Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Improve openability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

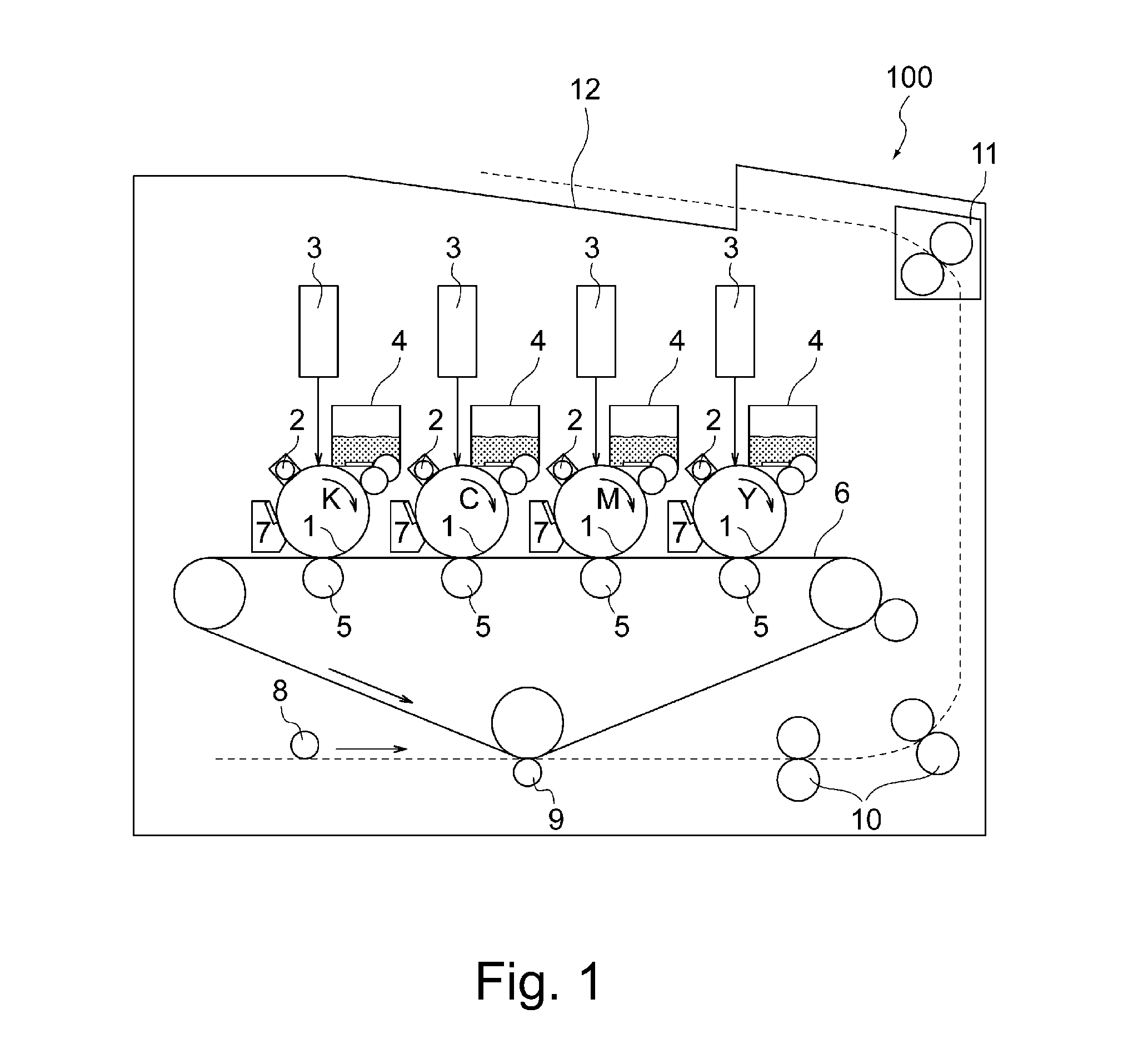

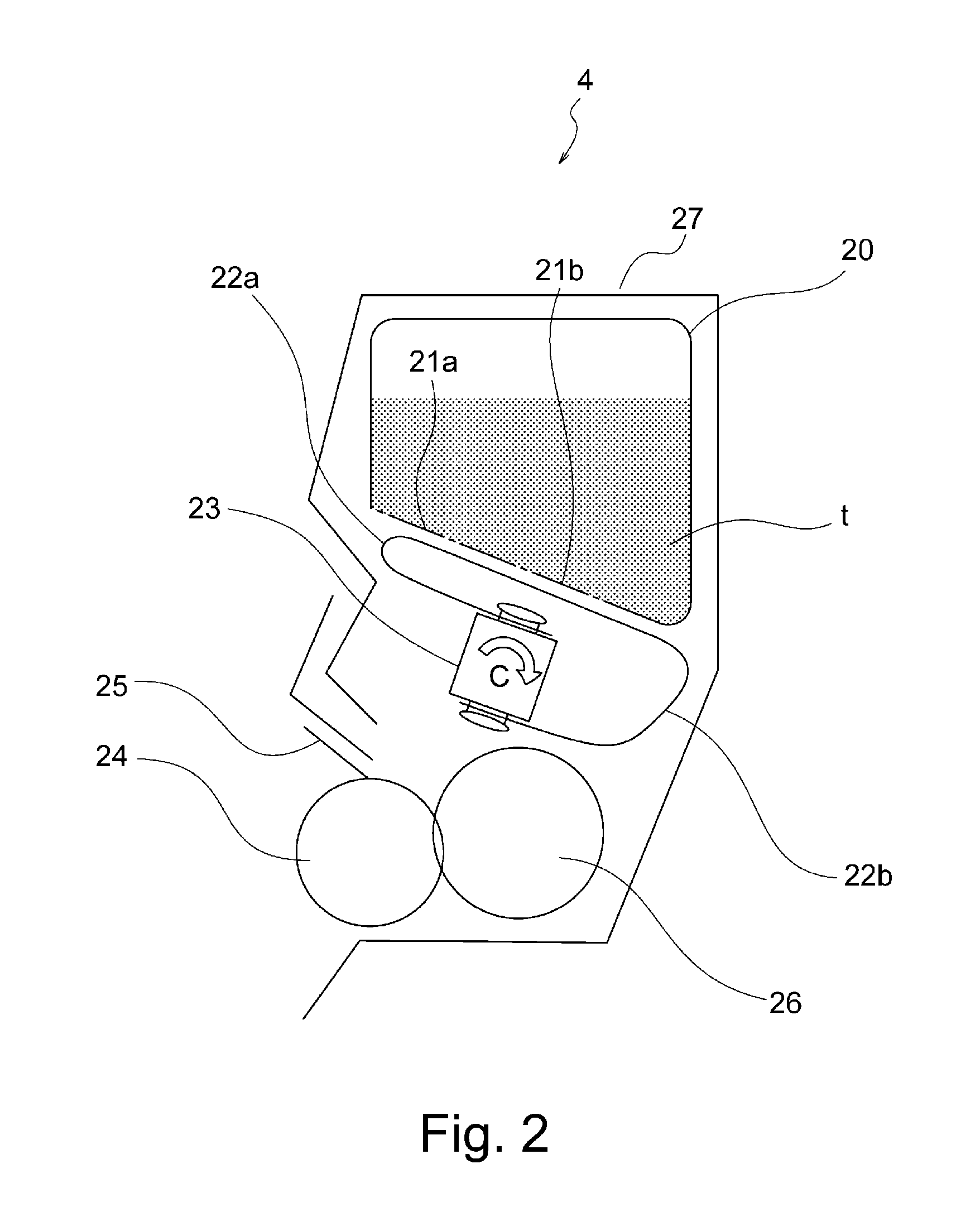

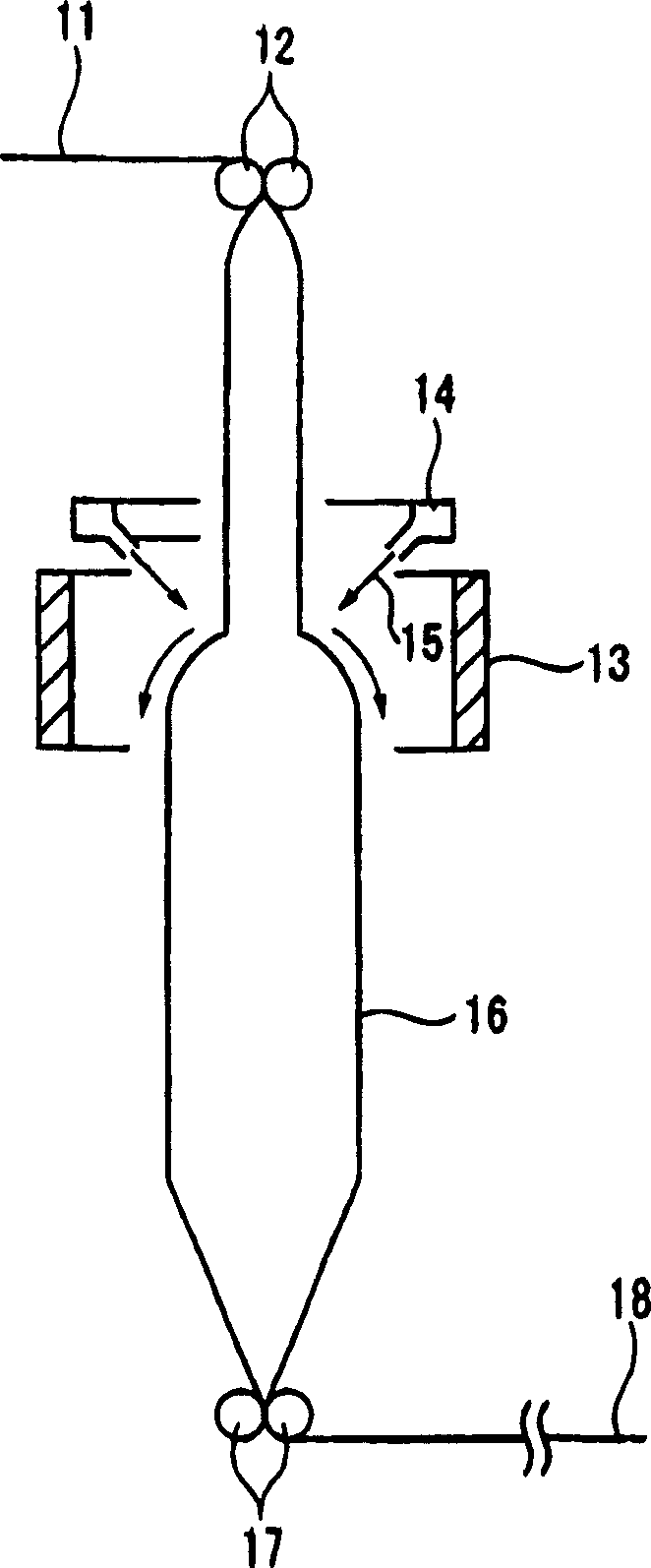

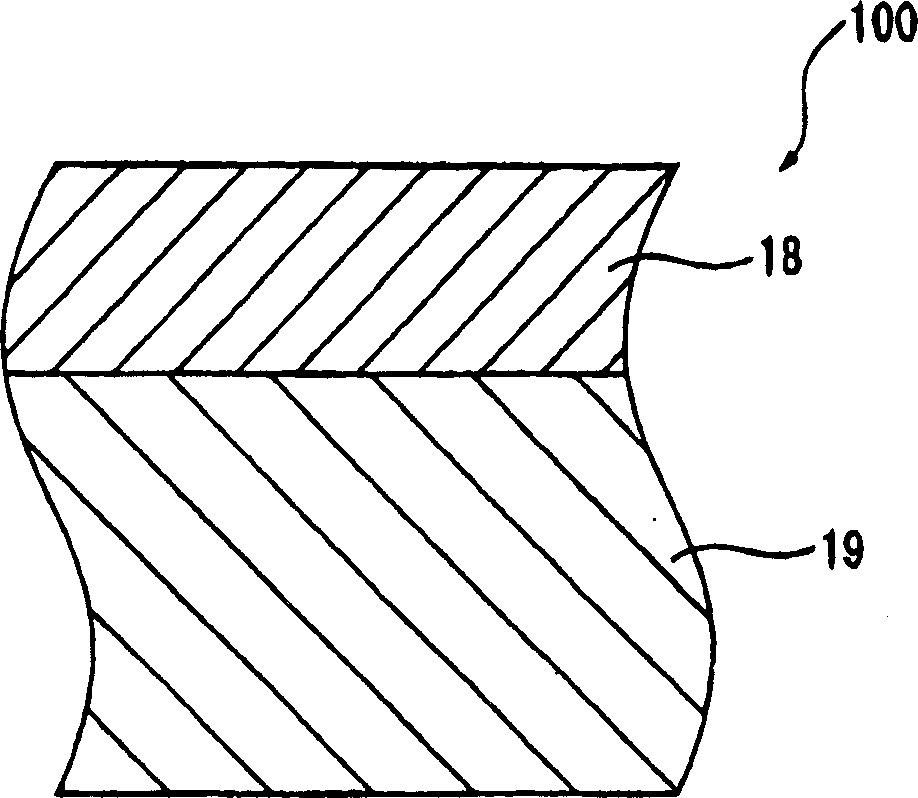

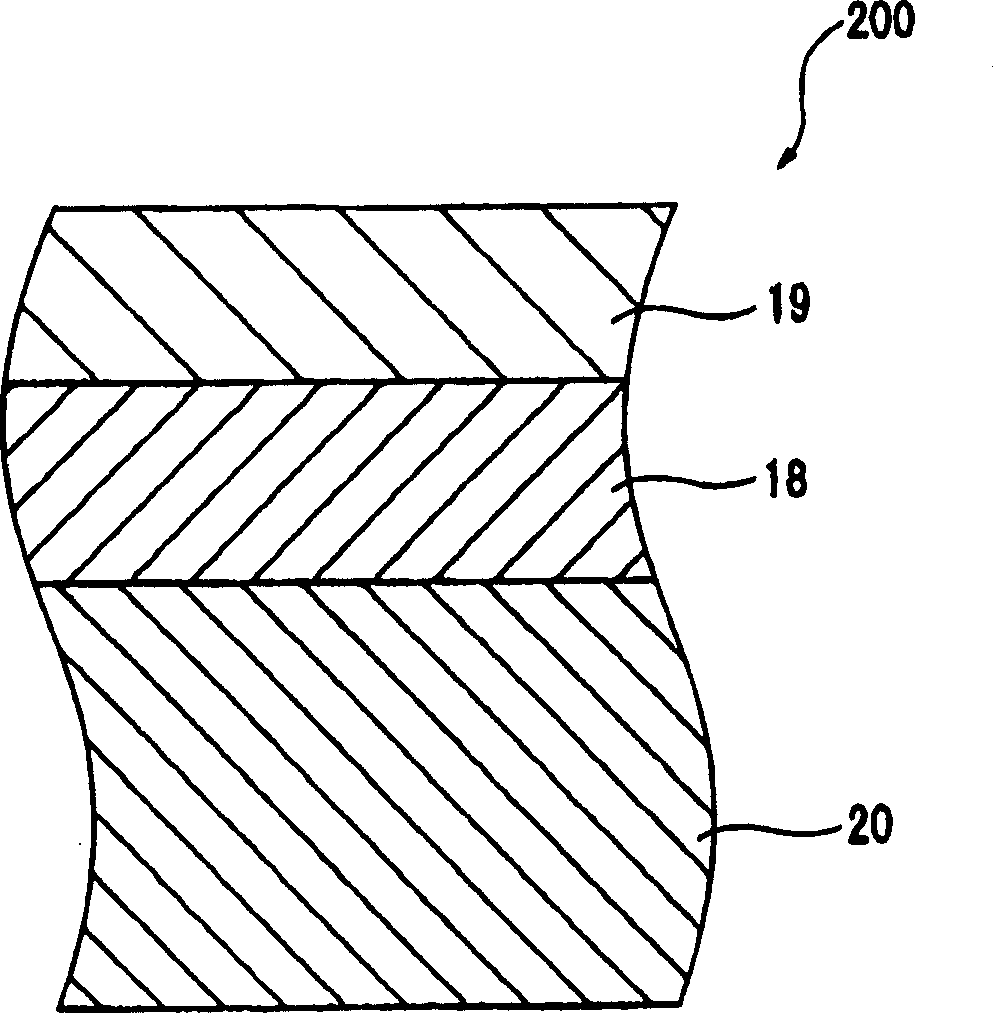

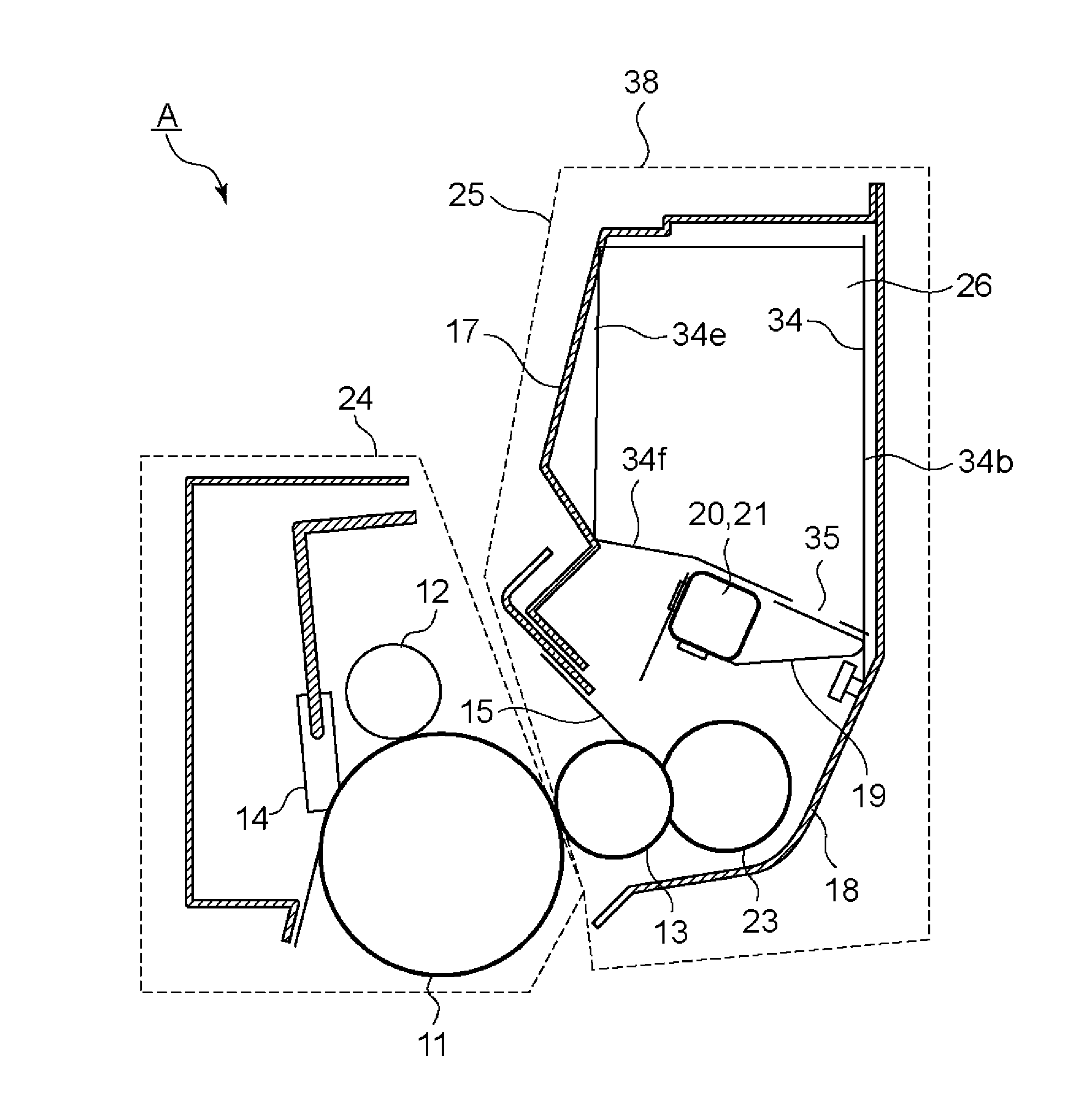

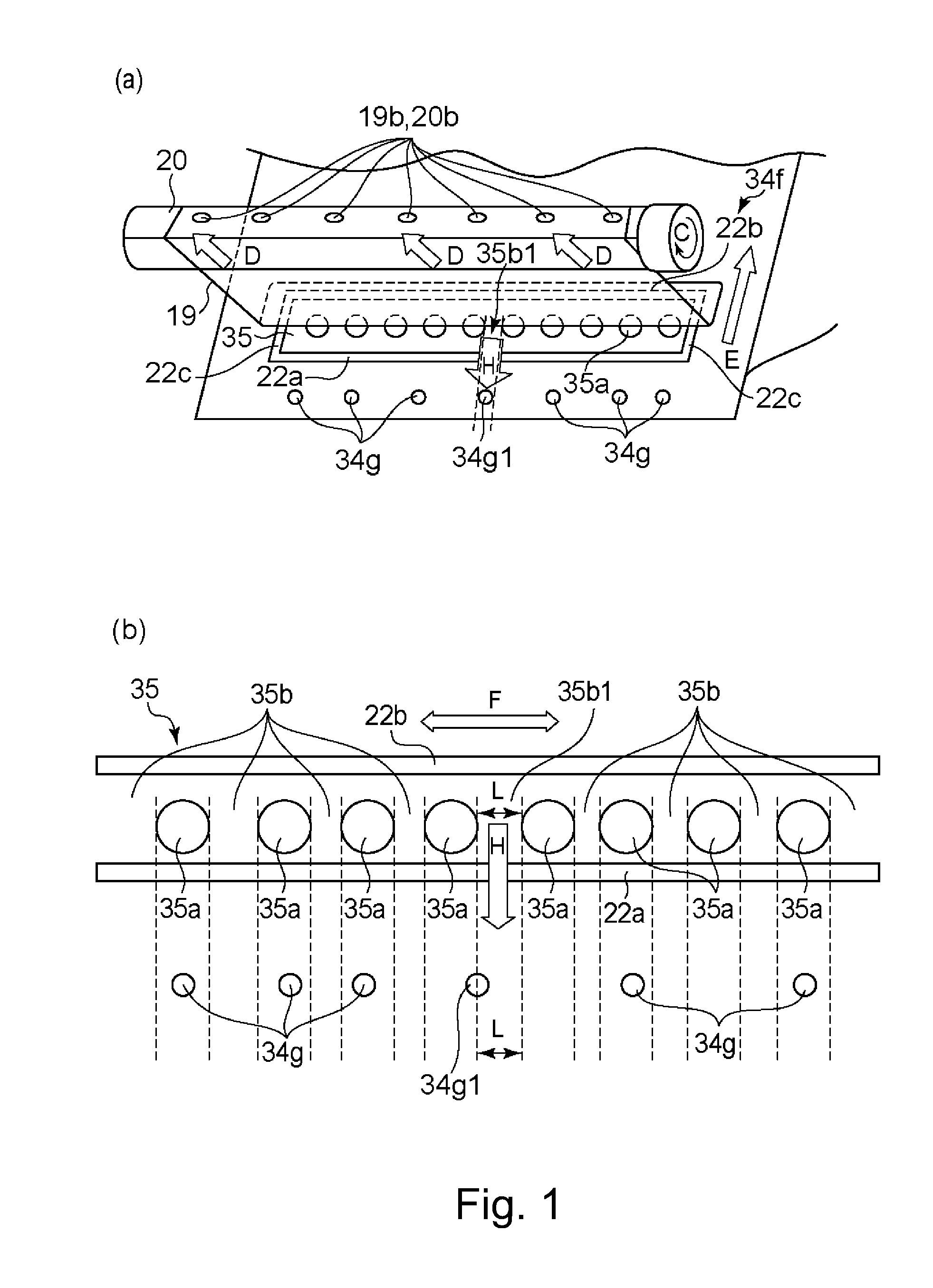

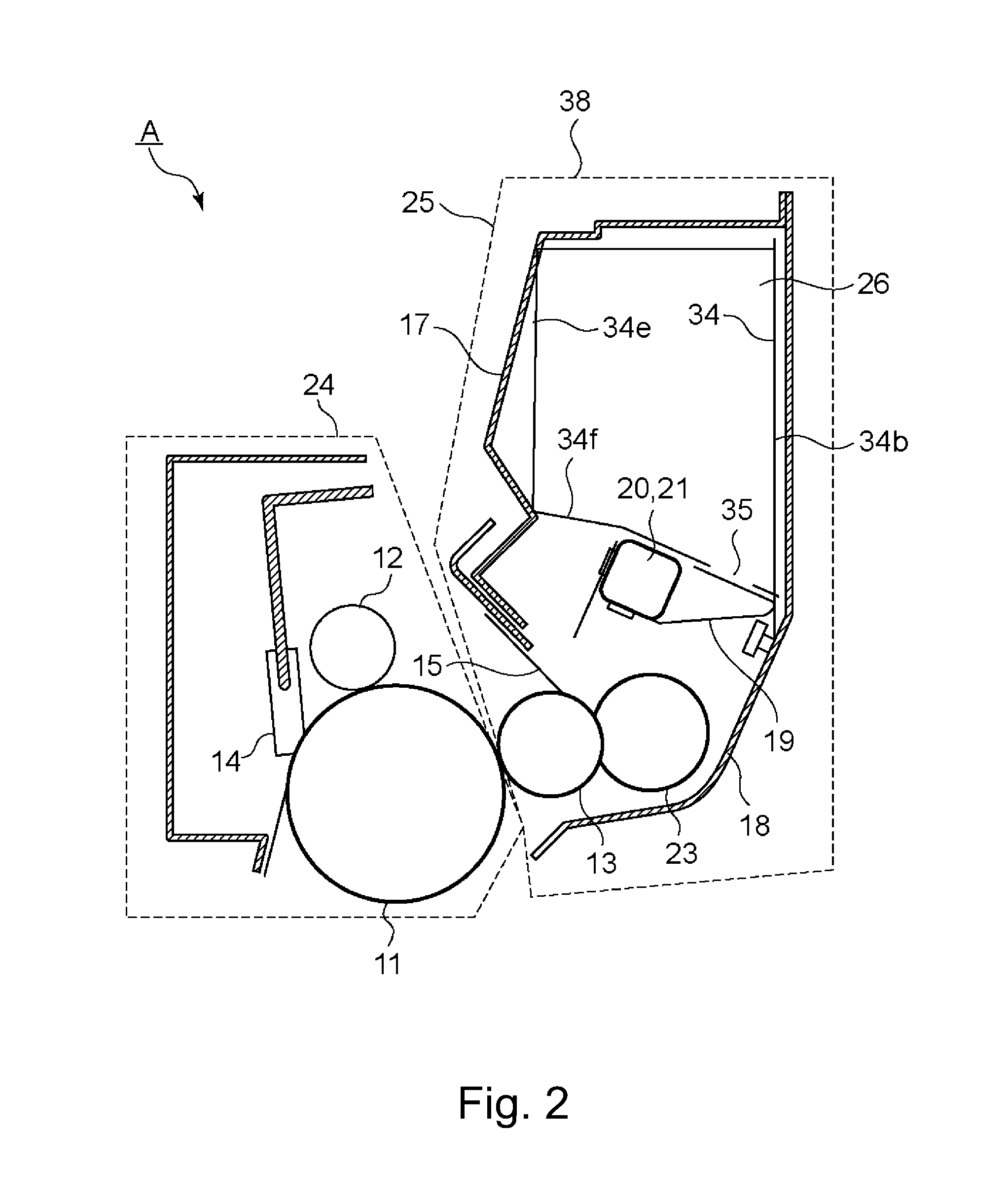

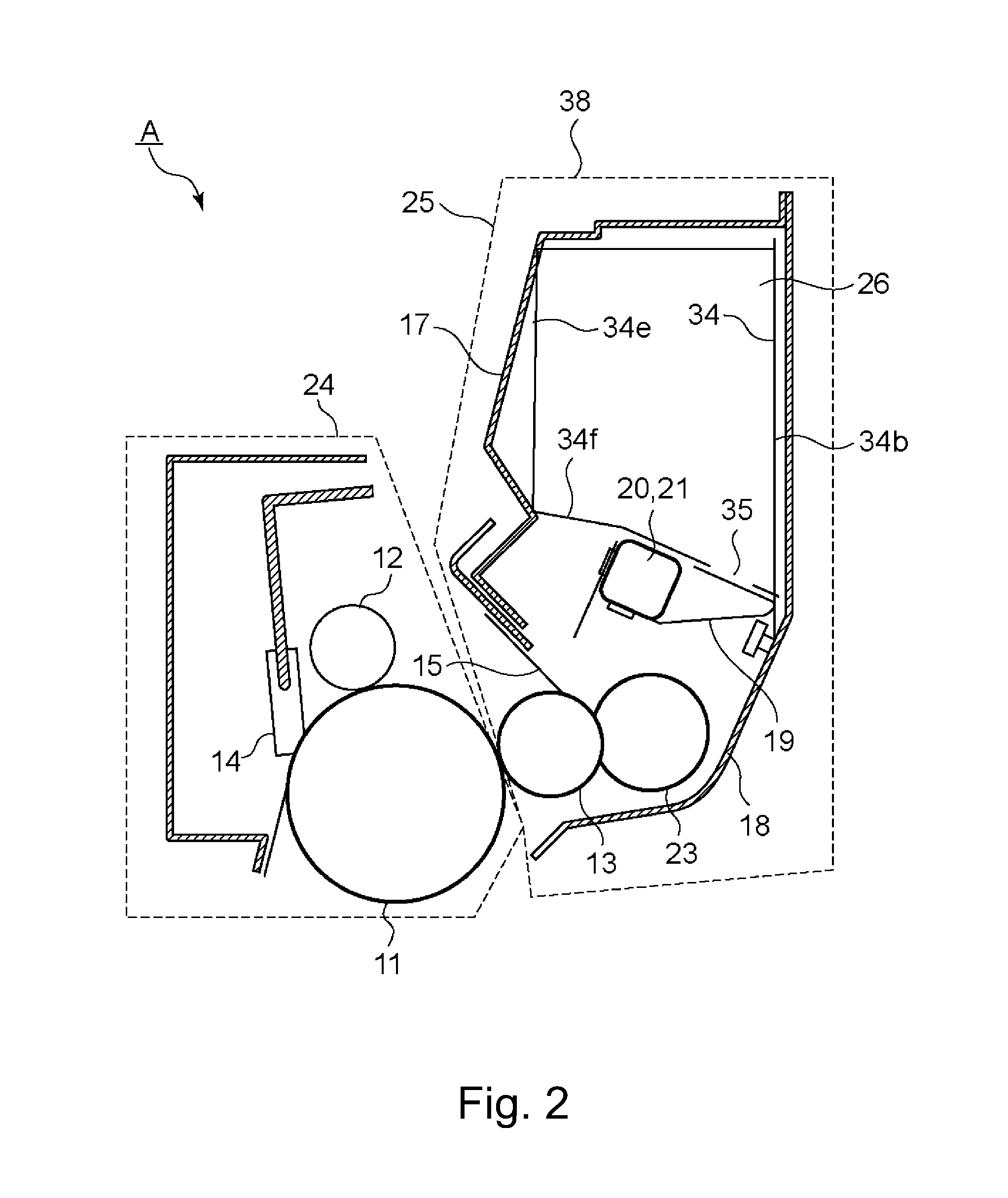

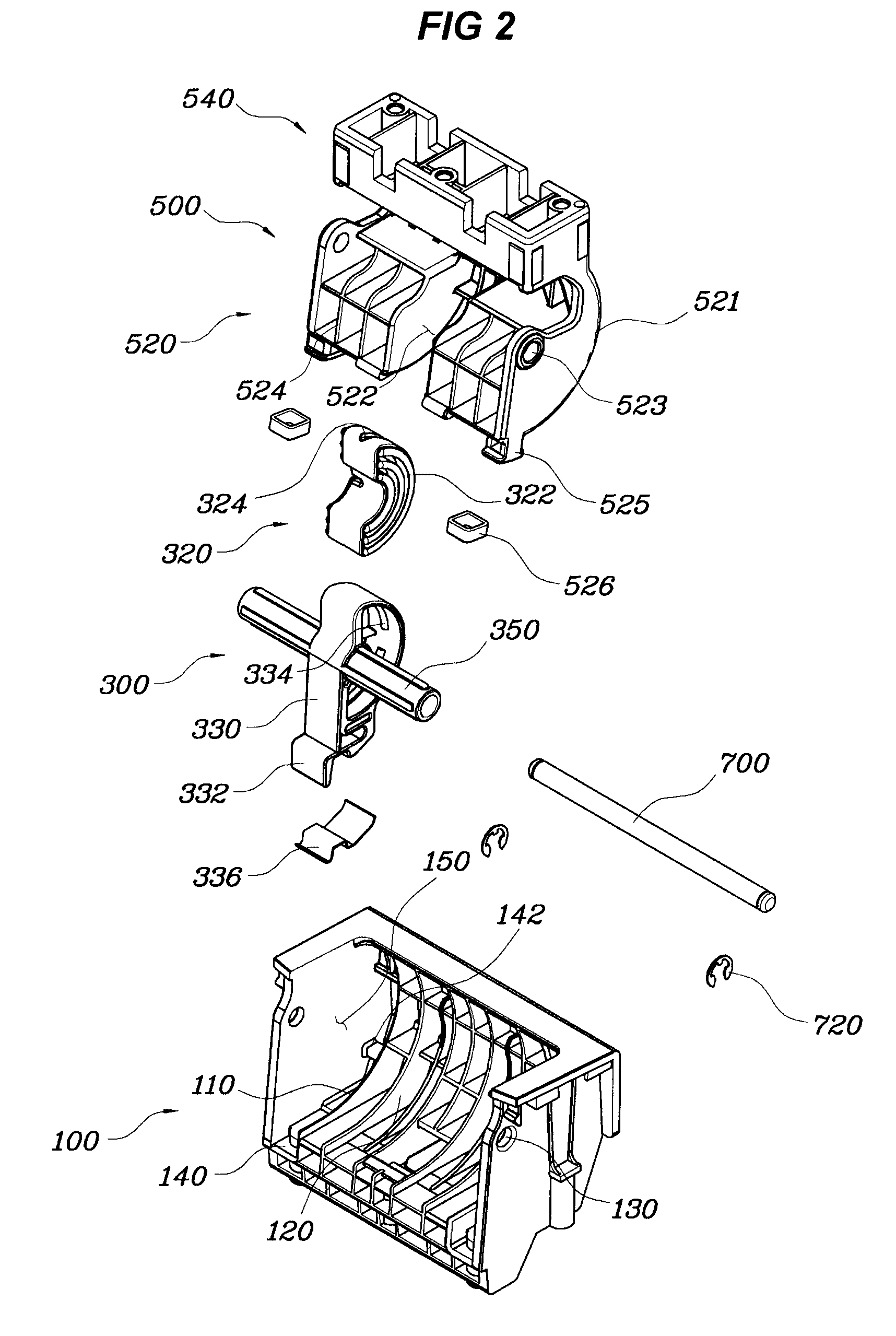

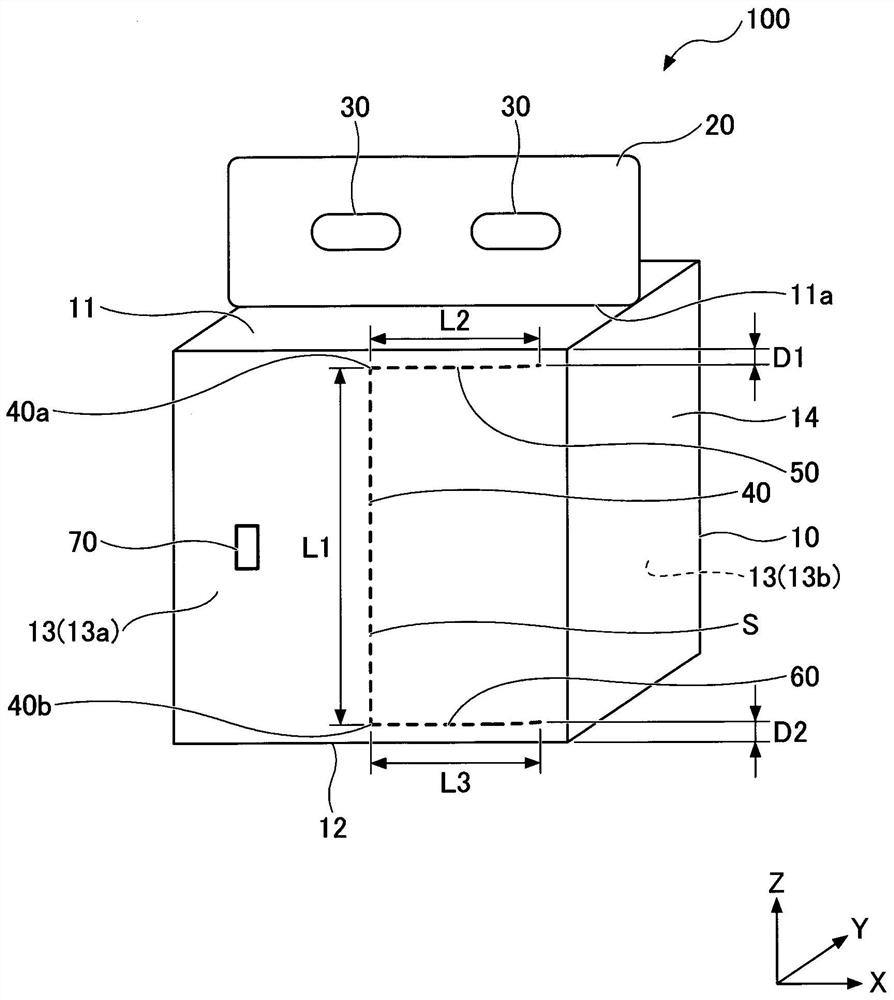

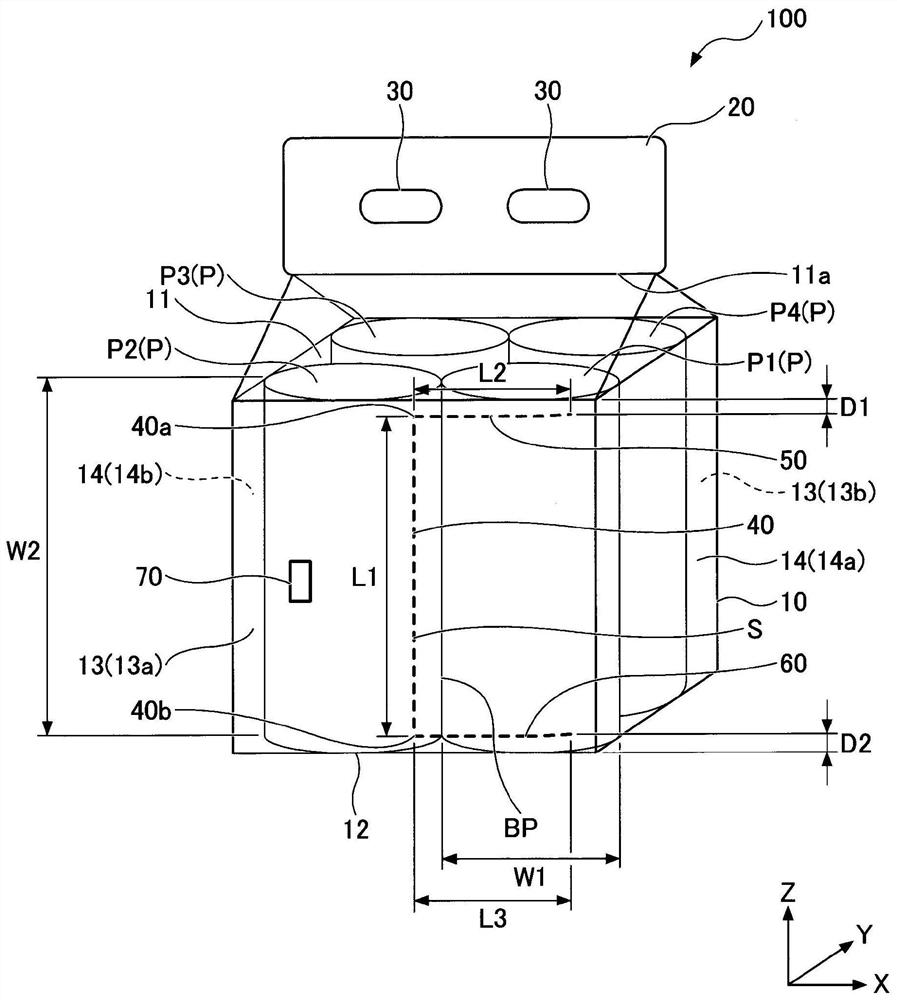

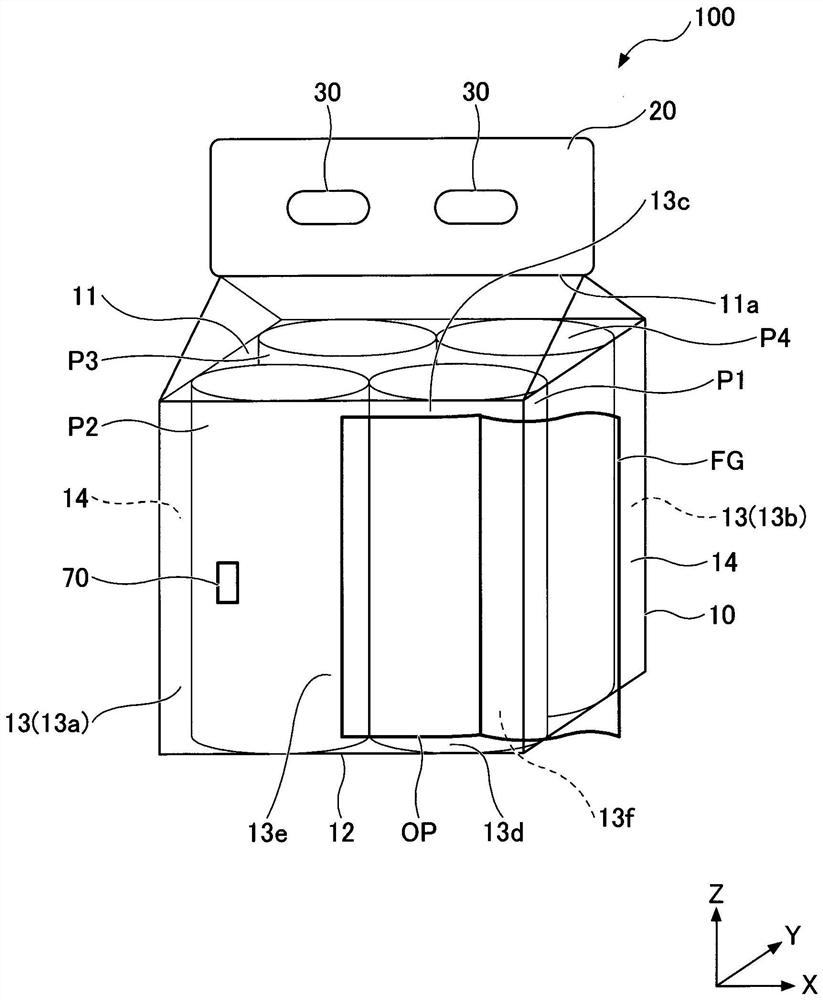

Developer accommodating unit, developing device, process cartridge and image forming apparatus

ActiveUS9207581B2Shorten sealing timeImprove openabilityElectrographic process apparatusEngineeringImaging equipment

Owner:CANON KK

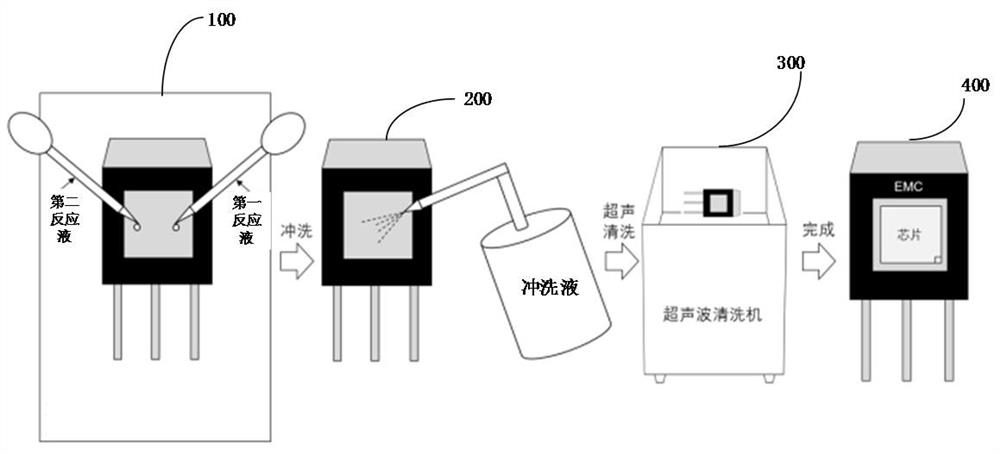

Laser unsealing method

ActiveCN105598589ASolve Kaifeng's conundrumIncrease success rateSemiconductor/solid-state device manufacturingLaser beam welding apparatusEngineeringInductor

The invention discloses a laser unsealing method. The method includes the steps that positions and depths of all elements and a chip in a plastic package device are positioned to obtain size, position and depth information of the elements and the chip in the device; according to the information, a preset unsealing area of the plastic package device is determined for unsealing and positioning; laser ablation is conducted on the plastic package device in a cross filling mode to remove molding materials on the surface of the plastic package device, so that inner lead bonding wires are just exposed out of a chip area, tin-lead welding points are just exposed near a resistor and a capacitor, and inductance is just exposed near an inductor. Acidic liquid is adopted to corrode a molding compound covering the chip till the chip is exposed. The method can well solve the problem that a traditional method can not unseal a plastic mixed integrated circuit easily, and effectively increases the unsealing success rate of the plastic package device.

