Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Improve mold opening efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

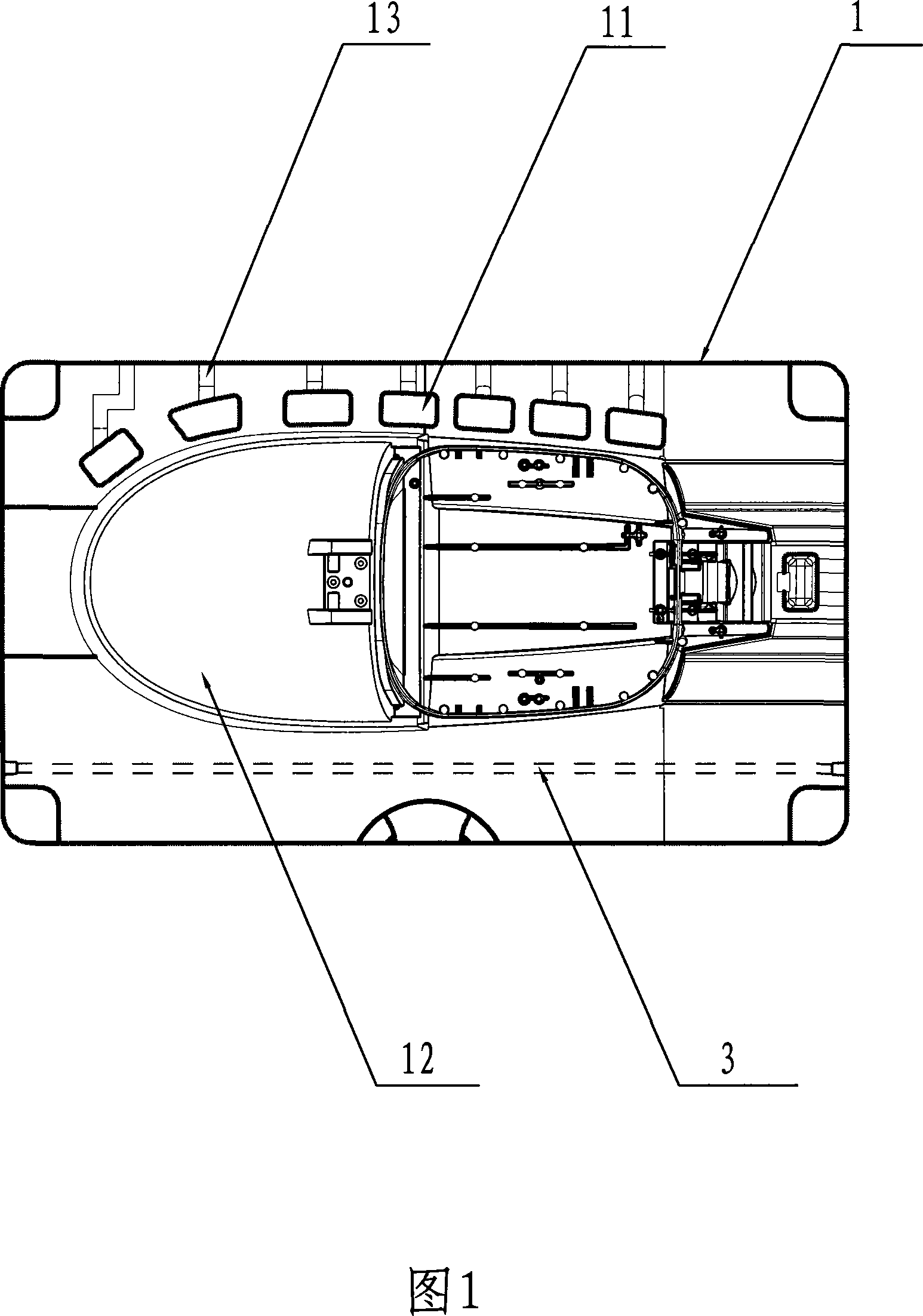

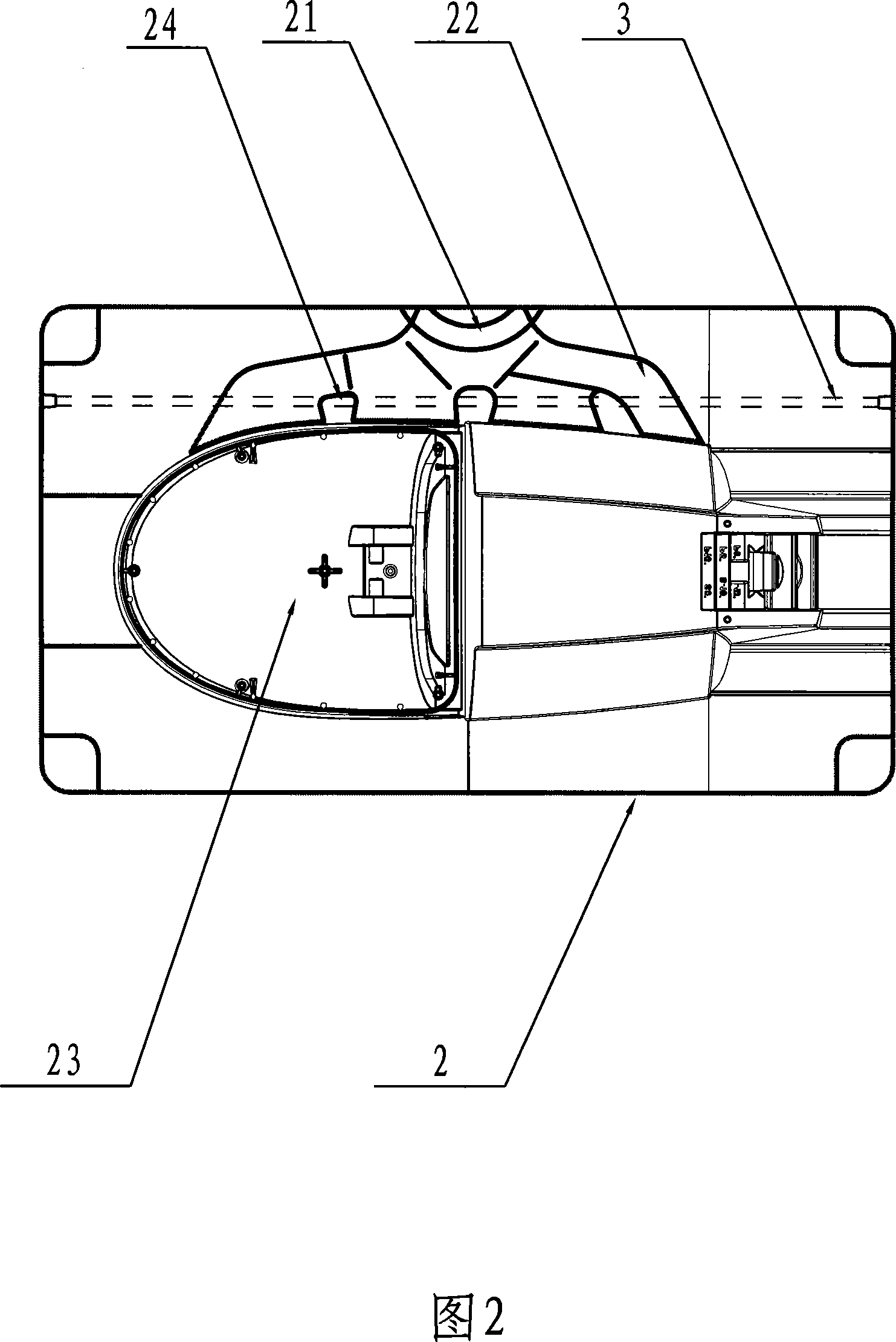

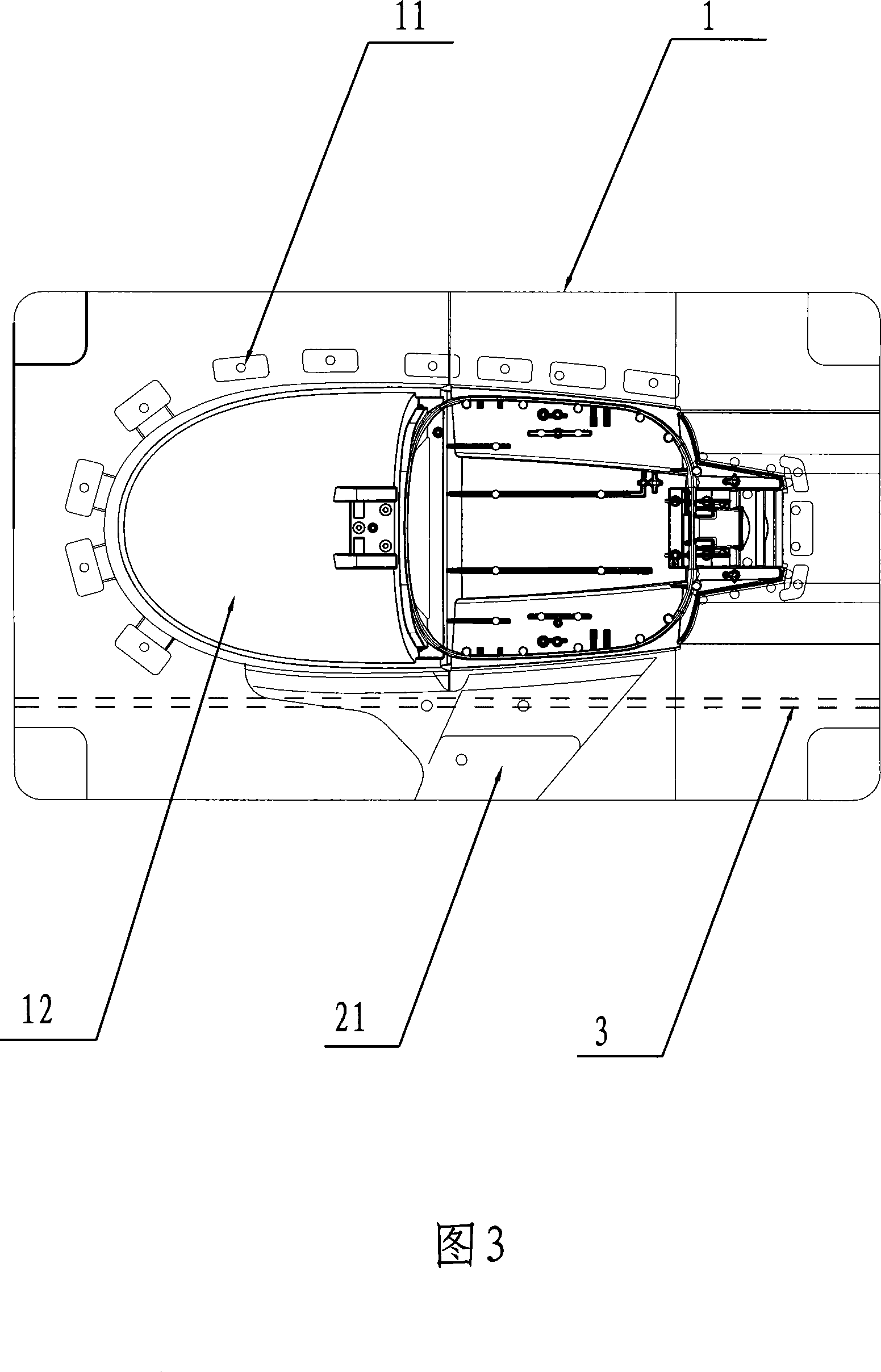

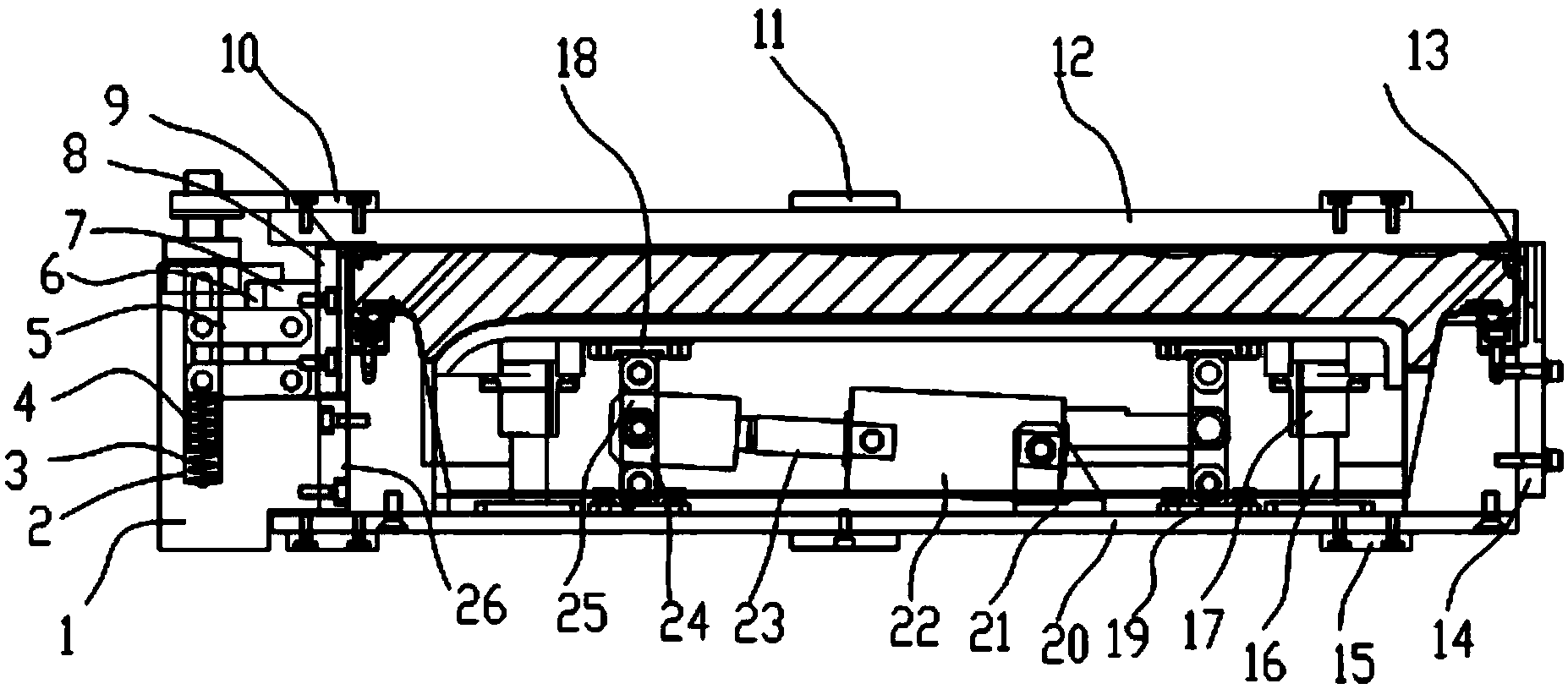

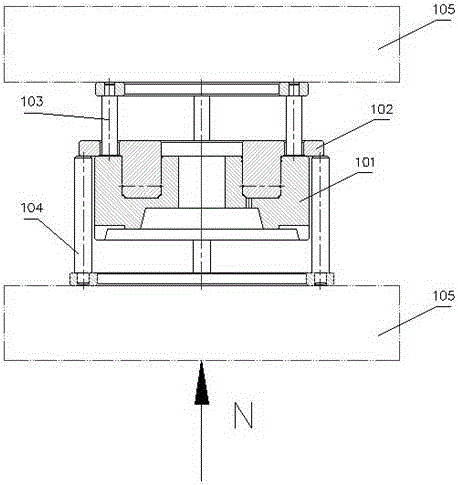

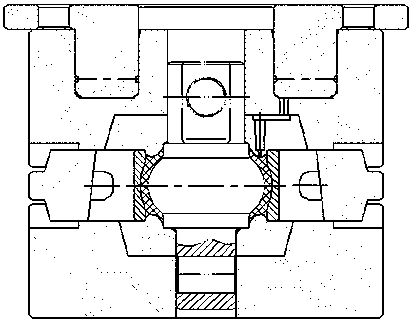

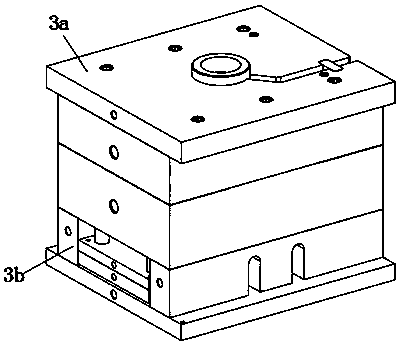

Mold for producing lamp frame reflecting body of selenium lamp

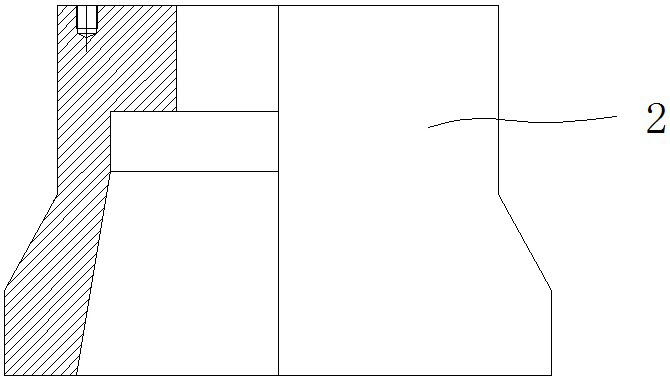

The invention in particular relates to a die for producing a reflecting body of a lamp frame of a selenium lamp. The invention comprises a terrace die and a cavity die, wherein a die cavity convex surface of the reflecting body of the lamp frame of the selenium lamp is arranged on the terrace die, a die cavity concave surface of the reflecting body of the lamp frame of the selenium lamp is arranged on the cavity die, the terrace die and the cavity die are combined to form a die cavity of the reflecting body of the lamp frame of the selenium lamp, a plurality of slag bags are arranged on a die combining surface of the cavity die, cooling water slots are arranged on the terrace die and the cavity die, a pourer of the die is arranged on the terrace die, the pourer adopts setback type pourer surface, slots are formed on a portion of the pourer which is communicated to the die cavity of the reflecting body of the lamp frame of the selenium lamp, the slag bags are arranged on one side of the concave surface of the die cavity of the reflecting body of the lamp frame of the selenium lamp, the concave surface is corresponded with the pourer, and a plurality of air discharging slots are arranged on the concave die which is on a portion of the slag bags. Due to the structure, the invention has the advantages of good air discharging, reasonable flow diversions of metal fluid, and the metal fluid can be flowed rapidly into the die cavity of the reflecting body of the lamp frame of the selenium lamp, parting surfaces are reasonable, mold openings are convenient, material explosion can be avoided effectively, and mold opening efficiency can be increased.

