Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Improve pickup rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

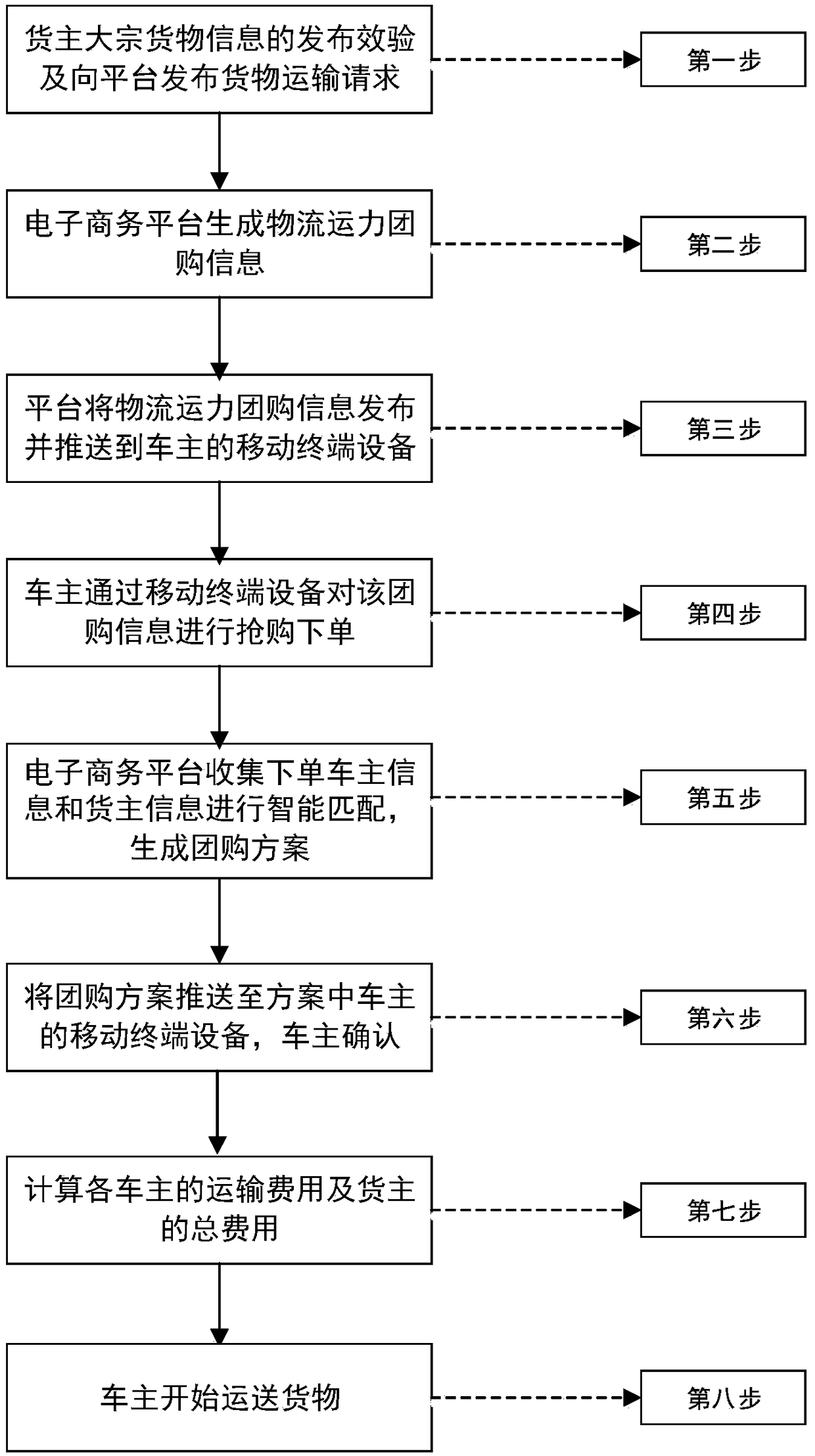

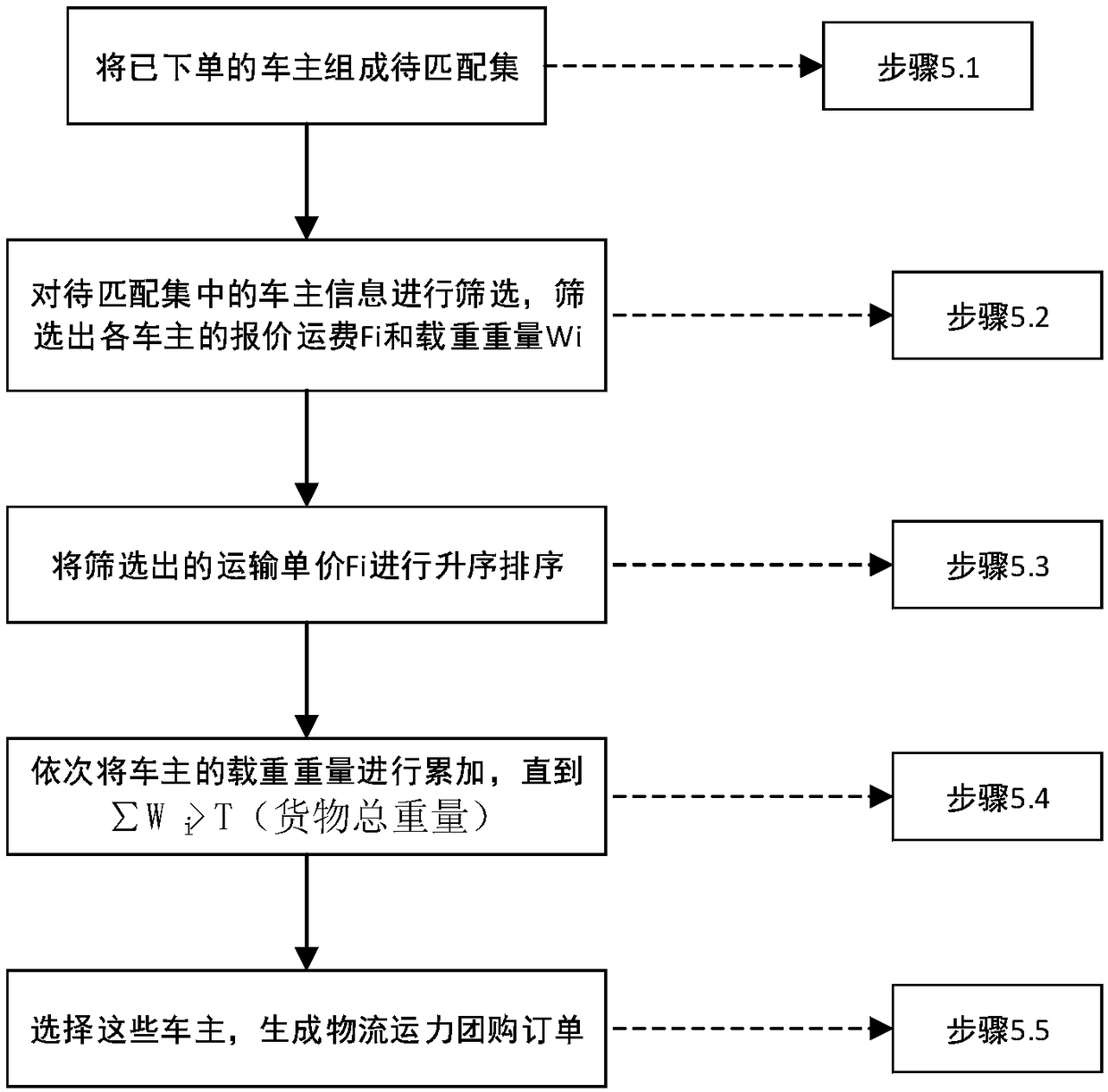

A vehicle-cargo matching optimization method based on a logistics transport capacity group

InactiveCN109409613AImprove Freight Transportation EfficiencyAvoid time costForecastingLogisticsBulk cargoLogistics management

The invention discloses a vehicle-cargo matching optimization method based on logistics transport capacity group purchase. The vehicle-cargo matching optimization method comprises the following steps:issuing verification of bulk cargo information of a cargo owner and issuing a cargo transportation request to a platform; the e-commerce platform receives the transport request and generates logistics transport capacity group purchase information; the platform issues and pushes the logistics transport capacity group purchase information to a mobile terminal device of a vehicle owner; the vehicleowner performs panic buying and ordering on the group buying information through the mobile terminal equipment; the e-commerce platform collects the owner information of the order-placing vehicle andthe owner information of the cargo for intelligent matching, and generates a logistics transport capacity group purchase scheme; Pushing the group purchase scheme to mobile terminal equipment conforming to the owner, and confirming by the owner; calculating the transportation cost of each vehicle owner and the total cost of the cargo owner; the vehicle owner starts to transport goods; according tothe method, a scientific vehicle-cargo intelligent matching model is set, so that the road freight transportation efficiency is improved, and the time cost and economic cost of cargo owners are reduced; according to the invention, the implementation of high-efficiency logistics transportation group purchase can be ensured, and the pickup rate of drivers can be improved.

Owner:NANJING UNIV

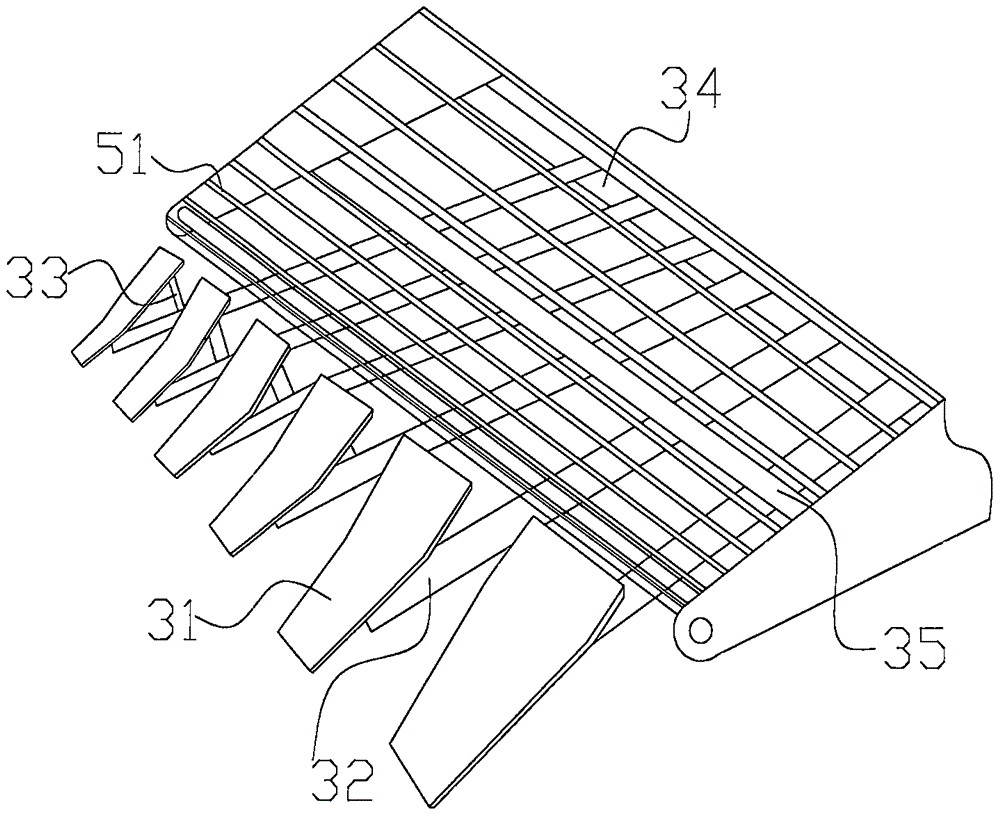

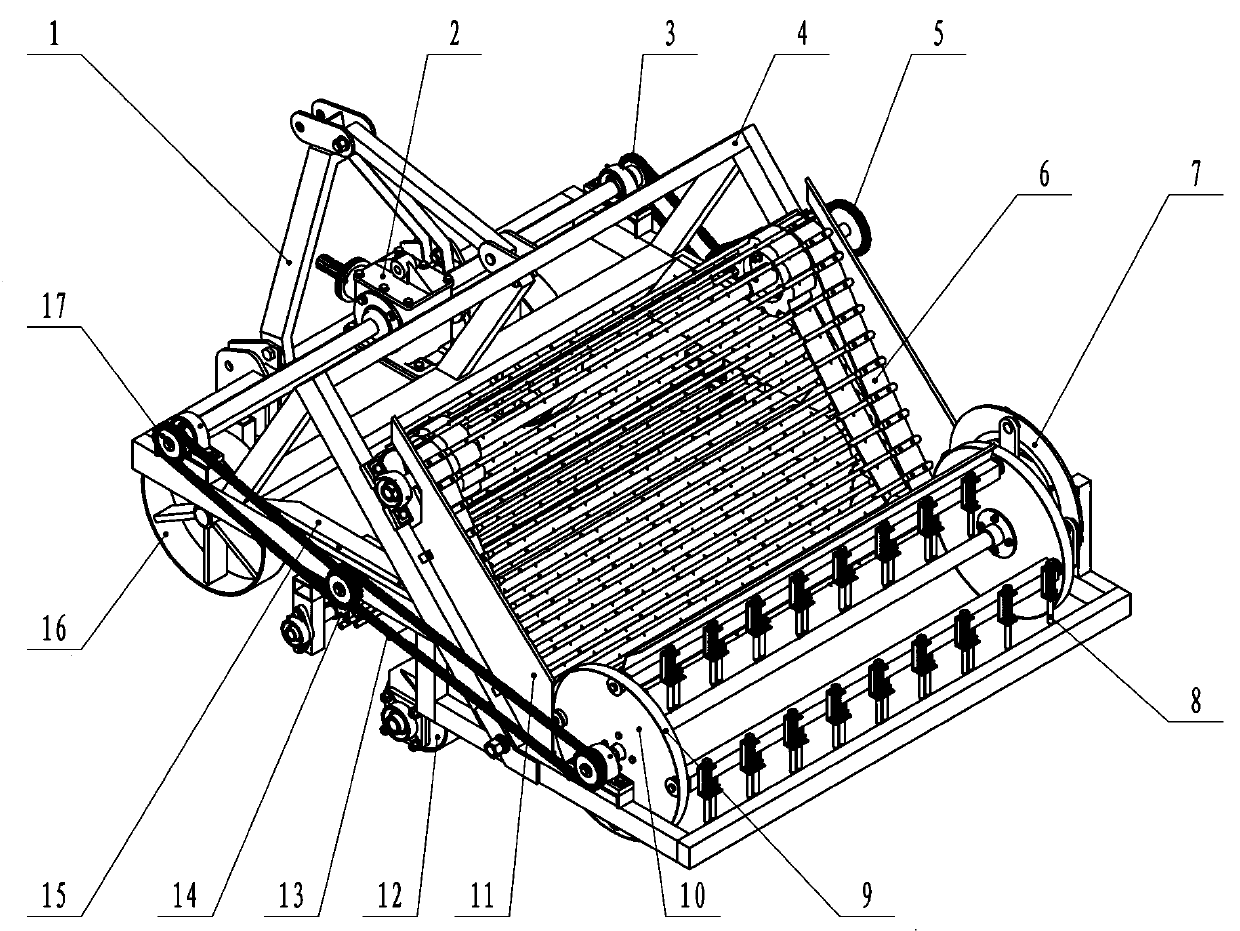

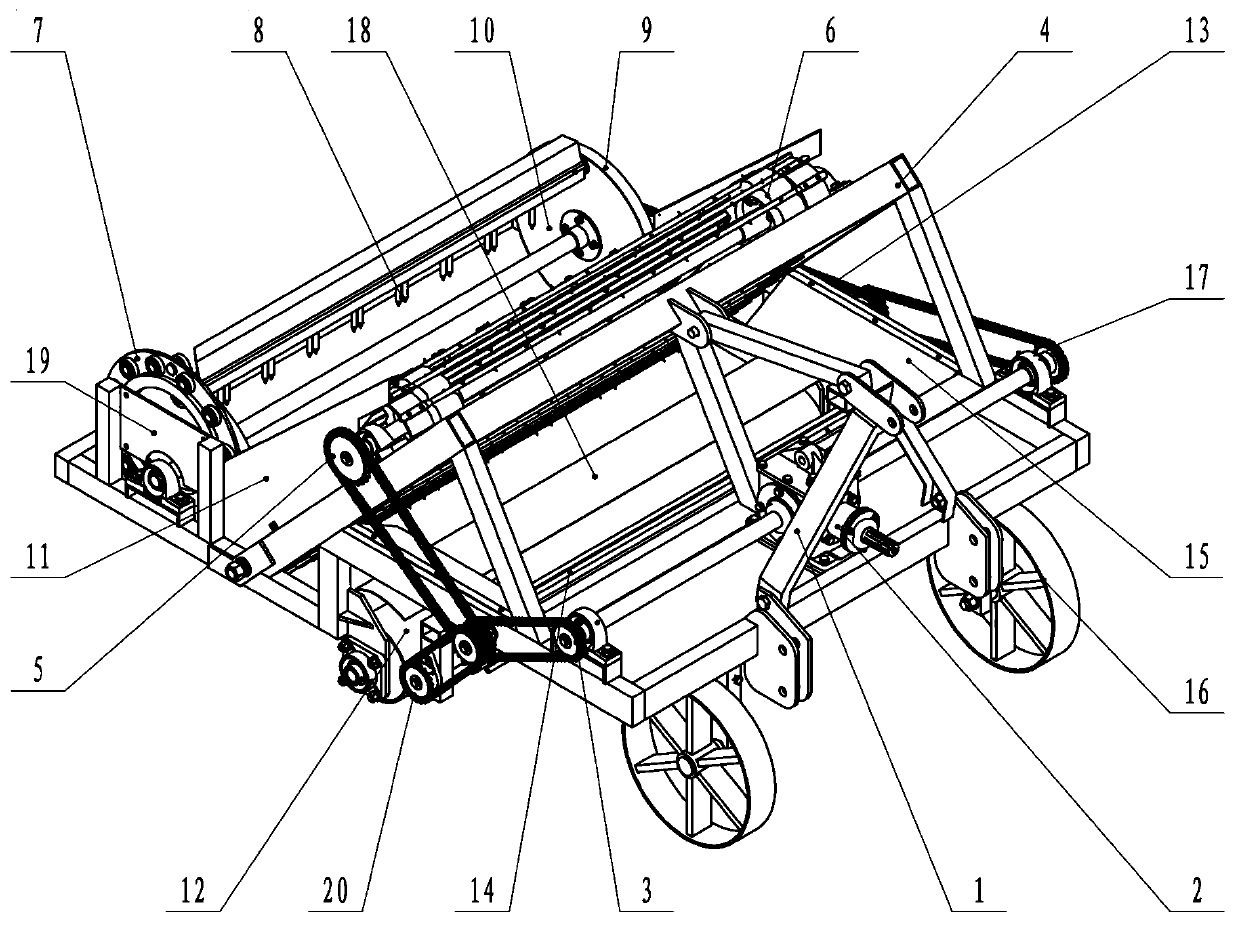

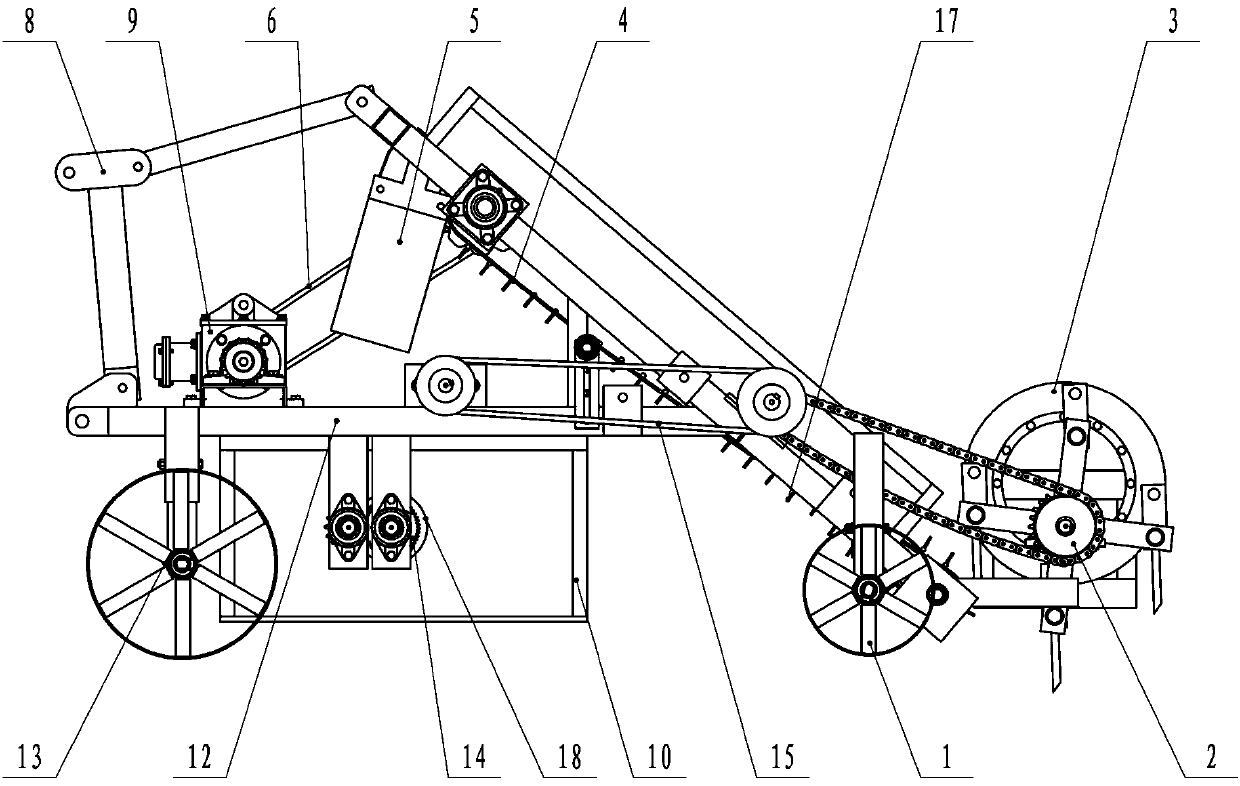

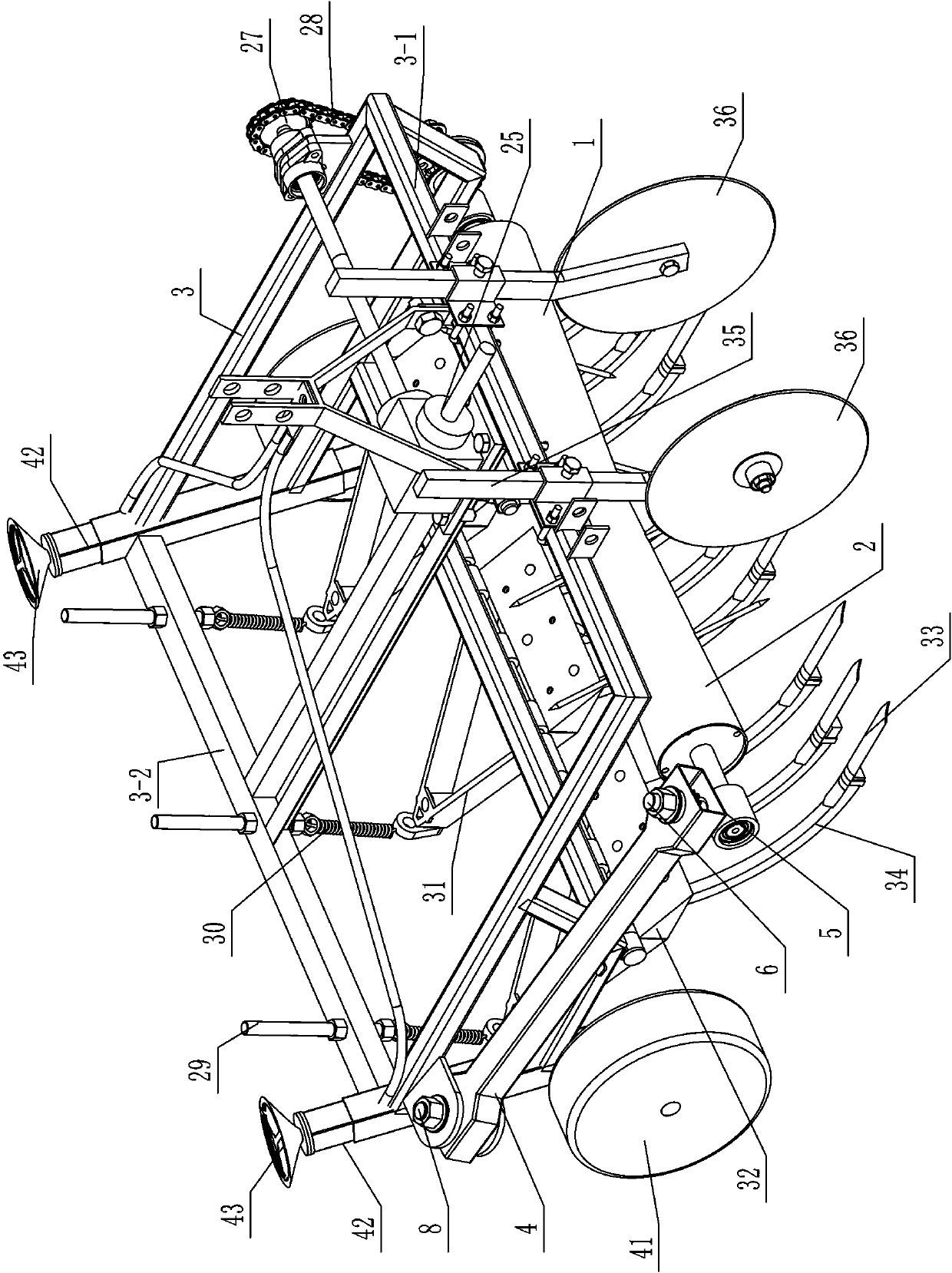

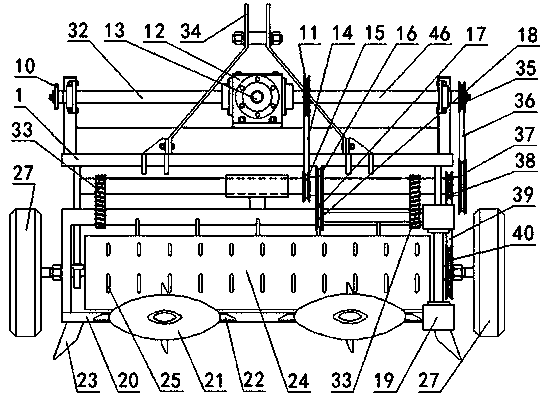

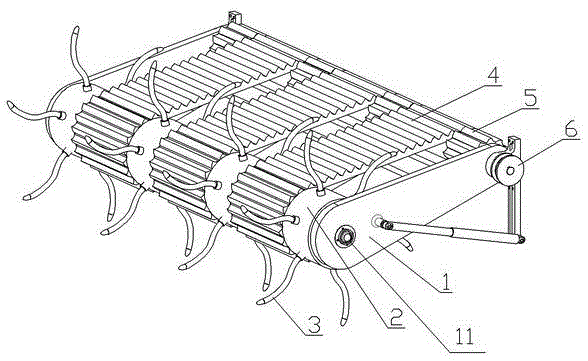

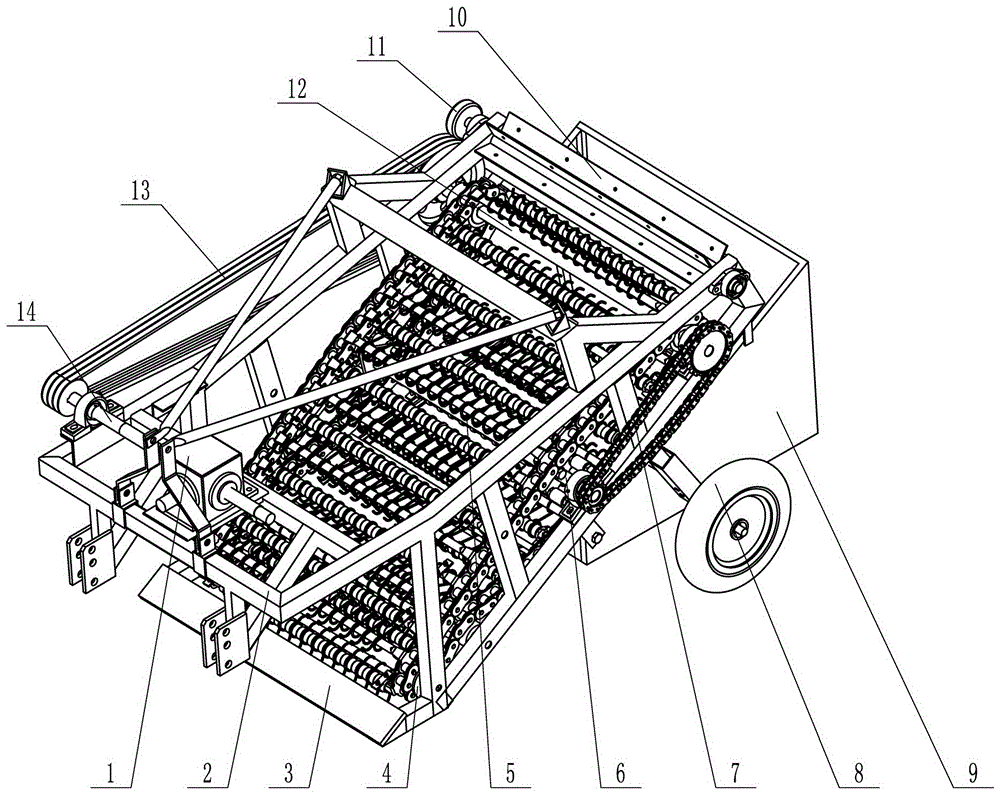

Film residue picker

InactiveCN106068710AHigh strengthExpand the scope of workHarvestersGatherer machinesEngineeringSurface conditions

