Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Improve screwing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

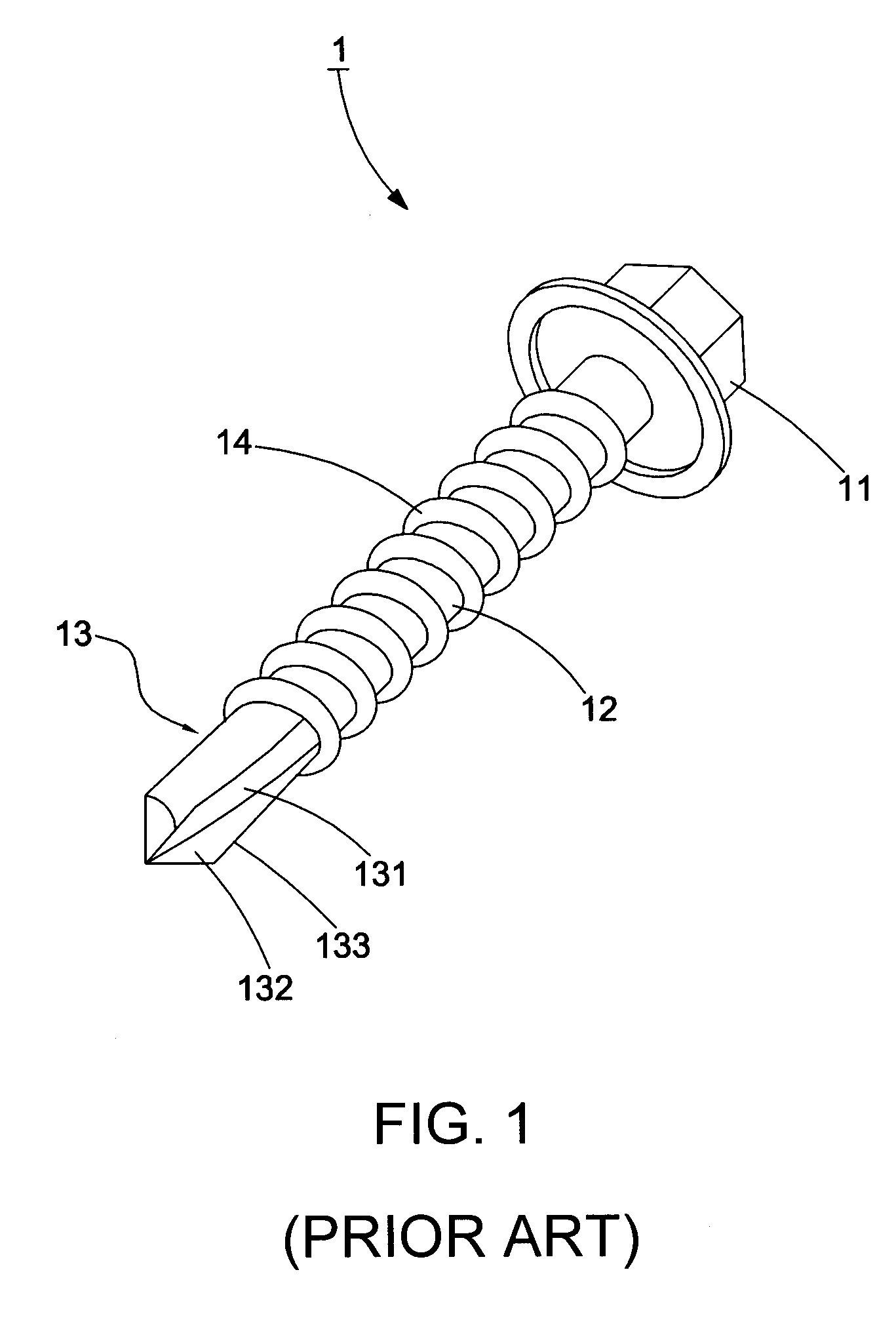

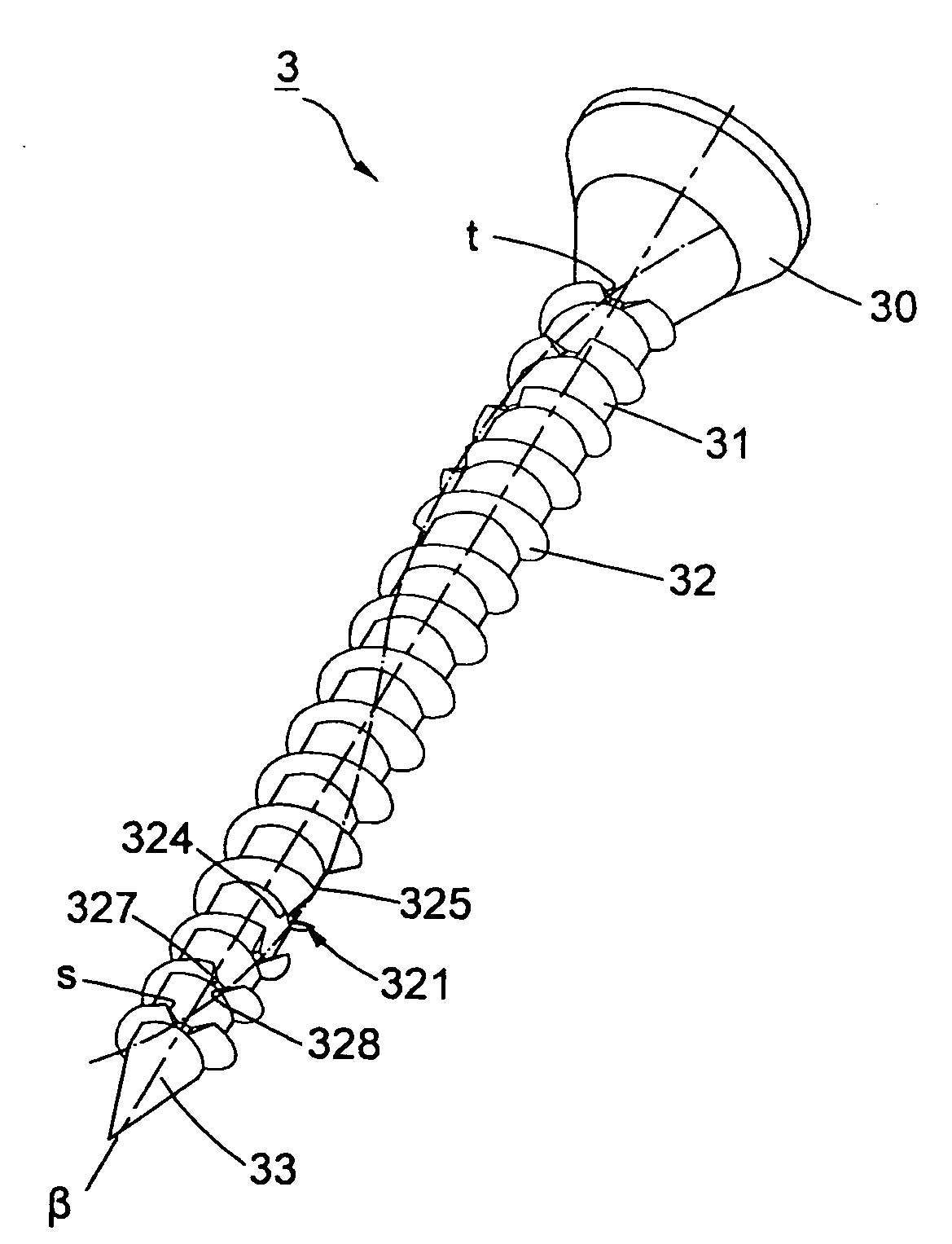

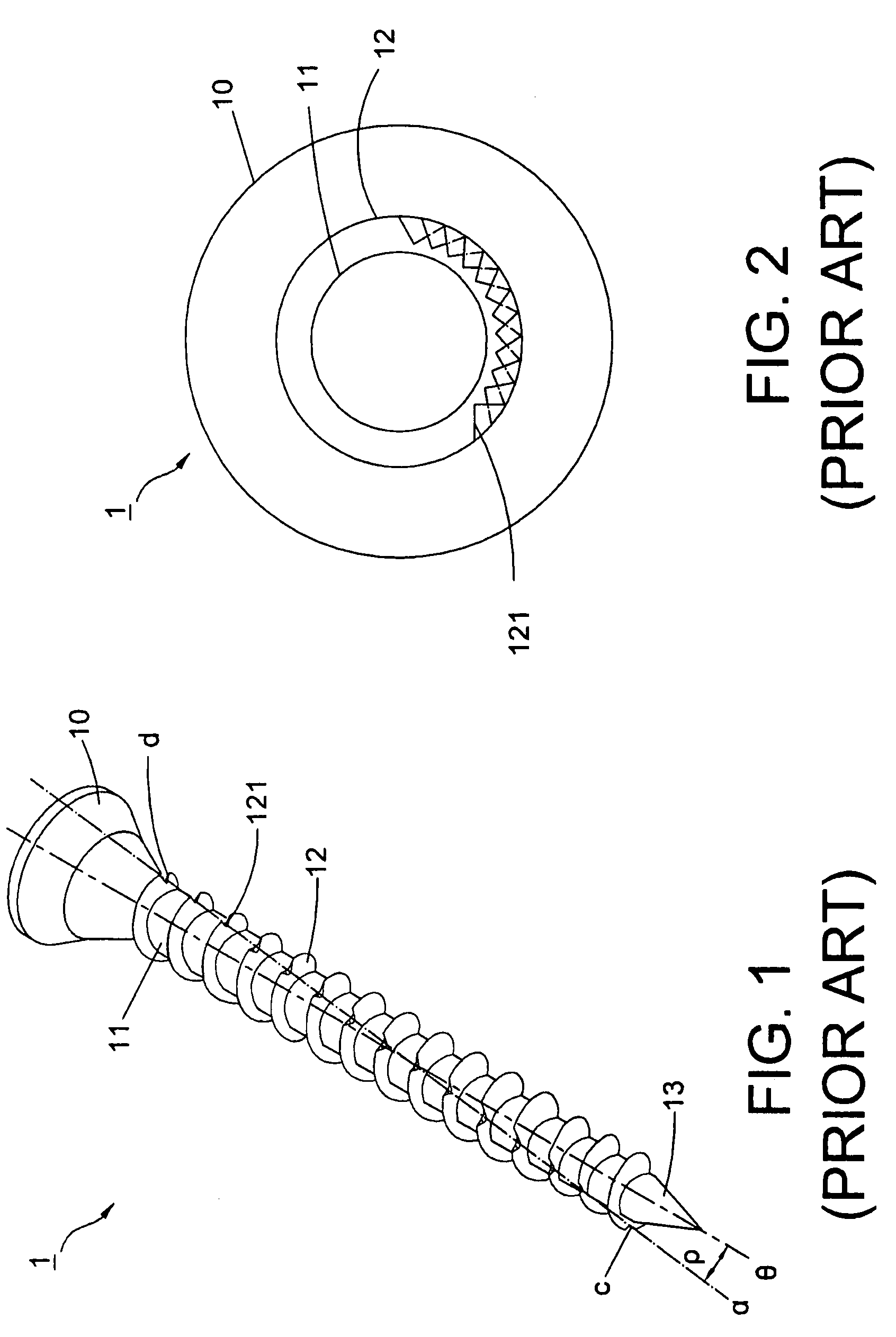

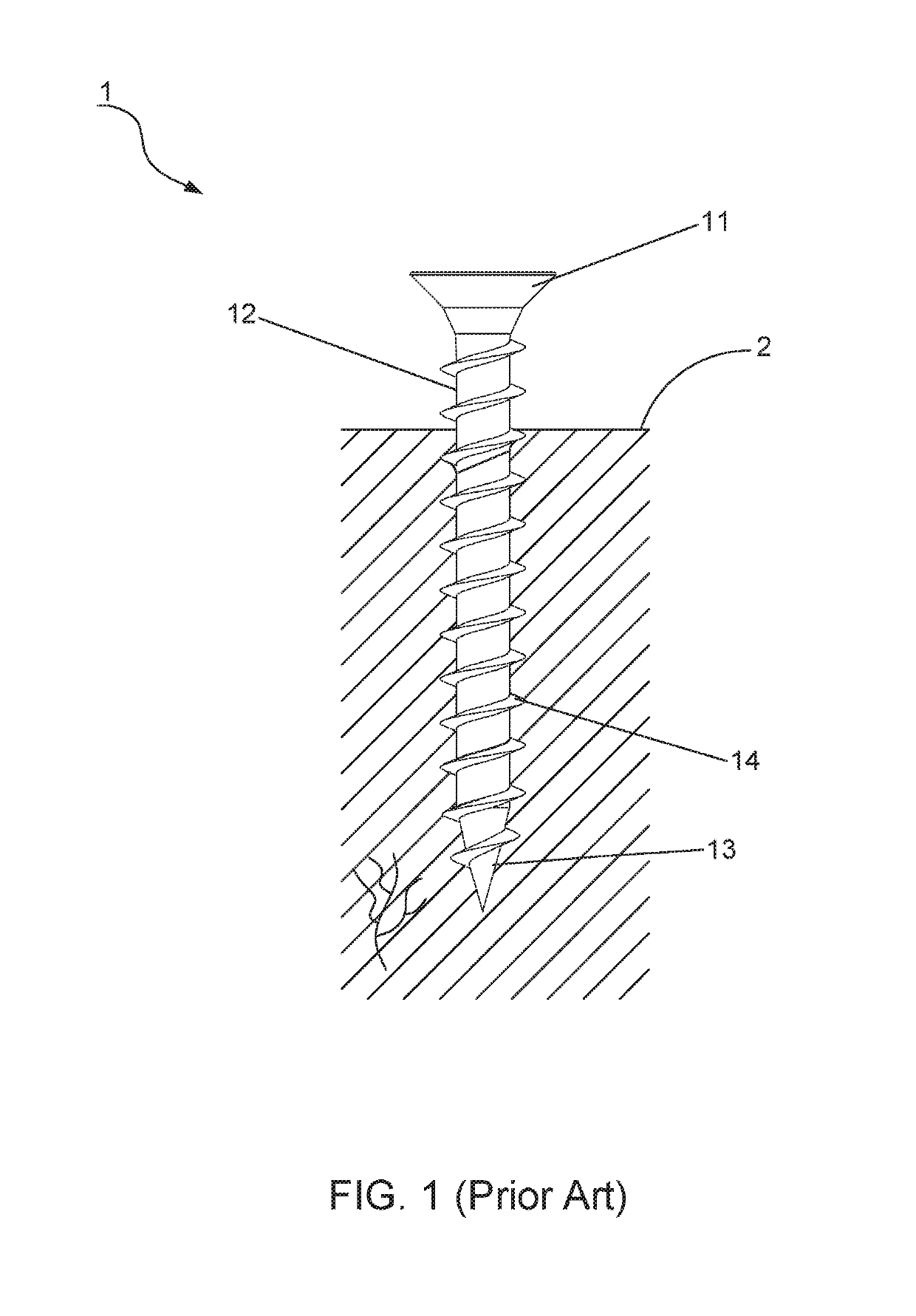

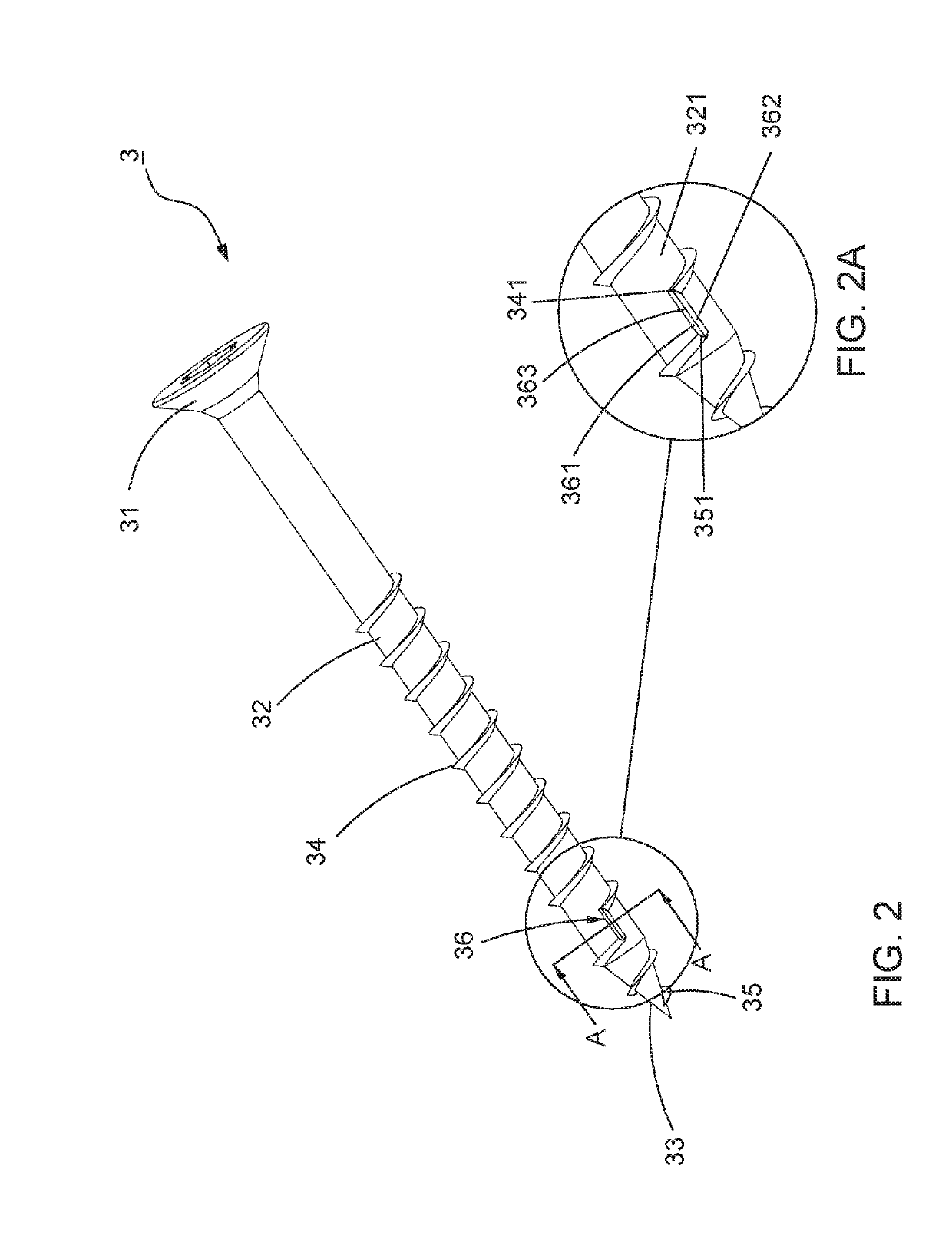

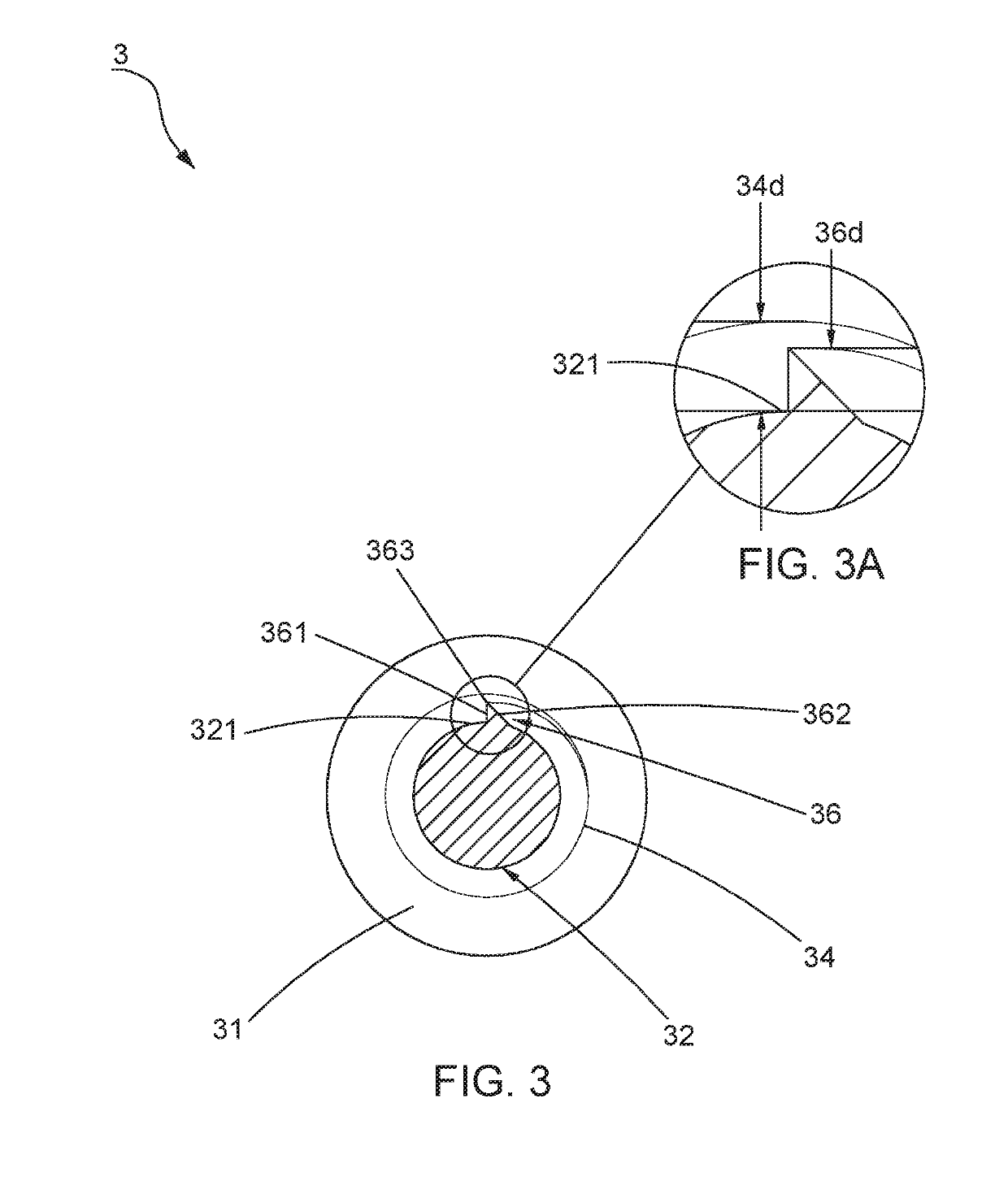

High screwing screw

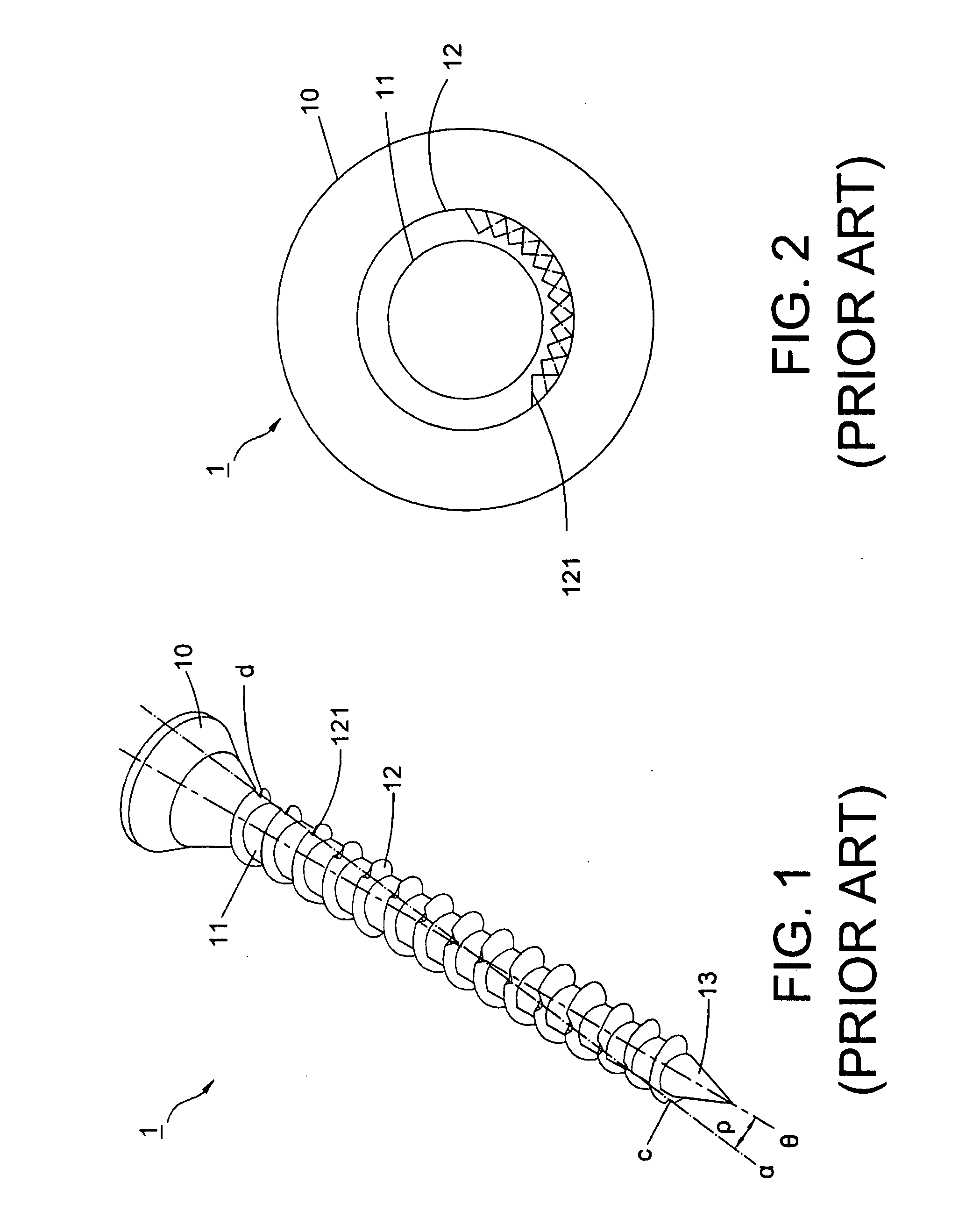

InactiveUS20090028665A1Improve screwing efficiencyImprove cutting effectScrewsMechanical engineeringEngineering

The present invention pertains to a screw notably comprising a shank with a plurality of flat surfaces; wherein, a lip is defined by the junction of any of two adjacent flat surfaces, and a rib located between two threads is protruded from the lip. While in operation, by means of the configuration of the ribs, the screw facilitates to increase the cutting capability for achieving a higher screwing speed and preserve a good resistance of extraction.

