Subsonic velocity vortex blowing type compressor blade

A compressor and subsonic technology, applied in the field of compressors, can solve the problems of limited application conditions, lack of application value, no practical application of turbines, etc., and achieve the effect of increasing blade load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

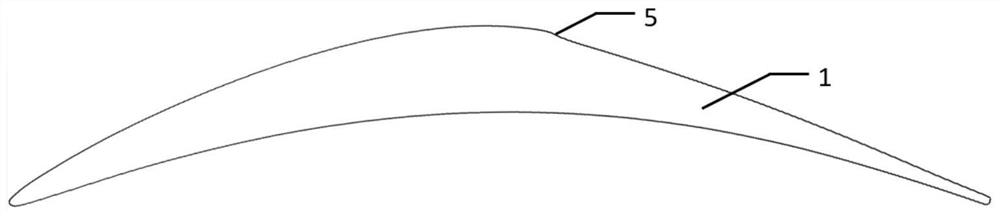

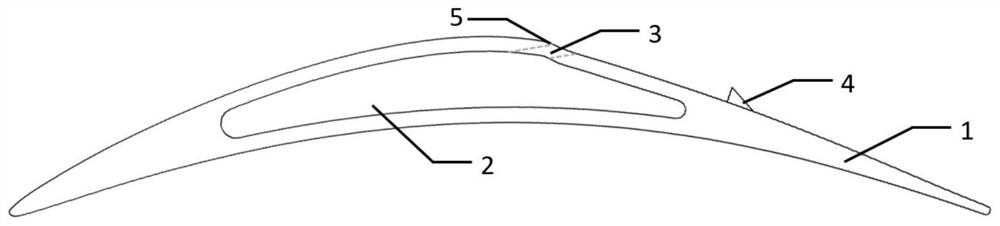

[0044] This embodiment is a subsonic vortex blowing compressor blade. The upper surface of the air blowing compressor blade is the suction surface, and the lower surface is the pressure surface. Between the suction surface and the pressure surface of the blade, there is an air blowing cavity 2 penetrating along the span direction of the blade. A row of air blowing holes 3 is arranged along the spanwise direction on the suction surface, and each air blowing hole communicates with the air blowing cavity. A row of vortex generators 4 is arranged along the spanwise direction on the trailing edge of the suction surface of the blade, and each vortex generator corresponds to each blowing hole one by one. During installation, the leading edges of the vortex generators are aligned with the leading edges of the blades.

[0045] The centers of the orifices of the air blowing holes are located at 58.7% of the chord length of the blade on the suction surface; the distance between the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com