Automatic mold opening auto spare part molding machine

A technology for auto parts and molding machines, which is applied in the field of auto parts manufacturing and can solve problems such as inability to automate machine production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

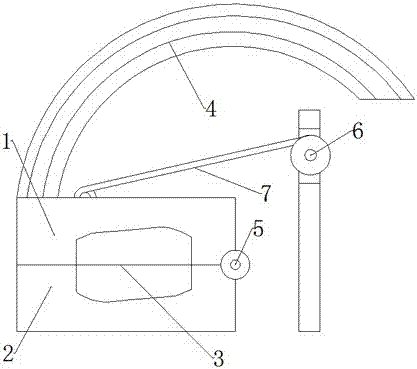

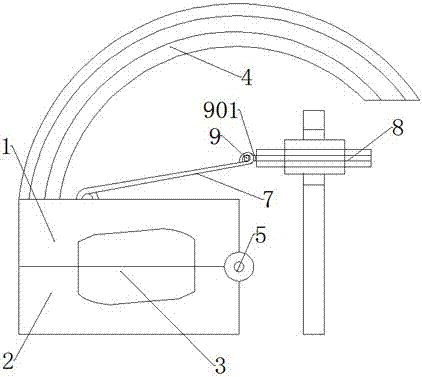

[0019] Automatic mold opening auto parts forming machine, including: upper mold 1, lower mold 2, forming groove 3 in upper mold 1 and lower mold 2, pull-up assembly connected to upper mold 1, and clamped to upper mold 1 The sliding groove 4 that guides the movement of the upper mold 1 is connected to the rotating shaft 5 between the upper mold 1 and the lower mold 2 . In order to conform to the rotation curve of the upper mold 1 according to the rotation axis 5 as the center of the circle, the sliding groove 4 is an arc-shaped groove; In the sliding groove 4, the movement follows the curve of the sliding groove 4, so that the movement of the upper mold 1 is more stable.

[0020] Such as figure 1 As shown, as an embodiment, the pulling assembly consists of: a rotating disk 6 placed next to the upper mold 1 , and a pull rope 7 wound on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com