Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Improve the diffusion capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

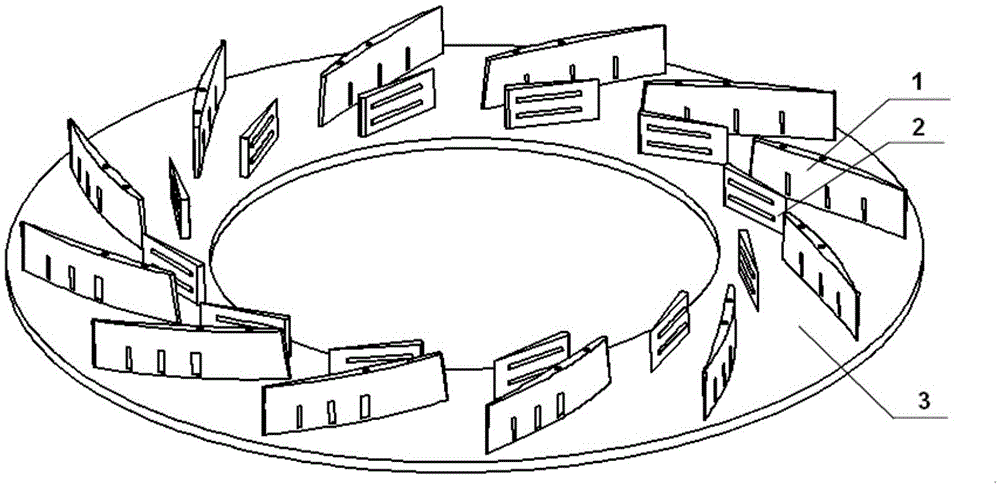

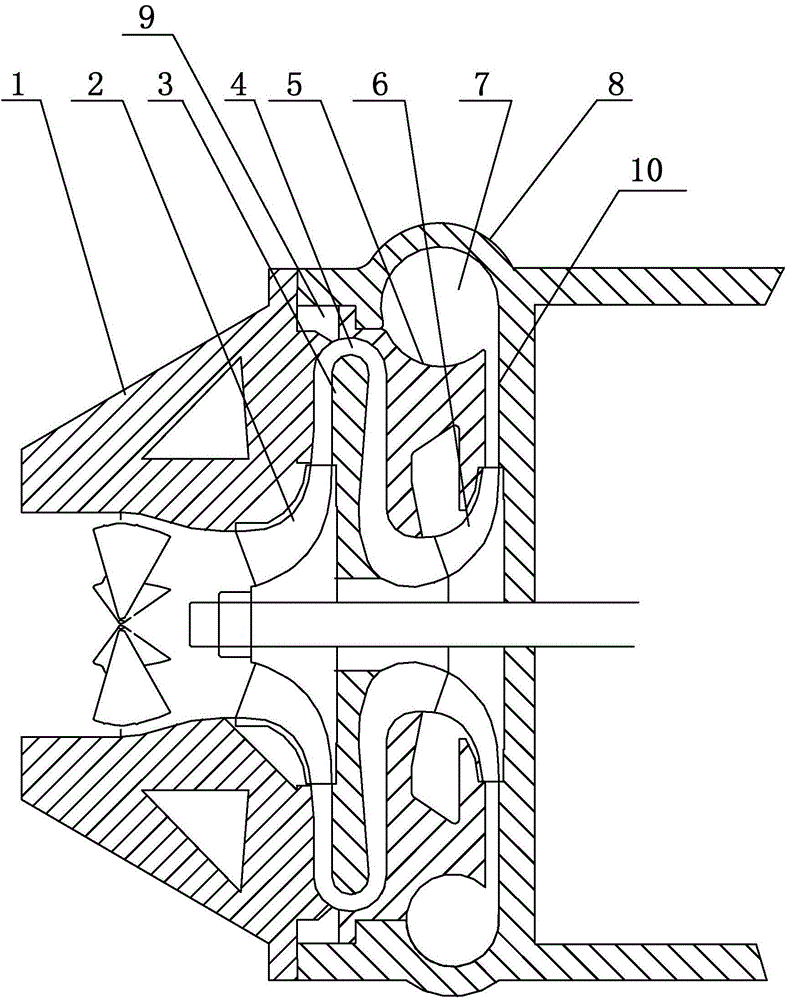

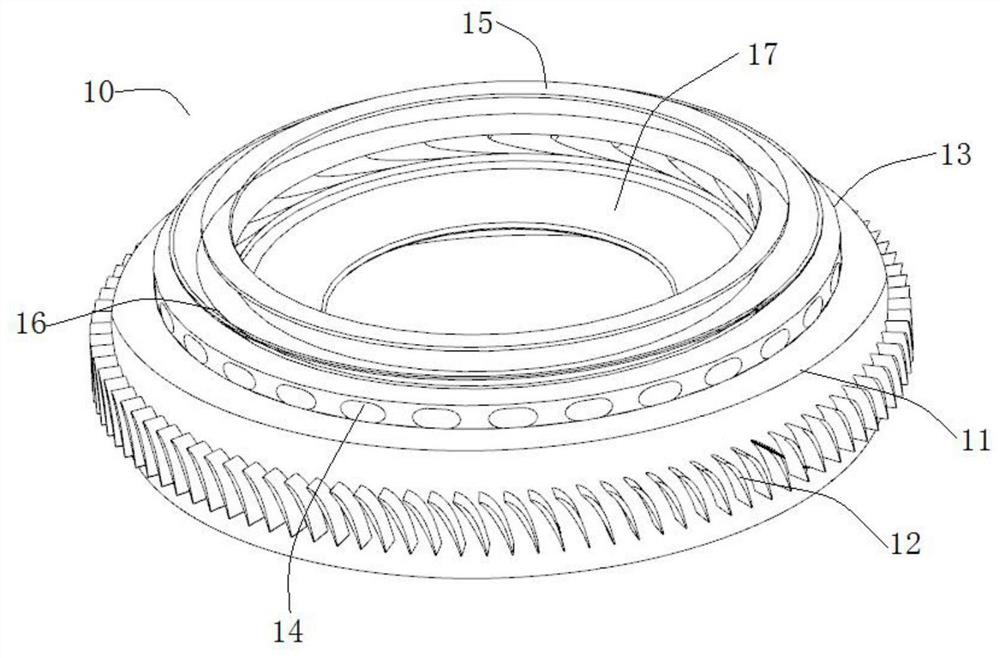

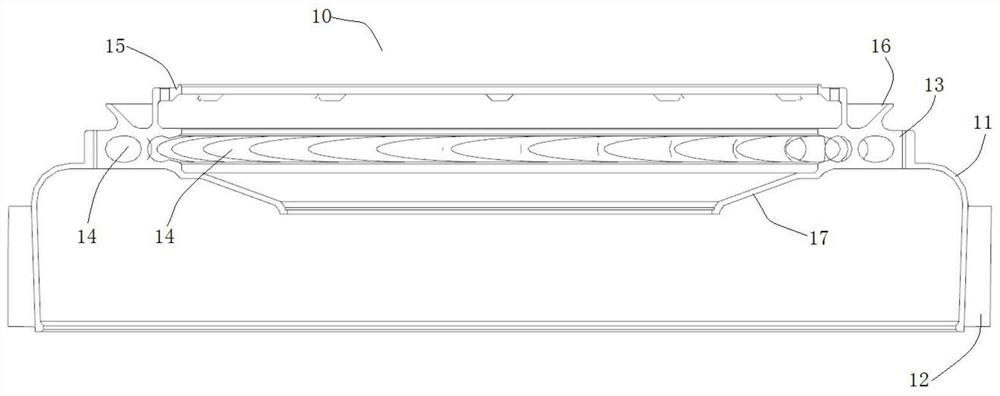

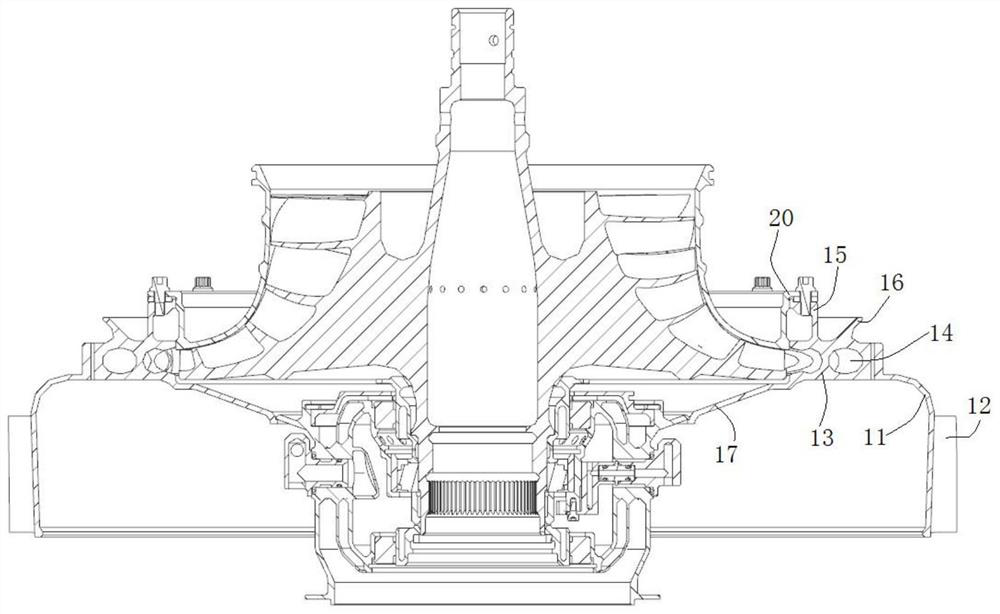

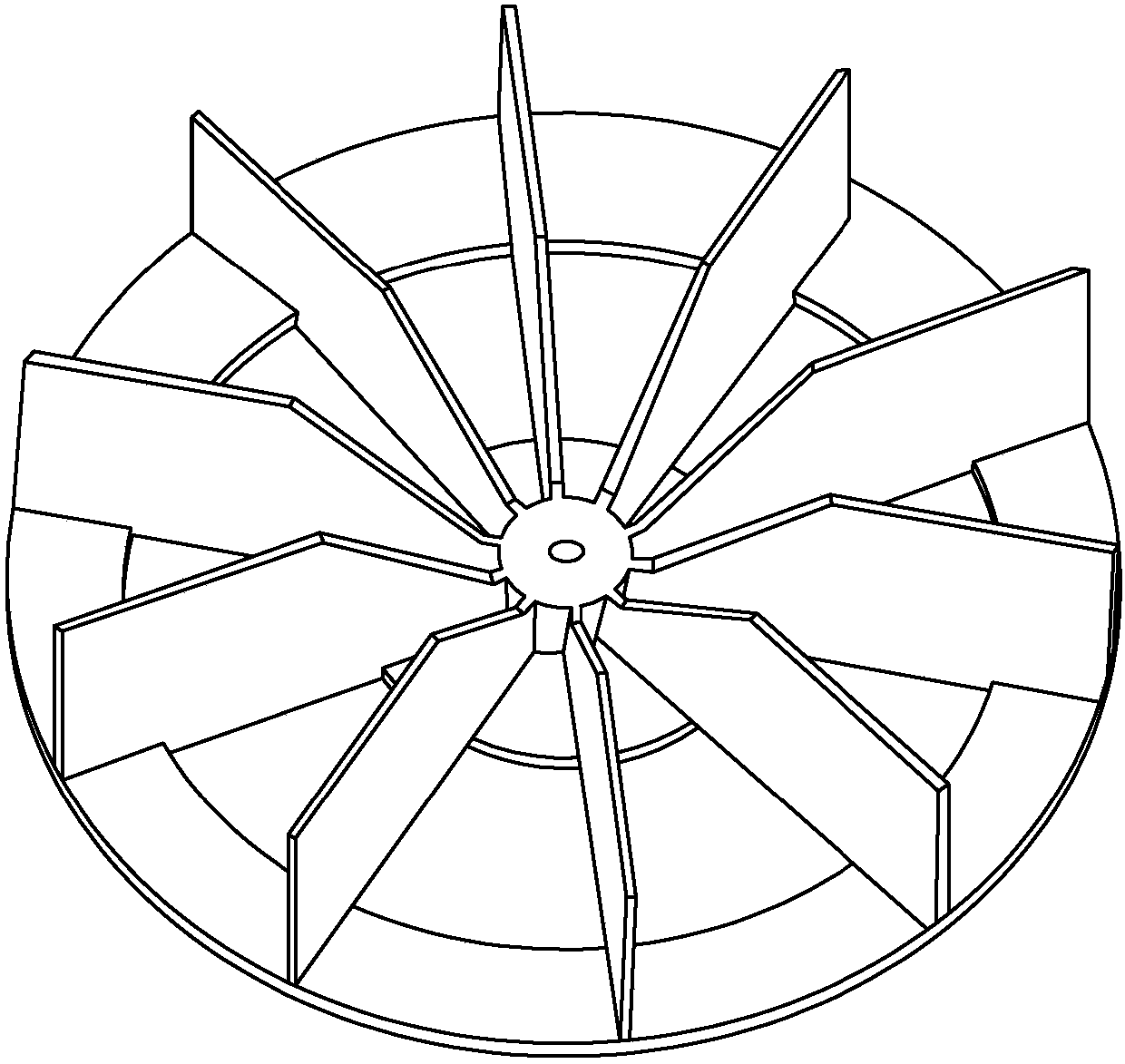

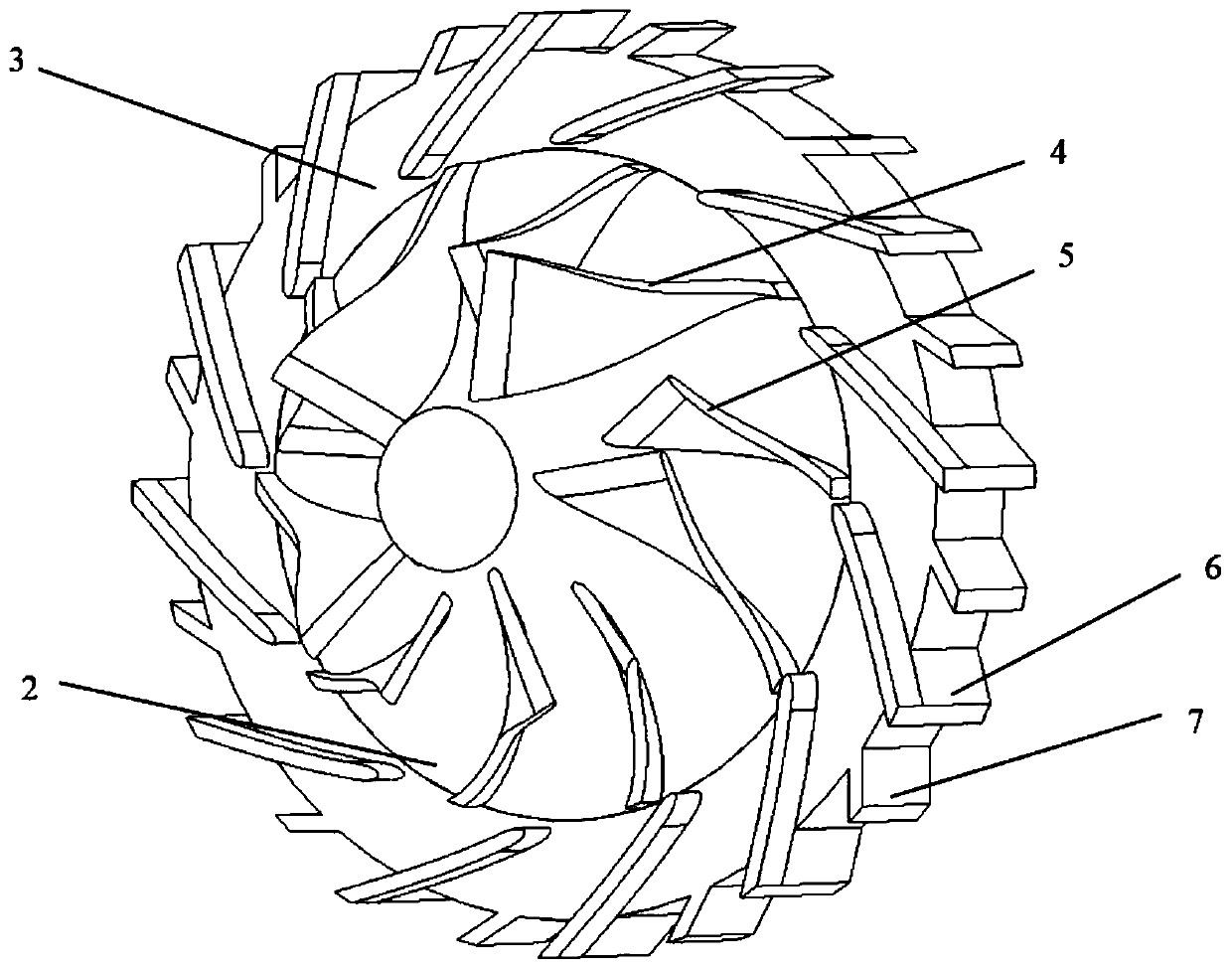

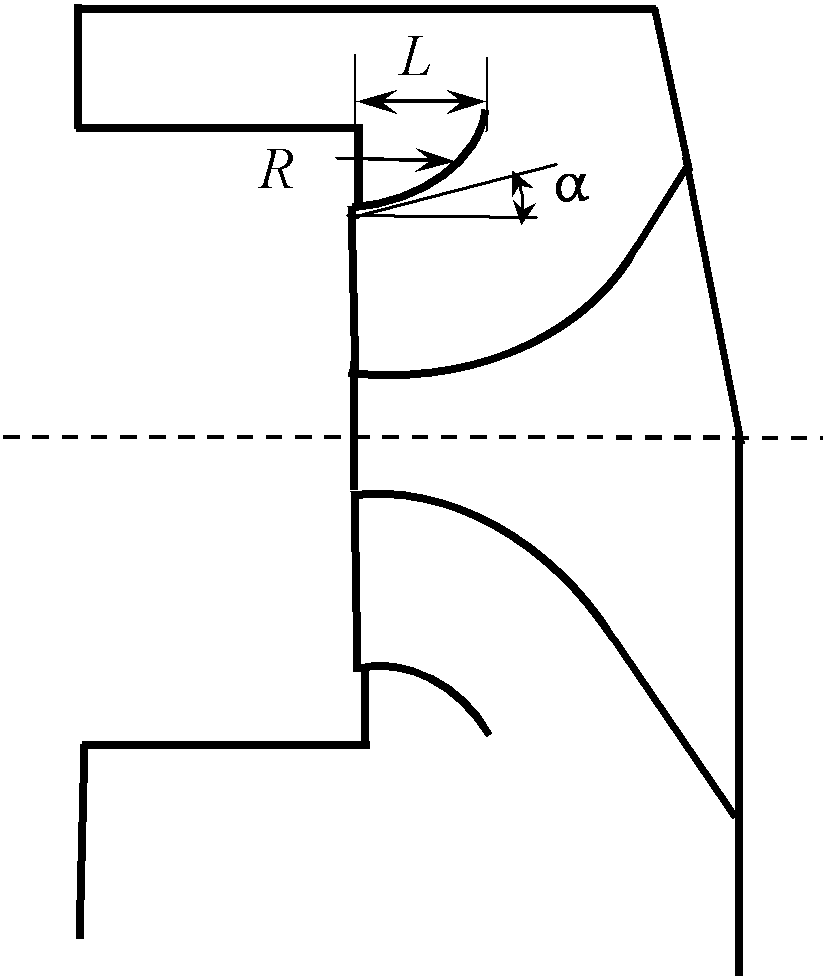

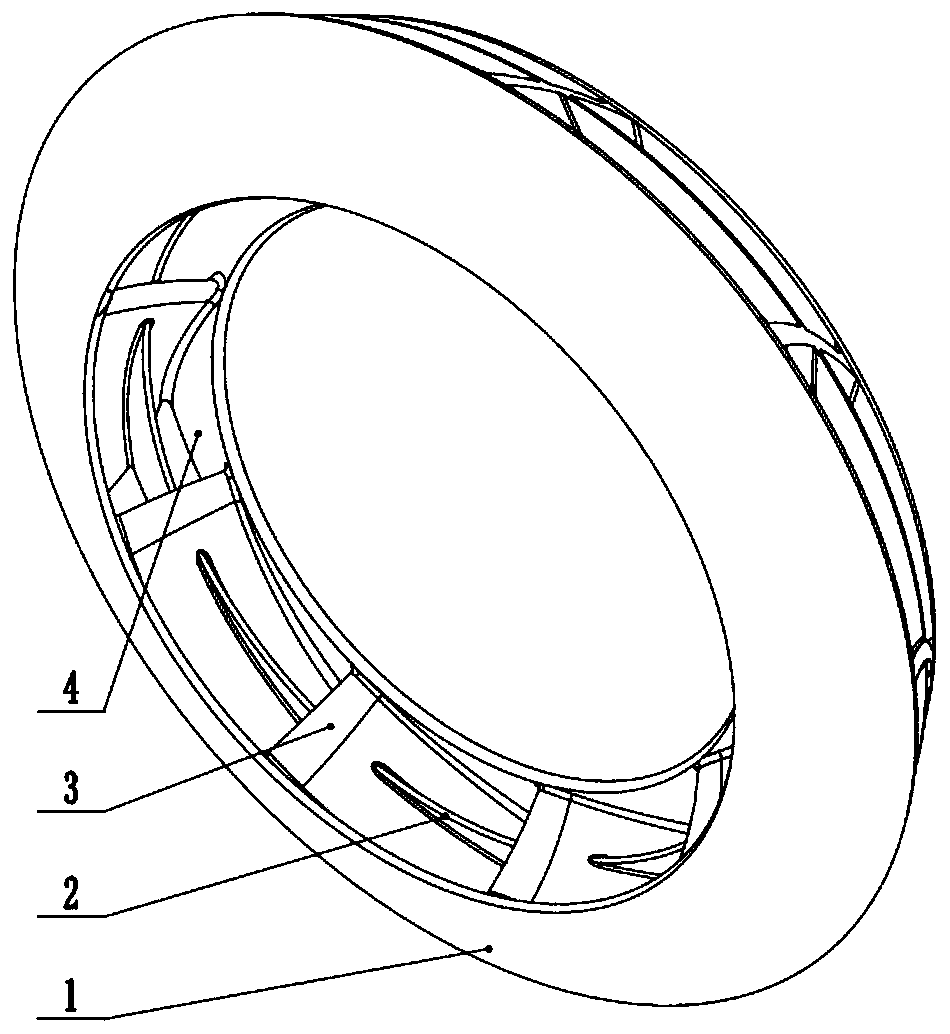

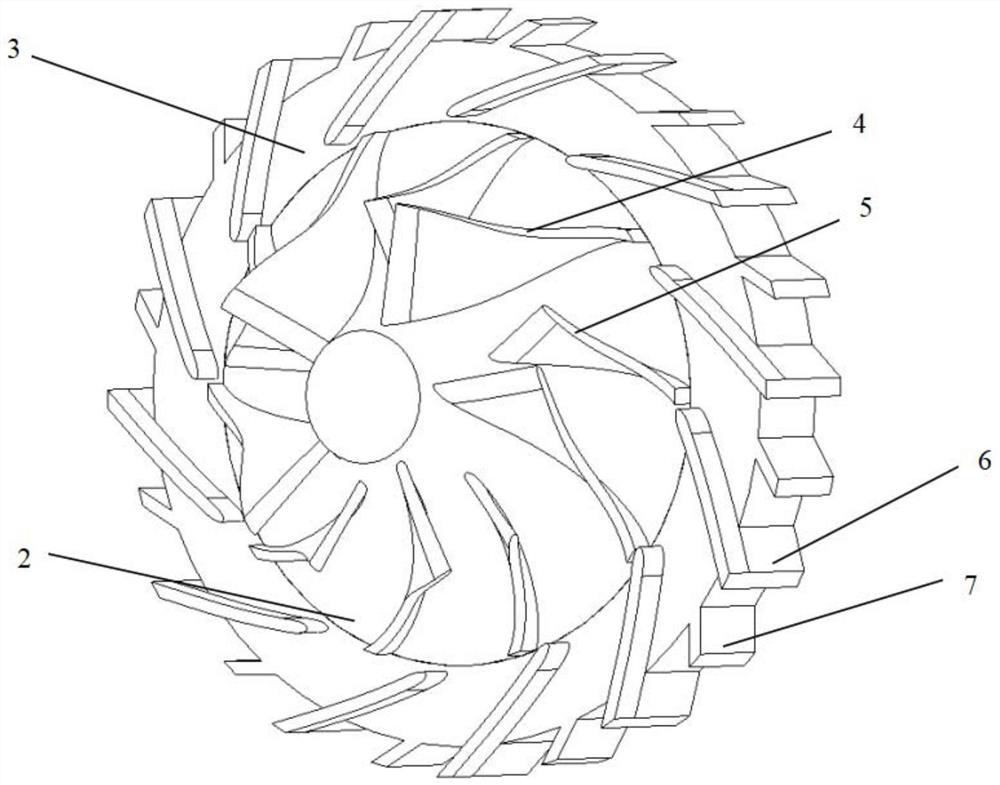

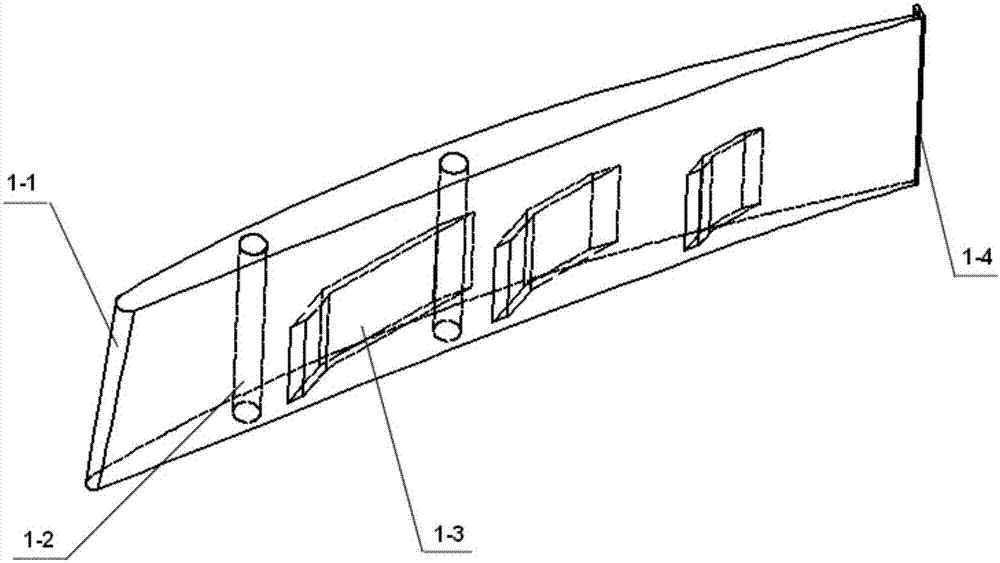

Pressure expander of centrifugal compressor

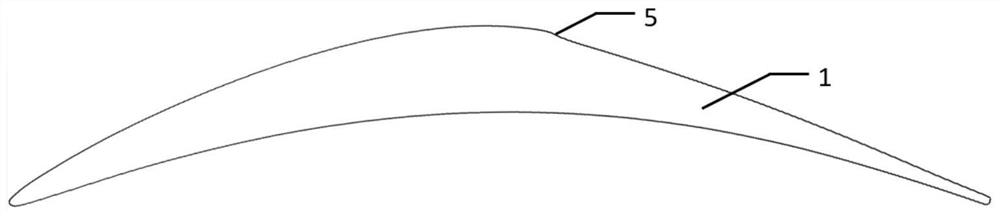

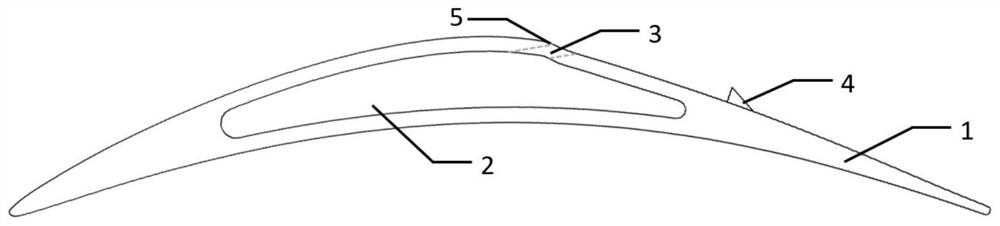

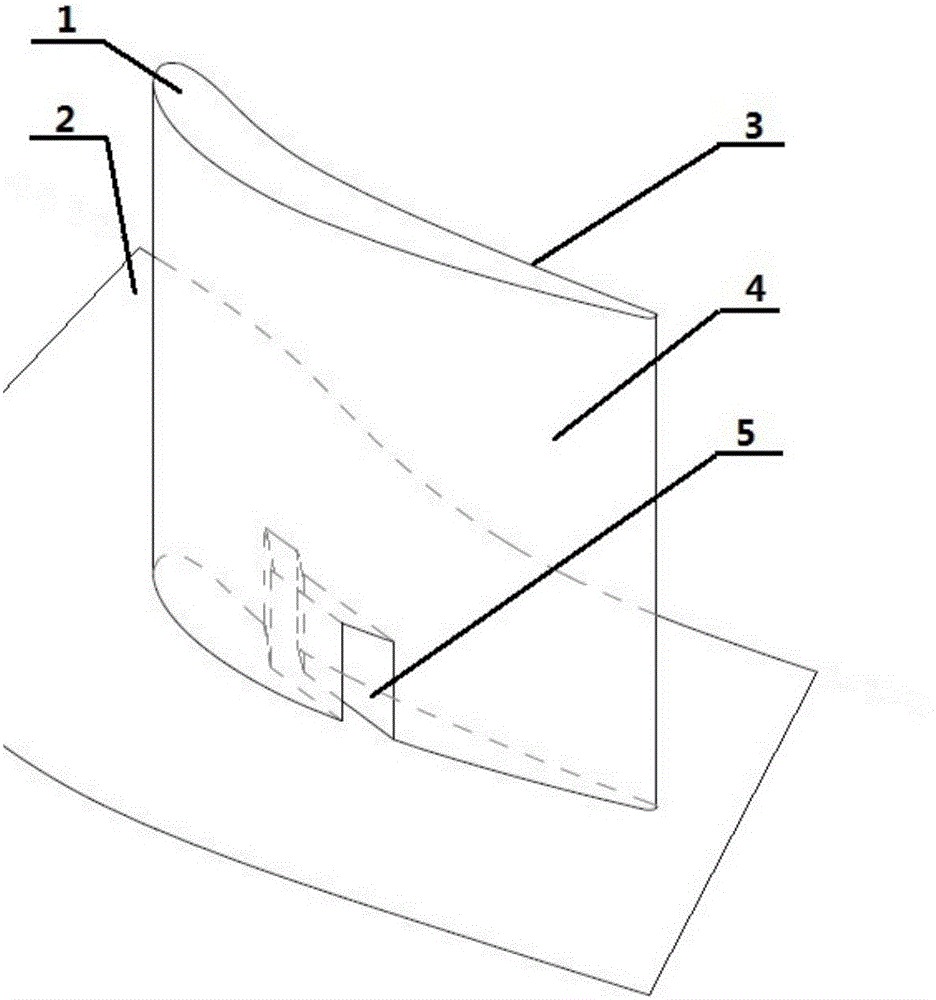

ActiveCN105650032AImprove the diffusion capacityImprove operational efficiencyEngine manufacturePump componentsSuction stressWork performance

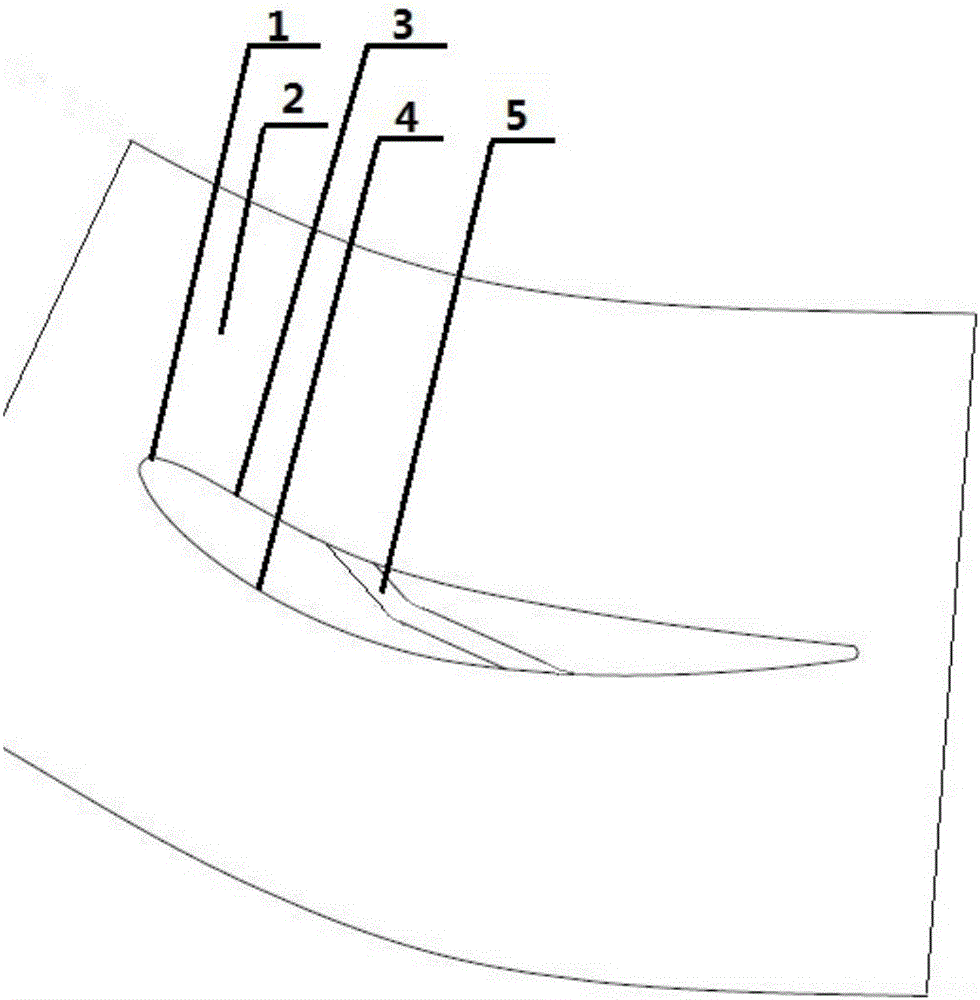

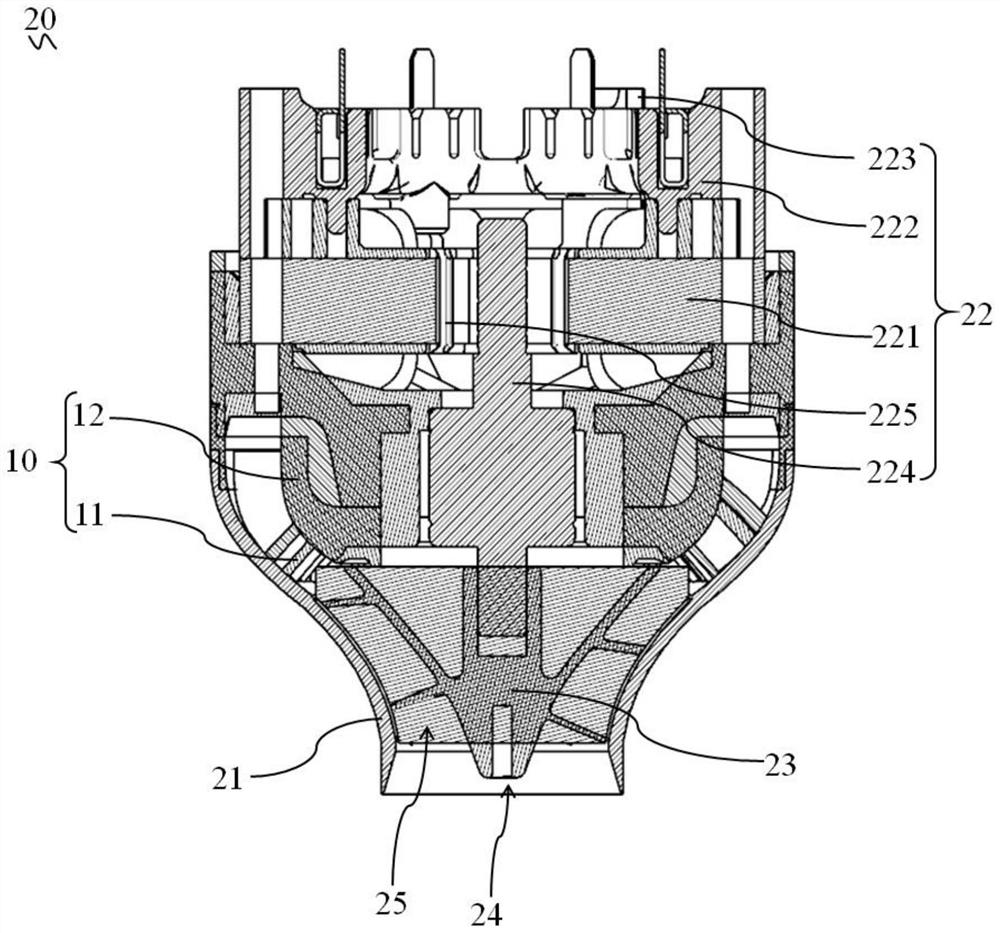

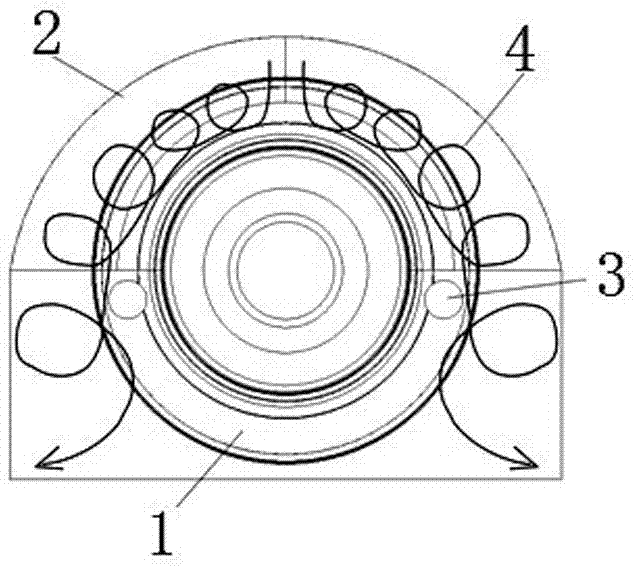

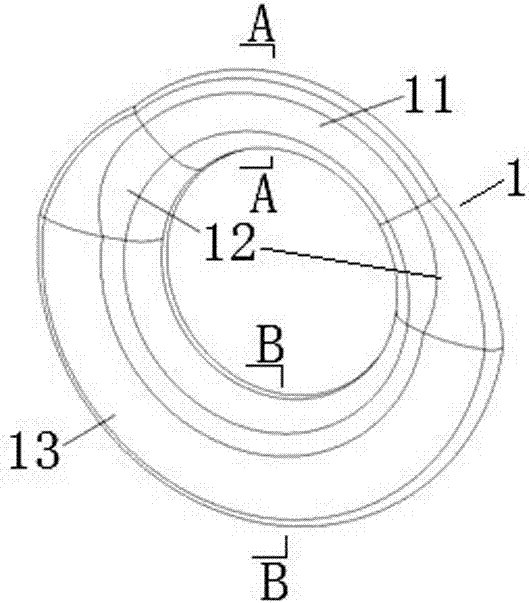

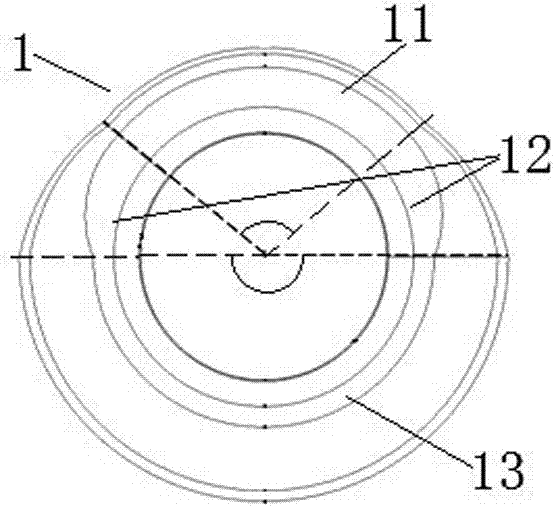

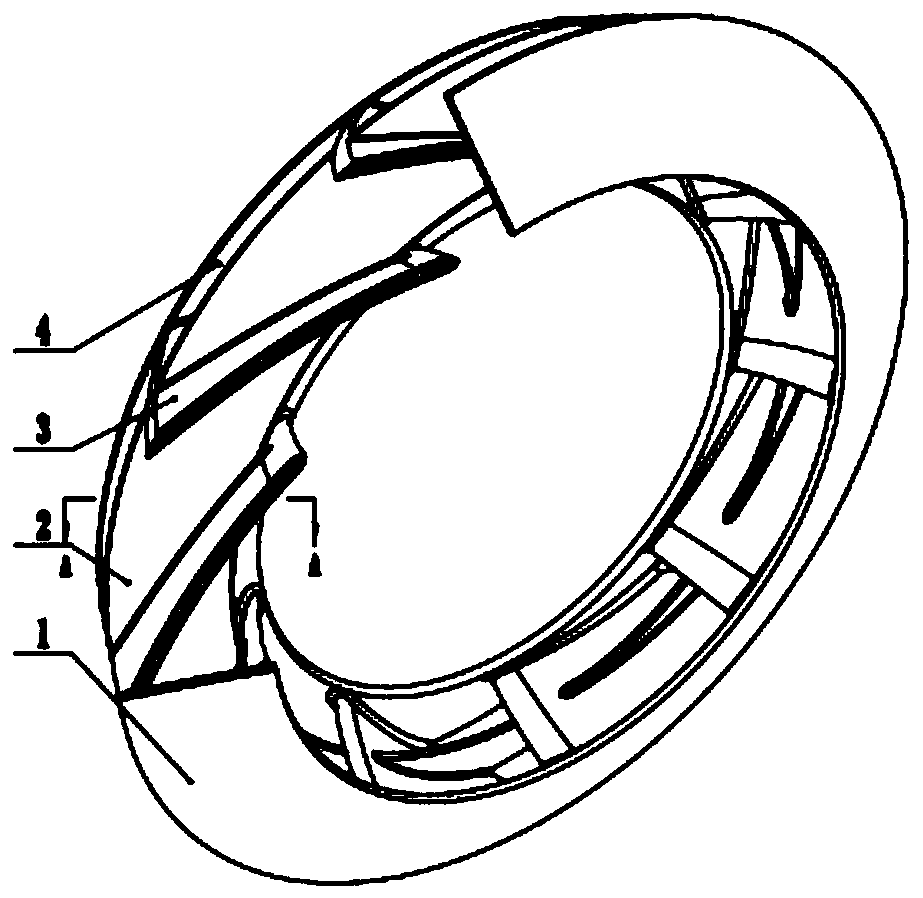

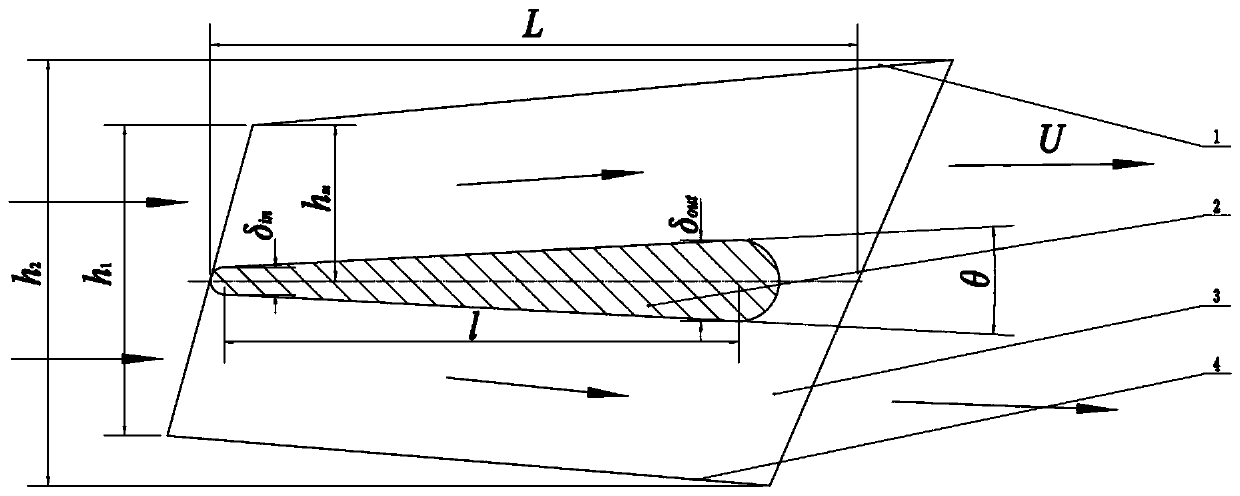

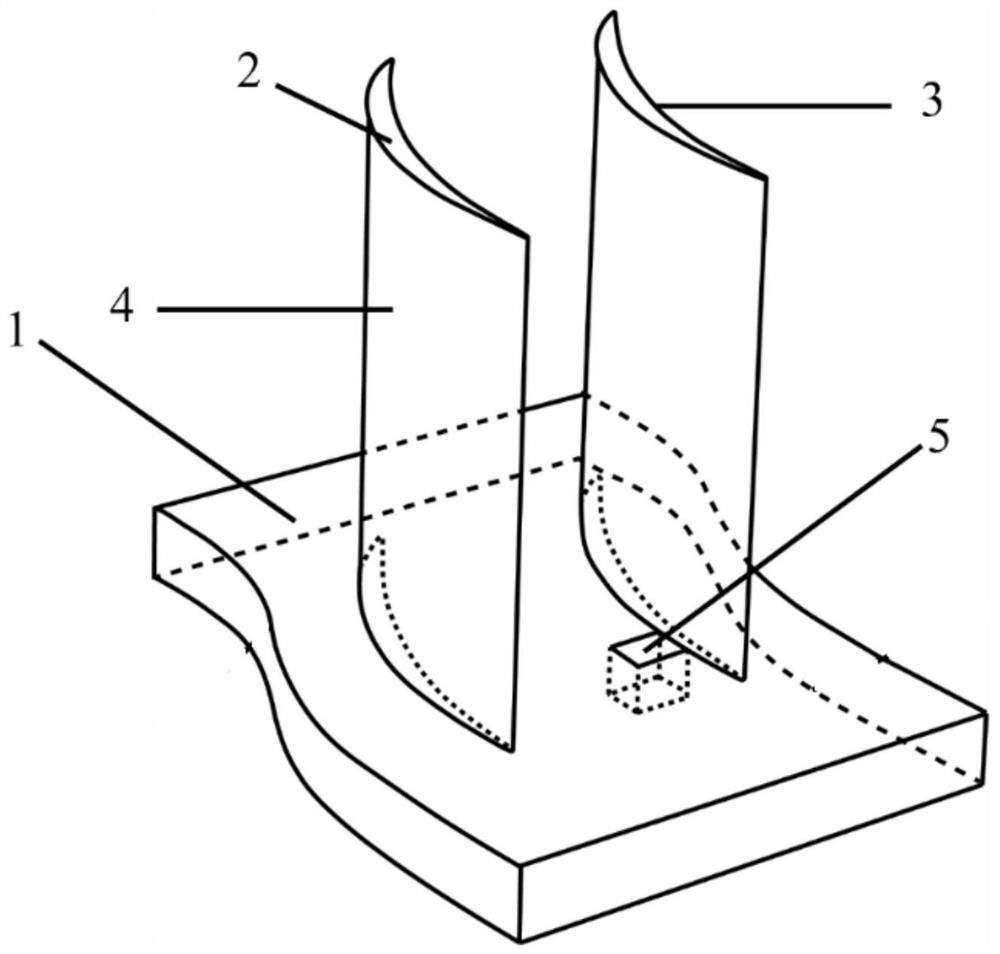

The invention discloses a pressure expander of a centrifugal compressor. The structure of the pressure expander is improved, and high application value is achieved for further improving working performance of the pressure expander. A short blade is arranged in runners of every two adjacent long blades; the front edges of the long blades are curved surfaces and are arranged obliquely, and the included angles between front edge lines and the central axis of a wheel disc are 6 degrees to 8 degrees; the radius of curvature of the front edges of the long blades is gradually increased from the wheel disc to a wheel cover; each long blade is provided with three broken-line-shaped channels penetrating through a corresponding pressure surface and a corresponding suction surface; tail edge wing tips are arranged on the portions, located on the pressure surfaces, of the rear edges of the long blades. Occurrence of separation of airflow on the surfaces of the blades is restrained through the short blades in the runners of the adjacent long blades; the pressure differences between the pressure surfaces and the suction surfaces are reduced through the broken-line-shaped channels, the adverse pressure gradient is reduced, and separate airflow on boundary layers of the suction surfaces at the tails of part of the blades is effectively blown away; increase of wing tip vortexes generated by the pressure differences between the suction surfaces and the pressure surfaces on the rear edges of traditional wing-type blades can be restrained through parabola-shaped winglets on the tail edges.

