Volute structure, centrifugal compressor and refrigeration equipment

A centrifugal compressor and volute technology, applied in mechanical equipment, non-variable-capacity pumps, non-displacement pumps, etc., can solve the problem of reducing the performance of centrifugal compressor units, the inability of gas to be sufficiently diffused, and the operation of the unit. Stability reduction and other problems, to achieve the effect of improving the diffusion effect, improving the operating stability and compressor performance, and increasing the critical speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

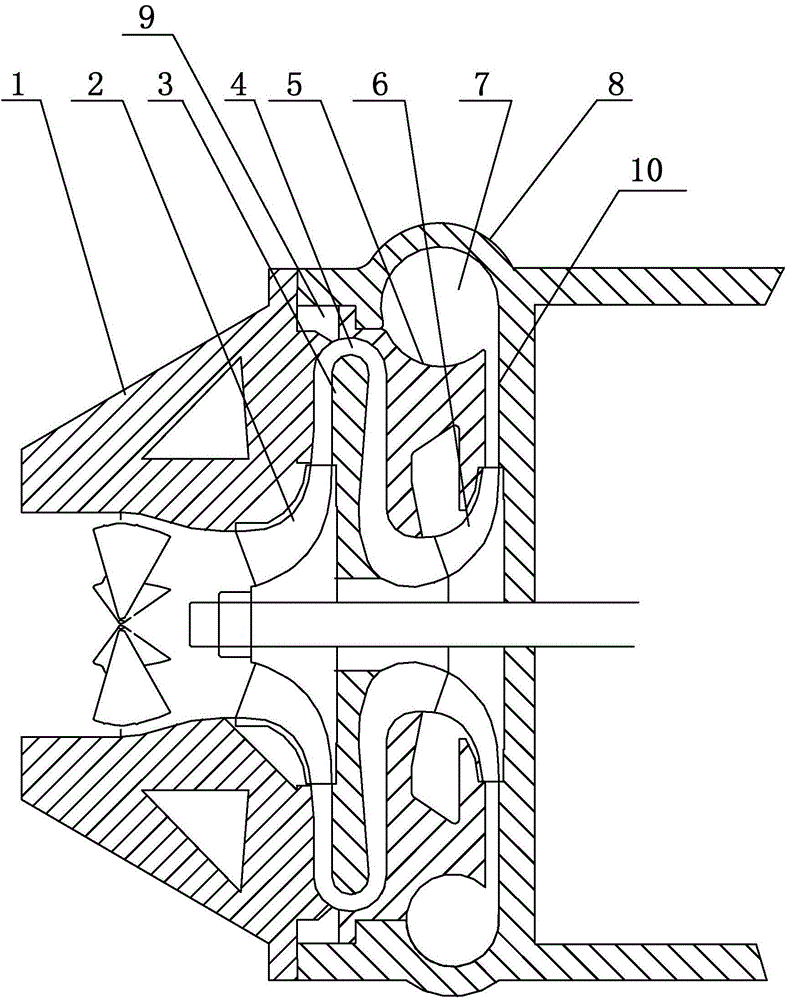

[0030] Combine below figure 2 A more detailed elaboration of the technical solution provided by the present invention, a technical solution obtained by replacing any technical means provided by the present invention or combining any two or more technical means or technical features provided by the present invention with each other All should be within the protection scope of the present invention.

[0031] In this paper, the front and rear refer to the direction of the airflow entering the volute structure, and the one located upstream of the airflow is the front, that is, figure 2 Left side shown; downstream of airflow is rear, i.e. figure 2 shown on the right.

[0032] Embodiments of the present invention provide a volute structure, which is preferably used in centrifugal compressors and similar products, and can be set as a forward-inclined volute structure (i.e. figure 2 In the arrangement shown, the inner arc-shaped cavity of the volute casing 7 is facing the upstr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com