Owner:CASIC DEFENSE TECH RES & TEST CENT

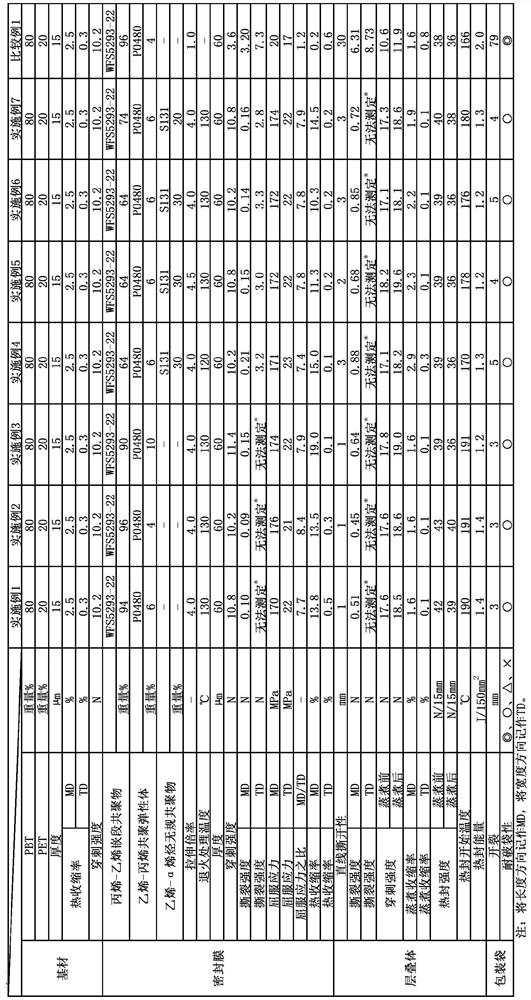

Heat-shrinkable polyester film and process for production thereof

InactiveUS20090270584A1High mechanical strengthExcellent perforated line openabilityWrappers shrinkageSynthetic resin layered productsPolyesterRefractive index

In the heat-shrinkable polyester film of the present invention, the main shrinkage direction is the longitudinal direction. In addition, the hot-water heat shrinkage ratios in the longitudinal direction and the width direction when the film is treated in hot water at 90° C. for 10 seconds, the refractive indexes in the longitudinal direction and the width direction and the natural shrinkage ratio after aging at 40° C. and 65% RH for 700 hours or more are each controlled in predetermined ranges. The heat-shrinkable polyester film of the present invention is manufactured by stretching an unstretched film at a ratio of 2.5 times or more and 6.0 times or less in the width direction at a temperature of Tg+5° C. or more and Tg+40° C. or less, passing the film in an intermediate zone that does not execute an active heating operation, heat-treating the film at a temperature of 100° C. or more and 170° C. or less over a period of 1.0 second or more and 10.0 seconds or less, cooling the film to a surface temperature of 30° C. or more and 70° C. or less, stretching the film at a ratio of 2.0 times or more and 7 times or less in the longitudinal direction at a temperature of Tg+5° C. or more and Tg+80° C. or less, and subsequently cooling the film at a cooling rate of 30° C. / second or more and 70° C. / second or less to a surface temperature of the film of 45° C. or more and 75° C. or less.