Owner:嘉兴芸诗娇电子商务有限公司

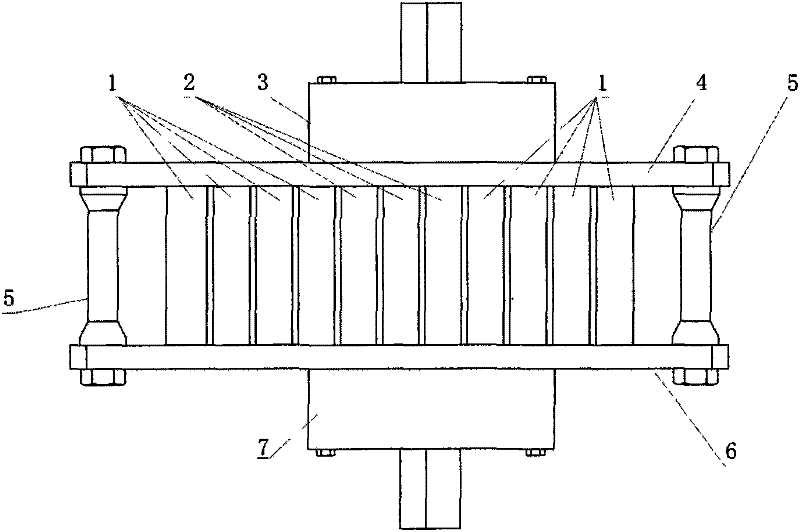

A compressor cascade experimental device

InactiveCN102287389AImprove performanceReduce lossesPump controlNon-positive displacement fluid enginesEngineeringCompressor cascade

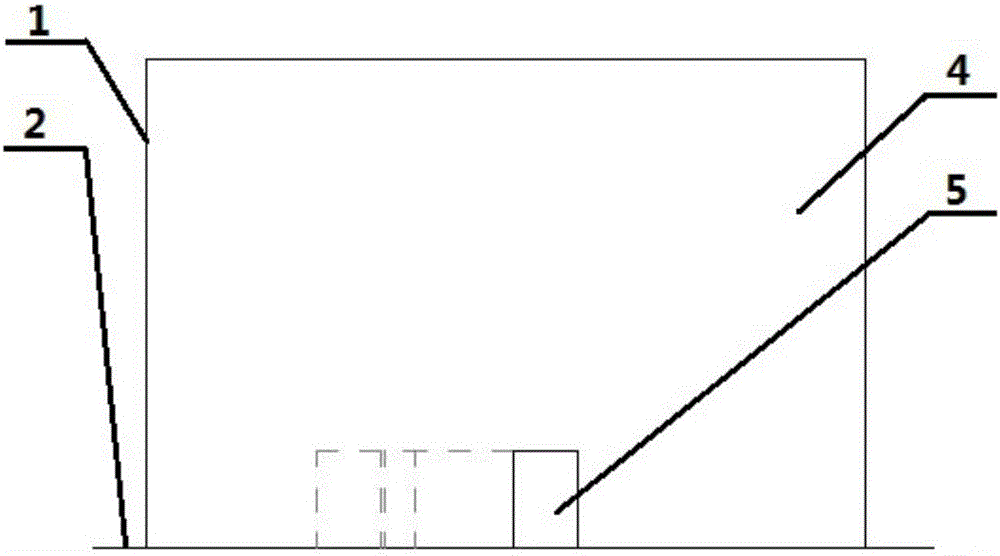

A compressor cascade experimental device includes an even number of blades and an odd number of suction blades. An even number of blades and an odd number of suction blades are installed on the mounting surfaces of the first grid plate and the second grid plate, and the suction blades are located at the center of the first grid plate and the second grid plate. There is an end wall suction slot between each mounting slot. The installation groove of the suction vane and the suction groove of the end wall are provided with through gas suction slots. The first suction hood and the second suction hood are respectively installed at the centers of the outer surfaces of the first grid plate and the second grid plate, and the central air hole of the suction cover corresponds to the gas suction slit and the end wall suction groove respectively. In the present invention, through the combined suction of the blade surface of the compressor cascade and the end wall of the cascade, and connecting the second suction cover and the first suction cover to the suction equipment, the surface of the blade and the surface of the blade under different gas suction quantities can be simultaneously performed. The combined suction experiment of the end wall of the cascade obtains the optimal suction volume of the compressor cascade and improves the pressure ratio and efficiency of the compressor cascade.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

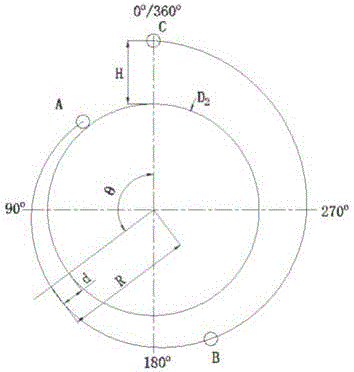

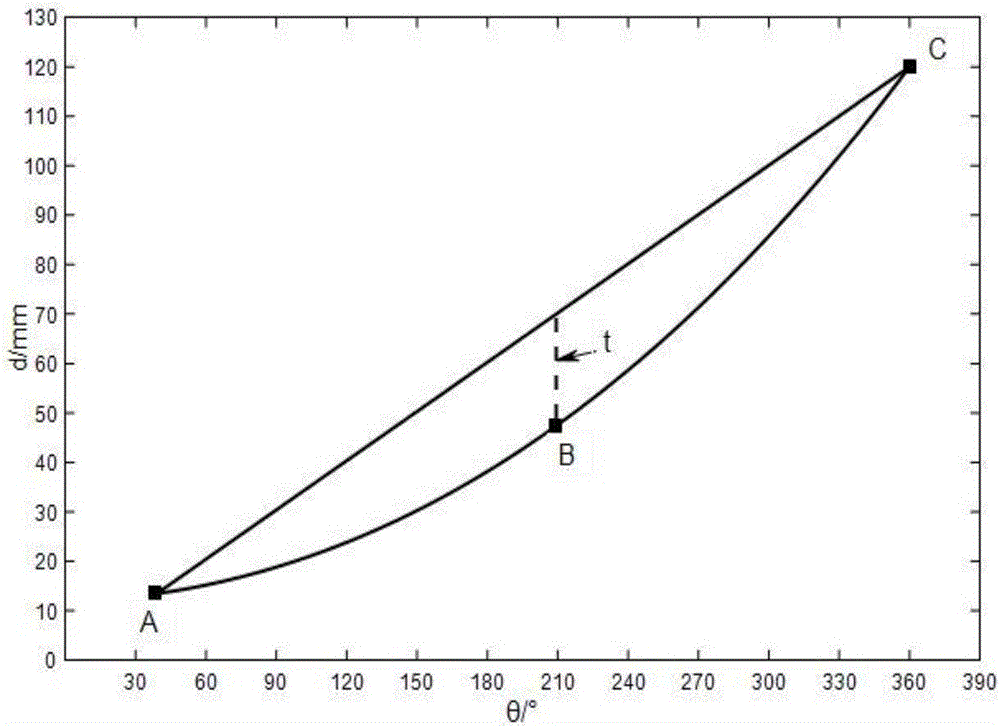

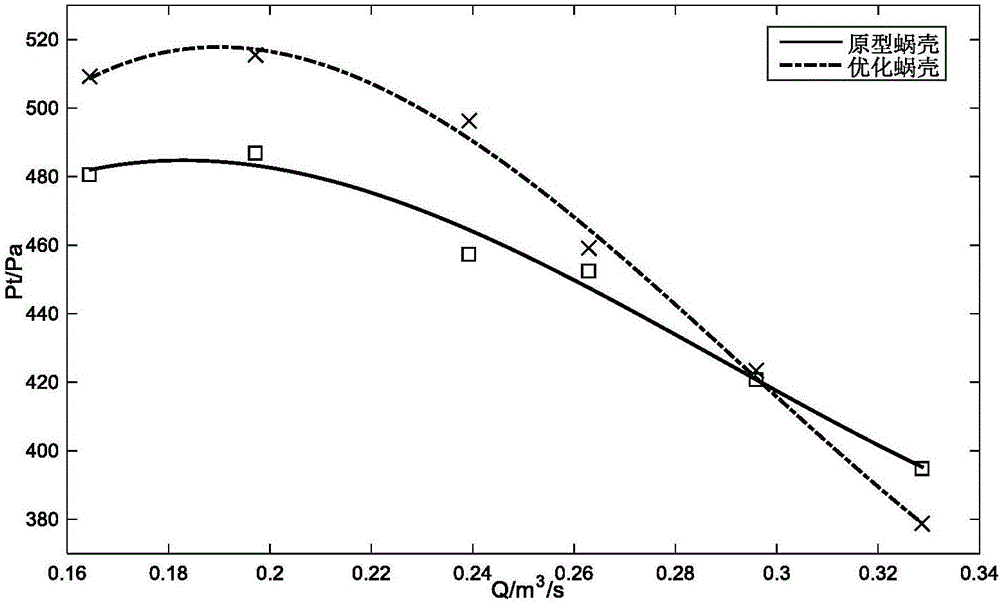

Centrifugal fan volute profile design method

InactiveCN106802974AImprove the diffusion capacityImprove machine efficiencyGeometric CADDesign optimisation/simulationEngineeringCentrifugal fan

The invention relates to a centrifugal fan volute profile design method. The method comprises the steps that three control points of A, B, and C are determined; coordinates on a theta angle distance d coordinate system of the three control points of A, B, and C are calculated and determined, three control points is drawn on the theta angle distance d coordinate system, and the three control points are fitted to a continuous curve; the coordinates of the three points of A, B, and C on the theta angle distance d coordinate system is converted into coordinates on a polar coordinate system; a volute profile is drawn. The centrifugal fan volute profile design method is simple, the volute profile drawn according to the method is capable of controlling volute sectional area distribution, and the volute sectional area increasing according to a designated law can be ensured; at the same time, by controlling the coordinate of A, centrifugal fan volute tongue position and volute tongue gap size can be controlled; the diffusion effect of the centrifugal fan volute can be effectively improved, fan outlet total pressure is increased in a certain range, the flow loss in the volute is reduced, and the fan overall efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

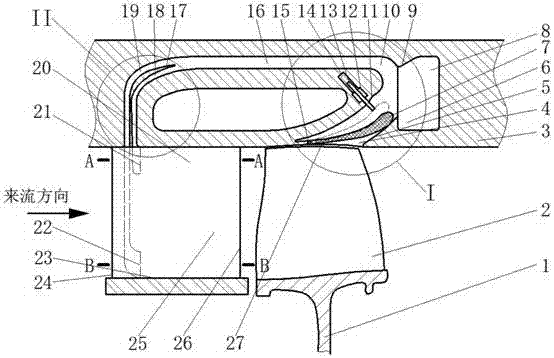

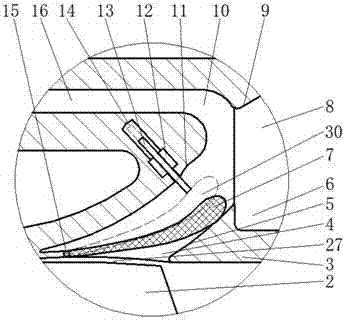

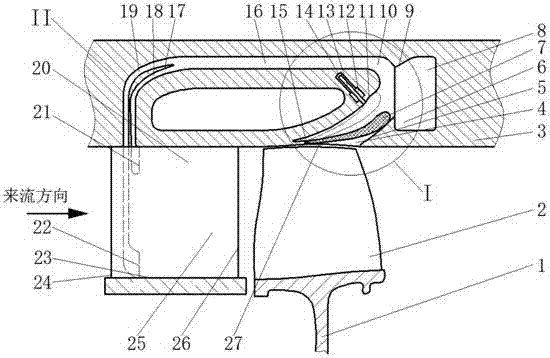

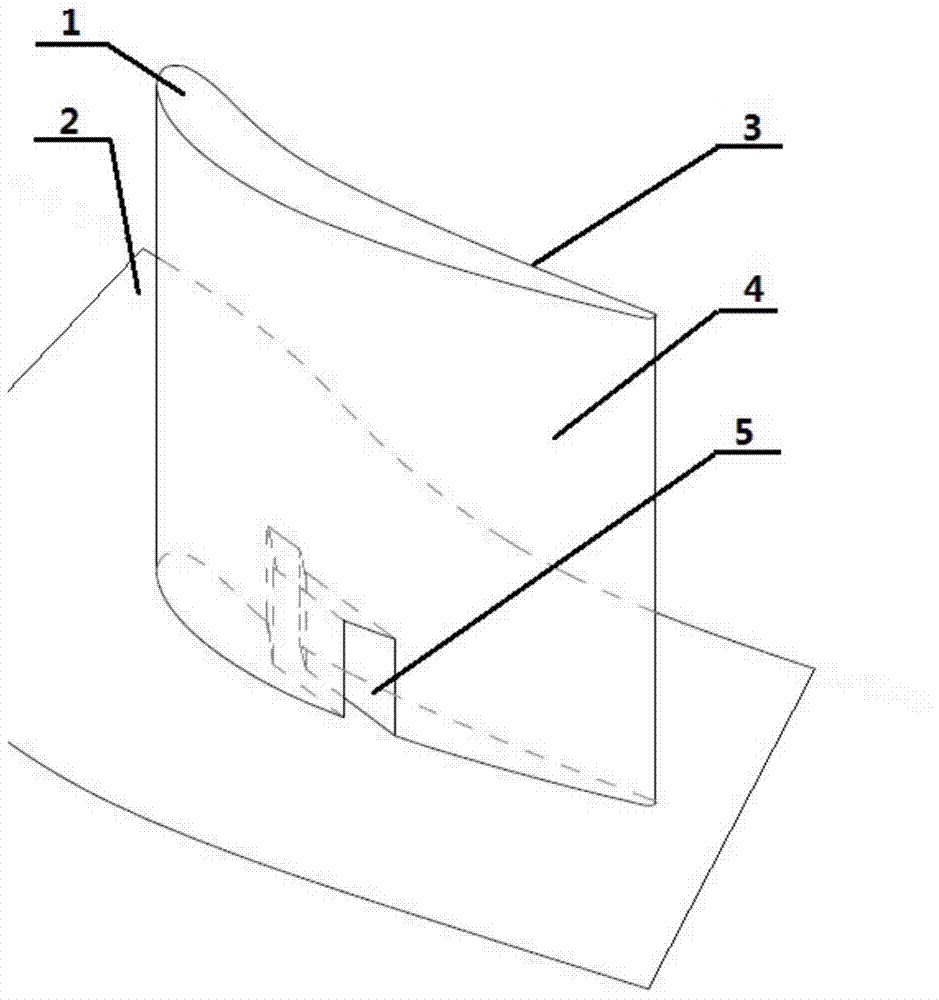

Self-adaption compressor for improving flow of rotor blade tip and stator angular region

ActiveCN107228095AImprove flow lossImprove working abilityPump componentsPump controlAirplaneGas turbines

The invention relates to the technical field of aircraft gas turbines and discloses a self-adaption compressor for improving flow of a rotor blade tip and a stator angular region. The self-adaption compressor comprises a stator blade, a rotor blade and a casing with a gas introducing circulation cavity. The gas introducing circulation cavity is formed inside the casing and composed of a gas introducing circulation cavity inlet, a high-pressure gas pressure-stabilizing cavity and a main gas introducing pipe. A flexible inlet side wall hinged to the inlet can regulate and control the open degree under the pressure differential effect in a self-adaption mode. The ultimate open degree position of the inlet is restrained by a hydraulically-controlled limiting supporting rod and a check block in the ultimate position of the flexible inlet side wall. The different ultimate open degrees can be set under different work states and are regulated within the open-degree range in a self-adaption mode. Through a self-circulation gas introducing structure, leakage flow of the rotor blade tip of the compressor and separation flow of the stator angular region of the compressor are improved. Through a foreign matter separating device, foreign matter entering the compressor is removed timely, and stable operation of the compressor is guaranteed. Through the high-pressure gas pressure-stabilizing cavity, needed high-pressure gas is provided for an aircraft and an engine.