Owner:ESSENCE METHOD REFINE

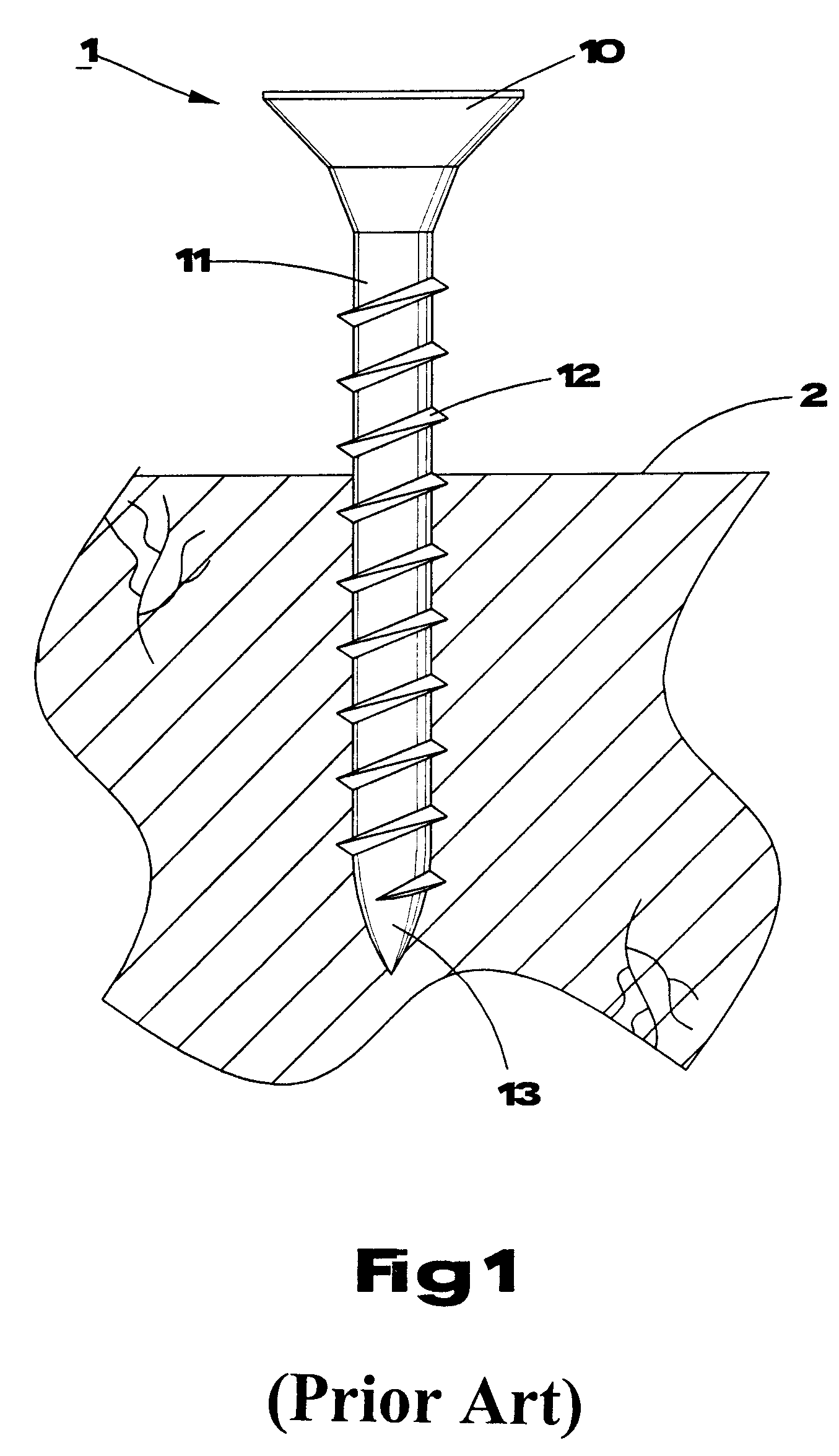

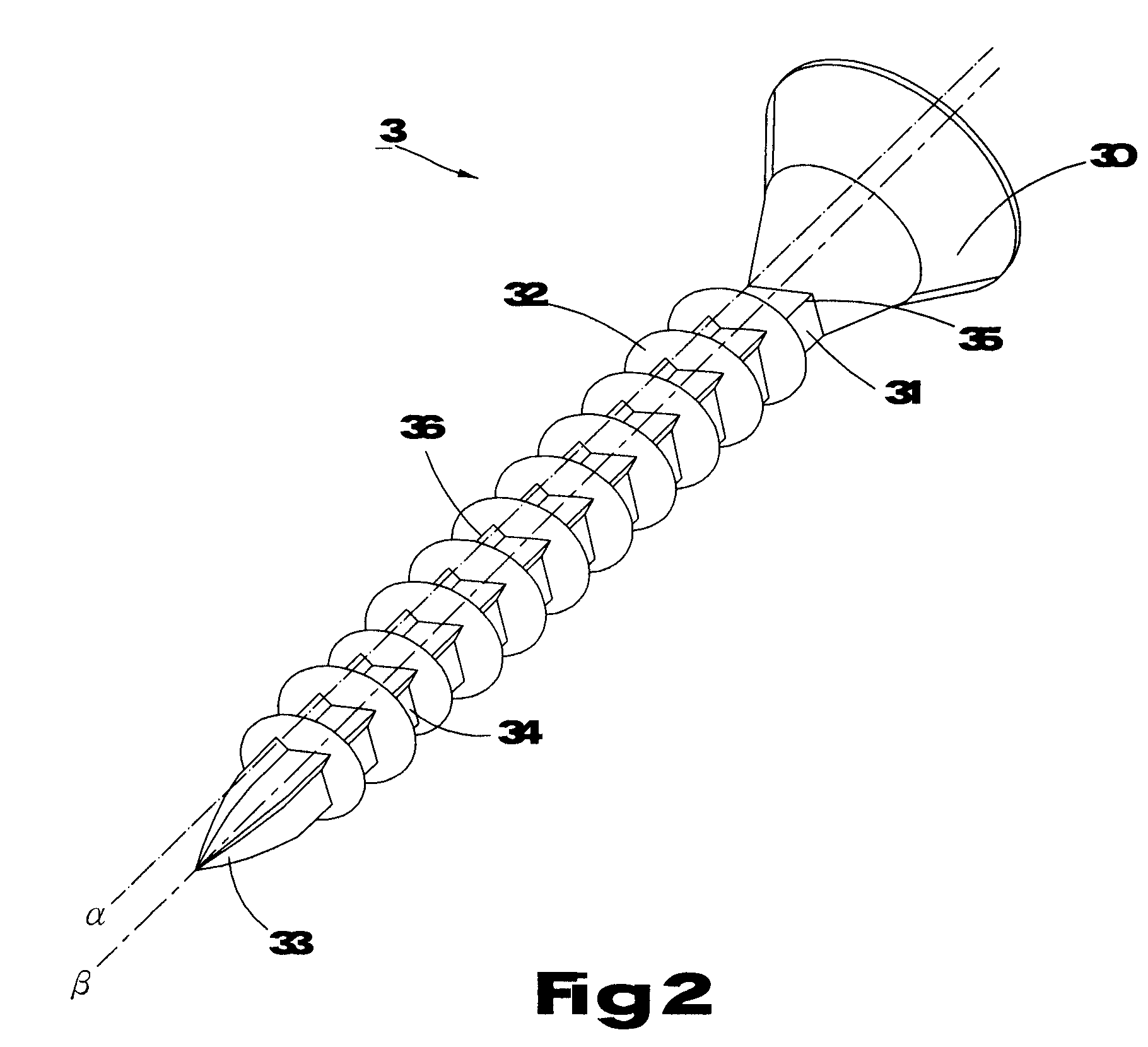

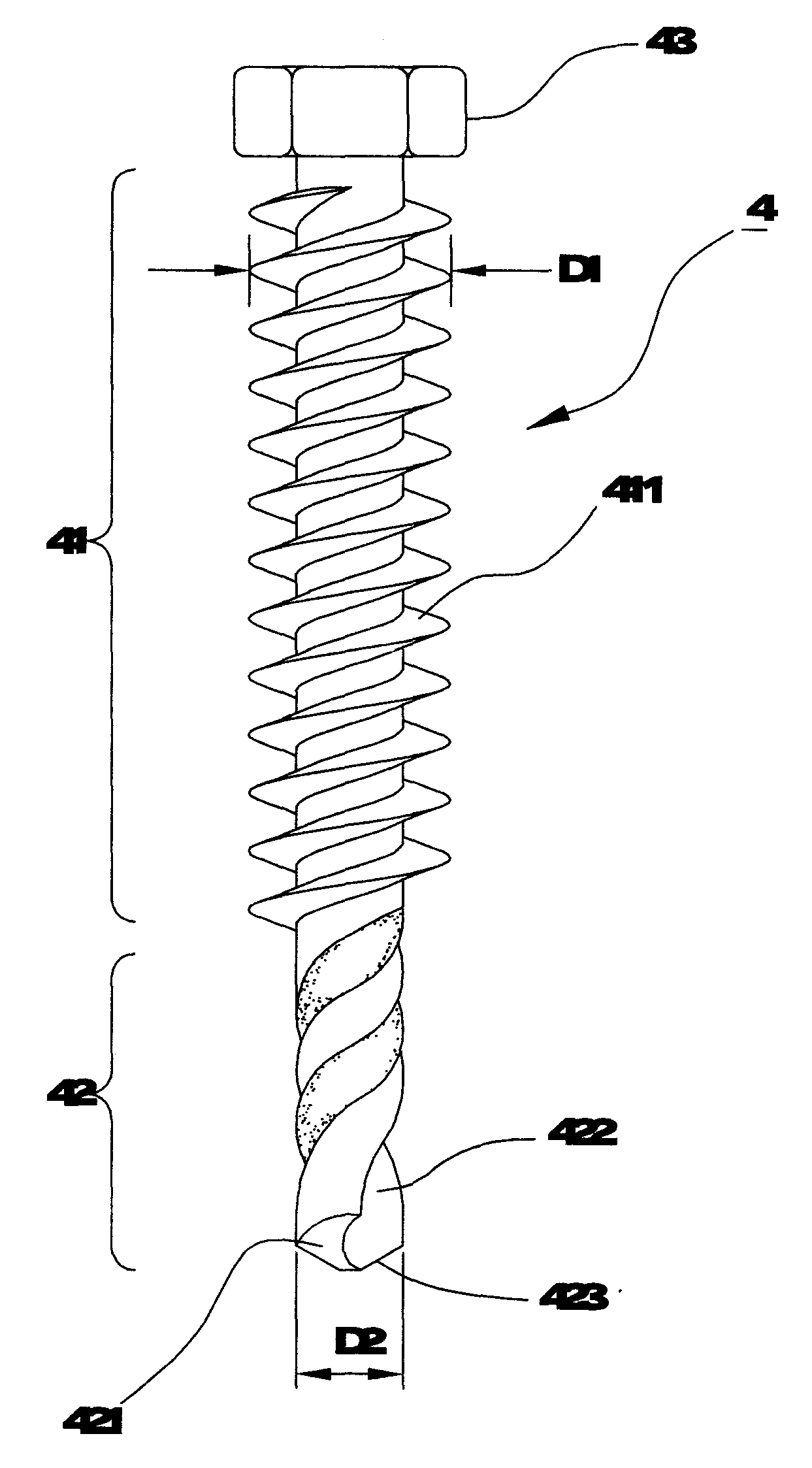

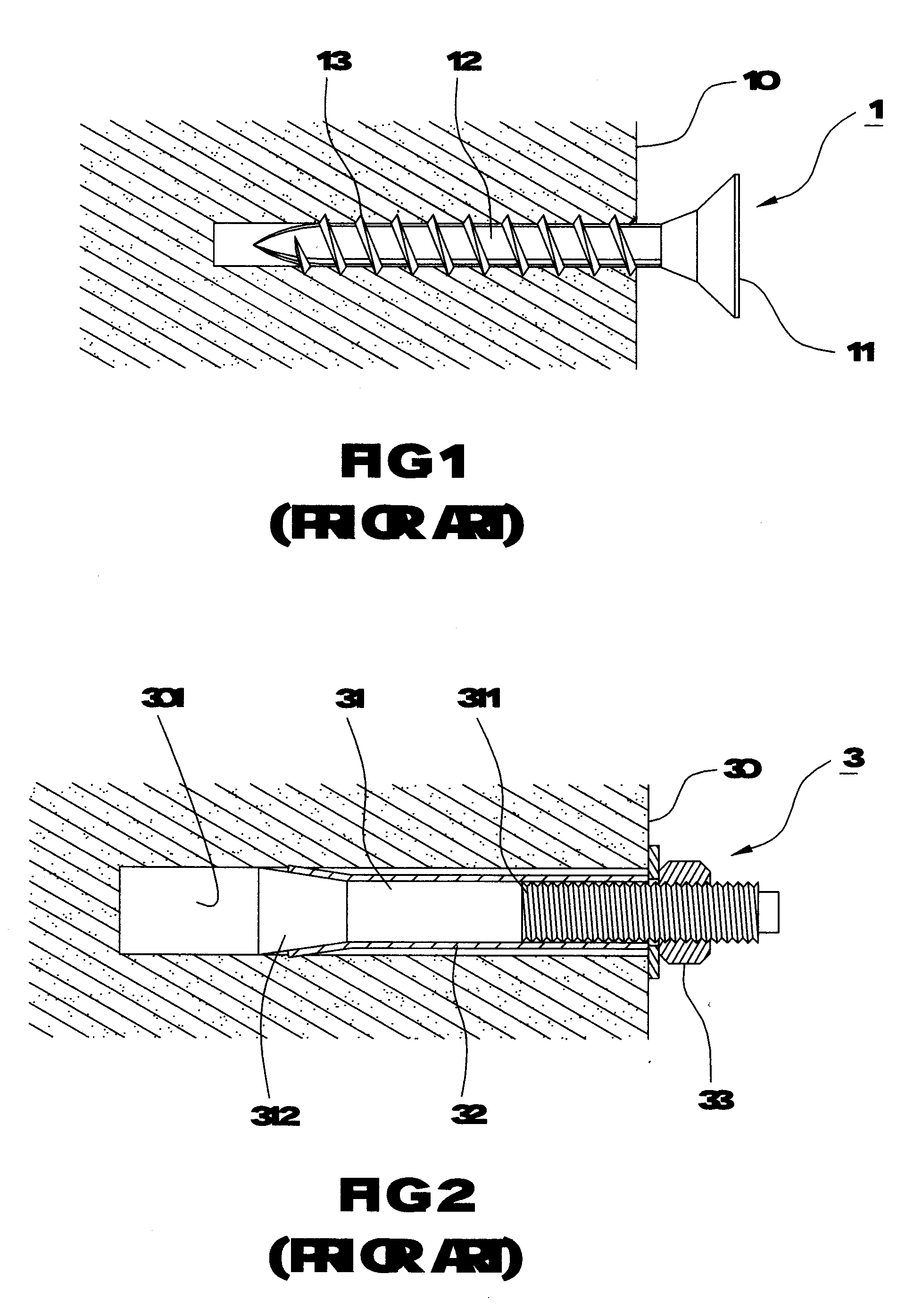

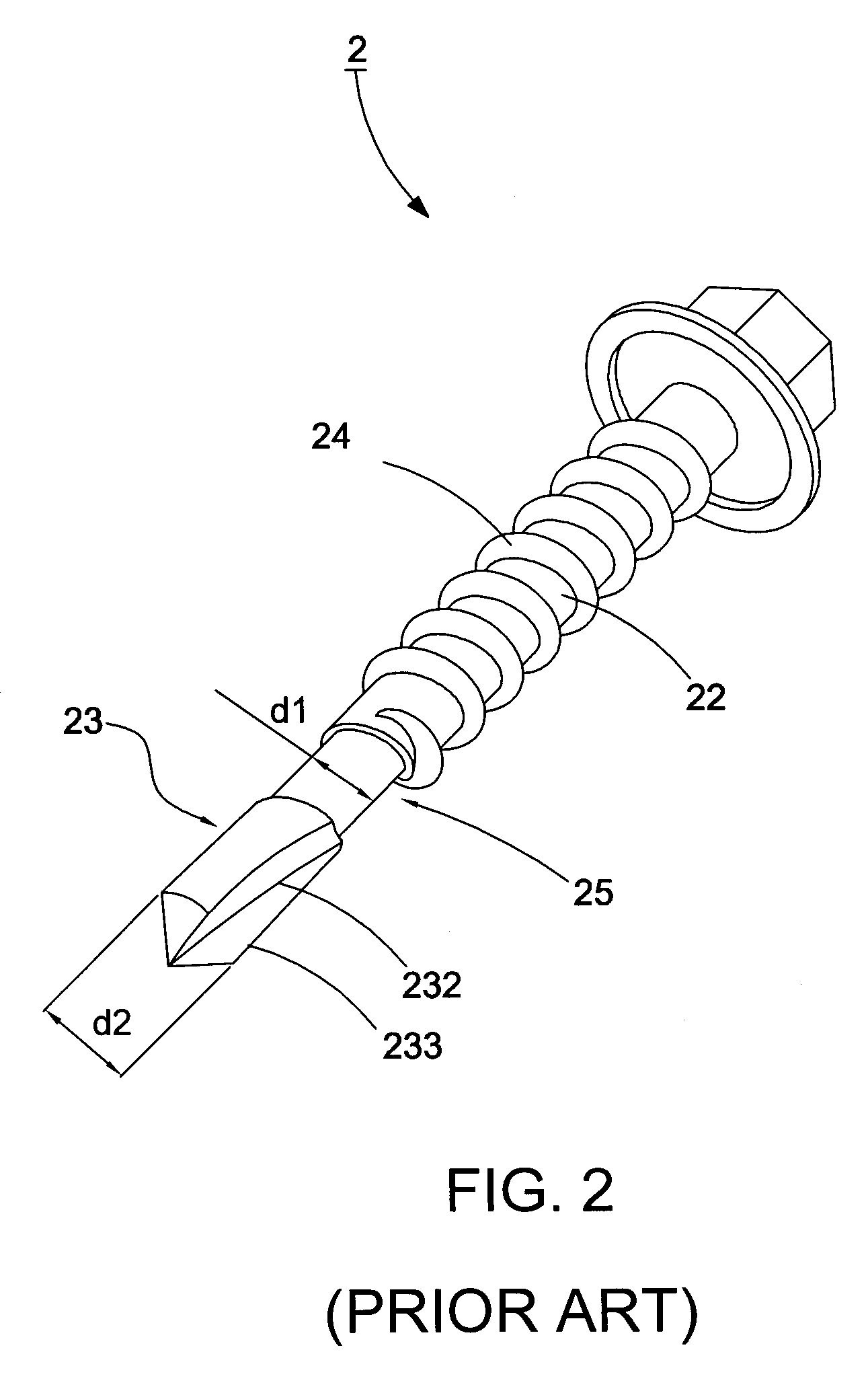

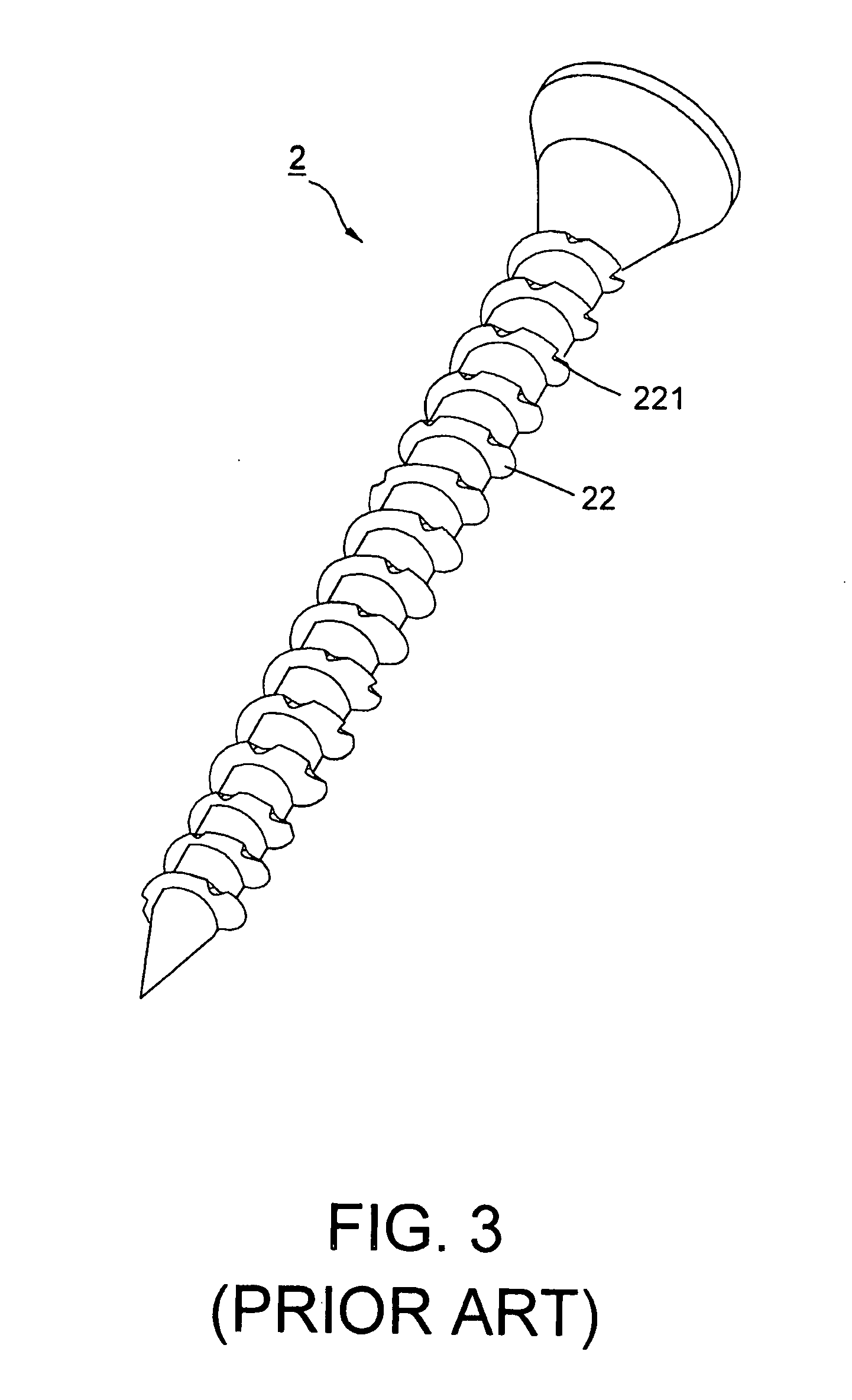

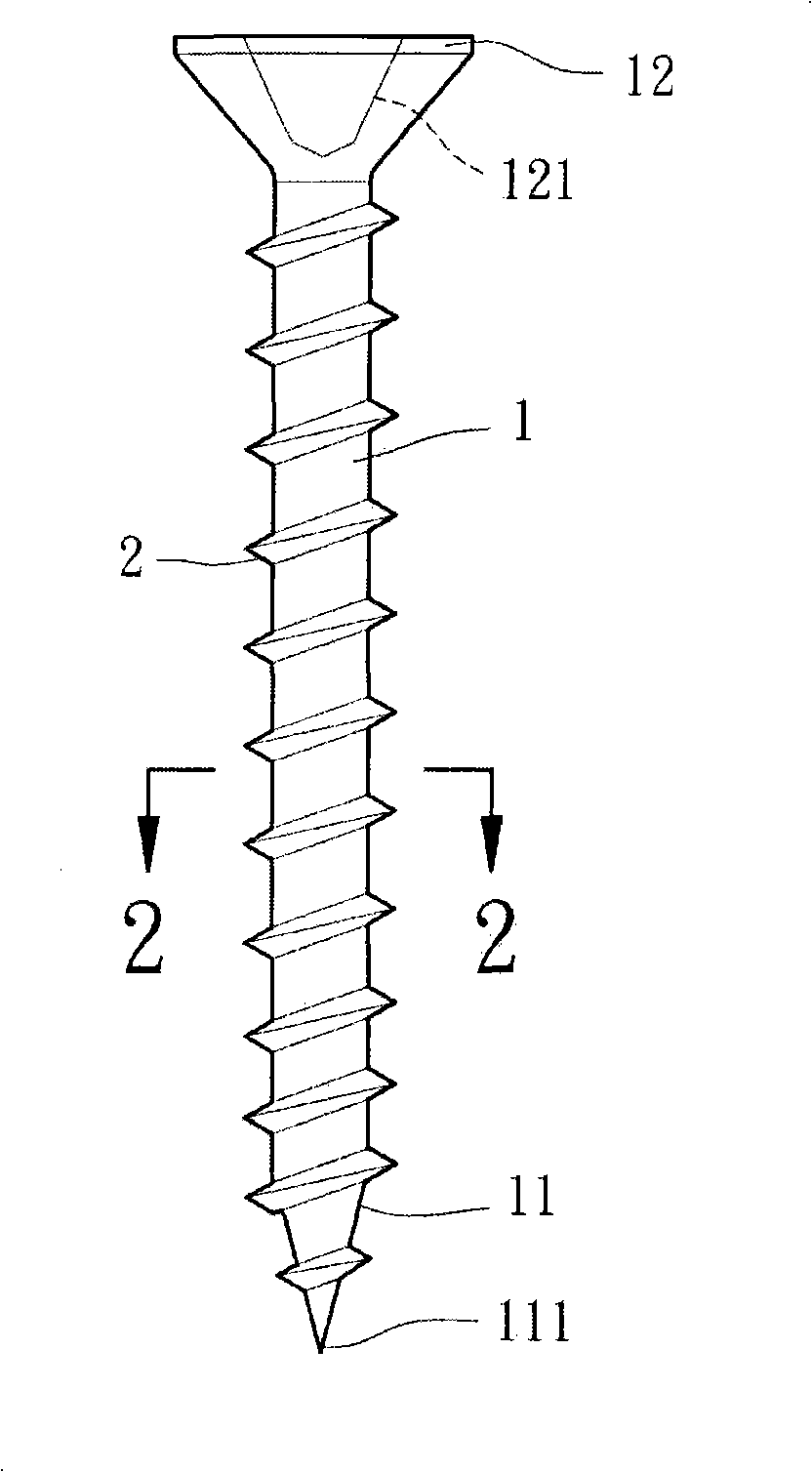

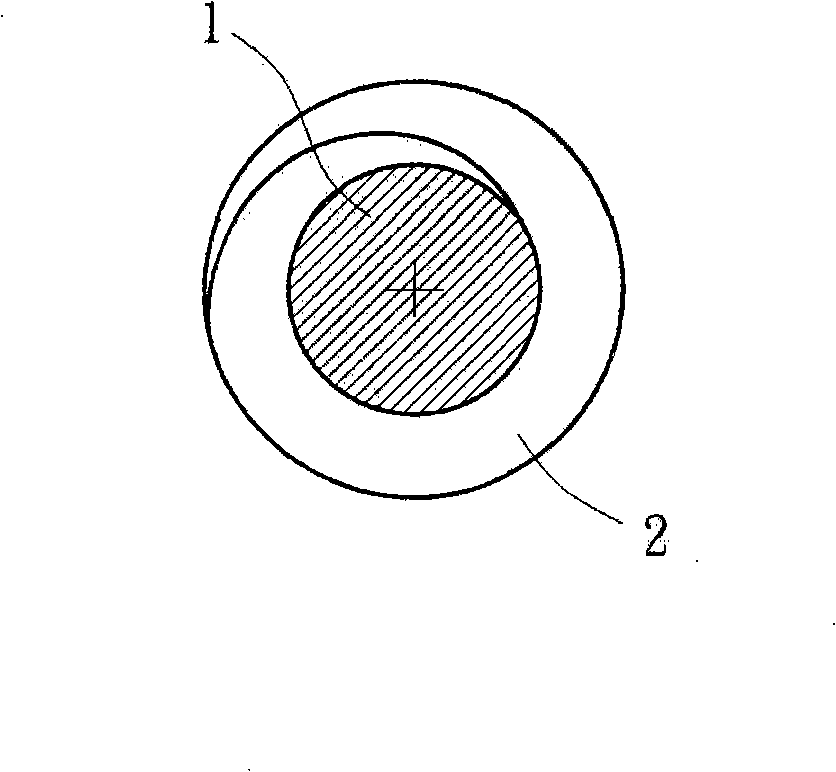

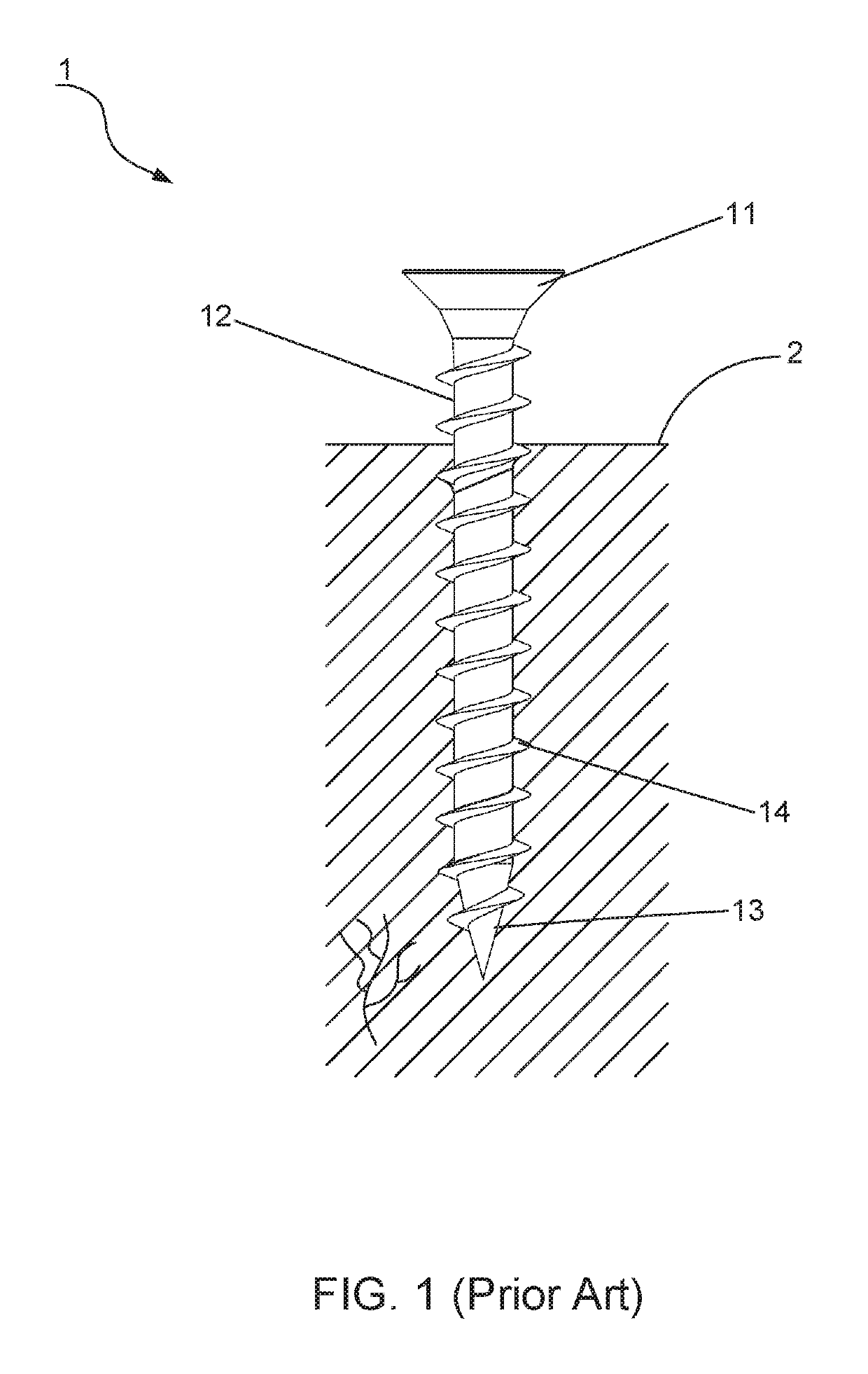

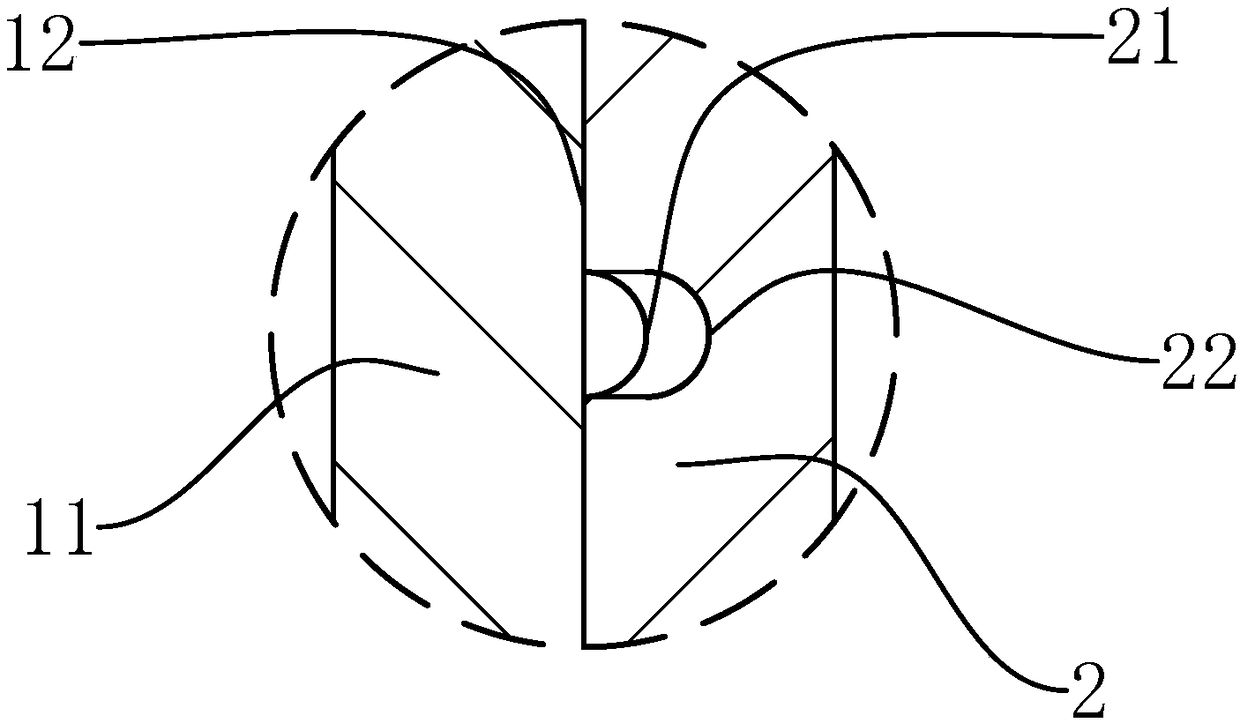

Concrete Screws

InactiveUS20080124188A1Improve screwing efficiencyShorten tightening timeSheet joiningScrewsFluteEngineering

The present invention pertains to a concrete screw comprising a threaded portion with threads spirally disposed thereon and a helical conveying portion. In particular, the outer diameter of the threads is greater than the diameter of the helical conveying portion, in which two angled surfaces formed on the end thereof; two flutes are respectively defined between the angled surfaces, a cutting edge is formed on the intersection of one side of each of angled surfaces and two flutes. While screwing, the screw can directly and facilely be firmly screwed into the wall, thus greatly saving the screwing time and increasing the screw efficiency.

