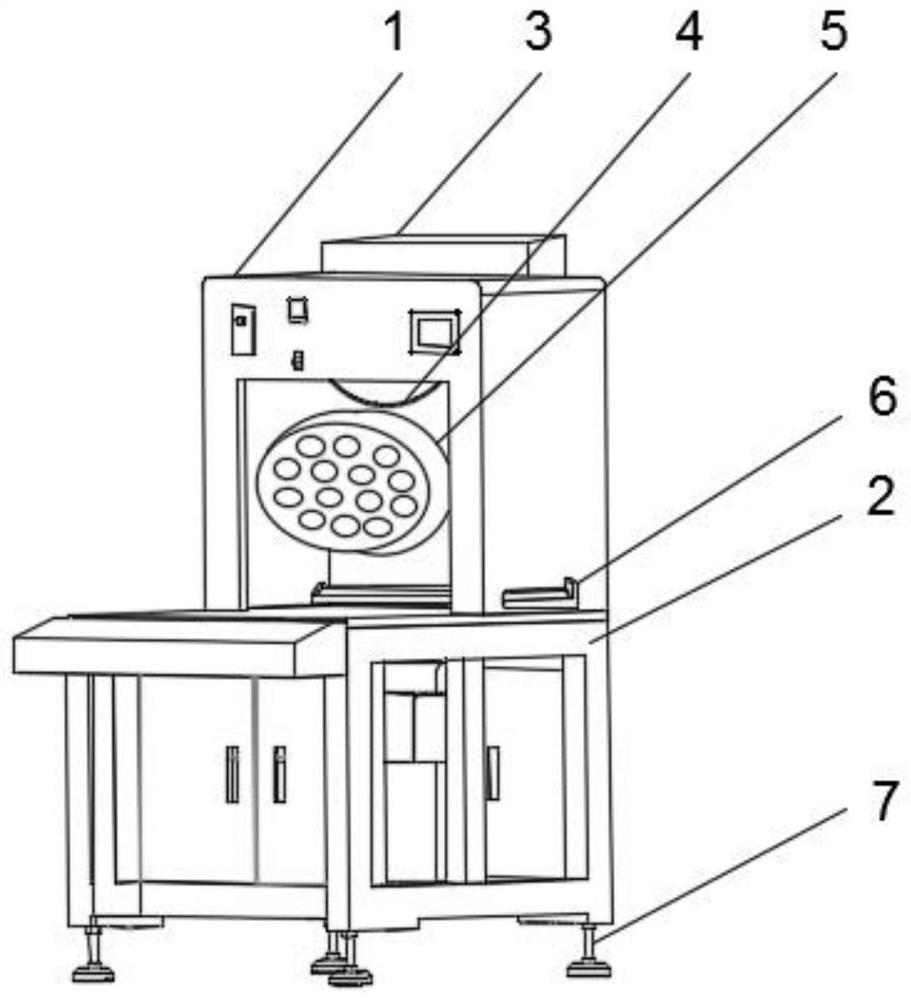

Cutting off equipment for carbon bar production and operation method thereof

A carbon rod and equipment technology, which is applied in the field of cutting equipment for carbon rod production, can solve the problems of low carbon rod efficiency, achieve the effects of improving production efficiency, saving cleaning work, and overcoming poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