Owner:BEIHANG UNIV

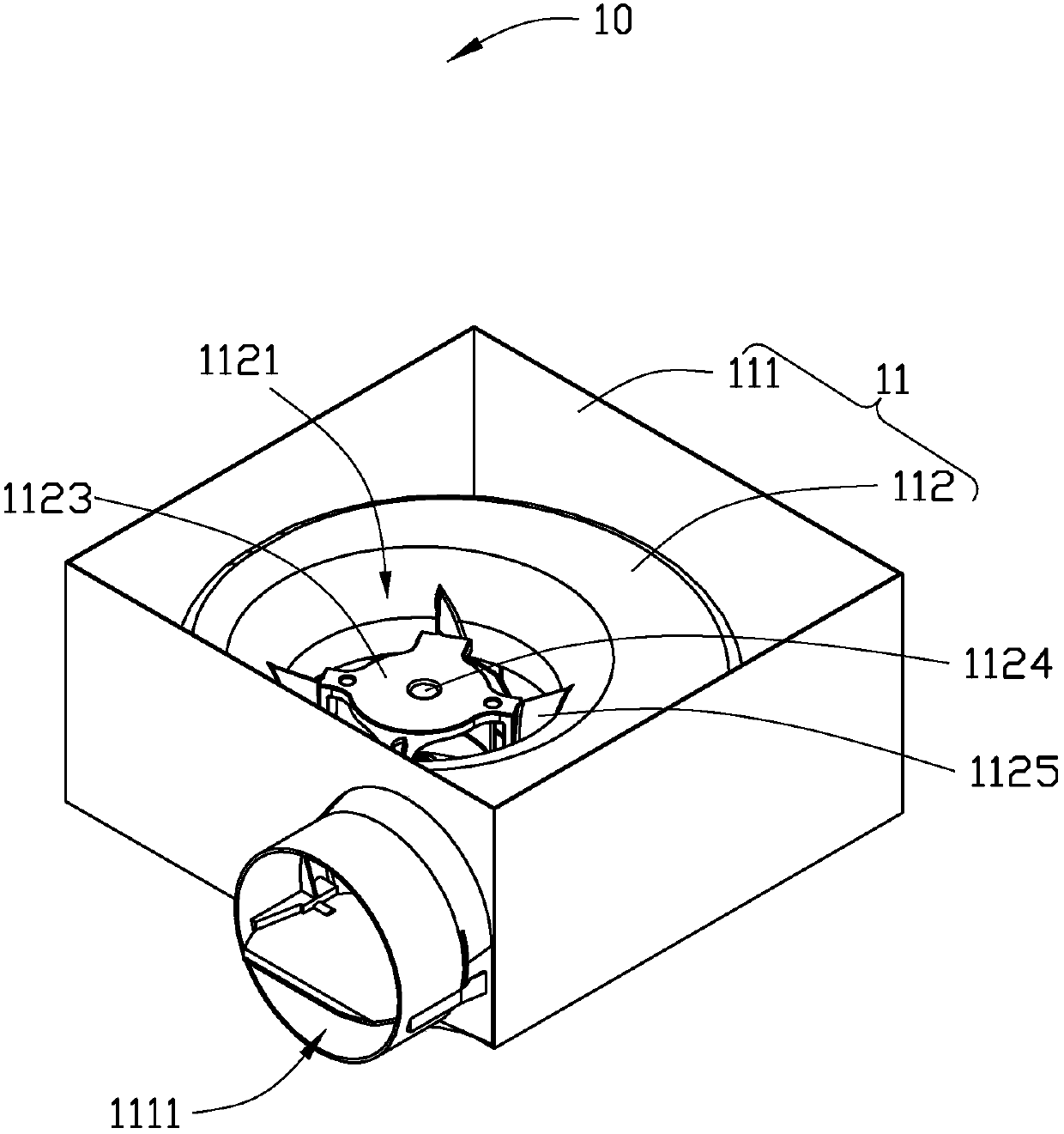

Volute structure, centrifugal compressor and refrigeration equipment

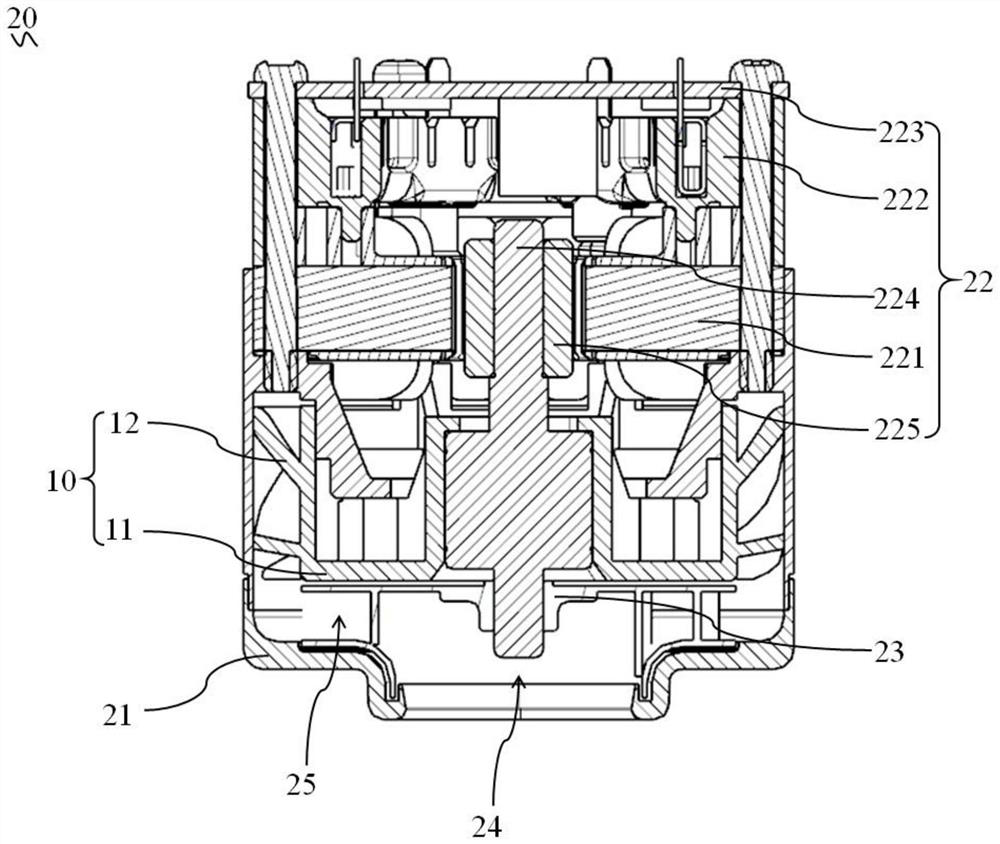

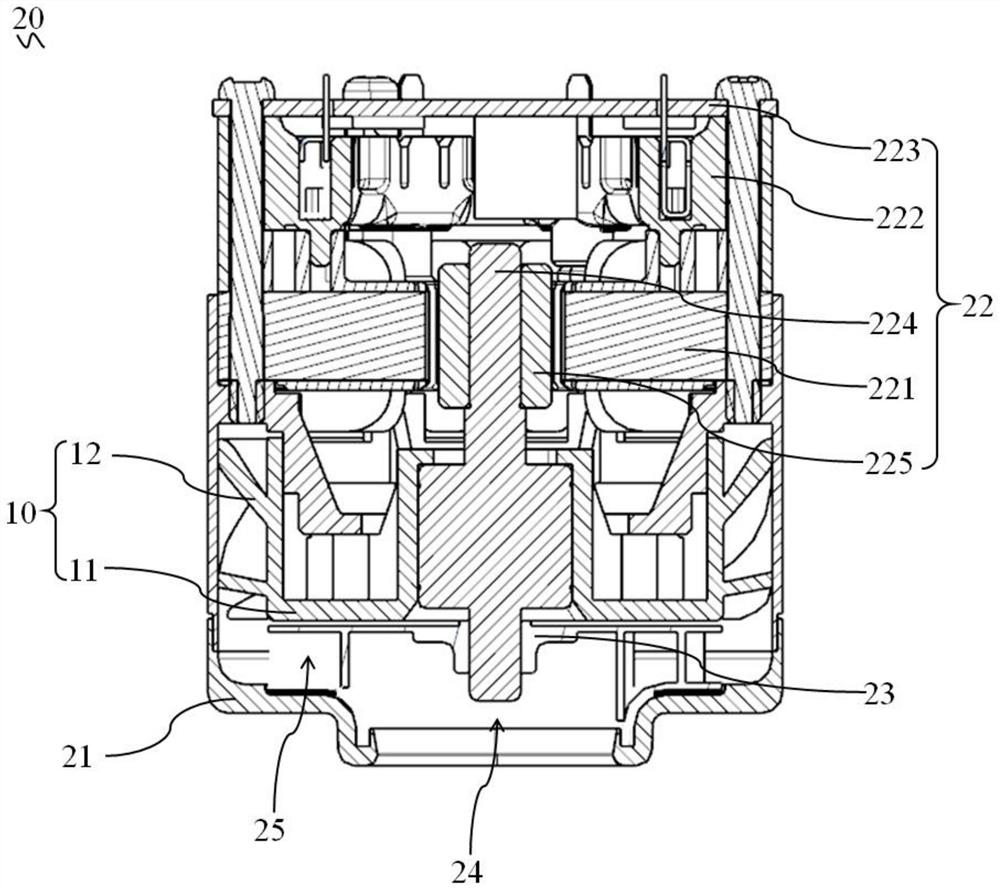

ActiveCN104454652ASmall footprintReduce Articulation FixationPump componentsPump installationsEngineeringRefrigeration

The invention discloses a volute structure, a centrifugal compressor and refrigeration equipment, and relates to the field of refrigeration equipment. An existing centrifugal compressor structure is optimized. The volute structure comprises a box body, a volute body and a return device. The volute body comprises an inner volute and an outer volute independent from the inner volute. A fluid channel is formed between the inner volute and the outer volute. The inner volute and the return device are arranged together. According to the technical scheme, the length of the section of a primary pressure expander can be increased so that the pressure expansion effect of gas entering the primary pressure expander can be improved, and then the unit performance of the centrifugal compressor is improved.

Owner:GREE ELECTRIC APPLIANCES INC

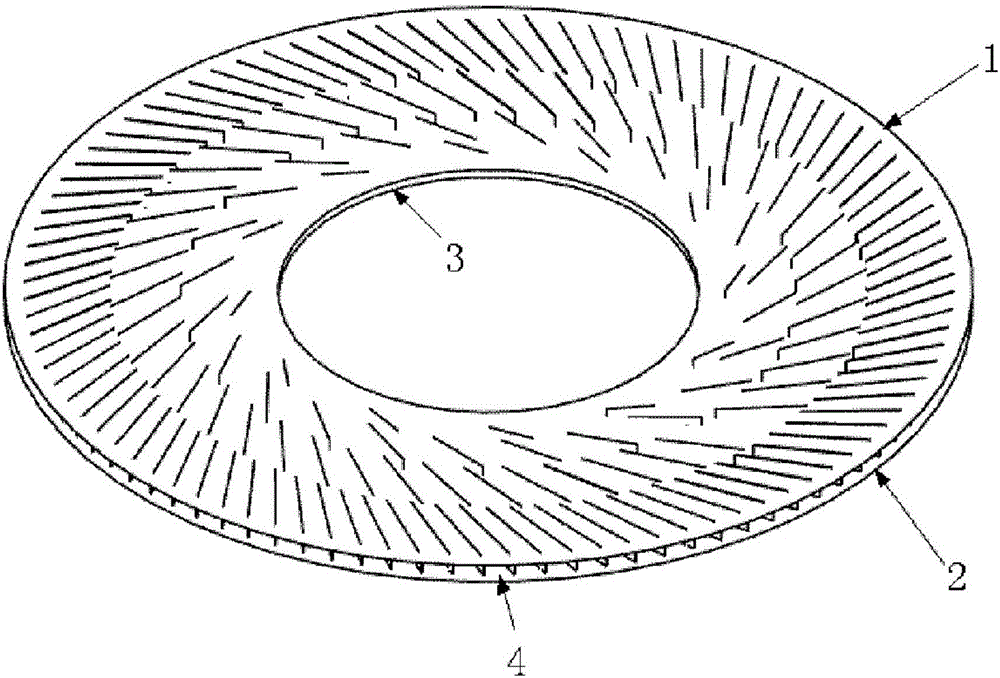

Pressure expander based on fractal blades

InactiveCN106089807AImprove the diffusion capacityImprove efficiencyPump componentsPumpsEngineeringCentrifugal compressor

The invention provides a pressure expander based on fractal blades. The pressure expander comprises an upper cover plate, a lower cover plate and a fractal blade group, wherein the fractal blade group is arranged between the upper cover plate and the lower cover plate in a clamping manner; a gas flow channel is formed among the upper cover plate, the lower cover plate and the fractal blade group; and after passing through the gas flow channel, the pressure of a gas flow is enlarged. The multi-stage fractal blades of the pressure expander disclosed by the invention can restrain flow separation, reduce flow blockage and flow loss, and improve the pressure expanding capacity and the pressure expanding efficiency of the pressure expander are improved, so that improvement of the efficiency of the whole machine, the reduction of the size of the whole machine and increase of the thrust-weight ratio / power-weight ratio are facilitated, the pressure expander disclosed by the invention is convenient to process and low in manufacturing cost, and can be directly mounted on a pressure expanding section of a centrifugal compressor, and the modifying and the upgrading of the compressor are facilitated.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

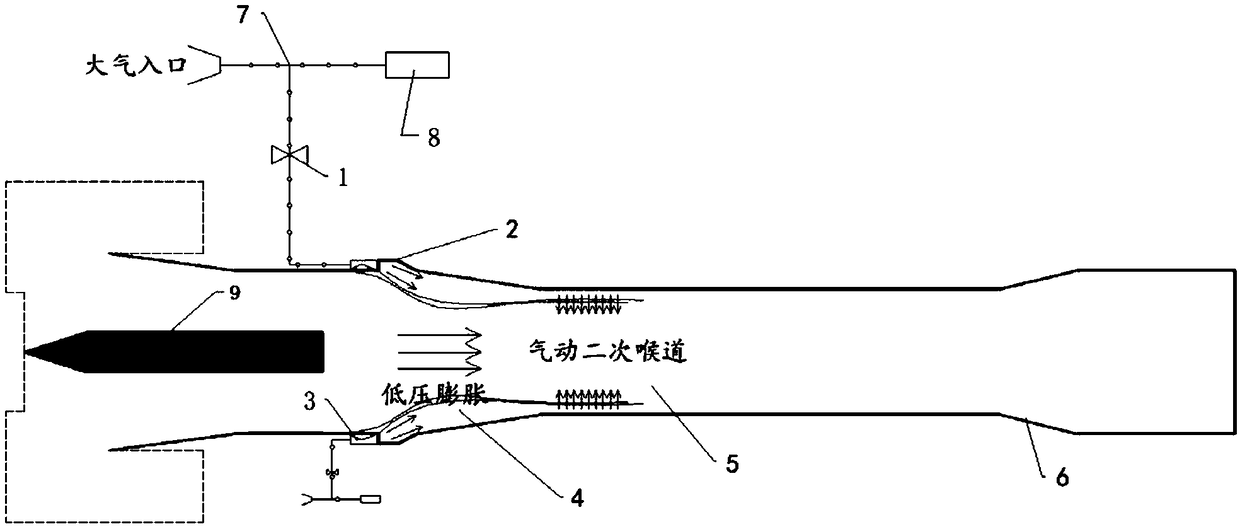

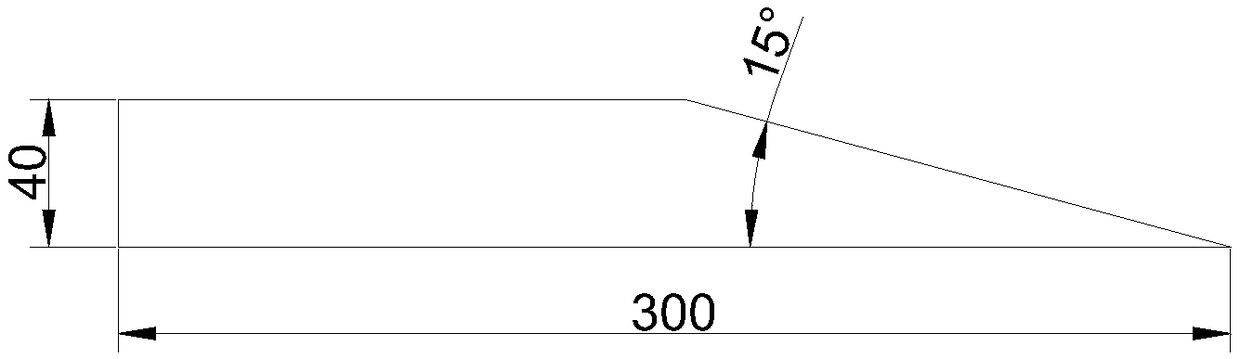

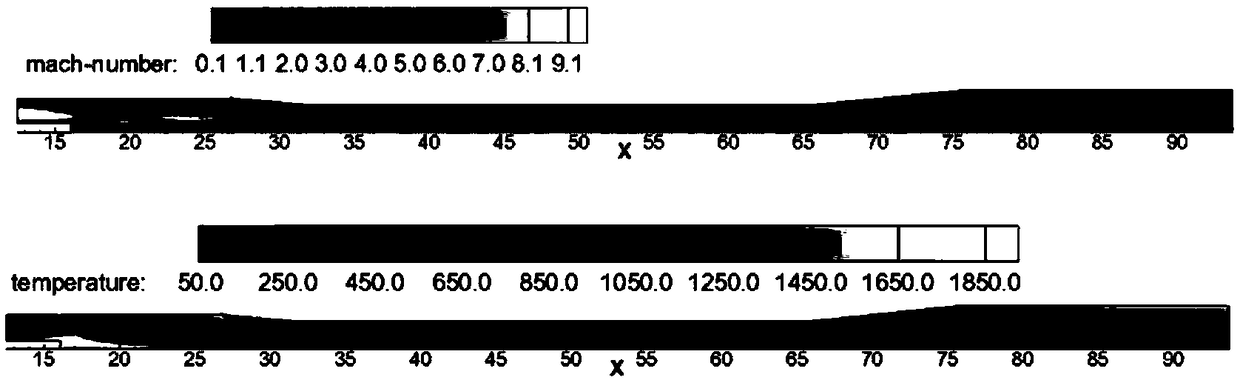

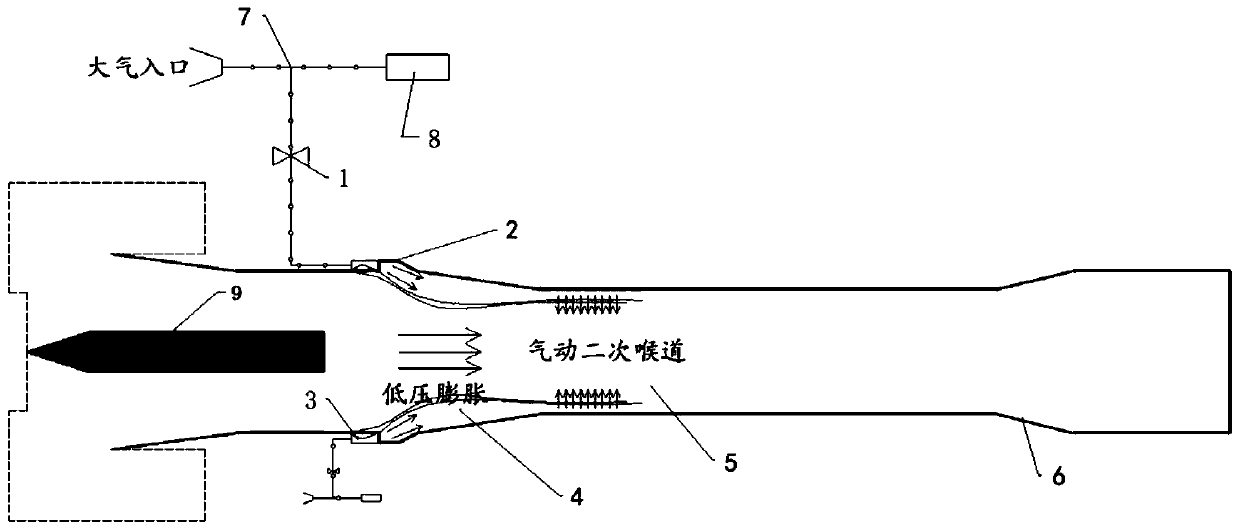

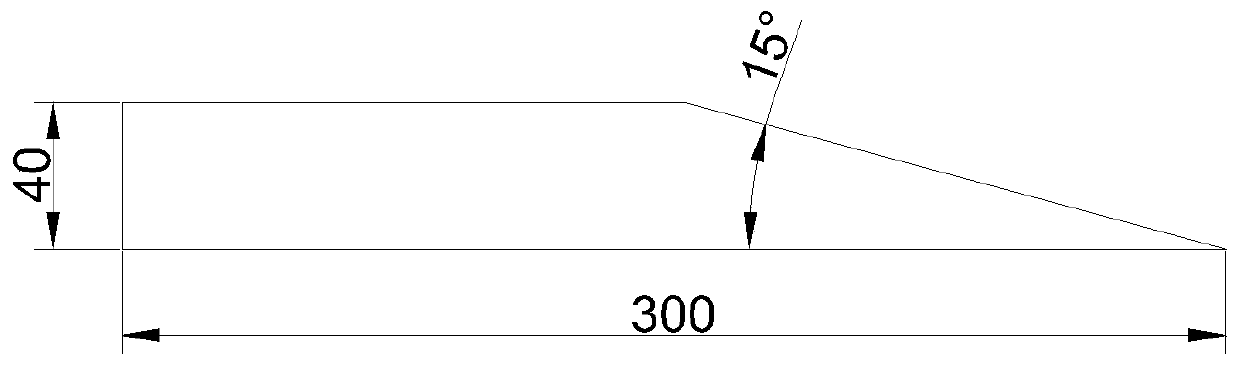

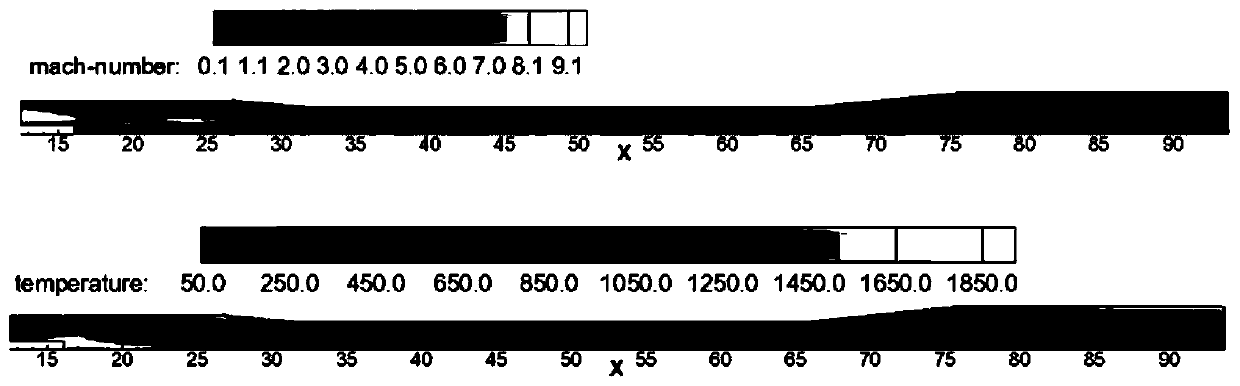

Ejection low total pressure cold medium secondary throat diffuser

ActiveCN109186927AImprove the diffusion capacityReduce heat loadAerodynamic testingCooling effectEngineering

The invention discloses an ejection low total pressure cold medium adjustable secondary throat diffuser. The ejection low total pressure cold medium adjustable secondary throat diffuser is used at thedownstream of a large hypersonic velocity wind tunnel experimental section, can adapt to operating condition of a wider range by adjusting the amount of ejection air, meanwhile, diffusion capacity isimproved, the working load of a back section ejector is reduced. In addition, a cold medium ejected flows at a near wall region, and the wall surface of the diffuser can be effectively protected frombeing in contact with high temperature fuel gas directly, and the construction cost brought by a cooling water sleeve can be reduced. The novel structure of the diffuser is characterized in that a side wall groove is added in the front of a diffuser convergence section, low total pressure normal temperature air is introduced at the position of the front edge of the groove and used as the cold medium, an air film is formed in the wall surface of the diffuser through the ejection and diffusion effect, the practical flow diameter of a secondary throat is adjusted, the static pressure recovery capability of secondary throat is adjusted at a greater degree, meanwhile, heat load of the wall surface of the secondary throat is reduced again, and the wall surface is cooled; and simulation verification is carried out, even though the ejection cooling medium is an atmospheric condition, the good diffusion and cooling effect can be achieved.

Owner:UNIV OF SCI & TECH OF CHINA

Diffusion and rectification integrated diffuser

PendingCN111622985AImprove work efficiencySmall pressure lossEngine manufacturePump componentsCombustion chamberEngineering

The invention discloses a diffusion and rectification integrated diffuser. The diffusion and rectification integrated diffuser comprises a centrifugal compressor wheel disc and a radial tubular diffusion section which are integrally formed; a plurality of rectification blades are evenly distributed in the circumferential direction of the centrifugal compressor wheel disc, an airflow rectificationchannel is formed between every two adjacent rectification blades; and a plurality of scattered through holes are formed in the circumferential direction of the radial tubular diffusion section from inside to outside, and an radial included angle between each through hole and the radial tubular diffusion section ranges from 20 degrees to 30 degrees. According to the diffusion and rectification integrated diffuser, pressure loss caused by diffusion can be effectively reduced, the working efficiency of a combustion chamber is improved; meanwhile, the shape design of the rectification blades limits the flowing direction of airflow, so that the overall structural size of a diffuser channel is shortened, and the working efficiency is further improved; and due to the integrally formed structuraldesign, the assembly difficulty of diffusion and flow guide is reduced, the overall weight of an engine is reduced, and the fuel economy and the overall performance of the engine are greatly improved.