Owner:CHANG CHEN CHIH +2

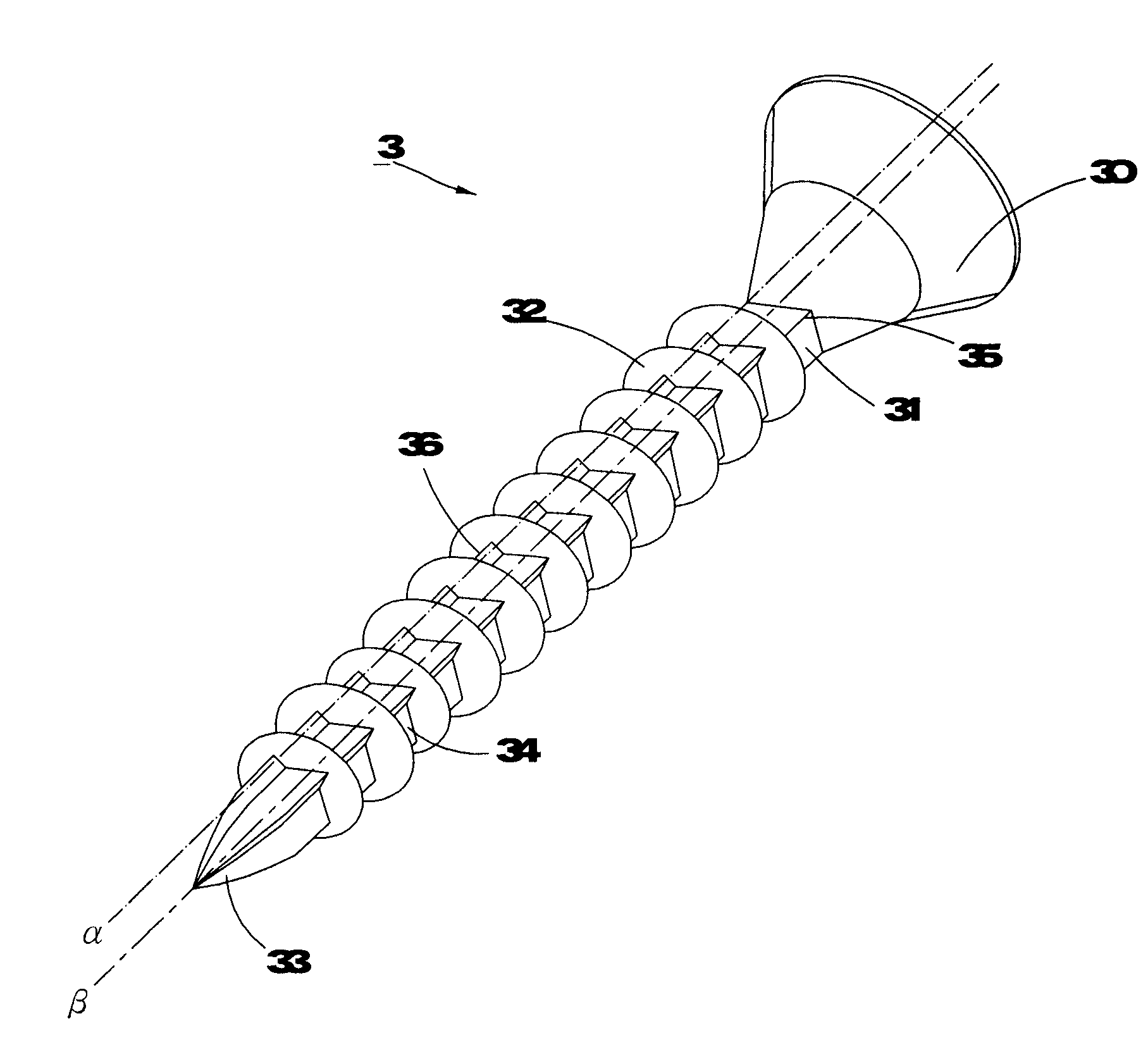

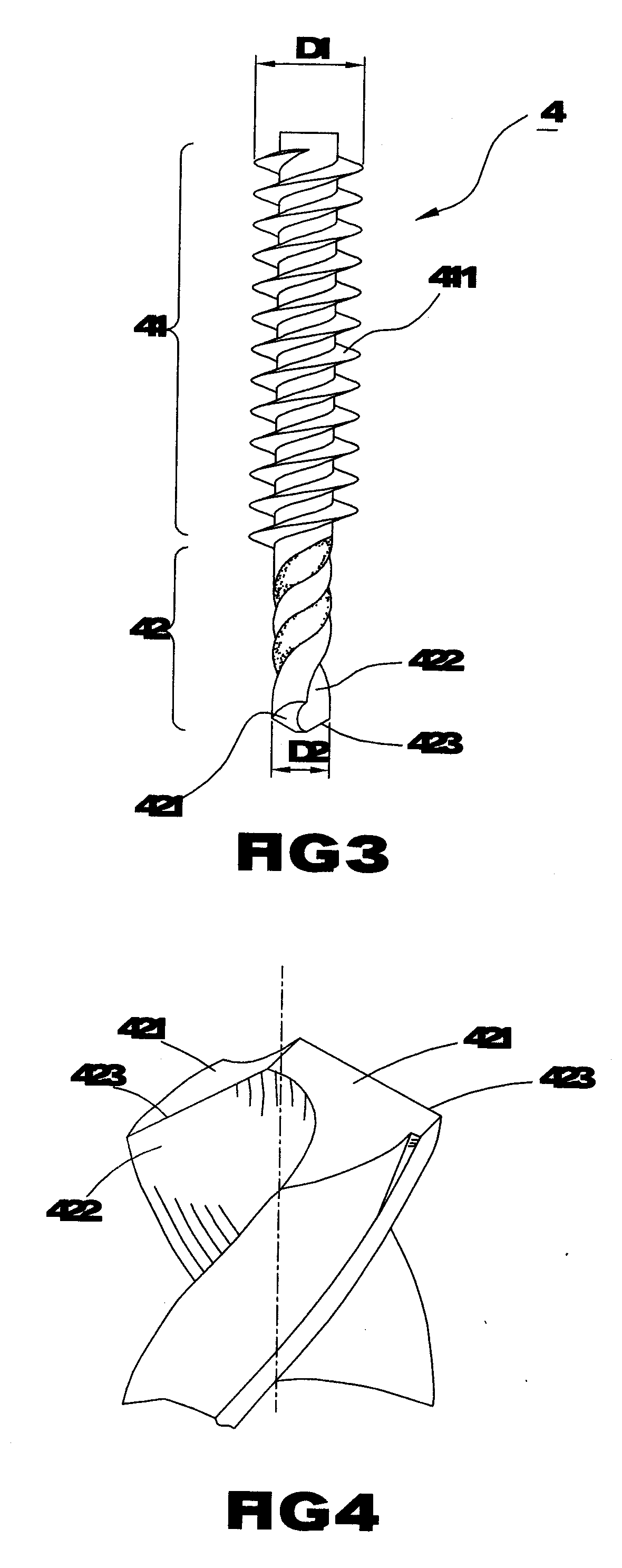

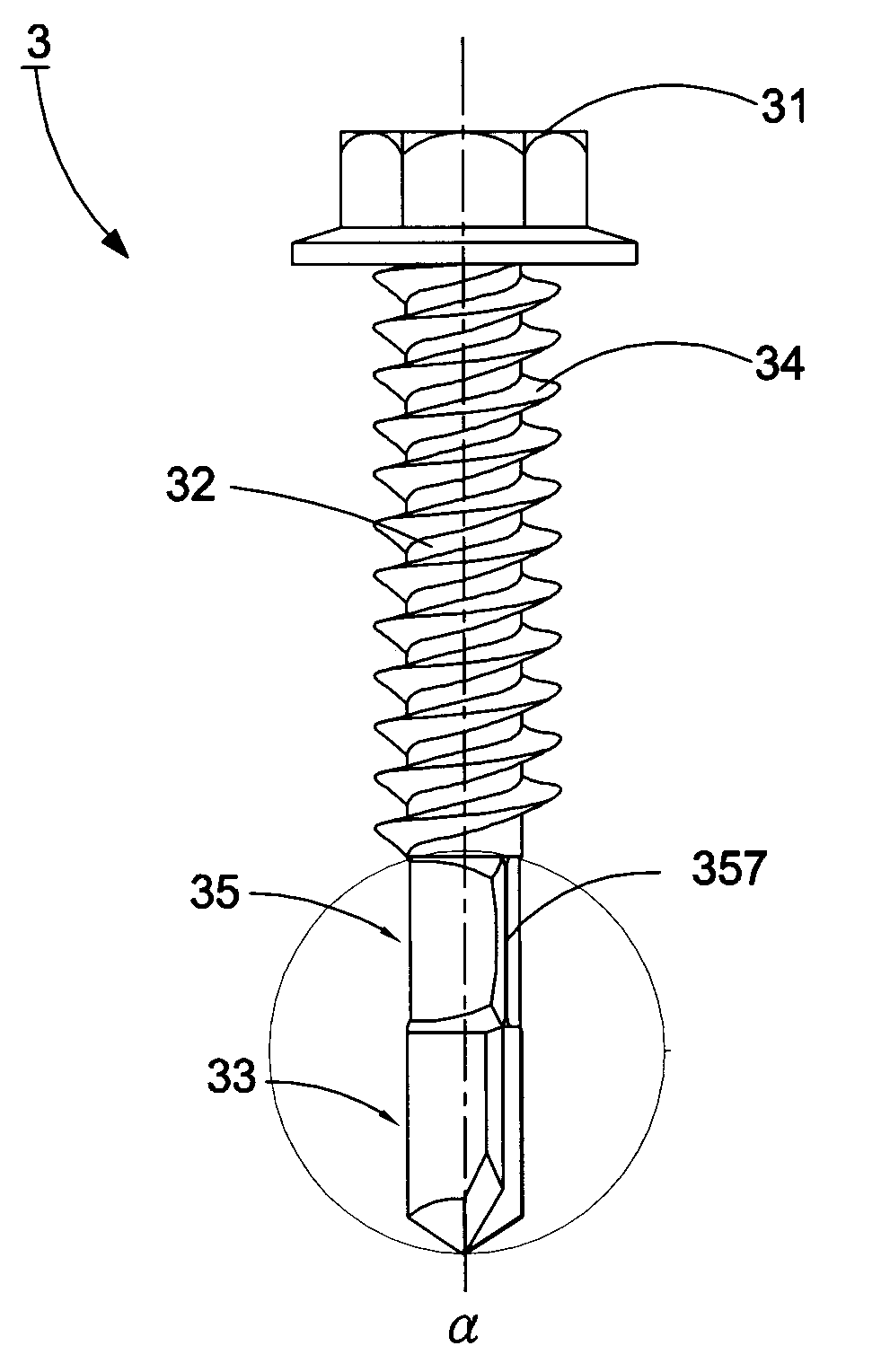

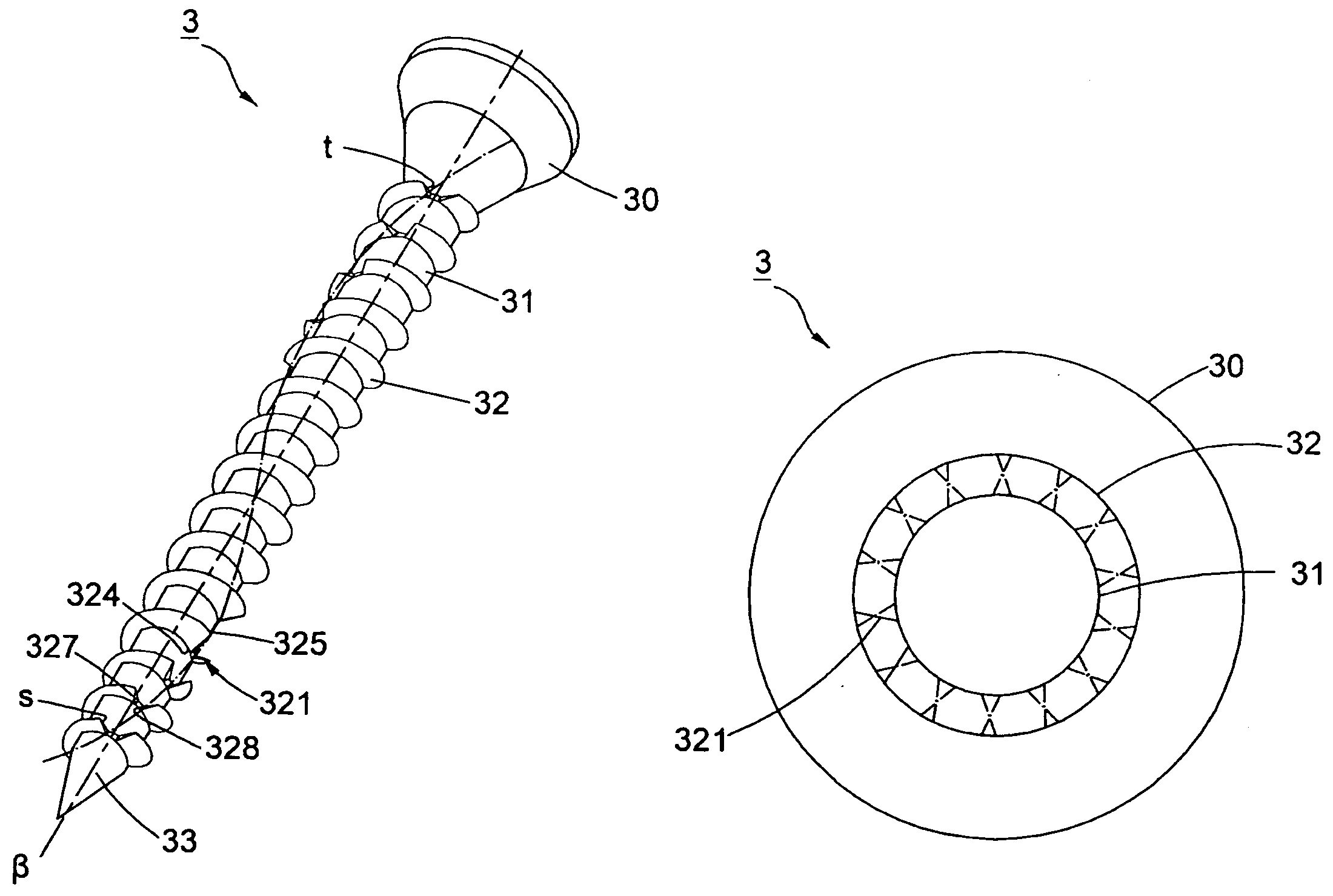

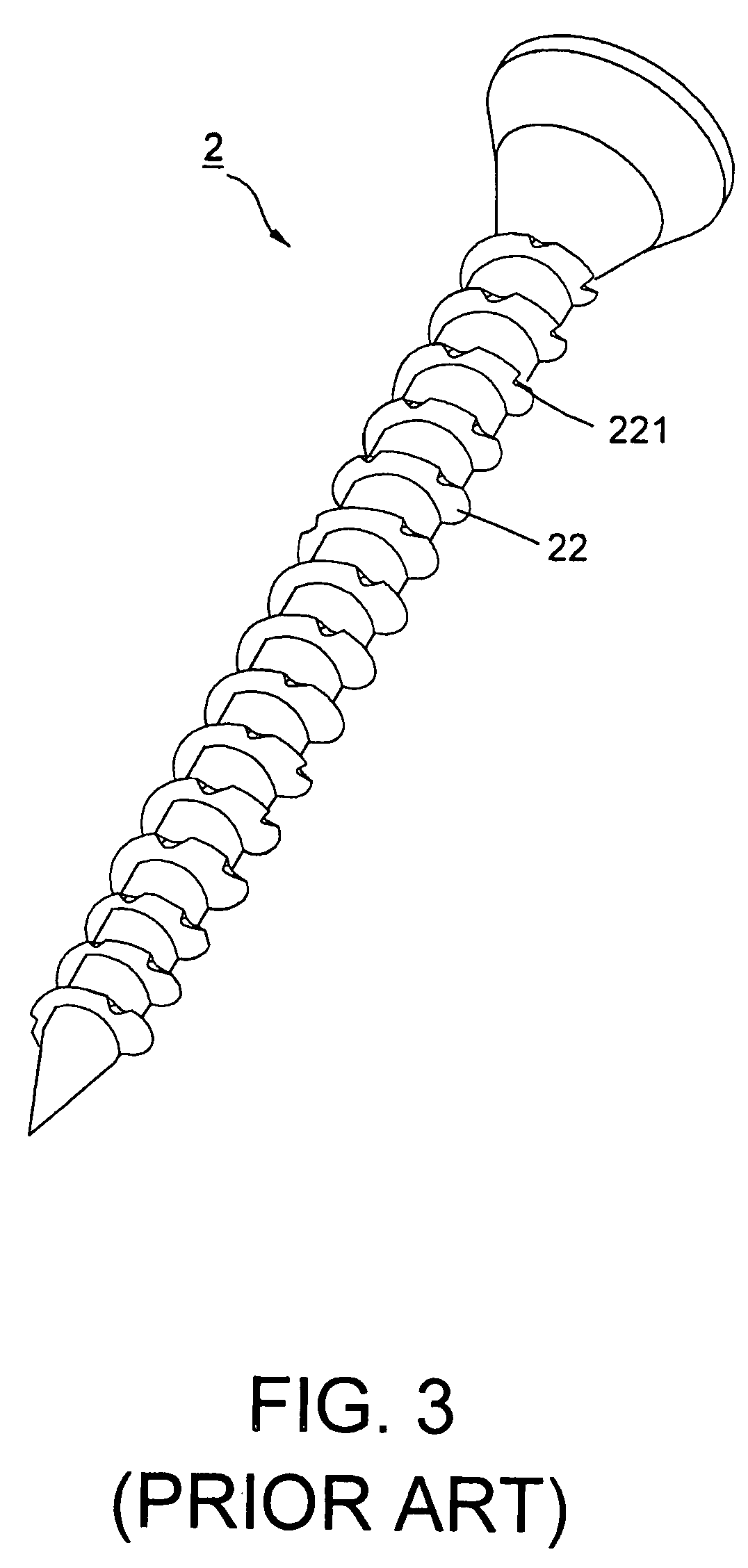

Self-drilling screw with multi-drilling portions

A self-drilling screw with multi-drilling portions mainly comprises a shank, a head and a drilling portion separately disposed on both ends of the shank, and a thread section spiraled on the shank. Wherein, at least one sub-drilling portion formed amid the drilling portion and the thread section further defines a sequence of indentations and prominent areas, and each indentation generates a cutting surface outwardly extended from one side thereof so as to converge the cutting surface with the adjacent prominent area at a cutting ridge. Accordingly, the application of the cutting ridges and the indentations facilitates the drilling portion with the chipping capability and renders an appropriate guidance to redundant debris, thereby efficiently achieving a swift screwing and the lowered screwing resistance to promote the screwing efficiency.

