Cake making machine

A technology of cake machine and cake mould, which is applied in food science, baking, special containers for baking, etc., and can solve problems such as reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

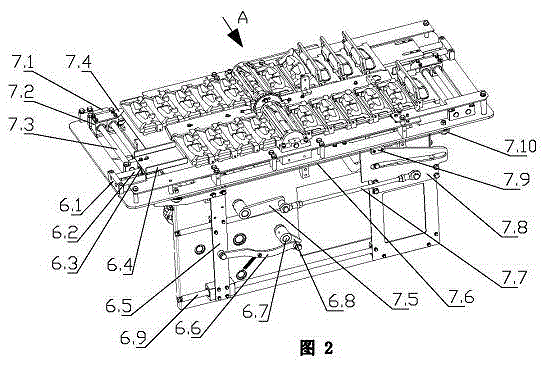

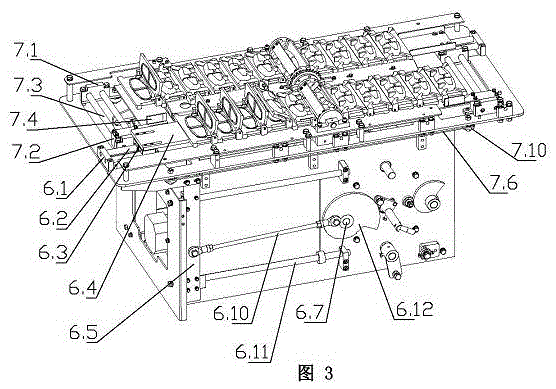

[0022] In the cake machine shown in Figure 1, the motor 13 is fixedly installed on the frame 10, the speed reducer 14 connected to the motor 13 through the coupling joint, and the main transmission shaft 15 connected to the speed reducer 14 through the chain drive, fixed The incomplete gear 19 and the locking convex arc disc 16 arranged on the main drive shaft 15, and the driven gear 18 which is intermittently externally meshed with the incomplete gear 19, the number of the driven gears 18 is four, and the four driven gears 18 There are locking concave arc discs 17 on each of them, and the four driven gears 18 are evenly distributed in the circumferential direction of the incomplete gear 19. The four driven gears 18 are fixedly connected to the longitudinal drive shaft 6.7, the return crank shaft 21, and the extruding material respectively. 4.7 on the camshaft and 20 on the push crankshaft (see Figure 10 ), the inner heating zone 1 and the outer heating zone 2 are arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com