Suction type double-fan straw collecting machine

A technology for collecting machines and straws, which is applied to agricultural machinery and tools, loaders, cutting equipment, etc. It can solve the problems of high failure rate of machinery and equipment, many blanking of work plots, and slow speed, so as to improve the straw picking rate, Solve the effect of slow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

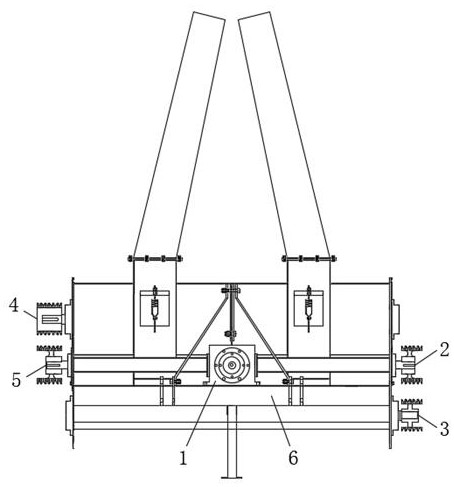

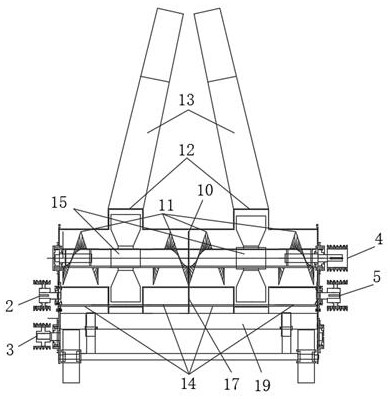

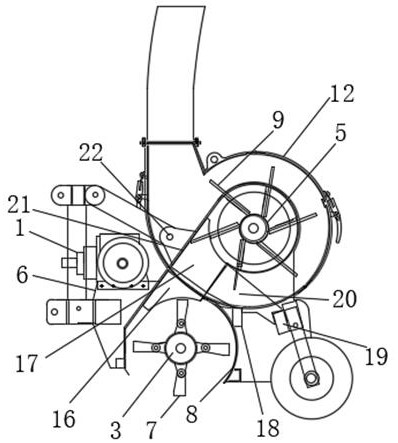

[0018] Such as Figures 1 to 4 As shown, a suction double-fan straw collector is characterized in that it includes a gearbox 1 fixed on the first beam 6, the gearbox 1 is rotationally connected with the first rotating shaft 2, and the first rotating shaft 2 and the second rotating shaft 3 The gearbox 1 and the third rotating shaft 5 are connected in rotation, the third rotating shaft 5 and the fourth rotating shaft 4 are connected by crawlers, the crushing knife group 7 is fixed on the second rotating shaft 3, and the four sides on both sides of the fourth rotating shaft 4 A symmetrical fan group 9 is provided at the equidistribution point, a main distribution plate 10 is provided in the middle of the fourth rotating shaft 4, and an auxiliary distribution plate 17 is provided at the front end of the main distribution plate position. The upper end of the plate 17 is connected to the front baffle 21, and the front baffle 21 is provided with a connection hole 22, and the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com