The invention discloses a film residue picker, comprising a tractive device, a film lifting device, a bundling device, a chain elevating device, a film discharging device and a travelling device; the film lifting device comprises a lifting shovel, a first cross beam and a second cross beam, a cylindrical auxiliary lifting shovel is hinged to the first cross beam, one end of the auxiliary lifting shovel far away from the cross beam is connected with the lifting shovel, the middle of the auxiliary lifting shovel is also connected with a spring, the auxiliary lifting shovel is connected with the second cross beam through a spring, the chain elevating device comprises an elevating chain that arranged in upward inclination, the bundling device comprises a bundling roller, the chain elevating device also comprises fixed side plates arranged at two ends of the elevating chain and a fixed cross beam arranged on the upper portions of the fixed side plates, and vibrating springs are connected between the fixed cross beam and the fixed side plates; the lifting shovels of a bundling unit are connected with a cross beam of a frame through springs, the lifting shovels can automatically adjust shoveling thickness according to surface conditions and can prevent excess soil on the surface to be shoveled up, and blockage of the chain elevating mechanism and the lifting shovels from being blocked.

Owner:GANSU AGRI UNIV

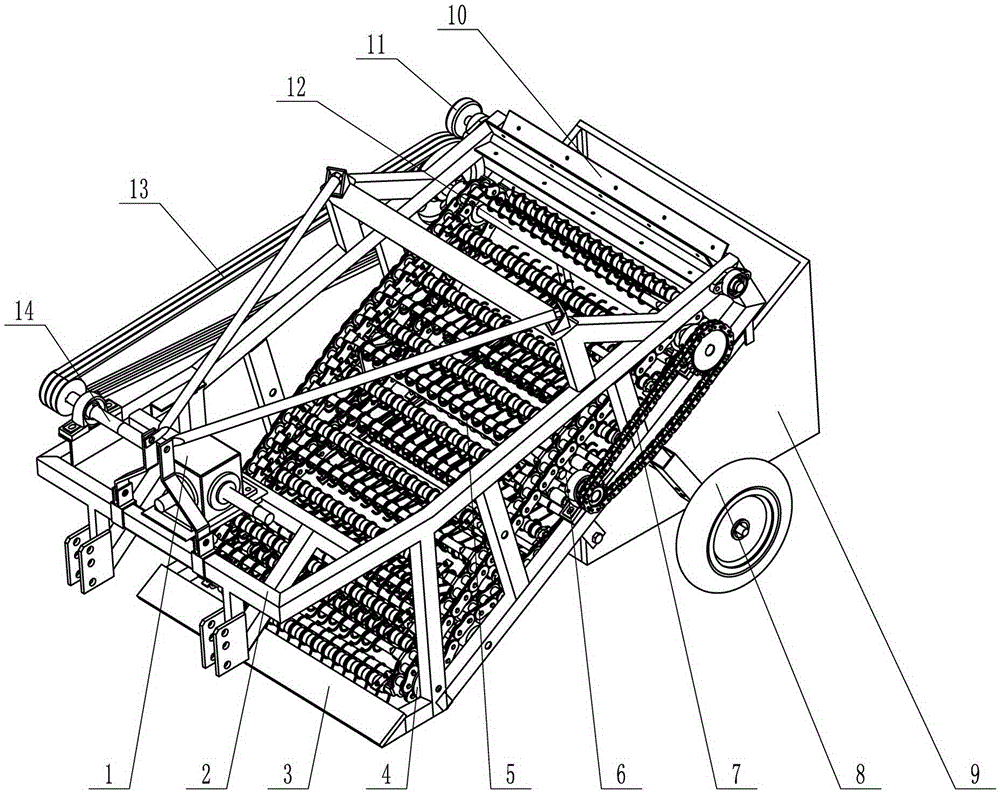

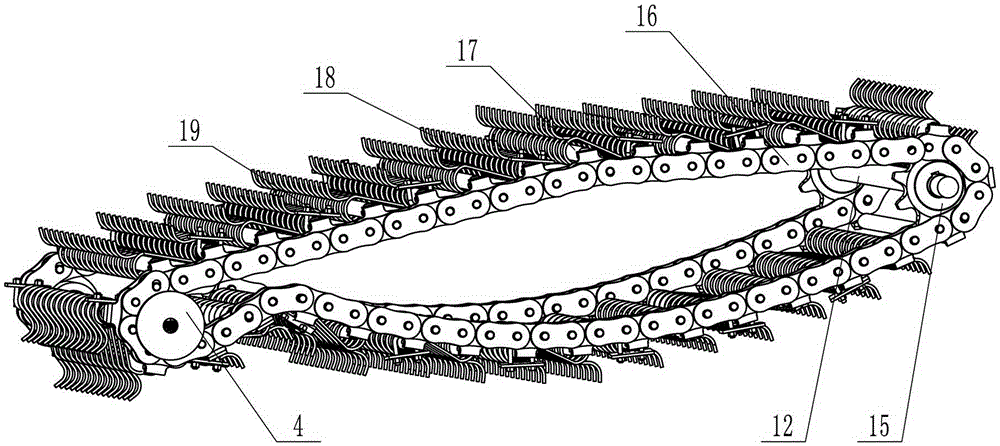

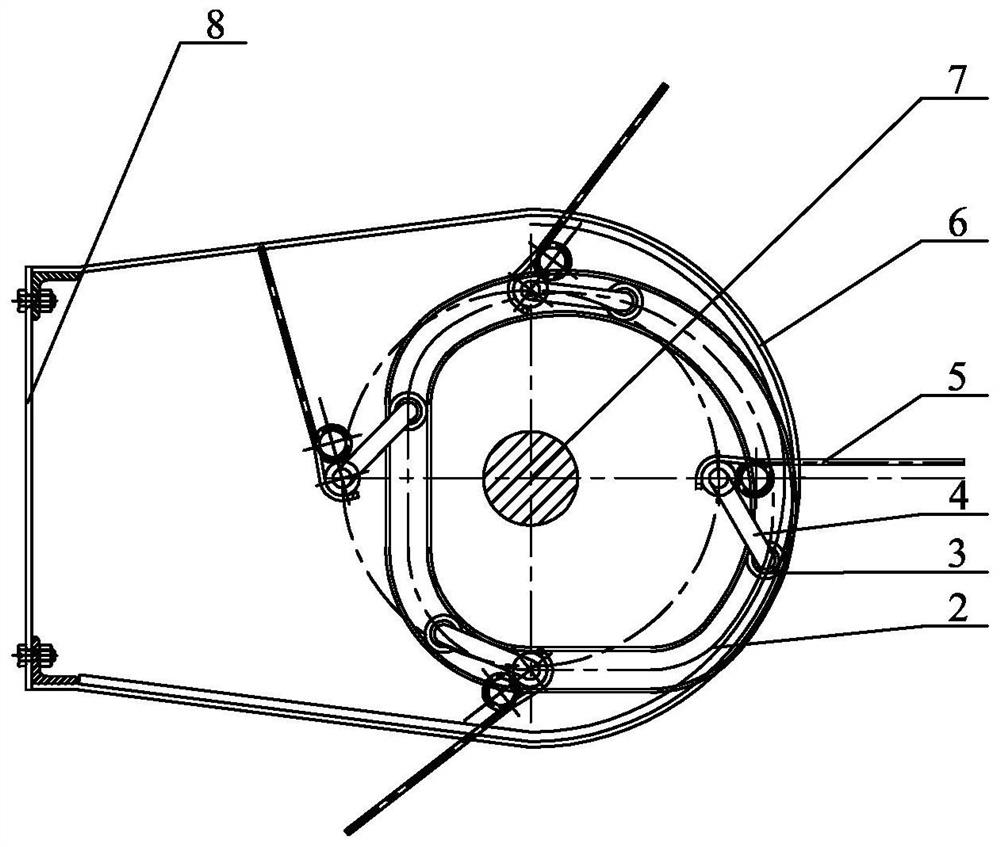

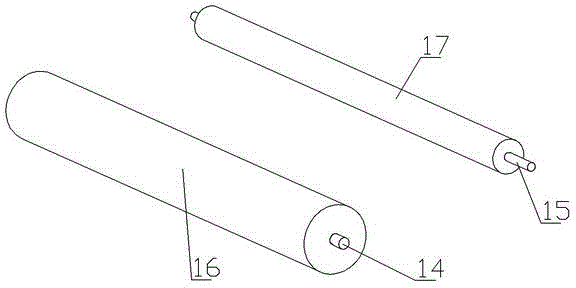

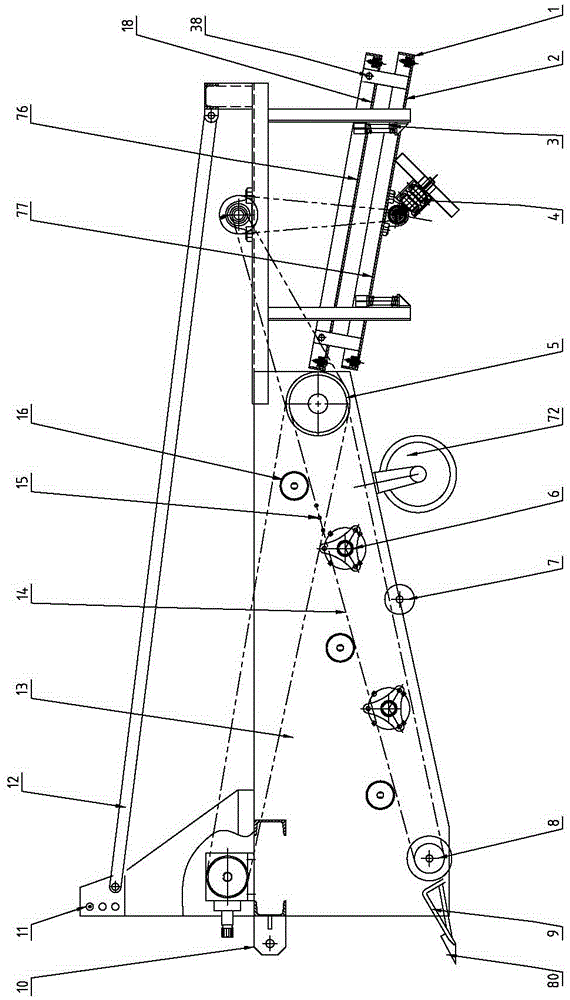

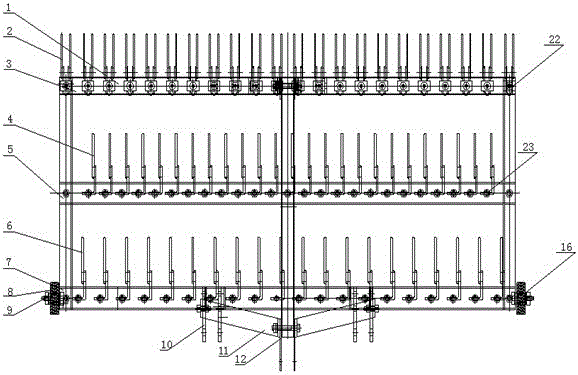

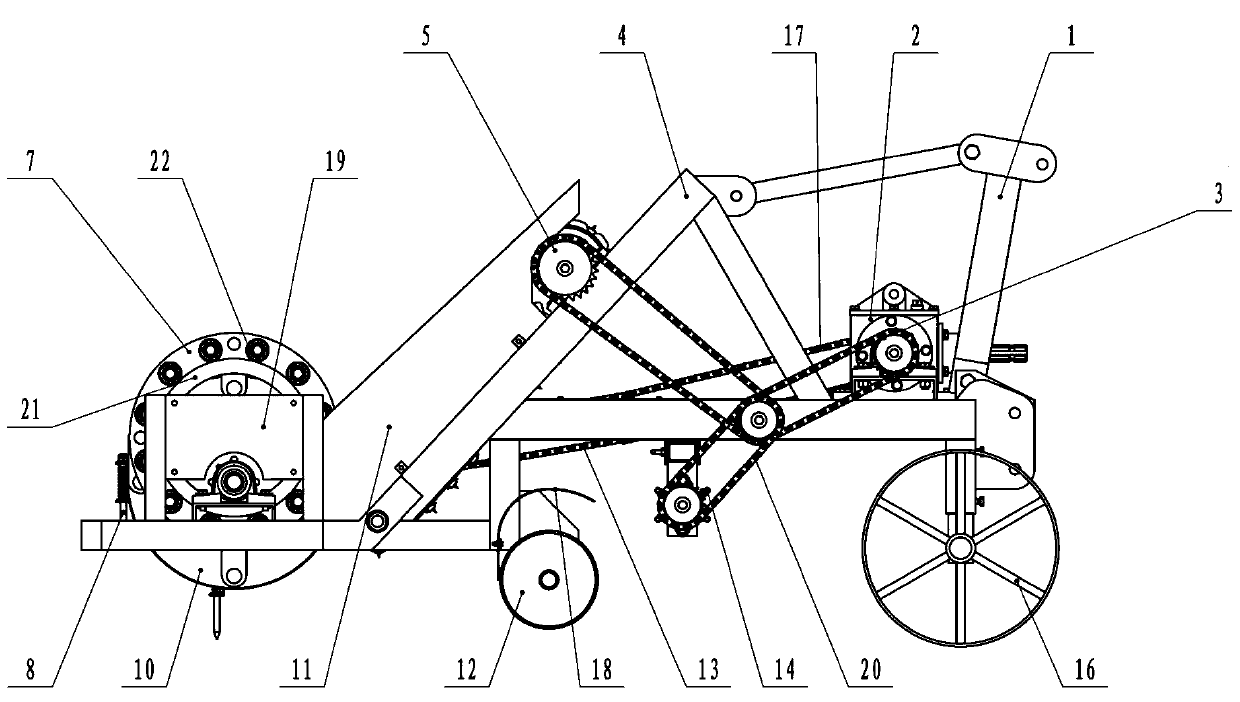

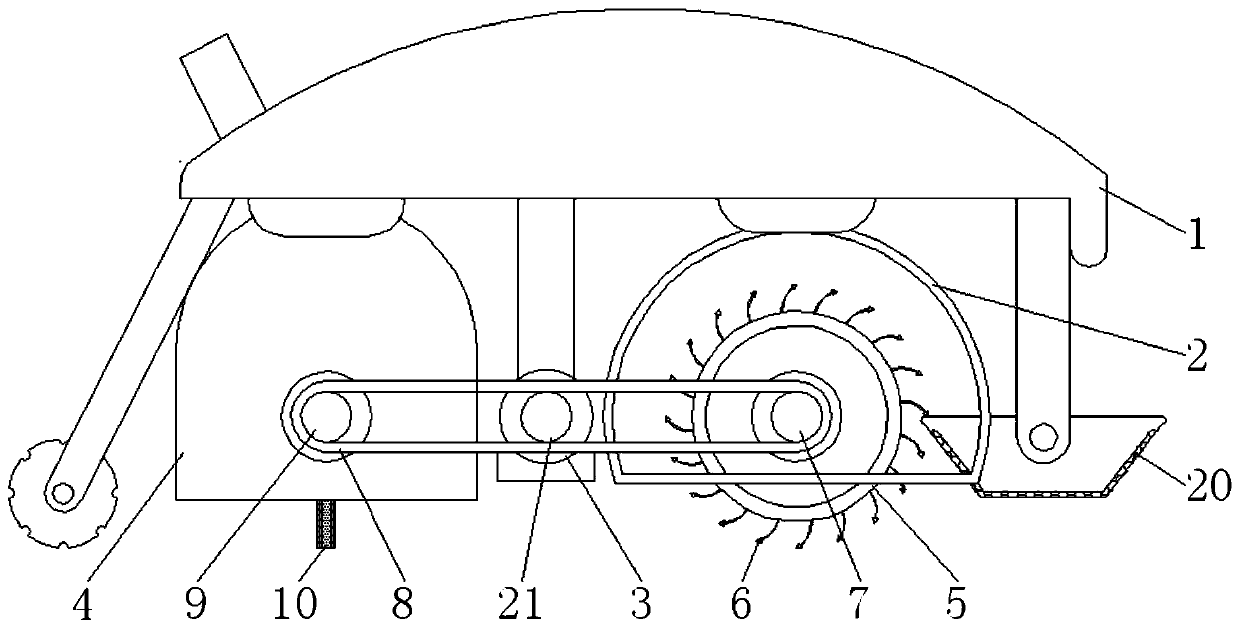

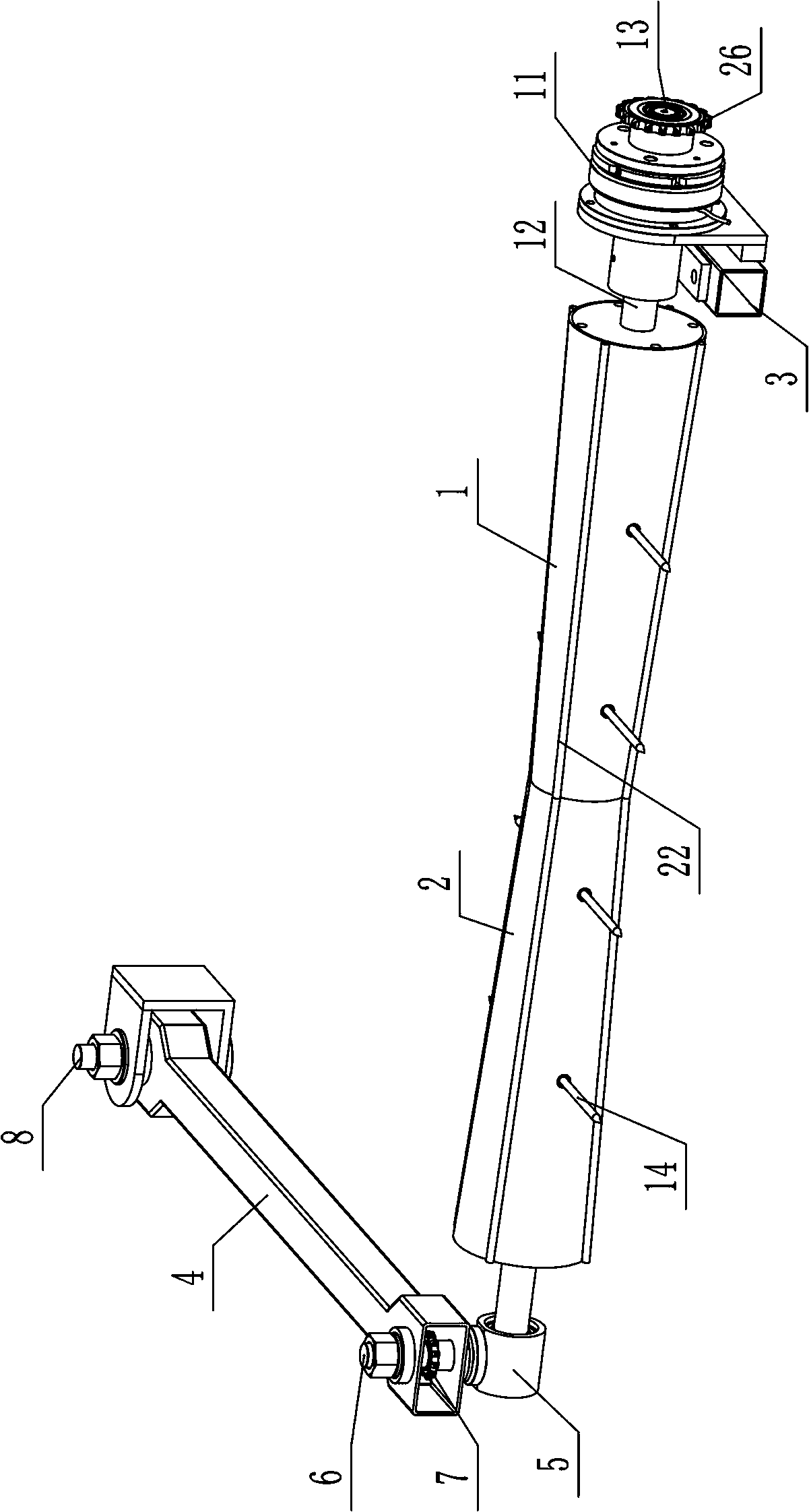

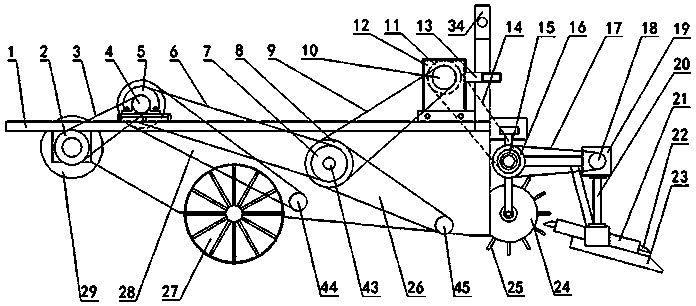

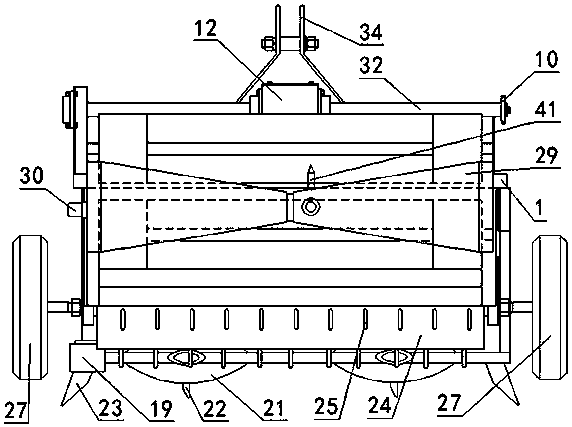

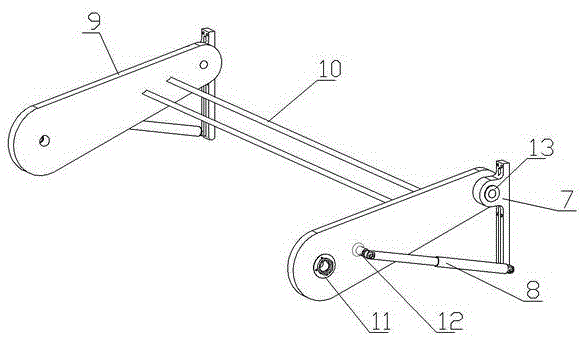

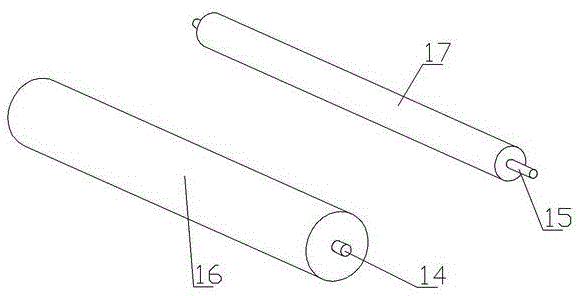

Chain-tooth type film residue recycling machine

InactiveCN105409364ARealize recycling operationsRecycling operation is stableGatherer machinesDrive shaftSprocket

The invention discloses a chain-tooth type film residue recycling machine. A film residue box, a driven shaft and a film unloading roller are arranged on the rear portion of a rack located above traveling wheels, a soil raising shovel and a carrying roller are arranged at the front end of the rack, a power output shaft of a gearbox drives the driven shaft, and a belt pulley arranged at the end of the driven shaft is in contact with a friction wheel arranged at the end of the film unloading roller; a film residue picking device is arranged between the carrying roller and the driven shaft, the film residue picking device comprises picking chains at the two sides, chain poles are evenly arranged between the picking chains in a spaced mode, every two adjacent chain poles, with one chain pole located in front and the other chain pole located at the back, form a group, each rear chain pole close to a transmission shaft is sleeved with a shaft sleeve, each front chain pole and the corresponding rear chain pole are provided with spring teeth in an abreast and spaced mode in the axial direction, each spring tooth is constituted by a spring tooth one-and-a-half-round section on the rear portion and a spring tooth one-round section on the front portion, the two ends of each spring tooth constitute a spring tooth tip, each spring tooth one-round section is arranged on the corresponding front chain pole in a sleeving mode, each spring tooth one-and-a-half-round section is arranged on the corresponding shaft sleeve in a sleeving mode, and a group of shaking wheels driven by a chain wheel located at the other end of the transmission shaft are arranged on the rack.

