Metal cup shell with continuous compaction pattern on surface and manufacturing method thereof

A kind of metal shell, technology of manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

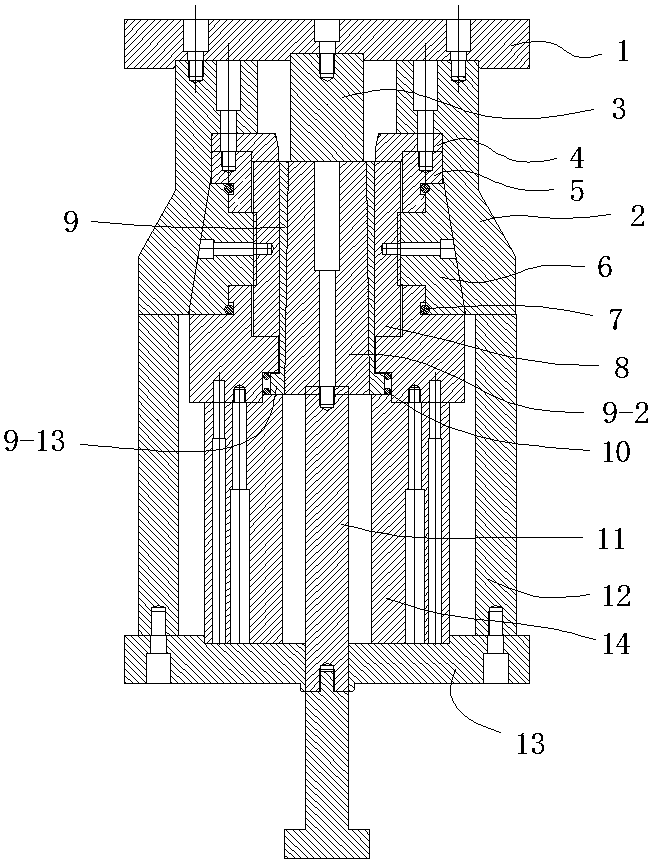

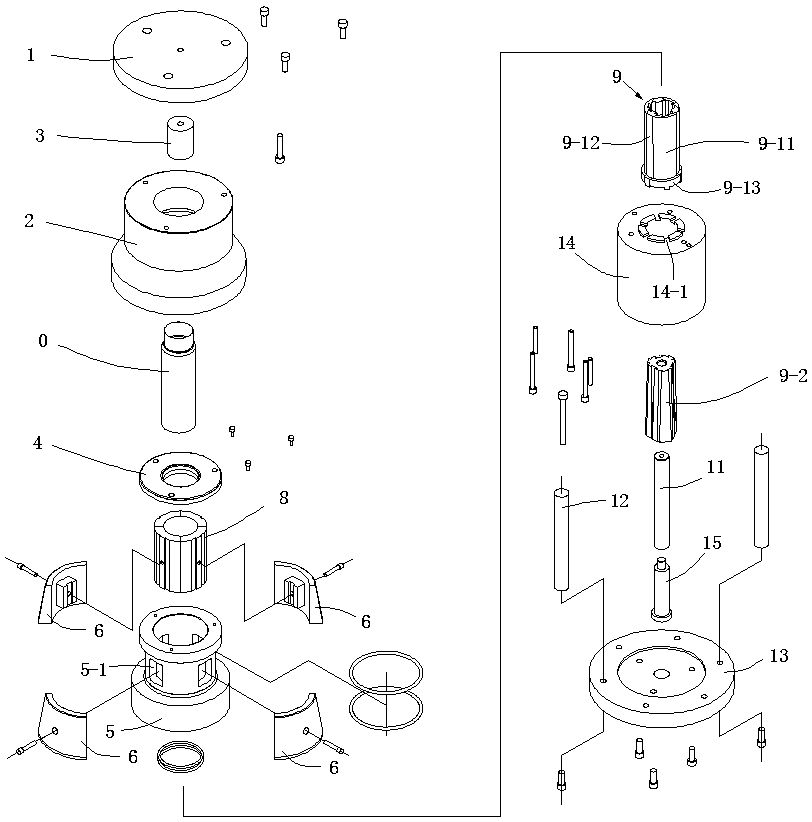

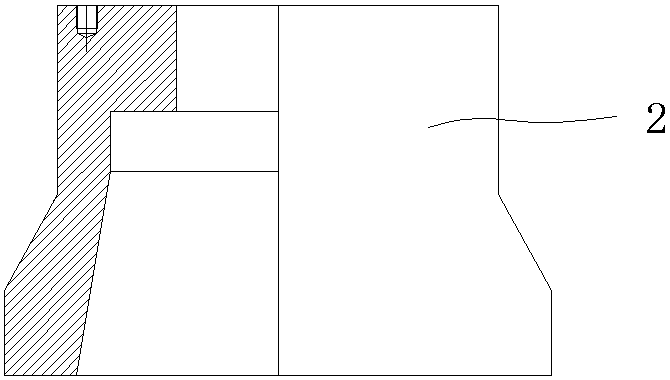

[0045] In order to make the technical solution of the present invention clearer, the following in conjunction with the attached Figures 1 to 24 , the present invention will be described in detail. It should be understood that the specific implementations described in this specification are only for explaining the present invention, and are not intended to limit the protection scope of the present invention.

[0046] The invention is a method for manufacturing a metal water cup shell with a surface continuously pressed pattern,

[0047] Step 1, intercepting the circular tube used for processing the outer shell of the metal water cup, and hydraulically forming the circular tube into the thin-walled metal shell of the water cup through water medium hydroforming;

[0048] Step 2, polishing the area of the thin-walled metal shell 0 to be patterned;

[0049] Step 3, using a continuous pattern pressing mold to carry out continuous pattern pressing on the thin-walled metal shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com