Owner:上海尚实航空发动机股份有限公司

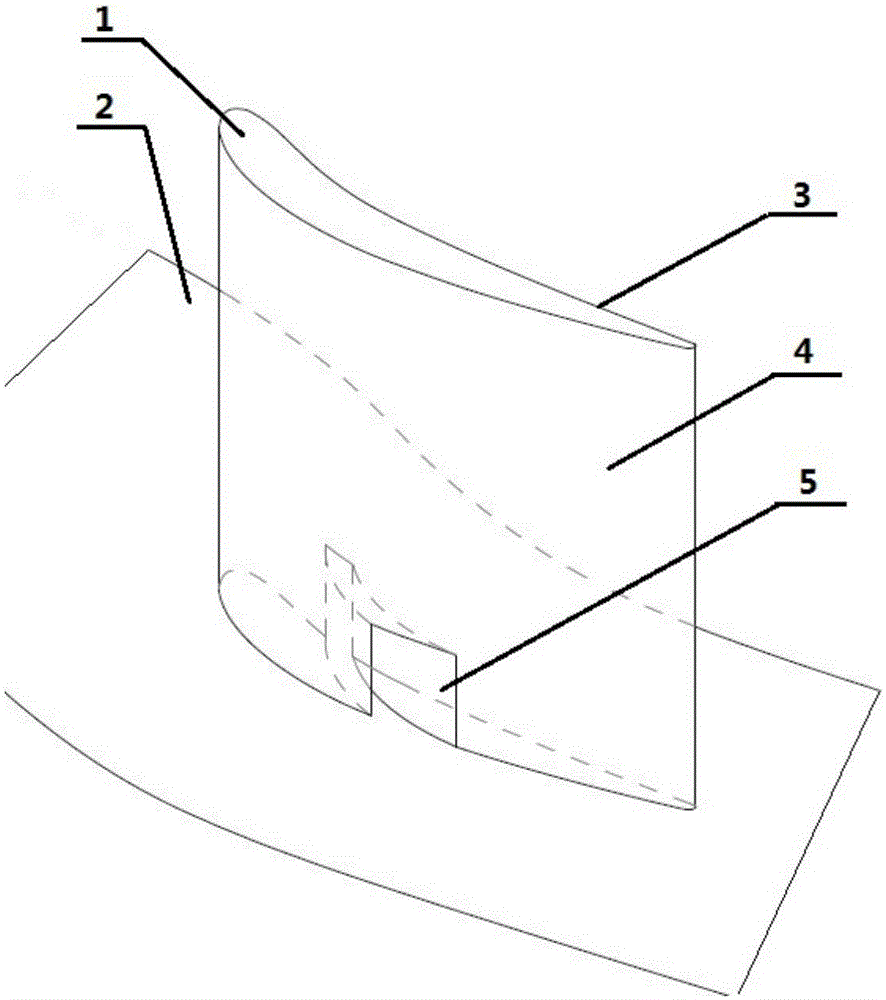

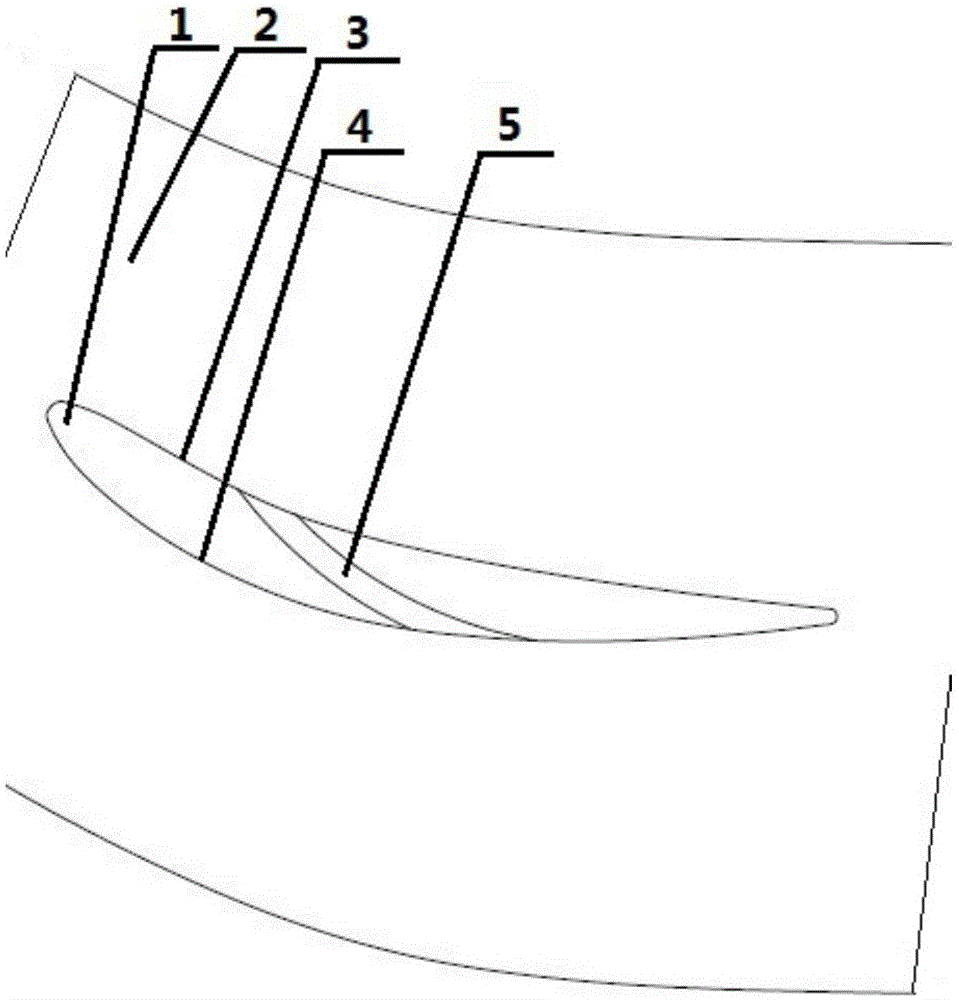

Compressor stator cascade with blade root provided with equal-width circular arc shaped channels

ActiveCN105156361ALarge circulation capacityIncrease kinetic energyPump componentsPumpsImpellerSuction stress

The invention provides a compressor stator cascade with a blade root provided with equal-width circular arc shaped channels, relating to passive flow control technology in the technical field of turbo-machinery. The adverse pressure gradient resistance is stronger, Coanda effects are additionally brought and corner separation is better inhibited by forming the equal-width circular arc shaped channels in an end wall of the blade root of the compressor stator cascade from a pressure surface to a suction surface, forming high-speed jet by utilizing self-differential pressure of blades, increasing the kinetic energy of low energy fluid at a corner and blowing down airflows on boundary layers of the suction surface and the end wall. The compressor stator cascade is characterized in that the channels are formed in the end wall of the blade root of the compressor stator cascade; the spanwise height is a constant value; the number of the channels can be one or multiple; inlets of the channels are formed in the pressure surface of the stator cascade and outlets are formed in the suction surface of the cascade; center lines of the channels are shaped like circular arcs; the two sides of the channels are equally distant from the center lines; and the outlets in the side walls of the channels are tangent to the downstream wall of the suction surface of the cascade. The compressor stator cascade has the beneficial effects of effectively inhibiting corner separation, increasing the cascade flow capacity, reducing the total pressure loss and increasing the pressure diffusion capacity.

Owner:BEIHANG UNIV

Centrifugal fluid equipment and centrifugal impeller used by centrifugal fluid equipment

InactiveCN107762971AImprove the diffusion effect and efficiencyGuaranteed mechanical strengthPump componentsPumpsImpellerTip position

A centrifugal fluid device and the impeller used therein, the impeller includes a plurality of blades, the blades are backward-curved blades, the starting ends of some or all of the blades are located on a circle with the impeller shaft as the axis and a diameter of D1 , the ends of all the blades are located on a circle with the impeller shaft as the axis and a diameter of D2, wherein, the D1 / D2=0.5~0.6; the inlet angle of the inner flow channel of each blade is formed at the beginning of each blade , the inlet angle is the angle between the outer extension line of the blade passing the starting end and the radius of the circle with a diameter D1 passing the starting end, and the value of the inlet angle is 60° to 80°; each of the blades The outlet angle of the inner flow channel of the blade is formed at the end, and the outlet angle is the angle between the outer extension line of the blade passing through the end and the tangent line of a circle with a diameter of D2 passing through the end and following the direction of impeller rotation. The value is from 165° to 175°. The invention can effectively improve the diffusion effect and efficiency of the centrifugal fluid equipment.

Owner:JOHNSON ELECTRIC SHENZHEN

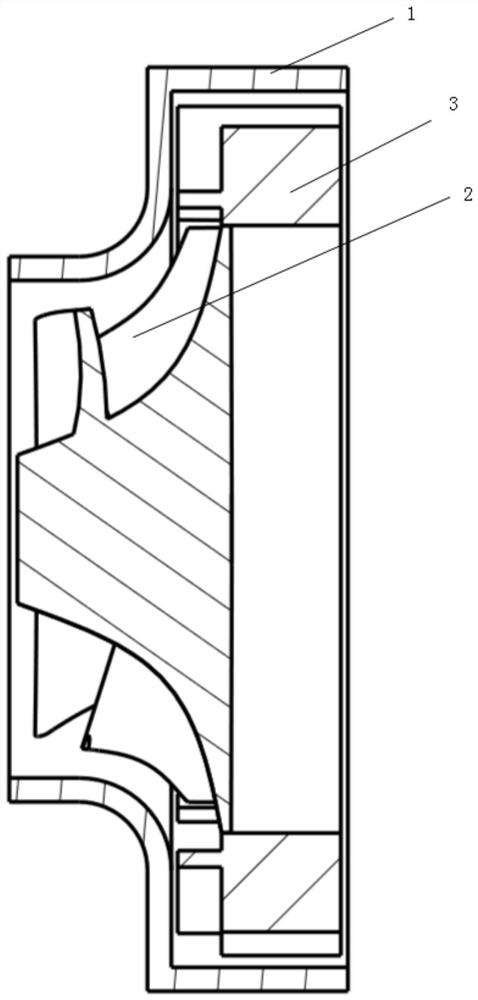

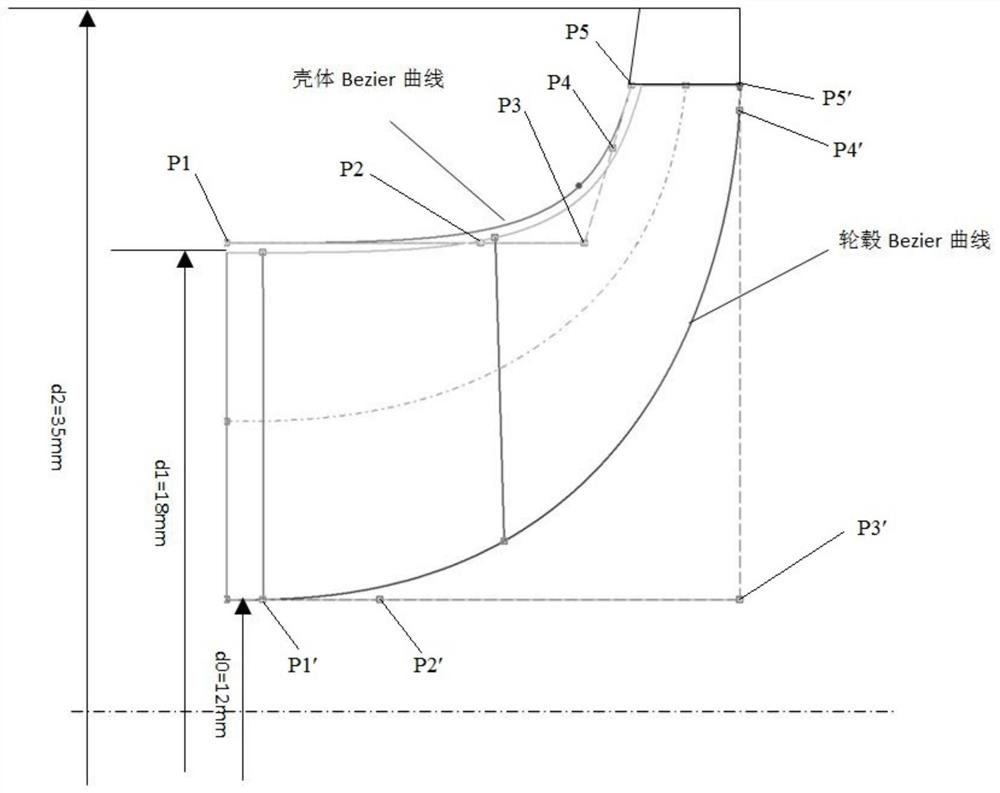

Design method of centrifugal compressor and diffuser structure

ActiveCN110608195AImprove flow statusReduce flow lossPump componentsPumpsEngineeringCentrifugal compressor

The invention discloses a design method of a centrifugal compressor and a diffuser structure. The centrifugal compressor comprises a shell, an impeller and a diffuser, wherein the impeller comprises ahub and impeller blades, the diffuser comprises diffuser blades; and the design method comprises the following steps that curve segments of the shell and the hub of the impeller adopt Bezier curve design, and curve segments of the impeller blades adopt 3D free curve design; and curve segments of the diffuser blades adopt spiral curve design. Through the parametric design method, a gas inlet angleat a gas inlet hole and a gas outlet angle at a gas outlet hole are optimized, a gas flow state is improved, the uniformity of an outlet gas flow is improved, the gas flow loss is reduced, and high gas compressing capability and diffusion capability are obtained under the condition of small size.

Owner:CHANGCHUN UNIV OF SCI & TECH

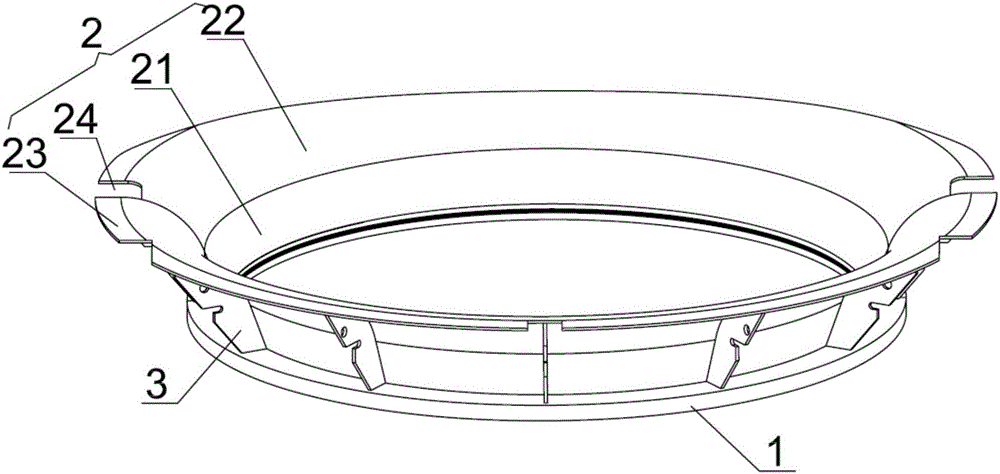

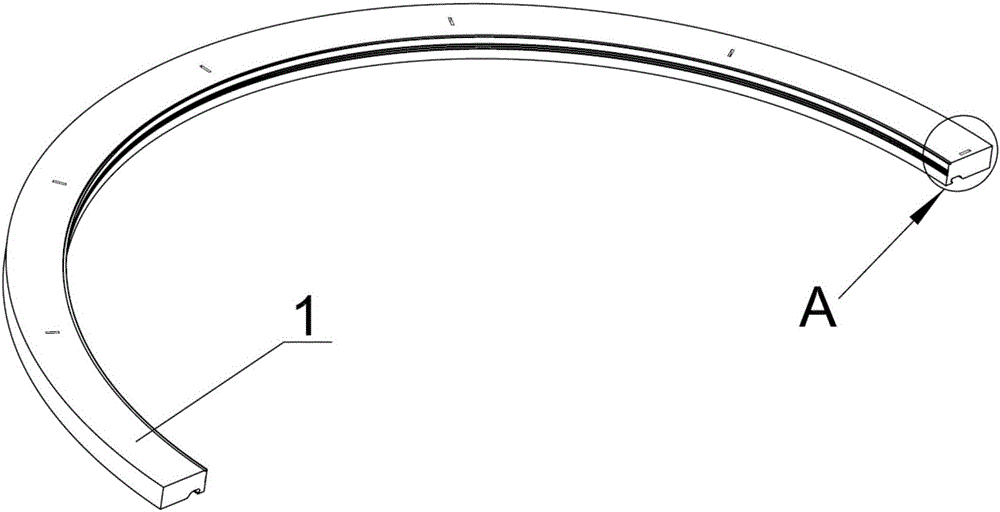

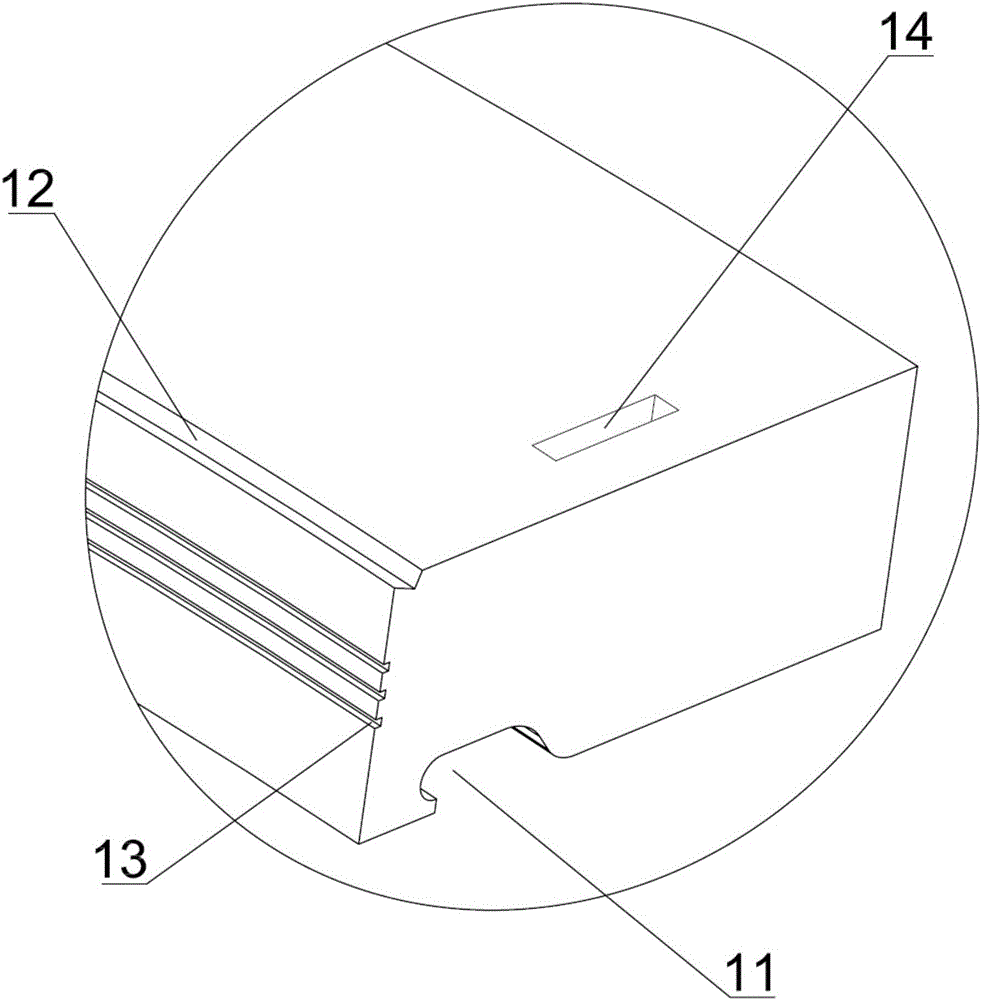

Deflector ring for exhaust hood of turbine

ActiveCN105065068AGuaranteed stabilityEasy to installMachines/enginesEngine componentsTurbineWater spray

The invention discloses a deflector ring for an exhaust hood of a turbine. The deflector ring comprises a flange assembly and a ring plate assembly fixedly connected with the flange assembly. A mounting and fixing spigot connected with the ring plate assembly is formed in the upper surface of the flange assembly, and a steam sealing mounting groove is formed in the inner wall of the flange assembly. The ring plate assembly comprises a skew line ring plate segment, an arc ring plate segment and an orthogonal straight line ring plate segment which are arranged to be of an integral structure. A plurality of supporting rib plates are fixedly connected between the upper surface of the flange assembly and the outer surface of the ring plate assembly, and lifting holes and water tube locating grooves for fixing a water spraying tube are formed in the supporting rib plates. The ring plate assembly is changed to a three-segment type structure with the skew line ring plate segment, the arc ring plate segment and the orthogonal straight line ring plate segment from an original full straight line type structure, so that the stability of a flow field in the diffusion process is guaranteed, and no obvious flow separation or vortex is generated; and the diffusion capacity is improved, and flow losses are reduced.

Owner:DEYANG DONGQI POWER STATION EQUIP

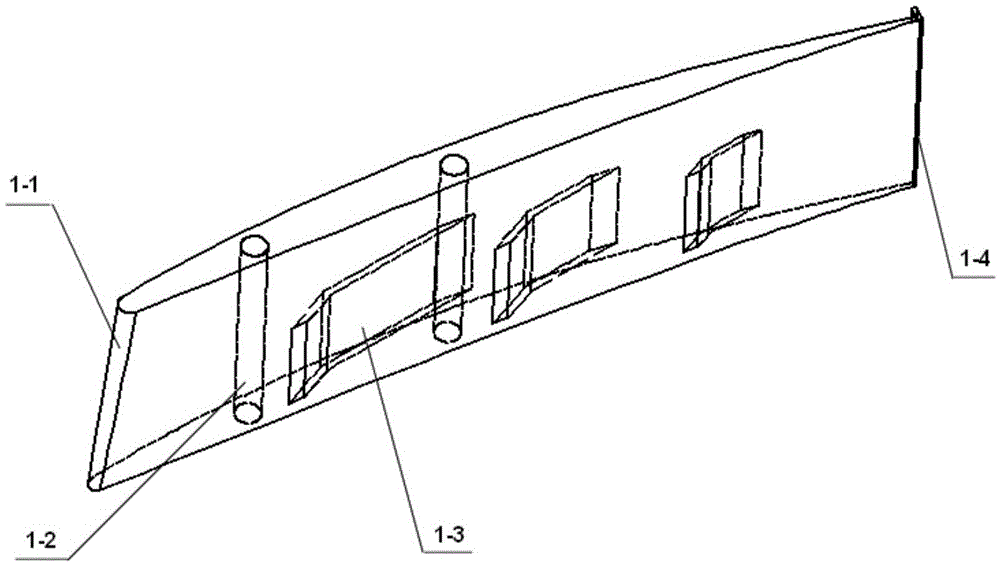

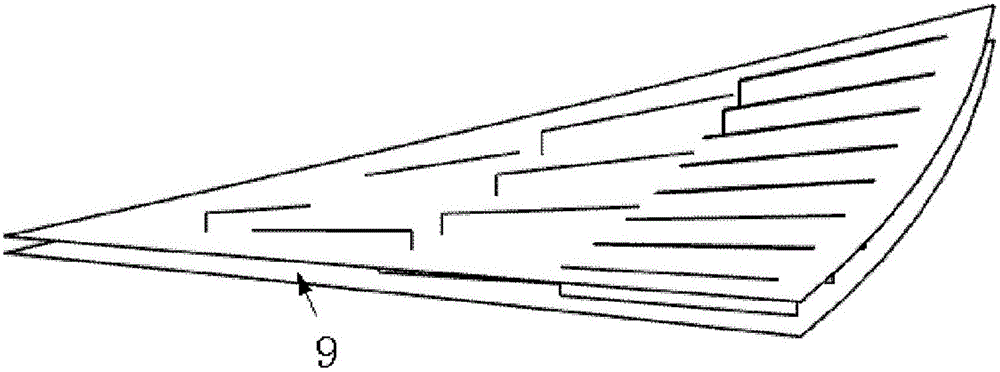

Subsonic velocity vortex blowing type compressor blade

ActiveCN113217462AEasy loadingEffective control of flow separationPump componentsPumpsSuction forceEngineering