Owner:CHAN LIANG ENTERPRISE

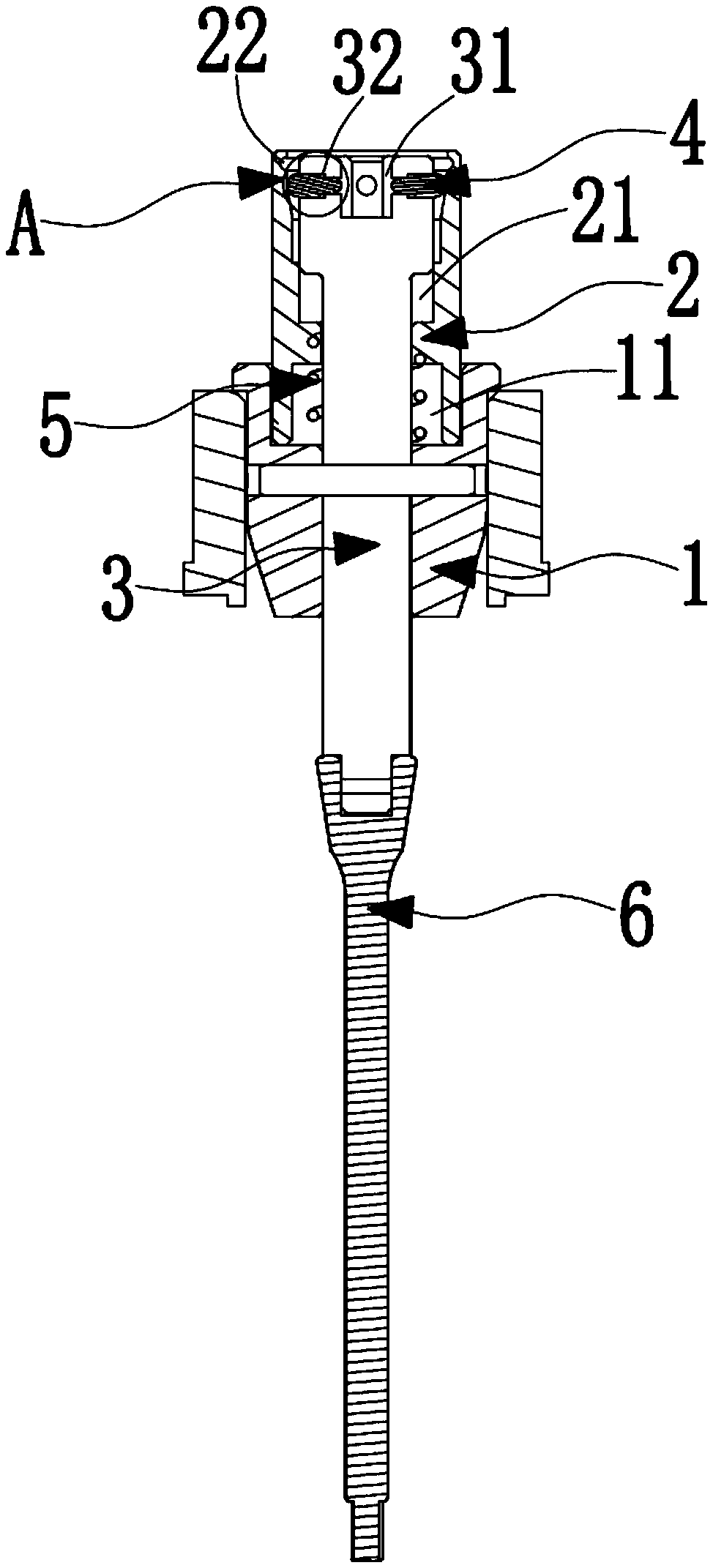

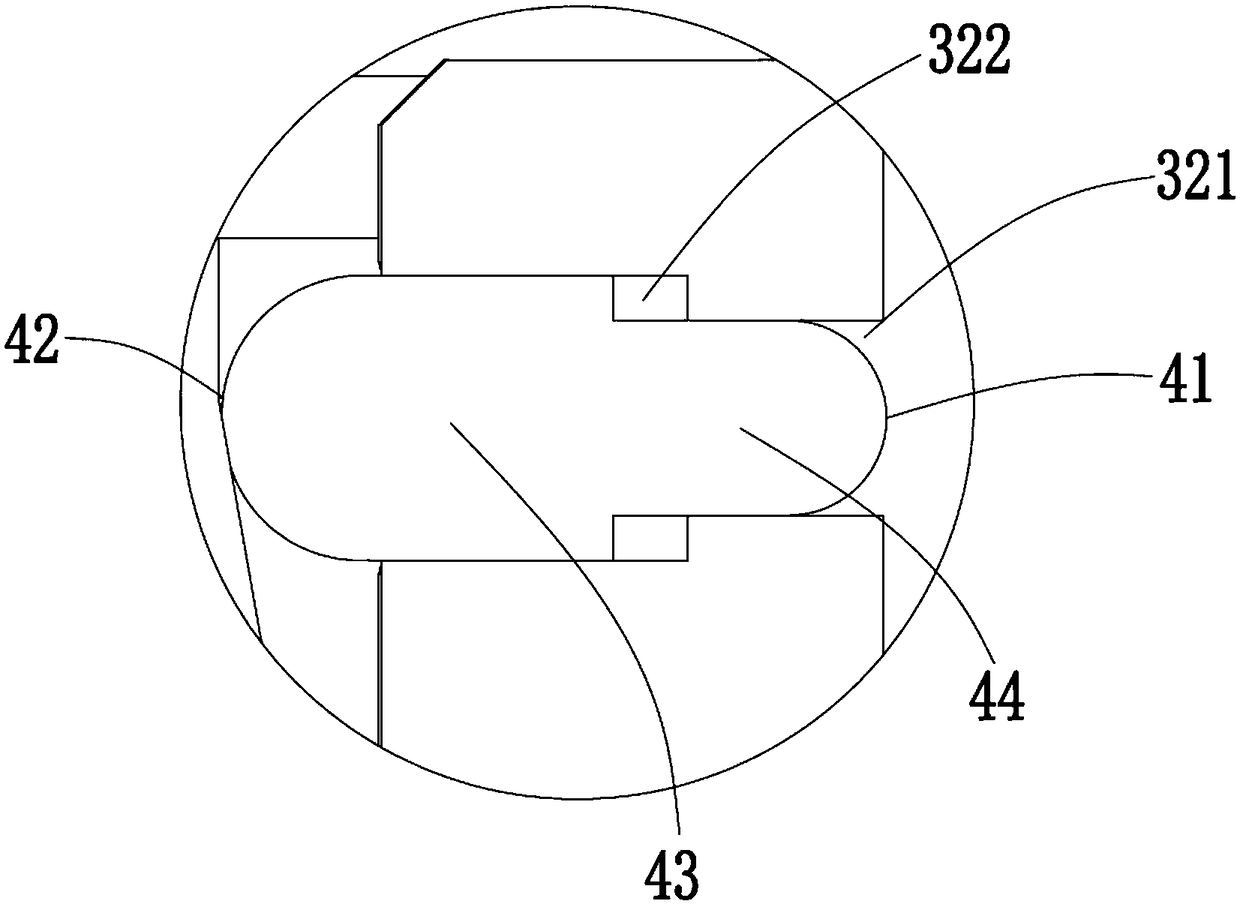

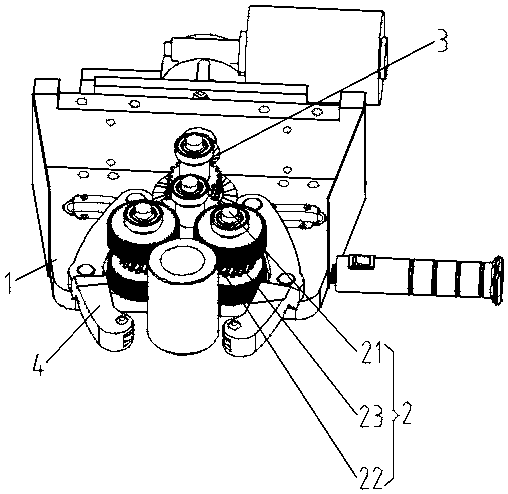

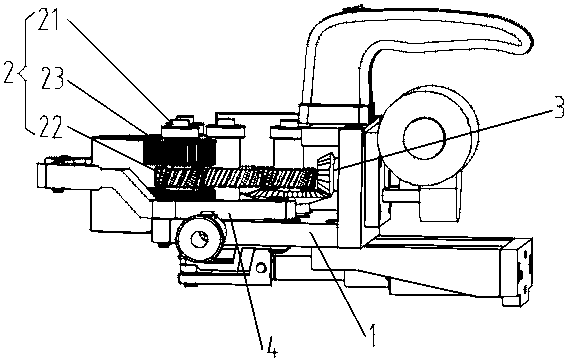

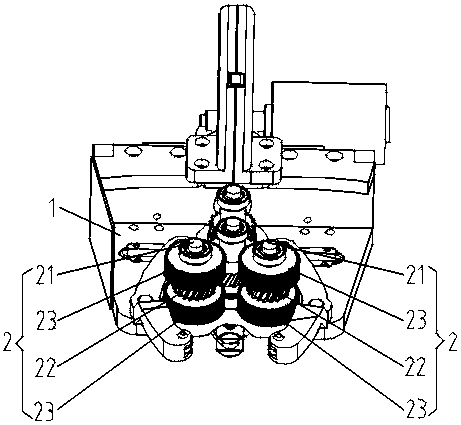

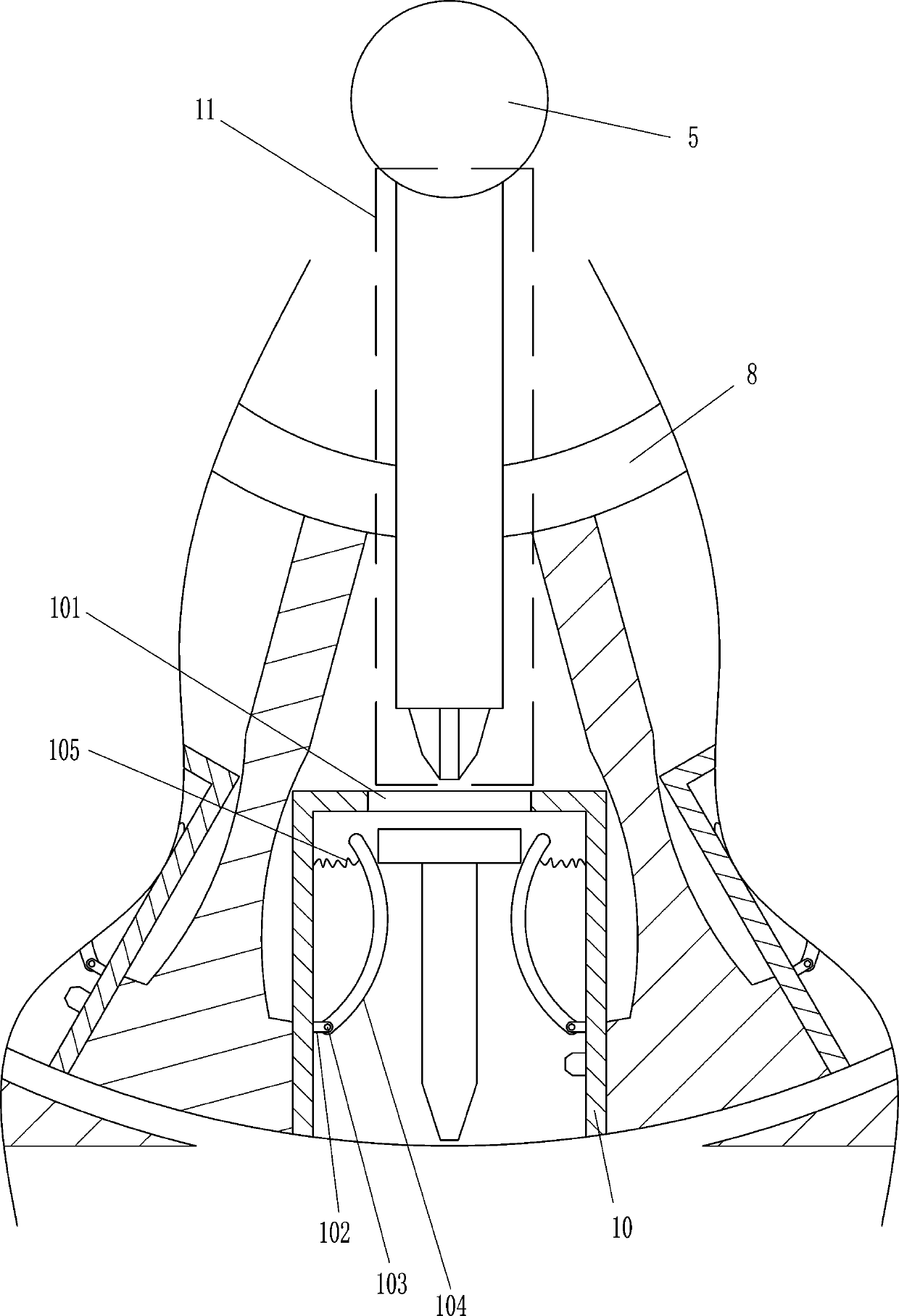

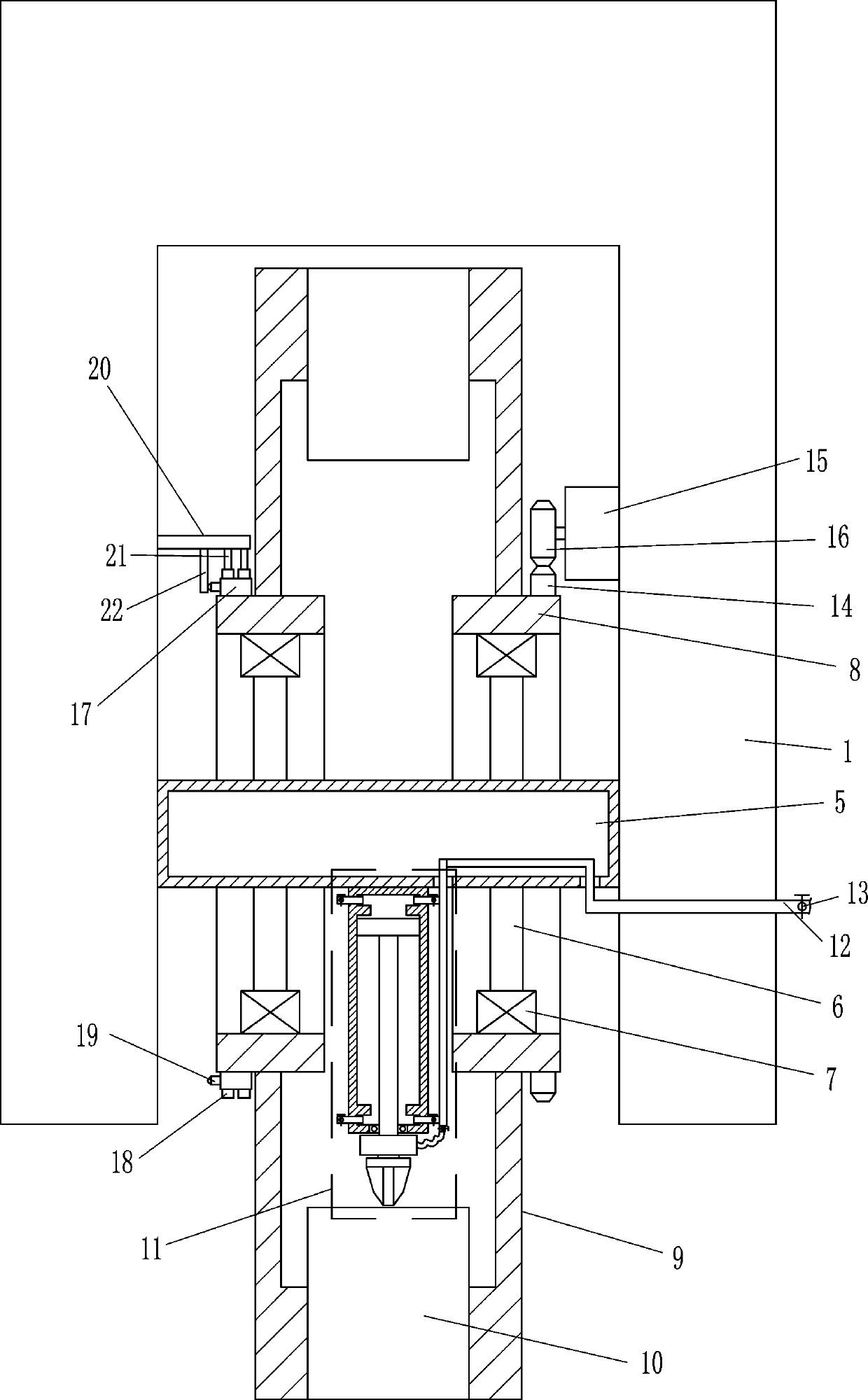

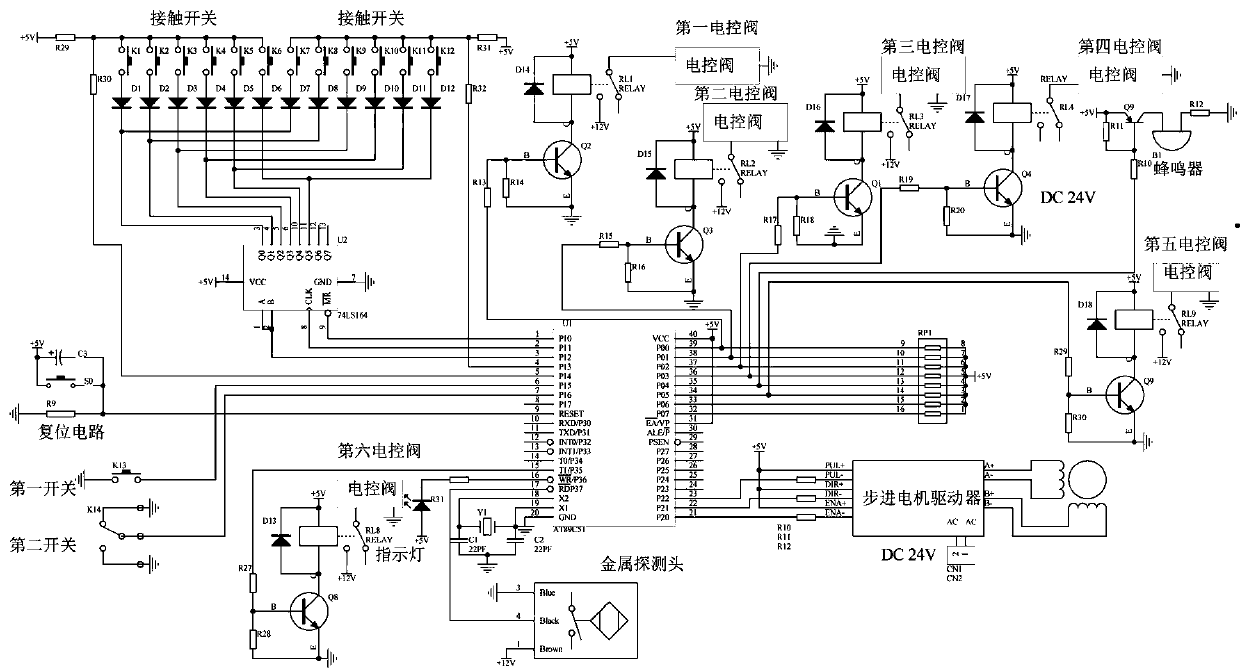

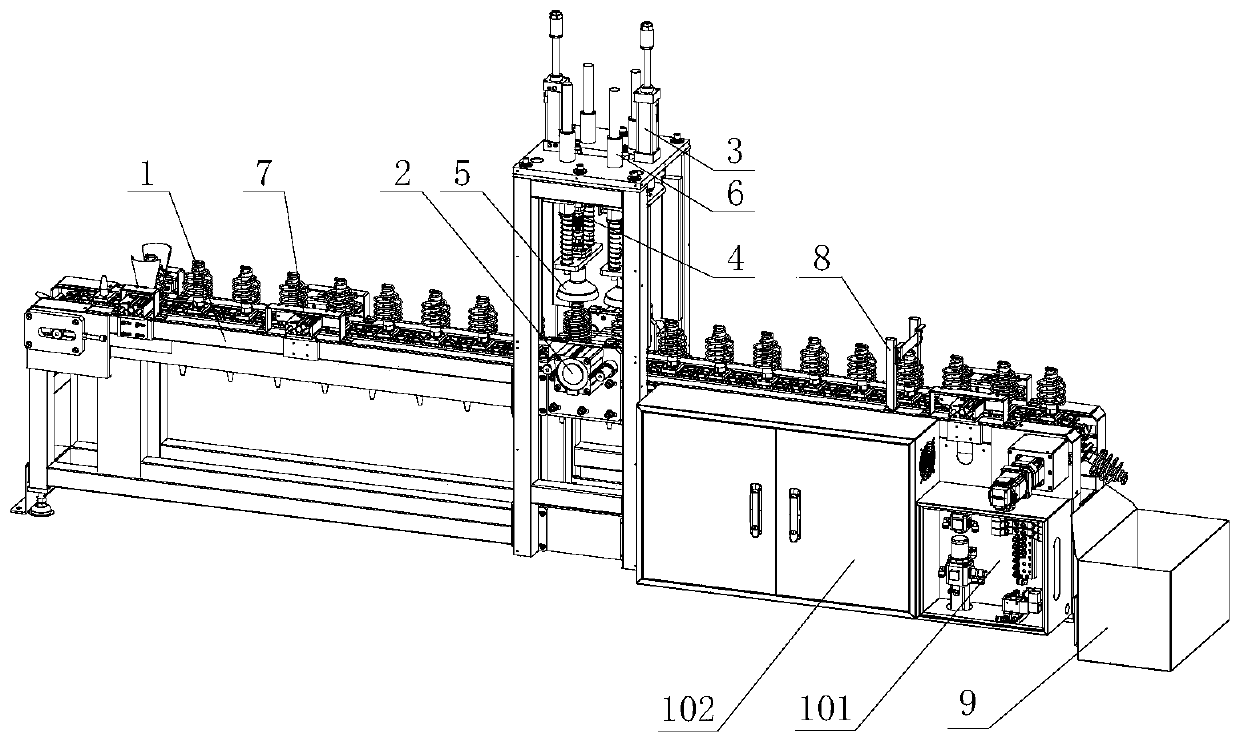

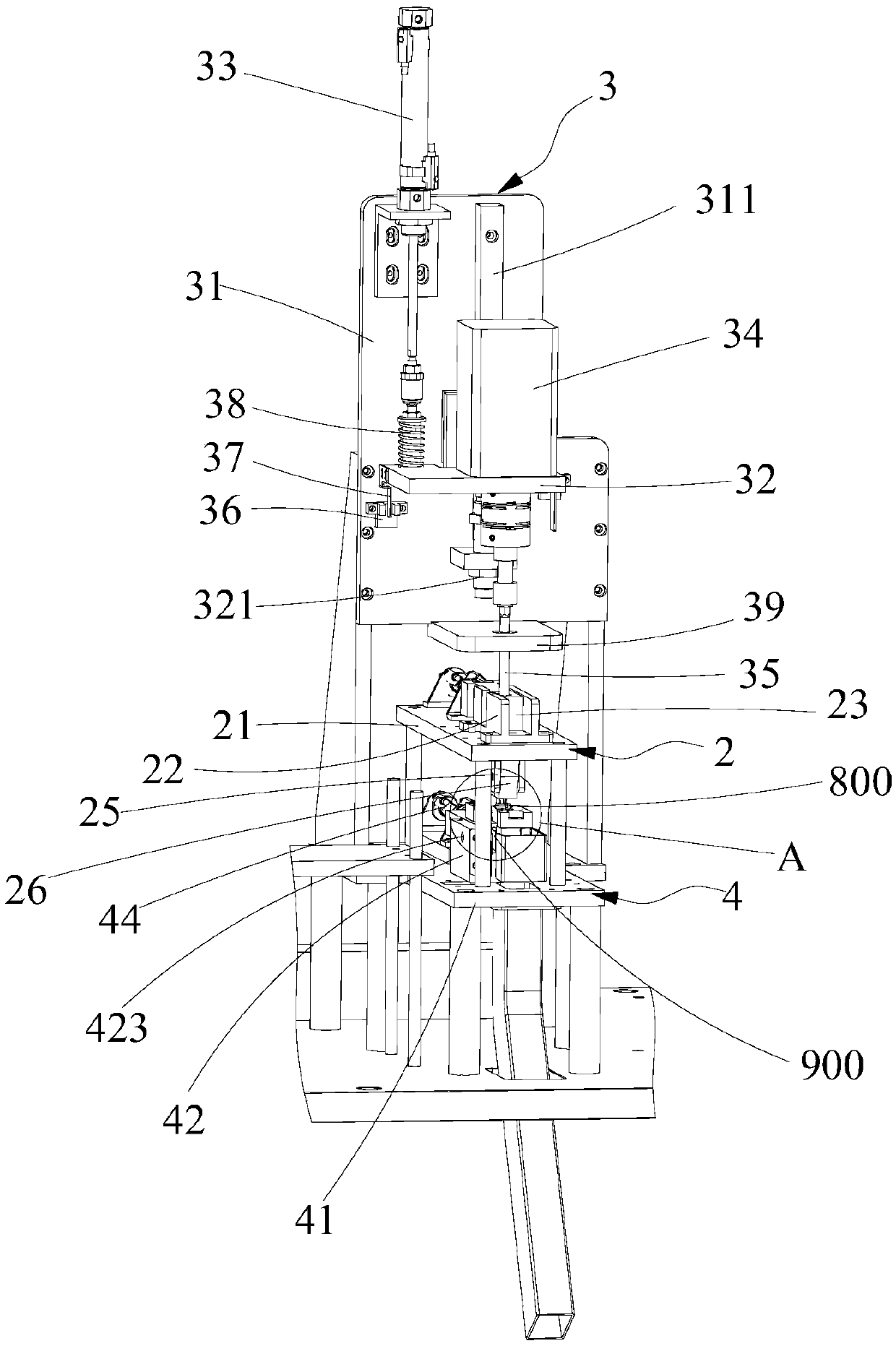

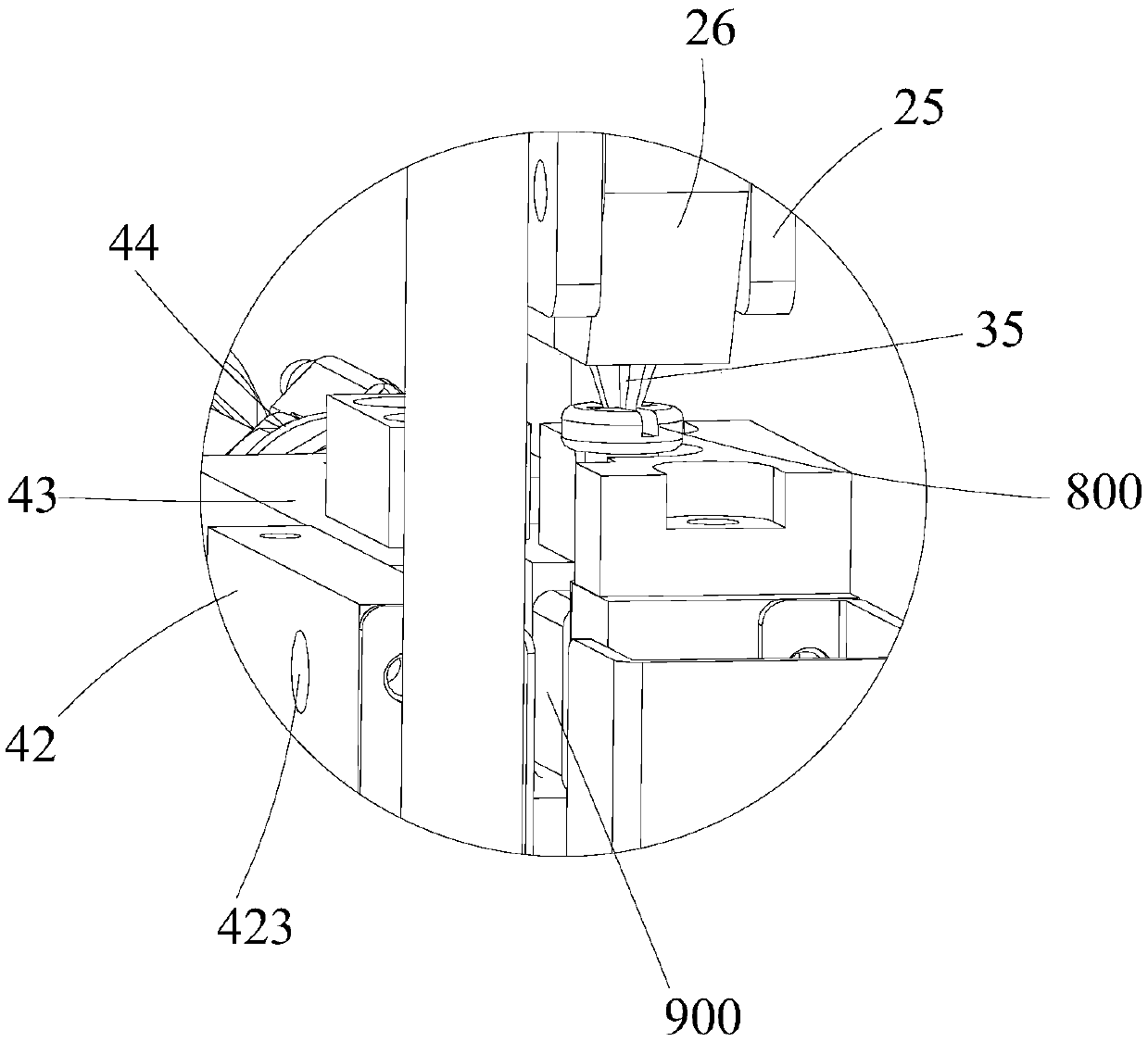

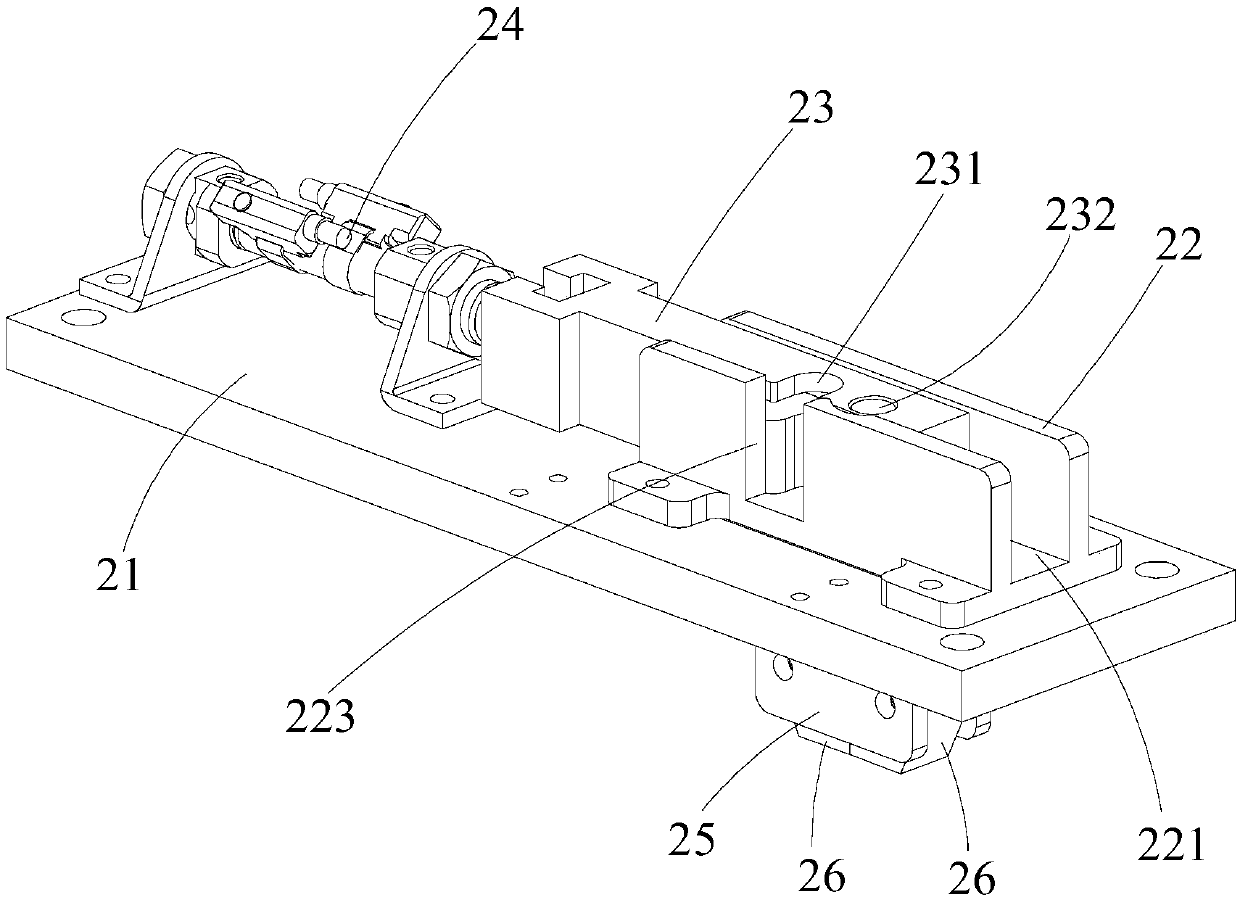

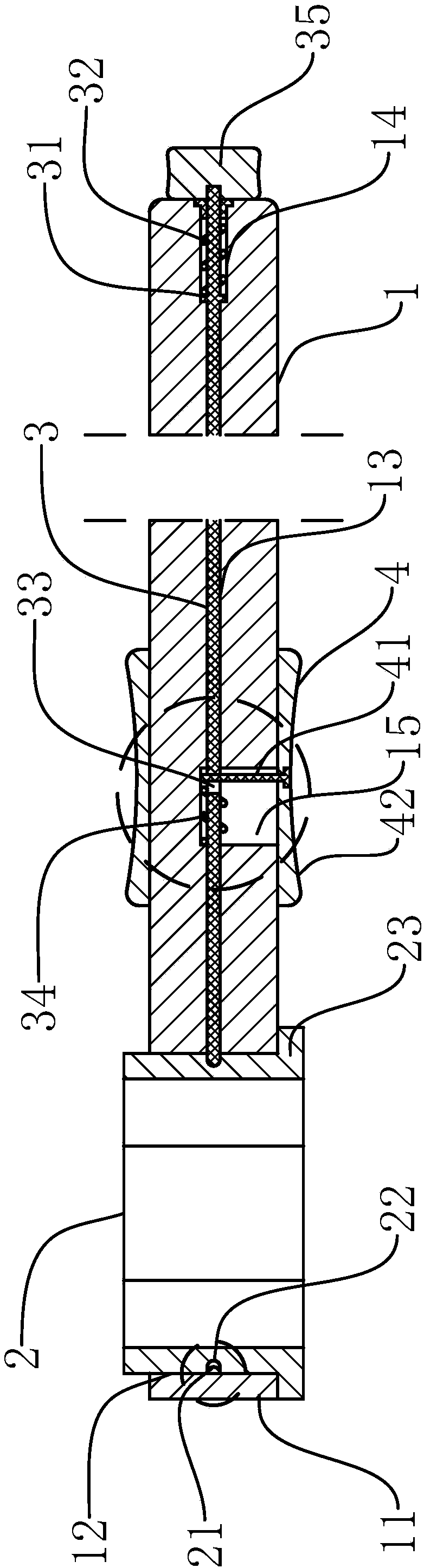

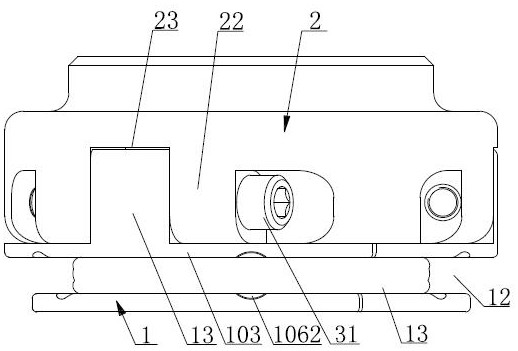

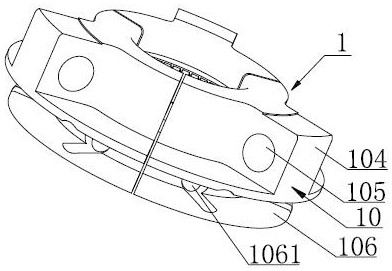

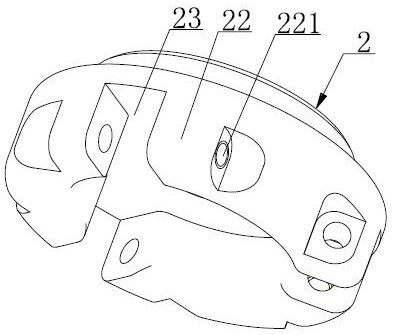

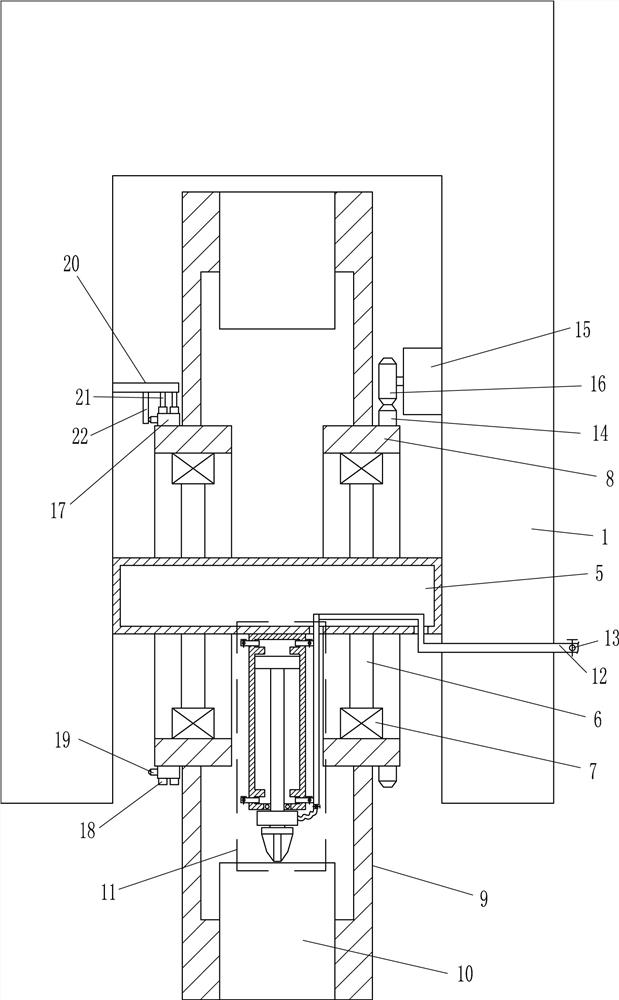

Electric screwdriver bit quick-replacing device and method, bit quick-replacing type screw tightening machine and tightening method of bit quick-replacing type screw tightening machine

PendingCN109128786AGuaranteed smoothnessGuaranteed stabilityMetal working apparatusNormal statePower output

The invention discloses an electric screwdriver bit quick-replacing device and method, a bit quick-replacing type screw tightening machine and a tightening method of the bit quick-replacing type screwtightening machine. The electric screwdriver bit quick-replacing device comprises a positioning sleeve, a floating sleeve is inserted in the positioning sleeve, a bit mounting shaft is inserted in aninner hole of the floating sleeve, and a set of through holes are formed in the groove walls of a quick-replacing groove of the bit mounting shaft, wherein pins are inserted in the through holes; thelength of the pins is greater than that of the through holes, and the two ends of the pins are outward protruding arc surfaces; in a normal state, the pins correspond to the first height of the floating sleeve, and at the first height, the distance from the hole wall of the inner hole to the side wall of the quick-replacing groove is less than the length of the pins; in a press-stopping state, the pins correspond to the second height of the floating sleeve, and at the second height, the distance from the hole wall of the inner hole to the side wall of the quick-replacing groove is not less than the length of the pins. When the pins correspond to the two different heights of the floating sleeve, different position states can be achieved, thus the electric screwdriver bit quick-replacing device can be matched with a power output piece of an electric screwdriver to be connected with and separated from the power output piece, conditions are created for quick replacing of bits, and automatic replacing is achieved conveniently.

Owner:KUNSHAN JIEYUN INTELLIGENT EQUIP CO LTD

Higher fastening screw

The present invention pertains to a higher fastening screw comprising a plurality of concavities formed on the threads, which are connected in sequence for being presented as a state of a single helix. Further, the concavities separately located adjacent to the screw head and to the drilling portion are disposed at relative positions for being accurately aligned by an imaginary line. In this manner, the configuration of the concavities would efficiently cut and sever the fibers of the object, so as to achieve a lower screwing resistance for a higher screwing efficiency and prevent the injuries to the operators.

