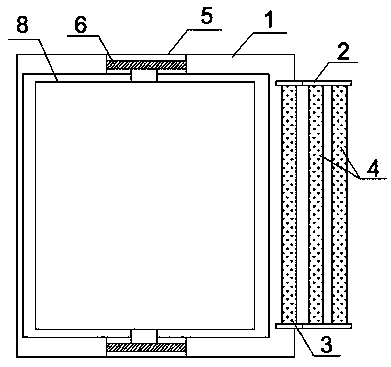

Tower type heat absorber and operation method

PendingCN111578528ASignificant progressReasonable structural designSolar heating energySolar heat collector controllersSolar lightHeat conservation

The invention provides a tower type heat absorber which comprises an upper collecting box, a lower collecting box and a heat absorbing pipe assembly arranged between the upper collecting box and the lower collecting box. A solar light secondary reflecting device is arranged at the upper end of the upper collecting box, the heat absorbing pipe assembly is a heat absorbing screen defined by a plurality of heat absorbing pipes, and the joints between the heat absorbing pipe assembly and the upper and lower collecting boxes are close to the peripheries of the upper and lower collecting boxes. Thesolar light secondary reflecting device comprises a posture adjusting device and a reflecting plate group, wherein the posture adjusting device comprises a machine frame and a reflecting plate angle adjusting assembly, and the reflecting plate group comprises reflecting plates which are arranged in the circumferential direction of the upper collecting box in an umbrella shape; and the inner edgesof the reflecting plates are hinged to the periphery of the upper collecting box, and the output end of the reflecting plate angle adjusting assembly is connected with the backs of the reflecting plates. According to the tower type heat absorber, the technical difficulty is low, system control is simple, the reflecting plates are additionally arranged at the top of the heat absorber, the solar light shielded by the lower collecting box can be reused, the light abandoning rate is reduced, the solar energy utilization rate is improved, and when the reflecting plates are placed down, a heat preservation effect can be achieved.

Owner:ZHEJIANG UNIV

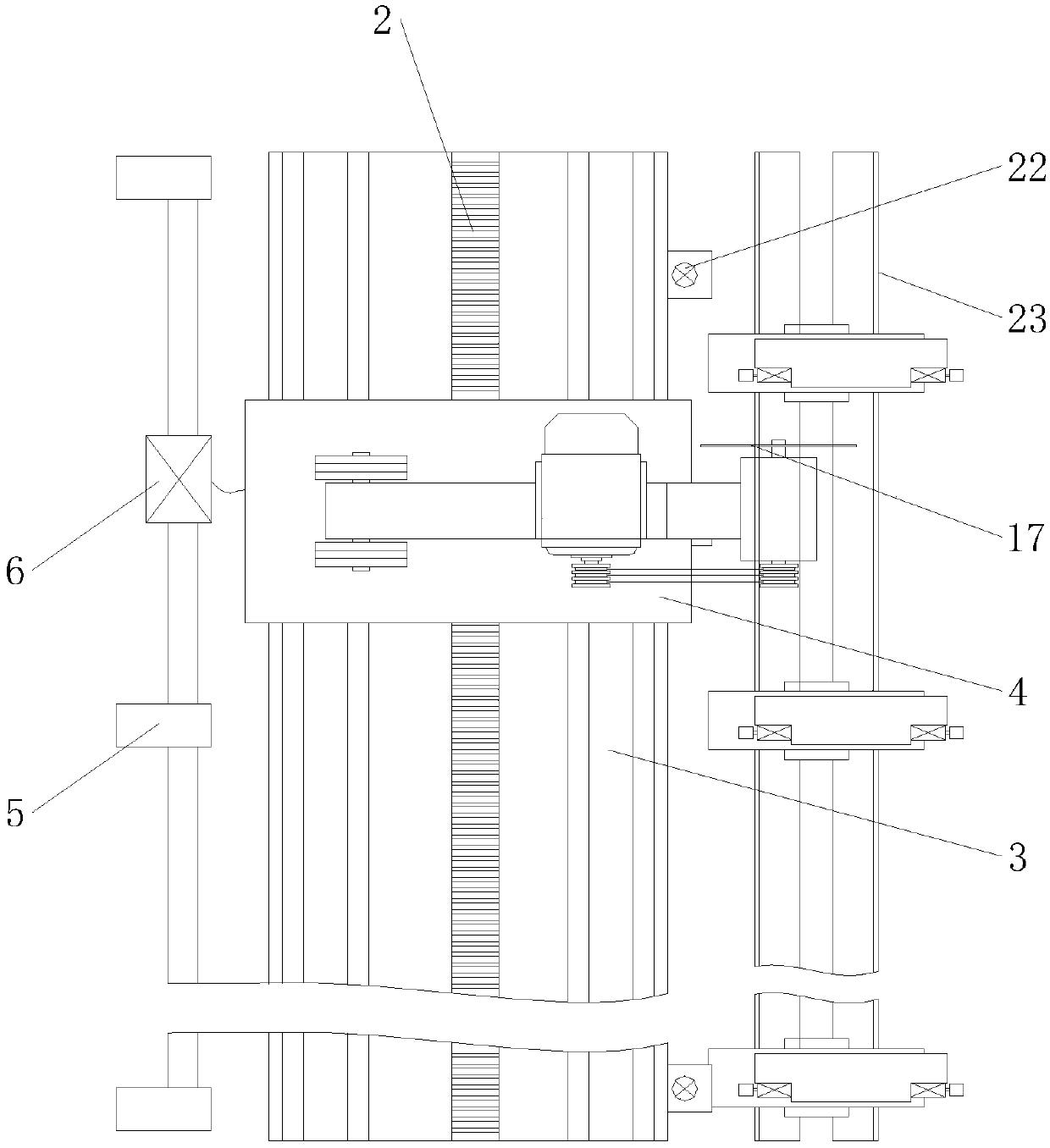

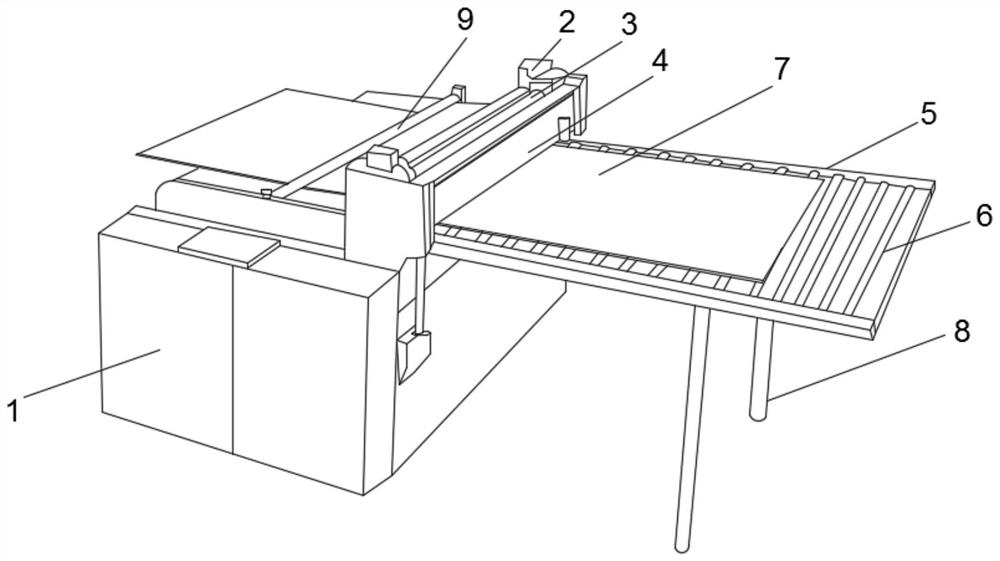

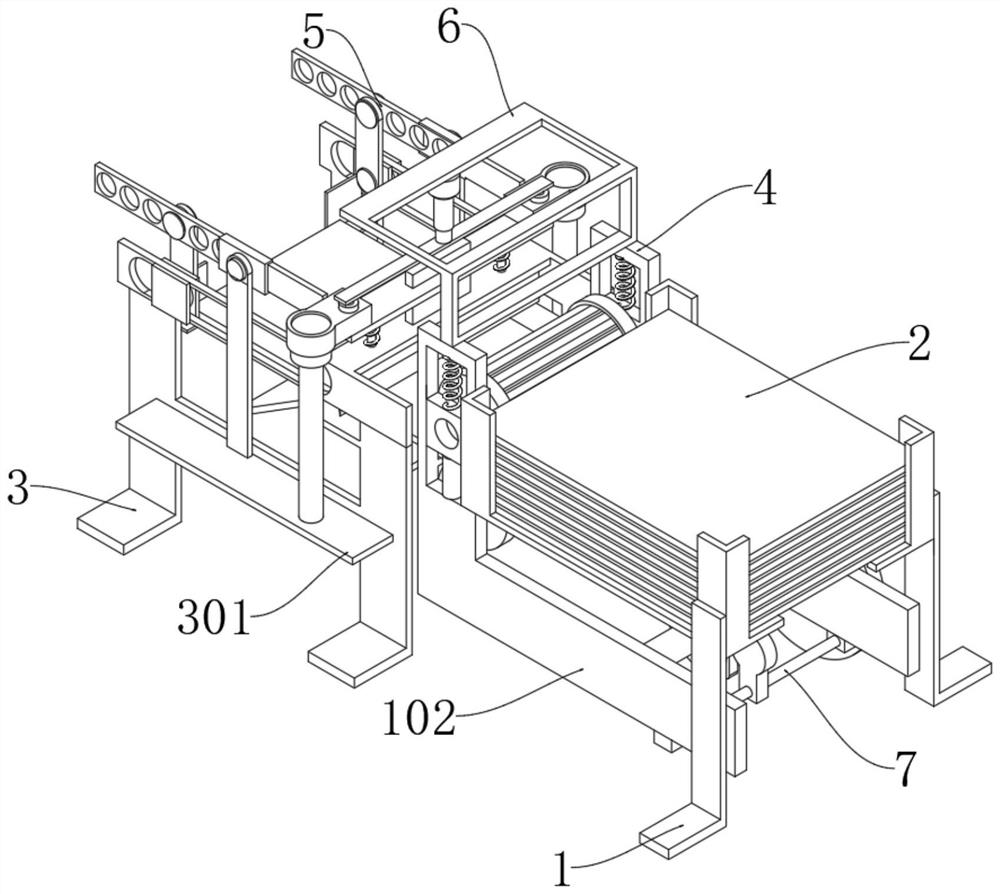

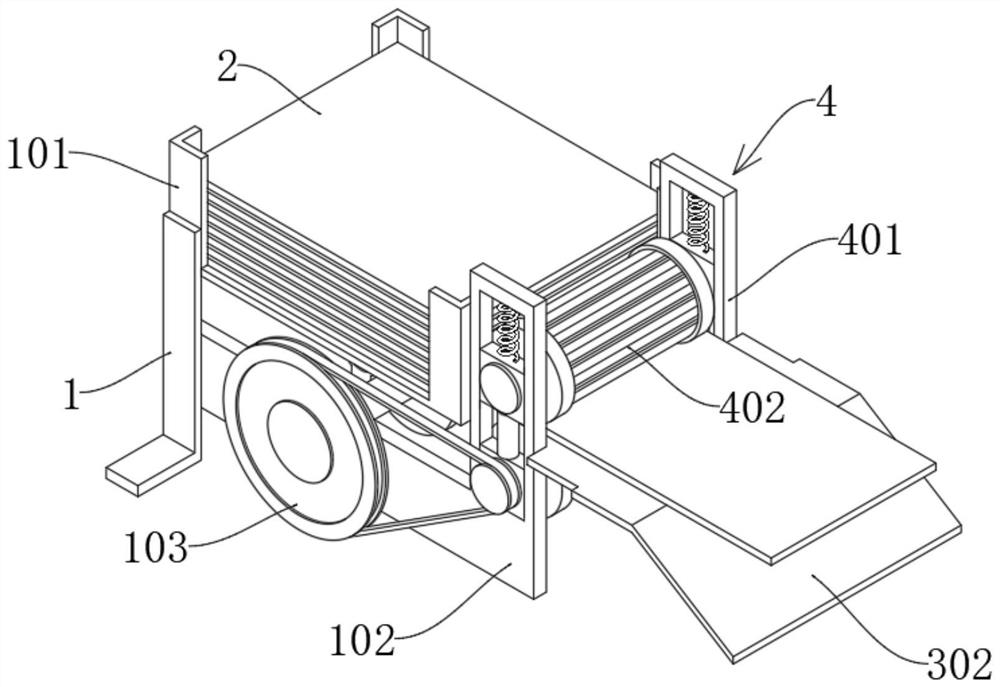

Cross sliding type automatic translation cutting device for artificial board

The invention discloses a cross sliding type automatic translation cutting device for an artificial board. The cross sliding type automatic translation cutting device comprises a bottom plate, a driving rack is arranged on the bottom plate, light rails are arranged on the two sides of the driving rack, and a translation cutting device is arranged on the light rails; the translation cutting devicecomprises a translation platform, a translation motor is arranged at the center of the bottom of the translation platform, the end of the translation motor is provided with a driving gear matched withthe driving rack, and multiple rollers matched with the light rails are arranged at the periphery of the translation motor; and a support frame is arranged on the top of the translation platform, a rotatable bracket is connected to the upper end of the support frame, a lifting air cylinder is connected to the lower end of the bracket, a rotating shaft is arranged at the other end of the bracket,and a cutting sheet is arranged at one end of the rotating shaft. The cross sliding type automatic translation cutting device for the artificial board has the characteristics of being high in cuttingefficiency, low in labor intensity and good in cutting stability.

Owner:ZHEJIANG LIANGYUE BOARD IND CO LTD

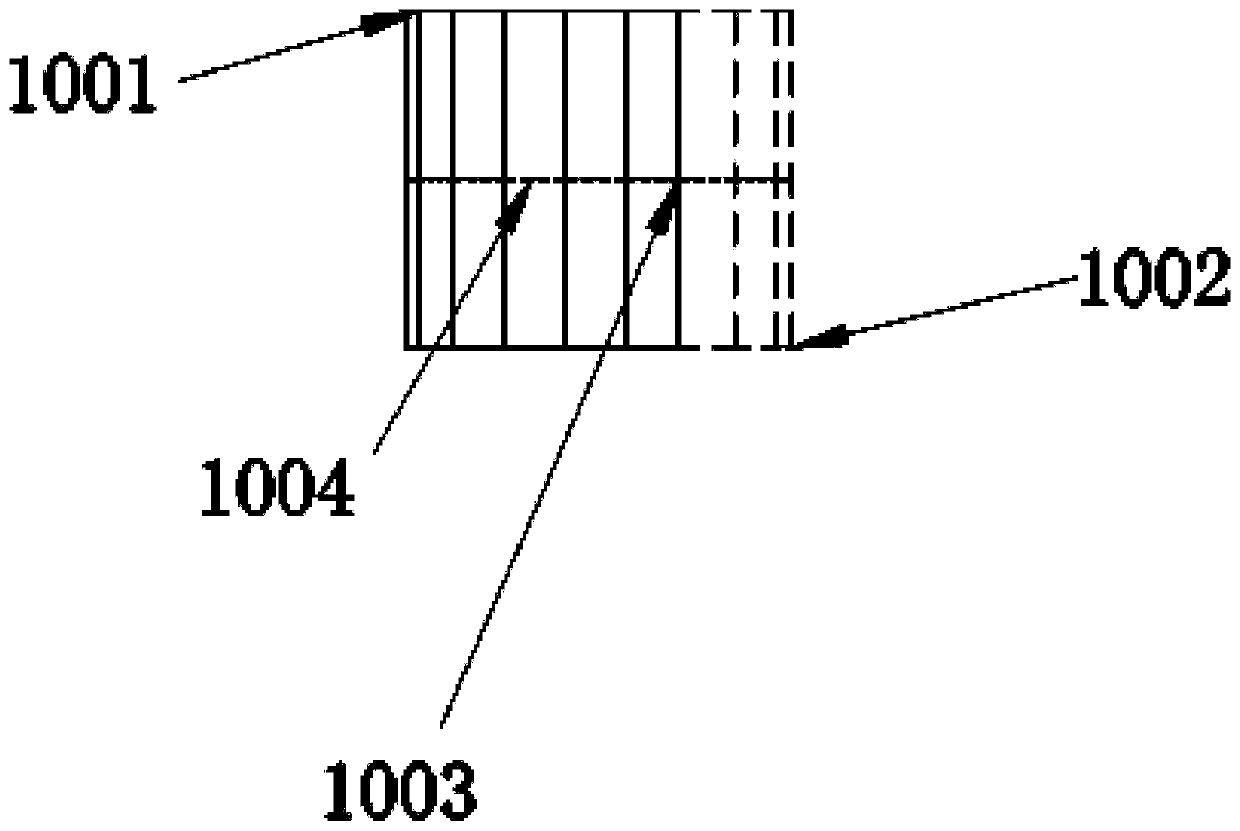

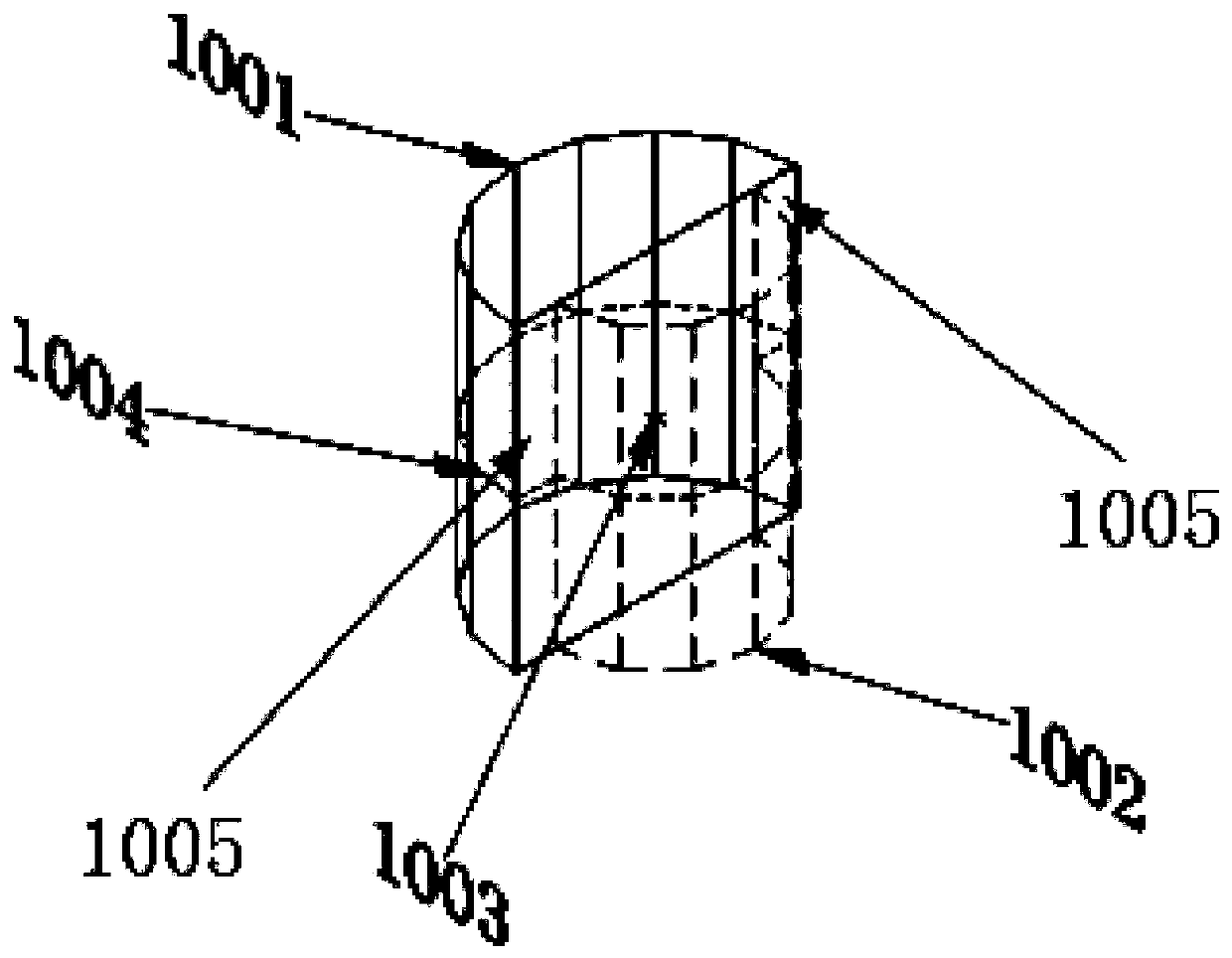

Tubular glass cut device and process

InactiveCN109626808AImplement automated truncationImprove truncation efficiencyGlass severing apparatusEngineeringMechanical engineering