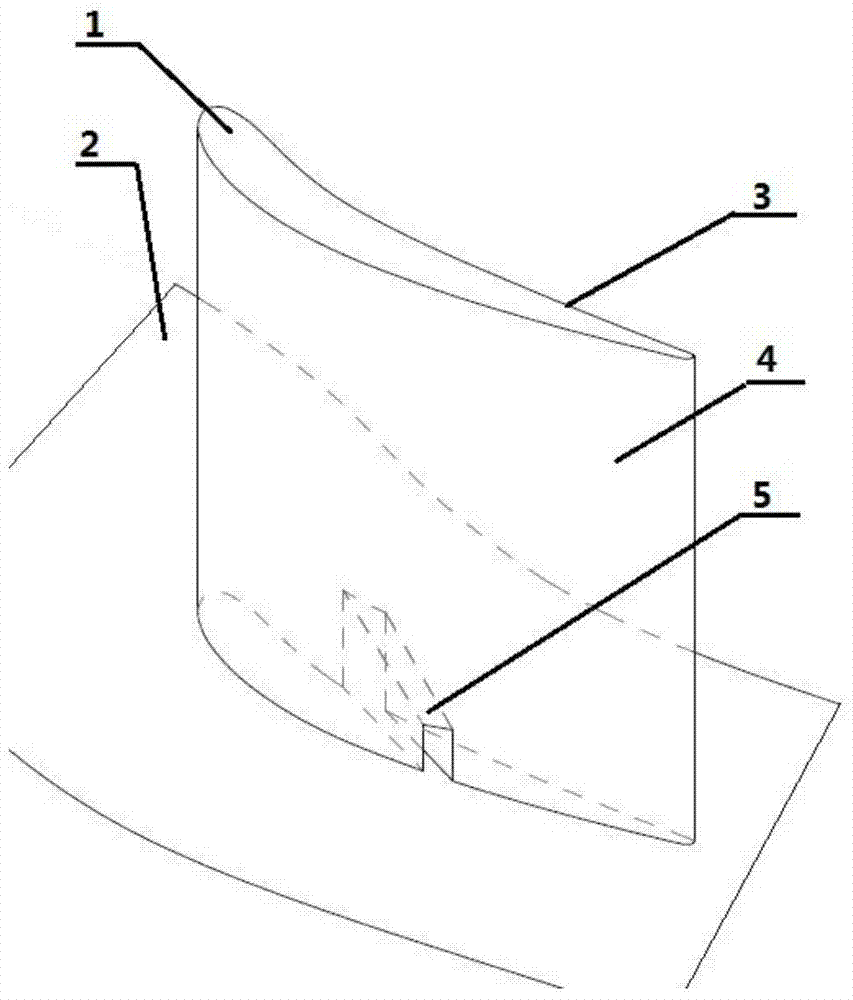

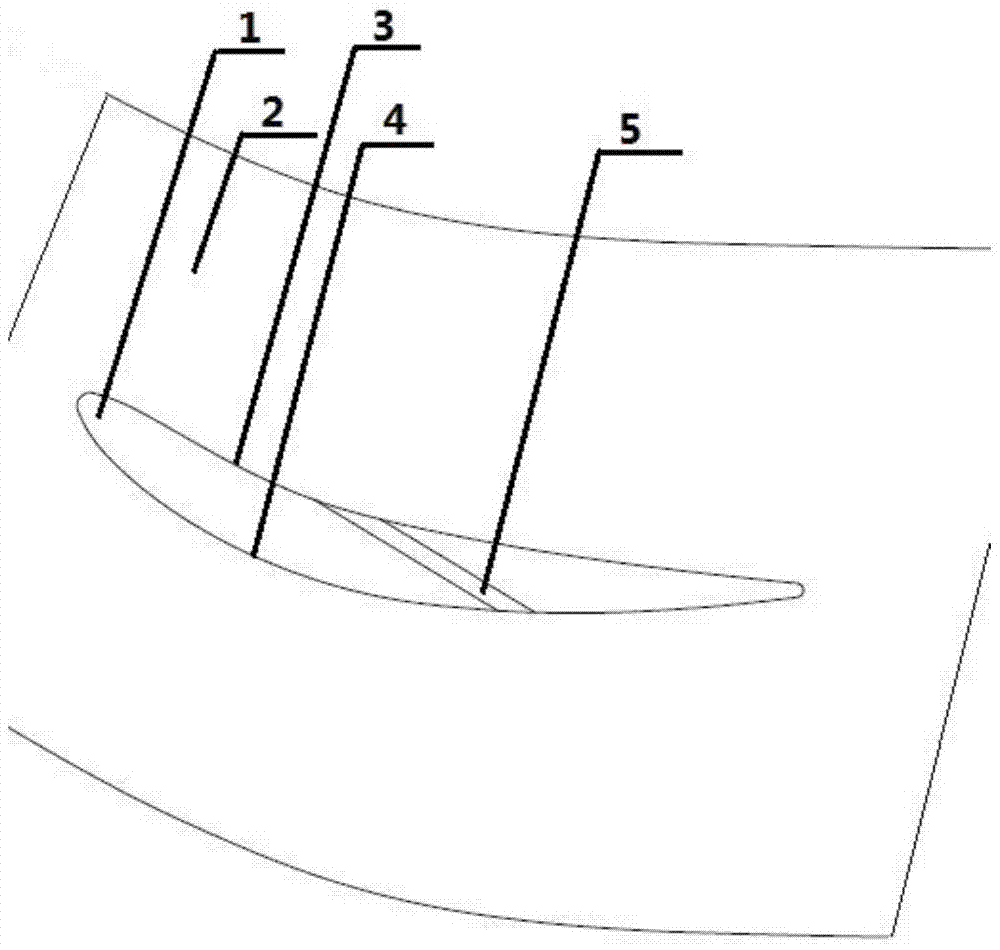

The invention relates to a subsonic velocity vortex blowing type compressor blade. A row of blowing holes are formed in the suction surface of the blowing type compressor blade in the spanwise direction, and all the blowing holes are communicated with a blowing cavity. A row of vortex generators are arranged at the rear edge of the suction surface of the blade in the spanwise direction, and the vortex generators are in one-to-one correspondence with the blowing holes. Each vortex generator is in a triangular pyramid shape, and the front edge of each vortex generator is consistent with the front edge of the blade in direction. According to the subsonic velocity vortex blowing type compressor blade, a flow control structure is innovated, and the flow separation of the suction surface of the blade is effectively controlled while the load of the subsonic velocity vortex blowing type compressor blade is increased through the blowing cavity penetrating through the blade in the blade expansion direction, the blowing holes formed in the suction surface of the blade and the vortex generators mounted at the rear edge of the suction surface of the blade, so that after high-energy fluid is injected into the blowing cavity, boundary layer separation is effectively restrained, complex working conditions in a compressor are adapted to a certain degree, and the pressure ratio and the load of the compressor are further improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

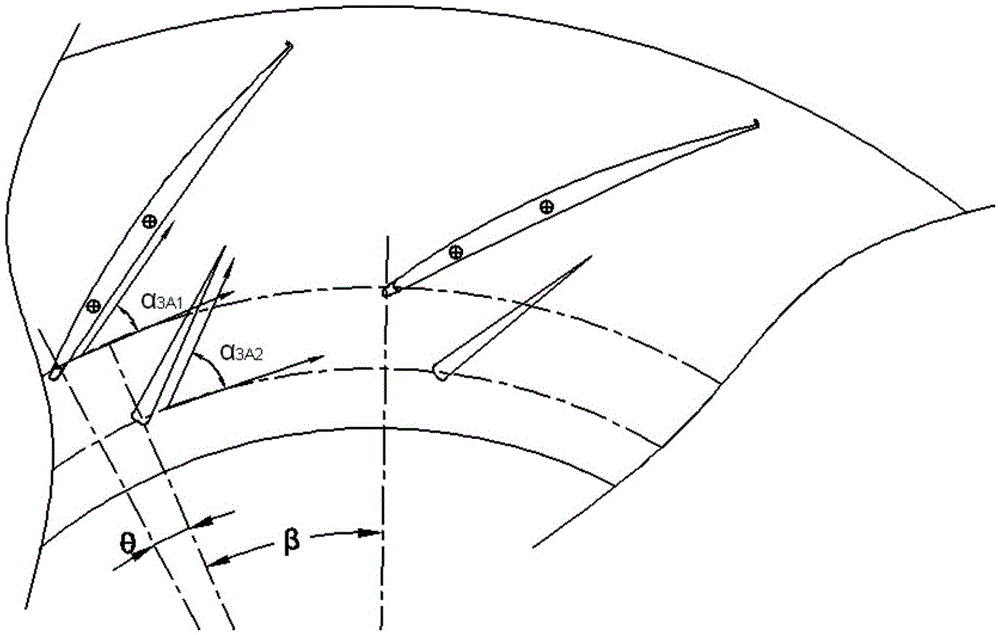

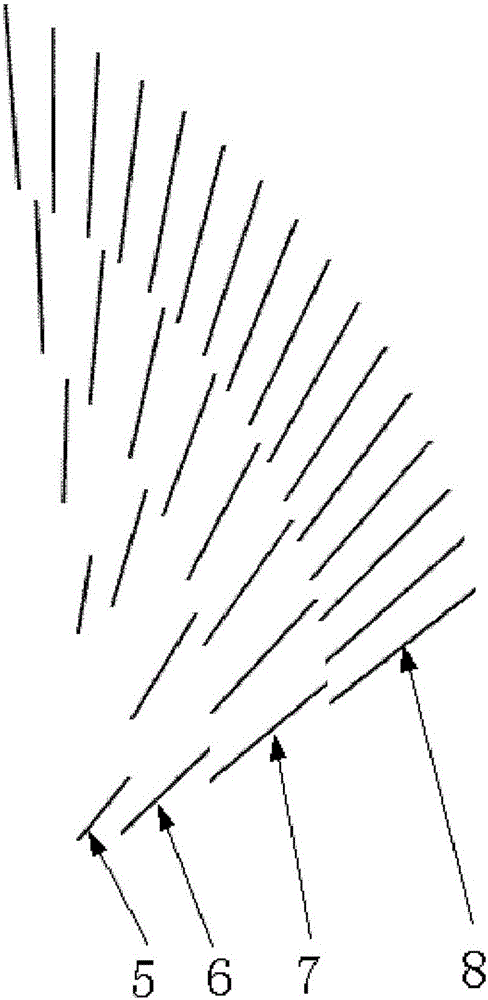

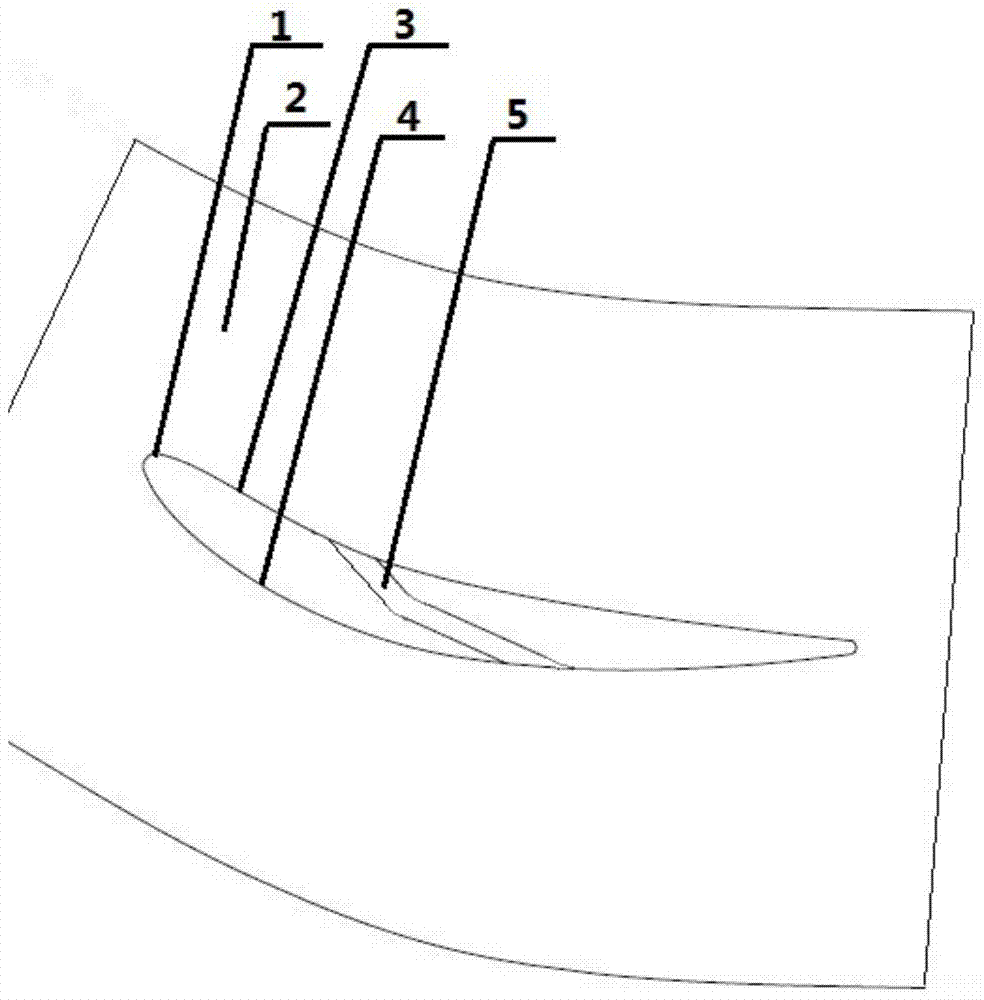

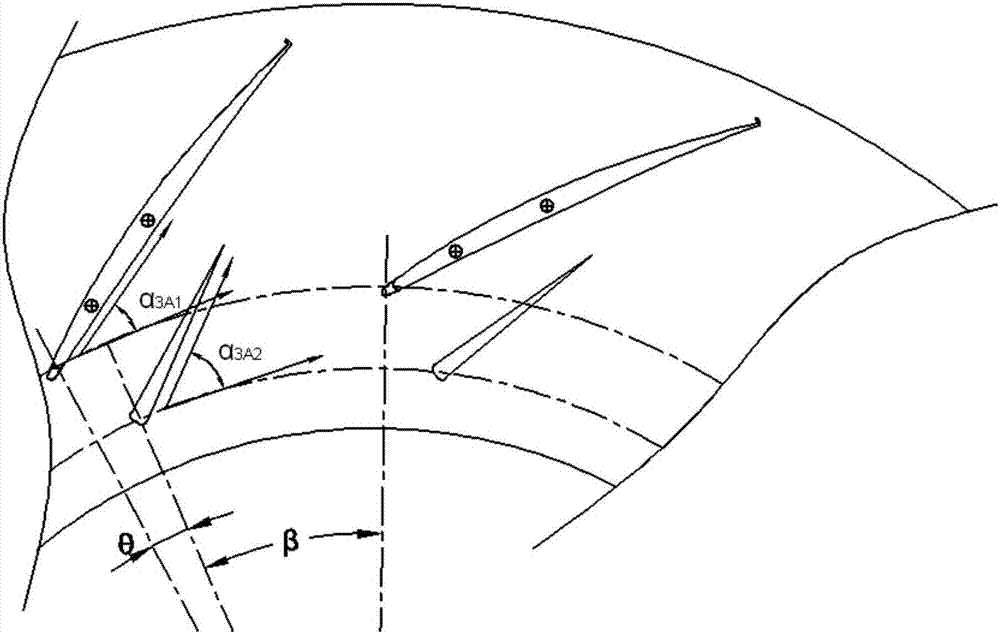

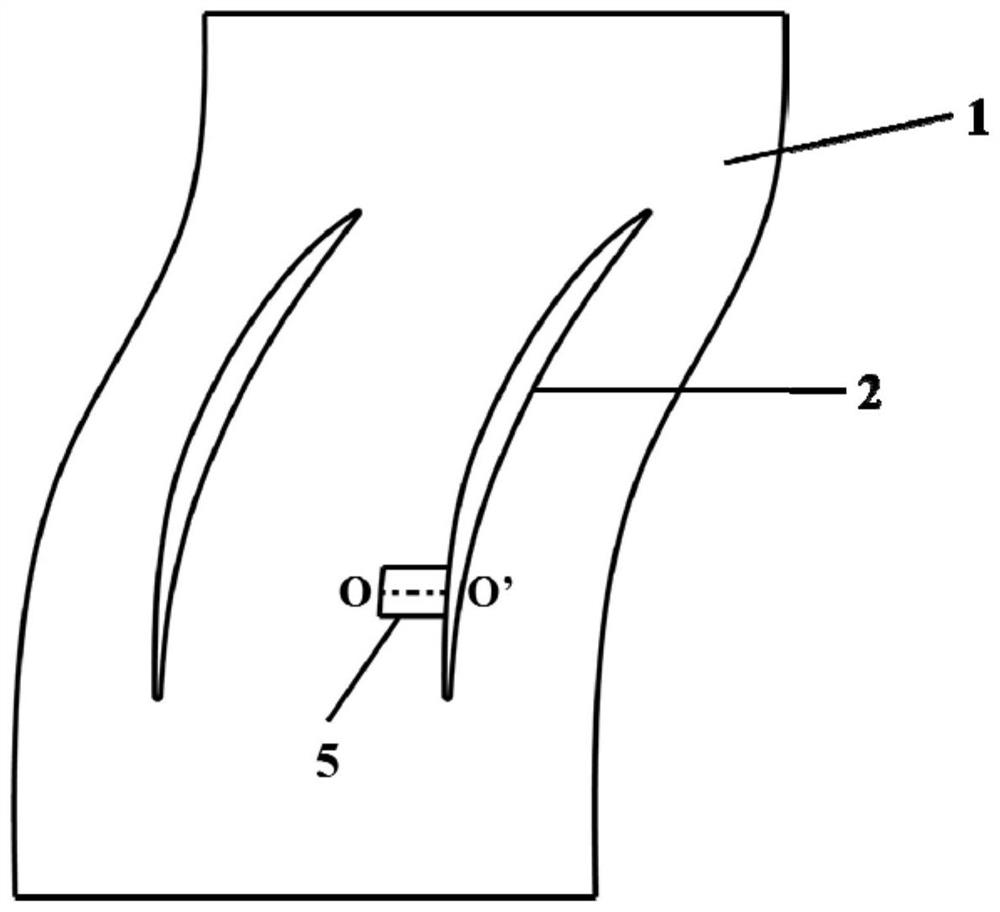

Compressor stator cascade with blade root provided with equal-width broken line shaped channels

ActiveCN105156356ALarge circulation capacityIncrease the effective jet flowPump componentsPumpsImpellerDifferential pressure

The invention provides a compressor stator cascade with a blade root provided with equal-width broken line shaped channels, relating to passive flow control technology in the technical field of turbo-machinery. The adverse pressure gradient resistance is stronger, Coanda effects are additionally brought and corner separation is better inhibited by forming the equal-width broken line shaped channels in an end wall of the blade root of the compressor stator cascade from a pressure surface to a suction surface, forming high-speed jet by utilizing self-differential pressure of blades, increasing the kinetic energy of low energy fluid at a corner and blowing down airflows on boundary layers of the suction surface and the end wall. The compressor stator cascade is characterized in that the channels are formed in the end wall of the blade root of the compressor stator cascade; the spanwise height is a constant value; the number of the channels can be one or multiple; inlets of the channels are formed in the pressure surface of the cascade and outlets are formed in the suction surface of the cascade; center lines of the channels are multiple broken lines; the two sides of the channels are equally distant from the center lines; and the directions of airflows at the outlets of the channels are basically consistent with the directions of ideal non-separation flow lines. The compressor stator cascade has the beneficial effects of effectively inhibiting corner separation, increasing the cascade flow capacity, reducing the total pressure loss and increasing the pressure diffusion capacity.

Owner:BEIHANG UNIV

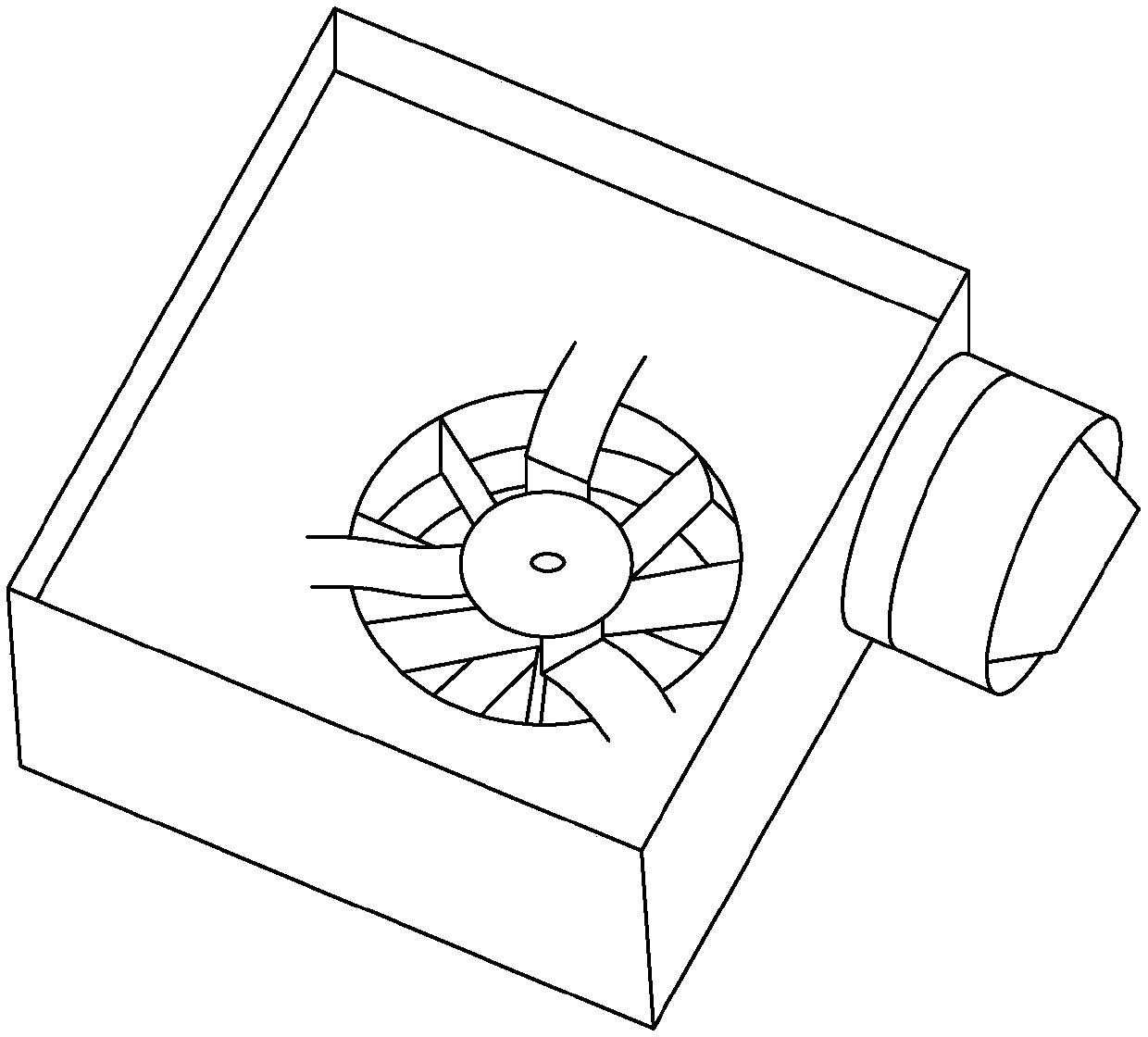

Diffuser, air supply device and dust collector

ActiveCN113074141AImprove the diffusion capacityReduce lossesPump componentsSuction cleanersEngineeringMechanical engineering

The invention belongs to the technical field of cleaning equipment, and particularly relates to a diffuser which comprises a base ring piece and a plurality of stationary blades connected to the base ring piece. The stationary blades are arranged in the circumferential direction of the outer ring wall of the base ring piece, each stationary blade is provided with an installation angle, the angle value of the installation angles is kept unchanged from the head to the middle of each stationary blade, and the angle value of the installation angles is gradually increased from the middle to the tail of each stationary blade. A first outlet mounting angle is formed at the blade root of the tail part of each stationary blade, a second outlet mounting angle is formed at the blade tip of the tail part of each stationary blade, and the angle value of the first outlet mounting angle is larger than or equal to that of the corresponding second outlet mounting angle. From the head to the tail of each stationary blade, the chord length of the blade root of each stationary blade is larger than or equal to the chord length of the blade tip of the stationary blade. Therefore, the flow separation phenomenon of the airflow near the outer wall of the diffuser is effectively regulated, controlled and inhibited, the airflow flowing through the diffuser is effectively guided, and the flow loss of the airflow caused by flow separation is remarkably reduced.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Guide ring structure of low-pressure exhaust cylinder of steam turbine

PendingCN106930789AImprove mainstream diffusion spaceReduce total pressure lossMachines/enginesEngine componentsEngineeringSteam turbine

The invention discloses a guide ring structure of a low-pressure exhaust cylinder of a steam turbine. The guide ring structure of the low-pressure exhaust cylinder of the steam turbine comprises a flared guide ring body. The guide ring body is divided into a top arc section and a bottom arc section in the circumferential direction in the moving sequence of vortexes formed by exhaust steam during acting. The circumferential section of the top arc section of the guide ring body is smaller than the circumferential section of the bottom arc section of the guide ring body. The guide ring body is of a variable cross section structure in the circumferential direction. According to the guide ring structure of the low-pressure exhaust cylinder of the steam turbine, it is ensured that good, orderly and effective control over the vortex moving downwards can be achieved through the back side of the bottom arc section of the guide ring body, namely the top arc section is designed according to the generated top vortex structure and the bottom arc section is designed according to the downward-moving vortex structure on the horizontal plane, so that the main flow diffusion space of the low-pressure exhaust cylinder and the diffusion performance of the whole low-pressure exhaust cylinder are improved, and the total pressure lose can be effectively and reliably reduced; and the guide ring structure of the low-pressure exhaust cylinder of the steam turbine is reliable, economical and practical.