Owner:ZYH YIN ENTERPRISE

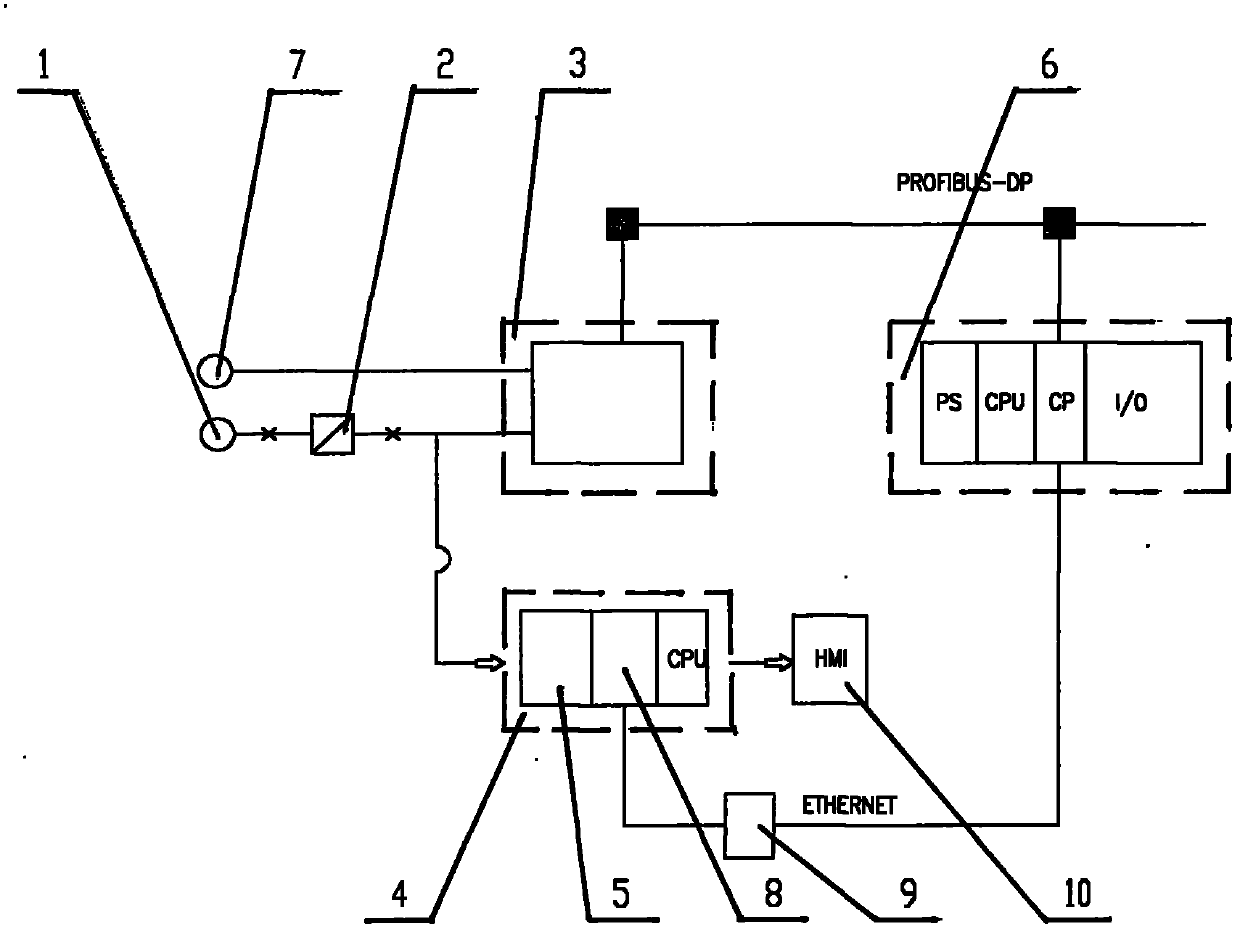

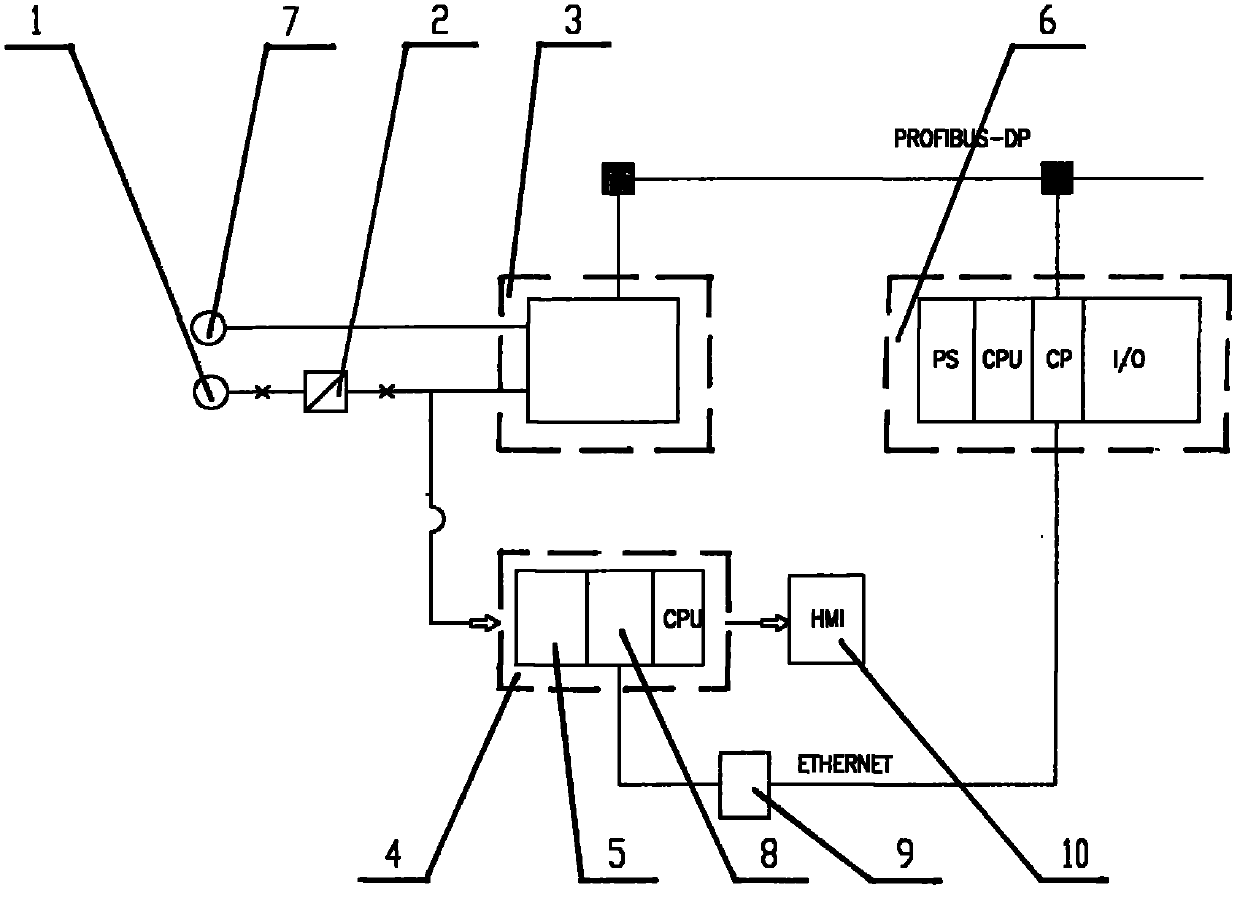

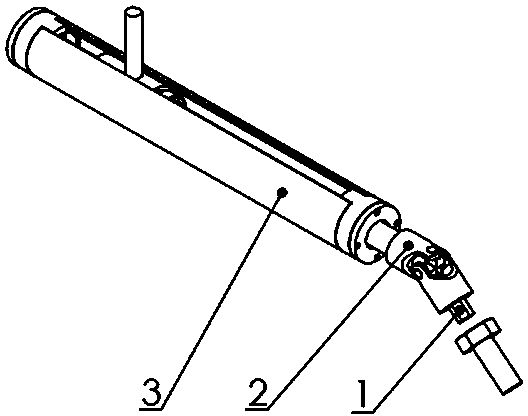

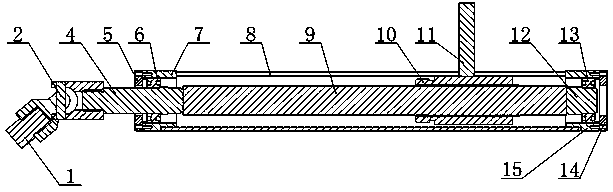

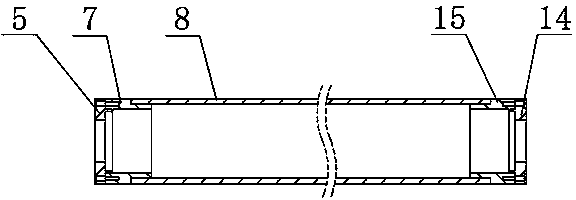

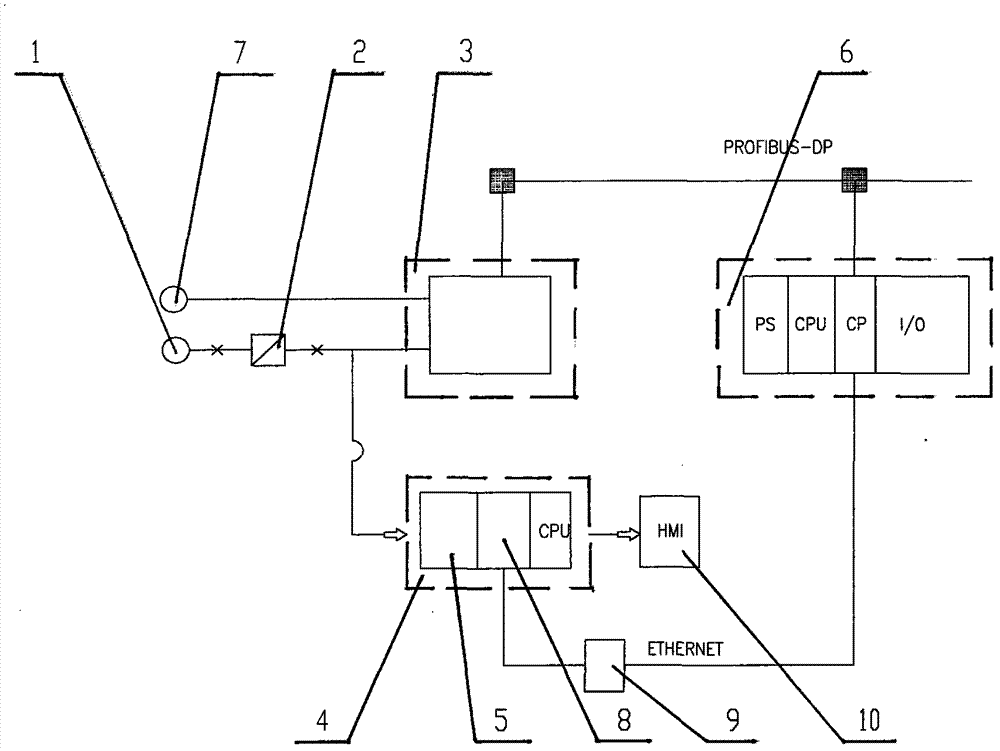

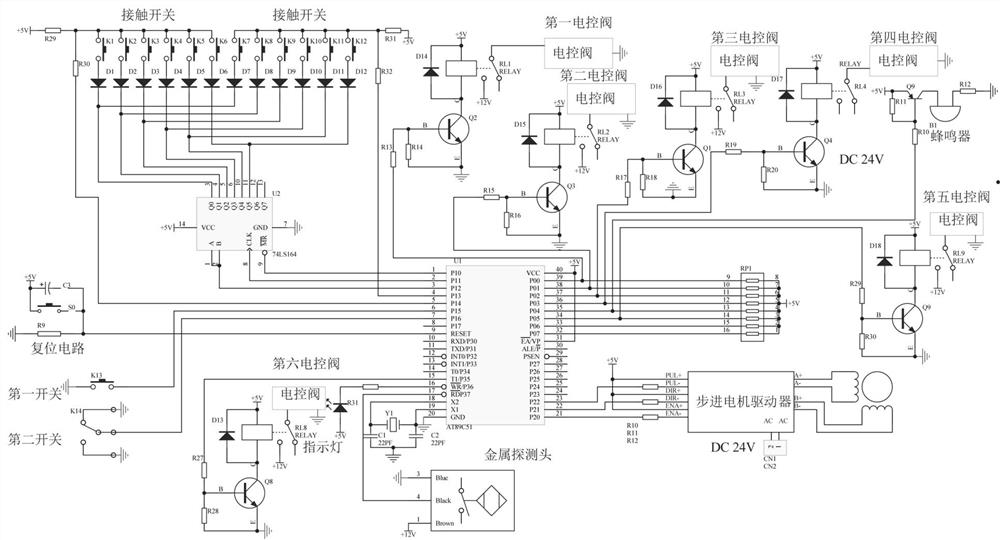

Method for filing and displaying coupling screwed torsion graph in real time

ActiveCN102169339AEasy backupEasy transferTotal factory controlProgramme total factory controlHuman–machine interfaceData acquisition

The invention relates to a method for filing and displaying a coupling screwed torsion graph in real time. The method comprises the following steps: converting a physical signal of a force sensor (1) into a standard analog signal through a converter (2), and then sending one path of standard analog signal into an on-site PLC (programmable logic controller) (3) while switching the other path of standard analog signal into a high-speed data acquisition card (5) of an industrial personal computer; transmitting the standard analog signal which is switched into the PLC (3) into a master PLC (6) through a network, performing the analog-to-digital conversion and calibration on the standard analog signal, and then generating a torsion value for controlling a main screwed torsion; generating a pulse signal by a rotary encoder (7), transmitting the pulse signal to the master PLC (6) through the PLC (3) and the network, and then converting the pulse signal into a real-time circle value by a FM (frequency modulation) module and finally outputting; performing the analog-to-digital conversion and digital quantity operation on the standard analog signal which is switched into the high-speed dataacquisition card (5) so as to obtain the torsion value while acquiring the real-time circle value from the master PLC (6); and drawing a variation trend graph of the torsion following the change of circle number on a HMI (human machine interface) (10), and storing the tube basic data and process data.

Owner:洛阳锐腾机械设备有限公司

Higher fastening screw

The present invention pertains to a high-speed fastening screw comprising a plurality of concavities on the threads connected in sequence in a single helix. Further, the concavities separately located adjacent to the screw head and to the drilling portion are disposed at relative positions for aligning with an imaginary line, hence efficiently cutting and severing the object fibers to enhance a screwing efficiency.

Owner:ZYH YIN ENTERPRISE

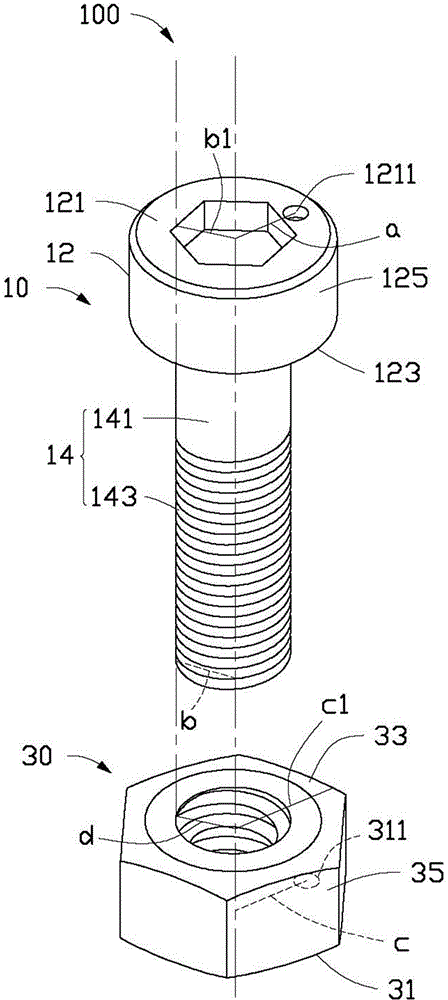

Threaded fastener and screwing method thereof

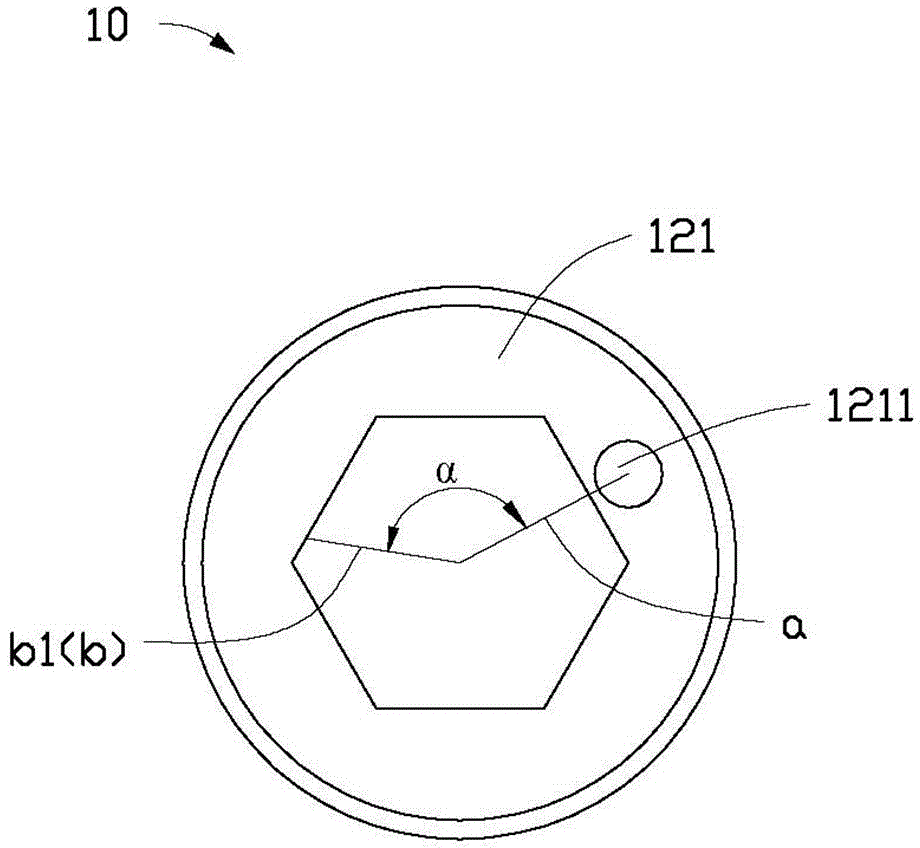

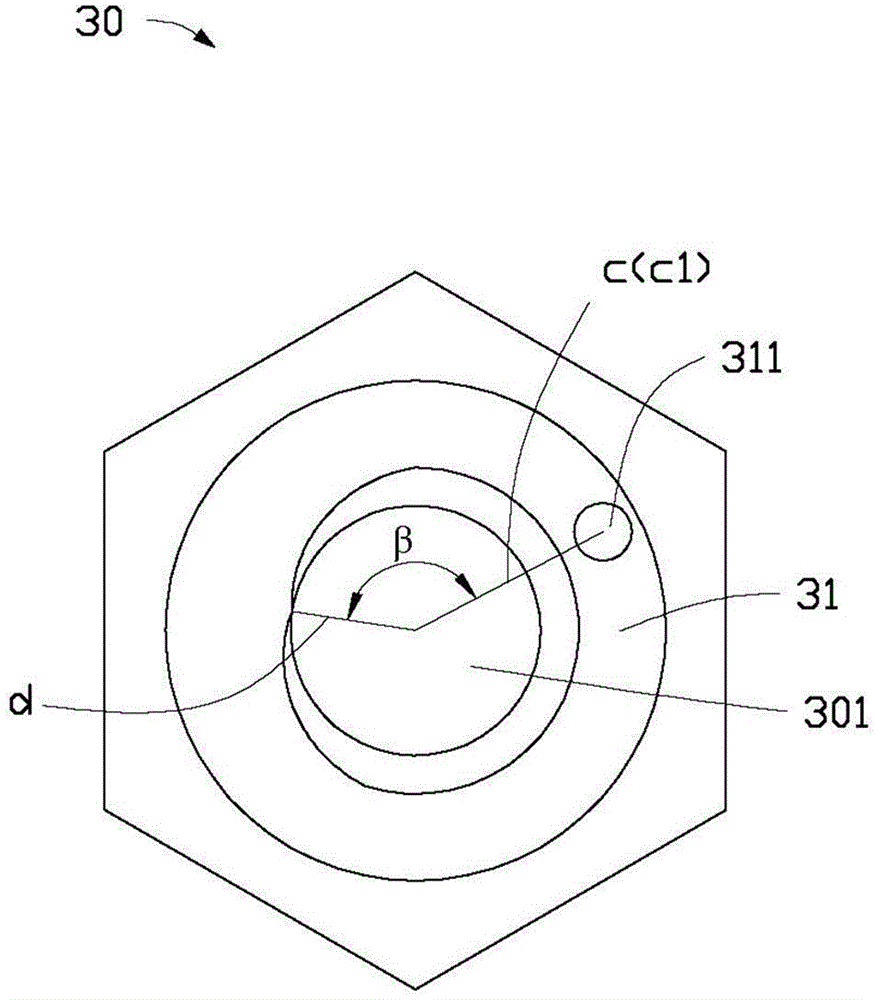

InactiveCN104632853AAvoid collision damageImprove screwing efficiencyPinsNutsEngineeringScrew thread

This invention provides a threaded fastener. The threaded fastener comprises a first screwing part with a threaded portion and a second screwing part matching the threaded portion and having a threaded hole. A first locating portion is arranged on the first screwing part. The central point of the first locating portion is vertically connected with a central axis of the threaded portion to for a first virtual line segment. The thread starting point of the threaded portion is vertically connected with the central axis to form a second virtual line segment. A second locating portion is arranged on the second screwing part. The central point of the second locating portion is vertically connected with a central axis of the threaded hole to form a third virtual line segment. The thread starting point of the threaded hole is vertically connected with the central axis to form a fourth virtual line segment. When the second screwing part is coaxial with the first screwing part, and the second virtual line segment is parallel to the fourth virtual line segment, the first virtual line segment is parallel to the third virtual line segment. This invention further provides a screwing method for the abovementioned threaded fastener. The method has high screwing efficiency without damaging screw teeth.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

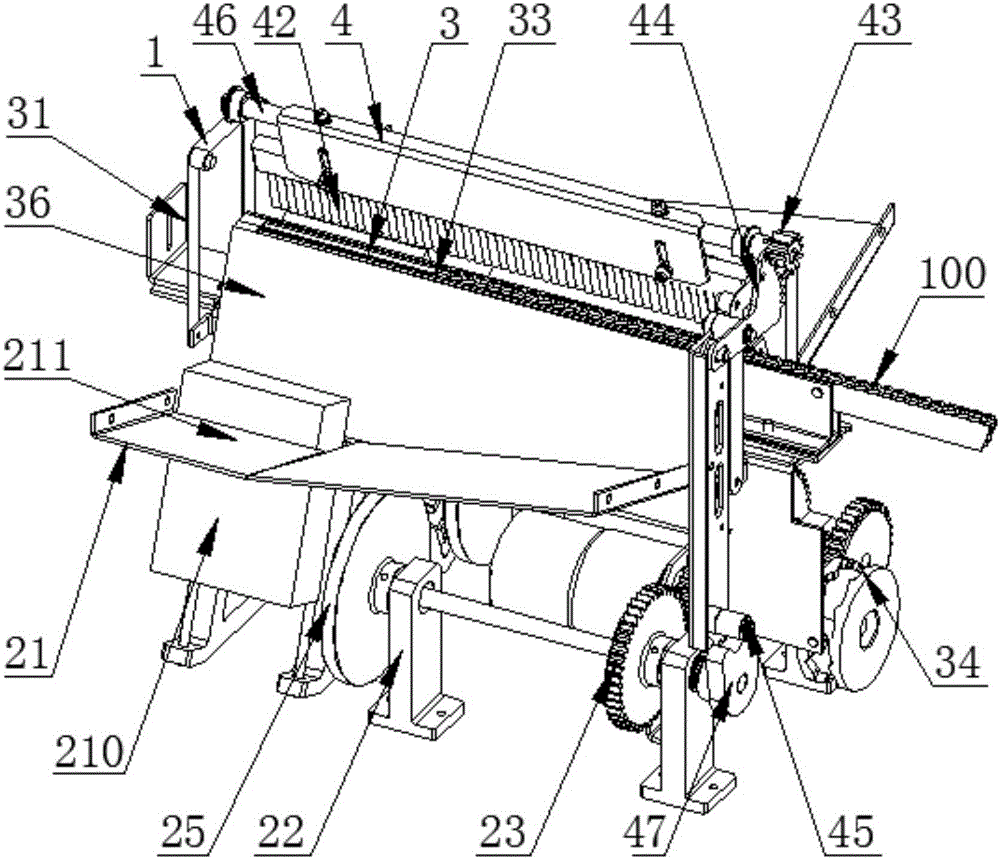

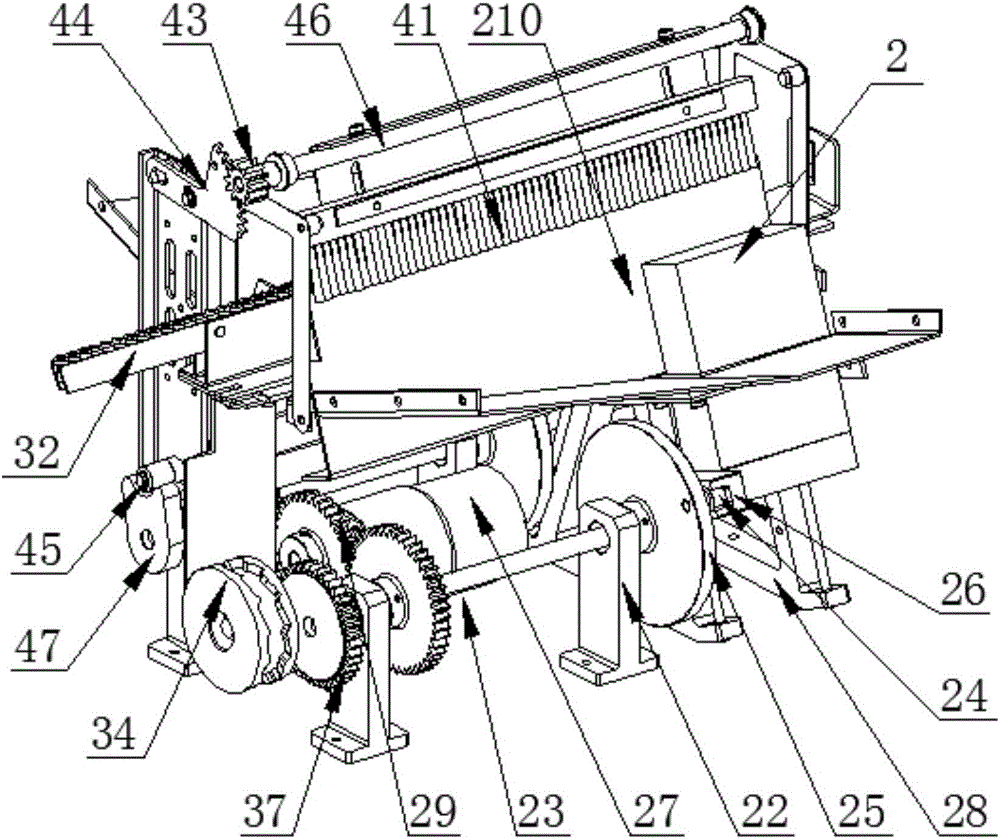

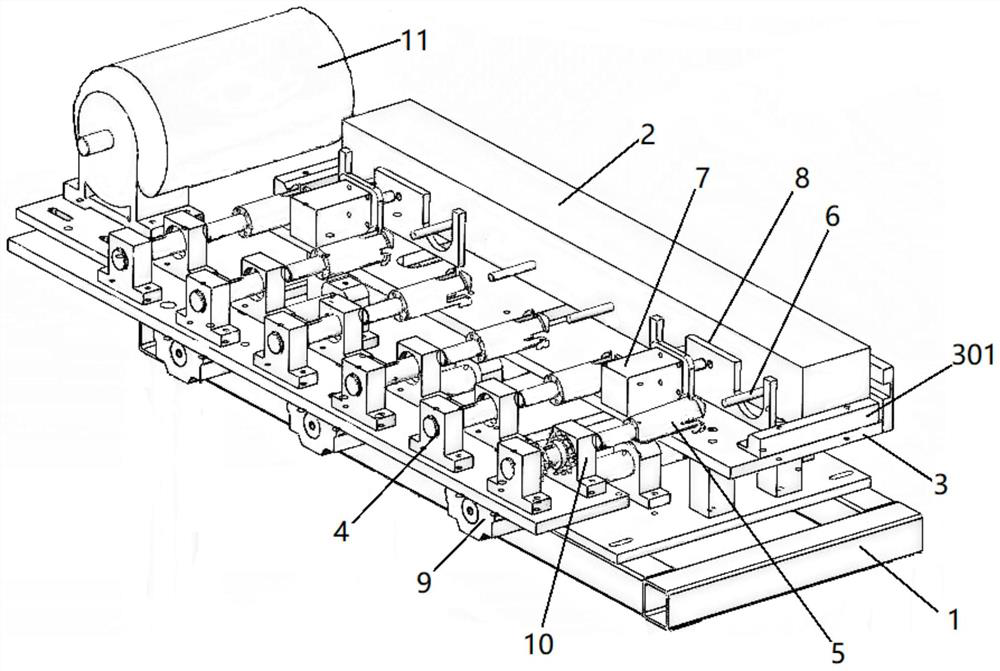

Screw feeding and conveying mechanism with double sliding blocks and double cams

InactiveCN106002224AReduce noiseIncrease the frequency of reaching the feeding mechanismMetal working apparatusCamPath line

The invention discloses a screw feeding and conveying mechanism with double sliding blocks and double cams. The screw feeding and conveying mechanism comprises a machine frame, a feeding mechanism, a conveying mechanism and a sweeping mechanism; the feeding mechanism comprises screw lifting push plates arranged on the two sides of the conveying mechanism respectively; the conveying mechanism comprises a conveying support, the conveying support is connected to a double-face vibrating cam in a matched mode through a vibrating rolling wheel, and a path line profile is arranged on each of the two faces of the double-face vibrating cam. According to the screw feeding and conveying mechanism, through the screw lifting push plates arranged on the two sides of the conveying mechanism, the noise caused by relative resting or free sliding of screws can be lowered; the screw feeding speed and the work efficiency are improved through the double-side alternate feeding mode; the feeding efficiency is high and is free of the influence of the sizes and the shapes of the screws and the number of the screws. The screw feeding and conveying mechanism has the beneficial effects that the noise is low, the efficiency is high and the adaptability is high.

Owner:SUZHOU QUANFENG PRECISION MACHINERY

Novel fastener wrench

The invention discloses a novel fastener wrench comprising a fastener connector used for connecting with a fastener, a universal coupling and a ball screw and nut pair portion. The fastener connector is connected with the ball screw and nut pair portion through the universal coupling, two ends of a ball screw are connected with a front connecting rod and a rear connecting rod respectively and coaxially, the ball screw is mounted in a screw guide sleeve, and two ends of the screw guide sleeve are respectively connected with a front bearing seat and a rear bearing seat. A front bearing is connected between the front connecting rod and the front bearing seat. A rear bearing is connected between the rear connecting rod and the rear bearing seat. A ball screw nut between the ball screw and the screw guide sleeve is connected with a handle fixedly, the handle extends out from a groove formed in the screw guide sleeve, and the groove in the screw guide sleeve extends along the axial direction of the ball screw. The novel fastener wrench mainly overcomes the defect that existing wrenches are inconvenient to operate in narrow and small spaces, and is small in needed space, convenient to use and high in utilization efficiency.

Owner:ZHEJIANG UNIV

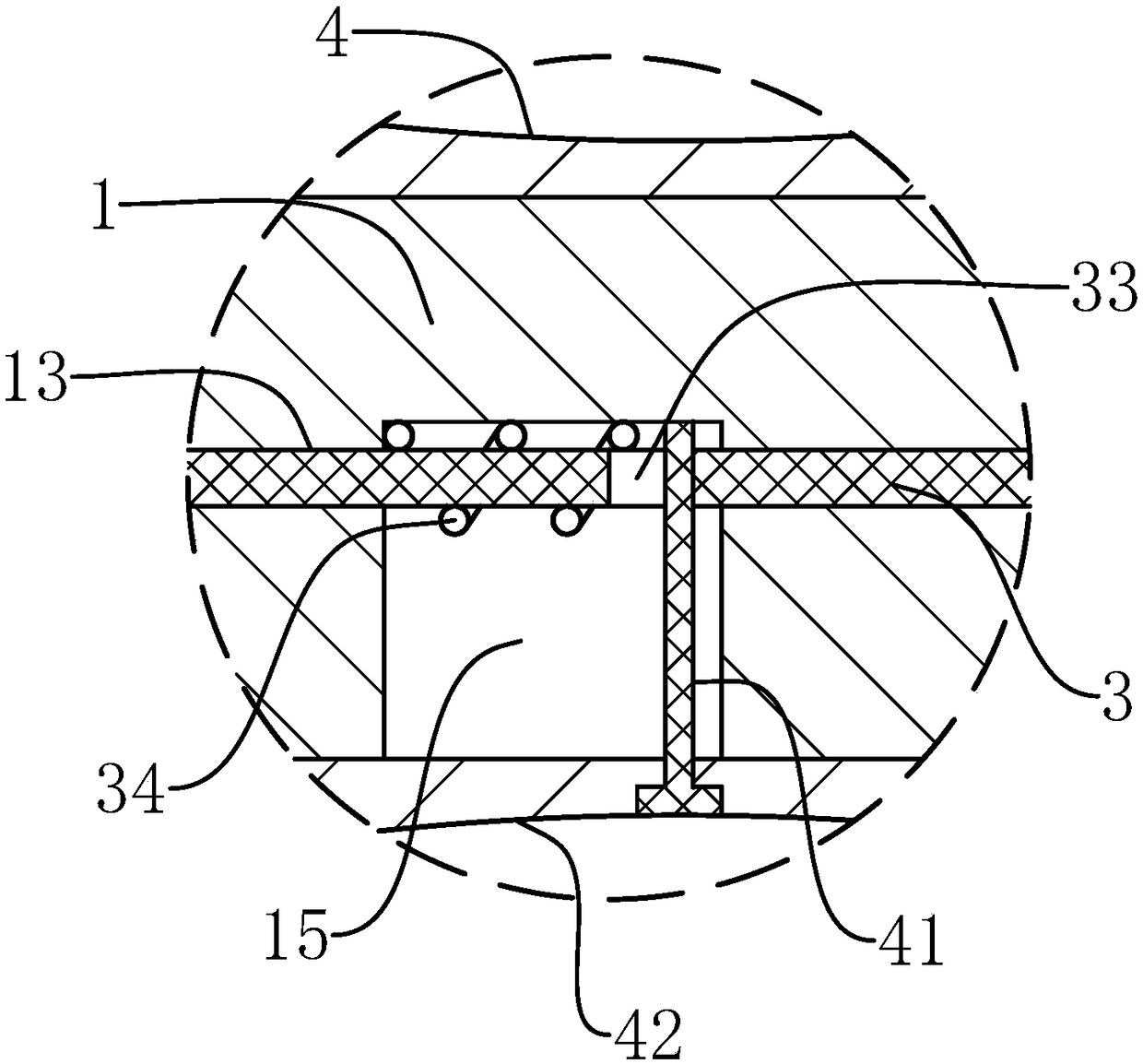

Sleeve screwing device

PendingCN110130586AImprove screwing efficiencySimple structureBuilding reinforcementsDriving modeEngineering

The invention discloses a sleeve screwing device, including a base. The end, near a sleeve, of the base is provided with the sleeve screwing device, the sleeve screwing device includes a sub-driven rotating shaft which is rotatably arranged at the end, near the sleeve, of the base, a driving part and a rolling wheel are arranged on the sub-driven rotating shaft; the end, away from the sleeve, of the base is provided with a driving device, a driving end of the driving device is connected with a driving part in a driving mode; the bottom of the base is provided with a sleeve holding device corresponding to the rolling wheel; and the device has the beneficial effects of sleeve continuous torsion, labor saving, high work efficiency, the compact structure, stable driving, large output torque and the stable rotation of the sleeve.