Owner:宁波久腾车灯电器有限公司

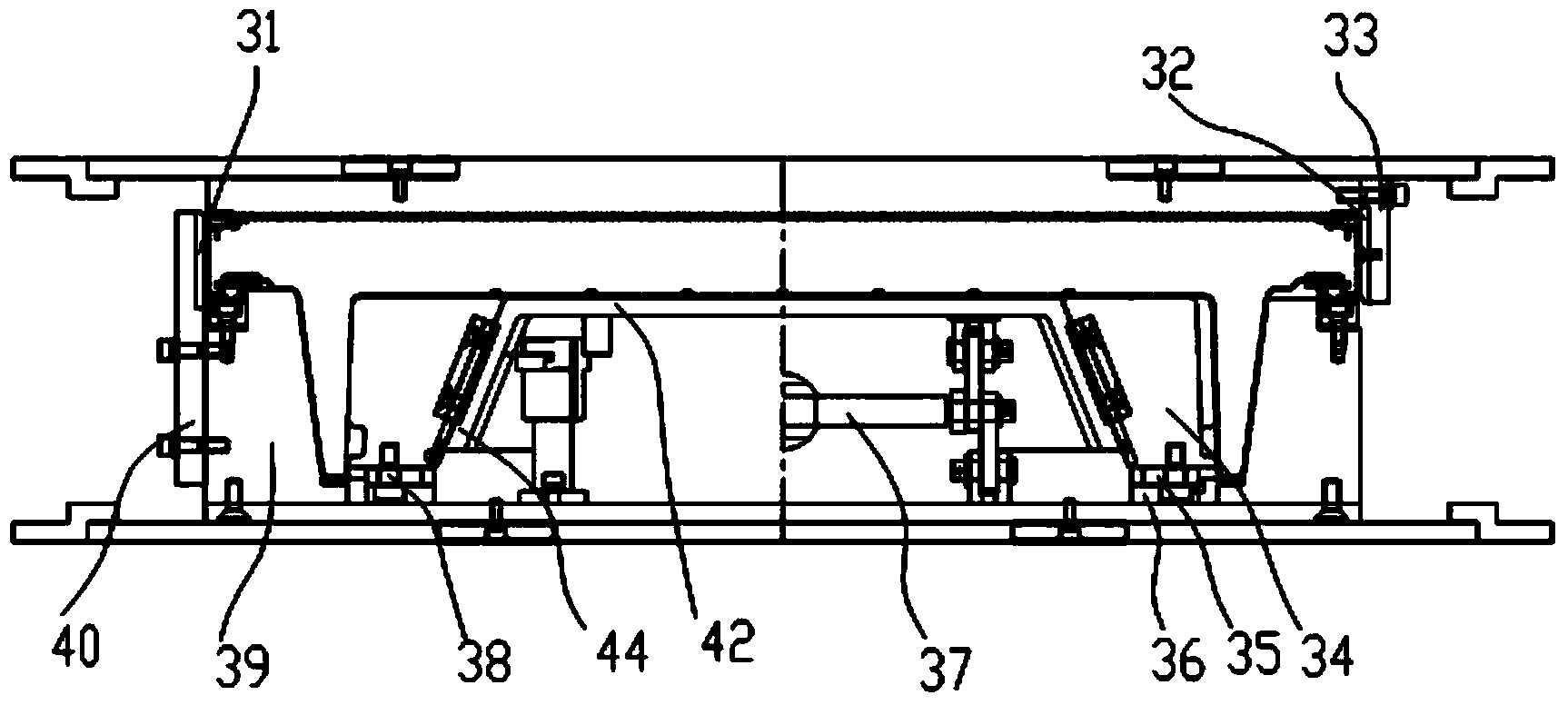

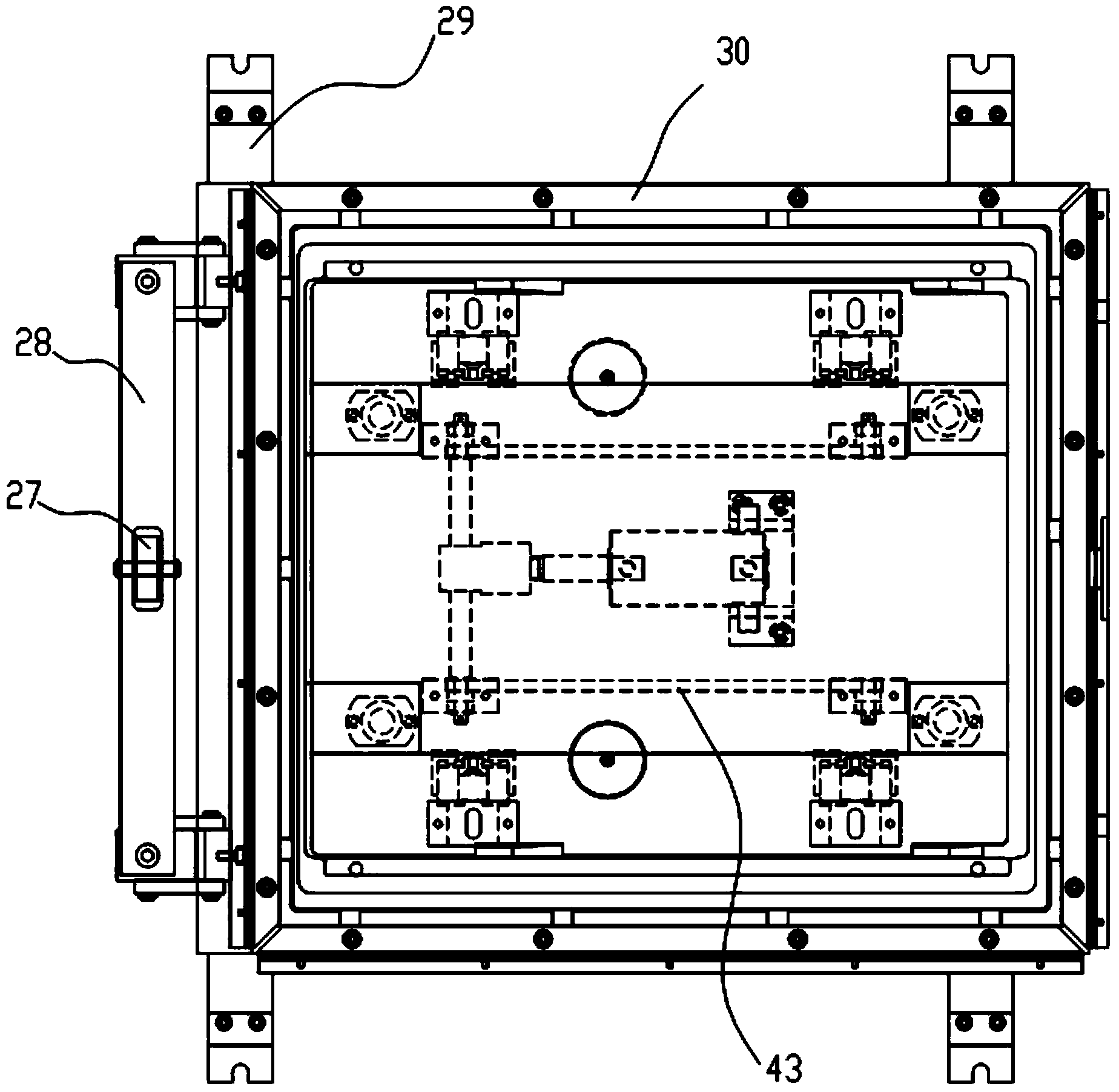

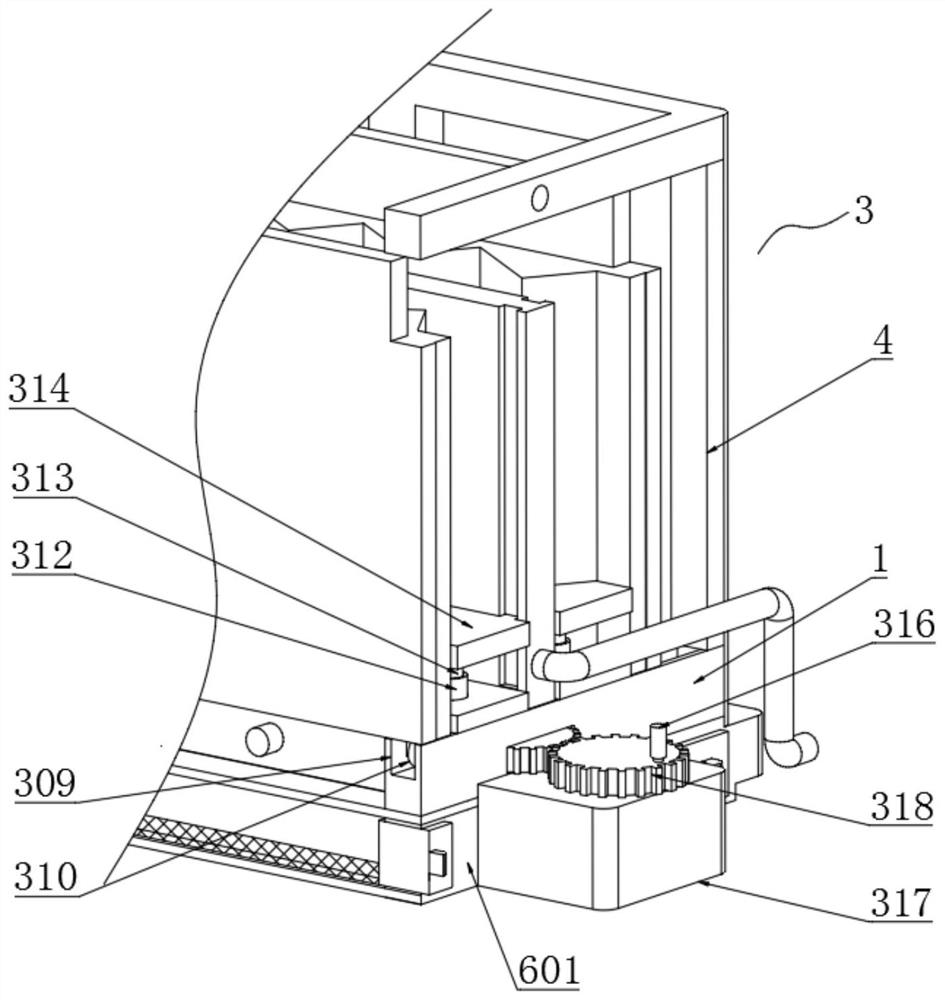

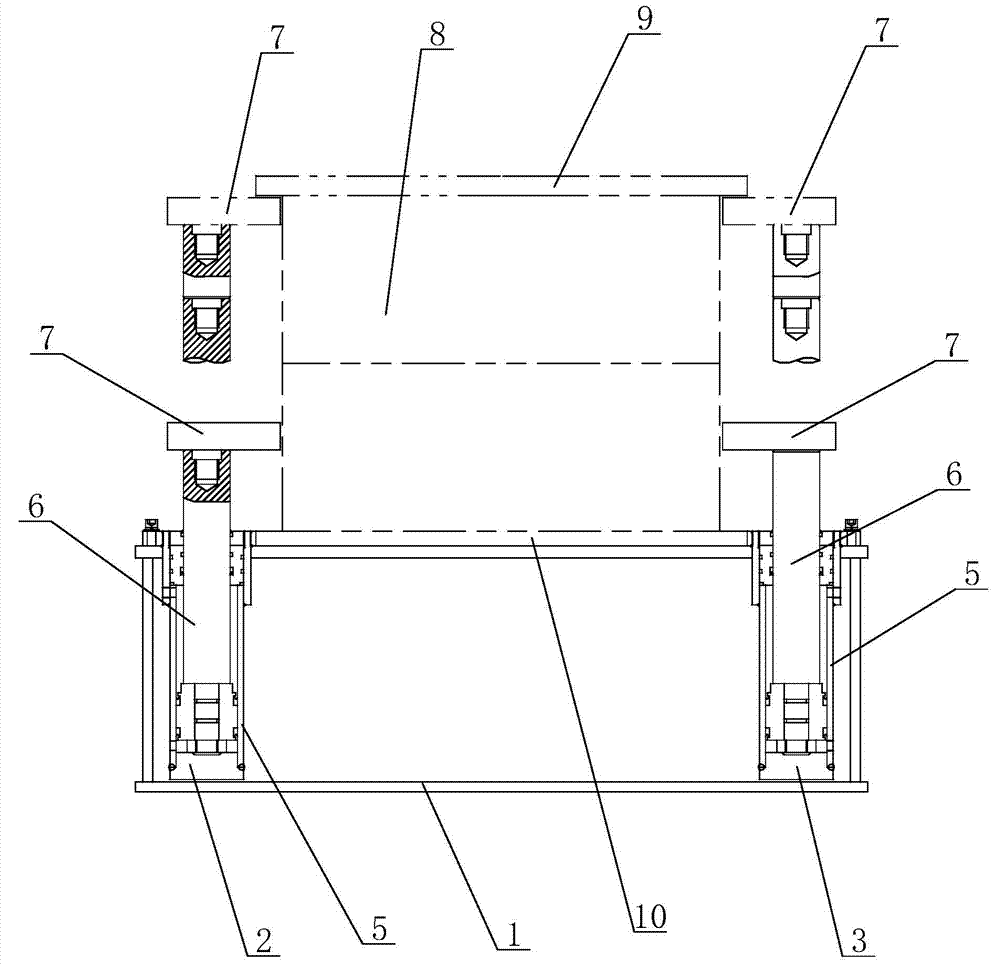

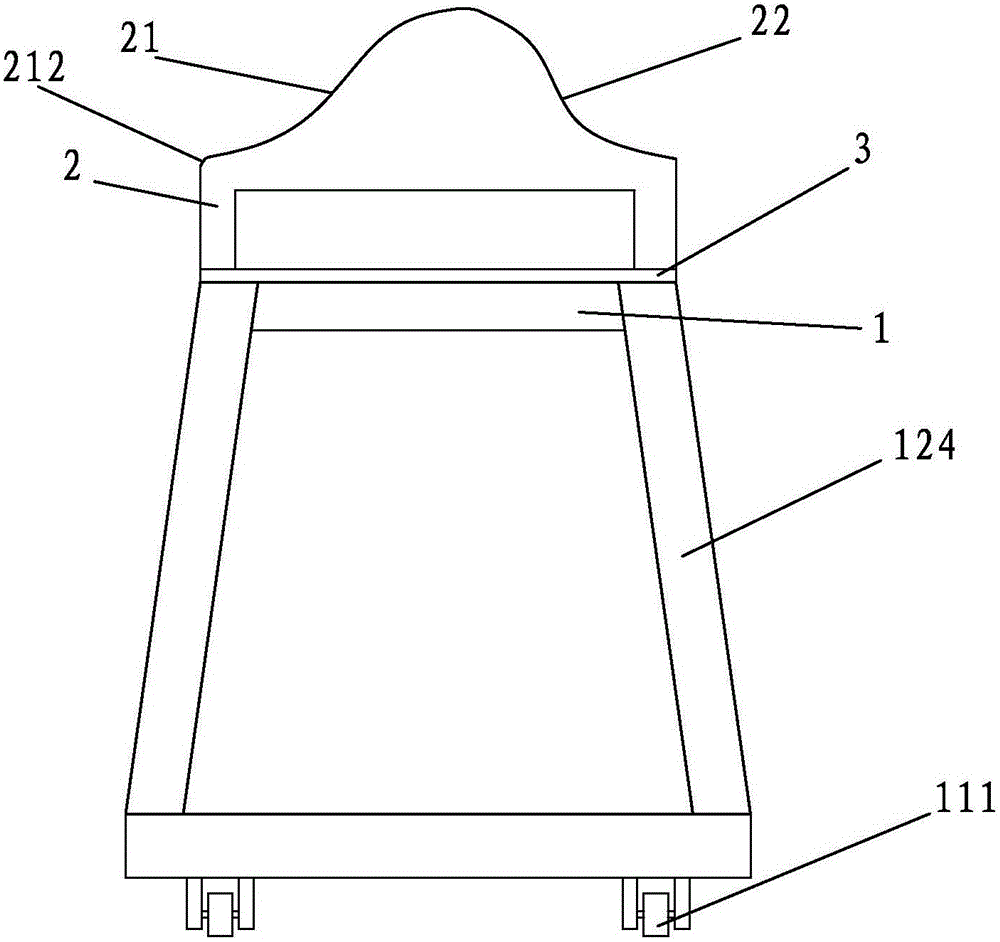

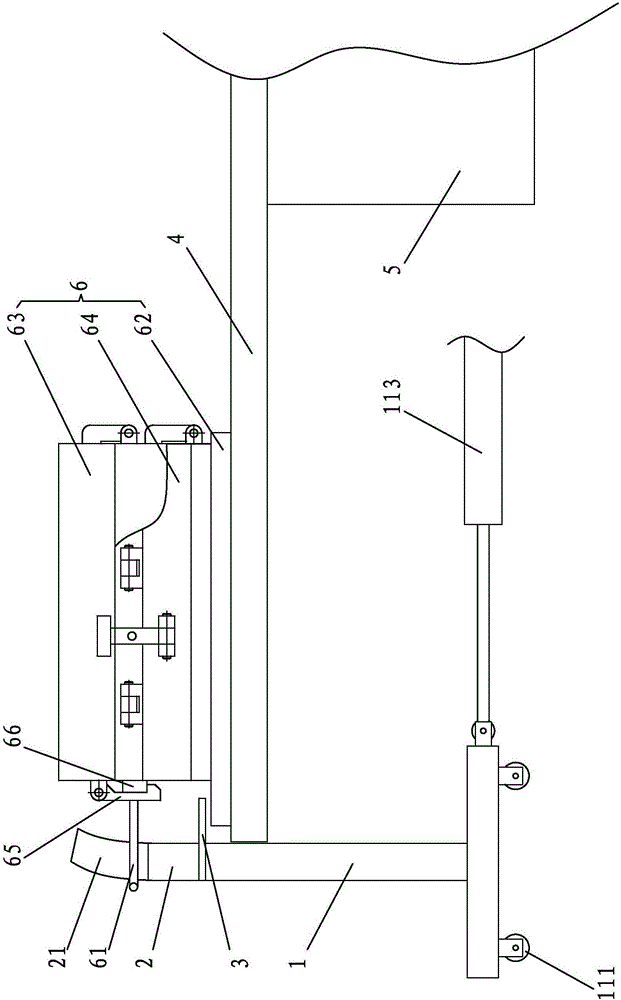

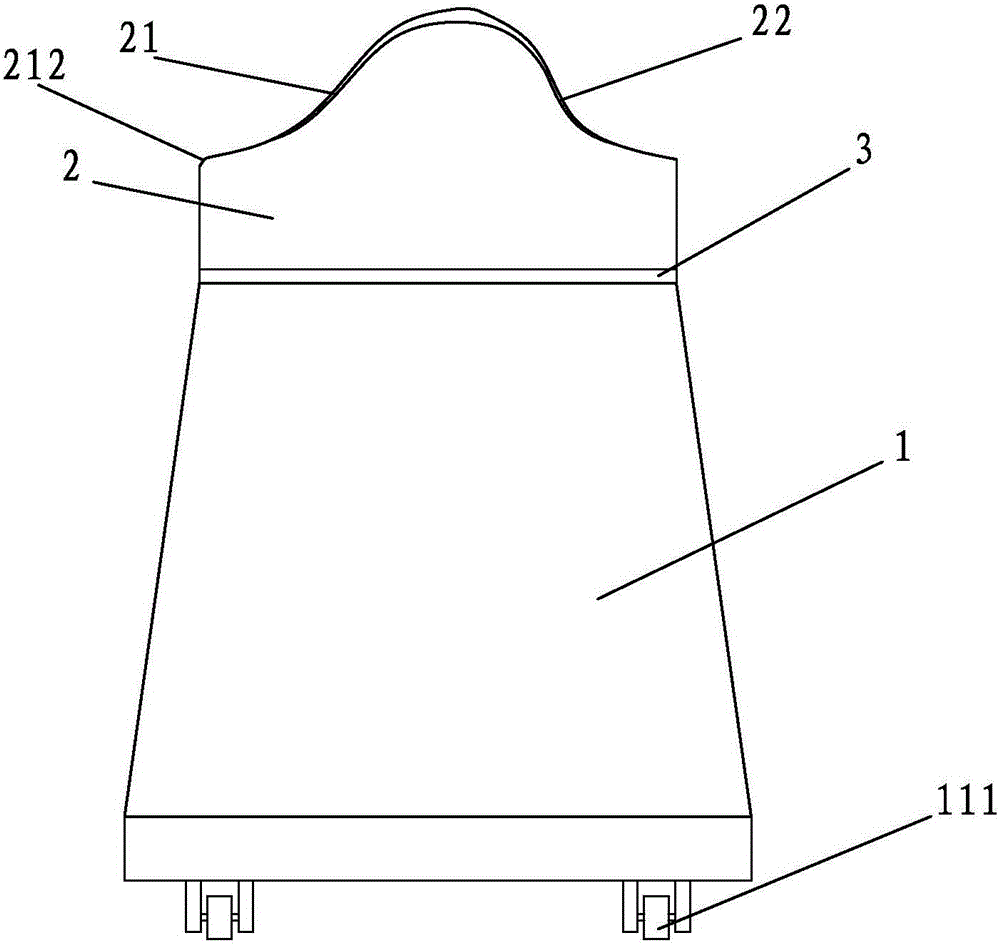

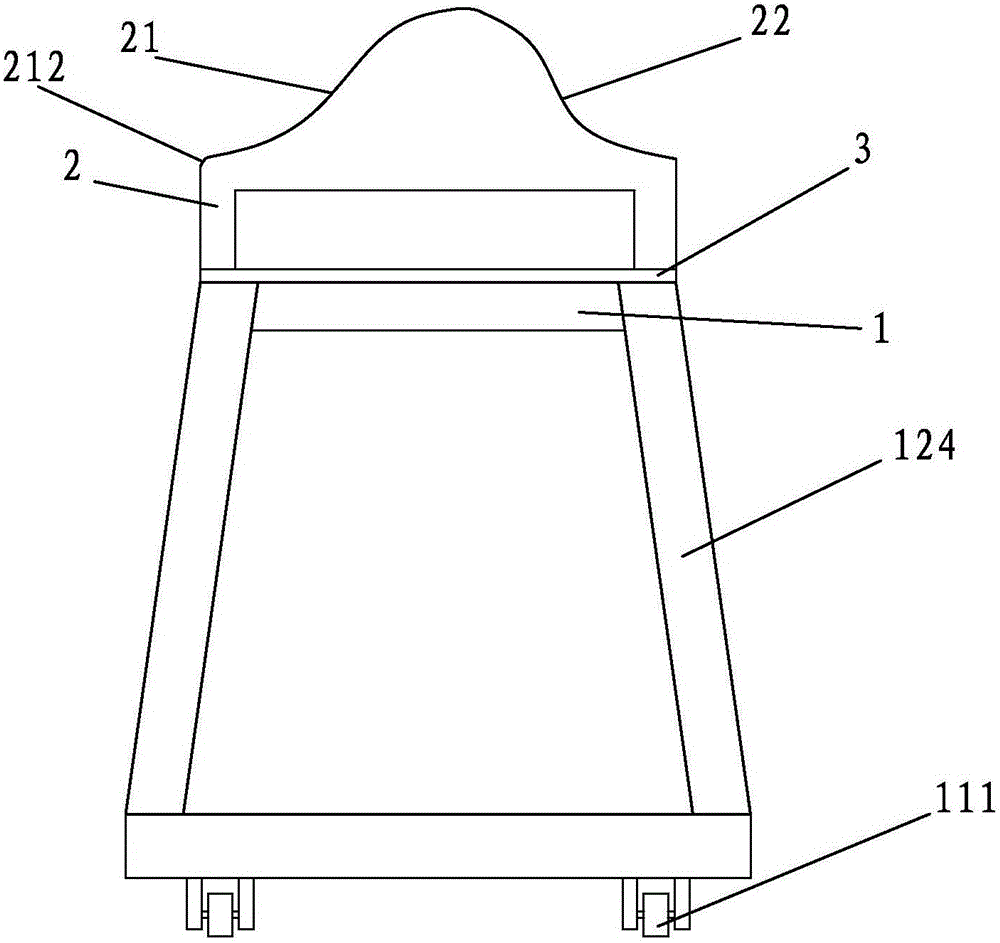

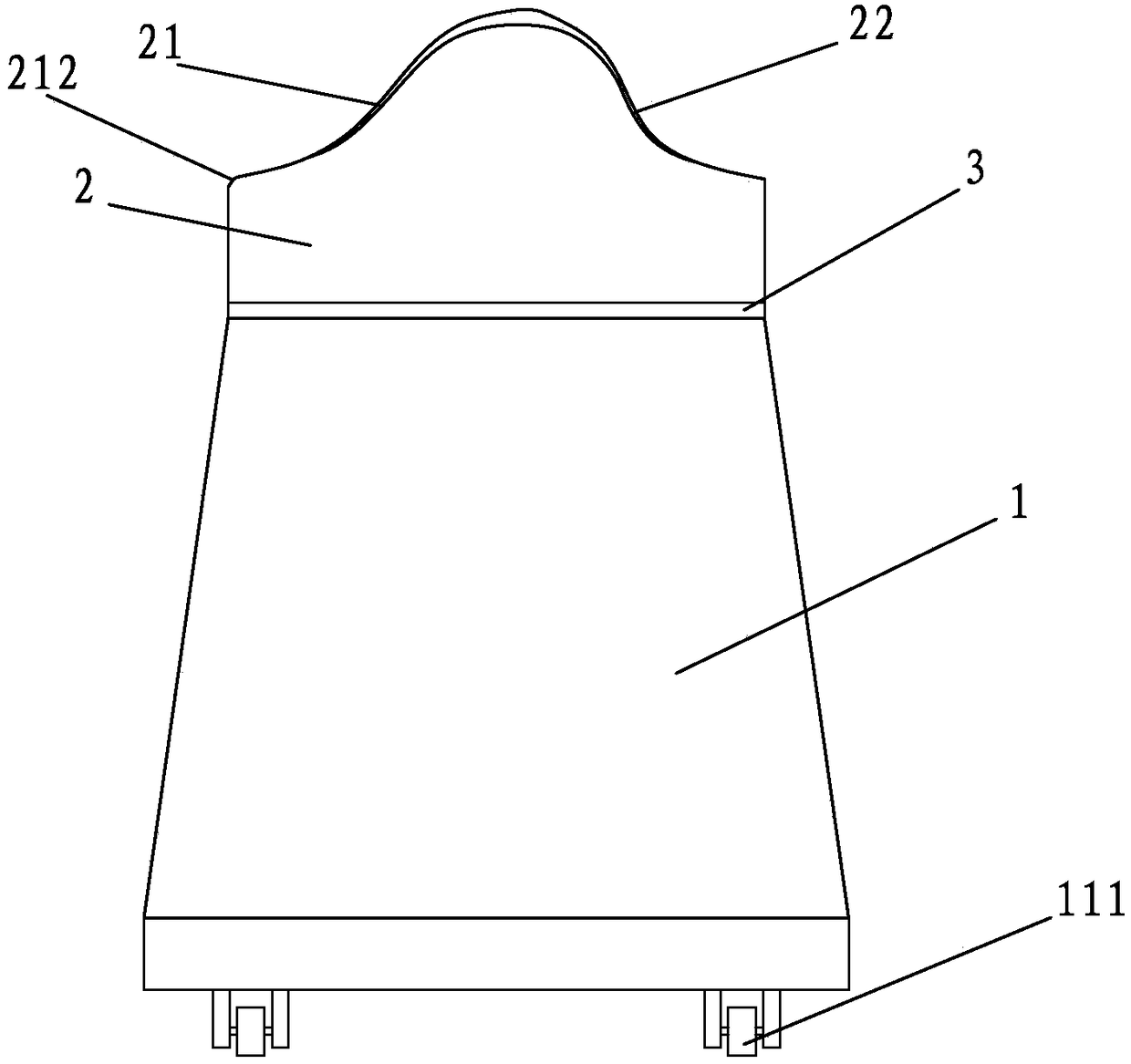

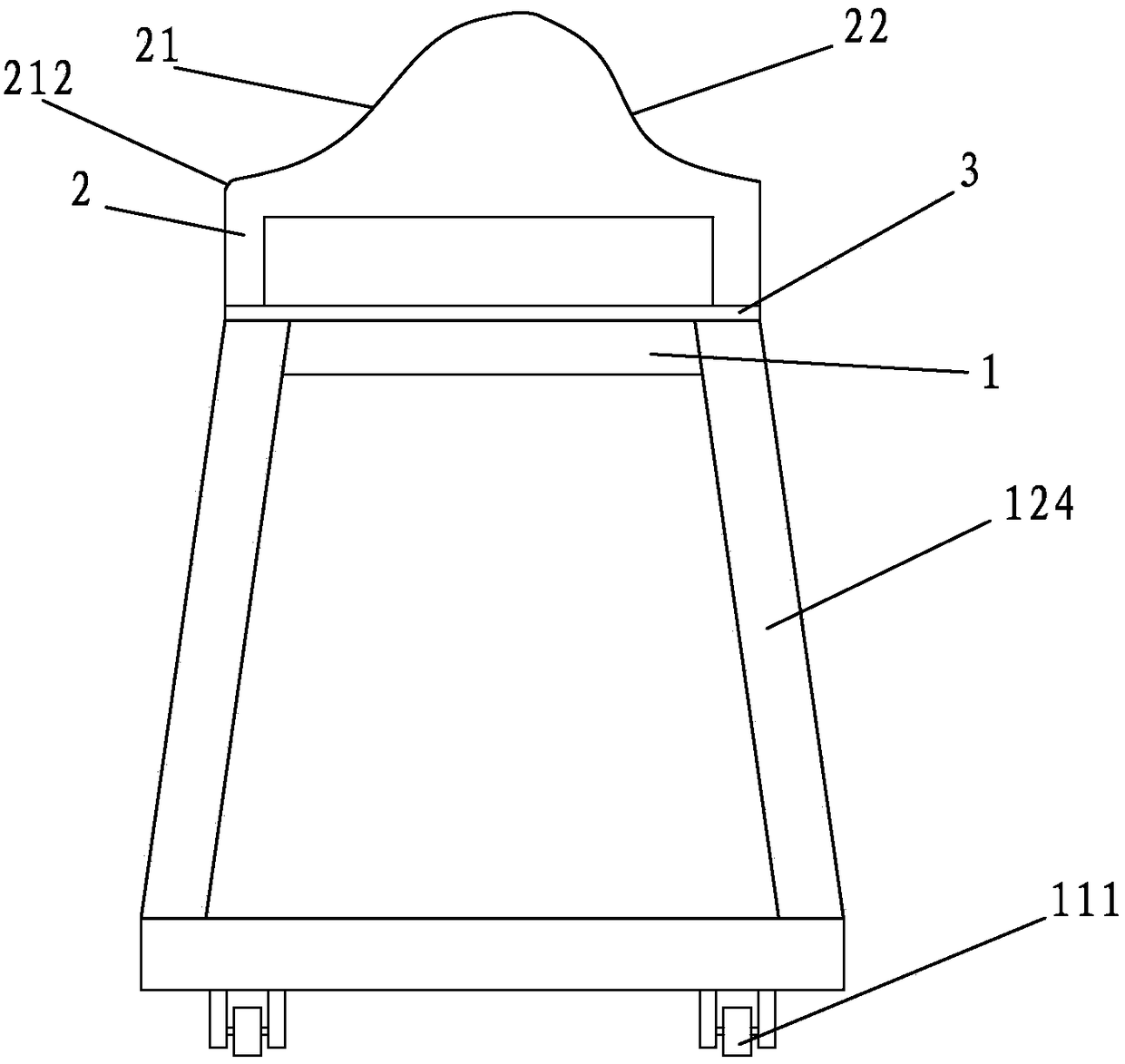

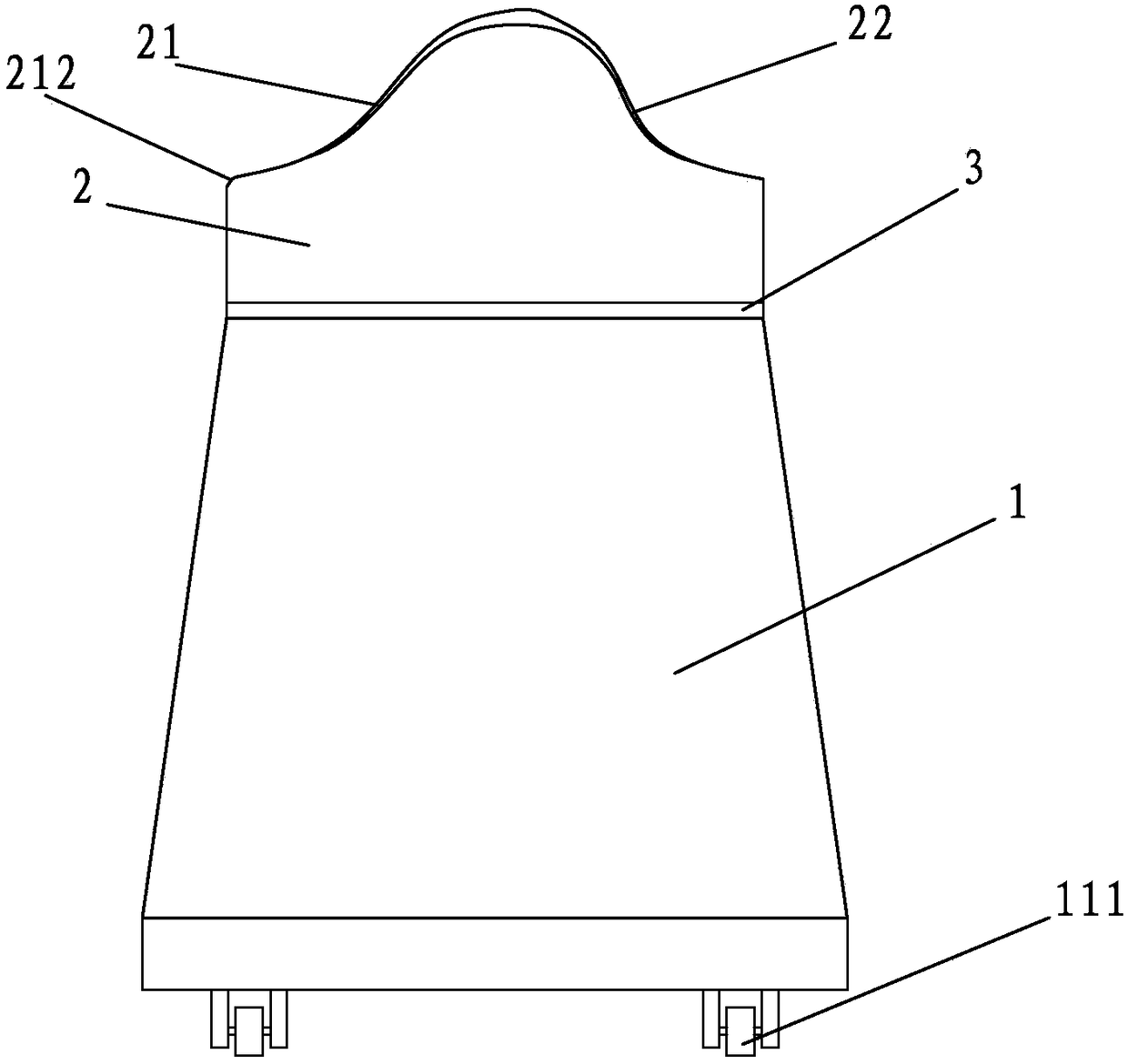

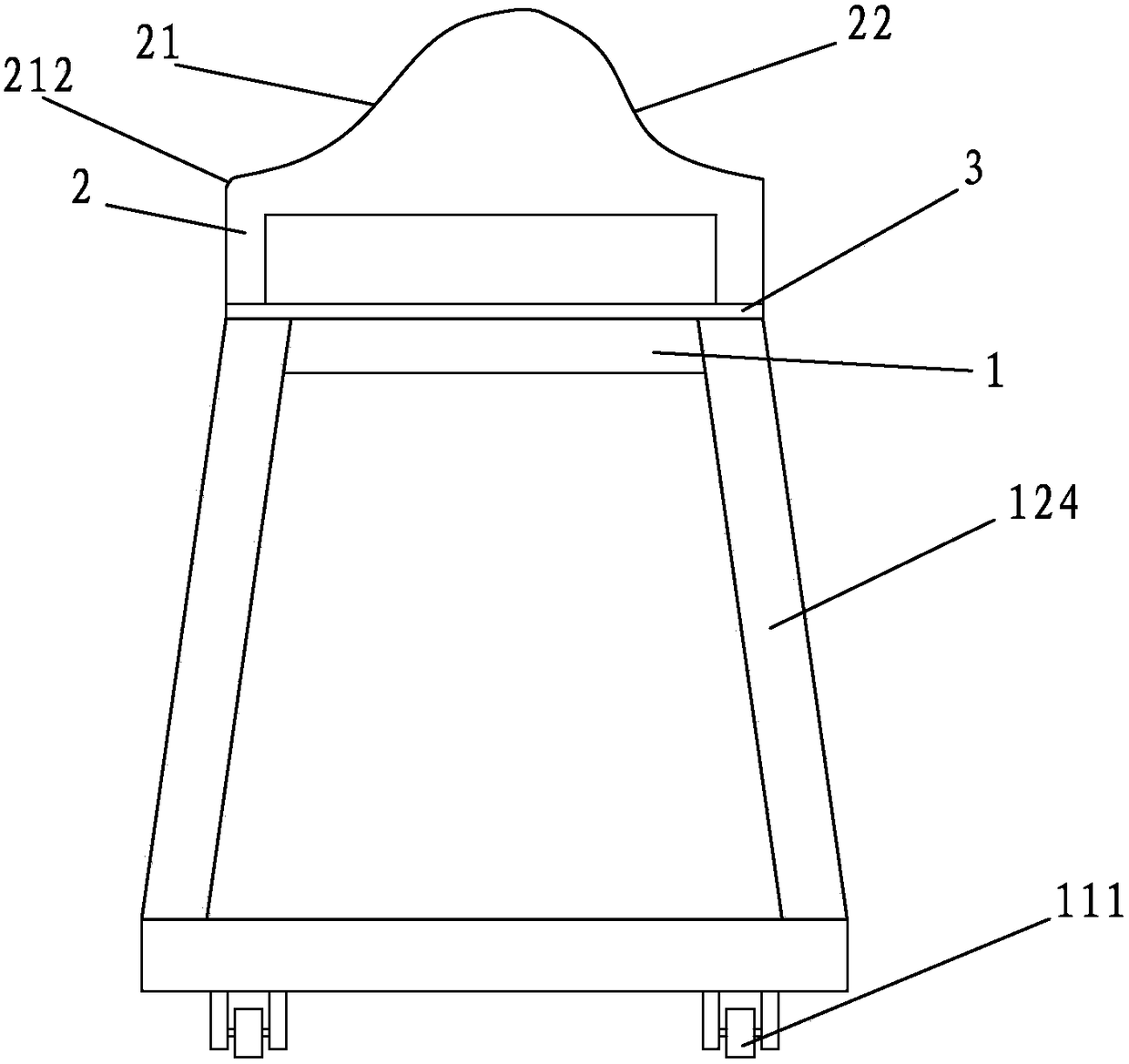

Refrigerator door body foaming mold

The invention relates to a refrigerator door body foaming mold. The refrigerator door body foaming mold comprises an upper mold and a lower mold, wherein the upper mold and the lower mold realize the opening and closing actions of the side face of the mold through a telescopic mechanism on the side face; the lifting of a lower mold plate is controlled by a single driving oil cylinder. According to the refrigerator door body foaming mold disclosed by the invention, since an air cylinder driving connecting rod is adopted, the lower mold is enabled to descend to break away from the contact with a refrigerator door body when the mold is opened and closed, so that the lower mold is prevented from breaking the refrigerator door body through pulling; meanwhile, the two sides of the lower mold shrink to break away from the contact with a hanging wall of the refrigerator door body, so that the hanging wall is prevented from being damaged when the mold is opened, and the action is controlled by only one single air cylinder; the refrigerator door body foaming mold is simple in integral structure, low in manufacturing cost and maintenance cost, high in working efficiency in using process, and low in energy consumption; as the side face of the mold is provided with a lifting mechanism, when the mold is opened, one side of the mold breaks away from the contact with the refrigerator door body in the presence of a spring force so as to relieve the interference with the refrigerator door body; the operation can be realized without additional driving force, so that the mold opening efficiency is high, the reliability is high, and the rate of finished products is high.

