Guide ring structure of low-pressure exhaust cylinder of steam turbine

A deflector ring and exhaust cylinder technology, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problem of not considering the aerodynamic performance of the deflector ring contour line, and the inability to use mainstream steam to effectively and reliably guide etc. problems, to ensure aerodynamic performance, reduce total pressure loss, and enhance reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

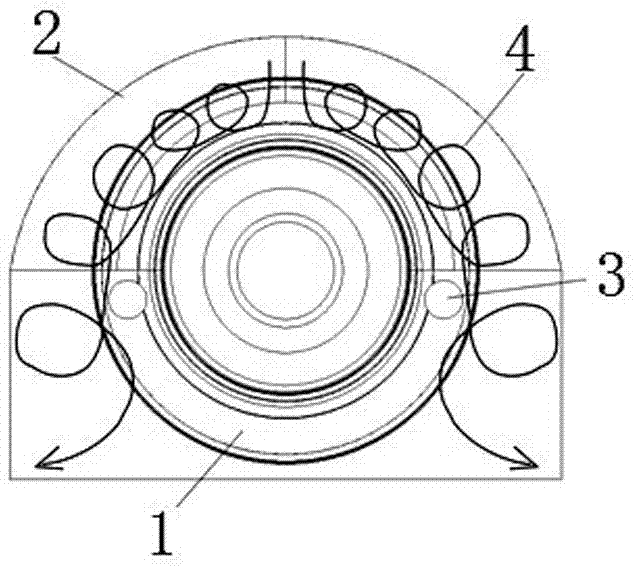

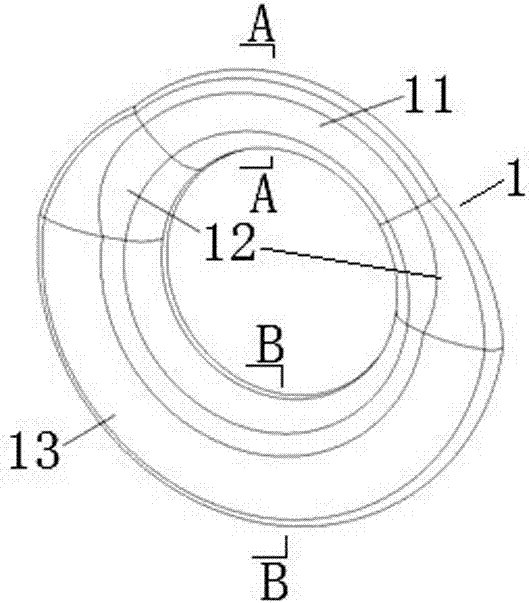

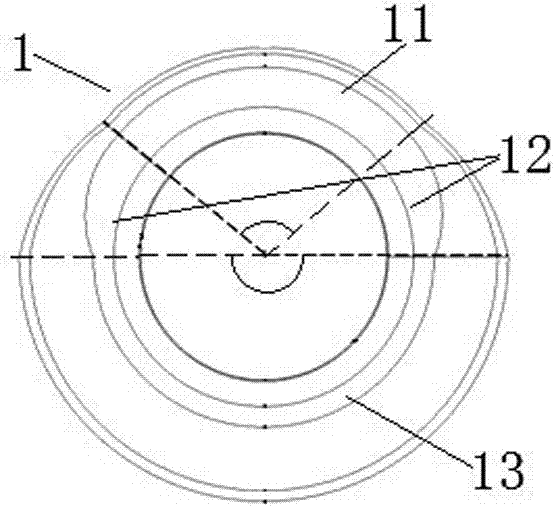

[0029] see Figure 2 to Figure 5 As shown, the present invention includes a guide ring body 1 with a trumpet-shaped structure, and the guide ring body 1 is applied to a steam turbine low-pressure exhaust cylinder with a downward exhaust steam structure.

[0030]The diversion ring body 1 is divided into a top arc section 11 and a bottom arc section 13 in the circumferential direction according to the movement sequence of the vortex formed by the exhaust steam during service, and there is a side part between the top arc section 11 and the bottom arc section 13 The arc section 12 , that is, the side arc section 12 is divided into two sections, which are located at the joints of the top arc section 11 and the bottom arc section 13 . Wherein, the included angle of the center of the top arc 11 is about 90°, the included angle of the center of the bottom arc 13 is about 180°, and the included angle of the center of each side arc 12 is about 45°.

[0031] The guide ring body 1 is com...

Embodiment 2

[0035] see Figure 7 As shown, the present invention includes a guide ring body 1 with a trumpet-shaped structure, and the guide ring body 1 is applied to a steam turbine low-pressure exhaust cylinder with a downward exhaust steam structure.

[0036] The guide ring body 1 is divided into a top arc segment 11 and a bottom arc segment 13 in the circumferential direction according to the movement sequence of the vortex formed by the exhaust steam during service. Wherein, the included angle of the center of the top arc 11 is about 120°, and the included angle of the center of the bottom arc 13 is about 240°, that is, the top arc 11 and the bottom arc 13 form a complete 360° circle in the circumferential direction.

[0037] The diversion ring body 1 is composed of several circumferential sections sequentially superimposed according to the designed circumferential track in its circumferential direction, that is to say, the top arc section 11 and the bottom arc section 13 of the dive...

Embodiment 3

[0040] The invention includes a diversion ring body with a trumpet-shaped structure, and the diversion ring body is applied to a steam turbine low-pressure exhaust cylinder with a downward exhaust steam structure.

[0041] According to the movement sequence of the vortex formed by the exhaust steam during the service process, the diversion ring body is divided into a top arc segment and a bottom arc segment in the circumferential direction. Wherein, the included angle of the center of the top arc is about 100°, and the included angle of the center of the bottom arc is about 260°, that is, the top arc and the bottom arc form a complete 360° circle in the circumferential direction.

[0042] The diversion ring body is composed of several circumferential sections sequentially stacked according to the designed circumferential trajectory in its circumferential direction, that is to say, the top arc section and the bottom arc section of the diversion ring body respectively have circum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center angle | aaaaa | aaaaa |

| Center angle | aaaaa | aaaaa |

| Center angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com