Owner:XINJIANG AGRI UNIV

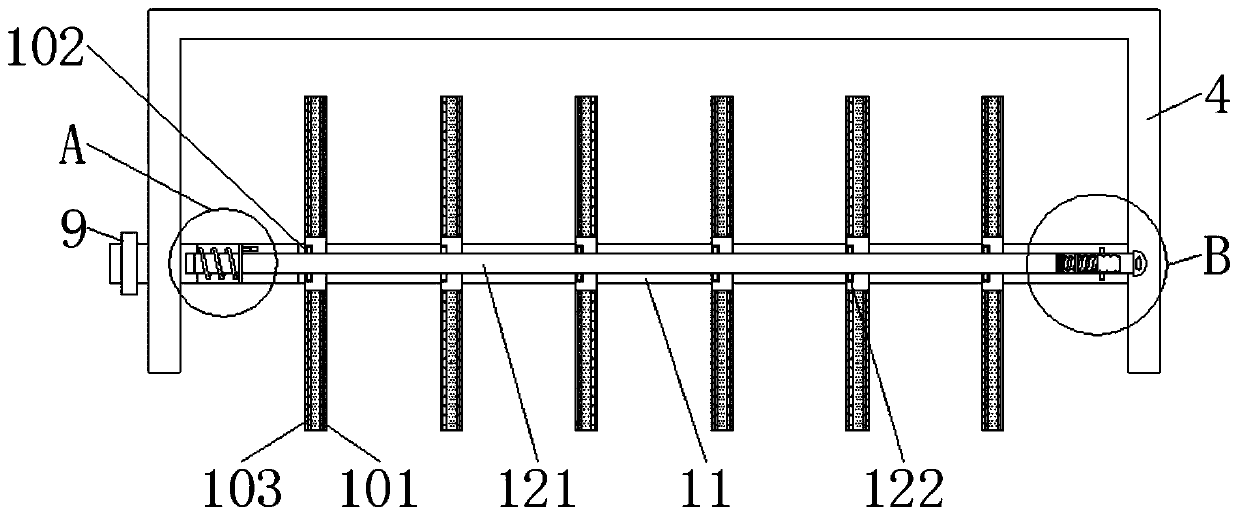

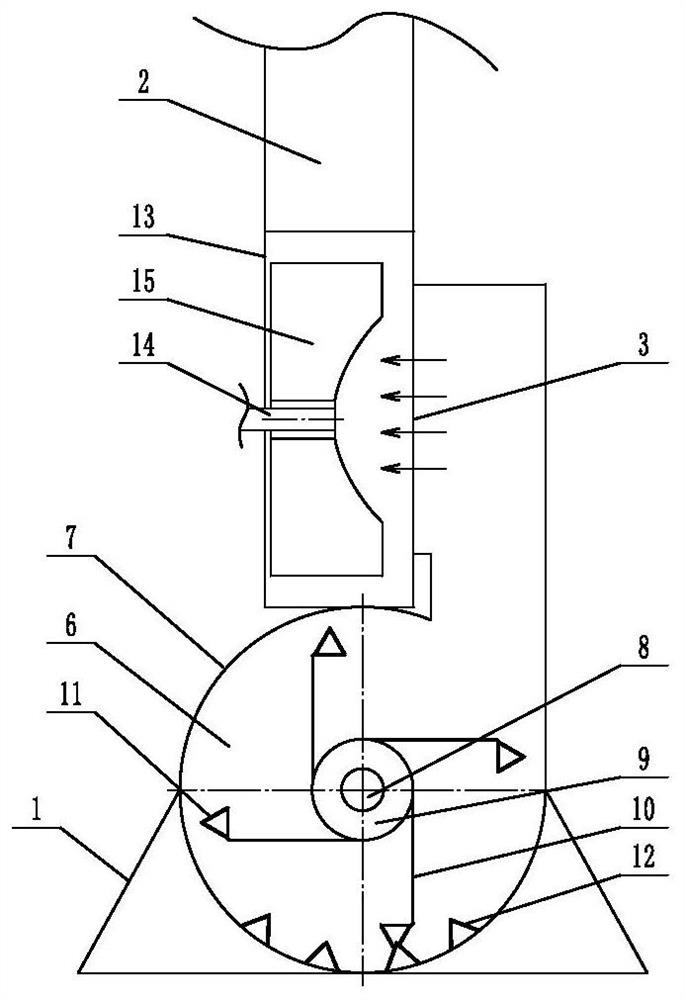

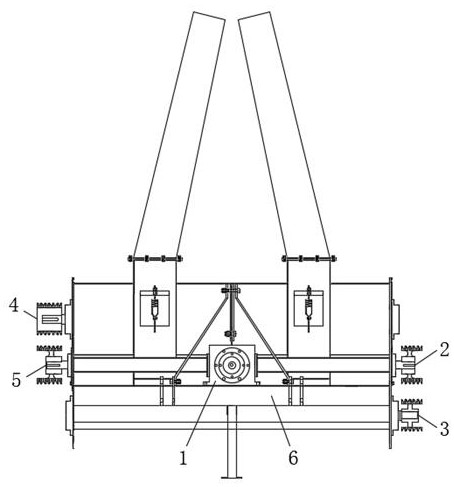

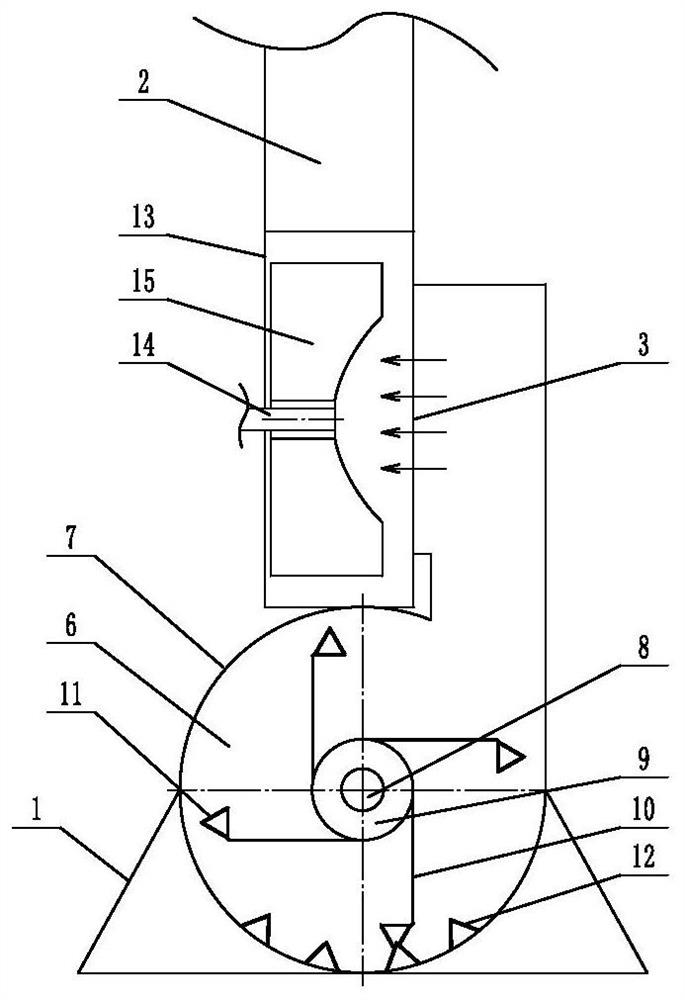

Shovel tooth and elastic tooth roller combined type peanut pickup device

ActiveCN112400478AEasy to pick upExtended service lifeHarvestersAgricultural engineeringStructural engineering

The invention discloses a shovel tooth and elastic tooth roller combined type peanut pickup device, and belongs to the technical field of agricultural machinery. The shovel tooth and elastic tooth roller combined type peanut pickup device comprises picking shovel teeth, roller protection plates, a picking roller, a roller sliding way and side plates; a center shaft of the picking roller penetratesthrough the side plates at the two sides to be installed on bearing pedestals, picking elastic teeth are evenly arranged on an elastic tooth shaft of the picking roller at intervals, and the roller protection plates are arranged between the adjacent picking elastic teeth; at the advancing front end of the pickup device, arc-shaped picking shovel teeth of the same structure are installed at the same position of each roller protection plate to form a row of shovel teeth; and the roller sliding way is fixedly installed in one side plate and is in sliding connection with the elastic tooth shaft on the picking roller. According to the pickup device, the peanut plants are shoveled up through the shovel teeth; the picking roller rotates along the roller sliding way, and the elastic teeth rotatearound the center shaft along with the roller and periodically and repeatedly swing due to the limitation of the roller sliding way, so that actions of lifting, pushing and returning to a station by the elastic teeth are realized; and the impact of the roller on a cam sliding way can be effectively reduced, large stress concentration is avoided, and the service life of the cam sliding way is prolonged.

Owner:JILIN AGRICULTURAL UNIV +2

Sugarcane leaf crushing and returning machine

InactiveCN108076838ASimple structureEasy to operateLoadersCrop conditionersTransmission systemEngineering

Provided is a sugarcane leaf crushing and returning machine comprising a transmission system, a frame, a front baffle plate, a flail chopper knife, a stationary knife, a knife roll, a rear baffle plate, a spacing wheel and a profiling leaf collector; the transmission system comprises a gearbox and a V-shaped conveyor belt; three points of the frame suspend on a wheel tractor; the flail chopper knife and the stationary knife are main work parts for crushing; the spacing wheel is a profiling wheel; the profiling leaf collector is mainly composed of a diagonal rod and a connecting board; the diagonal rod is composed of a bending rod and a bottom shovel by connecting though bolts; the diagonal rod is rigidly connected with the spacing wheel and is located on a same surface of the tractor wheels. The gap between the flail chopper knife and trenches can exceed the height of ridges, which well solves the problem that common flail chopper knife cannot pick sugarcane leaves; the machine has theadvantages of simple structure, convenient operation, small turning radius, avoiding being entangled and blocked by sugar cane leaves, high pickup rate and crushing rate, and low power consumption.

Owner:周宝东

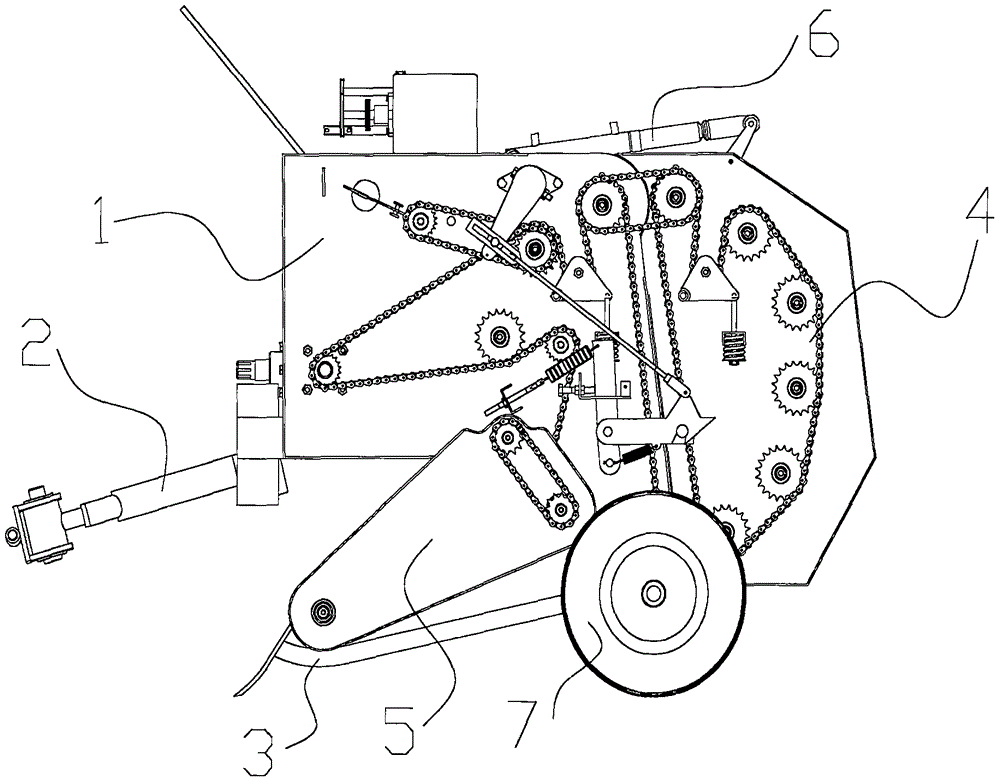

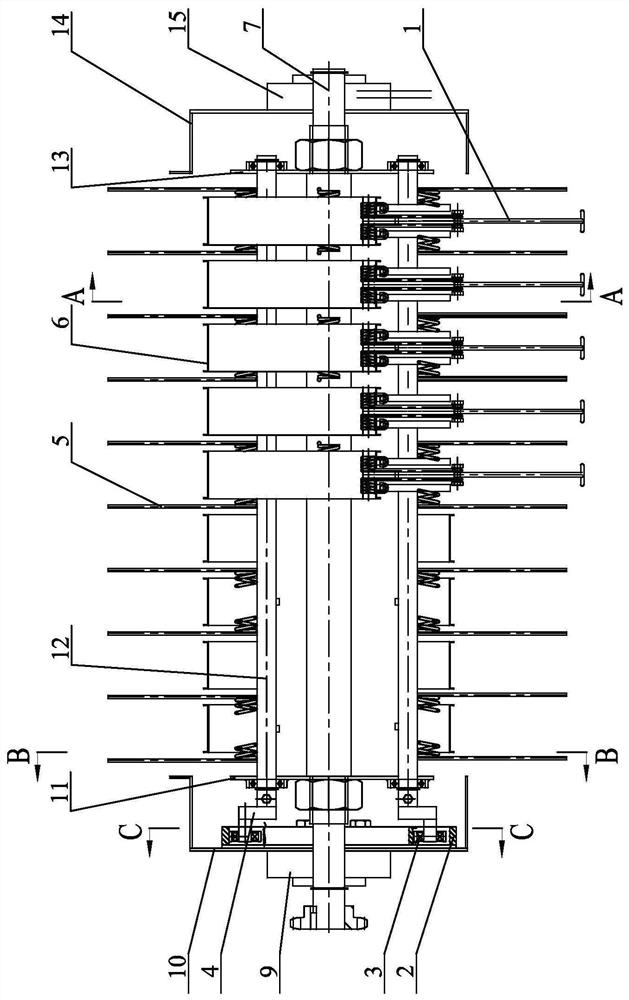

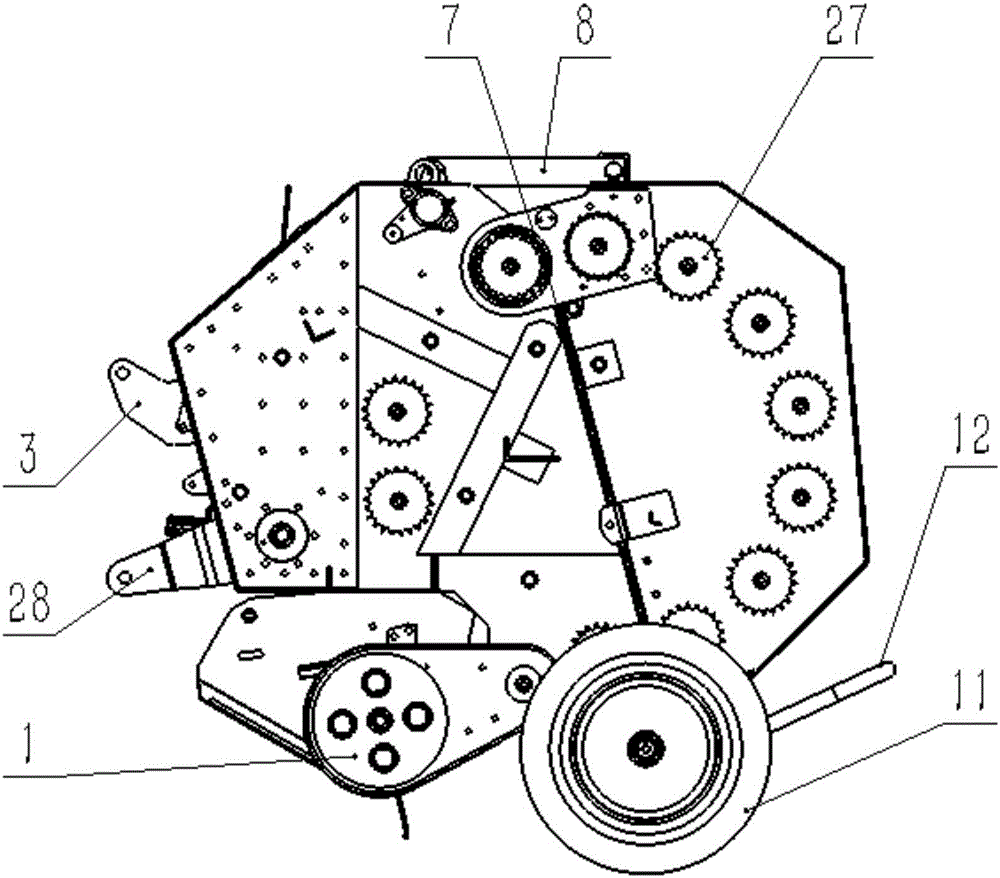

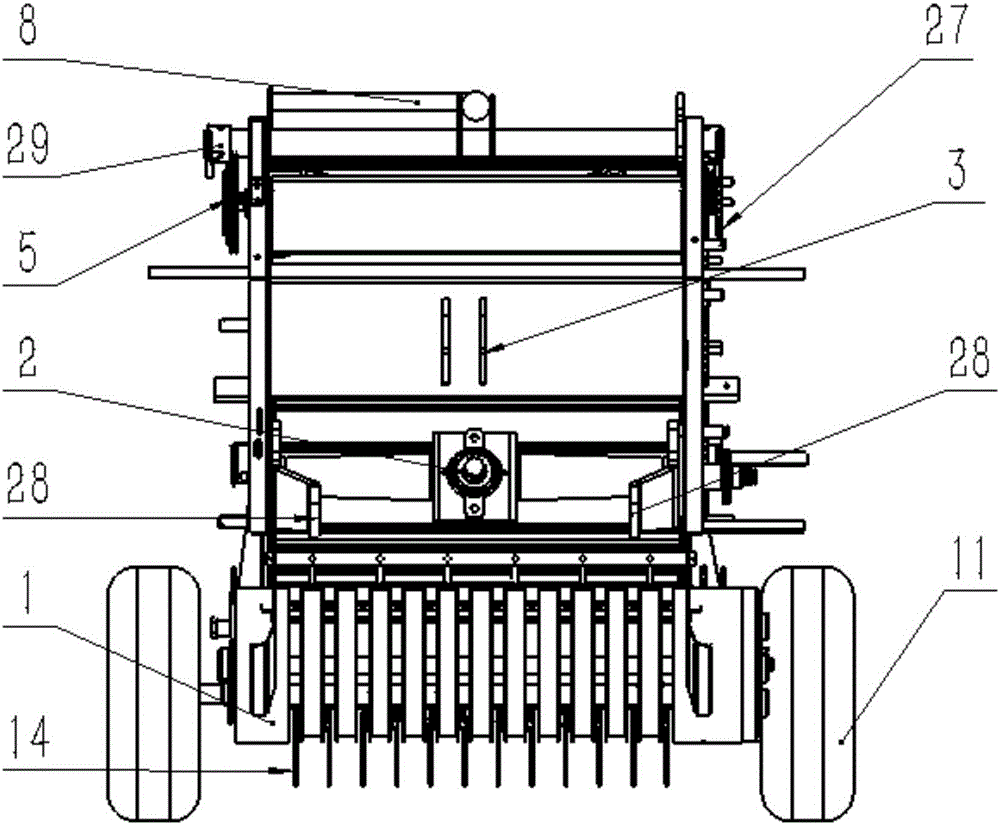

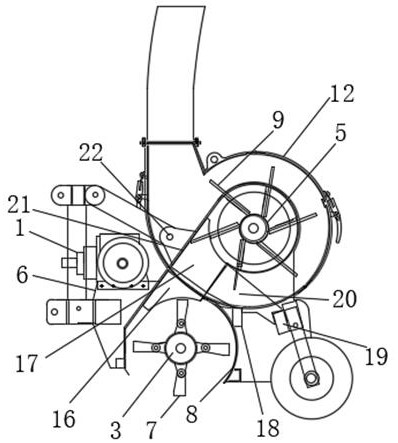

Round silage bale bundling machine

The invention relates to a round silage bale bundling machine which comprises a rack, a pickup device, a bundling and forming chamber and a bale putting device. The rack comprises a bundling machine framework, land wheels, a suspending mechanism, a power box, a pivot crank and a rope releasing mechanism. The pickup device comprises a tooth rake, a tooth spring, a pickup device central shaft, a clutch chain wheel, a tooth rake rod, a locking disc, a clutch compression spring, a pickup device driven chain wheel, a protective strip, a pickup device periphery plate and a pickup device connecting shaft. The bundling and forming chamber comprises a compression roller, a chain wheel and an air spring. The bale putting device comprises a rack reinforcing plate, a rack lower supporting rod, a bracket lifting lug, a bracket and a pull spring. Formed silage bales are externally tight and internally loose, are not easy to loosen and are convenient to transport and store. The pull spring added between the rack lower supporting rod and the bracket achieves an elastic function of the bale putting device, the broken pasture pickup rate is improved, and the working efficiency of the bundling machine is improved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

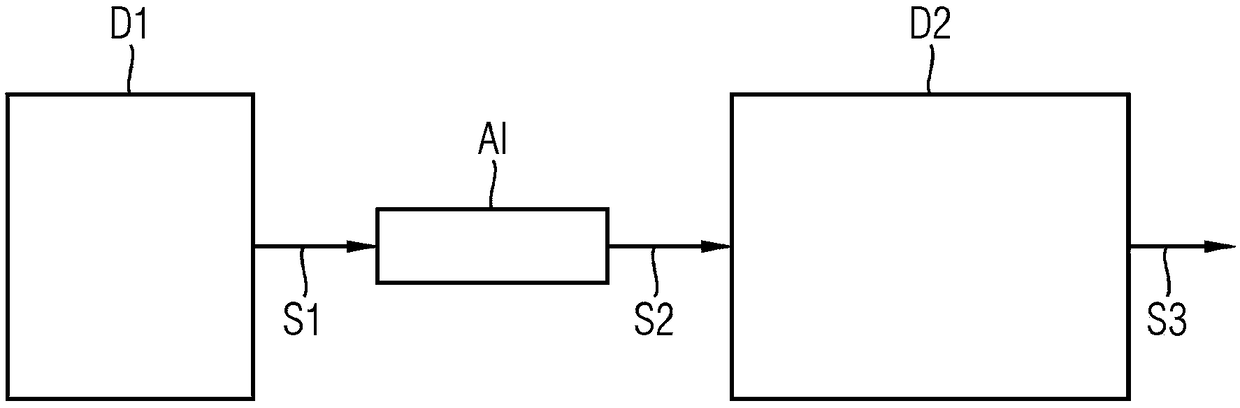

Optimization of an automated process for selecting and gripping an object by a robot

ActiveCN109500809AReduced torque consumptionReduce backlashProgramme controlProgramme-controlled manipulatorAlgorithmComputer vision

A method for optimizing an automated process to select and grip an object by a robot in an arrangement that includes a plurality of robots with regard to a specifiable optimization criterion, whereinthe objects to be potentially gripped irregularly occur with respect to their spatial position and a time of their arrival, where detection of objects to be potentially gripped by robots is performed,detection of a priority characteristic as well as an assignment to one of the robots for the objects to be potentially gripped via an automated learning algorithm, taking the optimization criterion into account, and where selection and gripping depending on the assignment and the priority characteristic is implemented.

