Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Improve smoking safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

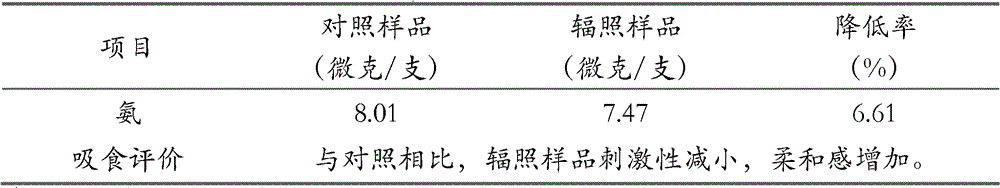

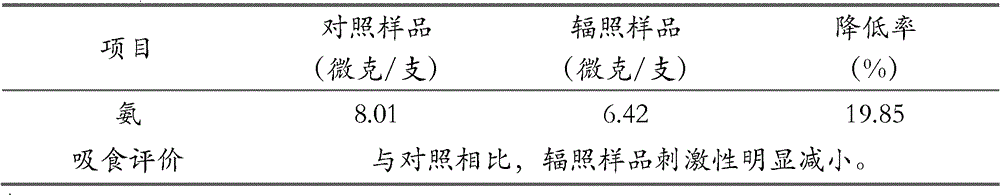

Method for reducing ammonia in mainstream smoke of cigarettes

InactiveCN102599647AImprove smoking safetyImprove irradiation efficiencyTobacco treatmentOperating temperatureX ray irradiation

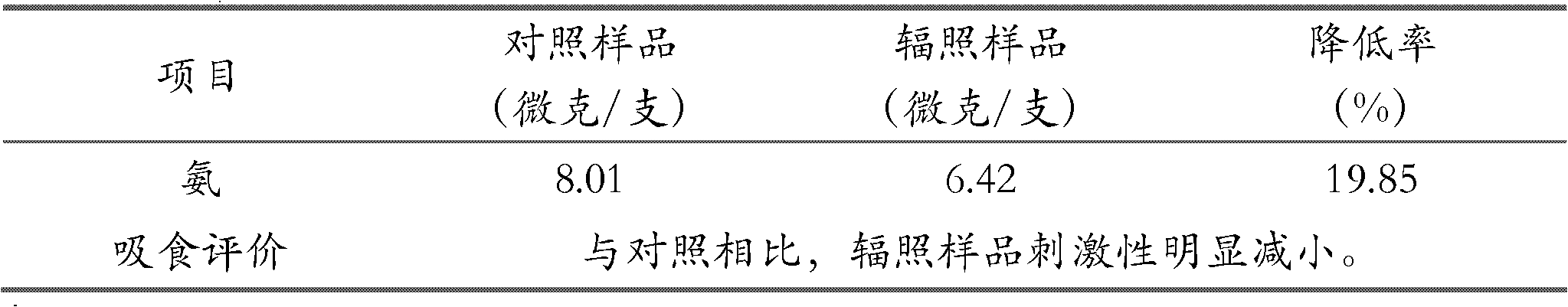

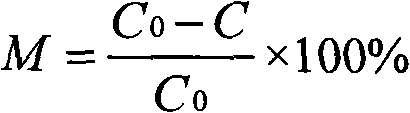

The invention discloses a method for reducing ammonia in mainstream smoke of cigarettes, which includes: packing tobacco / finished cigarettes with paper cartons with a stacking thickness of 26-72cm and a stacking density of 0.20-0.34g / cm<3>; placing the cigarette cartons on a conveying device at the conveying speed of 0.02-0.3m / s, and subjecting the cartons to electronic beam / X-ray irradiation generated by an electronic accelerator, wherein the electronic accelerator is 5-10MeV in energy, 0.3-20mA in beam current, 10-20kW in beam power, 100cm in largest scanning width, 5-15Hz in scanning frequency, 1-10kGy in irradiation dose and 5-35 DEG C in set operating temperature; allowing the cartons to pass a scanning widow of the electronic accelerator twice for irradiation, wherein the distance from the center of each carton to the scanning window of the electronic accelerator is 40-60cm in irradiation; and limiting the ambient humidity to be no larger than 60% in operation.

