Sleeve screwing device

A sleeve and driving device technology, applied in structural elements, building components, building reinforcements, etc., can solve the problems of manpower consumption, low efficiency, limited space, etc., and achieve the goal of improving screwing efficiency, high work efficiency, and saving manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

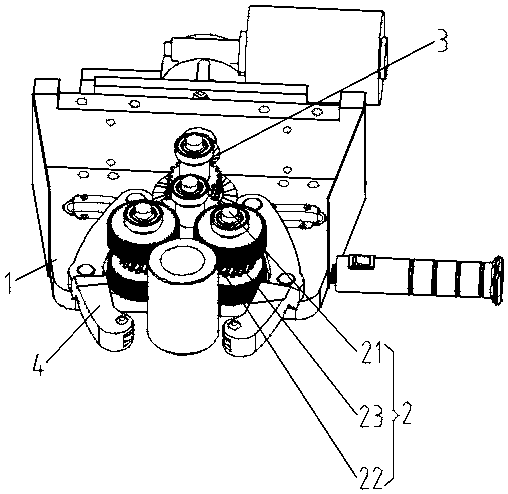

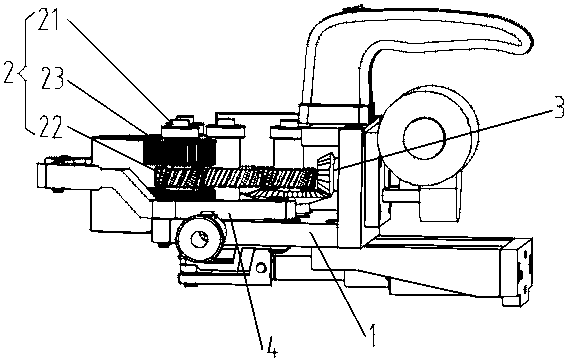

[0039] A kind of sleeve screwing device of this embodiment, such as figure 1 and figure 2 As shown, it includes a base 1, the end of the base 1 close to the sleeve is provided with a sleeve screwing device 2, and the sleeve screwing device 2 includes a driven shaft that is rotatably arranged at the end of the base 1 close to the sleeve 21, the driven shaft 21 is provided with a transmission member 22 and a roller 23; the end of the base 1 away from the sleeve is provided with a driving device 3, and the driving end of the driving device 3 is connected to the transmission member 22 in transmission ; The bottom of the base 1 is provided with a sleeve clamping device 4 corresponding to the rolling wheel 23 .

[0040] The base 1 is a hollow box-shaped frame structure, including a top plate and a bottom plate arranged in parallel. A working end plate is arranged between an end of the top plate close to the sleeve and an end of the bottom plate close to the sleeve to form a workin...

Embodiment 2

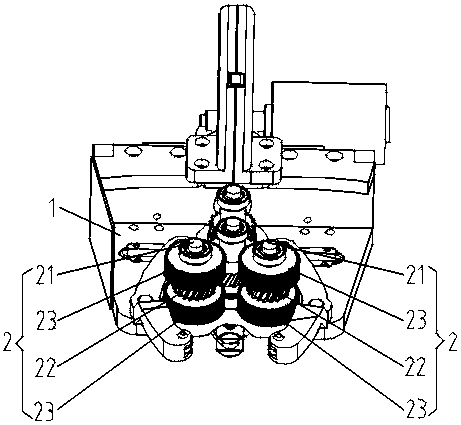

[0046] This embodiment is further optimized on the basis of embodiment 1, such as image 3 As shown, the two sides of the base 1 close to one end of the sleeve are respectively provided with sleeve screwing devices 2, and the driving device of the driving device 3 drives the sleeve screwing devices 2 on both sides at the same time, and the sleeve screwing devices 2 on both sides The sleeve screwing device 2 rotates in the same direction.

[0047] On both sides of the working end of the base 1, a sleeve screwing device 2 is respectively rotated through deep groove ball bearings, that is, a driven rotating shaft 21 is respectively rotated through deep groove ball bearings on both sides of the working end of the base 1, and Each driven shaft 21 is equipped with a transmission part 22 and a roller 23, and the transmission parts 22 on both sides are connected to the driving end of the driving device 3, that is, the driving end of the driving device 3 synchronously drives the transm...

Embodiment 3

[0050] This embodiment is further optimized on the basis of embodiment 1 or 2, such as image 3 As shown, the middle part of the driven shaft 21 is provided with a transmission member 22 , and the upper and lower sides of the driven shaft 21 are respectively sleeved with rolling wheels 23 .

[0051] The middle part of the driven shaft 21 is provided with a transmission part 22 through a flat key or an integral molding method, and roller wheels 23 are sleeved on the shaft sections of the driven shaft 21 located on both sides of the transmission part 22, that is, on the driven shaft. The upper and lower parts of 21 are provided with rolling wheels 23, the upper rolling wheels 23 are in contact with the upper outer circular surface of the sleeve, and the lower rolling wheels 23 are in contact with the lower outer circular surface of the sleeve. When rotating, the synchronous driving of the upper and lower rollers 23 can ensure the synchronous driving of the upper outer surface an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com