Diffusion and rectification integrated diffuser

A diffuser and diffuser section technology, which is applied to parts of pumping devices for elastic fluids, machines/engines, liquid fuel engines, etc., can solve problems such as complex manufacturing process, increased assembly difficulty, and large overall size , to achieve the effect of reducing processing difficulty and cost, reducing pressure loss, and reducing overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

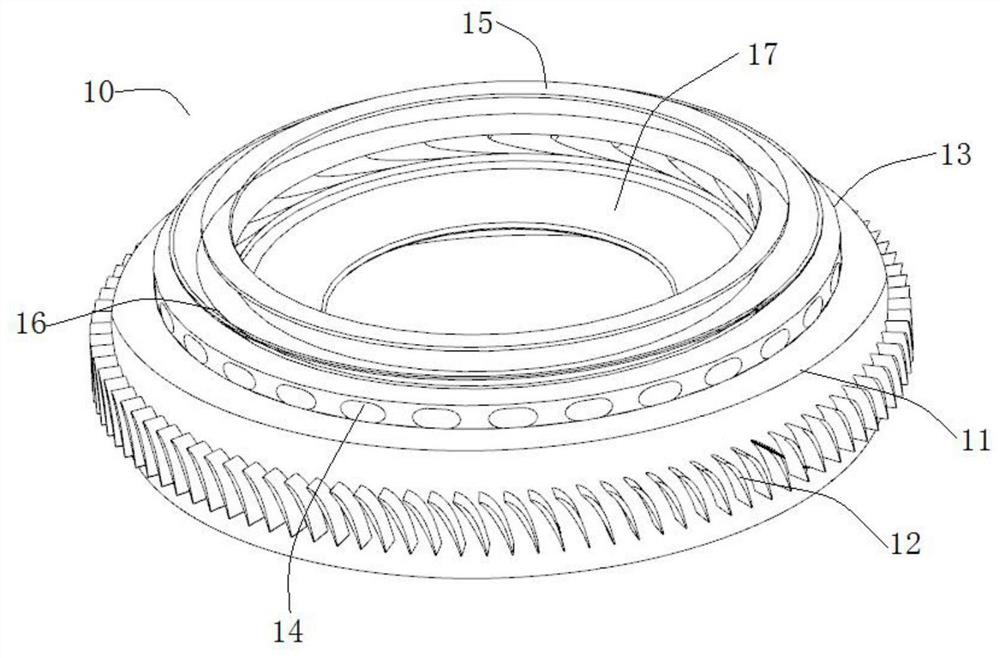

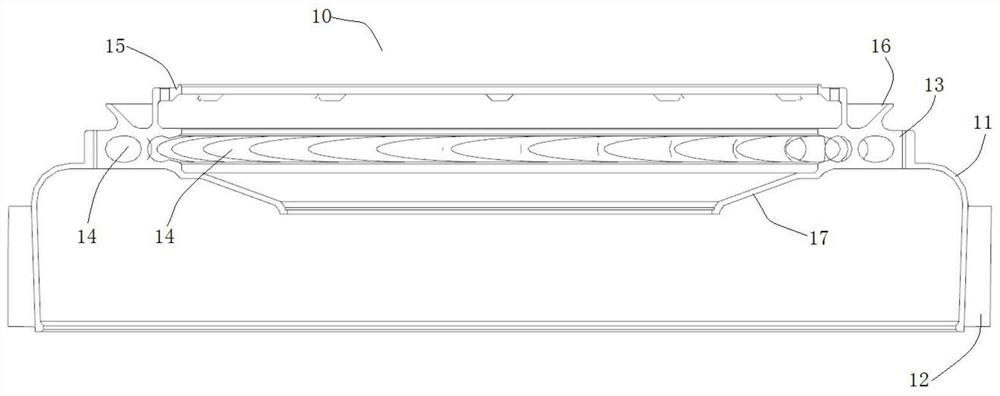

[0033] see figure 1 with figure 2 As shown, the present embodiment provides a diffuser and rectification integrated diffuser, the diffuser 10 is mounted on an aero-engine, including an integrally formed centrifugal compressor disc 11 and coaxially arranged on the centrifugal The radial tubular diffuser section 13 at the top of the compressor wheel 11, wherein: the centrifugal compressor wheel 11 is evenly distributed with a number of rectifying blades 12 in the circumferential direction, and an air flow rectifying channel is formed between two adjacent rectifying blades 12; Along the circumferential direction of the radial tubular diffuser section 13, a number of scattered through holes 14 are opened from the inside to the outside, and the radial angle between the through holes 14 and the radial tubular diffuser section 13 is 20° -30°. The integrated diffuser 10 can effectively reduce the pressure loss caused by the diffusion, improve the working efficiency of the combustio...