Owner:河南省科学院同位素研究所有限责任公司 +1

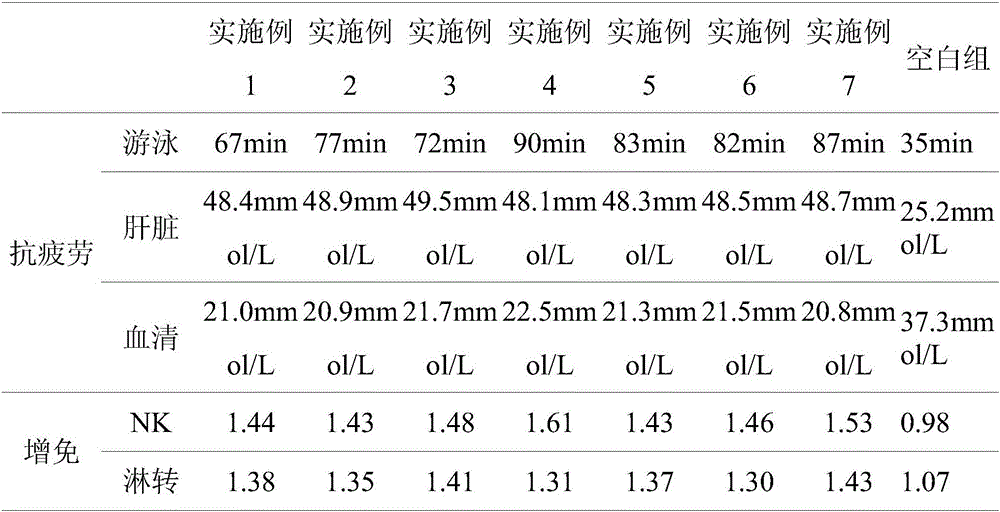

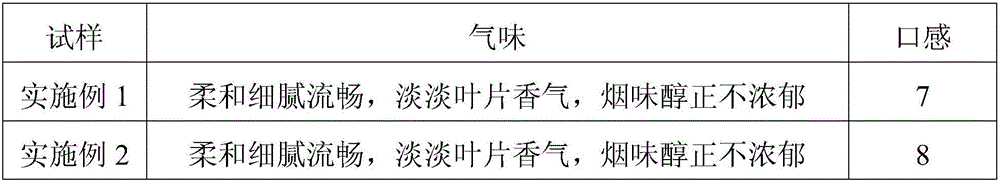

Clove-leaf non-tobacco cigarette and preparation method thereof

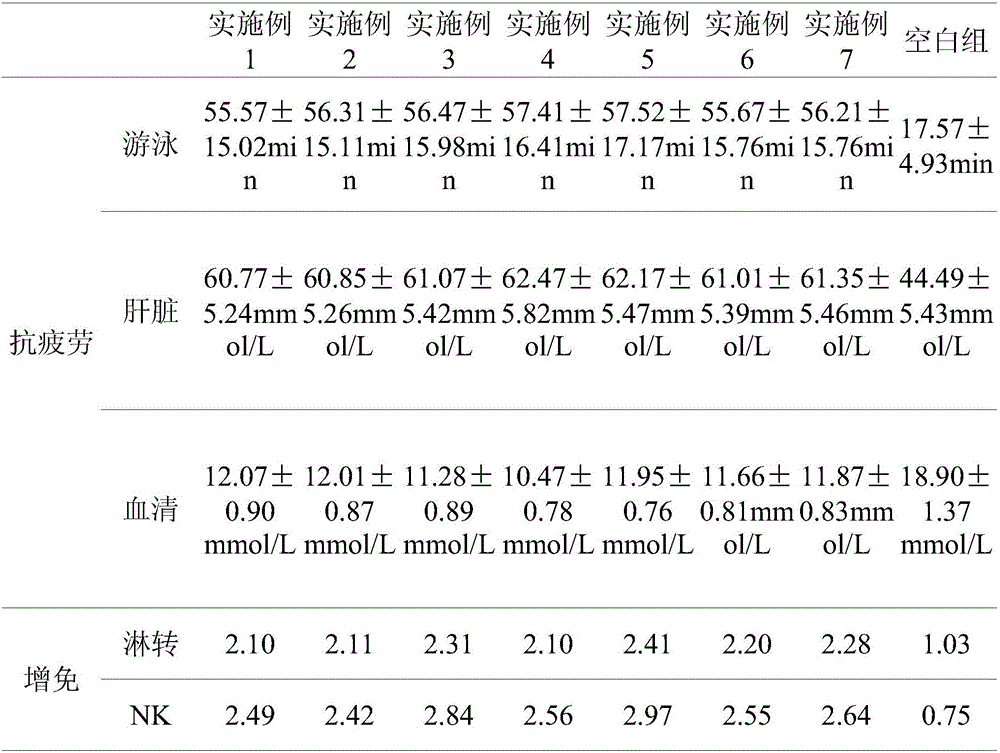

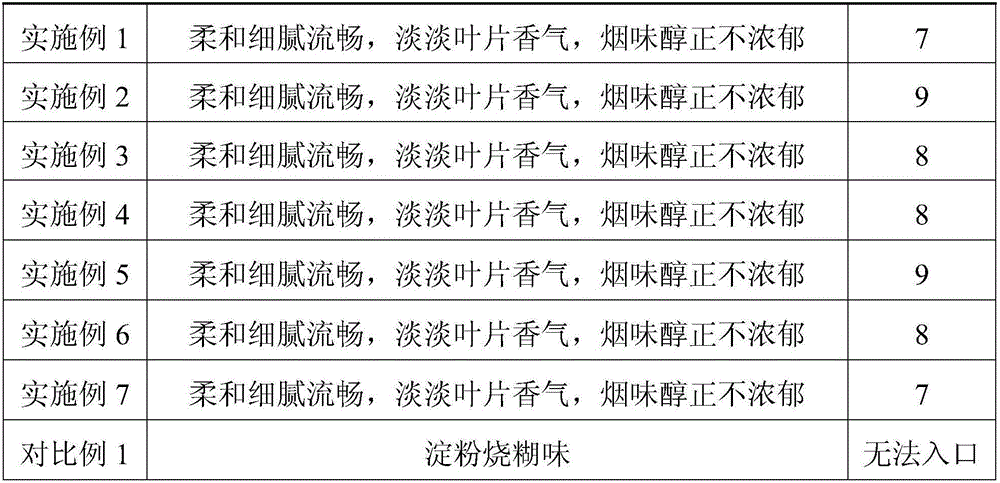

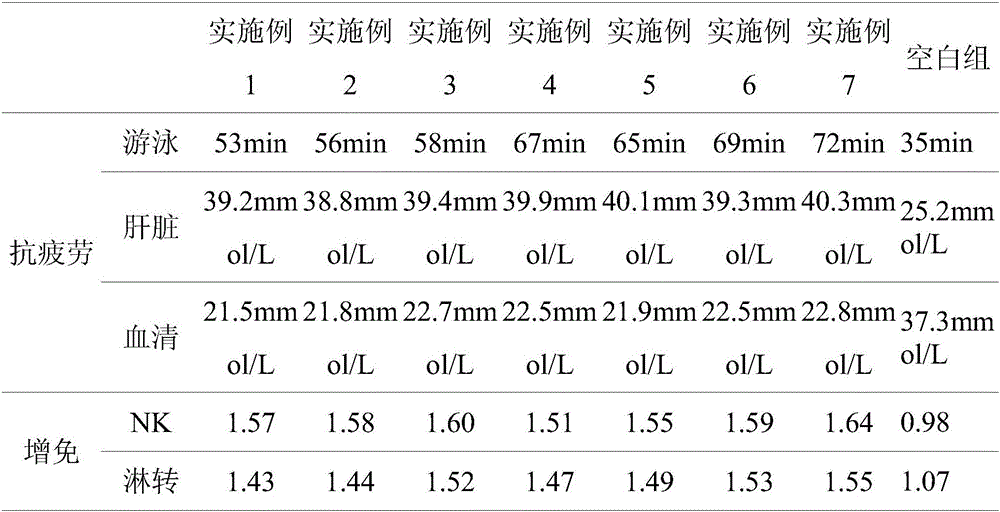

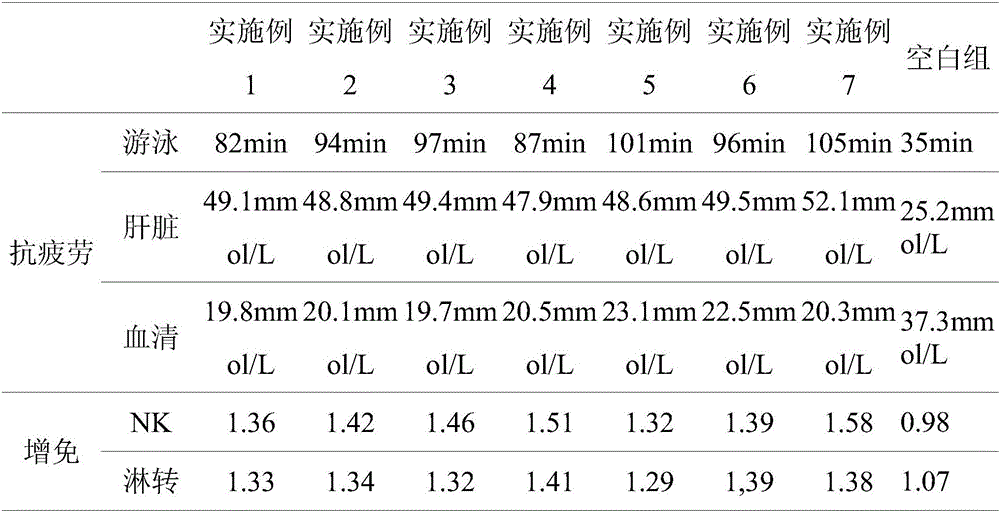

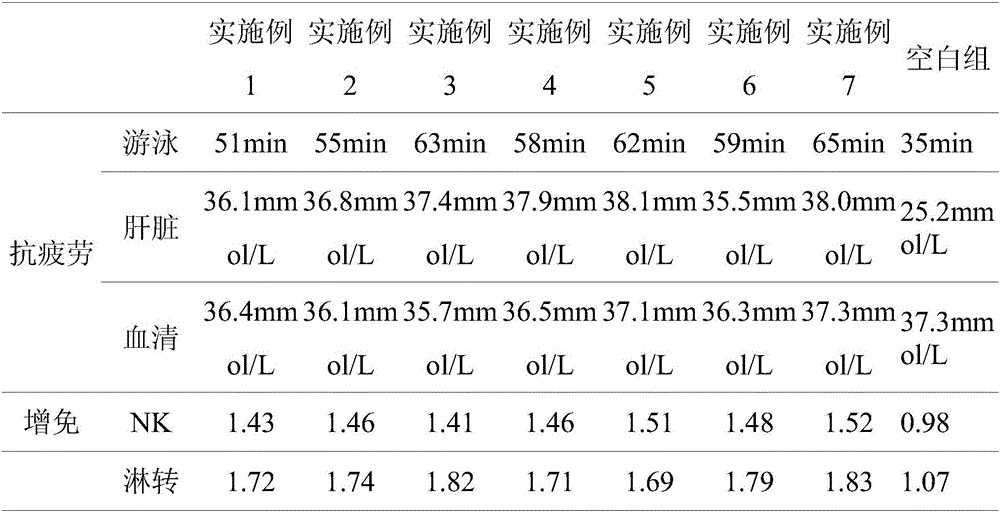

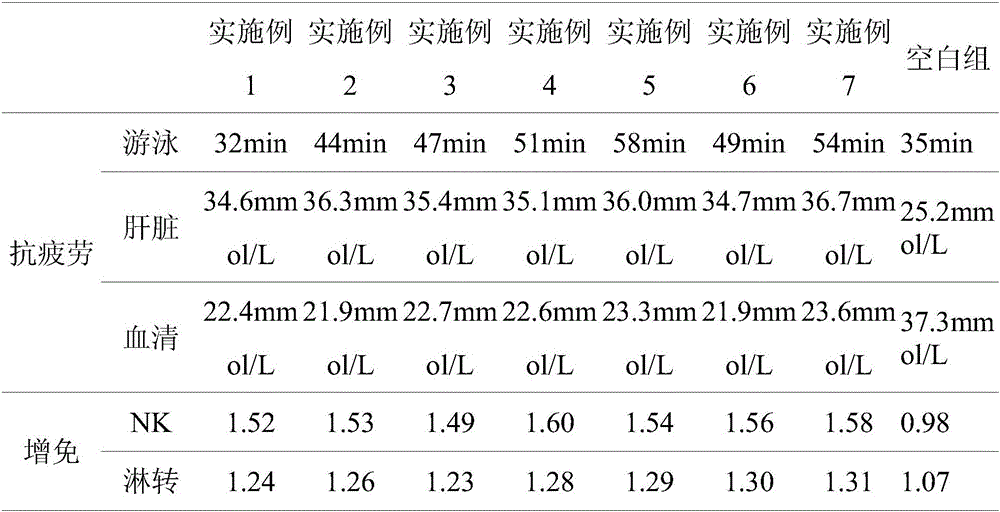

The invention discloses a clove-leaf non-tobacco cigarette and a preparation method thereof and belongs to the technical field of cigarettes. The problems of clove-leaf resource waste, poor taste and flavor of medical cigarettes, body harm, poor mildew resistance, unstable product aroma and taste, unstable guarantee period and the like in the prior art are solved. The preparation method of the cigarette comprises the steps that clove leaves are firstly soaked in hydrogen-rich normal saline with the hydrogen concentration of 0.3-0.8 mmol / L, then the soaked clove leaves are sequentially heated at the temperature of 40 DEG C for 5 minutes, heating is performed at the temperature of 40-50 DEG C for 5-15 minutes, heating is performed at the temperature of 50-55 DEG C for 3-8 minutes, then cooling is performed to reach room temperature, microwave drying is performed, moisture regaining is performed to reach the moisture content of 13-15%, the clove leaves are cut into cut tobaccos, a mildew preventive is added for even mixing, the cigarette is formed, and the clove-leaf non-tobacco cigarette is obtained. Resource waste is reduced, the aroma, taste and mildew resistance are good, the health of smokers is not influenced, and the cigarette also has the functions of fatigue resistance and immunity enhancement.

Owner:白山市禄程农林科技有限公司

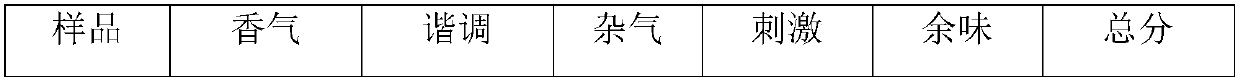

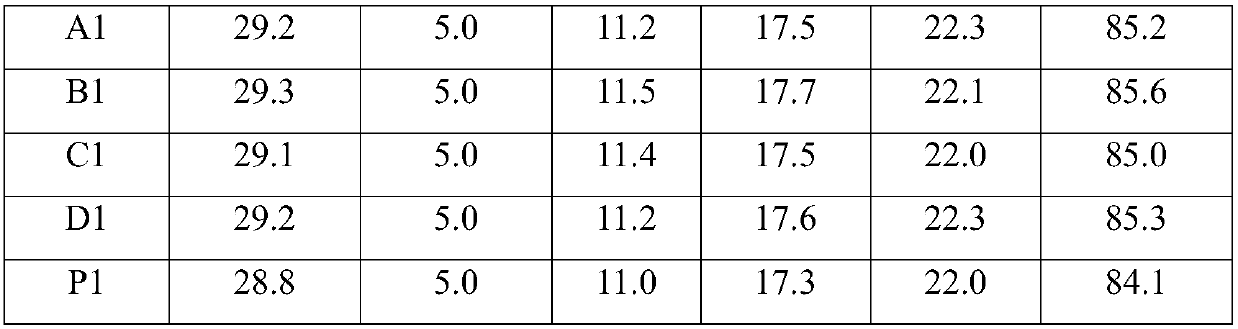

Tea-flower-aroma tobacco excipient and tobacco product

ActiveCN103478904AGreat tasteReduce spicy stimulationTobacco smoke filtersVegetable material additionFood flavorTobacco product

The invention belongs to the field of spices and tobacco, and relates to a tea-flower-aroma tobacco excipient and a tobacco product, in particular to a tobacco excipient containing tea flower extracts, application of the tobacco excipient in preparation of the tobacco product like cigarettes, and the tobacco product, containing the tobacco excipient, like the cigarettes. The cigarettes has a tea flower aroma which is consistent with an own fragrance of tobacco of the cigarettes, aroma and taste of the cigarettes are obviously improved, remaining taste is comfortable, smoke is delicate and soft, and spicy stimulation and mouth dryness sensation of the smoke is effectively reduced. The tobacco excipient which is a tobacco flavor is simple in preparation process, and original processing techniques and equipment of the cigarettes are unchanged in the process of adding of the tobacco excipient.

Owner:CHINA TOBACCO FUJIAN IND +1

Method for reducing content of typical nitrosamine of tobacco leaves

InactiveCN102106602ATSNA content decreasedReduce cancer riskTobacco treatmentHigh pressureNitrosamine

The invention discloses a method for reducing content of typical nitrosamine of tobacco leaves, comprising the following steps of: filling the tobacco leaves into a supercritical extraction kettle, regulating the extraction kettle, controlling temperature of each separation kettle to be 40-60 DEG C, opening a carbon dioxide steel cylinder, and pressurizing the system through a high-pressure pump; simultaneously, opening an entrainer pump to pump the entrainer, and mixing the entrainer and the carbon dioxide into mixed fluid, wherein the pump is alcohol, acetone or aqueous solution thereof; opening a flow regulating valve after the pressure of the extraction kettle comes up to 10-30 MPa, and regulating rotation frequency of a high-pressure plunger pump to perform pressurized circle extraction. The method provided by the invention has the following benefits that: the content of the typical nitrosamine of the tobacco leaves is reduced by more than 60% after the extraction process, so that risk of cancer to smokers is reduced, and smoking safety of cigarette products is improved; after being smoked and evaluated by experts, the processed tobacco leaves still can keep original fragrance and smoking taste well, original physical properties of the tobacco leaves are retained, and requirements of production and processing of the tobacco leaves are satisfied.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