Owner:TOYO TOYOBO CO LTD

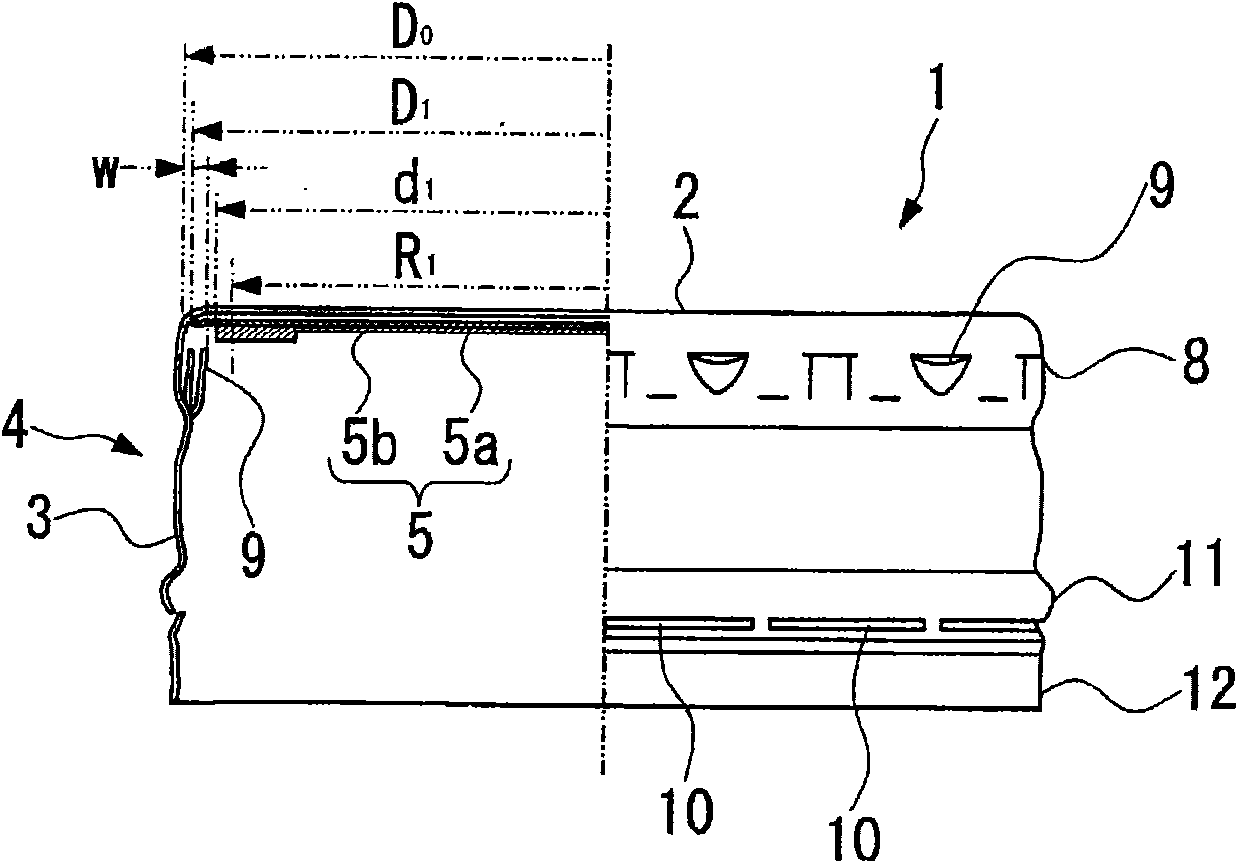

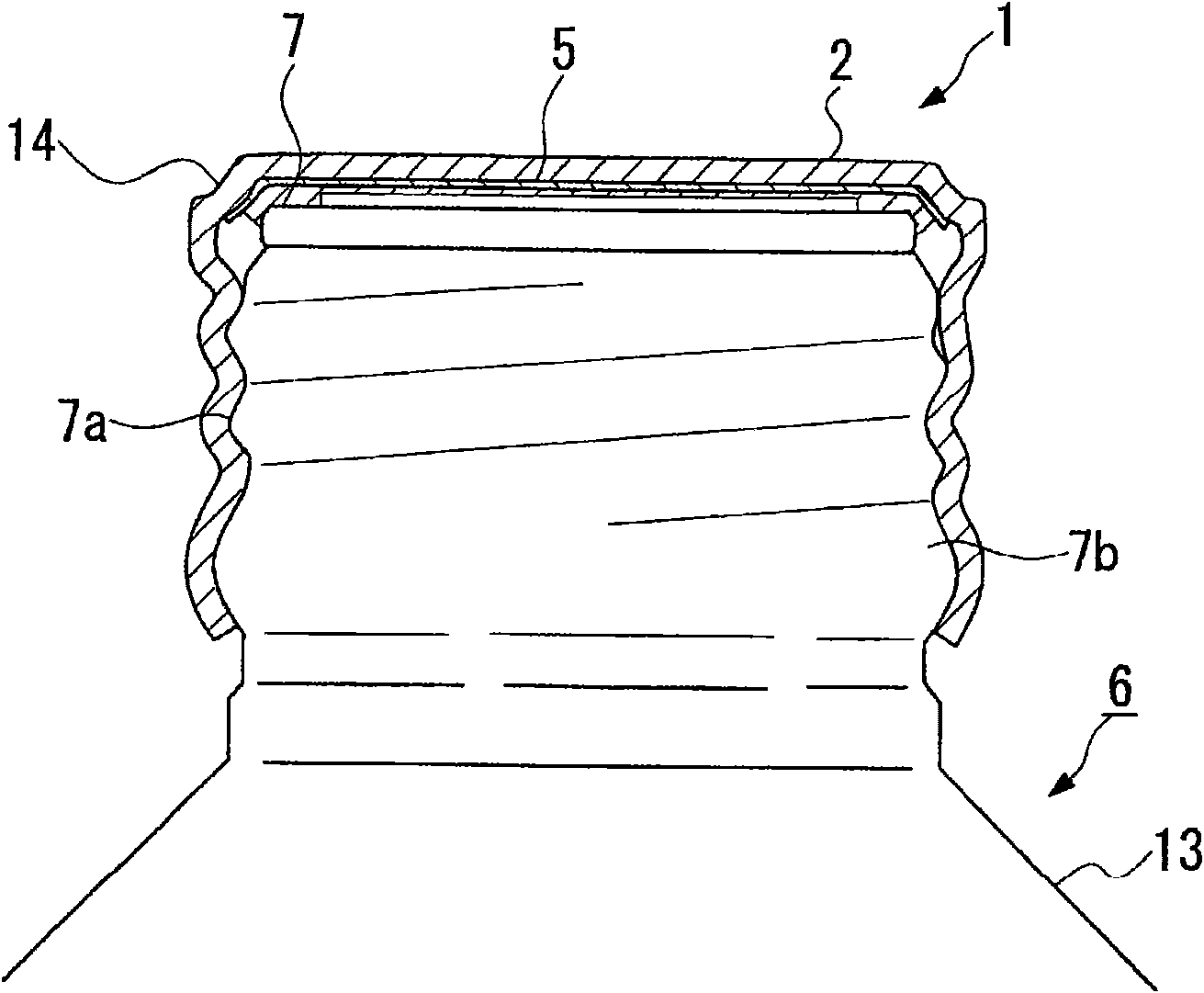

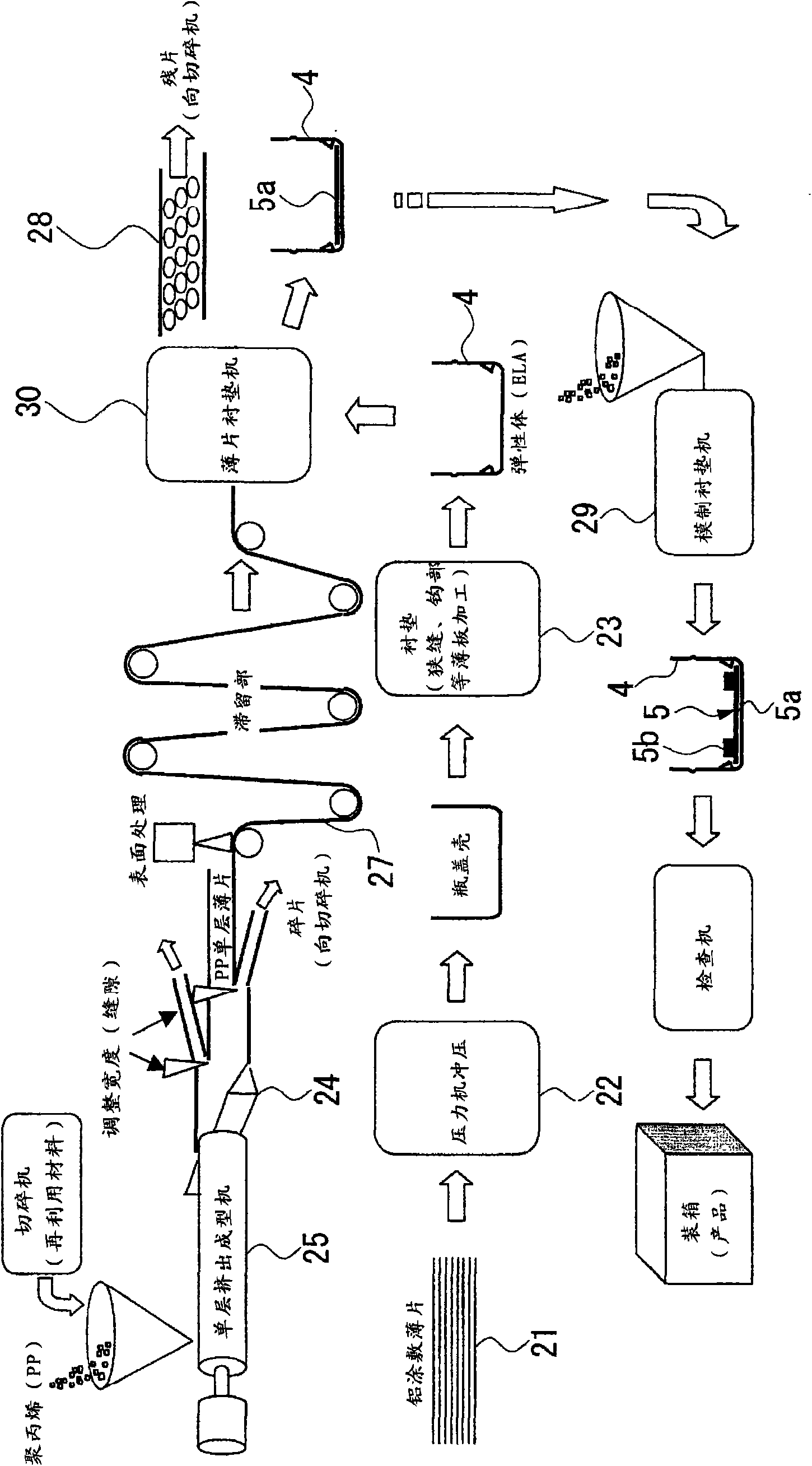

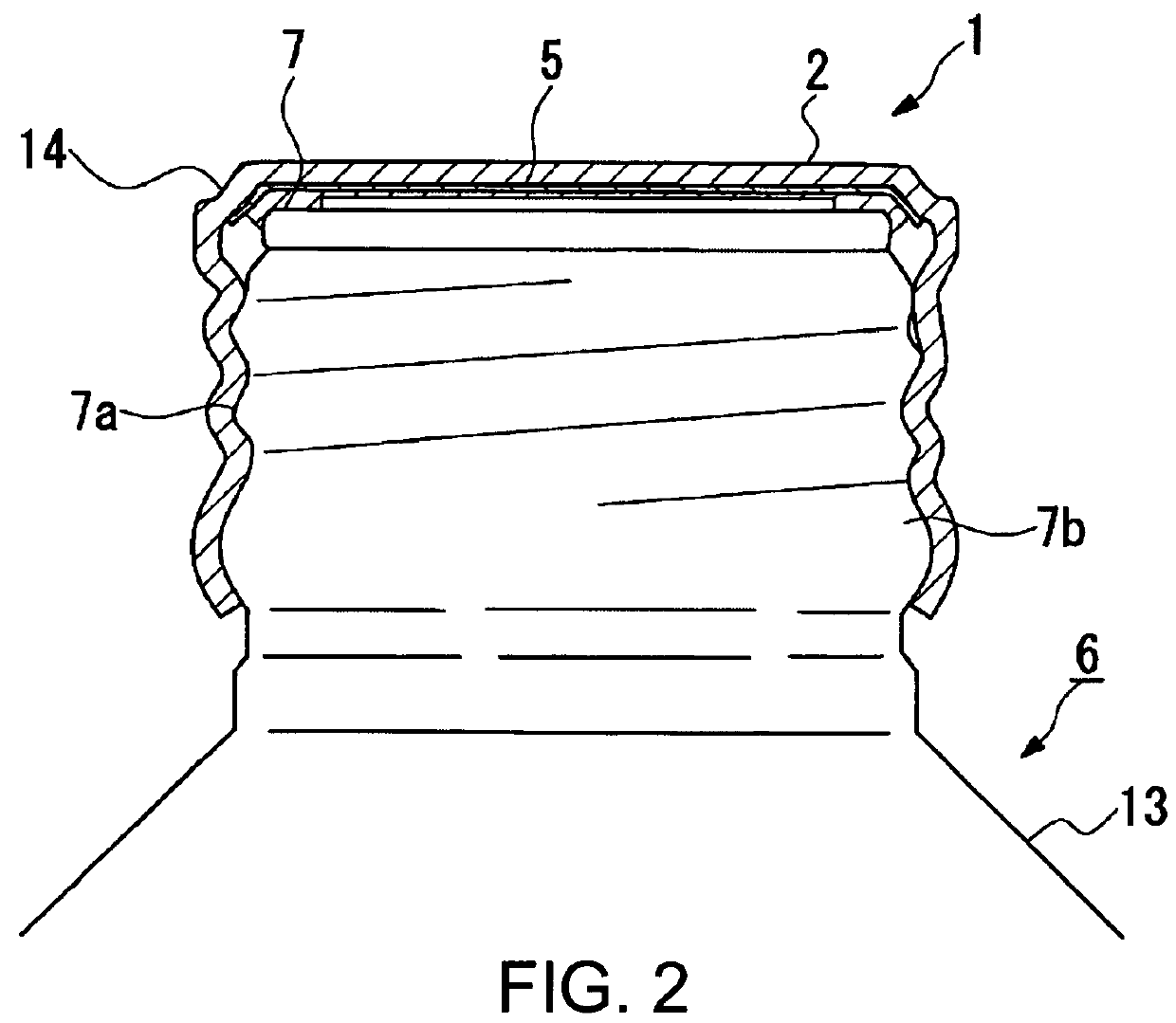

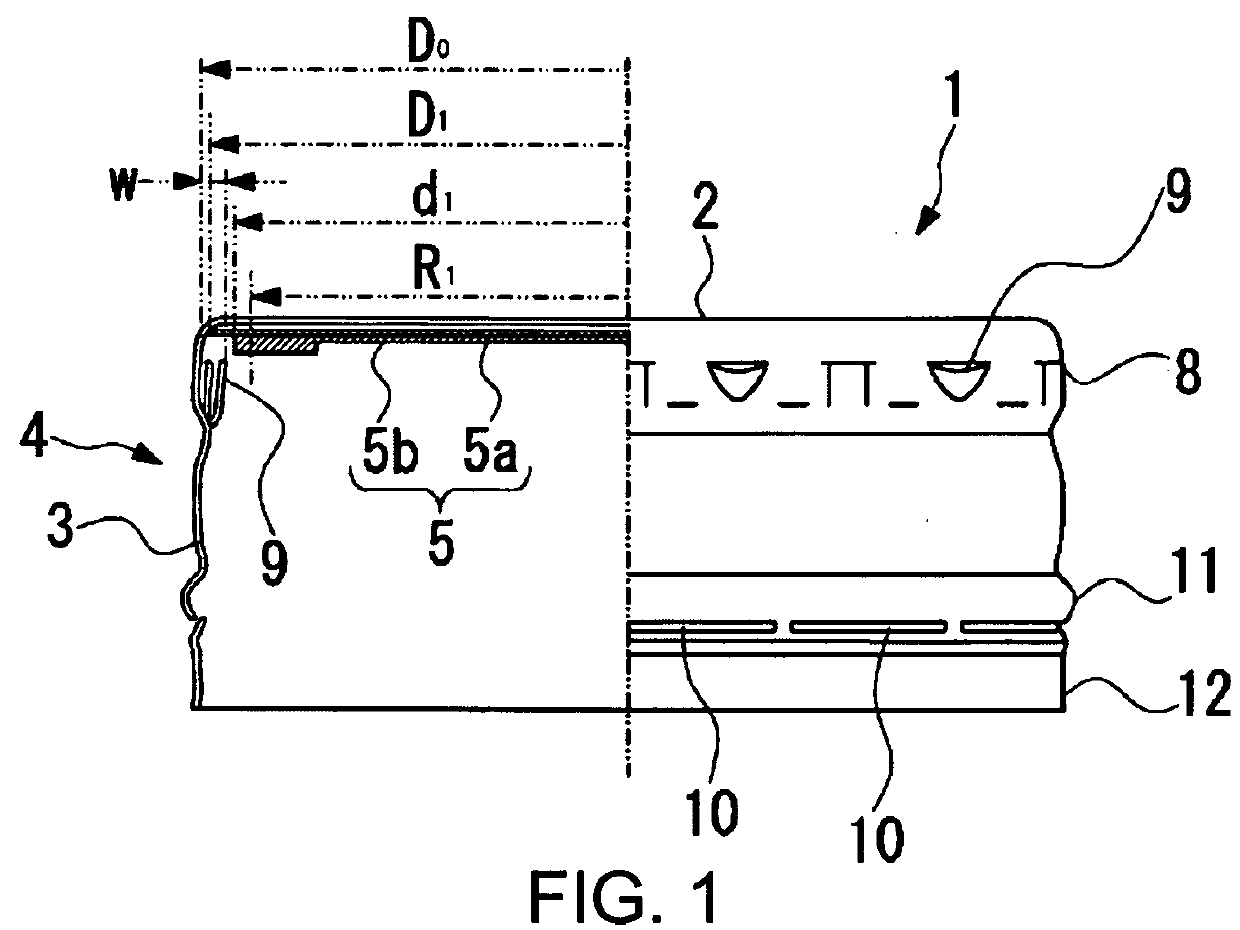

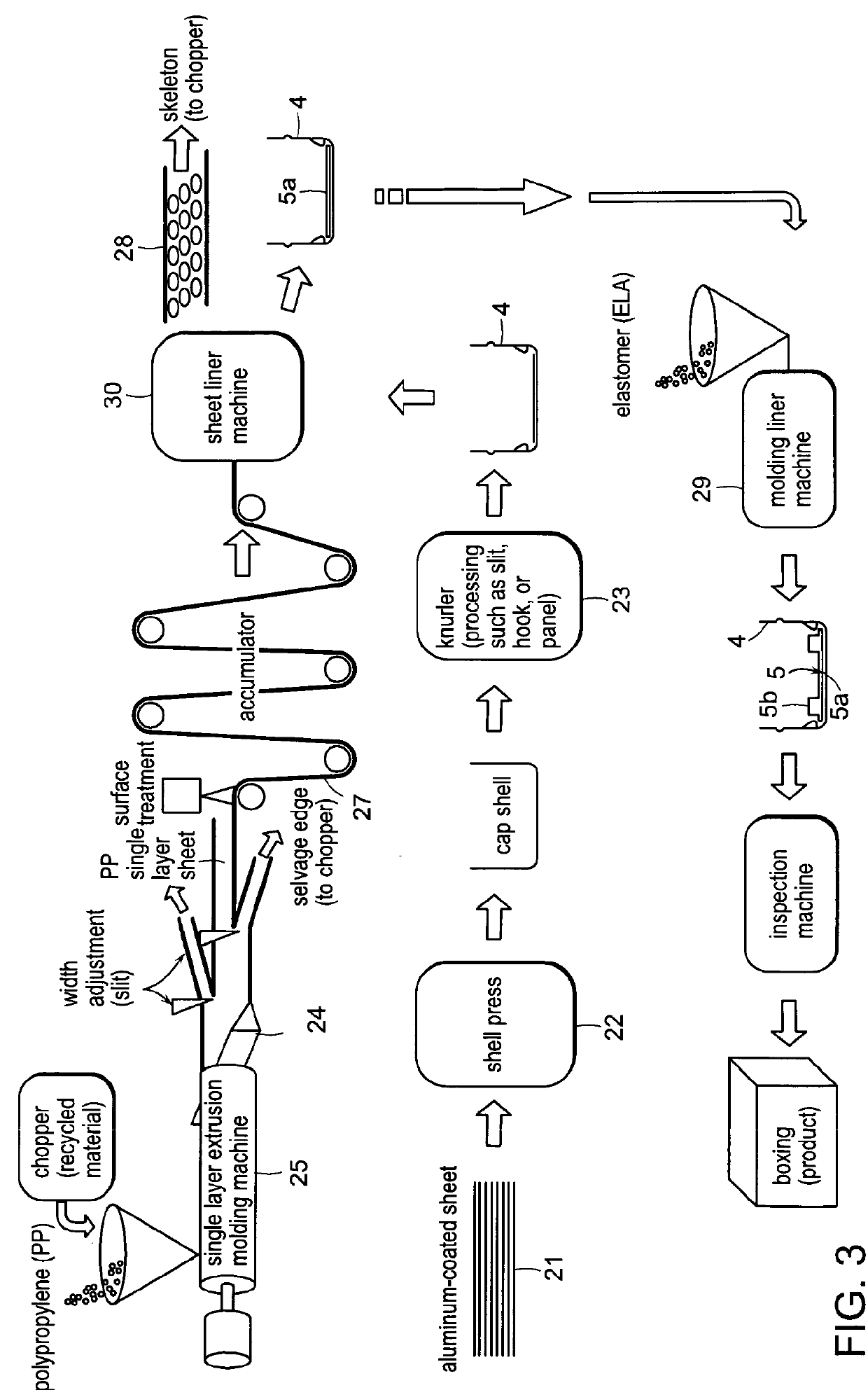

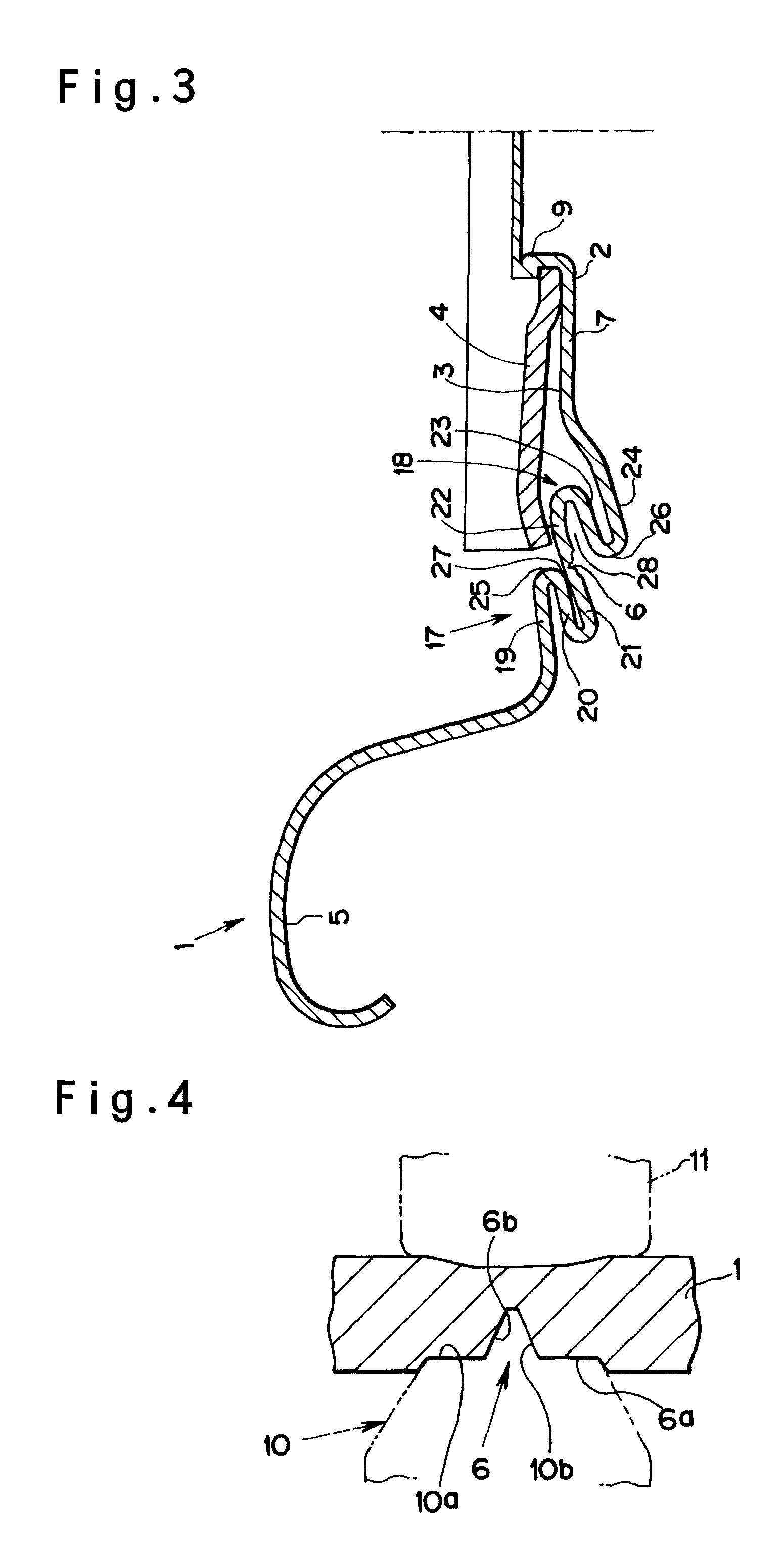

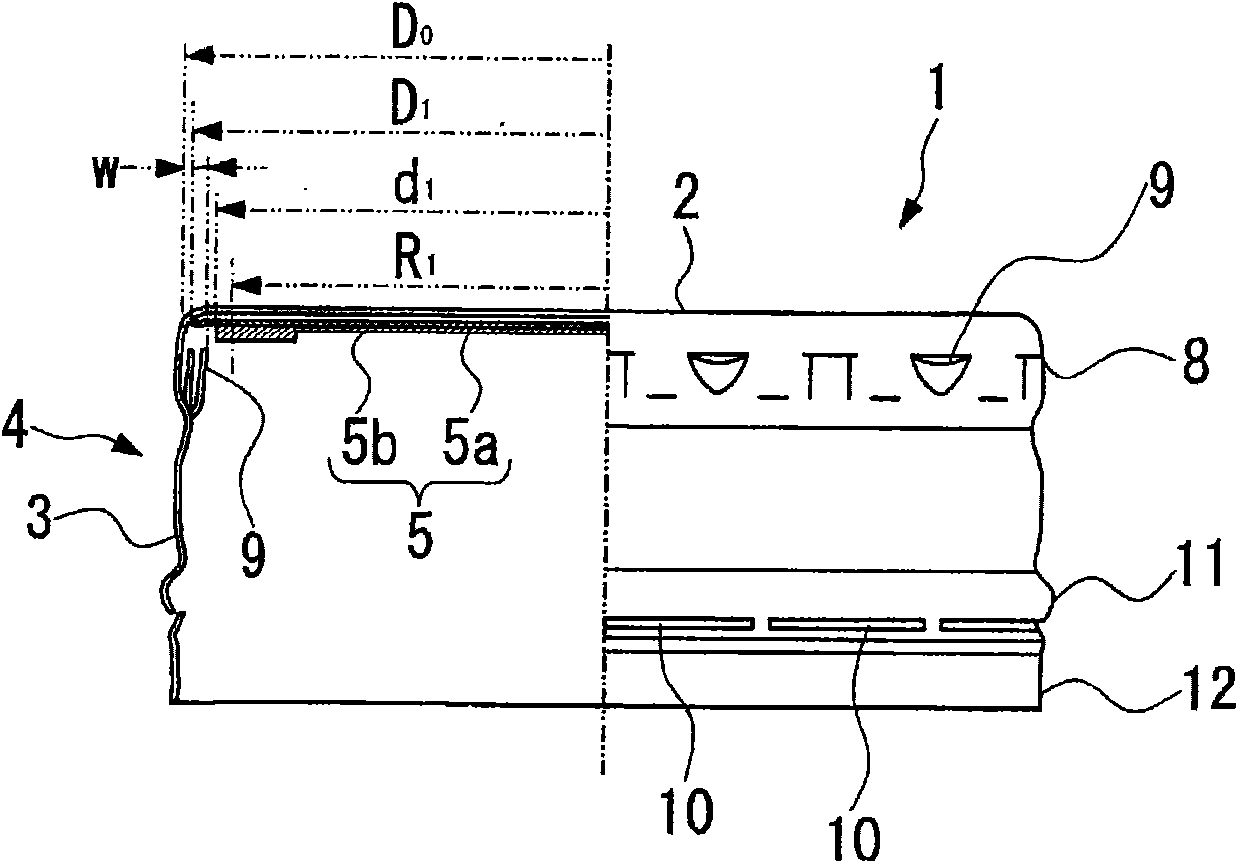

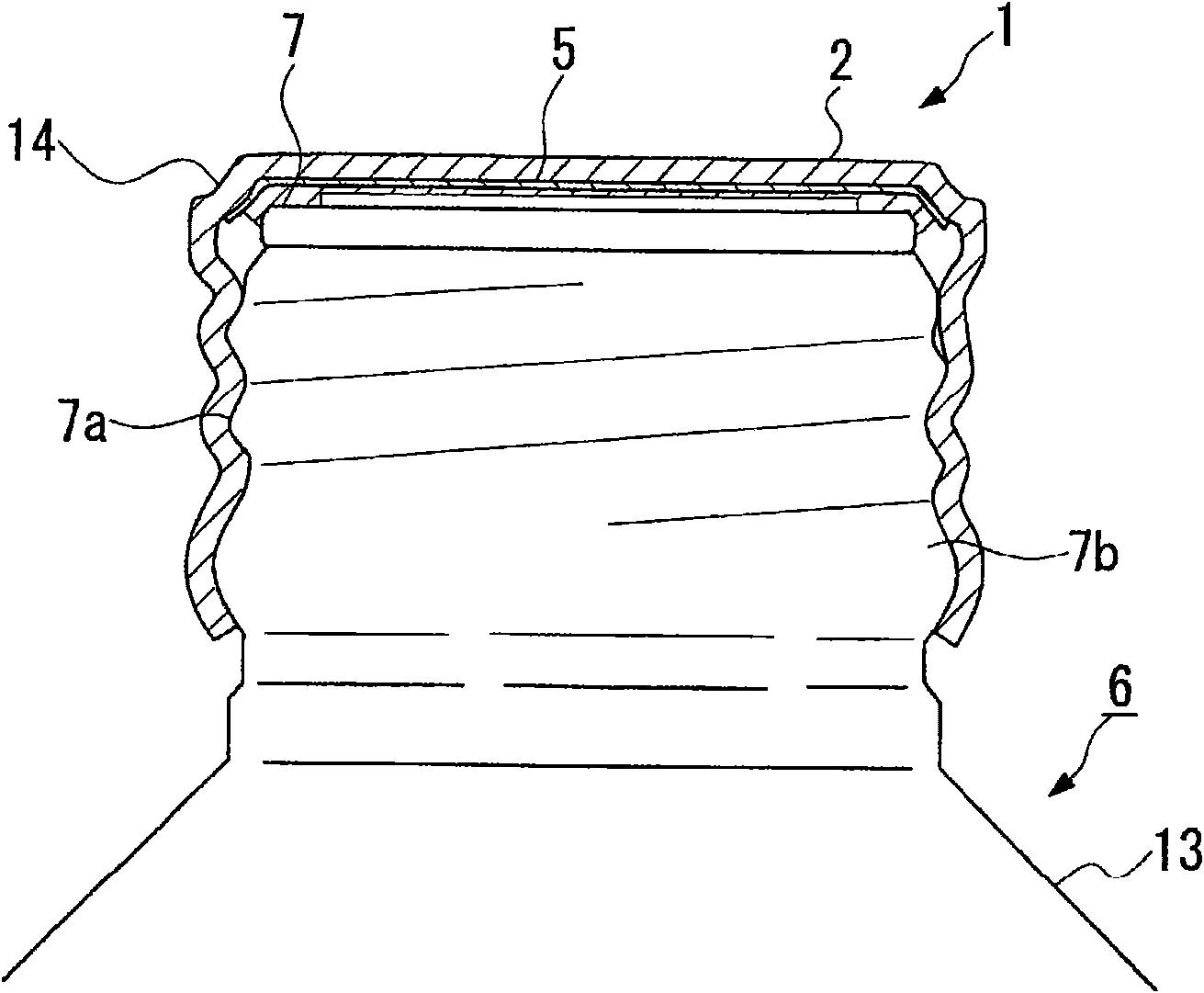

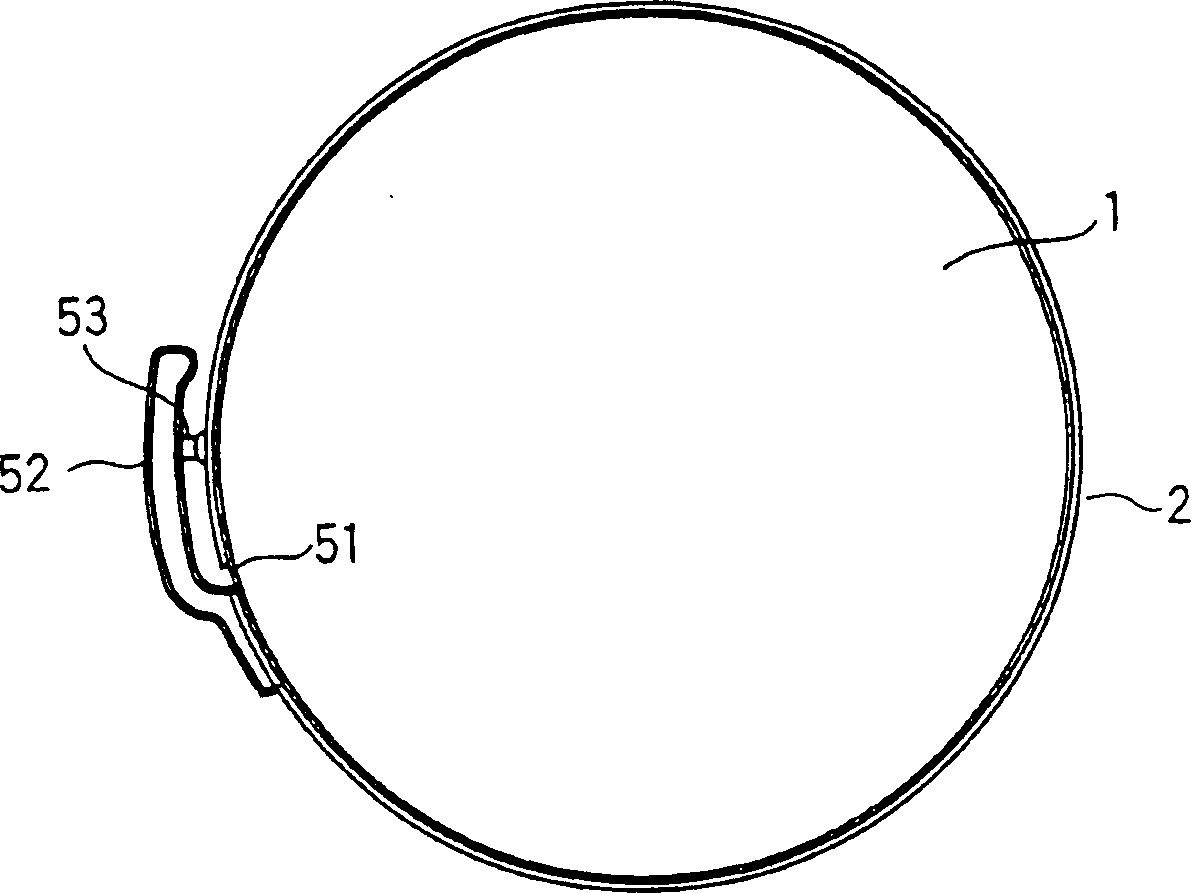

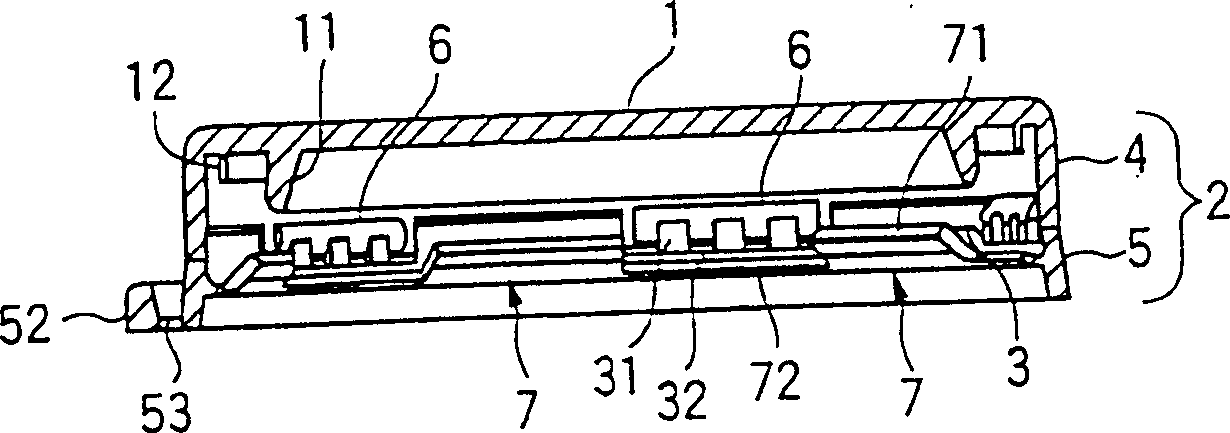

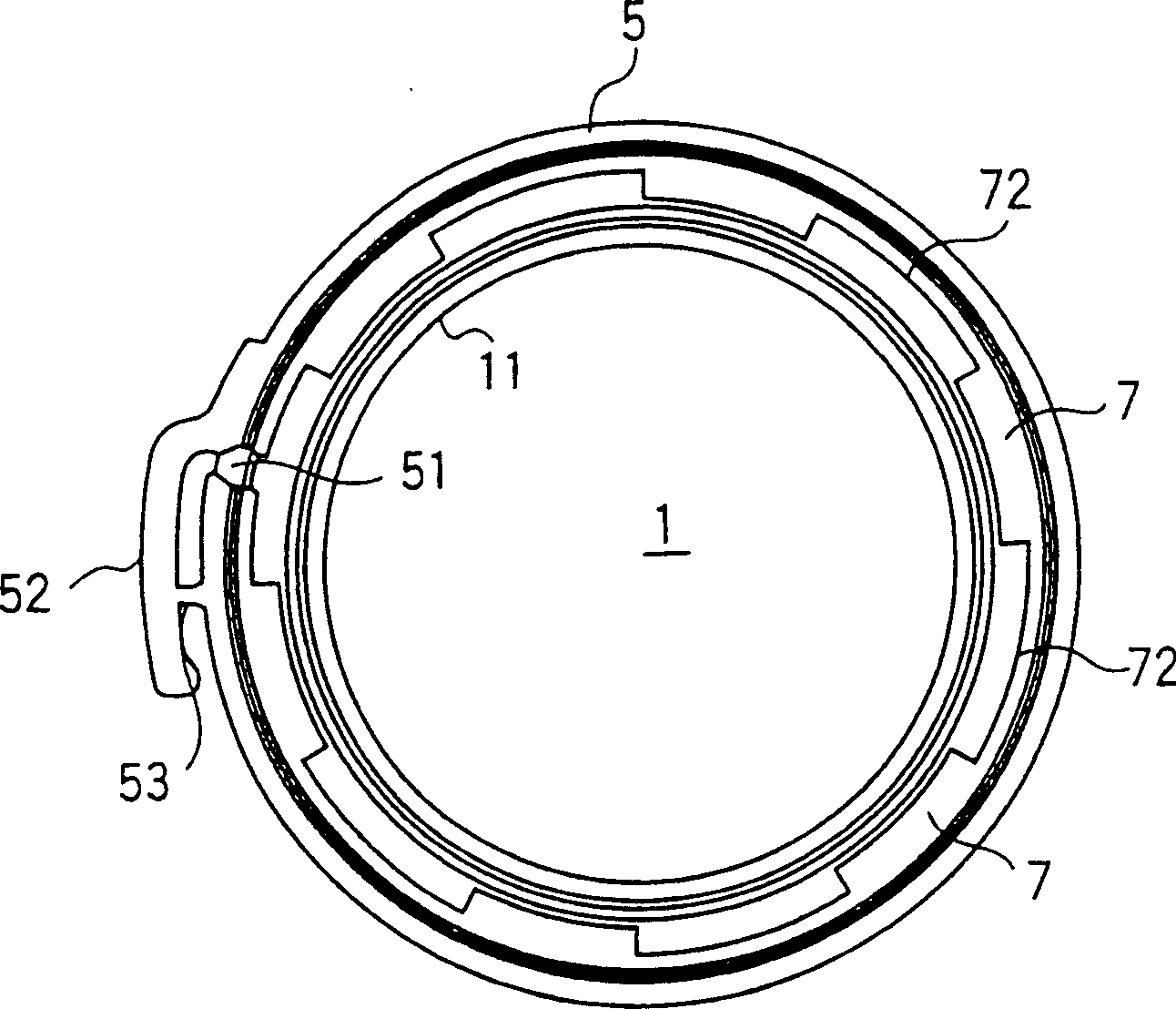

Liner-provided cap and cap-provided threaded container

ActiveCN101891031AHigh suitability for installationSmall unseal torque valueCapsClosure capsSoft layerEngineering

The present invention discloses a liner-provided cap and a cap-provided threaded container. The liner-provided cap for sealing the mouthpiece of the threaded container includes the cap shell (4) consisting of the top plate (2) and the tubular peripheral wall section (3) that hangs from the peripheral edge of the top plate (2), and the synthetic resin liner (5) provided on the inner surface of the top plate (2). The liner (5) includes the disk-shaped rigid sheet (5a) disposed in contact with the inner surface of the top plate (2), and the soft layer (5b) that is laminated to the rigid sheet (5a) and is more flexible than the rigid sheet (5a). The soft layer (5b) is concentric with the rigid sheet (5a) and is formed in an annular or disk shape with a diameter smaller than that of the rigid sheet (5a) so that the soft layer (5b) can be brought into contact with at least the mouthpiece.

