Fastener and bag having same

A buckle and component technology, applied in the direction of bags, fasteners, sacks, etc., can solve problems such as difficulty in opening, and achieve the effect of easy opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0076] First, the first embodiment of the bag with snap closure of the present invention will be described.

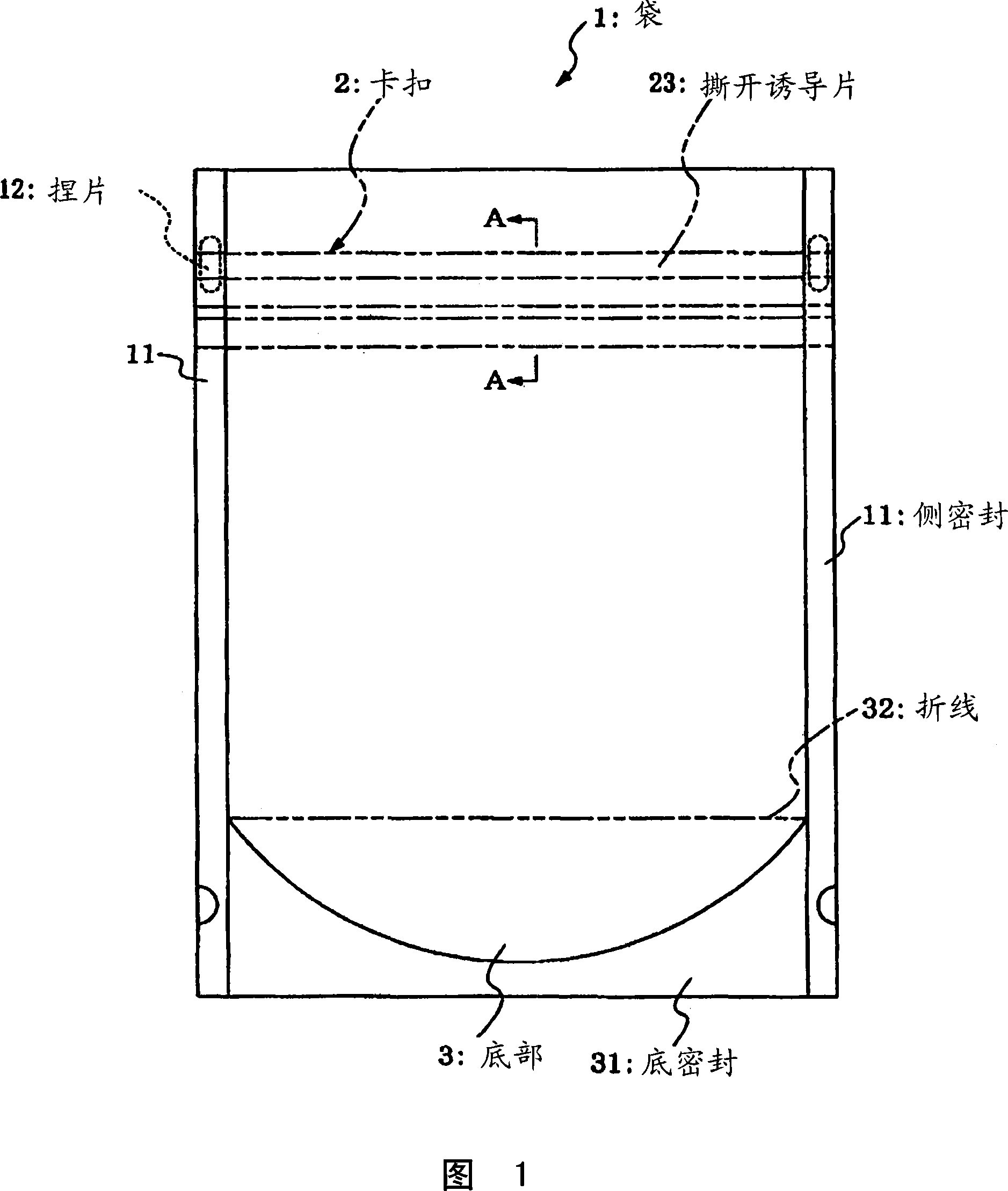

[0077] In addition, FIG. 1 is a schematic front view showing a first embodiment of a bag with a buckle according to the present invention.

[0078] The bag 1 shown in FIG. 1 is made by bagging base film 10a, 10b as a bag material with heat-sealed buckle 2, and in a state where the bottom 3 with the bottom seal 31 is folded at the fold line 32, along the A so-called stand-up pouch manufactured by applying a side seal 11 to the side edge.

[0079] In addition, in the illustrated example, the upper edge of the bag 1 is set as an unsealed portion, but the top seal 13 is performed after the contents are filled.