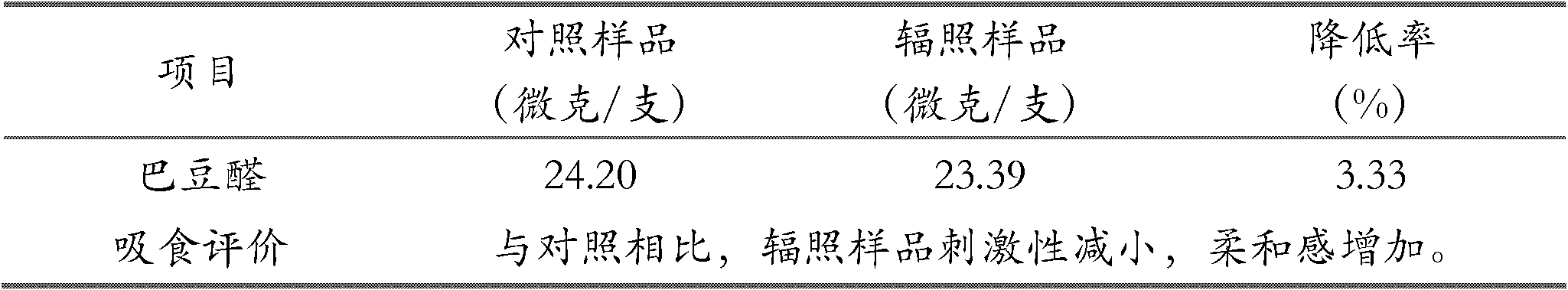

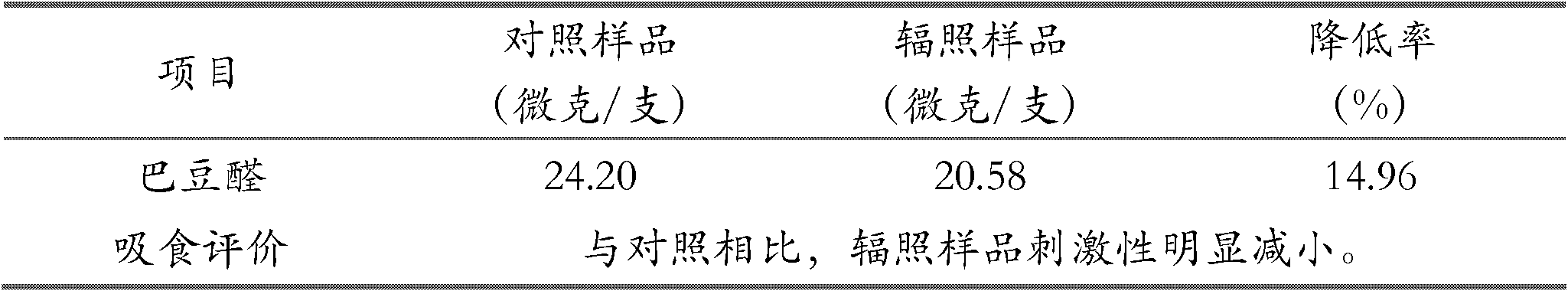

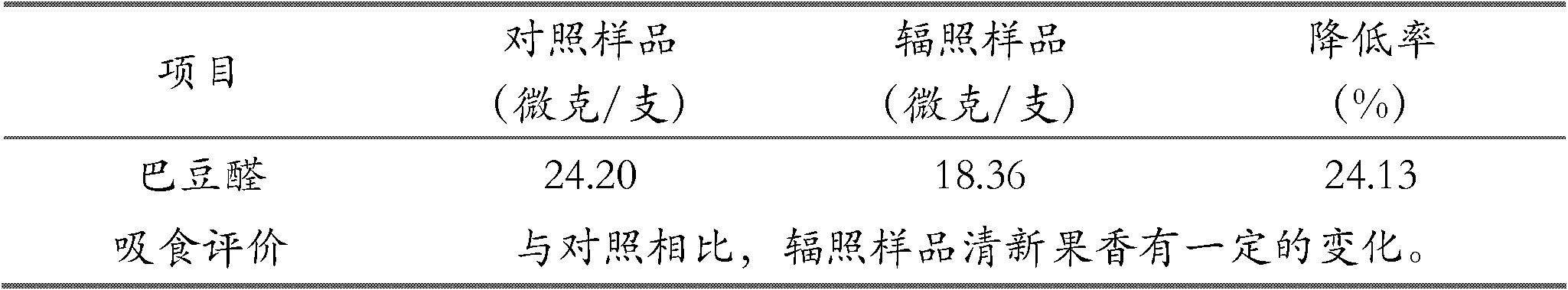

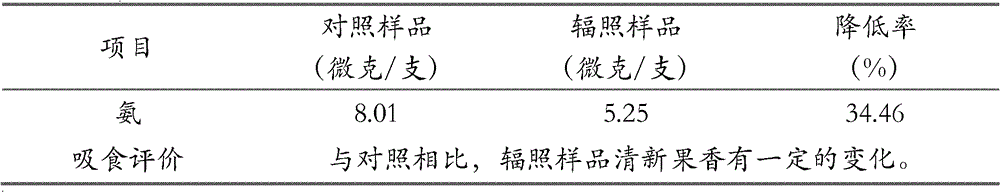

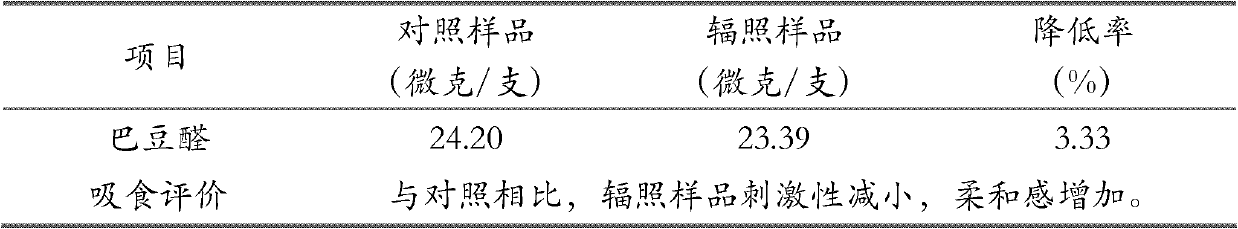

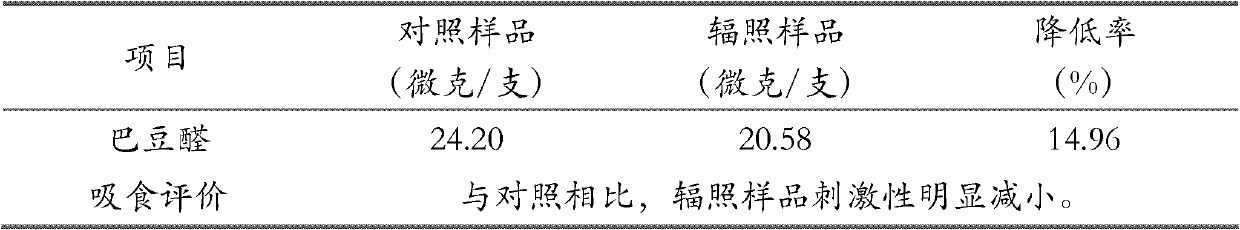

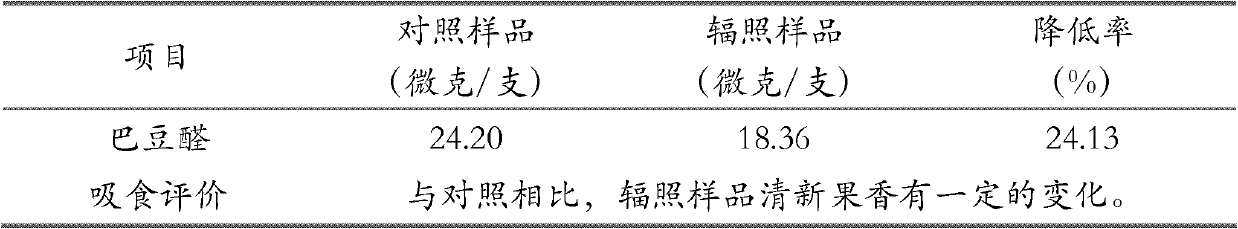

Method for reducing crotonaldehyde in mainstream smoke of cigarettes

InactiveCN102599646AImprove smoking safetyImprove irradiation efficiencyTobacco treatmentOperating temperatureX ray irradiation

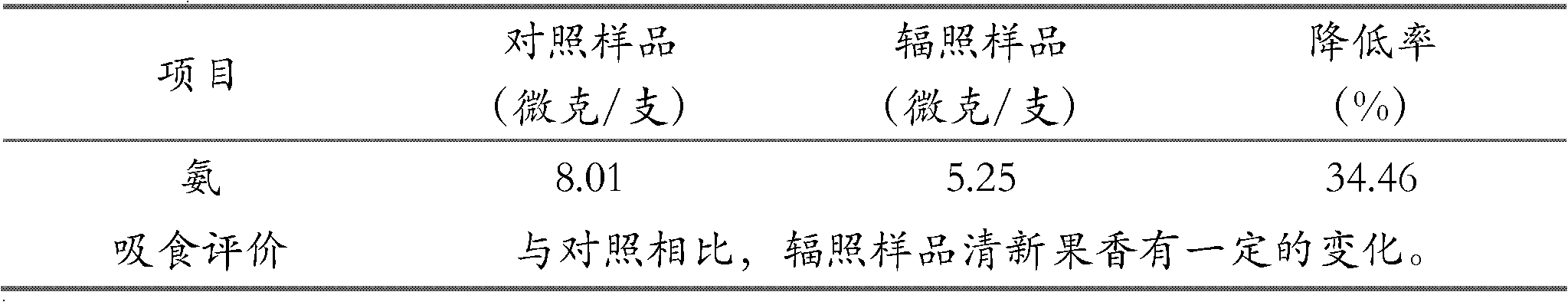

The invention discloses a method for reducing crotonaldehyde in mainstream smoke of cigarettes, which includes: packing tobacco / finished cigarettes with paper cartons with a stacking thickness of 26-72cm and a stacking density of 0.20-0.34g / cm<3>; placing the cigarette cartons on a conveying device at the conveying speed of 0.02-0.3m / s, and subjecting the cartons to electronic beam / X-ray irradiation generated by an electronic accelerator, wherein the electronic accelerator is 5-10MeV in energy, 0.3-20mA in beam current, 10-20kW in beam power, 100cm in largest scanning width, 5-15Hz in scanning frequency, 1-10kGy in irradiation dose and 5-35 DEG C in set operating temperature; allowing the cartons to pass a scanning widow of the electronic accelerator twice for irradiation, wherein the distance from the center of each carton to the scanning window of the electronic accelerator is 40-60cm in irradiation; and limiting the ambient humidity to be no larger than 60% in operation.

Owner:河南省科学院同位素研究所有限责任公司 +1

Ginseng/pseudo-ginseng leaves non-tobacco cigarette and preparing method thereof

InactiveCN106666814AImprove stabilityAvoid damageTobacco preparationTobacco treatmentNicotiana tabacumHydrogen

The invention discloses a ginseng / pseudo-ginseng leaves non-tobacco cigarette and a preparing method thereof, and belongs to the technical field of cigarettes. The problems in the prior art that resources of ginseng and pseudo-ginseng leaves are wasted, drug cigarettes are bad in taste, poor in mouthfeel, harmful to human body, poor in mildew resistance, and unstable in product smell mouthfeel and expiration date and the like are solved. The preparing method of the ginseng / pseudo-ginseng leaves non-tobacco cigarette comprises the steps of firstly soaking ginseng leaves and pseudo-ginseng leaves in a hydrogen-enriched normal saline solution with the concentration being 0.3-0.8 mmol / L respectively, then conducting stepwise heating on the soaked ginseng leaves and pseudo-ginseng leaves respectively, then cooling the temperature to the room temperature, conducting microwave drying, finally conducting resurgence on the dried ginseng leaves and pseudo-ginseng leaves respectively, and cutting the leaves into tobacco shreds; weighing the ginseng leaf tobacco shreds and the pseudo-ginseng leaf tobacco shreds according to the mass ratio of 1:1, adding a mildew preventive into the tobacco shreds, mixing the mixture uniformly, conducting cigarette molding to obtain the ginseng / pseudo-ginseng leaves non-tobacco cigarette. According to the ginseng / pseudo-ginseng leaves non-tobacco cigarette and the preparing method thereof, the waste of resources is reduced; meanwhile, the ginseng / pseudo-ginseng leaves non-tobacco cigarette is good in smell, mouthfeel and mildew resistance, has no influences on the health of a smoker, and has the functions of resisting fatigue and enhancing immunity.

Owner:白山市禄程农林科技有限公司

Selenium-enriched cigarette and preparing method thereof

InactiveCN107361399AReduce free radicalsIncrease blood selenium levelTobacco preparationTobacco treatmentMonopotassium phosphateSilicon

The invention provides a preparing method of selenium-enriched cigarette. The preparing method comprises the following steps of taking, by weight, 1,200-1,500 parts of selenium-enriched agent, 10-20 parts of organic silicon agricultural spray assistant, 3-6 parts of monopotassium phosphate and 30,000-40,000 parts of water are uniformly mixed to prepare a selenium-enriched strengthening leaf surface fertilizer solution; 15-20 days before cigarette leaves are harvested, the selenium-enriched strengthening leaf surface fertilizer solution is uniformly sprayed on the front face and back face of leaves, and the leaves are prevented from being showered in 24 hours after being sprayed; after being harvested, the cigarette leaves are prepared into tobacco shred according to a conventional processing method; a sodium selenite solution is taken to be uniformly sprayed on the prepared tobacco shred, the cut tobacco is prepared into cigarettes, and the mass of the selenium element added in each cigarette through the sodium selenite solution is 1.5-3.0 microgrammes. Therefore, the unique selenium-enriched cigarette is produced, and is high in selenium content, a smoker smokes harmful substances, and also takes in rich antimicrobial substance selenium at the same time, and the harm reducing and healthcare effect is improved; meanwhile, the cost is low, the technology is simple, and the taste of the traditional cigarette is further reserved.