The invention discloses a tubular glass cut device and process. The device includes a plurality of conveyor rollers, a rotating assembly, a cut assembly and a breaking assembly. The rotating assemblyincludes a set of contact plates, and revolving members are arranged on the contact plates. The cut assembly includes a hollow turntable, to-be-cut tubular glass passes through the hollow part of theturntable, the side wall of the turntable is uniformly provided with several cut cylinders, the output end of each cut cylinder is provided with an arc-shaped support chip, and the inner sides of thearc-shaped support chip are provided with an electric thermal resistor. The process includes the following steps that the conveying rollers are used for conveying tubular glass, the cut cylinders run,the electric thermal resistor winds the outer wall of the tubular glass, the revolving members on the contact plates drive the tubular glass to rotate, the electric thermal resistor is used for heating the broken portion of the tubular glass, and the breaking assembly is used for breaking the tubular glass. The invention provides the tubular glass cut device and process, automatic cut of the tubular glass is achieved, the tubular glass cut efficiency is improved, and the labor cost is reduced.

Owner:田秀霞

Chain cutting-off device and method thereof

The invention relates to the field of intelligent chain manufacturing, and provides a chain cutting-off device. The device comprises a chain cutting-off device body. The chain cutting-off device bodycomprises a cutting-off support, a cutting-off sliding plate, a horizontal cutting-off air cylinder, a cutting-off fixing block, a cutting-off hinge rod, a cutting-off connecting rod, a vertical cutting-off air cylinder and a cutting-off connecting block. The cutting-off sliding plate is arranged on the cutting-off support. The horizontal cutting-off air cylinder is arranged behind the cutting-offsliding plate, the cutting-off fixing block is fixedly arranged on the top of the cutting-off sliding plate, the cutting-off hinge rod is hinged to the upper portion of the cutting-off fixing block,the movable portion of the vertical cutting-off air cylinder is linked with the rear portion of the cutting-off hinge rod, and the cutting-off connecting rod is linked with the front portion of the cutting-off hinge rod through the cutting-off connecting block. The chain cutting-off device has the beneficial effects that a chain can be automatically cut off, and abrasion of a cut-off pin shaft isreduced; and pin shaft pieces are recovered through the arrangement of a blanking through hole.

Owner:温州速拓科技有限公司

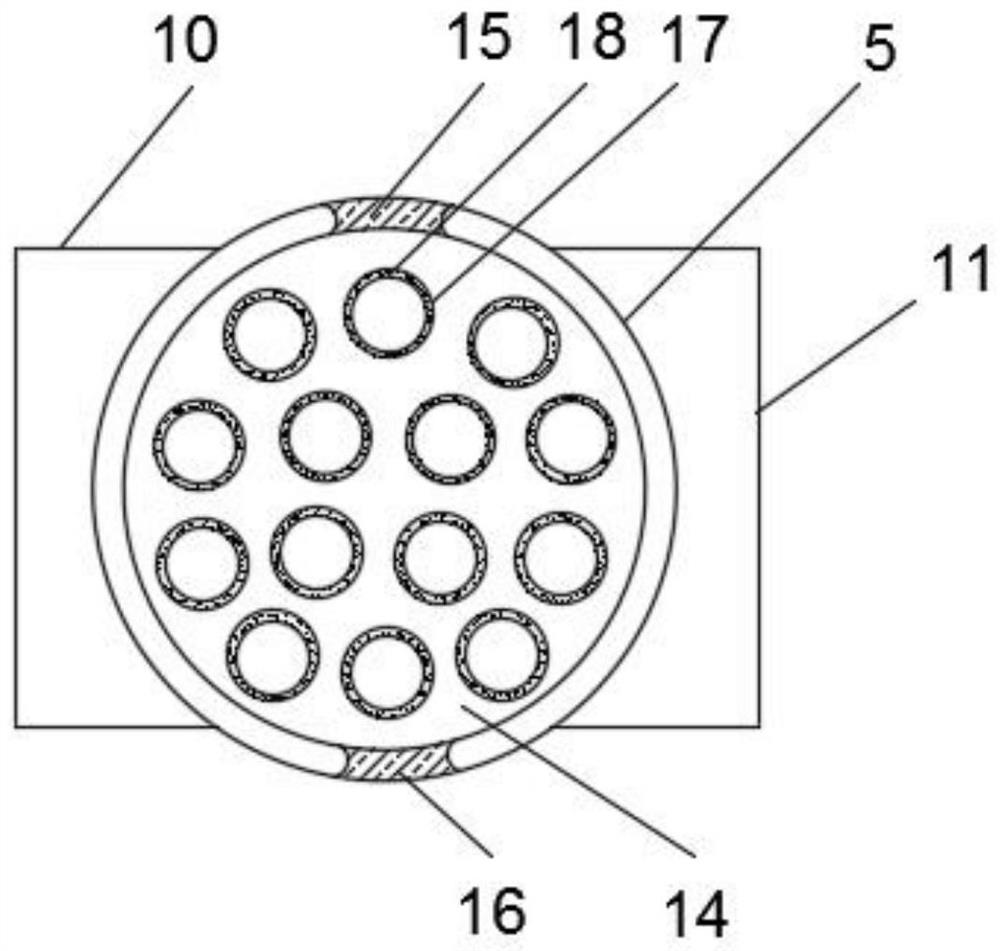

Vacuum tube wall type heat absorber

InactiveCN102840701AImprove light-to-heat conversion efficiencyLow heat loss coefficientSolar heat devicesSolar thermal energy generationEngineeringTower

The invention relates to vacuum tube wall type heat absorber. Straight-through vacuum tubes (1) are connected in series or parallel by U-shaped connection tubes (2) to form a single series heat absorbing module (17) or single parallel heat absorbing module (18). A plurality of series heat absorbing modules (17) or parallel heat absorbing modules (18) are connected in series or parallel by connecting tubes (11) to form the vacuum tube wall type heat absorber. The vacuum tube wall type heat absorber is in a two-dimensional curved surface or external cylinder or plane shape. The straight-through vacuum tubes (1) are arranged horizontally, vertically relative to the ground, slantwise or juxtaposedly in multiple rows. The vacuum tube wall type heat absorber is arranged on the top of a heat absorbing tower (7) unidirectionally or circumferentially. The back surfaces of the straight-through vacuum tubes (1) can be provided with compound parabolic concentrators (CPC) or plane or hemispherical secondary condensers (13).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

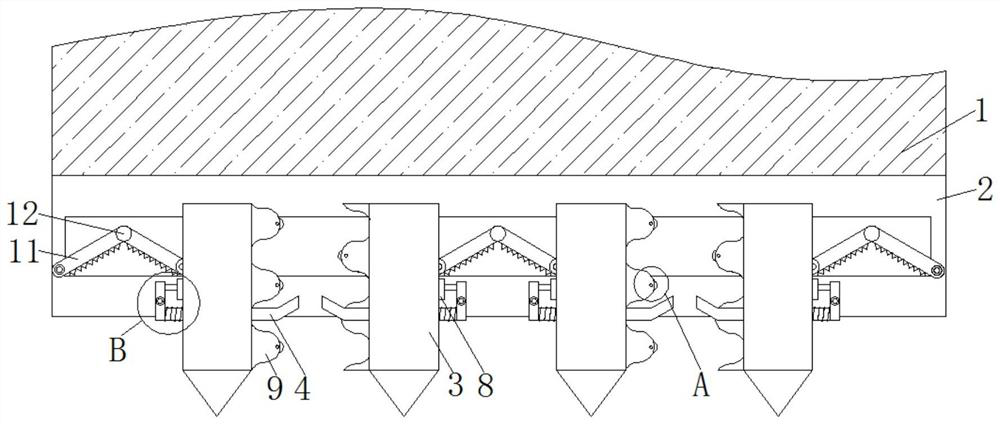

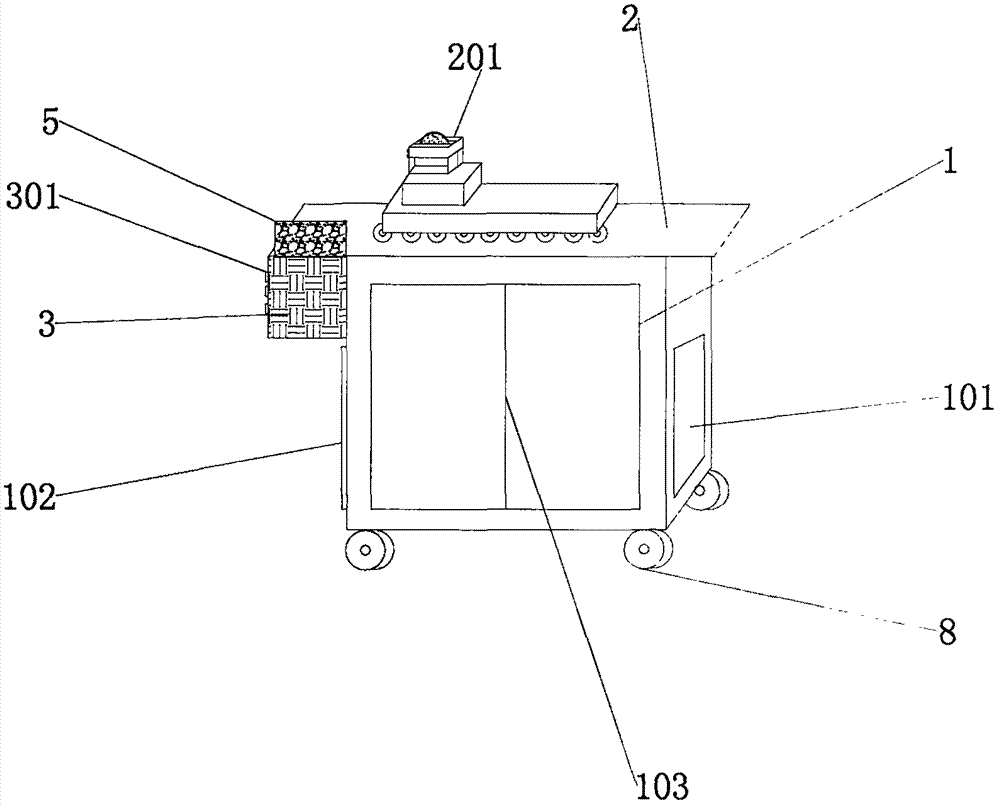

Cutting off equipment for carbon bar production and operation method thereof

InactiveCN111730765AImprove truncation efficiencyImprove stabilityWorking accessoriesStone-like material working toolsMechanical engineeringIndustrial engineering

The invention discloses cutting off equipment for carbon bar production and an operation method thereof. A first clamp ring, a second clamp ring, a fixed ring and a cutting knife are used in a cooperation manner, the cutting efficiency and stability of a carbon bar can be effectively improved, through the first clamp ring and the second clamp ring, the two ends of the carbon bar can be fixed, thestability of the carbon bar in the cutting off process can be effectively improved, multiple fixing rings, a telescopic clamping block, a first stretching ring and a second stretching ring are used ina cooperation manner, multiple carbon bars can be cut off at the same time, the carbon bar cutting off efficiency can be effectively improved, the problems that in the carbon bar cutting off processin the existing scheme, stability is poor, and the carbon bar cutting off efficiency is low can be solved, through cooperative use of a pulling plate, a storage base and a buffer plate, the chippingsgenerated in the process of cutting off the carbon bars can be collected, the work of carbon bar chipping cleaning can be effectively omitted, the carbon bar chippings can be recycled, and the influence of the chippings generated by carbon bar cutting on the production of the carbon bars can be avoided.

Owner:亳州市亚珠新材料有限公司

A chain cutting device and method thereof

The invention relates to the field of intelligent chain manufacturing, and provides a chain cutting-off device. The device comprises a chain cutting-off device body. The chain cutting-off device bodycomprises a cutting-off support, a cutting-off sliding plate, a horizontal cutting-off air cylinder, a cutting-off fixing block, a cutting-off hinge rod, a cutting-off connecting rod, a vertical cutting-off air cylinder and a cutting-off connecting block. The cutting-off sliding plate is arranged on the cutting-off support. The horizontal cutting-off air cylinder is arranged behind the cutting-offsliding plate, the cutting-off fixing block is fixedly arranged on the top of the cutting-off sliding plate, the cutting-off hinge rod is hinged to the upper portion of the cutting-off fixing block,the movable portion of the vertical cutting-off air cylinder is linked with the rear portion of the cutting-off hinge rod, and the cutting-off connecting rod is linked with the front portion of the cutting-off hinge rod through the cutting-off connecting block. The chain cutting-off device has the beneficial effects that a chain can be automatically cut off, and abrasion of a cut-off pin shaft isreduced; and pin shaft pieces are recovered through the arrangement of a blanking through hole.