Owner:SIEMENS AG

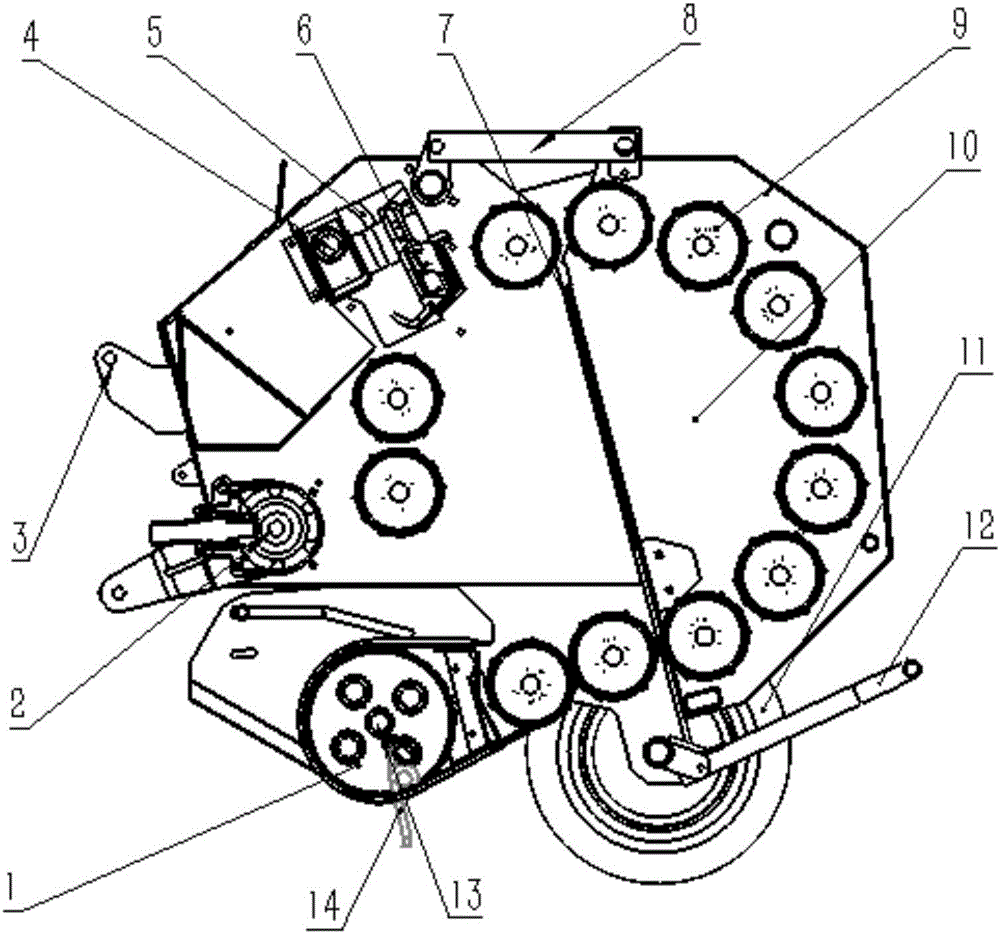

Double-barrel breaking type square bale baler

InactiveCN105265110AImprove pickup rateResidue reductionLoadersBalingEngineeringMechanical engineering

The present invention provides a double-barrel breaking type square bale baler which comprises a first group knife roller device, and a guide plate. The rotary drum of the first group knife roller device is provided with moving knives in a staggered arrangement. The guide plate is provided with fixed knives which are matched with the moving knives. The rotary drum of the first group knife roller device and the guide plate are also provided with a group of furrow pickup devices which are formed by furrow fixed knives arranged in the furrow outer cover on the guide plate and the furrow moving knives arranged on the rotary drum. According to the double-barrel breaking type square bale baler, the working efficiency is improved, the cost of use is reduced, and the safety is improved.

Owner:HUBEI YULONG MACHINERY

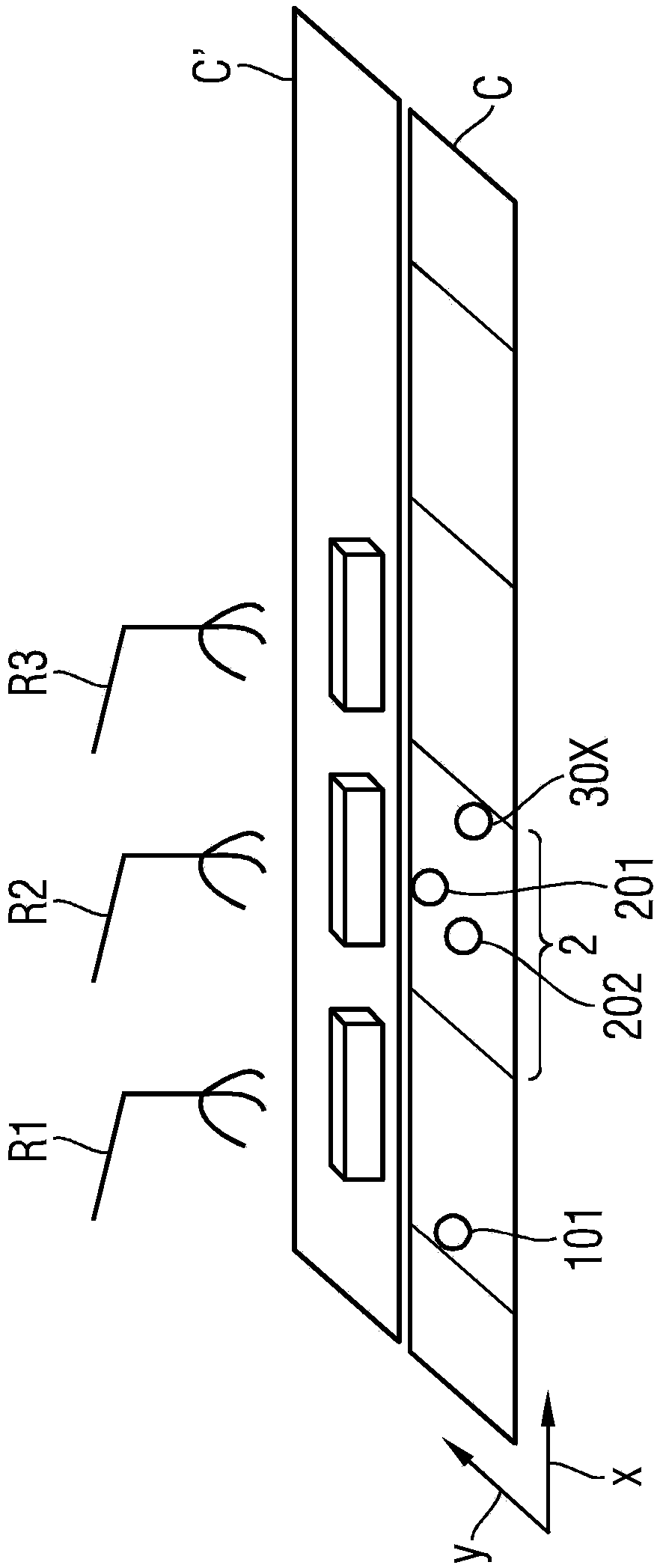

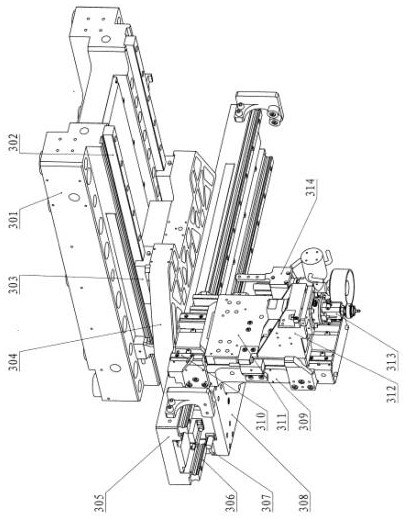

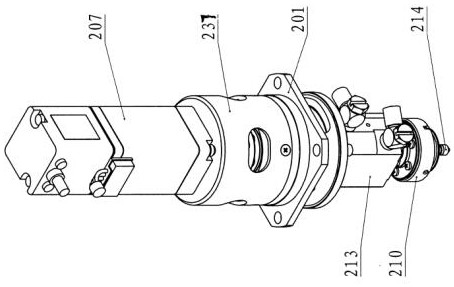

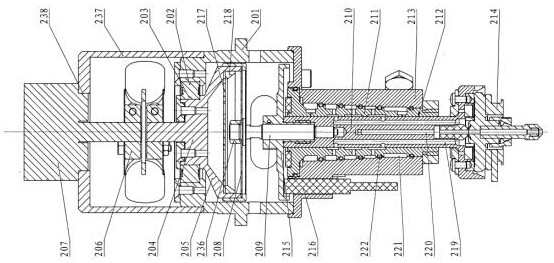

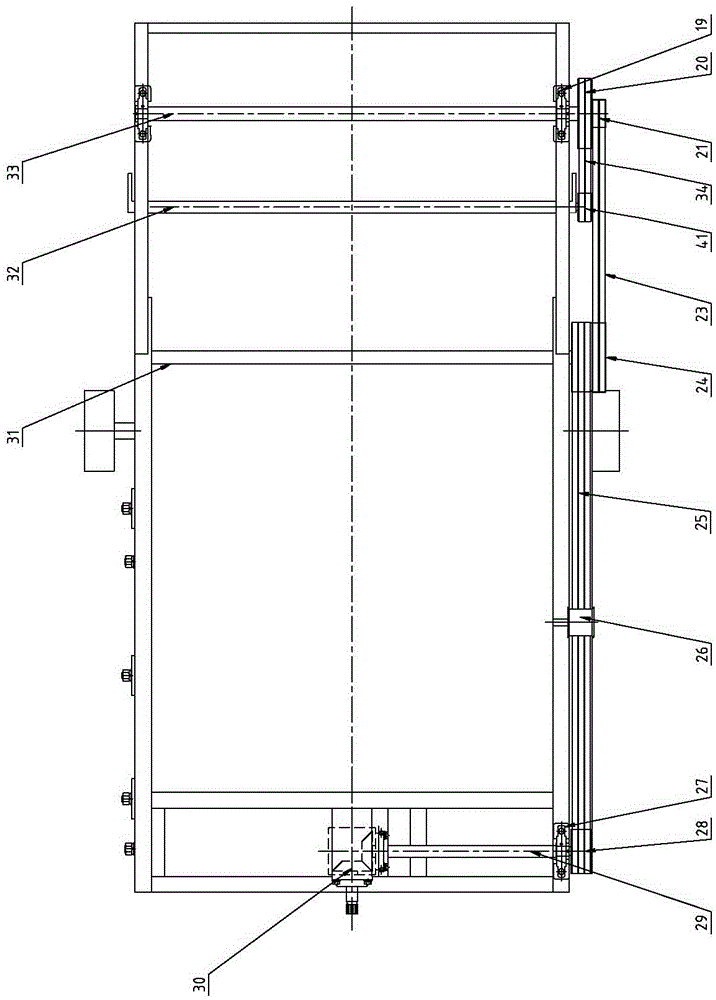

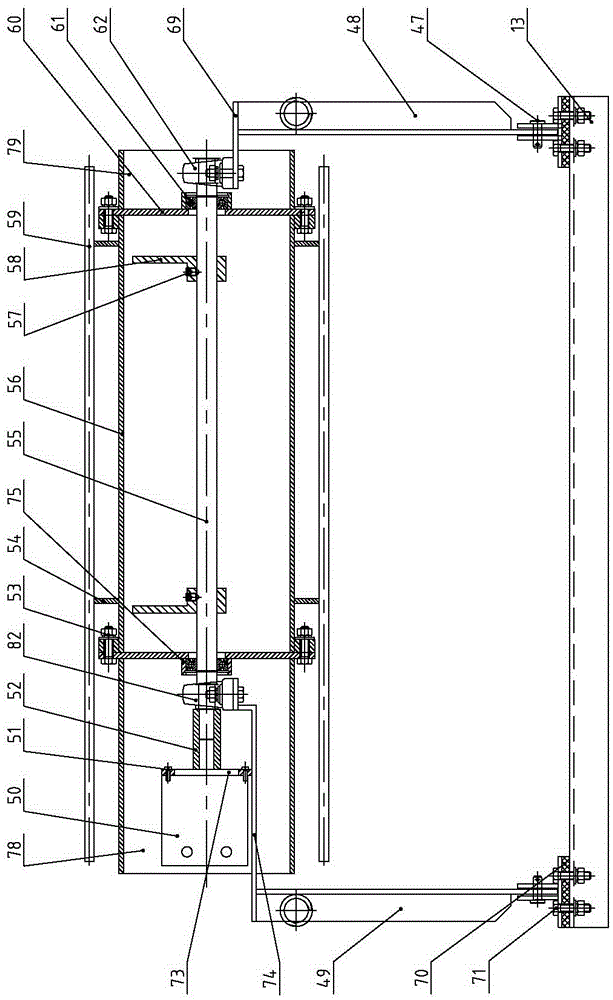

High-pickup-rate flexible chip mounting mechanism for adsorbing thin and brittle chips

PendingCN114173489AImprove pickup rateImprove adsorption stabilityPrinted circuit assemblingElectrical componentsElectric machineryDrive motor

The invention discloses a high-pickup-rate flexible chip mounting mechanism for adsorbing a thin and brittle chip, which can increase the force of a suction nozzle for pressing down the chip so as to improve the pickup rate, and can overcome the defect that the thin and brittle chip is easy to crush. A three-axis motion mechanical arm is designed, a high-pickup-rate flexible chip mounting head structure capable of rotating by 360 degrees is installed on a vertical plate base in the up-down Z-axis direction, a visual positioning system is arranged, a chip picked up by the flexible chip mounting head is photographed, a chip mounting head core shaft driving motor is controlled to rotate through comparison, and the chip mounting head core shaft driving motor is controlled to rotate. Adjusting the direction of the chip on the suction nozzle to an ideal position; through driving of the chip mounting head mandrel driving motor, undamped rotation of the chip mounting head mandrel in the air bearing is realized, accurate rotation of the suction nozzle is realized, and through vertical movement of the chip mounting head mandrel in the air bearing and elastic deformation of the annular elastic sheet group at the top end of the chip mounting head mandrel in the vertical direction, counter-acting force of a chip to the suction nozzle is absorbed. The contact force between the suction nozzle and the chip is controlled, and the pickup rate of the chip is improved.

Owner:西北电子装备技术研究所

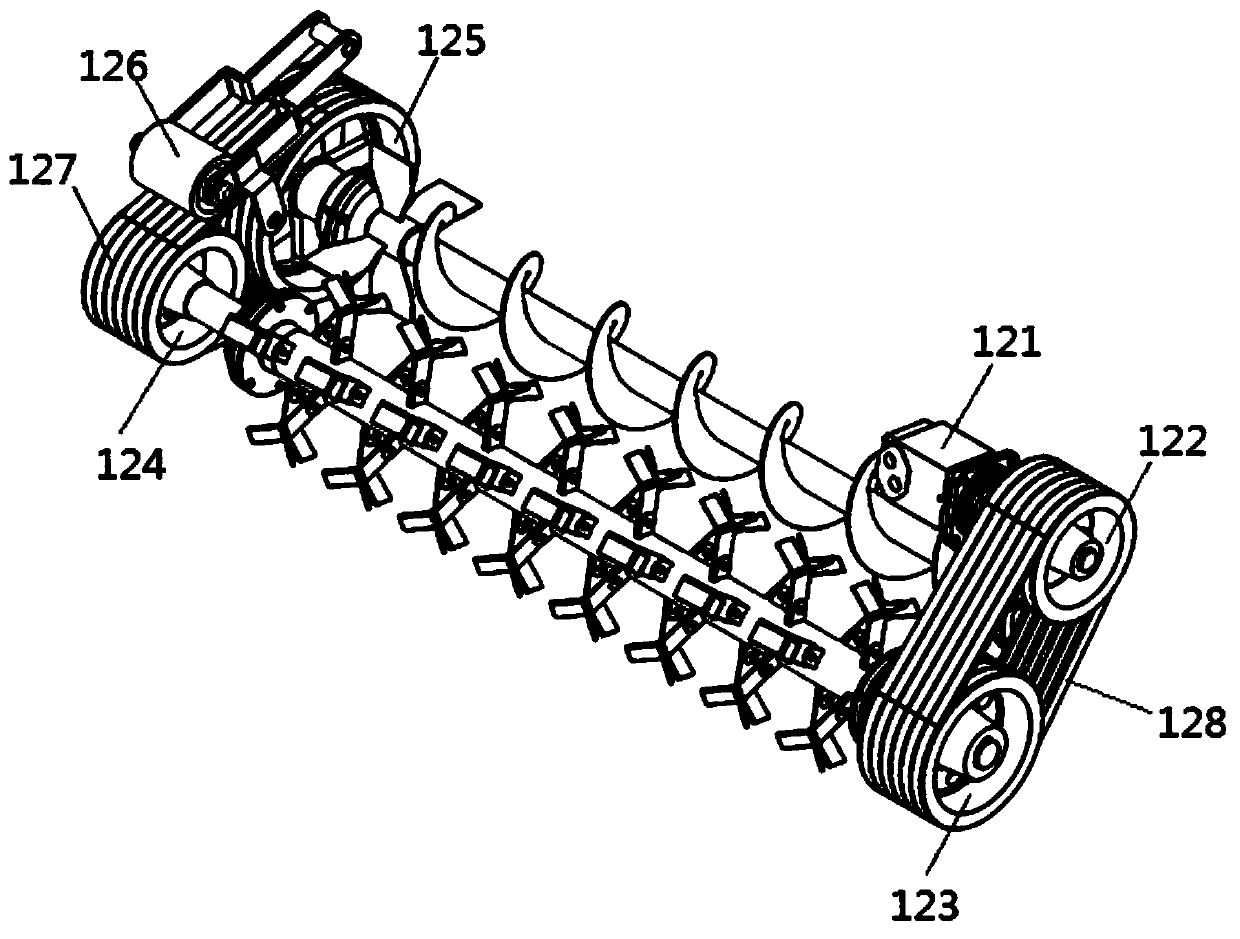

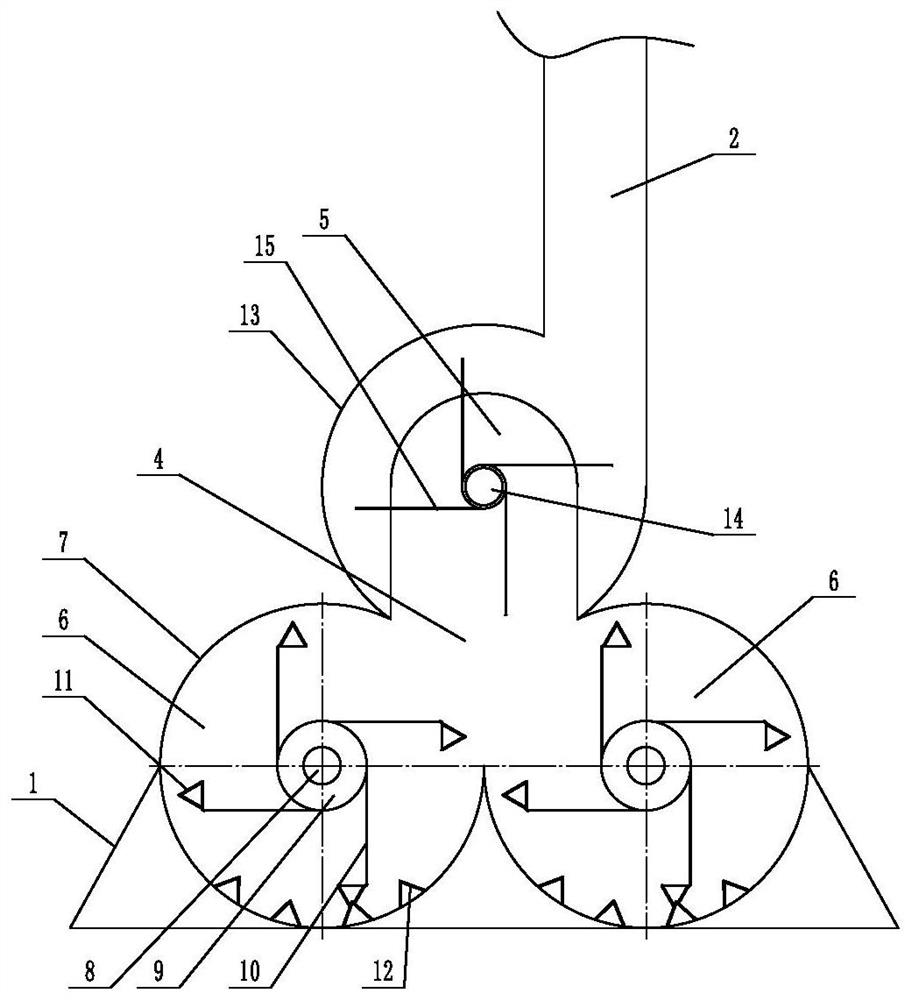

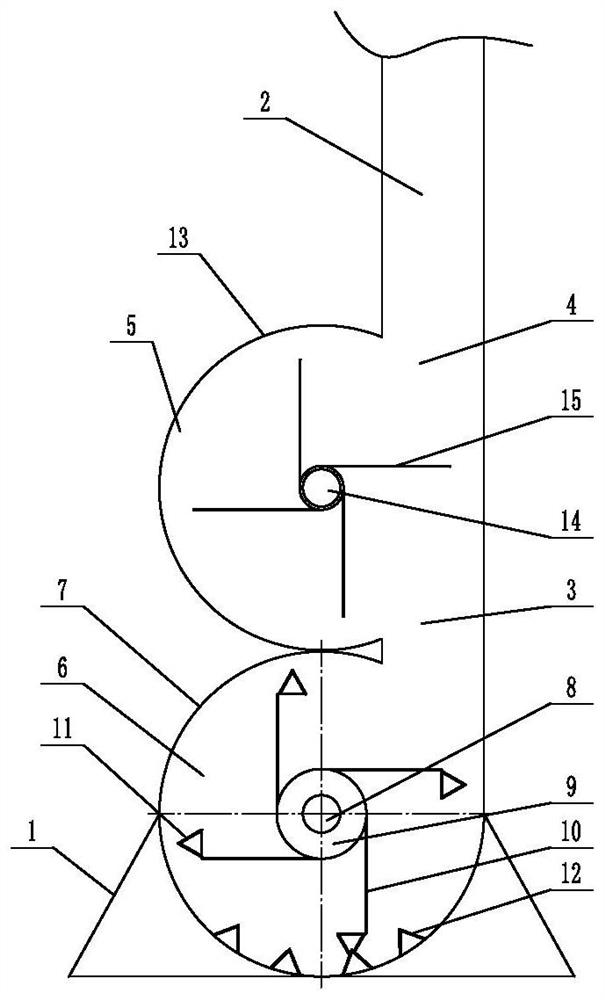

Shovel tooth and tooth roller combined type peanut pickup device

ActiveCN112400477AEasy to pick upIncreased pickup widthHarvestersSaving energy measuresAgricultural engineeringStructural engineering

The invention discloses a shovel tooth and tooth roller combined type peanut pickup device, and belongs to the technical field of agricultural machinery. The shovel tooth and tooth roller combined type peanut pickup device comprises picking shovel teeth, roller protection plates, a picking roller and side plates; the side plates are arranged at the two sides of the picking roller, a center shaft of the picking roller penetrates through the side plates at the two sides to be installed on bearing pedestals, cattail wheels of the picking roller are evenly arranged on the center shaft at intervals, and the roller protection plates are arranged between the adjacent cattail wheels; at the advancing front end of the pickup device, arc-shaped picking shovel teeth of the same structure are installed at the same position of each roller protection plate, and a row of picking shovel teeth are formed; during working, the arc-shaped picking shovel teeth move forwards, the working front ends of the shovel teeth go deep into the ground surface to shovel up peanut plants, and a picking action is achieved; and the cattail wheels of the picking roller rotate along with the center shaft, so that actions of lifting, pushing and returning to a station of the cattail wheels are realized. According to the shovel tooth and tooth roller combined type peanut pickup device, the peanut plants are shoveledby the shovel teeth; and the subsequent picking actions such as lifting and pushing are completed by the roller with the cattail wheels. The pickup device has the characteristics of small size, high pickup rate, low loss rate and the like.