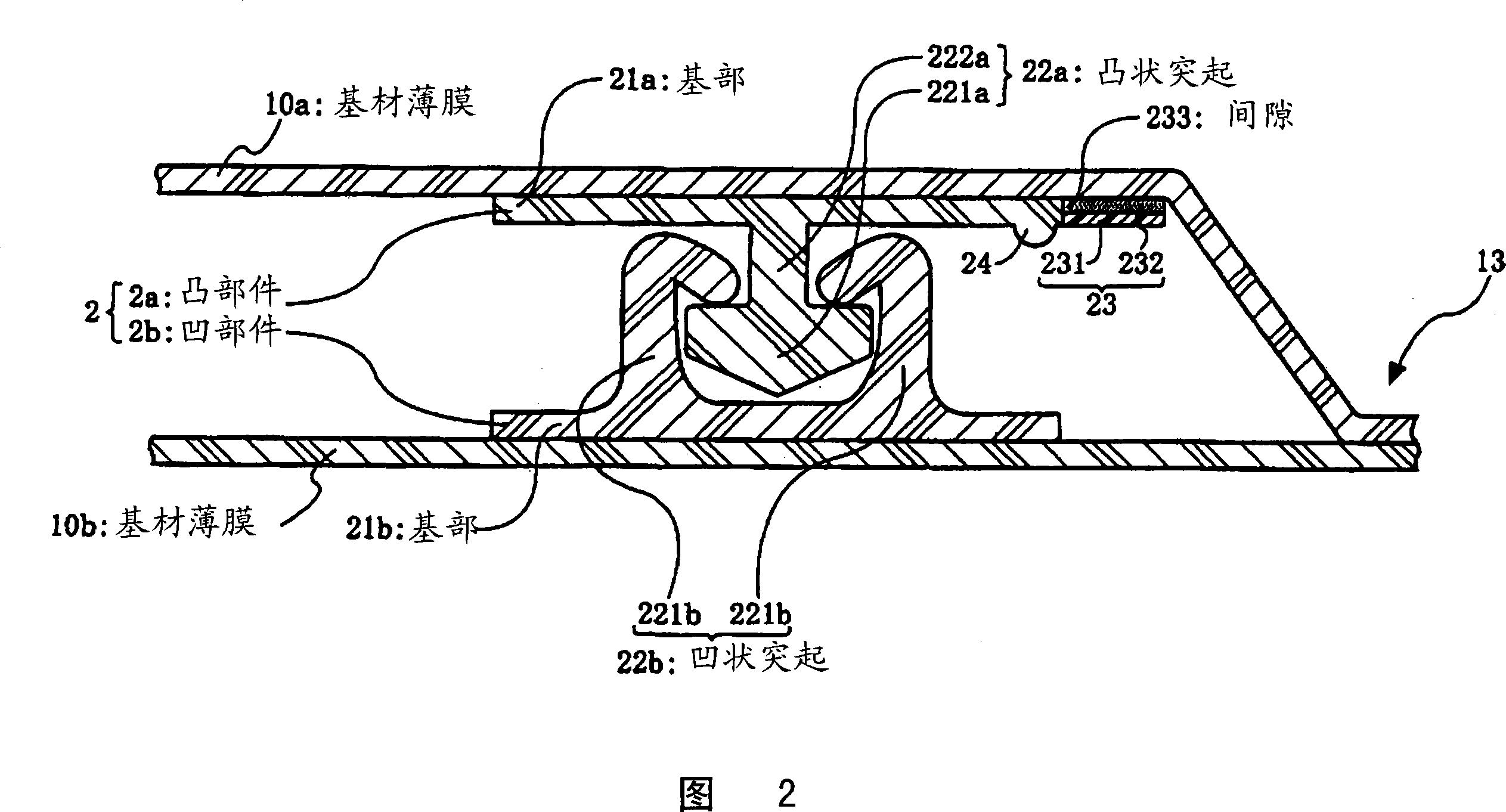

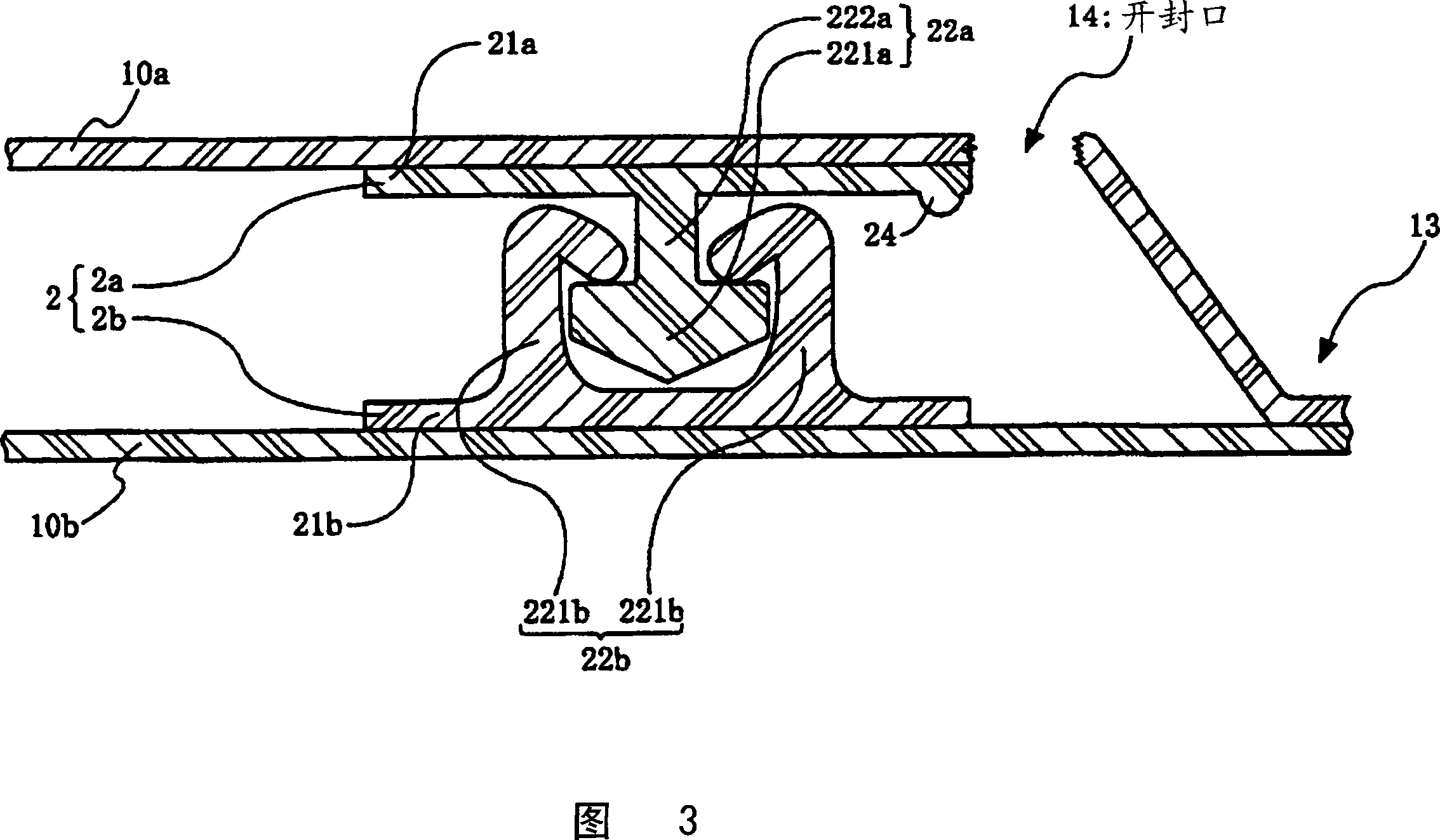

[0080] Here, FIG. 2 is a schematic cross-sectional view of a portion corresponding to the A-A section of FIG. 1 in a state where the top seal 13 is implemented, and the top seal 13 is implemented so that it is connected to the buckle 2 mounted on the top of the ba...

no. 2 approach

[0134] Next, a second embodiment of the bag with snap closure of the present invention will be described.

[0135] In addition, FIG. 11 is a schematic front view showing an embodiment of the bag with a snap of the present invention. The bag 1 shown in FIG. 11 is made by bagging the base film 10a, 10b as the bag material with the buckle 2 heat-sealed, and in the state where the bottom 3 with the bottom seal 31 is folded at the fold line 32, along the A so-called stand-up pouch manufactured by applying a side seal 11 to the side edge.

[0136] In addition, in the illustrated example, the upper edge of the bag 1 is set as an unsealed portion, but the top seal 13 is performed after the contents are filled.

[0137] Here, FIG. 12 is a schematic cross-sectional view showing a portion corresponding to the section C-C in FIG. 11 in a state where the top seal 13 has been applied. After filling the content between the concave member 2b and the base film 10b, the Top seal13.

[0138] ...

Embodiment 1

[0178] One side melt extrusion density is 926kg / m 3 , Low-density polyethylene (melting point: 110°C) with an MFR of 1.5g / 10min is used to extrude the convex part, while using a density of 900kg / m in the base material 3 , Atactic polypropylene with an MFR of 7.0g / 10min (melting point: 134°C), used in the heat-sealing layer with a density of 900kg / m 3 , MFR is 4.0g / 10min metallocene-based linear low-density polyethylene, they are extruded and supplied to one widthwise end of the convex member on the unsealing side of the bag, and while the convex member is formed, the The tear inducing sheet is integrally formed with the male member, resulting in the male member having the tear inducing sheet. At this time, the heat seal layer of the tear inducing sheet was formed at a distance of 0.6 mm so as to create a gap with the base of the convex member.

[0179] A female part having a tear-inducing piece was also formed to obtain a zipper belt having a pair of male parts and female pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com