Owner:温州速拓科技有限公司

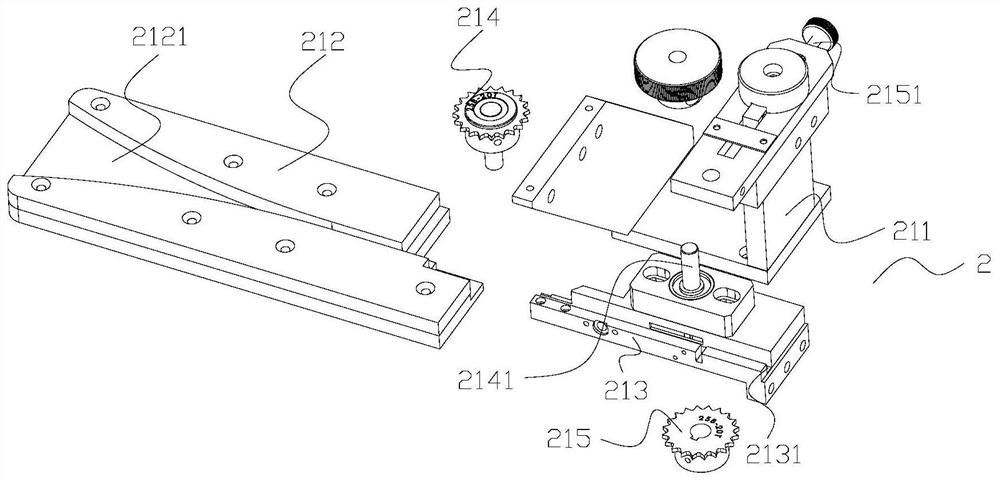

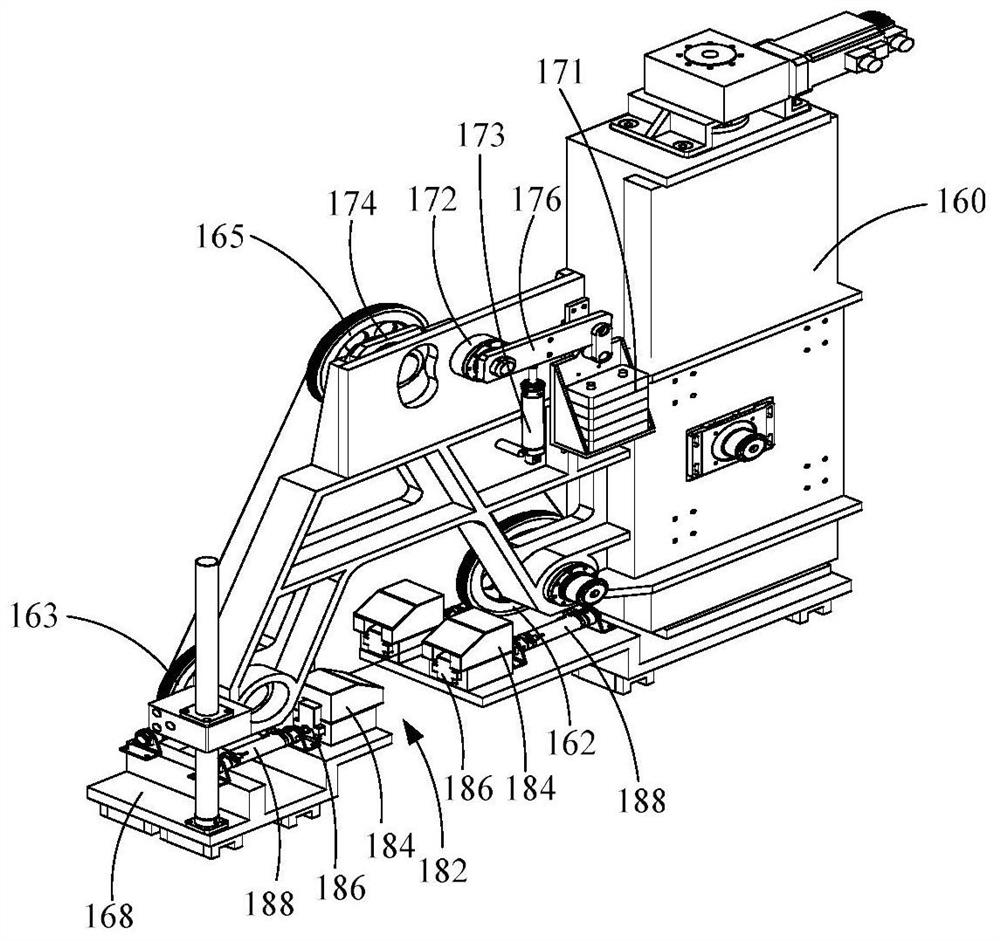

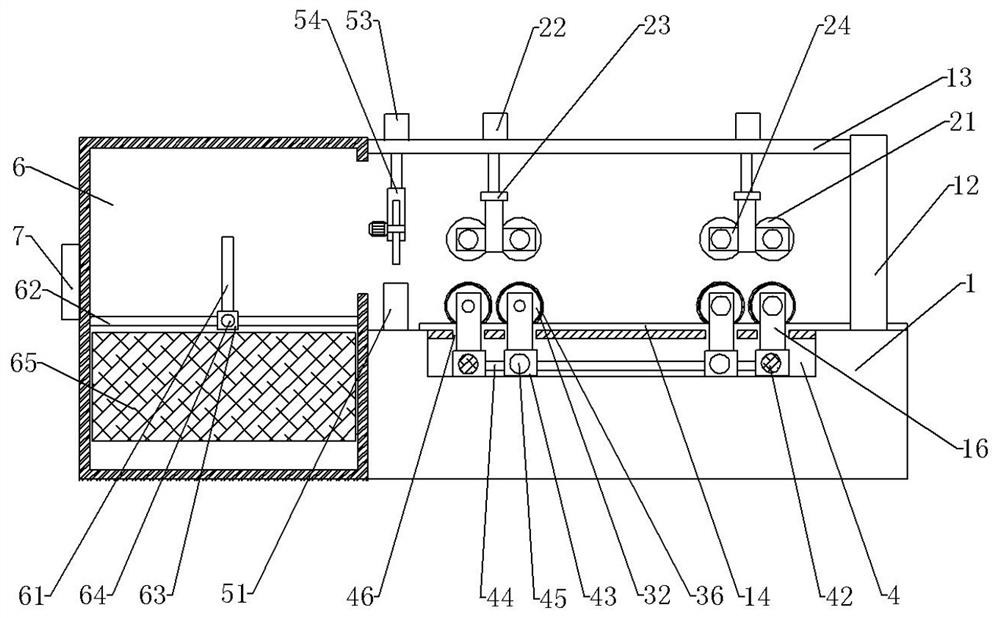

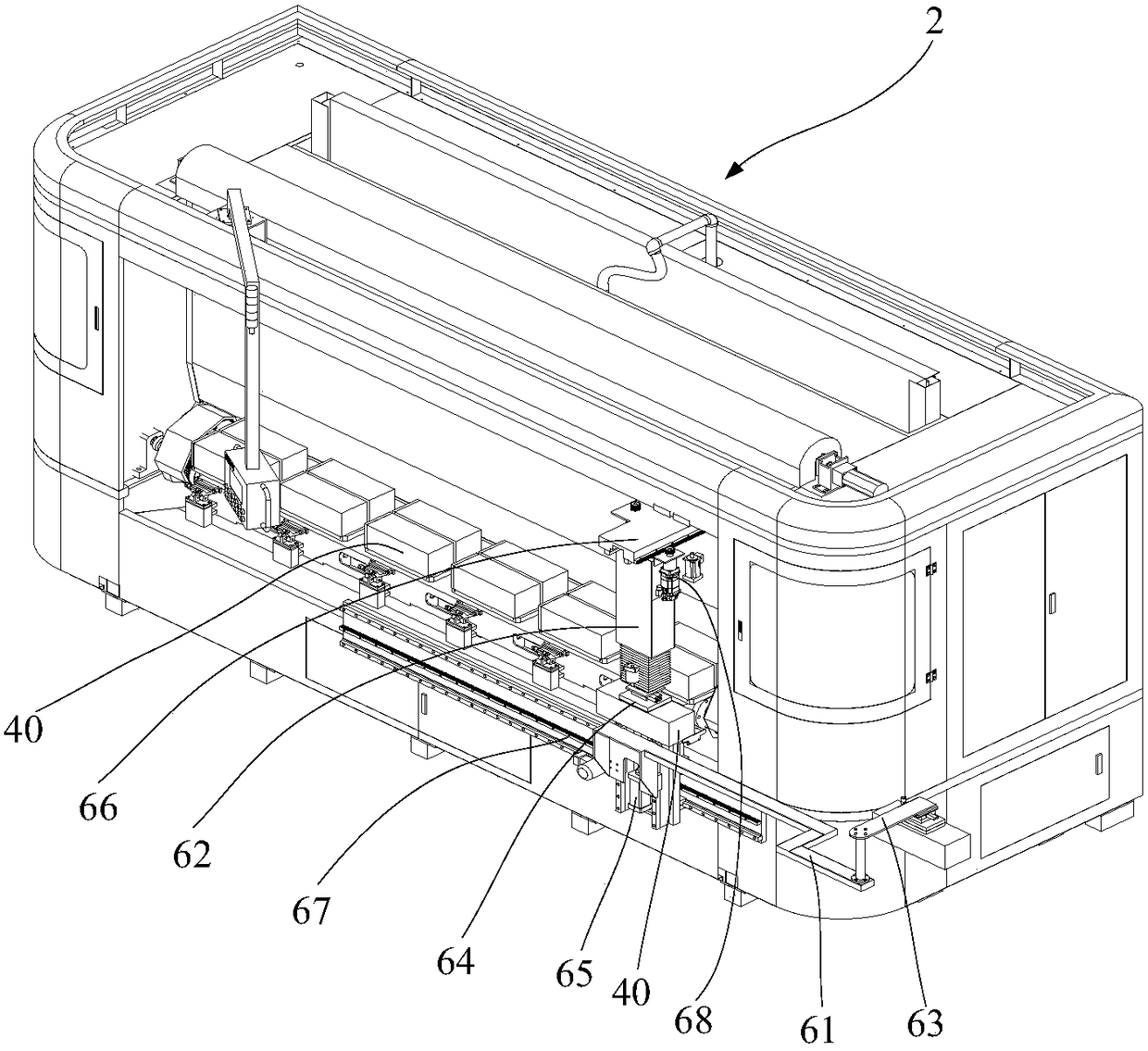

Silicon rod cutting equipment and silicon rod cutting method

PendingCN114516125AIncreased operating freedom and truncation efficiencyImprove cutting efficiencyWorking accessoriesFine working devicesWire cuttingStructural engineering

The invention discloses silicon rod cut-off equipment and a silicon rod cut-off method.The silicon rod cut-off equipment comprises a machine base, a material conveying table and at least two wire cutting devices, the at least two wire cutting devices are mutually independent, and therefore cut-off operation can be carried out on silicon rods to be cut on the material conveying table through the independent wire cutting devices; and the operation freedom degree and the cutting efficiency in the silicon rod cutting operation are improved. The linear cutting unit in the linear cutting device adopts the closed-loop cutting line, so that high-speed running of the cutting line can be kept, the cutting efficiency is improved, meanwhile, the closed-loop cutting line can run in the same running direction in the cutting-off operation, and therefore, the linear cutting unit can realize high-precision cutting-off operation, and the cutting efficiency is improved. According to the closed-loop cutting line, the problem that ripples exist on the cutting face due to operation reversing or operation speed of the cutting line in an existing cutting mode is solved, meanwhile, the total length of the cutting line needed by the linear cutting unit can be effectively reduced, parts such as a take-up barrel and a pay-off barrel are omitted, and the production cost is reduced.

Owner:TDG NISSIN PRECISION MACHINERY CO LTD

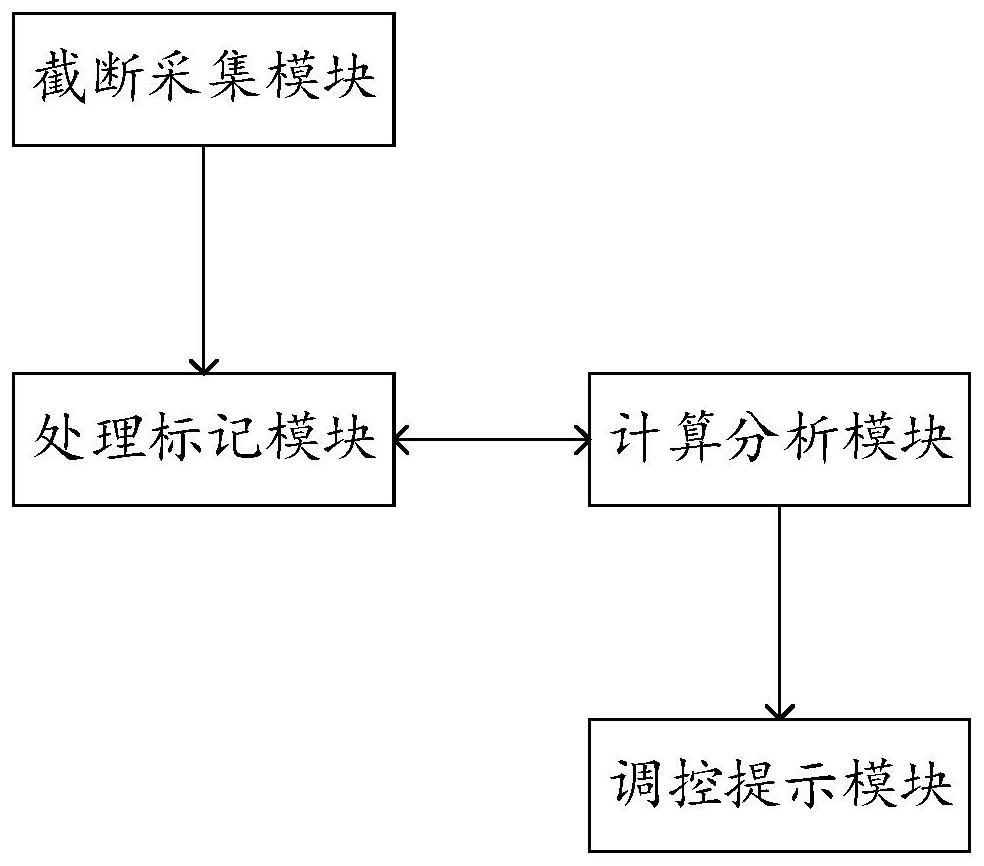

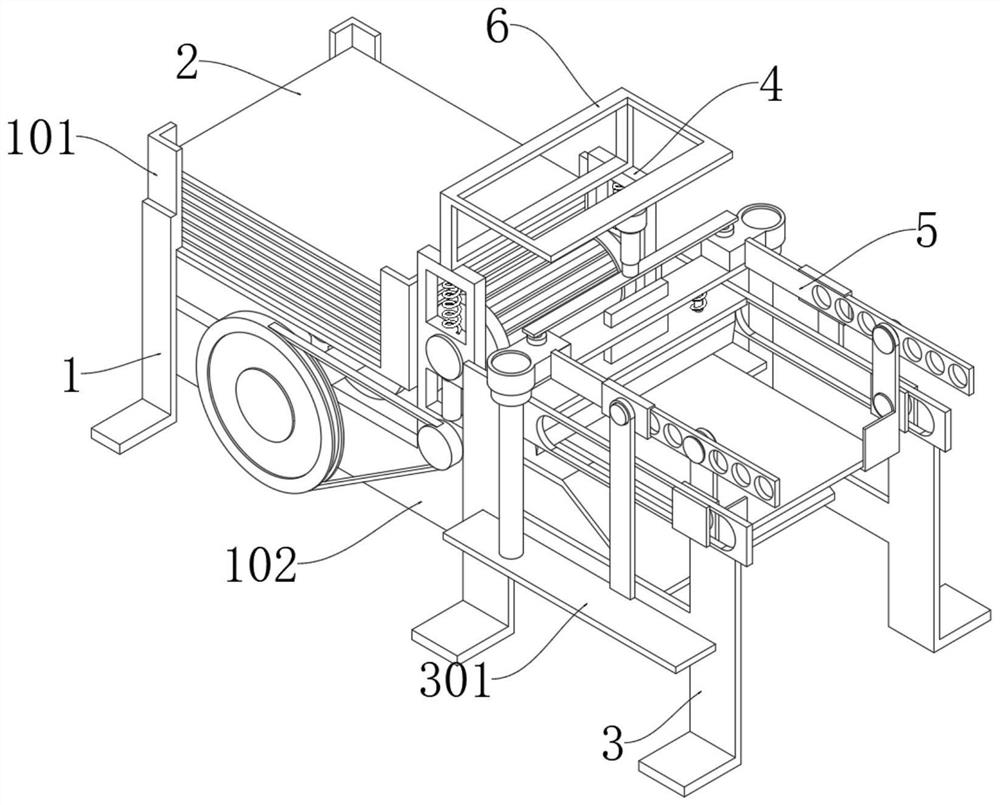

Aluminum roll decoiling and cutting-off mechanism for air conditioner machining

InactiveCN113478007ARealize monitoringRealize analysisShearing machinesStructural engineeringMachining

The invention discloses an aluminum roll decoiling and cutting-off mechanism for air conditioner machining. The mechanism comprises a cutting-off mechanism body, wherein a fixing frame is fixedly installed at one side of the upper end of the cutting-off mechanism body; a limited pillar is installed in the middle of the upper end of the cutting-off mechanism body; a conveying frame is fixedly connected to one side of the cutting-off mechanism body; a plurality of conveying columns are rotationally connected into the conveying frame; a plurality of supporting columns are fixedly installed at the lower end of the conveying frame; an aluminum roll body is installed at the upper end of the conveying frame; a cutting-off base and a rolling column are installed in the fixing frame; the rolling column is located at one side of the cutting-off base; a cutting knife is fixedly installed at the lower end of the cutting-off base; and the cutting-off comprises a cutting-off acquisition module, a machining marking module, a calculation analysis module and a regulation and control prompting module. The mechanism solves the technical problems that in an existing scheme, operation of the cutting-off mechanism cannot be monitored and analyzed in an all-around mode, and early warning and prompting cannot be conducted in time.

Owner:安徽奔腾五金制造有限公司

Cutting equipment for building boards

PendingCN113714547AThe truncation process is continuousImprove truncation efficiencyShearing machinesMetal working apparatusStructural engineeringMechanical engineering

The invention discloses cutting equipment for building boards, and belongs to the technical field of board processing. The cutting equipment for the building boards comprises a front support and a rear support, the rear support is fixedly connected with a material carrying frame, and the boards with the corresponding sizes are stacked in the material carrying frame in order; transmission frames are arranged below the material carrying frame and fixedly connected to the center of the rear support, a discharging table is fixedly connected to the centers of the front sides of the transmission frames, a material conveying mechanism is fixedly connected to the front sides of the upper ends of the transmission frames, and a mounting frame is fixedly connected to the upper side of the material conveying mechanism; and a cut-off assembly is arranged at the front end of the material conveying mechanism, the cut-off assembly is fixedly connected to the front support, and a continuous feeding assembly is arranged between the transmission frames. The cutting equipment solves the problem that in the prior art, the plate conveying and feeding process and the cutting-off process are not continuous.

Owner:朱六五

Winding paper drawing box with single-hand operation function

InactiveCN108937685AImprove truncation efficiencyEasy to useDomestic applicationsArticle deliveryEngineeringHand operations

The invention discloses a winding paper drawing box with a single-hand operation function. The winding paper drawing box comprises a bottom box, brackets, guide rollers, fixing rollers, a box cover, aserrated knife, an inner compression roller, a handle and an outer compression roller, wherein the right end of the upper plane of the bottom box is fixedly provided with the two brackets, the two brackets are rotationally provided with the two guide rollers in the vertical direction and the two fixing rollers in the horizontal direction through bearings, the right end of the box cover is fixedlyprovided with the serrated knife through bolts, the inner wall of the right end of the box cover is fixedly provided with the inner compression roller through bolts, the outer wall of the right end of the box cover is fixedly provided with the handle through bolts, and the handle is fixedly provided with the outer compression roller through bolts. The winding paper drawing box with the single-hand operation function has the advantages that the use is convenient, the cutting efficiency of winding paper is improved, and paper taking can be completed with the single hand.