Owner:安徽富村微量元素科技有限公司

Non tobacco cigarette of dendrobium and wolfberry leaves and preparation method thereof

InactiveCN106617272AImprove stabilityAvoid damageTobacco preparationTobacco treatmentFlavorHydrogen concentration

Non tobacco cigarette of dendrobium and wolfberry leaves and a preparation method thereof belongs to the technical field of cigarettes, and solves the problems of waste of dendrobium and wolfberry leaves resources, poor flavor of drug cigarettes, poor taste, the damage to the body, bad mildew resistance, the instability of the smell, taste and shelf life of the product. The preparation method of the cigarette is as follows: dendrobium leaves and wolfberry leaves are immersed in hydrogen-rich physiological saline with hydrogen concentration of 0.3 - 0.8mmol / L, then the soaked dendrobium leaves and wolfberry leaves are heated separately and sectionally, and dropped to the room temperature and dried by the microwave, and finally the dry dendrobium leaves and wolfberry leaves are resurgent respectively and cut into tobacco. Non tobacco cigarette of dendrobium and wolfberry leaves are made through taking dendrobium and wolfberry leaves in a quality ratio of 1: 1 and adding fungicides and mixing evenly. The cigarettes reduce the waste of resources, and have a good smell, taste and mildew resistance. The cigarettes neither affect the health of the smokers, but also have anti-fatigue and immune improving functions.

Owner:白山市禄程农林科技有限公司

Industrial-preservative-free green tea fragrance cigarette paper, and preparation method thereof

ActiveCN110952374AFull of smellLess irritatingVegetable material additionPaper/cardboardBiotechnologyGreen teas

The invention discloses industrial-preservative-free green tea fragrance cigarette paper, which is prepared from the following raw materials in percentage by mass: 75% of a wood papermaking raw material, 5-20% of green tea, and 5-20%of an additive. The preparation method comprises: pulping green tea and a cigarette paper raw material, adding an additive, and sequentially carrying out papermaking and slitting; and preparing a tea aroma preparation from a green tea aroma substance extract, and uniformly coating the surface of the made cigarette paper. The cigarette paper of the invention does not contain industrial preservatives, is close to tobacco smoking taste, reduces nicotine components, improves satisfaction, increases aroma and body fluid, promotes salivation and has a certain refreshing color.

Owner:CHINA TOBACCO ZHEJIANG IND

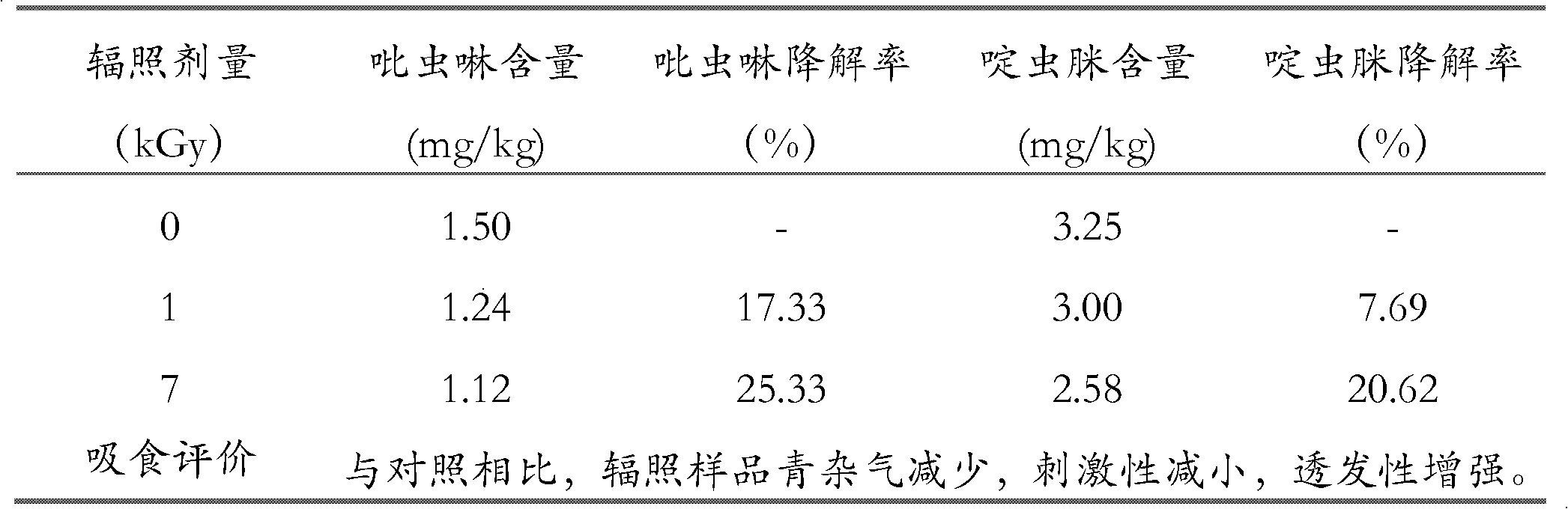

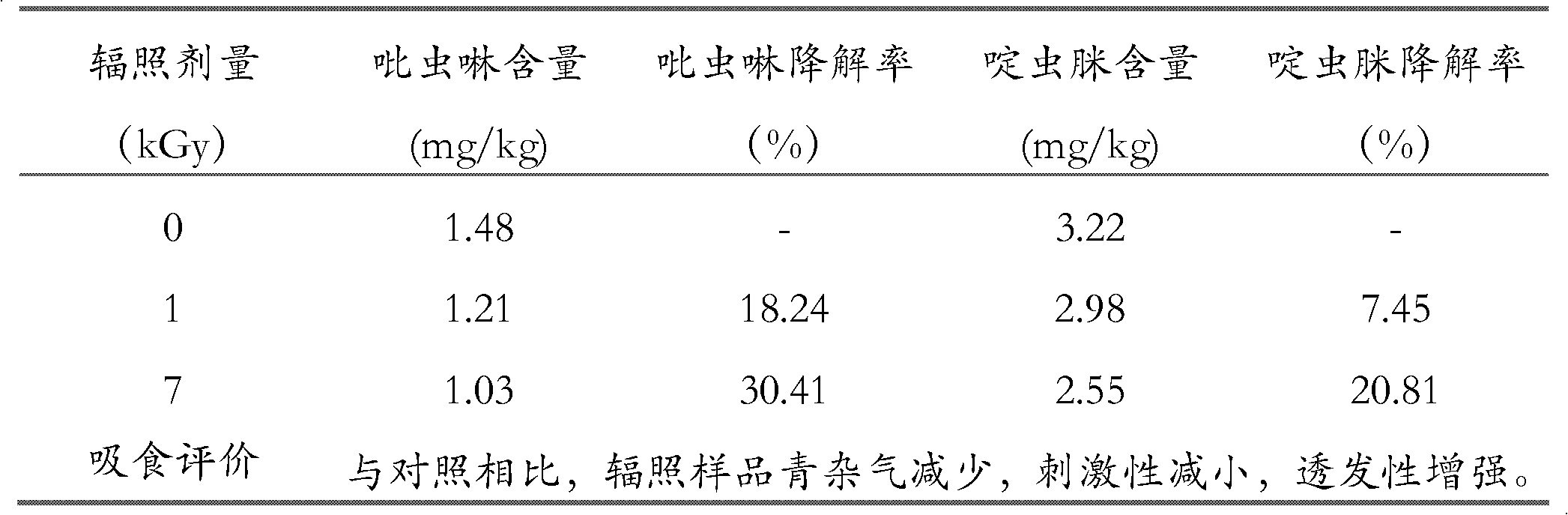

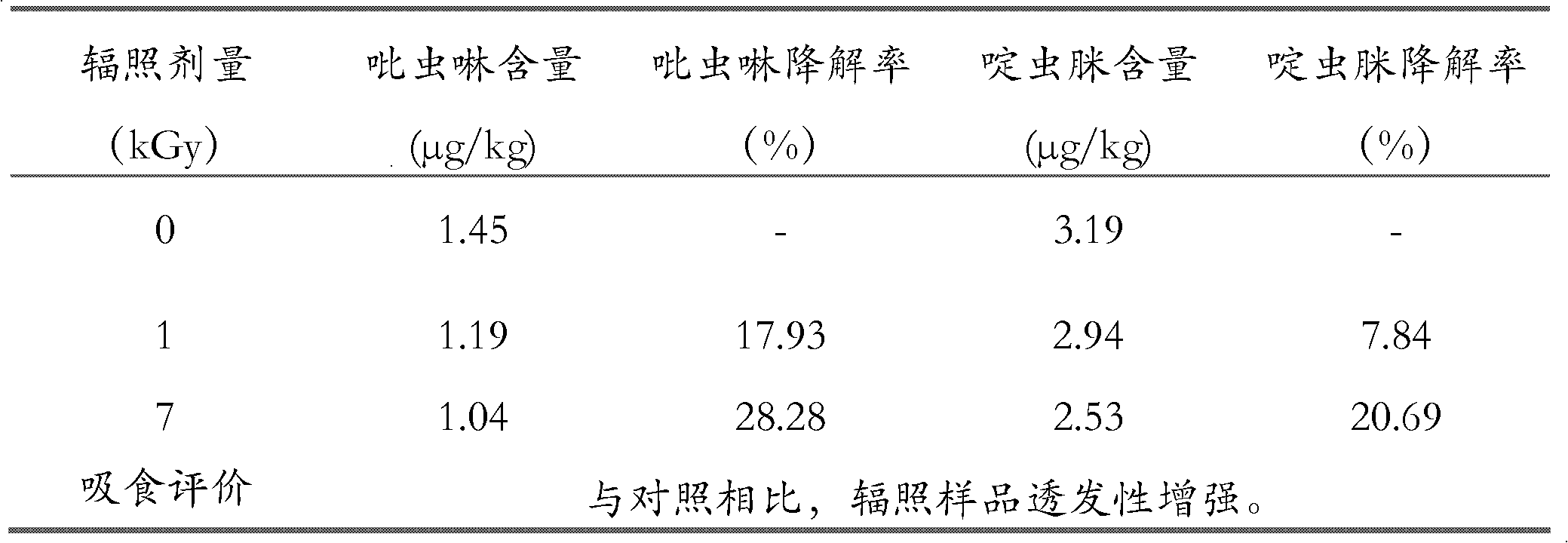

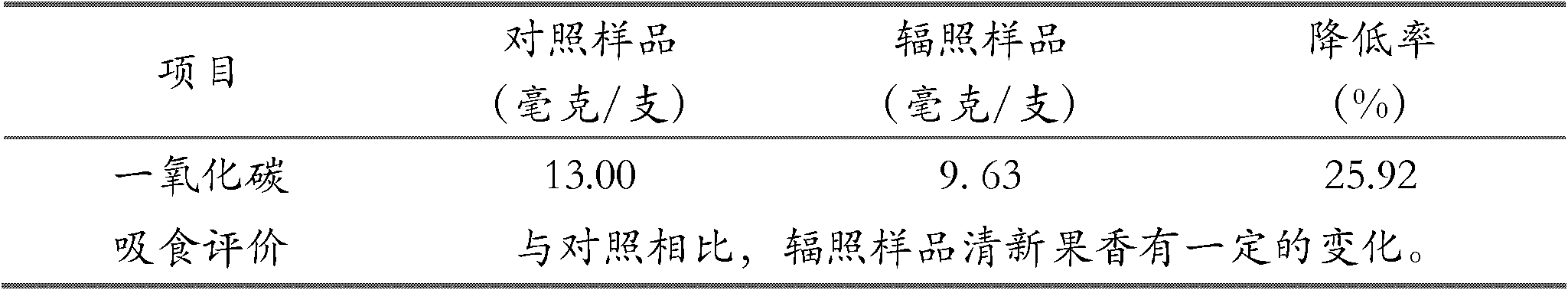

Method for lowering imidacloprid and acetamiprid residue in tobacco

The invention discloses a method for lowering imidacloprid and acetamiprid residue in tobacco, which comprises the following steps: packaging tobacco with a carton, wherein the accumulation thickness is 26-72cm, and the accumulation density is 0.20-0.34g / cm<3>; putting the tobacco cartons on a conveying device at a conveying speed being 0.02-0.3m / s; irradiating the tobacco cartons by an electronic beam or X ray generated by an electron accelerator, wherein the energy of the electron accelerator is 5-10MeV, the beam is 0.3-20mA, the beam power is 10-20kW, the maximum scanning width is 100cm, the scanning frequency is 5-15Hz, the radiation amount is 1-10kGy, and the working temperature is set to be 5-35DEG C; causing the tobacco cartons to pass through a scanning window of the electron accelerator to be irradiated, wherein the center of each tobacco carton is far away from the scanning window of the electron accelerator for 40-60cm during irradiation, and the environment humidity during working is limited to be less than or equal to 60%.