Owner:JILIN AGRICULTURAL UNIV +2

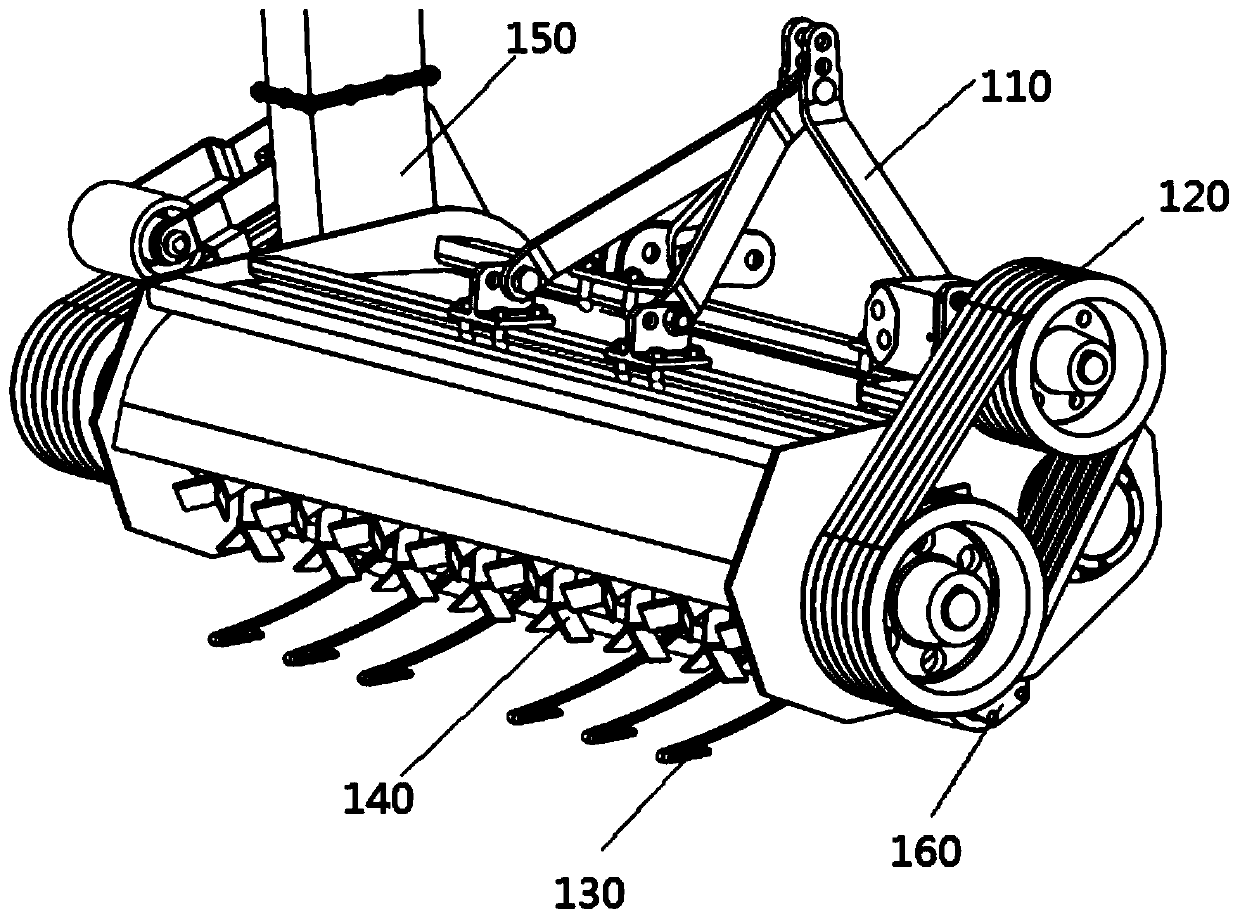

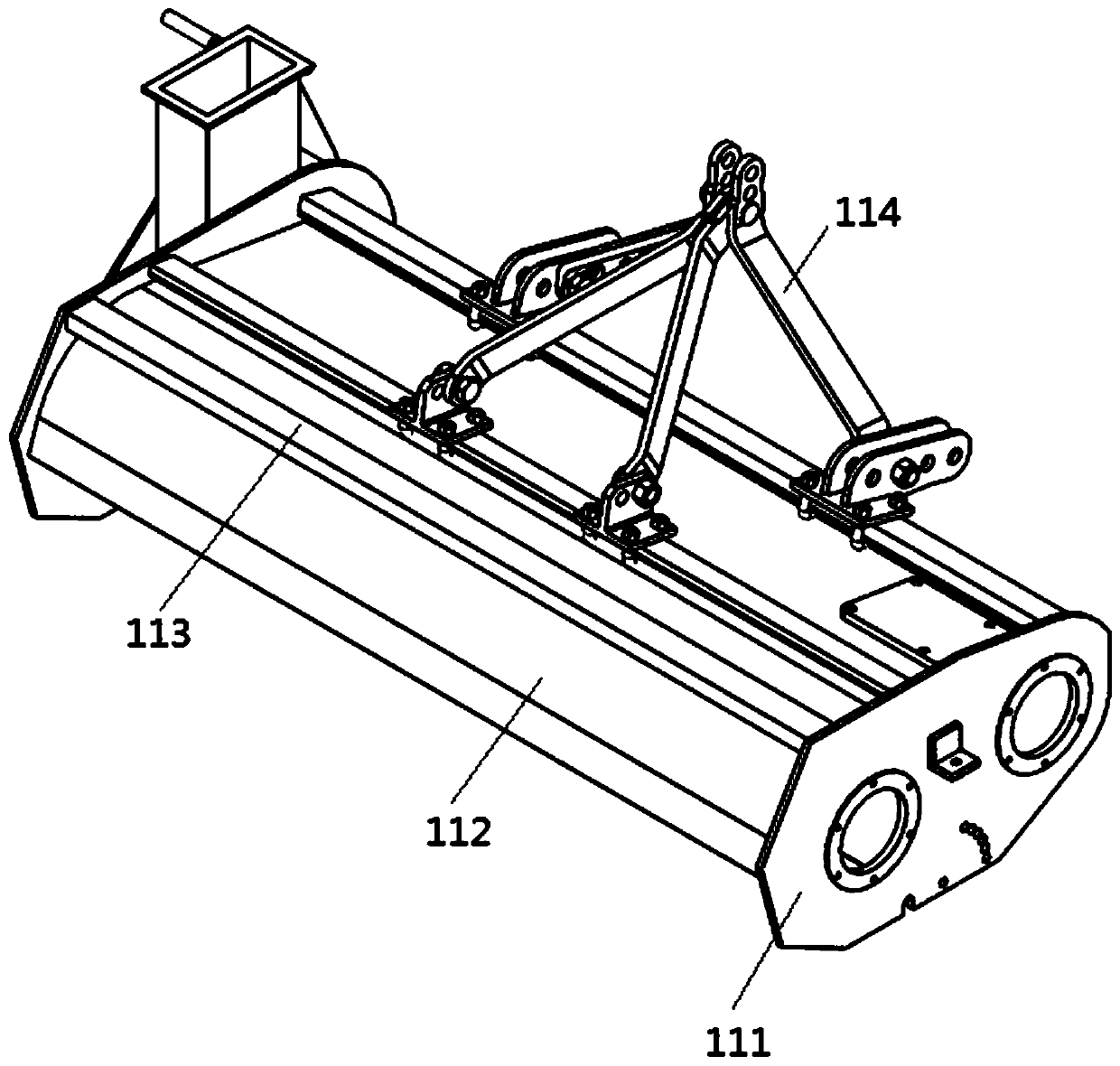

Lifting-type corn straw picking device with wheel belt

InactiveCN104686090AWorking height can be adjustedEasy to transportLoadersTransmitted powerAgricultural engineering

The invention discloses a lifting-type corn straw picking device with a wheel belt. The corn straw picking device comprises a machine frame, picking wheels, picking teeth and conveyor belts, wherein the picking wheels and the conveyor belts are mounted at the front end of the device at intervals; the picking wheels and the picking teeth are used for picking corn straws; the conveyor belts are used for transmitting power and transporting the straws. The operation height of the corn straw picking device disclosed by the invention can be regulated through oil cylinders, the design that the picking wheels and the conveyor belts are arrayed at intervals saves the space and reduces the energy consumption, and a certain of a soil filtering function is realized; the operation height can be adjusted, and the picking teeth can penetrate into a furrow and pick up the straws in the furrow, so that the picking rate is increased; blocking plates are not arranged on two sides of the corn straw picking device, so that the picking range is wider; a rubber barrel is stuffed between the picking wheels and a front shaft, and the rubber barrel can absorb a part of impact power generated by impacted picking teeth, so that the service life of the device is prolonged; the picking teeth and the picking wheels are connected by bolts, so that damaged picking teeth can be replaced at any time.

Owner:JILIN UNIV

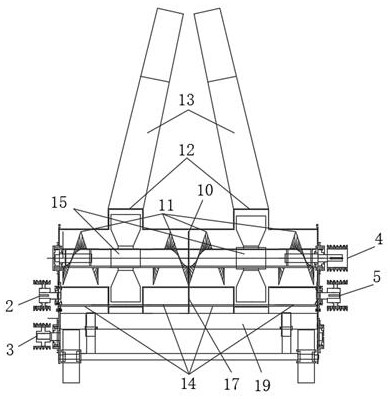

Suspension type Chinese artichoke harvesting machine with vibrating screen

A suspension type Chinese artichoke harvesting machine with a vibrating screen comprises a machine frame. A shovel board is fixed to the portion below the front part of the machine frame. A steering wheel is arranged behind the shovel board. A vibrating roller is arranged above a soil shaking rod. The two ends of the soil shaking rod are fixed to a rubber conveyor belt at equal intervals. The rubber conveyor belt is installed on a driving wheel and the steering wheel in a surrounding mode. A shaking wheel and a supporting wheel are arranged below the rubber conveyor belt. An upper suspension hinge shaft and two lower suspension hinge shafts are fixed to the portion above the front part of the machine frame. A vibrating screen frame is installed below the rear part of the driving wheel in an inclined mode. Two layers of screening nets are fixed to the vibrating screen frame. A double-shaft vibration exciter is installed on the vibrating screen. According to the suspension type Chinese artichoke harvesting machine, Chinese artichoke can be picked up thoroughly, and the working efficiency is high; due to the dual effects of the shaking wheel, the vibrating roller and the vibration exciter, most soil falls into the ground, Chinese artichoke is placed on the surface of the ground, no manual soil turning is needed, and a large amount of picking labor is decreased.

Owner:NINGXIA ZHONGWEI YIYUAN MACHINERY EQUIP R & D CO LTD

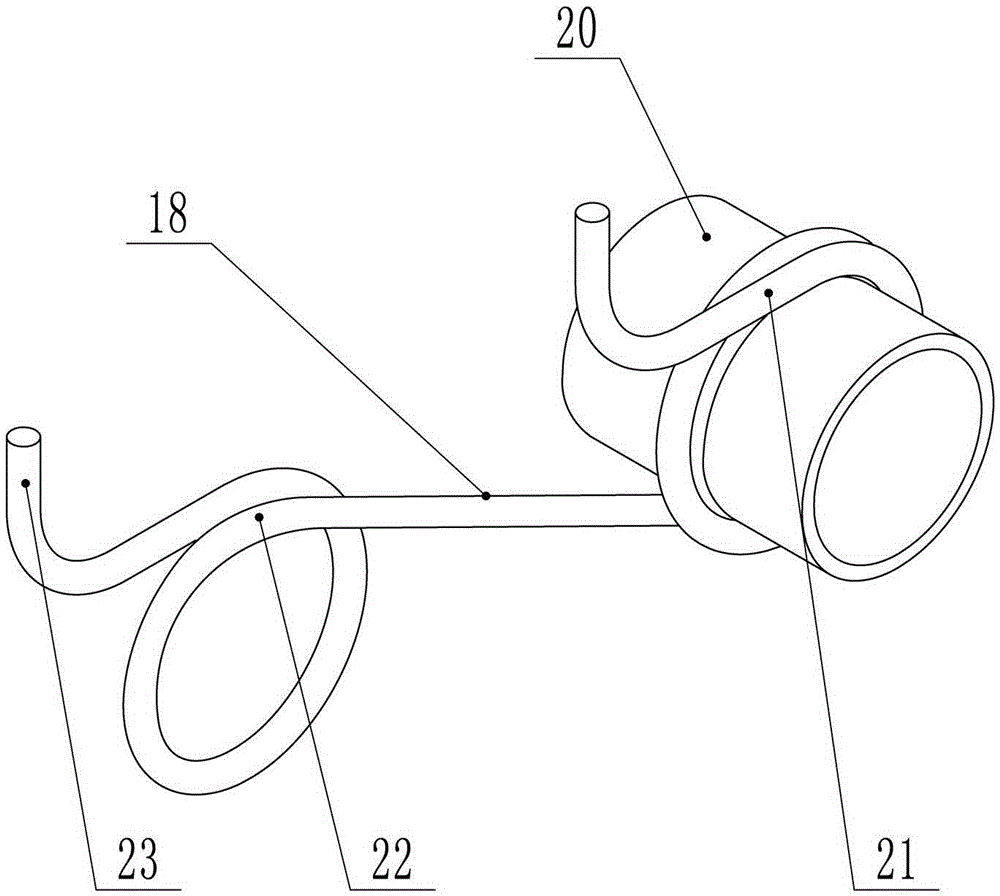

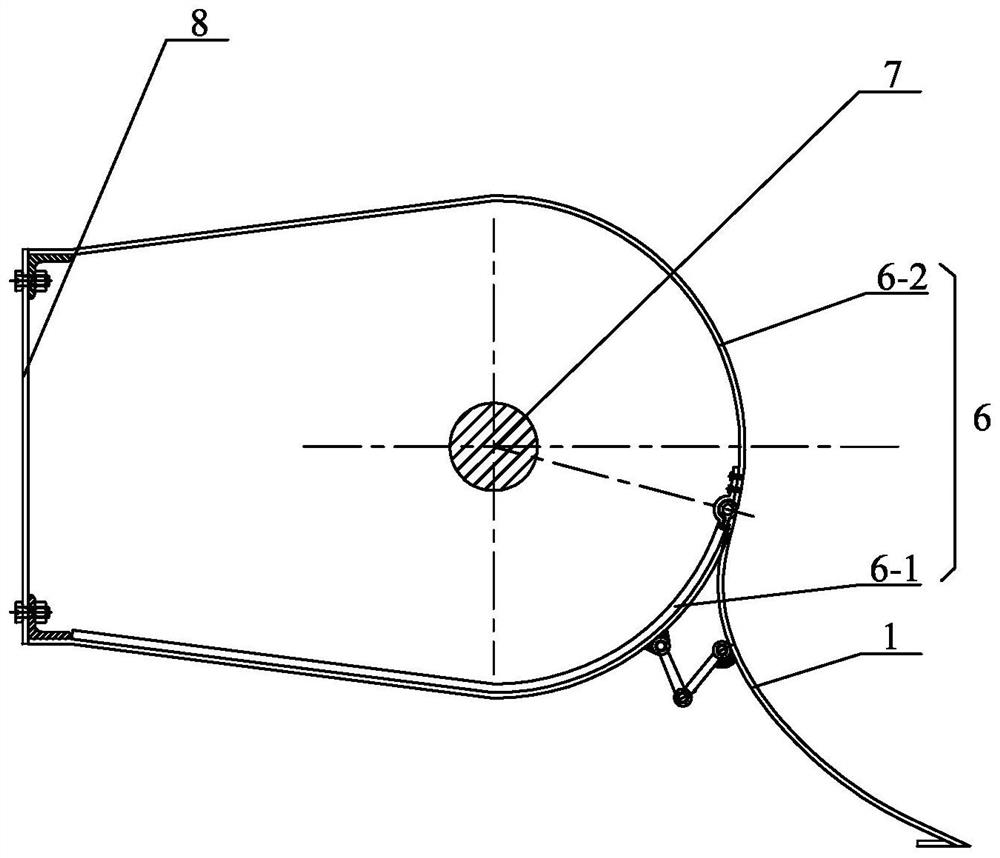

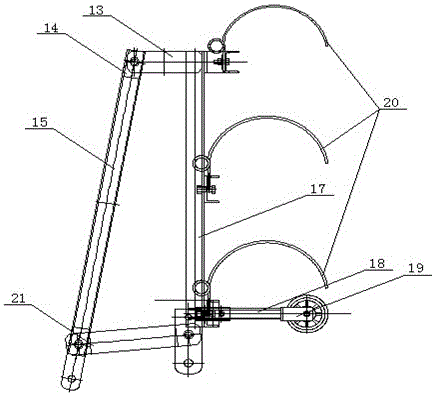

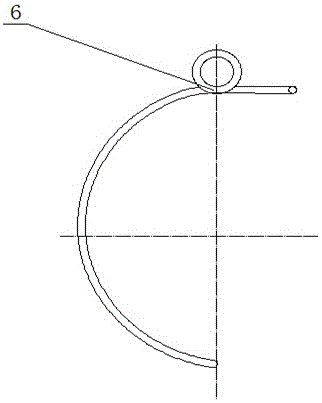

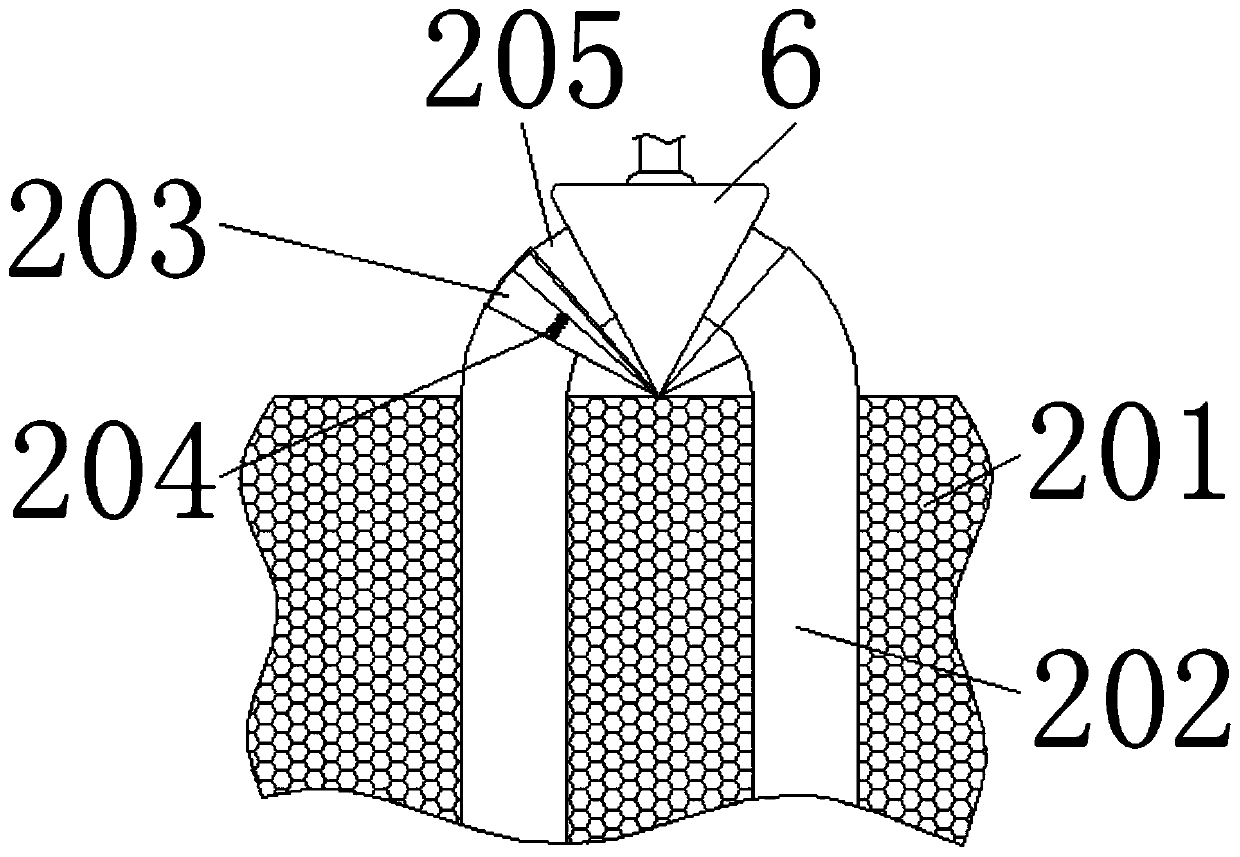

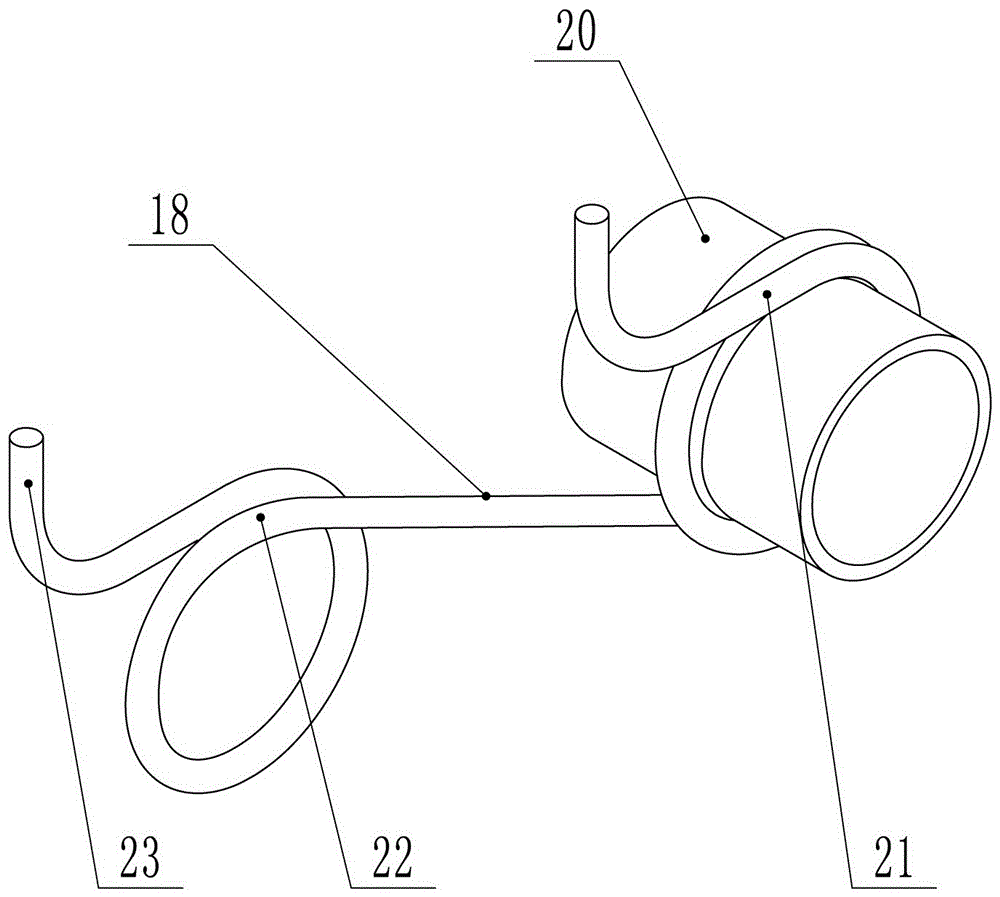

Method for manufacturing waste film reclamation plant

InactiveCN105794339AAvoid deformationReduce labor intensityGatherer machinesAgricultural engineeringTraction frame

The invention relates to the technical field of agricultural machinery, in particular to a method for manufacturing a waste film reclamation plant. The waste film reclamation plant is characterized by mainly comprising a film picking component, an elastic claw component and a frame, namely a traction frame (20), a film removing and picking mechanism (21) and a depth limiting land wheel (8). According to the method, three rows of elastic claws, namely the first elastic claws (6) with the diameter of 10, the second elastic claws (4) with the diameter of 8 and the third double-elastic claws (2) with the diameter of 6, fixed to the frame are adopted, 67 elastic claws are installed on a frame fixing plate, the elastic claws penetrate through center holes of M20 nuts to be clamped between the fixing plate and a bolt, and the upper sides of the elastic claws are connected and fixed through M20 nuts. The waste film reclamation plant has the advantages of being convenient to hang, high in mulching film picking rate, simple in structure, reliable in work and high in adaptability, and is an ideal mulching film picking and recovering device.