Owner:灵璧县楚汉风纸业有限公司

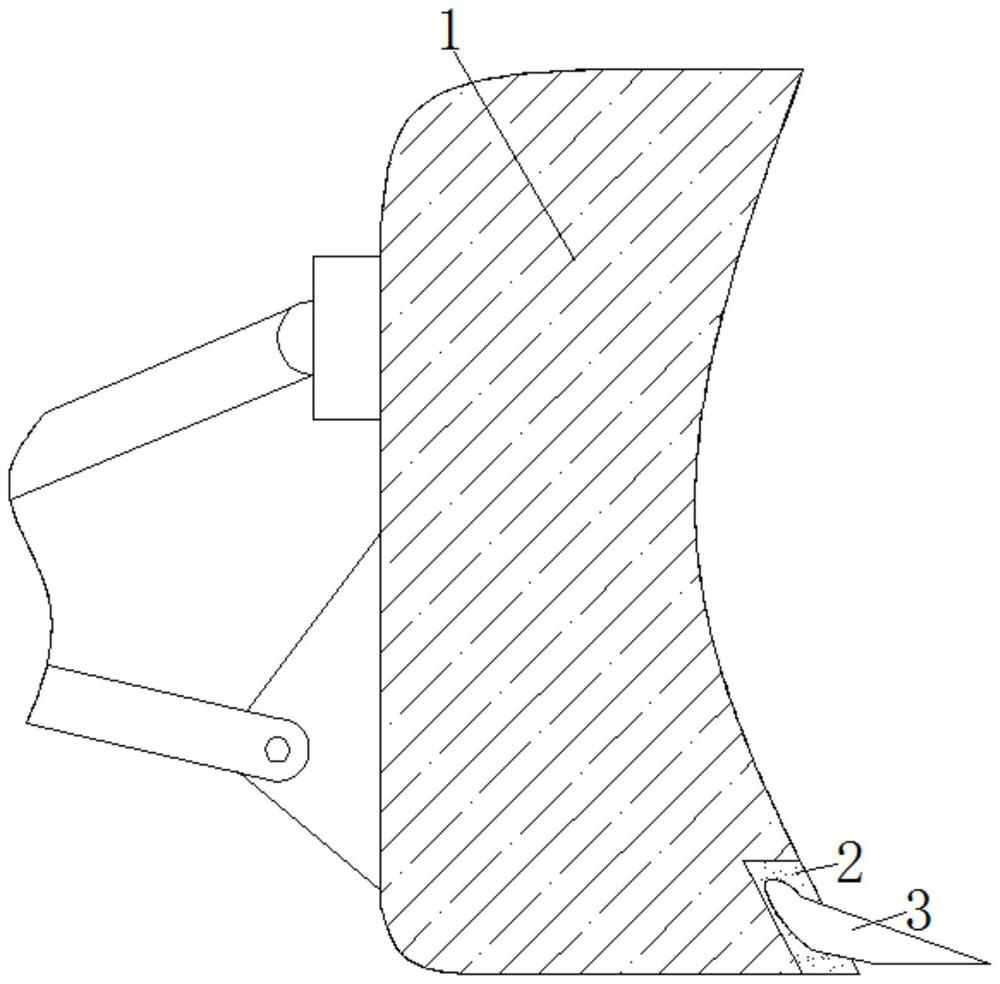

A kind of plant root cutting device for bucket

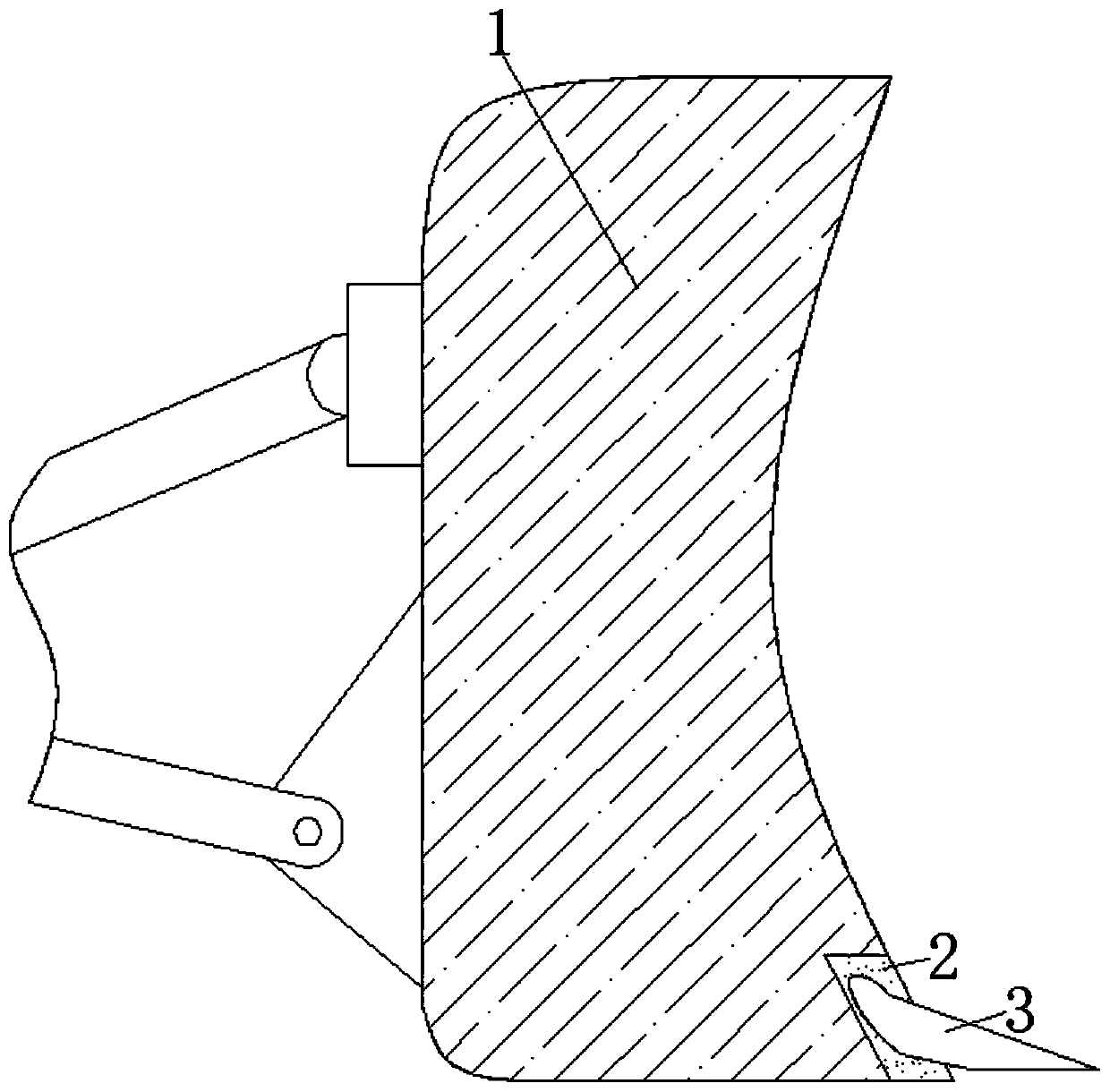

ActiveCN111155580BImprove work efficiencyGuaranteed uptimeMechanical machines/dredgersPlant rootsAgricultural engineering

A plant root cutting device for a bucket, the lower end of the forklift body is fixed with a shovel tip, the right side of the shovel tip is movably installed with a shovel knife, the middle and lower end of the shovel knife is movably installed with a stopper, and one end of the stopper runs through the And extending to the outside of the spatula is hinged with a baffle, the baffle is movably installed with the outer surface of the shovel tip through the fixed column, the side of the baffle close to the spatula is hinged with a pressure column, and the end of the pressure column away from the baffle is hinged with a The briquetting block is fixedly installed on the side of the briquetting block away from the pressure column and the side of the blade. Through the combined use of the press knife and the sawtooth column, the root system of the plant can be effectively cut off when the bucket body encounters the root system of the plant, which ensures the normal operation of the bucket body and reduces the physical strength of the staff. The staff first shovels the root system of the plant and then shovels the soil with the bucket body, which improves the working efficiency of the forklift and brings more effective operation convenience to the staff.