Owner:河南省科学院同位素研究所有限责任公司 +1

Filter material containing nanometer SOD and its preparation method and application in cigarette

A filter material containing nano-SOD with high effect to filter out tar is prepared through preparing filtering material and dipping in SOD solution or spraying the SOD solution on it.

Owner:王成余

Method for reducing ammonia in mainstream smoke of cigarettes

Owner:河南省科学院同位素研究所有限责任公司 +1

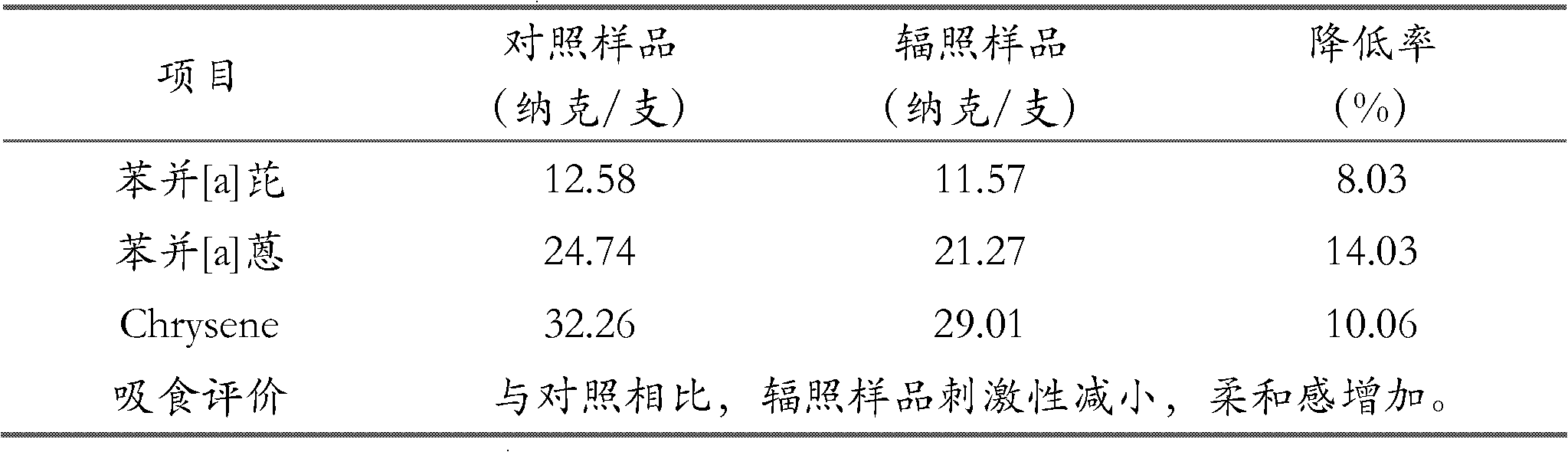

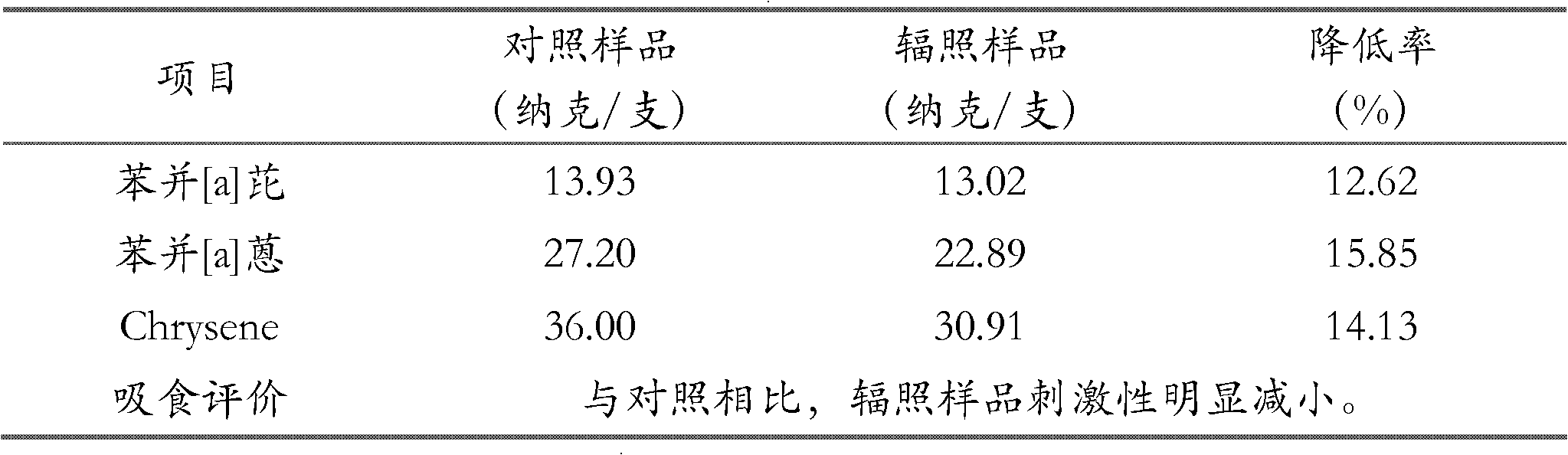

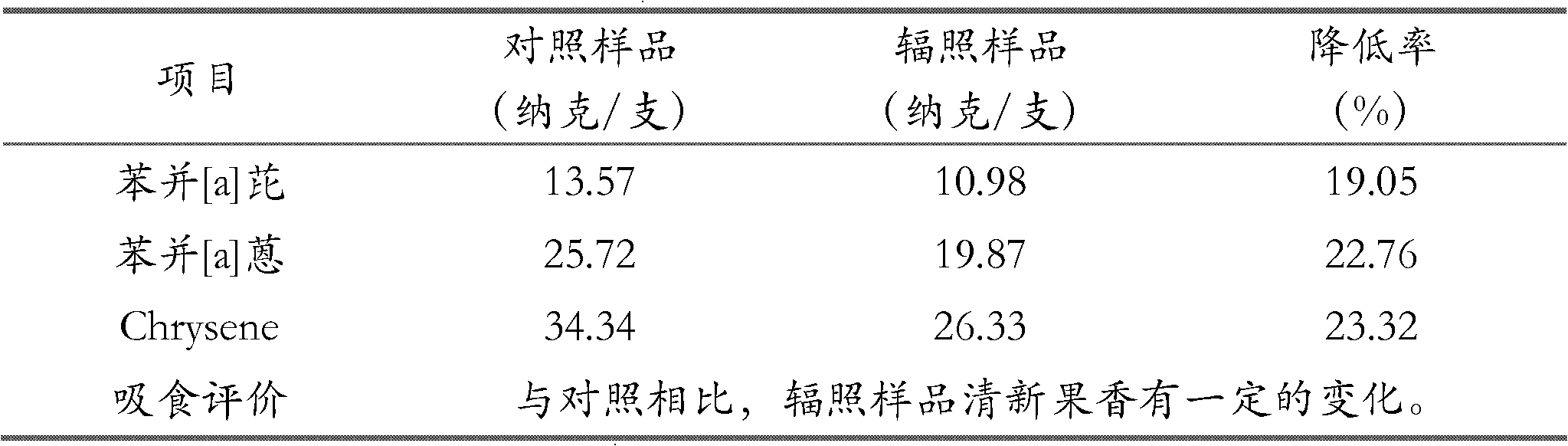

Method for reducing polyaromatic hydrocarbon content in tar of cigarette smoke

The invention discloses a method for reducing the polyaromatic hydrocarbon content in tar of cigarette smoke. The method comprises the steps: packaging tobacco leaves / finished products of cigarettes with cartons, wherein stacking thickness is 26-72cm and stacking density is 0.20-0.34g / cm<3>; and placing the tobacco leaf / cigarette carton on a conveyer at the conveying speed being 0.02-0.3m / s and irradiating the tobacco leaf / cigarette cartons with electron beams / X rays produced by an electron accelerator, wherein the electron accelerator has the energy being 5-10MeV, the beam flow being 0.3-20mA, the beam power being 10-20kW, the maximal scanning width being 100cm, the scanning frequency being 5-15Hz and the irradiation dose being 1-10kGy, the working temperature is set to be 5-35 DEG C, the tobacco leaf / cigarette cartons pass trough a scanning window of the electron accelerator twice to be irradiated, a distance between the center of each tobacco leaf / cigarette carton and the scanning window of the electron accelerator is 40-60cm during irradiation, and the ambient humidity is limited to be not more than 60% during working.

Owner:河南省科学院同位素研究所有限责任公司 +1

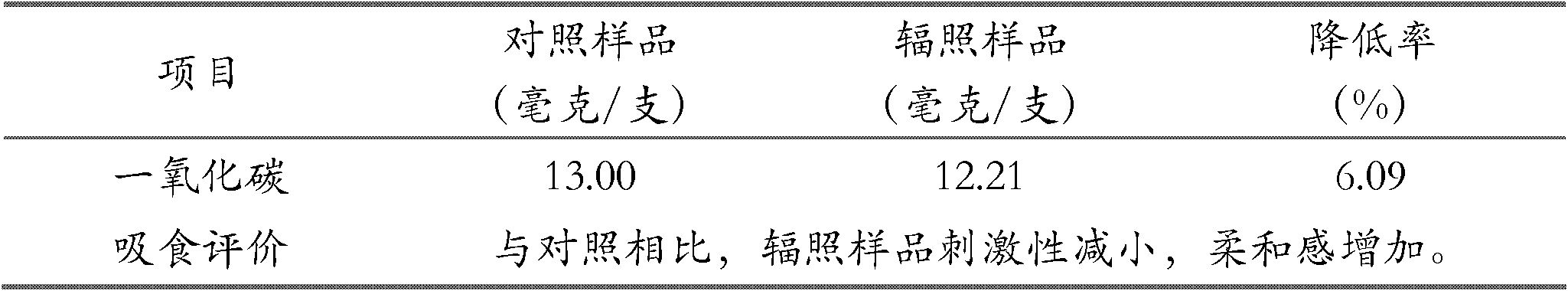

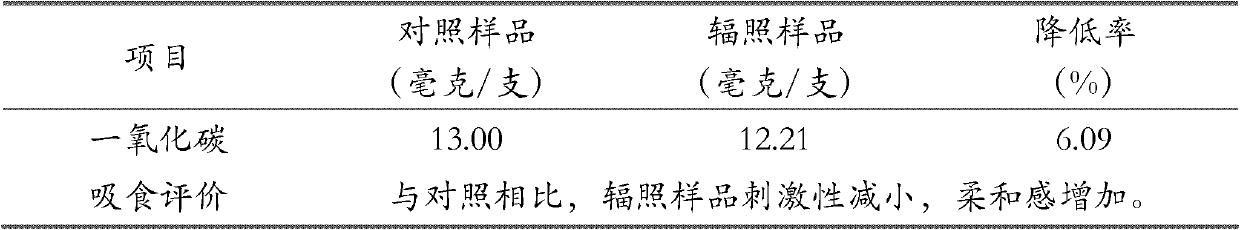

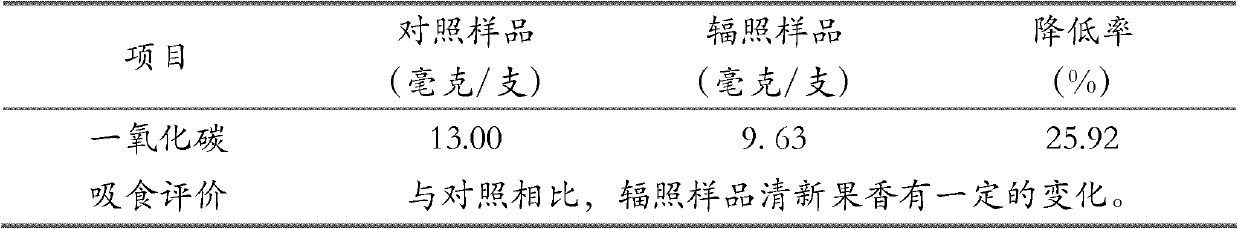

Method for lowering carbon monoxide content in main smoke of cigarette

The invention discloses a method for lowering carbon monoxide content in main smoke of cigarette. The method comprises the steps of: packaging tobacco leaves / cigarette finished product with cartons, wherein the stacking thickness is 26-72cm and the stacking density is 0.20-0.34g / cm<3>; and placing the cigarette cartons on a conveying device with conveying speed of 0.02-0.3m / s and irradiating withelectron beam / X ray generated by an electron accelerator, wherein the energy of the electron accelerator is 5-10MeV, the beam current is 0.3-20mA, the beam power is 10-20kW, the maximum scanning width is 100cm, the scanning frequency is 5-15Hz, the irradiation dose is 1-10kGy, the working temperature is set at 5-35 DEG C, the cigarette cartons pass through a scanning window of the electron accelerator twice to undergo irradiation, the distance between the center of the cigarette carton and the scanning window of the electron accelerator is 40-60cm during irradiation, and the ambient humidity is limited to be not more than 60% during working.