Owner:DONGFANG TURBINE CO LTD

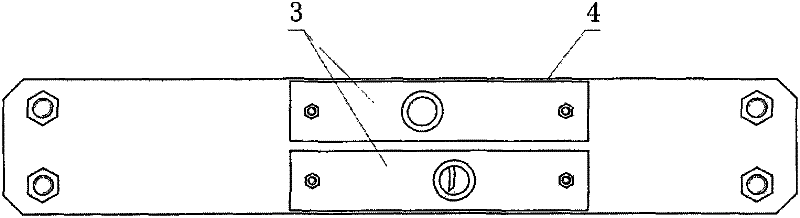

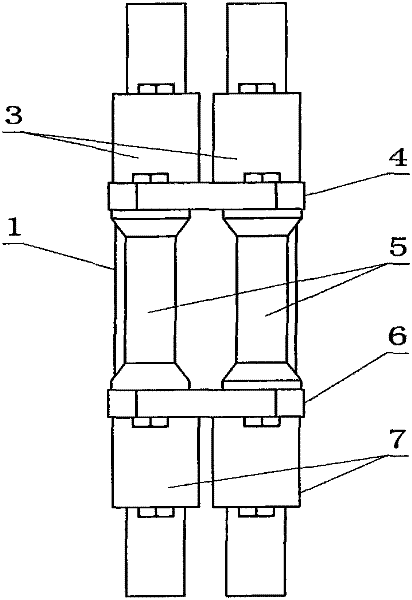

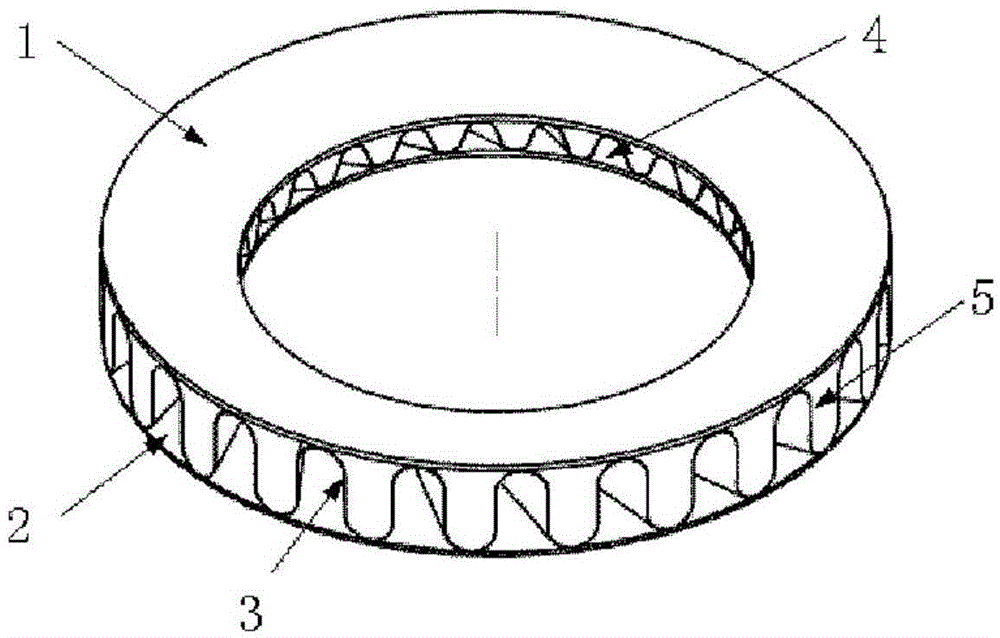

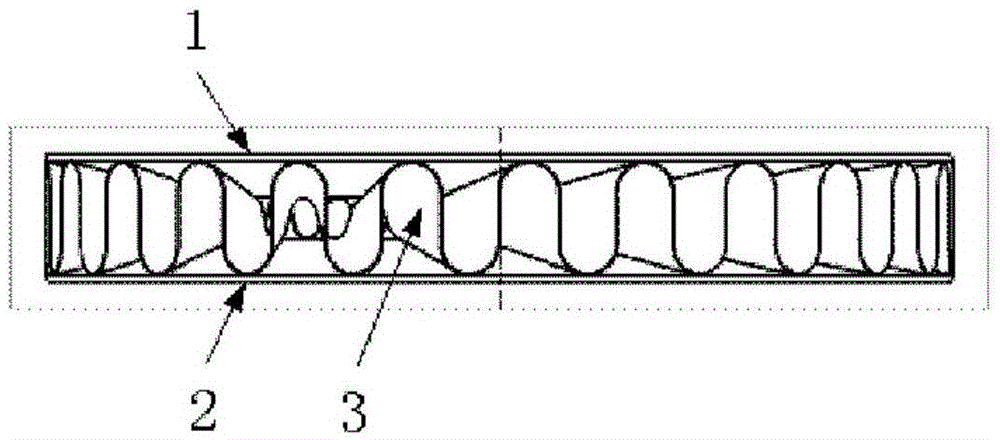

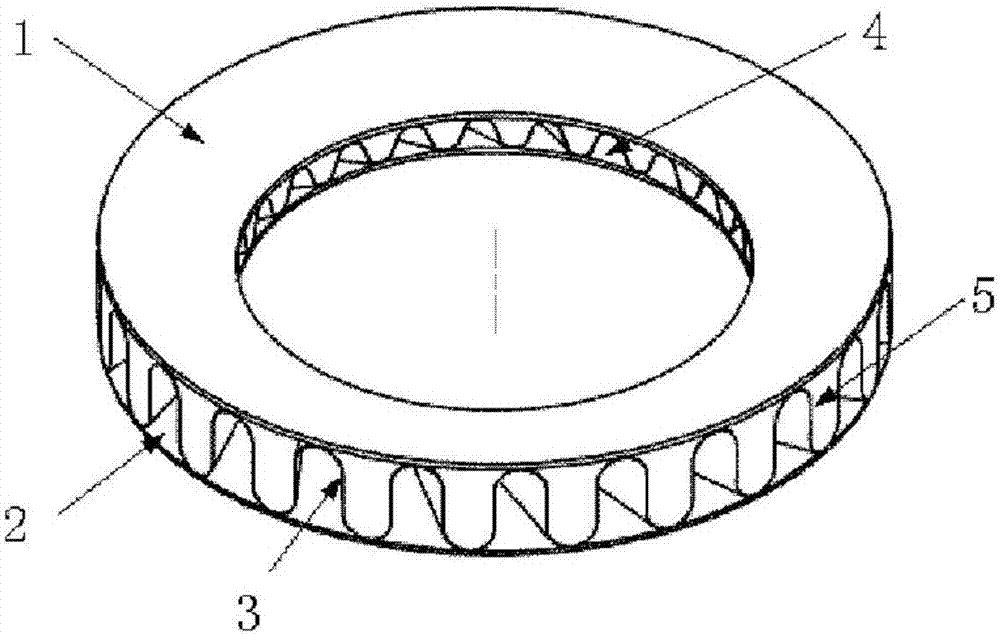

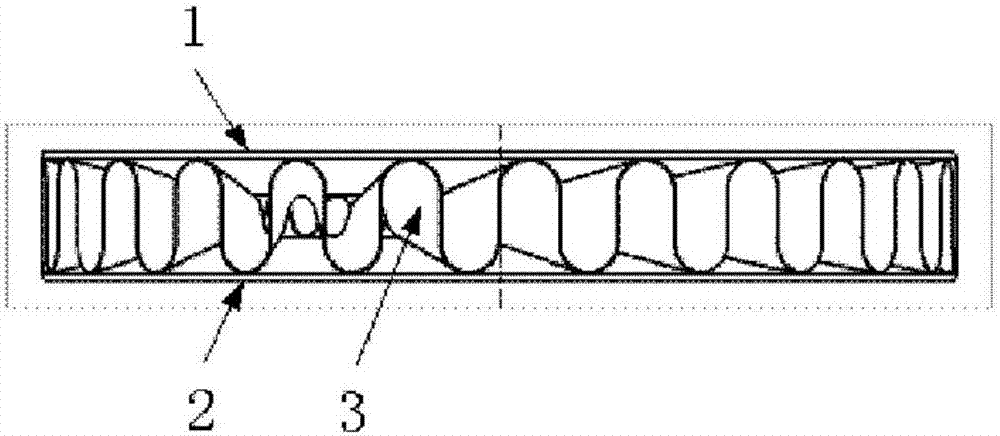

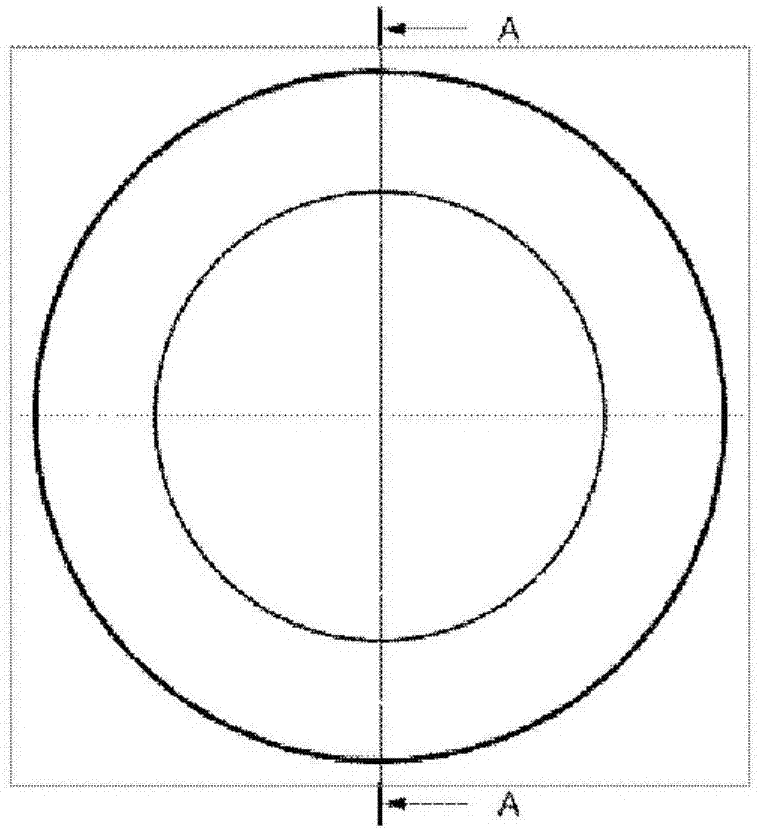

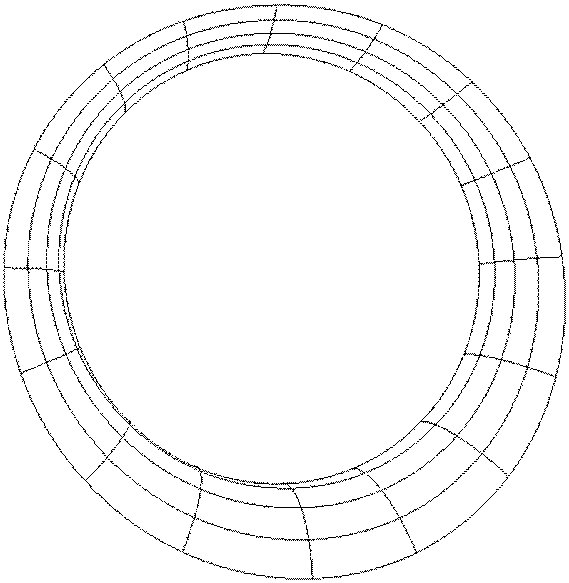

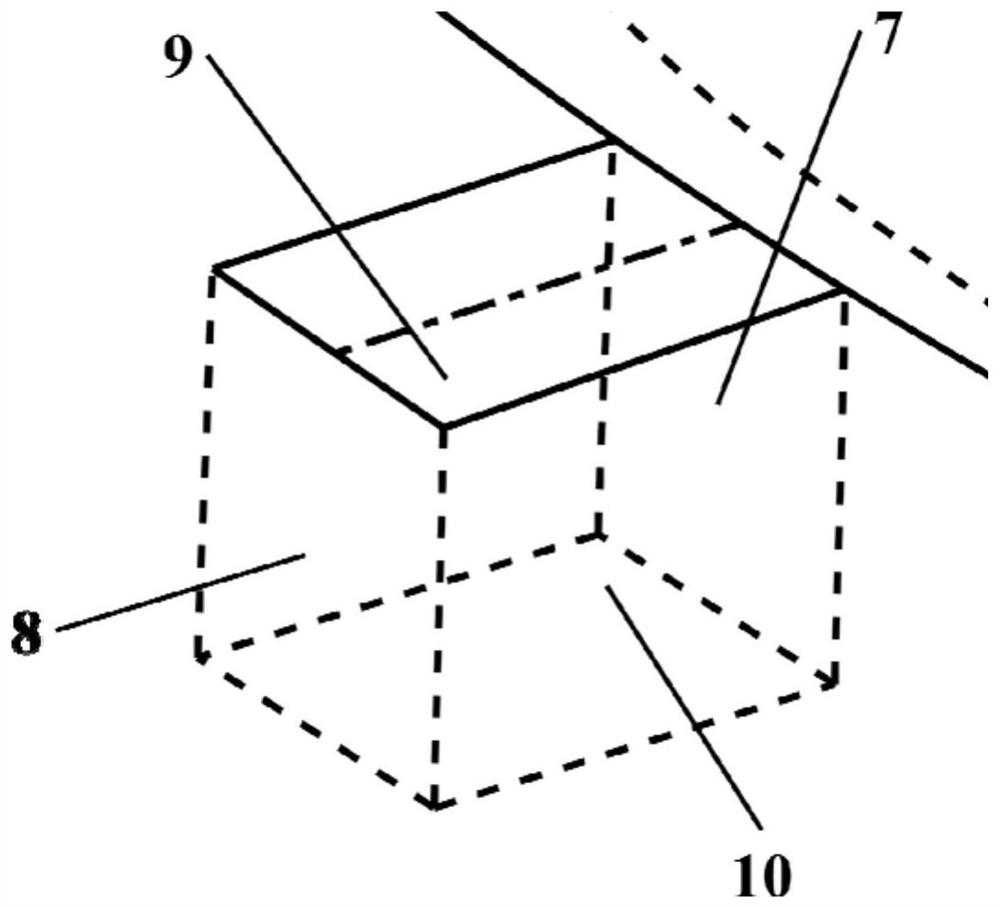

Fold-shaped pressure expander

The invention provides a fold-shaped pressure expander which comprises an upper cover plate, a lower cover plate and a folded structure. The fold-shaped structure is in an annular fold belt shape, the upper cover plate and the lower cover plate are of annular-plate-shaped structures, the folded structure is clamped between the upper cover plate and the lower cover plate, air flow channels are formed between the upper cover plate, the lower cover plate and the folded structure, the circulation cross sections of the air flow channels are gradually expanded in the increasing direction of radius, and the pressure of air flow is increased after air flow passes through the air flow channels. The fold-shaped pressure expander is large in air flow channel flow area and small in flowing blockage, efficiency of a compressor is improved, and the thrust-weight ratio is raised; the pressure expander is simple and compact in structure, low in weight, convenient to machine and mount and low in cost, and transformation and upgrading of the compressor are facilitated; the ends of wave crests and wave troughs for forming air flow channel air inlets are of specially-shaped structures, and the pressure expansion effect of the fold-shaped pressure expander is enhanced; rectifier channels are turned back to make air flow direction be converted to the direction of an air inlet of a next grade of an air pressing structure.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

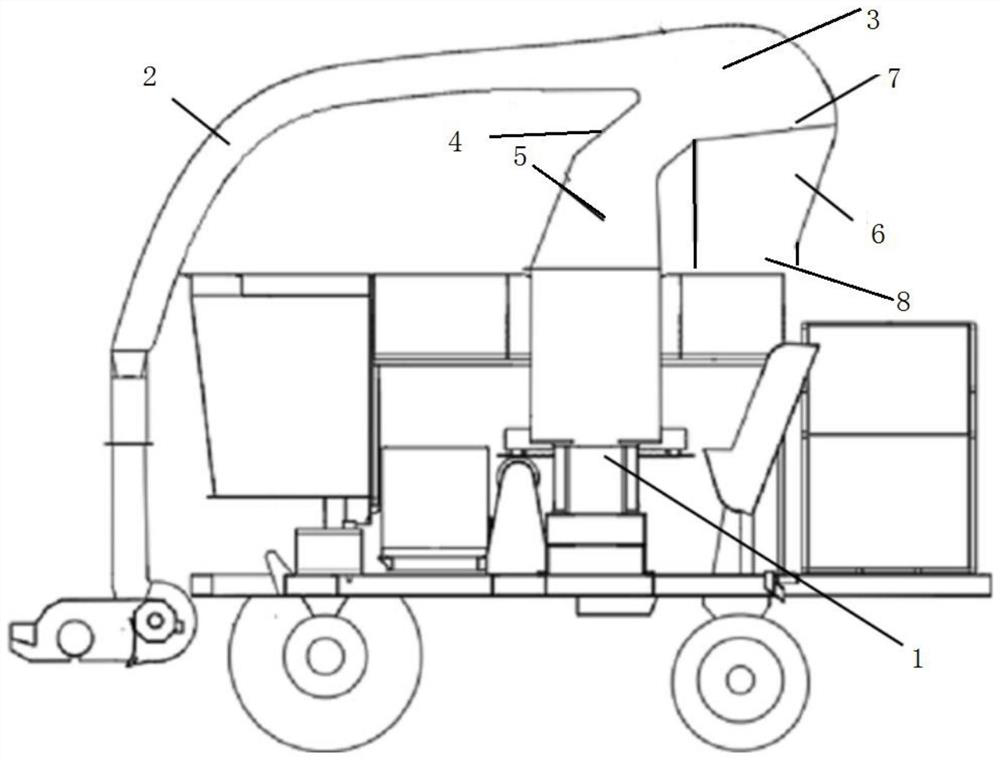

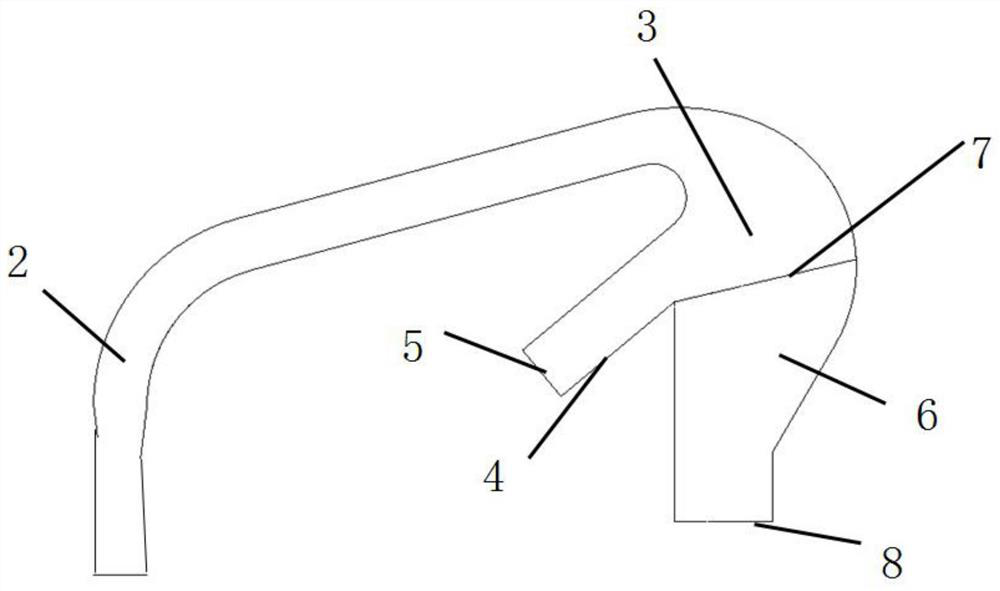

Dust removing device of protective self-propelled straw granulator

ActiveCN110976285AQuick releaseImprove the diffusion capacityGas current separationCuttersDust controlEnvironmental engineering

The invention discloses a dust removing device of a protective self-propelled straw granulator. The dust removing device comprises a straw channel, and the head end of the straw channel communicates with a cutting device of the protective self-propelled straw granulator. The tail end of the straw channel is inclined upwards and communicates with the inner wall of the top of a diffusion area. The bottom inner wall of the diffusion area communicates with one end of a gravity slope, and the other end of the gravity slope communicates with a straw granulator feeding port of the protective self-propelled straw granulator. The bottom of the diffusion area communicates with the top end of a deceleration area through a dust removing filtering screen, and the bottom end of the deceleration area communicates with a dust discharging channel. According to the dust removing device, based on the gravity sedimentation theory, the incoming speed of straw is reduced through the diffusion area, and thestraw passes through a gravity channel and slides into the feeding port through mass differences and the gravity action; and raising dust low in mass and small in particle passes through the dust removing filtering screen, enters the deceleration area, and is discharged to the ground.