Owner:昆山市三建模具机械有限公司

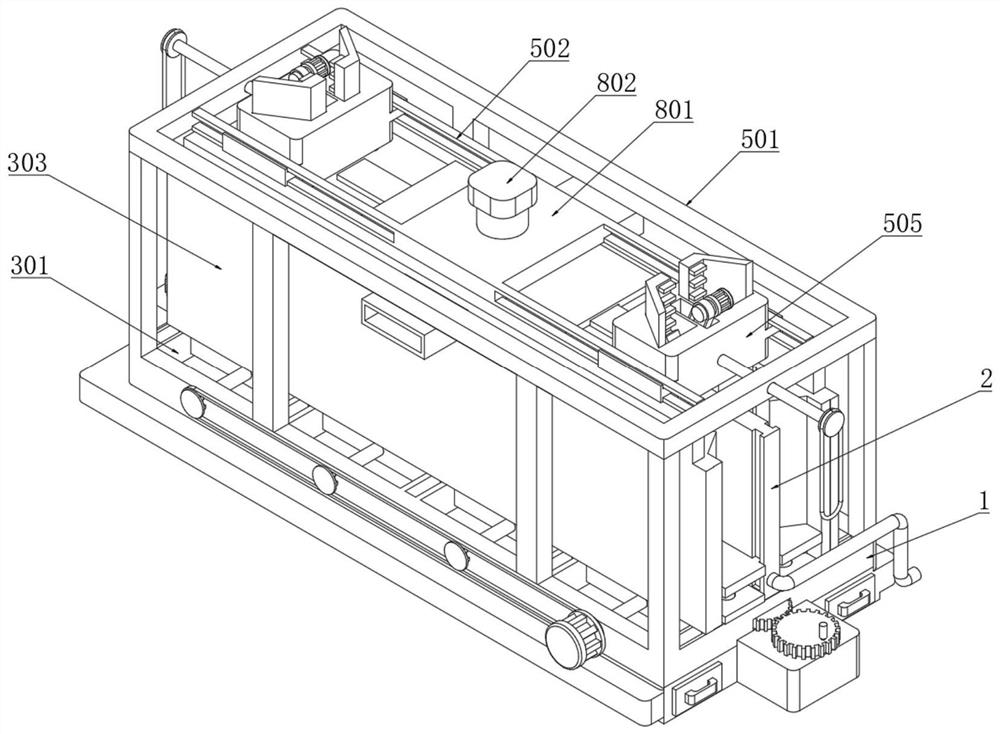

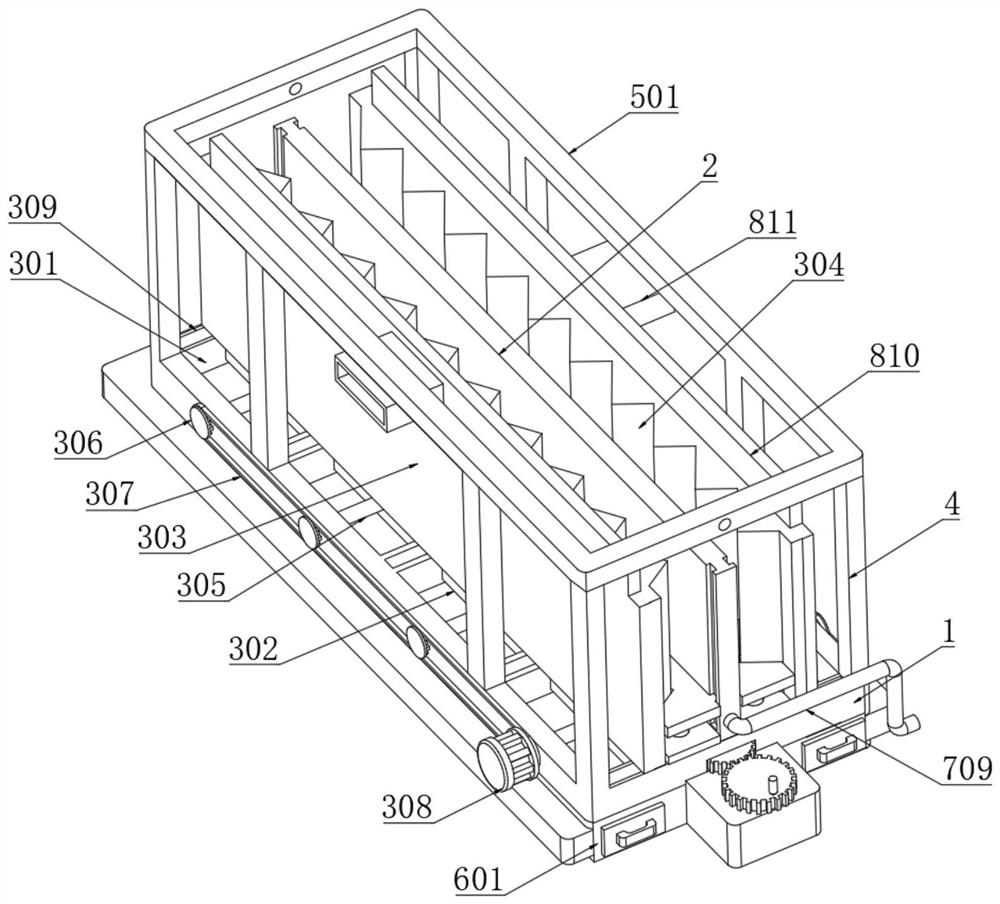

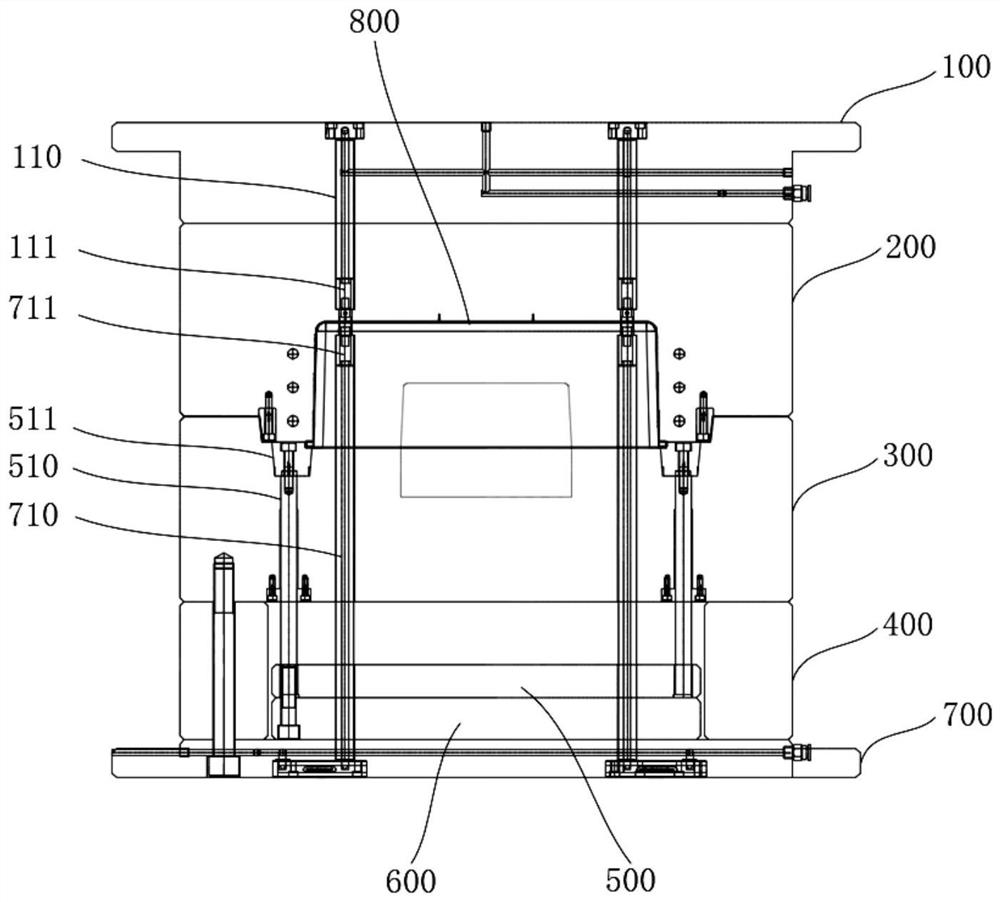

Environment-friendly construction method for building decoration

ActiveCN111890517AReduce resistanceImprove applicabilityDischarging arrangementMouldsElectric machineConstruction engineering

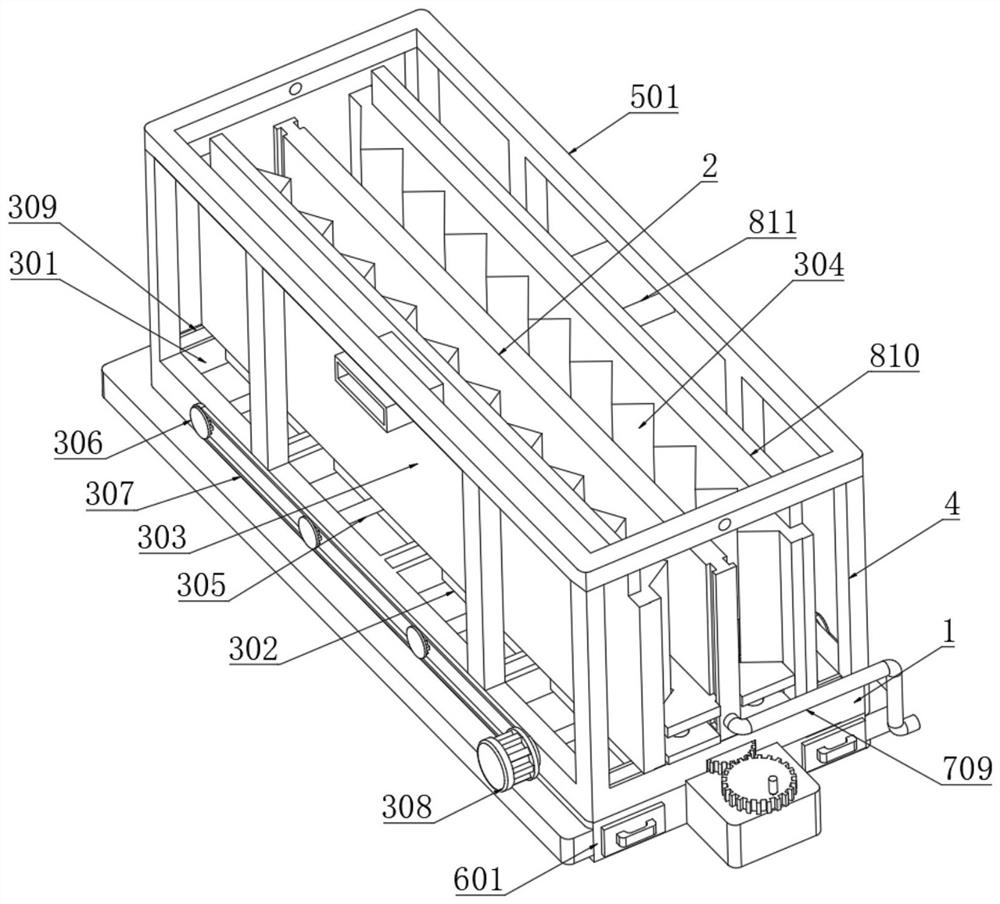

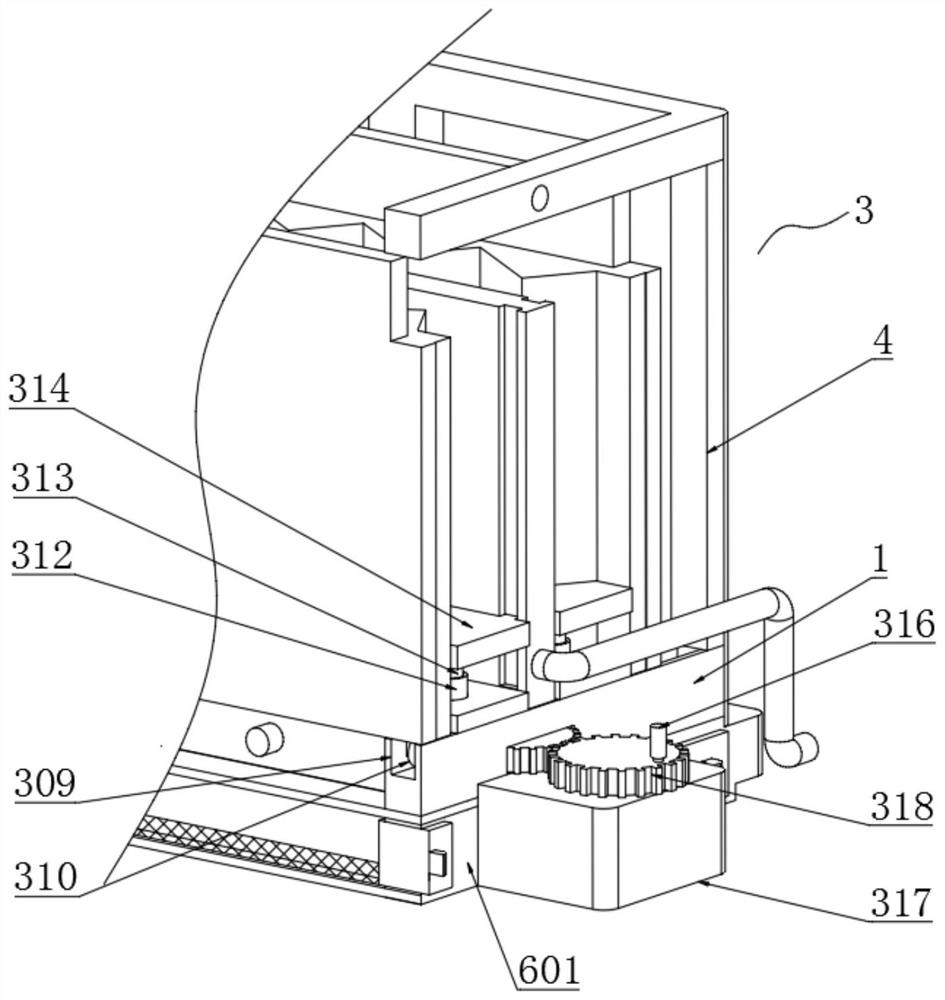

The invention discloses an environment-friendly construction method for building decoration. A stair die comprises a machine base, wherein a partition plate is fixedly connected to the middle of the top end of the machine base; each corner at the top end of the machine base is fixedly connected with a supporting plate; the top ends of the supporting plates are fixedly connected with length adjusting mechanisms; the bottom at the outer end of the machine base is fixedly connected with an energy utilization and heat-proof and cold-proof mechanism; and two ends of the partition plate are symmetrically and movably connected with die opening and width adjusting mechanisms. According to the environment-friendly construction method, the structure is scientific and reasonable, and use is safe andconvenient; the die opening and closing and width adjusting mechanisms are arranged, a rotating motor drives a chain wheel to rotate, and the chain wheel drives a lead screw to rotate together throughthe transmission of a chain, so that a movable plate and frameworks are pushed to move, and the distance between the two frameworks and the partition plate is adjusted so as to open and close the die; and meanwhile, through the cooperation of a rolling groove and a roller, the resistance of the two frameworks during moving is reduced, the consumption of kinetic energy is reduced, and the efficiency of the movement is improved.

Owner:广东田业建设有限公司

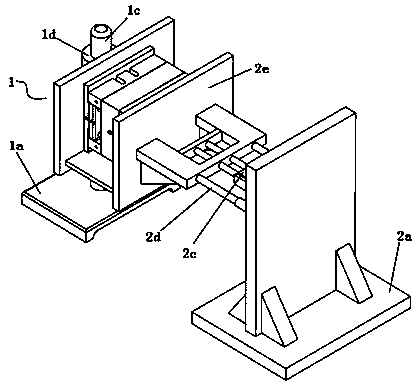

Metal cup shell with continuous compaction pattern on surface and manufacturing method thereof

The invention discloses a manufacturing method of a metal cup shell with a continuous compaction pattern on the surface. The manufacturing method comprises the following steps: 1, cutting out a circular pipe for processing a metal cup shell, and adopting water medium hydraulic forming to enable the circular pipe to form the thin-wall metal shell of a cup; 2, polishing the pattern to-be-compacted area of the thin-wall metal shell; and 3, adopting a continuous pattern compacting tool to carry out continuous pattern compaction on the thin-wall metal shell of the cup. According to the manufacturing method, a continuous pattern free of deviation and with high definition is compacted on the surface of the thin-wall metal shell of the cup, the thin-wall metal shell with a compacted pattern is ensured not to be out-of-round and not to break, and is high in yield and production efficiency.

Owner:ZHEJIANG HAERS VACUUM CONTAINERS CO LTD

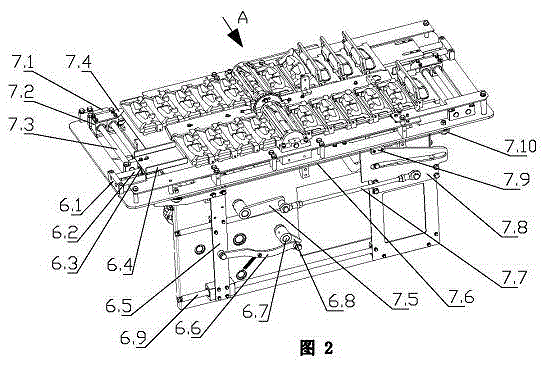

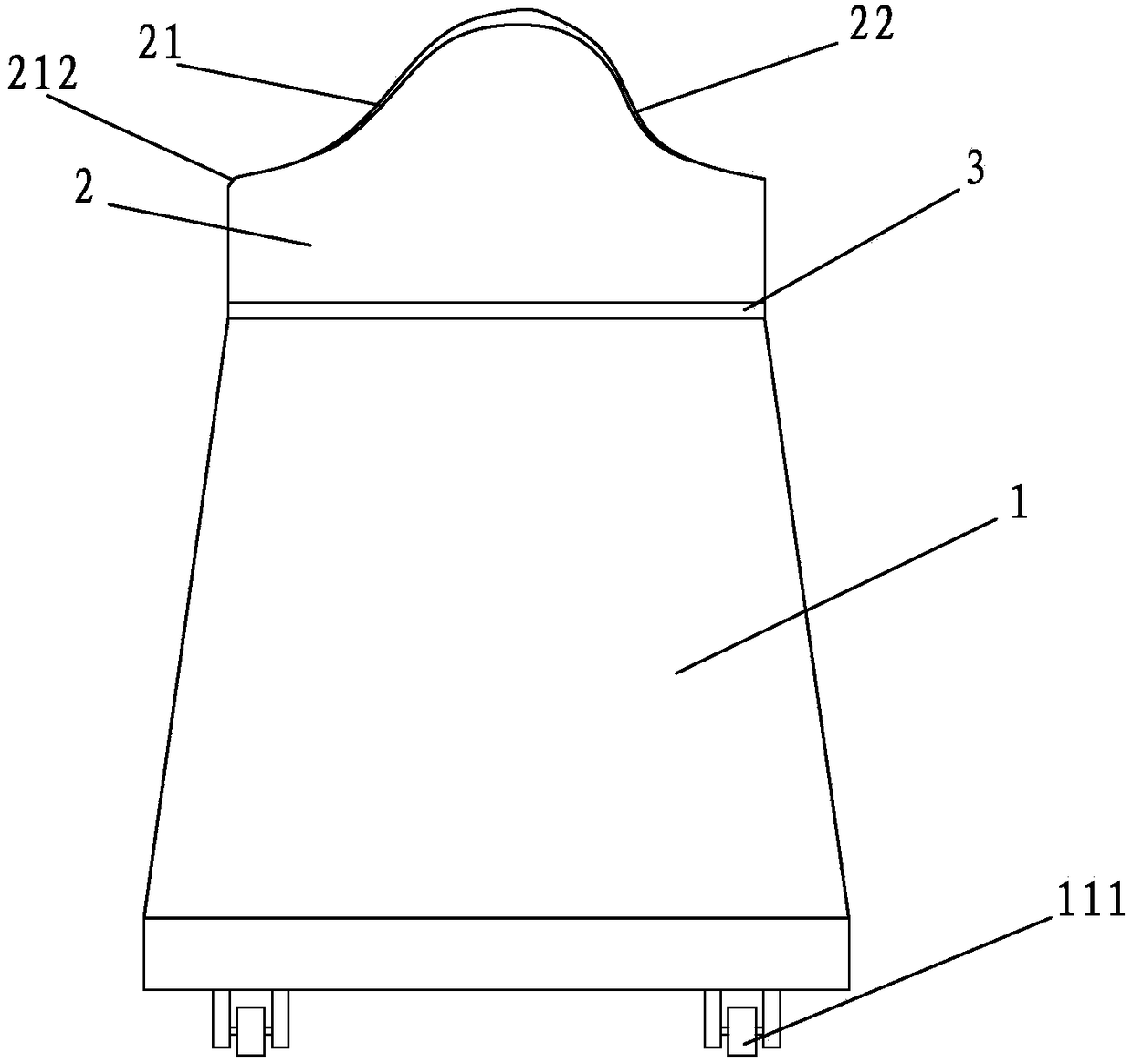

Cake making machine

InactiveCN105532772AFunction as a sliding bearingRealize automatic turningBaking vesselsRoasters/grillsPulp and paper industryInjection device

The invention discloses a cake making machine. The cake making machine comprises a machine frame, cake moulds and a material injection device comprising a material barrel. An inner heating zone and an outer heating zone are arranged on the table top of the machine frame in parallel. A mould turning device is arranged at the middle section of the table top of the machine frame. Two longitudinal mould pushing devices are longitudinally arranged at one group of opposite angles of the table top of the machine frame and are in transmission connection with a longitudinal driving shaft, and two transverse mould pushing devices are transversely arranged at the other group of opposite angles of the table top of the machine frame. A mould closing stopping block is arranged on the table top of the machine frame. A mould opening device comprising a mould opening rocker is further arranged on the machine frame. The mould opening device and the transverse mould pushing devices are both driven by a transverse crank. According to the cake making machine, the cake moulds can be automatically and circularly pushed and automatically turned over; the cake making machine is reasonable in structure and safe to use.

Owner:WUJIN DISTRICT HUTANG HUIFU MACHINERY EQUIP FACTORY

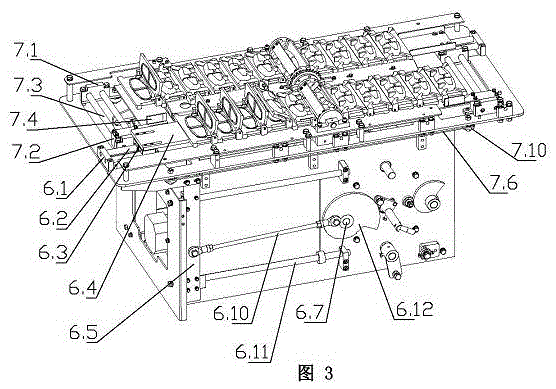

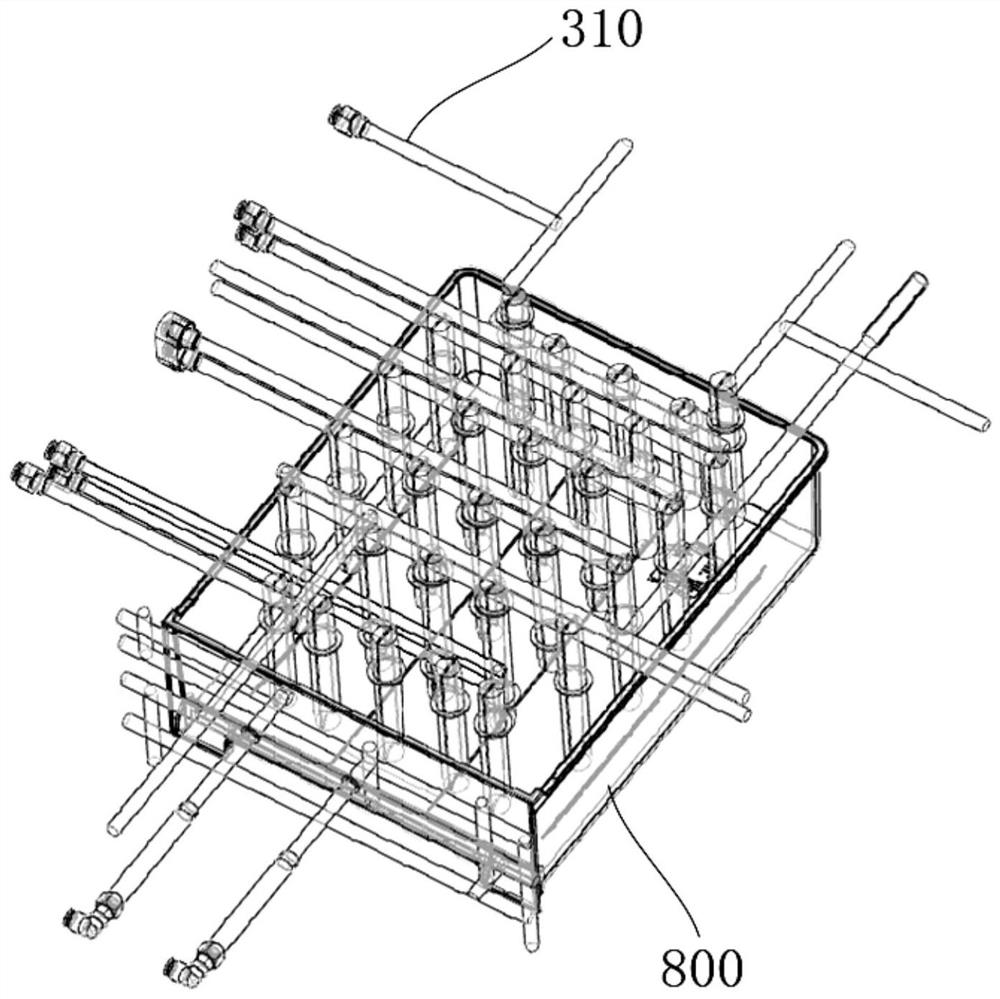

Cooling system for die

The invention specifically relates to a cooling system for a die, which belongs to the field of cooling systems. The cooling system for the die comprises a high pressure water source and a compressed air source, wherein the high pressure water source and the compressed air source are both connected with a control box; the high pressure water source is connected with a water tank; the water tank is connected with the control box; the control box is connected with a current equalizing valve; the current equalizing valve is connected with the die; the die is connected with a non-return valve; the non-return valve is connected with the control box; and the control box is connected with the water tank. The cooling system has the following advantages: latent heat of water is utilized, liquid gas absorbs considerable heat in the process of phase change, and high pressure air is cooperatively used to carry phase-changed water away so as to realize rapid cooling of the die and cleaning of a cooling medium in a cooling channel; thus, requirements for temperature control and rapid reduction of die temperature are met, die-opening efficiency is improved, and production power is enhanced.