Owner:滕州潍达智能科技有限公司

A kind of construction steel bar cutting device

Owner:河南航天建筑工程有限公司

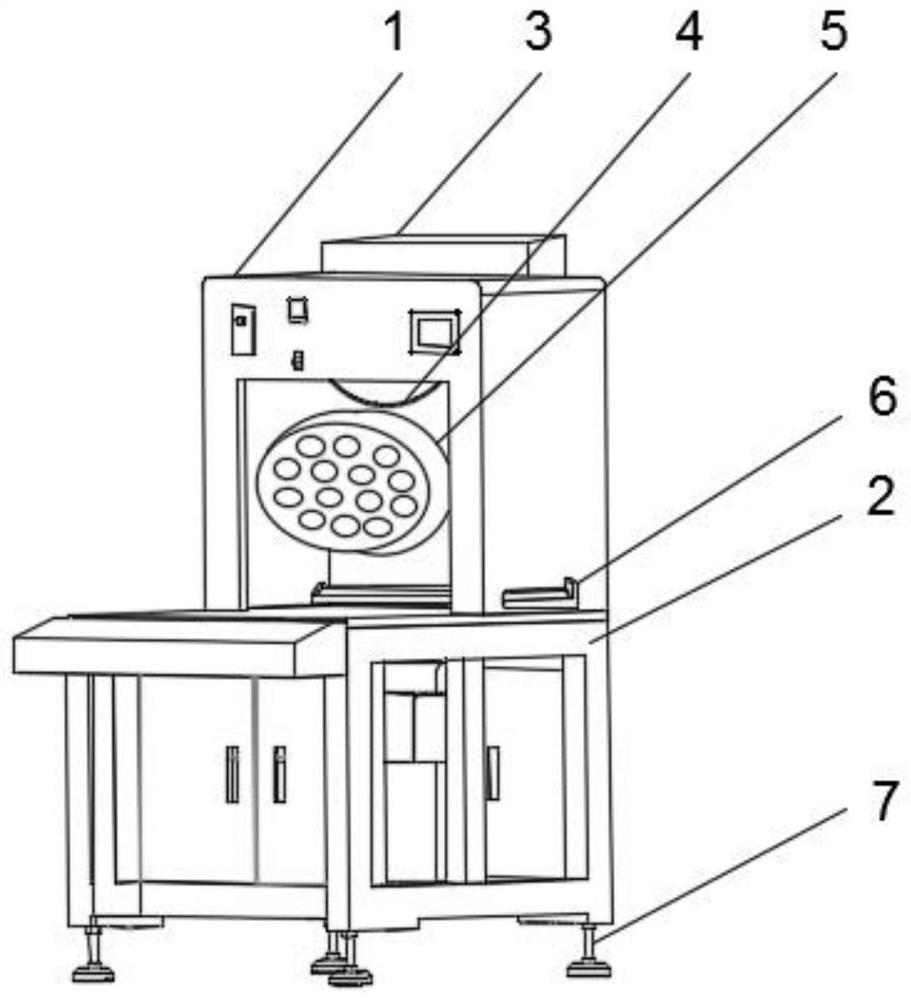

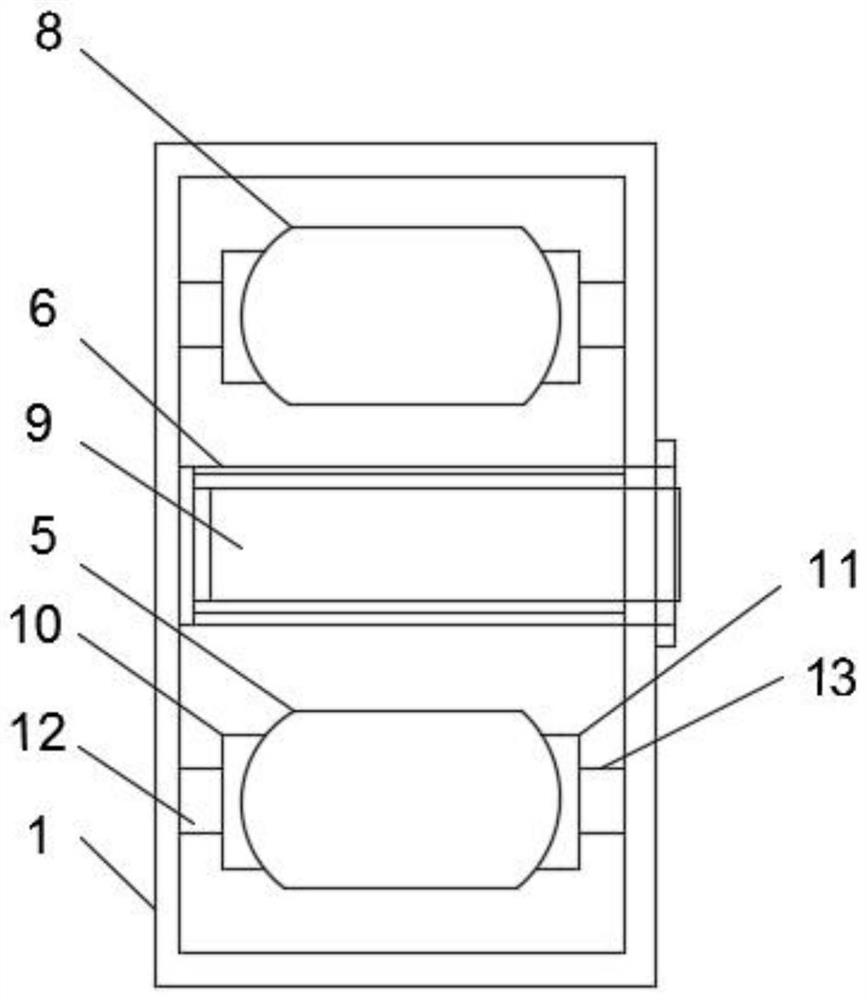

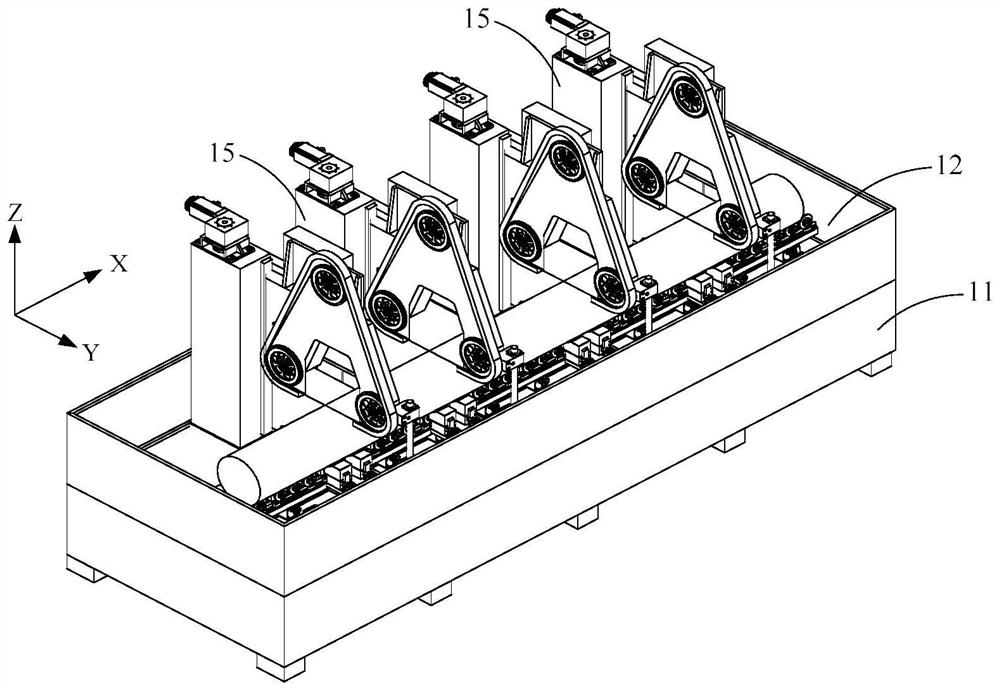

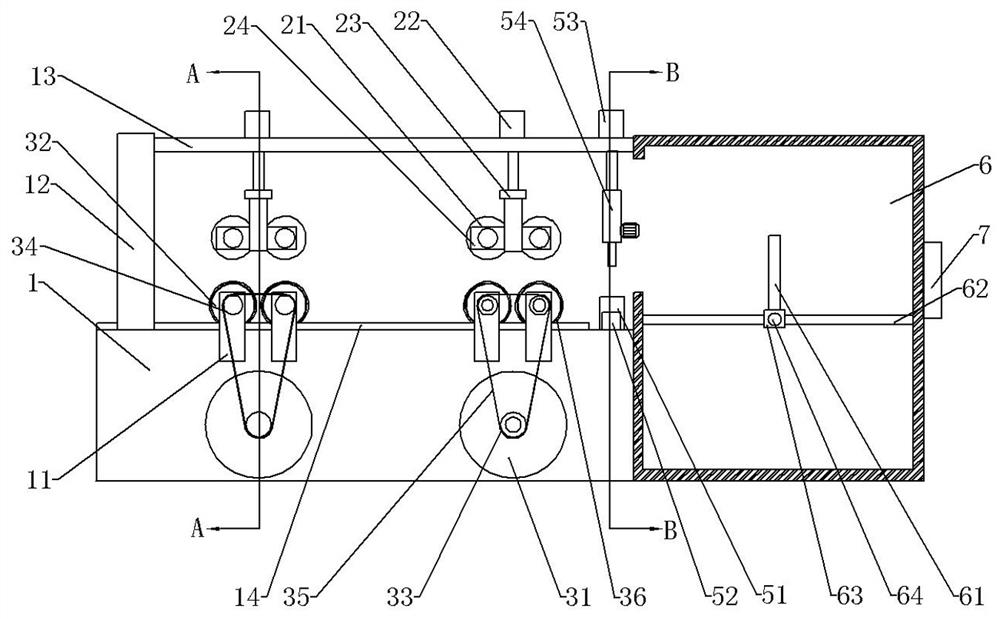

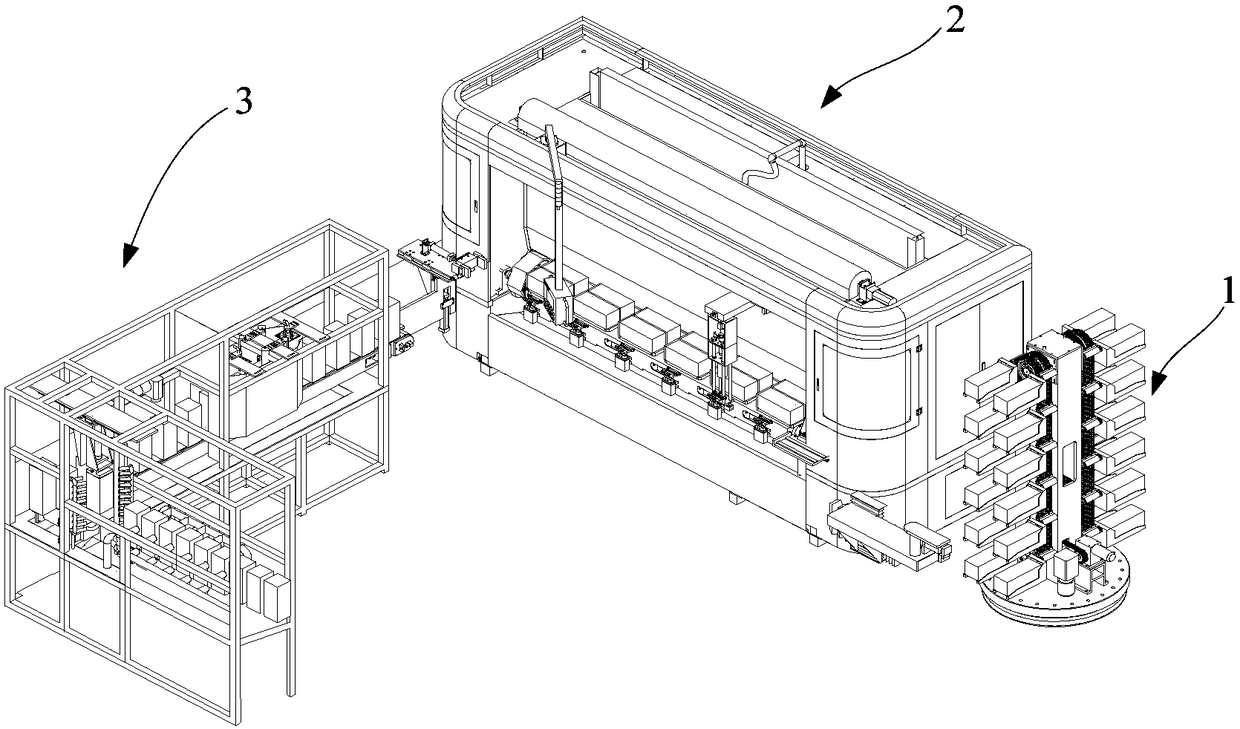

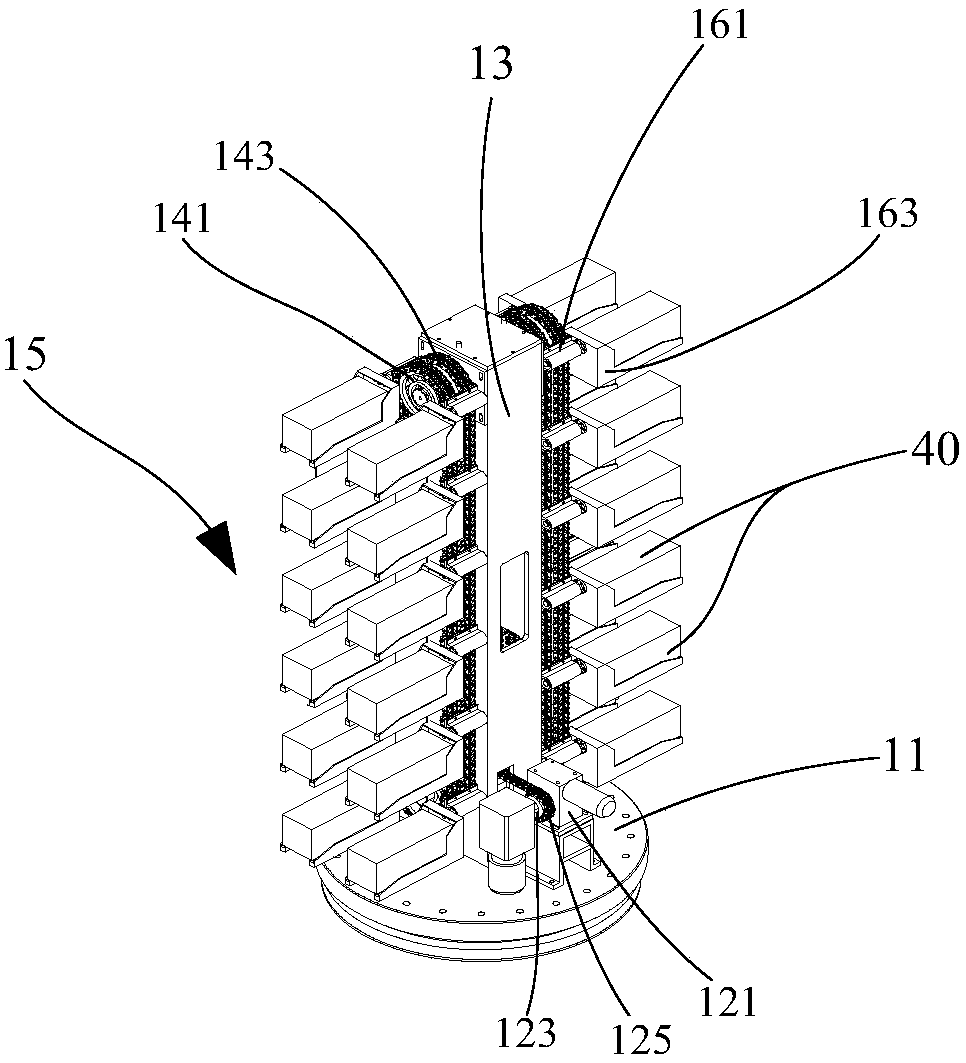

Silicon ingot cutting system and silicon ingot cutting method

The invention provides a silicon ingot truncation system and a silicon ingot truncation method. The silicon ingot truncation system comprises silicon ingot truncation equipment and silicon ingot storage equipment, wherein the silicon ingot truncation equipment is used for performing truncation on silicon ingots to form silicon cubes; and the silicon ingot storage equipment is located at the front end of the silicon ingot truncation equipment and is used for storing the silicon ingots and conveying the stored silicon ingots to the silicon ingot truncation equipment. Compared with the prior art, the silicon ingot truncation system and the silicon ingot truncation method have the advantages that the to-be-truncated silicon ingots can be well collectively stored in the silicon ingot storage equipment; during truncation, the silicon ingots stored in the silicon ingot storage equipment are conveyed to the silicon ingot truncation equipment for truncation to form the silicon cubes; the storing and conveying of the silicon ingots are convenient; and the truncation efficiency is greatly improved.

Owner:TDG NISSIN PRECISION MACHINERY CO LTD

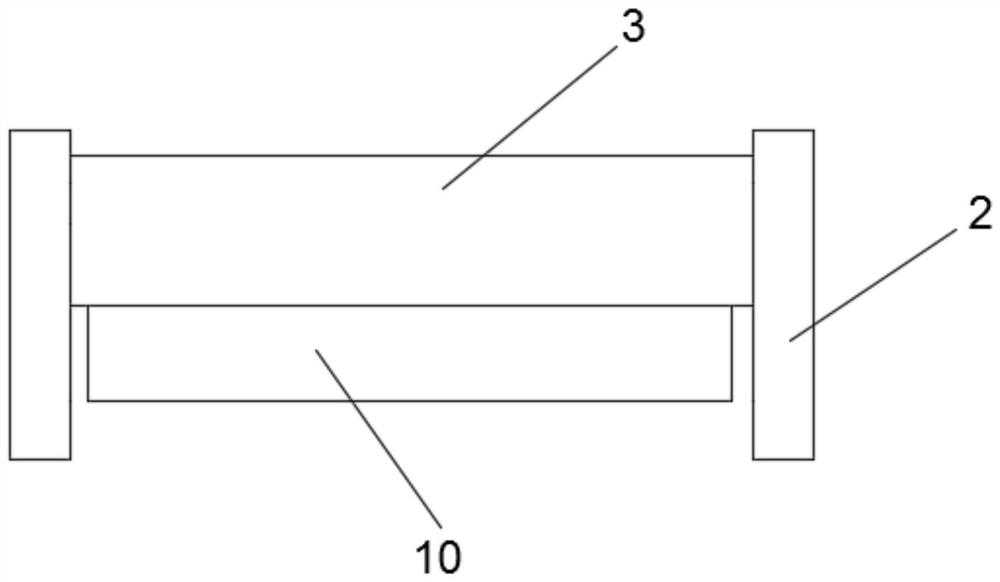

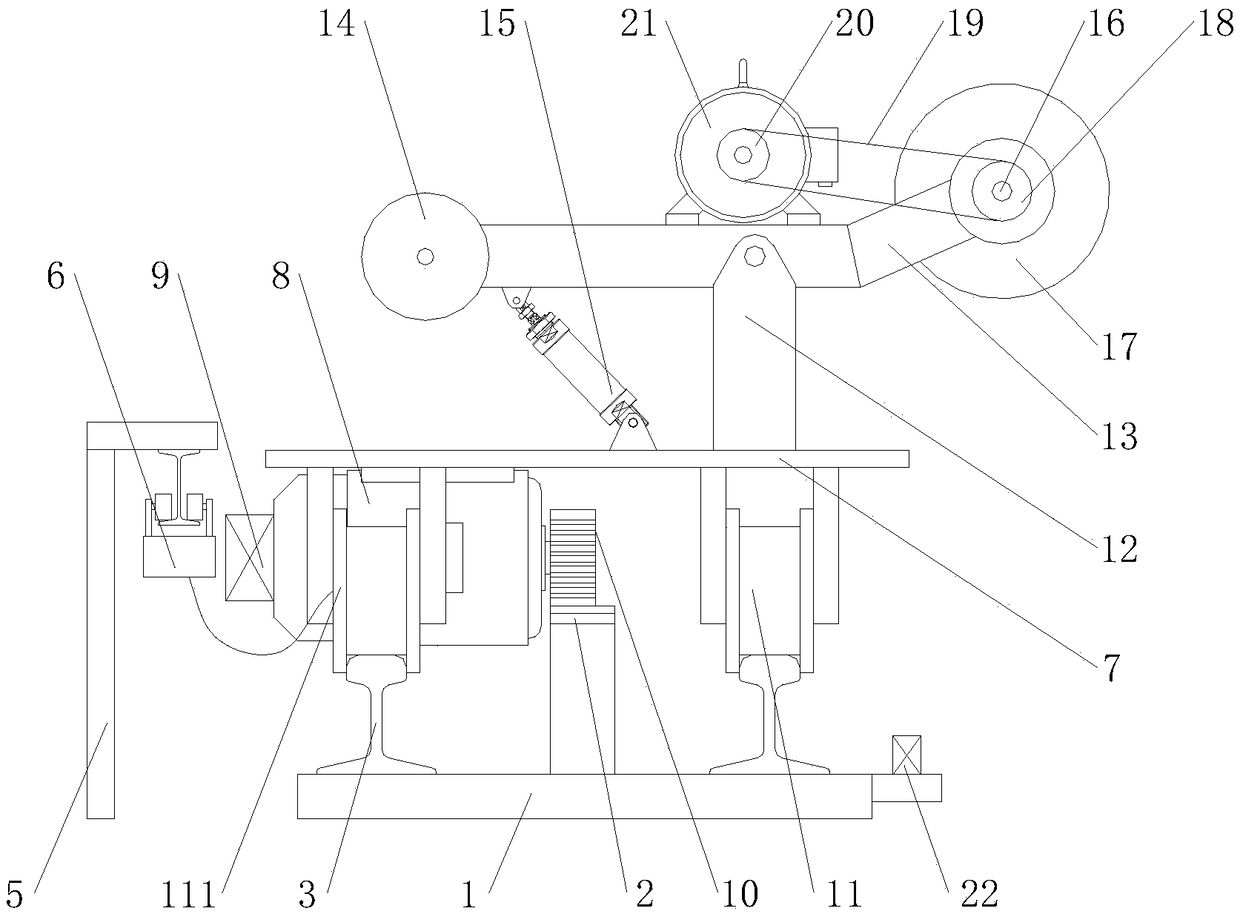

Cross-sliding-type automatic cutting machine for artificial boards

InactiveCN108772919APrevent disengagementImprove securityProfiling/shaping machinesWood working safety devicesLight railEngineering

The invention discloses a cross-sliding-type automatic cutting machine for artificial boards. The cross-sliding-type automatic cutting machine comprises a bottom plate. A driving rack is arranged on the bottom plate. Light rails are arranged on two sides of the driving rack. A cross-sliding cutting device is arranged on the light rails. A cable carriage is arranged on one side of the bottom platethrough a suspended rod. The cross-sliding cutting device comprises a cross sliding platform. A cross sliding motor is arranged at the center of the bottom of the cross sliding platform. A driving gear matched with the driving rack is arranged at the end part of the cross sliding motor. A support is arranged at the top of the cross sliding platform. A rotatable carrier is connected to the upper end of the support. A balance weight plate is arranged at one end of the carrier. A lifting cylinder is connected to the lower end, on one side of the balance weight plate, of the carrier. A rotating shaft is arranged at the other end of the carrier. A cutting sheet is arranged at one end of the rotating shaft. The other end of the rotating shaft is connected with a rotating motor through a driven pulley, a belt and a driving pulley which are connected in sequence. The cross-sliding-type automatic cutting machine has the advantages of high cutting efficiency and low labor intensity.

