Cutter deviation rectifying auxiliary device of automatic hardware cutting-off equipment

A technology of auxiliary device and cutting device, which is applied in the direction of automatic control device, metal processing equipment, feeding device, etc. It can solve the problems of offset of cutting opening, affect the cutting effect of hardware parts, and cannot meet the needs of manufacturers, so as to eliminate the deviation , Improve the truncation effect and improve the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

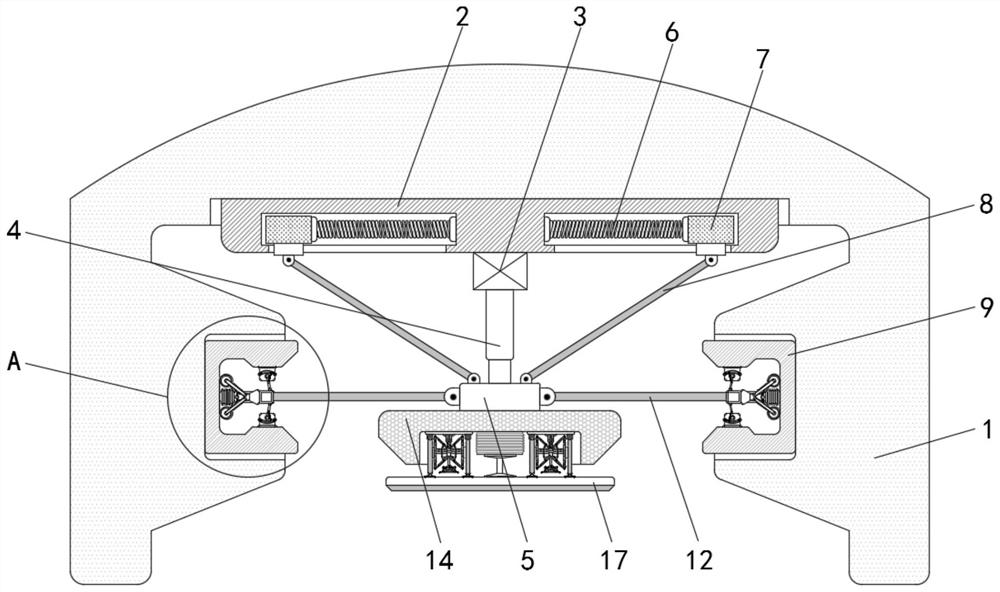

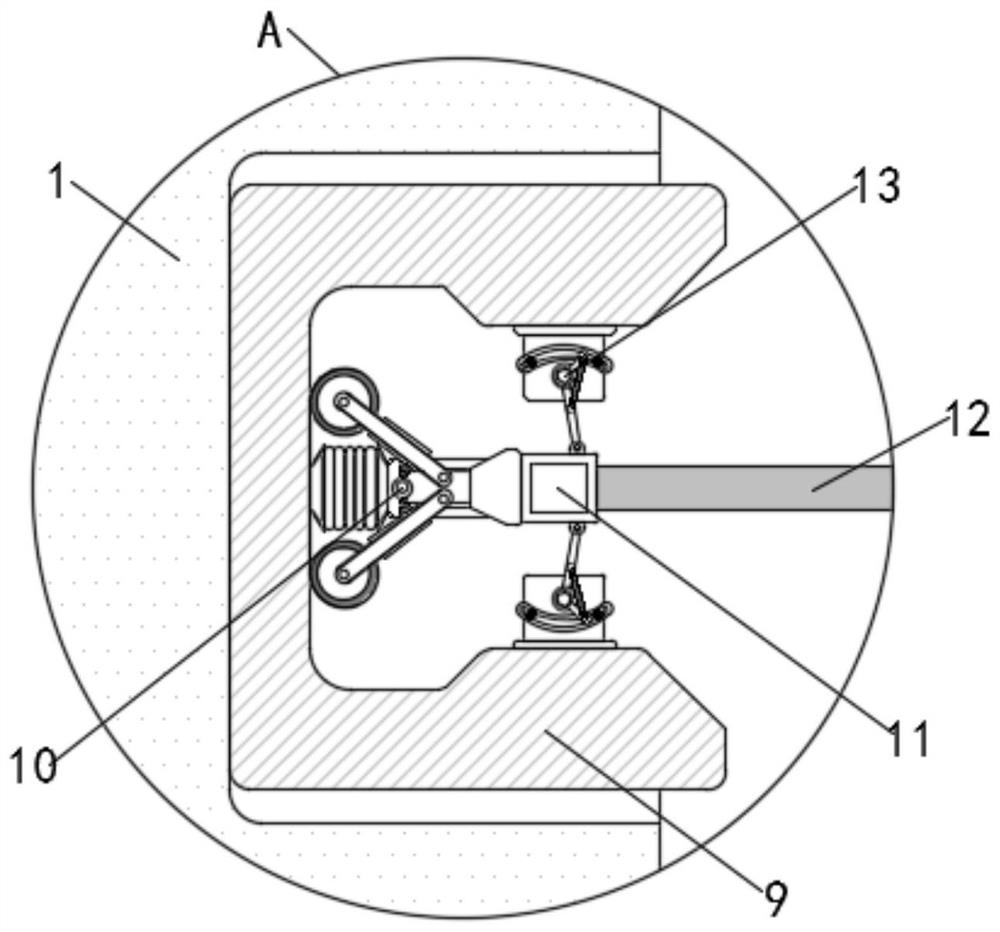

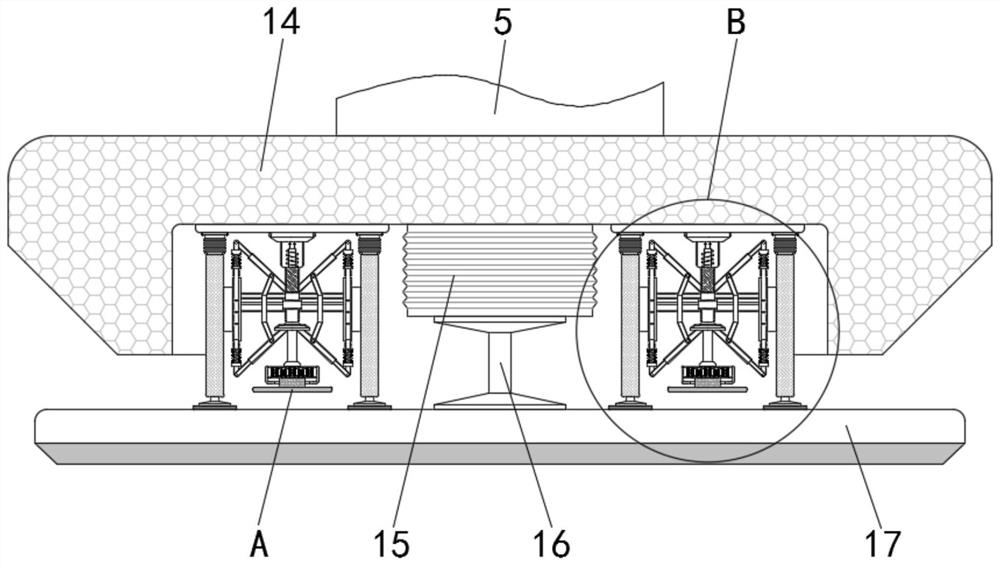

[0023] The present invention will be further described below in conjunction with accompanying drawing:

[0024] as attached figure 1 to attach Figure 5 Shown:

[0025] The present invention provides a tool correction auxiliary device for automatic hardware cutting equipment, which includes a main body 1, a fixed base 2 is fixedly installed on the top of the inner wall of the main body 1, and a driving device 3 is installed on the lower side of the fixed base 2. The lower side is provided with a driving telescopic rod 4, the lower end of the driving telescopic rod 4 is fixedly equipped with a movable part 5, and the inside of the fixed base 2 is provided with a movable groove, and the inner wall of the movable groove is provided with a spring mechanism 6, and the spring mechanism 6 The shaft end of the shaft is fixedly connected with a movable block 7, the lower side of the movable block 7 is movably equipped with a movable push rod 8, the lower end of the movable push rod 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com