Owner:STATE GRID CORP OF CHINA +1

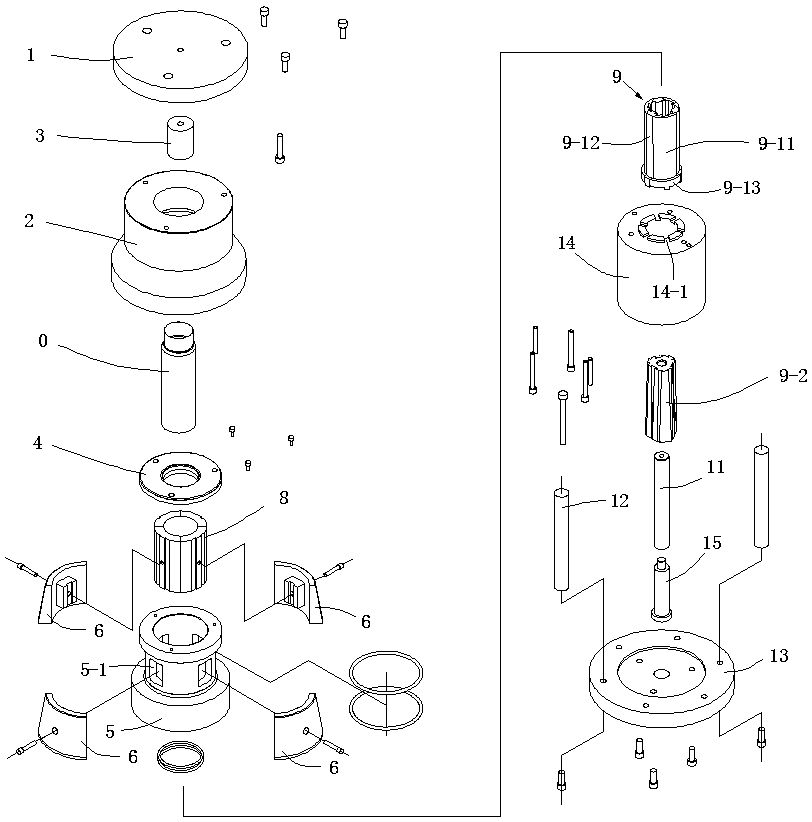

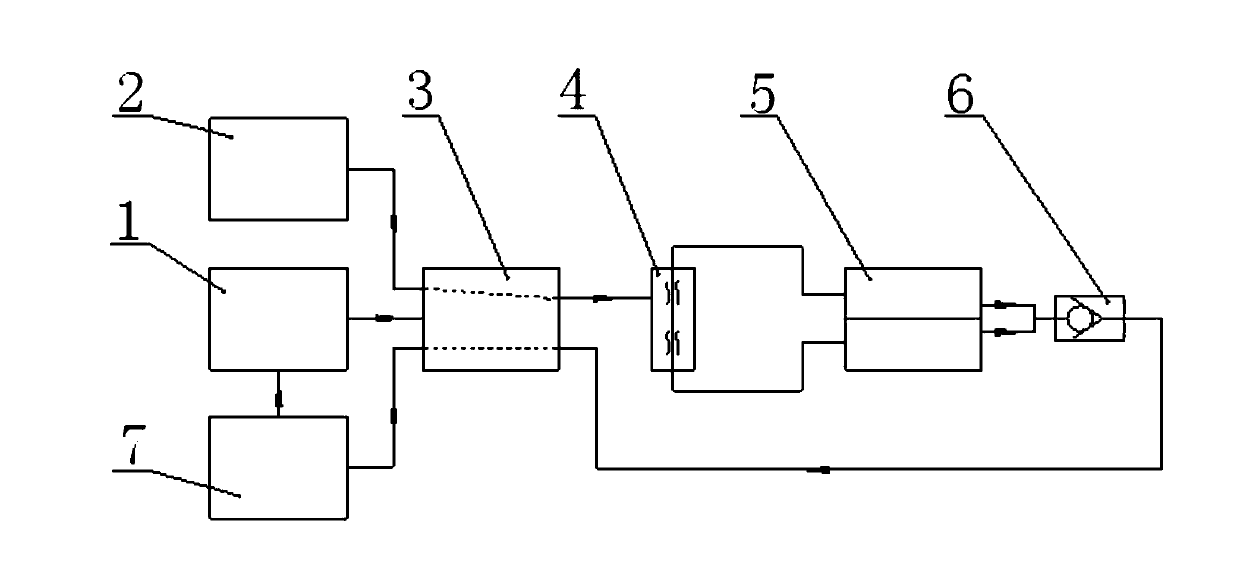

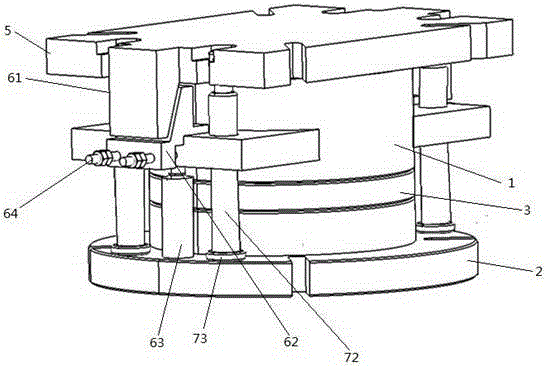

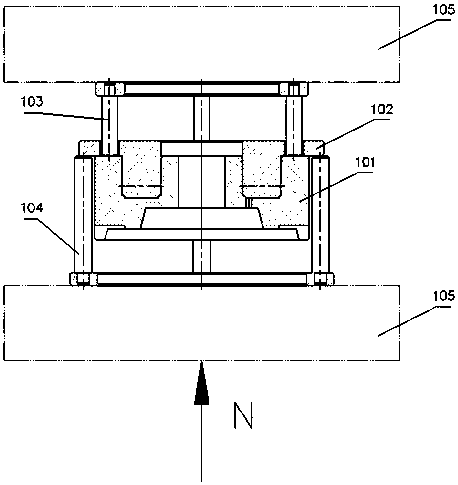

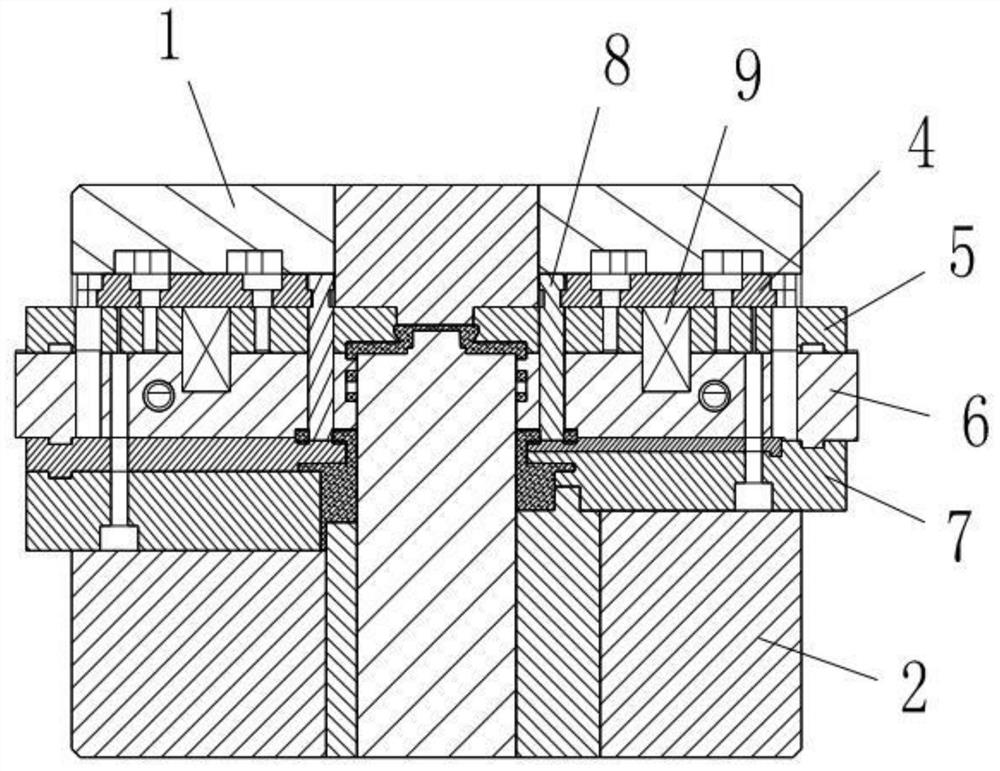

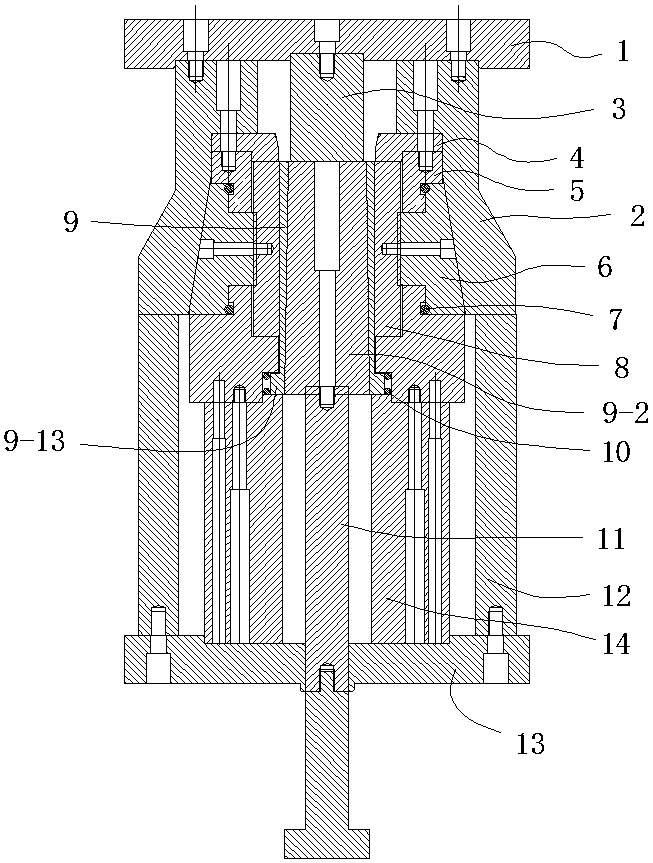

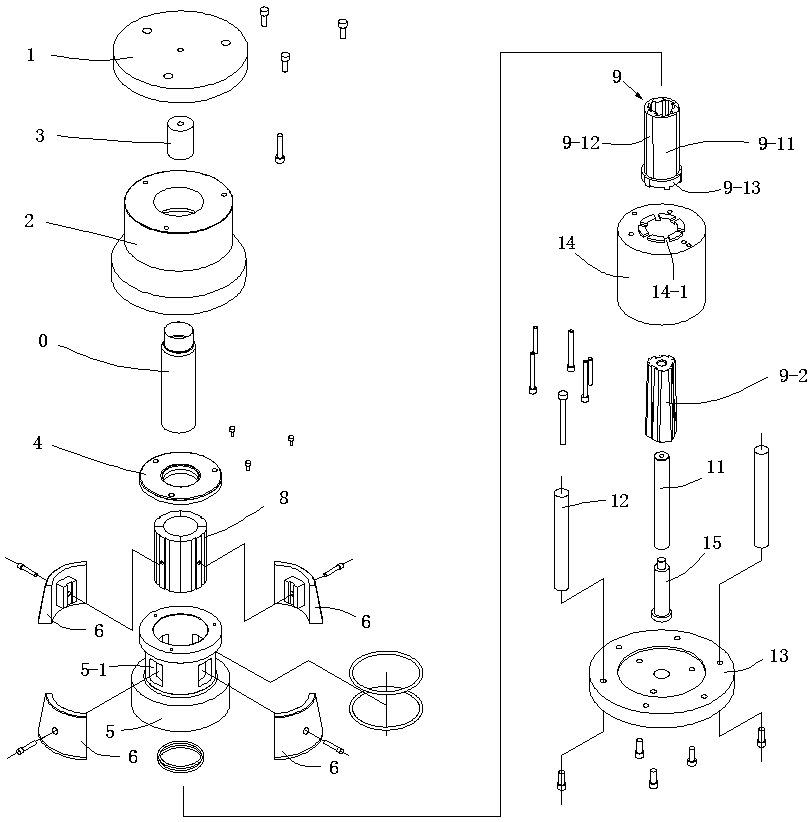

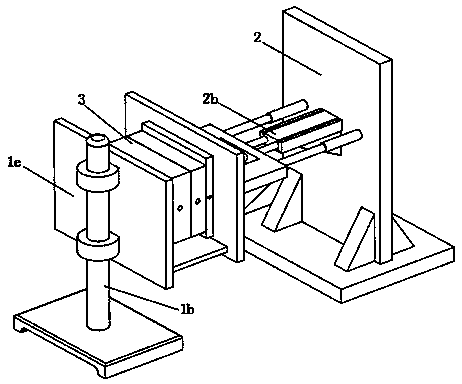

Spherical hinge die and die opening method thereof

ActiveCN106626171ASimplify the mold opening processImprove mold opening efficiencyRubber materialVulcanization

The invention discloses a spherical hinge die. The spherical hinge die comprises an upper die, a lower die and a middle die clamped between the upper die and the lower die, wherein the upper die, the middle die and the lower die are encircled to form a product vulcanization area; the product vulcanization area is isolated from the upper die and the lower die by virtue of an insert respectively; a rubber material is injected in a spherical hinge vulcanization area from a rubber injection hole of the upper die; and a rubber injection plug used for pressing the rubber material in the rubber injection hole of the upper die is arranged above the upper die. The spherical hinge die is characterized by further comprising a die opening device used for automatically separating the upper die from the rubber injection plug, and a pull rod device used for separating the upper die from the middle die. According to the spherical hinge die provided by the invention, the upper die and the rubber injection plug can be automatically separated to realize automatic die opening for the die, thus the die opening efficiency of the die is increased, and the manual labour intensity is lowered. The invention further provides a die opening method for the spherical hinge die.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

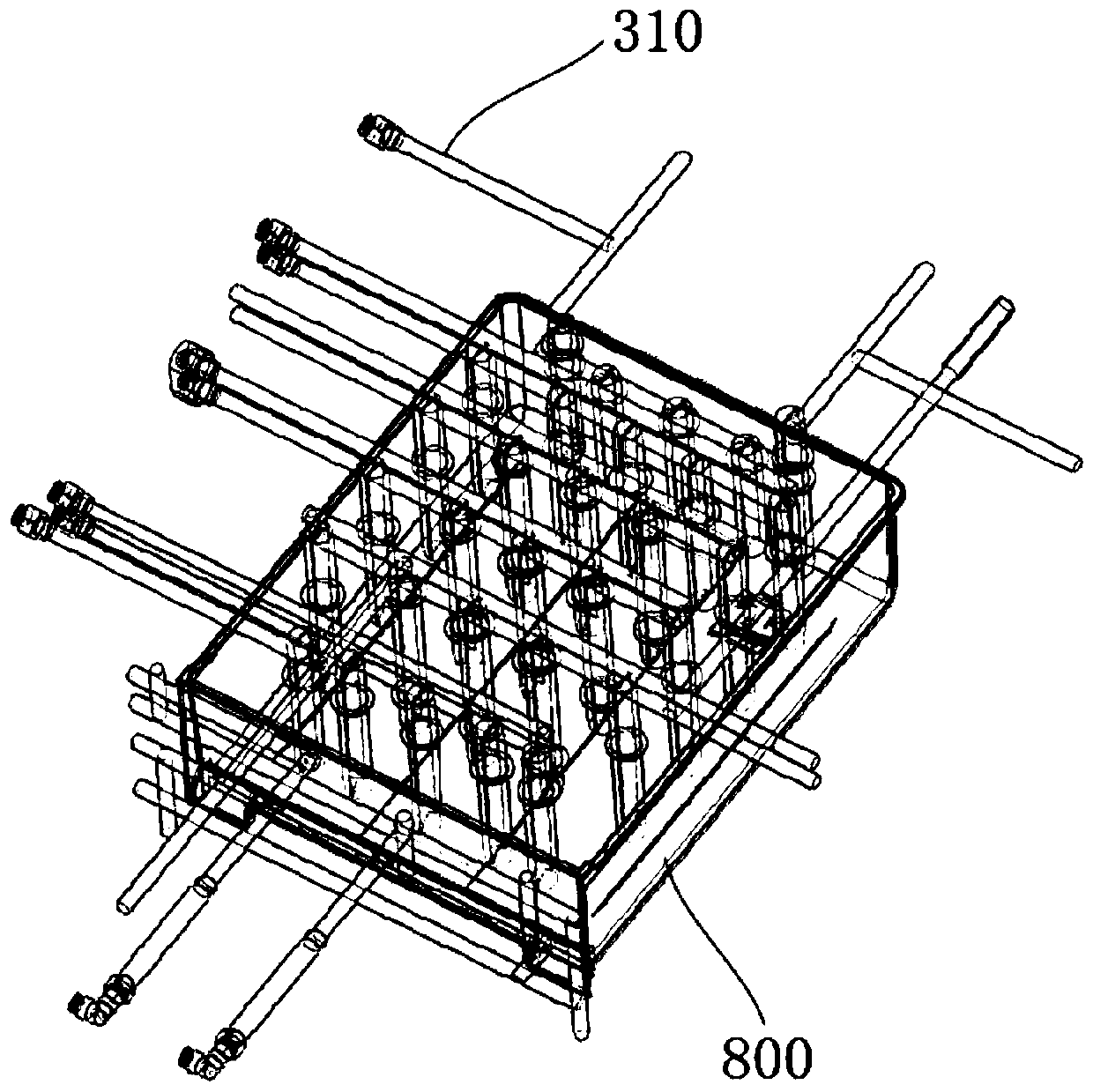

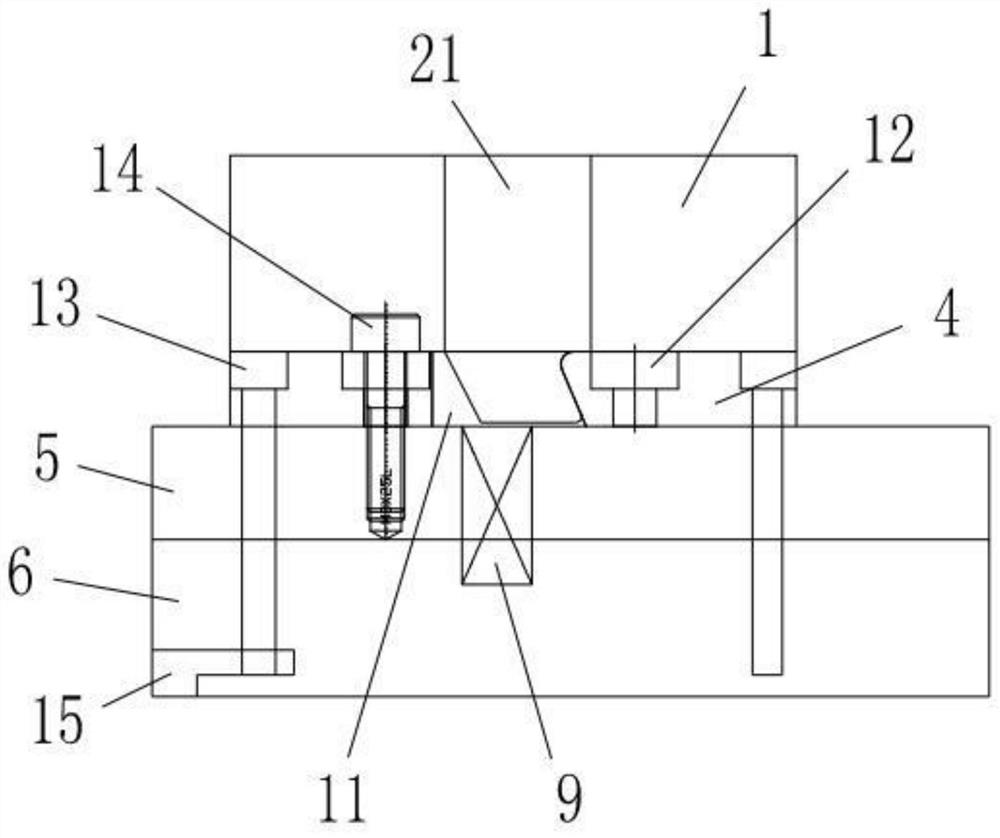

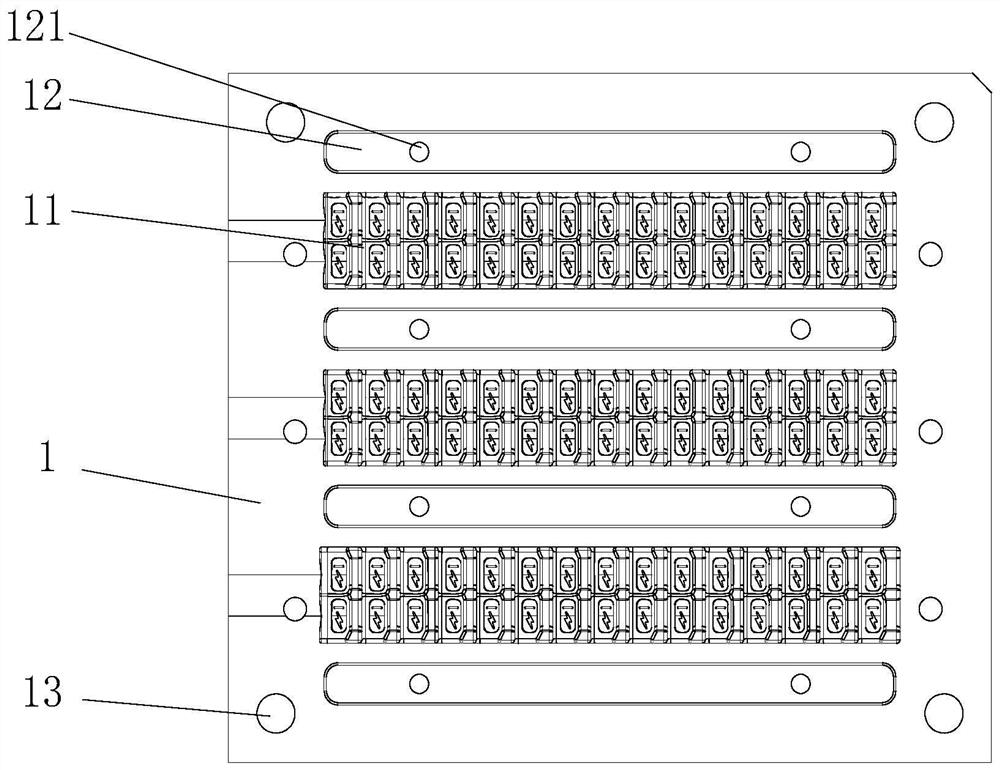

Gas ejection die structure for shortening forming period

The invention discloses a gas ejection die structure for shortening the forming period. The gas ejection die structure sequentially comprises a fixed die base plate, a fixed template, a movable template, square iron, an ejector pin plate, an ejector pin bottom plate and a movable die base plate from top to bottom. A first cooling water way is arranged in the fixed template, and a second cooling water way is arranged in the movable template. A plurality of first vertical gas guiding rods and a plurality of second vertical gas guiding rods are further included. A first transverse gas path is arranged in the movable die base plate, a second transverse gas path is arranged in the fixed die base plate, the ejector pin plate is provided with a plurality of ejector rods, and the movable templateis internally provided with ejector blocks corresponding to the multiple ejector rods in a one-to-one manner. The gas ejection die structure has the beneficial effects that the structure is compact and simple, and installation is easy; when a formed product is ejected out, stress is more uniform, and the ejection precision is higher; and during die sinking, the formed product is not prone to adhering into the fixed template, the die sinking efficiency is higher, formed product ejection is easier, the ejection time is shortened, and accordingly the forming period is greatly shortened.

Owner:深圳市三精模具有限公司

Strain-preventing injection mould

Owner:KUNSHAN SHUNKANGDA IND PROD DESIGN

Plastic compression mold opening device

InactiveCN104842477AImprove mold opening efficiencyImprove safety and reliabilityEngineeringMechanical engineering

Owner:WUXI XINHONGTAI ELECTRIC TECH CO LTD

Spherical hinge mold and its opening method

ActiveCN106626171BSimplify the mold opening processImprove mold opening efficiencyRubber materialVulcanization

The invention discloses a spherical hinge die. The spherical hinge die comprises an upper die, a lower die and a middle die clamped between the upper die and the lower die, wherein the upper die, the middle die and the lower die are encircled to form a product vulcanization area; the product vulcanization area is isolated from the upper die and the lower die by virtue of an insert respectively; a rubber material is injected in a spherical hinge vulcanization area from a rubber injection hole of the upper die; and a rubber injection plug used for pressing the rubber material in the rubber injection hole of the upper die is arranged above the upper die. The spherical hinge die is characterized by further comprising a die opening device used for automatically separating the upper die from the rubber injection plug, and a pull rod device used for separating the upper die from the middle die. According to the spherical hinge die provided by the invention, the upper die and the rubber injection plug can be automatically separated to realize automatic die opening for the die, thus the die opening efficiency of the die is increased, and the manual labour intensity is lowered. The invention further provides a die opening method for the spherical hinge die.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

A mold slider release mechanism

The invention discloses a mold sliding block unlocking mechanism, which comprises an upper mold core, a lower mold core and a slider demoulding assembly; Components; hanging grooves, screw sinking grooves and inserting rod sinking grooves are set on the movable plate, hanging blocks are set on the upper mold core; countersunk head guide nails are set on the backing plate; the upper end of the inserting rod has a countersunk The countersunk head structure enters the sinking groove of the insertion rod; the elastic movable end of the elastic ejector part cooperates with the movable plate; when the upper mold core is opened, the elastic ejector part can automatically push the movable plate upwards by one end distance, and the movable plate will bring the insertion rod upward The insertion rod is separated from the hole where the workpiece is formed, and the separation of the insertion rod is carried out synchronously with the mold opening action, which improves the mold opening efficiency; and when the upper mold core continues to move upwards, the hanging block will also cooperate with the inclined surface to drive the slider to come off. The mold assembly slides outward, which further improves the mold opening efficiency and ensures the stability of the slide block mold opening.