Owner:ZHEJIANG LIANGYUE BOARD IND CO LTD

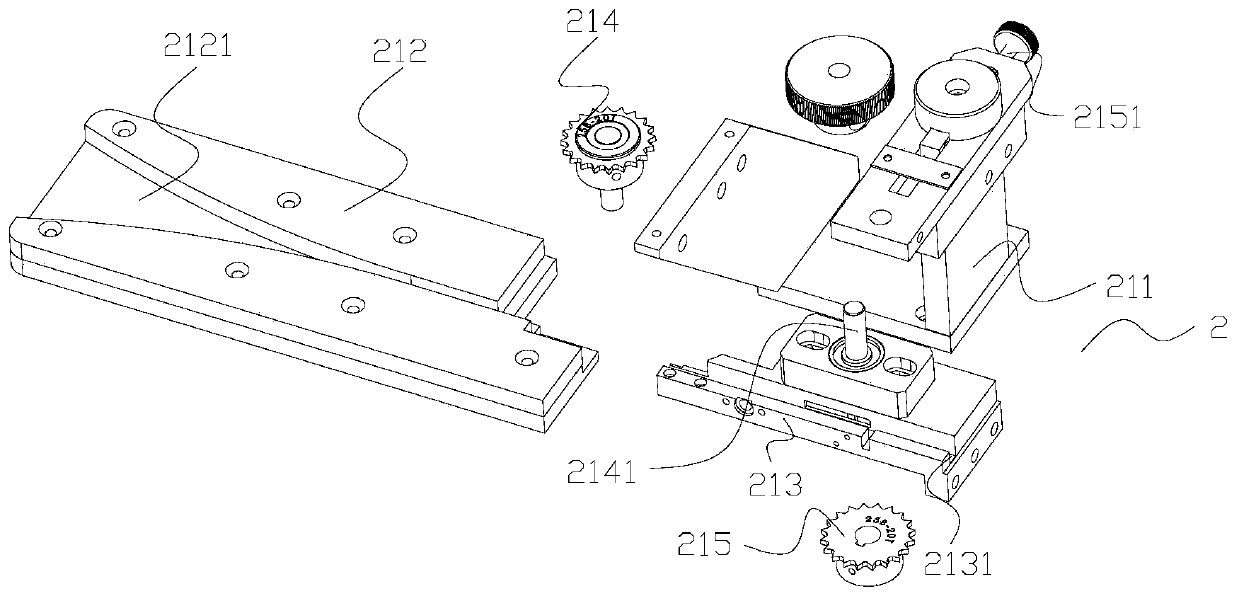

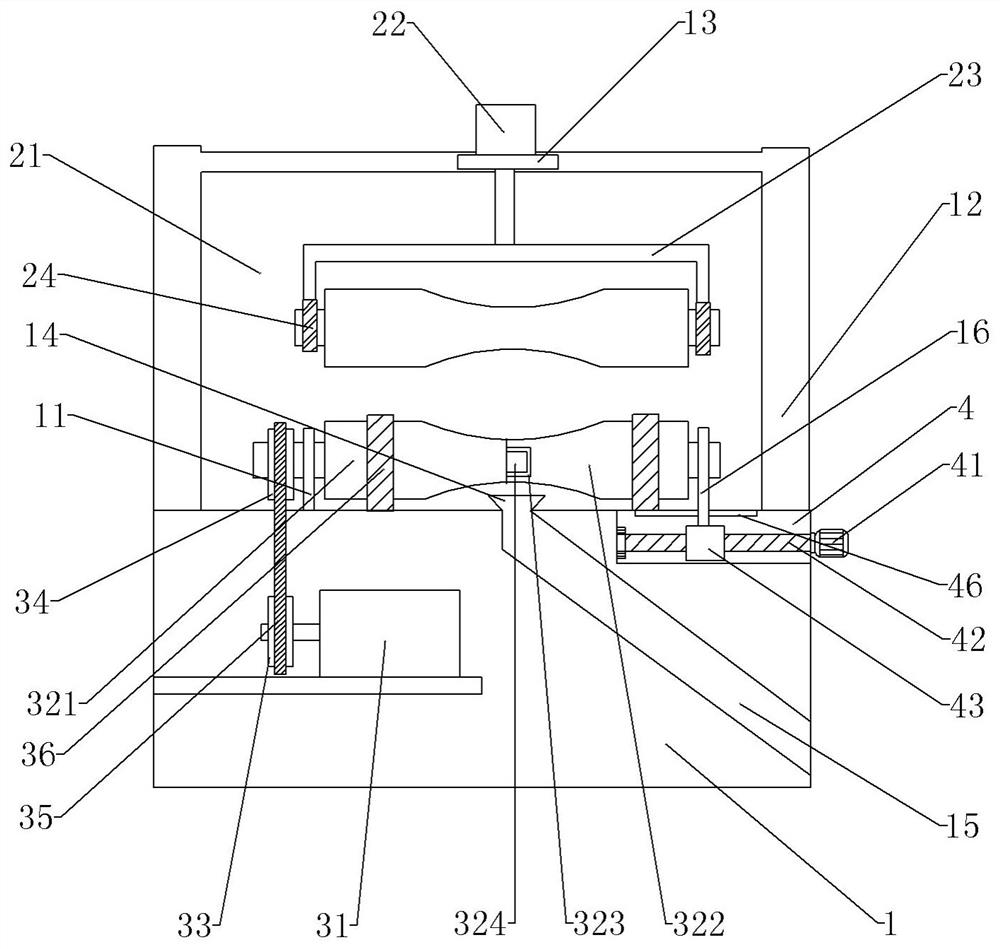

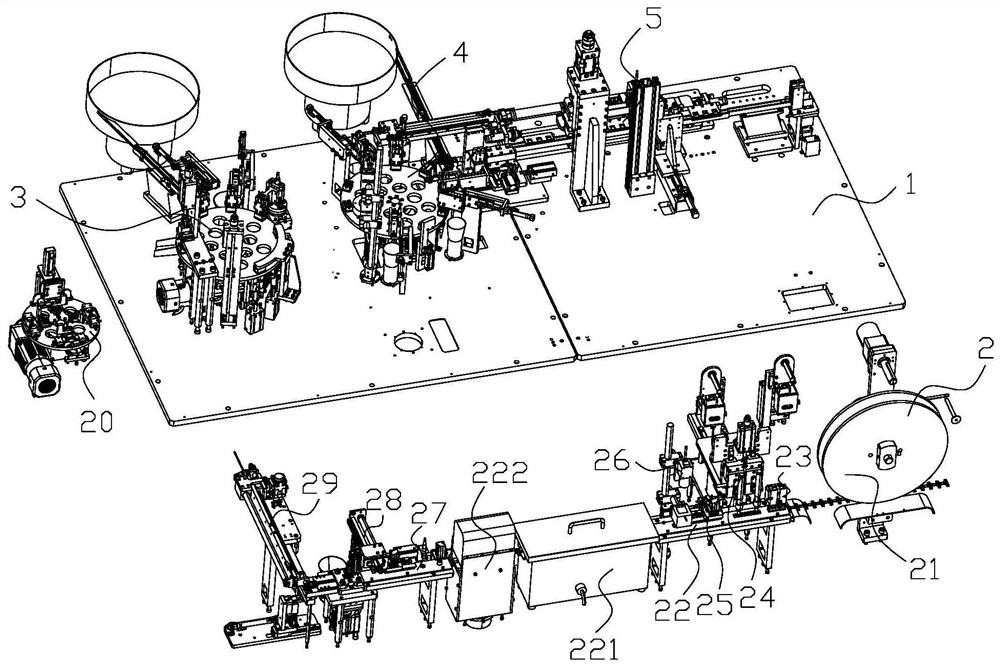

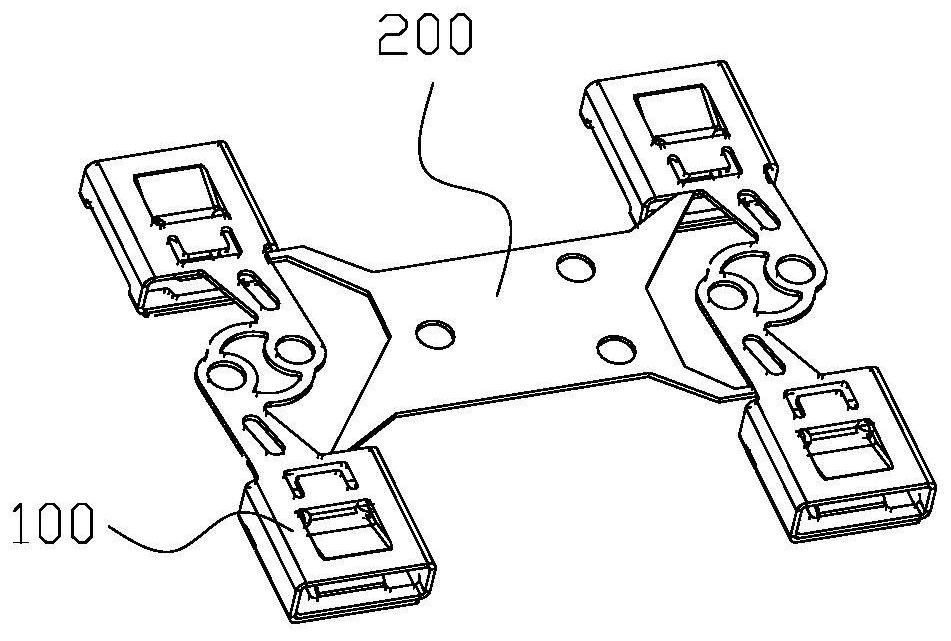

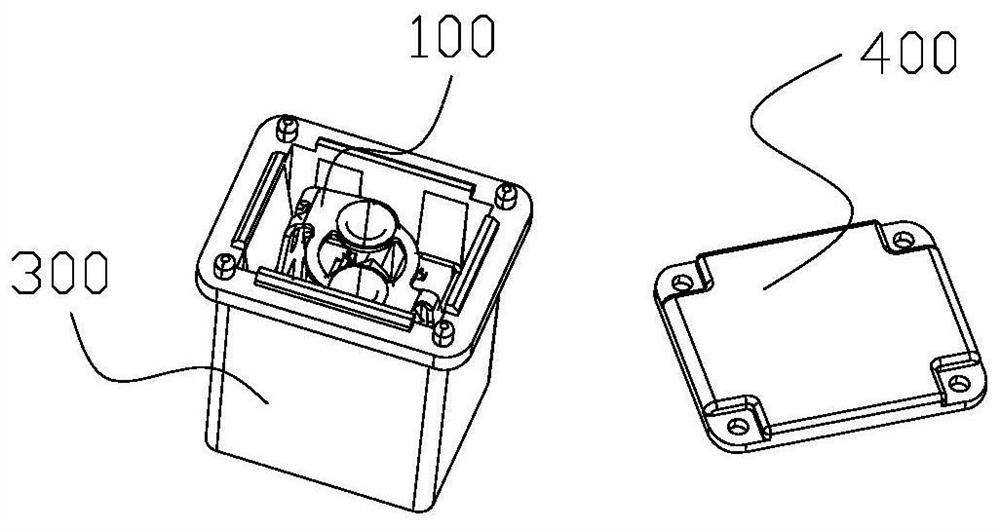

A kind of production equipment and process of fuse box

ActiveCN110802396BImprove flatnessPrecise positioningFuse device manufactureAssembly machinesPunchingMaterials science

The invention relates to the technical field of fuse boxes. A copper sheet conveying and processing device for a fuse box, comprising a copper sheet carrier tape assembly, a first copper sheet conveying bracket, a copper sheet flattening assembly, a copper sheet center punching assembly, a first copper sheet positioning and moving assembly, and a copper sheet punching assembly The detection component, the second copper sheet conveying bracket, the copper sheet cutting assembly and the copper sheet transfer assembly; the copper sheet flattening assembly is used for flattening the copper sheet; the copper sheet center punching assembly is used for punching the center of the copper sheet; the first copper sheet The positioning moving component is used to drive the copper sheet to move and locate; the copper sheet punching detection component is used for copper sheet detection; the copper sheet cutting component is used to cut off the copper sheet one by one; the copper sheet transfer component is used to transport the cut copper sheet . The advantages of this patent are to improve the conveying efficiency and conveying quality of copper sheets, improve the punching efficiency and punching quality; improve the truncation efficiency and truncation quality, and improve the overall conveying and processing efficiency of copper sheets.

Owner:TAICANG CITY LVDIAN INFORMATION TECH CO LTD

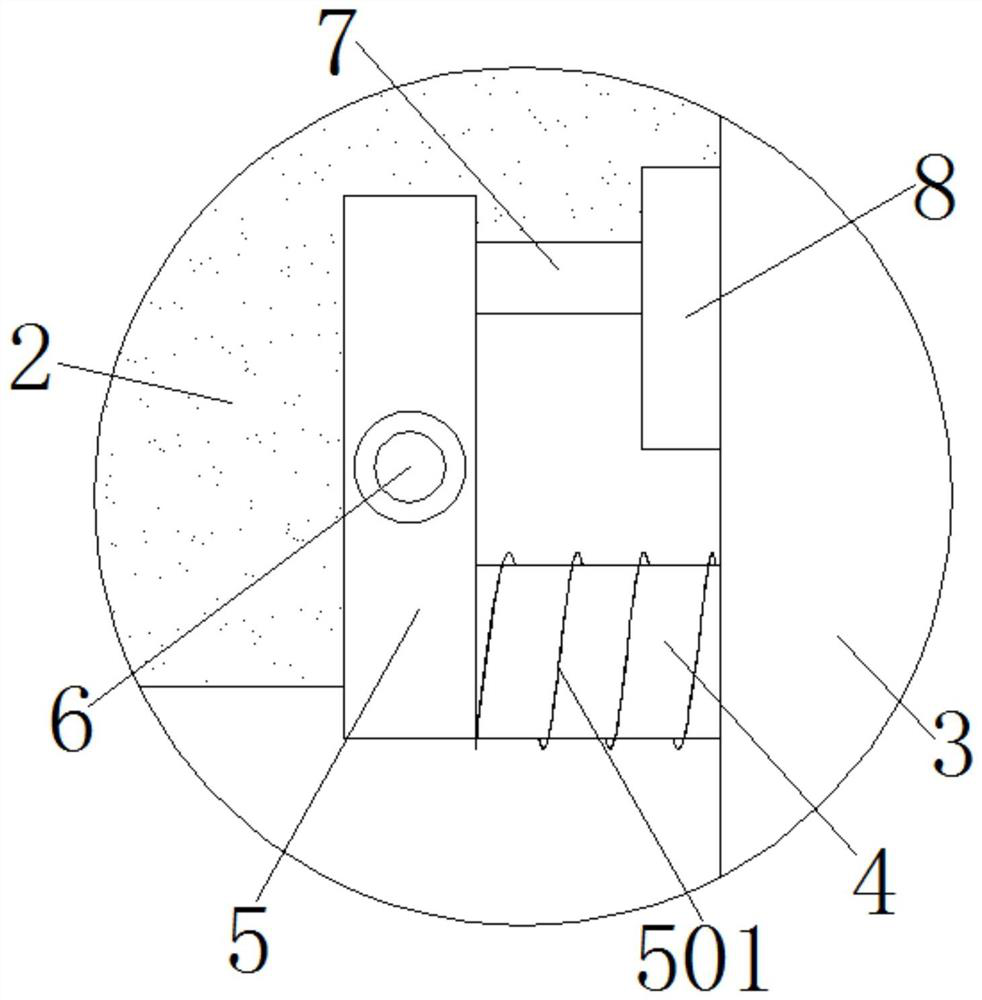

Automobile part intelligent cut-off equipment capable of improving cut-off efficiency

ActiveCN112916962AGuaranteed stabilityEasy to useLarge fixed membersPositioning apparatusEngineeringMachine

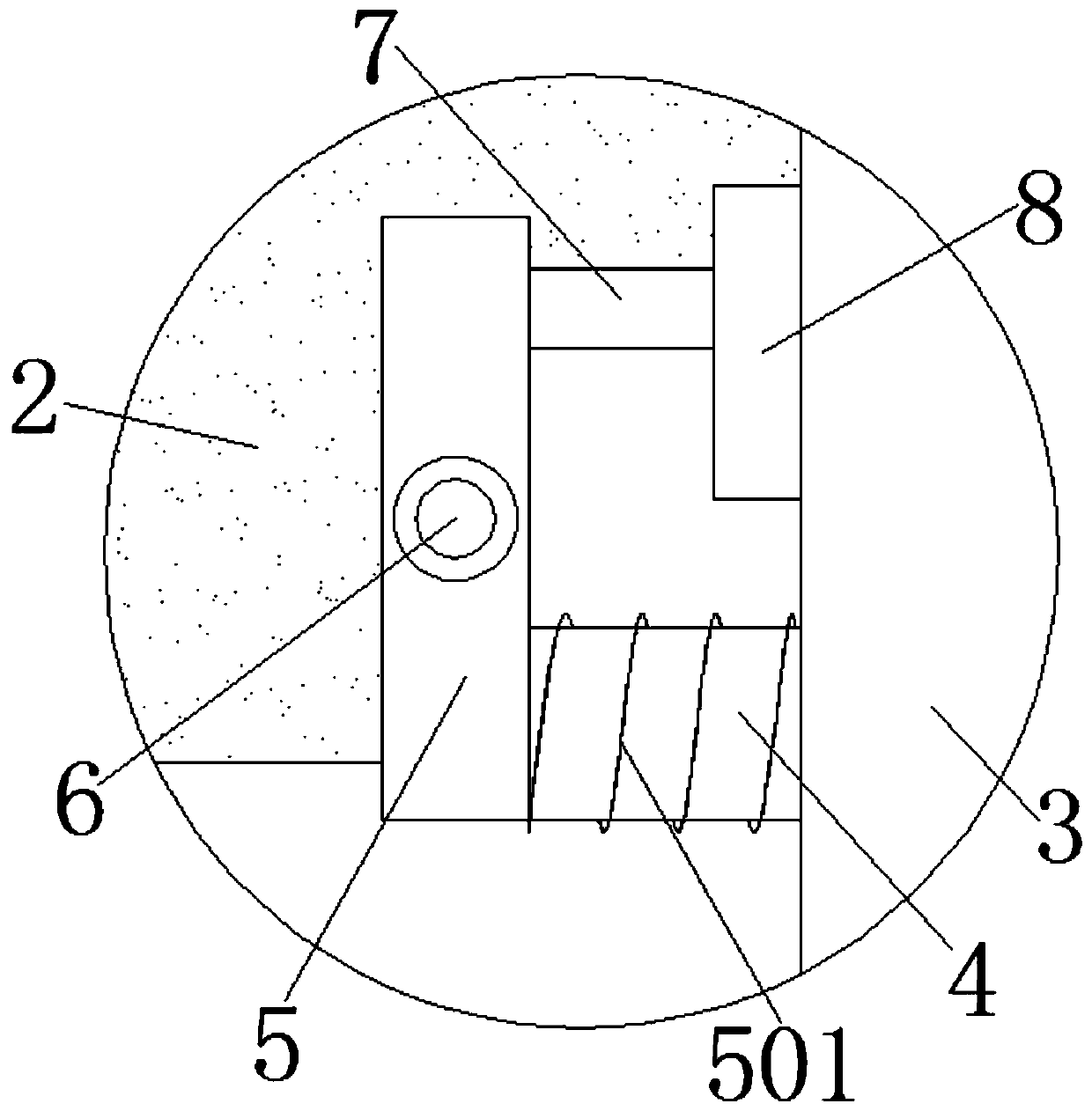

The invention relates to the technical field of automobile parts, and discloses automobile part intelligent cut-off equipment capable of improving the cut-off efficiency. The automobile part intelligent cut-off equipment comprises a cut-off machine body, a supporting seat is fixedly connected to the interior of the cut-off machine body, and a rotating groove is formed in the outer surface of the supporting seat; a rotating shaft is movably connected to the position, located in the rotating groove, of the outer surface of the supporting seat, a piston column is movably connected to the side surface of the rotating shaft, a pushing frame is movably connected to the other side of the rotating shaft, a buffer spring is movably connected to the interior of the pushing frame, and a reinforcing seat is movably connected to the other side of the pushing frame; and the interior of the reinforcing seat is movably connected with a pressure spring, and the interior of the cutting machine body is fixedly connected with a cut-off seat. The automobile part intelligent cut-off equipment achieves the effect of automatically cutting off automobile parts in the positioning process during use, reduces a certain workload, is simple to operate, and brings beneficial effects for subsequent machining of the automobile parts.

Owner:日照金运机械有限公司

Device for conveniently pruning branches and leaves of trees

ActiveCN107027527AConvenient truncationEasy to operateCuttersCutting implementsEngineeringKnife blades

The invention discloses a device for conveniently pruning branches and leaves of trees. The device comprises a connection rod and a cutting mechanism, the cutting mechanism comprises knife blades and a sliding rod, the knife blades comprise the fixed knife blade and the mobile knife blade, the fixed knife blade is installed at the upper end of the connection rod, the mobile knife blade is hinged to the fixed knife blade, a cutting gap is formed between the fixed knife blade and the mobile knife blade, the sliding rod is arranged in the connection rod, and the mobile knife blade is connected with the upper end of the sliding rod; a handle is installed at the lower end of the connection rod, the handle comprises a mobile handle body, a fixed handle body and an elastic mechanism, the fixed handle body is fixedly installed on the connection rod, the mobile handle body is connected with the fixed handle body and hinged to the lower end of the connection rod, the elastic mechanism comprises a supporting block and a first spring, the supporting block is installed at the connecting position of the fixed handle body and the mobile handle body, and the supporting block is sleeved with the middle of the first spring. The handle is squeezed so as to make the sliding rod slide downward, the sliding rod drives the mobile knife blade to rotate, so that the cutting gap is sealed, and accordingly, the branches in the cutting gap is cut off. The device can be operated only through one hand, and the device is convenient to use.