Owner:河南省科学院同位素研究所有限责任公司 +1

Ginseng/astragalus membranaceus leaf non-tobacco cigarette and preparation method thereof

InactiveCN106579543AImprove stabilityAvoid damageTobacco treatmentHydrogen concentrationNicotiana tabacum

The invention discloses a ginseng / astragalus membranaceus leaf non-tobacco cigarette and a preparation method thereof, and belongs to the technical field of tobacco. The invention solves the problems of resource waste of ginseng and astragalus membranaceus leaves, bad smell of drug tobacco, bad taste, body injury, poor mildew resistance, and unstable odor and taste, and quality guarantee time of product. The cigarette is prepared by respectively immersing ginseng and astragalus membranaceus leaves in hydrogen-enriching normal saline with hydrogen concentration of 0.3-0.8 mmol / L, and then respectively and segmentally heating the immersed ginseng and astragalus membranaceus leaves; cooling to room temperature, micro-wave drying; finally, respectively wetting back the dried ginseng and astragalus membranaceus leaves, and cutting to be tobacco shreds; taking ginseng tobacco shreds and astragalus membranaceus tobacco shreds at mass ratio of 1: 1, and adding the mildew preventive to evenly mix; molding the cigarette to obtain the ginseng / astragalus membranaceus leaf non-tobacco cigarette. The cigarette reduces the resource waste; the odor, taste and mildew resistance are good; the ginseng / astragalus membranaceus leaf non-tobacco cigarette cannot influence smoker's health, and has functions of resisting fatigue and improving immunity.

Owner:白山市禄程农林科技有限公司

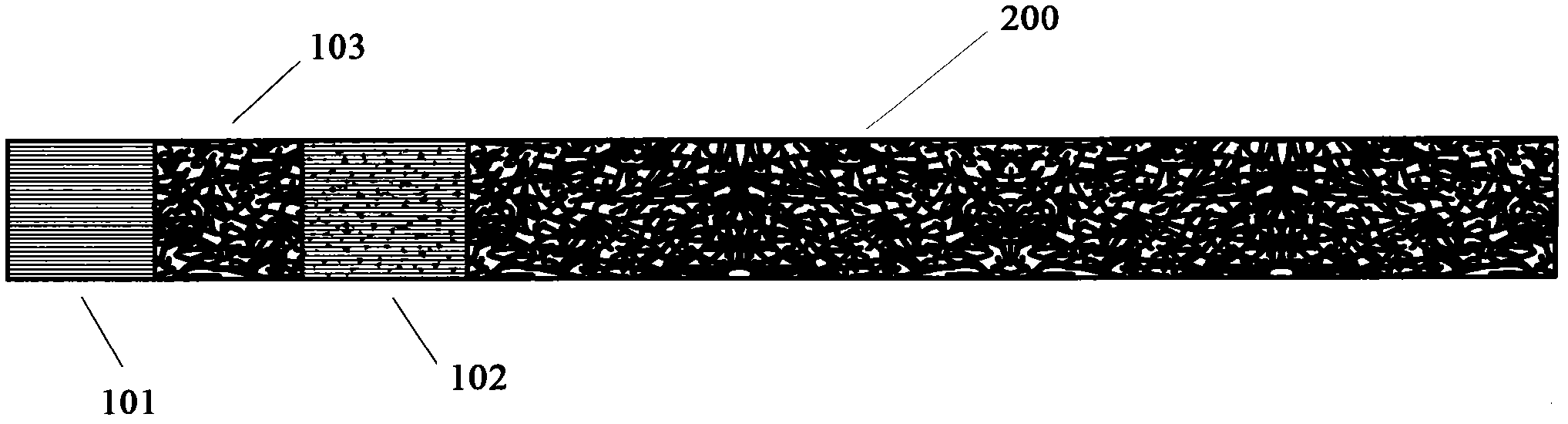

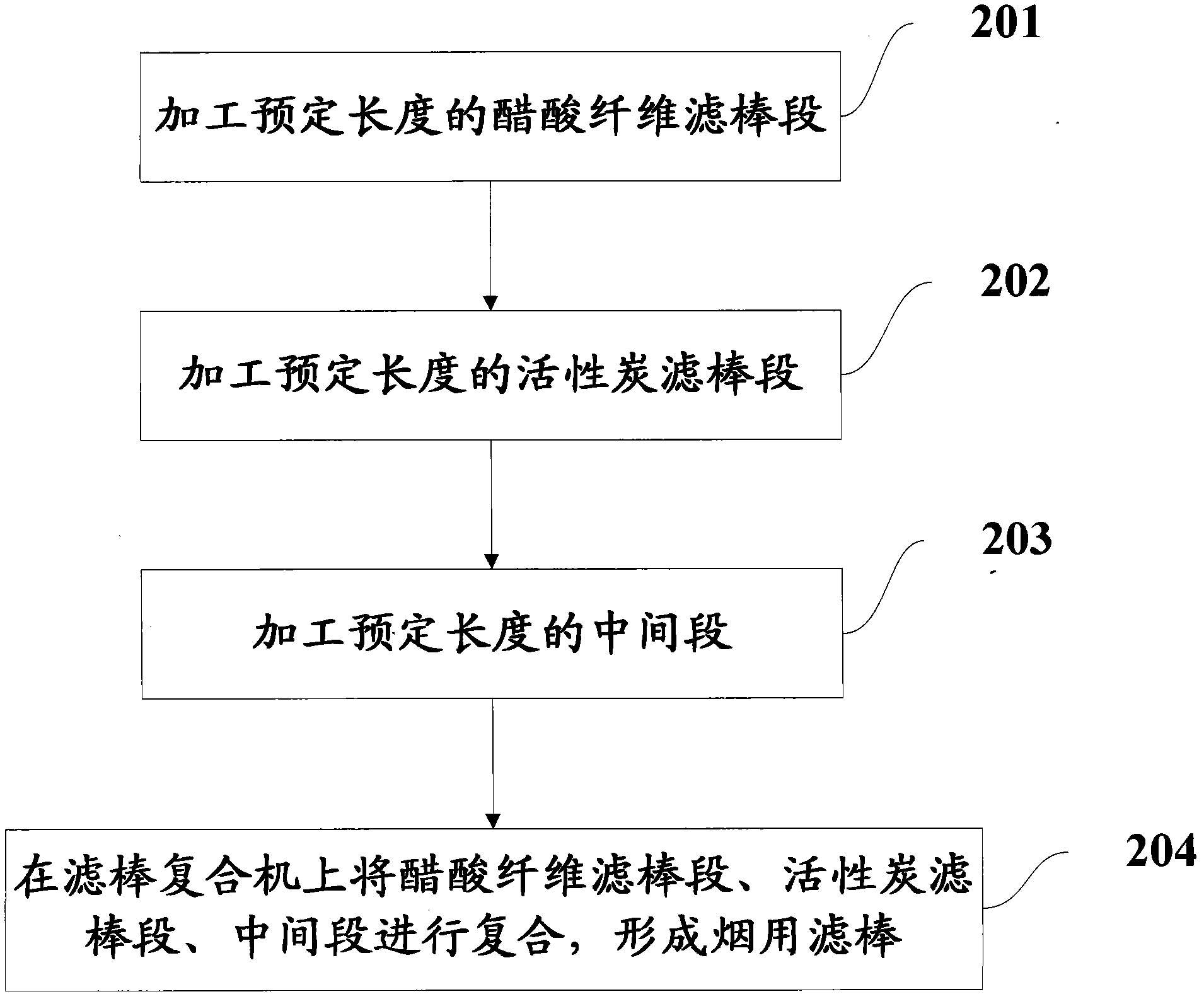

Filter stick for cigarette

The invention discloses a filter stick for a cigarette. The filter stick comprises an acetate fiber filter stick section, an active carbon filter stick section and a middle section, wherein the acetate fiber filter stick section is connected with the middle section; the middle section is positioned between the acetate fiber filter stick section and the active carbon filter stick section; and the active carbon filter stick section is connected with a cigarette body. Due to the adoption of the filter stick, the using quantity of acetate fiber tows is reduced, the consumption of wood pulp is lowered, and the natural environment is protected. The middle section is introduced, so that the design flexibility of a cigarette product is enhanced. By changing the lengths and pressure drops of three sections of materials, a ternary composite filter stick with different filtering efficiencies can be designed to meet the requirements of different products. Various functional tar reducing and harm relieving additives can be loaded into the middle section of the cigarette, so that a cigarette with low tar content and low harm is produced. Moreover, the active carbon filter stick is compounded in the filter stick, so that the functions of harmful substances in the cigarette can be weakened, and the smoking safety of the cigarette is enhanced.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Panax notoginseng leaf/panax quinquefolius leaf non-tobacco cigarette and preparation method thereof

The invention discloses a panax notoginseng leaf / panax quinquefolius leaf non-tobacco cigarette and a preparation method thereof, and belongs to the technical field of cigarettes. The invention aims at solving the problems in the prior art that resources of panax notoginseng leaves and panax quinquefolius leaves become wasted and medicinal cigarettes are poor in flavor and taste, harmful to body, poor in mildew resistance, unstable in product smell and taste, unstable in shelf life and the like. The preparation method of the cigarette comprises the following steps: soaking the panax notoginseng leaves and the panax quinquefolius leaves in hydrogen-enriched physiological saline that a hydrogen concentration is 0.3-0.8mmol / L; then, sequentially heating the soaked panax notoginseng leaves and panax quinquefolius leaves in a sectional mode; then, cooling heat to room temperature; conducting microwave drying; finally, conducting moisture regaining on the dried panax notoginseng leaves and panax quinquefolius leaves; cutting the processed panax notoginseng leaves and panax quinquefolius leaves into cut tobacco; preparing panax notoginseng leaf cut tobacco and panax quinquefolius leaf cut tobacco at the mass ratio of 1: 1; adding a mildew preventive and uniformly mixing the cut tobacco and the mildew preventive; and conducting rolling and shaping so as to obtain the panax notoginseng leaf / panax quinquefolius leaf non-tobacco cigarette. The cigarette can reduce resource waste and the cigarette is good in flavor, taste and mildew resistance; and the cigarette can avoid influence on smoker's health, and meanwhile, the cigarette has functions of resisting fatigue and boosting immunity.

Owner:白山市禄程农林科技有限公司

Acanthopanax leaf non-tobacco cigarette and preparation method thereof

InactiveCN106820248AImprove stabilityAvoid damageTobacco treatmentCigar manufactureHydrogen concentrationMicrowave

The invention discloses an acanthopanax leaf non-tobacco cigarette and a preparation method thereof, and belongs to the technical field of cigarettes. The problems that in the prior art, acanthopanax leaves are wasted, and the medicine cigarette is bad in smell and state, harmful to human body, not good in mildew resistance and unstable in product smell and taste and preservation time are solved. The preparation method of the cigarette comprises the steps of soaking the acanthopanax leaves in hydrogen-rich normal saline with a hydrogen concentration of 0.3-0.8mmol / L; sequentially heating the soaked acanthopanax leaves for 5min at the temperature of 40 DEG C, heating for 5-15min at the temperature of 40-50 DEG C, and heating for 3-8min at the temperature of 50-55 DEG C; then cooling to room temperature, drying by microwaves, resurging to a water content of 13-15%; chopping into scraps; adding into mildew preventive and mixing uniformly; and forming into the cigarette to acquire the acanthopanax leaf non-tobacco cigarette. The cigarette reduces resource waste, is good in smell, taste and mildew resistance, does not affect the health of a smoker, and also has the functions of resisting fatigue and improving immunity.

