Method for manufacturing waste film reclamation plant

A production method and a recycling machine technology, applied in the field of agricultural machinery, can solve the problems of low efficiency, high labor intensity of waste plastic film, and high picking cost, and achieve the effects of safe and reliable operation, simple structure and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

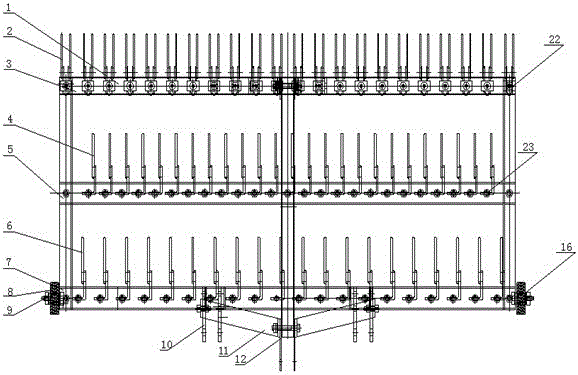

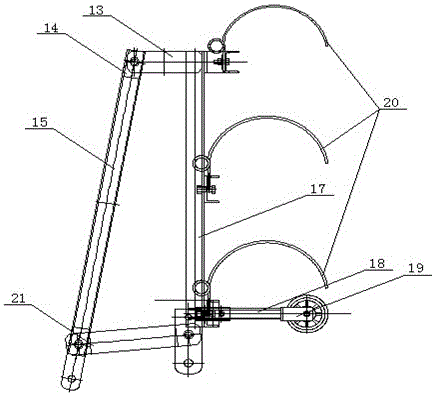

[0016] specific implementation plan

[0017] Below in conjunction with accompanying drawing, the working process of the present invention is described in detail.

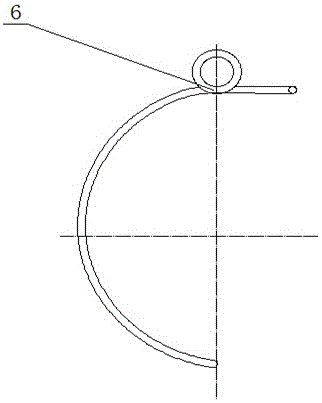

[0018] The spring teeth on the frame fixing plate of the present invention are preferably made of 65Mn spring steel, respectively selected from Φ10, Φ8, and Φ6 spring steels, which are not easy to deform and have high strength; the frame is composed of three main parts, namely the traction frame (20), the lifting The film picking mechanism (21) and the depth-limiting ground wheel (8); the manufacturing method of the waste film recovery machine is composed of three rows of spring teeth fixed on the frame, namely Φ10 spring teeth one (6), Φ8 spring teeth Teeth two (4), Φ6 double spring teeth three (2); there are 67 spring teeth on the fixed plate of the rack, and the spring teeth pass through the center hole of the M20 nut. M20 nuts are connected and fixed; the fixed plate 3 (3) is equipped with Φ6 double elastic tee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com