Owner:苏州雅特精密模具有限公司

One-piece pull rod sliding die

PendingCN113665070AImprove mold opening efficiencyAvoid bumping the moldStructural engineeringMechanical engineering

Owner:东莞市聚研硅胶科技有限公司

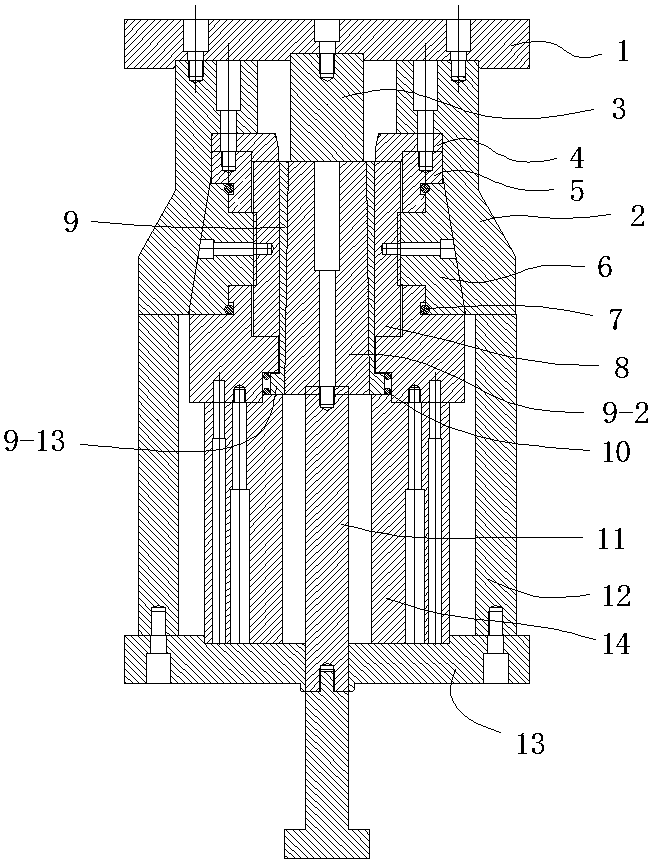

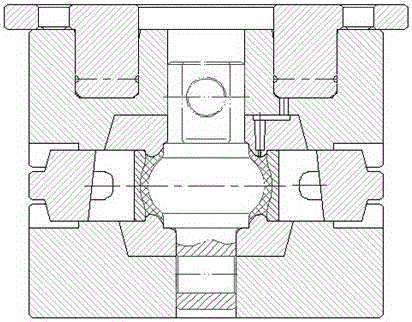

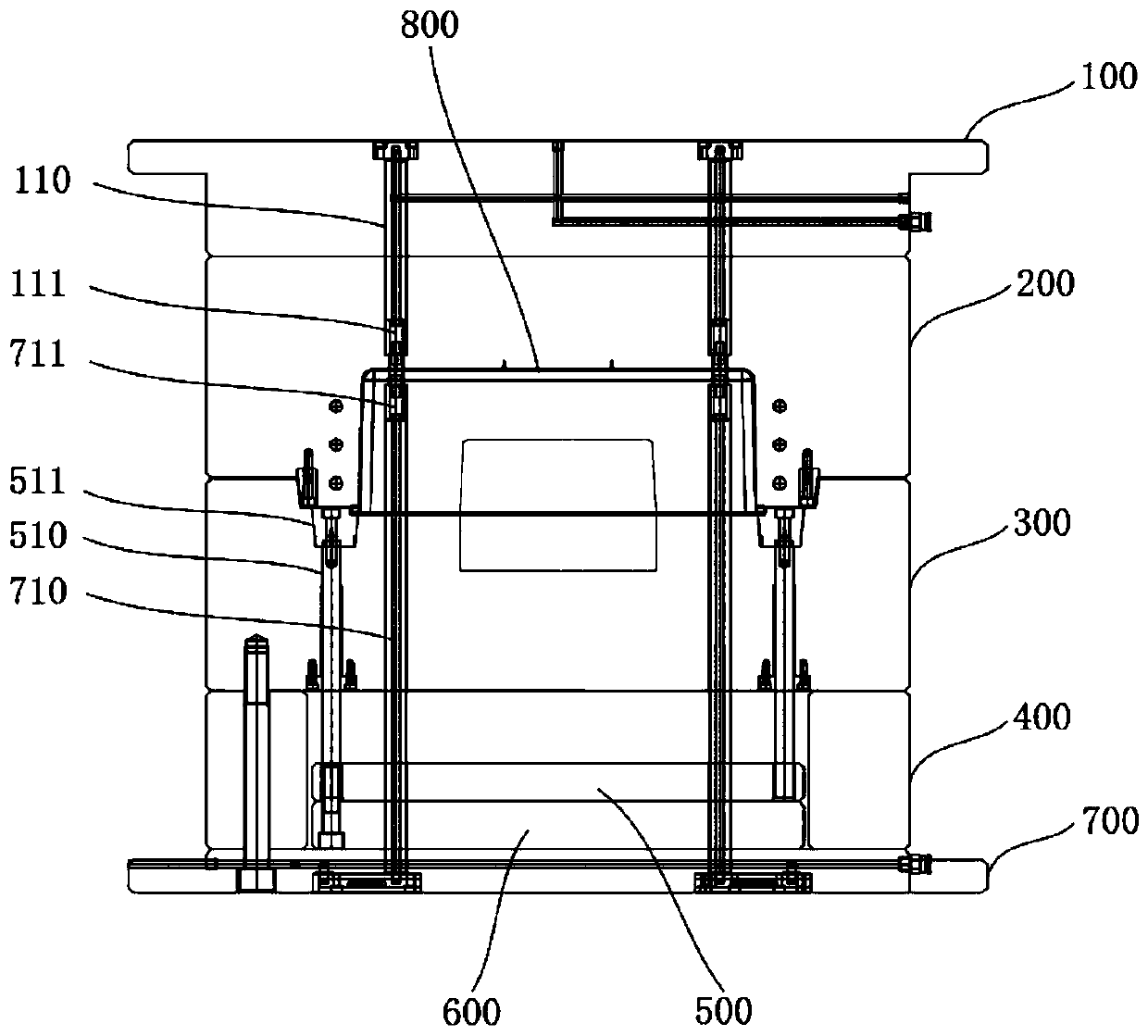

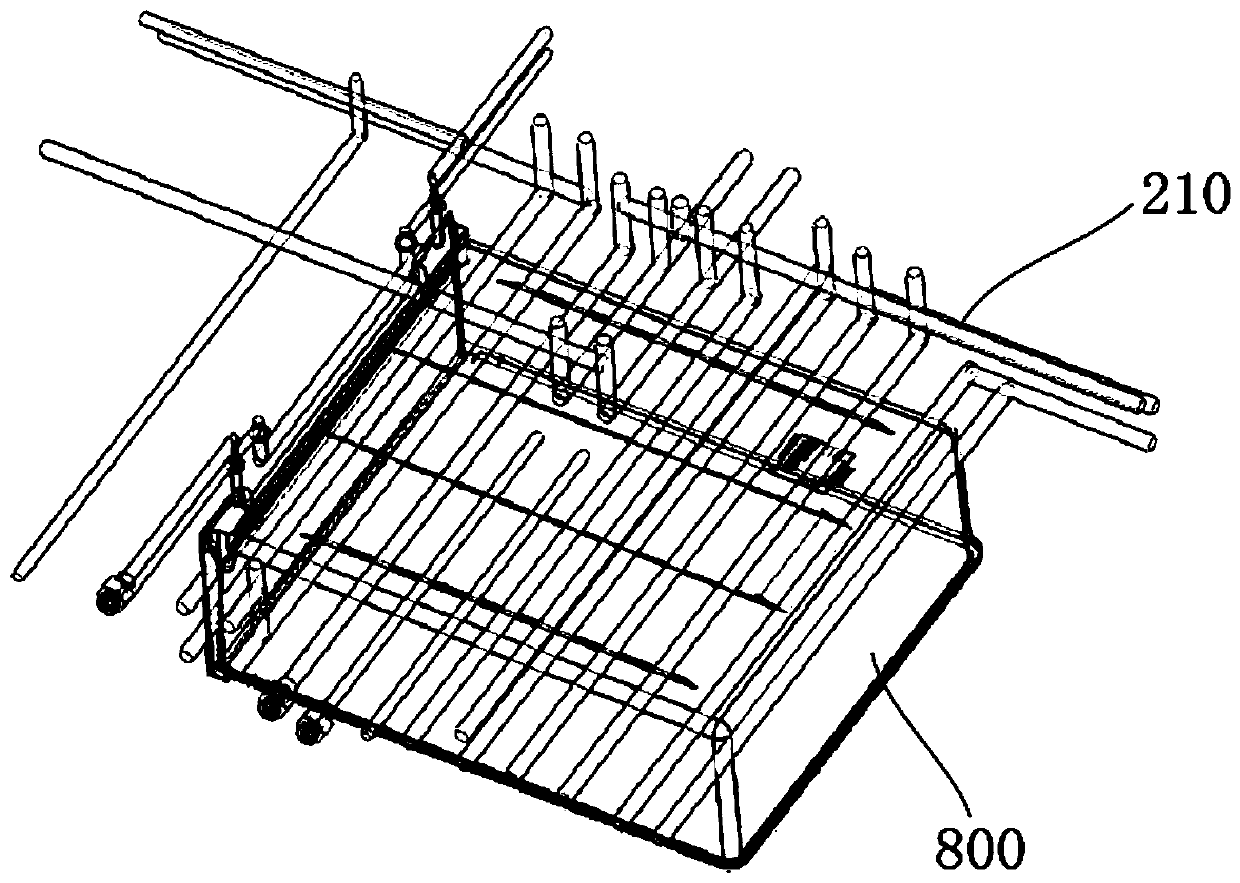

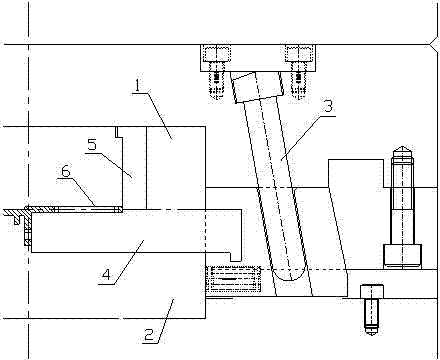

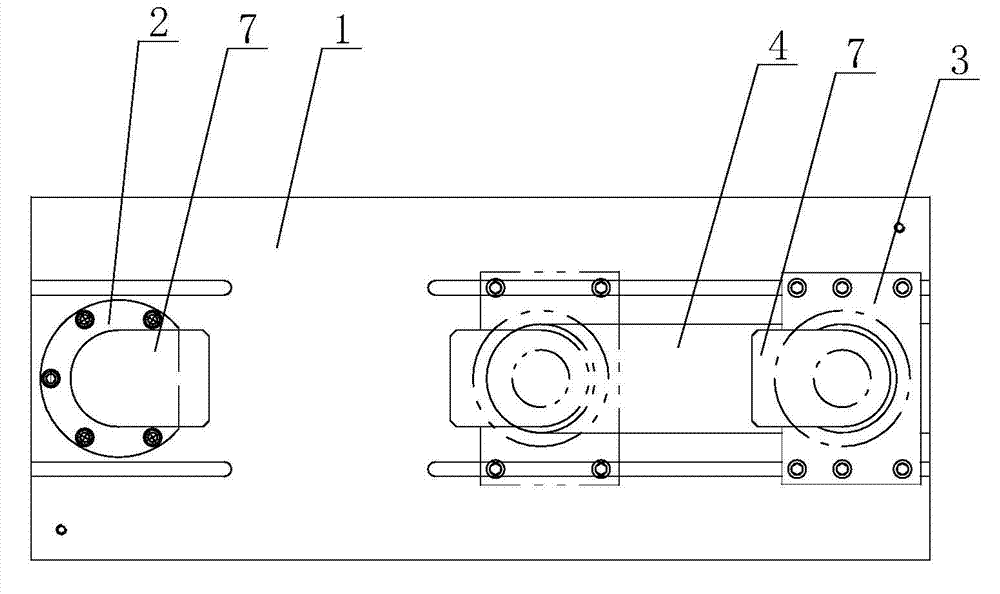

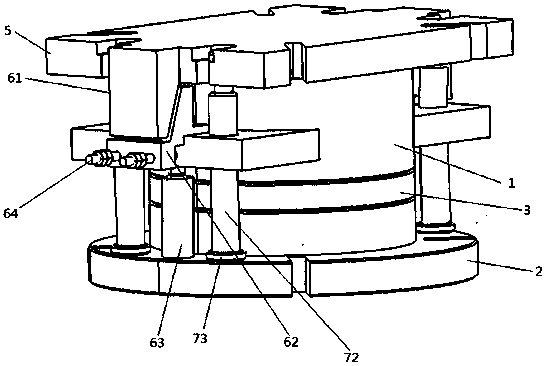

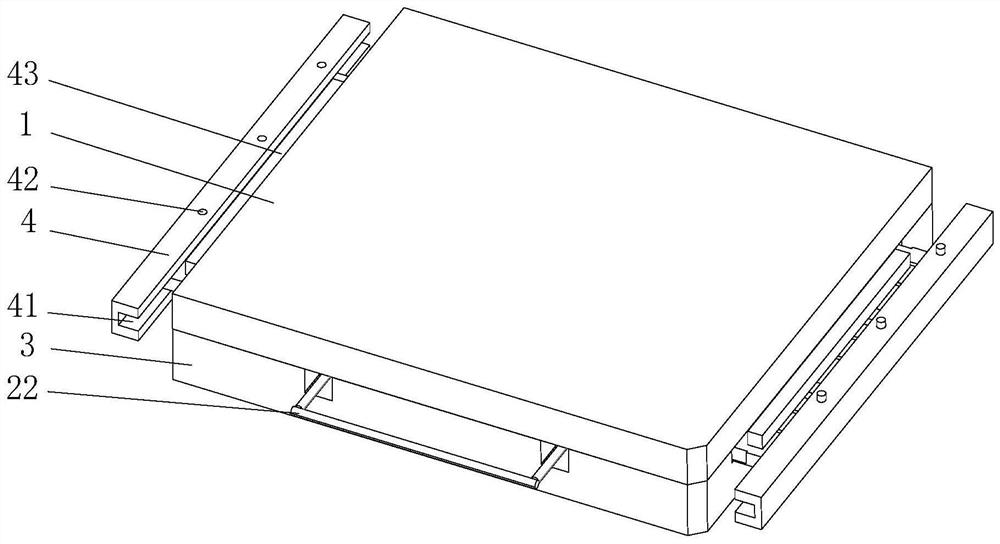

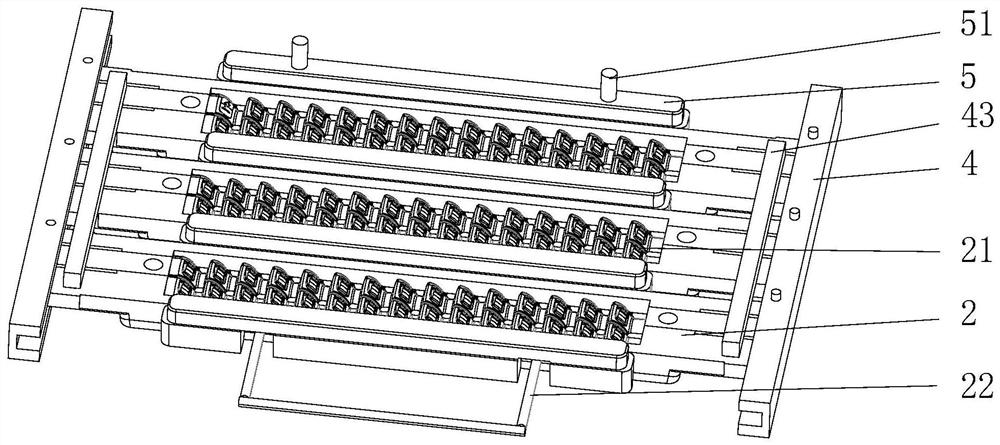

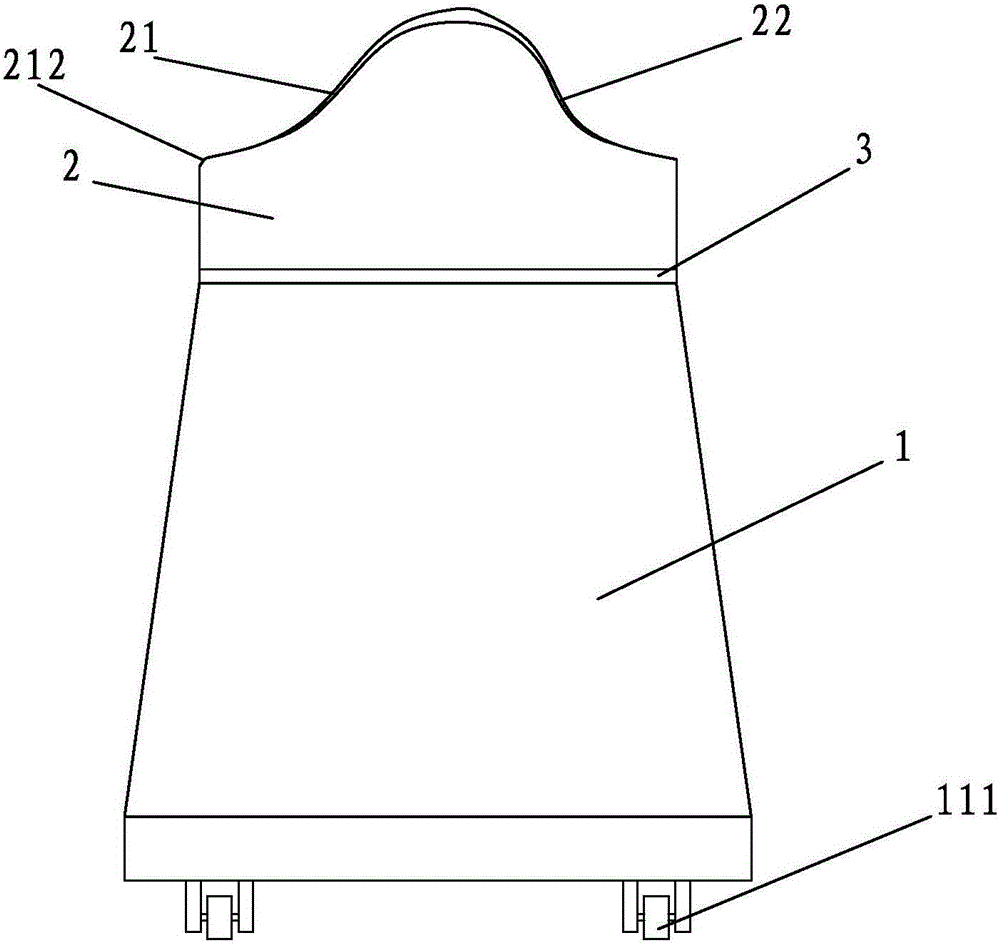

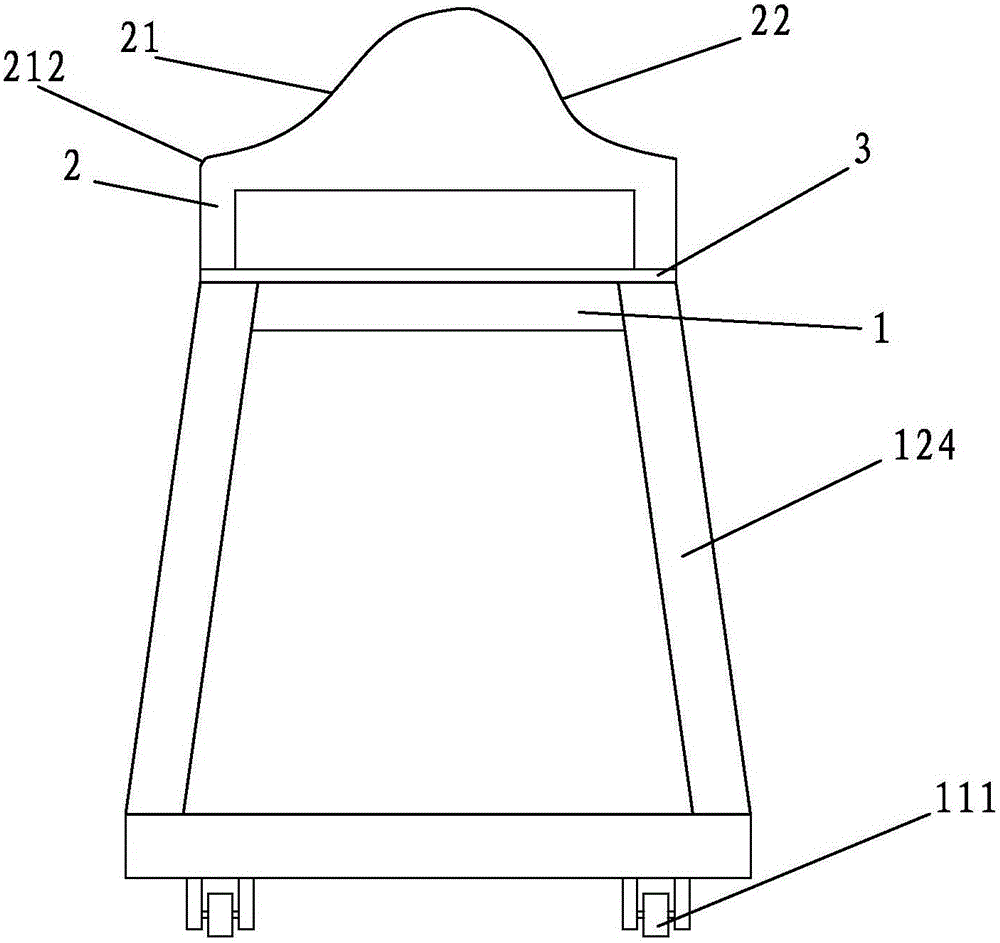

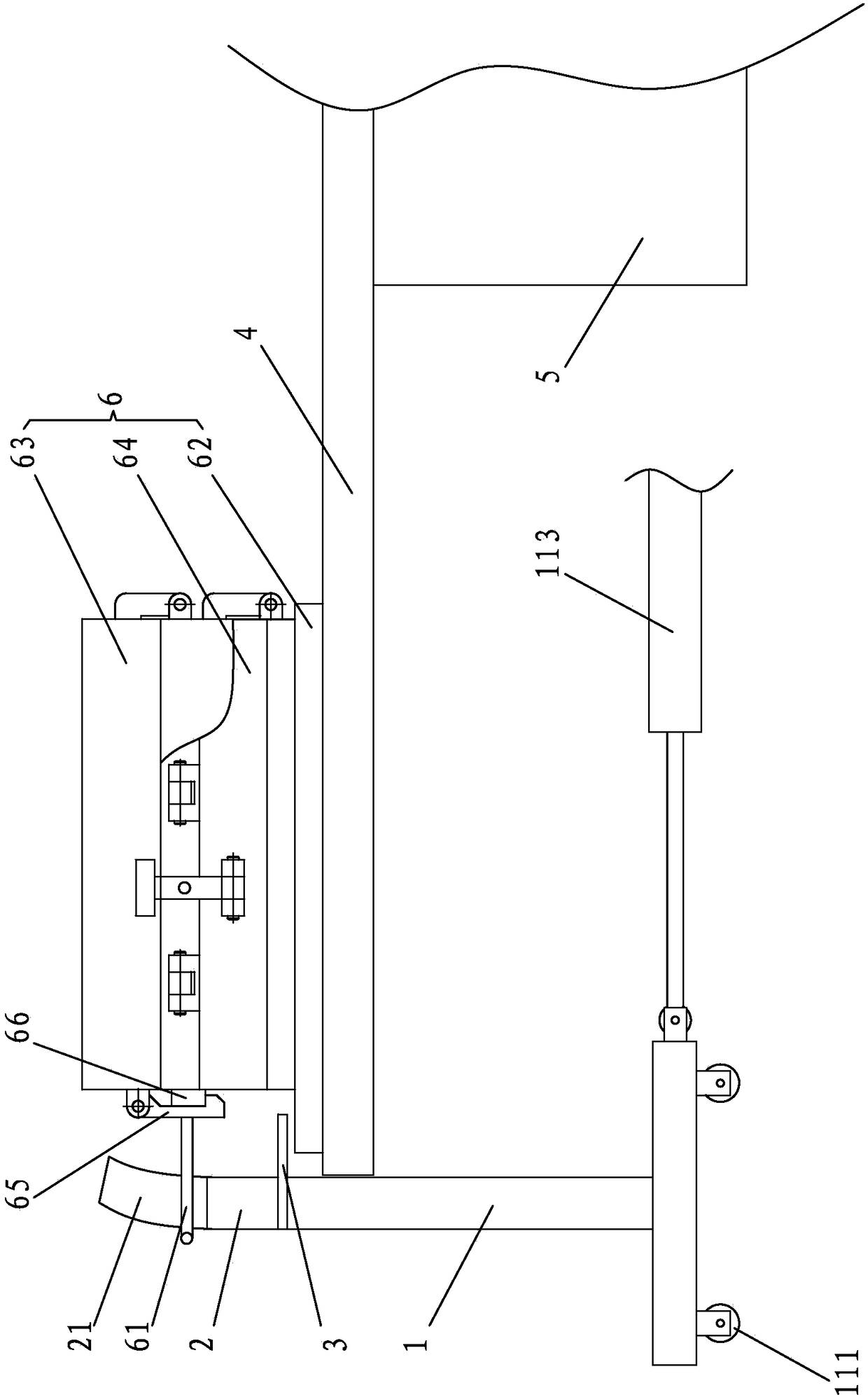

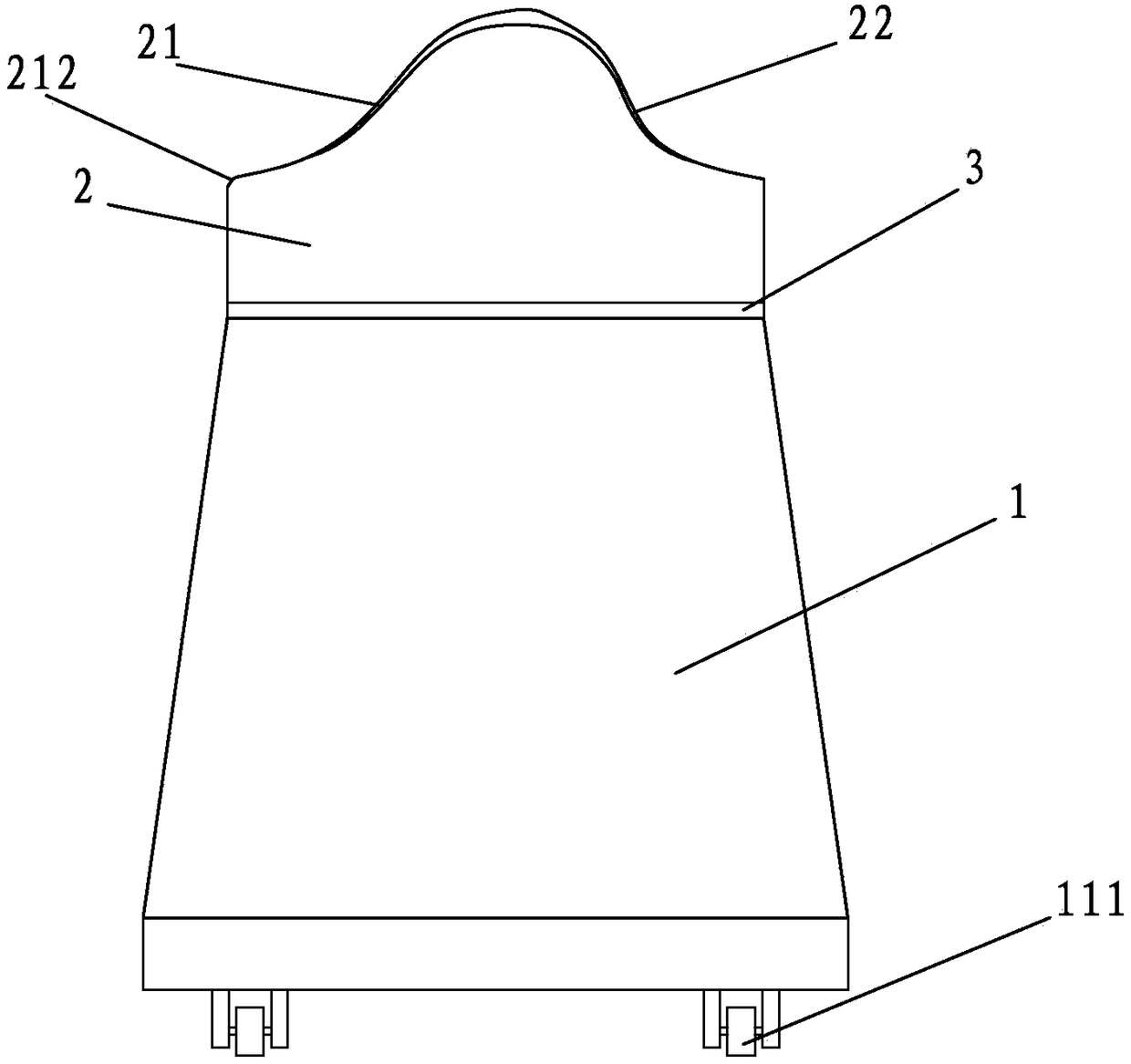

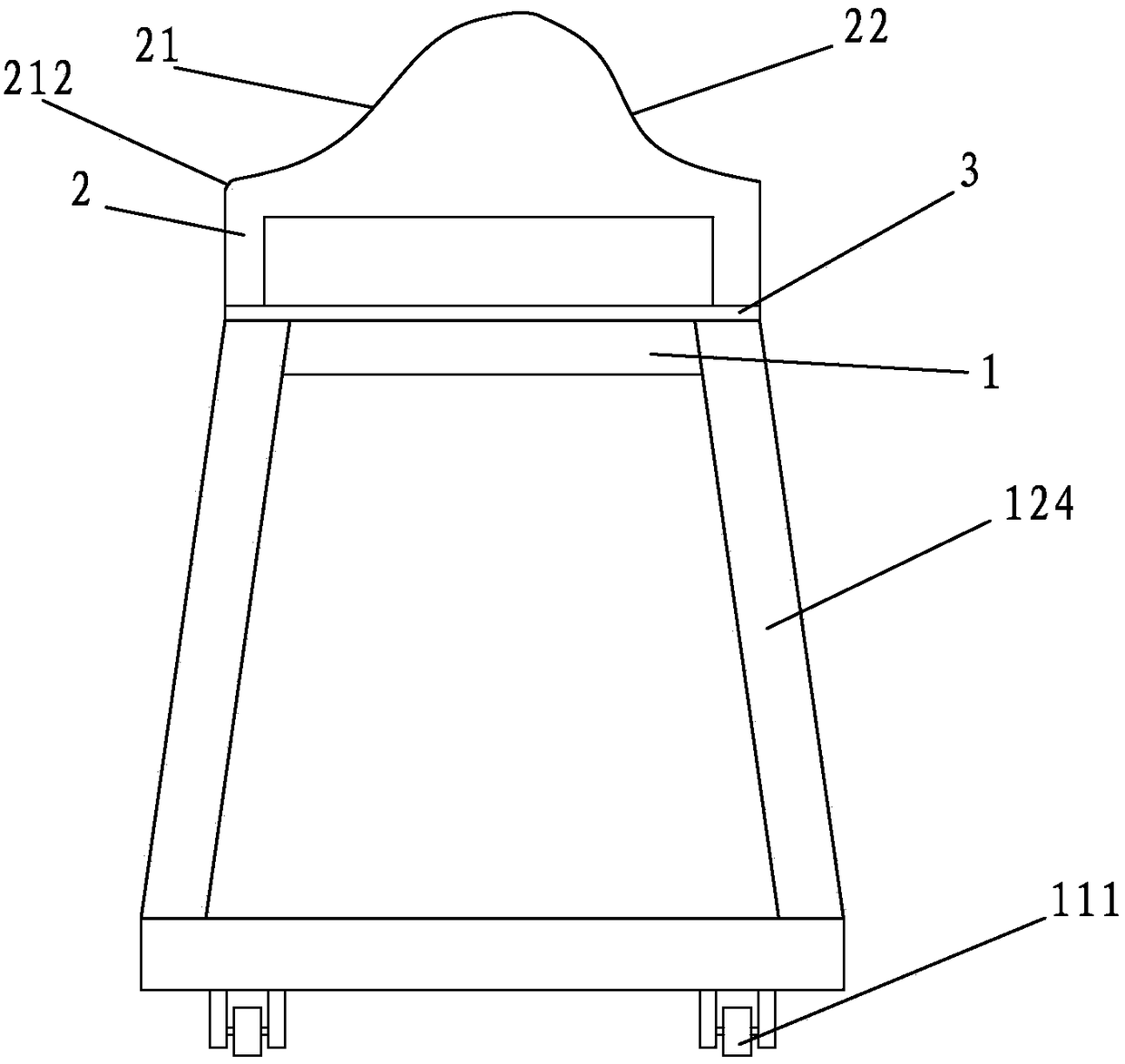

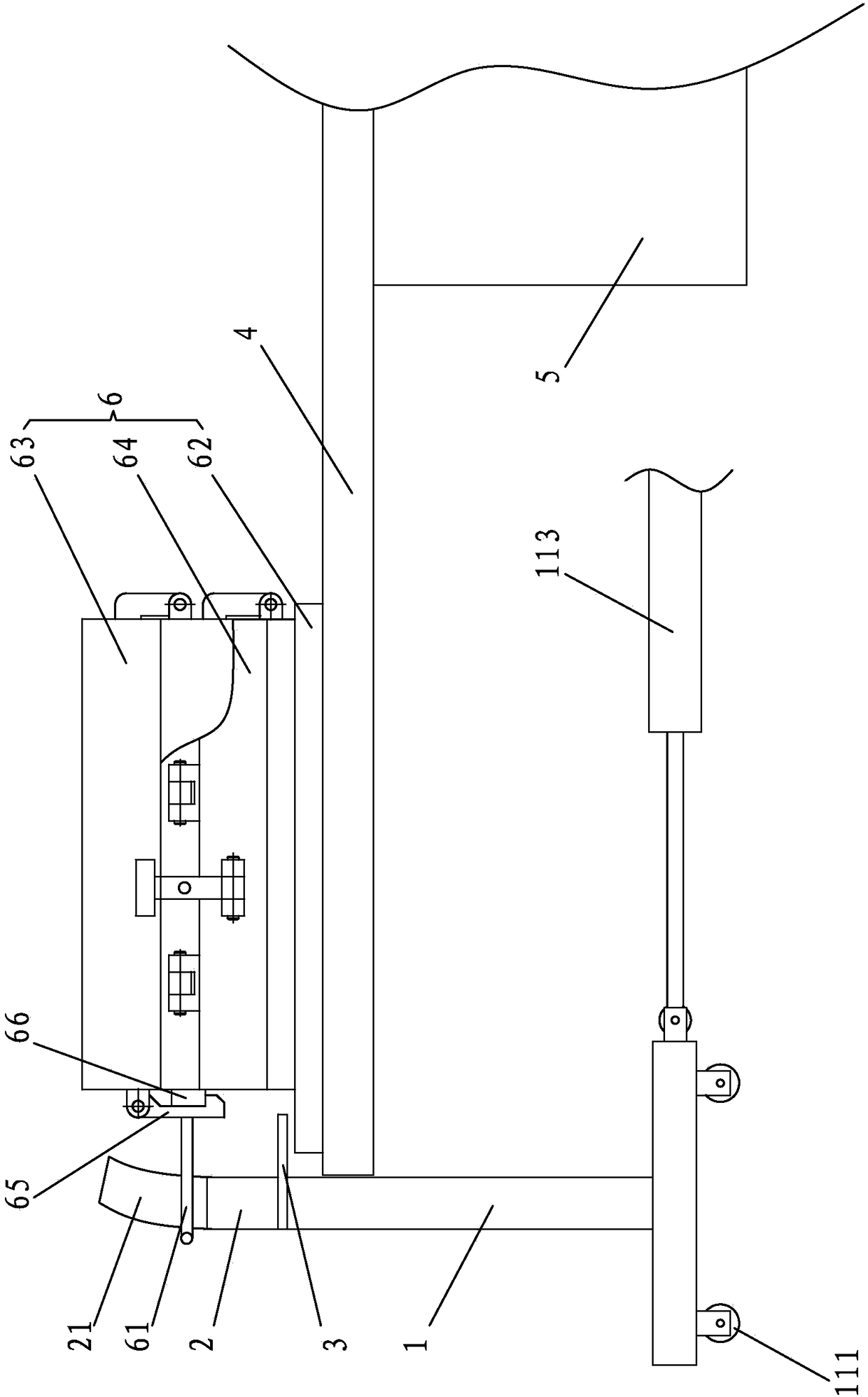

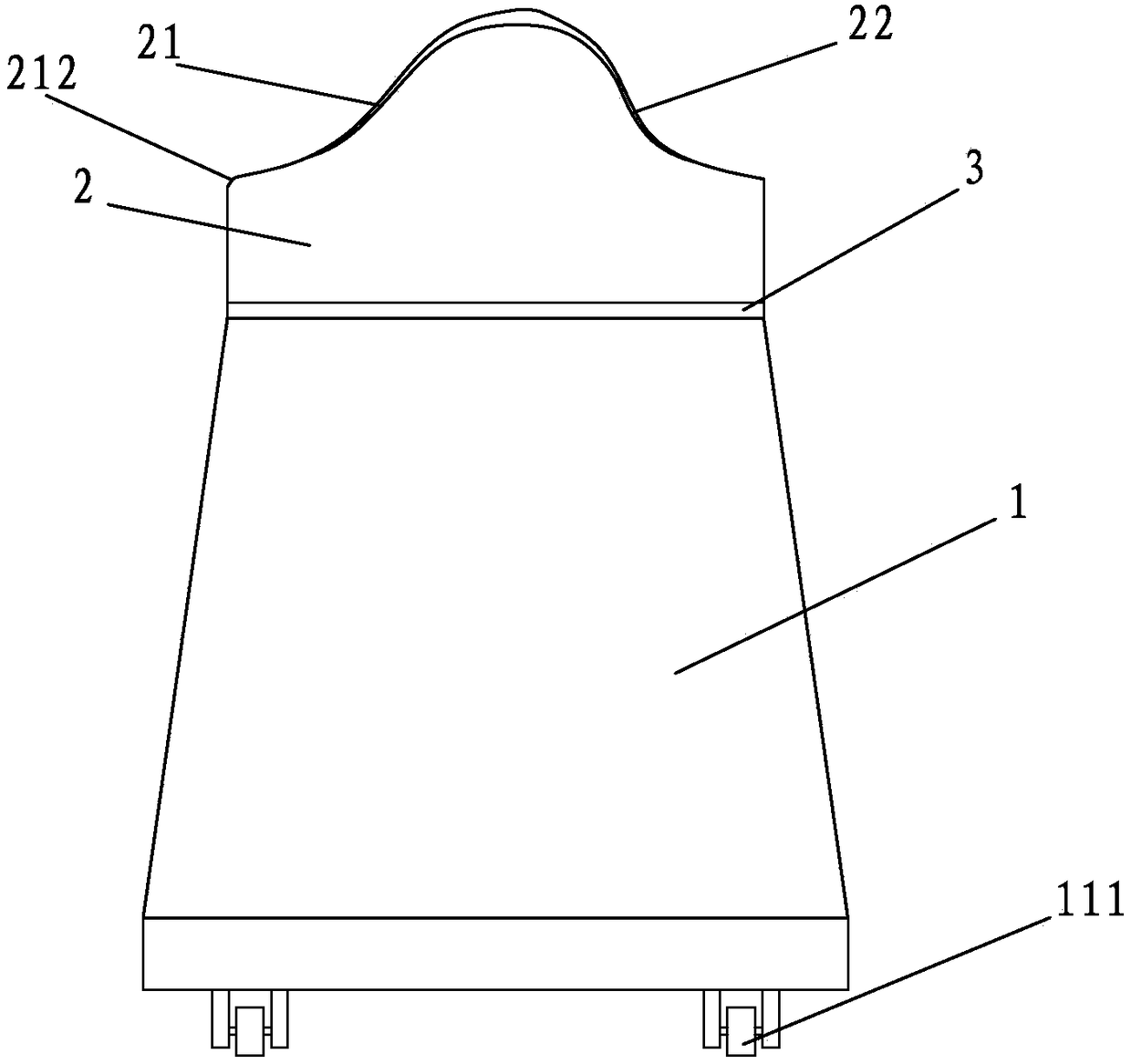

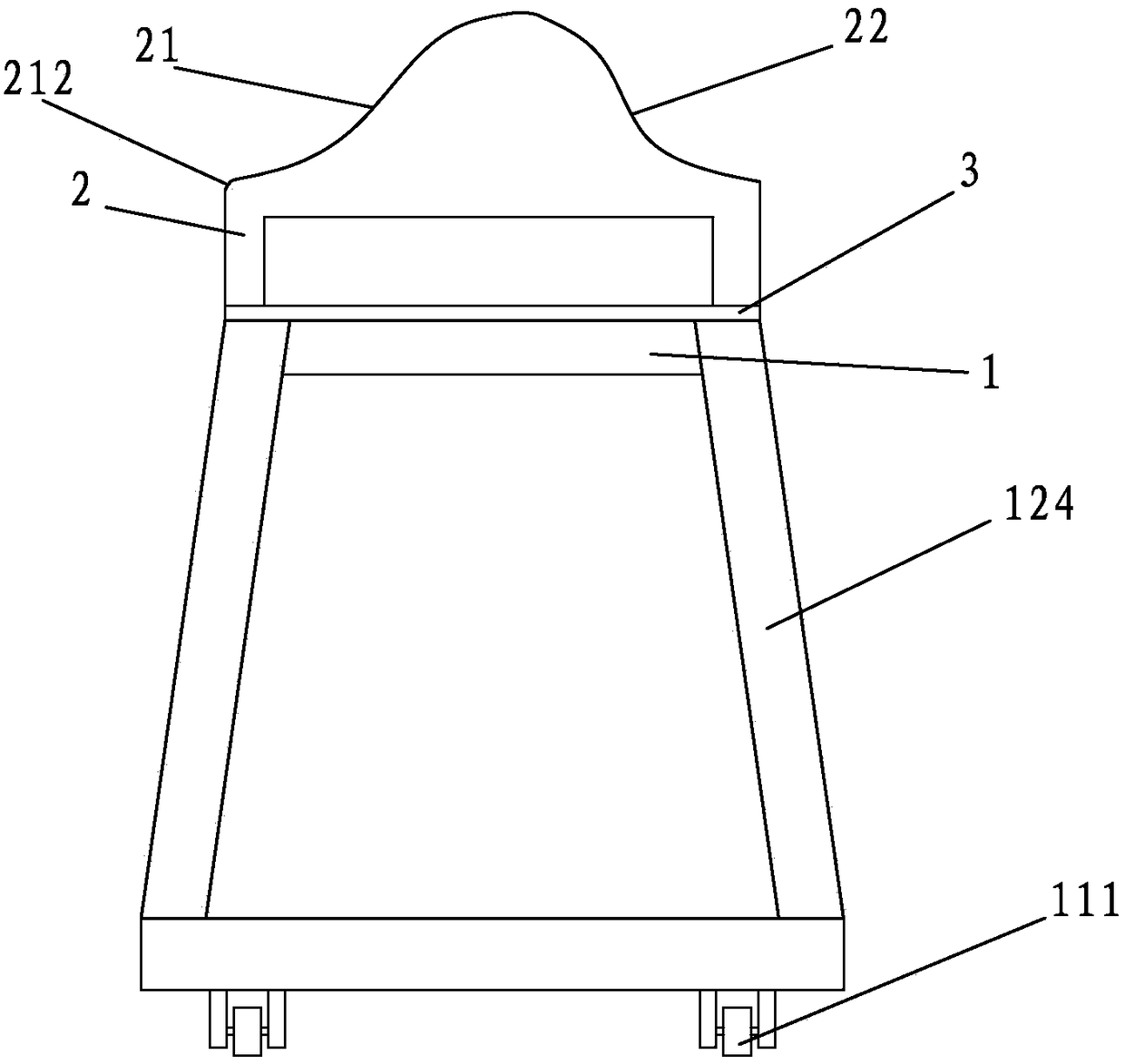

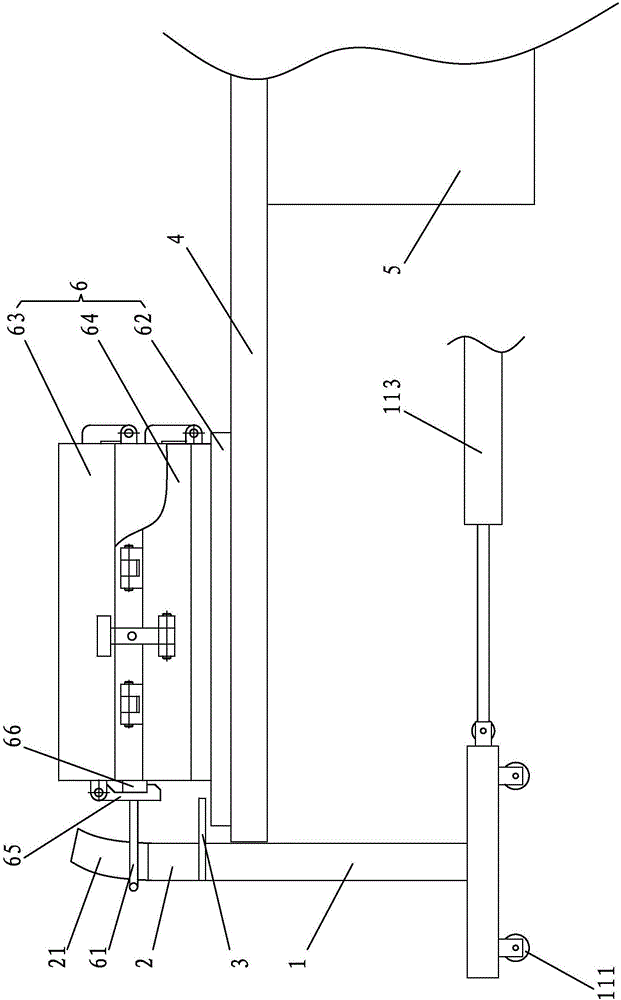

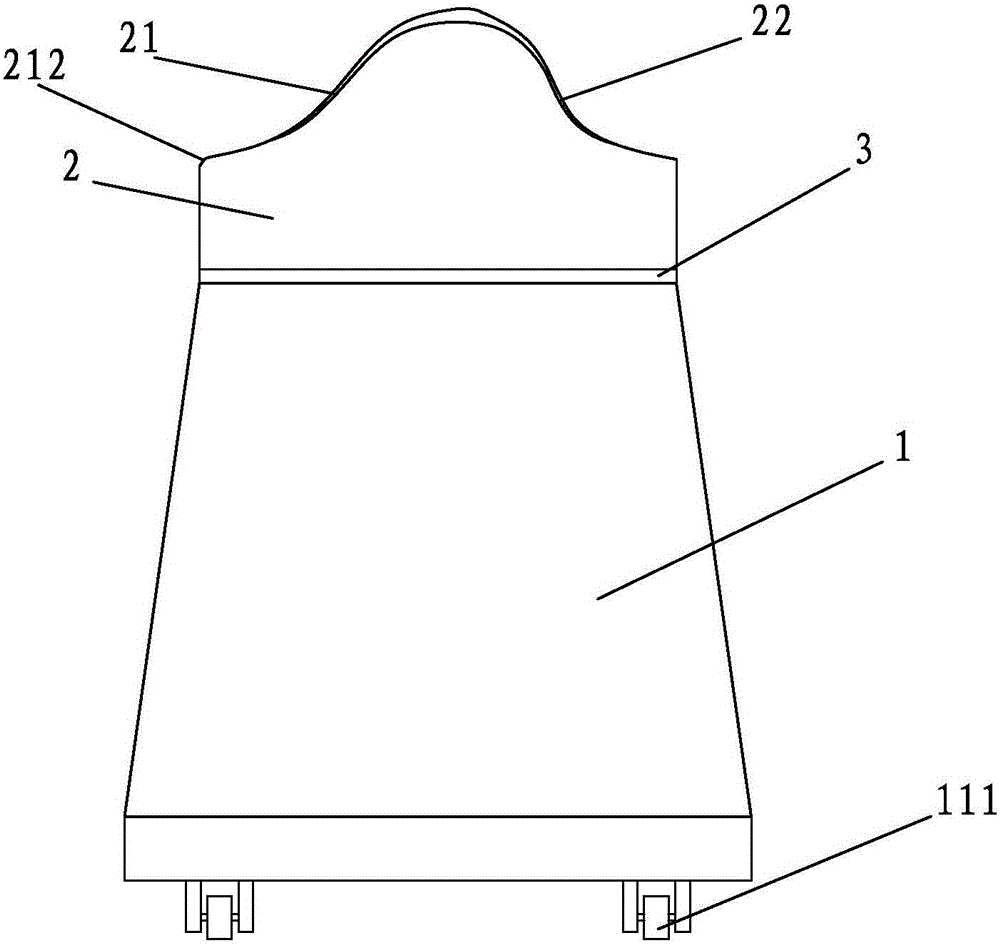

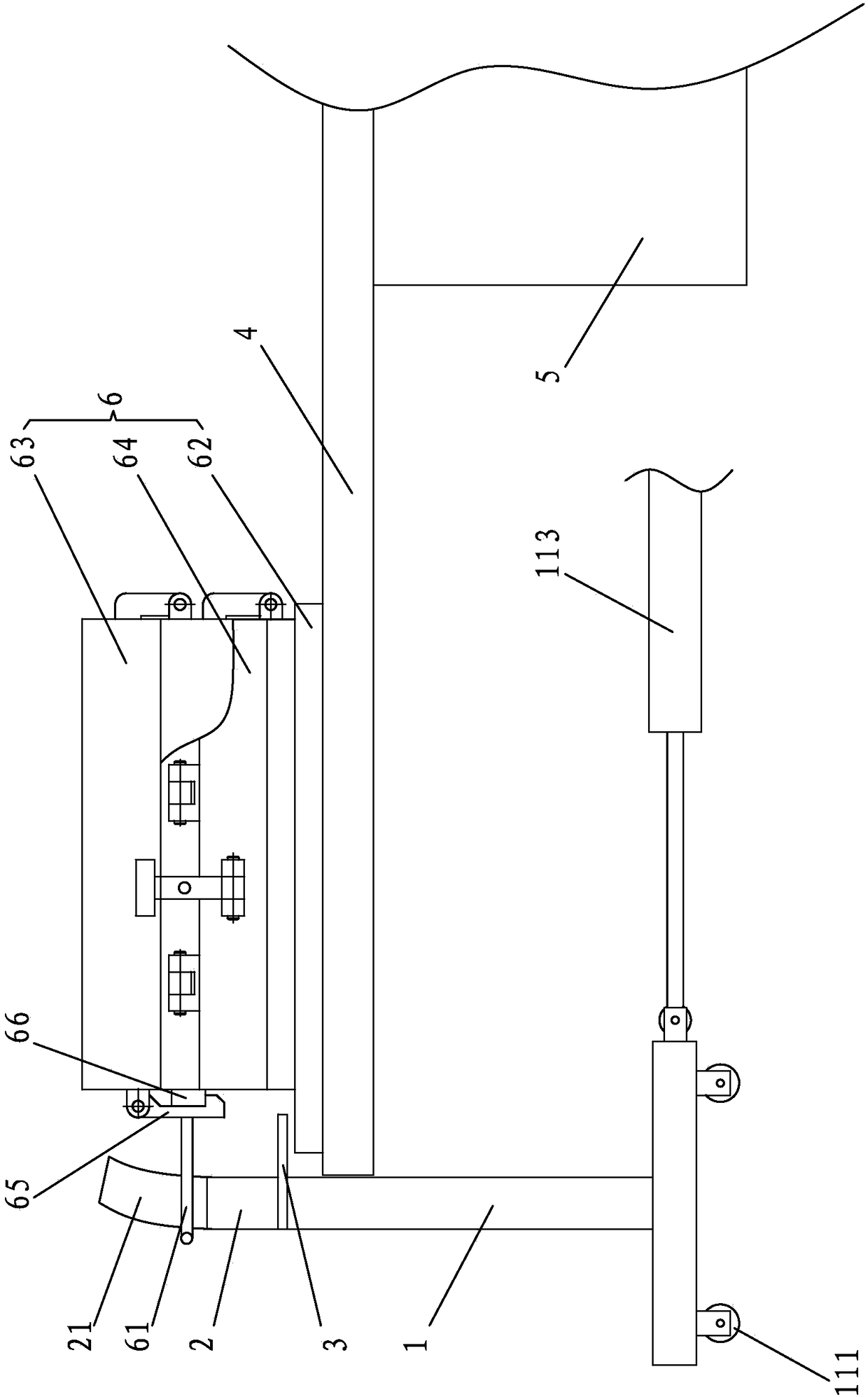

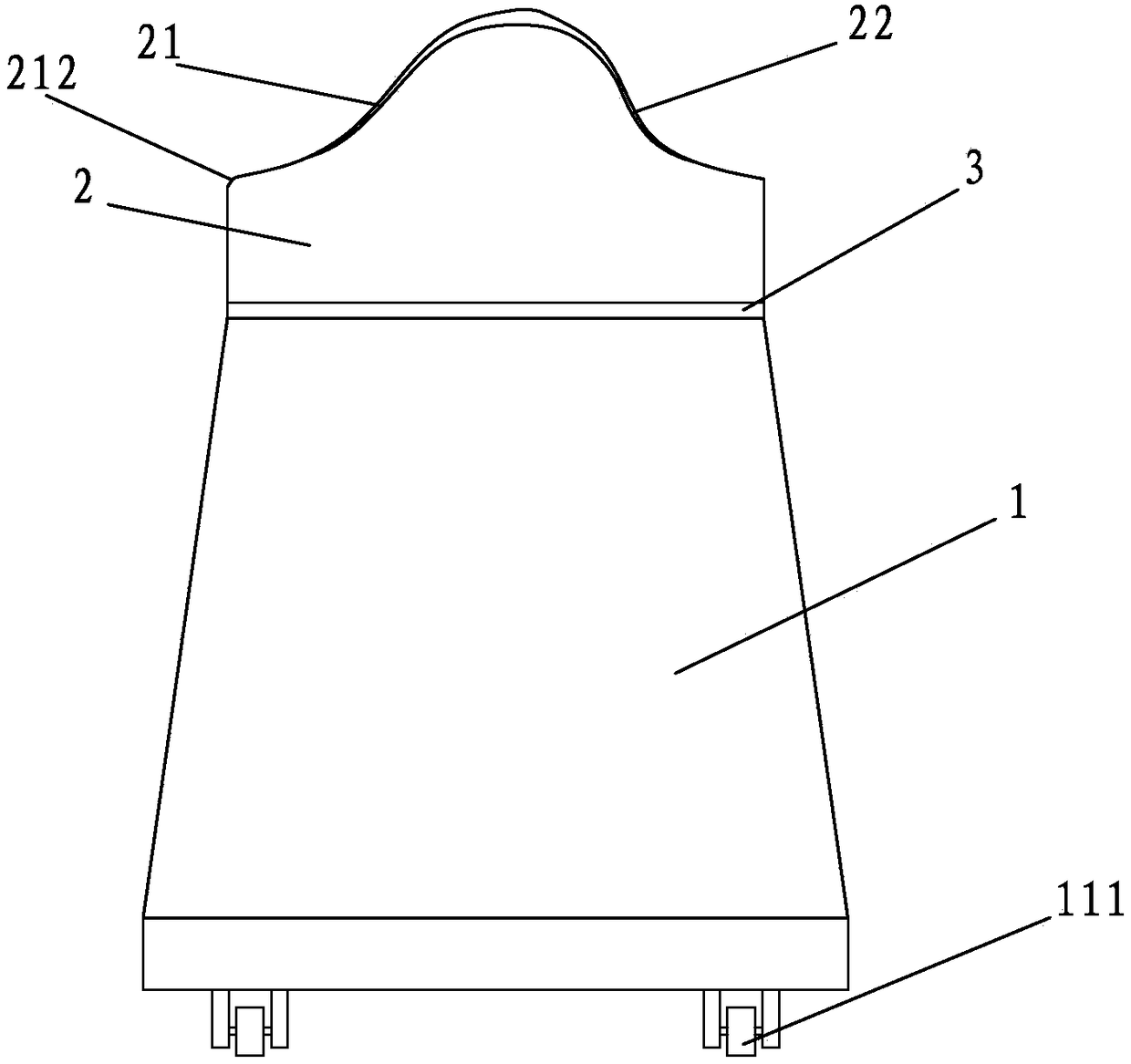

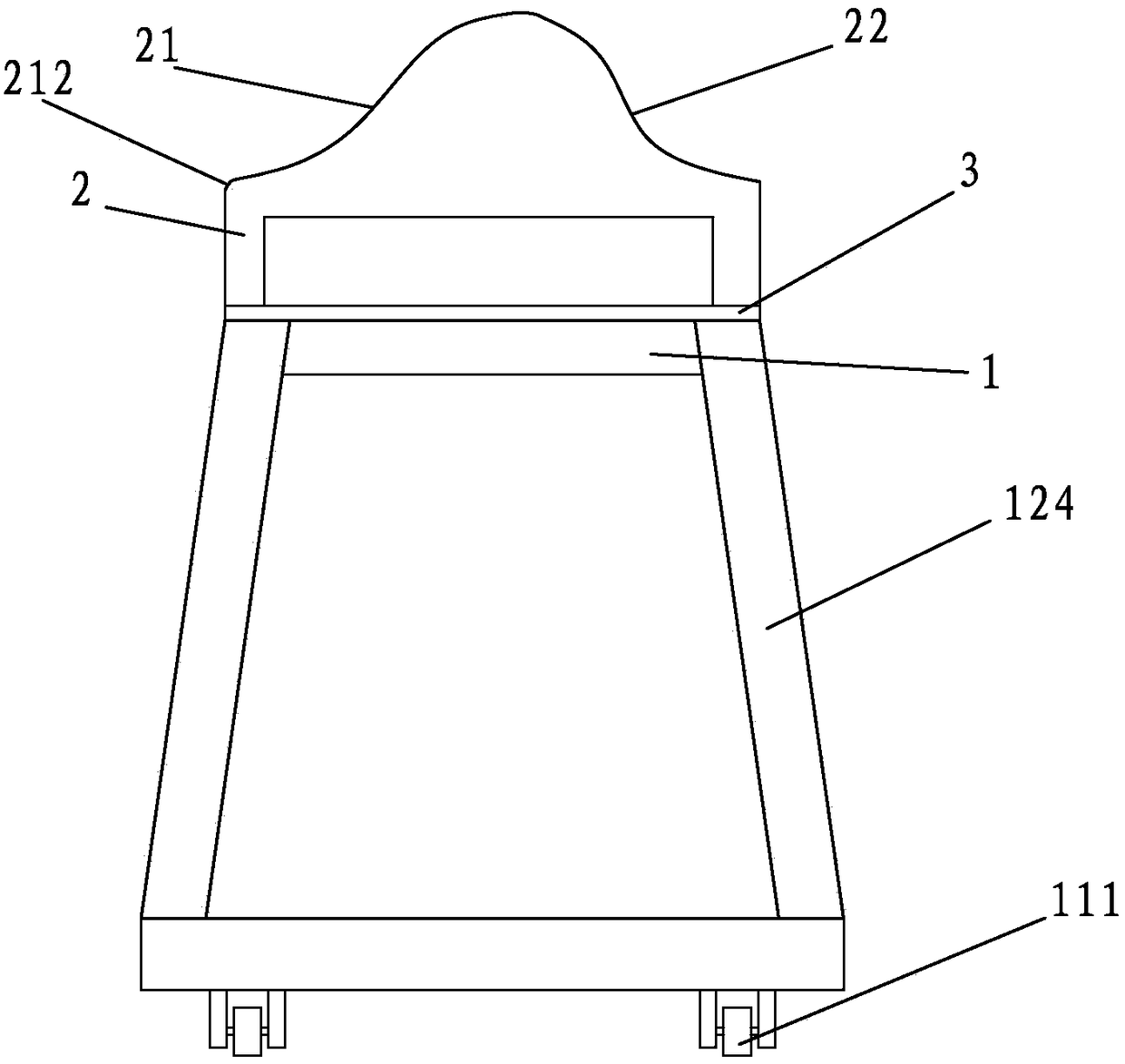

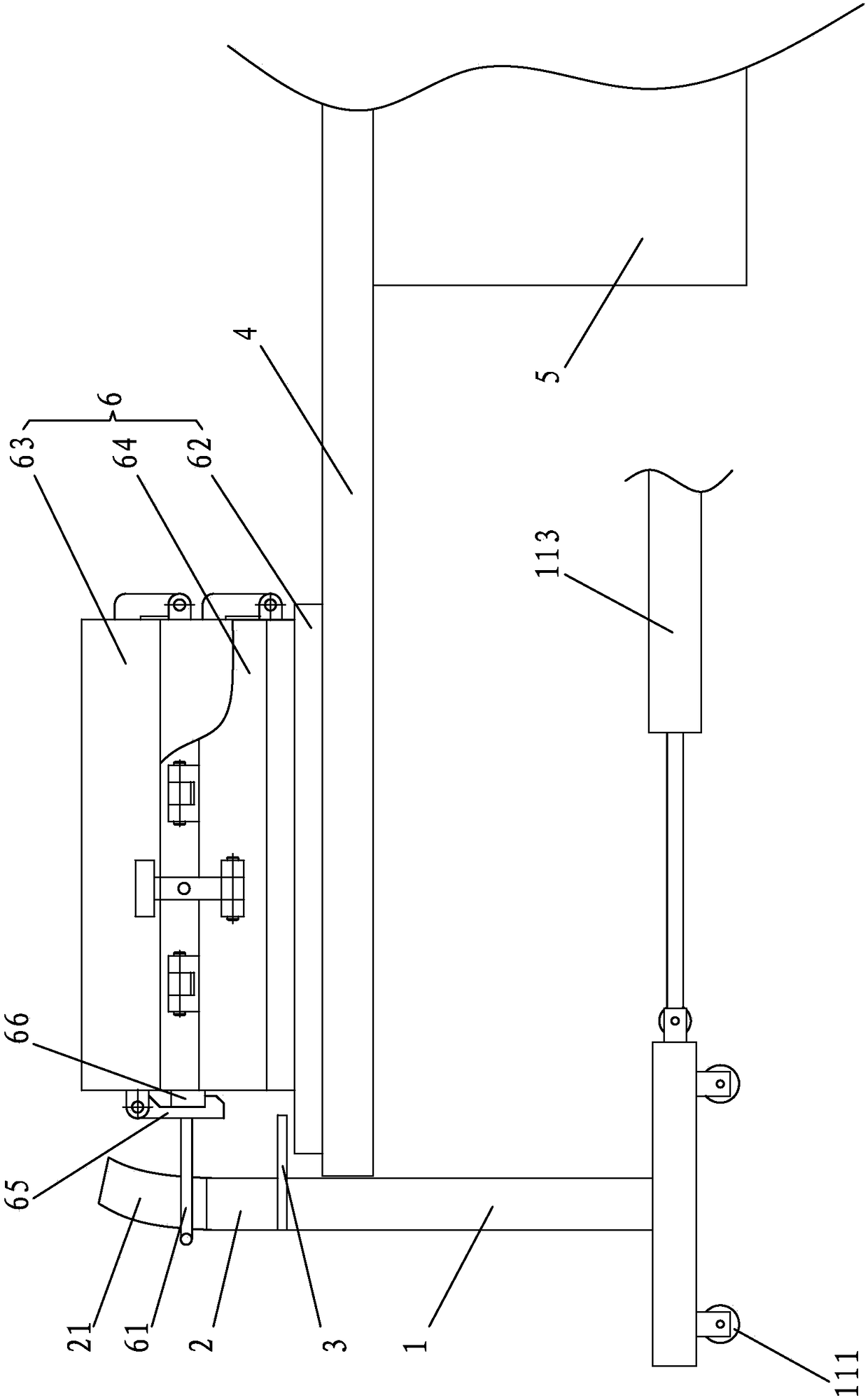

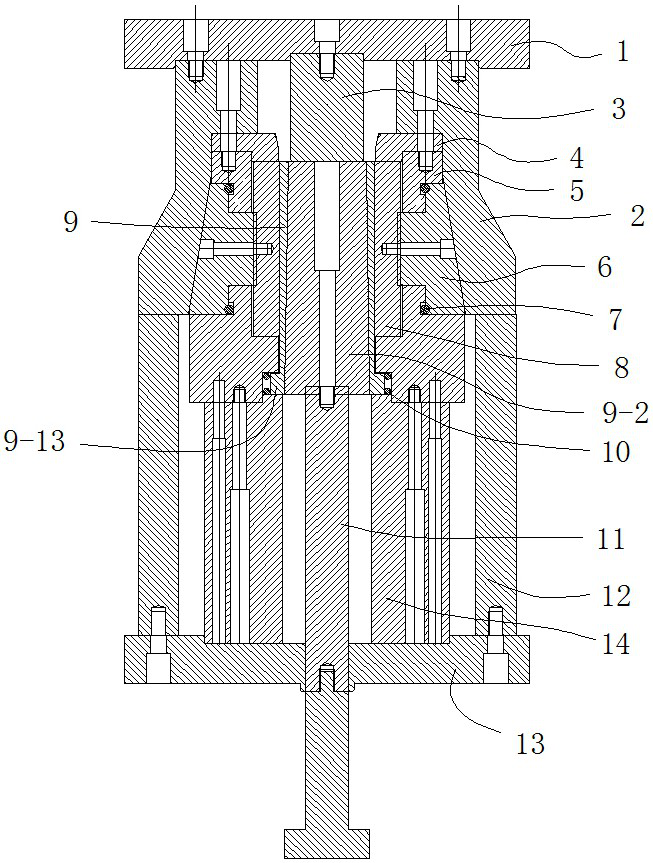

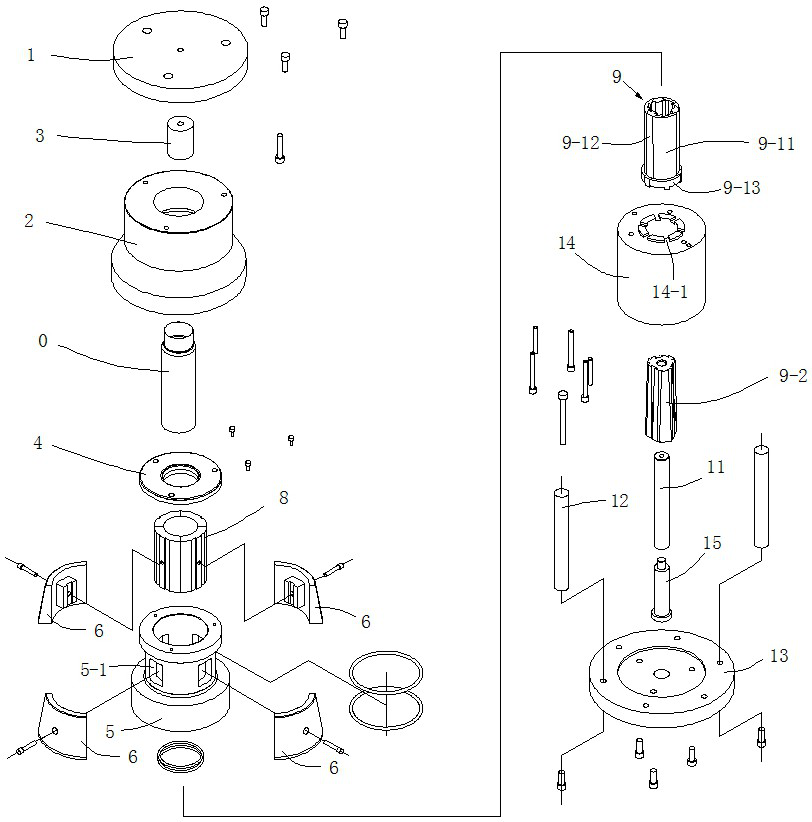

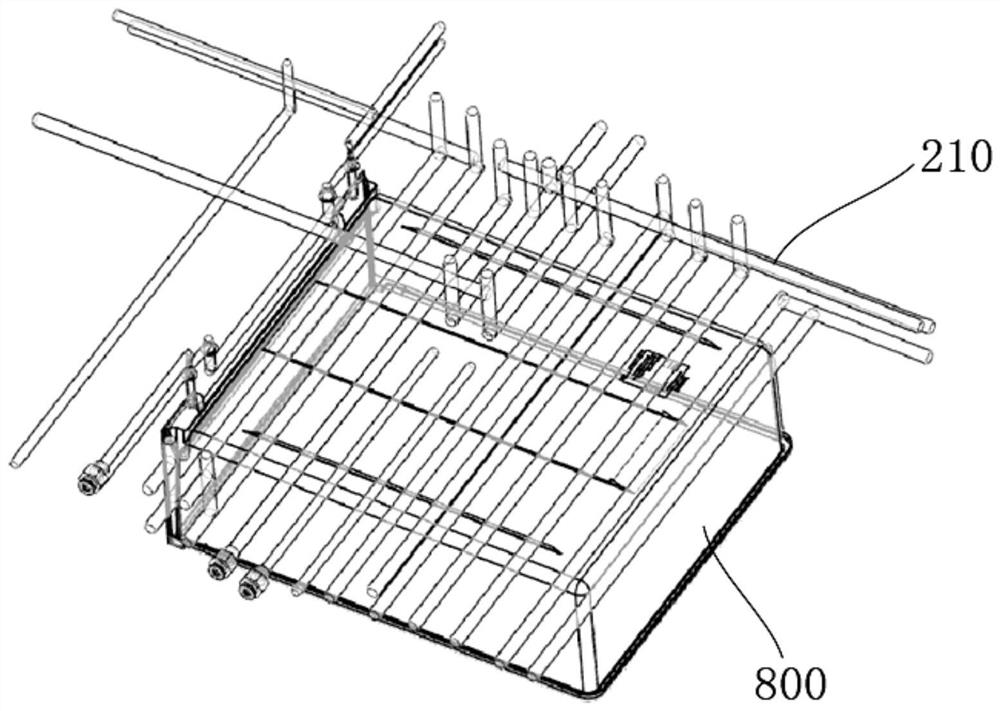

Pressing die for continuous pattern on surface of thin-walled metal shell of cup or kettle

PendingCN111332055AEven by forceGuaranteed integrityEmbossing decorationsThin walledMechanical engineering