Owner:白山市禄程农林科技有限公司

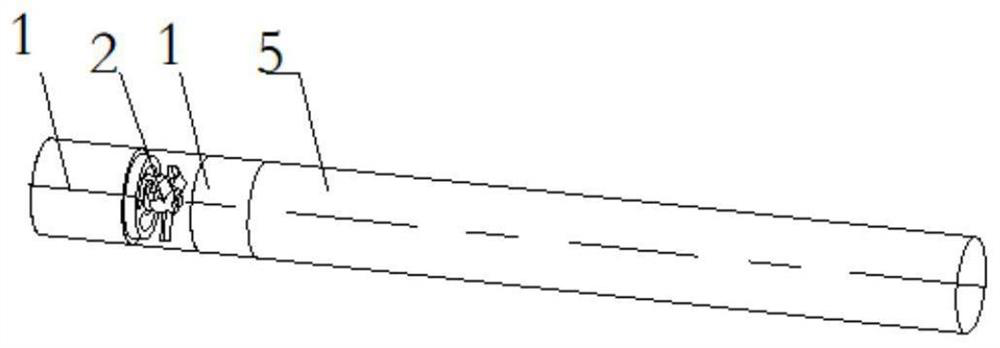

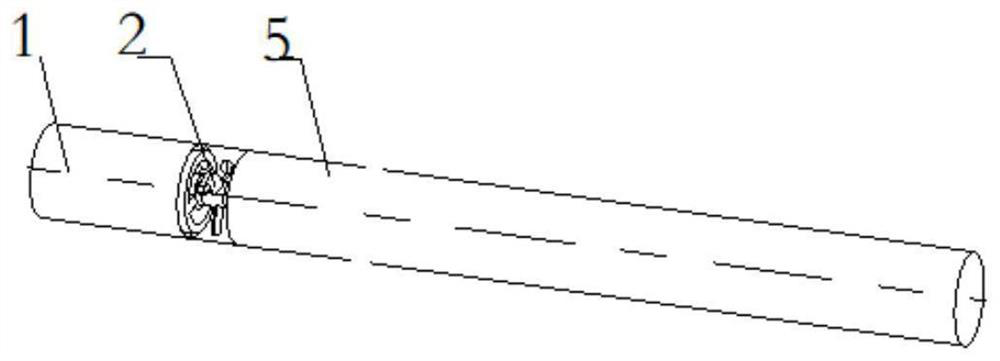

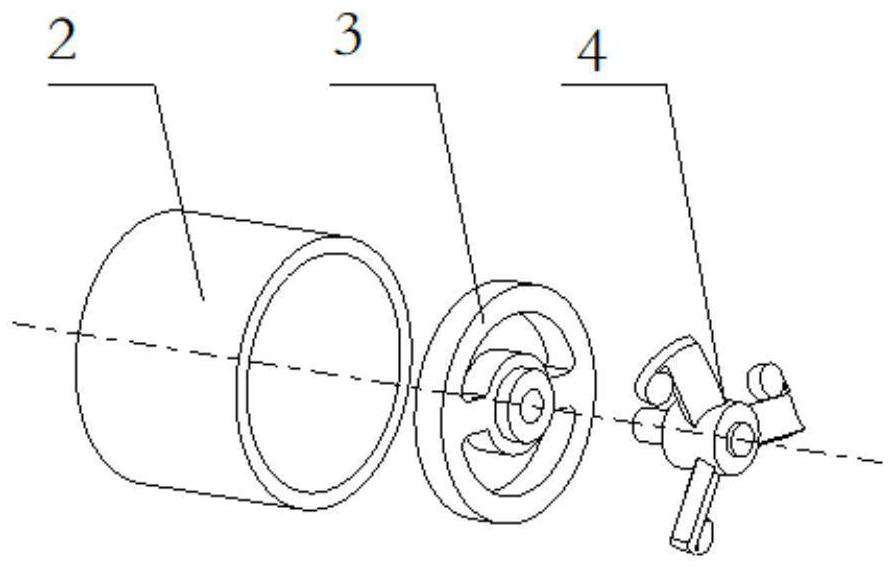

Cigarette capable of actively controlling smoke

PendingCN114652016AIncrease added valueNovel visual impactCigar manufactureTobacco smoke filtersEngineeringTurbofan

The invention relates to the technical field of cigarettes. In particular to a novel cigarette capable of actively controlling smoke and adjusting the proportion of the smoke and air to limit oil tar and achieve constant suction resistance. The cigarette comprises a filter tip (1) and a cigarette body (5) and is characterized in that a hollow circular tube volute (2) is arranged between the filter tip (1) and the cigarette body (5), a support (3) for supporting a turbofan impeller is arranged at one end of the hollow circular tube volute (2), and the turbofan impeller (4) is arranged in the hollow circular tube volute (2) and installed on the support (3) through a rotating shaft (4.2). The ratio of smoke to air can be effectively controlled, tar is further reduced, and meanwhile sensory stimulation of consumers is met.

Owner:WUHAN YANCHENG TECH CO LTD

Radix acanthopanacis senticosi/sanchi leaves non-tobacco cigarette and preparing method thereof

InactiveCN106617270AImprove stabilityAvoid damageTobacco preparationTobacco treatmentNicotiana tabacumEleutherococcus senticosus

The invention discloses a radix acanthopanacis senticosi / sanchi leaves non-tobacco cigarette and a preparing method thereof. The radix acanthopanacis senticosi / sanchi leaves non-tobacco cigarette solves the problems in the prior art that radix acanthopanacis senticosi leaves and sanchi leaves are wasted, the medical cigarette is poor in taste and mouthfeel, harms the body, and is not good in fungus resistance and unstable in product smell and mouthfeel and shelf life. The preparing method of the cigarette comprises the steps of firstly soaking the radix acanthopanacis senticosi leaves and the sanchi leaves into hydrogen-rich normal saline with the hydrogen concentration of 0.3-0.8 mmol / L respectively, afterwards conducting incremental heating on the soaked radix acanthopanacis senticosi leaves and sanchi leaves respectively, then cooling to a room temperature, conducting microwave drying, finally conducting moisture regaining on the dried radix acanthopanacis senticosi leaves and sanchi leaves respectively, and cutting the radix acanthopanacis senticosi leaves and the sanchi leaves into cut tobacco; taking the radix acanthopanacis senticosi leaf cut tobacco and the sanchi leaf cut tobacco with a mass ratio of 1:1, and adding mildew preventive to mix evenly, and shaping the cigarette to obtain the radix acanthopanacis senticosi / sanchi leaves non-tobacco cigarette. The radix acanthopanacis senticosi / sanchi leaves non-tobacco cigarette reduces resource waste, is good in smell, mouthfeel and fungus resistance, does not affect health of a smoker, and has the functions of resisting fatigue and improving immunity.

Owner:白山市禄程农林科技有限公司

A Novel Tobacco Moisturizer and Its Application

The invention discloses a novel tobacco humectant and a novel tobacco humectant application method. The novel tobacco humectant is natural propolis extractive or mixing solution of the natural propolis extractive and propylene glycol, glycerol or sorbitol, and the weight proportion of the natural propolis extractive and water, the propylene glycol, the glycerol or the sorbitol is 10-90%:90-10%. The novel tobacco humectant is sprayed evenly on tobacco, and the spraying proportion is 0.1-1.0% of the weight of the tobacco. The moisture content in the tobacco is measured according to the method stipulated by YC / T28.8-1996 Moisture Measurement of Cigarette Physical Properties. The result shows that the effect of the novel tobacco humectant is better than the widely-used traditional humectant such as the propylene glycol, the glycerol or the sorbitol at present.

Owner:CHINA TOBACCO GUANGXI IND +1

Method for reducing benzene-contained compounds in smoke of cigarettes and application thereof

InactiveCN102499457ALow in benzene compoundsImprove smoking safetyTobacco treatmentEnvironmental chemistryBenzene

The invention relates to a method for reducing benzene-contained compounds in smoke of cigarettes and application thereof. The method for reducing benzene-contained compounds in smoke of cigarettes is to spray corallite powder evenly on cut tobacco used by the cigarettes. The method can effectively reduce the benzene-contained compounds in the smoke of the cigarettes, and the cigarettes made of the tobaccos processed by the method is low in content of the benzene-contained compounds in the smoke while smoking of users, and smoking is safer.

Owner:庄信修 +1

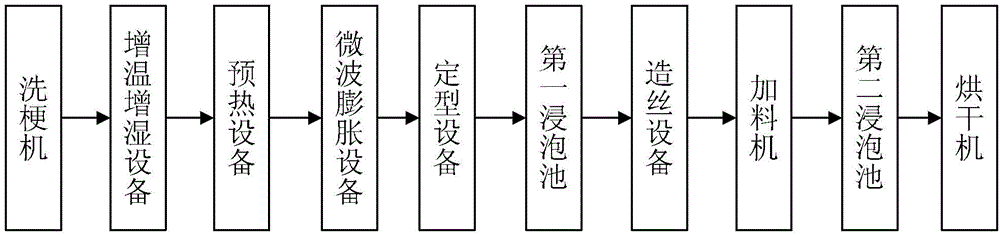

Raw materials for cigarettes, production method and equipment thereof

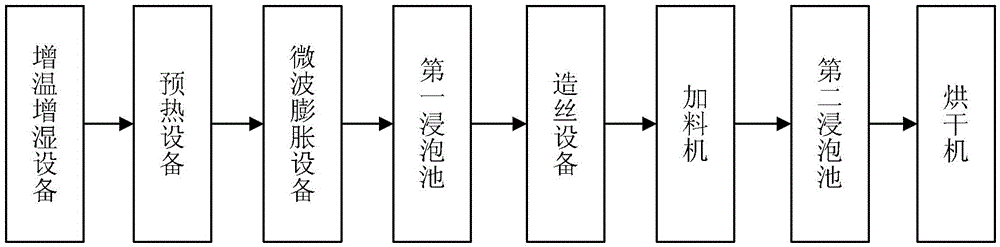

ActiveCN103169146BSimple production methodReduce water consumptionTobacco preparationTobacco treatmentFiberMicrowave

The invention provides raw materials for cigarettes, a production method of the raw materials for the cigarettes and equipment of the raw materials for the cigarettes. The production method of the raw materials for the cigarettes includes the following steps. Firstly, plant biomass is heated and moistened unit the water content reaches 35 wt% to 40 wt%. Secondly, materials are preheated after being heated and moistened until the water temperature of the materials reaches the boiling point. Thirdly, the preheated materials are expanded with micro waves until the water content reduces to 10 wt% to 20 wt%. Fourthly, water is added to the materials until the water content reaches 30 wt% to 40 wt%. Fifthly, the materials are machined to be fiber shreds. Sixthly, biological enzyme liquid is sprayed onto the fiber shreds, the fiber shreds with the biological enzyme liquid are soaked in water. Seventhly, drying is performed. The raw materials for the cigarettes, the production method of the raw materials for the cigarettes and the equipment of the raw materials for the cigarettes overcome defects in the prior art, have the advantages that water consumption in production is low, crushed raw materials for the cigarettes obtained in production are less, compatibility with tobacco shreds is perfect, woodiness texture is not obvious and can be applied to manufacture of high-grade cigarettes.

Owner:赵鸿

Method for reducing crotonaldehyde in mainstream smoke of cigarettes

InactiveCN102599646BImprove smoking safetyReduced crotonaldehydeTobacco treatmentAmbient humidityCrotonaldehyde

The invention discloses a method for reducing crotonaldehyde in mainstream smoke of cigarettes, which includes: packing tobacco / finished cigarettes with paper cartons with a stacking thickness of 26-72cm and a stacking density of 0.20-0.34g / cm<3>; placing the cigarette cartons on a conveying device at the conveying speed of 0.02-0.3m / s, and subjecting the cartons to electronic beam / X-ray irradiation generated by an electronic accelerator, wherein the electronic accelerator is 5-10MeV in energy, 0.3-20mA in beam current, 10-20kW in beam power, 100cm in largest scanning width, 5-15Hz in scanning frequency, 1-10kGy in irradiation dose and 5-35 DEG C in set operating temperature; allowing the cartons to pass a scanning widow of the electronic accelerator twice for irradiation, wherein the distance from the center of each carton to the scanning window of the electronic accelerator is 40-60cm in irradiation; and limiting the ambient humidity to be no larger than 60% in operation.