Owner:UNIVERSAL CAN CORP

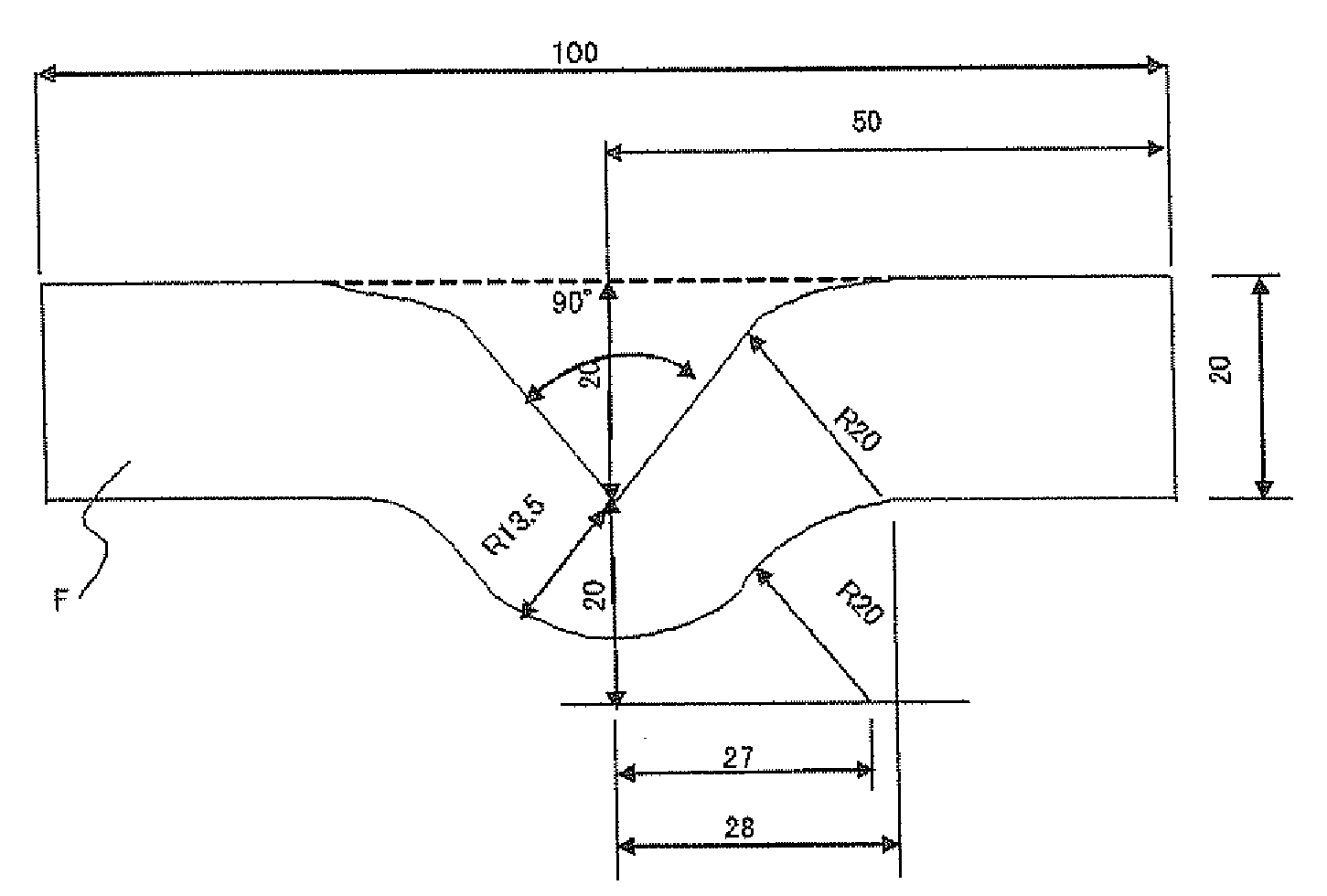

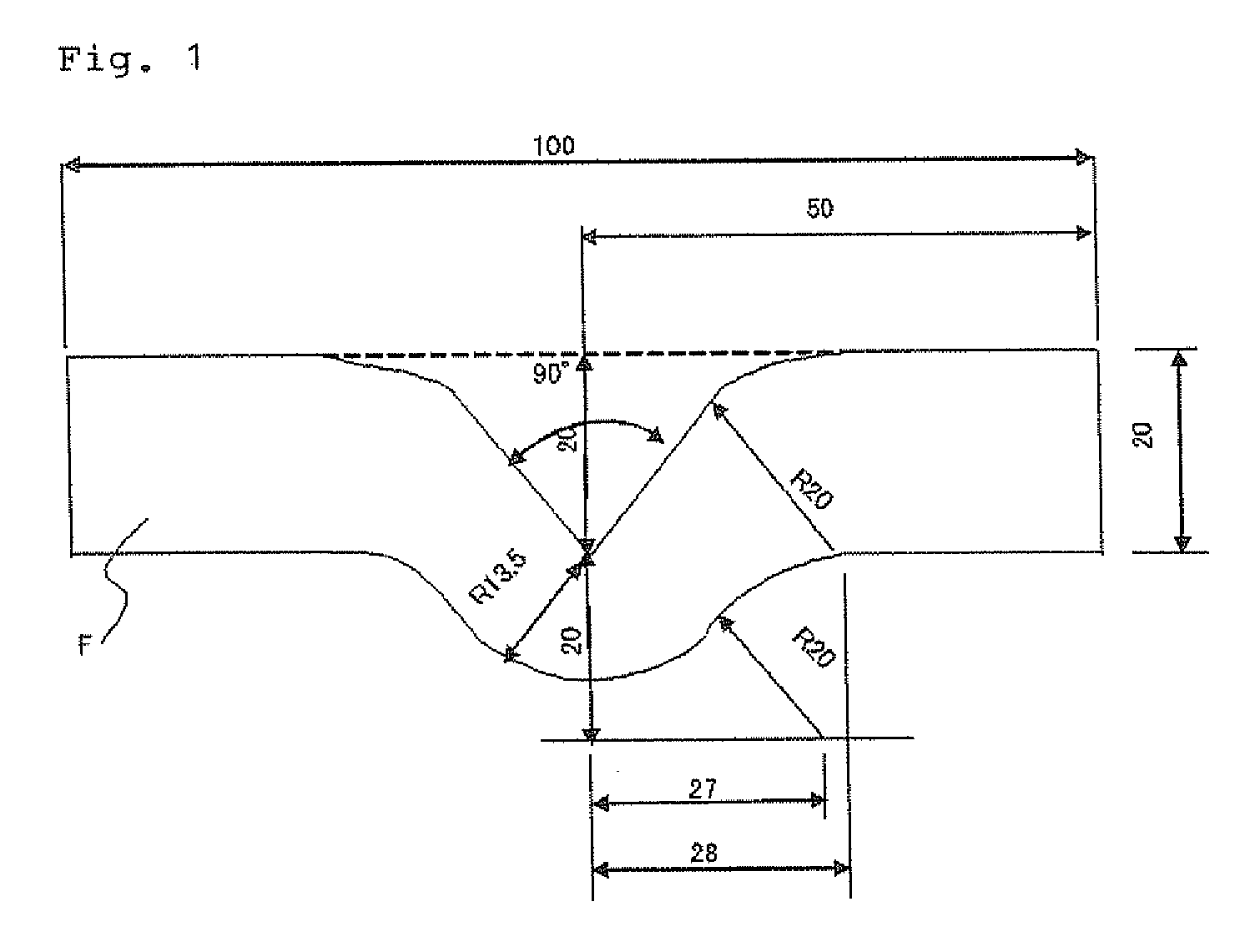

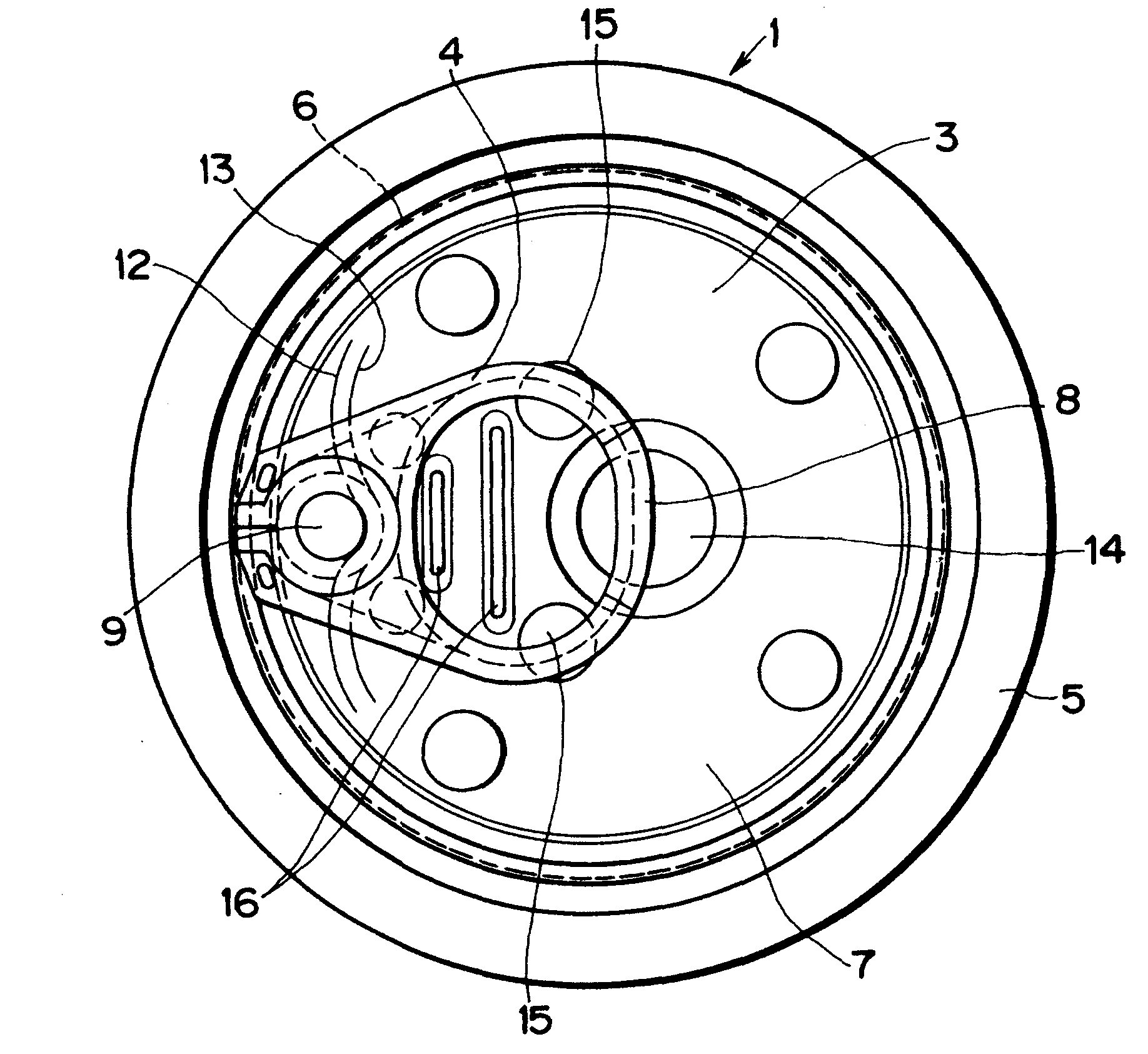

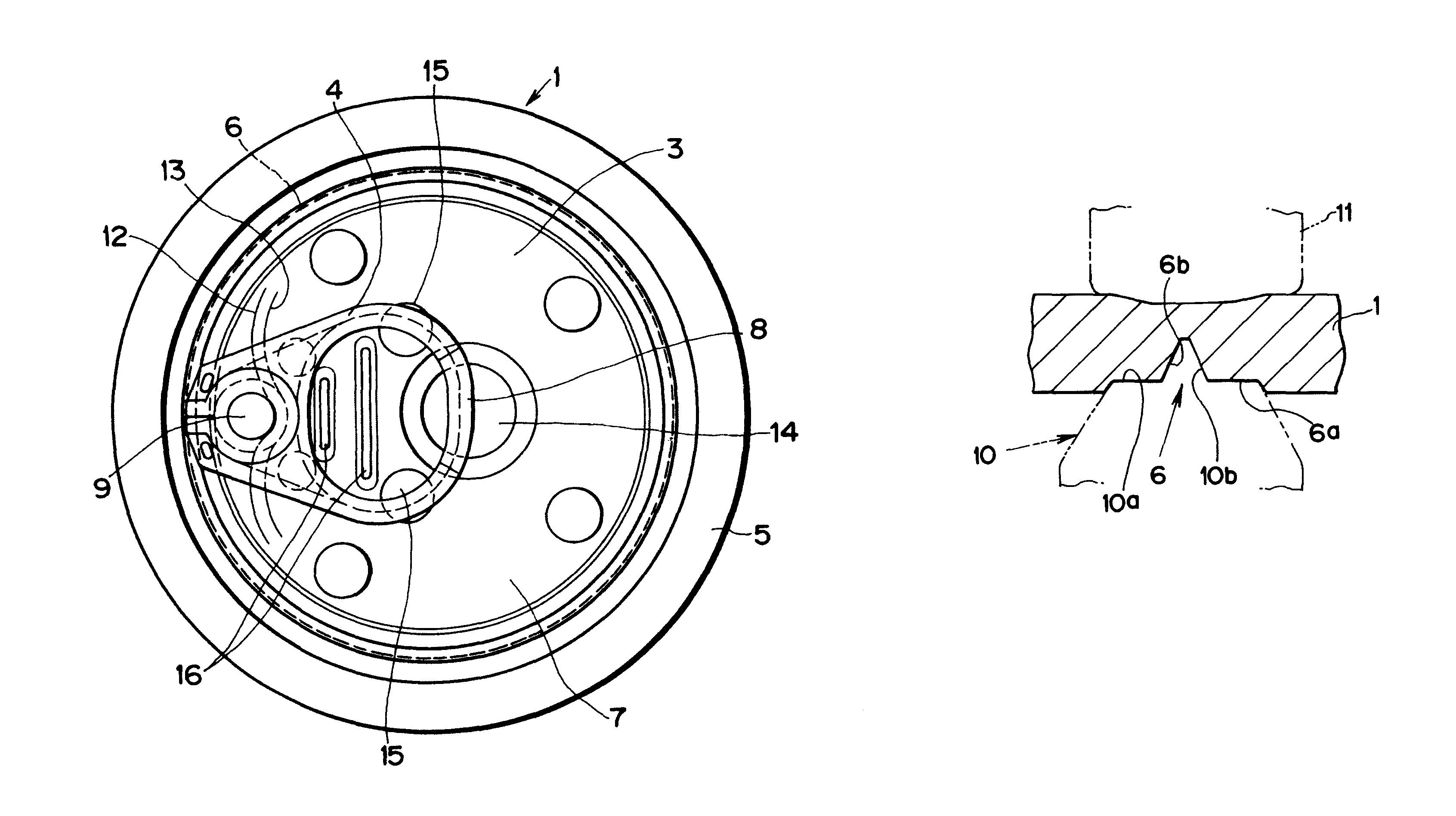

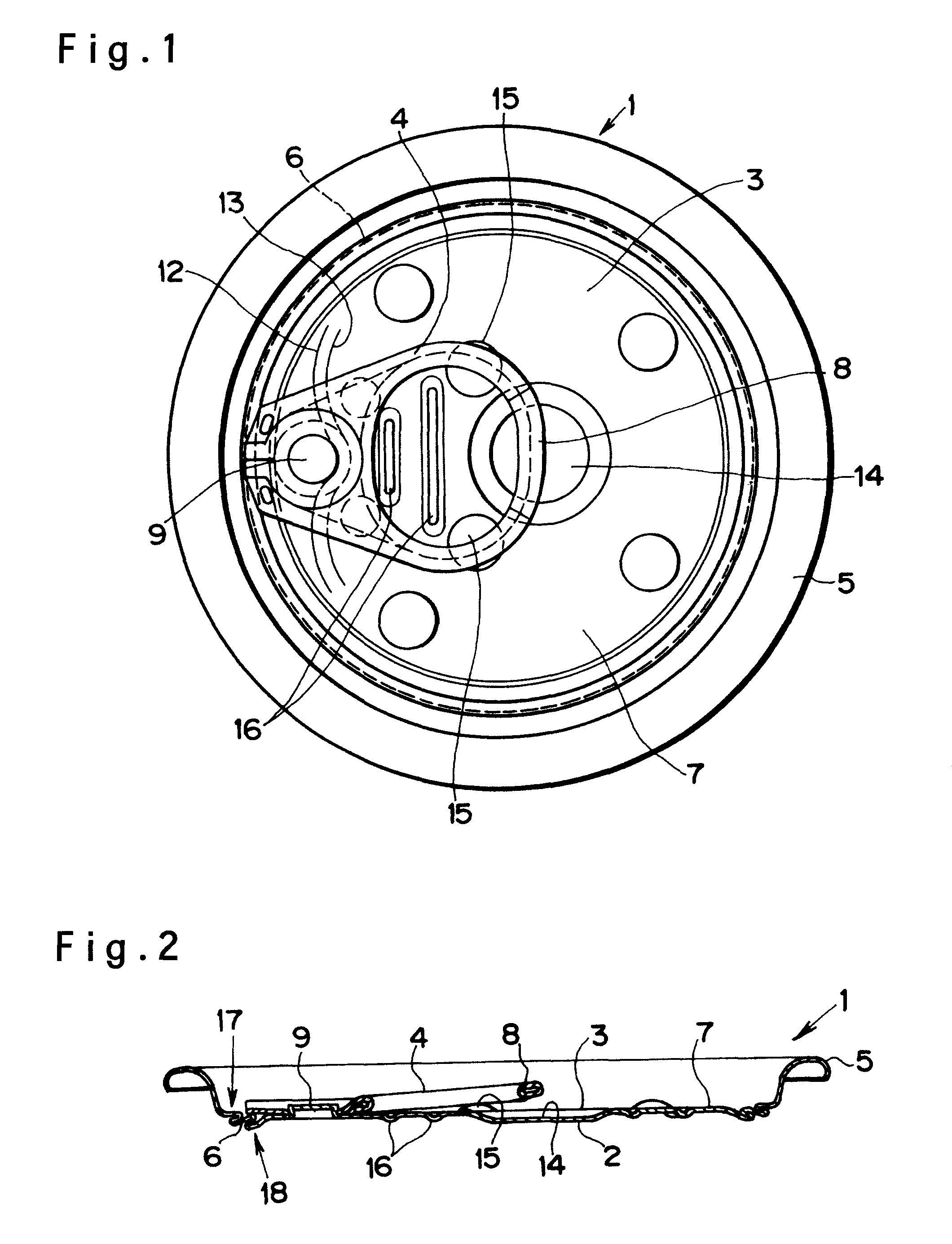

Easily-Openable Can Lid

An easy open can lid comprises an outer multilayered portion folded into three layers and enclosing the panel portion from outside of the score line, and an inner multilayered portion folded into three layers and enclosing the panel portion from inside of the score line. A leading edge of an outer protection portion as a folding portion between the first and second outer layers is flush with or situated outside of the score line, and a leading edge of an inner protection portion as a folding portion between the second and third inner layers is flush with or situated inside of the score line. An opening width of an inner interspace between the first and second inner layers is wider than that of an outer interspace between the second and third outer layers.

Owner:DAIWA CAN

Heat-shrinkable polyester film and process for production thereof

InactiveUS7829655B2High mechanical strengthImprove openabilityWrappers shrinkageSynthetic resin layered productsPolyesterRefractive index

In the heat-shrinkable polyester film of the present invention, the main shrinkage direction is the longitudinal direction. In addition, the hot-water heat shrinkage ratios in the longitudinal direction and the width direction when the film is treated in hot water at 90° C. for 10 seconds, the refractive indexes in the longitudinal direction and the width direction and the natural shrinkage ratio after aging at 40° C. and 65% RH for 700 hours or more are each controlled in predetermined ranges. The heat-shrinkable polyester film of the present invention is manufactured by stretching an unstretched film at a ratio of 2.5 times or more and 6.0 times or less in the width direction at a temperature of Tg+5° C. or more and Tg+40° C. or less, passing the film in an intermediate zone that does not execute an active heating operation, heat-treating the film at a temperature of 100° C. or more and 170° C. or less over a period of 1.0 second or more and 10.0 seconds or less, cooling the film to a surface temperature of 30° C. or more and 70° C. or less, stretching the film at a ratio of 2.0 times or more and 7 times or less in the longitudinal direction at a temperature of Tg+5° C. or more and Tg+80° C. or less, and subsequently cooling the film at a cooling rate of 30° C. / second or more and 70° C. / second or less to a surface temperature of the film of 45° C. or more and 75° C. or less.

Owner:TOYOBO CO LTD

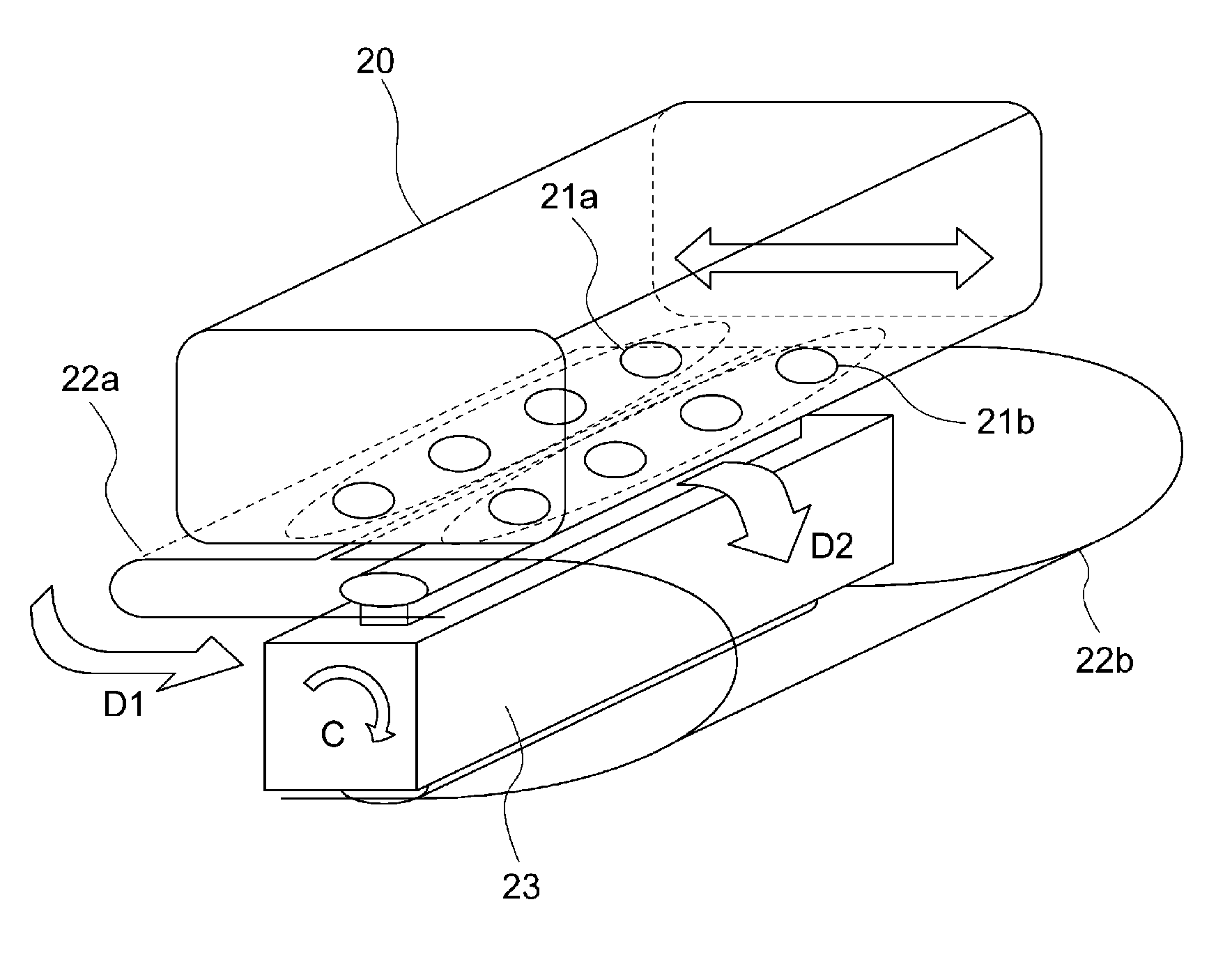

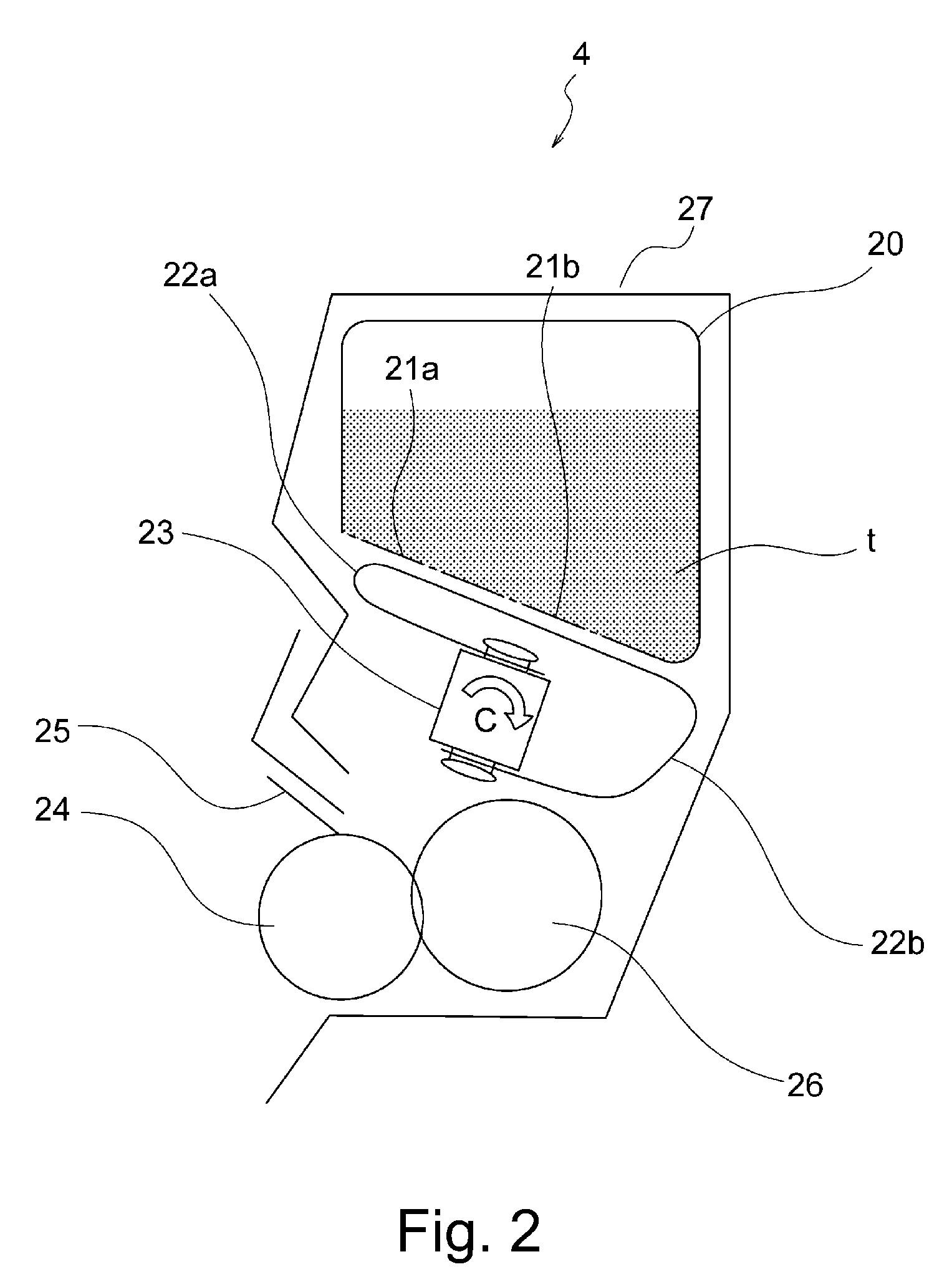

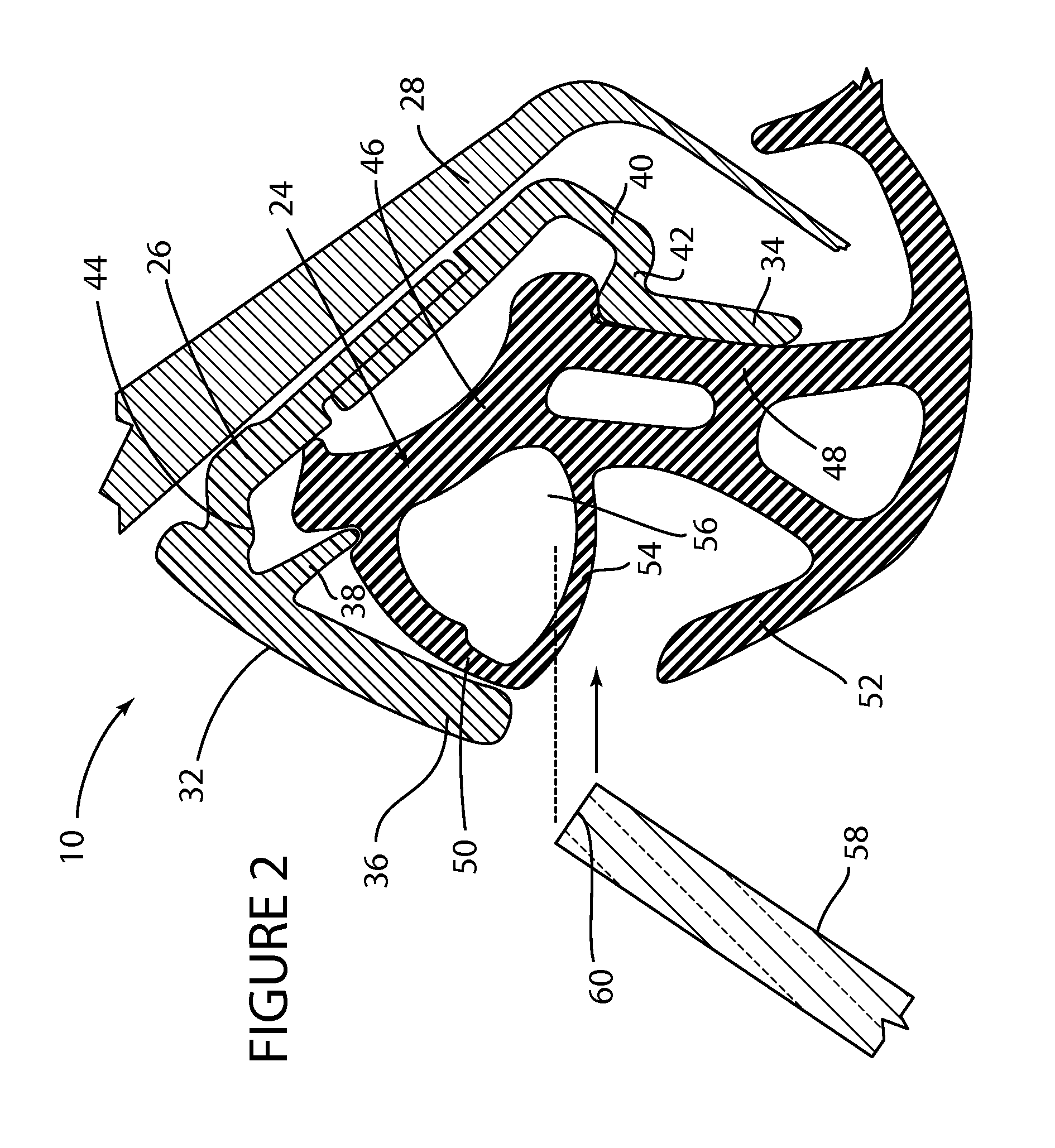

Developer accommodating unit, developing device, process cartridge and image forming apparatus

ActiveUS20140363196A1Shorten sealing timeImprove openabilityElectrographic process apparatusImaging equipmentMechanical engineering