Owner:场景美学设计(广州)有限公司

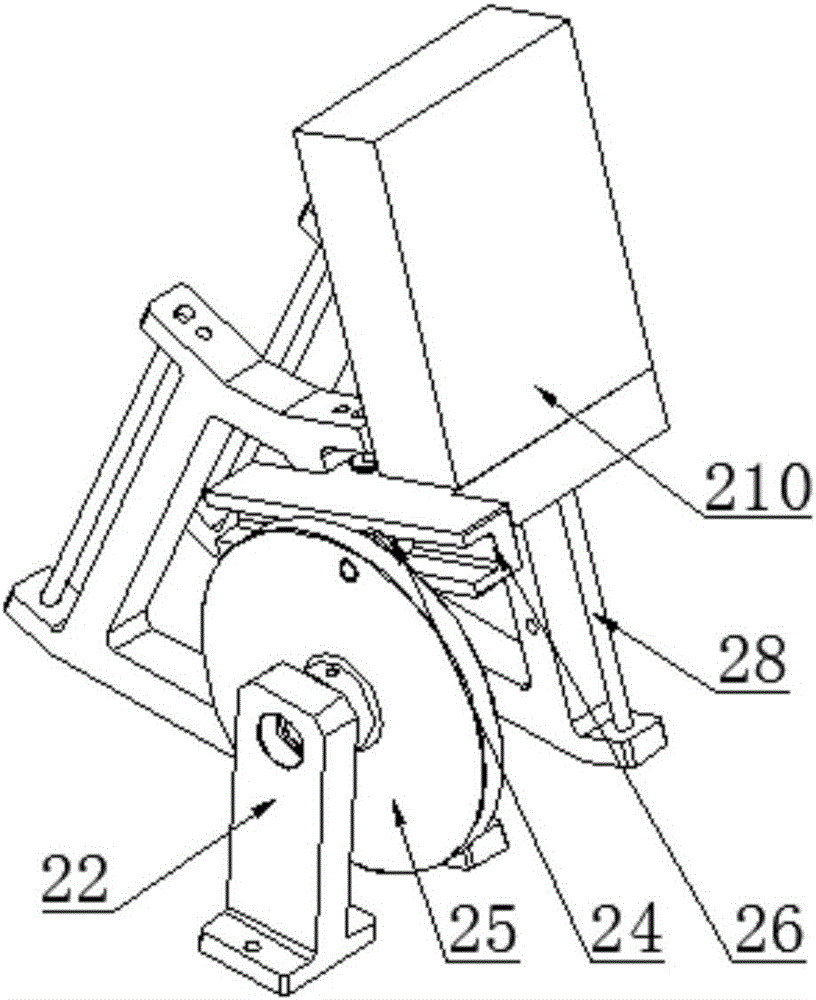

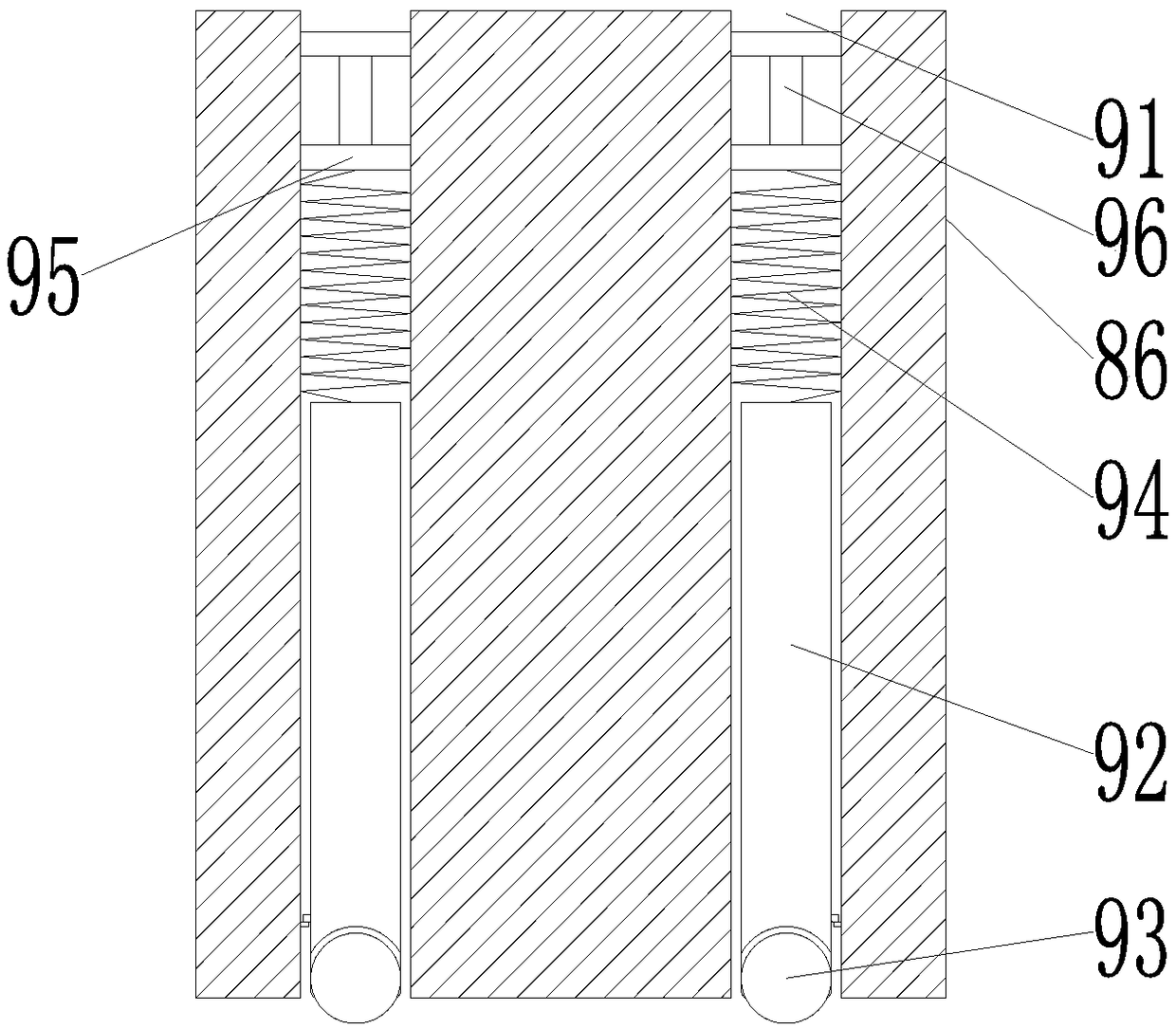

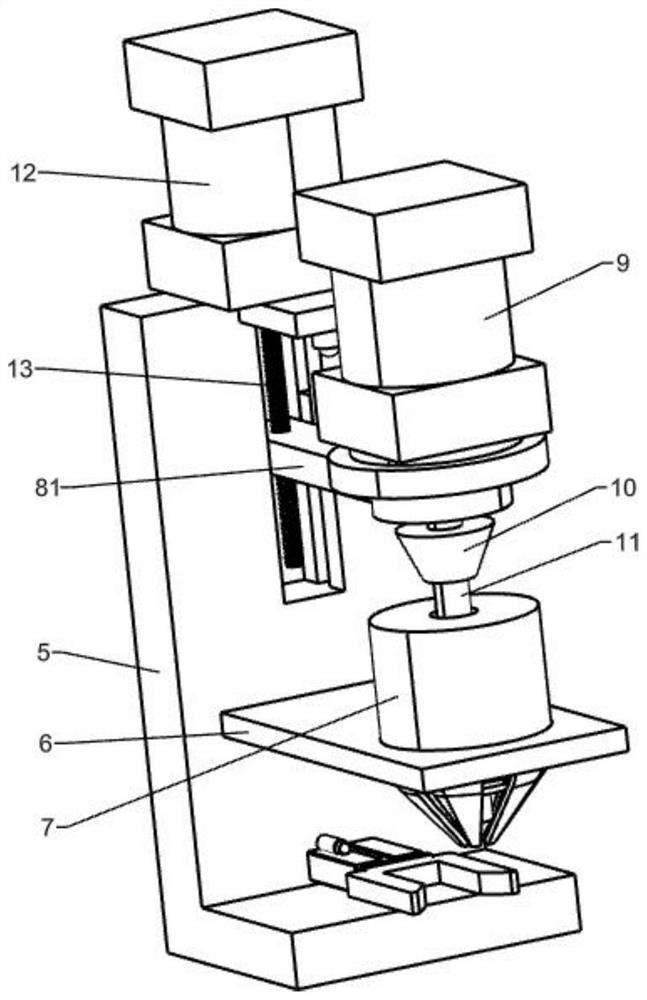

Rotating mechanism for freeze-storage tube cover screwing

InactiveCN108557735AHigh screw capping efficiencyWide range of applicationsThreaded caps applicationSprocketEngineering

The invention relates to the technical field of biological medical instruments, and particularly discloses a rotating mechanism for a freeze-storage tube cover screwing. The mechanism comprises a first rotating rod, a first fixing block, a first rotating column, a second rotating rod, a second fixing block and a second rotating column, a second chain wheel is arranged at the upper end of the firstrotating rod, the second rotating column is located below the first rotating column, the first rotating column is connected with the second rotating column through a plurality of transmission pieces,the lower end of the second rotating rod is movably sleeved with a cover screwing head through an adjusting mechanism, cover screwing openings matched with the tube cover of the freeze-storage tube in shape is formed in the cover screwing head, a first spring is arranged at the position, located between the second rotating column and the cover screwing head, of the second rotating rod, the two cover screwing openings are located right above clamping positions of two clamping grooves, a plurality of mounting holes are formed in the first rotating column in the axial direction, and the transmission pieces are arranged in the mounting holes. The mechanism has the characteristics that the cover screwing efficiency is relatively high, the labor cost is relatively low, the screwing effect is relatively good, and the application range is relatively wide.

Owner:ZHEJIANG SORFA MEDICAL PLASTIC

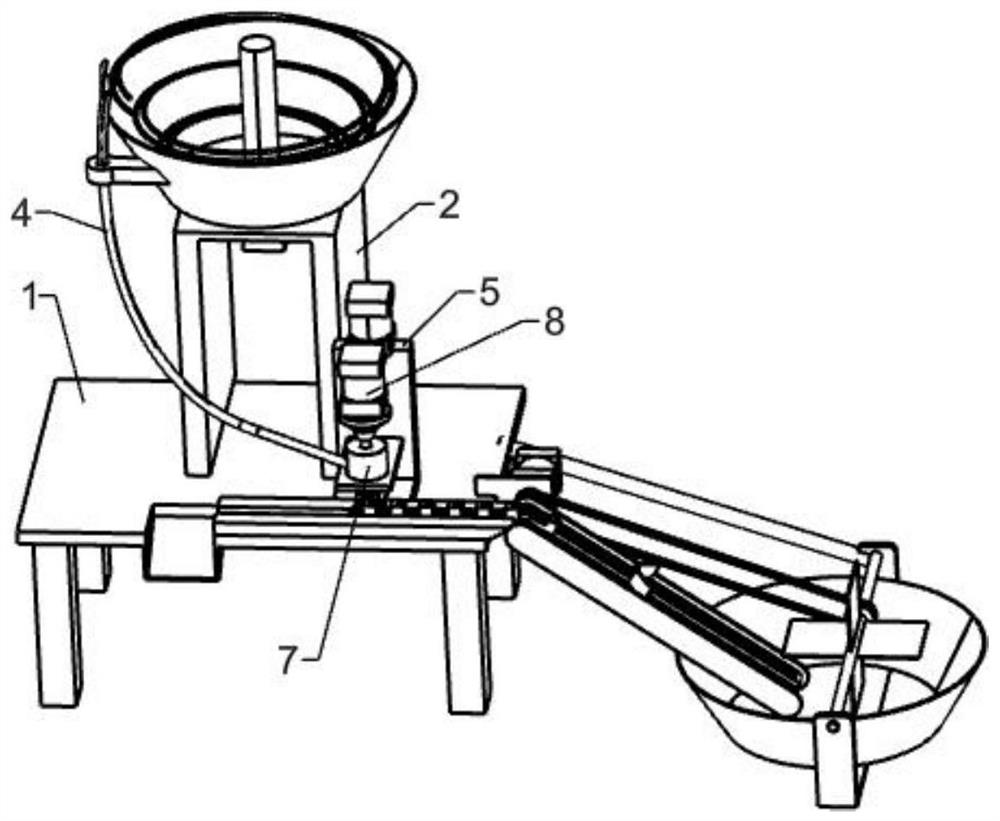

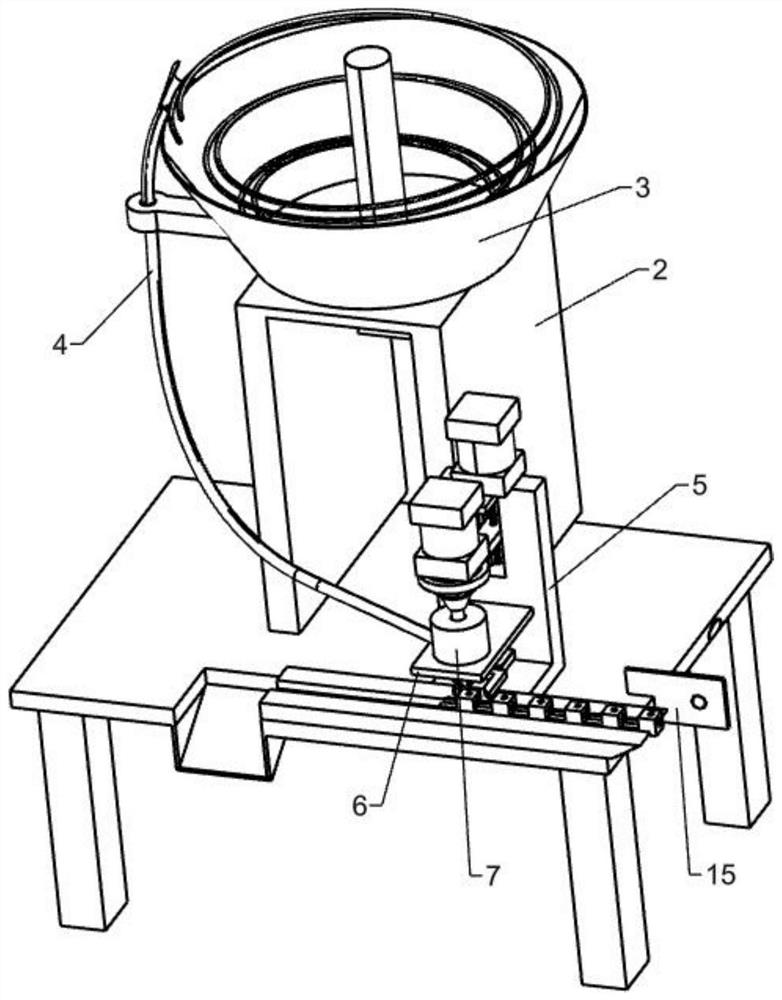

Terminal positioning screw assembling device

ActiveCN111843456APrevent fallingEasy to transportMetal working apparatusElectric machineryStructural engineering

The invention relates to a screw assembling device and particularly relates to a terminal positioning screw assembling device. The technical scheme is characterized in that the terminal positioning screw assembling device comprises a workbench and a clamping mechanism, wherein a connecting frame is mounted on the workbench; a vibratory material conveying disc is arranged on the connecting frame; aconveying pipe is mounted on the vibratory material conveying disc; an L-shaped plate is arranged on one side, close to the connecting frame, of the workbench; a fixed plate is mounted on the L-shaped plate; the clamping mechanism is arranged on the fixed plate and is matched with the conveying pipe. According to the terminal positioning screw assembling device, a conveying plate clockwise rotates to be matched with a conveyer; terminals can be conveyed to the conveyer; the terminals can be automatically fed, so that the terminal screwing efficiency can be improved; through an infrared sensor, an air cylinder can drive a limiting block to move forwards, fix and limit the terminals; and meanwhile, the infrared sensor is capable of starting a first motor and a speed reduction motor to operate, so that the terminals can be automatically screwed.

Owner:安徽奇盟光电科技有限公司

Double-sliding-block screw feeding and conveying mechanism

The invention discloses a double-slider screw feeding transmission mechanism, which includes a frame, a feeding mechanism, a feeding mechanism and a sweeping mechanism. The feeding mechanism includes a screw lifting push plate for sending screws to the feeding mechanism. The screw lifting push plate is provided with one on both sides of the feeding mechanism, and the feeding mechanism includes a feeding bracket, and the feeding bracket is connected with a vibrating cam through a vibrating roller. The present invention lowers the generated noise through the lifting and lowering of the push plates arranged on both sides of the feeding mechanism by the screws, and the relative static or free sliding between the screws; The size and shape of the screws themselves are different, and in the case of how many screws there are, they all have high feeding efficiency; so that the screw feeding and conveying mechanism provided by the present invention has the beneficial effects of low noise, high efficiency and strong adaptability.

Owner:SUZHOU QUANFENG PRECISION MACHINERY

Screw structure

InactiveCN101328922AImprove structural strengthImprove screwing efficiencyScrewsEngineeringScrew thread

The invention relates to a screw structure, which comprises a pole body and a screw thread part; one end of the pole body is provided with a conical surface, and the other end of the pole body is provided with a head part. The screw thread part is formed on the peripheral surface of the pole body and provided with a first screw tooth part and a second screw tooth part. An overlooking shape of the first screw tooth part is a polygon structure; each corner of the first screw tooth part is respectively provided with a tapping part; and a flat and straight part is formed between the adjacent tapping parts. The second screw tooth is arranged between the head part of the pole body and the first screw tooth part. A sharp cutting angle is formed by the tapping part, thereby reducing a resistance occurring when an object is screwed in and improving a screwing efficiency.

Owner:EASYLINK IND

Handheld screwing device

ActiveCN110253274APrevent fallingSave human effortMetal working apparatusEngineeringExternal connection

The invention relates to a screwing device, in particular to a handheld screwing device. According to the technical effect, the handheld screwing device can save manpower and is safe and high in efficiency. According to the technical scheme, the handheld screwing device includes a hand gripper, an external connection hose, an intermediate round box and the like; and the external connection hose is connected to the right side of the hand gripper, and a power line and an external connection air tube are arranged in the external connection hose. According to the handheld screwing device, screws are pushed into placing boxes, under the action of a spring, arc-shaped rods on the left and right sides can clamp the screws, and screwing can be facilitated and can be quicker; a servo motor can drive a connecting ring frame to rotate, the placing boxes accordingly driven to rotate, and the placing boxes can be rotated one by one to the positions under an impact screwing-in device; and the impact screwing-in device can screw the screw in the placing boxes to the desired positions, manpower is saved, and the screwing efficiency is improved.

Owner:无锡品知信息科技有限公司

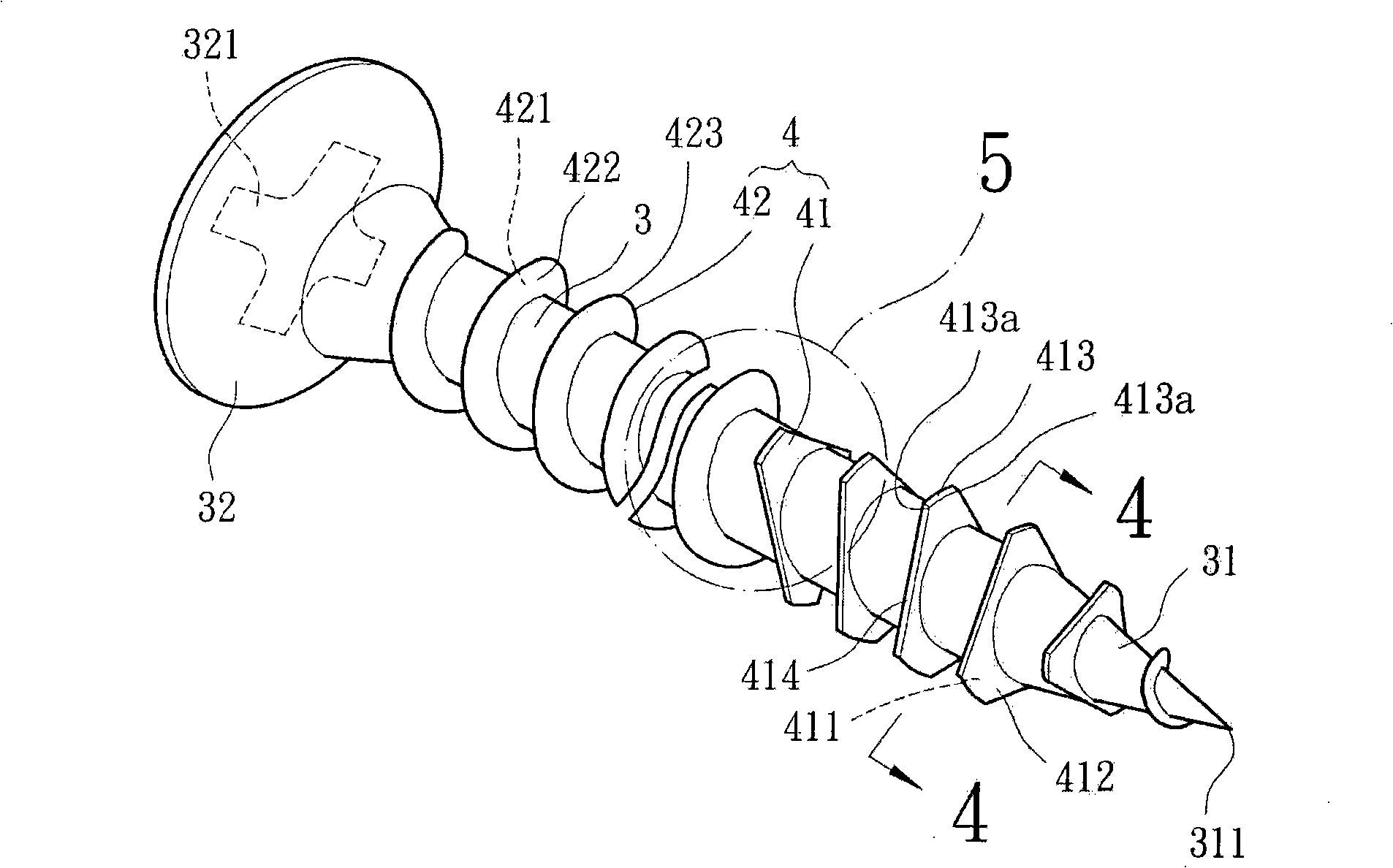

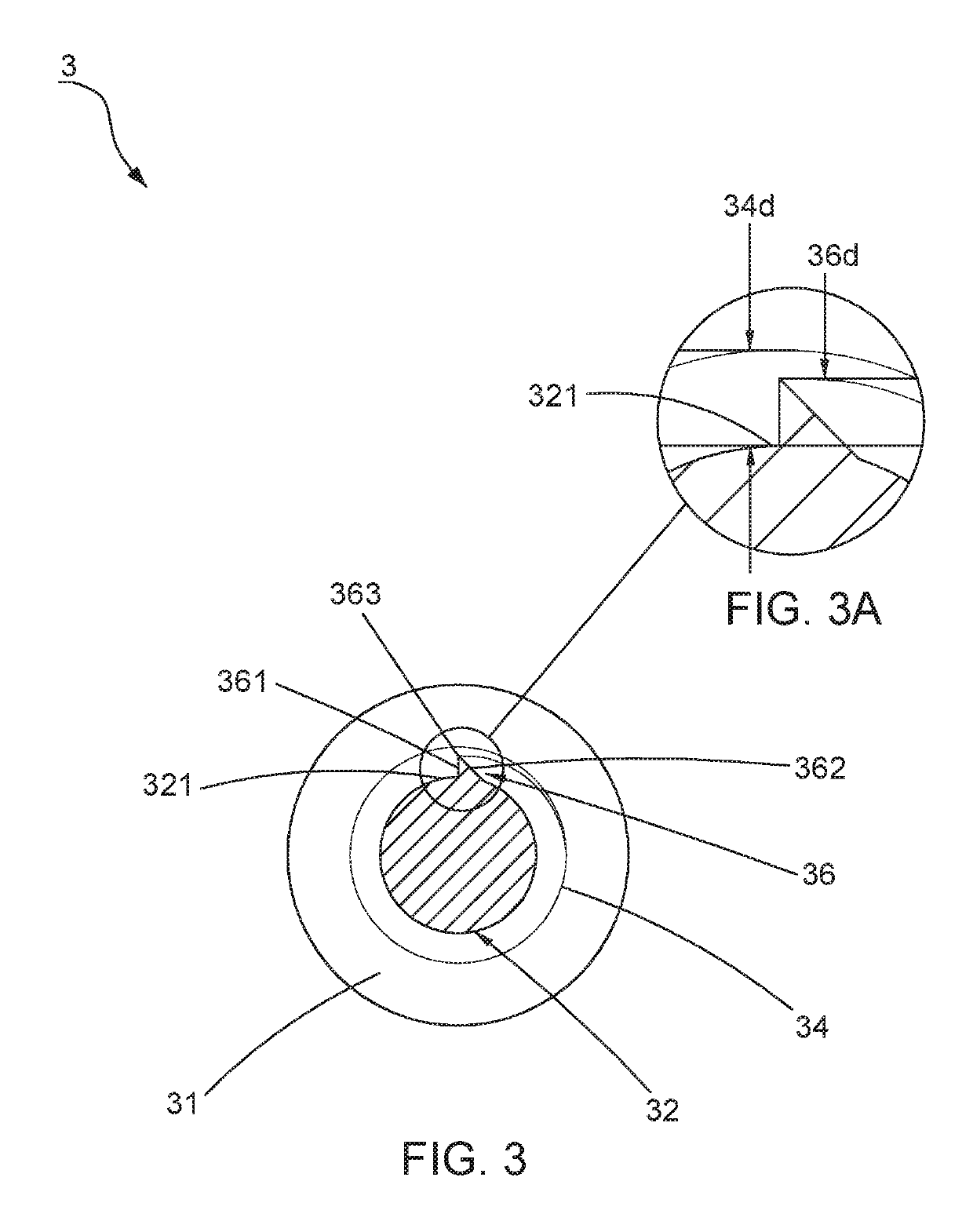

Screw

A screw includes a shank, a head connected thereto, a drilling portion opposite to the head, a first threaded section spirally formed on the shank, and a leading threaded section spirally extending upwards from the drilling portion. The two threaded section are disconnected so that a valley is formed between them. At least one cutting unit protrudes from the valley and has two ends connected to the first threaded section and the leading threaded section respectively. The leading threaded section assists the drilling portion in cutting and drilling into an object while screwing, and the cutting unit protruding from the valley severs fibers which are not cut by the leading threaded section completely to prevent the entanglement of the fibers. The valley helps accommodate and evacuate cut chips. Therefore, the drilling resistance is reduced effectively to increase the screwing efficiency.

