Bolt screw-in machine

A technology of screwing and screwing, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low screwing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

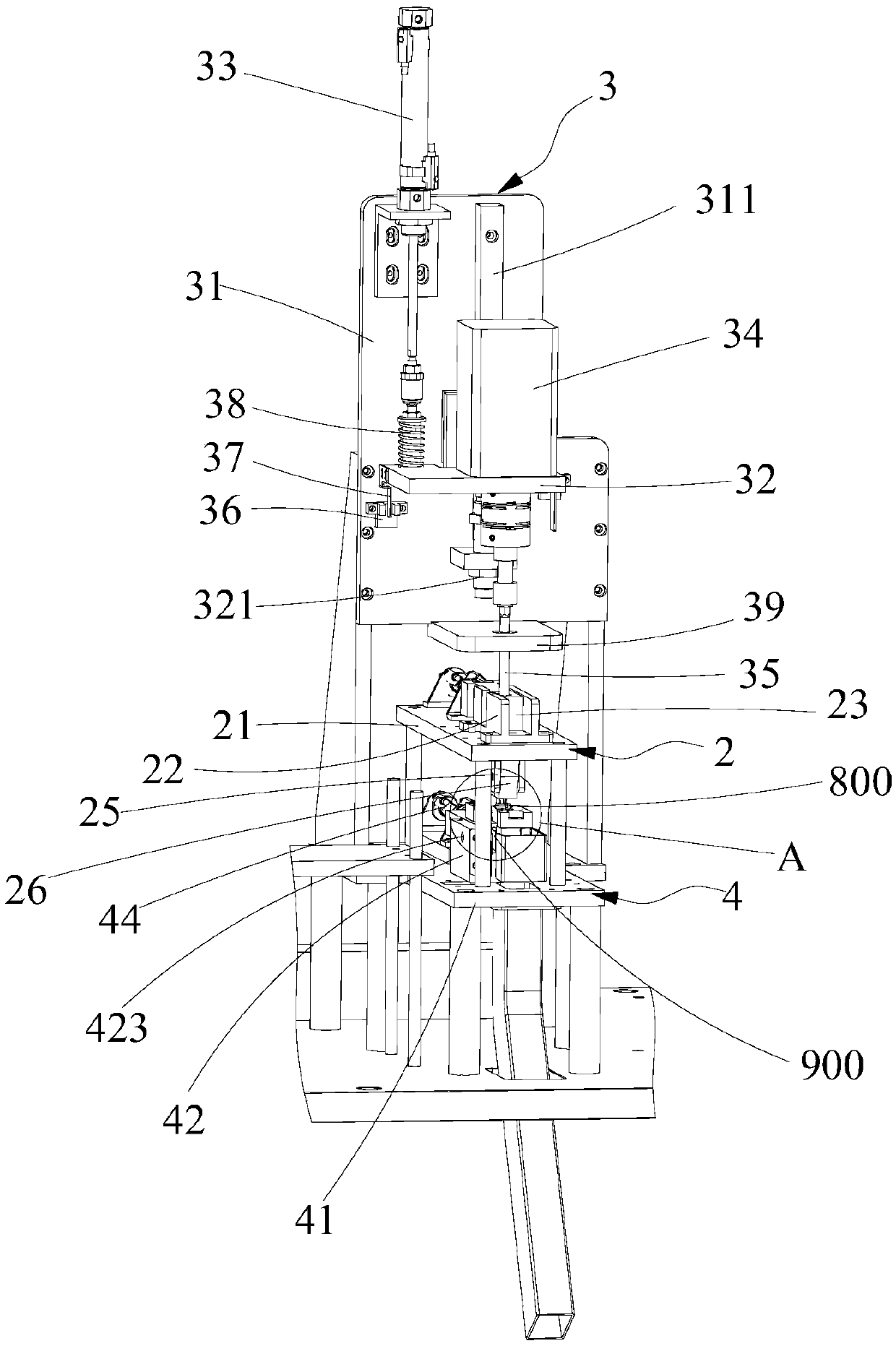

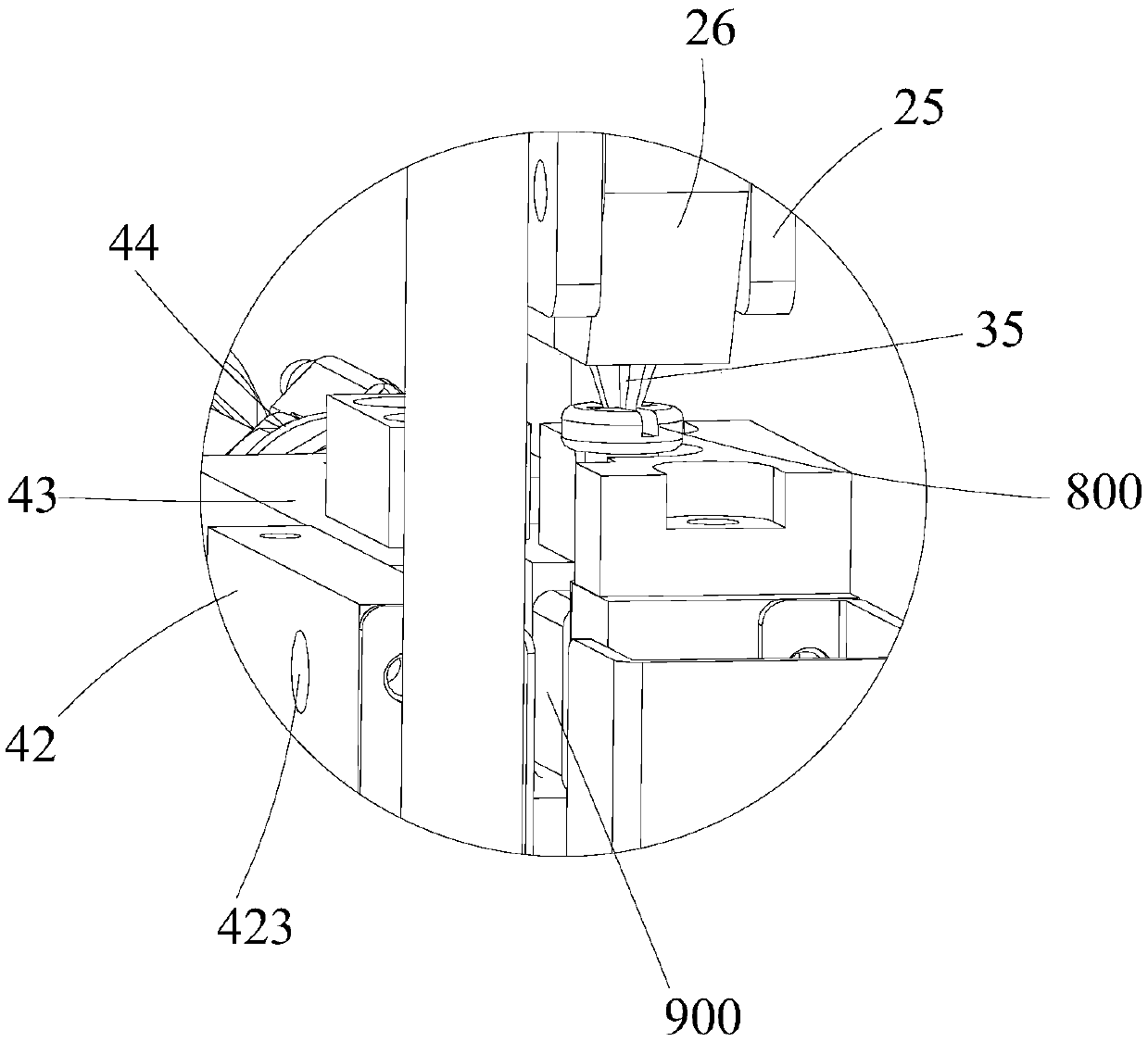

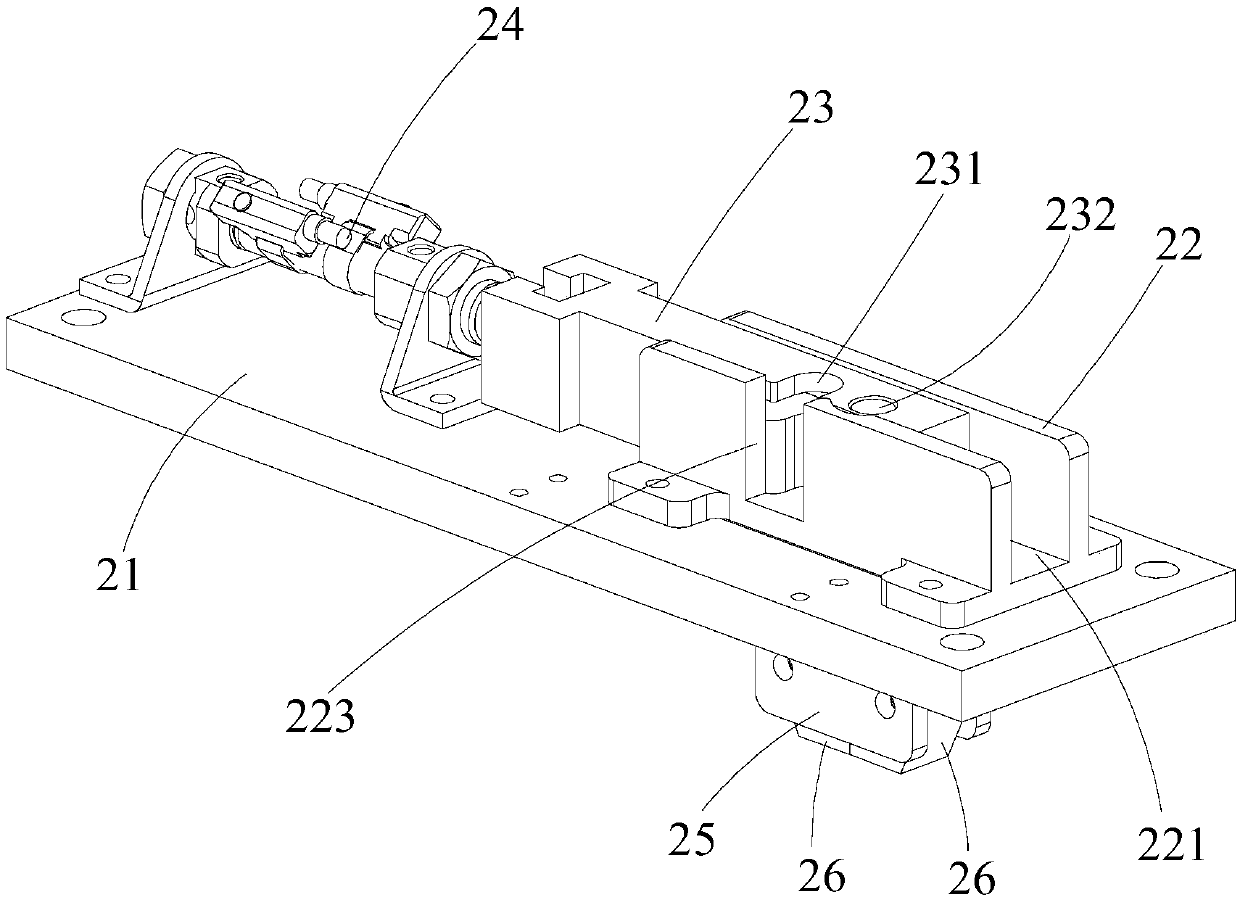

[0039] Further, see Figure 5 , as a specific embodiment of the screw screwing machine provided by the present invention, the screw-in lifting drive mechanism 33 is a screw-in lifting cylinder located on the screw-in mounting plate 31, and the piston rod of the screw-in lifting cylinder is screwed into the lifting plate 32. A buffer spring 38 is screwed in therebetween to avoid the rigid impact of the bit 35 and the screw 800 .

specific Embodiment approach

[0040] Further, see Figure 5 , as a specific embodiment of the screw screwing machine provided by the present invention, the screw-in installation plate 31 is provided with a screw-in guide plate 39, and the screw-in guide plate 39 is located at the screw-in lifting plate 32 away from the screw-in lifting drive mechanism 33. On one side, the screw-in guide plate 39 is provided with a screw-in relief hole for the bit 35 to pass through. The bit 35 is screwed into the relief hole to screw the screw 800 in, so as to ensure that the bit 35 with a certain length will not deviate when used.

[0041] Further, see Figure 5 , as a specific embodiment of the screw screwing machine provided by the present invention, the screw-in lifting plate 32 is provided with an oil pressure buffer 321, and the oil pressure buffer 321 is located on a side of the screw-in lifting plate 32 close to the screw-in guide plate 39. side. The oil pressure buffer 321 and the screw-in position sensor 36 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com