Owner:CANON KK

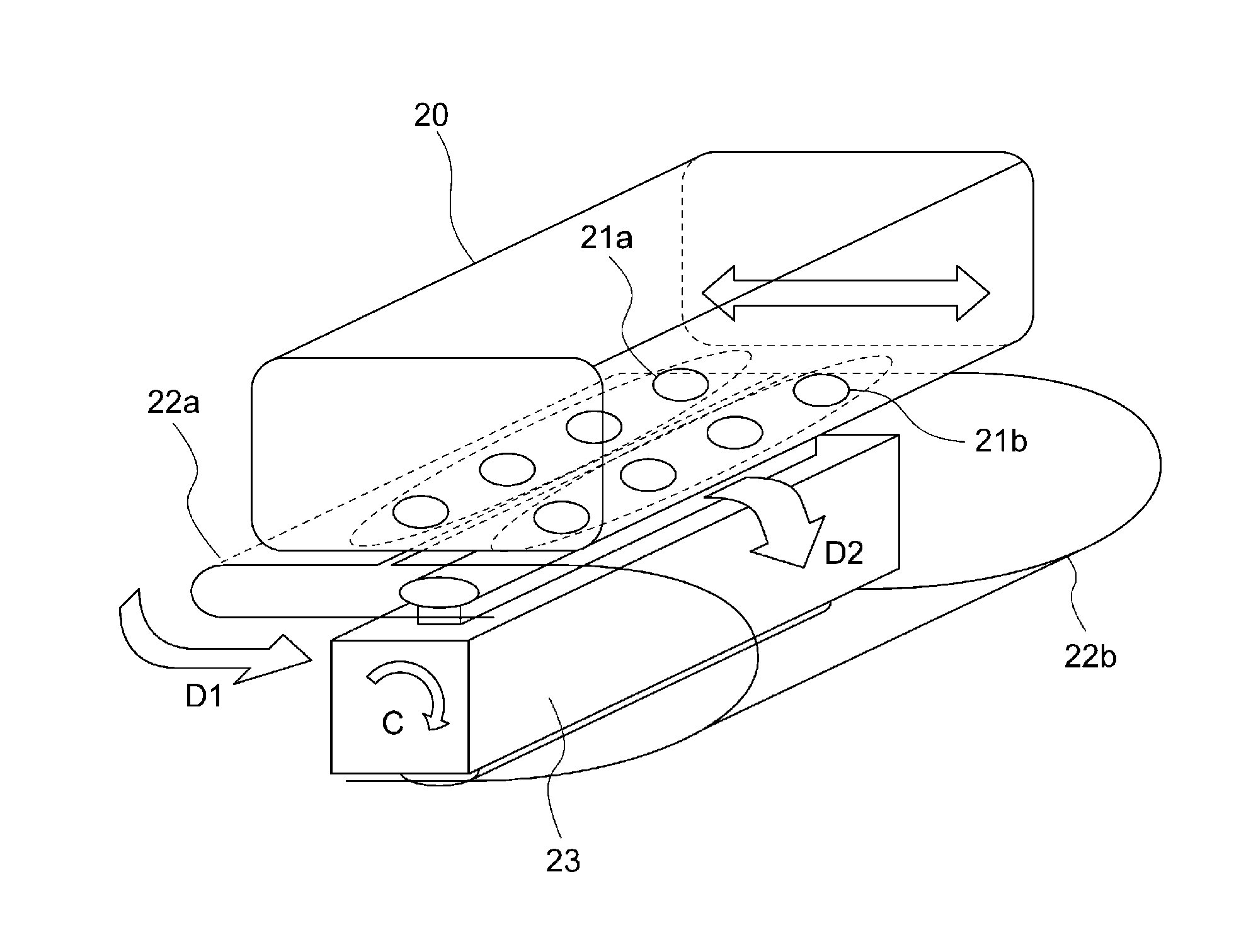

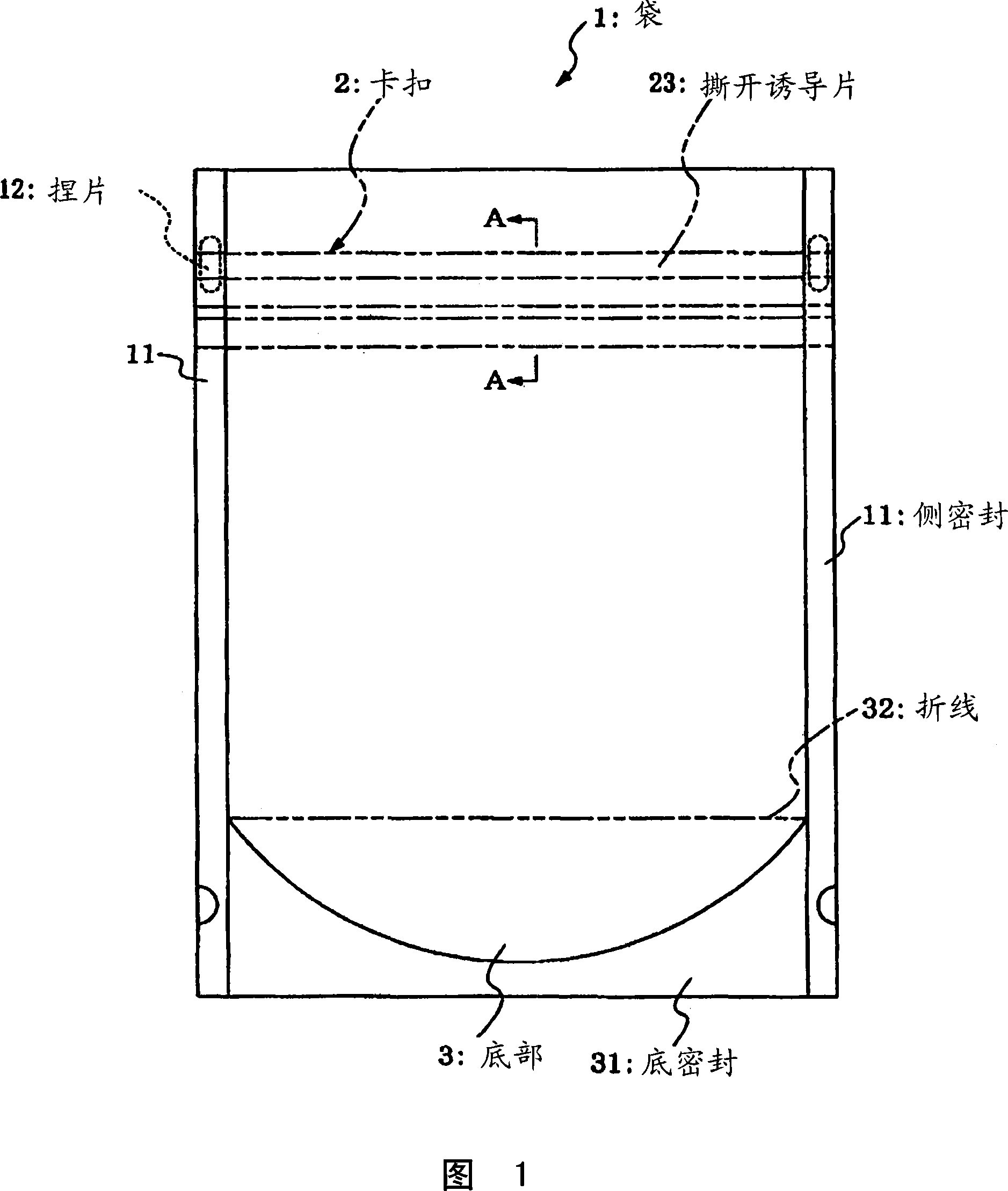

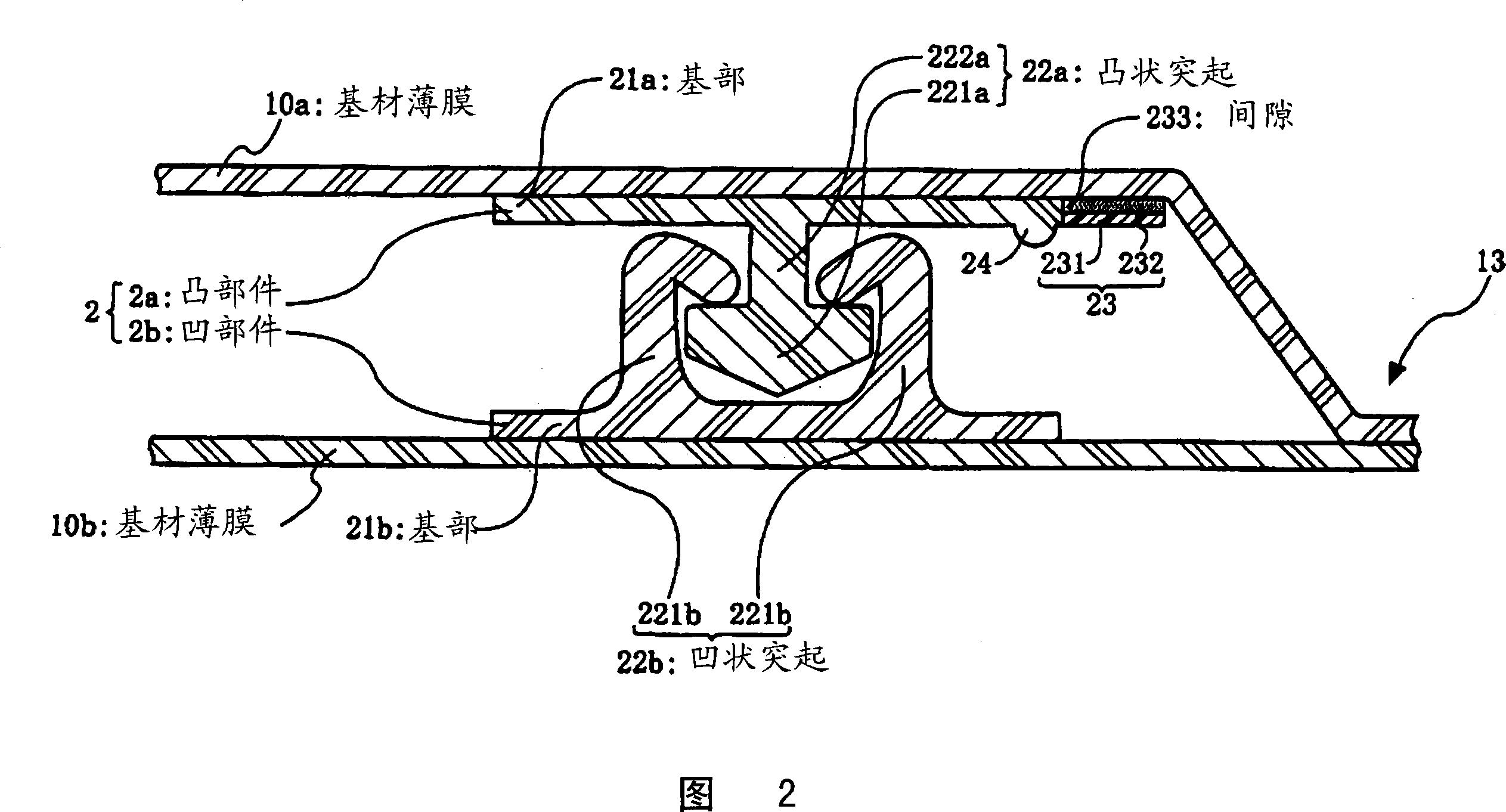

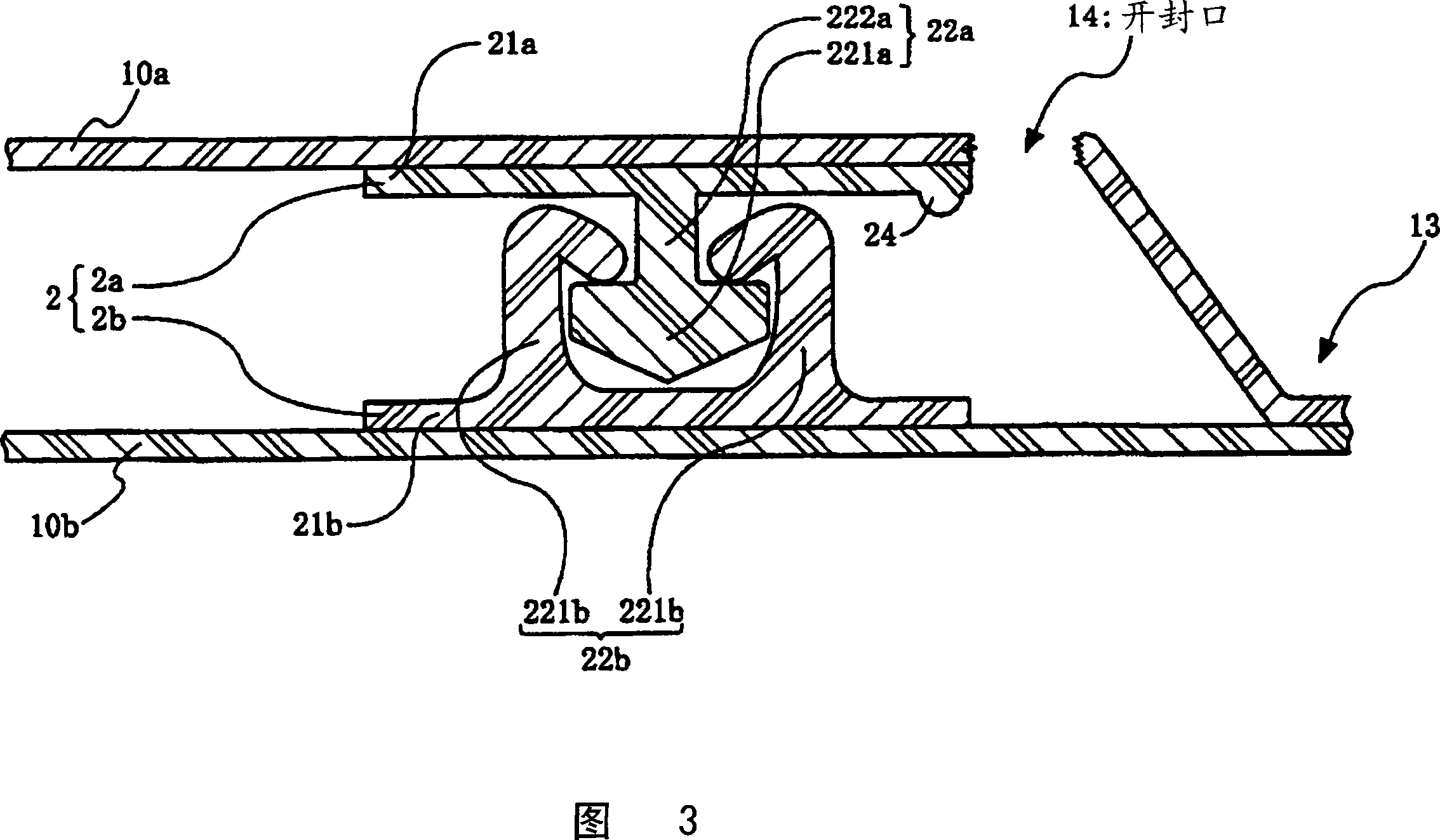

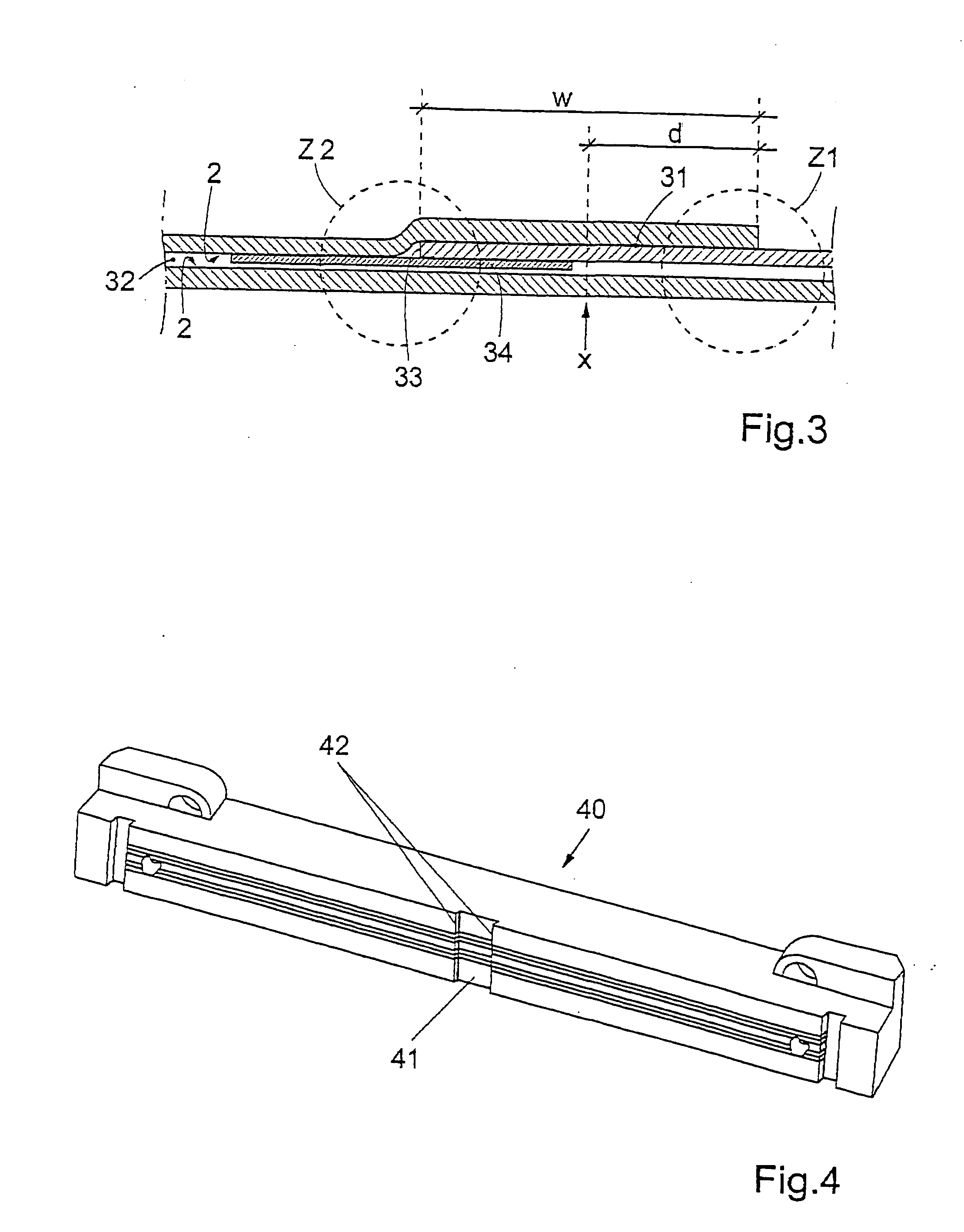

Fastener and bag having same

A tearing guide strip 23 is integrated with a base part 21a or 21b of at least one of a male member 2a and a female member 2b constituting a zipper 2 in a peelable manner to improve the tearing unsealing ability of a zipper-equipped bag provided with an interlocking type zipper enabling resealing and unsealing after the bag is unsealed.

Owner:IDEMITSU UNITECH CO LTD

Liner-provided cap and cap-provided threaded container

Provided is a liner-provided cap for sealing the mouthpiece of a threaded container, which includes the cap shell 4 consisting of the top plate 2 and the tubular peripheral wall section 3 that hangs from the peripheral edge of the top plate 2, and the synthetic resin liner 5 provided on the inner surface of the top plate 2. The liner 5 includes the disk-shaped rigid sheet 5a disposed in contact with the inner surface of the top plate 2, and the soft layer 5b that is laminated to the rigid sheet 5a and is more flexible than the rigid sheet 5a. The soft layer 5b is concentric with the rigid sheet 5a and is formed in an annular or disk shape with a diameter smaller than that of the rigid sheet 5a so that the soft layer 5b can be brought into contact with at least the mouthpiece.

Owner:UNIVERSAL CAN CORP

Easily-openable can lid

An easy open can lid comprises an outer multilayered portion folded into three layers and enclosing the panel portion from outside of the score line, and an inner multilayered portion folded into three layers and enclosing the panel portion from inside of the score line. A leading edge of an outer protection portion as a folding portion between the first and second outer layers is flush with or situated outside of the score line, and a leading edge of an inner protection portion as a folding portion between the second and third inner layers is flush with or situated inside of the score line. An opening width of an inner interspace between the first and second inner layers is wider than that of an outer interspace between the second and third outer layers.

Owner:DAIWA CAN

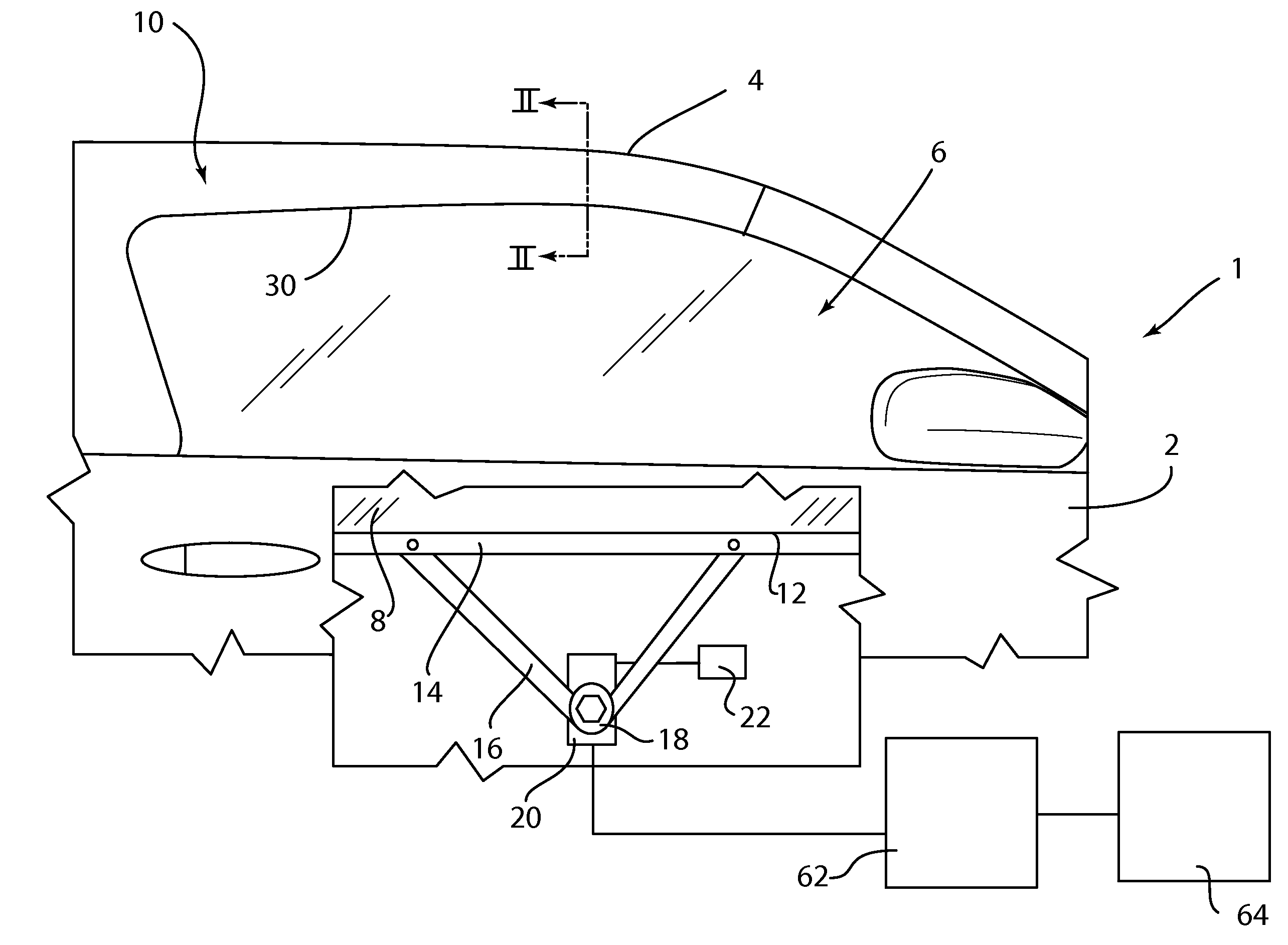

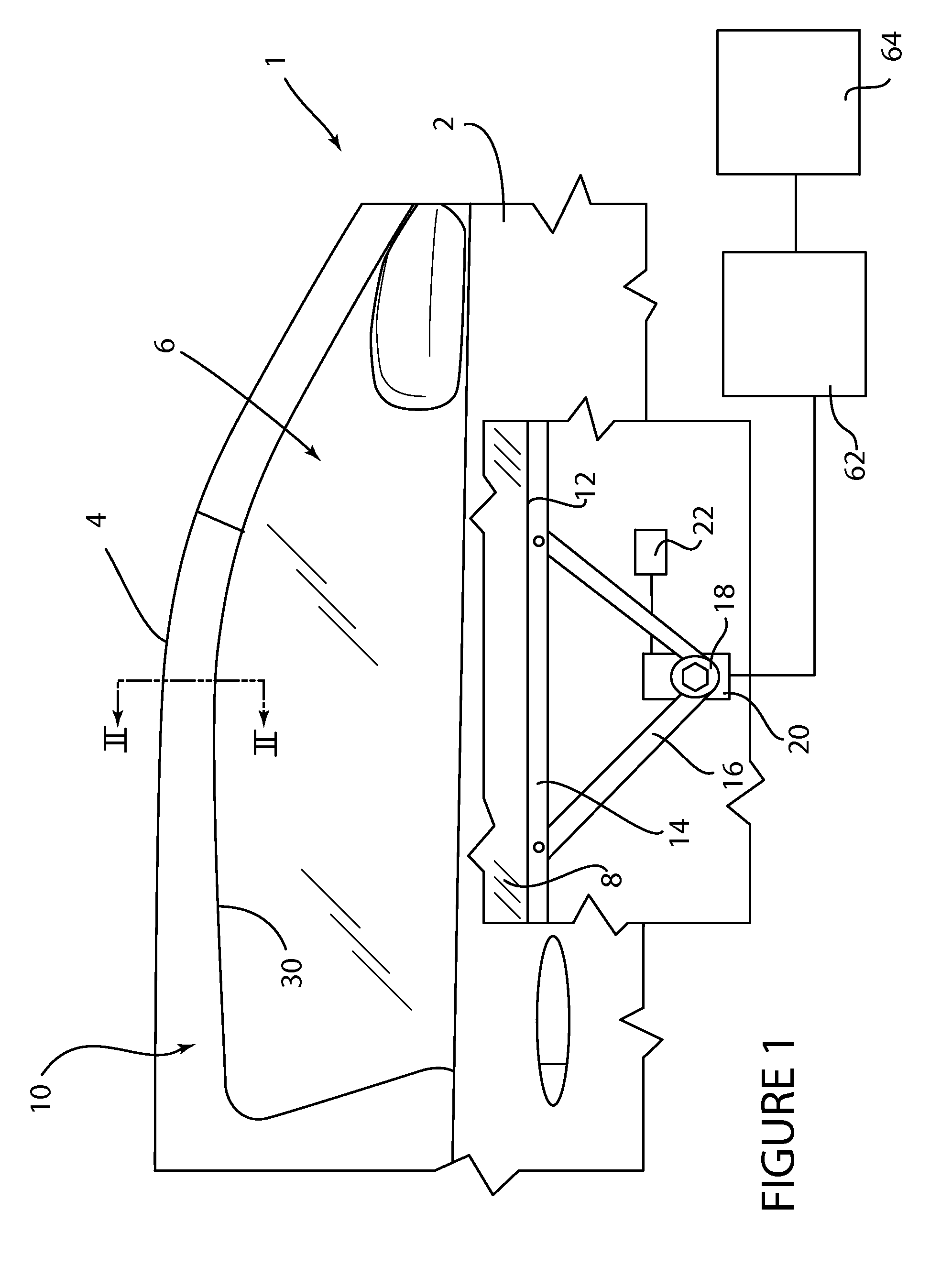

Two stage glass position for frameless vehicles

InactiveUS20140041302A1Good door openabilitySufficient sealing functionWindowsEngine sealsEngineeringElectrical and Electronics engineering

A motor vehicle has an openable door and a frameless door glass system comprising a moveable glass operable in two stages of engagement with a seal. The first stage provides a vertical gap between the glass and the seal prior to the door being opened and the second stage increases the level of engagement between the glass and seal relative the first stage upon detection of a predetermined event, such as a predetermined vehicle speed.

