Cross-sliding-type automatic cutting machine for artificial boards

A wood-based panel, traversing technology, applied in the direction of manufacturing tools, forming/shaping machines, special forming/shaping machines, etc., can solve the problems of long length of semi-finished products of wood-based panels, increased labor intensity of workers, and high labor intensity. The effect of cutting efficiency, high positioning accuracy and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

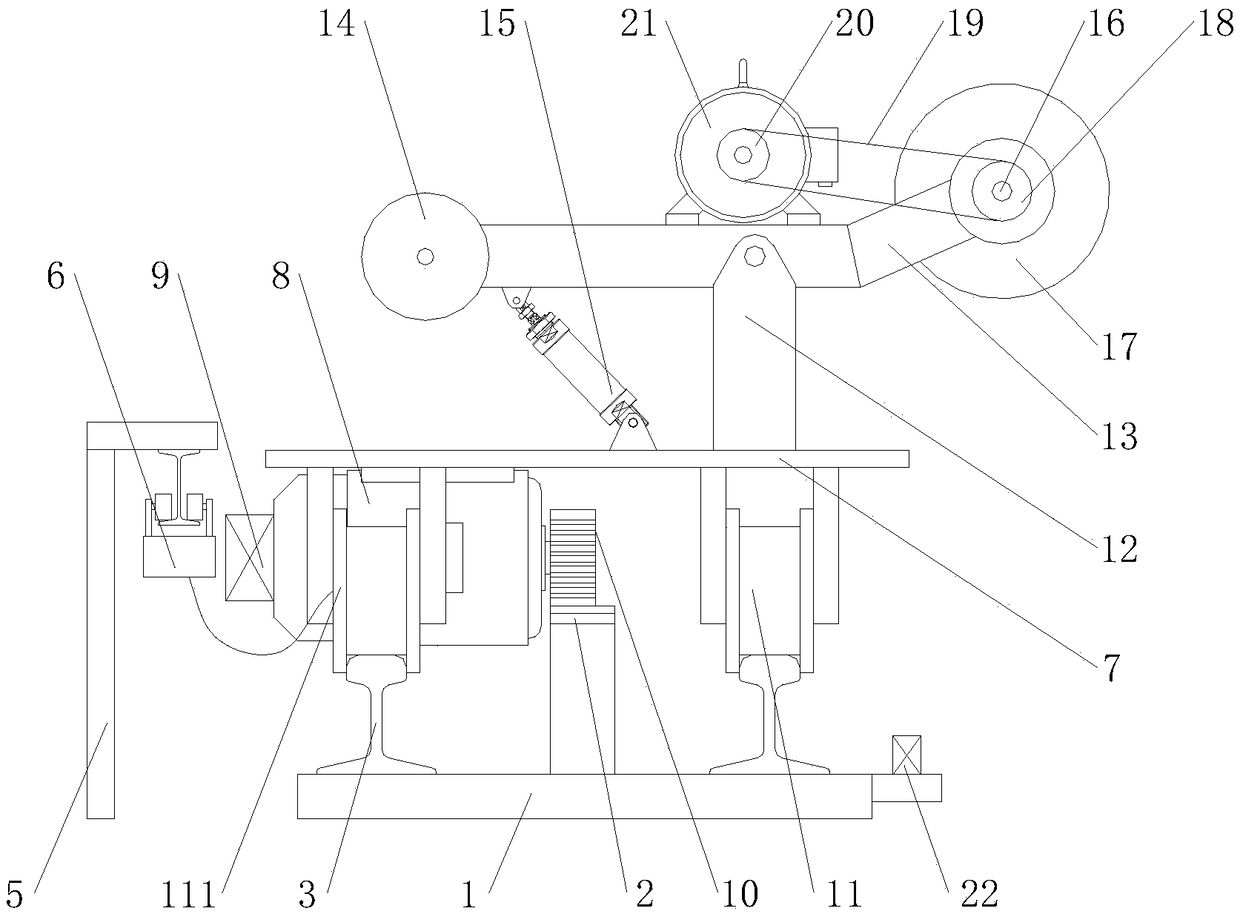

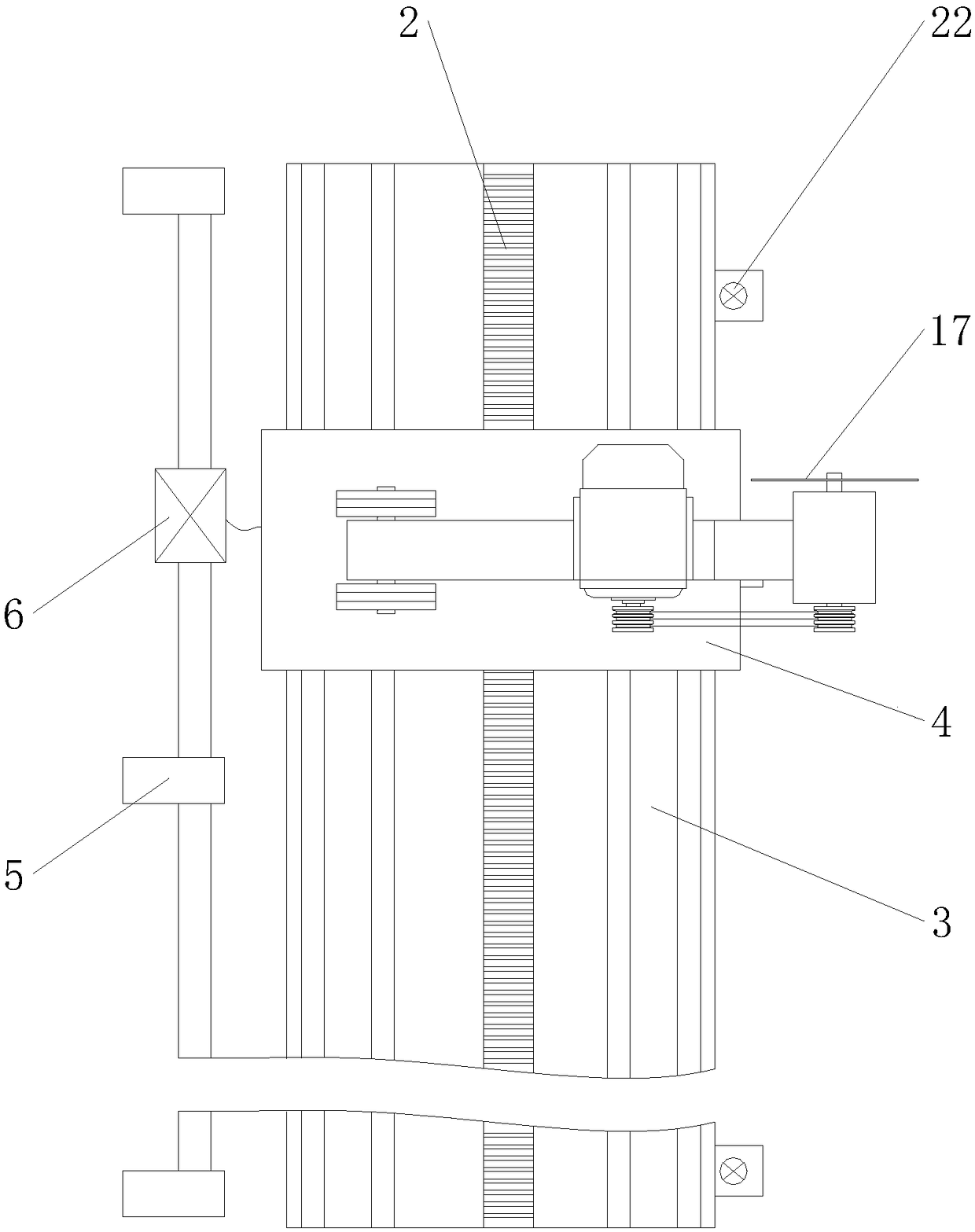

[0013] Example. A horizontally moving wood-based panel automatic cutting machine, which is composed of figure 1 As shown, including base plate 1, drive rack 2 is provided on base plate 1, light rail 3 is provided on both sides of drive rack 2, traverse section device 4 is provided on light rail 3, and base plate 1 side is provided with suspender 5 Cable slide frame 6; described traversing section device 4 comprises traversing platform 7, and the center of traversing platform 7 bottoms is provided with traversing motor 8, and traversing motor 8 is provided with encoder 9, and traversing motor 8 ends are provided with There is a driving gear 10 matched with the driving rack 2, a plurality of rollers 11 cooperating with the light rail 3 are arranged around the traversing motor 8, a bracket 12 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com