Mold for producing lamp frame reflecting body of selenium lamp

A reflector and lamp frame technology, applied in the field of molds, can solve the problems of poor cooling effect, poor exhaust, narrow setting of gate 21, etc., and achieve the effect of facilitating waste discharge and good exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

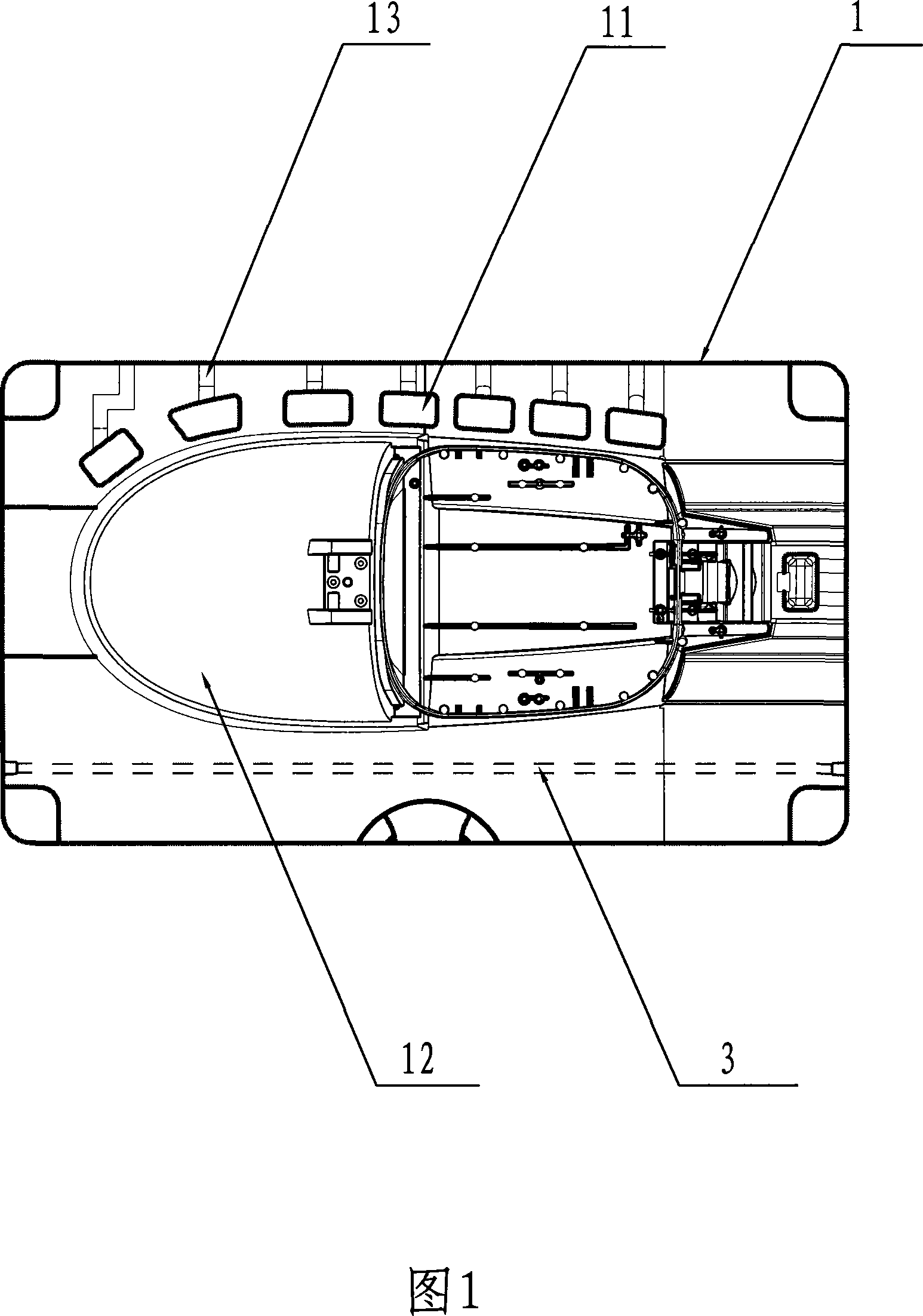

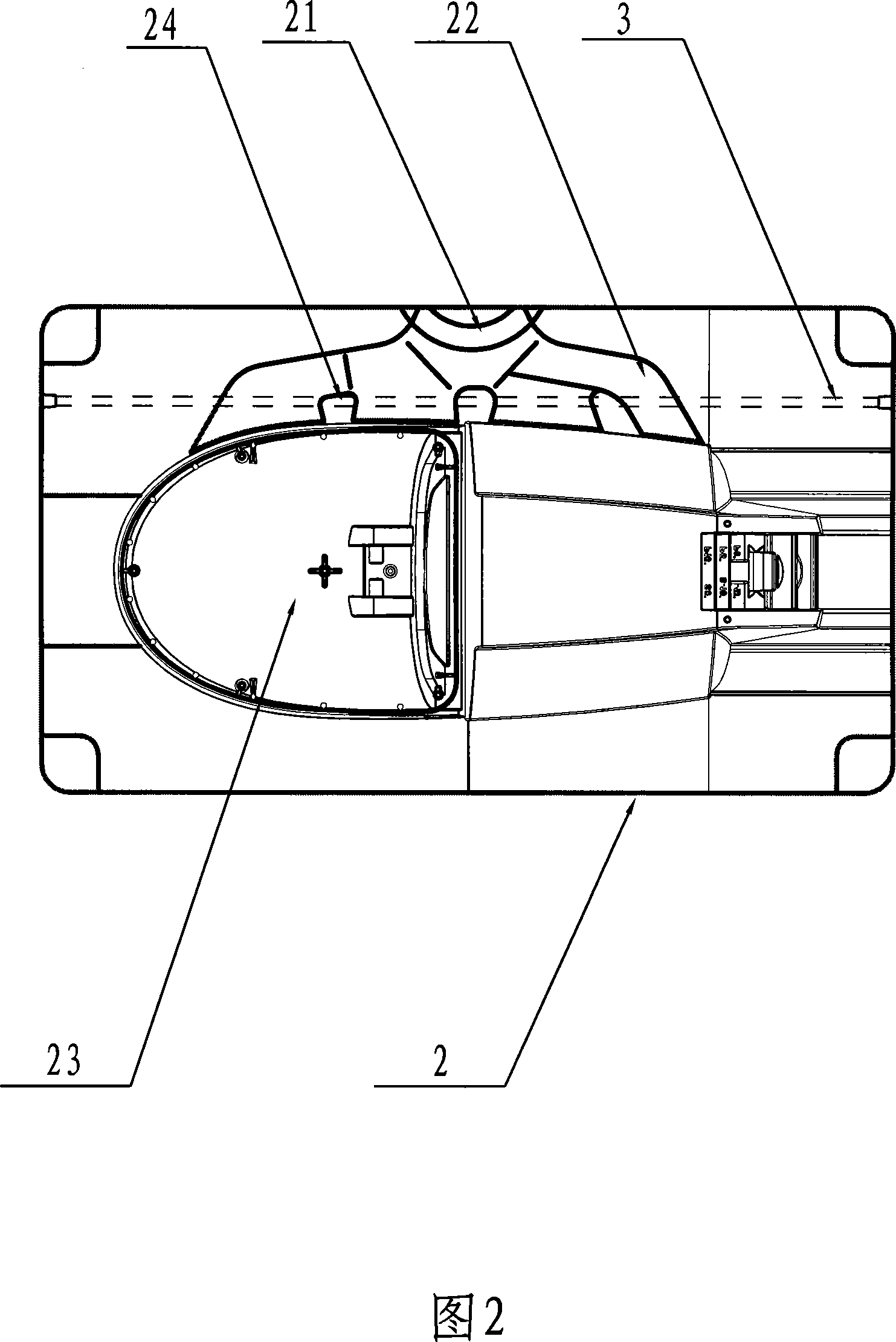

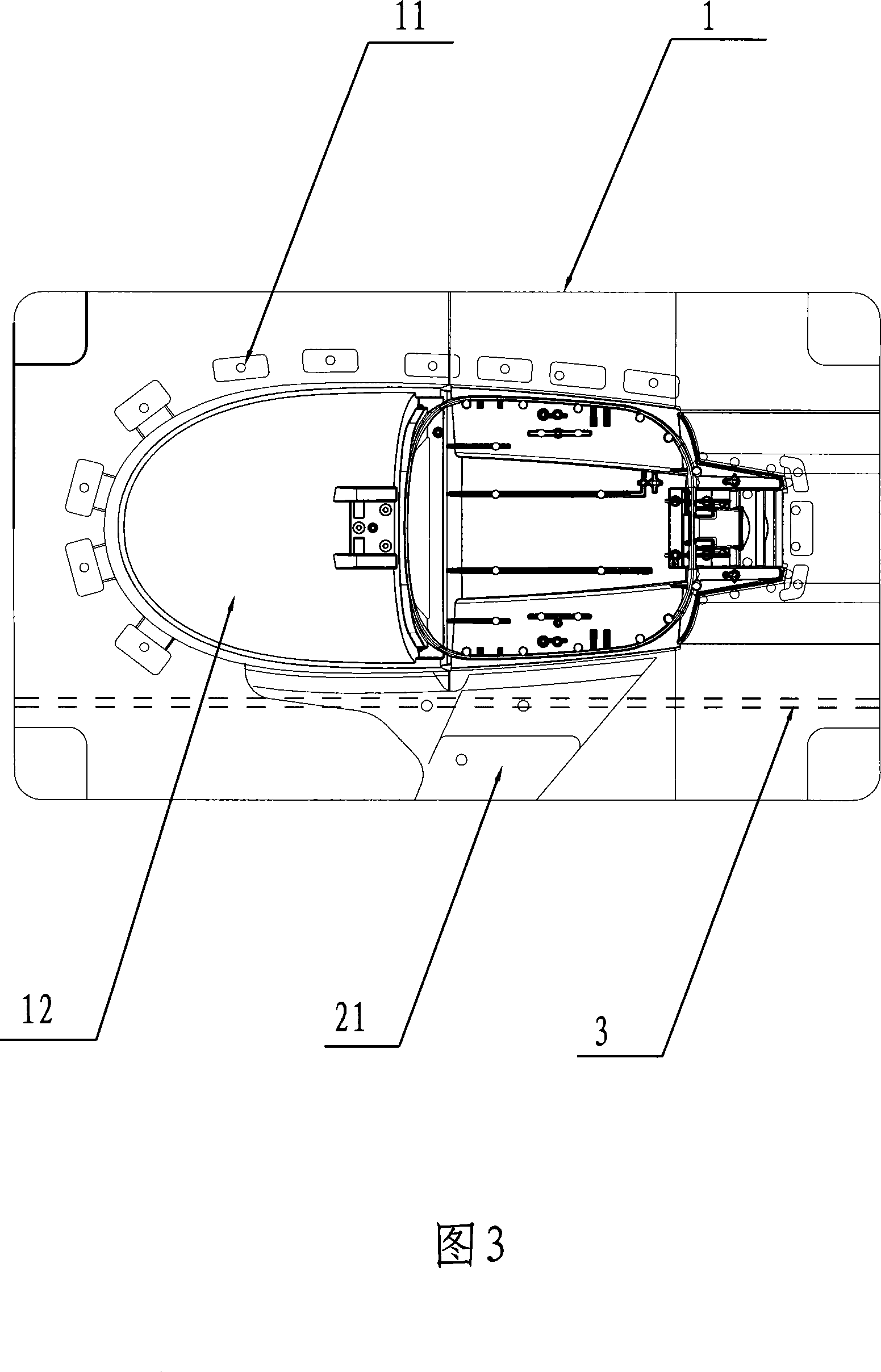

[0024] Embodiment 1: Fig. 1, as shown in Fig. 2, the present invention comprises die 1 and punch 2, and described die 1 is movable die, and described punch 2 is fixed die, and described die 1 and punch 2 are in the shape of a cuboid, the convex mold 2 is provided with a selenium lamp lamp frame reflector cavity convex surface 23, and the concave mold 1 is provided with a selenium lamp lamp frame reflector cavity concave surface 12, and the convex mold 2 and The die 1 is combined to form the reflector cavity of the lamp frame of the selenium lamp. A slag bag 11 and an exhaust groove 13 are arranged on the die 1. A sprue 21 is provided on the die 2. A sprue 21 is provided on the die 1. The punches 2 are provided with cooling water channels 3 .

[0025] There are seven slag bags 11, which are distributed on the side of the cavity concave surface 12 of the lamp frame reflector of the selenium lamp relative to the gate 21, and are arranged in a circle on the side of the concave sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com