Owner:EASTERN GANSU UNIVERSITY +1

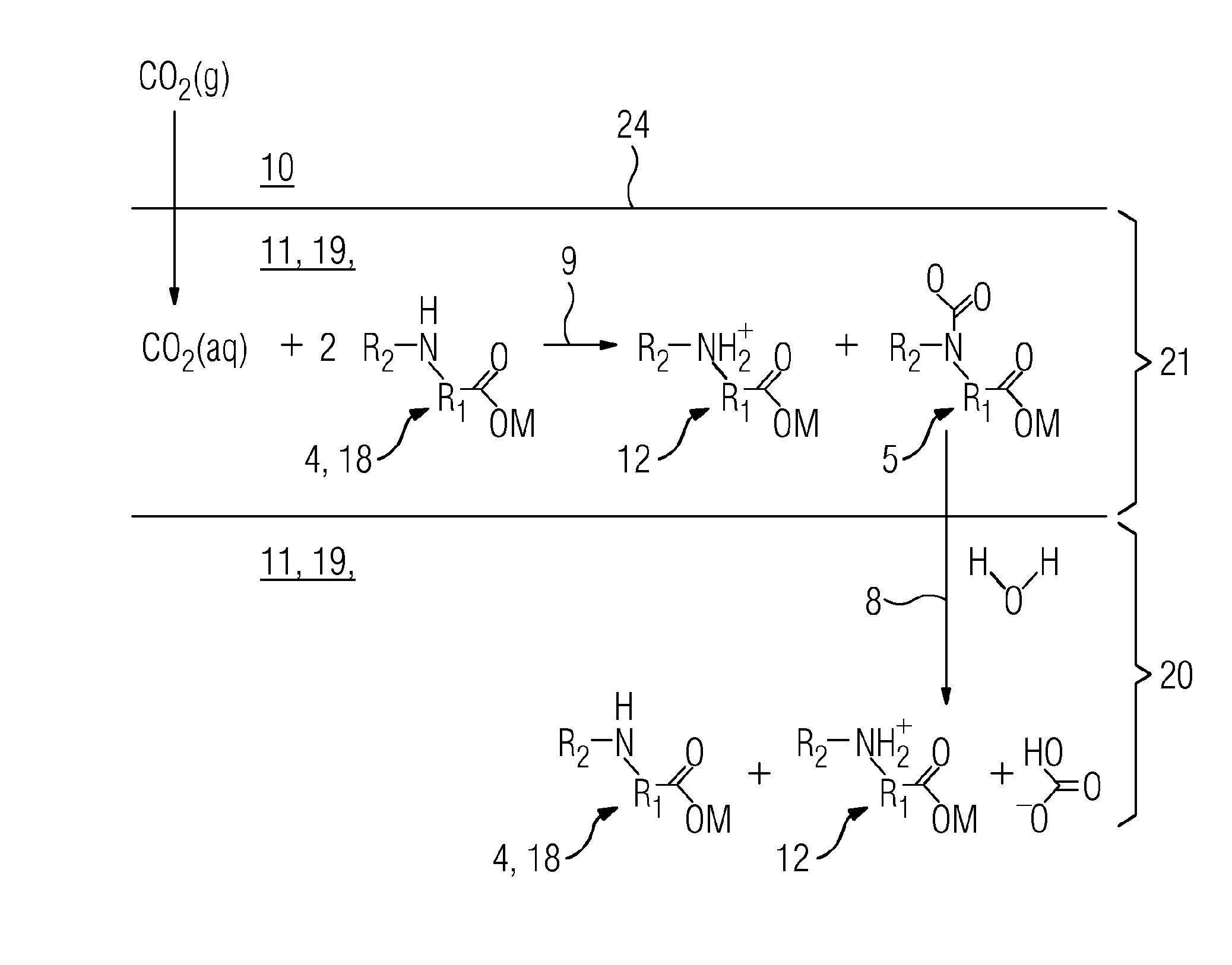

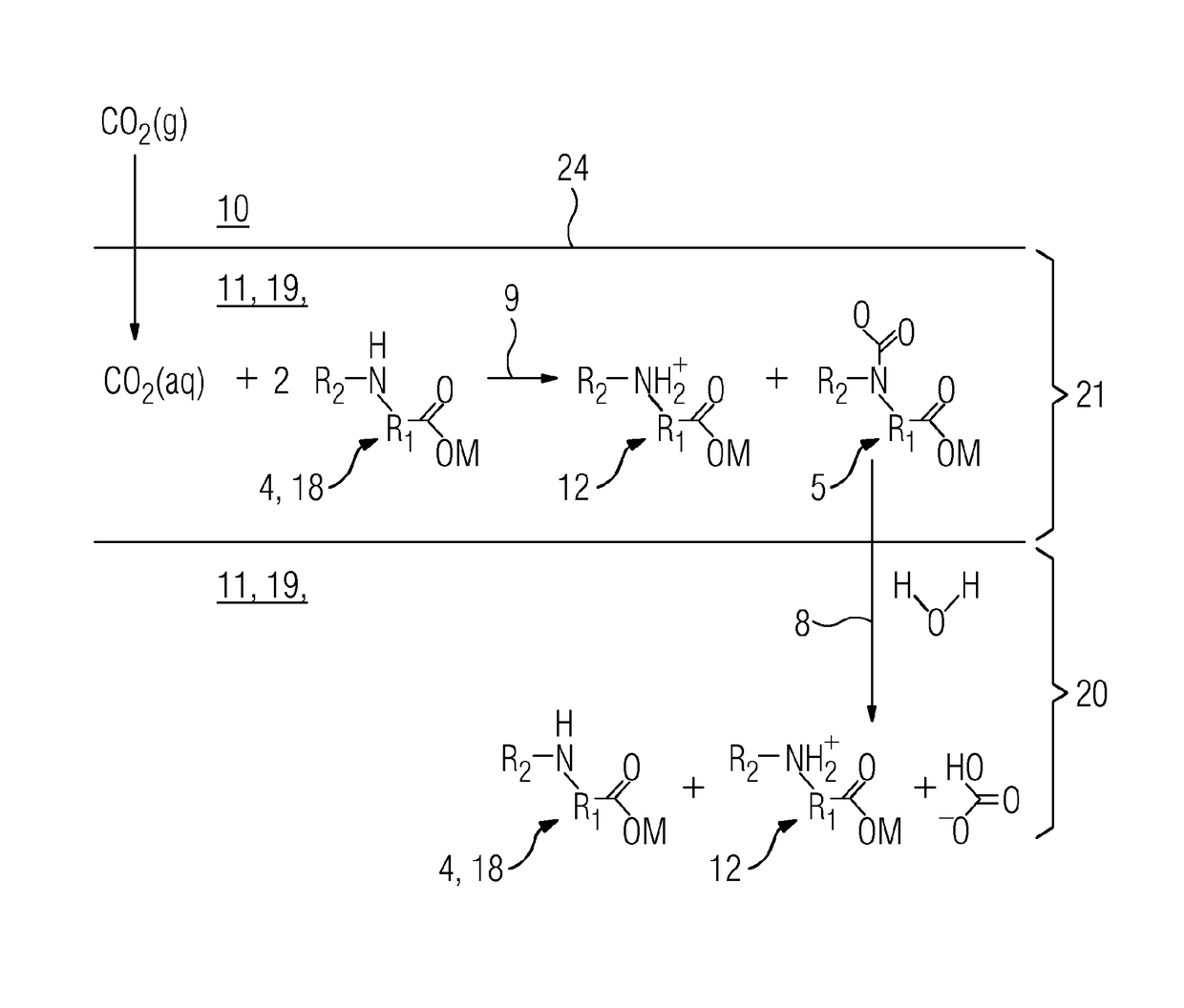

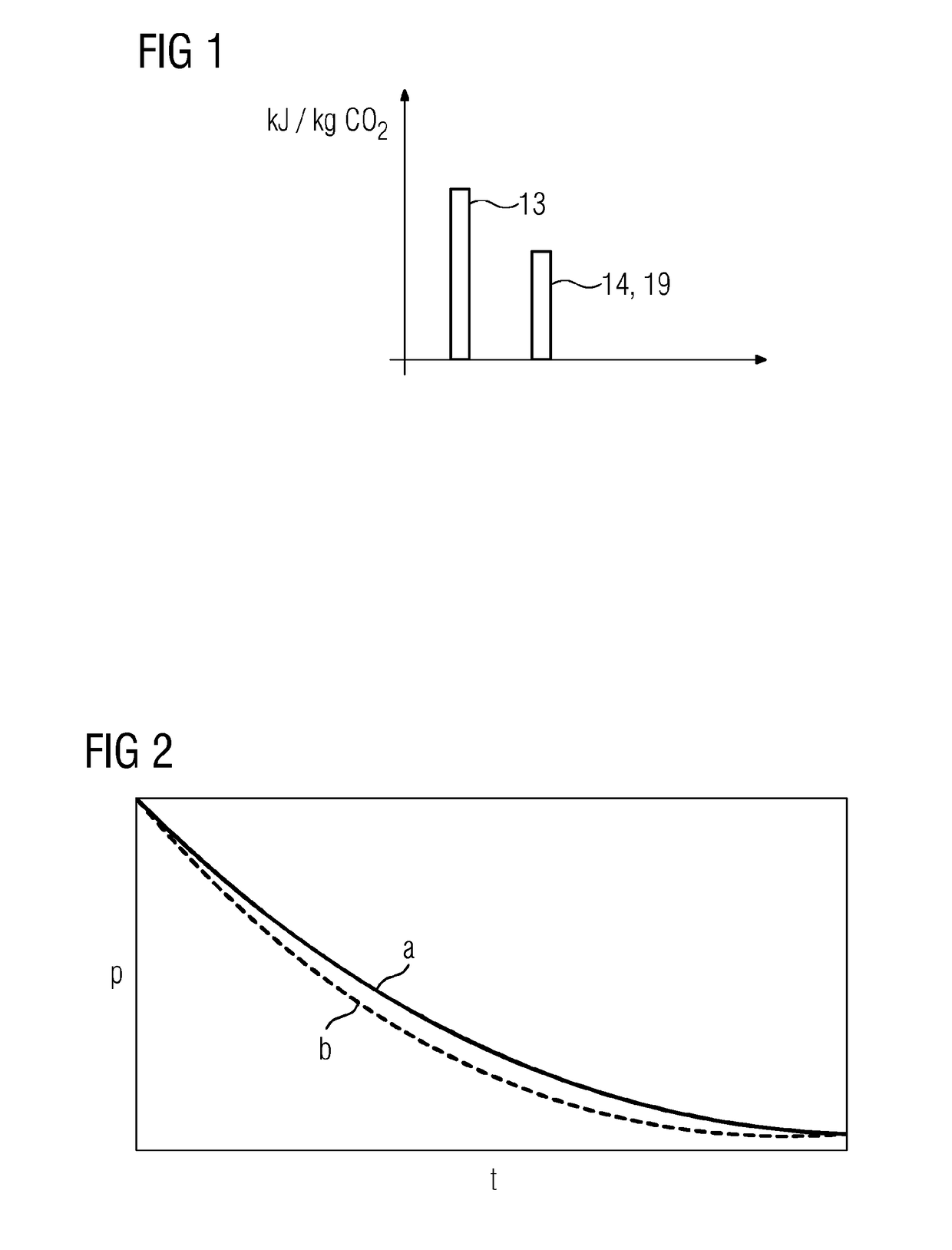

Scrubbing solution for absorption of carbon dioxide and method for accelerating the absorption by germanium dioxide

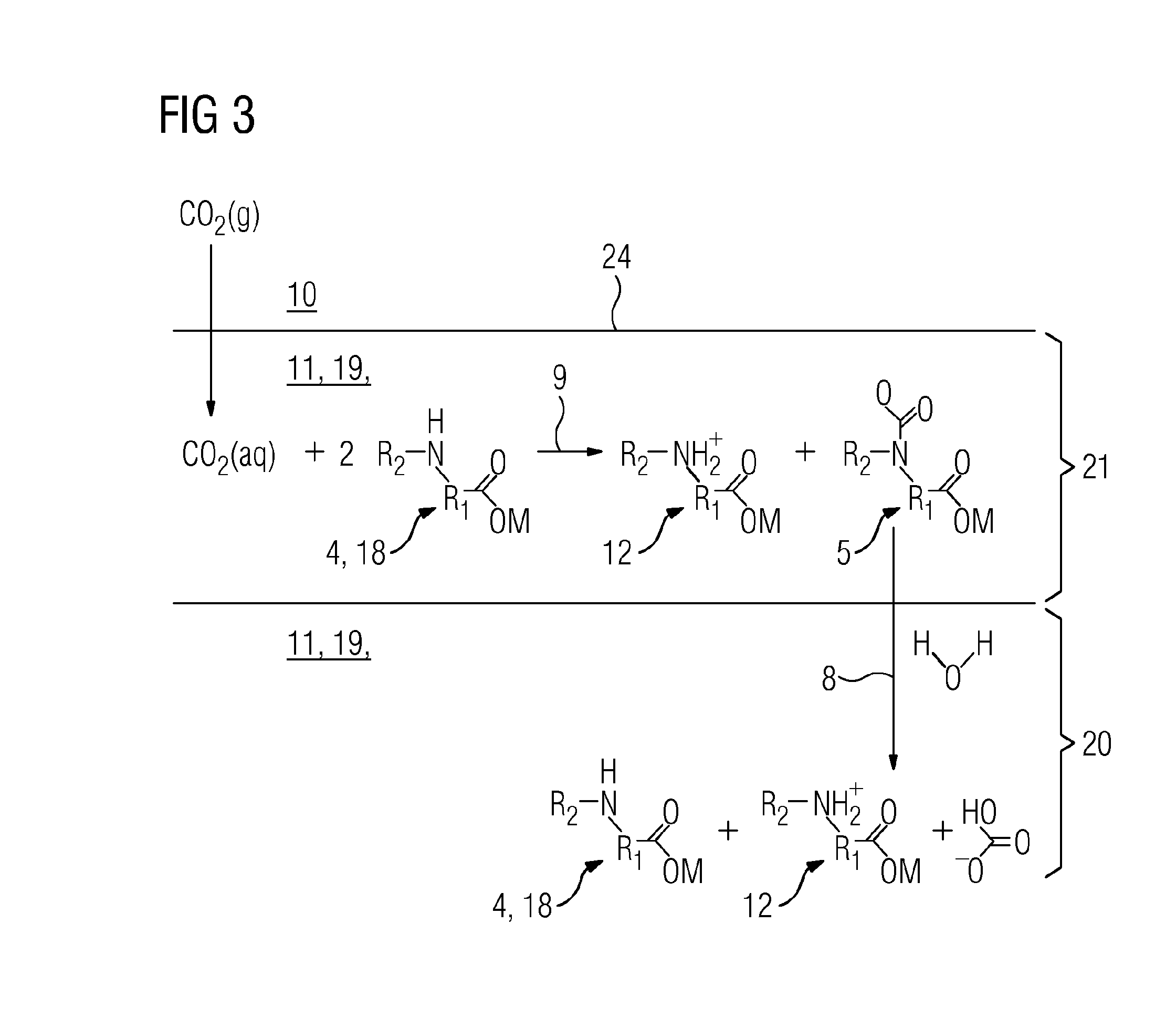

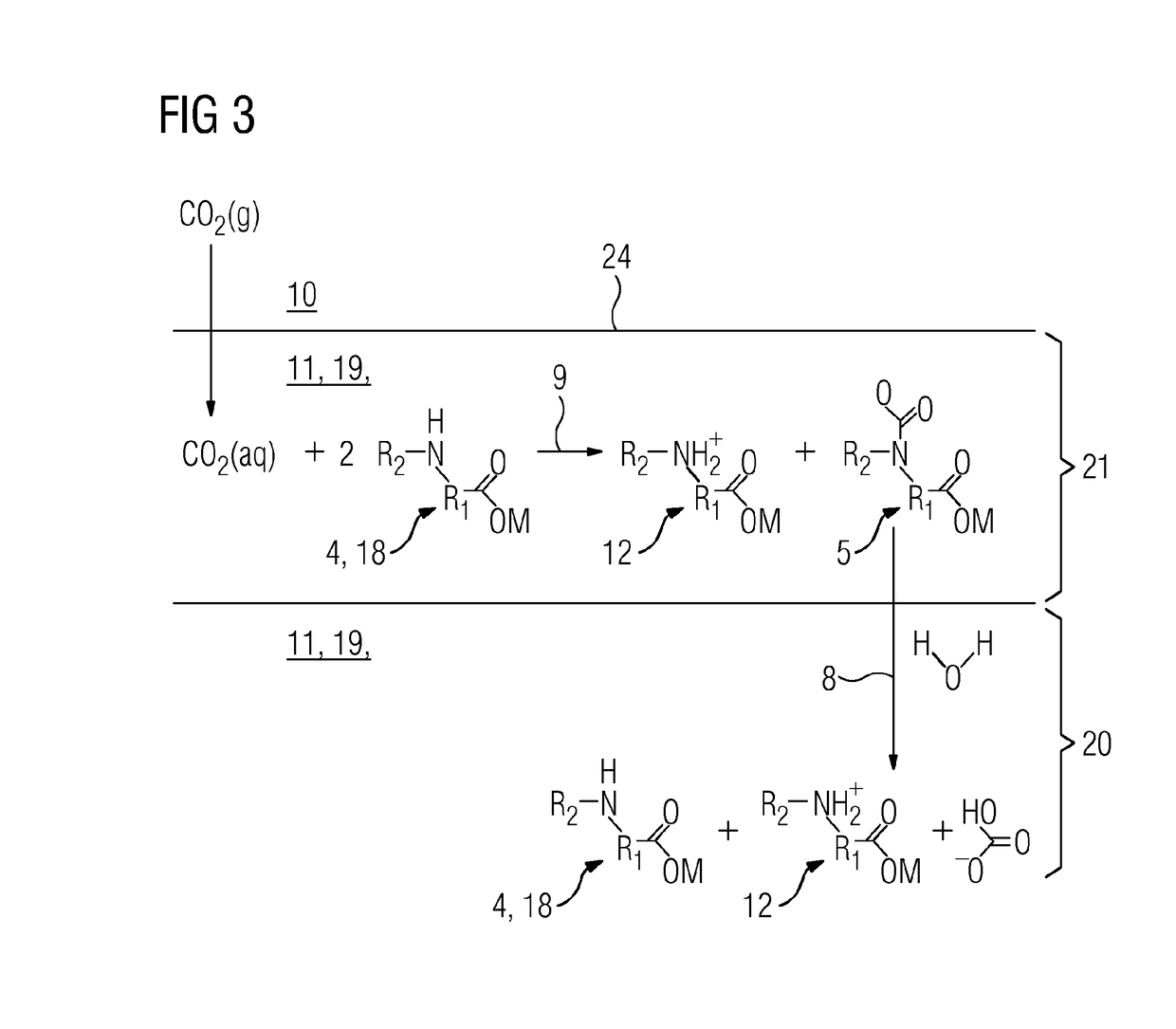

InactiveUS20150165375A1High absorption rateLow energy requirementGas treatmentDispersed particle separationAbsorption rateChemistry

A scrubbing solution is provided having an absorbent for carbon dioxide based on amines, or ethanolamines, or amino acid salts, or potash, or a combination thereof, and an additive activating the absorption rate, wherein the activating additive is a germanium dioxide. A corresponding method for accelerating the absorption of carbon dioxide is also provided, wherein a carbon dioxide-containing gas is contacted with such a scrubbing solution, wherein the carbon dioxide is physically dissolved in the scrubbing solution and is chemically absorbed with the participation of the absorbent, and wherein the germanium dioxide acts catalytically for at least one reaction step of the chemical absorption of the carbon dioxide.