Owner:张古权

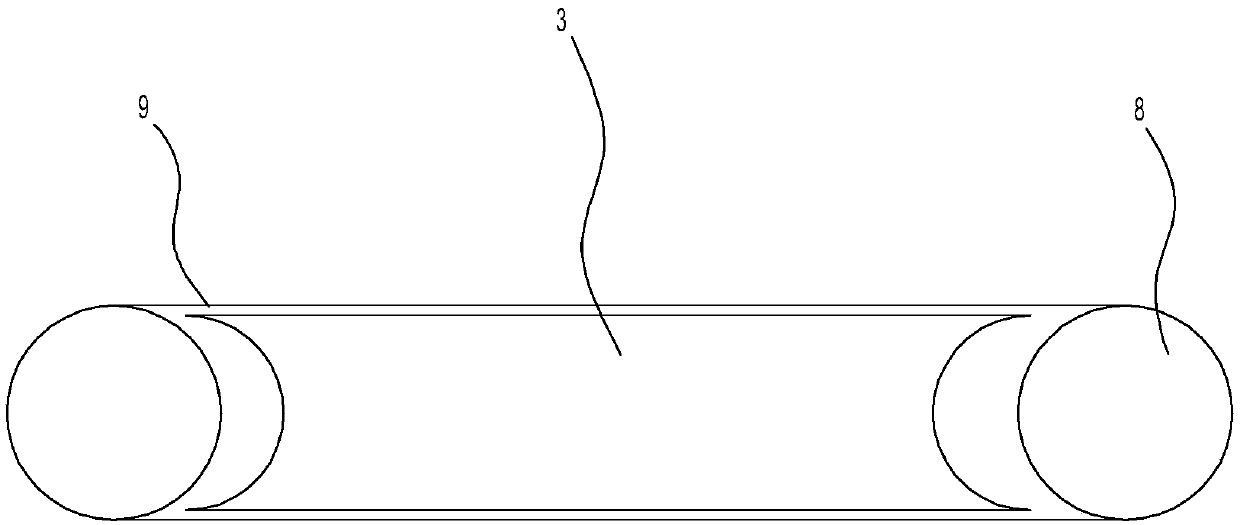

Film cutting mechanism for straw bale film wrapping machine and film cutting method thereof

PendingCN111017346AImprove truncation efficiencyIncreased bale wrapping efficiencyPackagingAgricultural engineeringFarm machine

The invention relates to the technical field of agricultural machinery operation, in particular to a film cutting mechanism for a straw bale film wrapping machine and a film cutting method thereof. The film cutting mechanism comprises a film clamping mechanism, a cutting mechanism and a driving mechanism for driving the film clamping mechanism to open and close; the film clamping mechanism comprises a main clamping plate and an auxiliary clamping plate, the horizontal cross section of the main clamping plate is in an inverted-T shape, and the horizontal cross section of the auxiliary clampingplate is of a U-shaped structure; the cutting mechanism comprises a vertical electric cylinder and a cutting part; the middle of the auxiliary clamping plate is provided with a vertical strip-shaped hole; and the driving mechanism comprises an X-shaped rotary frame, and the main clamping plate and the auxiliary clamping plate are fixed to the two ends of the X-shaped rotary frame correspondingly.According to the film cutting mechanism for the straw bale film wrapping machine and the film cutting method thereof, it can be achieved that the cutoff position after plastic film wrapping is automatically cut, and the cutoff efficiency and the straw bale wrapping efficiency are improved; an unwound plastic film can be cut, the situation that the ends of the cut plastic film adhere to each otheris avoided, through the film clamping mechanism, plastic film wasting caused by cutting line deflection is avoided, and the cost is reduced.

Owner:北京德邦大为科技股份有限公司

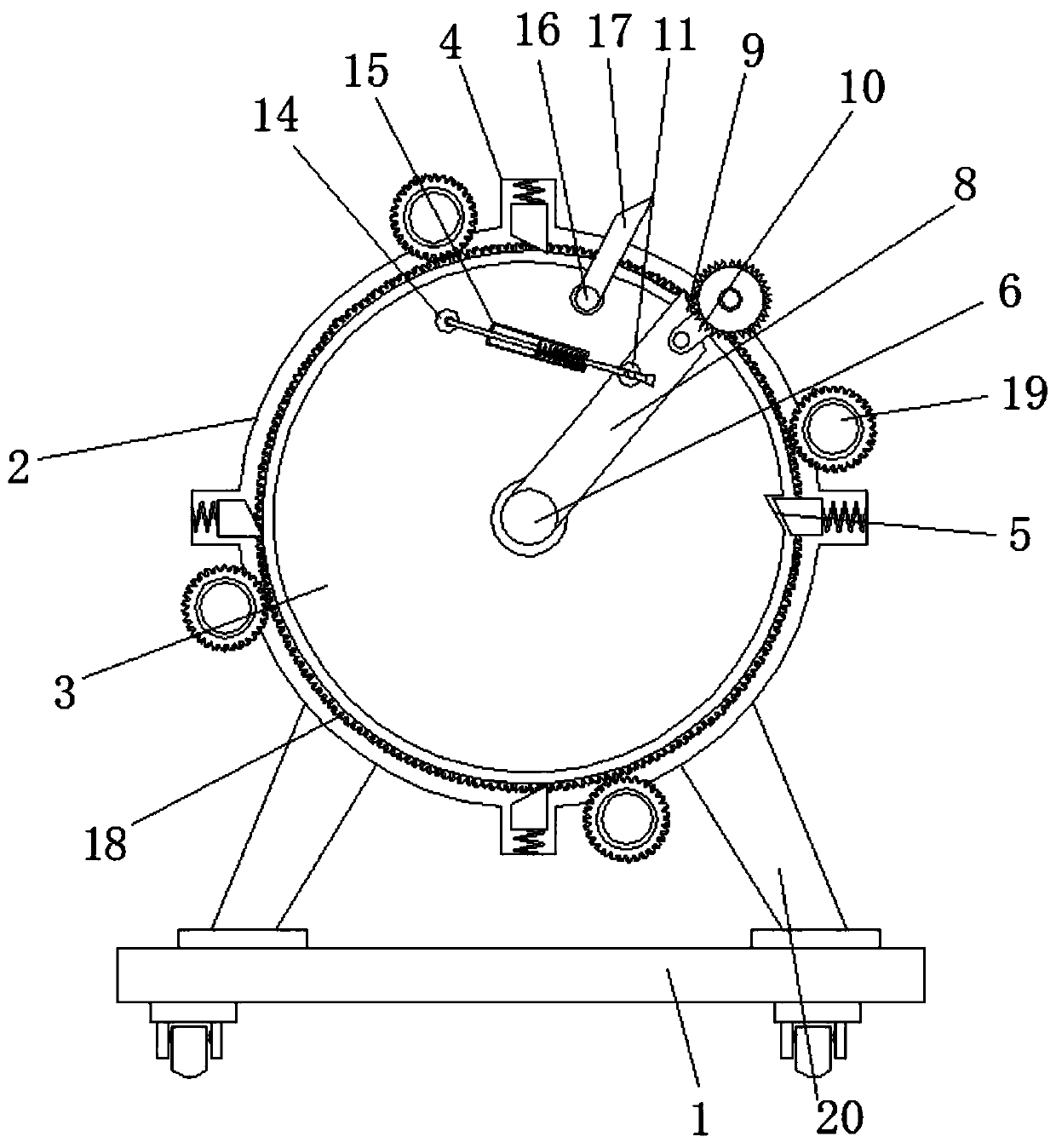

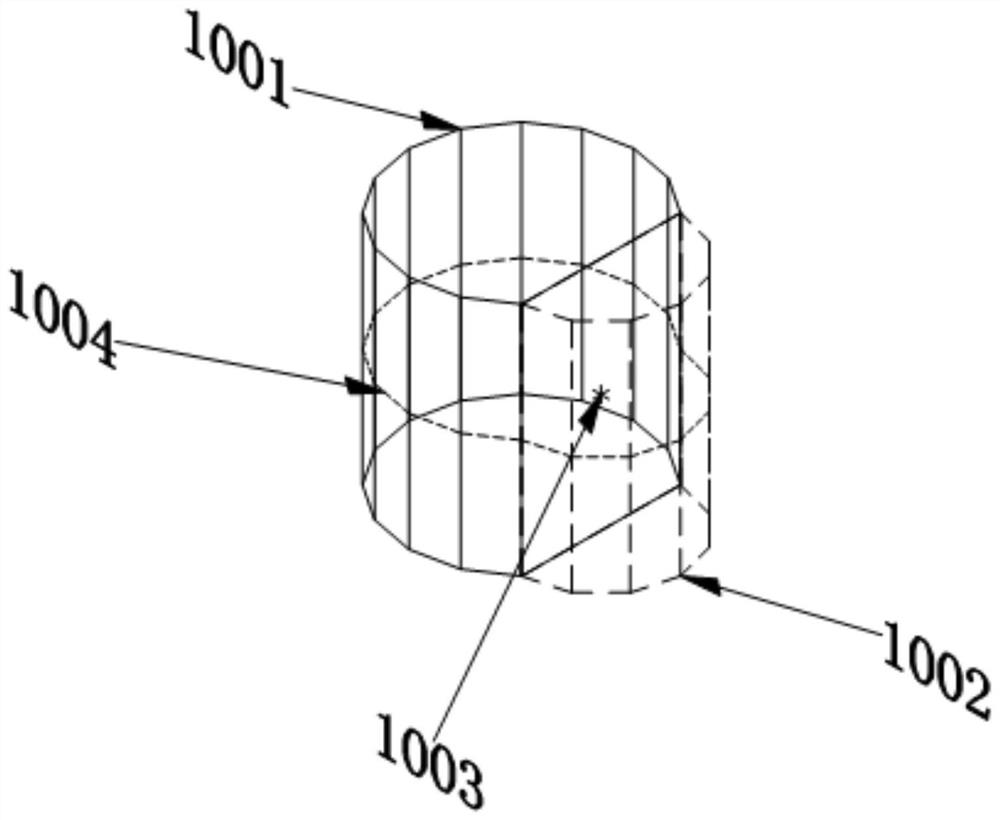

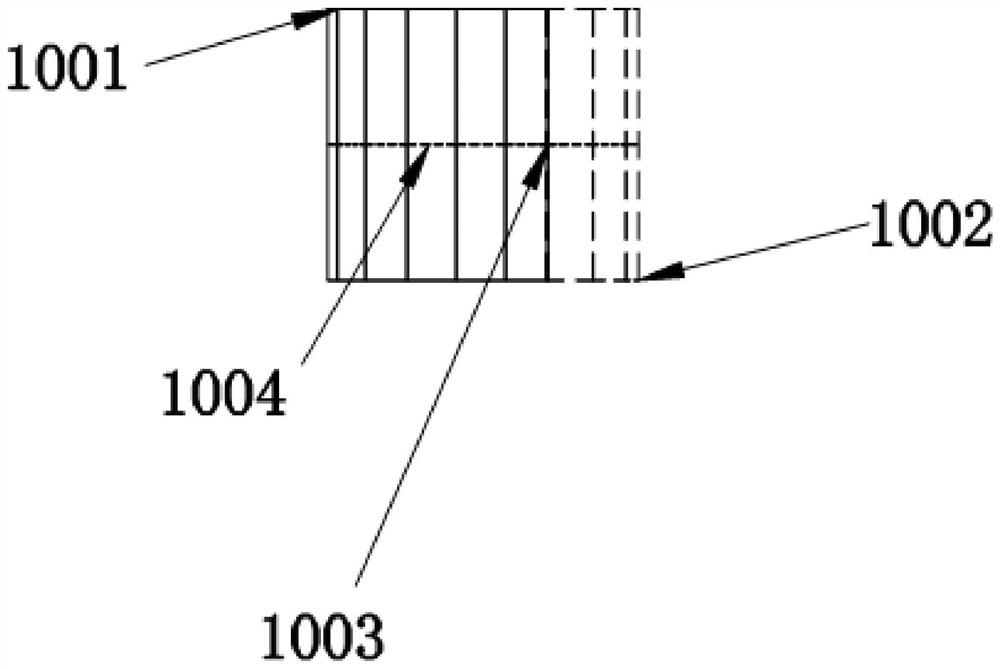

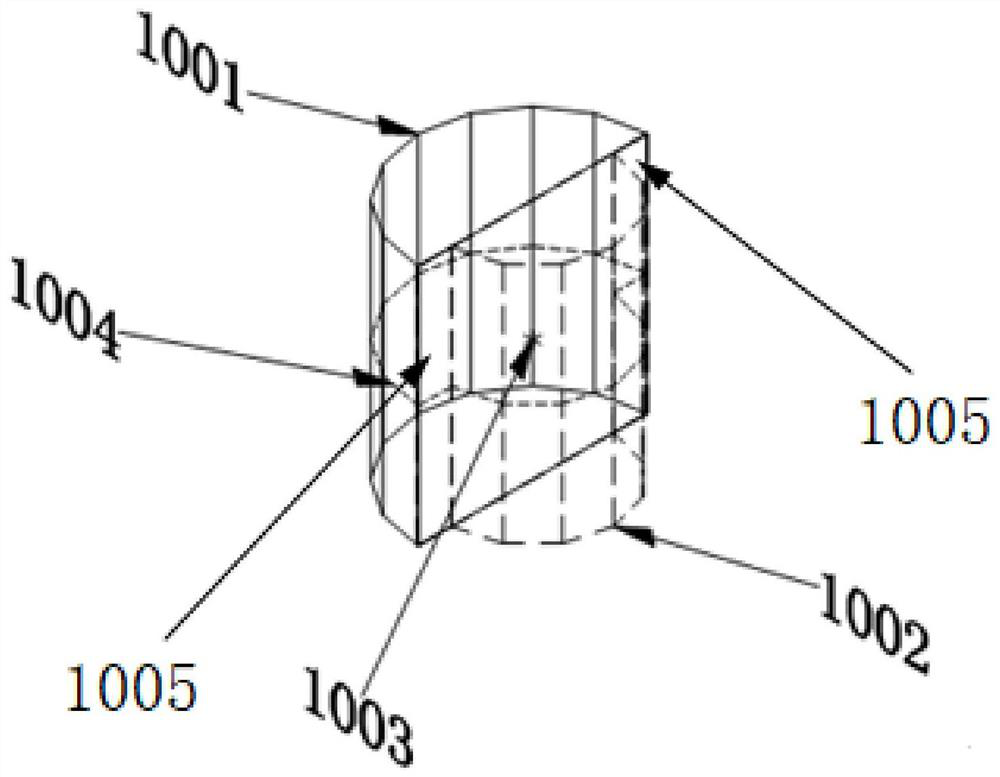

An external heat absorber structure for a tower photothermal power generation system

ActiveCN109798680BReduce the numberImprove truncation efficiencySolar heating energyAbsorbing elementsThermodynamicsHeliostat

The invention discloses an external heat absorber structure for a tower type photo-thermal power generation system. The external heat absorber structure comprises a first heat absorbing part and a second heat absorbing part, wherein the illuminated faces of the first heat absorbing part and the second heat absorbing part are curved surfaces, the illuminated area of the first heat absorbing part islarger than the illuminated area of the second heat absorbing part, the first heat absorbing part and the second heat absorbing part cooperate to form a heat absorber, and the heat absorber is disposed on a heat absorbing tower. When the tower type photo-thermal power generation system is located in the northern hemisphere, the first heat absorbing part is a north side heat absorber, and the second heat absorbing part is a south side heat absorber; and when the tower type photo-thermal power generation system is located in the southern hemisphere, the first heat absorbing part is a south sideheat absorber, and the second heat absorbing part is a north side heat absorber. When the heat absorber structure is designed to be with the illuminated area of the first heat absorbing part being larger than the illuminated area of the second heat absorbing part, more heliostats can be projected to the first heat absorbing part under the condition that the heat absorber has the maximum energy flow limit, that is, more heliostats can be arranged in a mirror field on one side of the first heat absorbing part so as to improve the optical efficiency of the mirror field, the utilization rate of the mirror field heliostats and the truncation efficiency of the heat absorber as much as possible.

Owner:ZHEJIANG SUPCON SOLAR TECHNOLOGY CO LTD

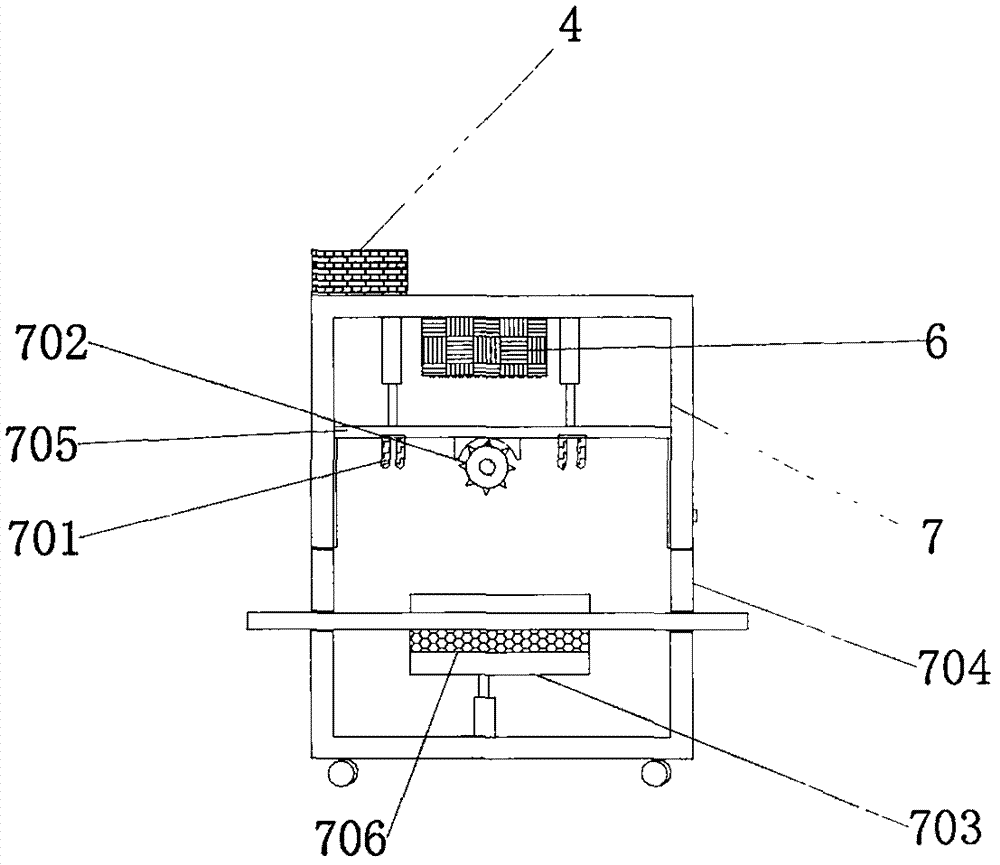

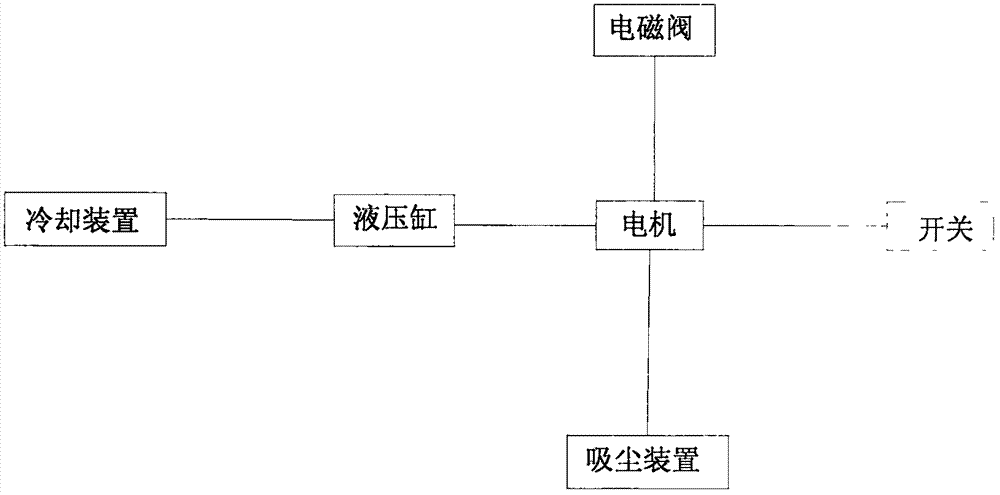

Automobile part rapid cutting-off machine

PendingCN107984019AQuick and easy to useFast truncationShearing machinesMaintainance and safety accessoriesEngineeringElectromagnetic valve

The invention discloses an automobile part rapid cutting-off machine. The machine comprises a cutting-off machine main body, a working table and a cutting-off device; the working table is arranged onthe upper side of the cutting-off machine main body and is fixedly connected with the cutting-off machine main body, the cutting-off device is arranged inside the cutting-off machine main body and isembedded in the cutting-off machine main body, and a motor is arranged on the left side of the cutting-off machine main body and is connected with the cutting-off machine main body in an embedding mode. According to the machine, a movable cutter can move left and right and up and down through a movable guide rail so that the cut-off position of a part can be more accurate and can not generate flaws, the rotary cutter is arranged so that the cutting speed can be higher, the efficiency can be higher, the automobile part can be cut off, the parts of other materials can also be cut off, the multipurpose performance of the machine is embodied, and a cooling device is further arranged in the cutting-off device so that cooling and dust clearing can be carried out on the cut part under the controlof an electromagnetic valve.