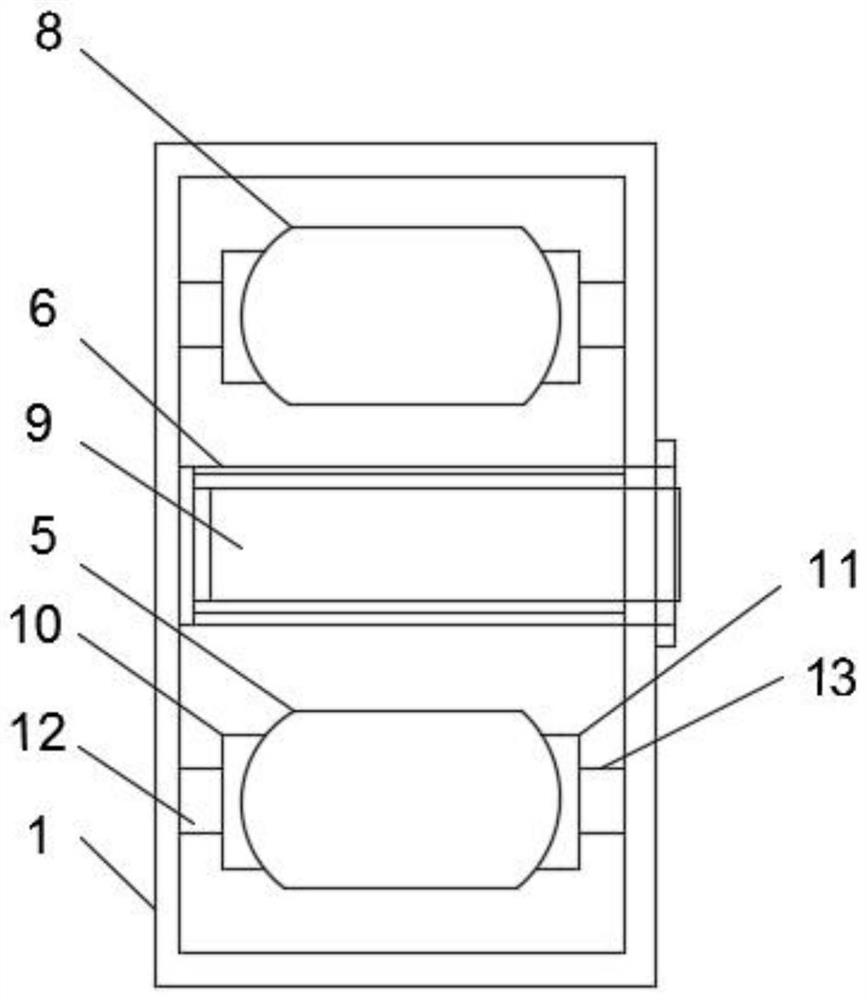

Method used

Image

Examples

Embodiment 1

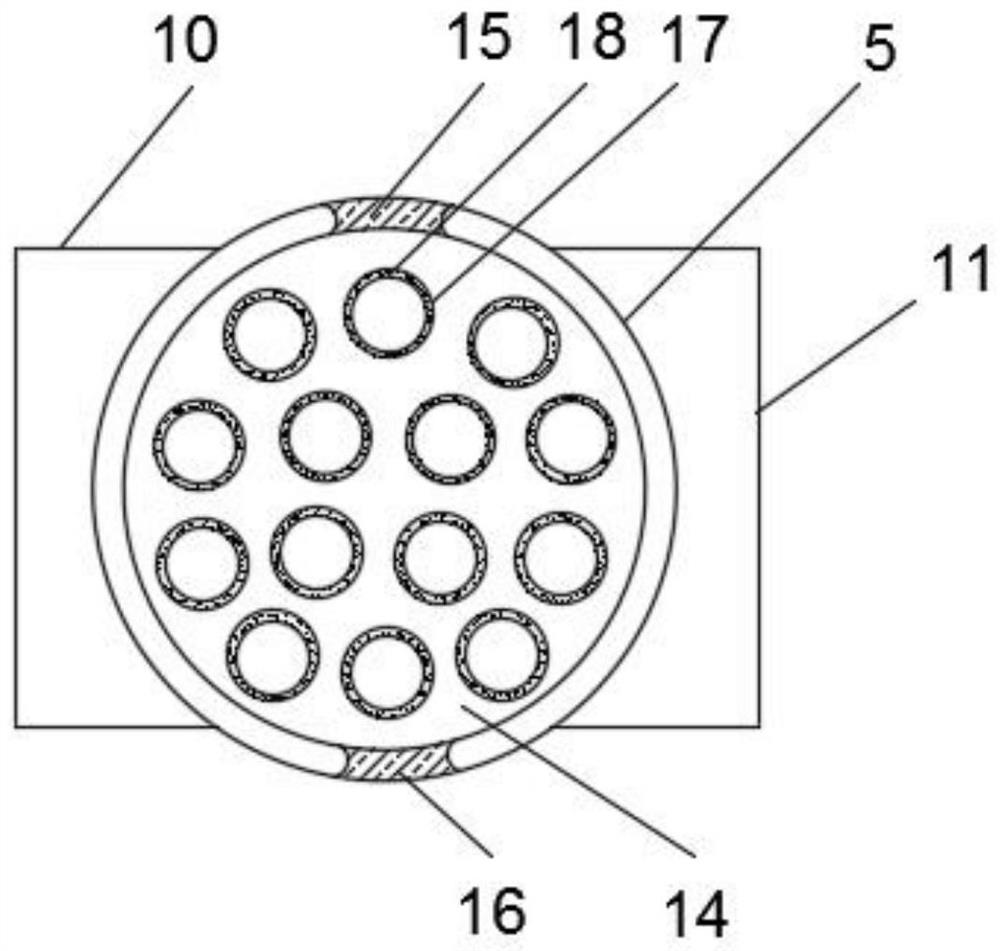

[0041] Several carbon rods pass through the first clamp ring 5 and the second clamp ring 8 successively through several fixed rings 17, wherein, the diameter of several carbon rods can be 100mm, when several carbon rods pass through several fixed rings 17 , the tightness between the carbon rod and the fixed ring 17 can be increased by the damping pad 18, and the expansion and contraction of the first tension ring 15 and the second tension ring 16 can increase the connection between the carbon rod and the first clamp ring 5 and the second clamp ring. To ensure the tightness between the rings 8, move several carbon rods back and forth in the first clamp ring 5 and the second clamp ring 8, adjust the cut-off position of the carbon rod, and adjust the cut-off position of the carbon rod through the hydraulic cylinder 3 and the lifting column move the cutting knife 4 down, and the cutting knife 4 moves down and cuts off the carbon rod between the first clamp ring 5 and the second cla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com