Owner:SIEMENS AG

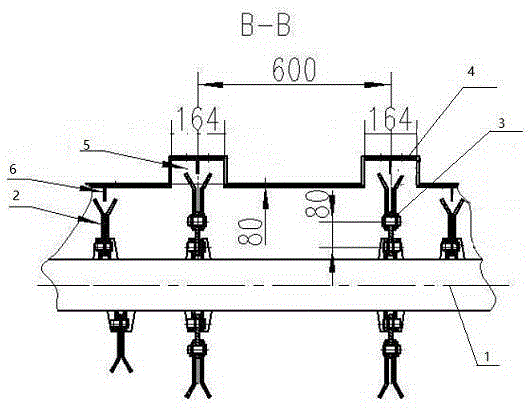

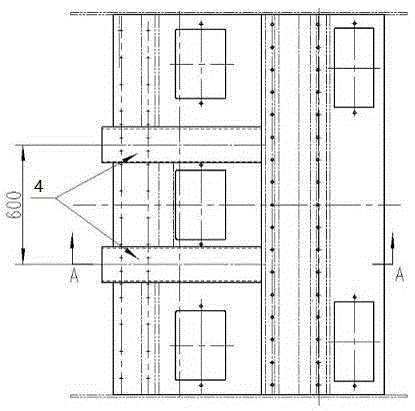

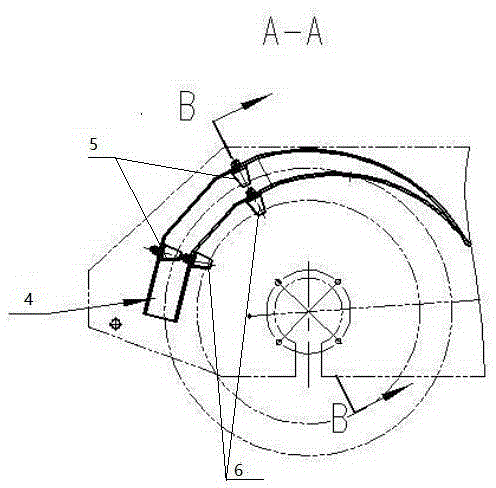

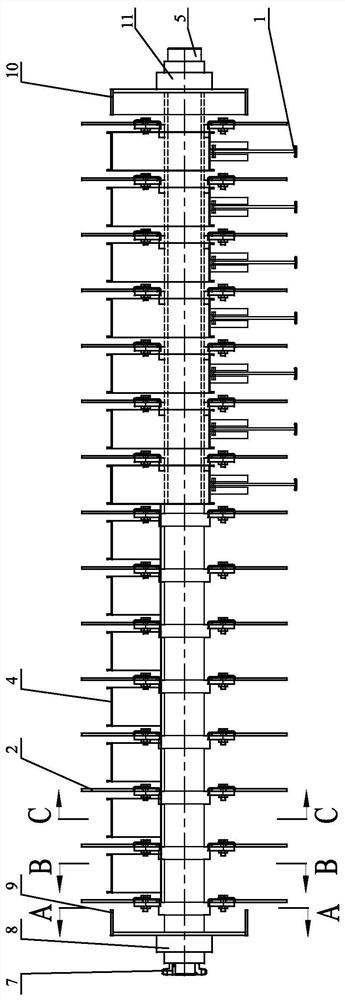

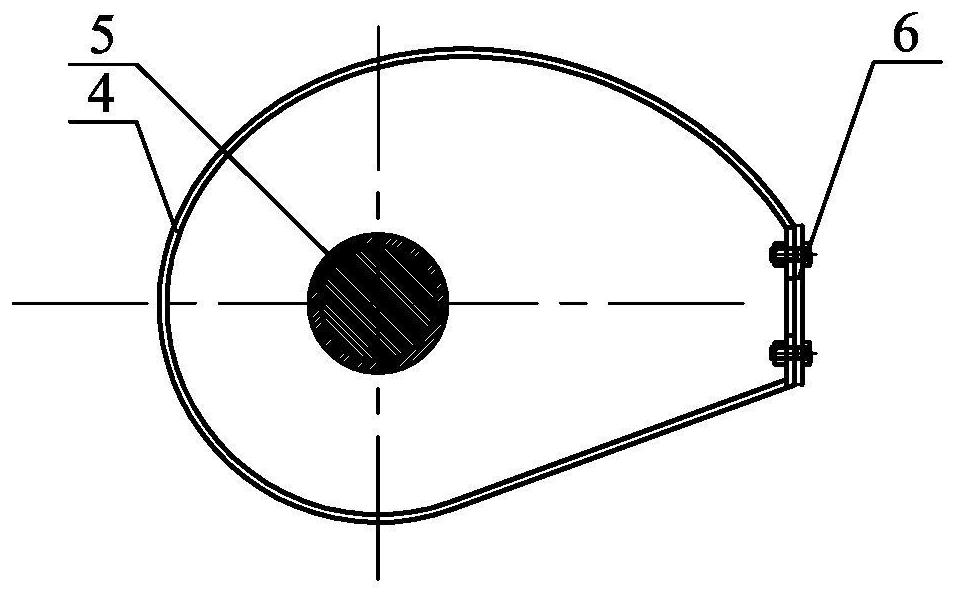

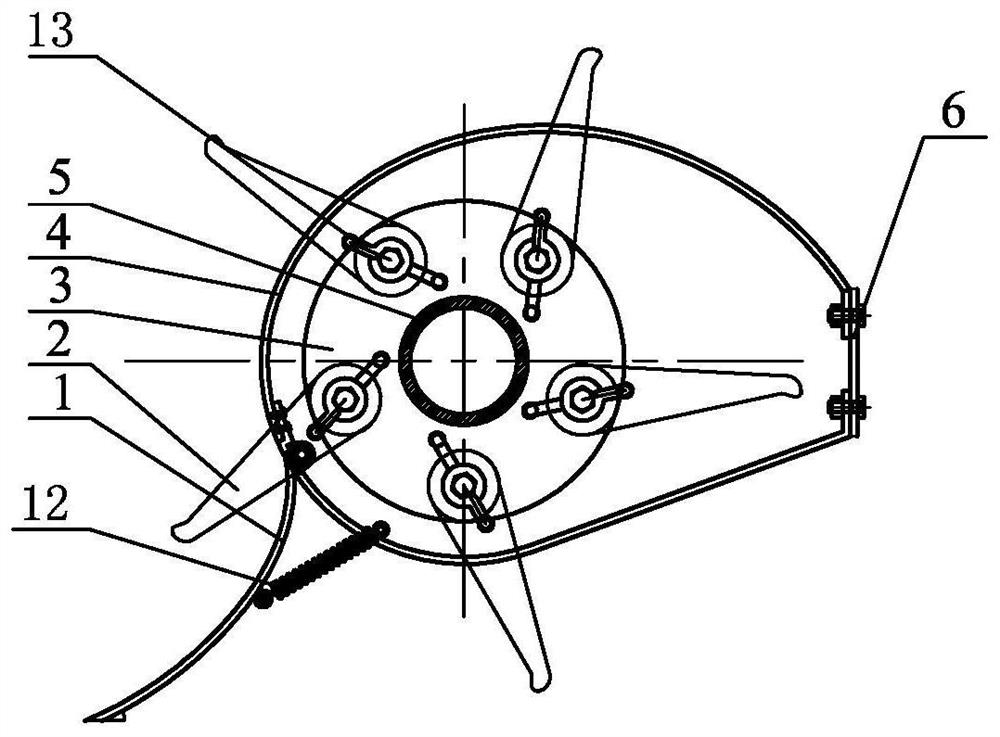

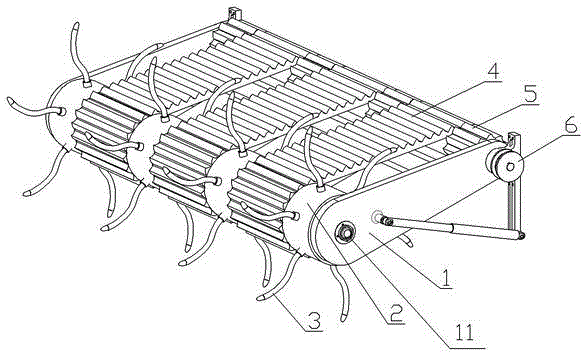

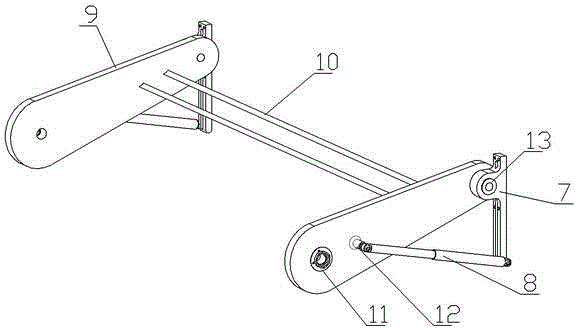

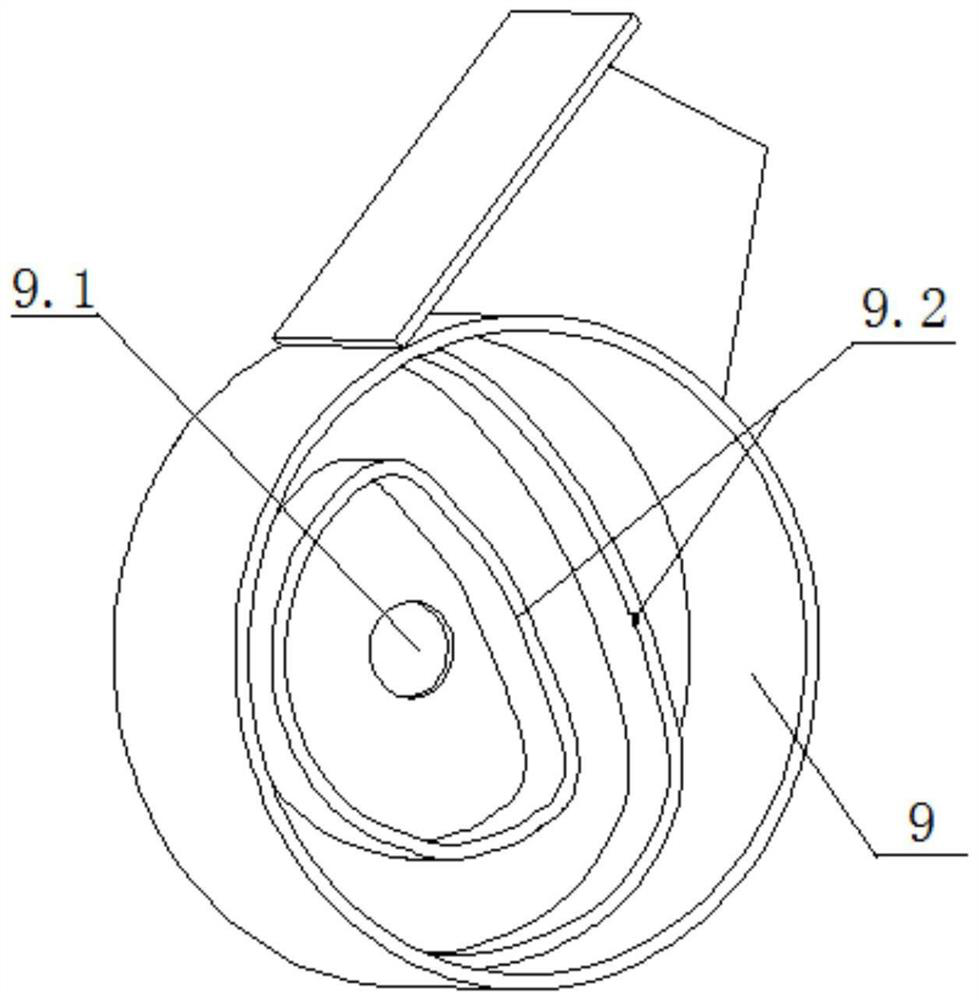

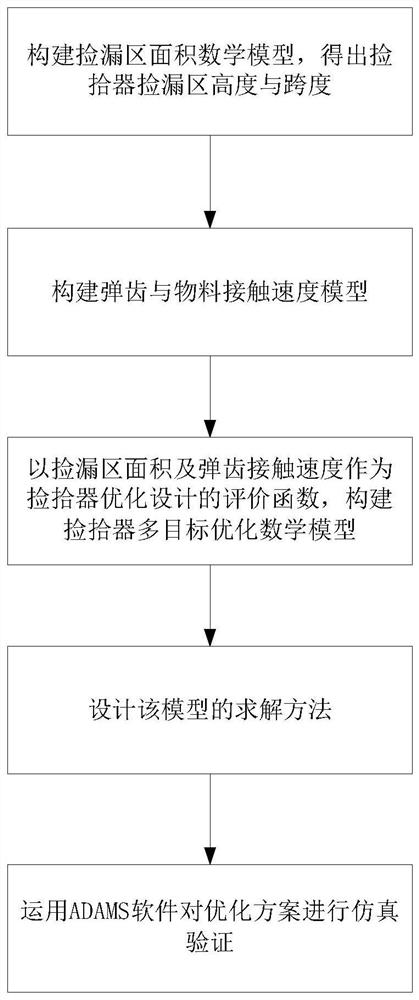

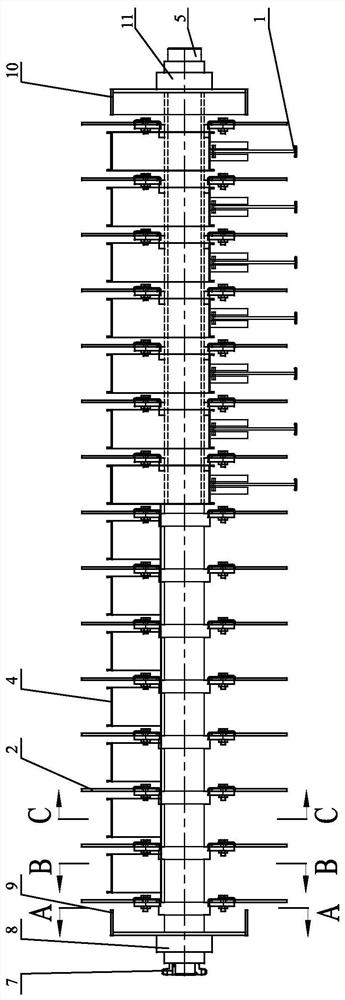

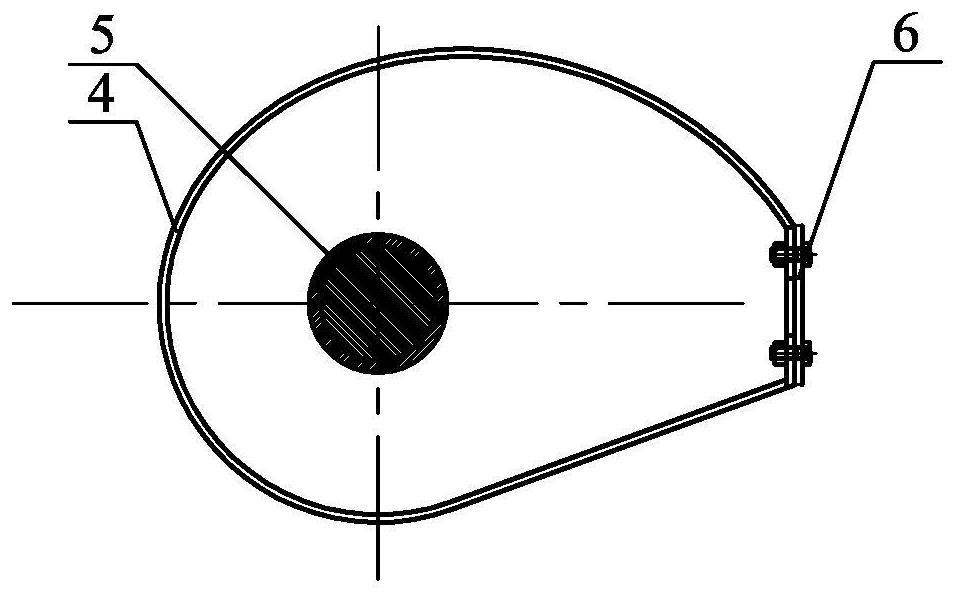

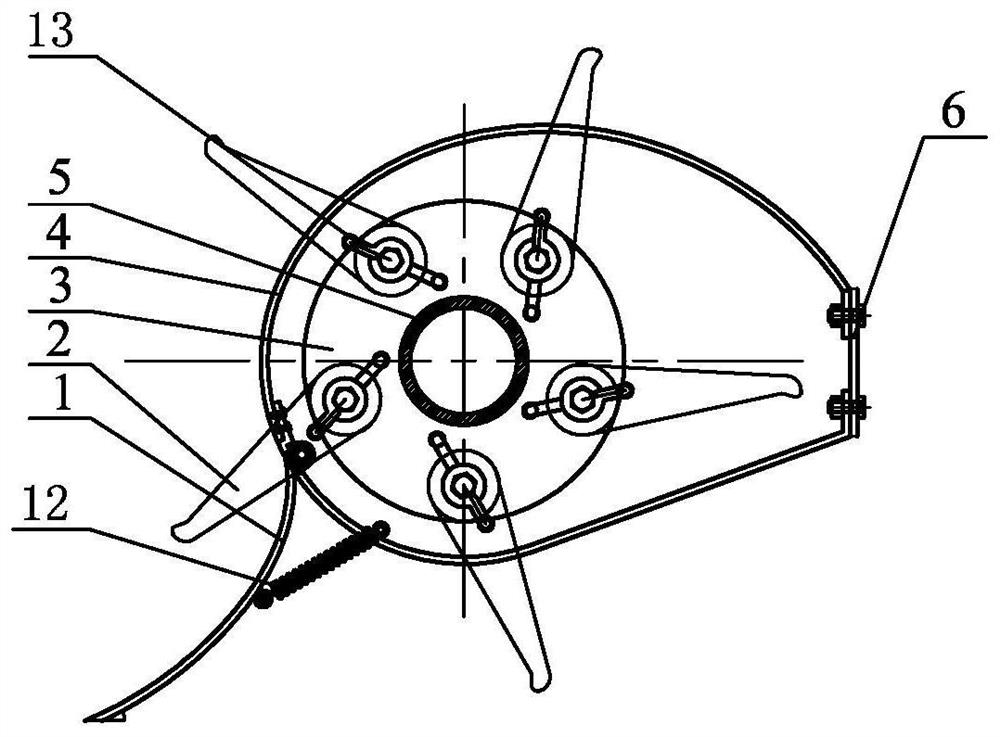

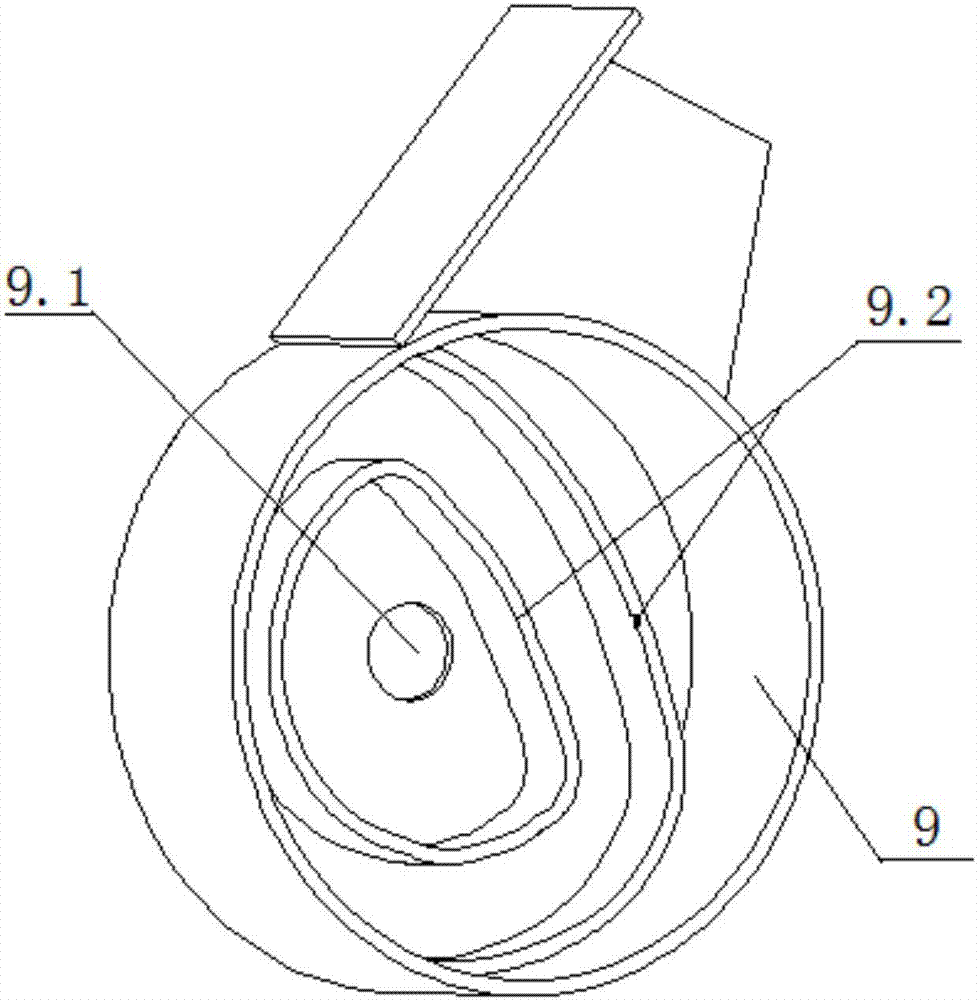

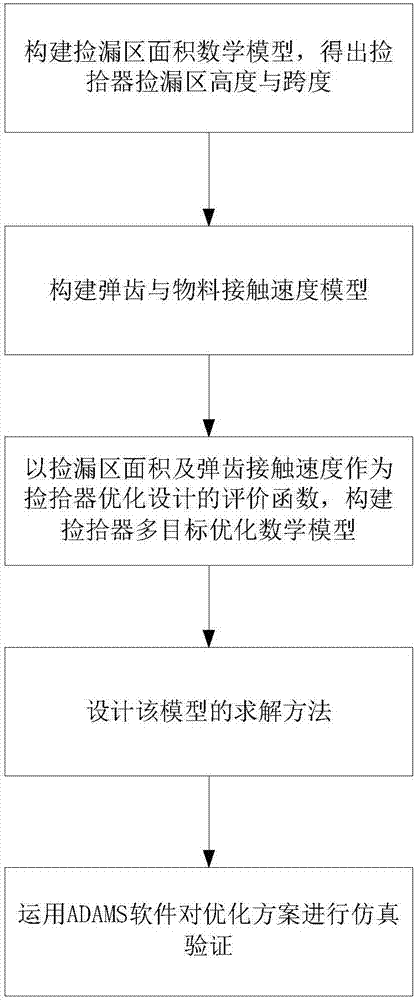

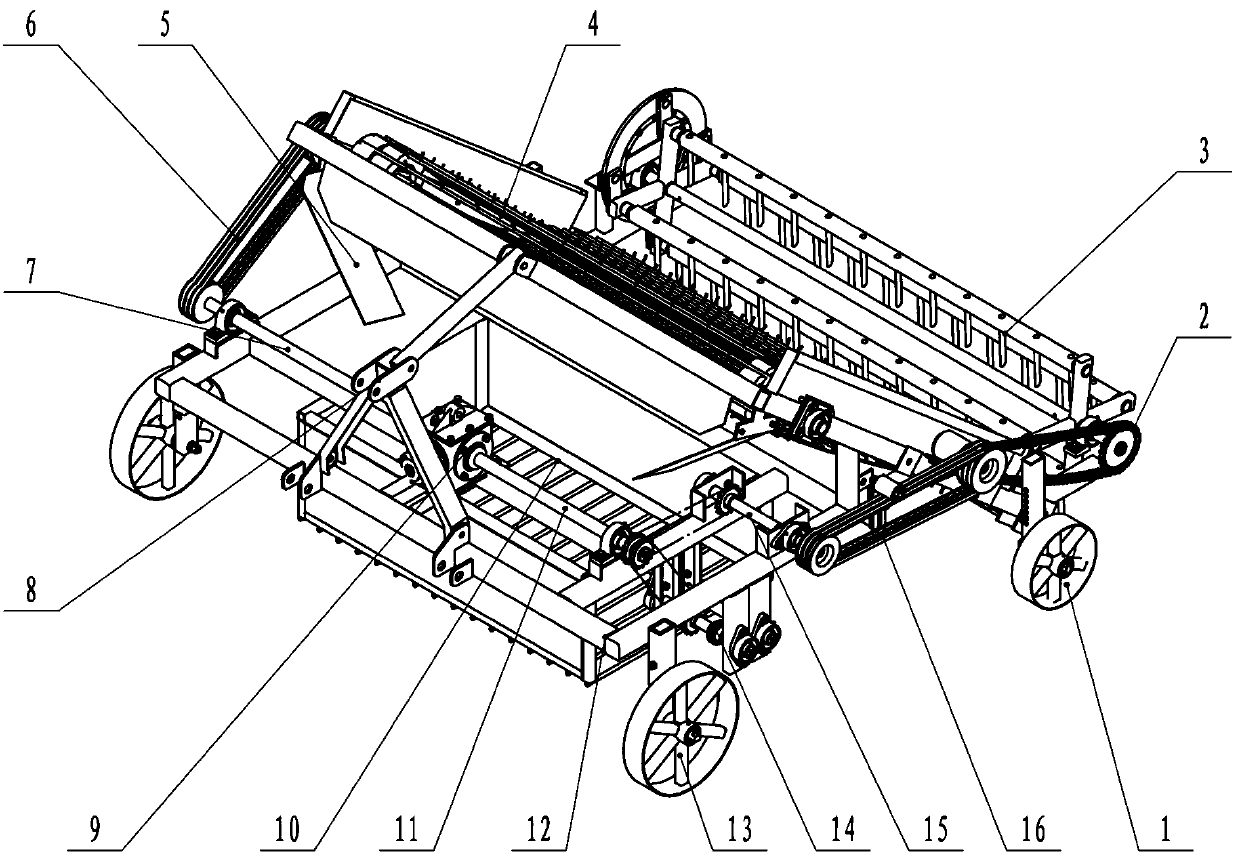

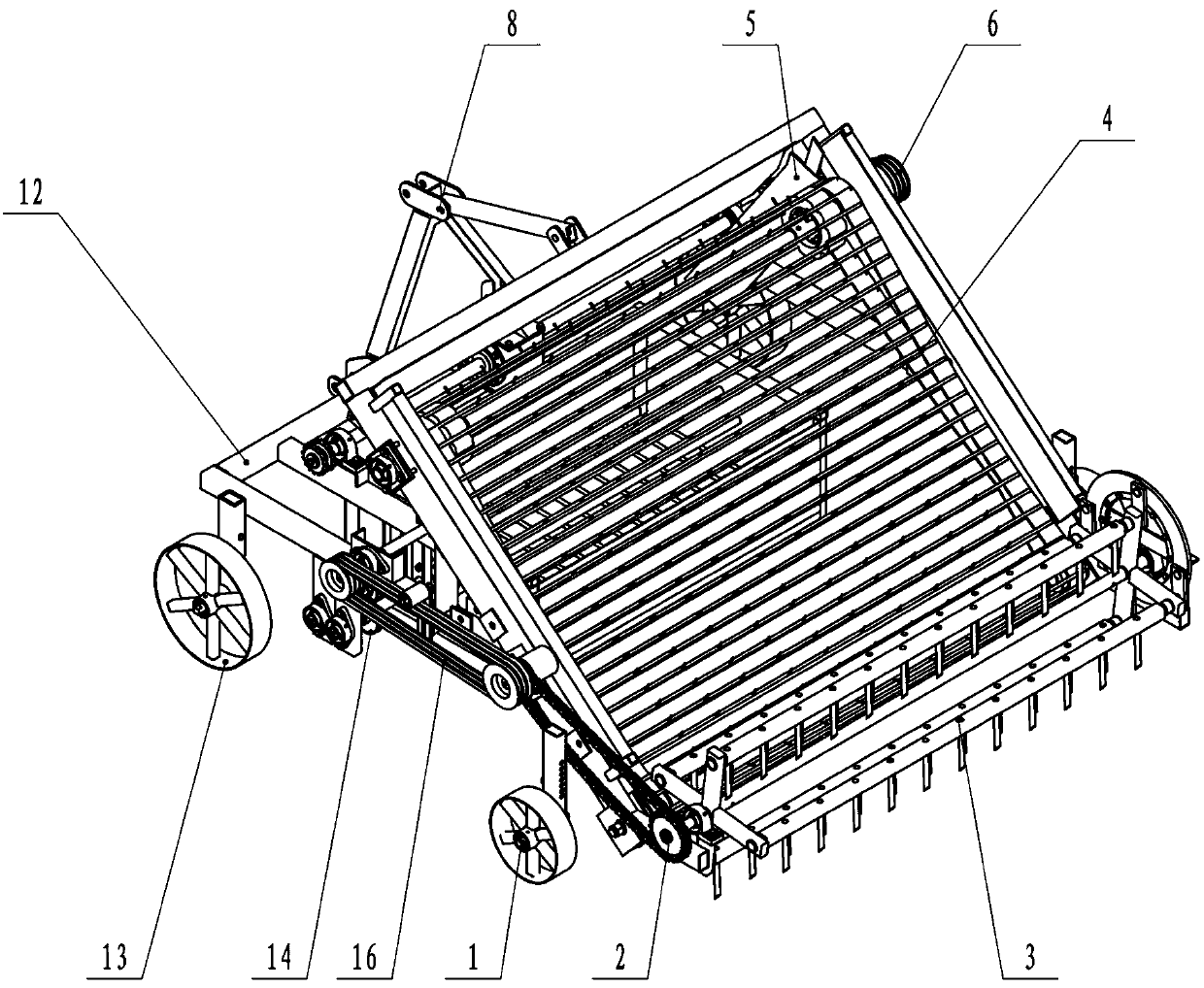

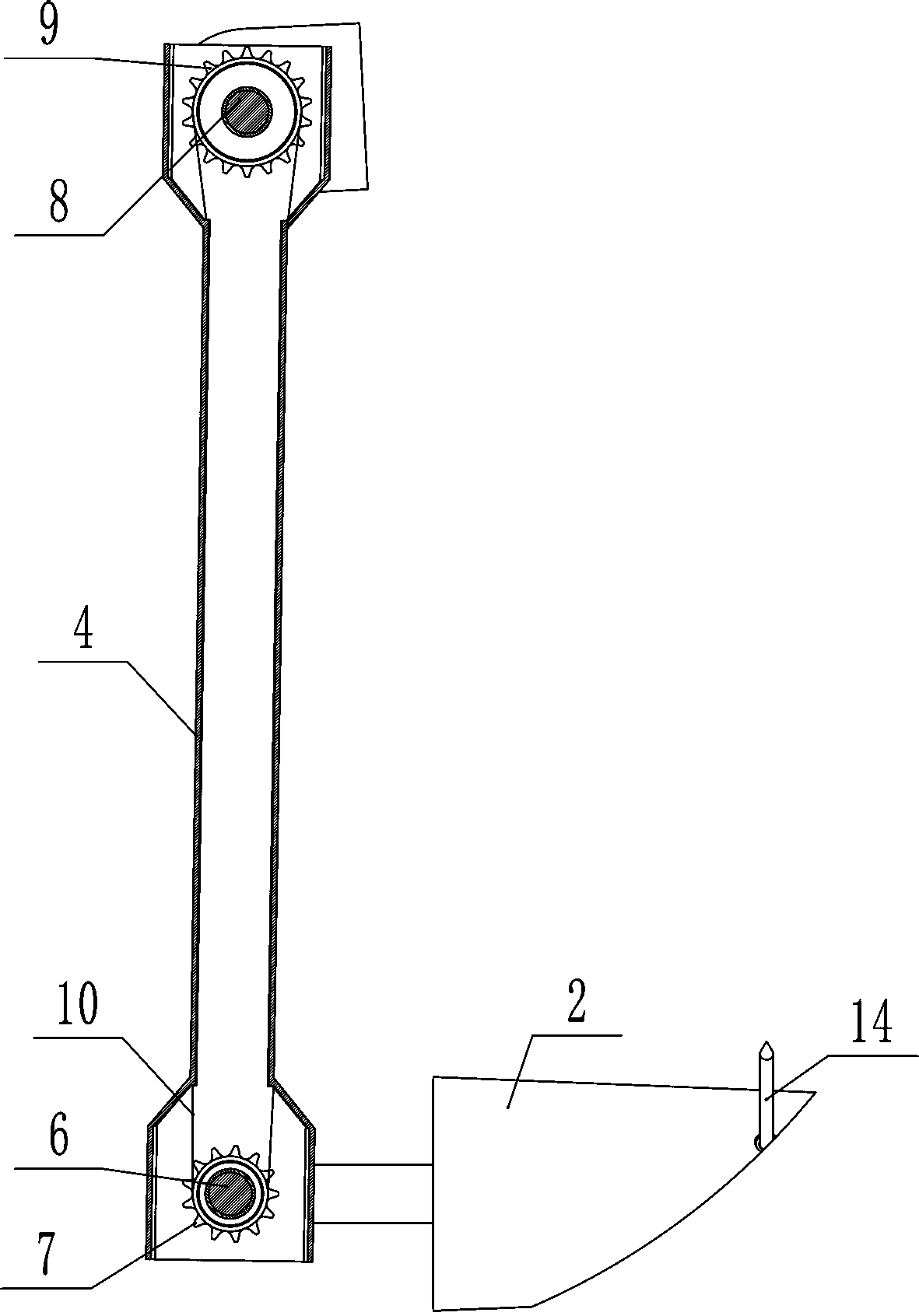

Optimal Design Method for Reducing the Missing Rate of Pickup in Baler

ActiveCN107491597BCompact structurePromote repairGeometric CADDesign optimisation/simulationMathematical modelProcess engineering

The invention discloses an optimal design method for lowering the omission factor of a bundling machine gatherer, and belongs to the technical field of straw recovery mechanical equipment. The design method comprises the following steps that: 1) constructing the mathematical model of the area of a leakage pickup region; 2) constructing an elastic claw and material contact speed mathematical model; 3) constructing a multi-objective optimization mathematical model of the gatherer; 4) solving the multi-objective optimization mathematical model of the gatherer; and 5) applying ADAMS (Automatic Dynamic Analysis of Mechanical Systems) software to carry out simulation verification on the optimized data. By use of the optimal design method disclosed by the invention, an optimal design algorithm is adopted to optimize each structural dimension of an existing gatherer, a relevant design parameter is subjected to analog simulation verification, and the gatherer which has the advantages of simple structure, compactness and convenience in maintaining and high pickup rate is obtained.

Owner:HUBEI UNIV OF TECH

A shovel tooth-tooth roller combined peanut picking device

ActiveCN112400477BEasy to pick upIncreased pickup widthHarvestersSaving energy measuresAgricultural engineeringEngineering

A shovel tooth-tooth roller combined peanut picking device belongs to the technical field of agricultural machinery. It includes pick-up shovel teeth, roller guards, pick-up rollers and side plates. Side plates are arranged on both sides of the pick-up drum. The wheels are evenly spaced on the central axis, and there are roller guards between adjacent pulleys. At the front end of the pick-up device, arc-shaped pick-up shovel teeth with the same structure are installed at the same position on each of the roller guards to form a Rows of pick-up shovel teeth; when working, the arc-shaped pick-up shovel teeth move forward, and the working front end of the shovel teeth goes deep into the ground to shovel up the peanut plants to realize the picking action; the pick-up roller rotates with the central axis to realize the pick-up wheel lifting The actions of lifting, pushing and emptying back to the station. In the present invention, the peanut plants are scooped up by the shovel teeth; the follow-up lifting, pushing and other picking actions are completed by the pulley roller. It has the characteristics of small size, high pick-up rate and low loss rate.