The invention discloses a pressing die for the continuous pattern on the surface of a thin-walled metal shell of a cup or a kettle. The pressing die comprises an upper die force applying positioning assembly, a lower die positioning assembly, a female die assembly and a male die assembly. The upper die force applying positioning assembly comprises a die closing ring. The lower die positioning assembly comprises a positioning cavity. The female die assembly comprises a female die defined by a plurality of female die blocks. An inclined face in sliding fit with the inclined inner wall of the dieclosing ring is arranged at the outer end of a die closing push block. The male die assembly comprises a male die defined by a plurality of male die blocks and a male die core. In the die closing state, the continuous groove pattern surrounding the inner wall of the female die corresponds to the continuous protruding edge pattern surrounding the outer wall of the male die. By the adoption of thepressing die for the continuous pattern on the surface of the thin-walled metal shell of the cup or the kettle, it can be guaranteed that the pressed continuous pattern on the surface of the thin-walled metal shell of the cup or the kettle is high in definition and free of deviation and can ensure that the thin-walled metal shell is not lost and cracked, the yield is greatly increased, and the production efficiency is greatly improved.

Owner:ZHEJIANG HAERS VACUUM CONTAINERS CO LTD

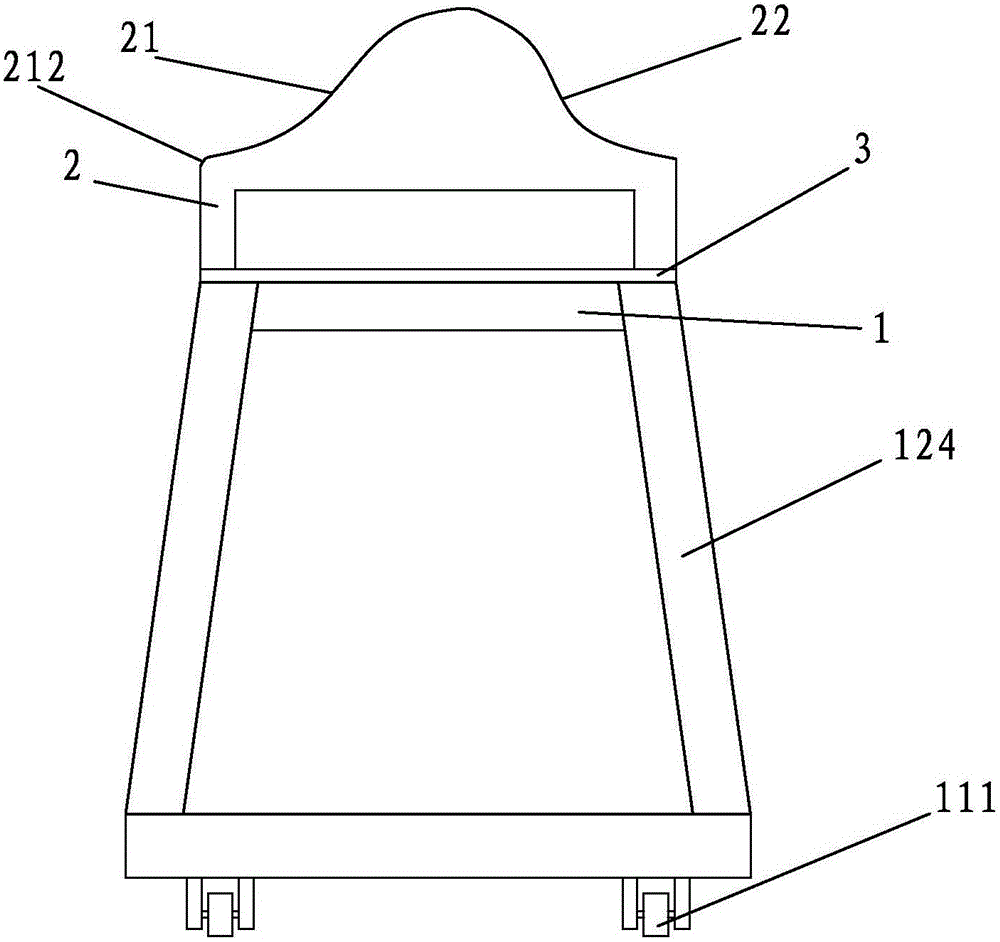

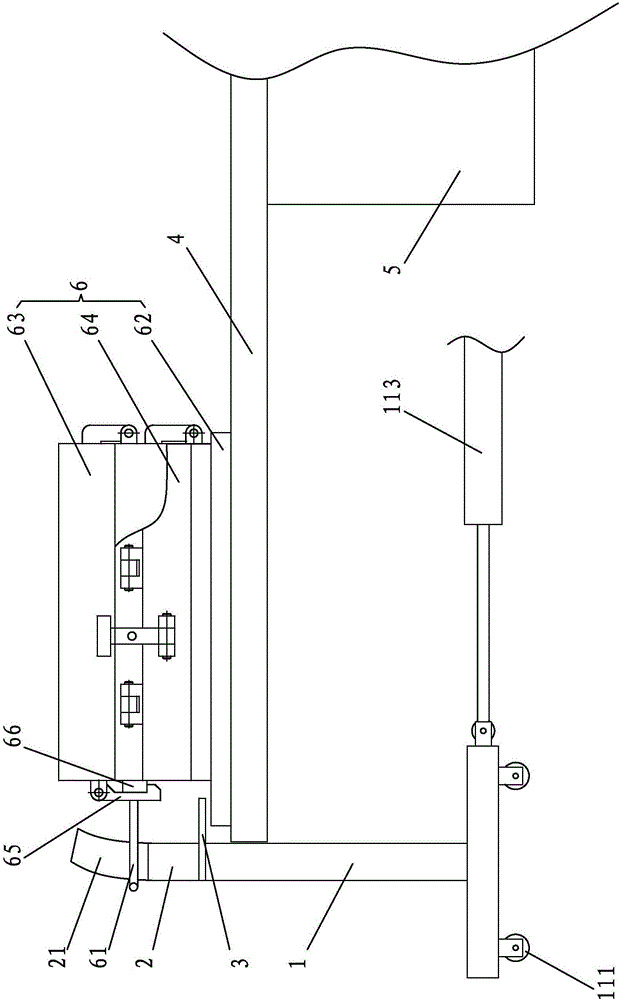

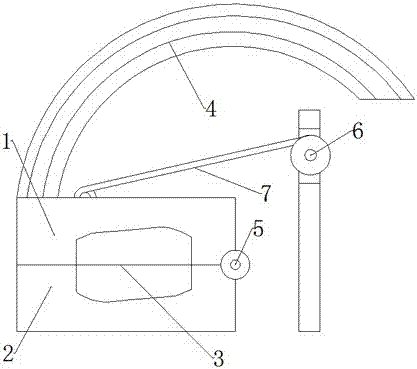

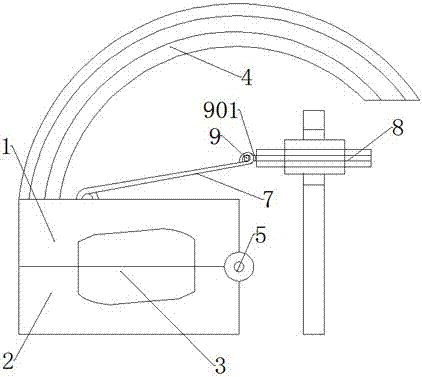

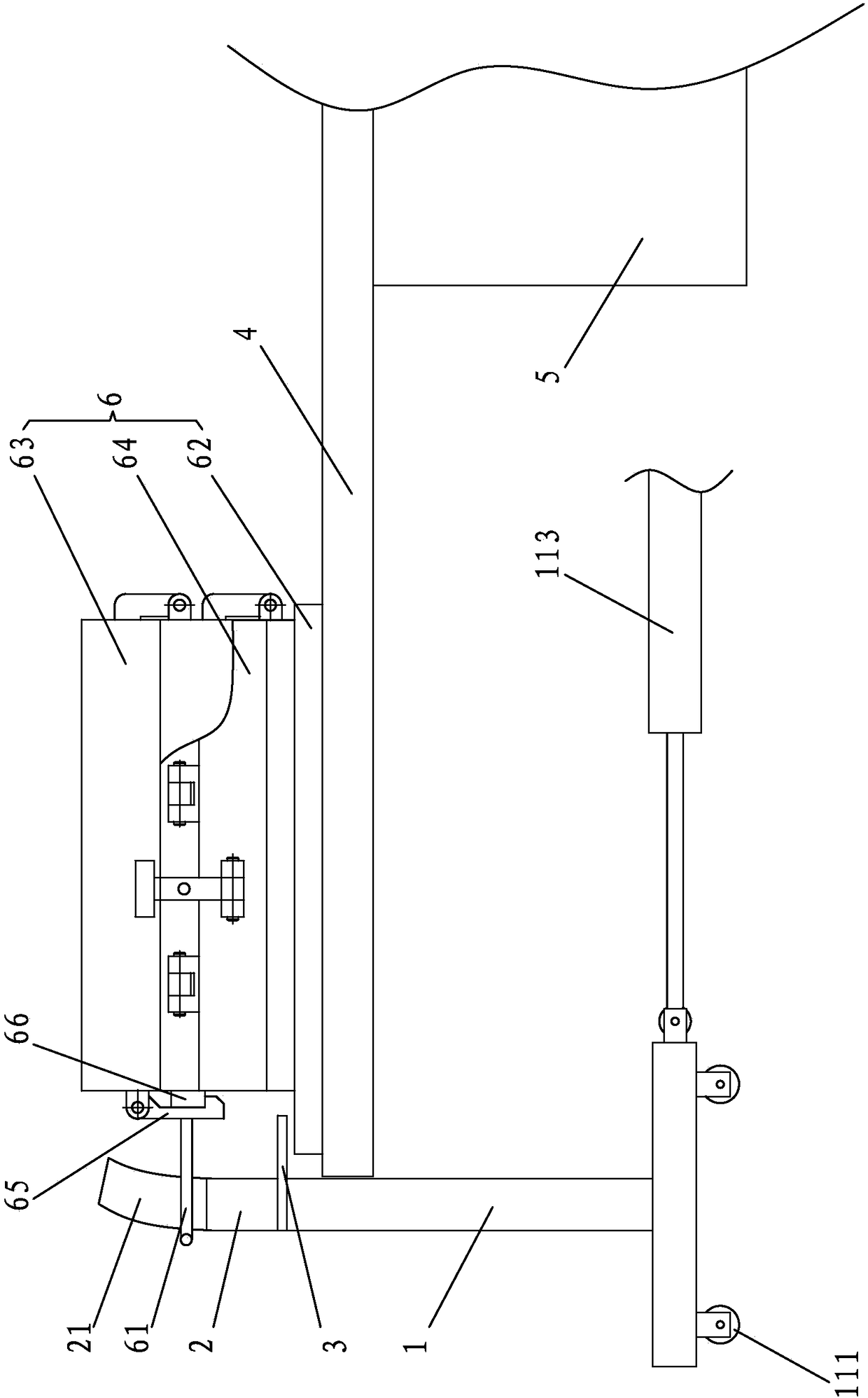

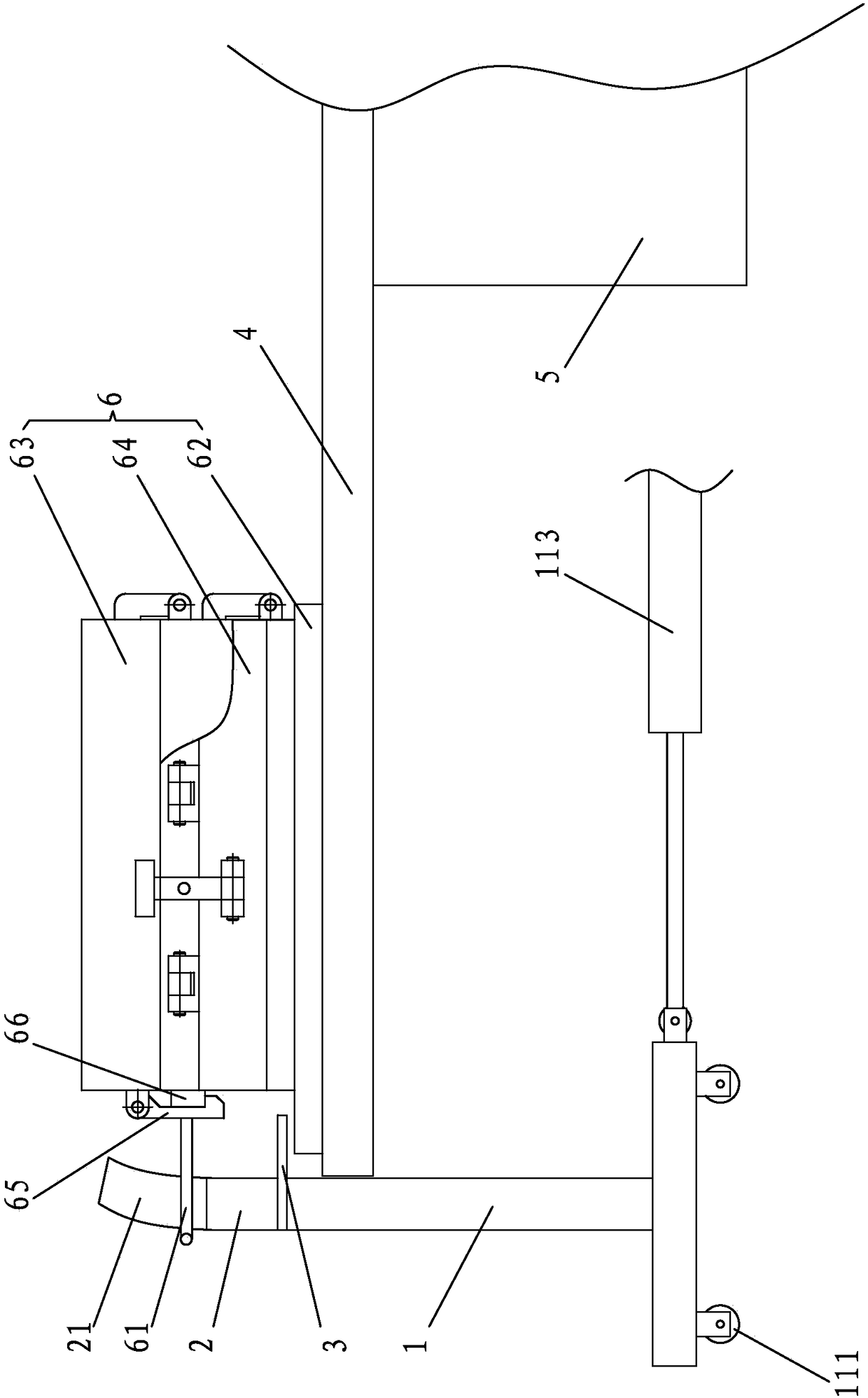

Vertical rotating shaft type automatic die opening device of injection molding machine and injection molding machine made by vertical rotating shaft type automatic die opening device

The invention provides a vertical rotating shaft type automatic die opening device of an injection molding machine. At a place where a fastener handle is connected with an upslope inclined edge, with the continuous operation of a disc, the fastener handle is subjected to an upward push force by the upslope inclined edge, a lifting prevention device limits a die bottom plate and allows no lower die to be lifted, and after the fastener handle walks a certain distance on the upslope inclined edge, the upslope inclined edge can separate an upper die from the lower die completely, so that automatic die opening can be realized in an operation process of the disc, and continuous automatic die opening can be realized in a continuous operation process of the disc. Furthermore, by adopting a die opening executing mechanism in a frame structure or in a metal tube or metal rod type, on the basis that the structural strength is ensured, the material usage and weight can be reduced greatly, and the cost and the practicability are reduced and improved significantly. Moreover, in a practical working process, a frame body bears the die opening executing mechanism and allows the die opening executing mechanism to be close to or far from the disc in a door opening or closing manner by depending on a vertical rotating shaft, the structure is simple and reasonable, and the movement is concise. The invention also provides an injection molding machine.