Owner:河南省科学院同位素研究所有限责任公司 +1

Manufacturing method for low-phenol paper-process reconstituted tobacco leaf

The invention provides a manufacturing method for a low-phenol paper-process reconstituted tobacco leaf. One portion of reconstituted tobacco leaf raw materials is taken according to parts by weight, 3 to 10 portions of ethanol (50 to 95%) are added, the backflow extraction is carried out for 50 to 70 minutes, and then extracted mixed solution is obtained and separated to obtain a solid phase part an a liquid phase part; the liquid phase part recycles the ethanol through vacuum concentration; the solid phase part is put into 4 to 10 portions of water after being dried till the moisture content is within 8 to 15% and is then extracted for 40 to 50 minutes under the temperature of 50 to 90 DEG C, so as to obtain the extracted mixed solution; vacuum concentration is carried out on the liquid phase part obtained by the separation of the extracted mixed solution till the density is within 1.1 to 1.3g / cm3, and the liquid phase part is adopted as a coating material; the solid phase part is defibered into a fiber sizing agent, the beating degree of the fiber sizing agent is within 20 to 400SR, the fiber sizing agent is diluted by water to obtain a papermaking seizing agent, and a substrate is prepared through papermaking; finally, the coating material is coated on the substrate, so as to obtain the finished reconstituted tobacco leaf through drying and split-cutting; and the reconstituted tobacco is a mixture containing one or two kinds of cabo, tobacco leaf and minced tobacco. The manufacturing method in the invention has obvious effect of reducing the phenol releasing quantity in smoke of the paper-process reconstituted tobacco leaf.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Tea tree flower-flavored tobacco accessories and tobacco products

ActiveCN103478904BGreat tasteReduce spicy stimulationTobacco smoke filtersVegetable material additionFlavorTobacco product

The invention belongs to the field of spices and tobacco, and relates to a tea-flower-aroma tobacco excipient and a tobacco product, in particular to a tobacco excipient containing tea flower extracts, application of the tobacco excipient in preparation of the tobacco product like cigarettes, and the tobacco product, containing the tobacco excipient, like the cigarettes. The cigarettes has a tea flower aroma which is consistent with an own fragrance of tobacco of the cigarettes, aroma and taste of the cigarettes are obviously improved, remaining taste is comfortable, smoke is delicate and soft, and spicy stimulation and mouth dryness sensation of the smoke is effectively reduced. The tobacco excipient which is a tobacco flavor is simple in preparation process, and original processing techniques and equipment of the cigarettes are unchanged in the process of adding of the tobacco excipient.

Owner:CHINA TOBACCO FUJIAN IND +1

Filter material containing nanometer SOD and its preparation method

InactiveCN100404100CSuitability for damageReduce contentTobacco smoke filtersFiltration separationTarFilter material

A filter material containing nano-SOD with high effect to filter out tar is prepared through preparing filtering material and dipping in SOD solution or spraying the SOD solution on it.

Owner:王成余

A kind of green tea fragrant cigarette paper without industrial preservatives and preparation method thereof

ActiveCN110952374BFull of smellLess irritatingVegetable material additionPaper/cardboardBiotechnologyGreen teas

Owner:CHINA TOBACCO ZHEJIANG IND

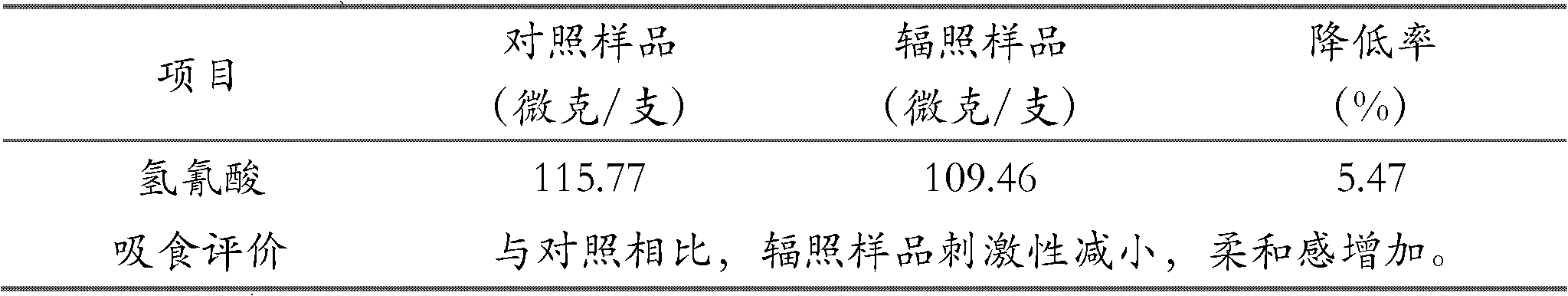

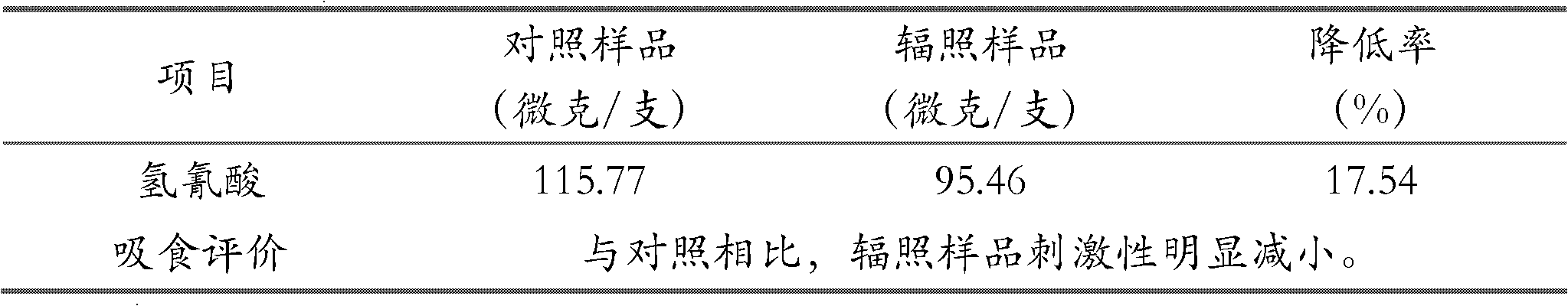

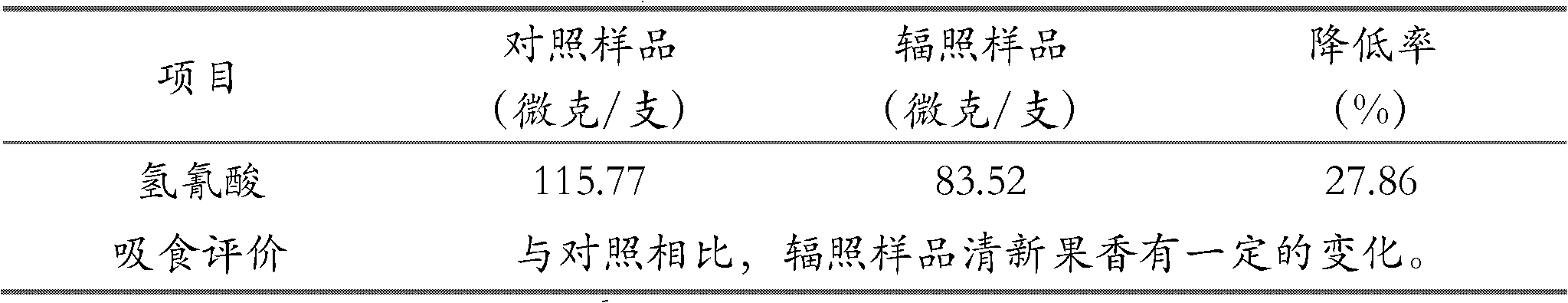

Method for reducing hydrocyanic acid in mainstream smoke of cigarette

InactiveCN102578700AReduce hydrocyanic acidImprove smoking safetyTobacco treatmentAmbient humidityX-ray

The invention discloses a method for reducing hydrocyanic acid in mainstream smoke of a cigarette. The method comprises the steps of: packaging tobacco leaves / finished cigarettes with a carton, wherein the stacking thickness of the tobacco leaves / finished cigarettes is 26-72cm and the stacking density of the tobacco leaves / finished cigarettes is 0.20-0.34g / cm<3>; and placing the cigarette carton on a transmitting device with the transmitting speed of 0.02-0.3m / s, and subjecting the cigarette carton to irradiation of electron beams / X-rays produced by an electronic accelerator, wherein the energy of the electronic accelerator is 5-10meV, the beam current is 0.3-20mA, the beam power is 10-20kW, the maximal scanning width is 100cm, the scanning frequency is 5-15Hz, the irradiation dose is 1-10kGy, the work temperature is set to be 5-35 DEG C, the cigarette carton is irradiated by passing through a scanning window of the electronic accelerator twice, the distance from the center of the cigarette carton to the scanning window of the electronic accelerator is 40-60cm during irradiation, and the ambient humidity is limited to be not more than 60% during working.

Owner:河南省科学院同位素研究所有限责任公司 +1

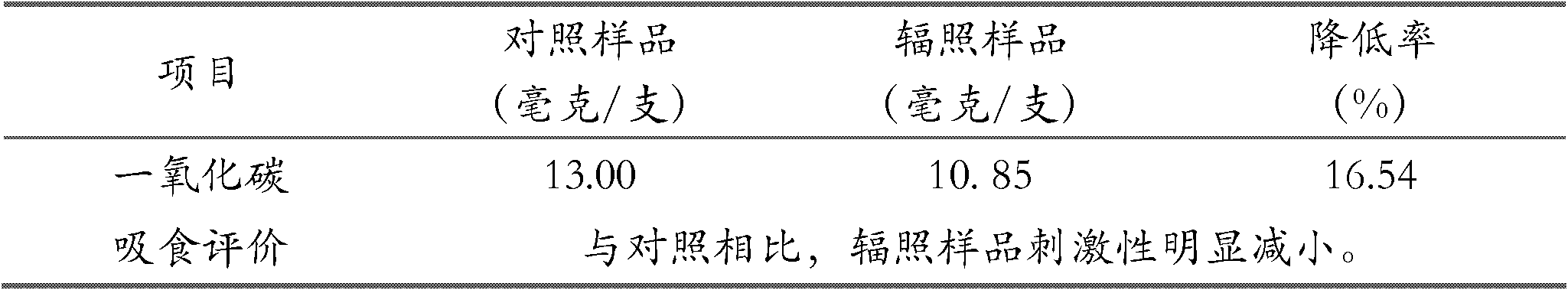

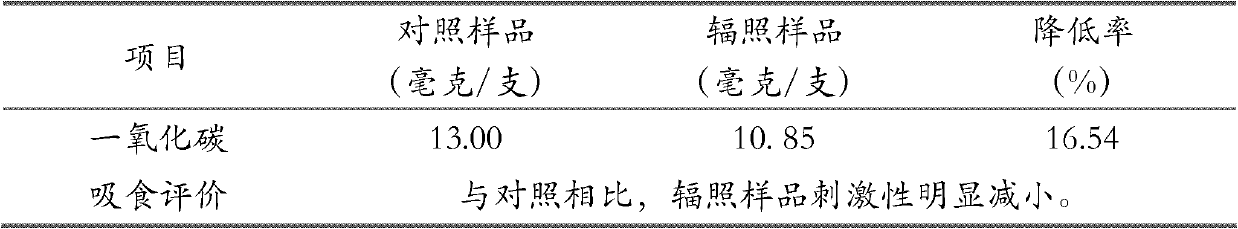

Method for lowering carbon monoxide content in main smoke of cigarette

InactiveCN102599645BLess carbon monoxideImprove smoking safetyTobacco treatmentAmbient humidityWorking temperature

The invention discloses a method for lowering carbon monoxide content in main smoke of cigarette. The method comprises the steps of: packaging tobacco leaves / cigarette finished product with cartons, wherein the stacking thickness is 26-72cm and the stacking density is 0.20-0.34g / cm<3>; and placing the cigarette cartons on a conveying device with conveying speed of 0.02-0.3m / s and irradiating withelectron beam / X ray generated by an electron accelerator, wherein the energy of the electron accelerator is 5-10MeV, the beam current is 0.3-20mA, the beam power is 10-20kW, the maximum scanning width is 100cm, the scanning frequency is 5-15Hz, the irradiation dose is 1-10kGy, the working temperature is set at 5-35 DEG C, the cigarette cartons pass through a scanning window of the electron accelerator twice to undergo irradiation, the distance between the center of the cigarette carton and the scanning window of the electron accelerator is 40-60cm during irradiation, and the ambient humidity is limited to be not more than 60% during working.

Owner:河南省科学院同位素研究所有限责任公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com