A pleated diffuser

A diffuser and pleat technology, applied in the field of pleated diffusers, can solve the problems of difficult machining accuracy, high cost, and difficult processing of tubular diffusers, and achieve low manufacturing cost, light weight, and improved thrust-to-weight ratio The effect of the power-to-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

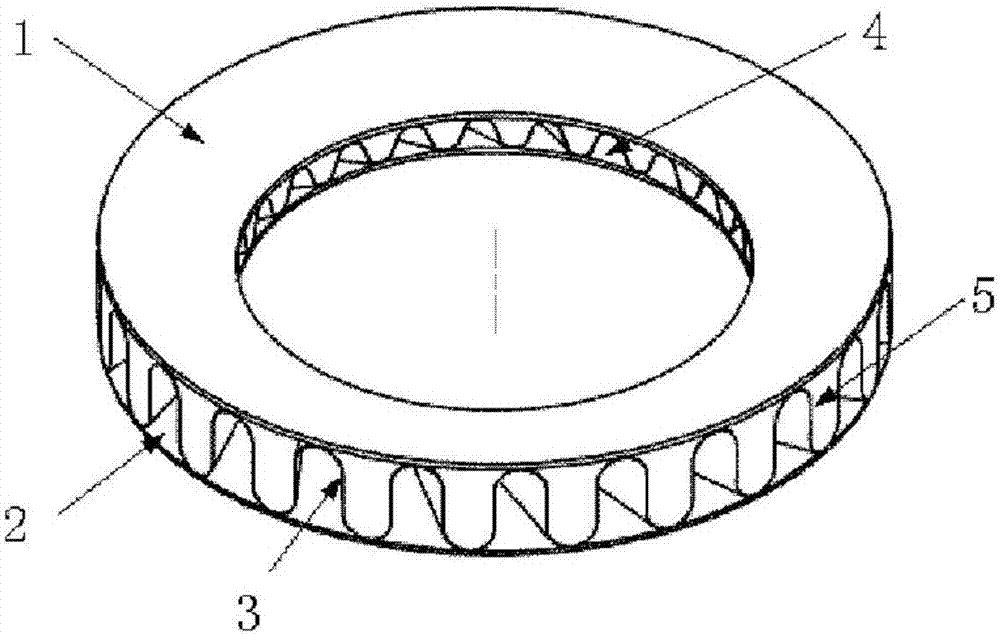

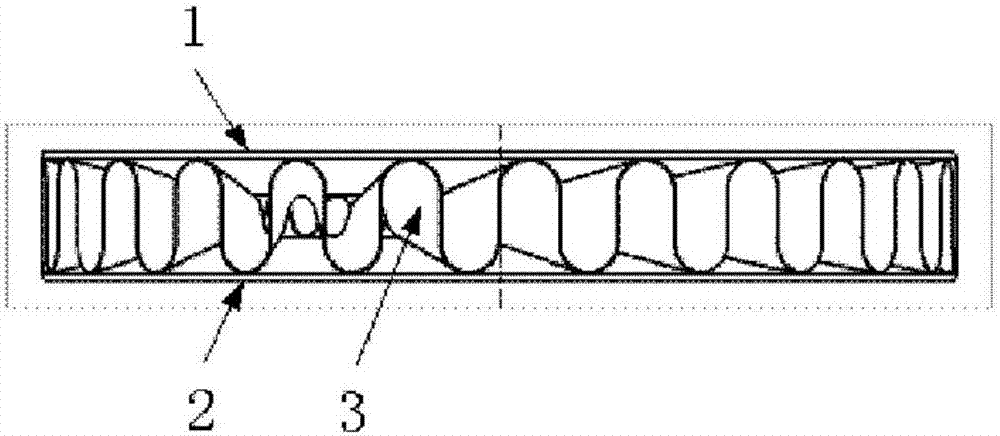

[0034] Such as Figure 1-6 As shown, the pleated diffuser of the embodiment of the present invention includes an upper cover plate 1, a lower cover plate 2 and a pleated structure 3, the pleated structure 3 is in the shape of an annular pleated belt, and the upper cover plate 1 and the lower cover plate 2 are annular Plate-shaped structure, the pleated structure 3 is sandwiched between the upper cover plate and the lower cover plate, and an air flow channel 8 is formed between the upper cover plate, the lower cover plate and the pleated structure, and the flow section of the air flow channel gradually expands along the direction of increasing radius , the pressure increases after the gas flow passes through the gas passag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com