Owner:FORD GLOBAL TECH LLC

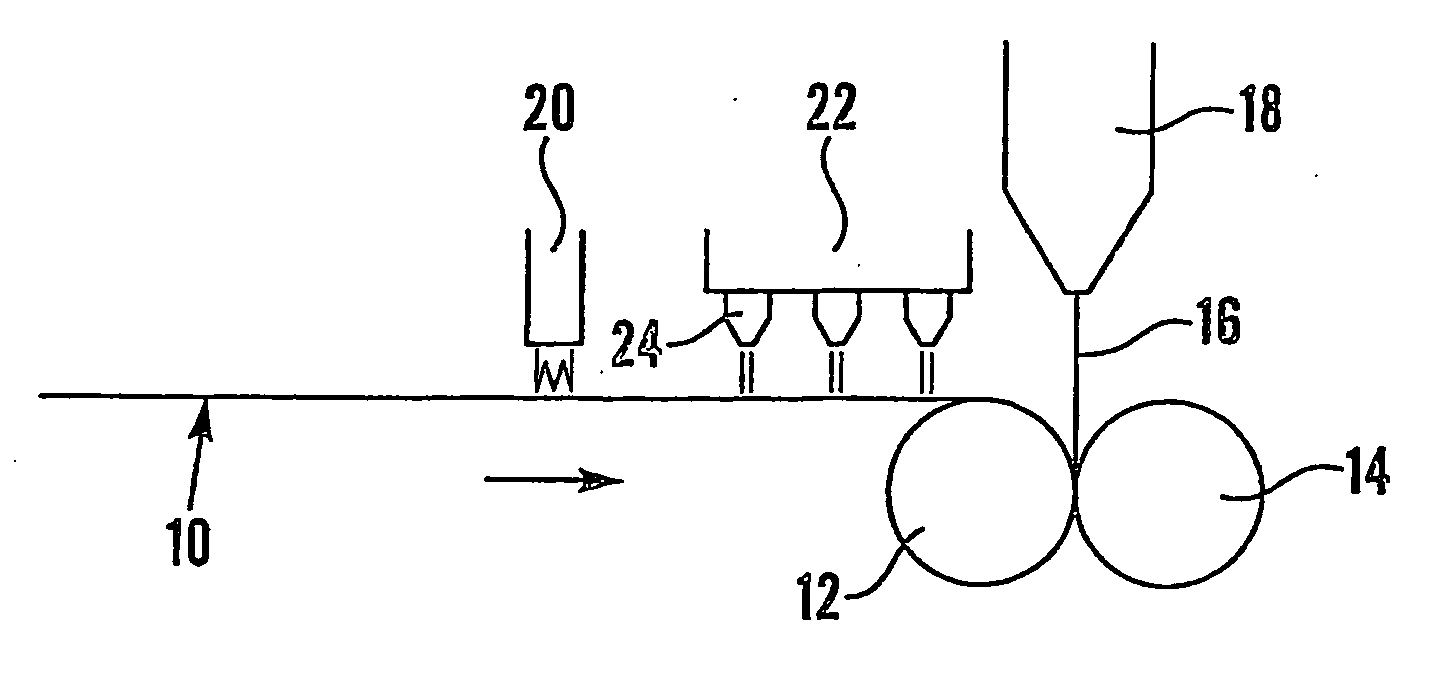

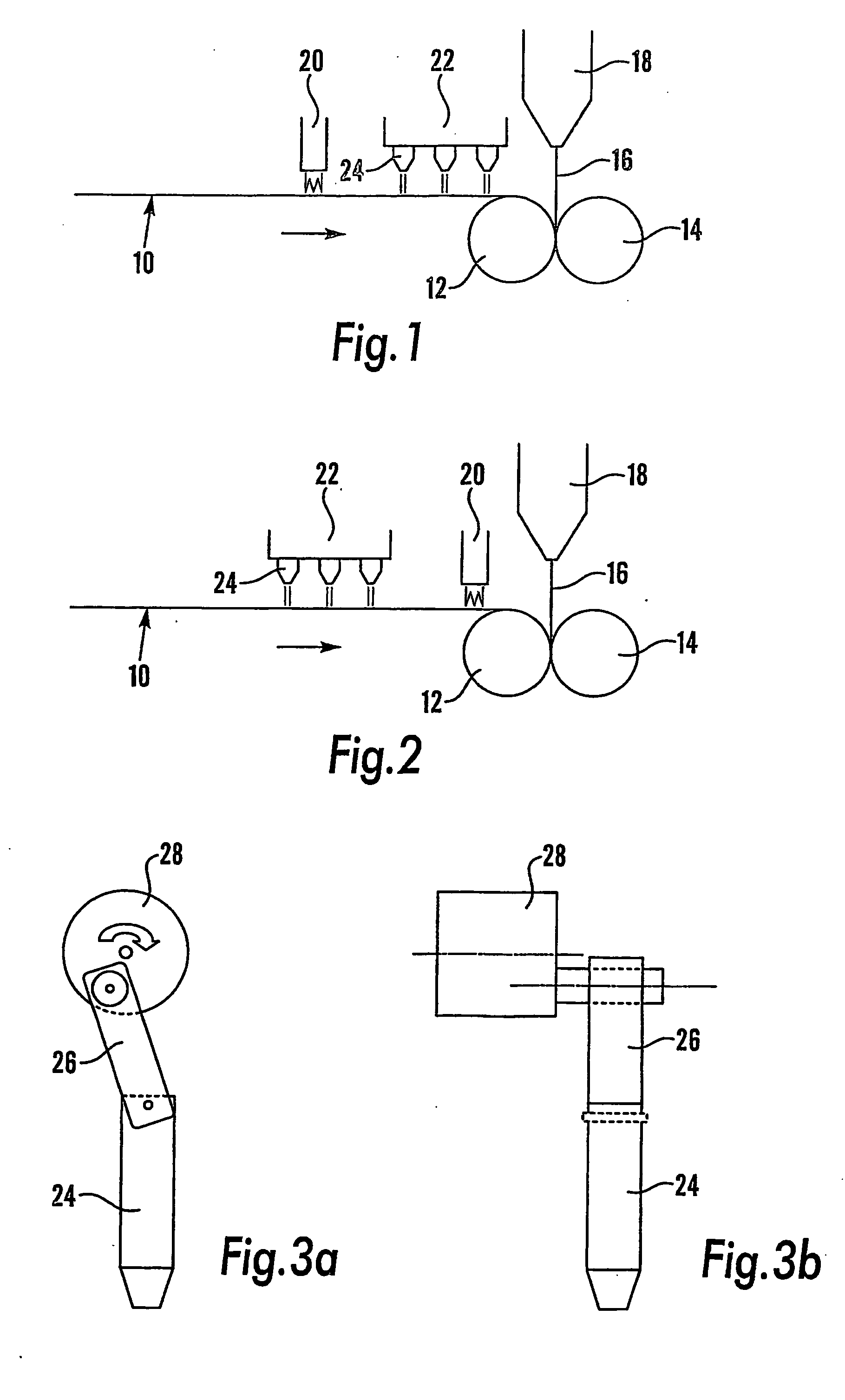

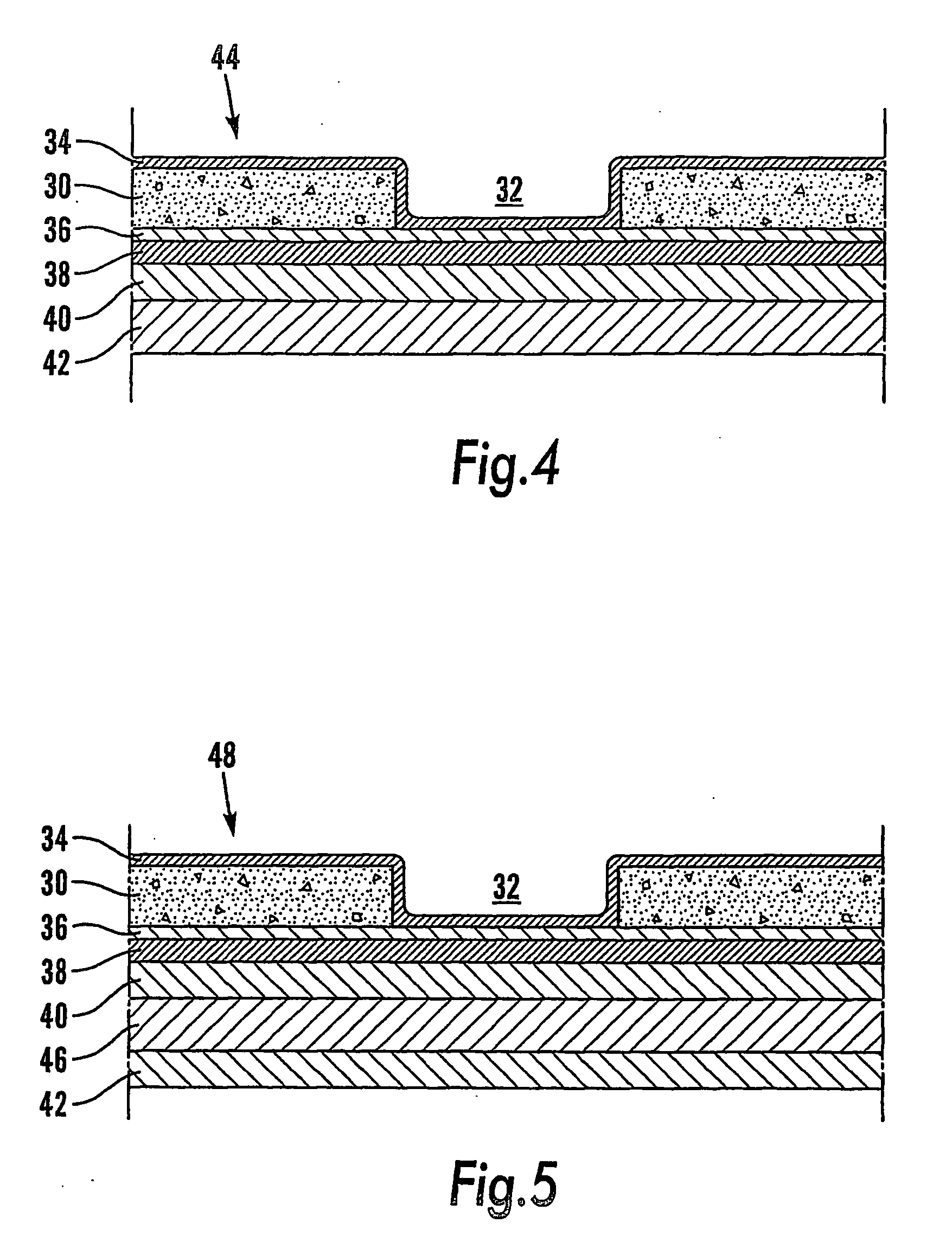

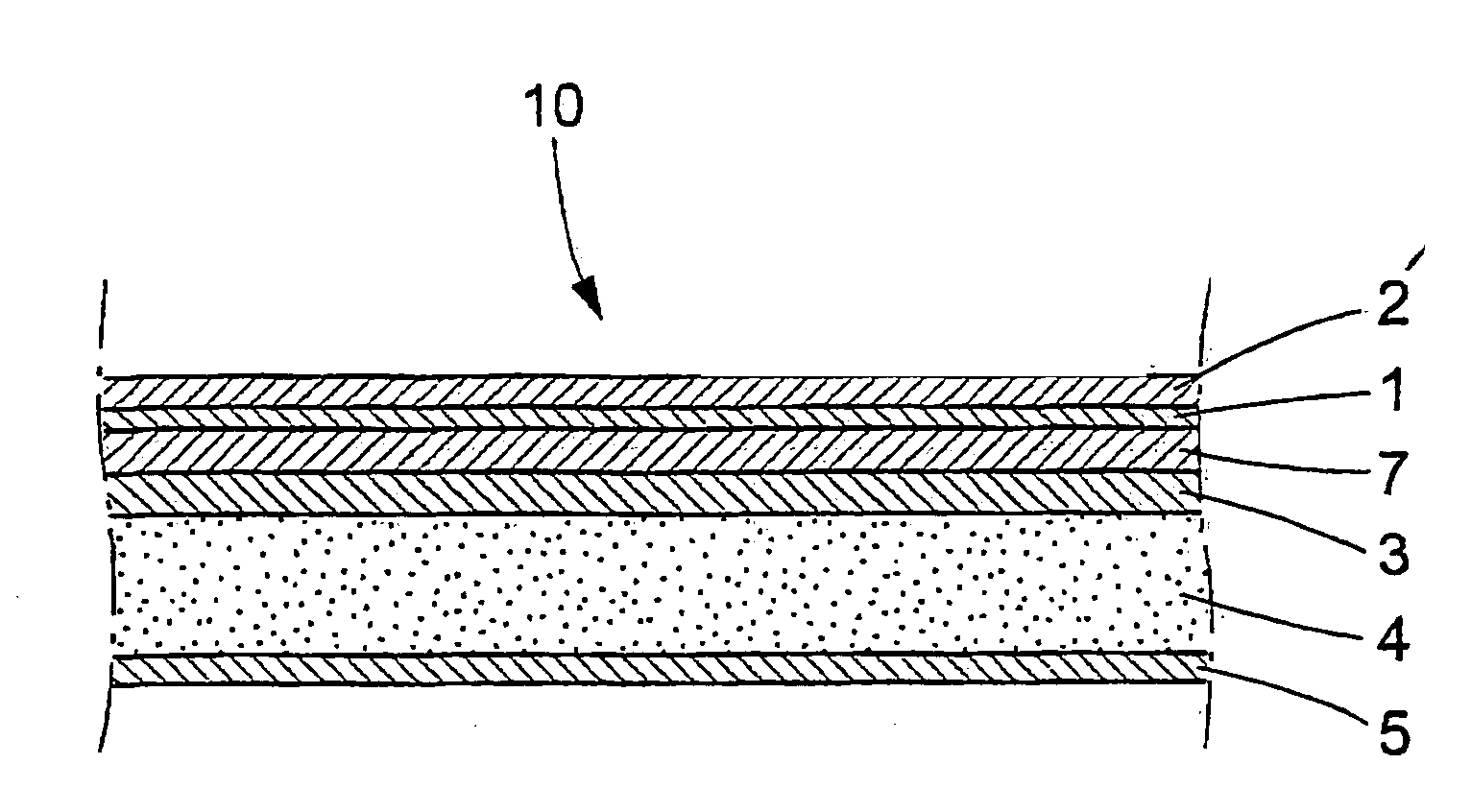

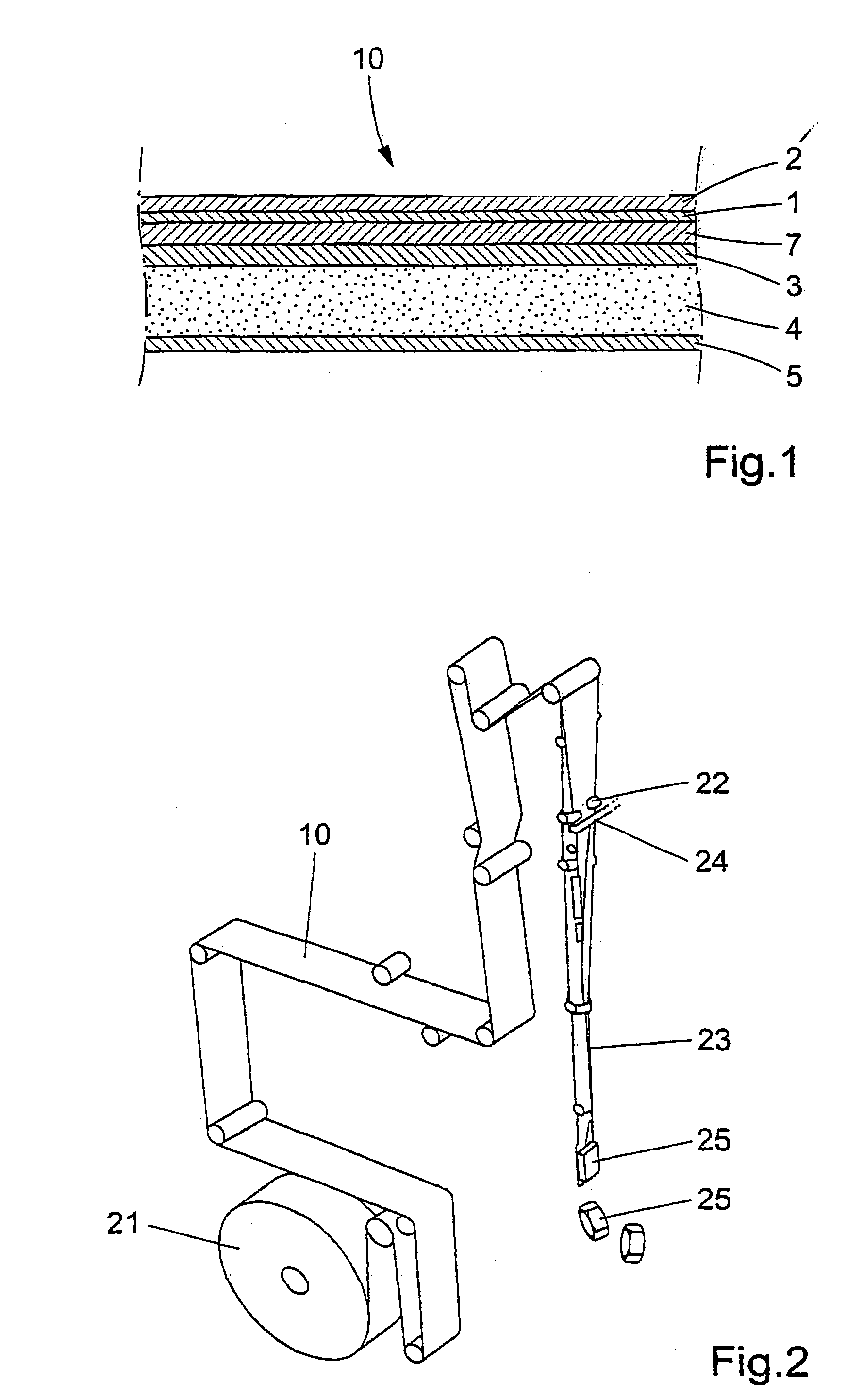

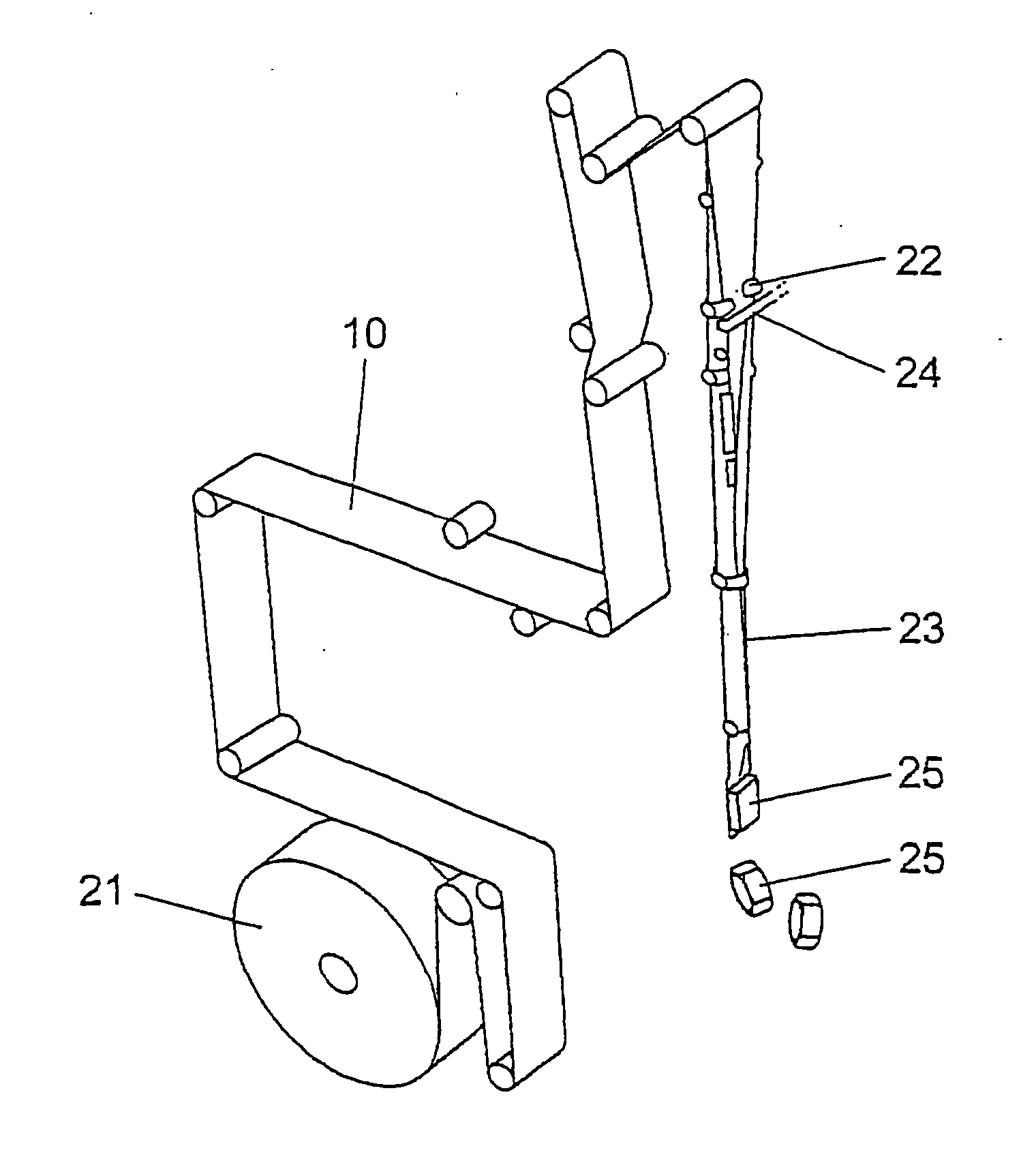

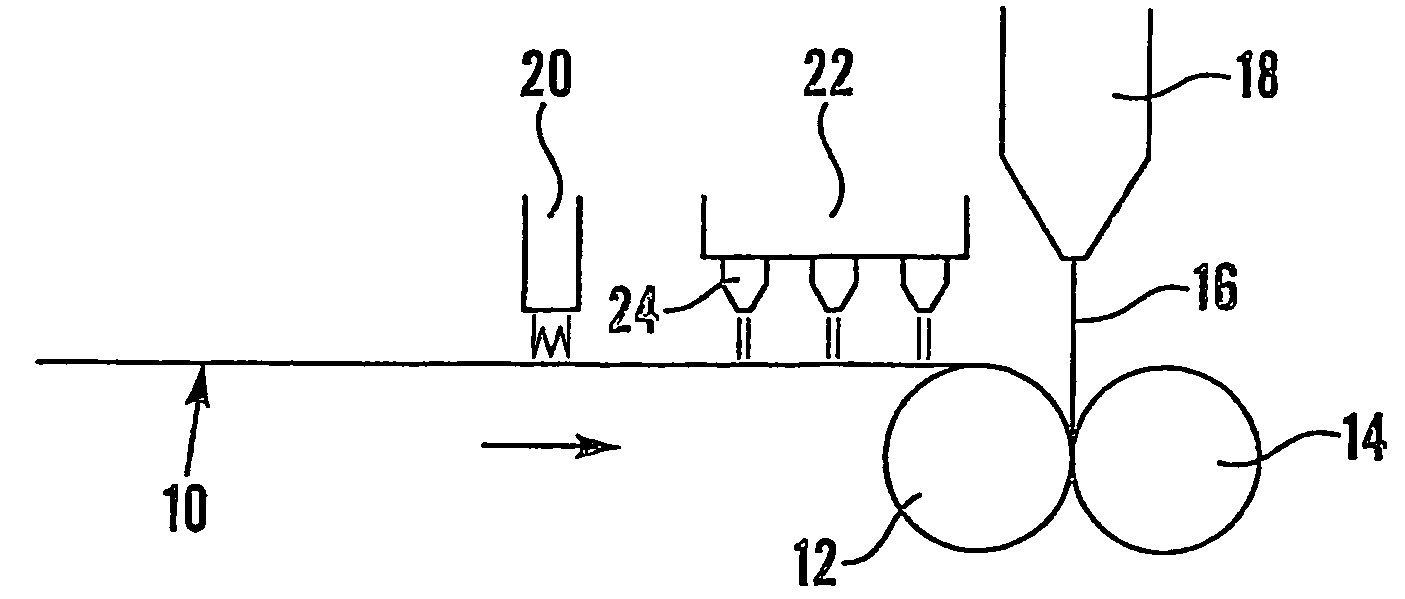

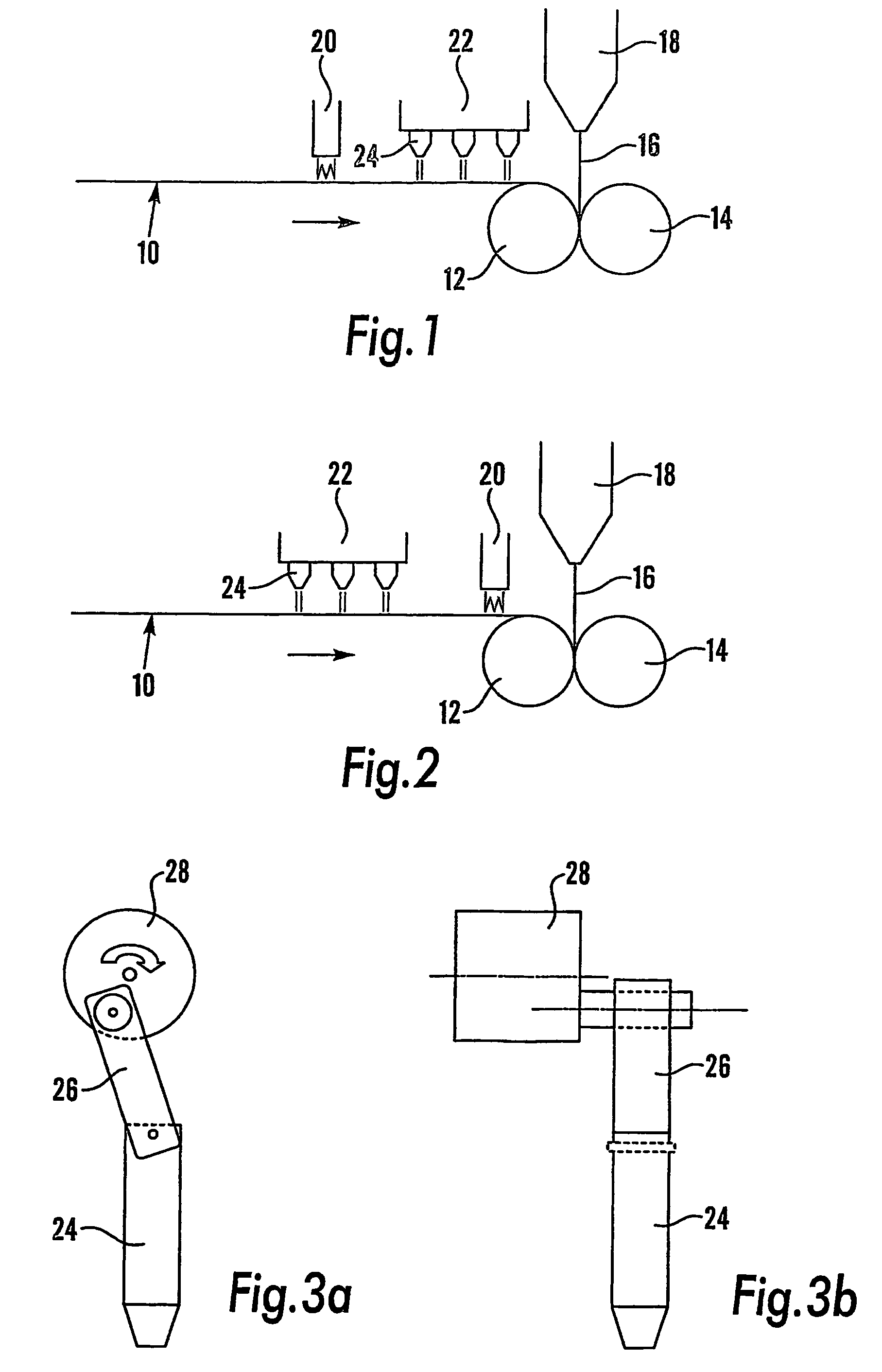

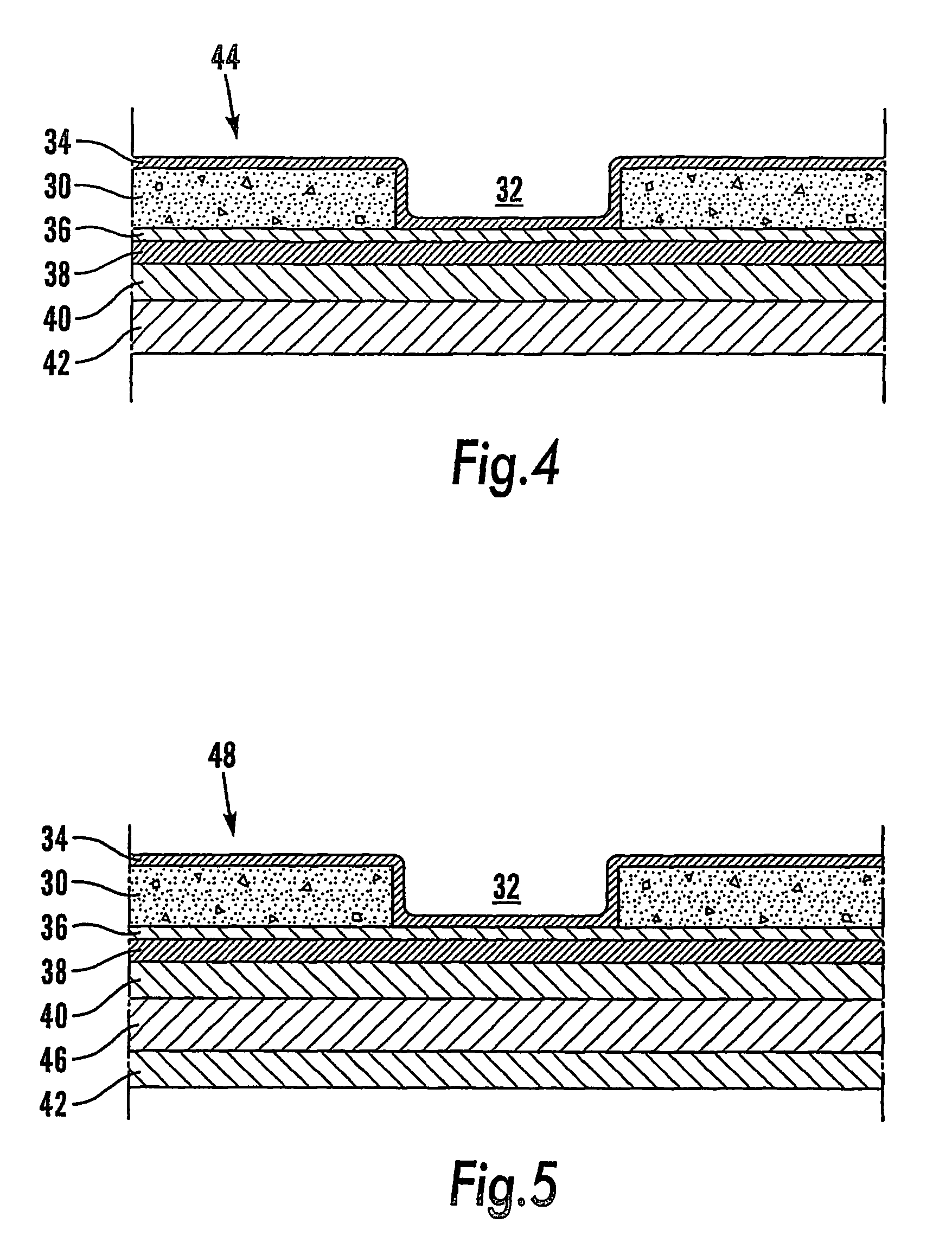

Method in production of packaging laminate

InactiveUS20070017632A1Improve adhesionImprove sealingAdhesive processesFlexible coversEngineeringFlame treatment

Method in connection with the continuous joining of a first layer (10, 38) of a first material and a second layer (16, 40) of a second material, to produce a packaging laminate (44, 48) comprising said first and second layers. According to the invention, a free surface of said first layer (10, 38) and / or a free surface of said second layer (16, 40) is subjected both to plasma treatment (24) and to flame treatment (20), where after said free surfaces are joined together (12, 14). The invention relates also to a packaging laminate thus produced and to a packaging container manufactured from such a packaging laminate.

Owner:TETRA LAVAL HLDG & FINANCE SA

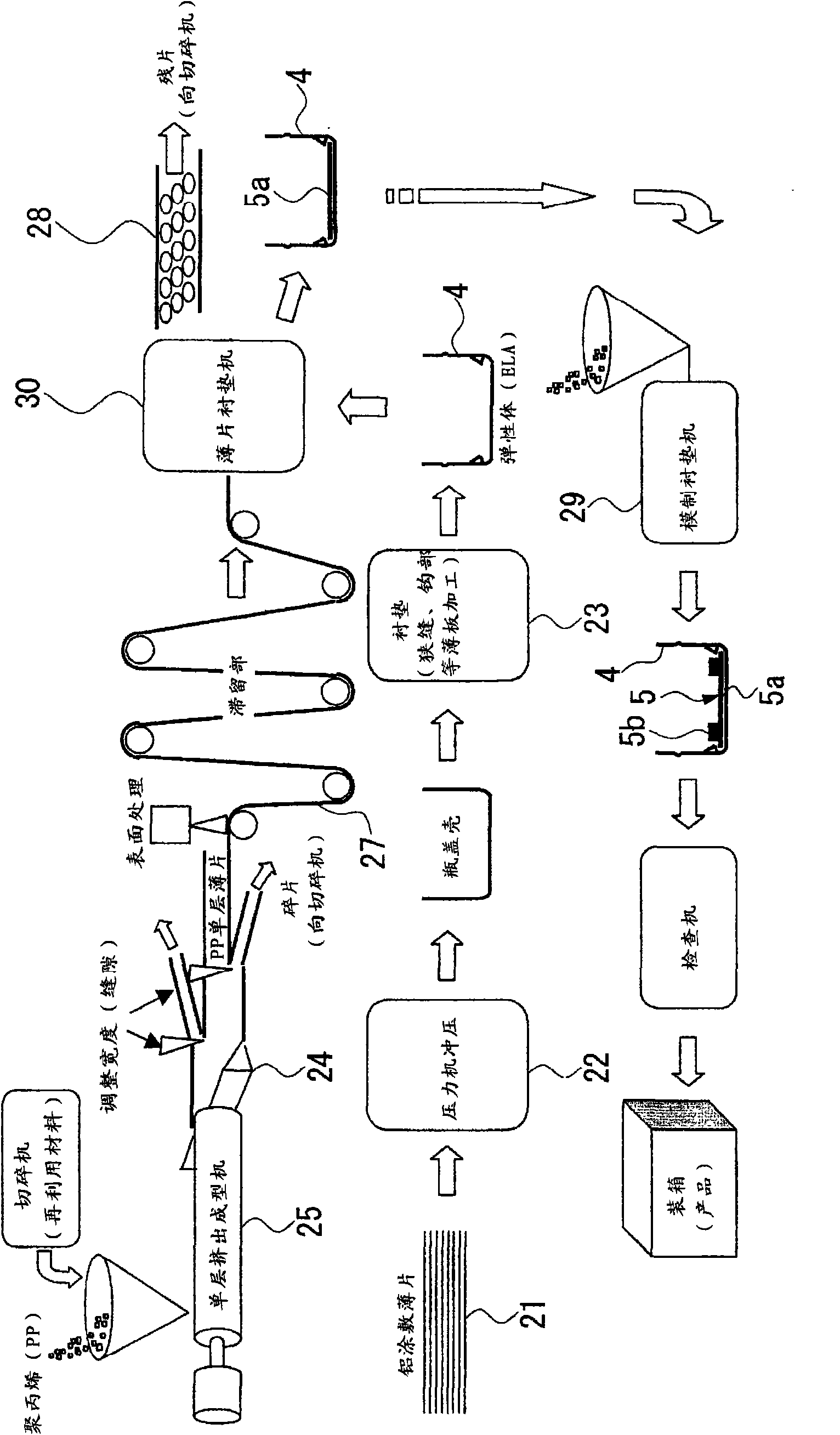

Easy-split stretched film, easy-split laminated film, easy-split bag, and manufacturing method for easy-split stretched film

ActiveCN1891756AExcellent straight cutImprove impact resistanceFlexible coversWrappersEngineeringRaw material

PROBLEM TO BE SOLVED: To provide an easily tearing stretched film having excellent linear cutting property and not causing interlayer exfoliation in a stretched film layer; and to provide an easily tearing laminate film and an easily tearing bag using the same, and a method for manufacturing an easily tearing stretched film.SOLUTION: The easily tearing stretched film includes a virgin raw material composed of 60 to 85 parts by mass of Ny6 and 15 to 40 parts by mass of MXD6, and a raw material containing a thermal history product prepared by melting and kneading Ny6 and MXD6 and having a melting point of the MXD6 of 233 to 238°C, wherein the content of the thermal history product is 5 to 40 mass% based on the total amount of the raw materials.