Owner:东营市东凯园区运营管理有限公司

Slide rail type automatic mold opening device of injection molding machine and injection molding machine composed of same

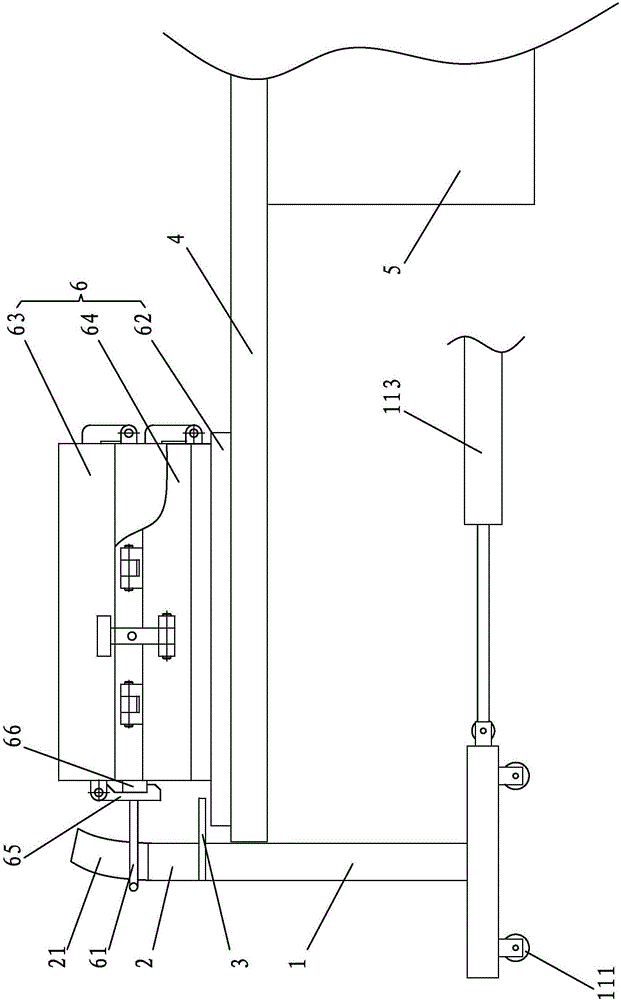

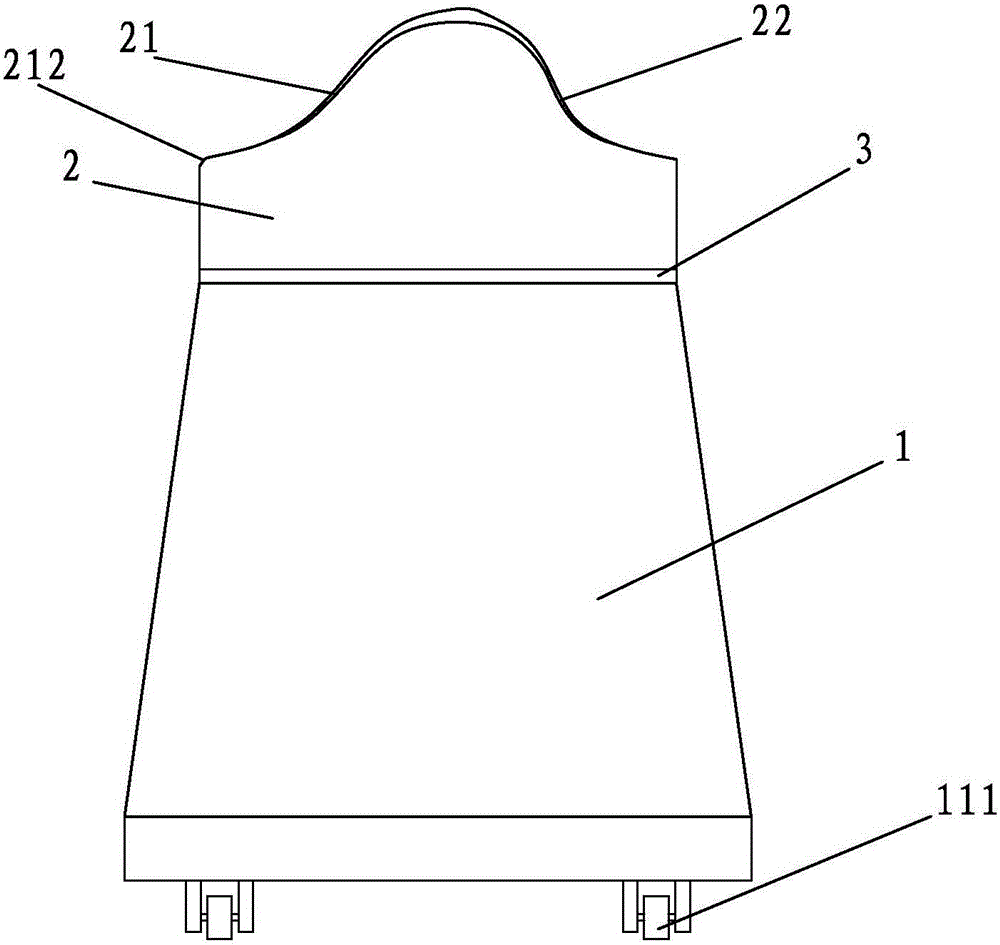

ActiveCN105922528AOvercoming mold opening one by oneOvercome efficiencyEngineeringInjection molding machine

The invention provides a slide rail type automatic mold opening device of an injection molding machine. At the joint of a buckle handle and an upslope bevel edge, along with continuous operation of a disk, the buckle handle bears upward push force of the upslope bevel edge, and an anti-uplift device limits a mold bottom plate so that a lower mold cannot be lifted up; after the buckle handle moves a certain distance on the upslope bevel edge, the upslope bevel edge can enable an upper mold to be completely separated from the lower mold; and accordingly, automatic mold opening can be realized in the operating process of the disk, and continuous and automatic mold opening can be realized in the continuous operating process of the disk. Moreover, by adopting a frame structure, a metal tube or a mold opening execution mechanism of a metal bar form, on the basis of guaranteeing the structural strength, consumption and weight of materials can be greatly reduced, the cost is remarkably lowered, and the practicality is improved. Furthermore, a frame is borne by a slide rail, the whole mold opening execution mechanism can get close to or away from the disk through guidance and carrying of the slide rail, so that various molds are opened in due time, or mold opening is stopped. The invention further provides the injection molding machine.

Owner:大名县益多环保科技有限公司

Horizontal rotary shaft type automatic mold opening device for injection molding machine and injection molding machine made therefrom

The invention provides a horizontal rotating shaft type automatic mold opening device of an injection molding machine. In the actual use process, the connecting position of a clamping buckle handle and an upper slope inclined side continuously operates long with a disc, the clamping buckle handle is affected by upward pushing force of the upper slope inclined side, an anti-lifting device limits a mold bottom plate, a lower mold is not lifted up, and after the clamping buckle handle walks for a certain distance on the upper slope inclined side, an upper mold and a lower mold are completely separated through the upper slope inclined side; in the operation process of the disc, automatic mold opening can be achieved, and in the continuous operating process of the disc, continuous automatic mold opening can be achieved; on the basis of ensuring structural strength, a mold opening execution mechanism in a manner of a frame structure or a metal pipe or metal rod can greatly reduce the use number and weight of materials, the cost is obviously reduced, and the practicability is obviously improved; a frame body can turn over up and down through a horizontal rotating shaft, the mold opening mechanism can be driven to be close to or away from the disc, the structure is simple and reasonable, and the action is concise; and the invention further provides the injection molding machine.

Owner:东营市东凯园区运营管理有限公司

Vertical shaft type automatic mold opening device of injection molding machine and injection molding machine made of it

The invention provides a vertical rotating shaft type automatic die opening device of an injection molding machine. At a place where a fastener handle is connected with an upslope inclined edge, with the continuous operation of a disc, the fastener handle is subjected to an upward push force by the upslope inclined edge, a lifting prevention device limits a die bottom plate and allows no lower die to be lifted, and after the fastener handle walks a certain distance on the upslope inclined edge, the upslope inclined edge can separate an upper die from the lower die completely, so that automatic die opening can be realized in an operation process of the disc, and continuous automatic die opening can be realized in a continuous operation process of the disc. Furthermore, by adopting a die opening executing mechanism in a frame structure or in a metal tube or metal rod type, on the basis that the structural strength is ensured, the material usage and weight can be reduced greatly, and the cost and the practicability are reduced and improved significantly. Moreover, in a practical working process, a frame body bears the die opening executing mechanism and allows the die opening executing mechanism to be close to or far from the disc in a door opening or closing manner by depending on a vertical rotating shaft, the structure is simple and reasonable, and the movement is concise. The invention also provides an injection molding machine.

Owner:东营市东凯园区运营管理有限公司

Seat adjusting handle injection mold for vehicle seat production

The invention relates to the technical field of injection molds, in particular to a seat adjusting handle injection mold for vehicle seat production. The seat adjusting handle injection mold for vehicle seat production comprises a fixed demolding part, a movable demolding part and a mold part; the fixed demolding part comprises a fixed base, and a positioning bolting module; the movable demoldingpart comprises a bearing positioning base, and a demolding driving module mounted on the side wall of the bearing positioning base and used for driving the mold part to move in the horizontal direction; the mold part comprises a fixed mold base and a movable mold base; the fixed mold base comprises a fixed template, a fixed molding core and a fixed molding cavity arranged in a mold closing direction in sequence; the fixed molding cavity is positioned in the fixed molding core; the movable mold base comprises a movable template, an ejection plate, a movable molding core and a movable molding cavity arranged in a mold opening direction; and in a mold closing injection state, accommodating space for storing adjusting handles to be injected is formed between the fixed molding cavity and the movable molding cavity. The seat adjusting handle injection mold for vehicle seat production is high in mold opening efficiency, simple in operation, low in labor intensity and excellent in quality of produced handles, and overcomes the defects of multiple injection molding parts.

Owner:定远县益徽科技服务有限公司

A kind of building decoration environmental protection construction method

ActiveCN111890517BReduce resistanceImprove applicabilityDischarging arrangementMouldsElectric machineSprocket

The invention discloses an environmentally friendly construction method for building decoration, which comprises a machine base, a partition plate is fixedly connected to the middle part of the top of the machine base, and a support plate is fixedly connected to each corner of the top of the machine base. The top of the support plate is fixedly connected to the length adjustment mechanism, the bottom position of the outer end of the machine base is fixedly connected with an energy utilization and heat and cold protection mechanism, and the two ends of the partition plate are symmetrically and movably connected with a mold opening and width adjustment mechanism. The structure of the present invention Scientific and reasonable, safe and convenient to use, equipped with mold opening and closing and width adjustment mechanism, the rotating motor drives the sprocket to rotate, and through the transmission of the chain, the sprocket drives the screw to rotate together, thereby pushing the movable plate and the template to move, adjusting the The distance between the two templates and the partition plate is used to open and close the mold. At the same time, through the cooperation of the rolling groove and the roller, the resistance when the two templates move is reduced, the kinetic energy consumption is reduced, and the moving efficiency is increased.

Owner:广东田业建设有限公司

Vertical rotation shaft type automatic mold opening device of disc type injection molding machine and injection molding machine

The invention provides a vertical rotation shaft type automatic mold opening device of a disc type injection molding machine. The vertical rotation shaft type automatic mold opening device comprises a frame body, a mold opening actuator and a lift-preventing device; the mold opening actuator is provided with an upslope inclination side, and the upslope inclination side is gradually heightened in the rotation direction of a disc. In the actual use process of the device, at the joint between a buckle handle and the upslope inclination side, the buckle handle receives the upward thrust of the upslope inclination side along with continuous operation of the disc, the lift-preventing device limits a mold bottom plate so that a lower mold cannot be lifted, after the buckle handle walks on the upslope inclination side for a certain distance, the upslope inclination side can completely separate an upper mold and the lower mold, and therefore automatic mold opening can be realized in the operation process of the disc, and continuous and automatic mold opening can be realized in the continuous operation process of the disc. In the actual work process, the frame body bears the mold opening actuator and enables the mold opening actuator to get close to or away from the disc through a vertical rotation shaft in a door opening and closing mode; the structure is simple and reasonable and the movement is simple. The invention further provides the injection molding machine.

Owner:迈道装备集团有限公司

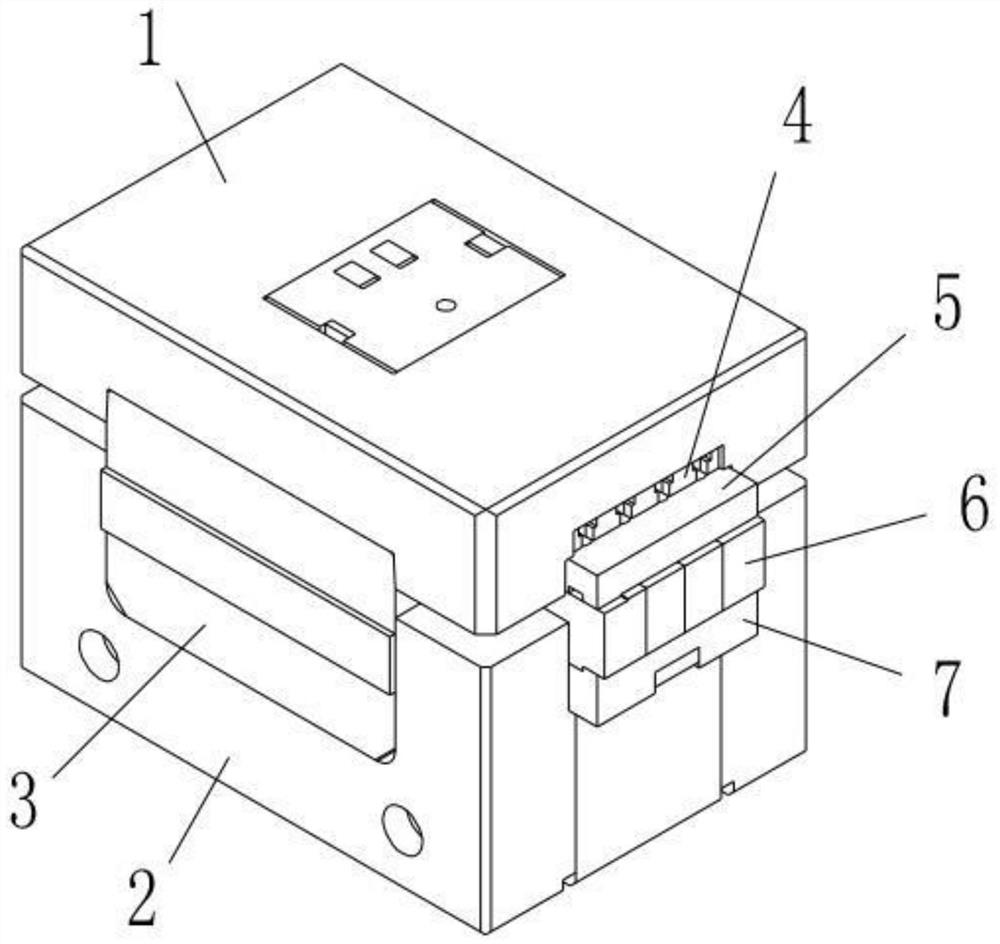

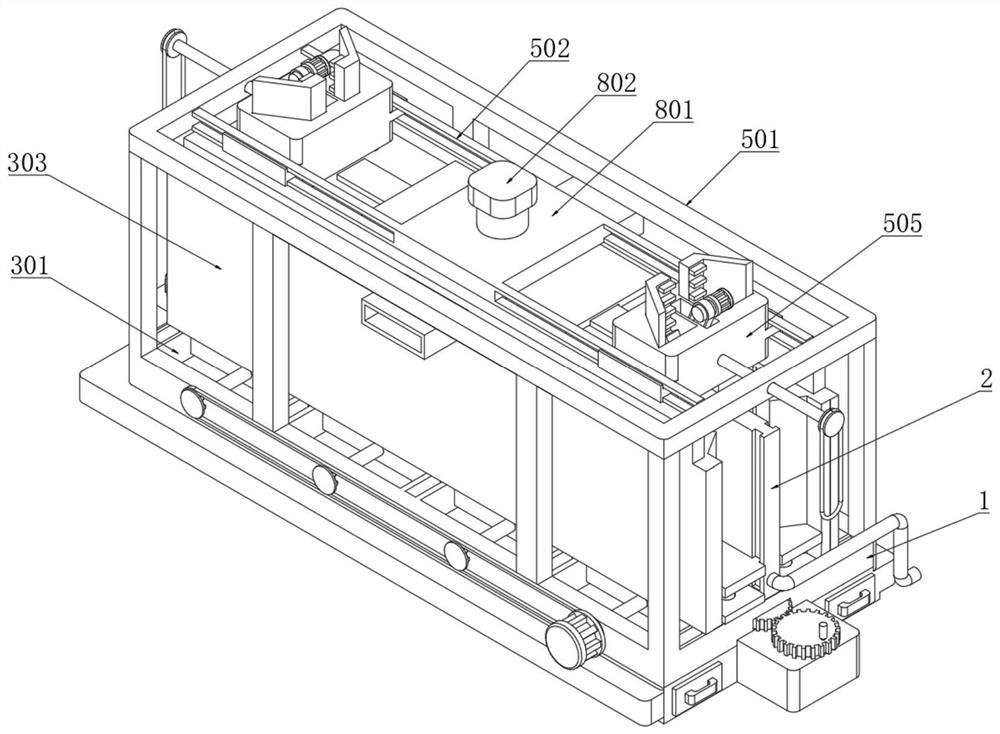

Automatic mold opening device of disk type injection molding machine and injection molding machine

InactiveCN105904687AHigh degree of mechanizationImprove mold opening efficiencyEngineeringActual use

This invention provides an automatic mold opening device of a disk type injection molding machine. The automatic mold opening device of the disk type injection molding machine comprises a frame body, a mold opening executing mechanism and an anti-raising device. The mold opening executing mechanism is provided with an upslope inclined edge which is gradually changed from low to high in the rotating direction of a disk. In this way, in the actual using process, the joint of a clamping buckle handle and the upslope inclined edge continues running along with the disk; the clamping buckle handle bears the upward thrust of the upslope inclined edge; the anti-raising device is used for limiting a mold bottom plate so that a lower mold cannot be raised up; when the clamping buckle handle walks on the upslope inclined edge for a certain distance, an upper mold and the lower mold can be completely separated through the upslope inclined edge; automatic mold opening can be achieved in the running process of the disk; and continuous automatic mold opening can be achieved in the continuous running process of the disk. Compared with the prior art, the automatic mold opening device of the disk type injection molding machine completely replaces an existing manual mold prying procedure, the mechanical degree is high, continuous automatic mold opening can be achieved, time and labor are saved, the mold opening efficiency is remarkably improved, cost is low, and practicability is high. The invention further provides one injection molding machine.

Owner:出菊萍

Automatic mold opening device for injection molding machine and injection molding machine made of it

The invention provides an automatic mold opening device for an injection molding machine. The automatic mold opening device comprises a rack body, a mold-opening execution mechanism and an anti-lifting device. The mold-opening execution mechanism is provided with an upslope bevel edge, and the upslope bevel edge is changed to be higher gradually in the rotation direction of a disc. In this way, in the practical application process of the automatic mold opening device, the connection position of a buckle handle and the upslope bevel edge continues to operate along with the disc; the buckle handle is subjected to upward pushing force of the upslope bevel edge; the anti-lifting device limits a mold bottom plate, and consequently a lower mold cannot be lifted; after the buckle handle travels for a certain distance on the upslope bevel edge, an upper mold and the lower mold can be separated completely through the upslope bevel edge; in the operation process of the disc, automatic mold opening can be achieved; and in the continuous operation process of the disc, continuous automatic mold opening is achieved. By means of the mold-opening execution mechanism which is of a frame structure and in the form of metal tubes or metal rods, on the basis that structural strength is guaranteed, material consumption and weight are greatly reduced; cost is remarkably lowered; and practicability is remarkably improved. The invention further provides the injection molding machine.

Owner:宁波科隆阁机械有限公司

A slide rail type automatic mold opening device for a disc type injection molding machine and the injection molding machine

The invention provides a sliding rail type automatic die opening device of a disc type injection molding machine. The sliding rail type automatic die opening device comprises a frame, a die opening execution mechanism and a lifting prevention device. The die opening execution mechanism is provided with an upslope bevel edge, and the upslope bevel edge is gradually heightened in the rotation direction of a disc. Thus, in the actual use process of the device, at the joint of a buckle handle and the upslope bevel edge, along with continuous running of the disc, the buckle handle bears upward pushing force of the upslope bevel edge, a die bottom plate is limited by the lifting prevention device, and therefore a lower die cannot be lifted up; and after the buckle handle walks on the upslope bevel edge for a certain distance, an upper die and the lower die are completely separated by the upslope bevel edge, automatic die opening can be achieved in the running process of the disc, and continuous automatic die opening can be achieved in the continuous running process of the disc. In addition, by means of bearing of a sliding rail on the frame, the whole die opening execution mechanism can be close to or far away from the disc by means of guiding and carrying of the sliding rail, and die opening on all the dies or die opening stopping is carried out in good time. The invention further provides the injection molding machine.

Owner:丰铁机械(苏州)有限公司

A metal water cup shell with surface continuous pressing pattern and its manufacturing method

The invention discloses a method for manufacturing a metal water cup shell with a surface continuously pressed pattern: step 1, intercepting a round tube for processing the metal water cup shell, and forming the round tube into a thin-walled metal shell of the water cup by hydroforming with an aqueous medium; Step 2, polishing the area where the pattern is to be pressed on the thin-walled metal shell; Step 3, using a continuous pattern pressing mold to perform continuous pattern pressing on the thin-walled metal shell of the water cup. The method for manufacturing the metal water cup shell with a surface continuously pressed pattern can ensure that the surface of the thin-walled metal shell of the water cup is pressed with a continuous pattern that does not deviate from the position and has high definition, and ensures that the thin-walled metal shell after the pattern is pressed does not Out of roundness does not break, high yield and high production efficiency.

Owner:ZHEJIANG HAERS VACUUM CONTAINERS CO LTD

Automatic mold opening auto spare part molding machine

InactiveCN107282786AMold opening is stable and smoothNo manual operationShaping toolsMolding machineSpare part

The invention discloses an automatic mold opening auto spare part molding machine. The automatic mold opening auto spare part molding machine comprises an upper mold, a lower mold, forming grooves formed in the upper mold and the lower mold, a pulling assembly connected to the upper mold, a sliding groove clamped to the upper mold and guiding the upper mold to move, and a rotating shaft connected between the upper mold and the lower mold. According to the automatic mold opening auto spare part molding machine, the rotating shaft is arranged between the upper mold and the lower mold, the upper mold is pulled through the pulling assembly, automatic mold opening is achieved, manual mold opening is not needed, the mold opening efficiency is high, manpower is saved, and cost is saved.

Owner:NANJING INST OF TECH

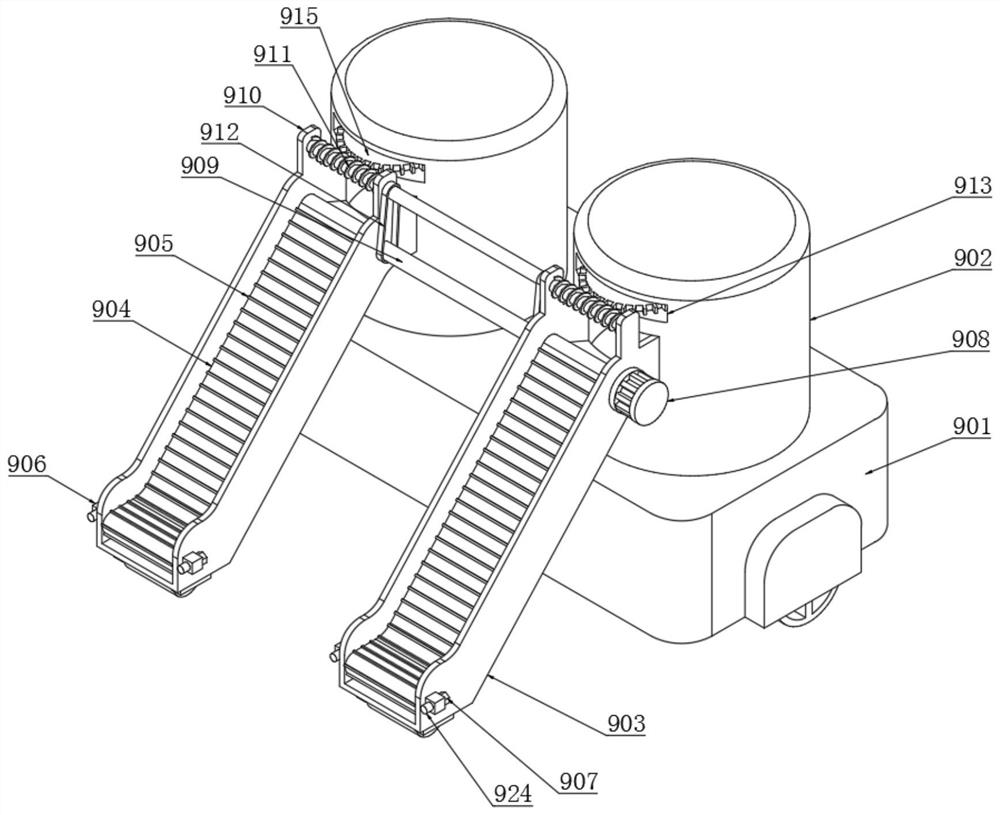

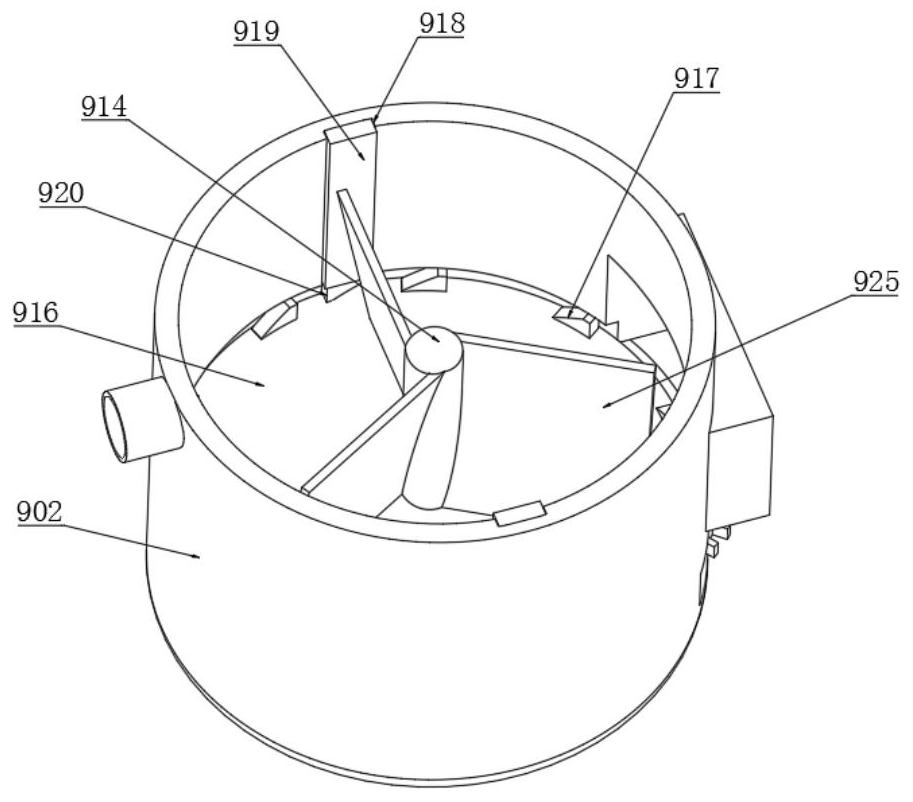

Architectural decoration environmental-protection construction system

InactiveCN111975951AScientific and reasonable structureEasy to useMouldsMould auxillary partsElectric machineryDrive motor

The invention discloses an architectural decoration environmental-protection construction system. Screening barrels are symmetrically and fixedly connected to the top end of a recovery box. The top positions of the outer ends of the screening barrels are fixedly connected with feeding channels, and the inner walls of the feeding channels are rotationally connected with conveying belts. Striker plates are evenly and fixedly connected to the outer ends of the conveying belts. Connecting blocks are formed at the positions, away from the screening barrels, of the two ends of the feeding channels.A second drive motor is fixedly connected to the position, corresponding to a rotating shaft of the corresponding conveying belt, of one end of each feeding channel. According to the system, locking nuts are rotated, so that locating pins and connecting blocks are fixedly connected, and therefore the feeding channel and a machine seat can be connected and fixed conveniently, the position between the feeding channels and the machine seat is prevented from deviating, and the effect of recovery to waste and impurities is guaranteed; and meanwhile, second drive motors and transmission rods cooperate to drive the two conveying belts to rotate, impurities discharged from the interior of a slag discharging groove are fed into the screening barrels, and the collection efficiency to impurities is improved.

Owner:郑觉敏

Air-cap mold structure that shortens molding cycle

Owner:深圳市三精模具有限公司

Vertical shaft type automatic mold opening device and injection molding machine for a disc type injection molding machine

The invention provides a vertical rotation shaft type automatic mold opening device of a disc type injection molding machine. The vertical rotation shaft type automatic mold opening device comprises a frame body, a mold opening actuator and a lift-preventing device; the mold opening actuator is provided with an upslope inclination side, and the upslope inclination side is gradually heightened in the rotation direction of a disc. In the actual use process of the device, at the joint between a buckle handle and the upslope inclination side, the buckle handle receives the upward thrust of the upslope inclination side along with continuous operation of the disc, the lift-preventing device limits a mold bottom plate so that a lower mold cannot be lifted, after the buckle handle walks on the upslope inclination side for a certain distance, the upslope inclination side can completely separate an upper mold and the lower mold, and therefore automatic mold opening can be realized in the operation process of the disc, and continuous and automatic mold opening can be realized in the continuous operation process of the disc. In the actual work process, the frame body bears the mold opening actuator and enables the mold opening actuator to get close to or away from the disc through a vertical rotation shaft in a door opening and closing mode; the structure is simple and reasonable and the movement is simple. The invention further provides the injection molding machine.

Owner:迈道装备集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com