Owner:TAIWAN SHAN YIN INT CO LTD

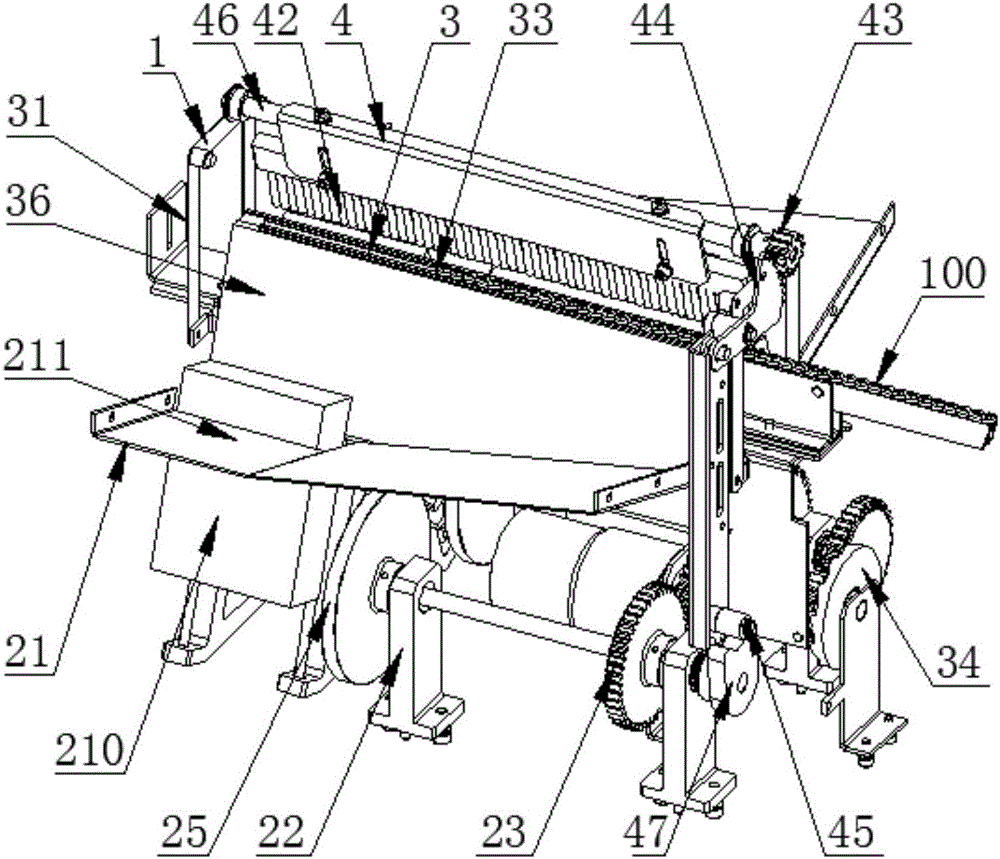

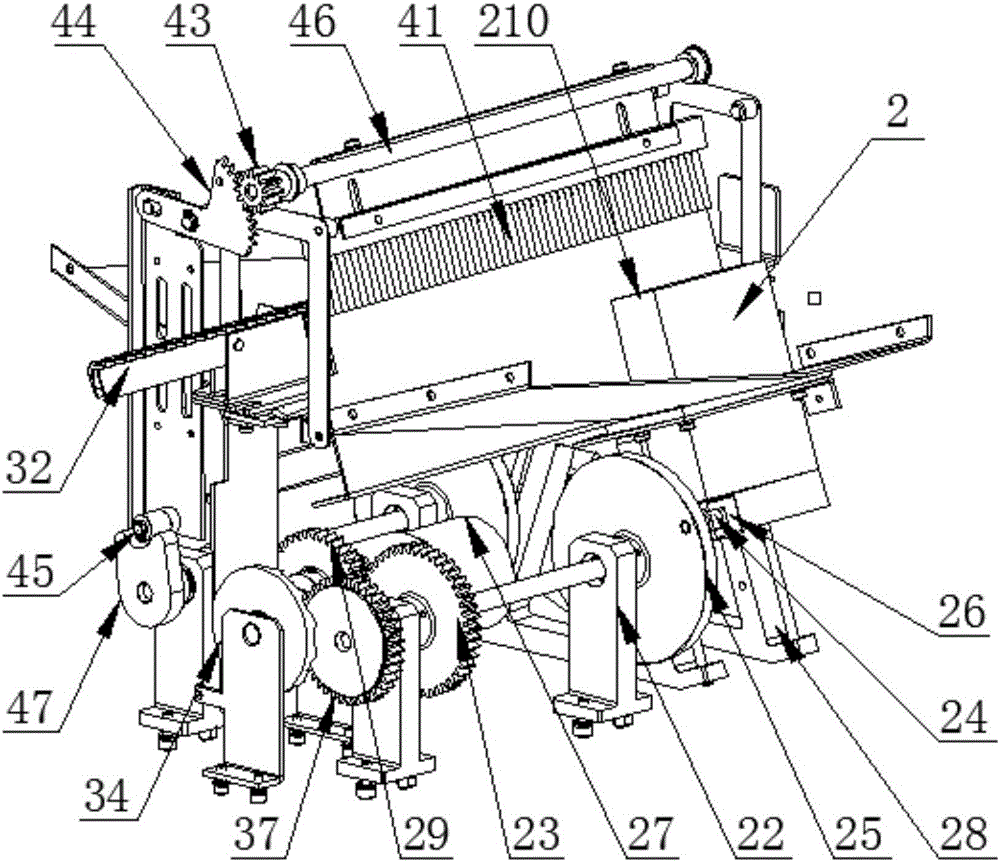

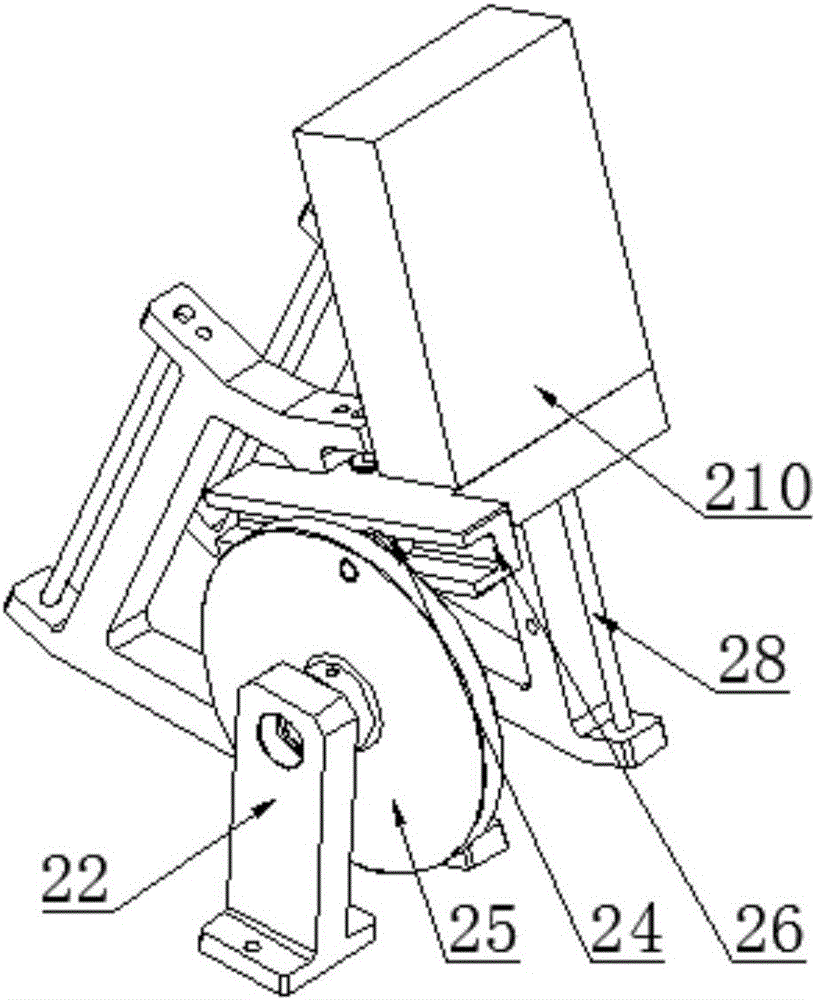

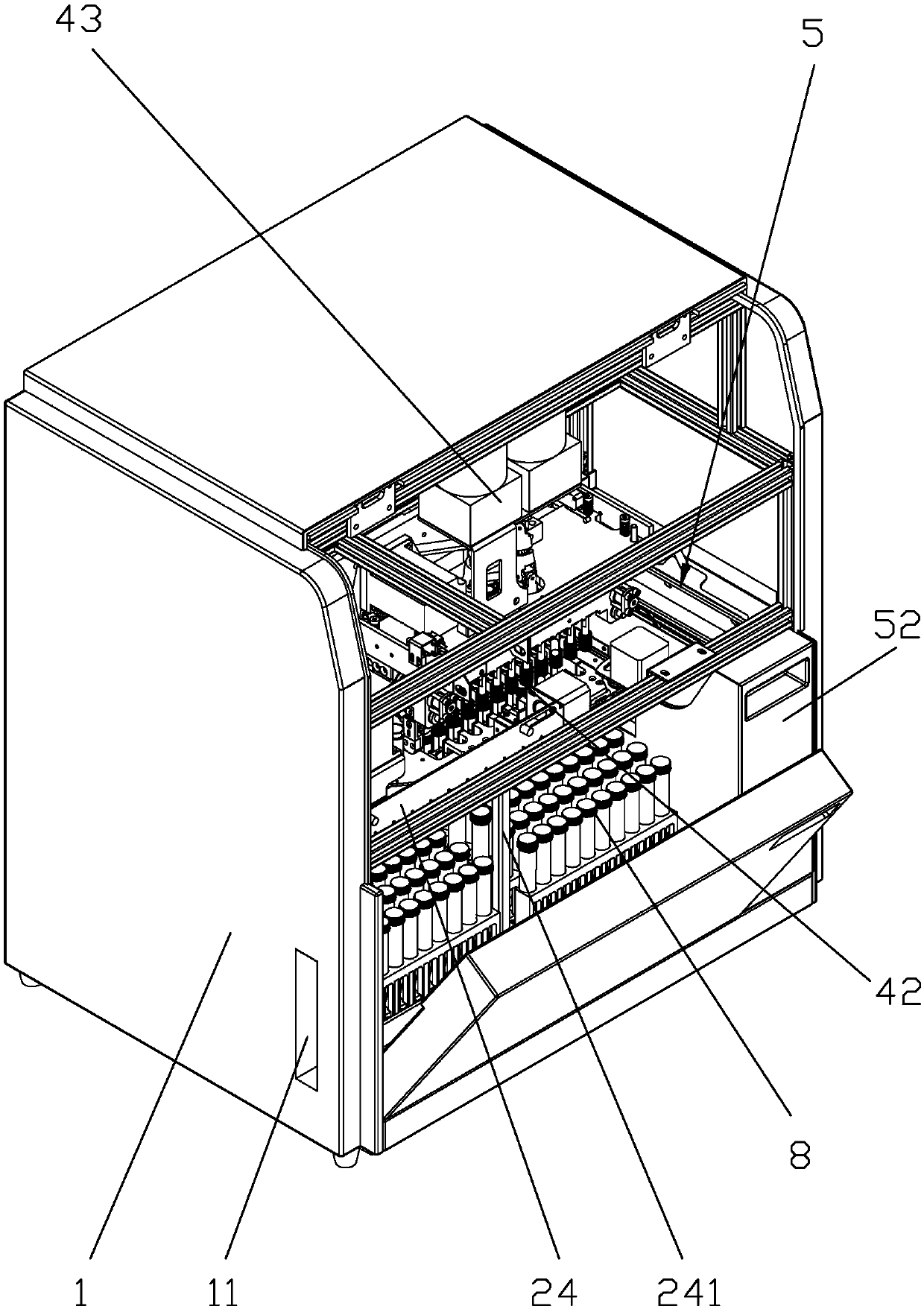

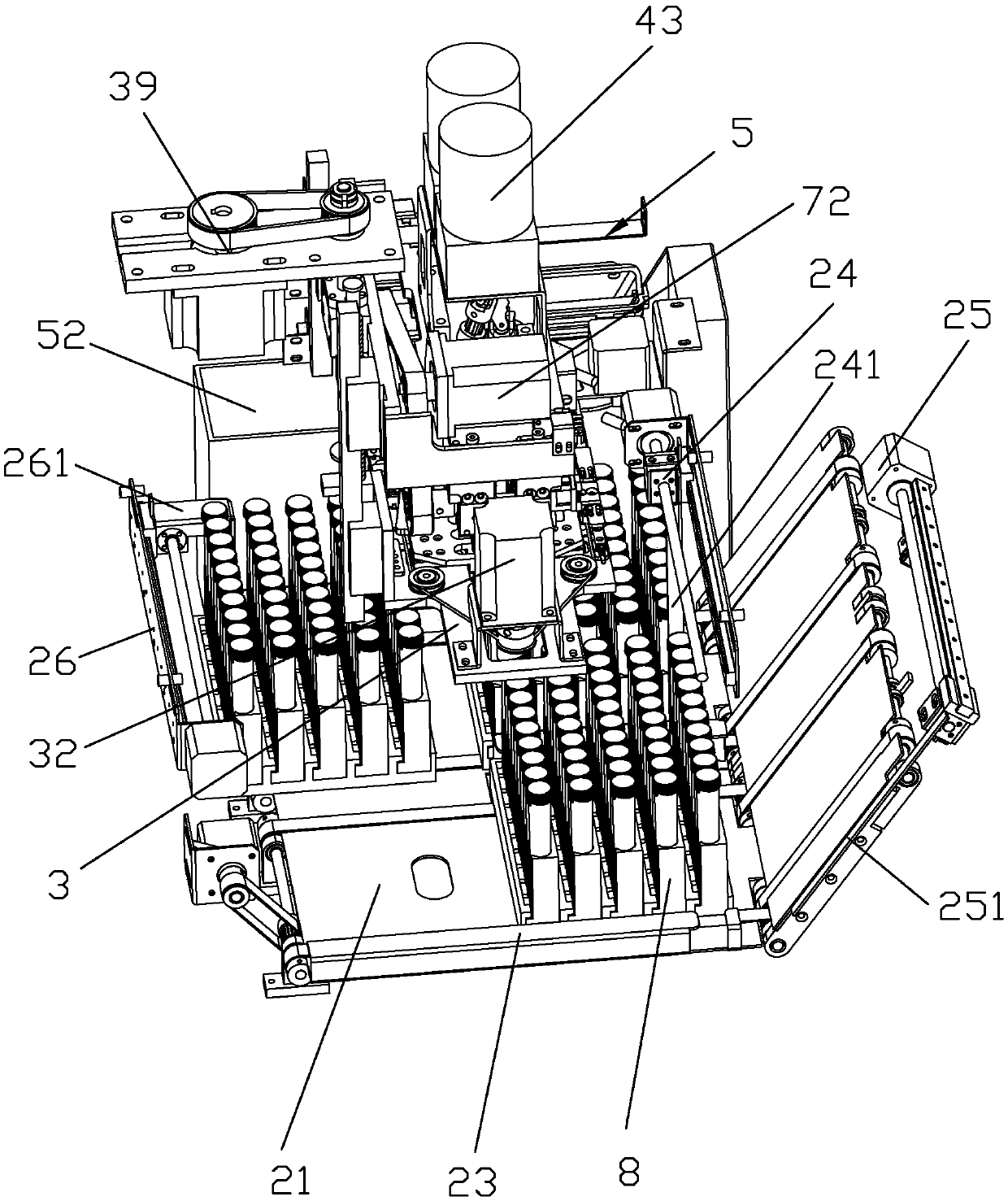

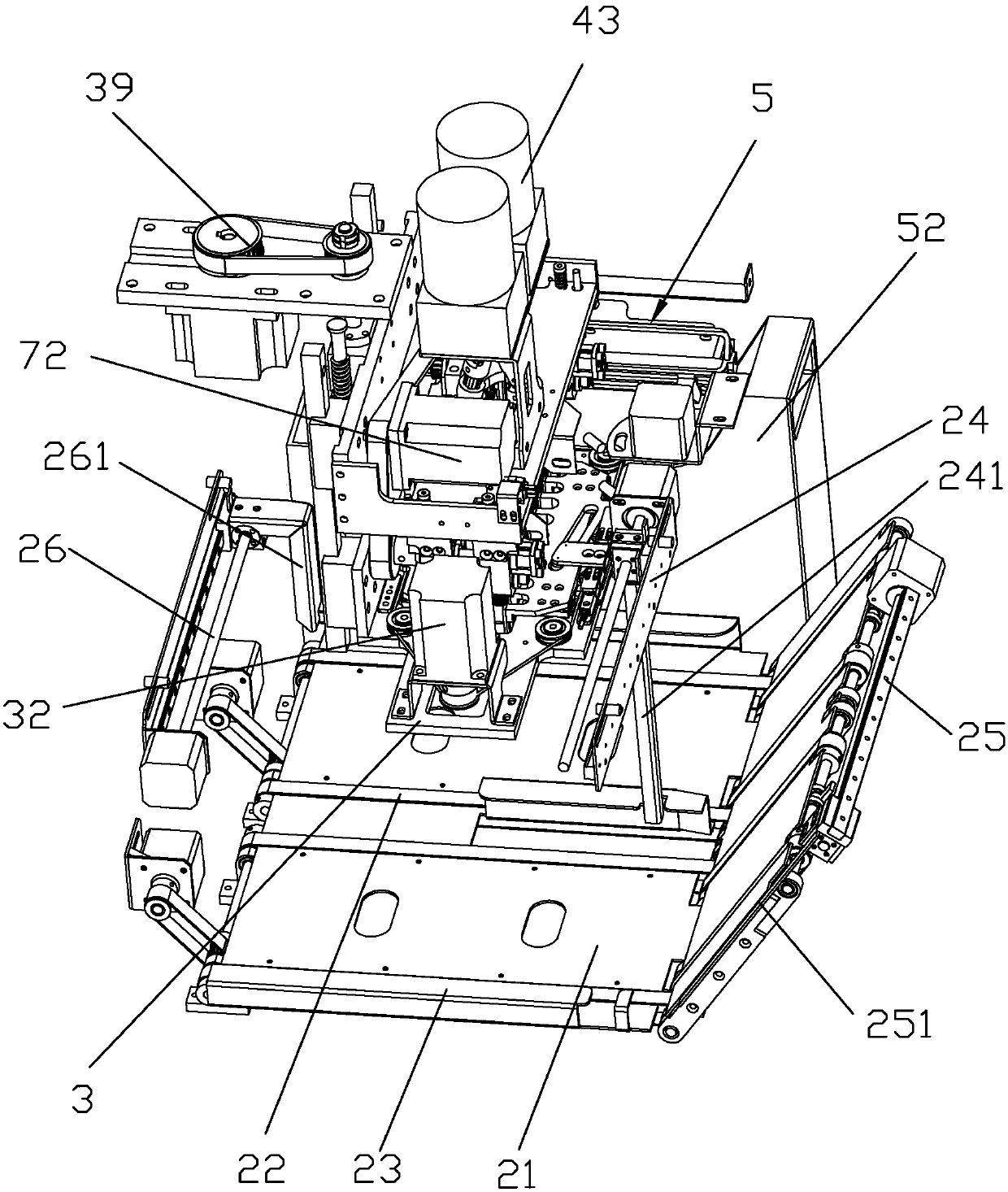

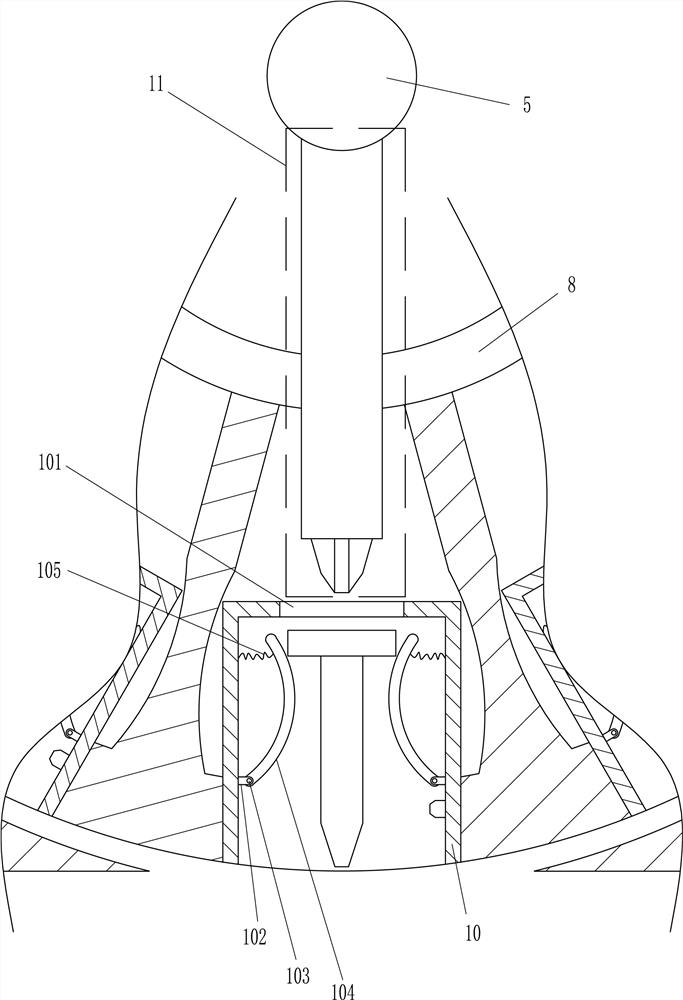

Urine collection tube uncovering machine

ActiveCN108033418AReduce volumeHigh degree of automationOpening closed containersBottle/container closureUrine CollectionsWaste management

The invention relates to the technical field of medical instruments, and discloses a urine collection tube uncovering machine. The uncovering machine comprises a machine shell, a material conveying plate is arranged at the inner bottom of the machine shell, a feeding conveying belt and a discharging conveying belt are arranged on the material conveying plate, and a discharging device is arranged on the left side of the material conveying plate; a cover discharging mechanism is arranged on the right side of the material conveying plate, and a clamping bottom plate is arranged above the materialconveying plate; a pair of symmetric pipe clamping pieces are arranged on the clamping bottom plate, and the pipe clamping pieces are longitudinally and slidably connected to the clamping bottom plate; a clamping driving mechanism for driving the pipe clamping pieces to slide longitudinally is arranged on the clamping bottom plate; a lifting device is arranged on the rear side of the clamping bottom plate, and a cover removal bottom plate is arranged at the upper end of the lifting device; a pair of symmetric cover removal bases are arranged below the cover removal bottom plate, and a movingmechanism for driving the cover removal bases to move longitudinally is arranged between the two cover removal bases; each cover removal base is provided with a row of cover removal rods, the cover removal rods are located above the pipe clamping pieces, and a cover removal motor for driving the cover removal rods to rotate is arranged above the cover removal bottom plate. The machine is compact in structure, small in size and rapid and reliable in work.

Owner:HANGZHOU LONGXIN TECH

Screw

A screw includes a shank, a head connected thereto, a drilling portion opposite to the head, a first threaded section spirally formed on the shank, and a leading threaded section spirally extending upwards from the drilling portion. The two threaded section are disconnected so that a valley is formed between them. At least one cutting unit protrudes from the valley and has two ends connected to the first threaded section and the leading threaded section respectively. The leading threaded section assists the drilling portion in cutting and drilling into an object while screwing, and the cutting unit protruding from the valley severs fibers which are not cut by the leading threaded section completely to prevent the entanglement of the fibers. The valley helps accommodate and evacuate cut chips. Therefore, the drilling resistance is reduced effectively to increase the screwing efficiency.

Owner:TAIWAN SHAN YIN INT CO LTD

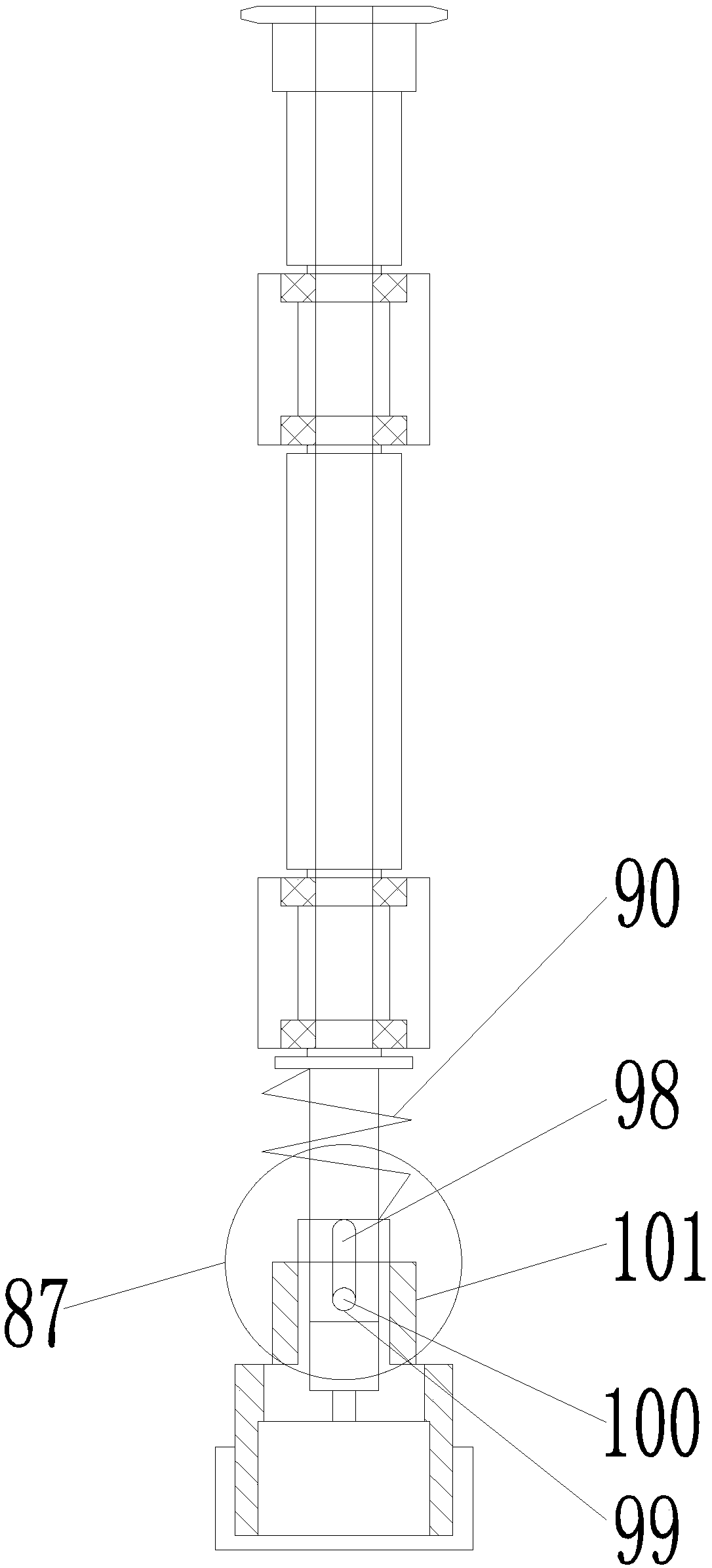

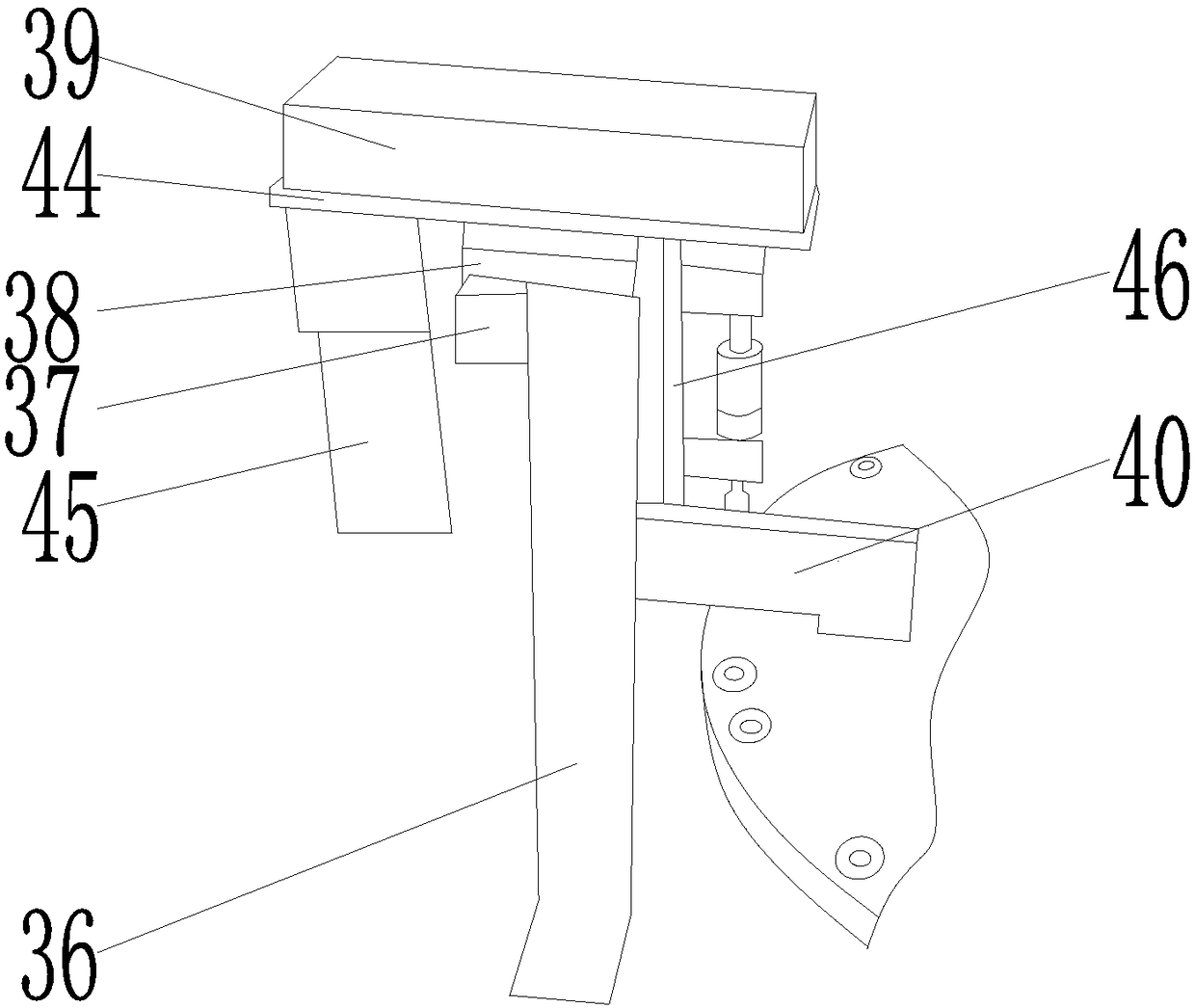

Screwing device of sleeper sleeve spiral rib

The invention relates to the technical field of sleeper production, and provides a screwing mechanism of a sleeper sleeve spiral rib. The screwing mechanism comprises a conveying line, fixing devices,a lifting electric cylinder, a screwing motor and a screwing sleeve. The fixing devices are arranged on the two sides of the conveying line. The lifting electric cylinder is arranged above the fixingdevices. The moving end of the lifting electric cylinder is connected with the screwing motor. An output shaft of the screwing motor is connected with the screwing sleeve. When a spiral rib sleeve iscarried to the positions of the fixing devices by the conveying line, the conveying line stops moving, the spiral rib sleeve is clamped by the fixing device, and the lifting electric cylinder arranged above the fixing devices is started to drive the screwing motor and the screwing sleeve to descend, so that the screwing sleeve is clamped with the spiral rib sleeve, and finally the screwing motoris started to drive the screwing sleeve to rotate, so that the spiral rib is screwed onto the sleeve. The screwing efficiency is high due to the adoption of mechanical screwing equipment; and moreover, the screwing force can be set according to the actual situations, the consistency of strength of screwing the spiral rib is ensured, a large amount of rework is avoided, and the production efficiency of the spiral rib sleeve is improved.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +3

Method for filing and displaying coupling screwed torsion graph in real time

ActiveCN102169339BEasy backupEasy transferTotal factory controlProgramme total factory controlHuman–machine interfaceData acquisition

The invention relates to a method for filing and displaying a coupling screwed torsion graph in real time. The method comprises the following steps: converting a physical signal of a force sensor (1) into a standard analog signal through a converter (2), and then sending one path of standard analog signal into an on-site PLC (programmable logic controller) (3) while switching the other path of standard analog signal into a high-speed data acquisition card (5) of an industrial personal computer; transmitting the standard analog signal which is switched into the PLC (3) into a master PLC (6) through a network, performing the analog-to-digital conversion and calibration on the standard analog signal, and then generating a torsion value for controlling a main screwed torsion; generating a pulse signal by a rotary encoder (7), transmitting the pulse signal to the master PLC (6) through the PLC (3) and the network, and then converting the pulse signal into a real-time circle value by a FM (frequency modulation) module and finally outputting; performing the analog-to-digital conversion and digital quantity operation on the standard analog signal which is switched into the high-speed data acquisition card (5) so as to obtain the torsion value while acquiring the real-time circle value from the master PLC (6); and drawing a variation trend graph of the torsion following the change of circle number on a HMI (human machine interface) (10), and storing the tube basic data and process data.

Owner:洛阳锐腾机械设备有限公司

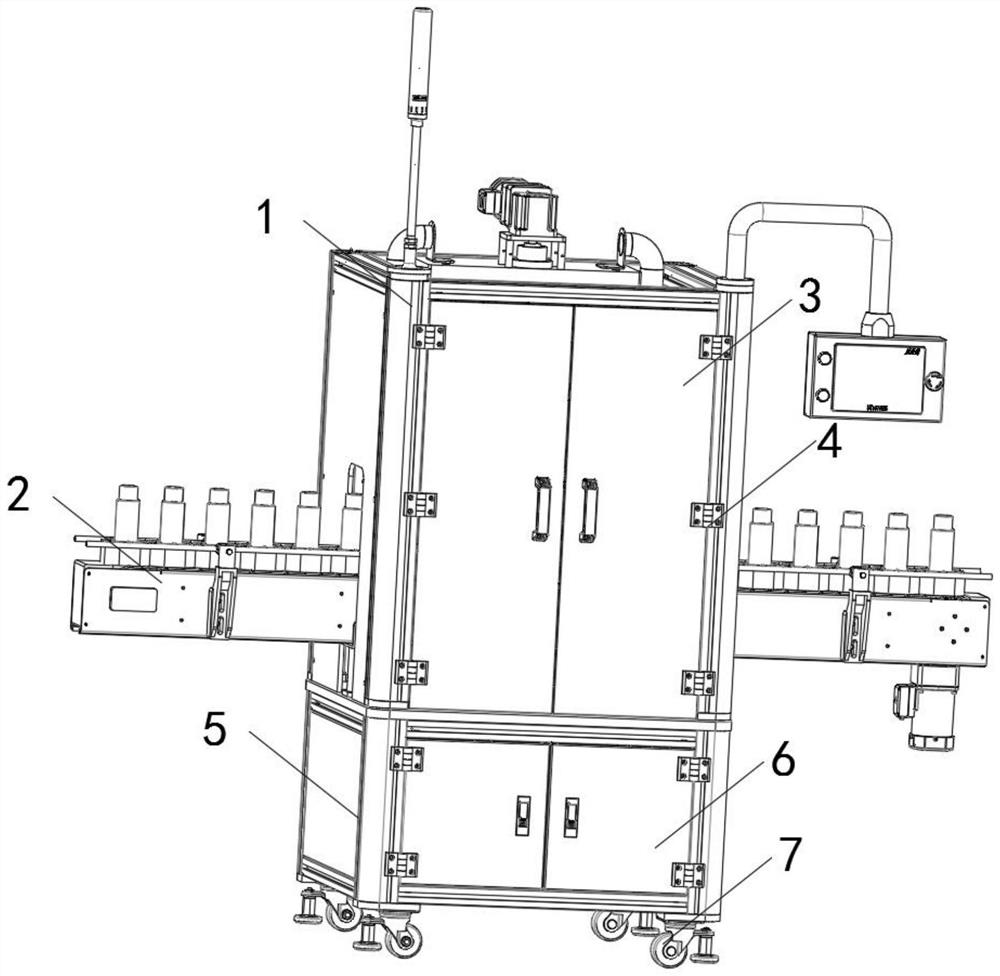

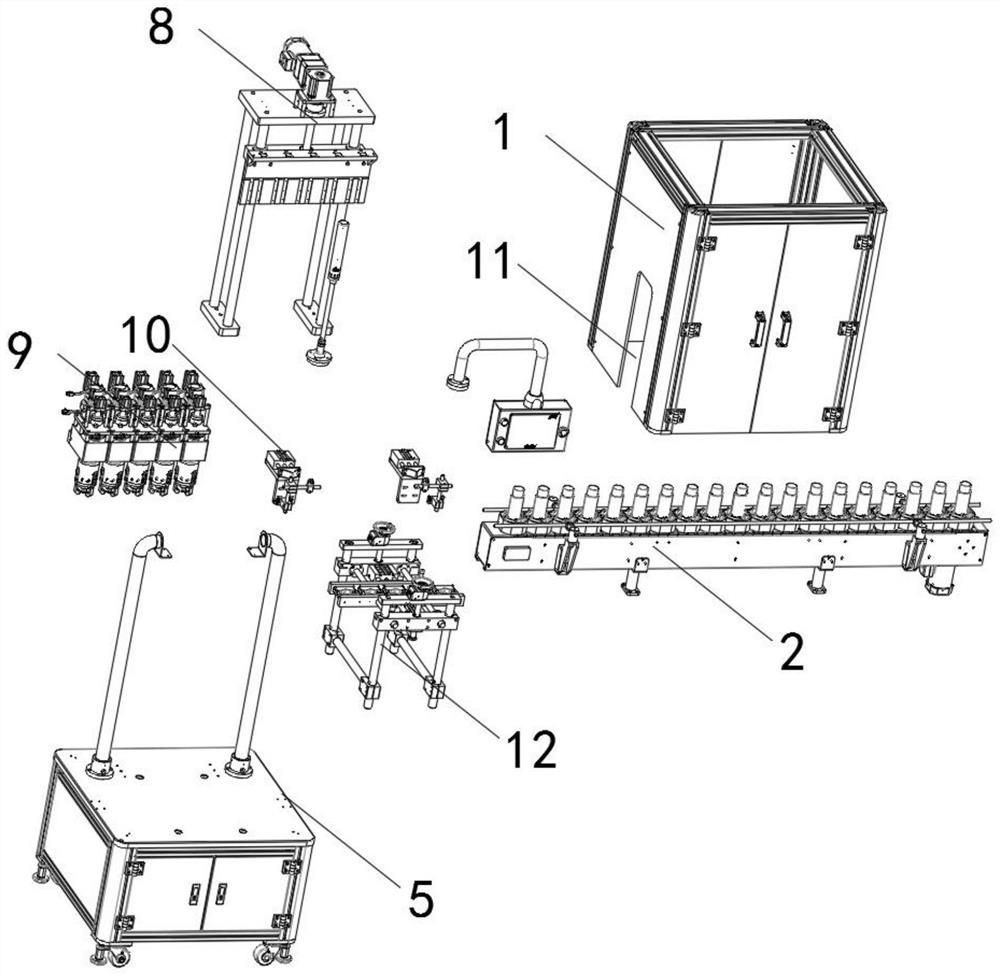

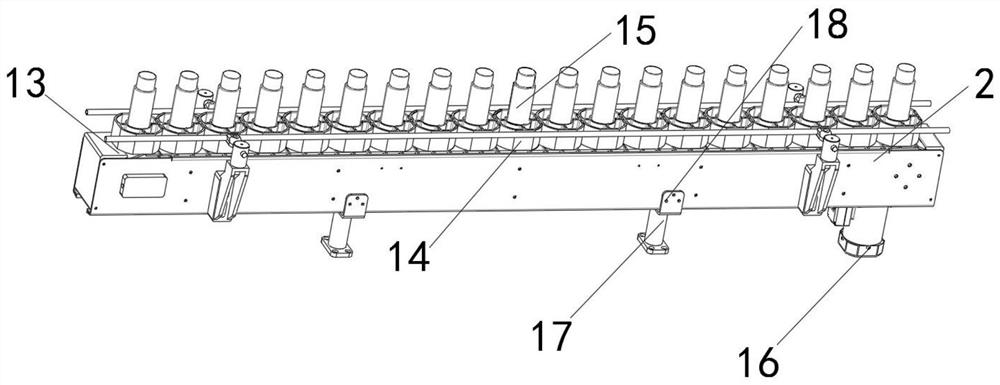

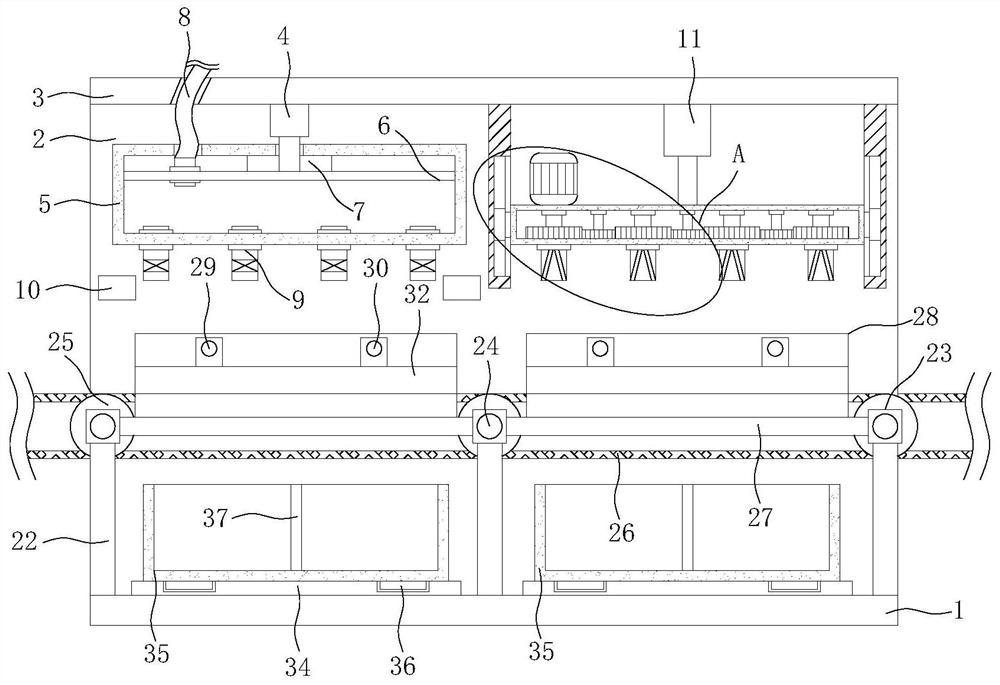

An infusion and capping device used in a genetic engineering preparation processing production line

ActiveCN109592626BQuality improvementAvoid wastingThreaded caps applicationSynchronising machinesElectric machinerySurgery

The invention discloses an infusion cap screwing device used for a genetic engineering preparation processing production line. The infusion cap screwing device comprises an upper sleeve box, a conveying table, a lower containing cabinet, a lifting seat, a preparation injection disc and clamping and supporting tables. The upper sleeve box is of a hollow cuboid structure, and the conveying table ishorizontally arranged below the middle portion of the upper sleeve box. The conveying table and the upper sleeve box are arranged in a penetrating manner. The infusion cap screwing device has the beneficial effects that a third motor is used for driving three clamping pieces to clamp the side wall of a bottle cap of a preparation containing bottle through a swing shaft, the cap is screwed in a rotating manner, the preparation containing bottle is sealed, the device can screw and seal the bottle cap immediately after preparation injection of the preparation containing bottle is conducted, the work efficiency of the device is improved, the phenomenon that after preparation injection, in the process that the preparation containing bottle is transferred to the cap screwing device, the preparation is spilled out from a bottle body or the preparation in the bottle body is volatized is avoided, it is ensured that the genetic engineering preparation is injected more sufficiently, and sprinkling waste is avoided; and in addition, the three clamping pieces are distributed in an arc manner, the force applying effect of the clamping pieces on the bottle cap is higher, the cap screwing efficiency is higher, and the quality is better.