Owner:JILIN AGRICULTURAL UNIV +2

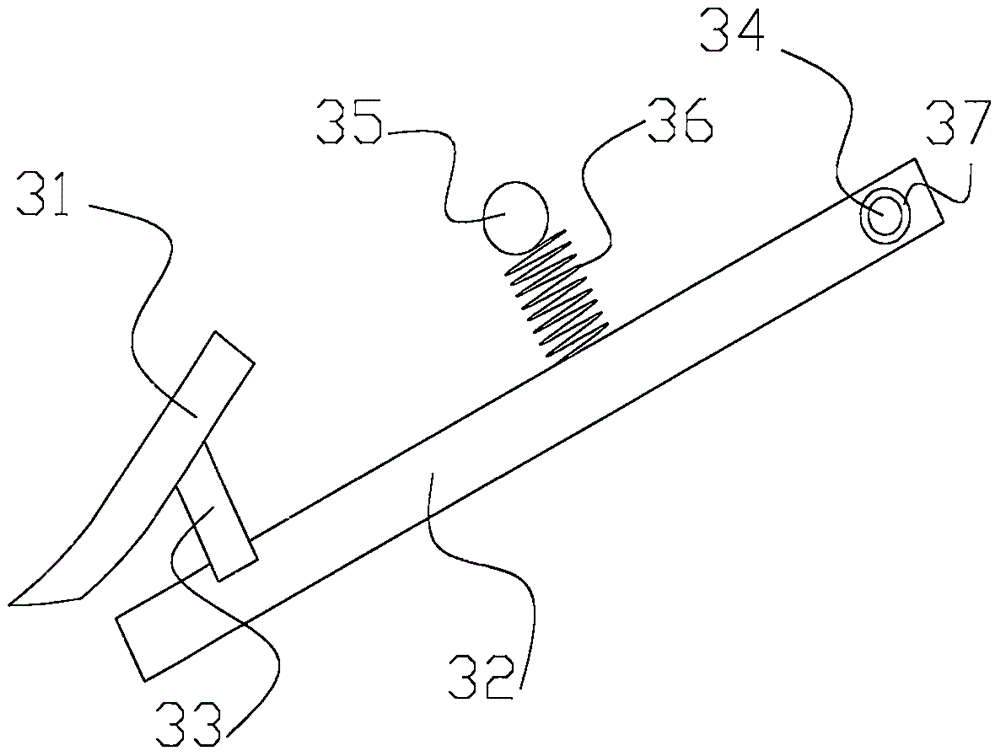

Rotary tooth type waste film picking machine with self-protection film picking teeth

PendingCN110915508AReduce Rigid CollisionsRealize self-protectionPlant protective coveringsStructural engineeringManufacturing engineering

The invention discloses a rotary tooth type waste film picking machine with self-protection film picking teeth. The rotary tooth type waste film picking machine comprises a rack, a traction frame, a supporting wheel, a film rolling shaft, a horizontal roller, a conveying chain, a film picking mechanism, transmission mechanisms and the like. The traction frame and a gear box are arranged on the front upper portion of the rack. The supporting wheel, the film rolling shaft and a pressing roller are sequentially arranged below the rack from front to back. The conveying chain is arranged on the upper middle portion of the rack. The film picking mechanism is arranged on the rear upper portion of the rack. The transmission mechanisms are arranged on the two sides of the rack. According to the design, springs are additionally arranged on the film picking teeth so that the film picking teeth can be self-protected, the service life of parts is prolonged, and the operation reliability of the parts is improved; due to the design that bearings are arranged between a planetary plate and a fixed plate, the friction force between the planetary plate and the fixed plate is reduced, the flexibilityof the film picking mechanism is improved, and power consumption is reduced; the horizontal roller is additionally arranged in front of the film picking mechanism, thus, it can be guaranteed that thefilm picking teeth work on the same plane, and the picking rate is increased; due to the design of a tooth frame plate protection ring, mulching films are effectively prevented from winding the film picking shaft; and due to the same-direction rotation design of the film rolling shaft and the conveying chain, the film rolling success rate is increased.

Owner:青海省农牧机械推广站 +1

Scrubbing solution for absorption of carbon dioxide and method for accelerating the absorption by germanium dioxide

InactiveUS9764283B2High absorption rateLow regeneration energy requirementGas treatmentDispersed particle separationEthanolaminesPotassium

A scrubbing solution is provided having an absorbent for carbon dioxide based on amines, or ethanolamines, or amino acid salts, or potash, or a combination thereof, and an additive activating the absorption rate, wherein the activating additive is a germanium dioxide. A corresponding method for accelerating the absorption of carbon dioxide is also provided, wherein a carbon dioxide-containing gas is contacted with such a scrubbing solution, wherein the carbon dioxide is physically dissolved in the scrubbing solution and is chemically absorbed with the participation of the absorbent, and wherein the germanium dioxide acts catalytically for at least one reaction step of the chemical absorption of the carbon dioxide.

Owner:SIEMENS AG

Front straw smashing recycling device

PendingCN110278759APrevent crushingAvoid Pick Up DifficultiesCrop conditionersMowersEngineeringMechanical engineering

The invention discloses a front straw smashing recycling device. The front straw smashing recycling device comprises a smashing recycling shell, a flail knife shaft, a plurality of flail knives, a stationary knife, a transverse shaft, a plurality of elastic teeth, a screw auger shaft, a blower and a driving mechanism, wherein the smashing recycling shell comprises a pair of side plates and a transverse beam, the side plates are spaced and oppositely arranged, and the two ends of the transverse beam are fixed to the side plates respectively; the flail knife shaft is rotationally supported between the side plates; the flail knives are uniformly arranged on the outer circumference surface of the flail knife shaft; the stationary knife is arranged in the smashing recycling shell; the transverse shaft is parallel to the flail knife shaft and is rotationally supported between the side plates; the elastic teeth are arranged on the transverse shaft at intervals and extend to the outer side of the flail knife shaft along the bottom of the flail knife shaft; the screw auger shaft is rotationally supported between the side plates; the blower is arranged on one side of the screw auger shaft; the driving mechanism drives the flail knife shaft and the screw auger shaft at the same time to rotate. During work, straw passes through the elastic teeth, the flail knives, the stationary knife and the screw auger shaft.

Owner:JILIN UNIV

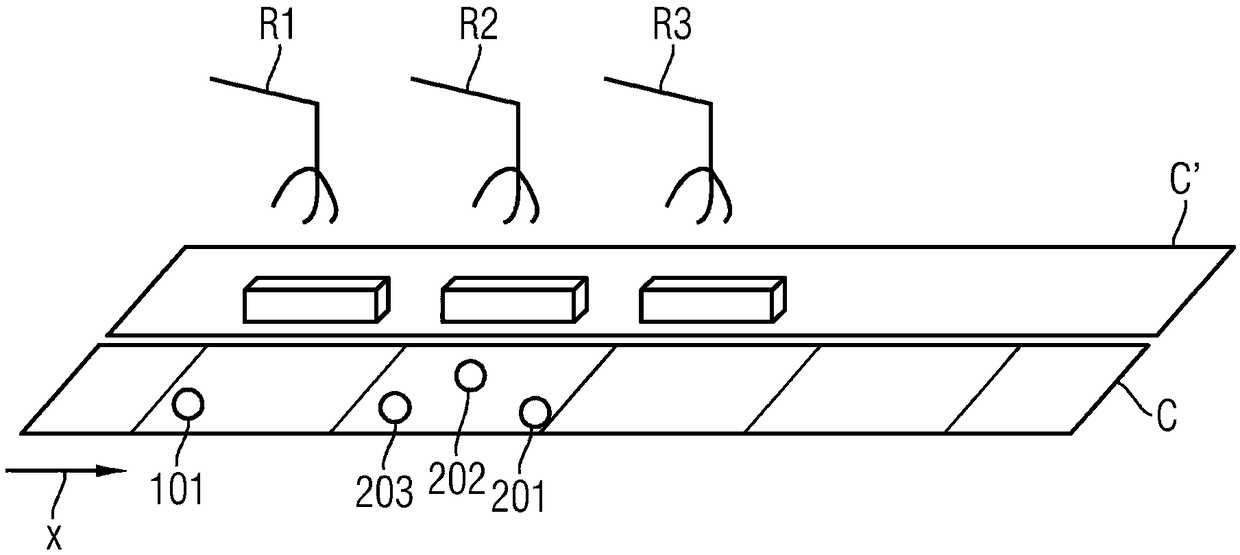

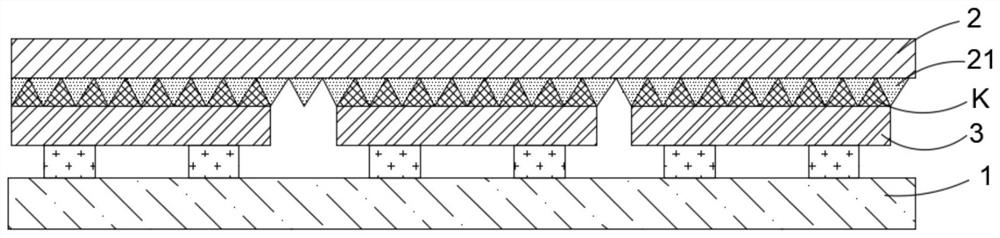

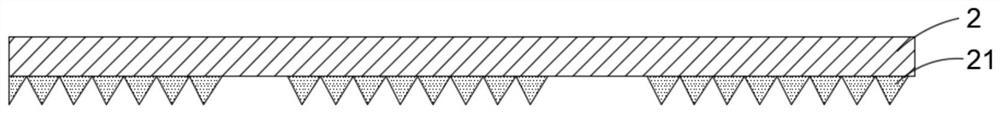

Light-emitting element transfer assembly and light-emitting element transfer method

PendingCN114823458AIncrease bonding areaImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsEngineering

The present invention discloses a light-emitting element transfer assembly and a light-emitting element transfer method, the light-emitting element transfer assembly comprising: a first substrate comprising a bonding area for bonding a light-emitting element; a plurality of patterned areas are arranged on at least one surface of the second substrate, each patterned area comprises a plurality of adhesive parts, and the adhesive parts can be connected with the to-be-bonded parts of the to-be-bonded light-emitting elements in an embedded mode. When the second substrate is in contact with the light-emitting element, the adhesive part of the second substrate can be connected with the to-be-bonded part of the to-be-bonded light-emitting element in an embedded manner, so that the bonding area between the adhesive part of the second substrate and the light-emitting element is effectively increased, and the bonding force of the second substrate to the light-emitting element is further increased; the pickup rate and the transfer efficiency of the light-emitting element by the second substrate are improved.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

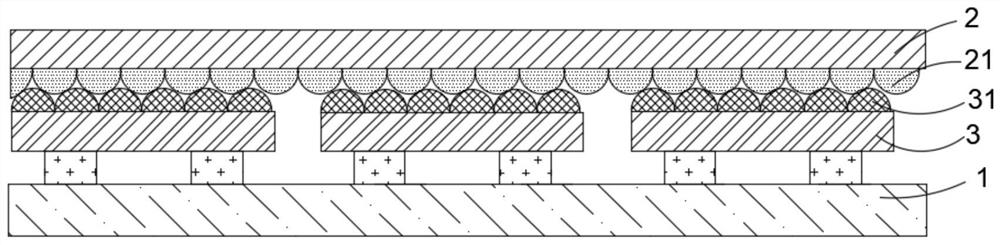

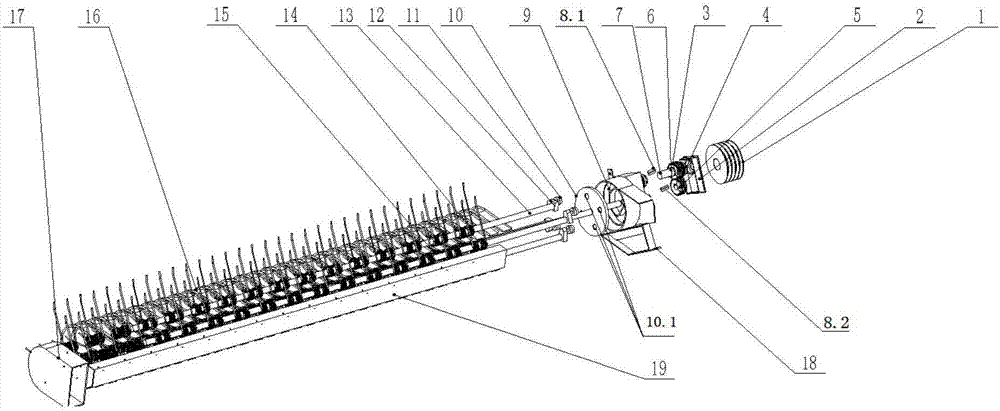

Optimal design method for lowering omission factor of bundling machine gatherer

ActiveCN107491597ACompact structurePromote repairGeometric CADDesign optimisation/simulationMathematical modelEngineering

The invention discloses an optimal design method for lowering the omission factor of a bundling machine gatherer, and belongs to the technical field of straw recovery mechanical equipment. The design method comprises the following steps that: 1) constructing the mathematical model of the area of a leakage pickup region; 2) constructing an elastic claw and material contact speed mathematical model; 3) constructing a multi-objective optimization mathematical model of the gatherer; 4) solving the multi-objective optimization mathematical model of the gatherer; and 5) applying ADAMS (Automatic Dynamic Analysis of Mechanical Systems) software to carry out simulation verification on the optimized data. By use of the optimal design method disclosed by the invention, an optimal design algorithm is adopted to optimize each structural dimension of an existing gatherer, a relevant design parameter is subjected to analog simulation verification, and the gatherer which has the advantages of simple structure, compactness and convenience in maintaining and high pickup rate is obtained.

Owner:HUBEI UNIV OF TECH

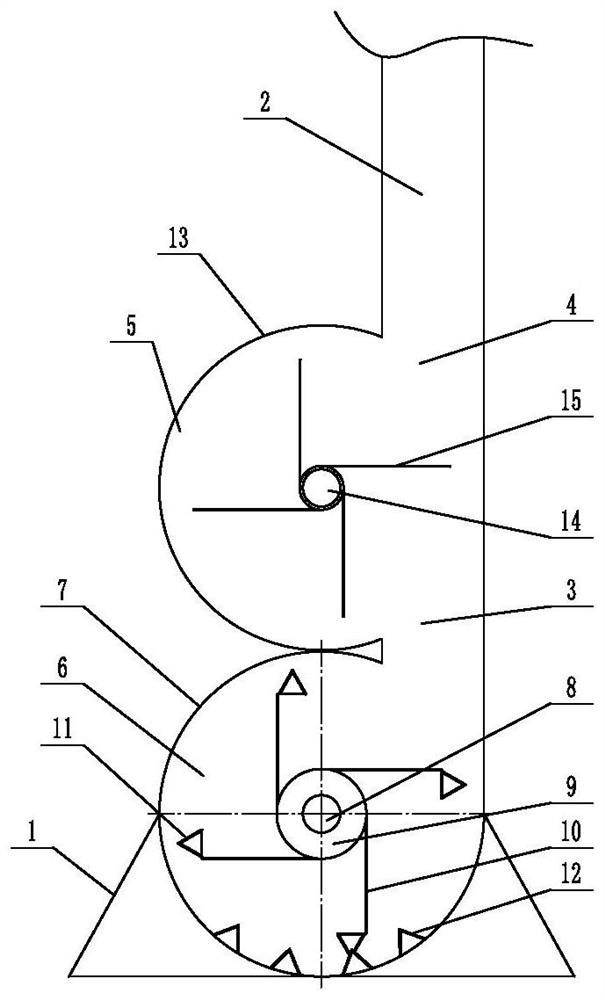

Spiral tooth type farmland waste film collecting machine

PendingCN109819699AEasy to reuseImprove pickup rateGatherer machinesAgricultural engineeringAgricultural machinery

The invention discloses a spiral tooth type farmland waste film collecting machine, and belongs to the technical field of residual film recycling agricultural machines. A film collecting box is arranged on the lower portion of the front lower portion of a rack, a film conveying device is obliquely arranged at the position, above the film collecting box, of the rack, the upper end of the film conveying device is located above the film collecting box, and the lower end of the film conveying device is located below the front portion of a spiral tooth film poking mechanism. The spiral tooth film poking mechanism is mounted at the tail of the rack, the motion track of film poking teeth on the spiral tooth film poking mechanism is cycloid motion when the machine advances, the film poking teeth are always kept vertically downwards when doing circumferential rotation, one end of the spiral tooth film poking mechanism and an output shaft on one side of the gearbox are in linkage, and a film conveying device and an output shaft on the other side of the gearbox are in linkage. According to the spiral tooth type farmland waste film collecting machine, farmland residual films are conveyed forwards to the film conveying device with the film poking teeth through the spiral tooth film poking mechanism, are bundled and guided by a guide plate and then fall onto a film rolling mechanism, and the residual films are rolled through the film rolling mechanism. The spiral tooth type farmland waste film collecting machine integrates the functions of the high residual film picking rate, efficientconveying of the residual films to the film collecting box, convenient reutilization of the recycled residual films and the like.

Owner:GANSU TAOHE TRACTOR MFG

Used plastic film collecting device used for farmlands

InactiveCN111010898AImprove work efficiencyImprove pickup rateGatherer machinesAgricultural engineeringPlastic film

The invention relates to the technical field of agricultural machines, and discloses a used plastic film collecting device used for farmlands. The used plastic film collecting device comprises a frame; the right side of the lower surface of the frame is fixedly provided with a film collecting box; the interior of the film collecting box is movably connected with a cylinder; the middle part of thefront face of the cylinder is fixedly connected with a linkage rotating wheel; and the outer surface of the cylinder is fixedly provided with arc-shaped film grippers. According to the used plastic film collecting device used for the farmlands, a way that large used plastic films and then small used plastic films are collected is employed to avoid that the small used plastic films cannot be collected due to the fact that a used plastic film collecting device only collects the large used plastic films and the small used plastic films clamped at the edges of the large used plastic films flutterdue to the fact that the large used plastic films and the small used plastic films are collected simultaneously; the small used plastic films wound around the arc-shaped film grippers can convenientlyslip into the film collecting box; soil mixed in the small used plastic films can slip out through leak holes in the film collecting box; and the used plastic film collecting device used for the farmlands prevents a worker from collecting the used plastic films for the second time, and improves the work efficiency and pickup rate of collecting the used plastic films.

Owner:周长虹

Residual film recovery machine

PendingCN109906689AImplement one-time collectionAchieve speedGatherer machinesPlastic recyclingEngineeringDisc cutter

The invention relates to a residual film recovery machine, and belongs to the field of agricultural film picking equipment. The machine comprises a frame which is used for fixing and installing various components and devices and is connected with a power machine through a three-point suspension method, a traveling mechanism arranged at the frame, a drive box disposed on the frame for transmittingpower, a disc cutter device disposed at the front end of the frame for cutting a root stubble and / or a mulch film, a profile film lifting device for lifting up the mulch film, a film rolling device for lifting up and rolling up the mulch film which is connected with the drive box and an interlocking unloading mechanism for quickly removing the mulch film on the film rolling device. The effective recovery of the mulch film and the orderly connection between working parts can be achieved, the effective and reliable work of processes of cutting the root stubble, lifting up the mulch film, rollingthe mulch film and removing the mulch film is achieved, and the picking efficiency and the mulch film picking rate are high.

Owner:GANSU AGRI UNIV

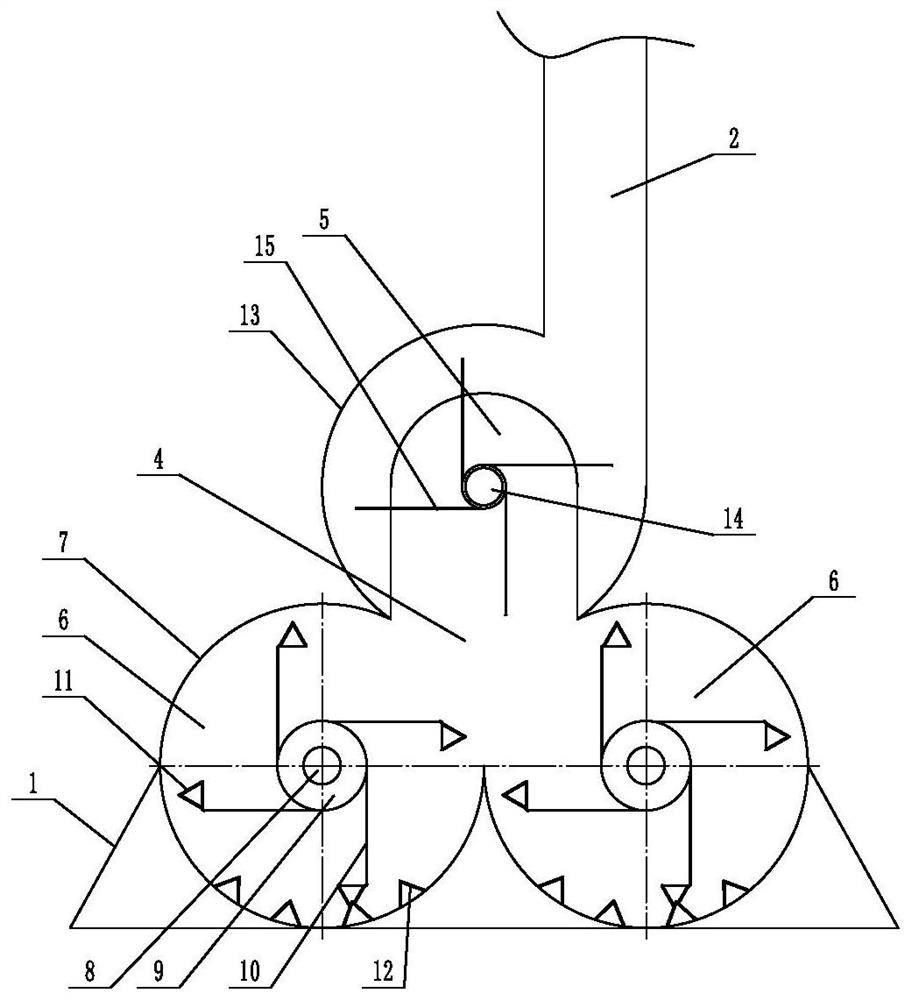

A combined straw collector

ActiveCN111937597BLong distanceImprove work efficiencyLoadersCuttersAgricultural scienceAgricultural engineering

The invention discloses a combined straw collector, which aims to solve the shortcomings of the straw collector, such as low height, short distance and low operation efficiency. The invention comprises a feeding hood, a throwing pipe, a blower combination unit installed between the feeding hood and the throwing pipe, the blower combination unit includes at least two collecting fans, and the collecting blower is provided with a grass inlet and a grass outlet, at least The grass inlet of a collecting fan is connected with the feeding hood, and the grass outlet of at least one collecting fan is connected with the throwing pipe, and the opening of the feeding hood is set downwards. The throwing pipe enables the stalks to be thrown outwards from the throwing pipe. The combined straw collector collects the straw and throws it with high height, long distance and high working efficiency.

Owner:陈孝中

Agricultural residual film recycling machine

PendingCN110786089AImprove pickup rateEasy to recycleMowersGatherer machinesReduction driveAgricultural engineering

The invention discloses an agricultural residual film recycling machine and relates to the technical field of agricultural machinery. The machine is structurally characterized in that a quadrangular frame is arranged on the upper portion of a rack, side plates are welded on two sides of the quadrangular frame, a film winding device, a conveyor B, a conveyor A, a speed reducer and a traction frameare sequentially arranged on the frame from left to right, a traveling wheel is arranged between the side plates through a transmission shaft, a cylindrical pickup is arranged at the right end of therack, elastic teeth are arranged on the surface of the pickup, a film pressing piece is arranged on the rear portion of the pickup, a support is arranged on the right portion of the pickup and is a quadrangular frame, a belt wheel B, a belt wheel C, a belt wheel D and two dampers arranged on the upper portion of the quadrangular frame, and a residual stubble treatment device is arranged on the lower portion of the quadrangular frame. The machine has the advantages that mulching films left in land can be recycled effectively, manual picking difficulty is lowered, and the machine is simple in structure, reliable in working, high in universality and convenient in use and maintenance.

Owner:柴生春

Suction type double-fan straw collecting machine

PendingCN113906909AImprove pickup rateSolve the problems of slow speed, high failure rate and easy blockingLoadersCuttersStructural engineeringMachine

The invention discloses a suction type double-fan straw collecting machine. The suction type double-fan straw collecting machine is characterized in that a gearbox is fixed to a first cross beam, the gearbox is rotationally connected with a first rotating shaft, the first rotating shaft is in crawler belt connection with a second rotating shaft, the gearbox is rotationally connected with a third rotating shaft, the third rotating shaft is in crawler belt connection with a fourth rotating shaft, a crushing cutter set is fixed to the second rotating shaft, symmetrical fan sets are arranged at quartering points on the two sides of the fourth rotating shaft, a main material distributing plate is arranged in the middle of the fourth rotating shaft, an auxiliary material distributing plate is arranged at a feeding port in the front end of the main material distributing plate, the upper end of the auxiliary material distributing plate is connected with a front baffle, a connecting hole is formed in the front baffle, and the lower end of the auxiliary material distributing plate is connected with a rear baffle and is connected with a first cross beam and a second cross beam; and four sets of auger blades are arranged on the two sides of the material distributing plates and between each fan set and the two ends of the fourth rotating shaft respectively, a sleeve is fixedly arranged outside each fan set, and the upper end of each sleeve communicates with a discharging barrel.

Owner:李景秋

Combined straw collector

ActiveCN111937597ALong distanceImprove work efficiencyLoadersCuttersAgricultural scienceAgricultural engineering

The invention discloses a combined straw collector, and aims to solve the problems of low throwing height, short distance and low operation efficiency of straw collection of a straw collector. The collector comprises a feeding cover, a throwing pipe and a draught fan combination unit installed between the feeding cover and the throwing pipe, the draught fan combination unit comprises at least twocollecting draught fans, grass inlets and grass outlets are formed in the collecting draught fans, at least one collecting draught fan grass inlet is communicated with the feeding cover, and the grassoutlet of at least one collecting draught fan is connected with the throwing pipe. An opening of the feeding cover is arranged downwards, and the collecting draught fans collect straw in the feedingcover and throw the straw to the throwing pipe, so that the straw is thrown outwards from the throwing pipe. The combined straw collector is high in throwing height, long in distance and high in operation efficiency after collecting straw.

Owner:陈孝中

Wheel belt liftable corn stalk picking device

InactiveCN104686090BWorking height can be adjustedEasy to transportLoadersTransmitted powerAgricultural engineering

Owner:JILIN UNIV

Sprocket Type Residual Film Recycling Machine

InactiveCN105409364BRealize recycling operationsRecycling operation is stableGatherer machinesDrive shaftSprocket

The invention discloses a chain-tooth type film residue recycling machine. A film residue box, a driven shaft and a film unloading roller are arranged on the rear portion of a rack located above traveling wheels, a soil raising shovel and a carrying roller are arranged at the front end of the rack, a power output shaft of a gearbox drives the driven shaft, and a belt pulley arranged at the end of the driven shaft is in contact with a friction wheel arranged at the end of the film unloading roller; a film residue picking device is arranged between the carrying roller and the driven shaft, the film residue picking device comprises picking chains at the two sides, chain poles are evenly arranged between the picking chains in a spaced mode, every two adjacent chain poles, with one chain pole located in front and the other chain pole located at the back, form a group, each rear chain pole close to a transmission shaft is sleeved with a shaft sleeve, each front chain pole and the corresponding rear chain pole are provided with spring teeth in an abreast and spaced mode in the axial direction, each spring tooth is constituted by a spring tooth one-and-a-half-round section on the rear portion and a spring tooth one-round section on the front portion, the two ends of each spring tooth constitute a spring tooth tip, each spring tooth one-round section is arranged on the corresponding front chain pole in a sleeving mode, each spring tooth one-and-a-half-round section is arranged on the corresponding shaft sleeve in a sleeving mode, and a group of shaking wheels driven by a chain wheel located at the other end of the transmission shaft are arranged on the rack.

Owner:XINJIANG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com