Owner:无锡市中吉橡塑机械有限公司

A device for cutting steel bars reserved for construction

Owner:湖北金丰建筑工程有限公司

Cutter deviation rectifying auxiliary device of automatic hardware cutting-off equipment

InactiveCN113231888AImprove truncation efficiencyIncrease productivityAutomatic control devicesFeeding apparatusStructural engineeringMechanical engineering

The invention provides a cutter deviation rectifying auxiliary device of automatic hardware cutting-off equipment. The cutter deviation rectifying auxiliary device comprises a main body, a fixed base is fixedly installed on the top of the inner wall of the main body, a driving device is installed on the lower side of the fixed base, a driving telescopic rod is installed on the lower side of the driving device, a movable part is fixedly mounted at the lower end of the driving telescopic rod, a movable groove is formed in the fixed base, a spring mechanism is mounted on the inner wall of the movable groove, and a movable block is fixedly connected to the shaft end of the spring mechanism. According to the cutter deviation correction auxiliary device of the automatic hardware cutting-off equipment, due to uncontrollable factors, a cutting-off cutter inclines, the lower end of a push rod is adjusted to drive an adjusting mechanism to achieve deviation correction of the cutting-off cutter, then the cutting-off cutter is reset, and therefore the purpose of effectively eliminating deviation of the cutting-off cutter is achieved; and meanwhile, the hardware cutting-off efficiency of the equipment and the production efficiency of manufacturers are improved, and the equipment is simple in structure, safe and reliable.

Owner:珠海可立自动化技术有限公司

External heat absorber structure for tower type photo-thermal power generation system

ActiveCN109798680AReduce the numberImprove truncation efficiencySolar heating energyAbsorbing elementsHeliostatEngineering

The invention discloses an external heat absorber structure for a tower type photo-thermal power generation system. The external heat absorber structure comprises a first heat absorbing part and a second heat absorbing part, wherein the illuminated faces of the first heat absorbing part and the second heat absorbing part are curved surfaces, the illuminated area of the first heat absorbing part islarger than the illuminated area of the second heat absorbing part, the first heat absorbing part and the second heat absorbing part cooperate to form a heat absorber, and the heat absorber is disposed on a heat absorbing tower. When the tower type photo-thermal power generation system is located in the northern hemisphere, the first heat absorbing part is a north side heat absorber, and the second heat absorbing part is a south side heat absorber; and when the tower type photo-thermal power generation system is located in the southern hemisphere, the first heat absorbing part is a south sideheat absorber, and the second heat absorbing part is a north side heat absorber. When the heat absorber structure is designed to be with the illuminated area of the first heat absorbing part being larger than the illuminated area of the second heat absorbing part, more heliostats can be projected to the first heat absorbing part under the condition that the heat absorber has the maximum energy flow limit, that is, more heliostats can be arranged in a mirror field on one side of the first heat absorbing part so as to improve the optical efficiency of the mirror field, the utilization rate of the mirror field heliostats and the truncation efficiency of the heat absorber as much as possible.

Owner:ZHEJIANG SUPCON SOLAR TECHNOLOGY CO LTD

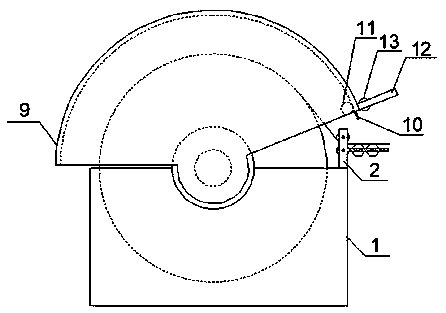

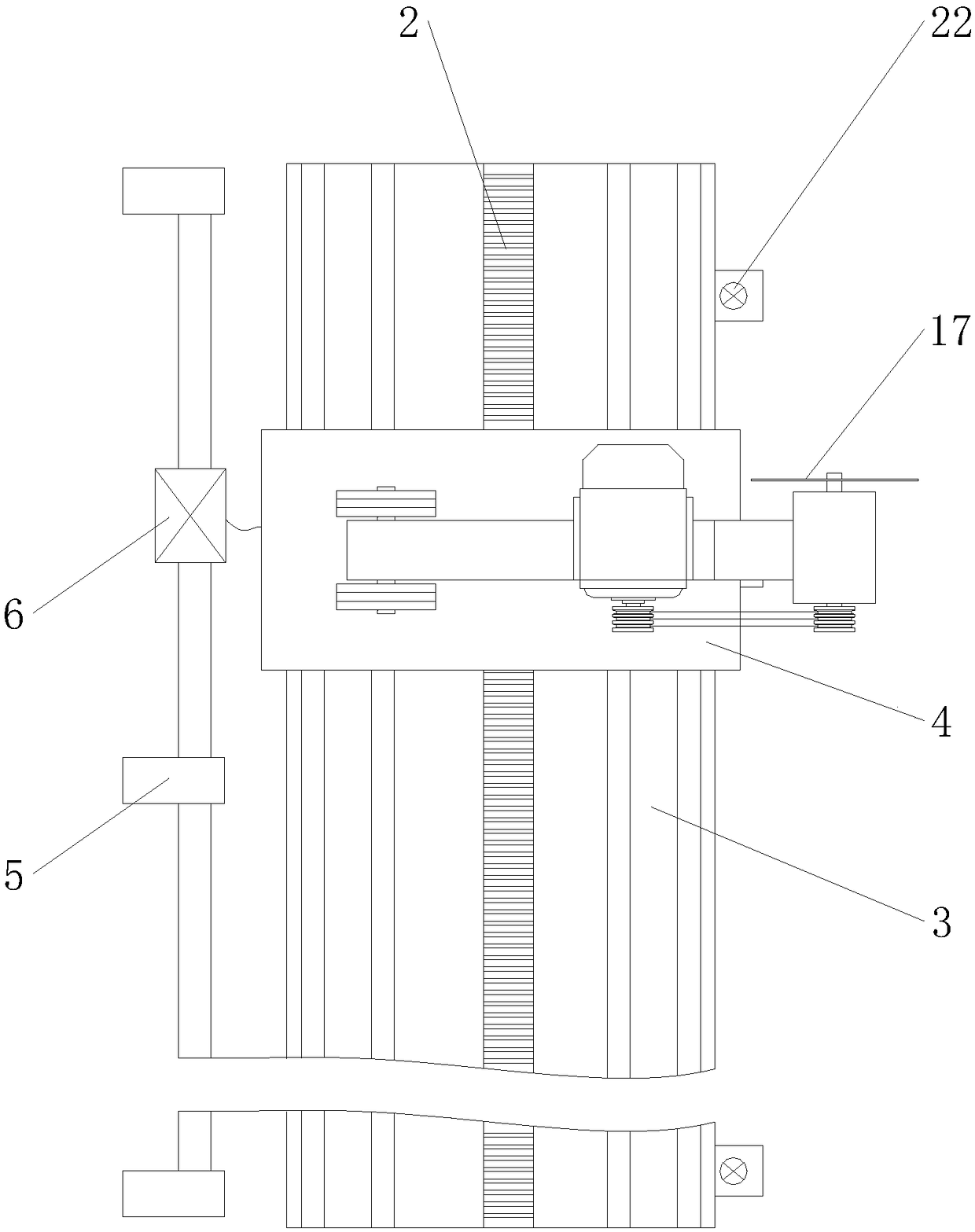

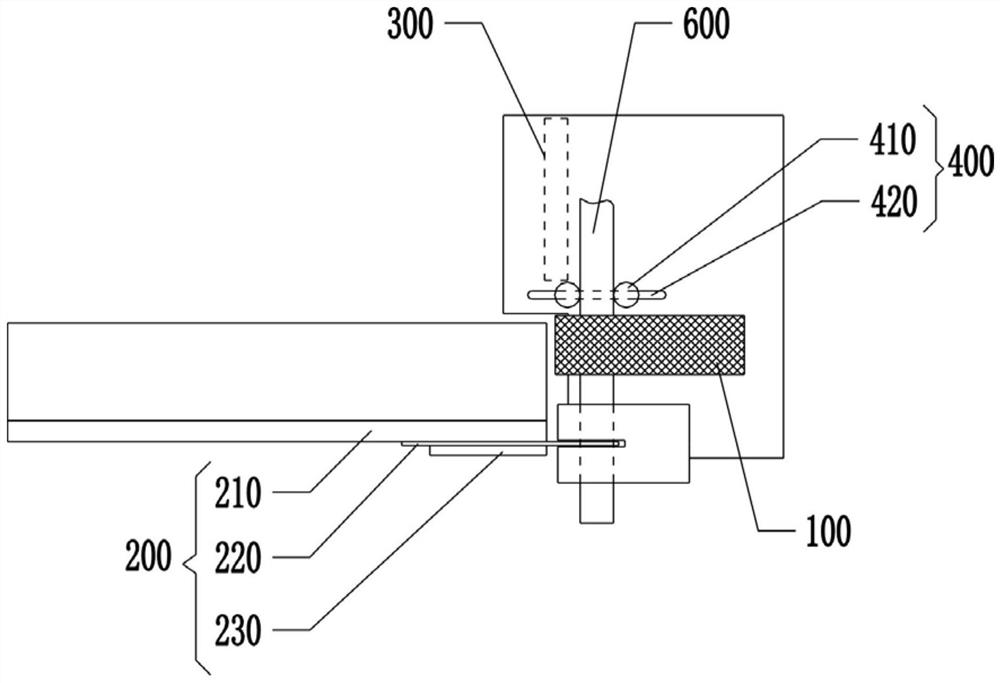

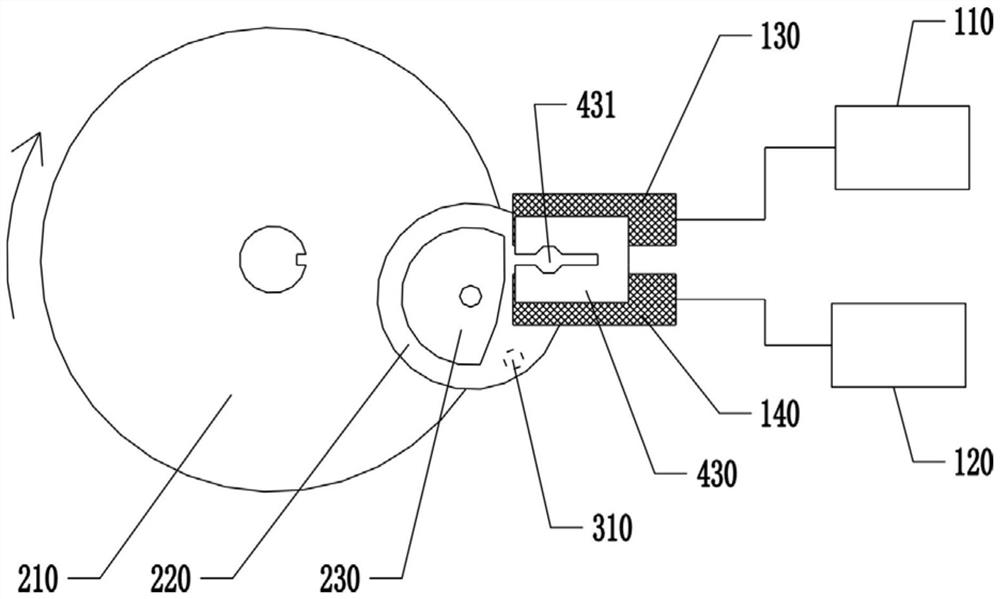

Fixed-length cut-off device and cut-off method

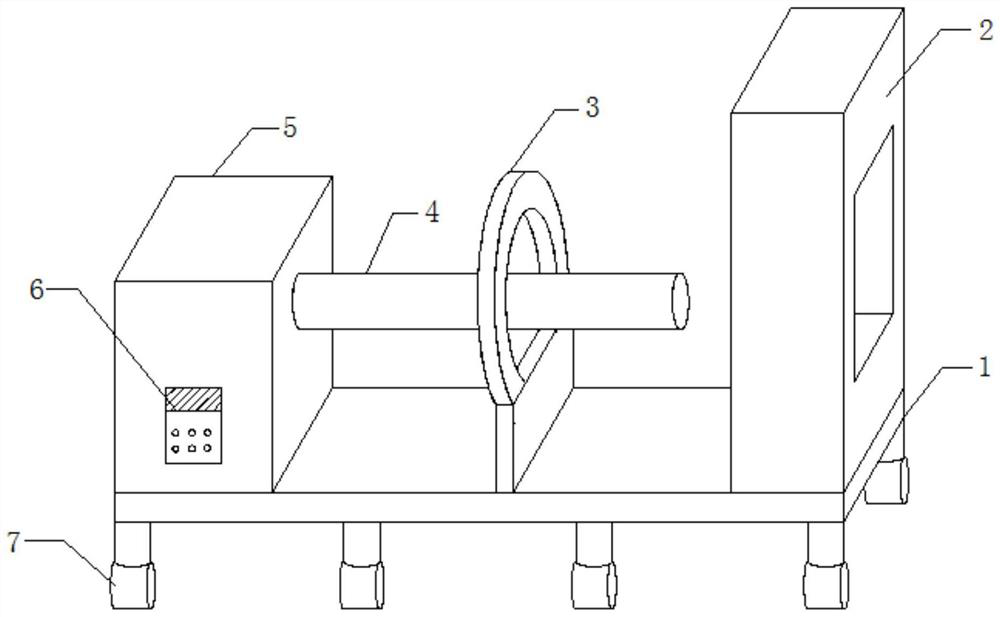

ActiveCN111604536AQuality assuranceEasy to operateTube shearing machinesShearing machine accessoriesEngineeringStructural engineering

The invention provides a fixed-length cut-off device and a cut-off method, and relates to the technical field of fixed-length cut-off devices. The fixed-length cutting-off device comprises a feeding mechanism, a cutting-off mechanism, a detection mechanism used for detecting the position of a blade and a control mechanism; the feeding mechanism is used for driving pipes to move forwards; the cutting mechanism comprises a rotary disc and the blade arranged on the rotary disc, and the cutting edge part of the blade extends out of the outer edge of the rotary disc; and the rotary disc can drive the blade to rotate at a fixed frequency to cut off the pipes in a fixed-length mode. According to the cut-off method, the position of the blade is detected mainly through the detection mechanism, andthen the time that the feeding mechanism drives the pipes forwards is controlled.

Owner:厦门蓬欣橡胶制品工业有限公司

Plant root system cutting device for bucket

ActiveCN111155580AImprove work efficiencyGuaranteed uptimeMechanical machines/dredgersPlant rootsAgricultural engineering

The invention relates to a plant root cutting device for a bucket. A shovel tip is fixedly arranged at the lower end of a forklift body, a shovel blade is movably arranged on the right side of the shovel tip, a stop block is movably arranged at the lower middle end of the shovel blade, one end of the stop block penetrates through and extends out of the shovel blade to be hinged with a baffle plate, the baffle plate is movably arranged on the outer surface of the shovel tip through a fixing column, a pressure column is hinged at the side, close to the shovel blade, of the baffle plate, a pressure block is hinged to the end, far away from the baffle plate, of the pressure column, and the side, far away from the pressure column, of the pressure block is fixedly arranged on the side face of the shovel blade. Through the matching use of a pressure knife and a sawtooth column, plant root systems can be effectively cut off when a bucket body encounters the plant root systems, accordingly thenormal operation of the bucket body is ensured, and the physical strength of workers is reduced; and workers are not required to shovel the plant root systems first and then shovel soil with the bucket body, so that the working efficiency of a forklift is improved, and more effective operation convenience is brought to the workers.

Owner:滕州潍达智能科技有限公司

Cutting device for pearl wool foaming machine

PendingCN112677394AIncrease productivityImprove product qualityMetal working apparatusWoolManufacturing engineering

The invention is applicable to the technical field of pearl wool production, and provides a cutting device for a pearl wool foaming machine. The cutting device comprises a base, wherein an air inlet piece is fixedly arranged at one end of the base, a die outlet head is fixedly arranged at one end of the air inlet piece, a screw is rotationally arranged at one end of the die outlet head, a heating ring is fixedly arranged at one end of the base, a cutting seat is fixedly arranged at one end of the base, a cutting hot melting plate is arranged in the cutting seat in a sliding mode, and the cutting hot melting plate is electrically connected with an external power supply. The cutting device has the advantages that the structure is simple and reasonable, two cutting openings are formed, so that the production speed is increased, the production efficiency is improved, hot melting is carried out immediately after cutting, and the production quality of products is guaranteed.

Owner:重庆新士腾包装制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com