Owner:IDEMITSU UNITECH CO LTD

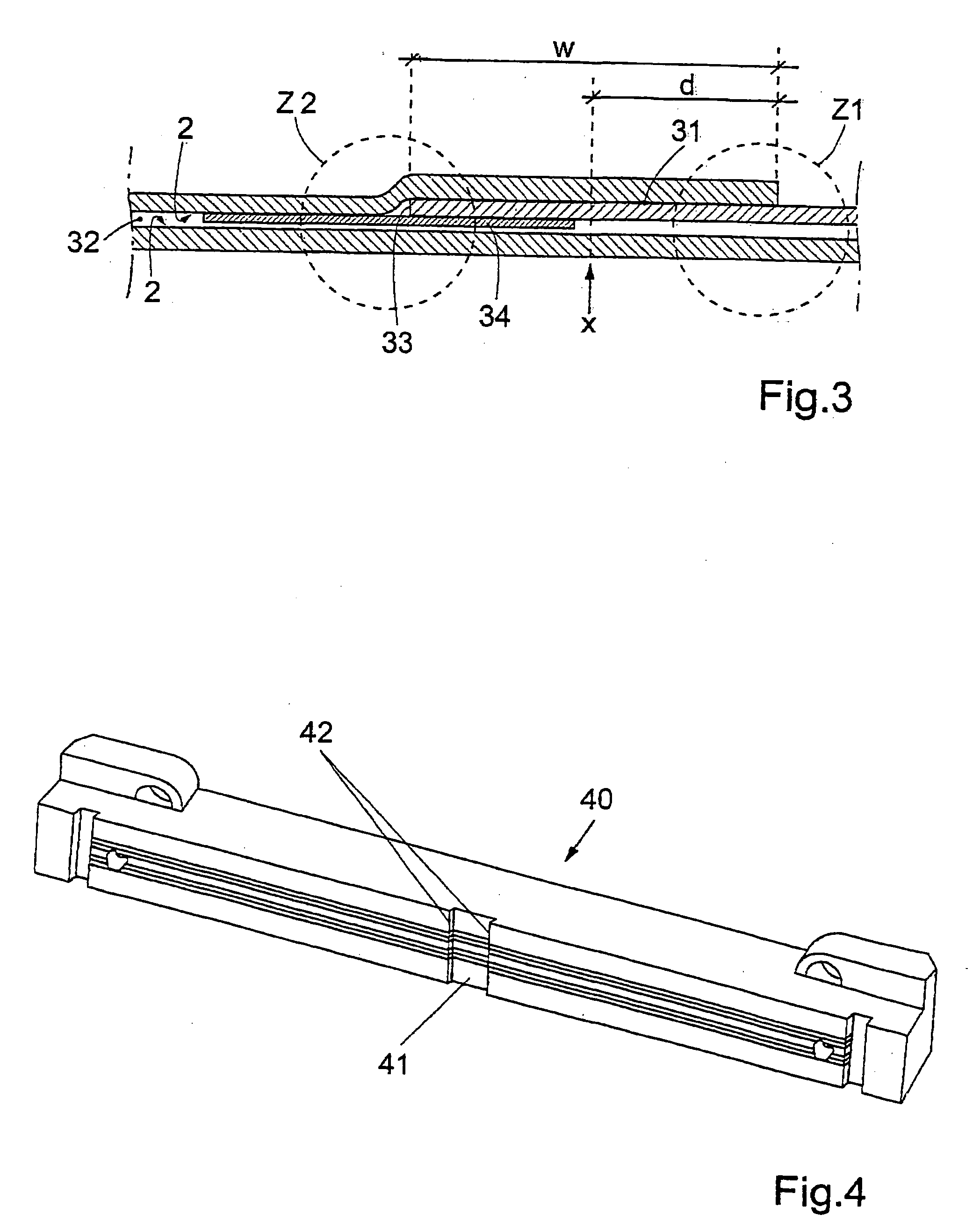

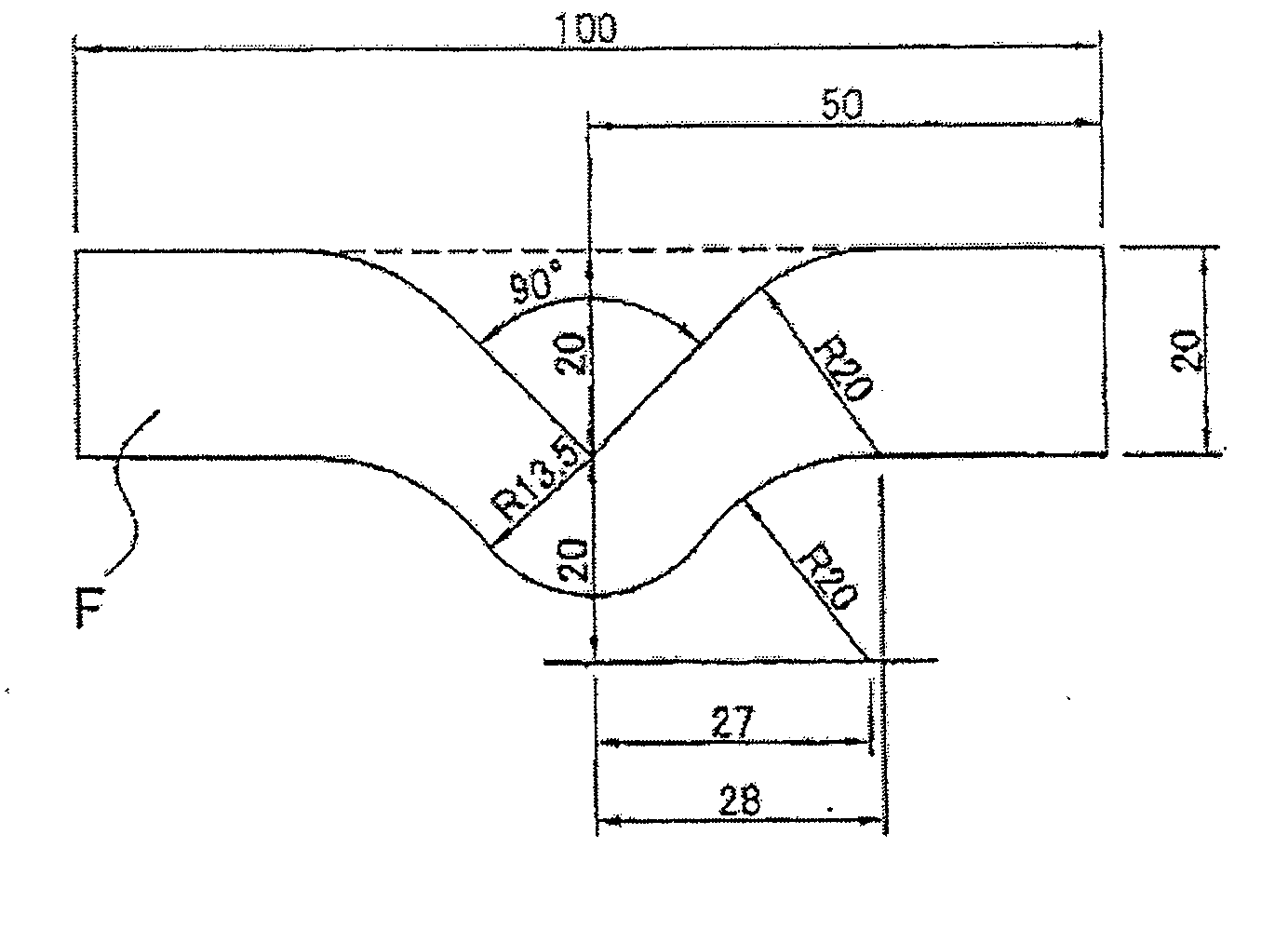

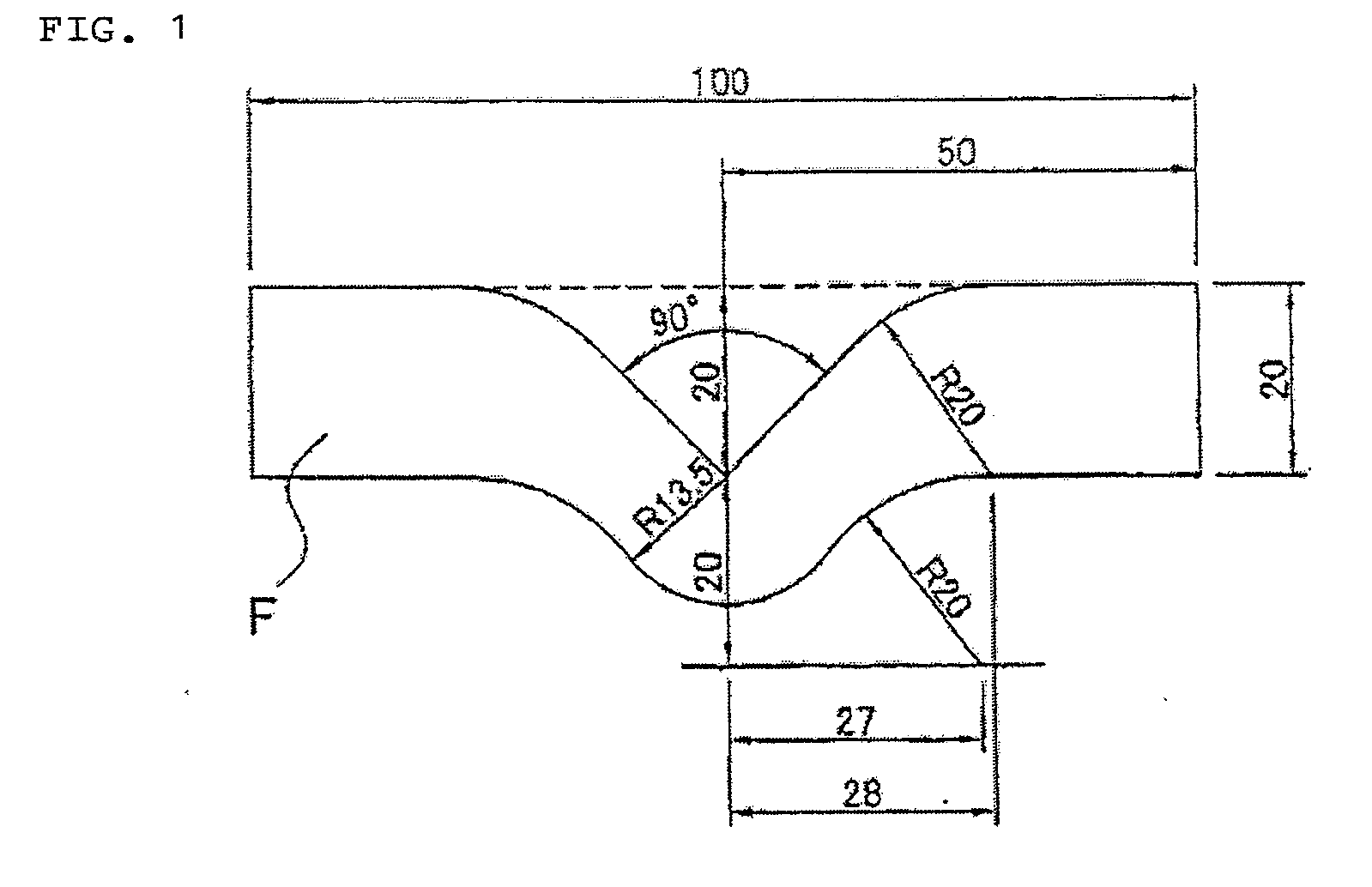

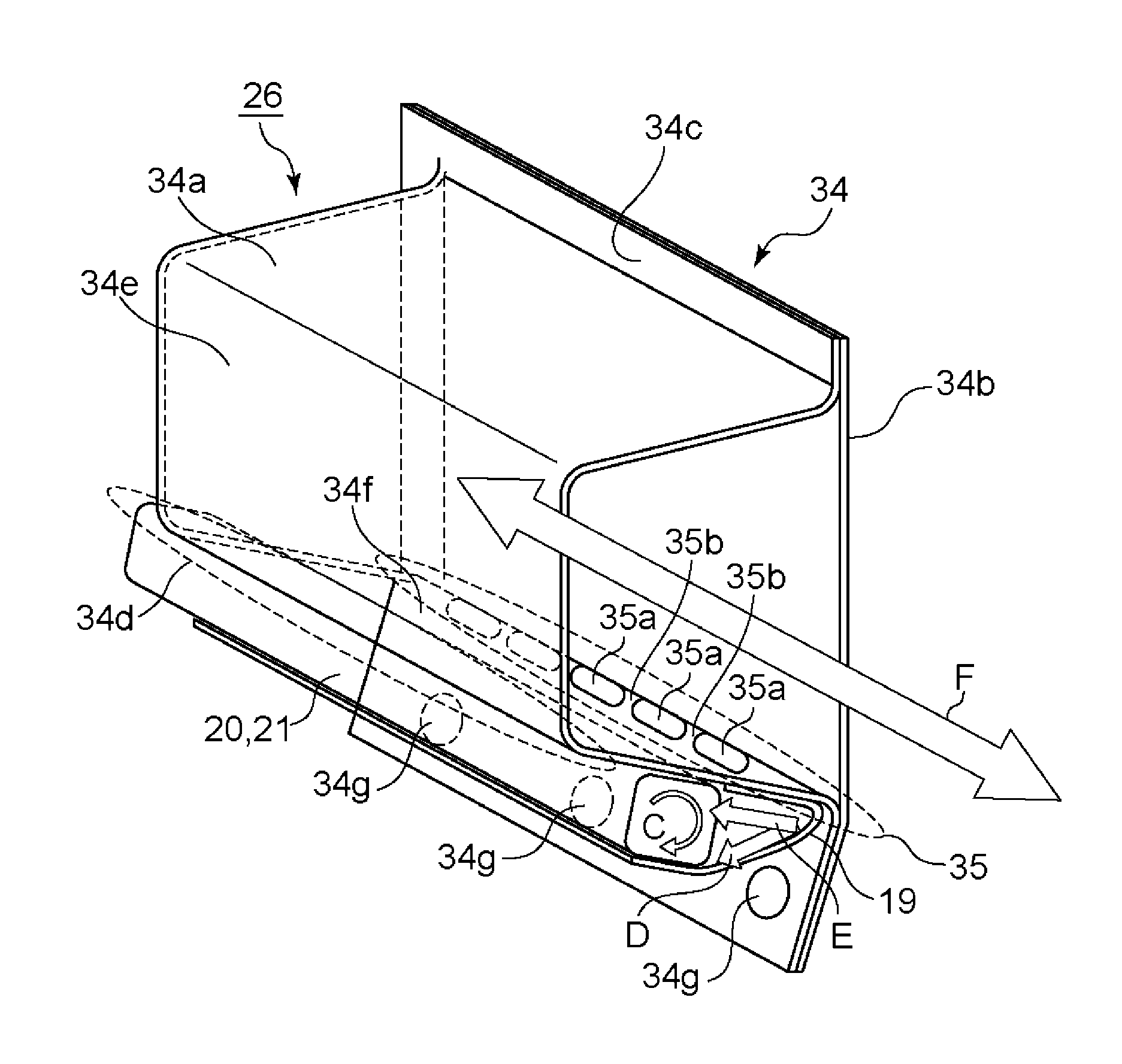

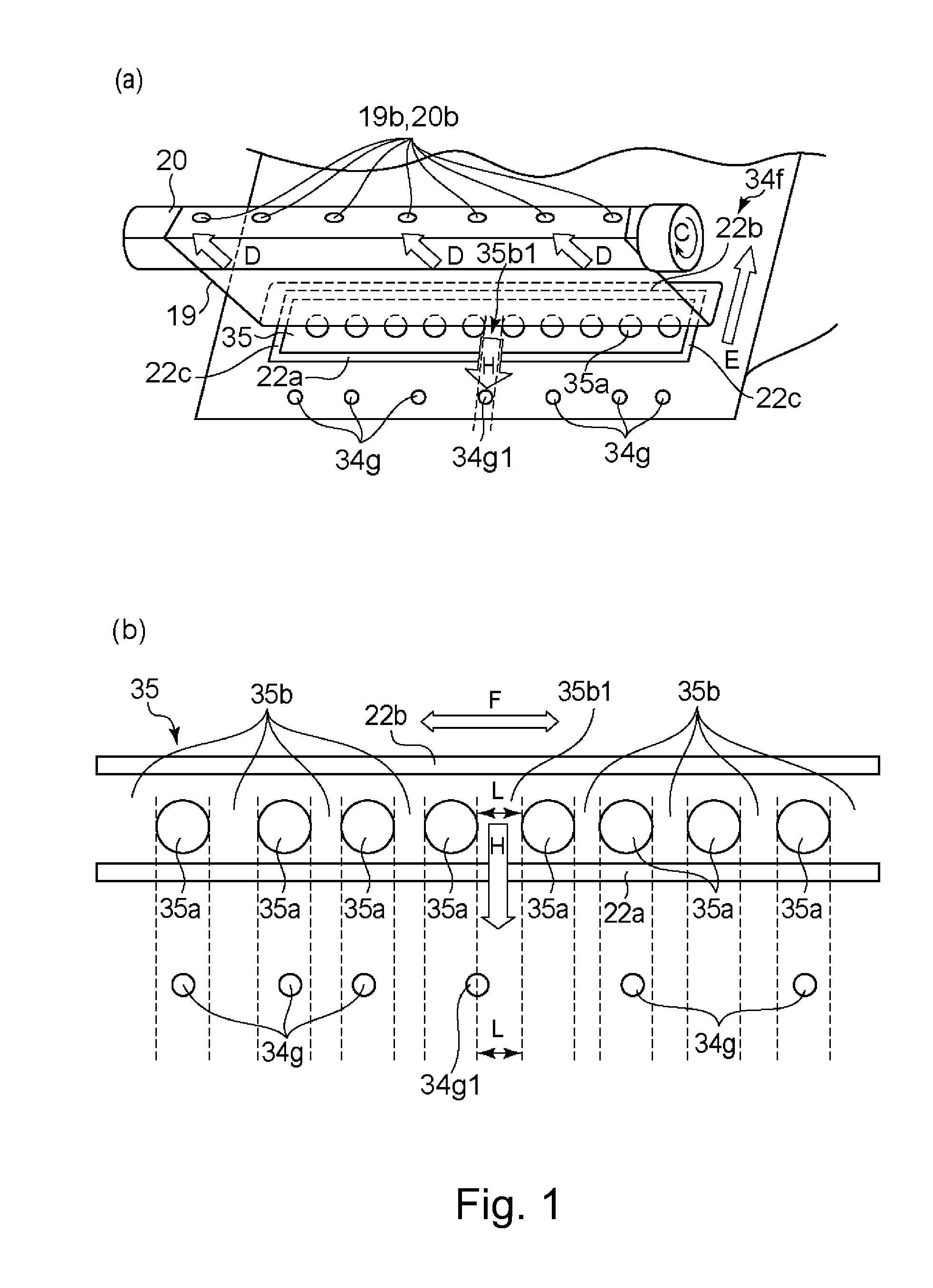

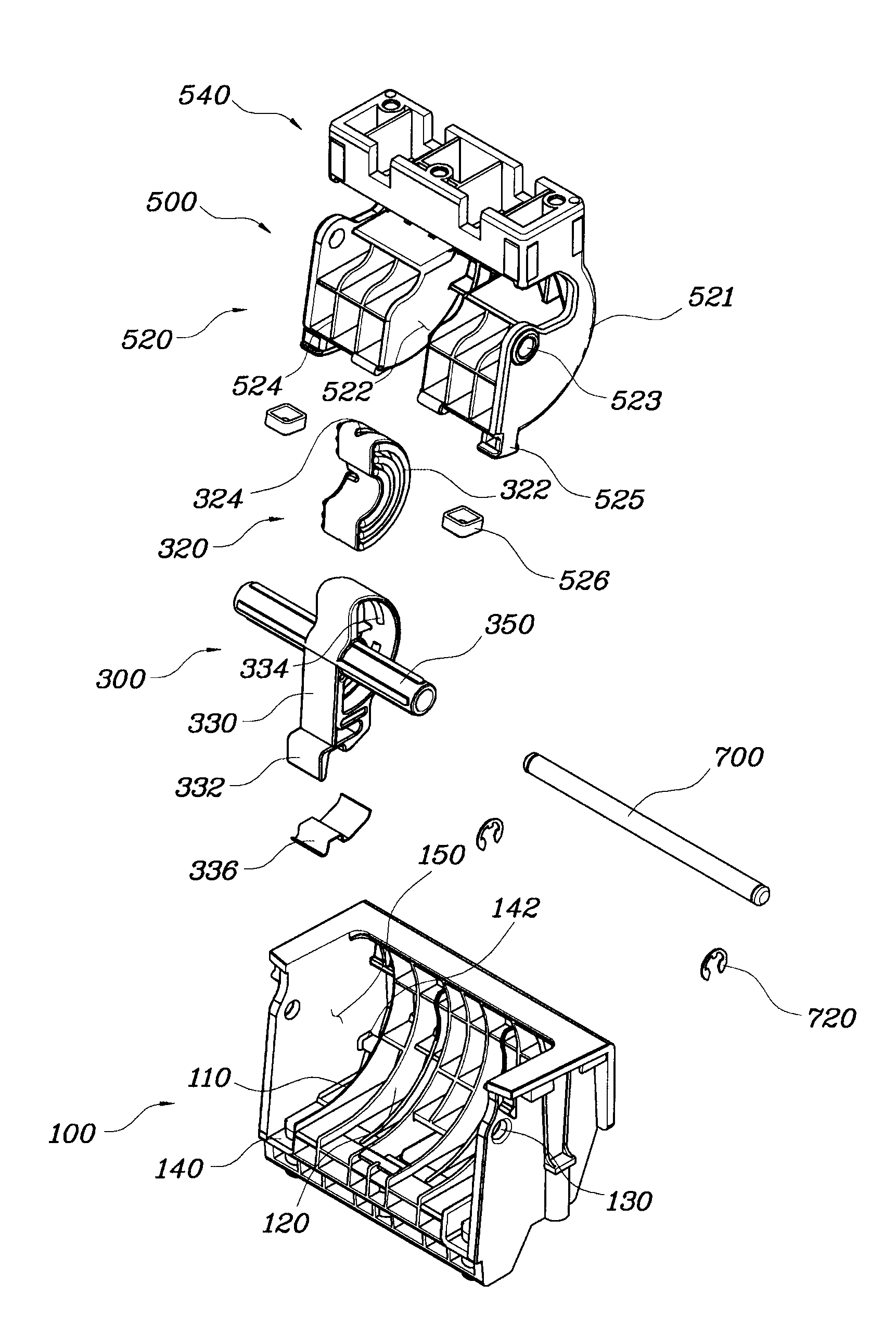

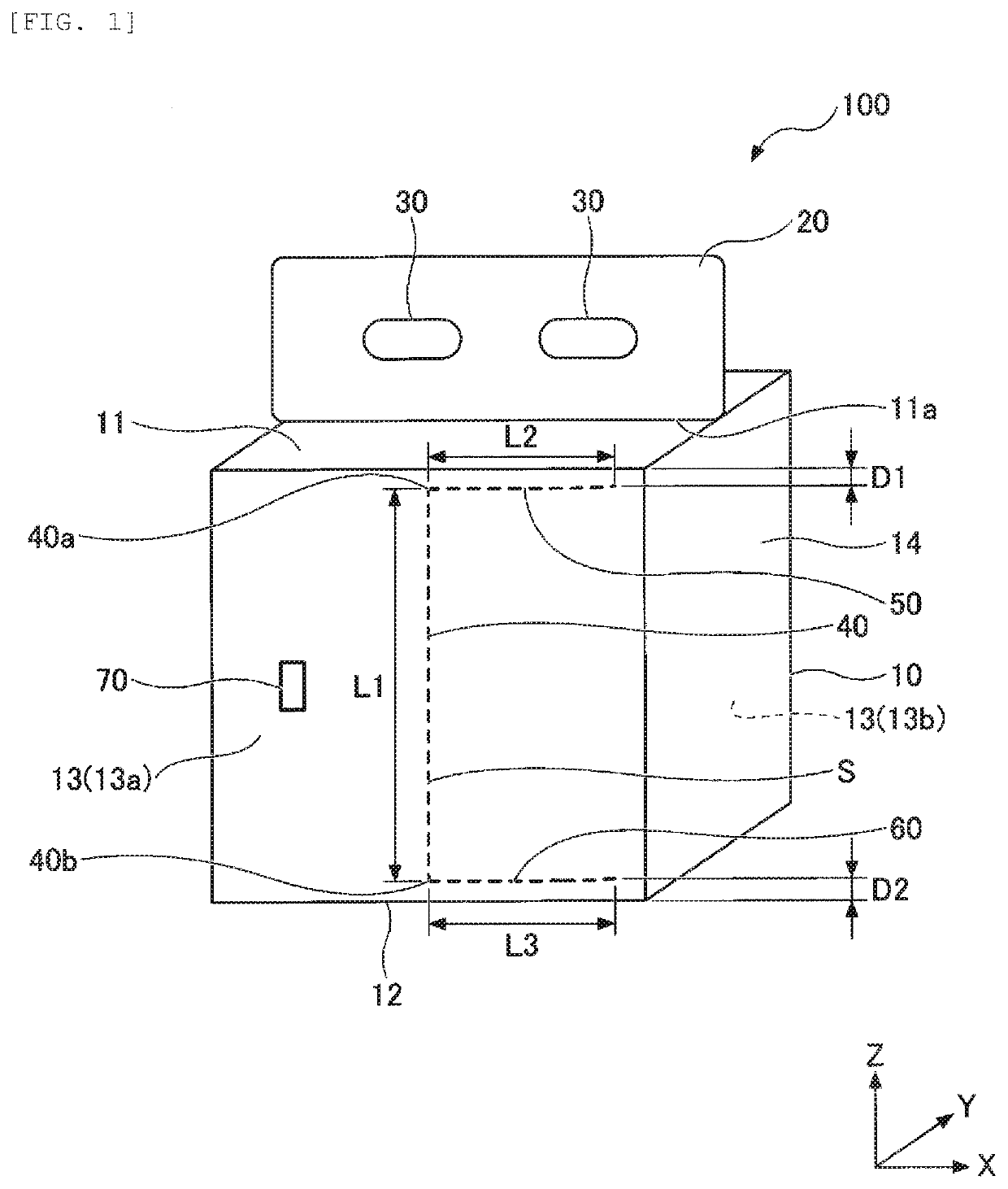

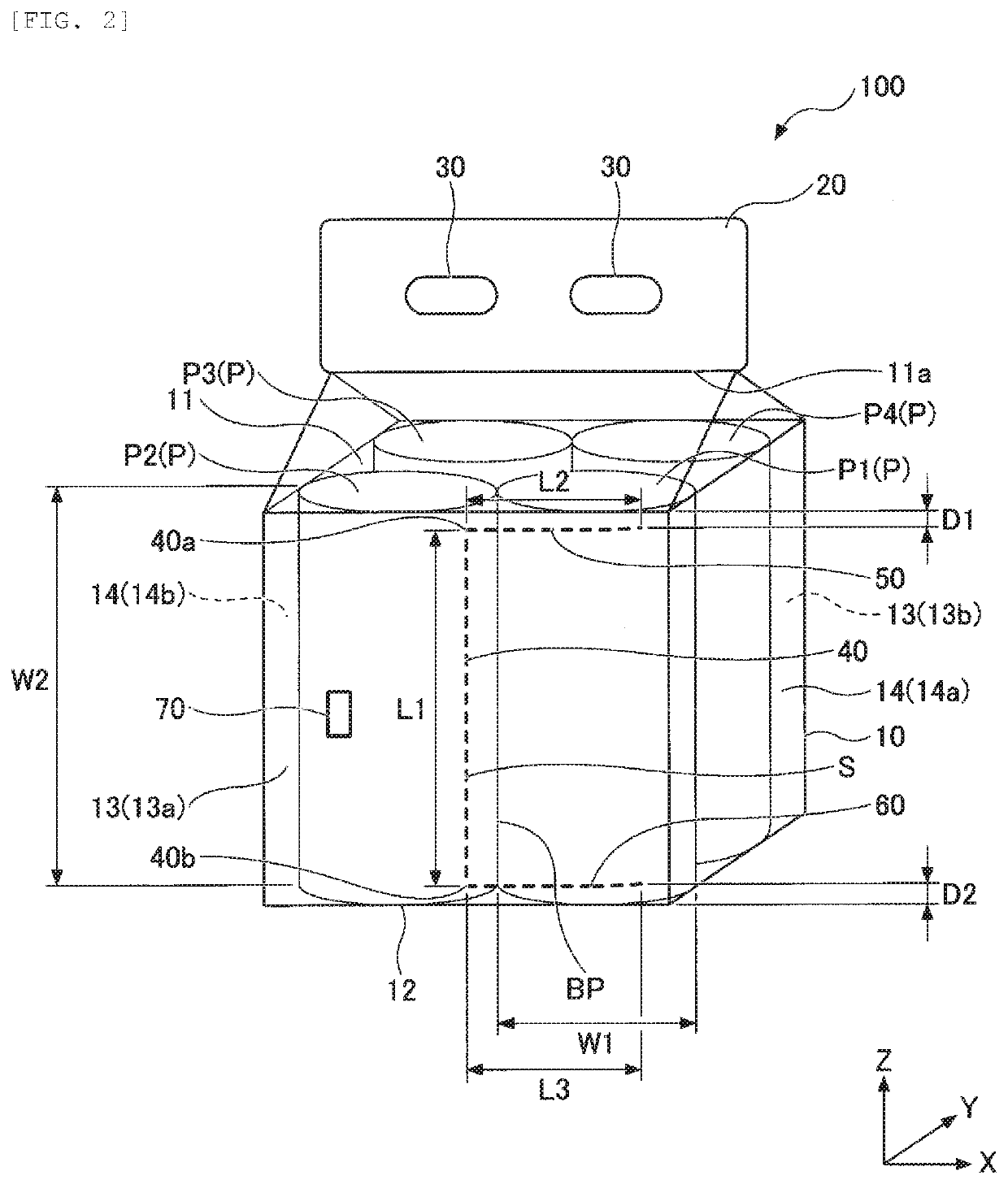

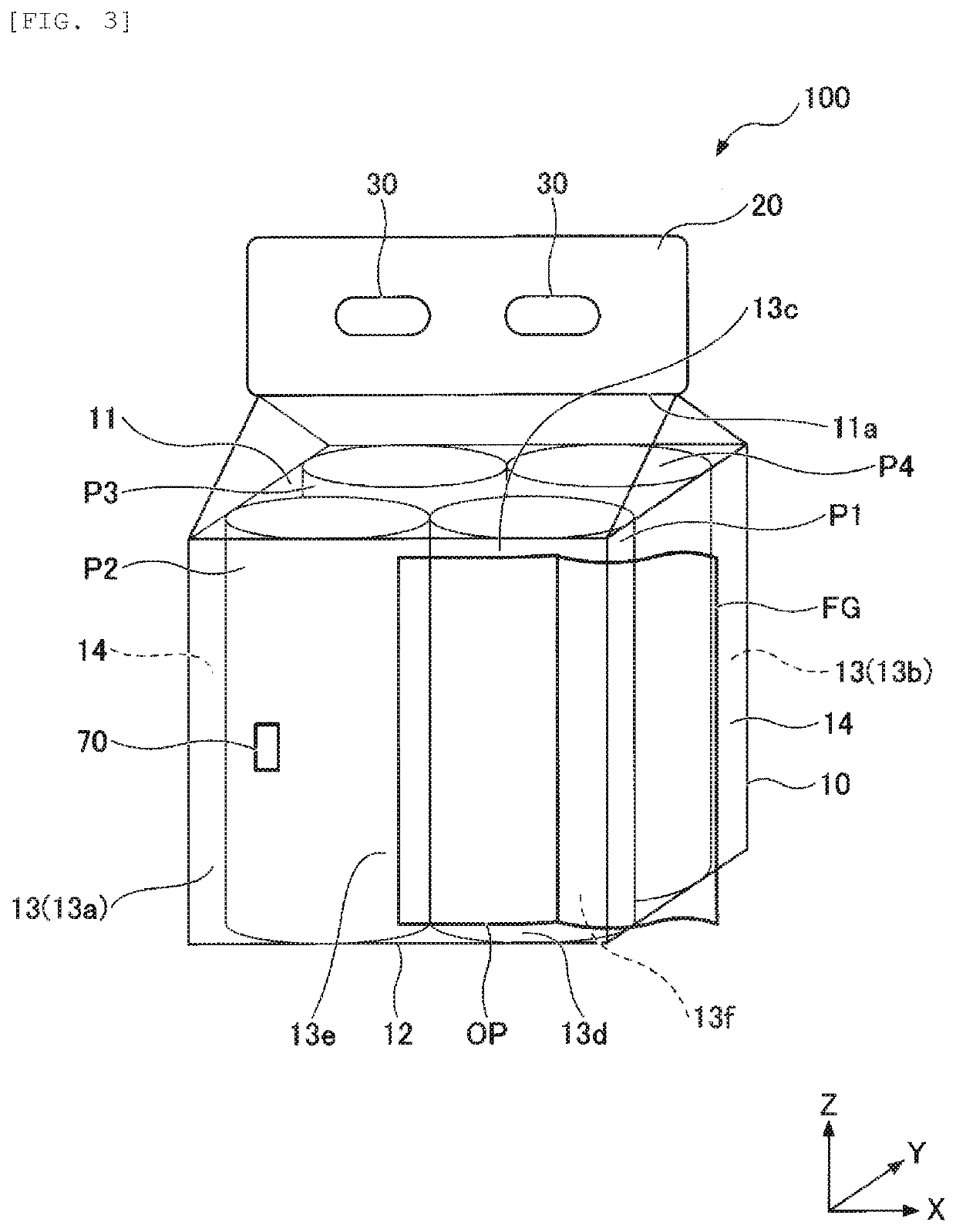

Developer accommodating unit, process cartridge, electrophotographic image forming apparatus

InactiveUS20130308973A1Easy to optimizeImprove openabilityElectrographic process apparatusEngineeringImaging equipment

With respect to an unsealing direction in which exposure of a discharging portion 35 advances, a fixing portion 34g of a developer accommodating member 34 is provided in a range of a region of a connecting portion 35b of the discharging portion 35.