Owner:深圳市合盛医疗科技有限公司

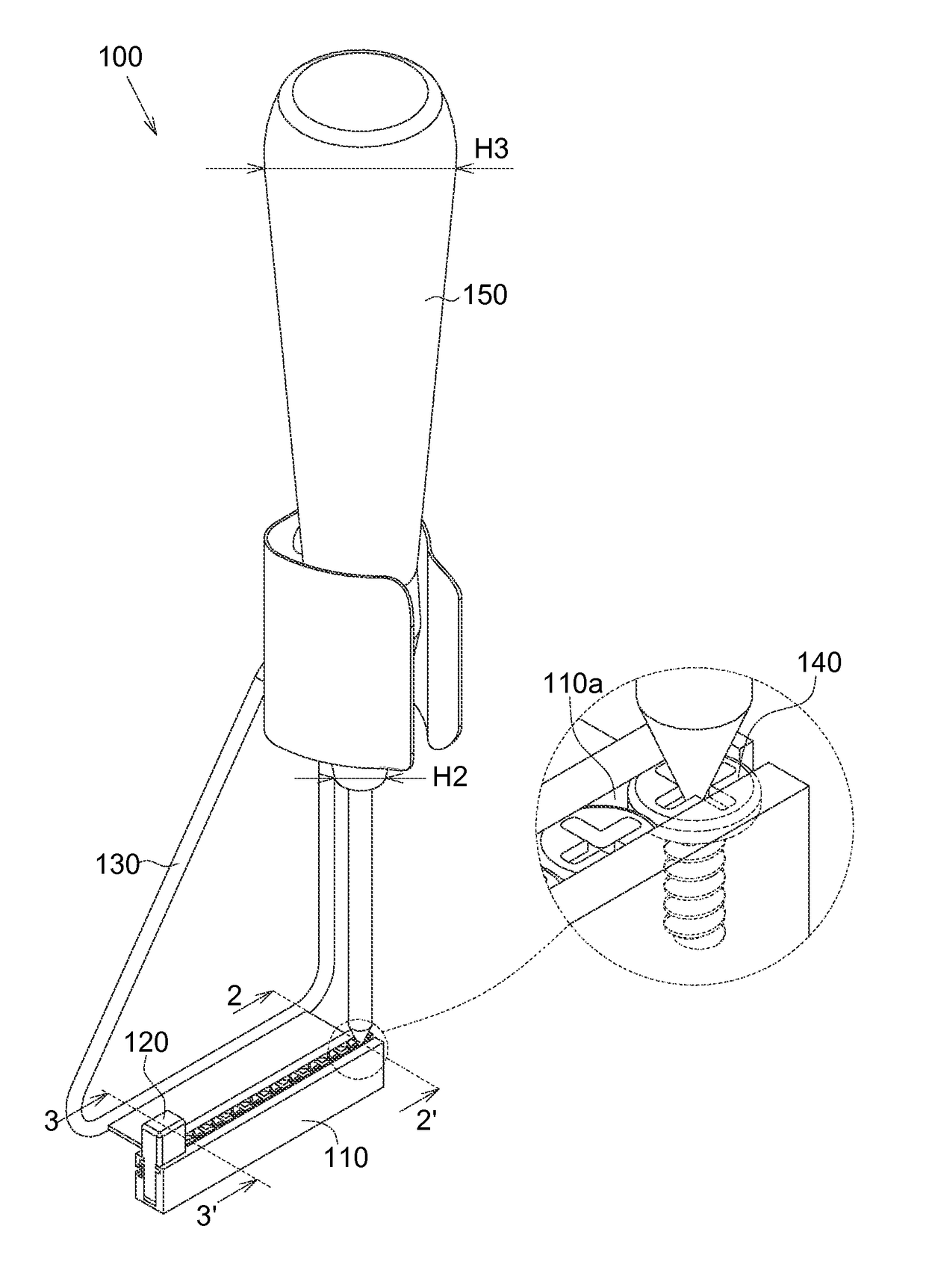

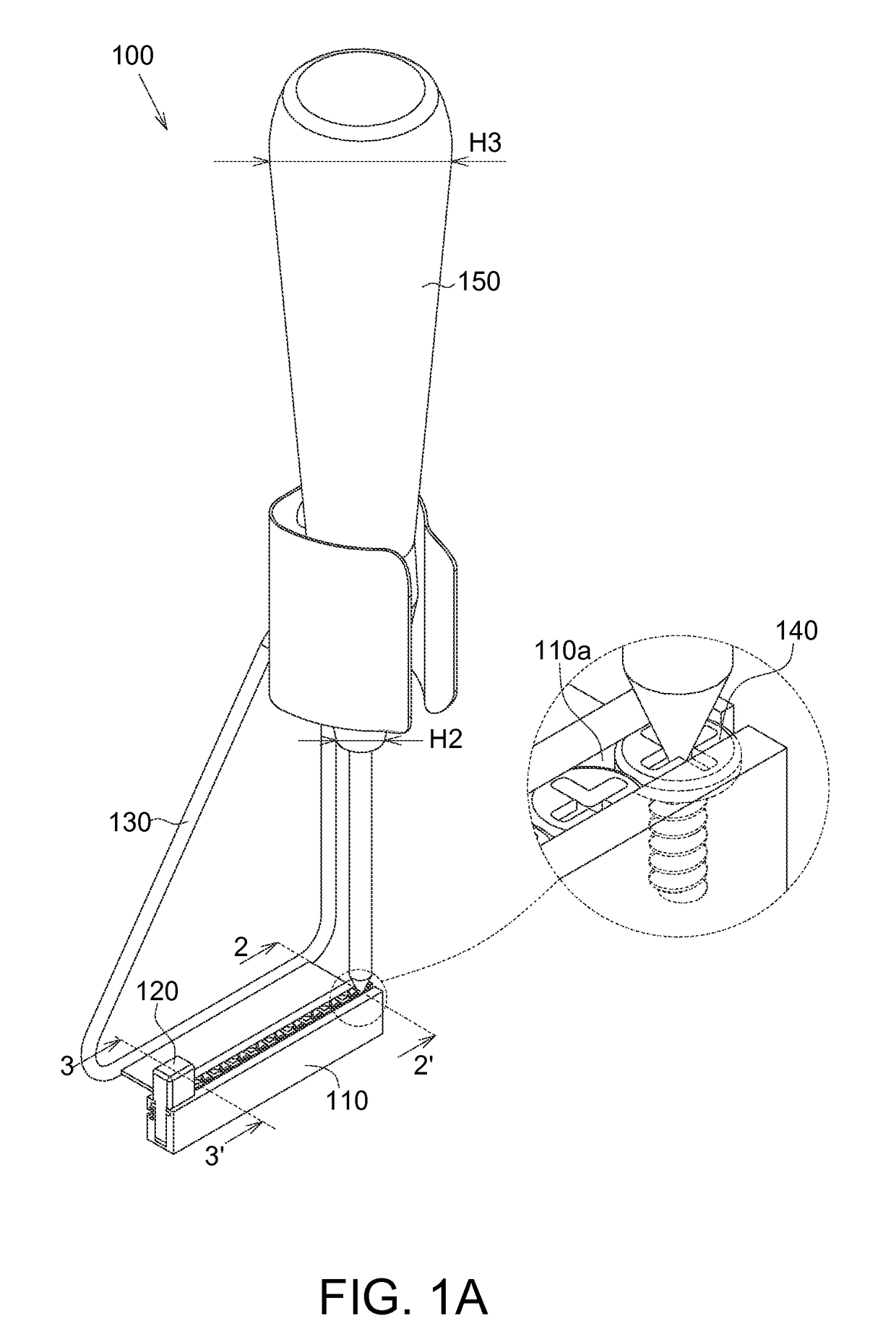

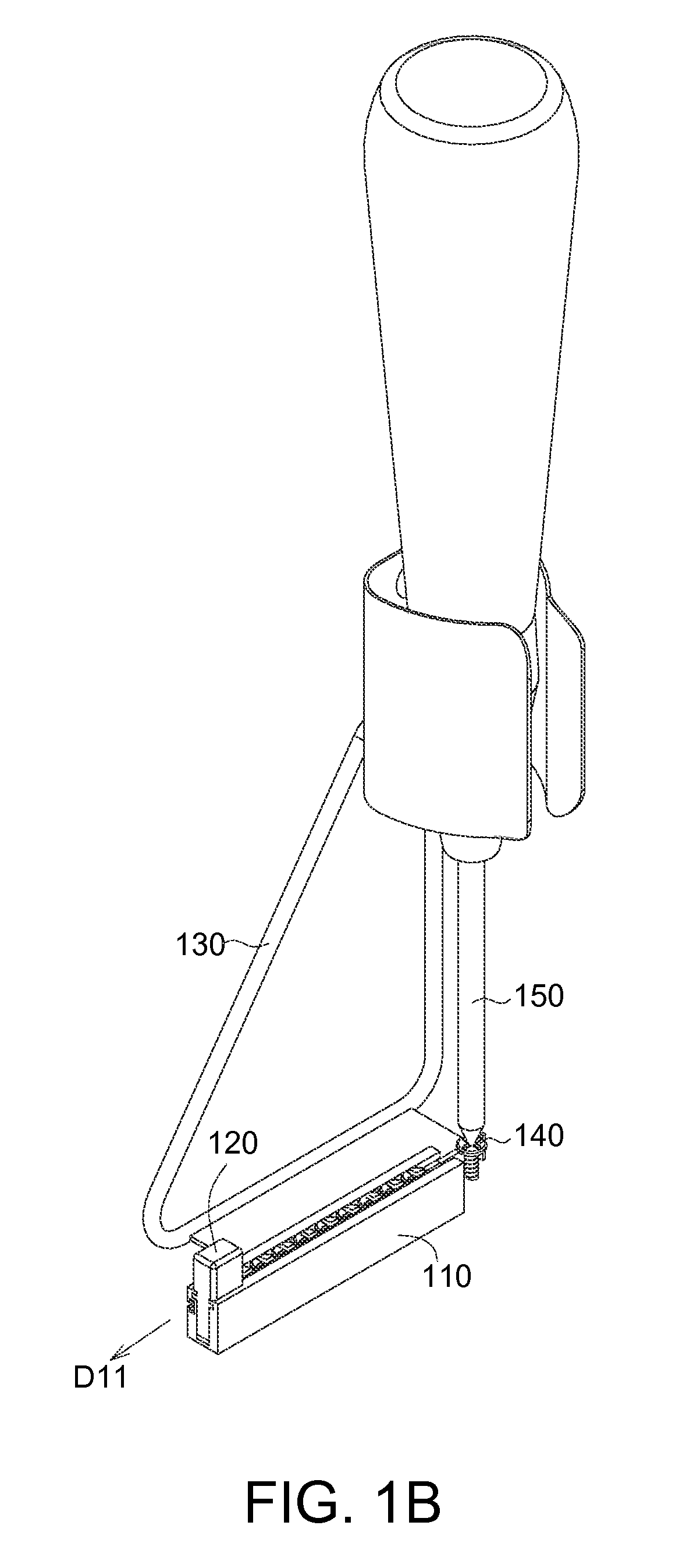

Screwing accessory device

InactiveUS9827653B2Improve screwing efficiencyStapling toolsSpannersEngineeringElectrical and Electronics engineering

Owner:WISTRON CORP

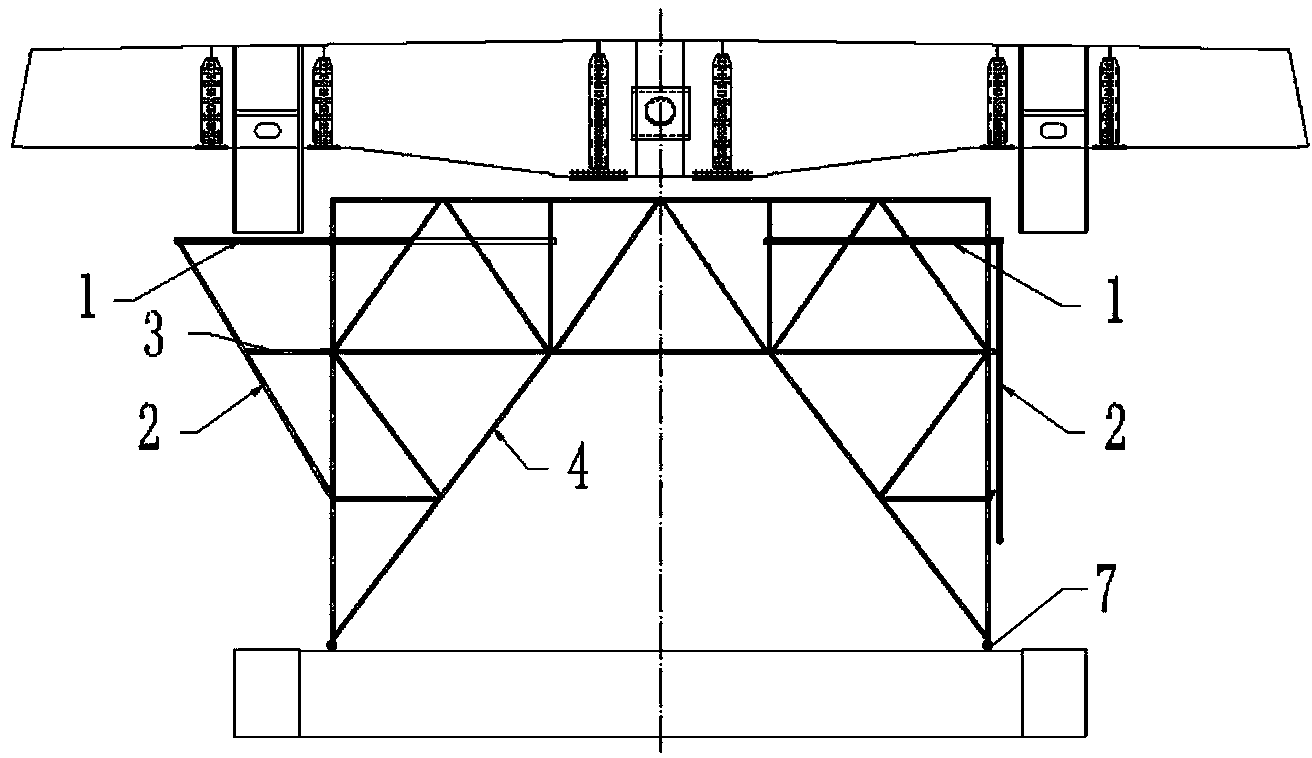

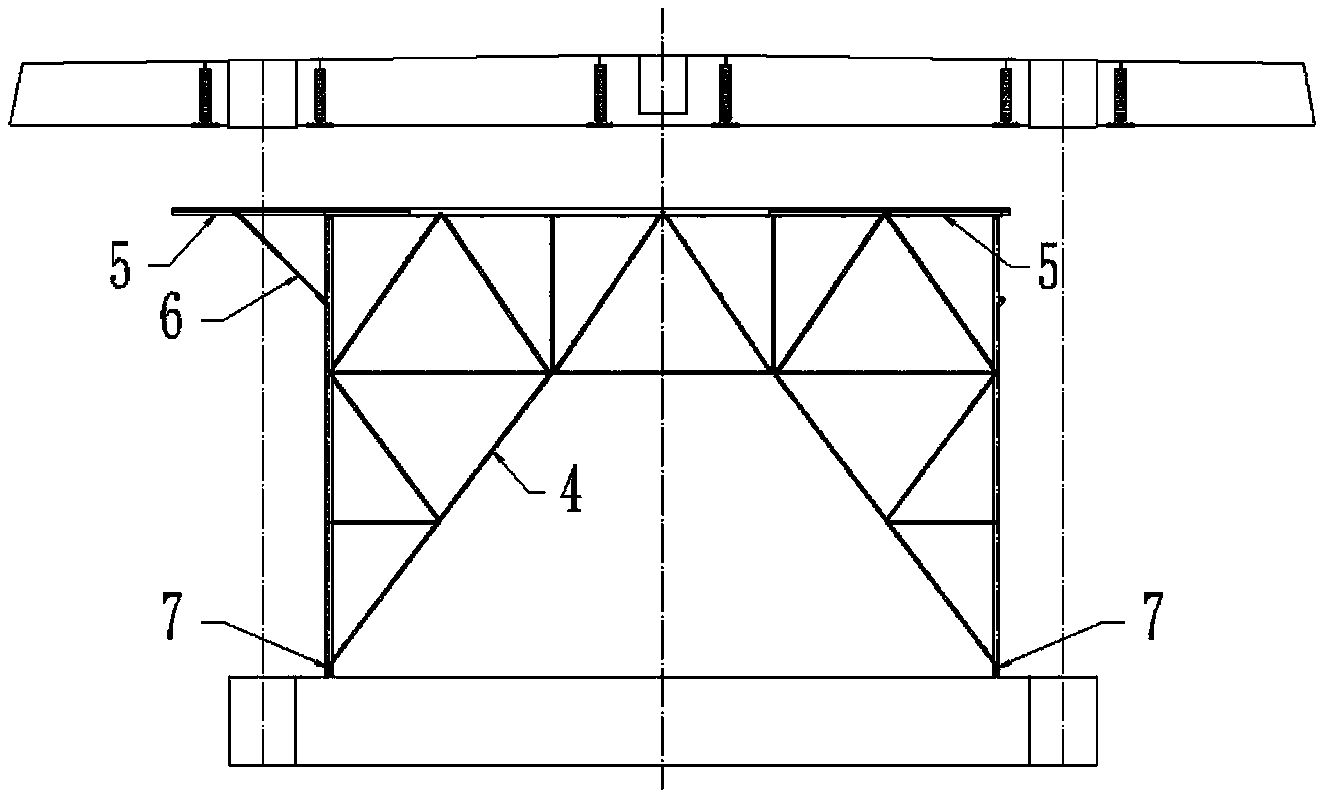

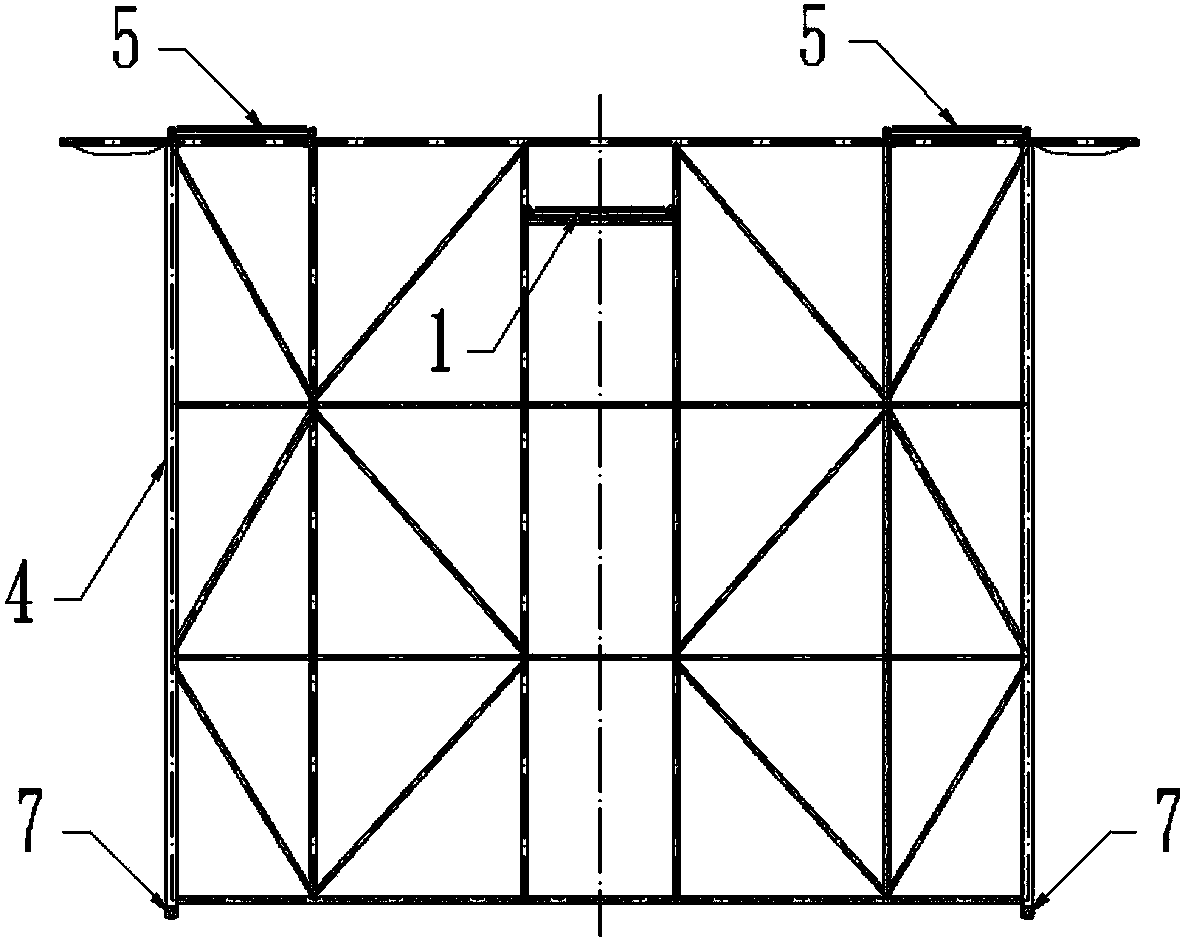

Steel girder rod piece assembling movable and telescopic high-strength bolt screwing platform

ActiveCN103088758BEasy to operateShorten construction timeBridge erection/assemblyArchitectural engineeringPipe support

The invention relates to a construction device for bridge section girder high-strength bolt construction, in particular to a steel girder rod piece assembling movable and telescopic high-strength bolt screwing platform which is convenient to erect and high in construction efficiency. The steel girder rod piece assembling movable and telescopic high-strength bolt screwing platform comprises a steel pipe support. Road wheels are arranged on the bottom of the steel pipe support, two mutually vertical telescopic sliding platforms are arranged on the upper portion of the steel pipe support, and the two mutually vertical telescopic sliding platforms comprise second sliding platforms vertically arranged on the top portion of the steel pipe support and first sliding platforms horizontally arranged below the second sliding platforms. The steel girder rod piece assembling movable and telescopic high-strength bolt screwing platform can reduce construction time, is simple in operation method, not only is suitable for high-strength bolt screwing in steel truss girder rod piece assembling, but also can improve work efficiency of the high-strength bolt screwing.

Owner:中铁大桥局集团第八工程有限公司 +1

Bolt screw-in machine

The invention discloses a bolt screw-in machine. The bolt screw-in machine comprises a discharge mechanism, a feeding mechanism and a screw-in assembly, wherein the screw-in assembly comprises a screw-in mounting plate, a screw-in lifting plate, a screw-in lifting drive mechanism, a screw-in drive motor, a screwdriver bit, a screw-in position sensor and a screw-in trigger piece, wherein the discharge mechanism comprises a discharge bottom plate and a discharge placing plate; a wiring frame of a to-be-screwed-in bolt is placed on the discharge mechanism; the feeding mechanism is used for feeding a bolt to a position below the screwdriver bit; the screw-in assembly is used for screwing in the bolt on the feeding mechanism into the wiring frame of the to-be-screwed-in bolt on the discharge mechanism; the screw-in lifting drive mechanism drives the screw-in lifting plate to move downwards, so that the screwdriver bit is in contact with the bolt on the feeding mechanism, and the screw-in drive motor drives the screwdriver bit to perform screw-in operation on the bolt; and while the screw-in trigger piece on the screw-in lifting plate triggers the screw-in position sensor, the screw-in drive motor stops rotation, so that the bolt is screwed into preset depth, and therefore, screw-in efficiency is improved.

Owner:SHENZHEN HAIPENGXIN ELECTRONICS

Automatic screw tightening device

PendingCN112809354AReduce human inputImprove screwing efficiencyMetal working apparatusScrew positionElectric machinery

The invention is suitable for the technical field of automatic mechanical equipment, and provides an automatic screw tightening device. The device comprises a workbench, and a clamping part arranged on the workbench in a sliding manner and used for clamping and fixing a to-be-screwed workpiece. The workbench is fixedly provided with a plurality of screw locking motors, an output shaft of each screw locking motor is fixedly connected with a torsion sleeve used for tightening a screw, and each to-be-tightened screw is placed in the corresponding torsion sleeve and is aligned with the to-be-screwed position of the to-be-screwed workpiece; and the workbench is further provided with a moving part, and the moving part is connected with the clamping part and drives the clamping part to move on the workbench. According to the embodiment of the device, the to-be-screwed workpiece is clamped by the clamping part, the to-be-screwed workpiece is driven to move by the moving part, and the plurality of screw locking motors drive the torsion sleeves to rotate so as to screw the screws on the to-be-screwed workpiece, so that automatic screw tightening is realized, the plurality of screws can be tightened at one time, and the working efficiency is effectively improved.

Owner:益阳市鹏程科技发展有限公司

Bottled cosmetic sealing canning device capable of achieving rapid sealing

InactiveCN112093750AShort processing timeIncrease productivityCapsThreaded caps applicationProcess engineeringMechanical engineering

The invention discloses a bottled cosmetic sealing canning device capable of achieving rapid sealing, and relates to the technical field of bottled sealing. The bottled cosmetic sealing canning devicecapable of achieving rapid sealing comprises a mounting plate, and a connecting plate is welded to the outer surface of the top of the mounting plate. Through cooperative use of a fixing plate, a hydraulic rod, an extrusion box, an extrusion plate, a connecting block, a connecting hose, discharging pipes and stopping blocks, cosmetics needing to be sealed in the following process can be subjectedto automatic filling and canning treatment firstly, and the interval time of automatic filling and canning treatment and following sealing treatment is short; the problem that cosmetic raw materialsare not sealed for a long time and react with air is avoided, the product quality is effectively guaranteed, the working efficiency is high, on one hand, the problem of low production efficiency is avoided, and on the other hand, the problem that the cosmetic raw materials are not sealed for a long time and react with the air due to low working efficiency is further avoided; and the product quality is further guaranteed.

Owner:浙江霄腾智能科技有限公司

Multifunctional wrench and assembling and using method thereof

InactiveCN108581907AImprove screwing efficiencySuitable for narrow space operationSpannersWrenchesEngineeringWrench

The invention provides a multifunctional wrench and an assembling and using method thereof, and belongs to the field of disassembling and assembling tools. The problems that existing wrenches are lowin operation efficiency and poor in flexibility are solved. The multifunctional wrench comprises a wrench handle of which the front end is provided with a wrench sleeve, and a wrench hole is formed inthe wrench sleeve; the multifunctional wrench further comprises a wrench head, the outer wall of the wrench head is provided with a limiting groove, and the groove wall of the limiting groove is provided with a positioning groove; the wrench head is arranged in the wrench hole; the wrench handle is provided with an adjusting hole, and an adjusting rod is arranged in the adjusting hole in a penetrating mode; the rear end hole wall of the adjusting hole and the rod wall of the adjusting rod are provided with a slide groove and a slide block correspondingly, and a compression spring is arrangedin the slide groove; and a rod groove is formed in the wrench handle. The multifunctional wrench further comprises an adjusting sleeve which sleeves the wrench handle, a connection rod, and a reset spring, wherein the wall of the adjusting rod is provided with a connection hole; one end of the connection rod is connected with the inner wall of the adjusting sleeve, and the other end of the connection rod is arranged in the connection hole in a penetrating mode; and the reset spring is located in the rod groove and sleeves the adjusting rod, and the two ends of the reset spring abut against thefront side wall of the rod groove and the connection rod. The wrench is higher in operation efficiency and flexibility.

Owner:温州利维科技有限公司

Cap grabbing head

The invention discloses a cap grabbing head. The cap grabbing head comprises a cap grabbing die, wherein the cap grabbing die comprises at least two independent arc-shaped cap grabbing die petals, each cap grabbing die petal structurally comprises an arc-shaped petal body, a top plate and a supporting plate are arranged on the inner side and the outer side of the petal body respectively, and the top plate is located at the top of the inner side of the petal body; a mounting base sleeves the cap grabbing die, a check ring is arranged on the inner wall of the mounting base, the top plate of each petal body is positioned at the bottom of the check ring of the mounting base, the supporting plate of each petal body is positioned at the bottom of the mounting base, each petal body is hinged to the mounting base, a space for each petal body to rotate around the corresponding hinge center is reserved between the mounting base and the petal body, and when the top plate of any petal body is pressed and blocked by a bottle cap, the lower end of the petal body can rotate towards the inner side of the mounting base around the corresponding hinge center. The cap grabbing head has the advantages that errors between the bottle cap and the cap grabbing die can be overcome, and the cap screwing efficiency is greatly improved.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

A hand-held screwdriver

The invention relates to a screw-driving device, in particular to a hand-held screw-driving device. Technical problem: Provide a hand-held screw-driving device that can save manpower, is safe, and has high efficiency. The technical solution is: a hand-held screw-tightening device, including a hand-held device, an external hose, an intermediate round box, etc.; the right side of the hand-held device is connected with an external hose, and the external hose is provided with a power cord and an external air pipe . In the present invention, by pushing the screw into the storage box, under the action of the spring, the arc-shaped rods on the left and right sides can clamp the screw, which can make screwing more convenient and fast; the connecting ring frame can be driven to rotate by the servo motor , so as to drive the placement box to rotate, so that the placement box can be rotated one by one to the right below the impact screw-in device; through the impact screw-in device, the screws in the placement box can be screwed to the desired position, thereby saving manpower and improving screw screwing efficiency .

Owner:无锡品知信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com