Owner:SHENYANG AGRI UNIV +1

A pleated diffuser

The invention provides a fold-shaped pressure expander which comprises an upper cover plate, a lower cover plate and a folded structure. The fold-shaped structure is in an annular fold belt shape, the upper cover plate and the lower cover plate are of annular-plate-shaped structures, the folded structure is clamped between the upper cover plate and the lower cover plate, air flow channels are formed between the upper cover plate, the lower cover plate and the folded structure, the circulation cross sections of the air flow channels are gradually expanded in the increasing direction of radius, and the pressure of air flow is increased after air flow passes through the air flow channels. The fold-shaped pressure expander is large in air flow channel flow area and small in flowing blockage, efficiency of a compressor is improved, and the thrust-weight ratio is raised; the pressure expander is simple and compact in structure, low in weight, convenient to machine and mount and low in cost, and transformation and upgrading of the compressor are facilitated; the ends of wave crests and wave troughs for forming air flow channel air inlets are of specially-shaped structures, and the pressure expansion effect of the fold-shaped pressure expander is enhanced; rectifier channels are turned back to make air flow direction be converted to the direction of an air inlet of a next grade of an air pressing structure.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Compressor stator cascade with equal-width broken-line grooves at the blade root

ActiveCN105156356BLarge circulation capacityIncrease the effective jet flowPump componentsPumpsEngineeringMulti segment

The utility model relates to a stator vane cascade of a compressor with equal-width broken-line grooves on the blade root, and relates to passive flow control technology in the technical field of impeller machinery. Its purpose is to open equal-width broken-line grooves from the pressure surface to the suction surface at the root end wall of the stator cascade of the compressor, use the pressure difference of the blade itself to form a high-speed jet, increase the kinetic energy of the low-energy fluid in the corner area, and blow off the suction surface and end. The airflow of the surface layer attached to the wall makes the ability to resist the reverse pressure gradient stronger, and additionally brings the Coanda effect, which better inhibits the separation of the corner area. The channel is located at the root end wall of the stator blade cascade of the compressor, and the spanwise height is a constant value. There can be one or more channels. The inlet of the channel is located on the pressure surface of the cascade, and the outlet is located on the suction surface of the cascade. The center line is a multi-segment broken line and the two side walls of the channel are equidistant from the center line, and the airflow direction at the outlet of the channel is basically consistent with the direction of the ideal non-separation flow line. The invention has the beneficial effects of effectively suppressing the separation of corner areas, increasing the flow capacity of the cascade, reducing the total pressure loss, and increasing the diffusion capacity.

Owner:BEIHANG UNIV

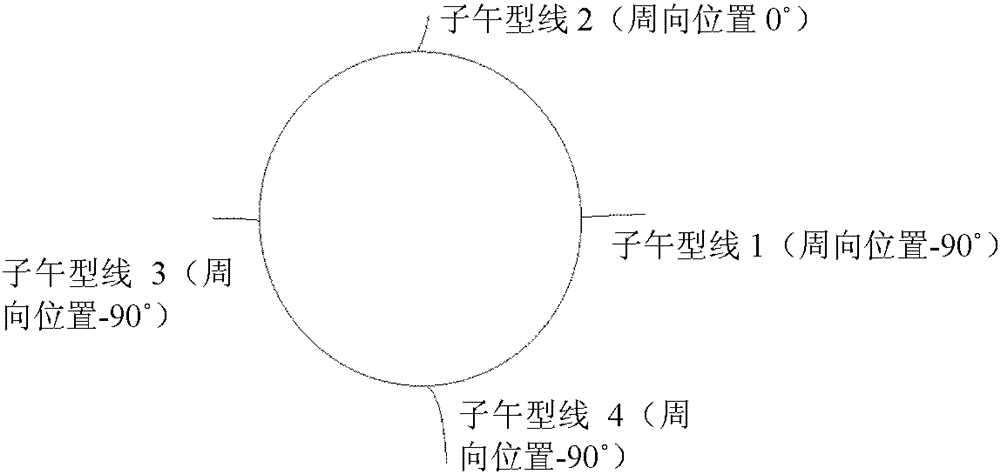

A diffuser end wall of a steam turbine exhaust system on one side

ActiveCN103244209BReduce back pressureHigh thermal efficiencyMachines/enginesEngine componentsTurbine bladeUnit operation

The invention provides a diffuser end wall of a turbine single-side exhaust system and relates to the technology of turbines. The end wall face adopts full three-dimensional modeling, different meridian lines at different circumferential directions are utilized to generate a non-axis-symmetrical full three-dimensional diffuser end wall curve. The diffuser end wall structure has the advantage that the end wall adapts to actual flow field distribution of a last stage turbine outlet, ensures that the exhaust system has good diffusion capability under the actual operation environment of a unit, turbine outlet back pressure is reduced, turbine power output is increased, unit heat efficiency is improved, and the end wall adapts to an exhaust volute conducting single-side radial exhausting, reduces circumferential flowing uneven degree in the single-side radial exhaust system, reduces last stage turbine blade load and fluctuation of air power in one circle and improves unit operation safety. The diffuser end wall structure mode is suitable for diffusers in all turbine exhaust systems conducting single-side radial exhausting.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

A secondary throat diffuser injecting low total pressure cold medium

ActiveCN109186927BImprove the diffusion capacityReduce heat loadAerodynamic testingThermodynamicsCooling effect

The invention discloses an ejection low total pressure cold medium adjustable secondary throat diffuser. The ejection low total pressure cold medium adjustable secondary throat diffuser is used at thedownstream of a large hypersonic velocity wind tunnel experimental section, can adapt to operating condition of a wider range by adjusting the amount of ejection air, meanwhile, diffusion capacity isimproved, the working load of a back section ejector is reduced. In addition, a cold medium ejected flows at a near wall region, and the wall surface of the diffuser can be effectively protected frombeing in contact with high temperature fuel gas directly, and the construction cost brought by a cooling water sleeve can be reduced. The novel structure of the diffuser is characterized in that a side wall groove is added in the front of a diffuser convergence section, low total pressure normal temperature air is introduced at the position of the front edge of the groove and used as the cold medium, an air film is formed in the wall surface of the diffuser through the ejection and diffusion effect, the practical flow diameter of a secondary throat is adjusted, the static pressure recovery capability of secondary throat is adjusted at a greater degree, meanwhile, heat load of the wall surface of the secondary throat is reduced again, and the wall surface is cooled; and simulation verification is carried out, even though the ejection cooling medium is an atmospheric condition, the good diffusion and cooling effect can be achieved.

Owner:UNIV OF SCI & TECH OF CHINA

Diffuser suitable for vane pump

InactiveCN110159594AImprove flow field distributionImprove performancePump componentsPumpsTest measurementEngineering

The invention discloses a diffuser suitable for a vane pump. The diffuser is composed of a front cover plate, a rear cover plate and guide vanes which are symmetrically arranged between the front cover plate and the rear cover plate; the front cover plate and the rear cover plate are each of a plane annular structure; isolation plates which are parallel to the planes of the front cover plate and the rear cover plate, crossed with the guide vanes and each of an annular structure are arranged between the front cover plate and the rear cover plate; and the radial length of the isolation plates ofthe annular structure is smaller than the radial length of the front cover plate or the rear cover plate. The inner diameter of the isolating plates is equal to the diameter of inlets of the guide vanes, and the outer diameter of the isolation plates is smaller than the diameter of outlets of the guide vanes. The diffuser structure can effectively improve the flow field distribution of the guidevanes or volutes of the diffuser of the vane pump, increase the flow stability, reduce the energy loss of fluid and improve the overall performance of the vane pump. After test measurement, it is found that the diffuser provided by the invention can improve the diffusion performance by 0.5%-2%, and the energy-saving effect is obvious.

Owner:XIHUA UNIV +1

Compressor stator with slotted blade root slots with taper-to-span height

ActiveCN105298925BIncrease kinetic energyLarge circulation capacityPump componentsPumpsImpellerJet flow

Owner:BEIHANG UNIV

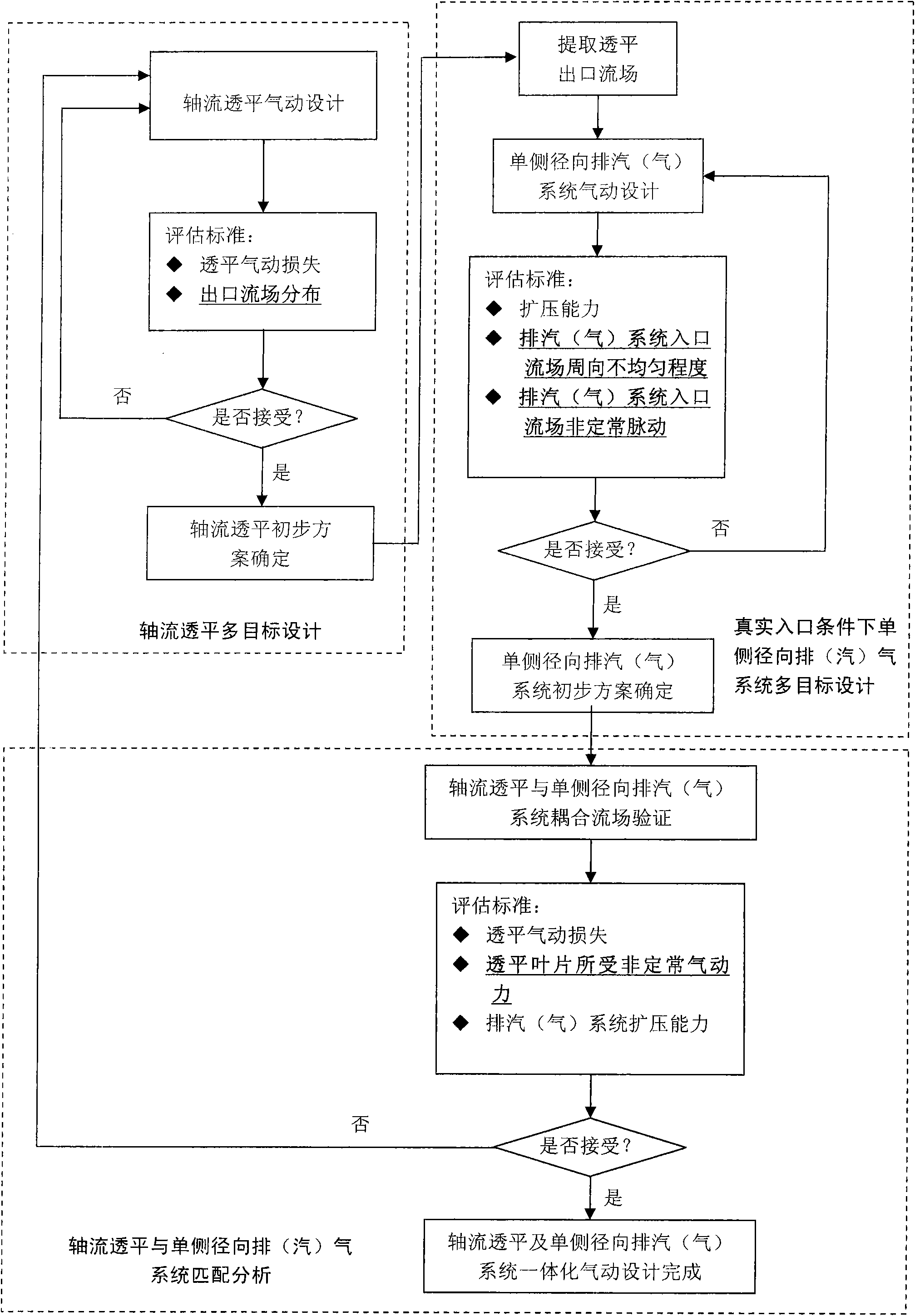

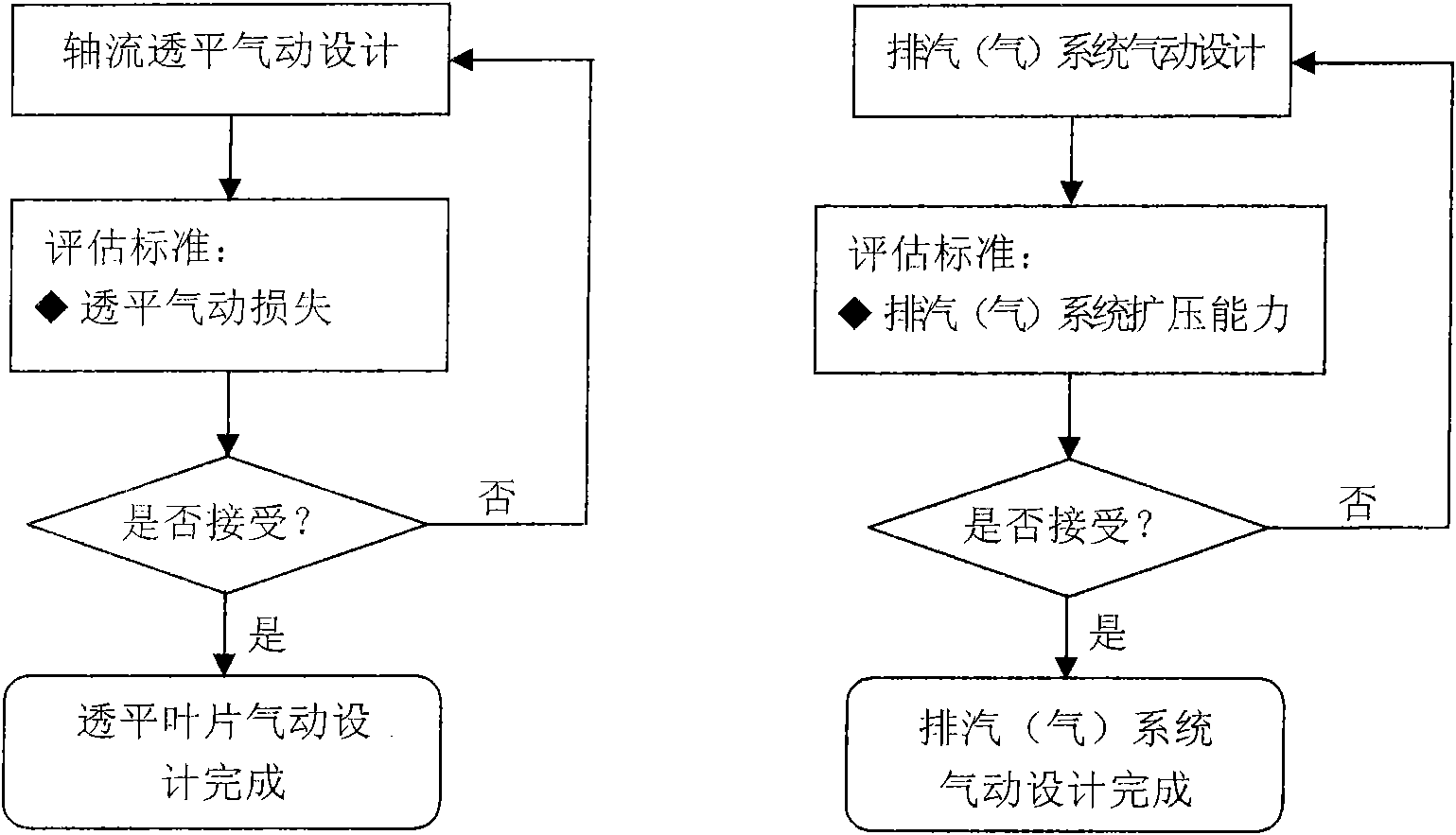

Integrated pneumatic design method of axial-flow turbine and single-side radial steam/gas discharging system

ActiveCN102373971BIncrease workImprove the diffusion capacityMachines/enginesEngine componentsTurbine bladeEngineering

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

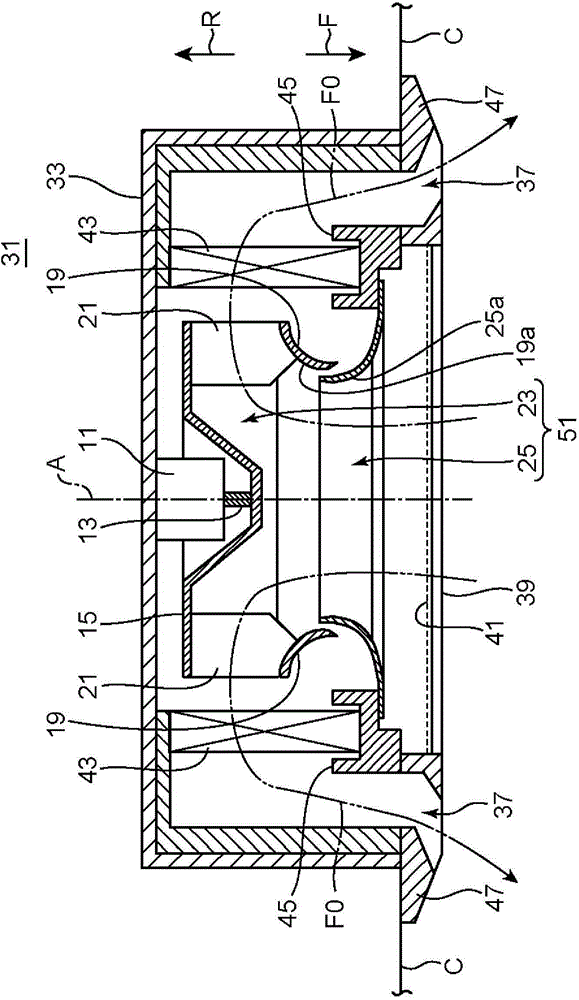

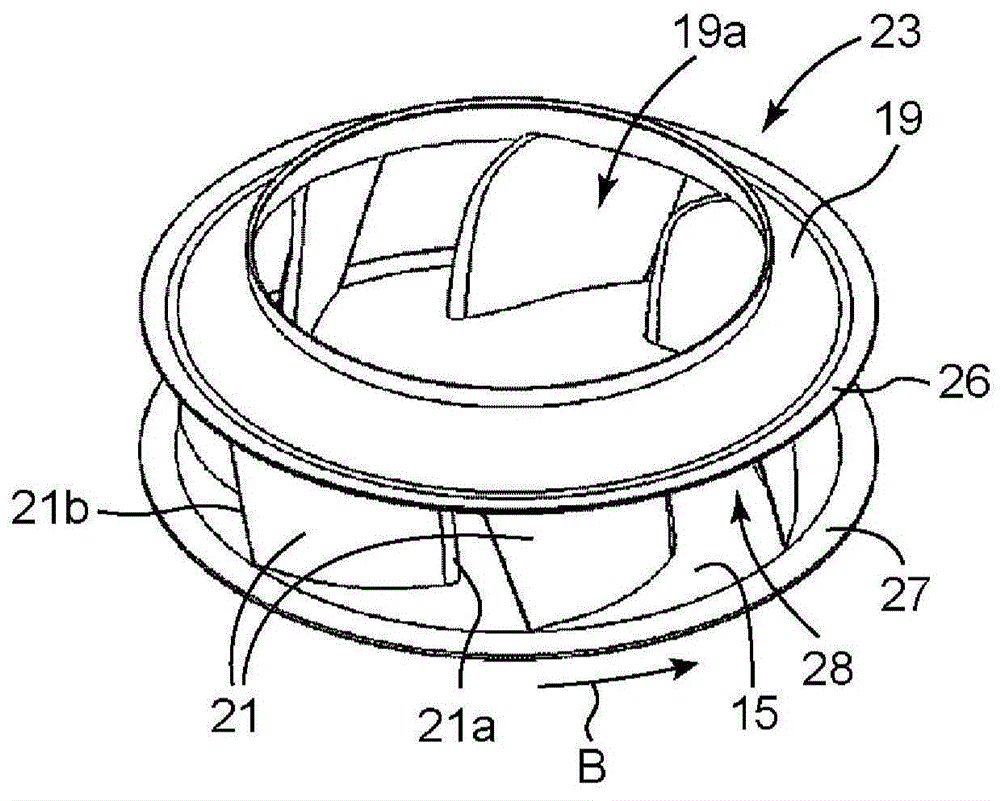

Centrifugal fan

InactiveCN104903590AImprove the diffusion capacityPump componentsRadial flow pumpsEngineeringCentrifugal fan

A centrifugal fan (23) is provided with a hub (15), blades (21), and a shroud (19). Each of the blades (21) has a curved section (21d) which is curved so as to be tilted to the side (21c1) on which an air current impinges when the connection end section (21c) where the blade (21) and the portion of the shroud (19) which protrudes inward are joined moves in the rotational direction of the centrifugal fan (23). The hub (15) has a hub-side diffuser ring (27) protruding to the outer peripheral side of the blades (21). The shroud (19) has a shroud-side diffuser ring (26) which protrudes to the outer peripheral side of the blades (21).

Owner:DAIKIN IND LTD

Design Method of Centrifugal Compressor and Structure of Diffuser

ActiveCN110608195BImprove flow statusReduce flow lossGeometric CADPump componentsEngineeringCentrifugal compressor

The invention discloses a design method of a centrifugal compressor and a diffuser structure. The centrifugal compressor comprises a shell, an impeller and a diffuser, wherein the impeller comprises ahub and impeller blades, the diffuser comprises diffuser blades; and the design method comprises the following steps that curve segments of the shell and the hub of the impeller adopt Bezier curve design, and curve segments of the impeller blades adopt 3D free curve design; and curve segments of the diffuser blades adopt spiral curve design. Through the parametric design method, a gas inlet angleat a gas inlet hole and a gas outlet angle at a gas outlet hole are optimized, a gas flow state is improved, the uniformity of an outlet gas flow is improved, the gas flow loss is reduced, and high gas compressing capability and diffusion capability are obtained under the condition of small size.

Owner:CHANGCHUN UNIV OF SCI & TECH

A protective self-propelled straw granulator dust removal device

ActiveCN110976285BQuick releaseImprove the diffusion capacityGas current separationCuttersDust controlEnvironmental engineering

The invention discloses a dust removal device for protecting a self-propelled straw granulator, which includes a straw passage, the head end of the straw passage communicates with a cutting device of the self-propelled straw granulator, and the tail of the straw passage The end is inclined upwards and communicates with the top inner wall of the expansion area, the bottom inner wall of the expansion area is communicated with one end of the gravity slope, and the other end of the gravity slope is connected with the straw granulator of the self-propelled straw granulator. The feed port of the machine is connected; the bottom of the diffusion zone is connected with the top of the deceleration zone through the dust filter, and the bottom of the deceleration zone is connected with the dust discharge channel. The present invention is based on the principle of gravity settlement, through the diffusion zone, the incoming material speed of bellflower is reduced, and the quality difference is used to make bellflower slide through the gravity channel and flow into the feeding port by gravity; Dust passes through the dust filter, enters the deceleration zone, and is discharged to the ground.

Owner:SHENYANG AGRI UNIV +1

Diffusers for centrifugal compressors

ActiveCN105650032BImprove the diffusion capacityImprove operational efficiencyEngine manufacturePump componentsLeading edgeSurface layer

The invention discloses a diffuser of a centrifugal compressor. Improving the structure of the diffuser and further improving its working performance have important application value. In the present invention, a short blade is arranged in the flow channel of two adjacent long blades; the leading edge of the long blade is a curved surface and is inclined, and the angle between the leading edge line and the central axis of the wheel disc is 6-8°; the curvature of the leading edge of the long blade is The radius gradually increases along the direction from the wheel disc to the wheel cover; the long blade is provided with three broken-line grooves passing through the pressure surface and the suction surface; the trailing edge of the long blade is located on the pressure surface with a trailing edge tip. In the present invention, the short blades located in the flow channels of adjacent long blades suppress the occurrence of airflow separation on the blade surface; the zigzag channel reduces the pressure difference between the pressure surface and the suction surface, reduces the reverse pressure gradient, and effectively blows off the suction surface of some blade tails. The surface layer separates the airflow; the parabolic winglet at the trailing edge can inhibit the growth of the wingtip vortex generated by the pressure difference between the suction surface and the pressure surface of the trailing edge of the traditional airfoil blade.

Owner:嘉兴芸诗娇电子商务有限公司

Compressor stator cascade with constant depth grooves in end wall

ActiveCN112228403BReduce the total pressure loss coefficientImprove the diffusion capacityPump componentsPumpsSuction forceEngineering

Owner:CIVIL AVIATION UNIV OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com