Owner:CANON KK

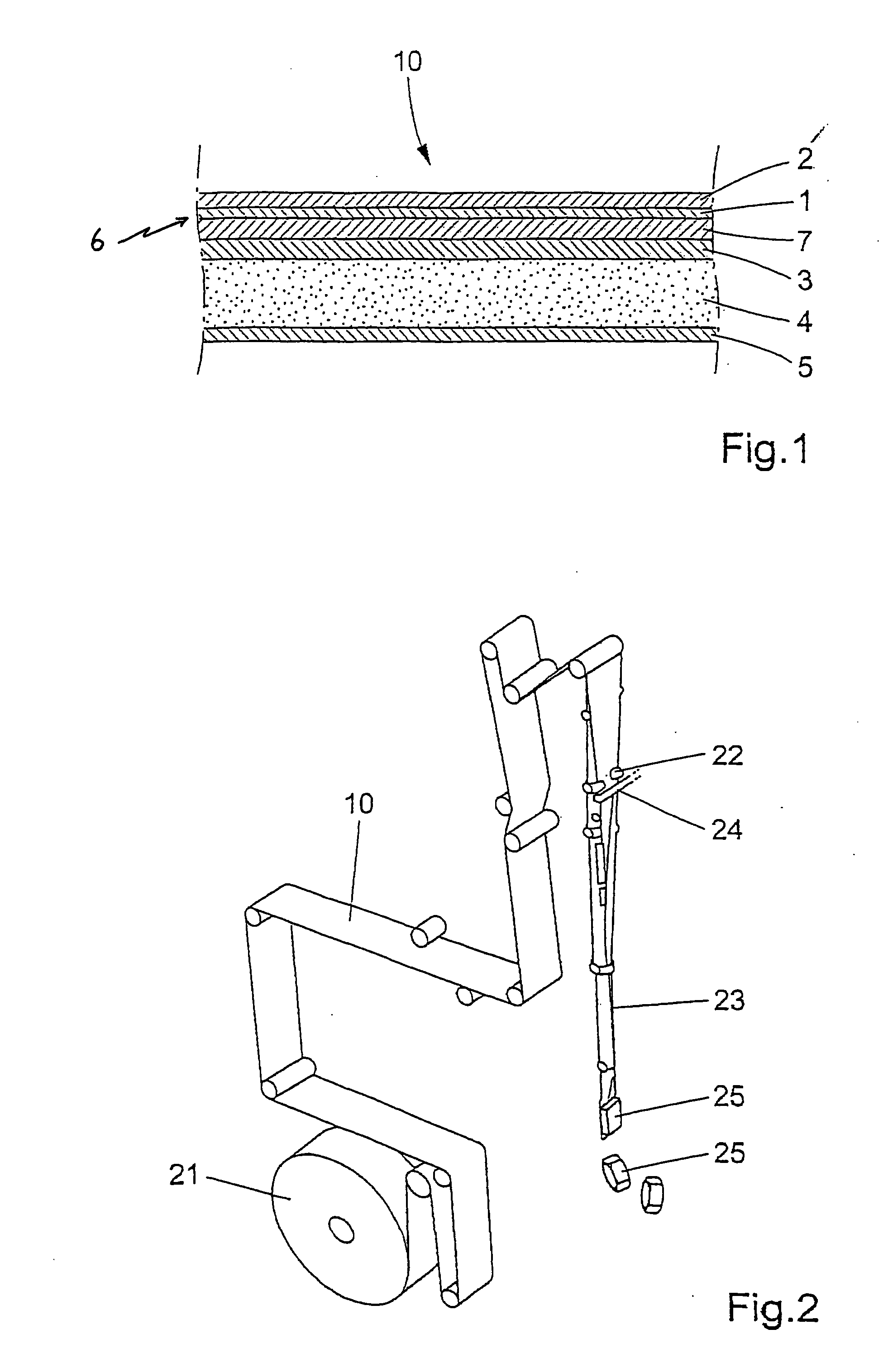

Packaging laminate, method of producing a packaging container and the packaging container

InactiveUS20040142130A1Considerable energy supplyStrong sealFlexible coversWrappersEngineeringPlastic property

Packaging laminate (10) for a packaging container, which packaging laminate comprises a structural base layer (4), and an inside layer (6). According to the invention, said inside layer (6) comprises a sealing ply (2) of a heat sealable thermoplastic material, which sealing ply is arranged to be the outermost layer on one side of the laminate (10), intended to be arranged on the inside of said container, said heat sealable thermoplastic material exhibiting a melt enthalply lower than 115 J / g. The invention also relates to a method of producing packaging containers from the packaging laminate, and to a packaging container produced from the packaging laminate.

Owner:TETRA LAVAL HLDG & FINANCE SA

Heat shrinkable polyolefin film and process for producing the same

ActiveUS20100093965A1Improve shrinkageExcellent perforated line openabilityMouldsSynthetic resin layered productsPolymer sciencePolyolefin

The inventive heat-shrinkable polyolefin film is high in shrinkability in the longitudinal direction that is its main shrinkage direction and excellent in finish properties after shrinkage, perforated line openability, and thermal blocking resistance. The heat-shrinkable polyolefin film is characterized by particular values with respect to hot-water heat shrinkage ratio in the longitudinal and width directions, right angle tear strength in the width direction, and heat-resistant peel strength.

Owner:TOYO TOYOBO CO LTD

Plastic ampule

ActiveCN102014845AEasy to removeImprove draining effectBottlesPharmaceutical containersAmpouleEngineering

Provided is a plastic ampule being handled suitably at the time of unsealing wherein remaining content liquid can be removed easily by performing a removal operation for dropping the remaining content liquid into a body portion by shaking the plastic ampule before use even when the content liquid remains in the hollow portion of a head portion. The plastic ampule comprises a body portion, a head portion (6) provided continuously to the mouth portion (3) of the body portion through a cut-off portion (10), and a knob portion (9) provided continuously to the head portion (6), the ampule being unsealed by twisting the knob portion (9) with fingers to cut the head portion (6) off the mouth portion (3), wherein the hollow portion (8) in the head portion (6) is formed in the shape of a bowl. Since the hollow portion (8) is formed in the shape of a bowl, content liquid remaining in the hollow portion (8) can be discharged easily, the plastic ampule can be unsealed easily, and the content liquid remaining in the hollow portion (8) is not scattered easily at the time of unsealing.

Owner:NIPPON ZOKI PHARM CO LTD

Developer accommodating unit, process cartridge, electrophotographic image forming apparatus

A developer accommodating unit for accommodating a developer for image formation includes a developer accommodating container including a flexible container provided with openings for permitting discharge of the accommodated developer and sealing member for sealing the openings by a bonding portion and for exposing the openings by being moved, an unsealing member, mounted on the sealing member, for moving the sealing member, and a frame which accommodates the developer accommodating container and the unsealing member and which includes a fixing portion for fixing the flexible container. In addition, connecting potion is disposed between the openings in the flexible container. With respect to an unsealing direction of the sealing member, the fixing portion and the connecting portion are provided so as to overlap with each other.

Owner:CANON KK

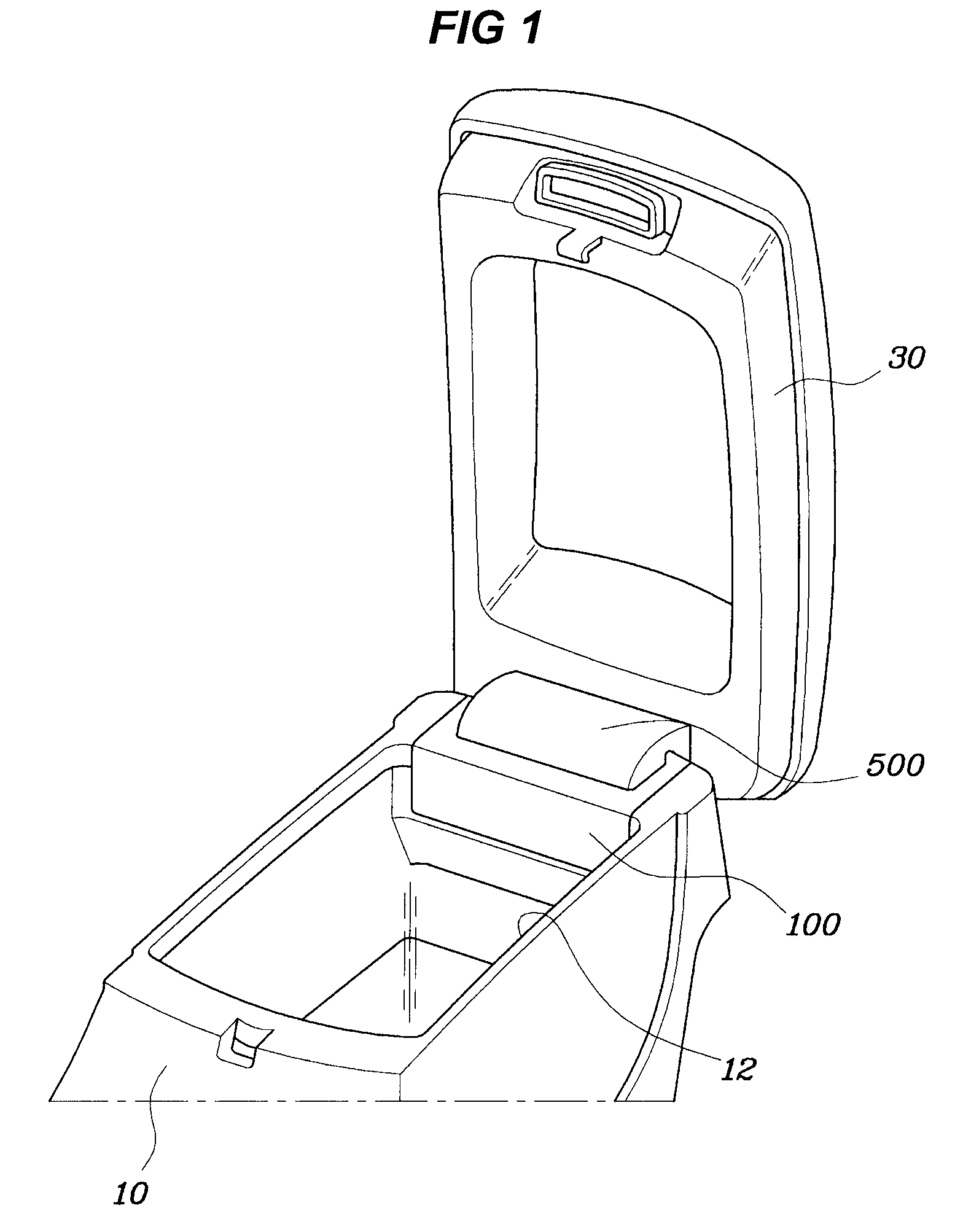

Armrest hinge unit for vehicle

ActiveUS8047592B2High strengthImprove opening and closing performancePassenger spaceArm restsHandrail

Owner:HYUNDAI MOTOR CO LTD +1

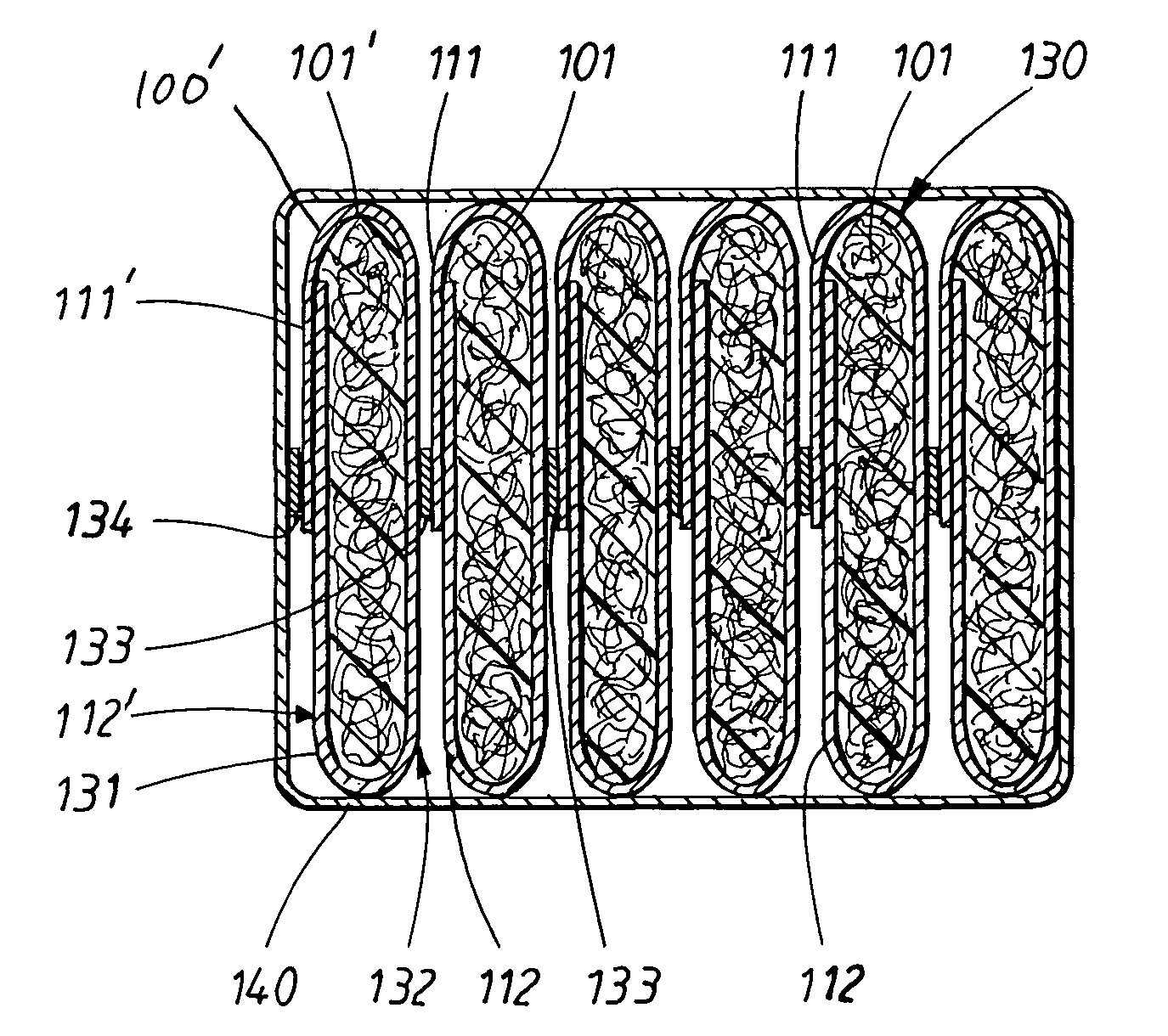

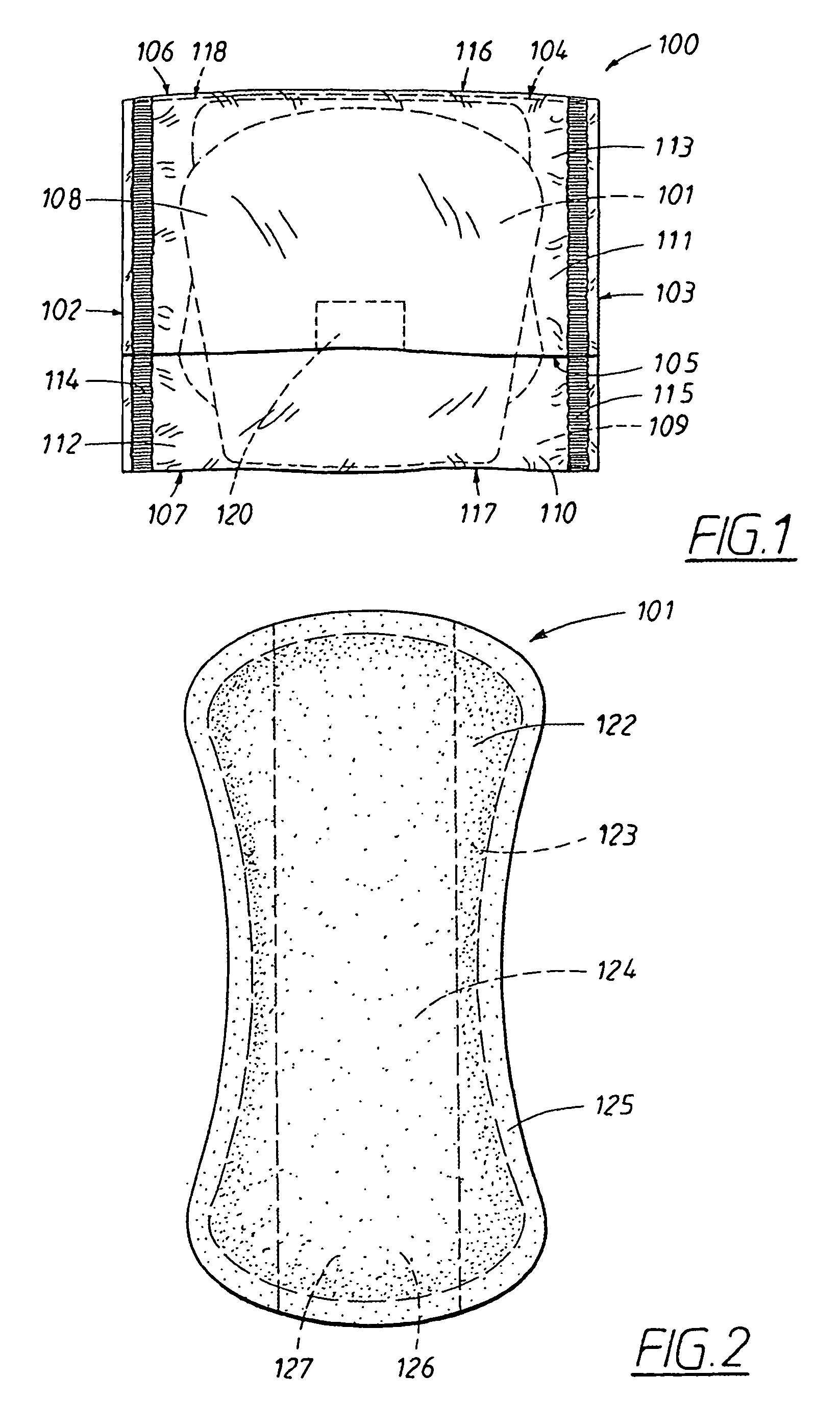

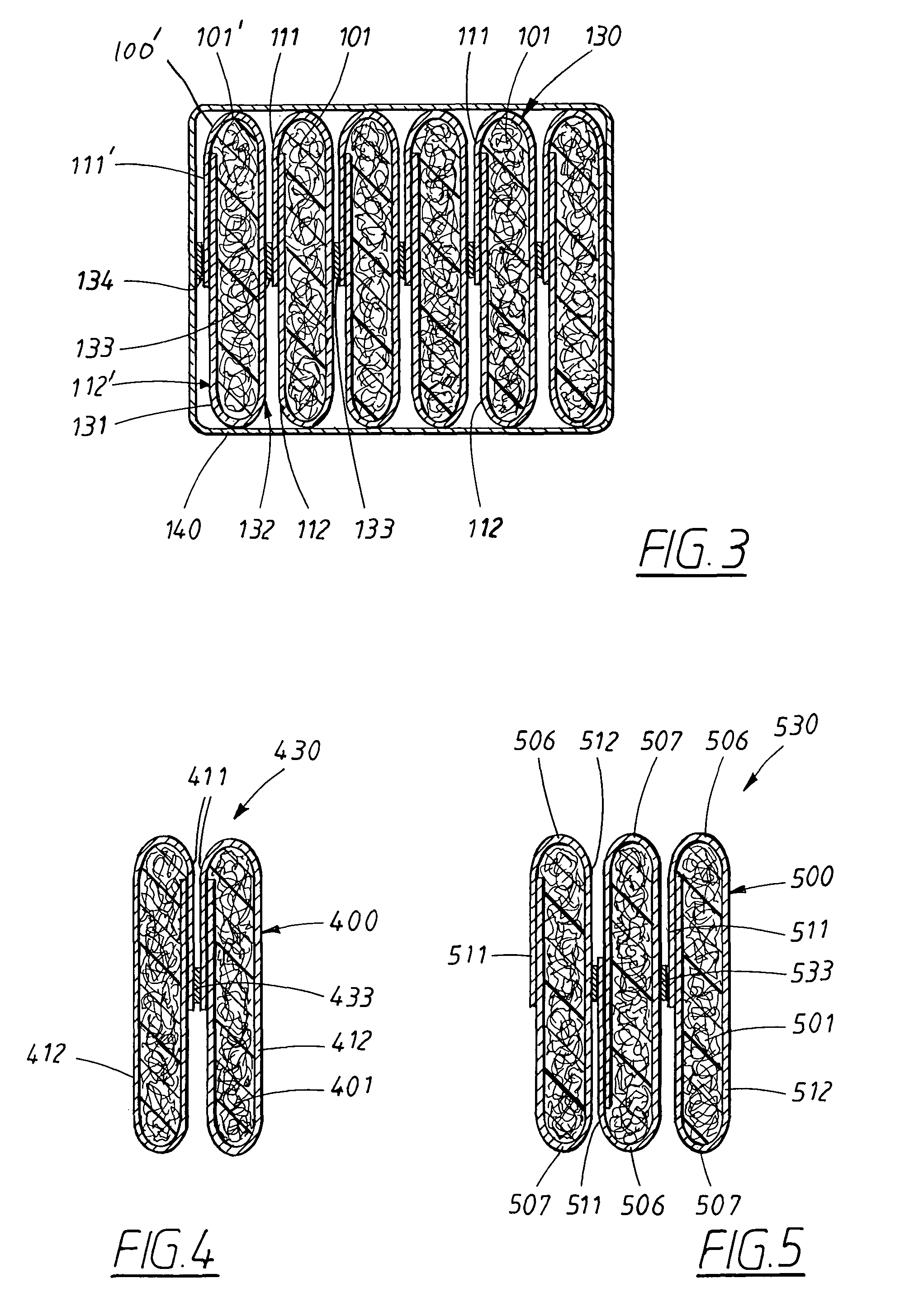

Opening arrangement for single-wrapped absorbent articles

Owner:SCA HYGIENE PROD AB

Laminate and packaging bag comprising same

ActiveCN112512806AImprove openabilityImprove heat resistanceSynthetic resin layered productsBagsPolytetramethylene terephthalateElastomer

Owner:TOYOBO CO LTD

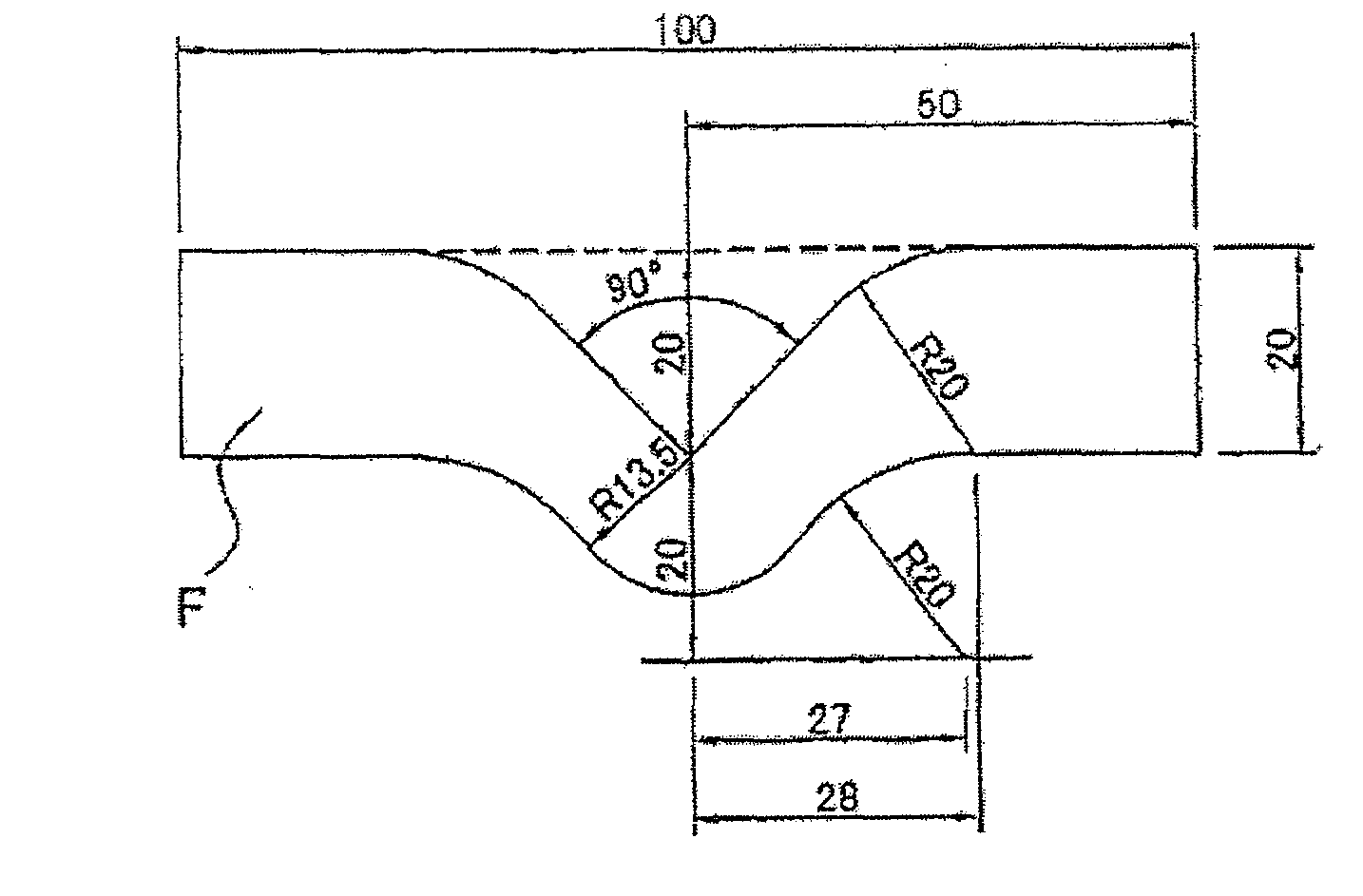

Reinforcing carbon fiber bundle, method for manufacturing the same and method for manufacturing composite using the same

ActiveUS9732195B2Improve openabilityImprove propertiesFibre typesThin material handlingFiber bundleCarbon fibers

There is provided a reinforcing carbon fiber bundle of the present invention is a reinforcing carbon fiber bundle with a sizing agent adhered to surfaces of carbon fibers, and characterized in that the sizing agent is constituted by at least two components, a first component does not melt at 150° C., and a second component in flowable at 150° C., and the reinforcing carbon fiber bundle is improved in impregnation property and openability and is excellent in workability and optimum for a composite.

Owner:TEIJIN LTD

Packaging laminate, method of producing a packaging container and the packaging container

InactiveUS20080041021A1Reduce sensitivityLow melt enthalpyFlexible coversWrappersEngineeringEnergy analysis

Owner:TETRA LAVAL HLDG & FINANCE SA

Liner-provided cap and cap-provided threaded container

ActiveCN101891031BHigh suitability for installationSmall unseal torque valueCapsClosure capsSoft layerBottle cap

The present invention discloses a liner-provided cap and a cap-provided threaded container. The liner-provided cap for sealing the mouthpiece of the threaded container includes the cap shell (4) consisting of the top plate (2) and the tubular peripheral wall section (3) that hangs from the peripheral edge of the top plate (2), and the synthetic resin liner (5) provided on the inner surface of the top plate (2). The liner (5) includes the disk-shaped rigid sheet (5a) disposed in contact with the inner surface of the top plate (2), and the soft layer (5b) that is laminated to the rigid sheet (5a) and is more flexible than the rigid sheet (5a). The soft layer (5b) is concentric with the rigid sheet (5a) and is formed in an annular or disk shape with a diameter smaller than that of the rigid sheet (5a) so that the soft layer (5b) can be brought into contact with at least the mouthpiece.

Owner:ALTEMIRA CAN MFG CO LTD

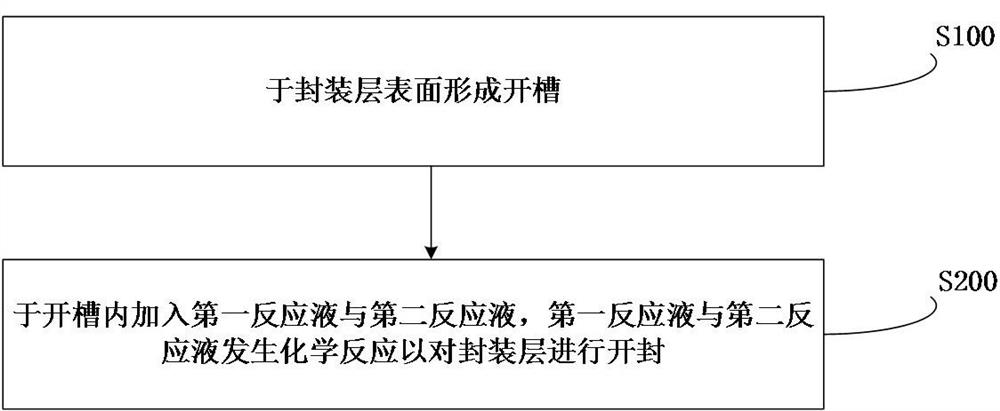

Unsealing method of plastic package device

ActiveCN114334749AUnpacking was successful and fastNo damageSemiconductor/solid-state device manufacturingPlastic packagingManufacturing engineering

The invention relates to an unsealing method of a plastic packaging device, which is used for unsealing a packaging layer of the plastic packaging device, and comprises the following steps: forming a slot on the surface of the packaging layer; and adding a first reaction solution and a second reaction solution into the open groove, and carrying out chemical reaction on the first reaction solution and the second reaction solution to unseal the encapsulation layer. According to the unsealing method of the plastic package device, the plastic package device can be unsealed successfully and quickly, and the unsealing effect is effectively improved.

Owner:SEMICON MFG ELECTRONICS (SHAOXING) CORP

Plastic cap

A plastic cap of this invention is opened by tearing-off and is comprising a top plate (1) provided with a sealing portion to be engaged with the mouth of a container, a skirt (2) extending perpendicularly from the top plate, and a tear-off portion (3) arranged around the skirt and defining an upper closure portion for resealing and a lower opening band, wherein in the inner surface of the skirt, at an upper position than the tear-off portion, a diametrically inwardly-directed protrusion which is engaged with a jaw of the container is formed peripherally intermittently, simultaneously, at a lower position than the tear-off portion, a flap piece (7) whose tip portion (71) is engaged with the jaw of the bottle is formed peripherally intermittently, and the engaged protrusion (6) and the flap piece are formed at least alternately in most of the peripheral direction. The plastic cap has excellent sealing reliability, easy openability, and tamper-evident property while the cap height is lowered and the resin weight of the resin is reduced.

Owner:JAPAN CROWN CORK CO LTD

Method in production of packaging laminate

InactiveUS7767051B2Improve adhesionImprove sealingAdhesive processesFlexible coversFlame treatmentEngineering

Method in connection with the continuous joining of a first layer (10, 38) of a first material and a second layer (16, 40) of a second material, to produce a packaging laminate (44, 48) comprising said first and second layers. According to the invention, a free surface of said first layer (10, 38) and / or a free surface of said second layer (16, 40) is subjected both to plasma treatment (24) and to flame treatment (20), where after said free surfaces are joined together (12, 14). The invention relates also to a packaging laminate thus produced and to a packaging container manufactured from such a packaging laminate.

Owner:TETRA LAVAL HLDG & FINANCE SA

Heat shrinkable polystyrene film and process for producing the same

The inventive heat-shrinkable polystyrene film is high in shrinkability in the longitudinal direction that is its main shrinkage direction, is excellent in perforated line openability, and has high toughness. The heat-shrinkable polystyrene film is characterized by particular values with respect to hot-water heat shrinkage ratio in the longitudinal and width directions, right angle tear strength in the width direction, and breaking energies in the longitudinal and width directions.

Owner:TOYOBO CO LTD

Packaging bag

ActiveUS20210002052A1Improve openabilityMaintain good propertiesBagsSacksEngineeringMechanical engineering

A packaging bag with a body for storing a plurality of articles to be packaged, wherein the body has a top surface part, a bottom surface part that opposes the top surface part in the vertical direction, and a plurality of lateral surface parts that are arranged between the top surface part and the bottom surface part; a slash part for opening is provided to at least one of the plurality of lateral surface parts; and the slash part has a first slit that extends from near the top surface part to near the bottom surface part in the vertical direction, and a second slit that is contiguous to one end of the first slit on the top surface part side and that extends in the traverse direction intersecting the vertical direction.

Owner:DAIO PAPER CORP

packaging bag

ActiveCN111699138BImprove openabilityExcellent extractabilityBagsSacksEngineeringMechanical engineering

Owner:DAIO PAPER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com