Embodiment 2

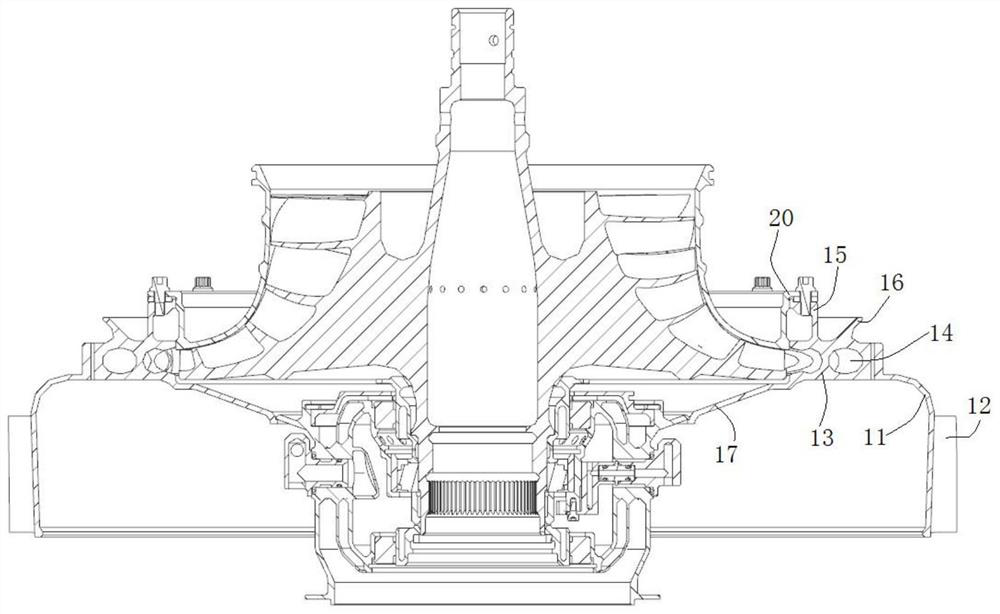

[0038] read on figure 1 with image 3As shown, the difference from the above-mentioned embodiment 1 is that, on the diffuser and rectification integrated diffuser, the top of the radial tubular diffuser section 13 is provided with a connecting flange 15, and the connecting flange 15 The end face is provided with a number of mounting holes, and is connected to the outer casing 20 of the compressor by bolts. Specifically, mounting holes are provided on the connecting flange 15, and bolts and gaskets are used to pass through the outer casing 20 of the compressor to interfere with the corresponding mounting holes, so that the integrated diffuser 10 is fixed on the On the outer casing 20 of the compressor.

[0039] read on image 3 with Figure 4 As shown, a middle connecting plate 16 is arranged on the top of the radial tubular diffuser section 13, and the middle connecting plate 16 is arranged on the outside of the connecting flange 15 in an annular cone structure, and is wel...

Embodiment 3

[0042] Different from the above embodiment 1 and / or embodiment 2, please continue to refer to figure 1 As shown, a number of rectifying blades 12 are evenly distributed on the circumferential edge of the centrifugal compressor disc 11, and an air flow rectifying passage is formed between two adjacent rectifying blades 12, and the shape design of the rectifying blades 12 limits the flow of air flow direction, thereby shortening the overall structural size of the diffuser channel and further improving the working efficiency of the diffuser.

[0043] In this example, see figure 1 with figure 2 As shown, the rectifying blades 12 are deflected counterclockwise by 2-10° along the axial direction of the centrifugal compressor disc 11; The counterclockwise deflection is 3-8°; more preferably, the rectifying blade 12 is deflected 5° counterclockwise along the axial direction of the centrifugal compressor disc 11 . The rectifying vanes 12 are formed by integrated manufacturing and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com